Page 1

DSC-T10

SERVICE MANUAL

Ver 1.1 2006.09

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Internal memory

Internal memory

ON BOARD

ON BOARD

Photo: Silver

Link

Link

SERVICE NOTE

PRINTED WIRING BOARDS

LEVEL 3

US Model

Canadian Model

AEP Model

UK Model

E Model

Australian Model

Hong Kong Model

Chinese Model

Korea Model

Argentine Model

Brazilian Model

Japanese Model

Tourist Model

REPAIR PARTS LIST

SCHEMATIC DIAGRAMS

The components identified by

mark 0 or dotted line with

mark 0 are critical for safety .

Replace only with part number specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

DIGITAL STILL CAMERA

DSC-T10_L3

Sony EMCS Co.

2006I0500-1

© 2006.9

Published by Kohda TEC9-852-129-11

Page 2

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

CAUTION

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. FLEXIBLE Circuit Board Repairing

•Keep the temperature of the soldering iron around 270°C

during repairing.

•Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

•Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

DSC-T10_L3

— 2 —

Page 3

TABLE OF CONTENTS

Section Title Page

1. SERVICE NOTE

1-3. Method for Copying or Erasing the Data in Internal

Memory (Internal Memory/Music) ·································1-2

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-2. Schematic Diagrams························································ 4-3

4-3. Printed Wiring Boards ···················································4-15

4-4. Mounted Parts Location ················································4-21

5. REPAIR PARTS LIST

5-2. Electrical Parts List ·························································5-6

DSC-T10_L3

— 3 —

Page 4

1. SERVICE NOTE

1-3. METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

(INTERNAL MEMORY/MUSIC)

The data can be copied/erased by the operations on the Setup screen. (When erasing the data, execute formatting the internal memory.)

Note 1: When replacing the SY-163 board, erase the data in internal memory of the board before replacement.

Note 2: When replacing the SY-163 board or the IC401 on the SY-163 board, execute formatting and initialize the internal memory after

replacement.

Method for Copying the Data in Internal Memory

Copy

Copies all images in the internal memory to a “M em ory Stick Duo”.

1 Insert a “Memory Stick Duo” having 64 MB or la rger capac ity.

2 Select [OK] with v on the control button, then press z.

The messag e “All data in internal memory will be copied Ready?” appears.

3 Select [OK] with v, then press z.

Copying starts.

To ca ncel the copying

Select [Cancel] in step 2 or 3, then pr ess z.

•Use a fully charged battery pack or the AC Adaptor (not supplied). If you attempt to copy image files

using a battery pack with little remaining charge, the battery pack may run out, causing copying to fail or

possibly corrupting the data.

•You cannot copy individual images.

•The original images in the internal memory are retained even after copying. To delete the contents of the

internal memory, remove the “Memory Stick Duo” after copying, then execute the [Format] command in

(Internal Memory Tool).

•You cannot select a folder copied on a “Memory Stick Duo”.

•Even if you copy data, a (Print order) mark is not copied.

Method for Formatting the Internal Memory

This item does not appear when a “Memory Stick Duo” is inserted in the camera.

Format

Formats the internal memory.

•Note that formatting irrevocably erases all data in the internal memory, including even protected images.

1 Select [OK] with v on the control button, then press z.

The message “All data in internal memory will be erased Ready?” appears.

2 Select [OK] with v, then press z.

The format is complete.

To canc el the formatting

Select [Cancel] in step 1 or 2, then press z.

Method for Formatting the Music

Format Music

If you cannot play back a M usic file for the Slide Show, the Music file might be corrupted. If

this happens, perform [Format Music].

When [Format Music] is performed, all the Music files are erased. Use the supplied software

“Music Transfer” to activate [Download Music].

1 Sel ec t [OK] with v on the control button, then press z.

The message “All data will be erased Ready?” appears.

2 Sel ec t [OK] with v, then press z.

All the Music files are erased.

To canc el the formatting

Select [Cancel] in step 1 or 2, then press z.

DSC-T10_L3

1-2

Page 5

Link

Link

4-2. SCHEMATIC DIAGRAMS

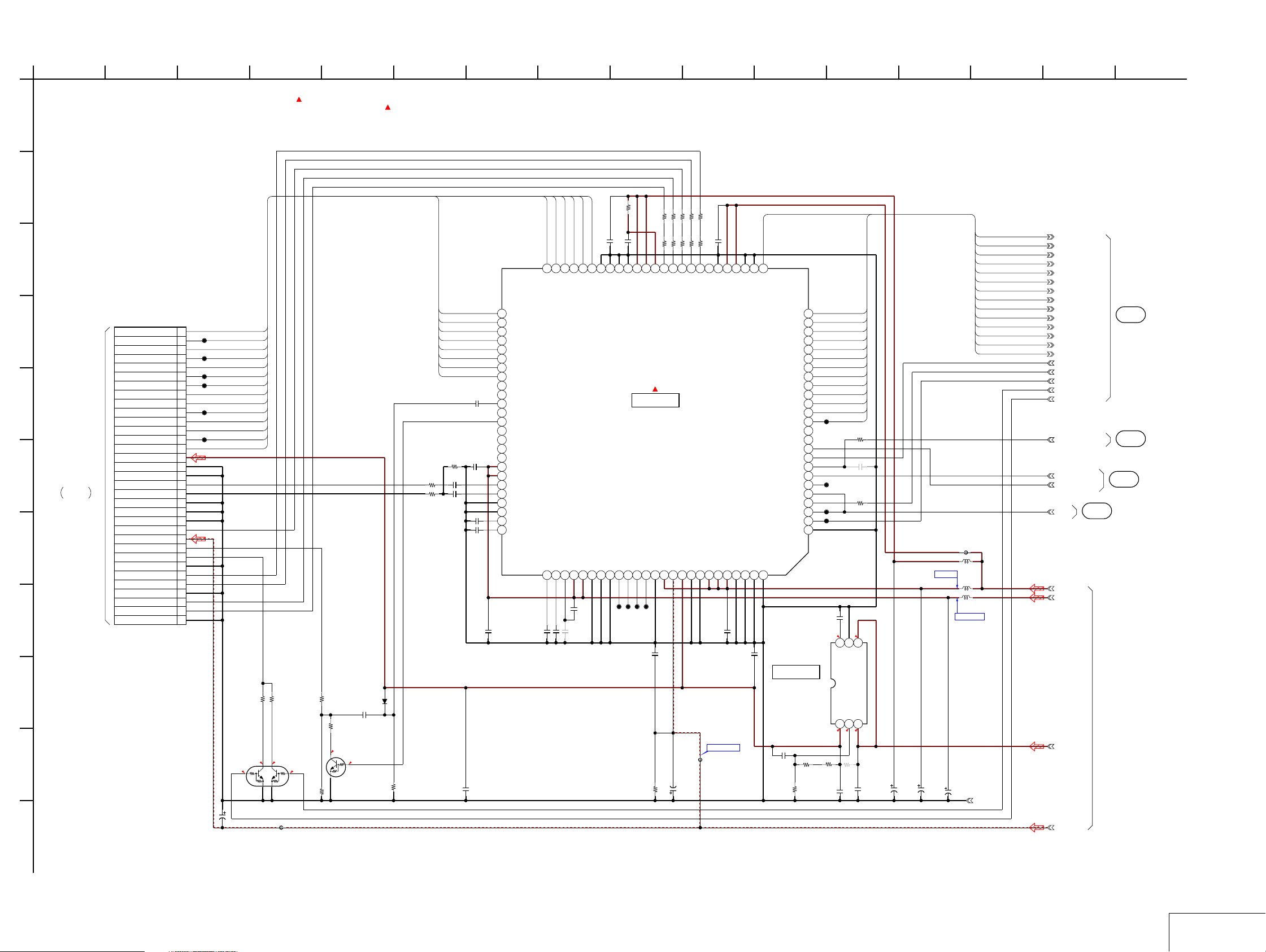

SY-163 BOARD (1/6)

(CCD SIGNAL PROCESS)

SY-163 BOARD (2/6)

(LENS DRIVE, OIS DRIVE)

SY-163 BOARD (3/6) (CAMERA DSP)

COMMON NOTE FOR SCHEMATIC DIAGRAMS

SY-163 BOARD (4/6) (SDRAM, SUPER AND)

SY-163 BOARD (5/6) (AUDIO, VIDEO)

SY-163 BOARD (6/6) (DC/DC CONVERTER)

DSC-T10_L3

Page 6

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

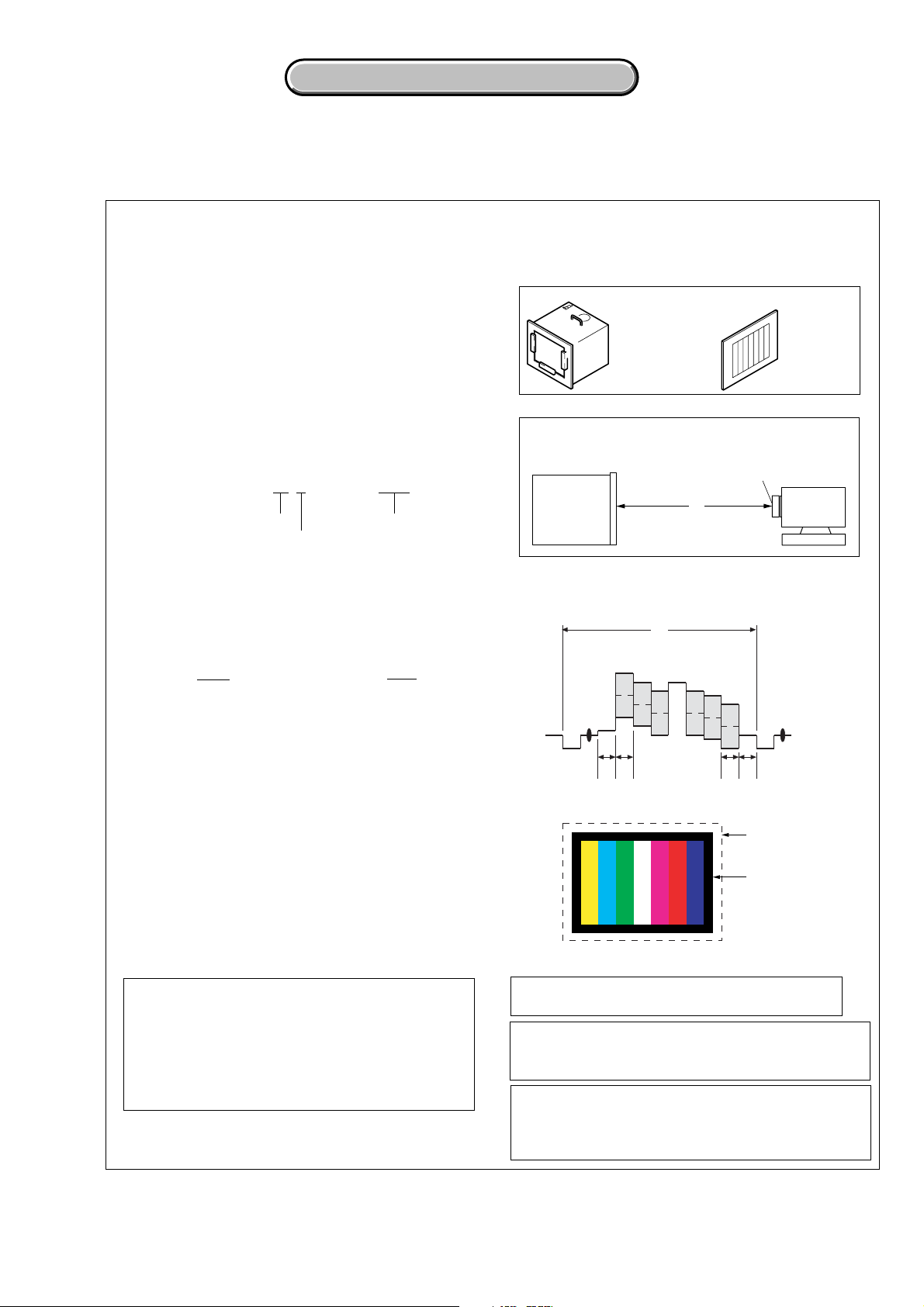

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

µF. 50 V or less are not indicated except f or electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

External dimensions (mm)

Case size

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

•Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors ha ve characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B: B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: not use circuit

(Measuring conditions voltage and waveform)

•Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference values

and reference wave forms.

(VOM of DC 10 MΩ input impedance is used)

•Voltage values change depending upon input

impedance of VOM used.)

1. Connection

Pattern box

Pattern box PTB-450

J-6082-200-A

or

Small pattern box

PTB-1450

J-6082-557-A

L = 24 cm (PTB-450)

L = 11 cm (PTB-1450)

Pattern box

Color bar chart

L

For PTB-450:

J-6020-250-A

For PTB-1450:

J-6082-559-A

Front of the lens

Camera

2. Adjust the distance so that the output wavefor m of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Fig.b (Picture on monitor TV)

Red

Blue

Electronic beam

scanning frame

CRT picture frame

DSC-T10_L3

Precautions for Replacement of Imager

• If the imager has been replaced, carry out all the adjustments

for the camera section.

• As the imager may be damaged by static electricity from

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with

dusts nor exposed to strong light.

When indicating parts by reference number, please

include the board name.

The components identified by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par une pièce portant le numéro

spécifie.

4-3

Page 7

1 165

SY-163 BOARD (1/6)

A

CCD SIGNAL PROCESS

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

B

C

D

E

F

CD-656

FLEXIBLE

LND001-LND033

Page 4-5

of Level 2

G

H

I

J

K

CN101

CAM_12V_CD

REG_GND

REG_GND

CCD_OUT

CCD_GND

REG_GND

REG_GND

REG_GND

CAM_-7.5V_CD

REG_GND

REG_GND

REG_GND

VHLD

CSUB

9

R119

HVSS2

AVSS2

B10

0

0.1u

C108

HVSS1

TPADCK

A10

CL104

4.7

4.7

R107

R108

0

1

R134

R133

H2A

HVDD1

HVDD2

HVDD3

IC101

TIMING GENERATOR

IC101

VSP00M21ZWDR

CL107

CL106

C127

0.1u

R118

100k

H1A

HVSS1

CCD SIGNAL PROCESS,

TPDMA9TPSHPB9TPSHDB8PVSSB7PVCCA8VLA7VHA6VMA5VMB6DVDD1B5DVDD1B4DVDD1E5DVSS1E6DVSS1F5DVSS1F6GNDS1

CL105

R111

R135

C110

10

15

4.7

4.7

R109

R110

0

0

1

R137

R136

0.1u

C111

RG

H2B

H1B

LASTH

GNDS2

DRVDD

C119

0.1u

CAM_-7.5V

FB101

22u

10V

C128

0.01u

DRVDD

DRVSS

CA_AD13

J1J2K1K2K3J3J4J5J6K4K5K6J7K7J8K10K9K8J9G7H7H6G6G5H5

DRVSS

B15

SOUT(CLPOB)

TK11100CSCB-G

C134

100p

R139

39k

±0.5%

B14

B13

B12

B11

B10

B9

B8

B7

B6

B5

B4

B3

B2

B1

B0

SCLK

CS

RESET

SDATA

SDL

MCK

VR

HR

TRIG

IC102

12V REG

IC102

R140

15k

±0.5%

CA_AD12

CA_AD11

CA_AD10

CA_AD9

CA_AD8

CA_AD7

CA_AD6

CA_AD5

CA_AD4

CA_AD3

CA_AD2

CA_AD1

CA_AD0

CL103

CL108

CL115

CL116

A1 A2 A3 A4 B1 B2 B3 C1 C2 C3 D3 D2 D1 E3 E2 E1 F3 F2 F1 G3 G2 G1 H3 H2 H1

C133

0.001u

R138

330k

±0.5%

C131

0.1u

R1.3

R12.5

/P0

6

Np

Vout2FB3Vin

1

/P0

R141

C126

R1.3/P0

XX

GND

R129

1k

R130

R13/P0

45

R13/P0

0

Vcont

XX

C132

1u

VHLD

V10

V5B

V5A

VST

V3A

V3B

V9

V8

V7

V6

V2

V1

V4

SWITCH

Q102

4

: Voltage measurement of the CSP ICs

and the Transistors with mark, are

not possible.

R131

R101

1800

R9.5/P0R9.5/P0

6

3

1

4

FB104

0

5

R102

1M

D101

1SS387CT(TL3SONY)

C103

R103

0.1u

220k

R8.8/P0.3

0

Q101

UN9213J-(K8).SO

SWITCH

3

33P

V10

33

CL111

V9

32

V8

31

CL112

V7

30

V6

29

CL113

V5B

28

CL114

V5A

27

V2

26

VST

25

CL109

V1

24

23

V3A

22

CL110

V3B

21

V4

20

19

18

17

16

15

14

13

12

RG

11

10

SHT

9

8

7

H2B

6

H1B

5

4

H2A

3

H1A

2

1

R132

3300

00

2

RN1904AFS(TLR3SONY)

C102

4.7u

10V

R106

100k

R112

R122

6122

V1

V2

V3B

V3A

V4

V3A

V3B

CMD9L

BYPDE8AVDD1D8AVDD2C8AVSS1C9AVSS2

D10

XX

0.1u

0.1u

C124

C129

V9

0.1u

C109

V2

V1A

V1B

HVSS3

C10

C116

0.001u

V4

V5A

V5B

V6

V7

V10

V8

VST

VHLD

C105

1u

C125

R123

0.1u

0

C106

0.1u

0

C120

0.1u

0

C121

0.47u

C122

0.47u

C130

4.7u

C117

V5A

H4

V5B

G4

V6

F4

V7A

E4

V7B

D4

V8

D7

V9(Vst)

D6

V10(Vhld)

D5

V13

C7

V15

C6

VSUB

C4

SUBSW

C5

STROBE(R/T)

E7

MSHUT(P/S)

F7

FIELD

H8

DACB

G8

DACA

F8

AVDD

J10

AVDD

H9

CCDIN

H10

CCDGND

G10

AVSS

G9

AVSS

F9

REFN

F10

REFP

E10

E9

0.1u

C123

C115

6.3V

138

FB103

L104

10uH

D_3.2V

L102

10uH

L103

10uH

CAM_2.9V

CA_AD0

CA_AD1

CA_AD2

CA_AD3

CA_AD4

CA_AD5

CA_AD6

CA_AD7

CA_AD8

CA_AD9

CA_AD10

CA_AD11

CA_AD12

CA_AD13

14117

15

CA_AD0

CA_AD1

CA_AD2

CA_AD3

CA_AD4

CA_AD5

CA_AD6

CA_AD7

CA_AD8

CA_AD9

CA_AD10

CA_AD11

CA_AD12

CA_AD13

XCS_FE

CLKTGO

CA_HD

VSUB_CONT_PRE

VSUB_CONT_POST

XIC_301_RST_OUT

IC_301_1_SO

XIC_301_1_SCK

CA_FD

D_3.2V

CAM_2.9V

@04

@01

@02

@03

(2/6)

(3/6)

(3/6)

(3/6)

(5/6)

(2/6)

(3/6)

(4/6)

(6/6)

CAM_12V

C114

C113

47u

47u

47u

6.3V

6.3V

REG_GND

CAM_-7.5V

05

DSC-T10_L3

4-6

SY-163 (1/6)

Page 8

1 914117

3

4

5

6122

8

10

13

15

16

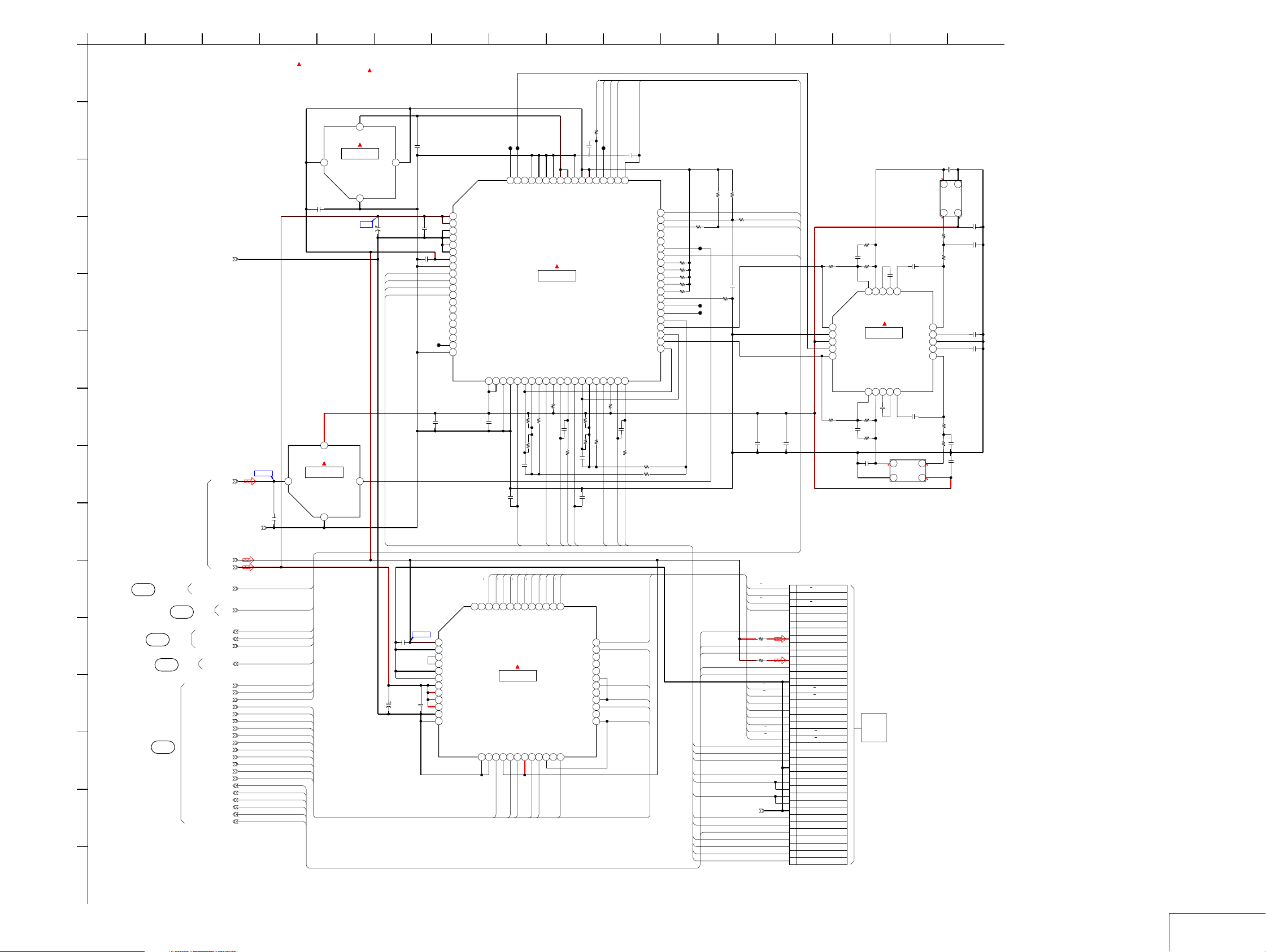

SY-163 BOARD (2/6)

A

LENS DRIVE, OIS DRIVE

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

B

C

D

E

F

G

H

I

J

K

@02

@05

(1/6)

(3/6)

@06

L

@07

M

(3/6)

N

O

(4/6)

@04

(3/6)

(6/6)

(6/6)

(5/6)

XIC_503_CPU_RESET

REG_GND

(P_GND)

XIC_301_RST_OUT

(1/6)

(3/6)

XIC_301_0_SCK

IC_301_0_SI

IC_301_0_SO

XKEY_IC_503

XCS_IC_503

IC_301_27M_CLKO

XCAM_DR_PS

ZOOM_B_DIR

ZOOM_EN

ZOOM_A_DIR

FOCUS_EN

FOCUS_B_DIR

FOCUS_A_DIR

IRIS_B_BRK

IRIS_B_DIR

IRIS_A_BRK

IRIS_A_DIR

XFC_RST_LED

FC_SENS

XZM_RST_LED

ZM_SENS

LENS_TEMP

OIS_TEMP

A_3.2V

D_3.2V

CA_FD

: Voltage measurement of the CSP ICs

and the Transistors with mark, are

not possible.

XCS_IC_503

IC_301_0_SI

IC_301_0_SO

XIC_301_RST_OUT

VCCD15

OP_IN2

J9

0.01u

C521

YAW_HALL+

GNDD3

OP_IP1

OUT1A

J10

0.0022u

C523

R559

C549

VCCD3

OP_OUT1

R540

PS

EN7

IN7

BR6

EN6

IN6

BR5

EN5

IN5

BR4

EN4

0

XX

H9

0.001u

VCCD3

OP_IN1

30k

C542

IC_301_27M_CLKO

RESET_N

DA1

K9

J8

120k

R517

39k

R515

YAW_HALLBIAS-

C5 A5 A2 C4 B2 C3 A1 C2 G1 E4 D4 F2

CLK

IA1K8IB1

CL513

SI

G6

8200

R519

YAW_HALLBIAS+

C539

XX

A5B4A4A3A7A2A9A8D2D9H10B3B2C2E5D5D6

SO

XSCS

OP_IN3

OP_OUT3

J7

C525

YAW_HALL-

XCAM_DR_PS

ZOOM_B_DIR

ZOOM_EN

ZOOM_A_DIR

FOCUS_EN

R542

UDIDEBUG

PITCH_AD

0.01u

10k

IRIS_A

UDITDI

UDITDO

UTITMS

UDITCK

UDITRST

YAW_AD

PWM3

PWM2

R518

1800

C533

0.1u

1.4

2

R545

R536

100k

10k

REG_GND

(SIG_GND)

0R537

C547

10u

IRIS_B

IRIS_A

IRIS_A

IRIS_B

ZOOM_A

ZOOM_B

ZOOM_A

ZOOM_B

FOCUS_B

FOCUS_A

FOCUS_B

FOCUS_A

XIC_301_0_SCK

XIC_503_CPU_RESET

XKEY_IC_503

C526

0.1u

390R203

220R204

CA_FD

R524

560k

R525

560k

LENS BLOCK is replaced as block,

so that there PRINTED WIRING BOARD

and SCHEMATIC DIAGRAM are omitted.

CN201

39P

IRIS_B

39

IRIS_A

38

IRIS_A

37

36

IRIS_B

N.C

35

34

N.C

33

FC_SENS_GND

32

FC_SENS_VCC

31

FC_SENS

ZM_SENS_GND

30

29

ZM_SENS_VCC

ZM_SENS

28

LENS_TEMP

27

26

REG_GND

25

ZOOM_A

24

ZOOM_B

ZOOM_A

23

ZOOM_B

22

21 FOCUS_B

FOCUS_A

20

19

FOCUS_B

18

FOCUS_A

YAW-

17

PITCH_HALLBIAS-

16

PITCH_HALLBIAS+

15

14

REG_GND

YAW+

13

12

PITCH+

11

PITCH+

PITCH-

10

PITCH-

9

REG_GND

8

YAW_HALL-

7

YAW_HALL+

6

OIS_TEMP

5

YAW_HALLBIAS-

4

3

YAW_HALLBIAS+

PITCH_HALL-

2

PIYCH_HALL+

1

19 20

16 17 18

C550

0.33u

OUT1

NC

V+

CRST

OUT2

C551

0.33u

R560

15k

C555

22u

R523

10k

12345

HO1

AM1

VREF1

IC510

PITCH/YAW SENSOR AMP

IC510

NJM3230SE7

VREF2

HO2

AM2

R526

10k

C554

22u

R561

15k

1.4 1.2

C536

0.1u

LENS

BLOCK

HI1

LO1

HI2

LO2

1112131415

12

GND

PITCH SENSOR

0.047u

0.047u

SE501

SCK

XDL

PIO0

B6 A6 B5

PIO1

PIO2

PIO3

VD

VB

CH3

CH2

CH1

CH0

1800R512

R527

1k

CL515

R546

100k

R547

100k

R548

100k

R549

C540

100k

XX

R550

100k

CL502

R551

100k

CL503

K4 G5 K5 J5 J6 D4 D7 F7 E7 G1 F4 G10 E4 C9 B9 B8 B7

XFC_RST_LED

FC_SENS

XZM_RST_LED

ZM_SENS

LENS_TEMP

YAW-

PITCH_HALLBIAS-

PITCH_HALLBIAS+

YAW+

PITCH+

PITCH-

YAW_HALL-

YAW_HALL+

OIS_TEMP

YAW_HALLBIAS-

YAW_HALLBIAS+

PITCH_HALL-

PITCH_HALL+

YAW SENSOR

C529

C530

OUTVref

Vcc

SE502

LIA1

LIB1

GND

LIB2

LIA2

1.3 2.9

R557

22k

R556

22k

67

8910

R555

22k

R558

22k

4

3

2.9

1

Vref

GND

Vcc

OUT

3

4

C553

0.1u

C534

0.1u

C531

0.047u

C532

0.047u

C535

0.1u

C552

0.1u

B1

VOUT

IC504

1.5V REG

VIN

B2

C511

1u

B1

VOUT

A_3.2V

C512

1u

REG_GND

M_5V

XIC_301_RST_OUT

XIC_503_CPU_RESET

IC_301_27M_CLKO

XFC_RST_LED

XZM_RST_LED

VIN

B2

XIC_301_0_SCK

IC_301_0_SI

IC_301_0_SO

XKEY_IC_503

XCS_IC_503

XCAM_DR_PS

ZOOM_B_DIR

ZOOM_EN

ZOOM_A_DIR

FOCUS_EN

FOCUS_B_DIR

FOCUS_A_DIR

IRIS_B_BRK

IRIS_B_DIR

IRIS_A_BRK

IRIS_A_DIR

FC_SENS

ZM_SENS

LENS_TEMP

OIS_TEMP

CA_FD

IC506

2.9V REG

IC506

TK63129BCB-G

A1

VCONT

GND

IC504

TK63115BCB-G

A1

VCONT

GND

M_5V

C509

22u

10V

A2

C203

22u

10V

PITCH-

PITCH+

YAW-

YAW+

C516

1u

A2

VM5_0

C1

VM5_1

C10

C513

0.1u

PGND

A1

PGND

E1

PGND

A10

PGND

C548

0.1u

C201

D_3.2V

0.1u

C202

0.1u

E10

DVCC

F1

DGND

F10

OUT0A

D1

OUT0B

B1

OUT1A

D10

OUT1B

B10

MD_IN0

E2

MD_BR0

F2

MD_EN0

G2

MD_IN1

E9

MD_BR1

F9

MD_EN1

G9

CL517

xMD_PS

G7

TEST

G4

K1

VCC

DGND

VREF

VLIM

RNFS

RNF

VM1

VM2

VM3

VM4

PGND1

PGND1

C546

0.1u

ZOOM_B

OUT7A

OUT7B

PGND2E7PGND2F5IN1G6EN1E5BR1D3IN2E3EN2F1BR2D5IN3B6EN3A7BR3A6IN4

C7

C515

1u

G2

F7

F6

G7

G3

G4

D1

D7

A4

G5

C1

E1

VCCA3K6VCCA3

C541

0.001u

ZOOM_B

OUT6A

OUT6B

IRIS_A_DIR

CL516

CPU_PIO_1

GNDA3

GNDA3

K7

K10

H2

PITCH_HALL+

ZOOM_A

ZOOM_A

FOCUS_B

OUT5A

OUT5B

IC201

LENS DRIVE

IC201

M63067WG-DF0T

IRIS_A_BRK

IRIS_B_DIR

CL514

MARK

CPU_PIO_0

OP_IP0

OP_OUT0

J1

0.0022u

C517

FOCUS_B

OUT4A

OUT4B

TEST2

TEST3

STABILIZATION DRIVE

OP_IN0

DA0

H1

K2

43k

R539

39k

R509

FOCUS_A

FOCUS_A

OUT3A

OUT3B

FOCUS_A_DIR

IRIS_B_BRK

TEST1

GNDD15

IC503

OPTICAL IMAGE

IC503

R2J30500LG

IA0K3IB0

J2

J3

120k

8200

R513

R511

PITCH_HALLBIAS-

PITCH_HALLBIAS+

IRIS_A

IRIS_B

IRIS_B

E2D2B1D6E6B7C6B4B5B3A3F4F3

OUT2A

OUT2B

FOCUS_B_DIR

VCCD15

OP_OUT2

J4

10k

R541

PITCH_HALL-

OUT1B

DSC-T10_L3

05

4-7

SY-163 (2/6)

Page 9

1

SY-163 BOARD (3/6)

A

CAMERA DSP

XX MARK:NO MOUNT

B

(6/6)

C

D

E

NO MARK:REC/PB MODE

REG_GND

A_3.2V

D_1.2V

D_3.2V

EVER_2.9V

D_1.8V

D_1.2V

F

G

±0.5%

H

I

J

K

L

M

N

O

P

Q

R

CA_AD0

CA_AD1

CA_AD2

CA_AD3

CA_AD4

CA_AD5

CA_AD6

CA_AD7

CA_AD8

CA_AD9

CA_AD10

CA_AD11

CA_AD12

CA_AD13

CLKTGO

VSUB_CONT_PRE

VSUB_CONT_POST

XCS_FE

CA_HD

CA_FD

IC_301_0_SO

IC_301_0_SI

XIC_301_0_SCK

ZOOM_A_DIR

ZOOM_B_DIR

ZOOM_EN

FOCUS_A_DIR

FOCUS_B_DIR

FOCUS_EN

IRIS_A_DIR

IRIS_B_DIR

IRIS_A_BRK

IRIS_B_BRK

XCAM_DR_PS

FC_SENS

ZM_SENS

XZM_RST_LED

XFC_RST_LED

LENS_TEMP

XIC_503_CPU_RESET

XCS_IC_503

IC_301_27M_CLKO

OIS_TEMP

MS_D0

MS_D1

MS_D2

MS_D3

MS_BS

MS_CLK

IC_301_VOUT

AU_2.9V

IC_301_AUIN

IC_301_AUOUT

XCS_AUDIO

XPWR_LED

XSHUTTER_SW

XAE_LOCK_SW

KEY_AD0

KEY_AD1

CRADLE_AD1

CRADLE_AD2

XSTATION_IN

XAV_JACK_IN

USB_D+

USB_D-

R741

220

R743

10k

2013

@04

@08

(5/6)

R742

22k

2

1.2 0

6

1

@09

@10

@11

3

4

@01

(1/6)

(1/6)

(2/6)

@05

(5/6)

(5/6)

(5/6)

00

(2/6)

(6/6)

@07

5

(2/6)

MIS-FLASHING

PREVENTION

EMH3T2R

22

USB_VBUS

MS_PWR_ON

XDD_RST_OUT

XPWR_OFF

XCS_DD

BATT_SENS

MODE_DIAL0

BATT_SIG

XACV_IN

DSP_DQ00

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

DSP_DQ08

DSP_DQ09

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28XFC_RST_LED

DSP_DQ29

DSP_DQ30

DSP_DQ31

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_QBA0

DSP_QBA1

DSP_DQM0

DSP_DQM1

DSP_DQM2

DSP_DQM3

XDSP_QCS0

XDSP_QWE

XDSP_QRAS

XDSP_QCAS

DSP_QCLKE

DSP_QCLK

L701

10uH

L702

10uH

C727

22u

6.3V

MAZS056008S0

L703

10uH

R726

C713

XX

XX

Q701

USB_VBUS

MS_PWR_ON

XDD_RST_OUT

XPWR_OFF

XCS_DD

BATT_SENS

MODE_DIAL0

BATT_SIG

XACV_IN

DSP_DQ00

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

DSP_DQ08

DSP_DQ09

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28

DSP_DQ29

DSP_DQ30

DSP_DQ31

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_QBA0

DSP_QBA1

DSP_DQM0

DSP_DQM1

DSP_DQM2

DSP_DQM3

XDSP_QCS0

XDSP_QWE

XDSP_QRAS

XDSP_QCAS

DSP_QCLKE

DSP_QCLK

IC_301_SD_VCC

C726

C706

10u

4.7u

C719

0.1u

C728

4.7u

R711

100k

D714

1u

68k

C730

R733

C729

1u

R725

1M

Q704

XX

XIC_301_RST_OUT

XIC_301_1_SCK

IC_301_1_SO

PANEL_8.5V

M_5V

ST_UNREG

XAF_LED

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

CN709

CN703

@12

@14

GND

GND

VCC1

VCC2

4.2VADJ

VBRT

COMAC

COMDC(H)

COMDC(L)

VD

HD

DCK

D7

D6

D5

D4

D3

D2

D1

D0

XCS

SI

SCLK

RESET

POFF(N.C.)

VSSG

PVDD

GND

COM

BL_L

BL_H

BL_H

BL_L

12P

STRB_CHARGE

XSTRB_FULL

I_PEAK

STRB_ON

M_5V

REG_GND

REG_GND

REG_GND

ST_UNREG

ST_UNREG

M_5V

XAF_LED

@13

(6/6)

@16

31P

@15

(6/6)

(4/6)

@18

(6/6)

@19

@03

(5/6)

(6/6)

@02

8 17

USB_VBUS

CA_AD0

CA_AD1

CA_AD2

CA_AD3

CA_AD4

CA_AD5

CA_AD6

CA_AD7

CA_AD8

CA_AD9

CA_AD10

CA_AD11

CA_AD12

IRIS_B_BRK

BRK2B

VSSQ

AC2

AC11

IRIS_A_BRK

BRK2A/EN2

VSSQ

IRIS_B_DIR

DIR2B

VSS

AA4

IRIS_A_DIR

DIR2A

VSS

AB4

ZOOM_EN

FOCUS_EN

ZOOM_A_DIR

ZOOM_B_DIR

FOCUS_B_DIR

DIR1A

DIR1B

BRK0B

BRK1B

BRK0A/EN0

BRK1A/EN1

VSS

VSS

VDD

VDD

VDD

TRACECLKY4TI2AY5TI2B

AC4

AC10

AA5

AB5

AC5

AC3

C312

0.1u

FOCUS_A_DIR

C313

0.1u

VSSQ

VDDQ

VDDQ

DIR0A

DIR0B

Note: IC301 is not supplied, but this is

TI3AW5TI3BW6TXD4

AB6

AC6

CA_AD13

VDDQ

ADIN13

ADIN7

ADIN8

ADIN9

ADIN10

ADIN11

ADIN12

IC301

CAMERA DSP, LENS CONTROL, MODE CONTROL

FRONT CONTROL, 32M FLASH

IC301

CXD4200AGL-00-T6

included in SY-163 complete board.

RXD4W7RTS4/SCK4Y7CTS4

AA6NCAA7NCAA8NCAC7

R317

XX

PG[0]/Port0

XPWR_OFF

PG[1]/Port1

AB8

XCS_IC_503

ADIN4

ADIN5

ADIN6

PG[2]/Port2W8PG[3]/Port3Y8PG[4]/Port4W9PG[5]/Port5

AB7

XCS_FE

XCS_AUDIO

XCS_PANEL

ADIN2

ADIN3

PG[6]/Port6Y9PG[7]/Port7

AC8

XCS_DD

ADIN1

AC9

XSTRB_FULL

C314

0.1u

ADIN0

PH[0]/Port8

W10

1k

R313

XSTATION_IN

VSSQ(PLLTGO)

PH[1]/Port9

AB9

XACV_IN

SYS_VD

NTVDI

VDDQ(PLLTGO)

PH[2]/Port10

PH[3]/Port11

AA9

W11

1k

R303

STRB_CHARGE

XAV_JACK_IN

CLKADI

PI[0]/Port12

AB10

R376

0

CA_FD

CCDFD

CLKTGI

PI[1]/Port13

PI[2]/Port14/DREQ

AA10

12

CA_HD

CCDHD

PI[3]/Port15/DACK

AB11

Y11

MS_PWR_ON

DUMCLP

PJ[0]/Port16

AC12

OPBCLP

CLKTGEXT

PJ[1]/Port17

PJ[2]/Port18

W12

XCAM_DR_PS

C316

0.1u

MD2

PJ[3]/Port19

AB12

Y10

XDD_RST_OUT

VSUB_CONT_PRE

MD1

RST

W13

C377

XX

R390

MD0

TEST0

AA12

0

43

1

X302

12MHz

VSS

VSS

TEST1

TEST2

AA11

AA14

C372

XX

R349

1k

2

VSSQ

TEST3

Y12

CLKTGO

EXTAL

CLKTGO

INT0

INT1

AB13

C373

XX

R350

1k

XSHUTTER_SW

VSSQ(LED)

INT2

W14

Y16

XAE_LOCK_SW

XBUSY

AVSS(PLL)

INT3

AB14

R351 1k

R358

MODE_DIAL0

10k

AVDD(PLL)

AN[0]

Y13

R321

C317

C318

NC

AN[1]

47k

OIS_TEMP

L302

10uH

10u

0.1u

AA13

R356 1k

R397

220k

KEY_AD0

NC

AN[2]

R398

1492

D715

CL-271HR-C-TS(ACCESS)

LED2

LED3

LED4

AN[3]

AN[4]

AN[5]

W15

AA16

Y14

AB15

R325 1k

220k

KEY_AD1

LENS_TEMP

XFC_RST_LED

XZM_RST_LED

LED1

AN[6]

AA15

47k

R328

CRADLE_AD1

R729

820

LCD_D7

LCD_D6

LCD_D2

LCD_D0

LCD_D1

LCD_D3

LCD_D4

LCD_D5

120

120

120

120

120

120

R360

R367

LED0

LCDD7

AN[7]

AN[8]

Y17

Y15

R359

10k

120

120

R369

R374

R370

R372

R375

R368

G19J23F19F20G21G22F22H22C21E22D20D21B21F21E21E23D23D22C23B23C22B22A22A21C20B20A20D19B19E20B18B17E17B13A19A18C19D18B16E19A17C18C15D17B15E18C16C17B14D16A15A16A11A14A13E15D15E16A12D14B12E14C14E13C13D13C12E12C11D11B11D12C10B10E10B9D10B8E11B7E9D7D8C5E7E8

LCDD0

LCDD1

LCDD2

LCDD3

LCDD4

LCDD5

LCDD6

VDDQ(SDRAM)

VDDQ(SDRAM)

VDDQ(SDRAM)

AVSSQ(AUDIO)

AVDDQ(AUDIO)

AN[9]

AN[10]

AN[11]

AVDD(AD)

AVSS(AD)

AVDDQ(VIDEO)

AVSSQ(VIDEO)

AB16

W16

AC13

AC16

AC14

AA19

C320

R366

10k

CRADLE_AD2

VSSQ(SDRAM)

VSSQ(SDRAM)

VSSQ(SDRAM)

AVSSQ(LED)

AVDDQ(LED)

0.1u

LCDHD

LCDVD

LCDCK

NTVDO

VSS

VDD

VDD

DQ16

DQ17

DQ18

DQ19

DQ20

DQ21

DQ22

DQ23

DQ24

DQ25

DQ26

DQ27

DQ28

DQ29

DQ30

DQ31

VSSQ

VDDQ

DQM3

DQM2

DQM1

DQM0

XQCS1

XQCS0

QCAS

QRAS

QCLKE

QCLK

QWE

AQ0

AQ1

AQ2

AQ3

AQ4

AQ5

AQ6

AQ7

AQ8

AQ9

AQ10

AQ11

AQ12

VSS

QBA0

QBA1

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

LED7

LED6

LED5

VOUT

VREF

VRP

VRN

VRL

VRH

AOUT

BATT_SENS

16

AIN

C321

0.1u

C376

0.1u

R327

220k ±0.5%

C319

0.1u

R326

100k

±0.5%

181510 11

CA_AD0

CA_AD1

CA_AD2

CA_AD3

CA_AD4

CA_AD5

CA_AD6

CA_AD7

CA_AD8

CA_AD9

CA_AD10

CA_AD11

CA_AD12

CA_AD13

CLKTGO

VSUB_CONT_PRE

VSUB_CONT_POST

XCS_FE

CA_HD

CA_FD

IC_301_0_SO

IC_301_0_SI

R340

LCD_HD

120

R341

LCD_VD

120

R315

LCD_CK

120

H23 G20 H21

CL310

FB311

C324

0.1u

W18AB18 Y18 AB19 AC15AC17 W17 AB17 AA18AA17AC18 AC19AB20 Y19 W19 AC20AC21 V23 M23 Y23 R23 W20 V19 AA20 Y20 AA21AC22 AB21AA22 W22 Y21 W21 AB22 V20 AB23 U19 Y22 U20 AA23 W23 T20 V22 T21 V21 T19 U21 R20 R19 P19 U22 R21 T22 P20 U23 P23 T23 R22 N20 N19 P21 N22 M21 P22 N21 K23 L23 M19 L22 M20 L20 L19 M22 K19 K22 J19 K21 J20 L21 H19 K20 H20 J22 F23 G23 N23 J21

C326

0.1u

AU_2.9V

L351

10uH

C375

10u

SYS_VD

C322

0.1u

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28

DSP_DQ29

DSP_DQ30

DSP_DQ31

C333

0.1u

DSP_DQM3

DSP_DQM2

DSP_DQM1

DSP_DQM0

XDSP_QCS0

XDSP_QCAS

XDSP_QRAS

DSP_QCLKE

DSP_QCLK

XDSP_QWE

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_QBA0

DSP_QBA1

DSP_DQ00

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

DSP_DQ08

DSP_DQ09

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

0.1uC323

C381

0.1u

IC_301_SD_VCC

XPWR_LED

IC_301_VOUT

C327

0.1u

C328

XX

C329

XX

C330

0.1u

C331

0.1u

IC_301_AUIN

IC_301_AUOUT

A_3.2V

XIC_301_0_SCK

ZOOM_A_DIR

ZOOM_B_DIR

ZOOM_EN

FOCUS_A_DIR

FOCUS_B_DIR

FOCUS_EN

IRIS_A_DIR

IRIS_B_DIR

IRIS_A_BRK

IRIS_B_BRK

XCAM_DR_PS

FC_SENS

ZM_SENS

XZM_RST_LED

LENS_TEMP

XIC_503_CPU_RESET

XCS_IC_503

IC_301_27M_CLKO

OIS_TEMP

MS_D0

MS_D1

MS_D2

MS_D3

MS_BS

MS_CLK

IC_301_VOUT

IC_301_AUIN

IC_301_AUOUT

XCS_AUDIO

XPWR_LED

XSHUTTER_SW

XAE_LOCK_SW

KEY_AD0

KEY_AD1

CRADLE_AD1

CRADLE_AD2

XSTATION_IN

XAV_JACK_IN

USB_D+

USB_D-

LCD_VD

LCD_HD

LCD_CK

LCD_D7

LCD_D6

LCD_D5

LCD_D4

LCD_D3

LCD_D2

LCD_D1

LCD_D0

XCS_PANEL

IC_301_1_SO

XIC_301_1_SCK

XIC_301_RST_OUT

STRB_CHARGE

XSTRB_FULL

STRB_CHG_CONT

STRB_ON

FC_SENS

SENS0

XIC_301_1_SCK

SCK1

SCS0

AA3NCAA1

C311

0.1u

Q305

XX

IC_301_1_SO

RXD1

VDDQ

AA2

7

STRB_ON

VSUB_CONT_POST

TXD1

VSUB_CONT

VDDQ

VDDQ

AB1

AB2

STRBON

VSSQ

AB3

MSHUT_EN

VSSQ

3

10uH

L303

D_1.8V

C302

0.1u

C382

10u

XCPU_CS0

C305

0.1u

C307

0.1u

R302

USB_D-

680

USB_D+

MS_CLK

MS_D0

MS_D1

MS_D2

MS_D3

MS_BS

XCPU_CS0

XCPU_CS4

XCPU_WE1

XCPU_RD

IC_301_27M_CLKO

CPU_D15

CPU_D14

CPU_D13

CPU_D12

CPU_D11

CPU_D10

CPU_D09

CPU_D08

CPU_D07

CPU_D06

CPU_D05

CPU_D04

CPU_D03

CPU_D02

CPU_D01

CPU_D00

XWP

CPU_A21

CPU_A20

L301

10uH

D_3.2V

3.2

0.2

IC352

TC7SZ04AFE(TE85R)

Vcc

5

4

OUT_Y

INVERTER

C303

0.1u

C304

C301

0.1u

10u

R362

150

R309

150R310

150R311

150R306

R308

150

150

R307

123

N.C.

3.1

IN_A

GND

IC352

C371

0.1u

4 21

: Voltage measurement of the CSP ICs

and the Transistors with mark, are

not possible.

EVER_2.9V

R383

47k

V1

VCC_F

VCC_F

W1

F1

VSS_F

F2

VSS_F

N1

VCCQ_F

P1

VCCQ_F

L1

VSSQ_F

VSSQ_F

M1

L3

CE_F

CLK_F

M4

G5

RESET_F

B1

VDD(PHY)

B5

VSS(PHY)

C2

AVDD1(PHY)

B2

AVDD2(PHY)

C1

AVDD3(PHY)

B4

AGND1(PHY)

B3

AGND2(PHY)

A6

AGND3(PHY)

D1

DVDD1(PHY)

B6

DGND1(PHY)

C9

ID

C8

VBUS

A7

RREF

0

A4

DM

A5

DP

A2

VDDQ

A3

VSSQ

FB306

E1

MSSCLK

FB307

D3

MSDATA0/MSDIO

FB308

E2

MSDATA1

FB309

F3

MSDATA2

FB310

D2

MSDATA3

E3

MSBS

D6

CS0

E4

CS3

D9

CS4

C6

WE0/DQMLL

D4

WE1/DQMLU

C7

RAS

D5

CAS

C4

CKE

F5

RD

C3

RD/WR

E5

BS

J1

CKO

G3

NC

E6

D15

J5

D14

G2

D13

H4

D12

K2

D11

D10

H3

D9

H2

D8

G4

K5

D7

K4

D6

J4

D5

J2

D4

J3

D3

K3

D2

F4

D1

H1

D0

L5

A25

K1

A24

N4

A23

A22

M3

A21

H5

L2

A20

P5

A19

A18

M2

V4

A17

A16

N2

T4

A15

A14

R5

T5

A13

A12

N3

A11

R4

A10

N5

A9

M5

L4

A8

P4

A7

A6

R1

P3

A5

P2

A4

T3

A3

A2

G1

A1

R2

A0

R3

C332

R312

47k

4.2 0.2

6

3

2

1

4

3.2

Q302

SSM6L16FE(TPLR3)

BATTERY CHARGE

DETECT

5 19

IC_301_0_SI

XIC_301_0_SCK

0.1u

0.1u

C308

C309

A8A10A9

VSS

SCK0

RXD0

AVSS(SENS)

AVDD(SENS)

VSSBK(SRAM)

VDDBK(SRAM)

VDDU1VSST2XWAITV2TDIU4TMSY2RTCKU5TDOY1TRSTU2TCKV5TO0W2TO1W4TO2Y6TO3U3NCV3NCW3NCY3NC

T1

CL301

CL302

CL303

CL304

0.1u

BATT_SIG

3

4

D301

1

2

3.10.2

MA4L11100AS0

5

R314

47k

6 23

C379

C378

XX

XX

R384

470k

FG1B

RSTA

RST_OUT

XIC_503_CPU_RESET

CL316

FG1A

SENS2

R352

10k

C374

0.1u

STRB_CHG_CONT

SENS1B

ZM_SENS

CL317

SENS1A

IC_301_0_SO

XIC_301_RST_OUT

TXD0

CL305

CL306

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

XCPU_CS4

XCPU_WE1

XCPU_RD

XBUSY

XWP

CPU_A20

CPU_A21

24

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

XCPU_CS4

XCPU_WE1

XCPU_RD

XBUSY

XWP

CPU_A20

CPU_A21

25

@17

(4/6)

(4/6)

LCD901

2.5 inch

COLOR

LCD

MONITOR

D901

BACKLIGHT

(6/6)

(4/6)

(1/6)

(2/6)

(1/6)

(5/6)

ST-131

LND001-LND012

Page 4-12

of Level 2

(6/6)

05

DSC-T10_L3

4-8

SY-163 (3/6)

Page 10

1

SY-163 BOARD (4/6)

A

SDRAM, SUPER AND

3

: Voltage measurement of the CSP ICs

and the Transistors with mark, are

not possible.

649

8

10

11

1225H7

13

XX MARK:NO MOUNT

XWP

XCPU_RD

XCPU_WE1

A-RE#

IC401

D-VCC

C402

0.1u

A-WE#

D-VCC

XBUSY

XIC_301_RST_OUT

A-WP#

A-R/B#

D-VCCQ

D-VCCQ

C409

A-RES#

D-VCCQ

0.1u

R401

C403

1k

XX

A-PRE

A-MRES#

D-VCCQ

D-VCCQ

C410

0.1u

A-VCC

D-VCCQ

A-VCC

D-VCCQ

A-VCC

D-VCCQ

A-VCC

D-GND

C404

0.1u

A-VCCQ

D-GND

A10

C405

C408

0.1u

0.1u

A-VCCQ

A-VCCQ

A-VCCQ

A-VCCQ

D-GND

D-GND

D-GND

D-GND

N11 P3 P6 A5 A9 B6 B8 N6 N8

REG_GND

A-VCCQ

D-GNDQ

C406

0.1u

A-VCCQ

D-GNDQ

A-VCCQ

D-GNDQ

A-GND

D-GNDQ

H11M11C12B11B12F2F12G1G11N12P10F1G12H12J1F11C4B4D4K2E2M12L3E3M3L11K10K12J11E11D12D10C10L12K11J10J12C9 D9 D11E10

A-GND

D-GNDQ

A-GND

D-GNDQ

A-GND

D-GNDQ

D-GNDQ

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

N10 P4 A1 A12 B1 B2 B3 B9 B10 C1 C2 C3 C11 D1 D2 D3 E1 E6 E7 E12 F10 G8 H5 J2 K1 K5 K6 K7 L1 L2 M1 M2 M6 N1 N2 N3 N4 P1 P11 P12 H1

CPU_D11

CPU_D10

A-DQ11

A-DQ10

D-DQM1

D-DQM2

DSP_DQM1

DSP_DQM2

CPU_D08

CPU_D09

A-DQ9

A-DQ8

D-BA0

D-DQM3

DSP_DQM3

DSP_QBA0

CPU_D06

CPU_D07

A-DQ7

D-BA1

DSP_QBA1

XDSP_QWE

CPU_D05

A-DQ5

A-DQ6

D-WE#

D-CE#

XDSP_QCS0

CPU_D03

CPU_D04

A-DQ3

A-DQ4

D-RAS#

D-CAS#

XDSP_QRAS

XDSP_QCAS

CPU_D12

CPU_D15

CPU_D13

CPU_D14

B

@02

C

D

E

F

G

I

J

(1/6)

(2/6)

(3/6)

@17

(3/6)

XIC_301_RST_OUT

XCPU_CS4

CPU_A21

CPU_A20

XCPU_WE1

XCPU_RD

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

@18

XBUSY

XWP

(3/6)

IC_301_SD_VCC

(6/6)

XIC_301_RST_OUT

XCPU_CS4

CPU_A21

CPU_A20

XCPU_WE1

XCPU_RD

XBUSY

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

D_3.2V

XWP

@16

(3/6)

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_QBA0

DSP_QBA1

DSP_DQ00

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

DSP_DQ08

DSP_DQ09

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28

DSP_DQ29

DSP_DQ30

DSP_DQ31

DSP_DQM0

DSP_DQM1

DSP_DQM2

DSP_DQM3

XDSP_QCS0

XDSP_QWE

XDSP_QRAS

XDSP_QCAS

DSP_QCLKE

DSP_QCLK

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_QBA0

DSP_QBA1

DSP_DQ00

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

DSP_DQ08

DSP_DQ09

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28

DSP_DQ29

DSP_DQ30

DSP_DQ31

DSP_DQM0

DSP_DQM1

DSP_DQM2

DSP_DQM3

XDSP_QCS0

XDSP_QWE

XDSP_QRAS

XDSP_QCAS

DSP_QCLKE

DSP_QCLK

D_3.2V

DSP_DQ00

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

DSP_DQ08

DSP_DQ09

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28

DSP_DQ29

DSP_DQ30

DSP_DQ31

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

A-DQ15

A-DQ14

A-DQ13

A-DQ12

D-DQ0

F9E9D8C8F8E8D7C7F4E5D6C6F3E4D5C5M10L10K9J9M9L9K8J8M5L5K4J4M4L4K3J3H9G10H10G9G2G3G4G5H2

D-DQ1

D-DQ2

D-DQ3

D-DQ4

D-DQ5

D-DQ6

D-DQ7

D-DQ8

D-DQ9

D-DQ10

D-DQ11

D-DQ12

D-DQ13

D-DQ14

D-DQ15

D-DQ16

D-DQ17

D-DQ18

D-DQ19

D-DQ20

D-DQ21

D-DQ22

D-DQ23

D-DQ24

D-DQ25

D-DQ26

D-DQ27

D-DQ28

D-DQ29

D-DQ30

D-DQ31

D-A0

D-A1

D-A2

D-A3

D-A4

D-A5

D-A6

D-A7

D-A8

D-A9

D-A10

D-DQM0

D-A11

H3 H8 H4 F7 F5 J7 J5 J6 F6 L6 M8 L8 L7 M7 N7 A2 A7 A11 P2 P7 P9 A4 A8 B5 B7 N5 N9 P5 P8 A3 A6

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_DQM0

C407

22u

6.3V

CPU_D02

CPU_D01

A-DQ2

A-DQ1

D-CKE

D-CLK

DSP_QCLKE

DSP_QCLK

CPU_A20

CPU_D00

A-DQ0

D-VCC

XCPU_CS4

A-ALE

A-CLE

64M SUPER AND

M6MGK4Z7B2ZFWG

D-VCC

D-VCC

C401

0.1u

A-CE#

IC401

256M SDRAM,

D-VCC

CPU_A21

DSC-T10_L3

05

4-9

SY-163 (4/6)

Page 11

1 914117

3

4

56

8

10

122

13

15

16

SY-163 BOARD (5/6)

A

AUDIO, VIDEO

XX MARK:NO MOUNT

B

(6/6)

C

D

E

CONTROL

SWITCH

F

BLOCK

(RL60530)

LND001-LND016

Page 4-14

of Level 2

XAE_LOCK_SW

XSHUTTER_SW

G

@06

(2/6)

XKEY_IC_503

H

@10

(3/6)

@03

I

@09

(3/6)

(1/6)

(3/6)

XAE_LOCK_SW

XSHUTTER_SW

XPWR_LED

XIC_301_1_SCK

IC_301_1_SO

IC_301_AUIN

IC_301_AUOUT

XCS_AUDIO

IC_301_VOUT

MS_VCC

M_5V

A_3.2V

D_3.2V

CN712

KEY_AD0

D_3.2V

KEY_AD1

REG_GND

REG_GND

XKEY_IC_503

REG_GND

MIC_GND

MIC_SIG

REG_GND

XPWR_ON

XPWR_LED

D_3.2V

KEY_AD0

KEY_AD1

AU_2.9V

BATT/XEXT

R740

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

0

10

9

8

7

6

5

4

3

2

1

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

XPOWER_ON

CRADLE_AD2

CRADLE_AD1

BATT/XEXT

CHARGE_V

CHARGE_V

CHARGE_V

CHARGE_V

CHARGE_V

ACV_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

N.C.

XSTATION_IN

SET_ID_IN

USB_VBUS

USB_GND

USB_DP

USB_DM

USB_GND

AU_LINE_OUT

A_GND

V_LINE_OUT

V_GND

XCHG_ON

XAV_JACK_IN

CN704

REG_GND

MS_VCC

MS_CLK

MS_D3

XMS_IN

MS_D2

MS_D0

MS_D1

MS_BS

REG_GND

STATIC_GND

MS_D0

MS_D1

MS_D2

MS_D3

MS_BS

MS_CLK

XMS_IN

XPWR_ON

ACV_UNREG

CHARGE_V

33PCN711

12P

LND601

: Voltage measurement of the CSP ICs

and the Transistors with mark, are

not possible.

SP+

@22

SP-

(6/6)

REG_GND

(SP_GND)

REG_GND

(MIC_GND)

R618

820

R613

REG_GND

(V_GND)

2.2k

R651

D_3.2V

10

D651

MA2S111-(K8).SO

IC_301_AUIN

IC_301_AUOUT

XCS_AUDIO

XIC_301_1_SCK

IC_301_1_SO

AU_2.9V

AU_2.9V

IC652

TK63129BCB-G

2.9V REG

IC652

B2

GND

A1

A2

16P

16

15

14

N.C.

13

12

11

10

9

8

7

6

5

4

3

2

1

KEY_AD0

KEY_AD1

XKEY_IC_503

XAE_LOCK_SW

XSHUTTER_SW

XPWR_LED

XKEY_IC_503

KEY_AD0

KEY_AD1

XAE_LOCK_SW

XSHUTTER_SW

XPWR_LED

XIC_301_1_SCK

IC_301_1_SO

IC_301_AUIN

IC_301_AUOUT

XCS_AUDIO

IC_301_VOUT

VIN

VOUT

VCONT

C605

C619

0.1u

4700p

C639

1u

B1

C638

1u

C601

C610

REC_OUT

A6

PB_IN

B6

VCC_A

C6

GND_D

C5

CS

D6

CLK

D5

DATA

E6

VDD

D4

VDD_PUMP

E5

10u

R604

C608

1u

0.47u

47k

0.01u

C611

B5

A5

AGC_IN

AGC_DET

CP1

F6

C653

1u

1u

C614

1k

R606

C4

A4

A3

GND_A

MIC_IN

MIC_OUT

IC601

AUDIO, VIDEO AMP

IC601

AN12918A-VB

VSSE4VSS_OF5CP2F4GND_PUMP

E3

1u

1u

C604

C618

C616

1u

0.01u

C612

B4

B3

VREF

MIC_REG

VIDEO_IN

F3

IC_301_VOUT

A2

F2

L602

10uH

M_5V

B2

VCC_SP

VCC_VD2GND_V

F1

C623

1u

VREF_SP

LINE_OUT

VIDEO_OUT

GND_SP

SP_LPF

SP_IN

EVR_OUT

GND_A

MUTE

R624

10

SP_+

SP_-

C617

10u

C615

1u

A1

B1

C1

C2

C3

D3

D1

E1

E2

MA2S111-(K8).SO

D602

C621

0.1u

C607

0.47u

C620

0.0022u

R609

R610

R621

R602

CRADLE_AD2

CRADLE_AD1

XSTATION_IN

10

10

10k

68

USB_VBUS

USB_D+

USB_D-

XAV_JACK_IN

CRADLE_AD2

CRADLE_AD1

XSTATION_IN

USB_D+

USB_D-

XAV_JACK_IN

USB_VBUS

REG_GND

(ACV_GND)

REG_GND

(USB_GND)

R730

0

REG_GND

CRADLE_AD2

CRADLE_AD1

XSTATION_IN

USB_D+

USB_D-

XAV_JACK_IN

USB_VBUS

R713

XX

D719

@12

FB701

R736

1k

1

D716

VMZ6.8NT2L

MAZS068008SO

C724

10u

@11

(3/6)

47kR722

(3/6)

(6/6)

C725

0.1u

3

2

D720

1

2

MA2S111-(K8).SO

3

2

D717

VMZ6.8NT2L

MS_CLK

MS_D3

XMS_IN

MS_D2

MS_D0

MS_D1

MS_BS

MS_D0

MS_D1

MS_D2

MS_D3

MS_BS

MS_CLK

XMS_IN

D721

C731

0.01u

0.01u

1

C732

XX

R737

2200

R724

3

LF701

4

47k

D718

MAZS068008SO

R739

XX

@08

(3/6)

@21

(6/6)

@20

(6/6)

MC-159

FLEXIBLE

LND001-LND033

Page 4-13

of Level 2

11 12

MEMORY

STICK

DUO

J

05

DSC-T10_L3

4-10

SY-163 (5/6)

Page 12

• Ref er to page 4-3 for mark 0.

1 128

SY-163 BOARD (6/6)

A

DC/DC CONVERTER

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

(5/6)

ACV_UNREG

CHARGE_V

BATT/XEXT

XACV_IN

BATT_SIG

MODE_DIAL0

REG_GND(MODE)

REG_GND (N.C.)

B

@20

@14

C

D

(3/6)

BT-029

FLEXIBLE

LND001-LND014

Page 4-13

of Level 2

E

@21

(5/6)

SP-

SP+

BATT_SENS

XDD_RST_OUT

MS_PWR_ON

@22

(5/6)

F

@13

(3/6)

G

@15

(3/6)

H

@05

(2/6)

(3/6)

XIC_301_0_SCK

IC_301_0_SO

IC_301_0_SI

I

J

MODE_DIAL0

CHARGE_V

CHARGE_V

CHARGE_V

BATT_GND

BATT_GND

BATT_GND

XCS_DD

XPWR_OFF

XMS_IN

XPWR_ON

XAF_LED

VL_3V

BATT_SIG

REG_GND

MA2SD32008S0

14PCN001

SP+

SP-

42 14

: Voltage measurement of the CSP ICs

and the Transistors with mark, are

not possible.

F001

(2A/32V)

Q002

1

8

2

3

7

MAZS120008SO

Q001

C007

0.22u

X001

D002

R005

R006

1k

1k

R007

10M

R004

330k

FDW2508P/GNL

4

4

C009

0.22u

CL001

CL002

CL003

CL004

CL005

SWITCH

R010

470

D005

MA2SD32008S0

C010

10u

PG8

G3J1K1J2K2H3J3K3K4J4H4J5K5G4A6B6C5C6A7B7C7D7B8A8A9

UNREG1-1

UNREG1-2

C8L2

C8L1

C8H1

C8H2

VO8

VO7

C7H2

C7H1

C7L2

C7L1

PG7

CE

SCLK

SI

SO

XRESET

XPWROFF

XPWRON1

XPWRON2

RTCBAT

OSCI

OSCO

C058

XX

(2A/32V)

2.9V

R030

1k

F002

044.2

R002

D003

470k

XCS_DD

XDD_RST_OUT

XPWR_OFF

XPWR_ON

R009

4700

D004

C056

MA2SD32008S0

0.1u

BATT_SENS

XCS_DD

XDD_RST_OUT

XPWR_OFF

MS_PWR_ON

XMS_IN

XPWR_ON

XAF_LED

(LENS COVER)

1

2

R003

1M

R073

33

S001

3

4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

5

6

4

R001

C001

470k

1u

4

SSM3K03FE(TPL3)

0

C005

0.1u

C006

C041

0.1u

SWITCH

C004

1u

C008

4.7u

C070

4.7u

XX

C002

10p

C003

12p

32.768kHz

7135

L003

22uH

BATT_SENS

MS_PWR_ON

C015

22u

C022

LL1-2

RS3

LL1-1

REG2F2

C016

220p

PWR1-3

VFB4

C021

PWR1-2

PSG4

1u

PWR1-1

TG4

UNREGMON

MS_PWR_ON

LX4

BG4

XX

R015

XX

REG1F1

VFB5

C011

LH1-4

VFB2

LH1-3

PG2

22u

1u

C014

C012

22u

L004

4.7uH

LH1-1

LH1-2

PG1-4

PG1-5

IC001

DC/DC CONVERTER,RESET

IC001

SC901571VOR2

LX2

PWR2

REG2F1

PG3

PG1-3

LX3

PG1-2

VO3

PG1-1

VL3

22u

C013

LDO1

XMSIN

B10A10 B9 E6 C9 D6 D8 D9 C10D10 E8 E7 E10 E9 F9 F8 F6 F7 G8 F10 G10 G9 H9 H10 H8

VFB1

AGND

MS_PWR

AGND

3.2V

2.2uHL009

VO1-2

MS_PWR_IN

DGND

VBUSIN

VO1-1

REG1F2

A2B2C3D3D4A1B1C2C1D2E4E5F3F4F5D1E1E2E3F1F2G1G2H2H1

LDO3IN

LDO3 (200mA)

VO5

REG4F1

C024

22u

LDO2IN

PORTB

PORTA

PGLED

REG5F1

REG5F2

PWR56OUT2

PWR56OUT1

UNREG2-2

UNREG2-1

REG4F2

2.9V

LDO2

VREF6

PG5-2

PG5-1

LX5-4

LX5-3

LX5-2

LX5-1

10

TEST

LED1

IREF

VREF

VFB6

GT6

R018 100k ±0.5%

R077

R031

10k ±0.5%

J9 J10 K9 K10 J8 K8 G7 H7 G6 H6 J6 K6 J7 K7 G5 H5 A5 B5 D5 A4 B4 C4 A3 B3 C8

C069

XX

6

1

8.5V REG

IC006

R049

XX

±0.5%

156

C068

1u

8.59.6

4

5

Vout

GND

Np

3

C067

0.001u

R048

XX

±0.5%

113

XAF_LED

Q008

UNR31A300LS0

SWITCH

4.1

4.1

0

1.8V

22u

C027

10uC028

L011

C061

4.7uH

C032

XX

10k

1M

C057

R078

0.022u

XX

C030

22u

R042

10

C031

0.001u

R036

47k

±0.5%

12V

D007

MA2SD32008S0

L007

10uH

C033

4.7u

D008

MA2SD32008S0

D009

MA2SD32008S0

IC005

5V REG

IC005

10

9

8

7

6

P_GND

SW

PS

LBI

VBAT

C034

/P4.2

1u

SN0510064DRCR

CPH5802-TL-E-S

SWITCHING

4.1

R4

3

C065

1u

4.1

4.1

C035

4.7u

R098

EN

VOUT

FB

LBO

P_PAD

GND

11

Q030

R-7.5/P0

4

5

2

1

0

L030

4.7uH

R099

100k

Vin

C066

2.2u

10

Vcont2GND

3.1 1.3

IC006

12345

4.1

5

R050

470k

C036

10u

TK70685HCL-G

C062

C063

2.2u

47u

10V

169

ST_UNREG

CAM_2.9V

EVER_2.9V

MS_VCC

D_1.8V

D_3.2V

A_3.2V

PANEL_8.5V

M_5V

CAM_-7.5V

CAM_12V

(3/6)

(1/6)

(3/6)

(5/6)

(3/6)

(1/6)

(3/6)

(4/6)

(2/6)

(2/6) (3/6) (5/6)

(3/6)

(2/6)

(5/6)

(3/6)

(1/6)

17

(5/6)

K

L

DSC-T10_L3

C043

F003

@12

05

(3/6)

(5/6)

@19

(3/6)

USB_VBUS

BL_H

BL_L

XMS_IN

(0.63A/32V)

L005

4.7uH

C018

1u

L002

C017

10uH

10u

1.2V

D006

MA2SD32008S0

4-11

0.1u

BL_H

(16V)

R014

C019

10

1u

±0.5%

D094

MAZS220008S0

D093

MAZS068008S0

D_1.2V

(3/6)

SY-163 (6/6)

Page 13

4-3. PRINTED WIRING BOARDS

Link

Link

SY-163 BOARD (SIDE A) SY-163 BOARD (SIDE B)

COMMON NOTE FOR PRINTED WIRING BOARDS

MOUNTED PARTS LOCATION

DSC-T10_L3

Page 14

4-3. PRINTED WIRING BOARDS

4-3. PRINTED WIRING BOARDS

4-3. PRINTED WIRING BOARDS

THIS NOTE IS COMMON FOR PRINTED WIRING BOARDS

• : Uses unleaded solder.

•

: Circuit board

: Flexible board

Pattern from the side which enables seeing.

: pattern of the rear side

(The other layers’ patterns are not indicated)

• Through hole is omitted.

• There are a few cases that the part printed on diagram

isn’t mounted in this model.

• C: panel designation

• Chip parts.

Transistor Diode

C

EB

654

46

123

3152

21

12

345

534

54

45

123

312

23

14

3

21321321

43

12

4

3

23

14

46

3152

12

31

4625

654

123

DSC-T10_L3

4-15

Page 15

R018

R401

R602

IC352

R604

CN201

R606

R609

R030

R031

R610

R036

R613

R618

C002

C003

C004

C005

C006

C007

C008

R621

C009

R624

C201

C202

C203

C010

C011

X001

C012

C013

C014

C015

C016

C401

C402

C403

C404

C405

C406

C407

C408

C409

C021

C022

C024

C601

S001

C027

C410

C604

C028

C605

C607

C608

C030

C031

C032

C610

C611

C036

C612

C614

C615

R651

C616

R077

C617

R078

C618

C619

C041

C620

C621

C623

C057

C058

C638

R099

C639

D005

Q102

C067

C068

C069

C070

Q302

Q305

C653

IC001

L301

IC006

D602

L302

L303

Q701

Q704

IC201

IC401

L701

L702

L703

IC601

FB104

FB306

FB307

FB308

FB309

FB310

FB311

R302

R303

D651

L351

R306

R307

R308

FB701

R309

R310

CN101

R311

R312

R313

R314

R509

R315

R317

R511

R512

R513

R515

R321

R517

R518

R519

R325

R131

IC652

R326

R132

R327

R328

R711

R713

R138

R139

C102

R527

R140

R141

CN703

R724

CN709

R725

C301

C302

R726

C303

R340

C304

R341

C305

R536

R537

C307

C308

CN711

R539

C309

CN712

R730

R349

R733

R540

R541

C311

X302

R736

C312

R542

C313

C314

R350

R351

C509

R545

C316

R546

R352

C317

R547

C318

R548

C319

R549

R356

R358

R741

R359

C511

R742

C512

C706

R743

C513

C320

R550

C515

R551

C321

C322

C516

C517

C323

R360

C324

C131

C326

R362

C327

C328

C134

C329

R559

R366

R367

C713

R368

R369

C521

C523

C330

C331

LF701

C525

C719

C332

C333

R370

R372

R374

R375

R376

C726

C727

C728

C729

C539

R383

C730

R384

C731

C732

C540

C541

C542

C546

R390

C548

C549

R397

R398

D301

L003

L009

C371

C372

C373

C374

C375

C376

C377

C378

C379

C381

IC301

C382

L602

D714

D716

D717

IC503

D718

IC504

D719

IC506

D720

R004

R005

R006

R007

R009

R203

R204

R010

R014

R015

CL301

CL302

CL303

CL304

CL305

CL306

P

13

4

6

A1B1C1D1E1F1G1H1J1K1L1M1N1P1

A2B2C2D2E2F2G2H2J2K2L2M2N2P2

A3B3C3D3E3F3G3H3J3K3L3M3N3P3

A4B4C4D4E4F4G4H4J4K4L4M4N4P4

A5B5C5D5E5F5G5H5J5K5L5M5N5P5

A6B6C6D6E6F6J6K6L6M6N6P6

A7B7C7D7E7F7J7K7L7M7N7P7

A8B8C8D8E8F8G8H8J8K8L8M8N8P8

A9B9C9D9E9F9G9H9J9K9L9M9N9P9

A10B10C10D10E10F10G10H10J10K10L10M10N10P10

A11B11C11D11E11F11G11H11J11K11L11M11N11P11

A12B12C12D12E12F12G12H12J12K12L12M12N12P12

1

23

1

2

3

A1B1C1D1E1F1

A2B2C2D2E2F2

A3B3C3D3E3F3

A4B4C4D4E4F4

A5B5C5D5E5F5

A6B6C6D6E6F6

B2

B1

A2

A1

34

12

3

2

4

1

1

2

34

CL310

C

BE

E

C

B

CL316

CL317

P

P

CL109

CL110

CL111

CL112

CL113CL114

1

3

6

4

1

3

4

5

1

3

46

4

2

1

3

CL503

CL513

CL514

A

B2

B1

A2

A1

CL001

CL005

AA19 AB19 AC19

A20 B20 C20 D20 E20 F20 G20 H20 J20 K20 L20 M20 N20 P20 R20 T20 U20 V20 W20Y20

AA20 AB20 AC20

A21 B21 C21 D21 E21 F21 G21 H21 J21 K21 L21 M21 N21 P21 R21 T21 U21 V21 W21Y21

AA21 AB21 AC21

A22 B22 C22 D22 E22 F22 G22 H22 J22 K22 L22 M22 N22 P22 R22 T22 U22 V22 W22Y22

AA22 AB22 AC22

B23 C23 D23 E23 F23 G23 H23 J23 K23 L23 M23 N23 P23 R23 T23 U23

C8 D8 E8 W8 Y8 AA8 AB8 AC8

A9 B9 C9 D9 E9 W9 Y9 AA9 AB9 AC9

A10 B10 C10 D10 E10 W10Y10

AA10 AB10 AC10

A11 B11 C11 D11 E11 W11Y11

AA11 AB11 AC11

A12 B12 C12 D12 E12 W12Y12

AA12 AB12 AC12

A13 B13 C13 D13 E13 W13Y13

AA13 AB13 AC13

A14 B14 C14 D14 E14 W14Y14

AA14 AB14 AC14

A15 B15 C15 D15 E15 W15Y15

AA15 AB15 AC15

A16 B16 C16 D16 E16 W16Y16

AA16 AB16 AC16

A17 B17 C17 D17 E17 W17Y17

AA17 AB17 AC17

A18 B18 C18 D18 E18 W18Y18

AA18 AB18 AC18

A19 B19 C19 D19 E19 F19 G19 H19 J19 K19 L19 M19 N19 P19 R19 T19 U19 V19 W19Y19

B1 C1 D1 E1 F1 G1 H1 J1 K1 L1 M1 N1 P1 R1 T1 U1 V1 W1 Y1 AA1 AB1

A2 B2 C2 D2 E2 F2 G2 H2 J2 K2 L2 M2 N2 P2 R2 T2 U2 V2 W2 Y2 AA2 AB2 AC2

A3 B3 C3 D3 E3 F3 G3 H3 J3 K3 L3 M3 N3 P3 R3 T3 U3 V3 W3 Y3 AA3 AB3 AC3

A4 B4 C4 D4 E4 F4 G4 H4 J4 K4 L4 M4 N4 P4 R4 T4 U4 V4 W4 Y4 AA4 AB4 AC4

A5 B5 C5 D5 E5 F5 G5 H5 J5 K5 L5 M5 N5 P5 R5 T5 U5 V5 W5 Y5 AA5 AB5 AC5

A6 B6 C6 D6 E6 W6 Y6 AA6 AB6 AC6

A7 B7 C7 D7 E7 W7 Y7 AA7 AB7 AC7

A8 B8

W23Y23V23

AA23 AB23

CL002

CL003

CL004

CL502

CL516

CL517

A1B1C1D1E1F1G1H1J1K1

A2B2C2D2E2F2G2H2J2K2

A3B3C3D3E3F3G3H3J3K3

A4B4C4D4E4F4G4H4J4K4

A5B5C5D5E5F5G5H5J5K5

A6B6C6D6E6F6G6H6J6K6

A7B7C7D7E7F7G7H7J7K7

A8B8C8D8E8F8G8H8J8K8

A9B9C9D9E9F9G9H9J9K9

A10B10C10D10E10F10G10H10J10K10

CL515

K5K6K7

K8

K9

K2

K3

K4

K10

K1

E10 F10 G10 H10 J10

E9 F9 G9 H9

J5J6J7J8J9

B5B6B7

B8

B10 C10 D10

A5A6A7

A8

A9 C9 D9B9

E1 F1 G1 H1 J1

E2 F2 G2 H2

J3J4J2

B1

A2

C1 D1

A3

A4

C2 D2

B3B4B2

A10

A1

E4 F4 G4D4

E5 G5D5

G6D6

E7 F7 G7D7

B2B1A2

A1

B

1

3

46

A1 B1 C1 D1 E1 F1 G1

A2 B2 C2 D2 E2 F2 G2

A3 B3 C3 D3 E3 F3 G3

A4 B4 C4 D4 E4 F4 G4

A5 B5 C5 D5 E5 F5 G5

A6 B6 C6 D6 E6 F6 G6

A7 B7 C7 D7 E7 F7 G7

S001

(LENS COVER)

A

B

C

D

1 2 3 4

Note: IC301 is not supplied,

but this is included in SY-163 complete board.

05

111-871-424-

SY-163 BOARD (SIDE A)

1

16

112

2

38

1

39

2

32

1

33

2

1

30

31

1

33

2

32

A_3.2V

D_3.2V

M_5V

D_1.2V

M_5V

D_3.2V

2.9V

D_3.2V

AU_2.9V

A_3.2V

IC_301_SD_VCC

D_1.8V

EVER_2.9V

D_3.2V

3.2V

2.9V

1.8V

DSC-T10_L3

SY-163 (8 layers)

: Uses unleaded solder.

4-18

SY-163 (SIDE A)

Page 16

SY-163 (8 layers)

: Uses unleaded solder.

SY-163 BOARD (SIDE B)

E

B

Q008

C

D002

C001

Q001

R003

CN001

D

R001

G

R111

R108

R107

R110

R109

D009

F001

S

1

14

R135

R134

R133

R137

R136

4

Q002

5

R073

C109

R119

D008

1

8

D_3.2V

L104

C115

C108

C125

R112

C555

C533

05

C111

C106

R122

C550

R524

C529

C065

R098

R048

R049

F002

R002

A

FB103

IC101

C120

R523

R560

1

2

C066

C062

D003

L102

A

C121

C123

C117

R123

C526

54321

6

SE502

(YAW)

C063

1

5

F003

CAM_2.9V

C114

CL103

C122

C116

C547

IC510

4

3

R129

C126

C124

R525

987

C531

C532