Page 1

DSC-T70/T75

SERVICE MANUAL

Ver. 1.0 2007.08

Revision History

Revision History

Internal memory

Internal memory

ON BOARD

ON BOARD

Photo: Silver

Link

Link

SPECIFICATIONS

DISASSEMBLY

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Korea Model

Argentine Model

Brazilian Model

Japanese Model

Tourist Model

SCHEMATIC DIAGRAMS

MODEL INFORMATION TABLE

SERVICE NOTE

• Precaution on Replacing the SY-183 Board

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

BLOCK DIAGRAMS

FRAME SCHEMATIC DIAGRAM

PRINTED WIRING BOARDS

REPAIR PARTS LIST

DIGITAL STILL CAMERA

DSC-T70/T75_L2

Sony EMCS Co.

2007H0800-1

© 2007.08

Published by Kohda TEC9-852-216-31

Page 2

SPECIFICATIONS

Camera

[System]

Image device: 7.18 mm (1/2.5 type) color CCD,

Primary color filter

Total pixel number of camera:

Approx. 8 286 000 pixels

Effective pixel number of camera:

Approx. 8 083 000 pixels

Lens: Carl Zeiss Vario-Tessar 3× zoom lens f =

6.33 – 19.0 mm (38 – 114 mm when

converted to a 35 mm still c amera) F3. 5 – 4.3

Exposure control: Automatic exposure, Scene

Selection (10 modes)

White balance: Automatic, Daylight, Cloudy,

Fluorescent 1, 2, 3, Incandescent, Flash

File format (DCF compliant):

Still images: Exif Ver. 2.21 JPEG compliant,

DPOF compatible

Movies: MPEG1 compliant (Monaural)

Recording media: Internal Memory (approx.

31 MB), “Memory Stick Duo”

Flash: Flash range (ISO sensitivity

(Recommended Exposure

Index) set to Auto): approx. 0.1 to 3.0 m

(4 inches to 9 feet 10 1/8 inches) (W)/

approx. 0.25 to 2.5 m (9 7/8 inches to

8 feet 2 1/2 inches) (T)

[Input and Output connectors]

Multi connector

USB communication : Hi-Speed USB (USB 2.0

: Video output

Audio output (Monaural)

USB communication

compliant)

[LCD screen]

LCD panel: Wide (16:9), 7.5 cm (3.0 type) TFT drive

Total number of dots: 230 400 (960×240) dots

[Power, general]

Power: Rechargeable battery pack NP-BD1, 3.6 V

NP-FD1 (not supplied), 3.6 V

AC-LS5K AC Adaptor (not supplied), 4.2 V

Power consumption (during shooting): 1.0 W

Operating temperature: 0 to 40 ºC (32 to 104 ºF)

Storage temperature: –20 to +60 ºC(–4 to +140 ºF)

Dimensions: 90.0×56.4×20.7 mm (3 5/8×

2 1/4×27/32 inches) (W/H/D, excluding

protrusions)

Mass (including NP-BD1 battery pack, paint pen

and strap etc.): Approx. 156 g (5.5 oz)

Microphone: Monaural

Speaker: Monaural

Exif Print: Compatible

PRINT Image Matching III: Compatible

PictBridge: Compatible

BC-CSD battery charger

Power requirements: AC 100 V to 240 V, 50/60 Hz,

2.2 W

Output voltage: DC 4.2 V, 0.33 A

Operating temperature: 0 to 40 ºC (32 to 104 ºF )

Storage temperature: –20 to +60 ºC (–4 to +140 ºF)

Dimensions: Approx. 62×24×91 mm (2 1/2×

31/32×3 5/8 inches) (W/H/D)

Mass: Approx. 75 g (2.7 oz)

Rechargeable battery pack NP-BD1

Used battery: Lithium-ion battery

Maximum voltage: DC 4.2 V

Nominal voltage: DC 3.6 V

Capacity : 2.4 Wh (680 mAh)

Design and specifications are subject to change

without notice.

DSC-T70/T75_L2

— 2 —

Page 3

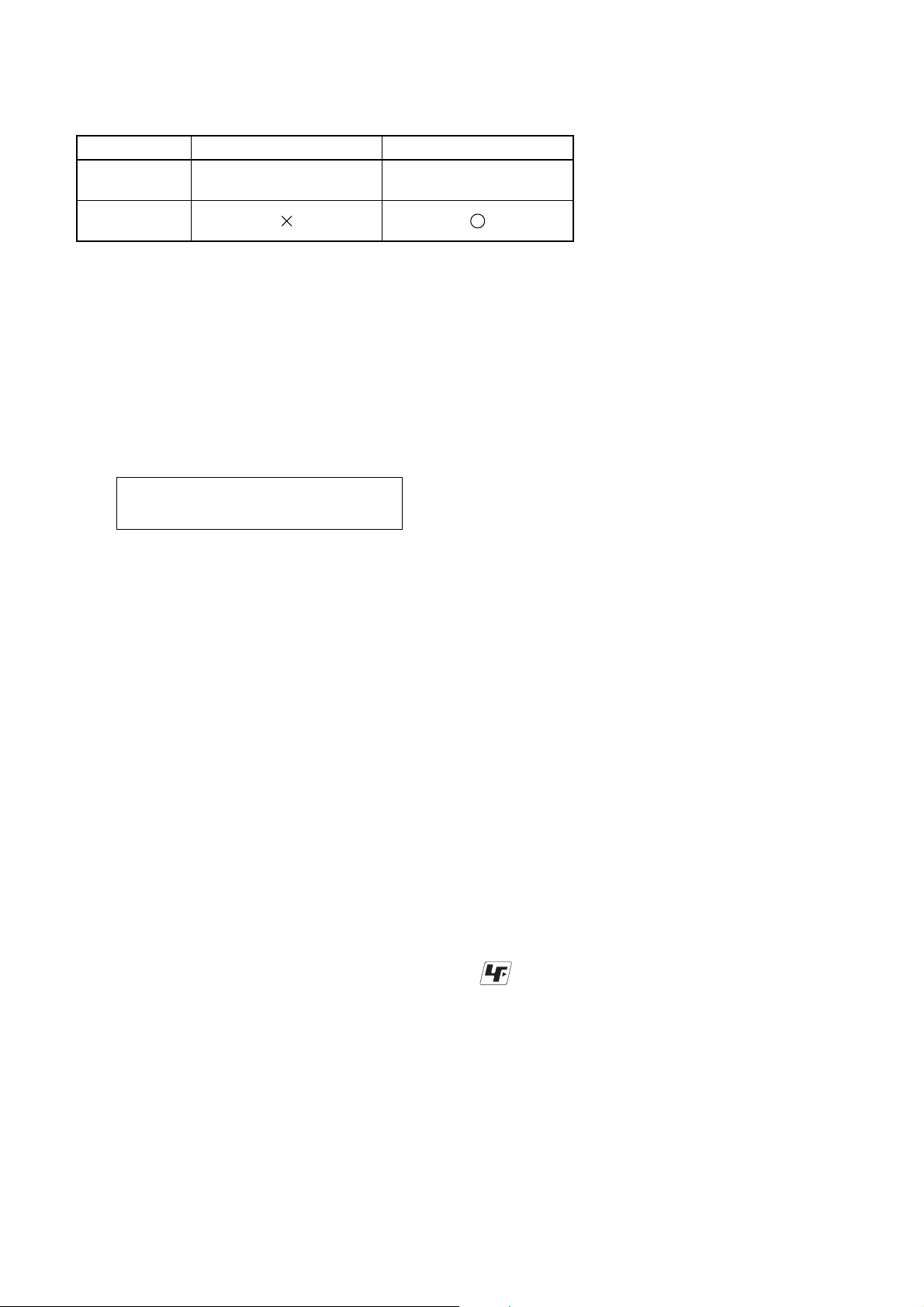

Model information table

Model

Destination

US, CND, AEP, UK, E, AUS,

HK, CH, KR, AR, BR, J, JE

DSC-T70

AEP, UK, E, KR

HD Output

Adaptor Cable

•Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

CH : Chinese model

CND: Canadian model

EE : East European model

HK : Hong Kong model

J: Japanese model

JE : Tourist model

KR : Korea model

MX : Mexican model

NE : North European model

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

CAUTION

DSC-T75

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. FLEXIBLE Circuit Board Repairing

•Keep the temperature of the soldering iron around 270°C

during repairing.

•Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

•Be careful not to apply force on the conductor when soldering

or unsoldering.

DSC-T70/T75_L2

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

Page 4

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. PRECAUTION ON REPLACING THE SY-183 BOARD

DESTINATION DATA

When you replace to the repairing board, the written destination data of repairing board also might be changed to original setting.

Refer to Service Manual ADJ, and perform “DESTINATION DATA WRITE”.

USB SERIAL No.

The set is shipped with a unique ID (USB Serial No.) written in it.

This ID has not been written in a new board for service, and therefore it must be entered after the board replacement.

Refer to Service Manual ADJ, and perform “USB SERIAL No. INPUT”.

1-2. SELF-DIAGNOSIS FUNCTION

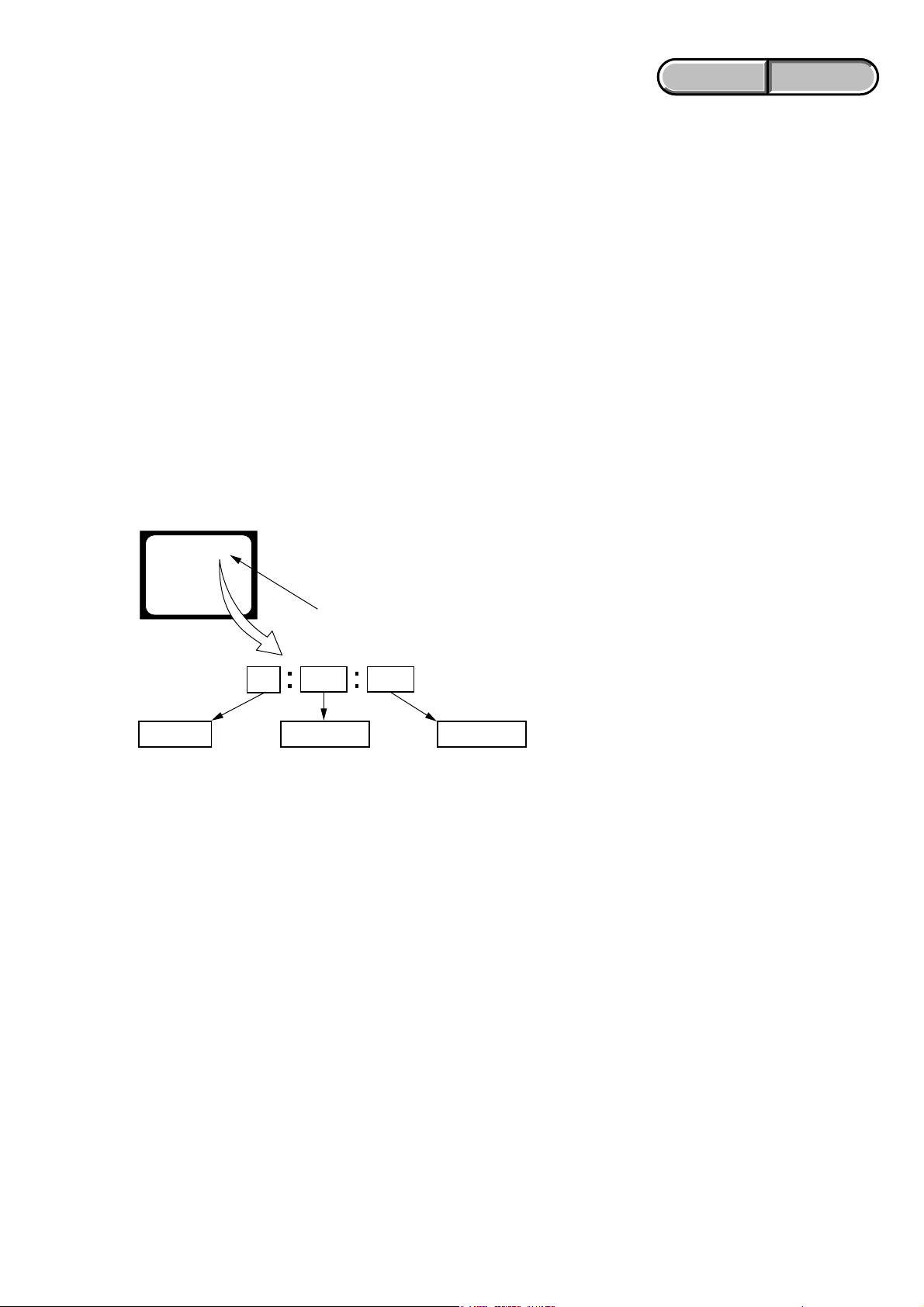

1-2-1. Self-diagnosis Function

When problems occur while the unit is operating, the self-diagnosis

function starts working, and displays on the LCD screen what to

do.

Details of the self-diagnosis functions are provided in the Instruction

manual.

LCD screen

Blinks at 3.2 Hz

0 0

Refer to “1-2-3. Self-diagnosis Code Table”.

Repaired by:

C : Corrected by customer

E : Corrected by service

engineer

3 2C

Block

Indicates the appropriate

step to be taken.

E.g.

13 ....Form a t t h e “ Memory Stick Duo”.

32 ....Turn o n power again.

1-2-2. Self-diagnosis Display

When problems occur while the unit is operating, the LCD screen

shows a 4-digit display consisting of an alphabet and numbers, which

blinks at 3.2 Hz. This 5-character display indicates the “repaired

by:”, “block” in which the problem occurred, and “detailed code”

of the problem.

Detailed Code

DSC-T70/T75_L2

1-1

Page 5

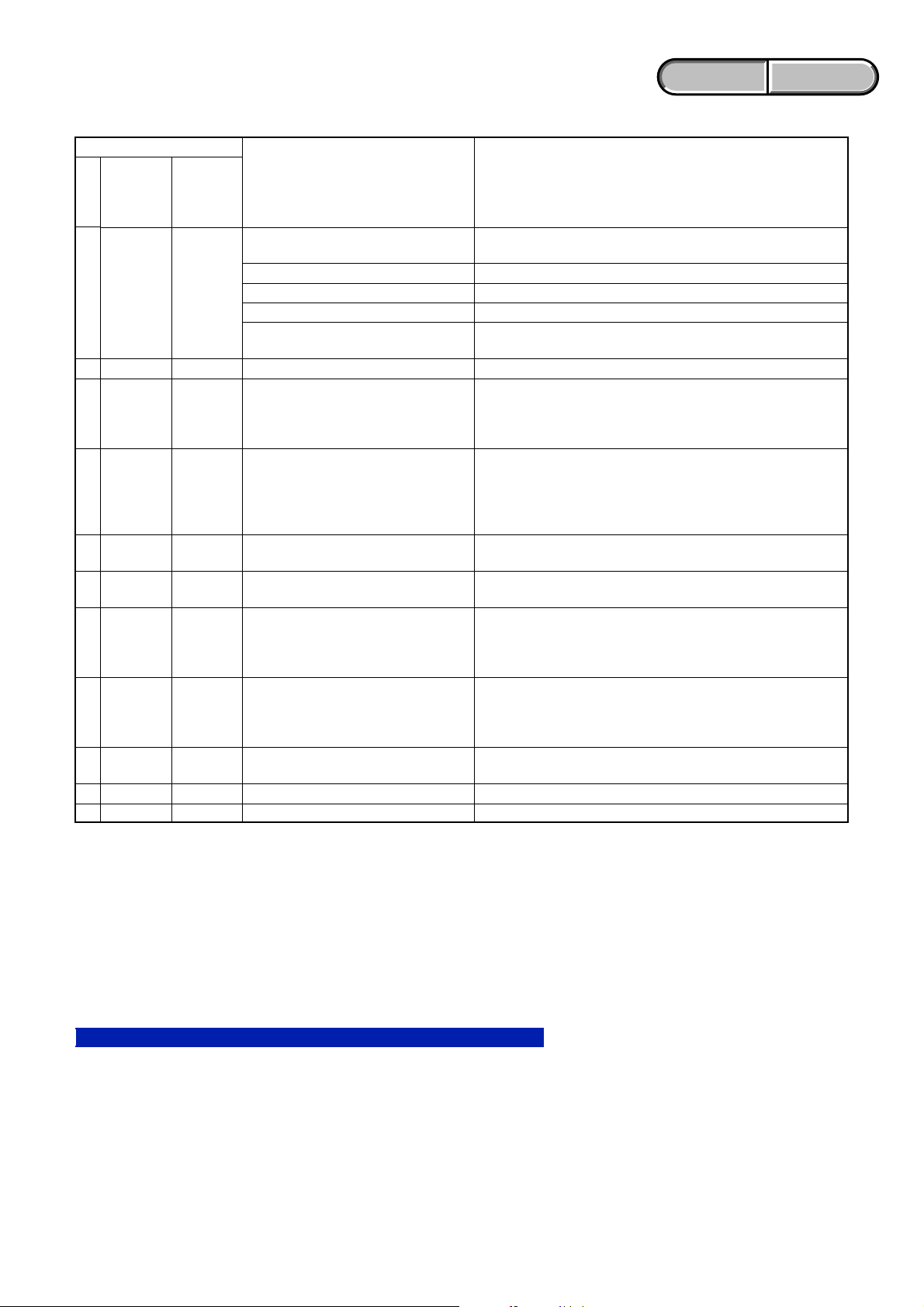

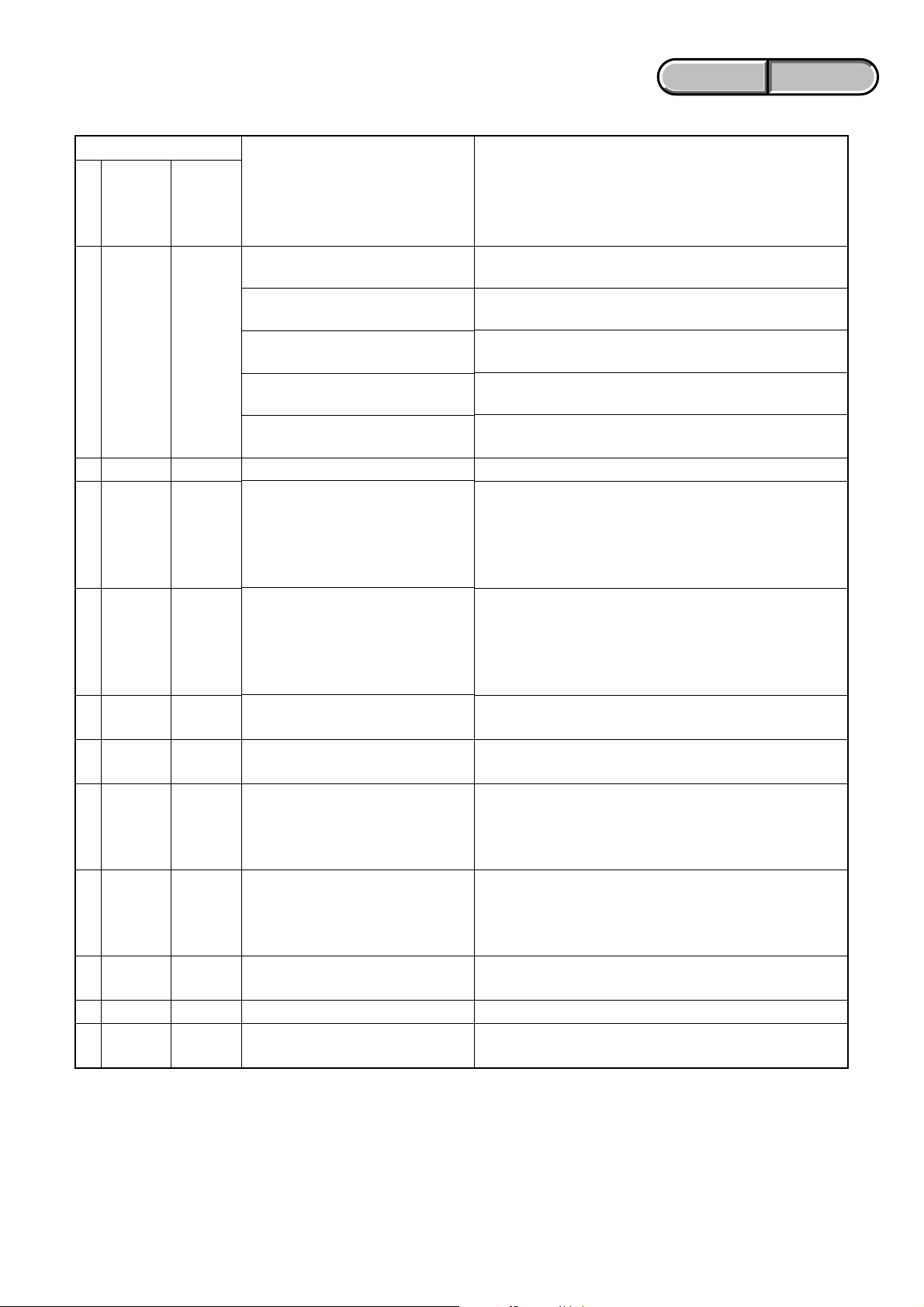

1-2-3. Self-diagnosis Code Table

Self-diagnosis Code

ENGLISH JAPANESE

ENGLISH JAPANESE

Function

Repaired by:

C

C

Block

13

32

Detailed

Code

01

01

Symptom/State

The internal memory has experienced a

format error.

“Memory Stick Duo” is unformatted.

“Memory Stick Duo” is broken.

“Memory Stick Duo” type error

The camera cannot read or write data

on the “Memory Stick Duo”.

Trouble with hardware

Format the internal memory.

Format the “Memory Stick Duo”.

Insert a new “Memory Stick Duo”.

Insert a supported “Memory Stick Duo”.

Turn the power off and on again, or taking out and inserting the

“Memory Stick Duo” several times.

Turn the power off and on again.

Retry turn the power on by the power switch. If it does not

E

61

00

Difficult to adjust focus

(Cannot initialize focus)

recover, check the focus reset sensor of lens block (pin ea of

CN401 on the SY-183 board). If it is OK, check the focus motor

drive IC (IC401 on the SY-183 board).

Retry turn the power on by the power switch. Check the zoom

reset sensor of lens block (pin wk of CN401 on the SY-183

board), if zooming is performed when the zoom button is

operated. If it is OK, check the zoom motor drive IC (IC401 on

E

61

10

Zoom operations fault

(Cannot initialize zoom lens.)

the SY-183 board).

E

E

62

62

02

10

Abnormality of IC for steadyshot.

Lens initializing failure.

Check or replacement of the IC for steadyshot (IC503 on the SY183 board).

Check or replacement of the IC for steadyshot (IC503 on the SY183 board).

Check the HALL element (PITCH) of optical image stabilizer

E

62

11

Lens overheating (PITCH).

(pin 1, 2 of CN401 on the SY-183 board). If it is OK, check

PITCH angular velocity sensor (SE502 on the SY-183 board)

peripheral circuits.

Check the HALL element (YAW) of optical image stabilizer (pin

E

62

12

Lens overheating (YAW).

6, 7 of CN401 on the SY-183 board). If it is OK, check YAW

angular velocity sensor (SE501 on the SY-183 board) peripheral

circuits.

E

E

E

62

91

92

20

01

00

Abnormality of thermistor.

Abnormality when flash is being charged.

Non-standard battery is used.

Check the OIS temp sensor of optical image stabilizer (pin 5 of

CN401 on the SY-183 board).

Checking of flash unit or replacement of flash unit. (Note)

Use the compatible battery only.

Note: After repair, be sure to perform “1-3. PROCESS AFTER FIXING FLASH ERROR”.

Correction

1-3. PROCESS AFTER FIXING FLASH ERROR

When “FLASH error” (Self-diagnosis Code E : 91 : 01) occurs, to prevent any abnormal situation caused by high voltage, settin g of the flash

is changed automatically to disabling charge and flash setting.

After fixing, this setting needs to be deactivated. Flash error code can be initialized by the operations on the HOME screen.

Method for Initializing the Flash Error Code

Initialize

Initializes the setting to the default setting. Even if you execute this function, the images

stored in the internal memory are retained.

1 Touch [Initialize].

The message “Initialize all settings” appears.

2 Touch [OK].

The settings are reset to the default setting.

To cancel the resetting

Touch [Cancel] or [BACK] in step 2.

•Make sure that the power is not disconnected during resetting.

DSC-T70/T75_L2

1-2

Page 6

ENGLISH JAPANESE

ENGLISH JAPANESE

1-4. METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

The data can be copied/erased by the operations on the HOME screen. (When erasing the data, execute formatting the internal memory.)

Note 1: When replacing the SY-183 board, erase the data in internal memory of the board before replacement.

Method for Copying the Data in Internal Memory

Copy

Copies all images in the internal memory to a “Memory Stick Duo”.

1 Insert a “Memory Stick Duo” with sufficient capacity.

2 Touch [Copy].

The message “All data internal memory will be copied” appears.

3 Touch [OK].

Copy starts.

To cancel the copying

Touch [Cancel] or [BACK] in step 3.

•Use a fully charged battery pack. If you attempt to copy image files using a battery pack with little

remaining charge, the battery pack may run out, causing copying to fail or possibly corrupting the data.

•You cannot copy individual images.

•The original images in the internal memory are retained even after copying. To delete the contents of the

internal memory, remove the “Memory Stick Duo” after copying, then execute the [Format] command in

[ Internal Memory Tool ] .

•When you copy the data in the internal memory to the “Memory Stick Duo”, all the data will be copied.

You cannot choose a specific folder on the “Memory Stick Duo” as the destination for the data to be

copied.

•Even if you copy data, a DPOF (Print order) mark is not copied.

Method for Formatting the Internal Memory

This item does not appear when a “Memory Stick Duo” is inserted in the camera.

Format

Formats the internal memory.

•Note that formatting irrevocably erases all data in the internal memory, including even protected images.

1

Touch [Format].

The message “All data internal memory will be erased” appears.

2

Touch [OK].

The format is completed.

To cancel the formatting

Touch [Cancel] or [BACK] in step 2.

DSC-T70/T75_L2

1-3

Page 7

ENGLISH JAPANESE

ENGLISH JAPANESE

1-5. HOW TO WRITE DATA TO INTERNAL MEMORY

Usually, the camera has been set so as to disable the data writing from the PC to the internal memory of the camera.

This setting must be changed temporarily when the data is to be written to the internal memory such as a case after the board replacement.

To change the setting, use the write enable tool “WriteEnableTool.exe”.

Data writing method

1) Connect the PC to the camera (USB mode: Mass Storage), and switch the driver to the “Sony Seus USB Driver”.

2) Start the Write Enable Tool and the SeusEX.

3) Click the [Activate Write Enable Mode] button of the Write Enable Tool.

4) Upon completion of the setting change, the following message will be displayed.

5) Return the driver to the original one, and connect the PC to the camera (USB mode: Mass Storage).

6) Write the data read out into the PC to the internal memory of the camera.

7) Disconnect the PC from the camera, and turn off the camera.

Note: By turning off the camera, the write enable setting is reset.

DSC-T70/T75_L2

1-4

Page 8

ENGLISH JAPANESE

1. SERVICE NOTE

ENGLISH JAPANESE

1-1. SY-183基板交換時の注意

仕向けデータ

補修用基板と交換する時,補修用基板に書かれている仕向けデータは元の設定と違っている場合があります。

ADJ編を参照して,「DESTINATIONDATAWRITE」を行ってください。

USBシリアルNo.

セットは,1台毎に異なる固有のID(USBSerialNo.)を書き込んだ後,出荷されています。

新品の補修用基板には,このIDが書き込まれていないので,基板交換後にIDを入力する必要があります。

ADJ編を参照して,「USBSERIALNo.INPUT」を行ってください。

1-2. 自己診断機能

1-2-1. 自己診断機能について

本機の動作に不具合が生じたとき,自己診断機能が働き,

LCD画面に,どう処置したらよいか判断できる表示を行い

ます。自己診断機能については取扱説明書にも掲載されて

います。

LCD画面

C : 3 2 : 00

1-2-2. 自己診断表示

本機の動作に不具合が生じたとき,LCD画面にアルファベッ

トと4桁の数字が表示され,3.2Hzで点滅します。この5文字

の表示によって対応者分類および不具合の生じたブロックの

分類,不具合の詳細コードを示します。

3.2Hz点滅

3 2C

対応者分類

C :お客さま自身で対応

E :サービスエンジニア

で対応 デュオ”をフォーマッ

ブロック分類

対応方法の違いにより分類

例 13 ・・・“メモリースティック

トする

32 ・・・電源を入れ直す

0 0

詳細コード

「1-2 -3 . 自己診断コード表」

を参照

DSC-T70/T75_L2

1-5

Page 9

1-2-3. 自己診断コード表

自己診断コード

対

応

者

ブロック

機能

詳細

コード

症状/状態

ENGLISH JAPANESE

ENGLISH JAPANESE

対応/方法

C

C

E

E

E

E

E

E

E

E

E

13

32

61

61

62

62

62

62

62

91

92

01

01

00

10

02

10

11

12

20

01

00

内蔵メモリにフォーマットエラーが

あった。

フォーマットしていないメモリー

スティックデュオを入れた。

メモリースティックデュオが

壊れている。

メモリースティックデュオの

タイプエラーを検出した。

メモリースティックデュオが

読み/書きできない。

ハードウェアトラブルを検出した。

フォーカスが合いにくい。

(フォーカスの初期化ができない)

ズーム動作の異常。

(ズームレンズの初期化ができな

い)

手振れ補正用ICの異常。

手振れ補正用ICの異常。

(レンズ初期化異常)

レンズオーバーヒート(PITCH)

レンズオーバーヒート(YAW)

サーミスタの異常。

フラッシュの充電異常。

規定外の充電池が使用された。

内蔵メモリをフォーマットする。

メモリースティックデュオをフォーマットする。

新しいメモリースティックデュオに交換する。

規格内のメモリースティックデュオを挿入する。

電源の入れ直し,またはメモリースティックデュオ

の挿し/外しを数回試す。

電源を入れ直す。

操作スイッチの電源を入れ直す。

復帰しない場合はレンズブロックのフォーカスリセットセ

ンサ(SY-183基板CN401eaピン)を点検する。異常なけ

ればフォーカスモータ駆動IC(SY-183基板IC401)を点検

する。

操作スイッチの電源を入れ直す。

ズームボタンを操作したときにズーム動作をすればレンズ

ブロックのズームリセットセンサ(SY-183基板CN401wk

ピン)を点検する。異常なければズームモータ駆動IC

(SY-183基板IC401)を点検する。

手振れ補正用IC(SY-183基板IC503)を点検または交換す

る。

手振れ補正用IC(SY-183基板IC503)を点検または交換す

る。

光学手振れ補正ブロックのホール素子(PITCH)(SY-183

基板CN4011,2ピン)を点検する。異常なければ

PITCH角速度センサ(SY-183基板SE502)周辺の回路を点

検する。

光学手振れ補正ブロックのホール素子(YAW)(SY-183

基板CN4016,7ピン)を点検する。異常なければYAW

角速度センサ(SY-183基板SE501)周辺の回路を点検す

る。

光学手振れ補正ブロックのサーミスタ(SY-183基板CN401

5ピン)を点検する。

フラッシュユニットを点検または交換する。(Note)

規定の充電池を使用する。

Note:交換後は,必ず「1-3.フラッシュ異常修理後の処置」を行って下さい。

DSC-T70/T75_L2

1-6

Page 10

ENGLISH JAPANESE

ENGLISH JAPANESE

1-3. フラッシュエラー発生時の対処法

本機はフラッシュエラー(自己診断コードE:91:01)が発生した場合,高電圧による異常を防止するために自動的にフラッシュ

充電および発光禁止の設定になります。

フラッシュエラー発生後はエラーの解除を行う必要があります。エラーの解除はホーム画面から初期化操作を実行することによ

り行います。

設定リセット

お買い上げ時の設定に戻します。

[設定リセット]を実行しても、内蔵メモリーに記録されている画像は削除されません。

1

[設定リセット]をタッチする。

[全ての設定内容をリセットし ます ]というメッセージが表示 される。

[実行]をタッチする。

2

設定リセットが 実行される。

設定リセットを中止するには

手順2で、[キャンセル]または[BACK]をタッチする。

設定リセット中は電源が切れないようにご注意ください。

1-4. 内蔵メモリのデータコピーおよび消去方法

内蔵メモリのデータコピーまたは消去はホーム画面の操作から実行可能です。(消去する場合は内蔵メモリの初期化を行いま

す。)

Note1:SY-183基板交換の際は,基板交換前に内蔵メモリのデータを消去して下さい。

内蔵メモリのコピー方法

コピー

内蔵メモリーに記録した画像を、メモリースティック デュオに一括コピーします。

1

充分な空き容量のあるメモリースティック デュオ を本体に入れる。

[コピー]をタッチする。

2

「内蔵メモリーのデータがすべてコピーされます」というメッセージが表示される。

3

[実行]をタッチする。

コピーが実行される。

コピーを中止するには

手順3で、[キャンセル]または[BACK]をタッチする。

•

充分に充電したバッテリーをご使用ください。残量の少ないバッテリーを使用して画像ファイ

ルをコピーすると、バッテリー切れのため、データを転送できなかったり、データを破損するお

それがあります。

•

画像ごとのコピーはできません。

•

データをコピーしても、内蔵メモリー内のデータは削除されません。内蔵メモリーの内容を消

去するには、 コピー後にメモリースティック デュオを本体から取りはずし、[内蔵メモ

リーツール]の[フォーマット]を行ってください 。

•

データのコピーをすると、メモリースティックデュオ内に新しいフォルダが作成されます。

コピー先のフォルダを指定することはできません。

•

データのコピーを行っても、

(プリント予約)マークの設定はコピーされません。

DPOF

内蔵メモリのフォーマット方法

“メモリースティックデュオ” が本機に入っている場合は表示されません。

フォーマット

内蔵メモリーの管理領域をフォーマット(初期化)します。

フォーマットすると、プロテクトしてある画像も含めて、すべてのデータが消去され、元に戻せ

ません。

1

[フォーマット]をタッチする。

「内蔵メモリーのデータがすべて消去されます」というメッセージが表示される。

[実行]をタッチする。

2

フォーマットを中止するには

手順2で、[キャンセル]または[BACK]をタッチする。

DSC-T70/T75_L2

1-7

Page 11

ENGLISH JAPANESE

ENGLISH JAPANESE

1-5. 内蔵メモリへデータを書き戻す方法

通常は,PCからカメラの内蔵メモリへデータを書き込むことはできない設定になっています。

基板交換後などに,内蔵メモリへデータを書き戻す場合には,この設定を一時的に変更する必要があります。

設定の変更には,書き込み許可ツール(WriteEnableTool.exe)を使用します。

書き戻し方法

1) カメラとPCをマスストレージ接続し,ドライバを"SonySeusUSBDriver"に切り替える。

2) 書き込み許可ツールとSeusEXを起動する。

3) 書き込み許可ツールの[Activate Write Enable Mode]ボタンをクリックする。

4) 設定の変更が終了すると,次のメッセージが表示されます。

5) ドライバを元に戻して、カメラとPCをマスストレージ接続する。

6) PCに読み出しておいたデータをカメラの内蔵メモリに書き込む。

7) カメラとPCの接続を解除し,カメラの電源をOFFにする。

注意:カメラの電源をOFFにすることにより,書き込み許可の設定が解除されます。

DSC-T70/T75_L2

1-8E

Page 12

NOTE FOR REPAIR

2. DISASSEMBLY

• Make sure that the flat cable and flexible board are not cracked of bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

• When remove a connector, don’t pull at wire of connector. It is possible that a wire is snapped.

• When installing a connector, don’t press down at wire of connector.

It is possible that a wire is snapped.

• Do not apply excessive load to the gilded fle xible board.

Cut and remove the part of gilt

which comes off at the point.

(Be careful or some

pieces of gilt may be left inside)

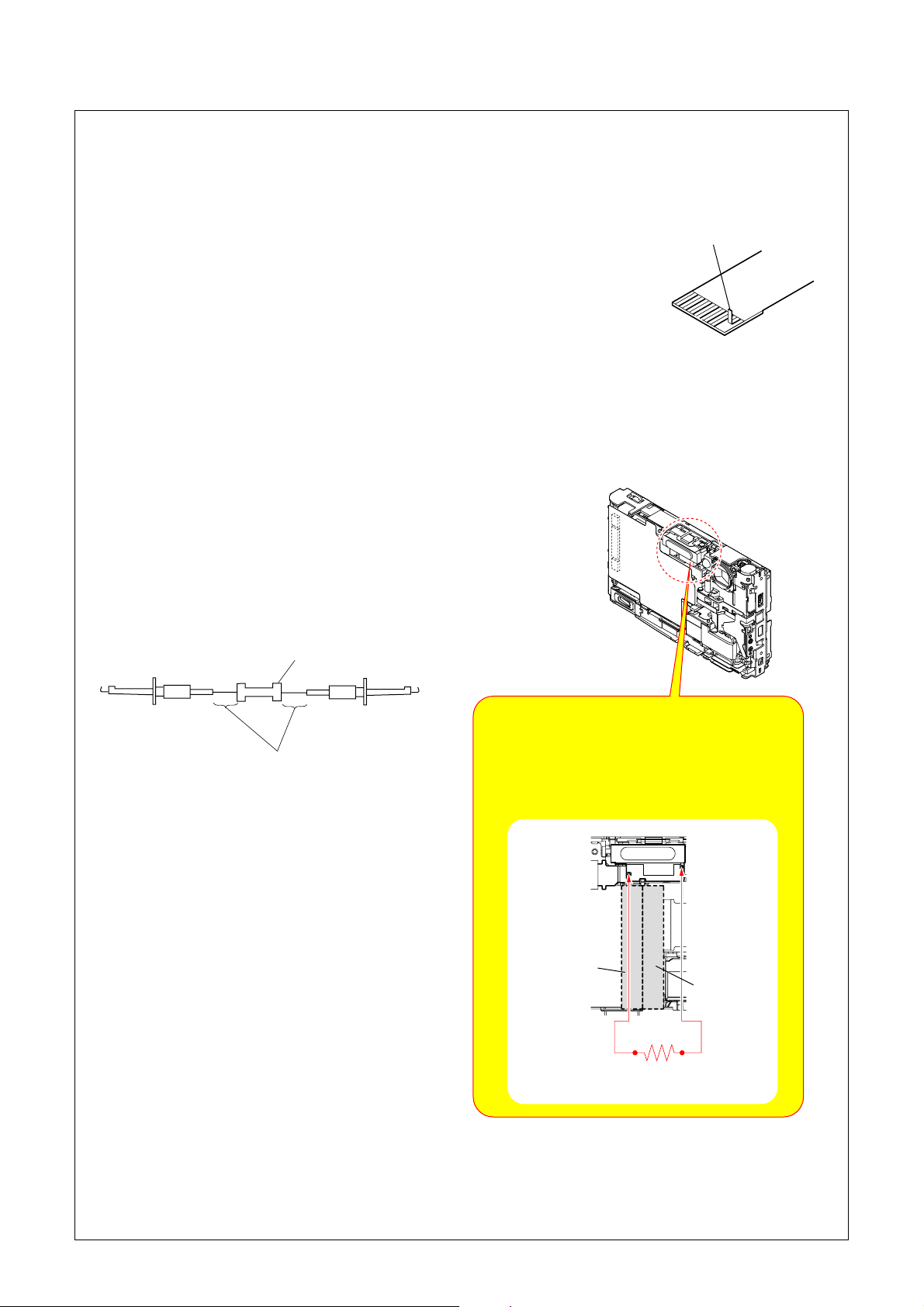

DISCHARGING OF THE ST-172 BOARD’S CHARGING CAPACITORS (C901, C902)

The charging capacitors (C901, C902) of the ST-172 board is

charged up to the maximum 315 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by

the charged voltage which is kept without discharg ing when the

main power of the unit is simply turned off. Therefore, the

remaining voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig, a small clip is attached to each end of

a resistor of 1 kΩ /1 W (1-215-869-11).

Wrap insulating tape fully around the leads of the resistor to

prevent electrical shock.

1 kΩ/1 W

Wrap insulating tape.

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points with the

short jig about 10 seconds.

To avoid the spark with the metal plate,

wrap the short jig with the insulation tape.

C902

C901

R:1 kΩ/1 W

(Part code: 1-215-869-11)

DSC-T70/T75_L2

2-1

Page 13

2-1. IDENTIFYING PARTS

SY-183 Board

MC-185 Flexible Board

Cabinet (Rear) Assy

Control Switch Block

(RL60570)

LCD Block

Battery Holder Assy

⋅ BT-039 Flexible Board

⋅ ST-172 Flexible Board

Cabinet (Front) Assy

- DISASSEMBLY FLOW -

2-2-1. OVERALL SECTION

- Cabinet (Front) Assy

- Cabinet (Rear) Assy

- LCD Block

2-2-2. SY-183 BOARD SECTION

- Lens Block

- MC-185 Flexible Board

- SY-183 Board

2-2-3. BATTERY HOLDER SECTION

- Flash Block

- BT-039 Flexible Board

- Battery Holder Assy

Lens Block

⋅ CD-710 Flexible Board

DSC-T70/T75_L2

2-2

Page 14

HELP

EXPLODED VIEW

HELP

2-2. DISASSEMBLY

2-2-1. OVERALL SECTION

Follow the disassembly in the numerical order given.

1 Cabinet (Front) Assy (1-1 to 1-9)

2 Cabinet (Rear) Assy (2-1 to 2-3)

3 LCD Block (3-1 to 3-4)

1-9

1-7

(#82)

3 LCD Block

3-1

3-2

3-3

2-2

2 Cabinet (Rear)

Assy

1-2

(#18/#29)

2-3

1-4

(Claws)

HARDWARE LIST

1-1

(#18/#29)

1-5

1-8

(Claws)

1-6

1-3

(#18/#29)

3-4

(Claws)

1 Cabinet (Front)

Assy

2-1

(#18/#29)

Note: High-voltage cautions

Discharging the Capacitor

Short-circuit between the two points with the

short jig about 10 seconds.

To avoid the spark with the metal plate,

wrap the short jig with the insulation tape.

DSC-T70/T75_L2

C902

C901

R:1 kΩ/1 W

(Part code: 1-215-869-11)

2-3

Page 15

EXPLODED VIEW

2-2-2. SY-183 BOARD SECTION

k

Follow the disassembly in the numerical order given.

1 Lens Block (1-1 to 1-2)

2 MC-185 Flexible Board (2-1 to 2-3)

3 SY-183 Board (3-1 to 3-3)

3 SY-183 Board

HARDWARE LIST

3-3

(Claw)

3-1

2-1

(#18/#29)

3-2

HELP

2-3

1-2

2-2

2 MC-185

Flexible Board

1-1

1 Lens Bloc

DSC-T70/T75_L2

2-4

Page 16

2-2-3. BATTERY HOLDER SECTION

EXPLODED VIEW

Follow the disassembly in the numerical order given.

1 Flash Block (1-1 to 1-7)

2 BT-039 Flexible Board (2-1)

3 Battery Holder Assy (3-1)

3 Battery Holder Assy

2 BT-039

Flexible Board

3-1

(Claw)

2-1

1 Flash Block

1-1

(Claw)

1-2

(Claws)

HELP

1-7

1-4

(Claw)

1-3

(Claw)

1-5

(Claws)

DSC-T70/T75_L2

1-6

2-5E

Page 17

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

SHEET (SY)

SY-183 board

DSC-T70/T75_L2

SHEET, ST2

MAIN FRAME

HELP

Page 18

3. BLOCK DIAGRAMS

Link

Link

OVERALL BLOCK DIAGRAM (1/2) POWER BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (2/2)

POWER BLOCK DIAGRAM (2/2)

DSC-T70/T75_L2

Page 19

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2)

CD-710 FLEXIBLE BOARD

18 14

IC001

CCD

IMAGER

28 - 30

20 2

3 - 14

16, 15

32, 33

31 12

1 G7

25

IRIS_A, A, B, B

FOCUS_A, A, B, B

ZOOM_A, A, B, B

FC_SENS

FC_SENS_GND

ZM_SENS

ZM_SENS_GND

LENS_TEMP

IC_401_TEMP

YAW

YAW_HALLBIAS

YAW_HALL

PITCH

PITCH_HALLBIAS

PITCH_HALL

CN401

36 - 39

18 - 21

22 - 25

31

33

28

30

27

5

13, 173, 4, 6, 7

9 - 12

1, 2, 15, 16

10

FC_SENS

XFC_RST_LED

ZM_SENS_1ST

XZM_RST_LED

LENS_TEMP

TZ_HALL_TEMP

ZOOM

RESET

SENSOR

LENS

ZOOM

MOTOR

LENS BLOCK

FOCUS

MOTOR

M

OPTICAL IMAGE

STABILIZER

FOCUS

RESET

SENSOR

M

(METER)

YAW

MOTOR

PITCH

MOTOR

IRIS

IRIS

MOTOR

M

LENS TEMP

SENSOR

OIS TEMP

SENSOR

M

HALL

ELEMENT

M

HALL

ELEMENT

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SY-183 BOARD (1/2)

CN301

IC002

HIGH

SPEED

BUFFER

B10, D10

G6, J8, J9, J7J3, J2, H2, J4

B1, D1

STABILIZATION

1, 16

IC503

OPTICAL

IMAGE

DRIVE

(8/10)

CCD_OUT

20

POWER_SAVE

23

H1 - H3

LH1

RG

V1, V2, V3A, V3B, V4,

V5A, V5B, V6 - V10

26 - 3738, 39 4 - 6

VST1, VST2

VHLD1, VHLD2

13, 14

LV

SUB

24

SUB_CONT

11

Q301

IRIS_A, A, B, B

FOCUS_A, A, B, B

ZOOM_A, A, B, B

D5, D6

G5

C9

A7

A3

A6

A5

A4, B4, B5

Q302

SWAOUT

CLK, DATA

SWBOUT

CA_FD

XDD_SYS_RST

CLK_IC_503

XIC_211_IC_503_RST

XCS_IC_503

13

PITCH/YAW

24, 25

10

IC506

SENSOR

AMP

(8/10)

L7

J8

H2, K1, K2

D1, D2, H1,

L227 8

L4

G9, F9, J9, F6,

F5, C4, E5, D10

F7, G5, E9, D9,

IC301

C5, B5

CCD SIGNAL

PROCESS,

E6, E7

TIMING

C8

GENERATOR

(6/10)

F11

IC401

LENS DRIVE

(7/10)

IRIS MOTOR

DRIVER

F2, E2, D2, B1

FOCUS

MOTOR

DRIVER

D6, E6, B7, C6

ZOOM

MOTOR

DRIVER

B4, B5, B3, A3

21J5

1

IC_211_0_SO, IC_211_0_SI, XIC_211_0_SCK

B7, B6, A6, A5, B4, A4, A3

B10, B8, B9, C6, C7, A8, A7,

E10

D11

J5

X201

36MHz

E11

K10, L10, K9

D4

F5, E5, D3, F1D5, A6, B6, C5

A2, C3, C4, A1

SE501

YAW

SENSOR

SE502

PITCH

SENSOR

XCS_FE, XIC_211_3_SCK, IC_211_3_SO

CA_AD00 - CA_AD13

CA_HD

CA_FD

GEN_TG_CLK

IC201

1

CLOCK

(2/10)

FC_SENS

3

GEN_SYS_CLK

5

OVERALL (2/2)

(PAGE 3-2)

2

GENERATOR

XDD_SYS_RST

VSUB_CONT_PRE,

VSUB_CONT_POST

XLENS_DRIVER_PS

IRIS_DIR_A, IRIS_BRK_A,

IRIS_DIR_B, IRIS_BRK_B

FC_DIR_A, FC_DIR_B, FC_BRK_A

ZM_DIR_A, ZM_DIR_B, ZM_BRK_A

XFC_RST_LED

ZM_SENS_1ST

XZM_RST_LED

LENS_TEMP

TZ_HALL_TEMP

XDD_SYS_RST

GEAR_ON

1

AF20, AE19, AF19, AE18

AC19, AC18, AE21, AF21, AE20,

AB21, AC21, AB20, AC20, AB19,

AE23

AF22

AF18

IC211

(1/2)

CPU

Y13

(3/10, 4/10, 5/10)

Y12

V19, D19, C25

R7, AF25

H11

W16, AD25, Y18, Y17

W18, AB26, W17AB23, AC26, AA23

Y10

M8

AD26

J8

AE3

AF3

W13

H10

U8

D17, B19, E17, A19,

U19

V8

AF8

AE8

AB13

AF12

AC12

V7

A13 - A15,

E16, A18, D16, A17

B18, D18, B17

Y1, AA1 E18, B23

B13 - B15

XIC_211_2_SCK

IC_211_CVOUT

VOUT_1

VOUT_2

XHD_EN

IC_211_2_SO, XIC_211_2_SCK

IC_211_2_SO,

XCS_AUDIO

IC_211_AUIN

IC_211_AUOUT

IC_211_CVOUT

Q232 - Q234

MSX_BS, MSX_D0 - MSX_D3, MSX_CLK

E6, D5

D6

A6

IC601

B6

AUDIO/VIDEO

AMP

(9/10)

Q231

BUFFER

USB_DP, USB_DM USB_DP, USB_DM

CLAMP

OVERALL (2/2)

(PAGE 3-2)

LCD_D0 - LCD_D7

LCD_CK, LCD_HD, LCD_VD

XCS_ PANEL

XDD_SYS_RST

MIC_SIG

A3

A1, C1

AU_LINE_OUT A_LINE_OUT

E2

V_LINE_OUT V_OUT

F1F3

IC_211_YOUT

IC_211_PBOUT

IC_211_PROUT

USB_VBUS USB_VBUS

2

XMS_IN

CN709

10 - 17

7 - 95, 616, 18 3, 4

4

3

CONTROL SWITCH

BLOCK (RL60570)

(1/2)

CN710

(1/2)

1

CN701

(1/2)

MC-185 FLEXIBLE

BOARD (1/2)

CN703

(1/2)

22

24

27

12

11

13

CN702

6

2 - 5, 7, 8

LCD901

(1/3)

3.0 inch

COLOR

LCD

MONITOR

(MICROPHONE)

ST-172 FLEXIBLE

BORAD (1/2)

SPSP

HD_Y

HD_PB

HD_PR

MEMORY

STICK

DUO

A : VIDEO SIGNAL

A : AUDIO SIGNAL

A : VIDEO/AUDIO SIGNAL

16

20

24

4

2

6

10, 12

SP901

(SPEAKER)

CN001

(1/2)

MULTI

CONNECTOR

DSC-T70/T75_L2

3-1

Page 20

3-2. OVERALL BLOCK DIAGRAM (2/2)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

FLASH

UNIT

ST-172 FLEXIBLE BOARD (2/2)

XE_A(H)

TRIGGER

TRIGGER_GND

XE_K(L)

Q001

FLASH

DRIVE

+

C901

CHARGING

( )( )

CAPACITOR

C902

CHARGING

CAPACITOR

SY-183 BOARD (2/2)

MC-185 FLEXIBLE

BOARD (2/2)

CONTROL SWITCH BLOCK

(RL60570) (2/2)

S002

POWER

S001

S005

(SHUTTER)

S003 S004

T W

(ZOOM)

D001

(POWER)

LCD901

(3/3)

BACKLIGHT

D001

+

T001

4 1

3

2

D002

AF illuminator/

self-timer lamp

ST_UNREG

15

1, 2

CONTROL,

CHARGE

CONTROL

7

IC001

FLASH

CN710

(2/2)

XPWR_ON

7

XDIRECT_PB

6

XAE_LOCK_SW

9

8

10

4

10

9

6

4

XSHUT_SW

KEY_AD_1

XPWR_LED

CN708

BL_H

BL_L

5, 6 1, 2

CN701

(2/2)

9

10

11

8

5

STRB_CHG

XSTRB_FULL

STB_CHG_CNT

STRB_ON1

XAF_LED

2

OVERALL (1/2)

(PAGE 3-1)

OVERALL (1/2)

(PAGE 3-1)

D701

XPWR_ON

XDIRECT_PB

XMS_IN

USB_VBUS

X001

32.768kHz

1

XDD_SYS_RST

XAF_LED

D7

D9

IC001

DC/DC

CONVERTER

(1/10)

F9

E10

D10

E7

K7

K6

C4

XDD_SYS_RST

IC_211_0_SO,

IC_211_0_SI,

XIC_211_0_SCK

F6

C10

D6

C9

C5

C6 - C8

XPWR_ON

BATT_SENS

XPWR_OFF

XIC_211_RST_REQ

XDD_SYS_RST

XCS_DD

IC_211_0_SO,

IC_211_0_SI,

XIC_211_0_SCK

D706

(MS ACCESS)

AE7

G8

W12

AB18

A23

H17, A24, G17

IC211

(2/2)

CPU

(3/10, 4/10, 5/10)

H8

XACV_IN

K8

XAV_JACK_IN

G9

IC_211_1_UI, IC_211_1_UO

D26, G19

TOUCH_PANEL_X

AB8

TOUCH_PANEL_Y

AF7

TOUCH_PANEL_SEL1

R2

TOUCH_PANEL_SEL2

T5

TOUCH

PANEL

I/F

Q706 - Q708

Q001,

Q002

D002

IC_211_1_UI, IC_211_1_UO

D001

TOUCH_PANEL_YU

TOUCH_PANEL_XL

TOUCH_PANEL_YL

TOUCH_PANEL_XR

CN703

(2/2)

7 7

ACV_UNREG

XAVC_DET

CHARGE_V

XAV_JACK_IN

10 19

28

CN707

4

1

5

2

34 - 39

29 - 33

8, 9

XPOWER_ON

ACV_UNREG

BATT_XEXT

CHARGE_V

XAV_JACK_IN

UART_Rx,

UART_Tx

LCD901

(2/3)

TOUCH

PANEL

26

23, 25

17, 21

15, 9

CN001

(2/2)

MULTI

CONNECTOR

DSC-T70/T75_L2

3-2

XPWR_LED

XAE_LOCK_SW

XSHUT_SW

KEY_AD_1

STRB_CHG

XSTRB_FULL

STB_CHG_CNT

STRB_ON1

Y9

N19

R19

AC8

V2

H9

H15

Y16

XCS_IC_202,

XIC_211_1_SCK,

IC_211_1_SO,

IC_211_1_SI

W20, H18, B24, G18

XDD_SYS_RST

BATTERY

B1, B5, C5, D5

AUTHENTICATION

B2

IC202

(2/10)

BT-039 FLEXIBLE

BOARD

CN704

CHARGE_V

E4

BATT_SIG

REG_GND

6

1 - 5 7 - 10

BATT_UNREG

BATT_SIG

BATT_GND

+

BH001

BATTERY

S

TERMINAL

( )

BOARD

-

Page 21

3-3. POWER BLOCK DIAGRAM (1/2)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CN001

MULTI

CONNECTOR

BH001

BATTERY

TERMINAL

( )

BOARD

+

S

-

CONTROL SWITCH

BLOCK (RL60570)

D001

(POWER)

S002

POWER

S001

BOARD

SY-183 BOARD (1/2)MC-185 FLEXIBLE

F001

ACV_UNREG

23, 25

BATT_XEXT

19

CHARGE_V

17, 21

XPOWER_ON

7 7

BT-039 FLEXIBLE

BOARD

BATT_UNREG CHARGE_V

BATT_SIG BATT_SIG

BATT_GND REG_GND

A

POWER (2/2)

(PAGE 3-4)

B

POWER (2/2)

(PAGE 3-4)

CN710

D_3.0V

5

XPWR_ON XPWR_ON

7

XDIRECT_PB

6

CN703

ACV_UNREG

34 - 3929 - 33

XACV_DET

10

CHARGE_V

XPWR_ON

CN704

7-10

6

1-5

XDD_SYS_RST

XIC_211_RST_REQ

XPWR_OFF

D002

Q001, 002

D001

IC202

BATTERY

AUTHENTICATION

(2/10)

P144_SOA0

P143_SIA0

TXRXE4

P142_XSCKA0

P120_INTP0

XRESETB2

D5

C5

XIC_211_1_SCK

B5

B1

IC_211_1_SI

IC_211_1_SO

XCS_IC_202

XACV_IN

D_3.0V

F002

C

POWER (2/2)

(PAGE 3-4)

F003

XDD_SYS_RST

XIC_211_RST_REQ

XDIRECT_PB

L004

XPWR_OFF

DDCBL_LX

F10

XSYS_RST

C9

XRESET_REQ

D6

C10

XPWR_OFF

XPWR_ON1

D7

XPWR_ON3

D9

DC/DC CONVERTER

IC001

(1/10)

MS_PWR_OUT

RTCBAT

DDC5_LX_1

DDC5_LX_2J3K3

DDC5_VO_1

DDC5_VO_2J2K2

LD03P1U_IN

DDC5_PSW

XPWR_ON2

LD03P1E_OUT

DDC1P8_LX

DDC1P8_VFB

DDC1P2_LX

DDC1P2_VFB

DDC12_LX_1

DDC12_LX_2J9K9

DDC12_PWR_OUT_1

DDC12_PWR_OUT_2J8K8

DDC12_VFB

DDCM7P5_LX

DDCM7P5_VFB F8

LD03P4_OUT H3

JD03P1U_OUT J5

LD01P5_OUT A6

LD01P8_OUT A7

DDCBL_VO F9

DDCBL_VL

DDC2P9_VO_1

DDC2P9_VO_2F1F2

DDC2P9_VFB

F3

H5

H4

H1

D8

F5

A8

B6

A4

B2

H8

J10

E10

G1

L001

L009

L008

XLV_ON

L002

D008

D006

B+ SWITCH

B+ SWITCH

D007

Q003

Q004

R008

IC002

SHUTTER DOOR DETECT

(1/10)

VDD 1

OUT

2

Q005

3.0V/1.8V

DISCHARGE

R005

D004

MS_VCC

L006

CN702

CN701

(2/2)

VL_3V

ST_UNREG

M_5.0V

EVER

D_1.8V

D_1.2V

CAM_13V

CAM_-7.5V

CAM_3.5V

USB_3.1V

D_1.5V

DDR_1.8V

BL_H

BL_L

D_3.0V

A_3.0V

9

2

MEMORY

STICK

DUO

ST-172 FLEXIBLE

BOARD (1/2)

BT001

LITHIUM

SECONDARY

BATTERY

E

POWER (2/2)

(PAGE 3-4)

MS_PWR_ON

G3

MS_PWR_ON

D

POWER (2/2)

(PAGE 3-4)

DSC-T70/T75_L2

3-3

Page 22

3-4. POWER BLOCK DIAGRAM (2/2)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SY-183 BOARD (2/2)

ST_UNREG

CAM_13V

CAM_-7.5V

BL_H

BL_L

A_3.0V

D_3.0V

M_5.0V

CAM_3.5V

D_1.8V

E

POWER (1/2)

(PAGE 3-3)

D_1.2V

DDR_1.8V

EVER EVER

B

POWER (1/2)

(PAGE 3-3)

C

POWER (1/2)

(PAGE 3-3)

D

POWER (1/2)

(PAGE 3-3)

IC507

2.8V REG

A_3.0V IC_503_2.8V

D_1.8V

D_1.5VD_1.5V

D_3.0V

M_5.0V

(8/10)

4 VOUT 3

VDD

CE

1

A

POWER (1/2)

(PAGE 3-3)

D_1.8V

D_3.0V

M_5.0V

L601

A_3.0V

D_3.0V

D_1.8V

D_1.2V

DDR_1.8V

XIC_211_RST_REQ

XPWR_OFF

XACV_IN

IC_211_1_SI

IC_211_1_SO

XIC_211_1_SCK

XCS_IC_202

MS_PWR_ON

R252

R253

L231

FB292

FB293

R255

XDD_SYS_RST

XIC_211_IC_503_RST

XDD_SYS_RST

H10

AB18

AU_AVCC

L211USB_3.1V

W12

G18

B24

H18

W20

T7

GPE_09

XRESET

IC211

CPU

(3/10)

(4/10)

(5/10)

XRESET_REQ

GPE_00G8

GPE_05K8

SIO1_RXD

SIO1_TXD

SIO1_SCK

GPS_04

GPE_15

AU_AVCC

GPS_13

IC503

OPTICAL

IMAGE

STABILIZATION

DRIVE

(8/10)

RESET_NA7

XDLA6

W7

D_3.0V

R712

D_1.8V

L602

D_1.8V

D_3.0V

M_5.0V

IC506

PITCH/YAW

SENSOR AMP

(8/10)

SE502

PITCH

SENSOR

SE501

YAW

SENSOR

IC601

AUDIO/VIDEO

AMP

(9/10)

D706

(MS ACCESS)

IC201

CLOCK

GENERATOR

(2/10)

D_1.8V

D_3.0V

XDD_SYS_RST

D_1.8V

D_3.0V

2.3V REG

IC303

(6/10)

4 VDD VOUT 3

6 Vin Vout 4

IC304

1.8V REG

(6/10)

BL_H

BL_L

ST_UNREG_ON

CAM_13V

CAM_-7.5V

LDO_2.3V

FE_1.8V

Q709,710

B+ SWITCH

CAM_3.5V

FB303

FB306

FB302

L702

L701

ST_UNREGST_UNREG

FB301 FB308

IC301

CCD SIGNAL

PROCESS,

TIMING GENERATOR

(6/10)

CN709

VDDL

VDD

XRESET

CN708

BL_H

BL_L

CN701

(2/2)

M_5.0V

D_3.0V

LCD901

22

23

3

1, 25, 6

3.0 inch

COLOR

LCD MONITOR

LCD

BACKLIGHT

ST-172 FLEXIBLE BOARD (2/2)

L001

12 - 15

7

6

DISCHARGE

R405

C355

Q303

-7.5V

D002

AF illuminator/

self-timer lamp

L303

L302

CN301

CAM_13V

CAM_-7.5V

CN401

ZM_SENS_VCC

FLASH CONTROL,

CHARGE CONTROL

T001

IC001

CD-710 FLEXIBLE

BOARD

16

25

29

CCD IMAGER

BUFFER AMP

LENS BLOCK

ZOOM

RESET

SENSOR

D001

IC001

IC002

HIGH SPEED

FLASH

UNIT

DSC-T70/T75_L2

3-4E

XDD_SYS_RST

D_3.0V

M_5.0V

Q305

3.0V/3.5V

DISCHARGE

E11

RSTB

R404

IRIS MOTOR DRIVER,

FOCUS MOTOR DRIVER,

ZOOM MOTOR DRIVER

FC_SENS_VCC

IC401

LENS DRIVE,

(7/10)

FOCUS

32

RESET

SENSOR

Page 23

4-1. FRAME SCHEMATIC DIAGRAM

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

FLASH UNIT

C901

(CHARGING CAPACITOR)

C902

(CHARGING CAPACITOR)

D002

AF illuminator/

( )

self-timer lamp

ST-172 FLEXIBLE

BOARD

SP901

(SPEAKER)

BT001

LITHIUM SECONDARY

( )

BATTERY

110

CN702

MEMORY STICK

( )

11

CONNECTRO

12

LEVEL3

SY-183 BOARD

(SIDE B)

BH001

(BATTERY TERMINAL)

+

10

S

-

BT-039 FLEXIBLE

BOARD

LCD901

BACKLIGHT

3.0 inch

COLOR

LCD MONITOR

TOUCH

PANEL

1

1

2

44

45

16 16

CN707 CN708CN709

CONTROL SWITCH BLOCK

(RL60570)

IC211

(Not supplied)

CN710

112

CN704

12 11

110

LEVEL3

SY-183 BOARD

(SIDE A)

238

139

CN703

19

CN701

218

1

238

139

CN301

238

139

CN401

119

LENS BLOCK

DSC-T70/T75_L2

MC-185

FLEXIBLE

BOARD

25

CN001

(MULTI CONNECTOR)

4-1

139

139

226

2728

1

LEVEL3

CD-710 FLEXIBLE

BOARD

IC001

(Not supplied)

FRAME

Page 24

Link

Link

4-2. SCHEMATIC DIAGRAMS

MC-185 FLEXIBLE BOARD

(MULTI CONNECTOR)

BT-039 FLEXIBLE BOARD

(BATTERY IN)

COMMON NOTE FOR SCHEMATIC DIAGRAMS

CONTROL SWITCH BLOCK

(RL60570)

ST-172 FLEXIBLE BOARD

(FLASH DRIVE)

DSC-T70/T75_L2

Page 25

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

µF. 50 V or less are not indicated e xcept for electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

External dimensions (mm)

Case size

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

•Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT → EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A : B+ Line

• B : B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A : not use circuit

(Measuring conditions voltage and waveform)

•Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference values

and reference waveforms.

(VOM of DC 10 MΩ input impedance is used)

•Voltage values change depending upon input

impedance of VOM used.)

1. Connection

Pattern box

Pattern box PTB-450

J-6082-200-A

or

Small pattern box

PTB-1450

J-6082-557-A

L = 24 cm (PTB-450)

L = 11 cm (PTB-1450)

Pattern box

Color bar chart

L

For PTB-450:

J-6020-250-A

For PTB-1450:

J-6082-559-A

Front of the lens

Camera

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Fig.b (Picture on monitor TV)

Red

Blue

Electronic beam

scanning frame

CRT picture frame

Precautions for Replacement of Imager

• If the imager has been replaced, carry out all the adjustments

for the camera section.

• As the imager may be damaged by static electricity from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with

dusts nor exposed to strong light.

DSC-T70/T75_L2

When indicating parts by reference number, please

include the board name.

The components identified by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par une pièce portant le numéro

spécifie.

4-2

Page 26

Schematic diagrams of the CD-710 flexible board and the SY-183 board are not shown.

Pages from 4-3 to 4-13 are not shown.

DSC-T70/T75_L2

Page 27

1 86

2

3

4

57

A

Pin

1

LND001

LND002

LND003

LND004

LND005

LND006

LND007

LND008

LND009

LND010

LND011

LND012

LND013

LND014

LND015

LND016

LND017

LND018

LND019

LND020

LND021

LND022

LND023

LND024

LND025

LND026

LND027

LND028

LND029

LND030

LND031

LND032

LND033

LND034

LND035

LND036

LND037

LND038

LND039

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

XPOWER_ON

UART_Tx

UART_Rx

BATT/XEXT

HD_Pr

HD_Pb

USB_VBUS

USB_GND

USB_GND

USB_DP

N.C.

USB_DM

USB_GND

USB_GND

USB_GND

AU_LINE_OUT

A_GND

V_LINE_OUT

V_GND

V_GND

HD_Y

XAV_JACK_IN

CHARGE_V

CHARGE_V

CHARGE_V

CHARGE_V

CHARGE_V

ACV_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

HD_Y

XPOWER_ON

UART_RX

BATT/XEXT

V_OUT

XAV_JACK_IN

UART_TX

USB_DP

USB_DM

A_LINE_OUT

ACV_UNREG

HD_PB

USB_VBUS

HD_PR

Note:CN001(MULTI CONNECTOR) is not supplied, but this is

included in MC-185 flexible complete board.

LND040

STATIC_GND

CN001

26P

ACV_GND

ACV_GND

XPOWER_ON

CHARGE_V

BATT_XEXT

CHARGE_V

ACV_UNREG

ACV_UNREG

CHARGE_V

2HD_Pr

4HD_Pb

USB_VBUS

6

USB_GND

8

USB_DP

10

USB_DM

12

USB_GND

14

A_OUT_L

16

18 A_GND

20 V_OUT

22 V_GND

HD_Y

24

XAV_JACK_IN

26

(MULTI CONNECTOR)

1

3ACV_GND

5

7

9UART_Tx

15UART_Rx

17

19

21

23

25

2

3

B

SY-183

(10/10)

CN703

C

PAGE 4-13

of LEVEL3

D

37

38

39

A

B

C

D

E

F

08

DSC-T70/T75_L2

4-14

MC-185 FLEXIBLE BOARD

MULTI CONNECTOR

E

F

MC-185

Page 28

• Refer to page 4-2 for mark 0.

241

3

A

Pin

LND001

1

LND002

2

3

LND003

SY-183

(10/10)

CN704

PAGE 4-13

of LEVEL3

B B

LND004

LND005

LND006

LND007

8

LND008

9

LND009

10

LND010

BATT_GND

BATT_GND

BATT_GND

BATT_GND

BATT_GND

BATT_SIG

BATT_UNREG

BATT_UNREG

BATT_UNREG

BATT_UNREG

BATT_GND

BATT_SIG

BATT_UNREG

BATT_GND

BATT_SIG

BATT_UNREG

Note: BH001 is not included in

LND011

LND012

LND013

BT-039 flexible complete board.

BH001

s

BATTERY

TERMINAL

BOARD

241

A

A

Pin

1

LND001

MIC_SIG

MIC_GND

LND002

2

3

SY-183

(10/10)

CN710

PAGE 4-13

B B

of LEVEL3

10

11

12

LND003

LND004

LND005

LND006

LND007

LND008

LND009

LND010

LND011

LND012

REG_GND

XPWR_LED

D_3.0V

DIRECT_PB

XPWR_ON

XSHUTTER_SW

XAE_LOCK_SW

KEY_AD1

REG_GND

REG_GND

D001

SML-412MWT86

(POWER)

3

A

CL001

CL002

S001

S002

POWER

S005

(SHUTTER)

NO

3

2

R001

2200

1

4

(MICROPHONE)

C C

BT-039 FLEXIBLE BOARD

BATTERY IN

08

C C

S004

(ZOOM)

LND021

STATIC_GND

D002

(TL3SONY)

(TL3SONY)

D003

32

1

D004

MAZW068H0LS0

D005

(TL3SONY)

S003

TW

D

E

D

E

DSC-T70/T75_L2

4-15

CONTROL SWITCH BLOCK

F

(RL60570)

CONTROL SWITCH BLOCK(RL60570) is replaced as block,

so that PRINTED WIRING BOARD is omitted.

08

F

BT-039, RL60570

Page 29

• Refer to page 4-2 for mark 0.

LND020

LND021

3

2518

2.2uH

L001

C001

22u

6.3V

2012

C

R008 33

SP901

(SPEAKER)

R007

4700

1/10W

1608

C005

XX

4

5

6

C007

50V

B

220p

D003

RB520S-40TE61

C002

1u

B

10V

4

BT001

LITHIUM SECONDARY

BATTERY

3

2

1

D002

DOR5352

AF illuminator/

self-timer lamp

3.7

1

3.7

2

5.0

3

0

4

1

2

SW

SW

VCC

F_ON

T001

4

3

17

FLASH CONTROL,

CHARGE CONTROL

21.9u

CHARGING

CAPACITOR

3.7

15

16

N.C

HGND

IC001

TPS65552RGTR

C902

315V

VBATT

57

A

R002

1M

+

-

0

LND030

LND031

5

6

7

8

R003

100

1005

260.0

1

2

3

TIG030TS-S-TL-E

FLASH DRIVE

4

Q001

LND026

TRIGGER

TRIG_GND

LND027

LND028

XE_A(H)

LND029

XE_K(L)

FLASH

UNIT

B

C

D001

FT02P80TP

C+

LND022

LND023

C-

13

14

N.C

N.C

PGND

12

PGND

11

CHG

10

XFULL

9

0

3.1

C901

21.9u

315V

CHARGING

CAPACITOR

C+

LND024

LND025

C-

R004

1M

2012

C004

0.033u

1 86

Pin

1

A

SY-183

(10/10)

CN701

PAGE 4-13

of LEVEL3

B

LND001

2

LND002

3

LND003

LND004

LND005

LND006

LND007

LND008

LND009

LND010

LND011

LND012

LND013

LND014

LND015

LND016

17

LND017

LND018

18

19

LND019

2

REG_GND

VL_3V

SP+

SP-

XAF_LED

AF_ANODE

M_5V

STRB_ON

STRB_CHG

XSTRB_FULL

STRB_CHG_CONT

ST_UNREG

ST_UNREG

ST_UNREG

ST_UNREG

REG_GND

REG_GND

REG_GND

REG_GND

SPEKER+

SPEAKER-

C

D

CL001

N.C

5

I_PEAK7G_IGBT

6

0

E

N.C

8

0

D

E

ST-172 FLEXIBLE BOARD

F

08

FLASH DRIVE

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

F

DSC-T70/T75_L2

4-16

ST-172

Page 30

Link

Link

4-3. PRINTED WIRING BOARDS

MC-185 FLEXIBLE BOARD

BT-039 FLEXIBLE BOARD

COMMON NOTE FOR PRINTED WIRING BOARDS

ST-172 FLEXIBLE BOARD

DSC-T70/T75_L2

Page 31

4-3. PRINTED WIRING BOARDS

21321321

3

345

21

123

654

EB

C

3152

46

123

654

3152

46

123

54

43

12

312

45

534

12

14

23

4625

31

12

4

3

14

23

4-3. PRINTED WIRING BOARDS

4-3. PRINTED WIRING BOARDS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS

• : Uses unleaded solder.

•

: Circuit board

: Flexible board

Pattern from the side which enables seeing.

: pattern of the rear side

(The other layers’ patterns are not indicated)

• Through hole is omitted.

• Circled numbers refer to waveforms.

• There are a few cases that the part printed on diagram

isn’t mounted in this model.

• C: panel designation

• Chip parts.

Transistor Diode

DSC-T70/T75_L2

4-17

Page 32

Printed wiring boards of the CD-710 flexible board and the SY-183 board are not shown.

Pages 4-18 and 4-20 are not shown.

DSC-T70/T75_L2

Page 33

MC-185 (2 layers), BT-039 (1 layer), ST-172 (2 layers)

: Uses unleaded solder.

MC-185 FLEXIBLE BOARD

LND001

LND003

LND005

LND007

LND009

LND011

LND013

LND015

LND017

LND019

LND021

LND023

LND025

LND027

LND029

LND031

LND033

LND035

LND037

LND039

LND002

LND004

LND006

LND008

LND010

LND012

LND014

LND016

LND018

LND020

LND022

LND024

LND026

LND028

LND030

LND032

LND034

LND036

LND038

25

1

08

CN001

(MULTI CONNECTOR)

CN001 (MULTI CONNECTOR) is not supplied,

Note :

but this is included in MC-185 flexible complete board.

226

2728

LND040

1-874-893- 11

C901

CHARGING

( )

CAPACITOR

C902

CHARGING

( )

CAPACITOR

ST-172 FLEXIBLE BOARD

FLASH UNIT

LND025

LND024

LND023

LND022

08

D002

AF illuminator/

( )

self-timer lamp

4

LND026

LND027

LND031

14

C004

LND030

6 5

1 2 3

85

Q001

LND029

R004

R002

LND028

SP901

(SPEAKER)

R003

9

12

C001

13

8

R008

IC001

17

CL001

5

16

1

4

R007

D003

C007

1

T001

4

A

D001

K

L001

C002

C005

2

3

BT001

-

+

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

LND020

LND021

1-874-892- 11

BT001

LITHIUM SECONDARY

( )

BATTERY

CAUTION

BH001

BATTERY

TERMINAL

( )

BOARD

DSC-T70/T75_L2

BT-039 FLEXIBLE BOARD

LND013

+

LND012

S

LND011

-

08

Note: BH001 is not included in

BT-039 flexible complete board.

LND010

LND009

LND008

LND007

LND006

LND005

LND004

LND003

LND002

LND001

1-874-894- 11

4-21E

LND014

LND012

LND013

LND011

LND010

LND008

LND009

LND007

LND002

LND006

LND004

LND001

LND005

LND003

LND018

LND016

LND017

LND015

LND019

MC-185, BT-039, ST-172

Page 34

NOTE

NOTE

5. REPAIR PARTS LIST

NOTE: Characters A to Z of the electrical parts list indicate location of exploded views in which the desired part is shown.

Link

Link

AB

OVERALL SECTION

Link

Link

BT-039 FLEXIBLE BOARD ST-172 FLEXIBLE BOARD

MC-185 FLEXIBLE BOARD

EXPLODED VIEWS

EXPLODED VIEWS

SY-183 BOARD SECTION

ELECTRICAL PARTS LIST

ELECTRICAL PARTS LIST

CC

B

C

BATTERY HOLDER SECTION

ACCESSORIES

ACCESSORIES

DSC-T70/T75_L2

Page 35

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

NOTE:

• -XX, -X mean standardized parts, so they may have some differences from

the original one.

• Items marked “*” are not stocked since they are seldom required for routine

service. Some delay should be anticipated when ordering these items.

• The mechanical parts with no reference number in the exploded views are not

supplied.

• Due to standardization, replacements in the parts list may be different from

the parts specified in the diagrams or the components used on the set.

• CAPACITORS:

uF: µF

• COILS

uH: µH

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , µPC... , µPC... ,

uPD..., µPD...

• Abbreviation

AR : Argentine model

AUS: Australian model

BR : Brazilian model

CH : Chinese model

CND : Canadian model

EE : East European model

HK : Hong Kong model

J: Japanese model

JE : Tourist model

KR : Korea model

NE : North European model

TW : Taiwan model

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

• Color Indication of Appearance Parts

Example:

(SILVER) : Cabinet’s Color

(Silver) : Parts Color

DSC-T70/T75_L2

5-1

Page 36

5. REPAIR PARTS LIST

DISASSEMBLY

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS

5-1-1. OVERALL SECTION

ns: not supplied

SY-183 board section

(See Page 5-3)

8

(6.5mm × 6.5mm)

2

1

HARDWARE LIST

#18/#29

5

4

LCD901

3

#82

7

(6mm × 14.5mm)

ns

6

#18

#29

#18

#29

#18/#29

CAUTION 1 :

For the part of 7 : CUSHION (RL MICROPHONE) (3-275-797-01),

cut NON WOVEN (T0.25) (3-076-631-01) into the desired length and use it.

CAUTION 2 :

For the part of 8 : SHEET (WATERPROOF SHEET) (3-280-761-01),

cut NON WOVEN (T0.25) (3-076-631-01) into the desired length and use it.

Ref. No. Part No. Description Ref. No. Part No. Description

1 3-272-252-01 GRIP

2 A-1284-139-A CABINET (FRONT) BLOCK ASSY (SILVER)

2 A-1284-140-A CABINET (FRONT) BLOCK ASSY (BLACK)

2 A-1284-141-A CABINET (FRONT) BLOCK ASSY (WHITE)

2 A-1284-142-A CABINET (FRONT) BLOCK ASSY (PINK)

3 1-480-344-11 SWITCH BLOCK, CONTROL (RL60570)

4 3-272-254-01 BRACKET, STRAP

* 5 3-272-255-01 SHEET (STRAP), ADHESIVE

6 3-272-253-01 CABINET (REAR (SKK)) (SILVER)

6 3-274-562-11 CABINET (REAR) (BLACK)

6 3-272-253-21 CABINET (REAR (SKK)) (WHITE)

6 3-272-253-31 CABINET (REAR (SKK)) (PINK)

7 CAUTION 1 CUSHION (RL MICROPHONE)

8 CAUTION 2 SHEET (WATERPROOF SHEET)

LCD901 A-1334-750-A FTS BLOCK ASSY (30SHGU07)

#18 2-635-591-21 SCREW (M1.4), NEW TRUSTAR P2 (Silver)

#29 2-662-396-01 SCREW (M1.4), NEW, TRUSTAR, P2 (Black)

#82 3-272-251-01 SCREW (M1.4), HEAD PRECISION (Silver)

DSC-T70/T75_L2

5-2

Page 37

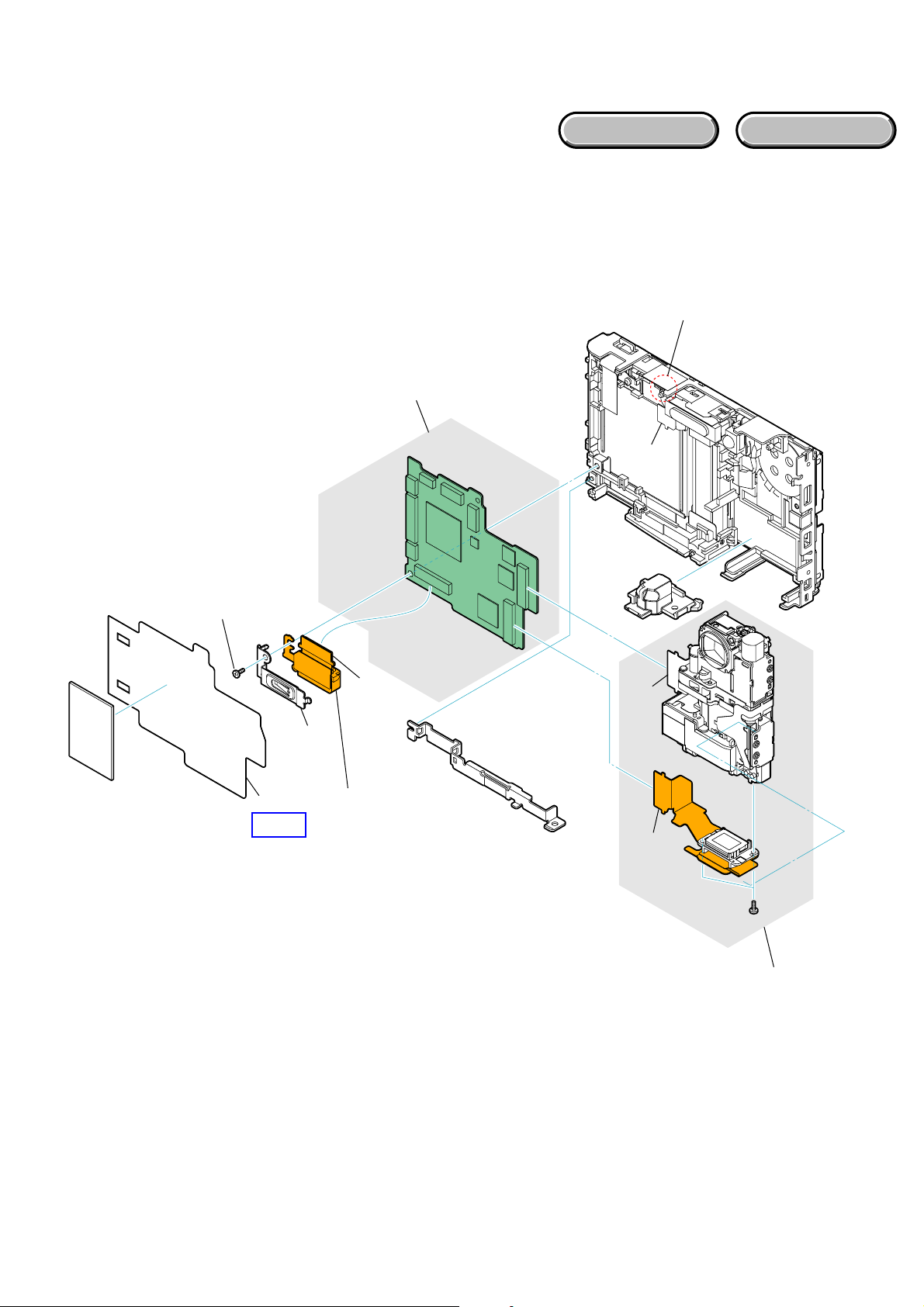

5-1-2. SY-183 BOARD SECTION

DISASSEMBLY

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

55

HARDWARE LIST

Battery Holder section

(See Page 5-4)

59

#18

#29

51

52

53

54

SY-183

56

58

(including IC001(CCD imager)

and CD-710 flexible

complete board.)

(Note)

#30

57

Note :

Ref. No. Part No. Description Ref. No. Part No. Description

51 3-272-209-01 SHEET (SY)

* 52 3-272-205-01 MULTI (2), PLATE

53 A-1334-225-A MC-185 FLEXIBLE BOARD, COMPLETE

* 54 3-272-204-01 MULTI (1), PLATE

55 A-1364-520-A SY-183 BOARD, COMPLETE (SERVICE)

56 3-272-203-01 SCREW, TRIPOD

57 A-1167-020-B LSV-1110A (SERVICE USE)

DSC-T70/T75_L2

Be sure to read "Precuations for Replacement of Imager"

on page 4-2.

58 A-1284-148-A CCD BLOCK ASSY (

and CD-710 flexible complete board.

* 59 3-272-428-01 SHEET, ELECTROSTATIC

#18 2-635-591-21 SCREW (M1.4), NEW TRUSTAR P2 (Silver)

#29 2-662-396-01 SCREW (M1.4), NEW, TRUSTAR, P2 (Black)

#30 3-086-156-11 SCREW B1.2 (White)

including IC001 (CCD imager)

5-3

) (Note)

Page 38

DISASSEMBLY

5-1-3. BATTERY HOLDER SECTION

102

BH001

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

104

(6mm × 25mm)

103

105

106

101

113

112

ns

111

C902

C901

110

109

CAUTION 1 :

For the part of 104 : SHEET (RL) (3-272-219-01),

cut SHEET, ADHESIVE (2-649-300-01) into the desired length and use it.

108

SP901

BT001

114

: BT001 (BATTERY, LITHIUM

SECONDARY)

Board on the mount position.

(See page 4-21.)

107

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

CAUTION

• Refer to page 5-1 for mark 0.

Ref. No. Part No. Description Ref. No. Part No. Description

101 1-874-894-11 BT-039 FLEXIBLE BOARD

102 X-2186-608-1 ASSY, BTH (S) (SILVER)

102 X-2186-609-1 ASSY, BTH (B) (BLACK)

102 X-2186-610-1 ASSY, BTH (W) (WHITE)

102 X-2186-611-1 ASSY, BTH (P) (PINK)

* 103 3-272-216-01 SHEET, ST2

104 CAUTION 1 SHEET (RL)

* 105 3-272-217-01 CUSHION (MICROPHONE)

106 X-2186-606-1 FRAME ASSY, MAIN

107 3-272-206-01 HOLDER, LENS

* 108 3-272-218-01 SHEET, LH

DSC-T70/T75_L2

* 109 3-272-210-01 SHEET, MCON

110 3-272-213-01 FILM, ST

0 111 1-480-416-11 FLASH UNIT (FL60570)

112 A-1334-226-A ST-172 FLEXIBLE BOARD, COMPLETE

* 113 3-272-208-01 CUSHION, AF

* 114 3-272-207-01 CUSHION, SP

*0BT001 1-756-566-11 BATTERY, LITHIUM SECONDARY

0 BH001 1-780-456-41 TERMINAL BOARD, BATTERY

*0C901 1-114-572-11 CAP, ELECT 21.9MF 315V

*0C902 1-114-572-11 CAP, ELECT 21.9MF 315V

* SP901 1-826-759-11 BUZZER, PIEZOELECTRIC (2.0CM)

5-4

Page 39

5-2. ELECTRICAL PARTS LIST

Ref. No. Part No. Description Ref. No. Part No. Description

1-874-894-11 BT-039 FLEXIBLE BOARD

********************

(BH001 is not included in BT-039 flexible complete board.)

< BATTERY TERMINAL BOARD >

0 BH001 1-780-456-41 TERMINAL BOARD, BATTERY

************************************************************

Electrical parts list of the CD-710 flexible

board is not shown.

Pages 5-6 is not shown.

BT-039

• Refer to page 5-1 for mark 0.

DSC-T70/T75_L2

5-5

Page 40

Ref. No. Part No. Description Ref. No. Part No. Description

A-1334-225-A MC-185 FLEXIBLE BOARD, COMPLETE

*******************************

(CN001 (MULTI CONNECTOR) is not supplied,

but this is included in MC-185 flexible complete board.)

< CONNECTOR >

MC-185

ST-172

CN001 (Not supplied) CONNECTOR, MULTIPLE (SOCKET)

************************************************************

A-1334-226-A ST-172 FLEXIBLE BOARD, COMPLETE

******************************

0 1-480-416-11 FLASH UNIT (FL60570)

< LITHIUM BATTERY SECONDARY >

*0BT001 1-756-566-11 BATTERY, LITHIUM SECONDARY

< CAPACITOR >

C001 1-100-611-91 CERAMIC CHIP 22uF 20% 6.3V

C002 1-165-908-11 CERAMIC CHIP 1uF 10% 10V

* C004 1-112-832-21 CERAMIC CHIP 0.033uF 10% 250V

C007 1-164-933-11 CERAMIC CHIP 220PF 10% 50V

*0C901 1-114-572-11 CAP, ELECT 21.9uF 315V

*0C902 1-114-572-11 CAP, ELECT 21.9uF 315V

< DIODE >

0 D001 6-501-141-01 DIODE FT02P80TP

* D002 6-501-364-01 DIODE DOR5352

D003 6-500-619-01 DIODE RB520S-40TE61

(MULTI CONNECTOR)

(AF illuminator/self-timer lamp)

< IC >

IC001 6-707-555-01 IC TPS65552RGTR

< COIL >

* L001 1-400-820-11 INDUCTOR 2.2uH

< TRANSISTOR >

*0Q001 6-551-686-01 TRANSISTOR TIG030TS-S-TL-E

< RESISTOR >

R002 1-218-989-11 RES-CHIP 1M 5% 1/16W

R003 1-218-941-11 RES-CHIP 100 5% 1/16W

R004 1-216-121-00 RES-CHIP 1M 5% 1/10W

R007 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R008 1-218-935-11 RES-CHIP 33 5% 1/16W

< SPEAKER >

* SP901 1-826-759-11 BUZZER, PIEZOELECTRIC (2.0CM)

< TRANSFORMER >

0 T001 1-445-108-21 TRANSFORMER, D.C-D.C CONVERTER

************************************************************

• Refer to page 5-1 for mark 0.

Electrical parts list of the SY-183 board is

not shown.

Pages 5-8 to 5-11 are not shown.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

DSC-T70/T75_L2

5-7

Page 41

Checking supplied accessories.

Note 1: This item is supplied with the unit as an accessory, but is

not prepared as a service part.

Power cord (mains lead)

(EXCEPT US, CND, BR, J)

0 1-823-947-71 (KR)

0 1-827-826-41 (AEP, E)

0 1-827-945-61 (AUS)

0 1-828-050-31 (JE)

0 1-832-106-31 (AR)

0 1-832-121-31 (CH)

0 1-832-169-31 (UK, HK)

Battery charger

(BC-CSD)

0 1-480-352-11 (J)

0 1-480-352-21 (US, CND)

0 1-480-352-31

(EXCEPT CND, US, J)

Paint pen

2-888-952-01 (Black) (BLACK Model)

2-888-952-11 (Gray)

(SILVER/WHITE/PINK Models)

Conversion (2P) Adaptor

0 1-569-007-12 (JE)

Rechargeable battery pack

(NP-BD1)

0 A-1336-393-A (J)

0 A-1336-394-A (US, CND)

0 A-1336-395-A (EXCEPT CND, US, J)

Conversion (2P) Adaptor

0 1-569-008-12 (E)

Battery case

(Note 1)

Wrist strap

2-050-981-01 (Gray)

(SILVER/WHITE/PINK Models)

2-050-981-11 (Black) (BLACK Model)

Adaptor plate

(HD1-A)

3-274-257-01

Instruction Manual

3-219-483-01 (JAPANESE) (J)

3-219-483-11 (ENGLISH) (CND, AEP, UK, AUS, E, HK, JE)

3-219-483-21 (FRENCH, ITALIAN) (CND, AEP)

3-219-483-31 (SPANISH, PORTUGUESE) (AEP, E, AR, JE)

3-219-483-41 (GERMAN, DUTCH) (AEP)

3-219-483-51 (TRADITIONAL CHINESE,

SIMPLIFIED CHINESE) (E, HK, JE)

3-219-483-61 (RUSSIAN, UKRAINIAN) (AEP)

3-219-483-71 (ARABIC, PERSIAN) (E)

3-219-483-81 (KOREAN) (KR, JE)

3-219-483-91 (POLISH, CZECH) (AEP)

3-219-484-11 (HUNGARIAN, SLOVAK) (AEP)

3-219-484-21 (SWEDISH, FINNISH) (AEP)

3-219-484-31 (NORWEGIAN, DANISH) (AEP)

3-219-484-41 (THAI, MALAY) (E)

3-219-484-51 (TURKISH, GREEK) (AEP)

3-219-484-61 (ENGLISH, SPANISH) (US)

3-219-484-72 (SIMPLIFIED CHINESE) (CH)

USB, A/V cable for

multi-use terminal

1-834-813-11

HD Output Adaptor Cable

(DSC-T75 only)

1-833-859-21

CD-ROM (Cyber-shot application software /

"Cyber-shot Handbook" / "Cyber-shot Step-up

Guide")

3-219-478-01 (EXCEPT J)

3-271-036-01 (J)

Cyber-shot Handbook (PDF)

The CD-ROM supplied contains all of language version of

the Instruction Manual in pdf (Cyber-shot Handbook.pdf) for printing.

The printed matter is not supplied. If required,

please order it with the part number below.

(Only for destination Japanese model)

日本国内については日本語のみが印刷での部品供給可能です。

3-219-480-01 (JAPANESE)

3-219-480-11 (ENGLISH)

3-219-480-21 (FRENCH)

3-219-480-31 (ITALIAN)

3-219-480-41 (SPANISH)

3-219-480-51 (PORTUGUESE)

3-219-480-61 (GERMAN)

3-219-480-71 (DUTCH)

3-219-480-81 (TRADITIONAL CHINESE)

3-219-480-91 (SIMPLIFIED CHINESE)

3-219-481-11 (RUSSIAN)

3-219-481-21 (ARABIC)

3-219-481-31 (PERSIAN)

3-219-481-41 (KOREAN)

3-219-481-51 (POLISH)

3-219-481-61 (CZECH)

3-219-481-71 (HUNGARIAN)

3-219-481-81 (SLOVAK)

3-219-481-91 (SWEDISH)

3-219-482-11 (FINNISH)

3-219-482-21 (NORWEGIAN)

3-219-482-31 (DANISH)

3-219-482-41 (THAI)

3-219-482-51 (MALAY)

3-219-482-61 (TURKISH)

3-219-482-71 (GREEK)

3-219-482-81 (UKRAINIAN)

• Refer to the page 5-1 for mark 0.

DSC-T70/T75_L2

5-12E

Page 42

HARDWARE LIST (1/5)

#1: M1.7 X 2.5

(Black)

2-635-562-11

2.5

#5: M1.7 X 3.5 (Tapping)

(Black)

3-080-204-01

3.5

#9: M1.7 X 5.0 (Tapping)

(Silver)

3-078-890-21

1.7

1.7

#2: M1.7 X 4.0

(Black)

2-635-562-31

#6: M1.4 X 1.7

(Silver)

2-598-474-01

#10:M1.7 X 4.0

(Silver)

2-599-475-31

4.0

1.7

1.4

1.7

#3: M1.7 X 2.5

(Red)

2-660-401-01

2.5

#7: M1.7 X 1.6

(Black)

7-627-552-18

1.6

#11:M1.7 X 4.0 (Tapping)

(Silver)

3-078-890-11

1.7

1.7

#4: M1.4 X 2.5 (Tapping)

(Dark Silver)

3-348-998-81

1.4

2.5

#8: M1.7 X 3.5 (Tapping)

(Silver)

3-078-890-01

1.7

3.5

#12:M1.7 X 5.0 (Tapping)

(Black)

3-080-204-21

5.0

#13:M1.7 X 2.5 (Tapping)

(Silver)

3-085-397-01

2.5

#17:M1.7 X 1.5

(Silver)

2-586-389-01

1.7 2.2

1.5

3.5

1.7

1.7

#14:M1.7 X 2.5

(Silver)

2-599-475-11

#18:M1.4 X 2.5

(Silver)

2-635-591-21

4.0

2.5

2.5

1.7

1.7

1.4

4.0

#15:M1.4 X 1.5

(Silver)

3-062-214-01

1.5

#19:M1.2 X 4.0 (Tapping)

(Red)

3-086-156-21

4.0

1.4

1.7

1.2

1.7

5.0

#16:M1.4 X 2.5

(Silver)

2-586-337-01

1.4

2.5

#20:M1.4 X 3.0

(Silver)

2-635-591-31

1.4

3.0

Page 43

HARDWARE LIST (2/5)

#21:M1.4 X 3.0

(Black)

2-662-396-21

#25:M1.7 X 3.0

(Black)

2-635-562-21

#29:M1.4 X 2.5

(Black)

2-662-396-01

3.0

3.0

1.4

1.7

#22:M1.7 X 5.0 (Tapping)

(Silver)

3-083-261-01

5.0

#26:M1.4 X 2.0

(Silver)

2-635-591-11

2.0

#30:M1.2 X 4.0 (Tapping)

(White)

3-086-156-11

1.7

1.4

#23:M1.7 X 4.0 (Tapping)

(Black)

3-080-204-11

4.0

#27:M1.4 X 2.0

(Black)

2-662-396-11

2.0

#31:M3.0 X 4.0

(Silver)

2-102-434-01

1.7

1.4

#24:B1.7 X 5.5 (Tapping)

(Black)

4-679-805-11

1.7

5.5

#28:M1.4 X 4.0 (Tapping)

(Dark Silver)

3-348-998-61

1.4

4.0

#32:M2.0 X 4.5 (Tapping)

(Silver)

2-102-498-01

2.5

#33:M3.0 X 6.0

(Silver)

3-077-331-21

6.0

#37:M2.0 X 6.0 (Tapping)

(Black)

3-080-206-31

6.0

3.0

1.4

2.0

3.5

#34:M3.0 X 8.0

(Black)

3-077-331-41

8.0

#38:M3.0 X 20.0 (Tapping)

(Silver)

7-685-651-79

20.0

1.2

3.0

#35:M4.0 X 6.0 (Tapping)

(Silver)

3-975-291-02

#39:M2.6 X 5.0 (Tapping)

(Black)

7-685-791-09

3.0

5.0

6.0

4.0

4.0

2.6

3.0

2.0

4.5

#36:M3.0 X 6.0

(Silver)

4-886-821-11

3.0

6.0

#40:M2.0 X 4.0 (Tapping)

(Silver)

7-685-851-04

2.0

4.0

Page 44

HARDWARE LIST (3/5)

#41:M3.0 X 8.0 (Tapping)

(Silver)

3-065-748-01

8.0

#45:M1.4 X 2.5

(Silver)

2-587-151-01

2.5

#49:M2.0 X 4.0

(Black)

2-630-005-31

3.0

1.4

#42:M2.0 X 4.0 (Tapping)

(Silver)

7-628-253-00

4.0

#46:M1.7 X 3.0

(Red)

2-660-401-11

3.0

#50:M2.0 X 3.0

(Red)

2-891-494-11

1.7

2.0

#43:M1.7 X 4.0

(Red)

2-660-401-31

4.0

#47:M1.4 X 3.0 (Tapping)

(Silver)

2-665-774-01

3.0

#51:M2.0 X 2.5

(Silver)

3-073-686-01

1.7

1.4

#44:M1.7 X 3.0 (Tapping)

(Silver)