Page 1

SERVICE MODE

SERVICE MODE

APPLICATION FOR ADJUSTMENT (SEUS)

SERVICE MODE

APPLICATION FOR ADJUSTMENT (SEUS)

SERVICE MODE

DSC-T1

Ver 1.2 2004. 04

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Link

Link

Before starting adjustment

Before starting adjustment

Adjusting items when replacing main parts and boards

Adjusting items when replacing main parts and boards

ADJUSTMENT

ADJUSTMENT

PREPARATIONS BEFORE ADJUSTMENT

PREPARATIONS BEFORE ADJUSTMENT

INITIALIZATION OF DATA

INITIALIZATION OF DATA

VIDEO SYSTEM ADJUSTMENTS

VIDEO SYSTEM ADJUSTMENTS

SECTION 6

ADJUSTMENTS

ADJ

CAMERA SYSTEM ADJUSTMENTS

CAMERA SYSTEM ADJUSTMENTS

LCD SYSTEM ADJUSTMENT

LCD SYSTEM ADJUSTMENT

Note : Be sure to carry out “Data Save”.

Contents of LEVEL 2 and LEVEL 3 Service Manual

CONTENTS

1. SERVICE NOTE

2. DISASSEMBLY

3. BLOCK DIAGRAMS

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

5. REPAIR PARTS LIST

OVERALL, POWER

CD-463, CN-198, ST-86

BOARD,

CONTROL SWITCH BLOCK

EXPLODED VIEWS

ELECTRICAL PARTS

LEVEL 2

a

a

LEVEL 3

✕

✕

✕

LD-140, MS-148, SY-95

BOARD,

FP-694, FP-695 FLEXIBLE

✕

a

(LD-140, MS-148, SY-95

BOARD, FP-695 FLEXIBLE)

9-876-280-52

Sony EMCS Co.

2004D1600-1

©2004.4

Published by DI CS Strategy Div.

Page 2

DSC-T1

TABLE OF CONTENTS

6. ADJUSTMENT

1. Before starting adjustment···············································6-1

1-1.

Adjusting items when replacing main parts and boards. ····

6-1. ADJUSTMENT·······························································6-3

1-1. PREPARATIONS BEFORE ADJUSTMENT·················6-3

1-1-1.List of Service Tools························································ 6-3

1-1-2.Preparations ·····································································6-4

1-1-3.Discharging of the flashlight power supply·····················6-4

1-1-4.Precaution ········································································ 6-6

1. Setting the Switch····························································6-6

2. Order of Adjustments ······················································6-6

3. Subjects ···········································································6-6

4. Preparing the Flash Adjustment Box·······························6-7

1-2. INITIALIZATION OF DATA ········································· 6-8

1-2-1.INITIALIZATION OF DATA ·········································6-8

1. Initializing All Pages Data ···············································6-8

2. Initializing Single Page Data ···········································6-8

3. 2F Page Adjustment Address···········································6-9

4. 4F Page Adjustment Address···········································6-9

5. 6E Page Adjustment Address ··········································6-9

6. 6F Page Adjustment Address·········································6-10

7. 8E Page Adjustment Address ········································6-11

8. 8F Page Adjustment Address·········································6-11

1-3. VIDEO SYSTEM ADJUSTMENTS····························· 6-12

1. Video Output Level Adjustment (SY-95 board) ············6-12

1-4. CAMERA SYSTEM ADJUSTMENTS························6-13

1. Data Setting during Camera System Adjustments ········ 6-13

2. Wide Limit Adjustment ·················································6-14

2-1. Adjusting method when the lens device is replaced:·····6-14

2-2.

Adjusting method when it is not necessary to replace

the lens device and when the SY-95 board is replaced: ····

3. Flange Back Adjustment ··············································· 6-15

4. Flange Back Check························································6-16

5. Picture Frame Setting ····················································6-17

6. F No. Compensation······················································6-18

7. Mechanical Shutter Adjustment ····································6-18

8. Light V alue Adjustment·················································6-19

9. Auto White Balance 3200K Standard Data Input ········· 6-20

10. Auto White Balance 5800K Standard Data Input ········· 6-20

11. Auto White Balance 5800K Check ·······························6-21

12. Auto White Balance 3200K Check ·······························6-21

13. CCD Linearity Check ····················································6-22

14. Color Reproduction Adjustment····································6-24

15. CCD White Defect Compensation Check ·····················6-25

16. CCD Black Defect Compensation Check ·····················6-26

17. Strobe Adjustment ·························································6-27

18. Auto Focus Illumination Check ····································6-28

1-5. LCD SYSTEM ADJUSTMENT ···································6-29

1. Data Setting during LCD System Adjustments·············6-29

2. LCD Initial Data Input (1)·············································6-29

3. VCO Adjustment (SY-95 board) ···································6-30

4. Bright Adjustment (SY-95 board)··································6-30

5. Contrast Adjustment (SY-95 board) ······························6-31

6. V COM Adjustment (SY-95 board)·······························6-31

7. White Balance Adjustment (1) (SY-95 board) ··············6-32

8. White Balance Adjustment (2) (SY-95 board) ·············6-32

6-2. SERVICE MODE··························································6-33

2-1. APPLICATION FOR ADJUSTMENT (SEUS) ············6-33

2-1-1.Using Method of SEUS ················································· 6-33

1. Connection·····································································6-33

2. Operation ·······································································6-33

2-1-2.Precaution on Use of SEUS···········································6-33

6-2

6-14

2-2. SERVICE MODE ··························································6-34

1. Setting the Test Mode ····················································6-34

2. Bit value discrimination ················································6-34

3. Switch check (1) ····························································6-35

4. Switch check (2) ····························································6-35

5. Switch check (3) ····························································6-35

6. LED check ·····································································6-36

7. Record of Use check······················································6-36

8. Self Diagnostics Log check ···········································6-36

* Color reproduction frame and AF illumination frame are

shown on page 6-38.

— 2 —

Page 3

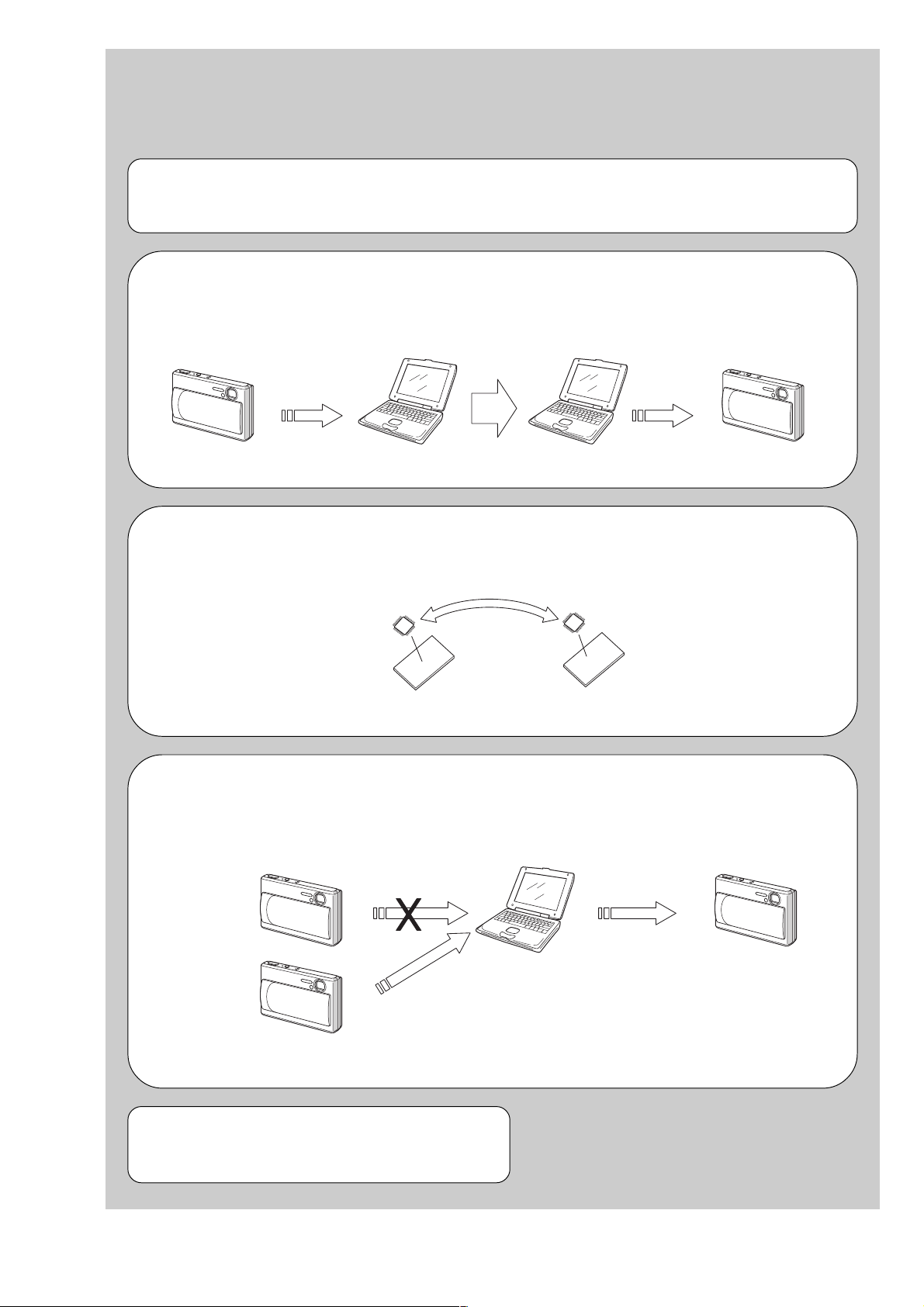

1. Before starting adjustment EVR Data Re-writing Procedure When Replacing Board

The data that is stored in the repair board, is not necessarily correct.

Perform either procedure 1 or procedure 2 or procedure 3 when replacing board.

Procedure 1

Save the EVR data of the machine in which a board is going to be replaced. Do wnload the saved data after a board

is replaced.

(Machine before starting repair)

SECTION 6

ADJUSTMENTS

PC PC

DSC-T1

(Machine after a board is replaced)

Save the EVR data

to a personal computer.

Download the saved

data to a machine.

Procedure 2

Remove the EEPR OM from the board of the machine that is going to be repaired. Install the removed EEPR OM

to the replaced board.

Remove the EEPROM and install it.

(Former board)

(New board)

Procedure 3

When the data cannot be saved due to defective EEPROM, or when the EEPROM cannot be removed or

installed, save the data from the same model of the same destination, and do wnload it.

(Machine to be repaired) (Machine to be repaired)

PC

Save the data.

(The same model of the same destination)

After the EVR data is saved and downloaded, check the

respective items of the EVR data.

(Refer to page 6-2 for the items to be checked.)

Download the data.

6-1

Page 4

DSC-T1

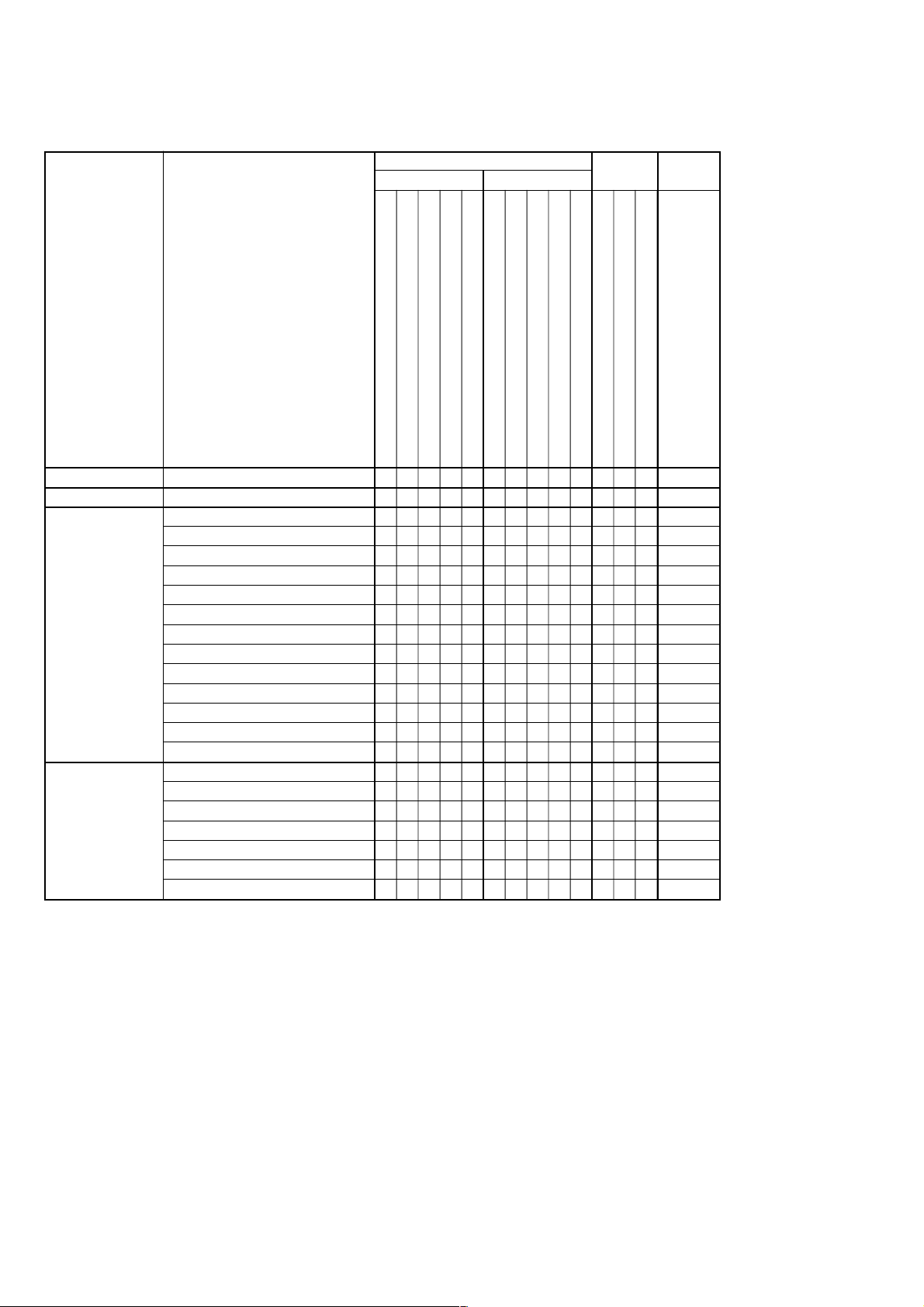

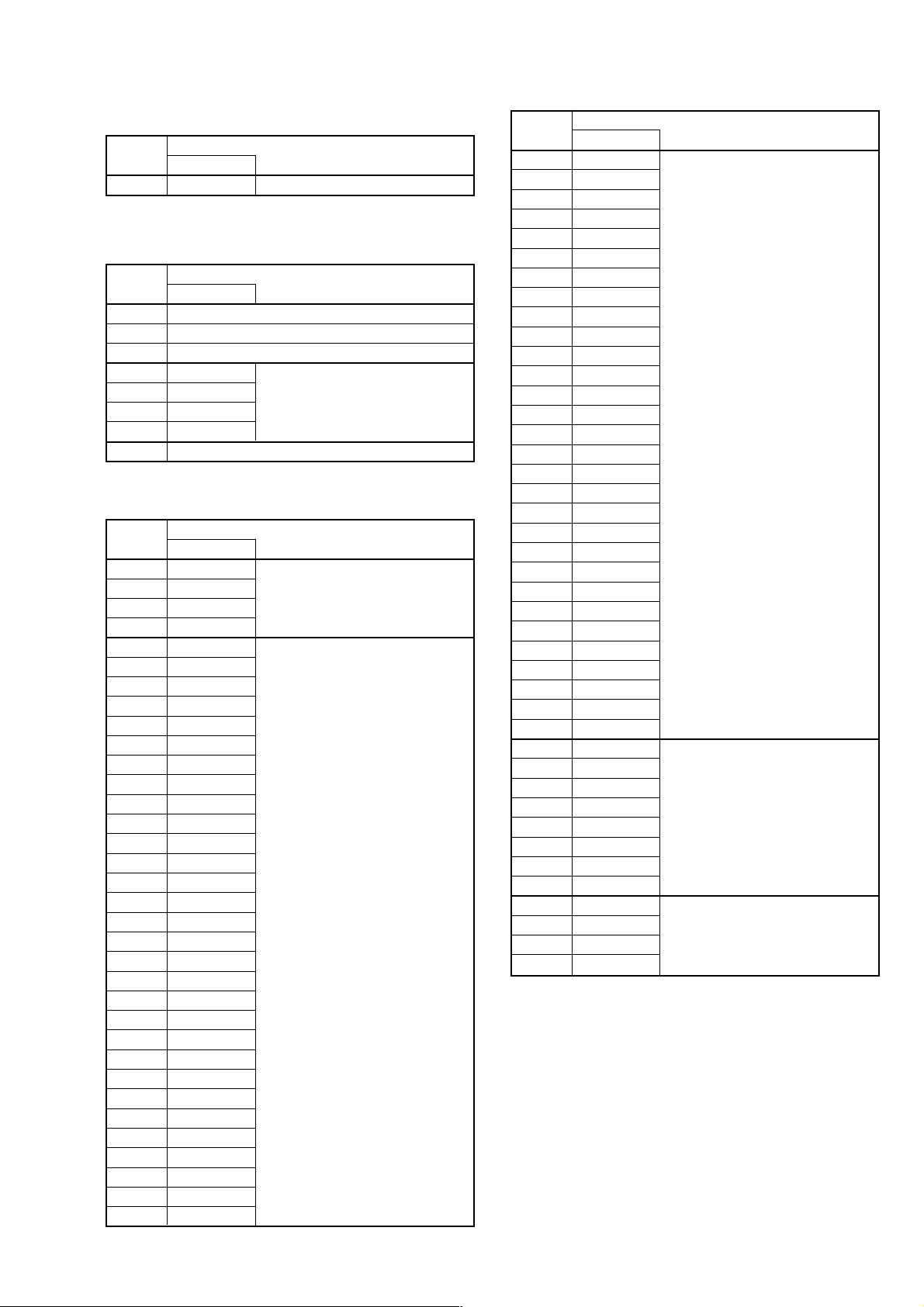

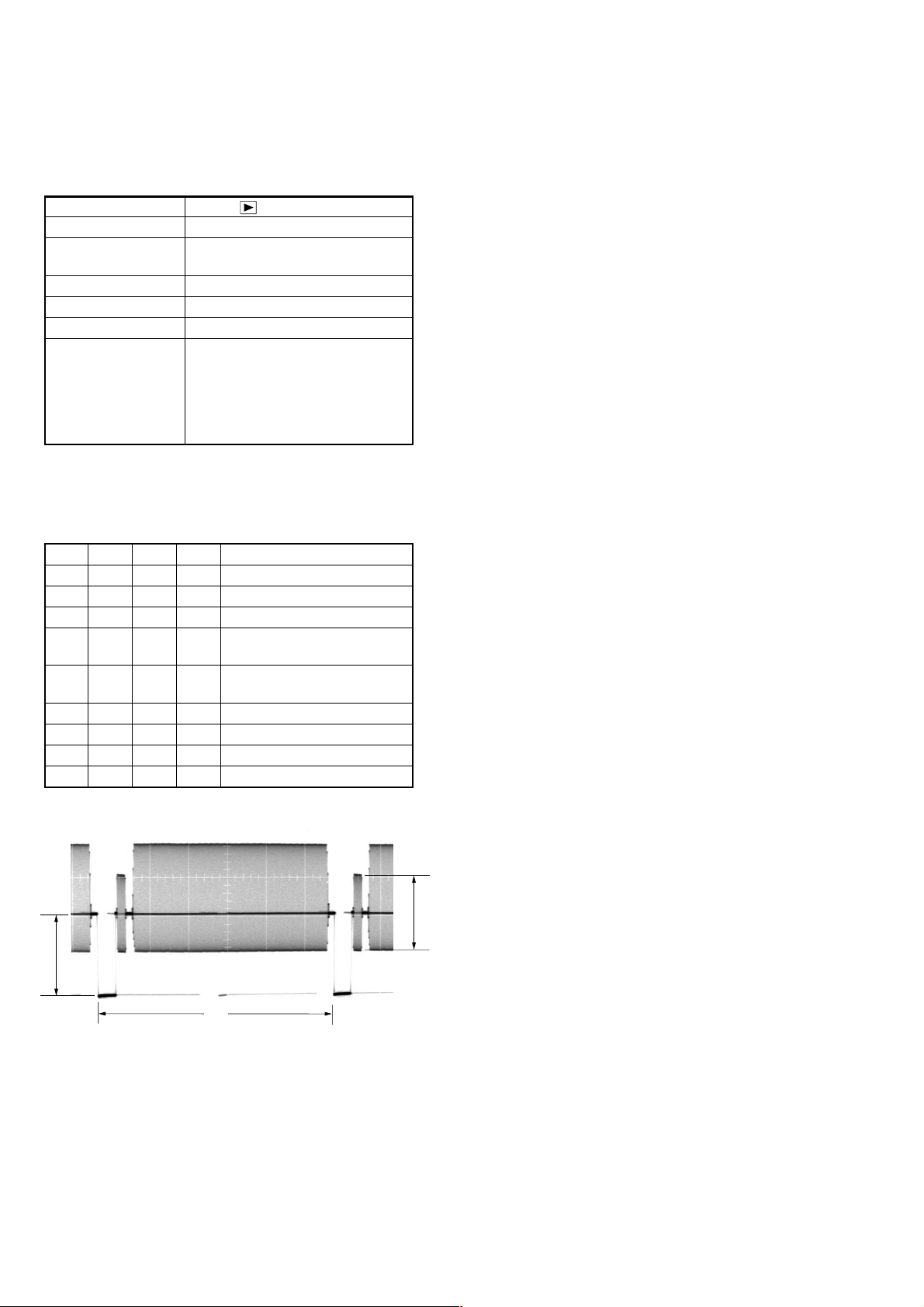

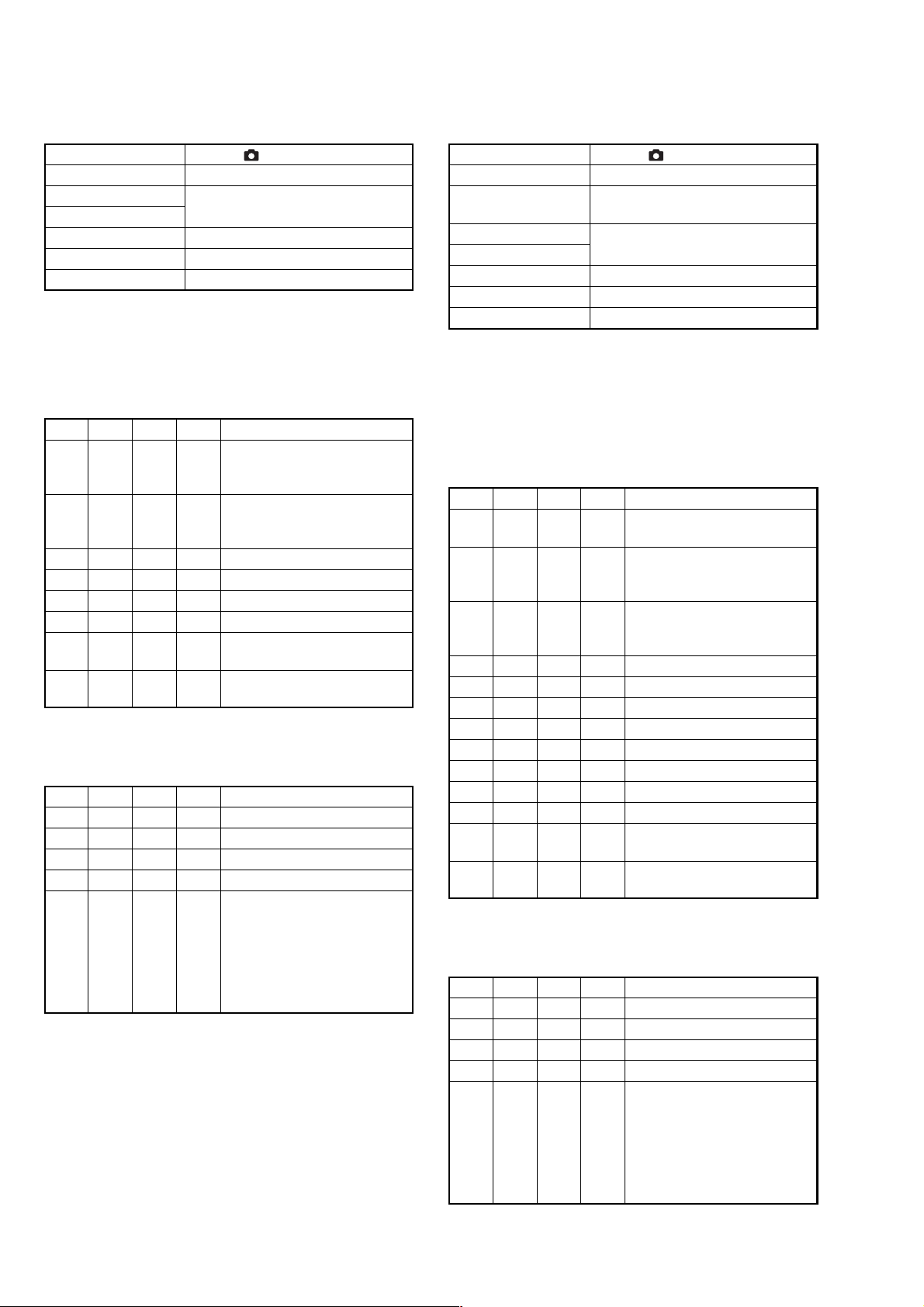

1-1. Adjusting items when replacing main parts and boards.

When replacing main parts and boards, adjust the items indicated by z in the following table.

Replaced parts Board

Block replacement

Parts replacement

replacement

EEPROM

replacement

Adjustment

Section

Initialization of data

Video

Camera

LCD

Adjustment

Initialization of data

Video output level adj.

Wide limit Adj.

Flange back adj.

F No. compensation

Mechanical shutter adj.

Light value adj.

AWB 3200K standard data input

AWB 5800K standard data input

CCD linearity check

Color reproduction adj.

CCD white defect compensation check

CCD black defect compensation check

Strobe adj.

Auto focus illumination check

LCD initial data input

VCO adj.

Bright adj.

Contrast adj.

V COM adj.

White balance adj. (1)

White balance adj. (2)

Table. 6-1-1.

IC803 (RGB drive, Timing.gen.) (LCD)

IC151 (Timing gen. S/H, AGC A/D conv.)

CCD block

Lens device

Xenon tube

LCD block LCD unit (LCD901)

LCD block Back light unit

MS-148 board

ST-86 board D003 (AF Illumination LED)

SY-95 board

SY-95 board IC301 (Camera DSP)

SY-95 board IC302 (Video amp.)

MS-148 board (COMPLETE)

ST-86 board (COMPLETE)

SY-95 board (COMPLETE)

SY-95 board IC501 (Camera system control)

(With built-in flash memory)

zz

zz z z

zzz

zz z z

zz z z z

zz z z z

zz z z z

zz z z z

zz z z z

zz z z z

zz z z z

zz z z z

zz z z z

zzz z z z

zzzzzz

zz

zzzz

zzzz

zzzzz

zz zzz

zzz z z z

zzz z z z

6-2

Page 5

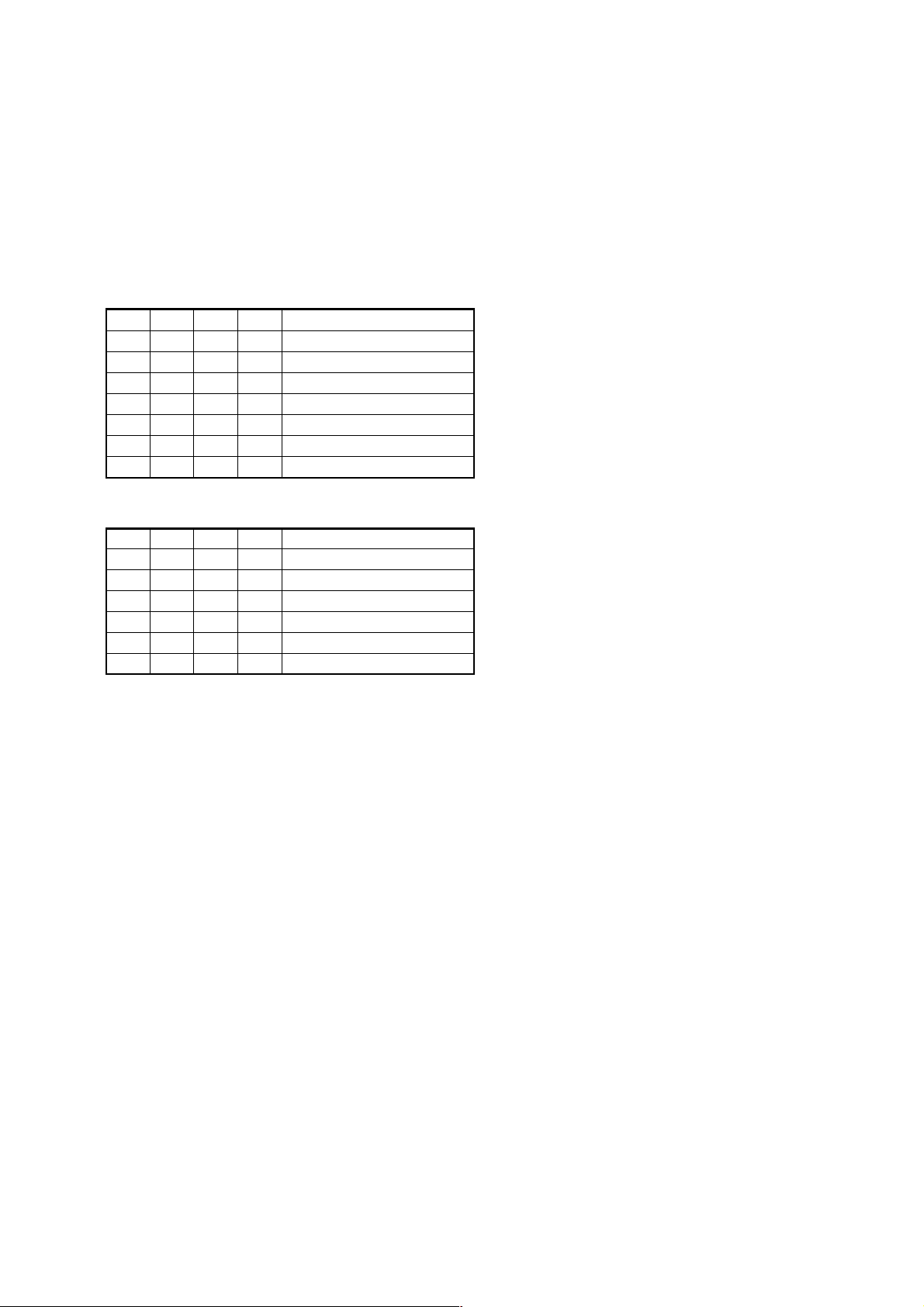

6-1. ADJUSTMENT

1-1. PREPARATIONS BEFORE ADJUSTMENT

1-1-1. List of Service Tools

• Oscilloscope • Color monitor • Vectorscope • AC power adapter

• Calculator which can hexadecimal calculation.

DSC-T1

J-1 J-2 J-3

Filter for color

temperature correction

(C14)

J-6080-058-A

J-4

J-7 J-8

Clear chart for

pattern box

For PTB-450:

J-6080-621-A

For PTB-1450:

J-6020-560-A

Cradle

1-817-742-11

J-5

Pattern box PTB-450

J-6082-200-A

or

Pattern box PTB-1450

J-6082-557-A

J-6

Siemens star chart

J-6080-875-A

J-9

Personal computer

with Windows98/

98SE/ME/2000/XP

installed and with

two USB ports

Clear chart for

pattern box

For PTB-450:

J-6020-250-A

For PTB-1450:

J-6020-559-A

Mini pattern box

J-6082-353-B

USB cable

1-823-073-11

J-10

Application for

adjustment (SEUS)

and HASP key

(Note)

Note : Contact our service headquarter of each area how to get the application for adjustment (SEUS) and HASP key.

J-11

Backgorund

paper

J-2501-130-A

Fig. 6-1-1.

6-3

Page 6

DSC-T1

1-1-2. Preparations

1) Connect the equipment for adjustments according to Fig. 6-1-4.

2) Start up the application for adjustment (SEUS).

Note1: Setting the “Forced Power ON Mode (Forced STILL Mode)”

1) Select page: 00, address: 01, and set data: 01.

2) Select page: 2F, address: 23, and write data: 01.

3) Save the data.

4) Wait for 3 sec.

The above procedure will enable the power (STILL mode) to

be turned on with POWER switch (Control switch block)

disconnected. After completing adjustments, be sure to exit the

“Forced Power ON Mode”.

Note2: Setting the “Forced Power ON Mode (Forced PLAY Mode)”

1) Select page: 00, address: 01, and set data: 01.

2) Select page: 2F, address: 23, and write data: 02.

3) Save the data.

4) Wait for 3 sec.

The above procedure will enable the power (PAL Y mode) to be

turned on with POWER switch (Control switch block)

disconnected. After completing adjustments, be sure to exit the

“Forced Power ON Mode”.

Note3: Exiting the “Forced Power ON Mode”

1) Select page: 00, address: 01, and set data: 01.

2) Select page: 2F, address: 23, and write data: 80.

3) Save the data.

4) Wait for 3 sec.

5) Select page: 00, address: 01, and set data: 00.

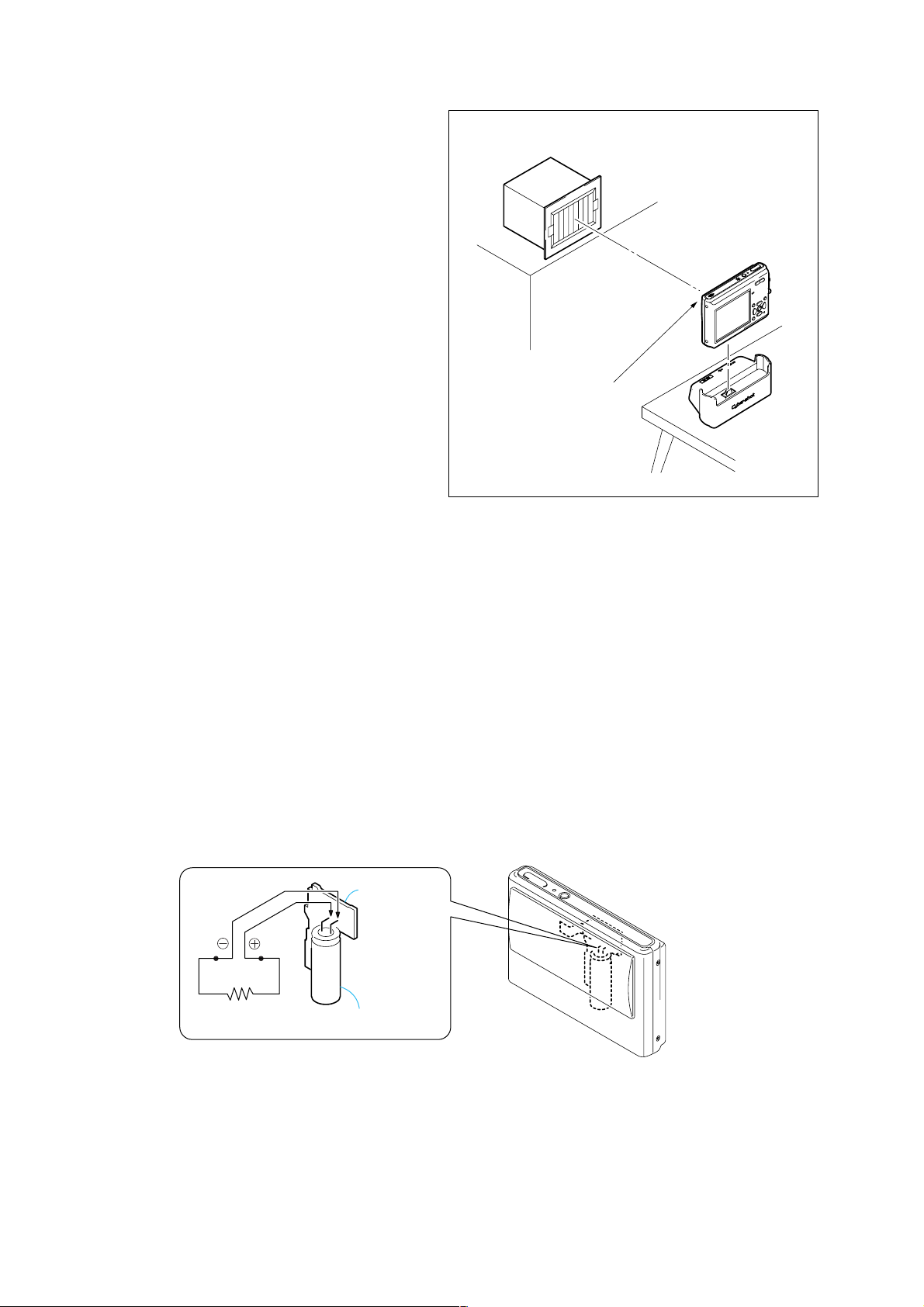

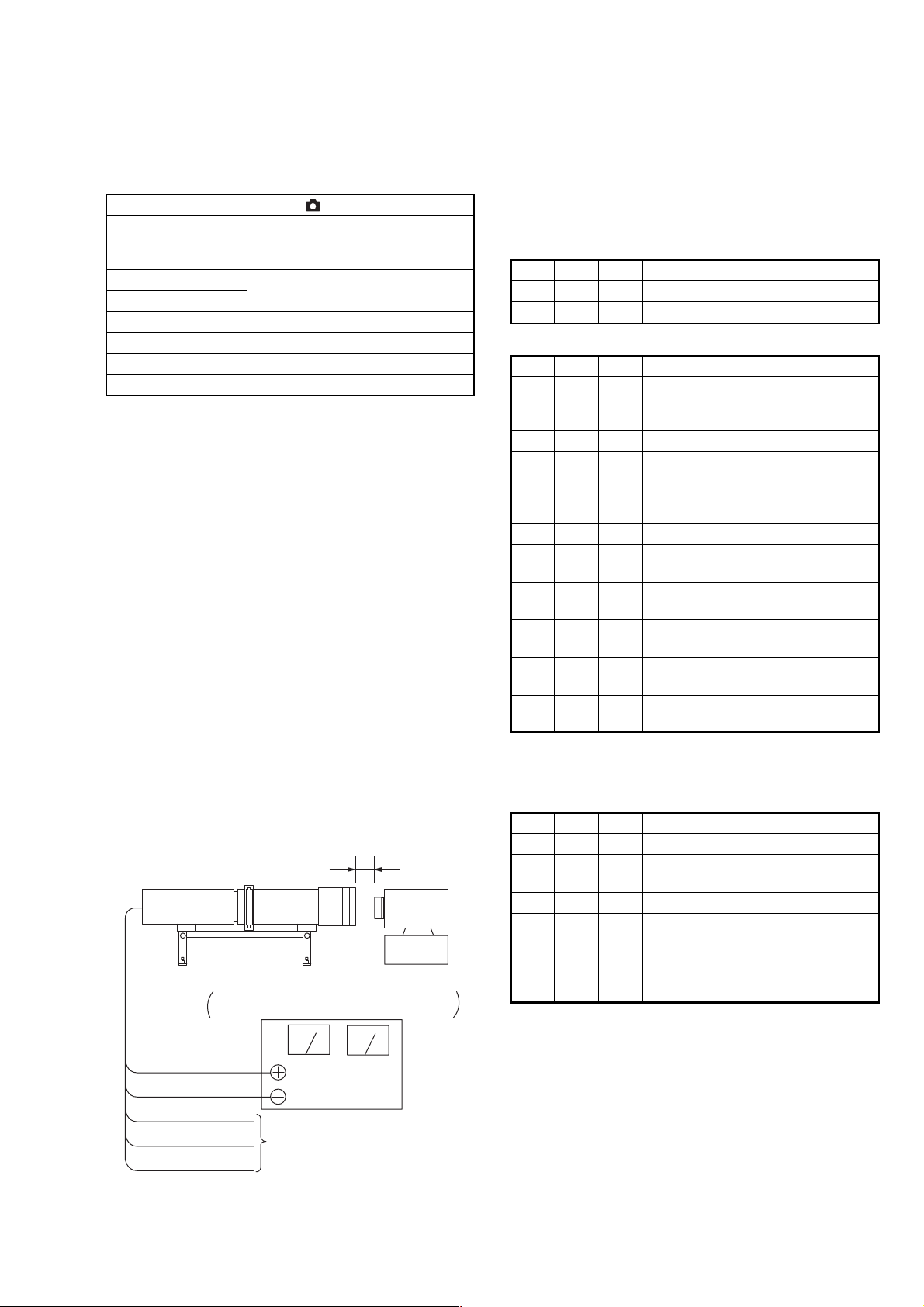

1-1-3. Discharging of the flashlight power supply

The capacitor which is used as power supply of flashlight is charged

with 200V to 300V voltage. When disassembling the unit, dischar ge

this voltage in order to protect service engineers from electric shock.

Pattern box

About 12cm (PTB-1450)

About 30cm (PTB-450)

Front of the lens

Fig. 6-1-2.

Discharge procedure

1. Remove the power supply (AC power adaptor or battery).

2. Fabricate the discharging jig as sho wn in Fig. 6-1-3 locall y by

yourself. Connect the discharging jig to the positive (+) and

negative (-) terminal of the flash v oltage charge capacitor . Allo w

ten seconds to discharge the voltage.

ST-86 BOARD

Shorting jig

(1kΩ / 1w)

Capacitor

Fig. 6-1-3.

6-4

Page 7

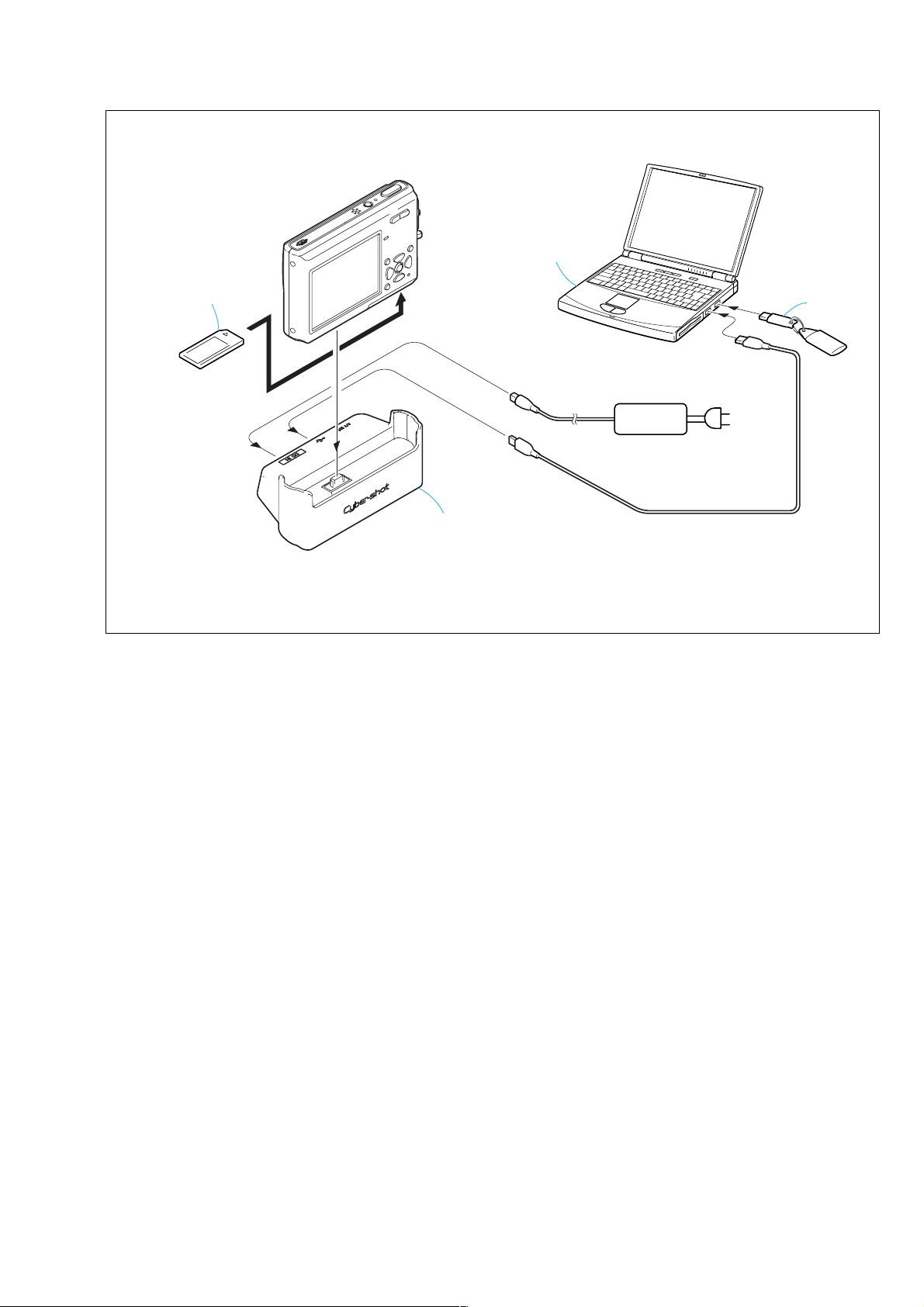

Memory stick DUO

Cradle

Personal computer

(with two USB ports)

AC IN

DC IN

USB

USB1

USB2

HASP key

AC power

adaptor

[CONNECTION OF EQUIPMENT]

DSC-T1

Note: When performing “Flange Back Adjustment”, connect the cables after

disassembling the cradle. Unless the cradle is disassembled, the USB

cable and the power cable will interfere with the flange back adjustment

jig or mini pattern box, and thus the subject cannot be set correctly.

Fig. 6-1-4

6-5

Page 8

DSC-T1

e

1-1-4. Precaution

1. Setting the Switch

Unless otherwise specified, set the switches as follows and perform

adjustments.

Switch settings

1. Mode switch....................................................... STILL (

2. Lens cover...................................................................... Open

3. ZOOM....................................................................WIDE end

2. Order of Adjustments

Basically carry out adjustments in the order given.

Color bar chart (Standard picture frame)

H

)

3. MACRO (

) .................................................................. ON

4. SCENE (Menu)............................................................... Auto

5. VIDEO OUT (SET UP of Menu) ................................. NTSC

Yellow

AAB

Video terminal

output waveform

Cyan

A=

Fig. a

White

Green

B

2

Magenta

Red

Blue

CD

Enlargement

A

3. Subjects

1) Color bar chart (Standard picture frame)

When performing adjustments using the color bar chart, adjust

the picture frame as shown in Fig. 6-1-5. (Standard picture

frame)

2) Clear chart (Color reproduction adjustment frame)

Remove the color bar chart from the pattern box and insert a

clear chart in its place. (Do not perform zoom operations during

this time.)

C=D

V

Difference in level

Fig.6-1-5.

Cyan

White

Green

Yellow

LCD screen or under scan

Fig. b

monitor TV picture

Adjust the camera position and direction to

obtain the output wavef orm shown in Fig. a

and the LCD screen or the monitor TV

display shown in Fig. b.

Red

Blue

Magenta

Picture fram

6-6

Page 9

4. Preparing the Flash Adjustment Box

m

A

A dark room is required to provide an accurate strobe adjustment.

If it is not available, prepare the flash adjustment box as gi ven below;

1) Provide woody board A, B and C of 15 mm thickness.

DSC-T1

woody board A (2 sheets)

400 mm

513 mm 513 mm 700 m

woody board B (2 sheets)

370 mm

700 mm730 mm

Fig. 6-1-6.

2) Apply black mat paint to one side of woody board A and B.

3) Attach background paper (J-2501-130-A) to woody board C.

4) Assemble so that the black sides and the background paper side

of woody board A, B and C are internal. (Fig. 6-1-7.)

woody board C (1 sheet)

700 mm

woody board A

woody board B

woody board

woody board B

woody board C

Fig. 6-1-7.

6-7

Page 10

DSC-T1

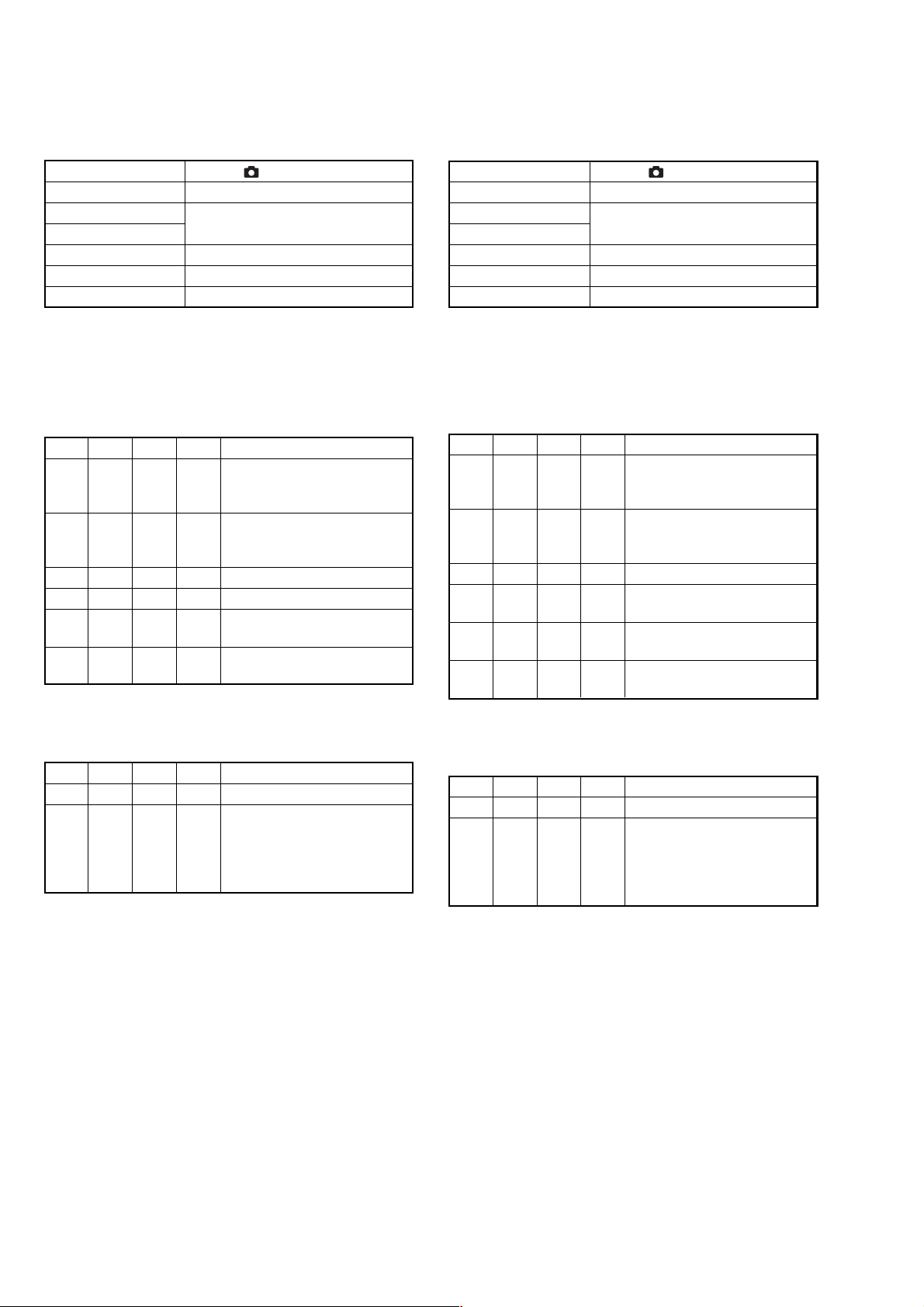

1-2. INITIALIZATION OF DATA

1-2-1. INITIALIZATION OF DATA

1. Initializing All Pages Data

By performing the following procedure, data of all the pages will

be initialized.

Initializing Method:

1) Select page: 00, address: 01, and set data: 01.

2) Click [Sector Write] on the SEUS screen to display the SEUS

SECTOR WRITE screen.

3) Check that the SET ID is “04”.

4) Click [All] of the ALL SELECT buttons to select all pages.

(Fig. 6-1-8. A)

5) Click [Write] to write the initializing data to the EEPROM of

the camera.

6) Wait for 3 sec.

7) Click [Close] to close the SEUS PAGE EDIT screen.

Modification of 4F, 8E Page Data

If all page data have been initialized, change the data of the “Fixed

data-2” address shown in the following tables by manual input.

1) Select page: 00, address: 01, and set data: 01.

2) Click [Page] on the SEUS screen, and input “4F” or “8E”.

3) Click [Address], and input the “Fixed data-2” address.

4) Click [Set], and input the new data.

Note: New data for changing are not shown in the table because they

are different in destination. When changing the data, copy the

data built in the same model. If copy the data built in the different

model, the camera may not operate.

5) Repeat steps 2 to 4 until all data of the “Fixed data-2” addresses

are changed.

6) Click [Save] to write the changed data to the EEPROM of the

camera.

7) Wait for 3 sec.

2. Initializing Single Page Data

By performing the following procedure, data of the page that you

want to initialize will be initialized.

Initializing Method:

1) Select page: 00, address: 01, and set data: 01.

2) Click [Sector Write] on the SEUS screen to display the SEUS

SECTOR WRITE screen.

3) Check that the SET ID is “04”.

4)

Click [All] of the option buttons of the target page. (Fig. 6-1-8. B)

5) Click [Write] to write the initializing data to the EEPROM of

the camera.

6) Wait for 3 sec.

7) Click [Close] to close the SEUS PAGE EDIT screen.

Note: When 4F page or 8E page is initialized, perform “Modification of

4F, 8E Page Data”. (Refer to “1. Initializing All Pages Data”.)

Processing after Completing Initializing of data

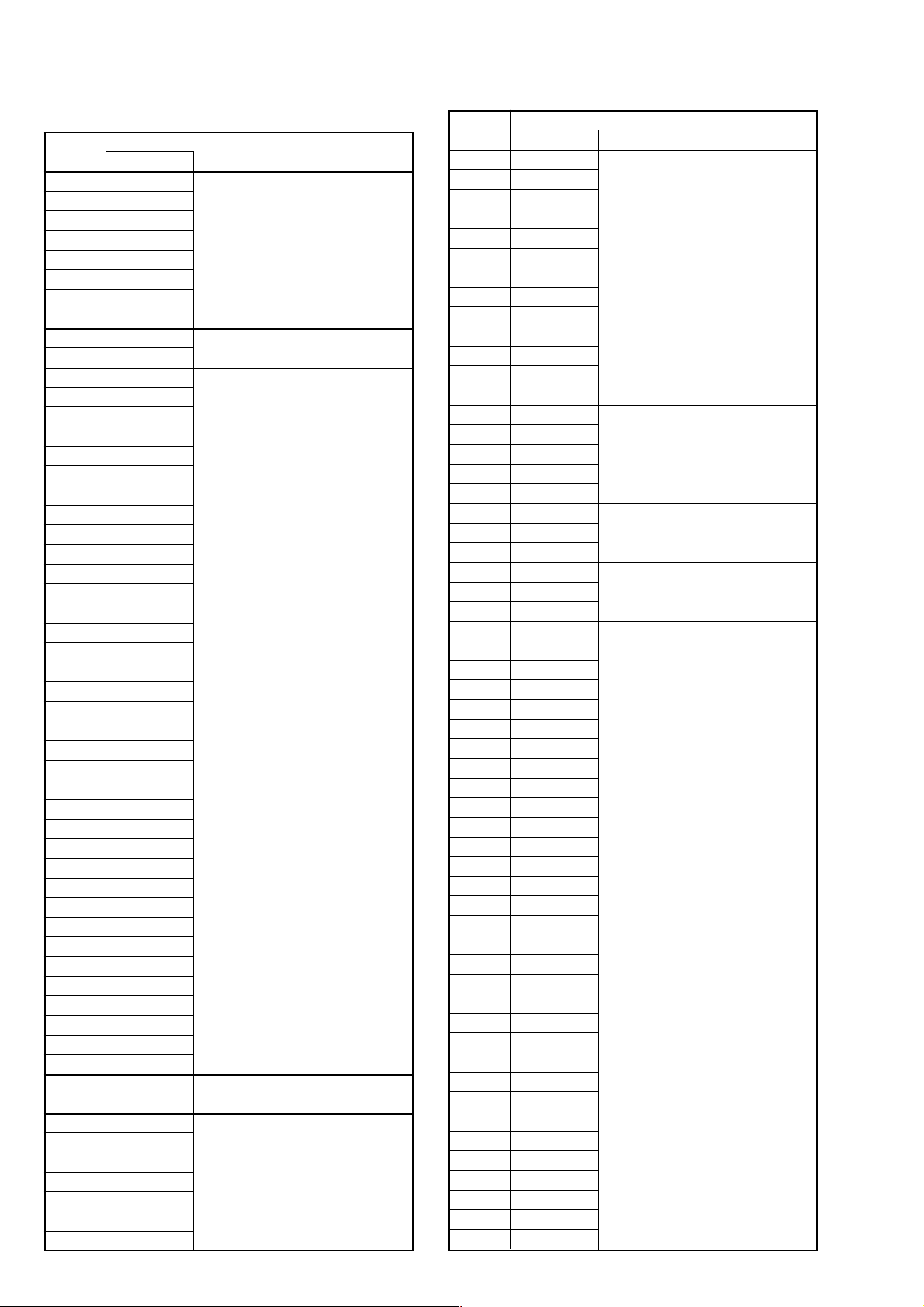

Order Page

Address

Data Procedure

1 20 00 29 Set the data.

2 20 01 29 Set the data.

3 Check “Receive Paket Error” is

displayed on the SEUS screen.

4 Turn on the po wer of the camera.

5 Click [Connect] on the SEUS

screen.

B

Processing after Completing Initializing of data

Order Page

Address

Data Procedure

1 20 00 29 Set the data.

2 20 01 29 Set the data.

3 Check “Receive Paket Error” is

displayed on the SEUS screen.

4 Turn on the po wer of the camera.

5 Click [Connect] on the SEUS

screen.

A

Fig. 6-1-8.

6-8

Page 11

DSC-T1

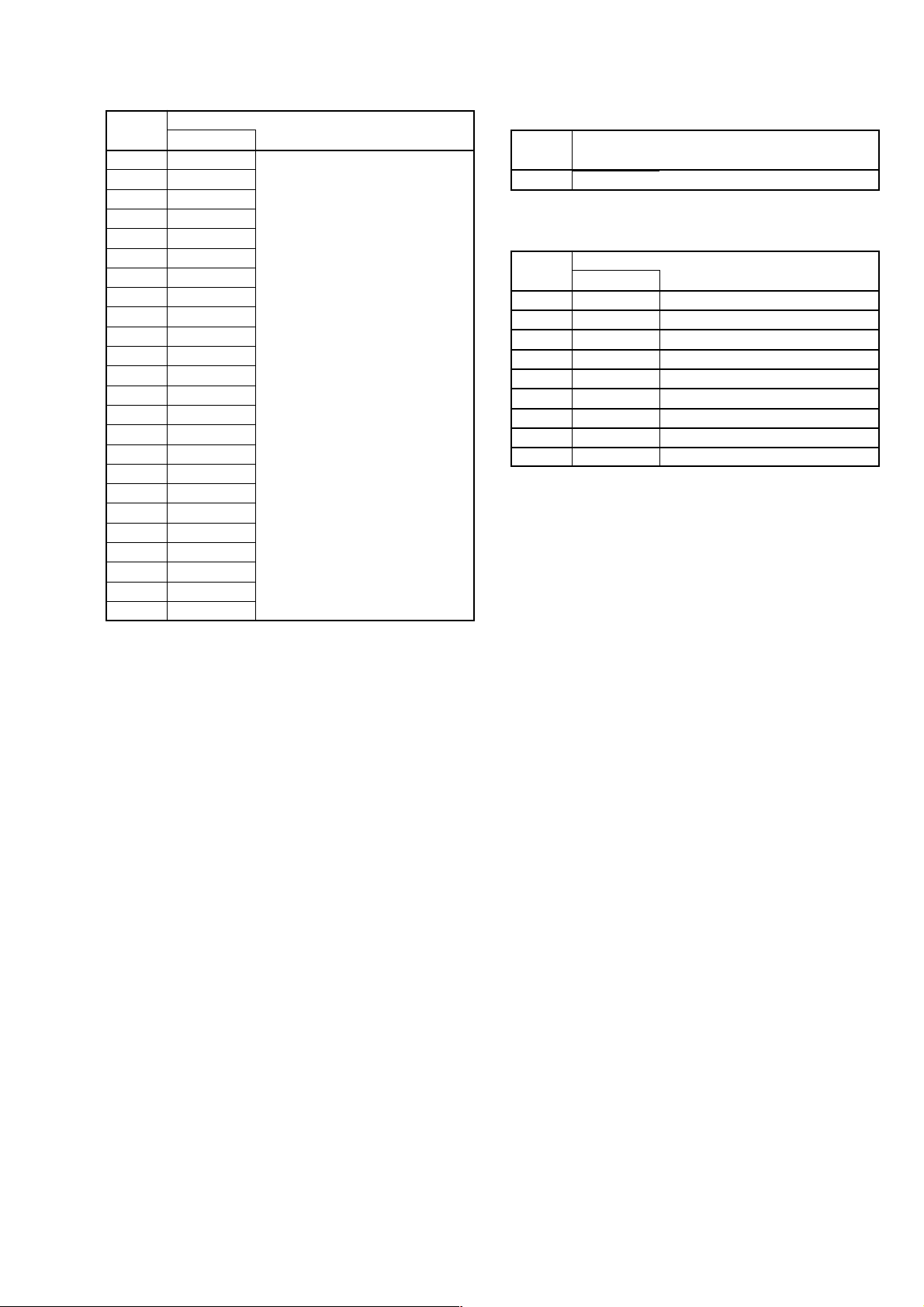

3. 2F Page Adjustment Address

Address Remark

Initial value

23 80 Test mode

Table. 6-1-2.

4. 4F Page Adjustment Address

Address Remark

46

47

88

94

95

96

97

A1

Initial value

00

00

00

00

Fixed data-2

Fixed data-2

Fixed data-2

Recording counter

(Refer to “Record of Use check” of

“SERVICE MODE”.)

Fixed data-2

Table. 6-1-3.

5. 6E Page Adjustment Address

Address Remark

00

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14

15

16

17

18

19

1A

1B

1C

1D

1E

1F

20

21

Initial value

00

00

00

00

21

00

0C

00

20

00

0D

00

21

00

0C

00

20

00

0D

00

21

00

0C

00

20

00

0D

00

00

00

00

00

00

00

AWB 5800K standard data input

AWB 3200K standard data input

Address Remark

24

25

26

27

28

29

2A

2B

2C

2D

2E

2F

30

31

32

33

34

35

36

37

38

39

3A

3B

3C

3D

3E

3F

40

41

60

61

62

63

64

65

66

67

72

73

74

75

Initial value

13

00

13

00

13

00

15

00

13

00

13

00

13

00

15

00

13

00

13

00

13

00

15

00

00

00

00

00

00

00

F1

FB

5E

65

F8

06

69

5C

12

00

18

00

AWB 5800K standard data input

Color reproduction adj.

Strobe adj.

Table. 6-1-4.

6-9

Page 12

DSC-T1

6. 6F Page Adjustment Address

Address Remark

10

11

12

13

14

15

16

17

18

19

1A

1B

1C

1D

1E

1F

20

21

22

23

24

25

26

27

28

29

2A

2B

2C

2D

2E

2F

30

31

32

33

34

35

36

37

38

39

3A

3B

3C

3D

3E

3F

40

41

42

43

44

45

46

Initial value

FF

FF

FF

FF

FF

FF

FF

FF

1C

E8

20

A8

1D

88

00

00

00

00

00

00

20

20

80

46

0A

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

FF

FF

00

00

00

00

00

00

00

AF illumination check

Wide limit adj./Flange back adj.

Flange back adj.

Wide limit adj/

Flange back adj

Flange back adj.

Address Remark

47

48

49

4A

4B

4C

4D

4E

4F

50

51

52

53

60

61

62

63

64

65

66

67

6B

6C

6D

B8

B9

BA

BB

BC

BD

BE

BF

C0

C1

C2

C3

C4

C5

C6

C7

C8

C9

CA

CB

CC

CD

CE

CF

D0

D1

D2

D3

D4

D5

D6

D7

Initial value

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

30

FE

6D

FF

00

00

10

6B

0F

F6

0F

F7

0F

F2

0F

F7

00

00

00

00

00

30

1B

12

0D

08

80

88

98

90

88

00

00

00

00

00

00

14

Flange back adj.

F No. standard data input

Light value adj.

F No. standard data input/

Mechanical shutter adj.

Mechanical shutter adj.

6-10

Page 13

6F page

Address Remark

DD

DE

EA

ED

D8

D9

DA

DB

DC

DF

E0

E1

E2

E3

E4

E5

E6

E7

E8

E9

EB

EC

EE

EF

Initial value

FF

FF

FF

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

00

Strobe adj.

7. 8E Page Adjustment Address

Address Remark

C8 Fixed data-2

Table. 6-1-6.

8. 8F Page Adjustment Address

Address Remark

23

24

25

28

29

2A

2B

2C

D0

Initial value

80

A2

91

80

80

80

80

45

80

VCO adj. (LCD)

V COM adj. (LCD)

Bright adj. (LCD)

White balance adj.(1) (LCD)

White balance adj.(2) (LCD)

White balance adj.(1) (LCD)

White balance adj.(2) (LCD)

Contrast adj. (LCD)

Video output level adj.

Table. 6-1-7.

DSC-T1

Table. 6-1-5.

6-11

Page 14

DSC-T1

1-3. VIDEO SYSTEM ADJUSTMENTS

1. Video Output Level Adjustment (SY-95 board)

Adjust the sync level of the composite video signal output.

Mode PLAY ( )

Signal No signal

Measurement Point Video terminal of AV OUT jack

of the cradle (75Ω terminated)

Measuring Instrument Oscilloscope

Adjustment Page 8F

Adjustment Address D0

Specified Value Sync level:

A=286 ± 5mV (NTSC mode)

A=300 ± 5mV (PAL mode)

Burst level:

B=286 ± 30mV (NTSC mode)

B=300 ± 30mV (PAL mode)

Switch setting:

VIDEO OUT (SETUP 2)......................................... (NTSC mode)

............................................ (PAL mode)

Adjusting method:

Order Page

1 00 01 01 Set the data.

260C1

3 80 70 01 Set the data.

4 8F D0 Change the data and set the sync

5 Check that the burst level (B)

6 80 70 00 Write the data.

7 Save the data.

8 Wait for 3 sec.

9 00 01 00 Set the data.

A

Address

Data Procedure

Read the data, and check it is “01”.

level (A) to the specified value.

satisfies the specified value.

B

H

Fig. 6-1-8.

6-12

Page 15

1-4. CAMERA SYSTEM ADJUSTMENTS

Before perform the camera system adjustments, check that the

specified values of “VIDEO SYSTEM ADJUSTMENT” are

satisfied.

1. Data Setting during Camera System Adjustments

Perform the following data setting before the camera system

adjustments.

Note: When the power is turned off, some data settings will be released.

So perform this data setting again when the power is turned off.

Order Page

1 00 01 01 Set the data.

2 4F B7 01 Set the data.

3 2F 23 01 Set the data.

4 60 C1 Read the data, and check it is “02”.

5 80 70 01 Set the data.

6 60 6C 01 Set the data.

7 60 2C 01 Set the data.

Address

Data Procedure

DSC-T1

After completing the camera system adjustments, release the

data setting.

Order Page

1 00 01 01 Set the data.

2 4F B7 00 Set the data.

3 2F 23 80 Set the data.

4 Save the data.

5 Wait for 3 sec.

6 00 01 00 Set the data.

Address

Data Procedure

6-13

Page 16

DSC-T1

2. Wide Limit Adjustment

Adjusted the dispersion of the wide-end of the inner focus lens.

Adjustment Page 6F

Adjustment Address 18, 19

2-1. Adjusting method when the lens device is replaced:

Adjusting method:

Order Page

Address

Data Procedure

1 00 01 01 Set the data.

2 6F 18 Set the data. (Note)

3 6F 19 Set the data. (Note)

4 7C 16 00 Set the data.

5 Save the data.

6 Wait for 3 sec.

7 Perform “Flange Back

Adjustment”.

Note: The data of the addresses 18 and 19, which must be set at Steps 2

and 3, are written on the lens device for service replacement. Four

digits hexadecimal number is written on the lens. Please set the upper

2 digits of the number to the address 18, and set the lower 2 digits to

the address 19.

2-2. Adjusting method when it is not necessary to

replace the lens device and when the SY-95 board

is replaced:

When the data of page: 6F, address: 18 and 19 can be

read from the defective board before replacing it. And

when both of the data are not “00”.

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 00 01 01 Set the data.

2 6F 18 Set the read data.

3 6F 19 Set the read data.

4 7C 16 00 Set the data.

5 Save the data.

6 Wait for 3 sec.

7 Perform “Flange Back

Adjustment”.

When the data of page: 6F, address: 18 and 19 can be

read from the defective board before replacing it. And

when both of the data are “00”.

1) Replace the lens device and perform “2-1. Adjusting method when

the lens device is replaced.”

When the data of page: 6F, address: 18 and 19 cannot be

read from the defective board.

1) Replace the lens device and perform “2-1. Adjusting method

when the lens device is replaced.”

Fig.6-1-10.

Note: The data of address 16 of page 7C, set at Step 4 of the adjustment

method of 2-1 and 2-2, is “01” in the state of shipment of the factory.

However, it is “00” when it is adjusted according to the service

manual.

6-14

Page 17

DSC-T1

3. Flange Back Adjustment

The inner focus lens flange back adjustment is carried out

automatically. In whiche v er case, the focus will be de viated during

auto focusing/manual focusing.

Mode STILL ( )

Subject Flange back adjustment jig or

minipattern box (Siemens star chart

with ND filter (Note1))

Measurement Point Data of page: 6F, address: 24, 3E, 3F

Measuring Instrument

Adjustment Page 6F

Adjustment Address 18 to 53

Specified value1 00

Specified value2 0A to 40

Note1: Dark siemens star chart.

Note2: If the data of page: 60, address: 02 is “01”, select page: 60, address:

01, and set data: 00.

Note3: When performing “Flange Back Adjustment”, connect the cables

after disassembling the cradle. Unless the cradle is disassembled,

the USB cable and the power cable will interfere with the flange

back adjustment jig or mini pattern box, and thus the subject cannot

be set correctly.

Preparations for the minipattern box:

1) The minipattern box is installed as shown in the following

figure.

Note: The attachment lenses are not used.

2) Install the minipattern box so that the distance between it and

the front of the lens of the camera is less than 3cm.

3) Make the height of the minipattern box and the camera equal.

4) Check that the output voltage of the regulated power supply is

the specified voltage.

5) Check that at both the zoom lens TELE end and WIDE end,

the center of the siemens star chart and center of the exposure

screen coincide.

Specified voltage:

The specified voltage varies according to the minipattern box, so

adjust the power supply output voltage to the specified voltage

written on the sheet which is supplied with the minipattern box.

Below 3 cm

Minipattern box

Camera

Regulated power supply

Output voltage : Specified voltage ±0.01Vdc

Output current : more than 3.5A

Preparations for the flange back adjustment jig:

1) Install the flange back adjustment jig so that the distance

between it and the front of the lens of the camera is less than

3cm.

2) Adjust the illumination intensity to the chart of the flange back

adjustment jig. (300 to 400 lux)

Data setting when the lens device is replaced:

Note4: Perform this data setting only when the lens device is replaced.

Order Page

Address

Data Procedure

1 00 01 01 Set the data.

2 6F 3E FF Set the data.

Adjusting method:

Order Page

Address

Data Procedure

1 Check that “1. Data Setting

during Camera System

Adjustments” is performed.

2 60 01 13 Set the data.

3 Wait for 1sec.

When the flange back

adjustment jig is used, check

that optimum image is obtained.

4 60 01 27 Set the data.

5 Wait until the movement of the

lens stops.

6 60 02 Read the data, and check it is “01”.

(Note5)

7 6F 3E Read the data, and check it

satisfies the specified value 1.

8 6F 3F Read the data, and check it

satisfies the specified value 1.

9 6F 24 Read the data, and check it

satisfies the specified value 2.

Note5: The adjustment data will be automatically input to page: 6F,

address: 18 to 53

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 60 01 00 Set the data.

2 Turn off the power and turn on

again.

3 Perform “Flange Back Check”.

4 If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

Red (+)

Black (–)

Yellow (SENS +)

White (SENS –)

Black (GND)

Need not connected

Fig.6-1-11.

6-15

Page 18

DSC-T1

4. Flange Back Check

Mode STILL ( )

Subject Siemens star

(1.0 m from the front of the lens)

(Luminance : 200 to 400 lux)

Measurement Point Check operation on TV monitor

(under scan mode)

Measuring Instrument

Specified Value The lens is focused.

Switch setting:

ZOOM ........................................................................... TELE end

MACRO ( ).........................................................................OFF

Checking method:

Order Page

1 Turn off the power and turn on

2 Place the siemens star 1.0 m from

3 Shoot the siemens star with the

4 60 8C 30 Set the data.

5 Observe the TV monitor and

6 60 2C 01 Set the data.

7 Press the ZOOM WIDE button

8 Shoot the Siemens star with the

9 Observe the TV monitor and

Address

Data Procedure

again

the front of the lens.

zoom TELE end.

check that the lens is focused.

and check that zoom operation is

normal.

zoom WIDE end.

check that the lens is focused.

Processing after Completing Adjustments:

Order Page

1 60 8C 00 Set the data.

Address

Data Procedure

6-16

Page 19

5. Picture Frame Setting

E=F

V

EF

Color bar chart picture frame

Effective picture frame

ABC

Mode STILL ( )

Subject Color bar chart and clear chart

(Standard picture frame)

About 30cm (PTB-450) or 12cm

(PTB-1450) from the front of the lens

Measurement Point Video terminal of A/V OUT jack of

the cradle

Measuring Instrument Oscilloscope and TV monitor

Specified Value A=C=B/2, E=F

Switch setting:

ZOOM ...........................................................................WIDE end

MACRO ( ).......................................................................... ON

SCENE (Menu setting)........................................................ AUTO

Setting method:

Order Page

Address

Data Procedure

1 Turn off the power and turn on

again

2 Shoot the color bar chart with

the zoom WIDE end.

3 Adjust the direction and distance

between the pattern box and

camera, and set the picture frame

to the specified position.

4 Perform “1. Data Setting during

Camera System Adjustments”.

5 Remove the color bar chart and

set the clear chart.

6 Check that the whole of the screen

is white. If not, adjust the direction

and distance slightly.

7 10 44 Read the data, and this data named

YH.

8 10 45 Read the data, and this data named

YL.

9 Perform the following

adjustments.

How to reset the zoom and focus when they deviated:

If the zoom and focus deviated due to some reason reset them in the

following method.

Order Page

Address

Data Procedure

1 60 90 00 Set the data.

2 60 91 00 Set the data.

3 60 92 YL Set the data. Note

4 60 93 YH Set the data. Note

5 60 01 79 Set the data.

6 Wait until the movement of the

lens stops.

7 60 07 Read the data, and check it is “01”.

8 60 01 00 Set the data.

Check on an oscilloscope

1. Horizontal period

A

A = C =

B

2

B

C

Fig. 6-1-12.

2. V ertical period

Fig. 6-1-13.

Check on the monitor TV (Underscanned mode)

DSC-T1

Note: YH and YL are the data read in the “Setting method”.

Fig. 6-1-14.

6-17

Page 20

DSC-T1

6. F No. Compensation

Adjusted the dispersion of the iris to every to every F number, and

compensate the exposure.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Measurement Point Data of page: 6F, address: 6B

Measuring Instrument

Adjustment Page 6F

Adjustment Address 60 to 64, 6B to 6D

Specified value 00

Note1:If the data of page: 60, address: 02 is “01”, select page: 60, address:

01, and set data: 00.

Switch setting:

ZOOM ...........................................................................WIDE end

Adjusting method:

Order Page

Address

Data Procedure

1 Check that “1. Data Setting during

Camera System Adjustments” is

performed.

2 Check the picture frame. If

deviated, perform “5. Picture

Frame Setting”.

3 60 01 BB Set the data.

4 Wait for 15 sec.

5 60 02 Read the data, and check it is “01”.

(Note2)

6 6F 6B Read the data, and check it

satisfies the specified value.

Note2: The adjustment data will be automatically input to page: 6F,

address: 60 to 64, 6B to 6D.

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 60 01 00 Set the data.

2 If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

7. Mechanical Shutter Adjustment

Adjust the dispersion of the opening/closing time and the closing

loss rate of the mechanical shutter. and compensate the exposure.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Measurement Point Data of page: 6F, address: 6B

Measuring Instrument

Adjustment Page 6F

Adjustment Address 6B to 6D, B8 to D7

Specified value 00

Note1: If the data of page: 60, address: 02 is “01”, select page: 60, address:

01, and set data: 00.

Switch setting:

ZOOM ...........................................................................WIDE end

Adjusting method:

Order Page

Address

Data Procedure

1 Check that “1. Data Setting during

Camera System Adjustments” is

performed.

2 Check the picture frame. If

deviated, perform “5. Picture

Frame Setting”.

3 60 01 AD Set the data.

4 Wait until the movement of the

shutter stops.

5 60 02 Read the data, and check it is “01”.

(Note2)

6 6F 6B Read the data, and check it

satisfies the specified value.

Note2: The adjustment data will be automatically input to page: 6F,

address: 6B to 6D, B8 to D7.

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 60 01 00 Set the data.

2 If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

6-18

Page 21

DSC-T1

8. Light Value Adjustment

Adjust the standard LV value.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Measurement Point Data of page: 10, address: 0C, 0D

Measuring Instrument Data of page: 6F, address: 65

Adjustment Page 6F

Adjustment Address 65 to 67

Specified value1 0FE0 to 1020

Specified value2 30 to 60

Specified value3 00 to 26

Note1: If the data of page: 60, address: 02 is “01”, select page: 60, address:

Switch setting:

ZOOM ...........................................................................WIDE end

Adjusting method:

01, and set data: 00.

Order Page

1 Check that “1. Data Setting during

2 Check the picture frame. If

3 60 01 0D Set the data.

4 Wait for 2 sec.

5 60 02 Read the data, and check it is “01”.

6 10 0C Read the data, and this data is

7 10 0D Read the data, and this data is

8 Calculate DLV using the

9 Check that DLV satisfies the

10 6F 65 Read the data, and check it

11 60 01 00 Set the data.

12 Wait for 1 sec.

13 60 12 A2 Set the data.

14 60 13 A8 Set the data.

15 60 14 8A Set the data.

16 Wait for 1 sec.

17 10 0C Read the data, and this data is

18 10 0D Read the data, and this data is

19 Calculate DAE using the

20 77 5E 00 Set the data.

21 Wait for 1 sec.

22 10 0C Read the data, and this data is

Address

Data Procedure

Camera System Adjustments” is

performed.

deviated, perform “5. Picture

Frame Setting”.

(Note2)

named D0C.

named D0D.

following equation

(Hexadecimal calculation)

DLV = D0C × 100 + D0D

specified value1.

satisfies the specified value2.

named D0C.

named D0D.

following equation

(Hexadecimal calculation)

DAE = D0C × 100 + D0D

named D0C.

Order Page

23 10 0D Read the data, and this data is

24 Calculate DAE100 using the

25 Check that the difference of DAE

Note2: The adjustment data will be automatically input to page: 6F,

Processing after Completing Adjustments:

Order Page

1 60 01 00 Set the data.

2 60 12 00 Set the data.

3 60 13 00 Set the data.

4 60 14 00 Set the data.

5 77 5E 1E Set the data.

6 Save the data.

7 Wait for 3 sec.

8 Perform next adjustment. If finish

Address

address: 65 to 67.

Address

Data Procedure

named D0D.

following equation

(Hexadecimal calculation)

DAE100 = D0C × 100 + D0D

and DAE100 satisfies the specified

value3. (Hexadecimal).

Data Procedure

the camera system adjustments,

release the data setting. (See “1.

Data Setting during Camera

System Adjustments”.)

6-19

Page 22

DSC-T1

9. Auto White Balance 3200K Standard Data Input

Adjust the white balance standard data at 3200K.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Measurement Point Data of page: 6E, address: 4F

Measuring Instrument

Adjustment Page 6E

Adjustment Address 04 to 21

Specified value 00

Note1: If the data of page: 60, address: 02 is “01”, select page: 60, address:

01, and set data: 00.

Switch setting:

ZOOM ...........................................................................WIDE end

Adjusting method:

Order Page

Address

Data Procedure

1 Check that “1. Data Setting

during Camera System

Adjustments” is performed.

2 Check the picture frame. If

deviated, perform “5. Picture

Frame Setting”.

3 6E 4F FF Set the data.

4 60 36 01 Set the data.

5 60 01 0B Set the data.

6 Wait for 5 sec.

7 60 02 Read the data, and check it is “01”.

(Note2)

8 6E 4F Read the data, and check it

satisfies the specified value.

Note2: The adjustment data will be automatically input to page: 6E,

address: 04 to 21.

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 60 01 00 Set the data.

2 60 36 00 Set the data.

3 Wait for 1 sec.

4 60 37 Read the data, and check it is “00”.

5 Perform “Auto White Balance

5800K Standard Data Input”.

If finish the camera system

adjustments, release the data

setting. (See “1. Data Setting

during Camera System

Adjustments”.)

10.Auto White Balance 5800K Standar d Data Input

Adjust the white balance standard data at 5800K.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Filter Filter C14 for color temperature

correction

Measurement Point Data of page: 6E, address: 4F

Measuring Instrument

Adjustment Page 6E

Adjustment Address 00 to 03, 24 to 41

Specified value 00

Note1: Before perform this adjustment, perform “Auto White Balance

Note2: If the data of page: 60, address: 02 is “01”, select page: 60, address:

3200K Standard Data Input”.

01, and set data: 00.

Switch setting:

ZOOM ...........................................................................WIDE end

Adjusting method:

Order Page

Address

Data Procedure

1 Place the C14 filter for color

temperature correction on the lens.

2 Check that “1. Data Setting during

Camera System Adjustments” is

performed.

3 Check the picture frame. If

deviated, perform “5. Picture

Frame Setting”.

4 6E 00 00 Set the data.

5 6E 01 00 Set the data.

6 6E 02 00 Set the data.

7 6E 03 00 Set the data.

8 6E 4F FF Set the data.

9 60 36 02 Set the data.

10 60 01 A5 Set the data.

11 Wait for 5 sec.

12 60 02 Read the data, and check it is

“01”. (Note3)

13 6E 4F Read the data, and check it

satisfies the specified value.

Note3: The adjustment data will be automatically input to page: 6E,

address: 24 to 41.

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 60 01 00 Set the data.

2 60 36 00 Set the data.

3 Wait for 1 sec.

4 60 37 Read the data, and check it is “00”.

5 Perform “Auto White Balance

5800K Check”.

If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

6-20

Page 23

DSC-T1

11.Auto White Balance 5800K Check

Check that the white balance standard data at 5800K are inputted

properly.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Filter Filter C14 for color temperature

correction

Measurement Point Data of page: 6E, address: 4F

Measuring Instrument

Specified value 00

Note1: Before perform this adjustment, perform “Auto White Balance

Note2: If the data of page: 60, address: 02 is “01”, select page: 60, address:

5800K Standard Data Input”.

01, and set data: 00.

Switch setting:

ZOOM ...........................................................................WIDE end

Adjusting method:

Order Page

Address

Data Procedure

1 Place the C14 filter for color

temperature correction on the lens.

2 Check that “1. Data Setting during

Camera System Adjustments” is

performed.

3 Check the picture frame. If

deviated, perform “5. Picture

Frame Setting”.

4 6E 4F FF Set the data.

5 60 36 04 Set the data.

6 60 01 3F Set the data.

7 Wait for 10 sec.

8 60 02 Read the data, and check it is “01”.

9 6E 4F Read the data, and check it

satisfies the specified value.

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 60 01 00 Set the data.

2 60 36 00 Set the data.

3 Wait for 1 sec.

4 60 37 Read the data, and check it is “00”.

5 Remove the C14 filter.

6 Perform next adjustments.

If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

12.Auto White Balance 3200K Check

Check that the white balance standard data at 3200K are inputted

properly.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Measurement Point Data of page: 6E, address: 4F

Measuring Instrument

Specified value 00

Note1: Before perform this adjustment, perform “Auto White Balance

Note2: If the data of page: 60, address: 02 is “01”, select page: 60, address:

3200K Standard Data Input”.

01, and set data: 00.

Switch setting:

ZOOM ...........................................................................WIDE end

Adjusting method:

Order Page

Address

Data Procedure

1 Check that “1. Data Setting during

Camera System Adjustments” is

performed.

2 Check the picture frame. If

deviated, perform “5. Picture

Frame Setting”.

3 6E 4F FF Set the data.

4 60 36 03 Set the data.

5 60 01 0F Set the data.

6 Wait for 10 sec.

7 60 02 Read the data, and check it is “01”.

8 6E 4F Read the data, and check it

satisfies the specified value.

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 60 01 00 Set the data.

2 60 36 00 Set the data.

3 Wait for 1 sec.

4 60 37 Check the data, and check it is

“00”.

5 Perform next adjustments.

If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

6-21

Page 24

DSC-T1

13.CCD Linearity Check

Data picking is done to keep output linearity of the CCD imager,

even if the input level of CCD imager changes.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Measurement Point

Measuring Instrument

Specified value1 97 to 103 (Note1)

Specified value2 94 to 106 (Note1)

Specified value3 92 to 108 (Note1)

Note1: Decimal number.

Note2: If the data of page: 60, address: 02 is “01”, select page: 60, address:

Note3: For the bit values, refer to “6-2. SERVICE MODE”, “2-2. 2. Bit

Switch setting:

ZOOM ...........................................................................WIDE end

Preparation:

01, and set data: 00.

value discrimination”.

Order Page

1 Check that “1. Data Setting during

2 Check the picture frame. If

3 75 09 Read the data, and memorize it.

4 75 09 04 Set the data.

5 77 F6 Read the data, and memorize it.

6 77 F6 Set Bit2 of the data to “0”. (Note3)

7 77 F7 Read the data, and memorize it.

8 77 F7 Set Bit6 of the data to “1”. (Note3)

9 77 F2 Read the data, and memorize it.

10 77 F2 Set Bit6 of the data to “0”. (Note3)

11 77 F2 Set Bit0 of the data to “0”. (Note3)

12 77 72 Read the data, and memorize it.

13 60 14 90 Set the data.

14 60 12 9F Set the data.

15 60 05 16 Set the data.

16 75 17 Read the data, and memorize it.

17 75 17 50 Set the data.

18 75 18 Read the data, and memorize it.

19 75 18 00 Set the data.

20 75 19 Read the data, and memorize it.

21 75 19 EC Set the data.

22 75 1A Read the data, and memorize it.

23 75 1A 27 Set the data.

24 75 1B Read the data, and memorize it.

25 75 1B 53 Set the data.

26 Wait for 2 sec.

Address

Data of page: 10, address: 80, 81, 82, 83

Data Procedure

Camera System Adjustments” is

performed.

deviated, perform “5. Picture

Frame Setting”.

Checking method:

Order Page

1 Perform “Preparation” before this

2 60 01 F9 Set the data.

3 Wait for 3 sec.

4 60 E1 Read the data, and check it is “08”.

5 10 80 Read the data, and this data is

6 10 81 Read the data, and this data is

7 Calculate DRG0 using the

8 10 82 Read the data, and this data is

9 10 83 Read the data, and this data is

10 Calculate DBG0 using the

11 60 01 00 Set the data.

12 60 E1 00 Set the data.

13 77 72 54 Set the data.

14 Wait for 2 sec.

15 60 01 F9 Set the data.

16 Wait for 3 sec.

17 60 E1 Read the data, and check it is “08”.

18 10 80 Read the data, and this data is

19 10 81 Read the data, and this data is

20 Calculate DRG1 using the

21 10 82 Read the data, and this data is

22 10 83 Read the data, and this data is

23 Calculate DBG1 using the

24 60 01 00 Set the data.

25 60 E1 00 Set the data.

26 77 72 0A Set the data.

27 60 12 A2 Set the data.

28 Wait for 2 sec.

29 60 01 F9 Set the data.

30 Wait for 3 sec.

31 60 E1 Read the data, and check it is “08”.

32 10 80 Read the data, and this data is

33 10 81 Read the data, and this data is

Address

Data Procedure

adjustment.

named D80.

named D81.

following equation

(Hexadecimal calculation)

DRG0 = D80 × 100 + D81

named D82.

named D83.

following equation

(Hexadecimal calculation)

DBG0 = D82 × 100 + D83

named D80.

named D81.

following equation

(Hexadecimal calculation)

DRG1 = D80 × 100 + D81

named D82.

named D83.

following equation

(Hexadecimal calculation)

DBG1 = D82 × 100 + D83

named D80.

named D81.

6-22

Page 25

DSC-T1

Order Page

34 Calculate DRG2 using the

35 10 82 Read the data, and this data is

36 10 83 Read the data, and this data is

37 Calculate DBG2 using the

38 60 01 00 Set the data.

39 60 E1 00 Set the data.

40 77 72 0A Set the data.

41 Wait for 2 sec.

42 60 01 F9 Set the data.

43 Wait for 3 sec.

44 60 E1 Read the data, and check it is “08”.

45 10 80 Read the data, and this data is

46 10 81 Read the data, and this data is

47 Calculate DRG3 using the

48 10 82 Read the data, and this data is

49 10 83 Read the data, and this data is

50 Calculate DBG3 using the

51 Convert DRG0, DBG0, DRG1, DBG1,

52

53 Check that R/G ratio (1) satisfies

54 Check that B/G ratio (1) satisfies

Address

Data Procedure

following equation

(Hexadecimal calculation)

DRG2 = D80 × 100 + D81

named D82.

named D83.

following equation

(Hexadecimal calculation)

DBG2 = D82 × 100 + D83

named D80.

named D81.

following equation

(Hexadecimal calculation)

DRG3 = D80 × 100 + D81

named D82.

named D83.

following equation

(Hexadecimal calculation)

DBG3 = D82 × 100 + D83

DRG2, DBG2, DRG3 and DBG3 to

decimal number, and obtain

DRG0’, DBG0’, DRG1’, DBG1’, DRG2’,

DBG2’, DRG3’ and DBG3’.

Calculate R/G ratio (1), B/G ratio

(1),

R/G ratio (2), B/G ratio (2),

R/G ratio (3) and B/G ratio (3),

using the following equations

(Decimal calculation)

R/G ratio (1) = (DRG1’ / DRG0’) × 100

B/G ratio (1) = (DBG1’ / DBG0’) × 100

R/G ratio (2) = (DRG2’ / DRG0’) × 100

B/G ratio (2) = (DBG2’ / DBG0’) × 100

R/G ratio (3) = (DRG3’ / DRG0’) × 100

B/G ratio (3) = (DBG3’ / DBG0’) × 100

the specified value 1.

(Decimal number)

the specified value 1.

(Decimal number)

Order Page

55 Check that R/G ratio (2) satisfies

56 Check that B/G ratio (2) satisfies

57 Check that R/G ratio (3) satisfies

58 Check that B/G ratio (3) satisfies

Processing after Completing Adjustments:

Order Page

1 60 01 00 Set the data.

2 60 E1 00 Set the data.

3 60 12 00 Set the data.

4 60 14 00 Set the data.

5 75 09 Set the data memorized at

6 77 F6 Set the data memorized at

7 77 F7 Set the data memorized at

8 77 F2 Set the data memorized at

9 77 72 Set the data memorized at

10 60 05 00 Set the data.

11 75 17 Set the data memorized at

12 75 18 Set the data memorized at

13 75 19 Set the data memorized at

14 75 1A Set the data memorized at

15 75 1B Set the data memorized at

16 Save the data.

17 Wait for 3 sec.

18 Perform next adjustments.

Address

Address

Data Procedure

Linearity check of low

luminance

the specified value 2.

(Decimal number)

the specified value 2.

(Decimal number)

Linearity check of very low

luminance

the specified value 3.

(Decimal number)

the specified value 3.

(Decimal number)

Data Procedure

“Preparation”.

“Preparation”.

“Preparation”.

“Preparation”.

“Preparation”.

“Preparation”.

“Preparation”.

“Preparation”.

“Preparation”.

“Preparation”.

If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

6-23

Page 26

DSC-T1

14.Color Reproduction Adjustment

Adjust the color reproduction of yellow, red, blue and cyan so that

proper color reproduction is produced.

Mode STILL ( )

Subject Color bar chart

(Standard picture frame)

Measurement Point Video terminal of A/V OUT jack of

the cradle

Measuring Instrument NTSC vectorscope

Adjustment Page 6E

Adjustment Address 60 to 67

Specified value 1 Data of page: 6E, address: 4F is “00”

Specified value 2 Each center of all color luminance

points should settle within each color

reproduction frame.

Note1: If the data of page: 60, address: 02 is “01”, select page: 60, address:

Switch setting:

Adjusting method:

01, and set data: 00.

ZOOM.................................................................... WIDE end

VIDEO OUT (SET UP of Menu) .................................NTSC

Order Page

1 Install the color bar chart.

2 Check that “1. Data Setting during

3 Check the picture frame. If

4 7A 00 Read the data, and this data is

5 7A 00 00 Set the data.

6 6E 4F FF Set the data.

7 60 01 AB Set the data.

8 Wait for 1 sec.

9 60 01 A9 Set the data.

10 Wait until the color of the screen

11 60 02 Read the data, and check it is “01”.

12 6E 4F Read the data, and check it

13 Adjust the GAIN and PHASE of

14 Check that each center of all color

Address

Data Procedure

Camera System Adjustments” is

performed.

deviated, perform “5. Picture

Frame Setting”.

named D00.

stops changing.

(Note2)

satisfies the specified value 1.

the vectorscope so that the burst

luminance point is set at the

specified position.

luminance points is set in each

color reproduction frame.

Processing after Completing Adjustments:

Order Page

1 60 01 00 Set the data.

2 7A 00 Set the data memorized at

3 Save the data.

4 Wait for 3 sec.

5 Perform “Color Reproduction

Burst position

Address

Data Procedure

“Adjusting method”.

Check”. If finish the camera

system adjustments, release the

data setting.

(See “1. Data Setting during

Camera System Adjustments”.)

Fig. 6-1-15.

Note2: The adjustment data will be automatically input to page: 6E,

address: 60 to 67.

6-24

Page 27

DSC-T1

15.CCD White Defect Compensation Check

The positions of the white defective pixel are detected, and check

that the pixels can be corrected.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Measurement Point Data of page: 60, address: 55

Measuring Instrument

Specified value 1 00 to 40

Specified value 2 00

Note: If the data of page: 60, address: 02 is “01”, select page: 60, address:

01, and set data: 00.

Switch setting:

ZOOM ...........................................................................WIDE end

Adjusting method:

Order Page

1 Install the clear chart.

2 Check that “1. Data Setting during

3 Check the picture frame. If

4 7D 64 Read the data, and memorize the

5 7D 64 1E Set the data.

6 7D 69 Read the data, and memorize the

7 7D 69 28 Set the data.

8 60 01 8B Set the data.

9 Wait for 30sec.

10 60 02 Read the data, and check it is “01”.

11 60 55 Read the data, and check it

12 60 01 00 Set the data.

13 Wait for 1sec.

14 7D 64 0F Set the data.

15 7D 69 C0 Set the data.

16 60 01 87 Set the data.

17 Wait for 30sec.

18 60 02 Read the data, and check it is “01”.

19 60 55 Read the data, and check it

Address

Data Procedure

Camera System Adjustments” is

performed.

deviated, perform “5. Picture

Frame Setting”.

data.

data.

satisfies the specified value 1.

satisfies the specified value 2.

Processing after Completing Adjustments:

Order Page

1 60 01 00 Set the data.

2 7D 64 Set the data memorized at

3 7D 69 Set the data memorized at

4 Save the data.

5 Wait for 3 sec.

6 Perform next adjustments.

Address

Data Procedure

“Adjusting method”.

“Adjusting method”.

If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

6-25

Page 28

DSC-T1

16.CCD Black Defect Compensation Check

The positions of the black defective pixel are detected, and check

that the pixels can be corrected. And conf irms that there is no trash

in the surface of the CCD imager, the optical f ilter and the inside of

the lens.

Mode STILL ( )

Subject Clear chart (Standard picture frame)

Measurement Point Data of page: 60, address: 55

Measuring Instrument

Specified value 1 00 to 30

Specified value 2 00

Note1: Check that there are no dust, no dirt and no reflection on the clear

Note2: If the data of page: 60, address: 02 is “01”, select page: 60, address:

Adjusting method:

chart.

01, and set data: 00.

Order Page

1 Check that “1. Data Setting during

2 Check the picture frame. If

3 7D 65 Read the data, and memorize the

4 7D 65 0A Set the data.

5 60 90 00 Set the data.

6 60 91 03 Set the data.

7 60 92 00 Set the data.

8 60 93 00 Set the data.

9 60 01 79 Set the data.

10 60 30 08 Set the data.

11 60 07 Read the data, and check it is “01”.

12 Check that the whole of the screen

13 60 01 8D Set the data.

14 Wait for 30 sec.

15 60 02 Read the data, and check it is “01”.

16 60 55 Read the data, and check it

17 60 01 00 Set the data.

18 Wait for 1 sec.

19 7D 65 0E Set the data.

20 60 01 89 Set the data.

21 Wait for 30 sec.

22 60 02 Read the data, and check it is “01”.

23 60 55 Read the data, and check it

Address

Data Procedure

Camera System Adjustments” is

performed.

deviated, perform “5. Picture

Frame Setting”.

data.

is white.

satisfies the specified value 1.

If the data is “00”, proceed to

“Processing after Completing

Adjustments”

satisfies the specified value 2.

Processing after Completing Adjustments:

Order Page

1 60 01 00 Set the data.

2 Wait for 1 sec.

3 60 2C 00 Set the data.

4 60 30 00 Set the data.

5 60 91 00 Set the data.

6 7D 65 Set the data memorized at

7 Save the data.

8 Wait for 3 sec.

9 Perform next adjustments.

Address

Data Procedure

“Adjusting method”.

If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

6-26

Page 29

DSC-T1

17.Strobe Adjustment

Adjust the light level and white balance when the strobe light flashes.

Mode STILL ( )

Subject Background paper (J-2501-130-A)

(50cm from the front of the lens)

Measurement Point

Data of page 6F, address: DC

Measuring Instrument Data of page 6E, address: 4F

Adjustment Page 6F 6E

Adjustment Address D8 to EF 72 to 75

Specified Value1 03 to 09

Specified Value2 00

Note1: Perform this adjustment in the dark room or use the flash

Note2: Any light other than the strobe light should not light up the plate.

Note3: After the power is turned on, this adjustment can be done only

Note4: If the data of page: 60, address: 02 is “01”, select page: 60, address:

adjustment box.

once.

01, and set data: 00.

Switch setting:

ZOOM ...........................................................................WIDE end

Adjusting method:

Order Page

Address

Data Procedure

1 Check that “1. Data Setting

during Camera System

Adjustments” is performed.

2 60 2C 01 Set the data.

3 60 90 00 Set the data.

4 60 91 00 Set the data.

5 60 92 FF Set the data.

6 60 93 FF Set the data.

7 60 6C 01 Set the data.

8 60 01 79 Set the data.

9 Wait for 5 sec.

10 60 07 Read the data, and check it is “01”.

11 6E 4F FF Set the data.

12 60 01 B9 Set the data.

13 Check the flashing.

14 60 02 Read the data, and check it is “01”.

(Note5)

15 6F D8 Read the data, and check it is “00”.

16 60 01 00 Set the data.

17 Wait for 5 sec.

18 60 ED Read the data, and check it is “02”.

19 Wait for 1 sec.

20 60 01 E7 Set the data.

21 Check the flashing.

22 60 02 Read the data, and check it is “01”.

23 6F D8 Read the data, and check it is “00”.

24 6F DC Read the data, and check it

satisfies the specified value 1.

25 6E 4F Read the data, and check it

satisfies the specified value 2.

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 60 01 00 Set the data.

2 60 2C 00 Set the data.

3 60 6C 00 Set the data.

4 60 90 00 Set the data.

5 60 91 00 Set the data.

6 60 92 00 Set the data.

7 60 93 00 Set the data.

8 If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

Note5: The adjustment data will be automatically input to page: 6F,

address: D8 to EF and to page: 6E, address: 72 to 75.

6-27

Page 30

DSC-T1

18.Auto Focus Illumination Check

Check the auto focus illumination optical axis.

Mode STILL ( )

Subject Background paper (J-2501-130-A).

(50cm from the front of the lens)

Measurement Point Monitor TV (under scan mode)

Measuring Instrument

Adjustment Page 6F

Adjustment Address 10 to 17

Specified Value 1 Center of luminance point should

settle within the specified frame.

Specified Value 2 Data of page: 6F, address: 10 is “00”.

Note1: Perform this adjustment in the dark room or use the flash

Note2: Any light other than the strobe light should not light up the plate.

Note3: If the data of page: 60, address: 02 is “01”, select page: 60, address:

adjustment box.

01, and write data: 00.

Switch setting:

SCENE (Menu) ................................................................... AUTO

Preparations:

1) Take a copy of the AF illumination axis frame with a clear

sheet. (Enlarge the frame in same size as the effective picture

frame of the monitor TV.)

Adjusting method:

Order Page

Address

Data Procedure

1 Turn off the power and turn on

again

2 00 01 01 Set the data.

3 AF 90 Read the data, and memorize it.

4 AF 90 Decrease the data from “5F”, and

stop it when the black frame just

appears on the monitor TV screen.

5 Attach the copied AF illumination

axis frame (transparent) on the

monitor TV screen. (The frame of

the AF illumination axis frame

and the gray frame of the monitor

TV screen must be agree.)

6 7B A9 06 Set the data.

7 60 01 EF Set the data.

8 Check that the AF illumination is

lit.

9 60 02 Read the data, and check it is “01”.

(Note4)

10 Check that center of the luminance

spot is set in the specified frame

of the AF illumination axis frame.

11 6F 10 Read the data, and check it

satisfies the specified value 2.

Fig. 6-1-16.

Processing after Completing Adjustments:

Order Page

Address

Data Procedure

1 60 01 00 Set the data.

2 AF 90 Set the data memorized at

“Adjusting method”.

3 Save the data.

4 Wait for 3 sec.

5 If finish the camera system

adjustments, release the data

setting.

(See “1. Data Setting during

Camera System Adjustments”.)

Note4: The adjustment data will be automatically input to page: 6F,

address: 10 to 17.

6-28

Page 31

DSC-T1

1-5. LCD SYSTEM ADJUSTMENT

Note: When replacing the LCD unit, be careful to pre vent damages caused

by static electricity.

Switch setting:

LCD ON/OFF ........................................................................... ON

1. Data Setting during LCD System Adjustments

Perform the following data setting before the LCD system

adjustments.

Note: When the power is turned off, some data settings will be released.

So perform this data setting again when the power is turned off.

Order Page

1 00 01 01 Set the data.

2 80 70 01 Set the data.

After completing the LCD system adjustments, release the data

setting.

Order Page

1 80 70 00 Set the data.

2 Save the data.

3 Wait for 3 sec.

4 00 01 00 Set the data.

Address

Address

Data Procedure

Data Procedure

2. LCD Initial Data Input (1)

Mode PLAY ( )

Signal Arbitrary

Adjustment Page 8F

Adjustment Address 20, 21, 23 to 2C

Adjusting method:

1) Select page: 00, address: 01, and set data: 01.

2) Select page: 8F, and set the data in the following table.

3) Save the data.

4) Wait for 3 sec.

5) Select page: 00, address: 01, and set data: 00.

Address

20

21

23

24

25

26

27

28

29

2A

2B

2C

Data

89

B8

B0

A2

91

3F

41

80

95

80

95

60

Remark

Fixed data

Fixed data

VCO adj.

Fixed data

Bright adj.

Fixed data

Fixed data

White balance adj. (1)

White balance adj. (2)

White balance adj. (1)

White balance adj. (2)

Contrast adj.

6-29

Page 32

DSC-T1

3. VCO Adjustment (SY-95 board)

Set the VCO free-run frequency. If deviated, the LCD screen will

be blurred.

Mode PLAY ( )

Subject Arbitrary

Measurement Point Data of page: 80, address: 02

Measuring Instrument

Adjustment Page 8F

Adjustment Address 23

Specified Value 01

Note1: A memory stick DUO must be inserted.

Adjusting method:

Order Page

Address

Data Procedure

1 Check that “1. Data Setting during

LCD System Adjustments” is

performed.

2 8F 34 32 Set the data.

3 80 00 00 Set the data.

4 80 01 00 Set the data.

5 80 00 01 Set the data.

6 Wait for 1 sec.

7 80 02 Read the data, and check it is “01”.

(Note2)

8 Wait for 1 sec.

9 If finish the LCD system

adjustments, release the data

setting.

(See “1. Data Setting during

LCD System Adjustments”.)

Note2: If the data is other than “01”, adjustment has errors. See the

following table.

Data of page: 80, Contents of adjustment error

address: 02

01 Normally finished

10 Reached an upper limit

20 Reached a lower limit

30 Time out

40 Out of adjustment range

50 Adjustment is impossible

4. Bright Adjustment (SY-95 board)

Set the level of the VIDEO signal for driving the LCD to the specified

value. If deviated, the screen image will be blackish or saturated

(whitish).

Mode PLAY ( )

Subject Arbitrary

Measurement Point Data of page: 80, address: 02

Measuring Instrument

Adjustment Page 8F

Adjustment Address 25

Specified Value 01

Note1: A memory stick DUO must be inserted.

Adjusting method:

Order Page

Address

Data Procedure

1 Check that “1. Data Setting during

LCD System Adjustments” is

performed.

2 8F 38 A8 Set the data.

3 80 00 00 Set the data.

4 80 01 00 Set the data.

5 80 00 03 Set the data.

6 Wait for 1 sec.

7 80 02 Read the data, and check it is “01”.

(Note2)

8 Wait for 1 sec.

9 If finish the LCD system

adjustments, release the data

setting.

(See “1. Data Setting during

LCD System Adjustments”.)

Note2: If the data is other than “01”, adjustment has errors. See the

following table.

Data of page: 80, Contents of adjustment error

address: 02

01 Normally finished

10 Reached an upper limit

20 Reached a lower limit

30 Time out

40 Out of adjustment range

50 Adjustment is impossible

6-30

Page 33

DSC-T1

5. Contrast Adjustment (SY-95 board)

Set the level of the VIDEO signal for driving the LCD to the specified

value. If deviated, the screen image will be blackish or saturated

(whitish).

Mode PLAY ( )

Subject Arbitrary

Measurement Point Data of page: 80, address: 02

Measuring Instrument

Adjustment Page 8F

Adjustment Address 2C

Specified Value 01

Note1: A memory stick DUO must be inserted.

Adjusting method:

Order Page

Address

Data Procedure

1 Check that “1. Data Setting during

LCD System Adjustments” is

performed.

2 8F 39 28 Set the data.

3 80 00 00 Set the data.

4 80 01 00 Set the data.

5 80 00 05 Set the data.

6 Wait for 1 sec.

7 80 02 Read the data, and check it is “01”.

(Note2)

8 Wait for 1 sec.

9 If finish the LCD system

adjustments, release the data

setting.

(See “1. Data Setting during

LCD System Adjustments”.)

Note2: If the data is other than “01”, adjustment has errors. See the

following table.

6. V COM Adjustment (SY-95 board)

Set the DC bias of the common electrode drive signal of LCD to the

specified value.

If deviated, the LCD display will move, producing flicker and

conspicuous vertical lines.

Mode PLAY ( )

Subject Arbitrary

Measurement Point Check on LCD display

Measuring Instrument

Adjustment Page 8F

Adjustment Address 24

Specified Value The brightness difference between the

section A and section B is minimum.

Note: A memory stick DUO must be inserted.

Adjusting method: