Sony HBD-NF620, HBD-NF720 Service Manual

V

HBD-NF620/NF720

SERVICE MANUAL

Ver. 1.2 2012.07

Photo: HBD-NF720

• HBD-NF620 is the Blu-ray discTM/DVD receiver in BDV-NF620.

• HBD-NF720 is the Blu-ray discTM/DVD receiver in BDV-NF720.

• In order to perform the operation checking, all the units contained in this unit are needed.

Model Name Using Similar Mechanism HBD-N790W/N990W

Mechanism Type BSX-3

Optical Pick-up Name KEM-480AAA

SPECIFICATIONS

Amplifier Section

POWER OUTPUT (rated)

Front L/Front R: 78 W + 78 W (at 3 ohms, 1

POWER OUTPUT (reference)

Front L/Front R: 100 W (per channel at

Subwoofer: 200 W (at 6 ohms, 80 Hz)

Inputs (Analog)

AUDIO (A UDIO IN) Sensitivity: 3.0 V/1.0 V

Inputs (Digital)

TV (Audio Return Channel/OPTICAL)

HDMI (IN 1)/HDMI (IN 2)

ideo Section

Outputs VIDEO: 1 Vp-p 75 ohms

HDMI Section

Connector Type A (19pin)

kHz, 1% THD)

3 ohms, 1 kHz)

Supported formats: LPCM

2CH (up to 48 kHz), Dolby

Digital, DTS

Supported formats: LPCM

5.1CH (up to 48 kHz),

LPCM 2CH (up to 96

kHz), Dolby

Digital, DTS

BD/DVD/Super Audio CD/CD System

Signal format system NTSC/PAL

USB Section

USB 1/2 port: Type A (For connecting

USB memory, memory

card reader, digital still

camera, and digital video

camera)

LAN Section

LAN (100) terminal 100BASE-TX Terminal

Wireless LAN Section (HBD-NF720 only)

Standards Compliance IEEE 802.11 b/g/n

Frequency and Channel 2.4 GHz - 2.4835 GHz

[CH1 -13]

FM Tuner Section

System PLL quartz-locked digital

synthesizer

Tuning range 87.5 MHz - 108.0 MHz

(50 kHz step)

Antenna (aerial) FM wire antenna (aer ia l)

Antenna (aerial) terminals 75 ohms, unbalanced

AEP Model

HBD-NF620/NF720

UK Model

Taiwan Model

HBD-NF720

Mexican Model

HBD-NF620

General

Power requirements Taiwan model:

120 V AC, 50/60 Hz

Mexican model:

110 V - 240 V AC,

50/60 Hz

AEP and UK models:

220 V - 240 V AC,

50/60 Hz

Power consumption

HBD-NF620 On: 80 W

Standby: 0.3 W (at the /

Power Saving mode)

HBD-NF720 On: 82 W

Standby: 0.3 W (at the

Power Saving mode)

Dimensions (approx.) 460 mm × 74 mm × 226

mm (w/h/d) (without

stand, incl. projecting

parts)

460 mm × 148 mm × 226

mm (w/h/d) (with stand

and cord cover attached)

Mass (approx.)

HBD-NF 620 3.5 kg

HBD-NF720 3.8 kg

Design and specifications are subject to change

without notice.

Standby power

Over 85% power efficiency of amplifier block is

achieved with the full digital amplifier, S-Master.

BLU-RAY DISCTM/DVD RECEIVER

consumption 0.3W.

9-893-453-03

2012G33-1

2012.07

©

Sony Corporation

Published by Sony Techno Create Corporation

HBD-NF620/NF720

Copyrights and

Trademarks

This system incorporates with

Dolby* Digital and the DTS**

Digital Surround System.

* Manufactured under license

from Dolby Laboratories.

Dolby and the double-D

symbol are trademarks of

Dolby Laboratories.

**Manufactured under license

under U.S. Patent Nos:

5,956,674; 5,974,380;

6,226,616; 6,487,535;

7,212,872; 7,333,929;

7,392,195; 7,272,567 &

other U.S. and worldwide

patents issued & pending.

DTS-HD, the Symbol, &

DTS-HD and the Symbol

together are registered

trademarks of DTS,

Product includes software.

© DTS, Inc. All Rights

Reserved.

This system incorporates High-

Definition Multimedia Interface

TM

(HDMI

) technology.

HDMI, the HDMI logo and HighDefinition Multimedia Interface

are trademarks or registered

trademarks of HDMI Licensing

LLC in the United States and

other countries.

Java is a trademark of Oracle and/

or its affiliates.

“BD-LIVE” and

“BONUSVIEW” are trademarks

of Blu-ray Disc Association.

“Blu-ray Disc” is a trademark.

“Blu-ray Disc,” “DVD+RW,”

“DVD-RW,” “DVD+R,” “DVDR,” “DVD VIDEO,” and “CD”

logos are trademarks.

“Blu-ray 3D” and “Blu-ray 3D”

logo are trademarks of Blu-ray

Disc Association.

“BRAVIA” is a trademark of

Sony Corporation.

“AVCHD” and the “AVCHD”

logo are trademarks of Panasonic

Corporation and Sony

Corporation.

, “XMB,” and “xross media

bar” are trademarks of Sony

Corporation and Sony Computer

Enter

tainment Inc.

“PlaySta ti on” is a registered

trademark of Sony Computer

Entertainment Inc.

Music and video recognition

technology and related data are

provided by Gracenote

Gracenote is the industry standard

in music recognition technology

and related content delivery. For

more information, please visit

www.gracenote.com.

CD, DVD, Blu-ray Disc, and

music and video-related data from

Gracenote, Inc., copyright ©

2000-present Gracenote.

Gracenote Software, copyright ©

2000-pr

esent Gracenote. One or

more patents owned by Gracenote

apply to this product and service.

See the Gracenote website for a

nonexhaustive list of applicable

Gracenote patents. Gracenote,

CDDB, MusicID, MediaVOCS,

the Gracenote logo and logotype,

and the “Powered by Gracenote”

logo are either registered

trademarks or trademarks of

Gracenote in the United States

and/or other countries.

®

Wi-Fi

, Wi-Fi Protected Access®

and Wi-Fi Alliance

registered marks of the Wi-Fi

Alliance.

Wi-Fi CERTIFIED™, WPA™,

WPA2™ and Wi-Fi Protected

Setup™ are marks of the Wi-Fi

Alliance (HBD-NF720 only).

WPA™, WPA2™ and Wi-Fi

Protected Setup™ are marks of

the Wi-Fi Alliance (HBD-NF620

only).

The Wi-Fi CERTIFIED Logo is a

certification mark of the

Wi-Fi Alliance (HBD-NF720

only).

Inc.

®

.

®

are

The Wi-Fi Protected Setup Mark

is a mark of the Wi-Fi Alliance

(HBD-NF720 only).

“PhotoTV HD” and the “PhotoTV

HD” logo are trademarks of Sony

Corporation.

MPEG L

ayer-3 audio coding

technology and patents licensed

from Fraunhofer IIS and

Thomson.

This product incorporates

proprietary technology under

license from Verance Corporation

and is protected by U.S. Patent

7,369,677 and other U.S. and

worldwide patents issued and

pending as well as copyright and

trade secret protection for certain

aspects of such technology.

Cinavia is a trademark of Verance

Corporation. Copyright 20042010 Verance Corporation. All

rights reserved by Verance.

Re

verse engineering or

disassembly is prohibited.

iPhone, iPo d, iP od c la ssi c , iP od

nano, and iPod touch are

trademarks of Apple Inc.,

registered in the U.S. and other

countries.

“Made for iPod,” and “Made for

iPhone” mean that an electronic

accessory has been designed to

connect specifically to iPod or

iPhone, respectively, and has been

certified by the developer to meet

Apple performance standards.

Apple is not responsible for the

operation of this device

compliance with safety and

regulatory standards. Please note

that the use of this accessory with

iPod or iPhone may affect

wireless performance.

Windo w s Me dia is either a

registered trademark or trademar k

of Microsoft Corporation in the

United States and/or other

countries.

This product contains technology

subject to certain intellectual

property rights of Microsoft. Use

or distribution of this technology

outside of this product is

prohibited without the appr

license(s) from Microsoft.

Content owners use Microsoft

PlayReady

technology to protect their

intellectual property, including

copyrighted content. This device

uses PlayReady technology to

access PlayReady-protected

content and/or WMDRMprotected content. If the device

fails to properly enforce

restrictions on content usage,

content owners may require

Microsoft to revoke the device’s

ability to consume PlayReadyprotected content. Revoca

should not affect unprotected

content or content protected by

other content access technologies.

Content owners may require you

to upgrade PlayReady to access

their content. If you decline an

upgrade, you will not be able to

access content that requires the

upgrade.

®

DLNA

, the DLNA Log o an d

DLNA CERTIFIED

trademarks, service marks, or

certification marks of the Digital

Living Network Alliance.

®

Opera

Browser from Opera

Software ASA. Copyright 19952010 Opera Software ASA. All

rights reserved.

All other trademarks are

trademarks of their respective

owners.

Other system and produc t na m es

are generally trademarks or

registered trademarks of the

manufacturers. ™ and ® marks

are not indicated in this document.

™

content access

™

or its

opriate

tion

are

This marking is located on the laser

protective housing inside the

enclosure.

This appliance is classified as a

CLASS 3R LASER product.

Visible and invisible laser radiation

is emitted when the laser protective

housing is opened, so be sure to

avoid direct eye exposure.

This appliance is classified as a

CLASS 1 LASER product. This

marking is located on the rear

exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specifi ed herein may result in hazardous radia-

tion exposure.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

®

2

TABLE OF CONTENTS

1. SERVICING NOTES ............................................. 4

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 11

2-2. Cover (Top) Block .......................................................... 12

2-3. TOUCH Board ................................................................ 13

2-4. Cover (Bottom) Block .................................................... 14

2-5. Shield (Drive) (HBD-NF620) ......................................... 15

2-6. BD Drive (BSX-3) .......................................................... 15

2-7. LED Board ...................................................................... 16

2-8. Wireless LAN Card (WLC1) (HBD-NF720).................. 16

2-9. Chassis (Middle) Block .................................................. 17

2-10. Bracket (Drive) ............................................................... 17

2-11. MB-149 Board ................................................................ 18

2-12. Bottom Cover .................................................................. 19

2-13. Optical Pick-up (KEM-480AAA) ................................... 20

2-14. Shield (PS) Block ............................................................ 20

2-15. Switching Regulator (SWR1) ......................................... 21

2-16. Bracket (PS) .................................................................... 22

2-17. Power Cord (AC1) .......................................................... 22

2-18. Heat Sink (AMP) ............................................................ 23

2-19. NX_AMP Board ............................................................. 23

2-20. How to Bend Wire (Flat Type) ........................................ 24

3. TEST MODE ............................................................ 25

4. ELECTRICAL CHECK ......................................... 34

5. DIAGRAMS

5-1. Block Diagram - SERVO Section - ................................ 35

5-2. Block Diagram - MEMORY Section - ............................ 36

5-3. Block Diagram - MAIN Section - ................................... 37

5-4. Block Diagram - AMP Section - ..................................... 38

5-5. Block Diagram - POWER SUPPLY Section - ................ 39

HBD-NF620/NF720

5-6. Schematic Diagram - MB-149 Board (1/11) - ................ 41

5-7. Schematic Diagram - MB-149 Board (2/11) - ................ 42

5-8. Schematic Diagram - MB-149 Board (3/11) - ................ 43

5-9. Schematic Diagram - MB-149 Board (4/11) - ................ 44

5-10. Schematic Diagram - MB-149 Board (5/11) - ................ 45

5-11. Schematic Diagram - MB-149 Board (6/11) - ................ 46

5-12. Schematic Diagram - MB-149 Board (7/11) - ................ 47

5-13. Schematic Diagram - MB-149 Board (8/11) - ................ 48

5-14. Schematic Diagram - MB-149 Board (9/11) - ................ 49

5-15. Schematic Diagram - MB-149 Board (10/11) - .............. 50

5-16. Schematic Diagram - MB-149 Board (11/11) - .............. 51

5-17. Printed Wiring Board - MB-149 Board (Side A) - .......... 52

5-18. Printed Wiring Board - MB-149 Board (Side B) - .......... 53

5-19. Printed Wiring Board

- NX_AMP Board (Component Side) - .......................... 54

5-20. Printed Wiring Board

- NX_AMP Board (Conductor Side) - ............................ 55

5-21. Schematic Diagram - NX_AMP Board - ........................ 56

5-22. Printed Wiring Boards - PANEL Section - ..................... 57

5-23. Schematic Diagram - PANEL Section - .......................... 57

5-24. Printed Wiring Board - FL Board - ................................. 58

5-25. Schematic Diagram - FL Board - .................................... 59

6. EXPLODED VIEWS

6-1. Cover (Bottom) Section .................................................. 77

6-2. Cover (Top) Section ........................................................ 78

6-3. LED Board Section ......................................................... 79

6-4. BD Drive Section (BSX-3) ............................................. 80

6-5. FL Board Section ............................................................ 81

6-6. Switching Regulator Section .......................................... 82

6-7. NX_AMP Board Section ................................................ 83

6-8. MB-149 Board Section ................................................... 84

7. ELECTRICAL PARTS LIST .............................. 85

3

HBD-NF620/NF720

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The fl exible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc refl ective surface by the objective lens in the optical

pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

RELEASING THE DISC SLOT LOCK

The disc slot lock function for the antitheft of an demonstration

disc in the store is equipped.

Releasing Procedure:

1. Press the [

2. Press the [HOME] button on the remote commander to enter

the home menu.

3. Touch the [x] and [Z] sensors simultaneously and hold down

unit “DEMO OFF” displayed on the fluorescent indicator tube

(around 5 seconds).

Note: When “DEMO.LOCK” is displayed, the disc slot lock is not re-

leased by turning power on/off with the [

ABOUT THE LENS CLEANING

Do not do the lens cleaning with the cotton bud etc. It causes the

trouble.

] button to turn on the system.

?/1

?/1

] button.

NOTE OF REPLACING THE IC101 AND IC501 ON

THE MB-149 BOARD

IC101 and IC501 on the MB-149 board cannot exchange with

single. When these parts are damaged, exchange the complete

mounted board.

NOTE OF REPLACING THE IC102, IC103, IC202 AND

IC203 ON THE MB-149 BOARD

Replacement of IC102, IC103, IC202 and IC203 on the MB-149

board used in this unit requires a special tool.

NOTE OF REPLACING THE TOUCH BOARD

When the TOUCH board is defective, exchange the complete

mounted board.

TEST DISC

Part No. Description Layer

J-6090-199-A BLX-104 Single Layer

J-6090-200-A BLX-204 Dual Layer

J-2501-307-A CD (HLX-A1)

J-2501-305-A HLX-513 Single Layer (NTSC)

J-2501-306-A HLX-514 Dual Layer (NTSC)

J-6090-077-A HLX-506 Single Layer (PAL)

J-6090-078-A HLX-507 Dual Layer (PAL)

Note: Refer to the service manual of BDP-BX1/S350 (Part No. 9-883-

989-1[]) (page 1-3 to 1-14E) for the use of BLX-104/204.

Operation and Display:

1. BLX-104

Procedure:

1. Select 23.976Hz/1080p.

2. Play “4.Motion picture”.

3. Check whether player can play back or not.

4. Check each outputs.

Video:

Composite/HDMI.

Audio:

Speaker out.

* When 1080/24p monitor is nothing, 1080i (59.94Hz or 50Hz)

can use instead of 1080/24p.

However this is temporary correspondence.

* When the output of HDMI is 1080p/1080i/720p, the signal of

composite is not output.

It is necessary to lower the output of HDMI to 480p or 576p or

less.

2. BLX-204

Procedure:

1. Select 1080i (59.94Hz or 50Hz).

2. Play “4.Motion picture”.

3. Check whether player can play back or not (Check the picture

and sound output).

3. CD (HLX-A1)

Procedure:

Check whether player can play back or not (Check the sound output).

4. HLX-513/514 (NTSC), HLX-506/507 (PAL)

Procedure:

1. After displayed Main Menu, select “1.Video Signal”.

2. Play “1.Color bar 100%” (Check the picture and sound out-

put).

3. Return to Menu.

4. Play “Demonstration 4:3” or “Demonstration 16:9” (Check the

picture and sound output).

4

HBD-NF620/NF720

NOTE OF REPLACING THE OPTICAL DEVICE (KEM480AAA) OR MB-149 BOARD

The password will be supplied to only service HQ, and

service center name, q’ty and all of software registered

information should be maintained by service HQ, and

Audio will ask to report the registration information.

Optical device (KEM-480AAA) for BD requires precise read out

functions and secure contents protection system for more than past

DVD/CD.

Therefore, in the case repaired as follows, the writing work of the

OP data is necessary.

• When the optical device (KEM-480AAA) is replaced (The

MB-149 board doesn’t replace).

• When both the optical device (KEM-480AAA) and MB-149

board are replaced.

• When the MB-149 board is replaced (The optical device

(KEM-480AAA) doesn’t replace) (In this case, do the work of

“3. Optical device (KEM-480AAA) replacement” other than

the replacement of new optical device).

Note: The servo adjustment is done while writing the OP data. The manual

adjustment is unnecessary.

LD ON TIME history doesn’t carry over.

Do not touch any optical block parts, turn table and during replac-

ing. BD laser diode is very sensitive.

1. Preparation

1-1. ESD Countermeasure

It is necessary to confi rm the state of static electricity in the work

space before the repair is started.

The static electricity resistance of the BD laser is weaker than that

of the DVD/CD laser.

Do work space and worker’s ESD countermeasures to prevent destruction by ESD.

1-2. Jig

• Digital camera (Recommend with macro mode)

• USB memory

• PC

• Barcode decoder (Refer to “1-3. Barcode decoder

(BDPRdec)”)

1-3. Barcode decoder (BDPRdec)

Jig name: BDPRdec.exe

Software contents:

• BDPRdec.exe : Barcode decoder software

• SavePath.ini : Decoded fi le destination setting fi le (Ini-

tial destination is “C:\BuData.txt”)

• TasmanBars.dll : Decode dll

• Uninst.exe : Uninstall the “BDPRdec.exe” from PC

Note: When working by OS of the version after VISTA, it is necessary

to change destination of the decoded fi le to save by UAC function

(user account function).

In that case, change the description in “SavePath.ini” (default de-

scription is “C:\BuData.txt”) other than C drive.

Install procedure:

1. Unzip the barcode decoder fi les to any PC folder.

2. Check the attached 2D code photo (OK_sample.JPG) drag &

drop onto “BDBUDec.exe”.

When the barcode decoder is used for the fi rst time, the pass-

word is necessary. It is unnecessary since the second times.

Note 1: The password will be supplied to only service headquarters, and

service center name/q’ty/all of software registered information

should be maintained by service headquarters.

Note 2: Do not change the decoded fi le name “BuData.txt”.

3. When “.NET frame work requirements” is displayed, down-

load following applications from Microsoft download site.

• Microsoft .NET Framework Version 2.0 Redistributable Pack-

age (x86)

http://www.microsoft.com/downloads/details.aspx?displaylan

g=en&FamilyID=0856eacb-4362-4b0d-8edd-aab15c5e04f5

• Microsoft .NET Framework 2.0 Service Pack 1 (x86)

http://www.microsoft.com/downloads/details.aspx?displaylan

g=en&FamilyID=79bc3b77-e02c-4ad3-aacf-a7633f706ba5

How to use:

Case 1 Drag & drop 2D code photo onto “BDPRdec.exe”.

Case 2 Drag & drop BU data fi le onto “BDPRdec.exe”.

Data fi le name be changed to specify format and end of

7 character are defi ned.

You can also enter the fi le path at the prompt.

5

HBD-NF620/NF720

2. Pass-fail judgment of the optical device (KEM-480AAA)

Perform pass-fail judgment to judge whether the repair of the optical device (KEM-480AAA) is necessary.

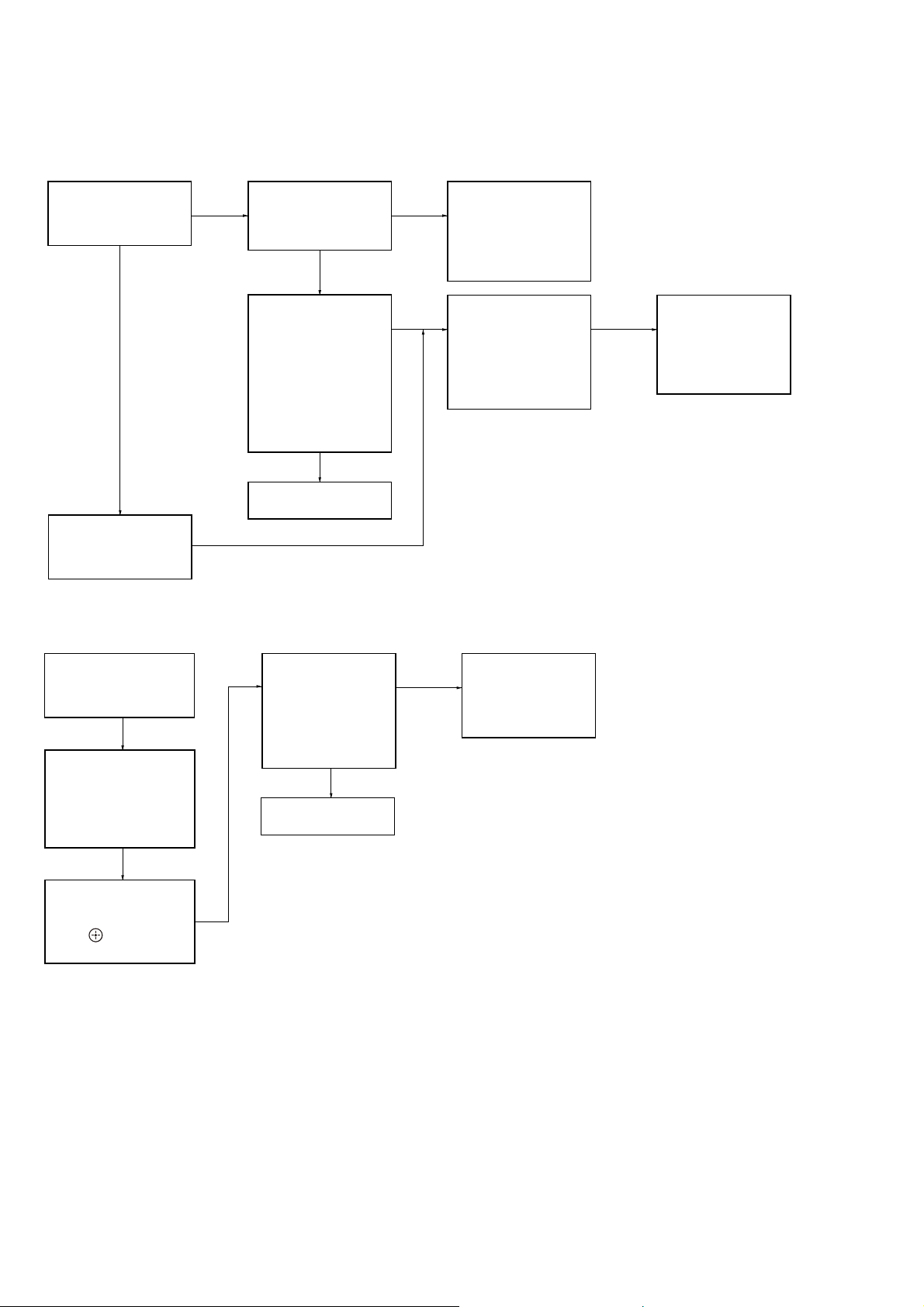

2-1. Flow of drive section check

Confirm whether

BD (BLX-104) can be

reproduced

YES

NO

Confirm whether the

drive voltage is the

following values

CN5301 pin 3 : 12 V

YES

NO

Confirm F5303,

F5305 to F5307

on the MB-149 board,

and replace it

when it has been

damaged

Confirm OP FFC cable

(Part No. 1-838-108-11)

and SPD FFC cable

(Part No. 1-828-312-51),

and replace it when it

has been damaged

Then, confirm whether

this unit operates

normally

YES

OK

Confirm whether

DVD (HLX-513)/

CD (HLX-A1) can be

reproduced

Note: Refer to “2-12. BOTTOM COVER” (page 19) about how to remove the BOTTOM COVER).

NO

NO NO

Confirm whether the

optical device IOP

is normal in the

service mode

(Refer to “2-2. Flow

of optical device

IOP check”)

2-2. Flow of optical device IOP check

Turn the power on,

and change function

to “BD/DVD”

Press the buttons on

the remote commander

in order of [DISPLAY],

[0], [2], [1] [SUBTITLE],

and enter the service

mode

Confirm whether

value is the

specification value

Specification value:

BD : ±3 mA

DVD/CD: ±3 mA

YES

OK

NO

Repalece the

optical device

(Refer to “3. Optical

device (KEM-480AAA)

replacement”)

Repalece the

optical device

(KEM-480AAA)

(Refer to “3. Optical

device (KEM-480AAA)

replacement”)

Press the buttons on

the remote commander

in order of [8], [7], [3],

[ ], and the

dIOP value is displayed

6

3. Optical device (KEM-480AAA) replacement

Flow of replacement:

Note: The photo in fl ow is an image.

Barcode label on

new optical device

(KEM-480AAA)

bottom side

Take photo (JPEG)

by digital camera

Change photo into

the text data with

the barcode decoder

HBD-NF620/NF720

Save the text data

to USB memory

(memory capacity

need not be 8GB)

Connect USB memory

with side USB connector

on this unit, and read the

text data by the service mode

Procedure:

1. Remove the INSULATOR (4 pieces) and broken optical device (KEM-480AAA) from LOADING ASSY.

2. Take photo of the barcode on new optical device (KEM480AAA) bottom side by digital camera.

3. Assemble the INSULATOR (4 pieces) to new optical device

(KEM-480AAA), fi x (Torque value: 2 kgf) it to LOADING

ASSY with screw, and assemble this unit.

4. Drag & drop the taken photo by step 2 to “BDPRDec.exe”, and

make the text data (File name: BuData.txt).

5. Save the text data to USB memory.

6. Connect USB memory with side USB connector on this unit,

and turn the power on.

– Rear view –

AUDIOTV

L

USB 1

VIDEO OUT

LAN (100)

OPTICAL

ANTENN A

COAXIAL

ARC

OUT

IN 2IN 1

FM

AUDIO INDIGITAL IN

75

R

SPEAKERS

FRONT R FRONT L SUBW OOFER

7. Press the [FUNCTION] button on the remote commander to

select “BD/DVD”.

8. Press the buttons on the remote commander in order of

[DISPLAY], [0], [2], [1], [SUBTITLE], and enter the service

mode.

9. Press the buttons on the remote commander in order of [8], [1],

[ENTER], and execute “[1] Drive OP data Write”.

10. Turn the power off after writing the OP data.

11. Turn the power on, and enter the service mode again.

12. Press the buttons on the remote commander in order of [8], [7],

[3], [ENTER], and the dIOP value is displayed.

13. Confi rm value is the following specifi cation value, and turn the

power off.

Specifi cation value:

BD : 3 mA

DVD/CD : 3 mA

14. Turn the power on, confi rm playback performance of the BD

(BLX-104)/DVD (HLX-513)/CD (HLX-A1).

15. Completely assemble this unit, and complete the repair.

7

HBD-NF620/NF720

Ver. 1.2

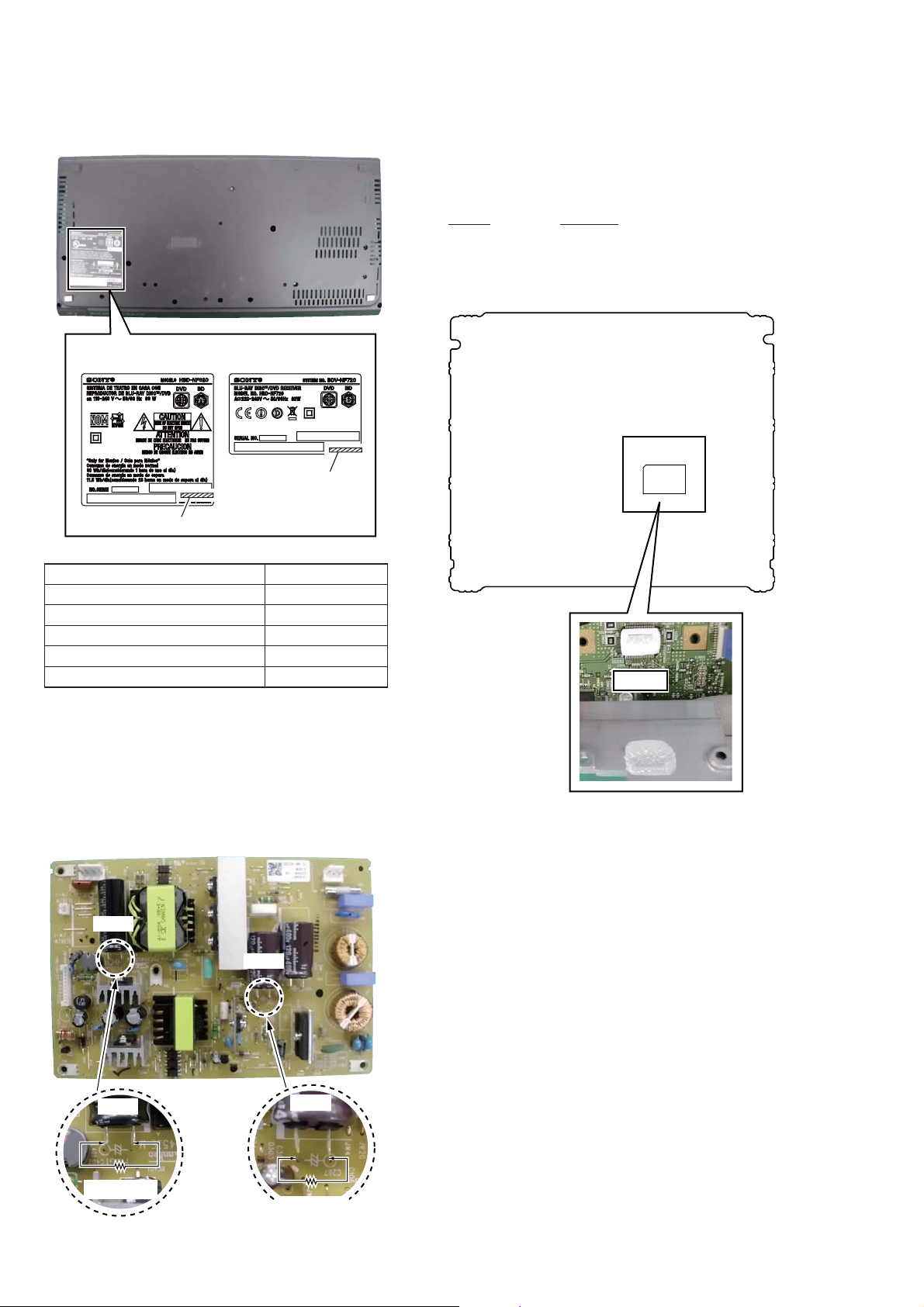

MODEL IDENTIFICATION

– Bottom side view –

The written example of model number label

Displayed characters/values are example.

Part No.

NOTE OF REPLACING THE IC3102 ON THE NX_AMP

BOARD AND THE COMPLETE NX_AMP BOARD

When IC3102 on the NX_AMP board and the complete NX_AMP

board are replaced, it is necessary to spread the compound between

parts and heat sink.

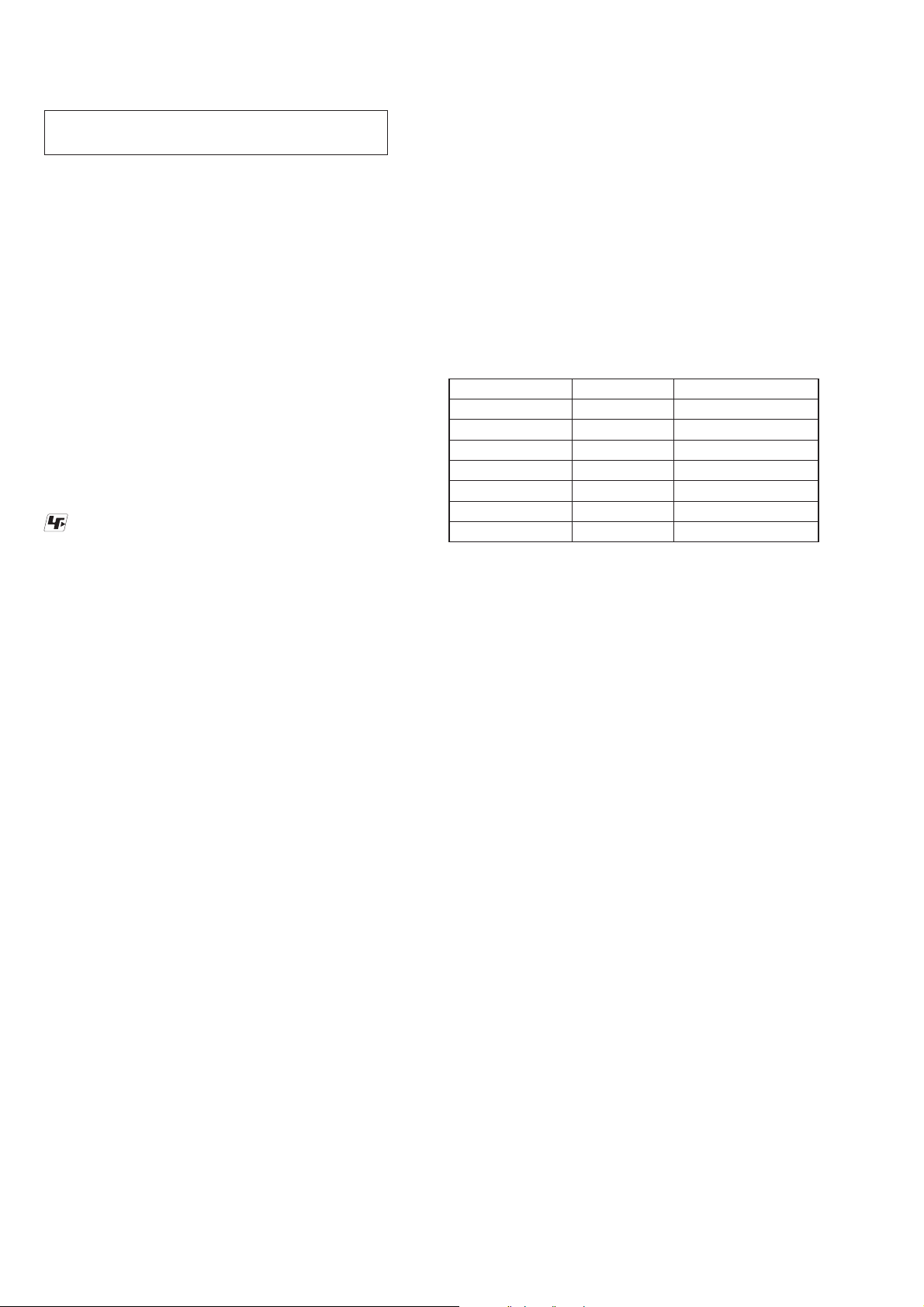

Part No. Description

J-2501-221-A THERMAL COMPOUND (G747)

Spread the compound referring to the fi gure below.

– NX_AMP Board (Component Side) –

IC3102

Part No.

Model Part No.

HBD-NF620: AEP model

HBD-NF620: Mexican model

HBD-NF720: AEP model

HBD-NF720: UK model

HBD-NF720: Taiwan model

4-409-035-0[]

4-409-058-0[]

4-414-959-0[]

4-414-959-1[]

4-417-438-0[]

CAPACITOR ELECTRICAL DISCHARGE PROCESSING

When checking the board, the electrical discharge is necessary for

the electric shock prevention.

Connect the resistor to both ends of respective capacitors.

• Switching regulator

C207, C402

– SWITCHING REGULATOR (Component Side) –

C402

C207

IC3102

ADVANCE PREPARATION WHEN CONFIRMING OPERATION

In order to perform the operation checking, all the units contained

in this unit are needed.

8

C402

800 :/2 W

C207

800 :/2 W

HBD-NF620/NF720

CHECKING METHOD OF NETWORK OPERATION

(NF720 only)

It is necessary to check the network operation, when replacing the

MB-149 board or wireless LAN card (WLC1). Check the operation

of wireless and wired LAN, according to the following method.

1. Checking Method of Wireless LAN Operation

Check that access point is recognized surely.

Necessary Equipment:

Wireless access point with router function (AP)

Procedure:

1. Press the [HOME] button on the remote commander to enter

the home menu.

2. Press the [m]/[M]/[<]/[,] buttons on the remote commander to select “Setup”“Network Settings”, and press the [ ]

button on the remote commander.

3. Select “Internet Settings”, and press the [ ] button on the remote commander.

4. Press the [m]/[M] buttons on the remote commander to select

“Wireless Setup (built-in)”, and press the [ ] button on the

remote commander.

5. The system starts searching for access points, and displays a

list of up available network name (SSID).

6. Check that access point (SSID) is displayed on the searching

result.

7. Press the [

Note: Refer to the instruction manual about details of the setting method.

] button to turn the power off.

?/1

2. Checking method of wired LAN operation

Check that access point is recognized surely.

Procedure:

1. Connect the main unit to the router or the hub, etc. with the

LAN cable.

2. Press the [HOME] button on the remote commander to enter

the home menu.

3. Press the [m]/[M]/[<]/[,] buttons on the remote commander to select “Setup”“Network Settings”, and press the [ ]

button on the remote commander.

4. Select “Internet Settings”, and press the [ ] button on the remote commander.

5. Press the [m]/[M] buttons on the remote commander to select

“Wired Setup”, and press the [ ] button on the remote commander.

6. Press the [m]/[M] buttons on the remote commander to select

“Auto”, and press the [ ] button on the remote commander.

7. Press the [,] button on the remote commander.

8. Press the [m]/[M] buttons on the remote commander to select

“Save & Connect”, and press the [ ] button on the remote

commander.

9. When “Internet Settings is now complete.” appears, then press

the [ ] button on the remote commander.

10. Press the [HOME] button on the remote commander to enter

the home menu.

11. Press the [m]/[M]/[<]/[,] buttons on the remote commander to select “Setup”“Network Settings”, and press the [ ]

button on the remote commander.

12. Press the [m]/[M] buttons on the remote commander to select

“Network Connection Diagnostics”, and press the [ ] button

on the remote commander.

13. Press the [<]/[,] buttons on the remote commander to

select “Start”, and press the [ ] button on the remote commander.

14. Confi rm that “Network connections are correct” is displayed.

15. Press the [

Note: Refer to the instruction manual about details of the setting method.

] button to turn the power off.

?/1

9

HBD-NF620/NF720

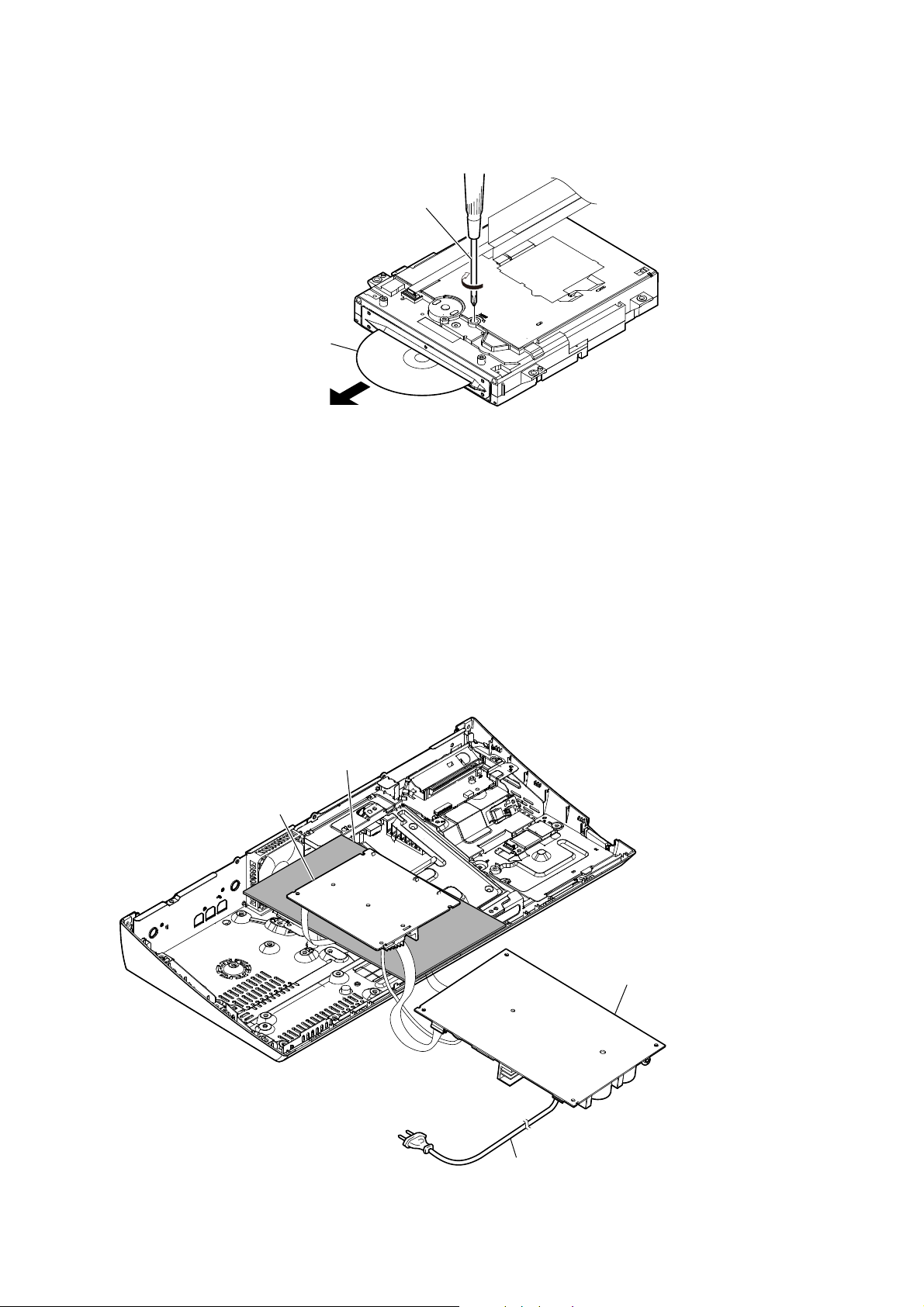

HOW TO EJECT THE DISC WHEN POWER SWITCH TURN OFF

The BD drive is taken out, and please rotate

the pulley in the direction of the arrow by

screwdriver etc. after detaching and take

out the disc.

disc

– BD drive bottom view –

NX_AMP BOARD SERVICE POSITION

insulating sheet

NX_AMP board

switching regulator (SWR1)

10

power cord

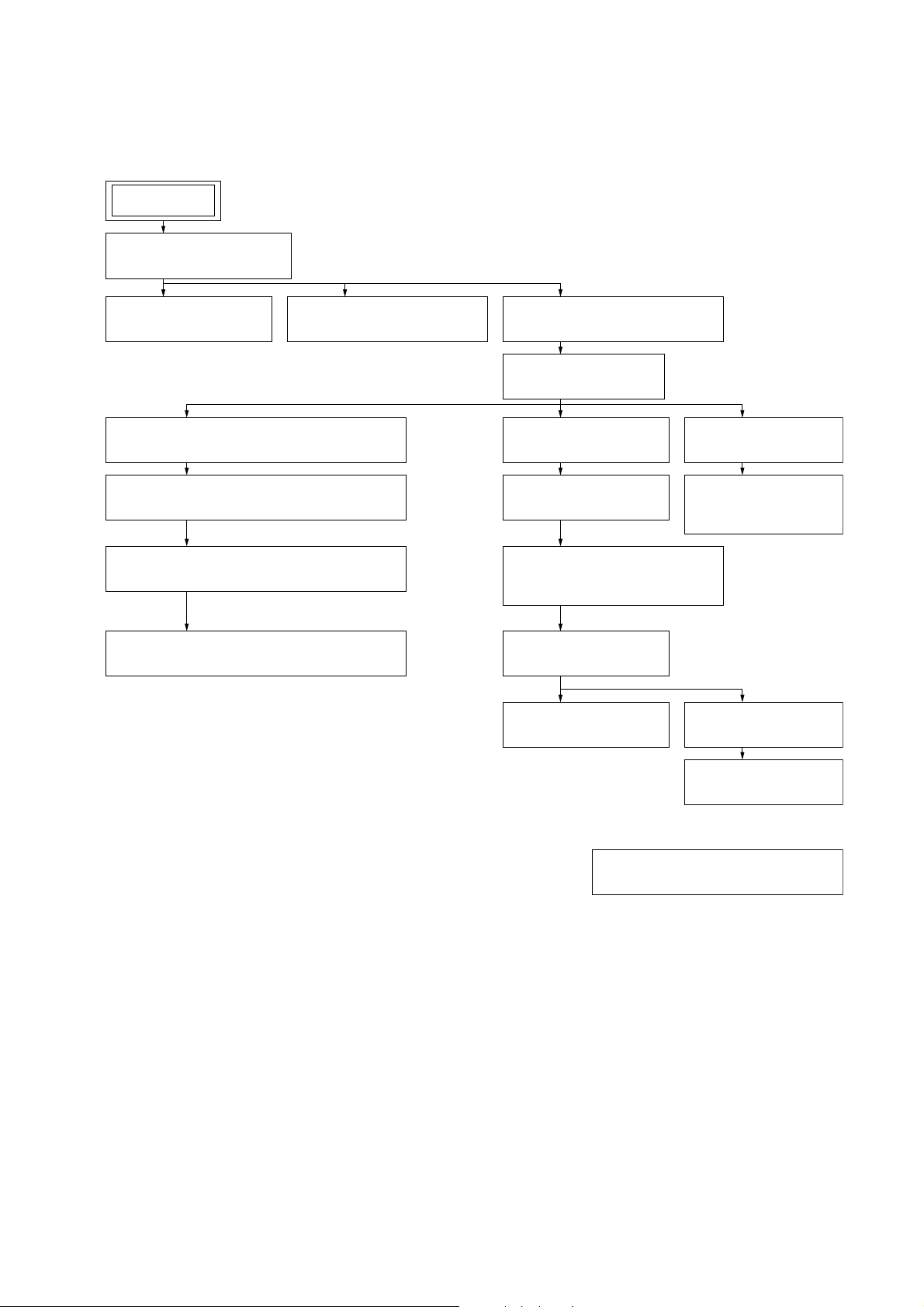

DISASSEMBLY

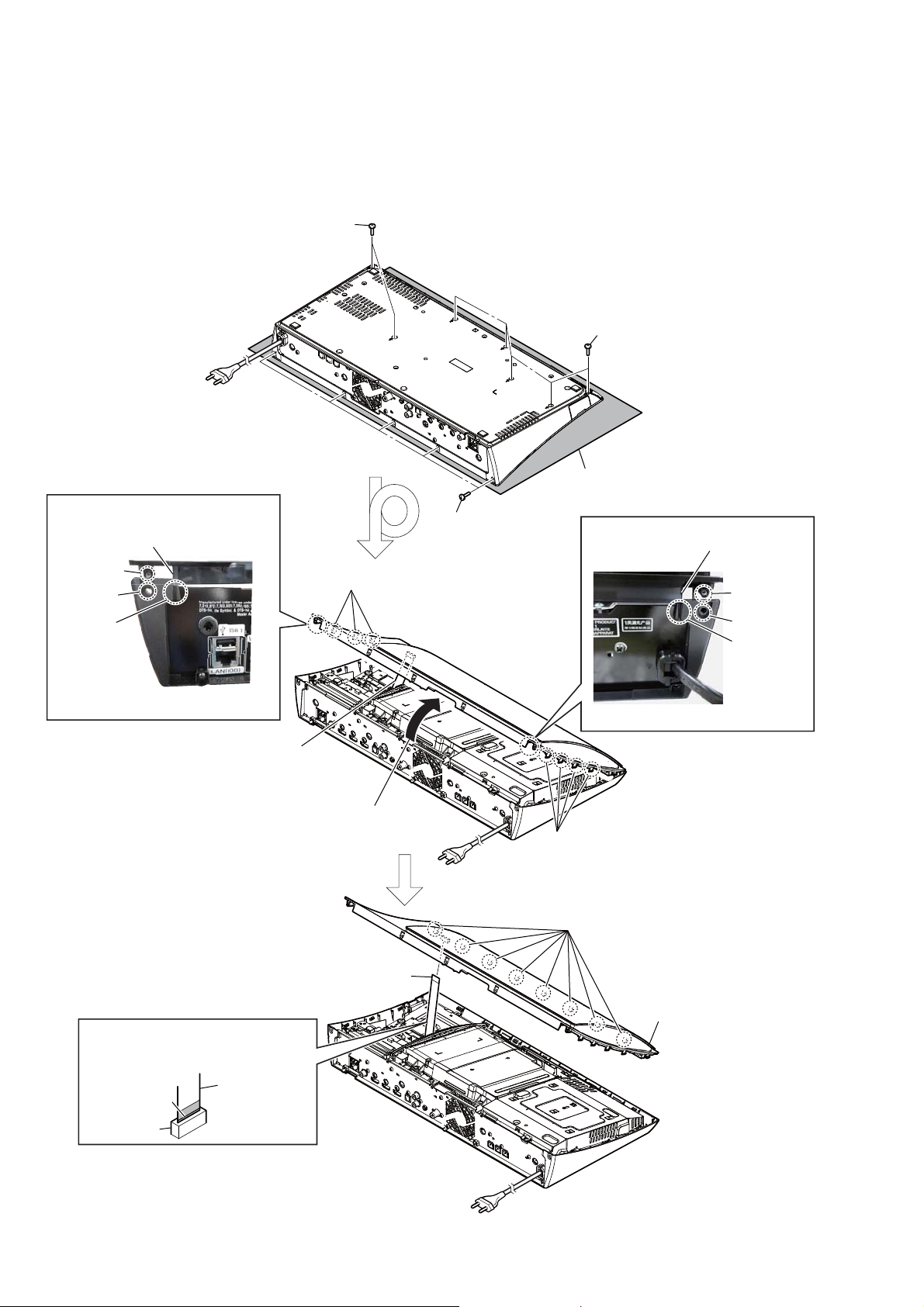

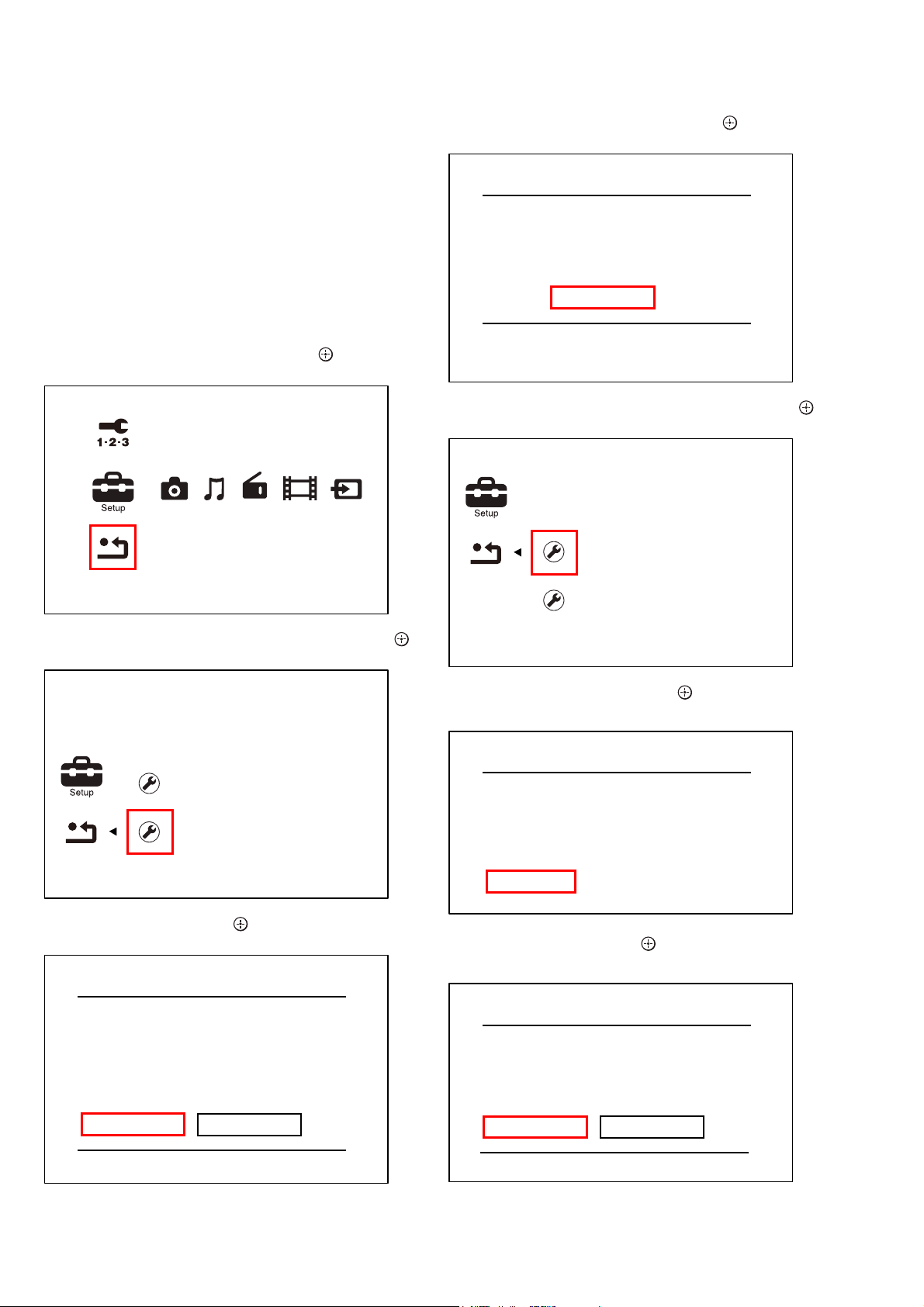

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

2-2. COVER (TOP) BLOCK

(Page 12)

HBD-NF620/NF720

SECTION 2

2-3. TOUCH BOARD

(Page 13)

2-8. WIRELESS LAN CARD (WLC1) (HBD-NF720)

(Page 16)

2-9. CHASSIS (MIDDLE) BLOCK

(Page 17)

2-10. BRACKET (DRIVE)

(Page 17)

2-11. MB-149 BOARD

(Page 18)

2-4. COVER (BOTTOM) BLOCK

(Page 14)

2-5. SHIELD (DRIVE) (HBD-NF620)

(Page 15)

2-6. BD DRIVE (BSX-3)

(Page 15)

2-7. LED BOARD

(Page 16)

2-14. SHIELD (PS) BLOCK

(Page 20)

2-15. SWITCHING REGULATOR

(SWR1)

(Page 21)

2-16. BRACKET (PS)

(Page 22)

2-17. POWER CORD (AC1)

(Page 22)

2-12. BOTTOM COVER

(Page 19)

2-13. OPTICAL PICK-UP

(KEM-480AAA)

(Page 20)

2-18. HEAT SINK (AMP)

(Page 23)

2-19. NX_AMP BOARD

(Page 23)

2-20. HOW TO BEND WIRE (FLAT TYPE)

(Page 24)

11

HBD-NF620/NF720

Note: Follow the disassembly procedure in the numerical order given.

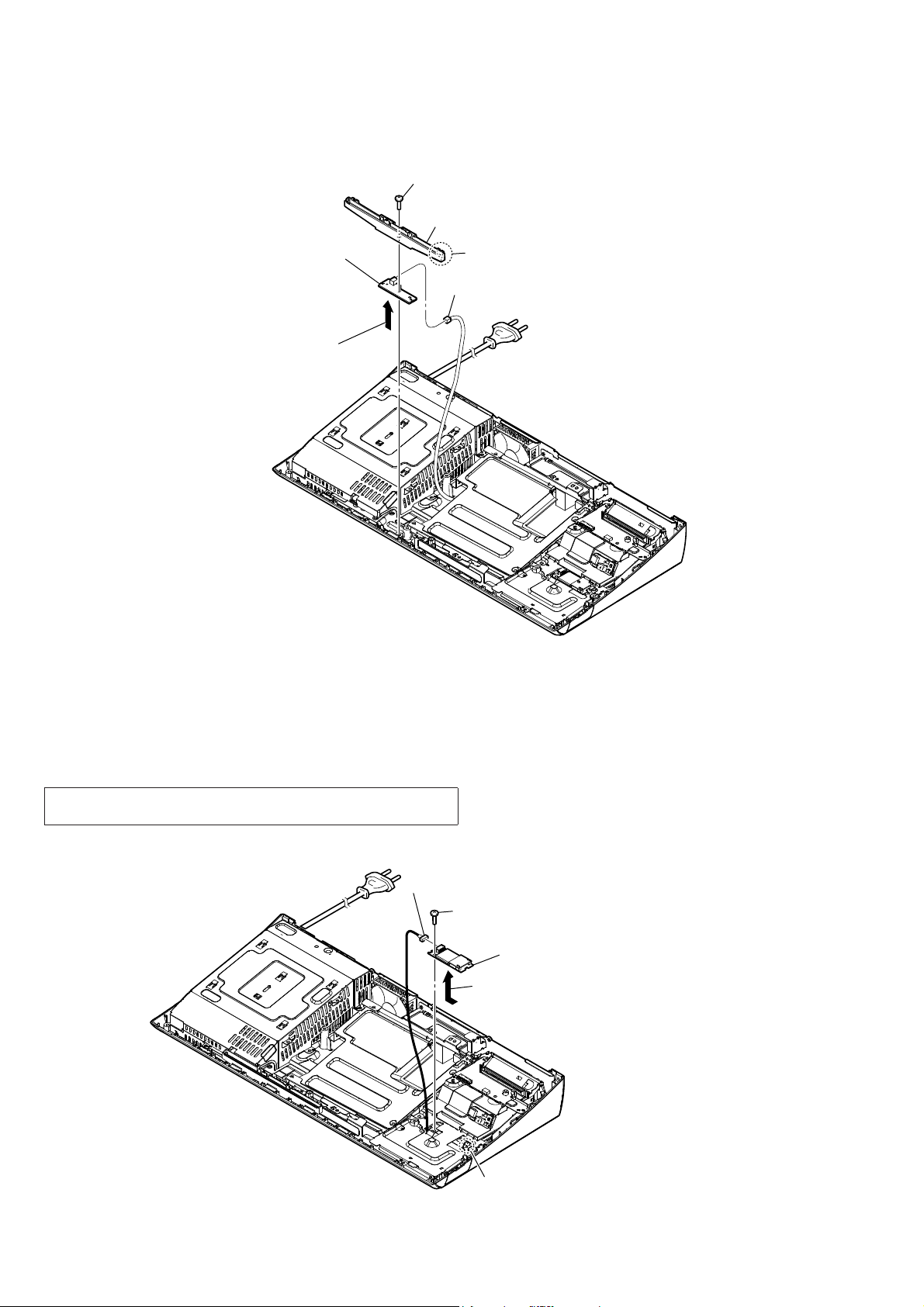

2-2. COVER (TOP) BLOCK

1 two screws

(BV DIA. 2.6 u 8)

– Rear bottom view –

Align this portion into the groove

Note 3:

and align screw boss beneath the

screw hole.

screw boss

screw hole

2 three claws

1 five screws

(BV DIA. 2.6 u 8)

1 five screws

(BV DIA. 2.6 u 8)

Please spread a sheet under a unit

Note 1:

not to injure cover (top).

Align this portion into the groove

Note 3:

and align screw boss beneath the

screw hole.

screw boss

groove

– Rear view –

Since the wire (flat type) (11core) is

Note 2:

connected, remove slowly.

When installing the wire (flat type),

Note 4:

ensure the coloured line.

No slanting after insertion.

coloured line

wire (flat type)

screw hole

groove

– Rear view –

3 Remove the cover (top) block

in the direction of an arrow.

2 four claws

– Rear top view –

4 eight claws

5 wire (flat type) (11 core)

(CN700)

6 cover (top) block

12

connector

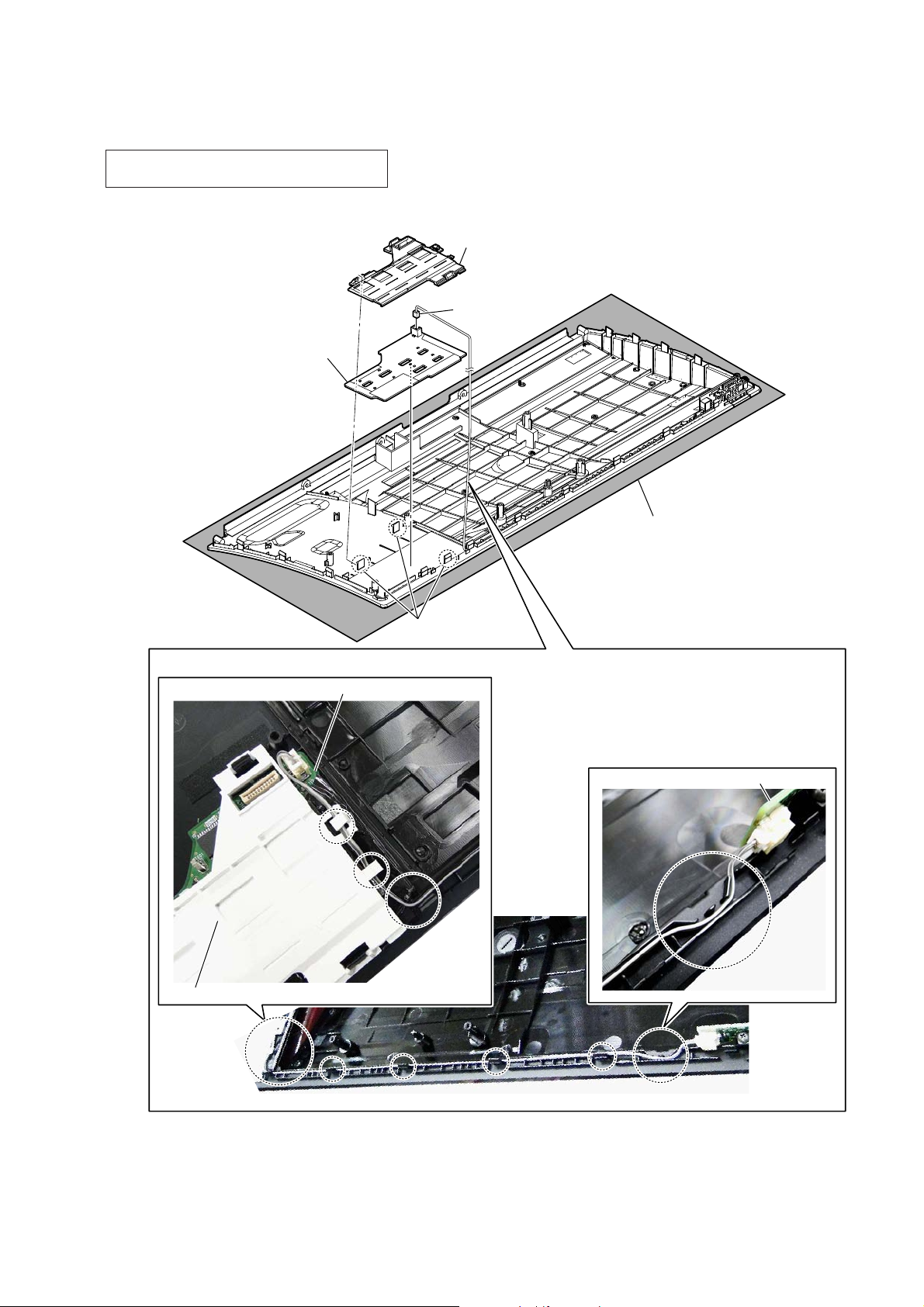

2-3. TOUCH BOARD

HBD-NF620/NF720

Note 1: When TOUCH board is defective, exchange

the complete mounted board.

4 TOUCH board

Since it is pasted by adhesion

Note 3:

sheet, remove carefully.

– Bottom view –

3 reflector (touch) assy

1 connector

(CN701)

2 three claws

Please spread a sheet under a unit

Note 2:

not to injure cover (top).

:iUe VettiQJ

reflector (touch) assy

TOUCH board

PWR_KEY board

13

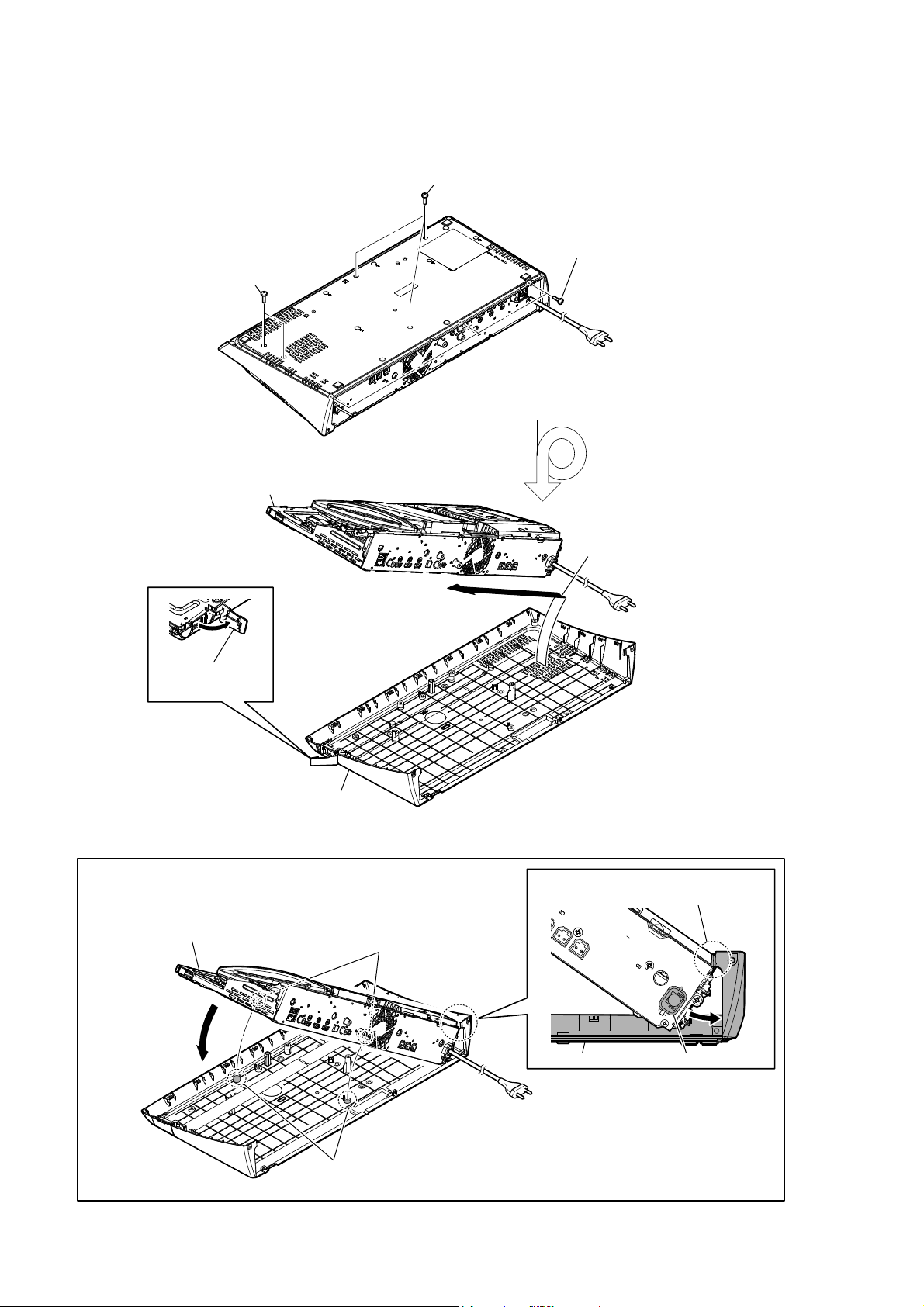

HBD-NF620/NF720

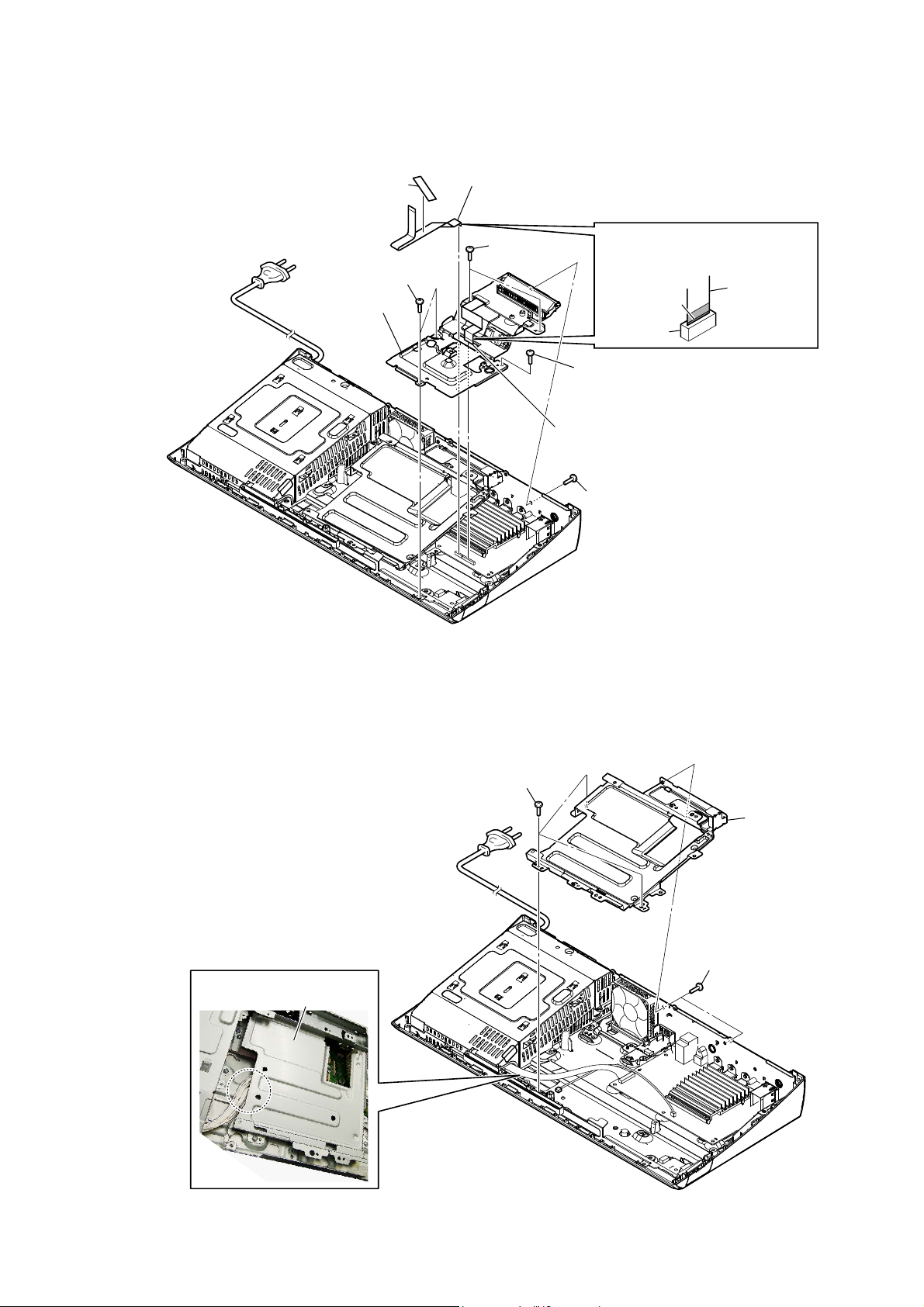

2-4. COVER (BOTTOM) BLOCK

1 three screws

(BV DIA. 2.6 u 8)

1 two screws

(BV DIA. 2.6 u 8)

4 chassis (main) block

2 Open the lid

(USB-side).

1 three screws

(BV DIA. 2.6 u 8)

– Rear bottom view –

3 Remove the chassis (main) block

in the direction of an arrow.

5 cover (bottom) block

+RZWRLQVWDOOWKHFRYHUERWWRPEORFN

2 Align two holes to two bosses and rest

down at cover (bottom) block.

– Rear top view –

– Rear top view –

1 Slant to fit the cord bushing underneath

the claw of cover (bottom) block.

two holes

cord bushingcover (bottom) block

two bosses

14

2-5. SHIELD (DRIVE) (HBD-NF620)

HBD-NF620/NF720

1 two screws

(BV3)

1 two screws

(BV3)

2 shield (drive)

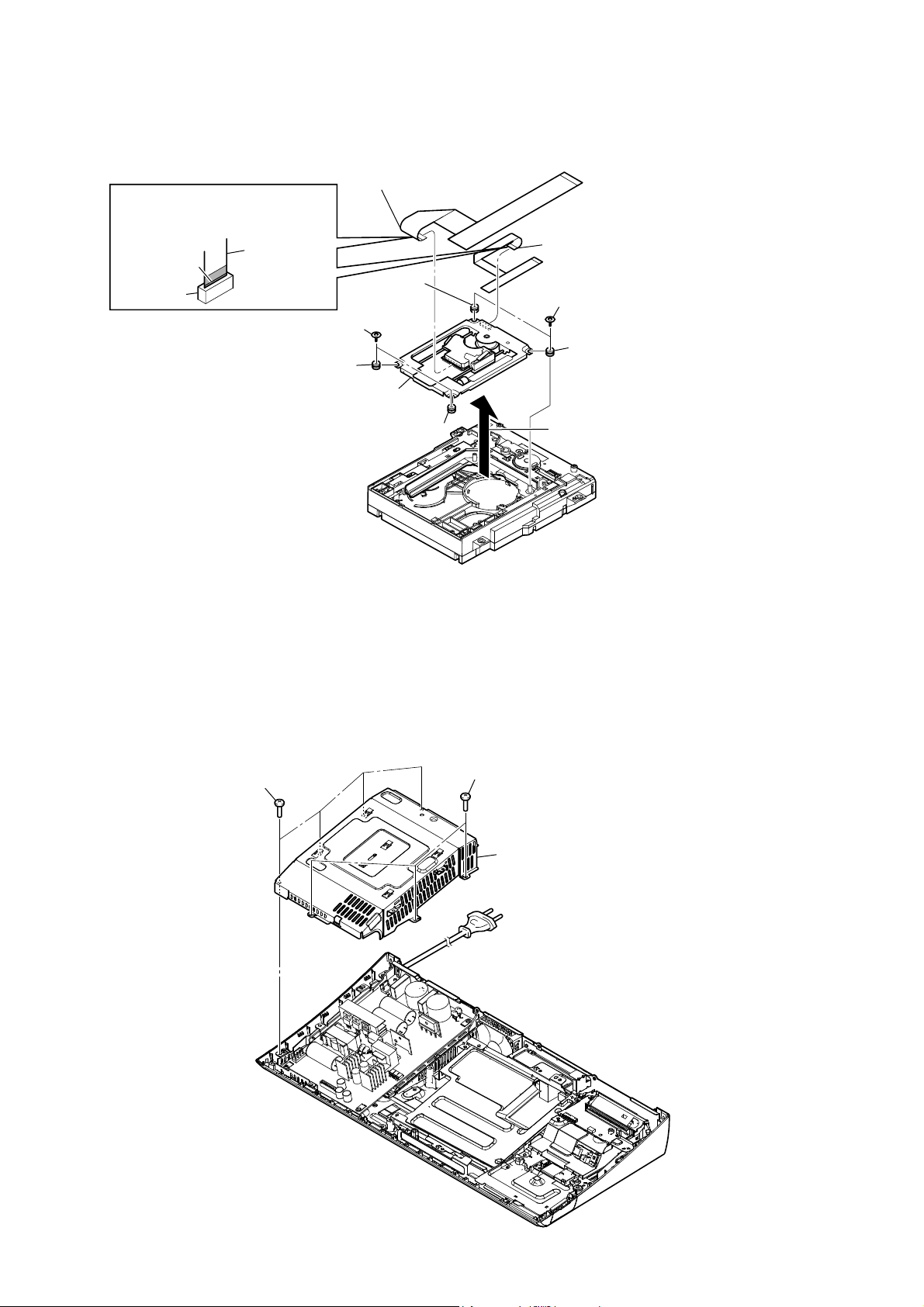

2-6. BD DRIVE (BSX-3)

8 sound sheet

2 Remove the BD drive block

in the direction of an arrow.

9 BD drive (BSX-3)

1 two screws

(BV3)

1 two screws

(BV3)

When installing the wire (flat type),

Note:

ensure the coloured line.

No slanting after insertion.

coloured line

connector

3 wire (flat type) (45P)

(CN1101)

5 wire (flat type)

(7 core) (CN1701)

4 wire (flat type)

(9 core) (CN1260)

wire (flat type)

7 bracket (slot)

6 three screws

(BV3)

15

HBD-NF620/NF720

2-7. LED BOARD

1 screw

(BV3)

3 cover (indicator) block

6 LED board

4 Remove the LED board in

the direction of an arrow.

2 claw

5 connector

(CN330)

2-8. WIRELESS LAN CARD (WLC1) (HBD-NF720)

Note: When the wireless LAN card (WLC1) is replaced, refer to “CHECKING

METHOD OF NETWORK OPERATION” on servicing notes (page 9).

4 connector

1 screw

(BV3)

5 wireless LAN card (WLC1)

3 Remove the wireless LAN card (WLC1)

in the direction of an arrow.

2 claw

16

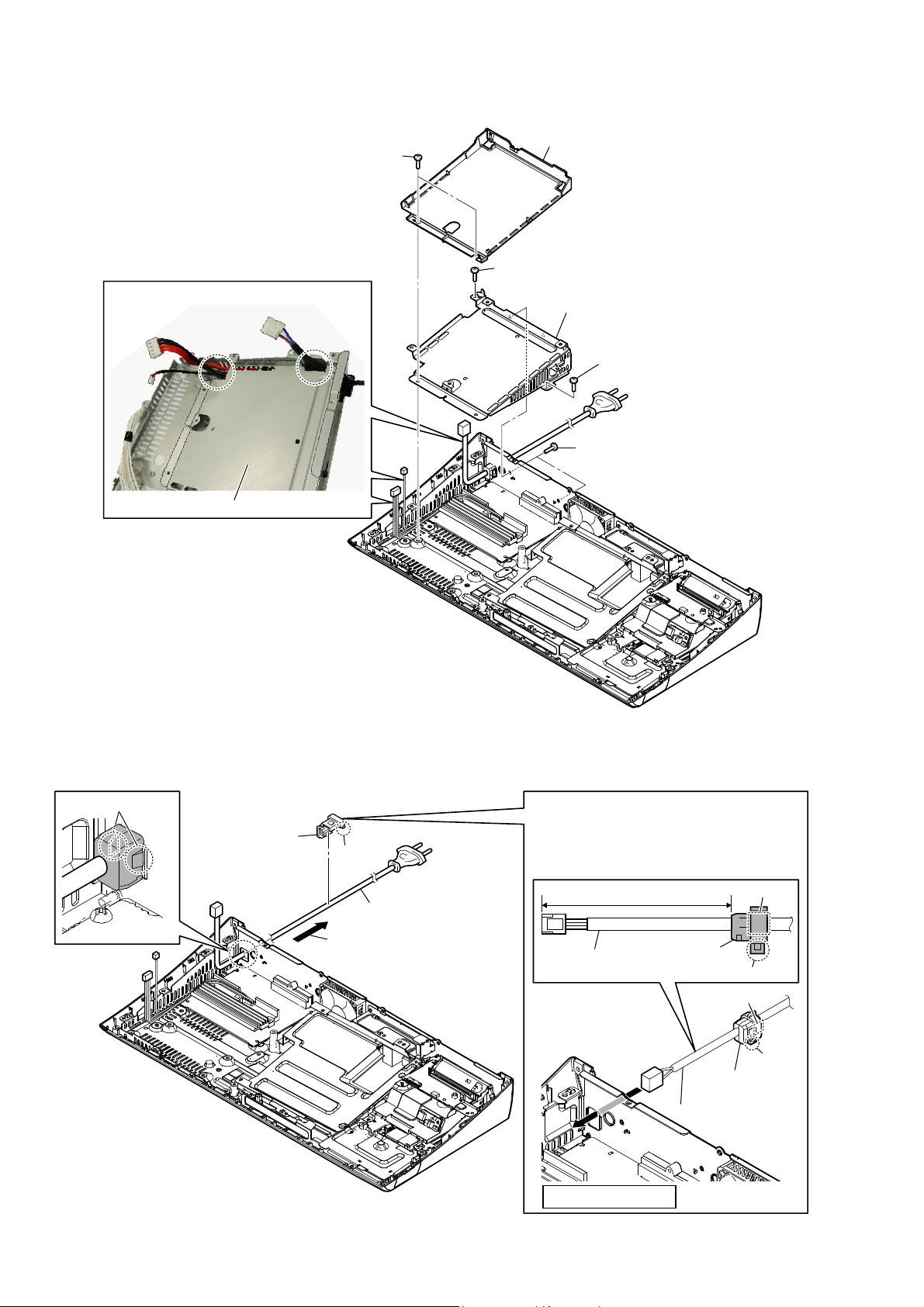

2-9. CHASSIS (MIDDLE) BLOCK

HBD-NF620/NF720

1 tape

5 two screws

(BV3)

6 chassis (middle) block

2 wire (flat type) (11 core)

(CN6303)

5 two screws

(BV3)

Note:

ensure the coloured line.

No slanting after insertion.

5 screw (BV3)

3 wire (flat type) (15 core)

(CN6304)

4 screw

(BV3)

When installing the wire (flat type),

wire (flat type)

coloured line

connector

2-10. BRACKET (DRIVE)

:LUHVHWWLQJ

2 three screws

(BV3)

3 bracket (drive)

1 two screws

(BV3)

bracket (drive)

17

HBD-NF620/NF720

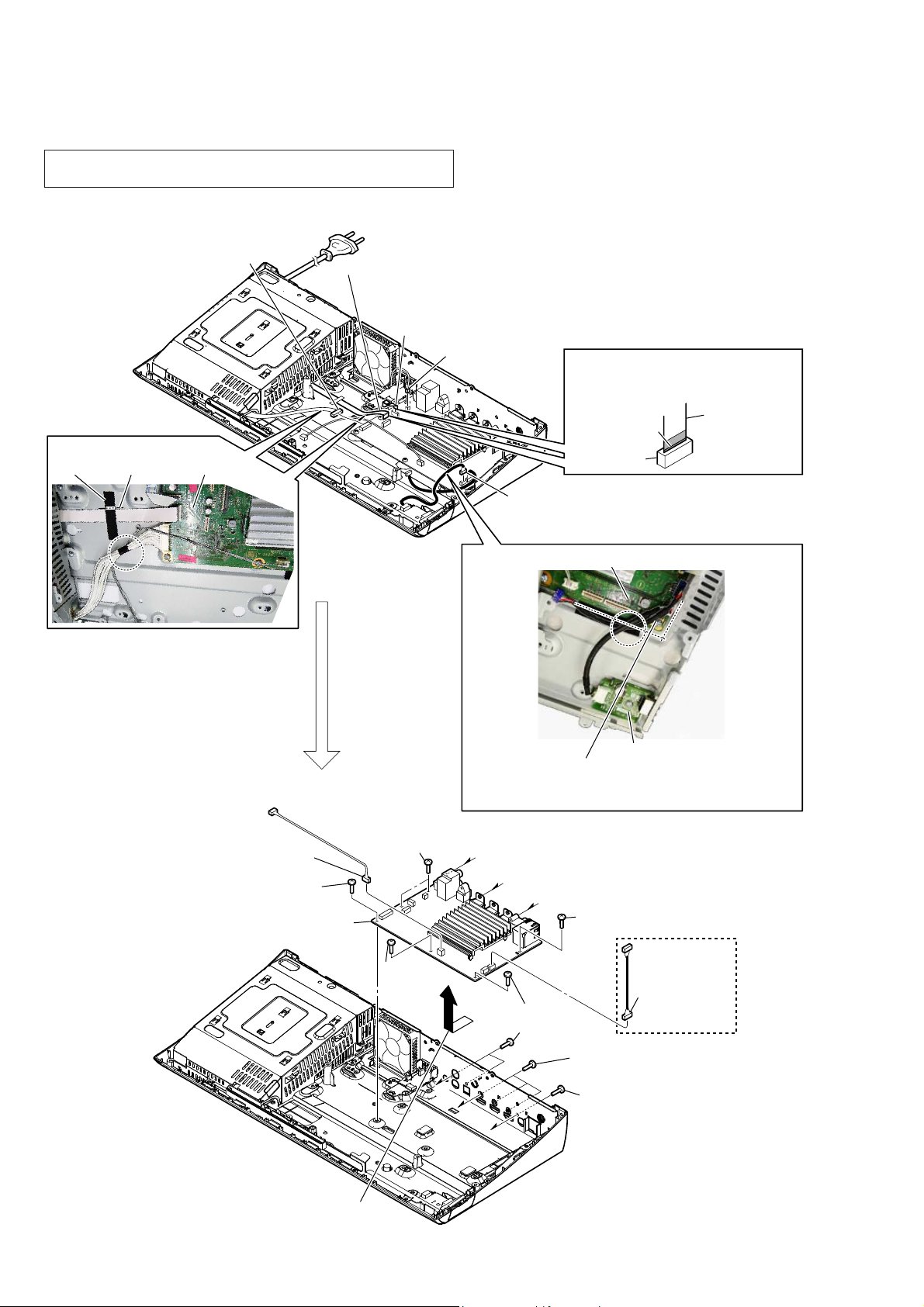

2-11. MB-149 BOARD

Note 1: When the MB-149 board is replaced, refer to “CHECKING METHOD

OF NETWORK OPERATION” on servicing notes (page 9).

1 connector

WireVeWWiQJ

tape guide line

(CN5301)

MB-149 board

2 wire (flat type) (22 core) (CN5905)

3 wire (flat type) (7 core) (CN5902)

4 connector

(CN1801)

When installing the wire (flat type),

Note 2:

ensure the coloured line.

No slanting after insertion.

coloured line

connector

wire (flat type)

qa connector

(CN6301)

8 screw

(BV3)

qs MB-149 board

8 two screws

(BV3)

A

5 connector (CN601)

MB-149 board

Arrange the wire connected with

Note 3:

the wireless LAN card to make the

outside of MB-149 board crawl.

B

C

USB board

8 screw (BV3)

18

9 Remove the MB-149 board

in the direction of an arrow.

8 screw

(BV3)

A

8 screw (BV3)

B

C

(NF720)

0 connector

(CN602)

6 two screws

(BV3)

7 three screws

(P3 u 3)

6 screw

(BV3)

2-12. BOTTOM COVER

FFC guide

5

Note 2:

unite the position of two holes of

FFC guide with two bosses of

bottom cover.

When installing the FFC guide,

4 Remove the

in the direction of an arrow.

FFC guide

6

claw

3

claw

1

hole

hole

boss

tape

hole

hole

boss

HBD-NF620/NF720

wire (flat type) (7 core)

2

When installing the wire (flat type),

Note 1:

ensure the coloured line.

No slanting after insertion.

coloured line

connector

bottom cover

8

Note 3:

unite the position of two holes of

bottom cover with two bosses of

loading assy.

When installing the bottom cover,

wire (flat type)

7 Remove the

boss

boss

loading assy

– BD drive bottom view –

:LUHIODWW\SHVHWWLQJ

wire (flat type) (9 core) wire (flat type) (9 core) wire (flat type) (7 core)

claw

in the direction of an arrow.

bottom cover

tape

flexible flat cable (45P)

– BD drive bottom view –

(FFC guide uninstalled)

claw

flexible flat cable

(45P)

OK NG

– BD drive bottom view –

(FFC guide installed)

19

HBD-NF620/NF720

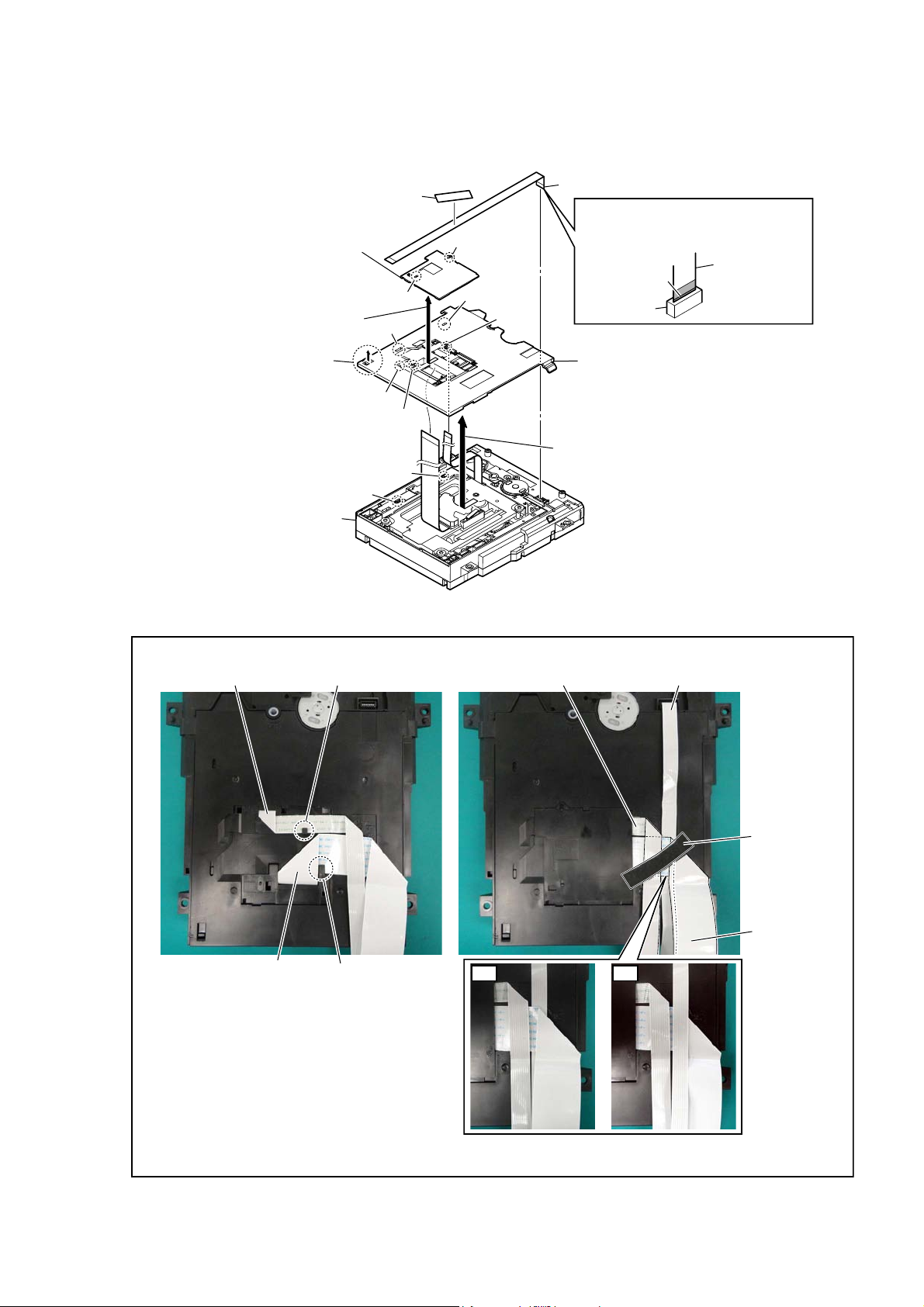

2-13. OPTICAL PICK-UP (KEM-480AAA)

When installing the wire (flat type),

Note:

ensure the coloured line.

No slanting after insertion.

coloured line

connector

wire (flat type)

1 two float screws (S)

4 flexible flat cable (45P)

5 insulator

5 insulator

6 optical pick-up

(KEM-480AAA)

5 insulator

– BD drive bottom view –

3 wire (flat type) (9 core)

1 two float screws (S)

5 insulator

2 Remove the optical pick-up block

in the direction of an arrow.

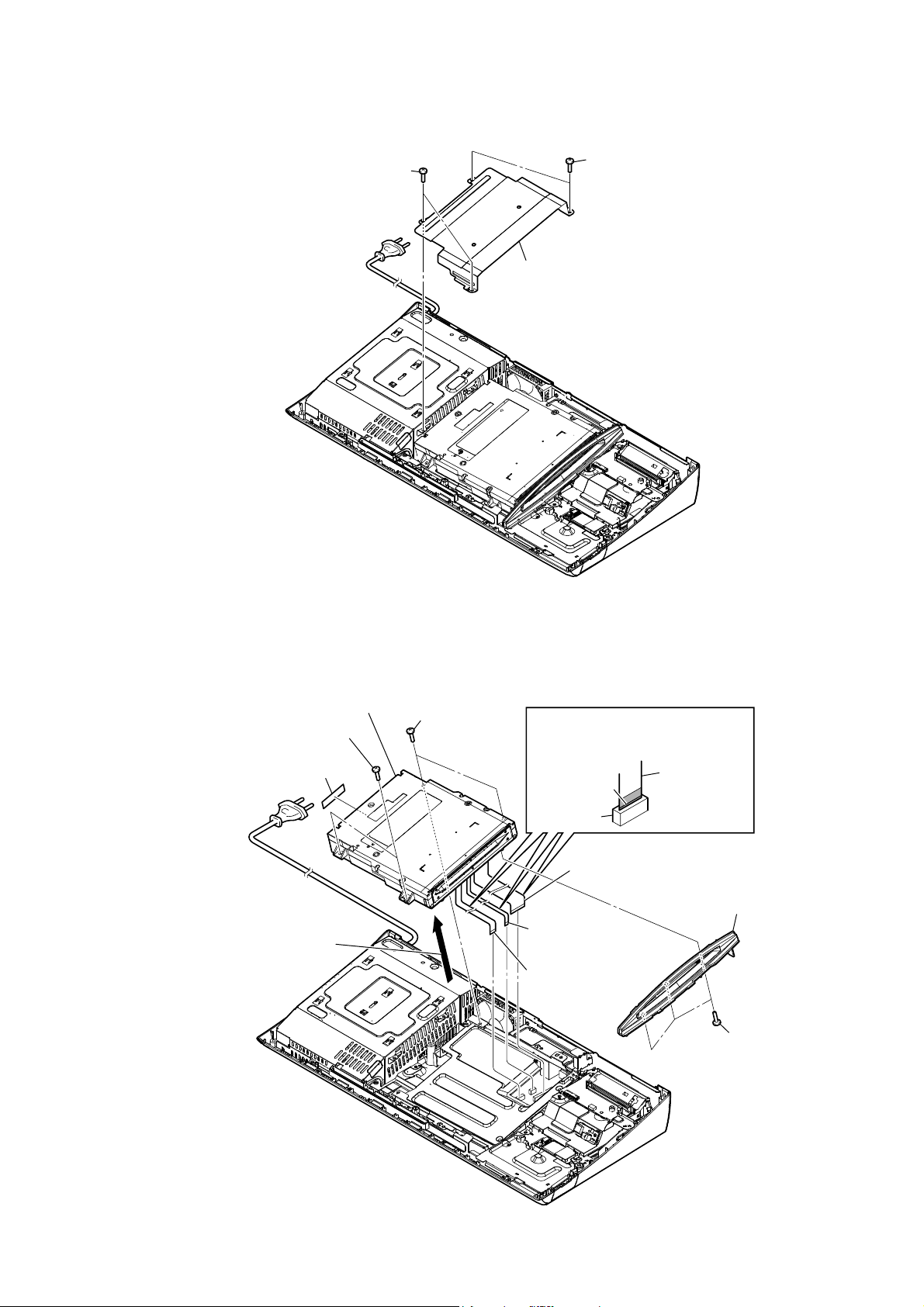

2-14. SHIELD (PS) BLOCK

1 four screws

(BV3)

1 three screws

(BV3)

2 shield (PS) block

20

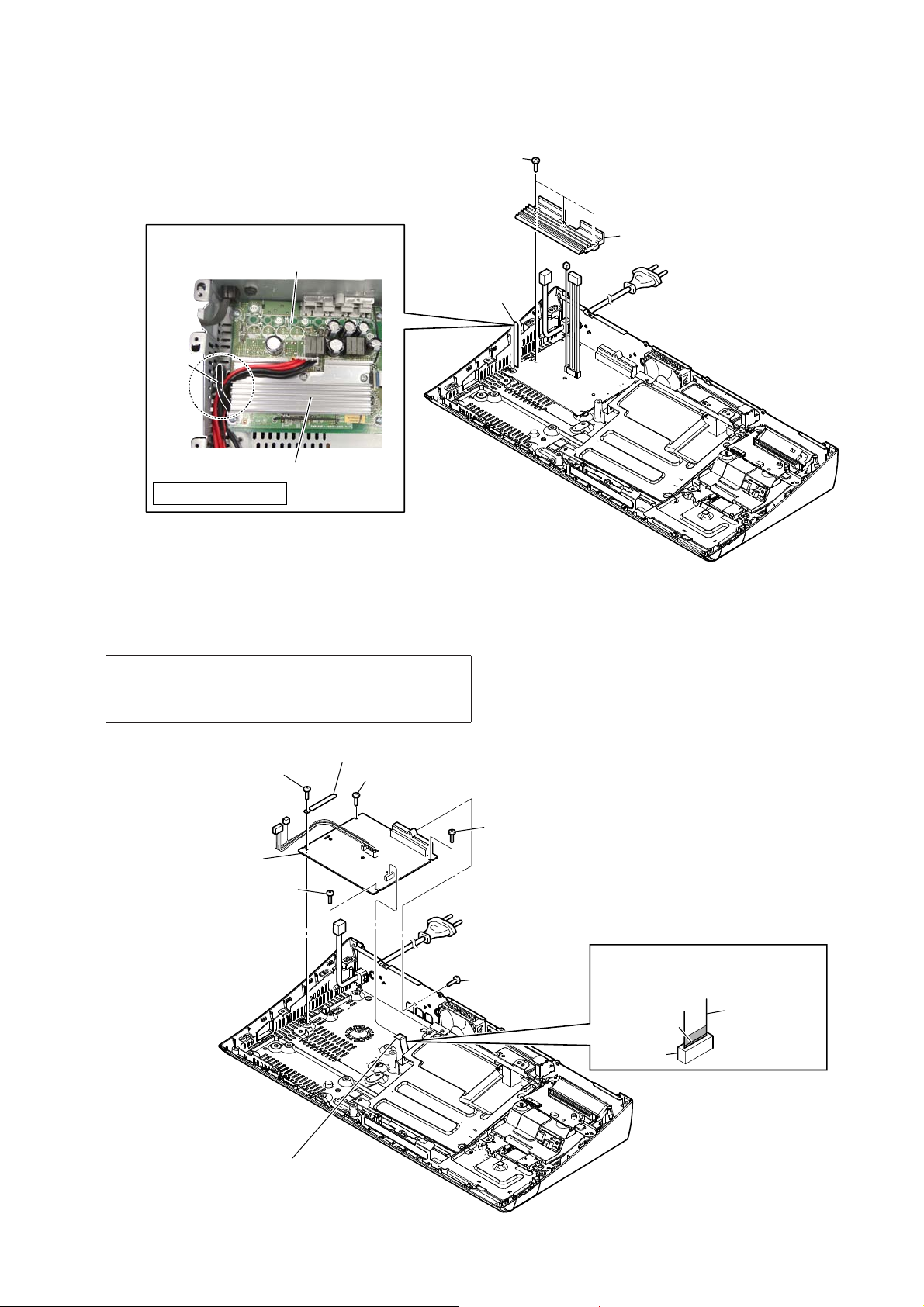

2-15. SWITCHING REGULATOR (SWR1)

1 power cord connector

(CN1)

5 two screws

(BV3)

6 switching regulator

(SWR1)

3 connector

(CN4)

2 connector

(CN101)

HBD-NF620/NF720

5 two screws

(BV3)

5 screw

(BV3)

4 connector

(CN301)

Switching regulator (SWR1) setting

switching regulator (SWR1)

power cord

Check that the C351 is bended to the

Note:

position as specified in the drawing.

coil

SAFETY STANDARD

21

HBD-NF620/NF720

2-16. BRACKET (PS)

WireVeWWiQJ

1 two screws

2 insulator (bottom)

(B3)

4 screw

(B3)

5 bracket (PS)

4 screw

(B3)

3 two screws

(B3)

bracket (PS)

2-17. POWER CORD (AC1)

1 two claws

4 cord bushing

(FBS001)

3 claw

5 power cord (AC1)

2 Remove the cord bushing

(FBS001) in the direction

of an arrow.

Cord bushing (FBS001) setting

When installing the cord bushing (FBS001),

Note:

mind the direction of claw at type No. mark

and align into the hole and press in fully.

type No.

FBS

001

claw

power cord

80 mm

cord bushing

(FBS001)

22

SAFETY STANDARD

cord bushing

(FBS001)

power cord

type No.

001

FBS

claw

2-18. HEAT SINK (AMP)

HBD-NF620/NF720

2 three screws

(transistor)

Wire setting

NX_AMP board

1 Remove wire

from the clamp.

clamp

heat sink (AMP)

SAFETY STANDARD

2-19. NX_AMP BOARD

Note 1: When the NX_AMP board is replaced, spread the compound

referring to “NOTE OF REPLACING THE IC3102 ON

THE NX_AMP BOARD AND THE COMPLETE NX_AMP

BOARD” on servicing notes (page 8)

3 heat sink (AMP)

4 clamp

3 screw

(B3)

5 NX_AMP board

3 screw

(B3)

1 wire (flat type) (22 core) (CN3504)

3 screw

(B3)

3 screw

(B3)

2 screw

(B3)

When installing the wire (flat type),

Note 2:

ensure the coloured line.

No slanting after insertion.

coloured line

connector

wire (flat type)

23

HBD-NF620/NF720

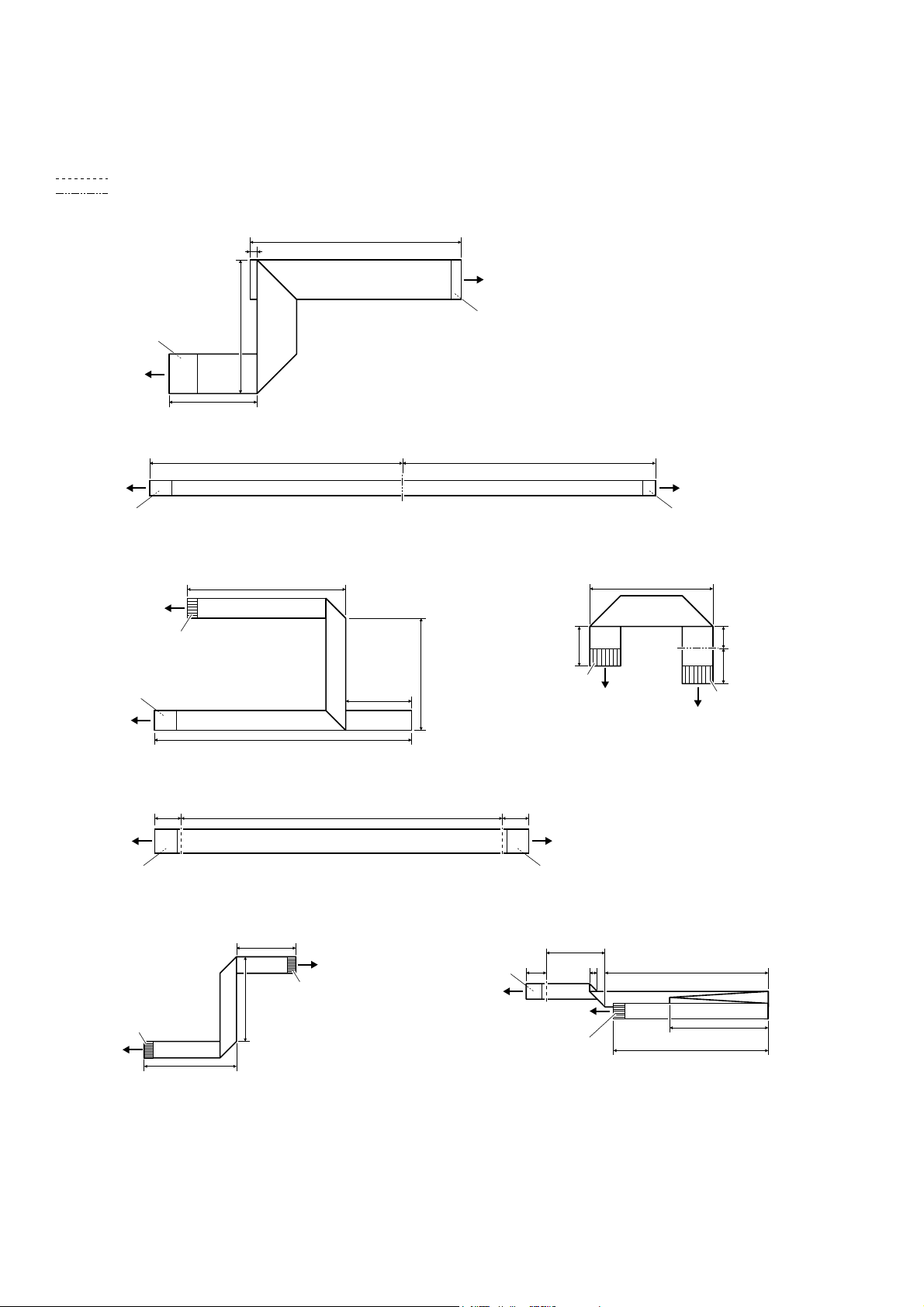

2-20. HOW TO BEND WIRE (FLAT TYPE)

: Mountain fold

: Valley fold

IOH[LEOHIODWFDEOH3OHQJWKPP5HI1R))&

120 mm

4 mm

MAIN board

(CN1101)

The lower side

is contact side.

optical pick-up

(KEM-480AAA)

ZLUHIODWW\SHFRUHOHQJWKPP5HI1R))&

MAIN board

(CN1701)

The lower side

is contact side.

ZLUHIODWW\SHFRUHOHQJWKPP5HI1R))&

optical pick-up

(KEM-480AAA)

The upper side is

terminal side.

The lower side

is contact side.

MAIN board

(CN1260)

76 mm

50 mm

115 mm 115 mm

72 mm

30 mm

117 mm

51 mm

The lower side

is contact side.

MS-486 board

The lower side

is contact side.

ZLUHIODWW\SHFRUHOHQJWKPP5HI1R))&

28 mm

9 mm

The upper side is

terminal side.

MAIN board

(CN5902)

tuner

5 mm

8 mm

The upper side is

terminal side.

IOH[LEOHIODWFDEOHFRUHOHQJWKPP5HI1R))&

12 mm12 mm 146 mm

MAIN board

(CN5905)

The lower side

is contact side.

ZLUHIODWW\SHFRUHOHQJWKPP5HI1R))& ZLUHIODWW\SHFRUHOHQJWKPP5HI1R))&

The upper side is

terminal side.

MAIN board

(CN6304)

42 mm

27 mm

31 mm

FL board

(CN903)

The upper side is

terminal side.

The lower side

is contact side.

MAIN board

(CN6303)

TOUCH board

The upper side is

terminal side.

NX_AMP board

The lower side

is contact side.

20 mm

8 mm

(CN700)

(CN3504)

9 mm

58 mm

35 mm

55 mm

24

SECTION 3

TEST MODE

HBD-NF620/NF720

COLD RESET

The cold reset clears data except BD/DVD data stored in the RAM

to initial conditions. Execute this mode when returning the unit to

the customers.

Procedure:

1. Press the [

2. Touch the [x] and [VOL –] sensors simultaneously and hold

down (around 5 seconds).

3. The message “RESET” appears on fl uorescent indicator tube,

then becomes standby states.

DEMO MODE

This mode let you lock the disc slot. When this mode is activated,

the disc will not eject when the [

sage “DEMO LOCK” will be displayed on the fluorescent indicator tube.

Procedure:

1. Press the [

2. Insert a disc.

3. Press the [HOME] button on the remote commander to enter

the home menu.

4. Touch the [x] and [Z] sensors simultaneously and hold down

until “DEMO.LOCK” or “DEMO OFF” displayed on the fluorescent indicator tube (around 5 seconds).

Releasing method:

Touch the [x] and [Z] sensors simultaneously and hold down until

“DEMO OFF” displayed on the fl uorescent indicator tube (arround

5 seconds).

] button to turn the power on.

?/1

] sensor is touched. The mes-

Z

] button to turn the power on.

?/1

PANEL TEST

Procedure:

1. Press the [

2. Press button in order of the [DISPLAY] [0] [0] [1]

[SUBTITLE] on the remote commander (Make the interval

when each button is pressed within two seconds).

3. All segments in fl uorescent indicator tube are lighted up. And

half segments in fl uorescent indicator tube are lighted up, oth-

ers half segments in fl uorescent indicator tube are lighted up,

then all segments in fl uorescent indicator tube are lighted up.

This operation is repeated.

4. When all segments in fl uorescent indicator tube are lighted up

in the state of step 3, press the [VOL +] button on the remote

commander and model information is displayed on the fl uores-

cent indicator tube.

Each time the [VOL +] button on the remote commander is

pressed, the display changes from destination information,

STR version in this order, and returns to the model information display.

Each time the [VOL –] button on the remote commander is

pressed, the version and date are switched.

5. In the state of step 3, press the [FUNCTION] button on the

remote commander and “K 0” is displayed on the fluorescent

indicator tube.

“K 0” value increases whenever a button or sensor on the unit

is pressed. However, once a button or sensor has been pressed,

it is no longed taken into account.

All button and sensors on the unit are pressed, “OK” and “K 7”

are alternately displayed on the fluorescent indicator tube.

6. In the state of step 3, press the [VOL –] button on the remote

commander and “RM” is displayed on the fluorescent indicator tube.

Confirm that “L RM R” is displayed on the fluorescent in-

dicator tube, while pressing the [VOL –] button on the remote

commander.

The remote control receiver (IC903 on the FL board and IC951

on the SIRCS board) may be defective when “L” and “R” are

not displayed.

] button to turn the power on.

?/1

Releasing method:

To release from this mode, press the [

DISC SLOT LOCK MODE

The EJECT operation by main unit, remote commander, and CEC

(path-through) can be prohibited.

Procedure:

1. Press the [\/1] button to turn the power on.

2. Insert a disc.

3. Press button in order of the [DISPLA Y] [0] [0] [4]

[SUBTITLE] on the remote commander.

(Make the interval when each button is pressed within two sec-

onds)

4. “TLK ON” is displayed on the fl uorescent indicator tube, and

the EJECT operation by main unit, remote commander, and

CEC (path-through) is prohibited.

Releasing method:

1. Press button in order of the [DISPLAY] [0] [0] [4]

[SUBTITLE] on the remote commander.

(Make the interval when each button is pressed within two sec-

onds)

2. “TLK OFF” is displayed on the fl uorescent indicator tube, and

the EJECT operation by main unit, remote commander, and

CEC (path-through) become effective.

?/1

] button.

25

HBD-NF620/NF720

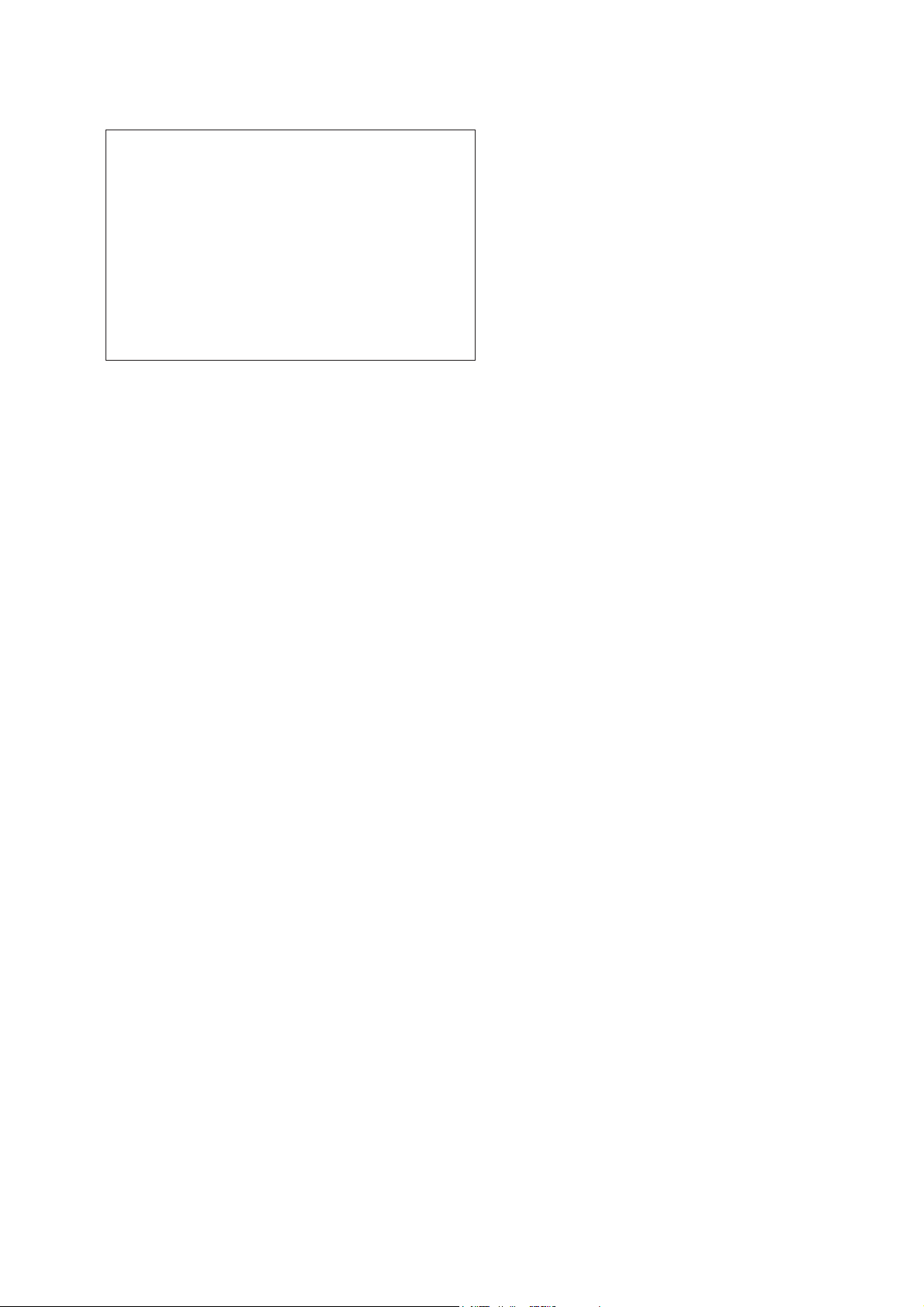

FACTORY INITIALIZE

Return all of the unit setting to their factory defaults.

Note 1: Disconnect the following connections when you use this mode.

Front USB

Rear USB

LAN

HDMI IN 1

HDMI IN 2

Note 2: The operation in this mode must use a remote commander and TV

monitor.

Procedure:

1. Press the [

] button to turn the power on.

?/1

2. Press the [HOME] button on the remote commander, and the

home menu is displayed.

3. Select “Setup” “Resetting”, and press the [

] button on the

remote commander.

Easy Setup

Resetting

6. The message “Close” appears, and press the [ ] button on the

remote commander.

Initialize Personal Information

Initialization complete.

Close

7. Select “Reset to Factory Default Settings”, and press the [ ]

button on the remote commander.

Reset to Factory Default Settings

Restore each setting to the factory d

4. Select “Initialize Personal Information”, and press the [ ]

button on the remote commander.

Reset to Factory Default Settings

Initialize Personal Information

Erase personal data when disposing

5. Select “OK”, and press the [ ] button on the remote commander.

Initialize Personal Information

The information below will be deleted.

Do you want to proceed?

- Playback history

- Internet video utilization information

Initialize Personal Information

8. Select “All Settings”, and press the [ ] button on the remote

commander.

Reset to Factory Default Settings

Parental Control Settings

Music Settings

System Settings

Network Settings

External Input Settings

All Settings

9. Select “Start”, and press the [ ] button on the remote commander.

All Settings

Restore all settings to the factory default

settings. The system will turn off after

reset.

26

OK

Cancel

Start

Cancel

10. Initialization ends when the message “WELCOME” on the

fl uorescent indicator tube disappears.

BD SERVICE MODE

[Wireless checking fail on M07.R.179]

Due to software bug in M07.R.179, currently Service mode do not support wireless checking features this version of software.

For service to confi rm the wireless checking, please update customer

sets to latest version of software. By using network upgrade method

or Disc upgrade method. After fi nish upgraded, Service member can

perform wireless checking as mention in wireless LAN checking pages.

Or

Confi rm wireless LAN connection from customer mode, in case of

Wireless connection successfully establish. The wireless Lan network

connection will be judge as OK.

Date: 26 January 2011

Note: The operation in this mode must use a remote commander and TV

monitor.

Setting method of the BD service mode:

1. Connect this unit with TV monitor.

2. Press the [

] button to turn the power on.

?/1

3. Press button in order of the [DISPLA Y] [0] [2] [1]

[SUBTITLE] on the remote commander. (Make the interval

when each button is pressed within two seconds)

4. Enter the BD service mode. The OSD menu on TV monitor

can be operated by remote commander.

HBD-NF620/NF720

1. Main Functions

• Diag

Performs unit test of devices installed on the board.

• Display Error Log

Error log is displayed. Displayed contents can also be saved in

an USB memory device.

• Factory Initialize

Restores the unit to its factory settings.

• Network

Checks the wired network connection.

• Version Up

Not used.

• System Information

Displays the system information of the unit.

Displays information such as the software version, drive infor-

mation, etc.

• EMC Test Mode

Not used.

• Drive

Write drive OP data and check drive.

• HDD mode

Not used.

27

HBD-NF620/NF720

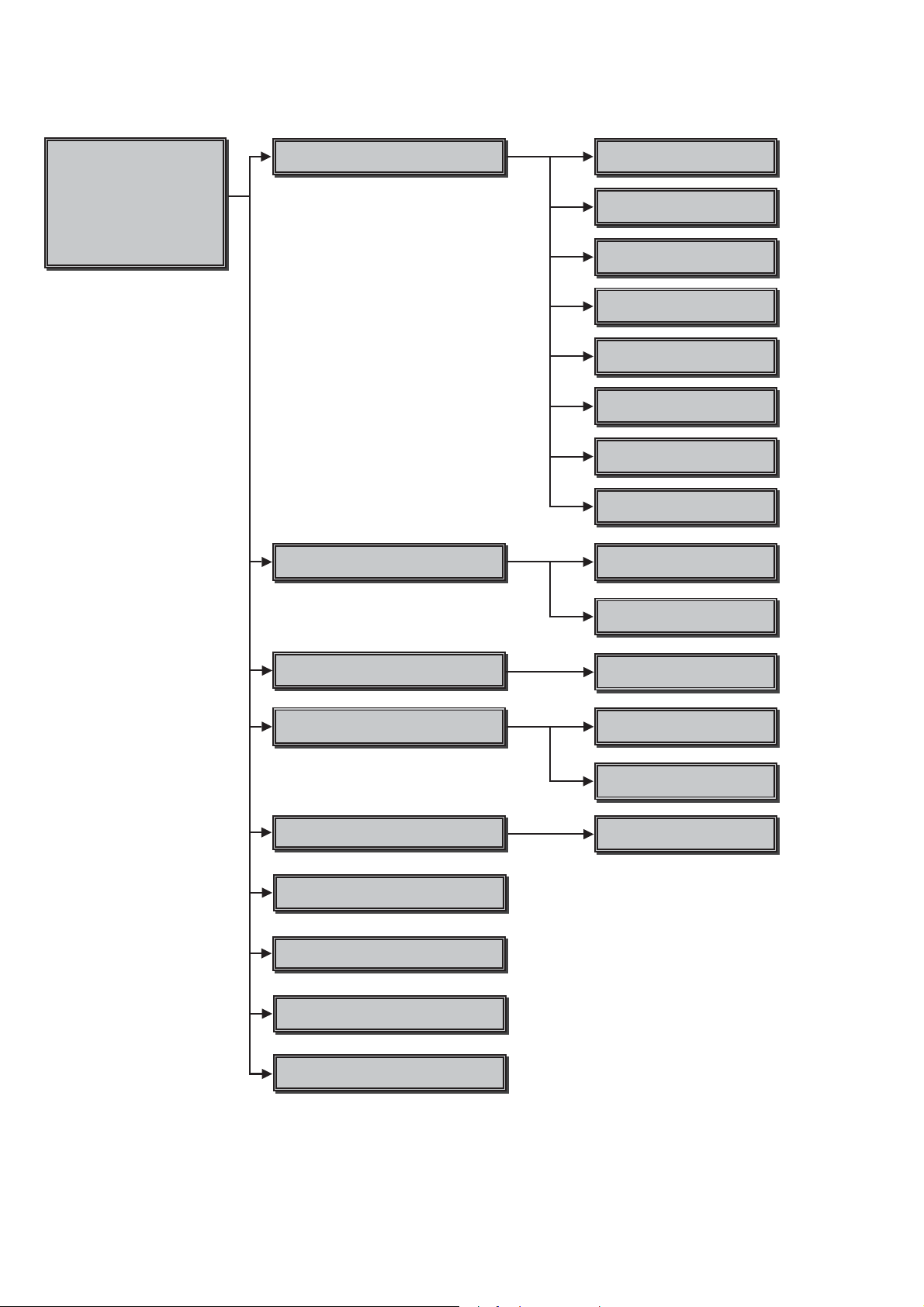

2. Menu Tree

Service Mode Menu

Service Mode Menu

[1] Diag

[1] Diag

[2] Log

[2] Log

[3] Factory Initialize

[3] Factory Initialize

[4] Network

[4] Network

[5] Version Up

[5] Version Up

[6] System Information

[6] System Information

[7] EMC Test Mode

[8] Drive

[9] HDD Mode

Diag

Diag Test

Log

Displays Error Log

Device Test

Front US%D$CIFcon test

Video Test

Video output test

$udio Test

$udio output test

$udio Input Test

Not used

:ireless L$N Test

Not used

Mic Test

Not used

HDMI Input Test

Not used

Transcoder Test

Not used

Error Log

Displays error log

Factory Initialize

Initialize default setting

Network

Network diagnosis for wired

Version Up

Not used

System Information

Displays system information

EMC Test Mode

Not used

Drive

Write drive OP data and check drive

HDD log

Not used

Start Initialize

Initialize default setting fot the unit

Ifconfig

View network status

Ping

Confirm network connection

Start Update

Not used

28

HDD Mode

Not used

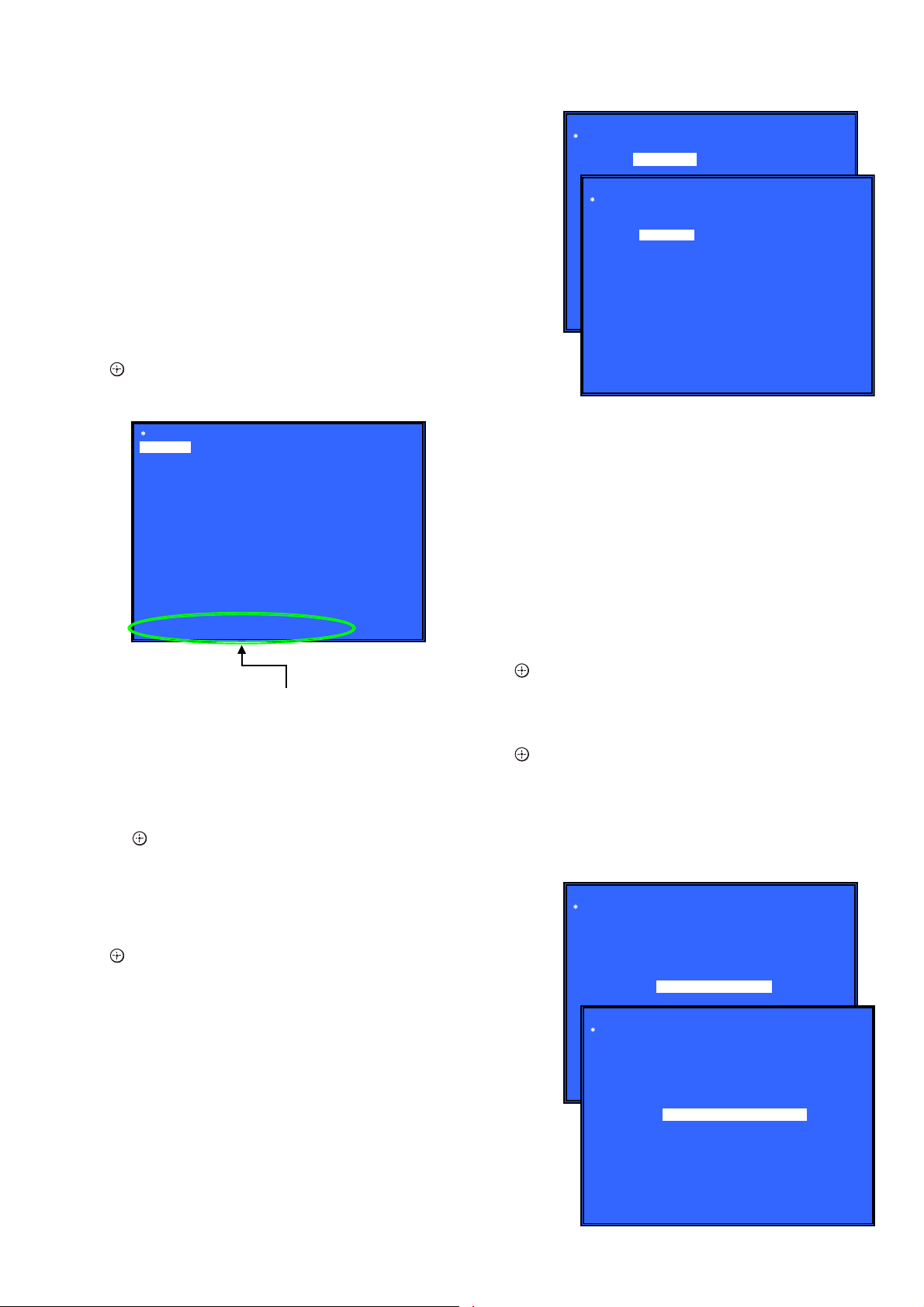

3. Service Mode Menu (Top Menu)

This is the top menu of service mode.

Each function is accessed from this screen.

Operation:

[1] Moves to Diag screen

[2] Moves to Log screen

[3] Moves to Factory Initialize screen (Not used)

[4] Moves to Network screen

[5] Moves to Version Up (DISC version update) screen (Not

used)

[6] Moves to System Information screen

[7] Moves to EMC test mode screen (Not used)

[8] Moves to Drive screen

[9] Moves to HDD mode (Not used)

[M]/[m] Moves the cursor

[ ] Moves to the screen of the item selected with the cursor

* Cursor is not displayed when the menu is fi rst displayed.

Service Mode Menu

[1] Diag

[1] Diag

[2] Log

[3] Factory Initialize

[4] Network

[5] Version Up

[6] System Information

[7] EMC Test Mode

[8] Drive

[9] HDD mode

HBD-NF620/NF720

Diag

Category:

Diag

(Screen 1)

(Screen 2)

HELP: [RIGHT] [UP] [ENT] [RET]

• Device Test: List of devices

USB Host : USB media check (front). Only one time.

D/A Converter : DAC wtite check (non-verifi cation).

Ifcon : Not used in this unit.

MIC : Only karaoke model used.

MFI : MFI read/write check.

IPC : Not used in this unit.

External HDMI : Not used in this unit.

Transcorder : Not used in this unit.

Device Test

Category: Device Test

USB Host

Device:

Front USB Media check ... OK

Checking...

HELP : [DOWN] [ENT] [(NUM)]

HELP (currently available keys, etc.) is displayed

4. Diag (Device Test)

This screen is used to test devices mounted on the board.

Screen 1: Selects the test category

Operation:

[<]/[,] Selects the category

[m]/[ ] Moves to the selected category

[RETURN] Returns to the service top menu

Screen 2: Device test

Selects the device to test after selecting Device Test in screen 1.

Operation:

[<]/[,] Selects the device to test

[ ] Executes the test

[M] Returns to selection of test category

[RETURN] Returns to selection of test category

• List of test categories

Device Test

Video Test

Audio Test

Audio Input Test (not used)

Wireless LAN Test (not used)

Mic Test (not used)

HDMI Input Test (not used)

Transcoder Test (not used)

5. Diag (Video/Audio Test)

This screen performs video and audio tests.

Screen 1: When video test category is selected

Operation:

[ ] Shows/hides the color bar

]/[RETURN] Returns to the selection of test category

[

M

Screen 2: When audio test category is selected

Operation:

[

] Plays back/stops the tone sound

]/[RETURN] Returns to the selection of test category

[

M

• Video test:

Outputs a color bar (composite & HDMI).

• Audio test:

TONE sound output (speaker & HDMI).

Diag

Category: Video Test

[ENT] Show Color Bar

Diag

Category: Audio Test

(Screen 1)

HELP: [UP][ENT][RET]

[ENT] Generate TONE Sound

(Screen 2)

HELP: [UP] [ENT] [RET]

29

Loading...

Loading...