Page 1

SERVICE MANUAL

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

FDL-PT222 US

MODEL COMMANDER DEST. CHASSIS NO.

–––––– –––––––––––– ––––– –––––––––––

MICROFILM

∗ Please file according to model size. .......

2.2

LCD COLOR TV

Page 2

FDL-PT222

SPECIFICATIONS TABLE OF CONTENTS

Section Title Page

1. GENERAL

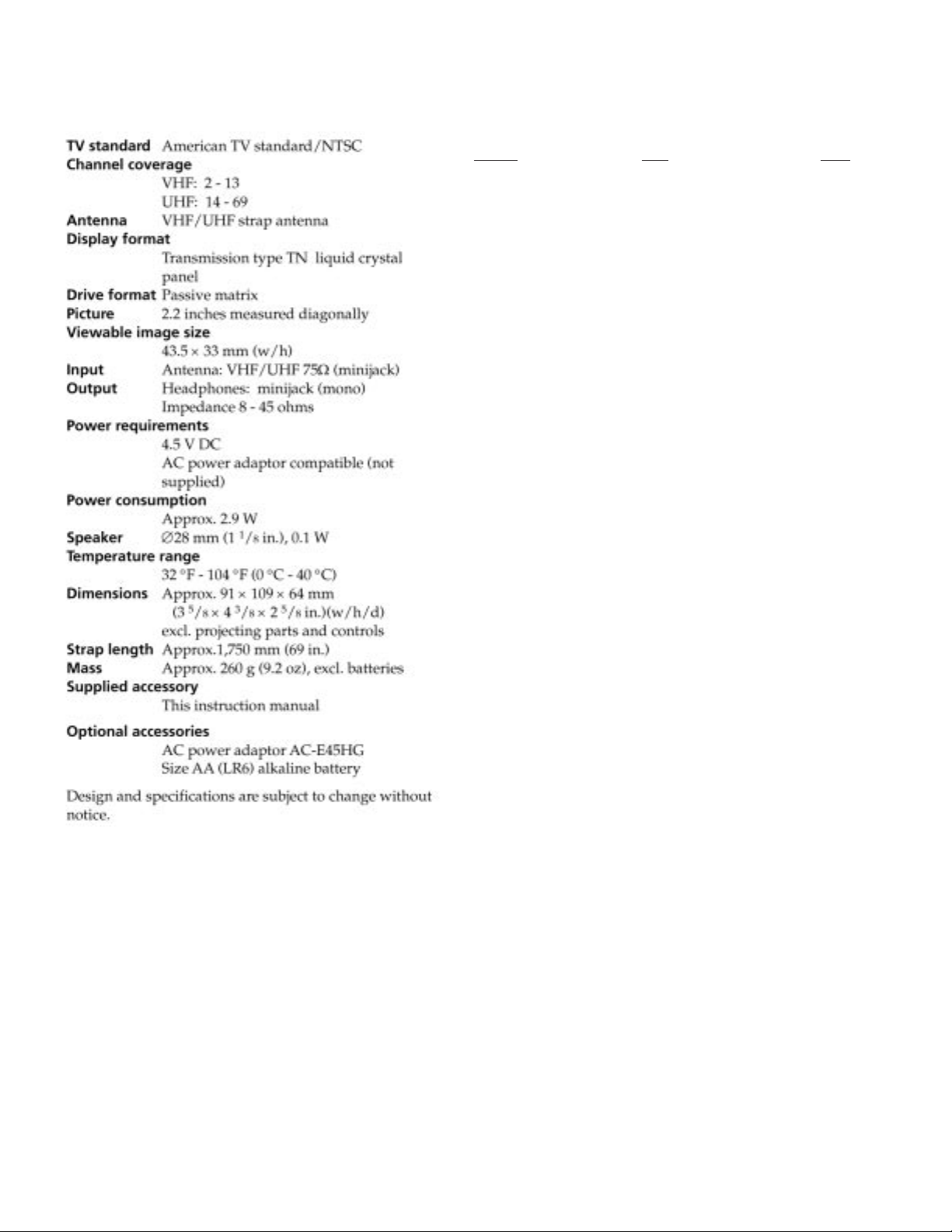

Power Sources (see fig. A) ...................................................... 3

Operation (see fig. B) .............................................................. 3

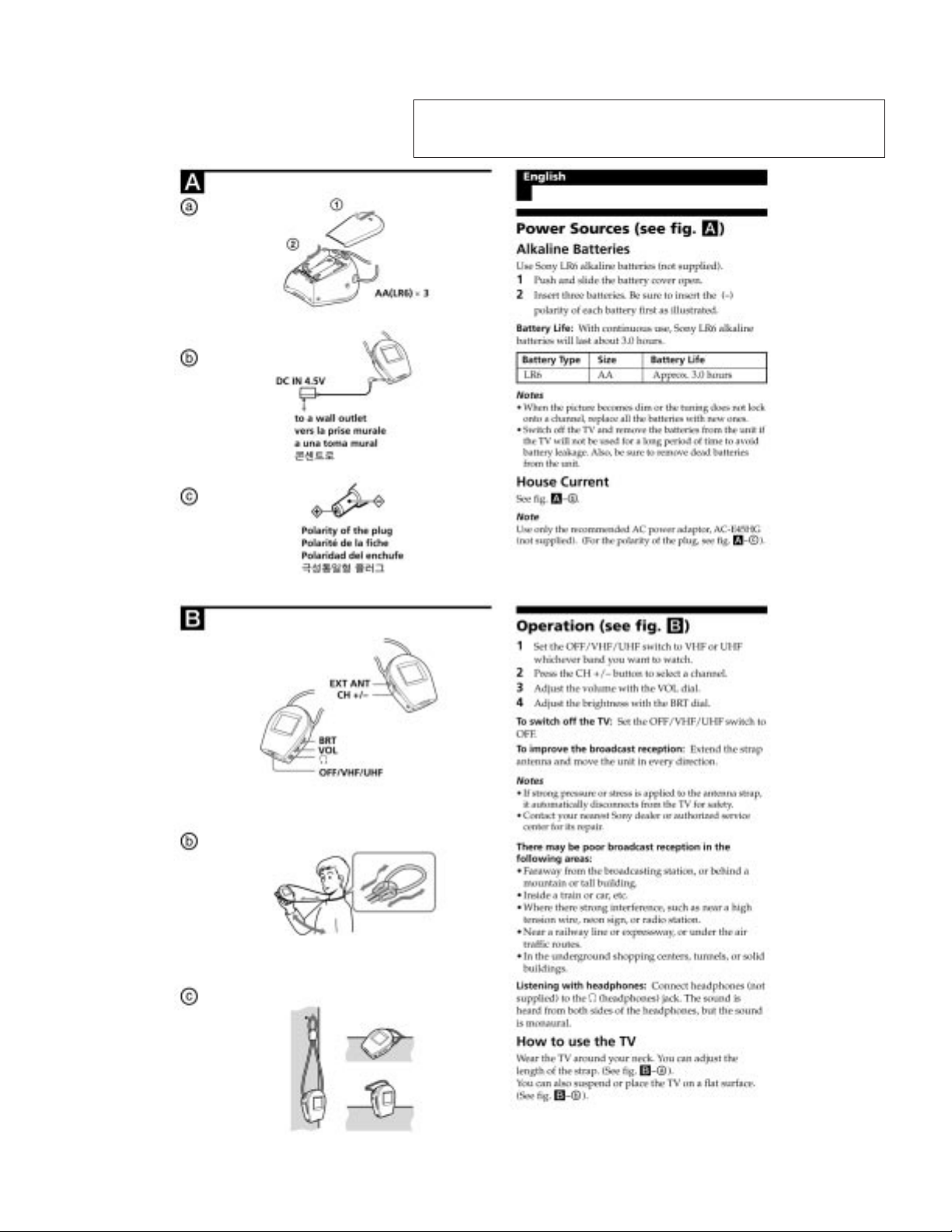

External Antenna Connection (see fig. C)............................... 4

WARNING .............................................................................. 4

2. DISASSEMBLY

2-1. Cabinets ........................................................................ 5

2-2. Service Position ............................................................ 6

3. CIRCUIT ADJUSTMENTS ............................................ 7

4. DIAGRAMS

4-1.Block Diagram (1)............................................................ 9

4-2.Block Diagram (2).......................................................... 11

4-3.Circuit Boards Location ................................................. 14

4-4.Printed Wiring Boards and Schematic Diagrams ........... 14

• T1 Board ..................................................................... 15

• A Board ....................................................................... 19

• B Board ....................................................................... 23

4-5.Semiconductors .............................................................. 27

5. EXPLODED VIEWS

5-1. Chassis Section .............................................................. 28

6. ELECTRICAL PARTS LIST........................................ 29

SHORT CIRCUIT THE ANODE OF THE PICTURE TUBE AND THE ANODE CAP TO THE METAL CHASSIS, CRT SHIELD, OR CARBON PAINTED ON THE CRT, AFTER REMOVING THE ANODE.

AN ISOLATION TRANSFORMER SHOULD BE USED DURING ANY SERVICE TO AVOID POSSIBLE SHOCK HAZARD, BECAUSE OF LIVE CHASSIS.

THE CHASSIS OF THIS RECElVER IS DIRECTLY CONNECTED TO THE

AC POWER LINE.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY SHADING AND MARK ! ON THE SCHEMATIC DIAGRAMS, EXPLODED VIEWS AND IN THE PARTS LIST ARE

CRITICAL TO SAFE OPERATION. REPLACE THESECOMPONENTS

WITH SONY PARTS WHOSE PART NUMBERS APPEAR AS SHOWN IN

THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY. CIRCUIT

ADJUSTMENTS THAT ARE CRITICAL TO SAFEOPERATION ARE IDENTIFIED IN THIS MANUAL. FOLLOW THESE PROCEDURES WHENEVER CRITICAL COMPONENTS ARE REPLACED OR IMPROPER OPERA-

TION IS SUSPECTED.

(CAUTION)

WARNING!!

– 2 –

Page 3

SECTION 1

GENERAL

The operating instructions mentioned here are partial abstracts from the

Operating Instructions Manual. The page numbers of the Operating

Instruction Manual remain as in the manual. (Part no : 4-083-376-11)

– 3 –

Page 4

– 4 –

Page 5

SECTION 2

DISASSEMBLY

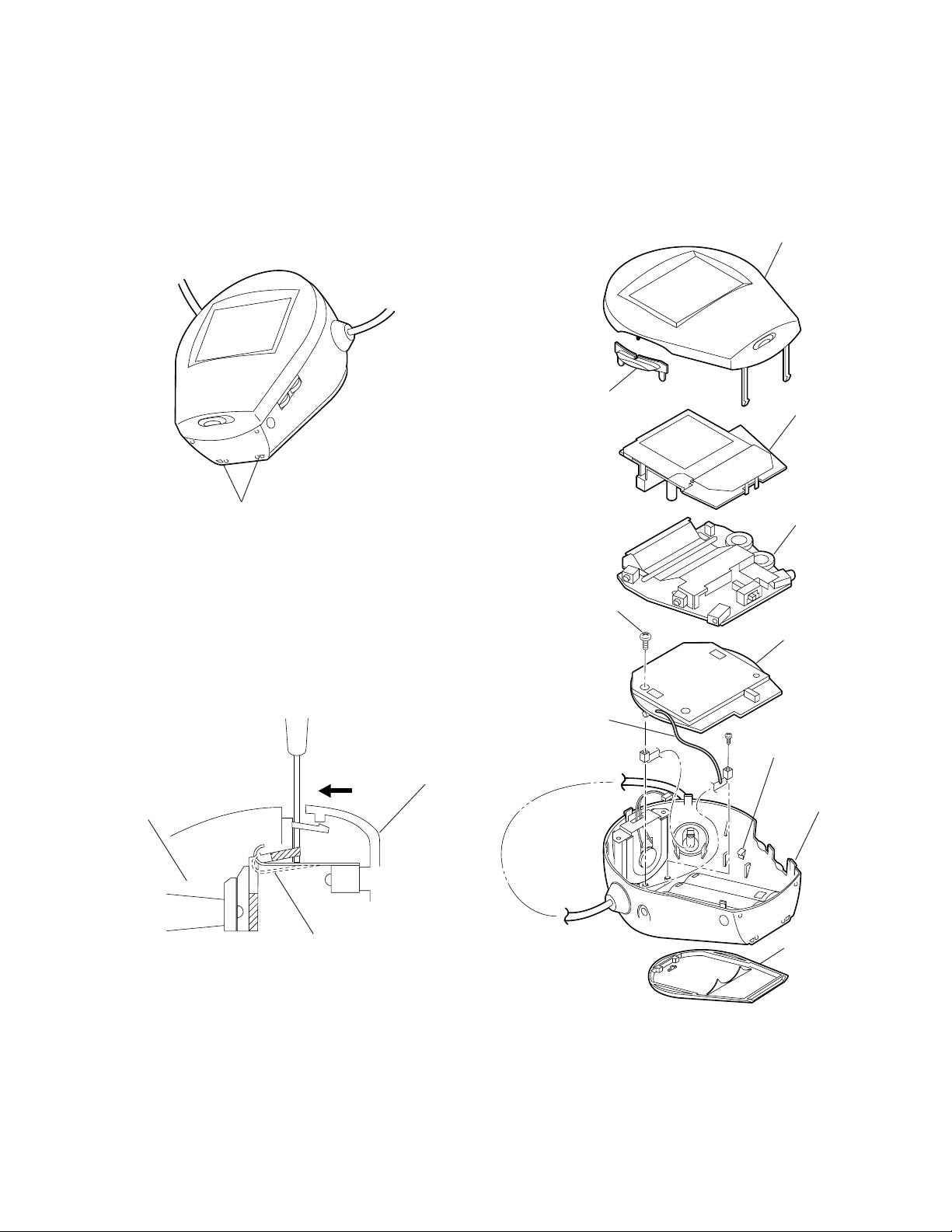

2-1. CABINETS

1. Remove the battery cover 8.

2. Push two claws with a screwdriver or equivalent on the bottom and

remove them.

FDL-PT222

1 front cabinet

2 channel button

3 B board

claw

3. While pushing the rear cabinet, remove claws of joints with

the front cabinet.

4. Insert a screwdriver or equivalent to the gap on the upper side of the

cabinet, and while pushing the lock spring, put it down to the rear cabinet

side.

5. Remove the channel button 2.

6. Disconnect CN501 (for speaker) on the A board.

7. Remove the B board 3 and the A board 4.

8. Remove solder for the lead wire (BLK) 9.

9. Remove a screw (+PTP2X6) 6 secured the T board 5.

10. Release the T1 board 5 from two claws (right and left) on the rear cabinet.

front cabinet

rear cabinet

lock spring

6 screw (+PTP2X6)

9 lead wire (BLK)

4 A board

5 T1 board

claw

7 rear cabinet

8 battery cover

– 5 –

Page 6

FDL-PT222

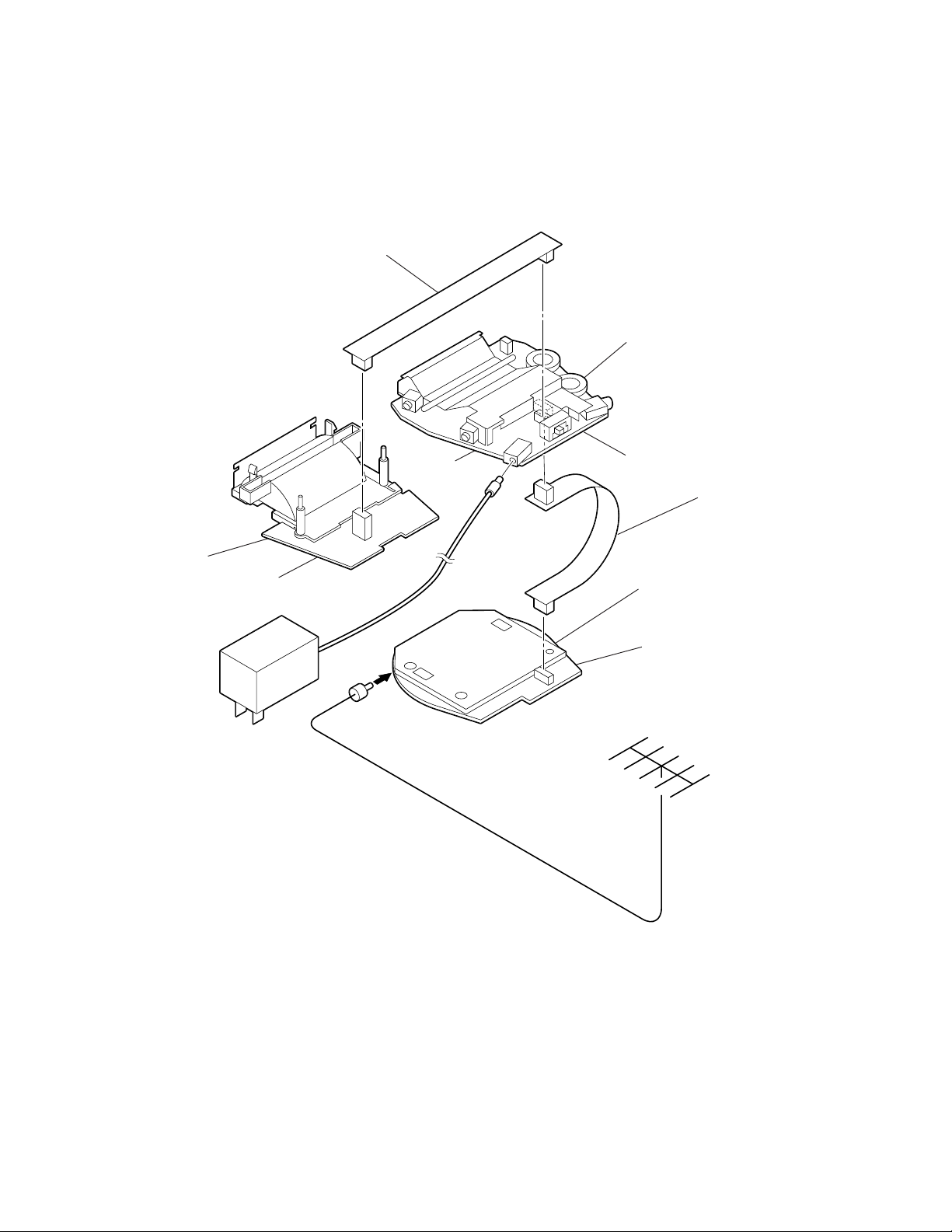

2-2. SERVICE POSITION

Cable for service

1-900-211-84

CN602

B board

CN301

AC power adaptor

J101

Mini-jack

CN601

A board

Cable for service

1-900-211-84

T1 board

CN201

Antenna

– 6 –

Page 7

SECTION 3

CIRCUIT ADJUSTMENTS

FDL-PT222

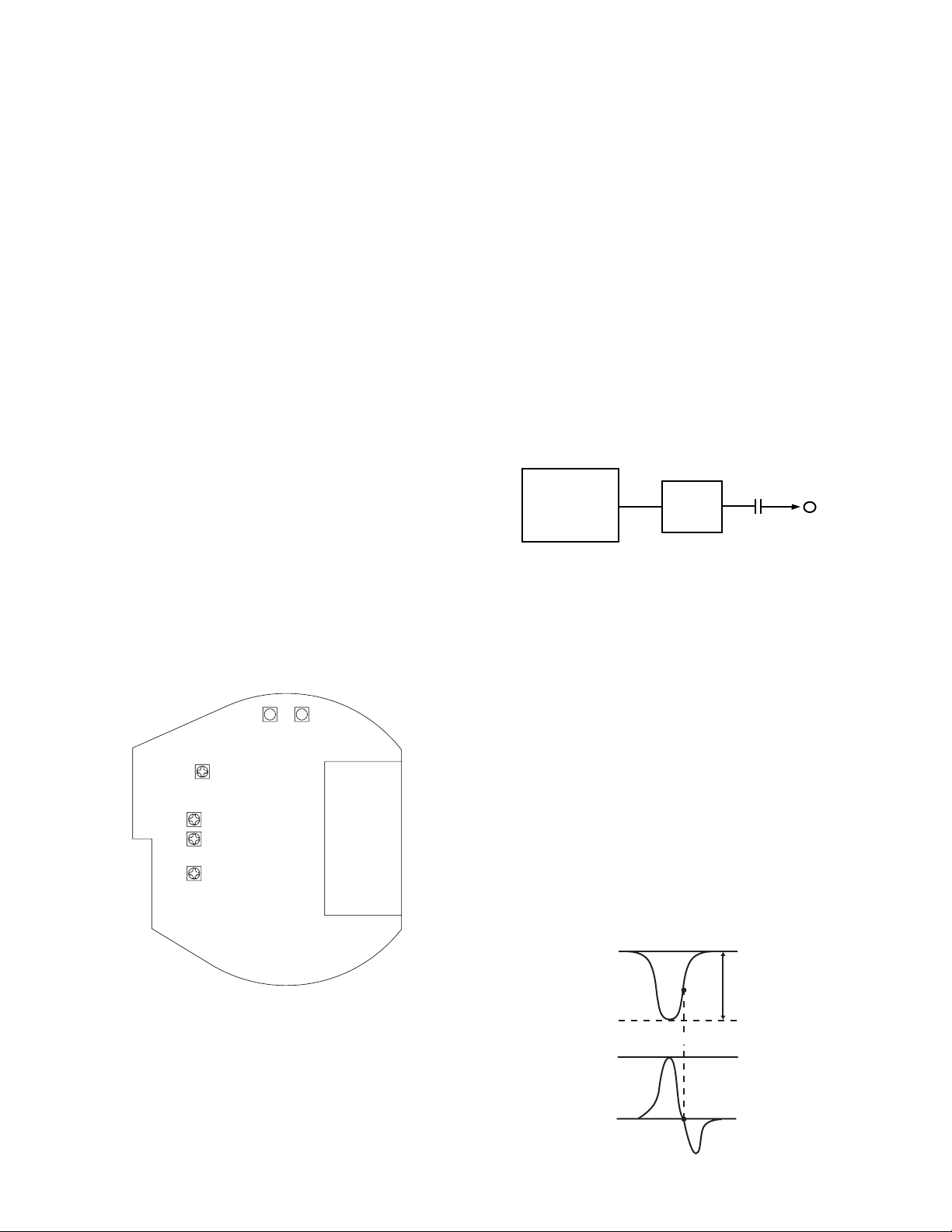

3-1.A BOARD ADJUSTMENT [+4.5V ALIGNMENT (RV601)]

Using a digital voltmeter measuring the voltage between

JL32 (+4.5V) and JL33 (GND). Adjust RV601 to obtain

the value shown below.

Standard Value = 4.45V± 0.05VDC

S601 position = UHF position

[+30.0V CHECK]

Check the voltage across JL29 (+30.0V) and JL33 (GND) .

Standard Value = 30.5V±1.5VDC

[AUDIO OUTPUT CHECK]

1. Feed the audio signal 1kHz 100% modulated.

2. Set RV501 to maximum.

3. Connect an oscilloscope between JL23 (SP) and JL15 (SP

GND).

4. Check the waveform on the oscilloscope becomes the standard value.

Standard Value = 1.5V-2.8Vp-p

[VIF.AFT COARSE ADJUSTMNT (T201, T202)]

[SETUP]

1. Set S601 on the A board to VHF position.

2. Apply no signal to JL18 (RF).

3. Connect a 1 kΩ resistor between JL77 (+4.5V) and

JL28 (RF AGC).

4. Apply a sweep signal across JL26 (IF) and JL27(IF GND).

(Fig. 3-1)

Note : Set the sweep signal for JL26 to -30±5dBm. Keep the

distance to the ATT output JL26 as short as possible.

0.01µF

SWEEP

MARKER

GENERATOR

fo=45.75MHz±5kHz

ATT

JL26

75Ω 6dB

Fig. 3-1

3-2.T1 BOARD ADJUSTMENT

- T1 board - (Component side)

T201

T202

RV201

RV002

RV004

RV001

TU101

[ADJUSTMNT]

1. Connect an oscilloscope between JL72 (VIDEO) and JL71

(A.GND) and apply an external voltage (MGC) to JL26 to

obtain a waveform as shown in Fig. 3-2 (make sure not to

clip the extremely short portion).Adjust T202 so that the position at 45.75 MHz is the lowest point.

Note : Align JL51 (MGC) external voltage for approximately

a 1.0 Vp-p. Make sure that the JL51 (MGC) external

voltage does not exceed 4.3VDC.

2. Remove the external voltage (MGC) from JL51.

3. Connect an oscilloscope between JL31 (AFT) and JL30

(D.GND) and make a coarse adjustment of T201 so that wav eform is close to zero at the 45.75 MHz position.

4. Remove the 1 kilohm resistor connected between JL77 (+4.5V)

and JL28 (RF AGC).

1Vp-p

45.75MHz

– 7 –

0

Fig. 3-2

Page 8

FDL-PT222

[AFT FINE ADJUSTMENT(T201)]

1. Connect a 1 kilohm resistor between JL77 (+4.5V) and JL28

(RF AGC).

Note : Perform this adjustment as the last step in the

process since drift may occur due to aging.

2. Switch the sweep signal to CW.

fo= 45.75 MHz±5 kHz, -30±5dBm

Apply the abov e signal between JL26 (IF) and JL27 (IF GND)

and then make a fine adjustment of T201 so that the level be-

tween JL31 (AFT) and JL30 (D.GND) reaches2.2V±0.4VDC.

3. Remove the 1 kilohm resistor connected between JL77 (+4.5V)

and JL28 (RF AGC).

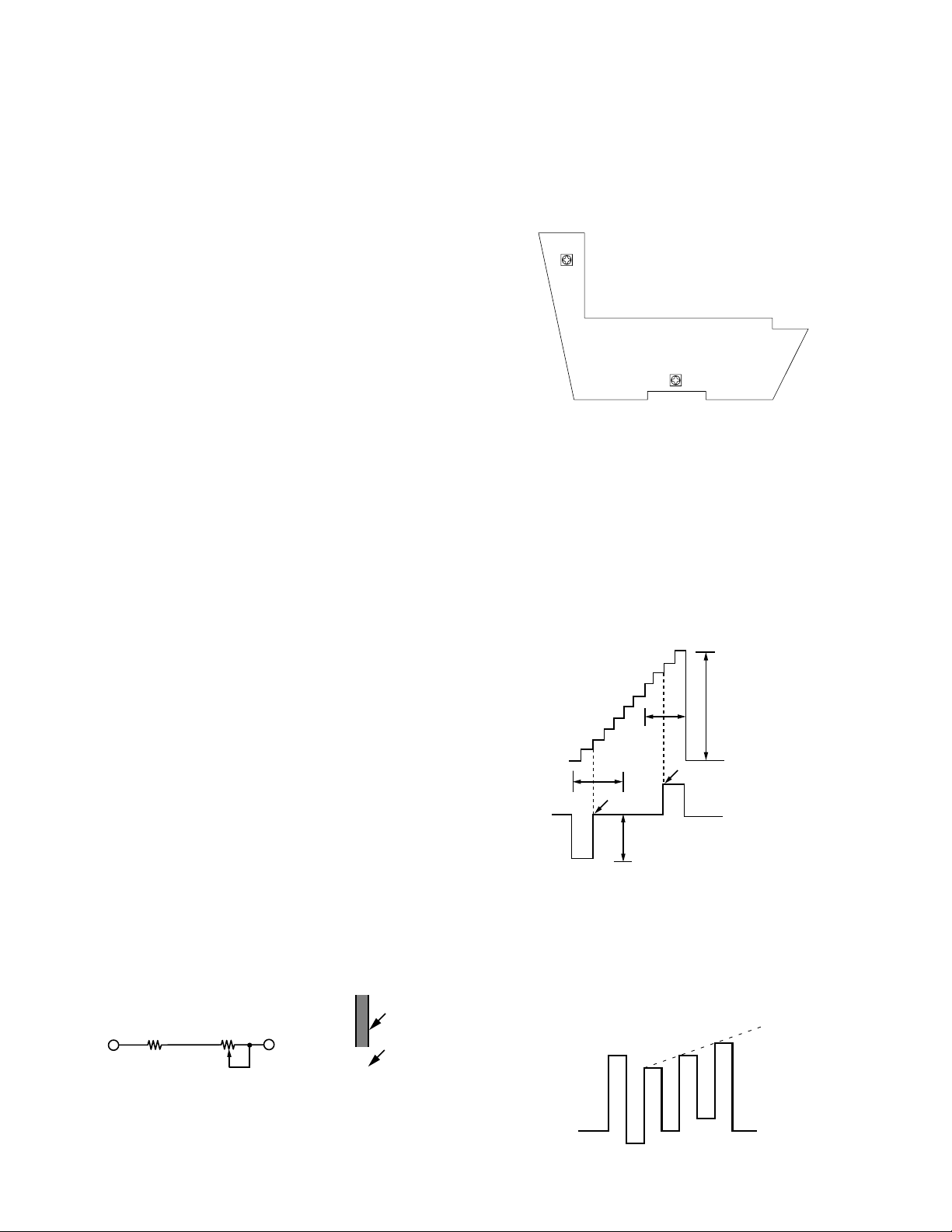

[RF. AGC ADJUSTMENT (RV201)]

1. Set S601 to VHF position and recei ve a VHF color bar signal

issued from a signal generator.

2. Adjust RV201 and align the screen for the optimal point so

that the snow noise disappears.

[CHANNEL DISPLAY POSITION ADJUSTMENT

(RV001, RV002, RV004)]

1. Set S601 to VHF position, a potentiometer (47kΩ±15kΩ)

across JL25(CS) and JL77 (+4.5 V) as sho wn in Fig. 2-6 and

short the points JL21(CH CAL) and JL30 (D.GND).

2. Receive channel 2 and align the channel display positions with

RV002(VP).

3. Receive channel 13 and align the display bar with R V004(VA).

4. Align while performing tracking to mutual interference in the

above steps 2 and 3.

5. Receive channels 3 & 4 and confirm that the display bar is

within the standards.

6. Set S601 to UHF.

7. Receive channel 14 and align the display position with

RV001(UP).

8. Receive channel 69 and confirm that the display bar is within

the standards.

Once again receive channel 14 and confirm that the display

bar is within the standards.

Note : Use caution since shifting channel 69 will also

cause channel 14 to shift.

9. Remove the potentiometer (47kΩ+15kΩ) you connected between JL25(CS) and JL77(+4.5V). Also remov e the short you

connected between points JL21 (CH CAL)and JL30(D.GND).

JL25 (CS)

JL77(+4.5V)

Display bar

3-3.B BOARD ADJUSTMENT

- B board (Component side)

RV301

RV402

[CONTRAST ADJUSTMENT (RV402)]

1. Receive the stepped waveform signal in 10 steps.

2. Observe the waveform across JL83(G) and JL67(GND).

3. Check the contrast changes by turning RV402.

4. Connect an oscilloscope between JL84 (AUTO CB) and JL67

(D. GND) and adjust R V402 so that the v oltage of A portion

becomes 2.2+-0.2V.

5. Check the waveform as shown in Fig. 3-5.

6. At the same time, check the points C and D are within the

period as shown in Fig. 3-5.

100 IRE

JL83

0 IRE

JL84

C

A=2.2

±

Fig. 3-5

[COLOR PHASE (TINT) ADJUSTMENT (RV301)]

1. Receive the color bar signal from the signal generator.

2. Observe the waveform across JL81(B) and JL67(D.GND).

3. Adjust RV301 (TINT) so that the waveform level becomes as

shown in Fig. 3-6.

Contrast changes

D

0.2VDC

15kΩ

Fig. 3-3

Channel No.

6

VR(47kΩ)

*Channel No. and display

bar are to be in line.

Fig. 3-4

Fig. 3-6

– 8 –

Page 9

4-1. BLOCK DIAGRAM (1)

SECTION 4

DIAGRAMS

STRAP

ANTENNA

J101

EXT ANT

TU101

TUNER

ANT

AGC

IF

UB

HB

LB

MB

BALUN

T101

+4.5V

CN201

UB12

2

VHF

3

H.P

IC201 VIF/SIF DET

IF

IF

RF AGC

INV.

Q205

CF202

AFT

6

7

3

4RV201

14

15

16

23

17

21

IF

IF

AGC OUT

AGC DL

E-VDL

FM DET

LIM

SYNC

AFT

AFT COIL

IF AMP

AGC IF

FM

DET

SYNC

SEP

AFT

DET

AMP

REF COIL

REF COIL

AUDIO

SIF

DET OUT

SYNC SEP

VIDEO

BUFFER

LIMITER 10

VIDEO

LLD

19

20

13

AUDIO

AUDIO

5

AUDIO

TO

A BOARD

CN502

CF203

AUDIO

VIDEO

CF201

BUFFER

Q202

18

22

9

VIDEO

IF

IF AMP

Q201

IF

FILTER

SWF201

IC001

SWITCH

Q010-012

TUNER CONTROOL

BS

28

U/V

27

BS

COMPOSITION

BAND

SELECT

TUNING

CONTROL

BAND

SELECT

AUTO

RETURN

3

HP

COMPARATOR

DEFEAT

OUTPUT

SIGNAL

DEFECT

DEF

H SYNC

AFC

SUD

14

FH

1

4

5

6

FH SWITCH

Q005

Q007

AFC SWITCH

TU

CHANNEL DISPLAY

CHANNEL DISPLAY

POSITION CH1

CHANNEL DISPLAY

POSITION CH12

BUFFER

Q001

RV001

POSITION CH13

RV002

V LOW

RV004

V HI

AMP

Q002

7

H SYNC

BT

26

UP

18

UA

22

20

VLP

19

VHP

23

VHA

24

VLA

BT

GEN.

INITIAL

SET

BAR

DISPLAY

POSITION

ADJUST

CHARGE/

DISCHARGE

CIRCUIT

BAR

OUTPUT

8

CS

10

V

30

U

31

INV., SWITCH

Q003,004

IND

UP DOWN SW11

T1 (TUNER, VIF/SIF DET)

– 9 –

– 10 –

Page 10

4-2. BLOCK DIAGRAM (2)

TO

T1 BOARD

CN201

UB 12

VHF

H.P

AUDIO

VIDEO

CN502

2

3

5

9

AUDIO

+4.5V

RV501

VOL

S601

(1/2)

IC501 HEADPHONE AMP

3

2

VCC

IC401

MONITOR CONTROL

CN601 CN301

VHF

H.P

2

3

2

3

UHF

VHF

OFF

AUDIO

6

V+

7

AUDIO

J501

2

SPEAKER

VIDEOVIDEO

VIDEO

9

9

VIDEO

BUFFER

Q403

SYNC. SEP.

Q303

4037R2

34

HSO

V IN

CL2

CLB

CLA

BESTB

TPR1B

CP

D2

D3

D4

D1

DB 10

1

2

3

4

5

6

7

8

9

12

VM BUFFER

13TPR1

Q407

SWITCH

Q406

CL2

CL2

CLB

CLB

CLA

CLA

RES

RES

TPR2

TPR1

VSS

24

CP

40

CP

22

38

21

37

20

36

D2

12

D2

28

D3

11

D3

27

10

D4

26

D1

9

D1

25

13

29

2

6

VM

23

VM

39

VM

4

3

LCD

MONITOR

H SYNC

IND

UP DOWN SW 11

BATTERY

J701

DC IN 4.5V

7

8

S601

(2/2)

UHF

VHF

OFF

S001 S002

-

CH

D701

H SYNC

7

T601

9

RV601

+4.5V

RV450

PORT SWITCH

Q601-603

BUFFER

Q401

BRT

DRIVE

Q701

DRIVE

Q702

F601

+4.5V

+

8

4

+30V

T701

3

2

4

1

5

+30V

1

+4.5V

6

7

3

11 11BRT

8

6

IND

FR701

LCD

BACK LIGHT

7

88

IND SWITCH

Q408

IC301 Y/C JUNGLE

VIDEO IN

29

SYNC SEP

TINT CONT

19 10

RV301

TINT

3.58MHz

VCXO IN

21 11

VCXO OUT

23 12

X301

HD IN

CONTRAST

R OUT

G OUT

B OUT

51

INV.

Q302

35 H IN

38 INB

R40

AUTO CB

23

R IN

28

G IN

29

27

B IN

XT1

XTD

20

21

30TGL VL

BUFFER

Q402

X401

4.5MHz

RV402

CONTRAST

VDG

VDR

VDG

VDR

VDB

VDB

VS2

VS2

17

18

33

34

16

32

15

31

A (POWER SUPPLY, LCD BACK LIGHT, HEADPHONE AMP)

– 11 –

B (Y/C JUNGLE, MONITOR CONTROL)

– 12 –

Page 11

MEMO

G

D

S

B1 E1

C2

B2 C1

E2

2

3

4

5

6

7

8

9

0

!¡

!™

!¢

!§

!¶

!•

–

1

G

D

S

B2 E2

C1

B1 C2

E1

B2 E2

C1

B1 C2

E1

B2 E2

C1

B1 C2

E1

!ª

B1 E1

E2

C1(B2)

C2

@º

B1

E2

C1

C2

@™

@£

(B2)

E1

(B2)

E1

E2

B1

C2

C1

@¡

B1

E1

C2

B2

C1

E2

G

S

S

D

G

D

B1

E1

C2

B2

C1

E2

B1

E2

C2C1(B2)

E2

B1

C1

C2E1(B2)

C2

B1

C1

E2E1(B2)

C2

B1

C1

E2

B2

E1

C2

Ver.1.5

Transistor

(FET)

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Transistor

Discrete semiconductot

(Chip semiconductors that are not actually used are included.)

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Diode

Source

Source

Anode

Anode

(NC)

(NC)

Cathode

Anode

Cathode

Common

Cathode

Cathode

Common

Cathode

Cathode

Common

Common

Common

Common

Cathode

Anode

Base

Emitter

Collector

Base

Emitter

Collector

Drain

Gate

Gate

Drain

Device Printed symbol Terminal name

Circuit

Terminal name of semiconductors in silk screen

printed circuit (

*

)

Anode

Anode

Anode Cathode

Anode Anode

Cathode

!£

Transistor

(FET)

Transistor

(FET)

!∞

Emitter

Collector

Base

Transistor

Source

Gate

Drain

Cathode

Anode

Anode

Cathode

Anode

Anode

4-3. CIRCUIT BOARDS LOCATION

Note: The symbol display is on the component slde.

The components identified by shading and mark

are critical for safety. Replace only with part number

B

specified.

The symbol indicate fast operating fuse.

Replace only with fuse of same rating as maked.

T1

A

4-4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

Note:

• Capacitors without voltage indication are all 50V.

• All resistors are in ohms.

kΩ=1000Ω, MΩ=1000kΩ

• Indication of resistance, which dose not have one for rating electrical power, is

as follows.

Pitch : 5mm

Rating electrical power :

•

•

•

•

: nonflammable resistor.

: fusible resistor.

: internal component.

: panel designation and adjustment for repair.

• All variable and adjustable resistors have characteristic curve B, unless otherwise

noted.

•

: earth-chassis.

• As to the voltage volue shown by the semiconductors on the Shematic Diagram,

see the another list

• Readings are taken with a color-bar signal input.

• Readings are taken with a 10MΩ digital multimeter.

• Voltages are dc with respect to ground unless otherwise noted.

• Voltage variations may be noted due to normal production tolerances.

• All voltages are in V.

• Circled numbers are waveform references.

•

•

: B+ bus.

: B– bus.

• : signal path.

Reference information

RESISTOR : RN MET AL FILM

: RC SOLID

: FPRD NONFLAMMABLE CARBON

: FUSE NONFLAMMABLE FUSIBLE

: RW NONFLAMMABLE WIREWOUND

: RS NONFLAMMABLE METAL OXIDE

: RB NONFLAMMABLE CEMENT

COIL : LF-8L MICRO INDUCTOR

:

CAP A CIT OR : T A T ANTALUM

: PS STYROL

: PP POLYPROPYLENE

: PT MYLAR

: MPS METALIZED POLYESTER

: MPP METALIZED POLYPROPYLENE

: ALB BIPOLAR

: ALT HIGH TEMPERATURE

: ALR HIGH RIPPLE

– 13 –

1

/

W

4

ADJUSTMENT RESISTOR

– 14 –

Page 12

T1 BOARD : IC001 AN5707NFAP

STOP DEF

13 14 15 17

CHCAL

L/H U/V

7 27 8

Vcc 5VBRT

AFC

H.P.

M.M.

H.syn

SUD

5

COMPARATOR

3

PLUSE WIDTH

2

SET

SIGNAL

DET

4

1

FH

DEFEAT

OUT

TUNING

CONTROL

UP

BSTOP

DN

INPUT

CONTROL

6

AUTO

INITIAL RESET

29

GND

RETURN

9

BT GENERATOR

26

16

32

25

26

BTNCNCNCNC

CHARGE/

DISCHAGE

12 11

10

C.S.

CHAMANU

T1 BOARD : IC201 M51348AFP

13AUDIO OUT

BUFFER

14E-VDL

LIMITER

15FM DET IN

FM DET

16LIMITER OUT

17AFT OUT

18VIDEO OUT

19REF COIL

20REF COIL

VIDEO

DET

VIDEO AMPAFT

2nd

Amp

1st

Amp

21AFT COIL

AGC

22SYNC SEP IN

23SYNC OUT

24

SYNC

SEP

IF AGC

DET

GND (SIF)

12

DC F/B

11

SIF IN

10

Vcc (SIF)

9

GND (VIF)

8

IF IN

7

IF IN

6

Vcc (VIF)

5

RF AGC DELAY

4

RF AGC OUT

3

AGC FILTER II

2

1IF AGC ADJ

AGC FILTER I

BAND

SW

BS ADD

BAR OUTPUT

BAR DISPLAY

POSITION

ADJUST

24

23

VHA VLA

28 BS

30 V OUT

31 U OUT

18 UP

20 VLP

19 VHP

21 CON

22 UA

G

• T1 BOARD WAVEFORMS

1

3.4Vp-p (H)

1

STRAP

ANTENNA

A

1

2

3 4

2

EXT ANT

T101

6

J101

TU101

G

ANT

IFMBLBHBUBTUAGC

R101

100

:CHIP

B

C105

C001

4.7

25V

:7L

DEF

STOP

CHCAL

IC001

AN5707NFAP

R001

100k

:CHIP

C002

6.3V

MANU

470p B:CHIP

47

:7L

C101

1/16V F:CHIP

R031

82k

:CHIP

Q004

UN2110-TX

9

10111213141516

CS

NC

CHA

VCC

UH

SUD

AFC

HSYNC

H.P

2

M.M

1 2 3 4 5 6 7 8

FH

V OUT

U OUT

NC

32

R011

10k

:CHIP

30V

MA152WK-TX

R022

27k

:CHIP

ULOW

RV001

47k

:CHIP

VLOW

RV002

47k

:CHIP

VHI

Q001

2SB709A-R

R008

270k

:RN-CP

1

2

4

1

4

3

6

D001

2

1

RV004

100k

:CHIP

5

3

30V

:RN-CP

2

4.5V

R012

330k

:CHIP

C011

10

16V

:7L

NC

BRT

1718192021222324

UP

C003

VHP

560p

CH:CHIP

VLP

CON

UA

R002

100k

VHA

:CHIP

VLA

R030

R003

0

68k

:CHIP

:CHIP

R023

:CHIP

R004

47k

:CHIP

1

4

6

3

5

R009

33k

R047

10k

:CHIP

0

2

Q002

XN4601

C012

F:CHIP

:CHIP

16V

R005

150k

1

NCBTU/VBSGND

25262728293031

C

D

E

F

Q010

XN1115

3

R046

47k

:CHIP

5

Q011

XN4215

Q012

XN2210

UN211D-TX

D002

R016

39k

:CHIP

C014

0.1 25V F:CHIP

C007

0.001 B:CHIP

R017

18k :CHIP

C008

0.47

25V

F:CHIP

2

43

Q007

Q003

UN2210-TX

MA157-TX

IF

R021

100k

:CHIP

B:CHIP

R013

56k :CHIP

C021

0.1

F:CHIP

F:CHIP

C004

47

6.3V

:7L

:CHIP

3.7Vp-p (H)

C016

0.1

25V

F:CHIP

R029

470

:CHIP

C005

0.01

R014

25V

39k

:CHIP

C006

0.1

25V

R010

2.2

:CHIP

R018

100k

4.5V

C210

0.01

B:CHIP

:CHIP

IF

2SC3837KT146Q

R216

1.2k

:CHIP

R218

68

R219

:CHIP

3

0.9Vp-p (H)

98765

R032

2.2k

:CHIP

C015

100p

AUDIO

CH:CHIP

R201

680

:CHIP

0.001

B:CHIP

680 :CHIP

:CHIP

10k :CHIP

131415161718192021222324

OUT

AUDIO

(SIF)

GND

C213

0.01

B:CHIP

C204

R208

R228

10k

VIDEO

Q202

2SB709A-R

SIF

:CHIP

1k

R221

4.5V

LLD

DELAY

0.01 B:CHIP

R241

180k

:CHIP

31

REF COIL

(VIF)

VCC

C215

47

6.3V

:7L

R202

220

:CHIP

CF201

TPS4.5MC

4

VIDEO

321 6

R209

1.8k :CHIP

DET OUT

REF COIL

IC201

M51348AFP

IF IN

IF IN

IF

IF

R224

1.5k

:CHIP

RV201

1k

:CHIP

R229

8.2k

:CHIP

R231

:FR-CP

L201

15µH

R205

R210

100k :CHIP

33k :CHIP

AFT OUT

GND

8

12

3

C203

0.1 25V F:CHIP

R212

(VIF)

C212

0.01 B:CHIP

:CHIP

680 :CHIP

LIMITER

VCC

SIF

R240

3

CF202

OUT

10k

(SIF)

C202

0.01

B:CHIP

VIDEO VIDEO

C205

21

R206

10

16V

1.8k :CHIP

:7L

CDA4.5MC

R213

C206

27p CH:CHIP

E-VDL

FM DETIN

SIF IN

DC F/B

109 11 12

21

3

CF203

C218

0.01

SFSL4.5MDB

B:CHIP

C234

0.01

B:CHIP

R242

C235

470

0.001

:CHIP

B:CHIP

T201 T202

45.75MHZ 45.75MHZ

T1

TUNER,

VIF, SIF DET

L205

Q201

0.82µH

:FR-CP

R234

C229

1.2k

0.01

:CHIP

B:CHIP

R220

390

47

:CHIP

:CHIP

R214

1k

B:CHIP

C209

0.01

C211

0.01

B:CHIP

R215

10

:CHIP

SWF201

F1248

I

132

SWF

GOO

4.5V

IF

:FR-CP

4

L206

R217

1µH

3.3k :CHIP

IF

4.5V

AFT

6

CH:CHIP

4.5V

R243

22k

:CHIP

ADJ

IF AGC

AGC

FILTER OUT

1 2 3 4 5 6 7

R235

5.6k

:CHIP

C222

10

16V

:7L

R226

R225

3.3k

4.7k

:CHIP

C223

:CHIP

1

C224

0.01

B:CHIP

C207

10p

SYNC OUT

AGC

:CHIP

C219

3.3

1

2

34

R223

SYNC SEP

OUT

FILTER IN

RF AGC

1k

C225

R230

:CHIP10:CHIP

AFT COIL

RF AGC

C226

0.01 B:CHIP

10

10

CN201

12P

1

D.GND

2

VHF

3

H.P

4

4.5V

5

AUDIO

6

30V

7

H.SYNC

8

IND

9

R233

:CHIP

VIDEO

10

A.GND

11

UP DOWN SW

12

UB

100

A.GND

C228

0.01

B:CHIP

C236

22

6.3V

:7L

Q203

UN2210

30V

B-¥SS10904.<U..>-T1.

TO

A BOARD

CN602

11

– 15 –

– 16 –

Page 13

1

A

B

C

D

E

2

98765

43

T1

[ ]

ELECTRONIC TUNRTR, VIF, SIF

T1 BOARD IC VOLTAGE LIST

Pin Volt Pin Volt Pin Volt

IC001 1 2.7

20

3 0.3

4 0.5

5 2.5

6 2.5

7 2.5

8 4.3

910 0.7

11 2.5

12 0

13 0.3

14 0.0

15 3.7

16 17 18 0

19 2.2

20 2.2

21 2.9

22 0.8

23 2.1

24 2.1

25 26 1.7

27 3.8

28 0

29 GND

30 0

31 0

32 0

IC201 1 3.4

2 3.4

3 1.6

4 3.3

5 4.2

6 3.4

7 3.4

8 GND

9 4.3

10 1.6

11 1.6

12 GND

13 1.8

14 3.5

15 2.1

16 1.5

17 2.4

18 2.0

19 1.9

20 1.9

21 3.4

22 3.4

23 0.4

24 1.7

T1 BOARD

DIODE

D001 B-7 8

D002 B-2 7

IC

IC001 C-2

IC201 B-6

TRANSISTOR

Q001 D-8 1

Q002 D-8 !•

Q003 B-8 1

Q004 B-8 1

Q007 B-2 2

Q010 D-10

Q011 D-7 !¶

Q012 D-7 1

Q201 D-6 2

Q202 B-3 1

Q203 D-4 1

VARIABLE

*

*

– T1 Board –

RESISTOR

RV001 B-3

RV002 B-3

RV004 B-3

RV201 B-3

T1 BOARD TRANSISTOR VOLTAGE LIST

BCE

Q003 0 3.7 GND

Q004 3.7 0.7 4.3

Q007 2.6 0.5 4.3

Q201 1.0 4.2 0.3

Q202 1.9 GND 2.6

Q203 0 3.5 GND

123456

Q002 0 1.7 2.2 29.5 1.7 2.2

< Component Side >

< Conductor Side >

– 17 –

– 18 –

Page 14

1

NC1NC 8

V+

2+INPUT 7

OUTPUT

100kΩ

50kΩ300Ω

3-INPUT

6

POWER

GND

4GND 5

BIAS

+

-

A BOARD : IC501 NJM2070M

2

43

98765

A

B

C

D

E

TO

T1 BOARD

CN201

DRY BATTERY

3PCS. 4.5V

CN602

12P

D.GND

VHF

H.P

4.5V

AUDIO

30V

H.SYNC

IND

VIDEO

A.GND

UP DOWN SW

UB

TO SPEAKER

2

J501

POWER SUPPLY,

A

LCD BACK LIGHT,

1

2

3

4

5

6

7

8

9

10

11

12

HEADPHONE AMP

AUDIO

VIDEO

CH -

S001

21

3

S002

CH +

21

3

R028

10k

:CHIP

C501

0.01

B:CHIP

UNREG

R617

UHF

68

:CHIP

VHF

S601

OFF

F601

1A

125V

VOL

30V

R509

120k

:CHIP

RV501

10k

R513

2.2

:CHIP

C506

0.1

25V

F:CHIP

1

3

2

Q601

2SD601A-R

C504

16V

:7L

B:CHIP

10

C503

0.01

C502

100

6.3V

:7L

1 2 3 4

R510

10k

:CHIP

30V

R601

47k

:CHIP

R608

47k

:CHIP

C602

F:CHIP 100p

UNREG

AUDIO

5678

R605

100 :CHIP

0.0047

B:CHIP

Q603

2SD1119-Q

C604R603R602

R604

330

:CHIP

C505

6.3V

C605

CH:CHIP

100

:7L

C507

0.22

F:CHIP

R501

4.7

:CHIP

R504

470

:CHIP

25V

R505

470

:CHIP

R506

390

:CHIP

R616

10k

:CHIP

T601

9

8

4

5

NC

NC

V+

+IN

OUTPAT

-IN

GND

GND

IC501

NJM2070M-TE2

VIDEO VIDEO

D605

1SS355TE

Q602

2SD601A-R

C601

C603

100 10V :7L

0.1

25V

B:CHIP

47k

0.1

:CHIP22:CHIP

25V

SB01-15CP

1

6

7

3

CH:CHIP

2

C610

220p

D602

R611

2.2k

:CHIP

SP

1

D603

SB05-05CP

B:CHIP

CN501

SP.GND

2

R610

100

:CHIP

C619

0.01

C611

2P

D406

MA157-TX

R450

100k

:CHIP

30V

Q401

UN2215

R451

82k

:CHIP

3

2

1

RV450

50k

BRT

VIDEO

CN601

12P

1

D.GND

2

VHF

3

H.P.

4

4.5V

5

D.GND

6

A.GND

7

H.SYNC

8

IND

9

VIDEO

10

A.GND

11

BRT

12

NC

TO

B BOARD

CN301

4.5V

R615

10k

:CHIP

10

:7L

C613

C612

220 16V :7L

0.01 B:CHIP

MA8360-TX

D604

C615

0.01 B:CHIP

C614

0.01 B:CHIP

Q610

2SB709A-R

D601

MA8043-M

R614

:CHIP

33k :CHIP

1

3

2

:CHIP

:FR-CP

R612

330

RV601

220

:CHIP

+4.5V

R613

560

L601

47µH

4.5V

C616

0.01

B:CHIP

C617

220

16V

:7L

– 19 –

F

G

H

DC IN 4.5V

B-¥SS10904.<U..>-A.. (02)

L701

100µH

R701

330

1/8W

:CHIP

Q701

2SC2873Y

C701

100

Q702

6.3V

:7L

2SC2873Y

D701

J701

1

+

3

2

-

11EQS04-TA1B

C702

0.22

2

3

9

C703

22p

T701

8

7

6

2kV

FR701

4

:PP

1

5

C704

0.1

25V

F:CHIP

– 20 –

Page 15

1

A

B

C

D

E

F

G

H

I

2

5

43

A

[ ]

AUDIO AMP, PC IN, BACK LIGHT

– A Board –

A BOARD

DIODE

D406 G-5 6

D601 G-4 3

D602 D-4 5

D603 G-4 4

D604 C-5 3

D605 C-4 3

D701 D-3 –

*

IC

IC501 G-5

TRANSISTOR

Q401 G-5 1

Q601 C-4 2

Q602 D-4 2

Q603 F-4 2

Q610 C-5 2

Q701 G-3 2

Q702 G-3 2

*

VARIABLE

RESISTOR

RV450 C-6

RV501 D-5

RV601 C-5

A BOARD IC VOLTAGE LIST

Pin Volt

IC501 1 -

20

3 0.6

4 GND

5 GND

6 1.3

7 3.4

8-

< Component Side >

A BOARD TRANSISTOR VOLTAGE LIST

BCE

Q401 13.9 30.5 13.4

Q601 0.5 1.2 GND

Q602 0.7 3.1 0.2

Q603 0.2 3.0 GND

Q610 30.7 0.5 30.7

Q701 0 3.0 GND

Q702 0 3.0 GND

– 21 –

< Conductor Side >

– 22 –

Page 16

2.0Vp-p (4.5MHz)

1

1.1Vp-p (4.43MHz)

2

1.0Vp-p (H)

3

0.7Vp-p (H)

4

4.1Vp-p (H)

5

1.4Vp-p (H)

6

1.4Vp-p (H)

7

1.4Vp-p (H)

8

• B BOARD WAVEFORMS

1

2

43

98765

10

11

A

4.5V

B

CN301

C

TO

A BOARD

CN601

D

E

F

G

12P

D.GND

VHF

H.P.

4.5V

D.GND

A.GND

H.SYNC

IND

VIDEO

A.GND

BRT

NC

1

2

3

4

5

6

7

8

9

10

11

12

R309

10

:CHIP

C301

47

6.3V

:7L

D303

MA8051

X301

3.58MHz

VIDEO

IC301

M52042FP

3

VIDEO

C307

4.7

25V

:7L

R311

150k

:CHIP

R320

1.5k

:CHIP

C314

4.7

25V

:7L

C313

0.0015

B:CHIP

Y/C JUNGLE,

B

MONITOR CONTROL

4.5V

R301

0

:CHIP

C303

C311

180p

0.01

B:CHIP

:CHIP

C302

15p

CH:CHIP

:CHIP

VCXO

2

VCC

VIDEOINSYNC

1 2 3 4 5 6 78109 11 12

4

R312

560

:CHIP

C308

680p

B:CHIP

R323

2.2M

:CHIP

R324

:CHIP

R303

470

VCXO

10k

OUT

SEP IN

VCXO

MONITER

ACC

FILTER

R313

3.3k :CHIP

R304

IN

VCXO

CONT

COLER

5

HD IN

SYNC

OUT

C309

470k :CHIP

Q303

2SB709A-R

1M :CHIP

R306

TINT

CONT

CLUMP

1SS355TE

R310

:CHIP

R314

0.1 25V B:CHIP

100k

:CHIP

C310

0.01

B:CHIP

D302

MA8051

D301

68k

RV301

47k

:CHIP

47k :CHIP

R305

FILTER

KILLER

CHROMA

TRAP

APC

Y OUT

C312

F:CHIP

C306

0.033

25V

B:CHIP

C304

0.1

25V

B:CHIP

SW

FILTER

CONTRAST

0.1

25V

OUT

KILLER

R OUT

R

131415161718192021222324

PIX

CONT

7

G OUT

G

:CHIP

:CHIP

B OUT

:CHIP

R307

GND

R315

B

R308

4.7k

22k

R403

47

:CHIP

R405

68k

:CHIP

1SS355TE

D405

C402

4.7

35V

:7L

47k

8

6

R318

39k

:RN-CP

R322

68k

:RN-CP

R

G

R316

270k

:CHIP

B

R317

4.7k

:CHIP

Q302

UN5210

CH:CHIP

C315

R431

33k

:CHIP

D401

1SS355TE

R416

47

:CHIP

47p

:CHIP

:CHIP

:CHIP

R406

R407

2.2k

R408

2.2k

680

2SD1819A-R

C403

22

6.3V

:7L

C415

100

6.3V

:7L

C418

F:CHIP

C419

B:CHIP

CH:CHIP

CH:CHIP

Q402

C405

22

6.3V

:7L

R404

100

:CHIP

0.1

25V

0.1

25V

C420

12p

C421

12p

C422

0.001

B:CHIP

0.001 B:CHIP

4.5V

R401

100

:CHIP

R402

C406

100

22

:CHIP

6.3V

:7L

C407

47

6.3V

:7L

R430

0

:CHIP

4.5V

12

13

14

15

16

17

18

19

20

21

22

R429

3.3k

:CHIP

C424 R423

R422

C425

4.7

25V

:7L

R418

1.5k

:CHIP

R419

10k :CHIP

1k :CHIP

X401

C423

4.5V

R420

4.5MHz

0.001 B:CHIP

RB401 RB402 RB403 RB404

TPR1B

2.2kx2

1/16W

TPR1

:CHIP

VDDC

CV3

CV2

CV1

PLLO

PLLO2

XTI

1

XTO

VSSC

23 24 25 26 27 28 29 30 31 32 33

10k :CHIP

C427

0.1

25V

F:CHIP

R409

68k

:CHIP

C409 C410

0.1

0.1

25V

25V

B:CHIP

B:CHIP

R410

39k

:CHIP

214321432143214

DB

D1D4D3

VDDB

BESTB

2.2kx2

2.2kx2

1/16W

1/16W

:CHIP

:CHIP

IC401

A71-2980

AUTOCB

AUTOC

VDDABTBIN

RIN

B

R

6.8k :CHIP

R428

:CHIP

RV402

C428

47k

0.01

:CHIP

B:CHIP

47k

XP4601

D2

GIN

G

Q406

3

CLA

CLB

CL2

2.2kx2

1/16W

:CHIP

TGLVLRBPALB

R424

2.7k :CHIP

C411

0.47

25V

F:CHIP

R411

1M

:CHIP

C412

0.47

25V

F:CHIP

C408

0.01

B:CHIP

D403

1SS355TE

VSSB

G2

R2

B2

INB

HSO

VS2

HIN

VIN

C432

0.001

B:CHIP

44

43

42

41

40

39

38

37

36

35

34

R417

4.7k

:CHIP

2.2kx2 1/16W :CHIP

4.5V

:CHIP

Q403

UN2215

R421

10k

:CHIP

:CHIP

R436

43

21

1234567891011

CP

SGD1B

MUTEB

VSSA

R427

10k

RB405

1k

D404

1SS355TE

Q408

UN5210

R413

22k

:CHIP

C413 R412

100p

CH:CHIP

C414 R415

100p

CH:CHIP

Q407

XP4601

22k

:CHIP

R414

:CHIP

22k

:CHIP

22k

4.5V

B-¥SS10904.<U..>-B.. (02)

FP401

1

N.C.

2

TPR2

3

VSS

4

VM

5

VDD

6

TPR1

7

N.C.

8

N.C.

9

D1

10

D4

11

D3

12

D2

13

RESTB

14

VS1

15

VS2

16

VDB

17

VDG

18

VDR

19

VD1

20

CLA

21

CLB

22

CL2

23

VM

24

CP

25

D1

26

D4

27

D3

28

D2

29

RESTB

30

VS1

31

VS2

32

VDB

33

VDG

34

VDR

35

VD1

36

CLA

37

CLB

38

CL2

39

VM

40

CP

41

N.C.

42

N.C.

43

N.C.

TO

LCD UNIT

– 23 –

– 24 –

Page 17

1

A

B

C

D

E

F

G

2

5

43

B

[ ]

CHROMA, LCD INTERFACE

– B Board –

B BOARD IC VOLTAGE LIST

Pin Volt Pin Volt Pin Volt

IC301 1 3.0

2 3.1

3 0.6

45 3.5

6 2.5

78-

9 2.8

10 3.0

11 2.9

12 3.1

13 GND

14 0.3

15 16 17 1.5

18 3.7

19 1.6

20 2.0

21 3.4

22 23 2.0

24 4.2

IC401 1 1.3

20

3 0.8

4 0.8

5 2.7

6 2.7

7 2.8

8 2.8

9 3.3

10 1.9

11 3.9

12 3.9

13 0

14 3.9

15 1.7

16 1.7

17 1.7

18 1.7

19 1.7

20 2.0

21 2.0

22 GND

23 3.4

24 25 3.8

26 3.3

27 0.9

28 0.9

29 0.9

30 0.8

31 0.3

32 3.8

33 GND

34 1.8

35 1.1

36 0

37 0.3

38 3.6

39 GND

40 0

41 2.1

42 0

43 3.5

44 GND

B BOARD

DIODE

D301 B-2 3

D302 B-2 3

D303 F-2 3

D401 C-3 3

D403 F-4 3

D404 F-4 3

D405 B-3 3

IC

IC301 C-3

IC401 C-4

TRANSISTOR

Q302 C-3 2

Q303 B-2 2

Q402 B-3 2

Q403 C-3 2

Q406 C-5 @º

Q407 B-5 @º

Q408 C-3 2

VARIABLE

RESISTOR

RV301 B-2

RV402 C-4

*

*

< Component Side >

B BOARD TRANSISTOR VOLTAGE LIST

BCE

Q302 0.3 3.5 GND

Q303 3.6 1.8 4.1

Q402 3.9 4.4 3.2

Q403 2.1 0 GND

Q408 0 3.8 GND

123456

Q406 GND -0.7 6.5 12.4 13.3 6.5

Q407 1.8 0 6.5 1.8 1.8 13.3

– 25 –

< Conductor Side >

– 26 –

Page 18

4-5. SEMICONDUCTORS

3

4

4

3

A

A

16

1

2

3

5

4

9

6

7

8

11

24

21

22

25

23

18

17

19

19

20

15

14

13

12

A71-2980

1

TOP VIEW

44 pin QFP

XN4601

1

2

1

SECTION 5

EXPLODED VIEW

NOTE:

• Items with no part number and no

description are not stocked because they

SB-01-15CP

SB05-05CP

6

5

3

are seldom required for routine service

• The construction parts of an assembled part

are indicated with a collation number in the

remark column.

5-1. CHASSIS SECTION

2

6

3

2

5

4

3

1

3

2

1

r : 7-685-104-19 +P 2x6

• Items marked " * " are not stocked since

they are seldom required for routine

service. Some delay should be anticipated

when ordering these items.

The components identified by shading and

mark

are critial for safety.

!

Replace only with part number specified.

AN5707NFAP

1

TOP VIEW

32 pin QFP

M51348AFP

M52042FP

1

TOP VIEW

24 pin SOP

NJM2070M

827365

14

8 pin SOP

UN2110

UN211D

UN2210

UN2215

UN5210

2SB709A

2SC3837KQ

2SD601A

B

E

XN4215

MA8043

XP4601

MA8051

MA8240

MA8360

1SS355

ANODE

CATHODE

11EQS04

1

2

3

1

2

2SC2873Y

6

5

6

5

4

3

2SD1119-Q

CATHODE

B

C

E

ANODE

2SD1819A

3

C

2

E

1

B

MA152WK

3

2

1

MA157

2

1

3

2

1

2

1

C

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

1 4-561-075-51 CABINET, FRONT

2 4-561-076-01 SWITCH, POWER

3 4-561-093-03 BUTTON, CHANNEL

4 4-561-090-01 SHIELD, PANEL

5 1-803-293-11 MODULE, INDICATOR (NTSC)

6 * 4-048-325-01 ILLUMINATOR

7 * A-1136-215-AB BOARD, COMPLETE

8 1-517-702-11 LIGHT, BACK

9 * 3-703-044-26 LABEL, CAUTION

11 * A-1299-522-AA BOARD, COMPLETE

12 4-561-096-01 INSULATING SHEET

13 4-561-091-01 SHIELD, TU

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

14 4-561-097-01 INSULATING SHEET (2)

15 ! 1-693-467-11 TUNER UNITPLETE

16 * A-1395-039-AT1 BOARD, COMPLETE

17 4-561-081-01 SPRING (C), BATTERY

18 4-561-080-01 SPRING (B), BATTERY

19 4-561-079-01 SPRING (A), BATTERY

20 4-561-078-02 CASE, BATTERY

21 1-504-847-11 SPEAKER (2.8cm)

22 4-561-130-01 PLATE, LOCK

23 4-561-077-01 CABINET, REAR

24 1-754-205-11 ANTENNA, STRAP

– 27 –

– 28 –

Page 19

SECTION 6

ELECTRICAL PARTS LIST

FDL-PT222

T1

• Items marked " * " are not stocked since they are

The components identified by shading and

are critial for safety.

mark

!

Replace only with part number specified.

When indicating parts by reference number,

please include the board name.

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

* A-1395-039-AT1 BOARD, COMPLETE

*********************

4-561-091-01 SHIELD, TU

4-561-096-01 INSULATING SHEET

4-561-097-01 INSULATING SHEET (2)

<CAPACITOR>

C001 1-126-794-11 ELECT 4.7µF 20% 25V

C002 1-126-513-11 ELECT 47µF 20% 6.3V

C003 1-163-135-00 CERAMIC CHIP 560pF 5% 50V

C004 1-126-513-11 ELECT 47µF 20% 6.3V

C005 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C006 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C007 1-163-009-91 CERAMIC CHIP 0.001µF 10% 50V

C008 1-164-005-11 CERAMIC CHIP 0.47µF 25V

C011 1-126-791-11 ELECT 10µF 20% 16V

C012 1-164-346-11 CERAMIC CHIP 1µF 16V

C014 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C015 1-163-251-11 CERAMIC CHIP 100pF 5% 50V

C016 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C021 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C101 1-164-346-11 CERAMIC CHIP 1µF 16V

C105 1-163-005-91 CERAMIC CHIP 470pF 10% 50V

C202 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C203 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C204 1-163-009-91 CERAMIC CHIP 0.001µF 10% 50V

C205 1-126-791-11 ELECT 10µF 20% 16V

C206 1-163-237-11 CERAMIC CHIP 27pF 5% 50V

C207 1-163-227-11 CERAMIC CHIP 10pF 0.50pF 50V

C209 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C210 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C211 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C212 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C213 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C215 1-126-513-11 ELECT 47µF 20% 6.3V

C218 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C219 1-115-873-11 ELECT 3.3µF 20% 50V

C222 1-126-791-11 ELECT 10µF 20% 16V

C223 1-115-871-11 ELECT 1µF 20% 50V

C224 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C225 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C226 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C228 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C229 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C234 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C235 1-163-009-91 CERAMIC CHIP 0.001µF 10% 50V

C236 1-126-514-11 ELECT 22µF 20% 6.3V

seldom required for routine service. Some delay

should be anticipated when ordering these

items.

• All variable and adjustable resistors have

characteristic curve B, unless otherwise noted.

RESISTORS

• All resistors are in ohms

• F : nonflammable

• CAPACITORS

PF : µµ F

• There are some cases the reference

number on one board overlaps on the

other board. Therefore, when ordering

parts by the reference number, please

include the board name.

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

<FILTER>

CF201 1-527-943-00 CERAMIC TRAP

CF202 1-760-642-11 DISCRIMINATOR, CERAMIC

CF203 1-577-559-21 FILTER, CERAMIC

<CONNECTOR>

CN201 1-785-361-11 CONNECTOR, BOARD T O BOARD

<DIODE>

D001 8-719-801-78 DIODE MA152WK-TX

D002 8-719-800-76 DIODE MA157-TX

<IC>

IC001 8-759-332-43 IC AN5707NFAP

IC201 8-759-176-91 IC M51348AFP-E1

<JACK>

J101 1-568-027-21 JACK, SMALL TYPE (EXT ANT)

<COIL>

L201 1-412-953-11 INDUCTOR 15µH

L205 1-412-938-11 INDUCTOR 0.82µH

L206 1-412-939-11 INDUCTOR 1µH

<TRANSISTOR>

Q001 8-729-216-22 TRANSISTOR 2SB709A-R-TX

Q002 8-729-402-84 TRANSISTOR XN4601-TW

Q003 8-729-424-76 TRANSISTOR UN2210-TX

Q004 8-729-424-38 TRANSISTOR UN2110-TX

Q007 8-729-424-45 TRANSISTOR UN211D-TX

Q010 8-729-403-45 TRANSISTOR XN1115-TX

Q011 8-729-422-54 TRANSISTOR XN4215-TW

Q012 8-729-424-76 TRANSISTOR UN2210-TX

Q201 8-729-031-37 TRANSISTOR 2SC3837KT146Q

Q202 8-729-216-22 TRANSISTOR 2SB709A-R-TX

– 29 –

Page 20

FDL-PT222

T1

B

The components identified by

shading and mark

cal for safety.

Replace only with part number

specified.

! are criti-

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

Q203 8-729-424-76 TRANSISTOR UN2210-TX

<RESISTOR>

R001 1-216-097-11 RES-CHIP 100K 5% 1/10W

R002 1-216-097-11 RES-CHIP 100K 5% 1/10W

R003 1-216-093-91 RES-CHIP 68K 5% 1/10W

R004 1-216-089-91 RES-CHIP 47K 5% 1/10W

R005 1-216-101-00 RES-CHIP 150K 5% 1/10W

R008 1-218-762-11 METAL CHIP 270K 0.5% 1/10W

R009 1-216-687-11 METAL CHIP 33K 0.5% 1/10W

R010 1-216-298-00 RES-CHIP 2.2 5% 1/10W

R011 1-216-073-91 RES-CHIP 10K 5% 1/10W

R012 1-216-109-00 RES-CHIP 330K 5% 1/10W

R013 1-216-091-00 RES-CHIP 56K 5% 1/10W

R014 1-216-689-11 RES-CHIP 39K 5% 1/10W

R016 1-216-689-11 RES-CHIP 39K 5% 1/10W

R017 1-216-079-00 RES-CHIP 18K 5% 1/10W

R018 1-216-097-11 RES-CHIP 100K 5% 1/10W

R021 1-216-097-11 RES-CHIP 100K 5% 1/10W

R022 1-216-083-00 RES-CHIP 27K 5% 1/10W

R023 1-216-295-91 SHORT 0

R029 1-216-041-00 RES-CHIP 470 5% 1/10W

R030 1-216-295-91 SHORT 0

R031 1-216-095-00 RES-CHIP 82K 5% 1/10W

R032 1-216-057-00 RES-CHIP 2.2K 5% 1/10W

R046 1-216-089-91 RES-CHIP 47K 5% 1/10W

R047 1-216-073-91 RES-CHIP 10K 5% 1/10W

R101 1-216-025-11 RES-CHIP 100 5% 1/10W

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

R235 1-216-067-00 RES-CHIP 5.6K 5% 1/10W

R240 1-216-073-91 RES-CHIP 10K 5% 1/10W

R241 1-216-103-00 RES-CHIP 180K 5% 1/10W

R242 1-216-041-00 RES-CHIP 470 5% 1/10W

R243 1-216-081-00 RES-CHIP 22K 5% 1/10W

<VARIABLE RESISTOR>

R V001 1-223-588-11 RES, ADJ, CARBON 47K (CHANNEL

R V002 1-223-588-11 RES, ADJ, CARBON 47K (CHANNEL

R V004 1-223-589-11 RES, ADJ, CARBON 100K (CHANNEL

R V201 1-223-583-11 RES, ADJ, CARBON 1K (RF AGC)

<SA W FILTER>

SWF201 1-767-766-12 FILTER, SAW

<TRANSFORMER>

T101 1-437-418-21 TRANSFORMER, BALUN

T201 1-411-278-11 COIL

T202 1-411-278-11 COIL

<TUNER>

TU101! 1-693-467-11 TUNER UNIT

DISPLAY POSITION 13ch)

DISPLAY POSITION 1ch)

DISPLAY POSITION 12ch)

R201 1-216-045-00 RES-CHIP 680 5% 1/10W

R202 1-216-033-00 RES-CHIP 220 5% 1/10W

R205 1-216-097-11 RES-CHIP 100K 5% 1/10W

R206 1-216-055-00 RES-CHIP 1.8K 5% 1/10W

R208 1-216-045-00 RES-CHIP 680 5% 1/10W

R209 1-216-055-00 RES-CHIP 1.8K 5% 1/10W

R210 1-216-085-91 RES-CHIP 33K 5% 1/10W

R212 1-216-045-00 RES-CHIP 680 5% 1/10W

R213 1-216-073-91 RES-CHIP 10K 5% 1/10W

R214 1-216-049-11 RES-CHIP 1K 5% 1/10W

R215 1-216-001-00 RES-CHIP 10 5% 1/10W

R216 1-216-051-00 RES-CHIP 1.2K 5% 1/10W

R217 1-216-061-91 RES-CHIP 3.3K 5% 1/10W

R218 1-216-021-00 RES-CHIP 68 5% 1/10W

R219 1-216-039-00 RES-CHIP 390 5% 1/10W

R220 1-216-017-91 RES-CHIP 47 5% 1/10W

R221 1-216-049-11 RES-CHIP 1K 5% 1/10W

R223 1-216-049-11 RES-CHIP 1K 5% 1/10W

R224 1-216-053-00 RES-CHIP 1.5K 5% 1/10W

R225 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R226 1-216-061-91 RES-CHIP 3.3K 5% 1/10W

R228 1-216-073-91 RES-CHIP 10K 5% 1/10W

R229 1-216-071-00 RES-CHIP 8.2K 5% 1/10W

R230 1-216-001-00 RES-CHIP 10 5% 1/10W

R231 1-216-001-00 RES-CHIP 10 5% 1/10W

R233 1-216-025-11 RES-CHIP 100 5% 1/10W

R234 1-216-051-00 RES-CHIP 1.2K 5% 1/10W

*************************************************************************************************************

* A-1136-215-AB BOARD, COMPLETE

*********************

<CAPACITOR>

C301 1-126-513-11 ELECT 47µF 20% 6.3V

C302 1-163-231-11 CERAMIC CHIP 15pF 5% 50V

C303 1-163-257-11 CERAMIC CHIP 180pF 5% 50V

C304 1-164-004-11 CERAMIC CHIP 0.1µF 10% 25V

C306 1-163-989-11 CERAMIC CHIP 0.033µF 10% 25V

C307 1-126-794-11 ELECT 4.7µF 20% 25V

C308 1-163-007-11 CERAMIC CHIP 680pF 10% 50V

C309 1-164-004-11 CERAMIC CHIP 0.1µF 10% 25V

C310 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C311 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C312 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C313 1-163-011-11 CERAMIC CHIP 0.0015µF 10% 50V

C314 1-126-794-11 ELECT 4.7µF 20% 25V

C402 1-115-866-11 ELECT 4.7µF 20% 35V

C403 1-126-514-11 ELECT 22µF 20% 6.3V

C405 1-126-514-11 ELECT 22µF 20% 6.3V

C406 1-126-514-11 ELECT 22µF 20% 6.3V

C407 1-126-513-11 ELECT 47µF 20% 6.3V

– 30 –

Page 21

FDL-PT222

B

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

C408 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C409 1-164-004-11 CERAMIC CHIP 0.1µF 10% 25V

C410 1-164-004-11 CERAMIC CHIP 0.1µF 10% 25V

C411 1-164-005-11 CERAMIC CHIP 0.47µF 25V

C412 1-164-005-11 CERAMIC CHIP 0.47µF 25V

C413 1-163-251-11 CERAMIC CHIP 100pF 5% 50V

C414 1-163-251-11 CERAMIC CHIP 100pF 5% 50V

C415 1-126-382-11 ELECT 100µF 20% 6.3V

C418 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C419 1-164-004-11 CERAMIC CHIP 0.1µF 10% 25V

C420 1-163-229-11 CERAMIC CHIP 12pF 5% 50V

C421 1-163-229-11 CERAMIC CHIP 12pF 5% 50V

C422 1-163-009-91 CERAMIC CHIP 0.001µF 10% 50V

C423 1-163-009-91 CERAMIC CHIP 0.001µF 10% 50V

C424 1-163-009-91 CERAMIC CHIP 0.001µF 10% 50V

C425 1-126-794-11 ELECT 4.7µF 20% 25V

C427 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C428 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C432 1-163-009-91 CERAMIC CHIP 0.001µF 10% 50V

<CONNECTOR>

CN301 * 1-779-896-11 CONNECTOR, BOARD TO BOARD 12P

<DIODE>

D301 8-719-988-61 DIODE 1SS355TE-17

D302 8-719-422-37 DIODE MA8051-TX

D303 8-719-422-37 DIODE MA8051-TX

D401 8-719-988-61 DIODE 1SS355TE-17

D403 8-719-988-61 DIODE 1SS355TE-17

D404 8-719-988-61 DIODE 1SS355TE-17

D405 8-719-988-61 DIODE 1SS355TE-17

<IC>

IC301 8-759-332-41 IC M52042FP-600C

IC401 8-759-368-68 IC A71-2980

<TRANSISTOR>

Q302 8-729-420-44 TRANSISTOR UN5210-TX

Q303 8-729-216-22 TRANSISTOR 2SB709A-R-TX

Q402 8-729-402-32 TRANSISTOR 2SD1819A-R-TX

Q403 8-729-902-99 TRANSISTOR UN2215-QRS(TX)

Q406 8-729-427-74 TRANSISTOR XP4601-TXE

Q407 8-729-427-74 TRANSISTOR XP4601-TXE

Q408 8-729-420-44 TRANSISTOR UN5210-TX

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

R307 1-216-089-91 RES-CHIP 47K 5% 1/10W

R308 1-216-073-91 RES-CHIP 10K 5% 1/10W

R309 1-216-001-00 RES-CHIP 10 5% 1/10W

R310 1-216-093-91 RES-CHIP 68K 5% 1/10W

R311 1-216-101-00 RES-CHIP 150K 5% 1/10W

R312 1-216-043-91 RES-CHIP 560 5% 1/10W

R313 1-216-113-00 RES-CHIP 470K 5% 1/10W

R314 1-216-097-11 RES-CHIP 100K 5% 1/10W

R315 1-216-081-00 RES-CHIP 22K 5% 1/10W

R316 1-216-107-00 RES-CHIP 270K 5% 1/10W

R317 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R318 1-216-689-11 METAL CHIP 39K 0.5%

R320 1-216-053-00 RES-CHIP 1.5K 5% 1/10W

R322 1-216-695-11 METAL CHIP 68K 0.5%

R323 1-216-129-00 RES-CHIP 2.2M 5% 1/10W

R324 1-216-073-91 RES-CHIP 10K 5% 1/10W

R401 1-216-025-11 RES-CHIP 100 5% 1/10W

R402 1-216-025-11 RES-CHIP 100 5% 1/10W

R403 1-216-017-91 RES-CHIP 47 5% 1/10W

R404 1-216-025-11 RES-CHIP 100 5% 1/10W

R405 1-216-093-91 RES-CHIP 68K 5% 1/10W

R406 1-216-045-00 RES-CHIP 680 5% 1/10W

R407 1-216-057-00 RES-CHIP 2.2K 5% 1/10W

R408 1-216-057-00 RES-CHIP 2.2K 5% 1/10W

R409 1-216-093-91 RES-CHIP 68K 5% 1/10W

R410 1-216-689-11 RES-CHIP 39K 5% 1/10W

R411 1-216-121-11 RES-CHIP 1M 5% 1/10W

R412 1-216-081-00 RES-CHIP 22K 5% 1/10W

R413 1-216-081-00 RES-CHIP 22K 5% 1/10W

R414 1-216-081-00 RES-CHIP 22K 5% 1/10W

R415 1-216-081-00 RES-CHIP 22K 5% 1/10W

R416 1-216-017-91 RES-CHIP 47 5% 1/10W

R417 1-216-065-91 RES-CHIP 4.7K 5% 1/10W

R418 1-216-053-00 RES-CHIP 1.5K 5% 1/10W

R419 1-216-073-91 RES-CHIP 10K 5% 1/10W

R420 1-216-049-11 RES-CHIP 1K 5% 1/10W

R421 1-216-073-91 RES-CHIP 10K 5% 1/10W

R422 1-216-073-91 RES-CHIP 10K 5% 1/10W

R423 1-216-069-00 RES-CHIP 6.8K 5% 1/10W

R424 1-216-059-00 RES-CHIP 2.7K 5% 1/10W

R427 1-216-049-11 RES-CHIP 1K 5% 1/10W

R428 1-216-089-91 RES-CHIP 47K 5% 1/10W

R429 1-216-061-91 RES-CHIP 3.3K 5% 1/10W

R430 1-216-295-91 SHORT 0

R431 1-216-085-91 RES-CHIP 33K 5% 1/10W

R436 1-216-073-91 RES-CHIP 10K 5% 1/10W

1/10W

1/10W

<RESISTOR>

R301 1-216-295-91 SHORT 0

R303 1-216-041-00 RES-CHIP 470 5% 1/10W

R304 1-216-061-91 RES-CHIP 3.3K 5% 1/10W

R305 1-216-089-91 RES-CHIP 47K 5% 1/10W

R306 1-216-121-11 RES-CHIP 1M 5% 1/10W

<NETWORK RESISTOR>

RB401 1-236-416-11 NETWORK, RES 2.2K

RB402 1-236-416-11 NETWORK, RES 2.2K

RB403 1-236-416-11 NETWORK, RES 2.2K

RB404 1-236-416-11 NETWORK, RES 2.2K

RB405 1-236-416-11 NETWORK, RES 2.2K

– 31 –

Page 22

FDL-PT222

A

The components identified by

shading and mark

cal for safety.

Replace only with part number

specified.

! are criti-

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

<VARIABLE RESISTOR>

R V301 1-223-588-11 RES, ADJ, CARBON 47K (TINT)

R V402 1-223-588-11 RES, ADJ, CARBON 47K (CONTRAST)

<CRYSTAL>

X301 1-567-505-11 OSCILLAT OR, CRYSTAL 3.58MHz

X401 1-760-601-21 VIBRAT OR, CRYSTAL 4.5MHZ

*************************************************************************************************************

* A-1299-522-AA BOARD, COMPLETE

C501 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C502 1-126-382-11 ELECT 100µF 20% 6.3V

C503 1-163-017-00 CERAMIC CHIP 0.0047µF 10% 50V

C504 1-126-791-11 ELECT 10µF 20% 16V

C505 1-126-382-11 ELECT 100µF 20% 6.3V

*********************

<CAPACITOR>

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

D603 8-719-938-75 DIODE SB05-05CP-TB

D604 8-719-018-15 DIODE MA8360-TX

D605 8-719-988-61 DIODE 1SS355TE-17

D701 8-719-210-21 DIODE 11EQS04-TA1B

<FUSE>

F601 ! 1-533-631-31 FUSE, MICRO 1A 125V

<IC>

IC501 8-759-046-84 IC NJM2070M-TE2

<JACK>

J501 1-563-282-11 JACK, SMALL TYPE ( 2)

J701 1-568-907-21 JACK, DC(POLARITY UNIFIED TYPE)

<COIL>

L601 1-412-031-11 INDUCTOR 47µH

L701 1-408-615-31 INDUCTOR 100µH

(DC IN 4.5V)

C506 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C507 1-164-222-91 CERAMIC CHIP 0.22µF 25V

C601 1-126-382-11 ELECT 100µF 20% 10V

C602 1-163-038-91 CERAMIC CHIP 0.1µF 25V

C603 1-164-004-11 CERAMIC CHIP 0.1µF 10% 25V

C604 1-163-017-00 CERAMIC CHIP 0.0047µF 10% 50V

C605 1-163-251-11 CERAMIC CHIP 100pF 5% 50V

C610 1-163-259-91 CERAMIC CHIP 220pF 5% 50V

C611 1-126-795-11 ELECT 10µF 20% 50V

C612 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C613 1-128-499-11 ELECT 220µF 20% 16V

C614 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C615 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C616 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C617 1-128-499-11 ELECT 220µF 20% 16V

C619 1-163-021-91 CERAMIC CHIP 0.01µF 10% 50V

C701 1-126-382-11 ELECT 100µF 20% 6.3V

C702 1-136-169-00 FILM 0.22µF 5% 50V

C703 1-109-879-11 CERAMIC 22pF 5% 2KV

C704 1-163-038-91 CERAMIC CHIP 0.1µF 25V

<CONNECTOR>

CN501 1-568-951-11 PIN, CONNECTOR 2P

CN601 * 1-770-605-11 CONNECTOR, BOARD TO BOARD 12P

CN602 * 1-770-605-11 CONNECTOR, BOARD TO BOARD 12P

<TRANSISTOR>

Q401 8-729-902-99 TRANSISTOR UN2215-QRS(TX)

Q601 8-729-422-29 TRANSISTOR 2SD601A-R-TX

Q602 8-729-422-29 TRANSISTOR 2SD601A-R-TX

Q603 8-729-421-15 TRANSISTOR 2SD1119-Q-TX

Q610 8-729-216-22 TRANSISTOR 2SB709A-R-TX

Q701 8-729-807-51 TRANSISTOR 2SC2873Y-TE12L

Q702 8-729-807-51 TRANSISTOR 2SC2873Y-TE12L

<RESISTOR>

R028 1-216-073-91 RES-CHIP 10K 5% 1/10W

R450 1-216-097-11 RES-CHIP 100K 5% 1/10W

R451 1-216-095-00 RES-CHIP 82K 5% 1/10W

R501 1-216-308-00 RES-CHIP 4.7 5% 1/10W

R504 1-216-041-00 RES-CHIP 470 5% 1/10W

R505 1-216-041-00 RES-CHIP 470 5% 1/10W

R506 1-216-039-00 RES-CHIP 390 5% 1/10W

R509 1-216-099-00 RES-CHIP 120K 5% 1/10W

R510 1-216-073-91 RES-CHIP 10K 5% 1/10W

R513 1-216-298-00 RES-CHIP 2.2 5% 1/10W

R601 1-216-089-91 RES-CHIP 47K 5% 1/10W

R602 1-216-089-91 RES-CHIP 47K 5% 1/10W

R603 1-216-009-91 RES-CHIP 22 5% 1/10W

R604 1-216-037-00 RES-CHIP 330 5% 1/10W

R605 1-216-025-11 RES-CHIP 100 5% 1/10W

<DIODE>

D406 8-719-800-76 DIODE MA157-TX

D601 8-719-421-82 DIODE MA8043-M(TX)

D602 8-719-989-93 DIODE SB01-15CP-TB

R608 1-216-089-91 RES-CHIP 47K 5% 1/10W

R610 1-216-025-11 RES-CHIP 100 5% 1/10W

R611 1-216-057-00 RES-CHIP 2.2K 5% 1/10W

R612 1-216-037-00 RES-CHIP 330 5% 1/10W

R613 1-216-043-91 RES-CHIP 560 5% 1/10W

– 32 –

Page 23

The components identified by

shading and mark ! are critical for safety.

Replace only with part number

specified.

REF. NO. PART NO. DESCRIPTION REMARK

–––––––– ––––––––– ––––––––––––– –––––––––

R614 1-216-085-91 RES-CHIP 33K 5% 1/10W

R615 1-216-073-91 RES-CHIP 10K 5% 1/10W

R616 1-216-073-91 RES-CHIP 10K 5% 1/10W

R617 1-216-021-00 RES-CHIP 68 5% 1/10W

R701 1-216-186-00 RES-CHIP 330 5% 1/8W

<VARIABLE RESISTOR>

R V450 1-223-901-21 RES, VAR 50K (BRT)

R V501 1-223-900-21 RES, VAR 10K (VOL)

R V601 1-223-581-11 RES, ADJ, CARBON 220 (+4.5V)

<SWITCH>

S001 1-571-532-21 SWITCH, TACTIL (CH -)

S002 1-571-532-21 SWITCH, TACTIL (CH +)

S601 1-762-368-11 SWITCH, SLIDE (OFF/VHF/UHF)

FDL-PT222

A

<TRANSFORMER>

T601 ! 1-431-580-11 TRANSFORMER, DC-DC CONVERTER

T701 1-427-918-11 TRANSFORMER, CONVERTER

************************************************************************************************************

MISCELLANEOUS

*****************

1-504-847-11 SPEAKER (2.8cm)

1-517-702-11 LIGHT, BACK

1-754-205-11 ANTENNA, STRAP

1-803-293-11 MODULE, INDICATOR (NTSC)

************************************************************************************************************

ACCESSORIES

*************

4-083-376-11 MANUAL, INSTRUCTION

– 33 –

Page 24

FDL-PT222

9-965-300-01

Sony EMCS Corporation

Ichinomiya T ec.

Quality Assurance Division

– 34 –

English

2001DR02-1

©2001.4

Loading...

Loading...