Page 1

FLAT WIDE DISPLAY

FWD-42LX1

REMOTE COMMANDER

RM-980

SPEAKER SYSTEM

SS-SP42FW

TABLETOP STAND

SU-42FW

SERVICE MANUAL

1st Edition

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

FWD-42LX1

Page 3

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

For the customers in the Netherlands

Voor de klanten in Nederland

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

Hoe u de batterijen moet verwijderen, leest u in de tekst

van deze handleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

FWD-42LX1

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

1 (P)

Page 4

Page 5

Table of Contents

1. Service Overview

1-1. Appearance Figure ......................................................................................1-1

1-2. Board Location............................................................................................1-1

1-3. Removing/Reinstalling the Cabinet ............................................................1-2

1-3-1. Cabinet Assembly ..................................................................... 1-2

1-3-2. Bezel Assembly..........................................................................1-3

1-4. Replacing the Board .................................................................................... 1-4

1-4-1. D2 Board/V Board/JT Board .....................................................1-5

1-4-2. S Board/FA Board ......................................................................1-6

1-4-3. G1 Board ....................................................................................1-7

1-4-4. K Board ......................................................................................1-8

1-4-5. F Board .......................................................................................1-8

1-4-6. H1 Board ....................................................................................1-9

1-4-7. H2 Board ....................................................................................1-9

1-4-8. H3 Board ..................................................................................1-10

1-4-9. SP Board...................................................................................1-10

1-4-10. U1 Board/U2 Board .................................................................1-11

1-5. Replacing the Main Parts ..........................................................................1-12

1-5-1. DC Fan .....................................................................................1-12

1-5-2. Lithium Battery ........................................................................1-12

1-5-3. LCD Module ............................................................................ 1-13

1-6. Service Position.........................................................................................1-14

1-6-1. Service Position of D2 Board/FA Board/G1 Board/

F Board/K Board/V Board/JT Board .......................................1-14

1-7. Packing of the LCD Module .....................................................................1-15

1-8. Replacing the Battery ................................................................................ 1-16

1-9. Performance and Specifications of This Unit ...........................................1-16

1-10. Unleaded Solder ........................................................................................ 1-16

1-11. Warning on Power Connection .................................................................1-17

FWD-42LX1

2. Electrical Alignment

2-1. Required Equipment....................................................................................2-1

2-2. Electric Adjustment in Service Mode .........................................................2-1

2-2-1. Service Mode .............................................................................2-1

2-2-2. Picture Mode ..............................................................................2-1

2-2-3. Adjust Picture (Picture quality adjustment) ...............................2-2

2-2-4. Adjust Sound (Sound quality adjustment) ................................. 2-2

2-2-5. Vivid/Standard Save...................................................................2-2

2-2-6. White Balance Adjustment ........................................................2-2

2-2-7. AD Calibration Adjustment ....................................................... 2-3

2-2-8. Factory Reset............................................................................2-17

2-2-9. Option Switch...........................................................................2-17

1

Page 6

3. Circuit Description

3-1. Outline.........................................................................................................3-1

3-2. D2 Board .....................................................................................................3-2

3-3. V Board .......................................................................................................3-4

3-4. H1 Board .....................................................................................................3-5

3-5. H2 Board .....................................................................................................3-5

3-6. H3 Board .....................................................................................................3-5

3-7. K Board .......................................................................................................3-5

3-8. SP Board......................................................................................................3-5

3-9. S Board........................................................................................................3-5

3-10. FA Board.....................................................................................................3-6

3-11. JT Board ...................................................................................................... 3-6

3-12. F Board........................................................................................................3-6

3-13. G1 Board .....................................................................................................3-6

4. Troubleshooting

4-1. Judgment When No Image is Displayed ..................................................... 4-1

4-2. Self-Diagnosis Function..............................................................................4-1

5. Semiconductor Pin Assignments

6. Spare Parts

6-1. Notes on Repair Parts..................................................................................6-1

6-2. Exploded Views ..........................................................................................6-2

6-3. Electrical Parts List .....................................................................................6-8

6-4. Packing Materials & Supplied Accessories .............................................. 6-40

6-5. SS-SP42FW...............................................................................................6-40

6-6. SU-42FW .................................................................................................. 6-40

7. Block Diagrams

Overall.........................................................................................................7-1

2

FWD-42LX1

Page 7

8. Schematic Diagrams

D2 ................................................................................................................ 8-2

F.................................................................................................................8-11

FA..............................................................................................................8-12

G1 .............................................................................................................. 8-13

H1 .............................................................................................................. 8-16

H2 .............................................................................................................. 8-16

H3 .............................................................................................................. 8-16

S.................................................................................................................8-16

SP ..............................................................................................................8-16

JT...............................................................................................................8-17

K ................................................................................................................ 8-18

U1 .............................................................................................................. 8-20

U2 .............................................................................................................. 8-21

V ................................................................................................................ 8-22

Frame Wiring ............................................................................................8-31

9. Board Layouts

D2 ................................................................................................................ 9-1

G1 ................................................................................................................ 9-4

F...................................................................................................................9-6

FA................................................................................................................9-8

JT.................................................................................................................9-8

H1 ................................................................................................................ 9-9

H2 ................................................................................................................ 9-9

H3 ................................................................................................................ 9-9

K ................................................................................................................ 9-10

V ................................................................................................................ 9-12

U1 .............................................................................................................. 9-14

U2 .............................................................................................................. 9-16

S.................................................................................................................9-18

SP ..............................................................................................................9-18

FWD-42LX1

3

Page 8

Page 9

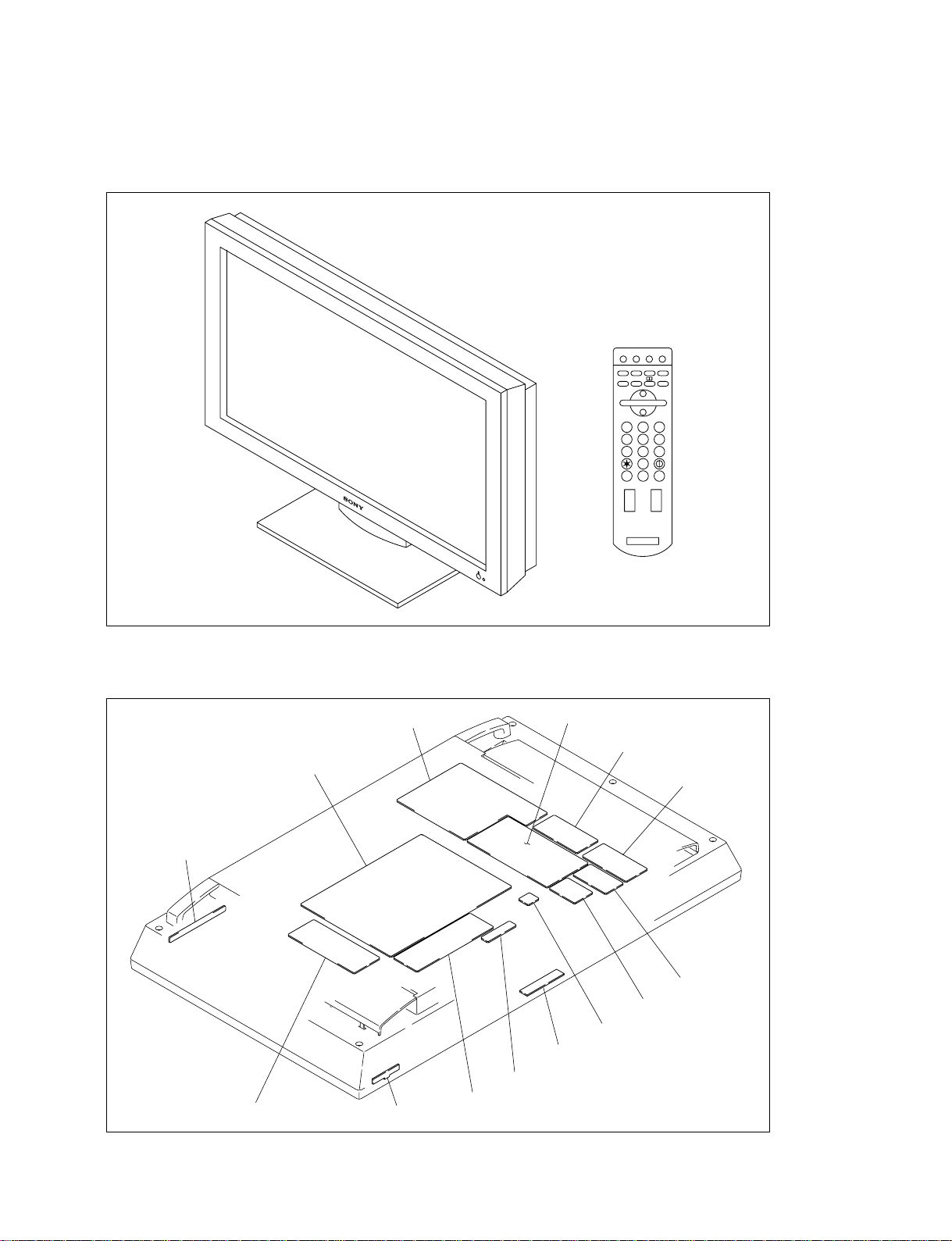

1-1. Appearance Figure

Section 1

Service Overview

1 2 3

4 5 6

7 8 9

0

ON SET OFF

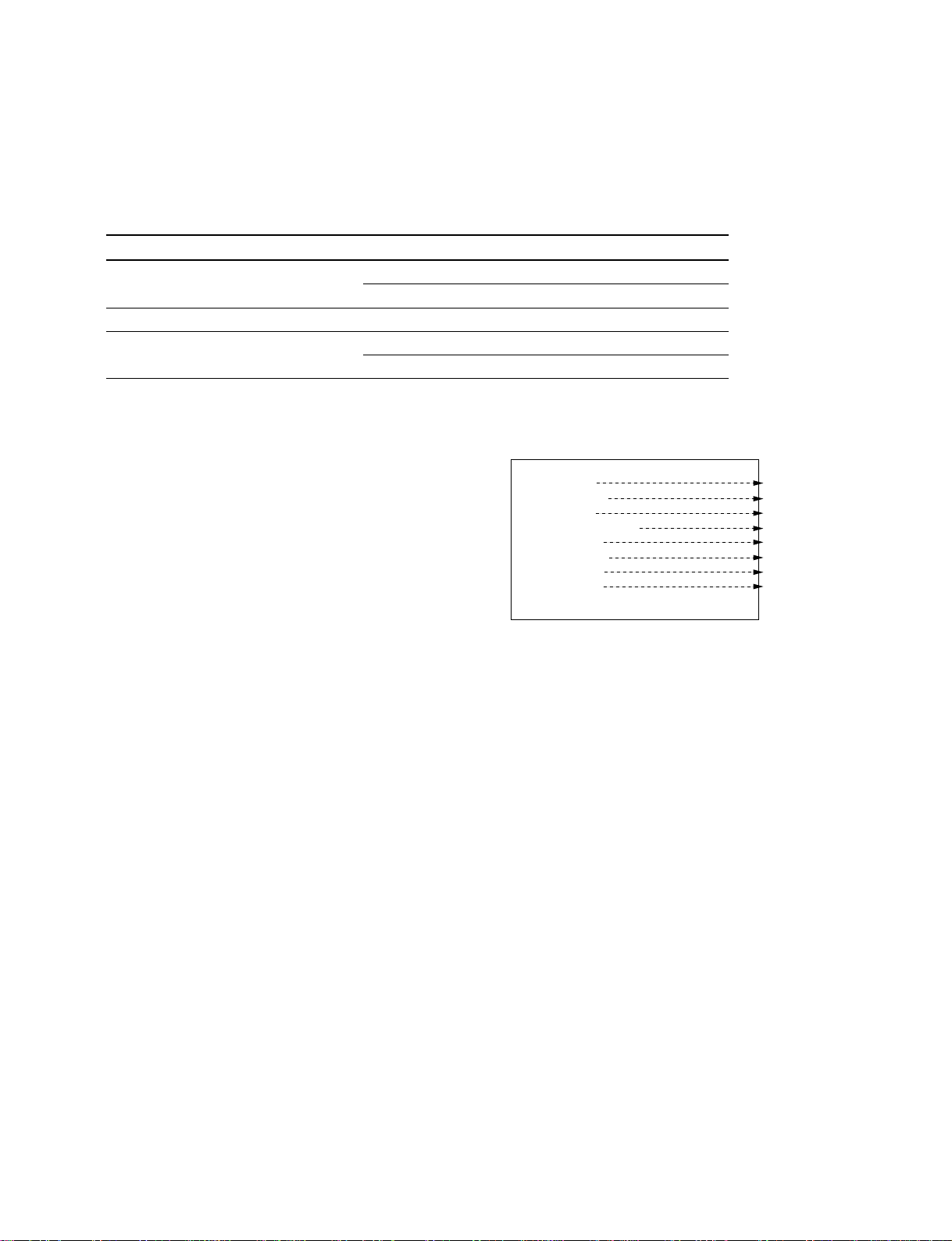

1-2. Board Location

H1 board

K board

G1 board

D2 board

H3 board

V board

U1 board

U2 board

JT board

FA board

S board

H2 board

SP board

F board

FWD-42LX1

1-1

Page 10

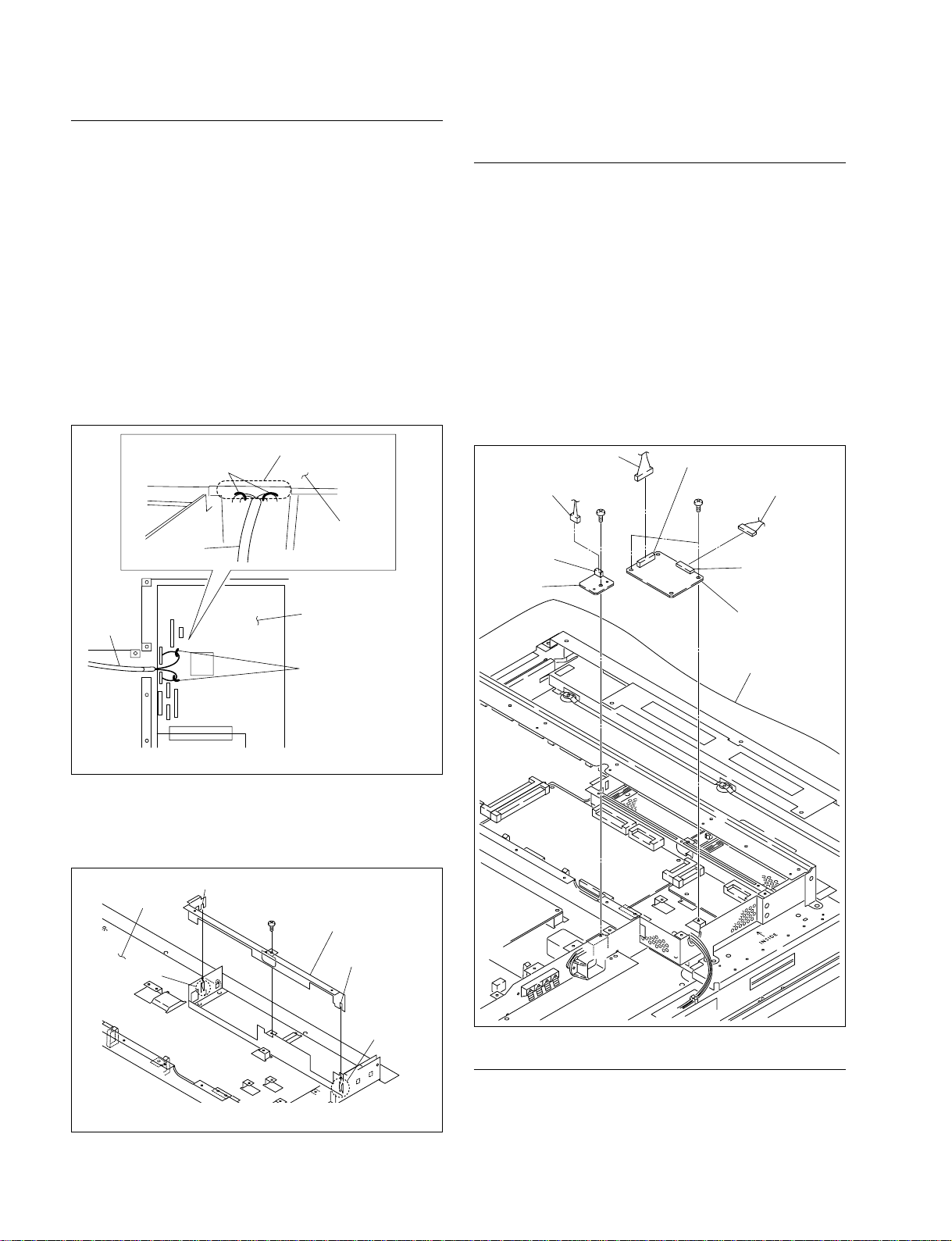

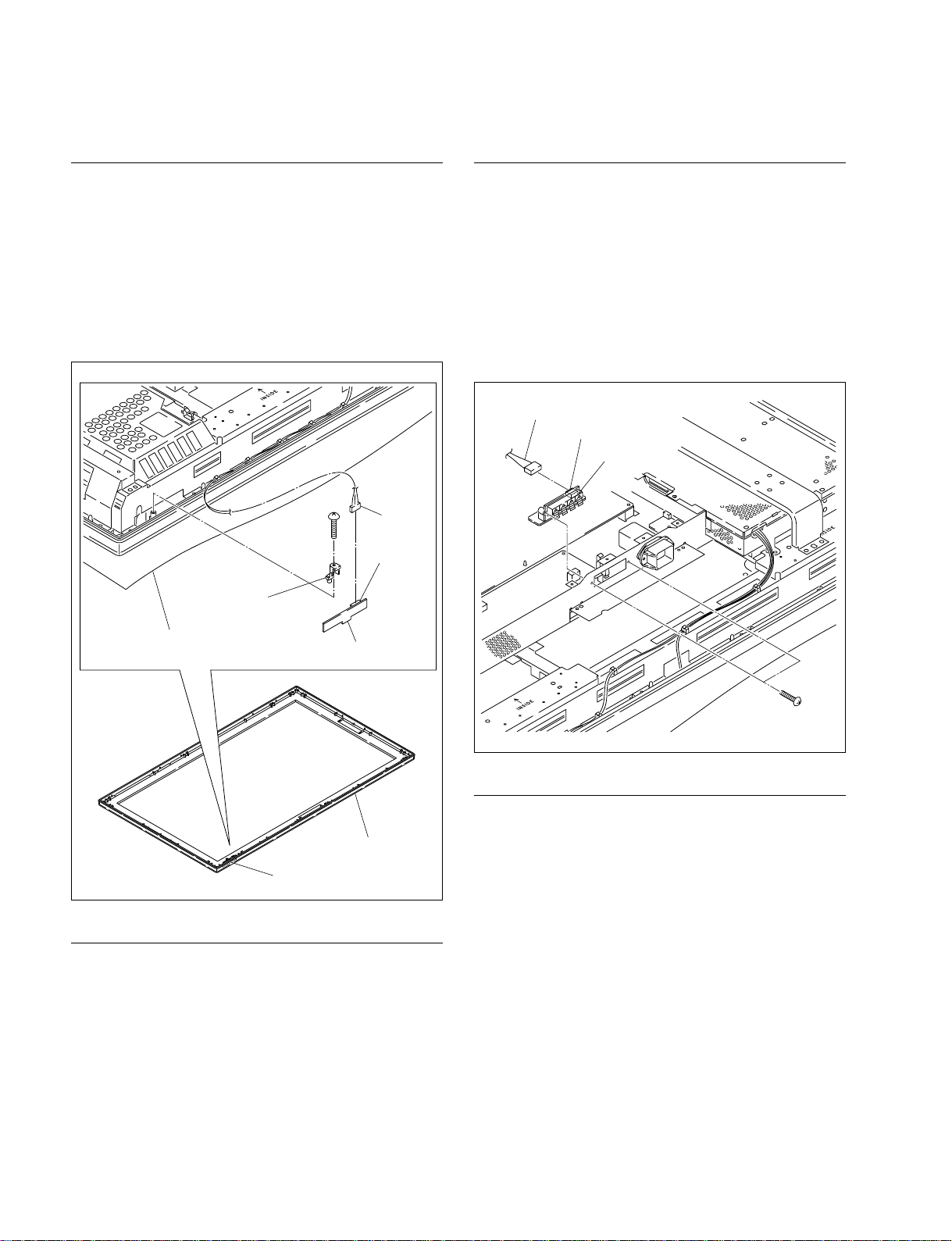

1-3. Removing/Reinstalling the Cabinet

n

When removing/installing the cabinet and replacing the board, place the unit on the conductive cushion.

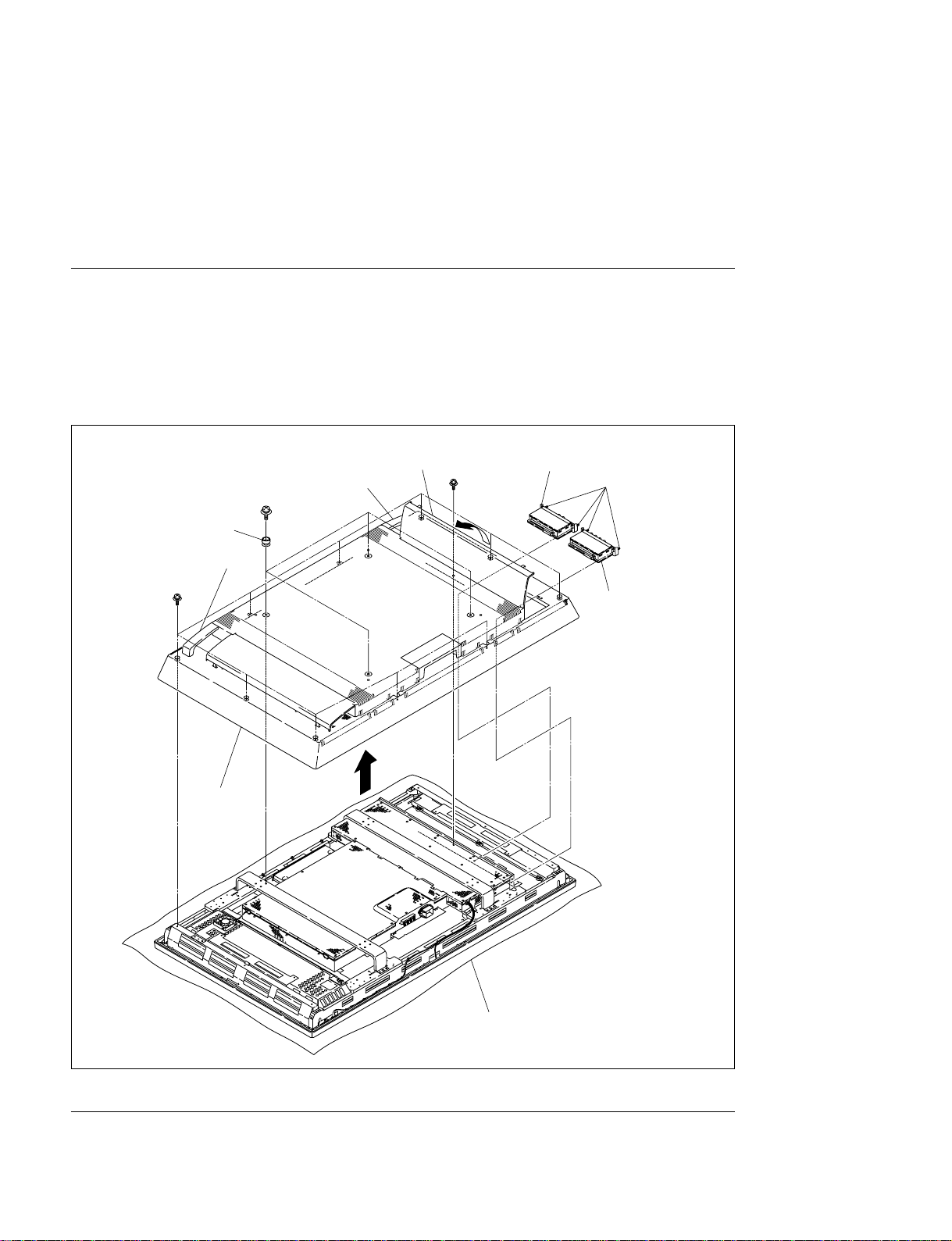

1-3-1. Cabinet Assembly

Removal

1. Open the cable side cover on the right side (viewed from backside) and loosen the four panel securing

screws, then remove the U1 block assembly and U2 block assembly.

2. Remove the four screws (PSW M6 x 20), then remove the four knobs.

3. Remove the ten screws (PSW4 x 10) and the screw (PSW3 x 12), then hold the two handles and

remove the cabinet assembly.

Knobs

PSW

4 x 10 (Black)

Cabinet

assembly

PSW

M6 x 20 (Black)

Handle

Cable side cover

Handle

U1 block

assembly

PSW

3 x 12 (Black)

Panel securing

screws

U2 block

assembly

Conductive cushion

Installation

4. Reattach the cabinet assembly in the reverse order of steps 1 to 3.

1-2

FWD-42LX1

Page 11

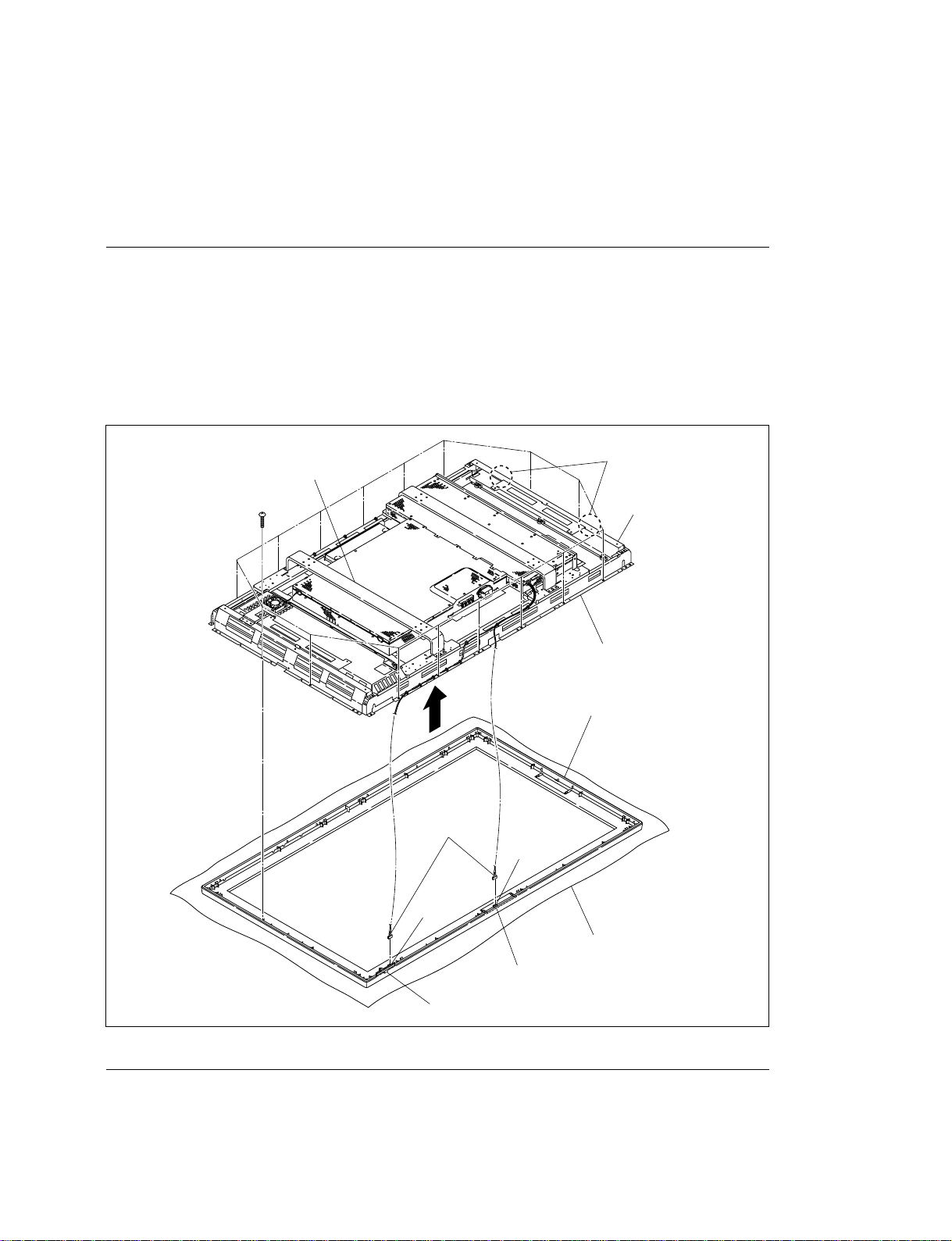

1-3-2. Bezel Assembly

m

. When removing the chassis assembly, be sure to work with more than two persons.

. Place the removed chassis assembly on the conductive cushion.

Removal

1. Remove the cabinet assembly. (Refer to Section 1-3-1.)

2. Disconnect the harness from the connector (CN9200) on the H2 board.

3. Disconnect the harness from the connector (CN9300) on the H3 board.

4. Remove the sixteen screws, then hold the arm (left side) and two portions A of the frame (V), and

remove the chassis assembly.

Arm

(on the left side when viewed from

backside of the unit)

BVTP4 x 10

Portions A

Frame (V)

Chassis assembly

Bezel assembly

Harnesses

CN9200

CN9300

H2 board

H3 board

Installation

5. Reattach the chassis assembly in the reverse order of steps 2 to 4.

6. Reattach the cabinet assembly. (Refer to Section 1-3-1.)

FWD-42LX1

Conductive cushion

1-3

Page 12

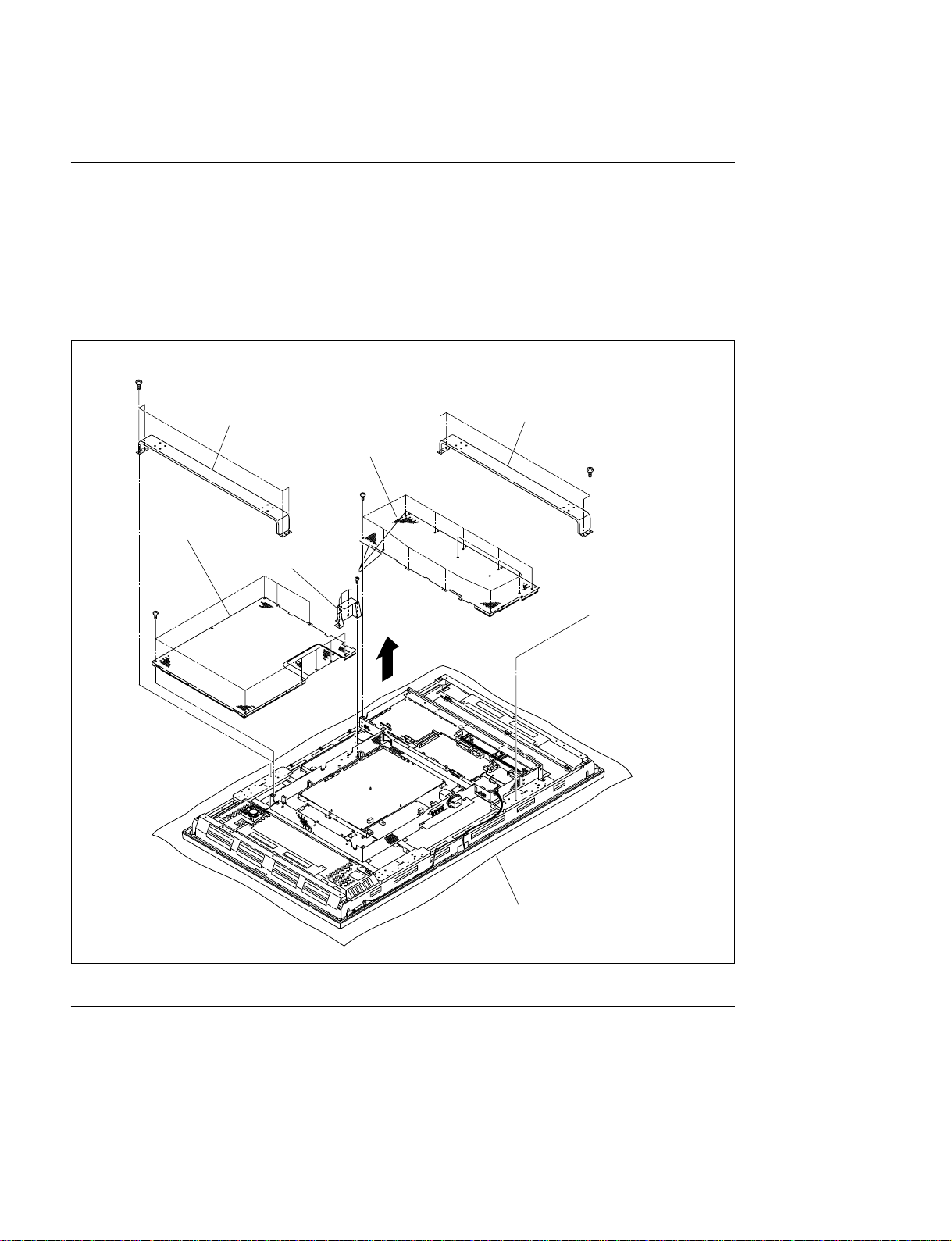

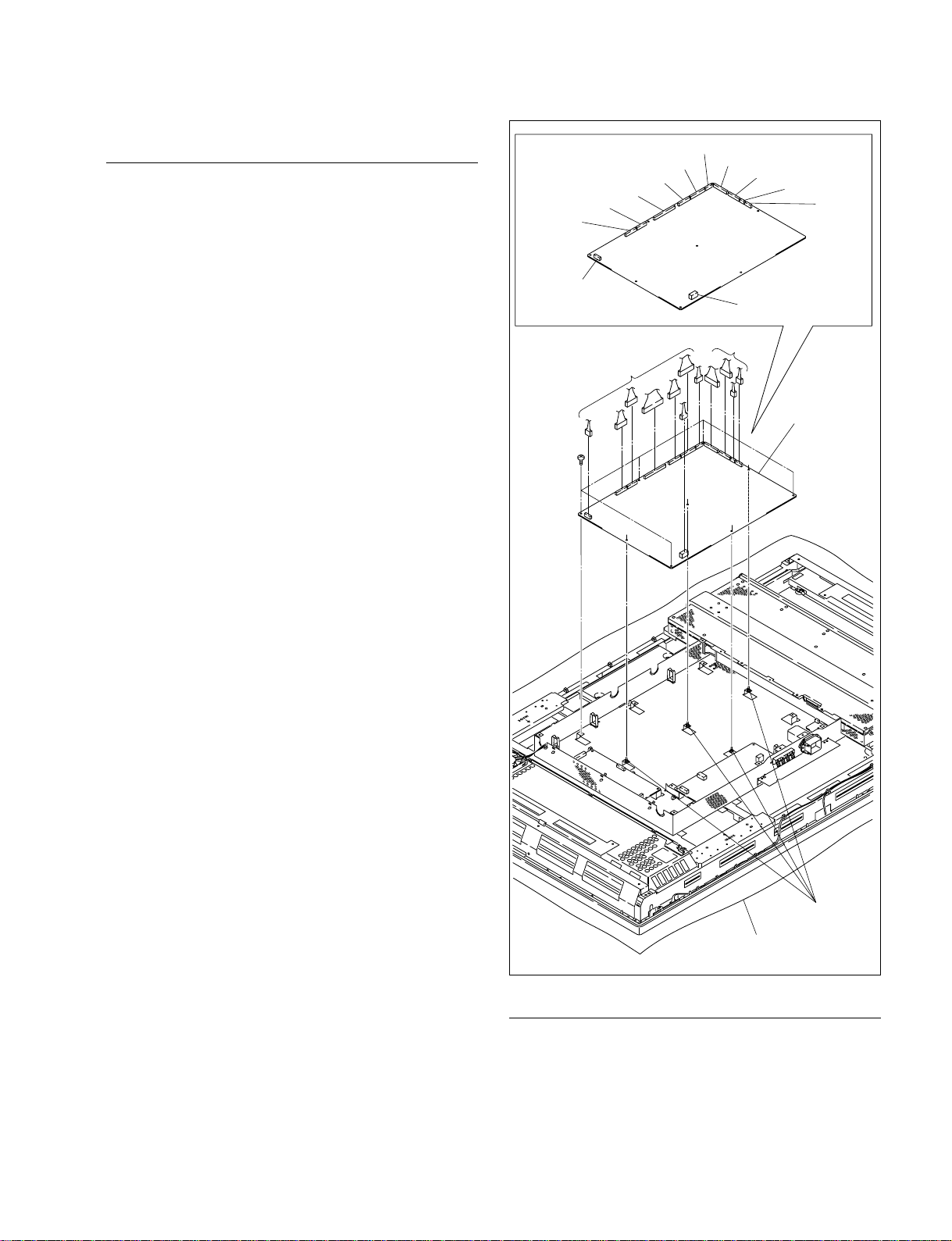

1-4. Replacing the Board

Removal

1. Remove the cabinet assembly. (Refer to Section 1-3-1.)

2. Remove the eight screws (BVTT4 x 8), then remove the two arms.

3. Remove the four screws (BVTT3 x 6), then remove the LVDS cable shield assembly.

4. Remove the ten screws (BVTT3 x 6), then remove the shield cover G assembly.

5. Remove the fifteen screws (BVTT3 x 6), then remove the shield cover D.

BVTT

4 x 8

Shield cover G

assembly

BVTT

3 x 6

Arm

(on the left side when viewed

from backside of the unit)

LVDS cable

shield assembly

Shield cover D

BVTT

3 x 6

BVTT

3 x 6

Arm

(on the right side when viewed

from backside of the unit)

BVTT

4 x 8

Conductive cushion

Installation

6. Reattach the LVDS cable shield assembly, shield cover G assembly, shield cover D and two arms in

the reverse order of steps 2 to 5.

7. Reattach the cabinet assembly. (Refer to Section 1-3-1.)

1-4

FWD-42LX1

Page 13

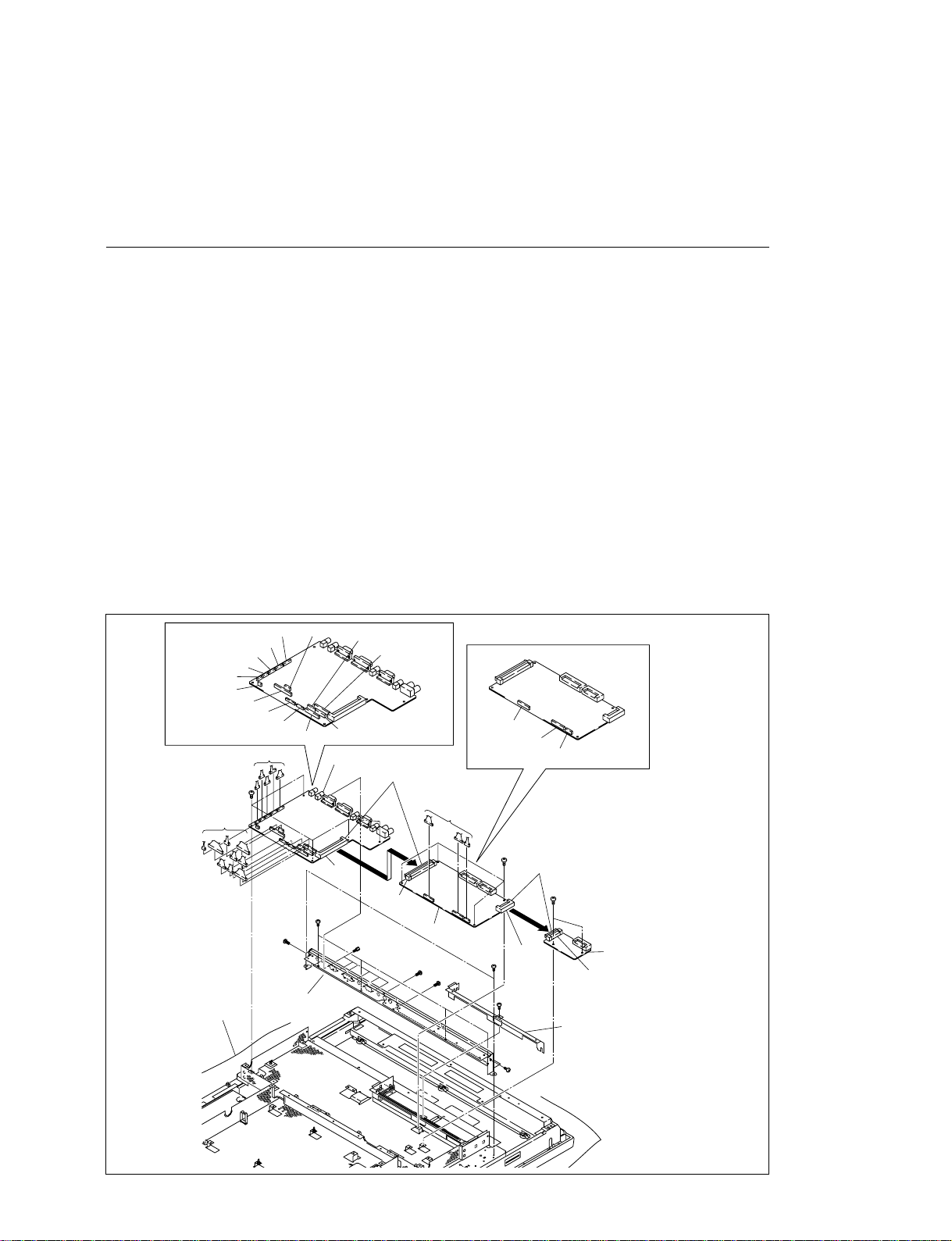

1-4-1. D2 Board/V Board/JT Board

m

After replacing the D2 board or V board, be sure to perform the “2-2-6. White Balance Adjustment” and

“2-2-7. AD Calibration Adjustment”.

Removal

1. Remove the cabinet assembly. (Refer to Section 1-3-1.)

2. Remove the arm on the right side and shield cover D. (Refer to steps 2 and 4 of Section 1-4.)

3. Remove the screw (BVTT3 x 6), then remove the connector cover assembly.

4. Disconnect the fourteen harnesses connected to the D2 board.

5. Disconnect the three harnesses from the connectors (CN3901-CN3903) on the V board.

6. Remove the five screws (BVTT3 x 6) securing the D2 board.

7. Remove the four screws (BVTT3 x 6) securing the V board and two screws (BVTT3 x 6) securing

the JT board.

8. Remove the nine screws (BVTT3 x 6), then remove the connector bracket assembly.

9. Remove the V board from the connector (CN1000) on the D2 board in the direction shown by the

arrow B.

10. Remove the JT board from the connector (CN3001) on the V board in the direction shown by the

arrow C.

11. Remove the six hexagonal screws and the screw (BVTP3 x 12), then remove the D2 board.

CN1203

CN1204

CN2202

CN1004

D2 board

Harnesses

Conductive

cushion

CN1206

CN1905

CN2200

Harnesses

BVTT

3 x 6

CN1209

CN2203

CN1003

BVTT

3 x 6

Connector

bracket

CN1001

CN1008

D2 board

CN1000

BVTT

3 x 6

CN1005

CN1002

Connectors

CN3900

Hexagonal

screws

BVTP

3 x 12

B

Harnesses

V board

BVTT

3 x 6

CN3903

CN3902

V board

BVTT

3 x 6

BVTT

3 x 6

Connectors

CN3001

BVTT

3 x 6

BVTT

3 x 6

CN3901

BVTT

3 x 6

C

CN2701

Connector cover

JT board

FWD-42LX1

1-5

Page 14

Installation

1-4-2. S Board/FA Board

12. Install the D2 board, V board and JT board in the

reverse order of steps 3 to 11.

m

. Be sure to securely connect the connector (CN1000)

on the D2 board and the connector (CN3900) on the

V board.

. Be sure to securely connect the connector (CN3001)

on the V board and the connector (CN2701) on the

JT board.

. Be sure to securely fix the LVDS harness with the

harness retainers to prevent the LVDS harness from

contacting the shield cover D. (Refer to Fig. A.)

No contact with shield case D

Harness retainers

LVDS

harness

LVDS

harness

Shield case D

D2 board

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the two arms, shield cover G assembly and

shield cover D. (Refer to steps 2 to 4 of Section 1-4.)

3. Disconnect the harness from the connector (CN9400)

on the S board.

4. Remove the screw, then remove the S board.

5. Disconnect the two harnesses from the connectors

(CN5900 and CN5901) on the FA board.

6. Remove the two screws, then remove the FA board.

CN9400

S board

Harness

Harness

BVTT

3 x 6

CN5900

BVTT

3 x 6

Harness

CN5901

FA board

Harness retainers

Fig. A.

. When attaching the connector cover assembly, be

sure to securely insert the two notches into the

portion A of the D base chassis. (Refer to Fig. B.)

D base

chassis

Portion A

notch

Fig. B.

BVTT

3 x 6

Connector

cover assembly

notch

Portion A

13. Reassemble this unit in the reverse order of steps 1 and 2.

1-6

Conductive cushion

Installation

7. Install the S board and FA board in the reverse order

of steps 3 to 6.

8. Reassemble this unit in the reverse order of steps 1 and 2.

FWD-42LX1

Page 15

1-4-3. G1 Board

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the arm on the left side and shield cover G

assembly. (Refer to steps 2 and 3 of Section 1-4.)

3. Disconnect the twelve harnesses from the connectors

(CN6000, CN6400-CN6410) on the G1 board.

4. Remove the five screws.

5. Remove the G1 board from the four board spacers.

CN6408

CN6410

CN6400

G1 board

BVTT

3 x 6

CN6401

CN6404

Harnesses

CN6409

CN6406

CN6407

CN6402

CN6405

CN6403

CN6000

Harnesses

G1 board

FWD-42LX1

Board spacers

Conductive cushion

Installation

6. Install the G1 board in the reverse order of steps 3 to 5.

7. Reassemble this unit in the reverse order of steps 1 and

2.

1-7

Page 16

1-4-4. K Board

1-4-5. F Board

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the arm on the left side and shield cover G

assembly. (Refer to steps 2 and 3 of Section 1-4.)

3. Disconnect the three harnesses from the connectors

(CN5000-CN5002) on the K board.

4. Remove the four screws, then remove the K board.

Harness

BVTT

3 x 6

CN5002

Conductive

cushion

K board

Harness

CN5000

Harness

CN5001

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the arm on the left side and shield cover G

assembly. (Refer to steps 2 and 3 of Section 1-4.)

3. Disconnect the three harnesses from the connectors

(CN8001-CN8003) on the K board.

4. Remove the four screws, then remove the F board.

Harnesses

BVTT

3 x 6

F board

CN8003

Conductive

cushion

CN8001

CN8002

Installation

5. Install the K board in the reverse order of steps 3 and

4.

6. Reassemble this unit in the reverse order of steps 1 and

2.

1-8

Installation

5. Install the F board in the reverse order of steps 3 and 4.

6. Reassemble this unit in the reverse order of steps 1 and

2.

FWD-42LX1

Page 17

1-4-6. H1 Board

1-4-7. H2 Board

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the two screws (BVTT3 x 6), then remove

the control button panel.

3. Remove the three screws (BVTP3 x 8), then remove

the H1 board.

4. Disconnect the harness from the connector (CN9100)

on the H1 board.

Opening

Control panel assembly

Harness

BVTT

3 x 6

Control button

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the bezel assembly. (Refer to Section 1-3-2.)

3. Remove the hook from the rib in the center of the

lower portion on the bezel assembly.

4. Slowly incline the H2 board in the direction shown by

the arrow, then remove it from the bezel assembly.

H2 board

Hook

(upper portion)

CN9200

Openings

Hook (upper portion)

Hook

(lower portion)

CN9100

Control

button panel

Conductive cushion

H1 board

BVTP

3 x 8

Harness

Installation

5. Install the H1 board in the reverse order of steps 2 to 4.

n

When attaching the control panel assembly, route the

harness through the opening.

6. Reattach the cabinet assembly.

(Refer to Section 1-3-1.)

FWD-42LX1

Rib

Conductive cushion

Bezel assembly

Bezel

assembly

H2 board

Installation

4. Install the H2 board.

n

When installing the H2 board, insert the two hooks

(upper portion) into the openings of the cabinet

assembly and push in the hook (lower portion).

5. Reassemble this unit in the reverse order of steps 1 and

2.

1-9

Page 18

1-4-8. H3 Board

1-4-9. SP Board

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the screw, then remove the light pipe and H3

board.

3. Disconnect the harness from the connector (CN9300)

on the H3 board.

Harness

CN9300

Light pipe

BVTP

3 x 12

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the arm on the left side and shield cover G

assembly. (Refer to steps 2 and 3 of Section 1-4.)

3. Disconnect the harness from the connector (CN9500)

on the SP board.

4. Remove the two screws, then remove the SP board.

Harness

CN9500

SP board

Conductive cushion

H3 board

H3 board

Bezel assembly

Installation

4. Install the light pipe and H3 board in the reverse order

of steps 2 and 3.

5. Reattach the cabinet assembly.

(Refer to Section 1-3-1.)

n

When attaching the cabinet assembly, be careful not to

catch the harness.

BVTP

3 x 12 (Black)

Installation

5. Install the SP board in the reverse order of steps 3 and

4.

6. Reassemble this unit in the reverse order of steps 1 and

2.

1-10

FWD-42LX1

Page 19

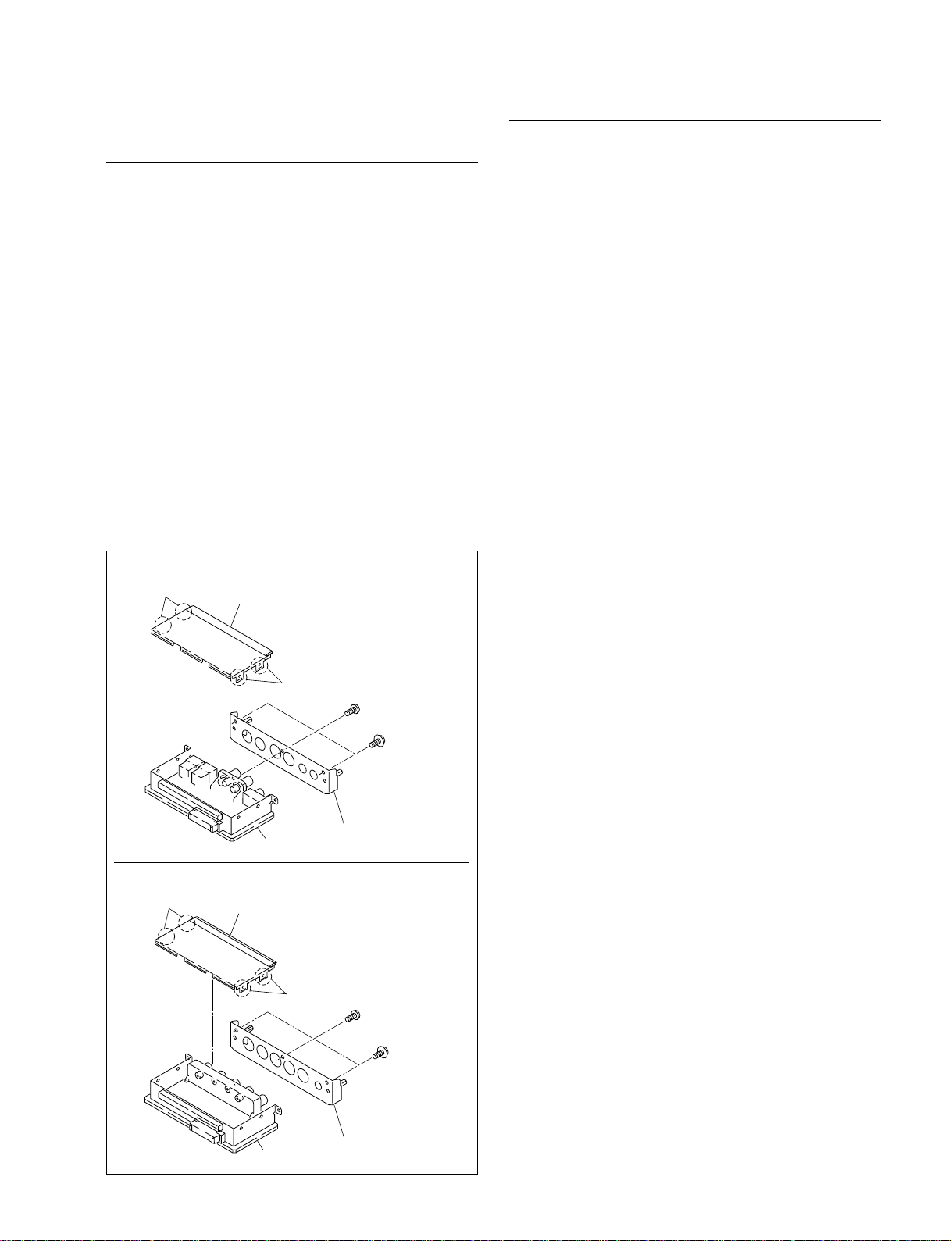

1-4-10. U1 Board/U2 Board

Installation

Removal

1. Remove the U1 block assembly and U2 block

assembly. (Refer to step 1 of Section 1-3-1.)

U1 block assembly

2. Expand the four portions A of the U1 block assembly,

then remove the cover.

3. Remove the screw (BVTP3 x 8) and two screws

(PSW3 x 8), then remove the U1 board from the U1

panel assembly.

U2 block assembly

4. Expand the four portions A of the U2 block assembly,

then remove the cover.

5. Remove the screw (BVTP3 x 8) and two screws

(PSW3 x 8), then remove the U2 board from the U2

panel assembly.

. U1 block assembly

Portions A

Cover

6. Install the U1 board and U2 board in the reverse order

of steps 2 to 5.

7. Reattach the U1 block assembly and U2 block

assembly to this unit.

(Refer to step 1 of Section 1-3-1.)

. U2 block assembly

Portions A

Cover

Portions A

U1 board

Portions A

BVTP3 x 8

(Black)

PSW3 x 8

(Black)

U1 panel assembly

BVTP3 x 8

(Black)

PSW3 x 8

(Black)

FWD-42LX1

U2 board

U2 panel assembly

1-11

Page 20

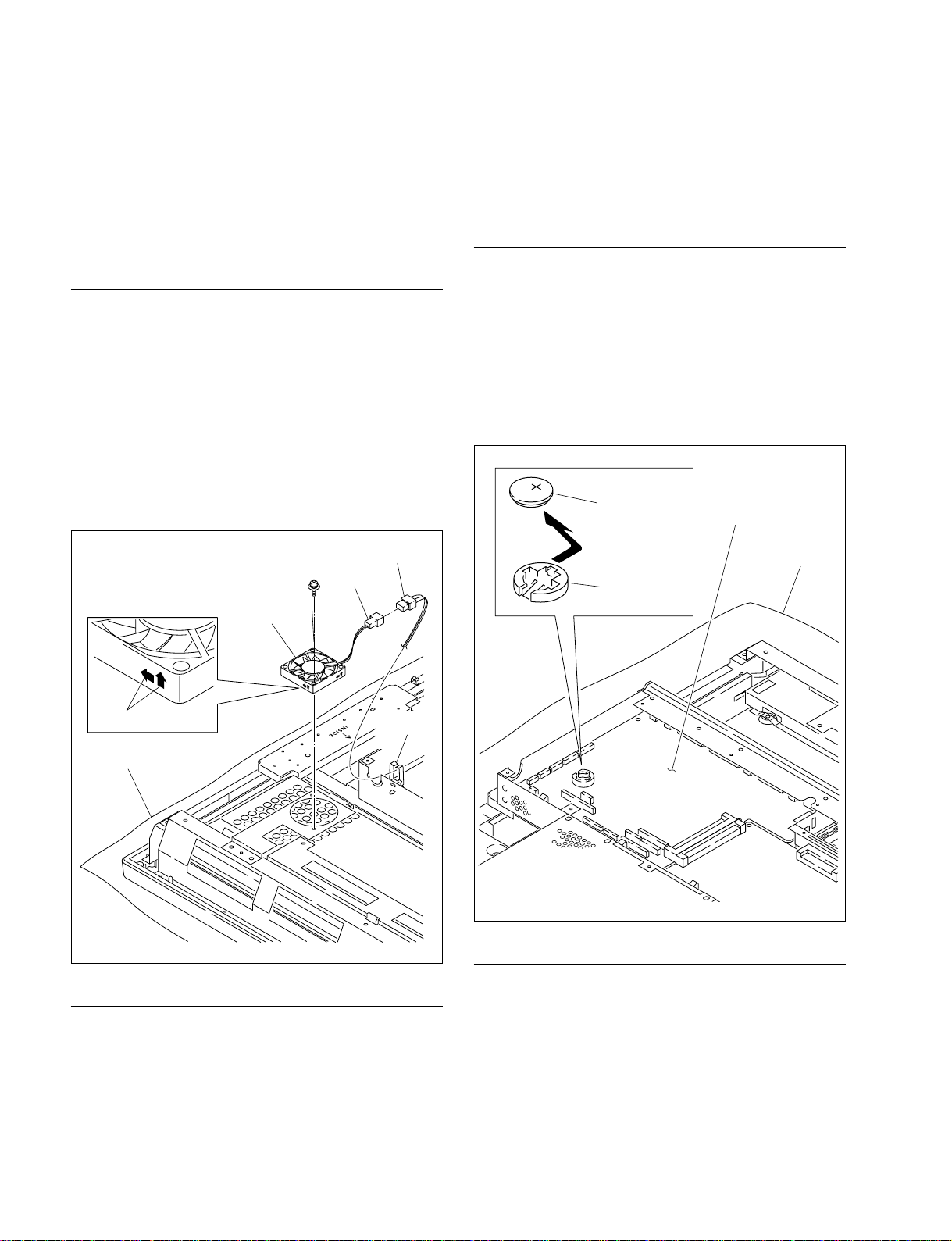

1-5. Replacing the Main Parts

1-5-2. Lithium Battery

1-5-1. DC Fan

n

When attaching the DC fan, be careful of the orientation of

the imprinting.

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the arm on the left side and shield cover G

assembly. (Refer to steps 2 and 3 of Section 1-4.)

3. Remove the harness from the clamper.

4. Remove the connector connecting the harness removed

in step 3 to the DC fan.

5. Remove the two screws, then remove the DC fan.

Harness

PSW

3 x 14

DC fan

Connector

n

Before replacing the battery, be sure to read “1-8.

Replacing the Battery”.

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the arm on the right side and shield cover D.

(Refer to steps 2 and 4 of Section 1-4.)

3. Remove the lithium battery from the battery holder on

the D2 board.

Lithium battery

Battery holder

D2 board

Conductive

cushion

Imprintings

Conductive cushion

Clamper

Installation

6. Reattach the DC fan in the reverse order of steps 3 to

5.

7. Reassemble this unit in the reverse order of steps 1 and

2.

Installation

4. Reattach the lithium battery.

5. Reassemble this unit in the reverse order of steps 1 and

2.

1-12

FWD-42LX1

Page 21

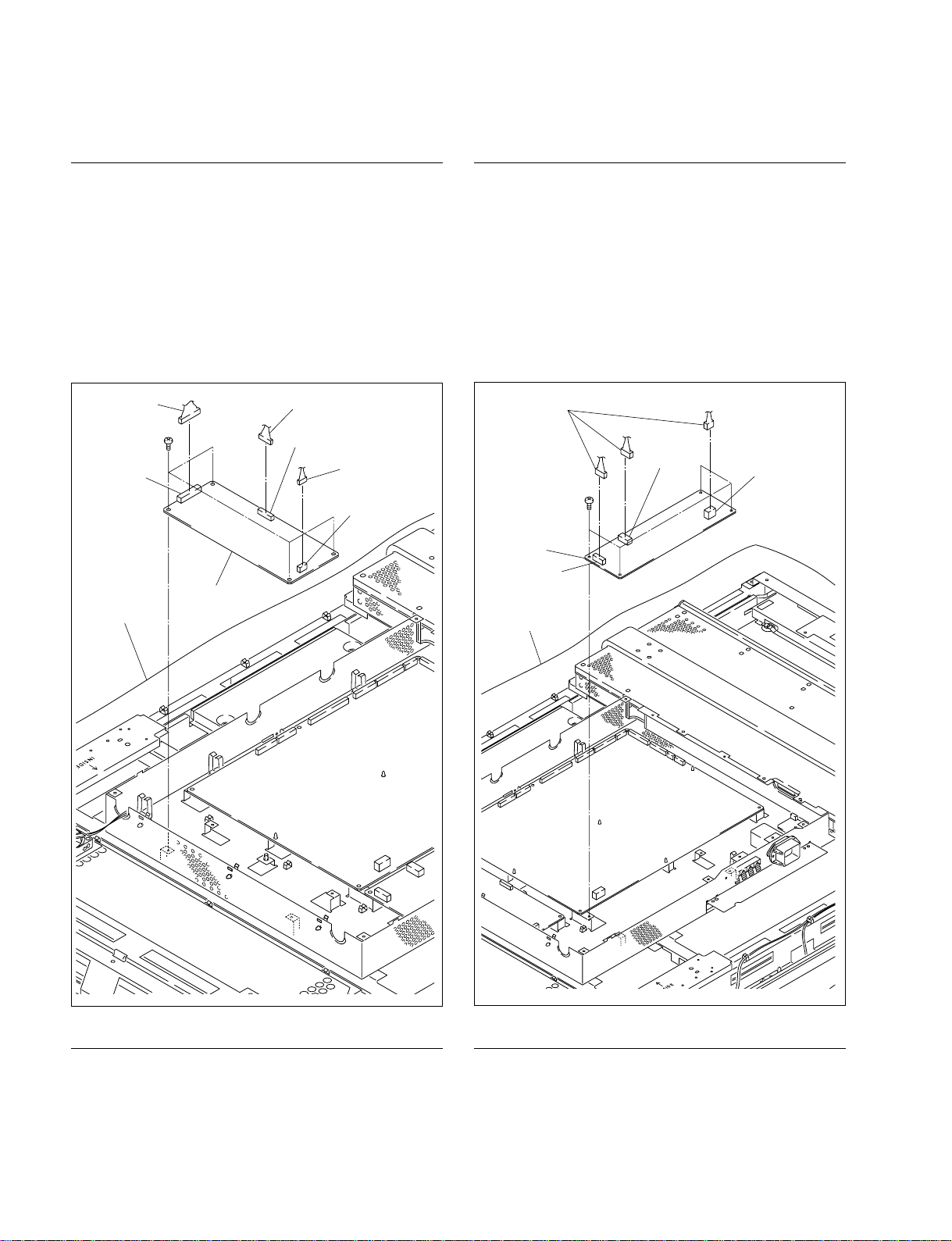

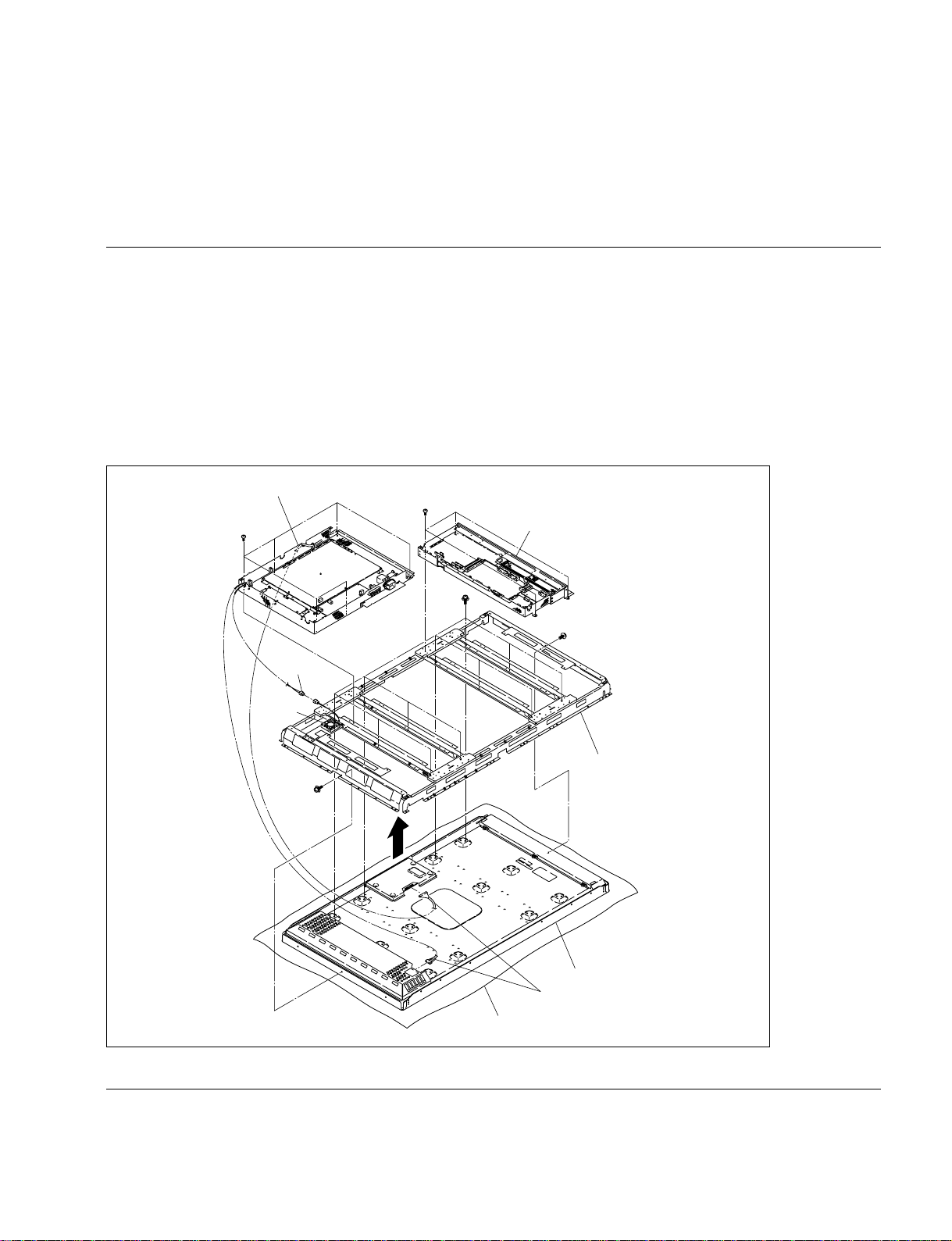

1-5-3. LCD Module

m

. When replacing the LCD module, be sure to work with two persons.

. After replacing the LCD module, be sure to perform the “2-2-6. White Balance Adjustment”.

Removal

1. Remove the cabinet assembly.

(Refer to Section 1-3-1.)

2. Remove the bezel assembly. (Refer to Section 1-3-2.)

3. Remove the two arms, shield cover G assembly and

shield cover D. (Refer to steps 2 to 4 of Section 1-4.)

4. Disconnect the harness from the control panel.

(Refer to steps 2 and 4 of Section 1-4-6.)

G base chassis assembly

BVTT

3 x 6

Connector

DC fan

BVTT

3 x 6

PSW

5 x 10

5. Remove the four screws (BVTT3 x 6), then remove

the D base chassis assembly.

6. Disconnect the connector from the DC fan.

7. Remove the six screws (BVTT3 x 6), then remove the

G base chassis assembly.

8. Disconnect the two harnesses from the LCD module.

9. Remove the two screws (PSW4 x 10) and twelve

screws (PSW5 x 10), then remove the frame assembly.

D base chassis assembly

PSW

4 x 10

PSW

4 x 10

Conductive cushion

Installation

10. Reattach the LCD module in the reverse order of steps 5 to 9.

11. Reassemble this unit in the reverse order of steps 1 to 4.

FWD-42LX1

Frame assembly

LCD module

Harnesses

1-13

Page 22

1-6. Service Position

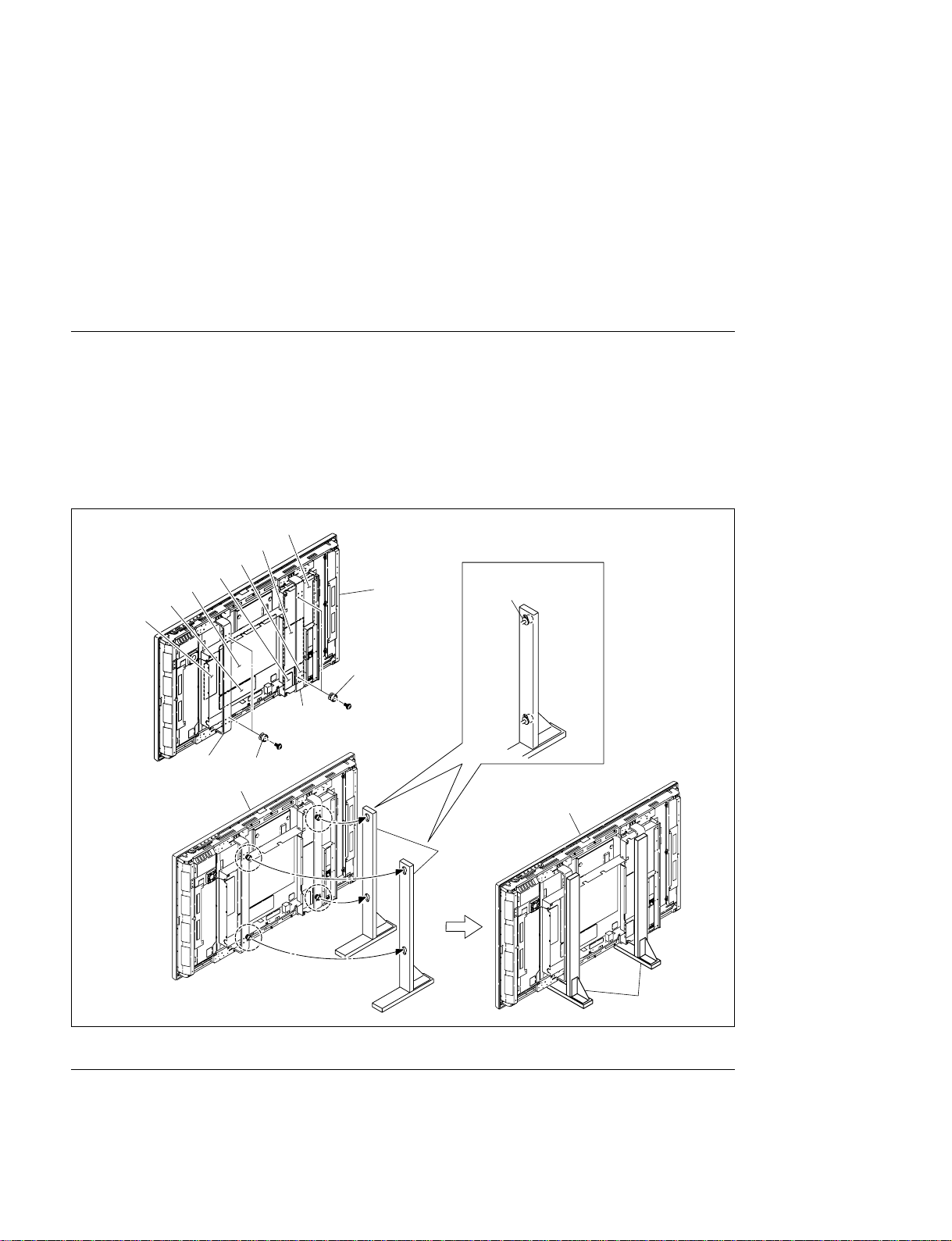

1-6-1. Service Position of D2 Board/FA Board/G1 Board/F Board/K Board/V

Board/JT Board

m

. When attaching this unit to the stands, be sure to work with two persons.

. After attaching this unit to the stands, make sure that the knobs are securely inserted into the holes of

the stands.

Removal

1. Remove the cabinet assembly. (Refer to Section 1-3-1.)

2. Remove the two arms, shield cover G assembly and shield cover D. (Refer to steps 2 to 4 of Section 1-4.)

3. Reattach the two arms removed in step 2 with eight screws.

4. Reattach the four knobs to this unit removed in step 1 with four screws.

5. Insert the four knobs into the holes of the two stands.

D2 board

V board

JT board

F board

K board

FA board

G1 board

Unit

Insert the four knobs

into the holes of stands.

Knobs

PSW

M6 x 20

Unit

Stands

Arm

Arm

PSW

M6 x 20

Knobs

Unit

Installation

6. Remove the two stands, four knobs and two arms in the reverse order of steps 3 to 5.

Stands

7. Reassemble this unit in the reverse order of steps 1 and 2.

1-14

FWD-42LX1

Page 23

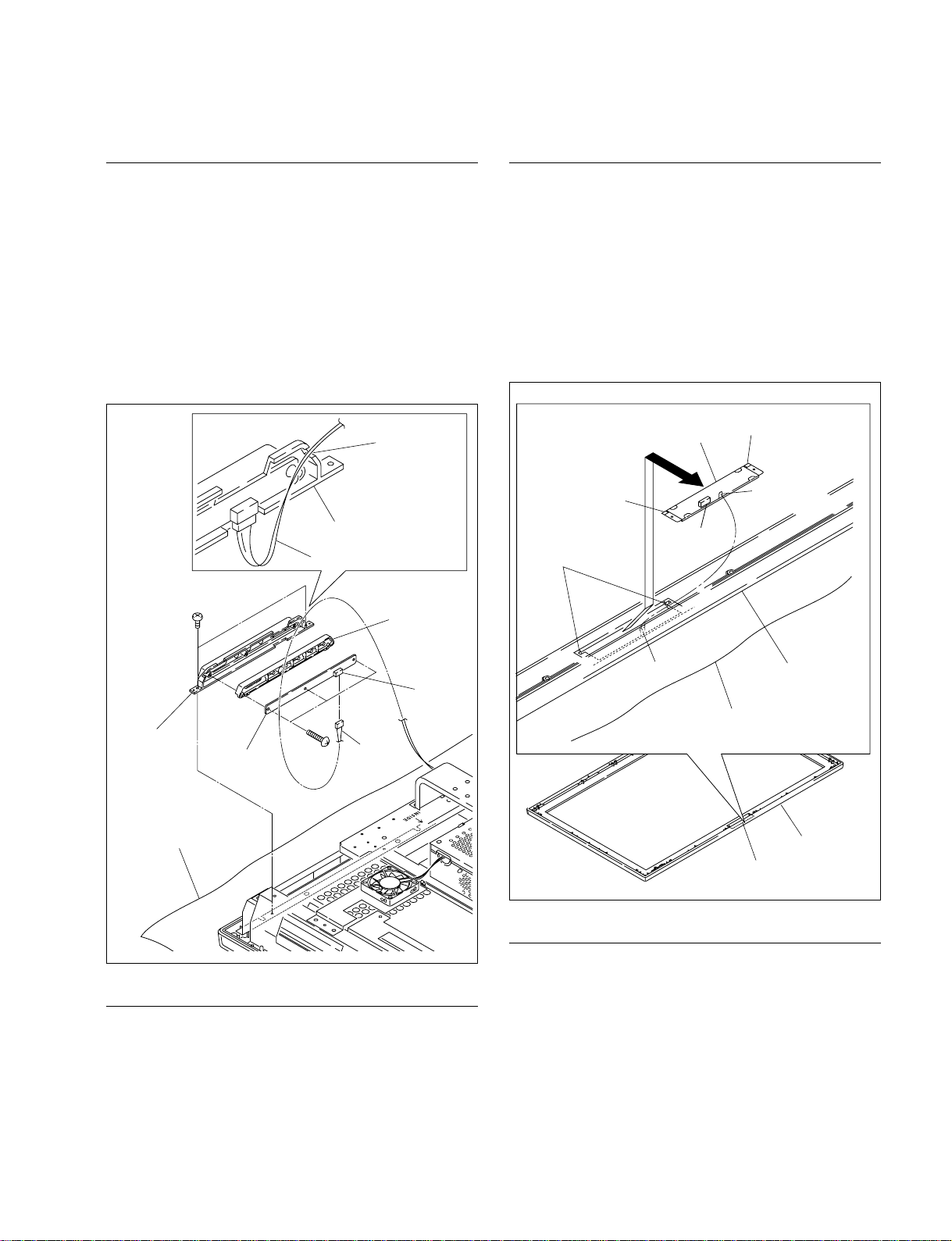

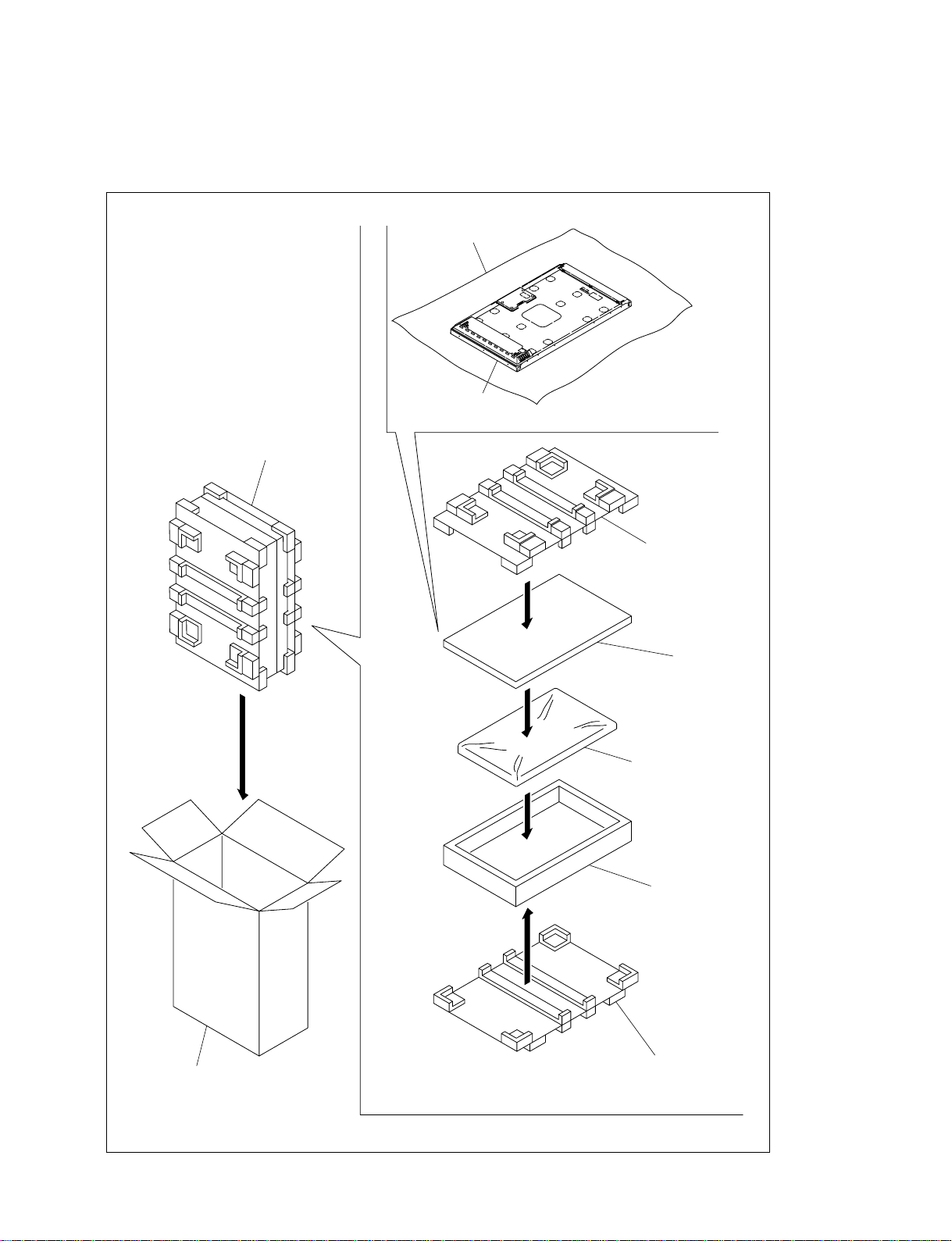

1-7. Packing of the LCD Module

. Send it to the SAMSUNG repair center providing service in eachcountry.

2 Capron sheet

1 LCD module

*The glass surface must face the capron sheet.

7 Individual packing carton

6 Cushion

8 Carton

5 Lid

4 LCD module

3 PP box

6 Cushion

FWD-42LX1

1-15

Page 24

1-8. Replacing the Battery

The lithium battery for clock is mounted on the D2 board.

c

When replacing the part, be sure to use the specified one

below.

Replacement with a part other than the specified part will

result in fire hazards and electric hazards.

3. Frame lock during two-screen display

During two-screen display, the image on the main screen

or left screen is frame-locked. The other image is not

frame-locked. Therefore, the display below may appear

when the vertical sync frequencies of both signals differ.

. Flicker occurs remarkably.

. Movement does not become smooth during motion

picture display.

Replacement part

Part name: Lithium battery (CR1220)

Part No.: ! 1-756-157-11

Replacing procedure

Refer to Section 1-5-2.

1-9. Performance and Specifications of

This Unit

1. Wide zoom

. No screen adjustment can be performed when the wide

zoom mode is selected.

→ Set wide switching to another mode so as to perform

screen adjustment and then switch the mode to the

wide zoom mode.

. The wide zoom mode can be selected only for an RGB

signal in which the component and composite signals

and RGB mode during one-screen display are set to

“DTV”.

In the RGB signal in which the wide zoom mode is set,

wide switching is also set to the full mode when the

RGB mode is switched from “DTV” to “PC”.

. The viewing of an image in which the wide zoom mode

is set may vary depending on the setting of a signal

format or cinema drive and the setting of an RGB mode.

In the cases described above, the trouble can be reduced by

making the vertical sync frequencies of both signals same

as each other.

1-10. Unleaded Solder

Boards requiring use of unleaded solder are printed with a

lead free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come

printed with the lead free mark due to their particular size.)

: LEAD FREE MARK

m

. Be sure to use the unleaded solder for the printed circuit

board printed with the lead free mark.

. The unleaded solder melts at a temperature about 40 dC

higher than the ordinary solder, therefore, it is recommended to use the soldering iron having a temperature

regulator.

. The ordinary soldering iron can be used but the iron tip

has to be applied to the solder joint for a slightly longer

time. The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful.

2. Flicker of interlace signal

. Flicker occurs when the RGB mode of an RGB signal is

set to “PC”.

→ Set the RGB mode to “DTV”.

. During two-screen display, flicker occurs when the

vertical resolution of the displayed image becomes less

than a half. In a motion picture signal, however, the

flicker causes no problem during operation.

1-16

FWD-42LX1

Page 25

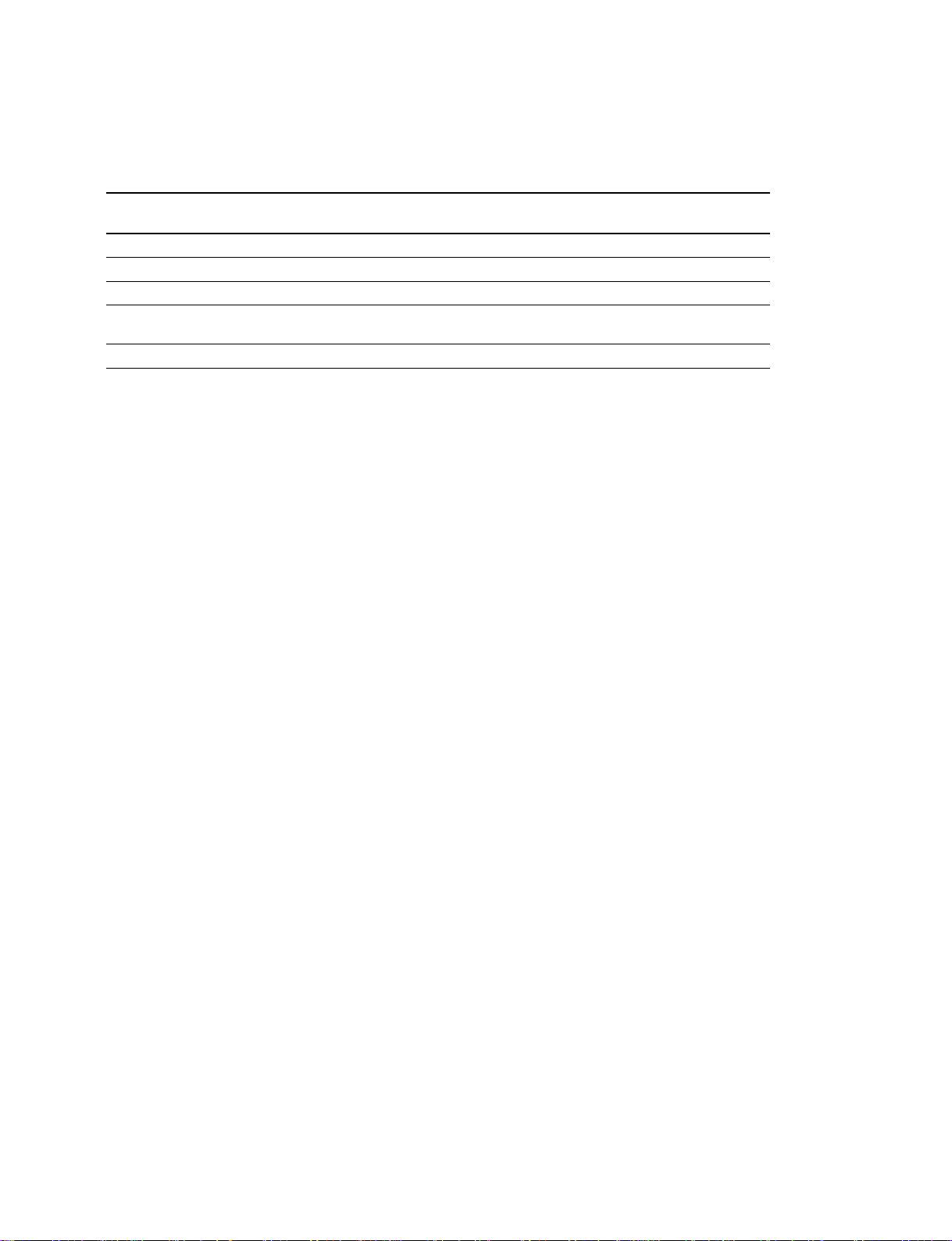

1-11. Warning on Power Connection

Use the proper power cord for your local power supply.

United States, Continental Europe UK, Ireland, Australia, Japan

Canada New Zealand

Plug type VM0233 COX-07/636 –

Female end VM0089 COX-02/VM0310B VM0303B VM1313

Cord type SVT H05VV-F CEE (13) 53rd (O, C) HVCTF

Minimum cord 10 A/125 V 10 A/250 V 10 A/250 V 10 A/125 V

set rating

Safety approval UL/CSA VDE VDE DENAN-HO

1) Use an appropriate rating plug which complies with local regulations.

1)

VM1296

FWD-42LX1

1-17

Page 26

Page 27

Section 2

Electrical Alignment

n

Be sure to perform adjustment in the service mode when making the repairs below.

Contents of repair Adjustment item

Repair related to picture quality AD Calibration Adjustment (Refer to Section 2-2-7.)

White Balance Adjustment (Refer to Section 2-2-6.)

When the panel module is replaced White Balance Adjustment (Refer to Section 2-2-6.)

When the D2 or V board is replaced AD Calibration Adjustment (Refer to Section 2-2-7.)

White Balance Adjustment (Refer to Section 2-2-6.)

2-1. Required Equipment

. VG (Programmable video signal generator)

VG-828 or the equivalent

. Remote commander RM-980 (Supplied for this unit)

. Chromaticity meter

2-2. Electric Adjustment in Service

Mode

Electric adjustment is performed using a remote

commander (RM-980) supplied for this unit.

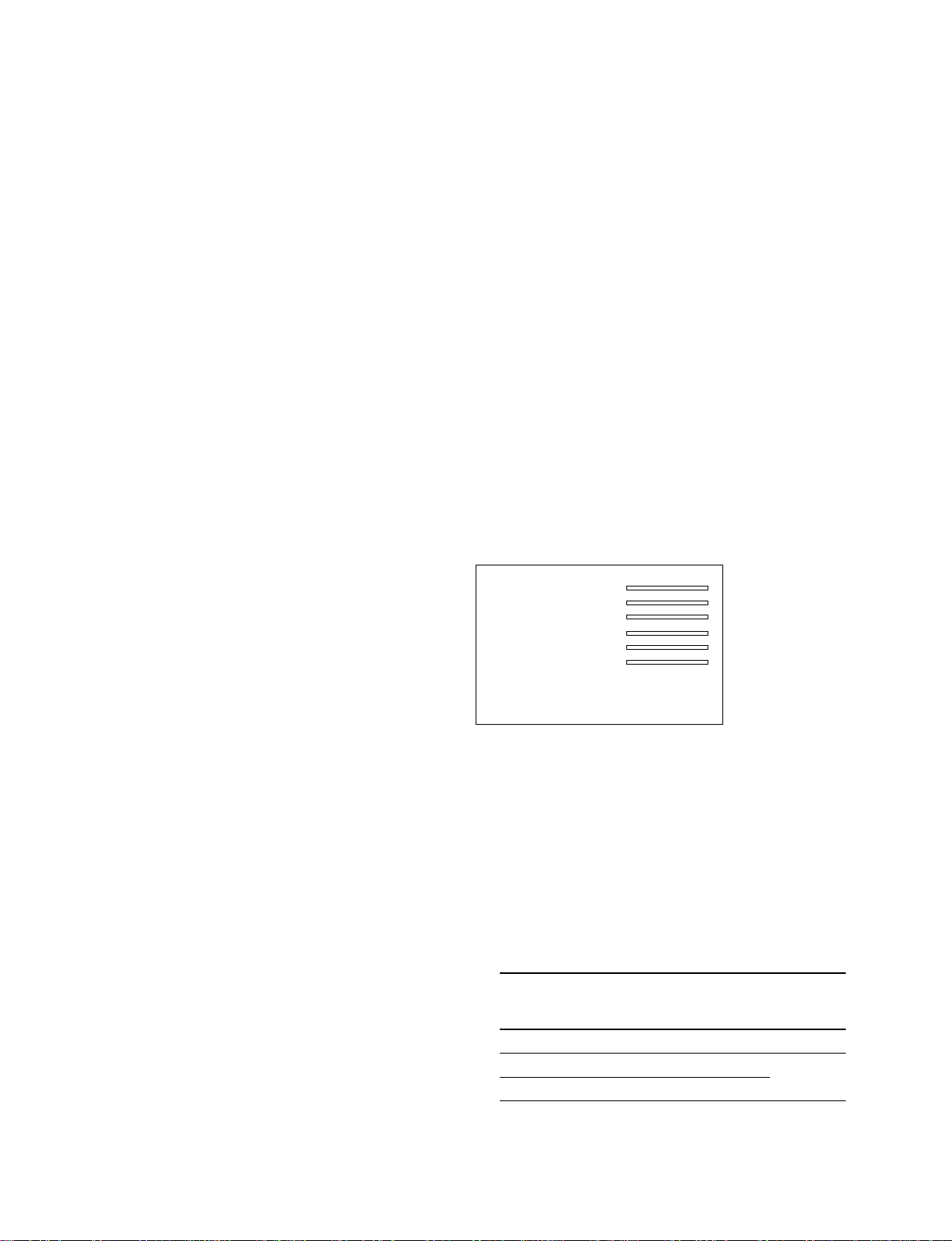

2-2-1. Service Mode

In addition to the ordinary user menu, “Service Mode” is

displayed when this unit is put into the service mode.

“Service Mode” is used for electric adjustment.

Start

To enter the service mode using RM-980, press the

[DISPLAY] → [5] → [VOL+], and [POWER|ON] keys

sequentially with this unit put into the standby state.

Cancellation

To cancel the service mode, put the unit into the standby

state again using a “STBY” key or turn off the power.

Viewing the screen

Service Mode

←

Picture Mode

Adjust Picture

Adjust Sound

Vivid/Standard Save

White Balance

AD Calibration

Factory Reset

Option Switch

1

2

3

4

5

6

7

8

1 Change in Picture Mode (Refer to Section 2-2-2.)

2 Picture quality adjustment (Refer to Section 2-2-3.)

3 Sound quality adjustment (Refer to Section 2-2-4.)

4 Change in initial values of Adjust Picture and Adjust

Sound (Refer to Section 2-2-5.)

5 White balance adjustment (Refer to Section 2-2-6.)

6 AD calibration adjustment (Refer to Section 2-2-7.)

7 Reset to factory-setting value

(Refer to Section 2-2-8.)

8 Special functions (Refer to Section 2-2-9.)

Commander function in service mode

Like user adjustment, six keys ([MENU], [ENTER], [&],

[*], [(], and [)]) are used for basic operation.

Other keys can also be operated in the same way as during

user adjustment.

2-2-2. Picture Mode

FWD-42LX1

Changes the picture mode as in the ordinary operation.

2-1

Page 28

2-2-3. Adjust Picture

(Picture quality adjustment)

Adjusts the picture quality.

Unlike ordinary operation, adjustment can be performed

even if the picture quality mode is “Vivid” and “Standard”.

2-2-4. Adjust Sound

(Sound quality adjustment)

Adjusts the sound quality.

Unlike ordinary operation, adjustment can be performed

even if the picture quality mode is “Vivid” and “Standard”.

2-2-5. Vivid/Standard Save

3. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Backlight: 50

Contrast: 50

Brightness: 75

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

Power Saving: Standard

This is a “Vivid/Standard” mode.

Saves the value, obtained when “Adjust Picture/Adjust

Sound” is changed and adjusted, to the factory-setting

value.

“Adjust Picture” must be saved for each entry.

The adjustment value of “Adjust Sound” is copied to all

entries once it is saved.

Execution (ENTER) is done after “Cancel” is changed to

“OK”.

2-2-6. White Balance Adjustment

n

To correctly adjust the white balance, perform aging in the

aging mode for 30 minutes before adjustment.

(Refer to Section 2-2-9.)

1. Connect this unit and a signal generator to which DVI

can be output.

2. Enter a full white screen of 70% to this unit.

Select DVI for input switching.

4. Select “White Balance”, “Color Temp”, and then

“Cool” by “PICTURE/SOUND CONTROL” in a

service mode menu. (Adjust color temperature “Cool”.)

←

R Drive: 100

G Drive: 100

B Drive: 100

R BackGround: 100

G BackGround: 100

B BackGround: 100

5. Set the DVI input to a full white screen of 70%.

6. Using a chromaticity meter, adjust so that “G Drive”

and “B Drive” satisfy the values below while

monitoring the measurement value.

“R Drive” is usually fixed to “100”.

. R Drive (red gain adjustment):

Adjustment range: 0 to 100

. G Drive (green gain adjustment):

Adjustment range: 0 to 100

. B Drive (blue gain adjustment):

Adjustment range: 0 to 100

Color Tolerance

temperature

Cool Neutral Warm

Specifications 11000K 9300K 6500K

x 0.276 0.285 0.314 0.9JND

y 0.282 0.294 0.324

2-2

7. Set the DVI input to a full white screen of 20%.

FWD-42LX1

Page 29

8. Adjust “R Background”, “G Background”, and “B

Background” so that the values in step 6 are satisfied.

. R BackGround (red brightness adjustment):

Adjustment range: 0 to 255

. G BackGround (green brightness adjustment):

Adjustment range: 0 to 255

. B BackGround (blue brightness adjustment):

Adjustment range: 0 to 255

9. Adjust steps 6 to 8 repeatedly so that the specified

values in step 3 are satisfied on a full white screen of

70% and 20% while making tracking.

10. Select “White Balance”, “Color Temp”, and then

“Neutral” by “PICTURE/SOUND CONTROL” in a

service mode menu. (Adjust color temperature “Neutral”.)

11. Perform the adjustment in steps 5 to 9.

12. Select "White Balance”, “Color Temp”, and then

“Warm” by “PICTURE/SOUND CONTROL” in a

service mode menu. (Adjust color temperature “Warm”.)

13. Perform the adjustment in steps 5 to 9.

NTSC/PAL

Adjusts NTSC/PAL signal calibration.

..

. NTSC/PAL

..

←

Composite Cal.

Y/C Cal.

Compornent Cal.

. Composite Cal.

Adjusts the Composite signal.

. Y/C Cal.

Adjusts the Y/C signal.

. Component Cal.

Adjusts the Component signal.

14. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in step 3) and exit the menu.

2-2-7. AD Calibration Adjustment

This unit has two slots (OPTION1 and OPTION2). AD

calibration adjustment is required for each input. Install

BKM-FW10/FW11 in the slot to be adjusted as required

and adjust it.

n

To correctly adjust the AD caribration, perform aging in

the aging mode for 30 minutes before adjustment.

(Refer to Section 2-2-9.)

AD calibration start-up screen

←

NTSC/PAL

SECAM

Analog RGB

AD Service Save

..

. Composite Cal.

..

Menu configuration

NTSC/PAL → Composite Cal.

←

Auto Cal.

Manual Control

. Auto Cal.

Performs the auto adjustment.

. Manual Control

Performs the manual adjustment.

n

The same screen is displayed in “Y/C Cal” and

“Component Cal”.

FWD-42LX1

2-3

Page 30

..

. Auto Cal.

..

Menu configuration

NTSC/PAL → Composite Cal. → Auto Cal.

SECAM

Adjusts the calibration of SECAM signal.

←

Auto Cal.

Target Y Cont.

Target Color

. Auto Cal.

Performs the auto adjustment.

After changing from “Cancel” to “OK”, press the

“ENTER” key.

. Target Y Cont.

Sets the threshold value of Y of the auto adjustment.

Setting range: 2,000 to 4,000

. Target Color

Sets the threshold value of C of the auto adjustment.

Setting range: 2,000 to 4,000

..

. Manual Control

..

Menu configuration

NTSC/PAL → Composite Cal. → Manual Control

..

. SECAM

..

←

Composite Cal.

Y/C Cal.

. Composite Cal.

Adjusts the Composite signal.

. Y/C Cal.

Adjusts the Y/C signal.

..

. Composite Cal.

..

Menu configuration

SECAM → Composite Cal.

←

Auto Cal.

Manual Control

←

Y Contrast: 230

C Level: 180

. Y Contrast

Adjusts the Y level.

Adjustment range: 0 to 255

. C Level

Adjusts the C level.

Adjustment range: 0 to 255

. Auto Cal.

Performs the auto adjustment.

. Manual Control

Performs the manual adjustment.

m

. The same screen is displayed in Y/C Cal.

. The operations of Auto Cal and Manual Control are the

same as NTSC/PAL.

2-4

FWD-42LX1

Page 31

Analog RGB

..

. Manual Control

..

Adjusts the calibration of Analog RGB signal.

..

. Analog RGB

..

←

RGB Cal..

Compornet Cal.

. RGB Cal..

Adjusts the RGB signal.

. Component Cal.

Adjusts the Component signal.

..

. RGB Cal..

..

Menu configuration

Analog RGB → RGB Cal..

←

Auto Cal..

Manual Control

Menu configuration

Analog RGB → RGB Cal.. → Manual Control

←

R Gain: 128

G Gain: 128

B Gain: 128

R Offset: 128

G Offset: 128

B Offset: 128

. R Gain

Adjusts the red gain.

Adjustment range: 0 to 255

. G Gain

Adjusts the green gain.

Adjustment range: 0 to 255

. B Gain

Adjusts the blue gain.

Adjustment range: 0 to 255

. R Offset

Adjusts the red offset.

Adjustment range: 0 to 255

. G Offset

Adjusts the green offset.

Adjustment range: 0 to 255

. B Offset

Adjusts the blue offset.

Adjustment range: 0 to 255

. Auto Cal.

Performs the auto adjustment.

After changing from “Cancel” to “OK”, press the

“ENTER” key.

. Manual Control

Performs the manual adjustment.

FWD-42LX1

..

. Component Cal.

..

Menu configuration

Analog RGB → Component Cal.

←

Auto Cal..

Manual Control

. Auto Cal..

Performs the auto adjustment.

After changing from “Cancel” to “OK”, press the

“"ENTER” key.

. Manual Control

Performs the manual adjustment.

2-5

Page 32

..

. Manual Control

..

Menu configuration

Analog RGB → Component Cal. → Manual Control

←

Y Gain: 128

Cb Gain: 128

Cr Gain: 128

Y Offset: 128

Cb Offset: 128

Cr Offset: 128

. Y Gain

Adjusts the red gain.

Adjustment range: 0 to 255

. Cb Gain

Adjusts the green gain.

Adjustment range: 0 to 255

. Cr Gain

Adjusts the blue gain.

Adjustment range: 0 to 255

. Y Offset

Adjusts the red offset.

Adjustment range: 0 to 255

. Cb Offset

Adjusts the green offset.

Adjustment range: 0 to 255

. Cr Offset

Adjusts the blue offset.

Adjustment range: 0 to 255

AD Service Save

1. AD calibration adjustment of video input signal

(NTSC signal)

(1) Automatic adjustment

Input a signal whose zone is displayed in the order of

white, yellow, cyan, green, magenta, red, blue, and black

as shown below.

75% indicates that the level in a white zone is 75 IRE.

Video adjustment of OPTION1 slot

1. Confirm that BKM-FW10 is installed in an OPTION1

slot.

2. Select the video signal of OPTION1 by input switching.

3. Input a 75% color-bar signal to the video input signal,

selected in step 2, in an NTSC format and display the

screen.

4. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Saves the adjustment value of the AD calibration.

After changing from “Cancel” to “OK”, press the

“ENTER” key.

2-6

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

5. Select “AD Calibration” “NTSC/PAL”, and then

“Composite Cal.” in a service mode menu.

6. Set “Target Y Cont.” and “Target Color” to an

arbitrary target value.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700”.

FWD-42LX1

Page 33

7. Select “Auto Cal.” and press the

[OK]

key.

Automatic adjustment is started.

During adjustment, after the display becomes black &

white, it is colored again and the adjustment is

completed about ten seconds later.

8. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the

[OK]

key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

Video adjustment of OPTION2 slot

9. Install BKM-FW10 in an OPTION2 slot.

10. Select the video signal of OPTION2 by input

switching.

11. Input a 75% color-bar signal to the video input signal,

selected in step 10, in an NTSC format and display the

screen.

12. Execute steps 4 to 8.

13. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 4 and 12) and exit the menu.

(2) Manual adjustment

Video adjustment of OPTION1 slot

1. Confirm that BKM-FW10 is installed in an OPTION1

slot.

2. Select the video signal of OPTION1 by input

switching.

3. Input a 75% color-bar signal to the video input signal,

selected in step 2, in an NTSC format and display the

screen.

4. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

5. Select “AD Calibration”, “NTSC/PAL”, “Composite

Cal.”, and then “Manual Control” in a service mode

menu.

6. Select “Adjust Y Contrast”. (Adjust the contrast.)

7. Move a slider and adjust so that the “R”, “G”, and “B”

values displayed on the right of the slider are nearer

“2700” as far as possible.

8. Select “Adjust C Level”. (Adjust the color.)

9. Move a slider and adjust so that the “R” and “G”

values displayed on the right of the slider are nearer

“0” and so that the “B” value displayed on the right is

nearer “2700” as far as possible.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700”.

10. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the [OK] key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

Video adjustment of OPTION2 slot

11. Install BKM-FW10 in an OPTION2 slot.

12. Select the video signal of OPTION2 by input

switching.

13. Input a 75% color-bar signal to the video input signal,

selected in step 12, in an NTSC format and display the

screen.

14. Execute steps 4 to 10.

15. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 4 and 14) and exit the menu.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

FWD-42LX1

2-7

Page 34

2. AD calibration adjustment of S_VIDEO input

signal (NTSC signal)

(1) Automatic adjustment

S_VIDEO adjustment of OPTION1 slot

1. Confirm that BKM-FW10 is installed in an OPTION1

slot.

2. Select the S_VIDEO signal of OPTION1 by input

switching.

3. Input a 75% color-bar signal to the S_VIDEO input

signal, selected in step 2, in an NTSC format and

display the screen.

4. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the values below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

5. Select “AD Calibration”, “NTSC/PAL”, “Y/C Cal.”,

and then “Composite Cal.” in a service mode menu.

6. Set an arbitrary target value by “Target Y Cont.” and

“Target Color”.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700”.

7. Select “Auto Cal.” and press the

[OK]

key.

Automatic adjustment is started.

During adjustment, after the display becomes black &

white, it is colored again and the adjustment is

completed about ten seconds later.

8. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the

[OK]

key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

S_VIDEO adjustment of OPTION2

9. Install BKM-FW10 in an OPTION2 slot.

10. Select the S_VIDEO signal of OPTION2 by input

switching.

11. Input a 75% color-bar signal to the S_VIDEO input

signal, selected in step 10, in an NTSC format and

display the screen.

12. Execute steps 4 to 8.

13. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 4 and 12) and exit the menu.

(2) Manual adjustment

S_VIDEO adjustment of OPTION1 slot

1. Confirm that BKM-FW10 is installed in an OPTION1

slot.

2. Select the S_VIDEO signal of OPTION1 by input

switching.

3. Input a 75% color-bar signal to the S_VIDEO input

signal, selected in step 2, in an NTSC format and

display the screen.

4. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as t return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

5. Select “AD Calibration”, “NTSC/PAL”, “Y/C Cal.”,

and then “Manual Control” in a service mode menu.

6. Select “Adjust Y Contrast”. (Adjust the contrast.)

7. Move a slider and adjust so that the “R”, “G”, and “B”

values displayed on the right of the slider are nearer

“2700” as far as possible.

8. Select “Adjust C Level”. (Adjust the color.)

2-8

FWD-42LX1

Page 35

9. Move a slider and adjust so that the “R” and “G”

values displayed on the right of the slider are nearer

“0” and so that the “B” value displayed on the right is

nearer “2700” as far as possible.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700”.

10. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the [OK] key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

S_VIDEO adjustment of OPTION2 slot

11. Install BKM-FW10 in an OPTION2 slot.

12. Select the S_VIDEO signal of OPTION2 by input

switching.

13. Input a 75% color-bar signal to the S_VIDEO input

signal, selected in step 12, in an NTSC format and

display the screen.

14. Execute steps 4 to 10.

15. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 4 and 14) and exit the menu.

3. AD calibration adjustment of video input

signal

(1) Automatic adjustment

Video adjustment of OPTION1 slot

1. Confirm that BKM-FW10 is installed in an OPTION1

slot.

2. Select the video signal of OPTION1 by input

switching.

3. Input a 75% color-bar signal to the video input signal,

selected in step 2, in a SECAM format and display the

screen.

4. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as t return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

5. Select “AD Calibration”, “SECAM”, and then

“Composite Cal.” in a service mode menu.

6. Set an arbitrary target value by “Target Y Cont.” and

“Target Color”.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700”.

7. Select “Auto Cal.” and press the

[OK]

key.

Automatic adjustment is started.

During adjustment, after the display becomes black &

white, it is colored again and the adjustment is

completed about ten seconds later.

8. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the

[OK]

key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

Video adjustment of OPTION2 slot

9. Install BKM-FW10 in an OPTION2 slot.

10. Select the video signal of OPTION2 by input

switching.

11. Input a 75% color-bar signal to the video input signal,

selected in step 10, in a SECAM format and display

the screen.

12. Execute steps 4 to 8.

FWD-42LX1

13. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 4 and 12) and exit the menu.

2-9

Page 36

(2) Manual adjustment

Video adjustment of OPTION1 slot

1. Confirm that BKM-FW10 is installed in an OPTION1

slot.

2. Select the video signal of OPTION1 by input

switching.

3. Input a 75% color-bar signal to the video input signal,

selected in step 2, in a SECAM format and display the

screen.

4. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

5. Select “AD Calibration”, “SECAM”, “Composite Cal.”,

and then “Manual Control” in a service mode menu.

6. Select “Adjust Y Contrast”. (Adjust the contrast.)

7. Move a slider and adjust so that the “R”, “G”, and “B”

values displayed on the right of the slider are nearer

“2700” as far as possible.

8. Select “Adjust C Level”. (Adjust the color.)

9. Move a slider and adjust so that the “R” and “G”

values displayed on the right of the slider are nearer

“0” and so that the “B” value displayed on the right is

nearer “2700” as far as possible.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700”.

10. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the

[OK]

key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

Video adjustment of OPTION2 slot

11. Install BKM-FW10 in an OPTION2 slot.

12. Select the video signal of OPTION2 by input

switching.

13. Input a 75% color-bar signal to the video input signal,

selected in step 12, in a SECAM format and display

the screen.

14. Execute steps 4 to 10.

15. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 4 and 14) and exit the menu.

4. AD calibration adjustment of S_VIDEO input

signal (SECAM signal)

(1) Automatic adjustment

S_VIDEO adjustment of OPTION1 slot

1. Confirm that BKM-FW10 is installed in an OPTION1

slot.

2. Select the S_VIDEO signal of OPTION1 by input

switching.

3. Input a 75% color-bar signal to the S_VIDEO input

signal, selected in step 2, in a SECAM format and

display the screen.

4. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

5. Select “AD Calibration”, “SECAM”, “Y/C Cal.”, and

then “Composite Cal.” in a service mode menu.

6. Set an arbitrary target value by “Target Y Cont.” and

“Target Color”.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700”.

2-10

FWD-42LX1

Page 37

7. Select “Auto Cal.” and press the

[OK]

key.

Automatic adjustment is started.

During adjustment, after the display becomes black &

white, it is colored again and the adjustment is

completed about ten seconds later.

8. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the

[OK]

key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

S_VIDEO adjustment of OPTION2 slot

9. Install BKM-FW10 in an OPTION2 slot.

10. Select the S_VIDEO signal of OPTION2 by input

switching.

11. Input a 75% color-bar signal to the S_VIDEO input

signal, selected in step 10, in a SECAM format and

display the screen.

12. Execute steps 4 to 8.

5. Select “AD Calibration”, “SECAM”, “Y/C Cal.”, and

then “Manual Control” in a service mode menu.

6. Select “Adjust Y Contrast”. (Adjust the contrast.)

7. Move a slider and adjust so that the “R”, “G”, and “B”

values displayed on the right of the slider are nearer

“2700” as far as possible.

8. Select “Adjust C Level”. (Adjust the color.)

9. Move a slider and adjust so that the “R” and “G”

values displayed on the right of the slider are nearer

“0” and so that the “B” value displayed on the right is

nearer “2700” as far as possible.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700”.

10. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the [OK] key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

13. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 4 and 12) and exit the menu.

(2) Manual adjustment

S_VIDEO adjustment of OPTION1 slot

1. Confirm that BKM-FW10 is installed in an OPTION1

slot.

2. Select the S_VIDEO signal of OPTION1 by input

switching.

3. Input a 75% color-bar signal to the S_VIDEO input

signal, selected in step 2, in a SECAM format and

display the screen.

4. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the item below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

S_Video adjustment of OPTION2 slot

11. Install BKM-FW10 in an OPTION2 slot.

12. Select the S_VIDEO signal of OPTION2 by input

switching.

13. Input a 75% color-bar signal to the S_VIDEO input

signal, selected in step12, in a SECAM format and

display the screen.

14. Execute steps 4 to 10.

15. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 4 and 14) and exit the menu.

FWD-42LX1

2-11

Page 38

5. AD calibration adjustment of component input

signal

For the component input signal of an INPUT2 terminal,

two types of signal paths are provided in consideration of

the two-screen display. In one signal path, a signal is

passed through CCP2. In the other signal path, a signal is

directly passed through a scaler. The AD adjustment at

that time is performed using CCP2 and a scaler.

Therefore, the two types of signal paths must be adjusted.

For the component input signal of OPTION1 and

OPTION2, only one type of path in which a signal is

passed through CCP2 is provided.

(1) Automatic adjustment (CCP2)

Component adjustment of INPUT2 terminal

1. Select the component signal of INPUT2 by input

switching.

2. Input a 75% color-bar signal to the component input

signal, selected in step 1, in a 720/60P format and

display the screen.

3. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

4. Select “AD Calibration”, “NTSC/PAL”, and then

“Component Cal.” in a service mode menu.

5. Set an arbitrary target value by “Target Y Cont.” and

“Target Color”.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700”.

6. Select “Auto Cal.” and press the [OK] key.

Automatic adjustment is started.

During adjustment, after the display becomes black &

white, it is colored again and the adjustment is

completed about ten seconds later.

7. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the [OK] key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

Component adjustment of OPTION1 slot

8. Confirm that BKM-FW11 is installed in an OPTION1

slot.

9. Select the component signal of OPTION1 by input

switching.

10. Input a 75% color-bar signal to the component input

signal, selected in step 9, in a 720/60P format and

display the screen.

11. Execute steps 3 to 7.

Component adjustment of OPTION2 slot

12. Confirm that BKM-FW11 is installed in an OPTION2

slot.

13. Select the component signal of OPTION2 by input

switching.

14. Input a 75% color-bar signal to the component input

signal, selected in step 13, in a 720/60P format and

display the screen.

15. Execute steps 3 to 7.

16. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 3, 11, and 15) and exit the menu

(2) Manual adjustment (CCP2)

Component adjustment of INPUT2 terminal

1. Select the component signal of INPUT2 by input

switching.

2. Input a 75% color-bar signal to the component input

signal, selected in step 1, in a 720/60P format and

display the screen.

2-12

FWD-42LX1

Page 39

3. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

Component adjustment of OPTION2

14. Confirm that BKM-FW11 is installed in an OPTION2

slot.

15. Select the component signal of OPTION2 by input

switching.

16. Input a 75% color-bar signal to the component input

signal, selected in step 15, in a 720/60P format and

display the screen.

17. Execute steps 3 to 9.

18. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 3, 13, and 17) and exit the menu.

4. Select “AD Calibration”, “NTSC/PAL”, “Component

Cal.”, and then “Manual Control” in a service mode

menu.

5. Select “Adjust Y Contrast”. (Adjust the contrast.)

6. Move a slider and adjust so that the “R”, “G”, and “B”

values displayed on the right of the slider are nearer

“2700“ as far as possible.

7. Select “Adjust C Level”. (Adjust the color.)

8. Move a slider and adjust so that the “R” and “G”

values displayed on the right of the slider are nearer

“0” and so that the “B” value displayed on the right is

nearer “2700“ as far as possible.

n

During factory setting, “Target Y Cont.” and “Target

Color” are adjusted by “2700“.

9. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the

[OK]

key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

Component adjustment of OPTION1

10. Confirm that BKM-FW11 is installed in an OPTION1

slot.

11. Select the component signal of OPTION1 by input

switching.

12. Input a 75% color-bar signal to the component input

signal, selected in step 11, in a 720/60P format and

display the screen.

13. Execute steps 3 to 9.

(3) Automatic adjustment (Scaler)

Color-bar signal containing white and black zones

n

A 100% color-bar signal is an output signal having the

level below.

For RGB: RGB peak voltages are 0.7 V, respectively.

For YUV: Y peak voltage 1 V

UV peak voltage 0.7 V

Component adjustment of INPUT2 terminal

1. Select the component signal of INPUT2 by input

switching.

2. Input a 100% color-bar signal to the component input

signal, selected in step 1, in a 720/60P format (not

requiring a separate sync signal) and display the

screen.

FWD-42LX1

2-13

Page 40

3. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

4. Select “AD Calibration”, “Analog RGB”, and then

“Component Cal.” in a service mode menu.

5. Select “Auto Cal.” and press the

[OK]

key.

Automatic adjustment is started.

When adjustment is completed, “ADC Finished” is

displayed in the center of the screen.

6. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the

[OK]

key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

Component adjustment of OPTION1 slot

7. Confirm that BKM-FW11 is installed in an OPTION1

slot.

8. Select the component signal of OPTION1 by input

switching.

9. Input a 100% color-bar signal to the component input

signal, selected in step 8, in a 720/60P format (not

requiring a separate sync signal) and display the

screen.

10. Execute steps 3 to 6.

Component adjustment of OPTION2 slot

11. Confirm that BKM-FW11 is installed in an OPTION2

slot.

12. Select the component signal of OPTION2 by input

switching.

13. Input a 100% color-bar signal to the component input

signal, selected in step 12, in a 720/60P format (not

requiring a separate sync signal) and display the

screen.

14. Execute steps 3 to 6.

15. After adjustment is completed, return the setting value

of “Adjust Picture” to the former value (value written

down in steps 3, 10, and 14) and exit the menu.

4) Manual adjustment (Scaler)

Component adjustment of INPUT2 terminal

1. Select the component signal of INPUT2 by input

switching.

2. Input a 100% color-bar signal to the component input

signal, selected in step 1, in a 720/60P format (not

requiring a separate sync signal) and display the

screen.

3. Start the service mode, select “Picture Mode” and then

“User1” by “Adjust Picture”, and set the items below.

n

After adjustment is completed, write down the setting

value before change so as to return the setting value of

“User1” to the former value.

Chroma: 50

Phase: 50

Noise Reduct.: Off

Dynamic Picture: Off

Color Correct: Off

Gamma Correct: Mid

4. Select “AD Calibration”, “Analog RGB”, “Component

Cal.”, and then “Manual Adjust” in a service mode

menu.

5. Select “Adjust Y Offset”.

6. Move a slider and adjust it to the value on whether “R”

value “1” of information display changes to the upper

position.

7. Select “Adjust Cb Offset”.

8. Move a slider and adjust it to the value on whether

“G” value “1” of information display changes to the

upper position.

9. Select “Adjust Cr Offset”.

10. Move a slider and adjust it to the value on whether “B”

value “1” of information display changes to the upper

position.

11. Select “Adjust Y Gain”.

12. Move a slider and adjust so that the “R”, “G”, and “B”

values of information display are nearer “4000” as far

as possible.

13. Select “Adjust Cb Gain”.

2-14

FWD-42LX1

Page 41

14. Move a slider and adjust so that the “B” value of

information displayed is nearer “4000” as far as

possible.

15. Select “Adjust Cr Gain”.

16. Move a slider and adjust so that the “R” value of

information displayed is nearer “4000” as far as

possible.

17. Select “AD Service Save” in the hierarchy of “AD

Calibration” and press the

[OK]

key.

The adjustment value is saved.

n

Save an adjustment value here. Notice that the

adjustment value is not saved even if adjustment is

completed.

Component adjustment of OPTION1 slot

18. Confirm that BKM-FW11 is installed in an OPTION1

slot.

19. Select the component signal of OPTION1.

20. Input a 100% color-bar signal to the component input

signal, selected in step 19, in a 720/60P format (not

requiring a separate sync signal) and display the

screen.

21. Execute steps 3 to 17.

Component adjustment of OPTION2 slot

22. Confirm that BKM-FW11 is installed in an OPTION2