Page 1

FLAT WIDE DISPLAY MONITOR

FWD-40LX2F

FWD-40LX2X

REMOTE COMMANDER

RM-FW001

SPEAKER SYSTEM

SS-SP40FW

SERVICE MANUAL

1st Edition (Revised 1)

Page 2

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

FWD-40LX2F

FWD-40LX2X

Page 3

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Lithiumbatteri - Eksplosjonsfare.

Ved utskifting benyttes kun batteri som

anbefalt av apparatfabrikanten.

Brukt batteri returneres

apparatleverandøren.

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch

der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ . Entsorgung

gebrauchter Batterien nach Angaben des

Herstellers.

ATTENTION

Il y a danger d’explosion s’il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du même

type ou d’un type équivalent recommandé par le

constructeur.

Mettre au rebut les batteries usagées conformément

aux instructions du fabricant.

For the customers in the Netherlands

Voor de klanten in Nederland

Hoe u de batterijen moet verwijderen, leest u in de tekst

van deze handleiding.

Gooi de batterij niet weg maar lever deze in als klein

chemisch afval (KCA).

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ

som rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande

föreskrifter.

VAROITUS

Paristo voi räjähtää jos se on virheellisesti

asennettu.

Vaihda paristo ainoastaan laitevalmistajan

suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden

mukaisesti.

Für Kunden in Deutschland

Entsorgungshinweis: Bitte werfen Sie nur entladene

Batterien in die Sammelboxen beim Handel oder den

Kommunen. Entladen sind Batterien in der Regel dann,

wenn das Gerät abschaltet und signalisiert “Batterie

leer” oder nach längerer Gebrauchsdauer der Batterien

“nicht mehr einwandfrei funktioniert”. Um

sicherzugehen, kleben Sie die Batteriepole z.B. mit

einem Klebestreifen ab oder geben Sie die Batterien

einzeln in einen Plastikbeutel.

For the customers in Taiwan only

FWD-40LX2F

FWD-40LX2X

1 (P)

Page 4

Notes on Wall Mounting

For Sony Dealers

Sufficient expertise is required for installing this product

on the wall. Be sure to read the instruction manual

provided with the Wall-Mount Bracket thoroughly to do

the installation work safely. Sony is not liable for any

damages or injury caused by mishandling or improper

installation.

Be sure to use the UL approved Wall-Mount Bracket

which is tested with FWD-40LX2F/40LX2X based on

IEC60950 and UL60950.

SONY is not liable for any damages or injury caused by

using any Wall-Mount Bracket which is not Approved by

UL.

Be sure to install the Display Unit securely to the wall

following the instructions given in the instruction manual

of the Wall-Mount Bracket.

If any of the screws are loose or fall out, the Display Unit

may fall and cause injury or property damage. Be sure to

use the appropriate screws for the material of the wall and

install the unit securely.

If the wall on which the Wall-Mount Bracket is installed is

unstable, uneven, or not perpendicular to the floor, the unit

may fall and cause injury or property damage.

The wall should be capable of supporting a weight of at

least four times the Display Unit weight, 104.0 kg. (The

Display Unit weight of FWD-40LX2F/40LX2X is

approximately 26.0 kg. )

Be sure to use the specified screws and attachment parts

properly following the instructions given in the instruction

manual of the Wall-Mount Bracket. If you use substitute

items, the Display Unit may fall, and cause bodily injury to

someone or damage to the Display Unit.

Be sure to assemble the bracket properly following the

instructed procedure explained in the instruction manual of

the Wall-Mount Bracket.

Be sure to tighten the screws securely in the designated

position.

If you fail to do so, the Display Unit may fall, and cause

bodily injury to someone or damage to the Display Unit.

Do not disassemble or make alterations to the parts of the

Wall-Mount Bracket.

If you do so, the Wall-Mount Bracket may fall and cause

injury or property damage.

Do not mount any equipment other than the specified

product.

If you mount equipment other than specified in the

instruction manual of the Wall-Mount Bracket, it may fall

or break, and cause injury or property damage.

Do not install the Display Unit over or under an airconditioner.

If the Display Unit is exposed to water leaks or air current

from an air-conditioner for a long time, it may cause a fire,

an electric shock or a malfunction of the Display Unit.

Do not allow the mains lead or the connecting cable to be

pinched.

If the mains lead or the connecting cable is pinched

between the unit and the wall or is bent or twisted by force,

the internal conductors may become exposed and cause a

short circuit or an electrical break. This may cause a fire or

an electric shock.

After proper installation of the Display Unit, secure the

cables properly.

If people or objects get tangled in the cables, this may

result in injury or damage to the Display Unit.

Be careful not to hurt your hands or fingers when installing

the Display Unit.

2 (P)

FWD-40LX2F

FWD-40LX2X

Page 5

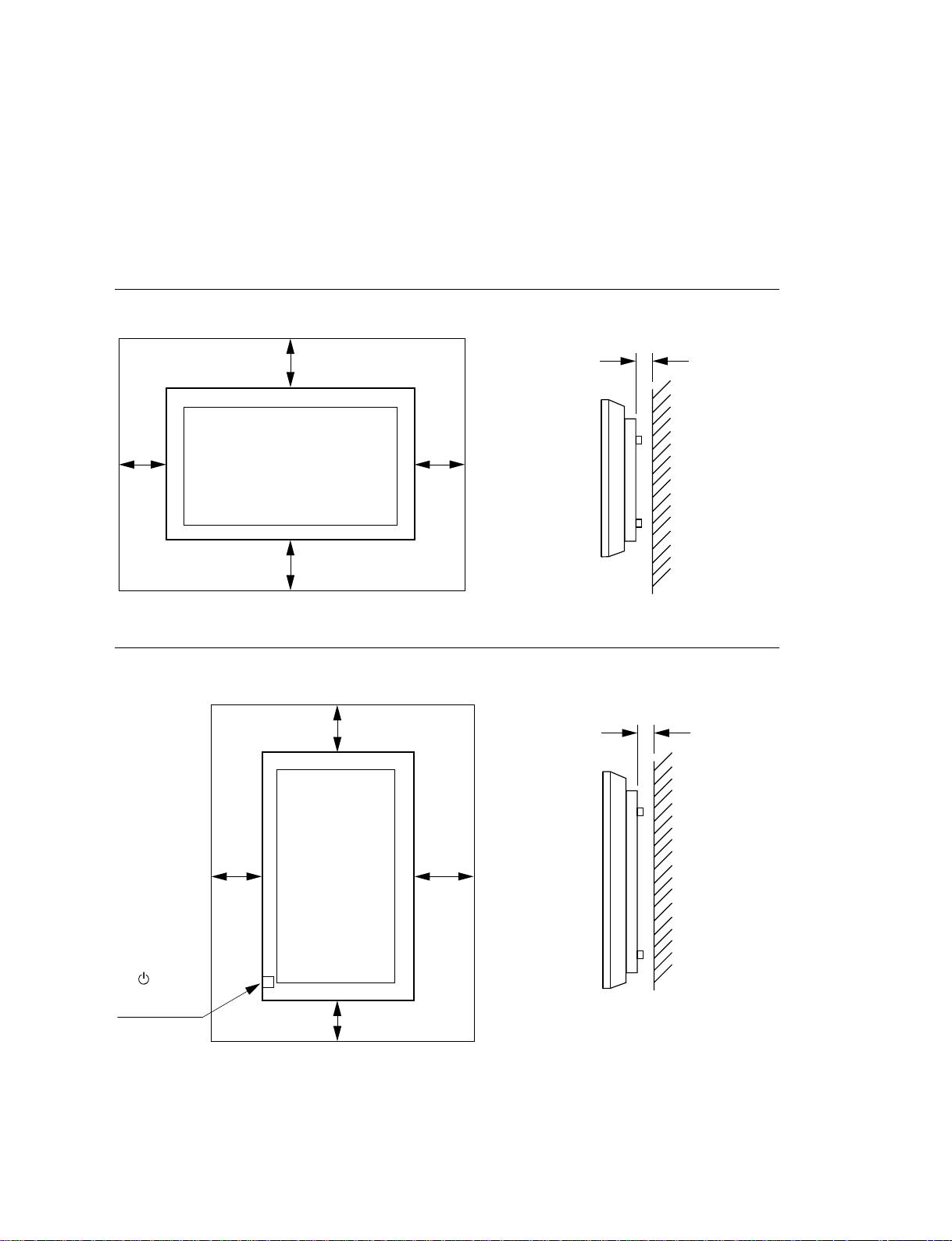

)

Caution

Provide an ample amount of space around the display

. When you set up the Display Unit, make sure there is more space around the display than that shown in

the figure below. This will allow for proper ventilation.

. Wile the unit is on, a certain amount of heat builds up inside. This can cause burns. Avoid touching the

top or rear of the unit when it is powered on or just after it has entered standby mode.

When mounting the display horizontally

2.5 (1)

25 (9 7/8)

10

(4)

7

25 (9

/8)

When mounting the display vertically

20 (4)

20

(9 7/8)

10

(4)

Unit : cm (inches

2.5 (1)

25

(9 7/8)

Make sure that

the POWER

switch is at the

lower right.

FWD-40LX2F

FWD-40LX2X

10 (4)

Unit : cm (inches)

3 (P)

Page 6

Page 7

Table of Contents

1. Service Overview

1-1. Appearance Figure ..........................................................1-1

1-2. Board Location ...............................................................1-1

1-3. Disassembly ....................................................................1-2

1-3-1. Cabinet Assembly .................................................1-2

1-3-2. Bezel Assembly/H1 Board/H2 Board/LOGO

Assembly ...............................................................1-3

1-3-3. A Board/JT Board .................................................1-4

1-3-4. G6 Board ...............................................................1-5

1-3-5. SP Board................................................................1-6

1-3-6. LCD Panel .............................................................1-7

1-4. Warning on Power Connection.......................................1-8

2. Troubleshooting

2-1. Judgment When No Image is Displayed ........................2-1

2-2. Self-Diagnosis Function .................................................2-1

5. Spare Parts

5-1. Notes on Repair Parts .....................................................5-1

5-2. Exploded Views.............................................................. 5-2

6. Diagrams

6-1. Overall Block Diagrams .................................................6-1

6-2. Frame Wiring.................................................................. 6-3

3. Circuit Description

3-1. A Board...........................................................................3-1

3-2. H1 Board.........................................................................3-2

3-3. H2 Board.........................................................................3-2

3-4. G6 Board.........................................................................3-3

4. Electrical Alignment

4-1. Service Mode ..................................................................4-1

4-1-1. Start .......................................................................4-1

4-2. White Balance Adjustment .............................................4-1

4-2-1. Preparation ............................................................4-1

4-2-2. Setting....................................................................4-1

4-2-3. Cool Adjustment ...................................................4-2

4-2-4. Neutral Adjustment ...............................................4-2

4-2-5. Warm Adjustment .................................................4-2

FWD-40LX2F

FWD-40LX2X

1

Page 8

Page 9

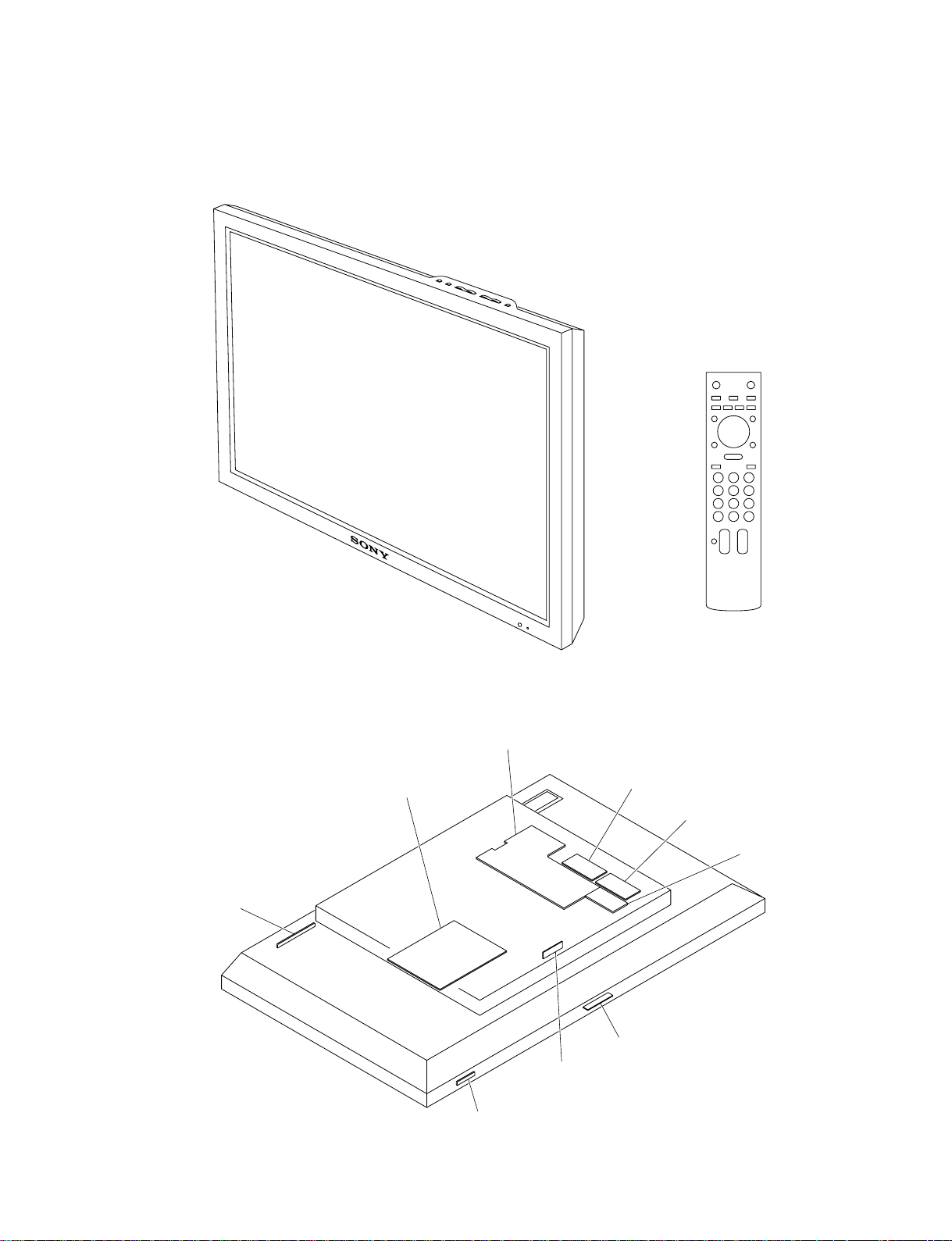

1-1. Appearance Figure

Section 1

Service Overview

1

2

3

4

5

6

7

8

9

SET

C

0

1-2. Board Location

H1 board

G6 board

A board

U20 board

U10 board

JT board

LOGO board

SP board

H2 board

FWD-40LX2F

FWD-40LX2X

1-1

Page 10

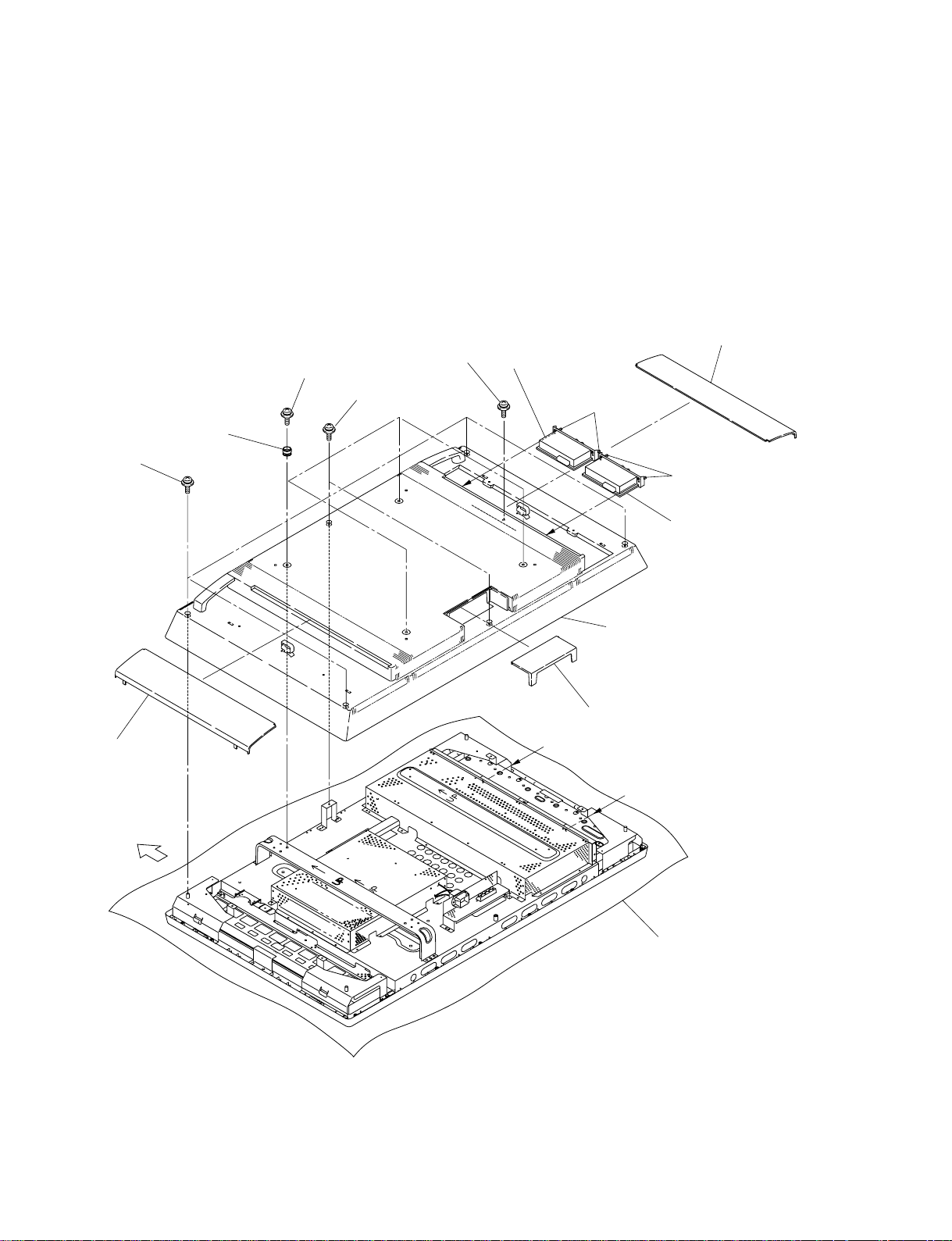

1-3. Disassembly

n

When removing/installing the cabinet and replacing the board, place the unit on the conductive cushion.

1-3-1. Cabinet Assembly

The illustration indicates FWD-40LX2F/S and FWD-40LX2F/B.

1 Side cable cover

0 Screw

7 Four screws

9 T wo screws

8 Four knobs

9 Four screws

4 U20 block assembly

3 Panel securing

A

screws

5 Panel securing screws

1 Side cable cover

Upper side

B

!- Cabinet assembly

2 Bottom cable cover

A

B

6 U10 block assembly

Conductive cushion

1-2

FWD-40LX2F

FWD-40LX2X

Page 11

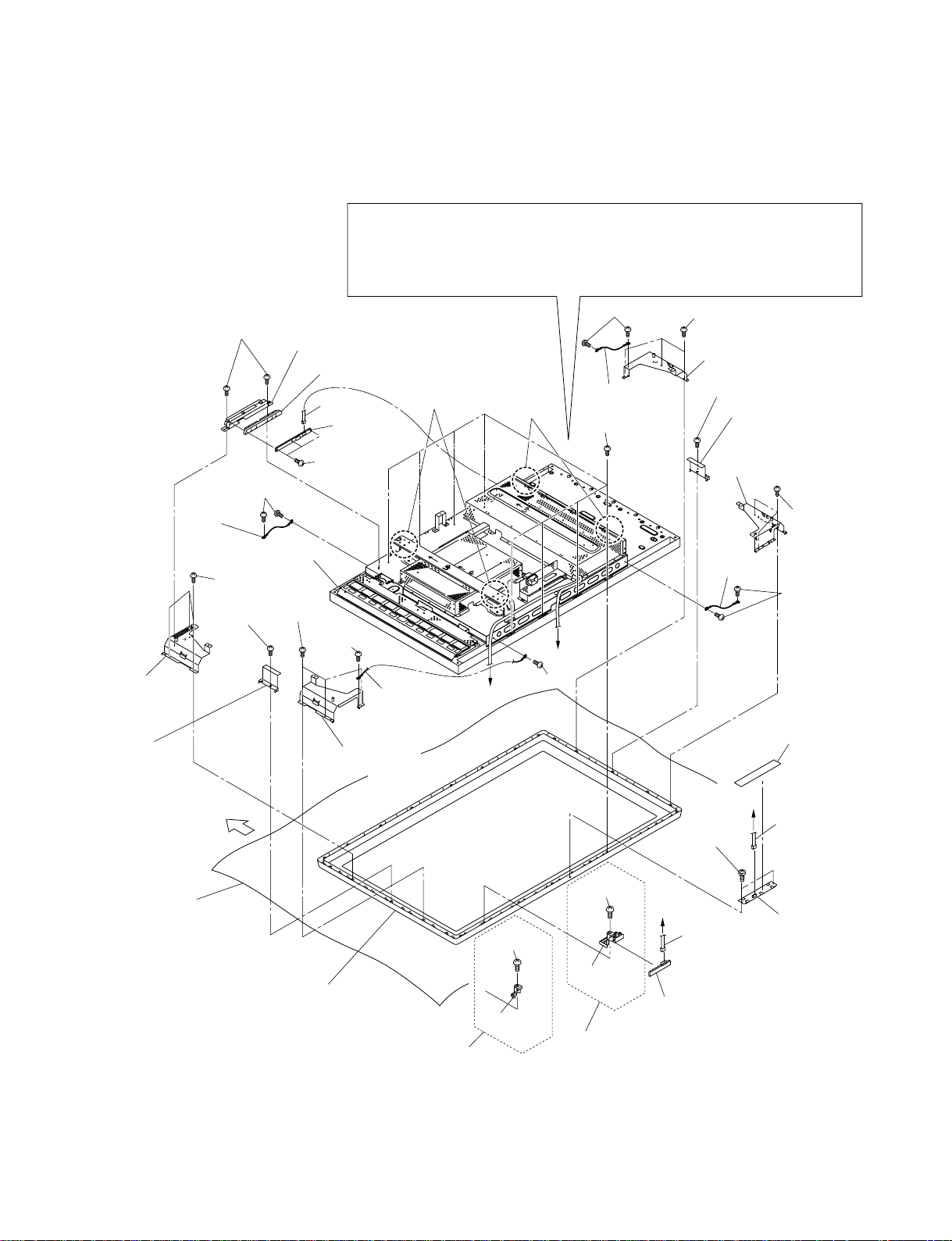

1-3-2. Bezel Assembly/H1 Board/H2 Board/LOGO Assembly

. Remove the cabinet assembly. (Refer to Section 1-3-1.)

m

. When removing the base chassis assembly, be sure to work with more than two persons.

. When removing the base chassis assembly, hold the four portions A and remove it from

the bezel assembly.

. Place the removed base chassis assembly on the conductive cushion.

7 Harness

!- Corner B

bracket

![ Side

bracket

(FWD-40LX2F/S,

FWD-40LX2F/B)

Upper side

1 T wo screws

6 Two

screws

!\ Base chassis

assembly

0 Three screws

!= Screw

8 Three

2 Control button panel

5 Control button

KCN1

4 H1 board

3 Three

screws

screws

6 Screw

9 Corner A

bracket

Portions A

7 Harness

Portions A

B

6 Screw

6 T wo screws

7 Harness

!] Eight screws

C

8 Three screws

9 Corner A bracket

!= Screw

1-3-3. A Board/JT Board

. Remove the cabinet assembly. (Refer to Section 1-3-1.)

8 Removing the lithium battery.

Remove the lithium battery in the

direction of the arrow.

Lithium battery

(CR1220)

Battery holder

1 Nine screws

CN2

CN7

CN18

CN19

6 A board

Upper side

CN10

CN16

CN17

5 Nine screws

6 A board

1 Eight screws

2 Shield cover

5 Two screws

7 JT board

3 Two connector screws

4 Two screws

1-4

Conductive cushion

FWD-40LX2F

FWD-40LX2X

Page 13

1-3-4. G6 Board

. Remove the cabinet assembly. (Refer to Section 1-3-1.)

2 Arm

3 Fourteen screws

CN951

CN901

CN950

CN931

5 Five screws

6 G6 board

1 Four screws

4 Shield cover G

6 G6 board

Upper side

Conductive cushion

FWD-40LX2F

FWD-40LX2X

1-5

Page 14

1-3-5. SP Board

. Remove the cabinet assembly. (Refer to Section 1-3-1.)

. Remove the arm and shield cover G. (Refer to Section 1-3-4.)

3 Two screws

5 Two screws

2 Screw

4 Inlet bracket

Upper side

CN901

SCN2

6 SP board

1 Nickel tape

Conductive cushion

1-6

FWD-40LX2F

FWD-40LX2X

Page 15

1-3-6. LCD Panel

. Remove each part. (Refer to Sections 1-3-1 to 1-3-5.)

1 Three screws

7 Aluminium tape

5 Four screws

7 Aluminium tape

2 Cable cover

7 Aluminium tape

Upper side

!- Gasket

!= Gasket

9 Cushion

4 LVDS cable

3 Tape

7 Aluminium tape

6 Base chassis

7 Aluminium tape

8 LCD panel

Conductive cushion

Attaching position of gaskets

9 Cushion

0 Cushion

FWD-40LX2F

FWD-40LX2X

0 Cushion

1-7

Page 16

1-4. Warning on Power Connection

Use the proper power cord for your local power supply.

United States, Continental Europe UK, Ireland, Australia, Japan

Canada New Zealand

Plug type VM0233 COX-07/636 –

Female end VM0089 COX-02/VM0310B VM0303B VM1313

Cord type SVT H05VV-F CEE (13) 53rd (O, C) HVCTF

Minimum cord 10 A/125 V 10 A/250 V 10 A/250 V 10 A/125 V

set rating

Safety approval UL/CSA VDE VDE DENAN-HO

1) Use an appropriate rating plug which complies with local regulations.

1)

VM1296

1-8

FWD-40LX2F

FWD-40LX2X

Page 17

Section 2

Troubleshooting

2-1. Judgment When No Image is

Displayed

The status in the case where “No image is displayed” is

displayed according to the number of times when the

POWER/STANDBY indicator in the lower-right position

of this unit’s front panel blinks in red. Blinking of two to

three times or five times is repeated after several seconds.

Number of blinking times Status

Two times An error code is detected from the

panel.

Three times When the sensor temperature

exceeds the allowable value

Five times 13 V power supply is detected.

Front side

2-2. Self-Diagnosis Function

The self-diagnosis function installed in this unit forcibly

shuts down this unit when the items below are detected

(abnormality is generated) or when the allowable value are

exceeded. The detected items and the allowable values are

as described below.

1. Panel error

This monitors the operation abnormality of a panel

inverter. This unit shuts down when the INV_DET signal

input from CN19 on the A board remains high after the

power is turned on.

2. Increase in sensor temperature

This detects the temperature of the A board and power

supply boards (G6 board). This unit shuts down when the

state in which the temperatures below were exceeded is

detected for two seconds or more.

. A board: 76 dC

. Power supply board: 100 dC

POWER/STANDBY

indicator

3. Abnormality of supply voltage

The DC voltage error detection in the A board is performed.

This unit is shut down when the voltage of 13 V becomes

6.9 V or less after the power is turned on.

The indicator flashes when an abnormal voltage is detected

for approximately 50 seconds. The power may be shut

down before the indicator starts flashing.

FWD-40LX2F

FWD-40LX2X

2-1

Page 18

Page 19

Section 3

Circuit Description

The main functions of each board in this unit are as

described below.

. A board

This board mounts an HD15 connector and two HDMI

connector interfaces. It processes a video signal together

with the signal from an option board using a scaler and

outputs data to the display panel. This board also outputs

the selected audio signal to the SP board.

. JT board

This is a relay board used for connecting the option

board and A board of slot 2.

. H1 board

This is a user interface board. This board mounts

[POWER], [INPUT]/[ENTER], [MENU], [UP],

[DOWN], [RIGHT], and [LEFT] buttons.

. H2 board

This board mounts two-color LED, which displays the

status of this unit, and a remote control photosensing

block.

. LOGO board

This is an LED board used for shining a SONY logo.

. SP board

This board mounts a speaker output terminal for audio

output.

. G6 board

This is a power board that has output voltages of STBY5

V, 5 V, 12 V, and 13 V.

3-1. A Board

The A board mounts HD15 (CN1), HDMI1 (CN12), and

HDMI2 (CN11) as a video input terminal. The signal from

option slot 1 is input from CN14, and the signal from

option slot 2 is input from CN13 through the JT board.

The RGB/YPbPr signals from HD15, and slots 1 and 2 are

directly input to a scaler circuit (U5). HDMI1 and HDMI2

signals are switched using an equalizer (U20), and the

selected TMDS signal is input to the scaler circuit. An

equalizer switches signals and controls the signal output,

by the port control (SEL_H and CE_H) from a scaler

circuit. The CVBS and Y/C signals from an option slot are

input through a p-type filter circuit to a scaler circuit. The

video signal from which an HDMI signal was eliminated is

input to a scaler circuit without passing through a switch

circuit. However, the RGB sync signals from slots 1 and

2, and HD15 are selected using a switching circuit (U3) by

HV_SA and HV_SB signals and input to a scaler circuit.

The input signal from HD15 is used for a video sync

signal. It is switched using a switching circuit (U4) by a

SYNC_MO signal and input to the port of a scaler circuit

that differs from the case of an H sync signal.

In a scaler circuit, resolution is converted according to the

display panel, and various picture qualities as well as wideangle setting or zoom setting are set and LVDS-transferred

to the panel through CN2.

FWD-40LX2F

FWD-40LX2X

There are the analog input from a mini-jack (CN3), slot 1,

or slot 2 and the digital input from HDMI in an audio

input. An analog audio signal is input to an audio processor circuit (U14). The audio signal from HDMI is output

from a scaler circuit as an I2S signal and input to U14. The

audio processor circuit is controlled by I2C to switch the

input and set the sound quality and volume. The selected

audio signal is passed through an amplifier circuit (U17)

and output to the SP board through CN10. The mini-jack

input cannot be only selected as the function of the main

unit only during HD15 input, but also it can be selected as

an audio input during conversion of DVI into HDMI. An

audio signal is muted by the software control of an audio

processor and the hardware control of an amplifier.

3-1

Page 20

This unit is used for BKM-FW20 that has RS-232C and

Control-S as an option board. The RS-232C (UART)

signal from an option slot is selected using a switching

circuit (U41). The signals from option slots 1 and 2 are

selected when OP1_RS_EN or OP2_RS_EN is set low on

the option side. OP1_RS_EN or OP2_RS_EN is low

during initial setting of BKM-FW20. Slot 2 has priority

when both OP1_RS_EN and OP2_RS_EN are low. The

selected RS-232C signal is connected to the control port or

firmware write port of a scaler circuit using a switching

circuit (U31). It is switched to the firmware write port

position when an FWE signal is set low on the option side

as the control of U31. The FWE signal is high during

initial setting of BKM-FW20. The signal (IR) from a

remote control photosensing block is shifted in level to a

signal (IRO) of 5 V to 3.3 V using U27, branching to each

option slot connector. The Control-S signals (OP1_IRI

and OP2_IRI) from the IRO signal and each option slot are

input to a switching circuit (U29), selected, and input to

the IR port of a scaler circuit. Which signal to select is

determined by controlling the OP1_S_EN and OP2_S_EN

signals from each option. When BKM-FW20 is not

connected, each signal is set high and an IRO signal is

selected. The IRI signal from each slot is selected when

OP1_S_EN and OP2_S_EN signals are set low. Slot 2 has

priority when both OP1_S_EN and OP2_S_EN signals are

low. The OP1_S_EN and OP2_S_EN signals are low

during initial setting of BKM-FW20.

The A board mounts a real time clock circuit (U11). The

real time clock circuit is controlled by I2C. A timer

function is controlled based on the time read operation by

polling from a scaler. During timer correction, a timer is

adjusted to an error of 3 ppm by outputting a pulse of 1 Hz

to CN8 and putting a correction value in the register of IC

according to the obtained measurement value. The

corrected value is obtained in the adjustment stage of a

single board at a factory and stored in memory. It is not

lost even in the state in which the power is not connected.

A button battery is connected to RTC. Even with the AC

power not connected, power is supplied to IC so that U11

operates continuously.

A PWM signal (LOGO_PWM) is output from a scaler

circuit to the LOGO board that shines a SONY logo. The

output signal of an amplifier circuit (U28) is integrated to

drive LED on the LOGO board as a DC signal. This LED

is turned on and off using the LOGO_EN signal from a

scaler circuit.

An option board is discriminated by discriminating

OP1_SENSE1, OP1_SENSE2, OP2_SENSE1, and

OP2_SENSE2 signals at the ADC port of a scaler circuit

using a voltage. These signals are passed through IC

(U30) and switched using the control signals (Q_SEL1 and

Q_SEL2) from the scaler circuit. Only when the power is

turned on, these signals are switched and the option board

is discriminated. After that, the output signal U30 is

switched to power temperature (PS_TEMP) and polled as a

self-diagnosis function.

3-2. H1 Board

A button input signal is sent to the A board as a DC

voltage signal. 1 V, 1.5 V, and 2.2 V are sent to an

ADC_IN2 signal when you press the [MENU], [INPUT],

and [LEFT] buttons. 1 V, 1.5 V, and 2.2 V are sent to an

ADC_IN1 signal when you press the [RIGHT], [DOWN],

and [UP] buttons. 0 V is sent when you press only the

[POWER] button as a PWR_KEY signal. Each signal is

set to 3.3 V when you press no button.

3-3. H2 Board

The H2 board mounts an infrared remote control photosensor (IU1) and sends data to the A board as an IR signal.

This board also mounts two-color LED (ID5) that displays

the status of this unit. The LED controls light emission by

controlling the cathode.

The backlight of LCD is controlled by the PWM signal

(BL_CONT) from a scaler circuit. The PWM signal is

inverted using Q20, integrated using R373 and C356, and

output to CN19 as a DC signal (INV_ADJ). The On/Off

signal (PBIAS) of a panel inverter is output from the

dedicated port of a scaler and then output from CN19 as an

INV_ON signal.

3-2

FWD-40LX2F

FWD-40LX2X

Page 21

3-4. G6 Board

AC input/rectification block

CN901 on the G6 board is connected to an AC inlet and

AC power is input from the AC inlet. The input AC power

is passed through an AC noise filter consisting of C910,

C901, C904, L901, L903, and L904 and bridge-rectified

using BD901.

PFC converter

AC power is rectified using BD901 and the power factor is

improved using a PFC converter consisting of Q911, IC911,

T911, D912, C920, and C921. Moreover, an output voltage

is increased and stabilized to 390 VDC. The smoothed

output voltage is supplied to a standby converter and main

converter.

Standby converter

5 V (5 VD and 5 VS) and 12 V are output from a switching

converter consisting of IC931 and T931. 5 VD is output

from CN931 (pins 2 to 4), and 5 VS is output from CN931

(pin 8). 12 V is output from CN950 (pins 6 and 7).

During standby, however, the output voltage that is not

increased, but smoothed is supplied from a PFC converter.

Main converter

17 V and 13 V are output from a switching converter

consisting of IC950, IC951, Q950, Q951, T950, and T913.

17 V is output from CN951 (pins 1 to 5), and 13 V is

output from CN950 (pins 2 and 3).

Main ON/OFF control

A PFC converter and main converter are turned on and off

by CN931 (pin 1) when a PS signal is set high and low

using a microcomputer. Q934 is turned on when a PS

signal is high. A PFC converter is turned on when Q931 is

turned on. A main converter is started when IC913 is

started after Q931 is turned on. Q934 is turned off when a

PS signal is low. A PFC converter and main converter

stop operation when Q931 is turned off and when IC913 is

stopped.

FWD-40LX2F

FWD-40LX2X

3-3

Page 22

Page 23

Section 4

Electrical Alignment

4-1. Service Mode

4-1-1. Start

1. Input any signal to this unit.

2. Turn on the power of this unit.

3. Perform the operation below using a remote controller

(RM-FW001) supplied for this unit with OSD not

displayed.

(1) Press the button two times.

(2) Press the [MUTING] button.

(3) Press the button.

(4) Press the [MUTING] button.

(5) Press the [MENU] button.

The service mode is started.

4-2. White Balance Adjustment

This unit is adjusted to the prescribed white balance during

factory setting. The average value of white balance is

written in the A board during factory setting. (AD calibration has also been adjusted during factory setting.)

Perform the adjustment in this section when white balance

adjustment is required.

Initial values of A board

**

*1

**

COOL 235 223 255 122 125 124

NEUTRAL 253 238 250 122 124 125

WARM 255 235 222 121 123 125

*1: GAIN

*2: OFFSET

4-2-1. Preparation

Required equipment

RED GREEN BULE RED GREEN BLUE

**

*1

**

**

*1

**

**

*2

**

**

*2

**

**

*2

**

. Signal generator

n

It is recommended to use 480i (HD15 Component) as a

connection signal. However, the signal to be actually

input can also be used.

. Color thermometer

Preparation

1. Input a signal to this unit and age for 30 minutes or

more.

4-2-2. Setting

1. Start the service mode. (Refer to Section 4-1-1.)

2. Select “HD15” by “INPUT SOURCE” in a menu.

n

Select according to the input signal when inputting any

signal.

n

To exit this screen, press the [MENU] button.

FWD-40LX2F

FWD-40LX2X

4-1

Page 24

4-2-3. Cool Adjustment

4-2-5. Warm Adjustment

1. Select “COOL” by “Color Temperature” in a menu.

2. Put the sensor of a color thermometer to the center of

the screen.

3. Input a fully white signal of 65% (IRE).

4. Change the R GAIN, G GAIN, and B GAIN values in

a menu and adjust so that x and y satisfy the specifications below.

COOL:

x = 272 ±1, y = 277 ±1

5. Input a fully white signal of 25% (IRE).

6. Change the R OFFSET, G OFFSET, and B OFFSET

values in a menu and adjust so that x and y satisfy the

specifications below.

COOL:

x = 269 ±3, y = 275 ±3

7. Repeat steps 3 to 6 to keep balance.

8. Exit the service mode using a [MENU] button.

The adjustment data is saved.

4-2-4. Neutral Adjustment

1. Select “Warm” by “Color Temperature” in a menu.

2. Put the sensor of a color thermometer to the center of

the screen.

3. Input a fully white signal of 65% (IRE).

4. Change the R GAIN, G GAIN, and B GAIN values in

a menu and adjust so that x and y satisfy the specifications below.

WARM:

x = 305 ±1, y = 315 ±1

5. Input a fully white signal of 25% (IRE).

6. Change the R OFFSET, G OFFSET, and B OFFSET

values in a menu and adjust so that x and y satisfy the

specifications below.

WARM:

x = 308 ±3, y = 317 ±3

7. Repeat steps 3 to 6 to keep balance.

8. Exit the service menu using a [MENU] button.

The adjustment data is saved.

1. Select “NEUTRAL” by “Color Temperature” in a

menu.

2. Put the sensor of a color thermometer to the center of

the screen.

3. Input a fully white signal of 65% (IRE).

4. Change the R GAIN, G GAIN, and B GAIN values in

a menu and adjust so that x and y satisfy the specifications below.

NEUTRAL:

x = 287 ±1, y = 294 ±1

5. Input a fully white signal of 25% (IRE).

6. Change the R OFFSET, G OFFSET, and B OFFSET

values in a menu and adjust so that x and y satisfy the

specifications below.

NEUTRAL:

x = 287 ±3, y = 293 ±3

7. Repeat steps 3 to 6 to keep balance.

8. Exit the service mode using a [MENU] button.

The adjustment data is saved.

4-2

FWD-40LX2F

FWD-40LX2X

Page 25

5-1. Notes on Repair Parts

1. Safety Related Components Warning

w

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

3. Stock of Parts

Parts marked with “o” at SP (Supply Code) column of

the spare parts list may not be stocked. Therefore, the

delivery date will be delayed.

Section 5

Spare Parts

4. Harness

Harnesses with no part number are not registered as

spare parts.

The components identified by mark contain confidential

information.

Strictly follow the instructions whenever the components

are repaired and/or replaced.

FWD-40LX2F

FWD-40LX2X

5-1

Page 26

Cover Block

5-2. Exploded Views

PSW

M6 x 20

11

10

2

8

11

8

12

12

16

17

7

13

13

BVTP

3 x 8

12

19

20

13

14

A

1

B

4

13

12

13

12

12

12

A

9

13

20

B

FWD-40LX2F/S

FWD-40LX2F/B

13

19

12

12

FWD-40LX2F/S

FWD-40LX2F/B

3

FWD-40LX2X

No. Part No. SP Description

1 A-1215-079-A o U10 BLOCK ASSY

2 A-1215-080-A o U20 BLOCK ASSY

3 X-2149-770-1 s BEZEL ASSY (FOR FWD-40LX2F/S)

X-2159-382-1 s BEZEL ASSY (FOR FWD-40LX2F/B)

X-2067-326-2 s BEZEL ASSY (FOR FWD-40LX2X)

4 X-2149-771-1 s CABINET ASSY

5 1-789-684-11 s MOUNTED CIRCUIT BOARD, LOGO

6 1-789-685-11 s MOUNTED CIRCUIT BOARD, H2

7 1-789-686-11 s MOUNTED CIRCUIT BOARD, H1

8 2-159-507-11 s CABLE COVER, SIDE

9 2-159-508-11 s CABLE COVER BOTTOM

10 2-580-594-01 s SCREW, +PSW M3X12

No. Part No. SP Description

11 2-580-602-01 s SCREW, +PSW M4X12

12 2-580-628-01 s SCREW, +BVST 3X6

13 2-580-639-01 s SCREW, +BVTP2 4X12

14 2-667-019-01 s HOOK

15 2-681-589-21 s LIGHT GUIDE (FOR FWD-40LX2F/S)

2-681-589-31 s LIGHT GUIDE (FOR FWD-40LX2F/B)

2-159-493-02 s LIGHT GUIDE (FOR FWD-40LX2X)

16 2-697-732-01 s CONTROL BUTTON PANEL

17 2-697-733-01 s CONTROL BUTTON

18 3-254-058-01 s SCREW

19 2-319-096-51 o CUSHION

20 2-319-096-41 o CUSHION

BVTP

3 x 8

15

FWD-40LX2F/S

FWD-40LX2F/B

18

5

15

6

5-2

7-628-000-10 s SCREW +PSW M6X20

7-685-646-79 s SCREW +BVTP 3X8 TYPE2 IT-3

FWD-40LX2F

FWD-40LX2X

Page 27

114

110

102

104

Chassis Block

114

110

114

103

114

116

115

101

113

119

119

119

112

116

118

106

110

116

116

109

114

114

120 120121

BVTP

3 x 8

117

107

No. Part No. SP Description

No. Part No. SP Description

101 ! 1-576-233-51 s FUSE (H.B.C.) (6.3A/250V)

102 ! 1-756-157-11 s BATTERY, LITHIUM

103 1-789-674-11 s MOUNTED CIRCUIT BOARD, G6

104 1-789-676-11 s MOUNTED CIRCUIT BOARD, A

(FOR FWD-40LX2F/S, FWD-40LX2F/B)

1-789-678-11 s MOUNTED CIRCUIT BOARD, A

111 2-580-594-01 s SCREW, +PSW M3X12

112 2-580-602-01 s SCREW, +PSW M4X12

113 2-580-606-01 s SCREW, +PSW M5X8

114 2-580-628-01 s SCREW, +BVST 3X6

115 2-890-185-11 s WIRE SADDLE

(FOR FWD-40LX2X)

105 1-789-682-11 s MOUNTED CIRCUIT BOARD, SP

116 2-890-185-01 s WIRE SADDLE

117 2-990-241-02 s HOLDER (A), PLUG

106 1-789-683-11 s MOUNTED CIRCUIT BOARD, JT

107 1-802-267-12 s LCD PANEL (40INCH WXGA TFT)

1-802-267-22 s LCD PANEL (40INCH WXGA TFT)

118 4-083-966-01 s SCREW, HEXAGON

119 2-580-591-01 s SCREW, PSW M3X5

120 2-898-753-01 s GASKET

1-802-267-32 s LCD PANEL (40INCH WXGA TFT)

108 1-820-823-11 s AC INLET

121 2-898-753-11 s GASKET

109 2-580-592-01 s SCREW, +PSW M3X8

110 2-580-593-01 s SCREW, +PSW M3X8

7-685-646-79 s SCREW +BVTP 3X8 TYPE2 IT-3

FWD-40LX2F

FWD-40LX2X

105

108

111

5-3

Page 28

Packing Block

208

201

204

202

212

205

213

203

214

210

206

207

209

No. Part No. SP Description

201 1-479-983-11 s REMOTE COMMANDER (RM-FW001)

202 9-885-099-05 s BATTERY COVER (FOR RM-FW001)

203 1-566-316-11 s CONNECTOR, CONVERSION

204 1-830-712-11 s CONNECTION CABLE (VIDEO CABLE)

205 X-2176-505-1 s CABLE HOLDER PACKING, 4P

206 2-890-214-01 s MANUAL,INSTRUCTION

(JAPANESE,ENGLISH,FRENCH,GERMAN,

SPANISH,ITALIAN,SIMPLIFIED CHINESE)

207 2-890-195-01 s ACCESSORY BOX

208 2-890-193-01 s CUSHION (UPPER)

209 2-890-194-01 s CUSHION (LOWER)

210 2-890-196-01 s PROTECTION BAG

211 2-890-192-01 s INDIVIDUAL CARTON

212 2-990-242-01 s HOLDER (B), PLUG

213 3-613-640-01 o PLUG,HOLDER C

214 ! ------------ CORD, POWER

(See Sec.1-4. Warning on Power Connection)

5-4

211

FWD-40LX2F

FWD-40LX2X

Page 29

SS-SP40FW

Overall Block

No. Part No. SP Description

304

304

301

303

304

304

303

302

301 A-1127-888-A s SPEAKER ASSY (40R) (RP) (SILVER)

A-1129-682-A s SPEAKER ASSY (40R) (RP) (PEARL WHITE)

302 A-1127-889-A s SPEAKER ASSY (40L) (RP) (SILVER)

A-1129-683-A s SPEAKER ASSY (40L) (RP) (PEARL WHITE)

303 2-580-602-01 s SCREW, +PSW M4X12

304 2-580-639-01 s SCREW, +BVTP2 4X12

FWD-40LX2F

FWD-40LX2X

5-5

Page 30

Board Connections

TOP SIDE

H1 Board

KCN1

6

CN202L CN201R

CTRL Board

CN101

4

CN1

CN951

3

G6 Board

INVERTER Board

CN950

CN931

2

5

ICN18

H2 Board LOGO Board

LCN1

SP Board

SCN2

1

CN7

CN2

CN4

CN18

CN19

A Board

CN17

CN10

CN16

8

JT Board

7

No. Part No. SP Description

1

1-910-031-70 s CONNECTOR ASSY (LVDS)

2

1-910-031-77 o CONNECTOR ASSY 8P MAIN

3

1-910-031-78 o CONNECTOR ASSY 12P MAIN

4

1-910-031-79 o CONNECTOR ASSY 14P POWER

5

1-910-031-80 o CONNECTOR ASSY 7P IR

6

1-910-031-81 o CONNECTOR ASSY 5P KEY

7

1-910-031-82 o CONNECTOR ASSY 3P LOGO

8

1-910-031-83 o CONNECTOR ASSY 4P SP

5-6

FWD-40LX2F

FWD-40LX2X

Page 31

6-1. Overall Block Diagrams

HDMI1

HDMI2

HDMI

PC_R/G/B

HS/PC_VS

HS

PC_VS

PC_CVBS

PC_HS VGA_HS/VS

OP1_HS/VS

OP2_HS/VS

PC_L/R

AU2_L/R

AU1_L/R

I

2

S_WS/DA/CL

RGB/YPbPr

YC

CVBS

H/V

AUDIO 1

RGB/YPbPr

YC

CVBS

H/V

AUDIO 1

MSTR1_SCL/SDA

I

2

C_3.3v

I

2

C_NVM

I

2

C_5v

FOR SCART(RGB)

L: H/V , H: VIDEO

AB : SEL

LL : HD15

HL : OP1

LH : OP2

PC_HS/VS

OP1_PY/PB/PR

H: HDMI1, L: HDMI2

H: ENABLE, L: DISABLE

L: RESET , H: NORMAL

L: MUTE

H: NORMAL

SPK_L/R

AUDIO_L/R

I

2

C_5V

I

2

C_5V

I

2

C_3.3V

LVDS

LCD

PANEL

HDMI_EQ

AU

JACK

NVM

D-AMP

TEMP

AUDIO

PROCESSOR

RTC

CORTEZ PLUS

SEL_H

CE_H

SELECTOR

SELECTOR

SYNC_MODE

HV_SB

HV_SA

OP2_PY/PB/PR

OP1_Y/C

OP2_Y/C

OP1_CVBS

OP2_CVBS

MUTE

RESET

HDMI_INPUT PORT

A/B/C_2

SV_4

A/B/C_3

B_1/C_1

SV_2

SV_1

HS/VS

MSTR2_SCL/SDA

I

2

S_OUT

MSTR0_SCL/SDA

A/B/C_4

A_1/SV_3

HD15

HDMI2

HDMI1

I2C_NVM

DDRx2

LPF

LPF

LPF

LPF

OPTION1

(U10 BLOCK)

OPTION2

(U20 BLOCK)

Overall (1/2)Overall (1/2)

Section 6

Diagrams

FWD-40LX2F

FWD-40LX2X

6-1

6-1

SIGNAL & I2C BLOCK

Overall (1/2)

Page 32

Overall (2/2) Overall (2/2)

2

C

I

NVM

2

I

C TRANS

HDMI1

HDMI2

HD15

OPTION1

(U10 BLOCK)

RS_OUT_EN

UART

S_OUT_EN

SIRCS IN

SIRCS OUT

QSENSE

RESET

ALARM

IR

5V 8 3.3V

CE_REMOTE1

2

I

C

CE_REMOTE2

2

C

I

TX/RX_PC

LEVEL

SHIFT

HP_DET1

HP_DET2

NVM

VGA_CAB

NVM

OP1_TX/RX

OP2_TX/RX

EDID2

INPUT H: PULG IN, L: NC

OUTPUT L: CONNECT REQUEST

INPUT H: PULG IN, L: NC

OUTPUT L: CONNECT REQUEST

2

I

C TRANS

EDID3

H: NC, L: PULG IN

2

C TRANS

I

EDID1

UART

SELECTOR

NAND

TX/RX

N_RS_

RCV_EN

OP_

RS_EN

VGA_SDA/SCL

UART

SELECTOR

N_OP_RS_EN

NOT

DSCA/DSCL_COM

SELECTOR

SEL_H

IRO

OP1_IRI

OP2_IRI

RS_RCV_E

L: OP1 or OP2(NORMAL)

H: OP1 5 OP2

CE_REMOTE

H: HDMI1, L: HDMI2

IR

SELECTOR

OP2_S_EN

OP1_S_EN

IRDATA

OP1 OP2 SEL

L L OP2

L H OP1

H L OP2

H H IRO

TXD/RXD

CORTEZ PLUS

VGA0_SDA/SCL

VGA1_SDA/SCL

UDI/O_0

BDATA11

IR0

LBADC_3/4

CONTROLLED_DEVICE_SDA

CONTROLLED_DEVICE_SCL

GPIO

LBADC_IN1/2

OCM_TIMER

OCM_CS1

BDATA14

PWM2

IPCLK3

IPCLK3

PWM0

PWER-KEY

ADC_IN1/2

LED_G1

LED_R1

LED_G2

LED_R2

L: OFF, H: ON

LOGO_EN

LOGO_PWM

RESET

L: RESET

H: NORMAL

INV_DET

L: ABNORMAL or OFF

H: NORMAL ON

BL_CONT

KEY

LED

L: OFF, H: ON

TO LOGO CIR

TO AUDIO DEC

LCD

PANEL

OPTION2

(U20 BLOCK)

RS_OUT_EN

UART

S_OUT_EN

SIRCS IN

SIRCS OUT

QSENSE

RESET

ALARM

OP1_QSENSE1/2

OP2_QSENSE1/2

GRESET

ALARM: PULSE OUT

UART

SELECTOR

SENSE1/2

QSENSE

SELECTOR

L: RESET , H: NORMAL

Q_SEL1

Q_SEL2

SEL1 SEL2 SELECT

L L OP1

H L OP2

6-2

6-2

RESET

POWER_OFF

TO POWER SUPPLY

DIPEXTCOAST

AU_ON

FOR AUDIO AMP

FOR PANEL LOGIC POWER

PPWERBDATA16

PPWR

FOR PANEL INSERTER POWER

PBIAS

PBIAS

CONTROL BLOCK

Overall (2/2)

FWD-40LX2F

FWD-40LX2X

Page 33

Frame Wiring Frame Wiring

LCD PANEL

6-2. Frame Wiring

AC INLET

H1

G6

CN951

17V

1

2

17V

3

17V

4

17V

5

17V

6

GND

7

GND

8

GND

9

GND

10

GND

11

DET

12

INV_ON/OFF

13

DIM

14

GND

CN901

1

L

N.C

2

N

3

SPEAKER

SPEAKER

SP

KCN1

ADC_IN2

GND

ADC_IN1

GND

PWR_KEY

CN950

DET

13V

13V

GND

GND

12V

12V

GND

GND

10

PS_TEMP

DIM

CN931

5VD

5VD

5VD

GND

GND

GND

5VS

SCN2

L+

LRR+

11

12

INV_ON/OFF

PS ON/OFF

Note: The components identified by mark contain confidential

information.

Strictly follow the instructions whenever the components

are repaired and/or replaced.

A

CN7

ADC_IN2

1

2

3

4

5

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

1

2

3

4

1

2

3

ADC_IN1

4

5

PWR_KEY

CN19

INV_DET

1

2

13V-G

3

13V-G

4

5

6

12V-G

7

12V-G

8

9

10

PS_TEMP1

11

INV_ON

12

INV_ADJ

13

CN18

1

POWER_OFF

2

5V-G1

3

5V-G1

4

5V-G1

5

6

7

8

5V-G1

CN10

AUDIO_L+

1

2

AUDIO_L-

3

AUDIO_R-

4

AUDIO_R+

GND

GND

GND

GND

GND

GND

NC

GND

GND

GND

CN2

GND

TXA10TXA10+

GND

TXA11TXA11+

GND

TXA12TXA12+

GND

TXA1CTXA1C+

GND

TXA13TXA13+

GND

NA

GND

GND

GND

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

2

3

4

5

6

7

8

9

DCC LUT SEL0

DCC LUT SEL1

DCC LUT SEL2

DCC SEL1

DCC SEL0

5V_PANEL

5V_PANEL

5V_PANEL

5V_PANEL

5V_PANEL

INVERTER

CN1

1

17.5V

2

17.5V

3

17.5V

4

17.5V

5

17.5V

6

GND

7

GND

8

GND

9

GND

10

GND

11

Panel_DET

12

BL_ON/OFF

13

VDIM

14

GND

CN101

1

Power

2

Power

3

Power

4

Power

5

Power

6

GND

7

GND

8

GND

9

NC

10

NC

11

RxIN0-

12

RxIN0+

13

GND

14

RxIN1-

15

RxIN1+

16

GND

17

RxIN2-

18

RxIN2+

19

GND

20

LVDS Clock-

21

LVDS Clock+

22

GND

23

RxIN3-

24

RxIN3+

25

GND

26

NA

27

NC

28

GND

29

NC

30

NC

31

NC

32

NC

33

NC

34

DCC SEL0

35

DCC SEL1

36

DCC LUT SEL0

37

DCC LUT SEL1

38

DCC LUT SEL2

39

NC

40

NC

41

NC

CTRL

1

2

3

4

1

2

3

4

5

6

7

8

9

1

2

3

CN17

GND

5V-G

IR

NC

NC

GREEN2

RED2

NC

NC

CN16

5V

GND

LOGO_ON

6-3

JT

U20

5

U10

Frame Wiring

6-3

FWD-40LX2F

FWD-40LX2X

H2

RED

GREEN

NC

NC

IR

5V

GND

GND

LOGO

5V

GND

LOGO_ON

GND(FOR EARTH)

ICN18

LCN1

1

2

3

4

5

6

7

8

CHASSIS GND

1

2

3

4

CHASSIS GND

A BCDEFGH

Page 34

Page 35

SAFETY CHECK-OUT

After correcting the original service problem,

perform the following safety checks before

releasing the set to the customer :

Check the metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC

leakage. Check leakage as described below.

LEAKAGE TEST

The AC leakage from any exposed metal part to

earth ground and from all exposed metal parts to

any exposed metal part having a return to

chassis, must not exceed 3.5 mA. Leakage

current can be measured by any one of three

methods.

1. A commercial leakage tester, such as the

Simpson 229 or RCA WT-540A. Follow the

manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The

Data Precision 245 digital multimeter is

suitable for this job.

3. Measuring the voltage drop across a resistor

by means of a VOM or battery-operated AC

voltmeter. The “limit” indication is 5.25 V, so

analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa

SH-63Trd are examples of a passive VOM

that is suitable. Nearly all battery operated

digital multimeters that have a 20 V AC range

are suitable. (See Fig. A)

FWD-40LX2F

FWD-40LX2X

To Exposed Metal

Parts on Set

0.15 µF 1.5 k

Fig A. Using an AC voltmeter to check AC leakage.

Z

Earth Ground

AC

voltmeter

(5.25V)

Page 36

FWD-40LX2F (WW)

FWD-40LX2X (WW) E

9-834-142-02

Printed in Japan

Sony Corporation 2007. 2 22

©2006

Loading...

Loading...