Page 1

DSC-T1

SERVICE MANUAL

Ver 1.0 2003. 10

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Link

Link

SPECIFICATIONS

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

US Model

Canadian Model

AEP Model

UK Model

E Model

Hong Kong Model

Australian Model

K orea Model

Chinese Model

Tourist Model

Japanese Model

PRINTED WIRING BOARDS

PRINTED WIRING BOARDSSPECIFICATIONS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

• For ADJUSTMENTS (SECTION 6), refer to SERVICE MANUAL, ADJ (987628051.pdf).

• For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (987628041.pdf).

• Reference No. search on printed wiring boards is available.

On the LD-140, MS-148 and SY-95 boards

This service manual provides the information that is premised the circuit board replacement service and not intended repair

inside the LD-140, MS-148 and SY-95 boards.

Therefore, schematic diagram, printed wiring board, waveforms, mounted parts location and electrical parts list of the

MS-148 and SY-95 boards

The following pages are not shown.

Schematic diagram .............................Pages 4-15 to 4-36

Printed wiring board............................Pages 4-45 to 4-52

are not shown.

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

Mounted parts location .............................

Electrical parts list................................... Pages 5-7 to 5-11

REPAIR PARTS LIST

REPAIR PARTS LIST

Pages 4-54 to 4-55

LD-140,

DIGITAL STILL CAMERA

Page 2

DSC-T1

x Camera

[System]

Image device

Total pixels number of camera

Effective pixels number of camera

Lens Carl Zeiss Vario-Tessar

Exposure control

White balance

File format (DCF compliant)

Recording media

Flash Recommended distance (ISO set to

[Input and Output connectors]

Multi connector

[LCD screen]

LCD panel

Total number of dots

7.66 mm (1/2.4 type) color CCD

Primary color filter

Approx. 5 255 000 pixels

Approx. 5 090 000 pixels

3× zoom lens

f = 6.7 – 20.1 mm (38 – 114 mm when

converted to a 35 mm still camera)

F3.5 – 4.4

Automatic exposure, Scene selection

(8 modes)

Automatic, Daylight, Cloudy,

Fluorescent, Incandescent, Flash

Still images: Exif Ver. 2.2 JPEG

compliant, DPOF compatible

Audio with still image: MPEG1

compliant (Monaural)

Movies: MPEG1 compliant

(Monaural)

“Memory Stick Duo”

Auto):

0.3 m to 1.5 m (11 7/8 inches to

59 1/8 inches) (W)

0.5 m to 1.5 m (19 3/4 inches to

59 1/8 inches) (T)

6.2 cm (2.5 type) TFT drive

211200 (960×220) dots

SPECIFICATIONS

[General]

Used battery pack

Power requirements

Power consumption (during shooting)

Operating temperature

Storage temperature

Dimensions

Mass Approx. 180 g (6.3 oz) (including

Built-in microphone

Built-in speaker

Exif Print Compatible

PRINT Image Matching II Compatible

xUC-TA USB cradle

[Input and Output connectors]

A/V OUT (MONO) jack (Monaural)

USB jack B

USB connection

DC IN jack

Camera connector

NP-FT1

3.6 V

1.6 W

0°C to +40°C (+32°F to +104°F)

–20°C to +60°C (–4°F to +140°F)

91 × 60 × 21 mm

(3 5/8 × 2 3/8 × 2 7/32 inches)

(W/H/D, excluding maximum

protrusions)

battery pack NP-FT1, “Memory Stick

Duo” and wrist strap)

Electret condenser microphone

Piezo-electric speaker

Minijack

Video: 1 Vp-p, 75 Ω, unbalanced,

sync negative

Audio: 327 mV (at a 47 kΩ load)

Output impedance 1 kΩ

High-Speed USB

(USB 2.0 High-Speed compatible)

x AC-LM5 AC Adaptor

Power requirements

Current consumption

Power consumption

Rated output voltage

Operating temperature

Storage temperature

Dimensions

Mass Approx. 170 g (6.0 oz) excluding

100 to 240 V AC, 50/60 Hz

0.2 A

10 W

4.2 V DC, 1.5 A

0°C to +40°C (+32°F to +104°F)

–20°C to +60°C (–4°F to +140°F)

Approx. 47 × 30 × 80mm

(1 7/8 × 1 3/16 × 31/4 inches)

(W/H/D, excluding projecting parts)

power cord (mains lead)

x NP-FT1 battery pack

Used battery

Maximum voltage

Nominal voltage

Capacity 2.4 Wh (680 mAh)

Lithium-ion battery

DC 4.2 V

DC 3.6 V

x Accessories

• AC-LM5 AC Adaptor (1)

• Power cord (mains lead) (1)

• UC-TA USB cradle (1)

• USB cable (1)

• NP-FT1 battery pack (1)

• A/V connecting cable (1)

• Wrist strap (1)

• “Memory Stick Duo” (32 MB) (1)

• Memory Stick Duo Adaptor (1)

• CD-ROM (USB driver SPVD-013) (1)

• Operating instructions (1)

— 2 —

Design and specifications are subject to change

without notice.

Page 3

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

DSC-T1

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY .

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair. Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

— 3 —

Page 4

DSC-T1

TABLE OF CONTENTS

1. SERVICE NOTE ........................................................1-1

2. DISASSEMBLY

2-1. DISASSEMBLY······························································2-1

2-2. SERVICE POSITION ·····················································2-3

2-3. CIRCUIT BOARDS LOCATION···································2-5

2-4. FLEXIBLE BOARDS LOCATION ································2-5

HELP (List of caution points is shown here.)

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2) ··························· 3-1

3-2. OVERALL BLOCK DIAGRAM (2/2) ··························· 3-3

3-3. POWER BLOCK DIAGRAM (1/2) ································3-5

3-4. POWER BLOCK DIAGRAM (2/2) ································3-7

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/2)·······················4-1

FRAME SCHEMATIC DIAGRAM (2/2)·······················4-3

4-2. SCHEMATIC DIAGRAMS

• CD-463 (CCD IMAGER)

SCHEMATIC DIAGRAM ······························4-7

• CN-198 (MULTI CONNECTOR)

SCHEMATIC DIAGRAM ······························4-9

• ST-86 (FLASH)

SCHEMATIC DIAGRAM ····························4-11

• CONTROL SWITCH BLOCK (PW-125)

SCHEMATIC DIAGRAM ····························4-13

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS ······················································5-1

5-1-1. OVERALL SECTION····················································5-3

5-1-2.BATTERY HOLDER SECTION ····································5-4

5-1-3.CABINET (REAR) SECTION ·······································5-5

5-2. ELECTRICAL PARTS LIST ··········································5-6

Parts list of the SY-95, MS-148 and LD-140 boards

are not shown.

Pages from 5-7 to 5-11 are not shown.

Shematic diagram of the SY-95, MS-148 and LD-140

boards are not shown.

Pages from 4-15 to 4-36 are not shown.

4-3. PRINTED WIRING BOARDS

• CD-463 (CCD IMAGER)

PRINTED WIRING BOARD ·······················4-41

• ST-86 (FLASH)

PRINTED WIRING BOARD ·······················4-42

• CN-198 (MULTI CONNECTOR)

PRINTED WIRING BOARD ·······················4-43

Printed wiring board of the

and FP-694 boards

Pages from 4-45 to 4-52 are not shown.

4-4. MOUNTED PARTS LOCATION ·································4-53

Mounted parts location of the SY-95, MS-148

and FP-695 boards are not shown.

Pages from 4-54 to 4-55 are not shown.

SY-95, MS-148, LD-140

are not shown.

— 4 —

Page 5

• NOTE FOR REPAIR

DSC-T1

SECTION 1

SERVICE NOTE

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the DSC-T1 is simply turned off. Therefore, the remaining

voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11)

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

Discharging the Capacitor

Short circuits between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

1 kΩ/1 W

Wrap insulating tape.

ST-86 B0ARD

Shorting jig

(1kΩ / 1w)

Capacitor

1-1

Page 6

DSC-T1

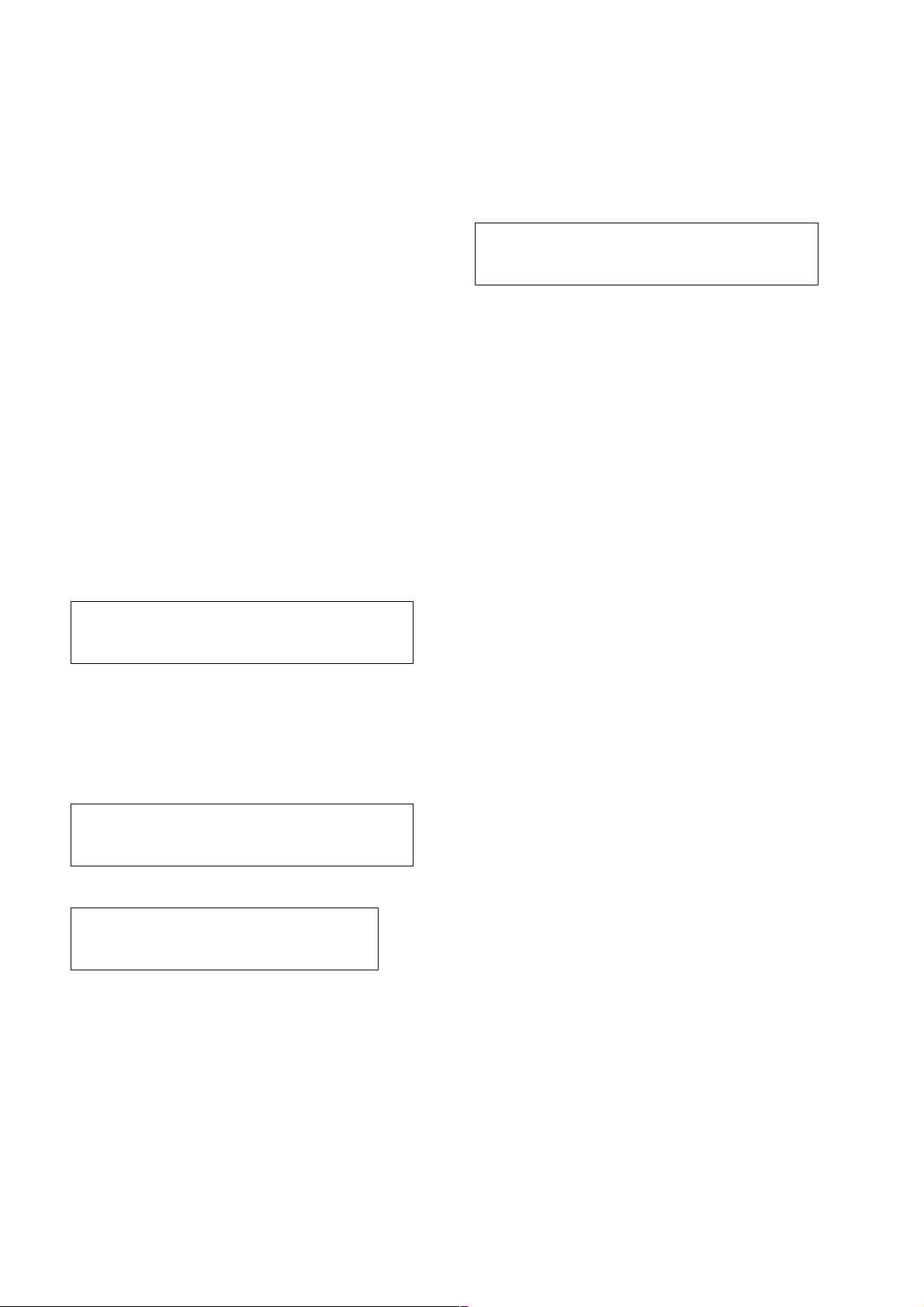

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

• E: ss: ss

The contents which can be handled

by customer, are displayed.

The contents which can be handled

by engineer, are displayed.

Display Code

C:32:01

C:13:01

E:91:01

E:61:00 *1

E61:10 *1

Note : The error code is cleared if the battery is removed, except defective flash unit.

*1: The error display is given in two ways.

Turn off the main power then back on.

Replace the memory stick.

Format the memory stick with the DSC-T1.

Checking of flash unit or replacement of

flash unit.

Checking of lens drive circuit

Countermeasure

Trouble with hardware.

• The type of memory stick that cannot be

used by this machine, is inserted.

• Data is damaged.

• Unformatted memory stick is inserted.

Abnormality when flash is being

charged.

When failed in the focus initialization.

Cause

Caution Display During Error

SYSTEM ERROR

MS ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

1-2E

Page 7

Link

Link

DSC-T1

2. DISASSEMBLY

DISASSEMBLY

DISASSEMBLY

SERVICE POSITION FLEXIBLE BOARDS LOCATION

SERVICE POSITION FLEXIBLE BOARDS LOCATION

HELP

HELP

CIRCUIT BOARDS LOCATION

CIRCUIT BOARDS LOCATION

Page 8

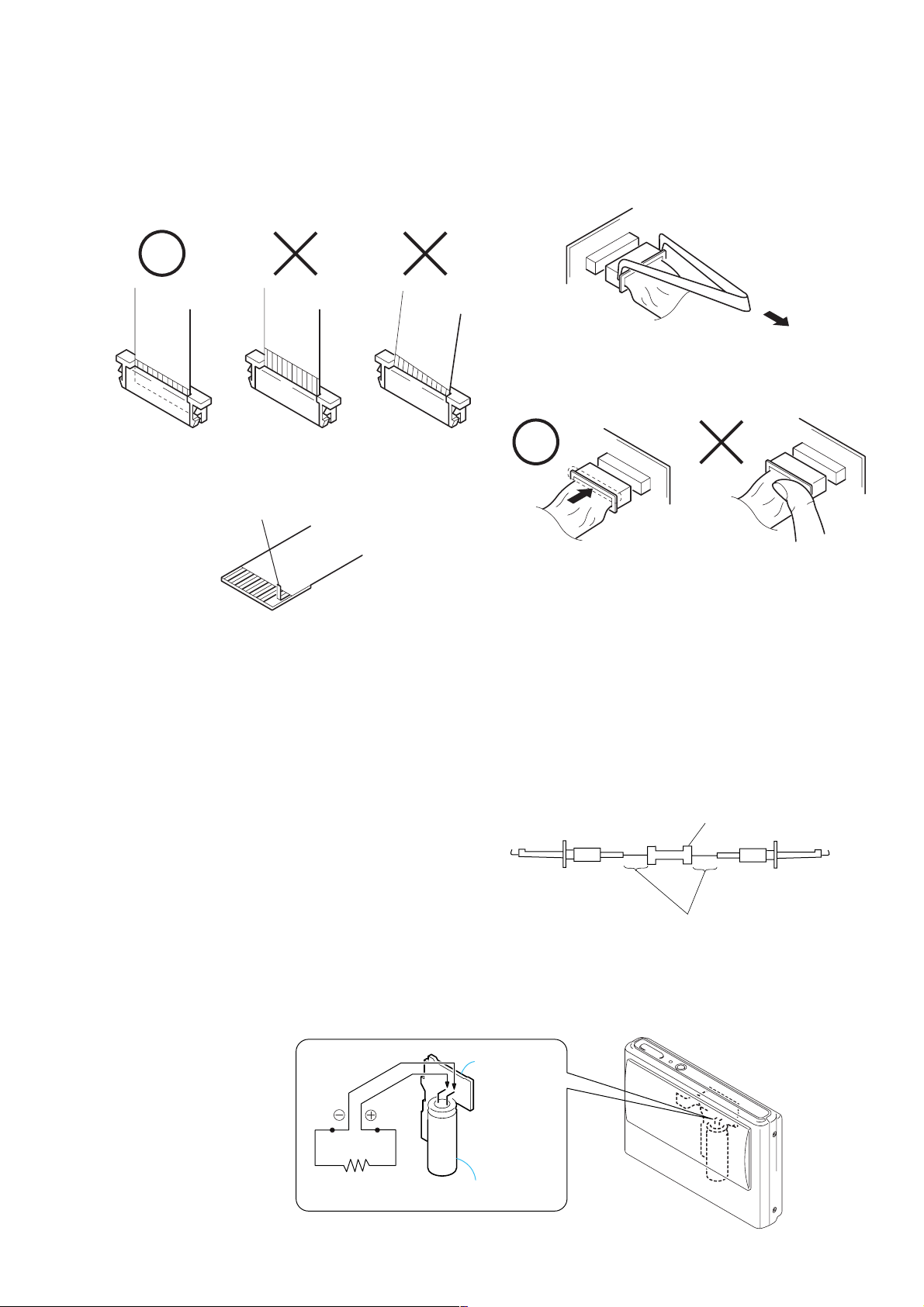

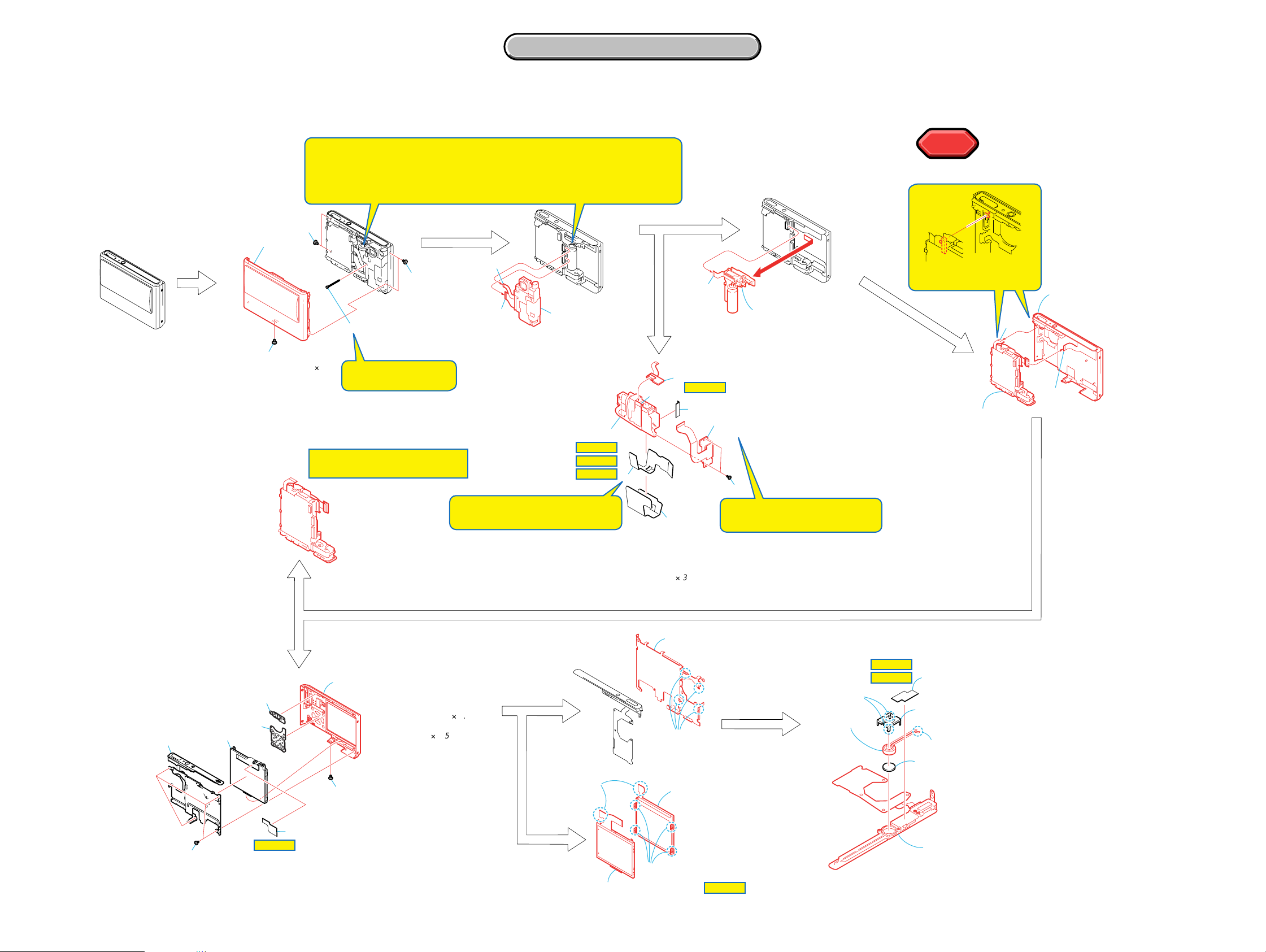

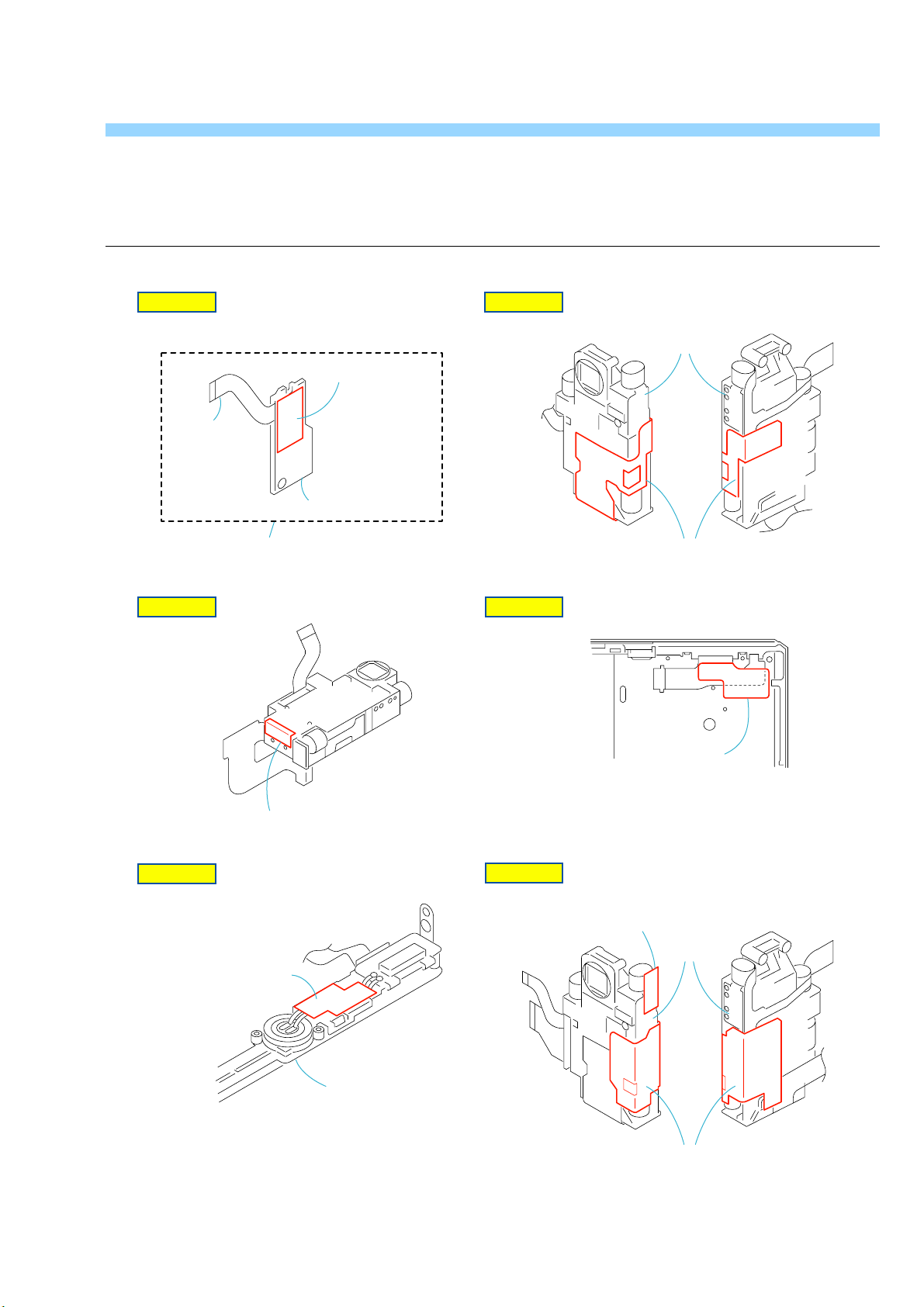

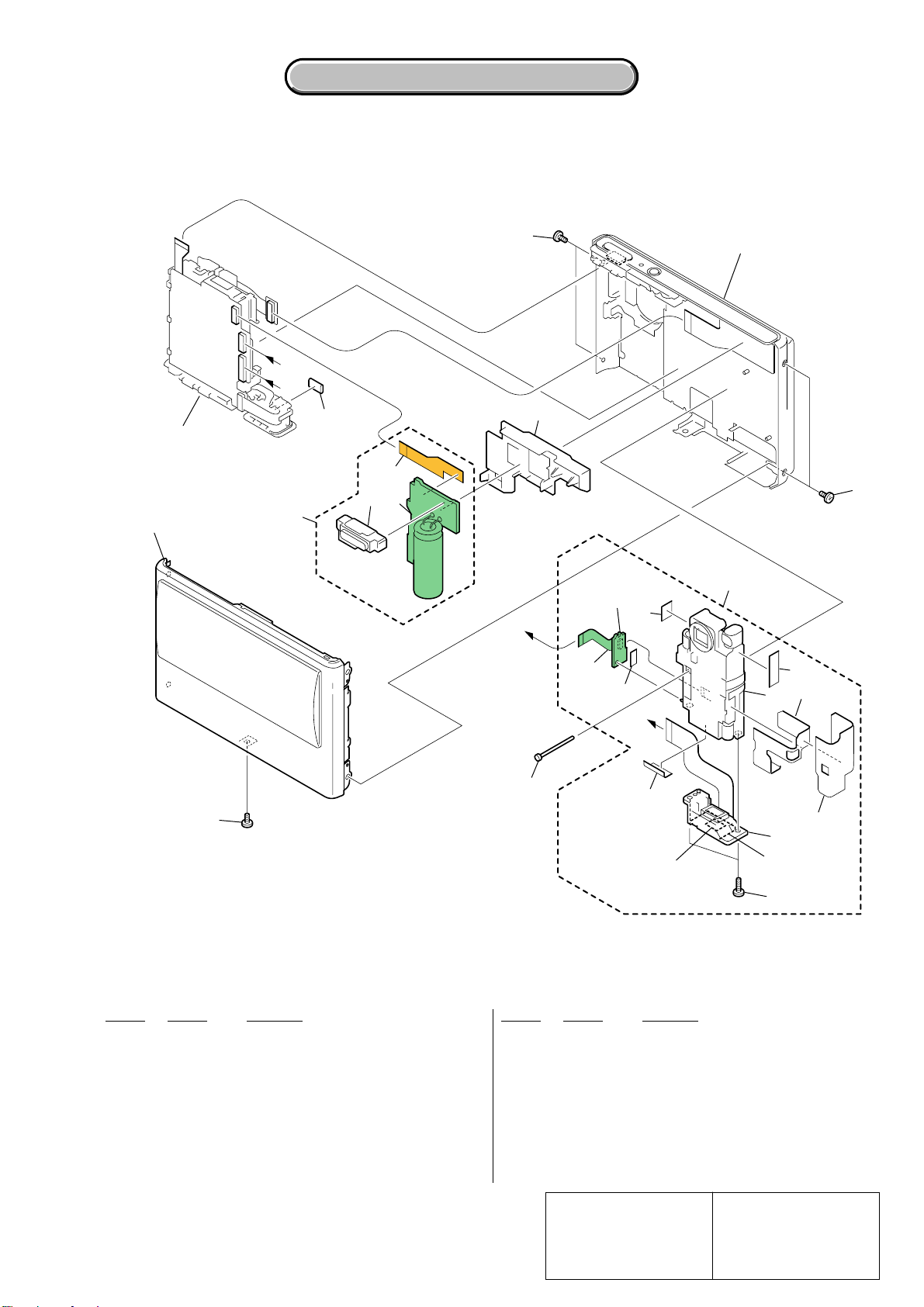

The following flow chart shows the disassembly procedure.

)

2-1. DISASSEMBLY

Note:

1

2

2. DISASSEMBLY

2. DISASSEMBLY

The power capacitor of the flash unit is charged up to 315 V maximum. If you touch

the capacitor terminal that is charged to high voltage, you will receive an electric

shock. This high voltage is not discharged even if you turned off the main power

of this set, and it residues. Discharge the residual voltage referring to the service

note (page 1-1).

HELP

HELP

(Sheet attachment positions and procedures of processing

the flexible boards/harnesses are shown.)

DSC-T1

1

1

Five screws (M1.4 ´ 2.5),

lock ace, p2 (special)

2

Cabinet (front) assembly

3

Lens shaft

HELP 08

(disassembly of the Battery holder section)

SY-95

1

3

Note:

Be careful not to drop

the lens shaft.

1

2

1

FP-695 board (21P)

2

CCD block

assembly (33P)

Note:

Do not peel off the radiation sheet as

much as possible. If you peel it off, be

careful not to damage the flexible board.

3

Lens section

8

LSV-850A

HELP 02

HELP 03

HELP 06

1

Copper leaf sheet

2

Flexible board (from LSV-850A)(21P)

4

Radiation sheet (CCD)

5

Insulating sheet (CCD)

6

Two tapping screws (B1.2 ´ 3.5)

Note:

When re-assembling,

1

3

FP-695 board (Including the LD-140 board)

2

4

HELP 01

5

7

CCD block

assembly

6

Note:

1

as a single unit since removing it

as a single unit requires adjustment.

1

FP-690 flexible

board (19P)

2

ST-86 board,

ST terminal cover

The CCD imager is not supplied

confirm the switch position.

1

SY-95

3

Battery holder

section

4

Cabinet (rear)

section

2

1

LCD unit

(ACX500EN-J) (25P

2

FP-693 flexible

board (16P)

2

HELP 05

8

Cabinet (rear) assembly

6

7

4

2

5

3

1

HELP 04

1

T ape (LCD)

2

Four screws (M1.4 ´ 2.5),

lock ace, p2 (special)

3

Screw (M1.4 ´ 2.5),

lock ace, p2 (special)

4

Control switch block,

LCD frame, etc.

5

LCD unit (ACX500EN-J)

Block light guide plate

6

Zoom button

7

SW button

1

Four claws

LCD frame

2

1

2

3

LCD unit (ACX500EN-J)

1

4

Block light guide plate

1

Remove the solderings

Four claws

2

HELP 09

5

Microphone

HELP 07

2

1

1

Harness protection sheet

2

T wo claws

3

3

6

Microphone holder

4

T wo solderings

6

Microphone cushion

4

7

Control switch block (PW-125)

2-1 2-2

Page 9

DSC-T1

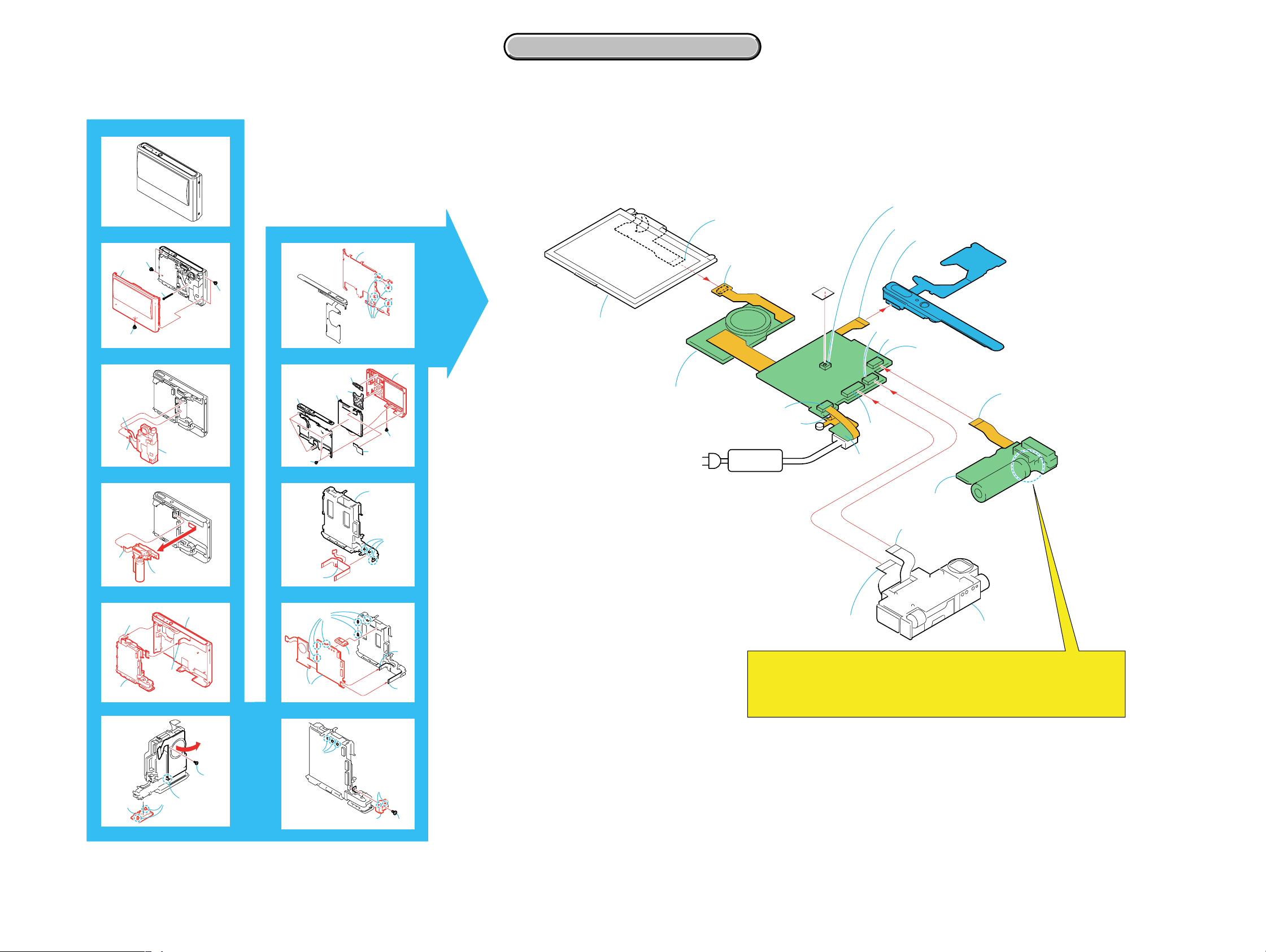

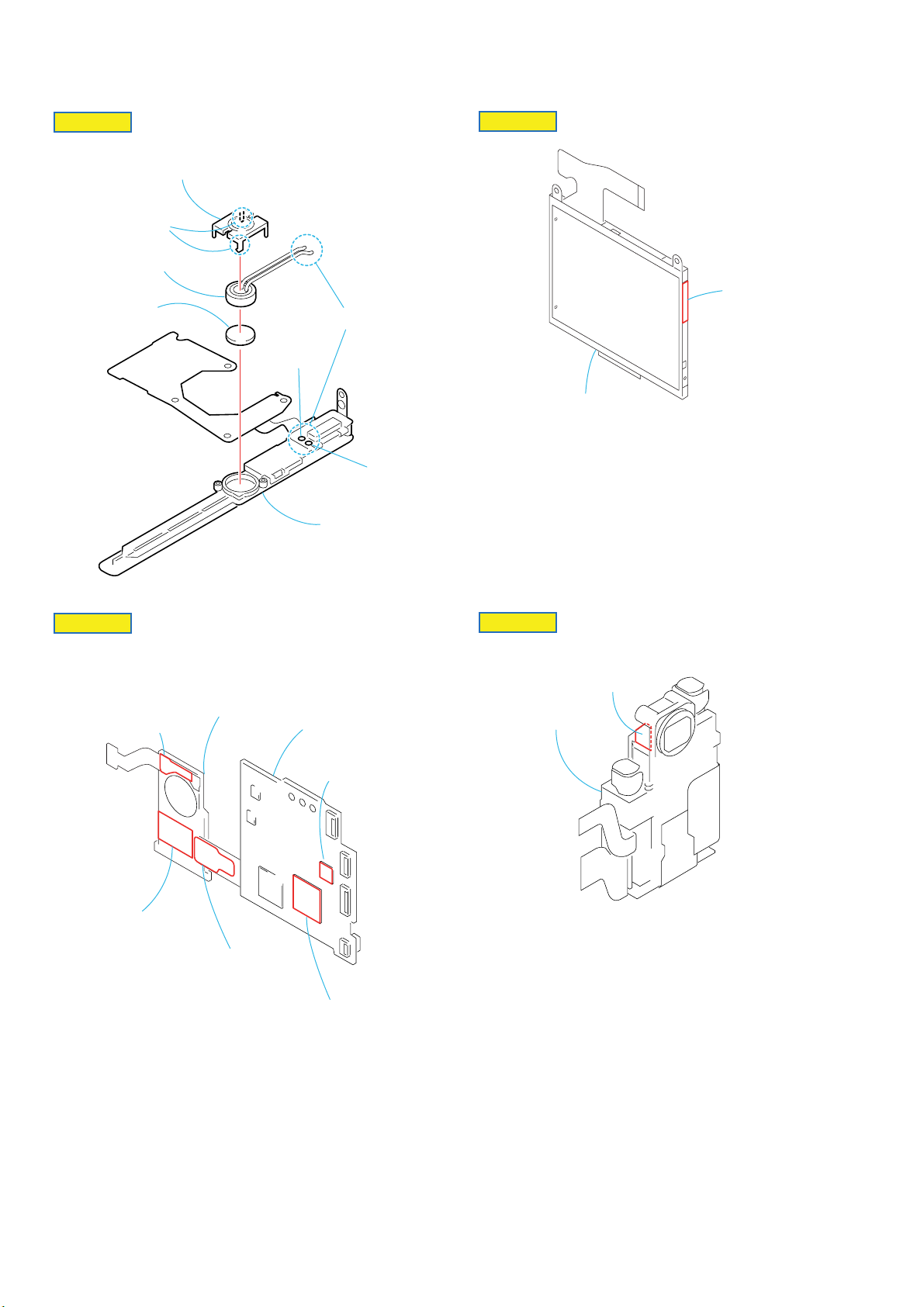

2-2. SERVICE POSITION

2. DISASSEMBLY

2. DISASSEMBLY

[SERVICE POSITION TO CHECK THE SY-95 BOARD]

Note1: By using an adhesive tape, press the LENS COVER switch (S401).

Note2: When checking the VIDEO AMP (SY-95 board IC302) or the USB circuit, connect the cradle.

(25P)

FP-693 flexible board (16P)

Control switch block (PW-125)

S401 LENS COVER switch (Note1)

1

2

3

1

1

2

CN402

1

LCD unit (ACX500EN-J),

Block light guide plate

CN701

CN703

SY-95 board

CN704

CN705

SY-95

FP-690

flexible board (19P)

CN702

CN-198 board

ST-86 board

6

7

4

1

2

3

5

2

8

MS-148 board

3

1

AC IN

3

AC power

adaptor

FP-695 board (21P)

1

1

3

SY-95

2

1

4

2

2

2

SY-95

3

4

Note :

CCD block

assembly (33P)

Lens section

The power capacitor of the flash unit is charged up to 315 V maximum. If you touch

the capacitor terminal that is charged to high voltage, you will receive an electric

5

1

shock. This high voltage is not discharged even if you turned off the main power

of this set, and it residues. Discharge the residual voltage referring to the service

note (page 1-1).

5

4

3

2

4

2

1

3

1

2-3 2-4

Page 10

2. DISASSEMBLY

NAME FUNCTION

CCD IMAGER

MULTI CONNECTOR

LENS DRIVE

MS I/O, LCD PANEL DRIVE

FLASH

CAMERA A/D CONVERTER, TIMING GENERATOR, CAMERA DSP, LENS CONTROL,

CAMERA SYSTEM CONTROL, HI CONTROL, AUDIO I/O, FLASH DRIVE,

DC/DC CONVERTER, CONNECTOR

CD-463

CN-198

LD-140

MS-148

ST-86

SY-95

MS-148

SY-95

ST-86

LD-140

CN-198

CD-463

FP-694

FP-693

FP-690

FP-691

FP-695

CONTROL SWITCH BLOCK

(PW-125)

2. DISASSEMBLY

2-3. CIRCUIT BOARDS LOCATION

DSC-T1

2-4. FLEXIBLE BOARDS LOCATION

The flexible boards contained in the lens block are not shown.

2-5E

Page 11

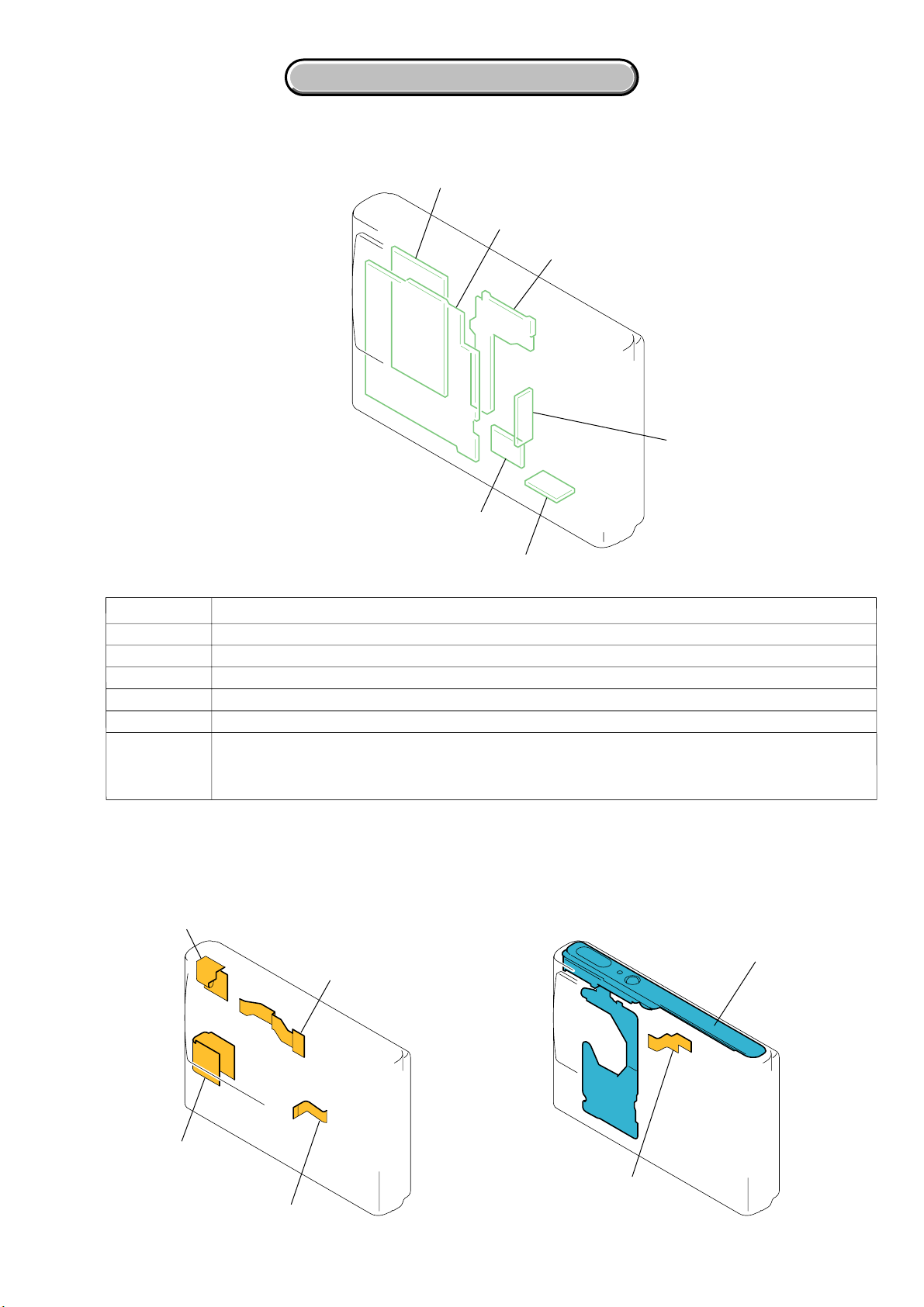

2003.10.29

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

DSC-T1

HELP 01

FP-695

flexible board

HELP 03

FP-695 board

HELP 02

LSV-850A

Adhesive sheet (LD)

LD-140 board

Radiation sheet (CCD)

HELP 04

HELP 05

Insulating sheet (CCD)

Harness

protection sheet

Tape (LCD)

HELP 06

Protection sheet (motor)

LSV-850A

Control switch block

(PW-125)

Copper leaf sheet

HELP

Page 12

DSC-T1

)

HELP 07

Microphone

Microphone

cushion

HELP 09

Microphone holder

Two claws

Sheet (BL

Two solderings

(Black)

LCD unit (ACX500EN-J)

(Red)

Control switch block

(PW-125)

HELP 10

MS protection sheet (S)

MS protection sheet (L)

MS-148 board

SY-95

Radiation sheet (D)

SY-95 board

Sheet

Electrostatic sheet (K)

HELP 11

Light interception

sheet (L)

LSV-850A

HELP

Page 13

HELP 08

s

(disassembly of the Battery holder section)

4

Claw

1

T wo claws

2

Cap (multi)

5

3

Screw

(M1.4

lock ace, p2

(special)

×

2.5),

qa

Three claws

9

Remove the

three solderings

8

SY holder

7

T wo claws

6

Screw

×

(M1.4

lock ace, p2

(special)

2.5),

DSC-T1

qg

Remove the

two solderings

SY-95

qh

MS-148 board

SY-95

qf

SY-95 board,

MS-148 board

qs

Battery

terminal board

ql

CN-198 board

qd

CN-198 board (6P)

q;

CN-198 board (19P)

w;

Battery holder

assembly

qk

Three claw

SY-95

qj

SY-95 board

wa

T wo solderings

ws

Lithium battery

wd

CN-198 board

HELP

Page 14

Link

Link

DSC-T1

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (2/2)OVERALL BLOCK DIAGRAM (2/2)

POWER BLOCK DIAGRAM (2/2)OVERALL BLOCK DIAGRAM (2/2)

Page 15

DSC-T1

BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2)

LENS UNIT

(LSV-850A)

LCD901

2.5INCH

COLOR LCD

PANEL

ND901

BACK

LIGHT

IRIS

SHUTER

FOCUS RESET

SENSOR

ZOOM RESET

SENSOR

FP-694

FLEXIBLE

8

9

7

10

6

11

12

14

16

21

24

1

3

CN402

IRIS

MOTOR

M

FOCUS

MOTOR

M

ZOOM

MOTOR

M

VR

VG

VB

PS1G

RGT,HCK1,2

REF,HST

WIDE,DWN

EN,VCK,

VST

CD-463 BOARD

IC001

CCD IMAGER

1-5,7-9

11-142021-24

V1A,B

V2

V3A,B

V4

V5A,B

V6

V7A,B

V8

15-11,9-7,5-2

X151

54MHz

XTAL

OSC

LD-140 BOARD

IRIS A

IRIS A

G4

IRIS B

18

21

8

11

12

15

5

2

CN002

IRIS B

FOCUS A

FOCUS A

FOCUS B

FOCUS B

ZOOM A

ZOOM A

ZOOM B

ZOOM B

H4

G5

H6

A6

B5

A4

B4

C1

D2

E1

E2

MS-148 BOARD

(1/3)

D6

C7

C6

Q801,802

A7

BUFFER

G2,F3

E4,F4

F7,E5

A3,B3

C3,A2

CN702

TG CLK

IC001

FOCUS MOTOR

ZOOM MOTOR

IC803

RGB DRIVE

TIMING GENERATOR

Note:

The CCD imager is not supplied

as

as a single unit requires adjustment.

17

H1A,B

H2A,B

RG

(1/8)

IC152

FREQUENCY DEVIDER

IRIS DRIVE

DRIVE

DRIVE

(2/2)

C1

C2

B1

D1

D2

F5

E3

F2

F1

A4

A5

SECTION 3

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SY-95 BOARD(1/2)

a single unit since removing it

Q004

BUFFER

51

FP-695

FLEXIBLE

G1

G2

H2

G3

C8

C7

B8

B7

B3

A2

B2

A1

FP-691

FLEXIBLE

(1/2)

Q805

LPF

18

20

19

15

17

16

12

14

13

11

8

CCD OUT

30

21

22

24

25

27

CN702

CN701

PANEL R

PANEL G

PANEL B

PANEL V

XSYS RST

HDO

86

37

42

48

51

33

10,13

113,17

20,109

112,115

125,119

118,121

84

CAM SO,SCK

EXT CLK

HR EN3

HR DIR3A

HR DIR3B

HR EN2

HR DIR2A

HR DIR2B

HR EN0

HR DIR0A

HR DIR0B

XFC RST SENS

XIR RST SENS

STRB ON

BL LEV

LED A

LED K

S/H

A/D CONV.

(1/8)

IC151

TIMING

GENERATOR

126-129 123,3

1

134,136,2,4,6

9,12,15,18,21

24,27,30,32

64

55

99

49,105

66,101,120

XCAM RST

TO

OVERALL

BLOCK DIAGRAM

(2/2)

(PAGE 3-3)

CA HD

CA F

CA F

V OUT

STRB ON

PANEL R

PANEL G

PANEL B

HDO

PANEL V

CA AD0

CA AD13

CLP DM

CLP OB

MCK TG

CA HD

CA F

HR DIR3A

HR DIR3B

HR EN0

HR DIR0A

HR DIR0B

HR EN2

HR DIR2A

HR DIR2B

XFC RST SENS

XZM RST SENS

Q302-Q304

(2/8)

IC302

VIDEO AMP

BUFFER

(AA,AB,Y)

(AA,AB,AC,

MC D0-D15

A18

Y18

AC16

(2/8)

IC301

CAMERA

Y17

AB18

N21

L21

P21

K20

L22

J21

M21

M20

N20

F21

F20

AB4

E23

C23

D23

C18

D17

F23

42

XSYS RST

DSP

T20

U,V,W,Y)

(J,K,L,M,

N,P,R,T,U)

D16

T23

AA7

AC12

AC9

MC A1-A25

SYS V

MC CKIO

AU LRCK

AU A IN

AU A OUT

CAM SO,SCK

SYS SO,SI,SCKSYS SO,SI,SCK

XCAM RST

CA F

EXT CLK

(J,M,N,P

R,T,V,M)

(21-24)

(E-H,

J-M)

(21-24)

AA8

A7

H1

C7

C23

AC12

A6

B11

A11

C11

A12

B12

(3/8)

IC501

CAMERA

SYSTEM

CONTROL

AB13

AD19

AC15

AB11

AD14

B16

C15

A15

D15

B15

D16

C22

D13

B13

C13

K2

D14

AB5

L4

F1

H23

V1

W1

AB7

MS SDIO/DATA0-3,MS BS, MS SCLK

XACCESS LED

XMS IN

SYS V

FR SO,SI,SCK

XSYS RST

XAE LOCK ON

XSHTR ON

STRB CHG

XSTRB FULL

XSTRB PWR ON

XUSB JACK IN

Q504

PRELAMP AF CONT

SELF TIMER LED

USBPHY D+,D-

MELODY

MELODY EW

Q501

MOD

AU A IN

AU A OUT

BEEP

2

E1

H4

H5

FP-691

FLEXIBLE

(2/2)

TO

OVERALL

BLOCK DIAGRAM

(2/2)

(PAGE 3-4)

(5/8)

IC601

AUDIO

AMP

MS-148

BOARD(2/3)

4,3,5,7,

2,8

LED DRIVE

D103

Q102

SP+

SP-

(ACCESS)

CN101

MEMORY

STICK

DUO

6

CONNECTOR

SP901

SPEAKER

CN-198

BOARD(1/2)

CN704

9

8

CN001

MIC IN

AU OUT

V OUT

MIC901

MIC

B4

A2

D1

B8

4

2

1

CONTROL SWITCH

BLOCK(PW-125)

(1/2)

AUDIO SIGNAL

VIDEO SIGNAL

VIDEO/AUDIO SIGNAL

10

12

CN001

MULTI

CONNECTOR

16

17

3-1 3-2

Page 16

DSC-T1

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-2. OVERALL BLOCK DIAGRAM (2/2)

MS-148 BOARD

(3/3)

S101

MODE SW

FP-691

FLEXIBLE

CN-198 BOARD

CN001

MULTI

CONNECTOR

11

13

14

24

3

2

1

(2/2)

VBUS

XMULTI JACK IN

XAV JACK IN

BATT/XEXT

ACV UNREG

BT901

BATTERY

TERMINAL

BT001

LITHIUM

BATTERY

(SECONDARY)

C

Q002

8 1

5

4

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SY-95 BOARD

(2/2)

CN704

VL 3V

11

12

13

14

15

18

17

4

5

6

CN705

F002

F003

F001

D015 D013

D8

D011

A10

B11

D9

OUT8A

E9

OUT8B

D1

D036

E5

D4

E4

USB JACK IN

3V

REG

BATTERY

CHARGER

FET DRIVE

(7/8)

IC001

DC/DC CONVERTER

(7/8)

IC003

ST UNREG

ACV UNREG

BATT UNREG

RESET

BATTERY IN

DETECT

Q406

LENS COVER

()

L8

K8

XRSTX

B7

BACK UP VCC

B9

A11

EVER 3.0V

BATT IN

A7

INIT CHARGE

D2

FAST CHARGE

E3

C7

SYS DD ON

D7

S401

OPEN

BATT SIG

DDCON SO,SCK

A 3.1V

D 1.2V

AU 2.8V

D 2.8V

A 2.8V

CAM 15.0V

CAM -8.0V

M 5V

ST 5V

STRB ON

BL LEV

LED A

LED K

CAM -0.5V

X402

32.768KHz

Q407

I/F

1

J8

B7

J4

J5

C8

C4

A3

A7

G2

G1

J1

H2

E8

C1

D3

D7

A5

H4

A9

TO

OVERALL

BLOCK DIAGRAM

(1/2)

(PAGE 3-1)

MODE DIAL

XLENZ CAP OPN

32KHz IN

32KHz OUT

XUSB JACK IN

XMULTI JACK IN

XAV JACK IN

BATT/XEXT

BATT SI

BATT SO

INIT CHARGE

FAST CHARGE

SYS DD ON

DDCON SO

DDCON SCK

XRSTX

BACK UP VCC

BATT IN

(4/8)

IC491

HI CONTROL

KEY AD0

KEY AD1

KEY AD2

XPOWER ON

XPWR LED ON

XCHARGE/XSTB LED

MS IN

FR SO

FR SI

XFR SCK

XSYS RST

SYS V

J6

H6

G6

B8

B2

B1

XAE LOCK ON

XSHTR ON

XUSB JACK IN

Q404

B6

D2

D1

E1

B3

B9

XMS IN

FR SO,SI,SCK

XSYS RST

SYS V

STRB CHG

XSTRB PWR ON

XSTB FULL

SELF TIMER LED

PRE LAMP AF CONT

STRB CHG

XSTRB PWR ON

XSTRB FULL

ST UNREG

Q651,652

(6/8)

Q653

(2/2)

IC651

STRB ON

SELF TIMER LED

PRE LAMP AF CONT

IGBT DRIVE

Q701

LED DRIVE

Q653

(1/2)

2

24

XAE LOCK ON

XSHTR ON

TO

OVERALL

BLOCK DIAGRAM

(1/2)

(PAGE 3-2)

CN703

FP-693

FLEXIBLE

FP-690

FLEXIBLE

1

6

15

16

17

19

CONTROL SWITCH

BLOCK(PW-125) (2/2)

12

13

14

5

7

8

3

10

9

CN001

S003-011,013

ZOOM,MENU,IMAGE SIZE/DELETE

DISPLAY/LCD BACK LIGHT,

UP,DOWN,RIGHT, LEFT,SET

S001

POWER

S002

SHUTTER

(POWER)

S012

RESET

ST-86 BOARD

Q001,002

T002

HIGH

XE A(H)

VOLTAGE

CHARGER

Q003

XE K(L)

FLASH

DRIVE

D003

(AF LED)

D004

D003

C003

/CHG

XENON

TUBE

(7/8)

IC007

D 1.8V

3-3 3-4

Page 17

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

DSC-T1

3-3. POWER BLOCK DIAGRAM (1/2)

CN-198

BOARD

1

2

3

24

C

ACV UNREG

BATT/XEXT

BT001

LITHIUM

BATTERY

(SECONDRY)

BATT UNREG

BATT SIG

Q407

I/F

CONTROL

SWITCH

BLOCK

(PW-125)

S001

POWER

D004

D003

S012

RESET

(POWER)

/CHG

CN001

FP-693

FLEXIBLE

5

4

3

11

10

9

CN001

MULTI

CONNECTOR

BT901

BATTERY

TERMINAL

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SY-95 BOARD(1/2)

BATT UNREG

ACV UNREG

EVER 3.0V

A5

H4

D7XRST X

A9BATT IN

C1

D3

H1

E8SYS DD ON

J1

H2

F8

F001

F002

F003

DDCON SO,SCK,XCS

ST UNREG

ACV UNREG

INIT CHARGE

FAST CHARGE

D013

D015

L002

L001

D011

D1

D4

E5

D2

E4

E3

E9

D9

B11

A11

A10

D8

B9

B7

A7

L8

K8

K7

C7

D7

BATTERY

CHARGER

OUT8A

OUT8B

3V REG

RESET

DIN

CLK

LD

SYS DD ON

FET

DRIVE

(7/8)

IC001

DC/DC CONVERTER

BATTERY IN

DETECT

VCC1A

VCC1B

VCC1C

OUT11A

OUT11B

OUT11C

OUT12A

OUT12B

OUT12C

VCH1A

VCH1B

VCH1C(FB4)

OUT2

VCH2

OUT3A

OUT3B

OUT3C

VCH3A(FB3)

VCH3B

VCH3C(FB6)

G11

G10

G9

H11

L006

H10

J11

L11

K10

J9

L10

K9

L9

F9VCC2

F10

E11

J3

K1

J2

J1

H4

H3

H2VCH3S

H1VCC GD

K6OUT4

J6VCH4

K5VCC5

L5OUT5

J5VCH5

F1OUT6

G1VCH6

G2ICH6

B1REF6

B5CBG

C8VLD04

B8VLD05

L005

L009

D026

(RECT)

L007

D017

(RECT)

D023

(RECT)

D021

(RECT)

D025

(RECT)

L008

L004

PANEL 13.5V

VL 3V

CN705

4

5

FB701

6

17

11

CN704

H8 BATT SENS

G8 ACV SENS

A7

BATT/XEXT

G2 BATT SI

G1

BATT SO

XPWR ON

B8

XPOWER LED ON

B2

B1

XCHARGE/XSTRB LED

(4/8)

IC491

HI CONTROL

BATT UNREG

Q002

8

4

BACK UP VCC

DDCON SO

DDCON SCK

XCS DD CON

INIT CHARGE

FAST CHARGE

DDCON SENS

1

5

LED A

LED K

BL LV

ST UNREG

LED A

LED K

BL LV

PANEL 13.5V

(7/8)

IC007

1.8V REG

L003

L010

32

AV 2.8V

A 2.8V

D 2.8V

D 1.8V

D 1.2V

1

TO

POWER

BLOCK DIAGRAM

(2/2)

(PAGE 3-7)

M 5V

ST 5V

CAM 15.0V

CAM -8.0V

8 4

VCC+

VCC-

3

2

1

(7/8)

SHUNT

REG

Q001

CAM -0.5V

IC003

-0.5V REG

A 3.1V

D 1.2V

3-5 3-6

Page 18

DSC-T1

3. BLOCK DIAGRAMS

3. BLOCK DIAGRAMS

3-4. POWER BLOCK DIAGRAM (2/2)

SY-95 BOARD(2/2)

ST UNREG

LED A

LED K

BL LV

PANEL 13.5V

AV 2.8V

A 2.8V

D 2.8V

D 1.8V

D 1.2V

TO

POWER

1

BLOCK DIAGRAM

(1/2)

(PAGE 3-6)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

D 2.8V

MS PWR ON

PANEL 13.5V

D 2.8V

AV 2.8V

(5/8)

BL LEV

IC601

ST 5V

A 3.1V

A 2.8V

AUDIO AMP

(3/8)

IC501

CAMERA

SYSTEM

CONTROL

(2/8)

IC302

VIDEO AMP

AD18

AD51

AB11

AC15

AC20

F22

MS PWR ON

STRB CHG

XSTRB PWR ON

XSTRB FULL

CAM DD ON

AMP OUT ON

Q305,306

Q302-304

PANEL

R,G,B

BUFFER

LED A

LED K

ST UNREG

STRB CHG

XSTRB PWR ON

XSTRB FULL

Q651,652

Q653

Q655,656

MT 5V

CN703

1

6

15

16

18

FLEXIBLE

FP-690

FLEXIBLE

MS-148 BOARDFP-691

Q101

IC803

RGB DRIVE

TIMING GENERATOR

A5

A4

Q001,002,T002

HIGH

VOLTAGE

CHARGER

D003

AF LED

ST-86 BOARD

VCC

C003

XE A(H)

9

CN101

MEMORY

STICK DUO

CONNECTOR

FP-694

FLEXIBLE

XENON

TUBE

CN402

LCD901

2.5INCH

COLOR LCD

20

1

3

UNIT

(ACX500EN-J)

ND901

BACK LIGHT

M 5V

ST 5V

CAM 15V

CAM -8.0V

CAM -0.5V

A 3.1V

D 2.8V

A 2.8V

AU 2.8V

A 2.8V

D 2.8V

D 1.2V

Q151,152

IC301

CAMERA

IC152

FREQUECY

DEVIDER

CAM DD ON

IC151

S/H,A/D CONV.

TIMING

GENERATOR

(2/8)

DSP

(1/8)

(1/8)

XFC RST LED

J22

XZM RST LED

V21

54MHz

XTAL

OSC

X151

CN702

33

17

IC001

CCD

IMAGER

CD-463 BOARD

Note:

The CCD imager is not supplied

as a single unit since removing it

as a single unit requires adjustment.

(6/8)

IC651

IGBT DRIVE

XFC RST LED

XZM RST LED

Q702

Q702

M 5V

D 2.8V

CN701

1

2

3

7

10

FP-695

FLEXIBLE

IC001

IRIS/FOCUS/

ZOOM DRIVE

F RST VCC

Z RST VCC

LD-140 BOARD

CN002

6

3

LENS UNIT

(LSV-850A)

FOCUS

RESET

SENSOR

ZOOM

RESET

SENSOR

3-7 3-8E

Page 19

SECTION 4

PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM (1/2)

1

A

FRAME SCHEMATIC DIAGRAM(1/2)

B

C

D

CD-463 BOARD

E

F

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

810 137

11

129

SY-95 BOARD(1/2)

33PCN702

1REG_GND

2V8

3V7B

4V7A

5V6

6VHLD

7V5B

8V5A

9V4

10VST

11V3B

12V3A

13V2

14V1B

15V1A

16REG_GND

17CAM_-8.0V_CD

18VSUB_CONT

19SHT

20REG_GND

21H1A

22H1B

23REG_GND

24H2A

25H2B

26REG_GND

27RG

28REG_GND

29REG_GND

30CCD-OUT

31REG_GND

32POWER_SAVE

33CAM_15V_CD

MS-148 BOARD

DSC-T1

144 1763

25P

CN402

1 LED_A

ND901

2 N.C.

3 LED_K

4 BL_THH

5 BL_THL

6 RGT

7VB

8VR

9VG

10 PSIG

11 HCK1

12 HCK2

13 CREXT

14 REF

15 HST

16 WIDE

17 REG_GND

18 VDDG

19 VSS

20 VDD

21 DWN

22 EN

23 VCK

24 VST

25 COM

FP-694

FLEXIBLE

BACK LIGHT

LCD901

2.5INCH

COLOR

LCD UNIT

(ACX500EN-J)

1825 15 16

19P

CN704

1REG_GND(AU)

CN705

2V_OUT

3REG_GND(AU)

4AU_OUT

5REG_GND(AU)

6REG_GND(USB)

7REG_GND(USB)

8USBPHY_D-

9USBPHY_D+

10REG_GND(USB)

11VL_3V

12VBUS

13VBUS

14VBUS

15XMULTI_IN

16NC

17BATT/XEXT

18XAV_JACK_IN

19NC

6P

1ACV_GND

2ACV_GND

3ACV_GND

4

5

6

FP-691

FLEXIBLE

1

2

3

4

5

6

7

8

9

10

CN101

GND

BS

DATA1

SDIO/DATA0

DATA2

INT

DATA3

SCLK

VCC

GND

10P

MEMORY

STICK

DUO

CONNECTOR

G

26PCN001

1

ACV_UNREG

ACV_UNREG

3

5

XLANC_JACK_IN

7

USB_LED

9

H

I

11

13

15

17

19

21

23

25

USB_HOST

USB_VBUS

XMULTI_IN

EXT_STRB_ON

V_OUT

V_GND

AUX

ACV_GND

ACV_GND

J

272829

MULTI CONNECTOR

2

ACV_UNREG

4

LANC_DC

6

LANC_SIG

XAV_JACK_IN

A_OUT_L

A_OUT_R

A_GND

BATT/XEXT

ACV_GND

8

10

D+

12

D-

AUX

14

16

18

20

22

24

26

CN-198 BOARD

BT001

LITHIUN BATTERY

(SECONDARY)

ACV_UNREG0

ACV_UNREG0

ACV_UNREG0

USB/LANC_GND

30

16

4-1 4-2

FRAME SCHEMATIC DIAGRAM (1/2)

Page 20

DSC-T1

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

FRAME SCHEMATIC DIAGRAM (2/2)

1

A

FRAME SCHEMATIC DIAGRAM(2/2)

25

B

C

D

E

463

ST-86 BOARD FP-690

FLEXIBLE

8107

1MIC_IN

2REG_GND

3XPOWER_LED_ON

4EVER_3.0V

5XPOWER_ON

6REG_GND

16P

CN001

7XAE_LOCK_ON

FP-693

19PCN703

1STB_UNREG

2STB_UNREG

3STB_UNREG

4STB_UNREG

5STB_UNREG

6STB_UNREG

7REG_GND

8REG_GND

9REG_GND

10REG_GND

11REG_GND

12REG_GND

13REG_GND

14REG_GND

15XSTRB_PWR_SAVE

16STB_FULL

17IGBT_ON

18AF_LED_5V

19AF_LED_K

8XSHTR_ON

9XRESET_SW

10XCHARGE/XSTRB_LED

FLEXIBLE

9

11EVER_3.0V

12KEY_AD0

13KEY_AD1

14KEY_AD2

15REG_GND

16NC

CONTROL SWITCH BLOCK

(PW-125)

11

F

G

H

I

LENS UNIT

(LSV-850A)

CN002

FOCUS_B

FOCUS_A

ZOOM_A

ZOOM_B

IRIS_A

IRIS_B

21P

1Z_RST_GND

2Z_RST_SENS

3Z_RST_VCC

4F_RST_GND

5F_RST_SENS

6F_RST_VCC

7N.C

8FOCUS_A

9

10

11FOCUS_B

12

13ZOOM_A

14ZOOM_B

15

16TEMP_OUT

17TEMP_GND

18

19IRIS_A

20

21IRIS_B

FP-695

FLEXIBLE

21PCN701

1M_5V

2M_5V

3D_2.8V

4REG_GND

5REG_GND

6REG_GND

7F_RST_VCC

8XFC_RST_SENS

9LENS_TEMP

10Z_RST_VCC

11XZM_RST_SENS

12HR_EN0

13HR_DIR0B

14HR_DIR0A

15HR_EN2

16HR_DIR2B

17HR_DIR2A

18HR_EN3

19HR_DIR3B

20HI_DIR3A

21XCAM_DR_PS

SY-95 BOARD(2/2)

LD-140 BOARD

J

FRAME SCHEMATIC DIAGRAM (2/2)

16

4-3 4-4

Page 21

Link

Link

DSC-T1

4-2. SCHEMATIC DIAGRAMS

CD-463 BOARD

CD-463 BOARD

CN-198 BOARD

CN-198 BOARD

COMMON NOTE FOR SCHEMATIC DIAGRAMS

COMMON NOTE FOR SCHEMATIC DIAGRAMS

(CCD IMAGER)

(CCD IMAGER)

(MULTI CONNECTOR)

(MULTI CONNECTOR)

ST-86 BOARD

ST-86 BOARD

CONTROL SWITCH BLOCK

CONTROL SWITCH BLOCK

(FLASH)

(FLASH)

(PW-125)

(PW-125)

Page 22

4-2. SCHEMATIC DIAGRAMS

About 30cm

Front of the lens

Pattern box

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

DSC-T1

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

Link

µF. 50 V or less are not indicated e xcept for electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

• Parts with * differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B: B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: VIDEO SIGNAL (ANALOG)

• A: AUDIO SIGNAL (ANALOG)

• A: VIDEO/AUDIO SIGNAL (ANALOG)

• A: VIDEO/AUDIO/SER V O SIGNAL

• A: SERVO SIGNAL

• Circled numbers refer to waveforms.

(Measuring conditions voltage and waveform)

• Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference values

and reference waveforms.

(VOM of DC 10 MΩ input impedance is used)

• Voltage values change depending upon input

impedance of VOM used.)

1. Connection

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Fig.b (Picture on monitor TV)

Red

Blue

When indicating parts by reference number, please

include the board name.

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

4-5

Page 23

4-2. SCHEMATIC DIAGRAMS CD-463 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS CD-463 PRINTED WIRING BOARD

DSC-T1

4-2. SCHEMATIC DIAGRAMS

1

CD-463 BOARD

A

CCD IMAGER

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

B

SIGNAL PATH

C

CHROMA

REC

PB

VIDEO SIGNAL

Y

Y/CHROMA

For Schematic Diagram

• Refer to page 4-41 for printed wiring board.

463

The CCD imager is not supplied

as a single unit since removing it

as a single unit requires adjustment.

IC001

CCD IMAGER

87

6

Vhld

7V48

Vst

V5A9V5B

V3A5V3B

10

11V612

14

V8

V7A13V7B

Rss317CCD-OUT18GND19GND20RG21H2B22H2A23H1B24H1A25GND26SUB27CSUB28VL

15VH16

925

1

3V24

V1A2V1B

ICX473CQZ-13

IC001

D

E

F

G

H

TO

SY-95 BOARD

(1/8)

CN702

(PAGE 4-15

of LEVEL3)

16

CAM_15V_CD

POWER_SAVE

REG_GND

CCD_OUT

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

VSUB_CONT

CAM_-8.0V_CD

REG_GND

REG_GND

VHLD

H2B

H2A

H1B

H1A

SHT

V1A

V1B

V3A

V3B

VST

V5A

V5B

V7A

V7B

14.9

R002

22k

10.6

0

Q002

DTC144EUA-T106

RG

R006

R003

0

2SC4250(T5LSONY1)

3900

1005

C001

0.1u

Q004

BUFFER

C004

5p

CH

DTC144EUA-T106

B16V

C002

0.1u

16V

B

R001

1500

3.5

0

Q001

SWITCHSWITCH

R005

1200

R004

1800

0

Q003

DTC144EHT2L

SWITCH

C003

0.1u

16V

12

C005

0.1u

16V

B

B

Precautions Upon Replaching CCD imager

•

V2

V4

V6

V8

The CD-463 board mounted as a repair part is not equipped

with a CCD imager.

When replaching this board, remove the CCD imager from the

old one and mount it onto the new one.

•

If the CCD imager has been replaced, carry out all the

adjustments for the camera section.

As the CCD imager may be damaged by static electrictiy from•

its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with dusts

nor exposed to strog light.

4-7 4-8

CD-463

Page 24

DSC-T1

For Schematic Diagram

• Refer to page 4-43 for printed wiring board.

4-2. SCHEMATIC DIAGRAMS CN-198 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS CN-198 PRINTED WIRING BOARD

A

B

C

D

1

CN-198 BOARD

MULTI CONNECTOR

XX MARK:NO MOUNT

TO

SY-95 BOARD

(8/8)

CN704

(PAGE 4-30

of LEVEL3)

XAV_JACK_IN

BATT/XEXT

XMULTI_IN

VL_3V

REG_GND(USB)

USBPHY_D+

USBPHY_D-

REG_GND(USB)

REG_GND(USB)

REG_GND(AU)

AU_OUT

REG_GND(AU)

V_OUT

REG_GND(AU)

VBUS

VBUS

VBUS

463

NC

FB001

2

1

DF3A8.2C(TPL3)

0uH

3

4

D003

1

2

LF001

FB002

0uH

2

1

3

4

LND026

STATIC_GND

D004

DF3A8.2C(TPL3)

D005

DF3A8.2C(TPL3)

FB003

0uH

4

NC

C001

100p

CH

1

2

3

4

3

D001

MA4L11100AS0

R002

R001

47k

4

100k

R003

0

D002

DF3A8.2C(TPL3)

8107

R004

0

1

23

1

23

1

4

ACV_UNREG

3

ACV_UNREG

5

XLANC_JACK_IN

7

USB_LED

9

USB_HOST

USB_VBUS

11

XMULTI_IN

13

EXT_STRB_ON

15

V_OUT

17

V_GND

19

AUX

21

ACV_GND

23

ACV_GND

25

CN001

MULTI

CONNECTOR

26P

11

ACV_UNREG

LANC_DC

LANC_SIG

USB/LANC_GND

XAV_JACK_IN

A_OUT_L

A_OUT_R

A_GND

BATT/XEXT

ACV_GND

AUX

12925

2

4

6

8

D+

10

D-

12

14

16

18

20

22

24

26

E

D008

XX

D009

DF3A8.2C (TPL3)

F

TO

SY-95 BOARD

(8/8)

CN705

(PAGE 4-30

of LEVEL3)

G

16

ACV_GND

ACV_GND

ACV_GND

ACV_UNREG0

ACV_UNREG0

ACV_UNREG0

BT001

LITHIUM

BATTERY

(SECONDARY)

SIGNAL PATH

VIDEO SIGNAL

CHROMA

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

AUDIO

Y Y/CHROMA SIGNAL

REC

PB

R005

XX

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

CN-198

4-9 4-10

Page 25

For Schematic Diagram

• Refer to page 4-42 for printed wiring board.

4-2. SCHEMATIC DIAGRAMS ST-86 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS ST-86 PRINTED WIRING BOARD

DSC-T1

A

B

C

1

ST-86 BOARD

FLASH

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

TO

FP-690 FLEXIBLE

(PAGE 4-26

of LEVEL3)

STB_UNREG

REG_GND

XSTRB_PWR_ON

STB_FULL

IGBT_ON

AF_LED_5V

AF_LED_K

CL001

Q001

CPH3205-SONY-TL-E

Q001,002

HIGH VOLTAGE

CHARGER

925

C004

47000pF

LND003

LND004

TRIGGER GND

LND002

IGBT

87

TRIGGER_IN

FLASH DRIVE

8

Q003

CY25AAJ-8-T13

6

7

5

R008

1M

463

T002

PFS

4

C002

0.01u

B

R001

4700

0

MCH3405-TL-E

R002

100k

R005

180

R003

120

Q002

00

2.7 268

R004

10k

1

3

2

5

D002

HAU160C030TP

C003

63uF

315V

LND001

XENON

TUBE

XE_A(H)

+

–

XE_K(L)

D

E

F

16

CL002

CL003

CL004

CL005

CL006

CL007

D001

MA111-(K8).S0

D003

S4G49(SONY)

(AF LED)

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

R006

47

R007

1M

4

0

1

2

3

4-11 4-12

ST-86

Page 26

DSC-T1

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

A

B

C

1

CONTROL SWITCH BLOCK(PW-125)

16P

CN001

1MIC_IN

2REG_GND

3XPOWER_LED_ON

4EVER_3.0V

5XPOWER_ON

TO

SY-95 BOARD

(8/8)

THROUGH

THE FP-693

FLEXIBLE

(PAGE 4-29

of LEVEL3)

6REG_GND

7XAE_LOCK_ON

8XHTR_SW

9XRESET_SW

10XCHARGE/XSTRB_LED

11EVER_3.0V

12KEY_AD0

13KEY_AD1

14KEY_AD2

15REG_GND

16NC

463

(POWER)

D004

S001

POWER

(Shutter)

S002

R001

470

MIC901

(MIC)

SIGNAL PATH

AUDIO

SIGNAL

S006

S010

87

R007

1500

925

D

E

F

S003

W

/CHG

(ZOOM)

R003

1200

D003

S004

R006

3300

S012

RESET

S005

R002

240

R008

1200

T

R004

1200

S007

MENU

S008

S009

(Image Size

/DELETE)

S011

R005

1500

R009

3300

S013

(Display/LCD back light

on/off)

16

CONTROL SWITCH BLOCK

Schematic diagram of the LD-140, MS-148

and SY-95 boards are not shown.

Pages from 4-15 to 4-36 are not shown.

4-13 4-14

Page 27

Link

Link

DSC-T1

4-3. PRINTED WIRING BOARDS

CD-463 BOARD

CD-463 BOARD

ST-86 BOARD

ST-86 BOARD

COMMON NOTE FOR PRINTED WIRING BOARDS

COMMON NOTE FOR PRINTED WIRING BOARDS

MOUNTED PARTS LOCATION

MOUNTED PARTS LOCATION

CIRCUIT BOARDS LOCATION

CIRCUIT BOARDS LOCATION

CN-198 BOARD

CN-198 BOARD

FLEXIBLE BOARDS LOCATION

FLEXIBLE BOARDS LOCATION

Page 28

4-3. PRINTED WIRING BOARDS

4-3. PRINTED WIRING BOARDS

THIS NOTE IS COMMON FOR WIRING BOARDS

(In addition to this, the necessary note is printed in each block)

(For printed wiring boards)

•

: Uses unleaded solder.

• : P attern from the side which enables seeing.

(The other layers’ patterns are not indicated)

• Through hole is omitted.

• Circled numbers refer to waveforms.

• There are a few cases that the part printed on diagram

isn’t mounted in this model.

• C: panel designation

BOARD INFORMATION

board name

CD-463

ST-86

CN-198

FP-694

LD-140

FP-695

MS-148

SY-95

parts location

(shown on page)

4-53

4-53

4-53

–

4-54

–

4-55

4-54

number of layers

pattern

layers not shown

2

4

4

2

4

1

6

8

• Chip parts.

Transistor Diode

C

–

2 and 3

–

–

2 and 3

–

2 to 5

2 to 7

5

5246

EB

31

21

345

IC001, IC151, IC301,

IC491, IC501, IC601

654

123

12

534

CSP IC

–

–

–

–

IC001

–

IC803

DSC-T1

43

12

3

43

12

31

4625

4

3

12

54

45

21321321

123

312

43

12

21

34

4

5

13

4-39

Page 29

DSC-T1

4-3. PRINTED WIRING BOARDS

CD-463 BOARD

28 25 20 15

A

1 5 10 14

B

C

LND001

LND002

LND003

LND004

LND005

LND006

LND007

LND008

LND009

LND010

LND011

LND012

LND013

LND014

LND015

LND016

LND017

LND018

LND019

LND020

LND021

LND022

LND023

LND024

D

16

LND025

LND026

LND027

LND028

LND029

LND030

LND031

LND032

LND033

123

Note:

The CCD imager is not supplied

as a single unit since removing it

as a single unit requires adjustment.

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

• Refer to page 4-39 for common note for printed wiring board.

R001

IC001

Q003

R004

1-860-520-

R005

E

C

B

C005

C003

C004

11

Q001

R006

R003

C001

R002

Q004

C002

Q002

45

• : Uses unleaded solder.

ST-86 BOARD(SIDE A)

A

B

C

Q001

R001

D001

C002

R004

R002

D

1-860-525-

E

16

R005

R003

D

SG

Q002

11

123

C003

MOUNTED PARTS LOCATION

MOUNTED PARTS LOCATION

D003AK

ST-86 BOARD(SIDE B)

LND002

CL001

45

2

T002

13

CL002

A

LND001

CL005CL006

CL007

CL003

CL004

LND003LND004

B

D002

C

R008

C004

85

Q003

14

1-860-525-

123

D

R006R007

11

E

16

4-41 4-42

CD-463/ST-86

Page 30

DSC-T1

• Refer to page 4-39 for common note for printed wiring board.

CN-198 BOARD(SIDE A)

A

B

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

4-2. SCHEMATIC DIAGRAMS 4-3. PRINTED WIRING BOARDS

• : Uses unleaded solder.

D005

421

3

4

3

R005

2

1

D004

FB003

FB002

4

1

D001

3

C001

2

21

FB001

LF001

2

3

D003

34

12

1

4

R004

2

3

R003

1

4

R002

D008

D002

R001

3

12

D009

MOUNTED PARTS LOCATION

MOUNTED PARTS LOCATION

211-860-527-

C

16

123

CN-198 BOARD(SIDE B)

2

BT001

LITHIUM BATTERY

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

(SECONDARY)

1

456

A

15 15

210 20

CN001

25

26

1-860-527-

21

B

CN-198

MULTI CONNECTOR

C

Printed wiring board of the FP-695, MS-148,

SY-95 and FP-694 boards are not shown.

456

123

16

4-43 4-44

Pages from 4-45 to 4-52 are not shown.

Page 31

4-3. PRINTED WIRING BOARDS

4-3. PRINTED WIRING BOARDS

DSC-T1

4-4. MOUNTED PARTS LOCATION

CD-463 BOARD

C001 A-4

C002 A-5

C003 A-4

C004 A-4

C005 A-4

IC001 A-3

Q001 A-4

Q002 A-5

Q003 A-4

Q004 A-5

R001 A-4

R002 B-5

R003 A-4

R004 A-4

R005 A-4

R006 A-4

ST-86 BOARD

C002 D-1

C003 D-2

* C004 C-1

D001 C-1

* D002 C-1

D003 B-3

Q001 C-1

Q002 D-1

* Q003 D-1

R001 C-1

R002 D-1

R003 D-1

R004 D-1

R005 D-1

* R006 D-1

* R007 D-1

* R008 C-1

* T002 B-2

CN-198 BOARD

BT001 C-2

C001 B-3

* CN001 B-3

D001 B-3

D002 B-3

D003 B-3

D004 B-3

D005 B-3

D008 B-3

D009 B-4

FB001 B-3

FB002 B-3

FB003 B-3

LF001 B-3

R001 B-4

R002 B-4

R003 B-3

R004 B-3

no mark : side A

* mark : side B

Mounted parts location of the LD-140, MS-148,

and SY-95 boards are not shown.

Pages from 4-54 to 4-55 are not shown.

4-53E

CD-463/ST-86/CN-198

Page 32

DSC-T1

CABINET (REAR) SECTION

CABINET (REAR) SECTION

NOTE

NOTE

5. REPAIR PARTS LIST

NOTE: Characters A to Z of the electrical parts list indicate location of exploded views in which the desired part is shown.

Link

Link

OVERALL SECTION

OVERALL SECTION

Link

Link

EXPLODED VIEWS

EXPLODED VIEWS

SY-95

A

BATTERY HOLDER SECTION

BATTERY HOLDER SECTION

ELECTRICAL PARTS LIST

ELECTRICAL PARTS LIST

ST-86 BOARD MS-148 BOARDCD-463 BOARD

ST-86 BOARD MS-148 BOARDCD-463 BOARD

B

LD-140 BOARD SY-95 BOARDCN-198 BOARD

LD-140 BOARD SY-95 BOARDCN-198 BOARD

B

A

A

ACCESSORIES

ACCESSORIES

B

B

Page 33

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

NOTE:

• -XX, -X mean standardized parts, so they may have some differences from

the original one.

• Items marked “*” are not stocked since they are seldom required for routine

service. Some delay should be anticipated when ordering these items.

• The mechanical parts with no reference number in the exploded views are not

supplied.

• Due to standardization, replacements in the parts list may be different from

the parts specified in the diagrams or the components used on the set.

• CAPACITORS:

uF: µF

• COILS

uH: µH

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

DSC-T1

When indicating parts by reference number,

please include the board name.

The components identified by mark 0 or

dotted line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque

0 sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

5-1

Page 34

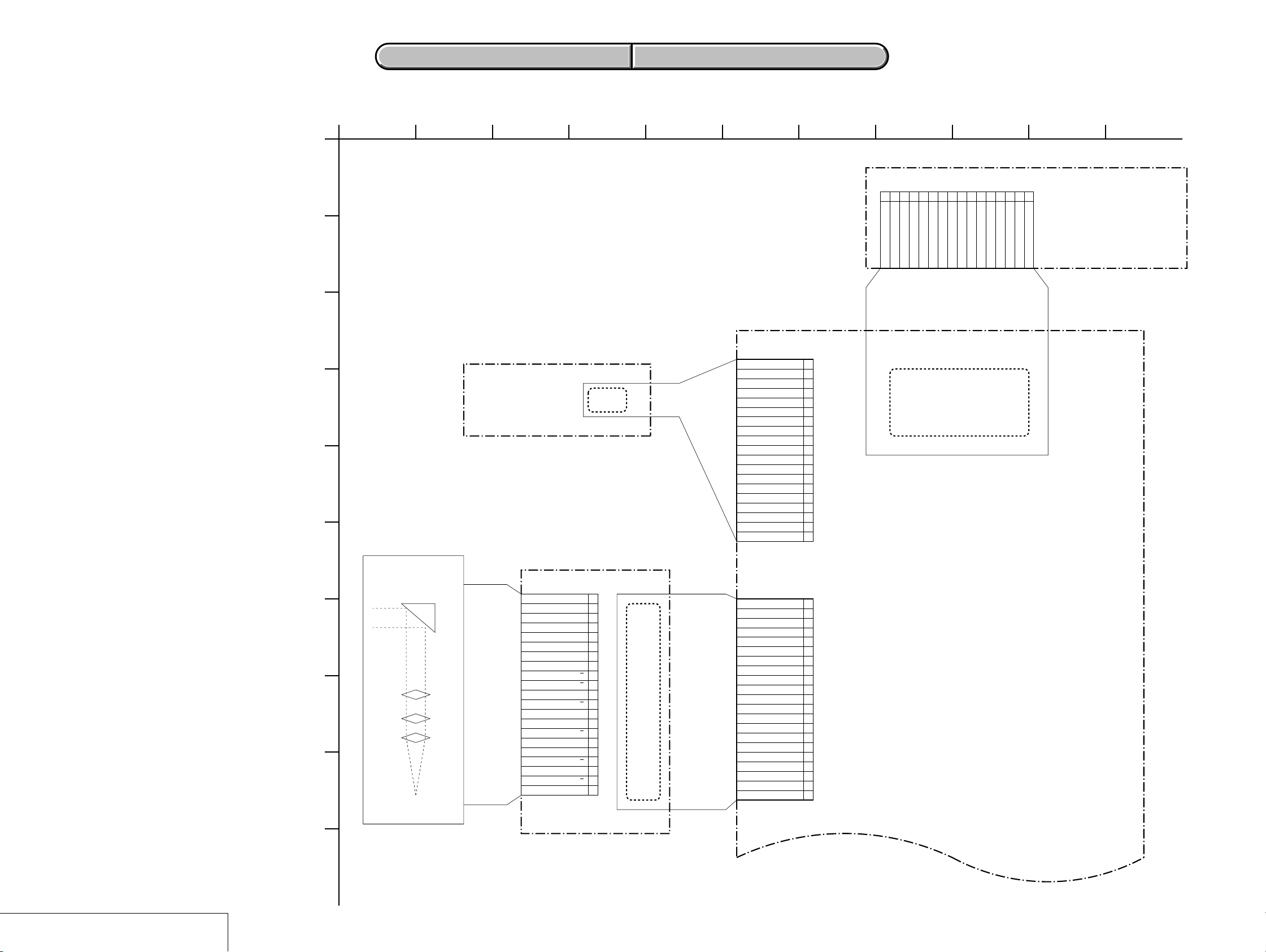

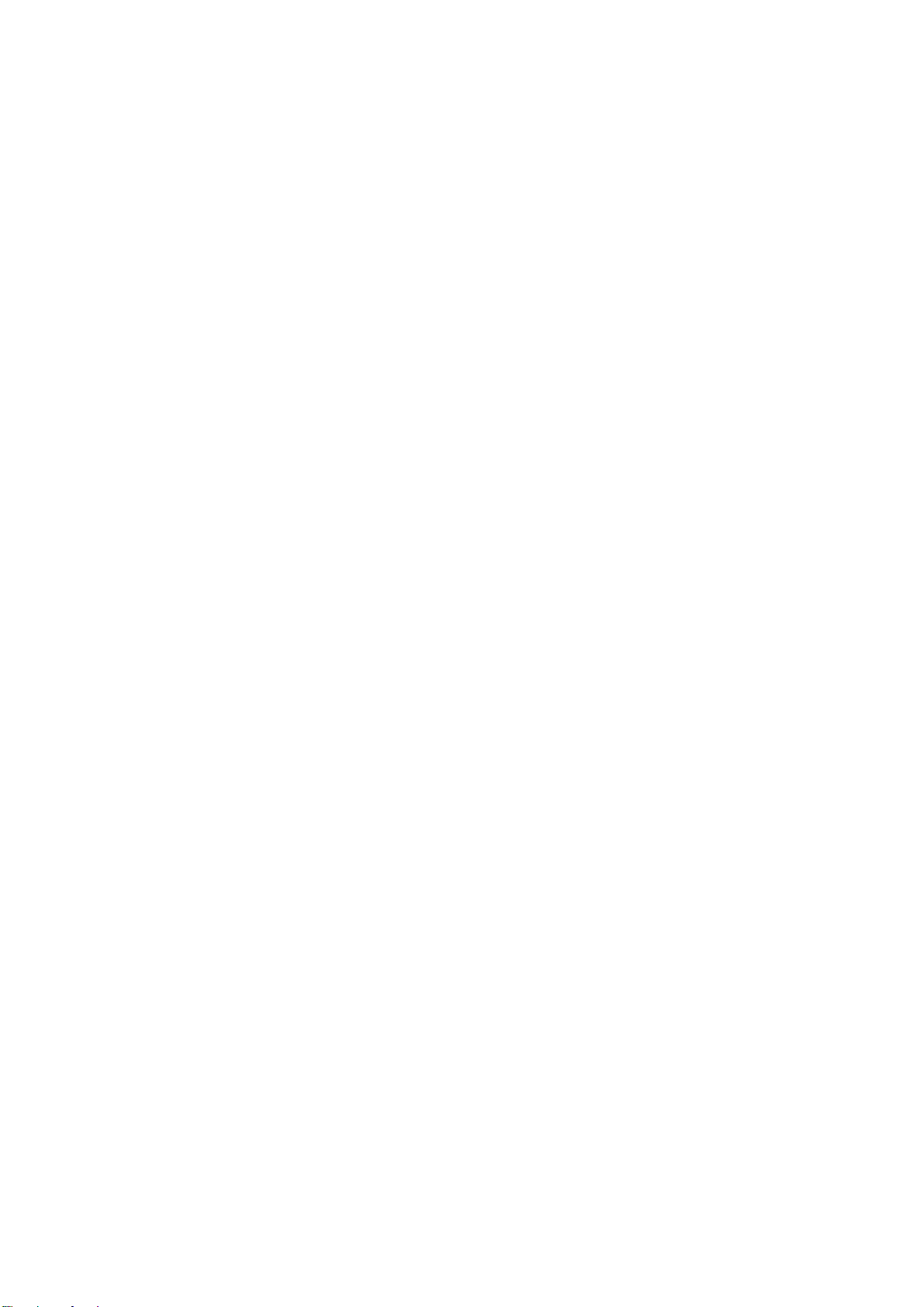

5-1. EXPLODED VIEWS

5-1-1. OVERALL SECTION

ns : not supplied

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

DSC-T1

SY-95

Battery holder section

(See page 5-4)

1

B

A

7

2

6

Cabinet (rear) section

(See page 5-5)

5

4

ns

7

3

LD-140 board

(Note 1)

9

17

B

15

14

A

ns

18

8

13

12

7

CCD imager

(Note 3)

Note 1: LD-140 board is included in the FP-695 complete board .

LD-140 board is not supplied as an independent service parts.

Note 2: CD-463 board is included in the CCD block assy.

CD-463 board is not supplied as an independent service parts.

Ref. No. Part No. Description Ref. No. Part No. Description

1 X-3953-789-1 CABINET (FRONT) ASSY

2 3-087-670-01 GASKET (K)

3 A-7078-867-A ST-86 BOARD, COMPLETE

0 4 1-478-385-11 LUMINOUS UNIT, STROBOSCOPE

5 1-860-515-11 FP-690 FLEXIBLE BOARD

6 3-086-275-01 COVER, ST TERMINAL

7 3-086-218-01 SCREW (M1.4), LOCK ASE, SPECIAL

8 3-086-236-01 SHEET (CCD), RADIATION

9 A-7097-088-A LENS BLOCK ASSY (SERVICE)

Note 3: The CCD imager is included in the CCD block assy .

The CCD imager is not supplied as a single unit since

removing it as a single unit requires adjustment.

10 A-7111-623-A CCD BLOCK ASSY

11 3-086-156-11 SCREW B1.2

12 3-086-238-01 SHEET (CCD), INSULATING

13 3-086-276-01 SHAFT, LENS

14 3-086-237-01 SHEET (LD), ADHESIVE

15 A-7078-877-A FP-695 BOARD, COMPLETE

16 3-088-401-01 SHEET, PROTECTION, COPPER LEAF

17 3-089-986-01 SHEET (L), LIGHT INTERCEPTION

18 3-089-781-01 SHEET (MOTOR), PROTECTION

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

5-3

specified.

16

10

CD-463 board

(Note 2)

11

(Supplied with CD-463 board)

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

Page 35

DSC-T1

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

5-1-2. BATTERY HOLDER SECTION

ns : not supplied

51

53

54

ns

52

BT901

ns

58

57

59

ns

MS-148

60

61

SP901

63

64

70

65

SY-95

55

56

SY-95 board

(Note)

68

Note : SY-95 board is included in the SY-MS complete board .

SY-95 board is not supplied as a single board since

removing it as a single board requires adjustment.

: BT001 (Lithium battery) CN-198 board on the mount position. (See page 4-43)

69

71

Ref. No. Part No. Description Ref. No. Part No. Description

51 A-7079-000-A SY-MS BOARD, COMPLETE (SERVICE)

52 1-860-517-11 FP-693 FLEXIBLE BOARD

53 1-860-516-11 FP-691 FLEXIBLE BOARD

54 X-3953-783-1 HOLDER ASSY, BATTERY

55 3-086-216-01 FOOT, RUBBER

63 3-086-221-01 SHEET (SPEAKER), ADHESIVE

64 3-086-218-01 SCREW (M1.4), LOCK ASE, SPECIAL

65 3-086-223-01 SHEET (L), PROTECTION, MS

66 3-086-219-01 HOLDER, SY

67 A-7078-870-A CN-198 BOARD, COMPLETE

BT001

66

67

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

64

56 3-086-210-01 LID, BT

57 3-355-424-01 SCREW, TAPPING

58 A-7078-865-A MS-148 BOARD, COMPLETE

59 1-860-518-11 FP-694 FLEXIBLE BOARD

60 3-086-222-01 SHEET (S), PROTECTION, MS

61 3-086-752-01 CUSHION (RING)

68 3-086-217-01 CAP (MULTI)

69 3-089-013-01 SHEET (K), ELECTROTATIC

70 3-089-250-01 SHEET (D), RADIATION

71 3-089-985-01 SHEET

BT901 1-780-061-11 TERMINAL BOARD, BATTERY

SP901 1-825-644-11 BUZZER, PIEZOELECTRIC

5-4

Page 36

5-1-3. CABINET (REAR) SECTION

ND901

101

103

102

106

107

109

114

115

110

111

108

104

116

LCD901

MIC901

ns

105

112

113

ns : not supplied

5. REPAIR PARTS LIST

5. REPAIR PARTS LIST

DSC-T1

Ref. No. Part No. Description Ref. No. Part No. Description

101 3-086-279-01 TAPE (LCD)

102 3-086-218-01 SCREW (M1.4), LOCK ASE, SPECIAL

103 3-086-234-01 FRAME, LCD

104 3-086-232-01 BUTTON, SW

105 3-086-233-01 BUTTON, ZOOM

111 3-086-277-01 CUSHION, MICROPHONE

112 3-086-274-01 HOLDER, MICROPHONE

113 3-086-278-01 SHEET PROTECTION, HARNESS

114 3-086-206-01 SHEET METAL, MODE RETAINER

115 3-086-207-01 SPRING (MODE), CLICK

106 X-3953-782-1 CABINET (REAR) ASSY

107 3-086-199-01 BASE, MODE

108 3-086-198-01 KNOB, MODE

109 3-086-200-01 SLIDER, MODE

110 1-478-171-11 SWITCH BLOCK,CONTROL (PW-125)

116 3-088-260-01 SHEET (BL)

LCD901 8-753-052-81 ACX500EN-J (2.5 INCH COLOR LCD UNIT)

MIC901 1-542-554-11 MICROPHONE

ND901 1-478-250-11 BLOCK LIGHT GUIDE PLATE (2.5)

5-5

Page 37

DSC-T1

CD-463 CN-198

ST-86

5-2. ELECTRICAL PARTS LIST

Ref. No. Part No. Description Ref. No. Part No. Description

A-7111-623-A CCD BLOCK ASSY

***************

not supplied CD-463 BOARD, COMPLETE

**********************

(CD-463 board is included in CCD BLOCK ASSY.)

< CAPACITOR >

C001 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C002 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C003 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C004 1-164-845-11 CERAMIC CHIP 5PF 0.25PF 50V

C005 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

< IC >

IC001 not supplied CCD IMAGER (Note)

< TRANSISTOR >

Q001 8-729-029-14 TRANSISTOR DTC144EUA-T106

Q002 8-729-029-14 TRANSISTOR DTC144EUA-T106

Q003 8-729-052-64 TRANSISTOR DTC144EHT2L

Q004 8-729-050-22 TRANSISTOR 2SC4250 (T5LSONY1)

< RESISTOR >

LF001 1-456-583-11 COIL, COMMON MODE CHOKE

R001 1-218-973-11 RES-CHIP 47K 5% 1/16W

R002 1-218-977-11 RES-CHIP 100K 5% 1/16W

R003 1-216-295-91 SHORT CHIP 0

R004 1-216-864-11 SHORT CHIP 0

************************************************************

A-7078-867-A ST-86 BOARD, COMPLETE

C002 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

0 C003 1-100-760-11 ELECT 63uF 99% 315V

C004 1-137-723-21 CERAMIC CHIP 0.047uF 10% 250V

D001 8-719-073-01 DIODE MA111-(K8).S0

0 D002 6-500-237-01 DIODE HAU160C030TP

D003 6-500-804-01 DIODE S4G49 (SONY)

< LINE FILTER >

< RESISTOR >

********************

< CAPACITOR >

< DIODE >

R001 1-218-955-11 RES-CHIP 1.5K 5% 1/16W

R002 1-218-969-11 RES-CHIP 22K 5% 1/16W

R003 1-218-960-11 RES-CHIP 3.9K 5% 1/16W

R004 1-218-956-11 RES-CHIP 1.8K 5% 1/16W

R005 1-218-954-11 RES-CHIP 1.2K 5% 1/16W

R006 1-218-990-11 SHORT CHIP 0

************************************************************

A-7078-870-A CN-198 BOARD, COMPLETE

*******************

< BATTERY >

0BT001 1-528-999-51 BATTERY (LITHIUN BATTERY (SECONDRY))

< CAPACITOR >

C001 1-164-874-11 CERAMIC CHIP 100PF 5% 50V

< CONNECTOR >

CN001 1-816-929-11 CONNECTOR, MULTIPLE 26P

< DIODE >

D001 8-719-077-54 DIODE MA4L11100AS0

D002 8-719-077-57 DIODE DF3A8.2C (TPL3)

D003 8-719-077-57 DIODE DF3A8.2C (TPL3)

D004 8-719-077-57 DIODE DF3A8.2C (TPL3)

D005 8-719-077-57 DIODE DF3A8.2C (TPL3)

D009 8-719-077-57 DIODE DF3A8.2C (TPL3)

< FERRITE BEAD >

FB001 1-500-284-21 INDUCTOR, FERRITE BEAD

FB002 1-500-284-21 INDUCTOR, FERRITE BEAD

FB003 1-414-228-11 INDUCTOR, FERRITE BEAD

< TRANSISTOR >

Q001 6-550-308-01 TRANSISTOR CPH3205-SONY-TL-E

Q002 8-729-056-01 TRANSISTOR MCH3405-TL-E

Q003 8-729-053-74 TRANSISTOR CY25AAJ-8-T13

< RESISTOR >

R001 1-218-961-11 RES-CHIP 4.7K 5% 1/16W

R002 1-218-977-11 RES-CHIP 100K 5% 1/16W

R003 1-218-942-11 RES-CHIP 120 5% 1/16W

R004 1-218-965-11 RES-CHIP 10K 5% 1/16W

R005 1-218-944-11 RES-CHIP 180 5% 1/16W

R006 1-216-805-11 METAL CHIP 47 5% 1/10W

R007 1-216-857-11 METAL CHIP 1M 5% 1/10W

R008 1-216-121-11 RES-CHIP 1M 5% 1/10W

< TRANSFORMER >

0 T002 1-437-987-31 TRANSFORMER , CONVERTER

************************************************************

Be sure to read “Precautions upon replacing CCD imager”

on page 4-7 when changing the CCD imager.

Note :

The CCD imager is not supplied as a single unit

since removing it as a single unit requires adjustment.

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

5-6

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

Page 38

LD-140 MS-148 SY-95

Ref. No. Part No. Description Ref. No. Part No. Description

A-7078-877-A FP-695 BOARD, COMPLETE

not supplied LD-140 BOARD, COMPLETE

************************************************************

**********************

**********************

(LD-140 board is included in FP-695 board)

A-7078-865-A MS-148 BOARD, COMPLETE

************************************************************

A-7079-000-A SY-MS BOARD, COMPLETE (SERVICE)

not supplied SY-95 BOARD, COMPLETE

(MS-148 board and SY-95 board are included in SY-MS board.)

************************************************************

***********************

(CN402 is not included in this complete board.)

*******************************

*********************

(IC301 is not included in this complete board.)

Electrical parts list of the LD-140, MS-148

and SY-95 boards are not shown.

Pages from 5-7 to 5-11 are not shown.

Page 39

DSC-T1

Checking supplied accessories.

Make sure that the following accessories are supplied with your camcorder.

Power cord (Main lead) (1)

(AUS model)

0

1-696-819-11

Power cord (Main lead) (1)

(AEP, E model)

0

1-769-608-11

Power cord (Main lead) (1)

(CH model)

0

1-782-476-13

Power cord (Main lead) (1)

(UK, HK model)

0

1-783-374-11

Power cord (Main lead) (1)

(JE model)

0

1-790-732-12

Power cord (Main lead) (1)

(J model)

0

1-791-637-13

Power cord (Main lead) (1)

(KR model)

0

1-776-985-11

Power cord (Main lead) (1)

(US, CND model)

0

1-790-107-22

NP-FT1 battery pack (1)

(not supplied)

AC-LM5 AC Adaptor (1)

(Except US, CND)

0

1-477-488-12

AC-LM5 AC Adaptor (1)

(US, CND)

0

1-477-488-21

CD-ROM

(USB Driver SPVD-013) (1)

(AEP, UK, E, HK, AUS, CH,

JE, KR model)

3-087-330-01

CD-ROM

(USB Driver SPVD-013 (I)) (1)

(US, CND, J model)

3-087-331-01

“Memory stick Duo” (1)

(MSA-M32A)

(not supplied)

UC-TA USB cradle (1)

1-817-742-11

A/V connecting cable (1)

1-824-111-11

2-pin conversion adaptor (1)

(JE model)

1-569-007-12

Memory stick Duo Adaptor(1)

(MSAC-M2)

(not supplied)

USB cable (1)

1-828-073-11

Wrist strap (1)

3-086-283-01

2-pin conversion adaptor (1)

(E model)

1-569-008-12

• Abbreviation

CND : Canadian model

AUS : Australian model

CH : Chinese model

HK : Hong Kong model

KR : Korea model

JE : Tourist model

J : Japanese model

Other accessories

3-085-733-01 MANUAL, INSTRUCTION SET (JAPANESE) (J)