Page 1

S®

Digital Video Player

Sony DVD Players

Models: DVP-S300 DVP-S570d

DVP-S330 DVP-C600d

DVP-S350 DVP-C650d

DVP-S360 DVP-C660

DVP-S500d DVP-C670d

DVP-S530d DVP-S3000

DVP-S550d DVP-S7000

Training Manual

DVP-S560d DVP-S7700

Troubleshooting

Course: DVD-03

Page 2

g

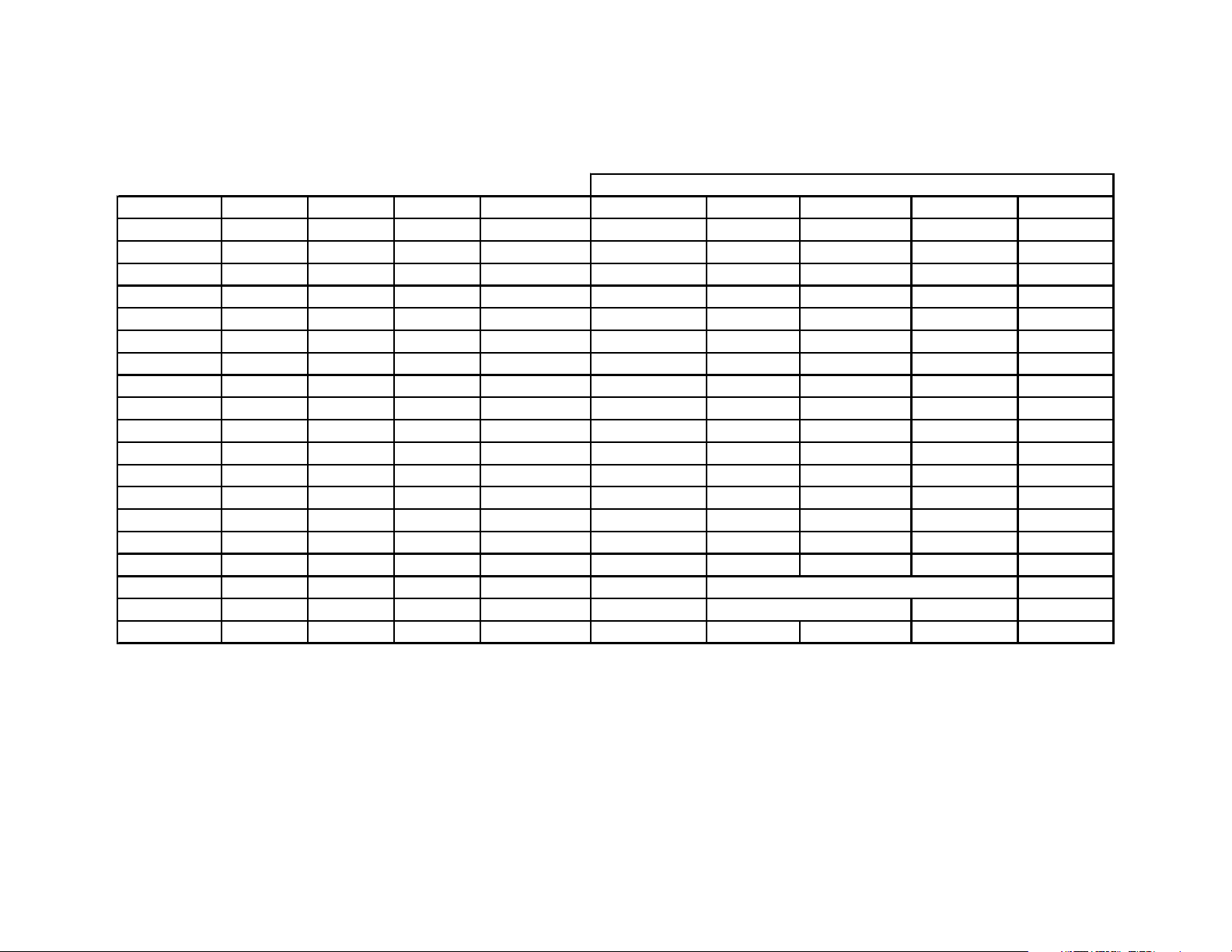

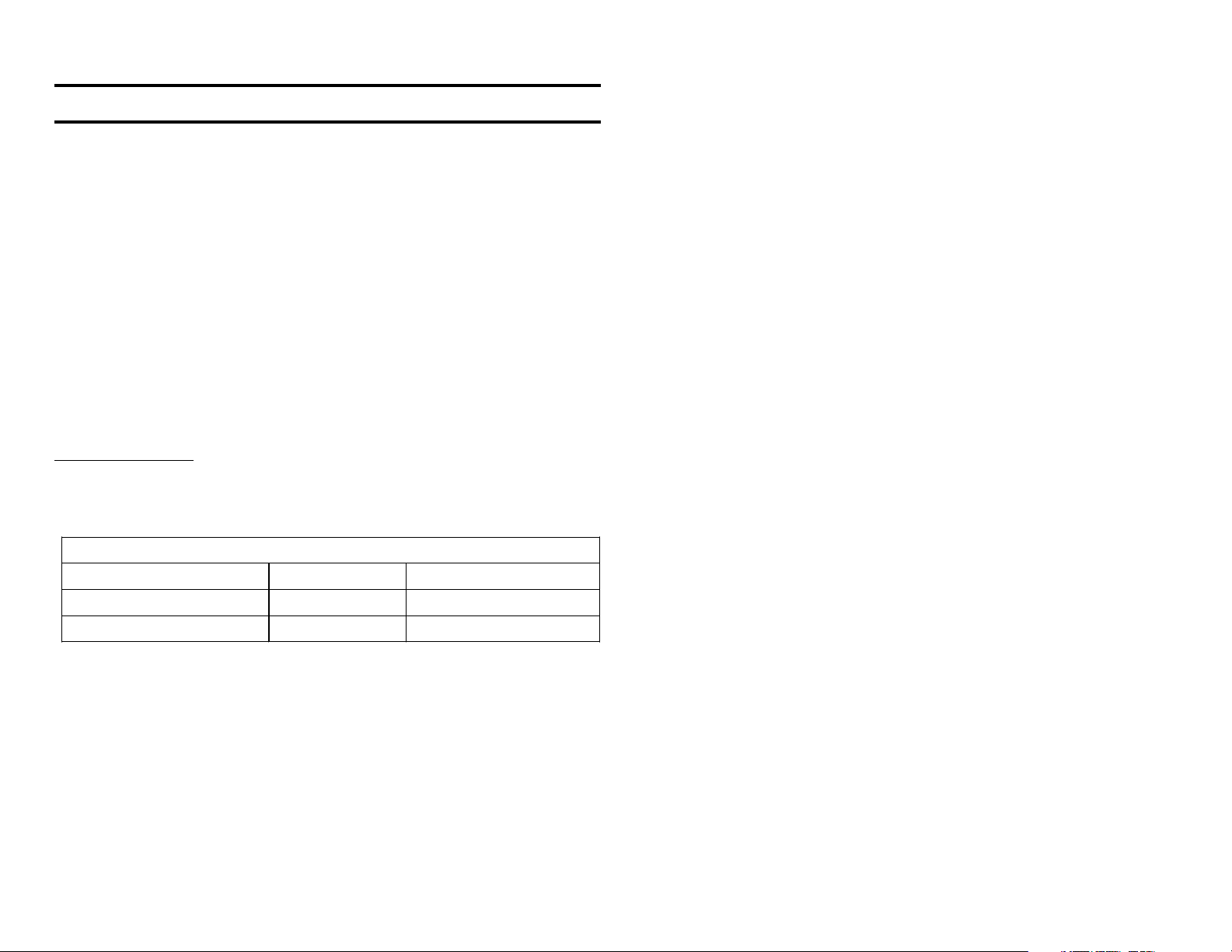

Internal IC Numbers

Model Gen Intro Year MSRP Optical RF Amp ARP A/V Decod A DSP Servo DSP

DVP S300 2 1997 $599.99 KHS180A SSI33P3720A CXD1865R L6402GQC27 MB86342PF CXD8730R

DVP S330 3 1999 $349.00 KHM220AAA SSI33P3722 CXD8784R CXD1930G none CXD8791Q

DVP S350 4 2000 $ KHM220AAA SSI33P3722 CXD9576R CXD1932Q none CXD9569R

DVP S360 4 2000 $299.00 KHM220AAA SSI33P3722 CXD9576R CXD1932Q none CXD9569R

DVP S500d 2 1997 $599.99 KHS180A SSI33P3720A CXD1865R L6402GQC27 MB86342PF CXD8730R

DVP S530d 3 1999 $499.00 KHM220AAA SSI33P3722 CXD8784R CXD1930G CXD1901R CXD8791Q

DVP S550d 3 1999 $599.00 KHM220AAA SSI33P3722 CXD8784R CXD1930G CXD1901R CXD8791Q

DVP S560d 4 2000 $399.00 KHM220AAA SSI33P3722 CXD9576R CXD1932Q CXD1939R CXD9569R

DVP S570d 4 2000 $599.00 KHM220AAA SSI33P3722 CXD9576R CXD1932Q CXD1939R CXD9569R

DVP C600d 2 1998 $699.00 KHS180A SSI33P3720A CXD1865R L6402GQC27 MB86342PF CXD8730R

DVP C650d 3 1999 $599.00 KHM220AAA SSI33P3722 CXD8784R CXD1930BQ CXD1901R CXD8791Q

DVP C660 4 2000 $449.00 KHM220AAA SSI33P3722 CXD9576R CXD1932Q CXD1939R CXD9569R

DVP C670d 4 2000 $549.00 KHM220AAA SSI33P3722 CXD9576R CXD1932Q CXD1939R CXD9569R

DVP S3000 1 1997 $699.00 KHS180A SSI33P3720A discrete ICs CXD2545Q

DVP S7000 1 1996 $999.00 KHS180A SSI33P3720A discrete ICs none CXD2545Q

DVP S7700 2 1998 $999.00 KHS180A SSI33P3720A CXD1865R L6402GQC27 none CXD8730R

Gen = Generation based upon internal ICs used.

MSRP = Manufacturer’s Suggested Retail Price (List price)

ARP = Advanced RF Processor (analog input, separate digital DVD & CD process, spindle motor control)

A/V Decod = (MPEG) Audio/Video Decoder

A DSP = Audio Digital Sound Processor (Dolby AC-3 decoding)

Servo DSP = Focus, Trackin

, Sled Digital Servo Processor

Page 3

Table of Contents

How to Use This Book 2

Modern Soldering Techniques 3

IC Removal - Which Method? 3

IC Installation 7

First Generation DVD Players

Symptom 1 - Intermittent loss of brighness during PB 11

Symptom 2 - No color or color change hue 13

Symptom 3 - No DVD disc detected at start up. CD PB OK 17

Symptom 4 - Intermittent or distorted DVD audio 19

Symptom 5 - No PB or picture freeze on some dual layer discs 21

Second Generation DVD Players

Symptom 1 - No response to the Power ON button 23

Symptom 2 - Powers OFF two seconds after turn ON 27

Symptom 3 - Plays CD, but not DVD discs 31

Symptom 4 - No PB. Disc stops spinning 33

Symptom 5 - One color, picture distortion or dark screen 35

Third Generation DVD Players

Symptom 1 - Green Power light does not stay ON 37

Chip Select Waveforms 47

Symptom 2 - Audio distortion after warm-up 49

Symptom 4 - Unit powers OFF during PB or if left ON 53

Symptom 5 - Picture freezes or powers OFF trying to PB

dual layer discs 55

Symptom 6 - DVD-C650 only - Powers ON, but no buttons

work. Error code E27 displayed 57

Symptom 7 - DVP-C650 only - Tray does not rotate 59

Symptom 8 - Tray does not Eject. Displays “LOCKED” 60

Fourth Generation DVD Players

Symptom 1 - No PB. Display = “No disc” or “C:13:00” 61

Symptom 2 - Powers OFF after powering ON 63

Symptom 3 - The tray open button has no effect 63

Symptom 4 - No chroma from the S video output jack 65

Symptom 5 - Digital picture blocks during the movie 69

Symptom 6 - Tray does not Eject. Displays “LOCKED” 70

Test Mode - Third Generation 71

Test Mode Access 71

Tests 71

Appendix

Service Bulletin List i

Service Bulletins iii

Symptom 3 - Spindle motor rotates immediately at Power

ON. No tray open 51

Page 4

1

NOTES

Page 5

How to Use This Book

Purpose

DVD players and camcorders have moved into the digital age where signal routing is less important than IC communications. You can learn a

little about how ICs communicate and add to your service strategy for

DVD player repairs by examining previous DVD player failures that have

occurred across the USA.

Book Structure

This book is organized into five sections:

Common Symptoms for DVD Players

DVD repairs across the USA were examined and repetitive symptoms

were extracted. For each common symptom, a strategy was developed

to determine which part has failed. This was done to each of the four

generations of DVD players.

Service Bulletins

The first page in this group contains a list of the DVD bulletins, a description of each bulletin, and the models to which the bulletin pertains. This

list is followed by the DVD service bulletins to date.

1. List of DVD Models categorized into generations

2. Table of Contents

3. Modern Soldering Methods

4. Common Symptoms for Sony DVD Players:

First Generation

Second Generation

Third Generation

Fourth Generation

5. Service Bulletins

List of DVD Models categorized into generations

Locate the DVD player you are working on in the chart and note the generation it falls in.

Modern Soldering Methods

Even though the technician has identified the defective part, the repair

cannot be completed unless the old part is removed without damaging the

board and the new part installed without solder bridges. This skill can

only be acquired by following all the steps that other technicians have

mastered.

Using this Book

1. Go to the “DVD Model List” before the Table of Contents.

2. From the DVD Model List, find your DVD model and note the generation it falls under.

3. Return to the Table of Contents to find the first, second, third or fourth

generation heading that corresponds to your DVD player.

4. Match the symptoms of your DVD player to the ones listed.

5. Go to the corresponding page for the troubleshooting information.

Mechanical problems like broken gears are not listed.

If your symptom is not listed, you do not have a common problem.

2

Page 6

Modern Soldering Techniques

This section is an excerpt from the Sony videotape (p/n T-MODSOL-9) by

the same name. This document only shows how to remove and install

multi-pin ICs used on many Sony products. The removal of these fine

lead large-scale integrated circuits (LSI) requires modern methods. After

replacing the IC, checking each pin for solder bridges is essential to prevent IC damage.

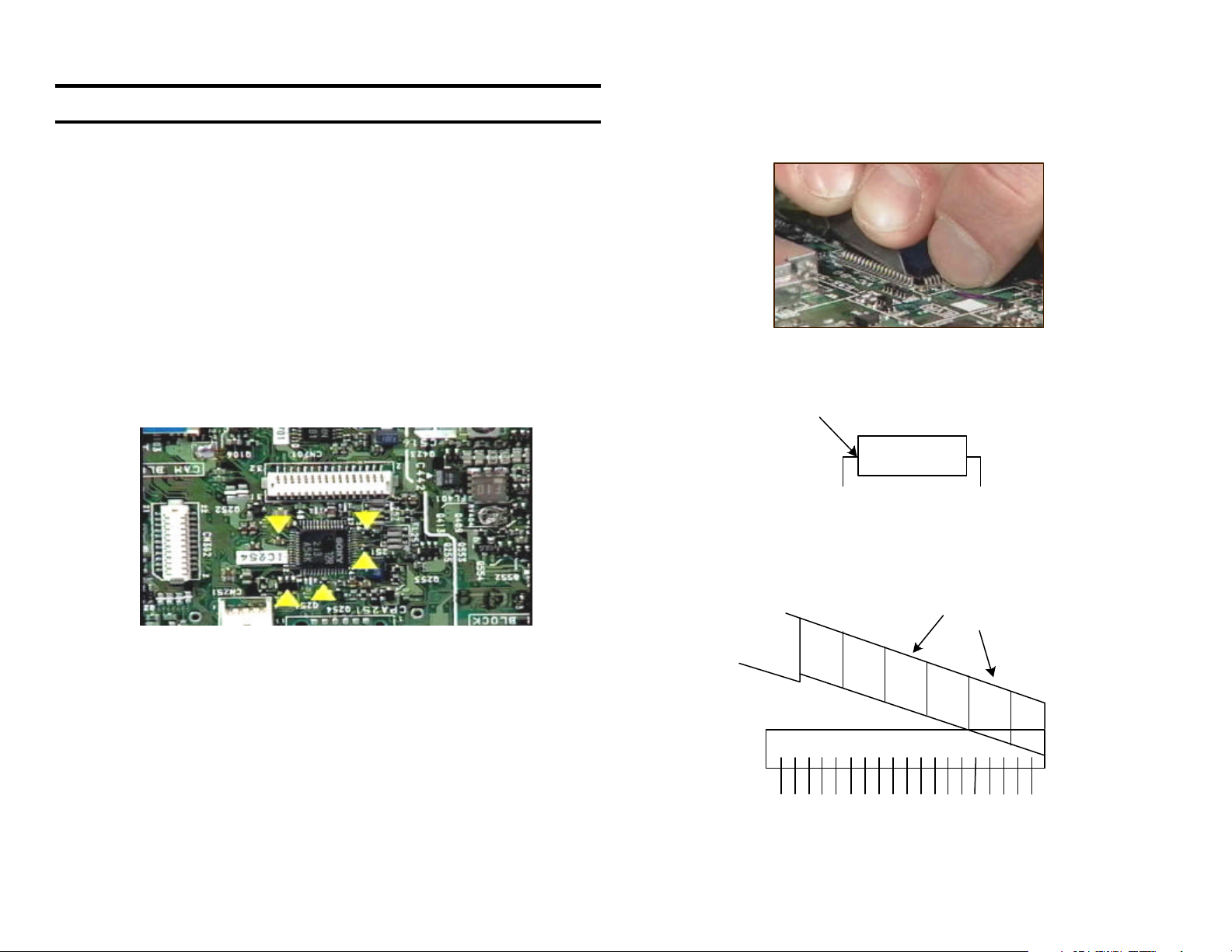

IC Removal - Which method?

Choose one of three methods for removing the ICs based upon the density of parts about the defective IC.

3

Use a sharp knife blade each time you remove an IC because the knife

was not originally intended to cut metal. Break off the old blade segments

of knife before cutting to expose a new sharp blade.

Cutting the IC’s leads in a high-density board is the best method for IC

removal. If there are many small parts about the defective IC the hot air

and Chip Quick removal methods may desolder local components. If you

choose the chip quick method, keep solder to a minimum on the IC pins.

Use the CUT OUT IC removal method when there

are many parts surrounding the IC

IC Removal - Cut Out method

This method requires a minimum of tools to cut the legs off the IC and

clean the board:

• Knife

• cutters

• dental pick

• soldering iron

• solder wick

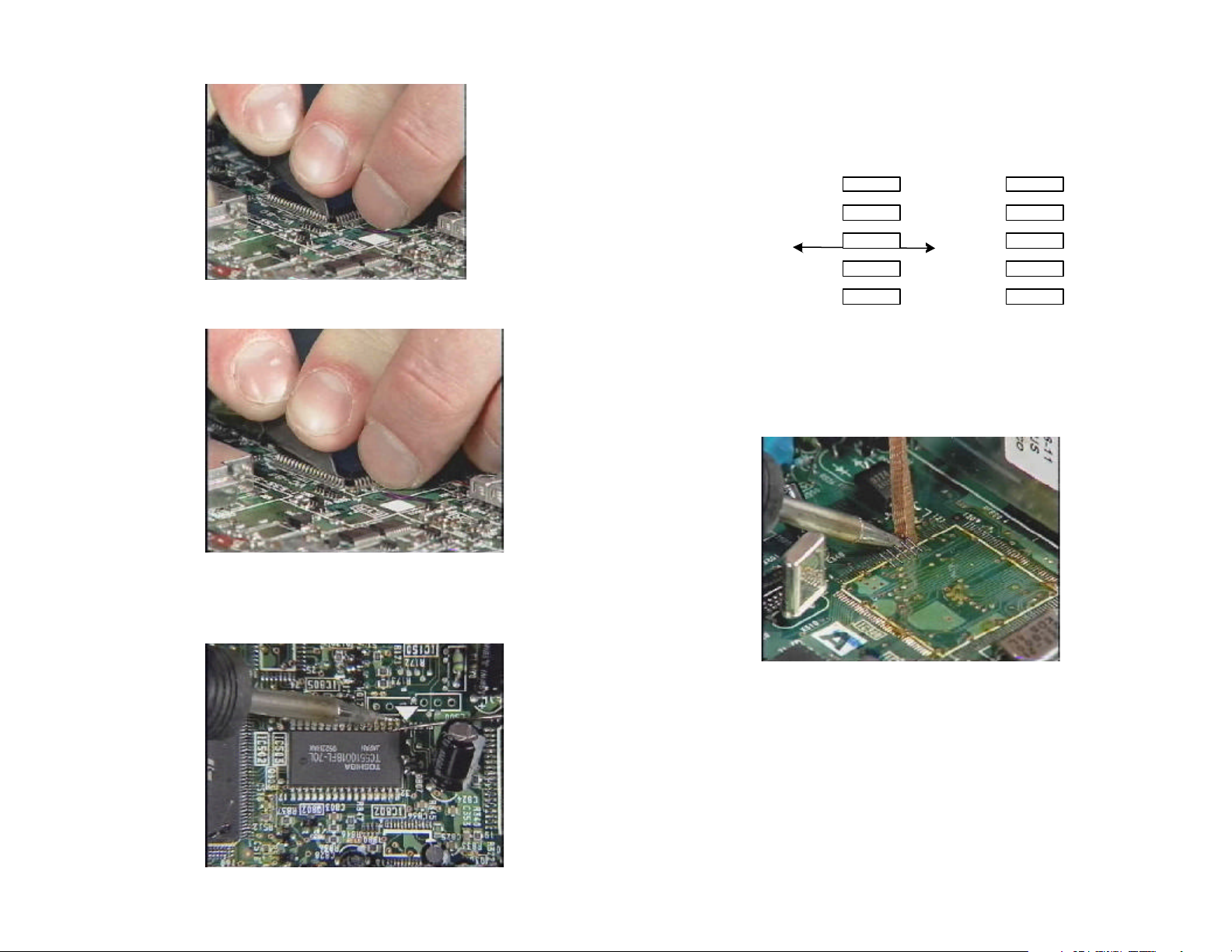

1. You must place the new blade at the legs where they meet the IC

body. Angle the blade into the body slightly to avoid slipping off the IC

legs.

2. Along the IC legs, hold the knife at a shallow 20 - 30 degree angle.

3. Place your finger above the blade for control as you press down and

rock the blade down.

20-30 degrees

Blade

IC

IC

Page 7

4. You should apply enough pressure to shear off 4-5 legs as you rock

the blade while pressing down. DO NOT let the blade point touch the

board.

6. Use a standard soldering iron to heat and push the legs off the lands.

Push only in the direction of the lands so they are not damaged.

Wipe across

the land

IC Lands

7. Remove the solder on the lands using a solder wick looped about the

soldering iron for better control.

5. Reposition the blade back along the legs and repeat. Do not cut the

last leg off or you will lose control and the blade point will hit the board.

Use cutters to nip these last IC legs or unsolder and lift the leg with a

dental pick. Remove the IC body.

4

Page 8

IC Removal - Hot Air method

This method requires the following:

• Hot Air Controller

• Desoldering Tips

• Flux Pen

• Tweezers

In the following steps you will use the Hot Air Controller to heat up all the

pins while you lift the IC off the board with tweezers.

5

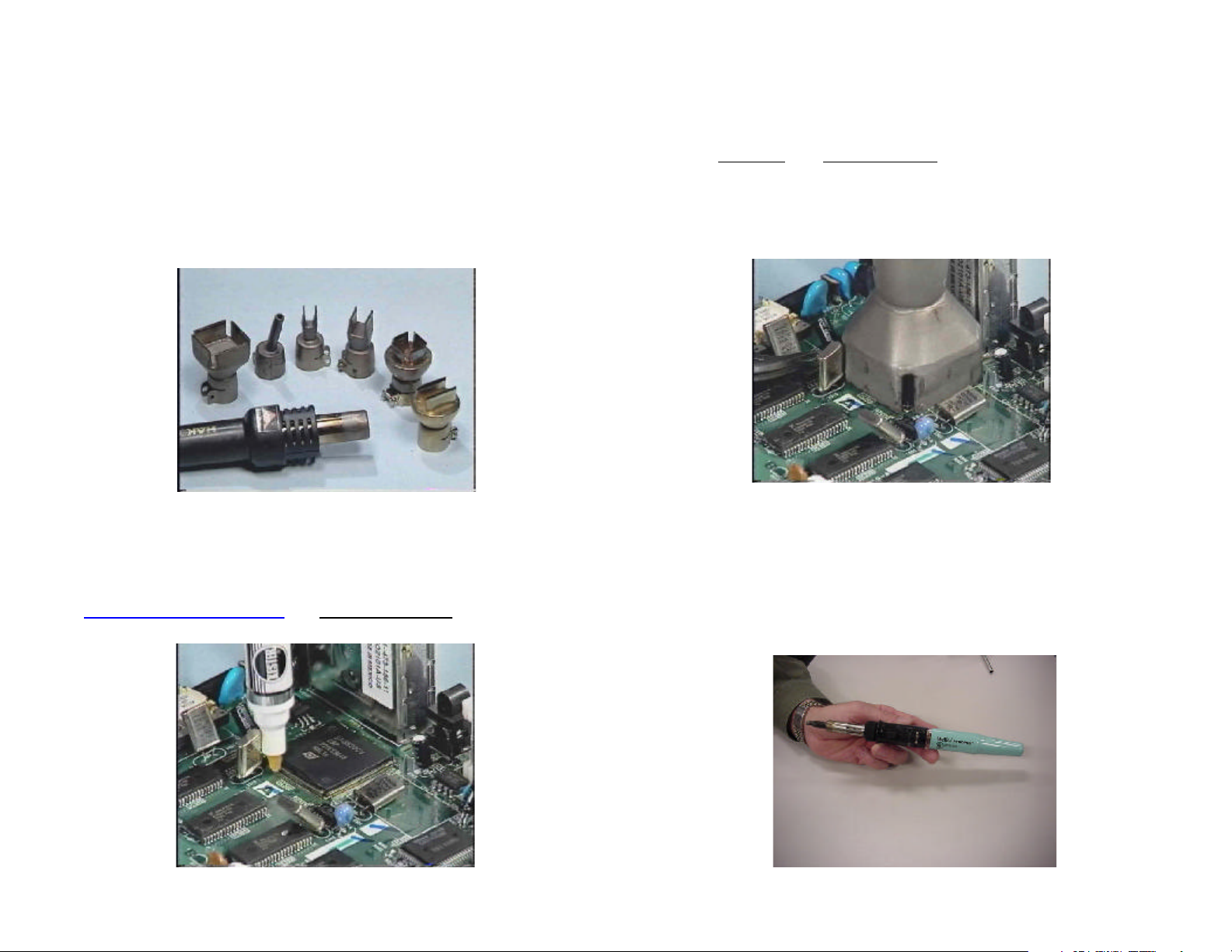

2. If you cannot find a hot air tip that will cover the IC, attach a single

1/8” (0.125”) diameter tip that will heat all the pins if you move the tip

around the IC pins.

3. Start at 0 air flow and maximum heat so the tip will warm up fast.

4. After warm up increase the air flow slightly (to #1 of 10) and position

the hot air tip over the pins of the IC. Do not touch the IC with the tip.

Count the nearby components and make sure they do not move away

by controlling the airflow. Insert tweezers at the corner of the IC.

1. Apply flux from a pen to remove the oxide layer from the IC pins during heating. Removing the oxide establishes a uniform temperature

on all the IC pins for removal and prevents an IC leg from still being

attached to the land when lifting the IC. These low residue pens are

made by Kester and distributed by companies such as

www.mcmelectronics.com and www.newark.com.

5. Gently lift the IC with the tweezers.

6. Remove the solder on the lands using a solder wick looped about the

soldering iron for better control.

IC Removal - Hot Air method using butane torch

The hot air controller is effective, but expensive. The butane torch is

similar in performance and inexpensive (about $100). In Weller’s PyroPen,

hot air comes from a controlled flame.

Page 9

Put safety goggles on before using the butane torch. Circle the IC leads

with the torch flame and flip the IC over when the IC is loose.

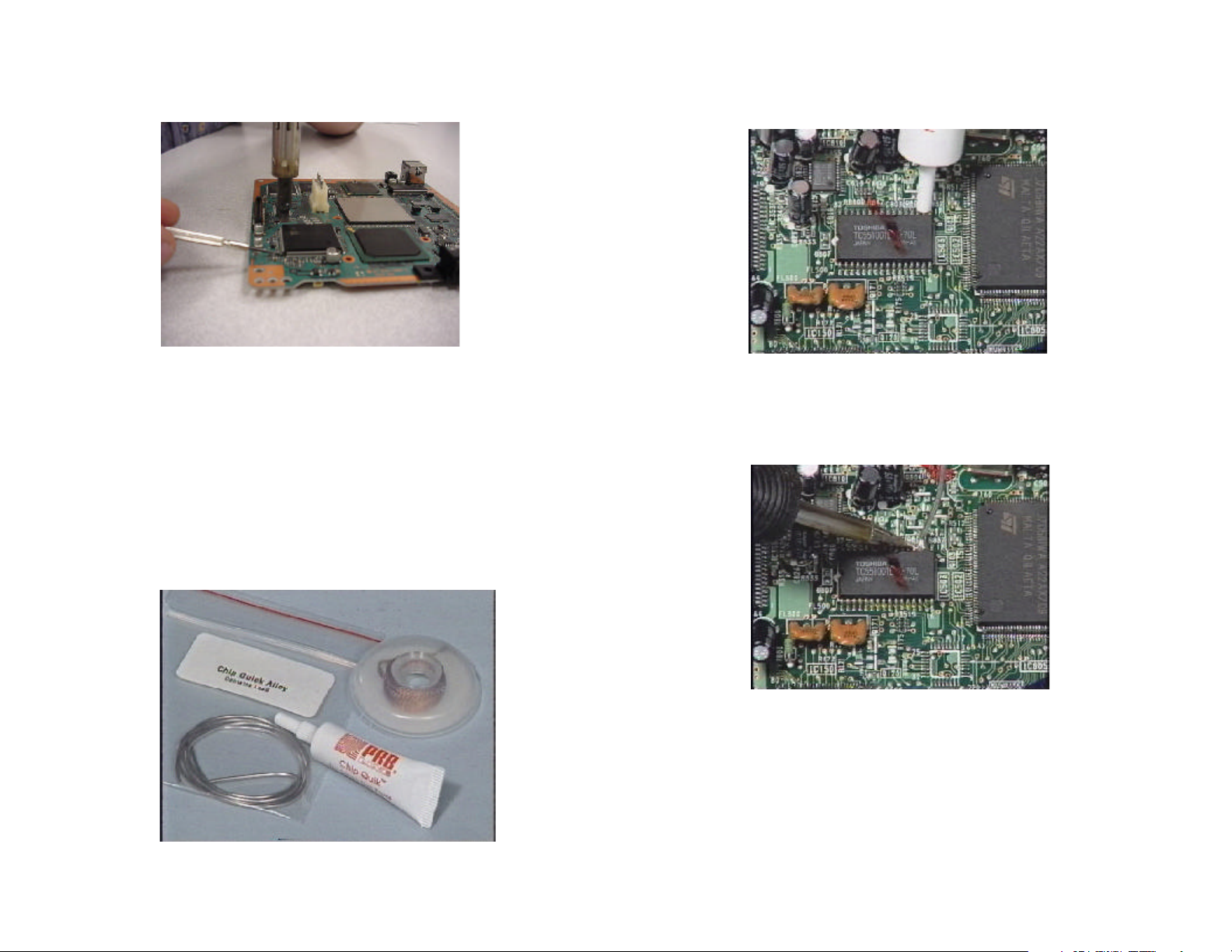

IC Removal - Chip Quick Method

Chip Quick is a low temperature solder that remains molten longer than

ordinary solder, giving you time to unsolder the IC. Chip Quick is best for

removing medium to large scale ICs when there are few parts about the

IC. This method takes about the same time as the hot air method and

requires about the same level of skill.

The Chip Quick package (P/N = T99856421) contains:

• Low Temperature Solder

• Flux

• Wick

1. Apply the Chip Quick flux to all the leads of the IC. (Medium size IC

shown for removal).

2. Melt the Chip Quick solder along the IC leads. Keep the solder molten

by running your iron along the IC leads.

3. Insert tweezers and lift the IC up.

6

Page 10

4. Remove the blobs of Chip Quick by heating and removing with a solder

sucker.

7

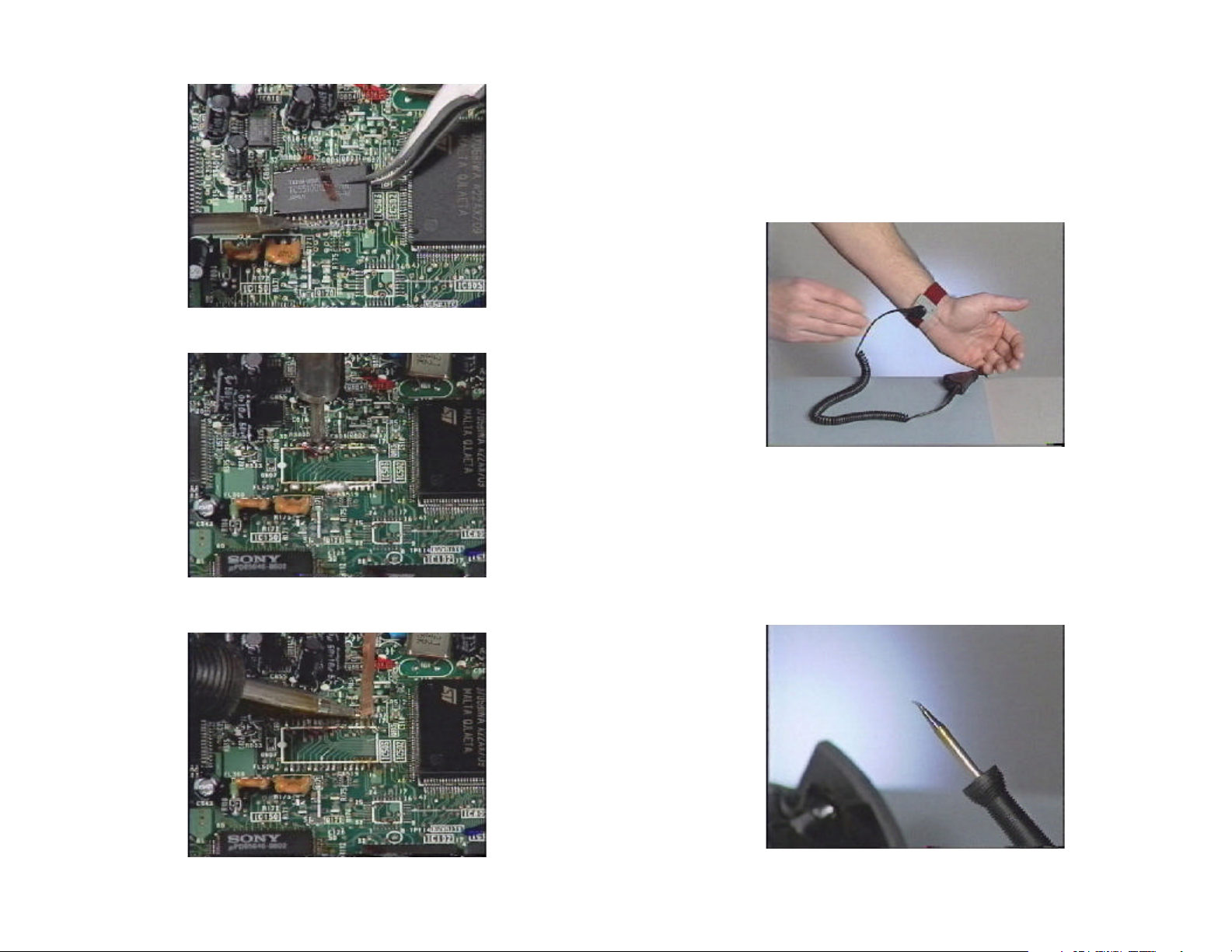

IC Installation

Once the solder and bridges are cleaned off with a solder wick, the new

IC can be installed. You must prevent static charges from damaging the

new IC by using a grounded wrist strap. The amount of static electric you

generate depends upon the humidity level and the clothing worn that day.

Some days you will not generate enough static electricity to damage the

new IC.

To solder all the IC leads without creating bridges, you need a constant tip

temperature soldering iron.

5. The remaining Chip Quick is removed with a solder wick. Move the

wick in the same direction as the lands of foil.

The constant tip temperature makes soldering uniform and increases the

speed of the soldering so you don’t have to resolder missed leads. Since

these constant tip temperature irons have a 5-10 second warm-up time

there is no reason to leave these irons on when in use.

Page 11

1. Whichever iron you use, clean the tip by dipping it into a cleaner or

tinner. Kester and Multicore manufacture these. A dirty tip will cause

you to mis-solder some IC leads as you drag the solder across the IC

pins.

2. Tin one land on the board, then position the IC over the lands.

3. With the IC in place solder the lead to the tined land.

5. Apply flux from a pen to all the IC leads to stop solder bridges.

6. Using the magnifying glass, place the iron’s tip furthest away from you

on the IC pins and apply enough solder for 10 lands. Using the flat

part of the iron, drag the solder blob down the pins in a side by side

motion (zigzag pattern) allowing the solder blob to touch (heat) each

IC lead and land. Only a small amount of solder resides at each land.

At first it looks at though the lead was not soldered.

4. Check the IC position and solder another lead to hold the IC in place.

8

Page 12

7. After soldering all the pins, run a dental pick across the pins to see if

movement reveals an unsoldered one.

8. Most technicians forget to inspect for bridges after installing the IC.

When power is turned ON, a bridge will take out the new IC or damage another related parts. Therefore it is important to inspect the pins

for bridges before approving your own work.

9

10. Remove the excess flux by spraying the area lightly with flux remover.

9. Using a low flux solder means you do not have to clean the board of

flux with a flux remover…

11. Place a towel over the work and dab the flux off with the stiff bristles of

the brush. This leaves the work clean without the cotton fibers leftover

had you used a cotton swab.

Sony is a registered trademark of Sony.

Chip Quick is a registered trademark of Chip Quick Inc; Mashpee, Mass.

Page 13

NOTES

10

Page 14

First Generation DVD

The first generation Sony DVD player consisted of two models, the DVPS3000 and the DVP-S7000. They housed separate laser assemblies to

play DVDs and CDs. Much of the video processing was done by discrete

medium size ICs. Failures across the country have been very low so

there is not much feedback history.

Symptom 1: Intermittent loss of brightness in the picture during PB

Cause: 1. Broken Video jack solder connection

2. A/V Decoder IC281 broke solder connection

3. A/V Decoder IC281 defective.

11

Repair Procedure

1. Check both video jacks for broken solder connections.

2. Press down on IC281 when the intermittent occurs. Resolder all the

pins if the condition responds to movement. Use flux on the pins to

prevent solder bridges and inspect the pins before powering the unit

on.

3. If the problem appears thermal, cool off the IC to see if the brightness

returns. Replace IC281.

Page 15

MB - 75 Board

Shield

X001

X002

IC002

X003

X280

R213

A/V

Decoder

IC281

1ST GENERATION - A/V DECODER / XTAL LOCATION SYMPTOM 1, 2

12

12/7/00

Page 16

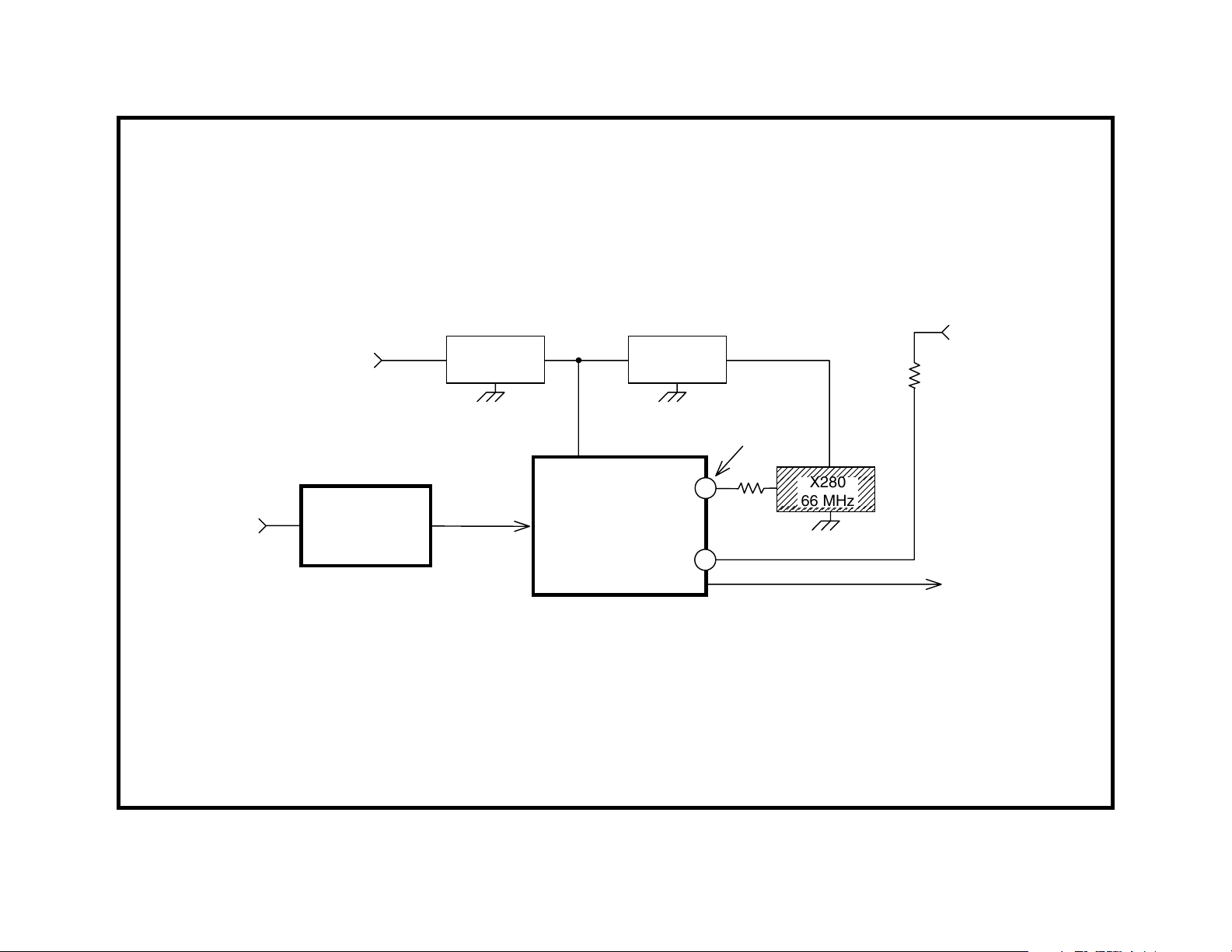

First Generation DVD

The first generation Sony DVD player consisted of two models, the DVPS3000 and the DVP-S7000.

Symptom 2: No color or colors changing in the picture.

Cause: 1. X280 (66MHz) crystal near IC281 on the main board.

2. X003 (27MHz) crystal in the “can” on the main board.

Repair procedure

1. Turn the unit ON. The Xtals will start immediately. Check the 66MHz.

crystal by placing a scope and frequency counter (using a X10 probe)

on the crystal (corner nearest IC281) or on either side of R213 that is

in series with the Xtal. If the signal is off frequency or below 0.9Vp-p,

replace the crystal.

2. Perform the 27MHz free run adjustment by grounding TP025 and setting RV001 for 27MHz

+100Hz at TP018.

13

Page 17

DECRYPT

IC184

3.3V

BUFFER

CONTROL

IC217

FL281 FL282

MPEG

VIDEO

DECODER

IC281

117

87

1V p-p

1.8Vdc

R213

220

X280

66 MHz

27 MHz

PLL IC002/16

R216

22

LETTERBOX

IC310

1ST GENERATION - 66 MHz XTAL SYMPTOM 2

14

12/28/0021DVD03

Page 18

15

D001

-5V

LPF

IC006

X003

27 MHz

27 MHz

FREE RUN

R027

100K

RV001

18

19

21

PLL

IC002

42

TP025

SHIELD ON

MB-78 BOARD

X003

16

4.7Vdc

MB-78 BOARD

R022

22

27 MHz

BUFF

IC012

RV001

27MHz

IC002

FL012

FL036

FL037

TP025

TP018

27MHz

TP018

MPEG AUDIO DEC IC381/27

VIDEO DECODER IC281/87

VIDEO ENCODER IC475/8

LETTER BOX IC310/91

SUB PIX IC312/123

VIDEO EQ IC317/89

DATA PROCESS IC181/3

DECRYPT IC184/21, 43

BUFF CONTROL IC217/24

27MHZ ADJ

1) GND TP025

2) ADJ. RV001

FOR 27MHz + 100HZ

AT TP018

1ST GENERATION - 27 MHz DISTRIBUTION SYMPTOM 2

22DVD03

1/8/01

Page 19

NOTES

16

Page 20

First Generation DVD

The first generation Sony DVD player consisted of two models, the DVPS3000 and the DVP-S7000.

Symptom 3: No DVD disc detected at start up. CDs

may PB OK.

Cause: Laser assembly or Spindle motor is at end of its life.

Repair procedure

You will check the DVD RF level and use that to determine if the laser

output is sufficient to play back DVDs.

1. Check the DVD laser output at CN760/pin 1 on the MB board. Although there may not be an eye pattern because the DVD only starts

to play, you should see RF at CN760/pin 1. Normally there is a 1.6Vpp eye pattern at CN760/pin 1. The minimum operating RF level is

0.9Vp-p. The CD RF test point is at a different location.

17

2. If the DVD RF level is above 0.9Vp-p, suspect the spindle motor. Even

though the DVD disc spins, replace the spindle motor (P/N = 1-698944-11). Often when the spindle motor is bad, the RF eye pattern is

not clear or the waveform squeezes and expands like a musical accordion before shutting down.

Page 21

CN980

MB-78 BOARDTT-701 BOARD

CN760

21

BOARD

LAYOUT

DVD

RF

2

22

27 mVp-p

CN980

12

34

MB-78 BOARD

12

34

5

TP891

CN886

IC765

AMP

CN760

2

1

IC770

RF

1.6Vp-p

RF PROCESS

IC770

1ST GENERATION - RF CHECK POINTS SYMPTOM 3/5

18

23DVD03

1/3/01

Page 22

First Generation DVD

The first generation Sony DVD player consisted of two models, the DVPS3000 and the DVP-S7000.

Symptom 4: Intermittent or distorted sound when playing DVD movies only (not CDs).

Cause: Audio Control IC380 is defective.

Repair Procedure

1. Replace IC380 CXD8603BR (P/N = 8-759-490-29).

19

Page 23

RF

TT-701

BD

RF

PROCESS

IC770

DATA

PROCESS

IC181

DECRYPT

IC184

BUFFER

CONT

IC217

AUDIO

AUDIO

CONTROL

CONTROL

IC380

IC380

DECODER

MPEG

AUDIO

DECODER

IC381

MPEG

VIDEO

LETTER

BOX

IC310

DIG

FILTER

IC801

IC312

D/A

CONV

IC802

SUB

PIX

NTSC

VID

ENCODER

IC475

AUDIO

OUT

VIDEO

OUT

1ST GENERATION - A/V PROCESS SYMPTOM 4

20

24DVD03

12/28/00

Page 24

First Generation DVD

The first generation Sony DVD player consisted of two models, the DVPS3000 and the DVP-S7000.

Symptom 5: No PB or Picture freezes when playing

parts on some dual layer (gold) discs.

Cause: 1. Laser getting weak.

2. ROM IC093 cannot PB marginal spec gold discs.

Repair procedure

You will measure the DVD RF level going to the servo (not video) stages

and use that level for making the laser performance judgement.

1. See service bulletin 47 to locate TP891 (same as CN886/pin 5). Less

than 0.95Vp-p means you should replace the optical assembly. Align

the unit for all three disc types (CD, DVD single and dual layer).

2. If the RF level is normal at approximately 1.5Vp-p, replace ROM IC093

as in service bulletin 43R2 depending upon the model.

21

Alignment after laser replacement

The Tilt, focus, and Tracking adjustments are performed automatically

from the test mode using the remote and test discs. After the test mode is

accessed and “drive automatic adjustment” is entered, you are prompted

to load the first DVD disc for alignment. Afterwards the screen prompts

you to replace the disc with a dual layer DVD and then finally with a CD to

complete the alignment. The procedure is as follows:

• Access the Test Mode by pressing the following buttons on the remote: Time, Clear, then Power.

• From the Test Mode Menu, select 1. Drive Auto Adjustment.

• From the Auto submenu, select 0. All (discs – one at a time).

• The screen will prompt you as to what disc to place on the tray and

what buttons to press to complete the alignment.

Page 25

NOTES

22

Page 26

Second Generation DVD

The second generation DVD players consist of models DVP-S300, DVPS500d, DVP-C600d, and DVP-S7700.

Symptom 1: No response to the Power ON button.

23

your unit from responding to the Power ON button. This is because

the front panel must be removed to reseat the encoder cable and it is

more important that you locate the problem. Either use your ohm

meter to locate a short at the power supply connector CN201 or repeatedly press the power button while monitoring the output voltages

to see which one is missing:

CN201/pin 1 = +5.2Vdc

Cause: There are three common causes for this symptom.

1. A damaged power supply;

2. A short on another board that causes no power supply output voltage;

or

3. A defective front panel encoder (ref #165 in the DVP-S500d service

manual) preventing IC604 from reading the power ON button by locking up its program so the unit may not turn ON (intermittent turn ON).

Repair Procedure:

The power supply runs all the time when 120VAC is input, producing E

+5V. The +3.3V, +5V and

turned ON. You first need to determine if the basic power supply is defective.

1. Unplug the cable from the only connector on the power supply, CN201.

Look for E+5Vdc at CN201/pin 6 (alternate test point is at PS312)

from the power supply board. If there is no voltage, the power supply

is inoperative. The most common cause is a shorted main oscillator

MOSFET transistor, Q103, which has taken out the main fuse. Q103

P/N = 9-880-437-01 which is a 2SK2798 for the USA models.

If the new Q103 fails or there is still no output voltage, replace the

associated control parts Q101, Q102 and D104.

+12V outputs are switched ON when the unit is

CN201/pin 2 = +5.2Vdc

CN201/pin 3 = Ground

CN201/pin 4 = +3.3Vdc

CN201/pin 5 = Ground

CN201/pin 6 = E5.Vdc

CN201/pin 7 = Ground

CN201/pin 8 = P Cont (input)

CN201/pin 9 = AU +12Vdc

CN201/pin 10 = AU Ground

CN201/pin 11 = AU –12Vdc

CN201/pin 12 = -12Vdc

CN201/pin 13 = Ground

CN201/pin 14 = Motor +12Vdc

CN201/pin 12 = Motor Ground

Use the +3.3V and 5V distribution diagrams in this book (symptom 2) to

locate the shorted IC.

2. If the power supply does produce the E+5, the front panel rotary encoder or a short in another board is suspected. The encoder is attached to a ribbon cable that plugs into CN103 of the front panel board.

Unplug the encoder, plug in the power supply cable and press the

power ON button to verify the defect.

3. If the unit still did not power up, you may leave the rotary encoder

cable detached while you look for the short circuit that is preventing

Page 27

Q103 OSC.

2SK2178

T101

D211

D211

Q211 SW.

2SJ488

P211

P312

CN201

14

MTR+12V

11

AV+12V

6

E+5V

Q101

2SK2798

HS-930 SU

BOARD

2ND GENERATION - POWER SUPPLY SYMPTOM 1

D104

2.4V

Q102

2SC2377

D611

Q312

INV.

IC611

3.3V REG.

Q311 SW.

2SA1679

P311

Q511,

Q512

SWITCH

P CONT.

P511

2

1

+5.2V

8

P CONT.

4

3.3V

11

AV-12V

12

-12V

4DVD03 1294

1/8/01

24

Page 28

25

FL88 BD.

POWER

ROTARY

ENCODER

JOG WHEEL

ENTER

BUTTON

P/N 1-475-685-11

CN103

MB78 BD.

IC604

IF MICON

HS930 SW BD.

POWER SUPPLY

P CONT.

IC611,Q311,

Q211

EVER

5V

2ND GENERATION - POWER ON SYMPTOM 1

18DVD03 1307

1/16/01

Page 29

NOTES

26

Page 30

Second Generation DVD

The second generation DVD players consist of models DVP-S300, DVPS500d, DVP-C600d and DVP-S7700.

Symptom 2: Powers OFF two seconds after turn ON

Cause: There are two causes for this symptom –

1. An internal IC short will load down a power supply voltage. This removes the voltages to the other ICs and communications end. Once

IC communications end, Syscon shuts down the DVD player because

it senses a defect.

2. At power ON the laser must be detected at home position or the unit

will detect a malfunction and shut down. If the sled motor is frozen,

the laser will not return to home.

Repair Procedure:

If the power supply board makes a chirping noise when you press the

power button, an output is being loaded down. Measure the output voltages to find out which one. The most common shorted ICs are:

27

If the power supply is OK, the sled may be defective on these older units.

Remove the lid that houses the mechanism and slide the laser away from

home at the spindle motor. At power ON, the laser should travel to the

spindle motor (home) then move outward. If home is not detected, the

laser assembly will incorrectly remain where it is and the unit will shut

down. The sled motor assembly is P/N = X-394-713-71.

2nd Generation Players - Shorted ICs

Function IC # Ref # in DVP-S500d

Large Gate Array (LGA) CX8728Q IC804

Audio DSP CX8730R IC506

Page 31

FL201

IC201, IC202

+3.3V

INTO

FL202

FL006

IC203

CN001/5

FL805

FL101

IC806, IC810

IC104, IC105, IC101

2ND GENERATION - MB-78 BD. -3.3V DISTRIBUTION (DVP-S500D)

7DVD03 1297

11/30/00

28

Page 32

29

+5.2V

INTO

CN001/7,8

F005

1.6A

F006

1.6A

FL003

FL007

FL007

FL005

FL001

FL008

D 5V

S 5V

A 5V

AU 5V

DP 5V

FL801

FL802

FL803

FL807

FL804

FL501

FL502

FL808

FL254

FL208

IC804

IC807

IC811

IC805, IC803

IC806

CN601/2 (FL-88 BD.)

OP AMPS: IC452, IC502,IC507

IC506, CN501 (CHECK)

IC506

IC806

CN252/9 (AU197 BD.)

IC252

CN252/25 (AU197 BD.)

OP AMP IC205

FL211

FL212

FL251

FL252

PLL IC209

OSD IC207

IC251

IC252

CN203/10, CN252/4 (AU-197 BD.)

2ND GENERATION - MB-78 BD. +5V DISTRIBUTION (DVP-S500d)

5DVD03 1295

12/28/00

Page 33

IC207 IC202IC201

CN252

F808

FL502

FL202

IC811

IC363

FL807

FL001

FL007

FL006

FL803

IC807

FL005

FL003

FL008

CN001 CN002

FL201

IC203

FL802

FL251

IC252

FL212

FL254

IC251 IC252

MB-78

BOARD

FL805

CN101

IC802

IC803

IC810

FL801

FL208

IC209

FL211

IC608

IC105IC101

FL101

CN251

TOP BOTTOM

2ND GENERATION - "FL" FILTER LOCATIONS

IC805

IC804

IC604

CN702

IC506

CN701

IC806

IC104

CN601

6DVD03 1296

1/8/01

30

Page 34

Second Generation DVD

The second generation DVD players consist of models DVP-S300, DVPS500d, DVP-C600d and DVP-S7700.

Symptom 3: Plays CD but not DVD discs

Cause: There are three common reasons that the player will only PB CDs:

1. The laser beam must be perpendicular to the disc. This is critical

when reading fine pitched DVD discs, but not for CDs. Therefore if

the tilt servo is not working, CDs will still play but not DVDs. Inspect

the Laser base unit for a crack in the plastic preventing tilt.

2. The laser assembly may have low output. As the laser output decreases with use, the RF eye pattern decreases in amplitude causing

skipping, and finally no DVD playback.

3. The spindle motor must turn faster when playing a DVD. As the motor

brushes wear down, the torque at the high speed cannot be maintained and the DVD does not reach the normal operating speed.

4. Corrupt EEProm data.

Repair procedure

1. Inspect the plastic base unit holder (DVP-S500d ref. #263) for cracks

that prevent the laser assembly from tilting.

You can also operate the tilt mechanism from the test mode under

section “Manual Adjust 2” for inspection. With the player OFF, press

the remote control TITLE, CLEAR, and then the POWER button to

enter the test mode. Using the number buttons, select

Operation, 5 Manual Adjust, then 2 Tilt Offset. After remembering the

original offset number, use the arrow buttons to change the offset

number and drive the tilt motor. As the motor turns, the laser assembly should be mechanically tilting. Return to the original offset number

before exiting (exit by pressing the power off button).

2 Drive Manual

31

detected when the RF level drops lower than 0.9Vp-p. Even when no

disc is detected at slightly below 0.9Vp-p, a DVD may still play in the

test mode, producing only a low amplitude eye pattern. No picture

appears when the servos are individually (manually) turned on for PB

in the test mode. See the Test Mode section of this book for further

information.

3. If the laser assembly tilts and the RF starts at 1Vp-p (minimum) before shutdown, the spindle motor could be worn. Replace the spindle

motor if the RF signal is above 1Vp-p (laser is OK). Sometimes a

defective spindle motor shows up in the test mode when the unit incorrectly identifies a 12cm DVD as an 8cm disc when attempting to do

the DVD drive adjustments. Enter the test mode and select

Manual Operation, 0 Disc Type, and 5 Disc Type Check.

4. The EEProm data may be defective but can be reset to default user

and service values from the Test Mode. After the default values are

entered, the player must be aligned. The procedure for resetting the

EEProm is as follows:

• Access the Test Mode by pressing Title, Clear, then Power buttons.

• From the Test Mode Menu, press 2. Drive Manual Operation

• From this sub menu select 7. Check for the memory access.

• Select 1. EEProm Default Set

• Press RETURN several times to go back to the initial Test Mode Menu

to begin automatic alignment.

• Select 1. Drive Auto Adjustment and follow the directions to adjust tilt,

focus and tracking sections.

: 2 Drive

2. On the MB-78 board monitor, check connector CN303/pin 1 for a RF

(eye pattern) signal when trying to play a DVD. The normal signal

level here is 1.2Vp-p. As the laser ages, this level decreases. Skipping occurs when the level drops to approximately 0.9Vp-p. No disc is

Page 35

2ND GENERATION - OPTICAL ASSEMBLY SYMPTOM 3

32

1/3/0119DVD03

Page 36

Second Generation DVD

The second generation DVD players consist of models DVP-S300, DVPS500d, DVP-C600d and DVP-S7700.

Symptom 4: No playback -

• Disc stops spinning, DVD logo on screen; or

• Disc stops spinning, Dark screen (no video), no

initial DVD picture logo, no sound.

Cause: There are two common causes for this no PB symptom -

1. ARP (IC806 in DVP-S500d) CXD1865R defective or

2. A/V Decoder (IC203 in DVP-S500d) L64020-D-QC-27 defective.

33

Repair procedure

1. Insert DVD and monitor the RF test point on the MB board (CN303/

pin 1). If there is a clear eye pattern at start up, the ARP IC806 must

be OK to support the servo system that produces this eye pattern.

The A/V decoder must be causing the dark screen. Replace the A/V

decoder IC203.

2. If RF is present but NO eye pattern is obtained at the CN303/pin 1 test

point, the servos are not functioning. If the RF is at least 1Vp-p, suspect the ARP IC806.

Page 37

PATTERN

RF FROM

OPTICAL

ASSEMBLY

SLED FOCUS

TRACKING

SPINDLE

LOADING

DRIVERS

EYE

IC806

ARP

IC502

SERVO

DSP

IC811

DECRYPT

IC203

A/V

DECODER

IC252

VIDEO

DECODER

VIDEO

OUTPUT

2ND GENERATION - VIDEO PROCESS SYMPTOM 4/5

34

20DVD03 1302

1/8/01

Page 38

Second Generation DVD

The second generation DVD players consist of models DVP-S300, DVPS500d, DVP-C600d, and DVP-S7700.

Symptom 5: Multiple Symptoms -

1. Color / Picture distortion (after warm up):

• only yellow color;

• large digital blocks during playback

2. Dark screen - no DVD logo at power ON.

Cause: A/V decoder (IC203 in DVP-S500d) L64020-D-QC-27 defective.

Repair procedure

1. Replace A/V decoder (8-759-564-38).

35

Page 39

NOTES

36

Page 40

Third Generation DVD

The third generation DVD players consist of models DVP-S330, DVPS530, DVP-S550 and DVP-C650d.

37

one end and bringing it around to unsolder the remaining connections. Chip Quick

Although any IC can short, the more commonly shorted IC is IC701,

fed by B+ filter FL701.

does this best. Lift the hot filter off with tweezers.

Symptom 1: Green power light does not stay on.

Cause: There are three common causes for the unit returning to the

standby (power OFF) state. Follow the repair procedure to determine

which one is the cause.

1. A defect in the power supply causes a loss of power to one or more

ICs, resulting in no communications. When there are no communications, Syscon shuts down the player.

2. Similarly, if an IC in the unit shorts the power supply, there will also be

no communications and the unit will shut OFF.

3. Incomplete communications between an IC and Syscon is considered

a defect and shutdown is the protection.

Repair Procedure:

Either a short circuit or a communications failure in an IC is what is causing the problem.

Short Circuit

1. Check all the output voltages from the power supply. If all the voltages are present, go to “Communications Failure”.

2. If any voltages are 0V, unplug the MB-85 board to see if you can

isolate the short. The power supply will regulate unloaded.

3. A short on the +12 volt line means either IC801 or IC802 is defective

since they are the only ICs (on the MB85 board) that use +12V. Remove IC802 and if it is shorted, check the sled motor by applying a

3Vdc from an external power supply to see if it will run.

4. A short on the 3.3 volt line means any one of a number of ICs on the

MB-85 board is bad. 3.3 volts feeds each IC through a three connection inductive “FL” filter chip component. This is shown on the 3.3V

Distribution Diagram. Not all the ICs listed are used in every DVD

player. The FL filter can be removed by applying excessive solder to

Communications Failure

There is an initial communications between IC201, IC202 and IC205/6 at

power ON. Once these three ICs have talked, Syscon IC202 communicates with the remaining ICs on the serial and parallel bus. Syscon uses

chip select pulses to select an IC, communicate with it and repeats this

pattern with the next IC. Since the pattern is the same, we can use the

chip select signal to determine which IC is not communicating.

1. Resolder IC205/6 and recheck the unit for operation.

2. If the unit works when ON but doesn’t turn ON consistently when the

power button is pressed, perform S/B 62R1 to insure reliable reset of

three ICs on the MB board.

3. IC202 sends chip select pulses to ICs on the MB-82/85 board in the

order listed in the chart. If IC202 gets no acknowledgement from an

IC, the

down. Therefore if a chip select pulse is missing at power ON, the IC

before it on the chain is not acknowledging. Check each chip select

source at DVD power ON with a scope and determine which signal is

missing. Suspect the previous IC on the list. For example, if chip

select XCS (#6) was missing, the A/V decoder IC401 may be defective. Replace IC401.

1. CS 1 - IC202/pin 10 SRAM IC204 / HGA IC601

2. CE IC202/pin 11 Flash ROM IC205/6

3. CS 3 IC202/pin 8 AV Decoder IC401

4. CS 4 IC202/pin 7 HGA IC601

5. CS 2 IC202/pin 9 AV Decoder IC401

6. XCS IC601/pin 111 ARP2 IC303

7. HCS - IC601/pin 118 Servo IC701

next chip select pulse will not output and the unit will shut

Power ON IC check sequence

Chip Select Source Destination IC

Page 41

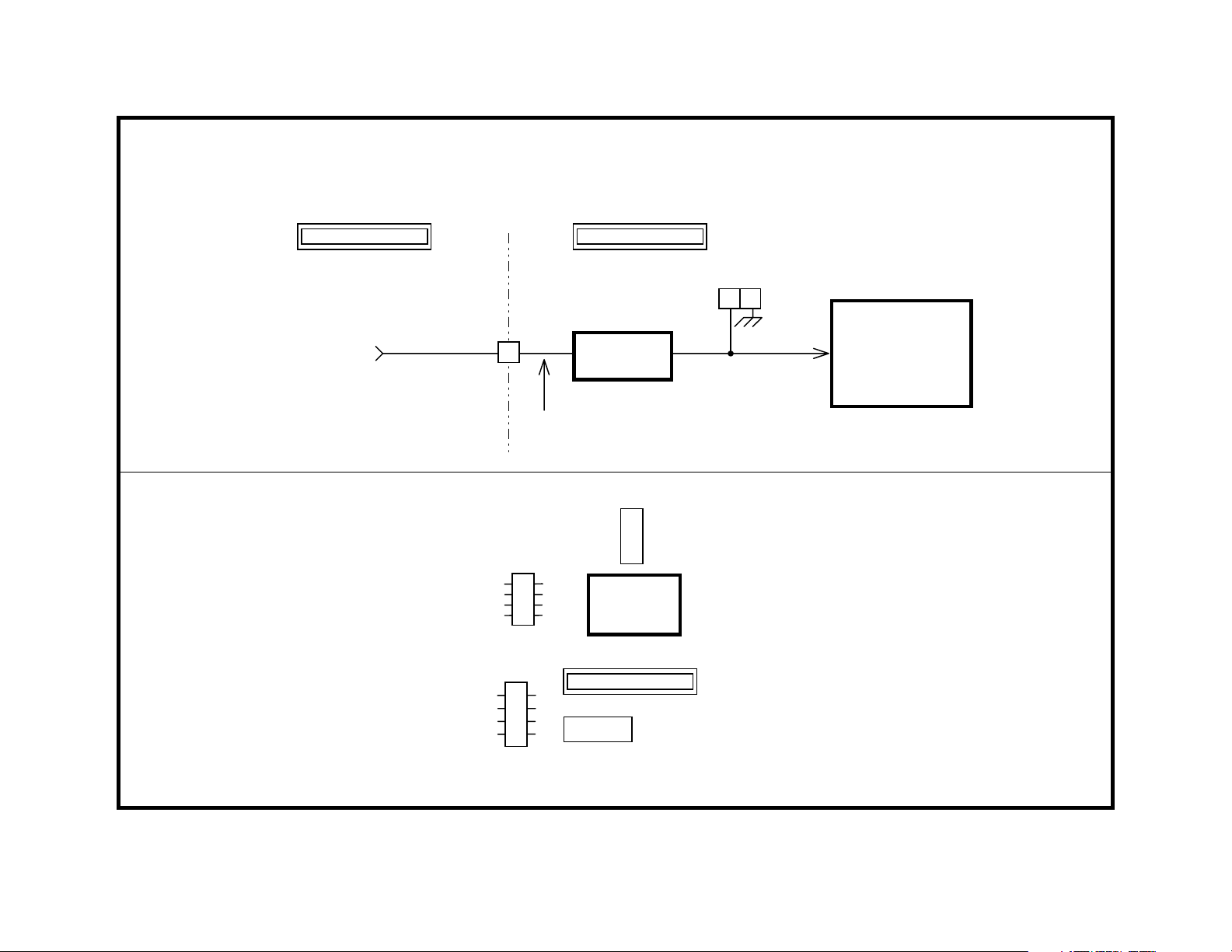

MECHANISM

OPTICAL

DEVICE

FOCUS

COIL

TRACK

COIL

TILT

M

SPINDLE CONTROL

IC802

RF

LD

IC001

AMP

TK-51 BD.

IC801

FOCUS

&

TRACKING

COIL TILT

MOTOR

FE

TE

PI

DRIVER

RF

RF

S.

DATA

CLK

IC304

DRAM

IC303

ARP2

DVD

DATA

CD

DATA,

CLK

IC401

AV

DECODER

PARALLEL BUS

Y,C

Y,P ,P

Y

SPDIF

ACHI-6,

CLK

IC403

IC403

SDRAM

b

r

IC501

AUDIO

DPS

AU212 BD.

S VIDEO

OUT

VIDEO

BUFFERS

COMPONENT

V OUT

COMPOSITE

V OUT

DIGITAL AUDIO OUT

IC902

DAC

IC905-7

DAC

5.1 CH

AC-3OUT

ANALOG

AUDIO

OUT

SPINDLE

M

SLED

M

LOADING

M

IC802

SPINDLE,

SLED &

LOADING

MOTOR

DRIVER

IC701

SERVO

SPINDLE

CONTROL

IC303

IC601

HGA

3.3V

POWER

BLOCK

FR150 BD.

BLOCK DIAGRAM

38

SYSTEM

CONTROL

MB-85 BD.

5V

12V

-12V

IC202

REC

IR

FLASH

P CONT.

IC205/

IC206

MEM.

IC201

INTERFACE

MICRO

IC204

SRAM

FL101 BD.

SERIAL BUS

IC201

EEPROM

DISPLAY

SWITCHES

13DVD03 1306

PANEL

12/28/00

Page 42

4. Sometimes when a chip select signal is missing, the IC it points to is

actually not defective. Usually a communications failure between IC202

and the remaining ICs on the serial or parallel bus is within the MB-82/

85 board. This could be caused by lack of power to non-communicating IC or it could just be defective.

Another possibility is that one of the programs in that IC cannot finish

because of a mechanical defect, so there is no acknowledgement

signal to complete the communications. For example, if IC701 is sending a sled drive move signal but the IC fails to receive a sled home

indication after a fixed time (“time out”), IC701 will not acknowledge

IC202.

39

Syscon IC202 will tell IC201 to shut down. In this failure example sled

driver IC802 is defective so the sled cannot move. Since IC701 is the

last chip in the chain, all the chip select signals are present. If the unit

shuts down with all the chip select pulses present, IC701 is not sending the final acknowledgment signal so the problem is at IC701 or its

slave ICs (IC801 or IC802). In this case, use the test mode to manually drive the focus, tracking and sled, tilt motors.

5. Inspect IC205/6 and check to see if this IC is one of the few units that

needs to be upgraded in the service bulletin # 61 for a 0.5-second lip

sync delay. This upgrade has no relation to the green to red power

light symptom.

Page 43

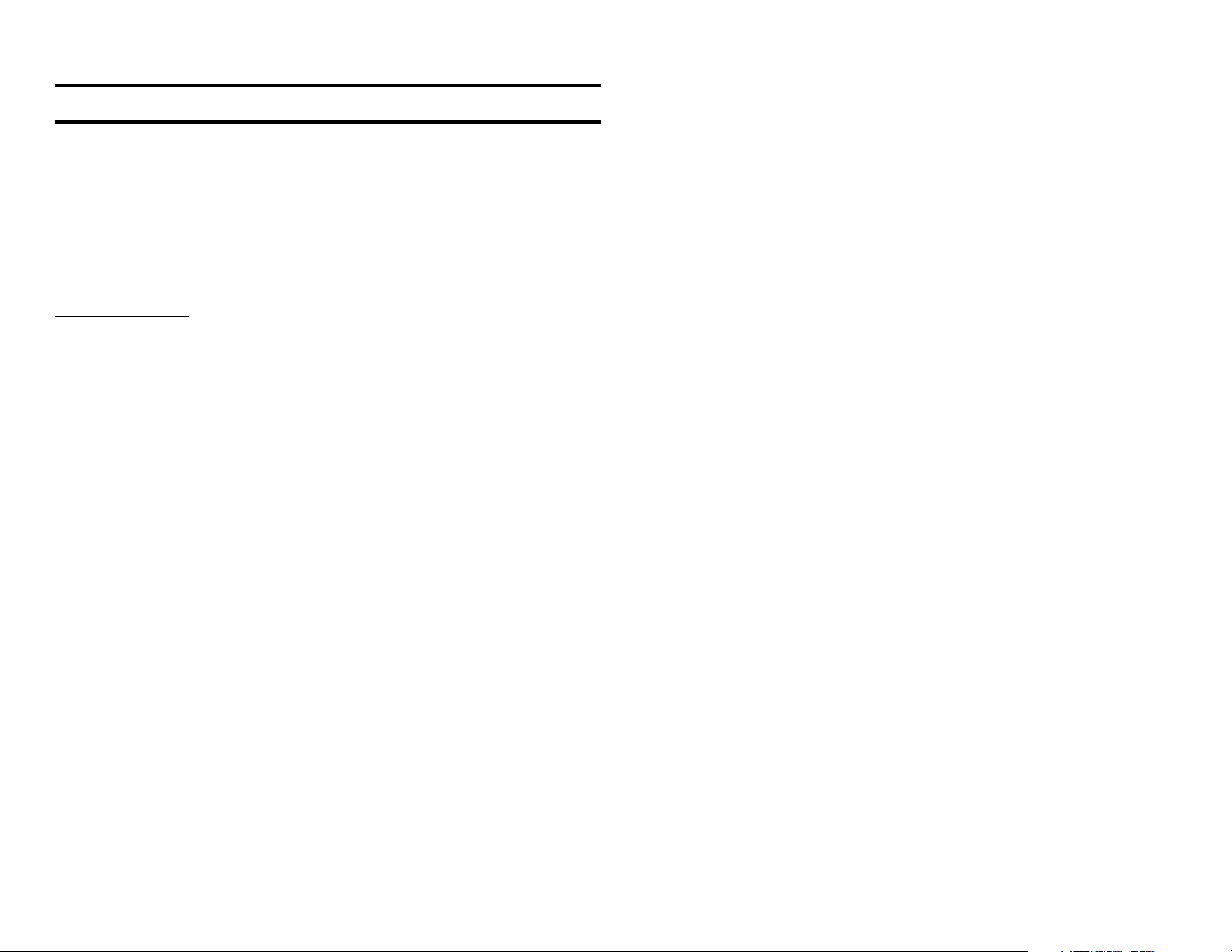

Green Power

Light Does Not

Stay On

Check All

Voltages

from Power

Supply

NG

Unplug Power

Supply Output

Cables

Measuring

Voltage at

P.S. Board

NG

Troubleshoot

P.S. Board

OK

OK

Communications

Failure

Short Circuit

on MB Board

Is Short on

+12V Line?

Is Short on

+5V or +3V

Line?

Yes

Yes

Did the Blue

Dolby Light

Come On?

Problem is

around

IC201, IC202,

IC205/6

IC801 or IC802

is Defective

Use +5V or

+3.3V

Distribution

Chart to Locate

Short

No

Yes

Support Remaining ICs on MB

Board. Follow Procedure to Locate

Missing chip Select Pulse.

Troubleshoot

Short on Other

Boards

3RD GENERATION - SYMPTOM 1 FLOW CHART

40

25DVD03

12/5/00

Page 44

SRV902

POWER

SUPPLY

BOARD

CN201

CN202

CN203

+3.3V

+5V +/-12V

EVER 5V

B301

3.3V,+5V,+12V

EVER 5V

-12V,

P CONT

41

AU208/212

AV010 BOARD

FR146/148/150

CONV BD.

FL97/99/101

DISPLAY BD.

CN001

MB-82/85

DIG PROC

BOARD

3RD GENERATION - POWER DISTRIBUTION

3DVD03 1293

11/30/00

Page 45

+12V

1 2 5 6 7

+5V

+3.3V

POWER

SUPPLY

CN202

FL501

FL503

7

1

CN001

FL301

18

1

CN003

IC401

(3.3V)

IC303

(3.3V)

IC701

(3.3V)

FL601

FL701

IC904

IC601

(3.3V)

IC202

(3.3V)

IC902

FL602

IC602

FL202

FL502

IC901

FL403

FL402

IC403

(3.3V)

IC402

(3.3V)

IC801

(+12V)

IC502

(3.3V)

FL404

FL014

FL002

FL401

FL303

FL005

IC304

(3.3V)

IC205/IC206

(3.3V)

FRONT

3RD GENERATION - 3.3V FILTER LOCATION

42

IC204

(3.3V)

FL204

FL205

BACK

IC802

(+12V)

2DVD03 1292

1/8/01

Page 46

43

+3.3V

INTO

CN001/6,7

GND

FL----

GND

FL104 FL404

FL104

OUTIN

FL401

FL403

FL402

FL701

FL005

FL202

FL204

FL205

FL301

FL303

FL601

IC401

IC401/161

IC403

IC402

IC701

CN003/9 TO TK-54 RF BD.

IC202

IC204

IC205/IC206

IC303

IC304

IC601

FL602

FL501

FL503

FL502

IC602

IC502

IC502

IC501

3RD GENERATION -3.3V DISTRIBUTION (MB-85 BOARD)

1DVD03 1291

11/30/00

Page 47

DOLBY

R285

EVER

5V

30 76

IC201

IF CON

POWER

71

CN201/

CN002

CN202/

CN006

SI

SO

POWER SUPPLY BD.

5

2

EVER 5V

CN001/

3.3V

CN202/

CN001

97

77

76

CN203

6 7

IC202

SYSCON

FR BD.

3

4

572

XIFCS

SO

SI

IC205/6

16 M FLASH

ROM

FL BD.

MB BD.

PARALLEL

BUS TO MEMORY

IM SRAM IC204

3RD GENERATION - INITIAL DATA COMMUNICATIONS SYMPTOM 1

44

9DVD03 1299

12/28/00

Page 48

45

CHIP

SELECTS

IC201

INTERFACE

CONTROL

CS

IC202

SYSTEM

CONTROL

SERIAL BUS

CS FROM

IC601

IC201

4k

EEPROM

CS FROM

IC202

IC205

FLASH

CS FROM

IC202

IC501

AUDIO

DSP

CS FROM

IC202

IC204

SRAM

CS FROM

IC202

IC902

AUDIO

2 CH

DAC

CS FROM

IC202

IC601

HGA

CS FROM

IC202

IC905

DAC

FRONT

CHIP

SELECTS

IC701

SERVO

CS FROM

IC601

IC906-7

DAC

REAR,

CENTER

CS FROM

IC601

PARALLEL BUS

TWO

CS FROM

IC202

PARALLEL BUS

IC401

AV

DECODE

IC303

ARP2

3RD GENERATION - SYMPTOM 1 - POWER OFF

CS FROM

IC601

12DVD 1301

12/1/00

Page 49

Power ON IC check sequence

IC401

IC601

IC202

81

120

1

35

Third Gen

MB board

Chip Select Source Destination IC

1. CS 1 - IC202/pin 10 SRAM IC204 / HGA IC601

2. CE IC202/pin 11 Flash ROM IC205/6

3. CS 3 IC202/pin 8 A/V Decoder IC401

4. CS 4 IC202/pin 7 HGA IC601

5. CS 2 IC202/pin 9 A/V Decoder IC401

6. XCS IC601/pin 111 ARP2 IC303

7. HCS - IC601/pin 118 Servo IC701

3rd Gen - Power ON Chip Select Sequence

46

Page 50

Chip Select Waveforms

All these chip select signals appear at power ON. The first five chip select signals also appear as long as the unit is ON. The last two only

appear at power ON and during the PB of a disc (or when the disc is

paused).

All waveforms are 3.3Vp-p taken at 10usec/div. time base.

CS 1 - IC202/pin 10 to SRAM IC204 / HGA IC601

47

CS 4 – IC202/pin 7 to HGA IC601

T

1

CH1!2.00 V= MTB10.0us- 1.16dv ch1-

CS 2 – IC202/pin 9 to A/V Decoder IC401

T

1

STOP

CH1!2.00 V= MTB10.0us- 1.16dv ch1-

CE – IC202/pin 11 to Flash ROM IC205/6

T

1

STOP

CH1!2.00 V= MTB10.0us- 1.16dv ch1-

CS 3 – IC202/pin 8 to A/V Decoder IC401

T

1

T

1

CH1!2.00 V= MTB10.0us- 1.16dv ch1-

These last two chip select signals only appear at power ON and during

disc PB.

T

1

CH1!2.00 V= MTB10.0us- 1.16dv ch1-

XCS – IC601/pin 111 to ARP2 IC303

HCS - IC601/pin 118 to Servo IC701

T

1

CH1!2.00 V= MTB10.0us- 1.16dv ch1-

CH1!2.00 V= MTB10.0us- 1.16dv ch1-

Page 51

3.3V

FL202

IC202

SYSCON

4 15 43 70 93

3.3V

14

5 4

IC207

POWER ON

RESET

# 2

# 2

R226

10k OPEN

*

R212 220 OHMS 0 OHMS

X3VRST

# 3

CN006

XFRRST

1

R257

100

3.3V

FRRST

1k 33 OHMS

8

IC201

IF CON

# 2

R252

*

77

P

CHECK

# 2 R251

1k 120 OHMS

*

FL601

XSDR

RST

IC601

HGA

114

R755

5.6k - 10k

X3VRST

MB BD. FL BD.

102

26

IC401

A/V

DECODER

IC701

SERVO

DSP

AS PER S/B 62

#2 = STEP 2

#3 = STEP 3

71

# 2

D701

*

2 3

# 3

R412

100 OHMS

OPEN

*

3RD GENERATION - SERVICE BULLETIN 62 (SYMPTOM 1)

48

*

CHANGE

8DVD03 1298

1/8/01

Page 52

Third Generation DVD

The third generation DVD players consist of models DVP-S330, DVPS530, DVP-S550 and DVP-C650d.

Symptom 2: Audio Distortion after warm up

Cause: 1. Failure in A/V Decoder IC401; or

2. Failure in Audio DSP IC501

Repair Procedure

Often the audio distortion occurs after the unit gets warm, appearing in

both front L & R channels but less in both rear AC-3 channels.

1. To determine which IC is defective, freeze the heat sink above IC401

on the MB board when the problem appears. If the problem does not

go away, IC501 on the bottom of the board is defective.

49

Page 53

VIDEO

OUTPUT

IC303

ARP2

SERVO

IC401

A/V DECODER

DVP-S330 ONLY

IC501

AUDIO DSP

IC902

D/A CONV

IC903-7

D/A CONV

AUDIO OUT

L/R FRONT

AUDIO

OUT

L/R REAR

CENTER

3RD GENERATION - AUDIO DISTORTION SYMPTOM 2

50

10DVD03 1300

12/28/00

Page 54

Third Generation DVD

The third generation DVD players consist of models DVP-S330, DVPS530, DVP-S550 and DVP-C650d.

Symptom 3: Multiple Symptoms

1. The spindle motor rotates immediately at power ON

instead of 5 seconds later.

2. The tray may not come out (displays “EJECT”).

3. There also may be a dark screen (no video

output, no initial DVD logo).

Cause: Spindle / tray / sled driver IC802 is defective. Video was muted

because communications were locked up by IC401.

Repair Procedure

IC802 will feel cooler than the similar IC801 next to it. IC802 may also

short the +12V line, producing symptom 1.

1. Remove the MB board, turn it over and replace IC802 (P/N = 8-759567-26).

51

Page 55

TK51 BD. MB BD.

IC001

RF AMP

IC401

A/V DECODE

IC303

ARP2

IC701

SERVO

DSP

IC202

SYSCON

IC601

HGA

+12V

IC802

SPINDLE

DRIVER

SLED

DRIVER

LOADING

DRIVER

M

M

M

3RD GENERATION - SERVO SYMPTOM 3

52

11DVD03 1300

12/28/00

Page 56

Third Generation DVD

The third generation DVD players consist of models DVP-S330, DVPS530, DVP-S550 and DVP-C650d.

Symptom 4: Unit goes back to standby mode during

playback or after being left ON in the stop mode.

Pressing the MB board makes the unit remain on

longer.

Cause: Broken solder connection at a major IC stops the communications chain and the unit goes into protection by powering OFF (standby).

Repair Procedure

1. Remove the capacitors around IC401 for clearance and resolder all

the pins. If you created solder bridges, you have not applied liquid

flux (Kester flux pen) at the foot of the IC legs or you touched the legs

close to the IC body with the iron. Remove the bridges with thin brad

solder wick. Inspect each pin carefully, then remount the electrolytic

capacitors.

53

Heat only the

feet and lands

2. While you have the MB board out, resolder the pins on IC206; and

3. Resolder the pins on IC202.

IC Body

Do NOT apply

heat here

Page 57

IC401

Electrolytic

Capacitors

around

IC401

MB

board

3RD GENERATION - RESOLDER IC401 SYMPTOM 4

54

1/8/01

Page 58

Third Generation DVD

The third generation DVD players consist of models DVP-S330, DVPS530, DVP-S550 and DVP-C650d.

Symptom 5: Picture freezes or shuts down when trying to play dual layer (gold) DVD movies.

Causes:

• User may have changed disc DVD PB settings

• ROM IC205 needs to be upgraded or the

• A/V decoder is defective.

Repair Procedure

1. Enter the Test Mode and reset the user and service EEProm data.

• Enter the Test Mode by pressing Title, Clear, Power.

• In the Test mode, select 2. Drive Manual Operation

• From this menu, select 6. Memory Check

• When the EEProm Data menu appears, follow the bottom directions

to return to default values by pressing the Clear button.

After you return the data to default levels you need to perform the

automatic adjustments* with test discs. See Automatic Adjustments.

55

* Automatic Adjustments

After replacing the Laser assembly, EEProm IC201 or Flash ROM IC205/

IC206, enter the test mode using the remote control and perform the “Drive

Auto Adjustment”. This alignment method uses three standard test discs

one at a time to adjust the following:

• DVD laser tilt angle for maximum RF level

• Focus gain and offset voltages to insure reliable RF data

• Tracking gain and offset voltages to locate data quickly

See the Test Mode section of this book for more details.

2. See service bulletin 58R1 to see if the DVD player has the older ROM

IC205 on the MB board. If it does, replace it with the larger IC206 (P/

N 8-759-594-81). To avoid cold solder connections when installing

the new IC, clean the unused foil pads with an eraser and apply flux

before soldering the new IC206 on the board. Afterwards perform the

automatic adjustments with all discs (CD, DVD - SL single and DVD –

DL dual layer). *

3. If the new IC206 ROM is already on the board according to service

bulletin 58R1 (MR27v1602d-xx, 2XX-1.95 version or greater), a defective A/V Decoder IC401 must be causing the picture problem.

Replace IC401.

Page 59

IC401

Electrolytic

Capacitors

around

IC401

MB

board

MR27V1602D-53

210B - 2.3

IC206 version

Flash ROM

IC206 or IC205

3RD GENERATION - FLASH ROM LOCATION SYMPTOM 5

56

1/8/01

Page 60

Third Generation DVD

This only applies only to multi DVD changer model

DVP-C650 –

Symptom 6: Unit powers ON but no buttons work.

Displays error code E27.

Cause: Ripped flex cable, reference # 180.

Repair Procedure

1. Replace the flex cable (P/N 1-791-200-11) and secure the new flex

cable so the rotating tray table does not shear it. See service bulletin

# 64.

Flex

Cable

57

Page 61

DVP-C650

Flex

Cable

58

Page 62

Third Generation DVD

This only applies only to multi DVD changer model

DVP-C650 –

Symptom 7: Tray does not rotate.

Cause: Tray Driver IC652 defective.

Repair Procedure

1. Replace IC652 (P/N = 8-759-522-08).

59

Page 63

Third Generation DVD

The third generation DVD players consist of models DVP-S330, DVPS530, DVP-S550 and DVP-C650d.

Symptom 8: Tray does not Eject.

Displays :”LOCKED”.

Cause: Nothing wrong with the unit. Tray is locked out in the display unit.

Use a SONY DVD remote to lock or unlock the tray.

Repair Procedure

Lock

1. With the unit OFF (red light), press the following buttons on the remote: 1, 4, 1, 1, power.

2. The unit will come ON. Once a disc is detected, the tray will no longer

respond to the eject button. The display will show LOCKED each

time the eject button is pressed.

Unlock

1. With the unit OFF (red light), press the following buttons on the remote: 1, 4, 1, 0, power.

2. The locked display will no longer appear and the tray open button will

work normally.

60

Page 64

Fourth Generation DVD

The fourth generation DVD players consist of models DVP-S350, DVPS560, DVP-S560, DVP-S570, DVP-C660d and DVP-C670d.

Symptom 1: No CD or DVD PB. No Disc or C:13:00

customer error code.

Cause: Tracking coil fuse F402 open.

Repair Procedure

1. Refer to service bulletin 68 to change resistor values that will lower

the tracking gain.

61

Page 65

IC404

SERVO

DSP

CXD 9569R

R425

100k

5

7

R460

100k

12

13

150k 82k

1.7V REF

IC403/14

*R418

150k 82k

-

+

*R416

11

IC401 1/4

FOCUS/TRACK

TILT DRIVER

4

5

CHANGE PER S/B 68

*

F402

CN201

21

TRACKING

COIL

22

4TH GENERATION - TRACKING DRIVE SYMPTOM 1

62

14DVD03 1304

1/8/01

Page 66

63

Fourth Generation DVD

The fourth generation DVD players consist of models DVP-S350, DVPS560, DVP-S560, DVP-S570, DVP-C660d and DVP-C670d.

Symptom 2:

1. Goes to Standby (red light) after powering ON.

2. Goes to Standby (red light) while playing a disc.

Cause: Syscon IC102 failure or there is nothing wrong.

Repair Procedure

1. First press the front panel power button. The power light should change

from red (standby) to green (ON), then back to red. (No light

⇒green light ⇒ red light). While the red light (standby) is ON,

light

press either the PLAY or TRAY OPEN/CLOSE button. If the unit powers ON again there is nothing wrong with the unit. This is normal. The

unit entered the standby state after pressing the latching front panel

power switch. Think of the front panel ON switch as a master power

switch. The DVD player will not respond to the remote unless this

master switch is ON (depressed).

2. If pressing the PLAY or TRAY button does not power the unit back up,

check for B+ by looking for Xtal activity (X101 = 2.4Vp-p, 1.6Vdc) at

IC102. Xtal activity means there is B+ but does not mean the entire

IC102 is OK. Replace IC102.

⇒ red

Fourth Generation DVD

The fourth generation DVD players consist of models DVP-S350, DVPS560, DVP-S560, DVP-S570, DVP-C660d and DVP-C670d.

Symptom 3: Pressing the tray open button does not

cause the tray to open.

Cause: Syscon IC102 failure.

Repair Procedure

If the display showed “STANDBY” after pressing the front panel power

button, the power supply was not loaded down by a short circuit and it is

OK.

Tray driver IC402, its controller, IC404 or SYSCON IC102 must be causing no tray movement. Replace IC102 first.

Page 67

3.3V

PLAY

X401

2MHz

IC404

IF CON.

POWER

SUPPLY

BOARD

P CON.

AI-17 BD.

X IF BUSY

X IFCS

SO

SI

9 24 55 76

1.6VDC

12.5MHz

IC102

SYSCON

53 54

X101

IC404

SERVO

DSP

110

C SOX

2.4V p-p

1.6VDC

IC104

FLASH

ROM

PARALLEL

BUS

PARALLEL

BUS

IC402 1/3

LOADING

DRIVER

M001

TRAY

MOTOR

M

4TH GENERATION - INITIAL COMMUNICATIONS SYMPTOM 2/3

64

15DVD03 1305

1/8/01

Page 68

Fourth Generation DVD

The fourth generation DVD players consist of models DVP-S350, DVPS560, DVP-S560, DVP-S570, DVP-C660d and DVP-C670d.

Symptom 4: Multiple Symptoms -

1. No chroma from the S video output jack; or

65

If these input signals are present at the test points of the extender board

but not at the rear panel jacks, replace buffer IC101 on the bottom of the

AI board.

Alternate Test Procedure

You can also check for chroma leaving the MB board at IC502/pin 77

without disassembly. IC502 is located to the right of the tray/laser assembly and accessible while the player is fully assembled.

2. No component video (Y, B-Y, R-Y) output. The composite video output is OK in both cases.

Cause: Output Video Buffer IC101 failure

Repair Procedure

In the following steps you will remove the MB board from under the mechanism deck and use the jig to operate the board and the mechanism outside the unit. This way you can check the video signal entering the video

buffer and verify IC101’s defect.

1. You can damage the laser when unplugging the laser assembly. To

prevent this, either short out the laser diode with a solder blob on the

ribbon cable or use an anti static mat with a wrist strap.

2. Set up the jig (P/N J-6090-100A) to operate the MB board outside the

unit (you have to take out the MB board anyway to replace IC101 so it

will take an extra two seconds to check the signal and prove IC101 is

the cause of this symptom).

3. Press power ON, insert a disc and press the play button to keep the

unit powered ON.

4. Check IC101’s input signals at the extender board’s CN103 pins:

Signal Level * Test point name CN103/pin

Composite video 1Vp-p JL103 25

S Video - Chroma 0.6Vp-p JL104 21

S Video - Luminance 0.9Vp-p JL105 17

Component Y 0.9Vp-p JL107 4

* Typical level taken from four sample movies +0.1V.

R506

IC502

77

61

60

1

Tray/laser assembly

1. Turn the DVD player ON by pressing the power button. The player

will enter Standby (red light). Press tray open or play to power the unit

ON. The power supply will remain ON and the front panel display will

light.

2. Within two seconds after a communications check is completed, the

color DVD logo will appear on the TV screen. The logo is shortly

replaced by an “Insert Disc” message on a blue stripe. If the message

is in B&W, place your scope probe at the left side of R506 behind

IC502. If there is signal (chroma) present, Video Buffer IC101 on the

bottom of the AI-17 board is defective. IC502/pin 77 = 0.6Vp-p, 10usec/

div.

T

Chroma

H sync pulses

1

PKD

CH1 200mV= MTB10.0us- 0.88dv ch1-

IC502/pin 77 = 0.6Vp-p, 10usec/div.

Page 69

MB BD. AI-17 BD.

VIDEO

OUTPUT

RF

FROM

OPTICAL

ASSEMBLY

IC302

ARP

VIDEO V

VIDEO Y

IC101

IC502

A/V DECODER

VIDEO C

77

IC101

VIDEO

VIDEO

BUFFER

BUFFER

Y, R-Y,

B-Y

4TH GENERATION - SYMPTOM 4/5

Y

C

COMPOSITE

VIDEO

S VIDEO

Y

R-Y

B-Y

16DVD03 1303

1/8/01

66

Page 70

67

Extender Jig

P/N J-6090-100A

MECHANISM DECK

4TH GENERATION - SERVICE POSITION SYMPTOM 4

1/8/0117DVD03

Page 71

NOTES

68

Page 72

Fourth Generation DVD

The fourth generation DVD players consist of models DVP-S350, DVPS560, DVP-S560, DVP-S570, DVP-C660d and DVP-C670d.

Symptom 5:

Picture is distorted or there are Digital blocks that

appear during the movie.

Cause: A/V Decoder IC502

Repair procedure

In older DVD players this symptom is characteristic of a weak laser. In

this newer DVD player model, this picture-related symptom is caused by

the A/V Decoder defect. Much MPEG unscrambling now takes place in

one very complex A/V decoder instead of discrete parts, making it easier

to relate a picture problem to one part. Replace IC502.

69

Page 73

Fourth Generation DVD

The fourth generation DVD players consist of models DVP-S350, DVPS560, DVP-S560, DVP-S570.

Symptom 6: Tray does not Eject. Displays :”LOCKED”.

Cause: Nothing wrong with the unit. Tray is locked out in the display unit.

Use a SONY DVD remote to lock or unlock the tray.

Repair Procedure

Lock and unlock are the same procedures. Each time the code is entered, the unit alternates between lock and unlock.

Lock

1. Press the front panel power switch and wait two seconds for the unit

to enter standby (red light). With the unit in standby (red light), press

the following five buttons on the remote in this order:

• 1,

• Angle Change,

• Sub-Title Change,

• 9,

• Power.

Unlock

1. With the unit in standby (red light), press the following five buttons on

the remote in this order:

• 1,

• Angle Change,

• Sub-Title Change,

• 9,

• Power.

2. The locked display will no longer appear and the tray open button will

work normally.

2. The unit will come on. The tray will respond to the eject button. However, once a disc is detected, the tray will no longer respond to the

eject button. The display will show LOCKED each time the eject button is pressed.

70

Page 74

Test Mode - Third Generation

71

In checking the A/V Decoder (CDX1930 IC401), the OSD words

“CHG_COLCON” mean this part of the IC is OK.

The test mode allows you to diagnosis problems and make adjustments

using the remote commander and TV monitor. The instructions and results are given on the TV screen (OSD).

Test Mode Access

1. Plug in the DVD player,

2. Select DVD on the remote,

3. Aim the remote at the DVD player; and

4. Press the TITLE, CLEAR and POWER buttons one after another.

The red standby light changes to green and the blue Dolby Digital light will

come on. The display will momentarily flash DIAG START as IC202 retrieves the program from the flash ROM IC205.

Exit

To leave the test mode, turn the power off.

Tests

The initial test mode menu shows seven options. Selecting a number

enters that option level. You can navigate through each menu of that

level using the remote’s PREV or NEXT keys. The RETURN key brings

you to the previous level.

0. Syscon Diagnosis

This is a communications test between IC202 and IC on the parallel bus

and is similar to the quicker checks that occur during power ON. If the unit

powers on, it will usually pass this check.

Writing information in and reading the same information checks most ICs.

When the two match, the IC is deemed good. This testing occurs when

the TV screen changes to a blue background. The IC is good if the original menu reappears.

In this check, the remainder of the video IC401 is tested by producing a

video patterns to confirm operation. The audio IC501 is instructed to

produce individual audio tones to each channel.

1. Drive Auto Adjustment

Automatically plays the disc and reloads new data into EEProm IC201.

This is used when memory IC201 or the optical assembly is replaced.

Test discs are required for these adjustments. The Super Audio CD

(SACD) procedure is in this generic test program, but this DVD player

cannot play SACDs.

2. Drive Manual Adjustment

Servo adjustments stored in EEProm IC201 can be altered manually. This

operation is useful if you want to determine if the player can identify the

disc type as the first step in playing the disc.

Servo Usage - Automatic Disc Identification

Servos used Servos NOT used

Sled moves laser

outward slightly

Laser Tilt motor resets platform to mid position at

Focus Tracking

Spindle motor kick Spindle motor servo (lock)

Within the Manual Adjustment is a Servo Control subsection that permits

you to turn on each servo separately for observation. You can also play

the disc and observe an eye pattern when all servos are on (sled does not

come on in PB).

Sled moves laser assembly to home position

at Manual Adj. entry (pressing the # 2 button)

Manual Adj. entry (pressing the # 2 button)

3. Mechanical Aging

This mode cycles the tray in, and then momentary plays the disc for identification. The number of cycles and the disc type found is displayed on

the TV screen.

4. Emergency History

This is the most valuable diagnostic information in the test mode. The

last failure is recorded in EEProm IC201 and displayed on the TV. Ten

codes may all pertain to one failure that affects various parts of the DVD

circuitry that is monitored. An emergency code list is found in the service

manual.

Page 75

### Syscon Diagnosis ###

Check Menu

TEST MODE (3RD GEN)

### Mecha Aging ###

0. Quit

1. All

0

2. Version

3. Peripheral

4. Servo

5. Supply

6. AV Decoder

7. Video

8. Audio

## Drive Auto Adjustment ##

0. ALL

1. DVD-SL

1

2. CD

3. DVD-DL

4. SACD

## Drive Manual Operation ##

1. Disc Type

2. Servo Control

3. Track/Layer Jump

2

4. Manual Adjustment

5. Auto Adjustment

6. Memory Check

0. Disc Check Memory

Adjustment Menu

Exit: RETURN

Operation Menu

Exit: RETURN

TEST MODE ACCESS

With the unit in standby, press

these 3 buttons on the remote at

the same time:

• TITLE

• CLEAR

• POWER

Test Mode Menu

0. Syscon Diagnosis

1. Drive Audo Adjustment

2. Drive Manual Operation

3. Mecha Aging

4. Emergency History

5. Version Information

6. Video Level Adjustment

Exit: Power Key

_

Model: DPX1230UC

Revision: 1.500

On Screen Display

Press OPEN key

Abort: STOP key

### EMG. History ###

Laser Hours CD 0h

DVD 2h

1. 82 05 01 06 00 61 00 00

00 00 00 00 00 00 00 00

2. 63 68 01 04 04 00 03 3F

68 00 03 00 00 FE FF 00

Select: 1 - 9 Scroll: UP/Down

(1: Last EMG.) Exit: Return

## Version Information ##

IF con. Ver. 1.000 (D6FD)

Group 02

SYScon. Ver. 1.500 (DOB5)

Model 20

Region 01

Servo DSP Ver. 1.000

Exit: RETURN

3

4

5

72

Page 76

APPENDIX

Page 77

i

y

Sony DVD Service Bulletin List - page 1/2

Applicable Models DVP -

Number Title S300 S330 S350/S360 S500d S530d S550d S560d S570d

43R2 No PB or PB stops

44 Intermittant sound

45 Intermittant color lock

46 Intermittant DVD PB

47 No Dual layer disc PB

48 Replacement TT-40 Bd

49 No test mode adjust

50 Background noise X X

51 Intermittant No Power On X X

52 No Dual layer disc PB

53 Button clicking noise in spks X X

54R1 Misc Video problems X X

No karaoke sound

55 Stops/pauses when X X

playing dual layer discs

57 Powers off after 2 secs X

58R1 Freezes at language change X

59 New test disc P/N X X X X X X X X

60 Pwr ON with E:07:00 X X

61 Lip sync / no subtitles X X X

62R1 Powers off after 2 secs X X

63R1 Powers off after spindle rotates X X X

No eject or loading

64 Tray doesn’t open (E:27 code)

65 Can’t plug in new optical pickup X X

66 Installing+B72 table loading part 102

68 "No disc" displa

or C:13:00 X X X

Page 78

y

Sony DVD Service Bulletin List - page 2/2

Applicable Models DVP Number Title C600d C650d C660 C670d S3000 S7000 S7700

43R2 No PB or PB stops X X

44 Intermittant sound X

45 Intermittant color lock X

46 Intermittant DVD PB X

47 No Dual layer disc PB X

48 Replacement TT-40 Bd X X

49 No test mode adjust X X

50 Background noise

51 Intermittant No Power On X

52 No Dual layer disc PB X X

53 Button clicking noise in spks

54R1 Misc Video problems X X

No karaoke sound

55 Stops/pauses when

playing dual layer discs

57 Powers off after 2 secs

58R1 Freezes at language change

59 New test disc P/N X X X X X X X

60 Pwr ON with E:07:00 X

61 Lip sync / no subtitles X

62R1 Powers off after 2 secs X

63R1 Powers off after spindle rotates X

No eject or loading

64 Tray doesn’t open (E:27 code) X

65 Can’t plug in new optical pickup

66 Installing table loading part 102 X X

68 "No disc" displa

or C:13:00 X X

ii

Page 79

y

S

Sony Service Company

National Technical Services

A Division of Sony Electronics Inc.

Park Ridge, New Jersey 07656

CONFIDENTIAL

Service Bulletin

Multi-Disc Pla

ers

csv-5

Model: DVP-S3000, DVP-S7000

Subject: NO PLAY OR PICTURE MAY STOP DURING

No.

Date:

October 26, 1999

PLAYBACK OF CERTAIN DVD TITLES.

Symptom:

(111A)

DVD disc-title Signal

AMERICAN The

Land of Nature

(IBMP-60002)

This symptom occurs when the DVD has played more than 7 minutes and before 27

Note:

minutes and 57 seconds. This countermeasure may apply to other titles not listed.

On occasion, Playback may stop, or No Play occurs, when a particular DVD

title is used. For example,

SYSCON ROM should be upgraded to

another DVD title that has this problem.

Version 1.8. If units require the SYSCON upgrade , then upgrade is done as

in warranty, regardless of warranty status.

Format

NTSC 42

The Man Who Fell To Earth", "The Matrix".

Version 1.8.

Autoflagg

Play time Region code

ALL

minutes

The description below is

the Sycon Rom if it is not

43R2

The

iii

Solution:

Model Part

DVP-S3000 8-759-526-

DVP-S7000 8-759-526-

Applicable Range: Dvps7000 ,

Replace IC 093 on the MB-80 or MB-75 board depending on model.

number

93

59

Description Version

IC

MX23C4100MC

-10-D7

ICMX23C8100MC

-10-D6

up to 826494,above 826494 should have 1.8

Ver 1.80

Ver 1.80

Page 80

y

S

Sony Service Company

National Technical Services

A Division of Sony Electronics Inc.

Park Ridge, New Jersey 07656

CONFIDENTIAL

Service Bulletin

Multi-Disc Pla

ers

csv-5

Model: DVP-S7000

Subject: INTERMITTENT SOUND

Symptom:

When DVD or Video CD playback is selected, line audio output and

CASE 2

Replace IC 380 with CXD8603BR on the MB-75 board.

REF DESCRIPTION PART

IC380 ICCXD8603BR 8-759-490-29

iv

(257)

Solution:

CASE 1:

digital audio output may have intermittent sound. When in CD mode there is

no problem.

playback, the digital audio output may have intermittent sound. The line audio

output in this case will be normal.

CASE 1:

No.

Date:

: When using a Kenwood Amp in DVD, Video CD, or CD

NUMBER

44

January 5, 1998

CASE 2

problem. If the cable is good, and the DVP-S7000 is good, the problem could

be the Kenwood Amp.

NOTE

Please make sure that the digital audio cable does not have a

: Ask the customer the manufacturer of the amplifier.

Applicable Serial No’s 80001 to 815644

Page 81

y

S

Sony Service Company

National Technical Services

A Division of Sony Electronics Inc.

Park Ridge, New Jersey 07656

CONFIDENTIAL

Service Bulletin

Multi-Disc Pla

ers

csv-5

Model: DVP-S7000

Subject: COLOR NOT LOCKING

Symptom:

(247)

Solution:

The color lock may become intermittent. After a few minutes of DVD play, the

colors may start to change. If the symptom is appearing, check the following.

1. Connect an Oscilloscope probe to TP021. If the waveform is not phaselocked, X003 is defective.

2. If the symptom is not appearing, you still should check 27MHz free run

frequency adjustment (Refer to SM page 7-2)

If you do have this color lock problem, replace the crystal X003 on the MB-75.

The part number is

free run frequency of 27MHz.

(1-767-401-11)

No.

Date:

. Next, refer to SM page 7-2 and adjust

45

January 5, 1998

v

Page 82

y

S

Sony Service Company

National Technical Services

A Division of Sony Electronics Inc.

Park Ridge, New Jersey 07656

CONFIDENTIAL

Service Bulletin

Multi-Disc Pla

ers

csv-5