Page 1

http://servis-manual.com/

Page 2

DSC-T1

• NOTE FOR REPAIR

SELF-DIAGNOSIS FUNCTION

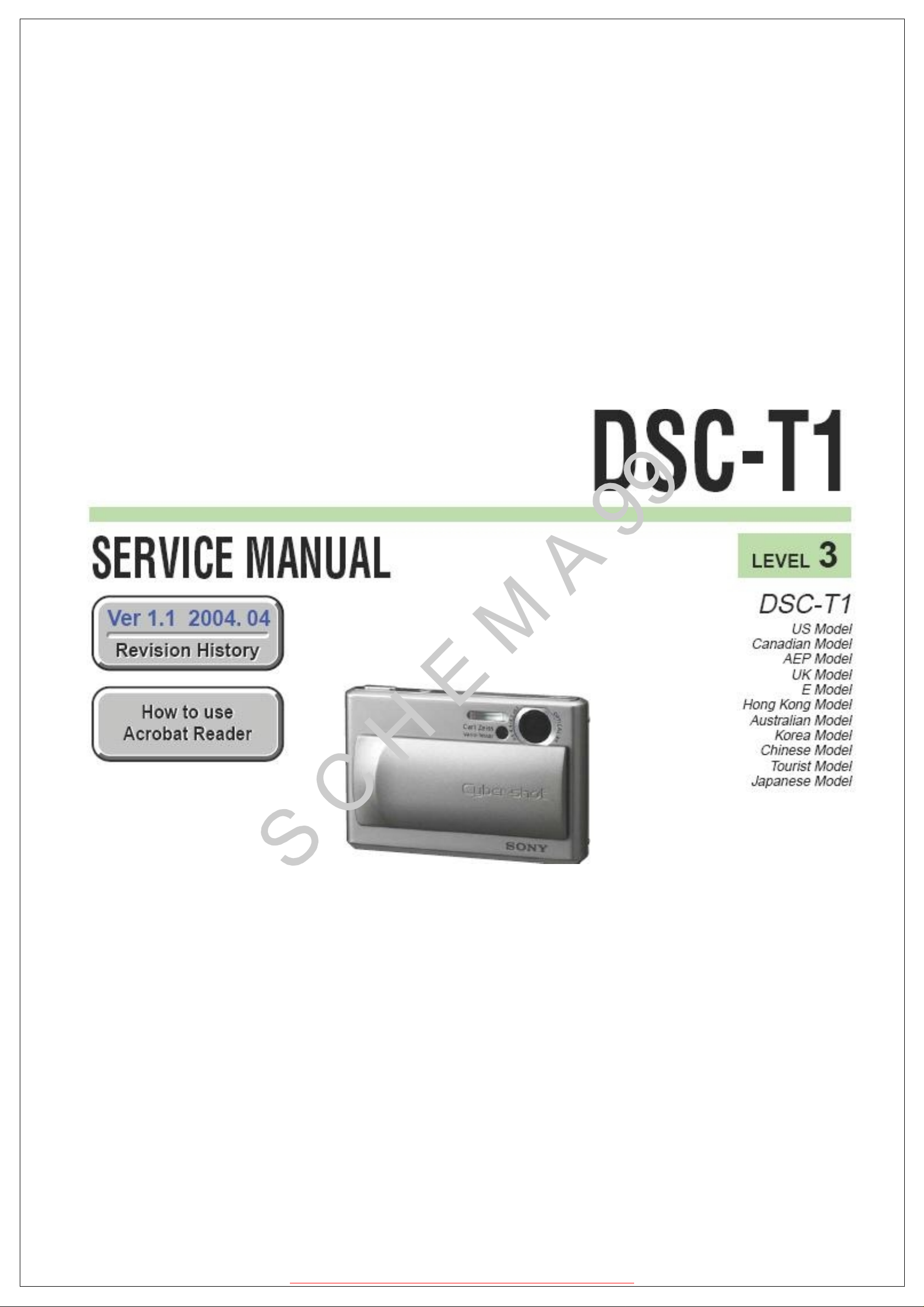

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

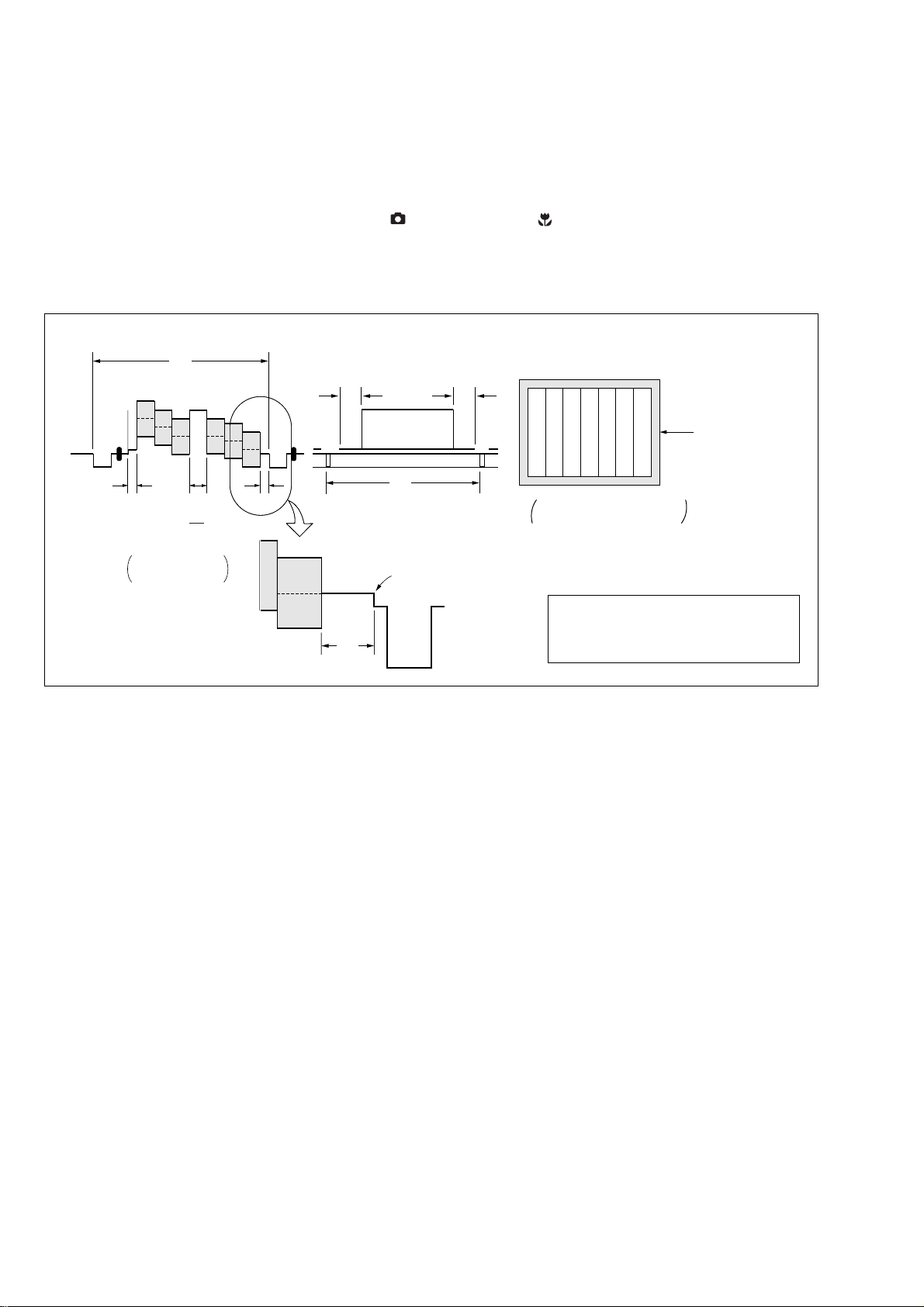

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the DSC-T1 is simply turned off. Therefore, the remaining

voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11)

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

Discharging the Capacitor

Short circuits between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

1 kΩ/1 W

Wrap insulating tape.

ST-86 B0ARD

Shorting jig

(1kΩ / 1w)

Capacitor

— 4 —

Page 3

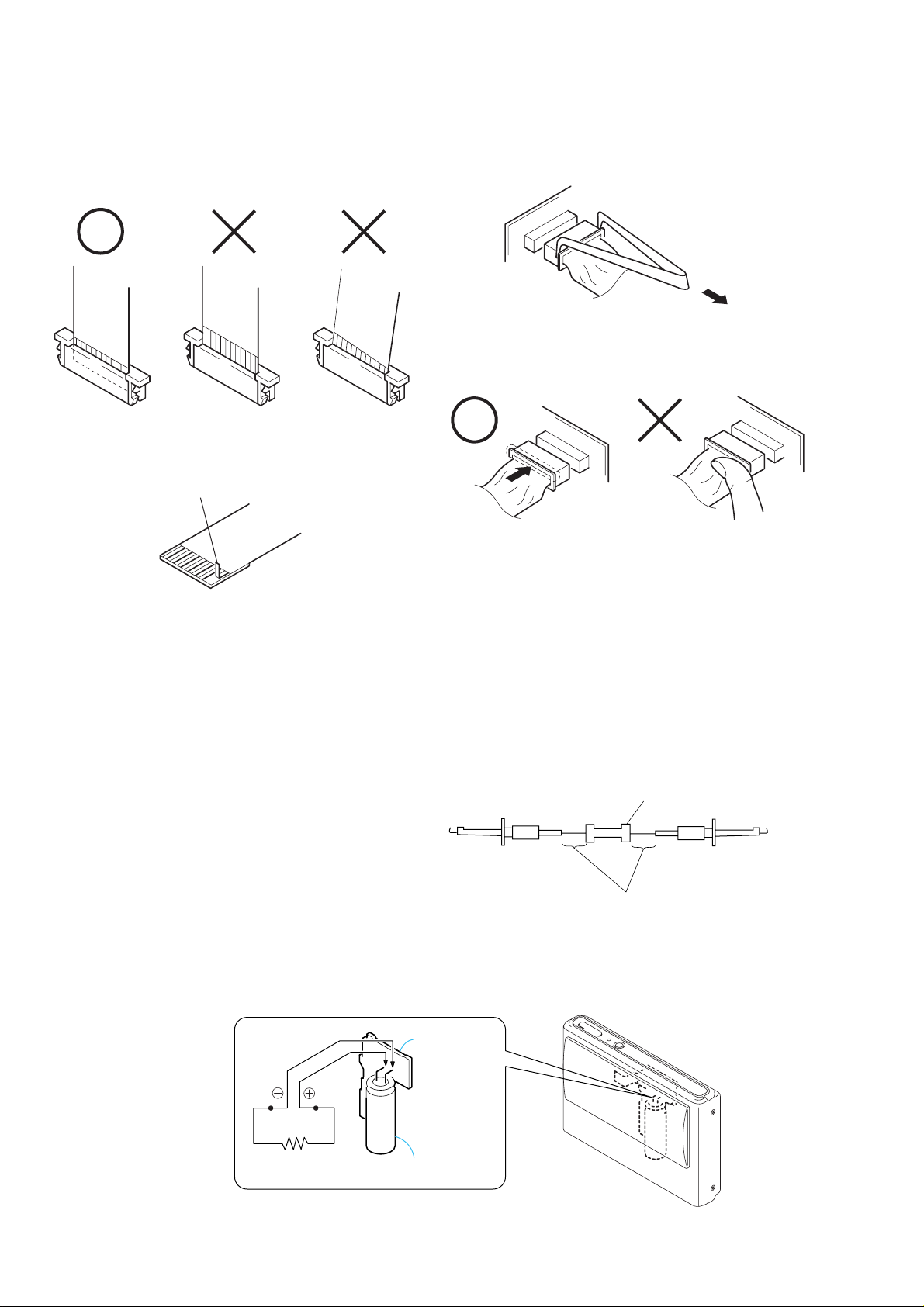

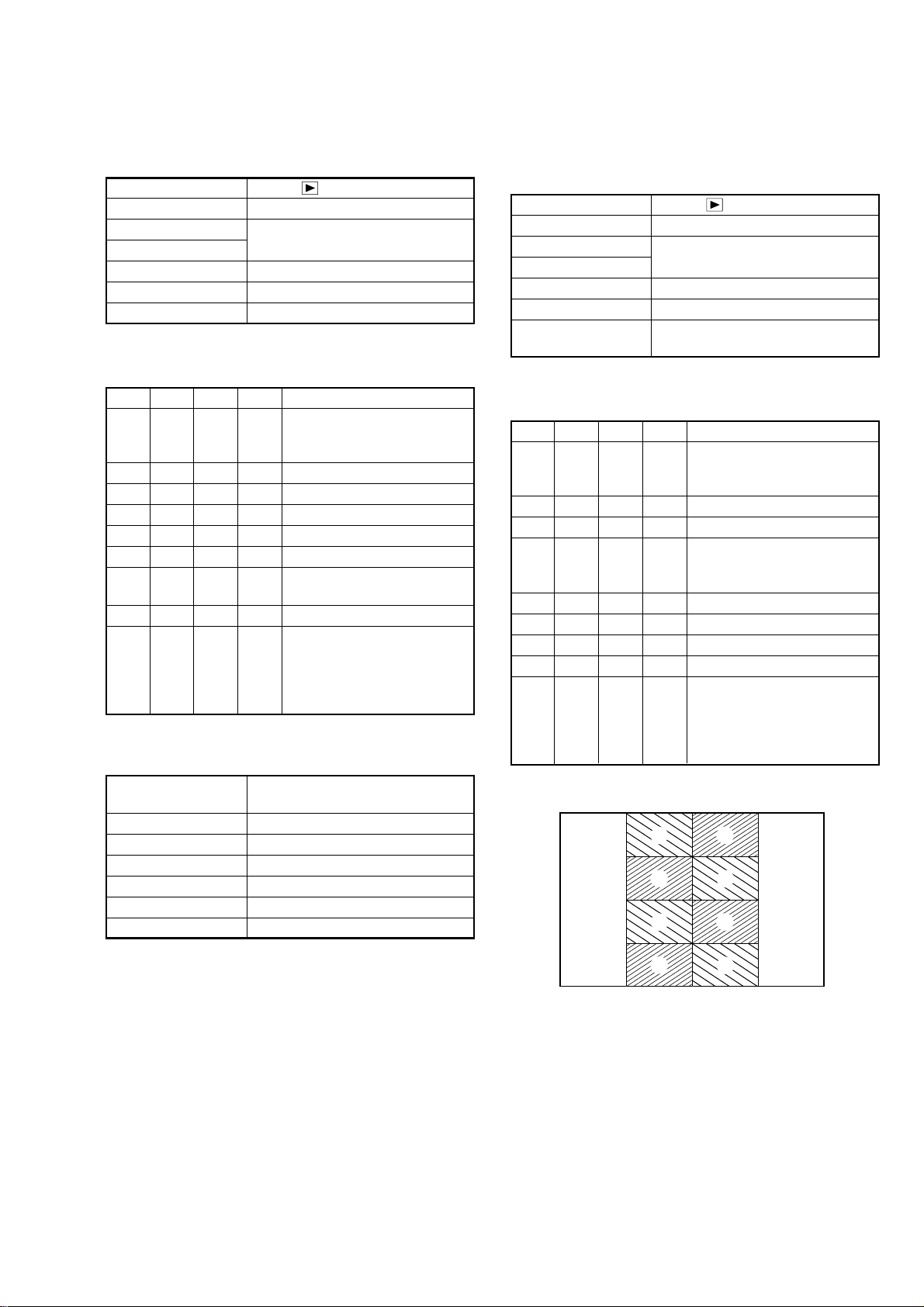

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

The contents which can be handled

by customer, are displayed.

• E: ss: ss

The contents which can be handled

by engineer, are displayed.

DSC-T1

Display Code

C:32:01

C:13:01

E:91:01

E:61:00 *1

E61:10 *1

Note : The error code is cleared if the battery is removed, except defective flash unit.

*1: The error display is given in two ways.

Turn off the main power then back on.

Replace the memory stick.

Format the memory stick with the DSC-T1.

Checking of flash unit or replacement of

flash unit.

Checking of lens drive circuit

Countermeasure

Trouble with hardware.

• The type of memory stick that cannot be

used by this machine, is inserted.

• Data is damaged.

• Unformatted memory stick is inserted.

Abnormality when flash is being

charged.

When failed in the focus initialization.

Cause

Caution Display During Error

SYSTEM ERROR

MS ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

— 5 —

Page 4

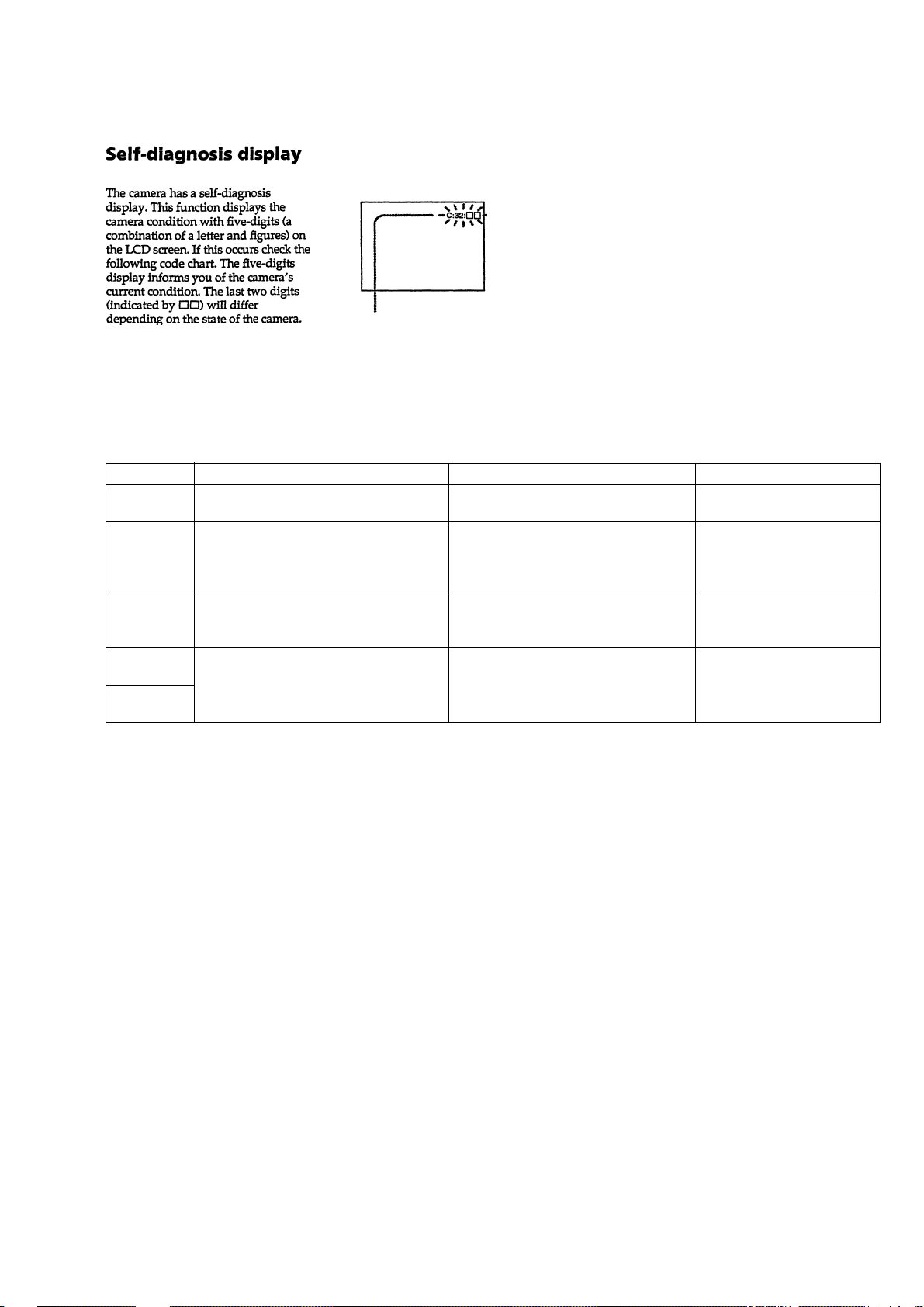

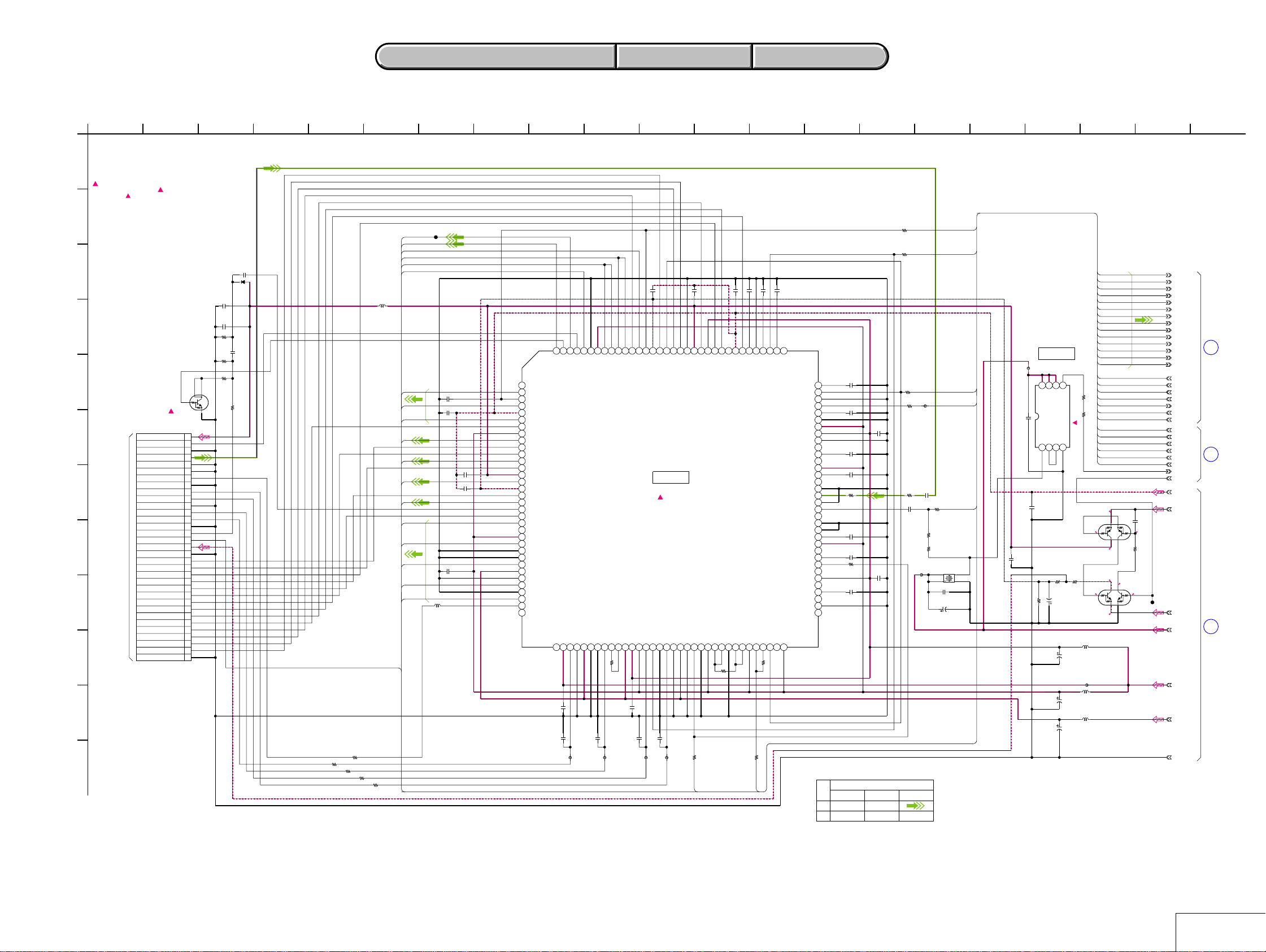

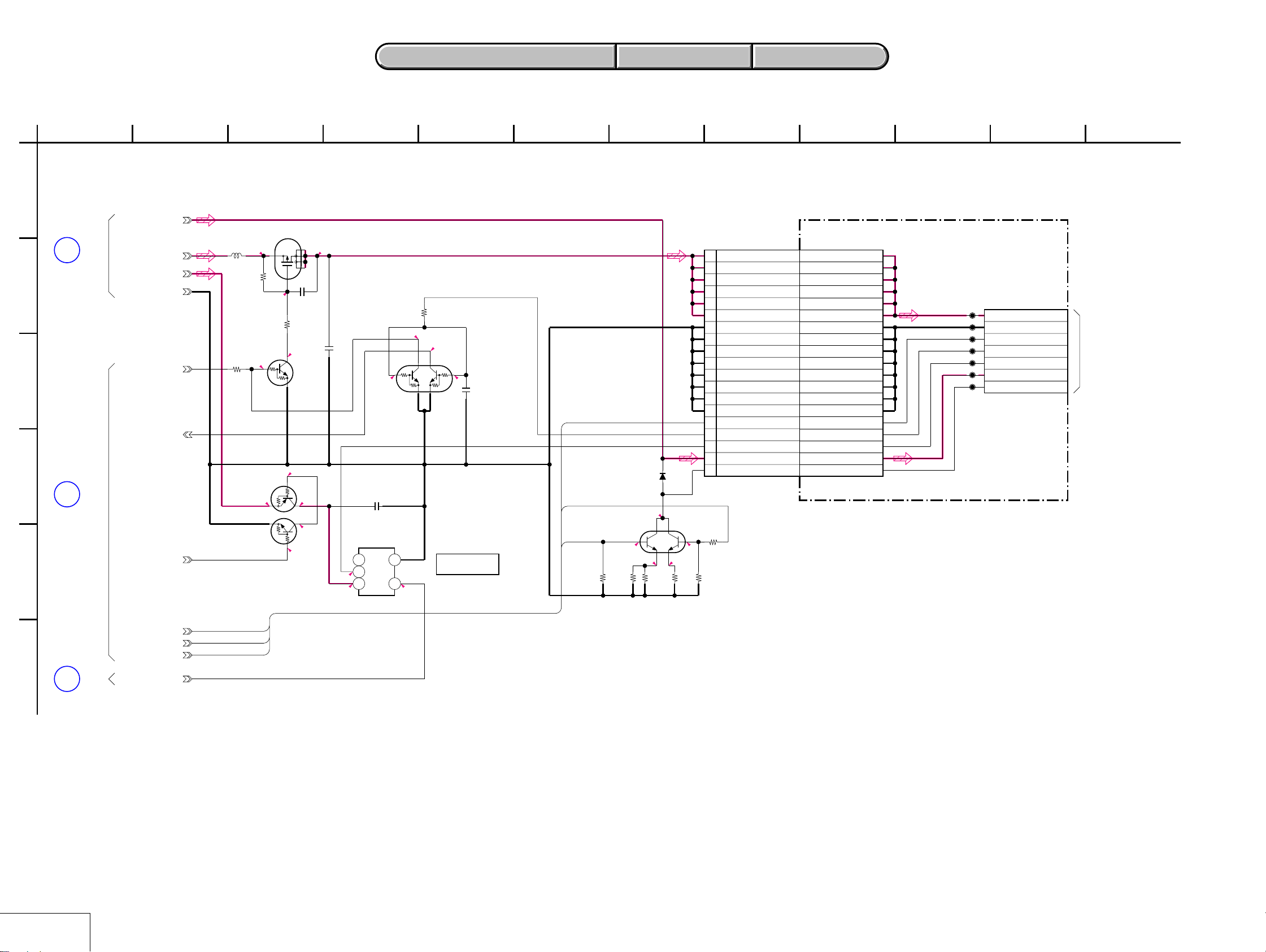

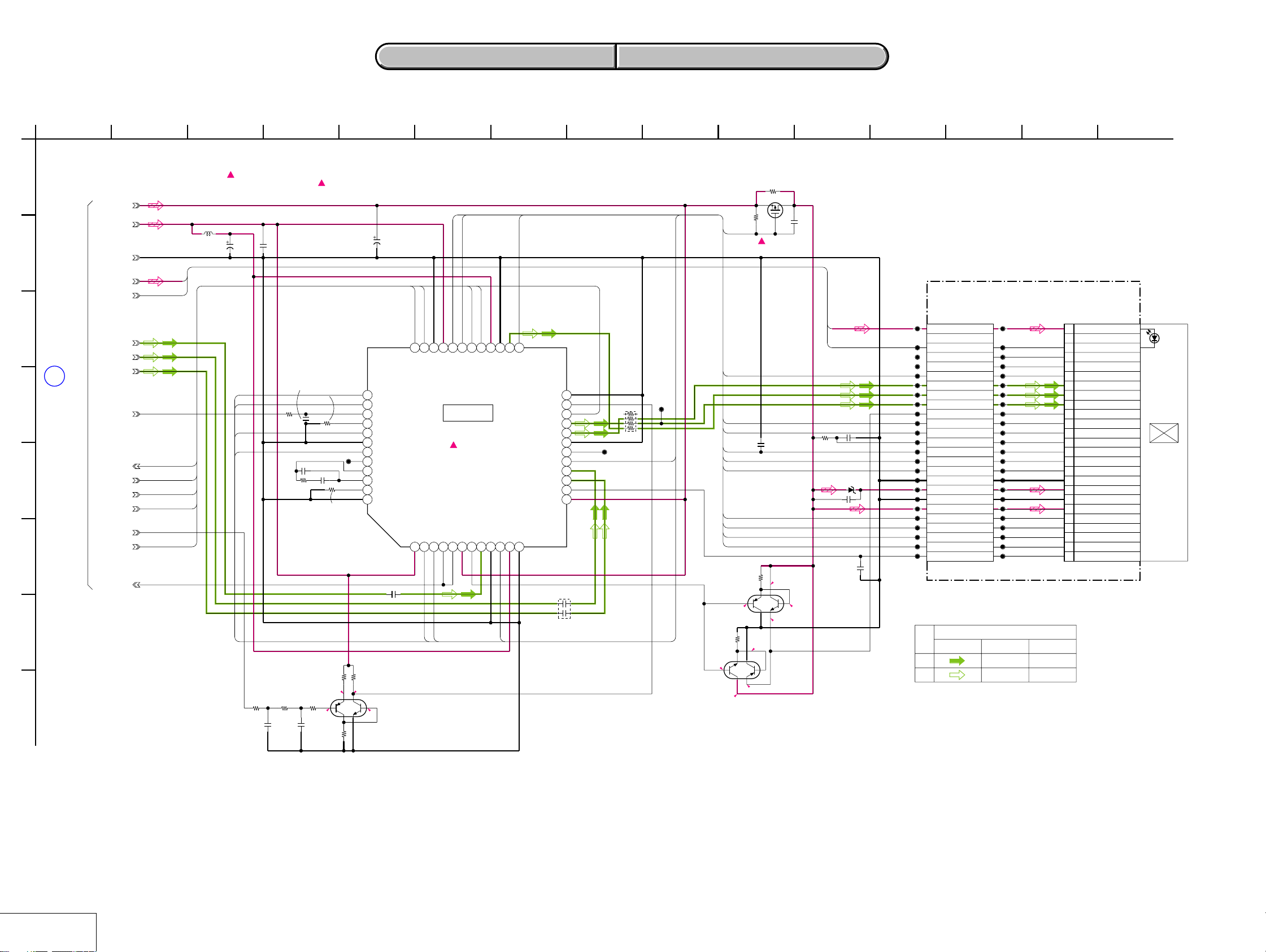

4-2. SCHEMATIC DIAGRAMS

COMMON NOTE FOR SCHEMATIC DIAGRAMS

COMMON NOTE FOR SCHEMATIC DIAGRAMS

Link

Link

SY-95 BOARD (1/8)

SY-95 BOARD (1/8)

(CAMERA A/D CONVERTER, TIMING GENERATOR)

(CAMERA A/D CONVERTER, TIMING GENERATOR)

SY-95 BOARD (2/8)

SY-95 BOARD (2/8)

(CAMERA DSP, LENS CONTROL)

(CAMERA DSP, LENS CONTROL)

SY-95 BOARD (3/8)

SY-95 BOARD (3/8)

(CAMERA SYSTEM CONTROL)

(CAMERA SYSTEM CONTROL)

SY-95 BOARD (7/8)

SY-95 BOARD (7/8)

SY-95 BOARD (8/8)

SY-95 BOARD (8/8)

MS-148 BOARD (1/2)

MS-148 BOARD (1/2)

(DC/DC CONVERTER)

(DC/DC CONVERTER)

(CONNECTOR)

(CONNECTOR)

(MS I/O)

(MS I/O)

DSC-T1

SY-95 BOARD (4/8)

SY-95 BOARD (4/8)

SY-95 BOARD (5/8)

SY-95 BOARD (5/8)

SY-95 BOARD (6/8)

SY-95 BOARD (6/8)

(HI CONTROL)

(HI CONTROL)

(AUDIO I/O)

(AUDIO I/O)

(FLASH DRIVE)

(FLASH DRIVE)

MS-148 BOARD (2/2)

MS-148 BOARD (2/2)

LD-140 BOARD

LD-140 BOARD

(LENS DRIVE)

(LENS DRIVE)

(LCD PANEL DRIVE)

(LCD PANEL DRIVE)

Page 5

DSC-T1

4-2. SCHEMATIC DIAGRAMS

1

SY-95 BOARD(1/8)

CAMERA A/D CONVERTER,TIMING GENERATOR(BLOCK)

A

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

:Voltage measurement of the CSP IC

and the Transistors with mark and

the IC with mark ,is not possible.

B

C151

0.22u

C

D

E

F

G

H

I

J

K

L

TO

CD-463 BOARD

(PAGE 4-7

of LEVEL2)

16

Q153

UNRL21300AS0

SWITCH

1

33PCN702

33CAM_15V_CD

32POWER_SAVE

31REG_GND

30CCD-OUT

29REG_GND

28REG_GND

27RG

26REG_GND

25H2B

24H2A

23REG_GND

22H1B

21H1A

20REG_GND

19SHT

18VSUB_CONT

17CAM_-8.0V_CD

16REG_GND

15V1A

14V1B

13V2

12V3A

11V3B

10VST

9V4

8V5A

7V5B

6VHLD

5V6

4V7A

3V7B

2V8

1REG_GND

D151

MA2S111-(K8).SO

C153

4.7u

C190

4.7u

R152

1M

34

2

B

1

2

R151

100k

C152

0.22u

B

2012

R160

100k

R153

0

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

CL151

D0

D1

XTG_CS

CAM_SO

XCAM_SCK

XFE_CS

L151

100uH

±10%

D2

C155

0.01u

B

D3

C156

0.1u

B

D4

D5

D6

C157

0.01u

D7

D8

D9

D10

D11

D12

D13

VSUB_CONT

R155

10

R156

10

10

R157

10R158

10

R159

B

C158

0.1u

B

C159

0.1u

B

L155

10nH

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

124

125V6126

SEN

TSDATA

CSP(CHIP SIZE PACKAGE)IC

XX

B

11

C160

0.1u

B

118

119

120

121V8122VL123

V7A

SDL

TRESET

IC151

CAMERA A/D CONVERTER,

TIMING GENERATOR

IC151

CXD3433GA-T4

C189

XX

B

FB158

FB159

0uH

0uH

9

127

128

129

130

131

132

133

134D0135

136

D1

ID/EXP

TSEN

WEN/FLD

NC

1

D2

2

3

RST

D3

4

VMM

5

D4

6

Vhld

7

VDD4

8

D5

9

V1A

10

Vst

11

D6

12

V1B

13

VHH

14

D7

15

VLL

16

V3A

17

D8

18

SUB

19

V3B

20

D9

21

DLLSL

22

AVD1

23

D10

24

SNCSL

25

SSGSL

26

D11

27

AVD2

28

TEST1

29

D12

30

VSS1

31

D13

32

RG

33

NC

34

NC36DRVDD37H1A38DRVSS39AVD340DVSS141VSS242H1B43ADCCK44ADCLKT45AVD446DVDD147VDD148H2A49HD50VSS351H2B52VSS53AVD554VSS555CLPOBIt56VSS457AVD658SHPt59XSHPT60VSS661SHDt62XSHDT63VDD264CLPDMIt65CLPDMT66VD67P4968AVD7

35

C177

0.1u

B

C186

C187

XX

B

FB156

0uH

SSI

SCK

VSS9

AVD9

TSCLK

R167

100

C178

0.1u

B

XX

B

C188

FB157

0uH

12

R161

0

R162

220

C161

0.01u

B

116VH117

V7B

AVSS3

R172

C162

0.1u

B

113V2114

115

V5A

V5B

VDDA2

R183

XX

220

C165

C163

C164

0.1u

1u

1u

B

B

B

103NC104CM105HR106

107

108

109V4110VM111NC112

REFP

REFN

TRST

LME

VR

AVSS2

MCKO

LMO

VSS8

AVD8

VDDA1

OSCI

CKO

LP2E

OSCO

VDD3

LP2O

PBLK

VSS7

CCDIN

TEST3

CKI

NC

TEST2

AVSA/B

L

AVDA/B

P38

LP1E

CLPOB

P50

VDDD

P6

LP1O

DLLRST

AVSS1

NC

R184

XX

R173

220

C166

120p

CH

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

CH

120pC167

C169

18p

CH

C170

18p

CH

R165

0

C173

1u

B

C174

0.47u

B

R181

XX

C176

0.47u

B

R163

220

R164

FB151

100

C168

0.1u

B

R166

100

C172

0.01u

B

C175

0.1u

B

FB153

0uH

XCAM_RST

CA_HD

CAM_F

0uH

C171

0.1u

B

MCKG

R185

XX

TG_CLK

R186

0

R187

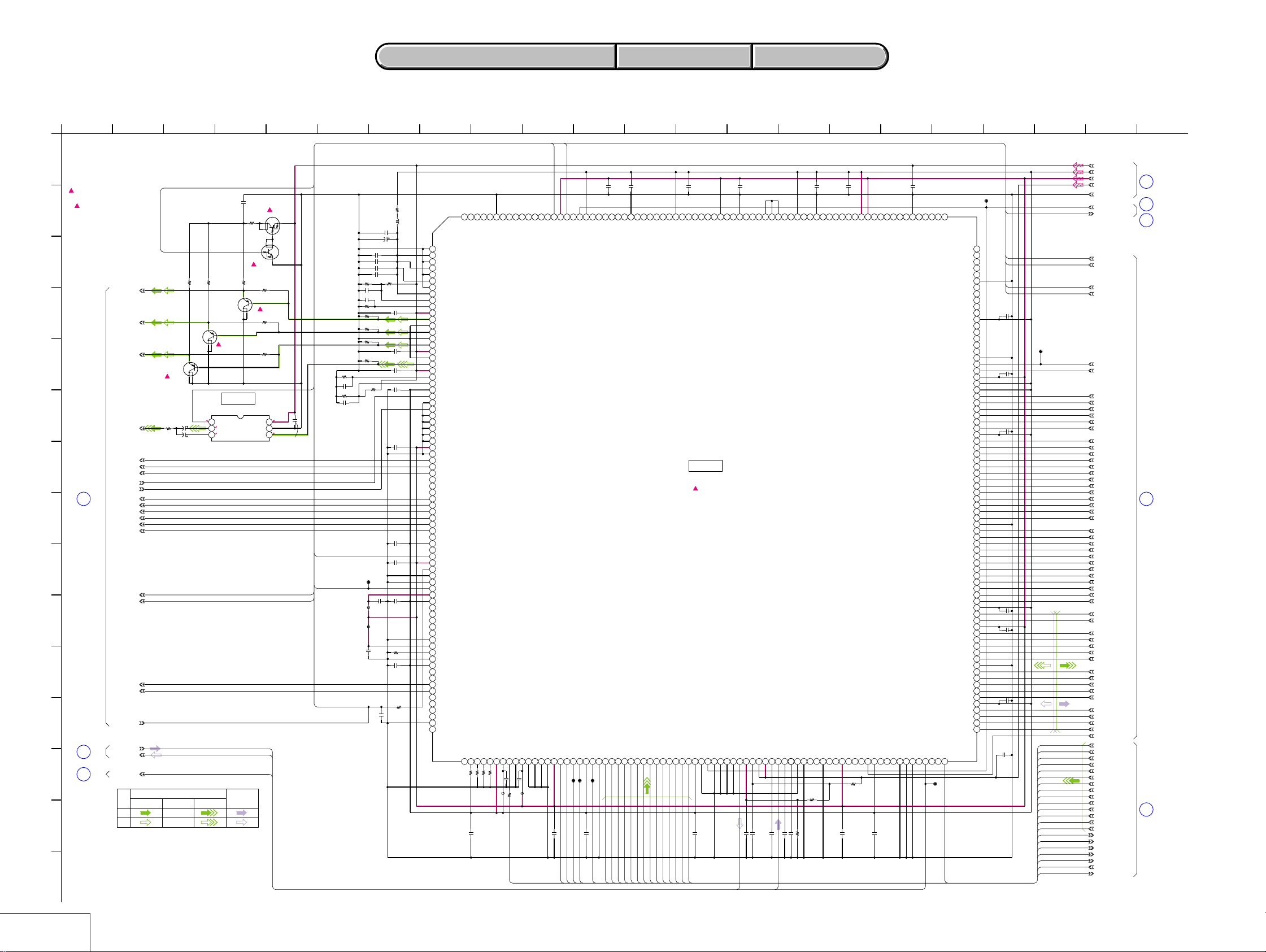

0

X151

54MHz

3

4

1

2

C192

0.1u

B

C194

22u

6.3V

1825 15 16

IC152

CLOCK GEN.

FB160

0uH

5Q6

7

8

xPR

VCC

xCLR

C193

0.1u

B

GND

1CK2D3xQ4

C191

1u

B

RN2907FE(TPLR3)

C180

4.7u

16V

B

R178

0

C181

R179

22u

100k

16V

TA

B

C183

100u

6.3V

C184

100u

6.3V

C185

100u

6.3V

IC152

TC7WH74FK(TE85R)

Q151

SWITCH

R177

0

Q152

RN1907FE(TPLR3)

SWITCH

L152

10uH

±20%

FB152

0uH

L153

10uH

±20%

L154

10uH

±20%

19144 1763

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

CA_HD

CAM_F

CL_POB

R190

CLP_DM

0

MCKTG

TG_CLK

R191

220

VSUB_CONT

CAM_F

CAM_SO

XCAM_SCK

XFE_CS

XTG_CS

XCAM_RST

15.0

4

1

3.7

5

3

6

14.9

-7.9

0.1

6

3

5

1

4

-8.0

20810 13 217

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

CA_HD

CAM_F

CLP_OB

CLP_DM

MCKTG

TG_CLK

VSUB_CONT

CAM_F

CAM_SO

XCAM_SCK

XFE_CS

XTG_CS

XCAM_RST

VER_EXT_CLK

CAM_DD_ON

CAM_-0.5V

CAM_15.0V

C179

0.1u

B

2.7

2

R174

82k

2.83.6

2

CL152

CAM_-8.0V

D_2.8V

A_2.8V

A_3.1V

REG_GND

(2/8)

1

(3/8)

2

(7/8)

3

SIGNAL PATH

CLPOB

CLPDM

REC

PB

CHROMA

VIDEO SIGNAL

Y/CHROMAY

4-15 4-16

SY-95 (1/8)

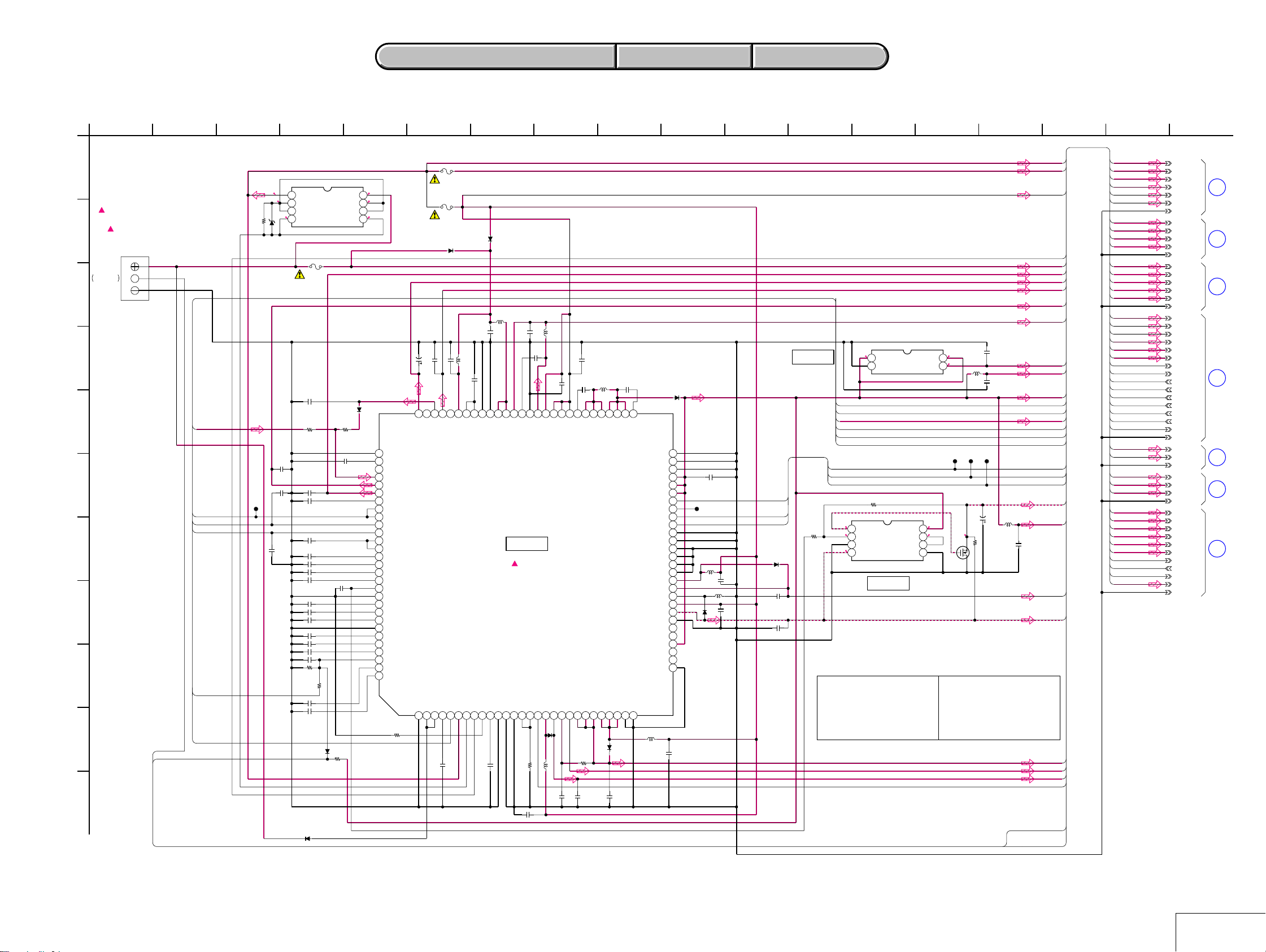

Page 6

DSC-T1

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

1

SY-95 BOARD(2/8)

CAMERA DSP,LENS CONTROL(KIW BLOCK)

A

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

( ) MARK:WHEN CONNECTED CRADLE and TV MONITOR.

:Voltage measurement of

the CSP IC and

the Transistors with

mark,is not possible.

B

AMP_OUT_ON

C

R310

R311

2200

Q302

EC3101C-PM-TL

R305

68

VIDEO SIGNAL

2200

2

1

4

3

EC3101C-PM-TL

2

1

4

3

0(2.8)

C322

100u

1

4V

C332

22u

6.3V

TA

Power Save

0.3(0.9)

2

Vout

0.3(0.9)

3

Vsag

P

Y/CHROMA

PANEL_G

D

PANEL_B

PANEL_R

E

F

V_OUT

HR_EN0

G

4

H

HR_DIR0A

HR_DIR0B

XZM_RST_SENS1

XFC_RST_SENS

(8/8)

HR_EN2

HR_DIR2A

HR_DIR2B

HR_EN3

HR_DIR3A

HR_DIR3B

I

PANEL_V

HD0

J

K

XZM_RST_LED

XFC_RST_LED

L

5

6

M

XRST_SYS

AU_AOUT

(5/8)

AU_AIN

STRB_ON

(6/8)

REC

N

PB

O

16

Q303

IC302

R312

2200

VIDEO AMP

AUDIO

SIGNALYCHROMA

3

NJM2578KJ1(TE3)IC302

2

C359

XX

R352

0

UNRL21300AS0

R304

Q302-304

BUFFER

1

4

R302

R303

GND

AU_AOUT

STRB_ON

Q305,306

SWITCH

UNRL11400AS0

3

4

4

1

Q305

XX

Q304

EC3101C-PM-TL

XX

XX

VIDEO_AMP_ON

Vcc

Vin

AU_AIN

AMP_OUT_ON

Q306

1

3

2

2.8

6

5

0(0.2)

4

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

VDDI_8

OPBCLP

HD0

CLP_DM

HD

DUMCLP

CL302

CA_HD

(NC)LCDCK

CCDHD

CL303

CAM_F

NTVDO

CCDFD

VDDE_15

VDDE_5

XXC328

11

(NC)DQ16

CLKTGI

AC16AC15AA17

CL304

MCKTG

9

Note:Resistor is mounted to the location FB306 is printed.

FB306

0

Note

L301

2

C302

C306

C307

R331

±0.5%

C308

0.1u

C360

4700p

10kR332

±0.5%

560R324

±0.5%

±0.5%

R326

560

±0.5%

R315 150

±0.5%

R316

2700

±0.5%

C361

0.022u

R317

±0.5%

C305

0.1u

C304

10u

B

PLLBYPASS

MC_CKIO

PANEL_V

HD0

XRST_SYS

R319 27k

±0.5%

18k

FB302

0uH

FB303

0uH

C315

10u

47uH

C362

4.7u

C357

4V

100u

1u

1uC303

0.1u

1u

18k

R334

27k

±0.5%

C310

XX

560R325

C311

0.1u

C317

0.1u

C318

0.1u

C319

XX

C312

0.1u

XXC313

CL301

C320

C314

10u

XX

R327

0

C316

XX

R318

C309

1k

0.1u

SDRAM_VSS0

A1

SDRAM_VDD0

A2

SDRAM_VSS1

M1

SDRAM_VDD1

N1

SDRAM_VSSQ0

A23

SDRAM_VDDQ0

A22

SDRAM_VSSQ1

M23

SDRAM_VDDQ1

N23

VREF1

B23E22D21C23E20D23F22E23G22E21F23H22G23H23J23F20G20F21H20J22G21H21J20K23K22K20L22J21R23T23U23V23U20R22R21V20T21W23Y23

VR01

VAVD0

G0

VAVS0

B0

VAVS1

R0

VAVD1

VAVS2

Y0

VAVD2

VR02

VREF2

VDDE_0

SENS0

SENS1

SENS2

SENS3

FG0A

FG0B

FG1A

FG1B

VDDI_0

GND_0

EN0

DIROA

DIROB

EN1(NC)

DIR1A(NC)

DIR1B(NC)

EN2

DIR2A

DIR2B

EN3

DIR3A

L21P22 N21T20 N20P23 M20R20 M21N22 L20L23 K21P20 M22P21

DIR3B

IRIS_COM(NC)

VDDE_1

PLLCKOUT(NC)

XRSTMON

VDDI_1

RSTX

GND_1

PLLGND1

CLKI

PLLVDI1

VDDE_2

PIO14(NC)

PIO13(NC)

PIO12(NC)

PIO11(NC)

PIO10(NC)

GND_2

PLLVDI2

CLKTGEXT

AA23AB23AC23

PLLGND2

VDDE_3

PIO09(NC)

U21T22V21U22V22W20W22Y20

PIO08(NC)

PIO07

PIO06

PIO05(NC)

PIO04(NC)

PIO03(NC)

PIO02(NC)

GND_3

AC22

PIO01(NC)

W21

Y22 Y21

C321

0.1u

GND_16

(NC)F_D1

(NC)F_D0

(NC)FCK27

PLLMD2

(NC)VOEN

PLLMD3

VDDE_4

C323

FB304

(NC)F_D2

CLKTGO

PLLGNDTG

PLLVDETG

10u

10u

C324

XX

0uH

R307

TG_CLK

(NC)F_VD

(NC)F_HD

(NC)F_FLD

PLLMD1

PIO00(NC)

PLLMD0

AA22

AB22AA21AB21 AC21AC20AB20 AC19AA20 AA19 Y19 AB19AC18 Y18 AA18 Y17AB18 AC17

0

R3530R3540R3550R356

PANEL_V

LCDVD

(NC)F_D4

(NC)F_D6

(NC)F_D3

(NC)F_D5

(NC)F_D7

MD0

VDDI_2

PLLVDITG

MD2

GND_4

MD1

0uH

FB305

XX

C326

CLP_OB

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

C330

0.1u

VDDE_14

(NC)DQ27

(NC)DQ26

CAMERA DSP, LENS CONTROL

CSP(CHIP SIZE PACKAGE)IC

ADIN04

ADIN03

ADIN02

CA_AD01

CA_AD02

CA_AD03

(NC)DQ29

(NC)DQ28

IC301

(KI(5M SA)BOARD)

ADIN00

ADIN01

XX

C331

CA_AD00

13

(NC)DQ30

VDDE_6

(NC)DQ31

IC301

CKADI

(NC)DQM0

NTVDI

(NC)DQM1

PLLGND3

VDDI_7

AUCKEXT

C334

XX

(NC)DQM2

PLLVDI3

(NC)DQM3

AVS_2

AU_AIN

GND_14

AOUT

C343

0.1u

A10B10

C10

D10D11C11A11B11D12A12D13B12C12A13B13C13A14B14C14A15D14B15C15A16B16D15B17C16A17B18A18D16C17C18A19D17B19C19D18A20B20C20D19B21A21C21B22D20C22D22

XCS0

VDDE_13

(NC)XCASVR

(NC)XRAS

(NC)QCLKE

SDRAM_CS0

SDRAM_CS1

AVS_1

AIN

VRL

AVDD_1

VRH

TRST

AC9 AB9 AC8 Y9 AA10 Y8 AA9 AB8 Y7 AA8 AC7 AC6 Y6 AB7 AA7 AC5 AC4 AC3 AA6

±0.5%

±0.5%

0.1u

0.1u

0.1u

10k

C341

C340

C342

R344

AU_AOUT

0.1u

C335

(NC)XCS3

VRN

0.1u

C336

(NC)XCS2

VRP

(CN)XCS1

AVDD_2

12

C327

C329

0.1u

XX

GND_15

(NC)DQ25

(NC)DQ20

ADIN11

CA_AD10

(NC)DQ21

ADIN10

CA_AD09

ADIN09

CA_AD08

(NC)DQ22

ADIN08

CA_AD07

(NC)DQ23

ADIN07

CA_AD06

(NC)DQ24

ADIN06

CA_AD05

ADIN05

CA_AD04

(NC)DQ19

(NC)DQ18

(NC)DQ17

ADIN13

GND_5

ADIN12

AA16AB16 Y16 AA15AA14AB15 Y15 AB14AA13 Y14 AB13 Y13AC14 Y12AA12AB12 Y11AC13 AB11AC12 AC11AC10 Y10AA11 AB10

AB17

CA_AD11

CA_AD12

CA_AD13

R345

5600

(NC)QCLK

TMS(NC)

GND_13

TCK(NC)

(NC)XWE

GND_6

(NC)AQ00

TDI(NC)

C345

0.1u

C346

0.1u

(NC)AQ01

TDO(NC)

(NC)AQ02

VDDI_3

(NC)AQ03

AUCK64(NC)

R346

10k

±0.5%

(NC)AQ04

XPWAD(NC)

VDDE_12

XPWDA(NC)

C348

XX

VDDI_6

AUCK

(NC)AQ05

VDDE_7

(NC)AQ07

(NC)AQ08

(NC)AQ09

(NC)AQ06

SOA(NC)

ADCK(NC)

SIA

SCLK(NC)

Y5 AB6 AB5 AA5 AB4 AB3 AA4 AC2

(NC)AQ10

GND_7

GND_12

APBD

C358

XX

(NC)AQ11

SHUTTER(NC)

STRB_ON

(NC)AQ12

STROBE1

CL305

(NC)BA1

(NC)BA0

STROBE3(NC)

STROBE2(NC)

A3C3B4A4B5A5B6B7C4D4C7D5A6A7C5D6C6D7D8D9A8B8C8A9B9C9

(NC)DQ00

SUBCNTL(NC)

VSUB_CONT

182 225 15 16

(NC)DQ01

(NC)DQ02

(NC)DQ03

(NC)DQ04

(NC)DQ05

(NC)DQ06

(NC)DQ07

(NC)DQ08

(NC)DQ09

(NC)DQ10

VDDE_11

(NC)DQ11

(NC)DQ12

(NC)DQ13

(NC)DQ14

(NC)DQ15

XWAITIN2

XWAITIN1

CSXRAM

RD_XWR

VDDE_10

GND_11

GND_10

VDDI_5

VDDE_9

VDDI_4

VDDE_8

XWAIT

WRHX

WRLX

GND_9

GND_8

XRST_SYS

AMP_OUT_ON

VIDEO_AMP_ON

PLLBYPASS

MC_CKIO

CL311

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

TG_CLK

CLP_OB

CLP_DM

CA_HD

CAM_F

MCKTG

VSUB_CONT

20810

19144 1763

CL310

C349

XX

C350

IRQ

CSX

BSX

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

D10

D11

D12

D13

D14

D15

XX

C351

1u

C352

1u

C353

XX

Y2 Y4 Y1 W4 W2 V4 W1 V2 V1 V3 U4 U1 U3 U2 T4 T2 R4 T1 T3 R2 R3 R1 P3 P4 P1 N4 P2 N3 N2 M3 M4 M2 L3 K3 L1 L4 L2 J3 K1 K4 J4 K2 H3 J1 J2 H4 G3 H1 H2 G4 G1 G2 F3 F1 F4 F2 E1 E3 E2 E4 D2 D3 D1 C2C1B2B1B3

AA1

W3

C354

0.1u

AB2 AC1 AA3 Y3 AB1 AA2

C337

0.1u

217

A_2.8V

D_2.8V

D_1.2V

AU_2.8V

REG_GND

SYS_V

XRST_SYS

AMP_OUT_ON

VIDEO_AMP_ON

PLLBYPASS

MC_CKIO

MC_XWAIT

IRQ_IMG

MC_XCS_IC301SDRAM

MC_XCS_IC301REG

MC_XBS

MC_XWE1

MC_XWE0

MC_RDXWR

MC_A1

MC_A2

MC_A3

MC_A4

MC_A5

MC_A6

MC_A7

MC_A8

MC_A9

MC_A10

MC_A11

MC_A12

MC_A13

MC_A14

MC_A15

MC_A16

MC_A17

MC_A18

MC_A19

MC_A20

MC_A21

MC_A22

MC_A23

MC_A24

MC_A25

MC_D0

MC_D1

MC_D2

MC_D3

MC_D4

MC_D5

MC_D6

MC_D7

MC_D8

MC_D9

MC_D10

MC_D11

MC_D12

MC_D13

MC_D14

MC_D15

AU_LRCK

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

TG_CLK

CLP_OB

CLP_DM

CA_HD

CAM_F

MCKTG

VSUB_CONT

(7/8)

7

(3/8)

8

(4/8)

8

(3/8)

9

(1/8)

1

SY-95 (2/8)

4-17 4-18

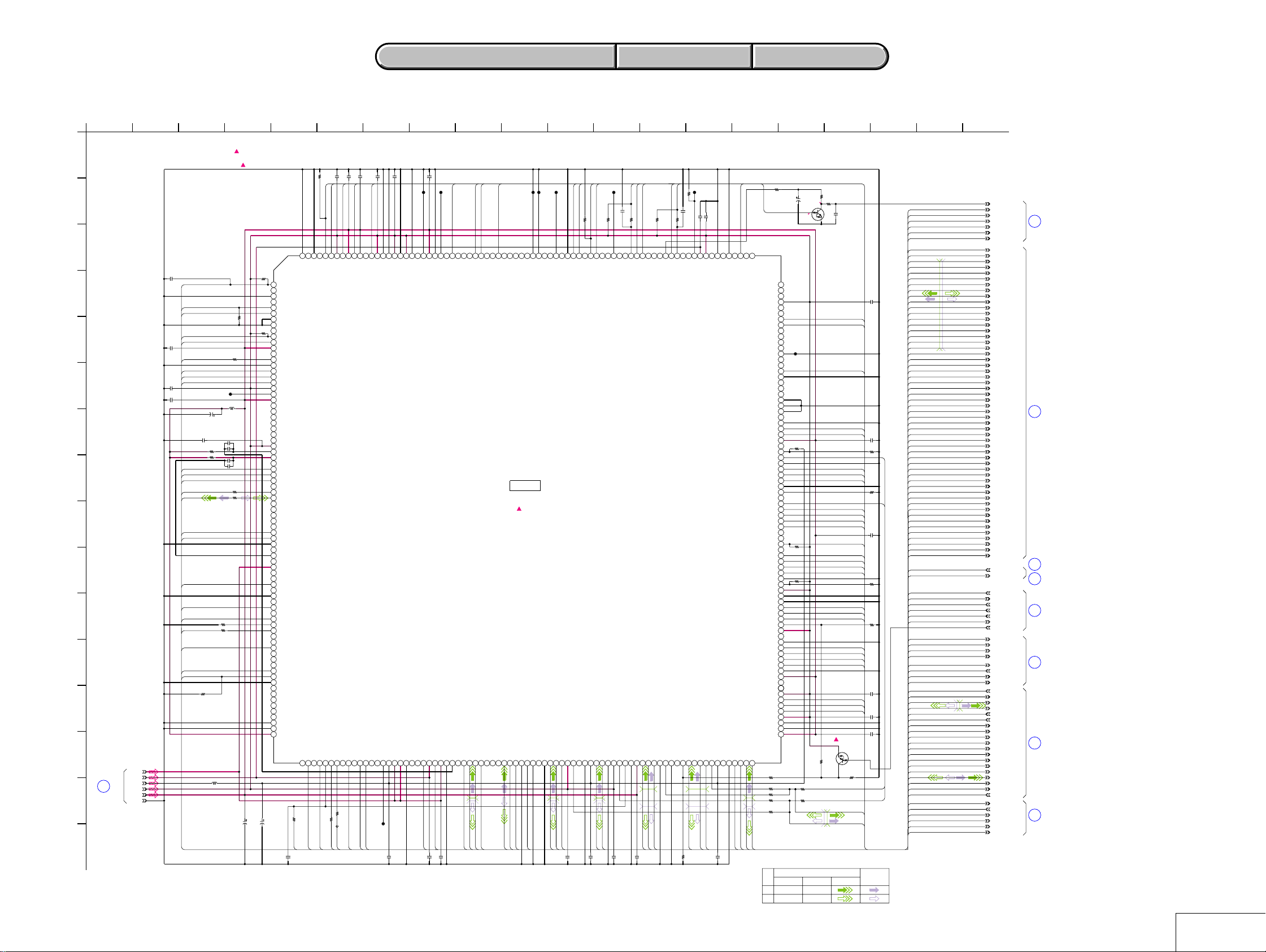

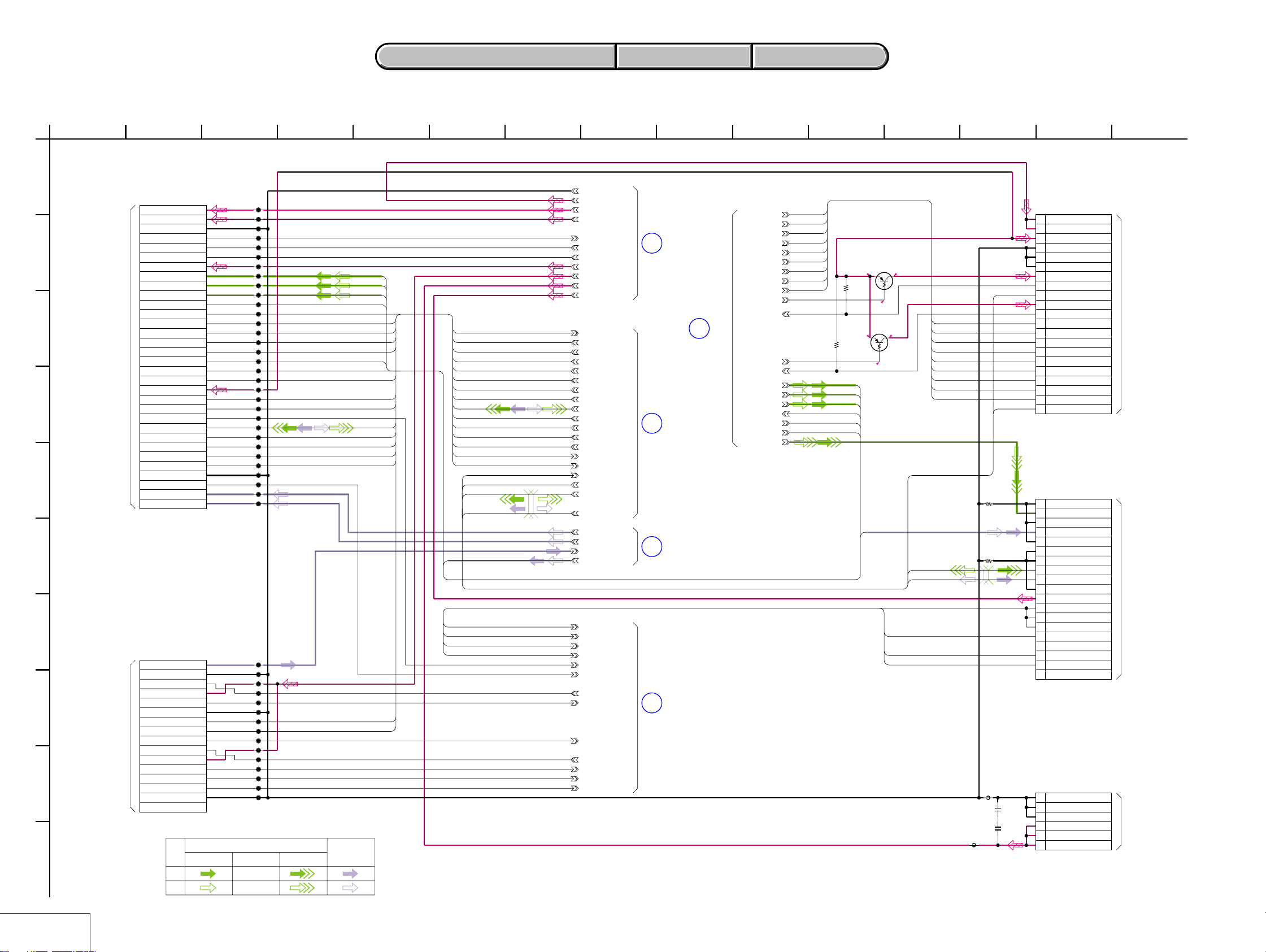

Page 7

DSC-T1

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

1

L501

C509

22u

4V

R503

100

C503

XX

100R504

C504

XX

R543

R515

22

10uH

NO MARK:REC/PB MODE

:Voltage measurement of

the CSP IC and

the Transistors with

mark,is not possible.

R566

XX

R510

22

CL512

L502

10uH

C512

B

10u

C513

10u

B

22

R512

R513

22

0

C502

22u

4V

SY-95 BOARD(3/8)

CAMERA SYSTEM CONTROL(EVR BLOCK)

A

XX MARK:NO MOUNT

B

C

D

E

F

G

H

I

J

K

L

M

N

A_2.8V

D_1.8V

A_3.1V

(7/8)

10

D_2.8V

D_1.2V

O

REG_GND

P

16

C505

C506

C507

0.1u

B

XX

XX

C510

XX

LENS_TEMP

VER_EXT_CLK

MC_CKIO

SYS_SI

CAM_SO

MC_MSD2

MC_XCS_IC301REG

MC_XCS_FLASH

MC_XWE0

C511

XX

SYS_SO

XCAM_SCK

FR_SI

MC_MSBS

MC_MSDIO

MC_XBS

XAU_HGL_SEL

AU_LRCK

XSYS_SCK

XFR_SCK

MC_MSD1

MC_XCS_IC301SDRAM

XACCESS_LED

XCAM_RST

R518

100k

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

11

CL504

CL509

XBEEP_MUTE

XAU_SP_MUTE

XAU_POWER_SAVE

47k

MC_JTAG_RTCK

R565

TMS

(NC)

(NC)TRACEPKT3

(NC)TRACEPKT4

AVRB(DA)

D9

H21 H22 H23 H24

MC_D9

MC_D4

RTCK

(NC)PIPESTAT2

D4

D17

SELF_TIMER_LED

C534

XX

VSS

PT[4]

(XAU_POWER_SAVE)

VMH

VDDQ

J1 J2 J3 J4

PT[6]

(NC)RTS5/SCK5

(XBEEP_MUTE)

ADGND(PHY)

ANOUT[3](NC)

PT[0]

(XAU_SP_MUTE)

AVDD1(PHY)_33

J21 J22 J23 J24

C533

TDO

VSS_F

(NC)RxD4

AVSS(DA2)

CAM_DD_ON

PU[6]

AVSS(PLL2)

(NC)PU[2]

D27(NC)

AMP_OUT_ON

(NC)PQ[4]

(NC)SCL(O/D)

D14

D19

MC_D14

XTG_CS

MC_D7

9

PQ[2]

D7

SP_VOL

XSTRB_FULL

TI2B

(SP_VOL)

ANOUT[2]

(NC)TO2

(NC)INT8

DACK3(NC)

ANOUT[1](NC)

CAM_F

INT2

AVSS(PLL3)(NC)

(NC)PIPESTAT1

(NC)TRACEPKT5

(NC)TRACEPKT2

(NC)TRACEPKT7

(NC)TRACEPKT0

IC501

CAMERA SYSTEM CONTROL

IC501

JSCIS001BF00GA-T6

CSP(CHIP SIZE PACKAGE)IC

D23

VSS

D12

D21

CK_F

G21 G22 G23 G24

H1 H2 H3 H4

PLLBYPASS

MC_CKIO

MC_D12

BL_MODE

CL503

7

C521

C519

C518

R507

XX

XX

100k

STRB_CHG

VSS

PU[0]

R508

47k

R511

100k

C501

22u

6.3V

TEST2

(NC)PU[4]

(NC)RTS4/SCK4

AN[5]

A2A3A4A5A6A7A8A9A10A11A12A13A14A15A16A17A18A19A20A21A22A23B1B2B3B4B5B6B7B8B9

AN[1](NC)

AVSS(AD)

XTAL(NC)

EXTAL

CKIO

VSSQ

VSS

TxD3(NC)

RxD2

TxD1

VDD

DREQ0(NC)

MSDATA2

VSSQ

CS5A

CS0

WE0/DQMLL

VDDQ

RD

VDD

D30(NC)

AN[11](NC)

AN[9](NC)

AN[3](NC)

AD/EXT(NC)

TEND(NC)

DREQ3(NC)

VDDQ

AVDD(PLL2)_12

AVDD(PLL1)_12

SCK3(NC)

B10B11B12B13B14

TxD2

SCK1

TxD0

DREQ1(NC)

MSBS

MSDATA0/MSDIO

B16B24 B15B23

CS6(NC)

B17

CS3(NC)

B18

WE2/DQMUL/ICIORD(NC)

B19

RAS(NC)

B20

A0(NC)

B21

BS

B22

D20

(XAU_HGL_SEL)

VSSQ

AN[7](NC)

C1

AVSS(PLL1)

C2

AN[2](NC)

C3

AVDD(AD)_30

C4

AN[0](NC)

C5

DACK2(NC)

C6

TCLK

C7C8C9

DREQ2(NC)

MD1

RxD3(NC)

C10C11C12C13C14C15C16C17C18C19C20C21C22C23C24

SCK2

RxD1(NC)

MSDIR

MSDATA1

CS5B(NC)

CS7/CE1(NC)

CS4

WE3/DQMUU/AH/ICIOWR(NC)

CAS(NC)

D26(NC)

D24

D22

VSSQ

AN[6](NC)

D1D2D3D4D5D6D7D8D9

ADRWCLK(NC)

AN[10](NC)

END(NC)

AN[8](NC)

AN[4](NC)

MD2

MD0

AVDD(PLL3)_12

DACK1(NC)

RxD0

DACK0(NC)

RST

SCS0

D10 D11 D12 D13 D14 D15 D16D17 D18 D19 D20 D21D22 D23 D24

R522

R521

22

1k

FR_SO

XSYS_RST

XCS_MC

C523

0.1u

MS_PWR_ON

SDA(O/D)

MSDATA3

MC_MSD3

VDDQ

MSSCLK

R548

15

FB523

0uH

MC_MSCLK

XPANEL_TG_CS

PQ[0]

CS2(NC)

MC_XWE1

C520

0.1u

MELODY

TO0

VDD

VDD

WE1/DQMLU/ICWE

CKE(NC)

RD/WR

MC_RDXWR

(NC)INT4

D18

VIDEO_AMP_ON

C522

XX

0.1u

FR_INT

INT0

VSSQ

VDDQ

RDY_F

D29(NC)

D31(NC)

E1 E2

CL507

CL502

VSS

ADVDD1(PHY)_33

TCK

VDD

VSSQ

VDDQ

VSSQUTMI

VDDQUTMI_30

(NC)PIPESTAT0

AVRT(DA)_30

C524

0.1u

VCC_F_18

D28(NC)

AVDD(DA2)_30

D25(NC)

AVSS(DA0)

D15

E3 E4 E21 E22 E23E24 F1 F2 F3 F4 F21F22 F23 F24 G1 G2 G3 G4

MC_D15

PRELAMP_AF_CONT

C530

C529

10u

B

0.1u

C527

XX

CL508

TEST1

ANOUT[0]

RxD5

AVDD(DA0)_30

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

12

CL510

MC_UPDATE

XXC556

XX

R562

TxD5

PT[2]

(NC)TI3A

(NC)PT[3]

(NC)PQ[6]

VMF

VIO_F_30

D5

VSSQ

D6

K1 K2 K3 K4

MC_D6

MC_D5

C535

0.1u

XX

R558

(NC)CTS4

XRESET_F

XSHTR_ON

1k

INT6

AGND1(PHY)

XCAM_DR_PS

XSTRB_PWR_ON

PU[5]

DVDD1(PHY)_12

K21 K22 K23 K24

MC_D8

C536

0.1u

13

100kR551

CL505

IRQ_IMG

XAE_LOCK_ON

XX

1u

XX

1k

XX

R559

C557

C538

C537

TO1

INT3

INT7

(NC)TO3

(NC)TRACECLK

(NC)TRACEPKT1

VSSIO_F

VBUSOTG0

VBUSCHG(NC)

VPH

DGND1(PHY)

D0

L21 L22 L23 L24 M1 M2 M3 M4 M21M22 M23 M24

L1 L2

L3 L4

MC_D0

R530

0

MC_JTAG_XTRST

TRST

D16(NC)

AB1AB2AB3AB4AB5AB6AB7AB8AB9

MD3

VDDQ

TEST0

MC_D13

(NC)PT[5]

(NC)STATUS0

SUSPENDN(NC) (NC)IOIS16

VSSUSBHS

AVDD31(PHY)_33

D13

A24

VPF

MC_A24

C539

0.1u

VCC_F_18

D1

MC_D1

R561

AB10AB11AB12AB13AB14AB15AB16AB17AB18AB19AB20AB21AB22AB23AB24AC1AC2AC3AC4AC5AC6AC7AC8AC9AC10AC11AC12AC13AC14AC15AC16AC17AC18AC19AC20AC21AC22AC23AC24AD2AD3AD4AD5AD6AD7AD8AD9AD10AD11AD12AD13AD14AD15AD16AD17AD18AD19AD20AD21AD22AD23

PU[1]

(NC)PQ[5]

(NC)PQ[1]

D11

D8

D3

MC_D11

MC_D3

XAU_LINE_MUTE

AA16AA17AA18AA19AA20AA21AA22AA23AA24

PT[1]

(NC)CTS5

AVDD(OTGCH0)_33

A15

D10

MC_A15

MC_D10

(NC)TRACESYNC

(NC)TRACEPKT6

VDDUSBOTG_12

MC_D2

R553

2700

MELODY

(NC)

(NC)TxD4

(NC)PU[7]

(NC)PU[3]

VDDQ

(NC)PQ[7]

INT5

PQ[3]

INT1

(NC)TI3B

(NC)TI2A

(NC)INT9

TDI

(NC)

(NC)

WAIT

MD4

(NC)CE2

(NC)STATUS1

VSSUSBOTG

(NC)CKIO2

VSS_F

A5

A7

VDD

(NC)

RPU

DMOTGCH0

VSSQ

A3

A1

A2

VSS

RREF

(NC)

DPOTGCH0

A21

A19

A6

A18

(NC)

(NC)

XCE_F

USBXTAL

A23

A25

A8

A16

AVSS(OTGCH0)

MD5

ACC_F

USBEXTAL

VSSQ

A9

A4

A14SCK0

VBUSHS

XWP_F

(NC)UCLK

VSSQUSB

A17

A13

A11

A12

HOLD

VDDUSB_12

(NC)VBUSEN

(NC)CIDOTG0

VDDQ

A22

A20

A10

VDDQUSB_30

VSSUSB

VBUSOTG1

VDDUSBHS_12

D2

R527

XX

R525 33

10

R528

33

10

R529

SIGNAL PATH

REC

PB

C552

3.3u

6.3V

P

AA10AA11AA12AA13 AA14AA15

CL506

Y21 Y22 Y23 Y24 AA1 AA2 AA3 AA4 AA5AA6 AA7 AA8 AA9

Y1 Y2 Y3 Y4

W21W22 W23W24

1.5k

±5%

R535

W1 W2 W3 W4

V21 V22 V23 V24

R550

U1 U2 U3 U4 U21U22 U23U24 V1 V2 V3 V4

XX

T21 T22 T23 T24

R557

XX

T1 T2 T3 T4

R21 R22 R23 R24

R1 R2 R3 R4

P21 P22 P23 P24

N1 N2 N3 N4 N21N22 N23N24 P1 P2 P3 P4

±0.5%

R533

±5%R531

XX

±0.5%

R532

XX

±5%

VIDEO SIGNAL

R554

10k

0

0

DTC144EMT2L

R536

0

YCHROMA Y/CHROMA

R555

4700

Q501

MOD.

C553

0.001u

VER_DMOTGCH0

VER_DPOTGCH0

MC_XCS_FLASH

Q502

DTA144EMT2L

VER_DPOTGCH0

VER_DMOTGCH0

B

INV.

USBPHY_D+

MC_XWAIT

R560

100k

USBPHY_D-

XFE_CS

MC_A21

MC_A19

MC_A18

MC_A23

MC_A25

MC_A16

MC_A14

MC_A17

MC_A13

MC_A11

MC_A12

MC_A22

MC_A20

MC_A10

1825 15 16

C540

XX

SYS_V

MC_A5

MC_A7

C543

XX

R552

XX

MC_A3

MC_A1

MC_A2

R538

510

±5%

MC_A6

C545

XX

MC_A8

R549

0

MC_A9

MC_A4

R539

XX

C546

XX

C547

0.1u

B

C548

0.1u

AUDIO

SIGNAL

XBEEP_MUTE

SP_VOL

XAU_HGL_SEL

XAU_POWER_SAVE

XAU_LINE_MUTE

XAU_SP_MUTE

VIDEO_AMP_ON

AMP_OUT_ON

MC_D0

MC_D1

MC_D2

MC_D3

MC_D4

MC_D5

MC_D6

MC_D7

MC_D8

MC_D9

MC_D10

MC_D11

MC_D12

MC_D13

MC_D14

MC_D15

MC_A1

MC_A2

MC_A3

MC_A4

MC_A5

MC_A6

MC_A7

MC_A8

MC_A9

MC_A10

MC_A11

MC_A12

MC_A13

MC_A14

MC_A15

MC_A16

MC_A17

MC_A18

MC_A19

MC_A20

MC_A21

MC_A22

MC_A23

MC_A24

MC_A25

MC_XBS

MC_RDXWR

MC_XWE0

MC_XWE1

MC_XWAIT

MC_XCS_IC301REG

MC_XCS_IC301SDRAM

MC_CKIO

AU_LRCK

IRQ_IMG

PLLBYPASS

XRST_SYS

SYS_V

XFR_SCK

FR_SI

XCS_MC

FR_SO

FR_INT

MC_UPDATE

XFE_CS

XTG_CS

XCAM_SCK

CAM_SO

XCAM_RST

VER_EXT_CLK

CAM_F

CAM_DD_ON

LENS_TEMP

XCAM_DR_PS

USBPHY_D+

USBPHY_D-

XAE_LOCK_ON

XSHTR_ON

BL_MODE

XPANEL_TG_CS

XACCESS_LED

MS_PWR_ON

MC_MSD1

MC_MSD2

MC_MSD3

MC_MSCLK

MC_MSBS

MC_MSDIO

SYS_SO

XSYS_SCK

SYS_SI

STRB_CHG

XSTRB_FULL

CAM_DD_ON

PRELAMP_AF_CONT

SELF_TIMER_LED

XSTRB_PWR_ON

19144 1763

20810

BEEP

XBEEP_MUTE

SP_VOL

XAU_HGL_SEL

XAU_POWER_SAVE

XAU_LINE_MUTE

XAU_SP_MUTE

VIDEO_AMP_ON

AMP_OUT_ON

MC_D0

MC_D1

MC_D2

MC_D3

MC_D4

MC_D5

MC_D6

MC_D7

MC_D8

MC_D9

MC_D10

MC_D11

MC_D12

MC_D13

MC_D14

MC_D15

MC_A1

MC_A2

MC_A3

MC_A4

MC_A5

MC_A6

MC_A7

MC_A8

MC_A9

MC_A10

MC_A11

MC_A12

MC_A13

MC_A14

MC_A15

MC_A16

MC_A17

MC_A18

MC_A19

MC_A20

MC_A21

MC_A22

MC_A23

MC_A24

MC_A25

MC_XBS

MC_RDXWR

MC_XWE0

MC_XWE1

MC_XWAIT

MC_XCS_IC301REG

MC_XCS_IC301SDRAM

MC_CKIO

AU_LRCK

IRQ_IMG

PLLBYPASS

XRST_SYS

SYS_V

XFR_SCK

FR_SI

XCS_MC

FR_SO

FR_INT

MC_UPDATE

VER_XUSB_JACK_IN

XFE_CS

XTG_CS

XCAM_SCK

CAM_SO

XCAM_RST

VER_EXT_CLK

CAM_F

CAM_DD_ON

LENS_TEMP

XCAM_DR_PS

USBPHY_D+

USBPHY_D-

XAE_LOCK_ON

XSHTR_ON

BL_MODE

XPANEL_TG_CS

XACCESS_LED

MS_PWR_ON

MC_MSD1

MC_MSD2

MC_MSD3

MC_MSCLK

MC_MSBS

MC_MSDIO

SYS_SO

XSYS_SCK

SYS_SI

STRB_CHG

XSTRB_FULL

CAM_DD_ON

PRELAMP_AF_CONT

SELF_TIMER_LED

XSTRB_PWR_ON

(5/8)

11

(2/8)

9

(2/8)

8

(4/8)

8

(4/8)

12

(1/8)

2

(8/8)

13

(6/8)

14

4-19 4-20

SY-95 (3/8)

Page 8

DSC-T1

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

1

25 15

SY-95 BOARD(4/8)

A

B

C

D

E

F

G

H

I

HI CONTROL(FR BLOCK)

XX MARK:NO MOUNT

(7/8)

15

VER_XUSB_JACK_IN

(3/8)

12

(2/8)

8

(3/8)

8

XMULTI_JACK_IN

XPOWER_LED_ON

XCHARGE/XSTRB_LED

(8/8)

16

BATT_UNREG

D_1.2V

D_2.8V

EVER_3.0V

BACK_UP_VCC

ACV_UNREG

REG_GND

BATT_IN

BATT_SIG

SYS_DD_ON

DDCON_SO

DDCON_SCK

XCS_DDCON

FAST_CHARGE

INIT_CHARGE

XRSTX

XCS_MC

MC_UPDATE

FR_INT

FR_SO

XFR_SCK

XSYS_RST

SYS_V

BATT/XEXT

USB_JACK_IN

AV_JACK_IN

KEY_AD0

KEY_AD1

KEY_AD2

MODE_DIAL0

XMS_IN

XPWR_ON

XRESET_SW

SYS_DD_ON

DDCON_SO

DDCON_SCK

XCS_DDCON

FAST_CHARGE

INIT_CHARGE

VER_XUSB_JACK_IN

MC_UPDATE

FR_SI

XMULTI_JACK_IN

USB_JACK_IN

AV_JACK_IN

XPOWER_LED_ON

XCHARGE/XSTRB_LED

MODE_DIAL0

XRESET_SW

NO MARK:REC/PB MODE

( ) MARK:WHEN ATTACHED BATTERY PACK.

:Voltage measurement of the CSP IC

and the Transistors with mark,is

not possible.

BATT_IN

BATT_SIG

XRSTX

XCS_MC

XMS_IN

UNR32A600LS0

R401

1M

0

Q404

INV.

FR_INT

FR_SI

FR_SO

XFR_SCK

XSYS_RST

SYS_V

BATT/XEXT

KEY_AD0

KEY_AD1

KEY_AD2

XMS_IN

XPWR_ON

R403

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

810 137

1234567

470k

XX

8

RB401

XPWR_ON

R453

BATT/XEXT

XX

2.9

R452

XX

Q409

XX

Q411

XX

XLENZ_CAP_ON

AV_JACK_IN

XSYS_RST

XMULTI_JACK_IN

0

R454

XX

R709

XX

Suffixed -14

R405

R448

R411

XX

XX

R409

470k

CL401

R413

470k

R412

R408

R415

100k

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

11

XRSTX

R496

R432

CL412

CL414

CL413

RB402

1kX4

1

2

4

3

6

5

7

8

1M

1k

C401

0.1u

Q405

XX

R406

0

XRESET_SW

XPOWER_ON

B8A8B7A7B6A6C6B5B4C4A3B3A4A5A2A1

XLANC_PWR_ON

BATT/XEXT

MS_IN

UDRIVE_IN

XCS_LCD

USB_CLK_EN

LANC_JACK_IN

XMULTI_IN

AV_JACK_IN

XRST_SYS

GND

BACK_UP_VCC

USB_UNREG_SW

XLANC_IC_ON

FAST_CHARGE

R497

1k

0R499

B2 B1 C2 C1 D3 D1 D2 E1 E2 H3 J3 J2 G4 A9 B9 C8

Q408

XX

R407

0

INIT_CHARGE

INIT_CHARGE

FAST_CHARGE

DDCON_SI XRSTX

XCHARGE/XSTB_LED

XPWR_LED_ON

XX

R410

R450

470k

47k

R420

0

±0.5%

C402

XX

100k

R429

USB_VBUS

USB_HOLD

DD_CON_SENS

IC491

MB89083LGA-G-105-ERE1

CSP(CHIP SIZE PACKGE)IC

MB89083LGA-G-107-ERE1

FR_SI

DDCON_SCK

DDCON_SO

100k

±0.5%

C407

0.1u

AVss

ACV_SENS

HI CONTROL

IC491

FR_SO

FR_SCK

0.1u

C403

AVCC

XCS_MC

0

R492

C492

0.1u

R433

100k

±0.5%

BATT_SENS

MOD0

±0.5%

1800

R495

R430

100k

±0.5%

MODE_DIAL1

VCI

CL402

CL403

C408

0.1u

KEY_AD4

MODE_DIAL0

(SUFFIXED-13)

(SUFFIXED-14)

MOD1

CPO

7.5k

±0.5%

R494

C491

0.01u

CL404

CL405

KEY_AD2

MODE_DIAL0

8

KEY_AD2

KEY_AD3

BATT_IN

SYS_V

KEY_AD1

KEY_AD0

1234567

H6G6J7H7J8J9H8H9G9G8F8F9F7D7J1H2

KEY_AD1

BACK_UP_VCC

32kHz_OUT

XCS_DDCON

USB_PWR_ON

SYS_DD_ON

MC_WAKE_UP

MC_UPDATE

USB_SUSPEND

XUSB_JACK_IN

R437

470k

R438

0

DTC115TMT2L

RB406

1kX4

KEY_AD0

32kHz_INXLENZ_CAP_OPN

BATT_SI

BATT_S0

BATT_SIO

LANC_SO

LANC_SI

CL411

47k

Q406

INV.

129

1234567

VSS

2.8

14463

8

RB408

10kX4

1

CL408

CL409

CL410

R424

10M

R425

330k

Q407

HN1L02FU(TE85R)

BATT SIG I/F

(0.1)

R428

47k

CL407

CL406

C9 D8 D9 E8 E9 F3 F2 F1 G1 G2 H1 H5 J5 J4 H4 J6

R439

470k

30.5 µs

X402

32.768kHz

2

700 mVp-p

C404

10p

CH

C405

10p

(3.1)

(0.1)

3

6

1

4

(2.8)

C406

0.1u

B

XCS_DDCON

R434

0

(2.8)

5

R431

D402

47k

MA4L11100AS0

R446

XX

4

3

1

2

D403

DF3A8.2C(TPL3)

R461

XX

BATT_SIG

SYS_DD_ON

FR_INT

MC_UPDATE

REG_GND

J

16

SY-95 (4/8)

DDCON_SCK

(LENS COVER OPEN)

XLENZ_CAP_ON

S401

XPOWER_LED_ON

XCHARGE/XSTRB_LED

DDCON_SO

FR_SI

FR_SO

XFR_SCK

XCS_MC

BATT_IN

SYS_V

USB_JACK_IN

VER_XUSB_JACK_IN

4-21 4-22

Page 9

DSC-T1

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

1

SY-95 BOARD(5/8)

AUDIO I/O(AU BLOCK)

A

XX MARK:NO MOUNT

B

C

D

C627

E

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

463

:Voltage measurement of the CSP IC

and the Transistors with mark,is

not possible.

C606

15000p

B

C611

0.022u

B

H5

J5

H6

J6

H7

J7

H8

J8

D2

NC

LPF2B

AGC_OUT

NC(HK)

J9

NC(HN)

C602

R601

4.7u

B

47k

C601

1u

C604

B

0.015u

C628

0.015u

XX

B

B

B

R610

R602

0

33k

C605

0.1u

B

G7

STBY

H9

LPF_SEL

G8

AGC_DET

G9

WHPF_OUT

F8

WHPF_BIAS

F9

WHPF_IN

E8

GAIN_SET

E9

MIC_OUT

D8

GND

D9

LINE_MUTE

C8

MIC_OFF

C9

MIC_IN

B8

NC

B3

LPF1A

LPF1B

LPF2A

LPF_OUT

REC_AMP_IN

IC601

AUDIO AMP/ADC

IC601

AN12908A-VB

CSP(CHIP SIZE PACKAGE)IC

H4

J4

AGND

REC_OUT

C614

0.47u

B

C616

J3

PB_IN

1u

B

H3

VOL_CTL

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

R611

10k

G3

J1

NC(HK)

NC(HN)

SPAGC_SW

SPAGC_DET

XAUDIO_MUTE

SP_LPF_0

BEEP_OUT

BEEP_MIX_IN

XBEEP_MUTE

VREF_SP

SP_OUT-

SP_GND

SP_OUT+

NC(HN)

NC(HK)

AGND

BEEP

NC

C2

J2

H1

H2

G1

G2

F1

F2

E1

E2

D1

C1

A2

C3

A1

R605

C617

0.47u

B

R606

R607

47k

C620

C623

0.001u

0

0

1u

B

C619

4.7u

B

B

1uC618

C621

0.047u

C622

0.047u

C624

10u

6.3V

8107

R613

2700

R614

68k

C629

0.47u

B

B

925

AU_AOUT

AU_AIN

XAU_POWER_SAVE

XAU_HGL_SEL

SP_VOL

XBEEP_MUTE

BEEP

5

11

(2/8)

(3/8)

F

G

16

17

(8/8)

MIC_IN

AU_OUT

SP+

SP-

NC(HK)C7NC(HN)B9MIC_SPYA8MIC_2VB7MIC_REBA7VREFB6VCCA6MUTE_TMGB5GNDA5MUTE_DRVRB4LINE_OUTA4VCC_SPA3VCC_SPB2SP_SAVE

A9

C615

B

10u

C607

B

1u

C608

B

1u

C610

B

0.1u

C603

B

1u

C613

1u

B

L602

10uH

XAU_SP_MUTE

XAU_LINE_MUTE

AU_2.8V

ST_5V

REG_GND

SIGNAL PATH

AUDIO

SIGNAL

REC

PB

4-23 4-24

18

(7/8)

SY-95 (5/8)

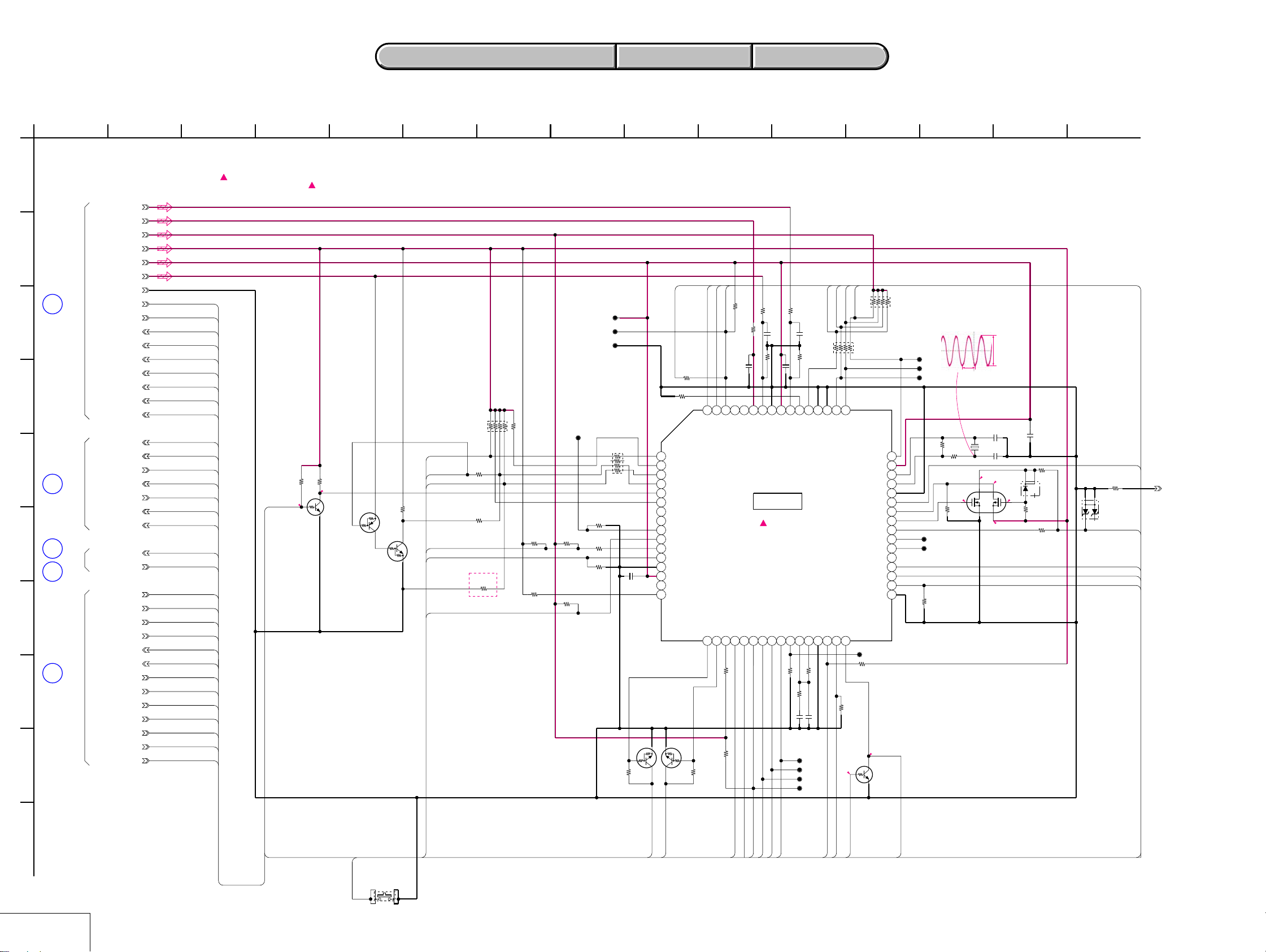

Page 10

DSC-T1

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

1

SY-95 BOARD(6/8)

FLASH DRIVE(ST BLOCK)

A

XX MARK:NO MOUNT

M_5V

(7/8)

19

B

ST_UNREG

ST_5V

REG_GND

STRB_CHG

C

XSTRB_FULL

D

(3/8)

14

CAM_DD_ON

E

NO MARK:REC/PB MODE

L651

3.6

2.2uH

R651

4700

DTA114EMT2L

DTC144EMT2L

R652

100k

Q651

DTC144EMT2L

SWITCH

0

Q656

SWITCH

4.9

Q655

SWITCH

R653

10k

4

3.6

UPA650TT-E1-A

6

5

2

1

3

C651

0.1u

B

3.5

0.1

4.8

0.1

2.8

Q652

SWITCH

0

C652

22u

C

TND721MH5-S-TL-E

0

4.8

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

463

R654

4700

0

2.9

6

1

45

0

3

5

4

IC651

IGBT DRIVE

2

22

C654

0.1u

B

IC651

123

Q653

RN1902FE(TPLR3)

FLASH CHARGE

DET

C655

1u

B

XSTRB_PWR_ON

SELF_TIMER_LED

PRELAMP_AF_CONT

R708

100k

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

8107

FP-690

XSTRB_PWR_ON

FP-690 FLEXIBLE is replaced as a block.

So that this PRINTED WIRING BOARD is omitted.

D701

MA2SD32008S0

2

0

R701

47

3.4

6

3

1

4

00

R703

R702

1k

47

1 STB_UNREG

2 STB_UNREG

3 STB_UNREG

4 STB_UNREG

5 STB_UNREG

6 STB_UNREG

7 REG_GND

8 REG_GND

9 REG_GND

10 REG_GND

11 REG_GND

12 REG_GND

13 REG_GND

14 REG_GND

15 XSTRB_PWR_ON

16 STB_FULL

17 IGBT_ON

18 AF_LED_5V

19 AF_LED_K

R705

10k

5

0

R704

10k

19PCN703

Q701

XP4501

LED DRIVE

STB_UNREG

STB_UNREG

STB_UNREG

STB_UNREG

STB_UNREG

STB_UNREG

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

STB_FULL

IGBT_ON

AF_LED_5V

AF_LED_K

FLEXIBLE

CL001

CL002

CL003

CL004

CL005

CL006

CL007

STB_UNREG

REG_GND

XSTRB_PWR_ON

STB_FULL

IGBT_ON

AF_LED_5V

AF_LED_K

11

TO

ST-86 BOARD

(PAGE 4-11

of LEVEL2)

12925

F

6

16

SY-95 (6/8)

(2/8)

XSTRB_PWR_ON

SELF_TIMER_LED

PRELAMP_AF_CONT

STRB_ON

XSTRB_PWR_ON

SELF_TIMER_LED

PRELAMP_AF_CONT

4-25 4-26

Page 11

DSC-T1

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

1

SY-95 BOARD(7/8)

DC/DC CONVERTER(DD BLOCK)

A

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

:Voltage measurement of

the CSP IC and

the Transistors with

mark,is not possible.

B

BT901

BATTERY

TERMINAL

BATT_UNREG

BATT_SIG

C

BATT_GND

C

D

E

VL_3V

F

SYS_DD_ON

XRSTX

BATT_IN

G

H

I

BL_LEV

J

BATT_SIG

BL_THH

INIT_CHARGE

K

16

CL016

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

810 137

F002

2A/32V

F003

2A/32V

D015

L001

C029

10u

C10

VCH8A

C031

10u

D10

C11

D11

VCH8B

GND8A

0.01uC033

MA2SD32008S0

L002

C036

10uH

10u

6.3V

B

F11

E10

E11

E9

VCH2

BOOT2

OUT8BD9OUT8A

GND8B

IC001

DC/DC CONVERTER

IC001

CXA8133GF

CSP(CHIP SIZE PACKAGE)IC

±0.5%

22

R052

1uC034

GND2

L005

10uH

C035

0.01u

6.3V

C037

1u

G11

F10

F9

VCC2

OUT2

4.7uH

L004

C040

0.1u

G9

G10

VCC1B

VCC1A

D025

MA2SD32008S0

VCC1C

C042

1u

C041

0.01u

H10

H11

OUT11AG8BOOT11

10R053

C076

4.7u

D013

MA2S111-(K8).S0

4V

100u

4.7uC009

10u

A10

ODP_SW

VLDO3

A11

0.001u

C028

VLDO1

10uH

C001

B11

B10

VCC8

VODP

C016

C9

B9

VLDO2

GND_REGE5MARKD4BATTD3CSKPD2ICHGD1VDCINE4CHG_SWE3FCHGE2ROSCE1CSCPF4GND_LOGF3GND6F2GND6G4FB6G3FB6G2ICH6F1OUT6G1VCH6H1VCC_GDH2VCH3SH3VCH3C(FB6)H4VCH3BJ1VCH3A(FB3)J2OUT3CK1OUT3BJ3OUT3AL1GND3CK2GND3B

C1

DRAIN1

SOURCE1

SOURCE1

GATE1

C018

C019

C021

C020

C008

C013

C010

R010

R012

±0.5%

R087

47k

±0.5%

D035

D036

FDW2508P/NQ002

SOURCE2

SOURCE2

F001

2A/32V

4.7u

33

4.7u

0.1u

0.01u

0.01uC017

0.01u

0.01u

0.01u

0.01u

0.1u

0.022uC012

0.022u

0.01uC022

1u

0.1u

47k

XX

0.01u

R095

8200

DRAIN2

GATE2

MA2SD32008S0

R030

470

C026

0.01u

0.1uC014

3.6

8

3.6

7

6

-2.3

5

D011

GND_LDOA

A9

LDO5SS

F8

CPSW

E8

VBCK

D8

VLDO4

C8

VLDO5

B8

BGR

A8

USB_PWR_ON

D7

SYSDDON

C7

XRESET

B7

CS

A7

ERR8

D6

ERR8

C6

ERR2

B6

ERR1

A6

ERR4

D5

SS_SYNC

C5

CBG

B5

GND_ANA

A5

ERR7

C4

SS5

B4

ERR5

A4

MODE7

B3

ERR3

B2

SS3

A2

ERR6

A1

REF6

B1

SS6

C3

SS2

C2

R045

150k

±0.5%

3.6

1

3.6

2

D009

RD12SB2

-2.3

4700p

C006

10u

6.3V

C067

4700p

C007

6.3V

3

4

C015

C027

C011

C023

C024

C005

C025

MA2SD32008S0

MA2SD32008S0

R009

470k

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

11

IC007

+1.8V REG

DDCON_SO

DDCON_SCK

XCS_DDCON

D023

MA2SD32008S0

C049

10u

33uHL009

C051

1u

C077

4.7u

C053

10u

L006

10uH

J11

OUT11B

L11

OUT12A

OUT11C

D017

RB161M-20TR

C043

9

C044

0.01u

K10

H8

BOOT12J9OUT12C

OUT12B

10u

10V

GND1A

GND1B

GND1C

VCH1A

VCH1B

VCH1C(FB4)

ROMWR

ROMWR

GND_GD

VOS72

VOS73

VOS71

GND3A

L007

10uH

MA2SD32008S0

DIN

DOUT

CLK

LD

TEST

TEST

TLD

GND4

OUT4

VCH4

OUT5

VCC5

VCH5

VCH7

VCC7

D026

H9

J10

K11

L10

C048

22u

K9

L9

L8

CL001

L7

K8

K7

J8

H7

J7

H5

H6

L6

L008

4.7uH

K6

J6

L5

K5

J5

L4

K4

D021

MA2SD32008S0

L3

K3

J4

A3

L2

C045

10u

B

12

IC007

2.9

12

LE

GND

XCS_DDCON

DDCON_SO

DDCON_SCK

R097

33k

±0.5%

IC003

R096

0.1

±0.5%

56k

1234

0

-8.0

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

OUT1

IN1-

IN1+

VCC-

IC003

CAM_-0.5V REG

TL082CPWR

R1114Q181D-TR-FA

VOUT

VCC+

OUT2

IN2-

5678

IN2+

,Q001

144 1763

L003

10uH

CL021 CL033

R028

47k

C080

4.7u

C002

10u

C030

L010

22u

10uH

4V

P

2.9

VDD

1.8

34

CL032

2.9

0-0.5

Q001

MCH3406-TL-E

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

C003

10u

ACV_UNREG0

ST_UNREG

ACV_UNREG

FAST_CHARGE

BATT_UNREG

PANEL_13.5V

BACK_UP_VCC

EVER_3.0V

A_3.1V

D_1.2V

D_1.8V

AU_2.8V

D_2.8V

INIT_CHARGE

SYS_DD_ON

BATT_IN

BL_LEV

XCS_DDCON

DDCON_SO

DDCON_SCK

CAM_-0.5V

A_2.8V

CAM_15.0V

CAM_-8.0V

BATT_SIG

BL_THH

VL_3V

XRSTX

M_5V

ST_5V

LED_A

LED_K

A_3.1V

A_2.8V

D_2.8V

CAM_15.0V

CAM_-8.0V

CAM_-0.5V

A_2.8V

D_2.8V

D_1.2V

AU_2.8V

A_3.1V

A_2.8V

D_2.8V

D_1.8V

D_1.2V

D_2.8V

D_1.2V

EVER_3.0V

ACV_UNREG

BATT_UNREG

BACK_UP_VCC

BATT_IN

BATT_SIG

SYS_DD_ON

DDCON_SO

DDCON_SCK

XCS_DDCON

FAST_CHARGE

INIT_CHARGE

XRSTX

AU_2.8V

ST_5V

M_5V

ST_5V

ST_UNREG

D_2.8V

PANEL_13.5V

M_5V

VL_3V

EVER_3.0V

ACV_UNREG0

BL_THH

BL_LEV

LED_K

LED_A

A_3.1V

A_2.8V

D_2.8V

CAM_15.0V

CAM_-8.0V

CAM_-0.5V

REG_GND

A_2.8V

D_2.8V

D_1.2V

AU_2.8V

REG_GND

A_3.1V

A_2.8V

D_2.8V

D_1.8V

D_1.2V

REG_GND

D_2.8V

D_1.2V

EVER_3.0V

ACV_UNREG

BATT_UNREG

BACK_UP_VCC

BATT_IN

BATT_SIG

SYS_DD_ON

DDCON_SO

DDCON_SCK

XCS_DDCON

FAST_CHARGE

INIT_CHARGE

XRSTX

REG_GND

AU_2.8V

ST_5V

REG_GND

M_5V

ST_5V

ST_UNREG

REG_GND

D_2.8V

PANEL_13.5V

M_5V

VL_3V

EVER_3.0V

ACV_UNREG0

BL_THH

BL_LEV

LED_K

LED_A

REG_GND

1825 15 16

(1/8)

3

(2/8)

7

(3/8)

10

(4/8)

15

(5/8)

18

(6/8)

19

(8/8)

20

4-27 4-28

SY-95 (7/8)

Page 12

DSC-T1

For Schematic Diagram

• Refer to page 4-47 for printed wiring board.

1

25 15

SY-95 BOARD(8/8)

CONNECTOR(CN,FP BLOCK)

A

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

PANEL_13.5V

PANEL_2.8V

REG_GND

BL_LEV

B

C

THROUGH THE

FP-691 FLEXIBLE

()

(PAGE 4-32)

D

E

TO

MS-148 BOARD

BL_THH

LED_K

LED_A

PANEL_B

PANEL_G

PANEL_R

XRST_SYS

SYS_SI

XPANEL_TG_CS

XSYS_SCK

SYS_SO

BL_MODE

PANEL_V

HD0

XACCESS_LED

D_2.8V

MS_PWR_ON

MSCLK

MS_IN

MS_DIO

MSDS

MSD3

MSD2

MSB1

MS_REG_GND

MODE_DIAL

SP+

SP-

F

G

MIC_IN

REG_GND

XPOWER_LED_ON

EVER_3.0V

TO

H

CONTROL SWITCH BLOCK

(PW-125)

CN001

THROUGH THE

FP-693 FLEXIBLE

()

(PAGE 4-13

of LEVEL2)

I

XPOWER_ON

REG_GND

XAE_LOCK_ON

XHTR_SW

XRESET_SW

XCHARGE/XSTRB_LED

EVER_3.0V

KEY_AD0

KEY_AD1

KEY_AD2

REG_GND

NC

SIGNAL PATH

J

16

CHROMA SIGNALY/CHROMAY

REC

PB

CL901

CL902

CL903

CL904

CL905

CL906

CL907

CL908

CL909

CL910

CL911

CL912

CL913

CL914

CL915

CL916

CL917

CL918

CL919

CL920

CL921

CL922

CL923

CL924

CL928

CL927

CL926

CL925

CL929

CL931

CL934

CL935

CL961

CL962

CL957

CL955

CL960

CL956

CL954

CL952

CL951

CL968

CL969

CL953

CL949

CL950

CL970

VIDEO SIGNAL

XPANEL_TG_CS

XACCESS_LED

MS_PWR_ON

AUDIO

PANEL_B

PANEL_G

PANEL_R

XRST_SYS

SYS_SI

XSYS_SCK

SYS_SO

BL_MODE

PANEL_V

HD0

MC_MSCLK

MC_MSDI0

MC_MSDS

MC_MSD3

MC_MSD2

MC_MSB1

XAE_LOCK_ON

XSHTR_ON

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

SYS_SI

XPANEL_TG_CS

XSYS_SCK

SYS_SO

BL_MODE

XACCESS_LED

MS_PWR_ON

MC_MSCLK

MC_MSDIO

MC_MSD1

MC_MSD2

MC_MSD3

MC_MSBS

XSHTR_ON

XAE_LOCK_ON

LENS_TEMP

XCAM_DR_PS

USBPHY_D-

USBPHY_D+

AU_OUT

USB_JACK_IN

XMULTI_JACK_IN

BATT/XEXT

AV_JACK_IN

810 137

REG_GND

M_5V

PANEL_13.5V

D_2.8V

BL_LEV

BL_THH

LED_K

LED_A

EVER_3.0V

ACV_UNREG

VL_3V

SYS_SI

XPANEL_TG_CS

XSYS_SCK

SYS_SO

BL_MODE

XACCESS_LED

MS_PWR_ON

MC_MSCLK

MC_MSDIO

MC_MSD1

MC_MSD2

MC_MSD3

MC_MSBS

XSHTR_ON

XAE_LOCK_ON

LENS_TEMP

XCAM_DR_PS

USBPHY_D-

USBPHY_D+

SP+

SP-

MIC_IN

AU_OUT

USB_JACK_IN

XMULTI_JACK_IN

BATT/XEXT

AV_JACK_IN

XMS_IN

MODE_DIAL0

XPOWER_LED_ON

XPWR_ON

XRESET_SW

XCHARGE/XSTRB_LED

KEY_AD0

KEY_AD1

KEY_AD2

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

SY-95 BOARD SIDE A SY-95 BOARD SIDE B

11

HR_EN0

HR_DIR0B

HR_DIR0A

HR_EN2

HR_DIR2B

HR_DIR2A

HR_EN3

HR_DIR3B

HR_DIR3A

PANEL_B

PANEL_G

PANEL_R

XRST_SYS

PANEL_V

HD0

2.8 0

R706

68k

R707

68k

HD0

DTA143TMT2L

2.9

AU_OUT

20

13

17

16

(7/8)

(3/8)

(5/8)

(4/8)

HR_EN0

HR_DIR0B

HR_DIR0A

HR_EN2

HR_DIR2B

HR_DIR2A

HR_EN3

HR_DIR3B

HR_DIR3A

XFC_RST_LED

XFC_RST_SENS

(2/8)

4

XZM_RST_LED

XZM_RST_SENS1

PANEL_B

PANEL_G

PANEL_R

XRST_SYS

PANEL_V

V_OUT

Q702

SWITCH

2.9

Q703

DTA143TMT2L

SWITCH

USB_JACK_IN

XMULTI_JACK_IN

BATT/XEXT

AV_JACK_IN

129

LENS_TEMP

HR_EN0

USBPHY_D-

USBPHY_D+

HR_DIR0B

HR_DIR0A

HR_EN2

HR_DIR2B

HR_DIR2A

HR_EN3

HR_DIR3B

HR_DIR3A

XCAM_DR_PS

FB704

0

Note

FB703

0

Note

Note:Resestor is mounted to the location

FB703 and FB704 are printed.

FB702

0uH

C702

0.1u

C701

FB701

0uH

0.1u

02.8

14463

21PCN701

1 M_5V

2 M_5V

3 D_2.8V

4 REG_GND

5 REG_GND

6 REG_GND

7 F_RST_VCC

8 XFC_RST_SENS

9 LENS_TEMP

10 Z_RST_VCC

11 XZM_RST_SENS

12 HR_EN0

13 HR_DIR0B

14 HR_DIR0A

15 HR_EN2

16 HR_DIR2B

17 HR_DIR2A

18 HR_EN3

19 HR_DIR3B

20 HI_DIR3A

21 XCAM_DR_PS

19PCN704

1 REG_GND(AU)

2 V_OUT

3 REG_GND(AU)

4 AU_OUT

5 REG_GND(AU)

6 REG_GND(USB)

7 REG_GND(USB)

8 USBPHY_D-

9 USBPHY_D+

10 REG_GND(USB)

11 VL_3V

12 VBUS

13 VBUS

14 VBUS

15 XMULTI_IN

16 NC

17 BATT/XEXT

18 XAV_JACK_IN

19 NC

6P

CN705

1 ACV_GND

2 ACV_GND

3 ACV_GND

ACV_UNREG0

4

ACV_UNREG0

5

ACV_UNREG0

6

TO

LD-140 BOARD

THROUGH THE

FP-695 FLEXIBLE

(PAGE 4-36)

TO

CN-198 BOARD

(PAGE 4-9

of LEVEL2)

TO

CN-198 BOARD

(PAGE 4-9

of LEVEL2)

)(

SY-95 (8/8)

4-29 4-30

Page 13

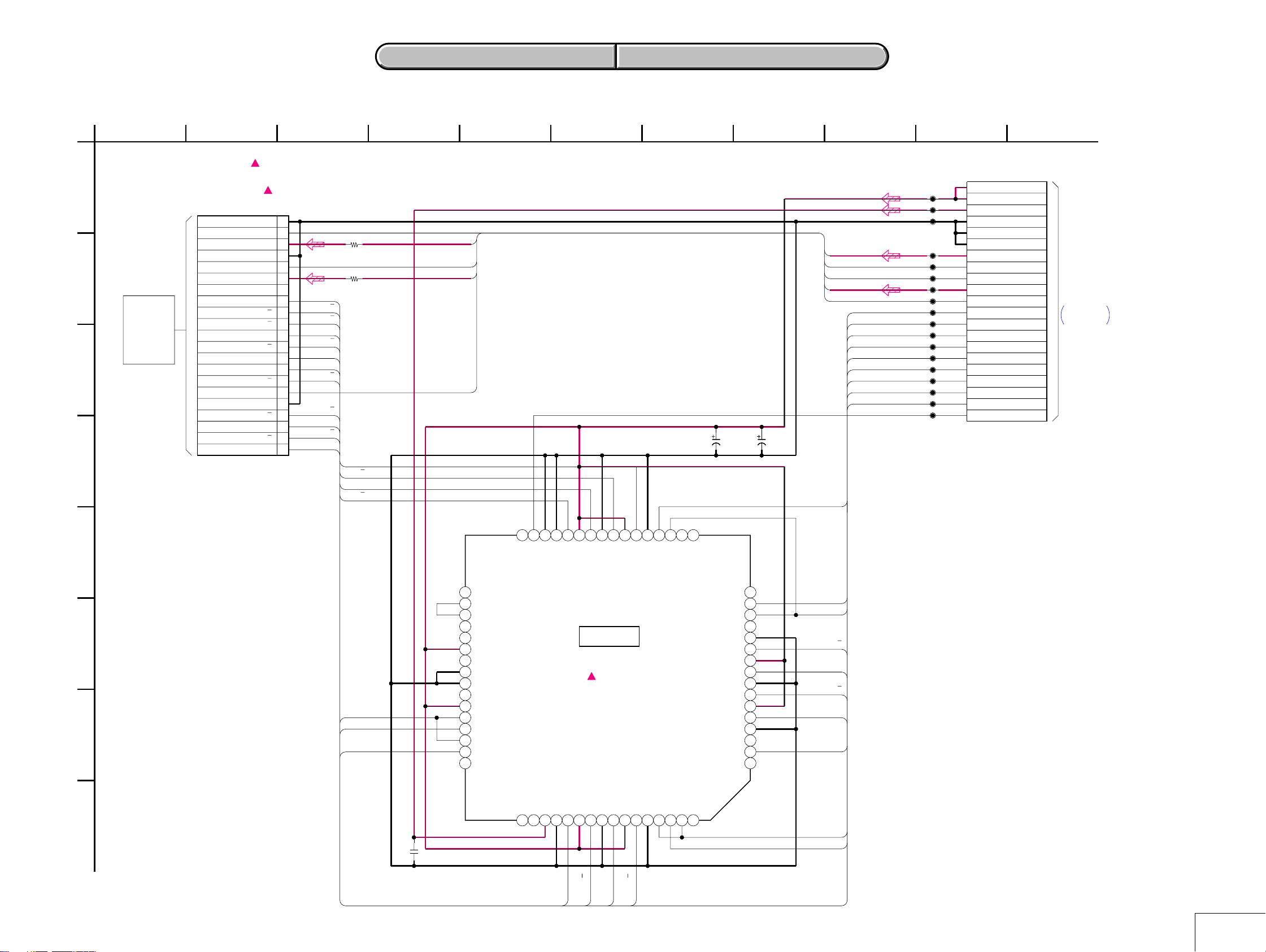

For Schematic Diagram

• Refer to page 4-51 for printed wiring board.

4-2. SCHEMATIC DIAGRAMS MS-148 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS MS-148 PRINTED WIRING BOARD

DSC-T1

1

MS-148 BOARD(1/2)

MS I/O(CN BLOCK)

A

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

B

MEMORY

STICK

DUO

CONNECTOR

C

D

REC

E

SDIO/DATA0

SIGNAL PATH

VIDEO SIGNAL

CHROMA

PB

CN101

SCLK

DATA3

DATA2

DATA1

GND

VCC

GND

Y

(2/2)

MSCLK

MS_IN

MS_DIO

MSBS

MSD3

MSD2

MSD1

8107

PANEL_13.5V

PANEL_2.8V

REG_GND

BL_LEV

LED_K

LED_A

PANEL_B

PANEL_G

PANEL_R

XRST_SYS

SYS_SI

XPANEL_TG_CS

XSYS_SCK

SYS_SO

PANEL_V

HDO

925

CL101

CL102

CL103

CL104

CL105

CL106

CL107

CL108

CL109

CL110

CL111

CL112

CL113

CL114

CL115

CL116

CL117

CL118

CL119

CL120

CL121

CL122

CL123

CL124

CL125

CL143

CL144

CL145

CL126

CL128

CL131

CL132

CL158

CL157

PANES_13.5V

PANEL_2.8V

REG_GND

BL_LEV

BL_THH

LED_K

LED_A

PANEL_B

PANEL_G

PANEL_R

XRST_SYS

SYS_SI

XPANEL_TG_CS

XSYS_SCK

SYS_S0

BL_MODE

PANEL_V

HD0

XACCESS_LED

D_2.8V

MS_PWR_ON

MSCLK

MS_IN

MS_DI0

MSBS

MSD3

MSD2

MSD1

MS_REG_GND

MODE_DIAL

SP+

SP-

11

TO

SY-95 BOARD

(8/8)

THROUGH

THE FP-691

FLEXIBLE

(PAGE 4-29)

SP901

(SPEAKER)

463

C103

0.1u

B

R104

220k

10P

10

R107

9

8

7

INT

6

5

4

3

2

BS

1

0

D101

XX

MSCLK

MSD3

MS_IN

MSD2

MS_DIO

MSD1

MSBS

SSM6E01TU

SWITCH

C101

XX

B

Q101

2.9

2.9

2

2.9

2.9

1

4

5

D102

MA2SD32008S0

3

6

0

R101

3300

2.9

S101

(MODE SW)

R106

2200

C102

22u

6.3V

R108

2.9

0

R105

820

SML-310LTT86

A

LND101

XX

AUDIO

Y/CHROMA SIGNAL

R102

1500

R103

1200

DTA144EMT2L

LED DRIVE

2.9

D103

(ACCESS)

STATIC_GND

Q102

1

16

4-31 4-32

MS-148 (1/2)

Page 14

DSC-T1

For Schematic Diagram

• Refer to page 4-51 for printed wiring board.

4-2. SCHEMATIC DIAGRAMS MS-148 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS MS-148 PRINTED WIRING BOARD

1

MS-148 BOARD(2/2)

LCD PANEL DRIVE(PD BLOCK)

A

XX MARK:NO MOUNT

PANEL_13.5V

PANEL_2.8V

B

C

(1/2)

1

D

E

XPANEL_TG_CS

F

G

H

16

REG_GND

LED_A

LED_K

PANEL_B

PANEL_G

PANEL_R

XRST_SYS

SYS_SI

XSYS_SCK

SYS_SO

PANEL_V

BL_LEV

810 137

11

12925 15

14463

NO MARK:REC/PB MODE

:Voltage measurement of the CSP IC

and the Transistors with mark,is

not possible.

Q801

BUFFER

XPOFF

RGT

HCK1

HCK2

REF

HST

WIDE

DWN

EN

VCK

VST

Q802

UP04601008S0

BUFFER

R815

10k

7.0

2

13.5

6

WIDE

HCK2

SYS_SO

E3SIE4

E5

E6

E7

SCK

VDD

WIDE

HCK2

GND1

IC803

RGB DRIVE,

TIMING GENERATOR

IC803

CXA3622GG

CSP(CHIP SIZE PACKAGE)IC

DWN

XPANEL_TG_CS

E1

E2

XCS

VCC1

XPOFF

D6VRD7

D5

GND2

XPOFF

TEST

D3

XVD

D2

HDO

HD

D1

VG

C7

VB

C6

N.C

C5

PWM

VCK

Gin

Rin

COM

VCC2

C819

EN

0.01u

CL801

C4

C3

C2

C1

B7

B6

RB801

10X4

CL802

VCK

UP04601008S0

R831

22k

2.8

1

C810

2.2u

25V

HCK1

F3

REF

F4

XCLR

F5

Filter1

F6

HST

F7

CLK/XWRT

G1

RGT

G2

HDO

G3

OP_OUT

G4

OP_IN

G5

Filter2

G6

VSS

G7

C805

2

02.8

Q805

UP04601008S0

LPF

TA

A

SYS_SI

XSYS_SCK

F1

F2

SO

VDDA2VSTA3DWNA4F_BACKA5EXTDAA6VCC3A7VPB1BinB2VSSB3ENB4BLDETB5XLED

A1

B

0.01u

VST

C820

C808

0.1u

B

47u

6.3V

R809

10k

C822

HCK1

REF

HST

RGT

R826

82k

±0.5%

C823

150p

CH

C812

R827

82k

±0.5%

560p

R821

C824

220p

CH

CH

±0.5%

XX

1/16W

0

CL803

0.1u

C811

R808

68k

R810

100k

±0.5%

1/16W

R830

10k

2.8

R828

46

4700

±0.5%

5

3

R829

10k

L802

47uH

LED_A

LED_K

SYS_SI

XPANEL_TG_CS

XSYS_SCK

SYS_SO

HDO

HDO

R820

100k

5

7.0

1

R832

SSM3J09FU(TE85L)

C814

0.1u

R818

10k

4

3

6.4

3

5

4

7.0

XX

C821

0.01u

Q803

REG,

LED_A

LED_K

BL_THH

BL_THL

CREXT

REG_GND

VDDG

REG_GND

N.C.

RGT

PSIG

HCK1

HCK2

REF

HST

WIDE

VDD

DWN

VCK

VST

COM

VB

VR

VG

EN

FLEXIBLE

CL401

CL402

CL403

CL404

CL405

CL406

CL407

CL408

CL409

CL410

CL411

CL412

CL413

CL414

CL415

CL416

CL417

CL418

CL419

CL420

CL421

CL422

CL423

CL424

CN402

25P

LED_A1

N.C.2

LED_K3

BL_THH4

BL_THL5

RGT6

VB7

VR8

VG9

PSIG10

HCK111

HCK212

CREXT13

REF14

HST15

WIDE16

REG_GND17

VDDG18

VSS19

VDD20

DWN21

EN22

VCK23

VST24

COM25

ND901

BACK

LIGHT

LCD901

2.5INCH

COLOR LCD

UNIT

(ACX500EN-J)

FP-694

LED_A

LED_K

R819

B

13.5

6

2

1

7.0

150k

7.6

C817

MA8036-TX

C816

C813

4.7u

D801

B

0.1u

1u B

B

CL804

CL805

CL806

CL807

CL808

CL809

CL810

CL811

CL812

CL813

CL814

CL815

CL816

CL817

CL818

CL819

CL820

CL821

CL822

CL823

CL824

CL825

CL826

CL827

SIGNAL PATH

VIDEO SIGNAL

CHROMA Y/CHROMAY

REC

PB

MS-148 (2/2)

4-33 4-34

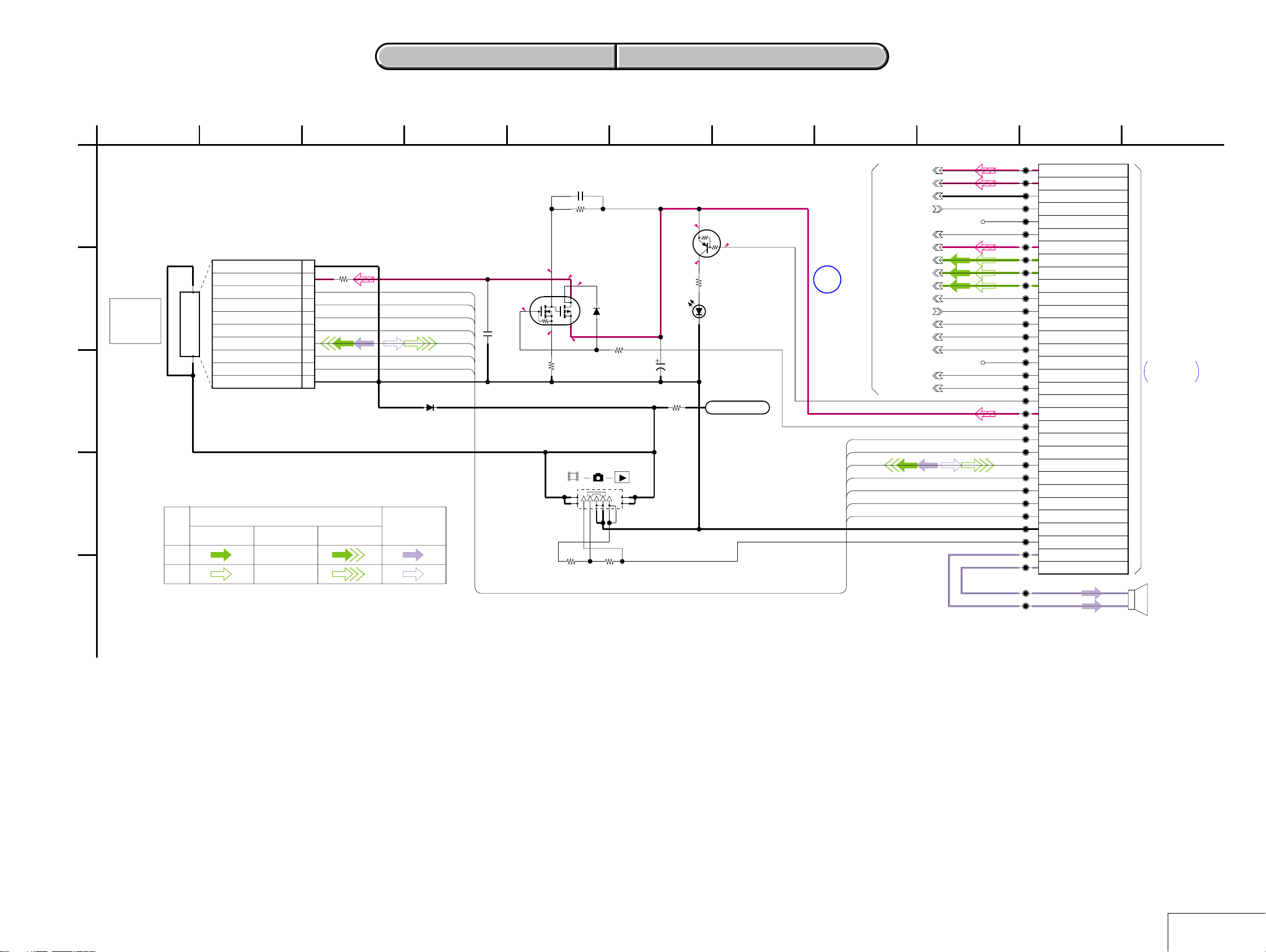

Page 15

For Schematic Diagram

• Refer to page 4-45 for printed wiring board.

4-2. SCHEMATIC DIAGRAMS LD-140 PRINTED WIRING BOARD

4-2. SCHEMATIC DIAGRAMS LD-140 PRINTED WIRING BOARD

DSC-T1

1

LD-140 BOARD

A

LENS DRIVE

XX MARK:NO MOUNT

B

LENS

UNIT

(LSV-850A)

C

D

LENS UNIT is replaced as a block.

So that there PRINTED WIRING BOARD and

SCHEMATIC DIAGRAM are omitted.

:Voltage measurement of

the CSP IC and

the Transistors with

mark,is not possible.

CN002

21P

1Z_RST_GND

2Z_RST_SENS

3Z_RST_VCC

4F_RST_GND

5F_RST_SENS

6F_RST_VCC

7N.C

FOCUS_A

8FOCUS_A

FOCUS_B

9FOCUS_B

FOCUS_A

10FOCUS_A

FOCUS_B

11FOCUS_B

ZOOM_A

12ZOOM_A

ZOOM_A

13ZOOM_A

ZOOM_B

14ZOOM_B

ZOOM_B

15ZOOM_B

16TEMP_OUT

17TEMP_GND

18IRIS_A

19IRIS_A

20IRIS_B

21IRIS_B

IRIS_A

IRIS_A

IRIS_B

IRIS_B

R002

IRIS_A

IRIS_A

IRIS_B

IRIS_B

8107463 11925

CL001

CL002

XZM_RST_SENS

220

220R001

Z_RST_VCC

XFC_RST_SENS

F_RST_VCC

LENS_TEMP

C009

F_RST_VCC

XFC_RST_SENS

LENS_TEMP

Z_RST_VCC

XZM_RST_SENS

HR_EN0

HR_DIR0B

HR_DIR0A

HR_EN2

HR_DIR2B

HR_DIR2A

HR_EN3

HR_DIR3B

HR_DIR3A

C008

XX

22u

10V

HR_DIR3B

CL003

CL004

CL005

CL006

CL007

CL008

CL009

CL010

CL011

CL012

CL013

CL014

CL015

CL016

CL017

CL018

M_5V

M_5V

D_2.8V

REG_GND

REG_GND

REG_GND

F_RST_VCC

XFC_RST_SENS

LENS_TEMP

Z_RST_VCC

XZM_RST_SENS

HR_EN0

HR_DIROB

HR_DIR0A

HR_EN2

HR_DIR2B

HR_DIR2A

HR_EN3

HR_DIR3B

HR_DIR3A

XCAM_DR_PS

TO

SY-95 BOARD

(8/8)

CN701

THROUGH

THE FP-695

FLEXIBLE

(PAGE 4-30)

E4H1H2G3H3G4F4H4H5G5F5H6G6H7G7F6

PS

E

NC

E5H8G8F7F8E6E7E8D8D7D6C8C7B8B7C6

VLIM

VREF

EN7

F

HR_EN2HR_EN2

HR_DIR2A

G

HR_DIR2B

IN7

VM4

OUT7A

RNFS

RNF

OUT7B

VM4

EN3

IN3

EN4

IN4

NC

NC

NC

NC

D5 A8 A7 B6 A6 C5 B5 A5 A4 C4 B4 A3 B3 A2 B2 C3

VM1

DGND

OUT2B

OUT2A

PGND1

IC001

FOCUS/ZOOM MOTOR DRIVE,

IRIS DRIVE

M50237WG-DF0T

CSP(CHIP SIZE PACKAGE)IC

VM2

OUT3A

VCC

PGND2

OUT3B

IC001

PGND2

PGND1

OUT1B

OUT4A

VM2

VM1

OUT1A

OUT4B

PGND1

PGND2

IN2

EN5

H

C001

16

0.1u

EN2

IN5

NC

EN6

NC

NC

IN1

EN1

BR6

PGND3

OUT6B

VM3

OUT6A

PGND3

OUT5B

VM3

OUT5A

PGND3

BR5

IN6

NC

D4 A1 B1 C2 C1 D3 D2 D1 E1 E3 E2 F1 F2 G1 G2 F3

NC

HR_DIR3A

HR_EN3

ZOOM_B

ZOOM_B

ZOOM_A

ZOOM_A

HR_DIR0B

HR_EN0

HR_DIR0A

FOCUS_A

FOCUS_A

FOCUS_B

FOCUS_B

4-35 4-36

LD-140

Page 16

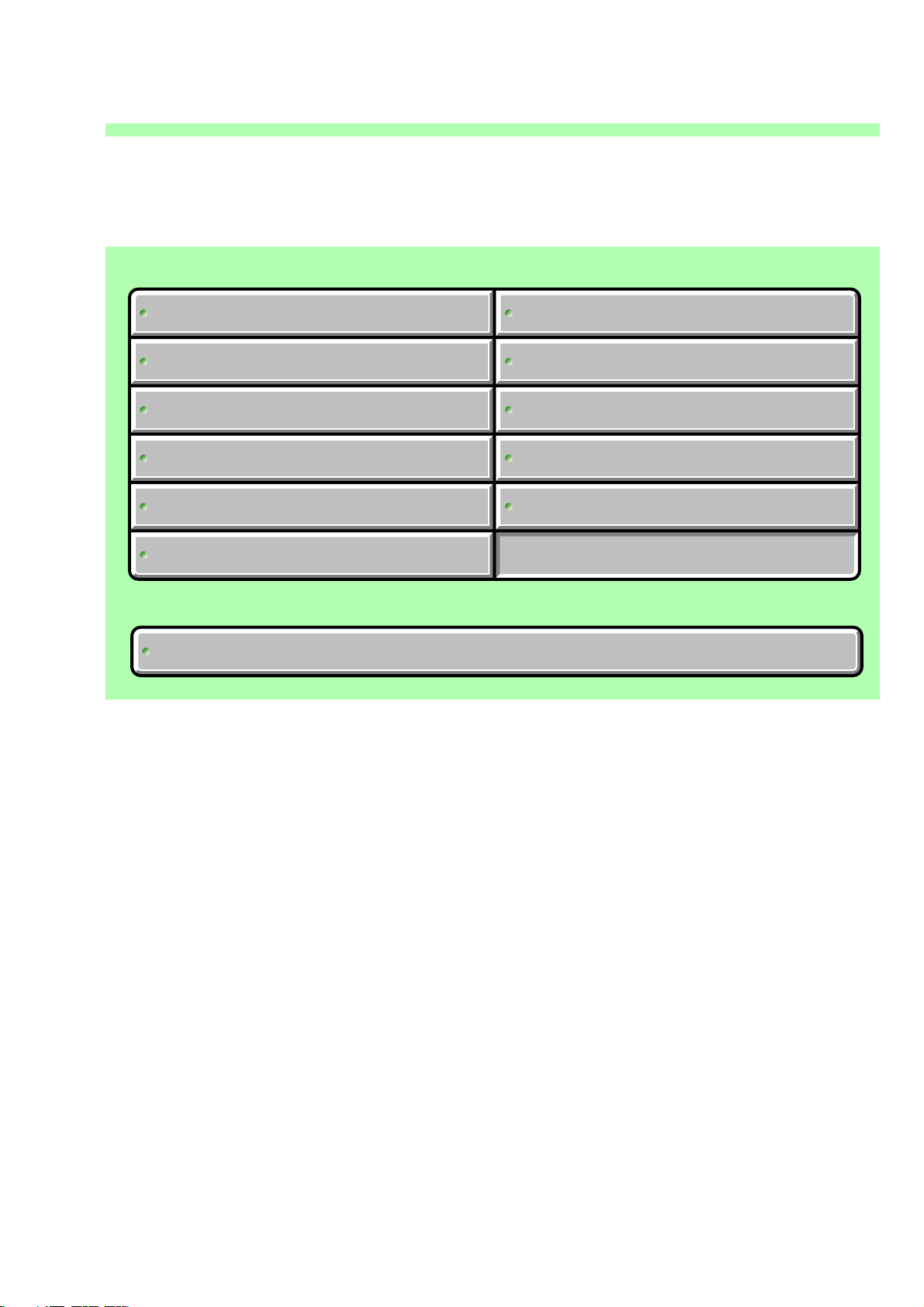

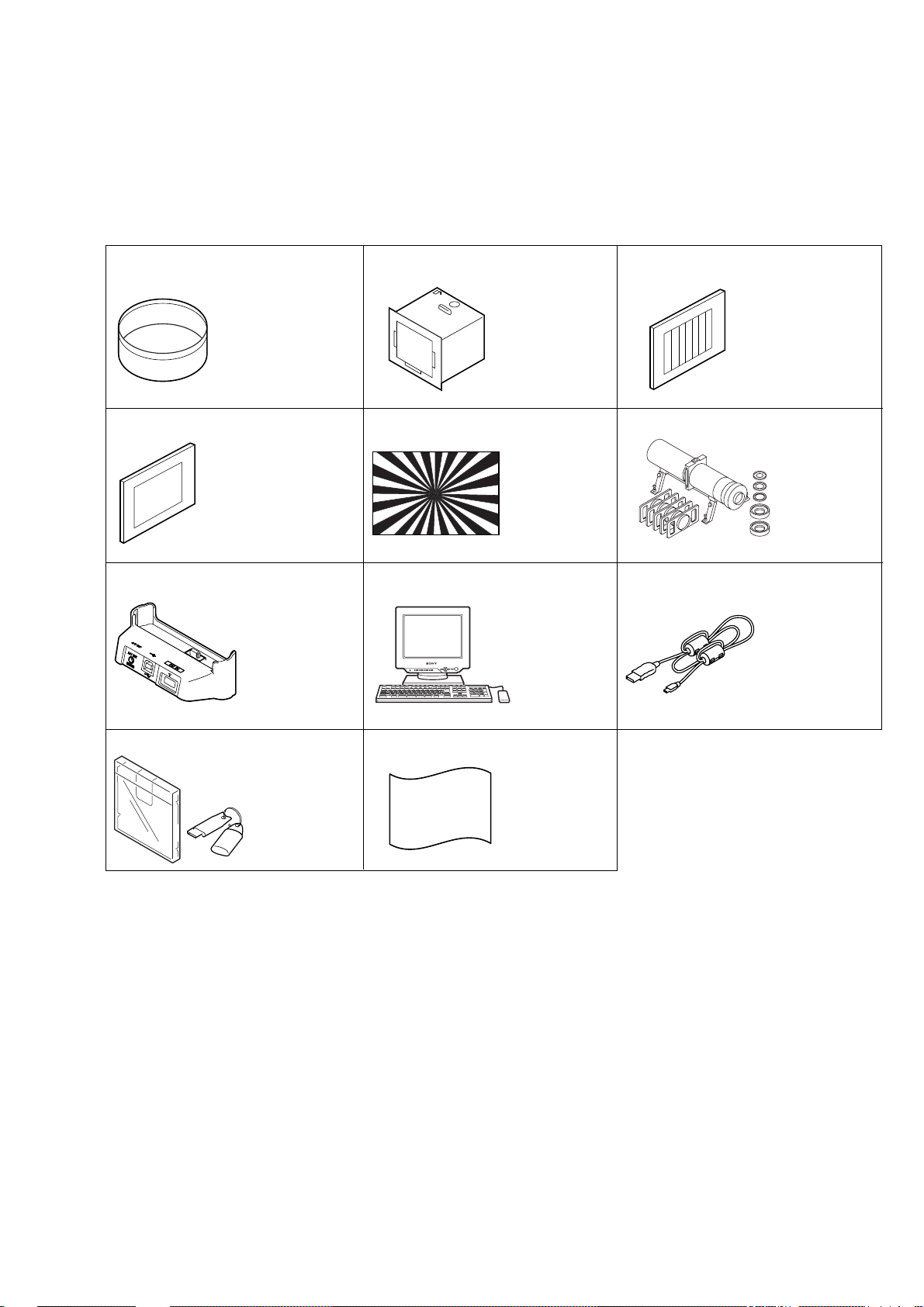

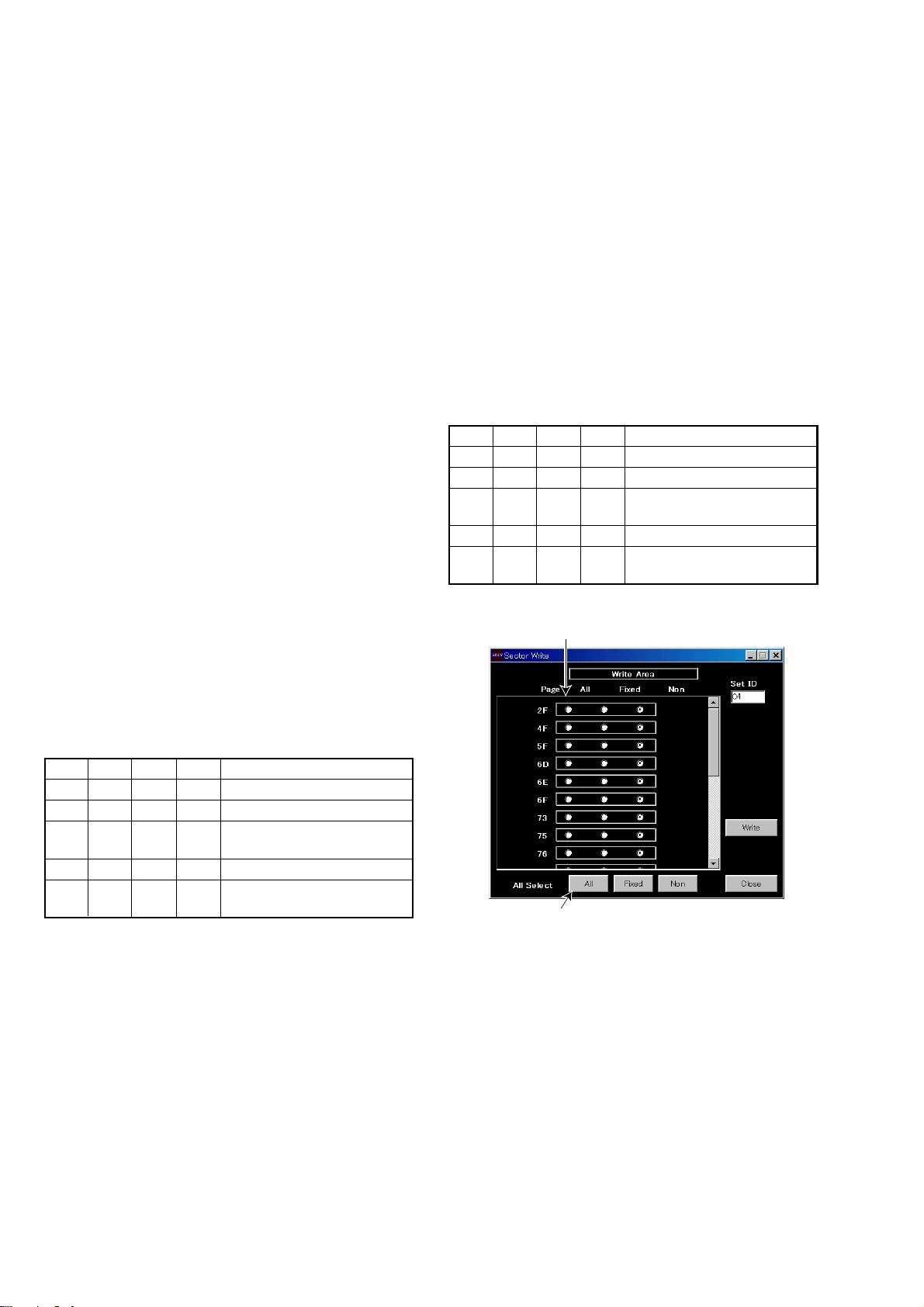

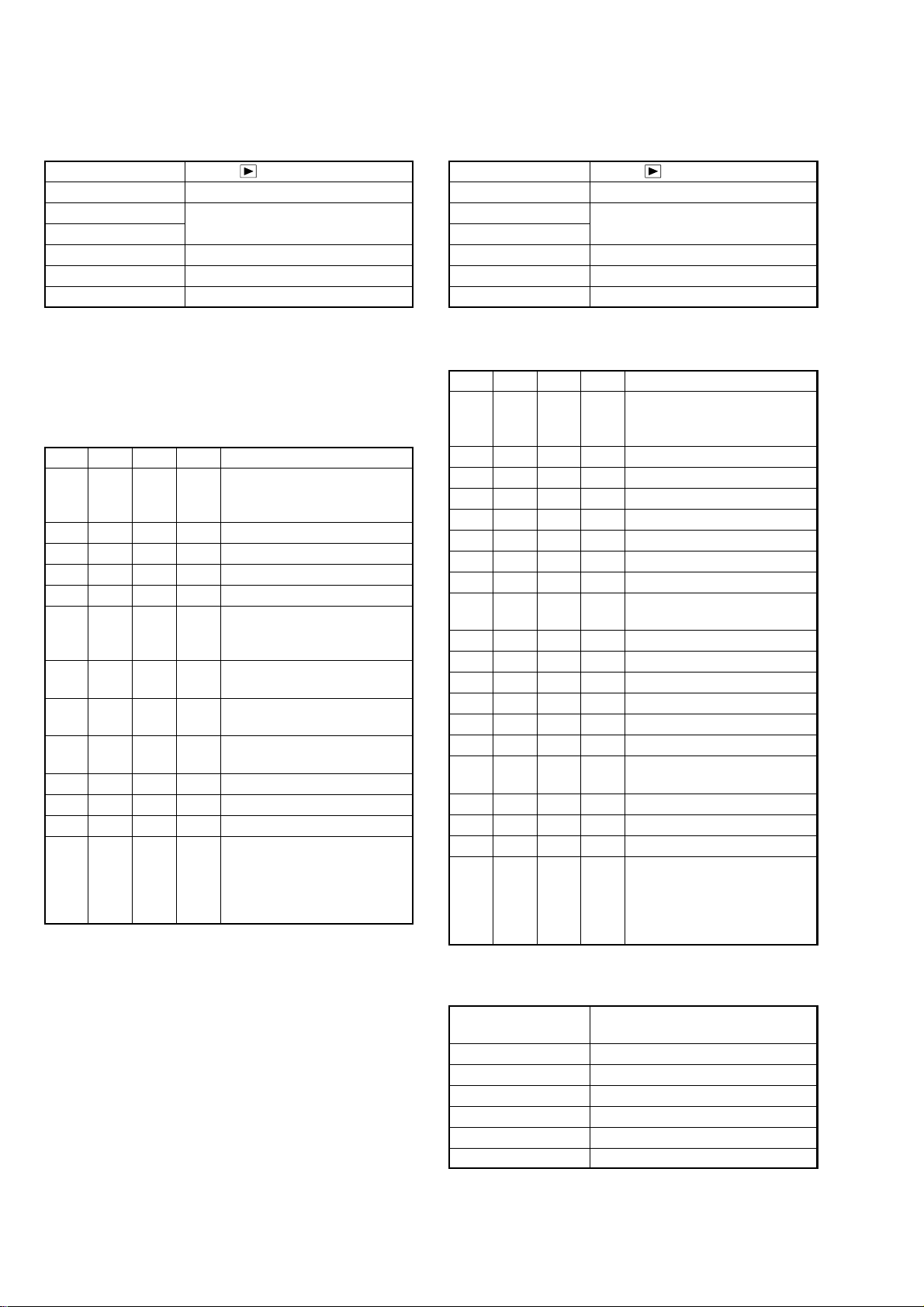

1. Before starting adjustment

EVR Data Re-writing Procedure When Replacing Board

The data that is stored in the repair board, is not necessarily correct.

Perform either procedure 1 or procedure 2 or procedure 3 when replacing board.

Procedure 1

Save the EVR data of the machine in which a board is going to be replaced. Do wnload the saved data after a board

is replaced.

(Machine before starting repair)

SECTION 6

ADJUSTMENTS

PC PC

DSC-T1

(Machine after a board is replaced)

Save the EVR data

to a personal computer.

Download the saved

data to a machine.

Procedure 2

Remove the EEPR OM from the board of the machine that is going to be repaired. Install the removed EEPR OM

to the replaced board.

Remove the EEPROM and install it.

(Former board)

(New board)

Procedure 3

When the data cannot be saved due to defective EEPROM, or when the EEPROM cannot be removed or

installed, save the data from the same model of the same destination, and do wnload it.

(Machine to be repaired) (Machine to be repaired)

PC

Save the data.

(The same model of the same destination)

After the EVR data is saved and downloaded, check the

respective items of the EVR data.

(Refer to page 6-2 for the items to be checked.)

Download the data.

6-1

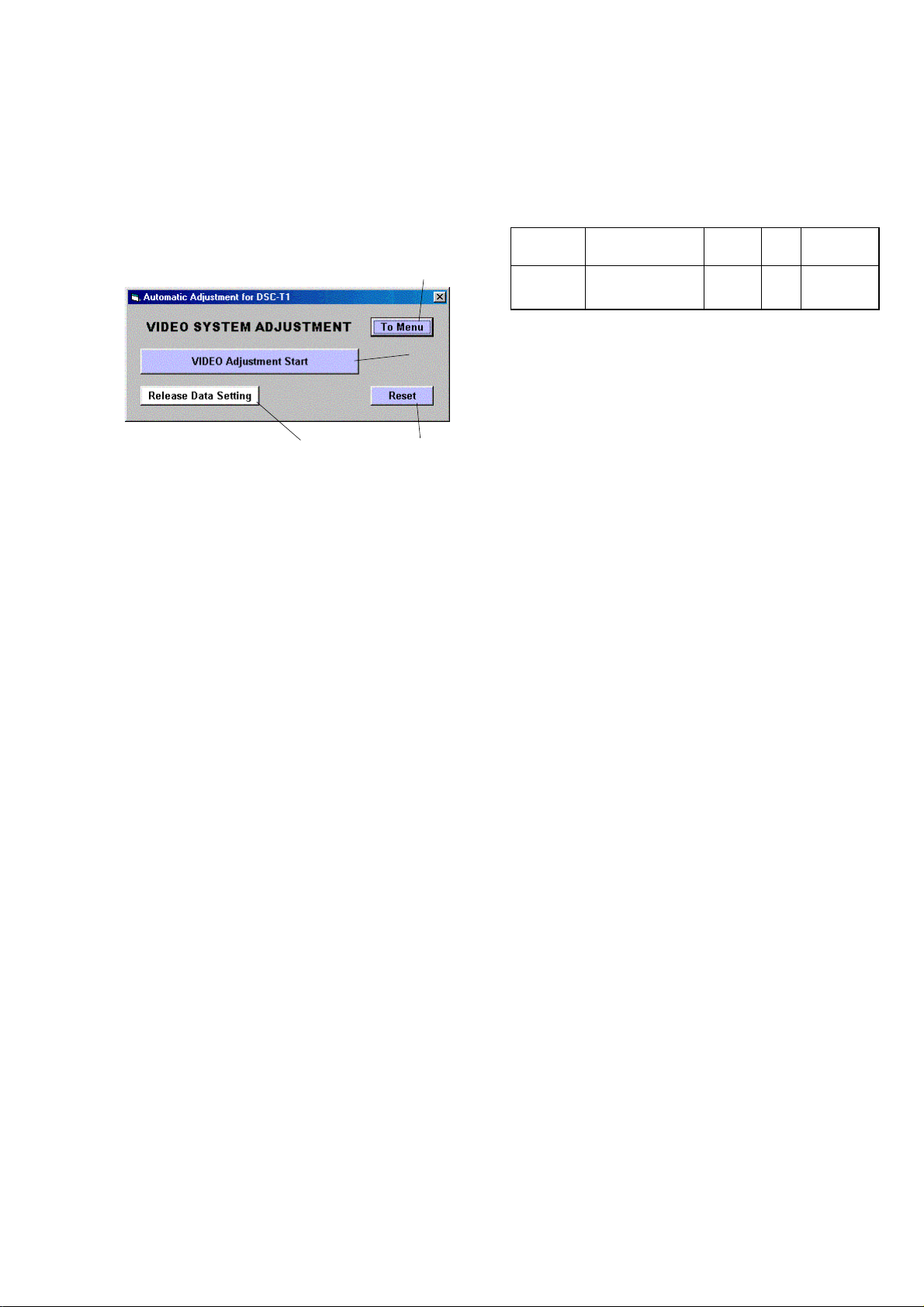

Page 17

DSC-T1

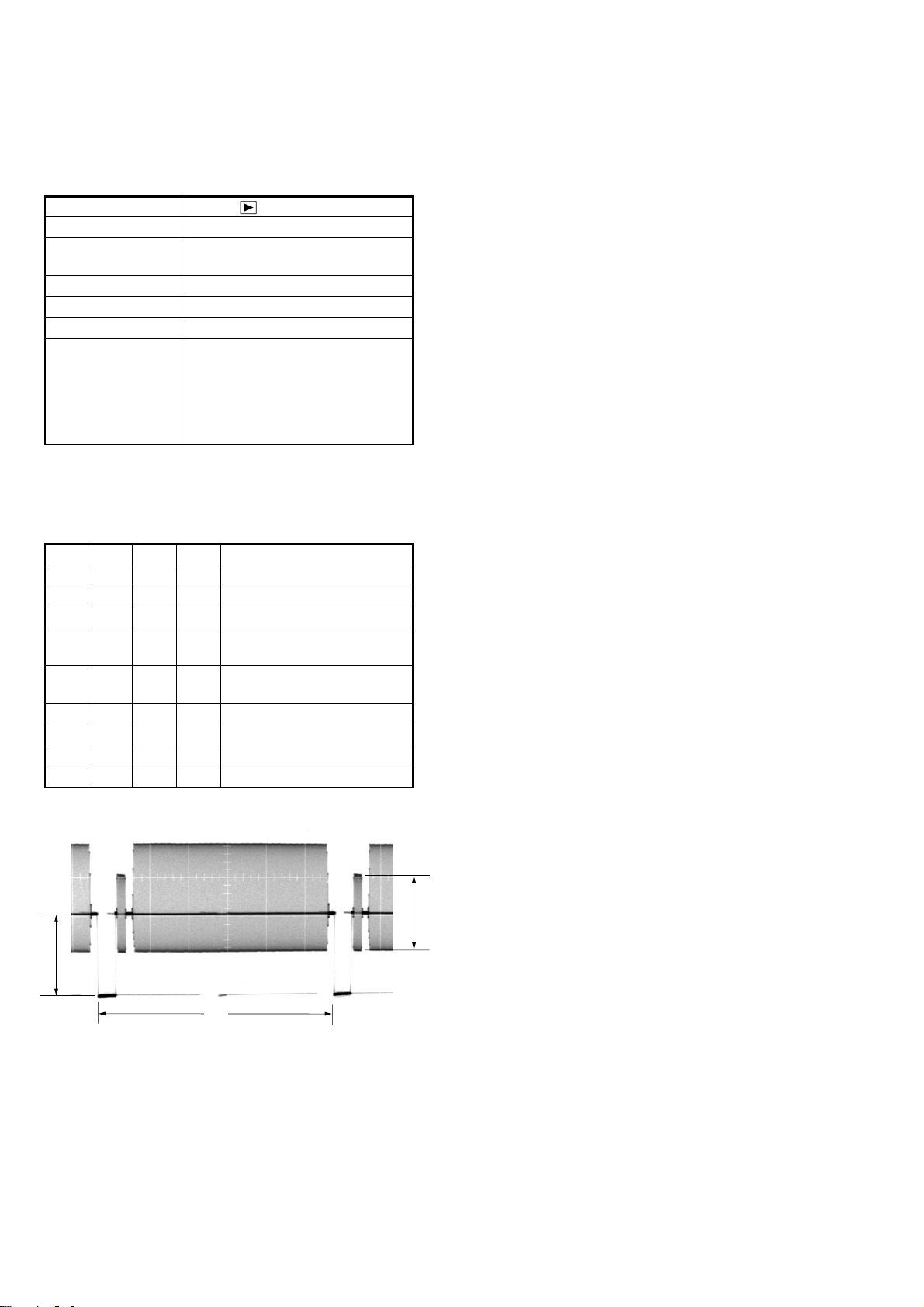

1-1. Adjusting items when replacing main parts and boards.

When replacing main parts and boards, adjust the items indicated by z in the following table.

Replaced parts Board

Block replacement

Parts replacement

replacement

EEPROM

replacement

Adjustment

Section

Initialization of data

Video

Camera

LCD

Adjustment

Initialization of data

Video output level adj.

Wide limit Adj.

Flange back adj.

F No. compensation

Mechanical shutter adj.

Light value adj.