Page 1

DVD MANUAL

V 99 E

Sony DADC

Page 2

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. From CD to DVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1. Format and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2. DVD Types and Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3. Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2. DVD-Video . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2. DVD-Video input media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. DVD-ROM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1. Data preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2. Formatting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3. Input media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4. Label Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1. Printing Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2. Printing Areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3. Label Film Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4. Film Specifications for Label Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5. Standard Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6. Colours . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.7. Label Film Data via Electronic Storage Media . . . . . . . . . . . . . . . . . . . . 17

4.8. Label Film Data via Electronic Data Transfer . . . . . . . . . . . . . . . . . . . . . 18

4.9. Production of the Label Film . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5. Disc Serialisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6. Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1. Printing Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2. Film Specifications for Production of Printwork and Stickers . . . . . . . . . 21

6.3. Specifications for Printwork and Stickers . . . . . . . . . . . . . . . . . . . . . . . 31

6.4. Packaging of Supplied Printwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7. Sony DADC The Company . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Page 3

Introduction

The objective of this manual is to facilitate the correct preparation of

input components for DVD productions with Sony DADC. Similar

manuals are available for our other products including CD-Audio, CDROM, MiniDisc and PlayStation Disc. These manuals can also be

downloaded from our website at http://www.sonydadc.com.

Compliance with the specifications in this manual will avoid confusion

and reduce the requirements for modifications. Rework may

considerably extend the production, thus making it more expensive.

Therefore, we advise you to provide these specifications to the staff in

charge with the preparation work, in particular external video, sound,

graphics and other premastering studios.

As the final product will depend on the quality of the input components

supplied, the adherence to the manual specifications represents an

essential contribution to the total quality of the product and service that

we provide to you as a customer.

In general, all Sony DADC prices and schedules are valid based on the

assumption that the input components provided by the customer meet

the manual specifications. When components do not meet the outlined

specifications, these are either returned or improved based on the

customerÕs request. Additional expenses and charges apply. Prices for

DVDs and special Services (e.g. carrier, editing, film exposure, film

generation etc.) are provided in our current price list.

Page 4

2

DVD, which stands for Digital Versatile Disc, is the

next generation of optical disc storage technology.

It is essentially an optical disc that can hold video as

well as audio and computer data. This new optical

disc can reach a capacity of up to 26 times the

capacity of a CD-ROM and encompasses prerecorded read only discs like DVD-Video, DVD-ROM,

DVD-Audio, SACD and recordable formats like

DVD-R, DVD-RAM, DVD+RW and DVD-R/W. For

movie applications, a DVD can store full length

movies in a high-quality digital video with surround

sound in several languages and a wide range of

interactivity as well as subtitles. Almost all DVD

players and DVD-ROM drives are equipped with an

additional laser diode or a special lens for playback

capability of existing Audio CDs and CD-ROMs.

Main Features

1.1. Format and Specifications

The DVD standard defines a disc that maintains the

overall dimensions of the current Compact Disc.

Therefore the backwards compatibility with existing

Audio CDs and CD-ROMs was easier to realise. The

table below demonstrates similarities and

differences of CD and DVD.

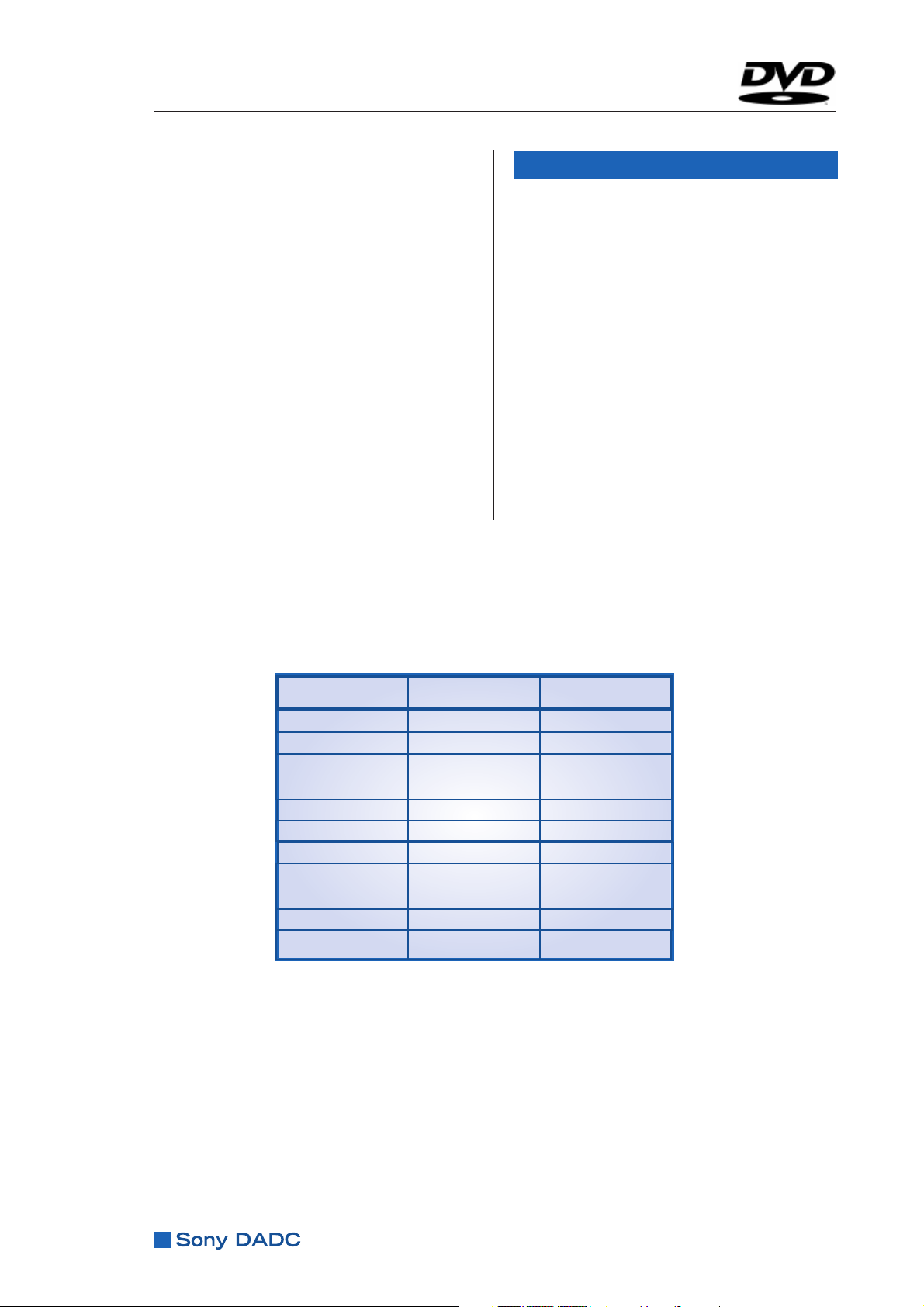

CD DVD

Disc diameter 120mm 120mm

Disc thickness 1.2mm 1.2mm

Disc structure single substrate two bonded

0.6mm substrates

Laser wavelength 780nm 650 / 635nm

Numerical aperture 0.5 0.6

Track pitch 1.µm 0.74µm

Shortest pit/land 0.83µm 0.4µm

length

Data layers 1 up to 4

Data capacity approx. 650 MB 4.7 GB - 17.1 GB

1. From CD to DVD

Page 5

3

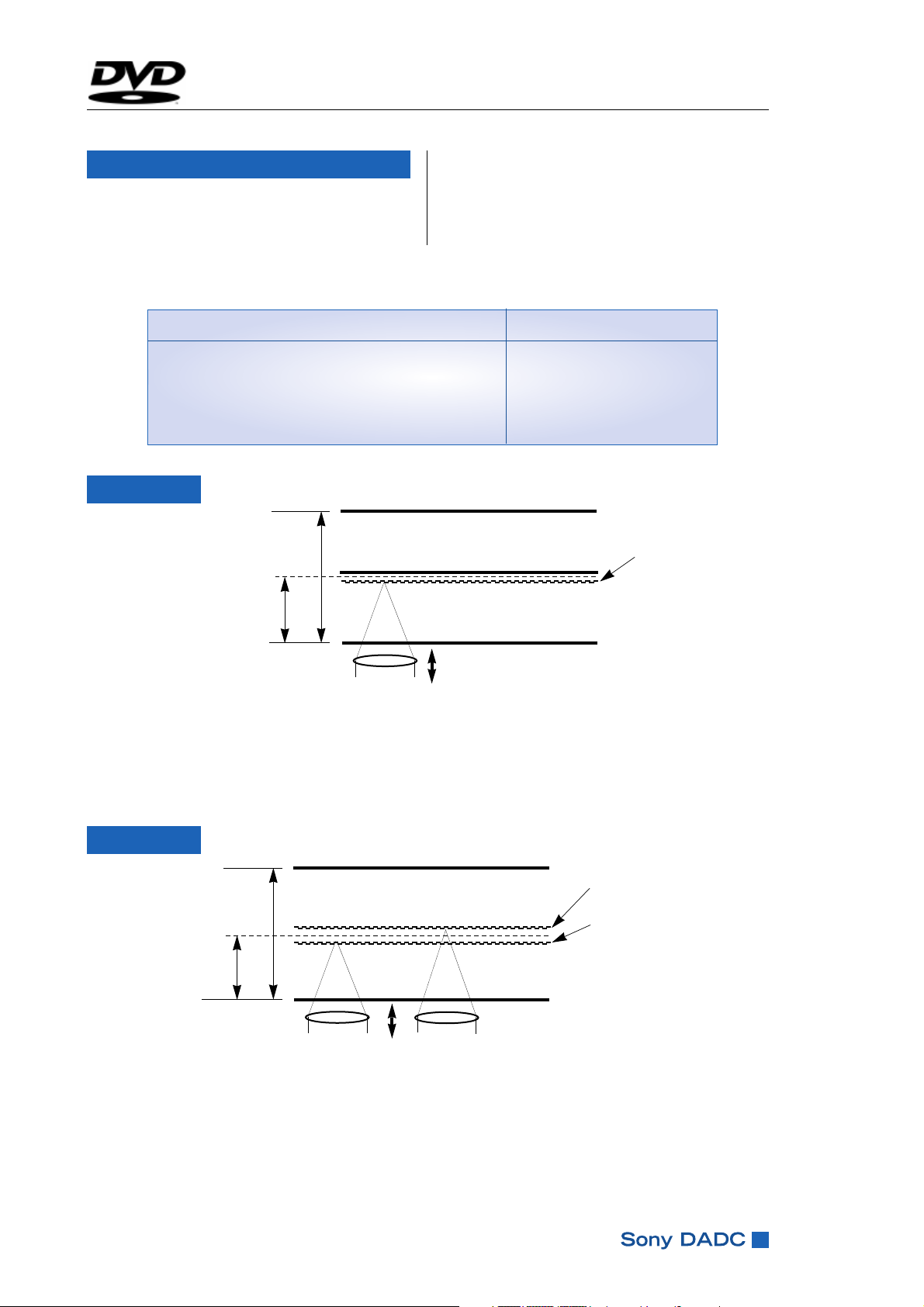

The DVD family

A DVD consists of two halves, where each half disc

is 0.6 mm thick holding one or two layers of

information.

The total capacity of a single side, dual layer DVD is 8.5 GB,

which is 13 times the data capacity of today’s CD-ROMs.

DVD-5

DVD-9

1.2mm

0.6mm

substrate

substrate

movable Iens

single side

single layer

1.2mm

0.6mm

substrate

substrate

movable Iens

single side

dual layer

The total capacity of a single side, single layer DVD is 4.7 GB,

which is 7 times the data capacity of today’s CD-ROMs.

Disc Type

Capacity 12 cm

4.7 GB

8.5 GB

9.4 GB

17.1 GB

DVD-5 single sided, single layer

DVD-9 single sided, dual layer

DVD-10 double sided, single layer

DVD-18 double sided, dual layer

1.2. DVD Types and Formats

semi reflective

layer

The DVD format provides multiple configurations of

data layers. Each layer provides additional data

capacity.

reflective

layer

reflective

layer

Page 6

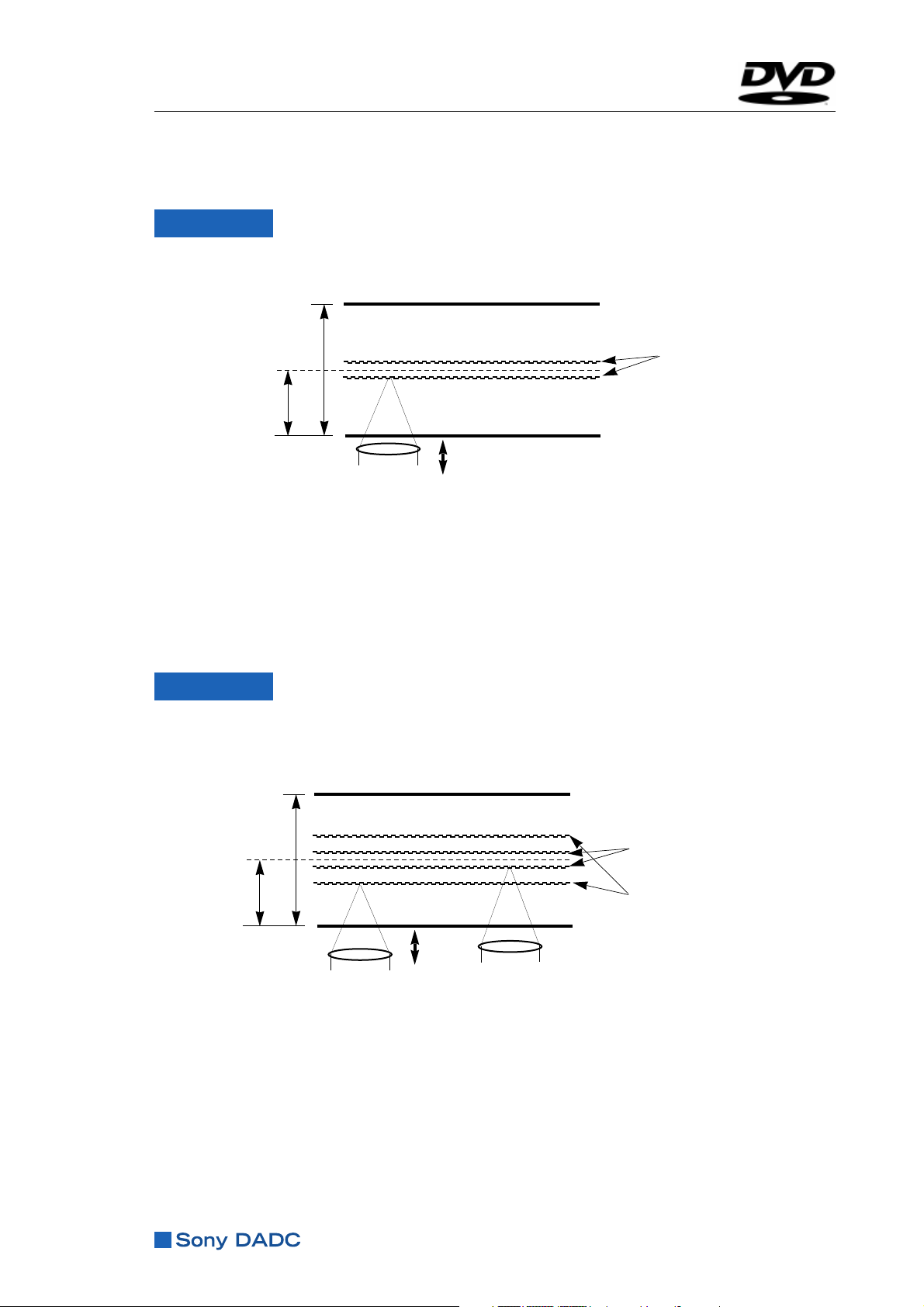

The total capacity of a double side, single layer DVD is 9.4 GB,

which is 14 times the data capacity of today’s CD-ROMs.

Note: disc has to be reversed to playback upper side.

The total capacity of a double side, dual layer DVD is 17.1 GB,

which is 26 times the data capacity of today’s CD-ROMs.

Note: disc has to be reversed to playback upper side.

Availability of DVD-18 is to be confirmed by Sony DADC.

The DVD family

DVD-10

DVD-18

1.2mm

0.6mm

substrate

substrate

movable Iens

1.2mm

0.6mm

substrate

substrate

movable Iens

semi reflective

layers

double side

single layer

double side

dual layer

4

reflective

layers

reflective

layers

Page 7

Statistical process controls and in-line inspection

systems form a key part of our production process.

Full 100% checks by means of automatic test

systems of label print and read-out sides are implemented with the strictest error criteria.

A team of highly qualified staff as well as auxiliary

means such as optoelectronic test devices, an

electron microscope with X-ray spectroscopy, an

atomic force microscope and climatic chambers are

available for permanent process control and

improvement, for systematic error analyses as well

as for maintaining the durability of our products.

The processes and procedures are certified according to ISO-9002. This is an essential reason for the

fact that Sony DADC has qualified, after successfully proving a 6-sigma quality, for ‘Ship to Stock’

Status to some of the largest international

computer manufacturers.

- Personal assistance by a member of

our Customer Service staff

- Authoring of DVD Video / Audio

- Premastering / formatting of DVD-ROM

( microUDF / ISO9660 Bridge format )

- Premastering / formatting

of all common DVD / CD formats

- On-line data transfer via 2Mbit ISDN

- Disc prototyping on CD-R / DVD-R

- Mastering of all DVD & CD formats

- DVD 5 / 9 / 10 disc production in short

turnaround times

- Screen and offset label printing on discs

- Support in artwork creation

- Disc serialisation

- Packaging / dispatching

- Drop shipment

We will be pleased to assist you in the solution of

your technical problems. If you are interested in an

electronic link for transmitting your master data and

other components to Sony DADC, we can offer our

know-how and our experience and will reserve

storage capacity for your data on our servers. If you

need further services, please inform our Customer

Service department so that we can assist you in the

realisation of your project.

1.3. Services

Our services comprise the following:

5

Services

Page 8

6

2. DVD-Video

2.1. General

DVD-Video is a new media for the distribution of

home videos. The digital nature of this new media

offers several new features to the consumer.

Amongst those features are:

● High video quality based on MPEG2 compression

and the ability to playback both aspect ratios of

4:3 and 16:9.

● A DVD-Video can hold up to 8 different audio

tracks (streams). Each track can be used for a

different language. It can also be utilised for high

quality stereo audio with a resolution of 16 bit

and 48 kHz, or for theatre quality surround

audio, like Dolby Digital AC-3.

● Up to 32 different streams of subtitles can be

placed on a DVD-Video, used as language

subtitles, as menu highlights or as instructions

for interactive functions.

● Digital copy protection via CSS and analogue

copy protection via Macrovision.

● Multibranching is another feature of DVD-

Video that simply offers the possibility to

playback one title with different parts of this

title, which can be interactively selected by the

viewer. In addition the multiangle option

allows a scene of a movie title to be viewed in

different angles.

● Every DVD-Video player implies a region code

corresponding to one of the six regions in the

world where it is sold. This regional coding

optionally enables playback of a DVD-Video title

only in certain regions.

● DVD-Video discs can be prepared with a

'Parental Lock' in order to restrict the playback

only by usage of a correct password.

2.2. Input media for DVD-Video

Sony DADC offers full authoring service for DVDVideo. For detailed information please refer to our

DVD-Video authoring manual or contact our

Customer Service department.

We also accept already authored DVD-Video titles.

As standard input media Sony DADC prefers a DLT

tape inlcuding DDP 2.0

DVD-Video

Page 9

7

DVD-ROM

The first step in formatting is the collection and

preparation of the input materials. You can submit

already formatted data as an image on tape or

leave the formatting of your data to us.

Unformatted data on storage media as well as

backup formats on tape or unformatted data

transmitted via ISDN first have to be converted into

a DVD-ROM compatible format. Please note that

these additional process steps take more time and

are more expensive. In order to arrange the data in

a desired sequence, please provide a detailed listing

of the file and directory structure of the final DVDROM.

If you submit a tape, please inform us whether

there is a DVD image or a backup format on this

tape. According to chapter 3.3. ( image on tape )

we are able to achieve shorter cycle times for your

orders and limit premastering costs as long as there

is an already formatted DVD image on tape.

When sending hard disks or exchange discs please

communicate the number of files and the data

quantity. Pack your data carrier carefully to avoid

damage during transportation. Moreover, we ask

you to mark your input carriers. Please be sure to

use adequate fibre pens which do not damage the

surface of the disc, particularly with CD-R.

3.1. Data preparation

Sony DADC formats data according to the UDFBridge ( UDF + ISO 9660 ) standard:

UDF-Bridge Format:

Is a new logical format for volume and file

structure on DVD-ROM discs to support the

interchange of information between a computer

system and dedicated DVD drives or players.

UDF-Bridge stands also for a combination between

the Universal Disc Format ( ISO/IEC 13346 ) and the

ISO 9660 standard.

3.2. Formatting

3. DVD-ROM

ISO 9660:

The ISO 9660 (level 1) file structure is limited to the

characters 'A - Z', '0 - 9' and. '_' (underscore) with

a maximum of 8 characters in length and 3

characters extension and a maximum of 8 directory

levels (including the root directory)

To avoid the restrictions of ISO 9660 level 1 and to

use longer file names Level 2/3 can also be used.

These levels restrict filenames to 30 characters and

directory names to 31 characters.

Joliet extension:

To meet the demand for Windows 95 file names

there was a extension designed called Joliet

format. This file system allows longer file and

directory names than ISO 9660 level 1 as well as

level 2/3, where file or directory Identifiers may be

up to 64 characters.

DVD-ROM images on tape

Sony DADC will accept ANSI labelled DVD-ROM

images either on DLT or SDX tape. We strongly

recommend that any tape compression is turned

off. The DVD Data Sector size can be 2048, 2054 or

2064 Bytes/Sector.

The DDP ( level 2.00 ) is either to be placed at the

front of the tape followed by the DVD Leadin-data

and the DVD Image or on a separate Floppy Disk.

The image is subjected to a logical incoming UDFcheck and can be used for direct mastering.

3.3. Input media

Through the naming and file structure of UDF the

UDF file system is much more powerful than the file

structure of ISO 9660.

However, the UDF-Bridge combines both the UDF

and ISO 9660 formats, and therefore the file

structure has to meet the ISO-9660 designation

agreement.

Page 10

8

DVD-ROM, DVD-R (Recordable),

DVD-RAM, DVD+RW, DVD-R/W

An already replicated DVD-ROM is a preferred

input media because it can be used immediately for

direct mastering.

In order to determine the input media, please mark

your input carriers with a catalogue number.

CD-R (Recordable), CD-ROM

If you wish to put the data of a series of CD-ROM’s

on one single DVD-ROM or if you wish to transfer

data from a CD-ROM to a DVD-ROM we have to

generate a new DVD-ROM image.

In order to arrange the data in a desired sequence,

please provide a detailed listing of the file and

directory structure of the final DVD-ROM.

Electronic data transmission via ISDN

For shortest transport times of components to Sony

DADC, we offer a data link via an ISDN primary rate

interface directly to our servers. This data offers a

range up to 2 Mbit / second.

DVD-ROM

The data of a 650 Mbyte CD-ROM are then copied

in approx. 47 minutes to our servers. With previous

compression of your data the transmission is still

reduced further.

After receiving a compressed image we

automatically carry out a decompression and a

checksum control. The production of a glass master

is then carried out on-line. Upon request the system

transmits a short e-mail to the sender and

acknowledges errorfree transmission.

If you are interested in this kind of transmission for

your DVD-ROM data and order components please

get in touch with us. We will be pleased to assist

you in establishing an electronic connection with

us.

Apple Macintosh / DOS SCSI hard

disk

Please only send us SCSI hard disks with a

description of the file and directory structure of the

final DVD-ROM.

Page 11

9

Label Printing

4. LABEL PRINTING

The following pages contain important

specifications on the DVD printing and the

film material required.

Please transmit this information to your

graphics artist or designer.

4.1. Printing Processes

Sony DADC uses screen printing processes for

printing DVDs as well as offset printing processes.

The following types of print can be processed:

● line prints with up to 4 colours (3 colours for

DVD-10)

● half-tone prints

● duplex and triplex prints

● Four-colour prints

(picture disc: offset/screen printing)

For particular requirements with respect to printing

quality in four-colour print, we offer the High

Definition Picture Disc. This is to be recommended

particularly with applications including

photographs, faces, landscapes or designs which

are similar to photographs.

A specific offset process is used which facilitates a

resolution that is about double that of the screen

print.

4.2. Printing Areas

On the following pages the three possible printing

areas on a DVD label are illustrated (specifications

F, G and H).

Please mind that there may be colour deviations

between the print on the aluminium coated part

and the non-aluminium coated interior parts.

Therefore, we advise to preprint an entire white

base to minimise colour deviations with specifications F, G, H.

4.3. Label Film Dimensions

Please ensure that your label films comply with the

required specifications F to H (see page 10 to 13).

Any necessary label film corrections are charged

according to our price list.

Page 12

10

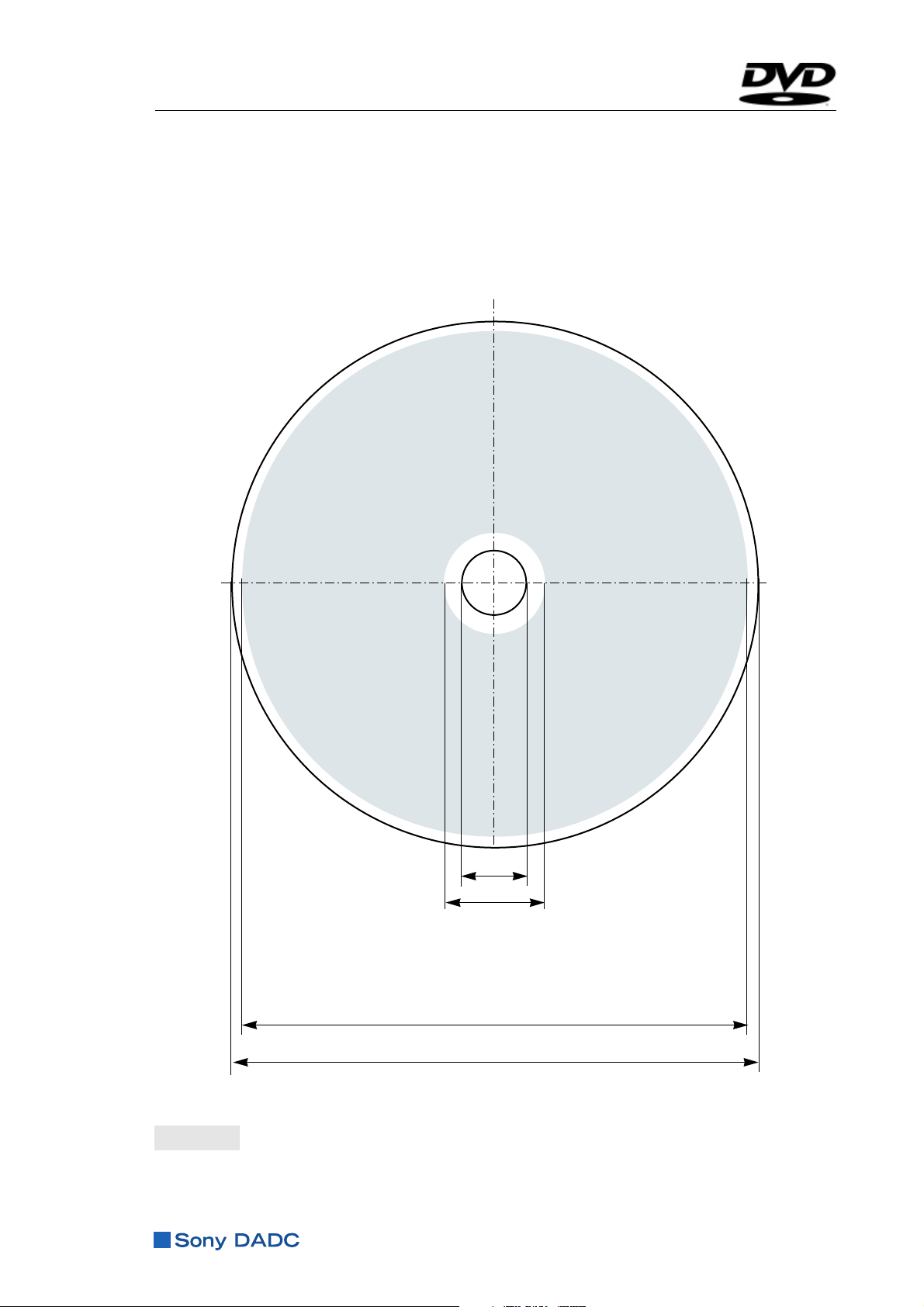

Specification F - Label Print DVD 5 / DVD 9

15 mm

117 mm

120 mm

23 mm

Printing area on the DVD

Label Printing

Page 13

11

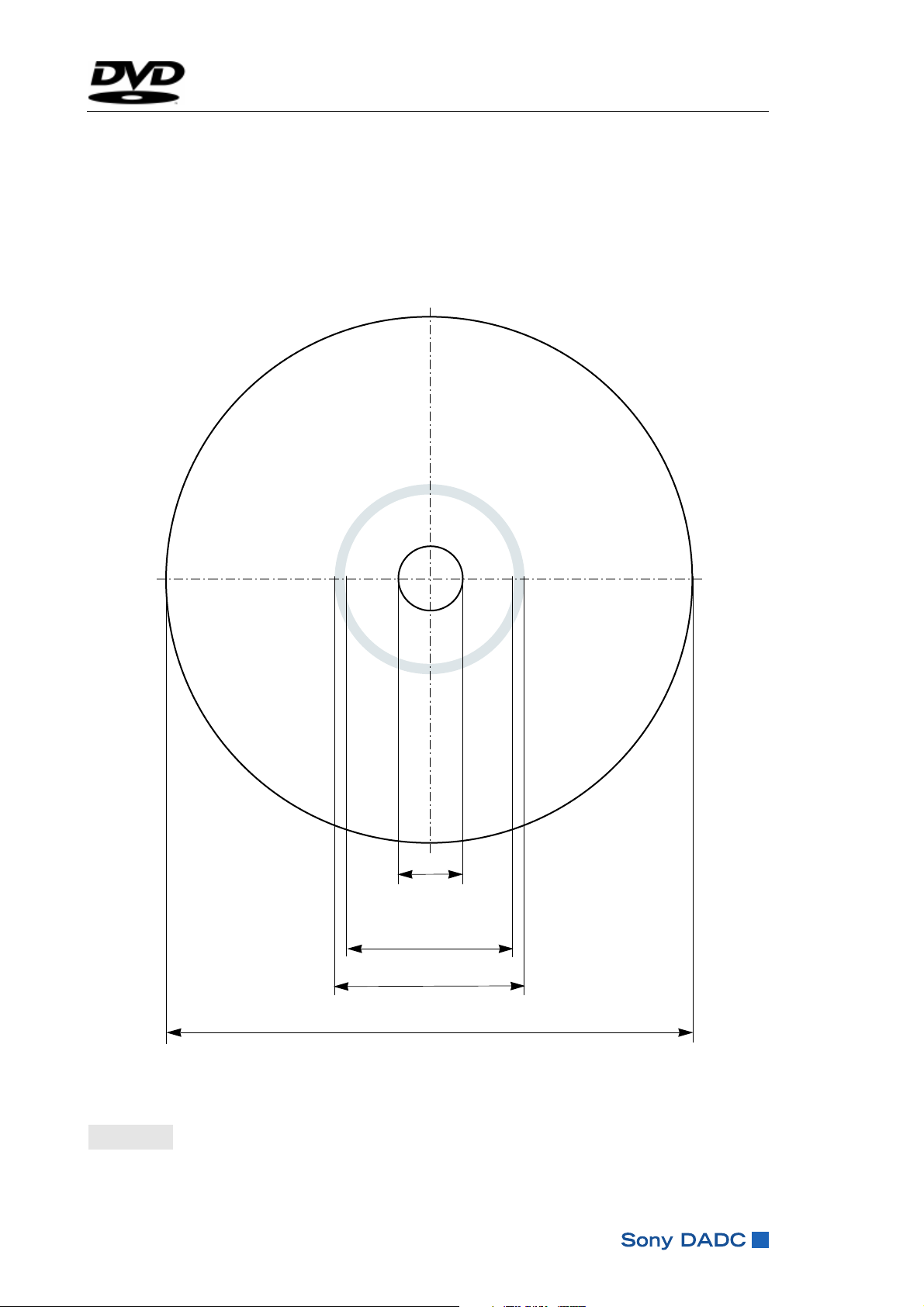

Specification G - Label Print DVD 10 Side A and B

15 mm

38,5 mm

43,2 mm

120 mm

Printing area on the DVD

Label Printing

Page 14

12

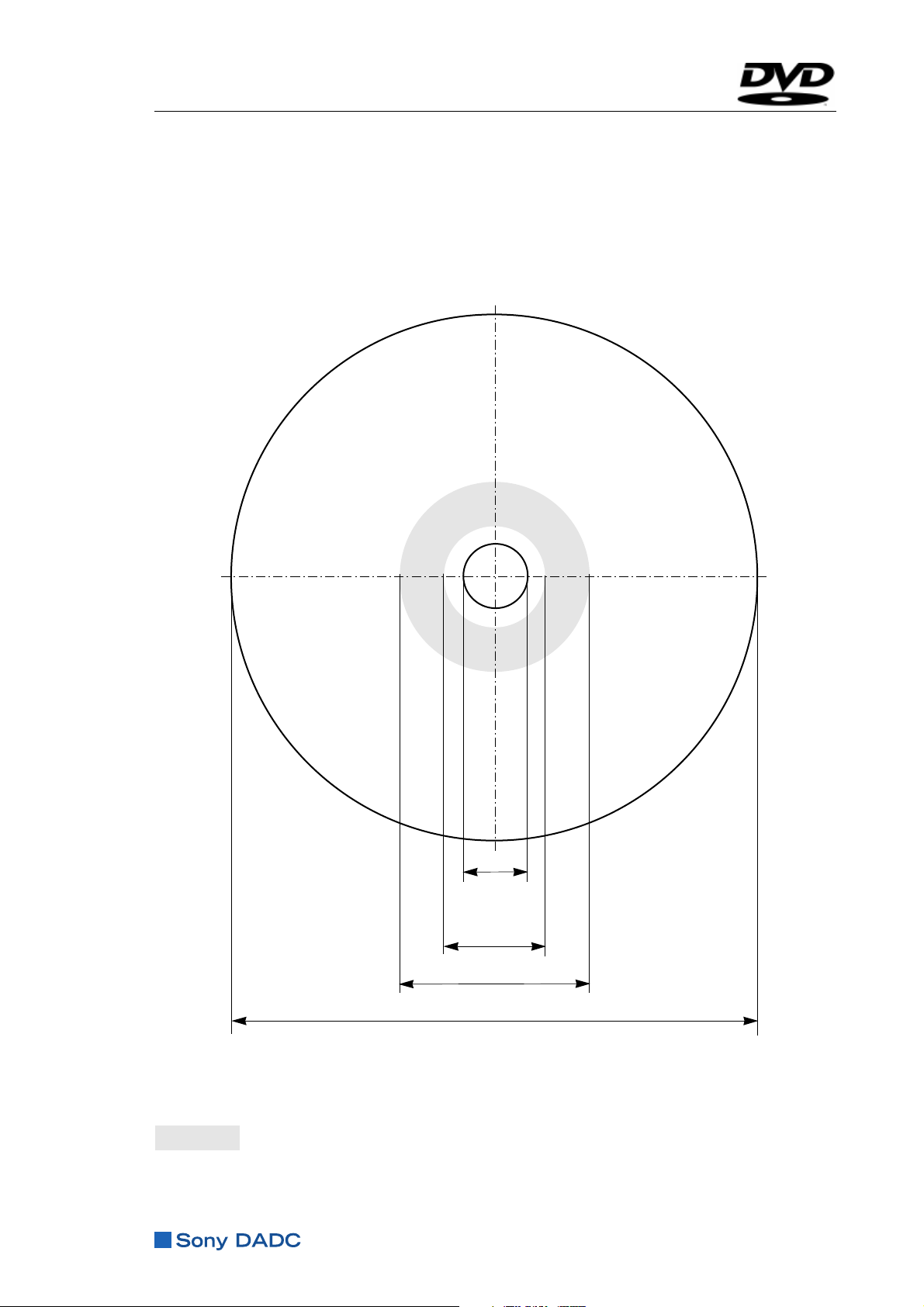

Specification H - Label Print DVD 10 Labelside A

15 mm

23 mm

43 mm

120 mm

Printing area on the DVD

Alternatively Sony DADC offers an extended

printing area for DVD 10. Please note that

Labelside A and Labelside B of specification H hold

different printing areas. This is required in order to

machine-read the barcode of the product.

Label Printing

Page 15

13

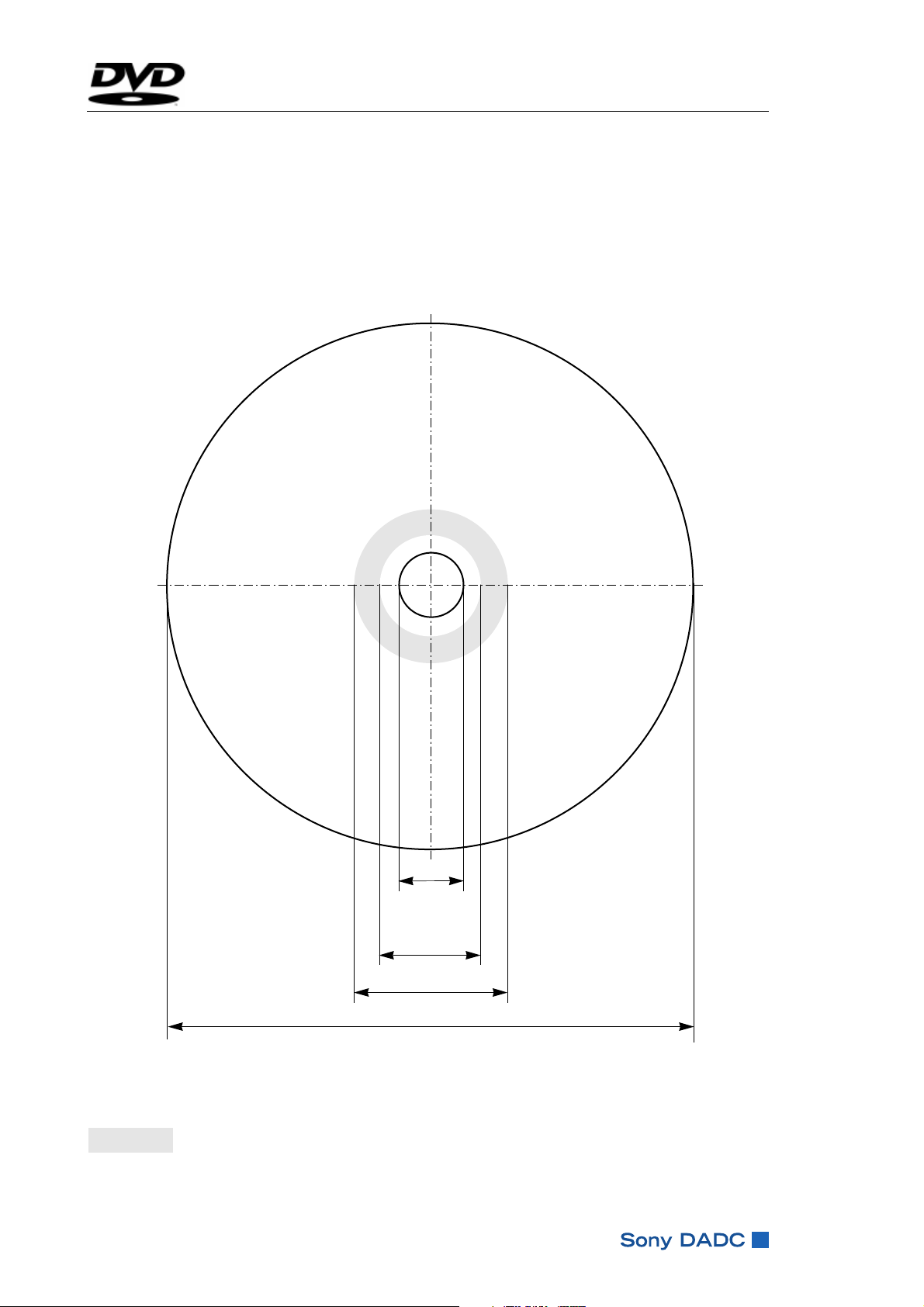

Specification H - Label Print DVD 10 Labelside B

15 mm

23 mm

35 mm

120 mm

Printing area on the DVD

Label Printing

Page 16

14

Film Specifications

min. 0,15mm min. 0,10mm

A a B b C c D d Ee Ff Gg

Hh Ii Jj Kk Ll Mm Nn Oo

Pp Qq Rr Ss Tt Uu Vv

© Î ® Û È ³ ¿ ‚ Õ •

min. 4pt (1,50mm) min. 5pt (1,88mm)

A a B b C c D d Ee Ff Gg

Hh Ii Jj Kk Ll Mm Nn Oo

Pp Qq Rr Ss Tt Uu Vv

© Î ® Û È ³ ¿ ‚ Õ •

Please mind that with serif type fonts (e.g. Times)

and with type faces such as ”light” with letter sizes

of 4 and/or 5 pt. the minimum line width of 0.10

and 0.15 mm is not achieved and thus an adequately larger letter size has to be selected.

Line width of

registration marks

0.1 mm

Film 1 Printing patternFilm 2

4.4. Film Specifications

for Label Print

Unless indicated otherwise in one of the special

printing processes below, we will need smooth, fullpage screen printing films (positive, right side

reading, emulsion up).

Line widths and letter sizes

● The line width has to be at least 0.10 mm in

positive print.

● The line width has to be at least 0.15 mm in

negative print.

● The letter size has to be at least 4 pt. (1.50mm)

in positive print.

● The letter size has to be at least 5 pt. (1.88mm)

in negative print.

Registration marks for screen printing

The registration marks have to be arranged in the

centre to the label film.

MUSIC OF

CD 001

Black

MUSIC OF

THE WORLD

CD 001

THE WORLD

P 307

min. 15

65

Versatile Disc

Versatile Disc

Digital

DVD001

Digital

DVD001

Page 17

15

Film Specifications

Density

To be able to process your label films optimally the

minimum film density has to be 3.0 in full tone.

Duplex/triplex print (half-tone print) with

Pantone colours

We will need smooth, full-page screen printing

films (positive, right side reading, emulsion up)

from you prepared as follows:

For duplex and triplex prints please use the following angle codes: 0˚, 15˚, 45˚ or 75˚. With other

angle codes a ‘moiré-free print’ is not provided.

Four-colour print - Picture Disc

We will need smooth, full-page screen printing

films (positive, right side reading, emulsion up)

from you prepared as follows:

To achieve favourable printing results we need a

compulsory colour copy such as Cromalin,

Matchprint, Pressmatch or test print.

Please take into account that there may be colour

deviations from the original copies due to the

different consistency of the base.

Four-colour print - High Definition Picture Disc

We will need smooth, full-page screen printing

films (positive, right side reading, emulsion down)

from you prepared as follows:

To achieve favourable printing results we need a

compulsory colour copy such as Cromalin,

Matchprint, Pressmatch or test print.

Please bear in mind that the base of the DVD

consists of polycarbonate with reflecting aluminium

coating and therefore there may be colour

differences compared to the printwork

(paper/carton).

To provide (as much as possible) conformity of

colours of printed matter (printwork) and the DVD

label print, we advise to preprint a full white base

on the DVD.

For Picture and/or High Definition Picture Disc printing Sony DADC can prepare four-colour

separation/litho production of the label films for

you. For materials required please refer to chapter

4.9. on page 19.

● Line width 54 l/cm

● Angle codes:

cyan 75˚

magenta 45˚

yellow 0˚

black 15˚

or angle codes similar to the

Hell and Crossfield system.

● Density 15 - 85 %

● Elliptic dot shape

● Line width 80 l/cm

● Angle codes:

cyan 75˚

magenta 45˚

yellow 0˚

black 15˚

or angle codes similar to the

Hell and Crossfield system.

● Registration marks to be centered only

as shown in diagram page 18/chapter 4.5.

● Line width 34 l/cm

● Angle code 45˚

● Max. density 15 - 85 %

● Elliptic dot shape

Page 18

16

Contrast between DVD

logo and background

admissible

Contrast between DVD

logo and background

not admissible

Standard Contents

4.5. Standard Contents

Catalogue number:

A catalogue number has to be printed on the DVD.

DVD Logo

A DVD logo also has to be shown on each DVDROM and DVD-Video in accordance with the DVD

specification. The DVD logo should be seen clearly

on the disc. Therefore, it has to be shown in highest

possible contrast, but in any case the contrast

between the logo and the background colour must

not be less than 50 %.

The generic DVD logo in accordance

with the DVD specification:

Deviations from the standardised DVD logo are not permitted. The DVD logo must not be distorted,

squeezed, decomposed, framed or composed of parts with different colours.

”Made in EU”

A designation of origin is not necessary on the

DVD. However, if such designation is requested, it

has to be ”Made in EU”.

Company address, label address

To protect your product against piracy and to

clearly state the holder of the rights, we ask you to

indicate the company name and address on the

label film or on the printwork.

DVD-ROM logo

DVD-Video logo

Page 19

17

Colours/Label Film Data

4.6. Colours

Sony DADC uses the Pantone Matching System

(PMS).

Please mark each label film with the Pantone colour

number requested by you. Please select your colour

from the Pantone Colour Selector 1000, except for

double impression (2x) colours.

When using Pantone colours 801 to 814, preprinting should be carried out with white colour in order

to achieve the luminescent effect similar to the

Pantone Colour Selector 1000.

When producing your films please mind that a base

of polycarbonate with reflecting aluminium coating

is printed and therefore there may be colour deviations compared to printing on paper.

To provide (as much as possible) a compliance of

the colours of printwork (e.g. booklets) with the

DVD label printing, we advise to preprint a full

white base on the DVD.

4.7. Label Film Data on

Electronic Storage Media

Sony DADC employs a Graphics Studio with the

following standard DTP (Desktop Publishing)

equipment:

HARDWARE

● Apple MAC G3

● Laser imager AGFA AccuSet 1000 with

Software Taipan RIP(resolutions up to 2400 dpi)

● Laser imager AGFA Avantra 25 with Software

Taipan RIP (resolutions up to 3600 dpi)

● 3M Desktop Colour Proofing System

● Drum scanner ”Chromagraph S3300”

(resolution up to 14000 dpi)

SOFTWARE

recommended software accepted software

● Quark X-Press ● Aldus Pagemaker

● Aldus Freehand ● Corel Draw (DOS)

● Adobe Illustrator

● Adobe Photoshop

Apple Macintosh Data

If your label films are produced on an Apple

Macintosh system you may transmit your designs to

us on electronic storage media for film burn-out.

DOS Data (Corel Draw)

If you have edited your designs under DOS, please

send us a placeable EPS file in which the text is

converted into curves and the image identification

set is switched on.

If you have used Corel Draw please send us the

CDR file.

Other hardware and software

If you operate another software or hardware format

please contact our Graphics Studio (tel. +43/62

46/880-448)

The following storage media can be accepted:

● ZIP disk, JAZ disk and CD-R

● 3.5” floppy disk in Mac or DOS format

● 44/88/200 MB cartridge /5.25”) in Mac format

● 270 MB cartridge (3.5”) in Mac format

● MO disk 230 MB (3.5”) in Mac format

Please do not forget:

● Laser printout: Attach a print-out of a

laser printer to your documents.

● Fonts: Indicate manufacturer and all

display settings, if necessary enclose

screen and printer fonts.

● TIFF and EPS files: All graphic files (logos,

company logos etc.) have to be supplied

in all cases.

● Changes: Beware of the major resolution

of the laser imager with fine lines,

outlines and half tones. In general these

become thinner.

● Marking: Your floppy or cartridge should

be marked to provide clear identification.

● Liability: We do not assume liability for

incomplete or defective files. Only submit

copies you have checked and stored

carefully.

DTP-labelfilm template DISC

All labelfilm templates can be downloaded as

QuarkXpress file from our website:

http://www.sonydadc.com. Upon request we will

provide a 3.5” disk with all DVD logos and the

copies of all label film specifications and printwork

specifications used by us as Tiff or EPS and/or

QuarkXPress files, respectively. Please contact our

Customer Service department in this respect.

Page 20

18

Label Film Data

INTERNET DATA TRANSFER

Data transfer via Internet is only suited for

”emergencies” such as sending missing

components including fonts, logos, Tiff or EPS files

due to the high transmission time of 100 KB per

minute.

Our Internet address is:

Graphics_Studio_DADC@sonydadc.com

Please inform our Graphics Studio prior to

transmission (Tel.: +43/6246/880-448).

Data compression:

All compression algorithms available for Apple

Macintosh (e.g. Stuffit, ”.sit”, Self Extracting

Archives for MAC ”.sea”, Disk-Doubler, ZIP, etc.)

can be used. Files edited under DOS/Windows can

be compressed using PkZip or WinZip.

4.8. Label Film Data via

Electronic Data Transfer

You also have the possibility to send us your data

(label film and printwork) via ISDN or Internet for

exposure. If you want to transmit data in such a

way we ask you to inform Customer Service.

ISDN DATA TRANSFER

Please note the following:

Our ISDN numbers are:

4-Sight: +43/6246/73692

Leonardo: +43/6246/73692

Hardware requirements:

All ISDN adapters, preferably the current ISDN

boards:

● Leonardo ● Planet ● 4-Sight

● Easy Transfer

Software requirements:

● 4-Sight Manager Version 4.3.1 or

● 4-Sight Broadcast

● Leonardo Pro

Data preparation:

Our server is ready to receive on workdays 24 hours.

Prior to the data transfer please inform our graphic

studio (Tel.: ++43/6246/880-448) in order to ensure

sufficient storage space. With ISDN a laser print-out

is not supplied compared to data delivery on

storage media. Therefore such a laser print-out

must be faxed to our Graphics Studio

(Fax: ++43/6246/880-392).

Data compression:

All compression algorithms available for Apple

Macintosh (e.g. Stuffit, ”.sit”, Self Extracting

Archives for MAC ”.sea”, Disk-Doubler, ZIP, etc.)

can be used. Files edited under DOS/Windows can

be compressed using PkZip or WinZip.

Data delivery:

Place all files (copy, fonts, Tiff/EPS, info file) in

a directory and mark it with your name and

the date (if necessary, abbreviations such as

”Release 11.4.99”).

Enclose a text document to the files containing

the following data:

● With label films: number of colours used

(4C or Pantone).

● With inlay card films: indication of front

and rear side.

● With other printwork films: all data

required for printing (e.g. 8-page

digipack).

● Fonts and Tiff/EPS files used.

● Contact address for technical inqueries

(graphics studio tel./fax)

● Name of Customer Contact at Sony DADC

● Order Information assoccated with the

Catalogue Number.

Data delivery:

Send us an e-mail with the following information:

● Contact address for technical inquiries

(graphic studio tel./fax)

● Name of Customers Contact at Sony DADC

● Order Information associated with the

Catalogue Number.

Page 21

19

Label Film Production

To be able to do this we will need the

following:

● Slides, photos, drawings

● Layout (for positioning of texts, logos,

graphics, etc.)

● Colour information (in cyan%,

magenta%, yellow% and black%)

● Indication of print specifications

(specification F, G or H)

● Indication of printing process

(screen printing or offset printing)

4.9. Production of the Label Film

We offer the production of finished printwork and

of label film by our Graphics Studio.

To be able to do this we will need a layout or a

sketch of your desired design with all information

required. After label film production you will receive

from us a fax copy for production release or for

modifications to be carried out. We are also able to

carry out the production of the colour separations

required (lithos) for four-colour printing (Picture Disc

or High Definition Picture Disc). Please contact our

Customer Service department in regards of film

production prices.

Please note that 2 to 3 days are needed for the

production of label films.

Page 22

Disc Serialisation

5. DISC SERIALISATION

Sony DADC Austria offers the possibility to apply an

individual code number for every disc of the DVDROM production, e.g. for identification purposes.

Your preselected code number is printed on the disc

with the ink-jet process.

The code number is printed approximately 5 mm

from the centre hole of a disc in arc form.

The number will be printed on the read-out side

and can only be seen from the read-out side.

(see drawing below)

Please note that this service may result in slightly

longer turn around time of your DVD-ROM order.

The most important data of an ink-jet printer

are indicated for disc numbering:

● Print image: 6 x 9 dot matrix, 3 mm high,

5 characters per 10 mm.

● The series or code number may consist of

a maximum of 28 characters using

numbers, letters and symbols. Of the

maximum 28 characters 9 characters can

be changed automatically (e.g. increasing

order of numbers).

● Admissible characters of the series or

code number are: letters ”a-z”, ”A-Z”,

numbers ”0-9” and symbols (selected

characters of the ISO 8859-1 set of

characters) in case you want to use

symbols please get in touch with our

Customer Service.

● It is not possible to underline characters

(e.g. 123456).

● A series or code number that changes can

only be printed once on the same disc.

● Due to limitation of space on the disc

surface the series or code number can be

applied in one line only.

● The selected numbers of a series or code

number can be increased or reduced by

any constant value. Other characters such

as letters or symbols remain unchanged.

● A maximum of 9 characters can be

increased or reduced.

Example:

BCDE123456789

ABC-123456789gh0m

123456789abcdef

00000-123456789-0000000

The numbers 123456789 are the

characters that can be changed.

● It is not possible to write in ”bold” or

”italics”.

Special requests (e.g. printing random

numbers which can be supplied on a DOS

compatible 3.5” floppy disk) should be

addressed directly to our Customer Service

department.

Example

20

Readout-side

Labelfilm

specifications F

B

C

D

E

1

2

3

4

5

6

7

8

9

Page 23

21

Packaging

6. PACKAGING

As part of our full service philosophy, we can

provide printwork and any special packaging

procurement for you. Due to high yearly volumes

we order with our qualified printwork suppliers, we

can offer competitive prices. If you wish to utilise

this service we request that your graphic studio

provides components according to chapter 6.2.,

with chapter 6.3. being valid for the printwork

carried out by us.

Sony DADC can also process text inserts and similar

printwork provided by you. In such cases please

ensure that these comply with chapters 6.3. to 6.5.

6.1. Printing Process

Generally, the printwork is manufactured by

qualified printers in four-colour offset print and the

use of additional special colours and varnishing is

possible.

6.2. Film Specifications for

the Production of Printwork

and Stickers

Non-compliance with the specifications and

any additional expenses caused shall be

charged separately.

●

Please arrange films in such a way that the

booklet is closed at the left. With special

products such as leporello, posters, etc.

please enclose a folding sample.

●

Films must have a bleed of 3 mm. The

cutting marks are arranged outside of the

bleed.

●

To avoid mismatches, please supply a

compulsory match print with all films.

However, please note that there may still

be slight colour deviations between proof

and printwork.

●

The films should not be damaged and

must be packed in a roll container or

carton to prevent folding.

●

If you request a colour match between

printwork and DVD label print, special

colours have to be specified in the same

colour system.

●

To protect your product against piracy and

to clearly identify the holder of the rights,

we ask you to indicate the name and

address of the music company on the

label film or on the printwork.

●

When producing your films please mind

that colour differences between the

printwork and the DVDs may occur, since

with the latter a base of polycarbonate with

reflecting aluminium coating is printed on

and therefore colour differences compared

to printing on paper may result.

●

To provide (as much as possible) a compliance of the colours of printwork (e.g.

booklet) with the DVD label print, we advise

to preprint a full white base on the DVD.

●

Send only smooth offset films (positive,

right reading, emulsion side down)

●

Optimum screening for printwork films:

70 l/cm

●

All printwork must have a catalogue

number.

●

Page number on all films.

●

Please do not indicate origin details except

for ”Made in EU”. Other data with regard

to origin are not admissible and will be

removed.

●

Please mark each film with the respective

colour.

Page 24

22

Film Specifications: Booklet for Amaray Box (king size)

3

120

3

180

Rear page

Title page

Explanation:

Area to be printed with text

Final dimension

Bleed

Minimum of blank film dimension

(at least 20 mm distance to final

dimension)

All dimensions in mm

120

Film Specifications: Booklet for Amaray Box

3

3

Page 25

23

Film Specifications: Booklet for Super Jewel Box

Film Specifications: Booklet for Super Jewel Box

Explanation:

Area to be printed with text

Final dimension

Bleed

Minimum of blank film dimension

(at least 20 mm distance to final

dimension)

All dimensions in mm

3

120

3

178

Rear page

Title page

120

3

3

Page 26

24

14

129,5

129,5

3

184

273

BACK PANEL

FRONT PANEL

Film Specifications: Cover Sheet for Amaray Box

Explanation:

Area to be printed with text

Final dimension

Bleed

Minimum of blank film dimension

(at least 20 mm distance to final

dimension)

All dimensions in mm

Film Specifications: Cover Sheet for Amaray Box

3

3

3

Page 27

25

13,5

7 16,5

23

6,5

6,5

137,5

R 3

6,5

6,5

6

5

11,5

34

76

186

12,5

top

oben

grain direction

no spine text here (not legible, locking area)

outside

Außenseite

Explanation:

Final dimension

Bleed

Minimum of blank film dimension

must have at least 20 mm distance

to final dimension

All dimensions in mm

Film Specifications: Inlay Card for Super Jewel Box

Film Specifications: Inlay Card for Super Jewel Box

199

150,5

3

3

3

Page 28

26

12,5

8,5

10

139,5

140

289,5

187

187

374

370,5

180

190,5

138 151,5

289,5

front page

rear page

head page 2 cover side

head page 1 tray side

3 mm bleed area

(all around)

head page 1 cover side

Film Specifications: ECOPAK

Explanation:

Final dimension

Bleed

Minimum of blank film dimension

must have at least 20 mm distance

to final dimension

All dimensions in mm

Film Specifications: ECOPAK

Page 29

27

Film Specifications - Booklet for Jewel Case

Film Specifications: Booklet for Jewel Case

Explanation: All dimensions in mm

Area to be printed with text

Final dimension

Bleed

Minimum of blank film dimension

(at least 20 mm distance to final dimension)

All films (except for cover page) must have page numbers.

Without page numbers, Sony DADC will not assume responsibility for correct assembly.

3 3

3

3

121

121

Rear page Title page

Folding line

33

120

Page 30

28

Film Specifications - Inlay Card for Jewel Case

Film Specifications: Inlay Card for Jewel Case (also backliner, inlay card with perforations at the back)

Explanation: All dimensions in mm

Area to be printed with text

Final dimension

Bleed

Minimum of blank film dimension

(at least 20 mm distance to final dimension)

Perforation lines

138

6,5

6,53

3

3

33

118

3

Page 31

29

Film specifications – 2-Piece Box Title Card

Film specifications: Title card for 2-piece thin Jewel Box (also Slim Jewel Case/2 Piece Box)

Explanation: Scale 1:2

All dimensions in mm

Area to be printed with text

Final dimension

Bleed

Minimum of blank film dimension

(at least 20 mm distance to final dimension)

3

3

3

(112,25)

2

8

3

155

2

3

3

7

3

36,5

3

15

45°

15°

280

120

119

Folding line

Title page

Interior page

Text

Bleed for option single page

Area to be printed with text for

option single page

End of folding line acc. to option

Option single page

Option double page

Text Text

Page 32

30

Film Specifications: 12 cm CD Carton Sleeve

Area to be printed with text

Final dimension

Bleed

Minimum of blank film dimension

(at least 20 mm distance to final dimension)

Film Specifications - 12 cm Carton Sleeve

Explanation: All dimensions in mm

5 5

CD insertion direction

125

FRONT

3

125125

TOP TOP

BACK

3

3

3

Page 33

Specifications for Printwork

31

Thickness: max. 1.8 mm measured

on folding side

Paper:

●

chlorine-free

●

wood-free

●

glossy double-coated on both sides

●

white art paper

Cover page:

●

min. 160 g/m2- 180 g/m

2

Condition at time of supply:

●

upright in carton box (see fig. page 44)

6.3. Specifications for Printwork and Stickers

When supplying ready-made printwork we ask you to comply with the following specifications:

Booklet

Validity for machine processing of the following standard packagings:

● Jewel Case

All dimensions in mm

Cover sheet Interior Number of interior Number of cover sheet Maximum number of

(mm)* Sheet (mm)* pages to be printed pages to be printed pages to be printed

0,15 0,08 36 4 40

0,15 0,07 40 4 44

0,15 0,06 48 4 52

0,15 0,05 56 4 60

*Paper thickness

0

121

-1

0

-1

Stitching wire

120

min 10 min 10

Page 34

Specifications for Printwork

32

● Barcode types: UPC/EAN128, Code 39, CODABAR, 2/5 Industrial

● Position: back, right, horizontal (see drawing)

● Barcode height: min. 11 mm

Position specifications for barcode (booklet)

All dimensions in mm

0

121 121

-1

Rear page

11

4 013859 777012

15

32

7

0

-1

Title page

0

-1

120

Page 35

33

Specifications for Printwork

Inlay Cards for Jewel Case

Validity for machine processing of the following standard

packagings:

● Jewel Case

Measuring condition: flat

Stitch

2

4

O

Processing specification:

The perforation stitches have to be in a ratio of 2:4 and can be tolerated in direction 1:1 (see drawing).

All dimensions in mm

P

aper:

● chlorine-free

● wood-free

● glossy double-coated on both sides

● white art paper

Cover page:

● 160 g/m

2

- 180 g/m

2

Condition at time of supply: upright in carton box (see fig. page 44)

Note: With inlay cards printed on both sides, the externally visible side has to be defined (please mark on the

films outside of the area to be printed).

NOT OK

Stitch

2

6

OK

Perforation line: fine stitch perforation (2:4)

Paper grain

(6,5 ±0,2)

0

-0,5

118

138 ±0,2

151 ±0,2

Page 36

34

Specifications for Printwork

● Barcode types: UPC/EAN 128, Code 39, CODABAR, 2/5 Industrial

● Position: right, vertical (see drawing)

● Alternative: right, horizontal (see drawing)

● Barcode height: min. 11 mm

Position Specifications for Barcode (Inlay Card):

All dimensions in mm

151 ±0,2

0

-0,5

118

138 ±0,2

POSITION VERTICAL

(6,5 ±0,2)

11

4 013859 777012

32

20

2,5

POSITION HORIZONTAL

32

11

4 013859 777012

20

5

Page 37

Specifications for Printwork

Cover Sheet for Amaray Box (king size)

All dimensions in mm

35

14

129,5

129,5

184

273

BACK PANEL

FRONT PANEL

+1

0

+0,5

0

+0,5

0

+0,5

0

P

aper:

● chlorine-free

● wood-free

● glossy double-coated on both sides

● white art paper

Cover page:

● 160 g/m

2

- 180 g/m

2

Condition at time of supply: upright in carton box (see fig. page 43)

Page 38

Thickness: max. 1.8 mm for Super Jewel Box

max. 3.0 mm for Amaray Box

(measured on folding side)

Paper:

●

chlorine-free

●

wood-free

●

glossy double-coated on both sides

●

white art paper

Cover page:

●

min. 160 g/m2- 180 g/m

2

Condition at time of supply:

●

upright in carton box (see fig. page 43)

Specifications for Printwork

top

Booklet

120 0 / -1

178 0/-1

20 +5/0

All dimensions in mm

20 +5/0

Amaray Box and Super Jewel BOX

36

Page 39

37

Specifications for Printwork

Super Jewel Box Inlay

13,5

7 16,5

23

6,5

+/-0,2

6,5

+/-0,2

137,5

+/-0,2

R 3

6,5

+/-0,2

6,5

+/-0,2

6

5

11,5

34

76

186

+/-0,2

12,5

top

grain direction

no spine text here (not legible, locking area)

outside

All dimensions in mm

P

aper:

● chlorine-free

● wood-free

● glossy double-coated on both sides

● white art paper

Cover page:

● 160 g/m

2

- 180 g/m

2

Condition at time of supply: upright in carton box (see fig. page 43)

Note: With inlay cards printed on both sides, the externally visible side has to be defined (please mark on

the films outside of the area to be printed).

Page 40

Specifications for Printwork

Paper: ● chlorine-free

● wood-free

● glossy double-coated on both sides

● white art paper

Cover page:

●

160 g/m2 – 180 g/m

2

Condition at time of supply: ● upright in carton (see fig. page 44)

2-Piece Box Title Card

Validity for machine processing of standard packaging: ● 2-Piece Box.

All dimensions in mm

38

280 ±0,5

0

155

-0,5

(137 ±0,5)

-Control dimension in folded state-

0

15

-0,5

+0,2

3

-0,3

End or folding line

acc. to option

2

120 ±0,5

15°

Option single side

Option double side

Paper grain

119

Title page

Interior page

Fine stitch perforation 2:4

2

7

45°

36,5

2

45°

8

137 ±0,5

Title front page

Page 41

39

Specifications for Printwork

12 cm Carton Sleeves and/or 12 cm Paper Pocket

(in various models, available printed and non-printed, formats see dimensional table)

Paper pocket optional with flap and/or

inspection window

R5

124 ±0,5 (B)

124 ±0,5 (H)

(18)(18)

max 28max 28

35

0

-0,5

min 10 min 10

Glue application

Folding edge

12 cm CD 125 ±0,5

38 cm CD 384 ±0,5

12 cm CD 125 ±0,5

38 cm CD 384 ±0,5

Paper: ● chlorine-free

● wood-free

Carton sleeve:

● art paper (carton)

● single coated: ~ 280 g/m

2

and thickness of approx. 0.40 mm

or double coated: ~ 285 g/m

2

Paper sleeve: ● offset paper

● 90 g/m

2

or 150g/m

2

Condition at time of supply: ● upright in carton (see fig. page 44)

Dimensional table* paper pocket

W H

Standard pocket 124

+–

0,5 124

+

–

0,5

Pocket with booklet 132

+1

0

132

+1

0

Special format 145

+1

0

190

+1

0

* For insertion in thermal plastic binding machines

Page 42

40

Specifications for Printwork and Stickers

Stickers

Stickers are processed as self-adhesive labels

supplied on rolls.

NICE PRICE

FROM SONY MUSIC

NICE PRICE

FROM SONY MUSIC

40 / 75

Max. 300

Min. 3

Max. 100

Sticker sizes to be

processed on machine:

min. 10x10 or Ø 15

max. 110x90 or Ø 90

● Possible core diameter: 40 or 75 mm

● Max. possible roll diameter: 300 mm

● Eliminate punching grid

(do not leave on the roll).

● Distance between the stickers:

at least 3 mm.

● Position stickers with letters or various

print in unwinding direction, if application

is to the upper side of the box.

● Punched paper base cannot be processed

further.

● Stickers not complying with the standard

cannot be processed on the machine and

will increase costs considerably.

All dimensions in mm

Unwinding direction

Reading direction

Unwinding direction

Reading direction

Stickers can be processed automatically on the

upper and lower side of the box. To indicate the

desired position of the sticker on the box please use

the diagram opposite.

Arrangement of stickers on the roll for the lower

side of the box.

Positioning of the sticker

V = position of the sticker on the front side (V/. /.)

H = position of the sticker on the rear side (H/. /.)

Example: V/A/1

sticker on position A1/front side

H/B/2

sticker on position B2/rear side

NICE PRICE

FROM SONY MUSIC

NICE PRICE

FROM SONY MUSIC

Position diagram

A1 B1 C1 D1

A2 B2 C2 D2

A3 B3 C3 D3

A4 B4 C4 D4

Page 43

41

Digipak Index

Pocket

Pocket

D04.1 DIG0001:

D04.1/A DIG0002:

D04.2 DIG0003:

D06.1 DIG0004:

D06.1 DIG0005:

D06.1 DIG0006:

D06.1/A DIG0031:

D06.2 DIG0007:

D06.2 DIG0008:

D08.1 DIG0009:

D08.1 DIG0022:

D08.2 DIG0010:

D08.2 DIG0024:

D10T.1 DIG0011:

D10C.1 DIG0030:

DM104.1 DIG0012:

Digipak Index

The Digipak, which consists of a compound of

plastics and carton, requires hand packaging.

Note:

The DIGIPAK packing format is patented.

If you have any questions, please ask your

Customer Service Contact who will be pleased to

provide information on the various special formats

and their processing possibilities.

Page 44

42

Delivery of Ready-made Printwork

6.4. Packaging of Supplied

Printwork

When supplying ready-made printwork please

note the following items:

● Delivery according to agreement

The delivery of ready-made printwork

should be carried out only following

previous agreement with the Sony DADC

Customer Service staff.

● Printwork delivery

Your printwork delivery must comply with

the Sony DADC specifications (dimensions,

paper type and thickness, catalogue

number, bar code, designation of origin,

perforation). Since packaging is carried out

automatically, please note that non

compliance with the specifications causes

unnecessary additional expenses and

longer processing time. Sony DADC reserve

the right to charge additional costs caused

by sorting, manual packaging or the return

of the goods delivered.

● Minimum quantity

The minimum quantity is 300. Due to

start-up losses as well as possible waste

please add to your delivery an additional

10% of printwork over and above the

number of DVDs ordered by you.

● Different printwork

Different printwork (such as inlay cards

and booklets or various DVD titles) have to

be delivered in separated cartons.

● Delivery in marked carton

If possible, delivery should be carried out in

cartons (see drawing page 40) provided

with adequate marking (see label, sample

carton).

● Delivery of stickers

Provide an adequate label on the carton

(see sample). Furthermore, the general

Sony DADC specifications for stickers shall

apply.

● Storage

In case that you deliver more printwork

than your DVD order and request storage,

we ask your to consult with Customer

Service.

Storage expenses will be settled monthly

according to the space required.

All dimensions in mm

Date: April 29, 1999

Catalogue-No.:

Date: Feb 28, 1996 Qty:

WAPCD29 901234567890

Qty: 1200

BL

Musterdruckerei Sony DADC Austria AG, Anif

Part-No.:

Supplier:

A123456789-Prod-Pack-123

125

A1234667890D

A1234667890D

A1234667890D

123456

1200

12

32

52

75

8

Page 45

The ready-made printwork for Inlay Cards for

Super Jewel Box, Coversheets for Amaray Box

and Booklets for Amaray Box and Super Jewel

Box should be delivered as follows:

●

upright (vertically or horizontally)

●

uniform orientation (title sheet always in

one direction)

●

crash-proof multi-use carton (optimally

approx. 30 cm long)

●

carton marked - catalogue number, title,

company name, type of printwork,

order number, number of pieces

Specifications for Printwork

43

All dimensions in mm

158 for Inlay Card for Super Jewel Box,

Coversheet Amaray Box,

Booklet for Amaray and Super Jewel Box

212

320

Catalogue-No.:

Date: Feb 28, 1995

WAPCD29 901234567890

Qty: 1200

BL

Musterdruckerei Sony DADC Austria AG, Anif

Supplier:

Part-No.:

A123456789-Prod-Pack-123

Qty:

1200

123456

Page 46

44

Specifications for Printwork

The ready-made printwork for Booklets and

Inlaycards for Jewel Case should be delivered

as follows:

●

upright (vertically or horizontally)

●

uniform orientation (title sheet always in

one direction)

●

crash-proof multi-use carton (optimally

approx. 30 cm long)

●

carton marked - catalogue number, title,

company name, type of printwork,

order number, number of pieces

305

125

All dimensions in mm

122 for Booklets

150 for Inlay Card

122 for booklets

150 for inlay cards

Catalogue-No.:

Date: Feb 28, 1995

WAPCD29 901234567890

Qty: 1200

BL

Musterdruckerei Sony DADC Austria AG, Anif

Part-No.:

125

Qty:

A1234667890D

Supplier:

A1234667890D

A123456789-Prod-Pack-123

A1234667890D

1200

123456

305

Page 47

45

Sony DADC Austria

7. Sony DADC –

The Company

Sony DADC Austria AG is a one hundred percent

daughter company of the Sony Corporation. Since

being founded in 1986 to cater for the

requirements of the European CD market, Compact

Disc has emerged as the dominant sound-carrier. In

1996 more than 900 million units were sold in

Europe. The CD has also become the basic

technology for other optical storage products

which include Laser Disc, MiniDisc, CD-ROM, CD-R,

CD-EXTRA, DVD or Play Station Disc that were

introduced on the market.

With a quantity of more than 300 million CDs

shipped annually Sony DADC is a leading

manufacturer of optical storage media in Europe.

Having two plants in Salzburg and the worldwide

network with subsidiaries in Japan, Hongkong,

Australia, USA, Canada, Mexico, Brazil and India,

Sony DADC guarantees to our customers the

highest levels of quality and service.

With separate development divisions and

worldwide network capabilities Sony DADC stays at

the forefront of CD production technology. This

enhances our ability to meet customer specific

requirements. Above all we create the basis for new

products in the future thus ensuring the Sony

Group will be your partner in the future also.

Sites: Factory I - Anif/Salzburg

Factory II - Thalgau/Salzburg

No. of employees: 1998 approx. 1000

Capacity: 1998 1.3 mio/day

Production quantity: more than 300 million units

annually

Customers: approx. 2500

(International and European music and film

companies, publishers, multimedia and

information providers as well as computer and

video game companies and the majority of

software and hardware manufacturers)

ISO 9002: Certification 1995

ISO 14001: Certification 1998

Facts and Figures:

Product Use Size Specification

Compact Disc Audio 12 cm max. playing time 77min.

8 cm max. playing time 21min. 50sec.

CD-ROM Information processing/ 12 cm max. 680 MB

Multimedia, Interactive

Entertainment 8 cm max. 192 MB

Video CD Video/Film 12 cm depending on combination

audio/video/data

MiniDisc Portable Audio 6.4 cm playing time approx. 74 min.

PlayStation Interactive

Disc Entertainment 12 cm max. 680 MB

CD EXTRA Multimedia, Audio, 12 cm max. 74 min. 30 sec.

Video, Data 8 cm max. 655 MB

MD recordable digitally re-record audio 6.4 cm 74 min

CD-R Write once audio / data 12 cm 74 min or 655 MB

DVD Video or ROM 12 cm 4.7 GB - 17.1 GB

Our products:

Page 48

Sony DADC

Customer Service

Niederalm 282

A-5081 Anif, Austria

Tel.: ++43-6246-880-555

Fax: ++43/6246-880-510

E-mail: sales@dadc.co.at

http://www.sonydadc.com

Loading...

Loading...