Page 1

DSC-S60/S80/S90/ST80

SERVICE MANUAL

Ver 1.1 2005.07

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Photo: DSC-S90/Silver

Link

Link

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

LEVEL 3

DSC-S60/S90

US Model

Canadian Model

Chinese Model

Tourist Model

DSC-S60/S80/S90/

ST80

AEP Model

UK Model

Hong Kong Model

E Model

DSC-S60/S80/S90

Australian Model

Korea Model

DSC-S90

Argentine Model

REPAIR PARTS LISTSERVICE NOTE

REPAIR PARTS LISTSERVICE NOTE

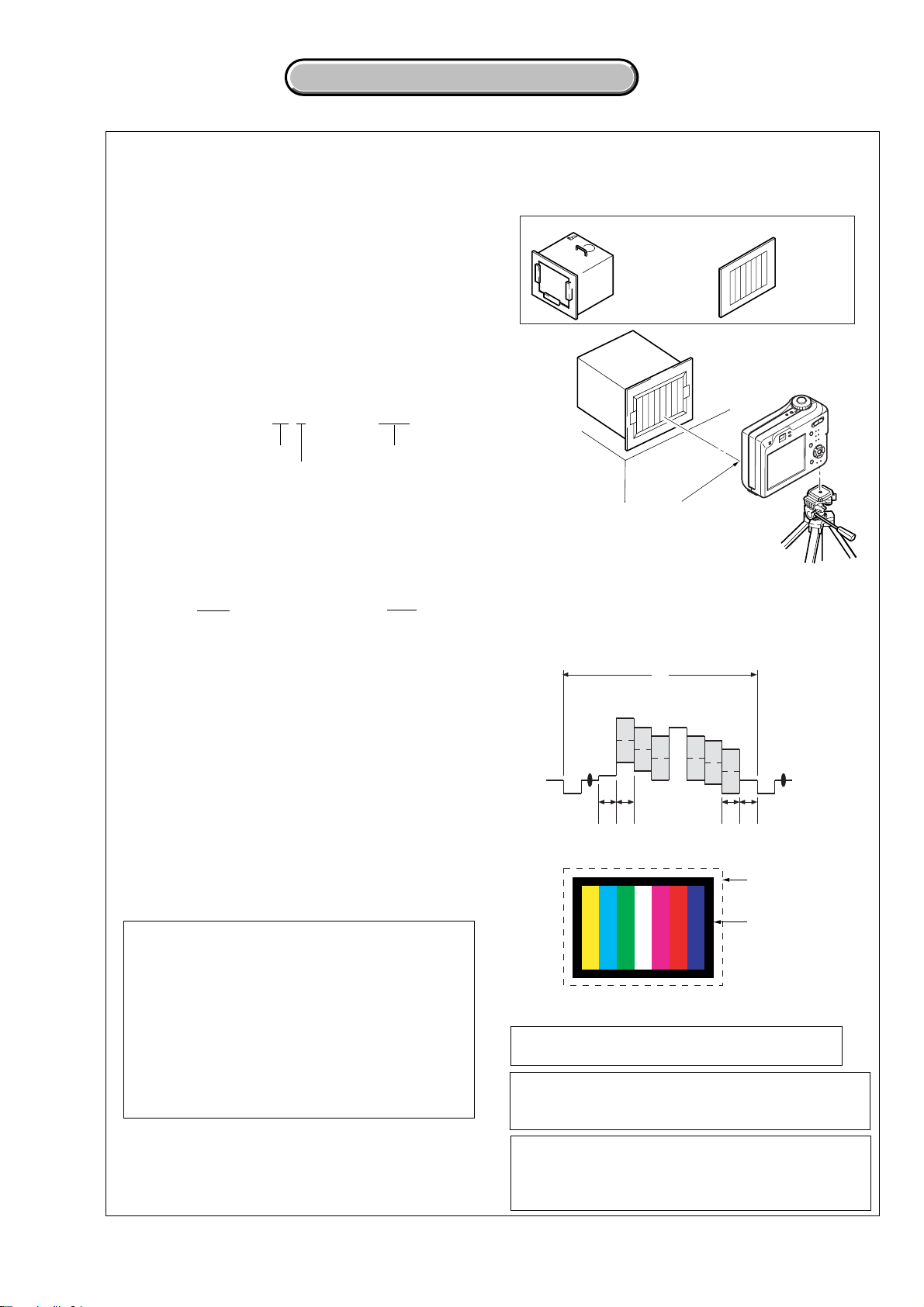

FRAME SCHEMATIC DIAGRAM

FRAME SCHEMATIC DIAGRAM

•For ADJUSTMENTS (SECTION 6), refer to SERVICE MANUAL, ADJ (9-876-869-51).

•For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (9-876-869-41).

• This service manual contains information for Japanese model as well.

• Reference No. search on printed wiring boards is available.

•Method for Copying or Erasing the Data in Internal Memory

The information that is not described in this Service Manual is described

in the LEVEL 2 Service Manual.

When repairing, use this manual together with LEVEL 2 Service Manual.

Contents of LEVEL 2 Service Manual

1. SERVICE NOTE

2. DISASSEMBLY

3. BLOCK DIAGRAMS

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

5. REPAIR PARTS LIST

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

OVERALL

POWER

CD-573, SW-446, ST-122,

MC-153, MS-271

CONTROL SWITCH

BLOCK

EXPLODED VIEWS

ELECTRICAL PARTS LIST

DIGITAL STILL CAMERA

DSC-S60/S80/S90/ST80

Sony EMCS Co.

2005G0500-1

© 2005.7

Published by DI Technical Support Department9-876-869-11

Page 2

TABLE OF CONTENTS

Section Title Page

1. SERVICE NOTE

1-5. Method for Copying or Erasing the Data in Internal

Memory ···········································································1-3

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. Frame Schematic Diagram ··············································4-1

4-2. Schematic Diagrams························································4-5

CH-169 (CCD SIGNAL PROCESS) ······························4-9

SY-126 (1/8) (CAMERA MODULE) ···························4-11

SY-126 (2/8) (CAMERA DSP, CPU) ····························4-13

SY-126 (3/8) (LENS DRIVE) ·······································4-15

SY-126 (4/8) (BURST FLASH, SDRAM)····················4-17

SY-126 (5/8) (AND FLASH) ········································4-19

SY-126 (6/8) (AUDIO)·················································· 4-21

SY-126 (7/8) (DC/DC CONVERTER)·························· 4-23

SY-126 (8/8) (CONNECTOR) ······································ 4-25

4-3. Printed Wiring Boards ···················································4-35

SY-126 ···········································································4-39

CH-169 ··········································································4-39

4-4. Waveforms·····································································4-49

4-5. Mounted Parts Location ················································4-51

5. REPAIR PARTS LIST

5-2. Electrical Parts List ························································· 5-6

DSC-S60/S80/S90/ST80

— 2 —

Page 3

p

1. SERVICE NOTE

1-5. METHOD FOR COPYING OR ERASING THE DATA IN INTERNAL MEMORY

The data can be copied/erased by the operations on the Setup screen. (When erasing the data, execute formatting the internal memory.)

Note: 1 When replacing the SY-126 board, erase the data in internal memory of the board before replacement.

Note: 2 When replacing the SY-126 board or the IC301 on the SY-126 board, execute formatting and initialize the internal memory after

replacement.

Method for Copying the Data in Internal Memory

Copy

Copies all images in the internal memory to a “Memory Stick”.

OK

Cancel

1 Insert a “Memory Stick” having 32 MB or larger capacity.

2 Select [OK] with v on the control button, then pre ss z.

The message “All data in internal memory will be copied Ready?” appears.

3 Select [OK] with v, then press z.

Copying starts.

Copying

102_COPY

See the following procedure.

Cancels the copying.

•Use batteries with enough capacity or the AC Adaptor (not supplied). If you attempt to copy image files

using batteries with little remaining charge, the batteries may run out, causing copying to fail or possibly

corrupting the data.

•You cannot copy individual images.

•The original images in the internal memory are retained even after copying. To delete the contents of the

internal memory, remove the “Memory Stick” after copying, then execute the [Format] command in

Internal Memory Tool.

•You cannot select a folder copied on a “Memory Stick”.

•The setting of (Print order) marks is not copied even when you copy data.

Method for Formatting the Internal Memory

Format

Formats the internal memory.

• Note that formatting irrevocably erases all data in the internal memory, including even protected images.

OK

Cancel

1 Select [OK] with v on the control button, then press z.

The message “All data in internal memory will be erased Ready?” appears.

2 Select [OK] with v, then press z.

The format is com

lete.

See the following procedure.

Cancels the formatting.

DSC-S60/S80/S90/ST80

1-3

Page 4

Ver 1.1 2005.07

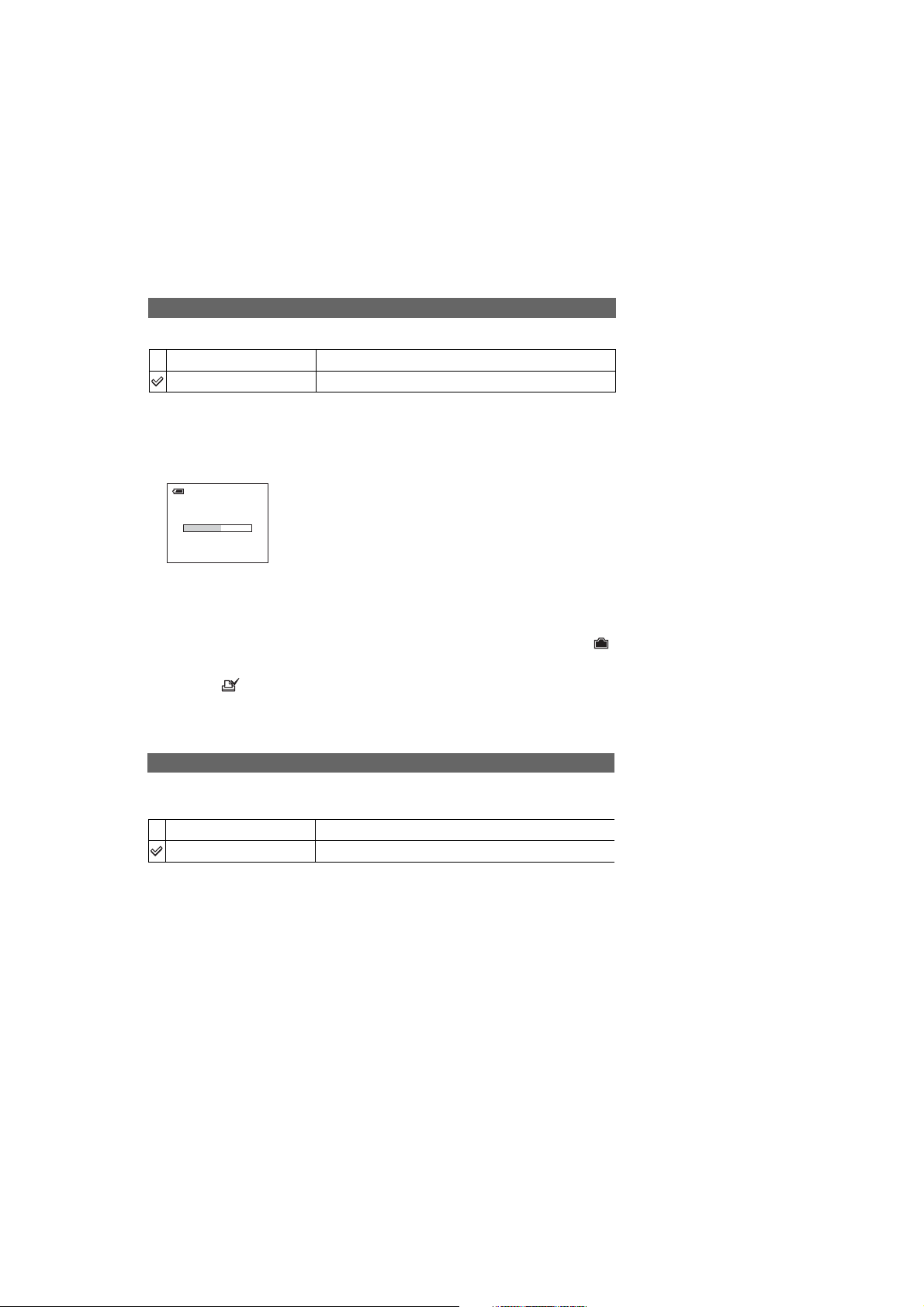

4-1. FRAME SCHEMATIC DIAGRAM

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

SP901

SPEAKER

BT001

LITHIUM

BATTERY

CN002

(MULTI CONNECTOR)

TO AV/USB MULTI CABLE OR CRADLE

18

16

14

12

10

8

6

4

2

A_GND

A_OUT

V_GND

V_OUT

D-

USB_GND

USB_VBUS

X_K.BATT

V_TH

ACV_GND

ACV_GND

NC

ACV_UNREG

MC-153

FLEXIBLE BOARD

(MULTI CONNECTOR)

32P

NC(XLANC_PWR_ON)

05

XAV_JACK_IN

KEY_AD1_C

KEY_AD2_C

XMULTI_IN

XACV_INUSB_GND

CRADLE_OND+

X_CGH_ON

NC(UART_SI)

NC(UART_SO)

XCAM_IN

ACV_GND

NC

V_BATT

BATT_UNREGACV_UNREG

BATT_UNREG

BT901

BATTERY

TERMINAL

CD-573

(CCD IMAGER)

GND

POWER_SAVE

GND

GND

GND

GND

GND

POWER_SAVE

BATT_TMP

X_K.BATT

123456789

X_K.BATT

BATT_TMP

BOARD

VHLD

VHLD

VST

V2

V1

V1

V2

VST

V5B

V3A

V3B

V3A

V3B

GND

CAM_-7.5V_CD

V5A

V4

1011121314151617181920212223242526272829303132333435363738

V6

V4

V5B

V5A

GND

CAM_-7.5V_CD

SY-126 BOARD

(1/8) (CAMERA MODULE)CP401

(2/8) (CAMERA DSP, CPU)

(3/8) (LENS DRIVE)

(4/8) (BURST FLASH, SDRAM)

(5/8) (AND FLASH)

(6/8) (AUDIO)

(7/8) (DC/DC CONVERTER)

(8/8) (CONNECTOR)

33PCN706

XCS

BL_L

KEY_AD1

BL_H

KEY_AD0

33

123456789

33PCN005

BL_L

BL_H

KEY_AD1

39PCN003

VSS

VR2

NC

VCOM KEY_AD0

39

XRESET

XRESET

XRESET

SCLK

SI

REG_GND

SI

XCS

SCLK

REG_GND

VSYNC

SCLK

SI

XCS

LENS

D0

21

FOCUS_B

REG_GND

REG_GND

19

20

F_RST_VCC

F_RST_GND

REG_GND

REG_GND

P_ADJ

P_ADJ

BLOCK

17

18

SHUTTER+

F_RST_SENS

PANEL_15V/NC

PANEL_AD

PANEL_AD

PANEL_15V

VSUB_CONT

VSUB_CONT

REG_GND

GND

GND

VSYNC

SHT

SHT

HSYNC

GND

GND

REG_GND

XAE_LOCK_LED

XSTRB_LED

XSTRB_LED

XAE_LOCK_LED

REG_GND

DCLK

D_3.2V

123456789

39

D_3.2V

REG_GND

REG_GND

D7

27P

CN601

D6

26

27

Z_RST_GND2

Z_RST_SENS2

D4

D5

24

25

FOCUS_A

Z_RST_VCC2

D2

D3

23

FOCUS_B

D1

1011121314151617181920212223242526272829303132

22

FOCUS_A

FP-200 FLEXIBLE

1011121314151617181920212223242526272829303132

VSYNC

HSYNC

REG_GND

REG_GND

REG_GND

D7

D6

D5

D4D0D2

D3

DCLK

REG_GND

REG_GND

D1

SW-446 BOARD

(CONTROL SWITCH, LCD PANEL)

C2-

HSYNC

NC

VDD

VCOMDC

VSH

VBC

D0D1D2D3D4D5D6D7DCLK

C2+NCNCNCVDC

1011121314151617181920212223242526272829303132333435363738

15

16

SHUTTER-

SHUTTER+

REG_GND

REG_GND

VGL

14

SHUTTER-

D_3.2V

D_3.2V

NC

12

13

IRIS_M_-

IRIS_M_+

XACCESS_LED

123456789

33

XACCESS_LED

COMOUT

11

IRIS_S_+

NCNCVVCOM

10

IRIS_S_-

8

9

Z_RST_VCC1

Z_RST_SENS1

NCNCVSS

123456789

6

7

TEMP_OUT

Z_RST_GND1

5

TEMP_GND

6PCN004

BL_H

BL_H

N.C.

N.C.

BL_L

BL_L

1ZOOM_B

2ZOOM_A

3

ZOOM_B4ZOOM_A

6

5

4

3

2

1

D901

BACKLIGHT

H2A

REG_GND

REG_GND

GND

GND

REG_GND

REG_GND

H1B

H1B

REG_GND

REG_GND

CCD

RG

GND

GND

H1A

1011121314151617181920212223242526272829303132333435363738

RG

H1A

GND

GND

MS_CLK

XMS_IN

MS_D2

MS_D3

FP-199

FLEXIBLE

10111213141516

MS_D3

MS_D2

XMS_IN

MS_CLK

GND

CAM_15.0V_CD

GND

CAM_15.0V_CD

GND

FP-201 FLEXIBLE

GND

GND

GND

CAM_15.0V_CD

CAM_15.0V_CD

REG_GND

MS_D0

MS_D1

MS_BS

REG_GND

10111213141516

MS_D1

MS_D0

MS_BS

REG_GND

REG_GND

CCD_OUT

CCD_OUT

REG_GND

REG_GND

MS-271

BOARD

3132

2930

2728

2526

2324

2122

1920

17

15

13

11

9

7

5

3

1

45P

CN701

1

VL_3V

XAV_JACK_IN

2

A_GND

3

4

AU_OUT

V_GND

5

V_OUT

6

XACV_IN

7

XMULTI_IN

8

KEY_AD2_C

9

10

KEY_AD1_C

USB_GND

11

12

D+

NC

13

14

D-

15

USB_GND

USB_VBUS

16

X_K.BATT

17

V_TH

18

ACV_GND

19

20

ACV_GND

ACV_GND

21

ACV_GND

22

ACV_GND

23

ACV_GND

24

ACV_GND

25

ACV_GND

26

ACV_GND

27

ACV_UNREG

28

ACV_UNREG

29

ACV_UNREG

30

ACV_UNREG

31

ACV_UNREG

32

ACV_UNREG

33

ACV_UNREG

34

BATT_UNREG

35

BATT_UNREG

36

BATT_UNREG

37

BATT_UNREG

38

BATT_UNREG

39

V_BATT

40

NC

41

SP+

42

X_CGH_ON

43

SP-

44

CRADLE_ON

45

MIC901

CN703

2P

2MIC_SIG

MIC

1MIC_GND

CN001

4P

1

BATT_GND

2

BATT_GND

3

BATT_UNREG

4

BATT_UNREG

ST-122

FLEXIBLE

BOARD

(FLASH DRIVE)

14P

ST_5V

D_3.2V

XAF_LED

CN704

10PCN702

1011121314

ST_GND

ST_GND

ST_GND

STRB_ON

STRB_CHG

XSTRB_FULL

STRB_CHG_CONT

A_3.2V

XAE_LOCK_SW

XSHTR_SW

MODE_DIAL1

123456789

MODE_DIAL0

REG_GND

N.C.

CONTROL

SWITCH

BLOCK

ST_GND

XPWR_ON

ST_UNREG

ST_UNREG

A_3.2V

123456789

ST_UNREG

XPWR_LED

10

39PCN001

H2B

GNDV6H2A

GND

39

123456789

39P

H2B

GND

GND

CN401

CH-169

BOARD

CCD SIGNAL

PROCESS

16P

MS_VCC

CN705

123456789

16PCN004

MS_VCC

MEMORY STICK

CONNECTOR

CN002

10P

1VSS

2BS

11

12

3DATA1

4 SDIO/DATA0

5DATA2

6INT

7DATA3

8SCLK

9VCC

10 VSS

MEMORY STICK

MEMORY

STICK

LCD901

COLOR LCD PANEL

DSC-S60/S80/S90/ST80

:S60/S80/ST80

2.0 INCH

:S90

2.5 INCH

4-1 4-2

FRAME

Page 5

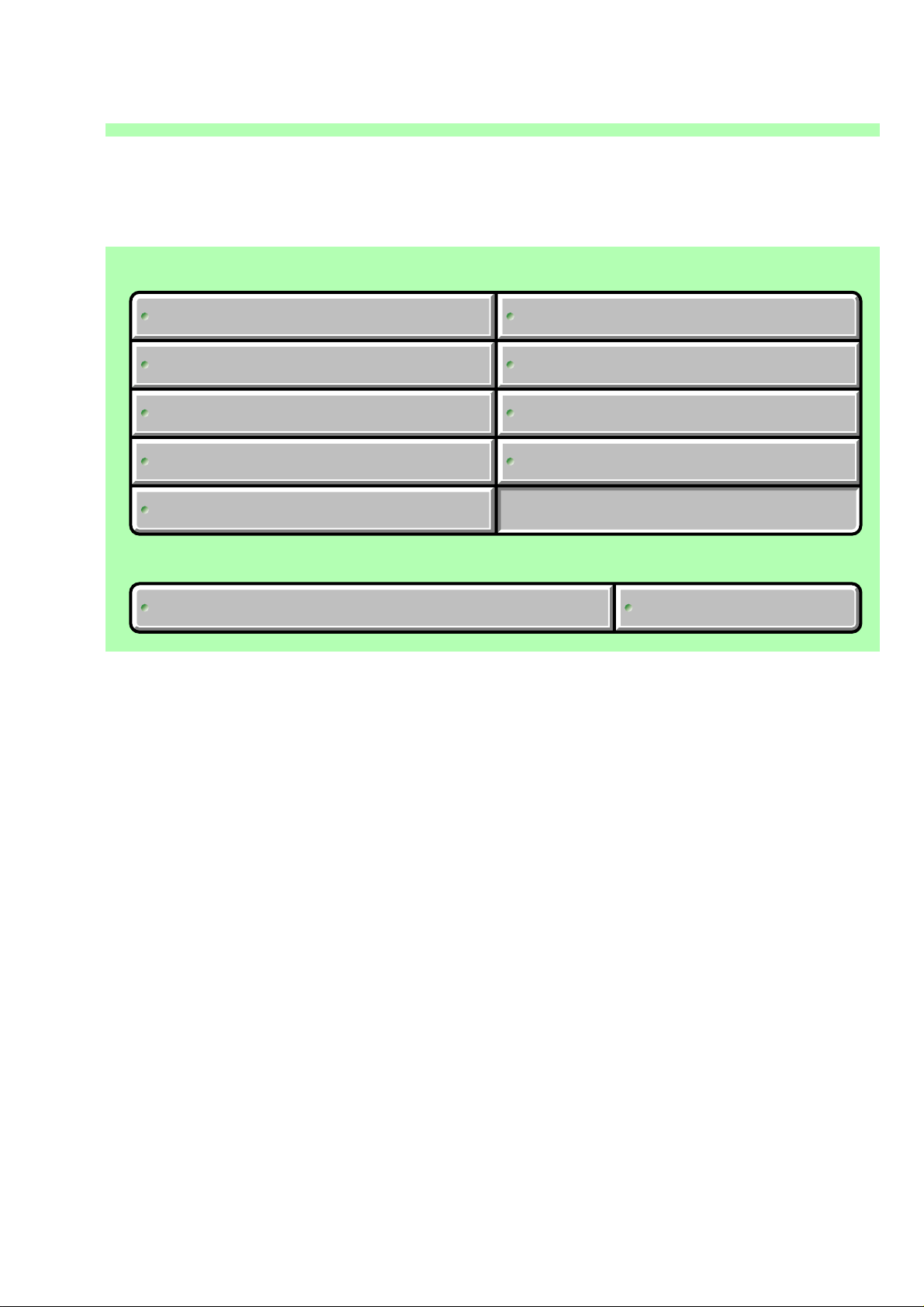

Link

Link

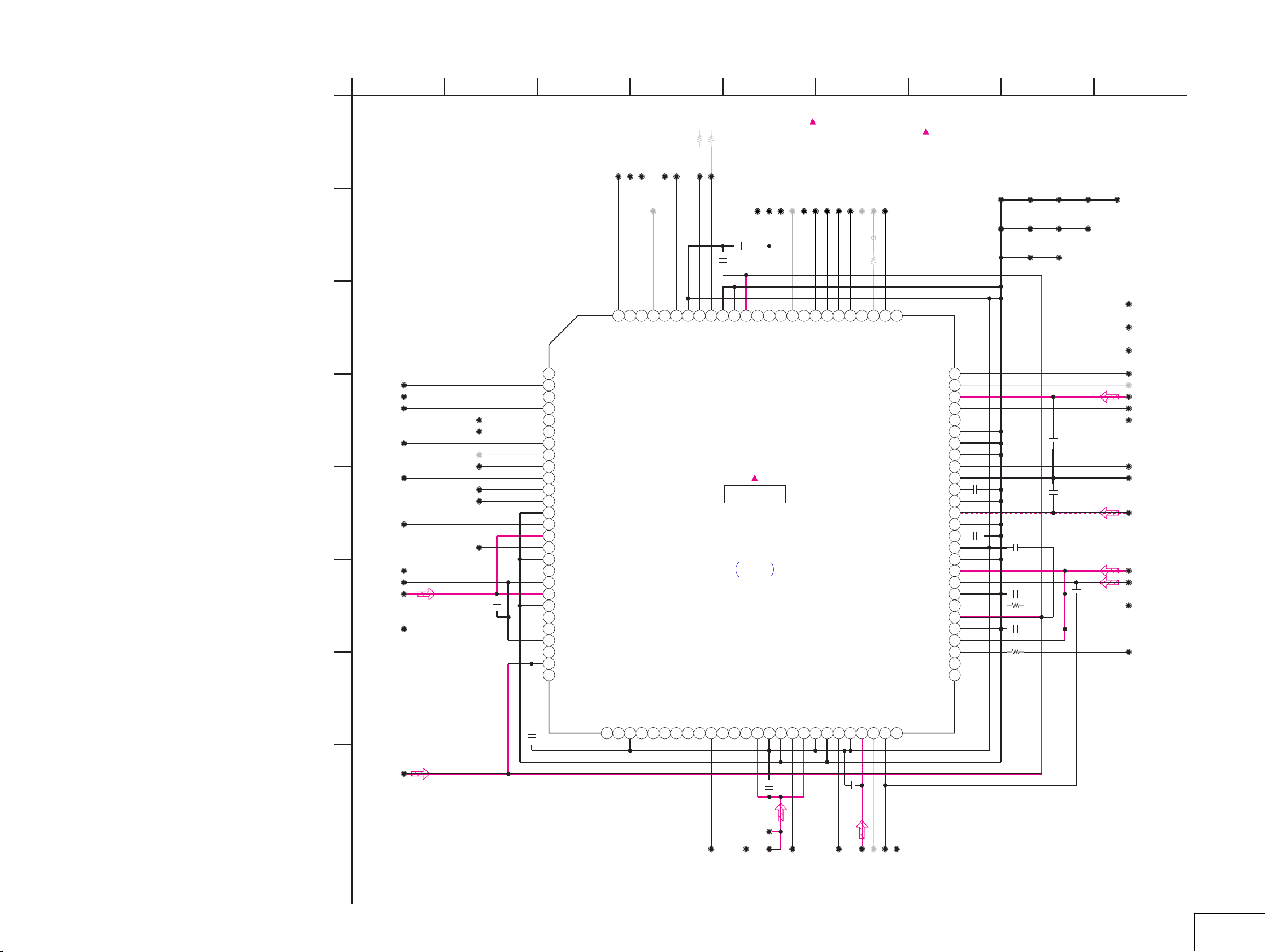

4-2. SCHEMATIC DIAGRAMS

CH-169 BOARD (CCD SIGNAL PROCESS)

CH-169 BOARD (CCD SIGNAL PROCESS)

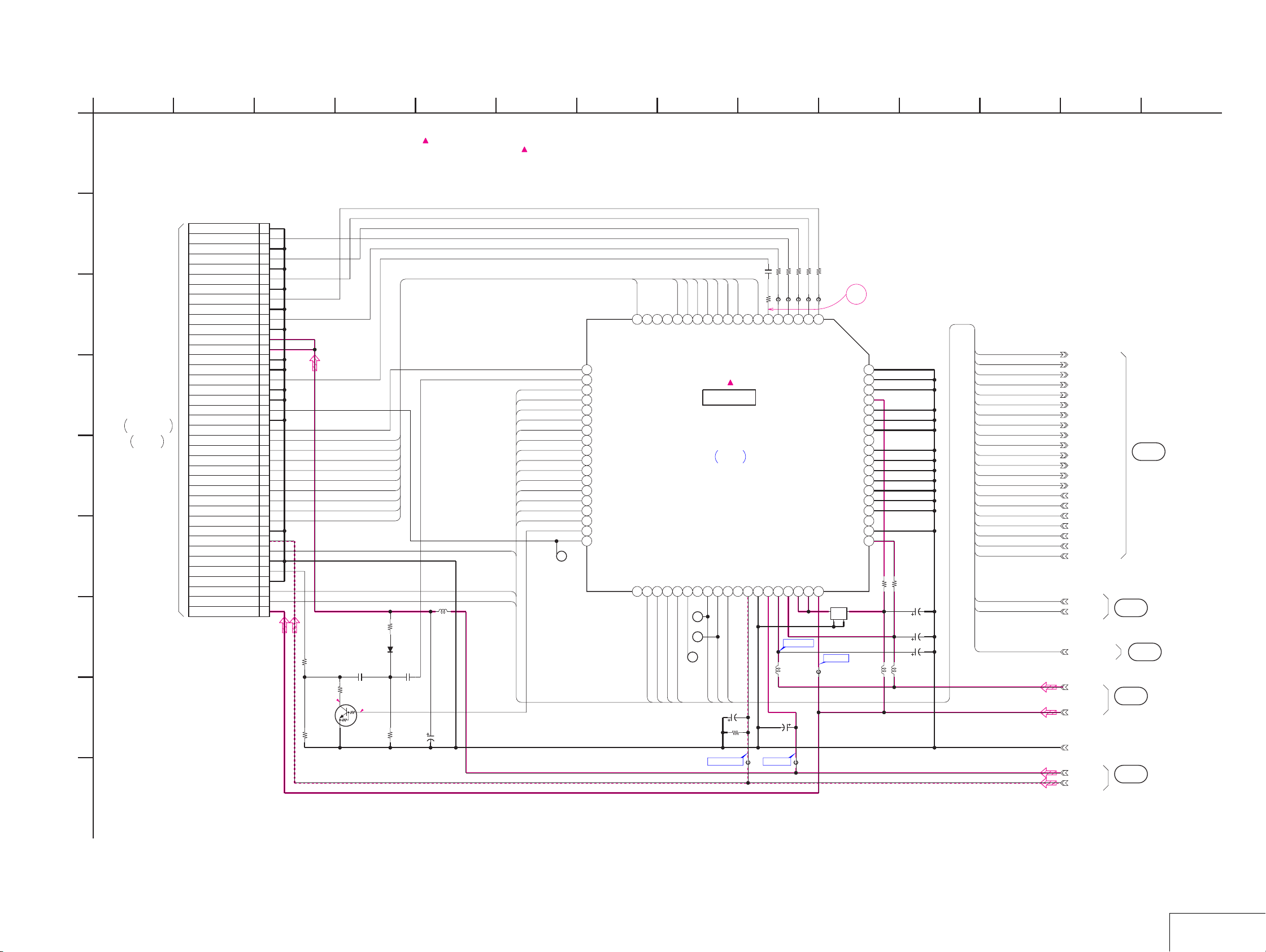

SY-126 (1/8) (CAMERA MODULE)

SY-126 (1/8) (CAMERA MODULE)

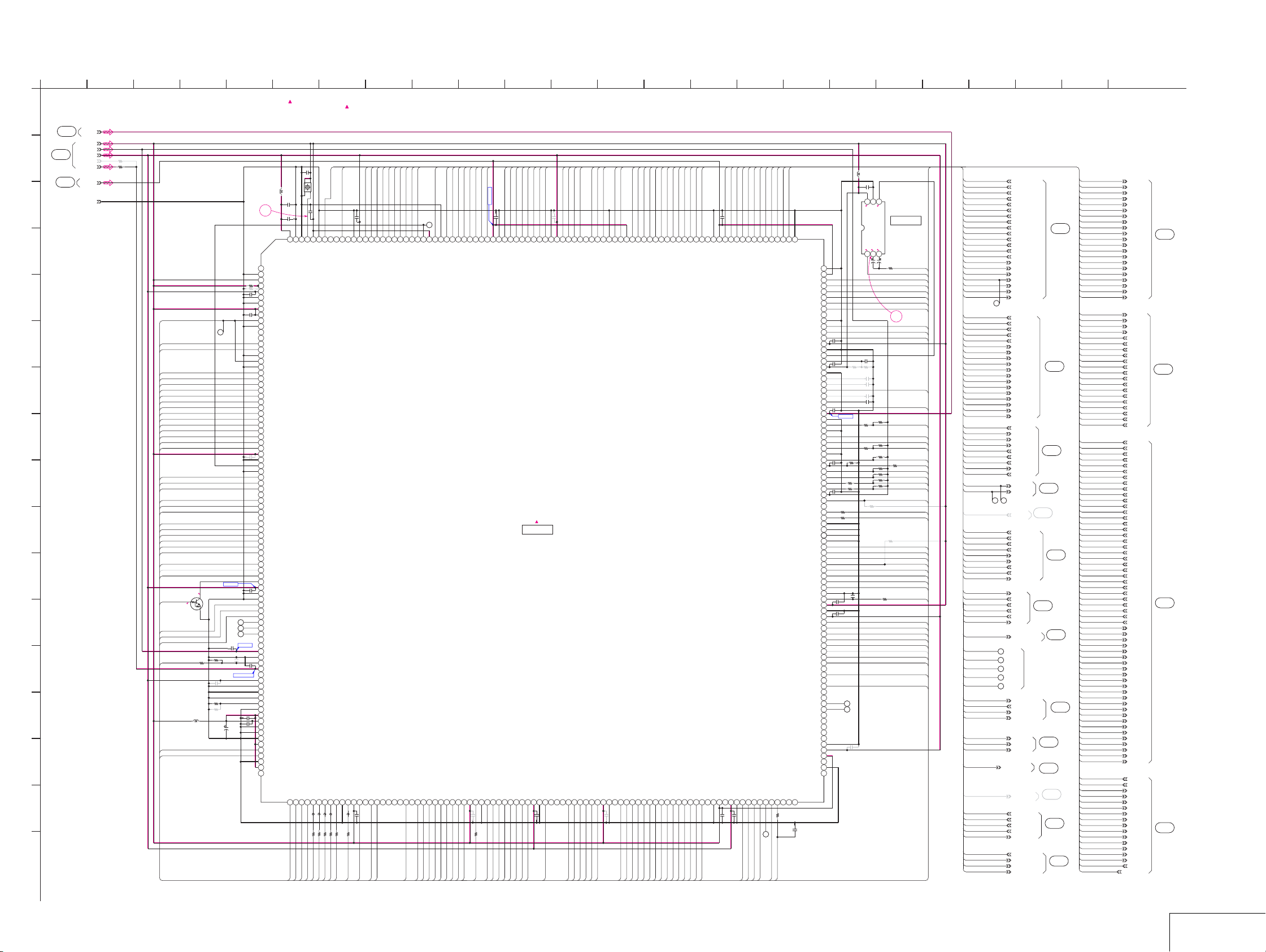

SY-126 (2/8) (CAMERA DSP, CPU)

SY-126 (2/8) (CAMERA DSP, CPU)

SY-126 (3/8) (LENS DRIVE)

SY-126 (3/8) (LENS DRIVE)

SY-126 (4/8) (BURST FLASH,SDRAM)

SY-126 (4/8) (BURST FLASH,SDRAM)

SY-126 (5/8) (AND FLASH)

SY-126 (5/8) (AND FLASH)

SY-126 (6/8) (AUDIO)

SY-126 (6/8) (AUDIO)

SY-126 (7/8) (DC/DC CONVERTER)

SY-126 (7/8) (DC/DC CONVERTER)

SY-126 (8/8) (CONNECTOR)

SY-126 (8/8) (CONNECTOR)

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

DSC-S60/S80/S90/ST80

Page 6

4-2. SCHEMATIC DIAGRAMS

Front of the lens

L = About 29 cm(PTB-450)

L = About 12 cm(PTB-1450)

L

Pattern box

Pattern box

Color bar chart

Pattern box PTB-450

J-6082-200-A

or

Small pattern box

PTB-1450

J-6082-557-A

For PTB-450:

J-6020-250-A

For PTB-1450:

J-6082-559-A

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

µF. 50 V or less are not indicated except for electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

External dimensions (mm)

Case size

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

•Parts with ★ differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT→ EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C: panel designation

• A: B+ Line

• B : B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C: adjustment for repair.

• A: not use circuit

• Circled numbers refer to waveforms.

(Measuring conditions voltage and waveform)

•Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference values

and reference waveforms.

(VOM of DC 10 MΩ input impedance is used)

•Voltage values change depending upon input

impedance of VOM used.)

Precautions for Replacement of CCD Imager

• The CD-573 board mounted as a repair part is not equipped

with a CCD imager.

When replacing this board, remove the CCD imager from

the old one and mount it onto the new one.

• If the CCD imager has been replaced, carry out all the

adjustments for the camera section.

• As the CCD imager may be damaged by static electricity

from its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with

dusts nor exposed to strong light.

1. Connection

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Fig.b (Picture on monitor TV)

Red

Blue

Electronic beam

scanning frame

CRT picture frame

When indicating parts by reference number, please

include the board name.

The components identified by mark 0 or dotted line with

mark 0 are critical for safety.

Replace only with part number specified.

DSC-S60/S80/S90/ST80

Les composants identifiés par une marque 0 sont

critiques pour la sécurité.

Ne les remplacer que par une pièce portant le numéro

spécifie.

4-5

Page 7

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

2

3

547

6

8

9

: Voltage measurment of the CSP ICs

CH-169 BOARD

A

CCD SIGNAL PROCESS

XX MARK:NO MOUNT

CL028

D6

CL027

D5

D4

CL026

CL025

R010

XX

D2

D3

CL024

CL023

D1

CL022

R011

D0

XX

Note:CH-169 board (CP401) is

included in SY-126

complete board.

B

C

1

CL030

D8

CL029

D7

CL031

D9

D

CL032

D10

CL033

D11 VM

E

DRVSS

DRV3V

D12

D13

CL034

CL035

CL074

CL056

F

CL043

VSUB

V5A

V5B

V1B

V3B

V1A

V3A

CL013

CL014

CL008

CL011

CL007

CL010

V2

CL009

C012

0.1u

NC

2

D8

3

D7

4

D9

5

V5A

6

V5B

D10

7

8

V1B

9

V3B

D11

10

V1A

11

V3A

12

ADVSS

13

D12

14

DRVDD

15

V2

16

ADVSS

17

D13

18

DRVSS

19

DRVDD

20

ADVSS

21

NC

22

VSUB

23

DRVSS

24

NC

25

DVDD2

26

NC

27

D6

V7A

CL016

C020

0.01u

C009

0.1u

V7A

100D2101D3102

DVSS1

95

96

97D098D199

ADVSS

ADVSS

103D4104D5105

94

CL041

93

DVDD1

XCAM_RESET

XCAM_SCK

CL042

RST

SCK

CL012

91V492

IC101

CCD SIGNAL PROCESSOR,

TIMING GENERATOR

IC101

AD80080ABBCZRL

SY-126

(1/8)

CP401

PAGE 4-11

of LEVEL3

Note: The number from CL001 to CL074 on CH-169 board

corresponds to the pin number of CP401 on SY-126 board.

Note: IC101 is not supplied, but this is

included in CH-169 complete board.

and the Transistors with mark, are

not possible.

CL036

SYNC

SYNC

CL039

86SL87

SL

CL037

85

MSHUT

MSHUT

CL038

84

STROB

CL048

R008 XX

83

STROB

V4

CL017

90

V7B

V7B

XCAM_SSI

CL040

SDATA

V6

CL015

88V689

MCK

DCLK

CL021

XX

FB001

82

SUSCK

81

SUSCK

CL060CL061CL062CL063CL064

GND

CL065CL066CL068

GND

C015

0.01u

C018

0.1u

C034

0.1u

GND

CL070

CL044

CL059

CL046

CL018

CL051

CL045

CL019

CL020

CL050

CL049

CL053

CL057

CL006

CL047

GND

NC

NC

CA_VR

V8

CAM_15V

CA_HR

V9

V10

CAM_-7.5V

FE3V

TCVDD

CCD_IN

TG_CKI

CL069

CL072CL073

NC

VD

80

V8

79

VH

78

HD

77

76

V9

REFB

REFT

CCDIN

75

74

73

V10

72

VM

71

70

69

VL

68

67

66

65

64

63

62

61

60

59

58

57

56

CLI

NC

55

NC

54

C008

0.1u

C007

0.1u

C010

0.1u

0.1uC005

0

R007

C011 0.1u

R009

0

AVDSS

AVDSS

ADVSS

AVDSS

ADVSS

VDVSS

ADVSS

ADVDD

TCVDD

AVDSS

VDVDD

ADVSS

ADVDD

DSC-S60/S80/S90/ST80

4-9

G

NC29NC30DVDSS231NC32NC33NC34NC35NC36NC37H138NC39NC40H241HVDD42HVSS43ADVSS44H345HVDD46HVSS47ADVSS48H449RGVSS50RGVDD51HL52TCVSS53RG

C013

0.1u

CL052

TG3V

H

05

28

C025

CL001

C024

0.1u

CL055

CL054

HVDD

CL003

H1

H2

H3

CL002

CL004

0.1u

CL058

CL067

RGVDD

CL005

HL

RG

TCVSS

4-10

CH-169

CL071

H4

Page 8

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

SY-126 BOARD (1/8)

A

CAMERA MODULE (CH BLOCK)

4

53

: Voltage measurment of the CSP ICs

and the Transistors with mark, are

not possible.

6122

8

914117

10

13

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

CN401

39P

1

CAM_15.0V_CD

CAM_15.0V_CD

CCD_OUT

POWER_SAVE

CAM_-7.5V_CD

VSUB_CONT

XSTRB_LED

XAE_LOCK_LED

D_3.2V

VHLD

GND

2

H2B

3

GND

4

H2A

5

GND

6

H1B

7

GND

8

H1A

9

GND

RG

10

11

GND

12

13

14

GND

15

GND

16

17

GND

18

GND

19

20

GND

21

22

VST

V1

23

V2

24

V3A

25

V3B

26

V4

27

V5A

28

V5B

29

V6

30

GND

31

32

33

GND

34

SHT

35

GND

36

37

38

39

MA2S111-(K8).SO

R401

4.7

R403

180k

R0/P1.2

R402

1M

Q401

UN9213J-(K8).SO

SWITCH

D401

C401

0.1u

50V

R2.9

/P0

R421

VST

V1

V2

V3A

V3B

V4

V5A

V5B

V6

VSUB_CONT_PRE

XSTRB_LED

XAE_LOCK_LED

L401

C402

100uH

1u

35V

C403

3.3u

35V

10

R404

100k

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

LND401

V10(VHLD)

20

SUSCK(SUB)

21

D0

22

D1

23

D2

24

D3

25

D4

26

D5

27

D6

28

D7

29

D8

30

D9

31

D10

32

D11

33

D12

34

D13

35

SYNC(ID)

36

MSHUT(WEN)

37

VST

18V819

V7A17V7B

(VST)V9

Note: CP401(CH-169 board) is included in

SY-126 complete board.

STROB(XFE_CS)

SL(XTG_CS)40XCAM_SSI41XCAM_SCK42XCAM_RESET43VSUB(CLPOB)44NC(CLPDM)45CA_HR46CA_VR47TG_CKI48MCK49CAM_-7.5V50VM51CAM_15V52TG3V53FE3V54HVDD55HVDD56DRV3V

38

39

FE_SEN

SSI/SDATA

SCK/SCKL

V4

V6

V5A

V5B

12V413

15V616

V5A14V5B

CP401

CAMERA MODULE

(CH-169 BOARD)

Note: The pin number of CP401 on SY-126

board corresponds to the number from

CL001 to CL074 on CH-169 board.

LND403

LND404

LND402

RST/RESET

HD/HR

C404

22u

16V

R420

100k

V3B

V3A

V3A11V3B

CP401

CH-169

PAGE 4-9

of LEVEL3

CKI

VD/VR/SDL

C405

V2

9V210

27

R408

0.1u

16V

V1

0

FB408

R407

4

5RG6

7

V1A8V1B

CCD_IN

CAM_2.9V

L402

10uH

CAM_15VCAM_-7.5V

0uH

FB401

6.8

R410

FB407

3

(H2B)H4

6.8

R412

FB406

2

(H2A)H2

C406

3.3u

35V

FB402

0uH

6.8

R414

FB405

1

(H1B)H3

(H1A)H1

6.8

R416

FB404

DRVSS

GND

GND

RGVDD

GND

GND

GND

(GND)HL

GND

GND

GND

GND

GND

GND

GND

(DLLSL)NC

(AVSA)TCVSS

(AVDA)TCVDD

FL401

12

34

D_3.2V

FB403

0uH

1

L403

10uH

CA_AD00

CA_AD01

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

0

0

R419

R418

C408

22u

6.3V

C409

22u

6.3V

C410

22u

6.3V

L404

10uH

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

HD/HR

VD/VR/SDL

CKI

VSUB_CONT_PRE

FE_SEN

XSTRB_LED

XAE_LOCK_LED

SSI/SDATA

SCK/SCKL

RST/RESET

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

CA_HD

CA_FD

CLKTGO

VSUB_CONT_PRE

XCS_FE

XSTRB_LED

XAE_LOCK_LED

SAN1_SO

XSAN1_SCK

XSAN_RST_OUT

CAM_2.9V

@02

@01

(2/8)

@03

(2/8)

(4/8)

(6/8)

(8/8)

(2/8)

(4/8)

(5/8)

(8/8)

@04

D_3.2V

REG_GND

CAM_15V

CAM_-7.5V

(7/8)

@05

(7/8)

B

C

D

CD-573

CN001

THROUGH THE

FP-201 FLEXIBLE

PAGE 4-7

of LEVEL2

E

F

G

H

I

05

DSC-S60/S80/S90/ST80

4-11

4-12

SY-126 (1/8)

Page 9

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

SY-126 BOARD (2/8)

A

CAMERA DSP, CPU

AU_3.2V

@06

(6/8)

D_3.2V

A_3.2V

D_1.2V

@07

B

C

(7/8)

@08

EVER_3.1V

EVER_2.8V

SD_3.2V

(4/8)

REG_GND

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

DSP_DQ16

E10

DQ16

D11

CPU_D11

DSP_DQ18

DSP_DQ17

D10

A10

DQ17

D10

AE11D9AB12D8AC11

CPU_D10

CPU_D09

DSP_DQ19

E11

DQ18

CPU_D08

10

DSP_DQ23

DSP_DQ22

DSP_DQ21

DSP_DQ20

SD_3.2V

D26

E12

B11

A11

B10

DQ23

DQ22

DQ21

DQ20

DQ19

VDDQ

CKO

VSSQ

AF8

AF9

AF10D7AC12D6AA12D5AE12D4AF12D3AF13D2AE13D1AA13D0AB13

XX

C120

0

R125

CPU_D07

CPU_D06

SAN_27M_CLKO

DSP_DQ24

0.1u

C122

D11

E26

VSSQ(SDRAM)

VDDQ(SDRAM)

CPU_D05

CPU_D04

DSP_DQ25

D12

DQ24

CPU_D03

DSP_DQ31

DSP_DQ30

DSP_DQ29

DSP_DQ28

DSP_DQ27

DSP_DQ26

D14

D13

E13

A12

B12

F12

DQ31

DQ30

DQ29

DQ28

DQ27

DQ26

DQ25

IC101

CAMERA DSP,CPU,LENS CONTROL,

MODE CONTROL,FRONT CONTROL

IC101

CXD3188BGG-T6

VDD

VSS

A25

AF14

AF15

AE14

AA14

0.1u

C123

CPU_D02

CPU_D01

CPU_D00

CPU_A25

DSP_AQ04

DSP_AQ03

DSP_AQ02

DSP_AQ01

XDSP_QRAS

B17

QCAS

A16

AF16

E25

QRAS

VDDQ

AE15

XX

C125

DSP_QCLKE

A18

A17

QCLKE

VSSQ(SDRAM)

VSSQ

NC

AB17

AB15

CPU_A15

D25

QCLK

A15

AC17

F15

VDDQ(SDRAM)

A14

AC18

CPU_A14

XDSP_QWE

D17

QWE

A13

AA15

CPU_A13

CPU_A12

DSP_DQM3

DSP_DQM2

DSP_DQM1

DSP_DQM0

XDSP_QCS0

XDSP_QCAS

XX

C124

B16

D15

E15

E14

F14

B15

F13

A16

A15

VSS

VDD

DQM3

DQM2

DQM1

DQM0

XQCS0

XQCS1

A24

A23

A22

A21

A20

A19

A18

AC15

CPU_A21

AC16

CPU_A20

AB14

CPU_A19

AE16

CPU_A18

AF17

CPU_A17

A17

AE17

CPU_A16

AC14

AC13

DSP_AQ00

DSP_QCLK

DSP_AQ06

DSP_AQ05

E16

B19

A19

B18

D16

D18

AQ6

AQ5

AQ4

AQ3

AQ2

AQ1

AQ0

A12

A11

A10

AE18

AF18A9AF19A8AE19A7AB16A6AC19A5AB19A4AB18A3AE20A2AF20A1AF21A0AE21

CPU_A11

CPU_A10

CPU_A09

CPU_A08

CPU_A07

CPU_A06

Q101

DTC144EMT2L

SWITCH

3.2

0

L101

10uH

4

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

LND116

R115

47k

R163

470k

C113

XX

R109

XX

±0.5%

C101

22u

6.3V

: Voltage measurment of the CSP ICs

and the Transistors with mark, are

not possible.

0.1u

C116

L102

10uH

C114

10u

6.3V

2

C115

0.1u

A6

A7

A4

A3

VSSQ

AVSS(PLL)

AVDD(PLL)

NC

A1

MD0

B2

MD1

C2

0

R165

MD2

D2

R166

XX

VDD

B1

C107

0.1u

CLKTGEXT

C1

VSS

D1

VDDQ

G2

C108

VDDQ(PLLTGO)

G1

0.1u

CLKTGO

E1

F1

VSSQ(PLLTGO)

F5

OPBCLP

DUMCLP

G5

CCDHD

H5

J5

CCDFD

VSS

A2

F2

CLKTGI

VSSQ

E2

ADIN0

K5

ADIN1

G4

ADIN2

H4

ADIN3

L5

ADIN4

H2

ADIN5

H1

J1

ADIN6

J2

ADIN7

ADIN8

M5

J4

ADIN9

ADIN10

K4

ADIN11

M6

ADIN12

K2

ADIN13

K1

VDDQ

L1

C109

XX

CLKADI

M1

NTVDI

N1

VSSQ

P1

DIR0A

L2

DIROB

N5

BRK0A

L4

BRK0B

M4

DIR1A

N6

DIR1B

M2

BRK1A

N2

BRK1B

P5

DIR2A

N4

DIR2B

P4

BRK2A

P6

BRK2B

R2

MSHUT_EN

R5

STRBON

R4

VSUBCONT

T4

SCK1

R6

RXD1

T2

TXD1

U2

SCS0

D_1.2V

C111

C104

XX

T5

VDD

R1

C110

0.1u

VSS

P2

AVSS(SENS)

U1

SENS0

U4

SENS1A

V4

SENS1B

U5

LND101

SENS2

W2

LND102

FG1A

V5

LND103

FG1B

W4

NC

W5

0.1u

A_3.2V

NC

Y2

AVDD(SENS)

T1

VSSBK(SRAM)

V2

RSTA

Y4

0.1uC112

VDDBK(SRAM)

V1

ID

EVER_2.8V

AA2

VDD(PHY)

W1

VSS(PHY)

AB1

VSS(PHY)

AB2

VBUS

AA4

680R108

±0.5%

RREF

Y1

AGND3(PHY)

AD2

AVDD3(PHY)

AF2

C105

0.1u

C106

0.1u

AA1

AC2

AB4

AE2

AF3

AC1

AD1

AE1

AE3

AF1

DVDD1(PHY)

DGND1(PHY)

VSS(PHY)

AGND1(PHY)

AVDD1(PHY)

DP

DM

AGND2(PHY)

AVDD2(PHY)

NC

SCK0Y5RXDO

AA5

XSAN0_SCK

SAN0_SI

AB5

SAN0_SO

TXD0

AF4

XSAN_RST_OUT

3

XXR102

R162

0

CLKTGO

CA_HD

CA_FD

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

FC_DIR_A

FC_DIR_B

FC_EN

ZM_DIR_A

ZM_DIR_B

ZM_EN

IRIS_M_EN

IRIS_M_IN

IRIS_S_IN

IRIS_S_EN

MSHUT_EN

STRB_ON

XSAN1_SCK

SAN1_SI

SAN1_SO

USB_VBUS

FC_SENS

ZM_SENS_1ST

ZM_SENS_2ND

XDD_RST_OUT

USB_DP

USB_DM

1

2

A5

EXTAL

RST_OUT

AC4

7

LCD_D0

LCD_D1

LCD_D2

LCD_D3

LCD_D4

LCD_D5

LCD_D6

MSDATA3

AB6

FB109

100

R121

MS_BS

XACCESS_LED

MSBS

VSSQ

AF5

100

R123

AF6

MS_CLK

C119

LED4F4LED3E4LED2D4LED1E5LED0

MSSCLK

LCD_D7

0.1u

B4

A9

B7

VSS

VDD

VDDQ

CS4

CS3

CS0

WE1

WE0

CAS

AF7

AC6

FB105

120

0.1u

C118

R124

XCPU_CS4

RAS

AB7

AE6

AB8

AC7

AB9

AE8

AE7RDAE9

XCPU_CS0

XCPU_WE1

4

12MHz

XZM_RST_LED

3

X102

0.1u

C117

B3

B6

VDDQ

VSSQ(LED)

MSDATA0

MSDATA1

MSDATA2

AE4

AE5

AC5

FB106

FB107

FB108

100

100

100

R118

R119

R120

MS_D3

MS_D2

MS_D1

MS_D0

LCD_CK

LCD_VD

LCD_HD

LND104

A8

D9

B5

B9

B8

E9

VSSQ

VDDQ

LCDD0D8LCDD1D7LCDD2E8LCDD3E7LCDD4D6LCDD5D5LCDD6E6LCDD7

LCDCK

LCDVD

NTVDO

LCDHD

CKE

RDXWR

D15

D14

D13

D12

AC9BSAC8

AB10

AC10

AB11

AE10

AF11

XCPU_RD

XCPU_BS

CPU_D15

CPU_D14

CPU_D13

CPU_D12

DSP_AQ07

D19

CPU_A05

AQ7

DSP_AQ08

E19

CPU_A04

AQ8

DSP_AQ09

E17

CPU_A03

B20

AQ9

DSP_AQ10

CPU_A02

AQ10

A20

DSP_AQ11

AQ11

CPU_A01

15

B13

B14

E18

AQ12

VSSQ(SDRAM)

VDDQ(SDRAM)

VSSQ

VDDQ

AF24

AF25

C127

0.1u

C126

B21

AC20

DSP_QBA0

0.1u

QBA0

XWAIT

DSP_QBA1

A21

AF22

QBA1

VDD

C128

0.1u

DSP_DQ00

D21

AF23

D22

DQ0

VSS

AB20

DSP_DQ01

TDI

DSP_DQ02

D20

DQ1

TDI

AE22

TMS

DQ2

TMS

AE23

DSP_DQ03

B22

RTCK

16 1811 122

DQ3

RTCK

DSP_DQ04

A22

AE25

TDO

DQ4

TDO

DSP_DQ05

A23

AC21

DQ5

TRST

LND117

DSP_DQ06

B23

AB21

TCK

DSP_DQ08

DSP_DQ07

E21

E20

DQ7

DQ6

TCK

TO2

AB22

AD25

R127

10k

STRB_CHG_CONT

DSP_DQ09

E23

B24

VSS

DQ9

DQ8

VSSQ(SDRAM)

VDDQ(SDRAM)

AVDDQ(LED)

AVSSQ(VIDEO)

AVDDQ(VIDEO)

PJ[3](PORT19)

PJ[2](PORT18)

PJ[1](PORT17)

PJ[0](PORT16)

DACK/PI[3](PORT15)

DREQ/PI[2](PORT14)

PI[1](PORT13)

PI[0](PORT12)

PH[3](PORT11)

PH[2](PORT10)

PH[1](PORT9)

PH[0](PORT8)

PG[7](PORT7)

PG[6](PORT6)

PG[5](PORT5)

PG[4](PORT4)

PG[3](PORT3)

PG[2](PORT2)

PG[1](PORT1)

PG[0](PORT0)

TO1

TO0

AC25NCAF26

C129

0.1u

17

AVSSQ(LED)

AVSSQ(AU)

AVDDQ(AU)

AVSS(AD)

AVDD(AD)

TRACECLK

19

L104

10uC146

4

5

6

Vin

Vcc

GND

IC103

VIDEO AMP

IC103

NJM2578KJ1(TE3)

Power Save2Vout3Vsag

3.2 3.2

1.3

1.3 0.3

1

C147

C148

22u

100u

6.3V

6.3V

A14

A13

DQ10

A24

DQ11

A25

DQ12

B25

DQ13

C25

DQ14

C26

DQ15

B26

NC

A26

F23

LED5

E22

LED6

D23

LED7

F22

F26

C133

0.1u

M25

VOUT

H26

C134

0.1u

VREF

J26

G26

R142

XX

N26

VRP

H23

VRN

G22

AOUT

K26

VRL

G23

VRH

H22

C135

1u

AIN

L26

M26

AU_3.2V

N25

AN[11]

G25

AN[10]

H25

AN[9]

J22

AN[8]

F25

AN[7]

J23

AN[6]

K22

AN[5]

J25

AN[4]

K25

AN[3]

L23

AN[2]

K23

AN[1]

L25

AN[0]

L22

P26

INT3

M21

INT2

P22

INT1

N21

INT0

P23

TEST3

M23

TEST2

N22

TEST1

M22

TEST0

N23

R23

P21

R25

T25

P25

T23

U23

R22

VSSQ

U26

RST

R26

VDDQ

T26

VSS

V26

VDD

W26

U25

V25

R21

V23

W23

T22

W25

Y26

Y25

U22

Y23

AA23

CTS4

V22

RTS4

AA25

TXD4

AA26

RXD4

AB25

TI3B

W22

TI3A

AB23

TO3

AC22

TI2B

AC23

TI2A

Y22

VSS

AC26

VDD

AB26

VDDQ

AE26

AE24

VSSQ

AD26

NC

AA22

R160

0

0R149

R139

C136

220k

0.1u

±0.5%

100k

R151

10k

10k

R130

10kR131

0.1u

C137

R132

10k

R140

10k

R133

C138

0.01u

0.1u

C130

0.1u

C131

LND105

LND106

C132

XX

V_LINE_OUT

R148

68

VIDEO_AMP_ON

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

3

XSTRB_LED

XPWR_LED

XAE_LOCK_LED

C143

0.1u

R145

XX

C139

XX

C140

XX

SAN_AUOUT

C141

XX

C142

0.1u

R135

±0.5%

XX

SAN_AUIN

R161

10k

KEY_AD2_C

PANEL_AD

P_ADJ

R150

KEY_AD1_C

10k

R138

47k

LENS_TMP1

BATT_SENS

KEY_AD1

R152

KEY_AD0

10k

R153

MODE_DIAL1

470k

R154

MODE_DIAL0

470k

CPU_R/XB

XAE_LOCK_SW

XSHUTTER_SW

R141

XX

VSUB_CONT_PRE

XCAM_DR_PS

MSHUT_DIR

MS_PWR_ON

-7.5V_ON

XAU_LINE_MUTE

VIDEO_AMP_ON

STRB_CHG

R134

1k

XDD_RST_OUT

XAV_JACK_IN

XACV_IN

XMULTI_IN

XSTRB_FULL

XCS_DD

XCS_EEPROM

XCS_PANEL

XCS_AUDIO

XCS_FE

XPWR_OFF

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

CA_HD

CA_FD

CLKTGO

VSUB_CONT_PRE

XCS_FE

XSTRB_LED

XAE_LOCK_LED

ZM_SENS_2ND

XZM_RST_LED

FC_SENS

LENS_TMP1

ZM_SENS_1ST

XCAM_DR_PS

ZM_EN

ZM_DIR_B

ZM_DIR_A

FC_EN

FC_DIR_B

FC_DIR_A

IRIS_S_EN

IRIS_M_IN

IRIS_S_IN

IRIS_M_EN

MSHUT_DIR

MSHUT_EN

SAN0_SI

XSAN0_SCK

SAN0_SO

XCS_DD

XDD_RST_OUT

XPWR_OFF

MS_PWR_ON

-7.5V_ON

BATT_SENS

SAN1_SO

XSAN1_SCK

SAN1_SI

XACV_IN

XMULTI_IN

XAV_JACK_IN

USB_VBUS

USB_DM

USB_DP

KEY_AD1_C

KEY_AD2_C

V_LINE_OUT

MS_CLK

MS_D3

MS_D2

MS_D0

MS_D1

MS_BS

SAN_27M_CLKO

TDI

TMS

RTCK

TDO

TCK

STRB_CHG

XSTRB_FULL

STRB_CHG_CONT

STRB_ON

CPU_A25

XCPU_CS4

CPU_R/XB

XSAN_RST_OUT

XCS_EEPROM

MODE_DIAL1

MODE_DIAL0

XAE_LOCK_SW

XSHUTTER_SW

XPWR_LED

SAN_AUIN

SAN_AUOUT

XCS_AUDIO

XAU_LINE_MUTE

2114

LND107

CA_AD00

CA_AD01

CA_AD02

CA_AD03

CA_AD04

CA_AD05

CA_AD06

CA_AD07

CA_AD08

CA_AD09

CA_AD10

CA_AD11

CA_AD12

CA_AD13

CA_HD

CA_FD

CLKTGO

VSUB_CONT_PRE

XCS_FE

XSTRB_LED

XAE_LOCK_LED

LND109

ZM_SENS_2ND

XZM_RST_LED

FC_SENS

LENS_TMP1

ZM_SENS_1ST

XCAM_DR_PS

ZM_EN

ZM_DIR_B

ZM_DIR_A

FC_EN

FC_DIR_B

FC_DIR_A

IRIS_S_EN

IRIS_M_IN

IRIS_S_IN

IRIS_M_EN

MSHUT_DIR

MSHUT_EN

SAN0_SI

XSAN0_SCK

SAN0_SO

XCS_DD

XDD_RST_OUT

XPWR_OFF

MS_PWR_ON

-7.5V_ON

BATT_SENS

SAN1_SO

XSAN1_SCK

LND108

SAN1_SI

XACV_IN

XMULTI_IN

XAV_JACK_IN

USB_VBUS

USB_DM

USB_DP

KEY_AD1_C

KEY_AD2_C

V_LINE_OUT

MS_CLK

MS_D3

MS_D2

MS_D0

MS_D1

MS_BS

SAN_27M_CLKO

LND110

LND111

LND112

LND113

LND115

STRB_CHG

XSTRB_FULL

STRB_CHG_CONT

STRB_ON

CPU_A25

XCPU_CS4

CPU_R/XB

XSAN_RST_OUT

XCS_EEPROM

MODE_DIAL1

MODE_DIAL0

XAE_LOCK_SW

XSHUTTER_SW

XPWR_LED

SAN_AUIN

SAN_AUOUT

XCS_AUDIO

XAU_LINE_MUTE

228

@20

@02

@14

(4/8)

@22

(8/8)

JTAG

@16

(5/8)

@03

@13

@09

(7/8)

@21

@10

(4/8)

@19

@01

(3/8)

(8/8)

(4/8)

@18

(7/8)

@17

232069

XCPU_CS0

XCPU_BS

CPU_A01

CPU_A02

CPU_A03

CPU_A04

CPU_A05

CPU_A06

CPU_A07

CPU_A08

(1/8)

CPU_A09

CPU_A10

CPU_A11

CPU_A12

CPU_A13

CPU_A14

CPU_A15

CPU_A16

CPU_A17

CPU_A18

CPU_A19

CPU_A20

CPU_A21

XCPU_RD

XCPU_WE1

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

DSP_DQ00

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

(1/8)

DSP_DQ08

(4/8)

(6/8)

DSP_DQ09

(8/8)

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28

DSP_DQ29

DSP_DQ30

DSP_DQ31

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_QBA0

DSP_QBA1

XDSP_QCS0

XDSP_QRAS

(7/8)

XDSP_QCAS

XDSP_QWE

DSP_DQM0

DSP_DQM1

DSP_DQM2

DSP_DQM3

DSP_QCLKE

DSP_QCLK

(1/8)

(4/8)

(5/8)

(8/8)

KEY_AD0

KEY_AD1

XCS_PANEL

LCD_VD

LCD_HD

LCD_CK

LCD_D7

LCD_D6

LCD_D5

LCD_D4

LCD_D3

LCD_D2

LCD_D1

LCD_D0

P_ADJ

PANEL_AD

(6/8)

XACCESS_LED

XCPU_CS0

XCPU_BS

CPU_A01

CPU_A02

CPU_A03

CPU_A04

CPU_A05

CPU_A06

CPU_A07

CPU_A08

CPU_A09

CPU_A10

CPU_A11

CPU_A12

CPU_A13

CPU_A14

CPU_A15

CPU_A16

CPU_A17

CPU_A18

CPU_A19

CPU_A20

CPU_A21

XCPU_RD

XCPU_WE1

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

DSP_DQ00

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

DSP_DQ08

DSP_DQ09

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28

DSP_DQ29

DSP_DQ30

DSP_DQ31

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_QBA0

DSP_QBA1

XDSP_QCS0

XDSP_QRAS

XDSP_QCAS

XDSP_QWE

DSP_DQM0

DSP_DQM1

DSP_DQM2

DSP_DQM3

DSP_QCLKE

DSP_QCLK

KEY_AD0

KEY_AD1

XCS_PANEL

LCD_VD

LCD_HD

LCD_CK

LCD_D7

LCD_D6

LCD_D5

LCD_D4

LCD_D3

LCD_D2

LCD_D1

LCD_D0

P_ADJ

PANEL_AD

XACCESS_LED

24135

@11

(4/8)

@12

(4/8)

(5/8)

@15

(4/8)

@23

(8/8)

05

DSC-S60/S80/S90/ST80

4-13 4-14

SY-126 (2/8)

Page 10

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

SY-126 BOARD (3/8)

A

LENS DRIVE (LD BLOCK)

4

53

: Voltage measurment of the CSP ICs

and the Transistors with mark, are

not possible.

6122

8

914117

10

13

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

B

C

D

E

F

LENS

BLOCK

LENS BLOCK is replaced as block,

so that there PRINTED WIRING BOARD

and SCHEMATIC DIAGRAM are omitted.

CN601

Z_RST_SENS2

Z_RST_GND2

Z_RST_VCC2

FOCUS_A

FOCUS_B

FOCUS_A

FOCUS_B

F_RST_VCC

F_RST_GND

F_RST_SENS

SHUTTER+

SHUTTER+

SHUTTER-

SHUTTER-

IRIS_M_+

IRIS_M_-

IRIS_S_+

IRIS_S_-

Z_RST_VCC1

Z_RST_SENS1

Z_RST_GND1

TEMP_OUT

TEMP_GND

ZOOM_A

ZOOM_B

-0.7

Q601

DTA143TMT2L

E5H8G8F7F8E6E7E8D8D7D6C8C7B8B7C6

SWITCH

NC

VLIM

VREF

EN7

IN7

VM4

OUT7A

RNFS

RNF

OUT7B

VM4

EN3

IN3

EN4

IN4

NC

27P

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2ZOOM_A

1ZOOM_B

FOCUS_A

FOCUS_B

FOCUS_A

FOCUS_B

SHUTTER+

SHUTTER-

IRIS_M_+

IRIS_M_-

IRIS_S_+

IRIS_S_-

ZOOM_A

ZOOM_B

ZOOM_A

ZOOM_B

R602

R603

R604

390

390

390

C601

0.1u

MSHUT_EN

MSHUT_DIR

SHUTTER+

SHUTTER-

FC_EN

FC_DIR_A

FC_DIR_B

R601

±0.5%

2.5

3.2

3.1

IRIS_S_-

IC601

PGND1

OUT1B

VM1

IRIS_S_+

OUT1A

C603

PGND1

M_5V

C604

0.1u

47u

10V

E4H1H2G3H3G4F4H4H5G5F5H6G6H7G7F6

NC

NC

IN2

EN2

NC

IN1

EN1

BR6

PGND3

OUT6B

VM3

OUT6A

PGND3

OUT5B

VM3

OUT5A

PGND3

BR5

IN6

NC

R607

1800

D4 A1 B1 C2 C1 D3 D2 D1 E1 E3 E2 F1 F2 G1 G2 F3

IRIS_M_-

IRIS_M_+

PS

NC

DGND

PGND1

OUT2B

VM1

OUT2A

IC601

LENS DRIVE

BD6756GLV-E2

A_3.2V

ZOOM_B

ZOOM_B

ZOOM_A

ZOOM_A

R610

6800

±0.5%

IRIS_M_IN

IRIS_M_EN

IRIS_S_IN

IRIS_S_EN

ZM_DIR_B

ZM_EN

ZM_DIR_B

ZM_DIR_A

FC_EN

FC_DIR_B

FC_DIR_A

IRIS_S_EN

IRIS_M_IN

IRIS_S_IN

IRIS_M_EN

MSHUT_DIR

MSHUT_EN

LND607

LND608

LND601

LND602

LND603

LND604

LND605

LND606

M_5V

A_3.2V

D_3.2V

REG_GND

ZM_SENS_2ND

XZM_RST_LED

FC_SENS

LENS_TMP1

ZM_SENS_1ST

XCAM_DR_PS

ZM_EN

ZM_DIR_B

ZM_DIR_A

FC_EN

FC_DIR_B

FC_DIR_A

IRIS_S_EN

IRIS_M_IN

IRIS_S_IN

IRIS_M_EN

MSHUT_DIR

MSHUT_EN

@24

(7/8)

@09

(2/8)

G

H

I

05

DSC-S60/S80/S90/ST80

4-15

C602

0.1u

NC

PGND2

VCC

NC

D5 A8 A7 B6 A6 C5 B5 A5 A4 C4 B4 A3 B3 A2 B2 C3

FOCUS_A

OUT3A

VM2

OUT3B

FOCUS_A

PGND2

OUT4A

FOCUS_B

VM2

FOCUS_B

OUT4B

PGND2

EN5

ZM_DIR_A

IN5

EN6

ZM_EN

NC

4-16

SY-126 (3/8)

Page 11

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

3

SY-126 BOARD (4/8)

A

BURST FLASH, SDRAM (MEMORY BLOCK)

4

: Voltage measurment of the CSP ICs

and the Transistors with mark, are

not possible.

5

6122

8

914117

10

13

XX MARK:NO MOUNT

@08

B

(2/8)

@25

(7/8)

@10

C

@03

(2/8)

(1/8)

(2/8)

(5/8)

(8/8)

D

@11

E

(2/8)

F

G

@12

(2/8)

(5/8)

H

I

@13

@14

@02

J

SD_3.2V

D_1.8V

D_3.2V

REG_GND

SAN_27M_CLKO

XSAN_RST_OUT

XCPU_CS0

XCPU_BS

CPU_A01

CPU_A02

CPU_A03

CPU_A04

CPU_A05

CPU_A06

CPU_A07

CPU_A08

CPU_A09

CPU_A10

CPU_A11

CPU_A12

CPU_A13

CPU_A14

CPU_A15

CPU_A16

CPU_A17

CPU_A18

CPU_A19

CPU_A20

CPU_A21

XCPU_RD

XCPU_WE1

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

(2/8)

(2/8)

(1/8)

(2/8)

(6/8)

(8/8)

XCS_EEPROM

SAN1_SI

SAN1_SO

XSAN1_SCK

SAN_27M_CLKO

XSAN_RST_OUT

XCPU_CS0

XCPU_BS

CPU_A01

CPU_A02

CPU_A03

CPU_A04

CPU_A05

CPU_A06

CPU_A07

CPU_A08

CPU_A09

CPU_A10

CPU_A11

CPU_A12

CPU_A13

CPU_A14

CPU_A15

CPU_A16

CPU_A17

CPU_A18

CPU_A19

CPU_A20

CPU_A21

XCPU_RD

XCPU_WE1

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

FB201

0uH

D_1.8V

FB202

0uH

D_3.2V

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

XCPU_BS

SAN_27M_CLKO

XCPU_WE1

XSAN_RST_OUT

XCPU_CS0

XCPU_RD

C202

L201

47uH

C209

10u

DSP_DQ00

FL201

34

12

VDDQ

CPU_D09

E1

F7D0E6D1E5D2G5D3E4D4G3D5E3D6G1D7G7D8F6

D9

D10

F5

D11

F4

D12

D5

D13

F3

D14

F2

D15

LND201

R203

XX

E2

WAIT

D3

XADV

C4

CLK

B4

XWE

C5

XRST

B5

10k

D6

E7

F8

1

XCS

2

SO

3

XWP

4

GND

Note: IC201 is not supplied, but this is

XWP

XCE

XOE

included in SY-126 complete board.

A0D8A1C8A2B8A3A8A4B7A5A7A6C7A7A2A8B2A9C2A10A1A11B1A12

E8

CPU_A01

CPU_A02

VCC

XHOLD

SCK

IC202

XX

CPU_A03

CPU_A04

SI

IC201

32M BURST FLASH

S99-50031-01-ER

CPU_A05

CPU_A06

8

7

6

5

IC201

CPU_A07

CPU_A08

CPU_A09

CPU_A10

CPU_A11

VCCQG6VCCQ

CPU_A12

A4

C1

CPU_A13

CPU_A14

VCCG4VCC

0.1uC207

0.1uC205

0.1u

VPP

NC

VSSQ

VSSQ

VSS

VSS

NC

A20

A19

A18

A17

A16

A15

A14

A13

C206

A5

D7

G2

G8

F1

A3

C3

CPU_A21

B3

CPU_A20

C6

CPU_A19

A6

CPU_A18

B6

CPU_A17

D4

CPU_A16

D1

CPU_A15

D2

DSP_DQ00

DSP_DQ01

DSP_DQ02 DSP_DQ13

DSP_DQ03

0.1uC208

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

C210

DSP_DQM0

XDSP_QWE

XDSP_QCAS

XDSP_QRAS

XDSP_QCS0

DSP_AQ11

DSP_QBA0

DSP_QBA1

DSP_AQ10

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_DQM2

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

0.1u

C211

0.1u

C212

0.1u

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

1

VDD

2

DQ0

3

VDDQ

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

10

DQ5

11

DQ6

12

VSSQ

13

DQ7

14

NC

15

VDD

16

DQM0

17

WE#

18

CAS#

19

RAS#

20

CS#

21

A11

22

BA0

23

BA1

24

A10

25

A0

26

A1

27

A2

28

DQM2

29

VDD

30

NC

31

DQ16

32

VSSQ

33

DQ17

34

DQ18

35

VDDQ

36

DQ19

37

DQ20

38

VSSQ

39

DQ21

40

DQ22

41

VDDQ

42

DQ23

43

VDD

44

VDDQ

45

DQ15

VSSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

VSSQ

DQ10

VDDQ

DQM1

DQM3

DQ31

VDDQ

DQ30

DQ29

VSSQ

DQ28

DQ27

VDDQ

DQ26

DQ25

VSSQ

DQ24

VSSQ

VSS

90

VSS

89

88

87

86

85

84

83

82

81

80

DQ9

79

78

DQ8

77

NC

76

VSS

75

74

NC

73

NC

72

CLK

71

CKE

70

A9

69

A8

68

A7

67

A6

66

A5

65

A4

64

A3

63

62

VSS

61

NC

60

59

58

57

56

55

54

53

52

51

50

49

48

VSS

47

46

C213

C214

0.1u

C215

0.1u

DSP_DQ15

DSP_DQ14

DSP_DQ12

DSP_DQ11

DSP_DQ10

DSP_DQ09

0.1u

DSP_DQ08

DSP_DQM1

DSP_QCLK

DSP_QCLKE

DSP_AQ09

DSP_AQ08

DSP_AQ07

DSP_AQ06

DSP_AQ05

DSP_AQ04

DSP_AQ03

DSP_DQM3

DSP_DQ31

DSP_DQ30

DSP_DQ29

DSP_DQ28

DSP_DQ27

DSP_DQ26

DSP_DQ25

DSP_DQ24

IC203

128M SDRAM

IC203

K4S283233F-HN1HT

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

DSP_DQ08

DSP_DQ09

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28

DSP_DQ29

DSP_DQ30

DSP_DQ31

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_QBA0

DSP_QBA1

XDSP_QCS0

XDSP_QRAS

XDSP_QCAS

XDSP_QWE

DSP_DQM0

DSP_DQM1

DSP_DQM2

DSP_DQM3

DSP_QCLKE

DSP_QCLK

DSP_DQ00

DSP_DQ01

DSP_DQ02

DSP_DQ03

DSP_DQ04

DSP_DQ05

DSP_DQ06

DSP_DQ07

DSP_DQ08

DSP_DQ09

DSP_DQ10

DSP_DQ11

DSP_DQ12

DSP_DQ13

DSP_DQ14

DSP_DQ15

DSP_DQ16

DSP_DQ17

DSP_DQ18

DSP_DQ19

DSP_DQ20

DSP_DQ21

DSP_DQ22

DSP_DQ23

DSP_DQ24

DSP_DQ25

DSP_DQ26

DSP_DQ27

DSP_DQ28

DSP_DQ29

DSP_DQ30

DSP_DQ31

DSP_AQ00

DSP_AQ01

DSP_AQ02

DSP_AQ03

DSP_AQ04

DSP_AQ05

DSP_AQ06

DSP_AQ07

DSP_AQ08

DSP_AQ09

DSP_AQ10

DSP_AQ11

DSP_QBA0

DSP_QBA1

XDSP_QCS0

XDSP_QRAS

XDSP_QCAS

XDSP_QWE

DSP_DQM0

DSP_DQM1

DSP_DQM2

DSP_DQM3

DSP_QCLKE

DSP_QCLK

@15

(2/8)

05

DSC-S60/S80/S90/ST80

4-17 4-18

SY-126 (4/8)

Page 12

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

23

65

7

8

94

: Voltage measurment of the CSP ICs

SY-126 BOARD (5/8)

A

AND FLASH

and the Transistors with mark, are

not possible.

XX MARK:NO MOUNT

B

C

D

E

F

@03

@26

@12

(2/8)

(4/8)

@16

(2/8)

(7/8)

(1/8)

(2/8)

(4/8)

(8/8)

D_3.2V

REG_GND

CPU_A20

CPU_A21

XCPU_RD

XCPU_WE1

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

XSAN_RST_OUT

CPU_A25

XCPU_CS4

CPU_R/XB

CPU_A20

CPU_A21

XCPU_RD

XCPU_WE1

CPU_D00

CPU_D01

CPU_D02

CPU_D03

CPU_D04

CPU_D05

CPU_D06

CPU_D07

CPU_D08

CPU_D09

CPU_D10

CPU_D11

CPU_D12

CPU_D13

CPU_D14

CPU_D15

XSAN_RST_OUT

CPU_A25

XCPU_CS4

CPU_R/XB

CPU_D06

CPU_D07

CPU_D14

C301

0.1u

D_3.2V

B11

C11

D11

C10

D10

C9

D9

C8

D8

C7

D7

D6

C6

D5

C5

D4

C4

D3

C3

D2

C2

B2

A2

DU

DU

DU

DU

I/O_7

VSS

I/O_8

DU

XMRES

DU

I/O_15

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

DU

CPU_D12

CPU_D05

CPU_D13

CPU_D15

F11DUE7

E8

E9

E10

E11DUB12

A12DUA11

DU

DU

I/O_16

I/O_14

I/O_6

I/O_13

CPU_D04

F8DUF9DUF10

VCC

I/O_5

IC301

32M AND FLASH

IC301

HN29V256A0BBP-30

L12

H11

H10

H9

H8

H7

G11

G10

G9

G8

G7DUF7

DU

I/O_11

I/O_4

I/O_12

DU

I/O_9

I/O_1

I/O_2

I/O_10

DU

DU

M12

DU

M11

DU

L11

DU

K11

DU

J11

K10

J10

K9

J9

K8

J8

K7

J7

J6

K6

J5

K5

J4

K4

J3

K3

J2

K2

L2

XCPU_CS4

XCPU_RD

CPU_A21

CPU_A20

XCE

DU

XRE

DU

VSS

DU

DU

DU

DU

DU

DU

DU

DU

DU

CLE

ALE

DU

DU

DU

CPU_D09

CPU_D01

CPU_D08

CPU_D00

CPU_D11

CPU_D03

CPU_D10

G

H

05

DSC-S60/S80/S90/ST80

4-19

DUB1DUE2DUE3XWEE4R/XBE5DUE6DUF3VSSF4XRESF5DUF6PREG6I/O_3G5DUG4DUG3XWPG2DUH6DUH5DUH4DUH3DUH2DUL1DUM1DUM2DU

A1

C302

0.1u

R301

10k

XCPU_WE1

CPU_R/XB

XSAN_RST_OUT

CPU_D02

CPU_A25

4-20

SY-126 (5/8)

Page 13

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

SY-126 BOARD (6/8)

A

AUDIO (AU BLOCK)

34 78

: Voltage measurment of the CSP ICs

and the Transistors with mark, are

not possible.

5

6

9102

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

C513

2200

R502

C510

470kR504

0.1u

0.01u

0.022u

C514

1u

R507

0

C518

XX

SAN_AUIN

10u

C507

B

CN703

2P

MIC901 MIC

1MIC_GND

2MIC_SIG

0.01u

@17

C6

C5

MIC_IN

PRE_OUT

IC502

AUDIO AMP

BH6414GLU-E2

R505

1k

C512

0.1u

D5

ALC_IN

IC502

C511

TAU

C515

1u

D4NCD6

ABIAS

F6NCE6

MIC_OUT

LINE_IN

AVCC

XSEN

DVDD

SCLK

SDATA

TEST

xRESET

xLINE_MUTE

@02

(2/8)

(1/8)

(2/8)

(4/8)

(8/8)

C516

0.1u

E5

F5

E4

F4

E3

F3

D3

F2

F1

SAN_AUOUT

XCS_AUDIO

XAU_LINE_MUTE

XSAN1_SCK

SAN1_SO

AU_3.2V

@06

(2/8)

IC503

2.8V REG

IC503

R1141Q281B-TR-FA

3.22.8

4

3

C521

1u

A_3.2V

@28

(7/8)

M_5V

REG_GND

C517

2.2u

1

VOUT

2

GND

VDD

CE

C

D

E

@27

(8/8)

SP+

SP-

AU_LINE_OUT

M_5V

R512

C508

B6

B5

MIC_REG

NC

A6

SP+

A5

NC

C4

SPVCC

C504

10u

0

C502

0.47u

A4

B4

A3

B3

A2

B2

NC

SPGND

NC

SP-

SPBIAS

NCB1BEEPC3NCC1SP_INC2EVR_OUTD1LINE_OUTD2MUTE_Tr_OUTE1MUTEGNDE2AGND

A1

C506

0.001u

F

DSC-S60/S80/S90/ST80

05

4-21 4-22

SY-126 (6/8)

Page 14

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

SY-126 BOARD (7/8)

A

DC/DC CONVERTER (DD BLOCK)

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

ACV_UNREG

B

@29

CRADLE_ON

(8/8)

C

BT901

BATTERY

TERMINAL

BATT_CHG_UNREG

V_BATT

D

REG_GND

E

ST-122

FLEXIBLE

LND001-LND014

PAGE 4-29

of LEVEL2

STRB_CHG_CONT

F

STRB_CHG

@18

G

H

I

(2/8)

CONTROL

SWITCH

BLOCK

LND001-LND010

PAGE 4-34

of LEVEL2

@19

(2/8)

XSTRB_FULL

STRB_CHG_CONT

STRB_ON

MODE_DIAL1

MODE_DIAL0

XAE_LOCK_SW

XSHUTTER_SW

XPWR_LED

XAE_LOCK_SW

J

K

SSM3K03FE(TPL3)

CN001

BATT_UNREG

BATT_UNREG

BATT_GND

BATT_GND

CN704

ST_UNREG

ST_UNREG

ST_UNREG

ST_GND

ST_GND

ST_GND

ST_GND

STRB_ON

XSTRB_FULL

STRB_CHG

XAF_LED

D_3.2V

CN702

XPWR_LED

A_3.2V

XPWR_ON

REG_GND

XSHTR_SW

MODE_DIAL0

A_3.2V

MODE_DIAL1

ST_5V

Q007

SWITCH

N.C.

4P

14P

10P

R-7.5/P0.1

R-7.5/P0

4

3

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

10

9

8

7

6

5

4

3

2

1

6.3V

10u

L001

C014

L010

G1

G2

H2

VFB1

LDO1

MS_PWR

MS_PWR_IN

XMSIN

AGNDB9AGNDE6DGNDC9VBUSIND6REG1F2D8VFB2D9PG2

A10

XMS_IN

USB_VBUS

914117

3.2V

10uH

4.7uH

C016

47u

F1

VO1-1F2VO1-2

1.2V

6.3V10u

C019

6.3V

C10

C017

22u

6.3V

C015

22u

6.3V

D1

LX2

D10

4.7uL003

LH1-1E1LH1-2E2LH1-3E3LH1-4

PWR2E8REG2F1E7PG3

0

R012

10p

C023

F003

C020

10V

1u

R035

2200

10

L004

4.7u

E4

IC001

DC/DC CONVERTER

IC001

SC901570VOR2

LX3E9VO3F9VL3F8RS3F6REG2F2F7VFB4G8PSG4

E10

4.7u

D002

L005

RB520S-30TE61

10V

C024

1u

/32V

0.63A

C025

1u

16V

13

10u

6.3V

C027

MS_PWR_ON

2.9V

C021

22u

6.3V

C1

LL1-1D2LL1-2

PG1-1E5PG1-2F3PG1-3F4PG1-4F5PG1-5

C035

1u

10V

R013

10

±0.5%

A1

PWR1-1B1PWR1-2C2PWR1-3

TG4

F10

G10

R027

MCH3405-TL-E

C050

0.1u

16V

D3

D4

DTG1

LX4G9BG4H9VFB5

10

Q001

DC CONTROL

C3

REG1F1

MS_PWR_ON

H10

L008

4.7u

0.8

C022 XX

R011 XX

B2

LDO3IN

VO5H8REG4F1

A2

LDO3

UNREGMON

PWR56OUT2

PWR56OUT1

UNREG2-2

UNREG2-1

C034

0.022u

R020 1M

R029

R034

4.1

LDO2IN

PORTB

PORTA

PGLED

VDADJ

REG4F2

33

100k

VREF6

PG5-2

PG5-1

LX5-4

LX5-3

LX5-2

LX5-1

TEST

C8

B3

LDO2

A3

C4

B4

LED1

A4

D5

IREF

B5

VREF

A5

H5

G5

K7

J7

K6

J6

GT6

H6

G6

VFB6

H7

G7

K8

J8

K10

K9

J10

J9

1.1

3

2

1

4.14.9

4

5

R018

100k

R016

4.9

Q002

CPH5812-S-TL-E

Q002,Q003

SWITCHING

LND001

LND003

100k

C003

C048

4700p

±0.5%

C030

C044

0.1u

1.8V

±0.5%

XX

0.047u

C047

0.001u

R023

470k

±0.5%

4.9 4.9

C013

10u

10V

C028

1u

10V

C029

10u

6.3V

R4.1/P0 R-8.6/P0

5.5

3

R030

10

Q004

CPH5802-TL-E

SWITCHING

L009

C038

4.7uH

1u

10V

D003

RB520S-30TE61

L006

4.7uH

C033

1u

10V

Q003

0

MCH3306-TL-E

R044

4700

15

4

5

2

1

0

C040

4.7u

16V

C031

4.7u

25V

R038

165

XX

R3.2/P0

1

STB

2

GND

R-8.6/P0

3

VEE

R-7.5/P0

4

REG3

IC002

15V/-7.5V REG

BA3986FV-E2

17

CAM_2.9V

@04

D_3.2V

CAM_15V

CAM_-7.5V

D_3.2V

A_3.2V

D_1.2V

EVER_3.1V

EVER_2.8V

M_5V

A_3.2V

D_3.2V

D_1.8V

D_3.2V

D_3.2V

A_3.2V

M_5V

D_3.2V

PANEL_15V

VL_3V

MS_VCC

USB_VBUS

XMS_IN

SAN0_SI

XSAN0_SCK

SAN0_SO

XCS_DD

XDD_RST_OUT

XPWR_OFF

MS_PWR_ON

8

REG1

R15.7/P0

7

VCC

R15/P0

6

REG2

5

N.C.

IC002

R037

XX

for PANEL

REG_GND

for ST

REG_GND

BL_L

@32

BL_H

(8/8)

USB_VBUS

XMS_IN

SAN0_SI

XSAN0_SCK

SAN0_SO

XCS_DD

XDD_RST_OUT

XPWR_OFF

MS_PWR_ON

-7.5V_ON

BATT_SENS

C045

4.7u

16V

C046

4.7u

16V

REG_GND

@24

@25

@26

@28

(1/8)

@05

(1/8)

@07

(2/8)

@31

@30

(8/8)

@20

(3/8)

(4/8)

(5/8)

(6/8)

(8/8)

(2/8)

3

D004

MA8120-TX

R040

470k

R014

22k

R036

10k

4

: Voltage measurment of the CSP ICs

and the Transistors with mark, are

not possible.

R-2.3/P0.1

5

R4.2R4.2

6

8

7

3

2

1

4

R-2.3

/P0.1

Q008

FDW2508P/GNL

SWITCH

C001

XX

C002

XX

F001

2A/32V

2A/32V

6122 18

33

XCS_DD

XSAN0_SCK

SAN0_SO

SAN0_SI

XDD_RST_OUT

XPWR_OFF

R003

10k

R041

4700

R001

R002

470

C006

2.2u

10V

C007

1u

16V

C012

0.1u

C049

0.1u

C010

12p

C011

12p

2.8V

RB520S-30TE61

C005

C004

0.22u

0.22u

10V

10V

15V

C009

C008

0.1u

R043

25V

1M

R006

R004

0

68k

R005

X001

10M

32.768kHz

F002

8 19

D001

3.1V

H1

PG8

G3

UNREG1-1

J1

UNREG1-2

K1

C8L2

J2

C8L1

K2

C8H1

H3

C8H2

J3

VO8

K3

VO7

K4

C7H2

J4

C7H1

H4

0.1u

16V

C7L2

J5

C7L1

K5

PG7

G4

CE

A6

SCLK

B6

SI

C5

SO

C6

XRESET

A7

XPWROFF

B7

XPWRON1

C7

XPWRON2

D7

RTCBAT

B8

OSCI

A8

OSCO

A9

4

B10

05

DSC-S60/S80/S90/ST80

4-23

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

4-24

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une piéce portant le numéro spécifié.

SY-126 (7/8)

Page 15

For Schematic Diagram

• Refer to page 4-39 for printed wiring board.

1

SY-126 BOARD (8/8)

A

CONNECTOR (CN BLOCK)

3 11 122

NO MARK:REC/PB MODE

XX MARK:NO MOUNT

45P

CN701

CRADLE_ON

B

C

X_CGH_ON

BATT_UNREG

BATT_UNREG

BATT_UNREG

BATT_UNREG

BATT_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

ACV_UNREG

D

MC-153

FLEXIBLE

LND001-LND045

PAGE 4-31

of LEVEL2

E

USB_VBUS

USB_GND

F

USB_GND

KEY_AD1_C

KEY_AD2_C

XMULTI_IN

G

XAV_JACK_IN

REG_GND

REG_GND

H

MS-271

CN004

THROUGH THE

FP-199 FLEXIBLE

PAGE 4-33

of LEVEL3

I

REG_GND

REG_GND

REG_GND

REG_GND

X_K.BATT

BATT_TMP

V_BATT

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

ACV_GND

V_TH

X_K.BATT

XACV_IN

V_OUT

V_GND

AU_OUT

A_GND

VL_3V

CN705

MS_VCC

MS_CLK

MS_D3

XMS_IN

MS_D2

MS_D0

MS_D1

MS_BS

45

SP-

44

43

SP+

42

N.C.

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

D-

14

NC

13

D+

12

11

10

9

8

7

6

5

4

3

2

1

16P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

SP-

SP+

REG_GND

R*/P0.4

Q703

SSM3K03FE(TPL3)

SWITCH

C701

XX

6.3V

47

R:REC MODE