HCD-GNX60/GNX70/

GX9900

SERVICE MANUAL

Ver. 1.1 2006.06

• HCD-GNX60/GNX70/GX9900 are the Amplifier,

CD player, tape deck and tuner

section in MHC-GNX60/GNX70/GX9900.

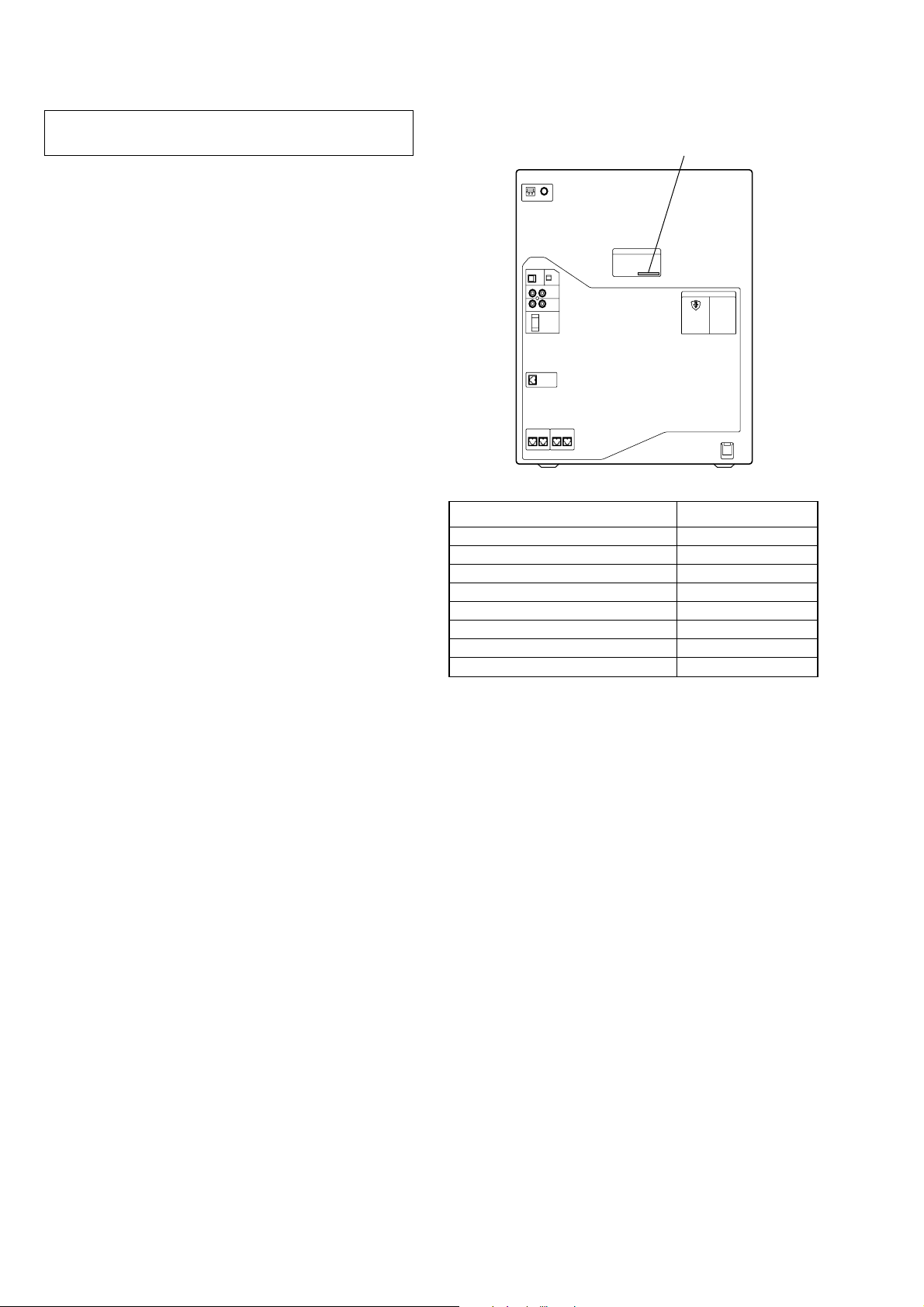

Photo : HCD-GNX70

Model Name Using Similar Mechanism HCD-GN880

CD CD Mechanism Type CDM74-F1BD81

Section Base Unit Name BU-F1BD81A

Optical Pick-up Name KSM-215DCP/C2NP

TAPE Model Name Using Similar Mechanism NEW

Section Tape Transport Mechanism Type CMAT5Z2

SPECIFICATIONS

US Model

HCD-GX9900

E Model

Australian Model

HCD-GNX60/GNX70

AUDIO POWER SPECIFICATION (MHC-GX9900 USA model only)

POWER OUTPUT AND TOTAL HARMONIC DISTORTION:

With 6-ohm loads, both channels driven, from 120 Hz – 10 kHz; rates 230

watts per channel minimum RMS power, with no more than 10% total

harmonic distortion from 250 miliwatts to rated output.

Amplifier section MHC-GX9900

Total harmonic distortion Less than 0.1%

(6 ohms at 1 kHz, 100 W)

MHC-GNX70

The following are measured at

Mexican model: AC 127 V, 60 Hz

Other models: AC 120, 220, 240 V, 60 Hz

DIN power output (rated) 170 + 170 watts (6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

220 + 220 watts (6 ohms at 1 kHz, 10% THD)

MHC-GNX60

The following are measured at

Mexican model: AC 127 V, 60 Hz

Brazil model: AC 127 V or 220 V, 60 Hz

Other models: AC 120, 220, 240 V, 50/60 Hz

DIN power output (rated) 150 + 150 watts (6 ohms at 1 kHz, DIN)

Continuous RMS power output (reference)

200 + 200 watts (6 ohms at 1 kHz,10% THD)

Inputs

VIDEO/MD (AUDIO) IN (phono jacks):

voltage 250/450 mV,

impedance 47 kiloohms

TV (AUDIO) IN (phono jack): voltage 250 mV,

impedance 47 kiloohms

MIC (phone jack): sensitivity 1 mV,

impedance 10 kiloohms

Outputs

PHONES (stereo mini jack): accepts headphones of

8 ohms or more

FRONT SPEAKER: Use only the supplied speaker

• SS-GNX100 (MHC-GNX70/GX9900)

• SS-GNX60 (MHC-GNX60)

SURROUND SPEAKER: Use only the supplied speaker

• SS-RSX80 (MHC-GNX70/GX9900)

Disc player section

System Compact disc and digital audio system

Laser Semiconductor laser (l=780 nm)

Emission duration: continuous

Laser Output Max. 44.6 mW*

*This output is the value measured at a

distance of 200 mm from the objective

lens surface on the Optical Pick-up Block

with 7 mm aperture.

Frequency response 2 Hz – 20 kHz (±0.5 dB)

Wave length 780 – 790 nm

Signal-to-noise ratio More than 90 dB

Dynamic range More than 90 dB

OPTICAL CD DIGITAL OUT (Square optical connector jack, rear panel)

(For MHC-GNX60/GNX70)

Wave length 660 nm

Output Level –18 dBm

– Continued on next page –

MiNi Hi-Fi COMPONENT SYSTEM

9-879-532-02

2006F02-1

© 2006.06

Sony Corporation

Home Audio Division

Published by Sony Techno Create Corporation

HCD-GNX60/GNX70/GX9900

Tape deck section

Recording system 4-track 2-channel stereo

Frequency response 50 – 13,000 Hz (±3 dB),

using Sony TYPE I tape

Tuner section

FM stereo, FM/AM superheterodyne tuner

FM tuner section

Tuning range 87.5 – 108.0 MHz

Antenna FM lead antenna

Antenna terminals 75 ohm unbalanced

Intermediate frequency 10.7 MHz

AM tuner section

Tuning range

North and Latin American models:

530 – 1,710 kHz

(with the interval set at 10 kHz)

531 – 1,710 kHz

(with the interval set at 9 kHz)

Other models: 531 – 1,602 kHz

(with the interval set at 9 kHz)

530 – 1,710 kHz

(with the interval set at 10 kHz)

Antenna AM loop antenna

Antenna terminals External antenna terminal

Intermediate frequency 450 kHz

General

Power requirements

North American model: 120 V AC, 60Hz

Australian model: 230 – 240 V AC, 50/60 Hz

Argentina model: 220 V AC, 50/60 Hz

Other models: 120 V, 220 V or 230 – 240 V AC, 50/60 Hz

Adjustable with voltage selector

Power consumption

MHC-GX9900 250 watts

MHC-GNX70 225 watts

MHC-GNX60 200 watts

Dimensions (w/h/d) (Approx.) 280 × 360 × 398.5 mm

Mass (Approx.)

HCD-GNX70 12.1 kg

HCD-GX9900 11.8 kg

HCD-GNX60 11.3 kg

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples

of a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

To Exposed Metal

Par ts on Set

AC

0.15 µF

1.5 kΩ

Voltmeter

(0.75 V)

Design and specifications are subject to change without notice.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

This appliance is classified as

a CLASS 1 LASER product.

This label is located on the rear

exterior.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

2

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

Unleaded solder

Boards requiring use of unleaded solder are printed with the lead

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

TABLE OF CONTENTS

HCD-GNX60/GNX70/GX9900

1. SERVICING NOTES ................................................ 4

2. GENERAL

Location of Controls........................................................ 5

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Side Panel, Top Case ....................................................... 8

3-3. Loading Panel Assy ......................................................... 8

3-4. Front Panel Assy.............................................................. 9

3-5. Tuner Pack ....................................................................... 9

3-6. Tape Mechanism Deck, Mic Board ................................. 10

3-7. Panel Board, CD-SW Board ............................................ 10

3-8. CD Mechanism Deck ...................................................... 11

3-9. Back Panel ....................................................................... 11

3-10. Primary Board ................................................................. 12

3-11. Power AMP PC Board Assy, Main Board ....................... 12

3-12. Surround Board, PA Board .............................................. 13

3-13. Power Transformer (T1200) ............................................ 13

3-14. Driver Board, SW Board ................................................. 14

3-15. CD Board ......................................................................... 14

3-16. Sensor Board ................................................................... 15

3-17. Motor (TB) Board ........................................................... 15

3-18. Motor (LD) Board ........................................................... 16

4. TEST MODE .............................................................. 17

5. MECHANICAL ADJUSTMENTS ....................... 21

6. ELECTRICAL ADJUSTMENTS

Deck section .................................................................... 21

CD Section ...................................................................... 22

7. DIAGRAMS

7-1. Circuit Board Location .................................................... 26

7-2. Block Diagram – CD Section – ...................................... 27

7-3. Block Diagram – Tape Section – .................................... 28

7-4. Block Diagram – Main Section – ................................... 29

7-5. Block Diagram – AMP Section – ................................... 30

7-6. Block Diagram – Display Section – ............................... 31

7-7. Printed Wiring Board – CD Board – .............................. 32

7-8. Schematic Diagram – CD Board – ................................. 33

7-9. Printed Wiring Board – CD Mechanism Boards – ......... 34

7-10. Schematic Diagram – CD Mechanism Boards – ............ 35

7-11. Printed Wiring Boards – Main Board –.......................... 36

7-12. Schematic Diagram – Main Board (1/3) – ..................... 37

7-13. Schematic Diagram – Main Board (2/3) – ..................... 38

7-14. Schematic Diagram – Main Board (3/3) – ..................... 39

7-15. Printed Wiring Boards – Panel Board – ......................... 40

7-16. Schematic Diagram – Panel Board – ............................... 41

7-17. Printed Wiring Board – CD-SW, Jog, Mic Boards – ...... 42

7-18. Schematic Diagram – CD-SW, Jog, Mic Boards – ........ 43

7-19. Printed Wiring Board – PA Board – ............................... 44

7-20. Schematic Diagram – PA Board – .................................. 45

7-21. Printed Wiring Board – Trans, Primary Boards – .......... 46

7-22. Schematic Diagram – Trans, Primary Boards – ............. 47

7-23. IC Pin Function Description ............................................ 50

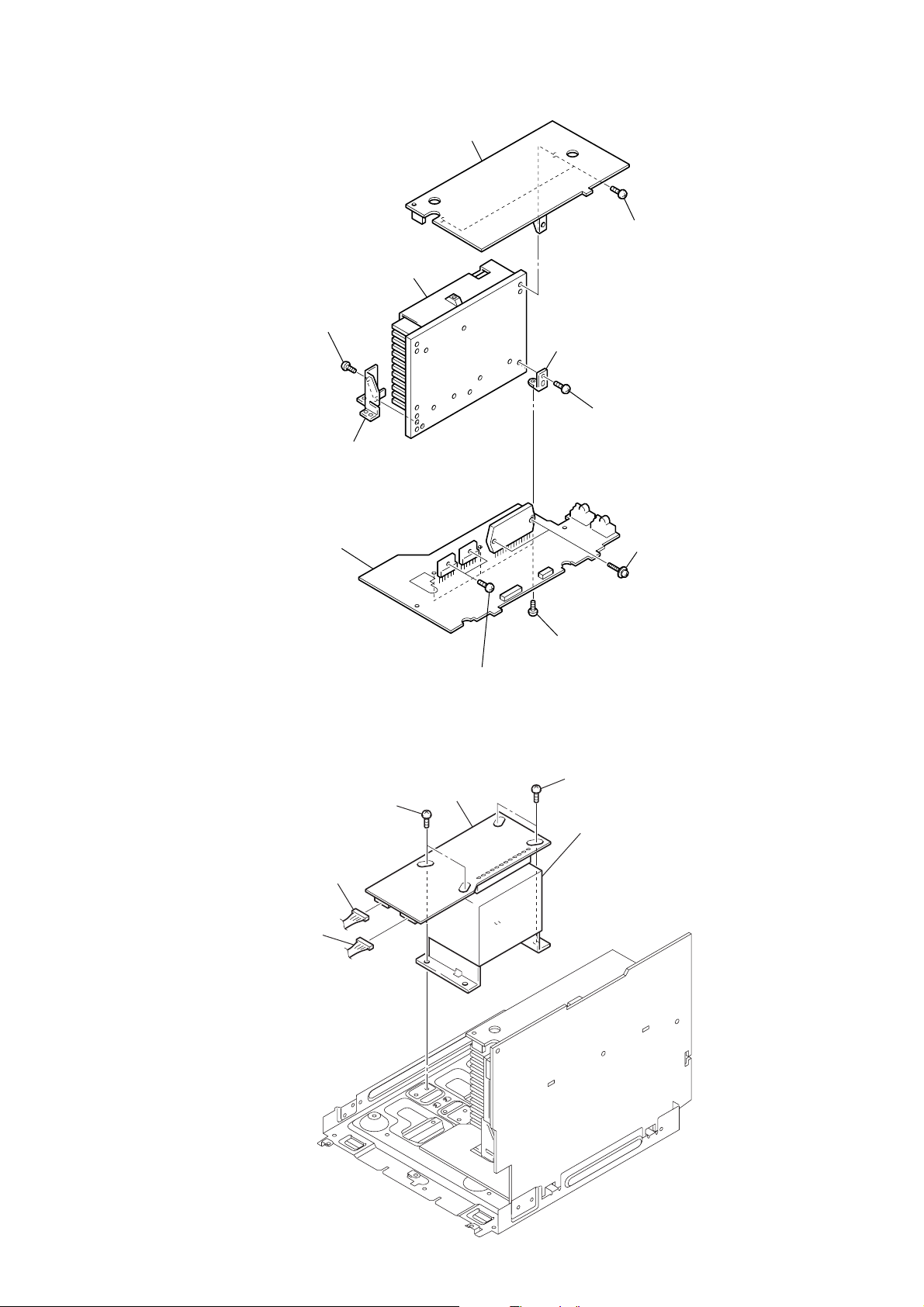

8. EXPLODED VIEWS

8-1. Case (Top), Rear Panel Section ....................................... 56

8-2. Front Panel Section ......................................................... 57

8-3. Chassis Section ................................................................ 58

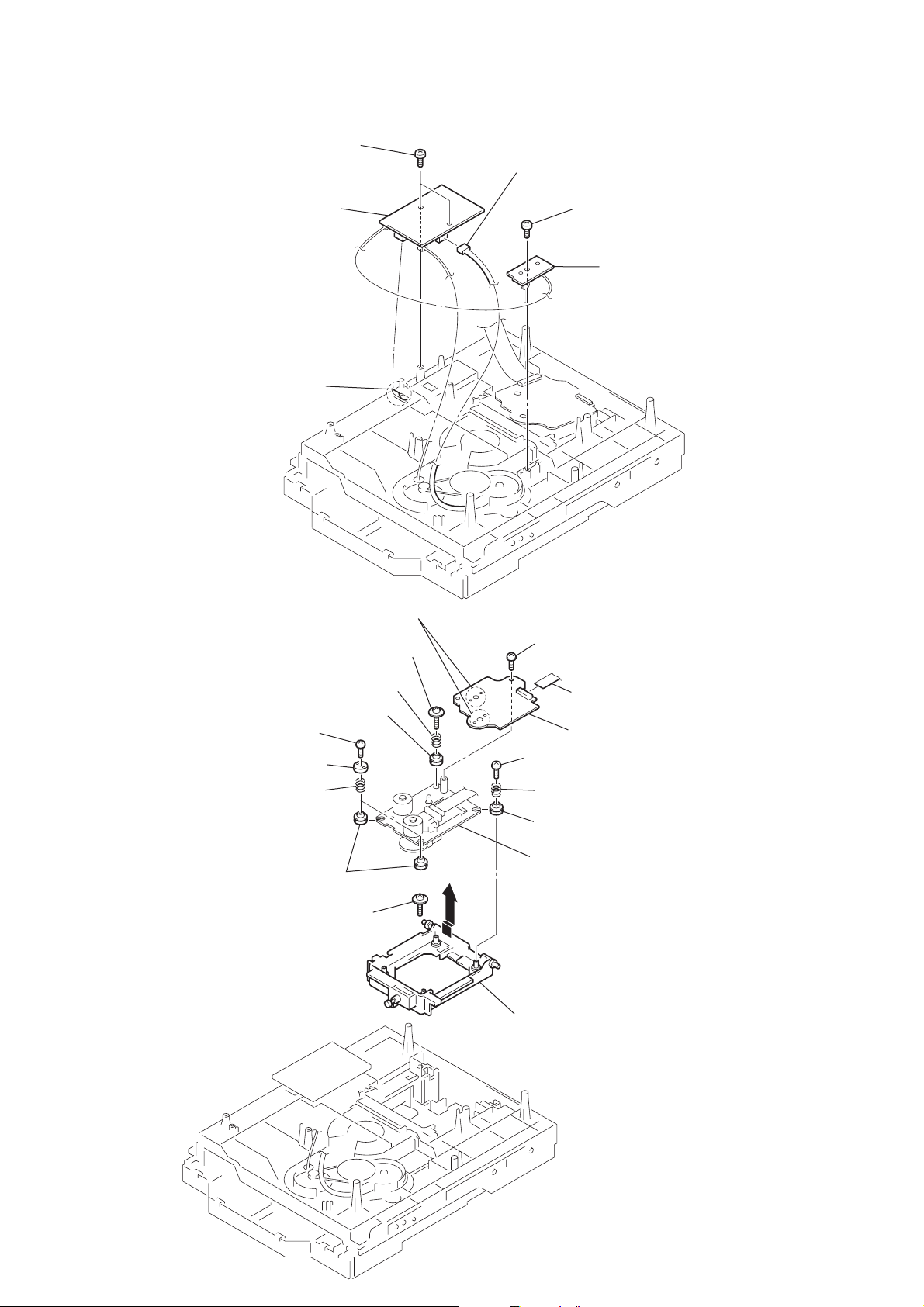

8-4. CD Mechanism Deck Section-1

(CDM74-F1BD81) .......................................................... 59

8-5. CD Mechanism Deck Section-2

(CDM74-F1BD81) .......................................................... 60

9. ELECTRICAL PARTS LIST ................................ 61

3

HCD-GNX60/GNX70/GX9900

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output several times.

• MODEL IDENTIFICATION

– Back Panel –

PA RT No.

MODEL PART No.

GNX60: E2, E3 models 2-547-454-0[]

GNX70: E2, E3 models 2-547-456-0[]

GX9900 model 2-547-458-0[]

GNX60: AR model 2-588-965-0[]

GNX60: E51 model 2-588-966-0[]

GNX70: AUS model 2-588-967-0[]

GNX70: E51 model 2-588-968-0[]

GNX60: AUS model 2-588-974-0[]

•Abbreviation

AR : Argentine model

E2 : 120 V AC Area in E model

E3 : 240 V AC Area in E model

E51 : Chilean and Peruvian model

AUS: Australian model

4

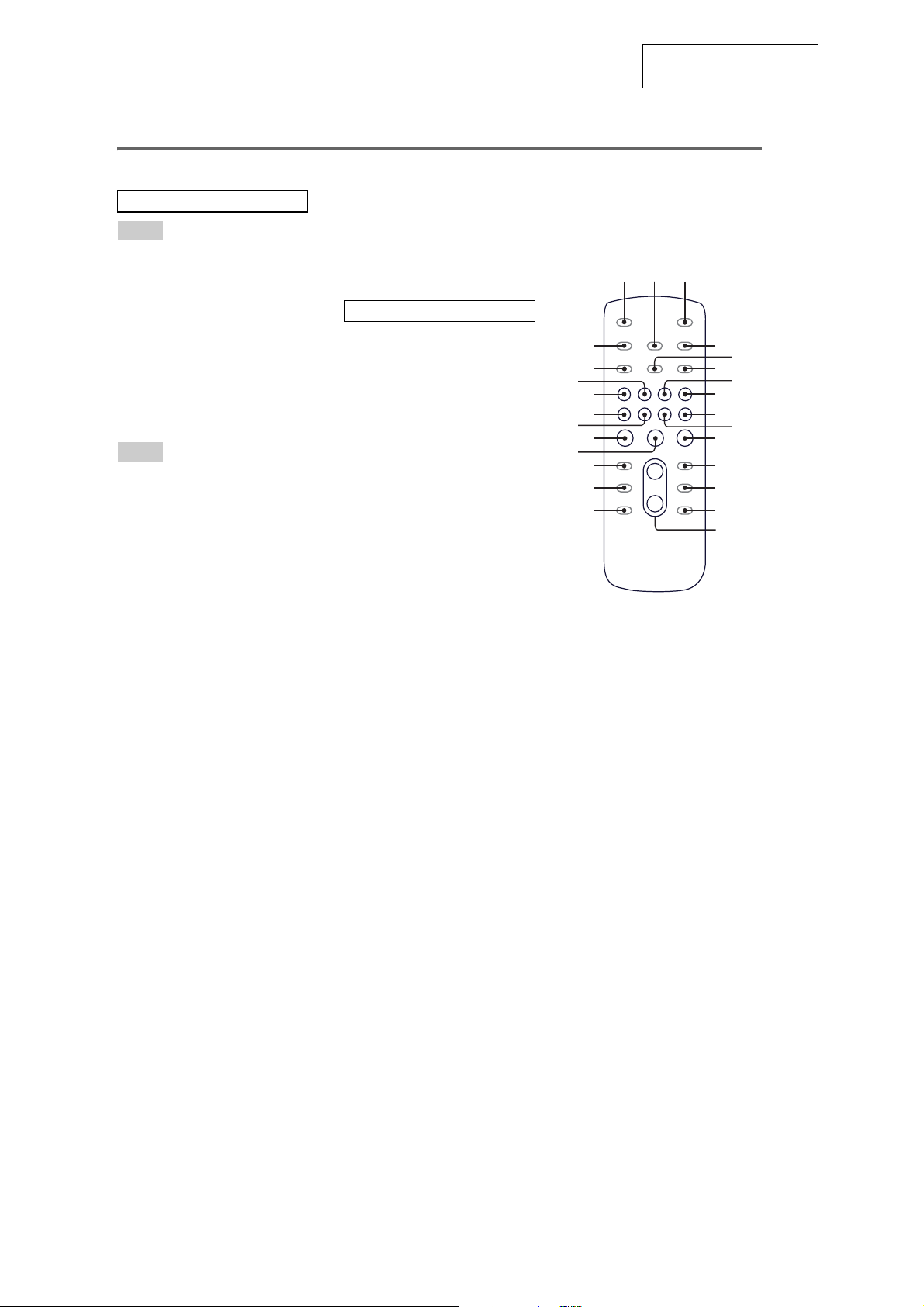

SECTION 2

657

GENERAL

LOCATING THE CONTROLS

List of button location s and reference pages

Main unit

ALPHABETICAL ORDER

A – D

ALBUM +/– ql

AMP MENU ed

AUTO/MANUAL

CD el

CD SYNC qd

Deck A ea

Deck B ws

DIRECTION qk

DISC 1 ~ 3 7

Disc tray 9

DISPLAY rd

Display rf

E – L

ECHO LEVEL wf

ENTER wa

EQ BAND qa

EX-CHANGE/DISC SKIP 6

GR

OOVE

ILLUMINATION rs

IR Receptor r;

eh

3)

2

M – R

MASTER VOLUME 8

MIC 1 (jack) wj

MIC 2 (jack) wh

MIC LEVEL wg

MP3 BOOSTER q;

4)

MPX

qk

OPERATION DIAL wl

PHONES (jack) wk

Power illuminator wd

REC PAUSE/START qh

S – Z

SOUND FLASH e;

SPEAKERS

SUR

SURR SPEAKER MODE

TA P E A/B ej

Ta

TUNER/BAND ek

TUNING +/– qj

TV eg

VIDEO/MD ef

X-ROUND buttons

X-ROUND JOG

X-ROUND OFF

3)

1

1)

ws ea

rg

3)

3

3)

4

3)

1

ROUND

pe lid

WA VE/FADER/BALANCE/

RANDOM/TWISTER

2)

rg

HCD-GNX60/GNX70/GX9900

SYMBOLS

?/1 (power) ra

Z OPEN/CLOSE 5

nN (play) qs

. > (go backward/forward)

m M (rewind/fast forward)

X (pause) qf

x (stop) qg

Z A (Eject A) es

B Z (Eject B) w;

Top Panel

1 2 3

This section is extracted

from instruction manual.

1)

For MHC-GNX100/GNX66/

GNX60

2)

For MHC-GNX88/GNX80/

qj

GNX77/GNX70/GX9900

3)

MHC-GNX100 only

ql

4)

For MHC-GNX88/GNX77/

GNX

66

4

Front Panel

rg

rf

rd

rs

ra

r;

el

ek

ej

eh

eg

ef

ed

es

ea

e;

wl

8

9

0

qa

qs

qd

qf

qg

qh

qj

qk

ql

w;

wz

ws

wd

wk wgwhwj

wf

5

HCD-GNX60/GNX70/GX9900

Remote control

ALPHABETICAL ORDER

A – E

ALBUM + qf

ALBUM – qh

CD wf

CLEAR qk

CLOCK/TIMER SELECT 2

CL

OCK/TIMER SET

DISC SKIP qd

DISPLAY wh

ENTER qs

EQ qj

F – Z

FM MODE 6

FUNCTION 8

PLAY MODE 5

REPEAT 6

SLEEP 1

4

TA P E wd

TUNER/BAND 7

TUNE

R MEMORY

wg

TUNING MODE 5

VOLUME +/– qg

The + button has

SYMBOLS

a tactile dot.*

?/1 (power) 3

x (s

top)

qa

X (pause) ql

N (play) w;

–. (go backward) ws

>+

(go forward)

wa

m (rewind) q;

M (fast forward) 9

wf

wa

ql

wh

wg

wd

ws

w;

qk

qj

qh

This section is extracted

from instruction manual.

312

4

5

6

7

8

9

q;

qa

qs

qd

qf

qg

*Use the tactile dot as a reference

when operating the system.

6

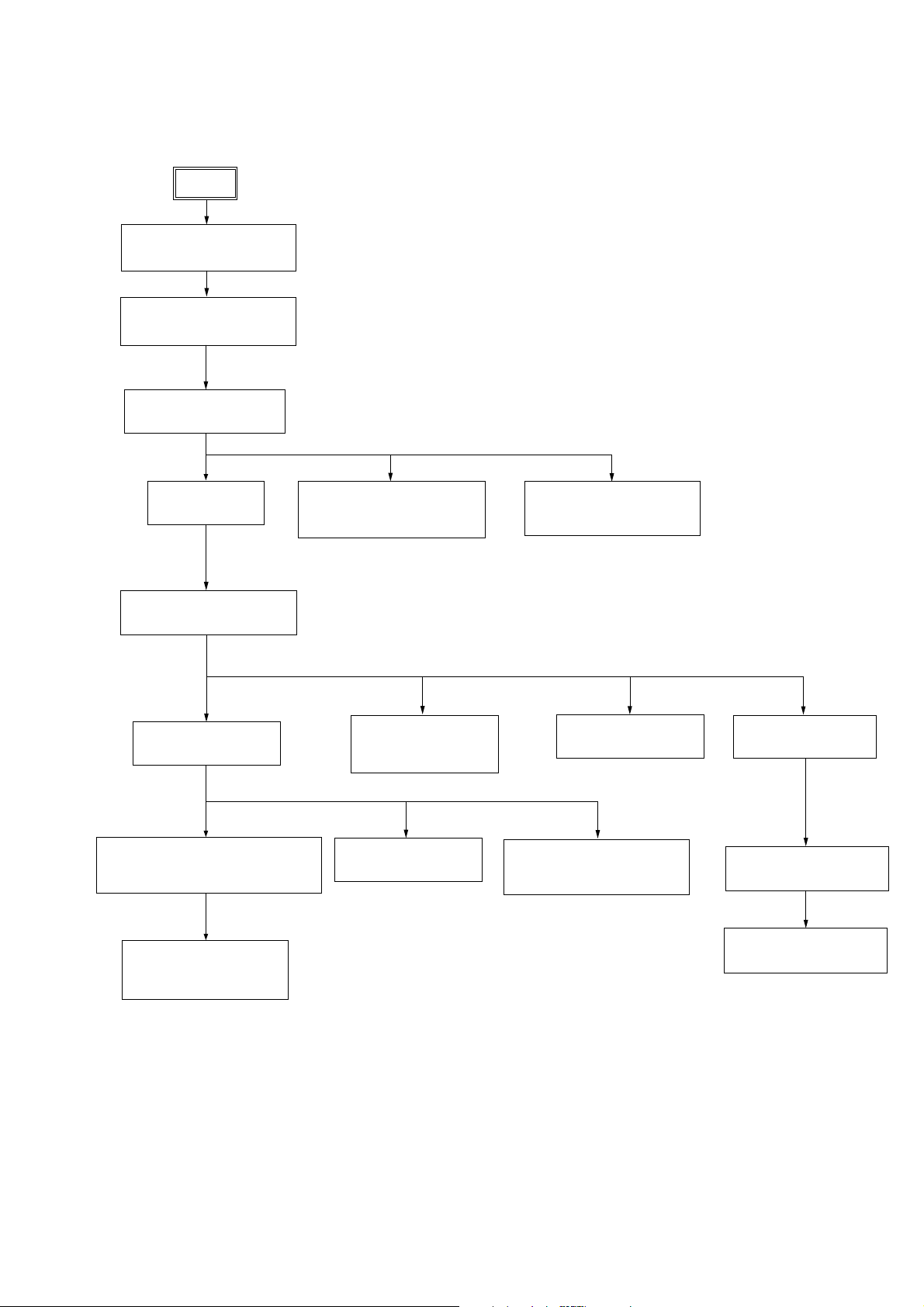

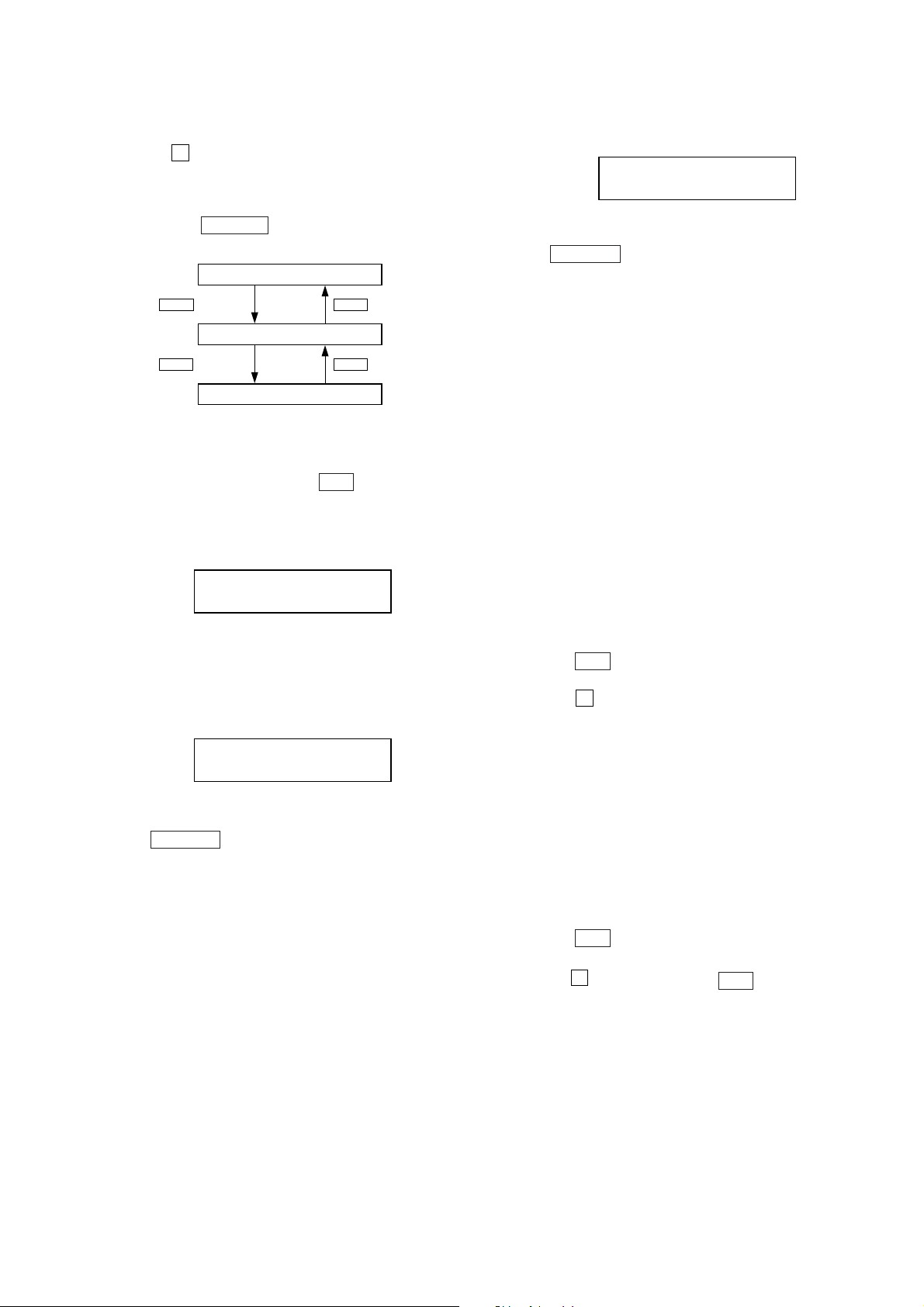

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

SET

3-2.SIDE PANEL, TOP CASE

(Page 8)

3-3.LOADING PANEL ASSY

(Page 8)

3-4.FRONT PANEL ASSY

(Page 9)

HCD-GNX60/GNX70/GX9900

SECTION 3

DISASSEMBLY

3-5.TUNER PACK

(Page 9)

3-8.CD MECHANISM DECK

(Page 11)

3-9.BACK PANEL

(Page 11)

3-11.POWER AMP PC BOARD ASSY,

MAIN BOARD

(Page 12)

3-6.TAPE MECHANISM DECK,

MIC BOARD

(Page 10)

3-14.DRIVER BOARD,

SW BOARD

(Page 14)

3-10.PRIMARY BOARD

(Page 12)

3-7.PANEL BOARD,

CD-SW BOARD

(Page 10)

3-15.CD BOARD

(Page 14)

3-13.POWER TRANSFORMER

(T1200)

(Page 13)

3-16.SENSOR BOARD

(Page 15)

3-17.MOTOR (TB) BOARD

(Page 15)

3-12.SURROUND BOARD,

PA BOARD

(Page 13)

3-18.MOTOR (LD) BOARD

(Page 16)

7

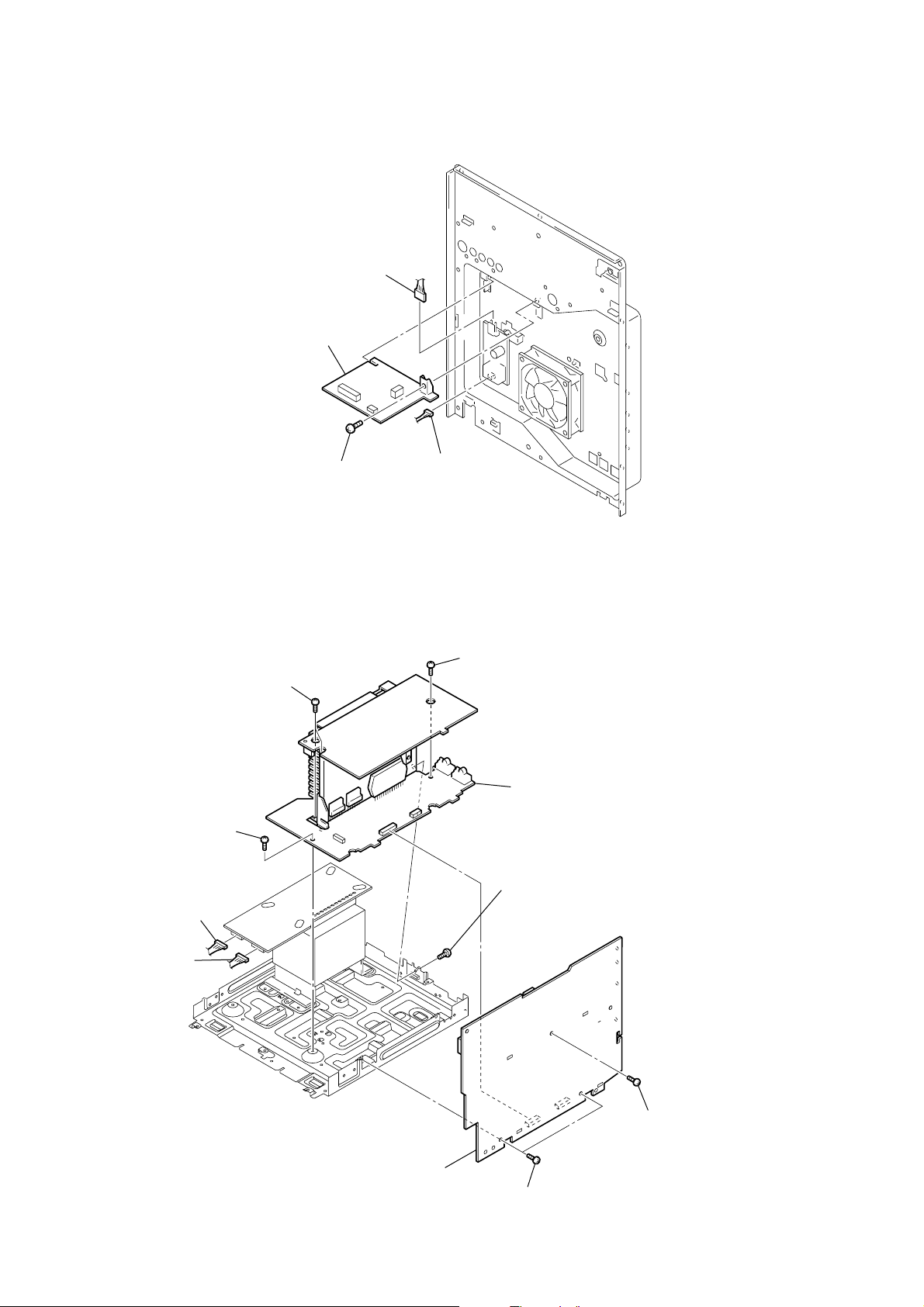

HCD-GNX60/GNX70/GX9900

)

Note: Follow the disassembly procedure in the numerical order given.

3-2. SIDE PANEL, TOP CASE

7

two screws

PANEL (SIDE-R)

0

9

6

screw

(case 3 TP2)

(3X8)

(case 3 TP2)

(3X12)

8

two screws

(+BVTP 3X10)

qd

CASE (TOP)

qs

qa

two screws

(+BVTP 3X10)

2

two screws

(case 3 TP2)

(3X12)

3-3. LOADING PANEL ASSY

CD mechanismdeck (CDM74-F1BD81)

1

Turn the pulley to the arrow direction.

Pulley

Front side

2

Pull out disc tray

loading panel assy

4

3

4

5

1

screw (case 3 TP2)

(3X8)

3

two screws

(+BVTP 3X10

PANEL (SIDE-L)

8

3-4. FRONT PANEL ASSY

1

two screws

(+BVTP 3X10)

2

three screws

(+BVTP 3X10)

3

screw

(+BVTP 3X10)

5

screw

(+BVTP 3X6)

4

screw

(+BVTP 3X10)

6

front panel assy

7

connector

(CN100)

8

CNP508

9

CNP509

q;

connector

(CN503)

lug

qa

connector

(CN1102)

qs

connector

(tape mechanism deck)

)

HCD-GNX60/GNX70/GX9900

3-5. TUNER PACK

2

CNP1

3

tuner pack

1

two screws

(+BVTP 3X6

4

cover (tuner)

9

HCD-GNX60/GNX70/GX9900

)

)

3-6. TAPE MECHANISM DECK, MIC BOARD

3

screw

(+BVTP2.6 (3CR))

2

cover (TCM)

4

tape mechanism deck

5

two screws

(+BVTP2.6 (3CR))

6

bracket (MIC)

1

four screws

(+BVTP2.6 (3CR)

7

two knobs (MIC)

3-7. PANEL BOARD, CD-SW BOARD

qa

three screws

(+BV3 (3CR))

qs

CD-SW board

9

claw

1

knob vol

8

MIC board

7

three screws

(+BVTP2.6 (3CR))

6

(+BVTP2.6 (3CR))

8

connector

(CNS902)

two screws

5

(+BVTP2.6 (3CR))

4

(+BVTP2.6 (3CR))

0

two screws

two screws

3

three screws

(+BVTP2.6 (3CR)

PANEL board

10

2

knob (AMS)

3-8. CD MECHANISM DECK

2

CD mechanism deck

4

connector

(CN701)

3

CNP505

HCD-GNX60/GNX70/GX9900

1

screw

(+BVTP 3X10)

3-9. BACK PANEL

2

connector

(CN1204)

7

connector

(CN580)

MAIN board

6

back panel

1

connector

(CN1200)

GNX70/GX9900 only

5

two screws

(+BVTP 3X10)

4

two screws

(+BVTP 3X10)

3

three screws (GNX60)

four screws (GNX70/GX9900)

(+BVTP 3X10)

11

HCD-GNX60/GNX70/GX9900

3-10. PRIMARY BOARD

4

PRIMARY board

1

connector

(CN101)

3

screw

(+BVTP 3X8)

2

connector

(CN201)

3-11. POWER AMP PC BOARD ASSY, MAIN BOARD

4

two screws

(+BVTP 3X6)

3

screw

(+BVTP 3X6)

1

connector

(CN1213)

2

connector

(CN1212)

5

screw

(+BVTP 3X6)

7

power AMP PC board assy

6

screw

(+BVTP 3X10)

12

q;

MAIN board

8

two screws

(+BVTP 3X10)

9

screw

(+BVTP 3X10)

3-12. SURROUND BOARD, PA BOARD

)

8

heat sink

3

two screws

(+BVTP 3X10)

4

holder

2

SURROUND board

q;

bracket

9

(+BVTP 3X10)

HCD-GNX60/GNX70/GX9900

1

two screws

(+BVTP 3X10)

screw

qa

PA board

3-13. POWER TRANSFORMER (T1200)

3

two screws

(+BVTP 4X8)

1

connector

(CN1213)

2

connector

(CN1212)

7

(+BVTP 3X10)

TRANS board

two screws

6

two screws

(transistor)

5

three screws

(+BVTP 3X10)

4

two screws (+BVTP 4X8)

5

power transfomer (T1200

13

HCD-GNX60/GNX70/GX9900

)

3-14. DRIVER BOARD, SW BOARD

1

two

screws

(+BTTP (M2.6))

4

DRIVER

2

wire (flat type) (CN702)

board

3

connector (CN703)

5

screw

(+BTTP (M2.6))

6

SW board

3-15. CD BOARD

9

t

wo screws

(BVTT M2.6)

0

t

wo stoppers (BU)

qa

two

coil springs

(insulator)

qs

two

1

(+PTPWH M2.6)

4

floating

(+PTPWH M2.6)

insulators

floating

screw

5

coil spring

(insulator)

7

insulator

screw

qg

Remove the four solderings of motor.

qf

s

crew (+BVTP 2.6x 8)

qh

qd

2

qj

CD

3

screw

(BVTT M2.6)

6

coil spring

(insulator)

8

insulator

qk

optical pick-up

(KSM-215DCP/C2NP)

h

older (213) ASSY

CN101 (flat type

board

14

3-16. SENSOR BOARD

2

t

ray

1

floating

(+PTPWH M2.6)

6

floating

(+PTPWH M2.6)

7

g

screw

8

(+BTTP (M2.6))

screw

ear (geneva)

s

crew

0

SENSOR board

9

connector

(

CN731)

HCD-GNX60/GNX70/GX9900

3

b

elt (table)

4

floating

(+PTPWH M2.6)

5

screw

p

ulley (table)

3-17. MOTOR (TB) BOARD

2

stopper

4

1

stopper

7

t

able motor assy (M741)

wire (flat type) 5 core (CN742)

3

8

MOTOR (TB) board

6

Remove the two solderings of motor.

5

two

screws

(+BTTP (M2.6))

15

HCD-GNX60/GNX70/GX9900

3-18. MOTOR (LD) BOARD

2

Remove the two solderings of motor.

5

l

oading motor assy (M751)

3

two

screws

(+BTTP (M2.6))

4

MOTOR (LD) board

1

b

elt (loading)

16

SECTION 4

TEST MODE

HCD-GNX60/GNX70/GX9900

[GC TEST MODE]

• This mode is used to check the fluorescent indicator tube,

LEDs, keys, MASTER VOLUME jog, OPERATION

DIAL jog, AMS jog, destination, software version and

VA CS level.

Procedure:

1. Press x button, [ENTER] button and [DISC 2] button

simultaneously.

2. All LEDs and segments in fluorescent indicator tube are lighted

up. All LEDs are lighted up in red color. If the system is turned

on, the `/1 LED is lighted up in green color.

3. When you want to enter the software version display mode,

press [DISC 1] button. The model and destination are displayed.

4. Each time [DISC 1] button is pressed, the display changes from

MC version, GC version, SYS version, CD version, CDDM

version, CDMA version, CDMB version, BDA version, BDB

version, ST version, TC version, TA version and TM version

in this order, and returns to the MC version display.

5. When [DISC 3] button is pressed while the version numbers

are being displayed except model and destination, the date of

the software creation appear. When [DISC 3] button is pressed

again, the display returns to the software version display. When

[DISC 1] button is pressed while the date of the software

creation is being displayed, the date of the software creation

is displayed in the same order of software version display.

6. Press [DISC 2] button, the key check mode is activated.

7. In the key check mode, the fluorescent indicator tube displays

“K 0 J0V0E0 X0”.

Each time a button is pressed, “K” value increases. However,

once a button has been pressed, it is no longer taken into

account.

“J” value increases in the manner of 0,1, 2, 3 ... if [OPERATION

DIAL] knob is turned clockwise, or it decreases in the manner

of 0, 9, 8, 7 ... if [OPERATION DIAL] knob is turned counter-

clockwise.

“V” value increases in the manner of 0,1, 2, 3 ... if [VOLUME]

knob is turned clockwise, or it decreases in the manner of 0,

9, 8, 7 ... if [VOLUME] knob is turned counter-clockwise.

“E” value increases in the manner of 0,1, 2, 3 ... if

knob is turned clockwise, or it decreases in the manner of 0,

9, 8, 7 ... if

8. When [DISC 3] button is pressed after all LEDs and segments

in fluorescent indicator tube light up, the fluorescent indicator

tube displays “VACS A+B APCC”. A is VACS level which is

triggerd by signal level, B is VACS level which is triggerd by

temperature and CC is VACS level which is triggerd by

APVACS (Abuse Protection VACS).

The signal level, which will trigger VACS A is shown in the

center area of fluorescent indicator tube.

9. When [EX-CHANGE/DISC SKIP] button is pressed after all

LEDs and segments in fluorescent indicator tube light up,

alternate segments in fluorescent indicator tube would light

up. If you press [EX-CHANGE/DISC SKIP] button again, another

half of alternate segments in fluorescent indicator tube would

light up. Pressing [EX-CHANGE/DISC SKIP] button again

would cause all segments lights up.

10. To release this mode, press three buttons in the same manner

as step 1, or disconnect the power cord.

.

knob is turned counter-clockwise.

>

.

>

[MC TEST MODE]

•This mode is used to check operations of the respective sections

of Amplifier, Tuner, and Tape.

Procedure:

* To enter MC Test Mode

1. Press x button, [ENTER] button and [DISC 3] button

simultaneously.

2. The CD ring indicators, TAPE A and TAPE B indicators flash

on the fluorescent indicator tube. The function is changed to

VIDEO.

* Check of Amplifier

1. Press [EQ BAND] button repeatedly until a message “GEQ

MAX” appears on the fluorescent indicator tube. GEQ

increases to its maximum.

2. Press [EQ BAND] button repeatedly until a message “GEQ

MIN” appears on the fluorescent indicator tube. GEQ decreases

to its minimum.

3. Press [EQ BAND] button repeatedly until a message “GEQ

FLAT” appears on the fluorescent indicator tube. GEQ set to

flat.

4. When the [MASTER VOLUME] knob is turned clockwise even

slightly, the sound volume increases to its maximum and a

message “VOLUME MAX” appears on the fluorescent

indicator tube.

5. When the [MASTER VOLUME] knob is turned counter-clockwise

even slightly, the sound volume decreases to its minimum and

a message “VOLUME MIN” appears on the fluorescent

indicator tub.

* Tape function

1. When a tape is inserted in Deck B and recording is started, the

function is changed to VIDEO automatically. When [CD SYNC]

button is pressed during recording in function, ALC (Automatic

Level Control) is turned on.

2. During recording, turn

rotation will change the function to TAPE B and rewind the

tape in deck B until the recording start position and playback

of the tape in deck B is started. If the [REC PAUSE/ START]

button is pressed for a pause and pressed again to resume

recording during recording time, when the tape in deck B is

rewind, the tape in deck B will be rewind until the position

where the pause is applied.

* To release MC Test mode.

1. To release this mode, press

2. The cold reset is enforced at the same time.

[COLD RESET]

• The cold reset clears all data including preset data stored in

the RAM to initial conditions. Execute this mode when

returning the set to the customer.

Procedure:

1. Press x button, [ENTER] button, and

simultaneously.

2. The fluorescent indicator tube becomes blank for a while, and

the set is reset.

m

knob to counter clockwise

M

button.

?/1

?/1

button

17

HCD-GNX60/GNX70/GX9900

[VACS ON/OFF]

•This mode is used to switch ON and OFF the VACS (Variable

Attenuation Control System).

Procedure:

1. Press

2. Press x button and [ILLUMINATION]

The message “VACS OFF” or “VACS ON” appears on the

fluorescent indicator tube.

[TUNER STEP CHANGE]

•The step interval of AM channels can be toggled between 9

kHz and 10 kHz.

Procedure:

1. Press

2. Press [TUNER/BAND] button repeatedly to select the “AM”.

3. Press

4. Press [ENTER] button and

system will turn ON automatically. The message “AM 9k

STEP” or AM 10k STEP” appears on the fluorescent indicator

tube and thus the channel step is changed.

[CD SERVICE MODE]

•This mode let you move the CD sled motor freely. Use this

mode when you want to clean the optical pick-up.

button to turn the set ON.

?/1

button to turn the set ON.

?/1

button to turn the set OFF.

?/1

button simultaneously.

button simultaneously. The

?/1

[AGING MODE]

This mode can be used for operation check of CD section.

• If an error occurs, the aging operation would stops and the

status is displayed.

• If there are no error occurs, the aging operation would

continues repeatedly.

Procedure:

1. Press

2. Select CD function.

3. Load three discs on the disc tray.

4. Press [PLAY MODE] button repeatedly to select the “ALL

DISCS” mode, and press the [REPEAT] button repeatedly to

select “REPEAT OFF” mode.

5. Press x button, [ENTER] button, and [EX-CHANGE/DISC

SKIP] button simultaneously.

6. Aging operation is started.

7. To release this mode, press

power cord to turn the power OFF.

Aging mode sequence:

button to turn the set ON

?/1

Start (from disc 1)

Disc chucking

button or disconnect the

?/1

Procedure:

1. Press

2. Select CD function.

3. Press x , [ENTER] button, and

simultaneously.

4. The CD service mode is activated. The message “SERVICE

MODE” appears.

5. With the CD in stop status, turn

rotation to move the optical pick-up to outside track, or turn

m

inside track. The message “SLED OUT” or “SLED IN”

appears on the fluorescent indicator tube.

6. To turn on or off the laser, press [DIRECTION] button. The

message “LASER ON” or “LASER OFF” appears on the

fluorescent indicator tube.

7. To release this mode, press

button to turn the set ON.

?/1

knob to counterclockwise rotation to move to

M

?/1

Z

m

button.

OPEN/CLOSE

knob to clockwise

M

button

TOC reading

Play first track for 2 seconds

Play last track for 2 seconds

EX-CHANGE open/close

Open the disc tray

Disc skip

Close the disk tray

Change the next disc

18

HCD-GNX60/GNX70/GX9900

• Display when an error occurred (CD Error Code Mode)

Procedure:

1. Press x button, [ENTER] button and [DISC 1] button

simultaneously to enter the error code display mode.

2. The fluorescent indicator tube displays the number of total

error.

3. Each time

m

knob is rotated, display change as

M

below.

Display of total error

>

>

+

direction

Display of Mechanical errors

+

direction

Display of no disc errors

–

.

–

.

direction

direction

4. To clear the error record, operate the cold reset. (Refer to the

“COLD RESET”)

5. To release this mode, press the

button or disconnect

?/1

the power cord to turn the power OFF.

1) Display of total error

Display

Em**Ed**

3) Display of no disc errors

Display

D*$$%%&&##00

D*: The number of mechanical error (“00” is latest one)

(Rotate

.

error)

$$: Error type

01: Focus error

02: GFS error

03: Setup error

%%: Not used

&&:

00: No disc judgment without chucking retry.

01: No disc judgment after chucking retry.

##: The state when judged as no disc

01: Stop

02: Setup

03: TOC reading

04: Access

05: Playback

06: Pause

07: Manual search (Play)

08: Manual search (Pause)

[CD REPEAT 5 LIMIT OFF MODE]

• The number of repeat for CD playback is 5 times when the

repeat mode is “REPEAT ALL”. This mode enables CD to

repeat playback for limitless times.

knob in the direction of either to display next

>

EM**: The number of mechanical errors.

ED**: The number of no disc errors after chucking the disc.

2) Display of mechanical errors

Display

M*$$%%&&##00

M*: The number of mechanical error (“00” is latest one)

(Rotate

.

error)

$$: Not used

%%: Loading related error (Second figure is not used)

D: Stop by the problem other than mechanical problem while

closing.

E: Stop by the problem other than mechanical problem while

opening.

C: Stop by the problem other than mechanical problem while

chucking up.

F: Stop by the problem other than mechanical problem while

chucking down.

&&: Emerging error

01: Stop while chucking up.

02: Stop while chucking up.

03: Time-out of EX-CHANGE open.

05: Time-out of EX-CHANGE close.

##: Not used

knob in the direction of either to display next

>

Procedure:

1. Press

button to turn the set ON.

?/1

2. Select CD function.

3. Press x button, [CD] button and [DISC 1] button

simultaneously to enter the CD repeat 5 limit off mode and

the message “LIMIT OFF” appears on the fluorescent

indicator tube .

4. To release this mode, operate the cold reset. (Refer to the

“ COLD RESET”)

[CD SHIP MODE (WITH MEMORY CLEAR)]

• This mode moves the optical pick-up to the position durable

to vibration and clears all data including preset data stored in

the RAM to initial conditions. Use this mode when returning

the set to the customer after repair.

Procedure:

1. Press

button to turn the set ON.

?/1

2. Select CD function.

3. Press x

button,

[CD]

button and

button simultaneously.

?/1

The set will power off automatically.

4. After the “STANDBY” blinking display finish, a message

“LOCK” appears on the fluorescent indicator tube and the

CD ship mode is set.

19

HCD-GNX60/GNX70/GX9900

[CD SHIP MODE (WITHOUT MEMORY CLEAR)]

•This mode moves the optical pick-up to the position durable

to vibration. Use this mode when returning the set to the

customer after repair.

Procedure:

1. Press

2. Select CD function.

3. Press [CD] button and

will power off automatically.

4. After the “STANDBY” blinking display finish, the message

“LOCK” appears on the fluorescent indicator tube and the

CD ship mode is set.

[CD POWER MANAGE]

•This mode let you switch on or off, the power supply to the

BU during TUNER function.

• When CD POWER is set to OFF, the power supply to the BU

is cut off during TUNER function. It will increase the time

taken to access CD when function change from TUNER to

CD but it will improve tuner reception.

• When CD POWER is set to ON, the power supply to the BU

is not cut off during TUNER function. It will reduce the time

taken to access CD when function change from TUNER to

CD but it will decrease tuner reception performance.

Procedure:

1. Press

2. Select CD function.

3. Press

4. Press x button and

will power on automatically.

5. The message “CD POWER ON” or “CD POWER OFF”

appears on the fluorescent indicator tube.

button to turn the set ON.

?/1

?/1

button to turn the set ON.

?/1

button to turn the set OFF.

?/1

?/1

button simultaneously. The set

button simultaneously. The set

[CD TRAY LOCK MODE]

•This mode let you lock the disc trays. When this mode is

activated, the disc tray will not open when

button or [EX-CHANGE/DISC SKIP] button is pressed. The

message “LOCKED” appears on the fluorescent indicator tube.

Procedure:

1. Press

2. Select CD function.

3. Press x button and

simultaneously and hold down until “LOCKED” or

“UNLOCKED” appears on the fluorescent indicator tube

(around 5 seconds).

[VIDEO/MD SWITCHING]

•This mode let you switch from VIDEO to MD and vice-versa.

Procedure:

1. Press

2. Select VIDEO function.

3. Press [VIDEO/MD] button and

The function will change to MD. Press the same buttons again

to change from MD to VIDEO.

[REMOTE COMMANDER DISABLE MODE]

• This mode let you disable the remote commander reception.

When this mode is activated, the set will not response if the

button on the remote commander is pressed. The message

“RemoteDisable” will be displayed on the fluorescent indicator

tube. Use this mode during aging to avoid disturbance.

• Procedure:

1. Press x button, [GROOVE] button and [DISC 2] button

simultaneously.

The message “RemoteDisable” appears on the fluorescent

indicator tube. To enable the remote commander reception,

press the same buttons again.

The message “RemoteEnable” appears on the fluorescent

indicator tube.

button to turn the set ON.

?/1

Z

button to turn the set ON.

?/1

OPEN/CLOSE

?/1

OPEN/CLOSE

Z

button

button simultaneously.

20

HCD-GNX60/GNX70/GX9900

set

MAIN board

CN510

Pin

1

(L-CH)

Pin

3

(R-CH)

MAIN board

CN510

Pin

2

(GND)

+

–

level meter

test tape

P-4-A100

(10 kHz, –10 dB)

SECTION 5

MECHANICAL ADJUSTMENTS

Precaution

1. Clean the following parts with a denatured alcohol-moistened

swab:

record/playback heads pinch rollers

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head

demagnetizer.

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to

the parts adjusted.

5. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

Torque Measurement

Mode Torque meter Meter reading

3.06 N • m to 6.96 N • m

FWD CQ-102C 31 to 71 g • cm

(0.43 – 0.98 oz • inch)

FWD

back tension

REV CQ-102RC 31 to 71 g • cm

REV

back tension

FF/REW CQ-201B 71 to 143 g • cm

FWD tension CQ-403A 100 g or more

REV tension CQ-403R 100 g or more

CQ-102C 2 to 6 g • cm

CQ-102RC 2 to 6 g • cm

0.19 N • m to 0.58 N • m

(0.02 – 0.08 oz • inch)

3.06 N • m to 6.96 N • m

(0.43 – 0.98 oz • inch)

0.19 N • m to 0.58 N • m

(0.02 – 0.08 oz • inch)

6.96 N • m to 14.02 N • m

(0.98 – 1.99 oz • inch)

9.80 N • m

(3.53 oz or more)

9.80 N • m

(3.53 oz or more)

SECTION 6

ELECTRICAL ADJUSTMENTS

DECK SECTION

1. Demagnetize the record/playback head with a head

demagnetizer.

2. Do not use a magnetized screwdriver for the adjustments.

3. After the adjustments, apply suitable locking compound to the

parts adjust.

4. The adjustments should be performed with the rated power

supply voltage unless otherwise noted.

5. The adjustments should be performed in the order given in

this service manual. (As a general rule, playback circuit

adjustment should be completed before performing recording

circuit adjustment.)

6. The adjustments should be performed for both L-CH and R-

CH.

7. Switches and controls should be set as follows unless otherwise

specified.

•Test Tape

Tape Signal Used for

P-4-A100 10 kHz, –10 dB Azimuth Adjustment

RECORD/PLAYBACK HEAD AZIMUTH ADJUST-MENT

DECK A DECK B

Note: Perform this adjustments for both decks

Procedure:

1. Mode: Playback

0 dB=0.775 V

21

HCD-GNX60/GNX70/GX9900

e

2. Turn the adjustment screw and check output peaks. If the peaks

do not match for L-CH and R-CH, turn the adjustment screw

so that outputs match within 1dB of peak.

Output

level

within

1dB

L-CH

peak

R-CH

peak

within

1dB

Screw

position

L-CH

peak

Screw

position

R-CH

peak

3. Mode: Playback

test tape

P-4-A100

(10 kHz, –10 dB)

L-CH

MAIN

board

CN510

set

R-CH

waveform of oscilloscope

pin

L

R

pin

1

pin

3

2

oscilloscop

H

V

CD SECTION

Note:

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens by an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

S-curve Check

Connection:

oscilloscope

CD board

TPO102 (FE1)

TP117 (VC)

Procedure:

1. Connect an oscilloscope to test point TPO102 (FE1) and TP

117(VC) on the CD board.

2. Turn the power on.

3. Put the disc (YEDS-18) in and turned power switch on again

and actuate the focus search. (actuate the focus search when

disc table is moving in and out)

4. Check the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within

2.4 ± 1 Vp-p.

+

–

in phase 45°90°135°180

good

°

wrong

4. After the adjustments, apply suitable locking compound to

the pats adjusted.

Adjustment Location: Playback Head (Deck A).

Record/Playback/Erase Head (Deck B).

S-curve waveform

symmetry

A

within 2.4

B

Note:

•Try to measure several times to make sure than the ratio

of A : B or B : A is more than 10 : 7.

•Take sweep time as long as possible and light up the

brightness to obtain best waveform.

Checking Location: CD board (SIDE B)

(See page 24.)

±

1 Vp-p

22

forward

reverse

HCD-GNX60/GNX70/GX9900

RFAC Level Check

Connection:

oscilloscope

CD board

TP124 (RFAC)

TP117 (VC)

+

–

Procedure:

1. Connect an oscilloscope to test point TP124 (RFAC) and TP

117(VC) on the CD board.

2. Turn the power on.

3. Put the disc (YEDS-18) in to playback the number five track.

4. Confirm that oscilloscope waveform is clear and check RFAC

signal level is correct or not.

Note: A clear RFAC signal waveform means that the shape “◊” can be

RFAC signal waveform

clearly distinguished at the center of the waveform.

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

level: 0.9 ± 0.4 Vp-p

E-F Balance Check

Connection:

oscilloscope

CD board

TPO103 (TE1)

TP117 (VC)

+

–

Procedure:

1. Connect an oscilloscpe to test point TPO103 (TE1) and TP117

(VC) on the CD board.

2. Turn the power on.

3. Select the function “CD”.

4. Press three buttons of [ENTER], M , and

[SURRUUND MODE] simultaneously to set the CD service

mode.

5. Put the disc (YEDS-18) in to playback the number five track.

6. Press the . button. The message “TRAVERSE” is

displayed. (The tracking servo and the sledding servo are

turned OFF)

7. Check the level B of the oscilliscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B x 100 = less than ± 22%

Tr averse Waveform

Center of

the waveform

Checking Location: CD board (SIDE B)

(See page 24.)

B

0V

level: 1.0 ± 0.5 Vp-p

8. Press the . button. The message “TRAVERSE” is

A (DC

voltage)

displayed. (The tracking servo and sledding servo are turned

ON)

Confirm the C (DC voltage) is almost equal to the A (DC

voltage) is step 5.

9. To exit from this mode, perform as follows.

1) Move the optical pick-up to the most inside track.

2) Press three buttons of x , [CLEAR], and [DISPLAY]

simultaneously. (cold reset)

Notes:

•Always move the optical pick-up to most inside track

when exiting from this mode. Otherwise, a disc will not

be unloaded.

• Do not run the sled motor excessively, otherwise the gear

can be chipped.

Tr averse Waveform

0V

Tr acking servo

Sled servo

OFF

Tr acking servo

Sled servo

ON

Checking Location: CD board (SIDE B) (See page 24.)

C (DC

voltage)

23

Loading...

Loading...