EXR-C205/XR-C340

SERVICE MANUAL

US Model

Canadian Model

EXR-C205

E Model

XR-C340

Refer to RM-X2S/X3S SERVICE MANUAL (9-960-039-∏)

issued previously for information of remote commander

(RM-X2S) supplied with XR-C340.

Specifications

Cassette Player section

Tape track 4-track 2-channel stereo

Wow and flutter 0.08% (WRMS)

Frequency response 30-18,000 Hz

Signal-to-noise ratio 58 dB

Tuner section

FM

Tuning range EXR-C205:

87.5-107.9 MHz

XR-C340:

FM tuning interval:

50 kHz/200 kHz

switchable

87.5-108.0 MHz

(at 50 kHz step)

87.5-107.9 MHz

(at 200 kHz step)

Antenna terminal External antenna connector

Intermediate frequency 10.7 MHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 65 dB (stereo),

68 dB (mono)

Harmonic distortion at1 kHz

0.5% (stereo),

0.3% (mono)

Separation 35 dB at 1 kHz

Frequency response 30-15,000 Hz

Capture ratio 2 dB

Photo : XR-C340

Model Name Using Similar Mechanism NEW

T ape Transport Mechanism T ype

Power amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance 4-8 ohms

Maximum power output 35 W × 4 (at 4 ohms)

General

Outputs Power antenna control

lead/Power amplifier

control lead/Telephone

mute control lead (XR-C340 only)

Rear line out (1)

Tone controls Bass ±8 dB at 100 Hz

Treble ±8 dB at 10 kHz

Power requirements 12V DC car battery

(negative ground)

Dimensions Approx. 188 × 58 × 184 mm

(w/h/d)

Mounting dimensions Approx. 182 × 53 × 164 mm

(w/h/d)

Mass Approx. 1.3 kg

Supplied accessories Parts for installation and

connections (1set)

Front panel case (1)

Rotary remote RM-X2S

(XR-C340 only)

Design and specifications are subject to change without

notice.

MG-25A-136

AM

Tuning range EXR-C205

530-1,710 kHz

XR-C340

AM tuning interval:

9 kHz/10 kHz switchable

531-1,602 kHz

(at 9 kHz step)

530-1,710 kHz

(at 10 kHz step)

Antenna terminal External antenna connector

Intermediate frequency 10.71 MHz/450 kHz

Sensitivity 30 µV

MICROFILM

FM/AM CASSETTE CAR STEREO

TABLE OF CONTENTS

SERVICING NOTES

1. GENERAL ................................................................... 3

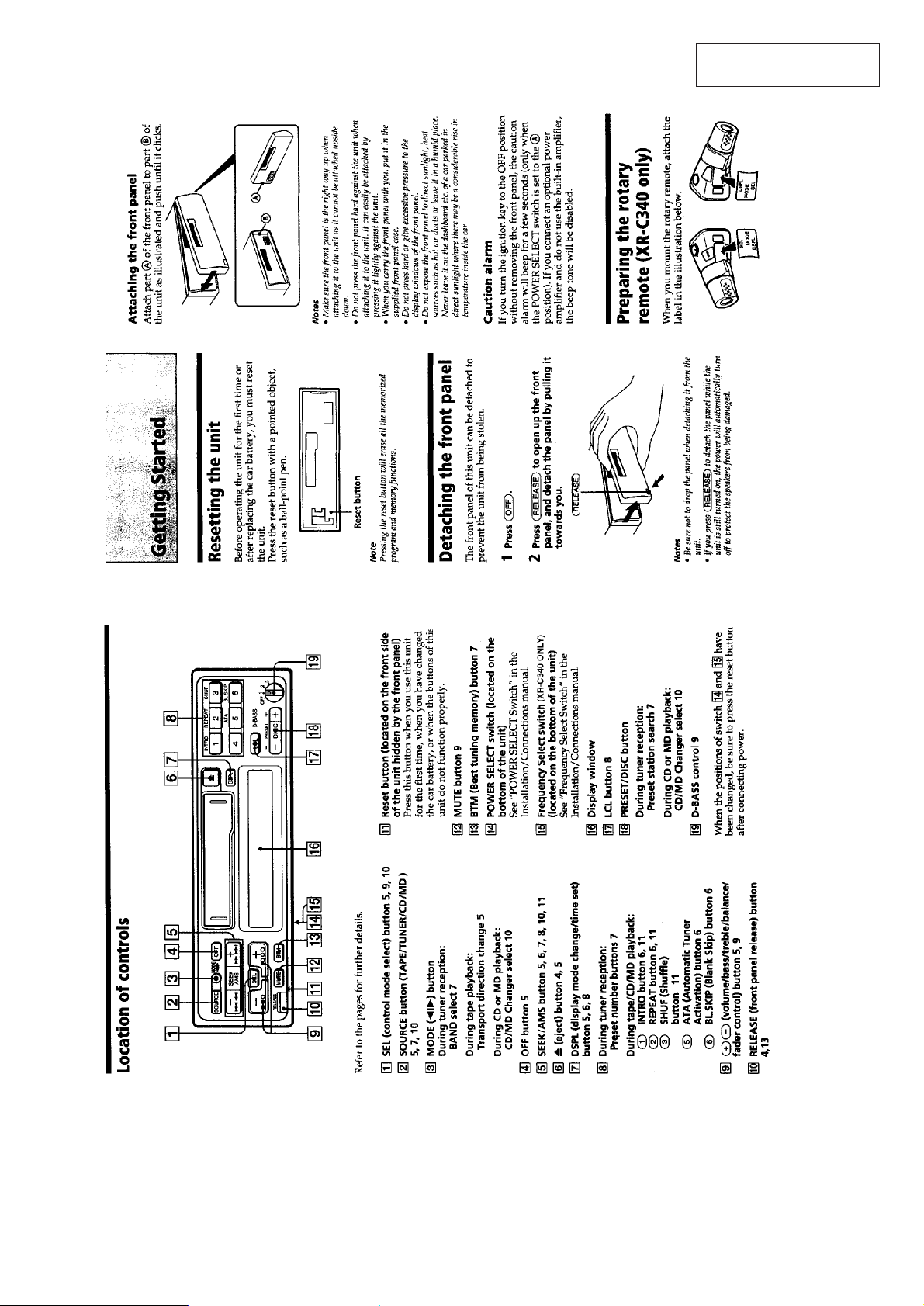

Location of Controls ........................................................ 3

Resetting the Unit ............................................................ 3

Detaching the Front Panel ............................................... 3

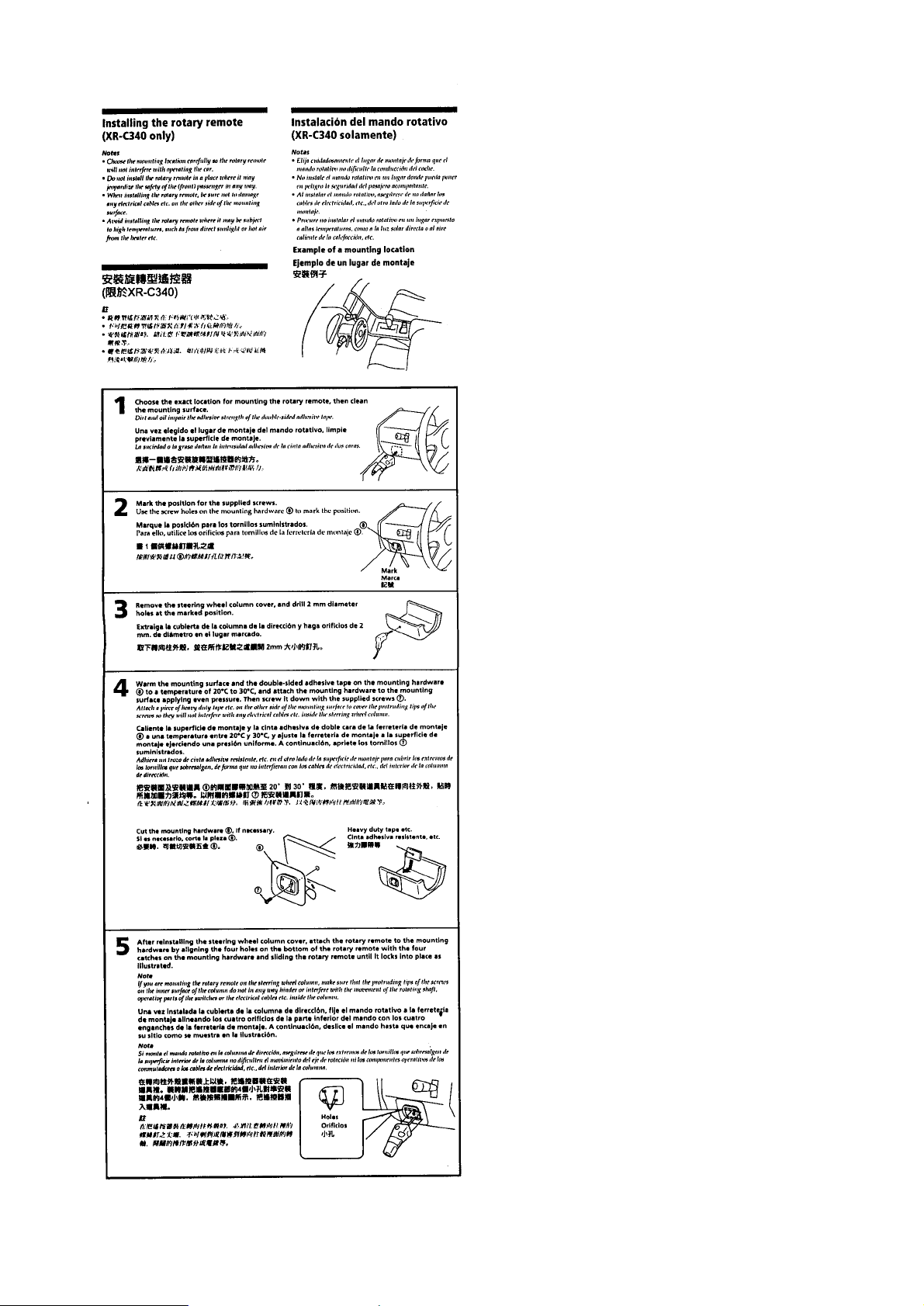

Preparing the Rotary Remote .......................................... 3

Setting the Clock ............................................................. 4

Using the Rotary Remote ................................................ 4

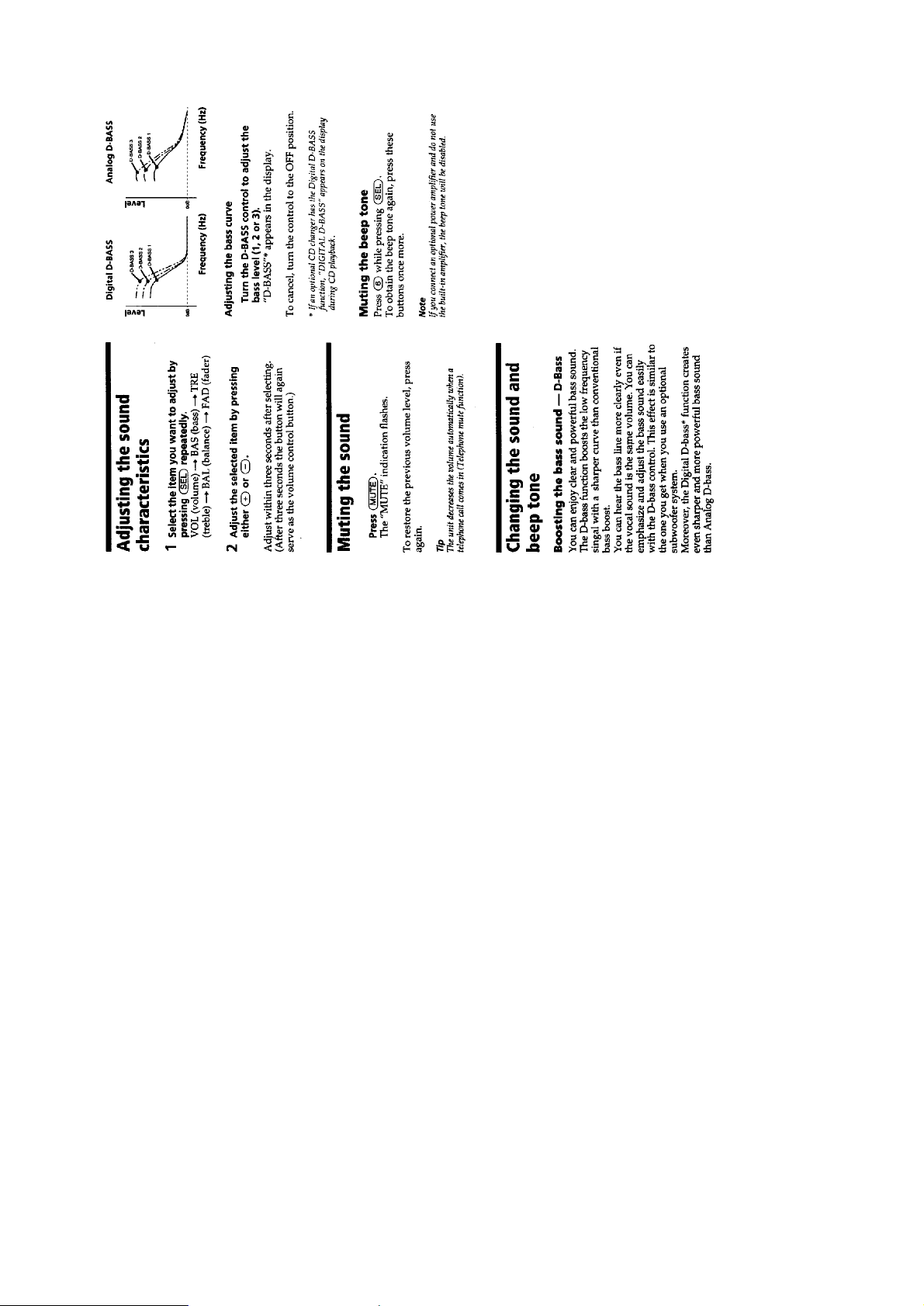

Adjusting the Sound Characteristics ............................... 5

Muting the Sound ............................................................ 5

Changing the Sound and Beep Tone................................ 5

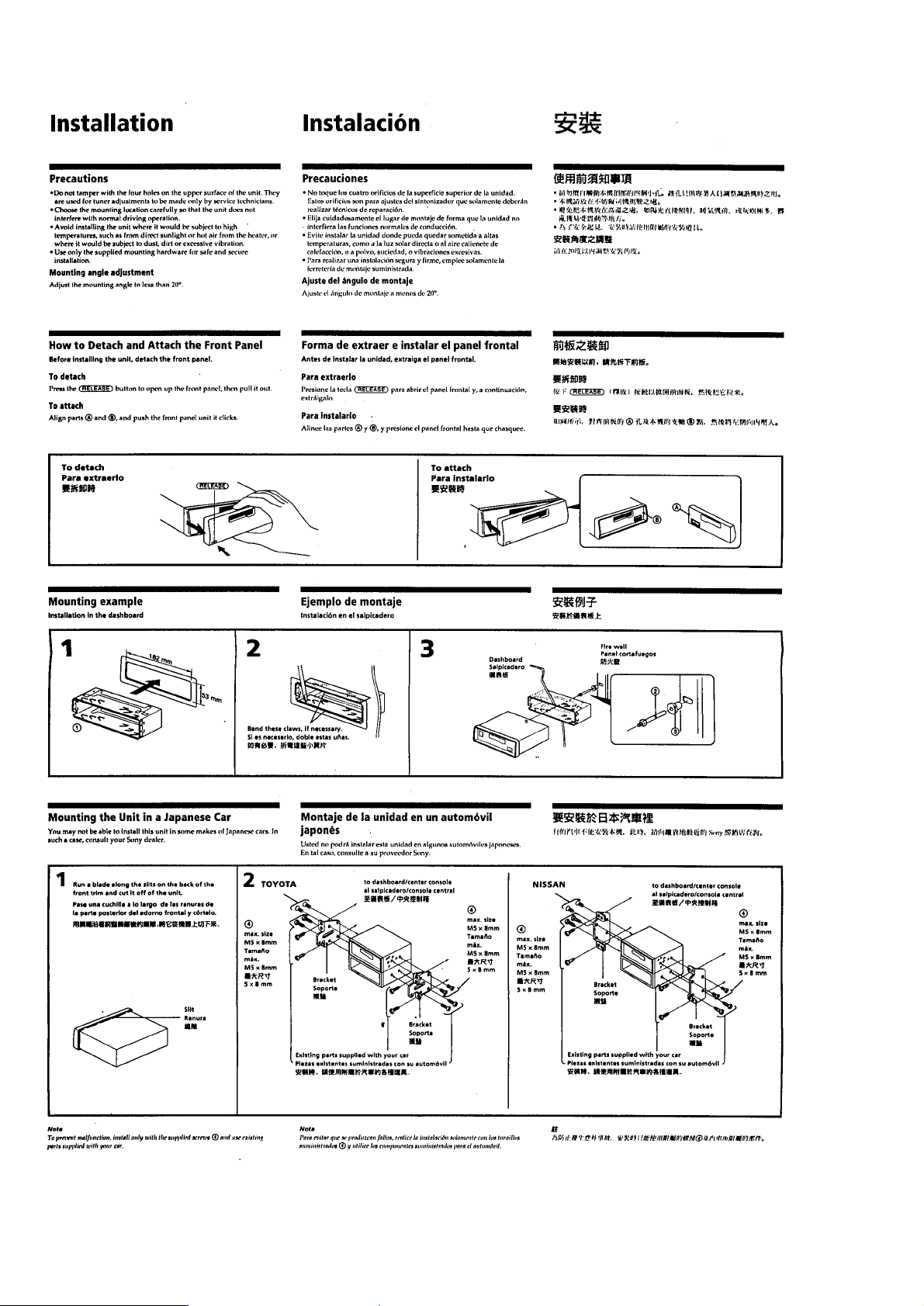

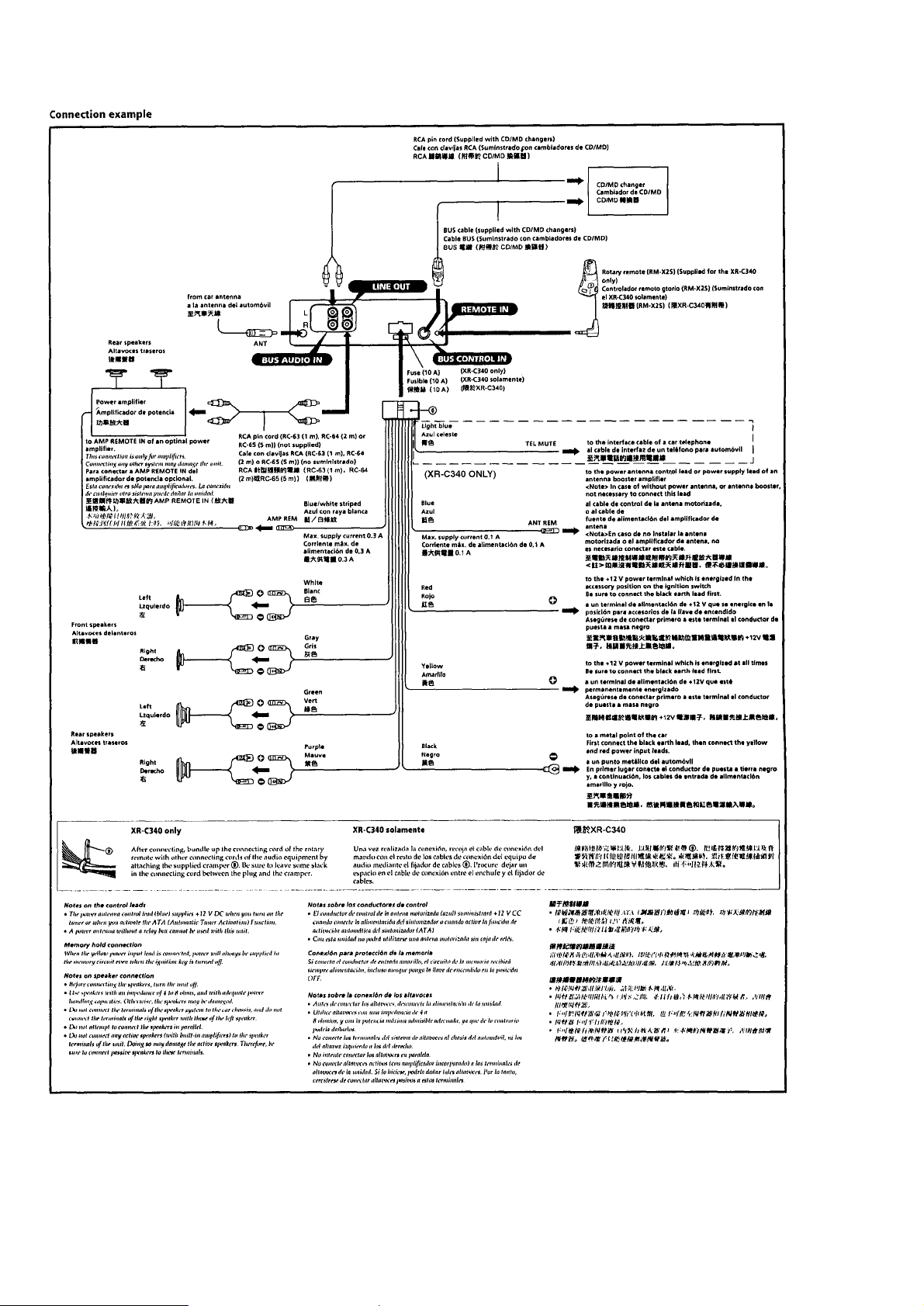

Installation ....................................................................... 6

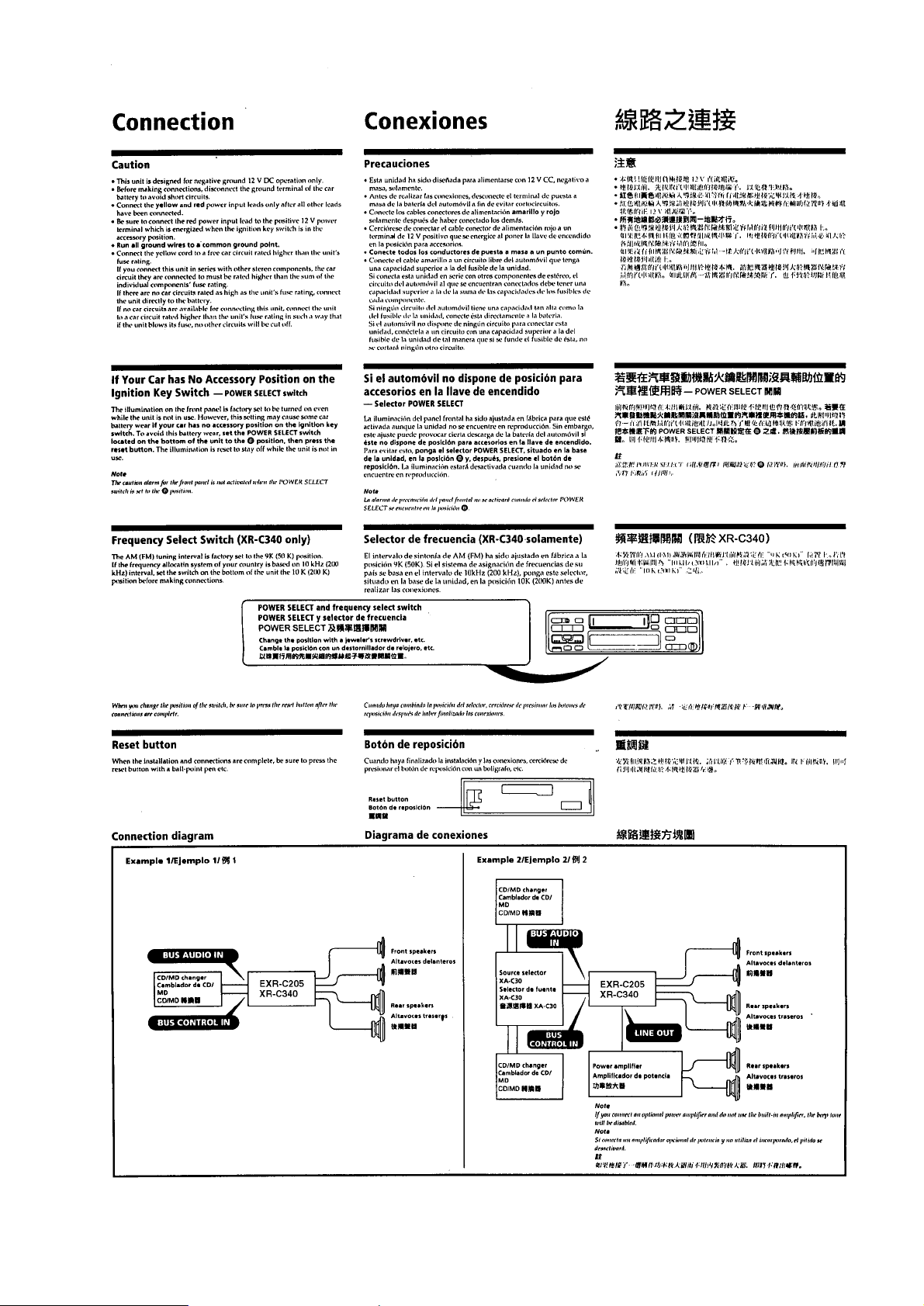

Connections ..................................................................... 7

2. DISASSEMBLY.......................................................... 10

3. ASSEMBLY OF MECHANISM DECK ........... 12

4. MECHANICAL ADJUSTMENTS ....................... 15

5. ELECTRICAL ADJUSTMENTS ...................... 15

6. DIAGRAMS

6-1. IC Pin Function Description ............................................ 16

6-2. Printed Wiring Board –MAIN Section– ......................... 20

6-3. Schematic Diagram –MAIN Section–............................ 23

6-4. Printed Wiring Board –KEY Section– ........................... 27

6-5. Schematic Diagram –KEY Section– .............................. 29

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

7. EXPLODED VIEWS .......................................... 31

8. ELECTRICAL PARTS LIST ................................ 34

– 2 –

SECTION 1

GENERAL

This section is extracted

from instruction manual.

– 3 –

– 4 –

– 5 –

– 6 –

– 7 –

– 8 –

– 9 –

SECTION 2

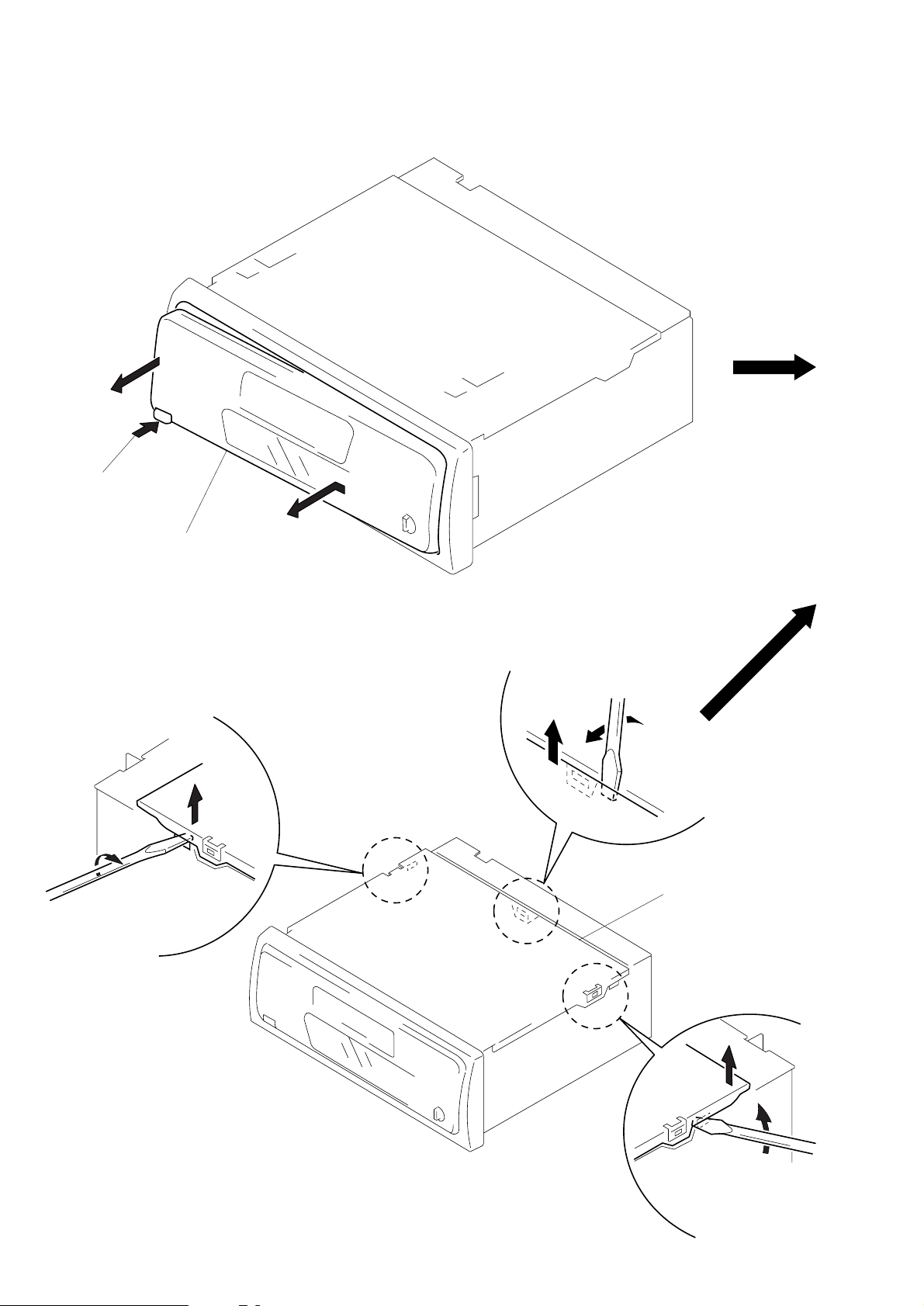

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

FRONT PANEL ASS’Y

1

Push the button

(release).

A

2

Remove the front panel ass’y

to the direction of the arrow A.

COVER ASS’Y

1

2

2

1

3

cover ass’y

2

1

– 10 –

SUB PANEL, MECHANISM DECK (MG-25A-136)

3

connector

(CN302)

2

sub panel

1

three screws

(PTT2.6 × 8)

5

screw

(PTT2.6 × 6)

6

mechanism deck

(MG-25A-136)

4

flexible flat cable

(CN301)

1

three screws

(PTT2.6 × 8)

MAIN BOARD, HEAT SINK

2

two ground point

screws

3

main board

1

5

heat sink

4

eight screws

(PTT2.6 × 10)

screw

(PTT2.6 × 8)

– 11 –

1

two screws

(PTT2.6 × 8)

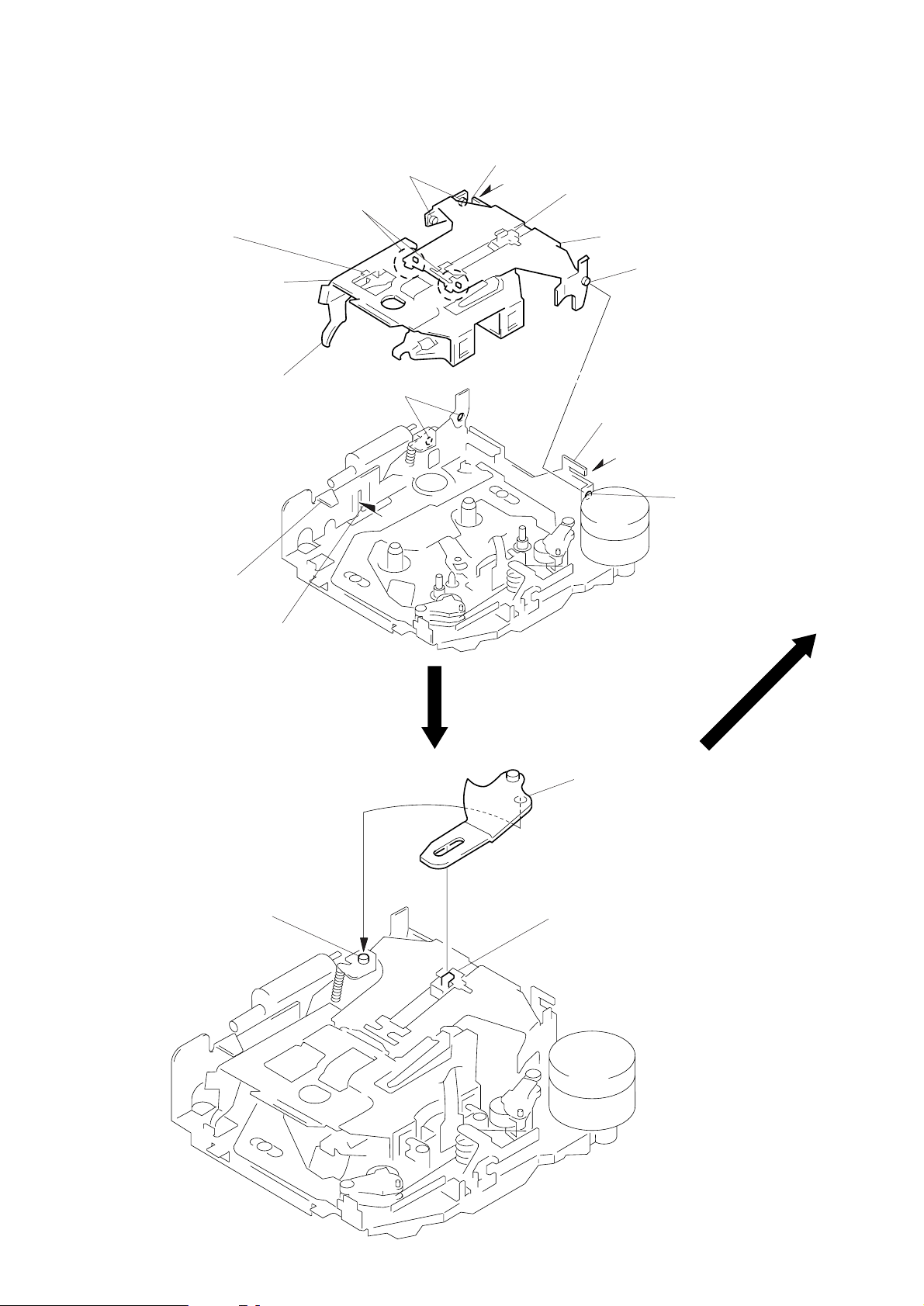

SECTION 3

ASSEMBLY OF MECHANISM DECK

Note: Follow the assembly procedure in the numerical order given.

HOUSING

4

Fit claw on B part.

3

2

Install the hanger onto

two claws of the housing.

Put the housing

under A part.

housing

A

part

5

Fit projection on C part.

C

part

7

Hold the hanger by bending the claw.

1

Install the catch to the hanger.

hanger

6

Fit projection on D part.

8

Hold the hanger by

bending the claw.

D

part

ARM (SUCTION)

B

projection

part

2

Move the arm (suction) in the arrow

direction and fit on projection.

1

Fit the arm (suction) on the shaft.

– 12 –

LEVER (LDG-A) / (LDG-B)

shaft

A

shaft

1

Fit the lever (LDG-A) on

shafts A – C and install it.

B

shaft

C

shaft

A

4

type-E stop ring 2.0

2

Pull the lever in the

arrow direction.

shaft

B

3

Fit the lever (LDG-B) on

shafts A and B and

install it.

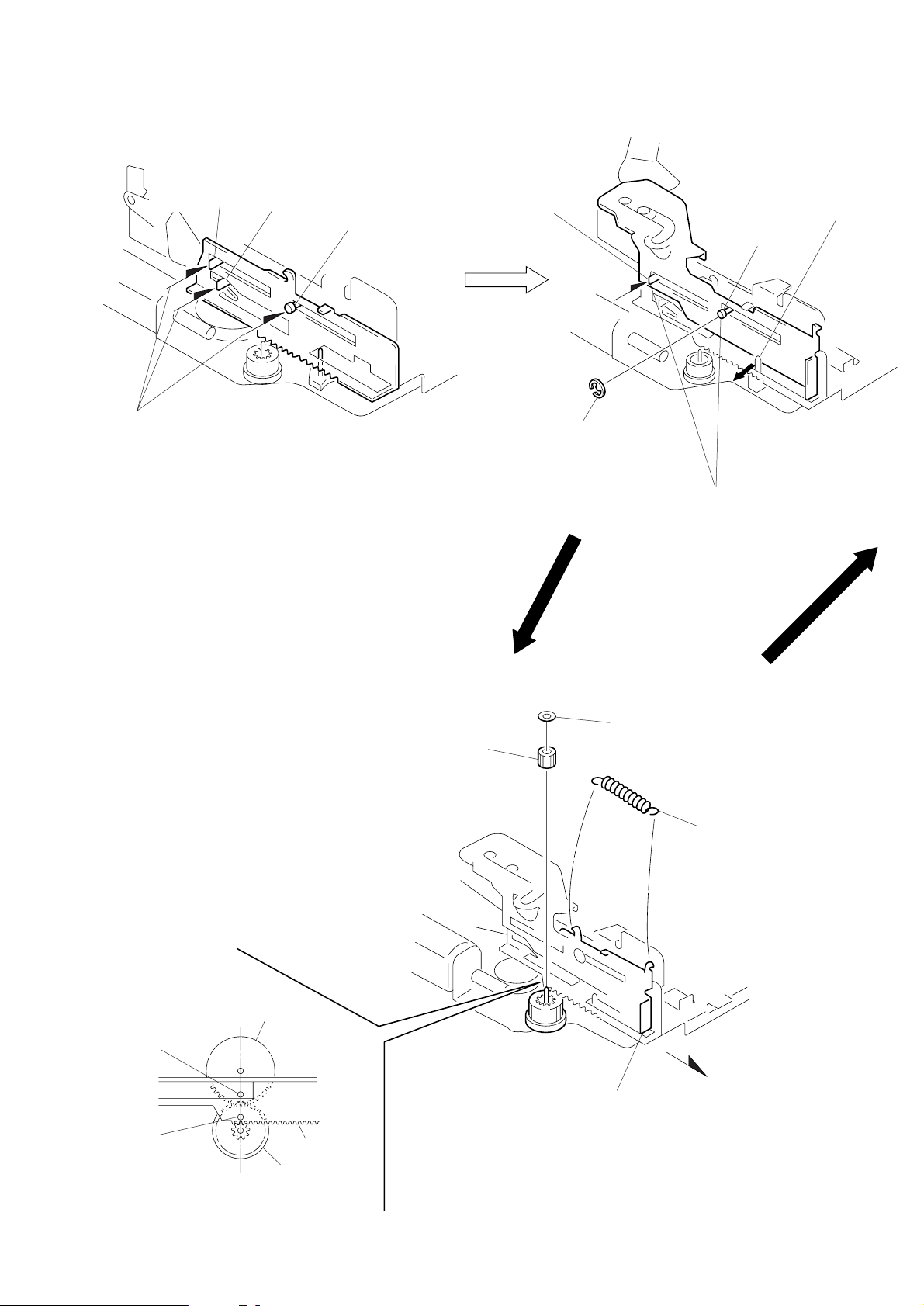

GEAR (LDG-FT)

hole

hole

gear (LDG-D)

lever (LDG-A)

gear (LDG-FB)

4

gear (LDG-FT)

5

polyethylene washer

1

2

Move the lever (LDG-B)

in the arrow direction.

tension spring (lever LDG)

3

Align hole in the gear (LDG-D)

with hole in the lever (LDG-A).

– 13 –

GUIDE (C)

1

three claws

2

guide (C)

– 14 –

Loading...

Loading...