Page 1

T

T

GTK-XB7

SERVICE MANUAL

US Model

Canadian Model

Ver. 1.0 2016.01

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC

DISTORTION:

(The United States model only)

Left/Right Channel:

With 3 ohms loads, both channels

driven, from 120

30 watts per channel minimum

RMS power, with no more than

0.7% total harmonic distortion from

250 milliwatts to rated output.

10,000 Hz; rated

Amplier section

he following are measured at

AC 120 V – 240 V, 50/60 Hz

Power Output (rated):

Left/Right Channel: 130 W + 130 W

(at 3 ohms, 1 kHz, 1% THD)

RMS output power (reference):

Left/Right Channel: 235 W + 235 W

(per channel at 3 ohms, 1 kHz, 30%

THD)

Speaker section

Speaker system:

Tweeter + Woofer

weeter L/R:

50 mm (2 in) × 3, cone type

Woofer:

160 mm (6 in) × 2, cone type

Inputs

AUDIO/PARTY CHAIN IN L/R:

Voltage 2 V, impedance 10 kilohms

Outputs

AUDIO/PARTY CHAIN OUT L/R:

Voltage 2 V, impedance 600 ohms

USB section and supported

audio formats

(USB) port:

Type A, maximum current 2.1 A

Supported bit rate:

MP3 (MPEG1 Audio Layer-3):

32 kbps

320 kbps, VBR

WMA: 32 kbps

Sampling frequencies:

MP3 (MPEG1 Audio Layer-3):

32/44.1/48 kHz

WMA: 44.1 kHz

192 kbps, VBR

BLUETOOTH section

Communication system:

BLUETOOTH Standard version 3.0

Output:

BLUETOOTH Standard Power Class 2

Maximum communication range:

Line of sight approx. 10 m (33 feet)

Frequency band:

2.4 GHz band (2.4000 GHz –

2.4835 GHz)

Modulation method:

FHSS (Freq Hopping Spread

Spectrum)

Compatible BLUETOOTH profiles

A2DP (Advanced Audio Distribution

Profile)

AVRCP (Audio Video Remote Control

Profile)

SPP (Serial Port Profile)

Supported codecs:

SBC (Sub Band Codec)

AAC (Advanced Audio Coding)

LDAC

1)

The actual range will vary depending

on factors such as obstacles between

devices, magnetic fields around a

microwave oven, static electricity,

reception sensitivity, antenna’s

performance, operating system, software

application, etc.

2)

BLUETOOTH standard profiles indicate the

purpose of BLUETOOTH communication

between devices.

2)

:

General

Power requirements:

AC 120 V, 60 Hz

Power consumption:

60 W

Standby power consumption:

When BLUETOOTH standby mode is

set to off: 0.5 W (eco mode)

When BLUETOOTH standby mode is

set to on: 2.8 W (all wireless network

ports on)

Dimensions (W/H/D) (Approx.):

330 mm × 650 mm × 340 mm (13 in

× 25 in × 13 in)

Mass (Approx.):

12 kg (26 lb 16 oz)

Quantity of the system:

1 piece

Supplied accessories:

1)

Remote control (1)

R03 (size AAA) batteries (2)

AC power cord (1)

Design and specifications are subject to

change without notice.

HOME AUDIO SYSTEM

9-896-261-01

2016A33-1

2016.01

©

Sony Video & Sound Products Inc.

Published by Sony Techno Create Corporation

Page 2

GTK-XB7

License and Trademark

Notice

s MPEG Layer-3 audio cAoding

technology and patents licensed

from Fraunhofer IIS and Thomson.

s Windows Media is either a registered

trademark or trademark of Microsoft

Corporation in the United States

and/or other countries.

s This product is protected by

certain intellectual property rights

of Microsoft Corporation. Use or

distribution of such technology

outside of this product is prohibited

without a license from Microsoft or

an authorized Microsoft subsidiary.

s The BLUETOOTH® word mark and

logos are registered trademarks

owned by Bluetooth SIG, Inc. and

any use of such marks by Sony

Corporation is under license. Other

trademarks and trade names are

those of their respective owners.

s The N Mark is a trademark or

registered trademark of NFC Forum,

Inc. in the United States and in other

countries.

s Android™ is a trademark of Google

Inc.

s Google Play™ is a trademark of

Google Inc.

s LDAC™ and LDAC logo are

trademarks of Sony Corporation.

s Apple, the Apple logo, iPad, iPhone,

and iPod touch are trademarks of

Apple Inc., registered in the U.S. and

other countries. iPad Air and iPad

mini are trademarks of Apple Inc.

App Store is a service mark of Apple

Inc.

s “Made for iPod,” “Made for

iPhone,” “Made for iPad” mean

that an electronic accessory

has been designed to connect

specifically to iPod , iPhone, or iPad

respectively, and has been certified

by the developer to meet Apple

performance standards. Apple is not

responsible for the operation of this

device or its compliance with safety

and regulatory standards. Please

note that the use of this accessory

with iPod, iPhone, or iPad may affect

wireless performance.

s All other trademarks and registered

trademarks are of their respective

holders. In this manual,

marks are not specified.

TM

and

®

SAFETY CHECK-OUT

After correcting the original service problem, perform the following safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs,

screws, and all other exposed metal parts for AC leakage.

Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes.).

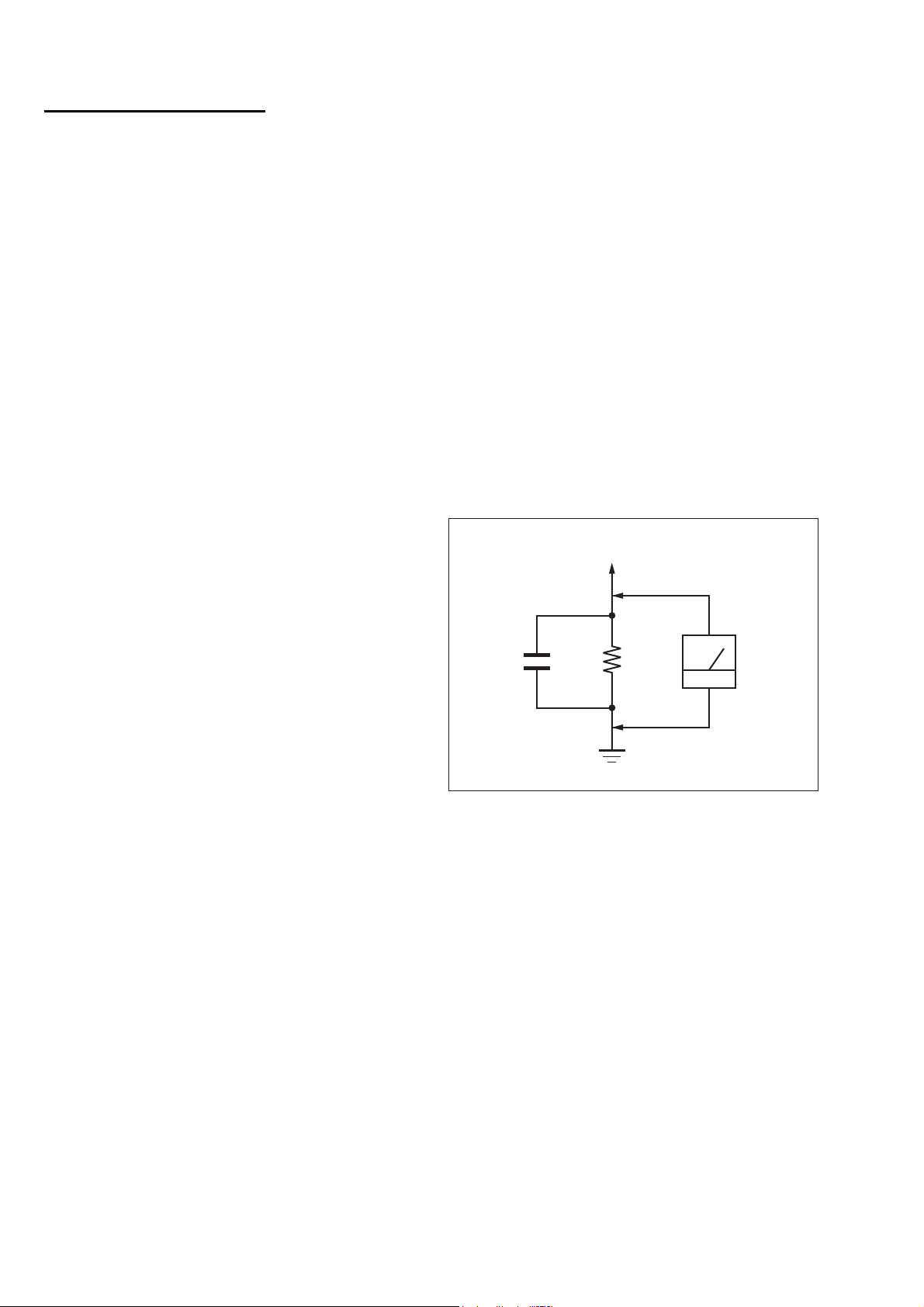

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2 V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

1.5 kΩ0.15 μF

Earth Ground

voltmeter

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

SAFETY-RELATED COMPONENT WARNING!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFIÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE

PAR DES PIÈCES SONY DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU DANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

À LA SÉCURITÉ!

2

Page 3

TABLE OF CONTENTS

GTK-XB7

1. SERVICING NOTES ............................................. 4

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 5

2-2. Top Cover Block ............................................................. 6

2-3. Fan Unit (M1) ................................................................. 7

2-4. PSU Board ...................................................................... 7

2-5. MAIN Board ................................................................... 8

2-6. USB + KEY Board .......................................................... 9

2-7. BT&NFC Board .............................................................. 9

2-8. CONTROL Board ........................................................... 10

2-9. Side Panel (R), Side Panel (L) ........................................ 11

2-10. Main Chassis Block ........................................................ 12

2-11. Bottom Cover + Plate ..................................................... 13

2-12. Front Panel Block ........................................................... 14

2-13. LB Board ......................................................................... 15

2-14. LA Board ......................................................................... 16

2-15. RGBF Board ................................................................... 17

2-16. RGBE Board ................................................................... 17

2-17. IR Board .......................................................................... 18

2-18. Tweeter (SP5).................................................................. 18

2-19. Tweeter (SP3, SP4) ......................................................... 19

2-20. Woofer (SP1, SP2) .......................................................... 20

3. TEST MODE ............................................................ 21

4. DIAGRAMS

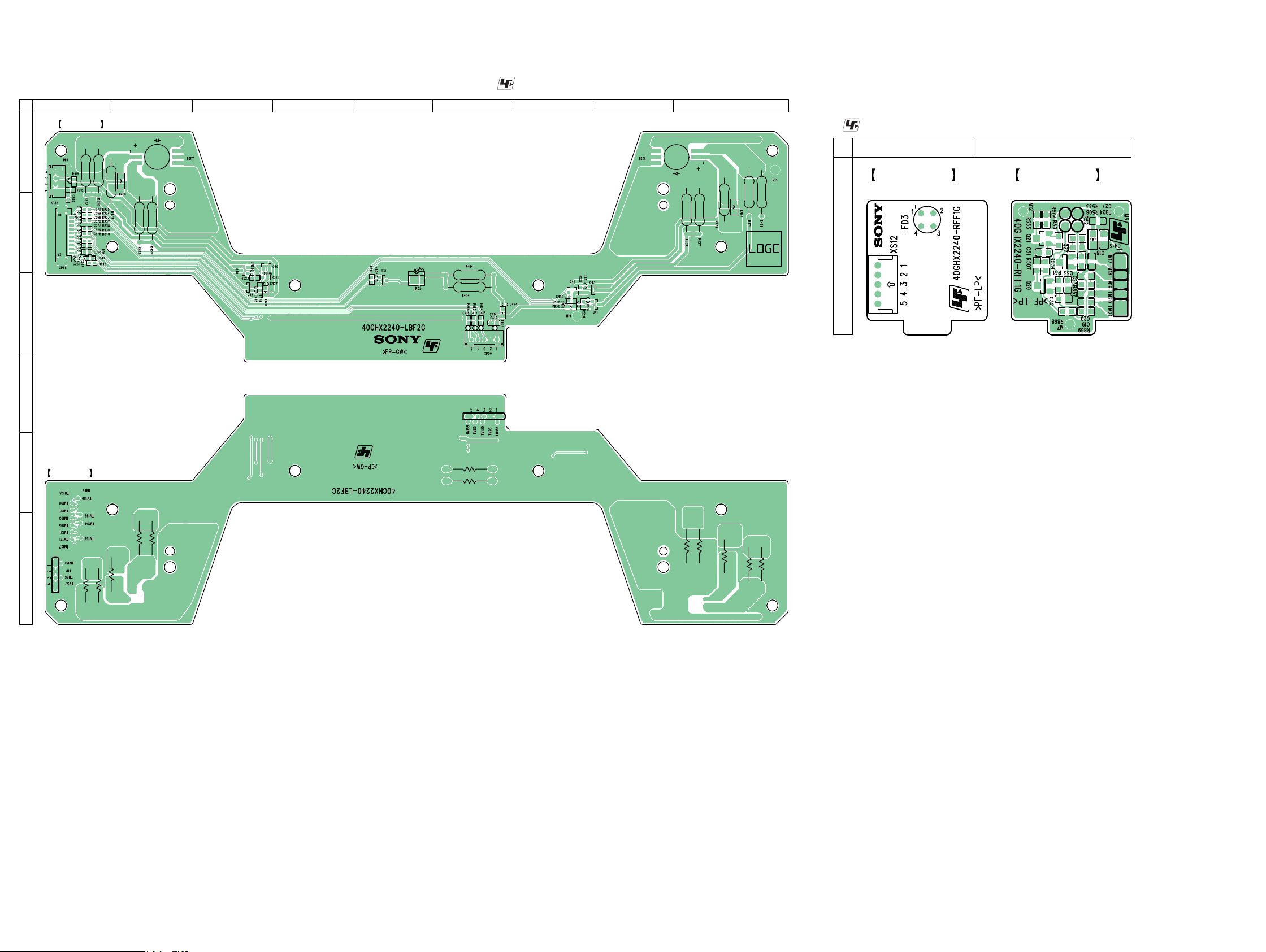

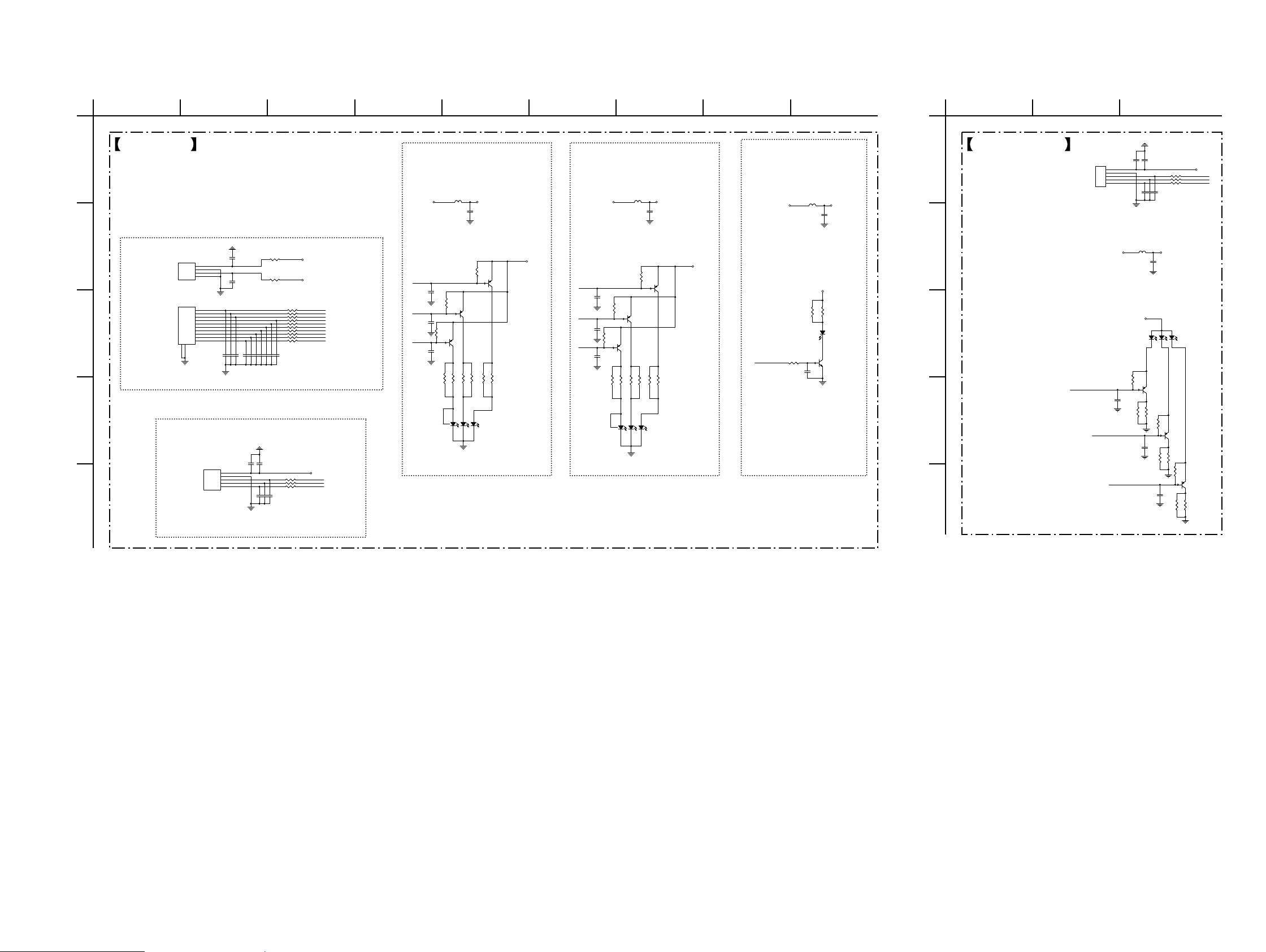

4-1. Block Diagram - OVERALL Section - ........................... 23

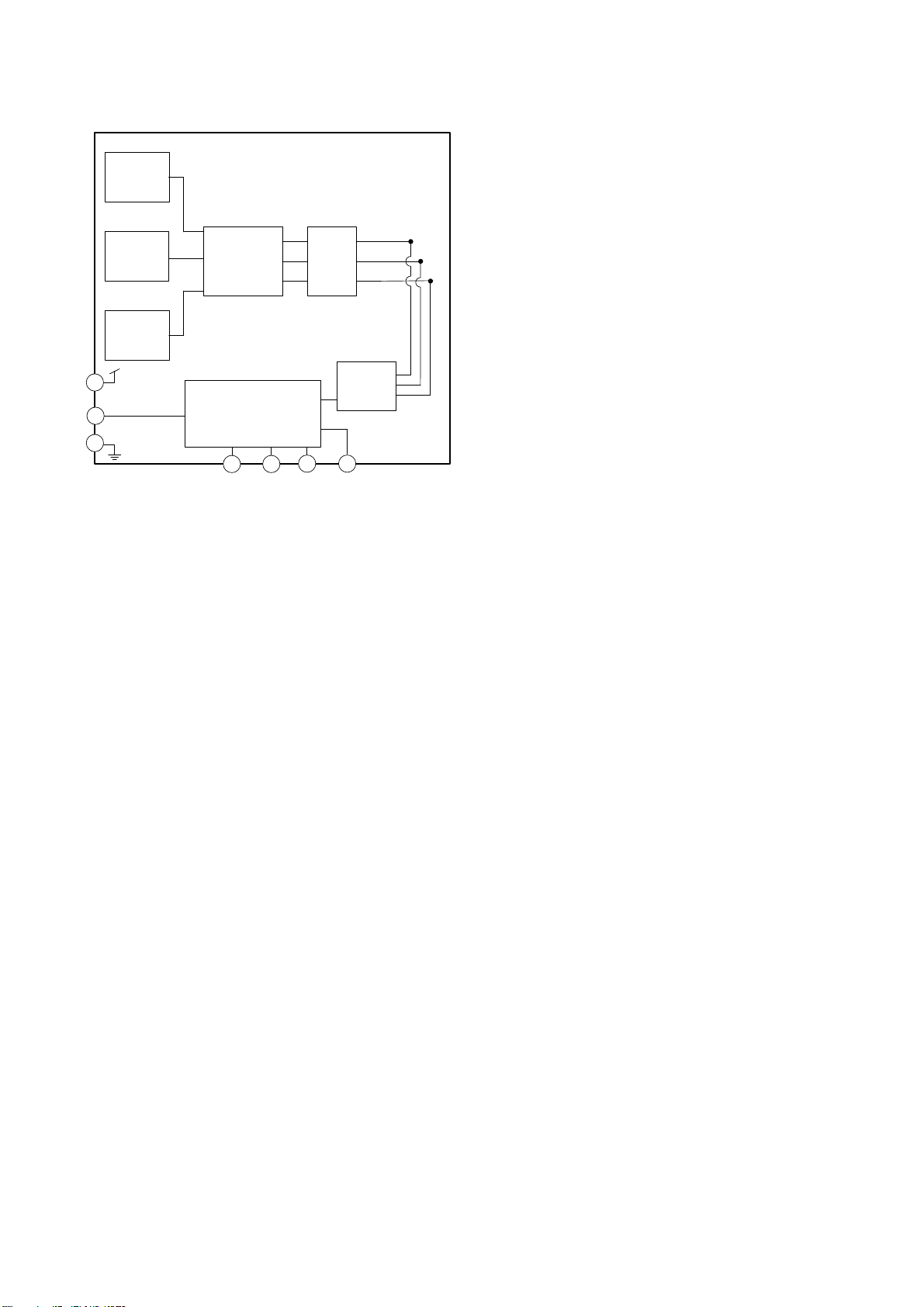

4-2. Block Diagram - POWER SUPPLY Section - ................ 24

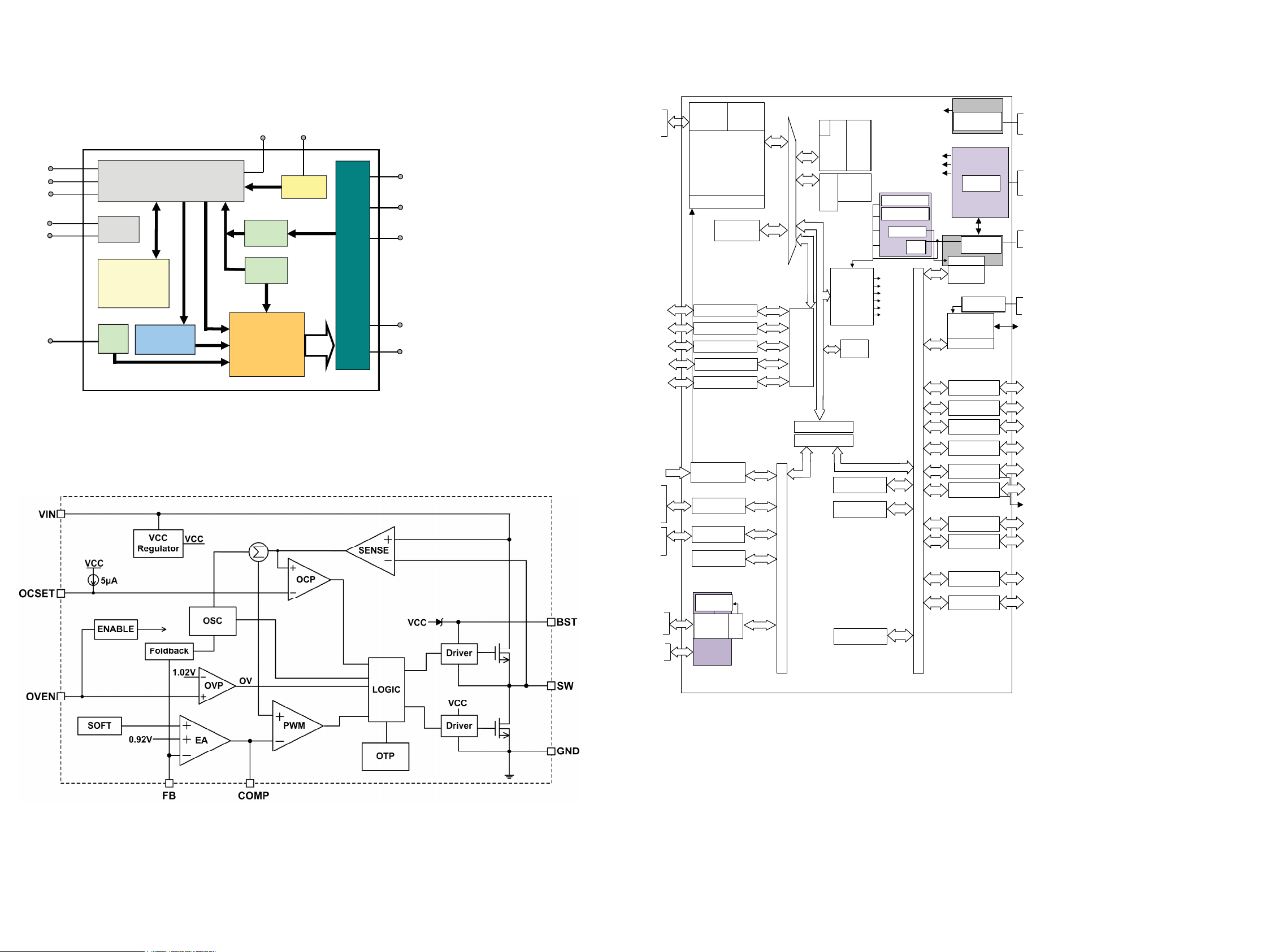

4-3. Printed Wiring Board - MAIN Board - ........................... 25

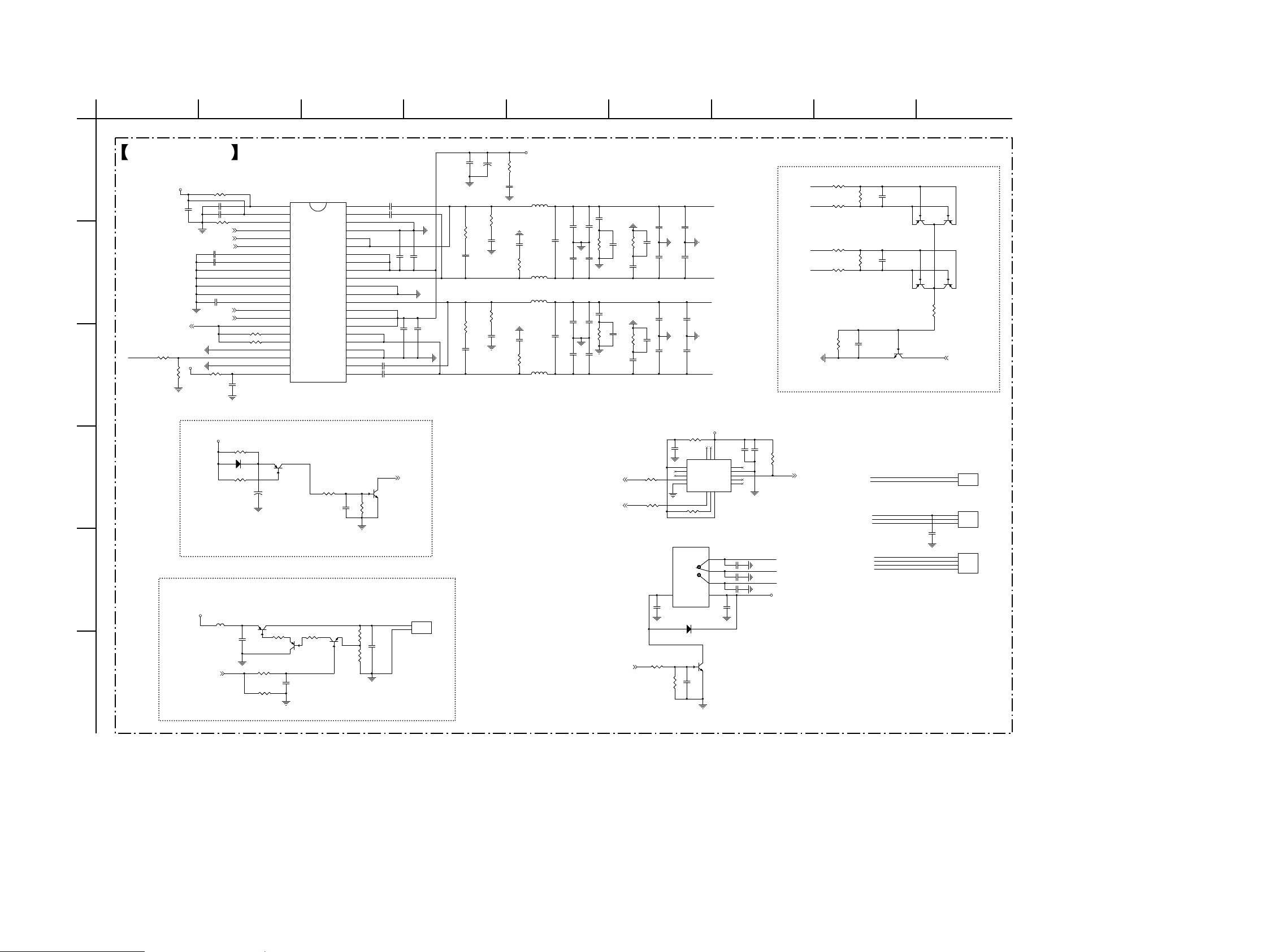

4-4. Schematic Diagram - MAIN Board (1/8) - ..................... 26

4-5. Schematic Diagram - MAIN Board (2/8) - ..................... 27

4-6. Schematic Diagram - MAIN Board (3/8) - ..................... 28

4-7. Schematic Diagram - MAIN Board (4/8) - ..................... 29

4-8. Schematic Diagram - MAIN Board (5/8) - ..................... 30

4-9. Schematic Diagram - MAIN Board (6/8) - ..................... 31

4-10. Schematic Diagram - MAIN Board (7/8) - ..................... 32

4-11. Schematic Diagram - MAIN Board (8/8) - ..................... 33

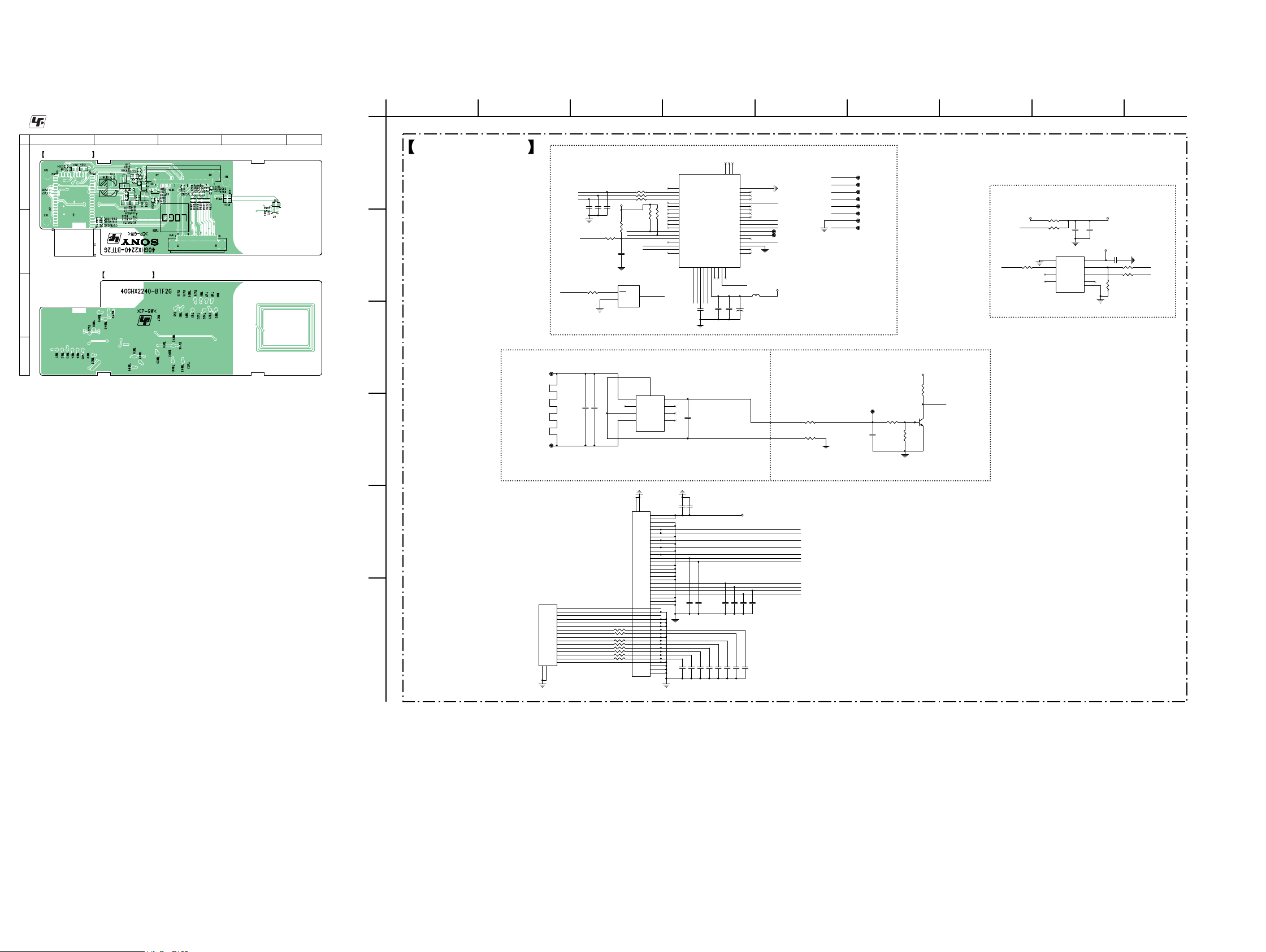

4-12. Printed Wiring Board - BT&NFC Board - ...................... 34

4-13. Schematic Diagram - BT&NFC Board - ........................ 34

4-14. Printed Wiring Board - USB + KEY Board - ................. 35

4-15. Schematic Diagram - USB + KEY Board - .................... 35

4-16. Printed Wiring Board - IR Board - .................................. 35

4-17. Schematic Diagram - IR Board - .................................... 35

4-18. Printed Wiring Board - CONTROL Board - ................... 36

4-19. Schematic Diagram - CONTROL Board - ...................... 37

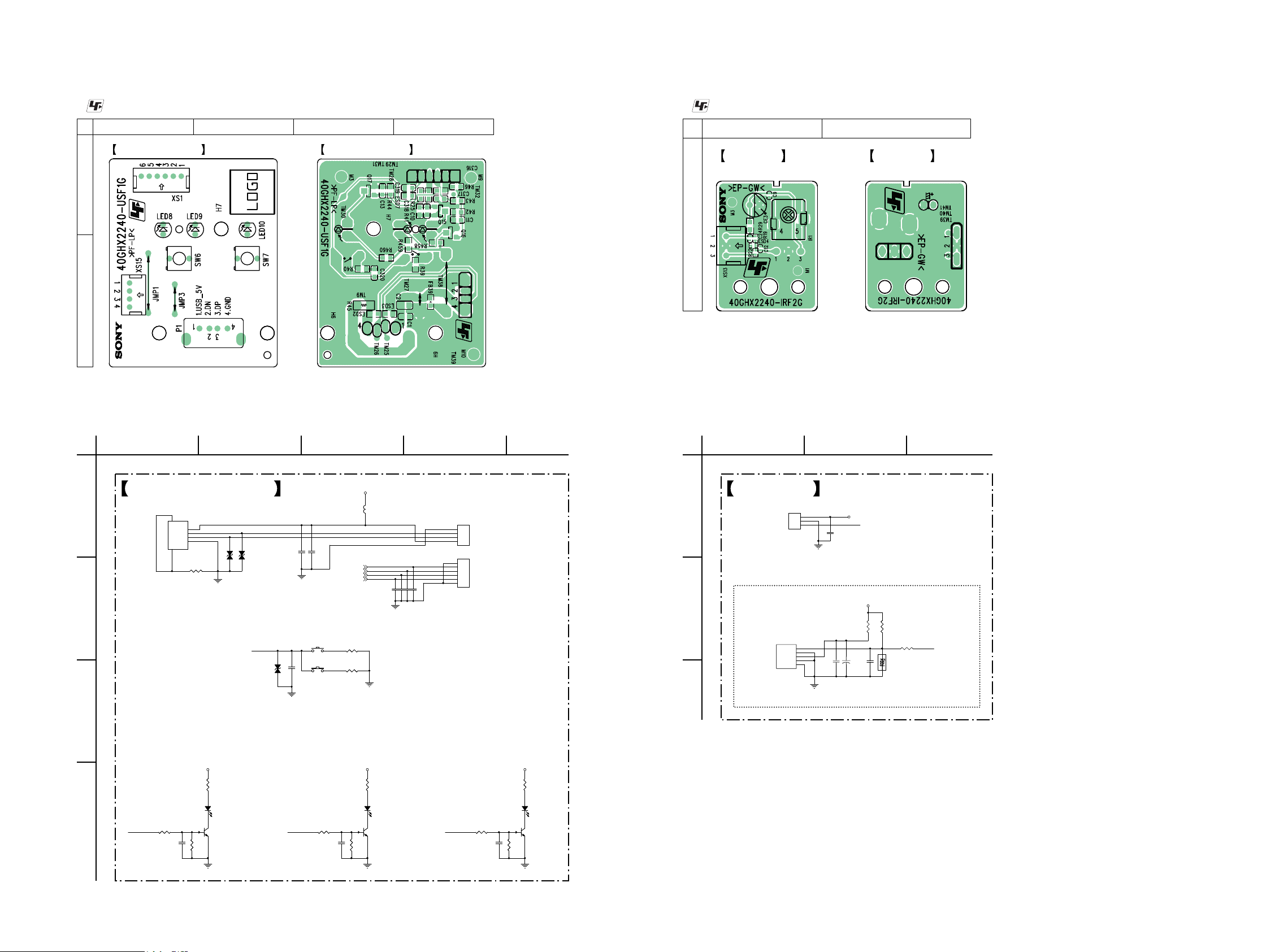

4-20. Printed Wiring Board - LA Board - ................................ 38

4-21. Printed Wiring Board - RGBE Board - ........................... 38

4-22. Schematic Diagram - LA Board - ................................... 39

4-23. Schematic Diagram - RGBE Board - .............................. 39

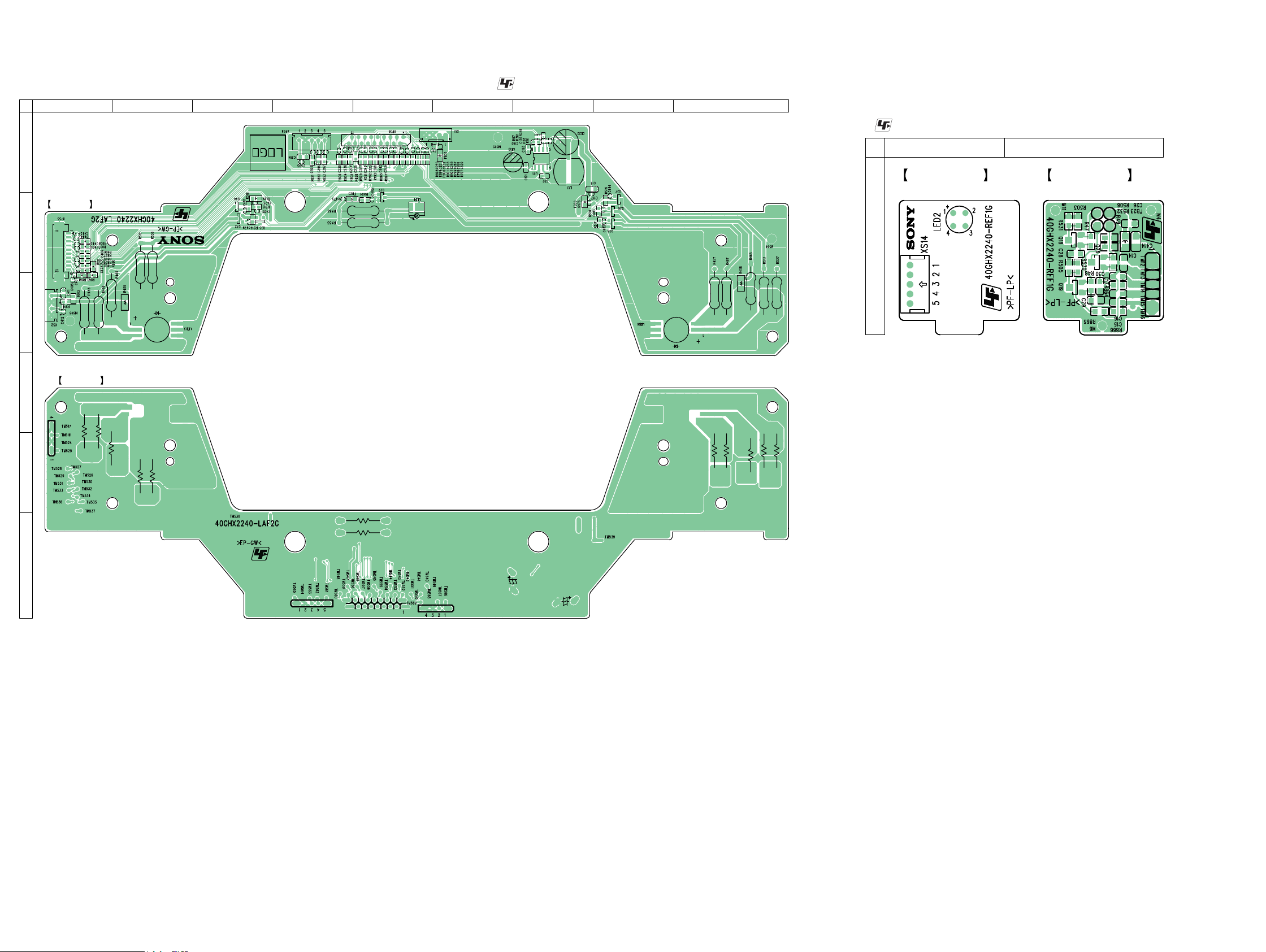

4-24. Printed Wiring Board - LB Board - ................................ 40

4-25. Printed Wiring Board - RGBF Board - ........................... 40

4-26. Schematic Diagram - LB Board - ................................... 41

4-27. Schematic Diagram - RGBF Board - .............................. 41

4-28. Printed Wiring Board - PSU Board - .............................. 42

4-29. Schematic Diagram - PSU Board - ................................. 43

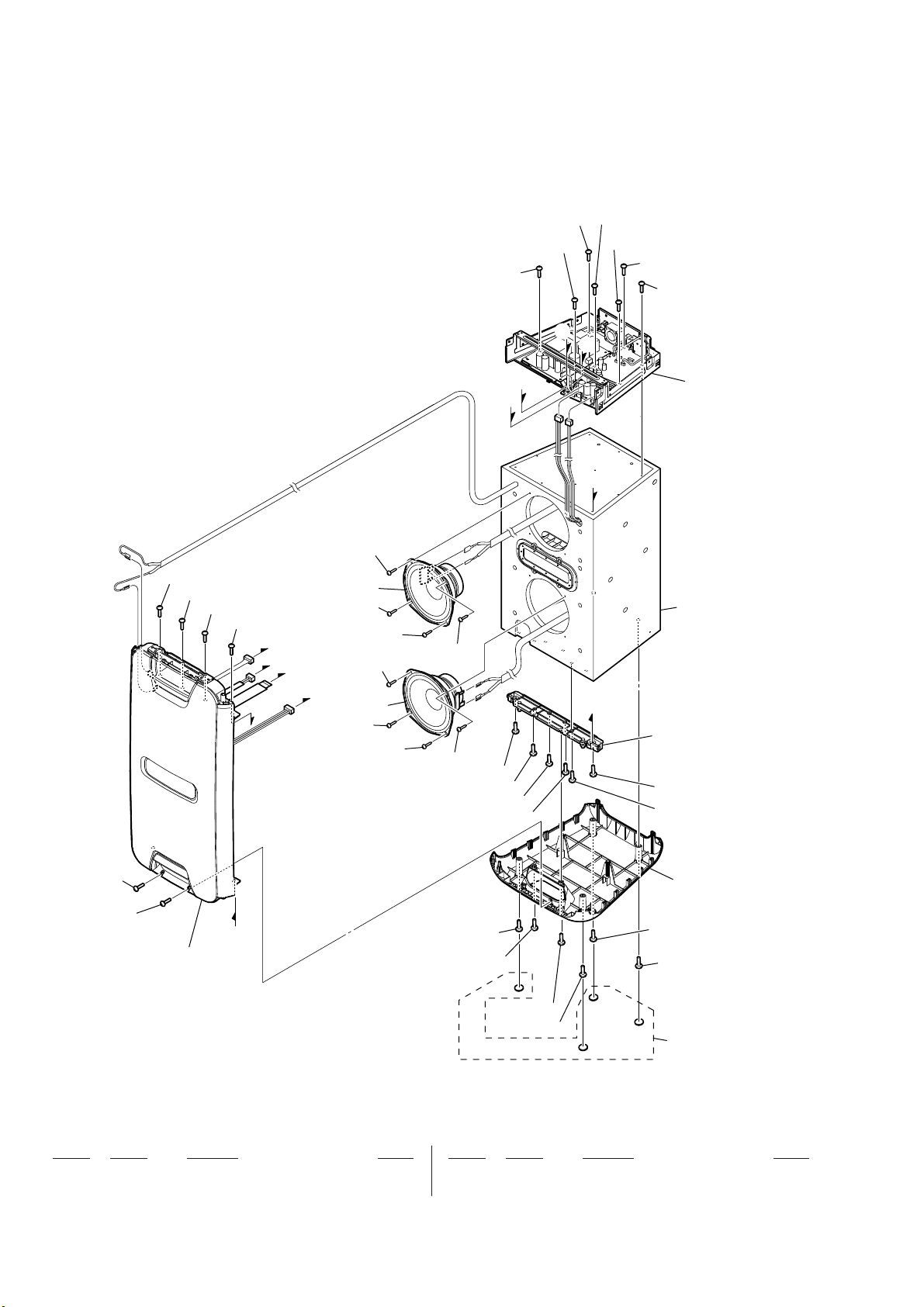

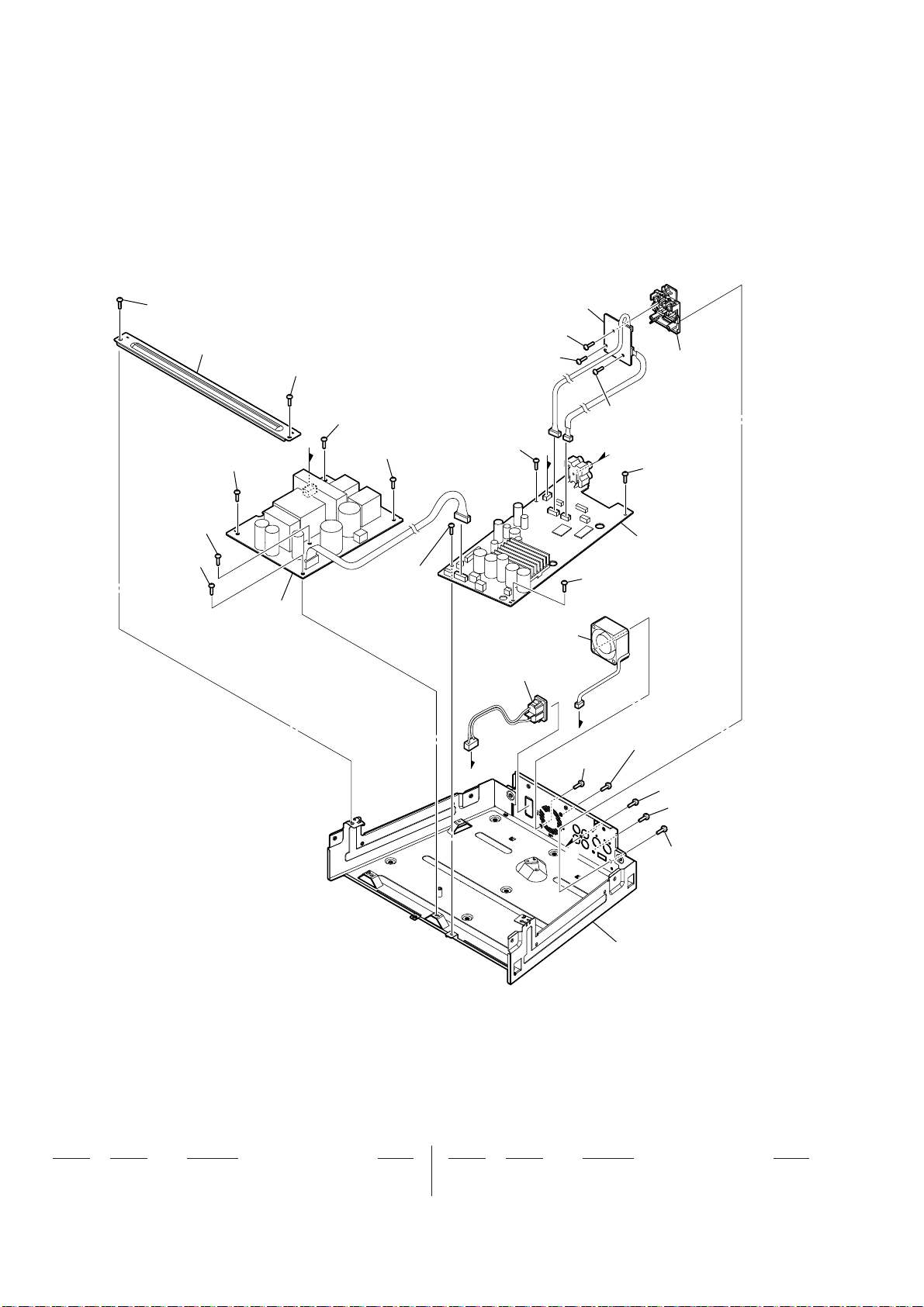

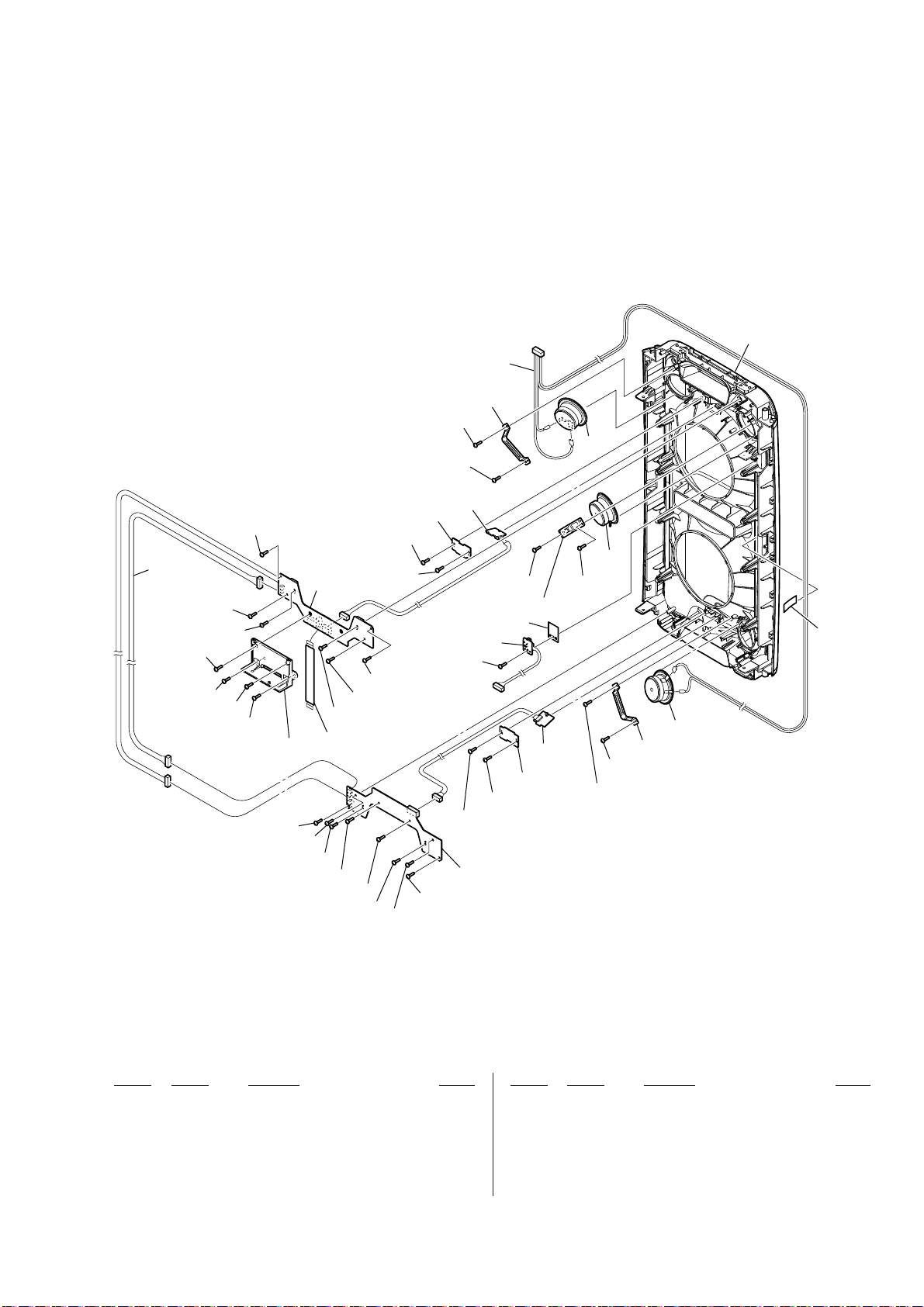

5. EXPLODED VIEWS

5-1. Side Panel Section .......................................................... 49

5-2. Cabinet Section ............................................................... 50

5-3. Top Cover Section........................................................... 51

5-4. MAIN Board Section ...................................................... 52

5-5. Front Panel Section ......................................................... 53

6. ACCESSORIES ....................................................... 54

3

Page 4

GTK-XB7

SECTION 1

SERVICING NOTES

The SERVICING NOTES contains important information for servicing. Be sure to read this section before repairing the unit.

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40 °C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350 °C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to fl ow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

REPAIRING THE BOARDS

When each boards installed in this unit are defective, replace the

mounted board.

Individual electrical parts that mounted on the each boards cannot

be replaced.

Printed wiring board and schematic diagram that have been described on this service manual are for reference.

4

Page 5

DISASSEMBLY

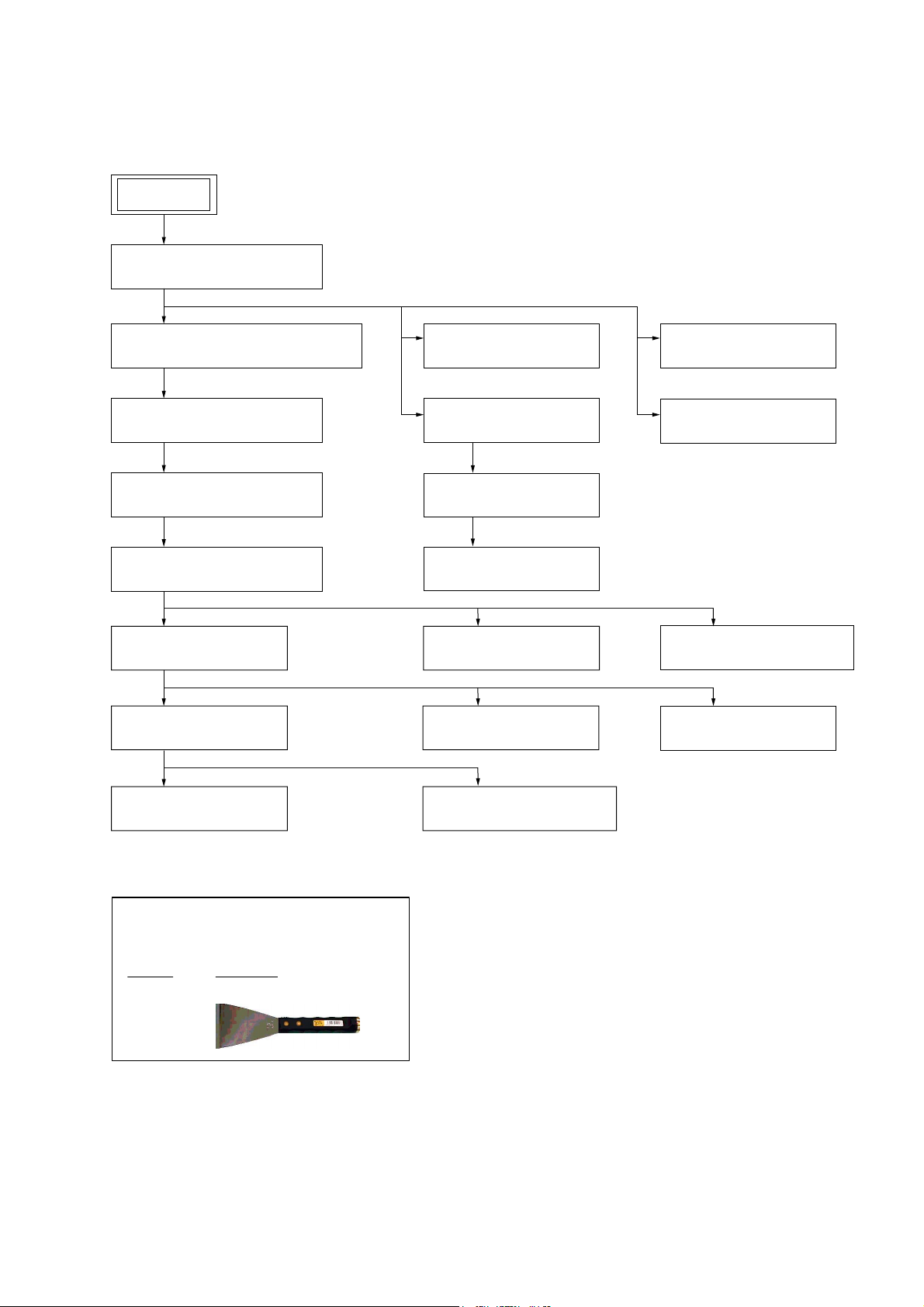

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

2-2. TOP COVER BLOCK

(Page 6)

GTK-XB7

SECTION 2

2-9. SIDE PANEL (R), SIDE PANEL (L)

(Page 11)

2-10. MAIN CHASSIS BLOCK

(Page 12)

2-11. BOTTOM COVER + PLATE

(Page 13)

2-12. FRONT PANEL BLOCK

(Page 14)

2-13. LB BOARD

(Page 15)

2-14. LA BOARD

(Page 16)

2-3. FAN UNIT (M1)

(Page 7)

2-4. PSU BOARD

(Page 7)

2-5. MAIN BOARD

(Page 8)

2-6. USB + KEY BOARD

(Page 9)

2-17. IR BOARD

(Page 18)

2-15. RGBF BOARD

(Page 17)

2-7. BT&NFC BOARD

(Page 9)

2-8. CONTROL BOARD

(Page 10)

2-20. WOOFER (SP1, SP2)

(Page 20)

2-18. TWEETER (SP5)

(Page 18)

2-16. RGBE BOARD

(Page 17)

JIG

When disassembling the unit, use the following

jig for speaker removal.

Part No. Description

J-2501-238-A JIG FOR SPEAKER REMOVAL

2-19. TWEETER (SP3, SP4)

(Page 19)

5

Page 6

GTK-XB7

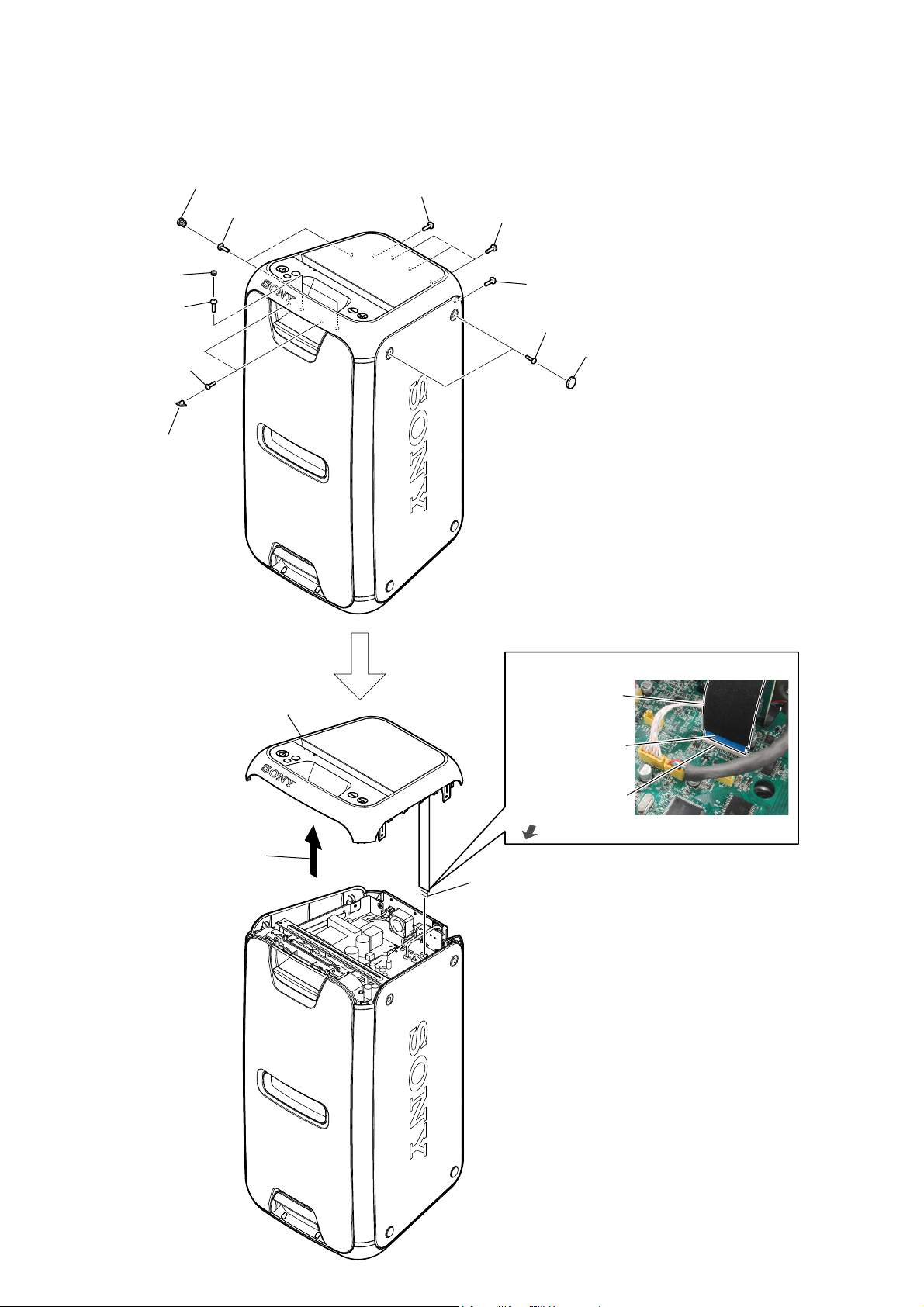

Note: Follow the disassembly procedure in the numerical order given.

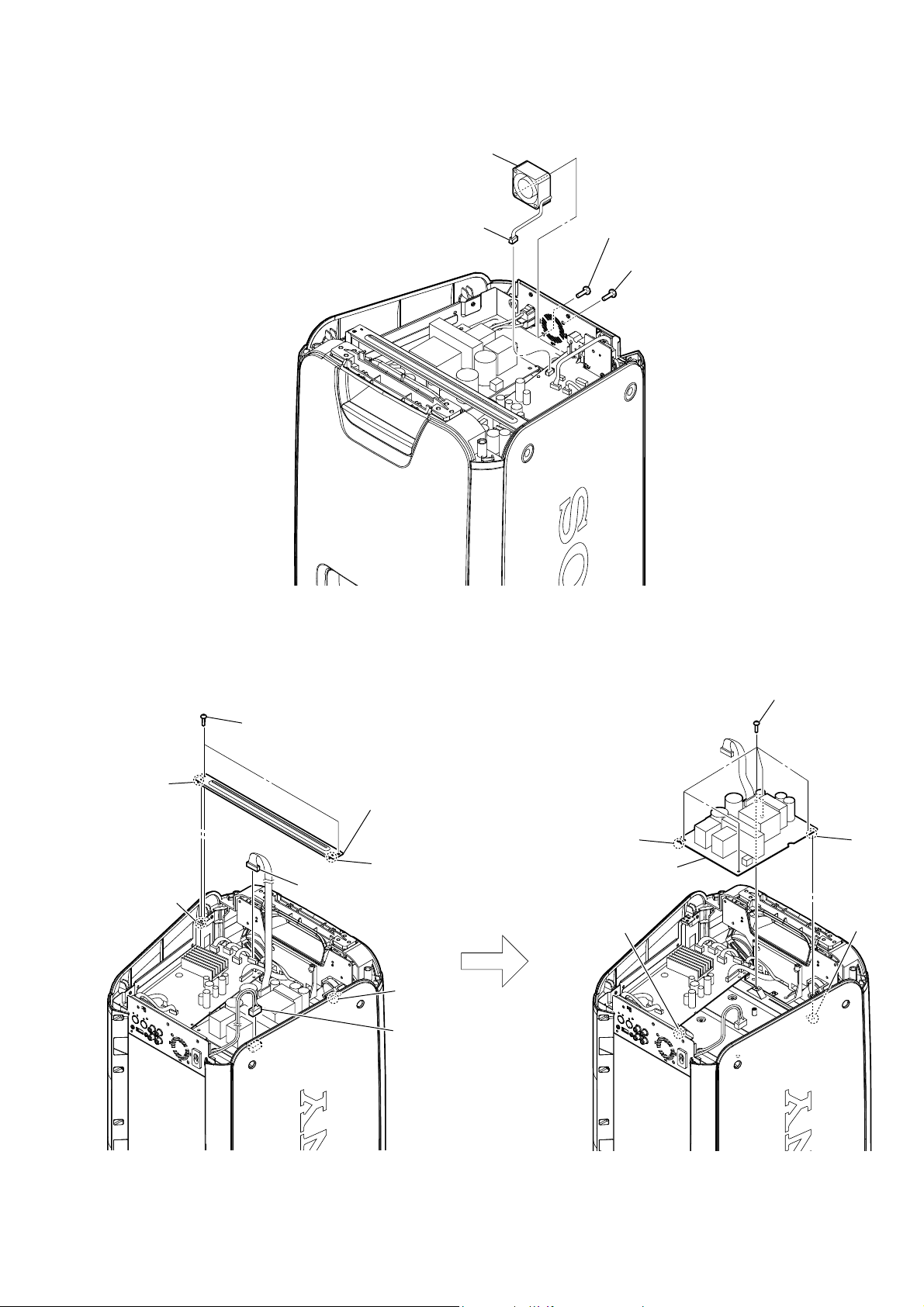

2-2. TOP COVER BLOCK

5 two rubber

(small circle)

6 two screws

8 two screws

7 two rubber (square)

2 two rubber (circle)

3 two screws

3 screw

4 three screws

3 screw

3 two screws

1 two rubber (large circle)

qa top cover block

9 Remove the top cover block

in the direction of the arrow.

)OH[LEOHIODWFDEOH))&WR0$,1VHWWLQJ

flexible flat cable

(FFC (to MAIN))

The opposite side is

the terminal side.

XP35

front side

0 flexible flat cable (FFC (to MAIN))

(XP35)

6

Page 7

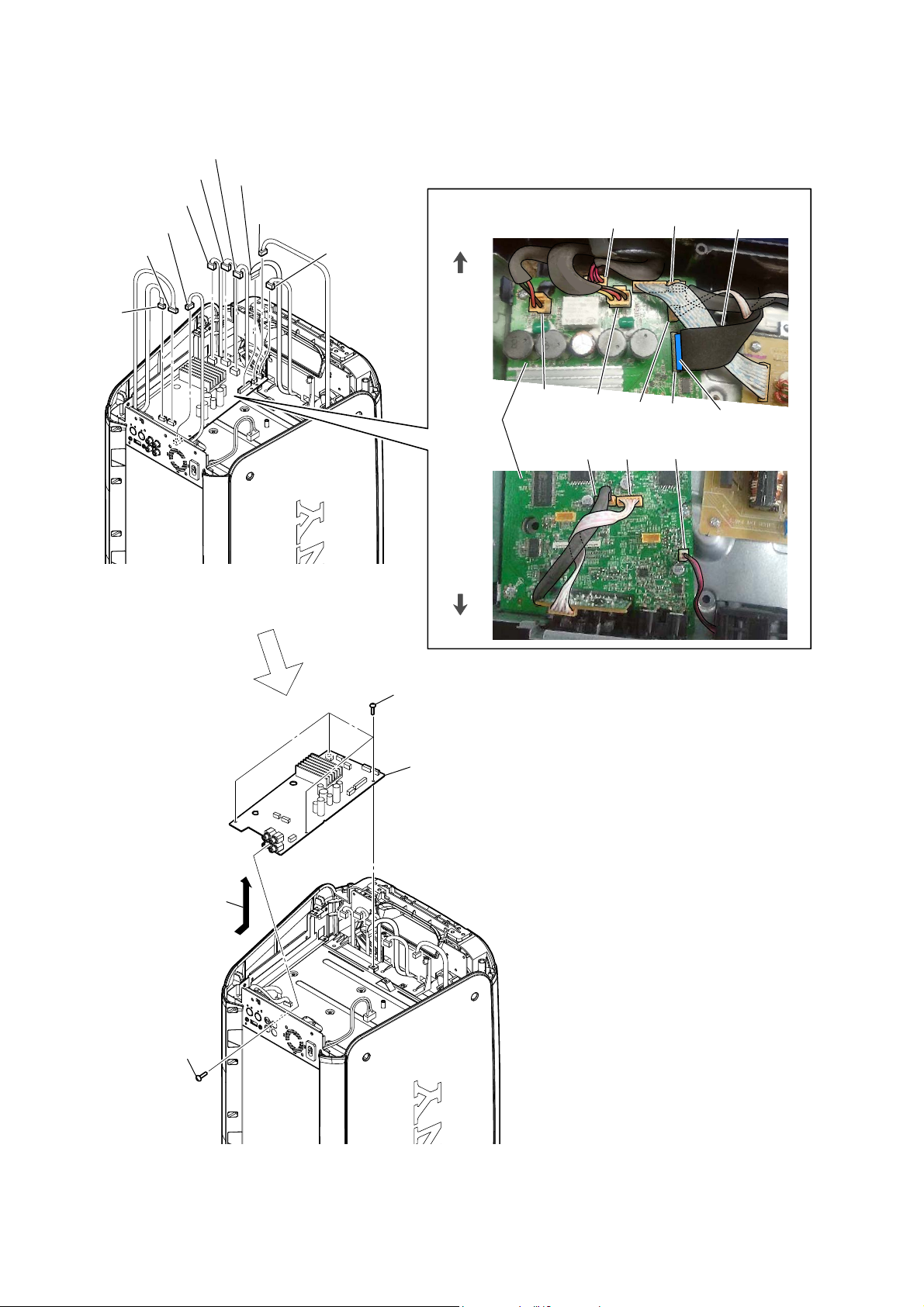

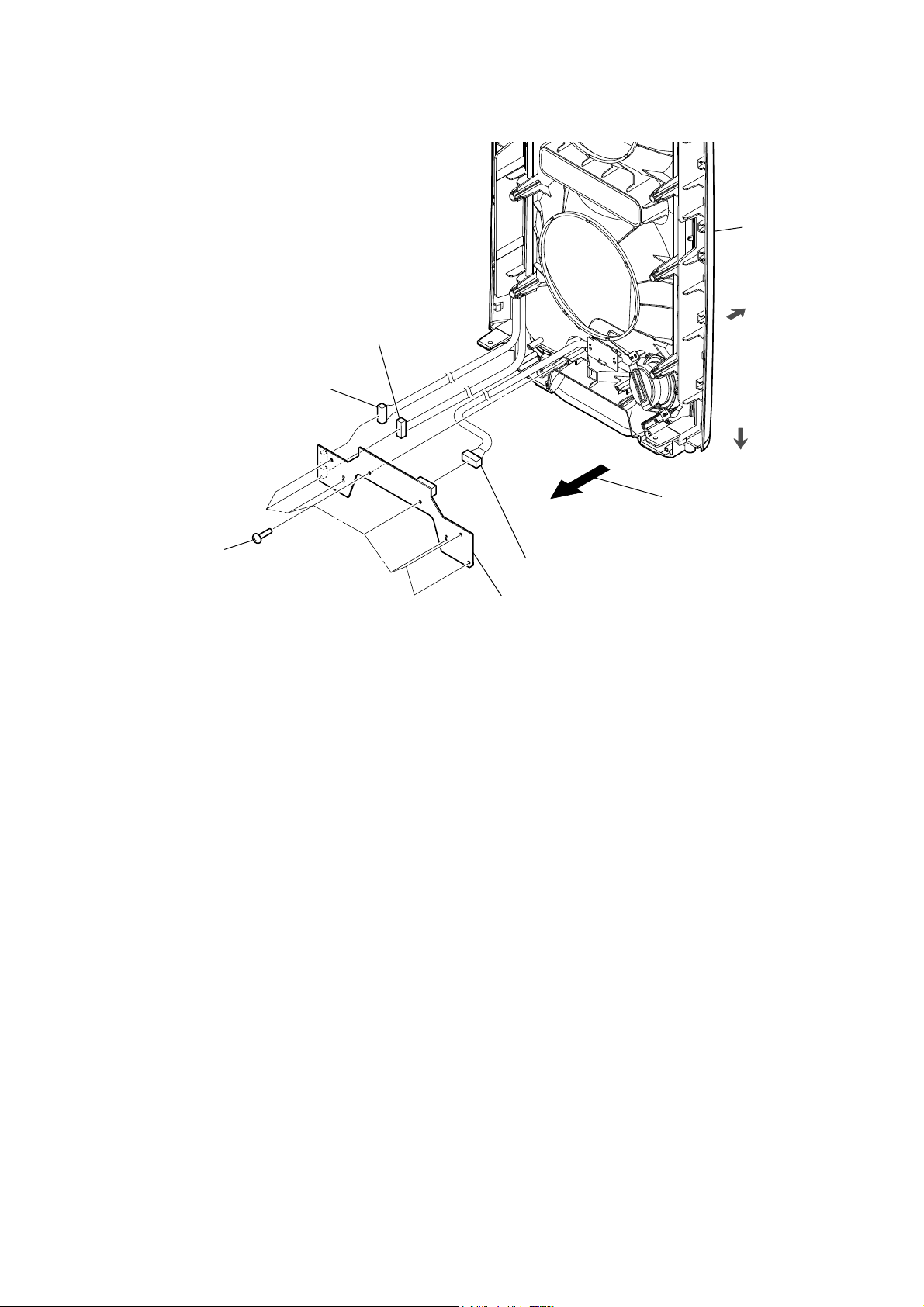

2-3. FAN UNIT (M1)

GTK-XB7

3 fan unit (M1)

2-4. PSU BOARD

1 connector (XP14)

2 screw

2 screw

hole

boss

1 two screws

3 connector (XP1)

2 reinforcement bracket

hole

boss

4 connector

(CN501)

ditch

6 PSU board

boss

5 five screws

hole

boss

– Rear view –

7

Page 8

GTK-XB7

2-5. MAIN BOARD

5 connector (XP10)

4 connector (XP21)

3 connector (XP14)

2 connector (XP7)

1 connector

(XP37)

6 connector (XP22)

7 flexible flat cable

(XP45)

8 connector (XP36)

9 connector

(XP25)

:LUHVHWWLQJ

front side

XP10 XP25

flexible flat cable

– Rear view –

MAIN board

rear side

qa four screws

qd MAIN board

XP21

XP22

XP37 XP7 XP14

XP36

XP45

The opposite side is

the terminal side.

qs Remove the MAIN board in

the direction of the arrow.

0 screw

8

Page 9

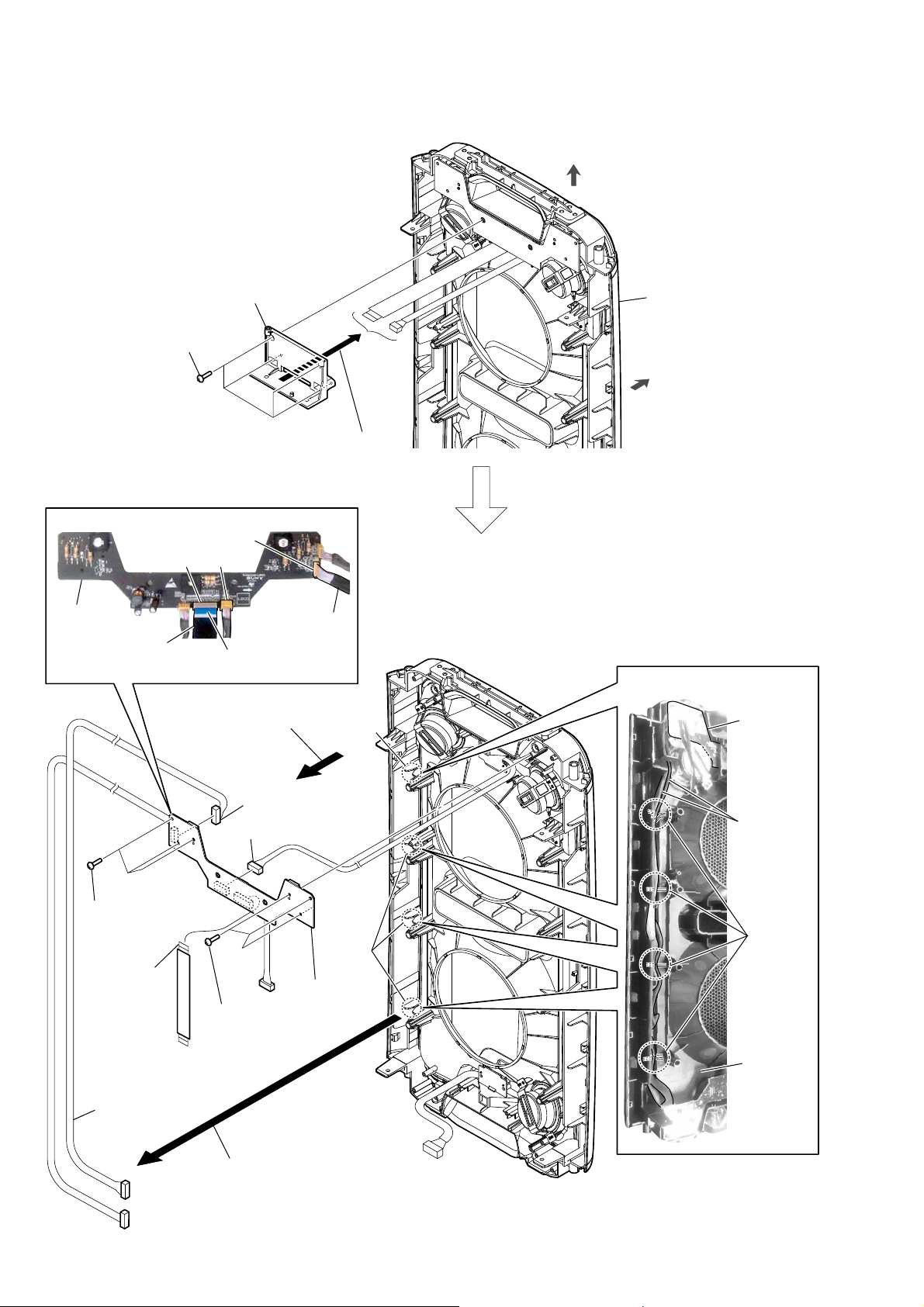

2-6. USB + KEY BOARD

GTK-XB7

2 USB + KEY board

1 three screws

2-7. BT&NFC BOARD

4 flexible flat cable (FFC (to BT&NFC))

(XP8)

5 BT board adhesive sheet

front side

top side

6 BT&NFC board

1 connector

(XP34)

2 Peel off the

adhesive sheet.

rear side

claw

3 flexible flat cable (to MAIN)

)OH[LEOHIODWFDEOHWR0$,1VHWWLQJ

Note:

to the BT&NFC board.

BT&NFC board

top cover block

Connect the side of short reinforcement plate

short

flexible flat cable

(to MAIN)

XP34

The opposite side is

the terminal side.

long

9

Page 10

GTK-XB7

2-8. CONTROL BOARD

6 CONTROL board

4 Remove the CONTROL board block

in the direction of the arrow.

2 eight screws

3 plate

5 flexible flat cable (FFC (to BT&NFC))

(XP16)

The opposite side is the terminal side.

1 connector

(XP8)

front side

top side

top cover block

rear side

10

Page 11

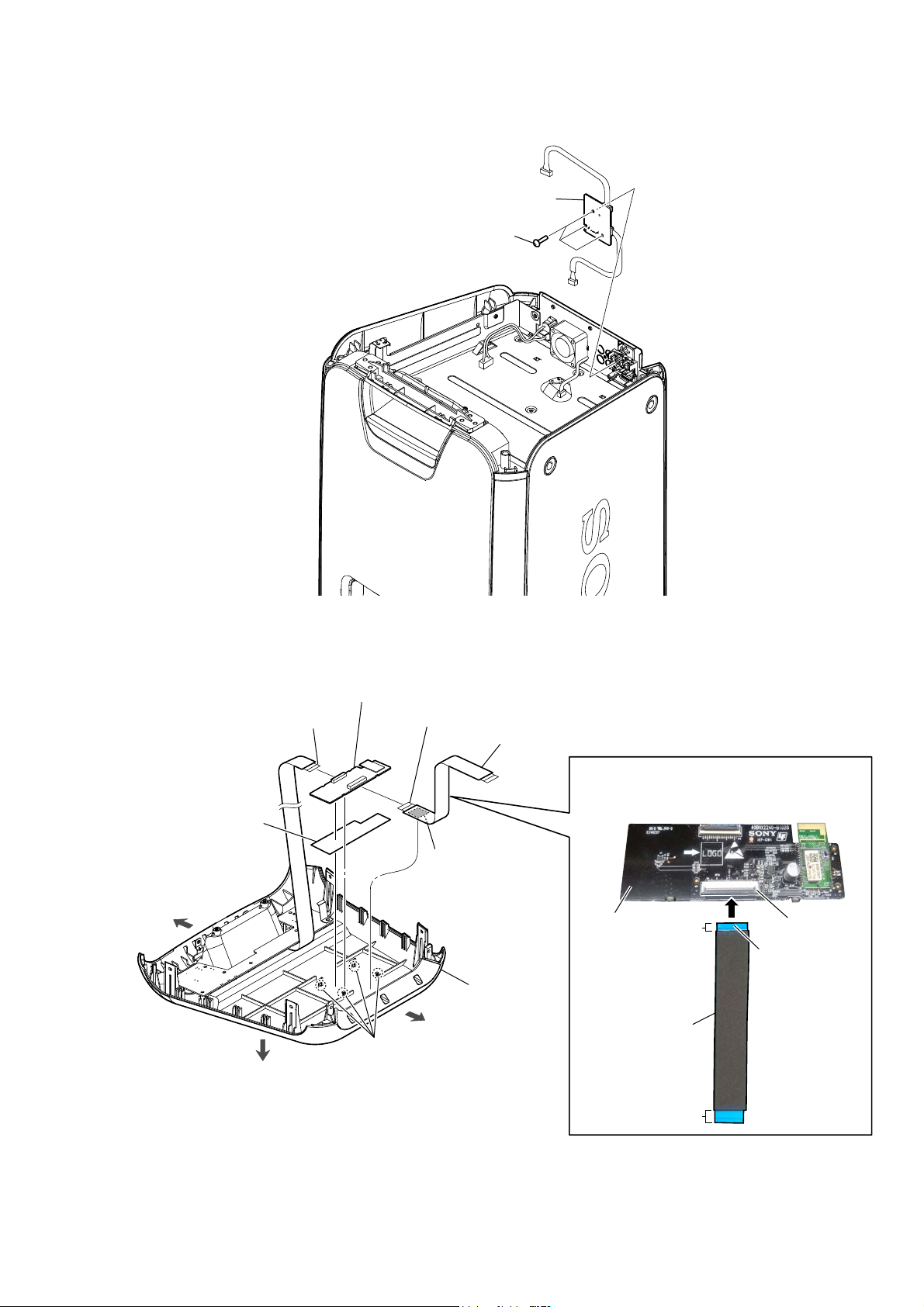

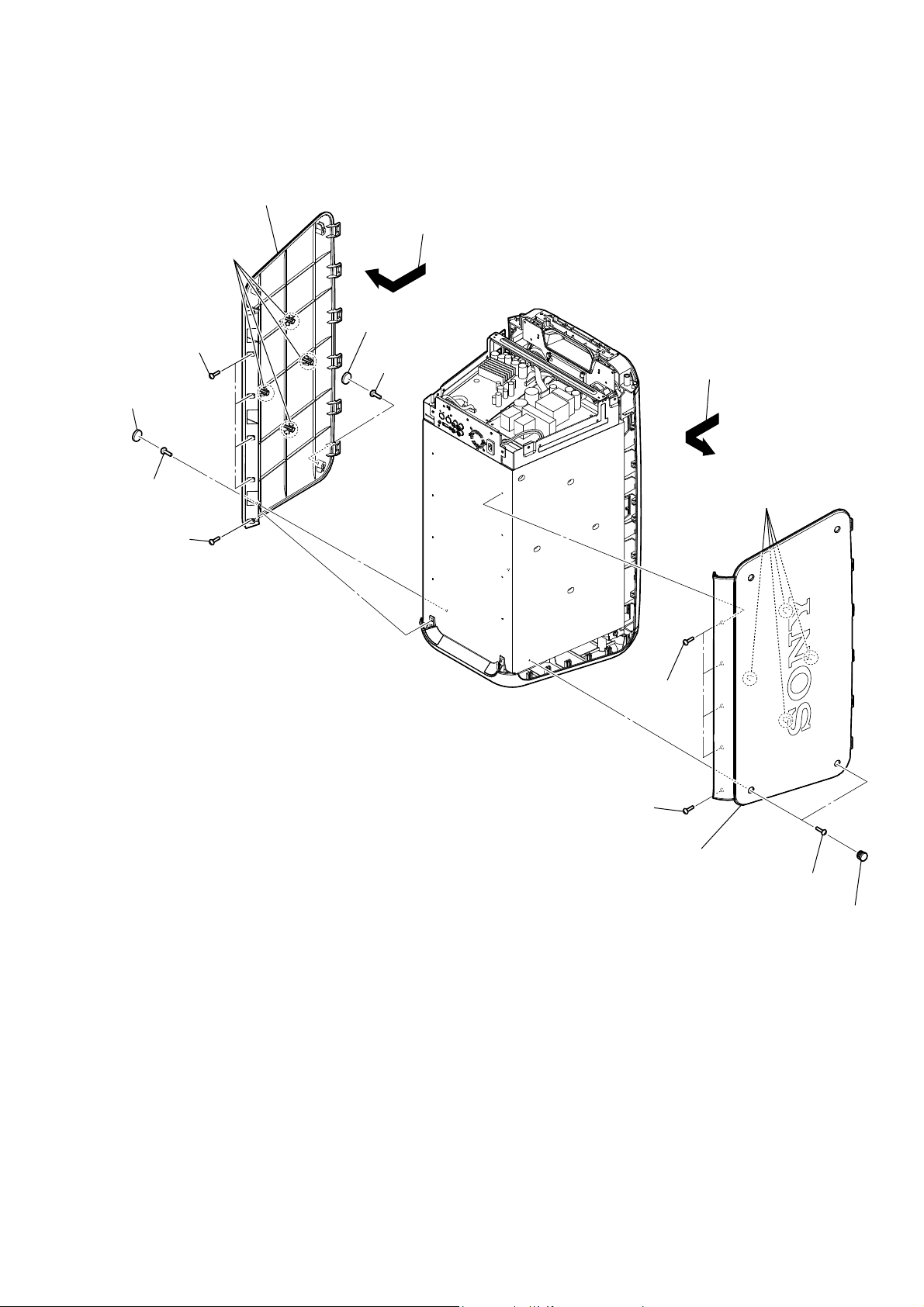

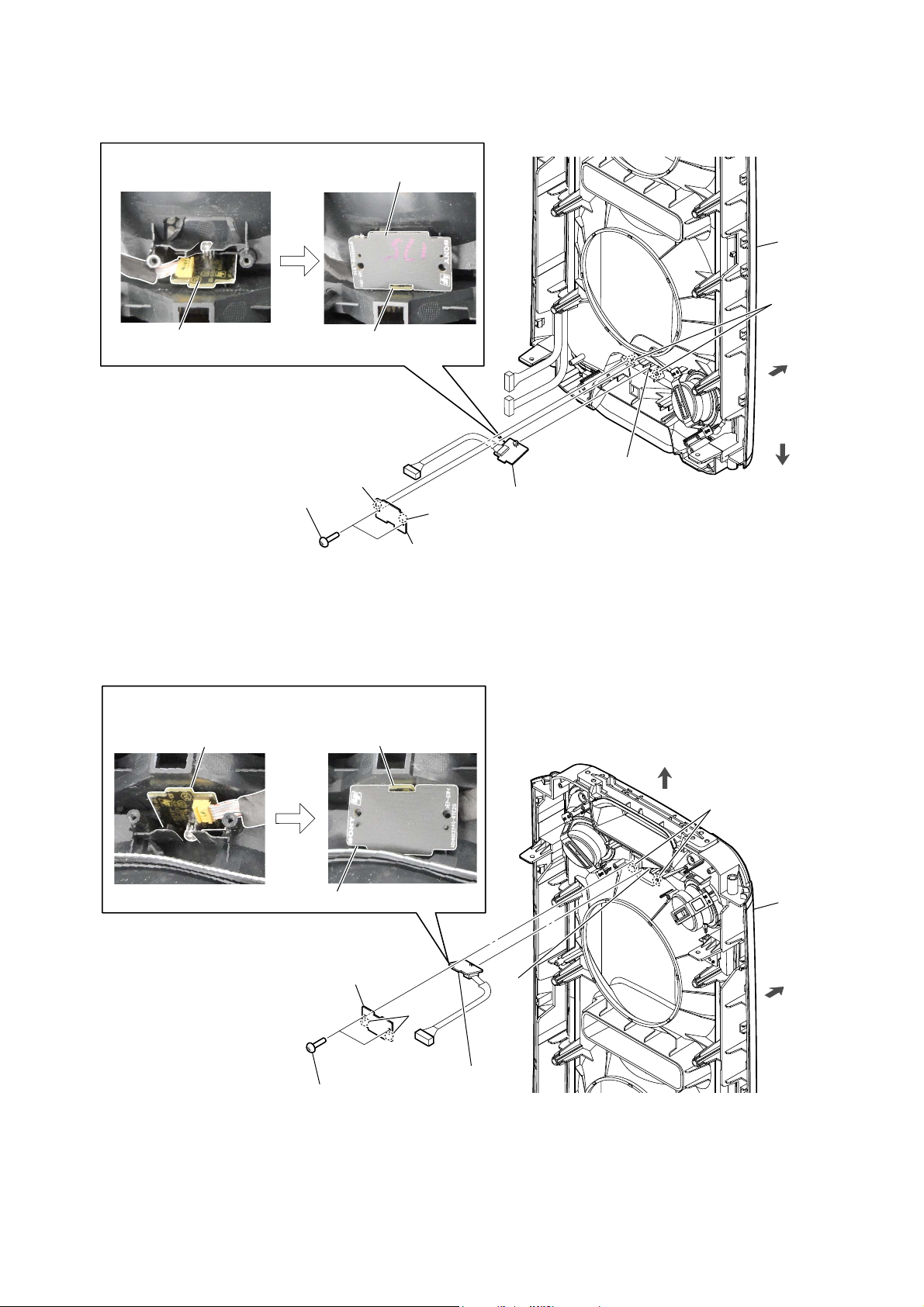

2-9. SIDE PANEL (R), SIDE PANEL (L)

GTK-XB7

5 side panel (R)

Note:

remove the used bond and use a new

bond to fix the side panel (R).

1 rubber (large circle)

When installing t

3 four screws

2 screw

3 screw

he side panel (R),

bond

4 Remove the side panel (R)

in the direction of the arrow.

1 rubber

(large circle)

2 screw

4 Remove the side panel (L)

in the direction of the arrow.

bond

– Rear view –

5 side panel (L)

Note:

remove the used bond and use a new

bond to fix the side panel (L).

3 screw

When installing t

3 four screws

he side panel (L),

2 two screws

1 two rubber (circle)

11

Page 12

GTK-XB7

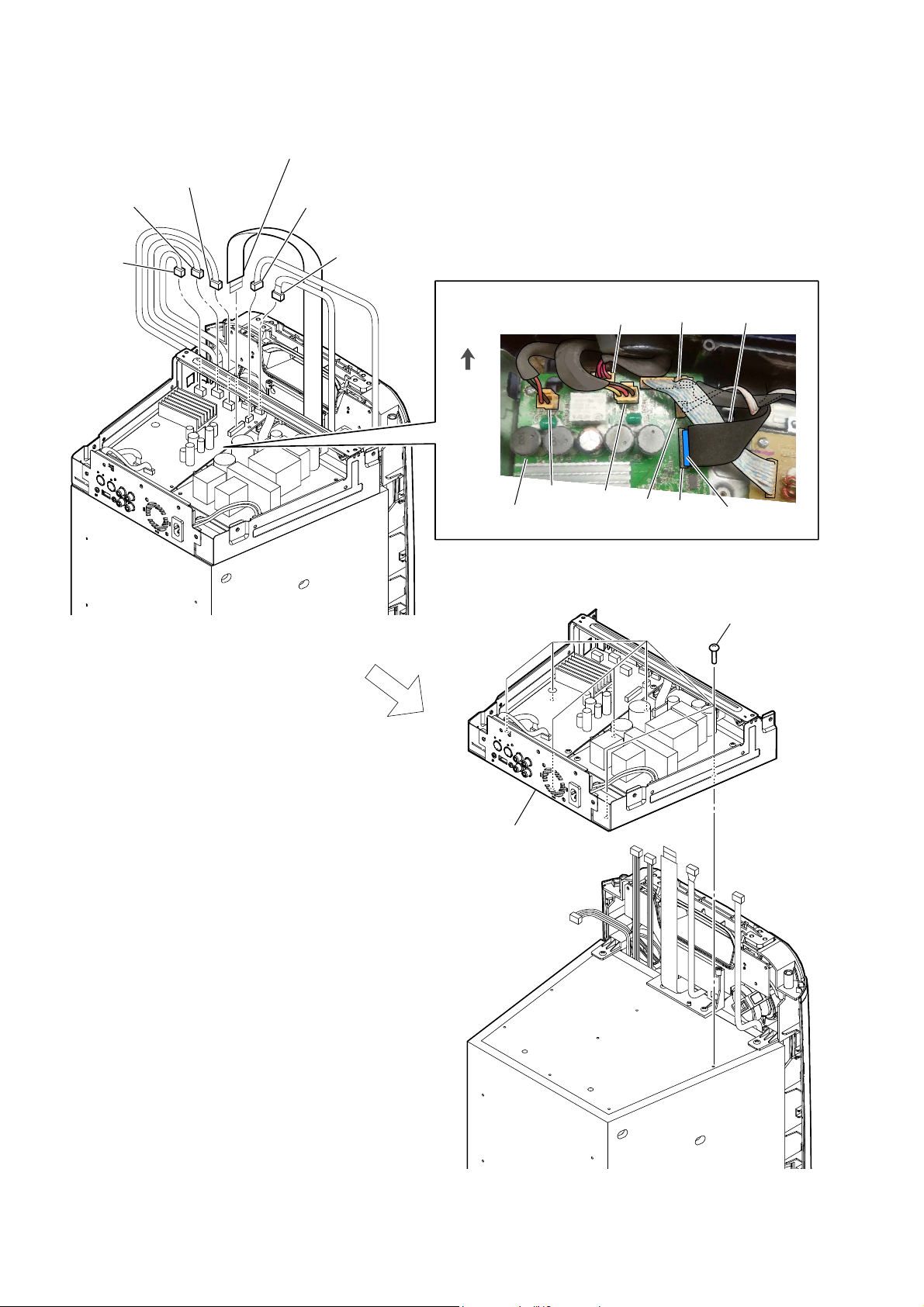

2-10. MAIN CHASSIS BLOCK

2 connector

(XP10)

1 connector

(XP21)

3 connector

(XP22)

4 flexible flat cable

(XP45)

5 connector

(XP36)

6 connector

(XP25)

:LUHVHWWLQJ

front side

MAIN board

XP21

XP10 XP25

XP22

XP36

flexible flat cable

XP45

The opposite side is

the terminal side.

– Rear view –

7 seven screws

8 main chassis block

12

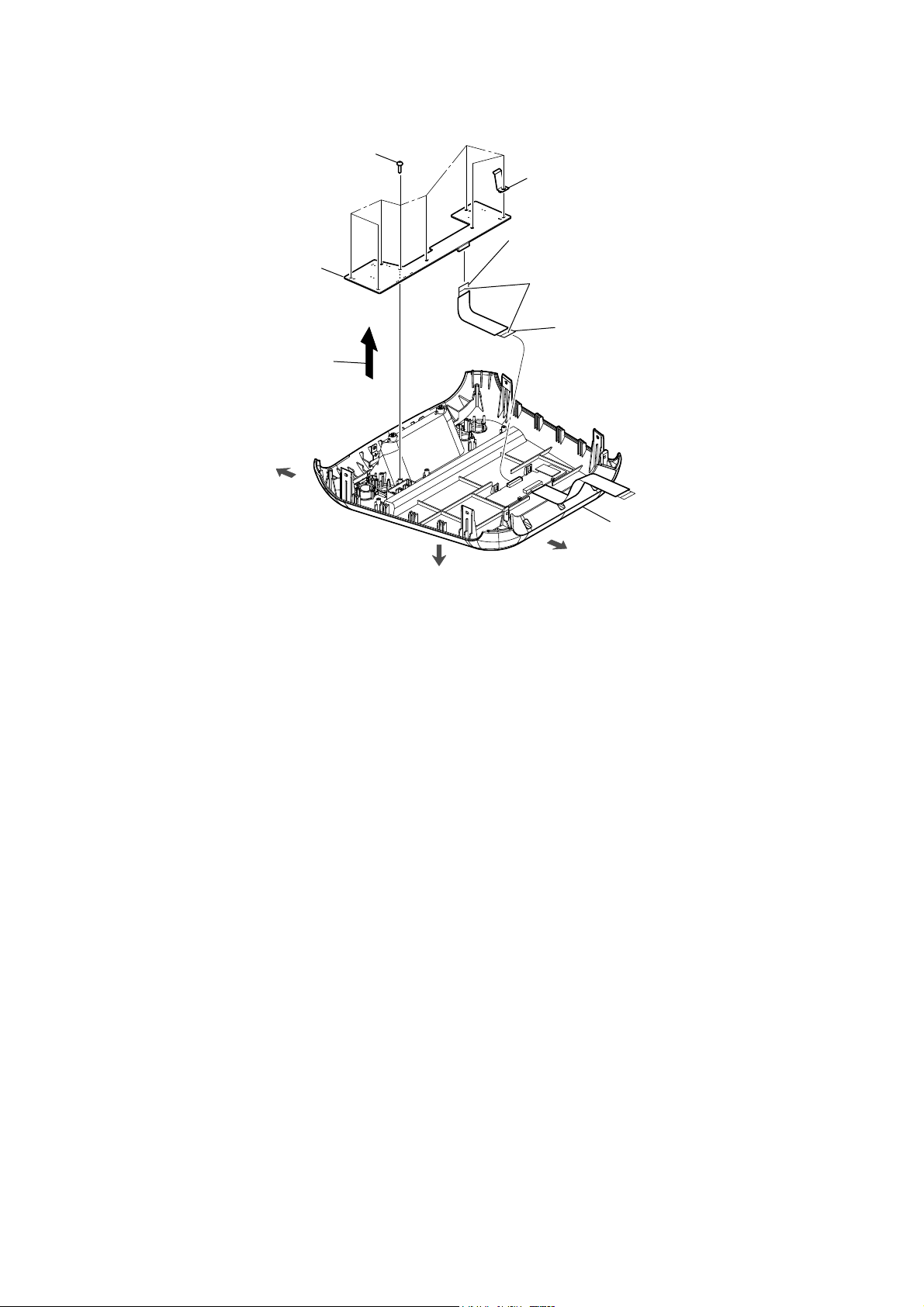

Page 13

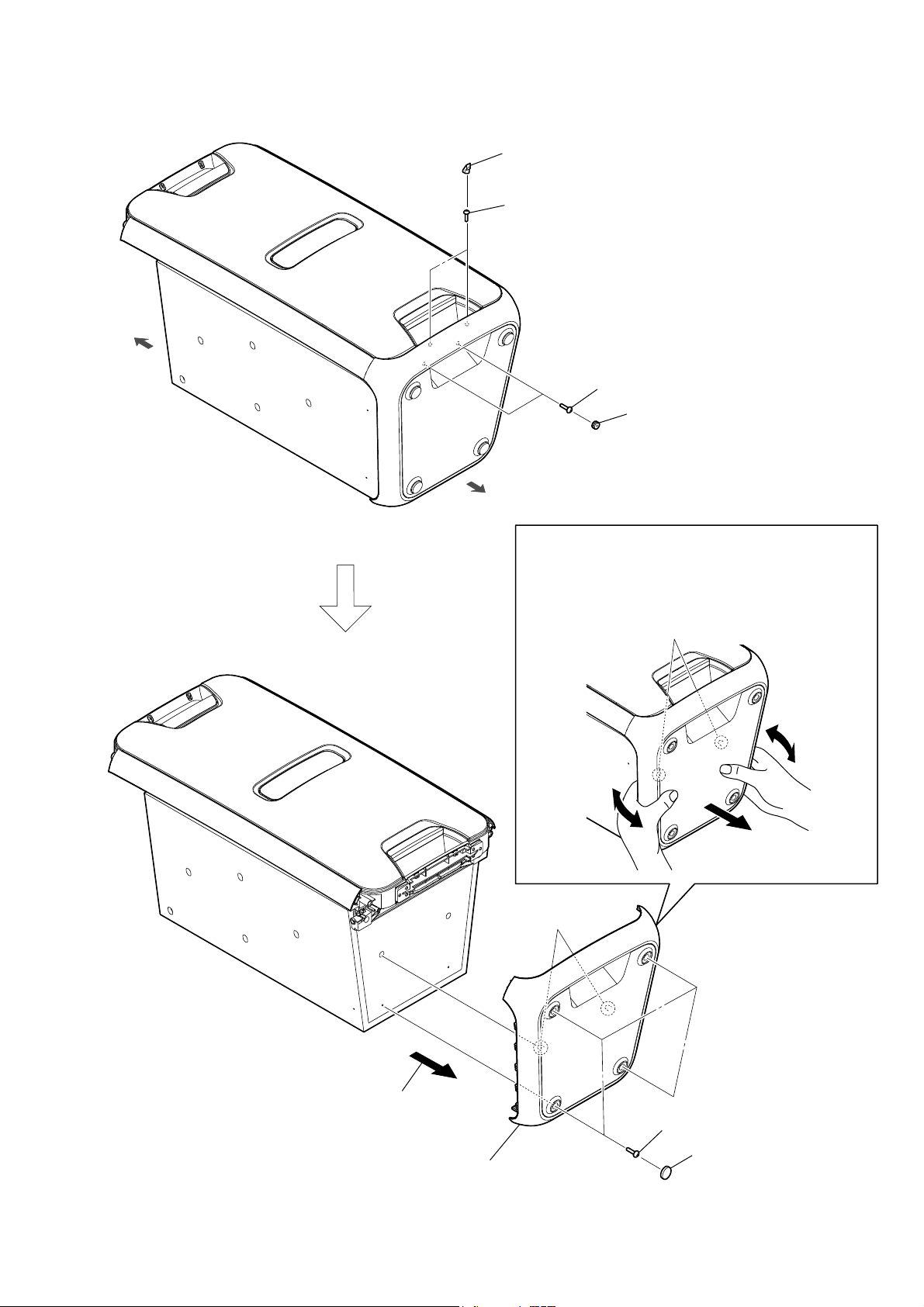

2-11. BOTTOM COVER + PLATE

top side

GTK-XB7

1 two rubber (square)

2 two screws

4 two screws

3 two rubber (small circle)

bottom side

+RZWRUHPRYHWKHERWWRPFRYHUSODWH

Note 1:

cover + plate slowly and remove the bond as shown figure.

Note 2:

carefully so as not to damage the bosses.

When removing the bottom cover + plate, move the bottom

When removing the bottom cover + plate, please remove

two bosses

bond

7 Remove the bottom cover + plate

in the direction of the arrow.

8 bottom cover + plate

Note 3:

remove the used bond and use a new

bond to fix the bottom cover + plate.

When installing the

6 four screws

5 four rubber (large circle)

bottom cover + plate,

13

Page 14

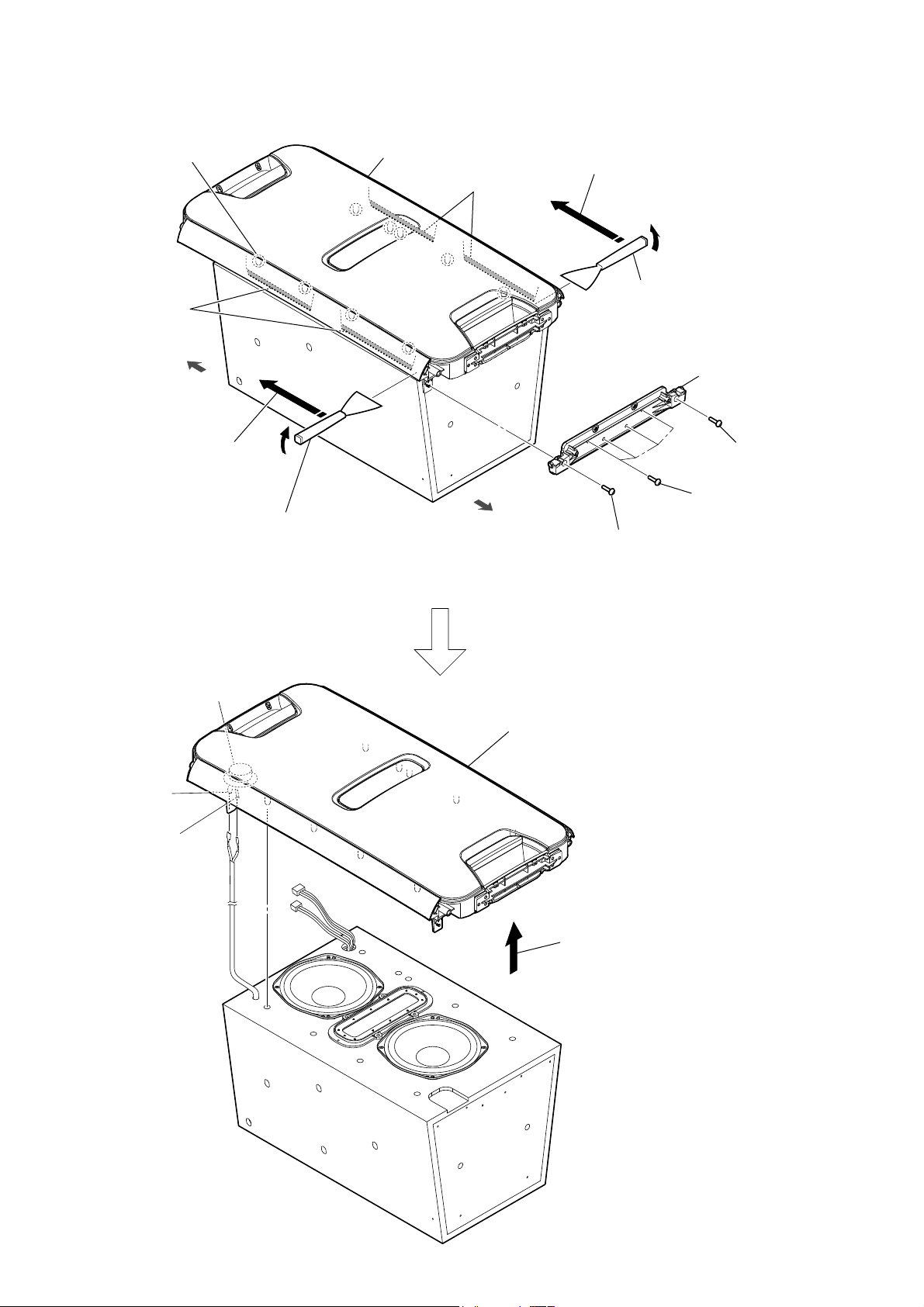

GTK-XB7

2-12. FRONT PANEL BLOCK

total nine bosses

cushion

top side

5 All bosses are removed while moving

jig in the direction of the arrow, and

front panel block is removed.

4 Insert the jig into a space and raise

front panel block.

Note 1: When using a jig, please work

so as not to injure the cushion.

front panel block

cushion

5 All bosses are removed while moving

jig in the direction of the arrow, and

front panel block is removed.

4 Insert the jig into a space and raise

front panel block.

Note 1: When using a jig, please work

so as not to injure the cushion.

3 prop (bottom)

1 screw

2 four screws

bottom side

1 screw

speaker unit (TW) (SP4)

7 tweeter terminal

(wide side)

7 tweeter terminal

(narrow side)

8 front panel block

Note 2:

remove the used bond and use a new

bond to fix the front panel block.

When installing the

6 Remove the front panel block

in the direction of the arrow.

front panel block

14

Page 15

2-13. LB BOARD

3 connector (XP56)

GTK-XB7

front panel block

front side

4 connector (XP37)

bottom side

1 eight screws

2 Remove the LB board block

in the direction of the arrow.

5 connector (XP50)

6 LB board

15

Page 16

GTK-XB7

2-14. LA BOARD

top side

1 four screws

:LUHVHWWLQJ

LA board

flexible flat cable

3 prop (upper)

XP55

XP54

XP38

The opposite side is

–)URQWYLHZ–

5 Remove the LA board block

in the direction of the arrow.

the terminal side.

2 Draw two cables

out from the hole.

cable

groove

front panel block

front side

:LUHVHWWLQJ

LA board

4 three screws

6 flexible flat

cable

(XP38)

0 cable

8 connector (XP55)

7 connector (XP54)

groove

qa LA board

4 three screws

9 Remove two cables from four

grooves of the front panel.

two cables

groove

front panel

block

16

Page 17

2-15. RGBF BOARD

GTK-XB7

+RZWRLQVWDOOWKH5*%)ERDUG

Install the RGBF board

into the slot.

1 two screws

mounting plate (bottom right)

Make sure that the projection

of the RGBF board is out.

hole

hole

2 mounting plate (bottom right)

3 RGBF board

slot

front panel block

boss

front side

bottom side

2-16. RGBE BOARD

+RZWRLQVWDOOWKH5*%(ERDUG

Install the RGBE board

into the slot.

– Rear bottom view –

Make sure that the projection

of the RGBE board is out.

mounting plate (bottom left)

2 mounting plate

(bottom left)

1 two screws

hole

3 RGBE board

slot

top side

boss

front panel block

front side

17

Page 18

GTK-XB7

2-17. IR BOARD

top side

3 flannel

2 IR board

front panel block

2-18. TWEETER (SP5)

front side

1 screw

front panel block

18

2 speaker plate

1 two screws

front side

bottom side

3 tweeter terminal

(wide side)

3 tweeter terminal

(narrow side)

4 speaker unit (TW) (SP5)

Page 19

2-19. TWEETER (SP3, SP4)

2 speaker plate

GTK-XB7

top side

front panel block

4 speaker unit (TW)

(SP3)

front side

3 tweeter terminal

(wide side)

1 two screws

3 tweeter terminal

(narrow side)

7 speaker unit (TW)

(SP4)

6 speaker plate

5 two screws

19

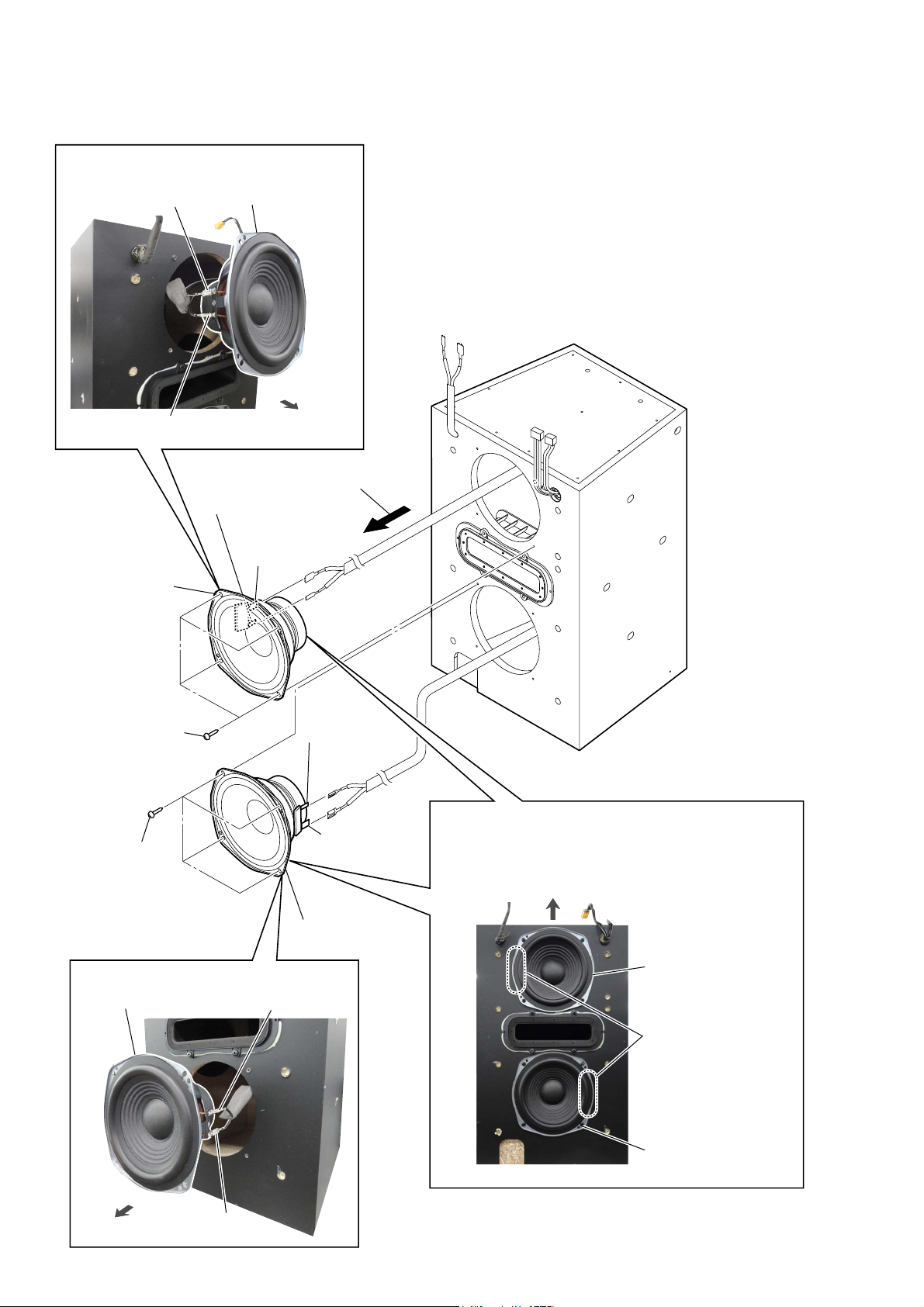

Page 20

GTK-XB7

2-20. WOOFER (SP1, SP2)

:LUHVHWWLQJ

woofer terminal

(wide side)

speaker unit (WF) (SP2)

woofer terminal

(narrow side)

4 speaker unit (WF)

(SP2)

1 four screws

1 four screws

front side

2 Remove the speaker unit (WF)

in the direction of the arrow.

3 woofer terminal

(narrow side)

3 woofer terminal

(wide side)

3 woofer terminal

(narrow side)

3 woofer terminal

(wide side)

,QVWDOODWLRQGLUHFWLRQIRUWKHVSHDNHUXQLW:)6363

When installing the speaker unit (WF) (SP1), (SP2), make

Note:

sure that there is a position of the speaker terminal to the

position shown in the figure below.

top side

20

:LUHVHWWLQJ

speaker unit (WF) (SP1)

front side

woofer terminal

(wide side)

4 speaker unit (WF)

(SP1)

speaker unit (WF) (SP2)

woofer terminal

(narrow side)

terminals position

speaker unit (WF) (SP1)

–)URQWYLHZ–

Page 21

SECTION 3

TEST MODE

SOFTWARE VERSION DISPLAY

It can confi rm the software version.

Procedure:

1. Press the [

2. Press the [FUNCTION] button to select the AUDIO IN function.

3. Press the button on the remote commander as following order.

[>] → [EXTRA BASS] → [.]

4. Each software versions are shown by the blinking frequency of

LEDs simultaneously.

Example:

When the MCU version is “v15”, the [

[EXTRA BASS] LED blinks 5 times.

When the MPEG version is “v07”, the [AUDIO IN] LED blinks 0

time, the [USB] LED blinks 7 times.

When the BT version is “v075”, the [SPEAKER ADD L] LED

blinks 0 time, the [SPEAKER ADD R] LED blinks 7 times, the

[PARTY CHAIN] LED blinks 5 times.

FACTORY RESET

It can reset all MPEG settings and clear the Bluetooth linked list.

Execute this mode when returning the this unit to the customer.

] button to turn the power on.

1

] LED blinks 1 time, the

1

GTK-XB7

Procedure:

1. Press the [1] button to turn the power on.

2. Press two buttons of the [FUNCTION] and [–] simultaneously

for 5 seconds.

3. The [1] LED blinks for 3 seconds, and then reboot the system.

21

Page 22

GTK-XB7

MEMO

MEMO

22

Page 23

4-1. BLOCK DIAGRAM - OVERALL Section -

GTK-XB7

SECTION 4

DIAGRAMS

GTK-XB7

2323

Page 24

GTK-XB7

d

4-2. BLOCK DIAGRAM - POWER SUPPLY Section -

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is printed in each block.)

For Printed Wiring Boards.

Note:

• : Pattern from the side which enables seeing.

(The other layers’ patterns are not indicated.)

Caution:

Pattern face side:

(Conductor Side)

Parts face side:

(Component Side)

Parts on the pattern face side seen

from the pattern face are indicated.

Parts on the parts face side seen from

the parts face are indicated.

For Schematic Diagrams.

Note:

• All capacitors are in μF unless otherwise noted. (p: pF) 50

WV or less are not indicated except for electrolytics and

tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specifi ed.

Note:

The components identifi ed by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specifi ed.

Note:

Les composants identifi és

par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par

une pièce portant le numéro spécifi é.

• Circuit Boards Location

PSU board

CONTROL board

LA board

IR board

RGBE board

LB board

BT&NFC board

USB + KEY boar

MAIN board

GTK-XB7

RGBF board

2424

Page 25

GTK-XB7

4-3. PRINTED WIRING BOARD - MAIN Board -

1 2 3 4 5 6 7 8 9

MAIN BOARD (COMPONENT SIDE)

A

B

C

D

• See page 24 for Circuit Boards Location.

MAIN BOARD (CONDUCTOR SIDE)

• : Uses unleaded solder.

E

F

G

H

I

GTK-XB7

J

2525

Page 26

GTK-XB7

4-4. SCHEMATIC DIAGRAM - MAIN Board (1/8) -

2

(1/8)MAIN BOARD

A

POWER INPUT

XP1

XP1

9PIN/2.0mm

9PIN/2.0mm

36V

PSON

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

AMP_36V

V_12V

C5

C2

0.1uF/50V/X7RC50.1uF/50V/X7R

B

C

STB_5V

C399

C399

C389

C389

C203

C203

100pF/50V/NP0

100pF/50V/NP0

33pF/50V/NP0

33pF/50V/NP0

2.2uF

2.2uF

U32

U32

SY8089

SY8089

43

VIN LX

R22

R22

47K

47K

1

5

EN

VFB

GND

2

VOUT=0.6*(82+18)/18=3.3V

L18 2.2uH/3.4AL18 2.2uH/3.4A

R335

R335

82K/1%

82K/1%

R336

18K/1%

18K/1%

R336

STB_3.3V

C48

C48

CE12

CE12

C391C391

++

100uF/16V/SMD

100uF/16V/SMD

1000pF/50V/X7R1000pF/50V/X7R

10uF/6.3V/X5R

10uF/6.3V/X5R

D

STB_5VĺSTB_3.3V

STB_3.3V

DS

Q11

C29

C29

R10

R10

0.1UF

0.1UF

100K

100K

E

3.3V_D1_EN

G

R2031KR203

1K

Q11

P_AP2305

P_AP2305

POWER CONTROL 3.3V

3.3V_D1

FB14 120/2AFB14 120/2A

• See page 44 for IC Block Diagrams.

386

36V_MAIN

C4

C1

0.1uF/50V/X7RC40.1uF/50V/X7R

100pF/50V/NP0C1100pF/50V/NP0

STB_5V

R101 1KR101 1K

1uF/16V

1uF/16V

C164

C164

U23

U23

4

VIN

1

SS

32

EN GND

C162

C162

EUP3504

EUP3504

0.01uF/50V/X7R

0.01uF/50V/X7R

POWER CONTROL 5V

+12V

R11

R11

C19

R239 10KR239 10K

C19

0.1UF

0.1UF

R236

R236

47K

47K

G

47K

47K

Q4

Q4

NPN_3DG3904M

NPN_3DG3904M

C21

C21

0.1UF

0.1UF

POWER CONTROL 12V

STB_3.3V

C127

C127

R43

R43

0.1UF

0.1UF

100K

100K

R28 10KR28 10K

C41

C41

R27

R27

47K

47K

0.1UF

0.1UF

POWER CONTROL 3.3V

5

VOUT

DS

Q2

P_AP2305Q2P_AP2305

R13

R13

47K

47K

D5 LL4148D5 LL4148

DS

Q13

Q13

G

P_AP2305

P_AP2305

R2041KR204

1K

Q17

Q17

NPN_3DG3904M

NPN_3DG3904M

R10020R100

20

FB16 120/2AFB16 120/2A

3.3V_D1_EN

FB15 120/2AFB15 120/2A

FB4 120/2AFB4 120/2A

C165

C165

1uF/16V

1uF/16V

V_12V

3.3V_D2

VCC_D

100pF/50V/NP0C2100pF/50V/NP0

36V

R375

R375

NC/5.6

NC/5.6

C330

C330

NC/330pF/50V

NC/330pF/50V

POWER_EN

POWER_EN

3.3V_D2_EN

5

36V_MAIN

FB5

FB5

120/2A

120/2A

CE1

CE1

C26

C26

++

0.1uF/50V/X7RC30.1uF/50V/X7R

100uF/50V

100uF/50V

1uF/50V/X7R

1uF/50V/X7R

Close to VIN

36V_MAIN

FB6

FB6

120/2A

120/2A

CE7

CE7

C27

C27

++

0.1uF/50V/X7R

0.1uF/50V/X7R

100uF/50V

100uF/50V

1uF/50V/X7R

1uF/50V/X7R

Close to VIN

+12V

FB7 120/2AFB7 120/2A

714

C278 0.01uF/50V/X7RC278 0.01uF/50V/X7R

U3

EUP3490U3EUP3490

1

BS

IN

OCSET

GND

6

4

C284 0.01uF/50V/X7RC284 0.01uF/50V/X7R

U4

EUP3490U4EUP3490

BS

IN

OCSET

GND

6

4

R253

R253

100K

100K

R373

R373

47K

47K

SW

FB

OVEN

COMP

GNDP

9

C22

C22

1500pF/50V/X7R

1500pF/50V/X7R

R57

R57

4.7K

4.7K

SW

FB

OVEN

COMP

GNDP

9

C23

C23

1500pF/50V/X7R

1500pF/50V/X7R

R75

R75

4.7K

4.7K

1

2

C189

C189

0.1uF

0.1uF

2

7

C3

R170

R170

220K

220K

1

2

7

C10

C10

R206

R206

220K

220K

CE8

CE8

C183

C183

++

100uF/16V

100uF/16V

0.1uF

0.1uF

3

5

8

R966

R966

2.2

2.2

3

5

8

R967

R967

2.2

2.2

BS

IN

SS

8

C190

C190

0.1uF

0.1uF

L10 22uH/3.6AL10 22uH/3.6A

R2033R20

33

C109

C109

D1

330pF/50V/X7R

330pF/50V/X7R

SS34/40V/3AD1SS34/40V/3A

L11 22uH/3.6AL11 22uH/3.6A

R69

R69

NC/33

NC/33

C114

C114

D3

NC/330pF/50V/X7R

NC/330pF/50V/X7R

SS34/40V/3AD3SS34/40V/3A

C47 0.01uF/50V/X7RC47 0.01uF/50V/X7R

U14

U14

AS5430A

AS5430A

SW

FB

COMPEN

GND

TP

4

9

R4

R140

R140

51K/1%R451K/1%

68K/1%

68K/1%

C6

CE2

CE2

++

470uF/10V

470uF/10V

VOUT=0.92*(68+15)/15=5.09V

Voven=1.02*(10+51)/10=6.22V

VOUT=0.92*(220+18)/18=12.16V

Voven=1.02*(200+15)/15=14.62V

3

5

67

R115

R115

15K/1%

15K/1%

R158

R158

220K/1%

220K/1%

CE5

CE5

++

100uF/16V

100uF/16V

R157

R157

18K/1%

18K/1%

L12 10uH/5AL12 10uH/5A

C152

C152

3900pF/50V/X7R

3900pF/50V/X7R

R259

R259

6.8K

6.8K

R153

R153

10K/1%

10K/1%

R5

200K/1%R5200K/1%

R163

R163

15K/1%

15K/1%

C9

R16

R16

68K/1%

68K/1%

CE11

CE11

++

100uF/16V

100uF/16V

VOUT=0.925*(68+2.2+15)/15=5.25V

FB11 120/2AFB11 120/2A

FB13 120/2AFB13 120/2A

C24

C24

ZD2

ZD2

0.1uF/16V/X7R

0.1uF/16V/X7R

ZMM6V2/6.2V

ZMM6V2/6.2V

10uFC6 10uF

C28

C28

ZD3

ZD3

BZV55C15

BZV55C15

0.1uF

0.1uF

10UFC9 10UF

R380

R380

2.2K

2.2K

C14

C14

10uF

R79

R79

15K/1%

15K/1%

10uF

STB_5V

+12V

USB_5V

2.1A

C25

C25

0.1uF/16V/X7R

0.1uF/16V/X7R

GTK-XB7

U2

U2

SGM203-2ADJ3

3.3V_D1

close to LDO

C17

C17

10uF/6.3V/X5R

10uF/6.3V/X5R

C16

C16

F

SGM203-2ADJ3

1

VIN

R23

R23

47K

47K

0.1UF

0.1UF

Vout=0.8*(1+15/12)=1.8V

5

VOUT

43

ADJ/SENSEEN

GND

2

R21

R21

15K/1%

15K/1%

R19

R19

12K/1%

12K/1%

1.8V_D

C206

C206

C30

C30

10uF/6.3V/X5R

10uF/6.3V/X5R

3.3V_D2

C75

C75

0.1UF

0.1UF

3.3Vĺ1.8V

U19

U19

CW1117

CW1117

32

input Vout

C155

C155

1uF

1uF

4.7uF

4.7uF

Vout=1.25*(1+R25/R44)=1.25V

ADJ/GND

1

4

Out

R44

R44

NC/120/1%

NC/120/1%

R250R25

3.3Vĺ1.2V

1.2V_D

C146

C146

10uF/6.3V/X5R

10uF/6.3V/X5R

FU1.0 821CFU1.0 821C

0

2626

Page 27

4-5. SCHEMATIC DIAGRAM - MAIN Board (2/8) -

GTK-XB7

D

A

B

C

DEBUG_TX

DEBUG_RX

3.3V_D2

FB8 500/200mAFB8 500/200mA

FB9 500/200mAFB9 500/200mA

R62 0R62 0

R68 2.2R68 2.2

3.3V_D2

C42

C42

100pF/50V/NP0

100pF/50V/NP0

C53

C53

10uF/6.3V/X5R

10uF/6.3V/X5R

C63

C63

4.7UF

C325

C325

10uF/6.3V/X5R

10uF/6.3V/X5R

Close to 8104WW

100uF/16V/SMD

100uF/16V/SMD

C44

C44

C43

C43

100pF/50V/NP0

100pF/50V/NP0

100pF/50V/NP0

100pF/50V/NP0

C55

C55

0.1UF

0.1UF

Close to 8104WW

C88

C88

4.7UF

4.7UF

4.7UF

Close to SDRAM

C67

C68

C67

C68

0.1UF

0.1UF

Close to 8104WW

C70

C70

4.7UF

4.7UF

C64

C64

CE9

CE9

++

2 9

386

5

714

(2/8)MAIN BOARD

FLASH

F3V3

R40

R40

10K

10K

U5

U5

1

CE#

VDD

2

SO

HOLD#

3

WP#

SCK

45

VSS SI

KH25L1606 16M FLASH

KH25L1606 16M FLASH

I2S_MCLK

MCLK_1MCLK_1

I2S_BCLK

BCLK_1BCLK_1

I2S_LRCK

LRCLK_1LRCLK_1

I2S_DATA_IN

DATA_IN_1DATA_IN_1

DSP_SDA

DSP_SCL

8

BT_TX

BT_RX 8

8

7

6

F3V3

C72

C72

4.7UF

4.7UF

R50 33R50 33

R52 33R52 33

R54 33R54 33

R56 33R56 33

F3V3

R41

R41

10K

10K

R45 33R45 33

C66

C66

5.6pF/50V/NP0

5.6pF/50V/NP0

C130

C130

SF_CK

SPI_D1

5.6pF/50V/NP0

5.6pF/50V/NP0

C129

C129

5.6pF/50V/NP0

5.6pF/50V/NP0

R591KR59

1K

M_A[0..11]

M_D[0..15]

M_BA[0..1]

M_DQM[0..1]

RAM_CLK

M_CAS

M_RAS

M_WE

SDRAM

R240 0R240 0

R241 0R241 0

R242 0R242 0

MA[0..11] (3)

DQ[0..15] (3)

BA[0..1] (3)

DQM[0..1] (3)

DCLK (3)

CAS# (3)

RAS# (3)

WE# (3)

AD_MCLK

AD_BCLK

AD_LRCK

DATA6

SRC_MCLK

SRC_BCLK

SRC_LRCK

C58 10uF/6.3V/X5RC58 10uF/6.3V/X5R

C59 0.1UFC59 0.1UF

BT_MFB_MPEG

AMP_RESET 11

R112 4.7KR112 4.7K

R139 4.7KR139 4.7K

R90 33R90 33

R91 33R91 33

D33

R301KR30

R371KR37

1K

1K

STB_3.3V

R70

R70

R71

R71

10K

10K

10K

10K

R73 1KR73 1K

R741KR74

D33

MCU_SDA

MCU_SCL

R33 33R33 33

R42 33R42 33

C46

C46

0.1UF

0.1UF

R39

R39

10K

10K

SF_CS

SPI_D0

STB_3.3V

I2C1_SDA

I2C1_SCL

BT_TX

BT_RXMPEG_TX

1K

I2C_SW

I2C_SCL

I2C_SDA

0.1UF

0.1UF

TP13TP13

RFDA3.3V

Crystal

R32 1KR32 1K

C40

C40

33pF/50V/NP0

33pF/50V/NP0

AMP_FAULT

I2C_SW

I2C_SCL

I2C_SDA

VCC1.2

C82

C82

1000pF/50V/X7R

1000pF/50V/X7R

C76

C76

0.1UF

0.1UF

RF3.3V

RFDA3.3V

XO

R66 33R66 33

TP59TP59

TP60TP60

RF3.3V

VCC1.2

D33

D33

USB_DP

AD_AVSS

LDSW/GPIO67

HOME/GPIO66

M_D0

M_D1

M_D2

M_D1

M_D3

M_D2

XO

VDD_12

CLKOUT

U6

U6

M_D3

M_D4

M_D4

XI

CLKIN

M_D5

M_D5

USB_DM

USB_DP

USB_DM

787776757473727170696867

79

USB_DP

USB_DM

PLL_VSS

PLL_VDD

USB_AVSS

M_D6

M_D7

M_D15

M_D14

M_D13

M_D7

M_D6

M_D14

M_D12

M_D13

M_D15

USB_AVDD

M_D12

M_D11

RAM_CLK

5.6pF/50V/NP0

5.6pF/50V/NP0

C45

C45

0.1UF

0.1UF

92

102

101

100

OPVIN

NC

CDLDO

NC

CDMDI

SRV_AVDD

V21

V165

DA_AVSS

DA_TEO

DA_FEO

DA_AVDD

SPDC_OUT/GPIO70

SC_OUT/GPIO71

GPIO72

DMEA

CARD_SENSE/GPIO74

SD_D0/GPIO75

SD_CLK/GPIO76

SD_SMD/GPIO77

GPIO78

GPIO79

CDVR

SPI_CE

SPI_D0

SPI_CLK

SPI_D1

R167 4.7KR167 4.7K

R89 4.7KR89 4.7K

R98 4.7KR98 4.7K

APC_AVSS

GPIO86

VFD_CLK

1

2345678

I2S_DATA_IN

I2S_DATA_OUT

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

SF_CS

SPI_D0

SF_CK

SPI_D1

D33

122

123

124

125

126

127

128

TP58TP58

91

99

OPVIP

VFD_STB

9089888786858483828180

9897969594

93

EFA

B

C

D

RFIS

RFSUM

AGCCAP

AD_AVDD

SPHE8104W-128

SPHE8104W-128

VFD_DATA

VDD_33

RESET_B

VSS

IR_IN/GPIO3

GPIO4

GPIO5

VDD_12

HSYNC/GPIO7

VSYNC/GPIO8

9

1011121314151617181920212223242526272829303132333435363738

MPEG_RXdebug_RX

MPEG_TX

I2S_LRCK

I2S_BCLK

I2S_MCLK

M_D0

D33

VCC1.2

R4933R49

R5133R51

33

33

MPEG_RST

debug_TX

VCC1.2

VDD_12

TV_AVSS

M_D11

M_D10

M_D10

TP3TP3

TV_DAC3

M_D9

M_D9

TP4TP4

TP5TP5

TV_DAC2

M_D8

M_D8

M_DQM1

C77

C77

VVCC3

TV_DAC1

TV_AVDD

M_DQM1

VSS

R6433 R6433

R361K R361K

VVCC3

VVCC3

V_FSADJ

V_FSADJ

TV_AVSS

TV_DAC0

TV_AVDD

SPDIF_IN/GPIO48

SPDIF_OUT/GPIO47

M_CLK

VDD_33

M_A11

M_A9

R650R650

M_A9

M_A8

D33

M_A11 GPIO25

C49

C49

65

66

AOUT_R

V_COMP

ADAC_AVSS

ADAC_AVDD

M_A8

M_A7

M_A6

M_A7

AOUT_L

AD_AVDD

AD_AVSS

M_DQM0

M_A6

AIN_R

GPIO54

GPIO53

GPIO52

GPIO51

GPIO50

M_A10

M_BA1

M_BA0

M_RAS

M_CAS

M_WE

VREF

M_A3

M_A2

M_A1

M_A0

M_A4

M_A5

10UF/6.3V/X5R

10UF/6.3V/X5R

AOUT_R

AOUT_L

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

DAC_VREF

M_A3

M_A2

M_A1

M_A0

M_A10

M_BA1

M_BA0

M_RAS

M_CAS

M_WE

M_DQM0

M_A4

M_A5

AVCC3

AD_VCC3

R133 33R133 33

R127 33R127 33

MPEG_RX

I2C_SDA

I2C_SCL

XP2

XP2

1

1

2

2

3

3

4

4

4PIN/2.0mm

4PIN/2.0mm

TP6TP6

C52

C52

C57

C57

C56

C56

1000pF/50V/X7R

1000pF/50V/X7R

0.1UF

0.1UF

0.1UF

0.1UF

D33

Digital

TP7TP7

SD33

C7

SDRAM

0.1UFC7 0.1UF

TP8TP8

RF3.3V

XI

R31 100KR31 100K

Y1 27MHz/30PPMY1 27MHz/30PPM

C39

C39

33pF/50V/NP0

33pF/50V/NP0

Put these circuits as

closer as possible to

MPEG DECODER.

AMP_FAULT

RF

0.1UF

0.1UF

4.7UF

4.7UF

TP9TP9

TP12TP12

AD_VCC3

Internal AD

VVCC3

Video DAC

AVCC3

Internal DA

C71

C71

0.1UF

0.1UF

TP10TP10

C73

C73

C74

C74

0.1UF

0.1UF

0.1UF

0.1UF

C78

C78

0.1UF

0.1UF

1.2V_D

RF3.3V

FB12 500/200mAFB12 500/200mA

C81

C81

C80

C80

0.1UF

0.1UF

Close to 8104WW

C65

C65

4.7UF

4.7UF

3.3V_D2

R55

NPN_3DG3904M

NPN_3DG3904M

R55

10K

10K

TP14TP14

MPEG_RST

MPEG_RST

C102

C102

0.1uF/16V/X7R

0.1uF/16V/X7R

Q5

Q5

C54

C54

10uF

10uF

E

R53

R53

10K

10K

D18

D18

LL4148

LL4148

R46 1KR46 1K

RESET

GTK-XB7

2727

Page 28

GTK-XB7

4-6. SCHEMATIC DIAGRAM - MAIN Board (3/8) -

D

A

B

C

E

2 9

386

5

714

(3/8)MAIN BOARD

SDRAM

U8

U8

23

MA0

A0

24

MA1

A1

25

MA2

A2

26

MA3

A3

29

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

DBA0

DBA1

SDCLK

DRAS#

DCAS#

DWE#

DQM0

DQM1

30

31

32

33

34

22

35

20

21

38

37

19

18

17

16

15

39

36

40

54

41

28

A4

A5

A6

A7

A8

A9

A10/AP

A11

BA0/A13

BA1/A12

CLK

CKE

CS

RAS

CAS

WE

DQML

DQMHNCVCCQ

NC

VSS

VSS

VSS

SDRAM_64Mb_M12L64164A-7T

SDRAM_64Mb_M12L64164A-7T

USB_5V

CE16

CE16

SD33

C95

C95

C96

C96

1000pF/50V/X7R

1000pF/50V/X7R

0.1UF

0.1UF

STB_3.3V

R954.7K R954.7K

R964.7K R964.7K

USB_EN

USB_EN

USB_FAULT

C79

C79

C35

C35

++

10uF/16V/X5R

10uF/16V/X5R

1uF/16V

1uF/16V

220uF/16V

220uF/16V

USB_FAULT

USB_5V

C38

C38

C11

C11

0.1uF/50V/X7R

0.1uF/50V/X7R

1uF/16V

1uF/16V

0.1UF

0.1UF

C97

C97

R102

R102

15K/1%

15K/1%

1K/1%

1K/1%

C100

C100

C98

C98

C99

C99

0.1UF

0.1UF

0.1UF

0.1UF

0.1UF

0.1UF

U10

U10

GMT_G527

GMT_G527

1

6

OUT 1

IN

4

2

3

FLGENGND

5

ILIM

R266

R266

++

CE14

CE14

220uF/16V

220uF/16V

SD33

C34

C34

1uF/16V

1uF/16V

USB_VCC1

R102+R266=16K,Ilim=2.25A_min,2.5A_typ

USB POWER SWITCH

F

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

VCC

VCC

VCC

VCCQ

VCCQ

VCCQ

VSSQ

VSSQ

VSSQ

VSSQ

C8

C8

0.1uF/50V/X7R

0.1uF/50V/X7R

2

4

5

7

8

10

11

13

42

44

45

47

48

50

51

53

1

14

27

3

9

43

49

6

12

46

52

USB_VCC1

DQ7

DQ6

DQ5

DQ4

DQ3

DQ2

DQ1

DQ0

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

SD33

SD33

C101

C101

100pF/50V/NP0

100pF/50V/NP0

USB PORT

DD+

DWE# WE#

DCAS# CAS#

DBA0 BA0

DBA1 BA1

SDCLK DCLK

Compatible for footprint

R771 NC/0R771 NC/0

FL1 ELE900FL1 ELE900

413

2

R772 NC/0R772 NC/0

DQ[0..15](2)

DQ[0..15]

MA[0..11]

MA[0..11](2)

BA[0..1]

BA[0..1](2)

DQM[0..1]

DQM[0..1](2)

DCLK

DCLK(2)

CAS#

CAS#(2)

RAS#

RAS#(2)

WE#

WE#(2)

23

ADC_KEY

Blue_LED5

Blue_LED6

Blue_LED7

RAS#DRAS#

D+

D-

4

ESD1

ESD1

NC/PRTR5V0U2X

NC/PRTR5V0U2X

XP37

1

R8300R830

0

R8310R831

0

R8320R832

0

R8330R833

0

C371 100pF/50V/NP0C371 100pF/50V/NP0

C372 100pF/50V/NP0C372 100pF/50V/NP0

C373 100pF/50V/NP0C373 100pF/50V/NP0

XP37

1

1

2

2

3

3

4

4

4PIN/2.0mm

4PIN/2.0mm

XP7

XP7

1

1

2

2

3

3

4

4

5

C374 100pF/50V/NP0C374 100pF/50V/NP0

5

6

6

6PIN/2.0mm

6PIN/2.0mm

HSD+

HSD-

USB sync

USB charge

BT sync

SGM7227U9SGM7227

R779 NC/0R779 NC/0

MODE

CHG_EN BT_update_EN

HXH

LLH

LHL

CHARGE_SWITCH

STB_3.3V

8

9

10

U9

S

OE

Vcc

1

2

D+

D-

345

7

USB_DP

HSD2+

6

USB_DM

HSD2-

GND

HSD1-

HSD1+

HSD-

HSD+

BM update_SWITCH

STB_3.3V

8

9

10

U11

U11

S

OE

Vcc

SGM7227

SGM7227

1

2

D+

D-

345

7

HSD2+

6

HSD2-

GND

HSD1-

HSD1+

USB_EN

USB_DP

USB_DM

BM_D+

BM_D-

S=1:2ĺON 1ĺOFF

S=0:1ĺON 2ĺOFF

CHG_EN

R94

R94

10K

10K

BM_update_EN

R111

R111

10K

10K

GTK-XB7

2828

Page 29

GTK-XB7

4-7. SCHEMATIC DIAGRAM - MAIN Board (4/8) -

2 9

(4/8)MAIN BOARD

A

STB_3.3V

FB48 500/800mAFB48 500/800mA

C341

C341

0.1UF

0.1UF

C342

C342

0.1UF

0.1UF

Close to MCU

C344

C344

C345

C345

0.1UF

0.1UF

MCU_3.3V

C347

C347

0.1UF

0.1UF

0.1UF

0.1UF

R956 1KR956 1K

B

STB_3.3V

MCU_3.3V MCU_3.3V

R123 4.7KR123 4.7K

POWER_KEY

ADC_KEY

I2C_SW

LL4148D4LL4148

D4

R114

R114

MCU_RST

27K

27K

R128 4.7KR128 4.7K

C121

C121

2.2uF

2.2uF

MCU_RST

C182

C182

0.1uF/16V/X7R

0.1uF/16V/X7R

Close to MCU

C

STB_3.3V

• See page 44 for IC Block Diagrams.

386

R142 10KR142 10K

R113 1MR113 1M

14.7456MHz/30PPM

14.7456MHz/30PPM

C112

C112

27pF/50V/NP0

27pF/50V/NP0

R374

R374

POWER_EN

LED_PW_EN

10K

10K

BM_update_EN

3.3V_D2_EN

Y3

Y3

MCU_3.3V

YIYO

C113

C113

R216 1MR216 1M

YI

YO

MCU_RST

R215 1MR215 1M

R120 33R120 33

30pF/50V/NPO

30pF/50V/NPO

UART2_TXUART2_TX

U16

U16

1

VDD

2

PC13

3

PC14/OSC32_IN

4

PC15/OSC32_OUT

5

PF0/OSC_IN

6

PF1/OSC_OUT

7

NRST

8

PC0

9

PC1

10

PC2

11

PC3

12

VSSA

13

VDDA

14

PA0

15

PA1

16

PA2

I2C1_SDA

I2C1_SCL

Blue_LED2

Blue_LED1

Party_Chain_In

NFC_INT

Party_Chain_Out

Blue_LED7

Blue_LED6

Blue_LED5

R39933 R 39933

R1480 R1480

MCU_3.3V

54

VDD

PA3

PB9

VSS

PF4

PF5

R39833 R39833

PB6

PB7

PB8

BOOT0

STM32F030R8T6

STM32F030R8T6

PA4

PA5

PA6

PA7

R12533 R12533

555657585960616263

PB3

PB4

PB5

PD2

PC12

PC4

PC5

PB0

PB1

PB2

R40333 R40333

R39033 R39033

64

171819202122232425262728293031

5

SW_G3157

Party_Chain_SW

R27833 R 27833

SWCLK

4950515253

PA14

PA15

PC10

PC11

48

R395 1MR395 1M

PF7

47

PF6

46

PA13

45

PA12

44

PA11

43

PA10

42

R126 33R126 33

PA9

41

FB68 220FB68 220

PA8

40

PC9

39

PC8

38

PC7

37

R118 33R118 33

PC6

36

PB15

35

R391 33R391 33

PB14

34

R369 1MR369 1M

PB13

33

R147 33R147 33

PB12

PB10

PB11

VSS

VDD

32

SWDIO

PW_LED1

PW_LED2

Blue_LED4

Blue_LED3

IR

Flash_LED4

Flash_LED3

FAN_PWM

BT_MFB_MCU

BT_RESET

VALID

USB_EN

12

PWMCLK

C250

C250

100pF/50V/NP0

100pF/50V/NP0R122 33R122 33

SPI3_MOSI

SPI3_SCK

SPI3_LE

714

R58 0R58 0

C319

C319

10uF

10uF

SPI3_MISO

PWMCLK

PWM5_G

PWM5_R

PWM5_B

PWM1_R

PWM1_B

PWM1_G

PWM2_G

3.3V_D1

R218

R218

NC/4.7K

NC/4.7K

PWM4_G

PWM4_B

PWM4_R

PWM3_G

PWM3_B

PWM3_R

PWM2_B

PWM2_R

3.3V_D1

R219

R219

NC/4.7K

NC/4.7K

LED Driver

U1

U1

1

2

3

4

5

6

7

8

9

10

11

12 13

GND

REXT

SDI

CLK

PWMCLK

LE

OUT15

OUT0

OUT14

OUT1

OUT2

OUT13

OUT3

OUT12

OUT4

OUT11

OUT5

OUT10

OUT6

OUT9

OUT7 OUT8

LED1642GWTTR

LED1642GWTTR

VDD

SDO

C318

C318

0.1UF

0.1UF

24

23

R540 11KR540 11K

22

21

20

19

18

17

16

15

14

D

STB_3.3V

SWDIO

SWCLK

4.7K

XP9

XP9

4

4

3

2

1

4PIN/2.0mm

4PIN/2.0mm

3

2

1

NFC_BT

SPI3_LE

Relay_EN

SPI3_SCK

SPI3_MOSI

SPI3_MISO

AUDIO_MUTE

G_INT

Y_Rest

CHG_EN

USB_FAULT

I2C2_SCL

R154 10KR154 10K

AMP_MUTE

MCU_3.3V

I2C2_SDA

STB_3.3V

R132

R132

R205

R205

4.7K

4.7K

4.7K

LED Control

FB10 120/2AFB10 120/2A

C12

C12

0.1uF/50V/X7R

0.1uF/50V/X7R

To CENTER

+12V

XP46

XP46

18PIN/1.0mm

18PIN/1.0mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

C244 100pF/50V/NP0C244 100pF/50V/NP0

C245 100pF/50V/NP0C245 100pF/50V/NP0

C246 100pF/50V/NP0C246 100pF/50V/NP0

C247 100pF/50V/NP0C247 100pF/50V/NP0

C248 100pF/50V/NP0C248 100pF/50V/NP0

C243 100pF/50V/NP0C243 100pF/50V/NP0

C304 100pF/50V/NP0C304 100pF/50V/NP0

C255 100pF/50V/NP0C255 100pF/50V/NP0

C277 100pF/50V/NP0C277 100pF/50V/NP0

C303 100pF/50V/NP0C303 100pF/50V/NP0

C256 100pF/50V/NP0C256 100pF/50V/NP0

C229 100pF/50V/NP0C229 100pF/50V/NP0

C230 100pF/50V/NP0C230 100pF/50V/NP0

C231 100pF/50V/NP0C231 100pF/50V/NP0

C257 100pF/50V/NP0C257 100pF/50V/NP0

C232 100pF/50V/NP0C232 100pF/50V/NP0

C233 100pF/50V/NP0C233 100pF/50V/NP0

C441 100pF/50V/NP0C441 100pF/50V/NP0

FB50 220FB50 220

FB51 220FB51 220

FB67 220FB67 220

FB66 220FB66 220

FB65 220FB65 220

FB64 220FB64 220

FB63 220FB63 220

FB62 220FB62 220

FB61 220FB61 220

FB60 220FB60 220

FB59 220FB59 220

FB58 220FB58 220

FB57 220FB57 220

FB56 220FB56 220

FB55 220FB55 220

FB54 220FB54 220

FB53 220FB53 220

FB52 220FB52 220

PWM5_G

PWM5_R

PWM5_B

Flash_LED3

Flash_LED4

PWM1_R

PWM1_G

PWM1_B

PWM2_R

PWM2_G

PWM2_B

LED_PW_EN

PWM3_R

PWM3_G

PWM3_B

PWM4_G

PWM4_R

PWM4_B

EEPROM

U34

U34

1

NC

2

NC

3

NC

45

GND SDA

NC/EEPROM_16Kb_M24C16

NC/EEPROM_16Kb_M24C16

VCC

WP

SCL

XP52

XP52

3PIN/2.0mm

3PIN/2.0mm

STB_3.3V STB_3.3V

8

7

6

1

1

2

2

3

3

C365

C365

0.1UF

0.1UF

R281 33R281 33

R282 33R282 33

C103

C103

0.1uF

0.1uF

R3931KR393

1K

FB49 220FB49 220

C249

C249

100pF/50V/NP0

100pF/50V/NP0

STB_5V

R3941KR394

1K

I2C2_SCL

I2C2_SDA

IR

E

XP36

XP36

1

1

2

2

3

3

4

4

4PIN/2.0mm

4PIN/2.0mm

F

GTK-XB7

2929

Page 30

GTK-XB7

4-8. SCHEMATIC DIAGRAM - MAIN Board (5/8) -

(5/8)MAIN BOARD

A

B

C

XP35

XP35

45PIN/0.5MM

45PIN/0.5MM

To BT Board

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

GND

GND

46

47

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

C353

C353

C354

C354

10uF

10uF

0.1UF

0.1UF

C355

C358

C358

C355

NC/15pF/50V/NP0

NC/15pF/50V/NP0

NC/15pF/50V/NP0

NC/15pF/50V/NP0

C306

C306

D

• See page 44 for IC Block Diagrams.

3862

STB_3.3V

BM_DBM_D+

BT_LRCK

R82733R827

33

BT_LRCK

BT_BCLK

R82633R826

33

BT_BCLK

BT_DATA

R82533R825

33

BT_DATA

NFC_BT

NFC_BT

BT_RESET

BT_RESET

BT_RX

BT_RX

BT_TX

BT_TX

BT_MFB

NFC_INT

C362

C362

C363

C363

C361

C359

C359

C361

C360

C360

NC/15pF/50V/NP0

NC/15pF/50V/NP0

NC/15pF/50V/NP0

NC/15pF/50V/NP0

15PF

15PF

15PF

15PF

15PF

15PF

C305

C305

C307

C307

0.1UF

0.1UF

10uF

10uF

0.1UF

0.1UF

C308 100pF/50V/NP0C308 100pF/50V/NP0

C309 100pF/50V/NP0C309 100pF/50V/NP0

C310 100pF/50V/NP0C310 100pF/50V/NP0

FB37 500/800mAFB37 500/800mA

FB38 500/800mAFB38 500/800mA

FB69 220FB69 220

FB70 220FB70 220

FB71 220FB71 220

FB72 220FB72 220

FB73 220FB73 220

FB74 220FB74 220

FB75 220FB75 220

FB76 220FB76 220

C311 100pF/50V/NP0C311 100pF/50V/NP0

C314 100pF/50V/NP0C314 100pF/50V/NP0

C312 100pF/50V/NP0C312 100pF/50V/NP0

C315 100pF/50V/NP0C315 100pF/50V/NP0

C313 100pF/50V/NP0C313 100pF/50V/NP0

NFC_INT

POWER_KEY

ADC_KEY

Blue_LED1

Blue_LED2

Blue_LED3

Blue_LED4

PW_LED1

PW_LED2

STB_5V

VCC_D

3

POWER_KEY

ADC_KEY

Blue_LED1

Blue_LED2

Blue_LED3

Blue_LED4

PW_LED1

PW_LED2

D2

BAT54CD2BAT54C

2

1

BT_MFB_MCU

BT_MFB_MPEG

5

1

LGRP

SRC_MCLK

MPEG_RST

R196 0R196 0

BT_DATA

BT_BCLK

BT_LRCK

3.3V_D1

C327

C327

C328

C328

10uF

10uF

R237 4.7KR237 4.7K

3.3V_D1 3.3V_D1

24-Bit I2S 24-Bit I2S

R365 1KR365 1K

AD_DATA

2

RCKI

3

NC

4

SDIN

5

BCKI

6

LRCKI

7

VIO

8

0.1UF

0.

1UF

C348

C348

DGND1

9

BYPAS

10

IFMT0

11

IFMT1

12

IFMT2

13

RST

14

MUTE

0.1UF

0.1UF

1

2

34

R909

R909

U27

U27

SRC4182

SRC4182

S: L-->B1

S: H-->B2

U24

U24

B2

GND

VCC

B1 A

74LVC1G3157GV

74LVC1G3157GV

NC/0

NC/0

714

28

MODE2

27

MODE1

26

MODE0

25

24

23

22

21

20

19

18

17

16

15

VCC_D

R238 4.7KR238 4.7K

R955

R955

NC/10K

NC/10K

SW_G3157DATA4

DATA6

R117 33R117 33

R137 33R137 33

R155 33R155 33

0.1UF

0.1UF

BCKO

LRCKO

SDOUT

VDD

DGND2

TDMI

OFMT0

OFMT1

OWL0

OWL1

RDY

6

S

5

SRC_BCLK

SRC_LRCK

DATA4

3.3V_D1

C234

C234

C326

C326

10uF

10uF

TP16TP16

VCC_D

R22847R228

47

C340

C340

C343

C343

0.1UF

0.1UF

10uF

10uF

GTK-XB7

3030

Page 31

4-9. SCHEMATIC DIAGRAM - MAIN Board (6/8) -

GTK-XB7

D

A

B

C

Audio IN

Audio OUT

C51

C51

10uF/6.3V/X5R

10uF/6.3V/X5R

A_OUT_R1

A_OUT_L1

C60

C60

10uF/6.3V/X5R

10uF/6.3V/X5R

2 9

(6/8)MAIN BOARD

C119

C119

10uF/6.3V/X5R

10uF/6.3V/X5R

Audio In_L AUX_IN_L

Audio In_R AUX_IN_R

C137

R187NCR187

NC

R186 5.1KR186 5.1K

R193 5.1KR193 5.1K

R190NCR190

NC

C137

470K

470K

C134

C134

470K

470K

10uF/6.3V/X5R

10uF/6.3V/X5R

INR+

INL+

7

C120

C120

AUDIO_MUTE

R177 20KR177 20K

R131 20KR131 20K

R183 470R183 470

R124

R124

10K

10K

R119

R119

10K

10K

C174

C174

10uF/6.3V/X5R

10uF/6.3V/X5R

C191

C191

10uF/6.3V/X5R

10uF/6.3V/X5R

386

C172

C172

10uF/6.3V/X5R

10uF/6.3V/X5R

10uF/6.3V/X5R

10uF/6.3V/X5R

R184 10KR184 10K

R194 10KR194 10K

INR+

INR-

INR_OUT

R180

R180

47K

47K

C198

C198

INR-

INL-

C117

C117

R188 20KR188 20K

C133 100pF/50V/NP0C133 100pF/50V/NP0

R197 20KR197 20K

C135 100pF/50V/NP0C135 100pF/50V/NP0

C145

C145

0.1UF

0.1UF

1uF

1uF

AUX_IN_L

AUX_IN_R

INR_OUT

INL_OUT

U927

U927

C136 1uFC136 1uF

14

LINP

13

LINN

12

OUTL

11

UVP

10

PGND

9

PVDD

AS9632

AS9632

1

RINP

2

RINN

3

OUTR

4

SGND

5

MUTE#

6

PVSS

78

CN CP

A_OUT_L1 A_OUT_R1

I2C_SDA

R195 30KR195 30K

INL_OUT

INL+

INL-

C116

C116

0.1UF

0.1UF

R8900R890

R370 NC/33R370 NC/33

C173

C173

10uF/6.3V/X5R

10uF/6.3V/X5R

3.3V_D1

R381

R381

1.5K

1.5K

R85 0R85 0

CE13

CE13

++

NC/100uF/16V/SMD

NC/100uF/16V/SMD

0

R48 1KR48 1K

5

VOL ADJ

U928

U928

1

2

3

45

LIN

LOUT

VSS

SDA SCL

NC/PT2257

NC/PT2257

3.3V_D1

8

RIN

7

ROUT

6

VDD

C321

C321

NC/0.1uF/25V/X5R

NC/0.1uF/25V/X5R

INR_OUT

INL_OUT

R8890R889

R371 NC/33R371 NC/33

C364

C364

NC/10uF

NC/10uF

R189

R189

100K

100K

R87 0R87 0

R88 0R88 0

R192

R192

100K

100K

714

3.3V_D1

R178

R178

R181

R181

4.7K

4.7K

4.7K

4.7K

16

15

14

12

11

10

NC/LVSL10180Z020/18V/2pF

NC/LVSL10180Z020/18V/2pF

C171

C197

C171

C197

1000pF/50V/X7R

1000pF/50V/X7R

1000pF/50V/X7R

1000pF/50V/X7R

C187

C187

NC/0.1uF/25V/X5R

NC/0.1uF/25V/X5R

1

6

2

3

5

4

AD_BCLK

AD_MCLK

AD_LRCK

AD_DATA

J1

RCA/4hJ1RCA/4h

WH RD

WH RD

AD_BCLK

AD_MCLK

AD_LRCK

AD_DATA 6

8

5

8

R182 5.6R182 5.6

VCC_D

AUX_IN_R

R90R9

AUX_IN_L

R140R14

R38 0R38 0

R82 0R82 0

A_OUT_RA_OUT_L

0

VCC_D

I2C_SCL

R92 0R92 0

C61

C61

10uF/6.3V/X5R

10uF/6.3V/X5R

Audio Out_R

C62

C62

10uF/6.3V/X5R

10uF/6.3V/X5R

Audio Out_L

R332

R332

NC/6.8K

NC/6.8K

CE22

CE22

++

220uF/16V

220uF/16V

0

0

Audio In_L

Audio In_R

Audio Out_L

Audio Out_R

3.3V_D1

C149

C149

0.1UF

0.1UF

C160 0.1UFC160 0.1UF

C186 10uFC186 10uF

21

FB22

FB22

500/200mA

500/200mA

ESD3

ESD3

U20

U20

1

AINR

CKS0

2

AINL

CKS2

3

CKS1

VCOM PDN

AGND

SCLK

VA

MCLK

VD

LRCK

DGND SDTO

ADC_AK5358A

ADC_AK5358A

ESD5

ESD5

NC/LVSL10180Z020/18V/2pF

NC/LVSL10180Z020/18V/2pF

21

DIF

ESD6

ESD6

21

413

5

6

7

89

FB77 500/800mAFB77 500/800mA

FB78 500/800mAFB78 500/800mA

FB79 500/800mAFB79 500/800mA

FB80 500/800mAFB80 500/800mA

ESD4

ESD4

NC/LVSL10180Z020/18V/2pF

NC/LVSL10180Z020/18V/2pF

NC/LVSL10180Z020/18V/2pF

NC/LVSL10180Z020/18V/2pF

21

R344 10KR344 10K

VCC_D

R303

E

Party_Chain_Out

R86 10KR86 10K

R84

R84

10K

10K

F

R301 10KR301 10K

Q22

Q22

NPN_3DG3904M

NPN_3DG3904M

Audio In_L

R303

10K

10K

R313

R313

15K

15K

Q762

Q762

PNP_3CG3906M

PNP_3CG3906M

R312 22KR312 22K

R353

R353

R351 68KR351 68K

C175

C175

2.2uF

2.2uF

82K

82K

R354

R354

68K

68K

R349 56KR349 56K

R352

R352

470K

470K

R314

R314

6.8K

6.8K

Audio Out_R

Party Chain

Audio In_R

RTL

Q25

Q25

NPN_3DG3904M

NPN_3DG3904M

C181

C181

2.2uF

2.2uF

R350

R350

680K

680K

R340 82KR340 82K

C180

C180

R338 68KR338 68K

10PF/50V/NPO

10PF/50V/NPO

R341

R341

68K

68K

R315 56KR315 56K

R339

R339

470K

470K

C177

C177

Q23

Q23

NPN_3DG3904M

NPN_3DG3904M

2.2uF

2.2uF

R364

R364

NC/10K

NC/10K

R342 10KR342 10K

C178

C178

10uF

10uF

C176

C176

R337

R337

680K

680K

STB_3.3V

VCC_D

R343

R343

10K

10K

Q763

Q763

PNP_3CG3906M

PNP_3CG3906M

RTL

R345

R345

22K

22K

R347 10KR347 10K

R346

R346

C179

C179

R348

22K

22K

10PF/50V/NPO

10PF/50V/NPO

R348

10uF

10uF

10K

10K

Q24

Q24

NPN_3DG3904M

NPN_3DG3904M

Party_Chain_In

Audio In_R

Audio In_L

R47 0R47 0

R83 0R83 0

C93 10uF/6.3V/X5RC93 10uF/6.3V/X5R

AOUT_R

C94 10uF/6.3V/X5RC94 10uF/6.3V/X5R

AOUT_L

Party_Chain_SW7

R15

R15

20K

20K

R17

R17

20K

20K

C86 10uF/6.3V/X5RC86 10uF/6.3V/X5R

C87 10uF/6.3V/X5RC87 10uF/6.3V/X5R

R24 10KR24 10K

C89 10uF/6.3V/X5RC89 10uF/6.3V/X5R

C91 10uF/6.3V/X5RC91 10uF/6.3V/X5R

R26 10KR26 10K

R209 33R209 33

R222

R222

4.7K

4.7K

R4041MR4041M

3.3V_D1

R224 100R224 100

CE10

CE10

100uF/16V/SMD

100uF/16V/SMD

A_OUT_R

A_OUT_L

V_12V VCC_4052

R2331KR233

1K

R2271KR227

1K

R360

R360

100K

100K

Vref

C185

C185

R361

R361

1uF

1uF

100K

100K

Vref

R4071MR4071M

R4051MR4051M

R4061MR4061M

S0: L-->nY0

S0: H-->nY1

12

14

15

11

1

5

2

4

10

9

6

78

U25

U25

X0

X1

X2

X3

Y0

Y1

Y2

Y3

A

B

EN

VEE GND

74HC4052

74HC4052

16

VCC

13

X

3

Y

VCC_4052

C184

C184

C83

C83

10uF/6.3V/X5R

10uF/6.3V/X5R

C85

C85

10uF/6.3V/X5R

10uF/6.3V/X5R

++

0.1UF

0.1UF

GTK-XB7

3131

Page 32

GTK-XB7

4-10. SCHEMATIC DIAGRAM - MAIN Board (7/8) -

(7/8)MAIN BOARD

A

B

I2S_DATA_OUT5

SRC_LRCK

SRC_BCLK

R23033R230

R261 33R261 33

R262 33R262 33

33

C148

C148

NC/12PF

NC/12PF

Y_DATA_IN

Y_LRCLK_IN

Y_BCLK_IN

C150

C150

C151

C151

NC/12PF

NC/12PF

NC/12PF

NC/12PF

Y_LRCLK_OUT11

Y_DATA_OUT11

C

• See page 44 for IC Block Diagrams.

3625

17

OPEN1

1.8V

IOVDD1

XOUT

PLLVSS2

PLLVSS1

C204

C204

C205

C205

C141

C141

0.1UF

0.1UF

0.1UF

0.1UF

0.1UF

0.1UF

R284

R284

R285

R285

16

SDA

SCL

XIN

IC_N

R37733R377

15

R37633R376

TP61TP61

R279 100R279 100

R283

R283

10K

10K

TP64TP64

14

13

12

11

10

9

C147

C147

10uF/6.3V/X5R

10uF/6.3V/X5R

NC/33

NC/33

NC/33

NC/33

33

33

R231 NC/47KR231 NC/47K

1.8V_D

I2C_SDA

I2C_SCL

I2C2_SDA

I2C2_SCL

3.3V

3.3V

Y_Rest 7

R260 1.5KR260 1.5K

R2751MR275

1M

Y2

C153

C153

39pF/50V/NP0

39pF/50V/NP0

3.3V

C208

C208

C140

C140

0.1UF

0.1UF

R392 0R392 0

R387 0R387 0

TP65TP65

3.3V

Y_MCLK11

C199

C199

NC/12PF

NC/12PF

R413 0R413 0

1.8V

C201

C200

C200

C201

NC/12PF

NC/12PF

NC/12PF

NC/12PF

C142

C142

0.1UF

0.1UF

10uF/6.3V/X5R

10uF/6.3V/X5R

3.3V_D1

Y_BCLK_OUT 11

C202

C202

NC/12PF

NC/12PF

1.8V

3.3V

R4120R412

R256

R256

NC/47K

NC/47K

0

24

23

222120

19

18

IRQ_N

TESTb

GPIO11

DVDD18_1

U13

U13

YSS952

YSS952

DVSS2

DVSS3

OPEN2

25

DVSS4

26

GPIO10

27

GPIO9

28

GPIO8

29

IOVDD2

30

GPIO7

31

DVDD18_2

32

GPIO6

33

GNDP

714

24.576MHz±30ppmY2 24.576MHz±30ppm

C154

C154

30pF/50V/NPO

30pF/50V/NPO

D

GPIO5

GPIO4

GPIO3

DVSS1

GPIO2

GPIO1

GPIO0

Y_DATA_IN

U17

U17

DVSS1_CORE

DVDD1_CORE

TAS5534

TAS5534

Y_BCLK_IN

PWM_P_6

PWM_M_6

PWM_P_5

PWM_M_5

VR_PWM

AVSS_PWM

AVDD_PWM

PWM_P_8

PWM_M_8

PWM_P_7

PWM_M_7

PWM_P_4

PWM_M_4

PWM_P_3

PWM_M_3

PWM_P_2

PWM_M_2

PWM_P_1

PWM_M_1

VALID

BKND_ERR

PSVC

LRCLKO

SCLKO

SDOUT

Y_LRCLK_IN

TEST

PLLVDD

8

1.8V

AMP_3.3V

56

55

54

53

52

C215 0.1UFC215 0.1UF

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

R295 33R295 33

R300 33R300 33

R304 33R304 33

R305 33R305 33

R289 2.2KR289 2.2K

AMP_3.3V

TP54TP54

GND

R309 33R309 33

GND

C211

C211

C212

C212

0.1UF

0.1UF

R286

R286

4.7K

4.7K

C227

C227

0.1UF

0.1UF

10uF/6.3V/X5R

10uF/6.3V/X5R

OUT2A

12

OUT2B

12

OUT1A

12

OUT1B

12

VALID

12

AMP_FAULT 5,12

AMP_3.3V

OUT2A/B : L

OUT1A/B : R

1234567

TGND

T_LRCLK

T_SCLK

T_SDIN1

C226

C226

0.1UF

0.1UF

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

C225

C225

10uF/6.3V/X5R

10uF/6.3V/X5R

PWM_HPM_L

PWM_HPP_L

PWM_HPM_R

PWM_HPP_R

AVSS

PLL_FLTM

PLL_FLTP

VR_ANA

AVDD

ASEL_VACS2

MCLK

OSC_RES

DVSS2_CORE

DVDD2_CORE

EMO_1

RESET

HP_SLE

PDN

MUTE

SDA

SCL

LRCLK

SCLK

SDIN1

SDIN2

SDIN3

SDIN4

VR_DIG

C216

C216

AMP_3.3V

R288

R288

4.7K

4.7K

C324

C324

0.1UF

AMP_3.3V3.3V_D1

++

CE23

CE23