Page 1

D98

OPERATION MANUAL

TROUBLESHOOTING MANUAL

CHASSIS

TABLE OF CONTENTS

CIRCUIT DESCRIPTION

D Board (Power Supply Section) ........................ 2

D Board (Deflection Section) .............................. 10

A Board ............................................................... 22

N Board .............................................................. 28

GENERAL TROUBLESHOOTING ......................... 30

P ARTS LEVEL BOARD REPAIR ........................... 41

TRINITRON® COLOR COMPUTER DISPLAY

MICROFILM

- 1 -

Page 2

CIRCUIT DESCRIPTION

ging

D BOARD POWER SUPPLY SECTION

Power Supply Electrical Circuit

The power supply is located on the D Board. It has three modes of operation that are controlled by a microprocessor. The

architecture is similar to discontinuous mode flyback converters and has photocoupler feedback for regulating the secondary

voltages. Circuit operation and troubleshooting are explained in the following sections:

Operation Modes Secondary Circuitry

AC Input Protection Circuits

Degauss Circuit Troubleshooting

Primary Circuitry

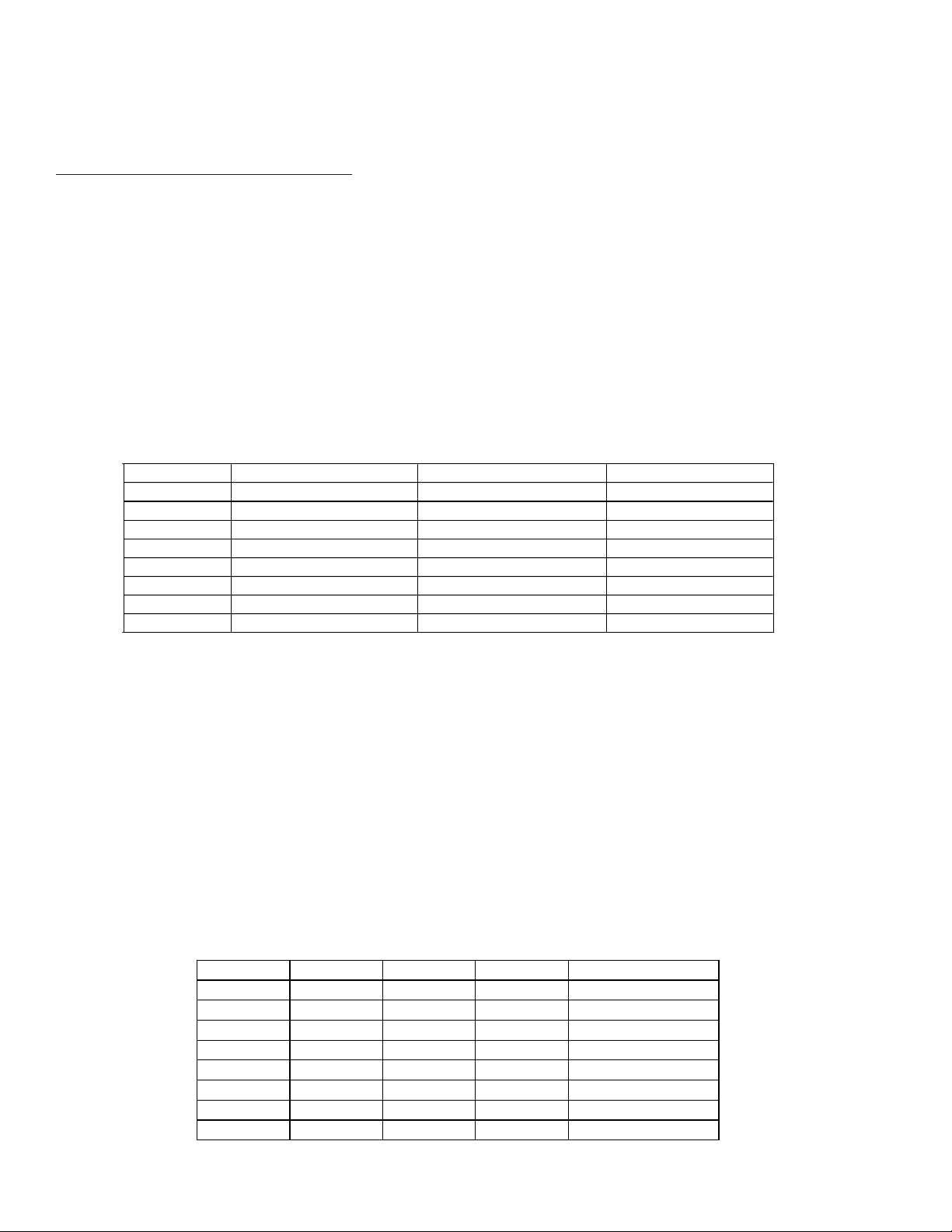

Operation Modes

The power supply has four modes of operation, ‘off’, ‘active off’, ‘suspend’ and ‘active on’. These modes are related to

power savings and are indicated by the front panel LED. Additional indications are failure diagnostics and aging mode.

The table below lists operation mode, condition and LED status.

Mode Syncs Condition LED

Of f NA AC Switch Off Of f

Active Off No H and V Low Power, Heater Off Amber

Suspend/ Standby No H or V Low Power, Heater On Amber 0.5s<- ->Green 0.5s

Active On H and V Present Phase Locked, Normal Operation Green

Failure 1NA HV or +B Failure Amber 0.5s<- -> Off 0.5s

Failure 2 NA H Stop, V Stop, Thermal Failure Amber 1.5s<- -> Off 0.5s

Failure 3 NA ABL Failure Amber 0.5s<- -> Off 1.5s

A

/Self Test No H and V Aging Raster or Test Pattern Green 0.5s<- -> Off 0.5s

Except for AC switch off, all modes of operation are controlled by the microprocessor located on the N Board. The failure

modes are detected by the microprocessor and the power supply is forced into active off mode. These functions are discussed later (Deflection).

With the AC cord attached to the monitor and connected to an AC source, the monitor will be off until the AC switch is

turned on. When the AC switch is turned on, the power supply starts and is in active off mode. The next step is active on

mode. The power saving modes are activated by the microprocessor based upon the presence of either H or V sync. If no

sync signals are present, the power supply is set to active off mode. If only horizontal sync is present the power supply

moves to suspend mode. If only vertical sync is present the power supply enters standby mode.

Power supply operation control signals are “Remote On/Off” and “Heater On/Off”. Remote On/Off is digital low for active

off and suspend modes. Heater On/Off is digital low for suspend mode. Suspend mode is similar to active off mode, but

with heater voltage on. To enter active on mode, the microprocessor must set remote on/off to digital high. Heater on/off is

also made digital high and the heater is turned on.

Output Off Active Off Suspend Standby Active On

B+ 0 120V 120V 180V

80V 0 55V 55V 78V

±

16.5V 0 8.7V 8.7V +16.5V

-16.5V 0 -12V -12V -16.5V

+12V 0 0 0 +12V

5V 0 +5V +5V +5V

Heater 0 0 3.2V 6.3V

±

H. Centering 0

5V

±

5V

±

8V

- 2 -

Page 3

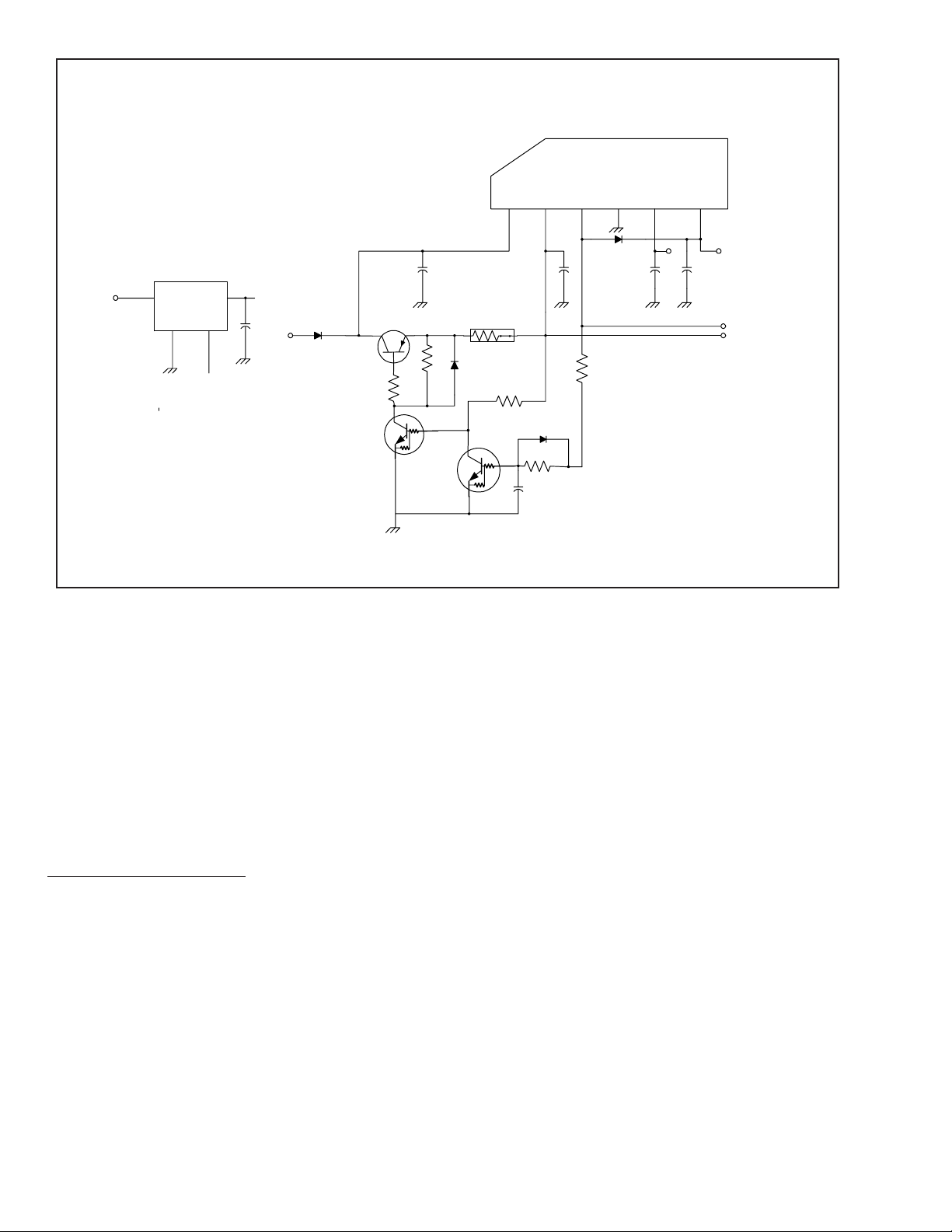

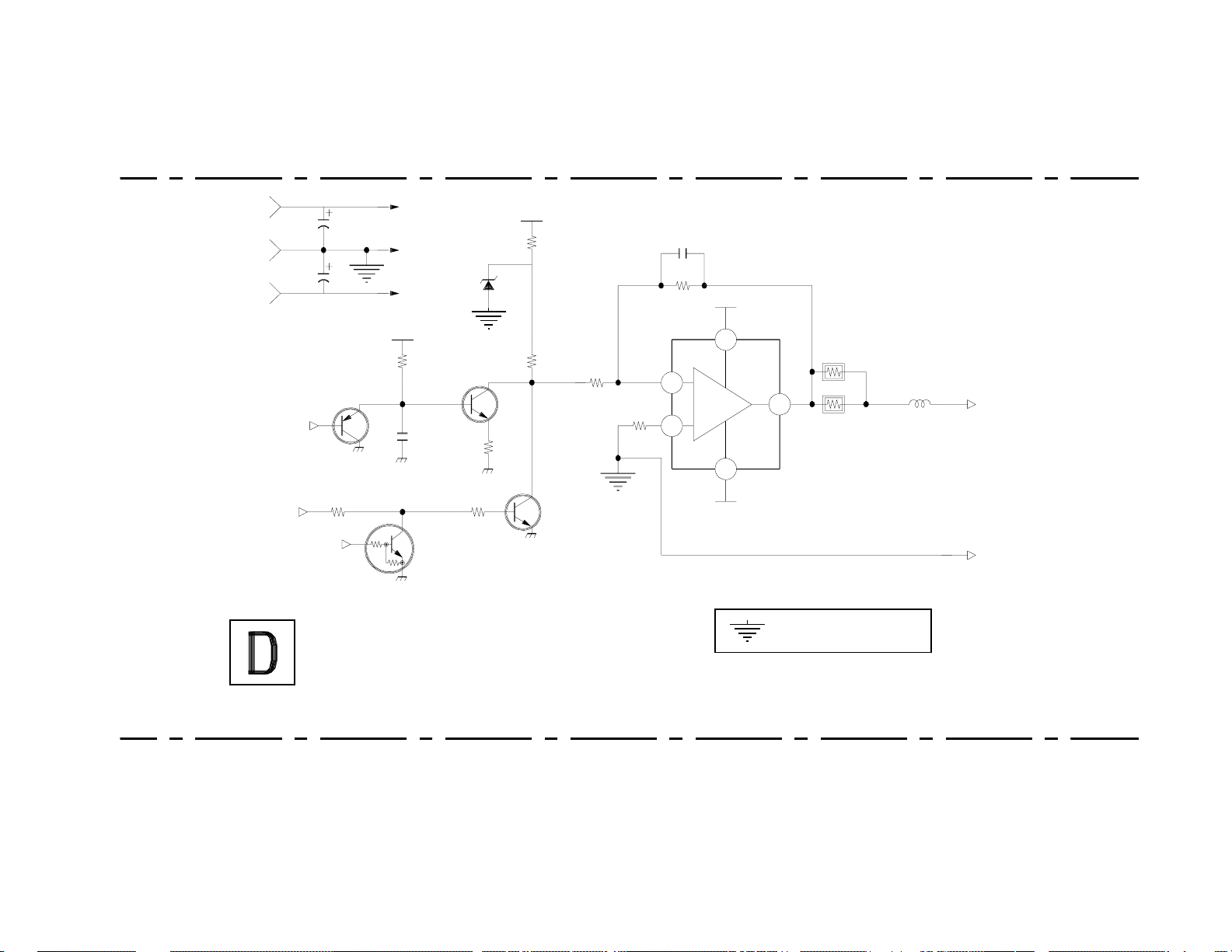

AC input and Degauss

CN600

C605

C606

F601

250V

DGC1

VR601

RY601

4A

LF602

C601

R601

C602

C604

C603

R602

AC SWITCH

CN601

DGC2

THP602

TH600

R672

D601

12V

D670

R603

0.68

10W

Q670

R670

R671

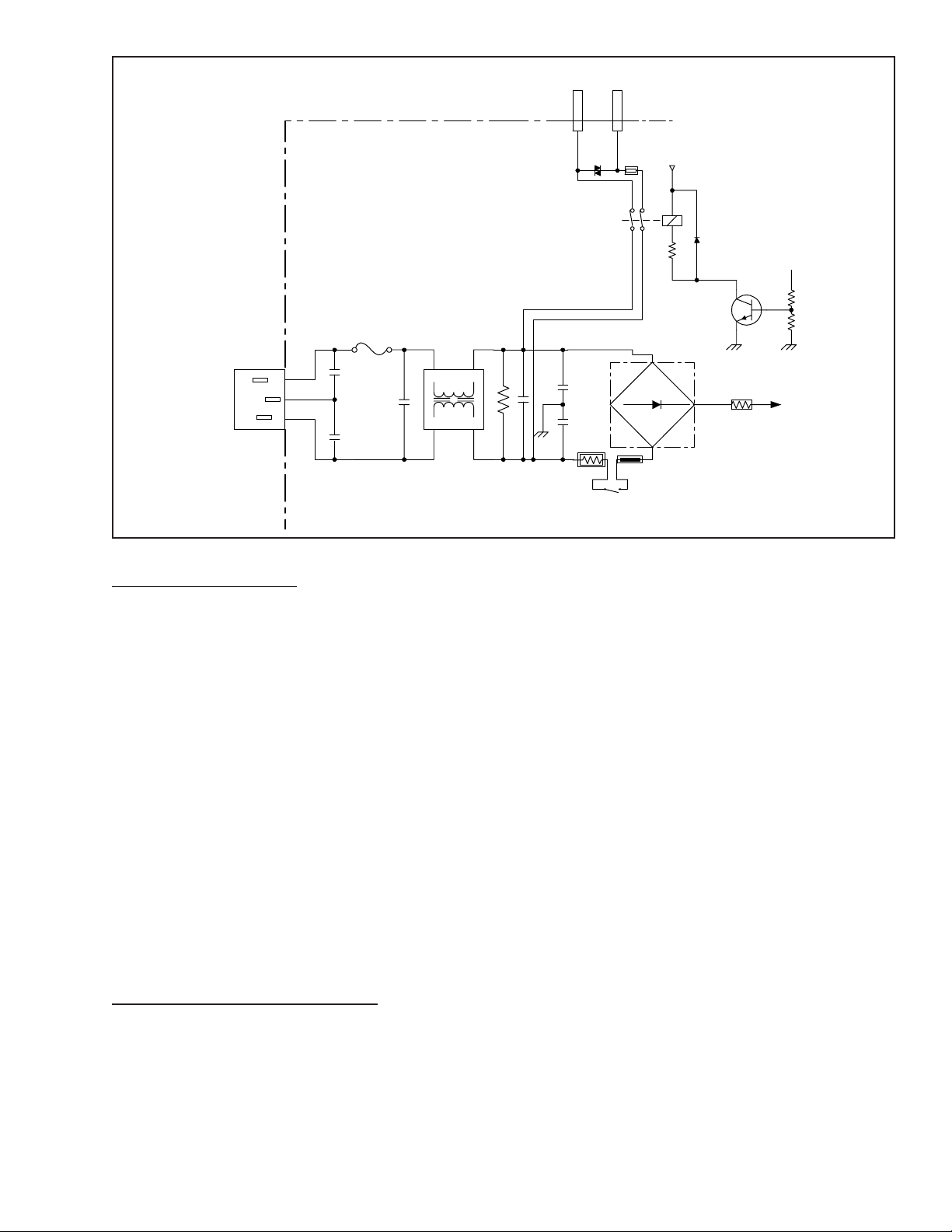

1. AC Input Section

The AC input section provides EMI filtering, input protection, surge limiting and CRT degauss operation. An AC switch is

also present for complete power off condition.

EMI Filter

The EMI filter comprises X-capacitors C601 and C602, Y-capacitors C603, C604, C605 and C606 and the line filter

transformer, LF602. Input protection is provided by F601 and surge current limiting by thermistor TH600 and resistors

R602 and R603. Degauss is explained in the next section.

The front panel AC switch is wired electrically between R602 and TH600 and when closed, completes the circuit. This

allows the bridge diode, D601, to full wave rectify the AC input voltage.

Degauss Circuit

The degauss circuit is used to demagnetize the CRT. After power on, the microprocessor located on the N Board sets the

degauss signal to digital high and through Q607 turns on relay RY601. This allows AC current into the degaussing coil

through posistor THP602. The current heats up the posistor and its affective resistance increases, this dampens the current

in the degauss coil to nearly zero. Duration time is approximately 5-6 seconds and the microprocessor then shuts off

RY601, which disconnects the degauss coil from the AC line. This operation should sufficiently demagnetize the CRT.

2. Primary Circuitry Section

IC601

The heart of the primary section is the AN8037 po wer supply controller, IC601. The following describes the functions of each

pin.

Pin 1 – TR - This is TR or transformer reset. Similar to a demagnetization function, this pin detects the falling edge of the

primary waveform during relaxation period. It allows the next conduction pulse only after reaching the bottom of the ringing

waveform. It contributes to the maximum on time setting.

- 3 -

Page 4

Pin 2 – OCP - Over current protection. Used to determine the overload level at which the timer latch is activated.

Pin 3 – CF – Oscillator. With a capacitor, determines the switching frequencies. (On/Off times.)

Pin 4 - CLM - Over current protection. If the voltage on this pin (primary current feedback) exceeds -0.18V, the power

supply will enter cycle-by-cycle current limit mode.

Pin 5 – GND- IC ground terminal.

Pin 6 – OUT- Output driver for switching transistor Q602.

Pin 7- VCC- IC supply voltage terminal. This voltage is nominally 17.5 volts during active on mode and 12 volts during

suspend or active off mode. The IC receives starting current via startup resistor (R613) until the auxiliary supply is availab le

from T601 VCC winding. If the voltage on this pin exceeds 19.4 volts (OVP), the power supply shuts off and can only be

restarted by disconnecting and reconnecting the A C line. Under v oltage lock out (ULV O) occurs when the voltage is less than

9.5 volts.

Pin 8 – SD- Used for OVP and timer latch functions. A capacitor determines the timing for OVP function.

Pin 9 - FB – Feedback terminal.

Operation

The power supply is a flyback type conv erter . It has both PWM and RCC characteristics. T he PWM controls the pulse width

of the gate drive. The RCC portion insures that the next conduction c ycle starts at zero v olts. Therefor e, the gate pulse wid th

varies and the switching frequency also varies. The on and off timing is determined by pins 3 and 1. Pin 1 detects the zero

voltage point or the valley on the relaxation ringing waveform.

When AC is applied to the power supply, start up current is supplied though R613 to pin 7 of IC601. Startup voltage is

approximately 15V. After start up, the voltage to pin 7 of IC601 is supplied through D605 connected to T601 pin 8. The f irst

mode of operation is active off mode and the VCC will be approximately 12 volts. The output drive pulse frequency will be

near 40kHz. or a type of frequency burst mode.

When the power supply enters active on mode, the switching frequency will vary between 65 and 120kHz., depending upon

input voltage and power lev el. The VCC le vel will be approximately 17.5 volts. O VP threshold is 19.4 v olts and UVLO is 9.5

volts. Therefore, if the VCC voltage is not correct, the power supply will not operate properly.

Feedback from the secondary side comes through IC603 and is connected to IC601 pin 9. (See diagram on page 5.)

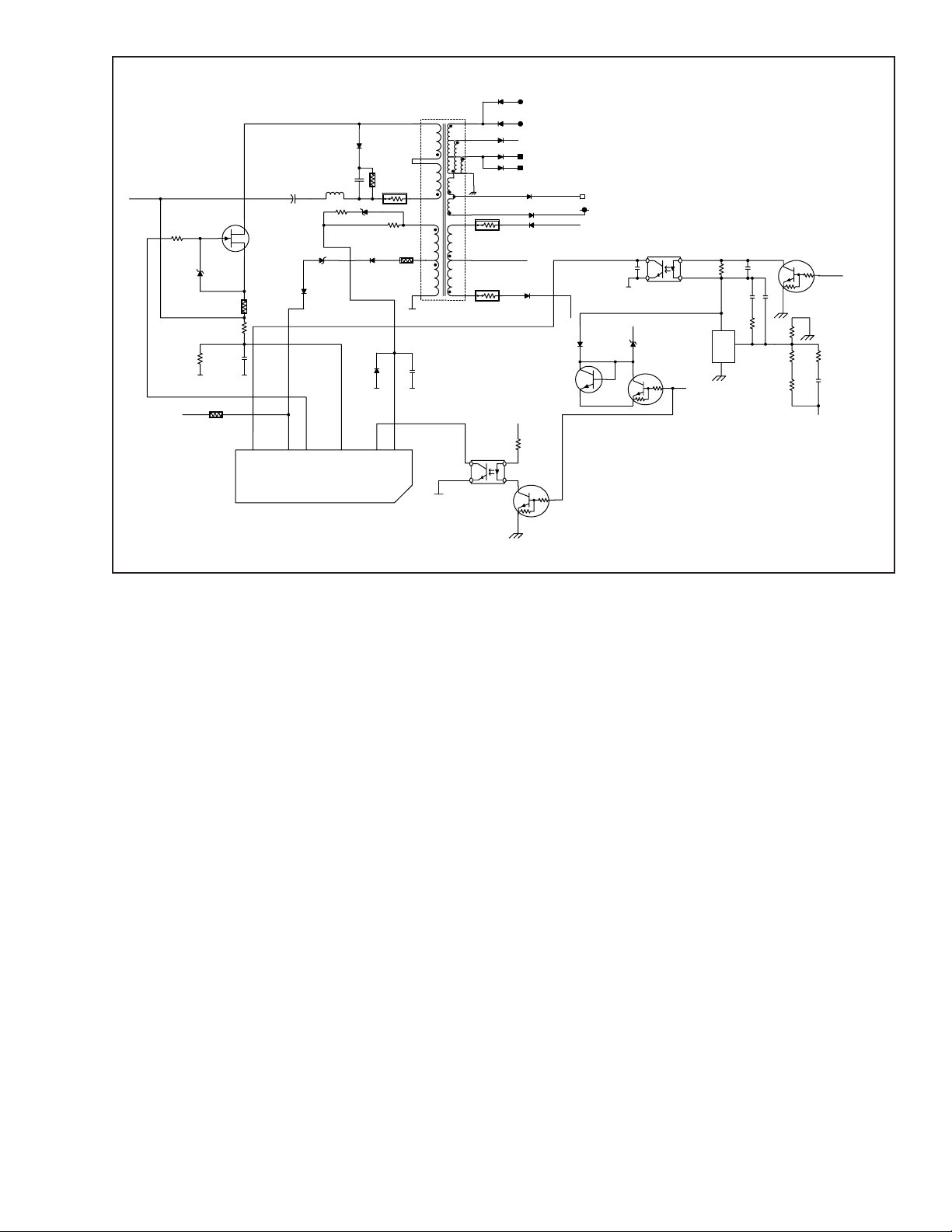

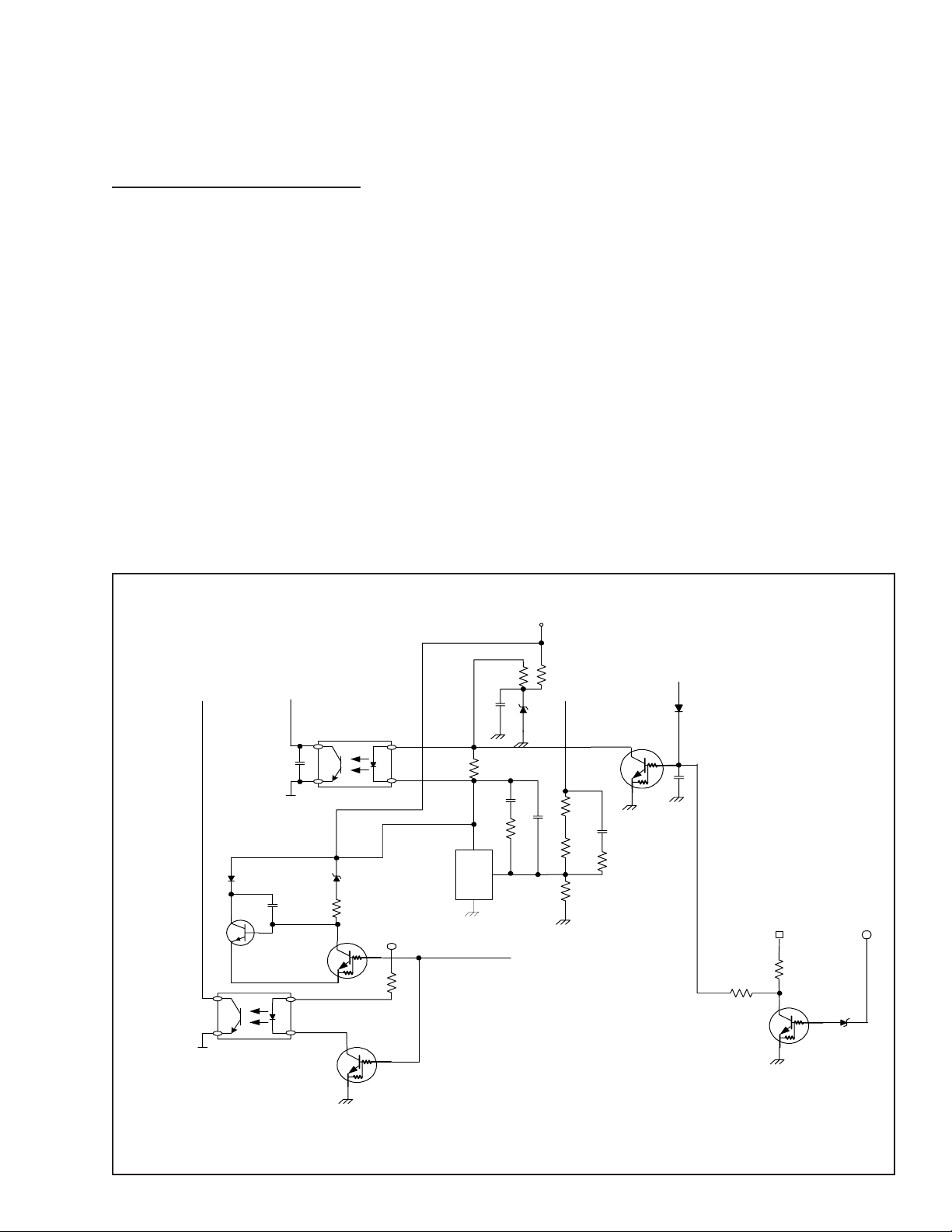

3. Secondary Circuitry Section

The secondary section consists of the following circuits. Rectifier diodes and filters for all output voltages, horizontal

centering, +5/12 volt regulator, +5 volt back up circuit, heater voltage regulator, voltage feed back circuit, standby mode

feedback, B+ detection and protection circuits. This section will describe each circuit and its function.

Secondary Rectifiers

The secondary rectifiers supply the following voltages, 180V (B+) deflection and video, 80V video, ±16V deflection and

regulators and 8 volt heater regulator.

Horizontal Centering

This circuit supplies IC502, which is used to adjust horizontal raster position on the CRT. The horizontal centering circuit

consists of fusible resistors R621 and R622, diodes D648 and D649 and filter capacitors C656 and C657. In respect to the

secondary ground, the horizontal centering ground is floating and connected to –H DY line. The v oltages in reference to this

floating ground are ±8 volts. Care should be taken to not short the floating ground to the secondary ground.

+5/12 Volt Regulator

IC605 is the voltage regulator for +5 and +12 volt lines. The output voltages are supplied to the microprocessor, deflection

- 4 -

Page 5

From D601

R606 C615

From D601

D603

R608

R613

Q602

R609

FB

C619

VCC

OUT

IC601

D608

CLM

D605

D615

D633

R615

2

CCP

TR

18

17

16

15

14

13

12

11

10

IC606

D656

D653

D654

D655

D652

-16V

-16V

PROTECTOR To IC604

16V

16V

D651

D650

D649

To HDY-

D648

To

IC501

Pin5

Q658

5V

Q605

80V

180V

To IC502 Pin 3

D631

16V

IC603

D632

Q656

IC652

REMOTE ON/

3

OFF

Q657

PWR

SHUTDOWN

R660

1

R663

2

R659

R668

C613

180V

T601

SRT

2

5

7

8

9

C614

14679

and video circuits. The +16.5 volt and the 8-volt lines supply the input v oltages for +12V and +5V re gulator sections, respectfully. During active off or suspend mode a standby back up circuit supplies the 16.5-volt line to the +5 volt section.

+5V Standby Circuit

Normally , the +8V line supplies the +5V regulator. During activ e off or suspend modes, the voltage supplying the +5 re gulator ,

IC605, will become very low . In order to pre v ent loss of the +5V, it is necessary to supply a back up v oltage. Supplying +16. 5V

line to the regulator through Q601 does this. Note: at this time the +16.5V has been reduced to 8.7 volts.

In Acti ve of f mode, Q607 is off, Q606 is on and Q601 is on. Through Q601, IC605 receiv es its input voltage for +5V. In Acti ve

On mode, Q607 is on, Q606 is off and Q601 is off. Since Q601 is off, IC605 must receive the +8 volt line through D610.

There is a time delay in this circuit, which is used to insure that during any transitions, the +5V line does not drop out. These

components are C636, R638 and D619.

Heater Voltage Regulator

Heater filament voltage is supplied by the 8-volt line and is re gulated by IC604. Heater on/off is used to turn the output on or off.

This is found at pin 4, VC. The output is off during active off and suspend modes.

Feedback Circuit

The feed back circuit is divided into two sections. One is for active off and suspend modes, the other for active on mode.

The following two sections explains the theory and operation.

Active Off and Suspend Mode Feedback

Feedback is provided by circuit elements IC603, D632, Q658 and Q656. The 16.5V line is regulated and the actual voltage

is 8.7. Due to this condition, B+ is no longer regulated and is reduced approximately 67%.

During active off and suspend modes, remote on/off is low and Q656 is off. Current flows through D632 when the 16.5 V

line is greater than 8.2 volts. This current biases Q658 and current from IC603 is allowed to sink to ground. The 16.5-volt

line supplies this current to IC603. The current through IC603 biases its transistor and sinks current from IC601 pin 9. IC601

then responds accordingly and adjusts its duty cycle in order to make the output voltage reach 8.7 volts. This completes the

feedback loop.

- 5 -

Page 6

+8V

IC604

PQ6RD83B

Heater

Regulator

1

I

G

34

VC

Heater

ON/OFF

Feedback Circuits

IC605

TDA8138A

2

1

T

T

U

U

P

P

N

I

IN

12

C623

Heater

2

O

out

D610

+8V

Q601

+5V BACK UP

R636

Q606

R635

R617

D618

R637

D619

C662

DISABLE

GND

4

3

R666

6

D607

C634 C635

OUTPUT 1

OUTPUT 2

7

+5V

REMOTE ON/OFF

+16V

Q607

R638

C636

When remote on/off is set high, Q656 is turned on and Q658 is turned off; this disables active off and suspend modes

regulation loop.

Active On Mode Feedback

As stated earlier, when Q656 is on, the acti ve of f and suspend mode re gulation is disabled. At this time, IC652 takes o ver and

the B+ line is regulated. IC652 is a shunt regulator and regulates the B+ voltage by sinking current from IC603 to ground.

The reference voltage at pin 2 determines the sink current into pin 3. The reference voltage is set to 2.495 volts by resistor

divider R659 and R660. Since the B+ is connected to the resistor divider, any changes in voltage is detected at the reference

terminal; the shunt regulator then tries to force the reference voltage to 2.495 volts by sinking more or less current into pin 3.

As mentioned before, IC603 biases its transistor accordingly and IC601 responds by changing the switching duty cycle in

order to keep the output voltage at 183 volts. The other components connected to pins 2 and 3 are for compensating frequenc y

response. This completes the feed back loop for active on mode.

4. Protection Circuits

There three protection circuits: OCP, O VP and secondary short circuits. OCP is pulse by pulse and is performed on the primary

side. OVP detects e xcessive output voltages. To detect secondary side short circuits, there is a circuit called B+ detect and it is

monitored by the microprocessor. The following will explain the operation of these functions.

OCP

OCP is activated if there is too much current passing through the power MOSFET, Q602. This condition will occur if either

the B+ line or 80 volt line is shorted.

R609 is the current sense resistor. Current through this resistor will cause a negative voltage drop in reference to ground.

R608, R606 and C615 couples this voltage drop to IC601 pin 4. If the voltage level exceeds –0.18 volts, the IC sets pulse by

pulse current limit and the output voltages are in affect very low. This condition is often audible and characterized by a

‘chirping’ sound.

OVP

The function of OVP is related to IC601 and the threshold is approximately 19.4 volts. This is sensed at pin 7 of IC601. Under

- 6 -

Page 7

normal operation, the VCC voltage is 17.5 v olts. In the e vent the re gulation loop was open or the control loop fails, the outp ut

voltages would rise rapidly. Likewise VCC will rise and when the threshold voltage is reached, IC601 would latch up. This

condition disables the output circuit at pin 6 and the power supply will not operate. Since the IC is now latched, only turning

the AC switch off and then on again can restart the power supply.

5. Secondary Short Circuit

B+ detect purpose is for determining secondary side short circuits. Sensing the node voltage of resistor divider R611 and

R612 does this. R611 is connected to +5V and –16.5 is connected to R612. If the node voltage exceeds 2.0 volts, the

microprocessor sets PWR Shut Down to digital high. In this event, Q657 is turned on and feedback current is bypassed to

ground from IC603. This causes unregulation and the output voltages become high. The VCC winding on the primary side

reflects this condition and exceeds 19.4 volts, which will cause IC601 to latch and disable the power supply. Turning the AC

switch off and then on again can only restart the power supply.

An additional short circuit protect is provided if the +12V, +5 or 3.3V lines are shorted. This is through circuit elements

D641, Q640 and Q657. During normal operation, through D641, the +5 volt line biases Q640 on. The 80 volt line is

connected to the collector of this transistor through R641. When the transistor is on, the collector voltage is nearly zero. This

point is connected to Q657 through R642 and Q657 is still off. If there is a short on any of the lower voltage lines, the +5

volt line will become lower than 3 volts and Q640 will turn off. In this case the collector voltage rises and Q657 will turn on.

Then through Q657 the feedback loop current is shorted to ground and causes OVP, which is sensed by IC601.

TO IC601

Pin 2

Q658

2SC3311A

ISS119

IC606

PC123FY2

TO IC601

Pin 9

D631

IC603

PC123FY2

FEED BACK

Q658

2SC311A

ACTIVE OFF

REGULATOR

Protection Circuits

3

2

5V

Q605

DTC124ESA

IC652

TL431BCLPRA

Remote ON/OFF

16V

1

Remote ON/OFF

180V

Power shut down

Q657

DTC124ESA

OVP

D640

1SS119

C640

2200p

R642

10K

80V

Short circuit

Protection

Q640

DTC124ES

5V

- 7 -

Page 8

6. Troubleshooting

Warning

Before attempting to fix the power supply, safety should be consider first. Never connect test probes to the primary side

circuits, unless proper isolation has been installed. If isolation for the AC mains is not present, serious harm can occur .

Never assume you are safe.

No Power

In the event that the monitor does not turn on, first check F601 and R615. If these parts are blown, the primary side circuitry

should be checked. If the fuses are not blown, then check the secondary side circuitry, especially the protection circuits. If

these circuits are causing a no power symptom, the problem can be more readily found.

AC Input and Degauss Circuit Trouble Shooting

For no power or nonoperating power supply, the AC input circuitry should be checked. Open or short circuit elements will

cause non-operation. F601, CN600, CN603 and CN2003 On the H Board should be checked first. The wiring between the

AC switch on the H Board and D Board should be checked. Check the front panel AC switch for continuity.

If all elements are correct, check whether F601 breaks when power is applied and the AC switch is closed. If the fuse does

blow, there may be problems with the primary circuitry or a component short.

The degauss will malfunction if CN601 is not connected. One problem could be loss of degauss signal from N Board. This

can be verified by using the manual degauss command found in the OSD menu. If the signal does not appear at R670, then

check the signal on the N Board and all connections. It is possible that the microprocessor does not function correctly .

The second step is to place a short across the AC terminals of RY601 for less than two seconds. If degauss operates then

check Q670 and RY601. If degauss does not work, check THP602 for an open condition and VA601 for a short condition.

Primary Section

Three main areas can diagnose primary circuit failures. These are IC601, Q602 and Feedback system.

Visible checks of these areas will aid in finding problems. The following will discuss each section.

IC601

First apply AC to the monitor and check IC601 pin 6 output. If the output on pin 6 is not present or briefly appears, there

could be problems with Q602 and related parts. Further, check VCC level at pin 7. If it less than 9 volts, the IC could be

in latch mode. If the voltage is very low, there could be a short on any of the IC pins. In reference to ground check the

impedance of pin 1, 6, 7 and 9. If any of these pins are shorted, replace the IC and check components connected to the

related pins. Pin 1 is especially vulnerable to damage. Take care that C619 and C616 are fully discharged before replacing

the IC.

Q602

The switching transistor can be damaged in various ways. These are related to voltage, current and temperature.

Check whether the transistor is shorted across drain and source terminals. If there is a short, R609, R615 and FS601 should

be checked. R609 is usually broken when Q602 fails. Additional components to check are D603, D604 and IC601. If

Q602 is shorted, all these parts should be replaced.

Failure of a secondary rectifier diode can also cause Q602 to fail. Check B+ and 80V diodes for open or short conditions.

There is also a clamp circuit, which is used to clip the turn off spike found on Q602 drain. If the clamp circuit is broken, it

can cause Q602 failures. Check D615, C622 and R619.

Secondary Circuit

Failure in the secondary circuits can be categorized by rectifier diodes, fusible resistors, regulators, +5 volt back up circuit,

feedback loops and protection circuits. These sections are interrelated and failure in one can af fect another. Consequently,

some failures will also affect the primary circuitry.

Rectifier Section

Rectifier diode failures are not common, but do occur. Deflection, video and N Board failures contribute to diode damage.

In the event a voltage is not present, check for shorts to ground, open or short diodes. Also check fusible resistors or any

zener diodes found on the voltage lines.

- 8 -

Page 9

Horizontal Centering

Loss of horizontal center adjustment can be affected by the rectifier diodes, fusible resistors, IC502 and related circuitry.

Measure the voltages in reference to the horizontal centering ground. Typically, the voltages are ±8 volts. However, the

adjustment setting can reduce the voltages by 1 volt. If there are no problems found with the diodes or fusible resistors, the

next step is to check the adjustment signal at Q517. If the adjustment signal is not present check the N Board and connections. Otherwise, check IC502 and related components.

+5/12 Volt Regulator

Loss of voltage due to shorts or device failures on either +5 or +12 volt output lines can occur. Consequently, IC605 can

be damaged and need replacing. Before replacing IC605 check for shorts or damaged parts along the output lines. If +12

volt does not appear, check the remote on/off signal. The N Board supplies this signal and it may be necessary to check it

and all connections.

+5 Volt Standby Circuit

Failure of this circuit can be affected by IC605. The remote on/off signal controls circuit operation and it may need

checking. In case the circuit does not work properly, check D619, R617 and Q601. If these components are good, check

the remaining circuit parts.

Heater Voltage Regulator

This circuit may be affected directly by fusible resistor R654 or D654. If these parts are good, check the regulator output

for a short to ground. Shorts can occur on the video board. In the case of an output short, IC604 may have been damaged.

If the IC appears to have no damage, check the connections and N Board for any problems with the heater on/off signal.

Feedback Circuit

Problems with feed back can cause power supply shut down or low voltages. First determine whether the power supply is

operating in active off, active on modes or not at all.

The power supply can be stuck in active off mode. The remote on/off signal, Q656 and IC603 can affect this condition.

Likewise, if the power supply is always in active on mode, the same items should be checked.

Checking for voltages at IC603 pins 1 and 2, IC652 pins 2 and 3 can solve more difficult problems. Additionally, IC603 pin

4 and IC601 pin 9 should be checked. If there are problems with these devices, B+ or 16.5 volt line, the feedback systems

will not work correctly. Also check the protection circuits.

Protection Circuits

OCP occurs when there is excessive current through Q602. Failures with Q504, Q505 or the video section commonly

cause this condition. These areas should be checked. OCP condition can also occur if R609 is open or if there are problems with IC606 or Q605.

OVP usually occurs when the feedback loop is open, secondary voltage shorts or loss of +5 volts. Isolate the OVP trigger

condition, by first checking the operation of the feedback loop and Q657. Either PWR shutdown or Q640 can turn on

Q657. The feedback loop can be verified by removing Q657 and measuring the B+ voltage level.

- 9 -

Page 10

D BOARD DEFLECTION SECTION

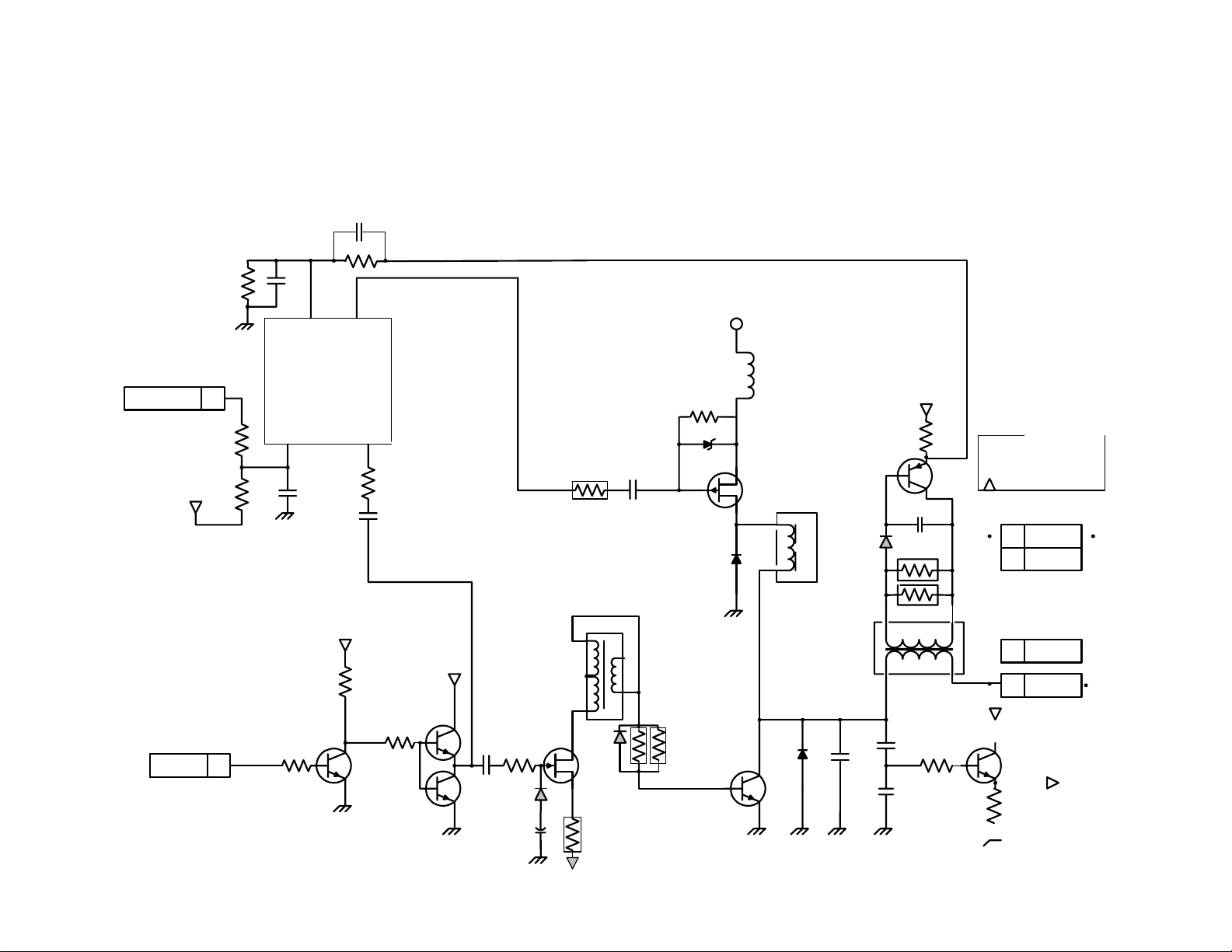

1. Horizontal Deflection Circuit

Overview

These circuit drive the DY(Deflection Yoke) for Horizontal Deflection. The H size and H shape control (IC805 and around) is

included in this page as well.

H Drive, H Out, Feedback

HD pulse supplied from N board is inverted by Q501 and switch Q504 through Q502,503. The drive current which

introduced in HDT by this switching will drive Q505(H OUT) and 1000v pulse appears on collector. D504 is the “Damper

Diode” which avoid the negative pulse and discharge the energy for next Horizontal Drive. Q514 is the buffer for the “H

FBP” feed back to N board and it will be the reference of phase/jitter control of DSP. T504( HST) is to sense the deflection

current going to DY. The voltage appeared on secondary side will be the feed back for H Size/Shape control.

H Size/Shape control

HD pulse also triggering the H Size/Shape control IC805 (pin#8). IC805 is “PWM IC” and it controls H and HV B+

chopper duty. H Shape coming from N board is already including the Size Information(DC Level). It will be supplied to

IC805 (pin#2) after pulled up to 12V through R813. H Reg Output(pin#20) is switching pulse of Q506(B+ chopper). The

energy supplement from 180v to H Def circuit (through T502) is controlled by the duty of this pulse. The H Shape input

and feedback voltage(pin#20) from T504 are compared by error amp (in IC805) and H Reg out pulse duty is controlled to

keep the level of these two the same.

T roubleshooting

See attached “FLOW CHART” and confirm if it’s really H Deflection issue.

No H Deflection / No Power

Check Q505, Q506 and D504 first. In case any of these shorted, check T501, Q504, R507 and D502.

Those parts might have been damaged.

If both of Q505, 506 were not broken, check the HD pulse at the gate of Q504.

If no pulse, check Q502, Q503, Q504.

Otherwise, check R512, D503 or try changing IC801.

Bad Distortion

Check pin#2 of IC805 and confirm that proper DC level and AC waveform.

If the distortion is on only right side, check all above (“No H Deflection”).

Otherwise, refer to the Troubleshooting of next section (“H Lin and Ringing Correction”).

- 10 -

Page 11

H Deflection Circuit

R517

R518

320

H DefINH Reg

Out

PWM IC805

H SHAPE

12V

2

7

H SHAPEINHD

IN

28

R512

- 11 -

R813

D503

D505

180V

L501

Q506

B+CHOP

5

2

Q518

12V

TO:

H Lin and

Ringing Circui t

4

HDYHDY-

3

CN801

HD out

T501 HDT

12V

1

12V

6

4

Q502

2

Q501

6

Q504

D502

T502

HOC

D504

C507

3

T504

2

HST

5

1

Q514

H DY+

2

H DY+

1

H FBP

TO CN801

#32

Q505

Q503

H-OUT

R507

-16V

Page 12

2. H Linearity and Raster/Distortion Ringing Correction Circuit

This section includes HLC Control circuit which is new in D98, S cap switching and HLC/S-Cap Damping circuits. These

circuits are placed directly on the “cool side” of DY which is in series with deflection current line.

H Centering circuit will be explained in next section.

HLC Balance Control and HLC damping

There is no HLC switch for this chassis. Instead of that, HLC(L502) effectiveness is changed by LCT(503) for each Fh

since T503 and L502 is in parallel. LCT is Cross Transformer which can change its inductance accordingly to the DC

current of secondly side. The current of secondly side controlled by DAC output of MICRO through Q507. *It can be

changed by register “HLC BAL”. R520 and C528 is damping circuit to avoid the Raster Ringing (mainly on left side of

picture) caused by HLC, DY and S-caps.

S-Cap switching and S-cap Damping

H Def current is distorted by resonance between S-Cap and DY to correct the linearity. Since the resonance frequency has

to be changed for each fH, S-Cap switching is controlled by MICRO

Switches are "On" when its gate is Hi(5V) and that moment, drain voltage should be grounded (0V).

L505, R522 and C513 is damping circuit to avoid Distortion Ringing (mainly on top of the picture) caused by S-caps and H

Control loop gain. L504, R523 and C527 is also the same purpose as above but only works when Q508 (Switch for the

Biggest S-Cap) is “On”.

Troubleshooting

See attached “FLOW CHART” and confirm if it’s really H lin issue.

Bad Linearity

Confirm that Raster is approximately in the center of the Bezel. If not, refer to next section (Raster Centering Circuit).

Check S-cap switches (Q508, 509, 510, 511, 512, 513) and confirm that H Linearity changes proportional to the value of

“S-Cap Direct”. Confirm that H LIN BAL changes by the register value of ”HLC Balance(Max/Min)”.

If it’s not working, check Q507 and the connection between N bd and D bd or, Check L502, T503.

Bad Top Distortion/ Left side Raster Ringing

Check damping circuits explained above or check the connection between N & D(HLC control line).

3. H. Raster Centering Circuit

Overview

H Centering is changed by supplying DC current to DY. D98 is taking the common level on DY cool(-) side and +/- 8V from

power supply transformer(T601 PIN#10, 11, 12. #11 is the common).

H Center Circuit

The DC current is outputted by powered OP-amp(IC502). This circuit is making “invert amp” with the gain of R549/R548

and input 1S Q515 collector. The level is controlled by MICRO”H CENT’ through Q517(buffer). Q516 is Stand by-MUTE

switch which activates when “Remote On/Off’ is Off(Lo).

Trouble Shooting

See attached “FLOW CHART” and confirm if it’s really H Center Circuit issue.

No Raster Centering Control

Check R621, 622(Right next the SRT) first. If it’s open, change IC502.

Confirm that voltage of Q5 l 5 base is changing accordingly to “H CENT MAX or MIN” register.

If not, change Q517 or check the connection between N and D.

Confirm that Q516 is Off. This circuit should not work when the Monitor is in Main mode.

Check IC502.

CAUTION!!

The heatsink of IC502 is connected to the H center(-) level, not GND! It could have up to 150V and should not be

touched to any other metals.

- 12 -

Page 13

H. DEFLECTION

CIRCUIT

H DY+

H DY+

H DY-

R520

C528

100

330p

2W

2kV

:RS

B

TO H. CENTERING CIRCUIT

2SK2098

R527

47k

4

S

Q509

C517

0.01

C518

0.68

250V

:PP

:PT

C521C522

R530

0.068

250V

:PP

Q512Q513

47k

IRLI530GIRLI530G

0.01

:PT

1

S

- 13 -

0.033

400V

:PP

C526

0.01

:PT

0

S

R529

2

S

0.15

250V

:PP

47k

C524C525

0.01

:PT

C519C520

0.33

250V

:PP

Q510Q511

IRLI530GIRLI530G

R528

47k

C523

0.01

:PT

3

S

R525

C515

L504

1.5

10mH

250V

:PP

47k

R543

47k

R536

SSSSSS

1M

C516

Q508

47

2SK2098

:PT

5

S

R523

1/2W

:FPRD

C527

4.7

250V

47

C514

0.17

400V

:FPRD

C513

2.2

250V

T503

:LCT

Q507

2SC2785-HFE

HLC CTRL

L505

2.2mH

R522

47

1/2W

6

2

1

R526

39

:RN

L502

:HLC

5

C537

0.22 :MPS

C511

0.22

:MPS

1

2

9

R519

2.2k

R747

7

L

A

B

N

I

L

.

H

C512

10

:FPRD

10

16V

H DY-

BOARD

H. LINEARITY AND RASTER/DISTORTION RINGING CORRECTION CIRCUIT

Page 14

FROM D648 IN P.S.

C656

HC+

HC+

R547

C538R545

R549

2

1

HC+

5

IC502

-

R546

TO H. DY(+) VIA T50

4

L503

(DRAIN OF Q506)

+

R541

3

HC-

!!!

IMPORTANT !!!

TO H. DY(-) VIA L50

R551

HC N

HC-

C545

Q515

D511

R550

R548

R542

Q516

STBY SW

R552

FROM PIN# 11 T601

FROM D649 IN A.S.

C657

Q517

- 14 -

H. CENT

R815

16V

REMOTE ON/OFF

Q802

CENTER VOLTAGE

=

COMMON

(ISOLATED)

(BOARD)

(19D98 H. CENTERING CIRCUIT)

Page 15

Rotation/Vertical Key Circuit

+5V

R735

Rotation Coil(CN702)

R775

R708

0

R709

C701

R707

C702

IC702

+16V

4

-16V

5

1

V+

+

V-

-

2

3

0

0

R736

R737

R729

C705

42

0

40

N-BOARD

D.TILT

59

IC1002(DSP)

ROTATION

3

IC1001

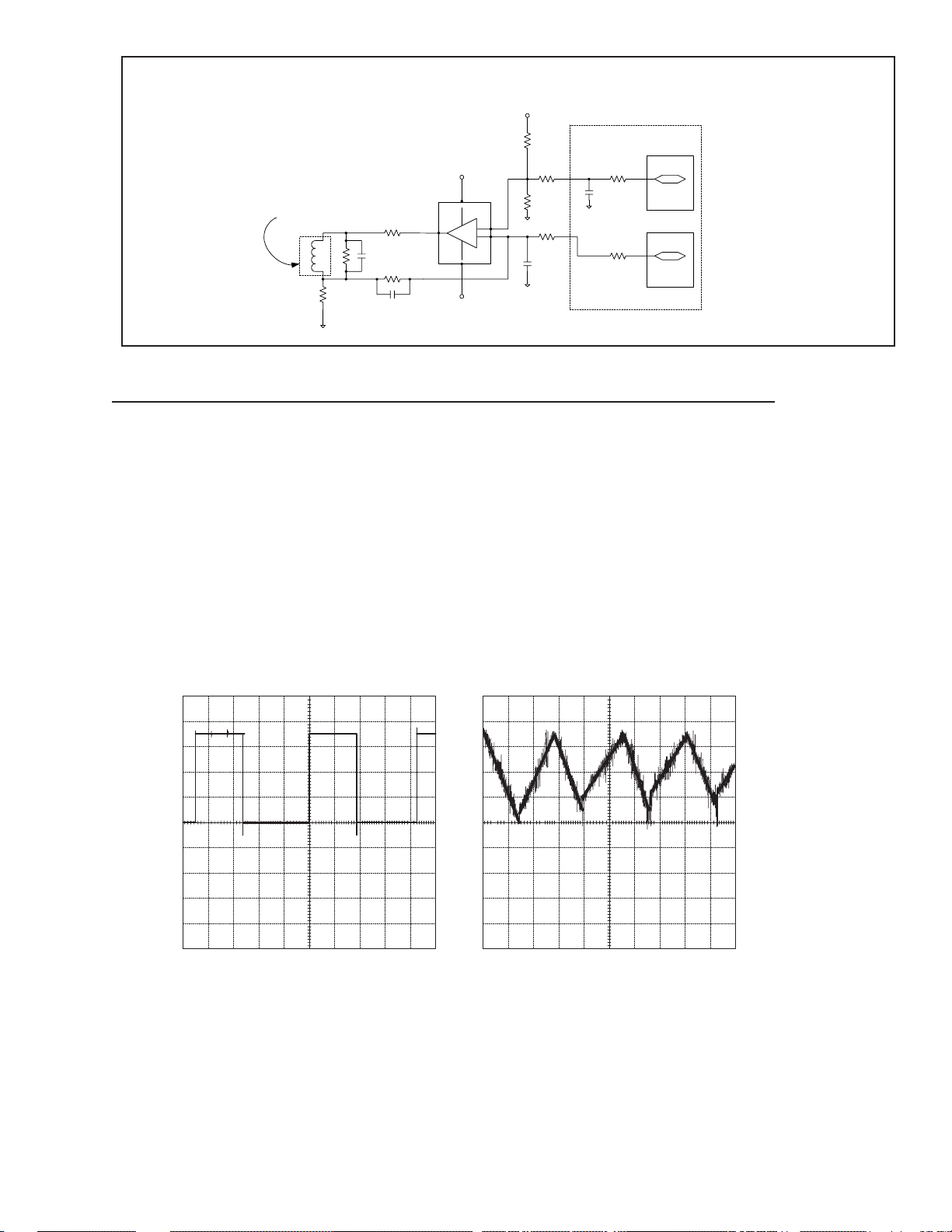

4. Rotation/Vertical Key Circuitry Mounted on the D/N Boards) Circuit

Theory of Operation

The Rotation/Vertical Key circuitry takes its input from the N-board via pins 40 (Rotation) and 42 (D.Tilt). D. (Dynamic)

TILT is generated by the DSP (IC1002) while Rotation is generated by the microprocessor (IC1001). Rotation is a PWM

waveform at approximately 40kHZ measuring 5V pk-pk at pin #3 of the microprocessor. While D.TILT is a triangular

waveform at the vertical scan rate, 1.0Vpk-pk in amplitude centered at 1.5V. Typical waveform patterns are provided as

figures #1 and #2 below. Rotation is filtered by the R729 and C705 combination and a DC offset is added to D.TILT from the

+5V line via R735. These two waveforms are added together and amplified by IC702. This amplifier is a transconductance

amplifier (it amplifies a low-level voltage into a high level current). The output current from pin 4 of IC702 flows through

R709 and the rotation coil and returns to ground through R708. The feedback is sensed at R708 and sent back to the amplifier

through R707. The DC level of the current through R708 is controlled by the Rotation signal while the triangular currant

amplitude is controlled by the D.TILT waveform.

FIGURE 1 FIGURE 2

T1 21.60us

T2 150ns

DT 21.75us

T1 1.10ms

T2 2.60ms

DT 13.70ms

Vertical Key Circuit Troubleshooting Hints

It is possible to have a malfunction of only the Vertical Key portion of the circuit. This can occur by a loss of signal from

D.TILT. First check if the Rotation function is working properly. There should be no more them a +/-15 degree picture

rotation by operating the rotation function through min-max extremes. When the Rotation function is at its full position (SV

at R729) the voltage at R708 should be a positive 2.25 vdc, approximately. And at its full negative position this voltage

should be a negative (-) 2.5 vdc approximately (NOTE: if D.TILT is open or shorted to ground these voltages will not be well

centered around 0V).

- 15 -

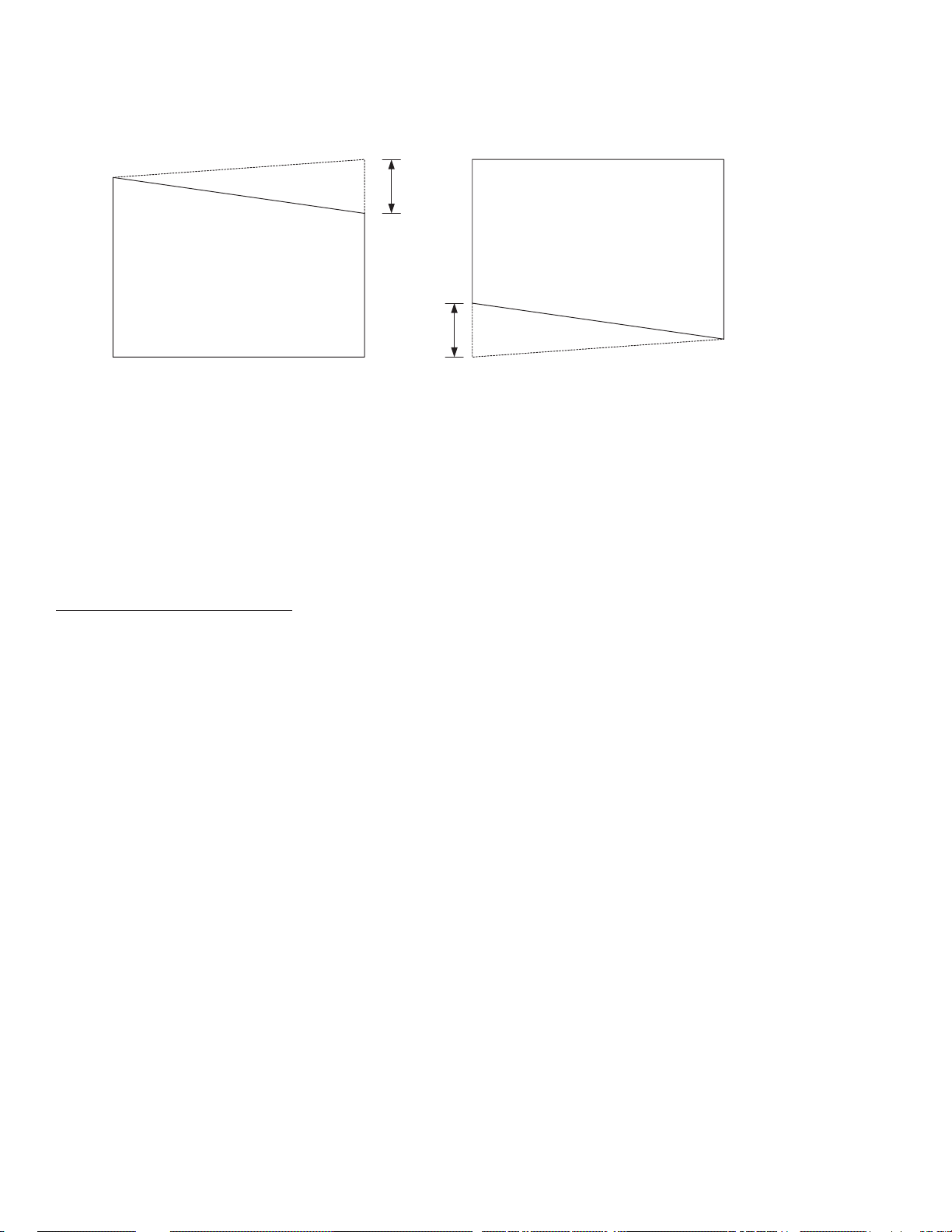

Page 16

Signal tracing should begin at pin 59 of IC1002 on the N board. The triangular output waveform at this point should change

+/-1 vdc by operating V.TrapSawBtm and V.TrapSawTop registers through function through min-max extremes. This same

signal should appear at pin 42 of CN801 and at the input side of R736. Screen movement for this function is as shown below:

1.5mm

1.5mm

V.TRAPTOP

(Dashed lines Indicate

Negative movement)

Movement

V.TRAPBTM

(Dashed lines Indicate

Negative movement)

Movement

Rotation Circuit Troubleshooting Hints

If Rotation does not work Vertical Key will not work. Signal tracing for a rotation problem can start at pin 3 of IC1001. The

Rotation signal will be a square waveform at 40kHz. This signal is filtered at the R729, C705 combination. If this waveform

is reaching R705 the problem is in the IC702 area.

5. Dynamic Focus Circuit

Overview

Both H and V Dynamic Focus Waveform originally formed by DSP.

H DF is amplified by Hi-speed OP Amp and also Transformer.

V DF is amplified by Transistor inverter.

H DF

IC703 is amplifying the H DF waveform formed by DSP. The voltage is re-amplified by T701 to about 600Vp-p and supplied

to FBT.

V DF

V DF waveform is buffered by Q707 and amplified by Q706 to about 200vp-p.

300v Vcc is made by FBT through D906. This voltage is also used for HV Protector.

Troubleshooting

See attached “FLOW CHART” and confirm if it is really a DF issue.

Bad H DF

Confirm that waveform from N board is correctly there(1Vp-p).

Check the voltage of pin#6 of IC703. If no output, change IC703. If there is wave form, change T701.

Bad V DF

Confirm that waveform from N board is around 3Vp-p. If it’s more than 3.3Vp-p, change the N board.

Check 300v from FBT.

- 16 -

Page 17

Dynamic Focus Circuit

+16V

H. DF FROM N BOARD

C707

V. DF FROM N BOARD

R723

Q706

R724

R734

H. DF TO FBT

PIN# 14 VIA R9

T701

:DFT

12

11

10

9

7

6

R742

V. DF TO FBT

PIN# 15 VIA R909

C711

2

3

4

5

C714

R733

R738

C728

R754

D905

R917

8

6

+16V

9

5

-

IC703

4

+

7

-16V

300V

C931

R727

Q707

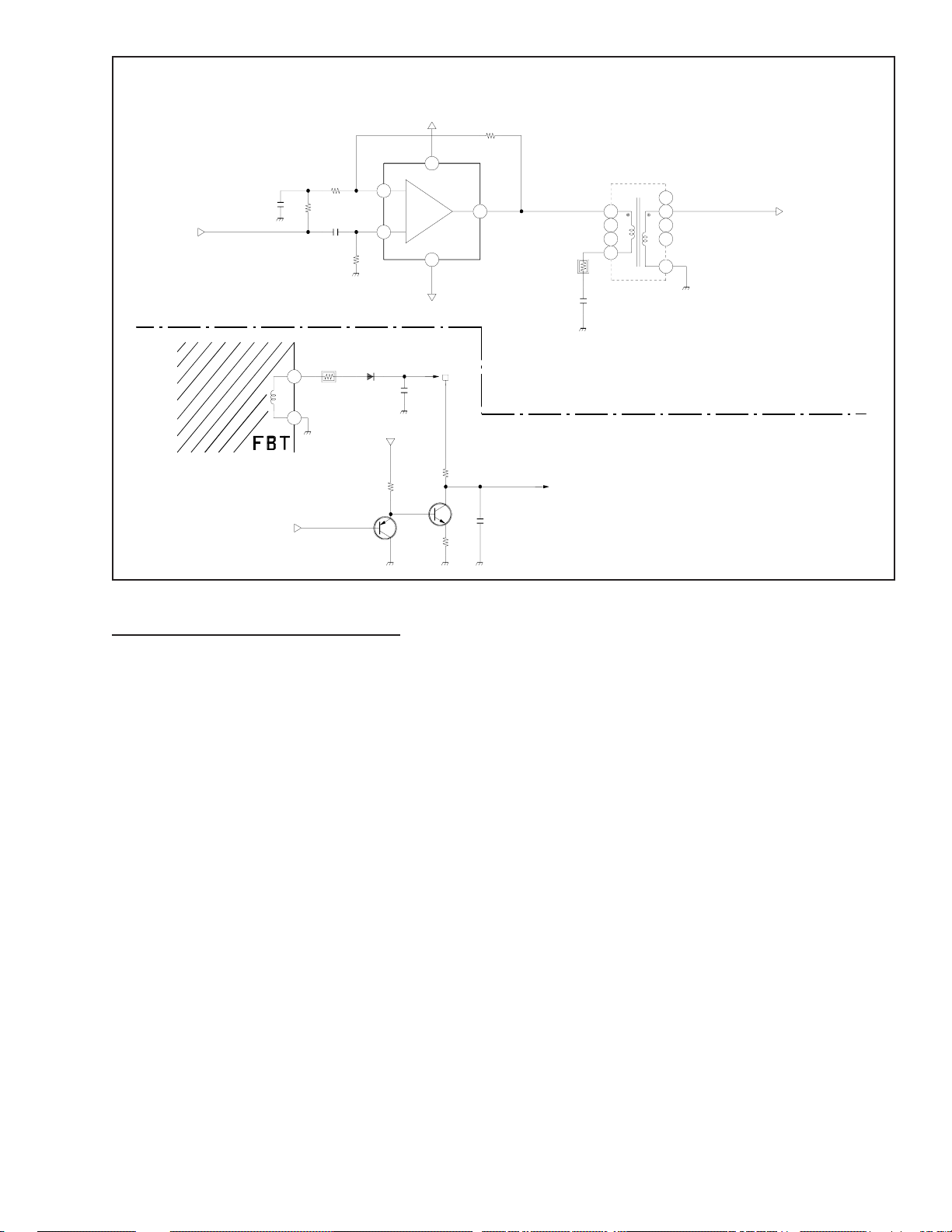

6. High Voltage Protect Circuit

This circuit generates the High Voltage supply for the anode and G2 (1000V) of the CRT. It consists of a high voltage driver

and regulator similar to a switching power supply function. In addition, there are High Voltage and Beam Current protection

circuits. All those circuits are similar to N3 or D1 chassis circuits.

High Voltage Regulation and Output Circuit

The HV Drive pulse is generated by IC805 and synchronized with Horizontal drive pulse. It is supplied to the Gate of Q902

the HV Out FET .

The HV Out Pulse approximately 700V, is generated by Q902 switching with the peak voltage being controlled by the

switching duty of Q901 (B+ chopper). Internal resistors and R903 and RV904 divide HV generated in the FBT. Since this

voltage is the feedback for HV Regulation control. Adjusting RV904 will result in changing the HV Regulation level(= HV

level). HV Feedback voltage is returned to IC805 at pin#12 to be compared with an internal reference voltage of IC805 at

pin#13. According to this feedback level, IC805 changes the pulse duty cycle. This pulse is felt at pin #18 of IC805 thereby

controlling the output of B+ chopper drive Q901.

G2 Voltage

G2 voltage at approximately 1000vdc is produced by the FBT rectifying the output voltage of T901 pin#2 through D906 and

C933. This voltage will be supplied to A board via CN 510, which contains the G2 control circuit.

HV Protect Circuit

HV Protect circuit will be activated by the Microprocessor when the signal at HV DET, CN801 pins#24 reaches a +5vdc

level. HV DET indicates the level of the primary current developed by the 300V winding of the FBT through R921, D908.

Beam Current Protect

Beam Current Protect will be activated when ABL DET at CN801 pin#1 reaches a level of 0V when operating in main mode.

ABL DET level is corresponding to the Beam Current which is supplied to FBT through R914 and D909. The voltage current

relationship is inversely proportional Volta ge (down) Current (up).

- 17 -

Page 18

Troubleshooting Hints

See attached FLOW CHART to confirm if is really an HV/Protect Circuit issue.

No HV / No Power

Perform basic checks of Q901 and Q902 first. If both Q901 and Q902 were not broken, check the HV Drive pulse at the gate

of Q901. If no pulse, check R911 and D903. Otherwise, check R910, D901 or try changing IC805.

No G2 Voltage

Check R918 and D906.

Protect Malfunction

To see if HV Prot or ABL Prot are suspect check the Shutdown Log data at the Shutdown Log register. Refer to Shutdown

Log Table below.

When an HV Shutdown is indicated, check all N board connections, R917, R921 and D905 or, replace T901 (FBT).

Where ABL Shutdown is indicated, check the voltage T901 pin#11.

If it is higher than 0.5v immediately prior to shutdown, check connections all the way to N board. Should the voltage reach

and remain at the 0 volt level, even after the first 2.0 seconds of Power On, check D909 and 904 or check White Balance.

SHUTDOWN LOG TABLE

Bit Register value Shutdown Mode Comment

bit7 128 N/A N/A

bit6 64 B+ Shutdown Explained later

bit5 32 S cap Shutdown Explained later

bit4 16 ABL Shutdown Hardware Controlled

bit3 8 HV Shutdown Hardware Controlled

bit2 4 HV U Shutdown Not Used

bit1 2 No Vertical Explained later

bit0 1 No H Pulse Explained later

7. Protection Circuitry Overview

Overview

The 19D98 chassis was developed with protection circuits other than HV/ABL.These protection circuits are controlled by

the N board mounted Microprocessor(IC1001);

- B+ Shutdown: Activates when the secondary of the power supply is overloaded.

- S Cap Switch Shutdown: Activates when any of S-Cap Switching FETs are broken.

- V Scan Shutdown: Activates when Vertical Deflection signal is absent or of insufficient level or of a distorted nature.

- H Scan Shutdown: Activates when Horizontal Deflection signal is absent or of insufficient level or of a distorted nature.

Troubleshooting Hints

B+ Shutdown

Refer to POWER SUPPLY section.

S Cap Switch Shutdown

In the event of failure of any S-Cap Switching FETs, and Remote or AC Power switch was turned Off/On, the Microprocessor detects FET gate damage and goes into shutdown mode. For these conditions, refer to the section of H Linearity

Circuit.

Vertical Scan Shutdown

If the V FBP feedback at pin #42 the Microprocessor becomes less than +2.5V, a Shutdown will be initiated. Power Supply

problems may also produce a similar type failure. For these conditions, refer to the V Deflection Circuit or the Power

Supply section.

Horizontal Scan Shutdown

If the H FBP feedback at pin #32 of the Microprocessor becomes lower than +2.5V, Shutdown will be initiated. Some

power Supply problems may also produce a similar type failure. For these conditions, refer to the H Deflection Circuit or

Power Supply sections.

- 18 -

Page 19

180V-2

HV REG DRIVE

PIN# 18 IC805

D901

C921R910

R901

Q901

B+ CHOPPER HV

S

D902

T902

R920

R919

L902

C923

1

FB903

FB902

D903

Q902

HV OUT

C933

C934

R812C802

- 19 -

HV DRIVE PIN# 19

IC805

R911

G2 (1KV)

R811

C801

D908

HV DET PIN# 24

CN801

TO CN510

D906

R922

FB904

S

R921

3

C922

R918

300V

D905

C931

R917

C924

4

1

2

5

7

9

10

8

6

T901

:FBT

HV

17

13

SG901

FV1

14

15

16

FV2

D904

11

C925

R906

C926

SG902

SG903

C930

ANODE OF CRT

R907

CRT VIA

RED FV LEAD

R908

R909

CRT VIA

BLK FV LEAD

C929

R913

R902

R903

RV904

H DF OUT

V DF OUT

D909

C927

R923

R810

12V

C829

IC805 PIN# 12

"HV FEEDBACK"

BOARD

19 D98 CHASSIS HV/PROTECTOR CIRCUIT

C919

R915

R914

ABL DET PIN# 1

CN801

12

Page 20

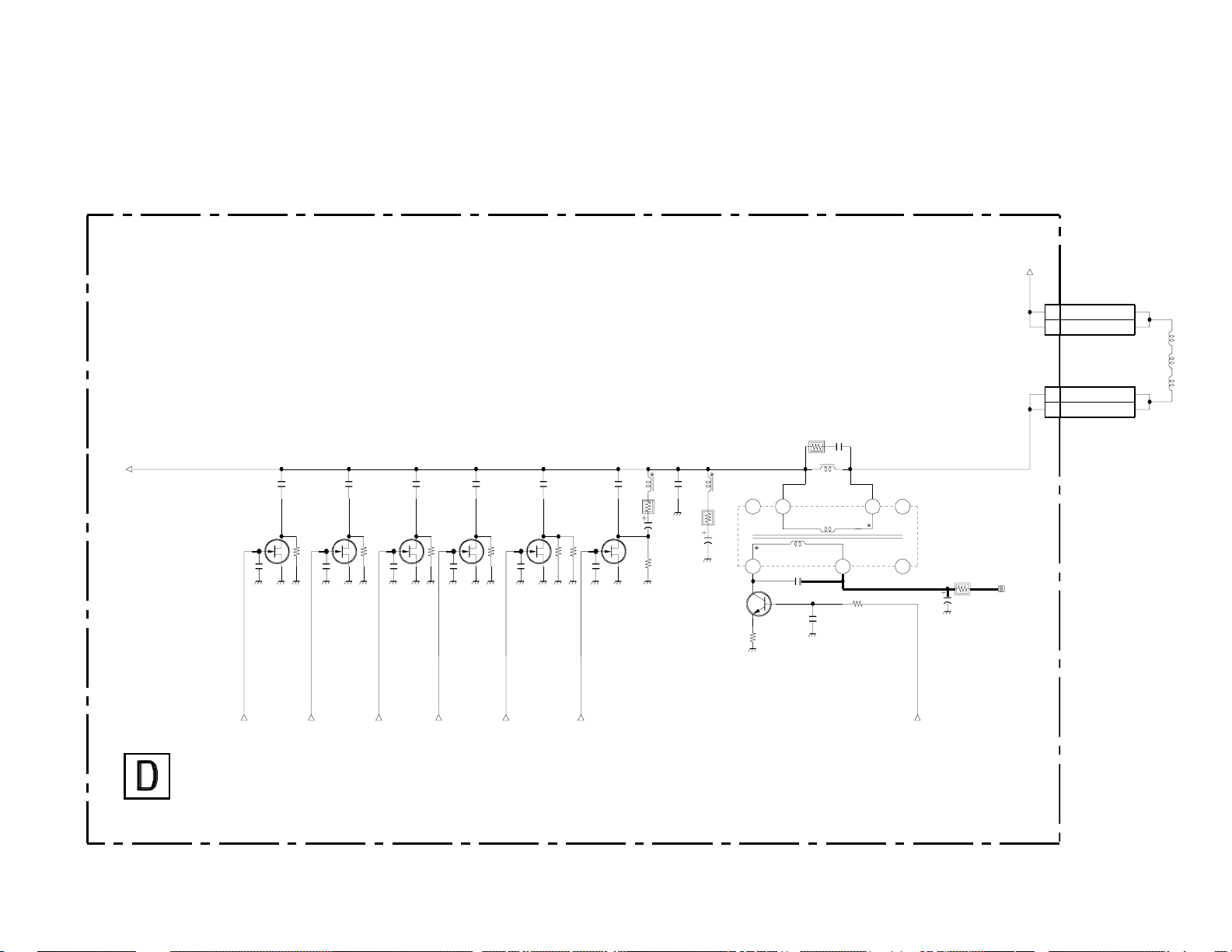

8. Vertical Deflection (D/N Boards) Circuit

Theory of Operation

The Vertical Deflection block takes its input from the N-board via pins 13 (VSAWN) and 15 (DCC2). These two signals are

generated by the DSP (IC1002) and are both centered on 1.5V. VSAWN is a sawtooth waveform that controls VSIZE. DCC2

is a DC reference that is compared to VSAWN at IC401. VCENTER is controlled by the shift of VSAWN relative to DCC2.

VSAWN and DCC2 are filtered heavily on the N-board by R1035, R1036, C1009 and C1010 and therefore require the use of

IC1007 as a buffer. Along with a buffer a retrace switch is also necessary to short R1036 and remove the filtering during the

retrace. The retrace switch is internal to the DSP and is found between pins 63 and 64 (see schematic on the following page).

IC401 serves as a transconductance amplifier (it amplifies a low level voltage into a high level current) for VSAWN and the

DC difference between VSAWN and DCC2. The current generated by IC401 is fed to the Vertical Deflection Coil. At the

return point of the Vertical Deflection Coil the current flows through R405 and R403 which generates a voltage across them

which is fed back to the amplifier via R404.

The Vertical Deflection Coil has a large inductance (3mH) and therefore it is very difficult to make large quick changes in the

current without high voltage. This situation occurs during the retrace time (+/-15V is not enough). A circuit internal to IC401

is used to raise the voltage at its output. This circuit works as a charge pump that generates about 40V at pin 6 during retrace

and this is added to +/-15V to generate a total of 55Vpk-pk at the output of IC401. Two external components are used for the

flyback generator. C403 is used as part of the charge pump, while D401 is used to block the high voltage of the flyback pulse

during retrace.

VFB Signal Generation

For D98 VFB is a DC signal. It is generated by rectifying the flyback pulse generated at pin 3. D405 and C409 do the

rectification while R417 and R418 the DC level appropriately. If the flyback generation at IC401 does not work (ie. IC401

malfunctions) then the DC level at this point will be reduced and trigger the Vertical Shutdown Protection Mode after one

second the set’s LED will blink amber for 1.5 sec. and then off for 0.5 sec. This is the indication of a scan failure.

Troubleshooting Hints

Vertical Scan Failure

The first step is to check the shutdown log of the monitor and make sure the microprocessor has detected a loss of VFB.

Once this has been verified the output of IC401 should be checked. If a normal output exists after the remote on/off bit is

turned on but the monitor still shuts down then the VFB detection circuit (see VFB signal generation section) is malfunctioning. If no output exists signal tracing should begin at IC1002 pin 1 for VSAWN and pin 2 for DCC2. In shutdown

mode both of these levels should be 1.5V DC. If the remote on/off bit is turned on a sawtooth waveform of about 1Vpk-pk

should appear on VSAWN while DCC2 stays at 1.5V this should last about 2 seconds until a loss of VFB is detected and

the monitor shuts down again. If these signals are good check for the same signals at the output of the N-Board pins 13

(VSAWN) and 15 (DCC2) by repeating the remote on/off step. If no signal is present the problem is with IC1007, if

present continue tracing to R410 and R406. If the signals make it this far the problem is likely in the IC401 area.

IC401

4567123

D401

R407

C403

D405

C409

R417

R416

V.FBP

R418

- 20 -

Page 21

IC401

V-DY througt CN510

- 21 -

RL

R405R403

C403 D401

3

Flyback Generator

TDA8177

5417

R402

LVDY

C402

R401

-16V

R404

C406

D-BOARD

62

+

V+

V-

-

C401

0

+16V

C404

63

+

+

/

-

0

-

64

R409 R1053 R1061

IC1007/1A

+5V

V+

+

R1042

V-

-

R1036

C1010

VSAWN

1

0

IC1002(DSP)

DCC2

2

R410

R1052

R1068

R1081

IC1007/2A

+5V

0

+

V+

V-

C1009

0

0

N-BOARD

0

R1082

R1054

0

Page 22

Heater and Focus Voltages

from D Board

Rear Input

Video

Select,RGB

Process

D/A Conv

OSD Generation

Timing Analysis

A/D Conv

2

I

DDC2Bi

Rear

Input

DDC2B

Front

input

DDC2Bi to N Board

Front Input

Syncs to N Board

C Communication

H Sync,V Sync and H fly

DDC

19 D98 Chassis A board Block Diagram

VIDEO "A" BOARD ELECTRICAL CIRCUIT

RGB Cathode Drv

D/A Level

Active

Video

for ASC

Beam

Current

Feedback

Cuttoff

Voltage

J001

G2 Voltage

G2,Cutoff

and Beam

Current

Feedback

CRT

The main function of the A Board is to receive incoming video signals and process them into the RGB video drives necessary

for the CRT cathodes. Video signals can be received from two sources: One is the conventional 15 D-sub connector and the

second is an additional input located at the front of the monitor consis ing of the female portion of the 15 D-sub. The purpose

of this second input is to allow easy hookup to a laptop computer with the aid of an additional video cable (provided).

The A board circuitry also buffers the Sync timing signals, and provides On Screen Display (OSD) video. The timing

analysis for the Auto Size Center function as well as the Analog to Digital conversion for the Color Restoration functions are

processed on the A-board also. Additional functionality’s include: the Display Data Channel information functions to the

DDC equipped host computer and all the CRT cathodes operating voltages such as the heater, G2 and focus are either

processed or passed to the CRT socket (J001).

A Board Functions

The A Board functions are divided into four operational sections which are described as follows.

1) Video Select and RGB Process Functions

- Video input selecting is controlled by Microprocessor.

- Sync Timing Buffering.

- RGB video signal amplification and adjustment according to white balance requirements, contrast and

brightness settings.

- On Screen Display mixing.

- D/A conversion for RGB CRT cathode cutoff G2 levels control.

2) On Screen Display Generator, Timing Analysis and A/D Conversion

- OSD RGB video pattern generation.

- Timing analysis for Auto Size Center function.

- Analog to Digital Conversion for Color Restoration function.

- 22 -

Page 23

3) G2 and Beam Current Sensing Functions

- Amplifies setup levels provided by Preamplifier A/D outputs for G2 control.

- Beam Current Feedback (BCF) sensing for Color Restoration function.

4) Display Data Channel Interface

- DDC2Bi

- DDC2B

1. RGB Signal Processing (A Board)

RGB Signal Select

The Video and Sync inputs from the rear D sub and front input connectors are applied to the inputs of IC008. Each input is

terminated by an 82 Ohm resistor which is seen as 75 Ohm termination due to effect of the input impedance of IC008. IC008

switches between inputs, at the user’s discretion, when the input select button on the front panel is accessed. A low on IC008

Pin (9) selects the rear D sub input. Sync timing signals are buffered by IC008 before being sent to the N board. Sync on

Green timings are passed to IC001 where the sync signal is isolated and then sent to the N Board.

RGB Signal Amplifiers

Selected and buffered RGB video signals are amplified by IC001. Here the individual Sub Contrasts, Brightness offsets, and

Contrast gain levels are set by the Microprocessor via I2 C control. The OSD RGB video signals from IC003 are mixed into

the main video channels inside IC001. IC002 provides a final amplifier stage for the RGB video signals. This video driver

is internally set to a gain of –14. Therefore at the output pins of IC002 (Pin1, 3 & 5) the waveform is inverted with typical

drives levels on the order of 45Vpp. The Video Driver IC002 drives the CRT cathodes via AC coupling.

RGB Cathode Cutoff Amplifiers

The Red cathode DC cutoff level is amplified by IC004. It is controlled by the D/A output of IC001. The Red cutoff level is

Video Select and RGB Process Functions

+12V

+5V

IC008

R1

R2

G1

G2

B1

B2

V1

V2

H1

H2

SW

Sync Processi ng Circuit

Logic Sync BufferIC006

27

30

35

21

22

To N Board

2

I

2

I

CLK

BPCLP

R OSD

G OSD

B OSD

OSD BLK

10

5

6

C

C

H Sync

V Sync

C Sync

+5V

IC001

228

11

18

12

14

13

17

20

9

24

7

27

1

2

3

4

5

6

30

8

9

D/A G2 Control

4

C105

R

G

B

Cutoff Circui t

R107

R105

IC004

4

9

V-

V+

+

R116

+12V

R108

R122

+80V

IC003

610

D104

R119

R120

D108

D120

C106

C206

C306

+B

D106

D206

D306

R115

C108

+B +B

R219

R220

CRT

R316

R320

8

5

9

3

1

11

Video

Driver

7

10

13

C121

- 23 -

To IC003 A/D

Converters

Green and Blu e

Beam Current Se nsi ng Ci rcui t

Page 24

clamped by discharging C106 via D106. The Green and Blue cathode Cutoff levels are clamped in a similar fashion. The

individual cathode cutoff levels are set for white balance by the Microprocessor via I2C communication with IC001.

Troubleshooting Hints

1) If the screen is blank with no output check:

- Video signals with proper cutoff levels are provided to the CRT cathodes.

- Supply voltages are at the appropriate levels and locations starting at CN305.

- Heater voltage is correct and present at the heater cathode.

- Diode shorts at the cathodes.

- Sync timing signals are present at the output of IC008.

- That there is I2C communication to IC001.

2) If the screen is lighted with no video check:

- Control, blanking and clamp signals to IC001, IC002, and IC008.

- +5V, +12V, and +80V to these circuits.

-For shorted diodes on the IC002 outputs.

3) If colors are wrong or missing and white balance cannot be adjusted check:

- Each individual color signal path comparing DC offset and peak to peak signal levels to each other to determine if

there is any single amplifier at fault.

- For shorted diodes on the IC002 outputs.

2. On Screen Display Functions

On Screen Display(OSD)

IC003 is the On Screen Display character and graphic generator. It provides RGB and Fast Blanking data to IC001 for

mixing with the main video channels when required. Outputs voltages are two dimensional, either 0V or 3.6V. IC003 is

controlled by the Microprocessor via the I2C bus. The sync timings necessary are V sync and H Fly. The reference oscillator is set by an 8MHz crystal X001.

Timing Analysis

Timing Analysis for the Auto Size Center function is provided by IC003. Time measurements are taken with V sync (pin6),

H sync (pin5) and Active Video (pin7). These measurements are then sent to the Microprocessor via I2C communication for

size and centering calculations.

A/D Conversion for Color Restoration

Coloration can be achieved by measuring the CRT beam current during the blanking time. This current is converted to a

voltage via a sensing circuit. This voltage is converted to a digital format by the Analog to Digital converters contained in

IC003. There are three A/D converters for the RGB beam current feedback (BCF) circuits. These digital representations of

the RGB beam currents are stored in the BCF Red, BCF Green, and BCF Blue registers at the time white balance is finished

on the production line. In the field the Color Restoration can be achieved by sampling the RGB beam currents again and

comparing these new values to the ones stored in the BCF registers. The Microprocessor then adjusts the cutoff voltages

until the measured beam current is equal with the values stored in the BCF registers. This function is not done automatically.

It is necessary for the end user to activate this function through the OSD menu from the front panel controls.

Troubleshooting Hints

1) No OSD is displayed, check:

- RGB and Fast Blanking inputs to IC001. If there are no signals then IC003 may be at fault.

- That +5V is supplied to IC003(Note: Pin 18 will read 3.6V)

- V Sync and H fly signals are at pins 4 and 7 of IC003 respectfully.

- That Crystal X001 is oscillating (8MHz).

- That there is I2C communication to IC003.

2) Auto Size Center Does is not working, check:

- That +5V is supplied to IC003.

- V Sync, H Sync, H fly, and Active Video signals are at pins 6, 5, 7 & 8 of IC003 respectively.

- That Crystal X001 is oscillating (8MHz).

- That there is I2C communication to IC003.

- 24 -

Page 25

From N

Board

To

IC001

D024

ASC

Measurement

R080

C106

Active

Video

From

IC001

Timing

Analysis

Display

Controller

IC003

5V

Regulator

IC009

PLL

Oscill

ator

Cutoff

Control

D/A from

IC001

Beam Current

Measurement

Beam

Current

A/D

2

IC

Interface

Same as R

channel

C037

From N

Board

R003

Red

Green

Blue

C038

Cutoff Circuit

R107

C105

Simillar to

Red Channel

R105

+80V

+12V

IC003

610

D104

8

9

11

Video

Driver

IC004

4

9

V-

V+

+

R116

7

10

13

R108

C121

R122

Beam Current Sensing Circuit

C106

5

3

1

R119

R120

D108

D120

C206

C306

+B

D106

D206

D306

R115

C108

+B +B

R219

R220

CRT

R316

R320

3) Color Restoration doesn’t work. Bad color after restoration, check:

- That the OSD is working. If not follow steps of 1).

- BCF registers on the Color Table. Look to see if any registers are abnormally low or high.

The following are typical ranges:

Mode 1 Mode 2 Mode 3

R BCF 110~140 130~160 105~135

G BCF 115~145 90~120 130~160

B BCF 125~155 45~80 180~230

If values seem strange, check voltages at the BCF pins (20,21,22) of IC003. With a full white image the voltage should be

around 2.5~4.5V. If levels seem strange check beam current sensing circuit (next section).

3. G2 and Beam Current Sensing

G2 Amplifier

The G2 reference is provided to IC005 Pin 5 by the IC001 D/A converter. The G2 voltage at the cathode is typically 500v ~

750V.

Beam Current Sensing Circuit

Sensing resistors R108, R208, and R308 convert the beam current flowing through the cutoff amplifier during the blanking

time into a voltage. This voltage is then AC coupled and clamped to ground. It is then rectified to a DC voltage and sent to

the A/D converters of IC003. Here it is converted to digital format and stored in the RGB BCF registers.

Troubleshooting Hints

1) If picture is black, check:

- G2 level at the cathode using HV probe.

- Input to G2 amp, Pin 5 of IC005.

- 25 -

Page 26

Cutoff

Control

D/A from

IC001

To IC003 A/D Converter

Range

1V-4V

Red

Green

Blue

Cutoff Circuit

C105

Similar to

Red

Channel

R107

R105

Beam Current Sensing Circuit

D104

C106

C206

C306

Video

Driver

IC004

2

4

6

9

V-

-

11

12

V+

+

2

13

R108

R116

R122

D105

R119

R120

5

7

10

13

6

Beam Current Sensing Circuit

C121

D120

D108

C108

D106

D206

D306

R115

+B +B

R219

R220

R316

R320

Range 1V-4V

G2 Control Circuit

R048

R049

R047

13

5

V+

3

V-

6

2

12

11

IC005

CRT

Range 400V-800V

R053

R048R064

D045

Q1

R045

C048

R31

From IC001 D/A Converter

- Heater voltage at the cathode.

-+12V, +5V, and G2 voltage coming from D board.

2) Color Restoration doesn’t work. Bad color after restoration, check:

- Check waveforms at pins 6, 11 and 14 of IC004.

- Trace these signals through the rectifier back to IC003.

- If there are no waveforms at pins 6,11, and 14 then IC004 may be suspect.

4. Display Data Channel Circuits (DDC)

This display can support two video sources. The front input supports DDC2B. While the rear input supports DDC2Bi. For

DDC2B (Front Cable) IC007 is a serial memory device providing Extended Display Identification or EDID data that is read

by the compatible Host Computer on Pin 5. The basic EDID format consist of 128 bytes which are described in the table

below. The 15 Pin VGA connector allocation is also described. The compatible Host Computer provides a V CLK on Pin 7

that is derived from the V Sync input and is used to set the timing of each data reading cycle. The data is clocked by the

input of IC007 Pin 6. The rear input supports DDC2Bi. The data is passed through the A Board to the Microprocessor on the

N Board via CN311.

Troubleshooting Hints

1. The DDCB circuit should be checked if error DDC messages or erroneous monitor identification data is indicated by

DDC2B the compliant Host Computer. Check that the V CLK and S CLK signals are input to IC007 on Pins 7 and 6. The

Data transition should be visible at Pin 5.

- 26 -

Page 27

DDC Data format and VGA Connector Allocations

Basic EDID consist of 128 bytes 15 pin VGA type connector

Number Description Pin No Assignment Pin No Assignment

8 Bytes Header 1 RED Video 11 Option

10 Bytes Vender/Product Identification 2 GREEN Video 1 2 Data(SDA)

2 Bytes EDID Version/Revision 3 BLUE Video 1 3 H SYNC

5 Bytes Basic Display Parameters/Features 4 Option 1 4 V SYNC

10 Bytes Color Characteristics 5 Return 15 Clock(SCL)

3 Bytes Established Timings 6 Red Return

16 Bytes Standard Timings 7 Green Return

72 Bytes Detailed Timing Description 8 Blue Return

1 Bytes Extension Flag 9 Option +5V

1 Bytes Checksum 10 Sync Return

Display Data Channel Circuits (DDC)

DDCSLC

DDCSDA

Host GND

To CN306

1

2

3

D012

R92

D013

D011

R77

D010

IC007

DDC28

Cable

V Sync From Front Input

Front

D018

Host GND

4

DDC SDA

3

DDC SCL

2

D007

1

DDC2Bi(Rear Cable)

NC

D006

D005

1

3

2

To N Board

4

- 27 -

Page 28

N BOARD SYNC AND CONTROL CIRCUITS

Overview

The N board performs H and V Sync processing within the Microprocessor (IC1001)and DSP (IC1002 Digital Signal

Processor) which generates shaping, centering, deflection drive pulse and other corrections. The DSP is controlled by the

Microprocessor using I2C BUS with the Microprocessor having an external EEP ROM. Other Video functions are controlled

by Microprocessor through the I2C bus.

MICROPROCESSOR

H Sync (sync out from Microprocessor) and V sync (sync out from Microprocessor) is buffered by internal sync processors

and will be sent to DSP and OSD (on A board). In the absence of Video Input, this output will be the Microprocessor’s free

running output. The Microprocessor directly outputs the control of H center, H Lin Balance, and Rotation by DAC outputs. In

Accordance with the monitor’s operating condition, it switches the Remote On/Off, Heater On/Off, Input select, S Caps, and

Degauss.

DSP (Digital Signal Processor)

This IC requires 3.3v VDD. The 3.3vdc is supplied from IC1006 (Regulator). The DSP outputs waveforms for the deflection

circuit with most of these going to D Board. Pin #1 is V SAW output and will go to D board through IC1007 acting as a

buffer. Pins#6 and #7 are for Dynamic Convergence. Pins #60, 61 are for Static Convergence. Pin #10 is H DF output and

#58 is V DF. Pin #59 is V Key output and #64 is H Shape. Pin #57 is PIN/KEY Bal out, this is supplied to the Phase Lock

Loop(PLL) Circuit of the DSP which is on pin#12 – 22. H Drive Pulse will be outputted from pin#25 after being modulated

by Bal correction and Moire correction(#22). This IC works with 3.3v VDD. The 3.3v is supplied from the IC1006 (Regulator)

Trouble Shooting Hints

See attached “FLOW CHART” to confirm N Board issues.

Incorrect/No Wave form from DSP

Check the 3.3vdc from IC1006, if O.K, confirm that I2C BUS is sending a pulse(0v-5v) to the DSP. Confirm that Reset

(pin#49) is HI and POC-IN(pin#30) is almost 1v.

No Communication or Microprocessor related failur e

Check CN1003, CN1004 connections first. If OK, then check 5v supply and to see if X1001 is oscillating, also

RESET(pin#54) is HI. In case of No Communication, confirm pin #38(RXD) is receiving pulse signal (0v-5v).

From A boad

H Sync in

V Sync in

HFDP

KEY SCAN

TXD/RXD

ABL

HVDET

C Sync in

IN PUT SW

REMOTE

DEGAUSS

HEATER

-S1

-S2

-S3

IC1001

MICRO

H CENT

ROTATION

H LIN BAL

IC1005

EEPROM

I2 C BUS

H SYNC OUT

V SYNC OUT

RESET

IC1003

RESET

XSC/YSC

XDC/YDC

HDF/VDF

H SHAP

V Key

HD

IC002

DSP

DCC

2

C BLANC

3.3V

V SAW

IC1007

BUFFER

N board

IC1006

DSP

5V

- 28 -

Page 29

System Block Diagram

IN VIDEO X2

IN SYNC X2

DISPLAY DATA COMMUNICATION BUS

(DDC)

HEATER

MAIN

AC

POWER SW

POWER SUPPLY

JIG

I/O(RS232C)

D BOARD

DC POWER

2

I

C-BUS

Deflection

PS Mode

VIDEO BLOCK

ASC Measurement

1Kv

SYNC PROC.&

CONTROL

N-BOARD

OSD

A-BOARD

Sync

FOCUS

BLOCK

FBT

I/O

RGB VIDEO

FOCUS/G2

STATIC/

DYNAMIC

FOCUS

H & V

DEFLECTI

I/O

ON

HV

D.CONV

H/V

DEF.

TILT

USER

CONT

H

BOARD

Alignment jig

(factory,service)

PC

(Host computer)

DIGITAL CONTROL COMMUNICATION DIAGRAM

HV sync

Micro

DDC

processor

IC1001

User conrol/

Power sw

2

I

C-BUS

VIDEO BOARD

A BOARD

DSP IC

IC002

EEPROM

Pre-AMP

IC001

OSD

IC003

BIAS

DRIVE

CONTRAST

BRIGHT

G2

Information for USER

SIZE(ZOOM)

CENT

GEOM(PIN,KEY.x)

CONV.(STAT,DYNAMIC)

FOCUS

N BOARD

- 29 -

Page 30

GENERAL TROUBLESHOOTING

Input crosshatch signal at prime

Mode 94KHz X 70 Hz

No Picture A

Missing Color or Abnormal Color

Visible Retrace or Visible Raster

Mis-convergence

Poor Focus

Unsynchronized Image

B

C

D

E

F

Abnormal Geometry

Abnormal Image Size

Shutdown I

No Communication

- 30 -

G

H

J

Page 31

NO PICTURE

A

Is amber

Power LED

Blinking?

No

Is

amber LED steady on?

No

Is green power LED On?

Yes

Does

A-Board make proper

contact with CRT gun?

Yes

Yes

No

No

Yes

I

(See Part Level Board Repair Section)

Check the video cable connection or

INPUT SELECT registers

Is Monitor beeping? (Small)

No

Press power switch, if LED does no turn on,

repair"power supply"

Carefully press A Board

to make proper contact with CRT gun

1

Yes

Repair Video circuit

or repair H deflection

12

2

Check heater, G2, red, green and blue cathode

voltage levels.

Repair Video if needed

12

Done

No

- 31 -

Can you get picture?

Yes

Page 32

MISSING COLOR

B

Yes

Check signal generator & cable

I

(See Parts Level Board Repair Section)

No

Yes

Are proper video

levels present

on CN307,on313

pin 2, 4 &6?

Yes

Is amber

Power LED

Blinking?

No

12

(See Parts Level Board Repair Section)

- 32 -

Page 33

VISIBLE RETRACE

C

Yes

Check white balance

adjustment and check "H

Blank" register value.

Check IC004, IC005,G2

control circuit. IC001

pin 6 and FBT

Check connections &

signal at CN309 pin 1I

Check CN309 Pin 3

3

No

No

No

Is G2 voltage correct?

Yes

Is

blanking pulse present on pin18

of IC001 on A-Board?

Yes

Is blanking

pedestal present in the

waveforms at pin 12 of

IC001?

Yes

Check IC002 and IC004

No

blanking pulse present on all

Is

cathodes?

Yes

Done

- 33 -

Page 34

MISCONVERGENCE

D

Reset and check,

Try adjusting convergence

using front panel controls

Yes

Try adjusting convergence

using DAS

Is the convergence

within spec ?

No

No

Is the convergence

now within spec?

Check the convergence

circuit(IC701,704)

Change DY and

readjust convergence

Is the convergence

within spec

now?

Yes

Yes

Done

Is the convergence

circuit(IC701,704)

OK ?

No

Repair &

adjust

B

Yes

No

Change CRT &

readjust

conergence

Done

- 34 -

Page 35

POOR FOCUS

E

Adjust focus

VRs on FBT

Age monitor and

check for focus

change

6

Yes

Improved

focus?

No

Check focus leads

from FBT to CRT

socket

Check video bond CRT

socket

No

Is dynamic focus

circuit OK ?

(See Parts Level Board

Repair section)

Yes

Replace CRT

and verify

focus

Done

- 35 -

Page 36

UNSYNCHRONIZED IMAGE

F

Check input

signals CN307 or CN313

pins 4,8 and 9

Check video

cable

Check sync

separation circuits

on video board

Check wire

dressing and

connection

(from N board)

OK but

no

still

syncro

No

No

No

Signals levels

correct?

Yes

Signals at CN309

pin 4, 5 or 7

OK?

Yes

Signals at CN

306 pins1 and

2 OK?

Yes

Check N board

10

Done

- 36 -

Page 37

ABNORMAL GEOMETRIC DISTORTION

G

Down load

factory settings

and readjust

3

(See Parts Level Board

Repair Section)

Does distortion change

a lot when changing to

inverse pattern

No

Identify distortion

problem and repair

(see board level repair)

See"H Deflection circuit"

"H Line/Ringing correction"

Explanation

57

or

No

Is geometric

distortion OK?

Yes

Done

- 37 -

Page 38

5

(See part level board

Repair Section)

4

ABNORMAL IMAGE SIZE

H

With user controls

adjust picture size

No

Does horizontal size

adjustment?

Yes

No

Does vertical size

adjustment ?

(See part level board

Repair Section)

Yes

Adjust monitor

Done

- 38 -

Page 39

Check power

supply

10

SHUT DOWN

I

No

Is amber

LED blinking

Yes

Check shut down

log registers in IC1001

and Repair refering to

the explanation of

"Shut down"

- 39 -

Page 40

NO COMMUNICATION

J

Yes

Check connections

Check connect settings

and connections

Check Power supply

No

No

No

Are connections

to monitor OK?

Yes

Are computer settings and

connections OK?

Yes

Is 5 volts present

at CN801 pin 43?

Yes

Check N board

10

Done

- 40 -

Yes

Page 41

PARTS LEVEL BOARD REPAIR

Parts Level Board Repair

(1) Power Supply

(2) Horizontal Delection

(3) High Voltage

(4) Vertical Deflection

(5) Horizontal Size

(6) Horizontal Center

(7) Key and Pin

(8) Key and Pin Balance

(9) Rotation

(10) N board

(11) Dynamic Focus

(12) Video

(13) Convergence

- 41 -

Page 42

POWER SUPPLY

1

Check F601

and D601

Check Q505,506,901,

902 and video board

Check

IC701,703,704,604,601,504

R617

Replace Q602,

Check D603,615

R609,615,IC601

Replace parts,

verify voltage

Yes

Yes

No

No

Does power

supply make

chirping noise?

No

Does Power supply

try to start?

No

Q602 OK?

Yes

Are D603,615

R609,615

IC601 OK?