HCD-C700/C900

SERVICE MANUAL

Ver 1.4 2004.08

Photo : HCD-C700

HCD-C700/C900 are the amplifier, DVD/CD and

tuner section in DAV-C700/C900.

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION:

Amplifier section

C700 MODEL

Stereo mode 50 W + 50 W (6 ohms at 1 kHz, THD 10 %)

Surround mode Front: 50 W + 50 W

C900 MODEL

Stereo mode 70 W + 70 W (4 ohms at 1 kHz, THD 10 %)

Surround mode Front: 70 W + 70 W

* Depending on the sound field settings and the source, there may be no sound output.

Inputs (Analog) VIDEO 1, 2:

Inputs (Digital) VIDEO 2 (optical):

Outputs (Analog) VIDEO 1 (AUDIO OUT):

Outputs (Digital) DIGITAL OUT (CD)

SACD/DVD system

Laser Semiconductor laser

Signal format system NTSC or NTSC/PAL

Frequency response (at 2 CH STEREO mode)

Signal-to-noise ratio More than 80 dB (VIDEO 1 (AUDIO) connectors only)

Harmonic distortion Less than 0.03 %

FM tuner section

System PLL quartz-locked digital synthesizer system

North American model: 87.5 – 108.0 MHz (100 kHz step)

Other models: 87.5 – 108.0 MHz (50 kHz step)

Antenna FM wire antenna

Antenna terminals 75 ohms, unbalanced

Intermediate frequency 10.7 MHz

With 6 ohm loads, both channels driven, from 120 – 10,000 Hz; rated

50 watts per channel minimum RMS power, with no more than 10 %

total harmonic distortion from 250 milliwatts to rated output.

Center*: 50 W

Rear*: 50 W + 50 W (6 ohms at 1 kHz, THD 10 %)

Subwoofer*: 100 W (3 ohms at 100 Hz, THD 10 %)

Center*: 70 W

Rear*: 50 W + 50 W (6 ohms at 1 kHz, THD 10 %)

Subwoofer*: 100 W (3 ohms at 100 Hz, THD 10 %)

Sensitivity: 150 mV

Impedance: 50 kilohms

Sensitivity: –

Voltage: 2 V

Impedance: 1 kilohms

PHONES:

Accepts low- and high-impedance headphones

Sensitivity: –

DVD (PCM): 2 Hz to 22 kHz (±1.0 dB)

CD: 2 Hz to 20 kHz (±1.0 dB)

US Model

Canadian Model

HCD-C700/C900

AEP Model

UK Model

E Model

Australian Model

Model Name Using Similar Mechanism NEW

Mechanism Type CDM53K-DVBU7

Base Unit Name DVBU7

Optical Pick-up Name KHM-240AAA

AM tuner section

System Tuner section:

Tuning range

North American model: 530 – 1,710 kHz (with the interval set at 10 kHz)

European, Middle Eastern, and Philipinne models:

Other models: 531 – 1,602 kHz (with the interval set at 9 kHz)

Antenna Loop antenna

Video section

Inputs Video: 1 Vp-p 75 ohms

Outputs Video: 1 Vp-p 75 ohms

General

Power requirements

North American model: 120 V AC, 60 Hz

European model: 220 – 240 V AC, 50/60 Hz

Australian and Asian models: 220 – 240 V AC, 50/60 Hz

Mexican model: 120 V AC, 60 Hz

Other models: 110 – 240 V/ 220 – 240 V AC, 50/60 Hz

Power consumption 105 W (120 V AC), 105 W (230 V AC)

Dimensions (approx.) 355 100 394 mm (14 × 4 × 15

Mass (approx.) 5.7 kg (12 lb 10 oz)

Operating temperature 5˚C to 35˚C (41˚F to 95˚F)

Operating humidity 5 % to 90 %

Design and specifications are subject to change without notice.

PLL quartz-locked digital synthesizer system

531 – 1,710 kHz (with the interval set at 9 kHz)

531 – 1,602 kHz (with the interval set at 9 kHz)

530 – 1,710 kHz (with the interval set at 10 kHz)

S-video:

Y: 1 Vp-p 75 ohms

C: 0.286 Vp-p 75 ohms

5

parts

/8 inches) (w/h/d) incl. projecting

COMPACT AV SYSTEM

HCD-C700

9-873-327-05

2004H16-1

© 2004.08

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

HCD-C700/C900

SELF-DIAGNOSIS

Self-diagnosis Function

(When letters/numbers appear in the

display)

When the self-diagnosis function is

activated to prevent the system from

malfunctioning. In this case a five-character

service number (e.g., C 13 00) with a

combination of a letter and digits appears on

the screen and the front panel display. Refer

to the following table.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

First three

characters of

the service

number

C 13

C 31

E XX

(xx is a number)

C:13:00

Cause and/or Corrective

Action

The disc is dirty.

, Clean the disc with a soft

cloth (page 9).

The disc is not inserted

correctly.

, Re-insert the disc

correctly.

To prevent a malfunction, the

system has performed the selfdiagnosis function.

, Contact your nearest Sony

dealer or local authorized

Sony service facility and

give the 5-character

service number.

Example: E 61 10

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output several times.

2

HCD-C700/C900

0.15µF

To Exposed Metal

Parts on Set

1.5kΩ

AC

voltmeter

(0.75V)

Earth Ground

Ver 1.4

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

This appliance is classified as

a CLASS 1 LASER product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

This caution

label is located

inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth Ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CHECKING OF OPERATIONS WITH REMOTE

COMMANDERS OF DIFFERENT MODELS

Some of the signal of remote commander vary between generation

of player.

Between DAV-S400/S500/S800/C450/C700/C900 and DAV-S550/

S880/C770/C900, remote commander signal codes of

“FUNCTION”, “BAND”, “ST/MONO” and “MEMORY” are

different.

Take notice of the above when you check the operation with remote

commanders of different models.

Fig. A. Using an AC voltmeter to check AC leakage.

NOTE OF REPLACING THE DVD BOARD

When replacing the DVD board, since the adjustment value is not

set up correctly, “Drive Auto Adjustment” can’t be performed.

In this case, initialize Memory in the following procedures.

Procedure:

1.Starting test mode. (See page 18)

2.Press the [2] key of the remote commander, and set the “DRIVE

MANUAL OPERATION”. (See page 24)

3.Press the [6] key of the remote commander, and set the “6. Memory

Check”. (See page 26)

4.Press the [CLEAR] key of the remote commander, and initialize

Memory.

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY-RELATED COMPONENT WARNING!!

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

3

HCD-C700/C900

TABLE OF CONTENTS

1. GENERAL ·········································································· 5

2. DISASSEMBLY ································································ 7

3. TEST MODE ···································································· 18

4. ELECTRICAL ADJUSTMENT ·································· 28

5. DIAGRAMS ······································································ 30

5-1. Block Diagrams

– RF/Servo, Video Section – ······································· 32

– CPU Section – ·························································· 33

– Power Section – ························································ 34

5-2. Printed Wiring Board – RF Section –························· 35

5-3. Schematic Diagram – RF Section – ··························· 36

5-4. Printed Wiring Board – DVD Section (Side A) –······· 37

5-5. Printed Wiring Board – DVD (Side B) Section –······· 38

5-6. Schematic Diagram – DVD Section (1/9) – ··············· 39

5-7. Schematic Diagram – DVD Section (2/9) – ··············· 40

5-8. Schematic Diagram – DVD Section (3/9) – ··············· 41

5-9. Schematic Diagram – DVD Section (4/9) – ··············· 42

5-10.Schematic Diagram – DVD Section (5/9) – ··············· 43

5-11.Schematic Diagram – DVD Section (6/9) – ··············· 44

5-12.Schematic Diagram – DVD Section (7/9) – ··············· 45

5-13.Schematic Diagram – DVD Section (8/9) – ··············· 46

5-14.Schematic Diagram – DVD Section (9/9) – ··············· 47

5-15.Printed Wiring Board – AMP Section (Side A) –······· 48

5-16.Printed Wiring Board – AMP Section (Side B) – ······· 49

5-17.Schematic Diagram – AMP Section (1/2) – ··············· 50

5-18.Schematic Diagram – AMP Section (2/2) – ··············· 51

5-19.Printed Wiring Board – I/O Section – ························ 52

5-20.Schematic Diagram – I/O Section (1/2) – ·················· 53

5-21.Schematic Diagram – I/O Section (2/2) – ·················· 54

5-22.Printed Wiring Board – Front Section – ····················· 55

5-23.Schematic Diagram – Front Section – ························ 56

5-24.Printed Wiring Board – SW Section –························ 57

5-25.Schematic Diagram – SW Section – ·························· 58

5-26.Printed Wiring Board – CDM Section – ···················· 59

5-27.Schematic Diagram – CDM Section – ······················· 60

5-28.Printed Wiring Board – Power Section (Side A) – ····· 61

5-29.Printed Wiring Board – Power Section (Side B) – ····· 62

5-30.Schematic Diagram – Power Section – ······················ 63

5-31.IC Block Diagrams ······················································ 64

5-32.IC Pin Function Description ········································ 67

6. EXPLODED VIEWS

6-1. Case (Top) Section ······················································ 77

6-2. Chassis Section ···························································· 78

6-3. Front Panel Section ····················································· 79

6-4. Overall Section (CDM53K-DVBU7) ··························80

6-5. Chassis (Mold) Assembly Section

(CDM53K-DVBU7) ···················································· 81

6-6. Chassis Section (CDM53K-DVBU7)·························· 82

6-7. Stocker (240) Overall, Optical Pick-up Section

(CDM53K-DVBU7) ···················································· 83

7. ELECTRICAL PARTS LIST ······································· 84

4

SECTION 1

GENERAL

Index to Parts and Controls

For more information, refer to the pages indicated in parentheses.

Front Panel

HCD-C700/C900

This section is extracted

from instruction manual.

1 POWER switch/indicator (32)

23DISC 1 (play) /A (open/close)-DISC 5

(play) / A (open/close) (32)

Front panel display (12)

4 ./> PREV/NEXT, PRESET +/–

(30, 33)

5 H (play) (32)

6 X (pause) (33)

7 x (stop) (32)

Rear Panel

VIDEO IN

VIDEO

IN

COAXIAL

AM

FM

75

VIDEO OUT

AUDIO OUT

L

R

VIDEO 1

AUDIO

IN

IN

AUDIO

VIDEO 2

L

OPTICAL

DIGITAL

R

FRONT R

REAR R

IN

DIGITAL

(CD ONLY)

DIGITAL

OUT

SPEAKER

CENTER

WOOFER

MONITOR

FRONT L

REAR L

SVIDEO

(DVD ONLY)

VIDEO

OUT

8 PHONES jack (32)

9

VOLUME control (32)

q; SOUND FIELD +/– (49)

qa DISPLAY (49, 62)

qs BAND (30)

qd FUNCTION (61)

qf

(remote sensor) (18)

qg Disc tray (32)

B

/B-Y PR/R-Y

P

Y

COMPOMENT VIDEO OUT

1 AM antenna (21)

2 VIDEO 1 jacks (23)

3 VIDEO 2 jacks (23)

4 DIGITAL IN (OPTICAL) jack (24)

5 DIGITAL OUT (OPTICAL) jack

6 MONITOR OUT (VIDEO/S VIDEO)

jacks (23)

7 COMPONENT VIDEO OUT jacks (23)

8 SPEAKER jacks (19)

9 FM 75Ω COAXIAL antenna jack (22)

5

HCD-C700/C900

Remote

123

456

7

89

>

10

10/0

1 TV [/1 (on/standby) (60)

2 OPEN/CLOSE (32)

3 NAME (63)

4 STEREO/MONO (62)

5 MEMORY (30)

6 CLEAR (37)

7 PLAY MODE (37)

8 AUDIO (47)

9 ANGLE (52)

q; SUBTITLE (53)

qa VOL +/– (62)

qs ./> PREV/NEXT, TV/PRESET

+/– (30, 33)

qd H PLAY/SELECT (32)

qf TITLE (35)

qg DVD DISPLAY (37)

qh C/X/x/c/ENTER (26)

qj DVD SETUP (56)

qk [/1 (on/standby) (32)

ql DISC SKIP (32)

w; TV/VIDEO (60)

wa REPEAT (40)

ws MUTING (33)

wd TIME (45)

wf FUNCTION (61)

Note

This remote control glows in the dark. However,

before glowing, the remote must be exposed to light

for awhile.

wg BAND (30)

wh Number buttons (35)

wj SOUND FIELD (49)

wk DISPLAY (49, 62)

wl ENTER

e; CONTROL DVD/TV switch (60)

ea m/M/

/ SLOW, TUNING +/–

(30, 41)

es x STOP (32)

ed X PAUSE (33)

ef DVD MENU (35)

eg O RETURN (36)

eh AMP MENU (26)

6

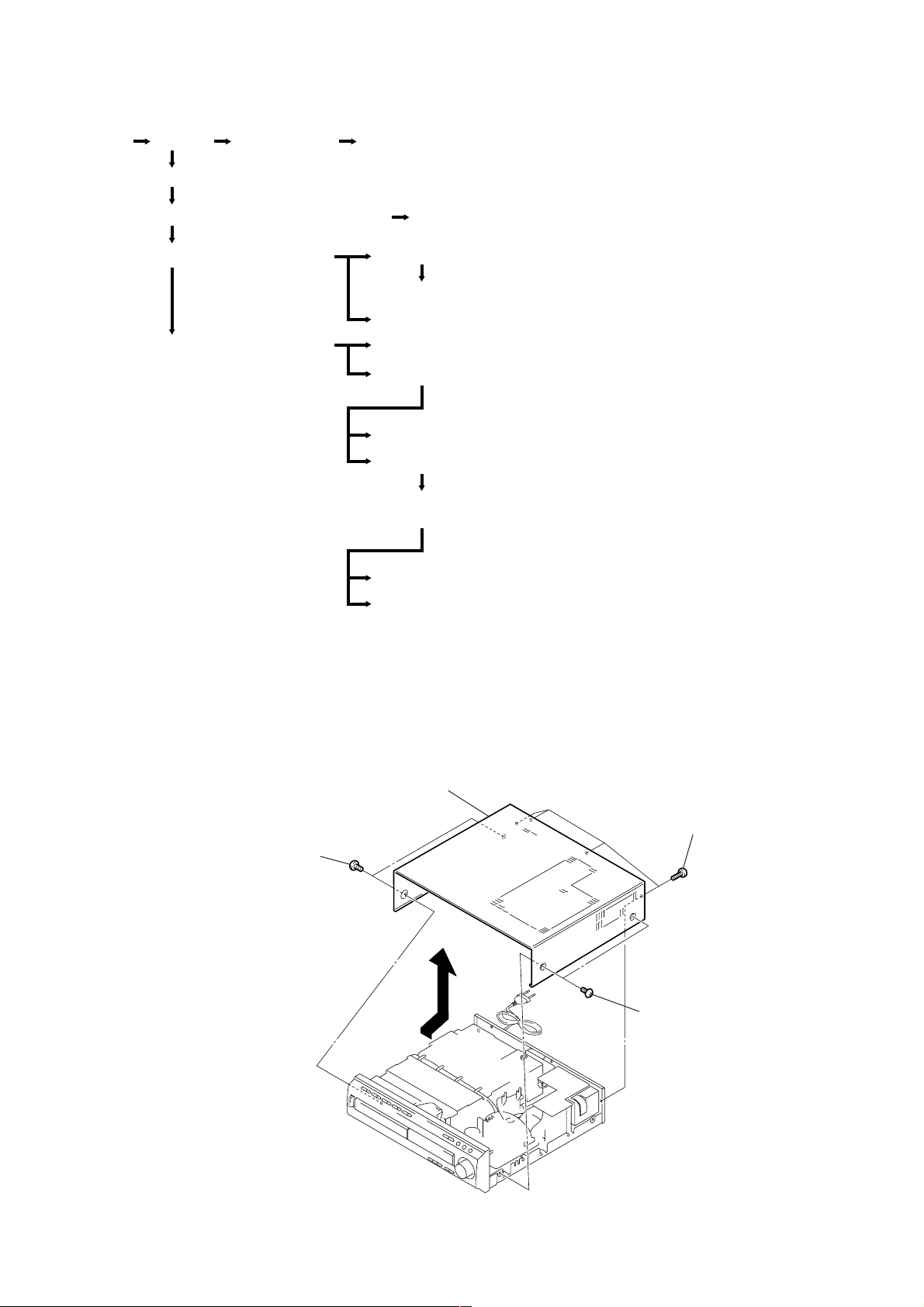

SECTION 2

y

DISASSEMBLY

• The equipment can be removed using the following procedure.

Case(top)

POWER board

Tuner unit section Front panel sectionSet

HCD-C700/C900

DVD mechanism deck (CDM53K-DVBU7)

Fitting base (magnet) assembly

Fitting base (guide) assembly,

Bracket (chassis)

Note: Follow the disassembly procedure in the numerical order given.

RF-240 board

DVD base unit (DVBU7)

Optical pick-up (KHM-240AAA)

CLAMP MOTOR board, Motor (clamp) assembl

Tray (240)

Chassis (mold B) section

LOAD MOTOR board, Motor (loading) assembly

Stocker section

Slider (selection), Tension spring (shutter),

slider (shutter)

Gear (Gear A), Gear (Gear B), Gear (U/D slider)

Gear (chucking)

2-1. CASE (TOP)

2

Two case screws

4

Case

3

Four screws,

+BVTP

(3 × 8)

1

Two case screws

7

HCD-C700/C900

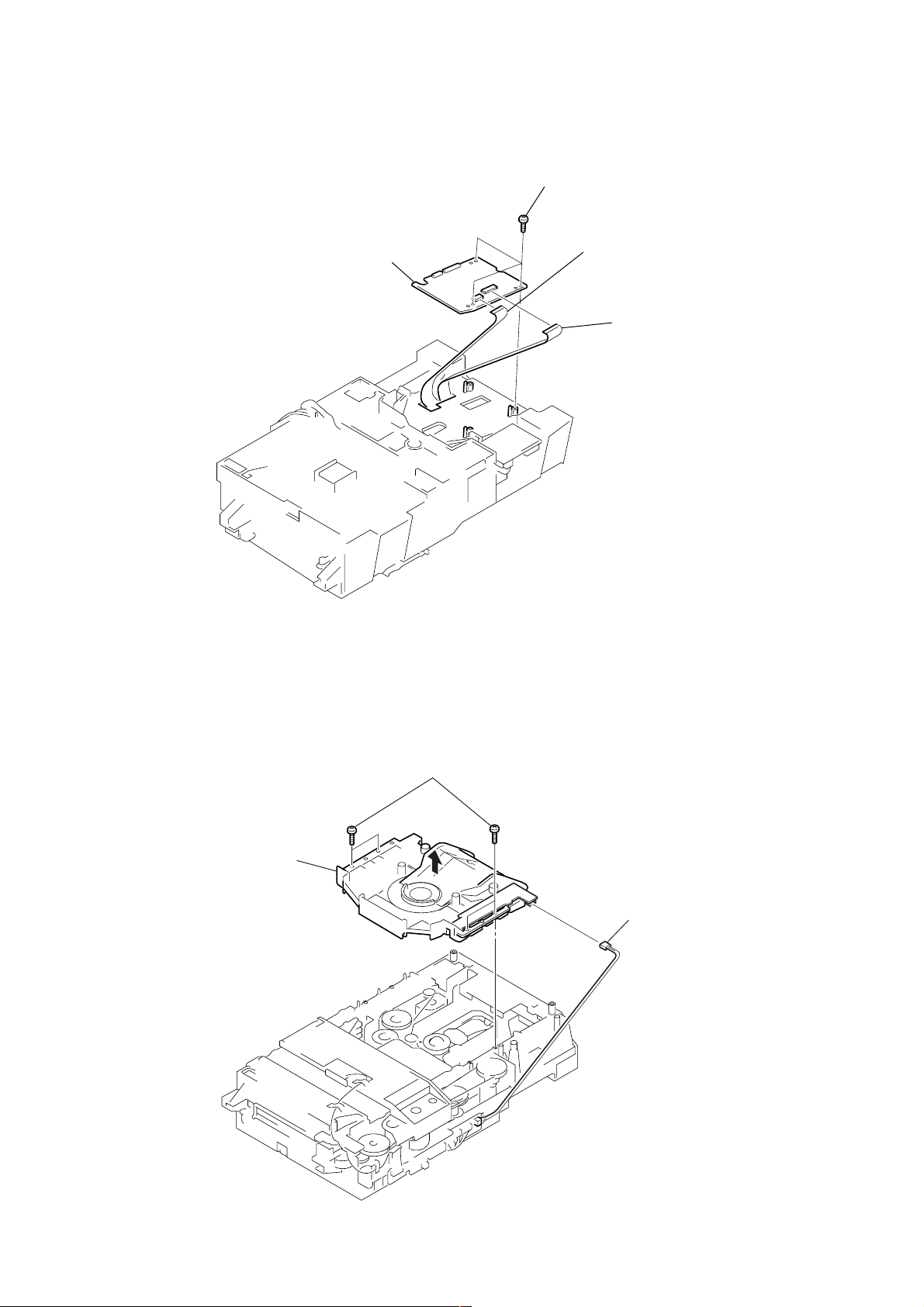

2-2. TUNER UNIT

1

Screw,

+BVTP

×

8)

(3

4

Flexible flat cable

(13core) (Tuner unit)

6

Tuner unit

5

Two screws,

+BVTP

(3 × 8)

2

Screw,

+BVTP

(3 × 8)

2-3. FRONT PANEL SECTION

2

Connector

(CN902)

8

Front panel

section

4

Wire

3

Screw,

+BVTP

(3 × 8)

3

Chassis

7

Flexible flat cable (17core)

(CN005)

HARNESS

PROCESSING

Power board

Wiring

stopper

6

Two claws

1

Connector

(CN309)

5

Five Screws,

+BVTP

(3

×

8)

8

2-4. POWER BOARD

d

2

Connector

(CN901)

3

Connector

(CN902)

6

Wire

5

Screw,

+BVTP

(3 × 8)

7

+BVTP

(3 × 8)

Four screws,

8

HCD-C700/C900

POWER boar

1

Connector

(CN905)

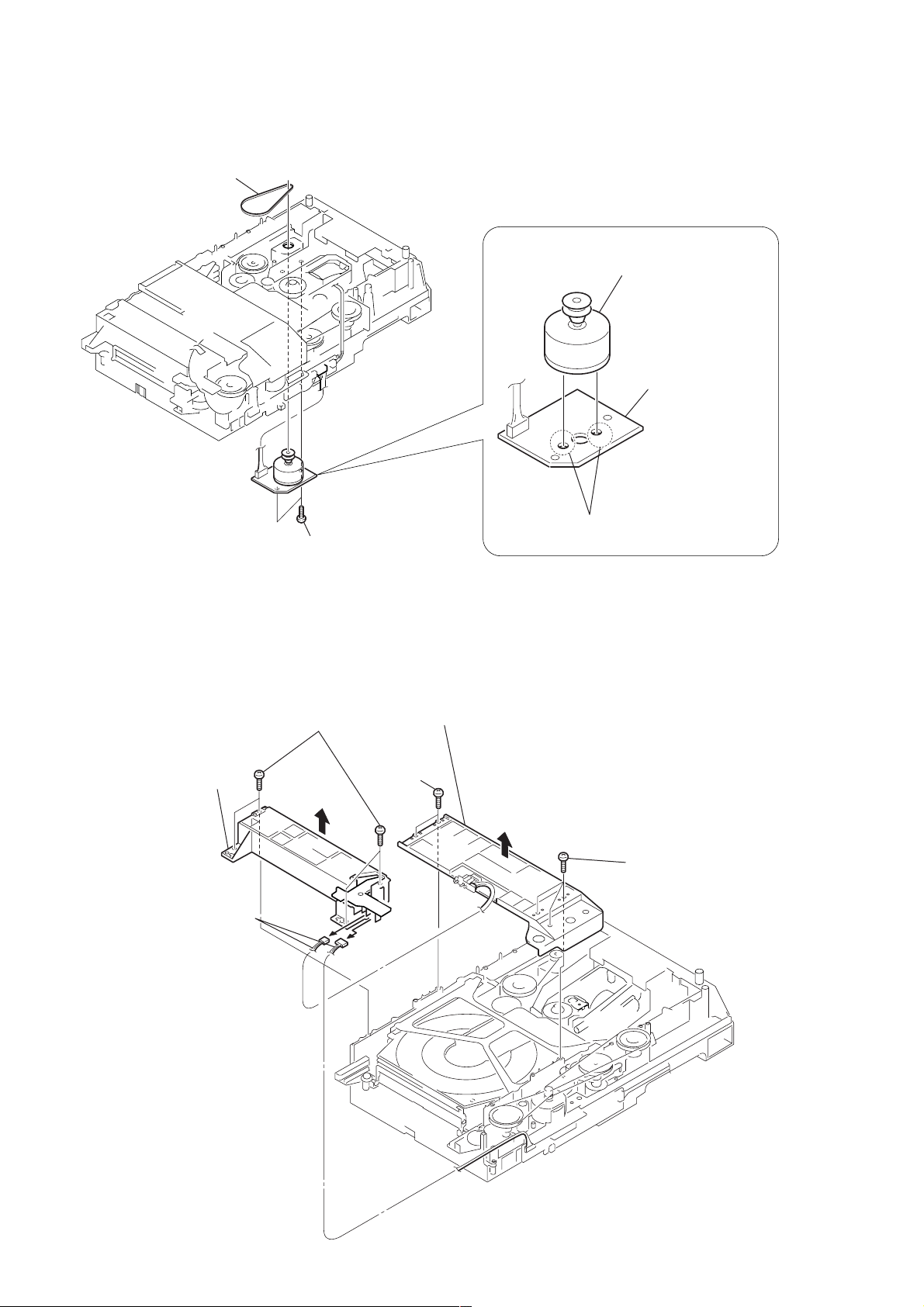

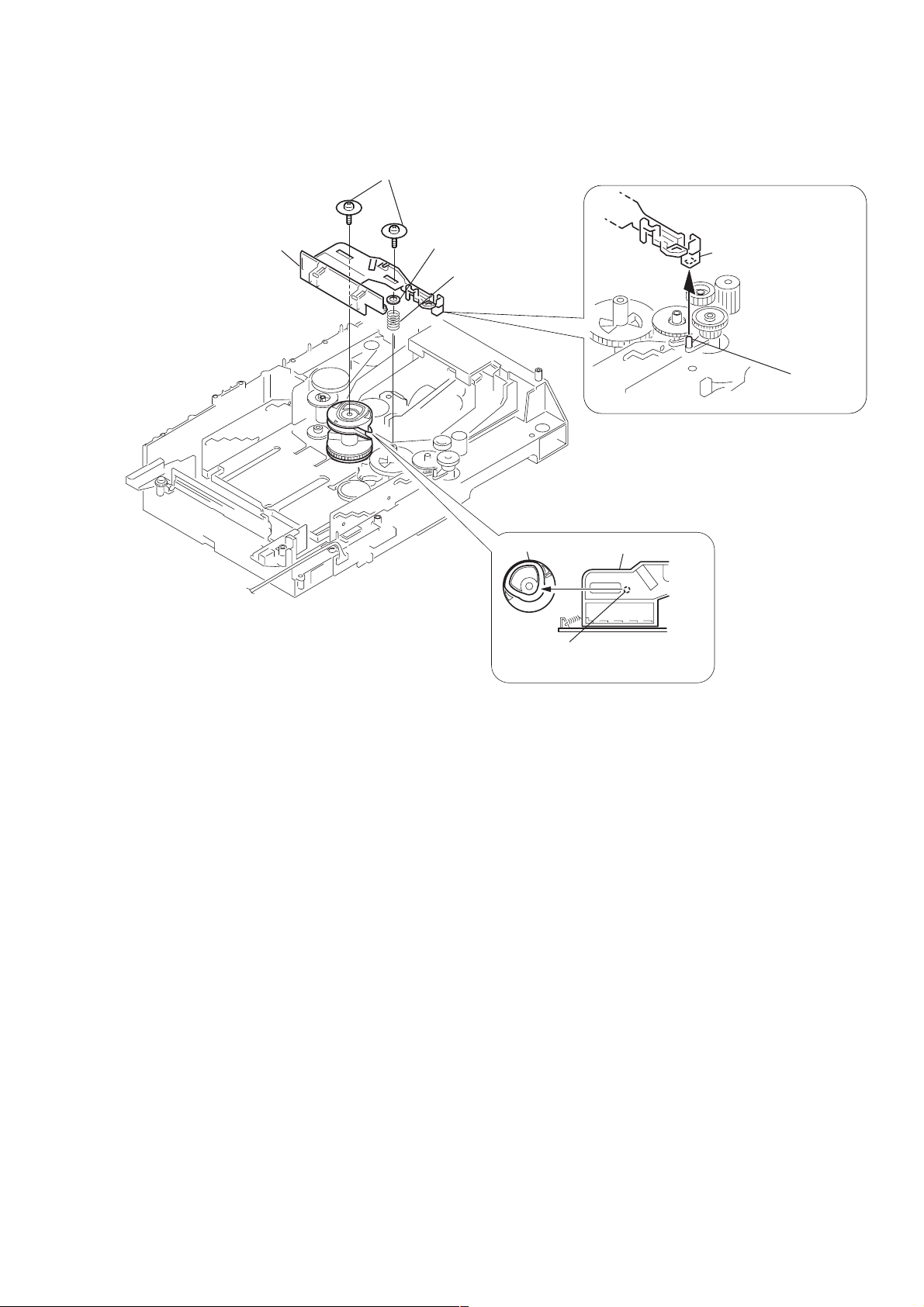

2.5. DVD MECHANISM DECK (CDM53K-DVBU7)

2

Two screws,

+BTP

(3 × 6)

HARNESS PROCESSING

MD cover

1

Two screws,

+BTP

(3 ×12)

5

+BVTP

(3 × 8)

4

Connector

(CN904)

4

MD cover

Four screws,

HARNESS PROCESSING

MD cover

Connector

(CN202)

9

Mechanism deck

(CDM53K-DVBU7)

3

Connector

(CN202)

8

Flexible flat cable

(9core) (CN004)

7

Flexible flat cable

(25core) (CN002)

6

Flexible flat cable

(17core) (CN701)

9

HCD-C700/C900

)

r

2-6. RF-240 BOARD

4

RF-240 board

1

Three screws

+BVTP

(2.6 × 8)

3

Flexible flat cable (9 core)

(CN003)

2

Flexible flat cable (26 core

(CN001)

2-7. FITTING BASE (MAGNET) ASSEMBLY

3

Fitting base (magnet)

assembly

2

Four screws

+BVTP

×

8)

(2.6

1

Connecto

(CN710)

10

2-8. DVD BASE UNIT (DVBU7)

)

2

DVD base unit

(DVBU7)

1

Two floating screws,

+

PTPWHM

(2.6 × 6

HCD-C700/C900

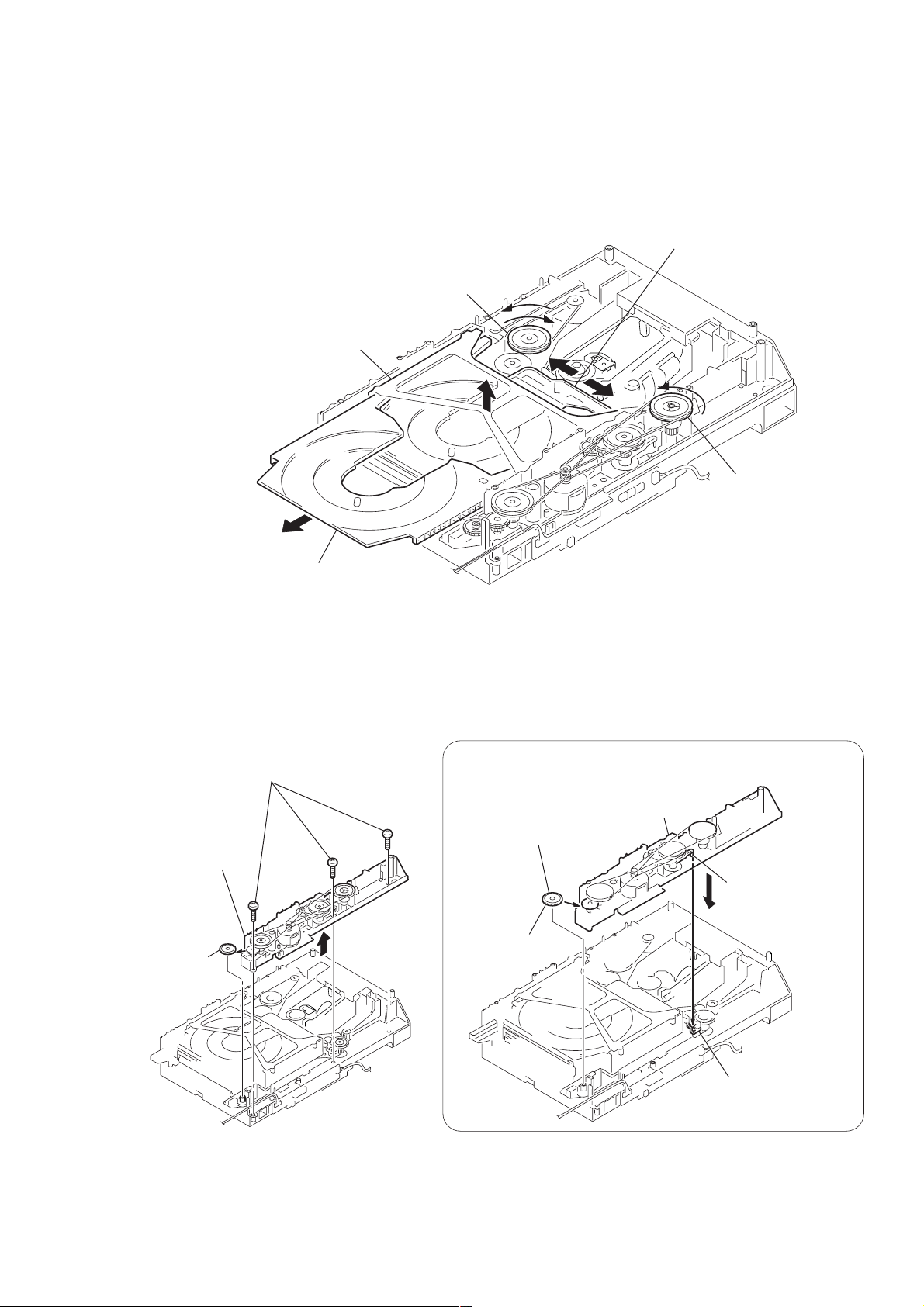

2-9. OPTICAL PICK-UP (KHM-240AAA)

1

2

Two step

screws (S)

Step screw (L)

6

3

Flexible flat cable

(26 core)

7

Three insulators

8

Optical pick-up

(KHM-240AAA)

5

Holder (240)

assembly

4

Flexible flat cable

(9 core)

11

HCD-C700/C900

2-10. CLAMP MOTOR BOARD, MOTOR (CLAMP) ASSEMBLY

1

Belt (mode)

5

Motor (clamp)

assembly (M701)

4

CLAMP MOTOR

board

2

Two screws

+BVTP

(2.6 × 8)

2-11. FITTING BASE (GUIDE) ASSEMBLY, BRACKET (CHASSIS)

2

3

Fitting base

(guide) assembly

1

Two connectors

(CN709, 715)

Four screws

+BVTP

(2.6 × 8)

4

Two screws

+BVTP

(2.6

6

Bracket

(chassis)

×

8)

3

Remove the two solderings

5

Three screws

+BVTP

(2.6

×

8)

12

2-12. TRAY (240)

1

Three screws

+BVTP

(2.6 × 8)

2

Insert the gear (eject)

under the gear (LD

deceleration).

1

Insert the portion A of

chassis (mold B) section

into the portion B of

slider (selection).

Gear (eject)

Portion A

Portion B of

slider (selection)

3

Gear (eject)

2

C

hassis (mold B)

section

C

hassis (mold B)

section

PRECAUTION DURING CHASSIS (MOLD B)

SECTION INSTALLATION

1

Rotating the pulley (LD), shift the slider (selection) in the arrow A direction.

2

Rotating the pulley (mode) in the arrow direction, adjust the tray (240) to be removed.

3

Rotating the pulley (LD), shift the slider (selection) in the arrow B direction.

4

Rotating the pulley (mode) in the arrow direction, remove the tray (240) to be removed.

HCD-C700/C900

Slider (selection)

Pulley (LD)

Stocker section

Tray (240)

2-13. CHASSIS (MOLD B) SECTION

A

B

Pulley (mode)

13

HCD-C700/C900

2-14. LOAD MOTOR BOARD, MOTOR (LOADING) ASSEMBLY

1

Belt (communication)

2

3

Belt (loading)

Belt (loading)

7

Motor (loading)

assembly (M702)

6

LOAD MOTOR

board

2-15. STOCKER SECTION

2

Two step screws (J)

4

Two screws

+BVTP

(2.6 × 8)

3

Stocker section

5

Remove the two solderings

PRECAUTION DURING STOCKER

SECTION INSTALLATION

Hook the portion A of tray (240)

to the slider (selection).

Portion A

of tray (240)

Sticking of

slider (selection)

14

1

Two step screws (J)

2-16. SLIDER (SELECTION), TENSION SPRING (SHUTTER), SLIDER (SHUTTER)

1

4

Slider (selection),

Tension spring (shutter),

Slider (shutter)

Two floating screws

+PTPWHM,

(2.6 x 6)

2

Washer, 8

3

Compression

spring (gear A)

PRECAUTION DURING SLIDER

(SELECTION) INSTALLATION (2)

HCD-C700/C900

Insert the slider (selection)

into the portion A.

Portion A

PRECAUTION DURING SLIDER

(SELECTION) INSTALLATION (1)

Gear (choking)

Insert a convex portion into

the groove of gear (chucking).

Slider (selection)

15

HCD-C700/C900

)

2-17. GEAR (GEAR A), GEAR (GEAR B), GEAR (U/D SLIDER)

6

Gear (gear B)

8

Gear (U/D slider)

7

Screw

+BVTP

(2.6 × 8)

5

Gear (gear A)

2

Washer

3

Compression spring

4

Gear (selection

1

Gear (relay)

PRECAUTION DURING GEAR (GEAR U/D SLIDER), GEAR (GEAR B), GEAR (GEAR A) INSTALLATION

3

Gear (gear B)

Portion A

Adjust the gear (gear B) with the

portion A as shown.

Slider (U/D)

1

Slide the slider (U/D)

fully in the arrow

direction.

2

Gear (U/D slider)

Slider (U/D) gear

4

Gear (gear A)

Gear

(gear B)

linearly

Adjust the gear so that it meshes with

the bottom tooth of slider (U/D) gear,

as shown.

16

Adjust so as to be aligned with

gear B linearly, as shown.

2-18. GEAR (CHUCKING)

HCD-C700/C900

PRECAUTION DURING

GEAR (CHUCKING) (2)

Rotary encoder

(S707)

Gear

(chucking)

NG

OK

Align with the slot of

rotary encoder.

PRECAUTION DURING

GEAR (CHUCKING) (1)

Rotary encoder (S707)

Align marking

2

1

3

Gear (chucking)

Rotary encoder (S707)

17

HCD-C700/C900

Ver 1.3 2003. 07

SECTION 3

TEST MODE

3-1. VERSION DISPLAY MODE

Procedure:

1. Press the A button on the main unit or ?/1 button on the

remote commander to turn the set on.

2. Press three buttons of FUNCTION , . PREV and A

(Disc 1) simultaneously for two seconds.

3. The message “VER. 1. XX ” is displayed for a moment.

3-2. JOG TEST MODE

Procedure:

1. Press the A button on the main unit or ?/1 button on the

remote commander to turn the set on.

2. Press three buttons of BAND , x and A (Disk 5) simul-

taneously.

3. The fluorescent indicator displays “JOG 0”. The value “JOG

0” increases like +1, +2, +3... if rotating the VOLUME knob

clockwisw,or it decreases like –1, –2, –3,.... if rotating counter-

clockwise.

4. To exit from this mode, press the POWER button to turn the

set off.

3-3. KEY TEST MODE

Procedure:

1. Press the A button on the main unit or ?/1 button on the

remote commander to turn the set on.

2. Press three buttons of DISPLAY , x and A (Disk 2) simul-

taneously.

3. The message “KEY NUM 0” is displayed and “0” blinks.

4. Each time a button is pressed, “KEY NUM 0” value increases.

However, once a button is pressed, it is no longer taken into

account.

5. When all buttons are pressed, “KEY NUM 20” appears and

the number blinking is stopped.

6. To exit from this mode, press the POWER button to turn the

set off.

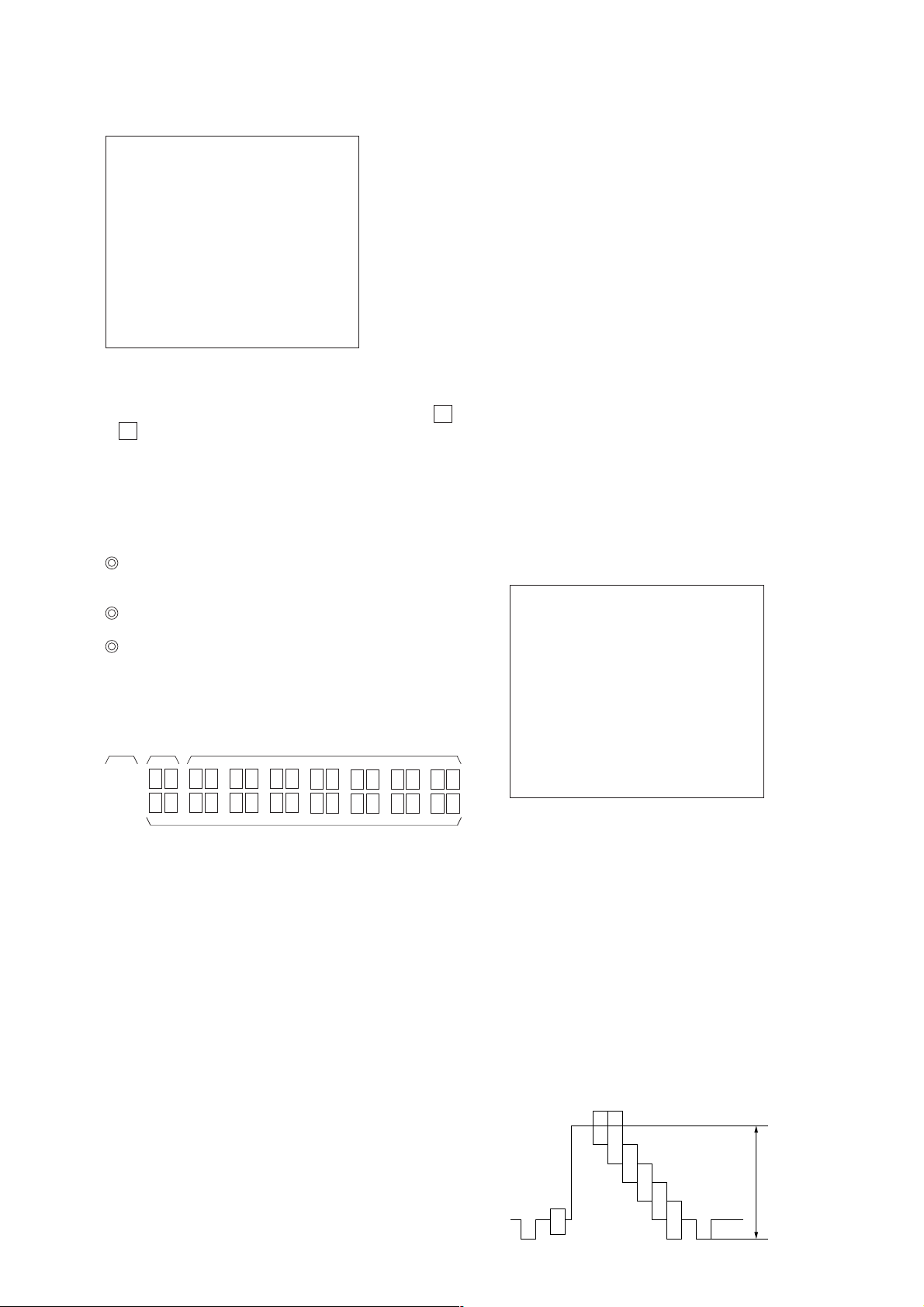

3-4. DISPLAY TEST MODE

Procedure:

1. Press the A button on the main unit or ?/1 button on the

remote commander to turn the set on.

2. Press three buttons of BAND , X and A (Disk 3) simul-

taneously.

3. All segments and five orange LEDs on the panel are turned on.

dts

D

D

ALL 1 DISCS AUTO TITLE TRACK CHAPTER INDEX HTUNED M MONO ST S

PRO LOGIC

DIGITAL FM AM

D

D

NTSC PBC ANGLE

4. When the NEXT > button is pressed, the display will light

up as follows. Five orange LEDs are still lit on.

ALL 1 DISCS AUTO TITLE TRACK CHAPTER INDEX HTUNED M MONO ST S

PRO LOGIC

DIGITAL FM AM

D

D

NTSC PBC ANGLE

5. Press the NEXT > button, confirm the display. Five orange

LEDs are turned off.

PCM

dB REPEAT 1

kHz PROGRAM

MHz SHUFFLE

dts

D

D

PCM

dB REPEAT 1

kHz PROGRAM

MHz SHUFFLE

3-5. OSD TEST MODE

Procedure:

1. Press the A button on the main unit or ?/1 button on the

remote commander to turn the set on.

2. Set the FUNCTION to DVD.

3. While pressing two buttons of DISPLAY and

x simultaneously, turn the VOLUME knob clockwise.

4. The Test Mode Menu is displayed on the TV screen.

5. To execute each function, select the number on the remote

commander.

6. See the following section for explanation in detail.

7. To exit from this mode, press the POWER button to turn the

set off.

3-6. DISC TRAY LOCK

Procedure:

1. Press the A button on the main unit or ?/1 button on the

remote commander to turn the set on.

2. Press two buttons of DISPLAY and . PREV

simultaneously for two seconds.

3. The message “LOCKED” is displayed and the tray is locked.

(Even if exiting from this mode, the tray is still locked.)

4. Press two buttons of DISPLAY and . PREV

simultaneously for two seconds again.

5. The message “UNLOCKED” is displayed and the tray is

unlocked.

6. To exit from this mode, press the POWER button to turn the

set off.

3-7. GENERAL DESCRIPTION

The Test Mode allows you to make diagnosis and adjustment easily

using the remote commander and monitor TV. The instructions,

diagnostic results, etc. are given on the on-screen display (OSD).

[TEST DISC LIST]

Use the following test disc on test mode.

1) DVD reference disc

HLX-501 (J-6090-071-A) (dual layer)

HLX-503 (J-6090-069-A) (single layer)

HLX-504 (J-6090-088-A) (single layer)

HLX-505 (J-6090-089-A) (dual layer)

2) SACD reference disc

HLXA-509 (J-6090-090-A)

Note:Do not use exiting test disc for DVD.

3-8. STARTING TEST MODE

Set the FUNCTION to DVD with the main unit power on. Next,

while pushing the x button and the [DISPLAY] button on the main

unit at the same time, turn the VOLUME knob to the right to start

Test Mode and display the menu shown below on the TV screen. At

the bottom of the menu screen, the model name and revision number

are displayed.

To execute each function, select the desired menu and press its

number on the remote commander. To exit from Test Mode, press

the [POWER] button.

Test Mode Menu

6. Press the NEXT > button, all segments are turned off.

7. Every pressing of the NEXT > button turns on each

segments in the same order.

8. To exit from this mode, press the POWER button to turn the

set off.

18

0. Syscon Diagnosis

1. Drive Auto Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Version Information

6. Video Level Adjustment

Exit: POWER Key

_

Model : HCX-1089_xx

Revision: 1.xxx Last Off:01

HCD-C700/C900

3-9. SYSCON DIAGNOSIS

The same contents as board detail check by serial interface can be

checked from the remote commander.

On the Test Mode Menu screen, press [0] key on the remote

commander, and the following check menu will be displayed.

### Syscon Diagnosis ###

Check Menu

0. Quit

1. All

2. Version

3. Peripheral

4. Servo

5. Supply

6. AV Decoder

7. Video

8. Audio

9. DSD Decoder

_

0. Quit

Quit the Syscon Diagnosis and return to the Test Mode Menu.

1. All

All items continuous check

This menu checks all diagnostic items continuously. Normally, all

items are checked successively one after another automatically

unless an error is found, but at a certain item that requires judgment

through a visual check to the result, the following screen is displayed

for the key entry.

### Syscon Diagnosis ###

Diag All Check

No. 2 Version

2-3. ROM Check Sum

Check Sum = 2005

Press x key to quit the diagnosis, or [PREV] key to repeat the

same item where an error occurred, or

[NEXT] key to continue the

check from the item next to faulty item.

Selecting 2 and subsequent items calls the submenu screen of each

item.

For example, if “5. Supply” is selected, the following submenu will

be displayed.

### Syscon Diagnosis ###

0. Quit

1. All

2. ARP Register Check

3. ARP to RAM Data Bus

4. ARP to RAM Address Bus

5. ARP RAM Check

_

Check Menu

No. 5 Supply

0. Quit

Quit the submenu and return to the main menu.

1. All

All submenu items continuous check

This menu checks 2 and subsequent items successively . At the item

where visual check is required for judgment or an error occurred,

the checking is suspended and the message is output for key entry .

Normally, all items are checked successively one after another

automatically unless an error is found.

Selecting 2 and subsequent items executes respective menus and

outputs the results.

For the contents of each submenu, see “Check Items List”.

Press NEXT Key to Continue

Press PREV Key to Repeat

_

For the ROM Check, the check sum calculated by the Syscon is

output, and therefore you must compare it with the specified value

for confirmation.

Following the message, press [NEXT] ke y to go to the next item, or

[PREV] key to repeat the same check again. To quit the diagnosis

and return to the Check Menu screen, press x or [ENTER] key. If

an error occurred, the diagnosis is suspended and the error code is

displayed as shown below.

### Syscon Diagnosis ###

3-3. EEPROM Check

Error 03: EEPROM Write/Reed N

Address : 00000001

Write Data : 2492

Read Data : 2490

Press NEXT Key to Continue

Press PREV Key to Repeat

_

General Description of Checking Method

2. Version

(2-2) Revision

ROM revision number is displayed.Error: Not detected.

The revision number defined in the source file of ROM (At

the beginning of mass production, the Flash ROM of IC107

is used, but midway it is replaced by the IC108 O TP R OM.

IC107 or IC108) is displayed with four digits.

Below IC107 are all IC107 or IC108.

(2-3) ROM Check Sum

Check sum is calculated.

Error: Not detected.

The 8-bit data are added at addresses 0x000F0000 ~

0x002EFFFF of ROM (IC107) and the result is displayed

with 4-digit hexadecimal number. Error is not detected.

Compare the result with the specified value.

(2-4) Model Type

Model code is displayed.

Error: Not detected.

The model code read from EEPROM (IC101) is displayed

with 2-digit hexadecimal number.

(2-5) Region

Region code is displayed.

Error: Not detected.

The region code determined from the model code is displayed.

19

HCD-C700/C900

3. Peripheral

(3-2) EEPROM Check

Data write → read, and accord check

Error 03: EEPROM write/read discord

Data 0x9249, 0x2942, 0x4294 are written to addresses

0x00~0xFF of EEPROM (IC101), then read and checked.

Before writing, the data are saved, then after checking, they

are written to restore the contents of EEPROM.

4. Servo

(4-2) Servo DSP Check

Data write → read, and accord check

Error 12: Read data discord

Data 0x9249, 0x2942, 0x4294 are written to the address

0x602 of RAM in the Servo DSP (IC302), then read and

checked.

(4-3) DSP Driver Test

Test signal data → DSP Driver

Error: Not detected.

Caution: Do not conduct this test with a mechanical deck

connected.

The maximum voltage is applied to the Servo Driver IC

(IC401, IC802). If mechanical deck is connected, the motor and optics could be damaged. Disconnect mechanical

deck following the output message, then enter specified 4or 5-digit number from the remote commander, and press

the [ENTER]. The test is conducted only when the input

data accord. Check the output level, then press the [NEXT]

to finish the test.

This test is skipped if “All” is selected.

Supplement: How to disconnect mechanical deck

Disconnect flat cables connected to the CN009 and CN010

of MB-82/85 board. Also, disconnect harness from the

CN201.

(5-3) ARP to RAM Data Bus

Data write → read, and accord check

Error 09: ARP ←→ RAM data bus error

Data 0x0001 to 0x8000 where one bit each is set to 1 are

written to the address 0 of RAM (IC303) connected to the

ARP (IC302) through the bus, then they are read and

checked. In case of discord, written bit pattern and read

data are displayed. If data where multiple bits are 1 are

read, the bits concerned may touch each other. Further, if

data where certain bit is always 1 or 0 regardless of written

data, the line could be disconnected or shorted.

(5-4) ARP to RAM Address Bus

Data write → other address read discord check

Error 10: ARP → RAM address bus error

Caution: Address and data display in case of an error is

different from the display of other diagnosis (de-

scribed later).

Before starting the test, all addresses of RAM (IC303) are

cleared to 0x0000.

First, 0xA55A is written to the address 0x00000, and the

address data are read and checked from addresses 0x00001

to 0x80000 while shifting 1 bit each. Next, the data at that

address is cleared, and it is written to the address 0x00001,

and read and checked in the same manner. This check is

repeated up to the address 0x80000 while shifting the address data by 1 bit each.

If data other than 0 is read at the addresses except written

address, an error is given because all addresses were already cleared to 0. In this check, the error display pattern is

different from that of other diagnosis; read data, written

address, and read address are displayed in this order. Ho wever, the message uses same template, and accordingly exchange Address and Data when reading. The following display, for example,

### Syscon Diagnosis ###

5. Supply

Caution: Do not conduct this check with a mechanical deck

connected.

An access is made to the stream supply and servo control

IC (IC302) and external RAM (IC303) using check data.

If mechanical deck is connected, the motor and optics

could be damaged. This check is also executed by the “All”

menu item.

Supplement: How to disconnect mechanical deck

Disconnect flat cables connected to the CN009 and

CN010 of DVD board. Also, disconnect harness from

the CN201.

(5-2) ARP Register Check

Data write → read, and accord check

Error 08: ARP register write, and read data discord

Data 0x00 to 0xFF are written to the TMAX register (address 0xC6) in ARP (IC302), then they are read and check ed.

5-4. ARP to RAM Address Bus

Error 10: ARP - RAM Address B

Address : 0000A55A

Write Data : 00000000

Read Data : 00080000

Press NEXT Key to Continue

Press PREV Key to Repeat

_

shows the data 0xA55A was read from address 0x00080000

though it was written to the address 0x00000000. This implies that these addresses are in the form of shadow. Also,

if the read data is not 0xA55A, another error will be present.

(5-5) ARP RAM Check

Data write → read, and accord check

Error 11: ARP RAM read data discord

The program code data stored in ROM are copied to all

areas of RAM (IC303) connected to the ARP (IC302)

through the bus, then they are read and checked if they accord. If the detail check was selected initially, the data are

written to all areas and read, then the same test is conducted

once again with the data where all bits are inverted between

1 and 0. If discord is detected, faulty address, written data,

and read data are displayed following the error code 11,

and the test is suspended.

20

HCD-C700/C900

6. AV Decoder

(6-2) 1930 RAM

Data write → read, and accord check

Error 13: AVD RAM read data discord

The program code data stored in ROM (IC107 or IC108)

are copied to all areas oo»RAM (IC504, IC505) connected

to the AVD (IC503) through the bus, then they are read and

checked if they accord. Further, the same test is conducted

once again with the data where all bits are inverted between

1 and 0. If discord is detected, faulty address, written data,

and read data are displayed following the error code 13,

and the test is suspended.

(6-3) 1930 SP

ROM → AVD RAM → Video OUT

Error: Not detected.

The data including sub picture streams in ROM (IC107 or

IC108) are transferred to the RAM (IC504, IC505) in AVD

(IC503), and output as video signals from the AVD (IC503).

They are output from all video terminals (Composite, Y/C).

7. Video

(7-2) Color Bar

AVD color bar command write → Video OUT

Error: Not detected.

The command is transferred to the AVD, and the color bar

signals are output from video terminals.

They are output from all video terminals (Composite, Y/C).

Check Items List

2) Version

(2-2) Revision

(2-3) ROM Check Sum

(2-4) Model Type

(2-5) Region

3) Peripheral

(3-2) EEPROM Check

4) Servo

(4-2) Servo DSP Check

(4-3) DSP Driver Test

5) Supply

(5-2) ARP Register Check

(5-3) ARP to RAM Data Bus

(5-4) ARP to RAM Address Bus

(5-5) ARP RAM Check

6) AV Decoder

(6-2) 1930 RAM

(6-3) 1930 SP

7) Video

(7-2) Color Bar

(7-3) Composit Out

(7-4) Y/C Out

(7-6) Component Out

(7-3) Composit Out

(7-4) Y/C Out

(7-6) Component Out

8. Audio

(8-2) ARP → 1930

Error 14 : ARP → 1930 video NG

15 : ARP → 1930 audio NG

(8-3) Test Tone

All channels

2ch Left

2ch Right

Front Left

Front Right

Rear Left

Rear Right

Center

Sub Woof er

9. DSD Decoder

(9-2) 2752 ID Chack

(9-3) 2752 RAM Check

8) Audio

(8-2) ARP → 1930

(8-3) Test Tone

9) DSD Decoder

(9-2) 2752 ID Check

(9-3) 2752 RAM Check

Error Codes List

00: Error not detected

01: RAM write/read data discord

02: Gate array NG

03: EEPROM NG

08: ARP register read data discord

09: ARP ←→ RAM data bus error

10: ARP ←→ RAM address bus error

11: ARP RAM read data discord

12: Servo DSP NG

13: 1930 SDRAM NG

14: ARP → 1930 video NG

15: ARP → 1930 audio NG

16: 1910 UCODE download NG

17: System call error (function not supported)

18: System call error (parameter error)

19: System call error (illegal ID number)

20: System call error (time out)

90: Error occurred

91: User verification NG

92: Diagnosis cancelled

21

HCD-C700/C900

Ver 1.2 2003. 05

3-10. DRIVE AUTO ADJUSTMENT

On the Test Mode Menu screen, press [1] key on the remote

commander, and the drive auto adjustment menu will be displayed.

## Drive Auto Adjustment ##

Adjustment Menu

0. ALL

1. DVD-SL

2. CD

3. DVD-DL

4. LCD

Exit: RETURN

Normally, [0] is selected to adjust DVD (single layer), CD, DVD

(dual layer), and SACD in this order. But, individual items can be

adjusted for the case where adjustment is suspended due to an error.

In this mode, the adjustment can be made easily through the

operation following the message displayed on the screen.

The disc used for adjustment must be the one specified for

adjustment. However, for SACD disc, use the player with initial

data if the disc is not available.

Note: After parts related to the servo circuit (RF amplifier, DSP, motor

driver, EEPROM (IC302) so on) are replaced, re-adjusting the servo

circuit is necessary. Select “ALL” at “DRIVE AUTO

ADJUSTMENT ” and adjust DVD-SL (single layer), CD and DVDDL (dual layer).

0. ALL

Select [0] and press [ENTER] key, and the servo set data in

EEPROM will be initialized. Then, 1. DVD-SL disc, 2. CD disc, 3.

DVD-DL disc, and 4. SACD disc are adjusted in this order. Each

time one disc was adjusted, it is ejected. Replace it with the specified

disc following the message. Though the message to confirm whether

discs other than SACD disc are adjusted is not displayed, you can

finish the adjustment if pressing the x button. During adjustment

of each disc, the measurement for disc type judgment is made. As

automatic adjustment does not judge the disc type unlike

conventional models, take care not to insert wrong type discs. Also,

do not give a shock during adjustment.

1. DVD-SL (single layer)

Select

[1], insert DVD single layer disc, and press [ENTER] key,

and the adjustment will be made through the following steps, then

adjusted values will be written to the EEPROM.

DVD Single Layer Disc Adjustment Steps

1. SLED TILT Reset

2. Disc Check Memory SL

3. Wait 300 msec

4. Set Disc Type SL

5. LD ON

6. Spdl Start

7. Wait 1 sec

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. CLVA ON

11. Wait 500 msec

12. Tracking ON

13. Wait 1 sec

14. Sled ON

15. Check CLV Lock

16. Auto LFO Adjust

17. Auto Focus Offset Adjust

18. Auto Tilt Position Adjust

19. Auto Focus Gain Adjust

20. Auto Focus Offset Adjust

21. EQ Boost Adjust

22. Auto LFO Adjust

23. Auto Track Gain Adjust, Search Check

24. 32Tj Fwd

25. 32Tj Rev

26. 500Tj Fwd

27. 500Tj Rev

28. All Servo Stop

29. Eep Copy Loop Filter Offset

22

HCD-C700/C900

2. CD

Select [2], insert CD disc, and press [ENTER] key, and the

adjustment will be made through the following steps, then adjusted

values will be written to the EEPROM.

CD Adjustment Steps

1. Sled Tilt Rest

2. Disc Check Memory CD

3. Wait 500 msec

4. Set Disc Type CD

5. LD ON

6. Spdl Start

7. Wait 500 msec

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. CLVA ON

11. Wait 500 msec

12. Tracking ON

13. (TC Display Start)

14. Wait 1 sec

15. Jitter Display Start

16. Sled ON

17. Check CLV ON

18. Auto LFO Adjust

19. Auto Focus Offset Adjust

20.

21. Auto Focus Gain Adjust

22. Auto Focus Offset Adjust

23. Eq Boost Adjust

24. Auto LFO Adjust

25. Auto Track Gain Adjust, Search Check

26. 32Tj Fwd

27. 32Tj Rev

28. 500Tj Fwd

29. 500Tj Rev

30. All Servo Stop

3. DVD-DL (dual layer)

Select [3], insert D VD dual layer disc, and press [ENTER] ke y , and

the adjustment will be made through the following steps, then

adjusted values will be written to the EEPROM.

DVD Dual Layer Disc Adjustment Steps

1. Sled Tilt Reset

2. Disc Check Memory DL

3. Wait 500 msec

4. Set Disc Type DL

5. LD ON

6. Spdl Start

7. Wait 1 sec, Layer 1 Adjust

8. Focus Servo ON 0

9. Auto Track Offset Adjust

10. Clva ON

11. Wait 500 msec

12. Tracking ON

13. Wait 500 msec

14. Sled ON

15. Check CLV Lock

16. Auto Loop Filter Offset Auto Focus Adjust

17.

18. Auto Focus Gain Adjust

19. Auto Focus Offset Adjust

20. Eq Boost Adjust

21. Auto Loop Filter Offset

22. Auto Track Gain Adjust, Search Check

23. 32Tj Fwd

24. 32Tj Rev

25. 500Tj Fwd

26. 500Tj Rev, Layer 0 Adjust

27. Fj (L1 -> L0)

28. Auto Track Offset Adjust L0

29. Clva ON

30. Wait 500 msec

31. Tracking ON

32. Wait 500 msec

33. Sled ON

34. Check CLV Lock

35. Auto Focus Filter Offset

36. Auto Focus Adjust

37.

38. Auto Focus Gain Adjust

39. Auto Focus Offset Adjust

40. Eq Boost Adjust

41. Auto Loop Filter Offset

42. Auto Track Gain Adjust, Search Check

43. 32Tj Fwd

44. 32Tj Rev

45. 500Tj fwd

46. 500Tj Rev, Layer Jump Check

47. Lj (L0 -> L1)

48. Lj (L1 -> L0)

49. All Servo Stop

23

HCD-C700/C900

4. LCD

Select [4], insert SACD disc, and press [ENTER] key, and the

adjustment will be made through the following steps, then adjusted

values will be written to the EEPROM. However, if SACD disc is

not available, use the player with initial data, skipping the SACD

adjustment. In this case, you can finish the adjustment if pressing

the x button.

SACD Adjustment Steps

1. Sled Tilt Reset

2. Set Disc Type CD

3. LD ON

4. Spdl Start

5. Wait 500 msec

6. Focus Servo ON 0

7. Auto track Offset Adjust

8.

9. CLVA ON

10. Wait 500 msec

11. Tracking ON

12. Wait 1 sec

13. Sled ON

14. Check CLV ON

15. Auto Focus Offset Adjust

17.

18. Auto Focus Gain Adjust

19. Auto Focus Offset Adjust

20. Eq Boost Adjust

21. Auto LFO Adjust

22. Auto Track Gain Adjust

23. 32Tj Fwd

24. 32Tj Rev

25. 500Tj Fwd

26. 500Tj Rev

3-11. DRIVE MANUAL OPERATION

On the T est Mode Menu screen, select [2], and the manual operation

menu will be displayed. For the manual operation, each servo on/

off control and adjustment can be executed manually.

## Drive Manual Operation ##

Operation Menu

1. Disc type

2. Servo Control

3. Track/Layer Jump

4. Manual Adjustment

5. Auto Adjustment

6. Memory Check

7. Sacd Water Mark

0. Disc Check Memory

_

Exit: Return

In using the manual operation menu, take care of the following

points. These commands do not provide protection, thus requiring

correct operation. The sector address or time code field is displayed

when a disc is loaded.

1. Set correctly the disc type to be used on the Disc Type

screen.

The disc type must be set after a disc was loaded.

The set disc type is cleared when the tray is opened.

2. After power ON, if the Drive Manual Operation was

selected, first perform “Reset SLED TILT” by opening 1.

Disc Type screen.

3. In case of an alarm, immediately press the x button to

stop the servo operation, and turn the power OFF.

Basic operation (controllable from front panel or remote

commander)

27. All Servo Stop */

[POWER] Power OFF

x Servo stop

[OPEN/CLOSE] Stop+Eject/Loading

[RETURN] Return to Opera tion Menu or Test Mode

Menu

[NEXT], [PREV] Transition between sub modes of menu

[1] to [9], [0] Selection of menu items

Cursor UP/DOWN Increase/Decrease in manually adjusted

value

24

HCD-C700/C900

0. Disc Check Memory

Disc Check

1. SL Disc Check

2. CD Disc Check

3. DL Disc Check

0. Reset SLED TILT

_

On this screen, the mirror time is measured to judge the disc and it

is written to the EEPROM. First load DVD SL disc and press [1],

next load CD disc and press [2], and finally load D VD DL disc and

press [3].

The adjustment must be executed more than once after default data

were written. External vibration or shock to the player must not be

given. Reference value for D VD is from 10 to 20, and for CD, from

28 to 4F.

Check that the value of CD is larger than that of DVD.

When those values are beyond a range perform this adjustment again.

From this screen, you can go to another mode by pressing [NEXT]

or [PREV] key, but you cannot enter this mode from another mode.

You can enter this mode from the Operation Menu screen only.

1. Disc Type

Disc Type

1. Disc Type Auto Check

2. DVD SL 12 cm

3. DVD DL 12 cm

4. CD 12cm

5. LCD 12 cm

6. DVD SL 8 cm

7. DVD DL 8 cm

8. CD 8 cm

9. LCD 8 cm

0. Reset SLED TILT

EMG. 00

1. Disc Type Auto Check

Disc Type

2. DVD SL 12 cm

3. DVD DL 12 cm

4. CD 12cm

5. LCD 12 cm

6. DVD SL 8 cm

7. DVD DL 8 cm

8. CD 8 cm

9. LCD 8 cm

0. Reset SLED TILT

TC. : : EMG. 00

CD 12 cm

Display when CD 12cm disc was selected

[0] Reset SLED TIL T Reset the Sled and Tilt to initial position.

[1] Disk Type Check Judge automatically the loaded disc. As

the judged result is displayed at the

bottom of screen, make sure that it is

correct.

If Disc Check Memory menu has not

been executed after EEPROM default

setting, the disc type cannot be judged.

In this case, return to the initial menu

and make a check for three types of discs

(SL, DL, CD).

[2] to [9] Select the loaded disc. The adjusted

value is written to the address of selected

disc. No further entry is necessary if [1]

was selected.

2. Servo Control

Servo Control

1. LD Off R.Sled FWD

2. SP Off L.Sled REV

3. Focus Off

4. TRK. Off

5. Sled Off

6. CLVA Off

7. FCS. Srch Off

On this screen, select the disc type. T o select the disc type, press the

number of the loaded disc. The selected disc type is displayed at the

bottom. Selecting [1] automatically selects and displays the disc

type. In case of wrong display, retry “Disc Check Memory”. Also,

opening the tray causes the set disc type to be cleared. In this case,

set the disc type again after loading.

In performing manual operation, the disc type must be set.

Once the disc type has been selected, the sector address or time

code display field will appear as shown below. These values are

displayed when PLL is locked.

Disc Type

1. Disc Type Auto Check

2. DVD SL 12 cm

3. DVD DL 12 cm

4. CD 12cm

5. LCD 12 cm

6. DVD SL 8 cm

7. DVD DL 8 cm

8. CD 8 cm

9. LCD 8 cm

0. Reset SLED TILT

SA. SI. EMG. 00

DVD SL 12 cm

Display when DVD SL 12cm disc was selected

0. Reset SLED TILT

SA. SI. EMG. 00

DVD SL 12 cm

On this screen, the servo on/off control necessary for replay is

executed. Normally, turn on each servo from 1 sequentially and

when CLVA is turned on, the usual trace mode becomes active. In

the trace mode, DVD sector address or CD time code is displayed.

This is not displayed where the spindle is not locked.

The spindle could run overriding the control if the spindle system is

faulty or RF is not present. In such a case, do not operate CLVA.

25

HCD-C700/C900

[0] Reset SLED TIL T Reset the Sled and Tilt to initial position.

[1] LD Turn ON/OFF the laser.

[2] SP Turn ON/OFF the spindle.

[3] Focus Search the focus and turn on the focus.

[4] TRK Turn ON/OFF the tracking servo.

[5] Sled Turn ON/OFF the sled servo.

[6] CLVA Turn ON/OFF normal servo of spindle

servo.

[7] FCS. Srch Apply same voltage as that of focus

search to the focus drive to check the

focus drive system.

→ Sled FWD Move the sled outward. Perform this

operation with the tracking servo turned

off.

← Sled REV Move the sled inward. Perform this

operation with the tracking servo turned

off.

↑ Tilt UP Move the tilt upward.

↓ Tilt DOWN Move the tilt downward.

The following menus are normally not used.

3. Track/Layer Jump

4. Manual Adjustment

5. Auto Adjustment

The persons who do not know well about these menus should not

use them.

6. Memory Check

EEPROM Data1

-– DL – CD LCD SL L0 L1

Focus Gain xx xx xx xx xx

TRK. Gain xx xx xx xx xx

FCS Balance xx xx xx xx xx

Focus Bias xx xx xx xx xx

TRV. Offset xx xx xx xx xx

L. F. Offset xx xx xx xx xx

EQ Boost xx xx xx xx xx

Mirror Time xx xx xx xx xx

_DOWN: Next Data

CLEAR: Default Set page.1/2

EEPROM Data1

-– DL – CD LCD SL L0 L1

RF Jitter xx -- xx xx xx

RF Level xx -- xx -- -FE Level xx -- xx -- -FE Balance xx -- xx -- -TRV. Level xx -- xx -- -Analog FRSW xx xx xx xx xx

PLL DacGain xx xx xx xx xx

_

UP : Prev Data

CLEAR: Default Set page.2/2

This screen displays current servo adjusted data stored in the

EEPROM. Though adjusted data can be initialized with the [CLEAR]

key, they cannot be restored after initialization.

So, before clearing, make a note of the adjusted data.

For reference, the drive has been designed so that the gain center

value is 20 and offset v alue is 80. Other v alues will be in a range of

10 to 80. If extreme value such as 00 or FF is set, adjustment will be

faulty . In such a case, check for disc scratch or cable disconnection,

then perform adjustment again.

7. Sacd Water Mark

4-12. MECHA AGING

### Aging Test MENU ###

Operation Menu

1.Changer Open/Close Test

2.Changer Exchange Test

_

Exit: RETURN

On the T est Mode Menu Screen, selecting [3] e xecutes the aging of

the mechanism. Start aging with PLAY. During aging, the repeat

cycle is displayed. Aging can be aborted at any time by pressing the

x key. After the operation is stopped, press the [RETURN] key

again to return to the Test Mode Menu.

26

HCD-C700/C900

3-13. EMERGENCY HISTORY

### EMG. History ###

Laser Hours CD xxxxxxxh

DVD xxxxxxxh

1. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

2. 00 00 00 00 00 00 00 00

00 00 00 00 00 00 00 00

Select: 1 – 9 Scroll: UP/DOWN

(1: Last EMG.) Exit: RETURN

On the Test Mode Menu screen, selecting [4] displays the

information such as servo emergency history. The history

information from last 1 up to 10 can be scrolled with ↑key

or↓key. Also, specific information can be displayed by directly

entering that number with ten keys.

The upper two lines display the laser ON total hours. Data below

minutes are omitted.

Clearing History Information

Clearing laser hours

Press [DVD DISPLAY] and [CLEAR] keys in this order.

Both CD and DVD data are cleared.

Clearing emergency history

Press [TITLE] and [CLEAR] keys in this order.

Initializing set up data

Press [DVD MENU] and [CLEAR] keys in this order.

The data have been initialized when “Set Up Initialized” message

is displayed. The EMG. History screen will be restored soon.

How to see Emergency History

34: Focus gain adjustment error

35: Tilt servo adjustment error

36: RF equalizer adjustment error

37: RF group delay adjustment error

38: Jitter value after adaptive servo operation is too large.

40: Focus servo does not operate.

41: With a dual layer (DL) disc, focus jump failed.50: CLV

(spindle) servo does not operate.

51: Spindle does not stop.

60: With a DVD disc, Syscon made a request to seek nonexistent

address.

61: With a CD disc, Syscon made a request to seek nonexistent

address.

62: With a CD disc, Syscon made a request to seek nonexistent

track No. and index No.

63: With a DVD disc, seeking of target address failed.

64: With a CD disc, seeking of target address failed.

65: With a CD disc, seeking of target index failed.

70: W ith a D VD disc, physical information data could not be read.

71: With a CD disc, TOC data could not be read.

80: Disc type judgment failed.

81: As disc type judgment failed, retry was repeated.

82: As disc type judgment failed, a measurement error occurred.

83: Disc type could not be judged within the specified time.

84: Illegal command code was received from Syscon.

85: Illegal command was received from Syscon.

3-14. VERSION INFORMATION

## Version Information ##

IF con. Ver: x. xxx (xxxx)

Group 00

SYScon. Ver: x. xxx (xxxx)

Model xx

Region 0x

31.12

2

1 : Emergency Code

2 : Don’t Care

These codes are used for verification of software designing.

3 : Historical order 1 to 9

Emergency Codes List

10: Communication to IC001 (RF-240 board) failed.

11: Each servo for focus, tracking, and spindle is unlocked.

12: Communication to EEPROM, IC101 (DVD board) failed.

13: Writing of hours meter data to EEPR OM, IC101 (D VD board)

failed.

14: Communication to Servo DSP IC302 (DVD board) failed, or

Servo DSP is faulty.

20: Initialization of tilt servo and sled servo failed. They are not

placed in the initial position.

21: Tilt servo operation error

Syscon made a request to move the tilt servo to wrong position.

22:

23: Sled servo operation error

24:

Syscon made a request to move the sled servo to wr ong position.

30: Tracking balance adjustment error

31: Tracking gain adjustment error

32: Focus balance adjustment error

33: Focus bias adjustment error

Servo DSP Ver:X.XXX

OPT Type:2 Laser

Exit: RETURN

On the Test Mode Menu screen, selecting [5] displays the ROM

version and region code.

The parenthesized hexadecimal number in version field is checksum

value of ROM.

3-15. VIDEO LEVEL ADJUSTMENT

On the Test Mode Menu screen, selecting [6] displays color bars

for video level adjustment. During display of color bars, OSD

disappears but the menu screen will be restored if pressing any key.

Measurement point : MONITOR OUT VIDEO

(75 Ω terminating resistance)

Measuring instrument : Oscilloscope

Adjustment device : RV501 on DVD board

Specified value :1.0 ± 0.02 Vpp

1.0 ± 0.02 Vp-p

27

HCD-C700/C900

SECTION 4

ELECTRICAL ADJUSTMENT

In making adjustment, refer to 5-2. Adjustment

Related Parts Arrangement.

Note: During diagnostic check, the characters and color bars can

be seen only with the NTSC monitor. Therefore, for

diagnostic check, use the monitor that supports both NTSC

and PAL modes

This section describes procedures and instructions necessary for

adjusting electrical circuits in this set.

Instruments required:

1) Color monitor TV

2) Oscilloscope 1 or 2 phenomena, band width over 100 MHz,

with delay mode

3) Frequency counter (over 8 digits)

4) Digital voltmeter

5) Standard commander

* RM-SS800 (1-418-838-11)

6) DVD reference disc

HLX-501 (J-6090-071-A) (dual layer)

HLX-503 (J-6090-069-A) (single layer)

HLX-504 (J-6090-088-A) (single layer)

HLX-505 (J-6090-089-A) (dual layer)

7) SACD reference disc

HLXA-509 (J-6090-090-A)

4-1. ADJUSTMENT OF VIDEO SYSTEM

1. Video Level Adjustment (DVD BOARD)

<Purpose>

This adjustment is made to satisfy the NTSC standard, and if not

adjusted correctly, the brightness will be too large or small.

Mode Video level adjustment in test mode

Signal Color bars

Test point

Instrument Oscilloscope

Adjusting element RV501

Specification 1.0 ± 0.02 Vp-p

Adjusting method:

1) In the test mode initial menu “6” Video Level Adjustment, set

so that color bars are generated.

2) Adjust the RV501 to attain 1.0 ± 0.02 Vp-p.

MONITOR OUT (VIDEO) connector

(75 Ω terminated)

1.0 ± 0.02 Vp-p

* Use only the designated remote control when adjusting this

system component.

Figure 5-1

2. S-terminal Output Check

<Purpose>

Check S-terminal video output. If it is incorrect, pictures will not

be displayed correctly in spite of connection to the TV with a Sterminal cable.

Mode

Signal Color bars

Test point

Instrument Oscilloscope

Specification 1.0 ± 0.1 Vp-p

Checking method:

1) In the test mode initial menu “6” Video Level Adjustment, set

so that color bars are generated.

2) Confirm that the S-Y level is 1.0 ± 0.1 Vp-p.

Video level adjustment in test mode

S VIDEO OUT (S-Y) connector

(75 Ω terminated)

1.0 ± 0.1 Vp-p

28

Figure 5-2

HCD-C700/C900

3. Checking S Video Output S-C (DVD BOARD)

<Purpose>

This checks whether the S-C satisfies the NTSC Standard. If it is

not correct, the colors will be too dark or light.

Mode Video level adjustment in test mode

Signal Color bars

Test point CN003 pin 2

Instrument Oscilloscope

Specification 286 ± 50 mVp-p

Connection:

2

3

CN003

Oscilloscope

75Ω

±1%

100µF

+

100k

±1%

Checking method:

1) Confirm that the S-C burst is 286 ± 50 mVp-p.

4-2. ADJUSTMENT RELATED PARTS

ARRANGEMENT

DVD BOARD (SIDE A)

2

1

RV501

VIDEO LEVEL ADJ

CN003

9

Figure 5-3

286 ± 50 mVp-p

29

HCD-C700/C900

d

• CIRCUIT BOARDS LOCATION

SECTION 5

DIAGRAMS

DS-1089 board

DDCON-1089 board

FU-1089 board

SW-1089 board

SENSOR board

CONNECTOR

board

CLAMP MOTOR

board

IN SW board

HP-1089 board

RF-240 board

COMPONENT board

I/O board

Tuner UNIT

DVD board

INIT/COUNT SW board

SENSOR 2 board

PW-1089 board

OUT SW board

FP-1089 board

AMP board

LOAD MOTOR boar

POWER board

30

HCD-C700/C900

d

d

THIS NOTE IS COMMON FOR PRINTED WIRING

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed

in each block.)

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

• C : panel designation.

• A : B+ Line.

• B : B– Line.

• H : adjustment for repair.

• Voltages and waveforms are dc with respect to ground

• Voltages and waveforms are dc with respect to ground in

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

• Abbreviation

: internal component.

Note:

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

under no-signal (detuned) conditions.

service mode.

Voltage variations may be noted due to normal production tolerances.

no mark : STOP

F : FM

J : CD

c : DVD

g : VIDEO

G : Y

d : CHROMA

r : B-Y

q : R-Y

AUS : Australian model

CND : Canadian model

HK : Hong Kong model

MX : Mexican model

MY : Malaysia model

SP : Singapore model

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

For printed wiring boards.

Note:

• X : parts extracted from the component side.

a

•

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor B) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component A) the parts face are indicated.

: Through hole.

• Indication of transistor

C

Q

CEB

These are omitte

These are omitte

EB

• WAVEFORMS

– RF-240 BOARD –

1

500mV/DIV 100ns/DIV

IC001 tl (SIGO) DVD PLAY

2

500mV/DIV 400ns/DIV

IC001 tl (SIGO) CD PLAY

3

1.8Vp-p

500mV/DIV 40ms/DIV

IC001 ra (TE) DVD PLAY

4

500mV/DIV 200ms/DIV

IC001 ra (TE) CD PLAY

5

190mVp-p

100mV/DIV 40ms/DIV

IC001 rs (FE) DVD PLAY

6

840mVp-p

1.5Vp-p

1.5Vp-p

1.8Vp-p

– DVD BOARD –– AMP BOARD –

7

3.5Vp-p

6.25ns (16MHz)

IC901 ek (X2)

8

3.8Vp-p

81.4ns (12.288MHz)

IC606 w; (XMCK)

qs

20.3ns (49.152MHz)

IC300 4

qd

IC305 qd (OUTL1+)

13

µ

s

9

3.5Vp-p

– I/O BOARD –

qf

74ns (13.5MHz)

IC607 qs (MCLK2)

0

2Vp-p

IC701 qf, qg Test Mode (Video)

H

qg

37ns (27MHz)

IC102 7

qa

(XTI)

3.4 Vp-p

IC701

H

9, 0

Test Mode (Video)

qh

60.6ns (16.5MHz)

IC103 td (X1)

H

Q700 E Test Mode (Video)

7.2 Vp-p

5 Vp-p

2.5Vp-p

2Vp-p

0.9Vp-p

– COMPONENT BOARD –

qj

1.5 Vp-p

H

IC703 9, q; Test Mode (Video)

qk

1.5 Vp-p

IC703

qs, qd

Test Mode (Video)

H

ql

1.5 Vp-p

IC703

H

qf, qg

Test Mode (Video)

500mV/DIV 40ms/DIV

IC001 rs (FE) CD PLAY

3131

HCD-C700/C900

5-1. BLOCK DIAGRAMS

– RF/SERVO, VIDEO SECTION –

OPTICAL PICK-UP

(KHM-240 AAA)

RF

DVD/CD

PDIC

A-D

E-H

ELEVATOR

UP/DOWN

(LOADING)

D704

DISC TRAY

ADDRESS DETECT

(MID OUT)

DVD/CD

LD MOD

LIMIT

SENSOR

FOCUS

COIL

TRACKING

COIL

SPINDLE

MOTOR

SLED

MOTOR

M701

M702

(DISC IN DETECT)

S702

(LID)

S701

S708

(OUT)

S704

(IN)

S703

(MID IN)

S705

(INIT)

S706

(COUNT)

M

M

M

M

Q703

S707

ROTARY

ENCODER

VC

DVD LD

CD LD

PD

VR

SW

FCS +/-

TRK +/-

SPM +/-

SLA +/SLB +/-

2

IC701

MOTOR DRIVE

7

.

2

IC702

MOTOR DRIVE

7

.

2

Q701

Q001

DVD LD

DRIVE

Q002

CD LD

DRIVE

3

.

2

6

6

.

22

3

E1

E2

E3

29

.

28

33

.

32

27

46

45

44

41

40

39

38

CKMP

CKMM

TRMP

TRMM

DSW1

CLAPSW0

CLAPSW1

MIC_MUTE

CLAPBSY

OTASUKE

ECHO_MUTE

MEGAMUTE

IC201

FGA

2

14

11

7

10

15

18

19

25

26

21

22

24

SPINDLE/SLED/LOADING

37

.

36

35

.

34

27

.

28

47

46

32

29

18

D0 - 3

15

SHA0 - 3

SHA19

XRST

RDN

11

WRN

10

CK

12

INT

CS5

48

IC001

DVD/CD RF AMP

DIGITAL SERVO

RF IN

A-D

A2-D2

E-H

VC

MIRR

DVD LD

SCLK

CD LD

SDEN

DVD PD

CD PD

LDON

LD SEL

IC401

FOCUS/TRACKING

COIL DRIVE

MOTOR DRIVE

FOCUS

COIL

DRIVE

TRACKING

COIL

DRIVE

SPINDLE

MOTOR

DRIVE

SLED

MOTOR

DRIVE

MUTE12

MUTE34

POWER SAVE

HD8-11

4

HA0- 3

5

2

4

HA19

1

9

8

65

CKSW1

56

57

OCSW1

78

OCSW2

SIGO

TZIN

PIIN

MON

TZC

DFT

SWD

SRD

VCI

TSDM

MUTE5

CS6X

IC503

16

22

8

111

114

.

117

120

169

176

123

166

165

167

168

164

27

26

30

31

11 MCK

9 XRST

2

7

10

6

4

3

2

232

5

235

.

.

7

237

10

240

218

203

215

200

.

.

213

198

210

195

.

.

208

193

.

205

192

31

34

.

36

39

22

23

25

26

41

44

45

43

224

221

220

120

121

122

46

231

12

29

182

180

227

229

223

190

191

228

226

PLAYBACK SIGNAL

WAD0-7

SD0-7

WCK

SDCK

XSHD

XSAK

SDEF

XSRQ

TDO

TDI

TCK

TMS

TRST

EXCKO

XMSLAT

MSREADY

SMUTE

MSDATO

MSDATI

MSCK

AV DECODER

HD0-15

HAD0-21

DTI0-7

CDIN2

CDIN1

CDBCK

CDLRK

ICLK

ISTART

IVAL

IERR

HWAITOB

HRWB

HSCB

TCK

TMS

TRST

IREQ

RSTB

ACLK

CRPCLK

SCLK

CLK

DMREQ1

DMREQ0

HIREQO

HAD23

HAD22

DMACK0

DMACK1

IC801

PROCESSOR

COMP OUT

CB/ROUT

CR/BOUT

SDDQ0-15

SDDQ0-15

SDAQ0-11

SDCS0B

SDCS1B

SDDQM0

SDDQM1

SDWEOB

SDCKSOB

SDRASOB

AVDD6

AVDD7

AVDD8

Y OUT

SDCLK

SDCKE

DO

VRIF

TDI

DSALFE

BCKAO

EXCKO

DQ0-7

A0-11

DCLK

DCKE

XWE

XCAS

XRAS

TDO

DSAL

DSAC

J601,602 (1/2)

VIDEO IN

VIDEO1

VIDEO IN

VIDEO2

80

74

77C OUT

20

63

66

177

157

.

.

174

159

.

.

171

162

IC504,505

.

.

168

164

.

.

16M

165

167

.

.

SDRAM

163

170

.

.

160

173

.

.

158

176

134

130

.

.

131

133

.

.

128

136

.

.

125

139

.

.

124

137

.

.

127

140

144

143

155

154

149

146

152

151

147

A3.3V

RV501

VIDEO

LEVEL

84

IC501

1.8V

181

1

REG

184

187

118

SPDIF

D3.3V

2

1

3

A

AUDIO-1

SECTION

IC700

INPUT SEL

2 5 4

IC701

7

IC702

OUTPUT SEL

11

14

12

8

9

7

16

1

2

VIDEO 5V

VIDEO AMP

2

INA

OUTA1

15

OUTA2

14

5

4

INB

13OUTB1

12OUTB2

6

7

INC

OUTC1

10

OUTC2

9

MUTE

7

4

2

3

IC703

VIDEO AMP

INC

INB

INA

MUTE

IC601

5V

REG

1

OUTC1

OUTC2

OUTA1

OUTA2

1

1

Q700,702,703

BUFFER

Q701,704

OFFSET

SWITCH

10

9

13OUTB1

12OUTB2

15

14

10V

3

Y

CB

CR

Y

C

43

2

VMUTE

VSEL2

VSEL1

CM

J600 (1/2)

VIDEO OUT

VIDEO1

VIDEO

J700

MONITOR

OUT

S VIDEO

1

D

MAIN

SECTION

Y

J666

COMPONENT

PB/B-Y

VIDEO OUT

PR/R-Y

• R-CH is omitted due to same as L-CH.

• Signal Path

29

D2.5V

SDATAL

SDATAC

SDATALF

SDATALS

DSBC

DSMCK

B

AUDIO

SECTION

IC804

2.5V

REG

TRST

1

CPU

SECTION

D3.3V

C

3

64

69

71

74DSALS

60

13

139

IC803

136

.

16M

134

SDRAM

131

162

152

.

151

159

.

.

157

149

.

154

148

141

142

143

144

145

: FM

: CD

: DVD

: VIDEO

: Y

: CHROMA

: B-Y

: R-Y

IC302

SERVO DSP

131

59

TE

41

40

FE

42

PI

36

35

44

33

37

38

47

48

46

45

27

39

SVC

40

FDRV+

48

FDRV-

1

TDRV+

3

TDRV-

4

SLE

5

MDSO

13

SPFG

45

SLDA

7

SLDB

10

LMP

16

LMM

17

LMCTL

15

TSD

22

SP MUTE

5

21

19

20

39

IC102

X102

27MHz

7

CLOCK

8

GEN

14

77

19

48

84

63

81

INT3

CPUCK

XDRVMUTE

XLDON

CS5X62CS4X

48/44.1K

RFIN1

128

RFIN2

135

ADC0

136

ADC1

137