SONY D EG5 X Service Manual

D-EJ985

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wavelength: λ = 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance

of 200 mm from the objective lens surface on

the optical pick-up block with 7 mm aperture.)

D-A conversion

1-bit quartz time-axis control

Frequency response

20 - 20 000 Hz

+1–2

dB (measured by JEITA CP-

307)

Output (at 4.5 V input level)

Line output (stereo minijack)

Output level 0.7 V rms at 47 kΩ

Recommended load impedance over 10 kΩ

Headphones (stereo minijack)

Approx. 5 mW + Approx. 5 mW at 16 Ω

Optical digital output (optical output connector)

Output level: –21 - –15 dBm

Wavelength: 630 - 690 nm at peak level

Power requirements

For the area code of the model you

purchased, check the upper left side of the

bar code on the package.

•Two Sony NH-14WM (A) rechargeable

batteries: 2.4 V DC

•Two LR6 (size AA) batteries: 3 V DC

•AC power adaptor (DC IN 4.5 V jack):

UK model: 230 - 240 V, 50 Hz

E, Korean and tourist

models: 100 - 240 V, 50/60 Hz

Hong Kong model: 230 V, 50/60 Hz

Chinese model: 220 V, 50 Hz

Battery life* (approx. hours)

(When you use the CD player on a flat and stable

surface.)

Playing time varies depending on how the CD

player is used.

When using G-PROTECTION

“1” “2”

Two NH-14WM (A) 43 44

(charged for

about 5 hours**)

External battery case 69 74

(two alkaline batteries***)

Two NH-14WM (A) and 113 120

external battery case

(two alkaline batteries***)

* Measured value by the standard of JEITA (Japan

Electronics and Information Technology

Industries Association).

** Charging time varies depending on how the

rechargeable battery is used.

*** When using Sony alkaline batteries LR6 (SG)

(produced in Japan)

Operating temperature

5°C - 35°C (41°F - 95°F)

Dimensions (w/h/d) (excluding

projecting parts and controls)

Approx. 135.0 × 135.0 × 16.2 mm

(5 3⁄8 × 5 3⁄8 × 21⁄32 in.)

Mass (excluding accessories)

Approx. 174 g (6.2 oz)

Design and specifications are subject to change

without notice.

AC power adaptor (1)

Headphones/earphones with remote control (1)

Rechargeable batteries (2)

Charging stand (1)

Battery carrying case (2)

Carrying pouch (1)

External battery case (1)

AC plug adaptor (1)*

* Supplied with tourist model only

Supplied accessories

SERVICE MANUAL

Ver 1.0 2002.10

SPECIFICATIONS

UK Model

E Model

Chinese Model

Tourist Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM-3325ER

Optical Pick-up Name DAX-25E

9-874-204-01 Sony Corporation

2002J0500-1 Personal Audio Company

C 2002.10 Published by Sony Engineering Corporation

PORTABLE CD PLAYER

D-EJ985

TABLE OF CONTENTS

1. SERVICING NOTES............................................... 3

2. GENERAL ................................................................... 6

3. DISASSEMBLY

3-1. Disassembly Flow ........................................................... 7

3-2. Upper Lid (A) Sub Assy ................................................. 7

3-3. Cabinet (Upper) Sub Assy .............................................. 8

3-4. Main Board, Optical Pick-up Section

(CDM-3325ER)............................................................... 8

4. ELECTRICAL CHECK .......................................... 9

5. DIAGRAMS

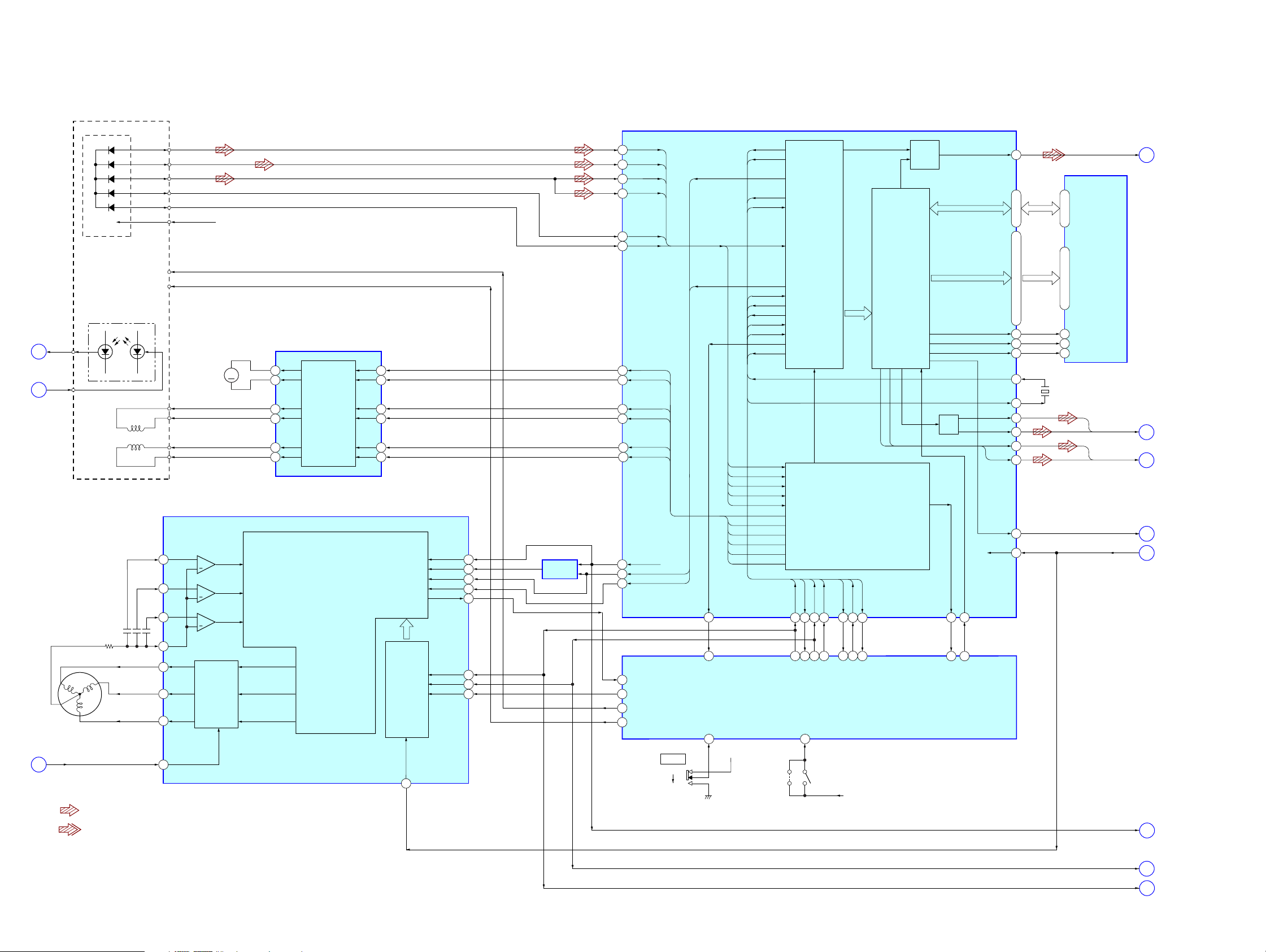

5-1. Block Diagram – MAIN Section (1/2) –....................... 10

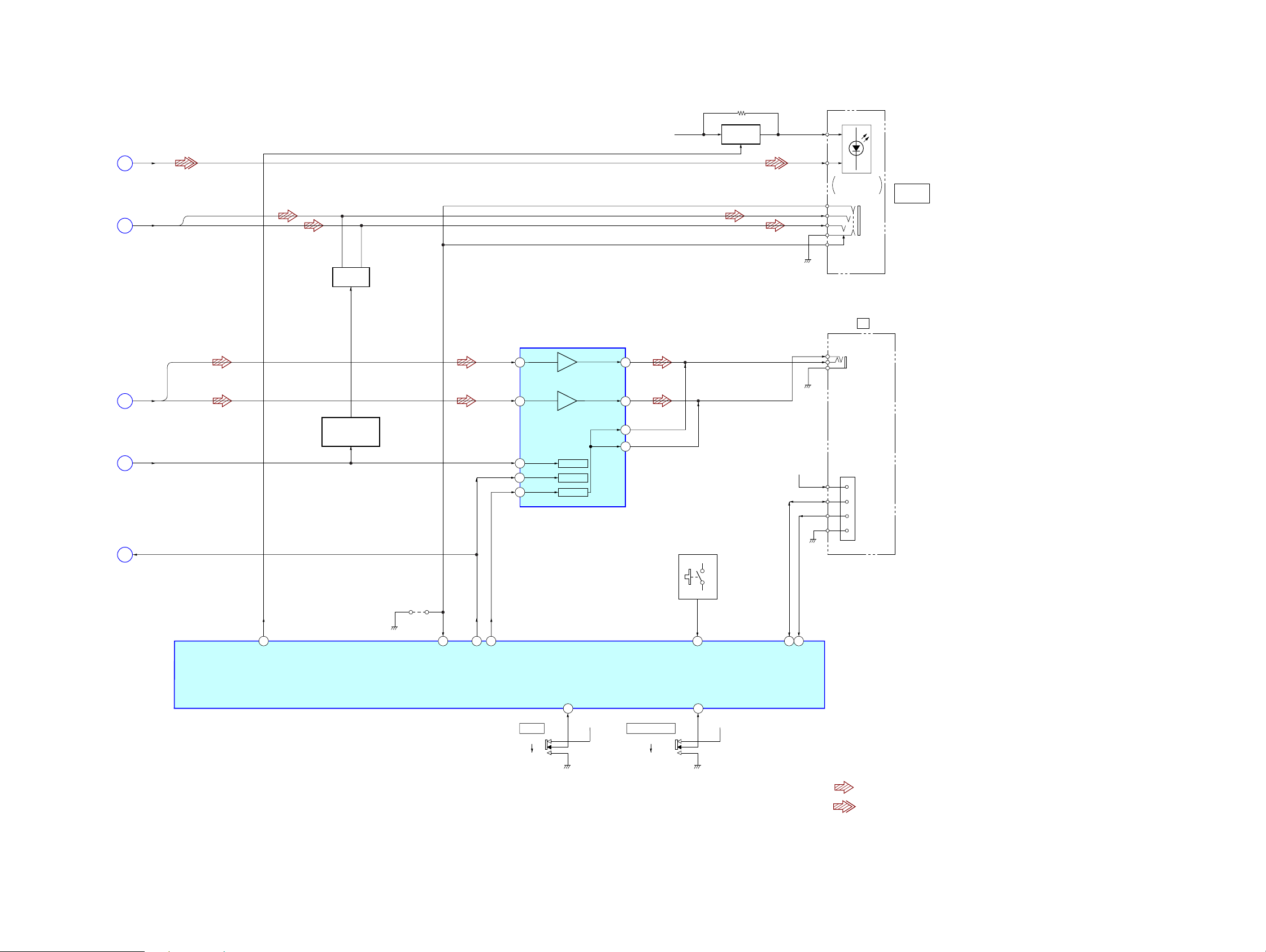

5-2. Block Diagram – MAIN Section (2/2) –....................... 11

5-3. Block Diagram – POWER Section –............................. 12

5-4. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 13

5-5. Printed W iring Board

– Main Board (Component Side) – ................................ 14

5-6. Printed W iring Board

– Main Board (Conductor Side) – .................................. 15

5-7. Schematic Diagram – MAIN Board (1/3) –.................. 16

5-8. Schematic Diagram – MAIN Board (2/3) –.................. 17

5-9. Schematic Diagram – MAIN Board (3/3) –.................. 18

5-10. IC Pin Function Description ........................................... 20

On AC power adaptor

•Use only the AC power adaptor supplied or

recommended in “Accessories (supplied/

optional).” Do not use any other AC power

adaptor. It may cause a malfunction.

Polarity of the plug

Notes on chip component replacement

•Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

•Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

6. EXPLODED VIEWS

6-1. Upper Lid, Cabinet (Upper) Section .............................. 27

6-2. Cabinet (Lower) Section ................................................. 28

6-3. Optical Pick-up Section (CDM-3325ER)....................... 29

7. ELECTRICAL PARTS LIST ............................... 30

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIA GRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANU AL OR IN SUPPLEMENTS PUBLISHED BY SONY.

2

SECTION 1

SERVICING NOTES

D-EJ985

About CD-Rs/CD-RWs

This CD player can play CD-Rs/CD-RWs recorded in the CD-D A

format*, but playback capability may vary depending on the quality of the disc and the condition of the recording device.

* CD-DA is the abbreviation for Compact Disc Dig ital Audio. It is

a recording standard used for the Audio CDs.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objecti ve lens.

BEFORE REPLACING THE OPTICAL PICK-UP BLOCK

Please be sure to check thoroughly the parameters as par the “Optical Pick-Up Block Checking Procedures” (Part No.: 9-960-027-

11) issued separately before replacing the optical pick-up block.

Note and specifications required to check are given below.

• FOK output: IC601 yg pin

When checking FOK, remove the lead wire to disc motor.

• RF signal P-to-P value: 0.4 to 0.6 Vp-p

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

During normal operation of the equipment, emission of the laser

diode is prohibited unless the upper lid is closed while turning ON

the S804. (push switch type)

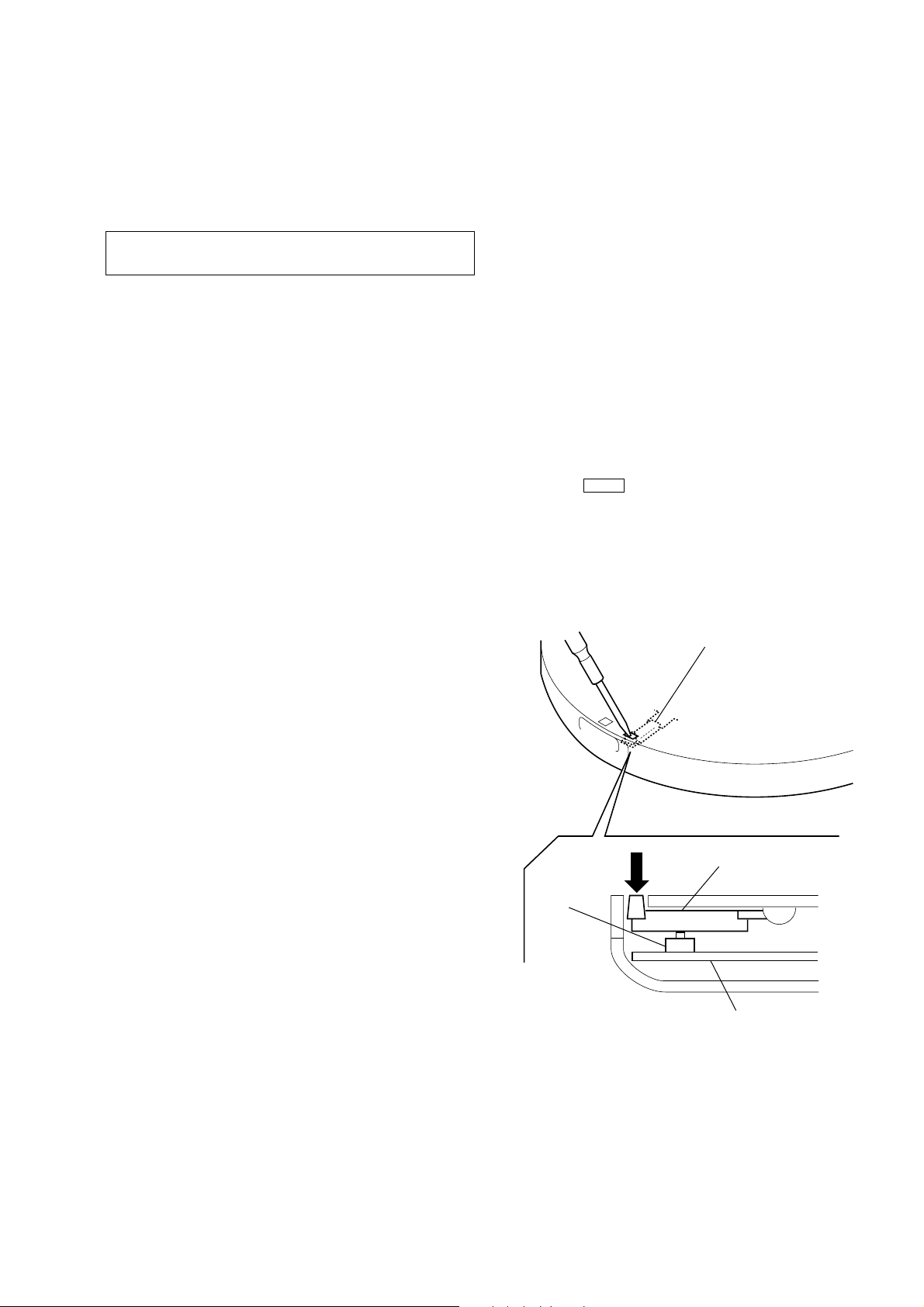

The following checking method for the laser diode is operable.

• Method:

Emission of the laser diode is visually checked.

1. Open the upper lid.

2. With a disc not set, turn on the S804 with a screwdri ver having

a thin tip as shown in Fig.1.

3. Push the

4. Observing the objective lens, check that the laser diode emits

light.

When the laser diode does not emit light, automatic power

control circuit or optical pickup is faulty.

In this operation, the objective lens will move up and down 4

times along with inward motion for the focus search.

N X button.

S804

detection lever

detection lever

MAIN board

Fig. 1 Method to push the S804

3

D-EJ985

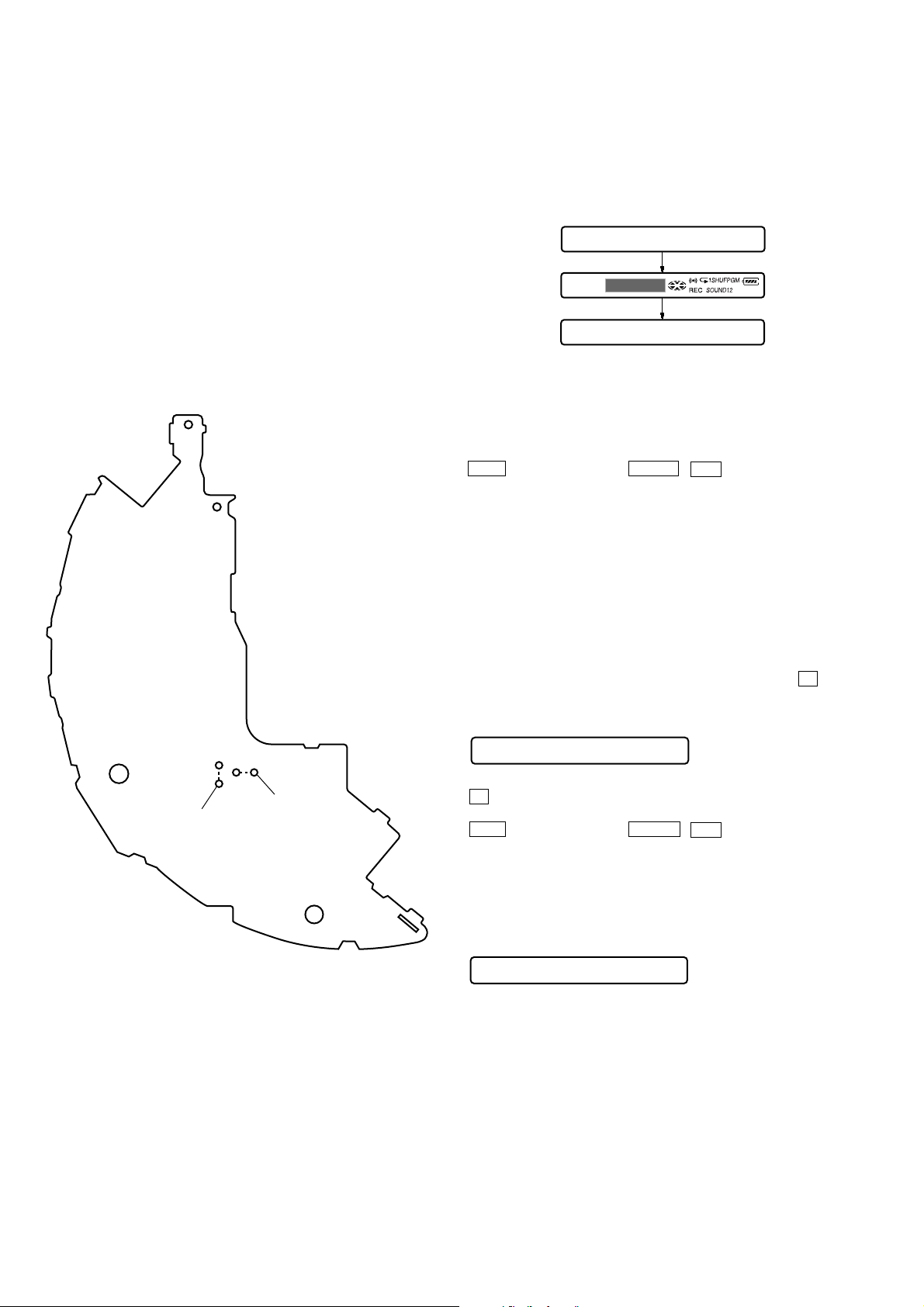

SERVICE MODE

In the Service mode, this set can check the following.

1. Service Mode Setting Method

To set the service mode, perform as follows.

1) Make sure that the power is not turned on.

2) Check for the following states:

CD lid open detection switch (S804) ....... OFF

Solder bridge at SL806 (OPEN)............... OPEN

[AVLS] switch (S802) .............................. NORM

[HOLD] switch (S801) ............................. OFF

[G-PROTECTION] switch (S803) ........... 1

3) Short the solder bridge at the SL807 (TEST) on the MAIN

board (see Fig. 2).

4) Turn the power on.

– MAIN Board (Component Side) –

2. Operation in Service Mode

When the Service mode is set, the LCD on the remote commander

displays the following.

Remote commander LCD display

Microcomputer

version display

All lit

Service mode

3. Operation of Buttons and Knobs in Service Mode

The following operation can be checked by operating the buttons

and knobs on the set and remote commander.

3-1 . Case without Setting a CD

N X button on the set and > N / . knobs on remote

•

commander

Optical pick-up movement (outward or inward)

Tracking/sled servo off

Note: Do not look directly at the laser beam from the optical pick-up.

Do not move forcibly the optical pick-up exceeding the most-outside or most-inside track.

VB102

888

DDDD

BASS12

SL806

(OPEN)

Fig. 2

SL807

(TEST)

3-2 . Case with Setting a CD

Cheking method:

1) Make sure that the power is not turned on.

2) Leave a solder bridge of the SL807 (TEST) on the MAIN board

shorted.

3) Turn the power on, and then set a CD and play it with the X

button on the remote commander.

Remote Commander LCD display

0000

• x button on the set and remote commander

All servos (focus/tracking/sled) off

• N X button on the set and > N / . knobs on remote

commander

Optical pick-up movement (outward or inward)

Tracking/sled servo off

• [PRT/ENT] button on remote commander

Tracking gain up mode

Remote Commander LCD display

(play mode)

Up0000

(For the rest, turn the power off and then turn it on again)

• [VOL +] / [VOL --] buttons on the set and [VOL +] / [VOL --]

knobs on remote commander

2-step volume setting

• [PLAYMODE] button on remote commander

CL V speed becomes 1 to 4 times each time the button is pressed

Tracking/sled servo on

4

Remote Commander LCD display

D-EJ985

010001

040004

(For the rest, turn the power off and then turn it on again)

• [SOUND] button on remote commander

Servo auto adjustment

4.Service Mode Releasing Method

To release the service mode, perform as follows.

1) Turn the power off.

2) Open the solder bridge at the SL807 (TEST) on the MAIN

board.

Note: Remove the solder completely.

5.Error Rate Check Display

The C1 error rate check display mode becomes active if the following operation is performed during the operation in the normal

mode.

1) Turn the power off, and cancel other service operations.

2) Turn the power on, and then set a CD and play it with the X

button on the remote commander.

Remote Commander LCD display

(1 time)

(4 times)

0000

3) Press the [SOUND] button on the remote commander to make

automatic adjustment.

4) Press the [PLAY MODE] button on the remote commander.

Remote Commander LCD display

010001

5) Press the [DISPLAY] button on the remote commander, and

the C1 error rate display will be activated and the LCD on the

remote commander will display as follows.

Remote Commander LCD display

Er****

Note: In the play state, press the [SOUND] button on the remote com-

mander before pressing the [PLAY MODE] button. Wrong order of

button operations will result in very large Er**** value.

6) Turn the power off.

7) Open the solder bridges at the SL807 (TEST) on the MAIN

board.

Note: Remove the solder completely.

**** value

0000 to 0099 : OK

more than 0100 : NG

5

D-EJ985

SECTION 2

GENERAL

This section is extracted from

instruction manual.

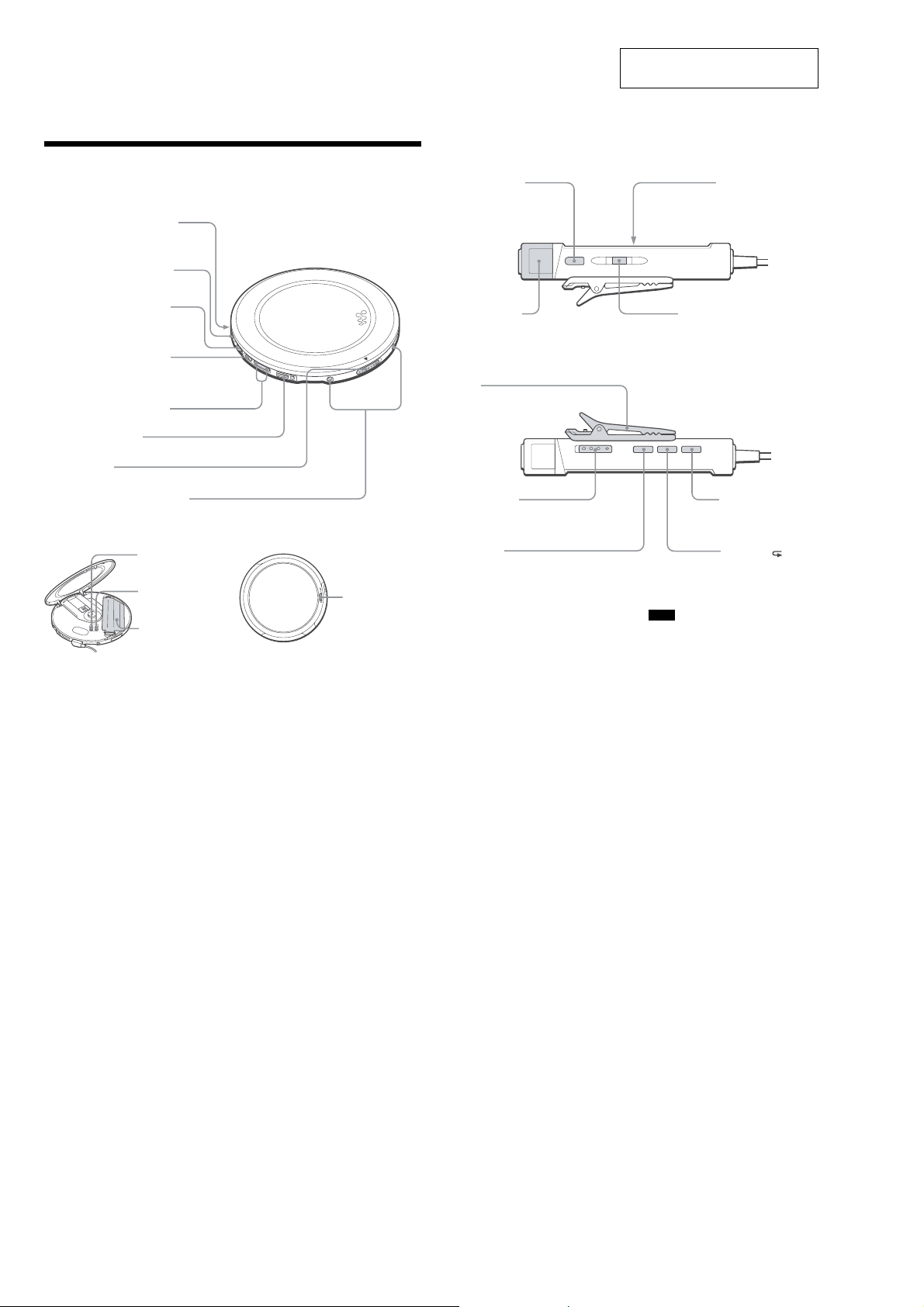

Locating the controls

For details, see pages in parentheses.

CD player (front)

1 EXT BATT (external battery)/

DC IN 4.5 V (external power input)

jack

2 LINE OUT (OPTICAL) jack

3 Jog lever (u (play/pause)•

./> (AMS/search))

4 x (stop) /CHARGE button•

CHARGE lamp

5 VOL (volume) +*/– buttons

6 i (headphones) jack

7 OPEN switch

8 Terminals for the charging stand

CD player (inside)

9 AVLS switch

q; G-PROTECTION

switch

qa Battery

compartment

*The button has a tactile dot.

CD player (rear)

qs HOLD switch

Remote control

qd x (stop) button

qf VOL (volume)

+/– control

qj Clip

ql DISPLAY

button

qg Display

qh Jog lever (u (play/pause)•

ENT (enter)•

./> (AMS/search))

w; SOUND buttonqk HOLD switch

wa P MODE/

(play mode/repeat)

button

Note

Use only the supplied remote control. You cannot

operate this CD player with the remote control

supplied with other CD players.

6

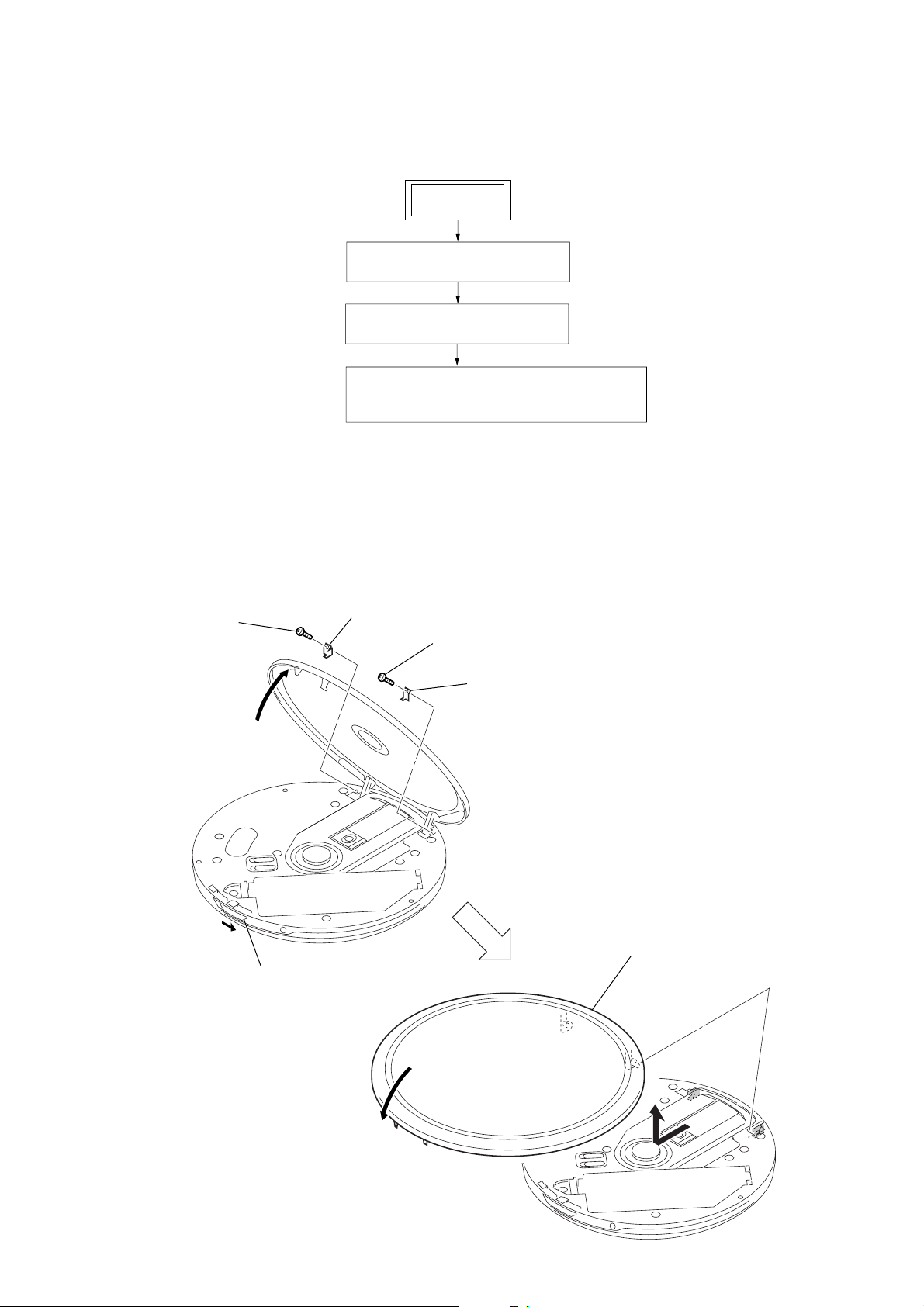

• This set can be disassembled in the order shown below.

3-1. DISASSEMBLY FLOW

3-2. UPPER LID (A) SUB ASSY

3-3. CABINET (UPPER) SUB ASSY

3-4. MAIN BOARD,

D-EJ985

SECTION 3

DISASSEMBLY

SET

(Page 7)

(Page 8)

OPTICAL PICK-UP SECTION (CDM-3325ER)

(Page 8)

Note: Follow the disassembly procedure in the numerical order given.

3-2. UPPER LID (A) SUB ASSY

3

2

screw (B2)

1

Open the upper lid (A) sub assy.

guide (L)

4

screw (B2)

5

guide (R)

6

Close the upper lid (A) sub assy a little

in the direction of arrow A,

then remove it in the direction of

arrow B.

A

B

7

D-EJ985

n

3-3. CABINET (UPPER) SUB ASSY

2

four screws (B2)

AVLS knob

G-PROTECTION knob

3

claw

1

screw (B2)

4

cabinet (upper) sub assy

3

claw

2

three screws (B2)

3

claw

7

spring (upper lid-2702)

5

Remove the solder.

S802

S803

Note : On installation of cabinet (upper) sub assy,

adjust the position of two switches (S802, S803)

and AVLS knob, G-PROTECTION knob.

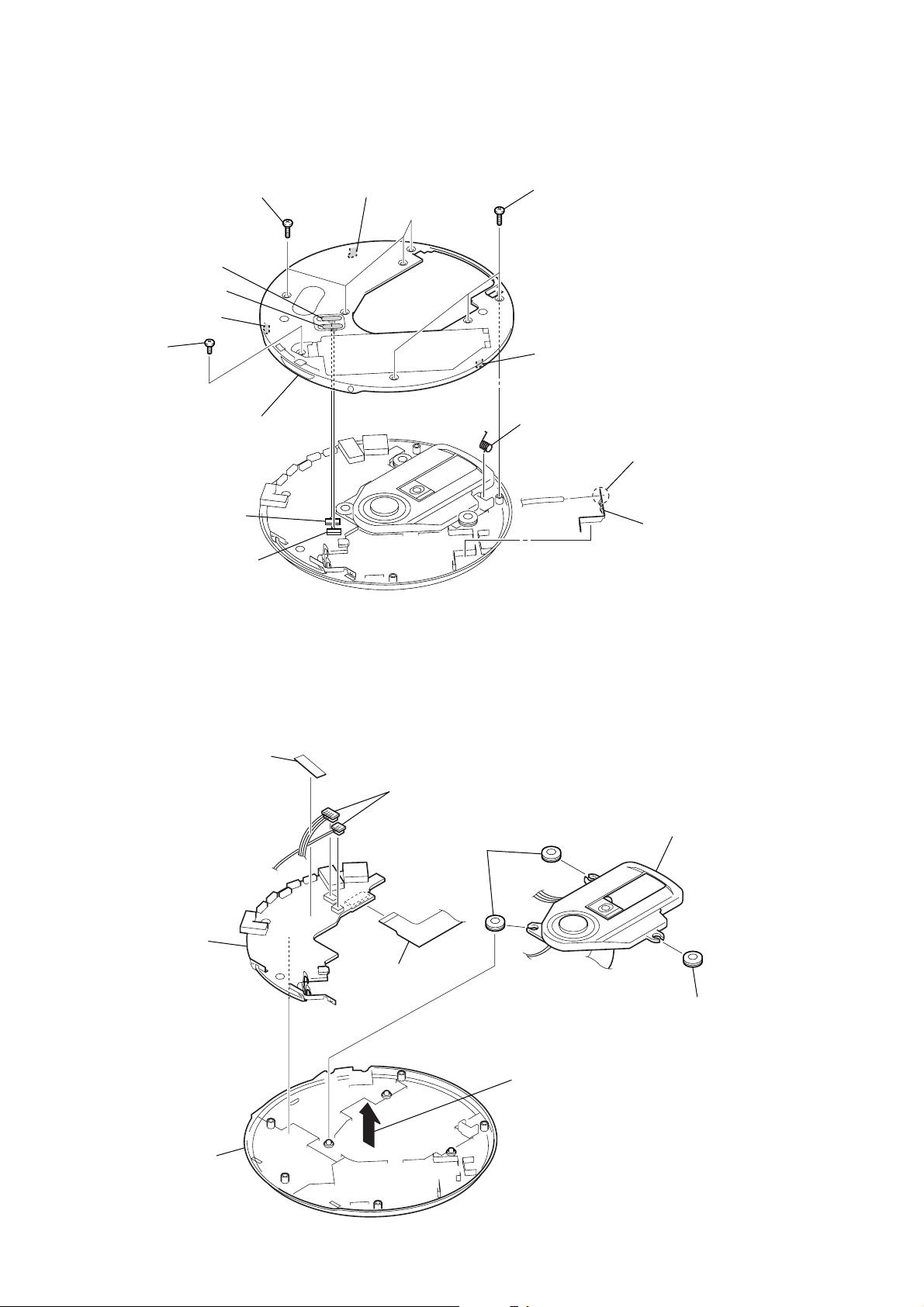

3-4. MAIN BOARD, OPTICAL PICK-UP SECTION (CDM-3325ER)

1

cushion

2

two connectors

(CN501, CN502)

7

two insulators

6

main board

6

battery terminal board

(relay)

8

optical pick-up section

(CDM-3325ER)

5

flexible board

(CN503)

7

insulator

3

Hold up both the main board and the optical

pick-up section at once, and remove them

form the cabinet (lower) assy.

4

cabinet (lower) assy

Note : Handle the flexible board with care whe

you hold up the optical pick-up section.

8

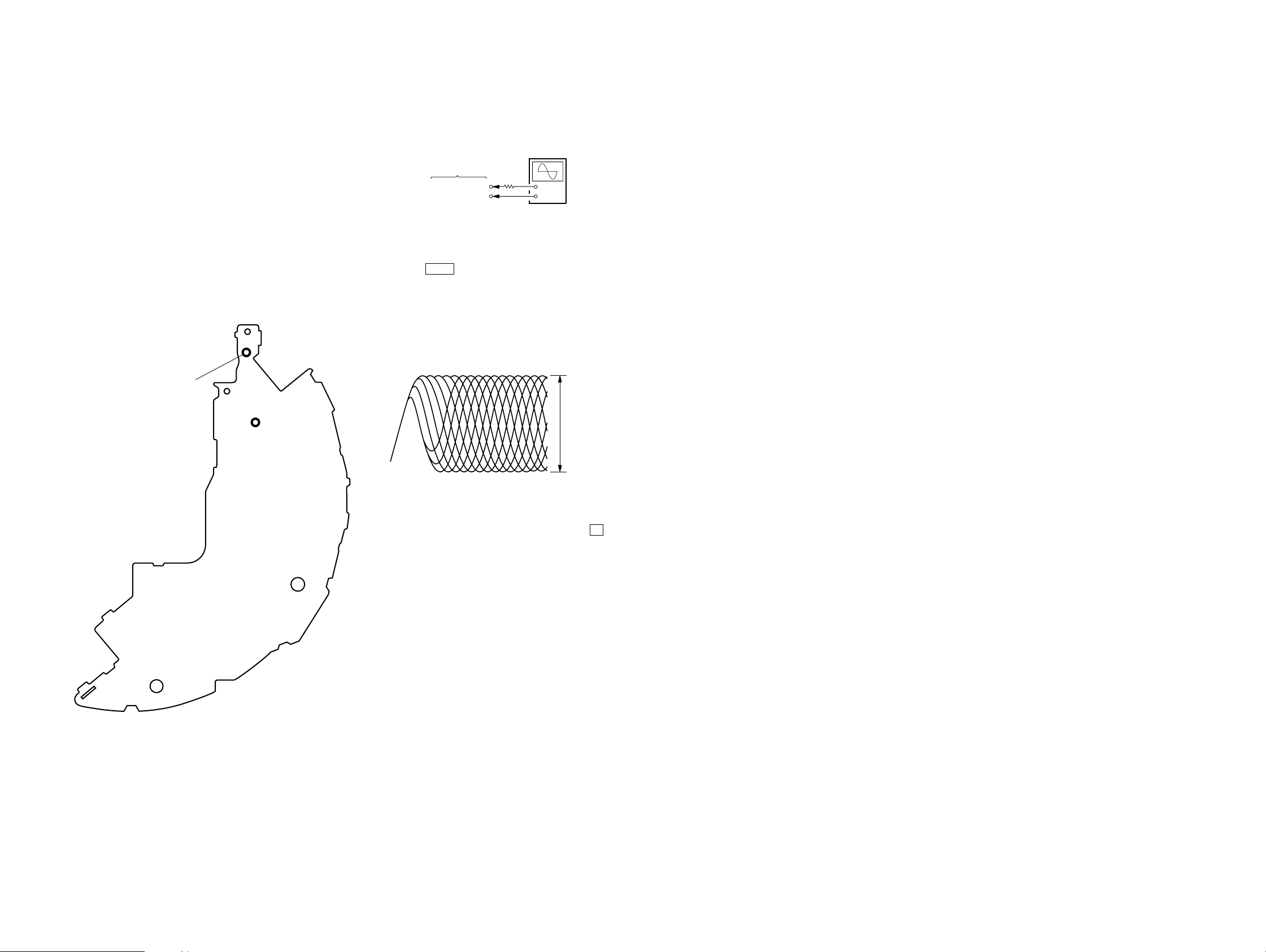

SECTION 4

ELECTRICAL CHECK

D-EJ985

The CD section adjustments are done automatically in this set.

In case of operation check, confirm that focus bias.

Precautions for Check

1. Perform check in the order given.

2. Use YEDS-18 disc (P art No.: 3-702-101-01) unless otherwise

indicated.

3. Power supply voltage requirement: DC4.5 V in DC IN jack.

(J401)

VOLUME : Minimum

AVLS switch : NORM

HOLD switch : OFF

G•PROTECTION switch : 1

Connecting and Checking Location:

– MAIN Board (Conductor Side) –

TP418

(GND)

Focus Bias Check

Condition:

• Hold the set in horizontal state.

Connection:

MAIN board

TP601 (RF)

TP418 (GND)

2 k

Ω

oscilloscope

(AC range)

+

–

Procedure:

1. Connect the oscilloscope to the test points TP601 (RF) and

TP418 (GND) on the MAIN board.

2. Set a disc. (YEDS-18)

3. Push the N X button.

4. Check the oscilloscope waveform is as shown below.

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

RF Signal reference Waveform (Eye Pattern)

VOLT/DIV : 100 mV (With the 10:1 probe in use)

TIME/DIV : 500 ns

TP601 (RF)

RF level

0.45 to 0.65 Vp-p

To watch the eye pattern, set the oscilloscope to AC range and

increase the vertical sensitivity of the oscilloscope for easy watching.

5. Stop revolving of the disc motor by pressing the x button.

99

D-EJ985

SECTION 5

DIAGRAMS

5-1. BLOCK DIAGRAM – MAIN Section (1/2) –

DETECTOR

A

(Page 12)

B

(Page 12)

C

(Page 12)

OPTICAL PICK-UP BLOCK

LASER DIODE

PD

LD

(FOCUS)

2-AXIS

DEVICE

(TRACKING)

M902

(SPINDLE)

V

U

W

VG

• SIGNAL PATH

: CD PLAY (ANALOG OUT)

: CD PLAY (OPTICAL OUT)

A

B

RF

E

F

VCC

DAX-25E

PD

OPSTB

OPGSW

LD

A

B

RF

E

F

VCPU B+

M901

M

(SLED)

U1

19

18

17

20

11

13

15

21

V1

W1

COM

U

V

W

VG

+

+

+

PREDRIVER

FOCUS/TRACKING COIL DRIVER

SLED MOTOR DRIVER

IC403 (1/2)

FO2

34

RO2

32

FO1

38

36

26

24

CONTROLLER,

RO1

H BRIDGE DRIVER

FO4

RO4

SPINDLE MOTOR DRIVER

IC404

CONTROL

CIRCUIT

RI2

RI1

RF AMP,

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR,

D-RAM CONTROLLER

IC601

A

92

B

91

RFDC

88

RFAC

81

E

89

F

90

FI2

17

18

FI1

40

41

FI4

21

FI4

22

SYNC

1

CPU

INTERFACE

XRST

6

PWM

APWM

XBRAK

DATA

CLK

XLTCH

24

23

2

FG

3

7

9

8

BUFFER

IC405

100

99

96

95

98

97

104

103

102

72

74

77

78

SFDR

SRDR

FFDR

FRDR

TFDR

TRDR

C176

MDP

MDS

FG/FGSEL

XDRVLT

HG XSTB

HG GUP

S801

HOLD

HOLD

OFF

SCOR

27

40

SCOR

HOLD

VCPU B+

WDCK

WFCK

MDS

XTAO

XTAI

RFAC

MDP

XSOE

SENS

R4M

XLAT

CLOK

SCOR

SDTO

RFDC

SFDR

SRDR

FFDR

FRDR

TFDR

TRDR

SL806

(OPEN)

E

F

B

A

SIGNAL

PROCESSOR

BLOCK

MEMORY

CONTROLLER,

BUS BOOST

BLOCK

SERVO

BLOCK

R4M

XSOE

XLAT

S804

DETECT

242232232021

2

XIN

VCPU B+

WDCK

26

12

XSOE

GRSCOR

SYSTEM CONTROLLER

SDTD

SENS

CLOK

XLAT

161415181711

MSCK

MSDTI

MSDTO

CLOSE

28

CD LID OPEN

()

DIGITAL

OUT

IC801 (1/3)

FOK

LPF

65

FOK

9

FOK

SYSM

25

13

AMUTE

DOUT

62

D0-D3

4, 3, 6, 5

A0-A10

116 – 113, 17 – 15, 13 – 11, 117

XRAS

1

XWE

2

XCAS

9

XTAI

47

XTAO

48

AOUT1

51

AOUT2

56

HPL

43

HPR

44

LRMU

61

XRST

28

D1 – D4A0 – A10

2, 3, 24, 25

9 – 12, 15 – 19, 21, 8

5

XRAS

4

XWE

23

XCAS

X601

16.9344MHz

D-RAM

IC602

DOUT

AOUTL,

AOUTR

HPL,

HPR

LRMU

XRST

SYNC

D

E

F

G

H

J

(Page 11)

(Page 11)

(Page 11)

(Page 11)

(Page11)

(Page 12)

SCK

SDTO

K

L

(Page 12)

(Page 12)

1010

5-2. BLOCK DIAGRAM – MAIN Section (2/2) –

D-EJ985

(Page 10)

(Page 10)

(Page 10)

(Page 10)

(Page 10)

VCC3

DOUT

D

AOUTL

HPL

HPR

AOUTR

MUTING

Q303

LINE MUTING

CONTROL SWITCH

Q302

13

12

17

18

15

IN_L

IN_R

MUTE_SW

PW_SW

BEEP

HEADPHONE AMP

IC301

MUTE SW

PW SW

BEEP

OUT_L

OUT_R

BEEPO_L

BEEPO_R

4

9

3

10

S805, 806, 808, 809

E

F

LRMU

G

XRST

H

B+ SWITCH

Q301

VCPU B+

OPTICAL

TRANSCEIVER

(LINE OUT JACK)

J302

i

VCPU 2V

4

3

TSB

2

RMKEY

GND

1

J301

LINE OUT

(OPTICAL)

SL807

(TEST)

6 24 79 30 2625

P21

SYSTEM CONTROLLER

IC801(2/3)

AD SEL

XRST

BEEP

S802

AVLS

LIMIT

NORM

39

AVLS

VCPU B+

S803

G-PROTECTION

2

1

AD KEY

ESP

38

31

TSB

AD RMKEY

VCPU B+

• SIGNAL PATH

: CD PLAY (ANALOG OUT)

: CD PLAY (OPTICAL OUT)

1111

Loading...

Loading...