Page 1

Self Diagnosis

Supported model

SERVICE MANUAL

MODEL NAME REMOTE COMMANDER DESTINATION CHASSIS NO.

KV-40XBR700

KV-40XBR700

RM-Y184 US SCC-S47G-A

RM-Y184 CND SCC-S48E-A

DX-1A

CHASSIS

9-965-919-01

KV-40XBR700

RM-Y184

TRINITRON® COLOR TELEVISION

Page 2

TABLE OF CONTENTS

KV-40XBR700

SECTION TITLE PAGE

Specifi cations ................................................................................. 4

Warnings and Cautions .................................................................. 5

Safety Check-Out ........................................................................... 6

Self-Diagnostic Function................................................................. 7

1. Disassembly

1-1. Rear Cover Removal.............................................................. 9

1-2. Chassis Assembly Removal................................................... 9

1-3. Service Position ..................................................................... 9

1-4. Picture Tube Removal .......................................................... 10

Anode Cap Removal Procedure................................................... 10

2. Set-Up Adjustments

2-1. Beam Landing ...................................................................... 11

2-2. V-PIN and V-CEN Adjustment .............................................. 12

2-3. Convergence ........................................................................ 12

2-3.1. Vertical and Horizontal Static Convergence ............. 12

2-3.2. Operation of BMC (Hexapole) Magnet..................... 12

2-3.3. TLH Plate Adjustment .............................................. 12

2-3.4. Screen Corner Convergence ................................... 13

2-3.5. Dynamic Convergence Adjustments ........................ 13

2-4. Focus Adjustment................................................................. 13

2-5. Screen (G2).......................................................................... 13

2-6. Picture Quality Adjustments ................................................. 14

2-6.1. Video Input - Two Picture Sub Contrast

Adjustment ............................................................... 14

2-6.2. Video Input - Sub Hue/Sub Color Adjustment.......... 14

2-6.3. RF Input - Two Picture Sub Contrast Adjustment ..... 15

2-6.4. RF Input - Sub Hue/Sub Color Adjustment .............. 15

2-7. White Balance (CRT) and Sub Bright Adjustment ............... 16

2-8. Raster Center Adjustment .................................................... 16

2-9. Picture Distortion Adjustments............................................. 16

2-9.1. NTSC (DRC) Full Mode Adjustment ........................ 16

2-9.2. 1080i HD Mode Adjustment ..................................... 17

2-9.3. Vertical Compressed Mode Check and

Confi rmation............................................................. 17

SECTION TITLE PAGE

3. Safety Related Adjustments

X

3-1.

HV Service Adjustments ...................................................... 18

3-2. B+ Max Confi rmation ........................................................... 18

3-3. HV Service Flowchart .......................................................... 18

4. Circuit Adjustments

4-1. Setting the Service Adjustment Mode.................................. 19

4-1.1. Resetting the Data ................................................... 19

4-2. Memory Write Confi rmation Method .................................... 19

4-3. Remote Adjustment Buttons and Indicators ......................... 19

4-4. Service Data Lists ................................................................ 20

5. Diagrams

5-1. Circuit Boards Location ........................................................ 48

5-2. Printed Wiring Board and Schematic Diagram Information.. 48

5-3. Block Diagram and Schematics

Block Diagram...................................................................... 49

A Board ................................................................................ 54

B Board ................................................................................ 61

BC Board.............................................................................. 75

C Board ................................................................................ 78

D Board ................................................................................ 81

DH Board ............................................................................. 88

HA Board.............................................................................. 90

HB Board.............................................................................. 92

S Board ................................................................................ 93

U Board ................................................................................ 94

W Board ............................................................................... 96

5-4. Semiconductors ................................................................... 98

6. Exploded Views

6-1. Chassis ............................................................................... 100

6-2. Picture Tube ........................................................................ 101

7. Electrical Parts List ....................................................................... 102

RV8001, RV8002 Confi rmation Method and

— 3 —

Page 3

SPECIFICATIONS

KV-40XBR700

Power requirements 120V, 60 Hz

Number of inputs/outputs

1)

Video

S Video

Audio

Audio Out

, PR

Y,P

B

Monitor Out 1

Control-S (in/out) YES

Speaker output(W)

Power Consumption(W)

In use(Max) 245W

2)

3)

4)

5)

15W Subwoofer

4

3

6

1

2

7.5W x 2

KV-40XBR700

Television system

American TV standard, NTSC

Channel coverage

VHF: 2-13/ UHF: 14-69/ CATV: 1-125

Picture tube

FD Trinitron® tube

Visible screen size

38-inch picture measured diagonally

Actual screen size

40-inch measured diagonally

Antenna

75 ohm external terminal for VHF/UHF

In standby 2W

Dimensions(W/H/D)

Mass

(mm)

1093 x 836 x 665 mm

1

/8 x 33 x 26

(in)

43

(kg) 138 kg

(lbs) 304 lbs.

incorporated under license from SRS Labs, Inc. and are protected

under United States Patent Nos. 4,748,669 and 4,841,572 with

numerous additional issued and pending foreign patents. Purchase of this product does not convey the right to sell recordings

made with the TruSurround technology.

1)

1 Vp-p 75 ohms unbalanced, sync negative

2)

Y: 1 Vp-p 75 ohms unbalanced, sync negative

1

in

/8

C: 0.286 Vp-p (Burst signal), 75 ohms

3)

More than 408 mVrms at the maximum volume setting (variable)

More than 408 mVrms (fi x)

4)

500 mVrms (100% modulation), Impedance: 47 kilohms

5)

Y: 1.0 Vp-p, 75 ohms, sync negative;

PB: 0.7 Vp-p, 75 ohms

PR: Vp-p, 75 ohms

TruSurround

by SRS

TruSurround is a trademark of

SRS Labs, Inc. SRS and the SRS

symbol are registered trademarks

™

of SRS Labs, Inc. in the United

States and in select foreign coun-

®

tries. SRS and TruSurround are

Supplied Accessories

Remote Commander RM-Y184

Two Size AA (R6) Batteries

Optional Accessories

Connecting cables: VMC-10/30HG, VMC-810S/820/830HGS, VMC-810S/820S,

RKG69HG, RKC-515HG

TV Stand: SV-40XBR7

Design and specifi cations are subject to change without notice.

SRS (SOUND RETRIEVAL SYSTEM)

The SRS (SOUND RETRIEVAL SYSTEM) is manufactured by

Sony Corporation under license from SRS Labs, Inc. It is covered

by U.S. Patent No. 4,748,669. Other U.S. and foreign patents

pending.

The word ‘SRS’ and the SRS symbol are registered trademarks of SRS Labs, Inc. BBE and BBE symbol are trademarks of

BBE Sound, Inc. and are licensed by BBE Sound, Inc. under U.S.

Patent No. 4,638,258 and 4,482,866.

— 4 —

Page 4

WARNINGS AND CAUTIONS

CAUTION

Short circuit the anode of the picture tube and the anode cap to the metal chassis, CRT shield, or carbon painted on the CRT,

after removing the anode.

WARNING!!

An isolation transformer should be used during any service to avoid possible shock hazard, because of live chassis. The chassis of

this receiver is directly connected to the AC power line.

! SAFETY-RELATED COMPONENT WARNING!!

KV-40XBR700

Components identifi ed by shading and ! mark on the schematic diagrams, exploded views, and in the parts list are critical for

safe operation. Replace these components with Sony parts whose part numbers appear as shown in this manual or in supplements

published by Sony. Circuit adjustments that are critical for safe operation are identifi ed in this manual. Follow these procedures

whenever critical components are replaced or improper operation is suspected.

ATTENTION!!

Apres avoir deconnecte le cap de l’anode, court-circuiter l’anode du tube cathodique et celui de l’anode du cap au chassis metallique

de l’appareil, ou la couche de carbone peinte sur le tube cathodique ou au blindage du tube cathodique.

Afi n d’eviter tout risque d’electrocution provenant d’un chássis sous tension, un transformateur d’isolement doit etre utilisé lors de tout

dépannage. Le chássis de ce récepteur est directement raccordé à l’alimentation du secteur.

! ATTENTION AUX COMPOSANTS RELATIFS A LA SECURITE!!

Les composants identifi es par une trame et par une marque ! sur les schemas de principe, les vues explosees et les listes de

pieces sont d’une importance critique pour la securite du fonctionnement. Ne les remplacer que par des composants Sony dont

le numero de piece est indique dans le present manuel ou dans des supplements publies par Sony. Les reglages de circuit dont

l’importance est critique pour la securite du fonctionnement sont identifi es dans le present manuel. Suivre ces procedures lors de

chaque remplacement de composants critiques, ou lorsqu’un mauvais fonctionnement suspecte.

— 5 —

Page 5

SAFETY CHECK-OUT

KV-40XBR700

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

1. Check the area of your repair for unsoldered or poorly soldered

connections. Check the entire board surface for solder splashes and

bridges.

2. Check the interboard wiring to ensure that no wires are “pinched” or

touching high-wattage resistors.

3. Check that all control knobs, shields, covers, ground straps, and

mounting hardware have been replaced. Be absolutely certain that

you have replaced all the insulators.

4. Look for unauthorized replacement parts, particularly transistors,

that were installed during a previous repair. Point them out to the

customer and recommend their replacement.

5. Look for parts which, though functioning, show obvious signs of

deterioration. Point them out to the customer and recommend their

replacement.

6. Check the line cords for cracks and abrasion. Recommend the

replacement of any such line cord to the customer.

7. Check the B+ and HV to see if they are specifi ed values. Make sure

your instruments are accurate; be suspicious of your HV meter if sets

always have low HV.

8. Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage

as described below.

Leakage Test

The AC leakage from any exposed metal part to earth ground and from

all exposed metal parts to any exposed metal part having a return to

chassis, must not exceed 0.5 mA (500 microamperes). Leakage current

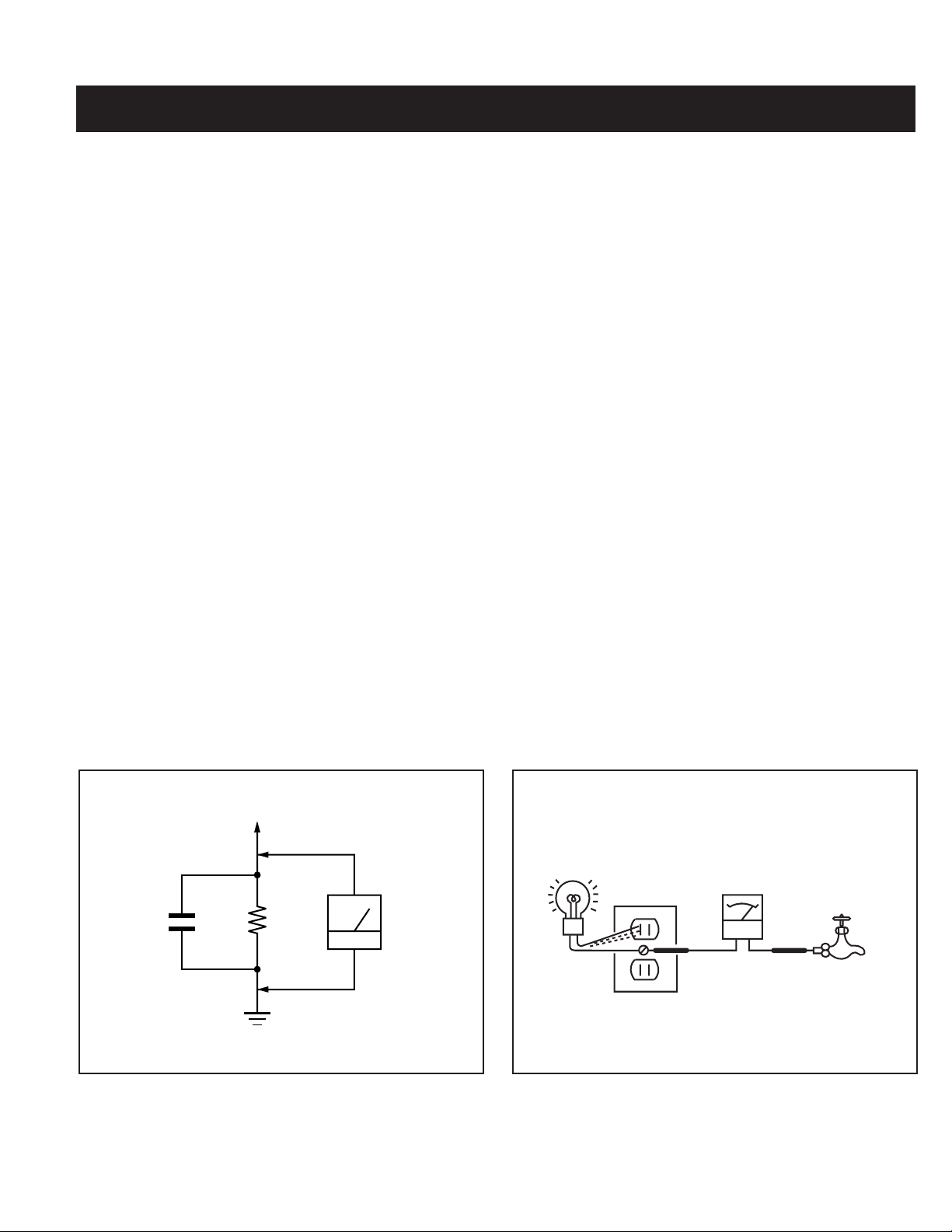

can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or

RCA WT-540A. Follow the manufacturers’ instructions to use these

instructions.

2. A battery-operated AC milliampmeter. The Data Precision 245 digital

multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a VOM

or battery-operated AC voltmeter. The “limit” indication is 0.75 V,

so analog meters must have an accurate low voltage scale. The

Simpson’s 250 and Sanwa SH-63TRD are examples of passive

VOMs that are suitable. Nearly all battery-operated digital multimeters

that have a 2 VAC range are suitable (see Figure A).

How to Find a Good Earth Ground

A cold-water pipe is a guaranteed earth ground; the cover-plate retaining

screw on most AC outlet boxes is also at earth ground. If the retaining

screw is to be used as your earth ground, verify that it is at ground

by measuring the resistance between it and a cold-water pipe with an

ohmmeter. The reading should be zero ohms.

If a cold-water pipe is not accessible, connect a 60- to 100-watt troublelight (not a neon lamp) between the hot side of the receptacle and the

retaining screw. Try both slots, if necessary, to locate the hot side on the

line; the lamp should light at normal brilliance if the screw is at ground

potential (see Figure B).

To Exposed Metal

Parts on Set

Trouble Light

AC Outlet Box

0.15 F

1.5 K Ω

Earth Ground

Figure A. Using an AC voltmeter to check AC leakage. Figure B. Checking for earth ground.

AC

Voltmeter

(0.75 V)

Ohmmeter

— 6 —

Cold Water Pipe

Page 6

KV-40XBR700

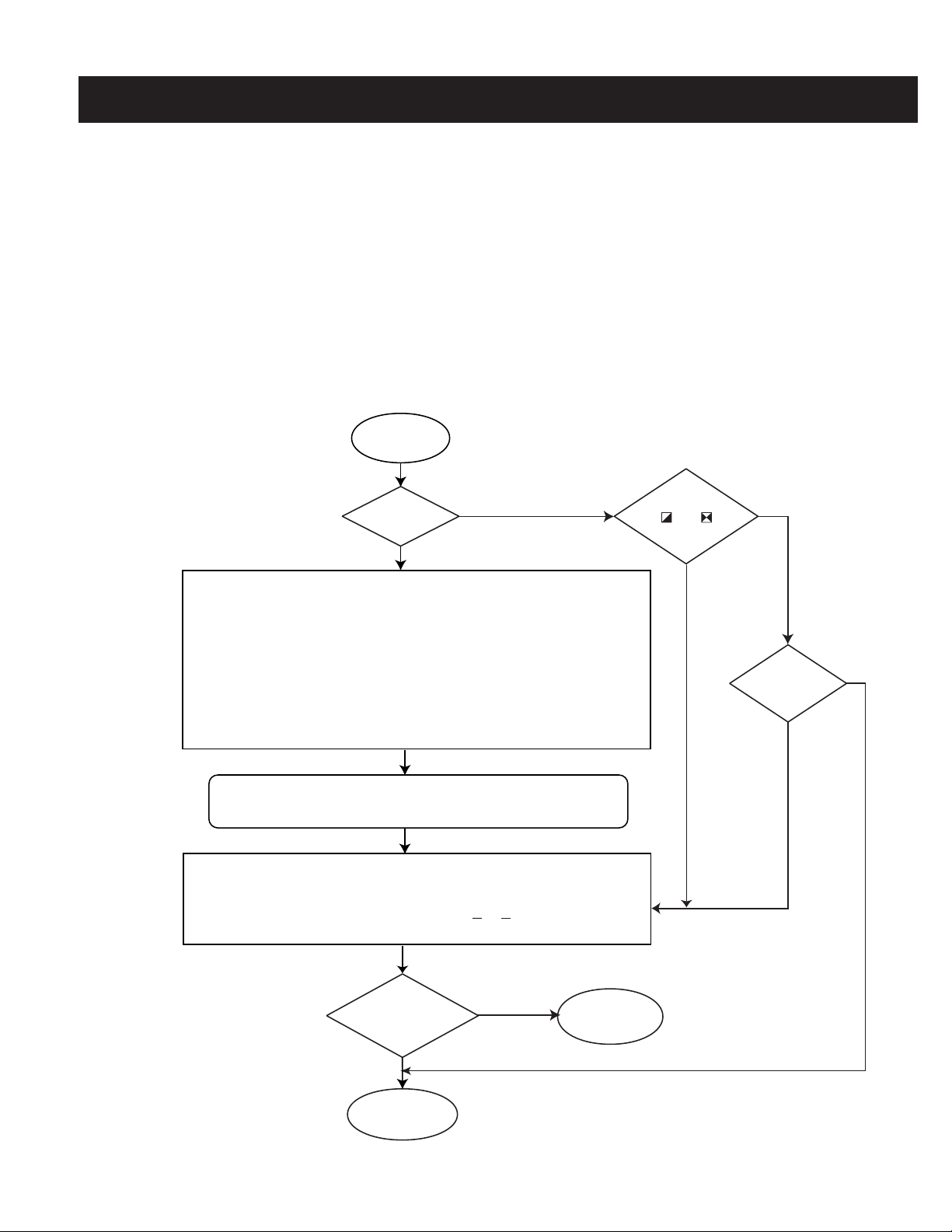

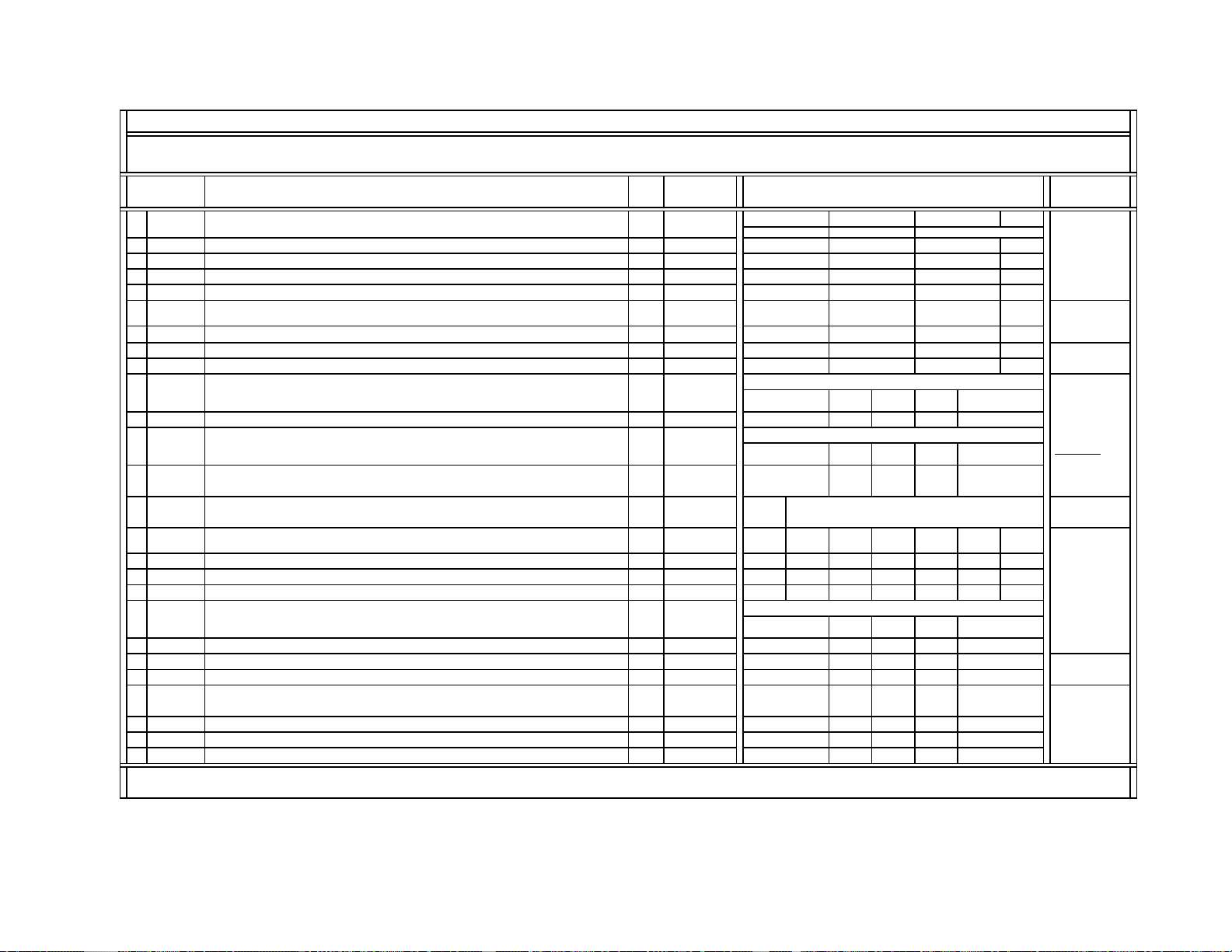

SELF-DIAGNOSTIC FUNCTION

Self Diagnosis

Supported model

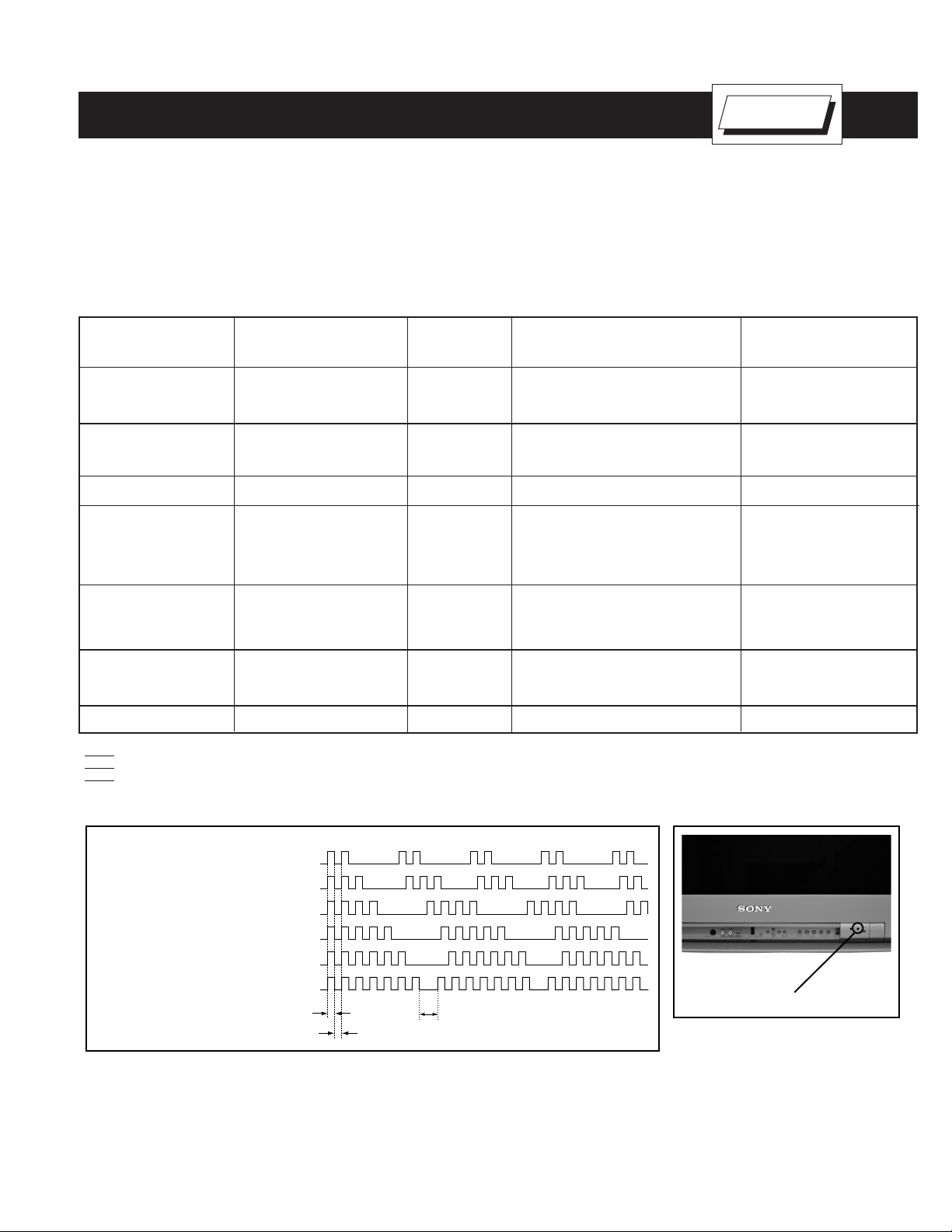

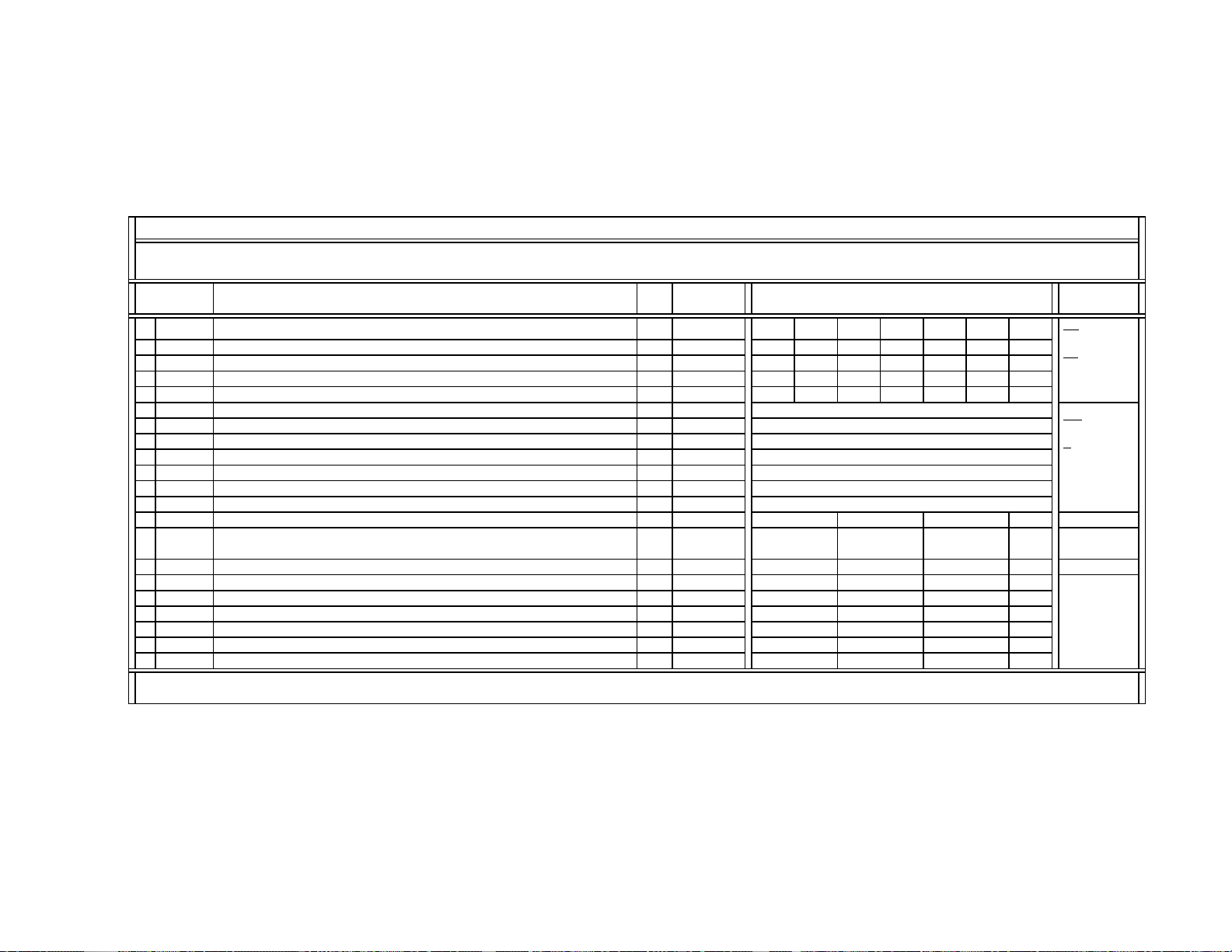

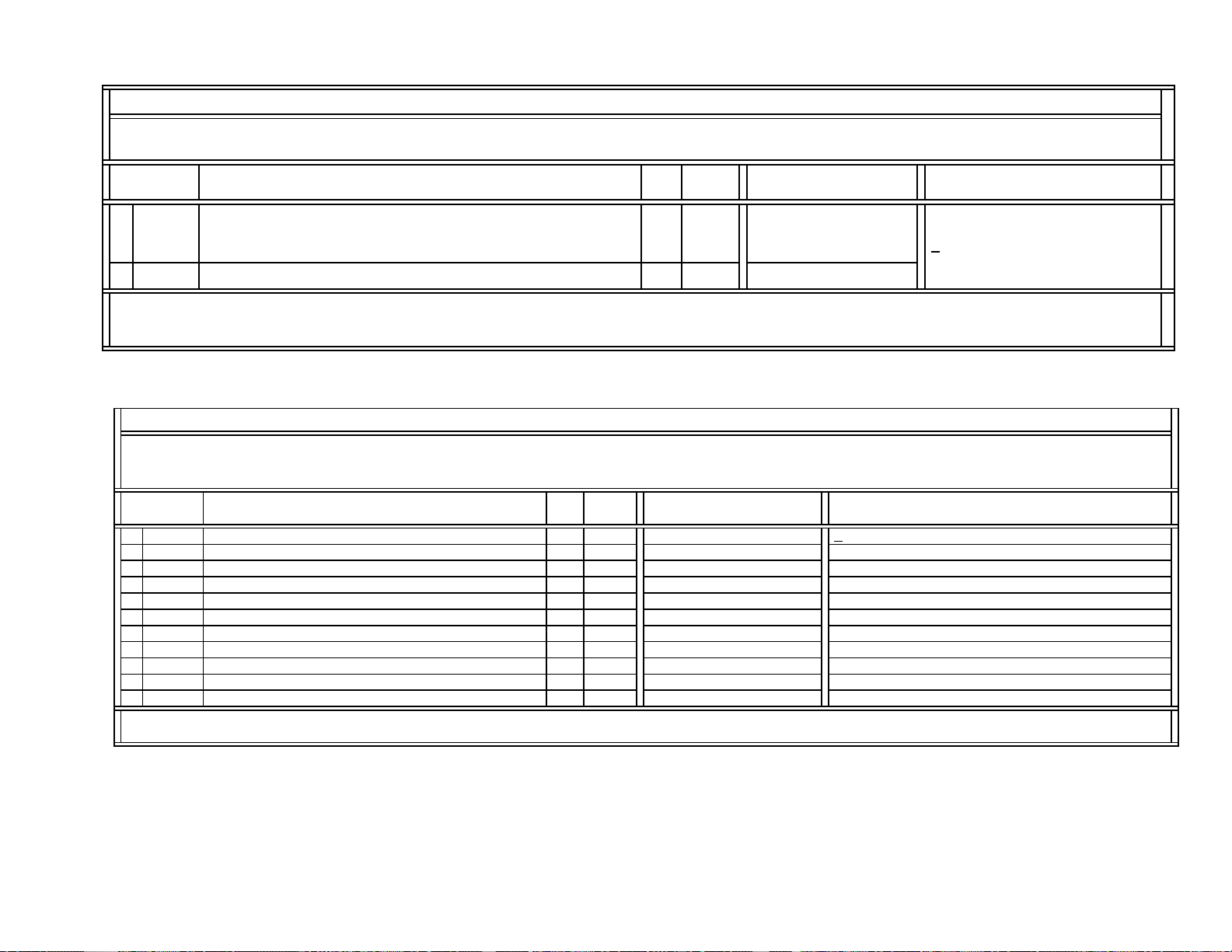

The units in this manual contain a self-diagnostic function. If an error occurs, the STANDBY/STEREO LED will automatically begin to fl ash. The number

of times the LED fl ashes translates to a probable source of the problem. A defi nition of the STANDBY/STEREO LED fl ash indicators is listed in the

instruction manual for the user’s knowledge and reference. If an error symptom cannot be reproduced, the Remote Commander can be used to review

the failure occurrence data stored in memory to reveal past problems and how often these problems occur.

Diagnostic Test Indicators

When an error occurs, the STANDBY/STEREO LED will fl ash a set number of times to indicate the possible cause of the problem. If there is more

than one error, the LED will identify the fi rst of the problem areas.

Results for all of the following diagnostic items are displayed on screen. No error has occurred if the screen displays a “0”.

No. of times STANDBY/

Diagnostic Item STEREO lamp fl ashes Display Result Probable Cause Location Detected Symptoms

Power does not turn on Does not light • Power cord is not plugged in. • Power does not come on.

• Fuse is burned out F6001 (A Board). • No power is supplied to the TV.

• AC power supply is faulty.

+B Overcurrent (OCP) 2 times 2:0 or 2:1 • H.OUT (Q5030) is shorted (D Board). • Power does not come on.

(See Note 1) • +B PWM (Q5003) is shorted (D Board). • Load on power line is shorted.

• IC9001, IC9002, IC9003 is shorted (C Board).

+B Overvoltage (OVP) 3 times 3:0 or 3:1 • IC6505 is faulty (D Board). • Has entered standby mode.

Vertical Defl ection Stopped 4 times 4:0 or 4:1 • ± 15V is not supplied (D Board). • Has entered standby state after

• IC5004 is faulty (D Board). horizontal raster.

• Vertical defl ection pulse is stopped.

• Power line is shorted or power

supply is stopped.

White Balance Failure 5 times 5:0 or 5:1 • Video OUT (IC9001-IC9003) is faulty (C Board). • No raster is generated.

(not balanced) • CRT drive (IC201) is faulty (A Board). • CRT Cathode current detection

• G2 is improperly adjusted (See Note 2). reference pulse output is small.

LOW B OCP/OVP 6 times 6:0 or 6:1 • +5 line is overloaded (A, B Boards). • No picture.

(overcurrent/overvoltage) • +5 line is shorted (A, B Boards).

(See Note 3) • IC6007 is faulty (A Board).

Horizontal Defl ection Stopped 7 times 7:0 or 7:1 • No picture.

Note 1: If a +B Overcurrent is detected, stoppage of the Vertical Defl ection is detected simultaneously. The symptom that is diagnosed fi rst by the microcontroller is displayed on screen.

Note 2: Refer to Screen (G2) Adjustment in Section 2-5. of this manual.

Note 3: If STANDBY/STEREO LED fl ashes six (6) times, unplug the unit and wait 10 seconds before performing the adjustment.

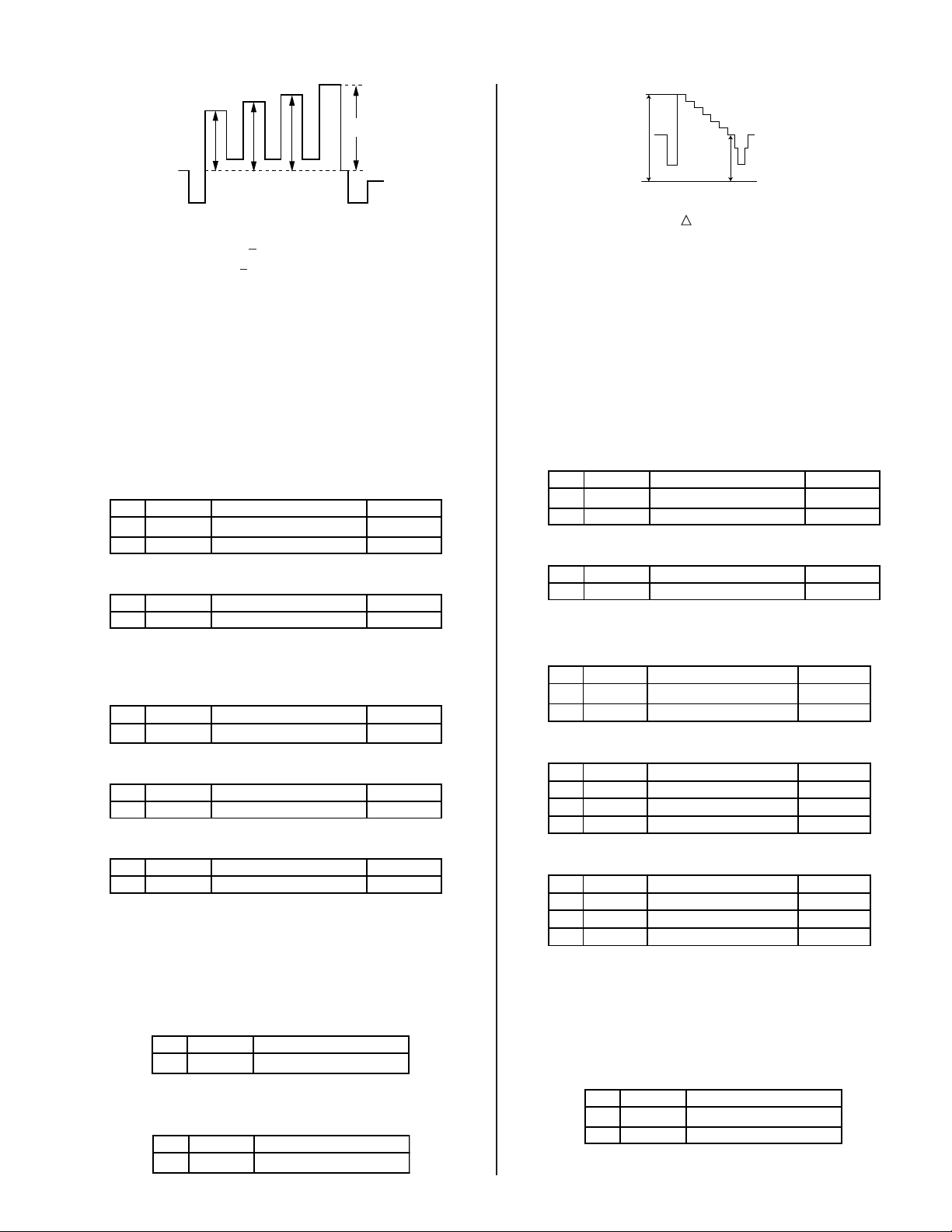

Display of STANDBY/STEREO LED Flash Count

Diagnostic items Flash count

+B Overcurrent (OCP) 2 times

+B Overvoltage (OVP) 3 times

Vert. Deflection Stopped 4 times

White Balance Failure 5 times

Low B OCP/OVP 6 times

Horiz. Deflection Stopped 7 times

Lamp ON 0.3 sec.

Lamp OFF 0.3 sec.

Lamp OFF 3 sec.

STANDBY/STEREO LED

* One fl ash count is not used for self-

diagnostic.

Stopping the STANDBY/STEREO LED Flash

Turn off the power switch on the TV main unit or unplug the power cord from the outlet to stop the STANDBY/STEREO LAMP from fl ashing.

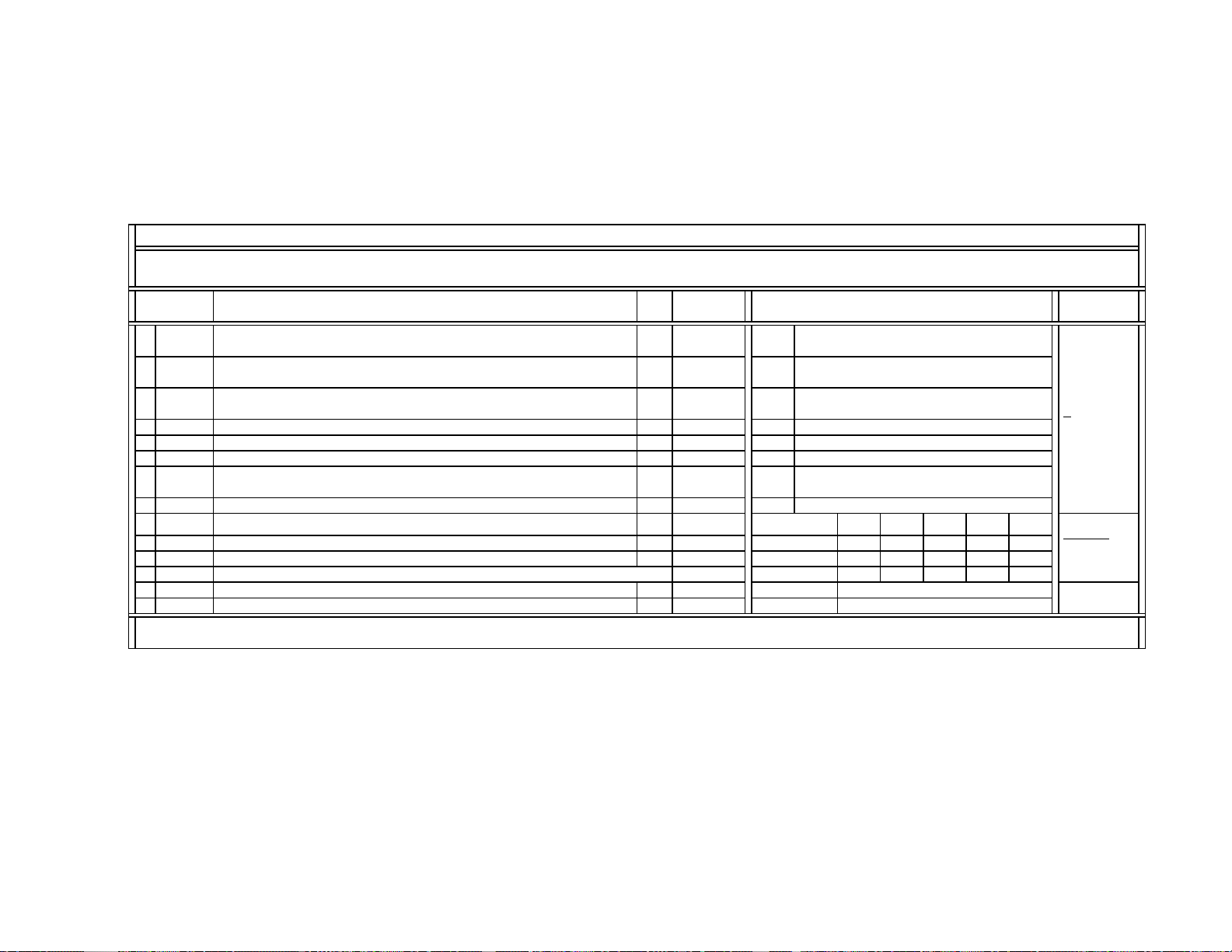

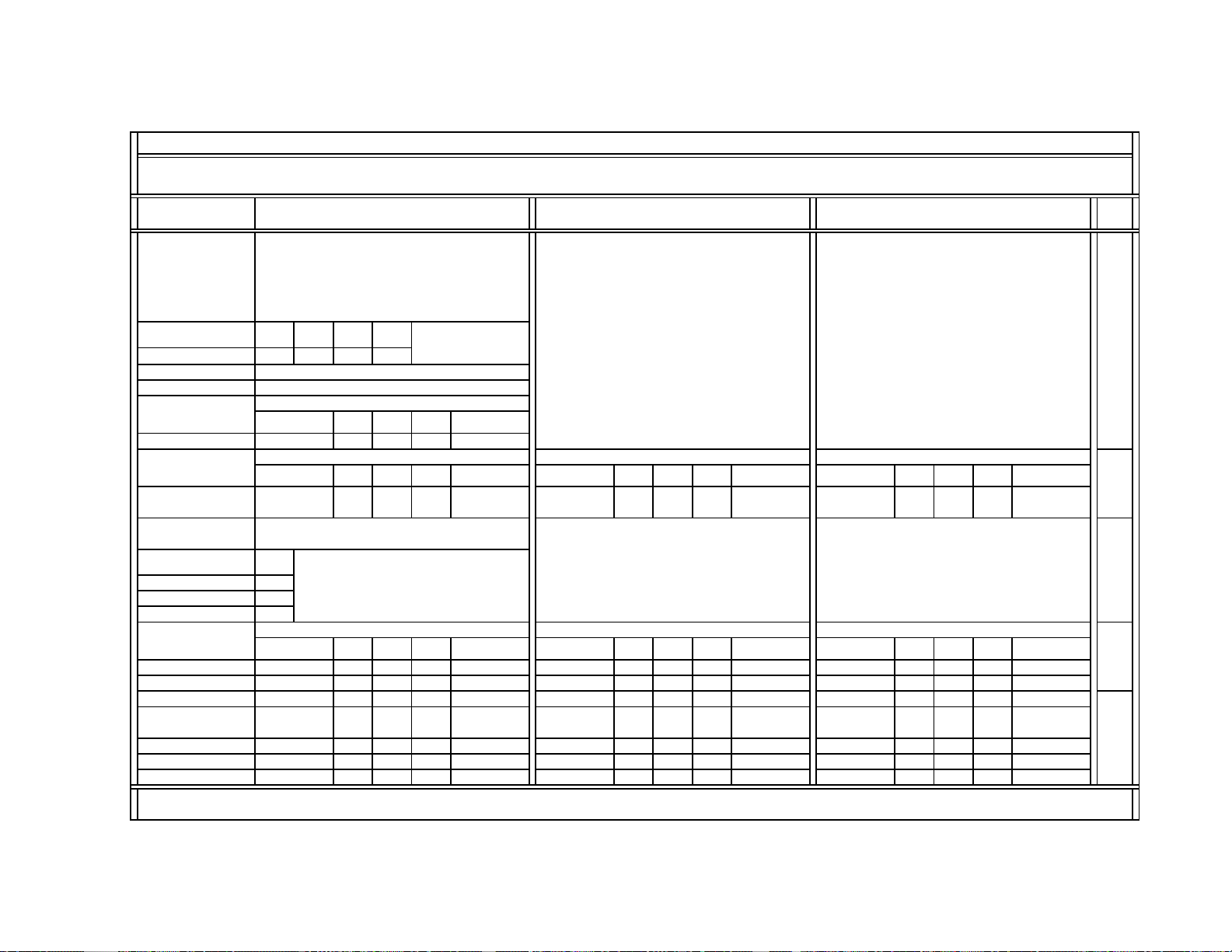

Self-Diagnostic Screen Display

For errors with symptoms such as “power sometimes shuts off” or “screen sometimes goes out” that cannot be confi rmed, it is possible to bring up

past occurrences of failure on the screen for confi rmation.

— 7 —

Page 7

KV-40XBR700

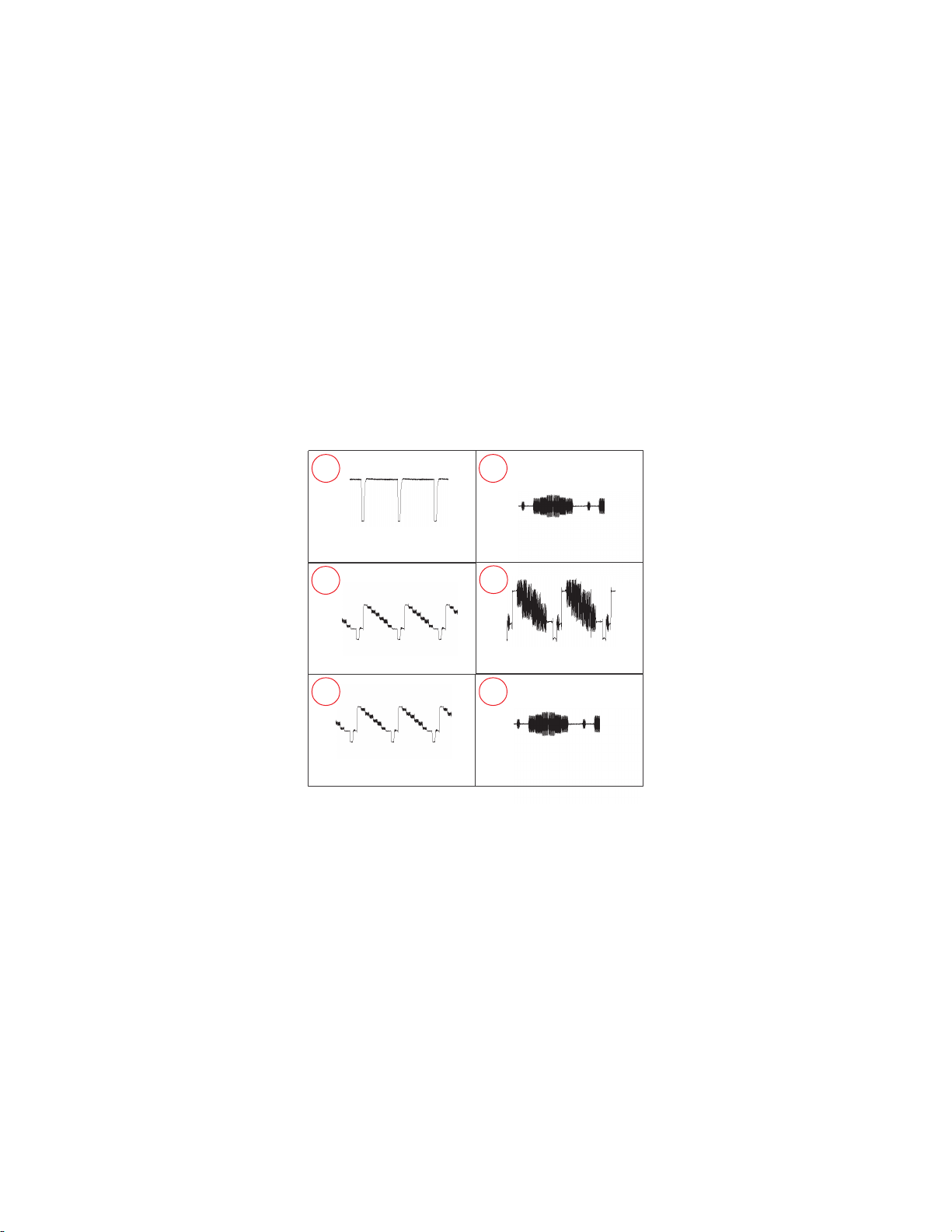

To Bring Up Screen Test

In standby mode, press buttons on the Remote Commander sequentially,

in rapid succession, as shown below:

DISPLAY

Channel 5 Sound volume - Power ON.

SELF DIAGNOSIS

2: +B OCP N/A

3: +B OVP N/A

4: V STOP 0

5: AKB 1

6: LOWB 0

Numeral “0” means that no fault

was detected.

Numeral “1” means a fault was detected

one time only.

7: H-STOP 0

Handling of Self-Diagnostic Screen Display

101: WDT 24

Since the diagnostic results displayed on the screen are not automatically cleared, always check the self-diagnostic screen during repairs. When you

have completed the repairs, clear the result display to “0”.

Unless the result display is cleared to “0”, the self-diagnostic function will not be able to detect subsequent faults after completion of the repairs.

Clearing the Result Display

To clear the result display to “0”, press buttons on the Remote Commander sequentially when the diagnostic screen is displayed, as shown below:

Channel

8

ENTER

Quitting the Self-Diagnostic Screen

To quit the entire self-diagnostic screen, turn off the power switch on the Remote Commander or the main unit.

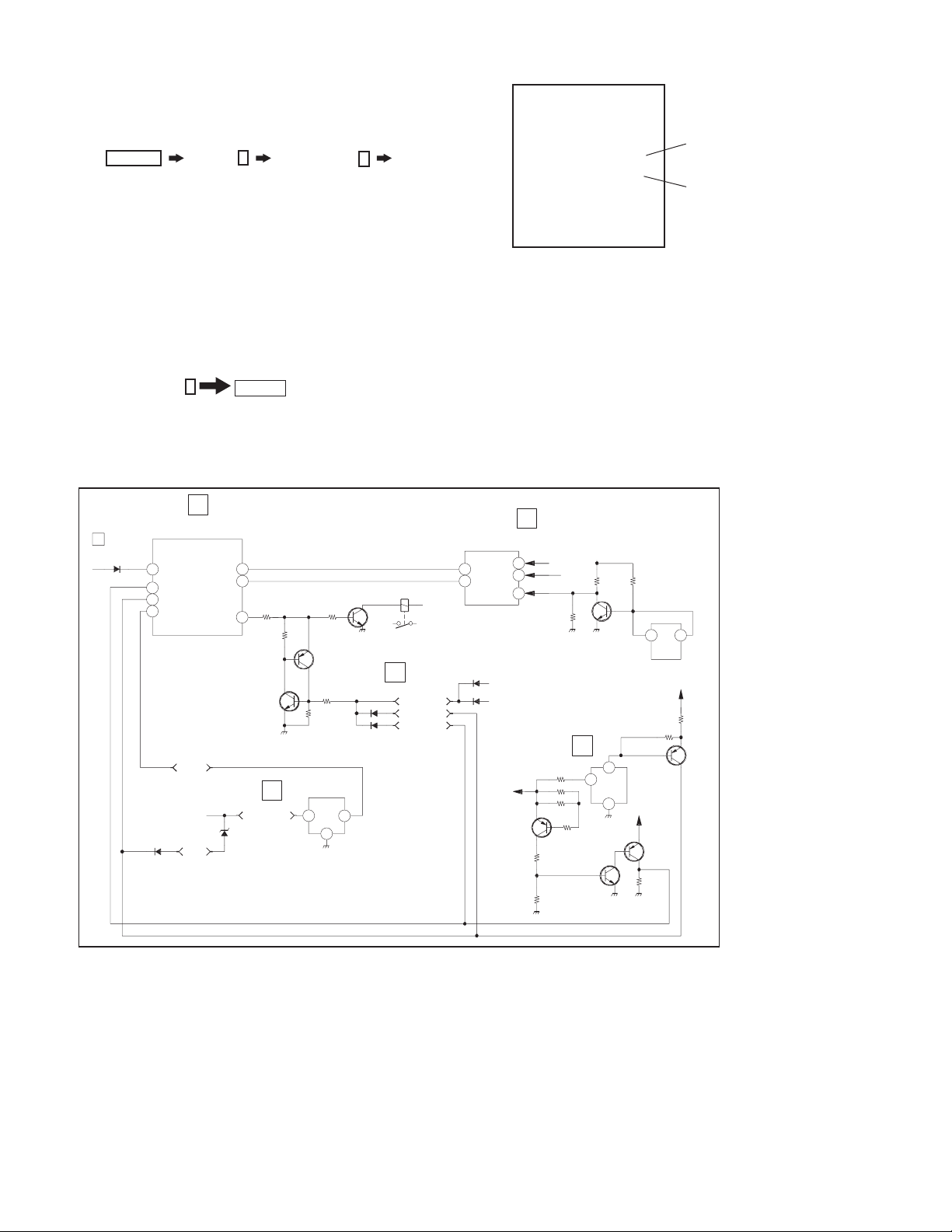

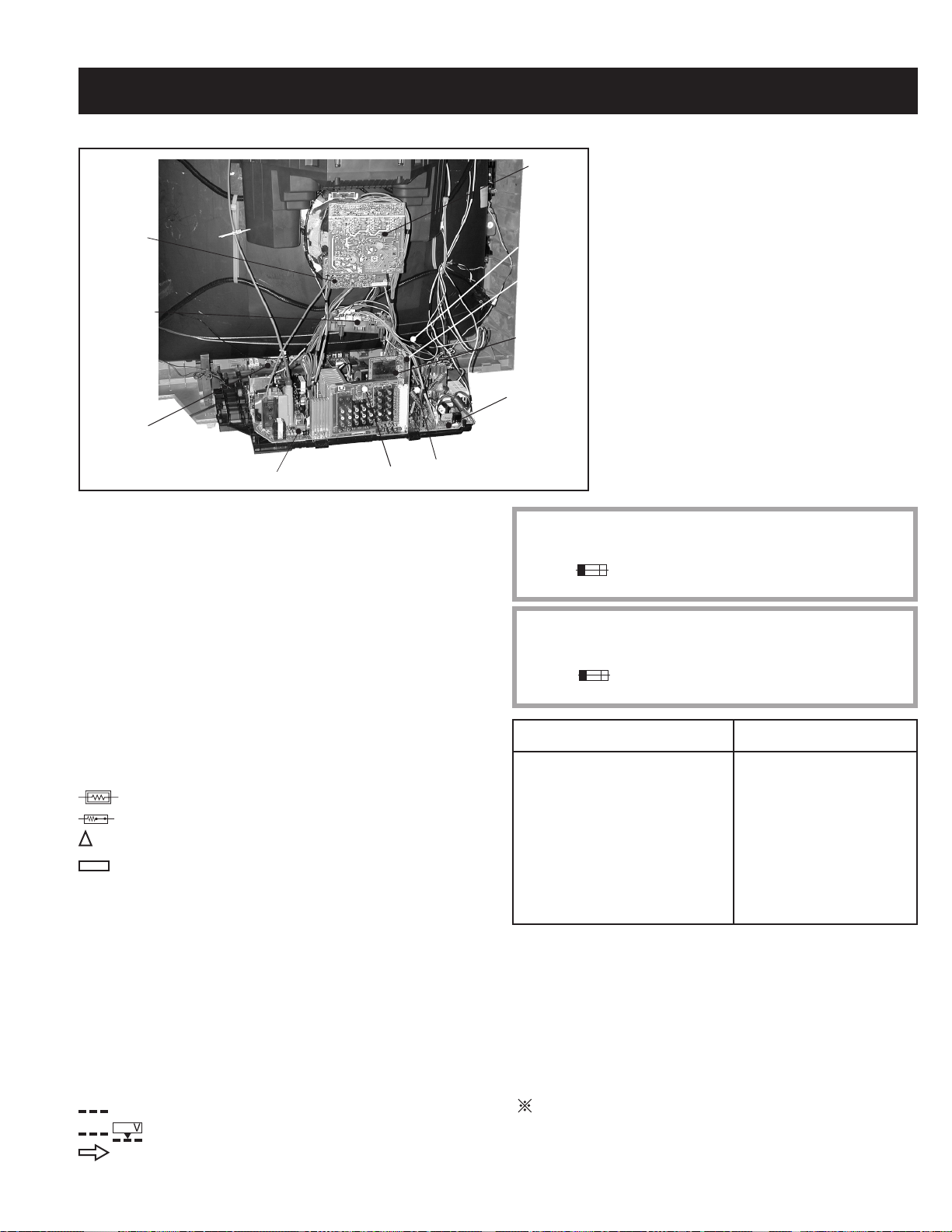

Self-Diagnostic Circuit

HA

STBY LED

STR

48

STBY-LED

OCP

44

45

OVP

43

LOW B ERR

D6018

A

IC701

MAIN UCOM

SET 5V

D6014

OVP

CLKO

DATO

AC RLY

29

30

69

Q6532

A

UNREG 7V

IC6007

I

Q6530

0

Q6527

A

IC201

Y/C JUNGLE

AKB

58

26

SCL

VPROT

25

RY6501

SET ON

D

200V OCP

D6537

D6501

0

OVP

+B OCP

SDA

HPROT

D8027

D8003

+B

Q6520

CRT

35

34

R5125

VDY -

D

1

Q6521

R5104 R5105

Q5018

2

IC6505

+B OVP

3

STBY 5V

Q6524

214

IC5007

I5V

Q6522

+B Overcurrent (OCP)

Occurs when an overcurrent

(more than 6A) on the +B

(135V) line is detected by

R6598/R6591. It will cause

Q6520 to turn on and force the

AC relay to turn off through

Q6532 and Q6530.

+B Overvoltage (OVP)

Occurs when 1) overvoltage

(more than +140V) on the

+B (135V) line is detected by

IC6505, or 2) an overvoltage

(more than 7.5 V) on the unreg

7V line is detected by D6014.

The AC relay will turn off

through Q6532 and Q6530.

Vertical Defl ection Stopped

Occurs when an absence of

the vertical defl ection pulse

is detected by IC201. Power

supply will shut down when

waveform interval exceeds 2

seconds.

White Balance Failure

If the RGB levels* do not balance within 2 seconds after the power is turned on, this error will be detected by IC201. TV will stay on, but there

will be no picture.

*(Refers to the RGB levels of the AKB detection Ref pulse that detects 1K).

Low B OCP/OVP Error

Occurs when set 5V is out.

Horizontal Defl ection Stopped

Occurs when either: 1) a +B overcurrent is detected (IC5007), or 2) overheating is detected (Thermistor TH5002).

— 8 —

Page 8

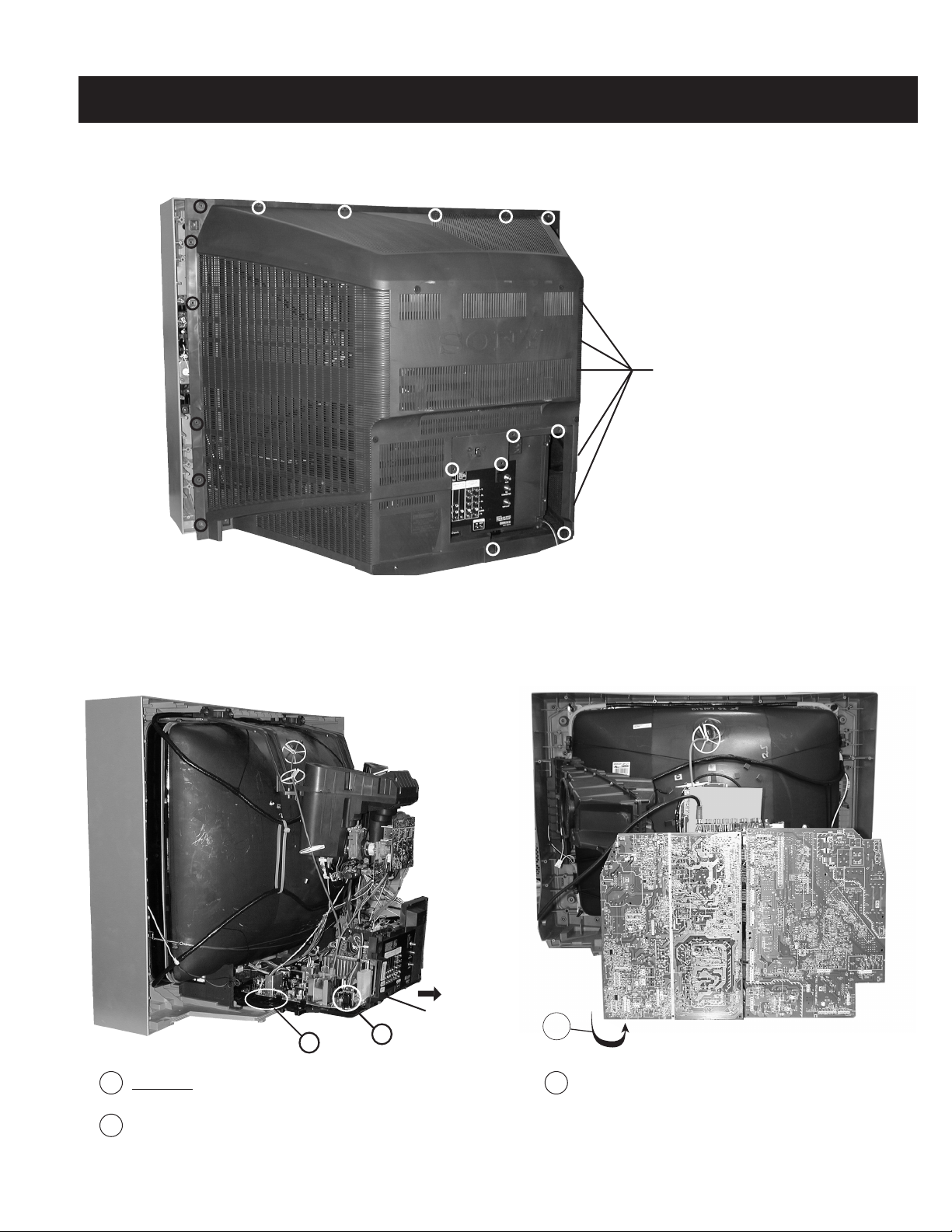

1-1. REAR COVER REMOVAL

KV-40XBR700

SECTION 1: DISASSEMBLY

Remove 22 (+BVTP 4x16) screws from areas

indicated with a circle or line.

1-2. CHASSIS ASSEMBLY REMOVAL 1-3. SERVICE POSITION

2

1

CAUTION! - Heat sink on IC5004 is -15V. Care must be

taken not to allow heat sink to touch any other components.

2

Gently pull the chassis assembly away from the bezel.

1

Chassis

Assembly

1

1

Pull up and rotate both the A and D Boards in order to

service the unit.

— 9 —

Page 9

1-4. PICTURE TUBE REMOVAL

KV-40XBR700

WARNING: BEFORE REMOVING THE ANODE CAP

High voltage remains in the CRT even after the power is disconnected. To avoid electric shock,

discharge CRT before attempting to remove the anode cap. Short between anode and CRT

coated earth ground strap.

Discharge the anode of the CRT and remove the

1

anode cap.

2

Unplug all interconnecting leads from the defl ection

yoke, neck assembly, degaussing coils and CRT

grounding strap.

3

Remove the Speaker Assemblies.

4

Remove the C Board from the CRT.

5

Remove the chassis assembly.

6

Loosen the neck assembly fi xing screw and remove.

7

Loosen the defl ection yoke fi xing screw and remove.

8

Place the set with the CRT face down on a cushion

and remove the degaussing coil holders.

9

Remove the degaussing coils.

10

Remove the CRT grounding strap and spring tension

devices.

11

Unscrew the four CRT fi xing screws [located on each

CRT corner] and remove the CRT [Take care not to

handle the CRT by the neck].

11

10

9

7

8

6

Coated

Earth

Ground

Strap

1

2

3

4

5

ANODE CAP REMOVAL PROCEDURE

WARNING: High voltage remains in the CRT even after the power is disconnected. To avoid electric shock, discharge CRT before attempting to remove

the anode cap. Short between anode and coated earth ground strap of CRT.

NOTE: After removing the anode cap, short circuit the anode of the picture tube and the anode cap to either the metal chassis, CRT shield, or

carbon painted on the CRT.

REMOVAL PROCEDURES

c

b

a

Anode Button

Turn up one side of the rubber cap in

the direction indicated by arrow

a

.

Use your thumb to pull the rubber

cap fi rmly in the direction indicated

by arrow

.

b

When one side of the rubber cap separates from

the anode button, the anode cap can be removed

by turning the rubber cap and pulling it in the

direction of arrow

.

c

HOW TO HANDLE AN ANODE CAP

1. Do not use sharp objects which may cause damage to the surface of the

anode cap.

2. To avoid damaging the anode cap, do not squeeze the rubber covering too hard.

A material fi tting called a shatter-hook terminal is built into the rubber.

3. Do not force turn the foot of the rubber cover. This may cause the shatter-hook

terminal to protrude and damage the rubber.

— 10 —

Page 10

SECTION 2: SET-UP ADJUSTMENTS

KV-40XBR700

The following adjustments should be made when a complete

realignment is required or a new picture tube is installed.

These adjustments should be performed with rated power supply

voltage unless otherwise noted.

The controls and switch should be set as follows unless otherwise

noted:

VIDEO MODE: STANDARD (RESET)

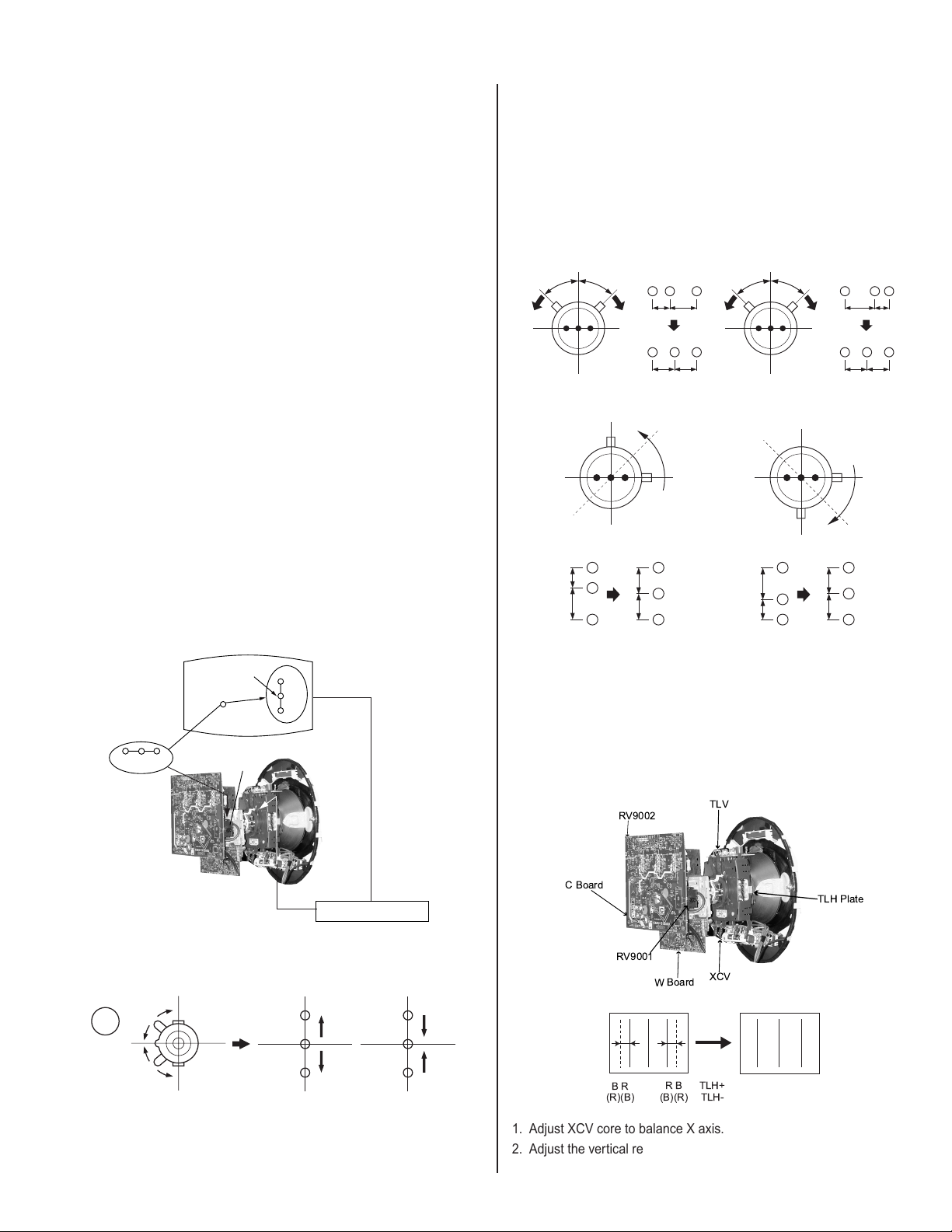

2-1. BEAM LANDING

Preparation:

• Input a white pattern signal.

• Face the picture tube in an East or West direction to reduce the

infl uence of geomagnetism.

NOTE: Do not use the hand degausser; it magnetizes the CRT .

1. Input white pattern from pattern generator. Set the PICTURE control

to maximum, and the BRIGHTNESS control to standard.

2. Perform Focus, G2 and White Balance adjustments.

3. Loosen the defl ection yoke mounting screw, and set the purity control

to the center as shown below:

Purity Control

Perform the adjustments in order as follows:

1. Beam Landing

2. Convergence

3. Focus

4. Screen (G2)

5. White Balance

Test Equipment Required:

1. Color Bar Pattern Generator

2. Degausser

3. DC Power Supply

4. Digital Multimeter

6. Move the defl ection yoke forward, and adjust so that the entire screen

becomes green.

7. Switch over the raster signal to red and blue and confi rm the

condition.

8. When the position of the defl ection yoke is determined, tighten it with

the defl ection yoke mounting screw.

9. If landing at the corner is not right, adjust it by using the disk magnets.

4. Input a green pattern from the pattern generator.

5. Move the defl ection yoke backwards, and adjust with the purity control

so that green is in the center and red and blue are even on both

sides.

Blue Red

Green

— 11 —

Purity control

corrects this area.

Disk magnets

or rotatable disk

magnets correct

thses areas (a-d).

Deflection yoke positioning

corrects these areas.

b

d

a

c

Page 11

KV-40XBR700

2-2. V-PIN AND V-CEN ADJUSTMENT

Preparation:

• Input a cross hatch pattern signal.

• Face the picture tube in a North/South direction and correct rotation.

• Set Video Mode to: Standard (Reset)

1. Adjust service mode CXA2150D-1 04 V-CEN so that the top pin and

bottom pin are symmetrical from top to bottom.

2. Adjust service mode CXA2150D-1 05 V-PIN so that the top pin and

bottom pin are symmetrical from top to bottom.

3. Lines should be straight from left to right. Check landing for side

effect.

2-3. CONVERGENGE

Preparation:

• Set the CONTRAST and BRIGHTNESS control to 50%.

• Input HD dot pattern.

2-3.1. VERTICAL AND HORIZONTAL STATIC

CONVERGENCE

1. Disconnect the dynamic convergence before adjusting static

convergence (CN5510), except for minor touch-up.

2. Adjust H.STAT convergence, RV9001, to converge red, green, and

blue dots in the center of the screen.

3. Adjust V. STAT magnet to converge red, green and blue dots in the

center of the screen.

2-3.2. OPERATION OF BMC (HEXAPOLE)

MAGNET

The respective dot positions result from moving each magnet interact.

Perform the following adjustments while tracking.

1. Use the V.STAT tabs to adjust the red, green and blue dots so that

they line up at the center of the screen (move the dots in a horizontal

direction).

HMC Correction HMC Correction

A>B

A=B

R

B

GB

R

AB

RGB

AB

C=D

R

G

B

A=B

VMC Correction

C<D

R

C

G

D

B

A<B

R

AB

RGB

AB

C=D

GB

R

G

B

VMC Correction

C<D

C

G

D

Center dot

R

G

B

RV9001

R G B

V. S TAT

V.STAT magnet

4. Tilt the V.STAT magnet and adjust static convergence to open or close

the V.STAT magnet.

1

B

G

R

B

G

R

2-3.3. TLH PLATE ADJUSTMENT

Preparation:

• Input a cross hatch pattern signal.

• Adjust PICTURE QUALITY to Standard, PICTURE and

BRIGHTNESS to 50%, and OTHER to Standard.

• Adjust unbalanced horizontal convergence of red and blue dots by

adjusting the TLH Plate on the defl ection yoke.

RB

TLV

XCV

TLH+

TLH-

TLH Plate

C Board

RV9002

RV9001

BR

(R)(B)

W Board

(B)(R)

1. Adjust XCV core to balance X axis.

2. Adjust the vertical red and blue convergence with V.TILT (TLV VR).

Note: Perform adjustments while tracking Item 1.

— 12 —

Page 12

KV-40XBR700

NO.

Register

Disp.

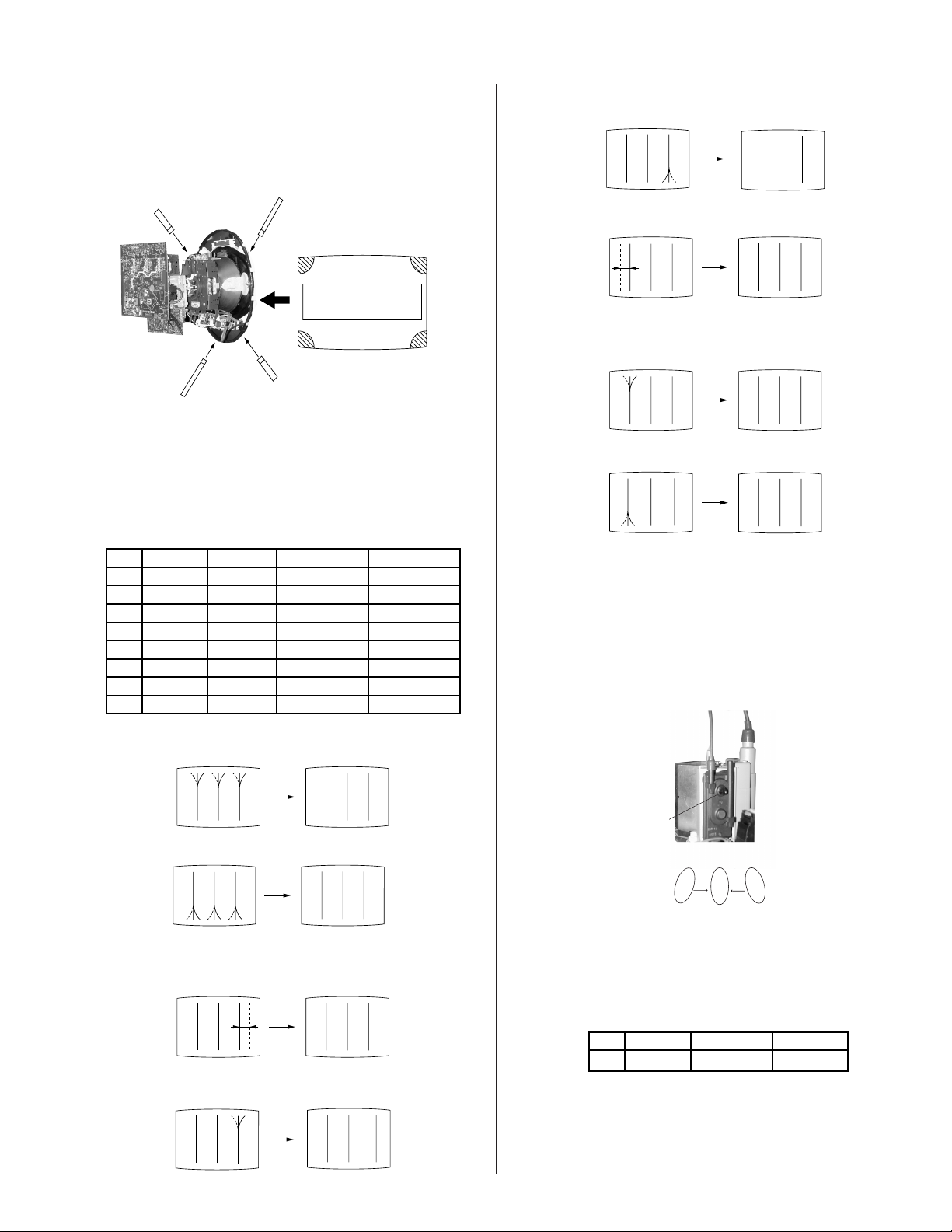

2-3.4. SCREEN-CORNER CONVERGENCE

Preparation:

• Input a cross hatch pattern signal.

1. Affi x a permalloy assembly corresponding to the misconverged areas.

b

d

a

a

a-d: screen-corner

misconvergence

cd

c

b

2-3.5. DYNAMIC CONVERGENCE

ADJUSTMENTS

Set dynamic convergence using the following service mode adjustment

data.

CXA8070AP

Function Data Length Initial Data

1 YBWU VCA9 0-63 31

2 YBWL VCA10 0-63 31

3 RSAP DC-AMP1 0-63 31

4 RUBW VCA5 0-63 31

5 RLBW VCA6 0-63 31

6 LSAP DC-AMP2 0-63 31

7 LUBW VCA10 0-63 31

8 LLBW VCA2 0-63 31

5. RLBW (Right Side Bottom C-BOW)

RB

6. LSAP (Left AMP)

BR

7. LUBW (Left Side Upper C-BOW)

BR

8. LLBW (Left Side Bottom C-BOW)

BR

2-4. FOCUS ADJUSTMENT

1. Input a dot signal.

2. Set Video Mode to STANDARD.

3. Adjust focus VR counter-clockwise to confi rm that the dot’s shape is

centered.

4. Input a HP monoscope signal.

5. Confi rm center focus with focus VR.

1. YBWU (Upper Y-BOW)

BR BR

2. YBWL (Bottom BOW)

BR BR

3. RSAP (Right AMP)

RB

4. RUBW (Right Side Upper C-BOW)

BR

FOCUS

DOT SHAPE:

2-5. SCREEN (G2)

1. Input a monoscope pattern (NTSC).

2. Set to service mode and adjust as follows:

CXA2150P-2

NO.

0 ALBK ALL_BLK 0

3. Adjust RV9002 on the C Board so that the voltage on red, green and

blue cathodes is 175 ± 2 VDC.

4. Adjust the hotizontal line at the top of the screen so it is cut off.

Note: Never set ALBK to 1 when external power supply is connected

to cathode.

— 13 —

Item Avg.

Page 13

KV-40XBR700

2-6. PICTURE QUALITY ADJUSTMENTS

Preparation:

• Set PRO MODE (Picture: MAX, GAMMA: 0).

• Dynamic-color: Off (=Trinitron: MID).

• Set the Service Mode to the following:

C2150P-4

NO. Name Control Function Avg. Data

06 UDCL Dynamic Color: OFF 0

08 UGRAM GRAMMA 5

15 DCTR DC-TRAN 2

16 DPIC DYNAMIC PIC: OFF 1

1. Input signal (480i):

• Color Bar Video 75 IRE (White) 75% modulation 7.5% Set-up.

• Color Bar RF 75 IRE (White) 75% modulation 7.5% Set-up.

2-6.1. VIDEO INPUT - TWO PICTURE SUB

CONTRAST ADJUSTMENT

Preparation:

• Input a Color Bar signal to VIDEO 1 (75 IRE 75%).

• Set picture mode: P&P (PRO MODE).

1. Set to Service Mode and adjust as follows:

2150P-4

NO. Name Control Function Avg. Data

00 UPIC PICTURE 63

02 UCOL COLOR 0

2150P-2

NO. Name Control Function Avg. Data

01 RGBS R ON 4

2103-2

NO. Name Control Function

02 SCON SUB-CONT

white

VR1

black

VR2

GND

VR1-VR2 = VR = 2.08 ± 0.05 Vp-p

5. Write data from Steps 3 and 4 above, into memory.

2-6.2. VIDEO INPUT - SUB HUE/SUB COLOR

ADJUSTMENT

Preparation:

• Input a Color Bar signal to VIDEO 1 (75 IRE 75%).

• Set picture mode: P&P (PRO MODE).

1. Set to Service Mode and adjust as follows:

2150P-4

NO. Name Control Function Avg. Data

00 UPIC PICTURE 63

02 UCOL COLOR 31

2150P-2

NO. Name Control Function Avg. Data

01 RGBS R ON 7

INITIAL DATA (IMPORTANT)

2150P-4

NO. Name Control Function Avg. Data

23 SCON SUB-CONT 8

2103-1

NO. Name Control Function Avg. Data

00 YLEV Y-OUT 23

2103-2

NO. Name Control Function Avg. Data

00 YLEV Y-OUT 23

2. Connect oscilloscope to Pin 1 of CN9001 (R.DRV) on the C Board.

3. Adjust MAIN (left) side contrast according to Service Mode for SCON.

2103-1

NO. Name Control Function

02 SCON SUB-CONT

4. Adjust SUB (right) side contrast according to Service Mode for SCON.

— 14 —

2. Connect an oscilloscope to Pin 5 of CN9001 (B. DRV) on the C Board.

3. Adjust MAIN (left) side color according to Service Mode for SCOL.

4. Adjust MAIN (left) side color according to Service Mode for SHUE.

2103-1

NO. Name Control Function

03 SCOL SUB-COL

04 SHUE SUB-HUE

5. Adjust SUB (right) side color according to Service Mode for SCOL.

6. Adjust SUB (right) side color according to Service Mode for SHUE.

2103-2

NO. Name Control Function

03 SCOL SUB-COL

04 SHUE SUB-HUE

Page 14

T

T

white

Control Function

Avg. Data

Control Function

Avg. Data

Control Function

Avg. Data

KV-40XBR700

VB4

VB3VB2VB1

COLOR: VB1 < VB4 (=VB1 + 0~90 mV)

HUE: VB2 < VB3 (=VB2 + 0~90 mV)

(HUE: Adjust data -2 STEP)

7. Write data into memory.

2-6.3. RF INPUT - TWO PICTURE SUB

CONTRAST ADJUSTMENT

Preparation:

• Input a Color Bar signal to RF (75 IRE 75%).

• Set picture mode: P&P (PRO MODE).

1. Set to Service Mode and adjust as follows:

2150P-4

NO. Name Control Function Avg. Data

00 UPIC PICTURE 63

02 UCOL COLOR 0

2150P-2

NO. Name Control Function Avg. Data

01 RGBS R ON 4

INITIAL DATA (IMPORTANT)

2150P-4

NO. Name Control Function Avg. Data

23 SCON SUB-CONT 9

2103-1

NO. Name Control Function Avg. Data

00 YLEV Y-OU

2103-2

NO. Name Control Function Avg. Data

00 YLEV Y-OU

Note: Use the same average data as 2-6.1., Items 3 - 4 after the

adjustment.

2. Connect an oscilloscope to Pin 1 of CN9001 (R. DRV) on the C

Board.

3. Adjust MAIN (left) side contrast according to service mode for SCON.

2103-1

NO. Name Control Function

02 SCON SUB-CONT

4. Adjust SUB (right) side contrast according to Service Mode for SCON.

2103-2

NO. Name Control Function

02 SCON SUB-CONT

23

23

VR1

black

VR2

GND

VR1-VR2 = VR = 2.08 ± 0.05 Vp-p

5. Write data from Steps 3 - 4 above, into memory.

2-6.4. RF INPUT - SUB HUE/SUB COLOR

ADJUSTMENT

Preparation:

• Input a Color Bar signal to RF (75 IRE 75%).

• Set picture mode: P&P (PRO MODE).

1. Set to Service Mode and adjust as follows:

2150P-4

NO. Name Control Function Avg. Data

00 UPIC PICTURE 63

02 UCOL COLOR 31

2150P-4

NO. Name Control Function Avg. Data

01 RGBS R ON 7

INITIAL DATA (IMPORTANT)

2150P-4

NO. Name

24 CLOF OFFSET for UCOL 8

25 HUOF OFFSET for UHUE 4

2103-1

NO. Name

01 CLEV CB & CR-OUT 20

20 CBOF CB-OFFSET 31

21 CROF CR-OFFSET 31

2103-2

NO. Name

01 CLEV CB & CR-OUT 19

20 CBOF CB-OFFSET 31

21 CROF CR-OFFSET 31

Note: Use the same average data as 2-6.2., Items 3-6 after the

adjustment.

2. Connect an oscilloscope to pin 5 of CN9001 (B. DRV) on the C Board.

3. Adjust MAIN (left) side color according to Service Mode for SCOL.

4. Adjust MAIN (left) side color according to Service Mode for SHUE.

2103-1

NO. Name Control Function

03 SCOL SUB COLOR

04 SHUE SUB HUE

5. Adjust SUB (right) side color according to Service Mode for SCOL.

— 15 —

Page 15

KV-40XBR700

2150P-1

T

NO.

NO.

NO.

6. Adjust SUB (right) side color according to Service Mode for SHUE.

2103-2

NO. Name Control Function

03 SCOL SUB COLOR

04 SHUE SUB HUE

VB4

VB3VB2VB1

COLOR: VB1 < VB4 (=VB1 + 0~90 mV)

HUE: VB2 < VB3 (=VB2 + 0~90 mV)

(HUE: Adjust data -2 STEP)

7. Write data into memory.

2-7. WHITE BALANCE (CRT) AND SUB

BRIGHT ADJUSTMENT

Preparation

• Input an all white 480I (15.734 KHz) signal into the VIDEO 1 input

terminal to perform the White Balance (highlight, cut-off) adjustments.

The parameters to adjust are in the CXA2150P in Service Mode.

1. Set the following:

Picture: Full Mode

Pro Mode

Color: Center

2. Adjust White Balance in the Service Mode and set the following data:

NO. Name Control Function Avg. Data

05 RDRV R-DRIVE Fix: 46

06 GDRV G-DRIVE Adjust

07 BDRV B-DRIVE Adjust

08 RCUT R-CUT OFF Fix: 41

09 GCUT G-CUT OFF Adjust

10 BCUT B-CUT OFF Adjust

2-8. RASTER CENTER ADJUSTMENT

Preparation:

• Input a monoscope signal.

• Set to NTSC (DRC) mode.

1. Set to Service Mode and adjust as follows:

CXA2150P-2

Name Control Function Avg. Data

06 AGNG AGING 1, AGING 2 2

CXA2150D-2

Name Control Function Avg. Data

02 HSIZ Horiz Size 45

CXA2150D-3

Name Control Function Avg. Data

00 HBLK Blanking Enable 0

2. Reduce HSIZ to see sides of raster.

3. Adjust H-Center with CXA2150D-2 00.

4. Adjust to the best screen position with H-CENT and write data.

5. Restore aging, HSIZ and HBLK to original condition.

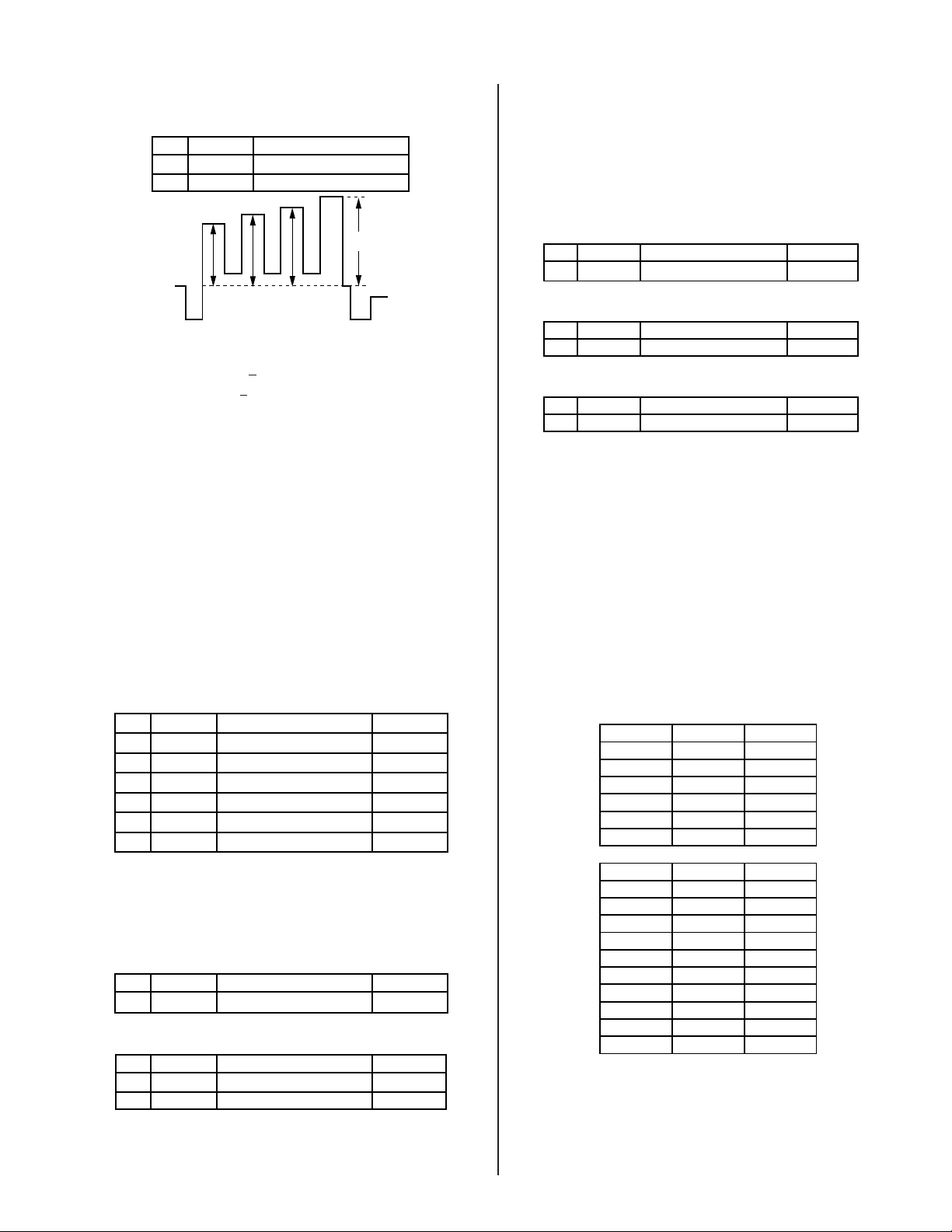

2-9. PICTURE DISTORTION ADJUSTMENTS

2-9.1. NTSC (DRC) FULL MODE

ADJUSTMENT

1. Face the picture tube in an east-west direction.

2. Complete V-PIN and V-CEN adjsuments fi rst (A2150-D1 05 V-PIN,

A2150-D1 04 V-CEN).

3. Input a monoscope and crosshatch signal. Adjust the picture

distortion with the following service parameters to balance the best

condition for these two signals.

A2150-D1 00 VPOS

A2150-D1 01 VSIZ

A2150-D1 02 VLIN

A2150-D1 03 VSCO

A2150-D1 04 VCEN

A2150-D1 05 VPIN

A2150-D1 07 HTPZ

3. Adjust Sub Brightness: Input an all black signal (to IRE 7.5% set up)

480i (15.75 KHz) signal into the VIDEO 1 input terminal. Adjust the

following parameter of CXA2150P-1:

4. Check Initial Data (Important).

CXA2150P-1

NO. Name Control Function Avg. Data

04 SBRT SUB-BRIGHT 20

2150P-1

NO. Name Control Function Avg. Data

00 SBOT SUB-BRT OFFSET 7

12 SBOF SUB-BRT OFFSE

5. Repeat Steps 2-4.

63

— 16 —

A2150-D2 01 HPOS

A2150-D2 02 HSIZ

A2150-D2 03 SLIN

A2150-D2 04 MPIN

A2150-D2 06 UCP

A2150-D2 07 LCP

A2150-D2 13 PPHA

A2150-D2 14 VANG

A2150-D2 15 LANG

A2150-D2 16 VBOW

A2150-D2 17 LBOW

Note: Make sure that the picture size is within specs. Vertical size is

11.7 ± 0.1 sq. and horizontal size is 15.6 ± 0.1 sq.

4. Write data into memory and then set the screen to 1080i mode.

Page 16

KV-40XBR700

A

CXA2150D-1

0. VPOS (V-POSITION)

1. VSIZ (V-SIZE)

2. VLIN (V-LINE)

3. VSCO (VS-COR)

7. HTPZ (H-TRAPEZOID)

CXA2150D-2

1. HPOS (H-POSITION)

15. LANG (L-ANGLE)

16. VBOW (AFC-BOW)

17. LBOW (L-BOW)

2-9.2. 1080i HD MODE ADJUSTMENT

1. Input a 1080i cross-hatch signal and an HD monoscope signal that

contains overscan markers.

2. Adjust the raster position per Section 2-8., only if this procedure was

not performed for full mode.

3. Adjust the geometry similar to Full DRC mode. Vertical size is 11.7

± 0.1 sq. and horizontal size is 15.6 ± 0.1 sq., if monoscope signal is

available. Otherwise, set the Vertical size to 91.0 ± 0.6% scan and

Horizontal size as 91.0 ± 0.6% scan.

4. Use the following register to adjust the horizontal parameter:

2150-D2 01 HPOS

Note: If necessary, touch up the geometry using the data register

listed above for Full mode.

5. Write the data into memory.

2. HSIZ (H-SIZE)

5. PIN (PIN AMP)

6. UCP (UP COR PIN COR)

7. LCP (LOW CO PIN COR)

13. PPHA (PIN PHASE)

14. VANG (AFC-ANGLE)

2-9.3. VERTICAL COMPRESSED MODE

CHECK AND CONFIRMATION

1. Input a monoscope and crosshatch signal.

2. Check vertical compressed mode.

— 17 —

Page 17

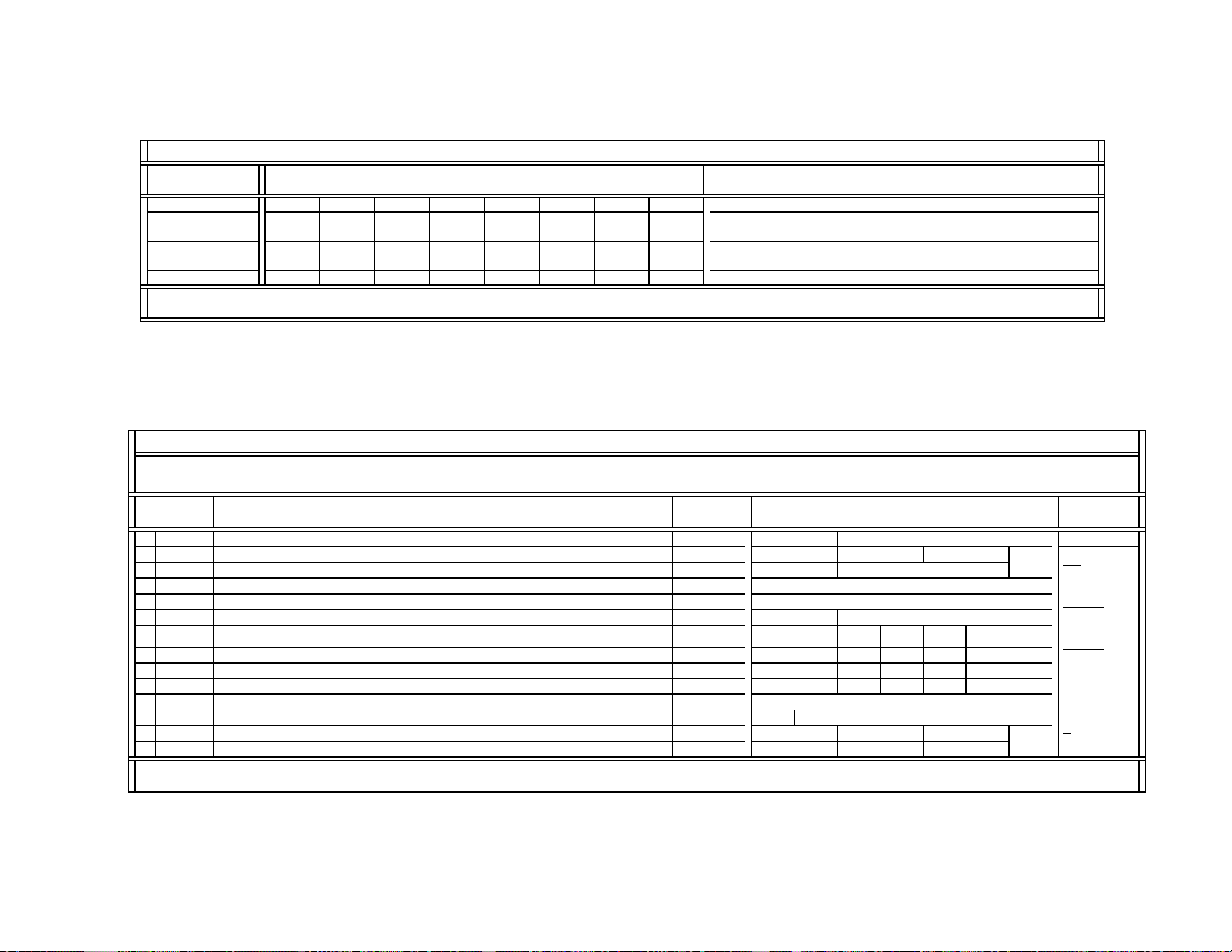

SECTION 3: SAFETY RELATED ADJUSTMENTS

3-1. X RV8001, RV8002 CONFIRMATION METHOD AND HV SERVICE ADJUSTMENTS

KV-40XBR700

3-2. B+ MAX CONFIRMATION

Standard............................................................................ 135.3 ± 1 VDC

Check Condition:

AC input voltage: 120 (± 2) VAC at Board Adjustment Process

130 (± 2) VAC at QC

120 (± 2) VAC at Overall Adjustment (after aging)

3-3. HV SERVICE FLOWCHART

Start

Is T8001

Changed?

Ye s

Replace RV8001, RV8002 with the same value:

HV project adjust and inspection

1. Turn RV8001 fully counter-clockwise.

2. Turn set on with black video signal then adjust RV8002 slowly to obtain

35.5kV.

3. Turn RV8001 clockwise slowly until hold down operation initially activates.

4. Adjust RV8002 clockwise, then turn the set on. Change video to white field then

slowly turn RV8002 counter-clockwise to get 34.8 ± 0.2kV. Confirm set does

NOT TURN OFF at this condition. If yes, then repeat from step 1 again.

5. Finally, set back RV8002 to 31.50kv + 0.2kv at video cut off (black video).

No

Note: If using a stabilized power supply, make sure that the distortion

factor is 3% or less.

Setting Mode:........................................................................... Full mode

Signal Input:................................................ Cross-hatch of NTSC at QC

Initial Setting:........................................................ Reset condition at QC

Confi rm Point:.......................................Across C6544 for B+ of D Board

Change any

or

marked parts

Ye s

No

Is D-Board

Replaced?

Ye s

No

If all adjustments are complete, then seal and secure RV8001, RV8002 with

epoxy to prevent any possible misadjustment by non-trained technical

Confirm +B, Vd and check hold-down on the D Board video with no signal (standard

reset mode) as follows:

1. Confirm +B across C6544 to make sure that it is 135.3 ± 1 Vdc.

2. Confirm Vd at Pin 2 CN5506 or at TP-Vd for 4.3V < Vd < 4.65 Vdc.

3. Apply 5.5 ± 0.5 Vdc at Pin 2 of CN5506, then confirm that set holds down.

service.

Is +B, Vd and

hold down

confirmed?

Ye s

Finish for

hold-down

check.

Start from

the beginning.

— 18 —

Page 18

SECTION 4: CIRCUIT ADJUSTMENTS

Y

ELECTRICAL ADJUSTMENTS BY REMOTE COMMANDER

Use the Remote Commander (RM-Y184) to perform the circuit adjustments in this section.

Test Equipment Required: 1. Pattern generator 2. Frequency counter 3. Digital multimeter 4. Audio oscillator

KV-40XBR700

4-1. SETTING THE SERVICE ADJUSTMENT

MODE

1. Standby mode (Power off).

2. Press the following buttons on the Remote Commander within one

second of each other:

DISPLAY

Channel 5 Sound Volume

+

Power

SERVICE ADJUSTMENT MODE VIEW

Device Item Data Item

Register

Item

2150P-1 0 +7 SERVICE

SBOT TV

WSL: 0

F/A FLAG:

CBA FLAG:

READING THE MEMORY

1. Enter into Service Mode.

2. Press 0 on the Remote Commander.

3. Press

ENTER

to read memory.

ADJUSTING THE PICTURE

1. Enter into Service Mode

2. Press 2 or 5 on the remote to select the device item.

3. Press

4. Press

5. Press

1

or 4 on the remote to select an item.

or 6 on the remote to change the data.

3

ENTER

MUTING

then

to write into memory.

4-1.1. RESETTING THE DATA

4-2. MEMORY WRITE CONFIRMATION

METHOD

1. After adjustment, pull out the plug from the AC outlet, then replace the

plug in the AC outlet again.

2. Turn the power switch ON and set to Service Mode.

3. Call the adjusted items again to confi rm they were adjusted.

4-3. REMOTE ADJUSTMENT BUTTONS AND

INDICATORS

WRITE

INTO MEMORY

ITEM UP

ITEM DOWN

TEST

RESET

DEVICE UP

DATA UP

DATA DOWN

DEVICE DOWN

EXECUTE

READ

MEMOR

Note: Be careful when using the remote! It will clear and re-initialize

ALL NVM data including defl ection adjustment data if not reset

properly as follows:

RESETTING THE DEFLECTION NVM DATA

1. Enter into Service Mode.

2. Press 7, then

MENU

, and then press

ENTER

on the remote.

RESETTING THE SYSTEM NVM DATA

1. Enter into Service Mode.

2. Press

7

, then 9, and then press

ENTER

on the remote.

RESETTING THE SYSTEM NVM DATA

1. Enter into Service Mode.

2. Press 8 and then press

ENTER

on the remote.

— 19 —

RM-Y184

Page 19

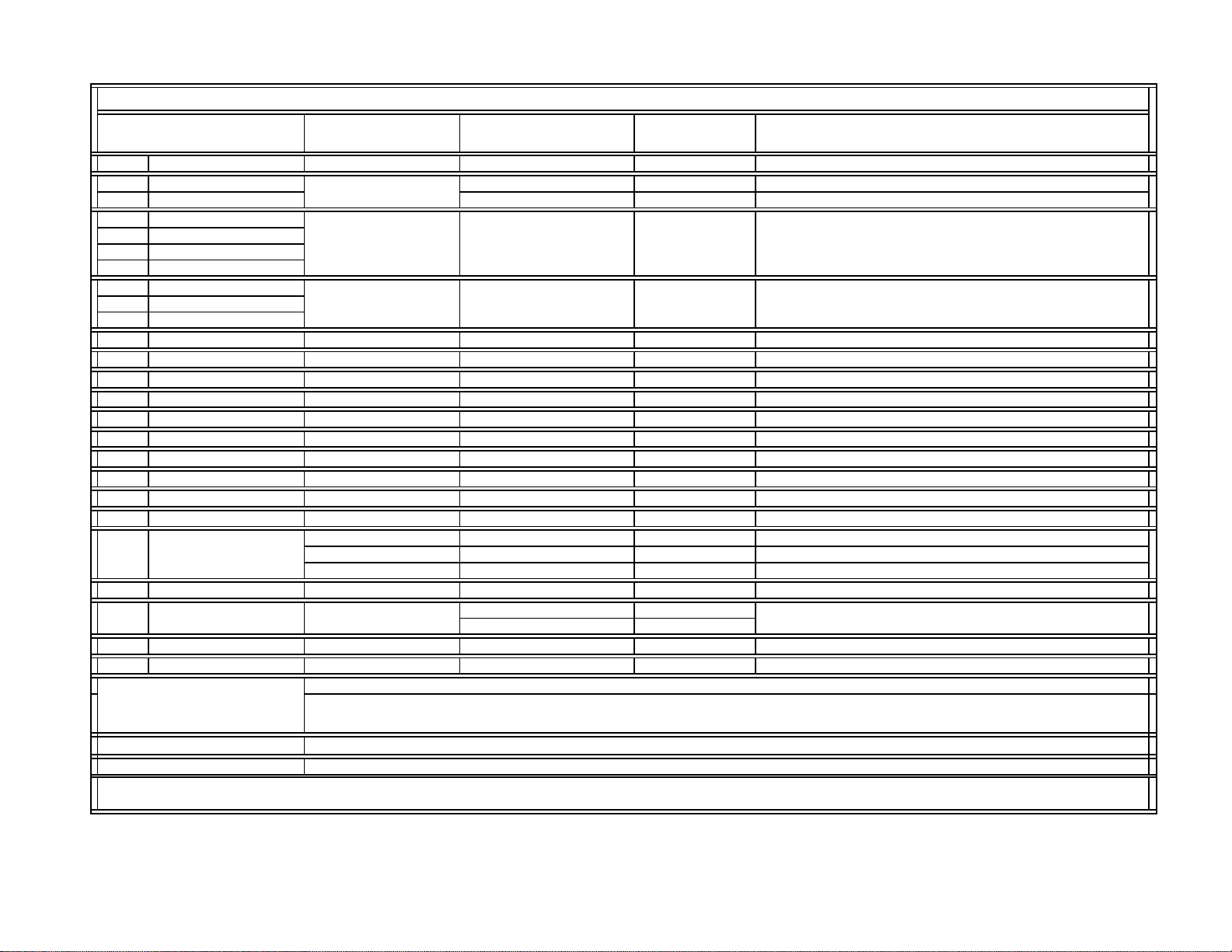

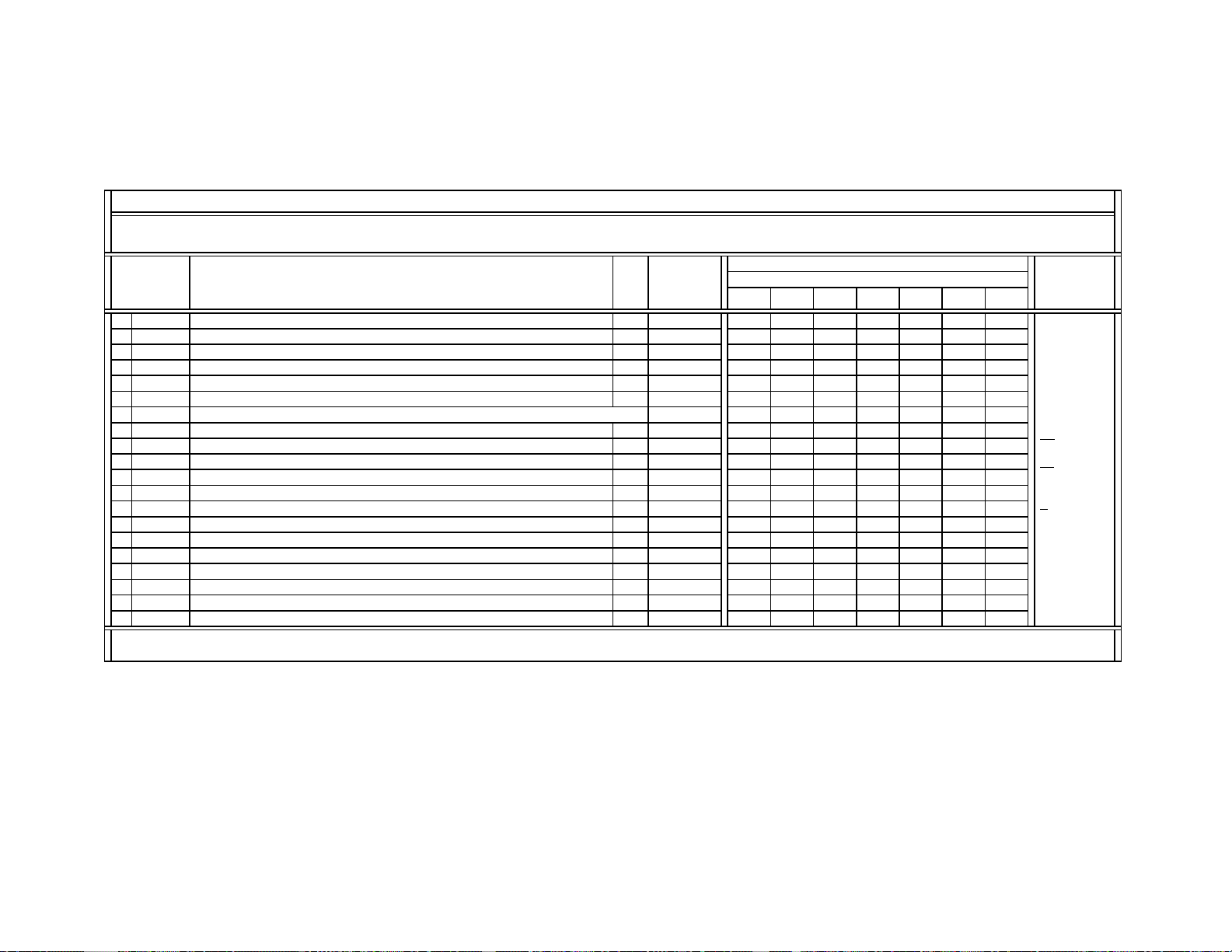

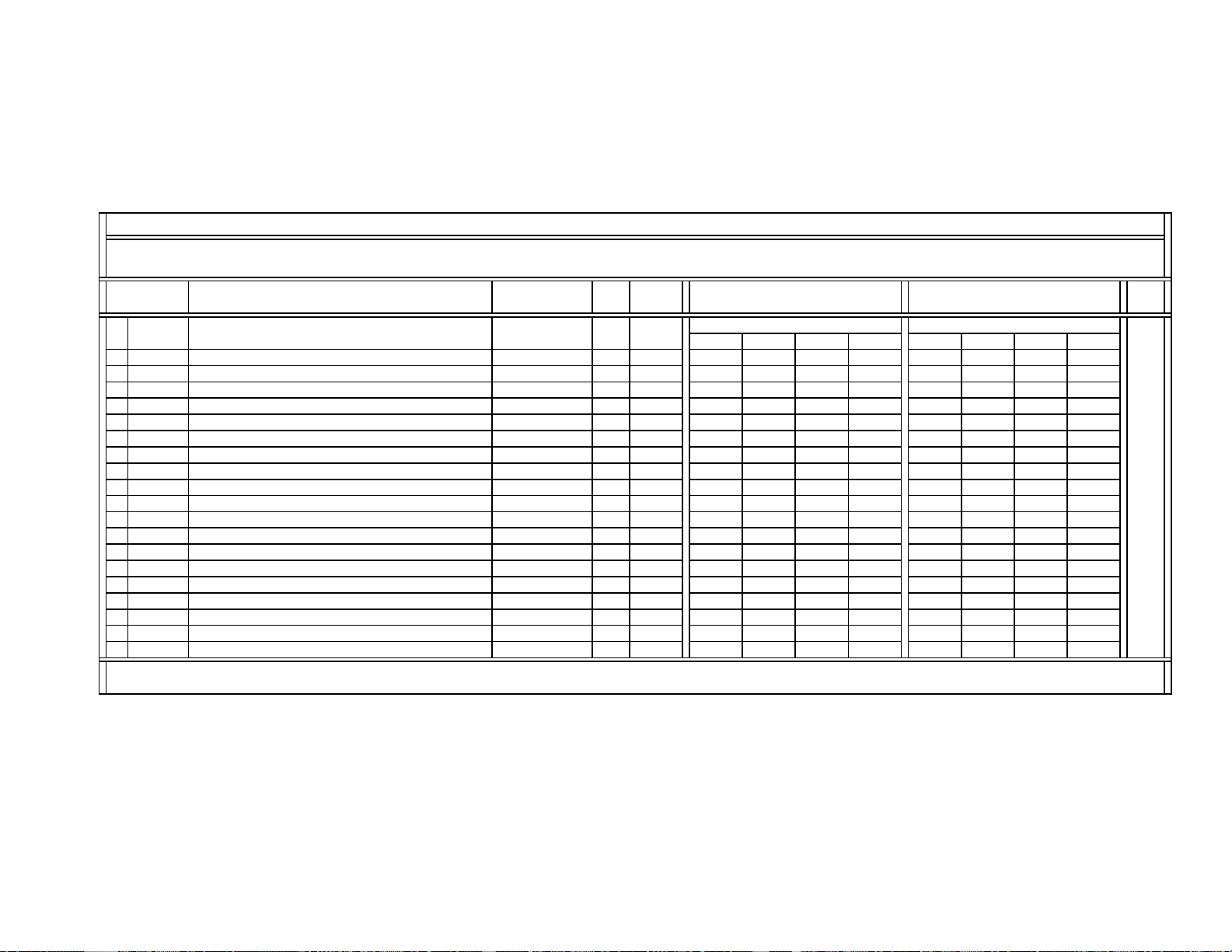

4-4. SERVICE DATA LISTS

V

BH3868FS

Controlled through CXA1315M ( IC4103 / S-board / 48h )

Controlled through MID-XA Micro ( IC3090 / B-board / 64h )

Controlled through MID-XA Micro ( IC3090 / B-board / 64h )

Controlled through MID-XA Micro ( IC3090 / B-board / 64h )

Controlled through MID-XA Micro ( IC3090 / B-board / 64h )

}

68h (Main)

6Ch (Sub)

}

}

s

DX1A-2001* Service List ------ Contents & Notes

Category Number & Name

# 1 3D-COMB µPD64082 IC3501 / BC-board B8h (W) & B9h (R) W&R: Write & Read

# 2-1 CXA2103-1 (Main) IC3048 (Main) / B-board 9Ah

# 2-2 CXA2103-2 (Sub) IC3110 (Sub) / B-board 9Eh

# 3-1 CXA2150P-1

# 3-2 CXA2150P-2

# 3-3 CXA2150P-3

# 3-4 CXA2150P-4

# 4-1 CXA2150D-1

# 4-2 CXA2150D-2

# 4-3 CXA2150D-3

# 5 CXA2151 CXA2151Q IC3001 / B-board 84h

# 6 D-CON

# 7 CXA2026 CXA2026AS IC5511 / D-board 8Eh

# 8 AP

# 9 TRUS NJM2180M IC4101 / S-board 2Eh

# 10 MID1 CXD9509AQ IC3408 / B-board 2Eh

# 11 MID2 CXD9509AQ IC3408 / B-board 2Eh

# 12 MID3 CXD9509AQ IC3408 / B-board 2Eh

# 13 MID5 CXD9509AQ IC3408 / B-board 2Eh

# 14

# 15

# 16 ID1 CXD2085M IC3603 / B-board 40h

# 17

# 18

# 19

DX1A-2001 System Micro &

Notes for Services

DX1A-2001 MID-XA Micro

DX1A-2001 CCD&Vchip Micro

Note:

* This service list is used for DX1A-2001 ONLY. Some service data is the same in DX1A-2001 & 2000, as noted in the data sheets.

OSD

SNNR

CCD&VCHIP

OP

ID

Device Name

CXA2103Q

CXA2150Q 86h

CXA8070P IC5513 / D-board DEh

M306V2ME-153FP IC701 / A-board 60h DX1A-2001 System Micro {V1.0

µPD64082 IC3501 / BC-board B8h (W) & B9h (R)

CXA2103Q IC3048 (Main) / B-board 9Ah

CXA2150Q IC201 / A-board 86h

CXP85840A-039Q

M306V2ME-153FP IC701 / A-board 60h DX1A-2001 System Micro {V1.0

M306V2ME-153FP IC701 / A-board 60h DX1A-2001 System Micro {V1.0

M306V2ME-153FP (MASK), Software Version 1.0, IC701/A-board (Slave Adress: 60h)

The system micro name, software&patch versions, and the status of NVM devices are displayed only when in the service catergory

(#19): ID.

MB94918RPF-G-137-BND (MASK), Software Version 12/08/00, IC3090/B-board (Slave Address: 64h)

CXP85840A-039Q (MASK), Software Version 2.14, IC3602/B-board (Main/Slave Address: 68h) & IC3601/B-board (Sub/Slave Address:

Device Reference

Number

IC201 / A-board

IC201 / A-board

IC7001 / A-board 82h

IC3602 (Main) / B-board

IC3601 (Sub) / B-board

Slave Address Comment

86hCXA2150Q

CCD&Vchip Micro (V2.14)

KV-40XBR700

— 20 —

Page 20

SERVICE DATA LISTS

Non-standard

g

(

g)

y

g

Non-standard

NSDS

g

p

g

p

(

p)

g)

A

g

g)

A

Y

(

)

(

)

(

)

p

Y

p

y

Y

p

)

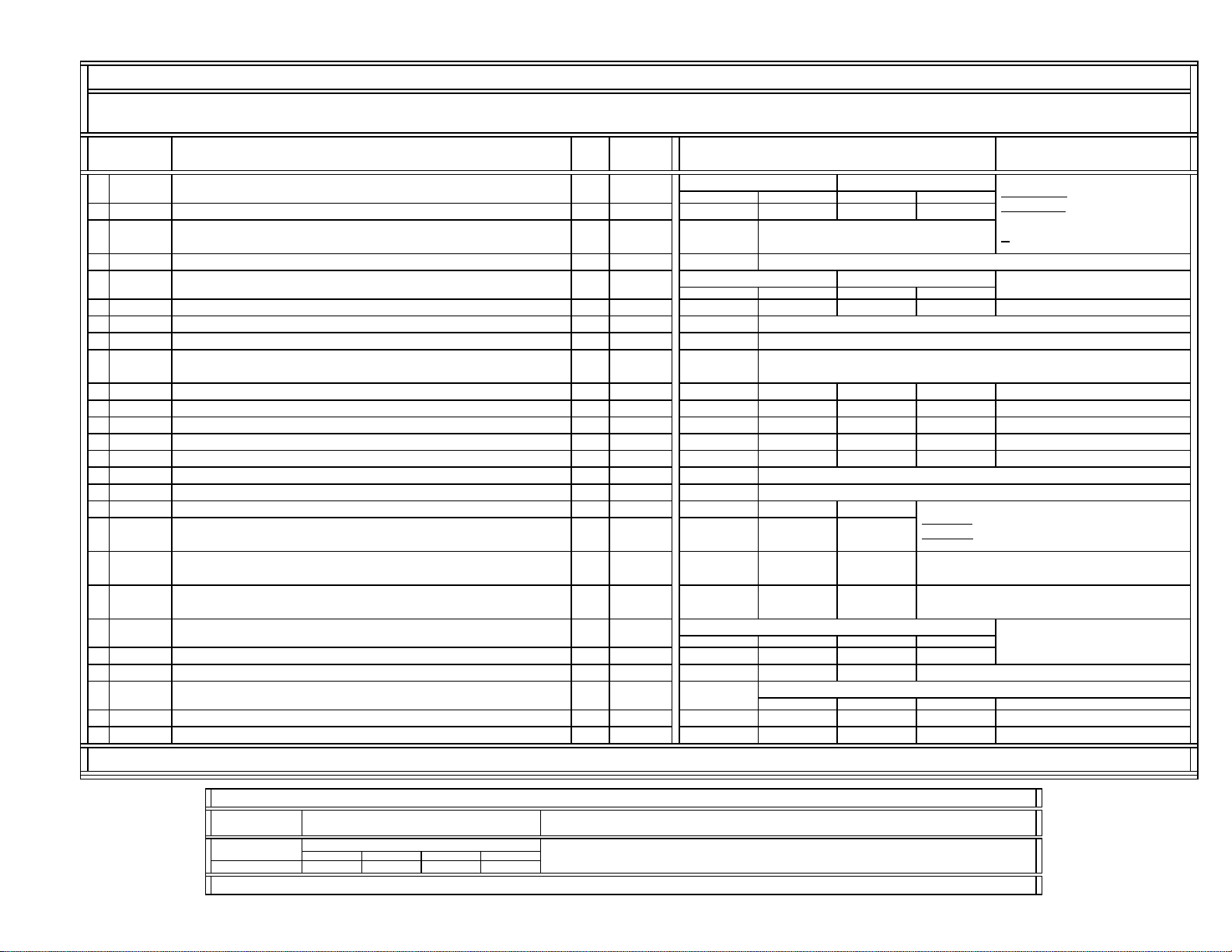

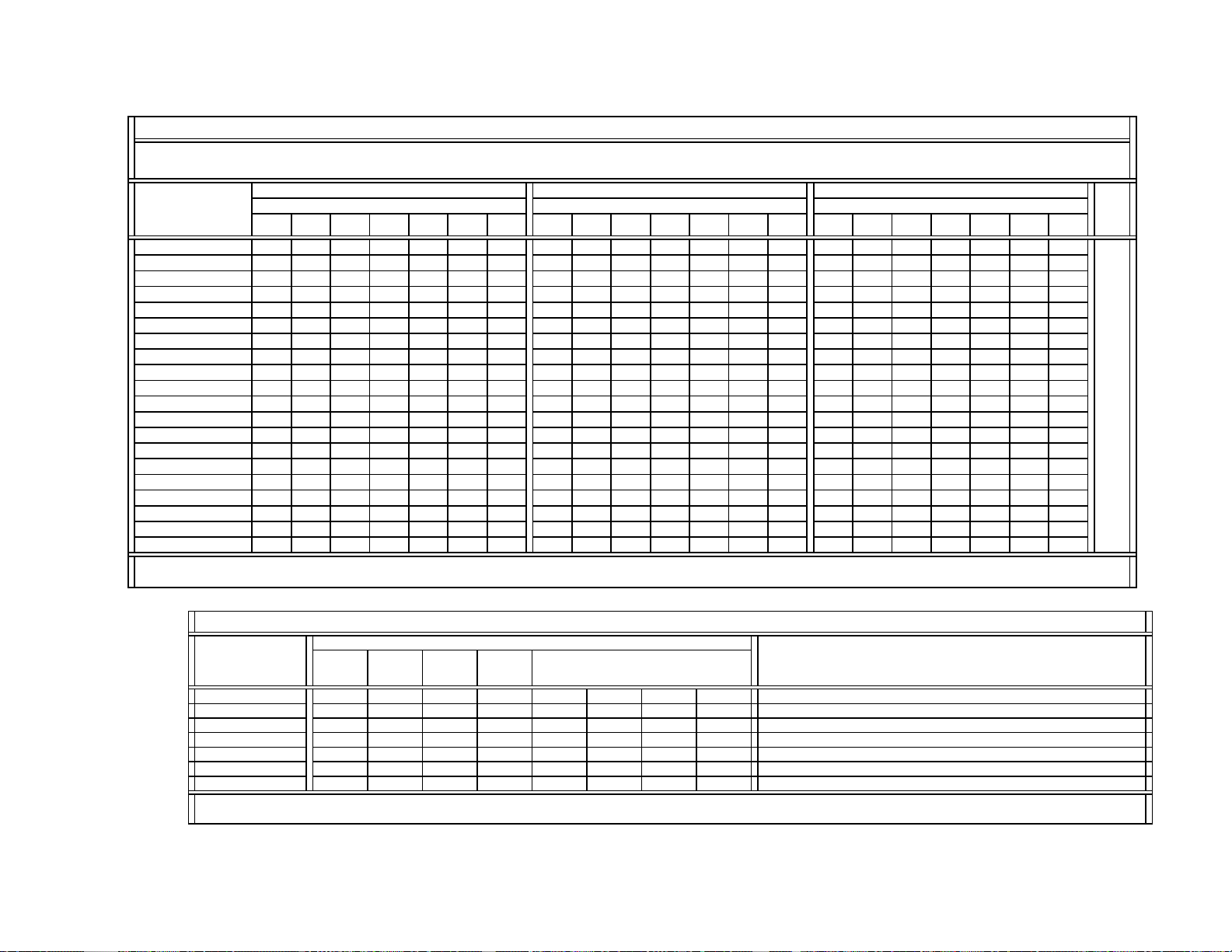

DX1A-2001&2000 SERVICE LIST (#1): 3D-COMB / mPD64082 (Part-1/4)

Device Name: mPD64082GF { 3D-Comb Filter / NEC } / IC3501 (BC-board) / P/N: 8-759-594-44 (SB#: V7372)

Slave Address: B8h (Write Address) / B9h (Read Address)

Register

No & Name

0

NRMD

1

YAPS

2

CLKS

3

4

MSS

5

KILS

6

CDL

7

DYCO

8

DYG

9

DCCO

10

DCG

11

12

CNRL

13

VTRH

14

VTRR

15

LDSR

16

VAPG

17

VAPI

18

19

Note: The same 3D-COMB service data is used for DX1A-2001&2000.

Operation mode settin

Y-output correction

V-aperture compensation & Y-peaking filterin

S

stem clock settin

Selection for standard/non-standard signal processin

Selection for inter-frame/inter-line

Killer

rocessing selection C 0~3 1

C-signal phase with respect to the Y-signal

Fine adjustment at 70 ns/ste

NRMD Setting-based Control Table for DYCO, DYGA, DCCO, DCGA NRMD = 0 NRMD = 1 NRMD = 2 NRMD = 3

DY detection coring level (Y motion detection corin

DY detection gain (Y motion detection gain) 0~15 10 10 10 10

DC detection corin

DC detection gain (C motion detection gain) 0~15 5555

Frame recersive YNR nonlinear filter limit level C 0~3 1

NRL

Frame recersive CNR nonlinear filter limit level C 0~3 1

Hysteresis for Hsync non-standard signal detection

out-of-Hsync intra-field

Sensitivity for Hsync non-standard signal detection

out-of-Hsync intra-field

Sensitivity for frame non-standard signal detection

out-of-Hsync inter-frame

VM&SNNR Setting-based Control Table for VAPG & VAPI

VAPG= VAPG1 - VAPG2

V-aperture compensation gain 0~70234

V-a

erture compensation convergence point 0~31 4 4 4

SNNR Setting-based Control Table for YPFT & YHFG

Y

PFT

PFG

eaking filter (BPF) center frequenc

Y

eaking filter (BPF) gain 0~15 7012 3

Control Register

Function & Link

rocessin

level (C motion detection corin

Data

Type

Data

Range

0~30133

C 0~3 3

C 0~3 1

0~30000

C 0~3 0

C 0~7 3

0~15 2222

0~15 5555

0~3 1 1 1

0~3 1 1 1

0~3 2 2 2

0~30000 0

Data Initial/Average Setting

(32V&36V CRTs)

Standard

Standard

UHF/VHF Video1~4 Video5&6

VAPG1 Data Based on MENU/VM Setting

VM = Off VM = Low VM = Mid VM = High

SNNR = 0 SNNR = 1 SNNR = 2 SNNR = 3

SVideoUHF/VHF & CVideo

Standard Non-standard

SVideoUHF/VHF & CVideo

Standard Non-standard

Video1~4

Video5&6

SNNR Setting (-Offset)

: CVideo1~4 & SVideo1~3 inputs

: YPbPr-480i/480p/1080i inputs

KV-40XBR700

Comment

CVideo (CV): CVideo1~4 inputs

SVideo (SV)

: Common data

C

: SVideo1~3 inputs

This setting continues to

the next page.

8

DX1A-2001&2000 SERVICE LIST (#1): 3D-COMB / mPD64082 (Part-2/4)

Register

No & Name

#16 VAPG (cont.

Note: The same 3D-COMB service data is used for DX1A-2001&2000.

Data Initial/Average Setting

(32V&36V CRTs)

VAPG2 Data Based on SNNR/Offset-setting

SNNR = 0 SNNR = 1 SNNR = 2 SNNR = 3

0000

Comment

— 21 —

Page 21

SERVICE DATA LISTS

a

yp

(

)

(ms)}

{

)}

g

y

)

KV-40XBR700

DX1A-2001&2000 SERVICE LIST (#1): 3D-COMB / mPD64082 (Part-3/4)

Register

No. & Name

20

YHCO

21

YHCG

22

HSSL

23

VSSL

24

ADCL

25

D2GA

26

KILR

27

OP1

28

NR1

29

NR2

30

WSL

31

HPLL H-PLL filter

32

BPLL

33

FSCF

34

PLLF

35

CC3N

36

HDP

37

BGPS

38

BGPW

39

TEST

40

WSC

41

LIND

42

PFGO

Control Register

Function & Link

SNNR Setting-based Control Table for YHCO & YHCG SNNR = 0 SNNR = 1 SNNR = 2 SNNR = 3

Data

Type

Data

Range

Data Initial/Average Setting

(32V&36V CRTs)

Y output high frequency component coring 0~3 1 1 1 1

Y output high frequency component coring gain 0, 1 0 0 0 0

Hsync slice level C 0~15 12

C: Common data

Vsync slice level C 0~15 8

ADC clock delay C 0~3 3

NRMD Setting-based Control Table for D2GA NRMD = 0 NRMD = 1 NRMD = 2 NRMD = 3

Moving detection gain 0~7 4 4 4 4

Killer detection reference C 0~15 3

Option1:

Selection of comb filter & recursive noise reduction t

C 0, 1 1

es

UHF/VHF CVideo1 SVideo1

This setting continues to

Noise reduction on/off 0, 1 0 0 1

SNNR control on/off C 0, 1 0

Noise level detection data 0~255

Must be set to 1 when MN signal is input.

Burst PLL filter

Burst extraction gain

PLL loop gain

0, 1 1

C

0, 1 1

C

0, 1 0

C

0, 1 1

C

Selection of a line-comb filter C separation filter characteristic 0, 1 0 0 0

1 Byte Data from Read Register WSL

UHF/VHF Video1~4 Video5&6

Video1~4

inputs

Video5&6

Fine adjustment of the system H-phase C 0~7 5

Internal burst gate start position

{Gate Start Position from Hsync center = 0.25 x BGPS +

C 0~15 4

2

Internal burst gate width

Gate Width = 0.25 x BGPW + 0.5 (ms

Test bit {0: Normal mode, 1: Test mode (forbidden settin

C 0~15 10

C 0, 1 0

Amount of noise detection coring C 0~3 1

UHF/VHF & Video1~4

DRC-M line-doubling setting for non-standard signals

Micro

0~63 2

(YPFG offset at GR on) --- Not used for DX1A --- 0~7 3

Video5&6

0

(Not used for DX1A)

This setting is used for non-standard

signals

such as Play Station signals.

Comment

(Not SNNR Offset Dat

YHCO&YHCG

settings are sent

to 3D-Comb

directl

the next page.

: CVideo1~4 & SVideo1~3

: YPbPr-480i/480p/1080i

Note: The same 3D-COMB service data is used for DX1A-2001&2000.

Register

No & Name

#28 NR1 (cont.

Note: The same 3D-COMB service data is used for DX1A-2001&2000.

CVideo2 SVideo2 CVideo3 SVideo3

0101

DX1A-2001&2000 SERVICE LIST (#1): 3D-COMB / mPD64082 (Part-4/4)

Data Initial/Average Setting

(32V&36V CRTs)

Comment

— 22 —

Page 22

SERVICE DATA LISTS

Y

g

YDLY

Y

(

)

(

)

(-offset)

(

)

g

g

Y

p

)

y

SSMD

g

A

7 [Adj.-2steps]

KV-40XBR700

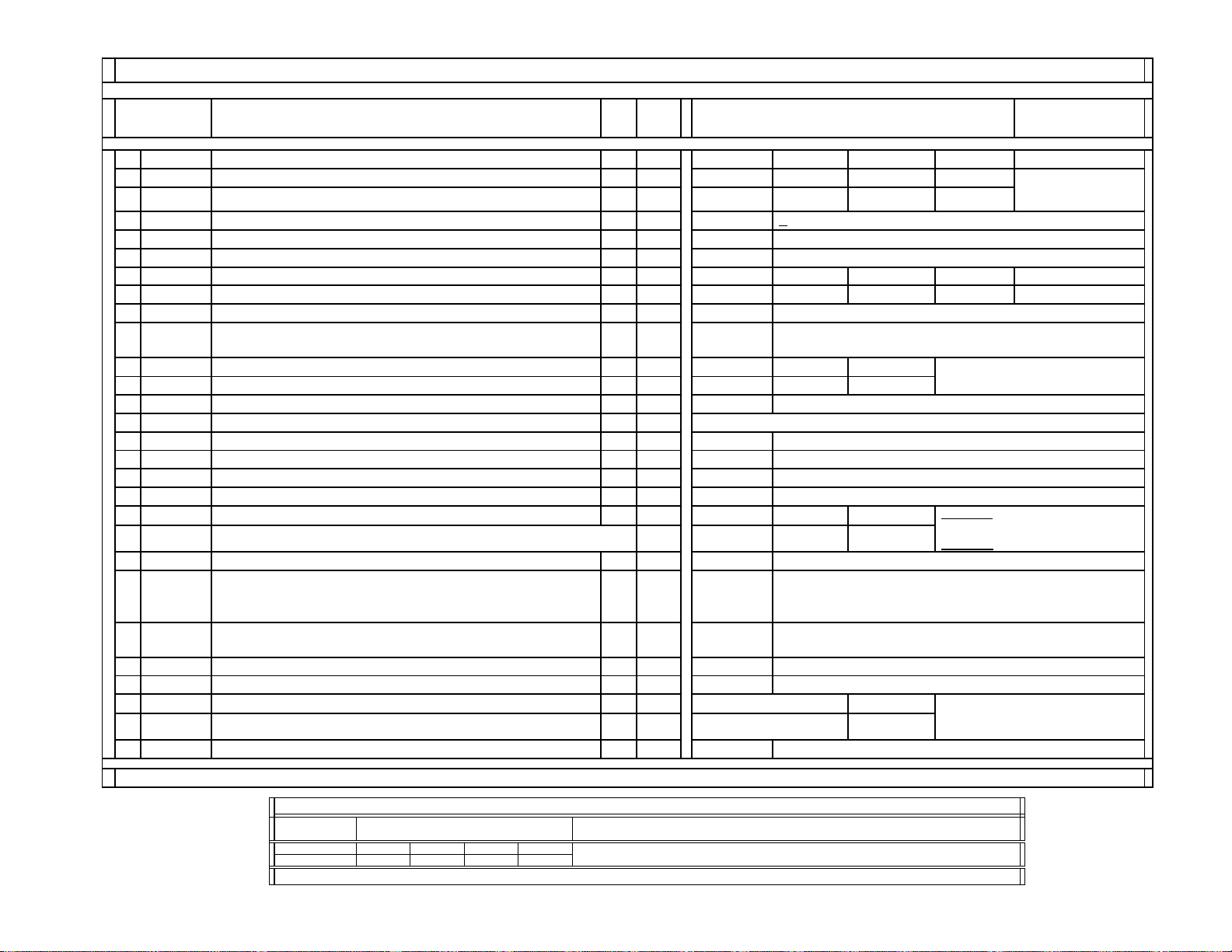

DX1A-2001&2000 SERVICE LIST (#2-1):

CXA2103-1 {Main}

Device Name: CXA2103Q { NTSC-YCT (Chroma Decoder) / SONY } / IC3048 (B-board) / P/N: 8-752-089-50 (SBorSD#: NA)

Slave Address: 9Ah { Main }

Register

No & Name

0

1

CLEV

2

SCON

3

SCOL

4

SHUE

5

6

SHAP

7

SHF0

8

PREO

9

BPF0

10

BPFQ

11

BPSW

12

TRAP

13

14

AFCG AFC Loo

15

CDMD

16

17

HMSK

18

HALI

19

PPH

20

CBOF

21

CROF

22

ATPD

23

DCTR

Note: The same CXA2103 service data (Main&Sub) is used for DX1A-2001&2000.

Y-Out

LEV

Cb&Cr-Out gains 0~63 20 55* 37 31*

Sub contrast

Sub color

Sub hue Adj. 0~15

Y/C delay time 0~3

SNNR Data-related Settings UHF/VHF CVideo SVideo

Sharpness 0~15 6444 0123

Sharpness f0 selector 0~3 0000

Sharpness pre/over-shoot ratio 0~3 3000

Chroma band filter f0 settin

Chroma band filter Q settin

Chroma band filter on/off 0, 1 1000

Y bolck chroma trap filter on/off 0, 1 0000

YPbPr-Output LPF on/off 0, 1 0000

LPF

V countdown s

H&Vsync slide level settin

Masking of macrovision signal on/off 0, 1 1 1 1

H automatic adjustment on/off 0, 1 0 0 0

H TIM phase adjustment for video 0~15 7 7 7

Cb-Offset1 of Cb IN (Pin34)

Cb-Offset2 of EXT Cb (Pin38)

Cr-Offset1 of Cr IN (Pin35)

Cr-Offset2 of EXT Cr (Pin39)

CXA2150P-4/#13 UBLK Setting-related Controls for ATPD & DCTR

Auto-pedestal Inflection Point 0~3 0

DC Transmission Ratio 0~3 0

ain 0~63 23 27* 35 31*

Control Register

Function & Link

Data

Type

Adj.

Adj.

Data

Range

0~15

0~15

Data Initial Setting & [Average Data]

UHF/VHF & Video

P&P-Left

(M)-DRC

UHF/VHF

7 [7]

7 [7]

0

0~3 3000

0~3 0333

UHF/VHF Video

Gain (PLL between Hsync & HVCO

0, 1 1 0 0

stem mode selector 0~3 3 3 3

0~3 0 0 0

UHF/VHF & Video

P&P-Left

(M)-DRC

0~(31)~63

UBLK = 0 UBLK = 1 UBLK = 2 UBLK = 3 UBLK = 4 UBLK = 5 UBLK = 6 UBLK = 7 UBLK = 0~7

(32V&36V CRTs)

P&P-Left

(M)-1080i

YPbPr-480i

P&P-Left

(M)-DRC

Video

P&P-Left

(M)-480i

7 [7]

7 [7]

7 [Adj.-2steps]

0

PbPr

480i

PbPr

480i

P&P-Left

(M)-1080i

31*0~(31)~63

P&P-Left

(M)-DRC

3131

YPbPr-480i

P&P-Left

(M)-480i

31*

31*31 31* 31

P&P & Favorite

123

111

Data Initial/Average Setting

Video: CVideo1~4 & SVideo1~3 Inputs

P&P-Left (M)-1080i&480i

1080i/480p signal, the signal from the main

chroma decoder is sent to MID/VDO input.

*: Settings not used

Adj.: Adjusted data

[Adj.-2steps]: The adjusted data - 2 steps

SNNR=0

-offset

: CVideo1~4 Inputs

CVideo

: SVideo1~3 Inputs

SVideo

*: Settings not used

(31): The center setting = 31

1232 0

2223 0

(32V&36V CRTs)

SNNR=1

-offset

P&P & Favorite

: If P&P-Left is

SNNR=2

Note

SNNR=3

-offset

Single

— 23 —

Page 23

SERVICE DATA LISTS

Y

g

YDLY

(

)

(

)

(-offset)

(

)

2

g

g

p

y

SSMD

g

j

A

)

)

)

)

3

2

CXA2103-2 {Sub}

DX1A-2001&2000 SERVICE LIST (#2-2):

Device Name: CXA2103Q { NTSC-YCT (Chroma Decoder) / SONY } / IC3110 (B-board) / P/N: 8-752-089-50 (SBorSD#: NA)

Slave Address: 9Eh { Sub }

Register

No & Name

0

1

CLEV

2

SCON

3

SCOL

4

SHUE

5

6

SHAP

7

SHF0

8

PREO

9

BPF0

10

BPFQ

11

BPSW

12

TRAP

13

14

AFCG AFC Loo

15

CDMD

16

17

HMSK

18

HALI

19

PPH

20 31

CBOF

21

CROF

22

ATPD

23

DCTR

Note: The same CXA2103 service data (Main&Sub) is used for DX1A-2001&2000.

Y-Out

LEV

Cb&Cr-Out gains 0~63 18 24

Sub contrast

Sub color

Sub hue Adj. 0~15

Y/C delay time 0~3

SNNR Data-related Settings UHF/VHF CVideo SVideo

Sharpness 0~15 6 4 4 0 1

Sharpness f0 selector 0~3 0 0 0

Sharpness pre/over-shoot ratio 0~3 3 0 0

Chroma band filter f0 settin

Chroma band filter Q settin

Chroma band filter on/off 0, 1 0 0 0

Y bolck chroma trap filter on/off 0, 1 0 0 0

YPbPr-Output LPF on/off 0, 1 0 0 0

LPF

V countdown s

H&Vsync slide level settin

Masking of macrovision signal on/off 0, 1 1 1

H automatic ad

H TIM phase adjustment for video 0~15 7 7

Cb-Offset1 of Cb IN (Pin34

Cb-Offset2 of EXT Cb (Pin38

Cr-Offset1 of Cr IN (Pin35

Cr-Offset2 of EXT Cr (Pin39

CXA2150P-4/#13 UBLK Setting-related Controls for ATPD & DCTR

Auto-pedestal Inflection Point 0~3 0

DC Transmission Ratio 0~3 0

ain 0~63 23 28

Control Register

Function & Link

Data

Type

Adj.

Adj.

Data

Range

P&P-Right

0~15

0~15

7 [Adj.-2steps] 7 [Adj.-2steps]

0~3 0 0 0

0~3 0 0 0

UHF/VHF Video

Gain

0, 1 1 0

stem mode selector 0~3 3 3

0~3 0 0

ustment on/off 0, 1 0 0

P&P-Right

0~(31)~63

UBLK = 0 UBLK = 1 UBLK = 2 UBLK = 3 UBLK = 4 UBLK = 5 UBLK = 6 UBLK = 7 UBLK = 0~7

Data Initial Setting & [Average Data]

UHF/VHF & Video

(S)

(32V&36V CRTs)

P&P-Right

(S)-DRC

UHF/VHF Video

7 [7]

7 [7]

7 [7] 7 [7]

00

UHF/VHF & CVideo

P&P-Right

(S)

(S)-DRC

31

31

P&P & Favorite P&P & Favorite

123

111

YPbPr-480i

P&P-Right

(S)

31* 31*

31* 31*310~(31)~63

P&P-Right

(S)-DRC

Video: CVideo1~4 & SVideo1~3 Inputs

P&P-Right (S)-DRC

480p signal, the signal from the sub chroma

decoder is switched to DRC path.

Adj.: Adjusted data

[Adj.-2steps]: The adjusted data - 2 steps

CVideo

SVideo

*: Settings not used

(31): The center setting = 31

Data Initial/Average Setting

(32V&36V CRTs)

: If P&P-Left is 1080i/

SNNR=0

-offset

SNNR=1

-offset

: CVideo1~4 Inputs

: SVideo1~3 Inputs

12

22

SNNR=2

KV-40XBR700

Note

SNNR=3

-offset

3

Single

20

30

— 24 —

Page 24

SERVICE DATA LISTS

V

p

g

g

0~(31)~63

g

0~(31)~63

ght

0~63

0~63

0~63

0~63

f

0~63

f

0~63

f

0~63

(

)

(63)

(63)

(63)

(63)

(63)

(63)

(63)

KV-40XBR700

DX1A-2001&2000 SERVICE LIST (#3-1):

CXA2150P-1 {Picture Controls: P1}

Device Name: CXA2150AQ { CRT Driver / SONY } / IC201 (A-board) / P/N: 8-752-093-35 (SBorSD#: NA)

Slave Address: 86h

Register

No & Name

Control Register

Function & Link

Data

Type

Data

Range

Data Initial Settings & [Average Data]

UHF

HF

CV SV

(32V&36V CRTs)

YPbPr

480i

YPbPr

480

YPbPr

1080i

P&P

0 SBOT Offset for SBRT 0~(7)~157777777

1 YOF Y_OFFSET: DC-offset for Y si

2 CBOF CB_OFFSET: DC-offset for Cb si

3 CROF CR_OFFSET: DC-offset for Cr si

4 SBRT SUB_BRIGHT: Sub Bri

5 RDRV R_DRIVE: R output drive C

6 GDRV G_DRIVE: G output drive Adj.

7 BDRV B_DRIVE: B output drive Adj.

8 RCUT R_CUTOFF: R output cutof

9 GCUT G_CUTOFF: G output cutof

10 BCUT B_CUTOFF: B output cutof

11 WBSW

WB_SW: White balance offset on/off

Related to UTMP settings

12 SBOF Offset for SBRT 0~

13 RDOF Offset for RDRV 0~

14 GDOF Offset for GDRV 0~

15 BDOF Offset for BDRV 0~

16 RCOF Offset for RCUT 0~

17 GCOF Offset for GCUT 0~

18 BCOF Offset for BCUT 0~

Note:

The same CXA2150 service data is used for DX1A-2001&2000.

nal 0~(7)~150000000

nal

nal

Adj.

31 31 31 33 30 31 13

31 31 31 42 36 31 23

24 [24]

46

36 [36]

33 [33]

C

Adj.

Adj.

0, 1

~127 63

~127 63

~127 63

~127 63

~127 63

~127 63

~127 63

0

(Cool)

63

63

63

63

63

63

63 60

11 [11]

22 [22]

Standard

0

(Neutral)

63

63

63

60

63

63

41

MovieVivid

1

(Warm)

63

63**

66**

73**

63**

66**

75**

Pro

0

Comment

CV:

CVideo1~4

SV

:

SVideo1~3

( ): Settings at

center

Adj.

:

Adjusted data

C

:

Common data

Initial Setting

= [Avg. Data]

**: The color

temperature

offset data

— 25 —

Page 25

SERVICE DATA LISTS

f

g

f

)

(

)

y

p

0~15

g

f

)

(0,

)

g

p

)

p p

)

A

t

g

Video1~4

KV-40XBR700

DX1A-2001&2000 SERVICE LIST (#3-2):

CXA2150P-2 {Picture Controls: P2}

Device Name: CXA2150AQ { CRT Driver / SONY } / IC201 (A-board) / P/N: 8-752-093-35 (SBorSD#: NA)

Slave Address: 86h

Register

No & Name

0 ALBK

1 RGBS

2 BLKB

PIC_ON: RGB output including AKB reference pulse on/of

(Setting = 0 for power on reset) --- G2 adjustment register settin

R_ON/G_ON/B_ON: R/G/B outputs on/of

(AKB reference pusle can not be turned on/off.) (0,1/0,1/0,1

BLK_BTM: RGB output bottom limit level (Black Limit)

AKB reference pusle DC-voltage

3 LIML PLIMIT_LEV: Threshold level for excessivel

4 PABL P_ABL: DC-level in RGB out

5 SABL S_ABL: S_ABL

6 AGNG

AGING_W/AGING_B: AGING_W/AGING_B modes on/of

(Set luminance to 80/01IRE flat-field signal.

ain C 0~3 0

7 AKBO AKBOFF: Automatic/Manual-Cutoff settin

8 SYPH SYNC_PHASE: Hsync delay with respect to Video (100%: H-period

9 CLPH CLP_PHASE: Internal clam

10 CLG

CLP_GATE: Switch for the gated internal clamp pulse with Hsync inpu

11 JAXS JAXIS: Color axis switch 0, 1

12 BLKO BLKO: Blankin

Note:

The same CXA2150 service data is used for DX1A-2001&2000.

switch 0, 1

Control Register

Function & Link

high inputs (White LimitC 0~3 0

ut detection for PEAK ABL C

ulse phase (100%: H-period

Data

Type

Data

Range

C 0, 1 1

C 0~7 7

C 0~3 3

C

0~3

1/0,1

C 0, 1 0

0~3 0000

0~3 3333

0, 1 0000

15

0

U/VHF &

0

3

0

0

0

Data Initial/Average Settings

(32V&36V CRTs)

YPbPr

YPbPr

480

YPbPr

1080i

480i

P&P

Comment

C:

Common data

Video1~4:

CVideo1~4 &

SVideo1~3

— 26 —

Page 26

SERVICE DATA LISTS

V

g

y

g

V

)

p

g

p

)

p

p

)

g

p

)

g

(

)

(

)

(

)

g

KV-40XBR700

DX1A-2001&2000 SERVICE LIST (#3-3):

CXA2150P-3 {Picture Controls: P3} (Part-1/3)

Device Name: CXA2150AQ { CRT Driver / SONY } / IC201 (A-board) / P/N: 8-752-093-35 (SBorSD#: NA)

Slave Address: 86h

Register

No & Name

Control Register

Function & Link

0 SYSM SYSTEM: Signal bandwidth settin

1 UVML VM_LEV: VM_OUT level

2 VMMO S

3 VMCR VM_COR: VM_OUT corin

stem Micro pin#40 0, 1 0000000

level 0~3 3333333

Data

Type

C

Data

Range

0~3 1111122

0~3 3

Data Initial/Average Settings (32V&36V CRTs)

UHF

CV SV

HF

Picture Mode: Vivid

YPbPr

YPbPr

480i

480p

YPbPr

1080i

P&P

4 VMLM VM_LMT: VM_OUT limit level 0~3 3333333

5 VMF0 VM_F0: VM_f0 0~3 2222222

MDL VM_DLY: VM_OUT phase (defined by phase difference from R_OUT

6

0~3 3333313

7 SHOF Offset for USHP = SHOF x 4 0~3 2223302

8 SHF0 SHP_F0: Shar

9 PROV PRE/OVER: Y si

10 F1LV SHP_F1: Shar

11 CDSP SHP_CD: Shar

12 LTLV LTI_LEV: Luminance transient im

13 LTMD LTI_MODE: LTI mode settin

14 CTLV CTI_LEV: Chrominance transient im

15 CTMD CTI_MODE: CTI mode settin

16 UBOF Offset for UBRT

17 UCOF Offset for UCOL = UCOF x 2

18 UHOF Offset for UHUE

19 MIDE MID enhancement settin

Note:

The same CXA2150 service data are used for DX1A-2001&2000.

ness circuit f0 0, 1 1111101

nal pre/over-shoot ratio 0~3 3331303

ness for higher f0 (4.2/5.6 MHz @ NORMAL mode

0~3 0333333

ness in part of high color saturation 0~3 3333333

rovement (LTI

0~3 3333333

0~3 0000001

rovement (CTI

0~3 0000020

0~3 0000000

Picture clarity adjustment

Picture clarity adjustment

Picture clarity adjustment

0~(7)~15 11 11 11 11 11 14 11

0~3 3333303

0~3 2222222

0~15 333711------

Comment

These settings

continue to

the next page.

CV

:

CVideo1~4

SV

:

SVideo1~3

C

:

Common data

( ): Settings at

center

— 27 —

Page 27

SERVICE DATA LISTS

V

480i

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

(

)

)

(

)

(

)

(

)

(

)

(

)

(

)

KV-40XBR700

DX1A-2001&2000 SERVICE LIST (#3-3): CXA2150P-3 {Picture Controls: P3} (Part-2/3)

Register

No & Name

#0 SYSM (cont.

#1 UVML

#2 VMMO

#3 VMCR

#4 VMLM

#5 VMF0

#6 VMDL

#7 SHOF

#8 SHF0

#9 PROV

#10 F1LV

#11 CDSP

#12 LTLV

#13 LTMD

#14 CTLV

#15 CTMD

#16 UBOF

#17 UCOF

#18 UHOF

#19 MIDE

Note:

The same CXA2150 service data are used for DX1A-2001&2000.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

cont.

Data Initial/Average Settings (32V&36V CRTs) Data Initial/Average Settings (32V&36V CRTs)

UHF

VHF

Picture Mode: Standard

CV SV

YPbPr

480i

YPbPr

480p

1111122 1111122 1111122

300

0000000 0000000 0000000

3333333 3333333 3333333

3333333 3333333 3333333

2222222 2222222 2222222

1333313 1111113 1111113

0333302 0333303 0111101

0111101 0000001 0000001

3331303 3331303 3331303

0333333 0000003 0000003

3333333 0000000 0000000

2222223 0000000 0000000

1111111 1111001 1111001

0000020 0000000 0000000

0000000 0000000 0000000

7777777 7777777 7777777

3333303 0000000 0000000

2222222 0000000 0000000

222610------ 11159------ 00048------

DX1A-2001&2000 SERVICE LIST (#3-3): CXA2150P-3 {Picture Controls: P3} (Part-3/3)

Register

No & Name

#1 UVML (cont.

#3 VMCR

#10 F1LV

#11 CDSP

#12 LTLV

#14 CTLV

#19 MIDE

Note:

The same CXA2150 service data are used for DX1A-2001&2000.

cont.

cont.

cont.

cont.

cont.

cont.

SNNR=0

(Offset)

SNNR=1

(Offset)

0000

0 + 1 + 2 + 3

0 - 1 - 2 - 3

0000

0000

0000

0000

Data Initial/Average Settings

SNNR=2

(Offset)

YPbPr

1080i

P&P

SNNR=3

(Offset)

Data Initial/Average Settings

UHF

HF

(32V&36V CRTs)

Picture Mode: Movie Picture Mode: Pro

CV SV

YPbPr

(32V&36V CRTs)

YPbPr

YPbPr

480p

1080i

P&P

UHF

VHF

CV SV

YPbPr

480i

Comment

YPbPr

480p

YPbPr

1080i

Note

P&P

See

next

page

— 28 —

Page 28

SERVICE DATA LISTS

0~63

g

0~63

r

0~63

0~63

p

)

y

g

g

GAMMA/GAMMA_L: RGB

(B

)

)

(

)

(

)

(

)

K

(

)

g

(7)

0 (Void data)

Device Name: CXA2150AQ { CRT Driver / SONY } / IC201 (A-board) / P/N: 8-752-093-35 (SBorSD#: NA) Slave Address: 86h

Device Name: CXD2085M { ID-1 Decoder / SONY } / IC3603 (B-board) / P/N: 8-752-395-13 (SD#: S98511B) Slave Address: 40h

Register

No & Name

0 UPIC PICTURE: Picture

1 UBRT BRIGHT: Bri

2 UCOL COLOR: Colo

3 UHUE HUE: Hue

SNNR Setting-related Controls for USHP

4 USHP SHARPNESS: Sharpness 0~63 31

5 UTMP Color Tem

6 UDCL DCOL: D

7 AXIS COL_AXIS: Color matrix settin

8 UGAM

9 AGAM GAMMA/GAMMA_L (Av Pro user control) --- Void Data

10 GSBO

11 GCOO Offset for UCOL 0~3 0000000

12 GHUO Offset for UHUE 0~3 0000000

13 UBLK Item # 15~18 pack FI data controls 0~7 7 7 7

14 ABL

15 DCTR

16 DPIC DPIC_LEV: Y si

17 DSBO Offset for SBRT 0~

18 ABLM ABL_MODE: ABL mode 0~3 1 1 1

Note:

The same CXA2150 service data are used for DX1A-2001&2000.

GAMMA_L: Slight GAMMA correction on/off (B

UGAM Setting-related Controls for GSBO, GCOO, GHUO

Offset for SBRT

(Av Pro user control) --- Void Data --- 0~7

UBLK Setting-related Controls for DCTR

DC_TRAN: Y signal DC transmission

8 types of DCTR data based on UBLK values

DX1A-2001&2000 SERVICE LIST (#3-4): CXA2150P-4 {Picture Controls: P4} (Part-1/4)

Control Register

Function & Link

htness

erature (0: Warm, 1: Neutral, 2: Cool

namic color settin

output GAMMA correction setting

8 types of GSBO data based on UGAM values

nal AUTO PEDESTAL level 0~3 2 2 2

7~6

Data

Type

Data

Range

Vivid

0~2 1

0~3 2

UHF/VHF

Video1~4

0~3 3 3 3

UHF/VHF

Video1~4

0~7

0~3/0,1

0~7

0~3/0,1

---

UGAM

= 7

Data Initial/Average Settings

(32V&36V CRTs)

YPbPr

1080i

Movie

31

28

33

31

34

0

22

40V

63

22

44

31

42

2

Standard

40V

50

26

35

31

48

1

2

Picture Mode: Vivid / Standard / Movie

YPbPr

YPbPr

480i

480p

33

Picture Mode: Vivid

YPbPr

YPbPr

480p

UGAM

= 4

YPbPr

1080i

UGAM

= 3

480i

77

UGAM

777

UGAM

= 6

= 5

0~3 0000000

UHF/VHF

Video1~4

Picture Mode: Vivid

YPbPr

YPbPr

480i

480p

YPbPr

1080i

7

0~3 3 3 3

3

2

~15 7 7 7

1

40V

UGAM

= 2

P&P

P&P

P&P

7

2

1

77

1

Pro

31

31

31

31

UGAM

= 1

Comment