Page 1

DSC-M1

SERVICE MANUAL

Ver 1.1 2005. 04

Revision History

Revision History

How to use

How to use

Acrobat Reader

Acrobat Reader

Link

Link

SPECIFICATIONS

SPECIFICATIONS

BLOCK DIAGRAMS

BLOCK DIAGRAMS

LEVEL 2

DSC-M1

US Model

Canadian Model

Australian Model

Chinese Model

E Model

Tourist Model

Hong Kong Model

Korea Model

Japanese Model

PRINTED WIRING BOARDS

PRINTED WIRING BOARDS

SERVICE NOTE

SERVICE NOTE

DISASSEMBLY

DISASSEMBLY

• For ADJUSTMENTS (SECTION 6), refer to SERVICE MANUAL, ADJ (9-876-778-51).

• For INSTRUCTION MANUAL, refer to SERVICE MANUAL, LEVEL 1 (9-876-778-41).

• Reference number search on printed wiring boards is available.

On the FP-035 FLEXIBLE, LD-175 and SY-114 board

This service manual provides the information that is premised the circuit board replacement service and not intended repair

inside the FP-035 FLEXIBLE, LD-175 and SY-114 board.

Therefore, schematic diagram, printed wiring board, waveforms, mounted parts location and electrical parts list of the

FLEXIBLE, LD-175 and SY-114 board

The following pages are not shown.

Schematic diagram .............................Pages 4-25 to 4-46

Printed wiring board ............................Pages 4-55 to 4-60

Waveforms ...........................................

are not shown.

FRAME SCHEMATIC DIAGRAMS

FRAME SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

SCHEMATIC DIAGRAMS

Mounted parts location .............................

Electrical parts list ................................... Pages 5-12 to 5-16

Page 4-62

REPAIR PARTS LIST

REPAIR PARTS LIST

Page 4-64

FP-035

DIGITAL STILL CAMERA

DSC-M1

9-876-778-31

Sony EMCS Co.

2005D1600-1

©2005.04

Published by DI Technical Support Section

Page 2

SPECIFICATIONS

x Camera

[System]

Image device

Total pixels number of camera

Effective pixels number of camera

Lens Carl Zeiss Vario-Tessar

Exposure control

White balance

File format (DCF compliant)

Recording media

Flash Recommended distance (ISO set to

7.66 mm (1/2.4 type) color CCD

Primary color filter

Approx. 5 255 000 pixels

Approx. 5 090 000 pixels

3 zoom lens

f = 6.7 – 20.1 mm (38 – 114 mm

converted to a 35 mm still camera)

F3.5 – 4.4

Automatic exposure, Scene

(9 modes)

Automatic, Daylight, Cloudy,

Fluorescent, Incandescent, Flash

Still images: Exif Ver. 2.2 JPEG

compliant, DPOF compatible

Movies: MPEG4 compli

“Memory Stick Duo”

Auto):

0.3 m to 1.8 m (11 7/8 inches to

70 7/8 inches) (W)

0.5 m to 1.7 m (19 3/4 inches to

67 inches) (T)

when

selection

ant (Stereo)

[Input and Output connectors]

Multi connector

USB communication

Hi-Speed USB (USB 2.0 compli

[LCD screen]

LCD panel

Total number of dots

6.2 cm (2.5 type) TFT drive

123 200 (560×220) dots

[Power, general]

Used battery pack

Power requirements

NP-FT1

3.6 V

ant)

Power consumption (during normal

shooting)

Operating temperature

Storage temperature

Dimensions

Mass Approx. 220 g (8 oz) (including

Microphone

Speaker Piezoelectric speaker

Exif Print Compatible

PRINT Image Matching II

PictBridge

1.4 W

0°C to +40°C (+32°F to +104°F)

–20°C to +60°C (–4°F to +140°F)

51.0×114.0×27.8 mm

(2 1/8×45/8×1 1/8 inches)

(W/H/D, excluding maximum

protrusions)

battery pack NP-FT1, “Memory St ick

Duo” and wrist strap)

Electret condenser microphone

Compatible

Compatible

x UC-MA Cyber-shot Station

[Input and Output connectors]

A/V OUT (STEREO) jack (Stereo)

USB jack B

USB connection

DC IN jack

Camera connector

Minijack

Video: 1 Vp-p, 75 Ω, unbalanced,

sync negative

Audio: 327 mV (at a 47 kΩ load)

Output impedance 1 kΩ

High-Speed USB

(USB 2.0 High-Speed compatible)

x AC-LM5/LM5A AC Adaptor

Input rating

100 V to 240 V AC,

50/60 Hz

AC-LM5

10 W

AC-LM5A

11 W

Output rating

Operating temperature

Storage temperature

Dimensions

Mass AC-LM5

4.2 V DC, 1.5 A

0°C to +40°C (+32°F to +104°F)

–20°C to +60°C (–4°F to +140°F)

AC-LM5

Approx. 47×30×80 mm

(1 7/8×1 3/16×3 1/4 inches)

AC-LM5A

Approx. 48×29×81 mm

(1 15/16×1 3/16×3 1/4 inches)

(W/H/D, excluding projecting parts)

Approx. 170 g (6.0 oz)

AC-LM5A

Approx. 160 g (5.6 oz)

excluding power cord (mains lead)

x NP-FT1 battery pack

Used battery

Maximum voltage

Nominal voltage

Capacity 2.4 Wh (680 mAh)

Lithium-ion battery

DC 4.2 V

DC 3.6 V

x Accessories

AC-LM5/LM5A AC Adaptor (1)

Power cord (mains lead) (1)

Cyber-shot Station UC-MA (1)

NP-FT1 battery pack (1)

Battery case (1)

USB cable (1)

A/V connecting cable (1)

Wrist strap (1)

“Memory Stick Duo” (32 MB) (1)

Memory Stick Duo Adaptor (1)

CD-ROM (USB driver SPVD-012) (1)

Operating instructions (1)

Design and specifications are subject to change

without notice.

DSC-M1

— 2 —

Page 3

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer.

1. Check the area of your repair for unsoldered or poorly-soldered

connections. Check the entire board surface for solder splashes

and bridges.

2. Check the interboard wiring to ensure that no wires are

"pinched" or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair . Point

them out to the customer and recommend their replacement.

4. Look for parts which, through functioning, show obvious signs

of deterioration. Point them out to the customer and

recommend their replacement.

5. Check the B+ voltage to see it is at the values specified.

6. Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

Unleaded solder

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

CAUTION :

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type.

DSC-M1

— 3 —

Page 4

TABLE OF CONTENTS

1. SERVICE NOTE ........................................................1-1

2. DISASSEMBLY

2-1. DISASSEMBLY ······························································2-1

2-2. SERVICE POSITION ·····················································2-7

2-3. CIRCUIT BOARDS LOCATION ·································2-10

2-4. FLEXIBLE BOARDS LOCATION ······························2-11

HELP (List of caution points is shown here.)

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2) ···························3-1

3-2. OVERALL BLOCK DIAGRAM (2/2) ···························3-3

3-3. POWER BLOCK DIAGRAM (1/2)································3-5

3-4. POWER BLOCK DIAGRAM (2/2)································3-7

4. PRINTED WIRING BOARDS AND

SCHEMATIC DIAGRAMS

4-1. FRAME SCHEMATIC DIAGRAM································4-1

4-2. SCHEMATIC DIAGRAMS

• FLASH UNIT (FL80000) (FLASH)

SCHEMATIC DIAGRAM ······························4-5

• FP-036 FLEXIBLE (MULTI CONNECTOR)

SCHEMATIC DIAGRAM ······························4-7

• FP-037 FLEXIBLE (CCD IMAGER)

SCHEMATIC DIAGRAM ······························4-9

• FP-039 FLEXIBLE (BATTERY)

SCHEMATIC DIAGRAM ····························4-11

• FP-040 FLEXIBLE (LITHIUM BATTERY)

SCHEMATIC DIAGRAM ····························4-12

• MS-252 (MS I/O, CONNECTOR)

SCHEMATIC DIAGRAM ····························4-13

• FP-038 FLEXIBLE (RELAY)

SCHEMATIC DIAGRAM ····························4-13

• FP-041 FLEXIBLE (LCD O/T SWITCH)

SCHEMATIC DIAGRAM ····························4-13

• CONTROL SWITCH BLOCK (PB80000)

SCHEMATIC DIAGRAM ····························4-15

• MOTOR UNIT (PI (SENSOR) BOARD) (PI SENSOR)

SCHEMATIC DIAGRAM ····························4-16

• PM-045 (1/2) (LCD PANEL DRIVE)

SCHEMATIC DIAGRAM ····························4-17

• PM-045 (2/2) (MIC AMP)

SCHEMATIC DIAGRAM ····························4-19

• CONTROL SWITCH BLOCK (PW80000) (1/2)

(FUNCTION KEY)

SCHEMATIC DIAGRAM ····························4-21

• CONTROL SWITCH BLOCK (PW80000) (2/2)

(CONNECTOR)

SCHEMATIC DIAGRAM ····························4-23

4-3. PRINTED WIRING BOARDS

• FP-036 FLEXIBLE (MULTI CONNECTOR)

PRINTED WIRING BOARD ·······················4-49

• FP-037 FLEXIBLE (CCD IMAGER)

PRINTED WIRING BOARD ·······················4-49

• FP-038 FLEXIBLE (RELAY)

PRINTED WIRING BOARD ·······················4-50

• FP-041 FLEXIBLE (LCD O/T SWITCH)

PRINTED WIRING BOARD ·······················4-50

• MS-252 (MS I/O, CONNECTOR)

PRINTED WIRING BOARD ·······················4-51

• FP-040 FLEXIBLE (LITHIUM BATTERY)

PRINTED WIRING BOARD ·······················4-51

• PM-045 (LCD PANEL DRIVE, MIC AMP)

RINTED WIRING BOARD ·························4-53

Printed wiring board of the FP-035, LD-175 and

SY-114 board are not shown.

Pages from 4-55 to 4-60 are not shown.

4-4. WAVEFORMS ······························································4-61

Waveforms of the SY-114 board are not shown.

Page 4-62 is not shown.

4-5. MOUNTED PARTS LOCATION ·································4-63

Mounted parts location of the SY-114 board is not

shown.

Page 4-64 is not shown.

5. REPAIR PARTS LIST

5-1. EXPLODED VIEWS ······················································ 5-1

5-1-1.OVERALL SECTION·····················································5-3

5-1-2.BATTERY HOLDER SECTION ····································5-4

5-1-3.LCD SECTION-1 ····························································5-5

5-1-4.LCD SECTION-2 ····························································5-6

5-1-5.LENS SECTION ·····························································5-7

5-2. ELECTRICAL PARTS LIST ··········································5-9

Electrical parts list of the FP-035, LD-175 and SY-114

board are not shown.

Pages from 12 to 5-16 are not shown.

DSC-M1

Shematic diagram of the FP-035, LD-175 and SY-114

board are not shown.

Pages from 4-25 to 4-46 are not shown.

— 4 —

Page 5

• NOTE FOR REPAIR

1. SERVICE NOTE

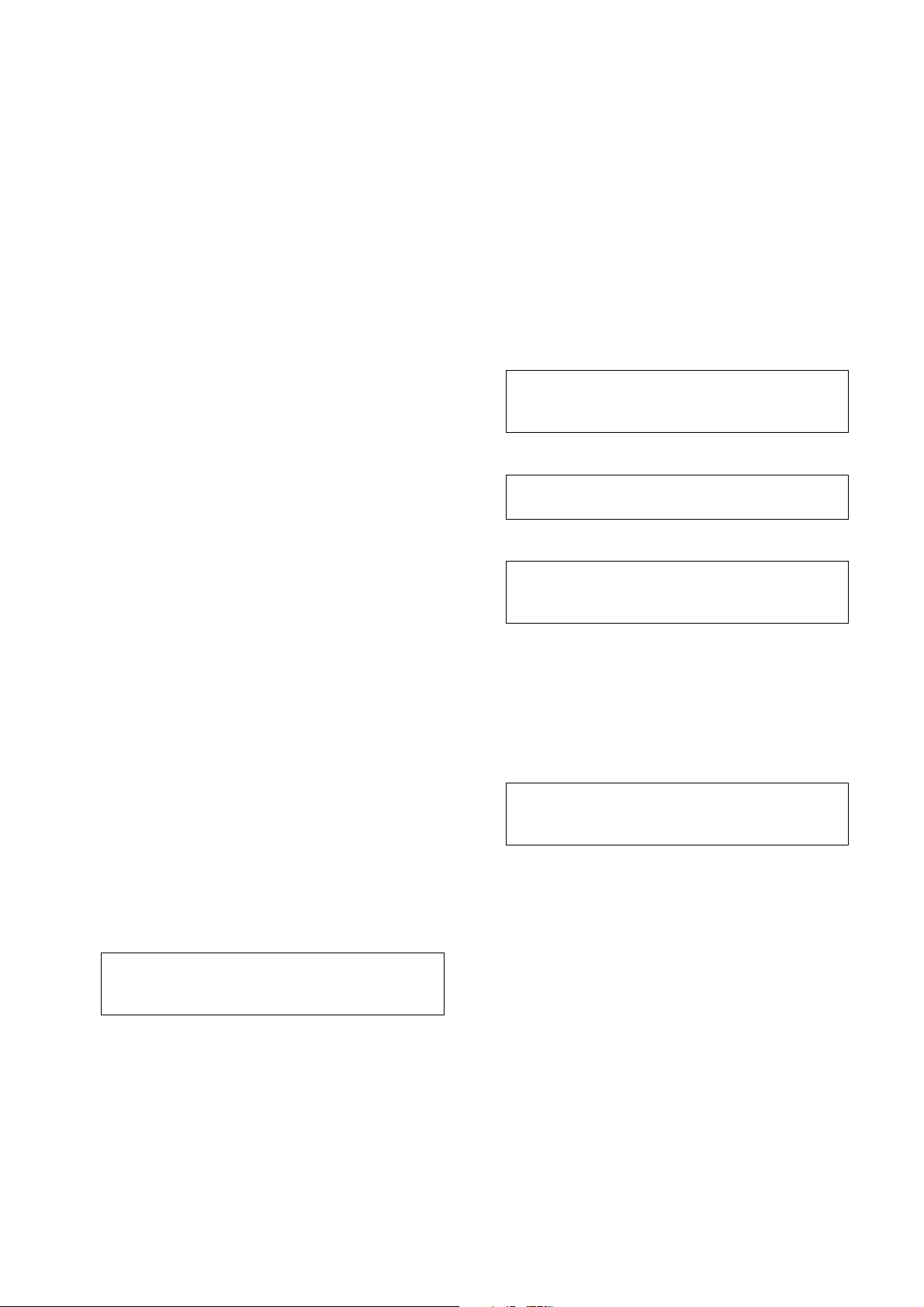

Make sure that the flat cable and flexible board are not cracked of

bent at the terminal.

Do not insert the cable insufficiently nor crookedly.

Cut and remove the part of gilt

which comes off at the point.

(Take care that there are

some pieces of gilt left inside)

When remove a connector, don't pull at wire of connector.

Be in danger of the snapping of a wire.

When installing a connector, don't press down at wire of connector.

Be in danger of the snapping of a wire.

[Discharging of the FLASH unit’s charging capacitor]

The charging capacitor of the FLASH unit is charged up to the

maximum 300 V potential.

There is a danger of electric shock by this high voltage when the

capacitor is handled by hand. The electric shock is caused by the

charged voltage which is kept without discharging when the main

power of the DSC-M1 is simply turned off. Therefore, the remaining

voltage must be discharged as described below.

Preparing the Short Jig

To preparing the short jig. a small clip is attached to each end of a

resistor of 1 kΩ /1 W (1-215-869-11)

Wrap insulating tape fully around the leads of the resistor to prevent

electrical shock.

Discharging the Capacitor

Short circuits between the positive and the negative terminals of

charged capacitor with the short jig about 10 seconds.

1 kΩ/1 W

Wrap insulating tape.

Caution

DSC-M1

Flash unit

1-1

Capacitor

Shorting jig

(1k

Ω

/ 1w)

Page 6

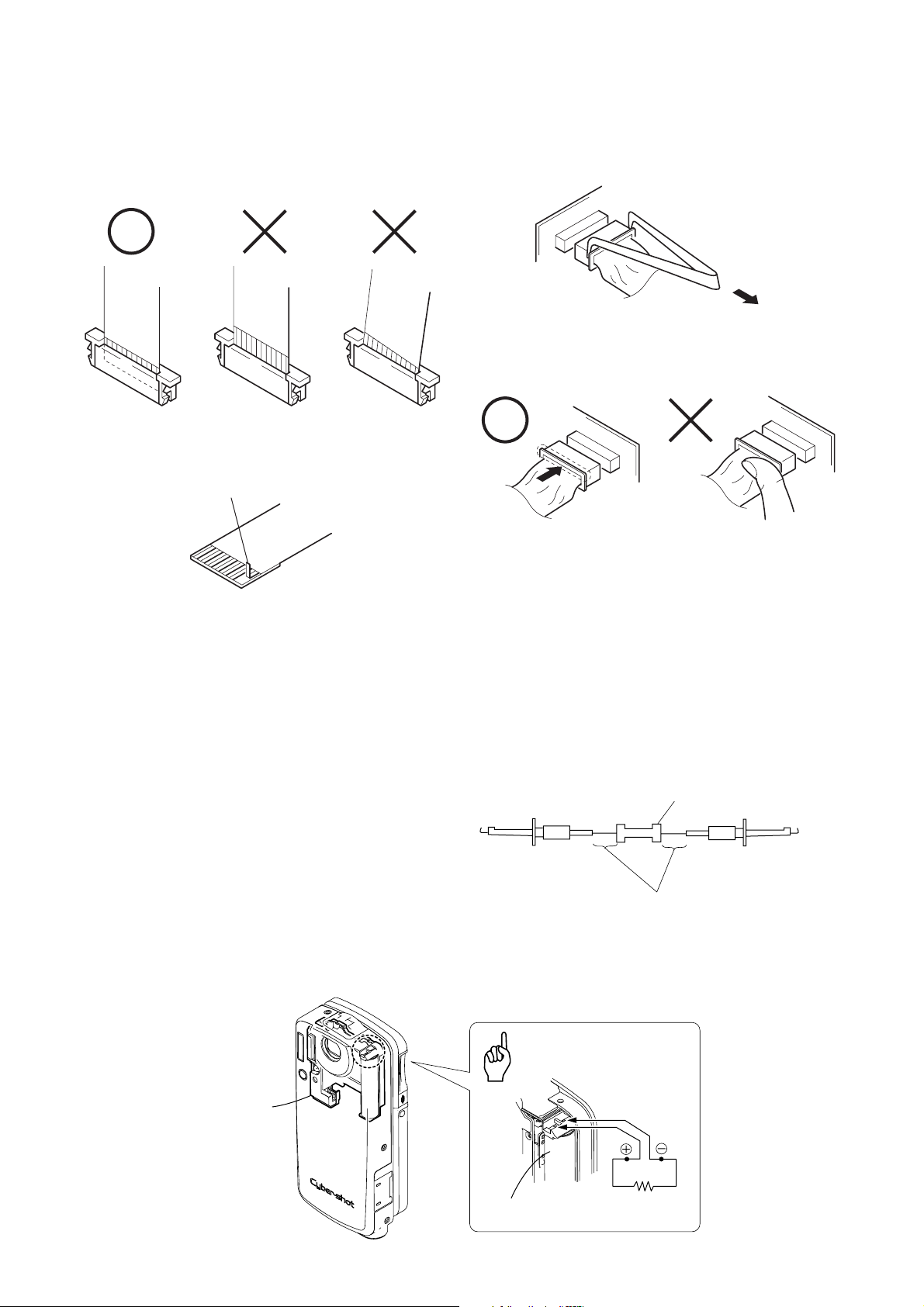

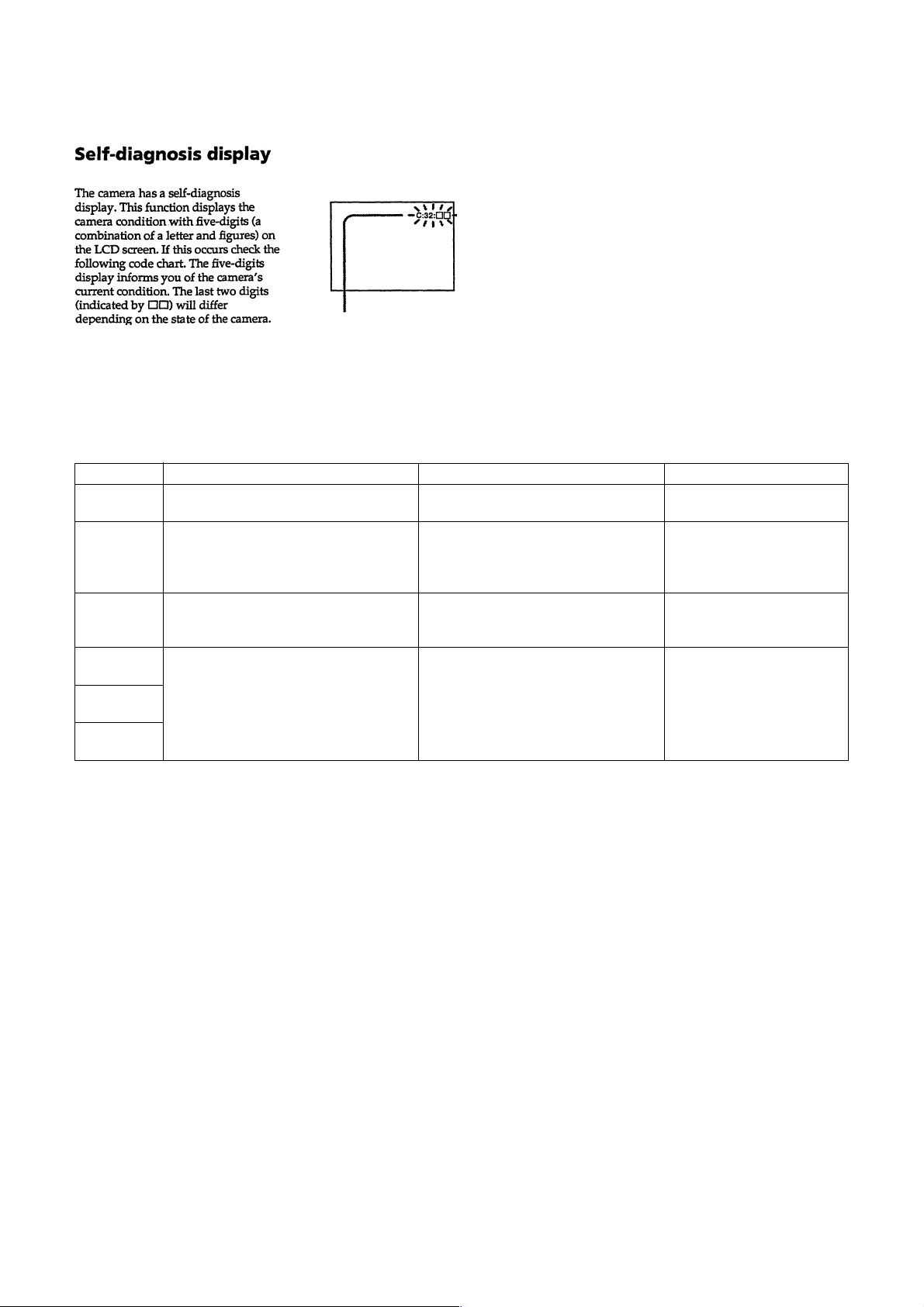

[Description on Self-diagnosis Display]

Self-diagnosis display

• C: ss: ss

The contents which can be handled

by customer, are displayed.

• E: ss: ss

The contents which can be handled

by engineer, are displayed.

Display Code

C:32:01

C:13:01

E:91:01

E:01:XX

E:61:00 *1

E:61:10 *1

Note : The error code is cleared if the battery is removed, except defective flash unit.

*1: The error display is given in two ways.

Turn off the main power then back on.

Replace the memory stick.

Format the memory stick with the DSC-M1.

Checking of flash unit or replacement of

flash unit.

Checking of lens drive circuit

Countermeasure

Trouble with hardware.

• The type of memory stick that cannot be

used by this machine, is inserted.

• Data is damaged.

• Unformatted memory stick is inserted.

Abnormality when flash is being

charged.

When failed in the focus initialization.

Cause

Caution Display During Error

SYSTEM ERROR

MS ERROR

Flash LED

Flash display

Flashing at 3.2 Hz

—

DSC-M1

1-2E

Page 7

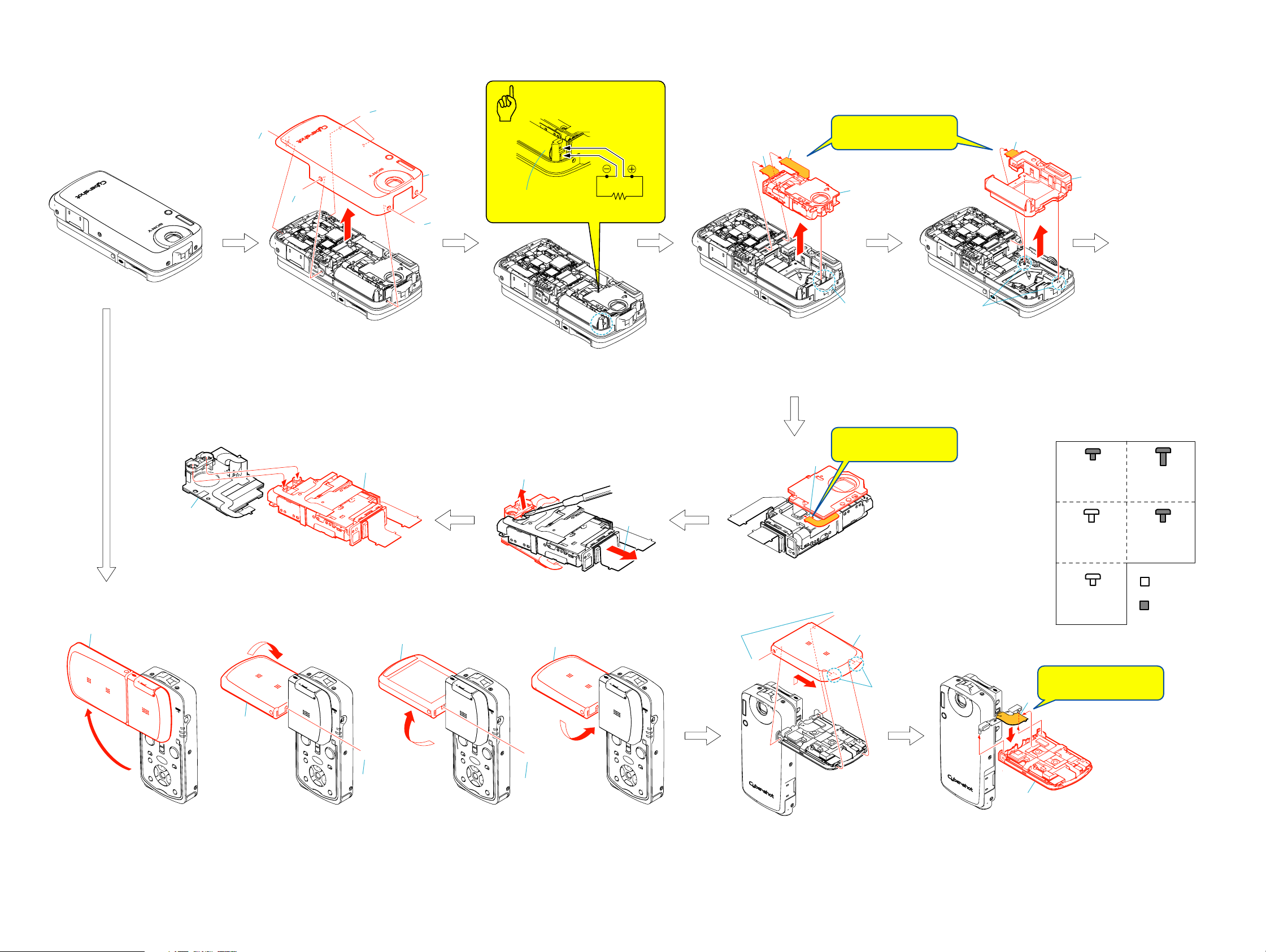

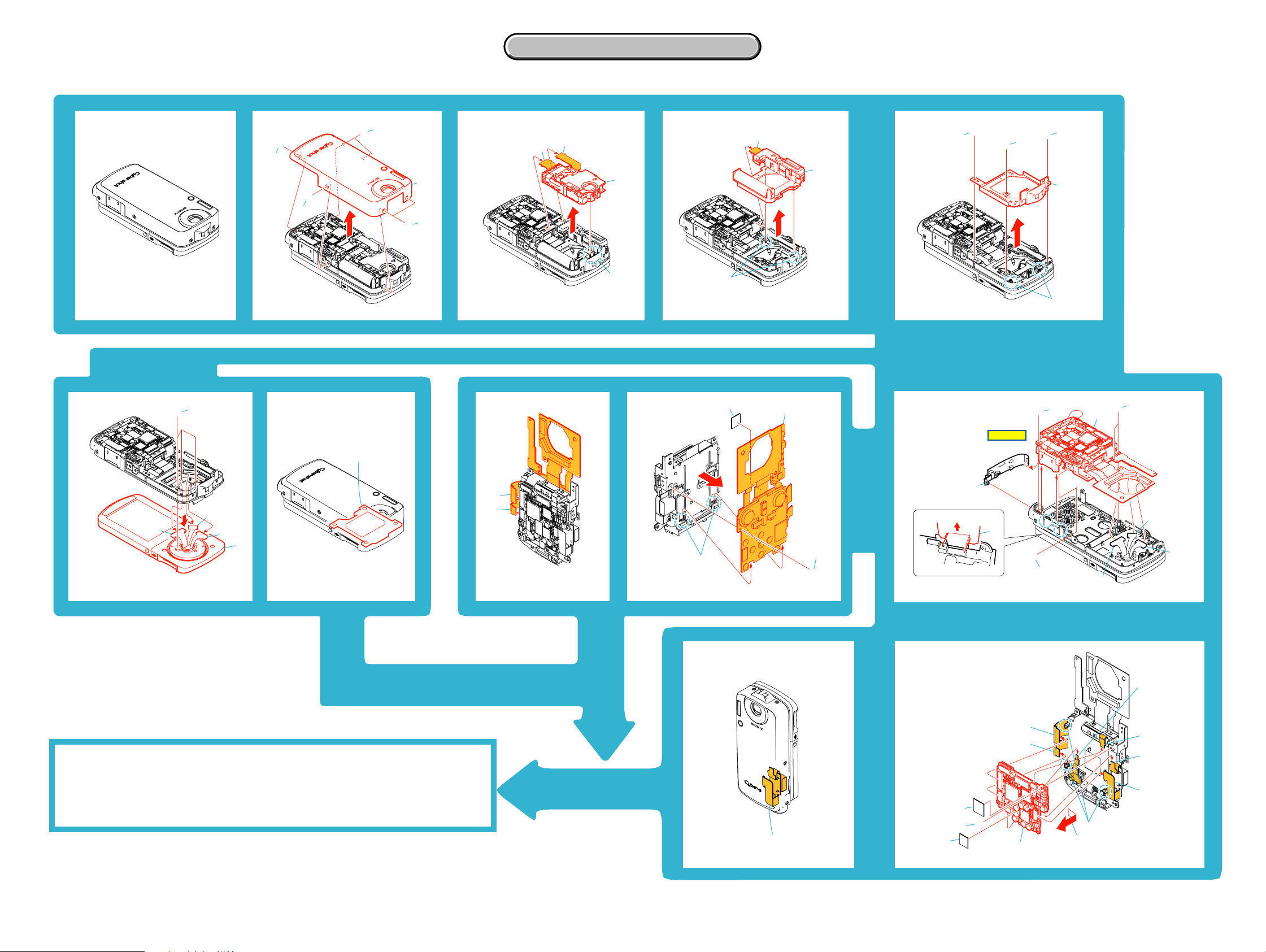

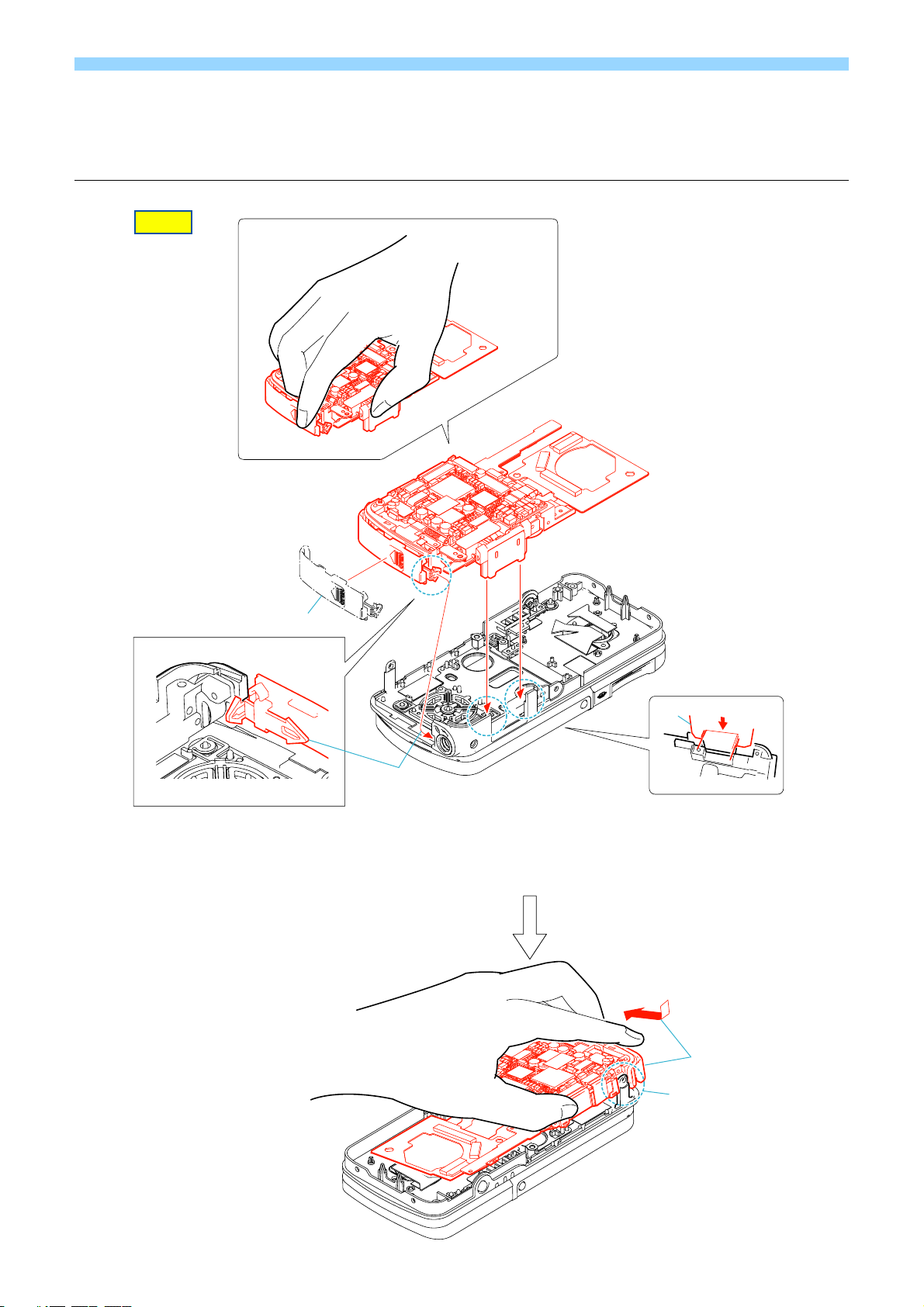

The following flow chart shows the disassembly procedure.

2-1. DISASSEMBLY

2. DISASSEMBLY

B

3

A

2

1

Two screws (M1.7x3) black

2

Screw (M1.7x3) black

3

Screw (M1.7x5) black

4

A

A

4

Two screws (M1.7x3) black

5

Cabinet (Front) assembly

Caution

Note: Be very careful not to

1

2

5

Capacitor

1

Discharging the capacitor

1

Shorting jig

Ω

/ 1W)

(1k

1

FP-035 flexble board (25P)

2

FP-037 flexble board (33P)

(From the CCD block assembly)

damage the flexible board.

4

3

3

Two claws

4

Lens section

1

1

2

3

2

3

Battery holder section,

(See page 2-3, 2-4)

Two claws

Flash unit (FL80000) (16P)

Flash unit (FL80000), ST frame (Upper), ST frame (Lower)

Note: Be very careful not to

damage the flexible board.

1

1

Motor unit (11P)

1

1

Motor unit, Lens barrier holder

2

Lens section

2

1

Push this portion with a driver

in the direction of the arrow a.

1

a

2

b

2

Remove the lens section

in the direction of the arrow b.

A

1

b

4

6

1

3

A

Screw

M1.7x3

2-515-483-21

C

Screw

M2x4

2-080-204-01

E

Screw

M1.7x3

2-515-488-21

B

Screw

M1.7x5

2-515-483-41

D

Tapping screw

M1.7x3.5

2-080-204-01

Silver

Black

A

a

a

2

A

c

d

A

2

Note: Be very careful not to

damage the flexible board.

4

f

DSC-M1

1

Turn over the LCD section in the direction of the arrow a.

2

Turn over the LCD section in the direction of the arrow b.

3

Screw (M1.7x3) black

3

4

Turn over the LCD section in the direction of the arrow c.

5

Screw (M1.7x3) black

6

Turn over the LCD section in the direction of the arrow d.

5

1

Two screws (M1.7x3) black

2

Two claws

3

Remove the P cabinet (C) assembly

in the direction of the arrow a.

2-1 2-2

5

4

FP-038 flexible board (29P)

5

Remove the P cabinet (M) assembly,

LCD, etc. in the direction of the arrow f.

Page 8

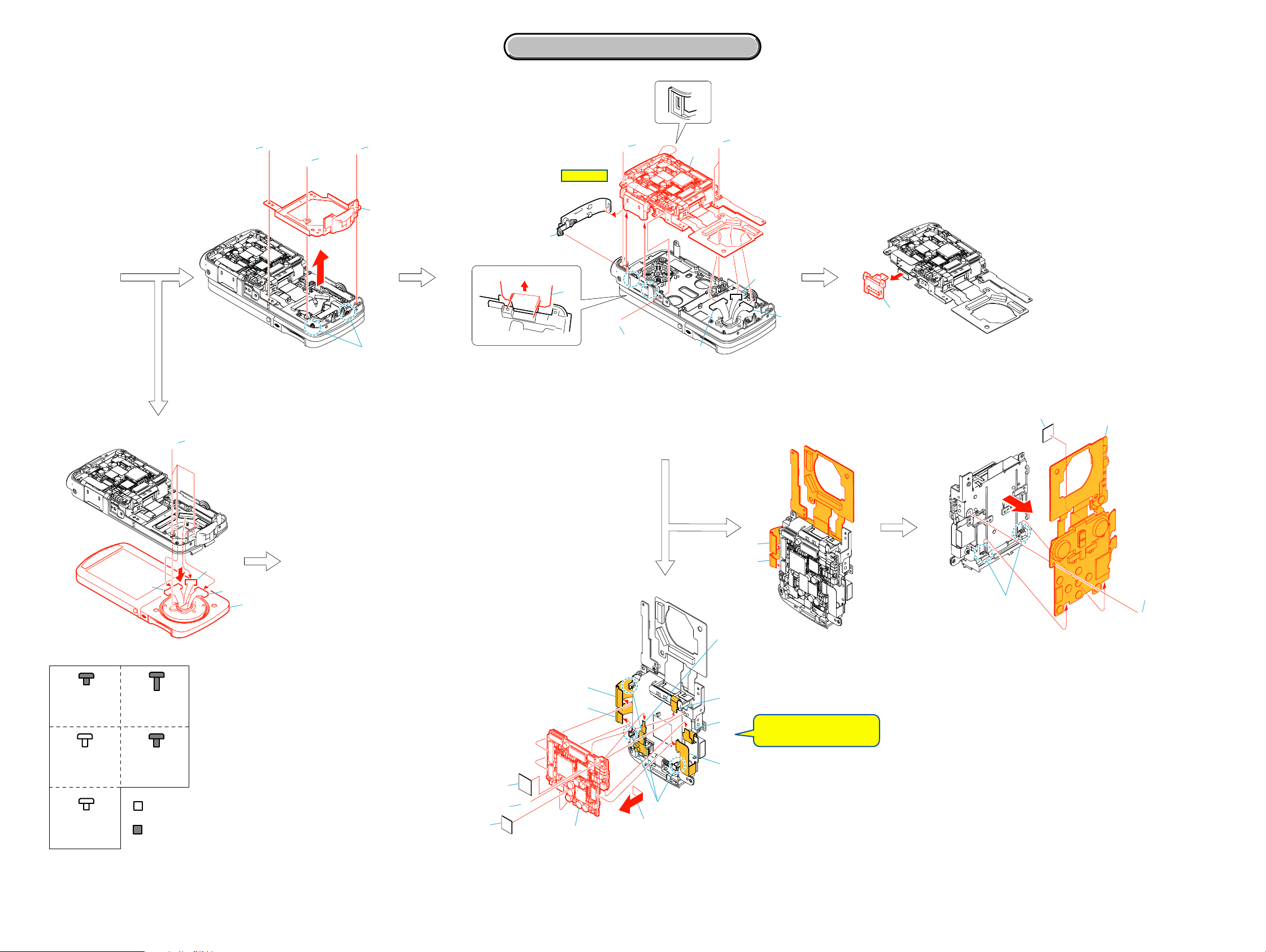

2. DISASSEMBLY

2. DISASSEMBLY

C

E

1

C

3

D

2

HELP 01

5

8

7

E

6

9

E

5

4

1

Screw (M1.7x3) silver

2

Tapping screw (M1.7x3.5) black

3

Screw (M2x4) silver

4

4

Two claws

5

Lens frame assembly

1

Harness (PD-130) (20P)

2

Harness (MA-154) (10P)

3

Harness (MS-121) (12P)

4

Two tapping screws (M1.7x3.5) black

5

Screw (M1.7x3) silver

6

Screw (M1.7x3) silver

1

4

D

2

3

Remove the multi holder assembly

7

in the direction of the arrow.

8

BT cover, BT arm

9

Battery holder section,

Multi holder assembly

1

Multi holder assembly

1

3

4

A

Screw

M1.7x3

2-515-483-21

C

Screw

M2x4

2-080-204-01

E

Screw

M1.7x3

2-515-488-21

1

B

Screw

M1.7x5

2-515-483-41

D

Tapping screw

M1.7x3.5

2-080-204-01

Silver

Black

1

Harness (PD-130) (20P)

2

Harness (MA-154) (10P)

3

Harness (MS-121) (12P)

4

Three screws (M2x4) silver

5

LCD section

1

2

3

5

Lens section (See page 2-5, 2-6)

1

FP-039 flexible board (11P)

2

Control switch block (PW80000) (39P)

3

Control switch block (PW80000) (19P)

4

FP-036 flexible board (19P)

5

Screw (M1.7x3) silver

6

Three claws

7

Remove the SY board

in the direction of the arrow.

8

FP-040 flexible board (6P)

9

FP-036 flexible board (6P)

0

SY radiation sheet

qa

Radiation sheet

qs

SY board

0

A

5

qa

2

3

qs

6

7

2

2

1

E

8

1

9

4

1

Control switch block (PW80000) (39P)

2

Control switch block (PW80000) (19P)

Note: Be very careful not to

damage the flexible board.

1

Screw (M1.7x3) silver

2

Two claws

3

Radiation sheet

4

Control switch block (PW80000)

DSC-M1

2-3 2-4

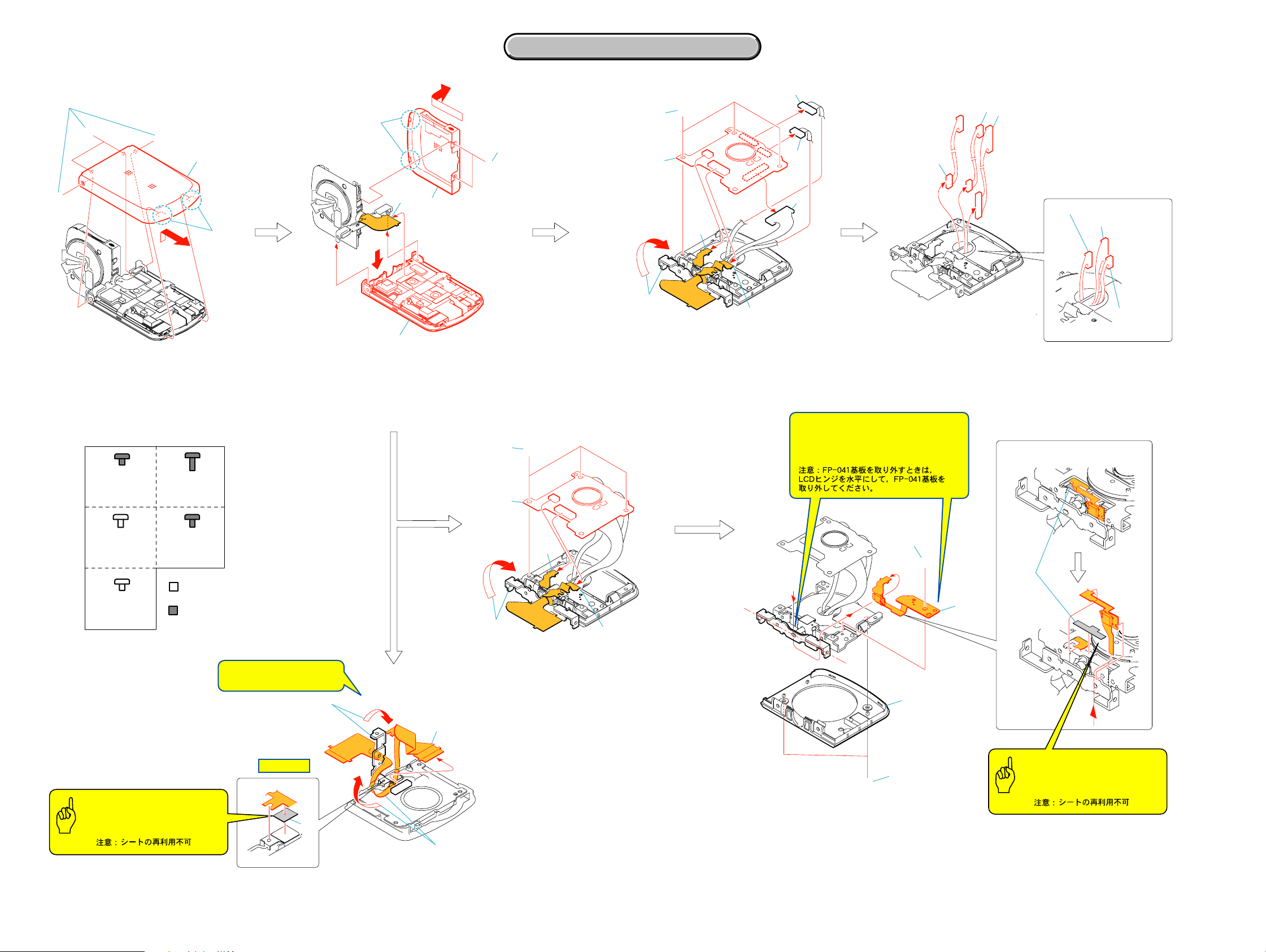

Page 9

2. DISASSEMBLY

2. DISASSEMBLY

1

A

A

1

Four screws (M1.7x3) black

2

Two claws

3

Remove the P cabinet (C) assembly

in the direction of the arrow.

A

b

E

4

3

1

5

2

1

FP-038 flexible board (29P)

2

Remove the P cabinet (M) assembly,

LCD, etc. in the direction of the arrow a.

3

Two screws (M1.7x3) black

a

2

3

A

4

Two claws

5

Remove the hinge cover,

MS holder assembly, etc. in the

direction of the arrow b.

2

8

4

1

1

Turn over the LCD hinge assembly

in the direction of the arrow.

2

Three screws (M1.7x3) silver

3

FP-038 flexible board (31P)

4

FP-041 flexible board (6P)

3

7

6

5

5

Harness (PD-130) (20P)

6

Harness (MA-154) (10P)

7

Harness (MS-121) (12P)

8

MS-252 board, Piezoelectric buzzer, etc.

2

1

1

Harness (PD-130) (20P)

2

Harness (MA-154) (10P)

3

3

Harness (MS-121) (12P)

Harness (MS-121)

Harness (PD-130)

Harness (MA-154)

A

Screw

M1.7x3

2-515-483-21

C

Screw

M2x4

2-080-204-01

E

Screw

M1.7x3

2-515-488-21

B

Screw

M1.7x5

2-515-483-41

D

Tapping screw

M1.7x3.5

2-080-204-01

Silver

Black

Note: Be very careful not to

damage the flexible board.

3

Note: To remove this FP-041 flexible board,

be sure to turn the LCD hinge to level, and then

2

E

5

4

remove this FP-041 flexible board.

(Japanese)

3

Bottom side

E

4

5

1

1

Turn over the LCD hinge assembly

in the direction of the arrow.

2

Three screws (M1.7x3) silver

a

2

3

3

FP-038 flexible board (31P)

4

FP-041 flexible board (6P)

5

MS-252 board,

Piezoelectric buzzer, etc.

2

DSC-M1

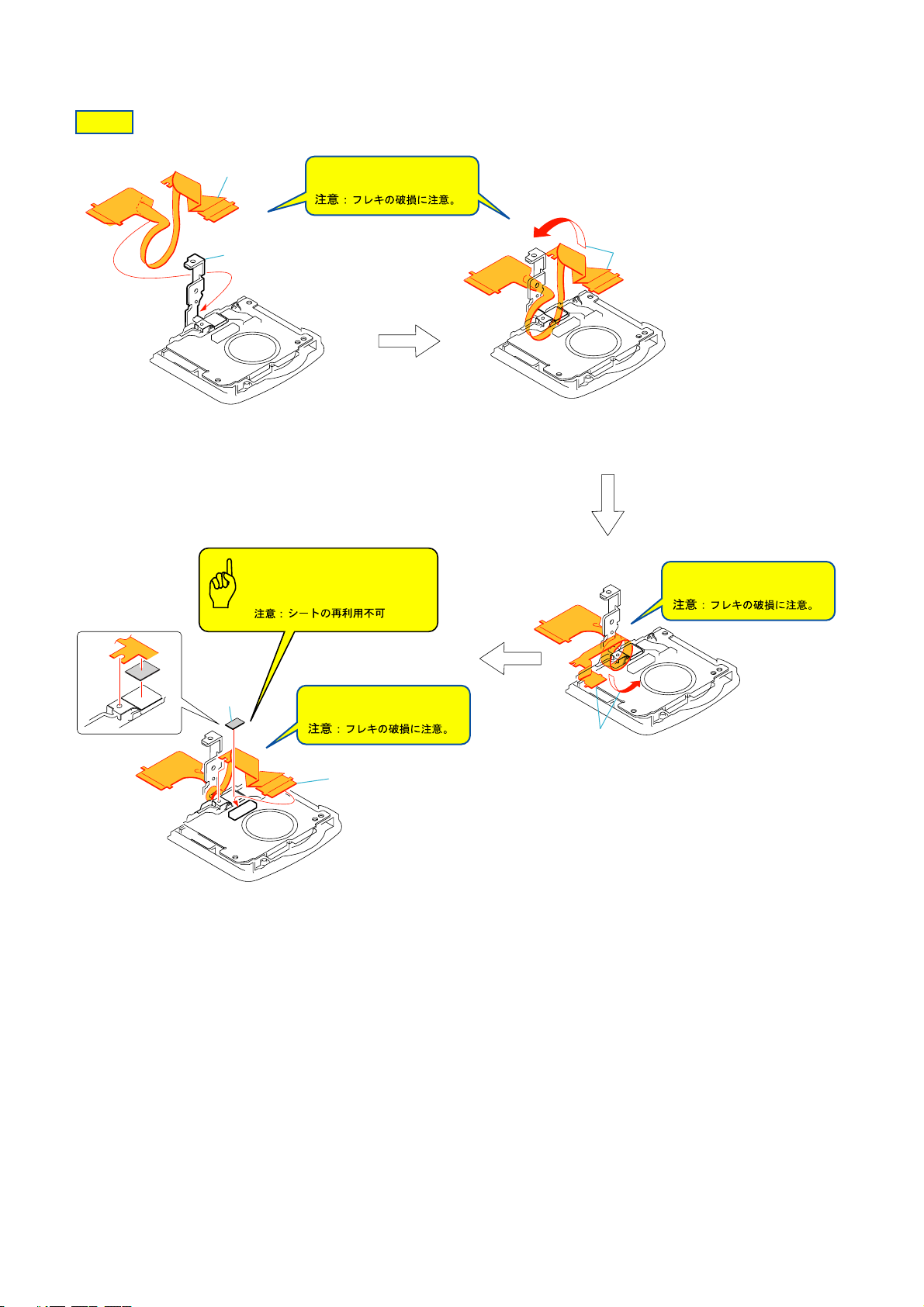

Caution

Note : The sheet cannot be reused.

(Japanese)

HELP 02

1

1

b

1

4

Peel off the hinge adhesive sheet (Upper).

2

FP-038 flexible board (31P)

3

Turn over the LCD hinge assembly

in the direction of the arrow a.

4

Remove the FP-038 flexible board

in the direction of the arrow b.

1

Two screws (M1.7x3) black

2

Hinge cabinet

3

Screw (M1.7x3) silver

4

Peel off the hinge adhesive sheet (Lower).

5

FP-041 flexible board

A

2-5 2-6

Caution

Note : The sheet cannot be reused.

(Japanese)

Page 10

2-2. SERVICE POSITION

2. DISASSEMBLY

2. DISASSEMBLY

C

4

A

B

3

5

1

2

4

2

3

E

1

C

3

D

2

5

A

2

1

A

3

4

MS-252 board

1

4

3

4

HELP 01

E

6

4

D

9

2

1

3

5

[SERVICE POSITION TO CHECK THE VTR SECTION]

Connection to Check the VTR Section (page 2-9)

1

2

2

1

E

FP-036 flexible board

8

2

7

E

5

2

3

0

A

5

qa

qs

1

6

7

3

8

1

9

4

DSC-M1

2-7 2-8

Page 11

2. DISASSEMBLY

2. DISASSEMBLY

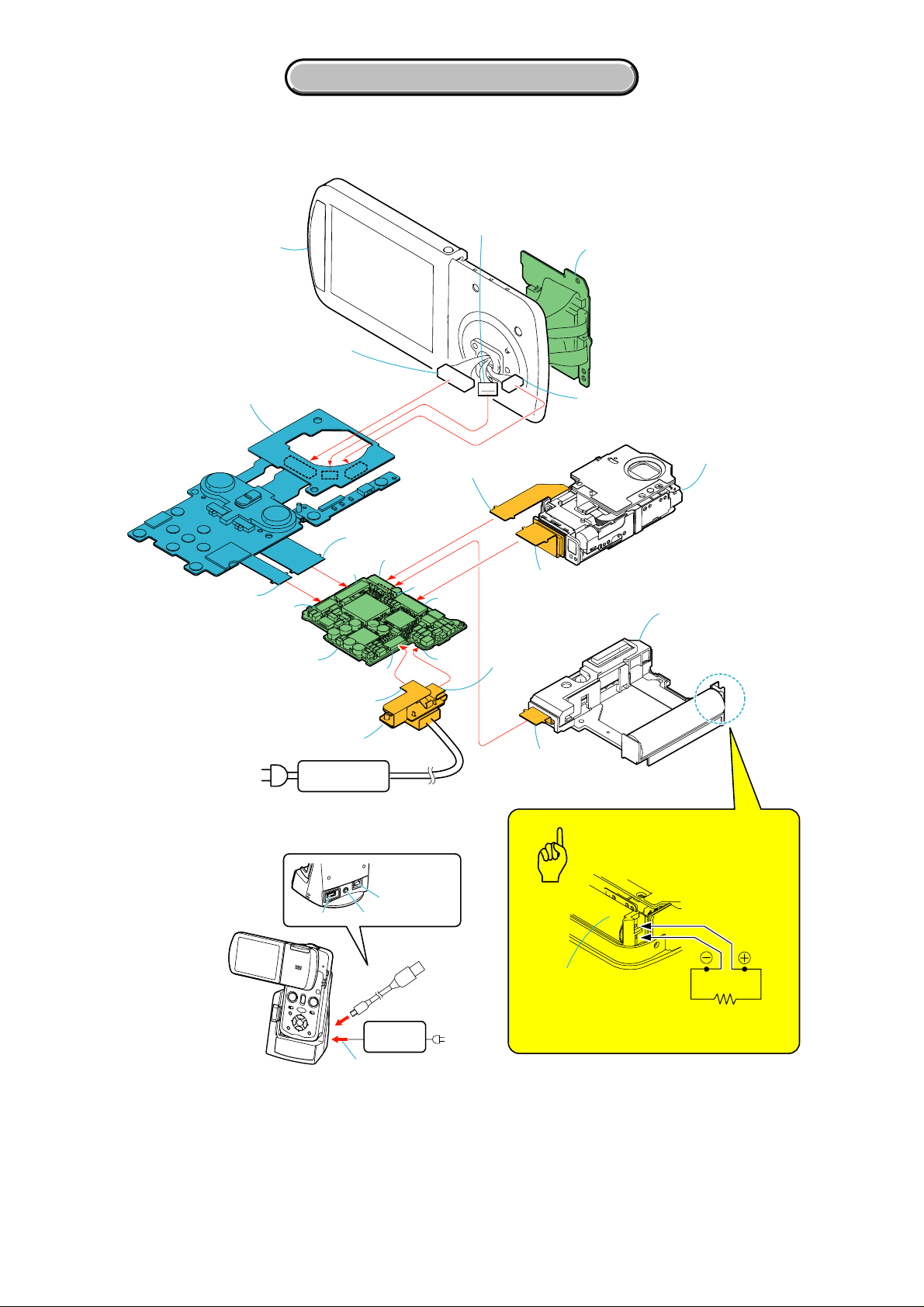

[SERVICE POSITION TO CHECK THE SY-114 BOARD]

Harness

(MA-154) (10P)

LCD section

Harness

(PD-130) (20P)

MS-252 board

Control switch block

(PW80000)

CN003

CN001

FP-035 flexible board

(25P)

PW80000 (39P)

CN702

PW80000 (19P)

SY-114 board

CN751

CN752

CN703

CN707

CN701

CN704

FP-036 flexible board

(19P)

FP-036 flexible board

AC IN

AC power

adaptor

DC-IN

Note1: When checking the VIDEO AMP (SY-114 board IC302)

or the USB circuit, connect the Syber-shot station (UC-MA).

CN002

Harness

(MS-121) (12P)

FP-037 flexible board

(33P)

FP-036 flexible board

(6P)

Flash unit

(FL80000)

(16P)

Caution

Lens section

Flash unit

Discharging the capacitor

DSC-M1

Syber-shot station

UC-MA (1-818-873-11)

DC IN jack

To DC IN jack

A/V OUT jack

USB connector

USB connector

(1-827-754-21)

AC power

adaptor

AC IN

2-9

Capacitor

Shorting jig

(1k

Ω

/ 1W)

Page 12

2. DISASSEMBLY

2. DISASSEMBLY

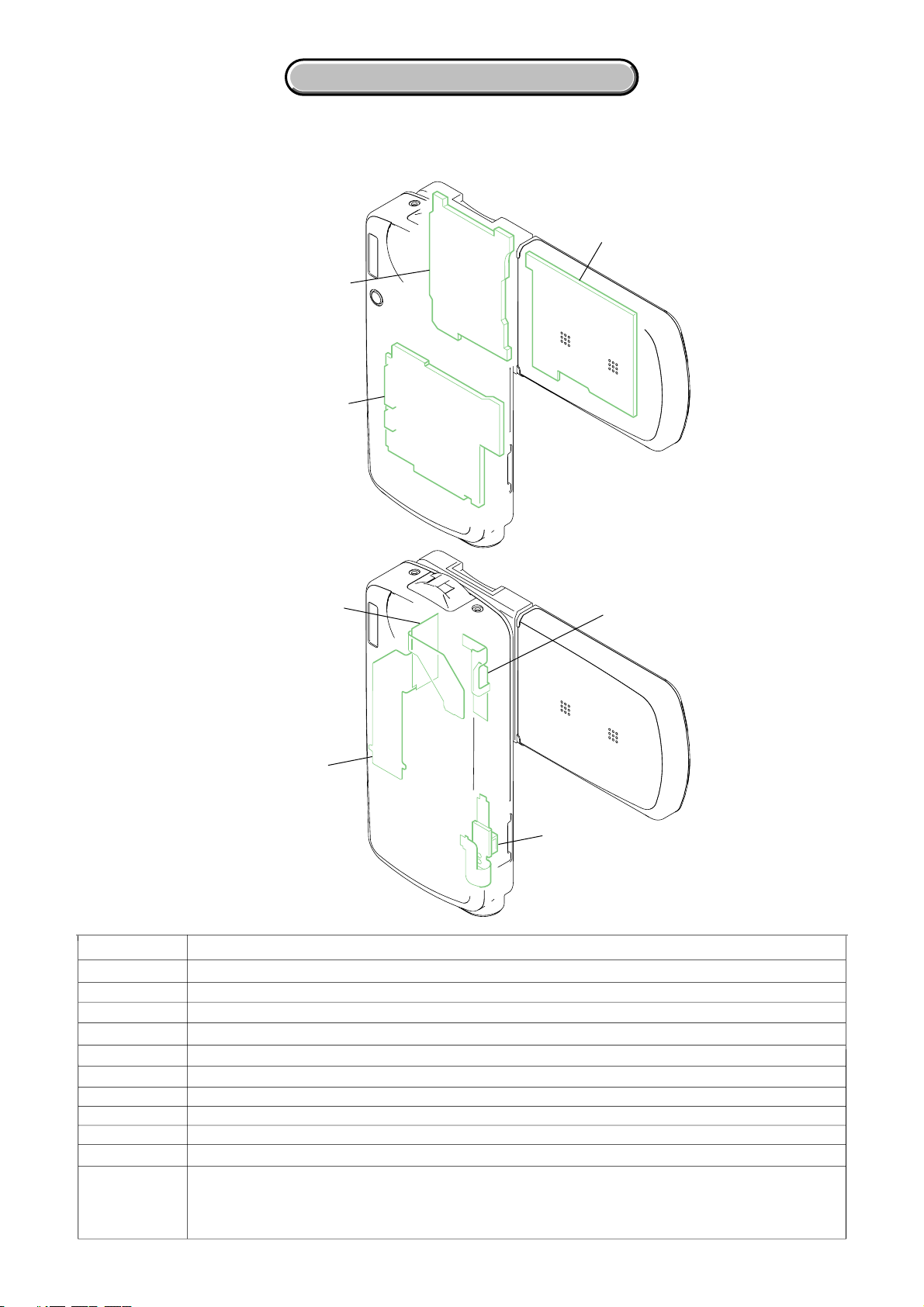

2-3. CIRCUIT BOARDS LOCATION

The flexible boards contained in the lens block are not shown.

MS-252

SY-114

PM-045

NAME

FP-035

FP-036

FP-037

FP-038

FP-039

FP-040

FP-041

LD-175

MS-252

PM-045

SY-114

LD-175

FP-035

FP-036

FUNCTION

LENS DRIVE/BARRIER IF, LED DRIVE

MULTI CONNECTOR

CCD IMAGER

RELAY

BATTERY

LITHIUM BATTERY

LCD O/T SWITCH

LENS DRIVE

MS I/O, CONNECTOR

LCD PANEL DRIVE, MIC AMP

CAMERA A/D CONV., TIMING GENERATOR, CAMERA DSP, LENS CONTROL,

CAMERA SYSTEM CONTROL, DIGITAL SIGNAL PROCESS, HI CONTROL, AUDIO I/O,

DC/DC CONVERTER, CONNECTOR, FLASH DRIVE, CONNECTOR

FP-041

DSC-M1

2-10

Page 13

2. DISASSEMBLY

2. DISASSEMBLY

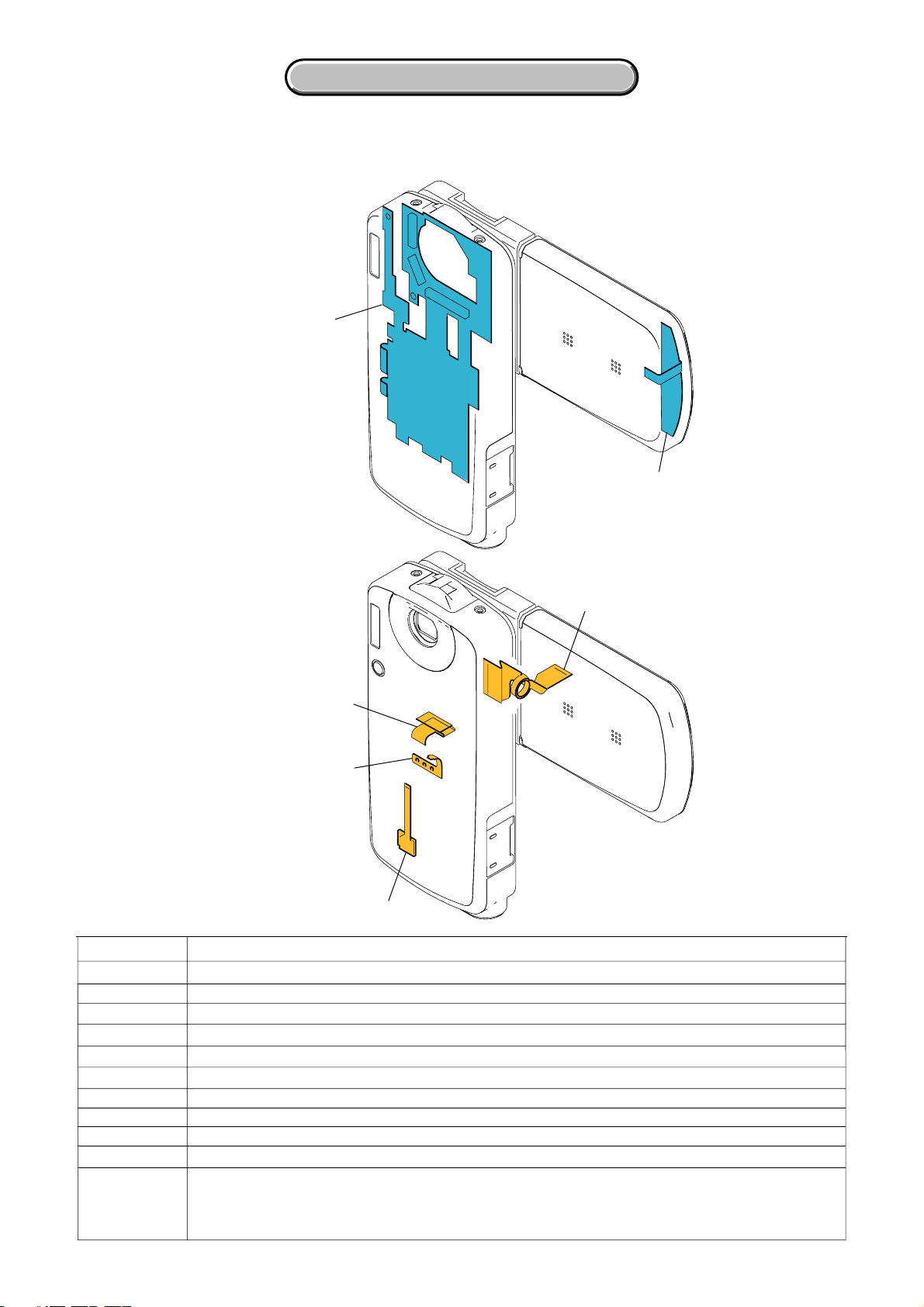

2-4. FLEXIBLE BOARDS LOCATION

The flexible boards contained in the lens block are not shown.

CONTROL SWITCH BLOCK

(PW80000)

CONTROL SWITCH BLOCK

(PB80000)

NAME

FP-035

FP-036

FP-037

FP-038

FP-039

FP-040

FP-041

LD-175

MS-252

PM-045

SY-114

FP-038

FP-037

FP-039

FP-040

FUNCTION

LENS DRIVE/BARRIER IF, LED DRIVE

MULTI CONNECTOR

CCD IMAGER

RELAY

BATTERY

LITHIUM BATTERY

LCD O/T SWITCH

LENS DRIVE

MS I/O, CONNECTOR

LCD PANEL DRIVE, MIC AMP

CAMERA A/D CONV., TIMING GENERATOR, CAMERA DSP, LENS CONTROL,

CAMERA SYSTEM CONTROL, DIGITAL SIGNAL PROCESS, HI CONTROL, AUDIO I/O,

DC/DC CONVERTER, CONNECTOR, FLASH DRIVE, CONNECTOR

DSC-M1

2-11E

Page 14

HELP 01

1

BT cover, BT arm

2

Multi holder assembly

3

BT arm

4

Claw

5

Aaaemble or install the Battery holder section, etc.

in the direction of the arrow.

1

4

3

2

5

HELP

Sheet attachment positions and procedures of processing the flexible boards/harnesses are shown.

DSC-M1

HELP

Page 15

HELP 02

2

1

LCD hinge assembly

1

2

FP-038 flexible board

Note: Be very careful not to

damage the flexible board.

Caution

Note : The sheet cannot be reused.

3

3

Twist the FP-038 flexible board.

Note: Be very careful not to

damage the flexible board.

5

5

Hinge adhesive sheet (upper)

6

FP-038 flexible board (31P)

Note: Be very careful not to

damage the flexible board.

4

4

6

Twist the FP-038 flexible board.

DSC-M1

HELP

Page 16

Link

Link

3. BLOCK DIAGRAMS

OVERALL BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (1/2)

OVERALL BLOCK DIAGRAM (2/2) POWER BLOCK DIAGRAM (2/2)

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (1/2)

POWER BLOCK DIAGRAM (2/2)OVERALL BLOCK DIAGRAM (2/2)

DSC-M1

Page 17

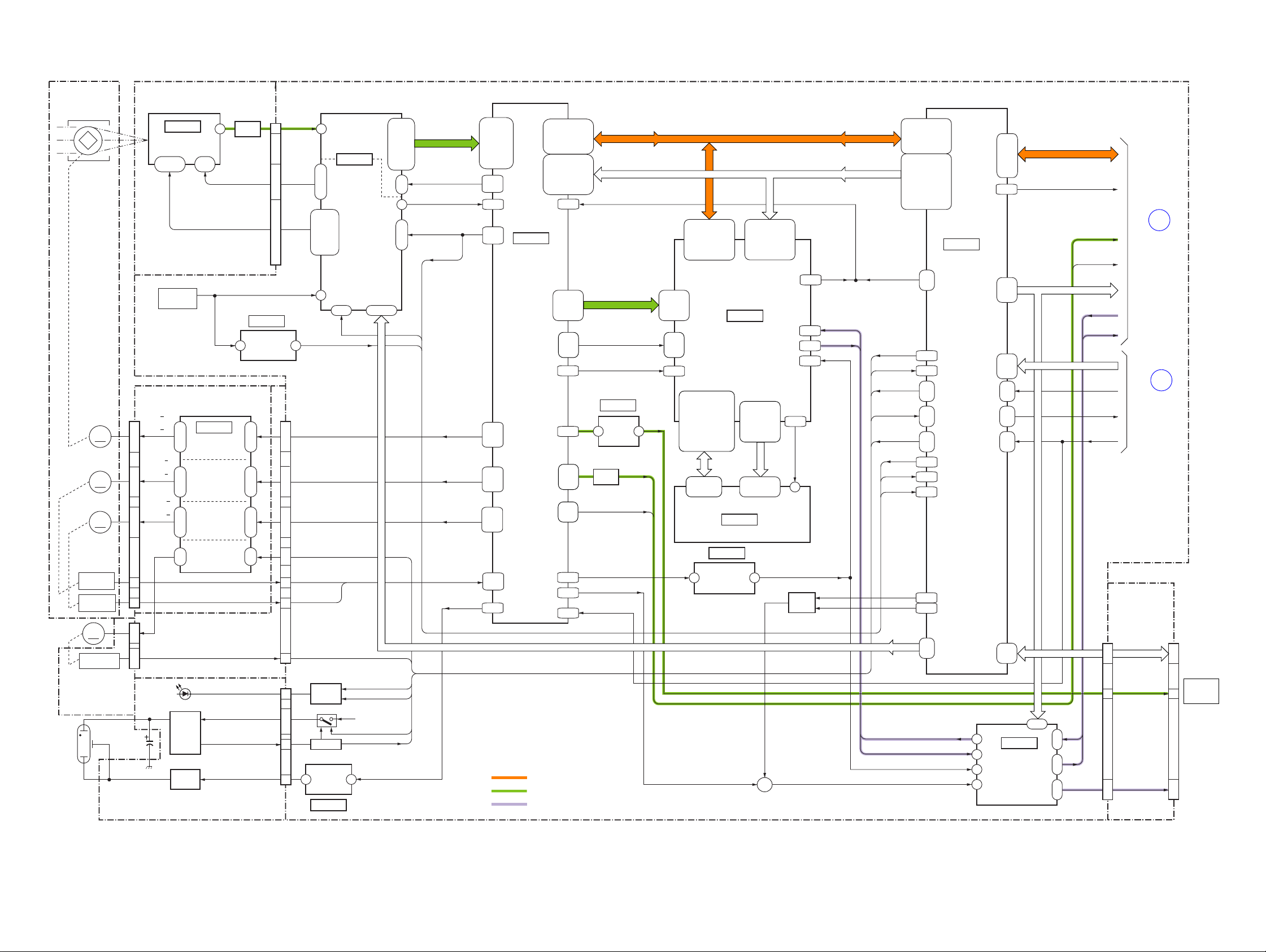

3. BLOCK DIAGRAMS

3-1. OVERALL BLOCK DIAGRAM (1/2)

LENS UNIT

IRIS

SHUTTER

ZOOM RESET

SENSOR

FOCUS RESET

SENSOR

LENS

BARRIER

MOTOR

LENS BARRIER

OPEN SENSOR

LENS UNIT

PI (SENSOR)

BOARD

XENON

TUBE

IRIS

MOTOR

M

ZOOM

MOTOR

M

FOCUS

MOTOR

M

M

PH001

FLASH UNIT (FL80000)

CCD BLOCK ASS'Y

FP-037 (FLEXIBLE BOARD)

IC001

CCD IMAGER

1-5,7,8,9

11-14

54MHz

XTAL OSC

V1A,V1B

V2

V3A,V3B

V4

V5A,V5B

V6

V7A,V7B

V8

X151

24-20

LD-175 BOARD

CN002

IRIS A

IRIS A

IRIS B

19

18

21

20

13

12

14

15

8

10

11

9

2

5

4

|

1

5

6

C901

MAIN

CAPACITOR

XE K(L)

CN501

XE A(H)

G4

H4

G5

IRIS MOTOR

H6

DRIVE

C1

ZOOM MOTOR

D2

DRIVE

E1

E2

A6

FOCUS MOTOR

B5

DRIVE

A4

B4

LENS BARRIER

E7

MOTOR DRIVE

D7

IC001

IRIS B

ZOOM A

ZOOM A

ZOOM B

ZOOM B

FOCUS A

FOCUS A

FOCUS B

FOCUS B

LENSV OUTA

LENSV OUTB

FP-035

(FLEXIBLE BOARD)

LENSV OPEN SENS

D003

(AF LED)

Q001, T002

HIGH

VOLTAGE

CHARGER

Q004

FLASH

DRIVE

17

Q004

BUFFER

H1A,H1B

H2A,H2B

RG

AF LED K

STB UNREG

STB FULL

IGBT ON

4

13

12

10

9

7

19

|

23

25

26

27

29

|

32

CK

(1/9)

IC152

FREQUENCY

DEVIDER

G1

H2

G2

G3

B3

B2

A2

A1

C8

B8

C7

B7

F7

F8

CN701

9

7

8

15

13

14

12

10

11

5

4

16

19

1

1

16

|

12

4

3

CCD OUT

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SY-114 BOARD (1/2)

HR EN3

HR DIR3A

HR DIR3B

HR EN0

HR DIR0A

HR DIR0B

HR EN2

HR DIR2A

HR DIR2B

STRB ON

Y13, AB13

Y14, AA13

AB14, Y15

AB15, AA14

AA15, Y16

AB16, AA16

AB17, AA17

AA18

Y18

AC16

Y17

AB18

N21

L21

P21

K20

L22

J21

M21

M20

N20

F20

F21

AB4

CAM SO, SCK

U4, V3, V2, W1

V4, W2, W4, Y4

Y2, AA1, W3, AA2

Y3, AA3, AC1, AB2

J3, L2, L4, L1, K3

L3, M2, M4, M3, N2

N3, P2, N4, P4, P3

R1, R3, R2, T3, T1

R4, T2, T4, U2, U3

T23

(2/9)

IC301

CAMERA

DSP

B21, D19

C20, B20

A20, D18

C19, B19

D22

C22

D20

B22

F23

E23

C23

D23

C18

D17

AC3

AC12

T20

VIDEO/AUDIO SIGNAL

VIDEO SIGNAL

AUDIO SIGNAL

MC D0 - MC D15

MC A1 - MC A25 MC A1 - MC A25

MC CKIO

(4/9)

IC101

CODEC

IC102

C3, A2, D4, B3, A3

D5, D6, C5, B5, A5

H8, C6, B6, D7, A7

G8, D8, B8, C8, G9

B9

MC A1 - MC A21

A0 - A11,

A13,A14

U19, T18, V20

U18, W20, Y21

N14, P15, AA21

Y20, W19, AA20

Y19, AA19

26-28,63-69

25,22,24,23

A0 - A11,

BA1,BA0

(4/9)

YO

RO

GO

BO

HD0

PANEL V

YC0 - YC7

HD

VD

FLD

FCK27

IC302

4

Q302-304

BUFFER

(2/9)

VIDEO

AMP

PANEL R

PANEL G

PANEL B

H9, D10, C10, G10

H10, A11, C11, C12

D12, H11, B12, A13

C13, D13, B13, G12

MC D0 - MC D15

AA3, W4

Y3, AA2

P9, R8

AA1, Y2

P11

V10

W10

AA9

DQ0 - DQ31

U20, U18, U21, U19

K20, U14, K18, K19

K15, K14, L21, L19

M19, M18, L14, M20

V OUT

2

N21, N19, N18, N20

M15, P19, P20, R21

R20, R19, R18, T20

T19, U21, N15, U20

3-14,77-88

32-43,48-59

DQ0 - DQ31

SDRAM

(2/9)

IC303

ADCK

AOUT

XSYS RST

FREQUENCY

1

DEVIDER

ADA ADCK

5

BEEP

+

51

HR EN3

HR DIR3A

HR DIR3B

HR EN0

HR DIR0A

HR DIR0B

HR EN2

HR DIR2A

HR DIR2B

LENSV ENB

LENSV DIR

XZM RST SENS

XFC RST SENS

CN702

CN707

Q653

2 4

86

37

42

48

51

33

10, 13

113, 17

20, 109

112, 115

125, 119

118, 121

84

Q703

LED

DRIVE

Q651,652

SW

IGBT

DRIVE

IC651

S/H

(1/9)

IC151

TIMING

GENERATOR

123,3

(8/9)

134,136

126-129

XCAM RST

PRELAMP AF CONT

SELF TIMER LED

ST UNREG

STRB CHRG

XSTRB FULL

STRB ON

2, 4

6, 9

12, 15

18, 21

24, 27

30, 32

64

55

99

49

66

101

120

EXT CLK

CA AD0 - CA AD13

CLP DM

CLP OB

MCK TG

CA HD

CAM F

CAM F

XZM RST SENS1

XFC RST SENS

SDR CLK

G21

71

CLK

Q501

MOD

W14

L21, L23, M24,K23

MC D0 - MC D15

H22, J21, J22, F24

K21, H21, M23, K22

G21, L24, F23, E23

V22, V21, V23, R22

W22, J22, W21, T22

R23, N21, P22, P21

P23, R21, M22, T21

P24, J21, J23, N22

J24, N23, T24, M21

T23

(3/9)

IC501

CAMERA

AD19

AC15

H23

C23

AC12

AB7

AD14

SYSTEM

A7

CONTROL

H1

G3

B6

B1

F21

F1

A6

MC CKIO

ADA SOA

C2

ADA SIA

H7

ADA ADCK

D2

STRB CHRG

XSTRB FULL

LENSV ENB

LENSV DIR

LENSV OPENSENS

PRELAMP AF CONT

SELF TIMER LED

XCAM RST

CAM F

EXT CLK

MELODY ENV

MELODY

B16

C15

A15

D15

B15

D16

C22

B11

A11

C11

D13

B13

C13

AB5

AB13

AB22

B23

D14

K2

MC MSDIO,D1-D3

MC MSBS

MC MSCLK

SYS SO, SI, SCK

FR SO, SI, SCK

XACCESS LED

PANEL R

PANEL G

PANEL B

HD0

PANEL V

MIC L

MIC R

SP+

SP-

XAE LOCK ON

XSHTR ON

PB MODE LED

REC MODE LED

XSYS RST

1

TO

OVERALL

BLOCK DIAGRAM

(2/2)

(PAGE 3-3)

TO

OVERALL

BLOCK DIAGRAM

(2/2)

(PAGE 3-3)

FP-036

(FLEXIBLE

2

BOARD)

(1/2)

CAM SO, SCK

A12

B12

ADA SOA

ADA SIA

ADA ADCK

BEEP IN

L1, M1

J1, K1

27

26

31

14

(6/9)

IC801

AUDIO

AMP

USBPHY D+, D-

SYS SO,SCK

38,35

MIC L

MIC R

71

77

SP+

SP-

17

16

2

4

CN703

16

14

2

6

4

VIDEO OUT

AUDIO L OUT

AUDIO R OUT

10

12

17

16

18

CN001

MULTH

CONNECTOR

(CRADLE)

DSC-M1

3-1 3-2

Page 18

3-2. OVERALL BLOCK DIAGRAM (2/2)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

CN001

MULTH

CONNECTOR

(CRADLE)

14

11

13

24

3

1

BATTERY

TERMINAL

FP-036

(FLEXIBLE

BOARD)

(2/2)

AV JACK IN

USB JACK IN

XMULTI JACK IN

BATT/XEXT

ACV UNREG

|

FP-040

(FLEXIBLE

BOARD)

BT001

LITHIUM

BATTERY

(SECONDARY)

FP-039

(FLEXIBLE

BOARD)

S

SY-114 BOARD (2/2)

CN703

11

19

10

9

4

|

6

CN704

CN706

1

VL 3V

|

3

CN705BT901

11

BATT UNREG

|

7

BATT SIG

6

5

REG GND

|

1

Q002

TO

OVERALL

BLOCK DIAGRAM

(1/2)

(PAGE 3-2)

D013

2

F002

F003

D015

F004

D036

VL 3V

D011

D8

A10

B11

D9

E9

D1

E5

D4

E4

Q409,411

ST UNREG

ACV UNREG

BATT UNREG

3V

REG

OUT8A

OUT8B

BATTERY

CHARGER

IC001

IC002

IC003

XAE LOCK ON

XSHTR ON

REC MODE LED

PB MODE LED

XSYS RST

FR SO, SI, SCK

BATT SIG

BATTERY IN

DETECT

FET DRIVE

(7/9)

DC/DC

CONVERTER

RESET

(7/9)

(7/9)

A11

L8

K8

B7

B9

B7

D2

E3

C7

D7

EVER 3.0V

X402

32.768KHz

Q407

I/F

DDCON SO, SCK

D 1.5V

D 2.8V

A 2.8V

AU 2.8V

A 3.1V

M 5V

ST 5V

CAM 3.1V

CAM 15.0V

CAM -8.0V

PANEL 5V

PANEL 8.5V

BL LEV

BL H

BL L

D 1.2V

CAM -0.5V

Q406

FR SO

D2

FR SI

D1

XFR SCK

E1

J4

32KHz IN

32KHz OUT

J5

A3

AV JACK IN

C8

XUSB JACK IN

XMULTI JACK IN

C4

A7

BATT/XEXT

BATT SI

G2

G1

BATT SO

C1

DDCON SO

D3

DDCON SCK

XRSTX

D7

A5

BACK UP VCC

H4

A9

BATT IN

INIT CHARGE

J1

H2

FAST CHARGE

E8

SYS DD ON

XCHARGE/XSTRB LED

KEY AD2

KEY AD1

KEY AD3

KEY AD0

XPWR ON

(5/9)

IC491

HI CONTROL

XSYS RST

MS IN

XLCD OPEN SW

Q753

LED

DRIVE

Q754

LED

DRIVE

XRESET SW

CN752

CN751

16

15

4

5

7

8

9

17

10

18

3

2

29

6

4

3

5

7

2

8

9

25

26

27

CN002

XMS IN

CN003

S213

RESET

9

10

8

6

11

5

7

4

15

14

13

9

10

8

6

11

5

7

4

15

14

13

CN004

CN005

XAE LOCK ON

XSHTR ON

REC MODE LED

PB MODE LED

B1

G6

H6

J7

J6

B8

B3

B6

Q404

MC MSDIO,D1-D3

MC MSBS

MC MSCLK

XACCESS LED

PANEL R

PANEL G

PANEL B

1

TO

OVERALL

BLOCK DIAGRAM

(1/2)

(PAGE 3-2)

B7

HD0

PANEL V

SYS SO, SI, SCK

MIC L

MIC R

SP+

SP-

BL LEV

BL H

BL L

CN752

33

34

20

23

21

39

36

37

16

18

11

12

14

XLCD OPEN SW

CN001

7

6

20

17

19

11

1

4

3

3

1

10

9

7

8

7

20

17

19

11

1

4

3

3

1

10

9

7

8

6

CN003

S204

SHUTTER

D201 (REC MODE)

D203 (PB MODE)

D202 (FLASH/CHARGE)

S212

START/STOP

S210

ZOOM

S214

POWER

S215

MODE

MS-252 BOARD

Q002

LED

DRIVE

CN002

24

23

22

15

13

31

28

30

19

11

9

8

1

3

FP-038

(FLEXIBLE

BOARD)

6

5

6

1

CN006

CONTROL SWITCH

BLOCK (PW80000)

S206-209,211,216

RIGHT,SET,DOWN,LEFT

UP,X1SHOTM

S201-203,205

DISPLAY,DUST,MENU

STILL/XMIP

4,3,5,7,

2,8

6

D004(ACCESS)

7

8

9

15

Q205

LPF

17

1

4

2

11

19

21

22

29

27

24

25

CN204

(LCD TURN)

(LCD OPEN)

CN001

MEMORY

STICK

DUO

SP901

SPEAKER

PM-045 BOARD

(1/2)

34

33

IC201

32

RGB

DRIVE

48

1

45

TIMING

42

GENERATOR

44

3

31

(2/2)

14

IC301

22

MIC AMP

CN203

2

3

4

S412

S411

20

21

22

26

24

VST,VCK,EN,DWN

28

XSTBY,PCG,HST,REF

24

WIDE,HCK2,HCK1,RGT

|

20

17

|

5

35

1

S001-003

PLAY/,

PHOTO/,

MOVIE

VIDEO/AUDIO SIGNAL

VIDEO SIGNAL

AUDIO SIGNAL

BL H

BL L

COM

PSIG

R

G

B

CN201

CN202

CN302

CN301

4

5

3

24

23

6

22

|

19

14

|

11

9

|

7

BACK LIGHT

2

1

3

1

1

LCD901

COLOR

LCD UNIT

MIC

L

MIC

R

CONTROL SWITCH

BLOCK (PB80000)

FP-041

(FLEXIBLE BOARD)

LED901

MIC901

MIC902

DSC-M1

3-3 3-4

Page 19

3-3. POWER BLOCK DIAGRAM (1/2)

SY-114 BOARD (1/2)

FP-036

(FLEXIBLE

BOARD)

CN703

9

CN704

4

6

CN705

11

BATT UNREG

7

BATT SIG

6

REG GND

5

1

CB701

CN001

MULTH

CONNECTOR

(CRADLE)

TERMINAL

BT901

BATTERY

BATT/XEXT

24

3

ACV UNRG

1

S

FP-039

(FLEXIBLE

BOARD)

FP-040

(FLEXIBLE

BOARD)

BT001

LITHIUM

BATTERY

(SECONDARY)

D202

(FLASH/CHARGE)

S214

POWER

S213

RESET

CN706

1

3

CN752

3

7

8

6

VL 3V

Q409,411

Q407

I/F

XRESET SW

EVER 3.0V

CONTROL

SWITCH

BLOCK

(PW80000)

(1/2)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

Q002

H8

G8

A7

G2

G1

B8

B1

BATT SENS

ACV SENS

BATT/XEXT

BATT SI

BATT SO

X PWR ON

XCHARGE/

XSTRB LED

F002

F003

D036

D015

D013

IC491

HI CONTROL

BACK UP VCC

DDCON SO

DDCON SCK

XCS DDCON

SYS DD ON

INIT CHARGE

FAST CHARGE

DD CON SENS

XSYS RST

XRSTX

BATT IN

F004

(5/9)

A5

H4

D7

A9

C1

D3

H1

E8

J1

H2

F8

B3

D 1.5V

INIT CHARGE

FAST CHARGE

L002

L001

EVER 3.0V

D011

D1

E5

D4

D2

E4

E3

D9

E9

B11

A11

A10

D8

B9

B7

A7

L8

K8

K7

C7

D7

BATTERY

CHARGER

FET

DRIVE

OUT8A

OUT8B

3V

REG

RESET

DIN

CLK

LD

SYS DD ON

IC001

DC/DC

CONVERTER

BATTERY IN

DETECT

(7/9)

VCC1A

VCC1B

VCC1C

OUT11A

OUT11B

OUT11C

OUT12A

OUT12B

OUT12C

VCH1A

VCH1B

VCH1C(FB4)

VCH7

VCC2

OUT2

VCH2

OUT3A

OUT3B

OUT3C

VCH3A(FB3)

VCH3B

VCH3C(FB6)

VCH3S

VCC GD

OUT4

VCH4

VCC5

OUT5

VCH5

OUT6

VCH6

ICH6

REF6

CBG

VLDO4

VLDO5

G11

G10

G9

H11

H10

J11

L11

K10

L10

F10

E11

J9

K9

L9

K3

F9

J3

K1

J2

J1

H4

H3

H2

H1

K6

J6

K5

L5

J5

F1

G1

G2

B1

B5

C8

B8

ST UNREG

ACV UNREG

L006

L005

D017

(RECT)

D023(RECT)

L009

D025

(RECT)

D026

(RECT)

L007

L008

D021

(RECT)

L004

BL H

BL L

BL LEV

Q003,004

EMERGENCY

DET

2

VSS

3

4

IC003

-0.5V REG

1

3

4

VDD

5

IC002

1.2V

REG

1

(7/9)

SHUNT

REG

Q001

(7/9)

5

Q005

L003

L010

AU 2.8V

PANEL 5V

ST 5V

PANEL 8.5V

PANEL 8.5V

AU 2.8V

PANEL 5.0V

BL LEV

BL H

BL L

ST UNREG

ST 5V

AU 2.8V

A 2.8V

D 2.8V

D 1.2V

D 1.5V

M 5V

1

TO

POWER

BLOCK DIAGRAM

(2/2)

(PAGE 3-7)

CAM 15V

CAM -8.0V

CAM -0.5V

CAM 3.1V

A 3.1V

XSYS RST

DSC-M1

3-5 3-6

Page 20

3-4. POWER BLOCK DIAGRAM (2/2)

( ) : Number in parenthesis ( ) indicates the division number of schematic diagram where the component is located.

SY-114 BOARD (2/2)

PANEL 8.5V

AU 2.8V

PANEL 5.0V

BL LEV

BL H

BL L

1

TO

POWER

BLOCK DIAGRAM

(1/2)

(PAGE 3-6)

ST UNREG

ST 5V

AU 2.8V

A 2.8V

D 2.8V

D 1.2V

D 1.5V

M 5V

CAM 15V

CAM -8.0V

CAM -0.5V

CAM 3.1V

A 3.1V

XSYS RST

D 2.8V

AU 2.8V

D 2.8V

D 1.2V

3

4

(3/9)

IC502

1.8V REG

Q803

REG

1

SP VCC

D 1.8V

(2/9)

IC301

CAMERA

DSP

IC302

VIDEO

AMP

IC303

FREQUENCY

DEVIDER

(4/9)

IC101

CODEC

IC102

SDRAM

(6/9)

IC801

AUDIO

AMP

(3/9)

IC501

CAMERA

SYSTEM

CONTROL

(2/9)

(2/9)

(4/9)

V21

J22

T20

AD18

AD19

AC15

AC20

D14

K2

XZM RST LED

XFC RST LED

XSYS RST

MS PWR ON

STRB CHRG

XSTRB FULL

CAM DD ON

XSYS RST

PANEL 8.5V

AU 2.8V

PANEL 5.0V

XSYS RST

BL LEV

BL H

BL L

AU 2.8V

A 3.1V

MS PWR ON

CN751

32

PANEL 2.8V

30

31

29

39

36

37

14

CONTROL SWITCH

BLOCK

(PW80000)(2/2)

11

10

CN003

CN001

CN002

ST UNREG

STRB CHRG

XSTRB FULL

M 5V

ST 5V

XSYS RST

XZM RST LED

8

10

9

11

1

4

3

6 6

2

3

XFC RST LED

D 2.8V

M 5V

CAM 15.0V

CAM -8.0V

CAM DD ON

CAM 3.1V

CAM -0.5V

A 2.8V

D 2.8V

MS-252 BOARD

8

10

9

11

1

4

3

CN005

CN003

Q001

2

3

CN004

Q651,652

Q653

Q655,656

Q701

Q151,152

X151

54MHz

XTAL

OSC

CN002

VCC

9

IC651

IGBT

DRIVE

Q702

(1/9)

IC151

TIMING

GENERATOR

(1/9)

IC152

FREQUENCY

DEVIDER

FP-038

(FLEXIBLE BOARD)

14

17

18

16

19

11

9

8

MIC 2.8V

12

CN001

MEMORY

STICK

DUO

CN707

16

STB UNREG

|

12

STB FULL

4

2

FLASH UNIT (FL80000)

FP-035

(FLEXIBLE

BOARD)

CN702

17

20

23

24

25

CN701

1

17

CCD BLOCK ASS'Y

FP-037

(FLEXIBLE BOARD)

PM-045 BOARD

16

13

12

14

11

19

21

22

18

Q001, T002

HIGH

VOLTAGE

CHARGER

D003

AF LED

3

31

CN204

XE A(H)

LD-175 BOARD

Z RST VCC

F RST VCC

IC001

IRIS/ZOOM/FOCUS

MOTOR DRIVE,

LENS BARRIER

MOTOR DRIVE

IC001

CCD

IMAGER

IC201

RGB DRIVE,

TIMING

GENERATOR

IC301

MIC

AMP

EVEN

CN002

CN501

LCD901

CN201

18

COLOR

LCD UNIT

BACK LIGHT

BL H

BL L

CN202

C901

MAIN

CAPACITOR

1

3

XENON

TUBE

LENS UNIT

3

6

ZOOM RESET

SENSOR

FOCUS RESET

SENSOR

LENS UNIT

PI (SENSOR)BOARD

PH001

11

LENS BARRIER

OPEN SENSOR

LED901

DSC-M1

3-7 3-8E

Page 21

4-1. FRAME SCHEMATIC DIAGRAM

1

4. PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

7 17

83 2010

11

122 915

13 19

16

18

22144

236 215

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

FP-041

FLEXIBLE BOARD

LCD O/T SWTICH

16

COLOR LCD UNIT

BACK LIGHT

CN001 10P

10

GND

9

VCC

8

SCLK

DATA3

7

INT

6

DATA2

5

SDIO/DATA0

4

3

DATA1

2

BS

1

GND

KEY_AD2_2M

6

N.C

5

REG_GND

4

REG_GND

3

N.C

2

XLCD_OPEN_SW

1

XSYS_SCK

SYS_SI

XPANEL_TG_CS

SYS_SO

SYS_SI

SYS_SO

XSYS_SCK

XPANEL_TG_CS

DIRECT SOLDER LAND

1

TEST2

2

RGT

3

B

4

R

5

G

6

PSIG

7

HCK1

8

HCK2

9

WIDE

10

TEST1

11

REF

12

HST

PCG

13

XSTBY

14

15

VSSG

N.C.

16

VSS

17

18

VDD

DWN

19

EN

20

VCK

21

VST

22

CS

23

COM

24

6PCN202

1

BL_H BL_REG

2

N.C.

3

BL_L IN2-

4

BL_THL

5

N.C.

6

BL_THH

CN006

CN005

20P

REG_GND

REG_GND

PANEL_R

XSYS_RST

PANEL_G

PANEL_B

PD-130 HARNESS

PANEL_B

PANEL_G

PANEL_R

REG_GND

REG_GND

XSYS_RST

20PCN003

6P

PANEL_2.8V

1011121314151617181920

1011121314151617181920

PANEL_2.8V

24PCN201

MIC_L

29

FP-038 FLEXIBLE BOARD

RELAY

123456789

MIC_L

BL_H

PANEL_V

PANEL_8.5V

PANEL_5V

BL_MODE

HDO

HDO

BL_H

PANEL_V

BL_MODE

PANEL_5V

PANEL_8.5V

1

MIC SIG(L)

PM-045 BOARD

(1/2)LCD PANEL DRIVE

(2/2)MIC AMP

KEY_AD2_2

MIC_R

XLCD_TURN_SW

AU_GND

AU_GND

KEY_AD2_2

AU_GND

MIC_R

AU_GND

KEY_AD2_2M

MS-252 BOARD

MS I/O,CONNECTOR

BL_THH

BL_LEV

BL_L

123456789

123456789

BL_L

BL_LEV

BL_THH

MIC_RMIC_L

2

2

MIC GND

2PCN302

29PCN204

MIC_2.8V

BL_LEV

PANEL_V

BL_L

BL_THH

BL_H

BL_MODE

101112131415161718192021222324252627282930

BL_H

PANEL_V

BL_L

BL_MODE

MIC_2.8V

BL_THH

BL_LEV

31PCN002

10PCN003

SP-

XLCD_OPEN_SW

AU_REG_GND

MIC_2.8V

SP+

KEY_AD2_2

10

MA-154

HARNESS

10

SP-

SP+

MIC_2.8V

KEY_AD2_2

AU_REG_GND

XLCD_OPEN_SW

10PCN001

1

MIC SIG(R)

CN301

PANEL_2.8V

PANEL_5.0V

PANEL_8.5V

PANEL_2.8V

XSYS_RST

HDO

PANEL_2.8V

PANEL_8.5V

PANEL_5.0V

XSYS_RST

HDO

PANEL_2.8V

MIC_L

AU_REG_GND

AU_REG_GND

MIC_R

123456789

123456789

MIC_L

MIC_R

AU_REG_GND

AU_REG_GND

CONTROL SWITCH BLOCK

(PW80000)

MIC GND

2P

CN203

6P

PANEL_B

PANEL_G

REG_GND

10111213141516171819202122232425262728

PANEL_B

REG_GND

REG_GND

MSD1

MS_REG_GND

MSBS

101112

MS-121 HARNESS

101112

MSD1

MSBS

MS_REG_GND

REG_GND

XPB_SW

XS/S/t_SW

XPHOTO/T_SW

N.C.

REG_GND

PANEL_R

REG_GND

PANEL_R

PANEL_G

MSD2

MS_DIO

MSD2

MS_DIO

CN002

REG_GND

REG_GND

XMS_IN

XMS_IN

SYS_SI

REG_GND

12PCN004

KSD3

KSD3

12P

XPANEL_TG_CS

XSYS_SCK

SYS_SI

REG_GND

XACCESS_LED

MSCLK

MSCLK

XACCESS_LED

1

2

3

4

5

6

SYS_SO

123456789

XSYS_SCK

XPANEL_TG_CS

MS_POWER_ON

A_3.1V

A_3.1V

MS_POWER_ON

31

SYS_SO

MS_REG_GND

123456789

123456789

MS_REG_GND

CONTROL SWITCH

BLOCK(PB80000)

FLASH UNIT(FL80000)

10111213141516

REG_GND

REG_GND

REG_GND

STB_UNREG

STB_UNREG

REG_GND

16PCN707

CN751

CN752

BT001

LITHIUM

BATTERY

(SECONDARY)

STB_UNREG

STB_UNREG

1

REG_GND

2

MC_MSBS

3

MC_MSD1

4

MC_MSDIO

5

MC_MSD2

6

XMS_IN

7

MC_MSD3

8

MC_MSCLK

9

XACCESS_LED

10

MS_PWR_ON

11

A_3.1V

12

MS_REG_GND

13

MS_REG_GND

14

MIC_2.8V

15

AU_GND

16

MIC_L

17

AU_GND

18

MIC_R

19

AU_GND

20

SYS_SO

21

XSYS_SCK

22

XPANEL_TG_CS

23

SYS_SI

24

PANEL_GND

25

PANEL_R

26

PANEL_G

27

PANEL_B

28

PANEL_GND

29

XSYS_RST

30

PANEL_2.8V

31

PANEL_5.0V

32

PANEL_8.5V

33

HDO

34

PANEL_V

35

BL_MODE

36

BL_H

37

BL_L

38

BL_THH

39

BL_LEV

1

REG_GND

2

XMODE_SW

3

XPWR_ON

4

XREC_MODE_LED_ON

5

XPB_MODE_LED_ON

6

EVER_3.0V

7

XCHARGE/XSTRB_LED

8

XRESET_SW

9

XS/S_SW

10

KEY_AD3

11

SP+

12

SP-

13

REG_GND

14

XLCD_OPEN_SW

15

XSHTR_ON

16

XAE_LOCK_ON

17

KEY_AD1

18

KEY_AD0

19

REG_GND

STB_UNREG

7N.C

8 REG_GND

9 REG_GND

10 LENSV_RST_LED

11 M_5V

CN501

FP-035 FLEXIBLE BOARD

LENS DRIVE/BARRIER IF,

LED DRIVE

3456789

2

1

25

M_5V

M_5V

REG_GND

REG_GND

XSTRB_PWR_ON

STB_FULL

IGBT_ON

AF_LED_5V

AF_LED_K

D_2.8V

REG_GND

REG_GND

F_RST_VCC

XFC_RST_SENS

SY-114 BOARD

(1/9) CAMERA A/D CONV. TIMING GENERATOR

(2/9) CAMERA DSP,LENS CONTROL

(3/9) CAMERA SYSTEM CONTROL

(4/9) DIGITAL SIGNAL PROCESS

39P

(5/9) HI CONTROL

(6/9) AUDIO I/O

(7/9) DC/DC CONVERTER

(8/9) CONNECTOR,FLASH DRIVE

(9/9) CONNECTOR

19P

CN706

VL_3V

12345

FP-040

FLEXIBLE BOARD

LITHIUM BATTERY

LENSV_OPENSENSE

LENSV_OPENSENSE

4 LENSV_OUTA

5

6

11P

Z_RST_VCC

LENS_TEMP

6P

VL_3V

REG_GND

VL_3V

2 LENSV_OUTB

3 LENSV_OUTA

HR_EN0

HR_DIR0B

XZM_RST_SENS

REG_GND

REG_GND

6

1 LENSV_OUTB

HR_DIR0A

25PCN702

HR_EN2

CN703

HR_DIR2B

101112131415161718192021222324

HR_DIR2A

19P

HR_EN3

HR_DIR3B

HR_DIR3A

LENSV_OUTB

LENSV_OUTA

LENSV_DIR

LENSV_ENB

XCAM_DR_PS

HR_DIR3A

HR_DIR3B

HR_DIR2A

HR_DIR2B

HR_DIR0A

HR_DIR0B

XZM_RST_SENS

Z_RST_VCC

LENS_TEMP

XFC_RST_SENS

F_RST_VCC

LENSV_ENB

XCAM_DR_PS

USB_VBUS

USB_GND

USB_GND

USB_GND

USB_GND

AV_JACK_IN

XMULTI_IN

BATT/XEXT

AU_OUT_L

AU_OUT_R

MOTOR UNIT

(PI (SENSOR)BOARD)

REG_GND

HR_EN3

HR_EN2

HR_EN0

THERMAL GLUING

REG_GND

REG_GND

D_2.8V

M_5V

M_5V

123456789

REG_GND

LENSV_DIR

LENSV_RST_LED

LENSV_OPENSENS

19

18

17

16

D+

15

N.C.

14

D-

FP-036

13

12

FLEXIBLE BOARD

11

MULTI CONNECTOR

10

9

8

A_GND

7

A_GND

6

5

A_GND

4

A_GND

3

V_OUT

2

A_GND

1

CN002

LD-175 BOARD

(LENS DRIVE)

33

V8

V7A

V7B

REG_GND

21P

1Z_RST_GND

2Z_RST_SENS

3Z_RST_VCC

4F_RST_GND

5F_RST_SENS

6F_RST_VCC

7N.C

8FOCUS_A

FOCUS_B

9

10FOCUS_A

11FOCUS_B

ZOOM_A

12

13ZOOM_A

14ZOOM_B

ZOOM_B

15

16TEMP_OUT

17TEMP_GND

IRIS_A

18

19IRIS_A

IRIS_B

20

21IRIS_B

FP-037 FLEXIBLE BOARD

CCD IMAGER

V6

V4

V2

V3B

V5B

VST

V3A

V5A

VHLD

6P

CN704

ACV_UNREG05ACV_UNREG06ACV_UNREG0

1 ACV_GND

2 ACV_GND

3 ACV_GND

4

2

4

LANC_DC

ACV_UNREG

26PCN001

ACV_UNREG3ACV_UNREG5XLANC_JACK_IN7USB_LED9USB_HOST11USB_VBUS13XMULTI_IN15EXT_STRB_ON

1

LENS-UNIT

V1A

V1B

REG_GND

10D+12

6

8

LANC_SIG

USB/LANC_GND

VSUB_CONT

CAM_-8.0V_CD

33PCN701

14

D-

AV_JACK_IN

H1A

SHT

REG_GND

18

20

22

16

A_GND

A_OUT_L

A_OUT_R

V_OUT19V_GND21AUX23ACV_GND25ACV_GND

17

LENS-BARRIER

IC001

CCD

IMAGER

1011121314151617181920212223242526272829303132

H1B

H2A

H2B

REG_GND

REG_GND

24

26

AUX

ACV_GND

BATT/XEXT

FP-039

FLEXIBLE BOARD

BATTERY

BATT_SIG

11PCN705

REG_GND

REG_GND

REG_GND

REG_GND

123456789

REG_GND

123456789

10

POWERSAVE

CAM_15V_CD

11

BATT_UNREG

BATT_UNREG

BATT_UNREG

BATT_UNREG

BATT_UNREG

RG

CCD_OUT

REG_GND

REG_GND

REG_GND

DSC-M1

4-1

4-2

FRAME SCHEMATIC DIAGRAM

Page 22

Link

Link

4-2. SCHEMATIC DIAGRAMS

FLASH UNIT (FL80000)

FLASH UNIT (FL80000)

FP-036 FLEXIBLE BOARD

FP-036 FLEXIBLE BOARD

FP-037 FLEXIBLE BOARD

FP-037 FLEXIBLE BOARD

FP-038 FLEXIBLE BOARD

FP-038 FLEXIBLE BOARD

FP-039 FLEXIBLE BOARD

FP-039 FLEXIBLE BOARD

FP-040 FLEXIBLE BOARD

FP-040 FLEXIBLE BOARD

FP-041 FLEXIBLE BOARD

FP-041 FLEXIBLE BOARD

(FLASH)

(FLASH)

(MULTI CONNECTOR)

(MULTI CONNECTOR)

(CCD IMAGER)

(CCD IMAGER)

(RELAY)

(RELAY)

(BATTERY)

(BATTERY)

(LITHIUM BATTERY)

(LITHIUM BATTERY)

(LCD O/T SWITCH)

(LCD O/T SWITCH)

MS-252 BOARD

MS-252 BOARD

CONTROL SWITCH BLOCK

CONTROL SWITCH BLOCK

MOTOR UNIT (PI (SENSOR) BOARD

MOTOR UNIT (PI (SENSOR) BOARD

(

PI SENSOR

(

PI SENSOR

PM-045 BOARD (1/2)

PM-045 BOARD (1/2)

PM-045 BOARD (2/2)

PM-045 BOARD (2/2)

CONTROL SWITCH BLOCK

CONTROL SWITCH BLOCK

(FUNCTION KEY)

(FUNCTION KEY)

CONTROL SWITCH BLOCK

CONTROL SWITCH BLOCK

(CONNECTOR)

(CONNECTOR)

(MS I/O, CONNECTOR)

(MS I/O, CONNECTOR)

)

)

(LCD PANEL DRIVE)

(LCD PANEL DRIVE)

(MIC AMP)

(MIC AMP)

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

WAVEFORMSCOMMON NOTE FOR SCHEMATIC DIAGRAMS

(PB80000)

(PB80000)

(PW80000) (1/2)

(PW80000) (1/2)

(PW80000) (2/2)

(PW80000) (2/2)

)

)

DSC-M1

Page 23

4-2. SCHEMATIC DIAGRAMS

4-2. SCHEMATIC DIAGRAMS

THIS NOTE IS COMMON FOR SCHEMATIC DIAGRAMS

(In addition to this, the necessary note is printed in each block)

(For schematic diagrams)

• All capacitors are in µF unless otherwise noted. pF : µ

Link

µF. 50 V or less are not indicated except for electrolytics

and tantalums.

• Chip resistors are 1/10 W unless otherwise noted.

kΩ=1000 Ω, MΩ=1000 kΩ.

• Caution when replacing chip parts.

New parts must be attached after removal of chip.

Be careful not to heat the minus side of tantalum

capacitor, Because it is damaged by the heat.

• Some chip part will be indicated as follows.

Example C541 L452

22U 10UH

TA A 2520

Kinds of capacitor

Temperature characteristics

External dimensions (mm)

• Constants of resistors, capacitors, ICs and etc with XX

indicate that they are not used.

In such cases, the unused circuits may be indicated.

• Parts with * differ according to the model/destination.

Refer to the mount table for each function.

• All variable and adjustable resistors have characteristic

curve B, unless otherwise noted.

• Signal name

XEDIT → EDIT PB/XREC → PB/REC

• 2: non flammable resistor

• 5: fusible resistor

• C : panel designation

• A : B+ Line

• B : B– Line

• J : IN/OUT direction of (+,–) B LINE.

• C : adjustment for repair.

• A : VIDEO SIGNAL (ANALOG)

• A : AUDIO SIGNAL (ANALOG)

• A : VIDEO/AUDIO SIGNAL (ANALOG)

• A : VIDEO/AUDIO/SERVO SIGNAL

• A : SERVO SIGNAL

• Circled numbers refer to waveforms.

(Measuring conditions voltage and waveform)

• Voltages and waveforms are measured between the

measurement points and ground when camera shoots

color bar chart of pattern box. They are reference values

and reference waveforms.

(VOM of DC 10 MΩ input impedance is used)

• Voltage values change depending upon input

impedance of VOM used.)

1. Connection

Pattern box Color bar chart

Pattern box PTB-450

J-6082-200-A

or

Small pattern box

PTB-1450

J-6082-557-A

Pattern box

About 28cm (PTB-450)

About 12cm (PTB-1450)

Front of the lens

Cyber-shot station (UC-MA)

1-818-873-11

For PTB-450:

J-6020-250-A

For PTB-1450:

J-6082-559-A

2. Adjust the distance so that the output waveform of

Fig. a and the Fig. b can be obtain.

H

Yellow

Cyan

White

Magenta

Green

AABBA=B

Fig. a (Video output terminal output waveform)

Red

Blue

Electronic beam

scanning frame

CRT picture frame

Precautions Upon Replacing CCD imager

• The FP-037 flexible board mounted as a repair part is not

equipped with a CCD imager.

When replacing this board, remove the CCD imager from

the old one and mount it onto the new one.

• If the CCD imager has been replaced, carry out all the

adjustments for the camera section.

• As the CCD imager may be damaged by static electricity

from its structure, handle it carefully like for the MOS IC.

In addition, ensure that the receiver is not covered with

dusts nor exposed to strong light.

DSC-M1

Fig.b (Picture on monitor TV)

When indicating parts by reference number, please

include the board name.

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

4-3

Page 24

4-2. SCHEMATIC DIAGRAMS

A

B

C

1

FLASH UNIT(FL80000)

FLASH

XX MARK:NO MOUNT

TO

SY-114 BOARD(8/9)

CN707

(PAGE 4-44

OF LEVEL 3)

XSTRB_PWR_ON

STB_UNREG

STB_UNREG

STB_UNREG

STB_UNREG

STB_UNREG

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

REG_GND

STB_FULL

IGBT_ON

AF_LED_5V

AF_LED_K

16P

5

7436

82 9

NO MARK:REC/PB MODE

FLASH UNIT(FL80000) is replaced as a block.

So that this PRINTED WIRING BOARD is omitted.

LND116

16

LND115

15

LND114

14

LND113

13

LND112

12

LND111

11

LND110

10

LND109

9

LND108

8

LND107

7

LND106

6

LND105

5

LND104

4

LND103

3

LND102

2

LND101

1

Q001

CPH3205-SONY-TL-E

CHARGER

290

1

3

2

0

D001

MA111-(K8).S0

R001

4700

R002

XX

R003

Q002

3

0

XX

2

R004

XX

C002

0.01u B

R005

1

270

T002

DC/DC CONVERTER

TRANSFORMER

PFS

2

1

3

4

D002

HAU160C030TP

C901

85u

315V

2

1

3

LND001

XE_A(H)

270

R008

1M

2

1

C004

0.1uF

350V

+

LND003

XENON

TUBE

+

–

–

XE_K(L)

Q004

TIG014TS-TL-E

FLASH DRIVE

LND002

TRIGGER_IN

LND004

TRIGGER GND

4

3

5

D

E

16

R007

1M

8

0

R006

47

1

2

3

4

5

6

D003

DOR5152

(AF LED)

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

5

6

7

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

DSC-M1

4-5

4-6

FL80000

Page 25

For Schematic Diagram

• Refer to page 4-49 for printed wiring board. • Ref. No.; 1,000 Series.

A

B

C

D

E

1

FP-036 FLEXIBLE BOARD

MULTI CONNECTOR

XX MARK:NO MOUNT

TO

SY-114 BOARD(9/9)

CN703

(PAGE 4-46

OF LEVEL 3)

TO

SY-114 BOARD(9/9)

CN704

(PAGE 4-45

OF LEVEL 3)

AV_JACK_IN

A_GND

V_OUT

A_GND

AU_OUT_R

A_GND

AU_OUT_L

A_GND

A_GND

BATT/XEXT

XMULTI_IN

USB_GND

USB_GND

USB_GND

USB_GND

USB_VBUS

N.C.

1087

47k

D003

594

2

1

R002

4

3

MAZR082H0AS0

100k

2

1

D004

LF001

4

3

1

2

1

2

3

4

D005

MAZR082H0AS0

26P

1

ACV_UNREG

3

ACV_UNREG

5

XLANC_JACK_IN

7

USB_LED

9

USB_HOST

USB_VBUS

11

XMULTI_IN

13

EXT_STRB_ON

15

V_OUT

17

V_GND

19

AUX

21

ACV_GND

23

ACV_GND

25

CN001

MULTI

CONNECTOR

27

28

29

AUX

2

4

6

8

D+

10

D-

12

14

16

18

20

22

24

26

ACV_UNREG

LANC_DC

LANC_SIG

USB/LANC_GND

AV_JACK_IN

A_OUT_L

A_OUT_R

A_GND

BATT/XEXT

ACV_GND

30

362

19P

LND001

1

LND002

2

LND003

3

LND004

4

LND005

5

LND006

6

LND007

7

LND008

8

LND009

9

LND010

10

LND011

11

LND012

12

LND013

13

LND014

D-

14

15

LND016

D+

16

LND017

17

LND018

18

LND019

19

6P

LND101

1ACV_GND

LND102

2ACV_GND

LND103

3ACV_GND

LND104

4ACV_UNREG0

LND105

5ACV_UNREG0

LND106

6ACV_UNREG0

MAZR082H0AS0

D001

1

2

3

4

3

4

D002

MAZR082H0AS0

2

1

3

4

MAZR082H0AS0

R001

11

F

DSC-M1

16

4-7 4-8

FP-036

Page 26

For Schematic Diagram

• Refer to page 4-49 for printed wiring board. • Ref. No.; 2,000 Series.

1

58

642 93

7

10

A

FP-037 FLEXIBLE BOARD

(Note)

CCD IMAGER

B

C

XX MARK:NO MOUNT

NO MARK:REC/PB MODE

R:REC MODE

P:PB MODE

Because the pin terminals that are shown by

the black boxes, are protected by shielding,

measurements of voltage and waveform are

not possible.

5

6

7V48

9

10

11V612

13

14

V8

V7A

V7B

Rss317CCD-OUT18GND19GND20RG21H2B22H2A23H1B24H1A25GND26SUB27CSUB28VL

15VH16

V5B

Vhld

ICX473CQZ-13

V5A

IC001

Note

Vst

V3B

V3A

1

3V24

V1A2V1B

IC001

CCD IMAGER

D

E

F

G

H

DSC-M1

TO

SY-114 BOARD(1/9)

CN701

(PAGE 4-29

OF LEVEL 3)

16

33P

R14.8

P0

1

R10.4

P0

R006

3

R003

3900

0

LND033

1CAM_15V_CD

LND032

2POWERSAVE

LND031

3REG_GND

LND030

4CCD_OUT

LND029

5REG_GND

LND028

6REG_GND

LND027

7RG

LND026

8REG_GND

LND025

9H2B

LND024

10H2A

11REG_GND

LND023

12H1B

LND021

13H1A

LND020

14REG_GND

LND019

15SHT

LND018

16VSUB_CONT

LND017

17CAM_-8.0V_CD

LND016

18REG_GND

LND015

19V1A

LND014

20V1B

LND013

21V2

LND012

22V3A

LND011

23V3B

LND010

24VST

LND009

25V4

LND008

26V5A

LND007

27V5B

LND006

28VHLD

LND005

29V6

LND004

30V7A

LND003

31V7B

LND002

32V8

33REG_GND

Q002

DTC144EUA-T106

SWITCH SWITCH

R002

22k

1

2

0

3

Q004

2SC4250(T5LSONY1)

BUFFER

R11.2

P0

2

R10.4

P0

DTC144EUA-T106

C001

0.1u

16V

B

C002

0.1u

16V

B

R001

1500

C004

XX

0

Q001

Note:IC001(CCD IMAGER) and Flexible board FP-037 are supplied as a pair because

they need adjustment after they are combined together.

Therefore,they are not supplied as an independent part.

They are supplied as the CCD BLOCK ASSY(A-1082-392-A).

R3.4

P0

1

2

3

R005

1200

4-9 4-10

Q003

DTC144EHT2L

SWITCH

0

0.1u

2

C003

16V

R004

1800

R12.1

P0

1

C005

0.1u

16V

B

3

B

FP-037

Page 27

For Schematic Diagram

• Ref. No.; 1,000 Series.

For Schematic Diagram

• Refer to page 4-51 for printed wiring board. • Ref. No.; 2,000 Series.

A

B

C

1

24

FP-039 FLEXIBLE BOARD

BATTERY

XX MARK:NO MOUNT

SY-114 BOARD(9/9)

(PAGE 4-45

OF LEVEL 3)

TO

CN705

3

FP-039 FLEXIBLE BOARD is replaced as a block.

So that this PRINTED WIRING BOARD is omitted.

11P

LND011

11BATT_UNREG

LND010

10BATT_UNREG

LND009

9BATT_UNREG

LND008

8BATT_UNREG

LND007

7BATT_UNREG

LND006

6BATT_SIG

LND005

5REG_GND

LND004

4REG_GND

LND003

3REG_GND

LND002

2REG_GND

LND001

1REG_GND

S

BT901

BATTERY

TERMINAL

A

B

1

FP-040 FLEXIBLE BOARD

LITHIUM BATTERY

XX MARK:NO MOUNT

TO

SY-114 BOARD(9/9)

CN706

(PAGE 4-45

OF LEVEL 3)

16

23

6P

LND001

1VL_3V

LND002

2VL_3V

LND003

3VL_3V

LND004

4REG_GND

LND005

5REG_GND

LND006

6REG_GND

Note :

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Note :

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

4

BT001

LITHIUM

BATTERY

(SECONDARY)

16

DSC-M1

4-11 4-12

FP-039/FP-040

Page 28

For Schematic Diagram