Page 1

CFD-V8

SERVICE MANUAL

Ver 1.3 2004.09

Model Name Using CD Section CFD-V7

Similar Mechanism Tape Section CFD-V7

CD Mechanism Type (Former Type/New Type) KSM-213RDP/KSM-213CDP

Optical Pick-up Type (Former Type/New Type) KSS-213R/KSS-213C

Tape Transport Mechanism Type MF-V5-117

Canadian Model

AEP Model

UK Model

E Model

Australian Model

CD player section

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wave length: 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of about 200

mm from the objective lens surface on the optical pick-up

block with 7 mm aperture.)

Spindle speed

200 r/min (rpm) to 500 r/min (rpm) (CLV)

Number of channels

2

Frequency response

20 - 20 000 Hz +1/–2 dB

Wow and flutter

Below measurable limit

Radio section

Frequency range

FM: 87.6 - 107.0 MHz or 87.6 - 108.0 MHz

AM: 531 - 1602 kHz or 530 - 1 710 kHz

Antenna

FM: Telescopic antenna

AM: Built-in ferrite bar antenna

SPECIFICATIONS

Cassette-corder section

Recording system

4-track 2 channel stereo

Fast winding time

Approx. 120 s (sec.) with Sony cassette C-60

Frequency response

TYPE I (normal): 80 - 10 000 Hz

General

Speaker

Full range: 10 cm dia., 3.2 Ω, cone type (2)

Outputs

Headphones jack (stereo minijack)

For 16 - 68 Ω impedance headphones

Power output

1.8 W + 1.8 W (at 3.2 Ω, 10 % harmonic distortion in AC

operation)

Power requirements

For CD radio cassette-corder: 120V AC, 60Hz (CND, TW)

220V AC, 60Hz (KR)

230V AC, 60Hz

(AEP, UK, AUS, CET, IT, SP)

9 V DC, 6 size D (R20) batteries

Power consumption

AC 20 W

9-961-329-04

2004I02-1

© 2004.09

– Continued on page 2 –

CD RADIO CASSETTE-CORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

Page 2

CFD-V8

Ver 1.2

Battery life

For CD radio cassette-corder:

FM recording

Sony R20P: approx. 13.5 h

Sony alkaline LR20: approx. 20 h

Tape playback

Sony R20P: approx. 7.5 h

Sony alkaline LR20: approx. 15 h

CD playback

Sony R20P: approx. 2.5 h

Sony alkaline LR20: approx. 7 h

Dimensions

Approx. 420 x 165 x 256 mm (w/h/d)

(16 5⁄8 x 6 1⁄2 x 10 1⁄8 inches) (incl. projecting parts)

Mass

Approx. 4.1 kg (9 lb. 1 oz) (incl. batteries)

Supplied accessory

AC power cord (1)

Design and specifications are subject to change without notice.

• Abbreviation

CND : Canadian

CET : East European & Russian

IT : Italian

SP : Singapore

AUS : Australian

TW : Taiwan

KR : Korean

Information

For customers in Europe

TABLE OF CONTENTS

Specifications ............................................................................... 1

1. SERVICING NOTES...................................................... 3

2. GENERAL

Location and Function of Controls ....................................... 4

3. DISASSEMBLY

3-1. Cabinet (Front) Sub ASSY, Cabinet (Rear) ................. 5

3-2. Control Board .............................................................. 5

3-3. Cabinet (upper) ............................................................ 6

3-4. Power Board, Inlet Board, BATT (R) Board,

BATT (L) Board ........................................................... 6

3-5. Volume Board, FM SW Board, Main Board ............... 7

3-6. PRE Board, Mechanism Deck,

Optical Pick-up Section, CD Board ............................. 7

3-7. Belt, M601 (Capstan / Reel Motor),

“HRP901 Head, Magnetic (Record/Playback)”,

HE901 Head (Erase) .................................................... 8

3-8. Optical Pick-up (KSS-213C) ....................................... 8

4. DIAL POINTER INSTALLATION .............................. 9

5. ADJUSTMENTS

5-1. Mechanical Adjustments............................................ 10

5-2. Electrical Adjustments............................................... 10

6. DIAGRAMS

6-1. IC Pin Function Descrintion ...................................... 13

6-2. Block Diagrams – Tuner/TC Section – .....................15

6-3. Block Diagrams – Main Section –............................. 16

6-4. Block Diagrams – CD Section –................................ 17

6-5. Printed Wiring Boards – Main Section – ................... 18

6-6. Schematic Diagrams – Main Section (1/3) –.............19

6-7. Schematic Diagrams – Main Section (2/3) –.............20

6-8. Schematic Diagrams – Main Section (3/3) –.............21

6-9. Printed Wiring Boards – Control/Power Section –...... 22

6-10. Printed Wiring Boards – Control/Power Section –.... 23

6-11. Schematic Diagrams – CD Section –......................... 24

6-12. Printed Wiring Boards – CD Section –...................... 25

This Compact Disc player is classified as a CLASS 1 LASER

product.

The CLASS 1 LASER PRODUCT label is located at the bottom

of the player.

CAUTION

Use of controls or adjustments or performance

of procedures other than those specified herein

may result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR IN

SUPPLEMENTS PUBLISHED BY SONY.

2

7. EXPLODED VIEWS

7-1. Front Cabinet Section ................................................ 30

7-2. Rear Cabinet Section ................................................. 31

7-3. Upper Cabinet Section...............................................32

7-4. Mechanism Deck Section (1) .................................... 33

7-5. Mechanism Deck Section (2) .................................... 34

7-6. CD Block Section ...................................................... 35

8. ELECTRICAL PARTS LIST ...................................... 36

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS

QUE PAR DES PIÈSES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU DANS LES SUPPÉMENTS

PUBLIÉS PAR SONY.

Page 3

SECTION 1

SERVICING NOTES

CFD-V8

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled

with care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode

emission, observe more than 30 cm away from the objective

lens.

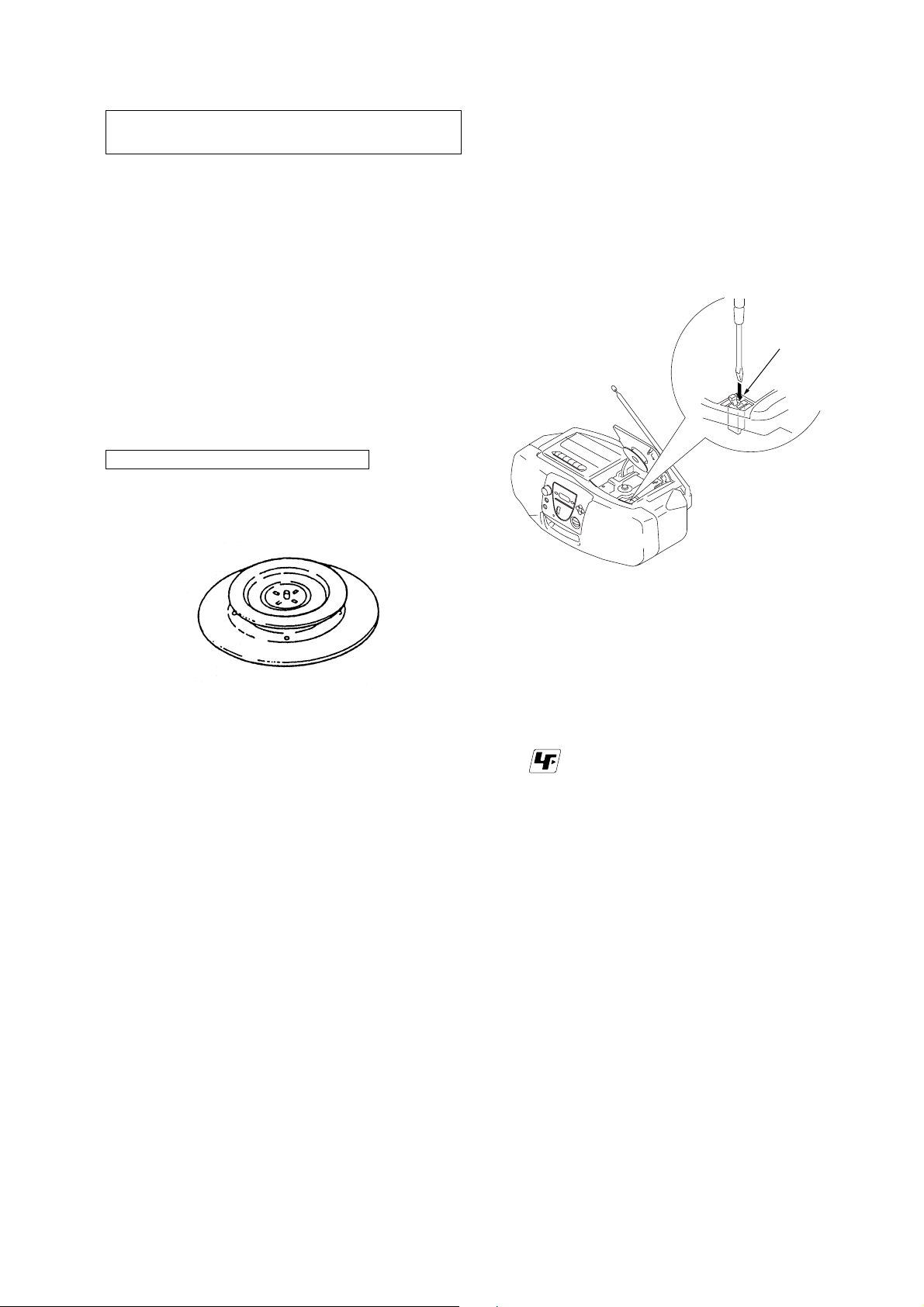

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig : X-4918-255-1

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

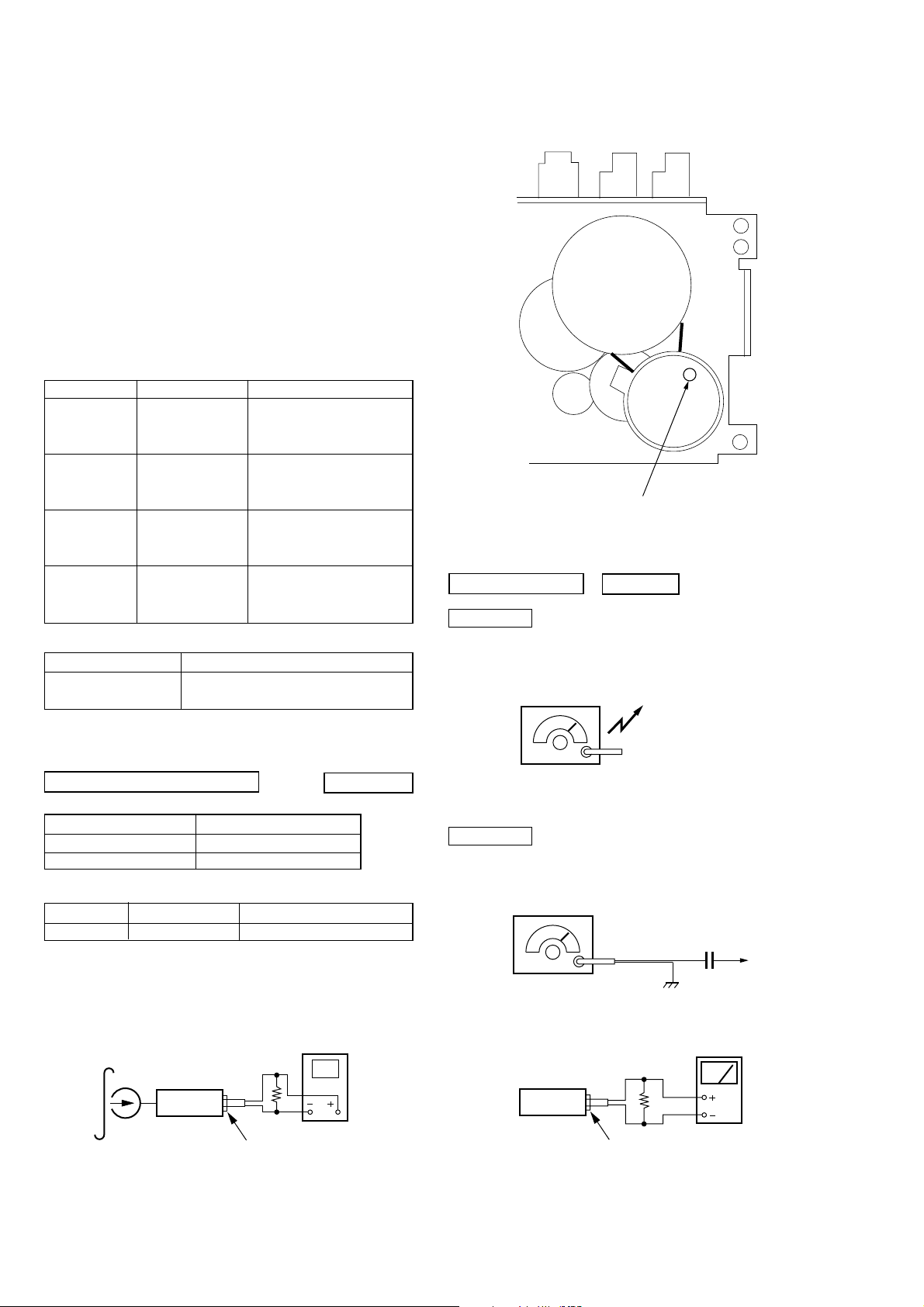

1. Press CD open knob.

2. Open the lid for CD.

3. Push on SWITCH (S801) as following figure.

4. Confirm the laser diode emission while observing the

objecting lens. When there is no emission, Auto Power

Control circuit or Optical Pick-up is broken.

Objective lens moves up and down once for the focus

search.

Insert a precision

screw driver and push

SWITCH (S801)

r

UNLEADED SOLDER

Boards requiring use of unleaded solder are printed with the

lead-free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed

with the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher

than ordinary solder.

Ordinary soldering irons can be used but the iron tip has to

be applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set

to about 350°C.

Caution: The printed pattern (copper foil) may peel away if

the heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to

flow) than ordinary solder so use caution not to let solder

bridges occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder

may also be added to ordinary solder.

3

Page 4

CFD-V8

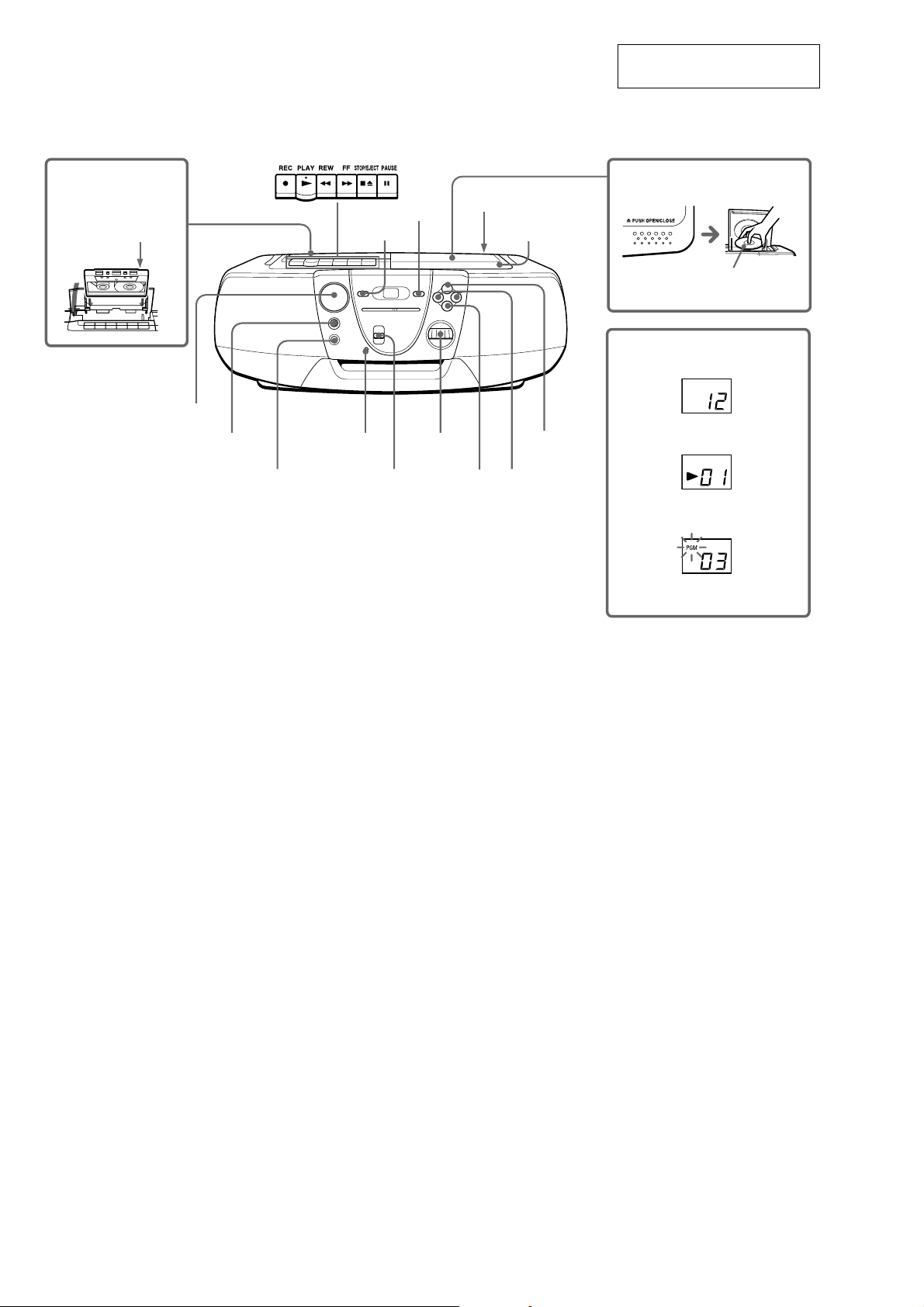

LOCATION AND FUNCTION OF CONTROLS

SECTION 2

GENERAL

This section is extracted from

instruction manual.

Inserting a cassette

With the side you want to

play facing upward

VOLUME

MEGA BASS

Loading a CD

PLAY MODE

ENTER

FM MODE (rear)

Z PUSH OPEN/CLOSE

With the labeled side up

Display

C

Total track number

OPR/BATT

TUNING

u

D

x

i

FUNCTION

.,>

Track number

E

Programd track

4

Page 5

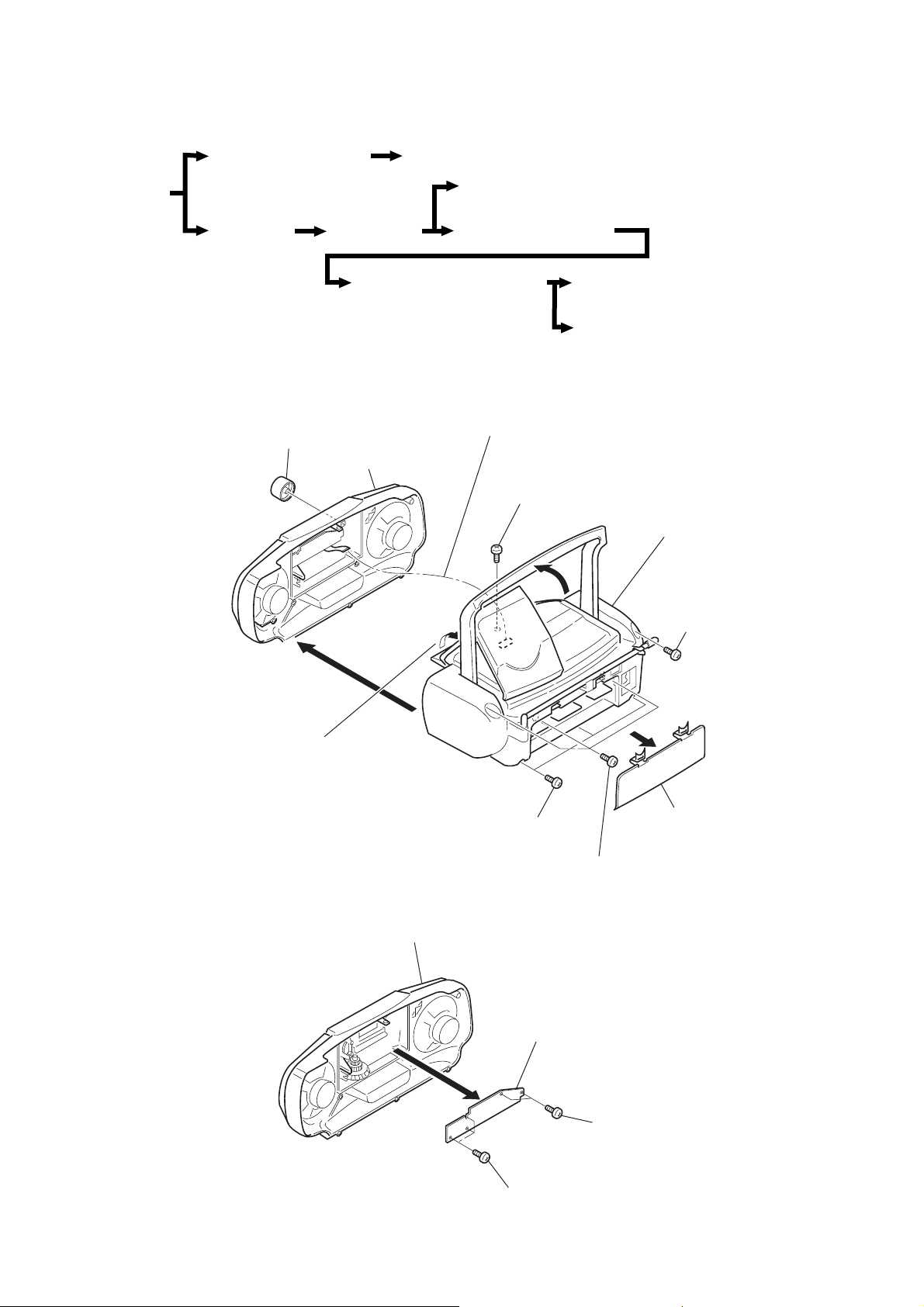

DISASSEMBLY

8

z

The equipment can be removed using the following procedure.

CFD-V8

SECTION 3

Cabinet (front) sub ASSY

Set

Cabinet (rear) Cabinet (upper)

Control board

Power board, Inlet board,

BATT (R) board, BATT (L) board

Volume board,

FM SW board, Main board

PRE board, Mechanism deck,

Optical pick-up section, CD board

Note : Follow the disassembly procedure in the numerical order given.

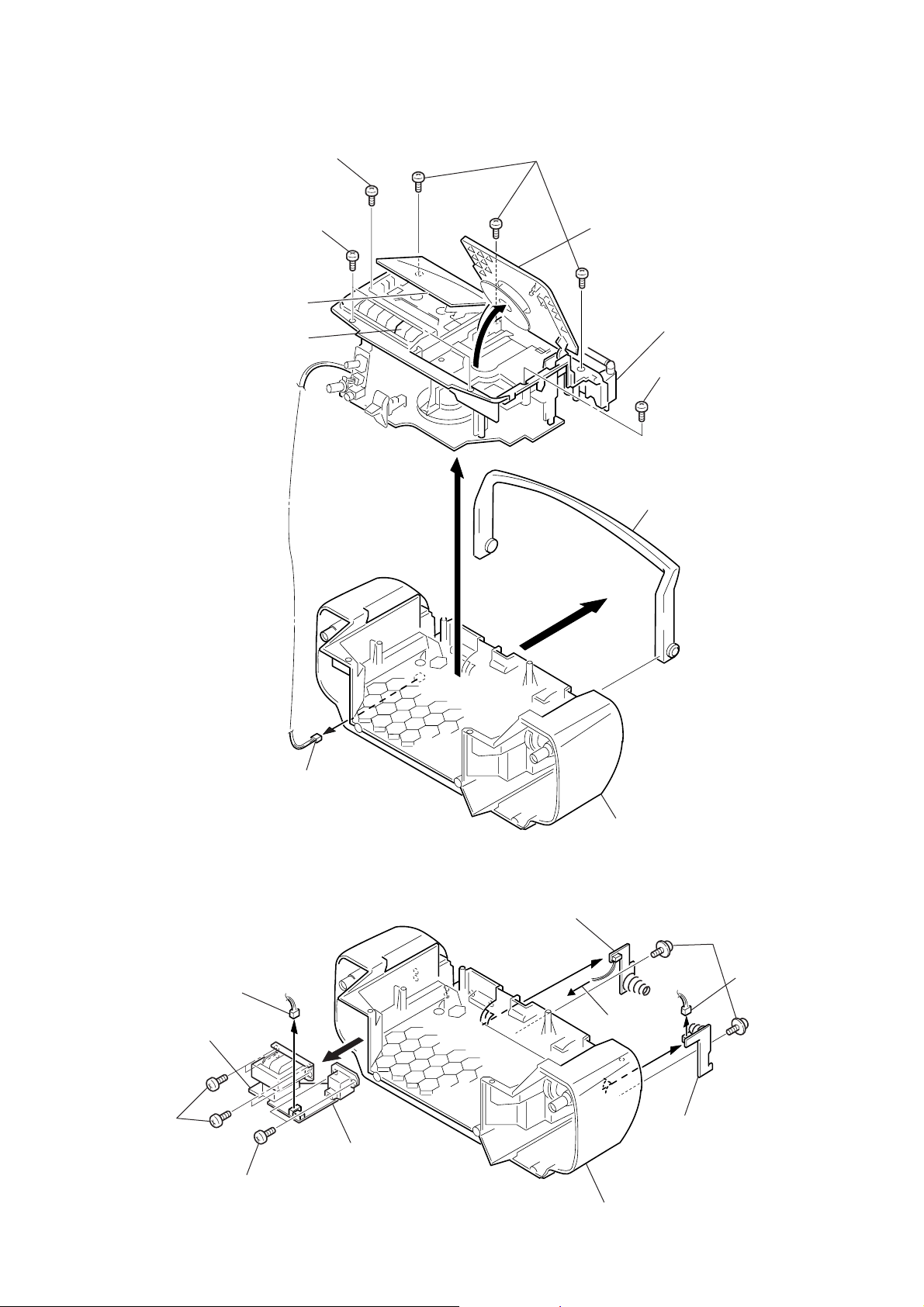

3-1. CABINET (FRONT) SUB ASSY, CABINET (REAR)

8

knob (vol )

cabinet (front) sub assy

0

Belt, M601 (capstan/reel motor),

“HRP901 Head, Magnetic (Record/playback)”,

HE901 Head (Erase)

Optical pick-up (KSS-213C)

flat cable (16core) (CN801)

7

screw

+BVTP 3

5

×

12

cabinet (rear)

4

screw

+BVTP 3

×

12

3-2. CONTROL BOARD

6

open the Lid (CD)

9

cabinet (front) sub assy

3

3

three screws

+BVTP 3

×

12

2

CONTROL board

three screws

+BVTP 3

×

12

1

lid, battery case

2

two screws

+BVTP 2.6

1

three screws

+BVTP 2.6

×

8

×

5

Page 6

CFD-V8

8

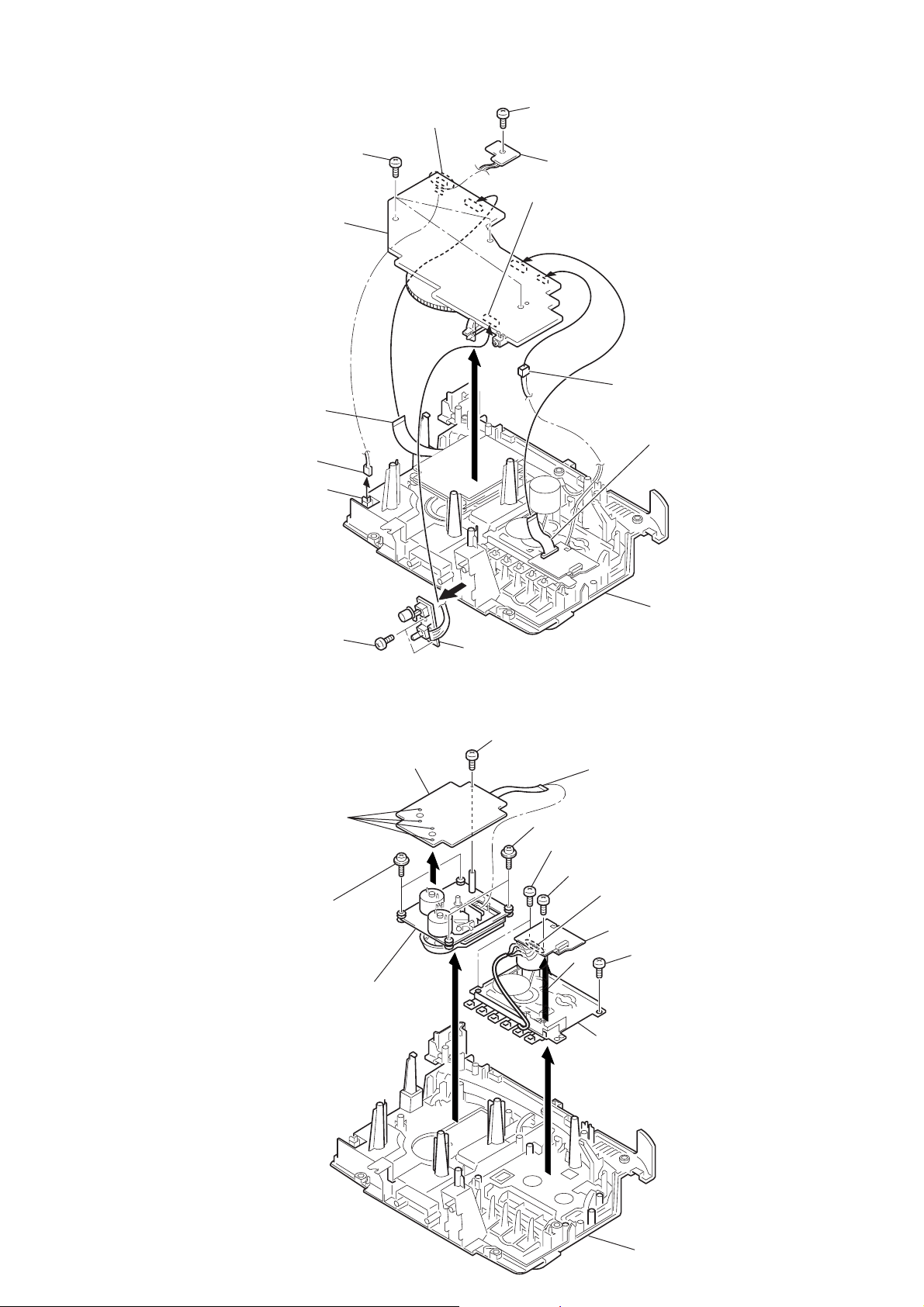

3-3. CABINET (UPPER)

6

two screws +BVTP 3 × 10

2

open the cassette holder assy by

pressing STOP/EJECT button.

5

screw +BVTP 3 × 12

STOP/EJECT

button

1

three screws

+BVTP 3

×

12

3

open the Lid (CD)

cabinet (upper)

4

screw

+BVTP 3

remove the handle in

the direction of the arrow.

×

12

8

9

7

CNP902

(POWER board)

3-4. POWER BOARD, INLET BOARD, BATT (R) BOARD, BATT (L) BOARD

BATT (R) board

4

CNP907

POWER board

a

3

8

a

cabinet (rear)

CNP907

7

5

two screws

+WH 3

×

8

6

CNP90

1

+BVTP 3 × 10

6

four screws

2

two screws

+BVTP 3 × 10

BATT (L) board

INLET board

cabinet (rear)

Page 7

)

3-5. VOLUME BOARD, FM SW BOARD, MAIN BOARD

)

4

remove solder

(four places)

0

three screws

+BVTP 3

MAIN board

×

10

5

screw

+BVTP 3

FM SW board

2

remove solder

(five places)

CFD-V8

×

10

7

wire, parallel (CN802)

(15 core)

6

KH801

1

two screws

+BVTP 3

S801

×

10

qa

3

VOLUME board

8

CNP304

9

wire, parallel (CNP303

(10 core)

cabinet(upper)

3-6. PRE BOARD, MECHANISM DECK, OPTICAL PICK-UP SECTION, CD BOARD

9

screw

8

remove solder

(four places)

6

two screws

+PWH 2.6

CD board

0

×

10

optical pick-up section

+BVTT 2

7

×

6

qa

wire, parallel (CNP701

(16 core)

6

two screws +PWH 2.6 × 10

1

two screws +BVTP 3 × 10

3

screw +BVTT 2 × 6

5

remove solder

(four places)

PRE board

1

4

screw

+BVTP 3

×

10

2

mechanism deck

cabinet(upper)

7

Page 8

CFD-V8

)

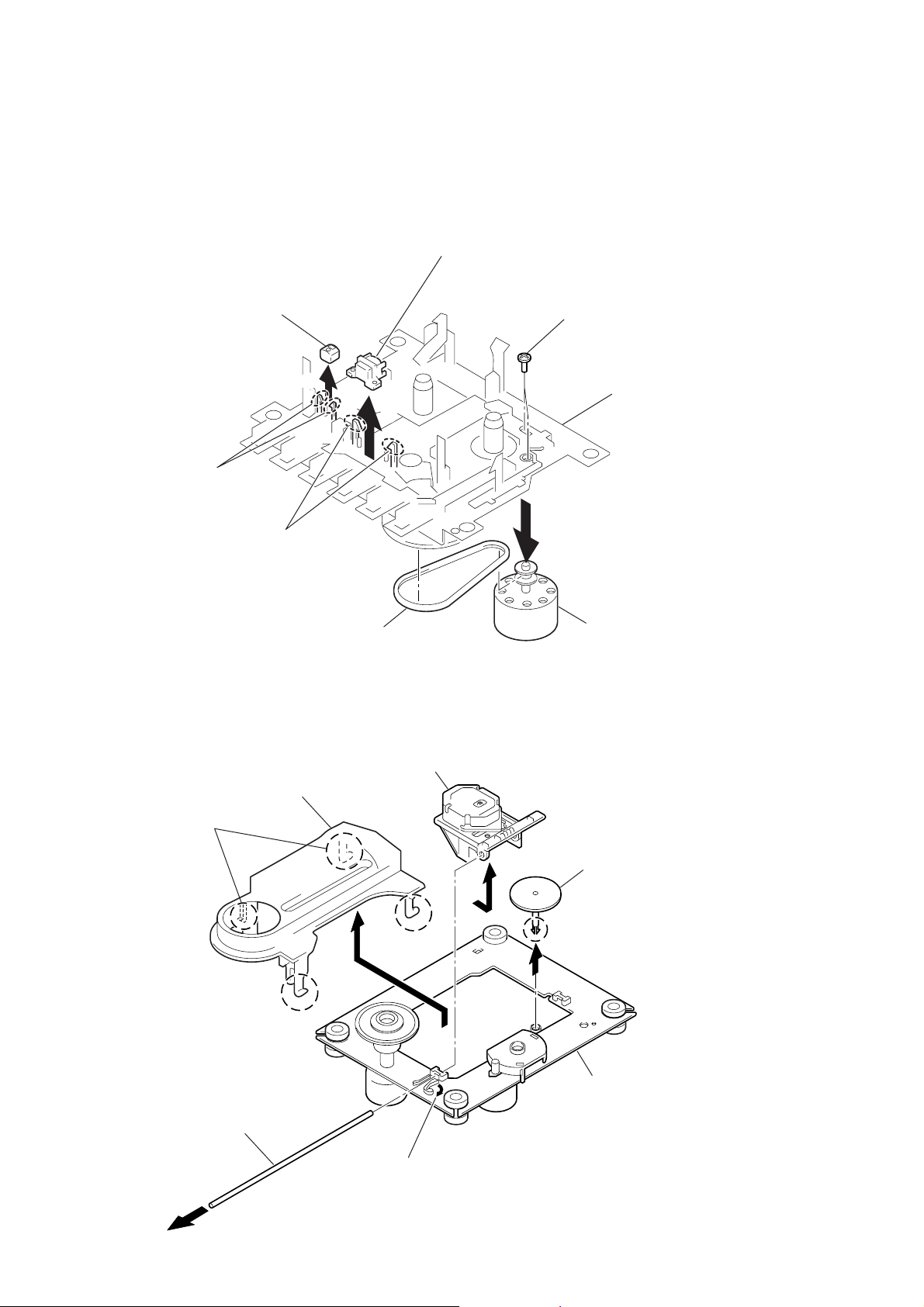

3-7. BELT, M601 (CAPSTAN / REEL MOTOR), “ HRP901 HEAD, MAGNETIC (RECORD/PLAYBACK) ”,

HE901 HEAD (ERASE)

HRP901 head, magnetic (record/ playback)

HE901 head (erase)

7

claws

5

claws

3-8. OPTICAL PICK-UP (KSS-213C)

8

3

belt

6

2

1

two screws

+B 2.6

×

5

mechanism deck

4

M601

(capstan/reel motor

claws

4

shaft, sled

cover, CD

claw

optical pick-up (KSS-213C)

1

claw

3

bend the stopper

5

gear

claw

2

chassis ASSY, motor (spindle)

8

Page 9

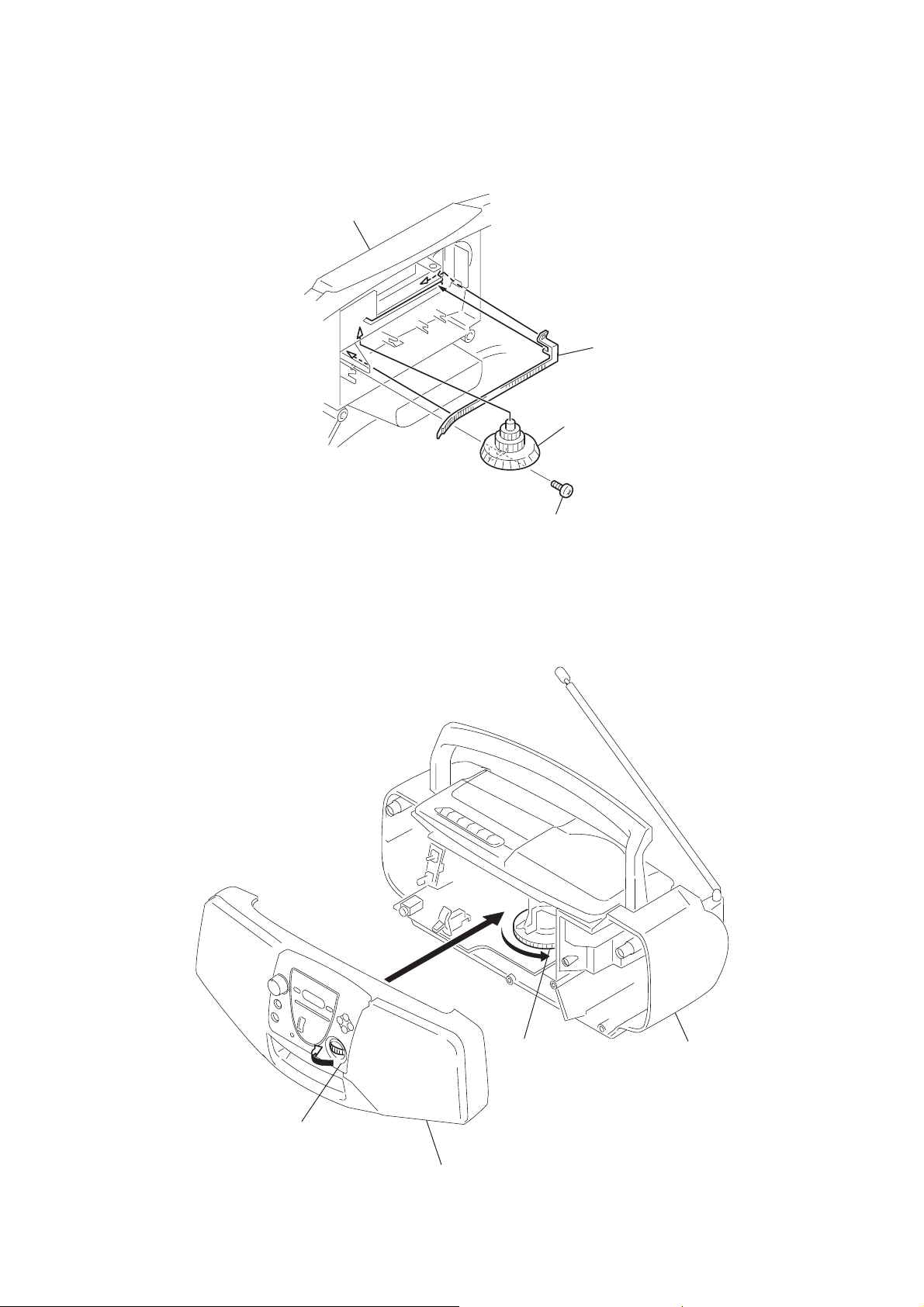

SECTION 4

)

DIAL POINTER INSTALLATION

Note : Follow the installation procedure in the numerical order given.

1 Align the pointer with the groove of “cabinet (front) sub ASSY” and insert it as shown in the illustration.

2 Align knob (TU) with “cabinet (front) sub ASSY” and fasten the screw.

Cabinet (front) sub ASSY

1

Pointer

knob (Tu)

CFD-V8

2

Screw (+BVTP 2.6 × 8)

3 Turn the tuning knob fully in the direction of the allow as shown in the illustration.

4 Turn the tuning capacitor gear fully in the direction of the allow as shown in the illustration.

5 Fasten the “cabinet (front) sub ASSY” and cabinet (rear) with the screws.

5

3

Tuning knob

4

Tuning capacitor gear

Cabinet (front) sub ASSY

Cabinet (rear

9

Page 10

CFD-V8

c

r

y

SECTION 5

ADJUSTMENTS

5-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan

2. Demagnetize the record/playback head with a head demagnetizer. (Do not bring the head demagnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power supply voltage (9V) unless otherwise noted.

Torque Measurement

Torque Torque Meter Meter Reading

1.77 – 5.88 mN•m

Forward CQ-102C (18 – 60 g•cm)

(0.25 – 0.83 oz•inch)

Forward

Back Tension

Fast Forward CQ-201B (45 – 95 g•cm)

Rewind CQ-201B (45 – 95 g•cm)

CQ-102C (1.0 – 5.0 g•cm)

Tape Tension Measurement

Torque Meter Meter Reading

CQ-403A

0.1 – 0.49 mN•m

(0.014 – 0.069 oz•inch)

4.42 – 9.31 mN•m

(0.62 – 1.32 oz•inch)

4.42 – 9.31 mN•m

(0.62 – 1.32 oz•inch)

more than 60g

(more than 2.12 oz)

Adjustment Location : Mechanism deck

Tape speed adjustment

control inside motor

TUNER SECTION

0dB = 1 µV

AM Section

Function switch : AM

Volume : MIN

AM RF signal

generator

Put the lead-wire

antenna close to

the set.

5-2. ELECTRICAL ADJUSTMENTS

TAPE RECORDER SECTION

Standard Output Level

Output terminal HP OUT

load impedance 32 Ω

output signal level 0.25V (–10dB)

Test Tape

Type Signal Used for

WS-48A 3kHz, 0dB Tape Speed Adjustment

Tape Speed Adjustment

Procedure :

Mode : Playback

test tape

WS-48A

(3kHz, 0dB)

set

Adjustment Value : 3,000Hz

Standard Value : 2,940 - 3,060Hz

Frequency difference between the beginning and the end of the tape

should be within 1.5% (45Hz).

32Ω

J301 (phones)

0dB = 0.775V

digital frequenc

counter

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

FM Section

Function switch : FM

Volume : MIN

FM RF signal

generator

22.5kHz frequency deviation by

1kHz signal.

Output level : as low as possible

set

32Ω

J301 (phones)

0.01µF

level mete

telescopi

antenna

terminal

10

Page 11

CFD-V8

)

2

8

4

5

4

3

6

7

4

oscilloscope

(AC range)

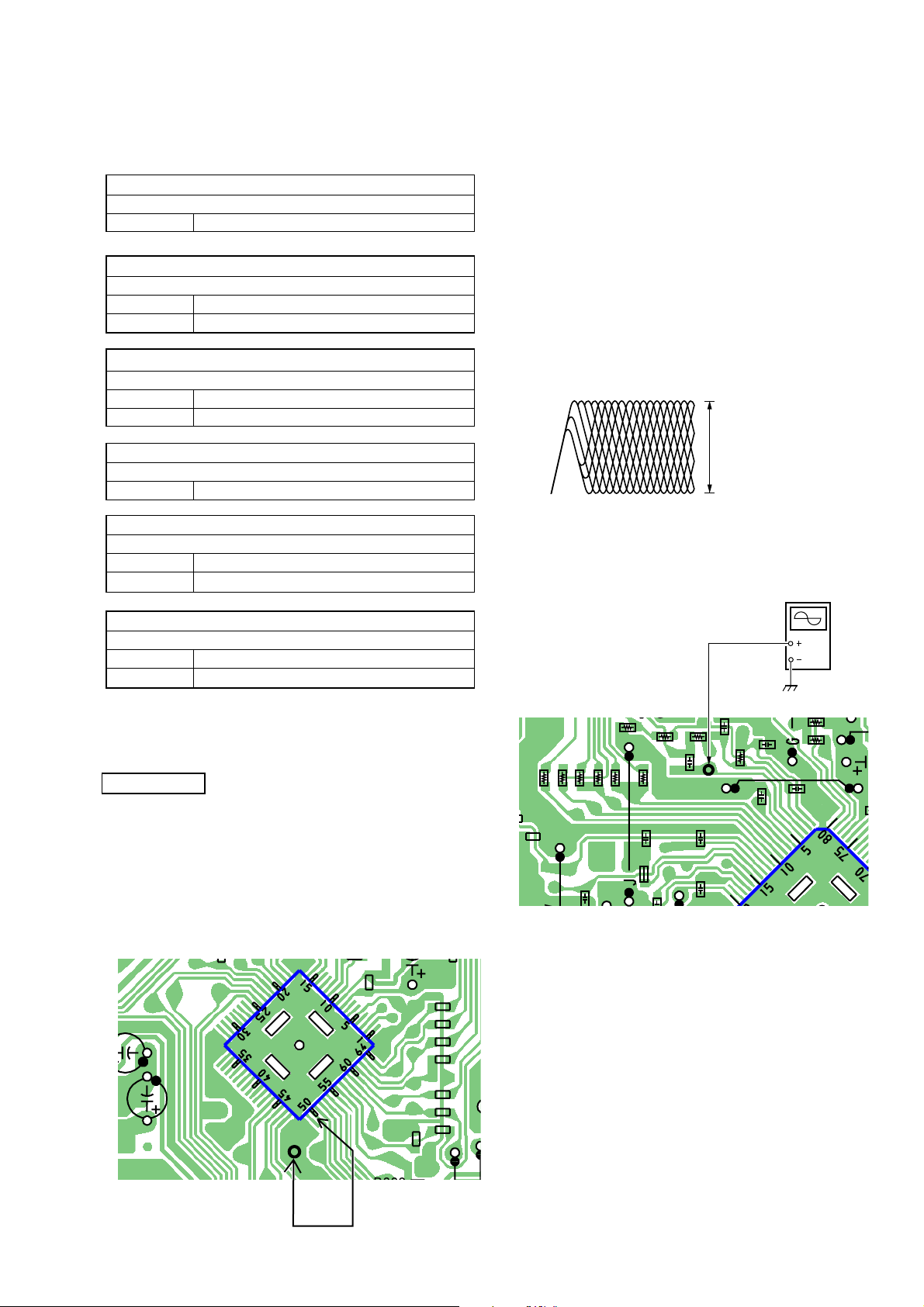

[CD BOARD] (Conductor side)

(GND)

TP (RF)

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T2 455kHz

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 520kHz

CT4 1,780kHz

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 620kHz

CT3 1,400kHz

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1 10.7MHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L2 86.5MHz

CT2 109.5MHz

CD section adjustments are done automatically in this set.

In case of operation check, confirm that focus bias.

Focus Bias Check

1. Connect the oscilloscope between TP (RF) and GND on CD

board.

2. Insert the disc (YEDS-18). (Part No. : 3-702-101-01)

3. Press the 7 button two times (LPC ON).

4. Confirm that the oscilloscope waveform is as shown in the figure below. (eye pattern)

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

• RF Signal Reference Waveform (eye pattern)

VOLT/TV : 200mV

TIME/DIV : 500 nS

RF level

0.7 – 1.0 Vp-p (LPC ON)

1.0 – 1.4 Vp-p (LPC OFF

When observing the eye pattern, set the oscilloscope for AC range

and raise certical sensitivity

L1 86.5MHz

CT1 109.5MHz

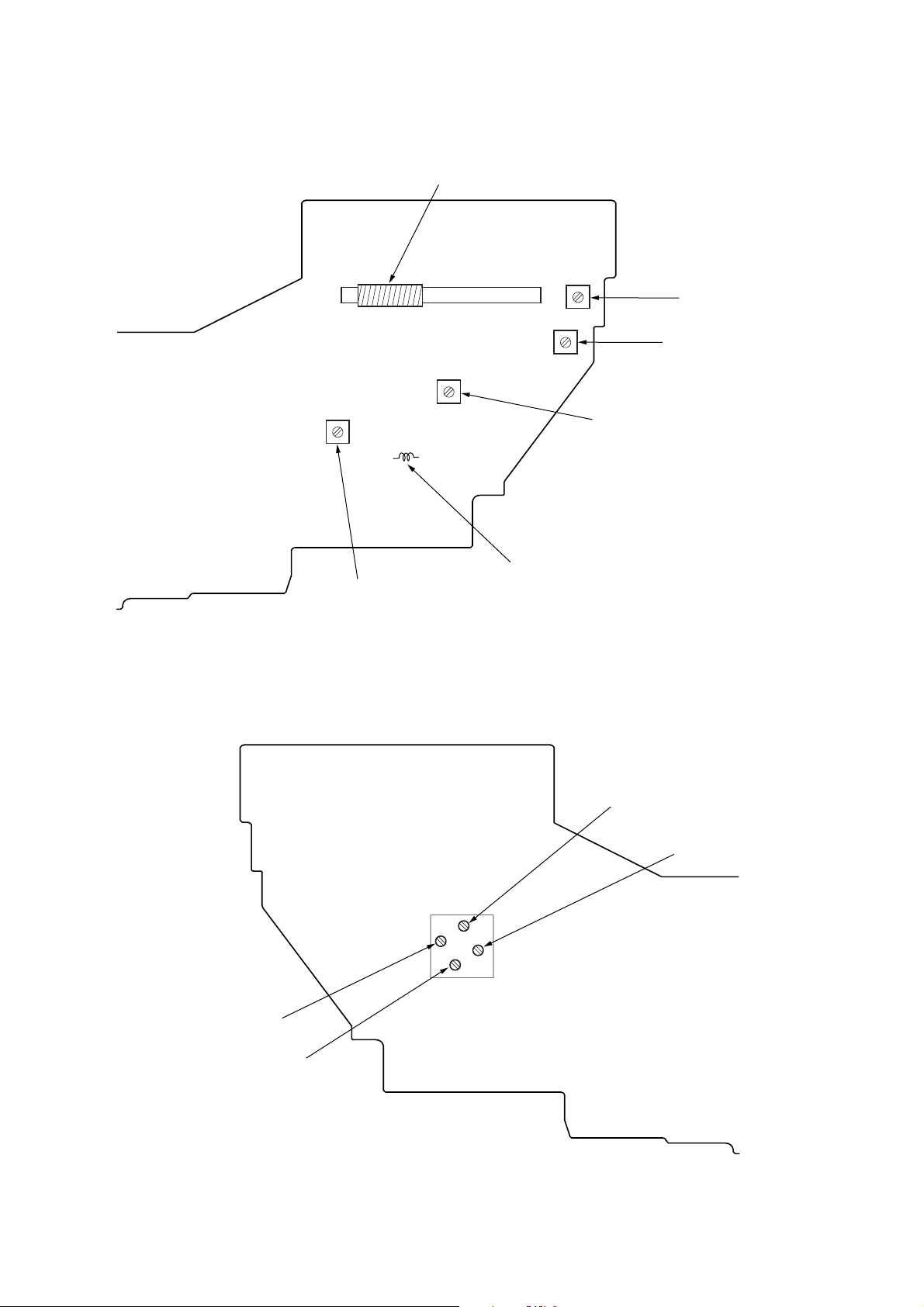

Adjustment Location : Main board (See page 12)

CD SECTION

How to put the set into CD Test Mode

1. Set the function switch to power off.

2. Set the function switch to CD.

3. Set Test mode by momentarily shorting both of the IC801 51pin

to GND. (Shorting the terminals momentarily is sufficient).

The set is into CD test mode (88 is displayed).

4. Turn the power off to release test mode.

[MAIN BOARD] (Conductor side)

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

C8

C844

C

R851

C801

IC801

C317

51pin

GND

TEST mode : momentarily short

R811

R810

C802

C810

R81

R81

R81

R81

R81

321

R711

R703

R710

R702

JW708

C705

R704

(RF)

C736

JC703

R708

TP

C734

C742

R709

8

R706

R705

R701

707

709

J

C731

C703

C743

IC701

R729

C7

C

R

11

Page 12

CFD-V8

t

t

Adjustment Location :

[MAIN BOARD]

(Component side)

L4 : AM Frequency

Coverage Adjustment

L3: AM Tracking Adjustment

L1 : FM Tracking Adjustment

T1 : FM IF Adjustmen

T2 : AM IF Adjustment

L2 : FM Frequency Coverage Adjustmen

[MAIN BOARD]

(Conductor side)

CT1 : FM Tracking Adjustment

CT3 : AM Tracking Adjustment

CT2 : FM Frequency

Coverage Adjustment

CT4: AM Frequency

Coverage Adjustment

12

Page 13

SECTION 6

DIAGRAMS

6-1. IC PIN FUNCTION DESCRINTION

IC801 µPD789316GK-503-9ET SIGNAL PROCESSOR, D/A CONVERTER, LCD DRIVE, SYSTEM CONTROL

Pin No. Pin name I/O Description

1 to 4 NC — Not used (open)

5IC—Connect to ground.

6 XT1 I Connect to ground.

7 XT2 — Not used (open)

8 VDD — Power supply terminal (B+ 3.3 V)

9 VSS — Ground terminal

10 CL1 I Oscillator terminal (4 MHz)

11 CL2 — Oscillator terminal (4 MHz)

12 RESET I Reset signal input

13 NC — Not used (open)

14 SYNC–R — Not used (open)

15 CE O Chip enable signal output

16 C–RST O Reset signal output to the LC78645E (IC701)

17 CAPH — Charge pump capacitor terminal

18 CAPL — Charge pump capacitor terminal

19 to 21 VLC0 to 2 — Capacitor connect terminal

22 to 25 COM0 to 3 O LCD common drive output

26 to 43 S0 to 17 — Not used (open)

44 to 48 S18 to 22 O LCD segment drive output

49 S23 — Not used (open)

50 ENTER I Key (ENTER) input

51 MODE I Key (MODE) input

52 PLAY I Key (H PLAY) input

53 FR I Key (l FR) input

54 FF I Key (L FF) input

55 STOP I Key (s STOP) input

56 DOOR I Door open/close input

57 WRQ I Command signal input

58 TEST I Test mode signal terminal input (TEST: L)

59 MUTE O Mute signal output

60 FSEQ I Frame SYNC signal input

61 DRF I DRF (Defect RF) input

62 DO O Serial data output

63 DIN I Serial data input

64 CLK I Clock signal input

CFD-V8

13

Page 14

CFD-V8

d

• Circuit Boards Location

VOLUME board

POWER board

PRE board

INLET board

BATT (R) board

BATT (L) board

FM SW boar

CONTROL board

MAIN board

CD board

14

Page 15

6-2. BLOCK DIAGRAMS –TUNER/TC SECTION–

ANT1

TELESCOPIC ANTENNA

FM

D1

CT3,L3

AM

TRACKING

D2

FM FREQUENCY

FERRITE-ROD

CT1,L1

FM

TRACKING

CT2,L2

COVERAGE

L3

AM

ANTENNA

L1

FM

RF

L2

FM

OSC

CT3

CT1

CT2

CV1-1

CV1-2

CV1-3

FM/AM

FRONT-END

IF AMP,DET,FM MPX

IC1

RF

IN

FRONT-END

FM RF OUT

FM OSC

AM RF

IN

FRONT-END

FM

AM

MIX

OUT

T2

AM IF

CF2

TU +6V

CF1

TU +6V

T1

FM IF

FM

IF IN

AM

IF IN

FM DET

AM DET

TU +6V

QUAD

DET OUT

MPX IN

CFD-V8

L OUT

MPX

LPF2

Q1

LPF1

R OUT

TU +6V

R-CH

S1

FM MODE

MONO

STEREO

CD

SECTION

(Page 17)

L4,CT4

AM FREQUENCY

COVERAGE

CD L-CH

CD R-CH

HRP901

RECORD/

PLAYBACK

HEAD

HE901

ERASE

HEAD

L4

AM

OSC

R-CH

TU IN L

CD IN L

CT4

CV1-4

TU +6V

AM OSC

PRE/REC

AMP

IC301

MUTE

L.LINE

22

L.RAD

24

MIC AMP

MIC

13

MUTE

PB AMP

L.IN

5

L.RO

4

PB AMP

REC

AMP(26dB)

DET

TAPE

ALC

1

BUFFER

REG

REF

6

T301

MONITOR

AMP

L.LO

20

(7dB)

LINE

BIAS

OSC

Q301

TAPE

17

15

LOGIC

REC

21

L.OUT

CD

TAPE

L.OUT

FM

CD

TAPE

MAIN

SECTION

(Page 16)

MAIN

SECTION

(Page 16)

S301

REC

PB

-2

-1

TU +6V

• R-CH is omitted : Same as

L-CH

• Signal path.

F : FM

f : AM

E : PLAY

a : REC

J : CD

1515

Page 16

CFD-V8

6-3. BLOCK DIAGRAMS –MAIN SECTION–

CD

SECTION

(Page 17)

TUNER/TC

SECTION

(Page 15)

L.OUT

RESET

S355

MEGA BASS

ON

OFF

RESET

Q801

RV352

VOLUME

CD +3.3V

D302

MUTE

Q101

R-CH

POWER

AMP

IC304

STANDBY

SWITCH

R-CH

J301

SP101

SPEAKER

(L-CH)

SP201

SPEAKER

(R-CH)

S801

CD DOOR

(OPEN/CLOSE)

DOOR

TUNER/TC

SECTION

(Page 15)

TU +6V

TAPE +6V

CD+ 3.3V

CD +6V

RESET

DIGITAL SIGNAL

PROCESSOR,

LCD DRIVE,

SYSTEM CONTROL

IC801(1/2)

TAPE

POWER

SWITCH

Q311,312

POWER AMP

B+

(+8.9V)

D314

+6.9V REG

Q309,

Q311

POWER

SWITCH

Q402,Q405

-1

-2

VOLTAGE

DET

FUNCTION

9V

AC

4.5V

S351-1

AM

FM

CD

D901-904

F901

T901

POWER

TRANSFORMER

CNJ901

AC IN

IC401

D309

FM

D303

D304

CD

+3.3V REG

Q310,

D308

(4MHz)

CL1

CL2

22

COM0

_

COM3

_

25

COM0-3

LCD401

LIQUID

CRYSTAL

DISPLAY

_

S22

_

48

S18

44

S0-S4

ENTER

S406

ENTER

MODE

S405

PLAY MODE

S404

CD CONTROL

PLAY

S403

FR

S402

STOP

FF

INITIAL

SWITCH

Q401

S401

D310

OPR/BATT

Q409

MOTOR

SWITCH

S601

(MD POWER)

CAPSTAN/REEL

MOTOR

M601

DRY BATTERY

SIZE "D"

(IEC DESIGNATION R20)

6PCS,9V

• R-CH is omitted : Same as L-CH

• Signal path.

F : FM

1616

Page 17

6-4. BLOCK DIAGRAMS –CD SECTION–

CFD-V8

OPTICAL PICK-UP

BLOCK

(KSS-213C)

LD

PD

REF

LD

PD

VR

CD RF/

SYSTEM SERVO

PROCESSOR

IC701

VC

A

B

C

D

E

F

LASER

POWER

CONTROL

G

Q701

VC

FIN1

FIN2

TIN1

TIN2

LDD

VREF

LDS

+

-

+

APC

TE

FE

SERVO

CONTROL

FDO

TDO

SPDO

RF

SLDO

PURPOSE

CONT5

CONT4

PORT

CONT2

CONT1

CONT3

EFMIN

XIN

DIGITAL

FILTER/

ERROR

CORRECTION

XOUT

D/A

COMMAND

INTERFACE

LCHO

RCHO

DRF

RES

WRQ

FSEQ

DO

DI

CL

CE

CD L-CH

CD R-CH

TUNER/TC

SECTION

(Page 15)

TRACKING

COIL

FOCUS

COIL

M702

SLED

MOTOR

M701

SPINDLE

MOTOR

SLED/SPINDLE MOTOR DRIVE,

TRACKING/FOCUS COIL DRIVE

IC702

T+

T-

F+

F-

+

-

+

-

SL+

SL-

SP+

SP-

VREF

LEVEL

LEVEL

LEVEL

LEVEL

SHIFT

SHIFT

SHIFT

SHIFT

MUTE

DRIVER

TIN

FIN

MUTE

SLIN

SPIN

RST

X701

33.86MHz

CE

DO

DIN

CLK

FSEQ

DIGITAL SIGNAL

PROCESSOR,

LCD DRIVE,

SYSTEM CONTROL

WRQ

IC801(2/2)

C-RST

DRF

RESET

MAIN

SECTION

(Page 16)

S701

(LIMIT)

SW

• Signal path.

J : CD

1717

Page 18

CFD-V8

2 3 4 5 6 7 8 91

A

B

C

D

E

F

Ver 1.2

6-5. PRINTED WIRING BOARDS – MAIN SECTION – z Refer to page 14 for Circuit Boards Location.

S801

MAIN

BOARD

KH2

S801

D1

D2

CND,AUS,TW

T1

KH801

C891

JC6

T2

ANT1

CD DOOR

(OPEN/CLOSE)

JC1

JC2

R5

R8

JW335

JW334

AEP,UK,CET,IT,KR,SP

C10

C30

C2

R2

R30

CF1

C14

C13

R4

C17

C19

CF2

C4

JW332

C1

C8

JW333

C3

C24

R1

IC1

C9

C18

Q1

C15

R9

C27

C20

C22

C25

R3

C12

JC5

AEP,UK,CET,IT,KR,SP

C23

JW331

L3

AM/LW

FERRITE-ROD

ANTENNA

AEP,UK,CET,IT,KR,SP

C21

CV-1

L2

CT2

C11

CT1

C32

R20

R11

CV1

CV1-2

CV1-1

C5

L1

CV1-4

CV1-3

C6

FM

TELESCOPIC ANTENNA

FM SW BOARD

KH1

11

1-861-375-

(11)

S1

FM MODE

t

STEREO

MONO

VOLUME BOARD

KH307

RV352

RV352

VOLUME

R123

C124

R223

R124

C224

R224

C123

A

CN802

JW330

JW328

D303

R314

C223

CD BOARD

(Page 25)

JW341

JW329

CT4

CT3

D304

D314

1-861-372-

MEGA BASS

r

R

CNP702

C7

JC7

L4

R315

S355

S355

OFF

T

ON

C171

C271

C314

D309

JW327

R319

11

(11)

: Uses unleaded solder.

z

Semiconductor

Location

Ref. No. Location

D1 A-1

D2 A-1

D301 D-8

D302 E-6

D303 D-4

D304 D-4

PRE BOARD

CNP303

(Page 22)

D

4

C401

JW303

3

2

1

4

R403

IC401

Q402

Q405

R418

R154

C254

D301

JW302

M

R404

JC303

R402

E

C

B

D308

C345

JW324

C841

R819

CN801

B

CN401

R818

R851

C346

Q311

C805

R805

Q312

R360

R349

C801

R809

R811

R810

JW315

C802

C810

D302

C851

TAPE CD/RADIO OFF

CNP305

R348

R354

R353

R801

R816

R815

R814

R813

R812

JW321

S351

FUNCTION

JW313

R352

R351

-1 -2

S351

JW323

AM

JC306

JW312

Q309

JW316

R344

R340

JC310

JW317

JW318

JW322

R341

JW314

C347

C156

JW319

R386

R342

OPR/BATT

C348

Q310

JW326

JW325

R806

Q801

C842

C843

C844

IC801

C317

CONTROL BOARD

(Page 22)

JW311

C256

C252

C152

D310

C351

Q101

CNP304

JW310

JW308

JW307

R253

Q201

R251

R151

JW309

C320

C349

C341

R153

4

KH306

JW306

C343

D311

R346

R345

C255

C155

C153

C154

IC304

C253

1

Q409

KH902

1

JW305

JW304

C316

S601

(MD POWER)

+

M601

CAPSTAN/REEL

MOTOR

-

INLET BOARD

C

CNP902

(Page 22)

D306

JC305

R415

R401

C402

JC302

R416

B

C

E

JC401

Q401

R417

CNP303

JW301

R254

1-861-370-

SP101

SPEAKER

(L-CH)

SP201

SPEAKER

(R-CH)

11

(11)

J301

i

D306 D-9

D308 C-5

D309 D-4

D310 E-7

D311 D-7

D314 E-4

IC1 C-3

IC304 E-7

IC401 D-8

IC801 D-5

Q1 B-3

Q101 E-7

Q201 E-7

Q309 D-7

Q310 C-5

Q311 C-6

Q312 C-6

Q401 E-9

Q402 E-8

Q405 E-8

Q409 C-8

Q801 D-5

FM

CD

Note:

• X : parts extracted from the component side.

• f : internal component.

• : Pattern from the side which enables seeing.

• Abbreviation

CET : East European & Russian

IT : Italian

SP : Singapore

AUS : Australian

TW : Taiwan

KR : Korean

CND : Canadian

1818

Page 19

6-6. SCHEMATIC DIAGRAMS – MAIN SECTION (1/3) –

C36

10p

CT3

CV1-3

C6

5p

10p

CFD-V8

Ver 1.2

*C7

2.2P

CND,AUS,TW

4.7P

AEP,UK,CET,IT,KR,SP

C32

4.7p

CV1-1

C5

3.3k

L1

C11

10p

C12

10p

R3

CT1

CV1-2

CT2

L2

C7

*

AEP,UK,CET,IT,KR,SP

CT4

CV1-4

JC7

L4

0

D1

1SS133T-77

D2

1SS355T-77

R1

220

R20

1k

C1

1000p

C23

10

50V

C24

0.01

JC6

JC5

ISS1

TU.L

TU.R

FM

TU.GND

TU +B

S-GND

ANT1

FM

TELESCOPIC

ANTENNA

KH1

4P

S1

1

(Page 20)

PX

M

C25

0.001

R4

C10

3.3k

C18

1

50V

C27

4700p

R8

22k

KRA302-RTK

*C19,20

0.022

0.01

Q1

SWITCH

R9

22k

C19

*

CND,AUS,TW

AEP,UK,CET,IT,KR,SP

C20

KH2

JC2

JC1

4P

0

0

R5

100

C8

4.7

50V

C9

4.7

50V

R30

220

R11

10k

*

C17

0.1

C22

1

IN

LPF1

LPF2

IN

TUN

GND

LED

C30

CF2

C3

0.01

C15

0.1

L-OUT

R-OUT

ST

QUAD

LED

2p

25V

C2

10p

T1

C4

22

4700p

AEP,UK,CET,IT,KR,SP

4.7p

C21

0

IN

RF

RF

RF

VCC

OUT

FM

AM

LOW

FM-RF

IN

AM

CUT

MIX

RF

GND

T2

C13

0.47

R2

0

330

50V

OSC

FM

C14

4.7

50V

OUT

OSC

AM

TA2111N

AGC

AFC

IC1

VCC

DET

IF

AM

CF1

IN

OUT

FM IF

1919

Page 20

CFD-V8

6-7. SCHEMATIC DIAGRAMS – MAIN SECTION (2/3) –

(Page 23)

1

(Page 19)

ISS1

TU.L

TU.GND

TU.R

TU +B

S-GND

C317

22

25V

ICP301

C346

0.01

C224

4700p

C345

0.01

KH307

5P

302

D

C223

0.47

50V

R223

R224

6.8k

1k

1SS355TE-17

Q311

KTB1241Y-AT

680

351

R

680

R352

680

353

R

R360

100k

680

354

R

Q312

KRC405

RTK

RV352(1/2)

20kB

KH306

5P

R151

4.7k

R251

4.7k

C347

220

10V

C316

50V

1

Q101

KRC410-RTK

JC305

0

2SD2396K

TK

311

D

Z 7.5-R

KD

RV352(2/2)

20kB

Q309

1k

345

R

D301

1SS355TE-17

JC401

0

1k

346

R

C343

0.01

Q201

KRC410-RTK

KTA1266-GR

R416

4.7k

C402

10

50V

Q401

INITIAL

SWITCH

R253

470

KTA1266-GR-AT

R418

10k

Q402

KRC402

D306

1SS355TE-17

C256

Q405

10V

47

C252

1000p

R417

C320

0.022

10k

C152

1000p

C156

10V

IC304

BA5417

CNP303

KH902

4P

4P

J301

C253

47

C254

470

10V

C255

0.1

10V

R254

100

R154

100

C349

10000p

C153

47

C351

47

10V

53

1

470

R

47

10V

C154

470

10V

C155

0.1

(Page 23)

IC401

MM1468XD

JC302

JC303

0

R404

1k

R401

100k

0

R386

3.3k

D310

L-34HD

R344

220

.3k

3

342

R

C341

3300

16V

3.3k

41

3

R

3.3k

340

R

R402

10k

JC310

C124

4700p

C123

0.47

50V

0

C314

47

10V

R319

4.7k

303

D

1SS355TE-17

R349

R348

1k

R123

1k

304

D

1SS355TE-17

Q310

KTC3203Y-AT

330

314

D

1SS355TE-17

R314

4.7k

C348

100

10V

D308

KTZ 3.9-RTK

R124

6.8k

CNP305

10P

JC306

0

309

D

S355TE-17

R315

1S

1k

FM

C171

10

50V

C271

10

50V

R403

R415

3.3k

T

T

D

D

U

U

N

-O

.G

L-O

P

R

D

D

N

N

+B

-G

-G

TU

M

TU

CO

U

TE

N

6V

U

3.3V

.G

CD

M

D

D

C

U

A

Q409

KTC3203Y-AT

MOTOR

SWITCH

S601

CNP304

4P

M601

C401

22k

100

10V

2

(Page 21)

2020

Page 21

CFD-V8

Ver 1.2

6-8. SCHEMATIC DIAGRAMS – MAIN SECTION (3/3) –

CN802

15P

• Refer to page 13 for IC Pin Function Description.

R810

GFS

FOK

CD DATAOUT

SQSO,ETC

CLK

CD DATA IN

R812

R813

R814

R815

R816

100

1k

1k

1k

100

100

C810

100p

(TEST MODE)

R809

1k

R811

10k

(Page 24)

2

(Page 20)

D.GND

L-OUT

R-OUT

CD 3.3V

TU +B

UCOM-GND

TU-GND

P.GND

CD 6V

AU MUTE

R805

220k

XLAT

CD-RESET

R801

22

*C801

0.1

0.01

C802

47

10V

C851

22p

R818

100

R819

100

C805

0.1

CND,AUS,TW,IT

AEP,UK,CET,KR,SP

VPP

R851

4.7k

C801

*

R806

220

Q801

KRC404-RTK

RESET

C842

0.1

C841

0.1

C843

0.1

C844

0.1

IC801

DIGITAL SIGNAL

PROCESSOR

LCD DRIVER

SYSTEM CONTROL

S0

S1

S2

S3

S4

CN801

16P

(Page 23)

S801

CD DOOR

(OPEN/CLOSE)

KH801

2P

C891

1000p

CND,AUS,TW,IT

2121

Page 22

CFD-V8

6-9. PRINTED WIRING BOARDS – CONTROL/POWER SECTION – z Refer to page 14 for Circuit Boards Location.

2 3 4 5 6 7 8 91

HRP901

RECORD/PLAY BACK

A

HEAD

L-CH

R-CH

B

HP901

ERASE

HEAD

D

MAIN BOARD

CNP305

(Page 18)

C

PRE BOARD

C303

R304

R105

C106

R303

R302

R309

CNP303

C301

JC302

C206

JC303

R111

JC301

R211

R205

IC301

R106

R206

R301

R101

C105

R201

C205

C304

R307

C101

C201

R202

C307

C103

R104

C107

R204

R103

C203

Q301

R102

C302

C204

R203

R306

R110

C104

C102

C202

C207

R210

T301

S301

-2

-1

R314

R315

R305

C306

R308

C305

1-861-502-

S301

PB

r

REC

11

(11)

CONTROL BOARD

S402

L

S404

7

S401

s

: Uses unleaded solder.

S405

PLAY MODE

S403

l

z

Semiconductor

Location

Ref. No. Location

D901 F-7

LCD401

LIQUID CRYSTAL

DISPLAY

R424

R423

R422

R421

CN401

S406

ENTER

1-861-371-

D902 E-7

D903 F-6

D904 E-6

IC301 B-3

Q301 C-3

Q303 C-2

11

(11)

B

BATT(R)

BOARD

BATT(L)

BOARD

INLET BOARD

CNJ901

-AC IN

D

JW336

JW337

DRY BATTERY

SIZE "D"

E

JW338

JW339

F

CNB907

1-861-374-

(IEC DESIGNATION R20)

6PCS, 9V

11

(11)

CNP908

1-861-373-

11

(11)

R901

D904

D903

C903

C905

CNP902

F901

C901

KH901

D902

D901

CNP907

MAIN BOARD

CN801

(Page 18)

1-861-377-

T901

POWER TRANSFORMER

11

(11)

POWER BOARD

KH904

1-861-376-

11

(11)

C

MAIN BOARD

KH902

(Page 18)

2222

Note:

• X : parts extracted from the component side.

• : Pattern from the side which enables seeing.

Page 23

6-10. SCHEMATIC DIAGRAMS – CONTROL/POWER SECTION –

C102

47

R102

R202

68

R103

68

68k

C103

0.047

C105

47p

C205

47p

C203

0.047

R203

68k

10V

C104

0.0022

C101

1000p

C107

470p

R110

100

C302

100

10V

R210

100

-2

-1

C202

47

10V

R101

15k

R201

15k

C207

470p

C201

1000p

C204

0.0022

C301

100

10V

R301

1M

R104

2.2k

R204

2.2k

IC301

TA2068N

R205

15k

R206

2.2k

R302

4.7k

C303

R111

4.7k

JC302

JC301

R106

2.2k

470

10V

0

R303

4.7k

0

R211

4.7k

R304

1k

R309

47

JC303

CFD-V8

Ver 1.2

S401

4.7k

R421

4.7k

R422

4.7k

R423

4.7k

R424

10P

(Page 21)

CN401

16P

0

C206

R105

15k

50V

C106

1

50V

1

CNP303

(Page 20)

S402

S403

S404

S405

S406

(Page 20)

KH904

2P

C305

470p

R308

22k

T901

C306

0.01

KH901

2P

CNP902

4P

T301

BIAS COIL

C304

47

10V

F901

*

*F901

3.15A/250V

T2.5AL/250V

R305

470

R306

6.8k

C307

0.0022

R314

470

CND,TW

AEP,UK,AUS,

CET,IT,KR,SP

R315

470

Q301

2SC1623

BIAS OSC

R307

10

D902

1N4002B

R901

2.2k

1N4002B

D904

1N4002B

1N4002B

D901

C905

0.022

D903

C901

0.022

C903

0.022

CNP907

3P

CNJ901

CNP908

2323

Page 24

CFD-V8

6-11. SCHEMATIC DIAGRAMS – CD SECTION –

701

S

CNP701

16P

707

R

10

KTN2907A

Q701

S-RTK

C702

10V

R724

47k

728

R

1k

220

10k

727

R

2.2k

C730

0.1

0.047

1

C728

C729

680

680

R725

R726

R731

2.2k

R

R719

R720

722

100

100

100

C726

1000p

C724

22p

C725

1000p

C721

C722

C720

22p

22p

22p

C723

0.01

R

R716

R718

R

717

1k

1k

1k

721

1k

C727

1000p

CNP702

15P

(Page 21)

C744

0.1

47

C701

1000p

C731

0.047

R710

R709

22k

4.7k

R708

C703

0.1

10k

100

100

10V

10V

747

C746

C

C745

R730

0.1

R729

R712

R701

R702

R703

R

R705

R706

100

C704

50V

1

C706

22p

47k

15k

15k

704

15k

15k

47k

C732

100

10V

C739

C738

C733

100

10V

C751

0.1

0.1

C750

100

0.1

10V

C707

R711

1

C734

C736

330

C708

100p

C742

4700p

C705

0.1

C743

4700p

4700p

0

JC703

0.1

IC701

LC78645NEUE

C709

X701

Hz

33.86M

C717

JC704

0.01

220

R715

FB701

150

O

C735

1000

6.3V

R714

150

C716

0.01

C711

0.01

0.1

R723

100

L706

0

C754

C755

0.01

0.01

BA6998FP-E2

JC702

0

JC701

0

IC702

R743

6.8k

R744

100k

R741

6.8k

C741

C740

0.1

470

10V

2424

Page 25

6-12. PRINTED WIRING BOARD – CD SECTION – z REFER TO PAGE 14 FOR CIRCUIT BOARDS LOCATION.

2 3 41

OPTICAL PICK-UP

BLOCK

CD BOARD

KSS-213C

CFD-V8

: USES UNLEADED SOLDER.

A

M701

JC701

JC702

IC702

SPINDLE MOTOR

M

JW713

JW710

R706

R701

JW709

1

2

JW711

R709

R705

C707

JW716

5

JW714

R703

R702

JW708

JW706

R712

CNP701

R710

R704

JC703

C708

JW705

10

R711

C705

C736

JW712

TP

(RF)

C742

JW707

C727

15

16

C734

R723

C704

R708

IC701

S701

(LIMIT)

JW722

C751

C701

JW725

C731

C703

C743

C709

JW703

Q701

JW715

B

C733

C750

C706

C

C738

C739

C732

D

R741

R727

R730

R729

C711

R728

C716

JW717

JW723

R726

C730

C746

C744

JW702

R707

C702

C728

C729

C747

C745

C717

FB701

R714

R715

JW701

JW718

C741

JW721

C740

M702

SLED MOTOR

R725

R724

C726

R731

R721

R722

R720

C721

C720

JC704

C735

1-861-503-

C723

C725

X701

JW728

C724

R719

R718

R716

C722

JW730

R744

M

R717

L706

JW719

CNP702

C754

11

(11)

JW720

R743

A

MAIN

BOARD

(Page 18)

C755

E

z

Semiconductor

Location

Ref. No. Location

IC701 D-2

IC702 A-3

Q701 B-2

Note:

• X : parts extracted from the component side.

• : Pattern from the side which enables seeing.

f

•

: internal component.

25

Page 26

CFD-V8

p

p

p

Ver 1.1

•Waveforms

– CONTROL/POWER SECTION –

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

Note:

The components identified by mark 0 or dotted

line with mark 0 are criti-

cal for safety.

Replace only with part

number specified.

• A : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 9 V and fed with regulated dc power

•Voltage and waveforms are dc with respect to ground

•Voltages are taken with a VOM (Input impedance 10 MΩ).

•Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

• Abbreviation

: internal component.

supply from battery terminal.

under no-signal (detuned) conditions.

no mark : FM (RADIO SECTION),

TAPE PLAY (TAPE SECTION)

(): AM (RADIO SECTION),

REC (TAPE SECTION)

Voltage variations may be noted due to normal production tolerances.

Voltage variations may be noted due to normal production tolerances.

F : FM

f : AM

E : PB

a : REC

J : CD

CND : Canadian

CET : East European & Russian

SP : Singapore

AUS : Australian

TW : T aiwan

KR : Korean

4

W or less unless otherwise

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

1

17.95 µsec

Q301 C

2

17.95 µsec

T301

– CD SECTION –

1

IC701 4

RF

2

29.53nsec

IC701 rk

XOUT

3.1Vp-

VOLT/DIV : 1 V AC

TIME/DIV : 5 µsec

30Vp-

VOLT/DIV : 1 V AC

(ATT : 1/10)

TIME/DIV : 5 µsec

0.7–1.0Vp-p

(LPC ON)

VOLT/DIV : 0.5 V AC

TIME/DIV : 0.5 µsec

1.1Vp-p

VOLT/DIV : 0.5 V AC

TIME/DIV : 0.2 µsec

26

(PLAY MODE)

3

0.6Vp-p

IC701 qd

(FE)

(PLAY MODE)

4

IC701 qg

(TE)

VOLT/DIV : 0.5 V AC

TIME/DIV : 1 msec

0.6Vp-

VOLT/DIV : 0.5 V AC

TIME/DIV :1 msec

Page 27

• IC BLOCK DIAGRAMS –MAIN SECTION–

IC1 TA2111N

FM OSC

AM RF IN

24 23

FM RF OUT

RF VCC

22 13

AM OSC

20

AFC

DET OUT

181921

MPX IN

17

LPF2

LPF1

141516

L-OUT

CFD-V8

R-OUT

AM

RF AMP

FM RF IN

FM

RF AMP

RF GND

AM LOW-CUT

AM

MIX

FM

AM

OSC

OSC

AF BUFFER

FM

MUTE

AM IF IN

FM

DET

FM IF

AMP

AM

DET

FM

MIX

AGC

5431 2 6 8 9 1210 11

AGC

FM/AM

MIX OUT

VCC

AM IF

AMP

7

• IC BLOCK DIAGRAMS –CONTROL/POWER SECTION–

IC301 TA2068N

L. LIN

15k

MIC

2324

LINE

I/EX

L. RAD

22

RADOI

REC

21

10k

6k

1k

10k

MONITOR

L. LO

7dB

AMP

VCC

LOGIC

AF

AMP

FM IF IN

181920

7dB

LEVEL

DET

GND

R. LO

MONITOR

DIVIDER

ST/MONO

FM/AM

TUN

LED

1k

AMP

VCO

TUN LED

DECODER

10k

LED

17

ST

ST LED

LINE

QUAD

1k

RADIO

TAPE

15

LINE

R. RAD

16

10k

6k

10k

14

R. LIN

MIC

13

IN

MUTE

TAPE

10k

–––––

TAPE

BUF AMP

A1

NAB

AMP1

1

2

AGC

L. PO

10k

10k

3

L. NF

BUF AMP

B1

10k

26dB 26dB

REC

AMP1

4

L. RO

ON

ALC1

REF AMP

5

6

L. IN

DET

REF

ON

ALC2

7

GND

BUF AMP

B2

2.1

10k

MUTE

8

R. IN

10k

REC

AMP2

10k

10k

9

R. RO

BUF AMP

MUTE

ON

10

R. NF

TAPE

–––––

NAB

AMP2

TAPE

A2

11

R. PO

MIC

AMP1

10k

1k

12

NF

MIC

27

Page 28

CFD-V8

• IC BLOCK DIAGRAMS –CD SECTION–

IC701 LC78645NE-U-E

LDS

FR

VVDD

PLL

VCEC

PCK

MIX

EQ

+

LPF

SLCO

SLCIST

EFMIN

RFVDD

RFVSS

FIN1

FIN2

TIN1

LDD

79 78 777675 74 73

80

APC

1

2

3

4

RF

5

6

7

8

9

SLICE

LEVEL

CONTROL

–

+

–

+

–

+

LEVEL SET

–

+

TBAL

VVSS

PCKIST

PD02

PD01

AGC

PH

BH

CONT1

CONT2

CONT3

72 71 70

69 68

GATE GATE

GENERALPURPOSE

PORTS

VSS

VDD5V

67

DRF

AUTO

ADJUST

DRF

66

*RES

DO

*WRQ

65 64 63

COMMAND

INTERFACE

8FS

DIGITAL

FILTER

1BIT

DAC

DI

62 61

MUTE

INTERPOLATION

ERROR

CORRECTION

AUDIO CD

C1-1, C2-2

EXTERNAL

DEEMPHASIS

ATTENUATION

GENERATOR

SERIAL

OUT

AUDIO IN

RAM

CLOCK

60

59

58

57

56

55

54

53

52

51

50

49

48

47

DATA

DATACK

LRSY

ASDFIN

ASDACK

ASLRCK

16MOUT

EFLG

C2F

XVSS

FSX/16MIN

XIN

XOUT

XVDD

CE

CL

TIN2

VREF

REFI

TEC

RFMON

JITTC

ADAVDD

ADAVSS

TDO

46

+

–

+

AUDIO

OUT

39 40

VDD

DOUT

LPF

TEST

LPF

LPF

SW

RAM

+

–

+

–

+

–

TRACK

JUMP

SW

21

S/H

22 23 24

FDO

SPDO

D/A

SLDO

25 26 27

GPDAC

CONT4

CONT5

SBCK/CONT6

CLV, CAV

CONTROL

28 29 30

DEFECT

SBCK/FG

FRAME SYNC DETECT,

PROTECT INSERT,

RUPTURE

DEFECT

V/*P

EFM DECODE

SUBCODE

DECODE CRC

FSEQ

MONITOR

SELECTOR

32 33 34 35 3631

MONI1

SIGNAL

MONI2

MONI3

MONI4

37 38

MONI5

(3.3V)VSS

MONI

CONT

–

+

–

+

JITTER

DETECT

A/D

TBAL

SERVO

PROCESSOR

10

11

12

13

FE

14

15

TE

16

17

18

19

20

RVSS

45

RCHO

RVSS

44

43

LVSS

42

LCHO

LVSS

41

28

Page 29

IC702 BA6998FP-E2

GND

T +

T –

28 27 26 25 24

DRIVE

BUFFER

TIN

NC

VREFI

23 22 21

VCC

VCC

VCC

NC

20 19 18 17 16

VCC

SLIN

SL +

DRIVE

BUFFER

SL –

VREF

CFD-V8

SPI

15

LEVEL

SHIFT

–

+

+

–

LEVEL

SHIFT

DRIVE

BUFFER

1 2 3 5 6

F –

F +

FIN

REGULATOR VOLTAGE DETECT,

BIAS VOLTAGE DETECT,

THERMAL SHUT DOWN

–

+

4

REG-B

RESET

REGOUT

7

8 9

MUTE

• IC BLOCK DIAGRAMS –MAIN SECTION–

IC401 MM1468XD

LEVEL

SHIFT

–

+

+

DRIVER

MUTING

GND

–

10 11 12 13 14

NC

SPIN

LEVEL

SHIFT

DRIVE

BUFFER

SP –

SP +

GND

+

SPOUT

–

CONT

GND

VM

1

NC

2

3

4

DET

DET

VCC

VH

VL

LATCH

VCC

8

TC

7

6

NC

VOUT

5

29

Page 30

CFD-V8

2

Ver 1.2

NOTE :

• -XX, -X mean standardized parts, so they

may have some difference from the original

one.

• Items marked “ * ”are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference

number in the exploded views are not

supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

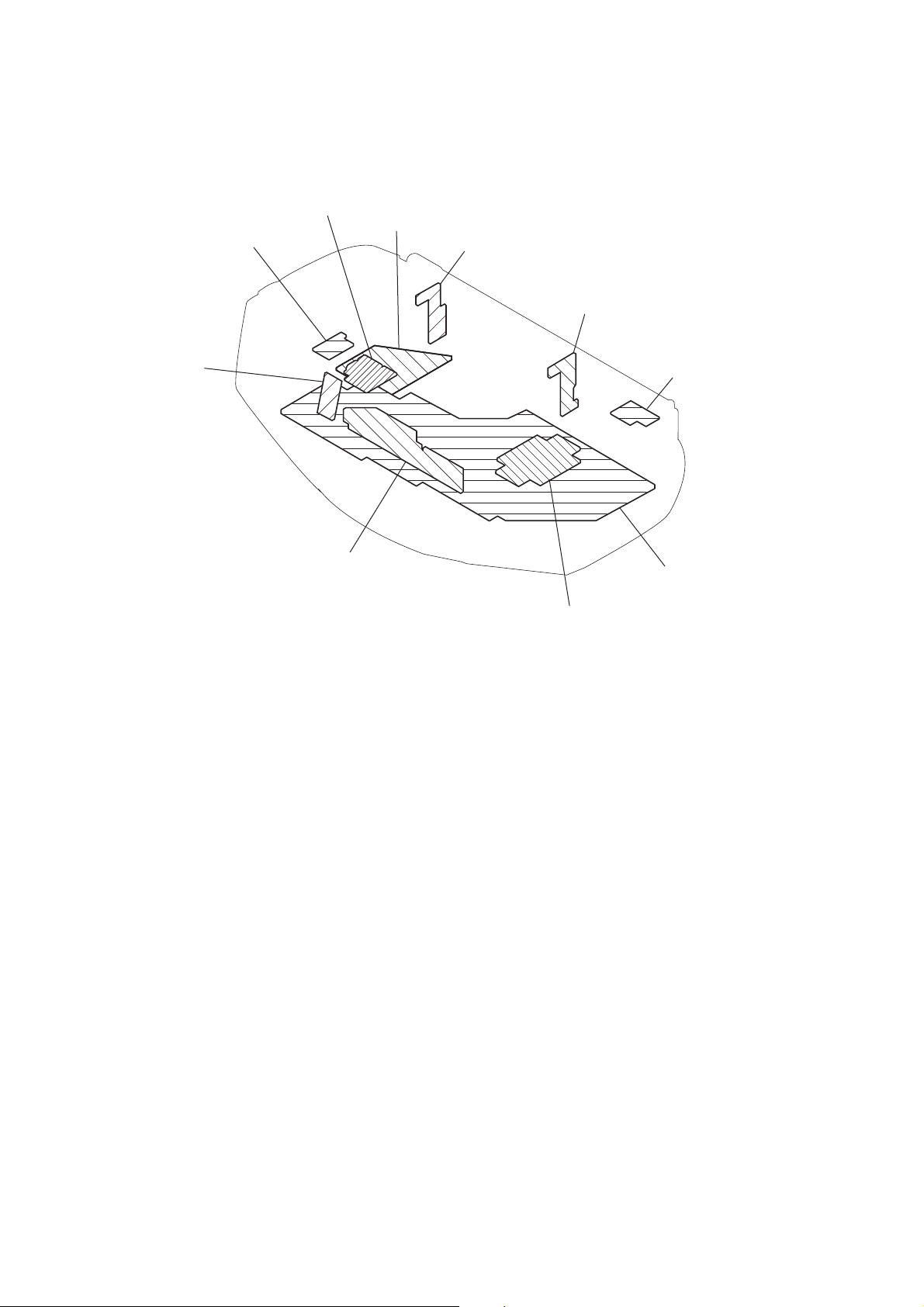

7-1. FRONT CABINET SECTION

SECTION 7

EXPLODED VIEWS

• Abbreviation

CND : Canadian

CET : East European & Russian

IT : Italian

SP : Singapore

AUS : Australian

TW : Taiwan

KR : Korea

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

#2

#2

#1

SP101

#1

11

#2

#2

11

#

13

12

11

9

6

11

#1

15

2

8

3

11

11

10

14

5

4

SP201

#1

1

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 3-259-518-01 WINDOW (LCD) (AEP,CET,KR,SP,UK)

1 3-259-518-11 WINDOW (LCD) (IT)

1 3-259-518-21 WINDOW (LCD) (CND,AUS,TW)

2 3-259-520-01 BUTTON (CD/P) (BX)

3 3-259-912-01 BUTTON (CD/R) (.)

4 3-259-911-01 BUTTON (CD/F) (>)

5 3-259-521-01 BUTTON (CD/S) (x)

6 3-031-552-61 KNOB (TU)

8 3-259-519-01 KNOB (VOL)

9 3-031-551-01 POINTER

10 3-031-558-02 SHAFT (TU)

11 4-951-620-01 SCREW (2.6X8), +BVTP

* 12 A-4542-902-A CONTROL BOARD, COMPLETE

13 X-3384-195-1 CABINET (FRONT) SUB ASSY

14 3-259-913-01 FRAME (BUTTON)

15 3-259-517-01 PANEL

SP101 1-529-723-21 SPEAKER (10cm) (L-CH)

SP201 1-529-723-21 SPEAKER (10cm) (R-CH)

#1 7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

#2 7-685-648-79 SCREW +BVTP 3X12 TYPE2 N-S

30

Page 31

CFD-V8

Ver 1.2

7-2. REAR CABINET SECTION

56

55

54

T901

#1

#2

#2

57

59

70

66

67

60

58

62

61

65

70

63

65

64

66

#1

#1

#1

53

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 3-226-989-21 CABINET (REAR) (TW)

51 3-226-989-31 CABINET (REAR) (AUS)

51 3-226-989-41 CABINET (REAR) (CND)

51 3-229-939-51 CABINET (REAR) (AEP,UK,IT,CET,KR)

51 3-229-939-71 CABINET (REAR) (SP)

* 52 A-4542-911-A INLET BOARD, COMPLETE

* 52 A-4542-912-A INLET BOARD, COMPLETE (CND)

* 52 A-4542-913-A INLET BOARD, COMPLETE (TW)

* 53 1-861-376-11 POWER BOARD

54 3-031-570-61 KNOB (FUNCTION)

55 3-259-522-01 BUTTON (MB)

56 3-031-561-01 SPRING (CASSETTE)

57 3-226-991-11 HOLDER CASSETE

58 3-226-993-11 LID CD

59 1-452-899-11 MAGNET

#1

52

69

(AEP,AUS,CET,IT,KR,SP,UK)

51

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

60 3-019-395-01 PLATE, CHUCKING

61 3-031-562-03 SPRING (CD)

62 4-951-620-11 SCREW (2.6X10), +BVTP

63 3-229-931-11 HANDLE

* 64 1-861-373-11 BATT (L) BOARD

65 3-028-154-01 TERMINAL (-), BATT

66 4-960-167-01 SCREW (3X8) (DIA. 10), +WH

* 67 1-861-374-11 BATT (R) BOARD

68 3-229-934-11 LID BATTERY

69 3-034-633-01 COVER (VOL SEL)

70 3-015-345-21 CUSHION

0 T901 1-433-576-11 TRANSFORMER, POWER (TW)

0 T901 1-433-577-11 TRANSFORMER, POWER (CND)

0 T901 1-435-921-11 TRANSFORMER, POWER

#1 7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

#2 7-685-648-79 SCREW +BVTP 3X12 TYPE2 N-S

68

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

(AEP,AUS,CET,IT,KR,SP,UK)

31

Page 32

CFD-V8

Ver 1.2

7-3. UPPER CABINET SECTION

ANT1

104

106

118

103

115

105

107

108

#1

#1

109

102

113

119

not supplied

110

114

112

#4

#1

117

116

#1

#1

120

123

#5

S801

122

126

127

121

KSM-213CDP

127

111

121

101

#1

125

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 101 A-4542-898-A MAIN BOARD, COMPLETE (AEP,CET,KR,SP,UK)

* 101 A-4542-899-A MAIN BOARD, COMPLETE (CND,AUS,TW)

101 A-4542-900-A MAIN BOARD, COMPLETE (IT)

102 4-960-167-01 SCREW (3X8) (DIA. 10), +WH

103 3-031-560-01 SHAFT (MD)

104 3-031-541-71 BUTTON (REC)

105 3-031-542-72 BUTTON (PLAY)

106 3-031-543-71 BUTTON (REW)

107 3-031-544-71 BUTTON (FF)

108 3-031-545-71 BUTTON (STOP)

109 3-031-546-71 BUTTON (PAUSE)

110 3-031-559-01 GEAR (PVC 2 BAND)

* 111 1-757-584-11 CABLE, FLEXIBLE FLAT (15 CORE)

* 112 1-757-688-11 CABLE, FLEXIBLE FLAT (10 CORE)

* 113 A-4542-903-A VOLUME BOARD, COMPLETE

* 114 1-757-583-11 CABLE, FLEXIBLE FLAT (16 CORE) (120mm)

115 3-922-112-41 DAMPER

116 3-922-112-21 DAMPER

117 3-226-990-11 CABINET (UPPER)

118 3-225-866-01 CUSHION (MD BUTTON)

119 4-951-620-11 SCREW (2.6X10), +BVTP

* 120 1-861-375-11 FM SW BOARD

121 3-921-725-11 SCREW (2.6X10), +PWH

122 3-226-992-01 TERMINAL (ANTENNA)

123 3-931-379-21 RUBBER, VIBRATION PROOF (RED)

124 1-757-689-11 CABLE, FLEXIBLE FLAT (16 CORE) (105mm)

* 125 A-4542-958-A CD BOARD, COMPLETE

126 3-923-736-01 COVER, CD

127 3-931-379-31 RUBBER, VIBRATION PROOF (GREEN)

ANT1 1-501-883-21 ANTENNA, TELESCOPIC

S801 1-692-960-11 SWITCH, PUSH (1 KEY) (CD DOOR)

#1 7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

#4 7-621-775-20 SCREW +B 2.6X5

#5 7-682-548-04 SCREW +B 3X8

123

121

#4

121

124

32

Page 33

7-4. MECHANISM DECK SECTION (1)

(MF-V5-117)

CFD-V8

HRP901

159

174

#3

171

172

157

155

153

HE901

158

169

156

154

168

151

167

160

161

162

170

163

164

165

166

152

#3

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

151 3-933-010-01 SPRING (S/P), TORSION

152 3-933-025-01 SPRING (P), TORSION

153 3-040-857-01 LEVER (P)

154 3-933-024-01 ROLLER, PINCH

155 3-933-019-01 SPRING (F/R), TORSION

156 3-933-028-01 SPRING (FWD), TORSION

157 3-933-016-01 GEAR (S REEL)

158 3-008-590-01 SLIDER (REC)

159 3-008-592-01 BASE (H), HEAD

* 160 3-008-588-01 SLIDER (REW)

* 161 3-008-589-13 SLIDER (FF)

* 162 3-008-587-01 SLIDER (STOP)

* 163 3-008-591-01 SLIDER (PAUSE)

164 3-933-004-01 CLAW, REEL

173

* 165 3-933-021-01 SLIDER (FRP)

* 166 3-933-006-01 SLIDER (EJECT)

167 3-934-833-01 SPRING (FRP)

168 3-022-794-02 SPRING (BT)

169 3-933-007-01 PLATE, LOCK

* 170 3-012-114-01 LEVER (FR)

171 3-222-727-01 LEVER (REC)

172 4-951-620-01 SCREW (2.6X8), +BVTP

* 173 A-4542-959-A PRE BOARD, COMPLETE

174 3-222-726-01 CHASSIS (TC)

HE901 1-543-876-11 HEAD (ERASE)

HRP901 1-500-691-11 HEAD,MAGNETIC(RECORD/PLAYBACK)

#3 7-685-853-04 SCREW +BVTT 2X6

33

Page 34

CFD-V8

7-5. MECHANISM DECK SECTION (2)

(MF-V5-117)

207

M601

204

S601

203

206

205

218

208

219

209

210

216

211

212

213

217

214

215

202

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

201 3-933-029-01 LEVER, ERASING PREVENTION

202 3-933-182-01 SPRING, CASSETTE

203 3-932-995-01 GEAR (MID)

204 X-3371-667-1 CLUTCH ASSY

205 3-932-997-01 GEAR (CAM)

* 206 3-932-999-01 SLIDER (SW)

207 3-932-998-01 SPRING (GROUND), TORSION

208 3-009-648-01 LEVER (S.OFF)

209 3-936-438-01 LEVER (K)

210 X-3373-572-1 REEL ASSY (N), T

211 3-933-020-11 BELT

201

#4

212 X-3377-877-3 FLYWHEEL ASSY

213 3-932-993-01 CHASSIS, OUTSERT

214 3-343-358-01 RING, RETAINING

215 3-933-005-01 SPRING (CAM), COMPRESSION

216 3-939-383-02 SPRING, COMPRESSION

217 3-937-760-01 SPRING (GROUND), COMPRESSION

218 3-934-336-01 BEARING

219 3-009-650-02 SPRING (K), COMPRESSION

M601 A-3320-446-A MOTOR ASSY (CAPSTAN/REEL)

(including PULLEY)

S601 1-762-679-11 SWITCH, LEAF (MD POWER)

#4 7-621-775-20 SCREW +B 2.6X5

34

Page 35

7-6. CD BLOCK SECTION (KSM–213RDP)

CFD-V8

Ver 1.3

253

251

257

252

M701

255

259

256

254

not

supplied

258

M702

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

251 X-2162-707-2 CHASSIS ASSY (RDP) (RP),

MOTOR (including M701 (SPINDLE))

* 252 2-647-408-02 GEAR (B)

* 253 2-169-065-01 GEAR (A)

254 2-169-388-01 TAPPING (M2), +PWB

0 255 8-820-161-02 OPTICAL PICK-UP (KSS-213R/C2RP)

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

256 2-626-908-01 SHAFT, SLED

257 2-174-500-01 SCREW (M2X3)

* 258 2-169-385-01 SPRING, SLED

* 259 2-169-384-01 SHAFT (S), GEAR

M702 X-2162-712-2 GEAR ASSY (R) (RP), MOTOR (SLED)

Les composants identifiés par une

marque 0 sont critiques pour la

sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

(including GEAR)

35

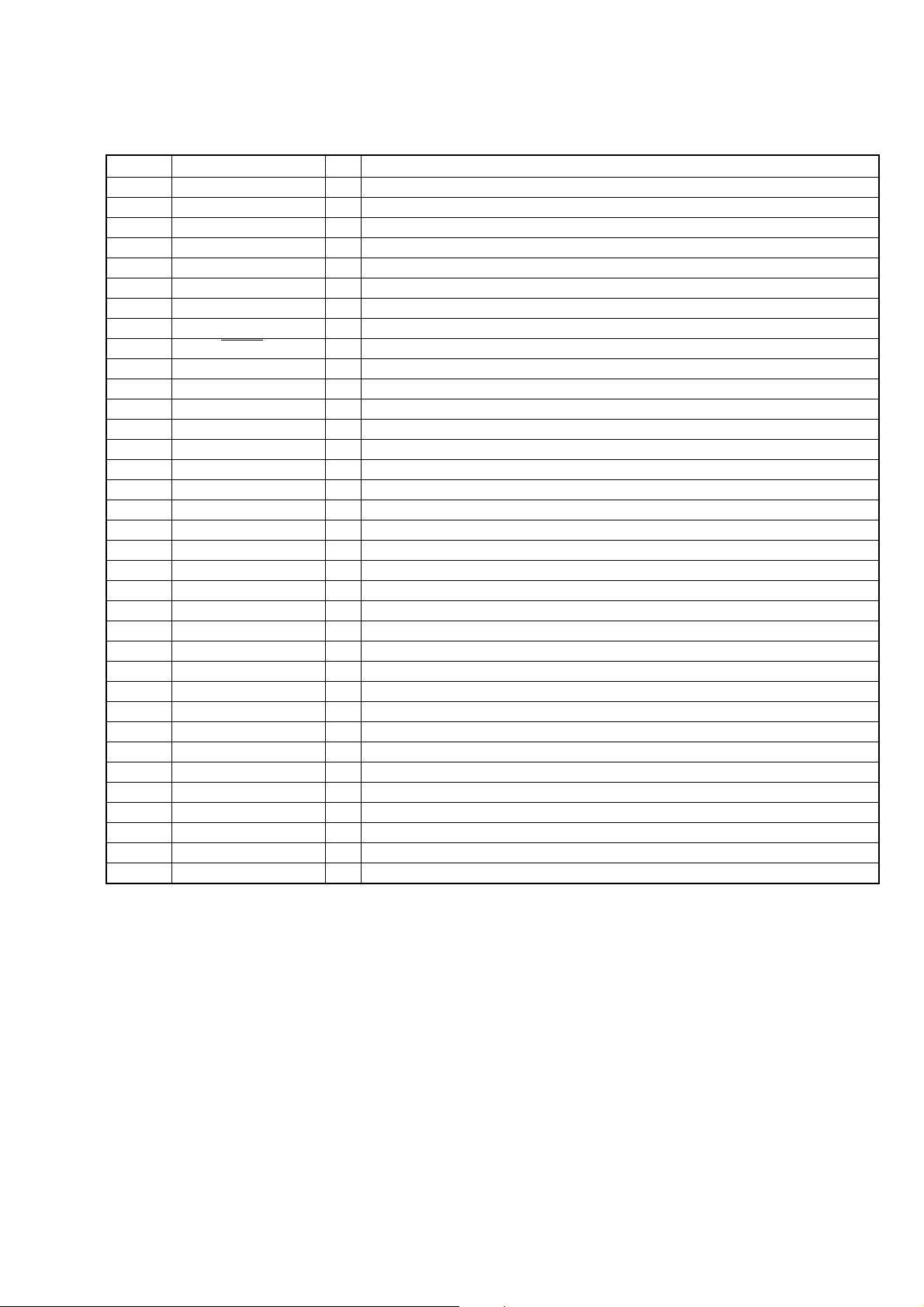

Page 36

CFD-V8

Ver 1.2

BA TT (L) BATT (R)

SECTION 8

ELECTRICAL PARTS LIST

CD

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-861-373-11 BATT (L) BOARD

************

3-028-154-01 TERMINAL (-), BATT

< CONNECTOR >

* CNP908 1-815-550-11 PIN, CONNECTOR (PWB) 2P

******************************************************

• Items marked “*” are not stocked since they are seldom required

for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. . uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

• Abbreviation

CND : Canadian

CET : East European & Russian

IT : Italian

C734 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C735 1-126-916-11 ELECT 1000uF 20% 6.3V

C736 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C738 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C739 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C740 1-126-935-11 ELECT 470uF 20% 10V

C741 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C742 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C743 1-164-156-11 CERAMIC CHIP 0.1uF 25V

SP : Singapore

AUS : Australian

TW : Taiwan

KR : Korean

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro spécifié.

When indicating parts by reference

number, please include the board.

* 1-861-374-11 BATT (R) BOARD

************

3-028-154-01 TERMINAL (-), BATT

******************************************************

A-4542-958-A CD BOARD, COMPLETE

*****************

< CAPACITOR >

C744 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C745 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C746 1-104-665-11 ELECT 100uF 20% 10V

C747 1-104-665-11 ELECT 100uF 20% 10V

C750 1-104-665-11 ELECT 100uF 20% 10V

C751 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C754 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C755 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C701 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C702 1-126-947-11 ELECT 47uF 20% 10V

C703 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C704 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C705 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C706 1-126-960-11 ELECT 1uF 20% 50V

C707 1-115-156-11 CERAMIC CHIP 1uF 10V

C708 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C709 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C711 1-162-974-11 CERAMIC CHIP 0.01uF 50V

C716 1-162-974-11 CERAMIC CHIP 0.01uF 50V

C717 1-163-021-91 CERAMIC CHIP 0.01uF 10% 50V

C720 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C721 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C722 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C723 1-162-974-11 CERAMIC CHIP 0.01uF 50V

C724 1-162-919-11 CERAMIC CHIP 22PF 5% 50V

C725 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C726 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C727 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C728 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C729 1-125-837-91 CERAMIC CHIP 1uF 10% 6.3V

C730 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C731 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C732 1-104-665-11 ELECT 100uF 20% 10V

< CONNECTOR >

CNP701 1-770-168-11 CONNECTOR, FFC/FPC 16P

CNP702 1-784-737-11 CONNECTOR, FFC 15P

< INDUCTOR >

FB701 1-469-701-21 INDUCTOR 0uH

< IC >

IC701 6-701-617-01 IC LC78645NE-U-E

IC702 6-701-787-11 IC BA5826FP-E2

< JUMPER RESISTOR >

JC701 1-216-864-11 METAL CHIP 0 5% 1/10W

JC702 1-216-864-11 METAL CHIP 0 5% 1/10W

JC703 1-216-864-11 METAL CHIP 0 5% 1/10W

JC704 1-216-813-11 METAL CHIP 220 5% 1/10W

< COIL >

L706 1-216-864-11 METAL CHIP 0 5% 1/10W

< TRANSISTOR >

Q701 8-729-054-57 TRANSISTOR KTN2907AS-RTK

C733 1-104-665-11 ELECT 100uF 20% 10V

36

Page 37

CFD-V8

Ver 1.2

CD CONTROL FM SW INLET

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

< RESISTOR >

< SWITCH >

R701 1-216-841-11 METAL CHIP 47K 5% 1/10W

R702 1-216-835-11 METAL CHIP 15K 5% 1/10W

R703 1-216-835-11 METAL CHIP 15K 5% 1/10W

R704 1-216-835-11 METAL CHIP 15K 5% 1/10W

R705 1-216-835-11 METAL CHIP 15K 5% 1/10W

R706 1-216-841-11 METAL CHIP 47K 5% 1/10W

R707 1-216-797-11 METAL CHIP 10 5% 1/10W

R708 1-216-833-11 METAL CHIP 10K 5% 1/10W

R709 1-216-837-11 METAL CHIP 22K 5% 1/10W

R710 1-216-829-11 METAL CHIP 4.7K 5% 1/10W

R711 1-216-815-11 METAL CHIP 330 5% 1/10W

R712 1-216-809-11 METAL CHIP 100 5% 1/10W

R714 1-216-811-11 METAL CHIP 150 5% 1/10W

R715 1-216-811-11 METAL CHIP 150 5% 1/10W

R716 1-216-821-11 METAL CHIP 1K 5% 1/10W

R717 1-216-821-11 METAL CHIP 1K 5% 1/10W

R718 1-216-821-11 METAL CHIP 1K 5% 1/10W

R719 1-216-809-11 METAL CHIP 100 5% 1/10W

R720 1-216-809-11 METAL CHIP 100 5% 1/10W

R721 1-216-821-11 METAL CHIP 1K 5% 1/10W

R722 1-216-809-11 METAL CHIP 100 5% 1/10W

R723 1-216-809-11 METAL CHIP 100 5% 1/10W

R724 1-216-841-11 METAL CHIP 47K 5% 1/10W

R725 1-216-819-11 METAL CHIP 680 5% 1/10W

R726 1-216-819-11 METAL CHIP 680 5% 1/10W

R727 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R728 1-216-833-11 METAL CHIP 10K 5% 1/10W

R729 1-216-813-11 METAL CHIP 220 5% 1/10W

R730 1-216-821-11 METAL CHIP 1K 5% 1/10W

R731 1-216-825-11 METAL CHIP 2.2K 5% 1/10W

R741 1-218-867-11 METAL CHIP 6.8K 5% 1/10W

R743 1-218-867-11 METAL CHIP 6.8K 5% 1/10W

R744 1-216-845-11 METAL CHIP 100K 5% 1/10W

< SWITCH >

S701 1-571-936-11 SWITCH, LEAF (LIMIT)

< VIBRATOR >

X701 1-795-158-21 VIBRATOR, CERAMIC (33.86MHZ)

******************************************************

* A-4542-902-A CONTROL BOARD, COMPLETE

**********************

S401 1-771-550-31 SWITCH, TACTILE (s)

S402 1-762-875-21 SWITCH, KEYBOARD (L)

S403 1-762-875-21 SWITCH, KEYBOARD (l)

S404 1-771-550-31 SWITCH, TACTILE (HS)

S405 1-786-050-21 SWITCH, KEY BOARD (PLAY MODE)

S406 1-762-875-21 SWITCH, KEYBOARD (ETER)

******************************************************

* 1-861-375-11 FM SW BOARD

***********

< CABLE HOLDER >

* KH1 1-565-385-11 HOLDER, CABLE 4P

< SWITCH >

S1 1-786-114-11 SWITCH, SLIDE (ST/MO)

******************************************************

* A-4542-911-A INLET BOARD, COMPLETE

(AEP,AUS,CET,IT,KR,SP,UK)

* A-4542-912-A INLET BOARD, COMPLETE (CND)

* A-4542-913-A INLET BOARD, COMPLETE (TW)

*******************

1-533-233- FUSE HOLDER

< CAPACITOR >

C901 1-162-995-11 CERAMIC CHIP 0.022uF 50V

C903 1-162-995-11 CERAMIC CHIP 0.022uF 50V

C905 1-162-995-11 CERAMIC CHIP 0.022uF 50V

< CONNECTOR >

0 CNJ901 1-526-838-11 INLET, AC 2P (-AC IN)

(AEP,AUS,CET,IT,KR,SP,UK)

0 CNJ901 1-540-009-11 INLET, AC (-AC IN) (CND,TW)

* CNP902 1-815-552-11 PIN, CONNECTOR (PWB) 4P

* CNP907 1-815-444-11 PIN, CONNECTOR (PWB) 3P

< DIODE >

D901 8-719-063-79 DIODE 1N4002B

D902 8-719-063-79 DIODE 1N4002B

D903 8-719-063-79 DIODE 1N4002B

D904 8-719-063-79 DIODE 1N4002B

< FUSE >

< CONNECTOR >