DPA-300

MICROFILM

SERVICE MANUAL

U.S and foreign patents licensed from Dolby Laboratories

Licensing Corporation.

SPECIFICATIONS

US Model

Canadian Model

Model Name Using Similar Mechanism NEW

MD Mechanism Type MDM-2BR

Base Unit Name MBU-2

Optical Pick-up Name KMS-210A/J-N

System

Recording format Picture MD recording system

Data compression/saving system

JPEG

FINE mode : 128kB

(the maximum 1,000 images)

STANDARD mode : 64kB

(the maximum 2,000 images)

Revolutions 400 rpm to 900 rpm (CLV)

Error correction Advanced Cross Interleave Reed

Solomon Code (ACIRC)

Laser Semiconductor laser ( λ = 780 nm)

Emission duration : continuous

Laser output Max 44.6 µW

* This output is the value measured at a

distance of 200 mm from the objective lens

surface on the Optical Pick-up Block with

7 mm aperture.

Sampling frequency 44.1 kHz

Coding Adaptive TRansform Acoustic Coding

(A TRAC)

Modulation system EFM (Eight to Fourteen Modulation)

Number of channels 2 stereo channels

Input VIDEO INPUT

Input signal : 1Vp-p

(75 Ω unbalanced)

Y/C INPUT, Mini DIN 4-pin

Luminance signal : 1Vp-p

(75 Ω unbalanced)

Chrominance signal : 0.286 Vp-p

(75 Ω unbalanced)

AUDIO IN (L/R)

Input level : 2 Vrms (full bit)

Input impedance : more than 47 kΩ

FS1/FS2 (RED/WHITE) connectors

Output VIDEO OUTPUT

Output signal : 1 Vp-p

(75 Ω unbalanced)

Y/C OUTPUT, Mini DIN 4-pin

Luminance signal : 1 Vp-p

(75 Ω unbalanced)

Chrominance signal : 0.286 Vp-p

(75 Ω unbalanced)

AUDIO OUT (L/R)

Output level : 2 Vrms (full bit)

Output impedance : more than 47 kΩ

— Continued on next page —

DIGITAL STILL RECORDER

SAFETY CHECK-OUT

General

Power requirements Sony AC Power Adaptor AC-DA300

(supplied) connected at the DC IN 12 V

Power consumption 20 W

Operating temperature 5 °C to 35 °C (41°F to 95°F)

Operating humidity 30% to 85%

Dimensions Approx. 280 × 80 × 290 mm

Mass Approx. 2.5 kg (5 lb. 8 oz)

Supplied accessories AC power adaptor AC-DA300

Design and specifications are subject to change without notice.

jack : 120V AC, 60Hz (US model)

1

(11

/8 × 31/4 × 111/2 inches)

(w/h/d, including projecting parts and

controls)

Remote commander RMT-DA300 (1)

Size AA (R6) batteries (2)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

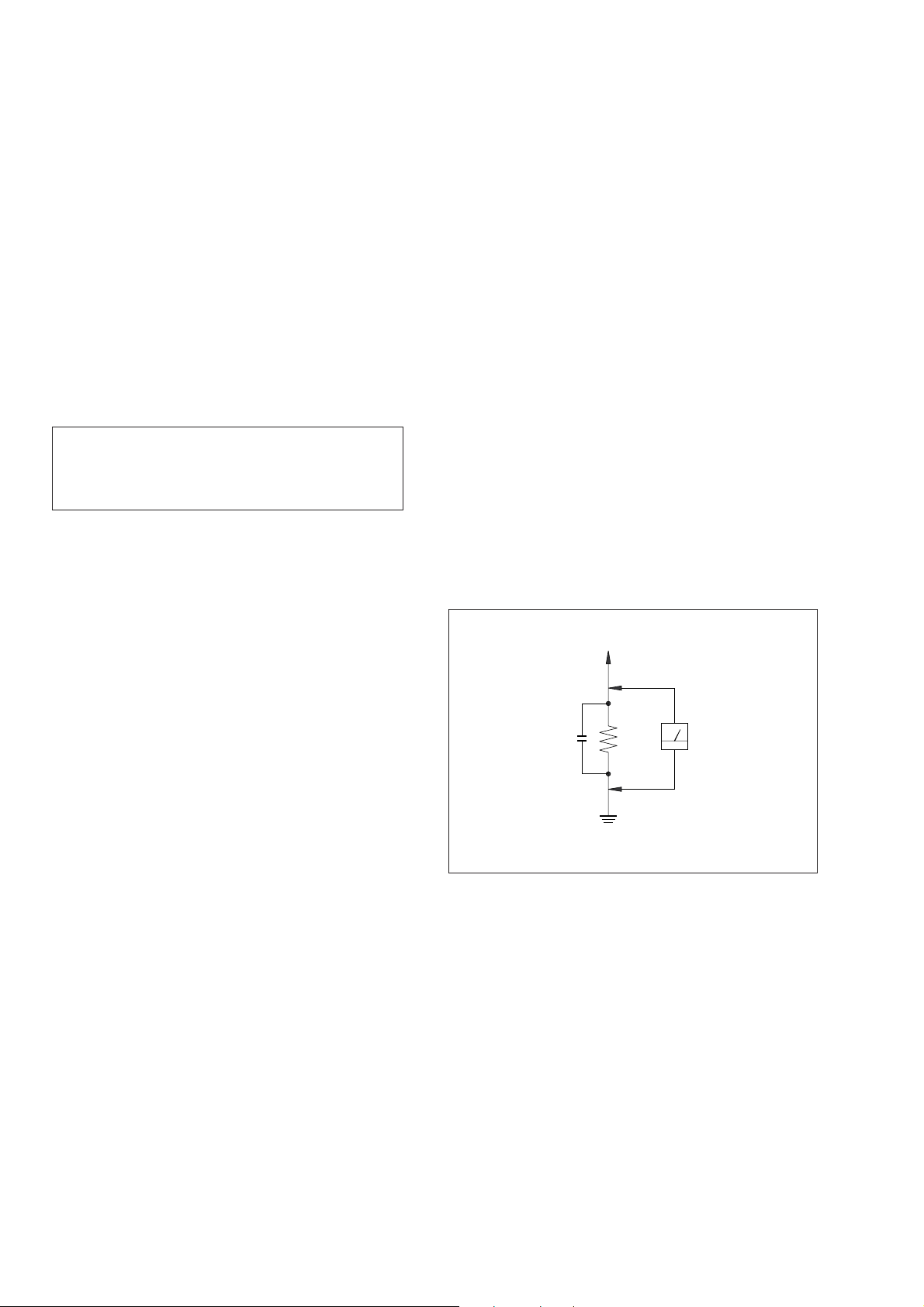

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

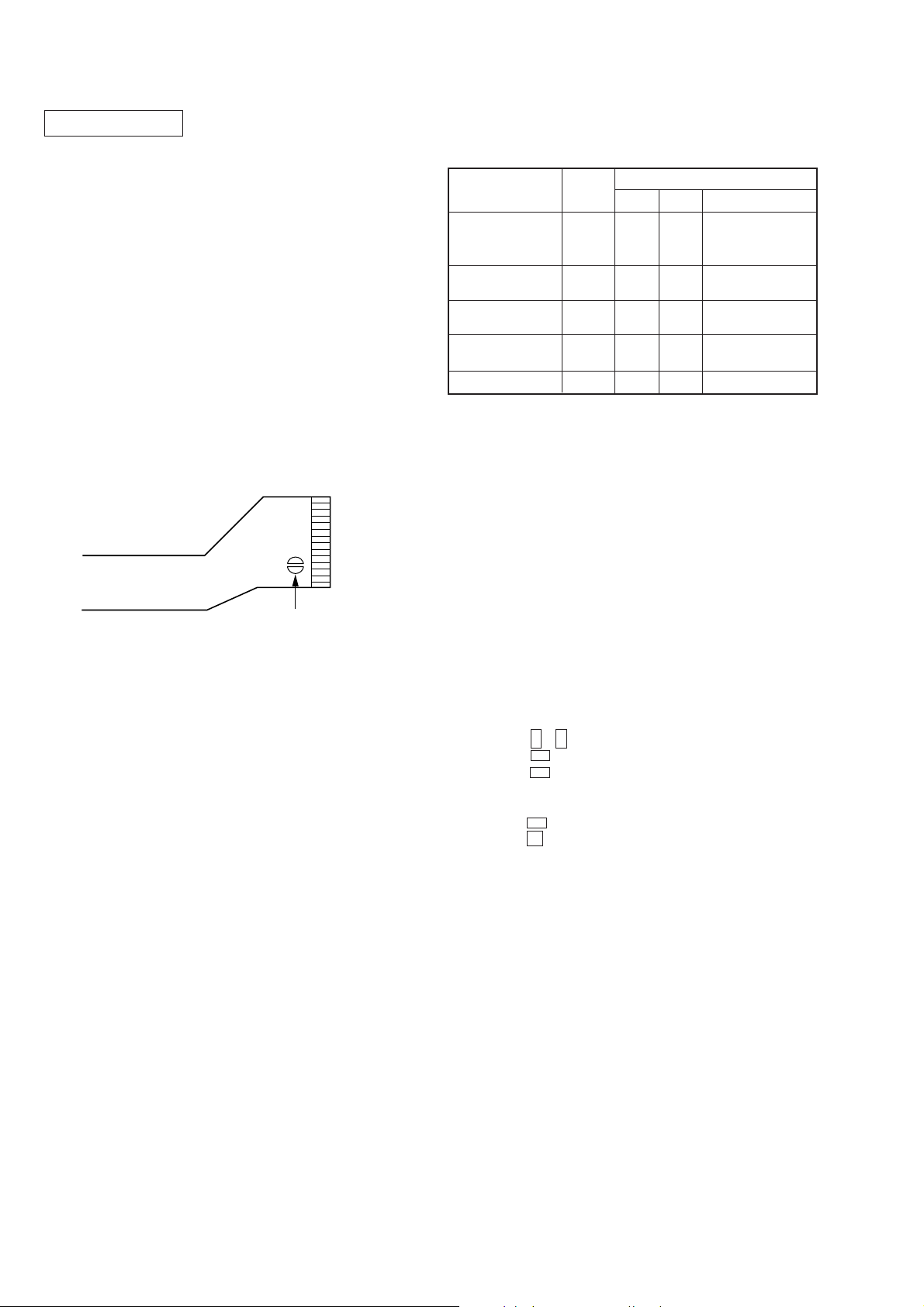

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

To Exposed Metal

Parts on Set

AC

µ

F 1.5k

0.15

Ω

voltmeter

(0.75V)

Earth Ground

Fig. A. Using an AC voltmeter to check A C leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

— 2 —

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

TABLE OF CONTENTS

1. SERVICING NOTE ··························································4

2. GENERAL ·········································································· 7

3. DISASSEMBLY

3-1. Upper Case ································································· 11

3-2. Front Panel, Panel Board and Video In Board ··········· 11

3-3. Picture Board, Power Board and Mechanism Deck

····················································································12

3-4. MD Mechanism Deck ················································ 13

3-5. Slider (MD Mechanism) ············································13

3-6. MD Base Unit (MBU-2) and Loading Motor Assy ··· 14

3-7. How to Attach the Slider (MD Mechanism) ·············· 14

4. TEST MODE ···································································· 15

5. ELECTRICAL ADJUSTMENTS ······························· 18

6. DIAGRAMS

6-1. Circuit Board Location··············································· 28

6-2. Block Diagram — BD Section —······························ 29

6-3. Block Diagram — MD Control Section — ··············· 31

6-4. Block Diagram — Video Control Section — ············33

6-5. Block Diagram — Video Process Section — ············35

6-6. Block Diagram — IR Section — ······························· 37

6-7. Block Diagram — Video Out Section — ··················· 39

6-8. Block Diagram — Video In Section — ····················· 41

6-9. Block Diagram — Audio Section — ························· 43

6-10. Block Diagram — Power Section — ························· 45

6-11. Printed Wiring Board — Picture Section — ·············· 47

6-12. Schematic Diagram — Picture Section (1/3) — ········ 51

6-13. Schematic Diagram — Picture Section (2/3) — ········ 55

6-14. Schematic Diagram — Picture Section (3/3) — ········ 59

6-15. Printed Wiring Board — BD Section —···················· 62

6-16. Schematic Diagram — BD Section — ······················ 65

6-17. Schematic Diagram — Video In Section — ·············· 69

6-18. Printed Wiring Board — Video In Section — ··········· 73

6-19. Printed Wirimg Board — MD Section —·················· 77

6-20. Schematic Diagram — MD Section (1/2) — ············· 81

6-21. Schematic Diagram — MD Section (2/2) — ············· 85

6-22. Printed Wiring Board — Power Section — ··············· 89

6-23. Schematic Diagram — Power Section — ·················· 91

6-24. Printed Wiring Board — Panel Section — ················ 94

6-25. Schematic Diagram — Panel Section — ··················· 97

6-26. IC Block Diagrams····················································· 99

6-27. IC Pin Function ························································ 111

7. EXPLODED VIEWS

7-1. Upper Case Section ·················································· 144

7-2. Front Panel Section ·················································· 145

7-3. Bottom Cabinet Section ··········································· 146

7-4. Mechanism Section (MDM-2BR)···························· 147

7-5. Base Unit Section (MBU-2)····································· 148

8. ELECTRICAL PARTS LIST ································· 149

— 3 —

SECTION 1

SERVICING NOTE

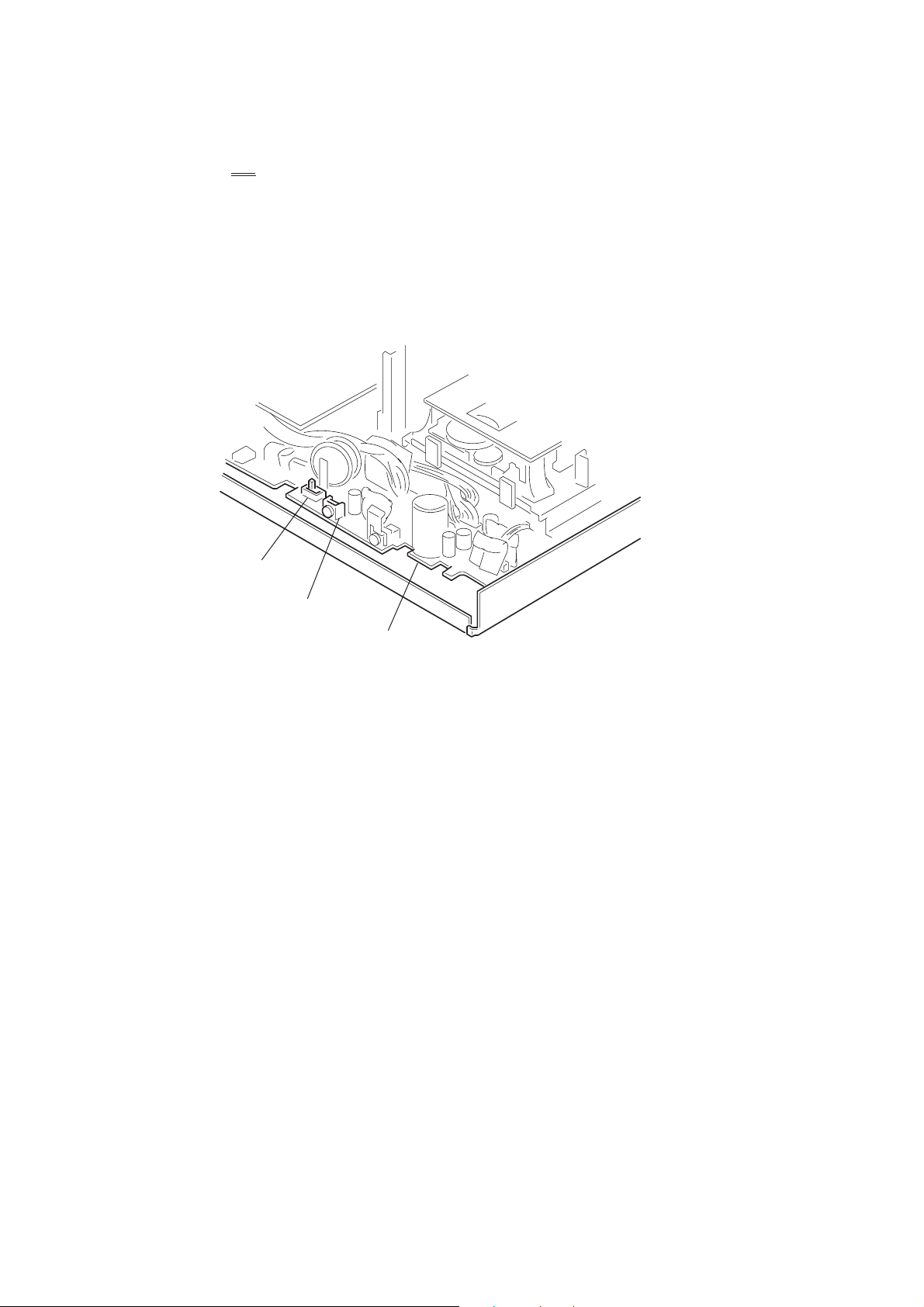

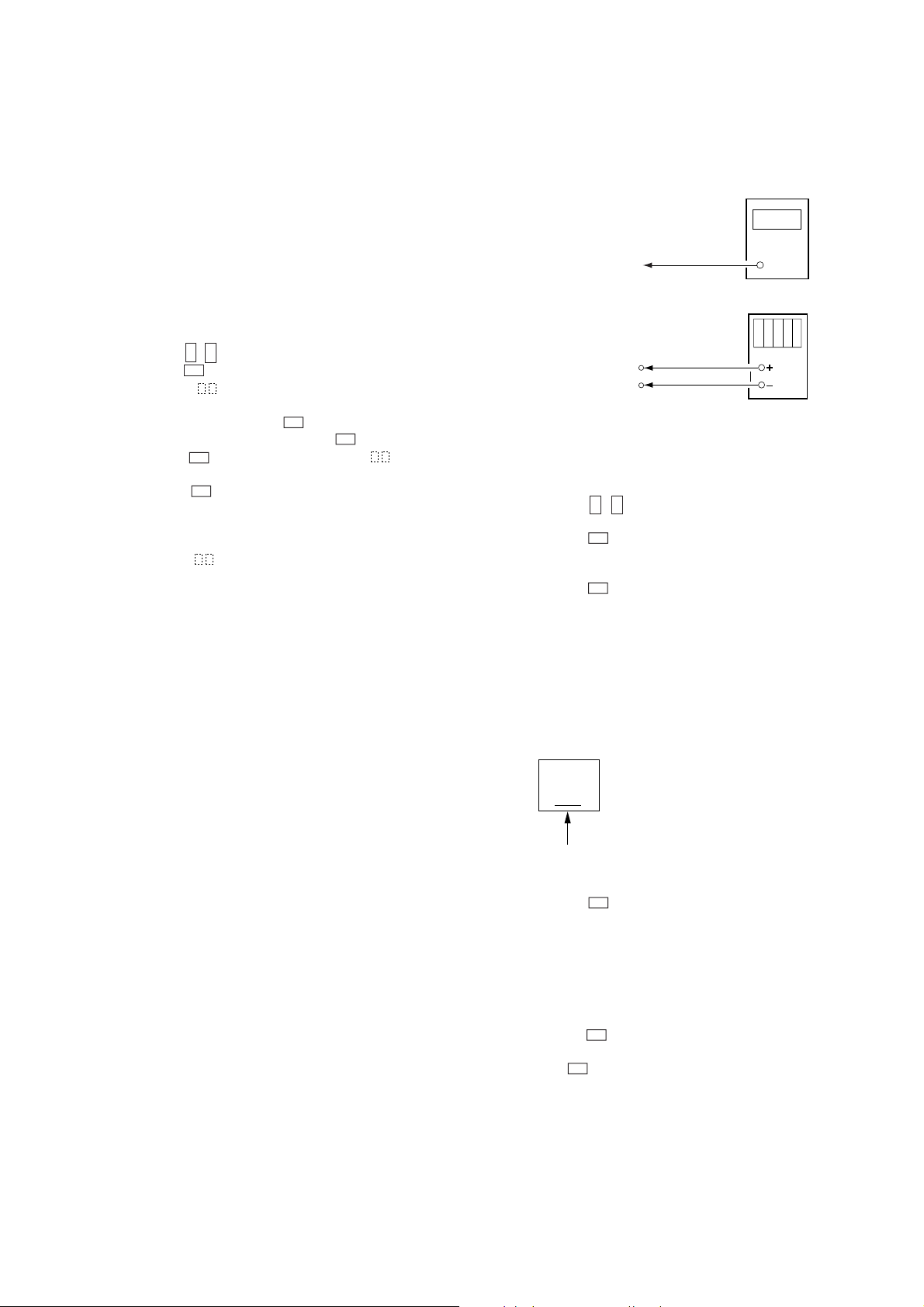

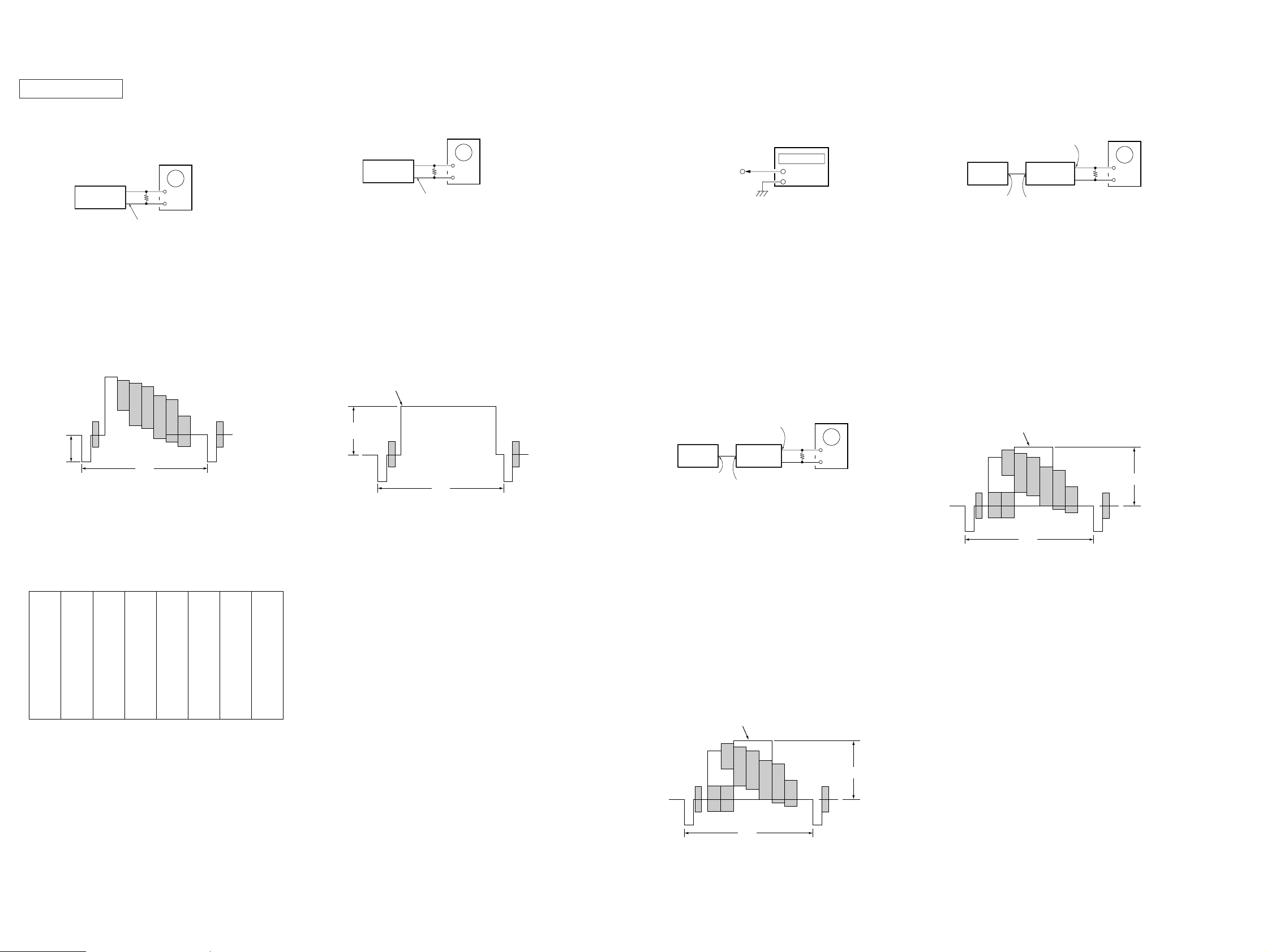

[About Switches on POWER Board]

• Backup Power ON/OFF Switch (S1351 B. UP ON)

Be sure to turn this switch to OFF when removing and inserting connectors to and from the circuit boards.

This switch protects semiconductors from breakdown due to static electricity.

Set this switch to ON during normal operation. The DPA-300 does not work unless this switch is set to ON.

• Reset Switch (S1352 RESET)

This switch resets forcibly system of DPA-300. Press the reset switch when microprocessor runs away, or when DPA-300 does not

operate normally, or when the main power is desired to turn ON, OFF and back ON momentarily during test mode, etc.

Rear Side

S1351

(B.UP ON)

S1352

(RESET)

POWER board

— 4 —

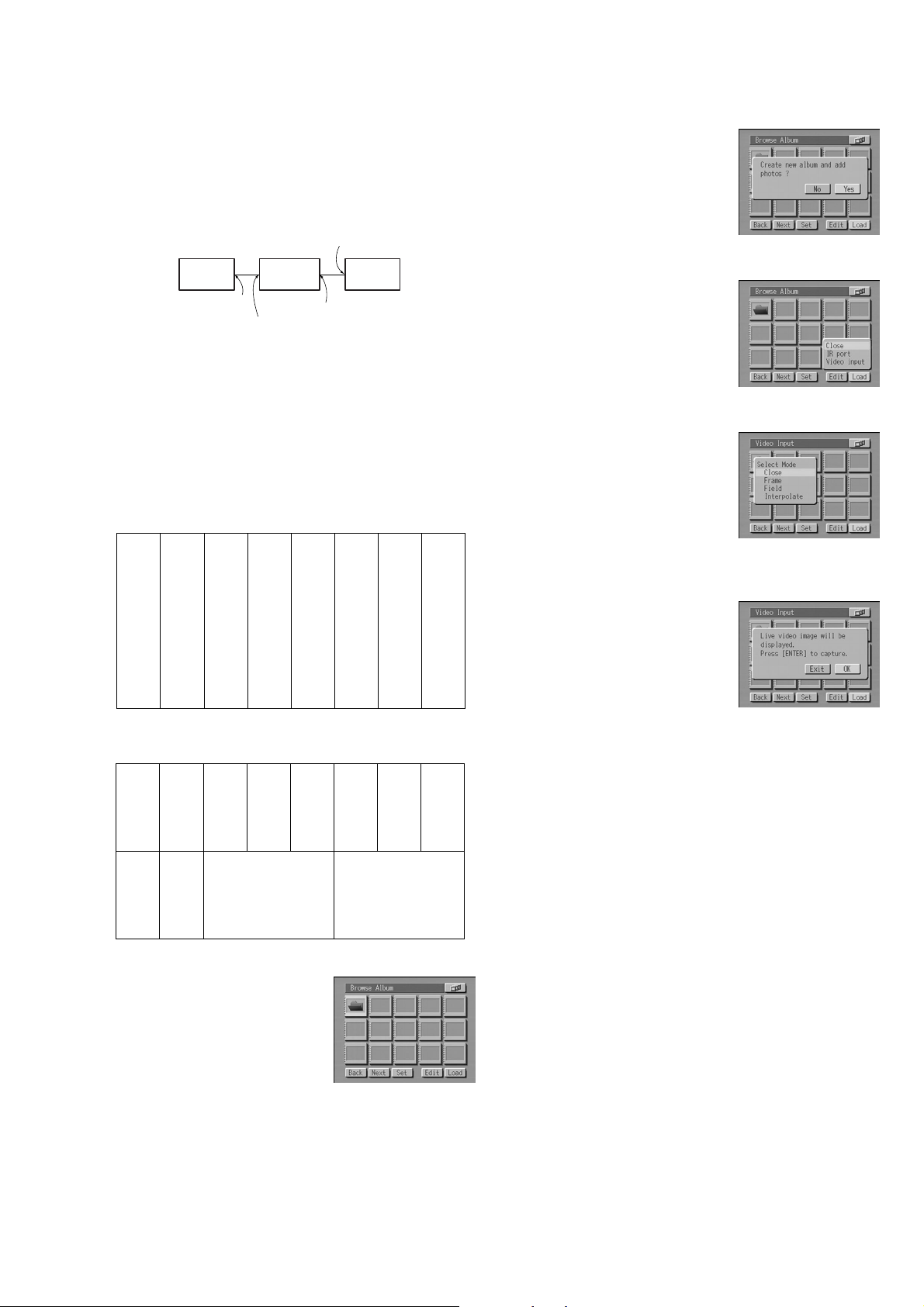

[How to Set the Mode Displaying the Through Picture]

Input the color bar signal and enter this mode as follows to check

the DPA-300 for voltages, waveforms and to implement a part of

adjustments.

Connection:

Color bar generator

DPA-300

Output

Video Input or

S-Video Input

Input

monitor

Video Output

When the equipment connection is completed, set up this mode by

following the procedures in the order given below.

4. Select “Load” using the f F g G button and press the ENTER

button.

The message “Create new album

and add photos?” appears.

5. Select “Yes” using the f F g G button and press the ENTER

button.

The new album to load the pictures

are created. When an album is

created, the loading menu appears.

1. Turn the main power ON. (Turn on the main power of color

bar generator, DPA-300 and monitor.)

2. Connect the color bar signal to video input.

Color bar signal specifications to be input

Color bar signal for voltage and waveform measurement

RED

RED

BLUE

BLUE

BLACK

BLACK

BLACK

CYAN

YELLOW

WHITE (75%)

Color bar signal for adjustment

CYAN

YELLOW

WHITE (75%)

Q

I

WHITE (100%)

GREEN

GREEN

MAGENTA

MAGENTA

6. Select “Video input” using the g G button and press the ENTER

button.

The display from which the modes

can be selected, appears

7. Select “Frame” using the g G button and press the ENTER

button.

Mode differs depending on the type

of input signal supplied from the

video equipment connected.

8. Select “OK” using the f F g G button and press the ENTER

button.

9. Color bars supplied to the Video Input connector, appear on

monitor when the ENTER button is pressed.

Note :When the ENTER button is pressed in the state of step 9, the

picture is loaded and the DPA-300 exits the Through mode.

When the ENTER button is pressed incorrectly, follow the

instruction shown on the monitor screen and return to the

state of step 9.

3. Insert the MD data disc.

List of album appears.

When the MD data disc has not been formatted, format it.

— 5 —

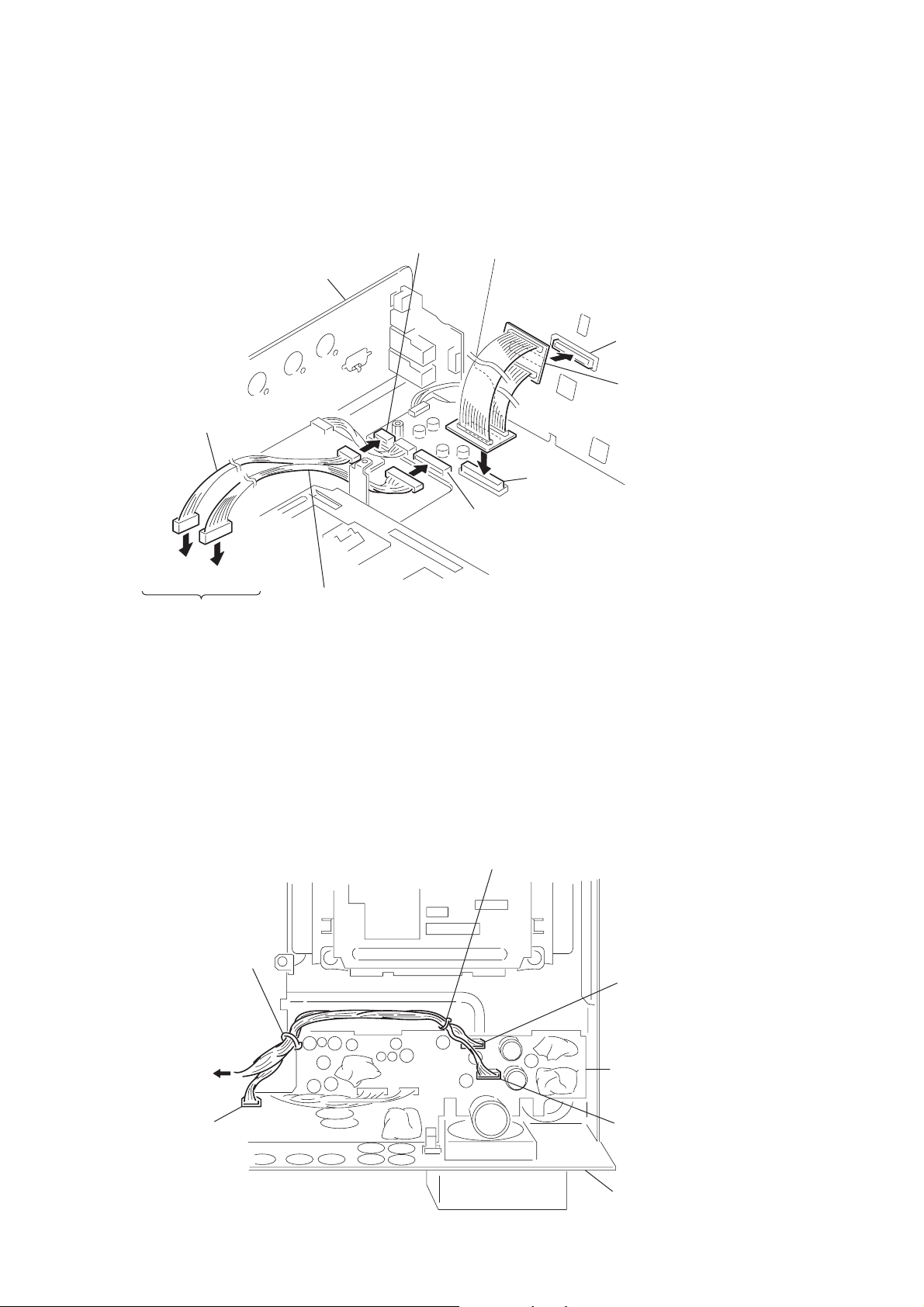

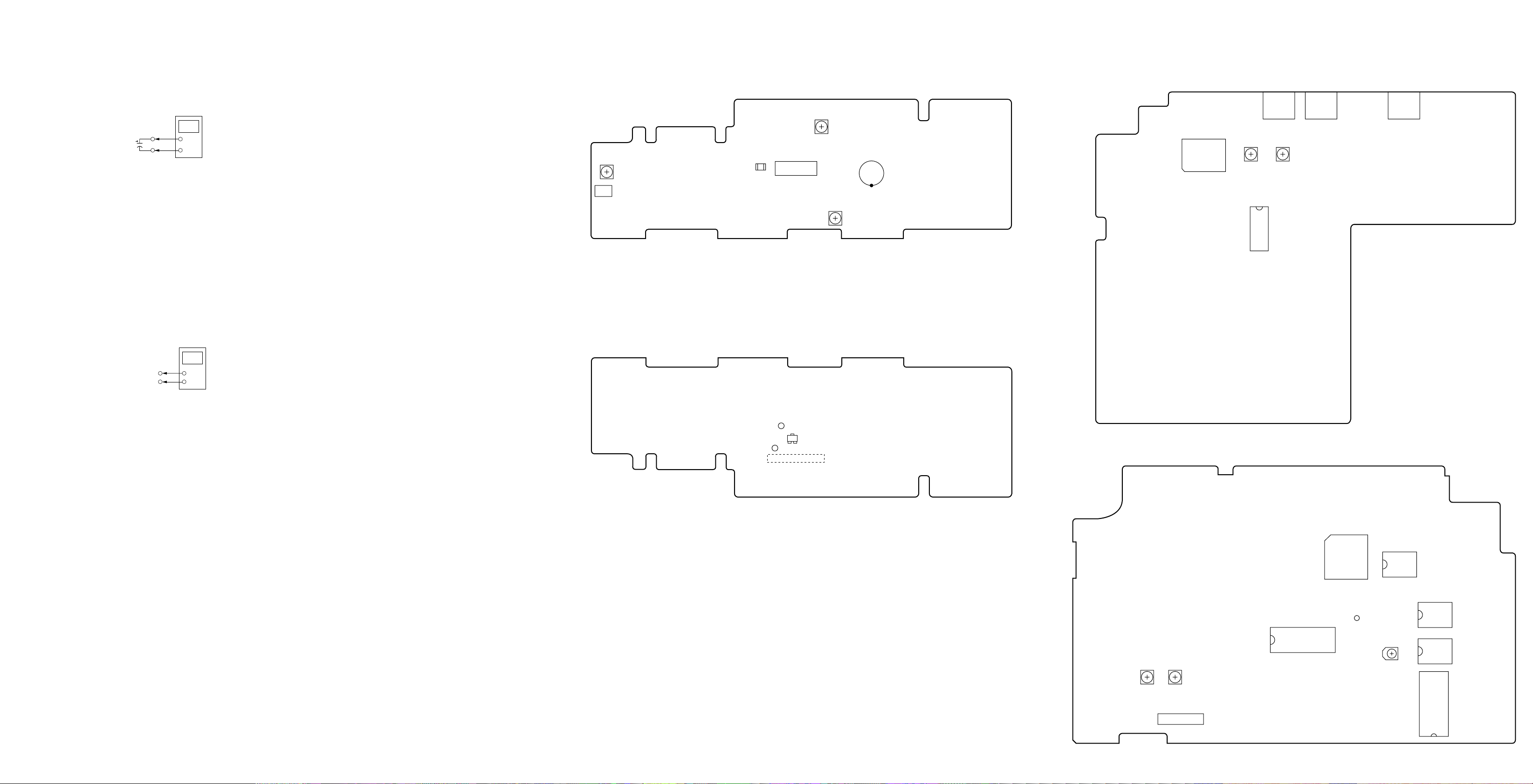

[About Extension Cable]

d

To check the MD board, connect the PICTURE board and the POWER board using the extension cables as shown before starting to check.

CN2007

Extension cable 5p

J-2501-120-A

to CN1004

to CN1001

POWER board

Rear panel

PICTURE board

CN4002

Extension cable 40p

J-2501-122-A

CN2003

CN2006

MD board

Extension cable 10p

J-2501-121-A

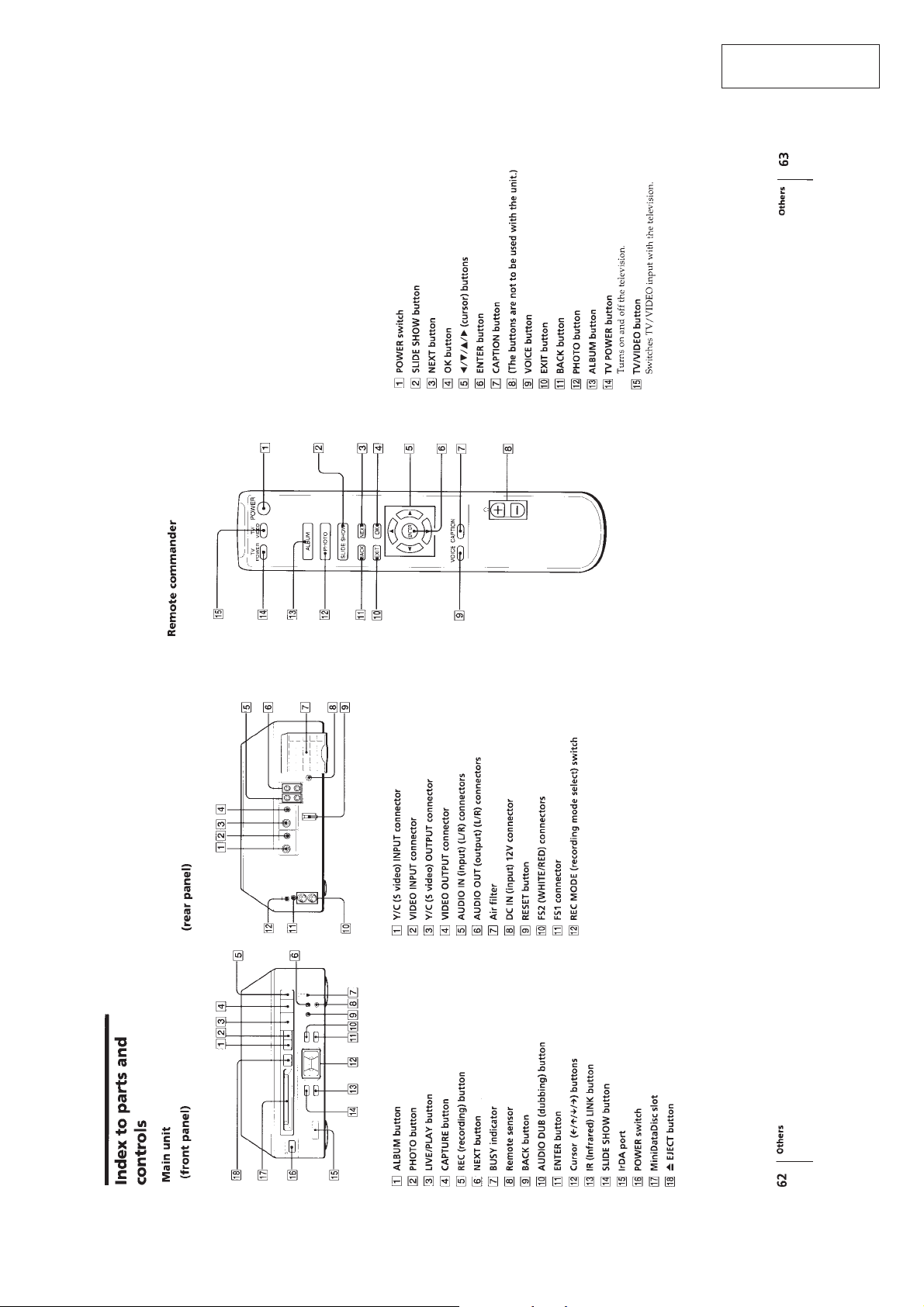

[How to Route the Cables]

Be sure to route the cables which connect the POWER board CN1002, CN1006, CN1007 and PICTURE board CN1001 as shown.

Lead pin (LP1003)

Lead pin

(LP1004)

CN1002

to CN1001

on PICTURE board

CN1007

Rear Side

POWER boar

CN1006

Rear panel

— 6 —

SECTION 2

GENERAL

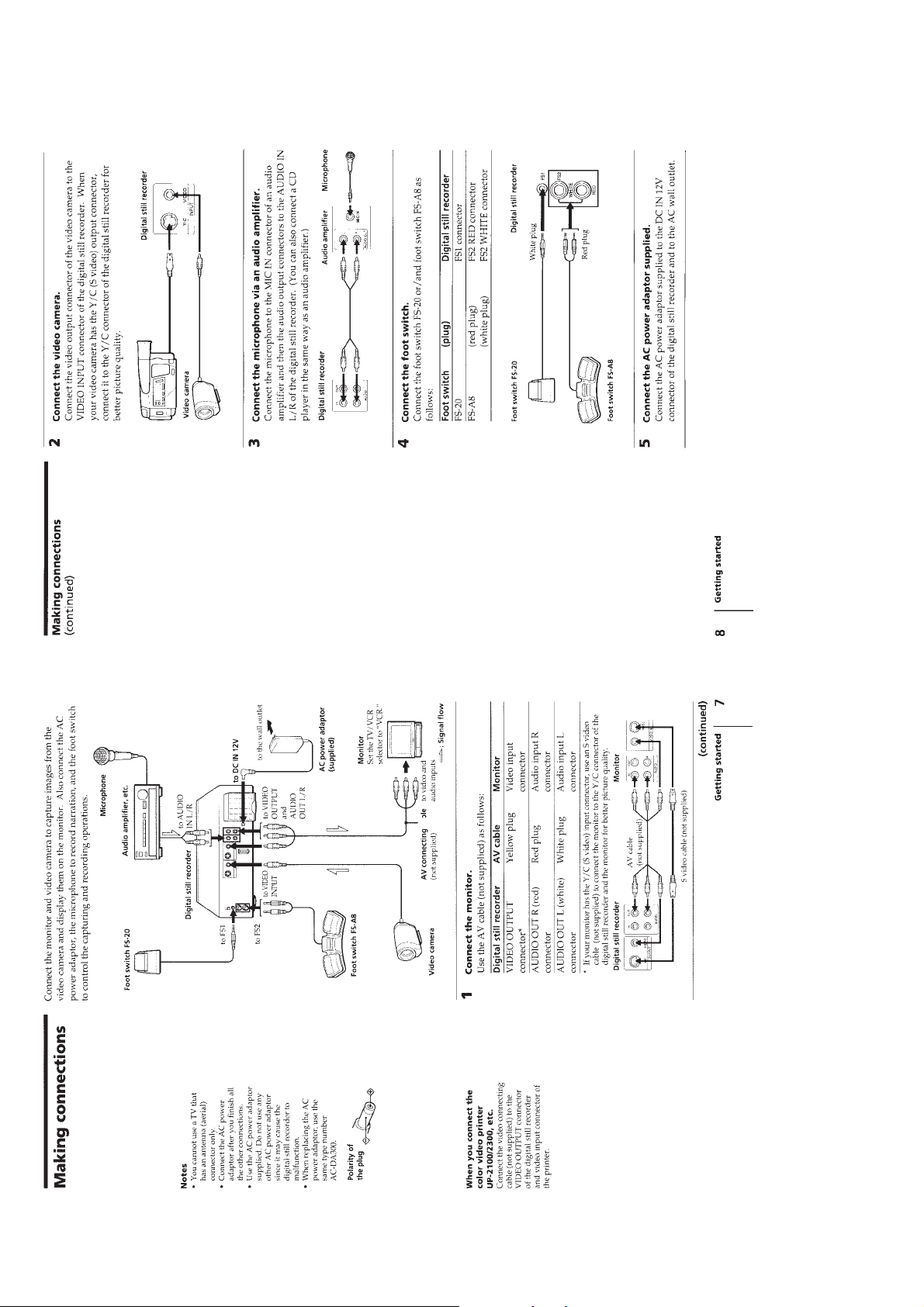

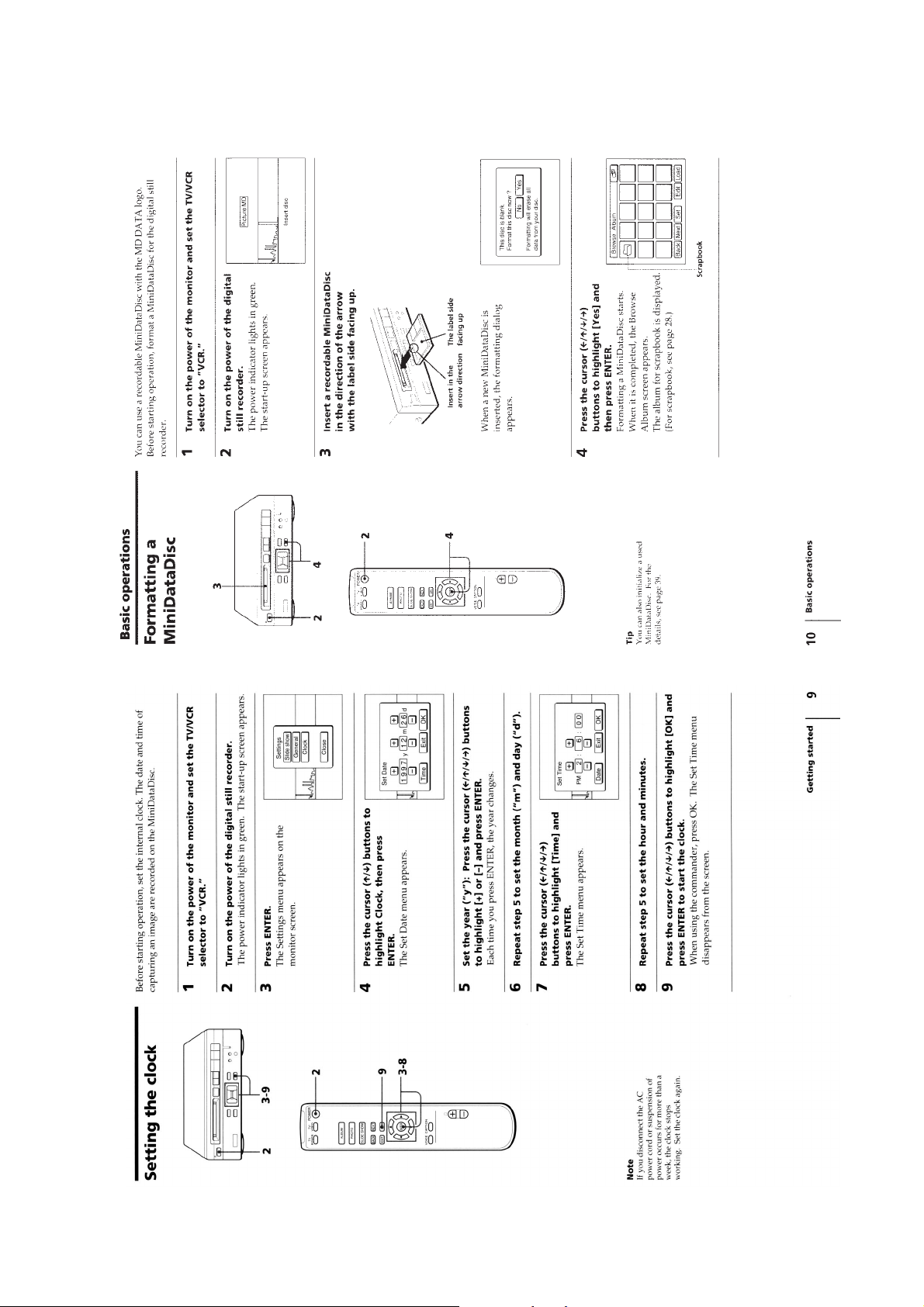

This section is extracted

from instruction manual.

— 7 —

— 8 —

— 9 —

— 10 —

SECTION 3

)

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

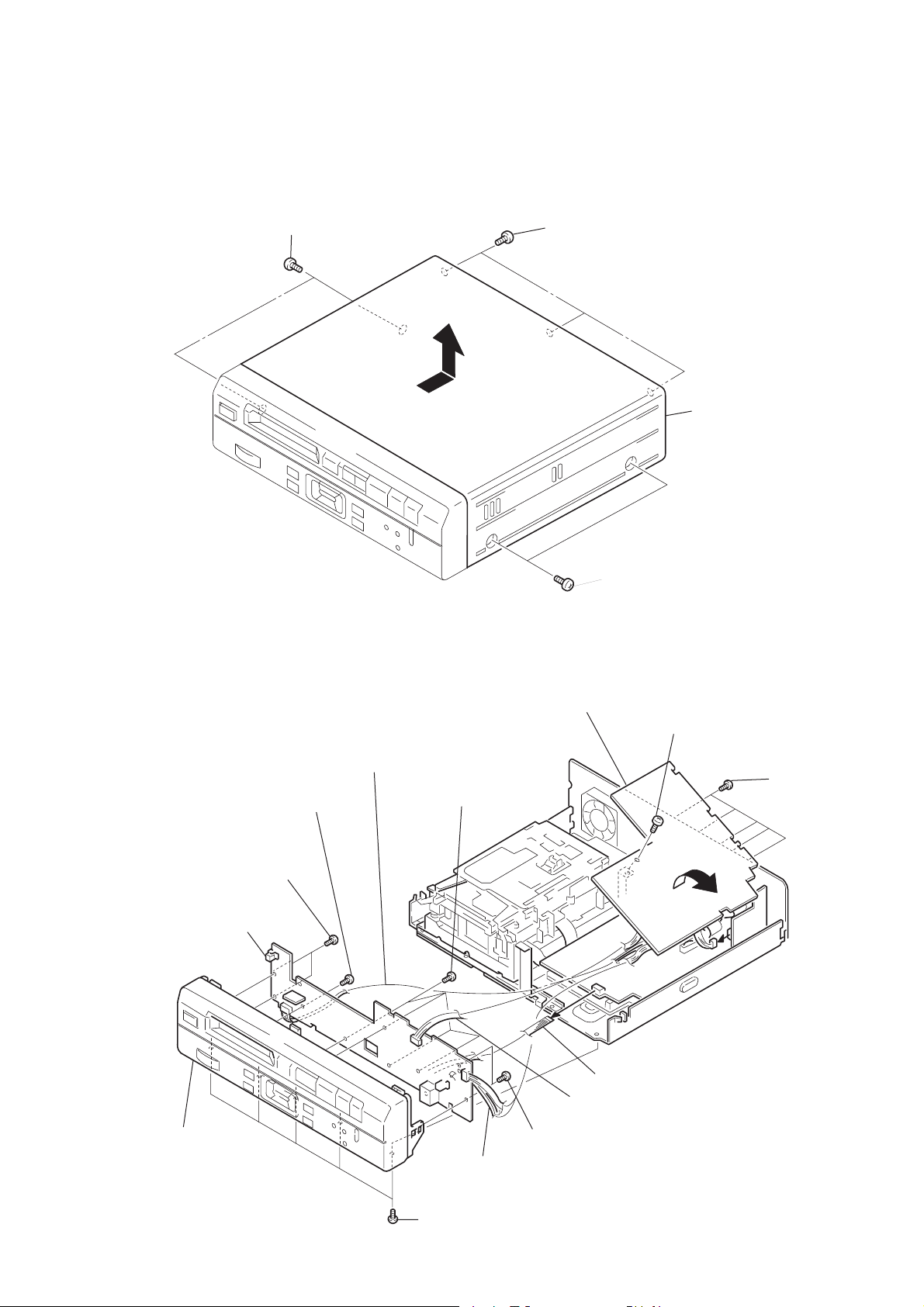

3-1. UPPER CASE

1

Two screws (M3 × 8)

A

3

Two screws (BV/RING)

4

Remove the upper

case by pilling it in

the directions shown

by the arrow

A

.

3-2. FRONT PANEL , PANEL BOARD AND VIDEO IN BOARD

4

8

Connector

(CN106 : VIDEO IN board)

!™

!¡

Screw (BVTP 2.6 × 8)

!º

Two screws

(BVTP 2.6

!¢

PANEL board

×

8)

Screw (BVTP 2.6 × 8)

2

Two screws (M3 × 8)

VIDEO IN board

3

Screw (BVTP 3 × 6)

2

Five screws

(BVTP 3

×

12

9

FRONT PANEL assy

7

Connector

(CN8201 : JACK board)

1

Five screws

(BVTP 3

×

8)

— 11 —

5

Connector (CN5003 : PICTURE board)

6

Connector (CN5002 : PICTURE board)

!£

Two screws (BVTP 2.6 × 8)

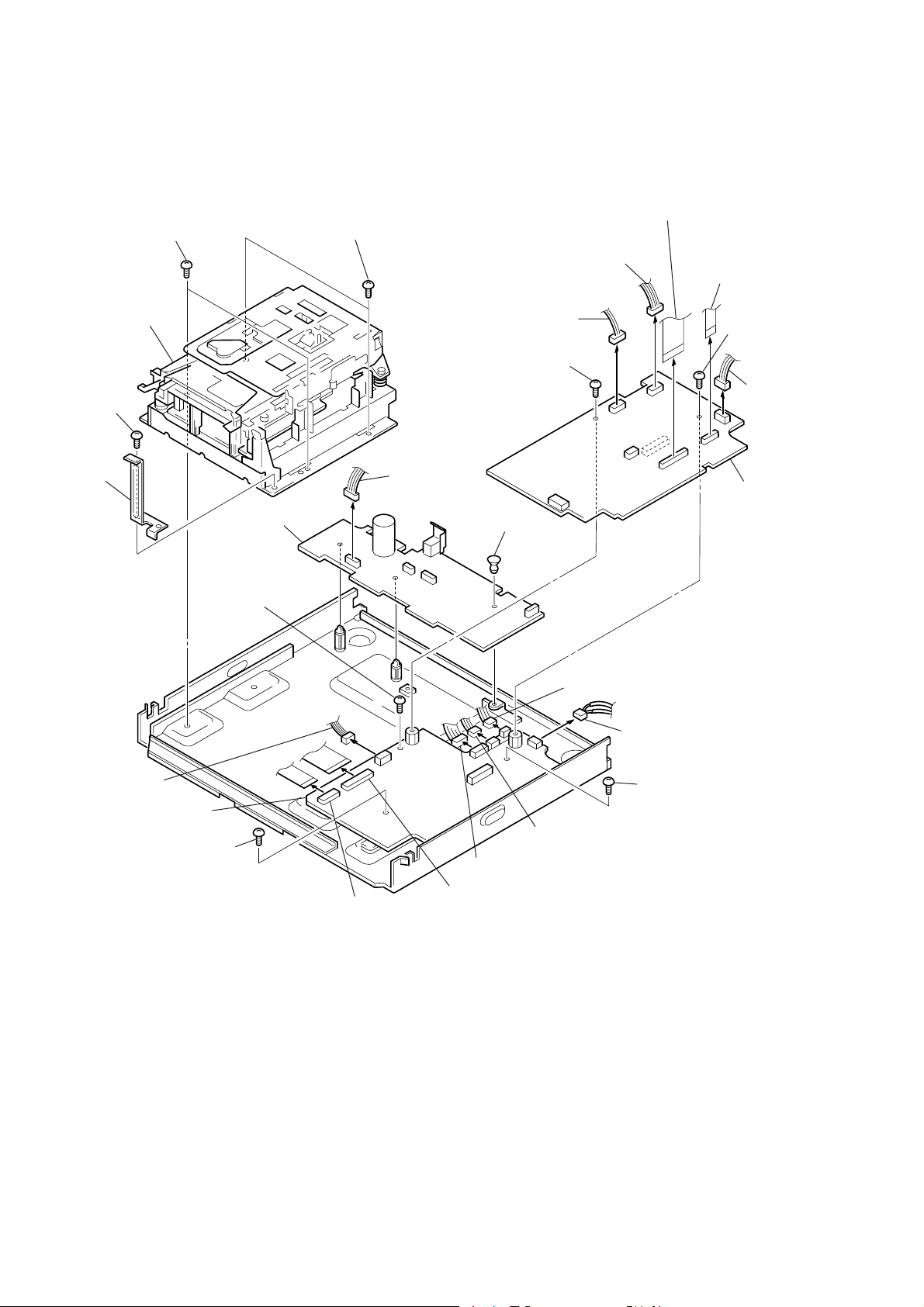

3-3. PICTURE BOARD, POWER BOARD AND MECHANISM DECK

)

@™

@£

Mechanism deck

(MDM-2BR)

!ª

Screw

(BVTP 3

@º

Stay plate

Two screws

(BVTP 3

×

6)

× 6)

!∞

@¡

Two screws (BVTP 3 × 6)

POWER board

!£

Connector

(CN1002)

5

(CN1002)

6

Screw

(BVTT 2.6

!¢

Nylon rivet

Connector

×

5)

1

(CN5001)

4

Connector

(CN1001)

Connector

2

(CN3002)

Connector

7

Screw

(BVTT 2.6

3

(CN3001)

8

PICTURE board

×

Connector

5

!§

Connector

(CN2005)

@¶

MD board

@∞

Screw (BVTP 3 × 6)

@¢

Screw

(BVTP 3

×

6)

!•

Connector (CN2001)

!º

!¡

Connector (CN2006)

!¶

Connector (CN2002)

9

Connector (CN2007)

!™

Connector (CN2501)

@§

Connector (CN2008)

Screw (BVTP 3 × 6)

— 12 —

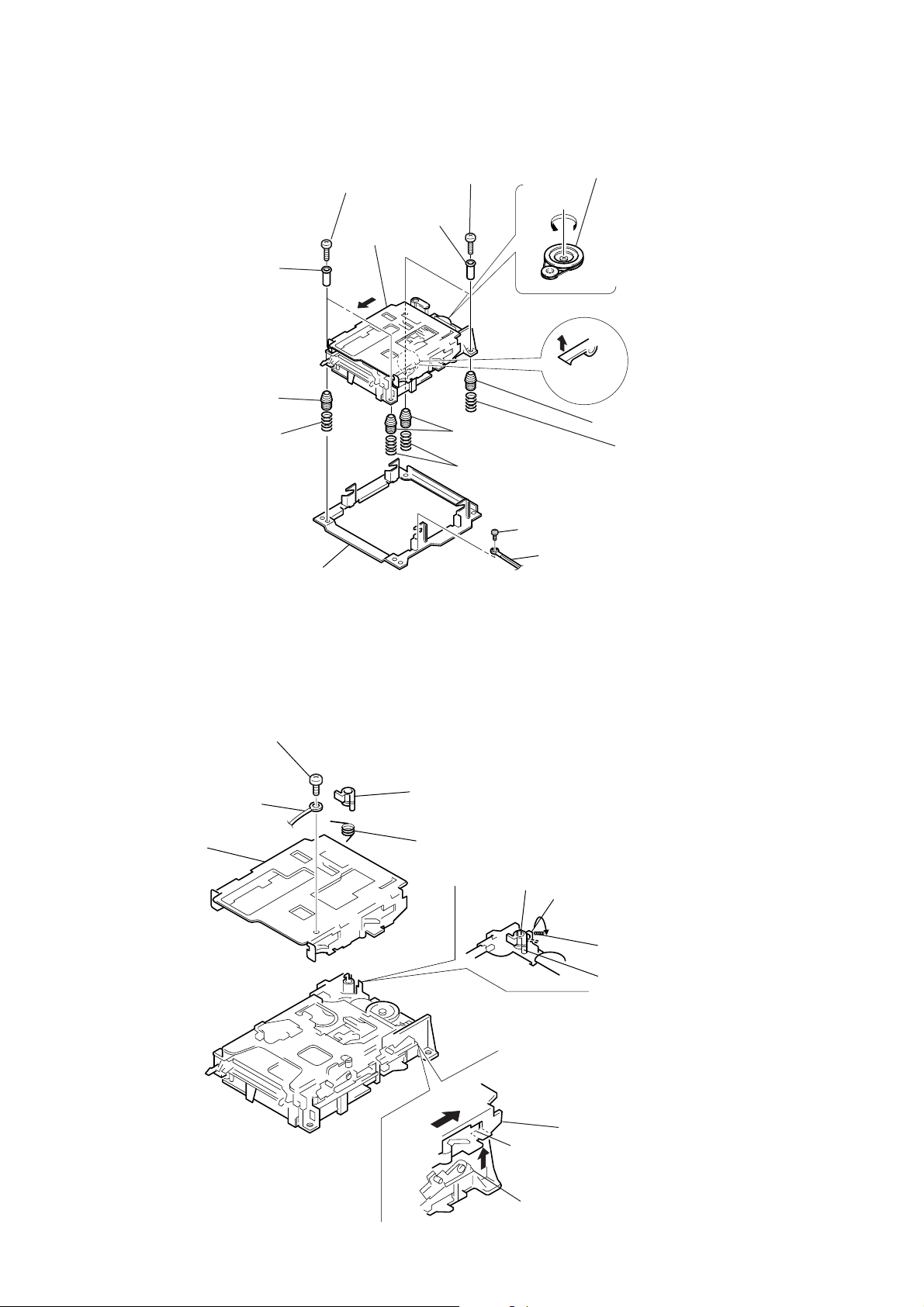

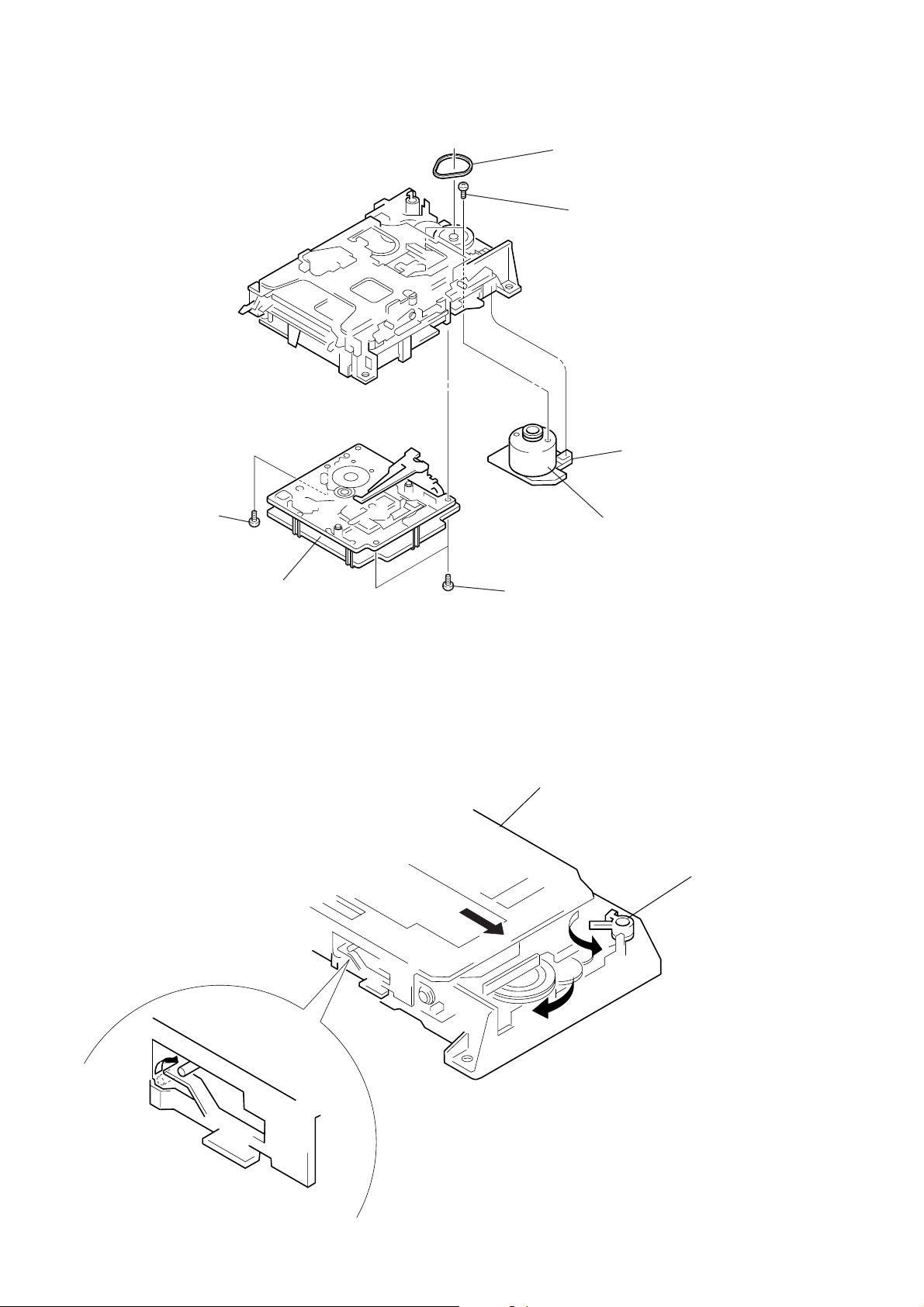

3-4. MD MECHANISM DECK

1

(B2.6

2

Two collars

(damper)

Two screws

×

18)

Slider

B

4

(B2.6

5

Two collars

(damper)

Two screws

×

18)

Pulley (BD)

A

3

Turn the pulley (BD) in the direction

of arrow

in the direction of the arrow

(Because the slider is caught by

the stopper in the middle,

move the stopper slightly up to

make the slider free as shown in

illustration

(BD) in the direction of the arrow

A further.)

A

, and move the slider

A

. Then turn the pulley

B

.

!™

Insulator (MD)

!£

Compression coil spring

Mounting bracket (MD)

3-5. SLIDER (MD MECHANISM)

3

Screw (PTT 2 × 4)

4

Ground terminal

8

Two insulators

(MD)

9

Lever (SLM)

Illustration

Two compression coil springs

6

Screw (BVTT 2.6 × 4)

7

Ground terminal

A

!º

Insulator (MD)

!¡

Compression coil spring

Slider

Torsion coil spring

Craw B

A

B

— 13 —

Craw C

Craw D

Craw A

1

Remove the torsion coil spring

from the claw A.

2

While removing the claw B,

lift up the lever (SLM) and remove it.

5

Move the claw C of the slider

in the direction of the arrow

while taking care not to be caught

by the craw D. Lift up the claw C

of the slider.

Remove the torsion coil spring

from the claw B.

A

3-6. MD BASE UNIT (MBU-2) AND LOADING MOTOR ASSY

1

Screw (BVTP3 × 6)

4

Belt (BD)

5

Two screws (B2.6 × 5)

6

Connector (CN192)

7

Loading motor assy

3

MD base unit (MBU-2)

3-7. HOW TO ATTACH THE SLIDER (MD MECHANISM)

2

Two screws (BVTP3 × 6)

3

Turn the pulley (BD) in the direction

of the arrow

in the direction of the arrow

and lock it with the lever (SLM).

B

C

to move the slider

2

Turn the lever (SLM) fully

in the direction of the arrow

A

C

B

,

A

.

1

Set the four projections of the lever

in the right and the left to the position

as shown.

— 14 —

SECTION 4

TEST MODE

[PREPARATION FOR USE OF TEST MODE]

Connect the equipment as shown below before starting the test mode.

Connection:

DPA-300 Monitor

VIDEO OUTPUT connector VIDEO INPUT connector

• How to Enter the Test Mode

While pressing the + button, press the RESET button.

• How to Exit the Test Mode

Remove the AC adapter from wall outlet.

There are two test modes. One is the audio test mode and the other

is the video test mode. When the DPA-300 enters the test mode,

main menu appears allowing operator to select either audio test mode

or video test mode. Select the desired test mode by pressing the

cross marked button ( , ), and press the ENTER button.

• Main menu

Close

Audio Test

Video Test

Capture Mode

Audio Test

Refer to the respective items for more details.

Audio Test Mode → Page 15

Video Test Mode → Page 17

n

N

AUDIO SECTION

[INTRODUCTION]

Enter the test mode referring to [PREPARATION FOR USE OF

TEST MODE] in the left column of this page.

All of the messages described as “displayed” in section

“ 5. ELECTRICAL ADJUSTMENT ” appears on monitor screen

during adjustment.

1. BASIC OPERATIONS OF THE TEST MODE

All operations are performed using the cross marked button

( , , n , N ), and press the ENTER button. The

n

N

respective buttons have the following functions.

Function Name Function

, button Changes parameters and modes

n

N

n button

N button

Proceeds onto the next steps.

Confirms the entry.

Returns to the previous step.

Stop operations.

2. SELECTING THE TEST MODE

Select the desired test mode from the ten test modes by pressing the

, buttons.

n

N

Display Contents

TEMP ADJUST

LDPWR ADJUST Laser power adjustment

EFBAL ADJUST Traverse adjustment

FBIAS ADJUST Focus bias adjustment

FBIAS CHECK Focus bias check

CPLAY MODE Continuous playback mode

CREC MODE Continuous recording mode

EEP MODE Non-volatile memory mode (*1)

Vol MODE

Ver. xx.xx

Virgin mode TOC all clear mode (*1)

Total Time

Temperature compensation offset

adjustment

The mode corresponding to the

electronic volume control mode (*1)

Displays version No. of MD

microprocessor

WR = x: xx (Laser total write hours)

SP = x: xx (Spindle rotation hours)

• For detailed description of each adjustment mode, refer to the

• If a different adjustment mode has been selected by mistake, press

*1: The EEP MODE, Vol MODE, Ver.xx.xx and Virgin mode are

— 15 —

“ 5. ELECTRICAL ADJUSTMENTS ”.

the N button to exit from it.

not used in servicing. If set accidentally , press the N button

immediately to exit it.

2-1. OPERA TING THE CONTINUOUS PLA YB ACK MODE

1. Entering the Continuous Playback Mode

1 Set the MO or CD disc in the unit. (Whichever recordable

discs or discs for playback only are available.)

2 Press the button or button and display “CPLAY

MODE”.

n

N

3 Press the n button to change the display to “CPLAY

IN”.

4 When access completes, the display changes to

“C1=

Note: The numbers “

”.

AD=

” displayed are undefinite numbers.

2. Changing the Parts to be Played-back

1 Press the n button during continuous playback to change

the display as below.

2-2. OPERATING THE CONTINUOUS RECORDING

MODE

1. Entering the Continuous Recording Mode

1 Set the MO disc in the unit.

2 Press the button or button and display “CREC

MODE”.

n

N

3 Press the n button to change the display to “CREC IN”.

4 When access completes, the display changes to “CREC

(

)” .

Note: The numbers “ ” displayed are undefinite numbers.

2. Changing the Parts to be Recorded

1 When the n button is pressed access is completed, the

display changes as below.

CPLAY MID

CPLAY OUT CPLAY IN

2 When access completes, the display changes to

“C1=

Note: The numbers “

AD= ”.

” displayed are undefinite numbers.

3. Exitting the Continuous Playback Mode

1 Press the N button. The display will change to “CPLA Y

MODE”.

2 Press the 6 button and remove the disc.

Notes:

1. The playback start address for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT: 700h cluster

CREC MID

CREC OUT CREC IN

2 When access completes, the display changes to “CREC

)” .

(

Note: The numbers “

” displayed sare undefinite numbers.

3. Ending the Continuous Recording Mode

1 Press the N button. The display will change to “CREC

MODE”.

2 Press the 6 button and remove the disc.

Notes:

1. The recording start address for IN, MID, and OUT are as follows.

IN : 40h cluster

MID : 300h cluster

OUT : 700h cluster

2. The N button can be used to stop recording anytime.

3. During the test mode, the erasing-protection tab will not be

detected. Therefore be careful not to set the continuous recording

mode when a disc not to be erased is set in the unit.

4. Do not perform continuous recording for long periods of time

above 5 minutes.

5. During continuous recording, be careful not to apply vibration.

2-3. NON-VOLATILE MEMORY MODE

This mode reads and writes the contents of the non-volatile memory .

It is not used in servicing.

If set accidentally, press the N button immediately to exit it.

— 16 —

3. FUNCTIONS OF OTHER BUTTONS

5. PRECAUTIONS FOR USE OF TEST MODE

Button Function

• Sets continuous playback when

LIVE/PLAY

pressed in the STOP state.

• When pressed during continuous

playback, the tracking servo turns on/off.

CAPTURE

PHOTO

ALBUM

IR LINK

Stop continuous playback and continuous

recording.

The sled moves to the outer circumference only

when this is pressed.

The sled moves to the inner circumference only

when this is pressed.

Switches the diaplay when pressed.

4. TEST MODE DISPLAYS

Each time the IR LINK button pressed, the display changes in the

following order.

Mode

display

Error rate

display

Address

Display

1. As loading related operations will be performed regardless of

the test mode operations being performed, be sure to check that

the disc is stopped before setting and removing it. Even if the

6 button is pressed while the disc is rotating during continuous

playback, continuous recording, etc., the disc will not stop

rotating. Therefore, it will be ejected while rotating. Be sure to

press the 6 button after pressing the N button and the rotation

of disc is stopped.

2. The erasing-protection tab is not detected in the test mode.

Therefore, operating in the recording laser emission modes

suchas continuous resord mode, traverse adjustment mode, etc.,

the recorded contents will be erased regardless of the position

of the tab. When using a disc that is not to be erased in the test

mode, be careful not to enter the continuous recording mode

and traverse adjustment mode.

VIDEO SECTION

[INTRODUCTION]

Enter the test mode referring to [PREPARATION FOR USE OF

TEST MODE] on page 15.

• VIDEO TEST MODE

Enter the video test mode by selecting VIDEO on the main menu.

The various video test signals are output from built-in

microprocessor in the video test mode.

1. MODE display

Displays “TEMP ADJUST”, “CPLAY MODE”, etc..

2. Error rate display

Error rates are displayed as follows.

C1=

AD=

C1= : Indicates C1 error

AD= : Indicates ADER

3. Address display

Address are displayed as follows.

h= s= (MO pits and CD)

h=

a= (MO grooves)

h= : Header address

a= : ADIP address

s= : SUB Q address

Note: “—” is displayed when the address cannot be read.

• Menu

Close

Color Bar

Blue Back

Half Tone

White

The menu as shown appears. Select the desired submenu by pressing

the cross marked button ( , ), and press the ENTER button.

n

N

Color Bar ............ The color bars signal is output.

Blue Back ........... All blue screen appears.

Half Tone ............ All gray screen appears.

White .................. 100% white signal is output.

• When a desired submenu is selected, the specified screen appears,

but the submenu remains on the display.

Press “Close” to clear the submenu. The submenu disappears

and the specified screen appears.

Return to the main menu of the test mode by pressing the ENTER

button.

— 17 —

SECTION 5

ELECTRICAL ADJUSTMENTS

AUDIO SECTION

[INTRODUCTION]

Enter the test mode referring to [PREPARATION FOR USE OF

TEST MODE] on page 15.

All of the messages described as “displayed” appears on monitor

screen during adjustment.

Precautions for Checking Laser Diode Emission

To check the emission of the laser diode during adjustments, never

view directly from the top as this may lose your eye-sight.

Precautions for Use of optical pick-up (KMS-210A)

As the laser diode in the optical pick-up is easily damaged by static

electricity, solder the laser tap of the flexible board when using it.

Before disconnecting the connector, desolder first. Before connecting

the connector, be careful not to remove the solder . Also take adequate

measures to prevent damage by static electricity . Handle the flexible

board with care as it breaks easily.

laser tap

Precautions for Adjustments

1) When replacing the following parts, perform the adjustments

and checks with ® in the order shown in the following table.

Optical

Pick-up

1. Temperature

compensation

offset adjustment

2. Laser power

adjustment

3. Traverse

adjustment

4. Focus bias

adjustment

5. Error rate check

IC171

G

¬¬

¬

¬¬ ¬

¬

GG

¬

¬¬

2) Set the test mode when performing adjustments.

After completing the adjustments, exit the test mode.

3) Perform the adjustments in the order shown.

4) Use the following tools and measuring devices.

• Check Disc (CD) TGYS-1 (Parts No. 4-963-646-01)

• Laser power meter LPM-8001 (Parts No. J-2501-046-A)

• Oscilloscope

• Digital voltmeter

• Thermometer

5) When observing several signals on the oscilloscope, etc.,

make sure that VC and ground do not connect inside the

oscilloscope.

(VC and ground will become short-circuited.)

BD Board

D101 IC101, IC121, IC191

¬¬¬

G

G

G

¬

Optical pick-up flexible board

• Abbreviation

MO : Recordable disc

CD : Disc for playback only

Creating Continuously Recorded Disc

* This disc is used in focus bias adjustment and error rate check.

The following describes how to create a continuous recording

disc.

1. Insert a MO disc (blank disc) commercially available.

2. Press the , buttons and display “CREC MODE”.

3. Press the n button and display “CREC IN”.

n

N

4. Press the n button again to display “CREC MID”.

“CREC (0300” is displayed for a moment and recording starts.

5. Complete recording within 5 minutes.

6. Press the N button and stop recording .

7. Press the § button and remove the MO disc.

The above has been how to create a continuous recording data for

the focus bias adjustment and error rate check.

Note :

• Be careful not to apply vibration during continuous recording.

— 18 —

Temperature Compensation Offset Adjustment

Laser Power Adjustment

Save the temperature data at that time in the non-volatile memory

as 25 ˚C reference data.

Note :

1. Usually, do not perform this adjustment.

2. Perform this adjustment in an ambient temperature of 22 ˚C to

28 ˚C. Perform it immediately after the power is turned on

when the internal temperature of the unit is the same as the

ambient temperature.

3. When D101 has been replaced, perform this adjustment after

the temperature of this part has become the ambient

temperature.

Adjusting Method :

1. Press the , buttons and display “TEMP ADJUST”.

n

N

2. Press the n button and select the “TEMP ADJUST” mode.

3. “TEMP =

” and the current temperature data will be

displayed.

4. To save the data, press the n button.

When not saving the data, press the N button.

5. When the n button is pressed, “TEMP =

SAVE” will be

displayed for some time, followed by “TEMP ADJUST”.

When the N button is pressed, “TEMP ADJUST” will be

displayed.

Specifications :

The “TEMP =

” should be within “E0 - EF”, “F0 - FF”, “00 -

0F”, “10 - 1F” and “20 - 2F”.

Connection :

Laser power

meter

Optical pick-up

objective lens

Digital voltmeter

BD board

TP (I + 5V)

TP (IOP)

Adjusting Method :

1. Set the laser power meter on the objective lens of the optical

pick-up. (When it cannot be set properly, press the ALBUM

button or PHOTO button and move the optical pick-up.)

Connect the digital volt meter to TP (IOP) and TP (I+5V).

2. Press the , buttons and display “LDPWR ADJUST”.

(Laser power : For adjustment)

n

N

3. Press the n button twice and display “LD $ 4B = 3.5 mW”.

4. Adjust RV102 of the BD board so that the reading of the laser

power meter becomes 3.45

+0.1

– 0

mW.

5. Press the n button and display “LD $ 96 = 7.0 mW”.

(Laser power : MO writing)

6. Check that the laser power meter and digital voltmeter readings

satisfy the specified value.

Specification :

Laser power meter reading : 7.0 ± 0.3 mW

Digital voltmeter reading : Optical pick-up displayed value ± 10%

(Optical pick-up label)

KMS

210A

27X40

B0825

lop = 82.5 mA in this case

lop (mA) = Digital voltmeter reading (mV)/ 1 (

Ω

)

7. Press the n button and display “LD $ 0F = 0.7 mW”.

(Laser power : MO reading)

8. Check that the laser power meter at this time satisfies the

specified value.

Specification :

Laser power meter reading : 0.70 ± 0.1 mW

9. Press the N button and display “LDPWR ADJUST”, and stop

laser emission.

(The N button is effective at all times to stop the laser

emission.)

— 19 —

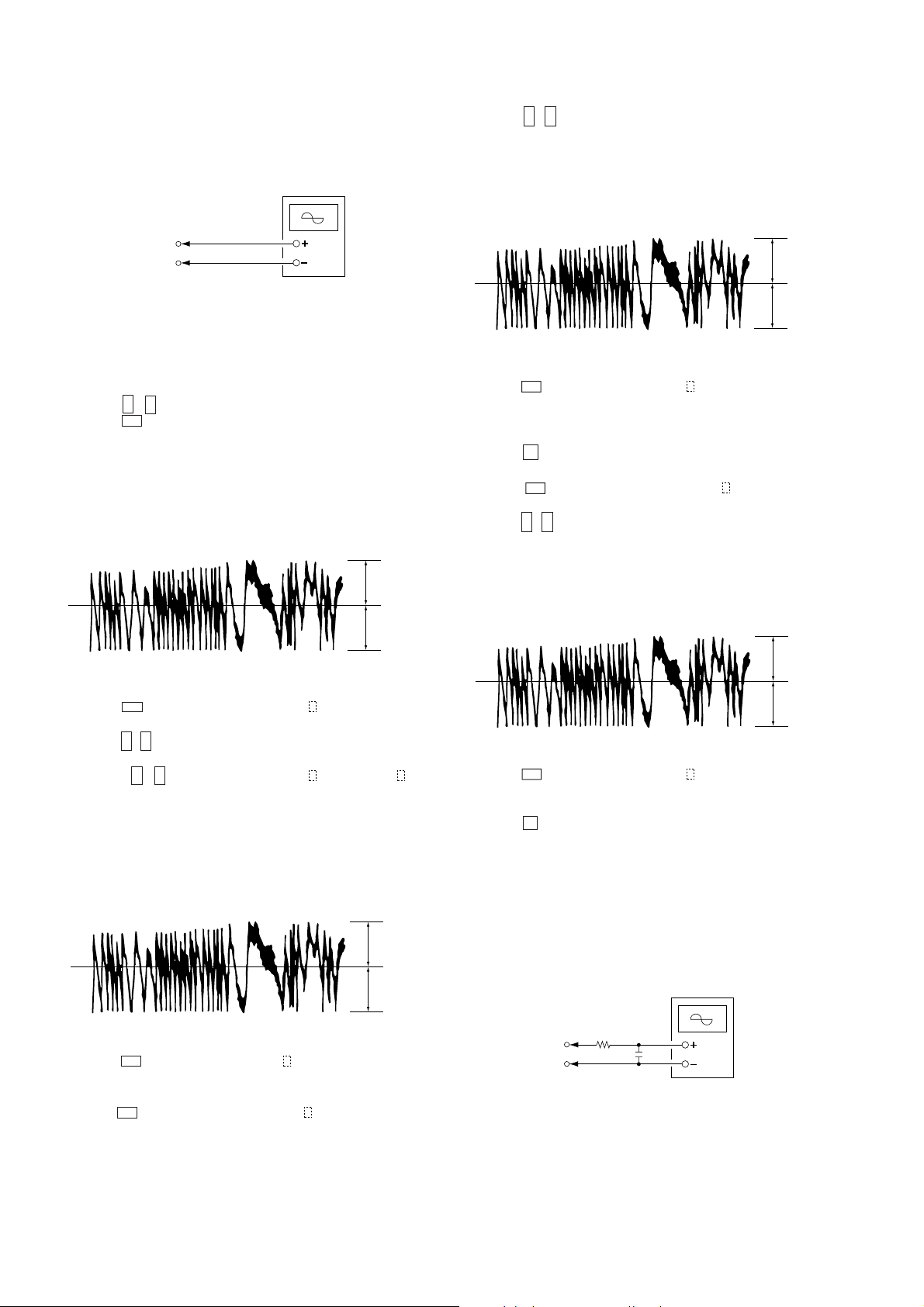

Traverse Adjustment

Connection :

Oscilloscope

11. Press the , buttons until the waveform of the oscilloscope

n

N

moves closer to the specified value.

In this adjustment, waveform varies at intervals of approx. 3%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

BD board

TP (TEO)

TP (VC)

Adjusting method :

1. Connect an oscilloscope to TP (TEO) and TP (VC) of the BD

board.

2. Load a MO disc (any available on the market).

3. Press the ALBUM button or PHOTO button and move the

optical pick-up outside the pit.

4. Press the , buttons and display “EFBAL ADJUST”.

5. Press the n button and display “EFBAL MO-W”.

n

N

(Laser power WRITE power/Focus servo ON/tracking servo

OFF/spindle (S) servo ON)

6. Adjust RV101 of the BD board so that the waveform of the

oscilloscope becomes the specified value.

(MO groove write power traverse adjustment)

(Traverse Waveform)

A

VC

B

Specification A = B

7. Press the n button and display “EFB = $

MO-R”.

(Laser power : MO reading)

8. Press the , buttons so that the waveform of the oscilloscope

becomes the specified value.

(When the , buttons are pressed, the

changes and the waveform changes.) In this adjustment,

n

n

N

N

of “EFB = $ ”

waveform varies at intervals of approx. 3%. Adjust the

waveform so that the specified value is satisfied as much as

possible.

(MO groove read power traverse adjustment)

(Traverse Waveform)

A

VC

B

(Traverse Waveform)

A

VC

B

Specification A=B

12. Press the n button, display “EFB = $ SA VE” for a moment

and save the adjustment results in the non-volatile memory.

Next “EFBAL CD” is displayed. The disc stops rotating

automatically.

13. Press the § button and remove the MO disc.

14. Load the check disc (MD) TDYS-1.

15. Press the n button and display “EFB = $

CD”. Servo is

imposed automatically.

16. Press the , buttons so that the waveform of the oscilloscope

moves closer to the specified value.

n

N

In this adjustment, waveform varies at intervals of approx. 3%.

Adjust the waveform so that the specified value is satisfied as

much as possible.

(Traverse Waveform)

A

VC

B

Specification A=B

17. Press the n button, display “EFB = $ SA VE” for a moment

and save the adjustment results in the non-volatile memory.

Next “EFBAL ADJUST” is displayed.

18. Press the § button and remove the test disc TDYS-1.

Note 1 : Data will be erased during MO reading if a recorded disc

is used in this adjustment.

Note 2 : If the traverse waveform is not clear, connect the

oscilloscope as shown in the following figure so that it

can be seen more clearly.

Oscilloscope

Specification A=B

9. Press the n button, display “EFB = $

SAVE” for a moment

and save the adjustment results in the non-volatile memory.

Next “EFBAL MO-P” is displayed.

10. Press the n button and display “EFB = $

MO-P”.

The optical pick-up moves to the pit area automatically and

servo is imposed.

— 20 —

BD board

TP (TEO)

TP (VC)

330k

Ω

10pF

DPA-300

Focus Bias Adjustment

Adjusting Method :

1. Load a continuously recorded disc (Refer to “Page 18 Creating

Continuously Recorded Disc”.).

2. Press the , buttons and display “CPLAY MODE”.

3. Press the n button twice and display “CPLAY MID”.

4. Press the N button when “C1 =

5. Press the , buttons and display “FBIAS ADJUST”.

6. Press the n button and display “ / a = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [a =] indicate the

focus bias value.

7. Press the , buttons and find the focus bias value at which

the C1 error rate becomes 220.

8. Press the n button and display “

9. Press the , buttons and find the focus bias value at which

the C1 error rate becomes 220.

10. Press the n button and display “

11. Check that the C1 error rate is below 50 and ADER is 00. Then

press the n button.

12. If the “(

button.

If below 20, press the N button and repeat the adjustment

from step 2 again.

13. Press the § button to remove the continuously recorded disc.

Note 1 : The relation between the C1 error and focus bias is as

Note 2 : As the C1 error rate changes, perform the adjustment using

C1 error

220

n

N

AD = ” is displayed.

n

N

n

N

/ b = ”.

n

N

/ c = ”.

” in “ - - ( ” is above 20, press the n

shown in the following figure. Find points a and b in the

following figure using the above adjustment. The focal

point position c is automatically calculated from points a

and b.

the average value.

Focus bias value

(F. BIAS)

b

c

a

Error Rate Check

CD Error Rate Check

Checking Method :

1. Load a check disc TGYS-1.

2. Press the , buttons and display “CPLAY MODE”.

3. Press the n button twice and display “CPLAY MID”.

4. “C1 =

n

N

AD = ” is displayed.

5. Check that the C1 error rate is below 20.

6. Press the N button, stop playback, press the § button, and

remove the test disc.

MO Error Rate Check

Checking Method :

1. Load a continuously recorded disc (Refer to “Page 18 Creating

Continuously Recorded Disc”.).

2. Press the , buttons and display “CPLAY MODE”.

3. Press the n button twice and display “CPLAY MID”.

n

N

4. “C1 = AD = ” is displayed.

5. If the C1 error rate is below 50, check that ADER is 00.

6. Press the N button, stop playback, press the § button, and

remove the continuously recorded disc.

Focus Bias Check

Change the focus bias and check the focus tolerance amount.

Checking Method :

1. Load a continuously recorded disc (Refer to “Page 18 Creating

Continuously Recorded Disc”.).

2. Press the , buttons and display “CPLAY MODE”.

3. Press the n button twice and display “CPLAY MID”.

4. Press the N button when “C1 =

5. Press the , buttons and display “FBIAS CHECK”.

6. Press the n button and display “ / c = ”.

The first four digits indicate the C1 error rate, the two digits

after [/] indicate ADER, and the 2 digits after [c =] indicate the

focus bias value.

Check that the C1 error is below 50 and ADER is 00.

7. Press the n button and display “

Check that the C1 error is not below 220 and ADER is not

above 00 every time.

8. Press the n button and display “

Check that the C1 error is not below 220 and ADER is not

above 00 every time.

9. Press the N button, next press the § button, and remove the

continuously recorded disc.

n

n

N

AD = ” is displayed.

N

/ b = ”.

/ a = ”.

Adjusting Points and Connecting Points

[BD BOARD] (SIDE A)

[BD BOARD] (SIDE B)

(IOP)

(I + 5V)

IC171

(VC)

RV101

TRAVERSE

Adj

IC101

D101

IC191

Note 1 : If the C1 error and ADER are above 00 at points a or b,

the focus bias adjustment may not have been carried out

properly. Adjust perform the beginning again.

RV102

LASER POWER

Adj

IC121

(TEO)

— 21 — — 22 —

DPA-300

r

+

–

75

Ω

DPA-300

Oscilloscope

Video Output (J106)

Color bar generator

S-Video Input

(J101)

Video Output

A

H

White (100 %)

VIDEO SECTION

[SYNC LEVEL ADJUSTMENT]

Connection:

Oscilloscope

75

Ω

DPA-300

Video Output (J106)

Adjustment Procedure:

1. Connect an oscilloscope and monitor to the Video Output (J106)

of the DPA-300.

2. Enter the video test mode. Output the color bar from the DP A-

300. (Refer to page 15.) After color bar output is confirmed,

disconnect a monitor.

3. Adjust RV3003 on the PICTURE board until the level (A)

satisfies the specification on an oscilloscope.

Waveform:

+

–

[WHITE LEVEL ADJUSTMENT]

Connection:

Oscilloscope

75

Ω

DPA-300

Video Output (J106)

+

–

Adjustment Procedure:

1. Connect an oscilloscope and monitor to the Video Output (J106)

of the DPA-300.

2. Enter the video test mode. Output the 100 % white signal from

the DP A-300. (Refer to page 15.) After the 100 % white signal

is confirmed, disconnect a monitor.

3. Observe waveform on an oscilloscope. Adjust RV3001 on the

PICTURE board until the level (A) of the color bar’s white

peak (100 %) satisfies the specification on an oscilloscope.

Waveform:

White (100 %)

[CLOCK ADJUSTMENT]

Connection:

Frequency counte

PICTURE board

TP4091 (DCLK)

+

–

Adjustment Procedure:

1. Connect a frequency counter to TP4091 (DCLK) on the

PICTURE board.

2. Turn the POWER switch of the DPA-300 to ON.

3. Adjust CT4001 on the PICTURE board until frequency of

TP4091 (DCLK) satisfies the specification.

Specification: 12.272725 MHz ± 30 Hz

Adjustment Location: PICTURE board

[ S INPUT Y-SIGNAL AMPLITUDE ADJUSTMENT]

Connection:

[Y OUTPUT AMPLITUDE ADJUSTMENT]

Connection:

Video Output (J106)

Color bar generator

Video Output

DPA-300

S-Video Input

(J102)

Oscilloscope

75

Ω

+

–

Adjustment Procedure:

1. Connect a color bar generator to the Video input (J102) of the

DPA-300.

2. Connect an oscilloscope and monitor to Video Output (J106) of

the DPA-300.

3. Output the 100 % white color bar signal from a color bar

generator.

4. Set the mode in which the Through picture is displayed. (Refer

to SERVICE NOTE on page 5.) After the mode is set, disconnect

a monitor.

5. Adjust RV402 of the VIDEO-IN board until the 100 % white

level (A) satisfies the specification on an oscilloscope.

Waveform:

A

H

Specification: 286 ± 15 mVp-p

(Measured in the 50 mV range of oscilloscope)

Adjustment Location: PICTURE board

- Reference -

Pattern of built-in color bar signal

CYAN

YELLOW

WHITE (100%)

GREEN

MAGENTA

RED

BLUE

BLACK

A

H

Specification: 714 ± 30 mVp-p

(Measured in the 100 mV range of oscilloscope)

Adjustment Location: PICTURE board

Adjustment Procedure:

1. Connect a color bar generator to the S-Video input (J101) of the

DPA-300.

2. Connect an oscilloscope and monitor to Video Output (J106) of

the DPA-300.

3. Output the 100 % white color bar signal from a color bar

generator.

4. Set the mode in which the Through picture is displayed. (Refer

to SERVICE NOTE on page 5.) After the mode is set, disconnect

a monitor.

5. Adjust RV403 of the VIDEO-IN board until the 100 % white

level (A) satisfies the specification on an oscilloscope.

Waveform:

White (100 %)

Specification: 714 ± 30 mVp-p

Adjustment Location: VIDEO-IN board

A

H

Specification: 714 ± 30 mVp-p

Adjustment Location: VIDEO-IN board

— 23 — — 24 —

DPA-300

r

[+6 V ADJUSTMENT]

Connection:

Digital Voltmeter

POWER board

C1204

C1501

+

–

Adjustment Procedure:

1. Connect a digital voltmeter across C1204 of the POWER board.

2. Adjust RV1 1 11 on the POWER board until the digital voltmeter

reading satisfies the specification.

3. Connect a digital voltmeter across C1501 of the POWER board.

4. Adjust RV1201 on the POWER board until the digital voltmeter

reading satisfies the specification.

Specification: 6.0 ± 0.1 V

Adjustment Location: POWER board

[+5.3 V ADJUSTMENT]

Connection:

Digital Voltmete

Adjusting Points and Connecting Points

[POWER BOARD] (SIDE A)

RV1111

+6V Adj

CN1901

[POWER BOARD] (SIDE B)

C1204

+6V Adj

CN1004

RV1121

+5.3V Adj

RV1201

+6V Adj

C1501

+6V Adj

[VIDEO-IN BOARD] (SIDE A)

IC401

J101 J102 J106

RV402

Y OUTPUT

AMPLITUDE

Adj

IC402

RV403

S INPUT

SIGNAL AMPLITUDE

Adj

POWER board

TP (M+5V)

TP (MGND)

+

–

Adjustment Procedure:

1. Connect a digital voltmeter to TP (M+5 V) and TP (MGND) of

the POWER board.

2. Adjust RV1 121 on the POWER board until the digital voltmeter

reading satisfies the specification.

Specification: 5.3 ± 0.1 V

Adjustment Location: POWER board

MGND

+5.3V Adj

M+5V

+5.3V Adj

IC1121

Q1001

[PICTURE BOARD] (SIDE A)

IC4004

TP4091

(DCLK)

IC4019

IC4010

IC1003

IC4011

RV3003

SYNC

LEVEL

Adj

RV3001

WHITE

LEVEL

Adj

CN1002

CT4001

CLOCK

Adj

IC4016

— 25 — — 26 — — 27 —

DPA-300

d

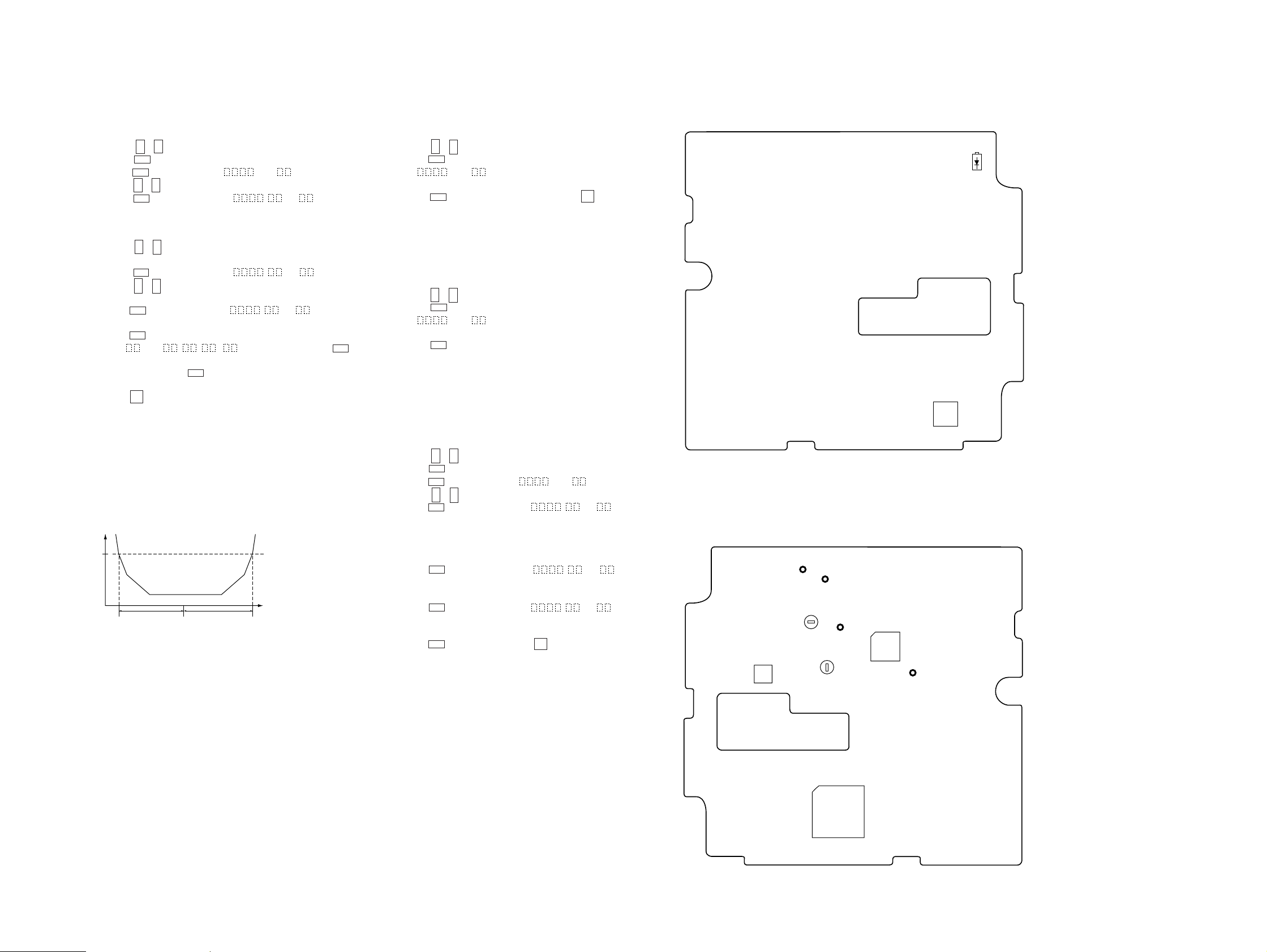

SECTION 6

DIAGRAMS

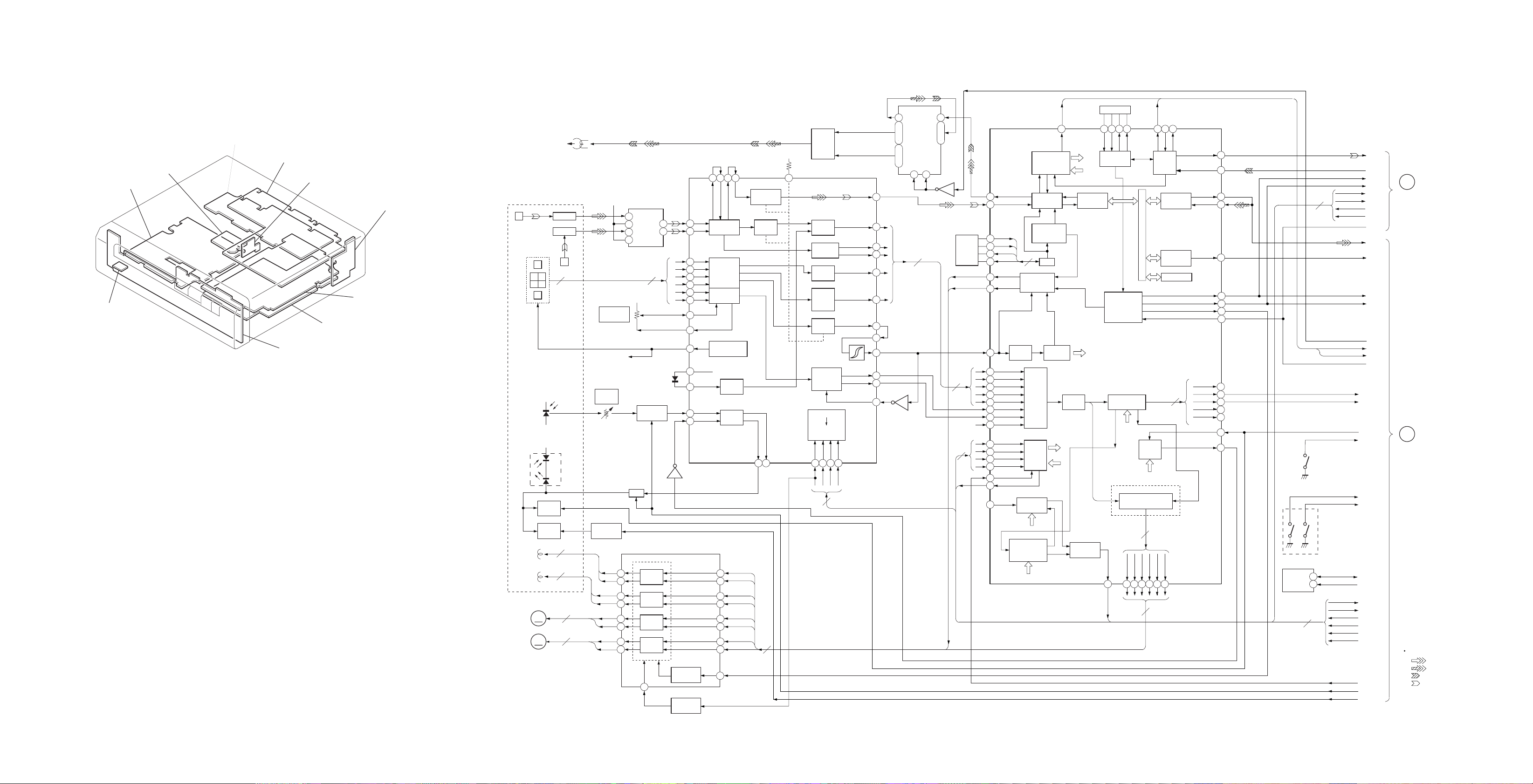

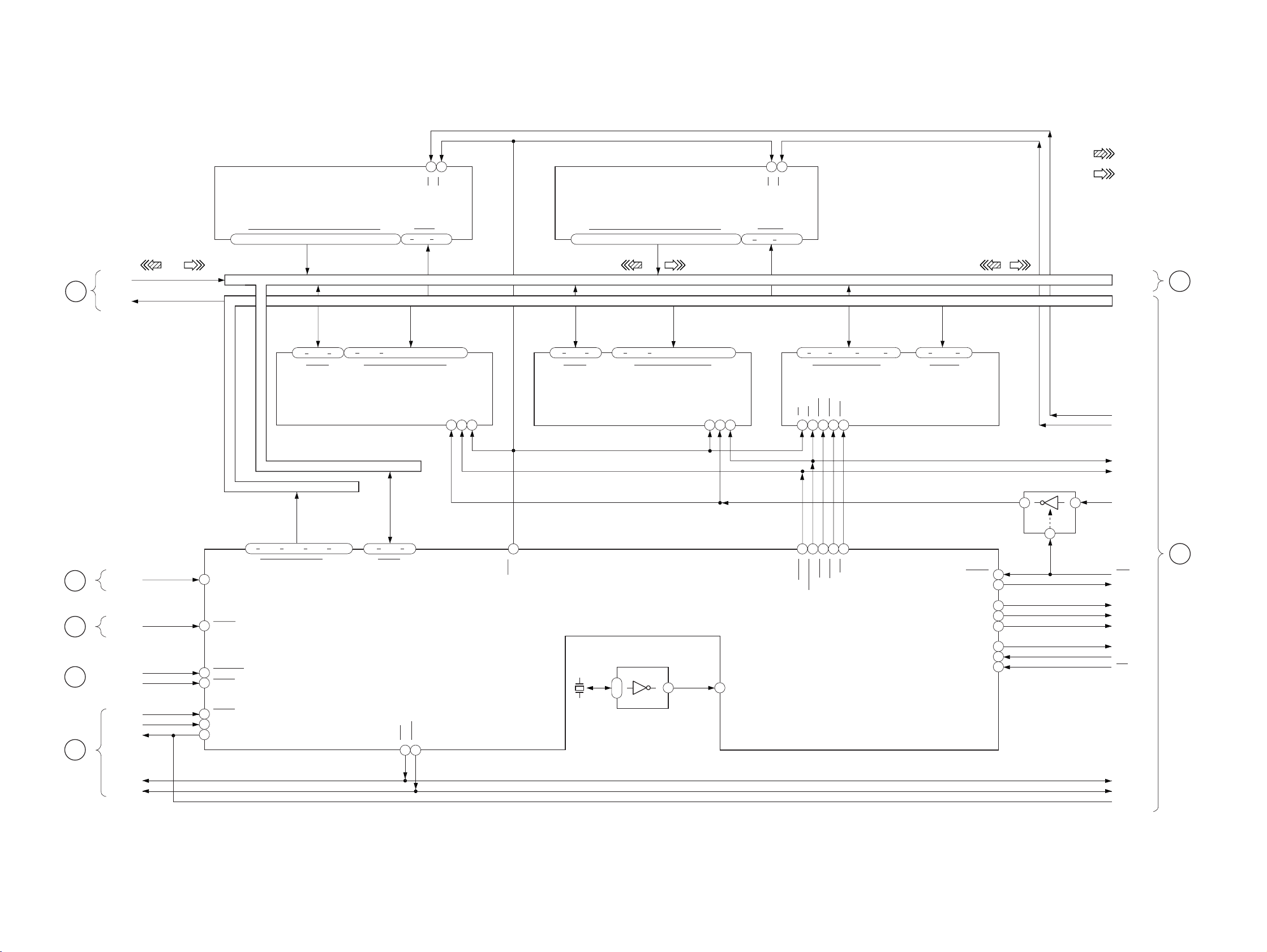

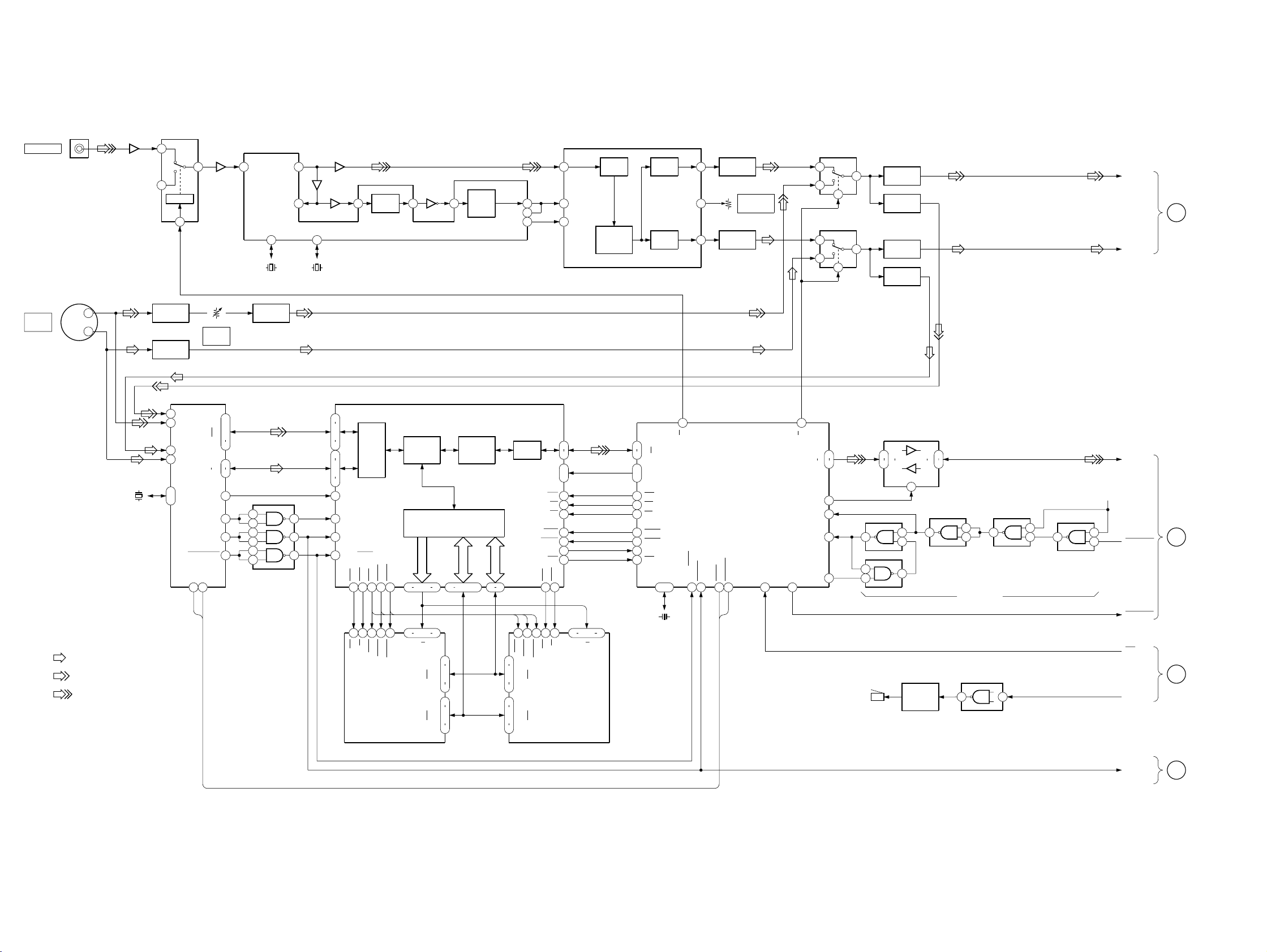

6-1. CIRCUIT BOARD LOCATION 6-2. BLOCK DIAGRAM — BD SECTION —

BD board

IRDA board

MOTOR board

POWER board

VIDEO IN board

DETECTION SW board

MD board

PANEL board

JACK board

PICTURE boar

HR901

OVER

WRITE

HEAD

OPTICAL PICK–UP BLOCK

(KMS–210A/J–N)

J

F

CDB

A

E

PD

HIGH

POWER

LD

L.F

MOD

H.F

MOD

TRACKING

COIL

FOCUS

COIL

M101

SLED

M

MOTOR

M102

MOTOR

16

M

SPINDLE

IV–AMP

IV–AMP

1

6

2

2

2

2

RV101

BALANCE

RV102

LASER

POWER

Q164

HF

MODULE

SWITCH

TRK–

TRK+

FCS+

FCS–

SLED+

SLED–

SPDL+

SPDL–

VC

E–F

IC172

2

3

BUFFER

6

5

VC

VC

Q101

LASER ON

SWITCH

Q162,163

APC

SLED/SPINDLE MOTOR DRIVE,

FOCUS/TRACKING COIL DRIVE

26

DRIVER

29

8

DRIVER

11

15

DRIVER

13

22

DRIVER

24

33

DIGITAL SIGNAL PROCESSOR.

DIGITAL SERVO SIGNAL PROCESSOR.

EFM/ACIRC ENCODER/DECODER

2

FILTER

SPFD

SPRD

5

VC

4

IC121

EFMO

45

58

CLTV

60

FILI

62

PCO

61

FILO

63

94

93

82

AUX

68

BOTM

65

PEAK

64

ABCD

66

FE

67

TE

77

SE

76

VC

69

SWDT

8

SCLK

9

XLAT

10

XRST

16

REC

24

SRDT

DIRC

7

RFI

PROCESSOR

ADIP

DEMOD

SERVO

CONTROL

SERVO

AUTO

SEQUENCER

SUBCODE

PROCESSOR.

READER/

GENERATOR

MOD/DMOD

TIMING

GENERATOR

4

DIGITAL

CLV

ANALOG

MUX

CPU

IF

EFM

EFM

PLL

ADIP

DECODER

14

SOSY

A/D

CONV

CONTROL

SENS

41

34

38

39

37

35

30

31

ADFG

33

26

29

4

27

18 2

11

|

OVER WRITE

HEAD DRIVE

14

IC181

15

|

17

1 19

5

2

IC102

4

IC182

3

|

9

Q181,182

HEAD

+5V

46 45 44 43 42

RF AGC

&EQ

J

48

1

47

7

6

4

2

IC151

CLOCK

DETECTOR

RESET

SWITCH

16

12

10

11

IC122

Q151

D101

2

3

4

5

6

7

8

9

1

I

A

B

C

D

E

F

FI

FO

VC

TEMPR

TEMPI

PD

APCREF

RF AMP

IV AMP

IV AMP

+2.5V

GENERATOR

+5V

TEMP

AMP

APC

TFDR

31

TRDR

32

FRDR

5

FFDR

6

SFDR

17

SRDR

18

SPFD

19

SPRD

20

FS4

3

BPF

AAPC

DAPC

8

DRIVE

AUX

SW

PEAK &

BOTTOM

ABCD

AMP

FOCUS

ERROR

AMP

AT

AMP

TRACKING

ERROR

AMP

SERIAL

PARALLEL

DECODER

SCLK

XRST

SWDT

17 1814 15 19 20

4

RF

AUX

BOTM

PEAK

ABCD

FE

ADFM

ADIN

TE

SE

TLB

XLAT

REGISTER

FILTER

51

52

49

53

DIFI

DICV

DIPD

DIFO

DIN

PLL

TIMING

GENERATOR

&

CLOCK

GENERATOR

PROCESSOR

SERVO DSP/PWM GENERATOR

FOCUS/TRACKING/

SLED SERVO & PWM

TRDR

SENS

12

TFDR

86851187

APC

PWM

GEN

FFDR

FRDR

899192

15

DIGITAL

6

SRDR

6

DQSY

AUDIO

IN/OUT

21

20

DIN

DOUT

AUDIO

DATA

CONTROL

ECC

ENCODER

DECODER

32K RAM

5

SFDR

DIDT

DODT

DFCT

SHCK

OFTRK

COUT

DTO

DTI

C2PO

BCK

LRCK

FS4

XTAI

FOK

WRPWR

LDDRLD

28

27

30

29

31

32

33

90

35

3

2

4

98

99

6

84

–1 –2

IC171

MEMORY

SDA

SCL

S101

LIMIT

5

6

6

4

S102–1

PROTECT

S102–2

REFLECT

DIDT

DODT

BCK

LRCK

SWDT

SCLK

XLAT

XRST

512FS

DATA

C2PO

BCK

LRCK

SCTX

SOSY

DOSY

512FS

FOK

SHCK

WRPWR

LIMIT

PROTECT

REFRECT

SDA

SCL

SENS

SRDT

XLAT

SCLK

SWDT

XRST

A

AUDIO

SECTION

(Page 43)

B

MD CONTROL

SECTION

(Page 31)

Signal Path

VIDEO(PB)

:

VIDEO(REC)

:

AUDIO(PB)

REC

LDON

MOD

:

:

AUDIO(REC)

— 28 — — 29 — — 30 —

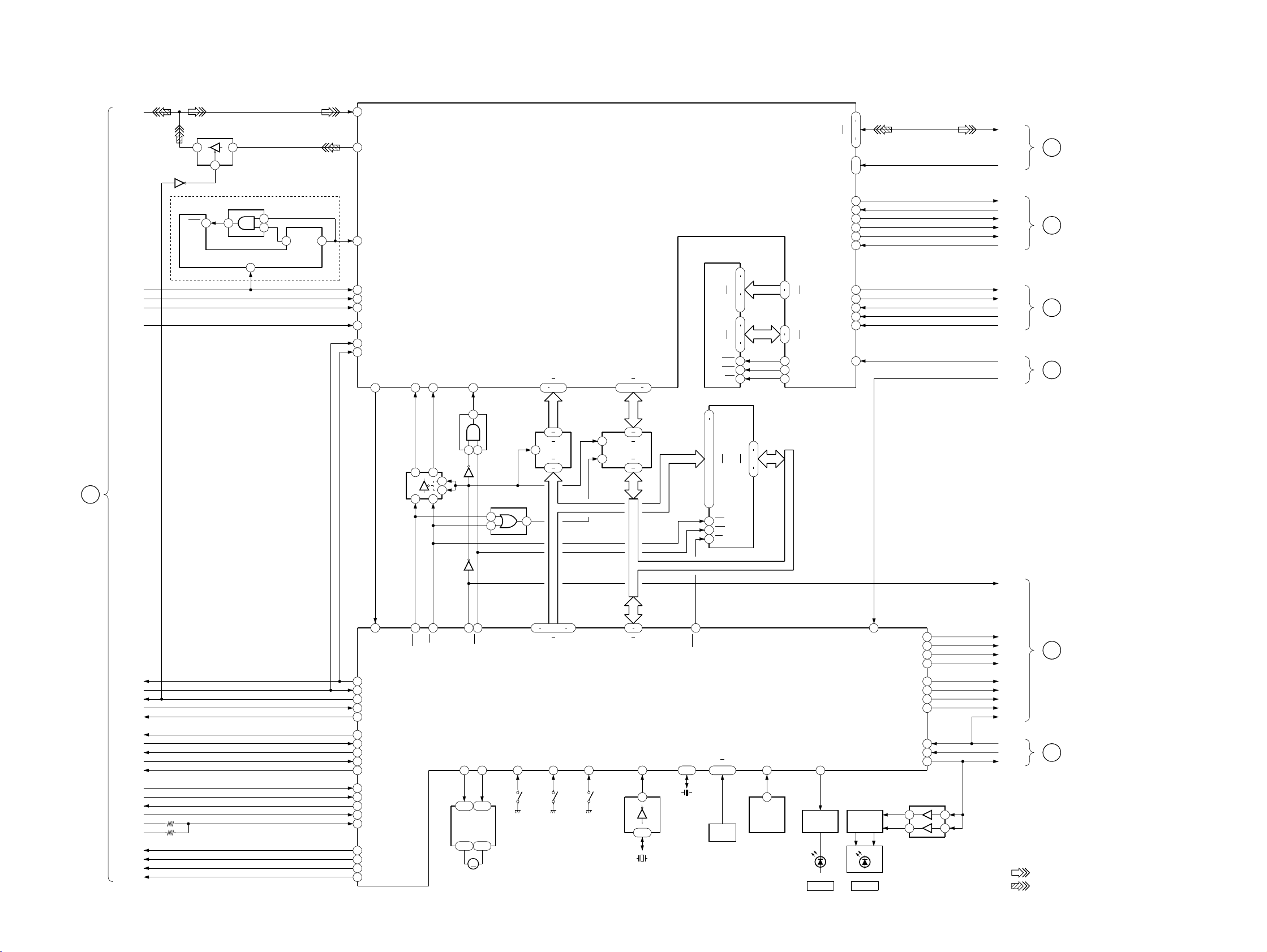

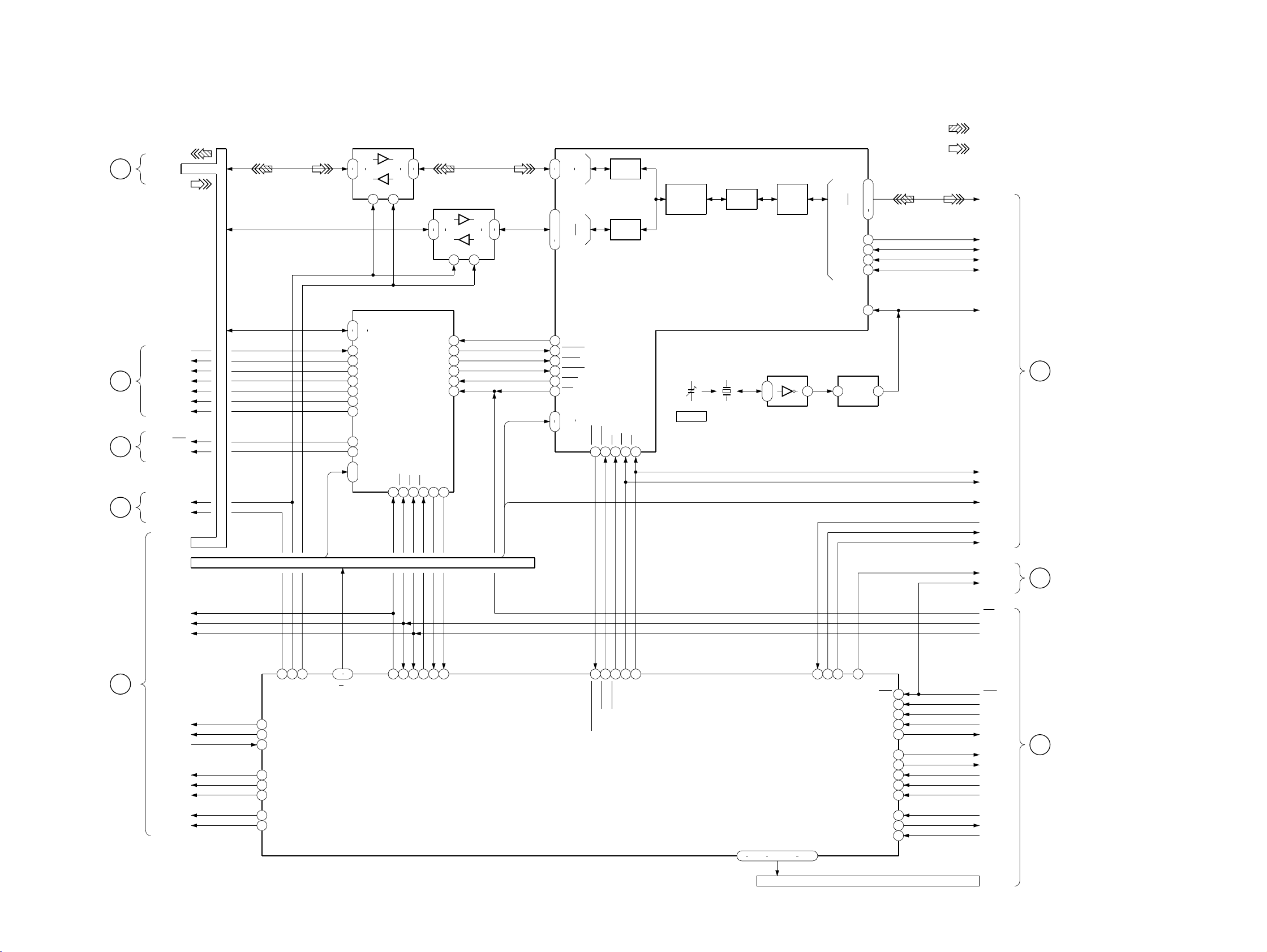

6-3. BLOCK DIAGRAM — MD CONTROL SECTION —

DPA-300

B

BD

SECTION

(Page 30)

DATA

LRCK

BCK

512FS

C2PO

IC2011

CLR

BUFFER

IC2003

1

1

26

DIVIDE-BY-6

CIRCUIT

IC2002

4

IC2001

CLK

2

5

DATA IN

6

DATA OUT

MD DATA

ENCODER/DECODER

IC2007

2

1

14

12QC

QA

10

WFCK

DRAM

IC2008

10

A0

13

9

LRCK

8

BCK

49

XTLI

7

C2PO

3

SQSY

98

XRST

93

XINT

BUFFER

IC2012

XCS96XRD

6

2

95

BUFFER

IC2010

3

5

1

7

IC2015

2 1

BUS

A0 A6

.

78 83

74

18 12

B1 B7

19

G

A1 A7

28

4

XWR

94

4

ADDRESS

BUFFER

IC2004

4

2

DIRECTION

OR

IC2006

2

1

DATA-BUS

BUFFER

IC2005

19

G

1

DIR

DB0 DB7

.

84 87.89

18 11

B1 B8

A1 A8

29

92

A9

I/O0

I/O7

RAS

CAS

WE

1M EEP ROM

IC2202

12

5

.

27

.

26

.

A0

23

.

25

.

A16

4

.

28

.

29

.

3

.

2

24

OE

31

WE

22

CE

.

16

20

.

9

2

5

.

24

27

8

23

7

13

D0

15

.

17

D7

21

MA0

37

38

21

14

22

23

24

MA9

MDB0

MDB7

XRAS

XCAS

XMWR

HDRQ/HSAC

XHAC/SDRQ

HDB0

HDB7

HA0

HA1

ADTO

ADTI

ACLK

XABS

AC2

XARQ

HINT

XHRD

XHWE

XHCS

66

64

.

62

58

53

.

.

54

43

42

41

44

45

46

56

69

70

67

68

55

D0-D7

HA0,1

ADTO

ADTI

ACLK

XALT

AC2

XARQ

HINT

DREQ1

DACK1

IORD

IOWR

MDCS

X.H RST

C

VIDEO

CONTROL

SECTION

D

AUDIO

SECTION

E

VIDEO

CONTROL

SECTION

F

VIDEO

PROCESS

SECTION

(Page 33)

(Page 43)

(Page 33)

(Page 36)

16

XRST

SQSY

REC

DQSY

XLAT

SWDT

SRDT

SCLK

SENS

SCTX

FOK

SHCK

WRPWR

LIMIT

PROTECT

REFLECT

SCL

SDA

LDON

MOD

19

DINT

28

XDRST

18

ATSY

34

RECPB

25

DQSY

30

XLAT

31

SWDT

32

SRDT

33

SCLK

78

SENS

24

SCTX

21

FOK

77

SHCK

22

WRPWR

92

LIMIT IN

93

PROTECT REFLECT

79

SCL

80

SDA

89

LDON

23

MOD

Q2002

DIG RST

.

.

OUT-SW

5

S191

LOAD OUT

DET

72 65

63

A0 A16

100

S192

LOAD IN

DET

61 54

PLAY-SW

SYSTEM CONTROL

REC-SW

7

S193

CHUCKING

DET

47

44

CS3

RD

26

11 10

LOADING MOTOR

29

46

XRST36

LD IN

1

.

17

LOADING

MOTOR

DRIVE

IC2301

.

913

M

M191

WR

LD OUT

2

.

.

A0 A6

IC2201

INVERTER

IC2203

88 81

10

3

.

17

X2202

32.768kHz

XCIN

XOUT

.

13 15

X2201

10MHz

50

CSO

XIN

KEY0

.

97 95

KEY

MATRIX

KEY2

.

94

RMC

6

2

REMOTE

CONTROL

RECEIVER

IC8101

BUSY

91

LED

DRIVER

Q8101

BUSY POWER

75

LED

DRIVER

Q8121,8122

D8121D8102

DA RST

DF LATCH

VOL DATA

X.H.RST

VOL CLK

HP VOL CE

LINE VOL CE

MIC MUTE

XAMUTE

POWER DOWN

5

7

RST

STB

27

26

35

37

73

3

4

76

20

12

38

LED

DRIVER

IC8121

DA RST

DF LAT

VOL DT

VOL CK

HP CE

LIN CE

M MUTE

AMUTE

P DWN

P DWN

S RST

STB

6

8

• Signal Path

G

AUDIO

SECTION

H

POWER

SECTION

: VIDEO (PB)

: VIDEO (REC)

(Page 43)

(Page 45)

— 31 — — 32 —

DPA-300

6-4. BLOCK DIAGRAM — VIDEO CONTROL SECTION —

CHINESE CHARACTER ROM

IC4015

• Signal Path

: VIDEO (REC)

12

10

CE

OE

PROGRAM ROM

IC4016

OE

1214

CE

: VIDEO (PB)

(Page 42)

(Page 40)

(Page 37)

(Page 32)

C

MD

CONTROL

SECTION

(Page 32)

I

VIDEO IN

SECTION

J

VIDEO OUT

SECTION

K

IR

SECTION

E

MD

CONTROL

SECTION

16

D0-7

HA0-1

IRQUART

DACK1

IORD

IOWR

D0-7

A1-2

22

23

24

27

28

13

12

D0

.17.19.22.24.26.28.14.16.18.20.23.25.27.29.

13

15

D0-15

D0-7

.

13 15 17 21

I/O1 I/O8 A0 A15

DATA-BUS D0-15

ADDRESS-BUS A1-23

A1-21,23

....

53 57 60 65 86 90 93 97 99

A1

INTP01VSYNC

INTP00M2FDO

INTP13/T1IRQSCC+

INTP12

INTP11HINT

DREQ/P03DREQ1

DACK/P04

12 5 27 26.2523

SRAM

IC4021

39 32 42 49

.

D0 D15A21 A23

D15

D0-15

.

A0

9 2 40 32 1

A1-16

..

IORD

2 3

A17

..

A1-18

DATA-BUS D0-15

ADDRESS-BUS A1-23

.31.

4

28..3

CE

NE

22 29 24

IOWR

OE

80

O0 O15

15

17.19.21.24.26.28.30.16.18.20.22.25.27.29.31

D8-15

.

13 15 17 21

I/O1 I/O8 A0 A15

MRD

X4002

4MHz

.

12 5 27 26

SRAM

IC4020

SYSTEM MICOM CPU

IC4003

1

.

7

INVERTER

IC4001

D0-15

A1-16

..4.28.

2523

2 71

.31.

3

OECENE

24 22 29

A0 A18

.

11 4 42 34 3 2

X1

...

A1-19

25710

D1 D15

CEUMWR

29 13 30

78 79 73 74 77

.

WE

UCAS

LCAS31RAS

LCAS

UCAS

LMWR/WE

DATA-BUS D0-15

ADDREDD-BUS A1-23

D0-15

3633.38.41

14

RAS

DRAM

IC4013

A1-10

17 20.23 28

A0 A9

DACK0/P02

DREQ0/P01

RESET

LCKOUT

CS1

CS2

CS3

INTP10

D0-15

A1-23

L

VIDEO

PROCESS

SECTION

(Page 35)

CS FONT1

CE

LMWR

SRAM DRIVE

IC4019

18

2

1G

1

UMWR

CS SRAM

M

30

68

83

84

85

14

15

29

RST

CLKIN

CS1

CS2

CS3

XDACK0

DRQ0

INT

IORD

IOWR

DACK1

VIDEO

PROCESS

SECTION

(Page 36)

— 33 — — 34 —

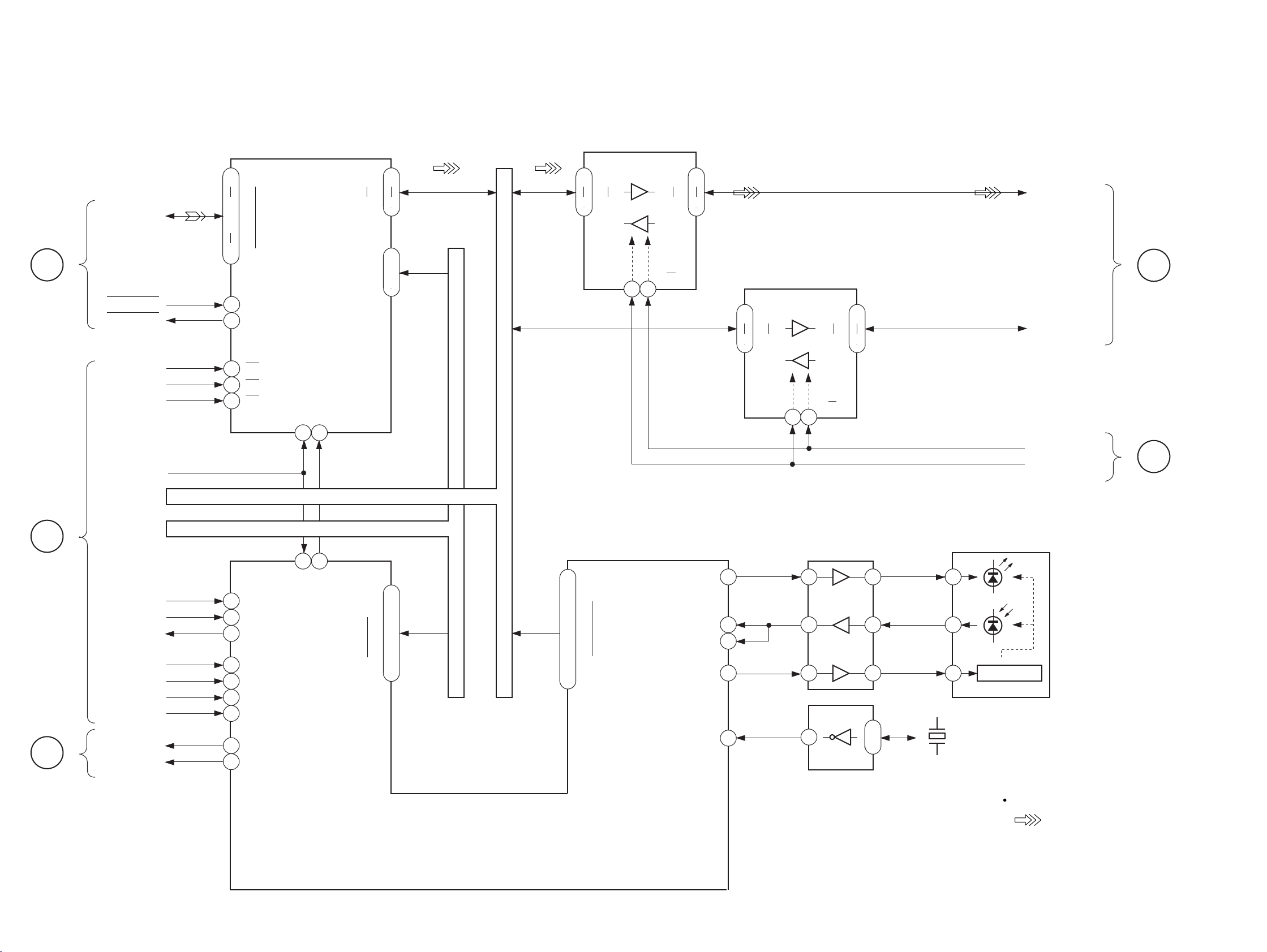

6-5. BLOCK DIAGRAM — VIDEO PROCESS SECTION —

DATA-BUS BUFFER

IC4010

HA1,2

2

A1

9

A8

DIR G

1

I/O DEMODULATOR

D0

31

D7

24

XMCWED12

VCOMUTE

16

PAL

18

NTSC

19

20

MUTE

43

OUT RESET

36

MI RESET

21

RST

BUZZER

38

5

A1

.

.

4

A2

(Page 34)

(Page 39)

(Page 42)

(Page 38)

L

VIDEO

CONTROL

SECTION

N

VIDEO

OUT

SECTION

O

VIDEO

IN

SECTION

P

IR

SECTION

D0-D15

XMCWED

VCO MUTE

NTSC

MUTE

IC3002 SEL

MI RST

RST

BEEP

BUF DIR

XBE MI

D0-15

D0-7

D8-15

DATA BUS D0-D15

D0-7

PAL

18

B1

11

B8

19

IC5004

50X RESET

RESET32WR35RD44CS

DATA-BUS BUFFER

IC4011

2

A1

9

A8

DIR G

1

END

10

37

STDBY

9

CLKEN

8

DINT

11

50X INT

13

DMA SEL0VDD

DMA SEL1

2

6

7

DPA-300

• Signal Path

: VIDEO (REC)

: VIDEO (PB)

91

DATA0

84

DATA7

82

.

18

B1

11

B8

19

HA1-10

HA1,2

81

79

74

58

59

64

92

100

12

.

3

CODE0

CODE7

END14

RESET

STBY

CLKEN

DINT

INT

ADDR0

ADDR9

DREQ

93

HOST

I/O

CODE

I/F

DACK95CS96WR97RD

98

ENCODE/

DECODE

UNIT

JPEG IMAGE

COMPRESSION/

DECOMPRESSION

PROCESSOR

CT4001

CLOCK

DCT

UNIT

IC4007

X4003

24.54545MHz

PIXEL

DATA

INVERTER

IC4008

1

.

3

PIXEL4

I/F

PIXEL11

CLOCK DIVIDER

5 1 5

COMP

STOP

EOS

DSYNC

DCLK

IC4009

48

.

47

.

45

40

33

36

37

39

63

QCK

PIX0-7

COMP

STOP

EOS

DSYNC

CLK

XRD

XWR

HA1,2

XDREQ

XDACK

XCS

R

VIDEO

OUT

SECTION

(Page 39)

(Page 37)

Q

IR

SECTION

HA1-6

RST OUT

IOWR

IORD

DACKIR

IRAEN

IRDRQX

CS 102

XH CS IR

H CS IRS

XIRD3

XIWR3

16

DACKIR6

IRAEN

5

IRDROX

4

84

CS 102

7

XH CS IR

8

XH CS IRS

XIRD3

2

XIWR3

3

44

XBE M1

37

45

BUF DIR

BE 50

ADDRESS BUS HA1-6

HA1-10

34 25

HA1 HA10

95

10

RST OUT

94

IOWR

83

IORD

17

CS IO1

DMA SEL0

18

DMA SEL1

GATE ARRAY

IC4004

36

43

40

DACK 5041XHCS 50

MD3605X DREQ

39

XWR2

XRD2

A1 - 10,16,19,21,23

52 58

69

67 70

.

.

72

79

19

47

93

MD CS

DACK M149XHCS M1

DREQ M1

CE ROM8M0

CS FONT1

..

74

ADDRESS BUS A1-23

RST

CLK IN

LMWR

UMWR

CS SRAM

CS1

CS2

CS3

DACK1

DRQ0

XDACK0

100

MD CS

X.H.RST

INT

IOWR

IORD

12

62

80

81

22

82

89

90

91

77

78

96

RST

CLK IN

LMWR

UMWR

CE

CS SRAM

CS FONT1

CS1

CS2

CS3

DACK1

DRQ0

XDACK0

A1-23

F

MD

CONTROL

SECTION

M

VIDEO

CONTROL

SECTION

(Page 32)

(Page 34)

— 35 — — 36 —

DPA-300

6-6. BLOCK DIAGRAM — IR SECTION —

S

VIDEO

IN

SECTION

(Page 42)

Q

VIDEO

PROCESS

SECTION

(Page 35)

K

VIDEO

CONTROL

SECTION

(Page 33)

14

P10

16

D0-7

HOST STB

VIN BUSY

CS-102

IOWR

IORD

RST-OUT

D0-15

HA1-6

DACKIR DACKX

XH CS IR

IRDRQX

H CS IRS

IRAEN

XIRD3

XIWR3

IRQUART

IRQSCC+

.

18

22

11

12

2

35

44

48

79

86

92

93

94

82

83

P17

P11

P22

CS

WR

RD

SA15

DRQX

SETUP

AEN

IOR

IOW

IRQUART

IRQSCC+

I/O DEMODULATOR

IC5003

RESET

P00

32 43

DATA-BUS D0-15

ADDRESS-BUS HA1-6

181654

IRBUSY

REGISTORV

31

D0

24

D7

5

A1

..

A2

4

20

.

SA0

21

.

23

.

28

.

30

.

SA5

32

D0-7

HA1-2

HA1-6

IR CONTROLLER

IC5002

D0-7

D8-15

HA1-6

60

61

64

65

68

69

71

72

DATA-BUS BUFFER

2

A1

A8

9

DIG

.

SO0

.

.

.

.

.

SO7

.

IC4006

1

19

B8

B1

ENABLE

G

RXDIR

RXDSH

GAINCTRL

11

18

TXO

CLK

DATA-BUS BUFFER

2

A1

A8

9

DIG

7

96

97

6

90

IC4005

1

19

11

B8

B1

ENABLE

G

BUFFER

IC112

2

9

5

INVERTER

IC5001

11

18

12

8

1

3

D0-7 MAR

T

VIDEO

OUT

SECTION

D8-15 MAR

BUFDIR

XBE MI

IRDA

RECEIVER/TRANSMITER

IC8001

3

.

7

2

6

36.864MHz

CONTROL

X4001

Signal Path

:VIDEO(PB)

(Page 39)

P

VIDEO

PROCESS

SECTION

(Page 35)

16

— 37 — — 38 —

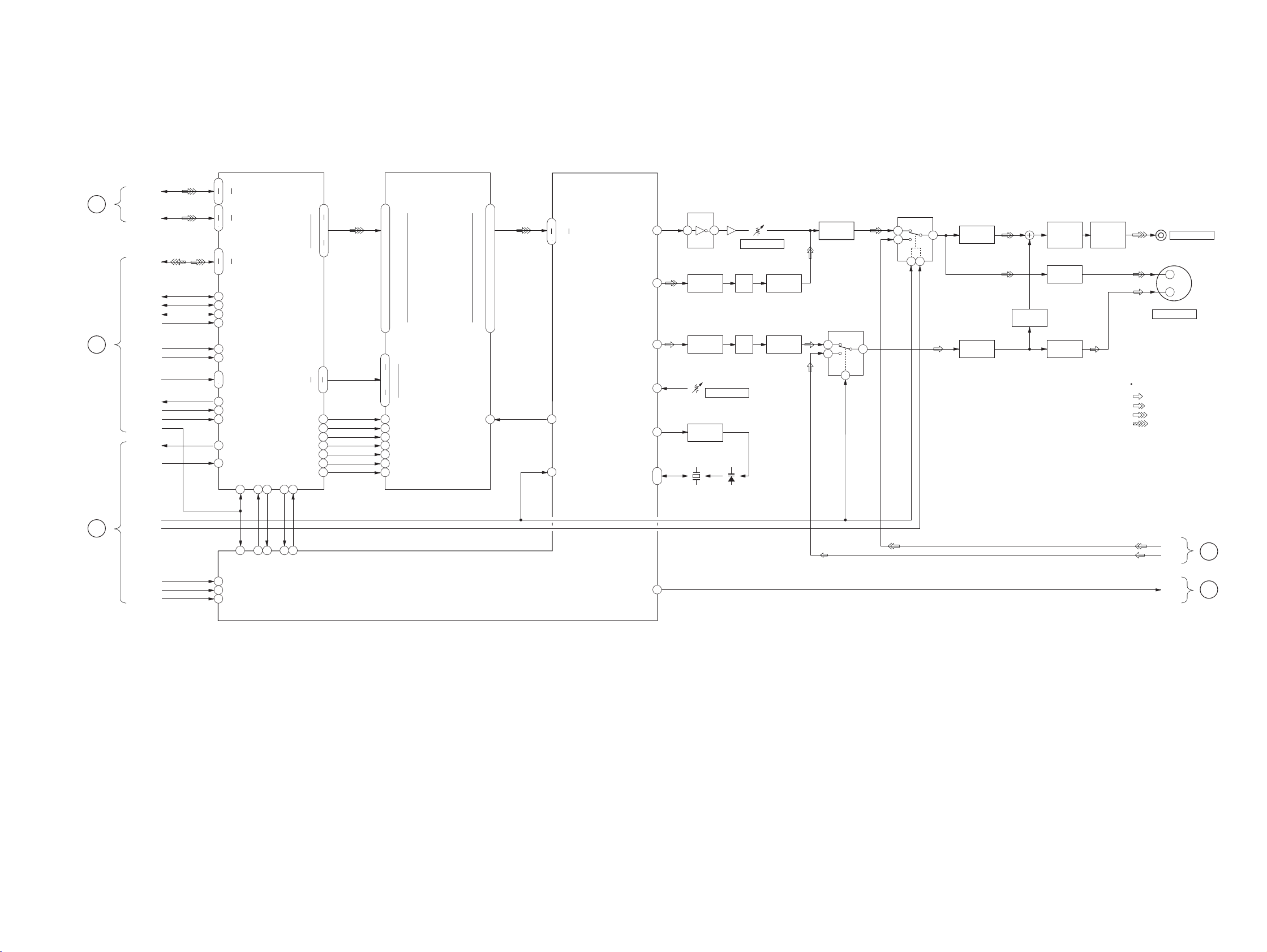

6-7. BLOCK DIAGRAM — VIDEO OUT SECTION —

DPA-300

T

IR

SECTION

(Page 38)

R

VIDEO

PROCESS

SECTION

(Page 36)

D0-7 MAR

D8-15 MAR

PIX0-7

DSYNC

EOS

STOP

COMP

XRD

XWR

HA1-2

XDREQ

XDACK

XCS

CLK

XMCWED

MI RST

PICTURE MEMORY CONTROLLER

25

18

1710D8

D15

81

PIX0

88

PIX7

DSYNC

91

92

EOS

STOP

93

94

COMP

128

XRD

1

XWR

8

.

7

XDRQ

2

3

XDACK

XCS

127

WEND

5

XRST

125

D0

D7

A1

.

A2

CLK

98 78

IC1005

ADRQ

77

ADAKADRAQN

75

SCLKSIOCLK

SDATSIODAT

73

VD0

VD15

VA0

VA8

OW1

WEL

WEH

RAS1

CAS

DSF

SE1

RAM

IC1003

5

63

56

.

54

47

29

37

.

7

.

10

.

12

.

15

.

17

.

20

.

22

.

43

.

45

.

48

.

50

.

53

.

55

.

58

.

60

37

34

.

31

27

271

2445

2544

2643

3940

4138

6369

W0/IO0

W15/IO15

A0

A8

DTX/OEX

LWEX

UWEX

RAS

CAS

DSF

SEX

SIO0

SIO15

4

.

6

.

9

.

11

.

14

.

16

.

19

.

21

.

44

.

46

.

49

.

51

.

54

.

56

.

59

.

61

SC

64

DIGITAL NTSC ENCODER

7691DIN0

DIN15

RAMSCK

74

YCON

57

IC2003

YDAO

CDAO

YVREF

NCPO

VXONI

.

VXONO

VDO

INVERTER

IC3004

62 6 7

46

33

43

27

8

.

7

Y BUFFER

Q3001

C BUFFER

Q3002

IC2002

LPF

X2001

14.31818MHz

Q3020 RV3003

RV3001

WHITE LEVEL

D2001,2002

SYNC LEVEL

LPF

LPF

Y BUFFER

Q3003

C BUFFER

Q3002

Y AMP

Q3016,3019

VIDEO SWITCH

IC3001

1

3

SW1

2

VIDEO SWITCH

IC3002

3

5

SW2

SW1

2

4

7

Y BUFFER

7

Q3010,3011

C BUFFER

Q3014

C BUFFER

Q3005-3007

VIDEO

AMP

Q3012,3013

Y BUFFER

Q3101,3102

C BUFFER

Q3013,3104

VIDEO

BUFFER

Q3017,3018

J106

VIDEO OUT

J104

3

4

YC(S) OUT

Signal Path

: CHROMA

: Y

: VIDEO (PB)

: VIDEO (REC)

N

VIDEO

PROCESS

SECTION

(Page 35)

16

MUTE

IC3002SEL

VCOMUTE

NTSC

PAL

58

59

60

65 72

MKTGI

VCOMUTE

NTSC

PAL

73

ADRREQ

70

71

FDO

64

VIN Y

VIN C

M2FD0

U

VIDEO IN

SECTION

J

VIDEO

CONTROL

SECTION

(Page 42)

(Page 33)

— 39 — — 40 —

DPA-300

6-8. BLOCK DIAGRAM — VIDEO IN SECTION —

VIDEO IN

SWITCH

IC201

1

3

LOGIC

2

CTLA

Q403

7

4FSC CLOCK

GENERATOR

IC402

V2 IN26

32FH

X401

500kHz

VIDEO IN

J102

Q401

DIGITAL COMB FILTER,

Y/C SEP

IC401

30

8

14.3M

11

X402

14.3MHz

Q404,421

Q406

Q405

Y

H SYNC

2

SEP.

Q408

22

BURST

BGP O

GATE

23 20

PULSE

BGP I

4FSC OUT

19

17

VO1

C IN

5

AD IN

25

CLPI

17

11

OCLK

A/D

CONV.

ADAPTIV

FILTER

OPRATION

D/A

CONV.

D/A

CONV.

AY0

VCC

CY0

Y BUFFER

31

Q408.411

RV402

33

39

Y OUT PUT

C BUFFER

Q409,412

LEVEL

Y INPUT

SELECTOR

IC203

1

3

2

C INPUT

SELECTOR

IC202

1

3

2

Y BUFFER

7

7

Q416

Y BUFFER

Q414

C BUFFER

Q415

C BUFFER

Q413

VIN Y

VIN C

U

VIDEO

OUT

SECTION

(Page 40)

J101

S VIDEO

IN

3

4

• Signal Path

: CHROMA

: Y

: VIDEO

X101

26.798MHz

Y BUFFER

Q407

Q407

C BUFFER

Q410

17

13

19

15

65

.

66

FRONT-END

IC104

AI31

AI41

AI22

AI32

XTALI

XTAL

HSYNC

VSYNC

ODD/EVEN

SCL

6

SCL

RV403

S INPUT

Y LEVEL

DY0

DY7

DUV0

DUV7

LLC2

SDA

5

SDA

Y BUFFER

Q419,420

JPEG

CASY

73

29

URAS

CASC

L CAS

ENCODER/DECODER

IC105

DCT/IDCT

AND

Q/Q-1

DRAM I/F

CONTROL

A0-8

.

.

A0 A8

DQ1

DQ8

DQ9

DQ16

93

26

64 59 56

2

5

.

7

10

31

34

.

37

39

83 87 90

16 19 22

AND

ENCODER

AND

DECODE

AD0-7

.

.

55

74 81

BD0-7

36

61

SEL S/O

I/O SEL

HSTBI

HHDET

HSTBO

HD0

HD7

HCLR

DATA-BUS BUFFER

IC110

DIR

1

BUZZER

SWITCH

Q103

18

B1

11

B8

IC111

IC109

3

1

2

16

IC109

11

12

13

69

IC109

4

5

NAND GATE

INVERTER

IC106,109

BUZZER CONT.

D0-7

B+

VIN BUSY

HOST STB

RST

S

IR

SECTION

(Page 37)

O

VIDEO

BEEP

PROCESS

SECTION

(Page 35)

22

15

37

41

39

38

BZ101

BUZZER

2

A1

9

A8

IC106

8

12

13

10

IC106

11

62

I/F

14

28

RAS

2

DQ1

5

.

7

DQ8

10

31

DQ9

34

.

37

DQ16

39

29

URAS

HA0

HA1

RSTI

DACK

DREQ

50

27OE13

L CAS

.

WR

RD

CS

INT

OE2

20

6

.

7

3

4

5

1

8

10

11

WE2

51

.

16 19 22

26

A0 A8

W

DRAM

IC102

13

D0-7

HOST

D0

14

7

D7

2

HA0

.

.

1

HA1

5

WR

4

RD

3

CS

6

RSTO

64

DACK

46

DREQ

45

INT

XTALO

13 15

X102

16MHz

SEL R/F

VIDEO INPUT

CONTROL MICOM

IC108

.

XTAL

ODD/EVEN

.

VSYNC31IICLK50IICDATA49RSTI

29

SDA

SCL

27

54

.

53

.

50

45

62

55

30

1

38

2

4

41

5

12

40

13

V/H SYNC

NAND GATE

3

6

11

IC103

30

27

Y0-7

.

24

21

39

35

C0-7

.

33

31

MCLK98

HBLK

42

VBLK

43

ODV/EVEN

44

PIXEL

OE1

WE1

52

53

27OE13W14

I/F

54

RAS

65

28

RAS

DRAM

IC101

V SYNC

16

I

VIDEO

CONTROL

SECTION

(Page 33)

— 41 — — 42 —

Loading...

Loading...