HBD-TZ130

SERVICE MANUAL

Ver. 1.2 2011.01

• HBD-TZ130 is the amplifi er, DVD/CD and tuner

section in DAV-TZ130.

This system incorporates with Dolby* Digital and Dolby Pro Logic

adaptive matrix surround decoders.

* Manufactured under license from Dolby Laboratories.

Dolby, Pro Logic, and the double-D symbol are trademarks of

Dolby Laboratories.

This system incorporates High-Defi nition Multimedia Interface

(HDMI™) technology.

HDMI, the HDMI logo and High-Defi nition Multimedia Interface are

trademarks or registered trademarks of HDMI Licensing LLC.

“BRAVIA” is a trademark of Sony Corporation.

MPEG Layer-3 audio coding technology and patents licensed from

Fraunhofer IIS and Thomson.

Windows Media is a registered trademark of Microsoft Corporation in

the United States and/or other countries.

US Model

Canadian Model

E Model

Australian Model

Chinese Model

Model Name Using Similar Mechanism NEW

DVD Drive Mechanism Type CDM85

Optical Pick-up Name KHM-313

AUDIO POWER SPECIFICATIONS

for the U.S. models

POWER OUTPUT AND TOTAL

HARMONIC DISTORTION:

(FTC)

Front L + Front R With 3 ohms loads,

both channels driven,

from 180 - 15,000 Hz;

rated 23 watts per

channel minimum

RMS power, with no

more than 1% total

harmonic distortion

from 250 milli watts to

rated output.

9-889-971-03

2011A04-1

2011.01

©

Sony Corporation

Published by Sony Techno Create Corporation

SPECIFICATIONS

Amplifi er Section

POWER OUTPUT (rated):

Front L + Front R 32 W + 32 W (at 3

ohms, 1 kHz, 1% THD)

POWER OUTPUT (reference):

Front L/Front R/

Surround L/Surround

R: 43 watts (per channel

at 3 ohms, 1 kHz)

Center: 89 watts (per

channel at 6 ohms, 1 kHz)

Subwoofer: 89 watts (at

6 ohms, 100 Hz)

Inputs

TV/CABLE : Pin jack

CD/DVD System

Laser Diode Properties

Emission Duration:

Continuous

Laser Output*: Less

than 1,000 μW

* This output is the value measurement at a dis-

tance of 200 mm from the objective lens surface on the Optical Pick-up Block with 7 mm

aperture.

USB Section

(USB) port:

Maximum current: 500 mA

– Continued on next page –

DVD RECEIVER

HBD-TZ130

Ver. 1.2

Tuner Section

System PLL quartz-locked

digital synthesizer

Tuning range

North American and Brazilian models:

87.5 MHz - 108.0 MHz

(100 kHz step)

Other models: 87.5 MHz - 108.0 MHz

(50 kHz step)

Antenna (aerial) terminals

75 ohms, unbalanced

Intermediate frequency

10.7 MHz

Video Section

Outputs VIDEO: Pin jack

HDMI OUT: HDMI

19-pin

General

Power requirements

North American models:

120 V AC, 60 Hz

Argentine models: 220 V - 240 V AC,

50/60 Hz

Brazilian models: 127 V - 240 V AC,

50/60 Hz

Latin American models:

110 V - 240 V AC,

50/60 Hz

Other models: 220 V - 240 V AC,

50/60 Hz

Power consumption On: 67 W

Standby: <1 W*

* Valid when the system is in the following status:

– [Control for HDMI] is set to [Off].

Dimensions (approx.) 360 mm × 56 mm ×

342 mm (14

2

incl. projecting parts

Mass (approx.) 2.6 kg (5 lb. 12 oz.)

1

/4 in × 13 1/2 in) (w/h/d)

1

/4 in ×

SAFETY CHECK-OUT (US MODEL)

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

0.15 μF

voltmeter

(0.75 V)

Design and specifi cations are subject to

change without notice.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE

PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

SPECIAL COMPONENT NOTICE

The components identifi ed by mark 9 contain confi dential infor-

mation.

Strictly follow the instructions whenever the components are repaired and/or replaced.

NOTICE POUR COMPOSANTS SPÉCIAUX

Les composants identifi és par la marque 9 contiennent des infor-

mations confi dentielles.

Suivre scrupuleusement les instructions chaque fois qu’un composant est remplacé et / ou réparé.

2

HBD-TZ130

Ver. 1.2

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

For European models:

This appliance is classifi ed as

a CLASS 1 LASER product.

This marking is located on the

rear exterior of unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

NOTES ON CHIP COMPONENT REPLACEMENT

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

FLEXIBLE CIRCUIT BOARD REPAIRING

• Keep the temperature of soldering iron around 270 °C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

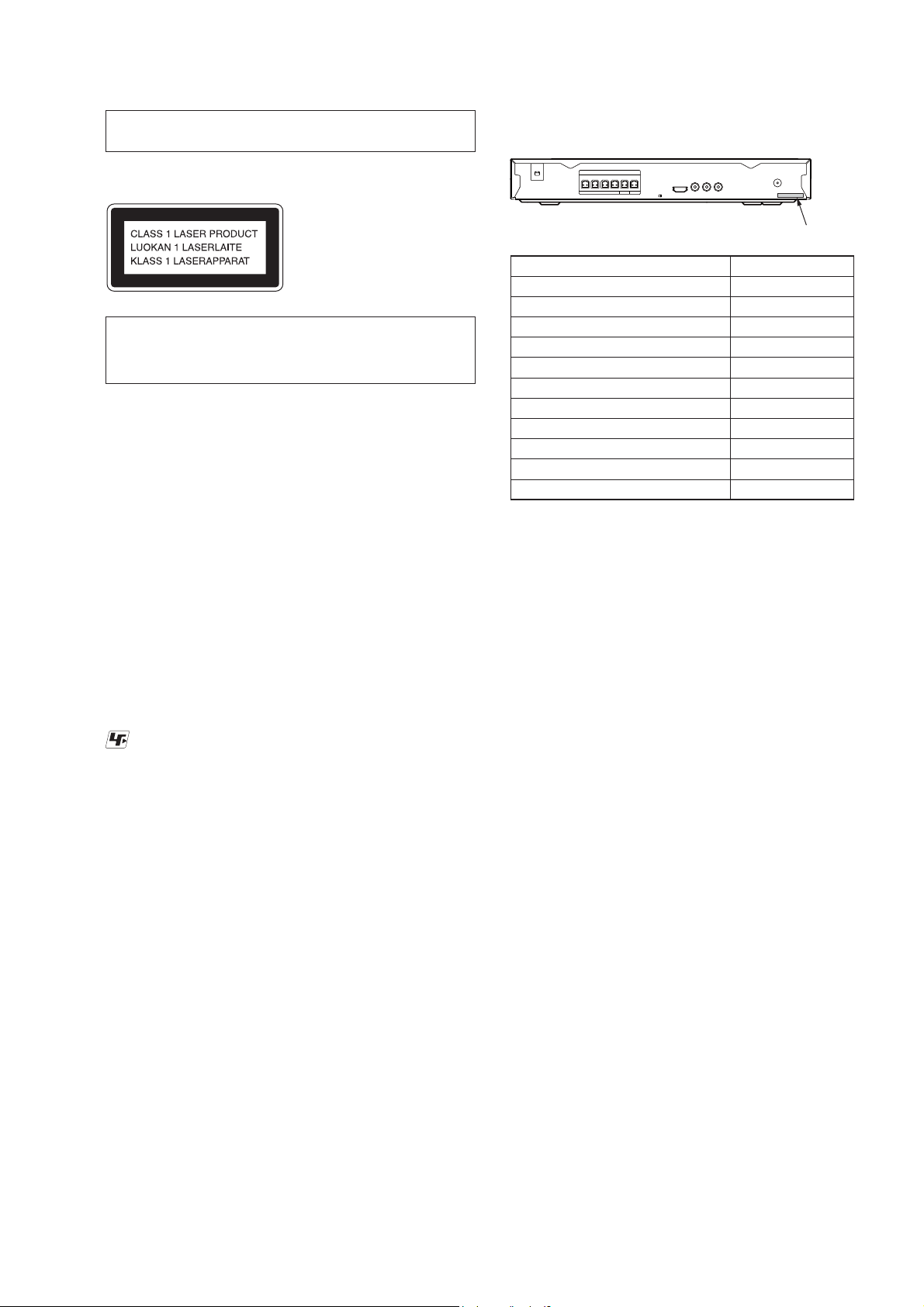

MODEL IDENTIFICATION

– Back Cabinet –

Parts No.

Model Part No.

SP model GSE200276-0001

AUS model GSE200276-0004

TH model GSE200276-0007

CH model GSE200276-0008

E32 model GSE200276-0009

US model GSE200276-0011

CND model GSE200276-0012

E3, SAF model GSE200276-0013

E12 model GSE200276-0015

AR model GSE200276-0017

BR model GSE200276-0018

• Abbreviation

AR : Argentina model

AUS : Australian model

BR : Brazilian model

CH : Chinese model

CND : Canadian model

E3 : 240V AC area in E model

E12 : 220 – 240V AC area in E model

E32 : 110 – 240V AC area in E model

SAF : South African model

SP : Singapore model

TH : Thai model

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

3

HBD-TZ130

TABLE OF CONTENTS

1. SERVICING NOTES

............................................. 5

2. DISASSEMBLY

2-1. Top Cover ....................................................................... 9

2-2. Door ................................................................................ 10

2-3. Front Cabinet Section ..................................................... 10

2-4. CONTROL Board, STANDBY Board ............................ 11

2-5. USB Board ...................................................................... 11

2-6. MAIN Board ................................................................... 12

2-7. POWER Board ................................................................ 12

2-8. DVD Mechanism Deck Section ...................................... 13

2-9. Optical Pick-up ............................................................... 13

3. DIAGRAMS

3-1. Block Diagram ................................................................ 15

3-2. Printed Wiring Board –Main Section (1/2)– ................... 16

3-3. Printed Wiring Board –Main Section (2/2)– ................... 17

3-4. Schematic Diagram –Main Section (1/2)– ...................... 18

3-5. Schematic Diagram –Main Section (2/2)– ...................... 19

3-6. Printed Wiring Boards –Display Section– ...................... 20

3-7. Schematic Diagram –Display Section– .......................... 21

3-8. Printed Wiring Board –Power Section– .......................... 22

3-9. Schematic Diagram –Power Section– ............................. 23

4. EXPLODED VIEWS

4-1. Overall Section ............................................................... 24

4-2. Front Cabinet Section ..................................................... 25

4-3. Chassis Section ............................................................... 26

4-4. DVD Mechanism Deck Section ...................................... 27

4

SECTION 1

SERVICING NOTES

HBD-TZ130

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH

1. Open the case and turn POWER on with no disc inserted.

2. Confi rm that the following operation is performed while ob-

serving the objecting lens from the clearance of DVD mechanism deck.

1) Confi rm that laser beam is spread.

2) Up and down motion of the objective lens. (2 times)

DISC TRAY LOCK

The disc tray lock function for the antitheft of an demonstration

disc in the store is equipped.

Setting Procedure :

1. Press the [

2. Press the [FUNCTION] button to set DVD/CD function.

3. Insert a disc.

4. Press the [x] button and the [Z] button simultaneously for fi ve

seconds.

5. The message “LOCKED” is displayed and the tray is locked.

Releasing Procedure :

1. Press the [x] button and the [Z] button simultaneously for fi ve

seconds again.

2. The message “UNLOCKED” is displayed and the tray is unlocked.

Note: When “LOCKED” is displayed, the tray lock is not released by

turning power on/off with the [

] button to turn the set on.

?/1

?/1

] button.

How to open the disc tray when power switch turns off

Insert a tapering driver into the aperture of the unit bottom, and

slide it in the direction of the arrow.

Insert a screwdriver from between the front panel and

the chassis and slide the rod in the direction of the arrow.

disc tray

Precaution when installing a new OP unit/

Precaution before unsoldering the static electricity

prevention solder bridge

On cleaning discs, disc/lens cleaners

• Do not use cleaning discs or disc/lens cleaners (including wet

or spray types). These may cause the apparatus to malfunction.

IMPORTANT NOTICE

Caution: This system is capable of holding a still video image or onscreen display image on your television screen indefi nitely. If you leave

the still video image or on-screen display image displayed on your TV

for an extended period of time you risk permanent damage to your television screen.

Projection televisions are especially susceptible to this.

When installing a new OP unit, be sure to connect the wire (fl at

type) (24 core) fi rst of all before removing the static electricity

prevention solder bridge by unsoldering.

Remove the static electricity prevention solder bridge by unsoldering after the wire (fl at type) (24 core) has already been connected.

(Do not remove nor unsolder the solder bridge as long as the OP

unit is kept standalone.)

5

HBD-TZ130

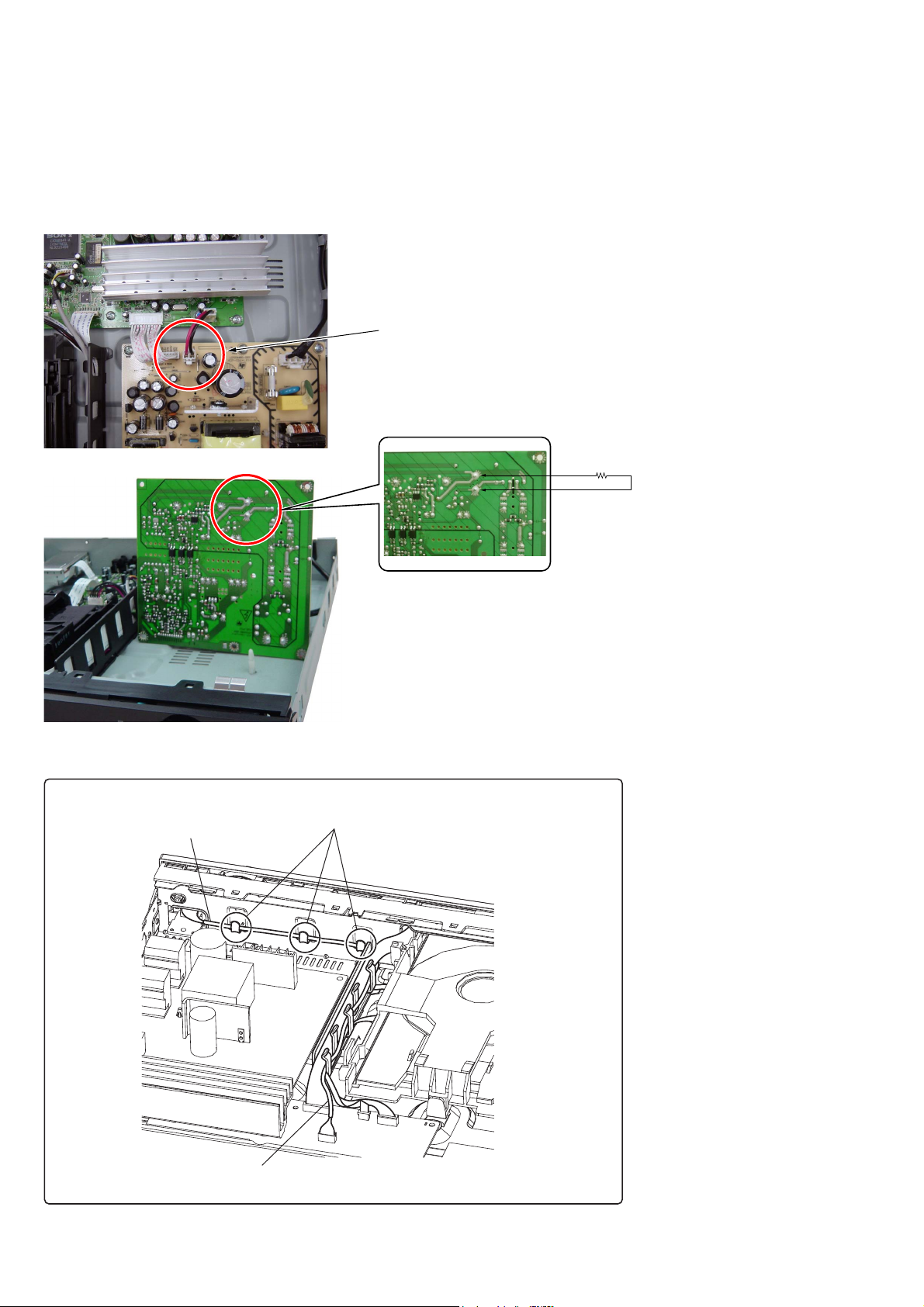

Discharge the charged electricity in capacitors to prevent electric shock as follows

When disassembling the machine, be sure to discharge the charged electricity in the following capacitors.

Use a resistor of 800 ohms, 2 Watts for discharging the following capacitors.

POWER board

C906: 390V

C936, C944 and CN902: 32V

Point of capacitor discharge for C936 and C944:

Connect to the red and black wires of CN902.

800:/2W

Arranging the USB wire

USB wire

Point of capacitor discharge for C906:

Connect to the foot of C906.

Have the USB wire spread on the inside

of the claws of the chassis.

USB wire

6

Version display

• Confi rmation procedure of version only

1. Press the [

2. Press the [EJECT] button. (State of “Tray open”)

3. After press the “STOP” button, the “DISPLAY” button press.

4. The version information appears to the TV.

Model No. DAV-TZ130 CEL

Release : 2010.08.26C

MPEG : 2.15.23 MCU : 2.15.24

Region : 2 HdcpKey : Yes

5. Press the “ENTER” button on the remote.

6. The system will return to normal mode.

] button to turn the set on.

?/1

OK

HBD-TZ130

7

HBD-TZ130

DISASSEMBLY

• This set can be disassembled in the order shown below.

SET

2-1. TOP COVER

(Page 9)

SECTION 2

2-2. DOOR

(Page 10)

2-3. FRONT CABINET SECTION

(Page 10)

2-4. CONTROL BOARD,

STANDBY BOARD

(Page 11)

2-5. USB BOARD

(Page 11)

2-6. MAIN BOARD

(Page 12)

2-8. DVD MECHANISM DECK SECTION

(Page 13)

2-9. OPTICAL PICK-UP

(Page 13)

2-7. POWER BOARD

(Page 12)

8

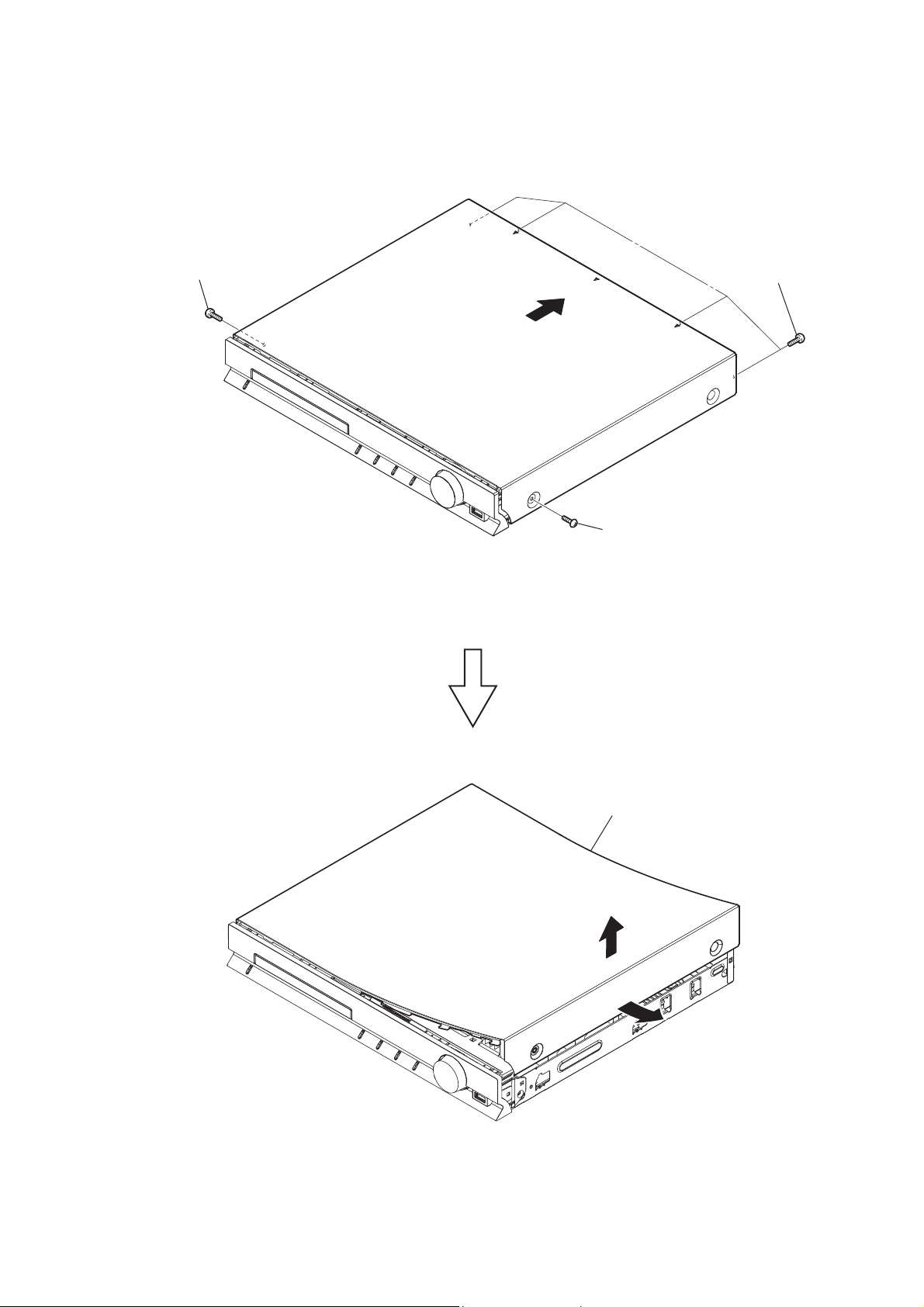

Note: Follow the disassembly procedure in the numerical order given.

2-1. TOP COVER

HBD-TZ130

2 screw

(case screw)

3 four screws

(+BVTT 3 u6)

4

1 screw

(case screw)

7 top cover

6

5 Raise one side of the case.

9

Loading...

Loading...