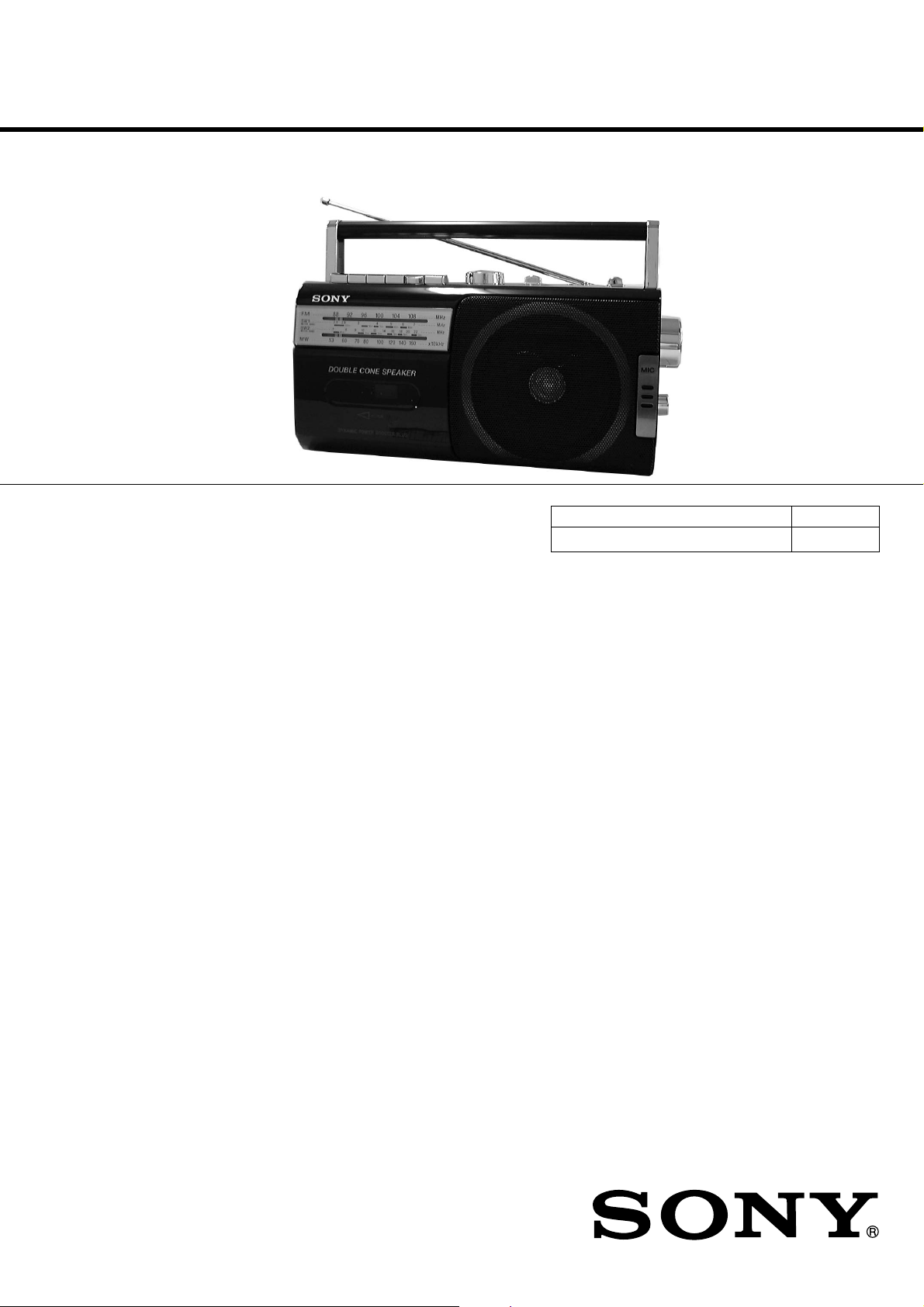

SONY CFM S1MK2 Service Manual

CFM-S1MK2

SERVICE MANUAL

Ver 1.1 2003.05

E Model

Model Name Using Similar Machanism NEW

Tape Transport Mechanism Type MF-M20-117

• Frequency range

FM: Saudi Arabia: 87.6 - 107 MHz

Other models: 87.6 - 108 MHz

MW: 530 - 1 605 kHz

SW1: 2.3 - 7 MHz

SW2: 7 - 22 MHz

• Aerials FM/SW: Telescopic aerial

MW: Built-in ferrite bar aerial

• Recording system 2-track 1 channel mono

• Frequency response 80 - 8 000 Hz

• Speaker Full range: 12 cm (4 3/4 inches) dia., 6Ω, cone

type (1)

• Outputs Earphones jack

For 8 Ωimpedance earphones

SPECIFICATIONS

• Maximum power output 1.4 W

• Power requirements 110 - 120, 220 - 240 V AC

selectable, 50/60 Hz

6 V DC, 4 R20 (size D) batteries

• Power consumption AC 8 W

• Battery life

FM recording: Sony R20P: approx. 18 h

Sony alkaline LR20: approx. 50 h

Tape playback: Sony R20P: approx. 12 h

Sony alkaline LR20: approx. 30 h

• Dimensions Approx. 287 X 147 X 110 mm (w/h/d)

(11 3/8 X 5 7/8 X 4 4/8 inches) (incl. projecting parts)

• Mass (incl. batteries) Approx. 2 kg (4 lb. 7 oz)

• Supplied accessory Mains lead (1)

Design and specifications are subject to change without

notice.

9-874-212-02

2003E0200-1

© 2003.05

RADIO CASSETTE-CORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

CFM-S1MK2

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. GENERAL

Location and Function of Controls .................................... 2

2. DISASSEMBLY

2-1. Cabinet (Front) ASSY................................................. 3

2-2. MD ASSY................................................................... 3

2-3. Record/Playback Head (HRP101),

Reel/Capstan Motor (M101),Belt ............................... 3

2-4. Jack Board, Main Board, Fine Tune Board ................ 4

2-5. Battery Terminal Board, Power Board, ...................... 4

2-6. Note on Instalation ...................................................... 5

2-7. Dial Pointer Setting .................................................... 5

3. ADJUSTMENTS

3-1. Mechanical Adjustments............................................. 6

3-2. Electrical Adjustments ................................................ 6

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS LIST

ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

4. DIAGRAMS ...................................................................... 9

4-1. Block Diagrams ......................................................... 11

4-2. Schematic Diagrams -Main Section (1/2) - ............. 12

4-3. Schematic Diagrams -Main Section (2/2) - ............. 13

4-4. Printed Wiring Boards .............................................. 14

5. EXPLODED VIEWS

5-1. Front Cabinet Section ............................................... 16

5-2. Rear Cabinet Section ................................................ 17

5-3. Mechanism Deck Section-1(MF-M20-117) ............. 18

5-4. Mechanism Deck Section-2(MF-M20-117) ............. 19

6. ELECTRICAL PARTS LIST ........................................ 20

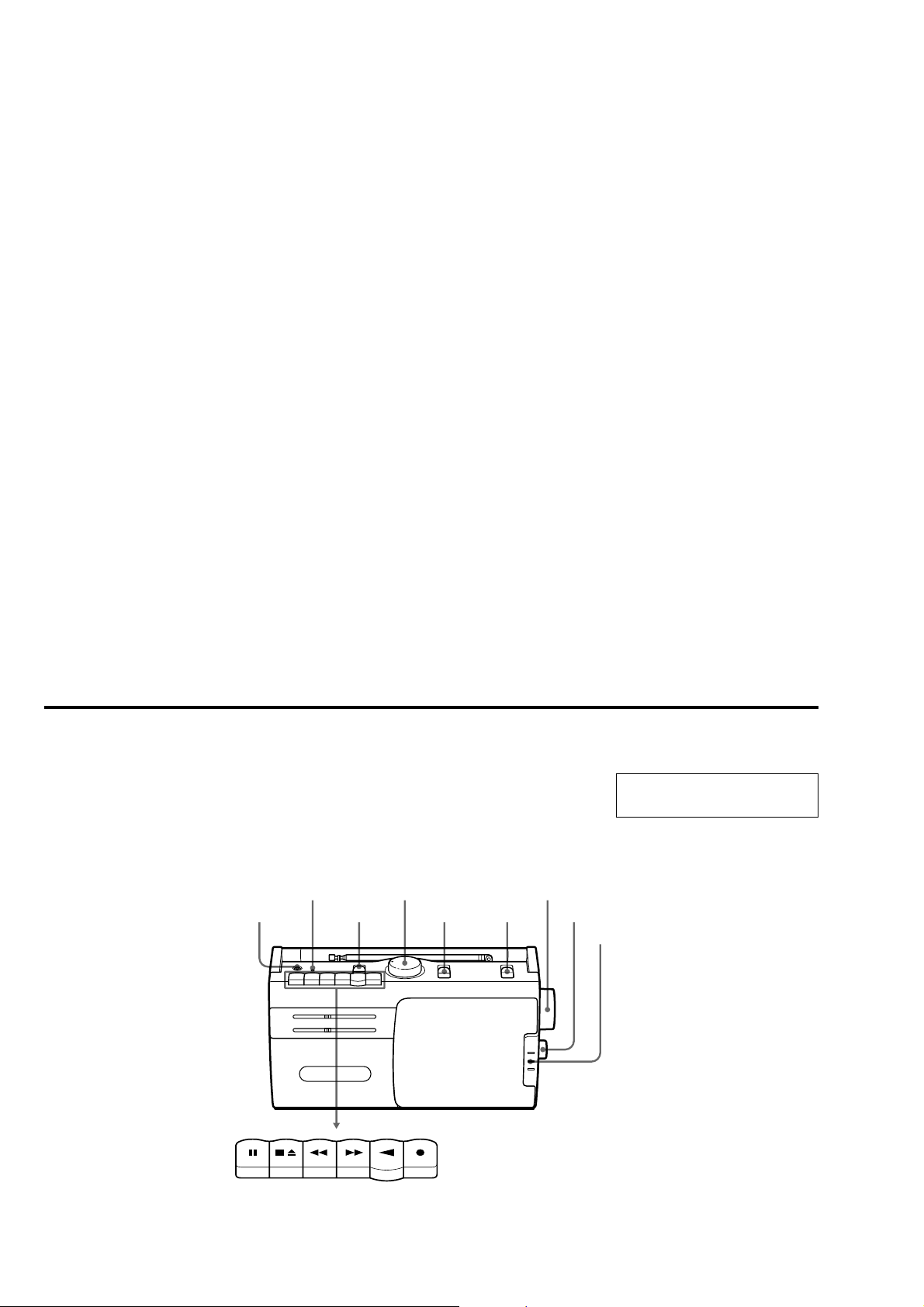

Location and Function of Controls

@

PAUSE

STOP/EJECT

SECTION 1

GENERAL

VOLUMEOPR/BATT

DPB

FF REW PLAY REC

BAND

This section is extracted from

instruction manual.

TUNING

FINE TUNINGFUNCTION

MIC

2

r

SECTION 2

4

)

DISASSEMBLY

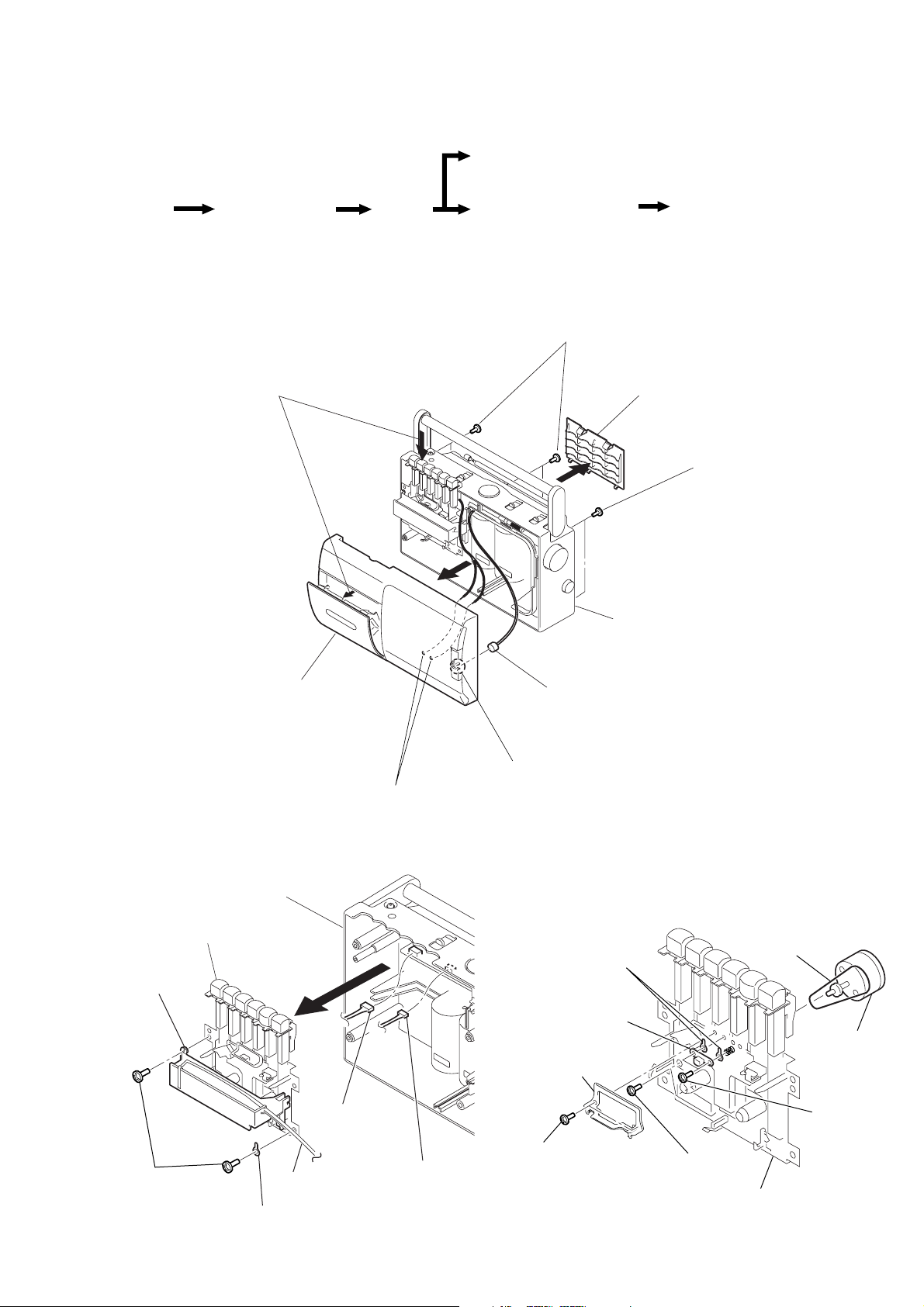

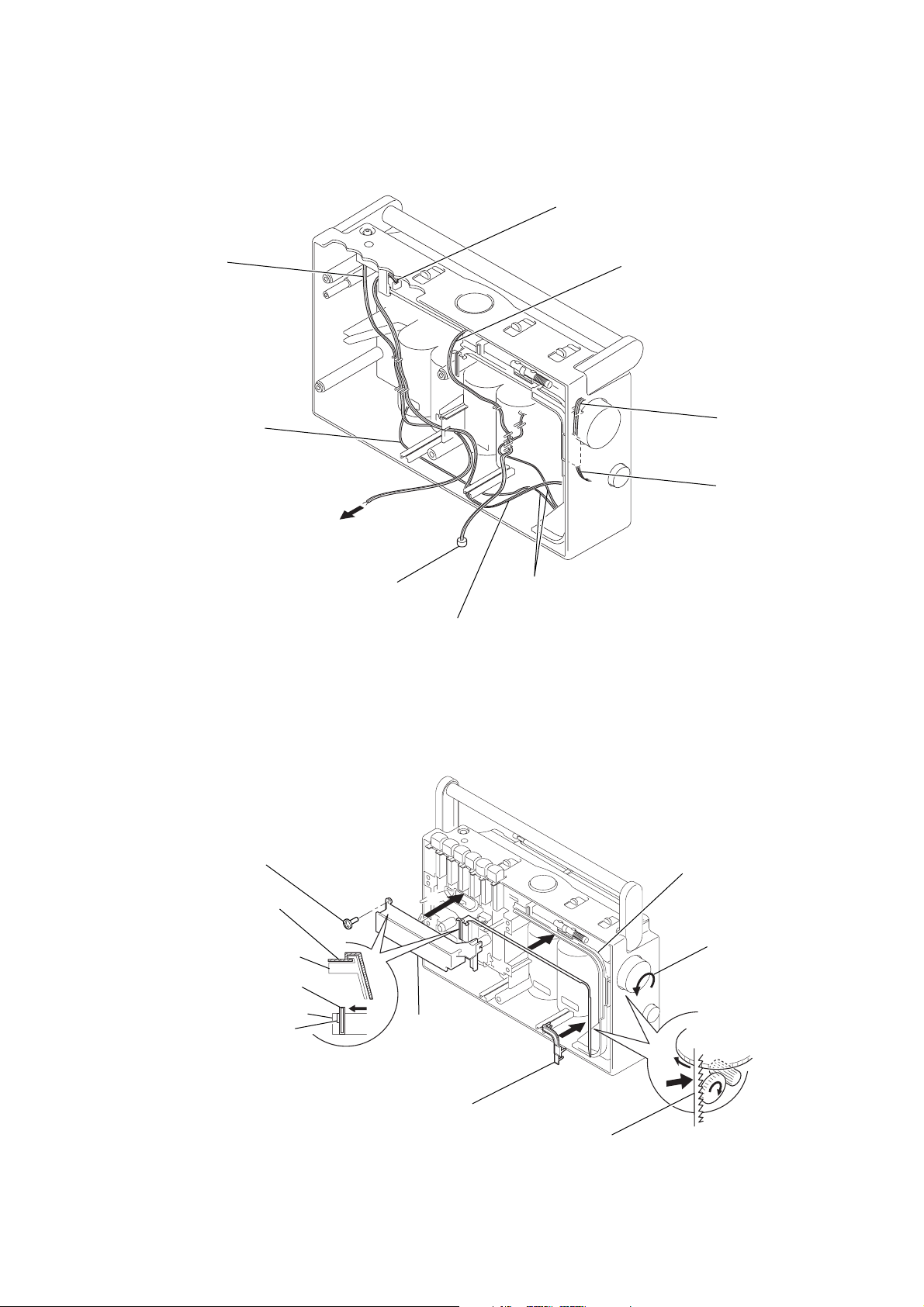

• The equipment can be removed using the following procedure.

CFM-S1MK2

Record/playback head (HRP101),

Reel/capstan motor (M101), Belt

Set

Cabinet (front) assy

MD assy

JACK board, MAIN board,

FINE TUNE board

Note : Follow the disassembly procedure in the numerical order given.

2-1. CABINET (FRONT) ASSY

Press the STOP/EJECT button

3

4

2

Screws + BVTP 3X14

1

BATTERY TERMINAL board,

POWER board

Lid, Battery case

2

Rear assy, Cabinet

Screws + BVTP 3X1

2-2. MD ASSY

MD ASSY

Chassis(B)

1

Screws

+ BVTP 3X10

Cabinet(front) ASSY

Rear assy, cabinet

pointer

Lug

6

Remove solder (two places)

3

4

Connector

(CNP102)

Connecto

2

(CNP101)

Microphone

Claws

5

2-3. RECORD/PLAYBACK HEAD (HRP101), REEL/CAPSTAN MOTOR (M101), BELT

8

5

4

Record/playback

head (HRP101)

2

Guide, tape

1

Screws Tapping+B

Lug (T), plate

6

Screws + P2X 5

MD ASSY

Belt

Reel/capstan

7

motor (M101

3

Screws

+ PTT 2X 5

3

CFM-S1MK2

t

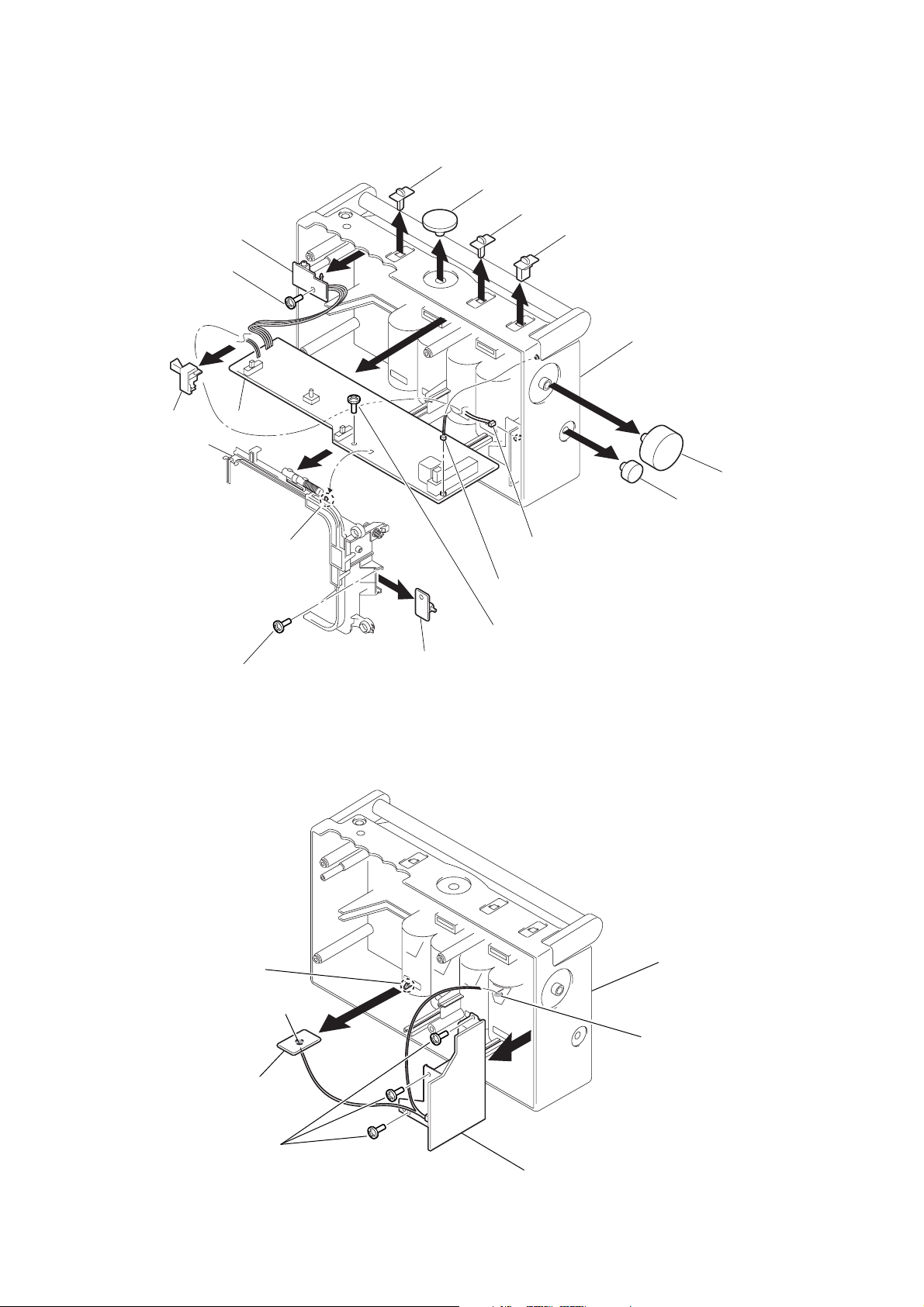

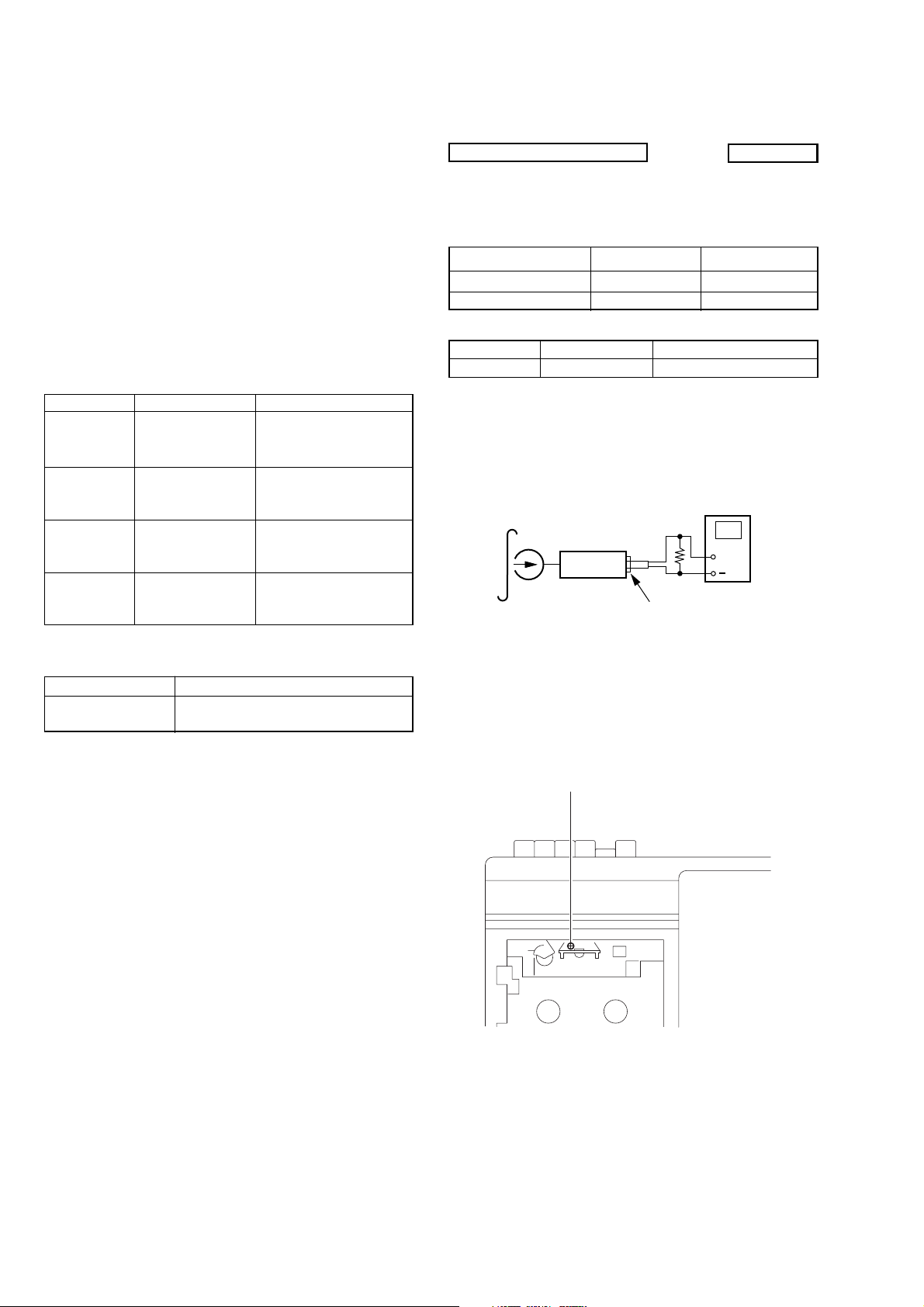

2-4. JACK BOARD, MAIN BOARD, FINE TUNE BOARD

JACK board

Knob(sound)

1

1

Knob(vol)

Knob(function)

1

Knob(band)

1

3

Screw +BVTP 3X10

Bracket(PWB)

Chassis(A)

9

4

MAIN board

7

Claw

Screws + BVTP 3X10

8

4

4

0

2-5. BATTERY TERMINAL BOARD, POWER BOARD

5

6

FINE TUNE board

2

Connector (CNP901)

Connector (CNP1)

Screw +BVTP 3X10

Rear assy, Cabinet

1

Knob(FT)

1

Knob(tune)

1

Claw

3

Remove solder

BATTERY TERMINAR board

5

Screws + BVTP 3X10

2

6

POWER board

Rear assy, Cabine

4Remove Solder

4

2-6. NOTE ON INSTALATION

1

Turn the knob(tune)

fully counterclockwise.

Pointer

Chassis(A)

6

6

Hold the left side of pointer,

then insert the gear section

of pointer to groove of chassis(A).

2

Fit the pointer to the

chassis(B).

5

Set the left side of the

pointer to the convex

portion (a) on the

chassis(B).

Chassis(B)

6

3

7

Bracket(P)

4

Screw + BVTP 3X14

Pointer

Chassis(B)

Pointer

(a)

Chassis(B)

Dress the lead wires as shown in figure.

CFM-S1MK2

Main board (KH102)

To jack board

To battery terminal board

To speaker

(SP1)

2-7. DIAL POINTER SETTING

MIC (ECM101)

Power board (CN901)

Main board (KH101)

Main board (KH1)

Fine tune board (KH2)

Power board (KH901)

5

CFM-S1MK2

)

SECTION 3

ADJUSTMENTS

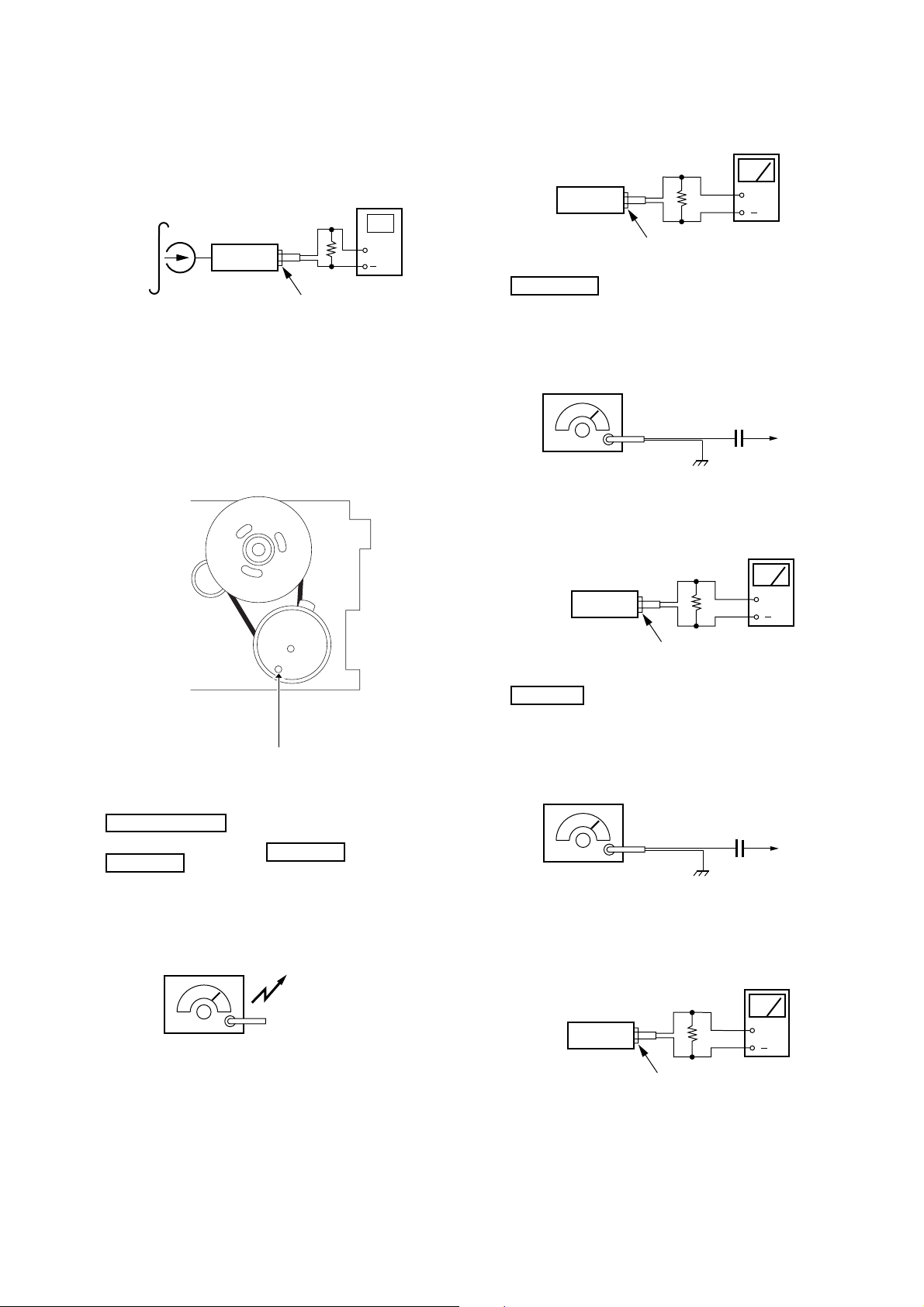

3-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1.Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan

2.Demagnetize the record/playback head with a head demagnetizer.

(Do not bring the head demagnetizer close to the erase head.)

3.Do not use a magnetized screwdriver for the adjustments.

4.After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power sup

ply voltage unless otherwise noted.

Torque Measurement

Tor que Torque Meter Meter Reading

Forward CQ-102C

Forward

Back Tension

CQ-102C

Fast Forward CQ-201B

Rewind CQ-201B

Tape Tension Measurement

Torque Meter Meter Reading

CQ-403A

1.77 to 5.88 mN•m

(18 to 60 g•cm)

(0.25 to 0.83 oz•inch)

0.01 to 0.49 mN•m

(1 to 5 g•cm)

(0.014 to 0.069 oz•inch)

4.42 to 9.31 mN•m

(45 to 95 g•cm)

(0.63 to 1.31 oz•inch)

4.42 to 9.31 mN•m

(45 to 95 g•cm)

(0.63 to 1.31 oz•inch

more than 100g

(more than 3.53 oz)

)

3-2. ELECTRICAL ADJUSTMENTS

TAPE RECORDER SECTION

FUNOTION switch : TAPE (RADIO OFF)

SOUND switch : OFF

VOLUME : MIN

Standard Output Level

Output terminal Earphone Speaker

load impedance 8Ω 6Ω

output signal level 0.25V (–10dB) 0.775V (0dB)

Test Tape

Type Signal Used for

WS-48A 3kHz, 0dB Tape Speed Adjustment

Record/Playback Head Azimuth Adjustment

Procedure :

1.Playback Mode

test tape

P-4-A100

(10kHz, -10dB)

set

8

Ω

J101 (Earphone jack

2.Rotate the screw to adjust level meter reading to the maximum.

Note : Adjust to the maximum peak though there may be two or

three peakes

3.After the adjustment, lock the adjustment screws with suitable

locking compound.

Adjustment Location :

0dB=0.775V

level meter

+

Head azimuth adjustent screw

6

Tape Speed Adjustment

y

r

c

r

c

r

Procedure :

Mode : Playback

test tape

WS-48B

(3kHz, 0dB)

set

digital frequenc

counter

8Ω

+

J101 (Earphone jack)

level mete

8Ω

set

J101 (Earphone jack)

SW Section

BAND switch : SW1, SW2

FINE TUNING control : mechanical center

CFM-S1MK2

+

Adjustment Value :3,000Hz

Standard Value :2,990 to 3,010Hz

Frequency difference between the beginning and the end of the tape

should be within 1.0% (30Hz).

Adjustment Location :

tape speed adjustment

control inside motor

AM RF signal

generator

30% amplitude

modulation by 400Hz signal

output level : as low as possible

set

FM Section

Function switch : FM

Volume : MIN

FM RF signal

generator

12pF

level mete

8Ω

J101 (Earphone jack)

telescopi

antenna

terminal

+

TUNER SECTION

MW Section

Function switch : MW

Volume : MIN

AM RF signal

generator

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

µ

0.01 F

0dB=1µV

22.5kHz frequency deviation by

400Hz signal.

Output level : as low as possible

Put the lead-wire

antenna close to

the set.

8Ω

set

J101 (Earphone jack)

telescopi

antenna

terminal

level mete

+

7

CFM-S1MK2

t

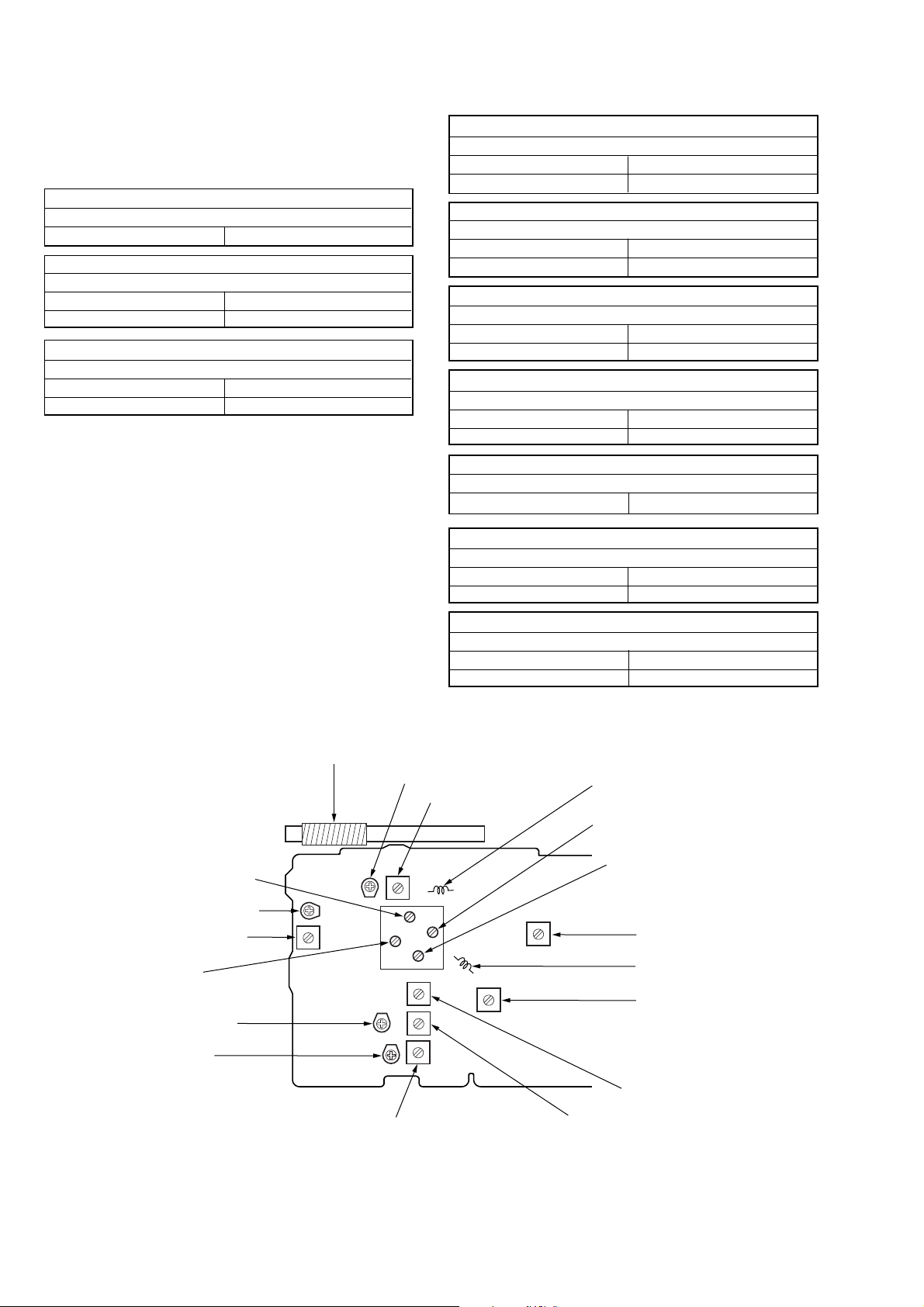

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

< > : Saudi Arabia model

AM(MW/SW) IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1 455kHz

MW FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 520kHz <516kHz>

CT4 1,680kHz <1,630kHz>

MW TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 600kHz

CT3 1,400kHz

SW1 FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L7 2.2MHz

CT7 7.3MHz

SW1 TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L6 2.2MHz

CT6 7.3MHz

SW2 FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L9 6.8MHz

CT9 22.5MHz

SW2 TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L8 6.8MHz

CT8 22.5MHz

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

L5 10.7MHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L2 86.50MHz <87.35MHz>

CT2 109.50MHz <107.80MHz>

Adjustment Location : MAIN board (Component side)

L3: MW Tracking Adjustment

[MAIN BOARD]

(Component side)

CT3 : MW Tracking Adjustment

CT6 : SW1 Tracking Adjustment

L6 : SW1 Tracking Adjustment

CT4: MW Frequency

Coverage Adjustment

CT9 : SW2 Frequency

Coverage Adjustment

CT7 : SW1 Frequency

Coverage Adjustment

Adjust for a maximum reading on level meter.

CT8 : SW2 Tracking Adjustment

L8 : SW2 Tracking Adjustment

L7 : SW1 Frequency

Coverage Adjustment

FM TRACKING ADJUSTMENT

L1 86.50MHz <87.35MHz>

CT1 109.50MHz <107.80MHz>

L1 : FM Tracking Adjustment

CT1 : FM Tracking Adjustment

CT2 : FM Frequency

Coverage Adjustment

T1 : AM (MW/SW) IF Adjustmen

L2 : FM Frequency

Coverage Adjustment

L5 : FM IF Adjustment

L4 : MW Frequency

Coverage Adjustment

L9 : SW2 Frequency

Coverage Adjustment

8

Loading...

Loading...