Page 1

DMP-1000P

SERVICE MANUAL

Printer Section

SPECIFICATIONS

Printer section

Printing system Sublimation dye transfer printing

(Yellow/Magenta/Cyan 3 pass)

Effective pixels 1,376 (H) × 1,024 (V) dot

Printing size 114 (H) × 85 (V) mm (maximum)

(41/2 × 33/8 inches)

Gradations 256 levels (8 bits), per colour (24 bits)

Approx. 16,770,000 colours

Printing time (excluding data transmission time)

Approx. 100 seconds per sheet

Input/output connectors VIDEO INPUT connector (phono jack

× 1)

1 Vp-p, 75 ohms (unbalanced),

sync nagative

S VIDEO INPUT connector

(4-pin mini-DIN × 1)

Y: 1 Vp-p, 75 ohms (unbalanced),

sync negative

C: 0.286 Vp-p (colour burst),

75-ohms (unbalanced)

VIDEO OUTPUT connector

(phono jack × 1)

1 Vp-p, 75 ohms (unbalanced),

sync negative

3.5" Floppy disk drive

Print cartridge and Print paper (100 × 140 mm (4 × 55/8 inches))

DPM-50STA (Standard papers)

Power requirements 220 - 240 V AC, 50/60 Hz, 0.6 A

Power consumption 72 W (printing)

13 W (stand by mode)

AEP Model

Automatic Feeder Section

Operating temperature 5 °C to 35 °C (41 °F to 95 °F)

Dimensions Approx. 301 × 83 × 246 mm

(w/h/d, excluding protruding parts)

(12 × 33/8 × 97/8 inches)

Mass Approx. 3 kg (6 lb 10 oz)

Supplied accessories AC power cord (1)

Automatic feeder (1)

Video connecting cable (1)

BNC-PIN cable adapter (2)

Instruction Manual (1)

Warranty (1)

Automatic feeder section

Maximum Printing Quantity 25 sheets

(1, 2, 3, 4, 5, 10, 25 selectable)

Print paper VP-standard print paper

(100 × 140 mm (4 × 5 5/8 inches) (v/h),

cut paper)

Operating temperatures 5 °C to 35 °C (41 °F to 95 °F)

Dimensions Approx. 149 × 32 × 185 mm

(5 7/8 × 1 5/16 × 7 3/8 inches) (w/h/d)

excluding projecting parts

Mass Approx. 360 g (13 oz)

Design and specifications are subject to change without notice.

9-928-154-11

COLOUR PRINTER

Page 2

TABLE OF CONTENTS

1. GENERAL

Identifying the Parts..................................................... 1-1

Setting Up .................................................................... 1-1

Printing ......................................................................... 1-4

Making V arious Prints.................................................. 1-6

For Y our Information ................................................... 1-9

2. DISASSEMBLY ...................................................... 2-1

3. MECHANICAL ADJUSTMENTS.................... 3-1

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

4. ELECTRICAL ADJUSTMENTS...................... 4-1

5. DIAGRAMS

5-1. Block Diagram – VIDEO Section – ........................... 5-1

5-2. Block Diagram – MAIN Section –............................. 5-3

5-3. Block Diagram –FLOPPY DISK DRIVE

CONTROL/EEPROM Section – ................................. 5-5

5-4. Block Diagram – HEAD/SENSOR/MOTOR/

POWER SUPPLY Section – ........................................ 5-7

5-5. Frame Schematic Diagram .......................................... 5-9

5-6. Notes for Printed Wiring Board and

Schematic Diagram ...................................................... 5-12

5-7. Printed Wiring Board – VS-39 Board – ..................... 5-13

5-8. Schematic Diagram – VS-39 Board – ......................... 5-13

5-9. Printed Wiring Board – FE-39 Board – ....................... 5-14

5-10. Schematic Diagram – FE-39 Board –.......................... 5-14

5-11. Printed Wiring Board – VI-39 Board – ...................... 5-15

5-12. Schematic Diagram – VI-39 Board – .......................... 5-17

5-13. Printed Wiring Board – DK-39E Board – .................. 5-23

5-14. Schematic Diagram – DK-39E Board (1/3) – ............. 5-25

5-15. Schematic Diagram – DK-39E Board (2/3) – ............. 5-30

5-16. Schematic Diagram – DK-39E Board (3/3) – ............. 5-35

5-17. Printed Wiring Board – SW-39 Board – .................... 5-37

5-18. Schematic Diagram – SW-39 Board – ........................ 5-39

5-19. Printed Wiring Boards

– MD-39/JD-39/RD-39/HP-39 Boards – .................... 5-41

5-20. Schematic Diagram

– MD-39/JD-39/RD-39/HP-39 Boards – .................... 5-43

5-21. Printed Wiring Boards

– Automatic Feeder Section –...................................... 5-46

5-22. Schematic Diagram

– Automatic Feeder Section –...................................... 5-47

5-23. IC Pin Function Description ........................................ 5-53

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by

the manufacturer.

Discard used batteries according to the manufacturer’s instructions.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

ADVARSEL

Eksplosjonsfare ved feilaktig skifte av batteri.

Benytt samme batteritype eller en tilsvarende type

anbefalt av apparatfabrikanten.

Brukte batterier kasseres i henhold til fabrikantens

instruksjoner.

VARNING

Explosionsfara vid felaktigt batteribyte.

Använd samma batterityp eller en likvärdig typ som

rekommenderas av apparattillverkaren.

Kassera använt batteri enligt gällande föreskrifter.

VAROITUS

Paristo voi räjähtää, jos se on virheellisesti asennettu.

V aihda paristo ainoastaan laitevalmistajan suosittelemaan tyyppiin.

Hävitä käytetty paristo valmistajan ohjeiden mukaisesti.

6. EXPLODED VIEWS............................................. 6-1

7. ELECTRICAL PARTS LIST ............................ 7-1

Confidential

DMP-1000P (AEP)

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

– 2 –

Page 3

SECTION 1

GENERAL

This section is extracted from

instruction manual.

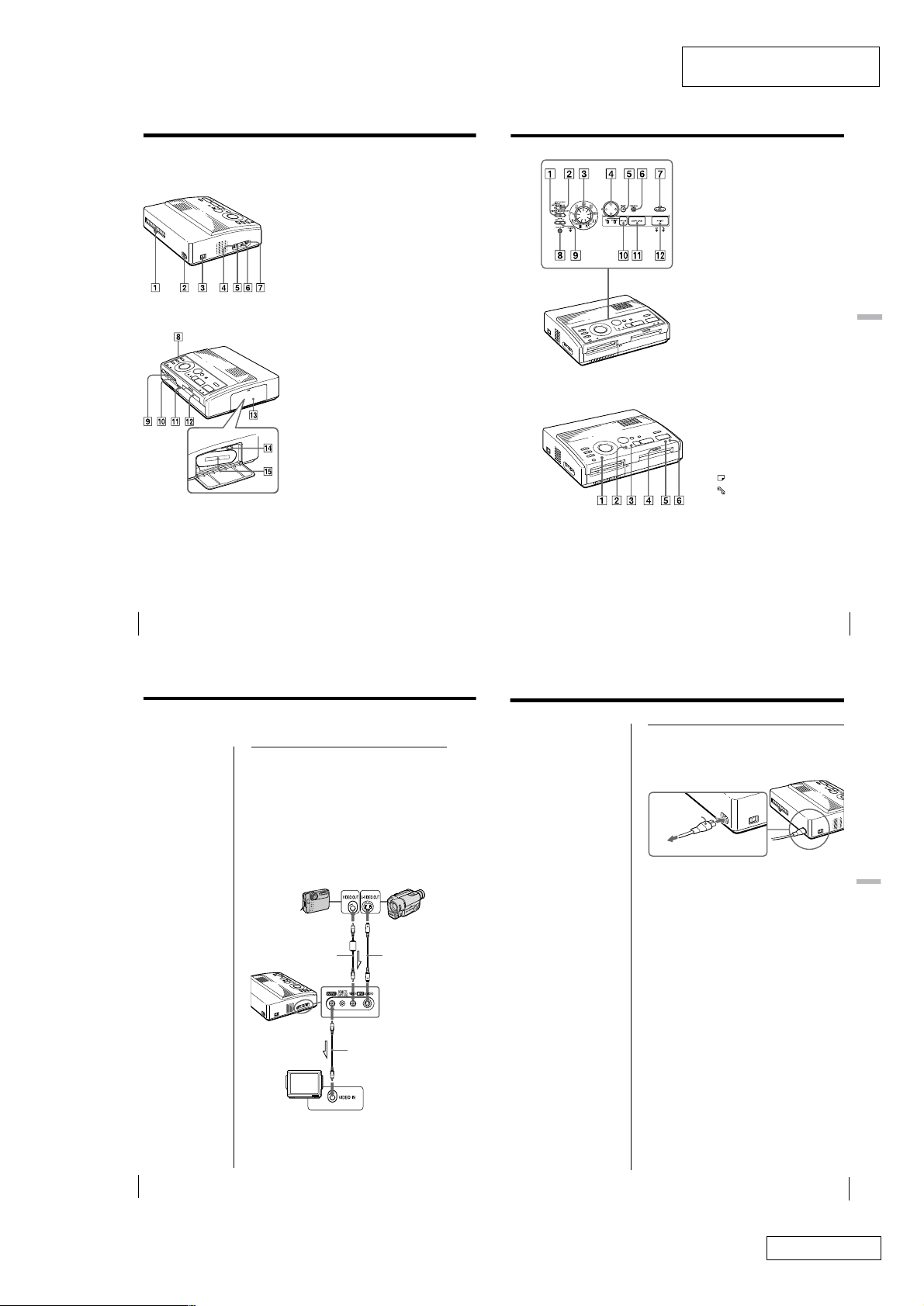

Identifying the partsIdentifying the parts

See the pages given in parentheses for use of the parts.

1 Paper outlet (page 47)

2 AC power connector (page 9)

3 POWER switch (page 10)

4 VIDEO OUTPUT connector (page 8,

19)

5 REMOTE CAPTURE jack (page 39)

6 VIDEO INPUT connector (page 8)

7 S VIDEO INPUT connector (page 8)

8 Operation panel (page 7)

9 3.5-inch floppy disk insertion slot

(page 19)

0 3.5-inch floppy disk eject button

(page 19)

qa Cover for the automatic feeder

(page 17)

qs Paper inlet/outlet for manual

feeding (page 17, 47)

qd Cartridge door (page 13, 14)

qf Eject lever (page 14)

qg Print cartridge (page 13, 14) (not

supplied)

Cartridge compartment

Operation Panel

1 MIRROR IMAGE SELECT switch

(page 30)

2 INPUT SELECT switch (page 20, 23)

3 Print mode dial (page 21, 24, 26, 28,

32, 34)

4 Arrow buttons (B/b/V/v) (page

24)

5 ENTER button (page 24)

6 CLEAR ALL button (page 21)

7 SAVE button (page 36)

8 CLOCK SET button (page 10)

9 DATE switch (page 38)

0 PICTURE button (page 23, 25)

qa CAPTURE button (page 21, 24)

qs PRINT button (page 22, 25)

Indicators

1 POWER indicator (page 10)

2 INPUT indicator (page 21, 45)

3 MEMORY indicator (page 21, 45)

4 Print indicator (page 22, 25, 45)

5

Paper supply indicator (page 45)

6

Ribbon error indicator (page 45)

Getting

Started

GB

Getting Started

6

Setting Up

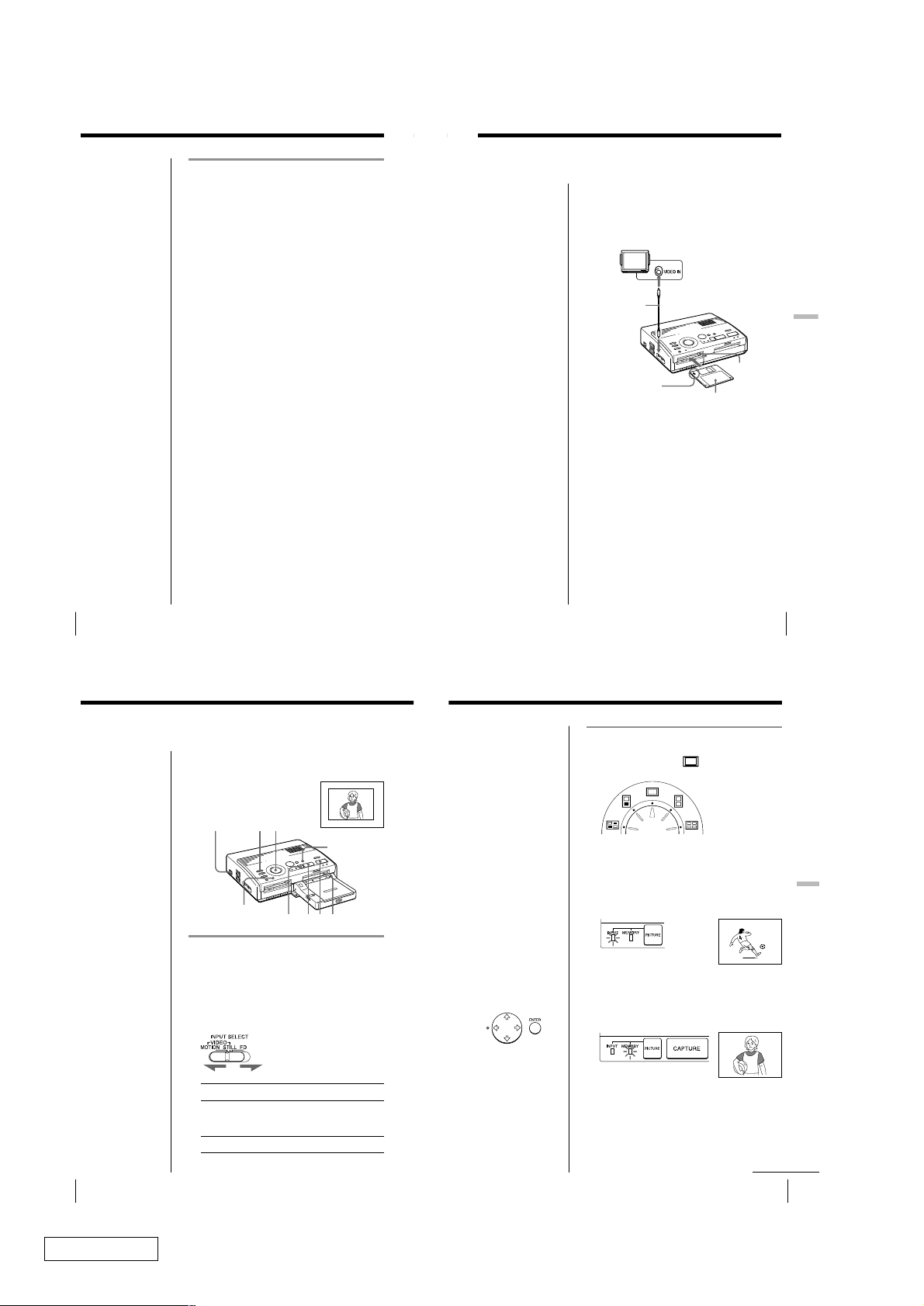

Connecting the printer

Connecting to the video equipment

When printing images from the video equipment such

as a VCR or camcorder, use the supplied video

connecting cable to connect the video equipment and

the printer. Also connect the printer to the television to

display the images to be printed.

For printing operations, see page 20.

If the video equipment

has the S-video output

connector

Connect it to the S VIDEO

INPUT connector of the

printer using the optional

S-video connecting cable

so that you can get better

picture quality. In this

case, you do not need to

connect the video

connector.

When both the S VIDEO

INPUT and VIDEO INPUT

connectors of the

printer are connected

The input signals from

the S VIDEO INPUT

connector are

automatically selected.

Notes

• Before making

connections, turn off

the power of the

printer, the video

equipment and

television.

• See also to the

instruction manuals for

the video equipment.

GB

Setting Up

8

Digital still camera or

video camera

equipped with the

video output

connector

Video connecting

cable (not supplied)

To VIDEO

INPUT

Television

Set input selector to

“VIDEO.”

Video camera or

Or

etc. equipped with

the S-video output

connector

S-video connecting

cable (not

supplied)

To S VIDEO

INPUT

To VIDEO OUTPUT

Video connecting

cable (supplied)

l

: Signal flow

Getting Started

Connecting the AC power cord

After you make connections, connect the supplied AC

power cord to the AC power connector of the printer

and then to the AC outlet.

AC Power cord

(supplied)

To the AC outlet

Setting Up

GB

7

Setting Up

GB

9

1-1

Confidential

DMP-1000P (AEP)

Page 4

Adjusting the clock

You can save the time when the images are captured

from the video equipment by adjusting the clock of the

printer. Once you adjust the clock, the clock is

maintained with the battery even if you turn off the

power.

1

Turn on the power of the printer.

The POWER indicator lights up.

4

Press b.

The cursor moves to the next item.

5

Repeat steps 3 and 4 to set all items: month, date,

year, hour and minute.

If you want to set the previous item, press B.

POWER switch

2

Press and hold CLOCK SET, then press b.

The clock setting display appears on the television.

3

Press V/v to set the month.

Pressing V increases the number.

Pressing v decreases the number.

GB

Setting Up

10

Using optional supplies

(print packs)

You need an optional print pack. The pack contains

print paper and ink ribbon cartridge for printing.

The following types of print packs are available:

Print Model Print paper Print cartridge

Standard DPM-50STA Standard type for 50 prints

POWER indicator

6

Press CLOCK SET.

The clock setting display disappears.

Displaying the clock

When the INPUT indicator is on, press CLOCK SET to

display the current time on the center of the screen. To

turn off the time display, press CLOCK SET again.

Loading the print cartridge

Insert the print cartridge into the printer.

Use only the print cartridge supplied with the print

paper packed in the same carton.

Caution

Never put your hand into

the cartridge

compartment. The

thermal head reaches

high temperatures,

especially after repeated

printing.

1

Press PUSH to open the cartridge compartment lid.

Setting Up

Setting Up

GB

11

Note

Use the set of the print

paper and ink ribbon

cartridge supplied

together in the same

carton. If you use them in

different combination,

proper printing results

may not be obtained, or

paper jam or other trouble

may occur.

GB

Setting Up

12

Confidential

DMP-1000P (AEP)

1-2

Notes

• If the print cartridge is

not loaded when you

turn on the printer, the

warning sound beeps

and the ribbon error

indicator lights up.

• When installing the ink

ribbon cartridge, stand

it as illustrated so that

dust will not get on the

ink ribbon.

• Do not touch the ink

ribbon or place the

print cartridge in a

dusty location.

Fingerprints or dust on

the ink ribbon may

result in imperfect

printing.

2

Wind up the ink ribbon to remove the slack.

While pressing the

center of the reel, wind

the ink ribbon in the

direction of the arrow.

Wind the ribbon

until the black

line comes to the

left edge.

3

Insert the print cartridge firmly until it clicks into

place and close the cartridge compartment lid.

If the print cartridge does not click into place

Remove the print cartridge, and then re-insert it.

Labeled side

continued

Setting Up

Setting Up

GB

13

Page 5

Loading the print cartridge (continued)

To replace the print cartridge

If the ribbon indicator flashes and the inserted paper

emerges after you insert the paper and the paper is

automatically loaded, remove the print paper and

replace the print cartridge.

Open the cartridge compartment lid and push up the

eject lever. Remove the used print cartridge and

replace it with a new one.

To load the half-used ink ribbon cartridge

Wind the ribbon

until the black

line comes to the

left edge.

Notes on storing the

print cartridge

• Avoid placing the

cartridge in a location

subject to:

– high temperatures

– high humidity

– excessive dust

– direct sunlight

• When you are going to

store a partially-used

cartridge for an

extended period of

time, store it in its

original bag.

GB

Setting Up

14

If ink ribbon should tear

Repair the ribbon with transparent tape. There should

be no problem with using the remaining portion of the

ribbon. Before loading the ink ribbon cartridge into the

printer, turn the reel until the transparent tape can no

longer be seen.

Eject lever

Paper supply indicator

Ribbon error indicator

Push up the eject lever,

then remove the used

print cartridge.

While pressing the

center of the reel, wind

the ink ribbon in the

direction of the arrow.

Repair with

transparent tape.

Inserting the print paper

Inserting the print paper using the

supplied automatic feeder

By using the supplied automatic feeder, you can

supply the print paper automatically.

1

Open the lid of the paper tray by sliding the switch

on front to the right.

Notes on using

automatic feeder

• If trouble occurs in

feeding the print paper,

the lamp on the printer

flashes. Remove the

feeder from the printer

and check that there is

no paper jammed in the

printer. When you

reinstall the feeder and

press the print button,

the printer prints the

set number of copies

again.

• The feeder can hold up

to 25 sheets of paper.

When you add paper to

a partially full feeder,

make sure that the total

number of sheets does

not exceed this limit. If

you do, the paper may

jam.

• Do not place different

types of paper in the

feeder. If you do, the

paper may jam.

• To insert paper after

the feeder is attached to

the printer, first remove

the feeder from the

printer and then insert

the paper into the

feeder.

• While printing, do not

open the feeder lid. If

you do, the paper may

jam.

2

Make sure that the spacer is raised.

Spacer

3

Riffle the print paper to avoid jamming the print

paper.

Make sure not to touch the printing surface (the

glossy side where nothing is printed).

Setting Up

Setting Up

GB

15

Inserting the print paper (continued)

To print a number of

copies not specified on

the dial

Insert the desired number

of sheets and set the dial

to 25.

GB

Setting Up

16

4

Insert print paper with its printing surface (the side

where nothing is printed) facing up.

Make sure not to touch the printing surface and not

to bend the corners of the paper. You can load up

to 25 sheets of print paper or the print paper

designed for the printer into the feeder.

Make sure that the metal tabs on both sides fir over

the print paper.

Printing surface

Front

Paper

Metal tab

5

Turn on the printer and press MEMORY or

CAPTURE to store an image for printing.

For the details, refer to “Printing” in the operating

instructions of the printer.

6

Turn the dial to set the number of copies to be

printed continuously.

You can set 1, 2, 3, 4, 5,10 or 25 copies. Turn the

dial until the desired number appears in the

window. Make sure it clicks at that time.

Otherwise, you may get the wrong number of

copies.

2

To stop continuous

printing

Set the dial to 1. Printing

stops after the current

printing finishes.

If print paper runs out

during continuous

printing

Remove the feeder from

the printer. Then, insert

more print paper into the

feeder and reinstall the

feeder to the printer. The

printing resumes

automatically.

Notes on inserting the

print paper manually

• Insert the print paper

straight along the guide

to the left of the paper

port. If the paper is

positioned to the right

or slanted, the printing

area may get out of

position.

• The paper may not be

loaded automatically if

you do not insert the

paper firmly.

7

Press “Push” on the cover of the automatic feeder,

then insert the feeder until it clicks.

8

Press the print button of the printer.

The print paper is automatically loaded into the

printer and printing starts.

Inserting the print paper manually

Insert the print paper sheet by sheet. This section

explains how to insert the standard type print paper.

Use the print paper designated for this printer only.

1

Turn on the power of the printer.

The POWER indicator lights up.

2

Follow printing procedures.

For details, see pages 20 to 39.

3

Insert the print paper straight with its blank

printing surface facing up, along the guide to the

left of the paper port.

Insert the paper until less than 2 cm (approx. 0.8

inches) remains. The paper is automatically loaded

when printing starts.

Guide

Less than 2 cm

Setting Up

Setting Up

GB

17

1-3

Confidential

DMP-1000P (AEP)

Page 6

Inserting the print paper (continued)

GB

Setting Up

18

Notes on handling the print paper

• You cannot type on the printing surface before

printing. If you want to write greetings or draw on

the printing surface after printing, use an oil ink pen.

• When handling the print paper, do not touch the

printing surface (glossy side where nothing is

printed).

• Do not place the print paper in a dusty location.

Fingerprints or dust on the printing surface may

result in imperfect printing.

• Use the print paper designed for the printer only. If

you use a different type of paper, the printer may not

print properly or may malfunction.

• Do not fold or bend the print paper.

Notes on storing the print paper

• Avoid placing the print paper in a location subject to:

– high temperatures

– high humidity

– excessive dust

– direct sunlight

• When you are going to store the partially-used print

paper for an extended period of time, store it in its

original bag.

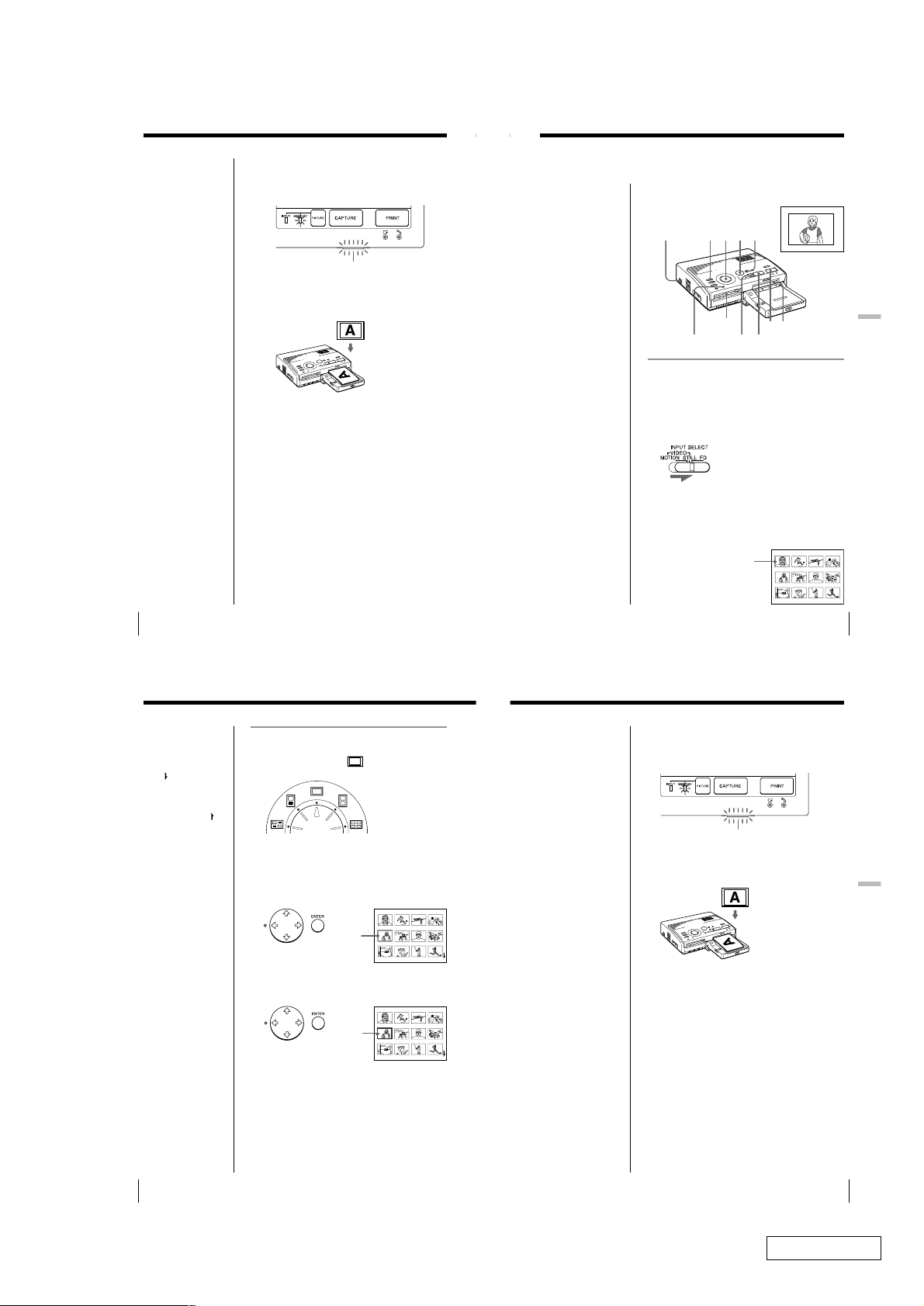

Using the floppy disk

When printing images recorded on the floppy disk,

insert the floppy disk into the insertion slot for the 3.5inch floppy disk of the printer. Also connect the printer

to the television to display the images to be printed.

For printing operations, see page 23.

Video connecting

cable (supplied)

To VIDEO

OUTPUT

With the arrow facing

left forward and insert

the disk firmly, facing

down.

Ejecting the floppy disk

Press the floppy disk eject button.

Usable floppy disks

You can use a 3.5-inch 2HD 1.44MB floppy disk in the

Notes

• Before making

connections, turn off

the power of both the

printer and television.

• If the floppy disk does

not fit properly, do not

attempt to force it into

the slot. Confirm the

inserting direction

again and re-insert it

into the slot.

MS-DOS format.

Television

Set input selector

to “VIDEO.”

Floppy disk

Floppy disk

eject button

Setting Up

Setting Up

GB

19

Printing

Printing an image from the video

equipment

You can capture the input image from the video

equipment connected to the VIDEO INPUT connector

of the printer and print it in full-size (standard print).

Preparation1Preparation

POWER indicator

Preparations

1

Turn on the printer and television and set the input

selector of the television to “VIDEO.”

The POWER indicator turns on.

2

Set INPUT SELECT to “VIDEO MOTION” or

“VIDEO STILL.”

To Selector position

Print the motion picture VIDEO MOTION

while compensating for the

image blur

Print the still image VIDEO STILL

GB

Printing

20

2

PICTURE

1

Standard print

CLEAR ALL

34 5

Blur compensation

When you set INPUT

SELECT to “VIDEO

MOTION,” the selected

image appears on the

screen and the horizontal

red line moves from the

top to the bottom on the

left half of screen, then

moves from the top to the

bottom on the right half of

screen. In this sequence, if

there is motion blur on

the image, the printer

automatically

compensates for the

image (blur

compensation).

When the blur

compensation ends, the

screen darkens once and

the print image appears in

the screen.

Re-selecting the image

Press B before pressing

PRINT. The playback

picture appears on the

screen.

You can also re-select the

image by pressing

PICTURE instead of

pressing B. (You cannot

capture a image while the

MEMORY indicator lights

up. Press CAPTURE

while the MEMORY

indicator goes off.)

If you press CLEAR ALL,

the printer is reset to

stand by mode.

Perform printing

procedures from the

beginning.

Printing

1

Set print mode dial to “ (standard)”.

2

Start playback on the video equipment.

While the INPUT indicator lights up, the playback

picture appears on the screen (input picture).

For details on playing back on the video

equipment, refer to the instruction manual of your

equipment.

Input image

3

Press CAPTURE when the picture you want to

print appears on the screen.

The selected full-size image appears in the screen,

and the MEMORY indicator lights up.

Print image

continued

Printing

Printing

GB

21

Confidential

DMP-1000P (AEP)

1-4

Page 7

Printing an image from the video equipment (continued)

4

Press PRINT.

The print indicator flashes and the print paper

is automatically loaded. The paper supply

indicator flashes while loading the print paper.

Printing an image recorded on the

floppy disk

You can select an image recorded on the floppy disk

and print it in full-size (standard print).

Notes

• While printing, never

move or turn off the

printer; the print

cartridge or paper may

become stuck. If this

happens, turn the

printer off and on, and

resume printing from

the beginning.

• Do not insert another

sheet of print paper

until you remove the

printed sheet.

• During printing, the

print paper is partially

ejected from the paper

outlet several times.

Never pull out the

paper forcibly.

• It is not recommended

to select an image while

pausing the video

equipment because the

picture quality will be

lost.

• Avoid storing the paper

with the printed faces

contacting each other or

contacting with rubber

or plastic products

including vinyl

chloride or plasticizer

for an extended period

of time; the ink may

transfer on to them.

If the print paper is not

loaded

The print indicator and

the paper supply

indicator flash.

Insert the print paper.

GB

Printing

22

Print indicator

Printing direction

The image displayed on the digital camera is

printed in the direction as shown below.

Displayed image

Printed image

5

Remove the print from the printer.

When printing ends, the print paper

automatically emerges from the print outlet.

The print indicator turns out.

Printing the same image again

Make sure that the desired image is displayed on

the screen, then press PRINT.

With the supplied automatic feeder, you can print

the same image continuously up to 25 sheets.

Capturing a picture by using the optional foot

switch

You can use the optional foot switch FS-20 to select

the disired image instead of using CAPTURE.

For details, see “Capturing a picture by using the

optional foot switch” on page 39.

Notes

• Avoid getting liquids

on the floppy disk or

using floppy disks in

areas subject to high

humidity. Otherwise,

data may be rendered

unreadable.

• When the access

indicator is lit, do not

eject the floppy disk.

Otherwise, the disk

may crash.

Preparation1Preparation

POWER indicator PICTURE

2

Preparation

123

3

45

CAPTURE

Standard print

Preparations

1

Turn on the printer and television and set the input

selector of the television to “VIDEO.”

The POWER indicator lights up.

2

Set INPUT SELECT to “FD.”

3

Insert the floppy disk on which you record images

into the floppy disk insertion slot. (page 19)

While the printer is accessing the floppy disk, the

access indicator flashes. When the printer ends

reading images, recorded images are displayed as

thumbnails.

White

frame

(cursor)

Printing

Printing

GB

23

Printing an image recorded on the floppy disk (continued)

Scrolling the pages

When multiple pages

exist, you can change the

pages back and forth. To

display the next page

(when

bottom-right), move the

white frame to the bottom

line of the image list and

press v. To display to the

previous page (when

appears at the top-right),

move the white frame to

the top line and press V.

The access lamp flashes

and pages switches.

Cancelling the selection

Move the white frame to

the image you want to

cancel the selection and

press ENTER. The blue

frame disappears and the

selection is canceled.

Selecting multiple

images

Repeat steps 2 and 3 until

you select all images you

want to print.

Displaying the image in

full-size

Move the white frame to

the desired image, then

press CAPTURE in step 3.

The selected full-size

image appears in the

center of the screen.

To display the next or

previous full-size image,

press v (next image) or V

(previous image).

If you want to re-select

the image, press

PICTURE to return to the

image list then repeat

steps 2 and 3.

Note

The displayed full-size

image may not

correspond with the

actual print in details.

GB

Printing

24

appears at the

Printing

1

Set print mode dial to “ (standard)”.

2

Press the arrow (B/b/V/v) buttons to move the

white frame (cursor) to the image you want to

print.

Move the white frame up (V), down (v), rightward

(b) , or leftward (B).

Move the

white frame.

3

Press ENTER.

The blue frame appears inside the white frame and

the selected image is specified to be printed.

The white

frame

changes to

blue.

Notes

• An image which is

damaged or has some

trouble does not appear

in the image list.

• If there are no images

stored in the floppy

disk, “NO FILE”

appears on the display.

• If you press PRINT

while displaying the

actual print image, only

the displayed image is

printed.

• If you press PRINT

while displaying the

thumbnail list, all

images with the blue

frame are printed.

• While printing, never

move or turn off the

printer; the print

cartridge or paper may

become stuck. If this

happens, turn the

printer off and on, and

resume printing from

the beginning.

• Do not insert another

sheet of print paper

until you remove the

printed sheet.

• During printing, the

print paper is partially

ejected from the paper

outlet several times.

Never pull out the

paper forcibly.

• Avoid storing the paper

with the printed faces

contacting each other or

contacting with rubber

or plastic products

including vinyl

chloride or plasticizer

for an extended period

of time; the ink may

transfer on to them.

If the print paper is not

loaded

The print indicator and

the paper supply

indicator flash.

Insert the print paper.

4

Press PRINT.

The print indicator flashes and the print paper is

automatically loaded. The paper supply indicator

flashes while loading the print paper.

Print indicator

Printing direction

The image displayed on the digital camera is

printed in the direction as shown below.

Displayed image

Printed image

5

Remove the print from the printer.

When printing ends, the print paper automatically

emerges from the print outlet.

The print indicator turns out.

Printing the same image again

Press PRINT.

With the supplied automatic feeder, you can print the

same image continuously up to 25 sheets.

Printing other images

Press PICTURE so that the thumbnail screen appears,

then perform steps 1 to 5.

Printing multiple images continuously

You can print multiple images continuously up to 25

sheets using the supplied automatic feeder.

Printing

Printing

GB

25

1-5

Confidential

DMP-1000P (AEP)

Page 8

Making Various Print

Making split prints

GB

Making Various Prints

26

Printing images from the video

equipment

You can make prints divided into multiples of 1/2-, 1/

4- or 1/16-size pictures. You can also select the same

image, or different images for the split print.

Before you begin

1 Turn on the printer and television and set the input

selector of the television to “VIDEO.”

2 Set INPUT SELECT to “VIDEO MOTION” or

“VIDEO STILL.”

1

Select the type of split using the print mode dial.

You can select 2-split, 4-split, 16-split planes of the

same image or different images.

2-split printing using

different images

4-split printing

using different

images

16-split printing using

different images

2-split printing using

the same image

4-split printing

using the same

image

16-split printing using

the same image

When you select “VIDEO

MOTION”

When you set INPUT

SELECT to “VIDEO

MOTION,” the selected

image is blurcompensated in step 2.

Re-selecting the image

Press CLEAR ALL. The

selected image is removed

and the printer returns to

stand by mode.

Perform printing

procedures from the

beginning.

You can also re-select the

image by pressing B.

When you set to split

printing with the different

images and re-select the

image by pressing B, only

a image that you most

recently selected is

removed.

When you set to split

printing with the same

images, you can also

press PICTURE to display

the input picture, then reselect a new image. (You

cannot capture a image

while the MEMORY

indicator lights up. Press

CAPTURE while the

MEMORY indicator goes

off.)

2

Select the image.

• When selecting the same image for all the split

planes:

1 Turn on the video

equipment and start

playback.

2 Press CAPTURE when the

picture you want to print

appears on the screen.

The memory image is

displayed in the split

planes selected in the step

1.

• When selecting the different images for each split

plane:

1 Turn on the video equipment and start

playback.

2 Press CAPTURE when the picture you want to

print appears on the screen.

The memory image is displayed in the first

plane of the split planes selected in the step 1.

After a while, the memory image disappears

and the input picture automatically appears.

3 Repeat step 2 until you select images for all

split planes.

When you select 4split printing

The selected pictures are allocated as follows:

upper left t upper right t lower left t

lower right.

When you select 4-split printing

3

Press PRINT.

The print indicator flashes while printing, and the

selected image is printed.

Making Various Prints

Making Various Prints

GB

27

Making split prints (continued)

Printing the date

You can print the date

when the image was

saved by setting DATE to

“ON.”

GB

Making Various Prints

28

Printing images from the floppy disk

You can make prints divided into multiples of 1/2-, 1/

4- or 1/16-size pictures. You can select the same image,

or different images for the split print.

Before you begin

1 Turn on the printer and television and set the input

selector of the television to “VIDEO.”

2 Set INPUT SELECT to “FD.”

3 Insert the floppy disk into the floppy disk slot.

1

Select the type of split using the print mode dial.

You can select 2-split, 4-split, 16-split planes of the

same image or different images.

2-split printing using

different images

4-split printing

using different

images

16-split printing using

different images

2

Select the image.

• When selecting the same image for all the split

planes:

1 Press arrow button to move the white frame to

the image you want to print, then press

ENTER. (The blue frame appears inside the

white frame.)

2 If you want to make other same image prints,

repeat step 1.

2-split printing using

the same image

4-split printing

using the same

image

16-split printing using

the same image

Re-selecting the image

Move the white frame to

the image you want to

cancel the selection for

and press ENTER. The

blue frame disappears

and the selection is

canceled.

If you want to re-select

the image after displaying

the actual print image,

press PICTURE to return

to the thumbnail screen,

then repeat step 2.

Re-selecting the type of

the split

Press PICTURE so that

the thumbnail screen

appears. Re-select the

split type using the print

mode dial. You can use

the selected images, or

change the selection.

Canceling the operation

Press CLEAR ALL. The

selected image is removed

and the printer returns to

stand by mode.

Perform printing

procedures from the

beginning.

Note

If you press PRINT when

the actual print image is

displayed, only the

displayed image is

printed.

• When selecting the different images for each split

plane:

1 Press the arrow button to move the white

frame to the image you want to print, then

press ENTER. (The blue frame appears inside

the white frame.)

2 Repeat step 1 to select images for the split

planes in the desired order.

The pictures are placed

from the upper left to the

lower right on the sheet in

order of the selection, not

in order of the image list.

You can also select an image from the different

pages.

If you select more images than the number of

the split planes, the images are automatically

placed on the next print.

To check the actual print image

Press CAPTURE.

The actual print image appears in the center of the

screen.

To display multiple split prints, press V or v.

When you select 4split printing using a

same image

3

Press PRINT.

The print indicator flashes while printing, and the

selected image is printed.

When you select 4split printing using

different images

Making Various Prints

Making Various Prints

GB

29

Confidential

DMP-1000P (AEP)

1-6

Page 9

Making a mirror image print

You can make a mirror image or upside-down mirror

image when you print a picture from video equipment.

You can use this feature with the standard printing

(page 20 to 22) and split printing (page 26 to 27).

Before you begin

1 Turn on the printer and television and set the input

selector of the television to “VIDEO.”

2 Set INPUT SELECT to “VIDEO MOTION” or

“VIDEO STILL.”

1

Set MIRROR IMAGE SELECT to the desired type of

image reversal.

Vertically reversed

(upside-down image)

No reversal

(original image)

2

Start playback on the video equipment.

While the INPUT indicator lights up, the playback

picture appears on the screen (input picture).

3

Press CAPTURE when the picture you want to

print appears on the screen.

The selected picture appears. When you set

MIRROR IMAGE SELECT to “V” or “H,” “R”

(reversed) mark appears on the lower right of the

screen.

Note

You cannot make a mirror

image print when you

want to print the image in

the floppy disk.

GB

Making Various Prints

30

Horizontally

reversed

(mirror image)

: Indicates an upside-down

mirror image.

: Indicates a mirror image.

4

Press PRINT.

The mirror image is printed.

Making a mirror image print in the split

printing mode

Set MIRROR IMAGE SELECT to the desired type

before performing the printing procedures in the

“Printing images from the video equipment” (page 26).

When you use different images

You can change the mirror image type for each split

plane.

Example

• Plane 1 and 3: vertically reversed

• Plane 2 and 4: horizontally reversed

Vertically

reversed

Horizontally

reversed

To change the mirror image type for each split plane,

change the MIRROR IMAGE SELECT setting each time

before you press CAPTURE.

When you use the same image

The same mirror image in the split planes is printed.

Making Various Prints

Making Various Prints

GB

31

Making a label for a floppy disk

You can make a label for a floppy disk by using the

sticker-type print paper.

The selected image is printed as large picture on one

label, and 3 thumbnail images with lines are printed on

the other label. The total number of images is printed

at the bottom left of the label.

Before you begin

1 Turn on the printer and television and set the input

selector of the television to “VIDEO.”

2 Set INPUT SELECT to “FD.”

1

Select “ (FD label print)” using the print mode

dial.

FD label print

2

Select the image for printing.

1 Insert the floppy disk into the floppy disk slot.

2 Press the arrow buttons to move the white

frame to the image you want to print, then

press ENTER.

When printing the input

image from the video

equipment

You cannot make a label

for a floppy disk.

Printing the date

You can print the date

when the image was

saved by setting DATE to

“ON.”

GB

Making Various Prints

32

The selected image is placed on the upper half

of the print and the leftmost of the thumbnail

on the lower half.

Cancelling the selection

Move the white frame to

the image you want to

cancel the selection and

press ENTER. The blue

frame disappears and the

selection is canceled.

To remove the all selected

images, press CLEAR

ALL.

Perform printing

procedures from the

beginning.

Note

You cannot type on the

printing surface before

printing. If you want to

write greetings or draw

on the printing surface

after printing, use an oil

ink pen.

3 Repeat step 2 to select images for the other 2

thumbnails.

4 Press CAPTURE if you want to check the

actual print image.

To display multiple print images, press V or v.

The first

selected image

The second and

third selected

images

Total images

Date (when set

to print)

3

Insert the sticker type paper into the printer, then

press PRINT.

The print indicator flashes while printing, and the

label for the floppy disk is printed.

You can use each part of the label for the floppy

disk. Cut the paper so it fits the label side.

Making Various Prints

Making Various Prints

GB

33

1-7

Confidential

DMP-1000P (AEP)

Page 10

Making an index list of images

You can make an index list of images saved in a floppy

disk. When you want to search for the recorded image,

you can find the desired images immediately with this

index list.

Before you begin

1 Turn on the printer and television and set the input

selector of the television to “VIDEO.”

2 Set INPUT SELECT to “FD.”

1

Select “ (Index print)” using the print mode

dial.

Index print

2

Insert the floppy disk into the floppy disk slot.

All the images recorded in the floppy disk are

displayed in a thumbnail list.

If there are multiple pages, press V or v to display

the next or previous page.

About date printing

The date when the image

was saved is printed

regardless of the DATE

setting. However, the date

does not appear on the

displayed image.

GB

Making Various Prints

34

Notes

• If the number of images

is less than that of split

planes, planes without

images remain blank.

• If the number of image

is over 43, the image

number 43 or more is

not printed.

To display the actual print image

Press CAPTURE.

All the images recorded in the floppy disk are

displayed as the thumbnail images.

3

Press PRINT.

The print indicator flashes while printing, and the

index list of the recorded images on the floppy disk

is printed.

The size of each image depends on the number of

the images.

• When the number of images is 1 to 12

The images are made into the

size of 12 thumbnails. Each

thumbnail has the

corresponding image

number.

• When the number of images is 13 to 20

The images are made into the

size of 20 thumbnails. Each

thumbnail has the

corresponding image

number.

• When the number of images is over 21

The images are made into the

size of 42 thumbnails. Each

thumbnail has the

corresponding image

number.

Making Various Prints

Making Various Prints

GB

35

Recording the video picture as

a still image

You can record the playback picture from the video

equipment as a still image onto the floppy disk.

Before you begin

1 Turn on the printer and television and set the input

selector of the television to “VIDEO.”

2 Set INPUT SELECT to “VIDEO MOTION” or

“VIDEO STILL.”

1

Set the print mode dial to “ (standard)” or split

When you set the print

mode dial to the split

mode

You can also record the

picture in the split mode.

In this case, only the most

recently selected picture

is recorded onto the

floppy disk.

Re-selecting the image

Press PICTURE before

pressing SAVE. The

playback picture appears

on the screen. Follow step

2. (You cannot capture a

image while the

MEMORY indicator lights

up. Press CAPTURE

while the MEMORY

indicator goes off.)

You can also re-select the

image by pressing the

arrow (B) instead of

pressing PICTURE.

If you press CLEAR ALL,

the printer is reset to

stand by mode.

Perform printing

procedures from the

beginning.

GB

Making Various Prints

36

printing mode.

2

Select the image to be recorded.

For details of operating procedures, refer to the

pages for the corresponding printing mode.

1 Turn on and start playback on the video

equipment.

2 Press CAPTURE when the picture you want to

record appears on the screen.

3

Insert the floppy disk into the floppy disk slot.

Insert a floppy disk formatted in the MS-DOS

format. Check that the write protect switch on the

disk is set to the write enable position.

4

Press SAVE.

The access indicator of the floppy disk drive lights

up, and the displayed image is recorded onto the

floppy disk.

About file name of the recorded image

The image is recorded with the file name “MVC-###f

.jpg.” The number “###” is sequentially allocated

following the largest file number (same as the image

number) recorded in the floppy disk.

If an error message appears

Error message Meaning

DISK ERROR The inserted floppy disk is not

DISK FULL There is not enough space to

DISK PROTECT The write protect tab on the

formatted.

Insert a disk in the MS-DOS

format.

record the image.

Replace the floppy disk with new

one.

inserted floppy disk is set to write

protect position. Set it to the write

enable position and then record

the image.

Making Various Prints

Making Various Prints

GB

37

Confidential

DMP-1000P (AEP)

1-8

Page 11

Printing the date

39

GB

Making Various Prints

Making Various Prints

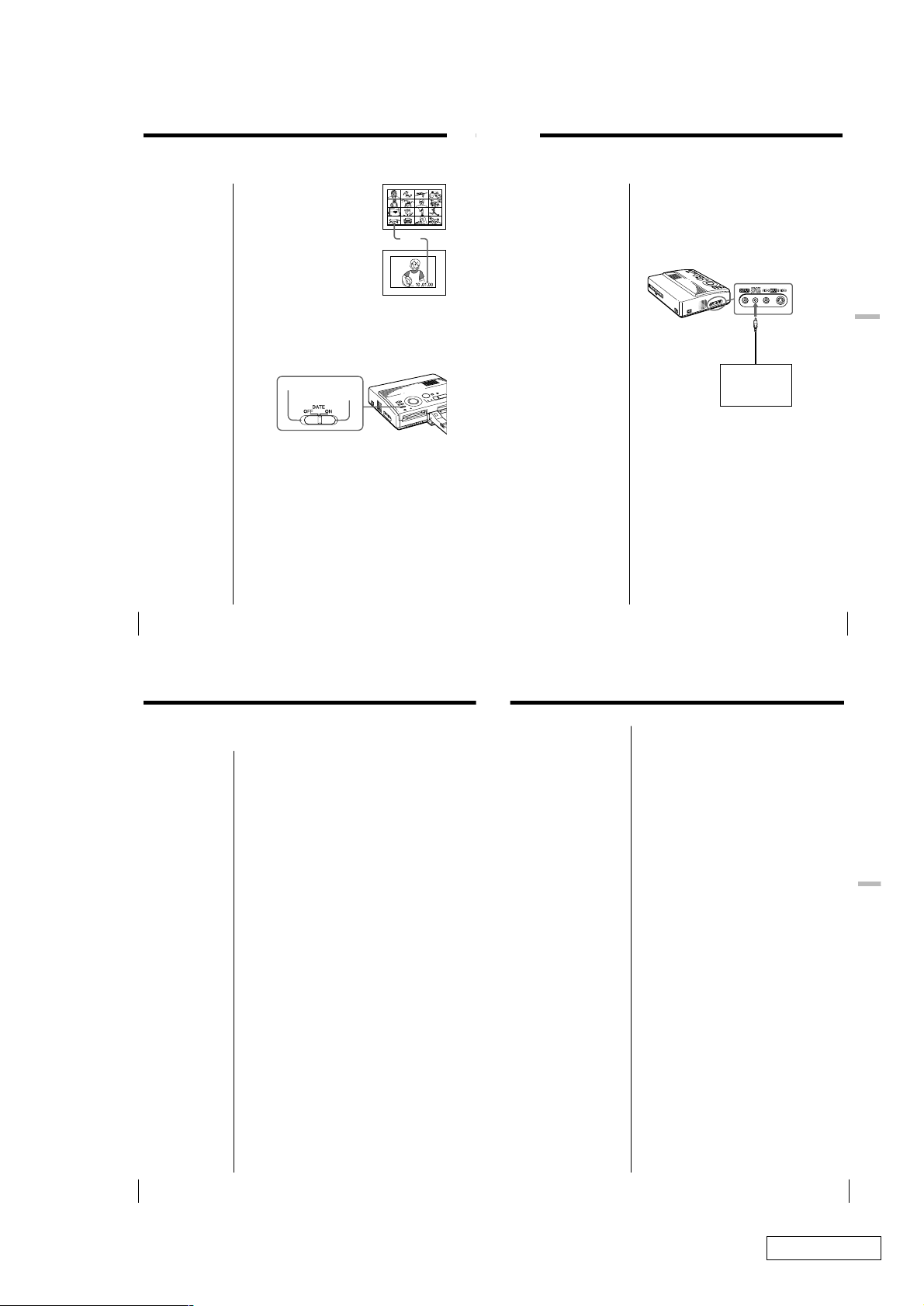

Capturing the picture using

the optional foot switch

When you make a print from the video equipment, you

can use the optional foot switch FS-20 to select the

desired image remotely.

Connecting the optional foot switch

Connect the optional foot switch FS-20 to REMOTE

CAPTURE jack on this unit.

Using the optional foot switch

When you select the desired picture, use the optional

foot switch instead of pressing CAPTURE.

Notes

• Turn off the power of

this unit before

connecting the optional

foot switch.

• You cannot use other

remote controller for

this unit.

Optional foot

switch FS-20

To REMOTE

CAPTURE

GB

Making Various Prints

38

When printing the image in the

floppy disk, you can print the

date shot with the Digital

Mavica.

Note that you cannot print the

date when you print the image

from the video equipment.

Before you begin

1 Turn on the printer and television and set the

input selector of the television to “VIDEO.”

2 Set INPUT SELECT to “FD.”

1

Set DATE to “ON.”

Date is not printed.

Date is printed.

2

Select the desired print using the print mode

dial.

You can select standard printing (page 20, 23),

split printing (page 26 to 29), label printing

(page 32) or index printing (page 34).

3

Select the image for printing.

1 Insert the floppy disk into the floppy disk

slot.

2 Press the arrow buttons to move the white

frame to the image you want to print, then

press ENTER.

4

Press PRINT.

The selected image is printed with the date.

Date

For Your Information

Precautions

On safety

• Operate the printer on 220 to 240 V AC, 50/60 Hz

only.

• Be careful not to set or drop any heavy objects on the

power cord, or to damage the power cord in any

way. Never operate this printer with a damaged

power cord.

• Should any solid object or liquid fall into the cabinet,

unplug the printer and have it checked by qualified

personnel before operating it any further.

• Never disassemble the printer.

• To disconnect the power cord, pull it out by the plug.

Never pull the power cord itself.

• When the printer is not going to be used for an

extended period of time, disconnect the power cord

from the wall outlet.

• Do not handle the printer roughly.

• To reduce the risk of electrical shock, always unplug

the printer from electrical outlet before cleaning and

servicing the printer.

On installation

• Avoid placing the unit in a location subject to:

– vibration

– high humidity

– excessive dust

– direct sunlight

– extremely high or low temperatures

• Do not use electrical equipment near the unit. The

unit will not work properly in electromagnetic fields.

• The unit is designed to operate horizontally. Never

attempt to operate the printer in a tilted position. If

the unit was placed on its side or with its top panel

facing down, make sure to remove the paper tray

and check that the print papers are set properly

before starting operation.

• Do not place heavy objects on the printer.

• Leave enough room around the printer so that the

ventilation holes are not blocked. Blocking these

holes may cause internal heat build-up.

On moisture condensation

If the printer is brought directly from a cold location to

warm location or placed in an extremely warm or

humid room, moisture may condense inside the unit.

In such cases the printer will probably not work

properly and may even develop a fault if you persist in

using it. If moisture condensation occurs, turn off the

power and do not use the printer for at least one hour.

On transport

When you transport the printer, remove the print

cartridge from the printer and put the unit in the

original box with the protective packaging.

If you no longer have the original box and packing

parts, use the substitutive packing material so that it

will not be damaged while transporting.

On cleaning

Clean the cabinet, panel and controls with a soft dry

cloth, or a soft cloth lightly moistened with a mild

detergent solution. Do not use any type of solvent,

such as alcohol or benzine, which may damage the

finish.

For Your Information

GB

For Your Information

40

For Your Information

GB

41

Confidential

1-9

DMP-1000P (AEP)

Page 12

Precautions (continued)

On floppy disks

To protect data recorded on floppy disk, note the

following:

• Avoid storing floppy disks near magnets or magnetic

fields such as those of speakers and televisions,

permanent erasure of disk data may result.

• Avoid storing floppy disks in areas subject to direct

sunlight or sources of high temperature, such a

heating device. Floppy disk warping of damage may

result, rendering the disk useless.

• Avoid contact with the disk’s surface by opening the

disk shutter plate. If the disk’s surface becomes

blemished, data may be rendered unreadable.

• Avoid getting liquids on the floppy disk or using

floppy disks in areas subject to high humidity.

Otherwise, data may be rendered unreadable.

• Be sure to use the floppy disk case to ensure

protection of important data.

• Use only a 2HD type disk head cleaner when

cleaning the disk drive.

• Even when you use a 3.5 inch 2HD floppy disk,

image data may not be recorded and/or displayed

depending on the using environment. In this case,

use the other brand disks.

Back up recommendation

To avoid the potential risk of data loss, always copy

(back up) data to the other floppy disk.

On print paper

Use the set of the print paper and print cartridge

supplied together in the same carton. If you use them

in different combination, proper printing results may

not be obtained, or paper jam or other trouble may

occur.

Chart for various print mode

Split printing using the same image (page 26, 28)

Standard printing

(page 20, 23)

Date printing

(page 38)

Mirror printing

(page 30)

2-split printing

Split printing using different images (page 26, 28)

2-split printing

Floppy disk

label printing

(page 32)

4-split printing 16-split printing

4-split printing

Index printing (page 34)

16-split printing

GB

For Your Information

42

GB

For Your Information

50

Confidential

DMP-1000P (AEP)

1-10

1-10 E

Page 13

SECTION 2

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

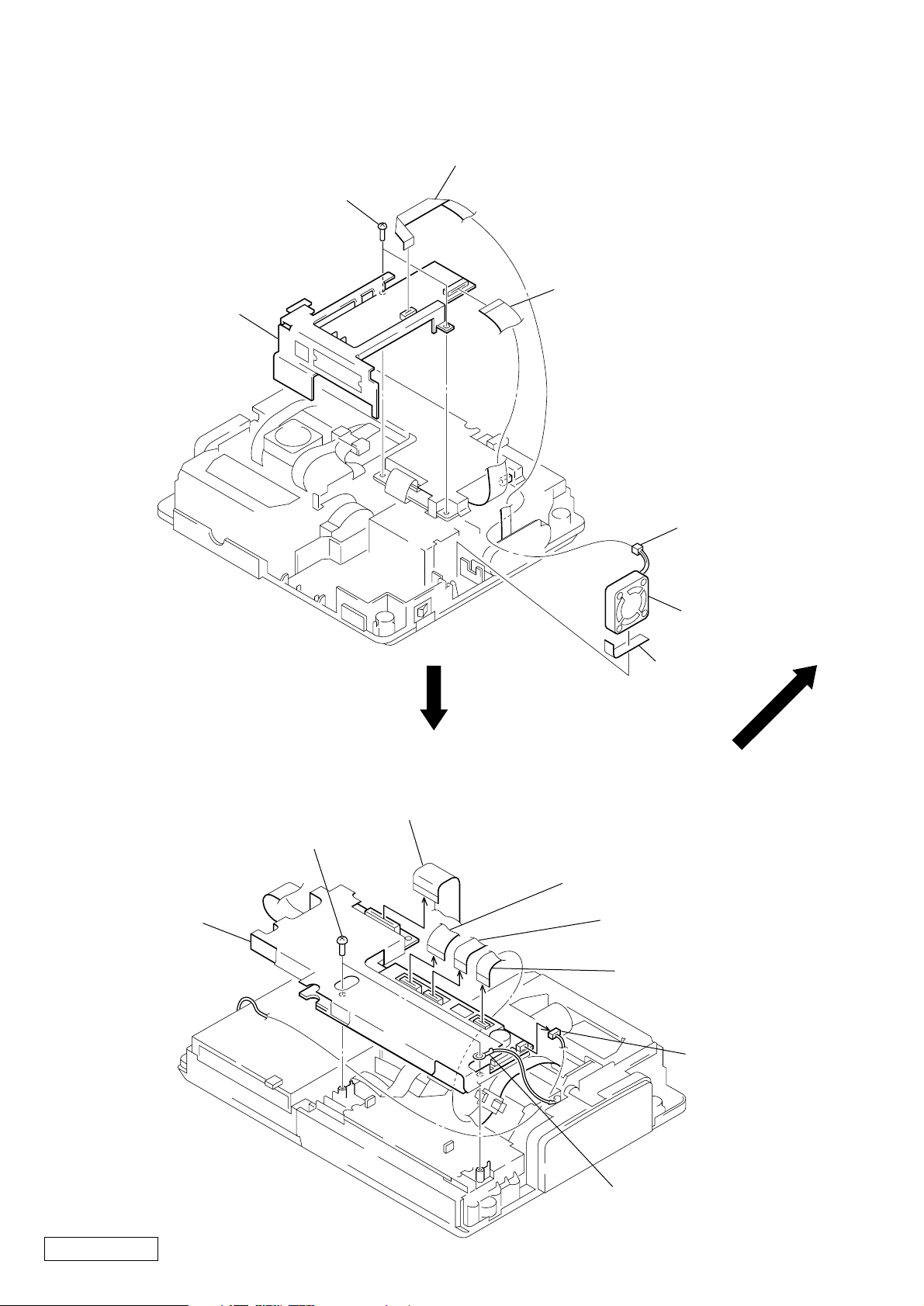

UPPER CABINET ASSY

2 upper cabinet Assy

3 flat cable (DKSW39

(CN504)

1 two screws

(BVTP3 × 20)

DC FAN (HEAD FAN) (M901)

1 connector

(CN1938)

2 two screws

(BTP2.6 × 12)

1 two screws

(BVTP3 × 20)

4 cushion, fan

3 DC fan (head fan) (M901)

2-1

Confidential

DMP-1000P (AEP)

Page 14

VI-39 BOARD SECTION, DC FAN (POWER FAN) (M905)

)

k

4 flat cable (VIVS39)

(CN101)

5 two screws

(BV2.6 × 8)

6 VI-39 board section

4 flat cable (VIDK20)

(CN102)

1 connector

(CN402)

DK-39E BOARD SECTION

5 DK-39E board section

2 DC fan (power fan

(M905)

3 cushion

(9 × 50 × 0.2)

1 flat cable (DKFD39)

(CN2100)

3 two screws

(BV2.6 × 8)

1 FP-700 flexible board

(CN501)

1 flat cable (ADFE13)

(CN503)

1 flat cable (ADHE13)

(CN502)

2 mini jack bloc

Confidential

DMP-1000P (AEP)

4 harness

2-2

Page 15

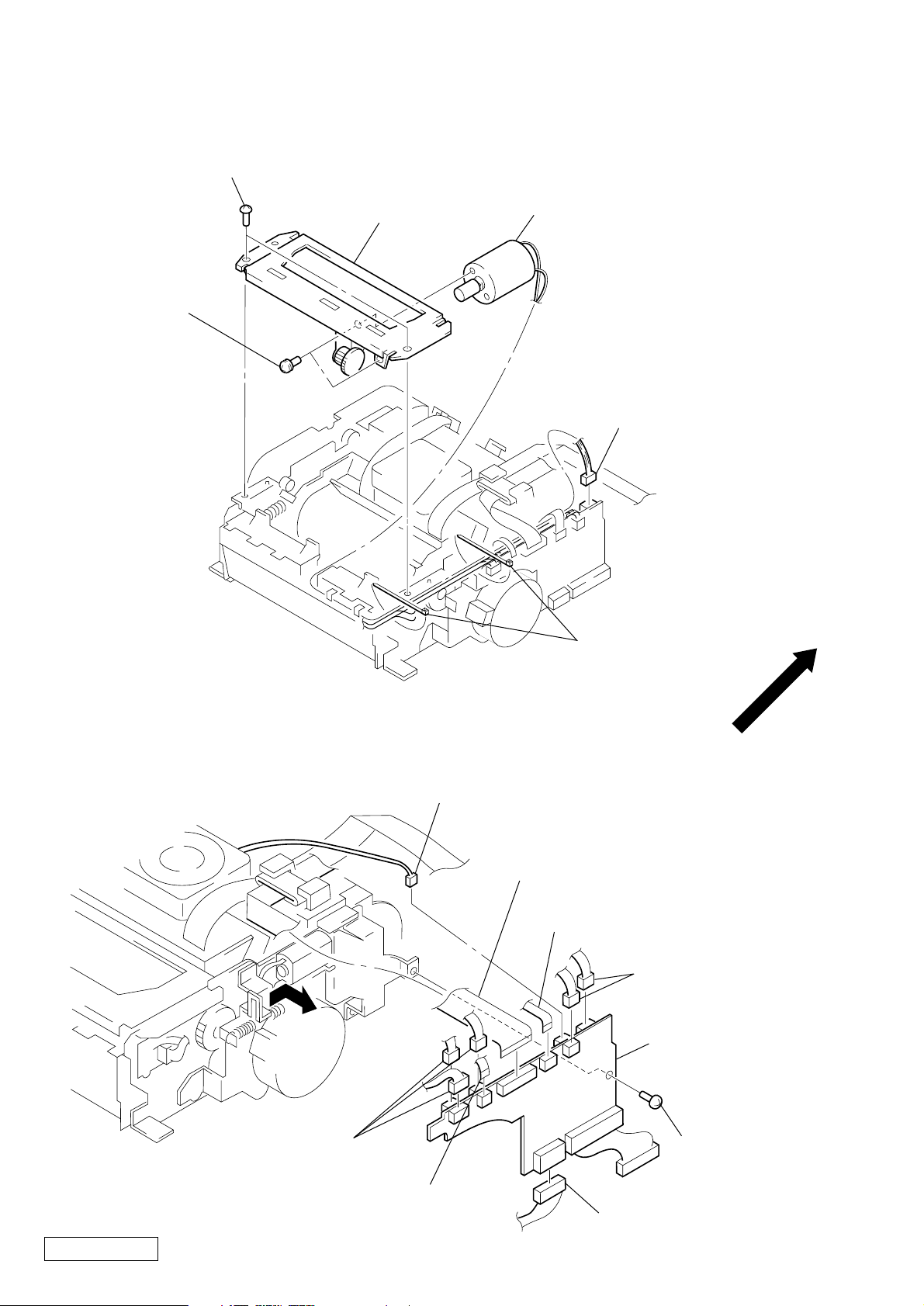

FLOPPY DISK DRIVE (3.5 inch)

s

5 floppy disk drive (3.5 inch)

2 two screws

(BV2.6 × 8)

4 screw

(M2 × 3)

1 flat cable (DKFD39)

3 FD bracket Assy

4 two screw

(M2 × 3)

ESCUTCHEON (60) BLOCK ASSY, MECHANISM DECK SECTION

6 two screws

(BV2.6 × 8)

4 flat cable (POHE13)

(CN202)

3 connector

(CN201)

1 two screws

(BV2.6 × 8)

1 two screws

(BV2.6 × 8)

2 escutcheon (60) block Assy

6 two screws

(BV2.6 × 8)

7 machanism deck section

5 core (FPC)

2-3

Confidential

DMP-1000P (AEP)

Page 16

HEAD MOTOR BLOCK ASSY (HEAD UP/DOWN) (M902)

3 two screws

(BVTT2.6 × 6)

4 HM bracket Assy

5 two screws

(PS3 × 4)

6 head motor block Assy (head up/down)

(M902)

2 connector

(CN1940)

MD-39 BOARD

1 two clamps (LOW TYPE)

2 connector

(CN1938)

1 FP-700 flexible board

(CN1936)

1 FP-703 flexible board

(CN1934)

2 two connectors

(CN1940, 1941)

4 Removal the MD-39 board

to direction of the arrow.

Confidential

DMP-1000P (AEP)

2 three connectors

(CN1931, 1932, 1935)

1 FP-702 flexible board

(CN1933)

2-4

3 screw

(BVTT2.6 × 6)

2 connector

(CN1942)

Page 17

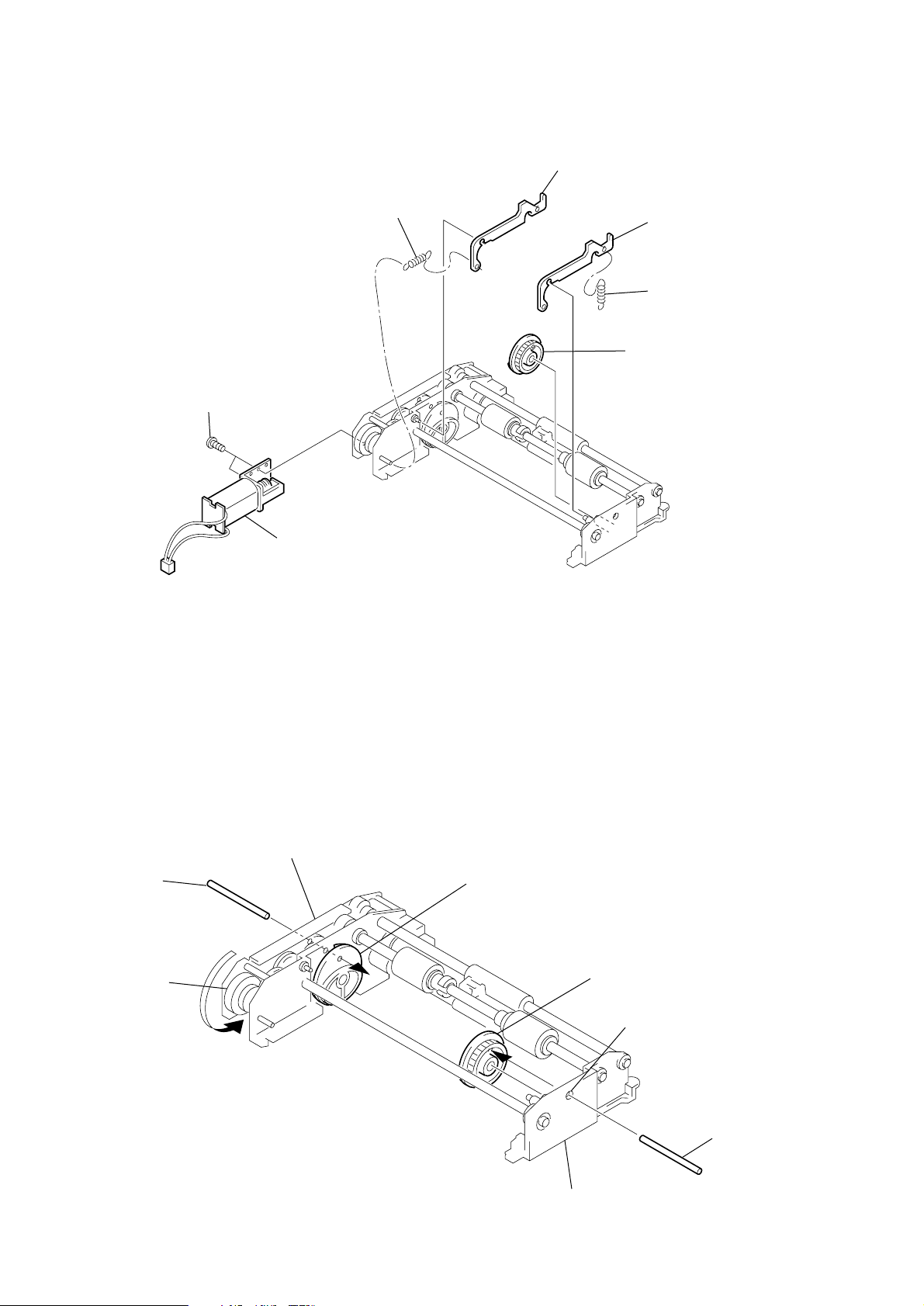

DC MOTOR (STEPPING MOTOR) (PLATEN) (M904), REEL MOTOR BLOCK ASSY (RIBBON) (M903)

)

6 reel motor block ass’y (ribbon) (M903)

5 two screws

(PS2 × 4)

3 two screws

(BVTT2.6 × 6)

2 DC motor (stepping motor

(platen) (M904)

4 motor bracket Assy section

3 two screws

(BVTT2.6 × 6)

CAUTION FOR INSTALLING

Cabinet (upper) Assy

Install the Indication dial to the switch (S100) on the FR-23 board as shown in the figure.

Indication dial

S100

FR-23 board

1 two screws

(BVTT2.6 × 6)

Fig.1

2-5

Confidential

DMP-1000P (AEP)

Page 18

Phase adjusting of Feeder cam Assy

1) Remove each part in numerical order in the figure.

(Refer to Fig.2)

4 Feed lock

1 Two screws

3 Tension spring

2 Feeder motor Assy

6 Feed lock

5 Tension spring

7 Feeder cam (R) Assy

Fig.2

2) Rotate the gear (A) 8 in the direction of arrow, and pierce the

Pin (ø1) 9 through from a positioning hole on the reinforcement to the feeder cam (L) Assy. (Refer to Fig.3)

3) Pierce the Pin (ø1) 0 though a positioning hole on the side

plate (R) in the state of step 2), then install the feeder cam (R)

Assy 7. (Refer to Fig.3)

4) Pull out the two Pins (ø1) 9 and 0, then install each part 1

to 6 in reverse order of removing. (Refer to Fig.2)

Reinforcement

9 Pin (ø1)

8 Gear (A)

Feeder cam (L) Assy

7 Feeder cam (R) Assy

Positioning hole

0 Pin (ø1)

FIg.3

2-6 E

Side plate (R)

Page 19

SECTION 3

)

MECHANICAL ADJUSTMENTS

Replacing the Thermal Head

1) Before replacing the head, print the stair-step pattern with the

old head (faulty head).

Note 1: Only when the head is not entirely damaged with black or

white lines.

Note 2: To reproduce the stair-step pattern, refer to “Adjusting

Method 1” in “4. Electrical Adjustments”.

2) Remove the upper cabinet. (Refer to “2. Disassembly”.)

3) Remove the flat cables 1 (POHE13) and 2 (ADHE13) from

the thermal head. (Refer to Fig. 1)

4) Remove the two screws 3 (BVTT2.6 × 6) and remove the

harnesses 4 and fan holder 5. (Refer to Fig. 1)

5) Remove screw 6, (PS2.6 × 4) and remove the ribbon guide

7. (Refer to Fig. 2)

6) Remove the two screws 8 (PSW2.6 × 8) and remove the ther-

mal head 9 from the heat sink 0. (Refer to Fig. 2)

Note: Do not remove the screw qs fixing the heat sink 0 and head

arm qa.

7) Replace the thermal head 9.

Note: Make sure that the silicon grease (white) does not stick onto

the printing screen of the thermal head. If it does, remove with

alcohol.

8) Assemble in the reverse order of steps 2) to 6).

9) Perform “Head Voltage Adjustment” of “4. Electrical Adjustments” (Page 4-3).

5 fan holder

1 flat cable

(POHE13)

3 two screws

(BVTT2.6 × 6)

4 harness

2 flat cable

(ADHE13)

qs two screws

Note: Do not remove

0 heat sink

9 thermal head

the screw.

7 ribbon guide

Fig. 2

6 screw

(PS2.6 × 4)

8 two screws

(PSW2.6 × 8

qa head arm

Fig. 1

Confidential

3-1 E

DMP-1000P (AEP)

Page 20

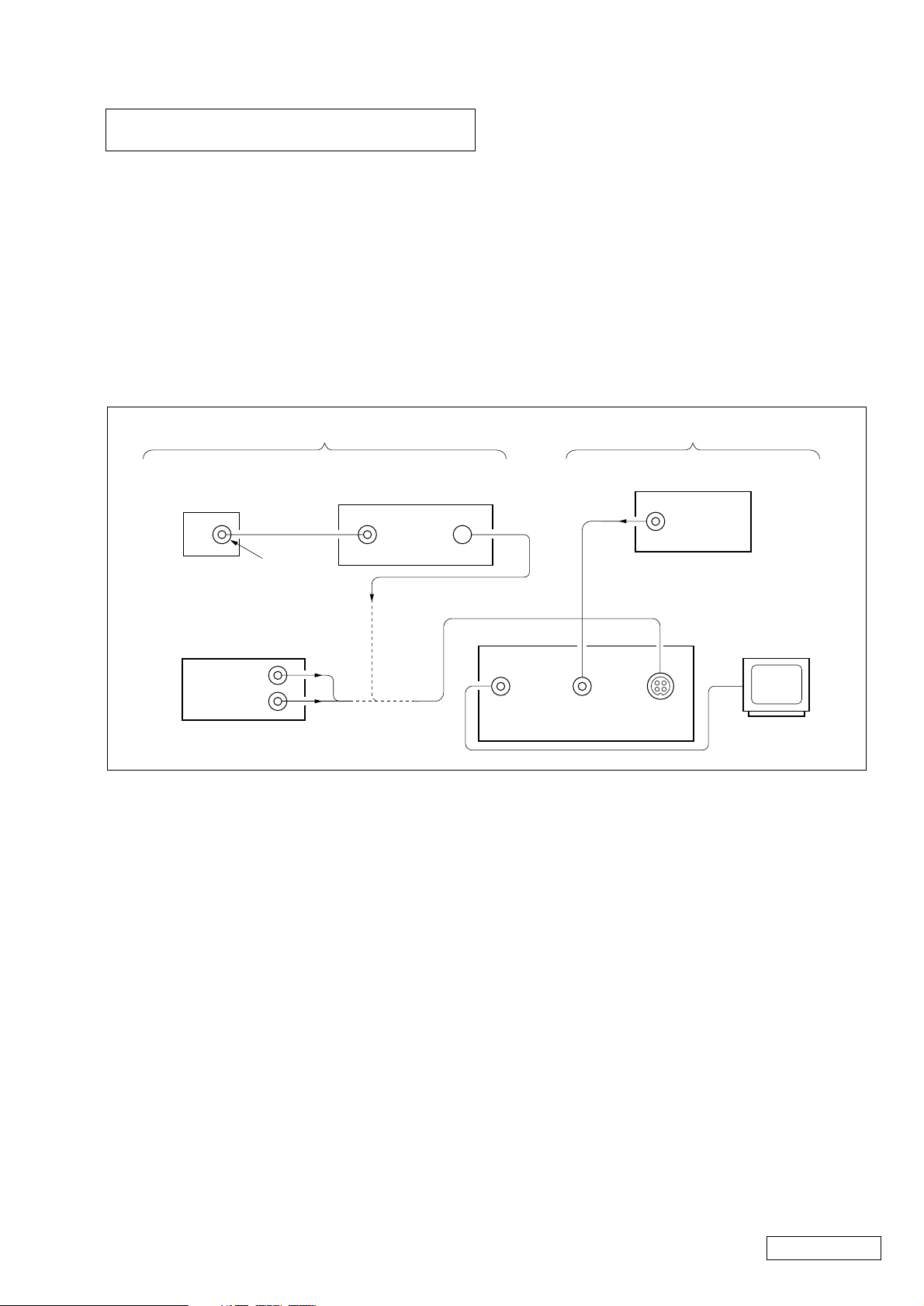

SECTION 4

ELECTRICAL ADJUSTMENTS

During the adjustment, see the Adjustment and Adjustment Pats on page 4-7.

Pre-Adjustment Preparations

1. Equipment required

Electrical adjustment requires the following measuring equipment.

(1) Monitor TV

(2) Oscilloscope: 2 phenomena, bend 30 MHz or more, with de-

lay mode (use 10 : 1 probe unless otherwise specified)

(3) Frequency counter

(4) Pattern generator

(5) Digital voltmeter

(6) Video print paper

(7) Video print cartridge

(8) Vector scope

If S-VIDEO is designated

• If pattern generator does not provide Y/C separate

output terminals

Pattern Generator

VIDEO OUT

(75 Ω)

VTR with S-VIDEO terminal (E-E mode)

VIDEO IN

S-VIDEO OUT

2. Connection of Equipment

Following the designation of input terminal (S-VIDEO or VIDEO),

connect measuring units as shown in Fig. 4-1 and make adjustment.

The input terminal is designated with ( ) in the signal column.

Unless otherwise designated, either input terminal may be used.

Note: In the adjustment where the S-VIDEO input is designated, if ad-

justment was made with the VIDEO input. The specification of

this set will not be satisfied. Always follow the designation.

If adjustment was made using the VTR with S-VIDEO OUT terminal as a signal source, the performance of this set depends on that

VTR. Therefore, use the pattern generator with the Y/C separate

output terminals, if possible.

If VIDEO is designated

Pattern Generator

VIDEO OUT

(75 Ω)

• If pattern generator provide

Y/C separate output terminals

Pattern Generator

Y OUT (75 Ω)

Chroma OUT

(75 Ω)

VIDEO

OUT

Fig. 4-1

VIDEO IN

Set

Monitor TV

S-VIDEO

IN

4-1

Confidential

DMP-1000P (AEP)

Page 21

3. Input Signal Check

V

V

The video circuit adjustment uses as adjustment signals the video

signals obtained from the pattern generator, and therefore these

video output signals must be within the specification.

(1) When S-VIDEO is input

Connect an oscilloscope to the Y signal pin of the S-VIDEO IN

connector, and check that the sync signal of Y signal is 300 mV,

video amplitude is 700 mV, and the setup level is 0 mV. (If using

the VTR with S-VIDEO OUT terminal, check further that the

chroma signal and burst signal do not remain.)

Also, connect an oscilloscope to the chroma signal pin of the SVIDEO IN connector, and check that the burst signal amplitude of

chroma signal is 300 mV and it is flat, and moreover, the amplitude ratio of burst signal to chroma signal is 0.30 : 0.66. The Y

signal and chroma signal used for adjustment are shown in

Fig. 4-2.

Setup level: Potential difference between black and pedestal

(2) When VIDEO is input

Connect an oscilloscope to the VIDEO IN terminal, and check

that the sync signal amplitude of VIDEO signal is 300 mV, video

amplitude is 700 mV, the setup level is 0 mV, and the burst signal

amplitude is 300 mV and it is flat. Also, check that the level ratio

of burst signal to red signal is 0.3 : 0.66.

The VIDEO signal (color bars) used for adjustment is shown in

Fig. 4-3.

White (Approx. 100%)

Burst signal

Approx.

Approx.

0.3 V

0.7 V

Red

Horizontal sync signal

(To be flat)

Approx.

0.3 V

Y signal

White (100%)

Black

Approx. 700 mV

Pedestal

Horizontal

sync signal

Chroma signal

300 ± 10 m

Chroma

amplitude

Burstsignal

to be flat

Burst amplitude : chroma amplitude = 0.30 : 0.66

Fig. 4-2 Color bar signals of pattern generator

(at terminating resistance 75 Ω)

Fig. 4-3 Color bar signal of pattern generator

(at terminating resistance 75 Ω)

Approx.

300 m

Confidential

DMP-1000P (AEP)

4-2

Page 22

POWER SUPPLY BLOCK

[Head V oltage Adjustment]

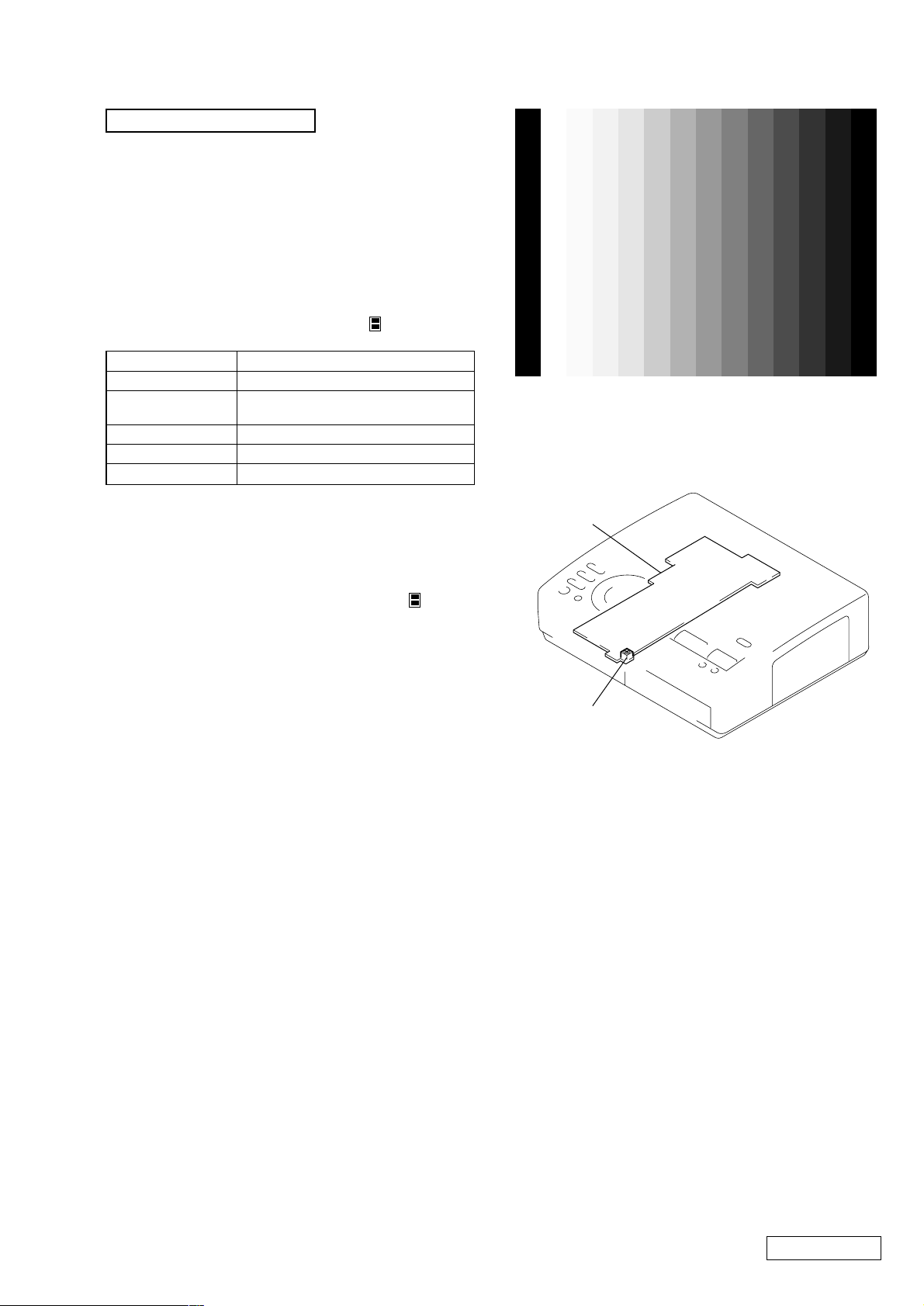

Before performing this adjustment, print the stair-step pattern

(Note 2) two times continuously with the old head (Note 1) or

normal unit. The second print will be used as a sample of the print

density.

Note 1: Only when the old head (faulty head) is not entirely damaged

with black or white lines.

Note 2: To print the stair-step test pattern, turn on the power switch while

pressing the S1714 (SAVE) and S1717 (ENTER) on the SW-39

board.

(Press the S1714 (SAVE) and S1717 (ENTER) until a peep is

heard.) Set the S1701 (Rotaly switch) to the position, and press

the S1706 (print), then the print will start.

Mode Test mode (Note 2)

Signal Test pattern (Stair-step)

Measuring points

Measuring instrument Digital Voltmerter

Adjustment part VR201

Specification Print density should be the same as the sample

+: CN1943 2 pin (MD-39 board)

–: CN1943 3 pin

Fig. 4-4 Stair-step pattern

* VR201 is in the power block (1-468-364-31).

Adjustment Location:

Adjustment Procedure:

(1) To print the stair-step test pattern, turn on the power switch

while pressing the S1714 (SAVE) and S1717 (ENTER) on

the SW-39 board.

(Press the S1714 (SAVE) and S1717 (ENTER) until a peep

is heard) Set the S1701 (Rotaly switch) to the position,

and press the S1706 (print), then the print will start.

(2) After printing, repeat (1) immediately.

(3) Compare the second printed pattern density with that of the

sample, and if the density differs, perform the following ad-

justment.

(4) Adjust VR201 according to the print density.

If darker than the sample: Decrease the head voltage.

If lighter than the sample: Increase the head voltage.

(5) Print the stair-step pattern two times continuously.

(6) Compare the second printed pattern density with that of the

simple, and if the density differs, repeat steps (3) to (6).

Note: Only one print is required after the second time.

(7) Turn off the power switch.

power block

VR201

4-3

Confidential

DMP-1000P (AEP)

Page 23

VIDEO BLOCK

[Free-Run Frequency Adjustment (1)] (VI-39 board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN) (Note 1)

Measuring point IC108 qk pin

Measuring equipment Frequency Counter

Adjustment part CT102

Specification value 4.433619 MHz ± 30 Hz

Note 1: Connect IC108 5 pin to the GND via 0.1µF capacitor (chroma

signal grounded.)

Adjustment Procedure:

(1) Connect IC108 7 pin to the GND via 1 MΩ resisitor.

(2) Adjust CT102 so that the frequency counter reading satisfies

the specification value.

[Free-Run Frequency Adjustment (2)] (DK-39E board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point IC407 <zzc> pin

Measuring equipment Frequency Counter

Adjustment part CT500

Specification value 14.21875 MHz ± 100 Hz

Adjustment Procedure:

(1) Adjust CT500 so that the frequency counter reading satisfies

the specification value.

[910fh Adjustment] (DK-39E board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point IC401 qa pin (or CL427)

Measuring equipment Digital Voltmeter

Adjustment part CT401

Specification value 2.5 ± 0.1 Vdc

Adjustment Procedure:

(1) Adjust CT401 so that the digital voltmeter reading satisfies

the specification value.

[Y/C Separation CHROMA Level] (VI-39 board)

Mode VIDEO Input

Signal Color bar (VIDEO IN)

Measuring point CL129

Measuring equipment Oscilloscope

Adjustment part RV102

Specification value 300 ± 5 mVp-p

Adjustment Procedure:

(1) Adjust RV102 so that the A level (white) of waveform on

the oscilloscope satisfies the specification value.

A

H

Fig. 4-6

[1H Delay Adjustment] (VI-39 board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point FL106 3 pin

Measuring equipment Oscilloscope

Adjustment part RV105, 250, CT250

Adjustment Procedure:

(1) Set RV105 so that the luminescent spot of center.

(2) Set R V250 and CT250 so that the luminescent spots of phase

and gain.

[D/A Output Y Level Adjustment] (DK-39E board)

Note: Turn of the power switch once, then turn it on again.

Mode VIDEO Input

Signal Color bar (VIDEO IN)

Measuring point J1802 (OUTPUT)

Measuring equipment Oscilloscope

Adjustment part RV401

Specification value 700 ± 5 mVp-p

[Y/C Separation Y Level Adjustment] (VI-39 board)

Mode VIDEO Input

Signal Color bar (VIDEO IN)

Measuring point CL138

Measuring equipment Oscilloscope

Adjustment part RV103

Specification value 700 ± 10 mVp-p

Adjustment Procedure:

(1) Adjust RV103 so that the A level (white) of waveform on

the oscilloscope satisfies the specification value.

White (100%)

A

H

Fig. 4-5

Confidential

DMP-1000P (AEP)

Adjustment Procedure:

(1) Adjust RV401 so that the A level (white) of waveform on

the oscilloscope satisfies the specification value.

White (100%)

A

H

Fig. 4-7

4-4

Page 24

[D/A Output CHROMA Level Adjustment] (DK-39E board)

Mode VIDEO Input

Signal Color bar (VIDEO IN)

Measuring point J1802 (OUTPUT)

Measuring equipment Oscilloscope

Adjustment part RV402

Specification value 681 ± 5 mVp-p

Adjustment Procedure:

(1) Adjust R V402 so that the A level (Red) of waveform on the

oscilloscope satisfies the specification value.

(2) Turn off the power switch.

White (100%)

A

[A/D Input R-Y/B-Y Level Adjustment]

(VI-39, DK-39E board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point CL407, 408

Measuring equipment Oscilloscope

Adjustment parts RV106, 405

Specification value

CL407 (R-Y) 1.05 ± 0.01 Vp-p

CL408 (B-Y) 1.20 ± 0.01 Vp-p

Adjustment Procedure:

(1) Connect on oscilloscope to the CL408.

(2) Adjust RV106 so that the A level (B-Y) of waveform on the

oscilloscope satisfies the specification value.

Blue

H

Red

Fig. 4-8

[A/D Input Y Level Adjustment] (DK-39E board)

Note: Turn off the power switch once, then turn it on again.

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point CL409

Measuring equipment Oscilloscope

Adjustment part RV404

Specification value 1.30 ± 0.01 Vp-p

Adjustment Procedure:

(1) Connect on oscilloscope to the CL409 (from IC407 yf pin

to the point via R478).

(2) Adjust RV404 so that the A level (white) of waveform on

the oscilloscope satisfies the specification value.

White (100%)

A

H

A

Yellow

Fig. 4-10

(3) Connect on oscilloscope to the CL407.

(4) Adjust RV405 so that the A level (R-Y) of waveform on the

oscilloscope satisfies the specification value.

Red

Yellow

A

Fig. 4-11

Fig. 4-9

4-5

Confidential

DMP-1000P (AEP)

Page 25

[HUE Level Adjustment] (VI-39 board)

Mode VIDEO Input

Signal Color bar (S-VIDEO IN)

Measuring point J1802 (OUTPUT)

Measuring equipment Vector scope

Adjustment part RV105

Specification value Yellow phase 167 ± 4 deg

Adjustment Procedure:

(1) Connect on vector scope to the J1802.

(2) Press the S1707 (CAPTURE).

(3) Check yellow phase satisfies the specification value.

(4) If NG, press the S1708 (PICTURE) and lights on the D1733

(INPUT)

(5) A little adjust the RV105 and press the S1707.

(6) Repeat steps (2) to (5) until yellow phase satisfies the speci-

fication value.

90 °

167 ± 4 °

180 °

Yellow

Fig. 4-12

Reference : B-Y Waveform (CL408)

•

•

Fig. 4-13

0 °

A

If yellow phase is under 163 °,

extend the A level.

If yellow phase is over 171°,

shorten the A level.

Confidential

DMP-1000P (AEP)

4-6

Page 26

Adjustment Parts and Measuring Points:

– DK-39E Board (side A) –

RV404

A/D Input Y Level

Adjustment

RV405

A/D Input R/Y Level

Adjustment

CT401

910fh Adjustment

CN501 CN503

176 133

1 132

IC503

IC407

8944

8845

– DK-39E Board (side B) –

CL408

CL407

CL409

CL427

RV401

D/A Output Y Level

Adjustment

IC401

RV402

D/A Output Chroma Level

Adjustment

CT500

Free-run Frequency (2)

Adjustment

IC506

IC505

4-7

Confidential

DMP-1000P (AEP)

Page 27

– VI-39 Board (side A) –

j

CN102

20 1

1

3

FL106

RV105

HUE Level Adjustment

CT102

Free-Run Frequency (1)

Adjustment

IC108

RV106

A/D Input B/Y Level

ustment

Ad

– VI-39 Board (side B) –

– MD-39 Board (component side) –

CT250 RV250

1H Delay Adjustment

RV102

Y/C Separation Chroma Level

Adjustment

CL138

CL129

RV103

Y/C Separation Y Level

Adjustment

– VS-39 Board (component side) –

Confidential

DMP-1000P (AEP)

CN1943

4

1

J1802

OUTPUT

4-8

4-8 E

Page 28

5-1. BLOCK DIAGRAM – VIDEO Section –

J1801

VIDEO

INPUT

VIDEO AMP

Q104, 123

CLAMP

Q124

RV102

Y/C SEPARATION

CHROMA LEVEL

RV103

Y/C SEPARATION

Y LEVEL

SECTION 5

DIAGRAMS

Y/C SEPARATOR

IC105

AD IN

25

41

CVRF

YVRF

33

INSL

10

11

AYO

ACO

OCLK

37

YMCK

17

YO

16

CT410

910fh

Y BUFFER

Q412

R-Y BUFFER

Q411

MCKO

AFH

WEVN

26

VD

27

32

2

IC402

4

R-Y

Y/C MIX

IC103 (1/2)

31

39

Y IN

18

Y/C

MIX