Page 1

CFD-V25/V35

MICROFILM

SERVICE MANUAL

Photo: CFD-V35

US Model

Canadian Model

CFD-V25/V35

E Model

CFD-V25

Model Name Using

Similar Mechanism

Optical Pick-up Type KSM-213CDM/C2NP

T ape Transport Mechanism Type MF-V10-117

CD Section

Tape Section

NEW

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

With 3.2 Ω loads, both channels driven from 150 – 10,000 Hz; rated 2W per

channel-minimum RMS power, with no more than 10 % total harmonic

distortion in AC operation.

CD player section

System Compact disc digital audio system

Laser diode properties Material: GaAlAs

Wavelength:780 nm

Emission duration : Continuous

Laser output : Less than 44.6 µW

(This output is the value measured at a distance

of about 200 mm from the objective lens surface

on the optical pick-up block with 7 mm

aperture.)

Spindle speed 200 r/min (rpm) to 500 r/min (rpm) (CLV)

Number of channels 2

Frequency response 20 – 20,000 Hz + 1/-2 dB

Wow and flutter Below measurable limit

Radio section

Frequency range FM : 87.6 – 108 MHz

AM : 530 – 1,710 kHz

Aerials FM : Telescopic aerial

AM : Built-in ferrite bar aerial

Cassette-corder section

Recording system 4 -track 2 channel stereo

Fast winding time Approx. 120 s (sec.) with Sony cassette

C-60

Frequency response TYPE1 (normal) : 70 – 10,000 Hz

General

Speakers Full range : 10 cm dia., 3.2 Ω, cone type

(2)

Outputs Headphones jack (stereo minijack)

For 16 – 64 Ω impedance headphones

Power output (excluding US model)

2.3 W + 2.3 W (at 3.2 Ω, 10 % harmonic

distortion)

Power requirements For CD radio cassette-corder :

120V AC, 60 Hz

9V DC, 6 size D (R 20) batteries

For memory controller :

3V DC, 2 size AA (R 6) batteries

Power consumption AC 20W

— Continued on next page —

CD RADIO CASSETTE-CORDER

Page 2

TABLE OF CONTENTS

1. SERVICE NOTES····························································3

SAFETY CHECK-OUT

2. GENERAL ··········································································4

3. DISASSEMBLY

3-1. Front Cabinet, Control (1) Board, Control (2) Board,

Headphone Board ······························································· 9

3-2. Upper Cabinet····································································· 9

3-3. Optical Pick-up ·································································10

3-4. Mechanism Deck, Rec sw Board, Main Board,

Power Board, Primary Board, Batt Board ························ 10

4. ADJUSTMENTS

4-1. Mechanical Adjustment ····················································11

4-2. Electrical Adjustment ······················································· 11

4-3. Tuner Section···································································· 12

4-4. Reference ·········································································· 15

5. DIAGRAMS

5-1. Circuit Board Location ····················································· 17

5-2. IC Pin Function ································································ 18

5-3. Block Diagram ································································· 20

5-4. Printed Wiring Board························································23

5-5. Schematic Diagram – Tuner/System Section – ················ 27

5-6. Schematic Diagram – Power Section – ····························31

5-7. Schematic Diagram – CD Section – ·································35

5-8. IC Block Diagrams ··························································· 38

6. EXPLODED VIEWS

6-1. Front Cabinet Section ······················································· 39

6-2. Upper Cabinet Section······················································40

6-3. Rear Cabinet Section ························································ 41

6-4. Mechanism Deck Setion (1) (MF-V10-117) ···················· 42

6-5. Mechanism Deck Setion (2) (MF-V10-117) ···················· 43

6-6. Optical Pick-up Section (KSM-213CDM/C2NP) ············44

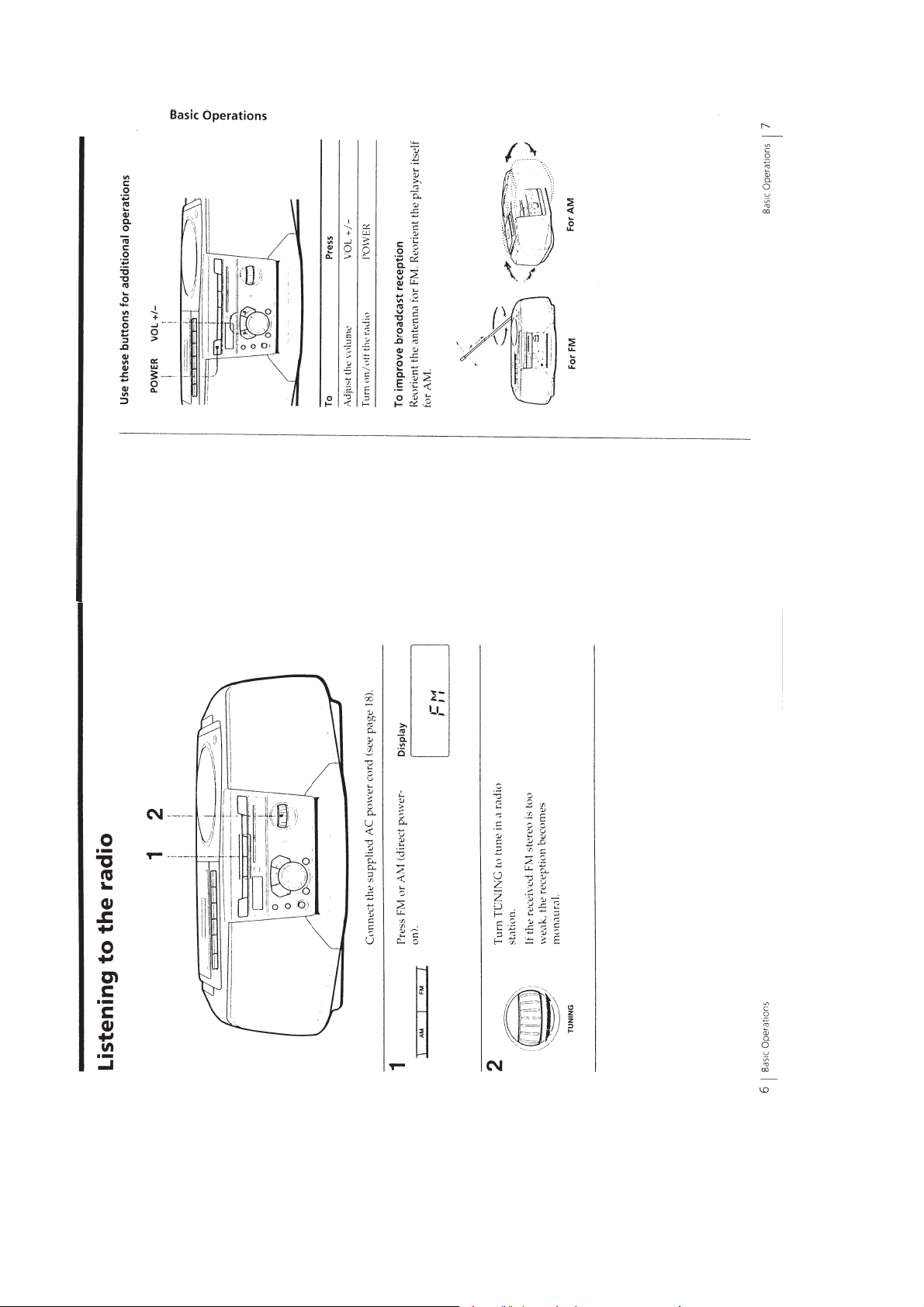

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

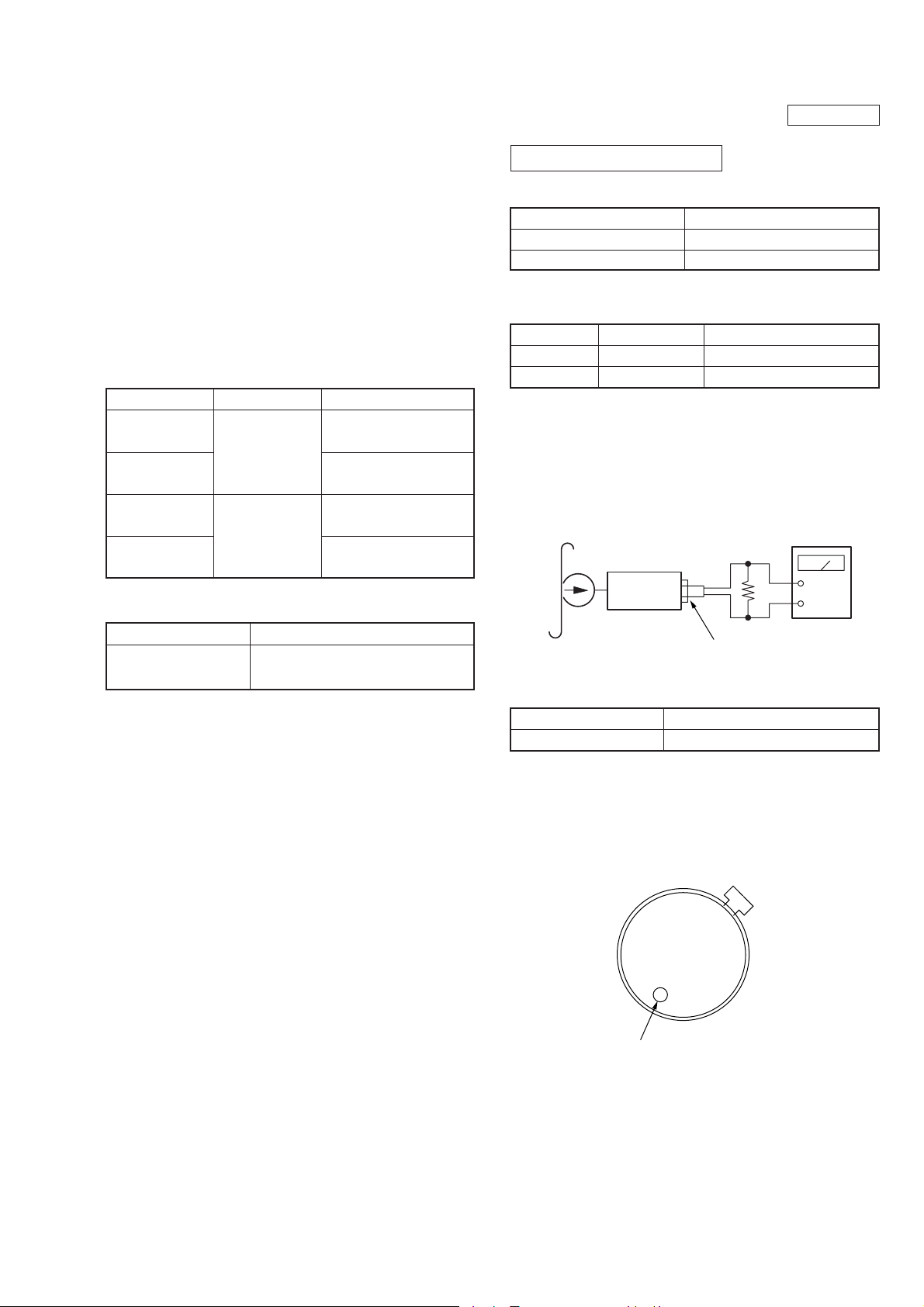

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. F ollow the man ufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or batter y-operated A C voltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accura te low-voltage

scale. The Simpson 250 and Sanwa SH-63T rd are examples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

T o Exposed Metal

Parts on Set

7. ELECTRICAL PARTS LIST······································· 45

Battery life For CD radio cassette-corder:

FM recording

Sony R20P : approx. 13.5 h

Sony alkaline LR20 : approx. 19 h

Tape playbac k

Sony R20P : approx. 7.5 h

Sony alkaline LR20 : approx. 15 h

CD playback

Sony R20P : approx. 2.5 h

Sony alkaline LR20 : approx. 6 h

Dimensions Approx. 425 × 160 × 246 mm (w/h/d)

(16 3/4 × 6 3/8 × 9 3/4 inches) (incl. projecting

parts)

Mass Approx. 4.2 kg (9 lb. 4 oz) (incl. batteries)

Supplied accessories AC power cord (1)

Remote controller (1)

Design and specifications are subject to change without notice.

Optional accessories

Sony MDR headphones series

AC

0.15

µ

F

Fig. A. Using an A C v oltmeter to check A C leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

1.5 k

Ω

Earth Ground

À LA SÉCURITÉ!

Voltmeter

(0.75 V)

— 2 —

Page 3

SECTION 1

Insert a precision screw driver

and push SWITCH

SERVICE NOTES

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

The following caution label is located inside the unit.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc., on clothing and the human body.

During repair , pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig : X-4918-255-1

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Press CD open knob.

2. Open the lid for CD.

3. Push on SWITCH as following figure.

4. Confirm the laser diode emission while observing the objecting

lens. When there is no emission, Auto Power Control circuit or

Optical Pick-up is broken.

Objective lens moves up and down once for the focus search.

— 3 —

Page 4

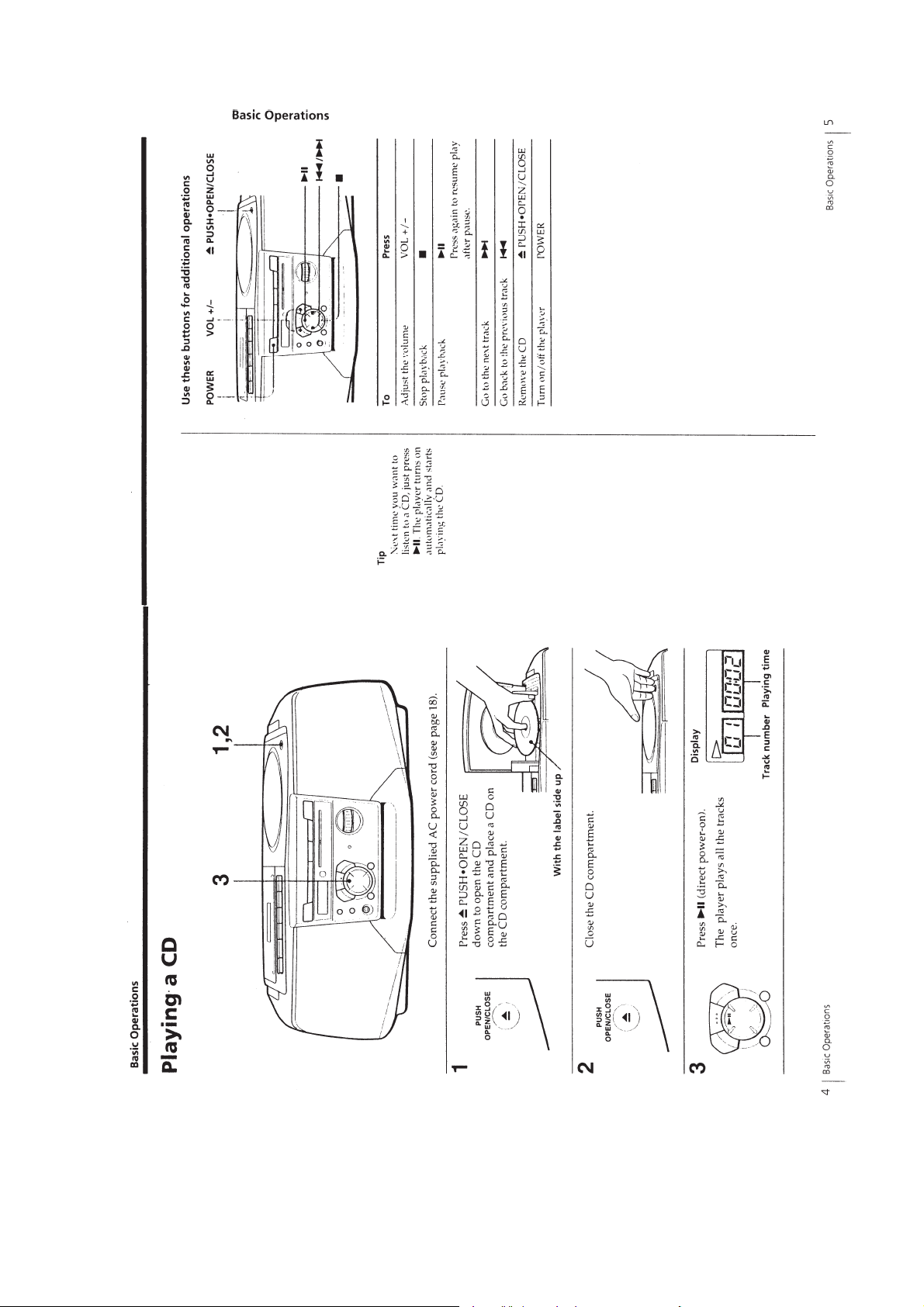

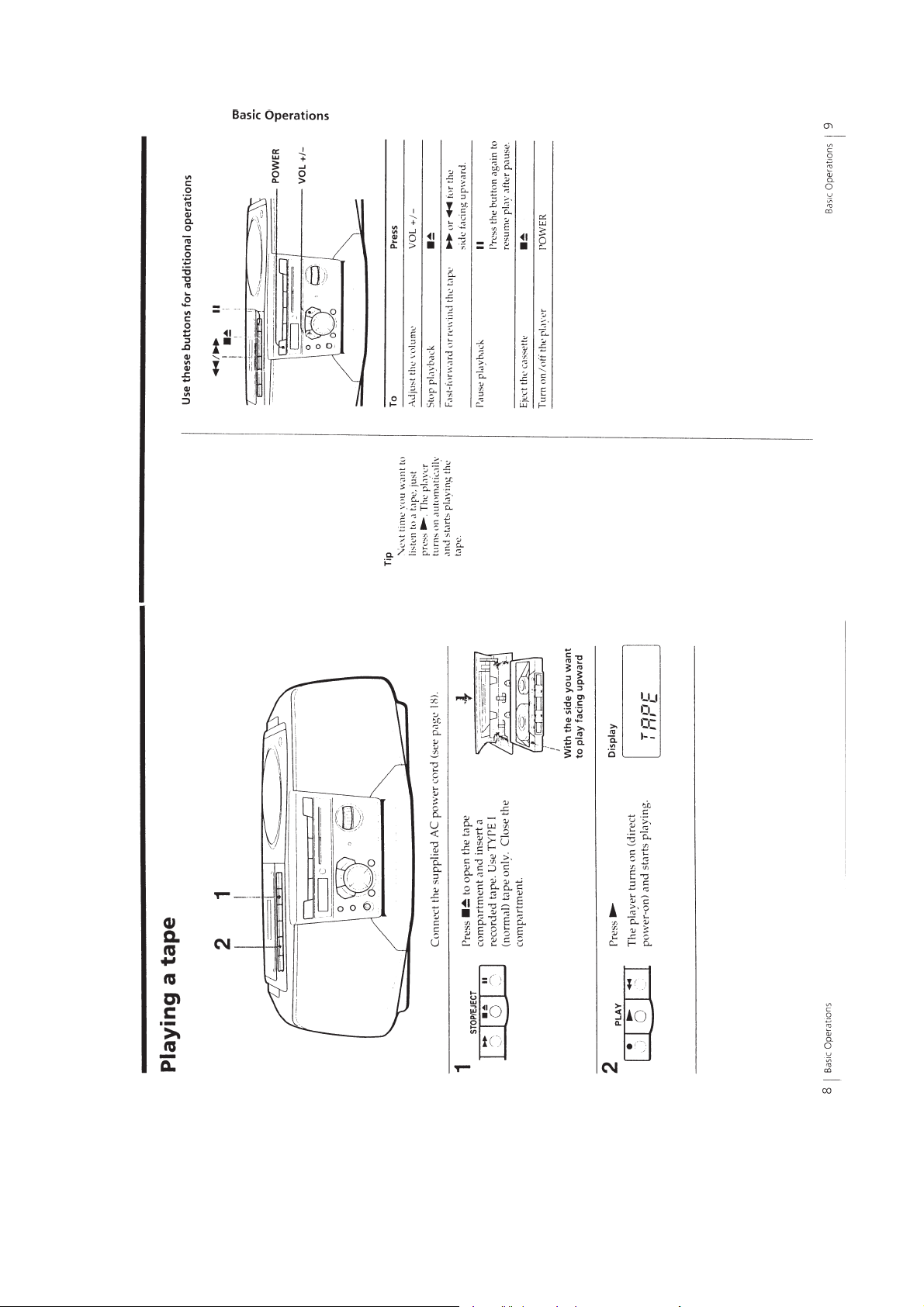

LOCATION OF CONTROLS

SECTION 2

GENERAL

This section is extracted

from instruction manual.

54321

!ª

!• !¶ !§ !∞ !¢ !£ !™ !¡ !º 9 8

1 POWER button

2 Tape operating buttons

3 FUNCTION buttons

4 LOOP button

5 OPEN/CLOSE button

6 Remote sensor

7 OPR/BATT indicator

8 TUNING knob

9 PRESET SOUND MODE buttons (V35 only)

!º TONE (H) button (V25 only)

6

7

!¡ CD operating

!™ TONE (L) button (V25 only)

!£ 2

!¢ DISPLAY/ENTER button

!∞ VOLUME – button

!§ PLAY MODE button

!¶ MEGA BASS button

!• VOLUME + button

!ª Information display

Remote commander (RMT-CV25A) (V25)

(RMT-CV35A) (V35)

!™

!¡

!º

9

8

7

1

2

3

4

56

1 POWER (AC ONLY) button

2 Number buttons

3 VOL +/– buttons

4 CD operation buttons

5 CD button

6 TAPE button

7 LOOP button

8 BAND select buttons

9 TONE H/L buttons (CV25A)

!º MODE button

!¡ MEGA BASS button

!™ SOUND button (CV35A)

— 4 —

Page 5

— 5 —

Page 6

— 6 —

Page 7

— 7 —

Page 8

— 8 —

Page 9

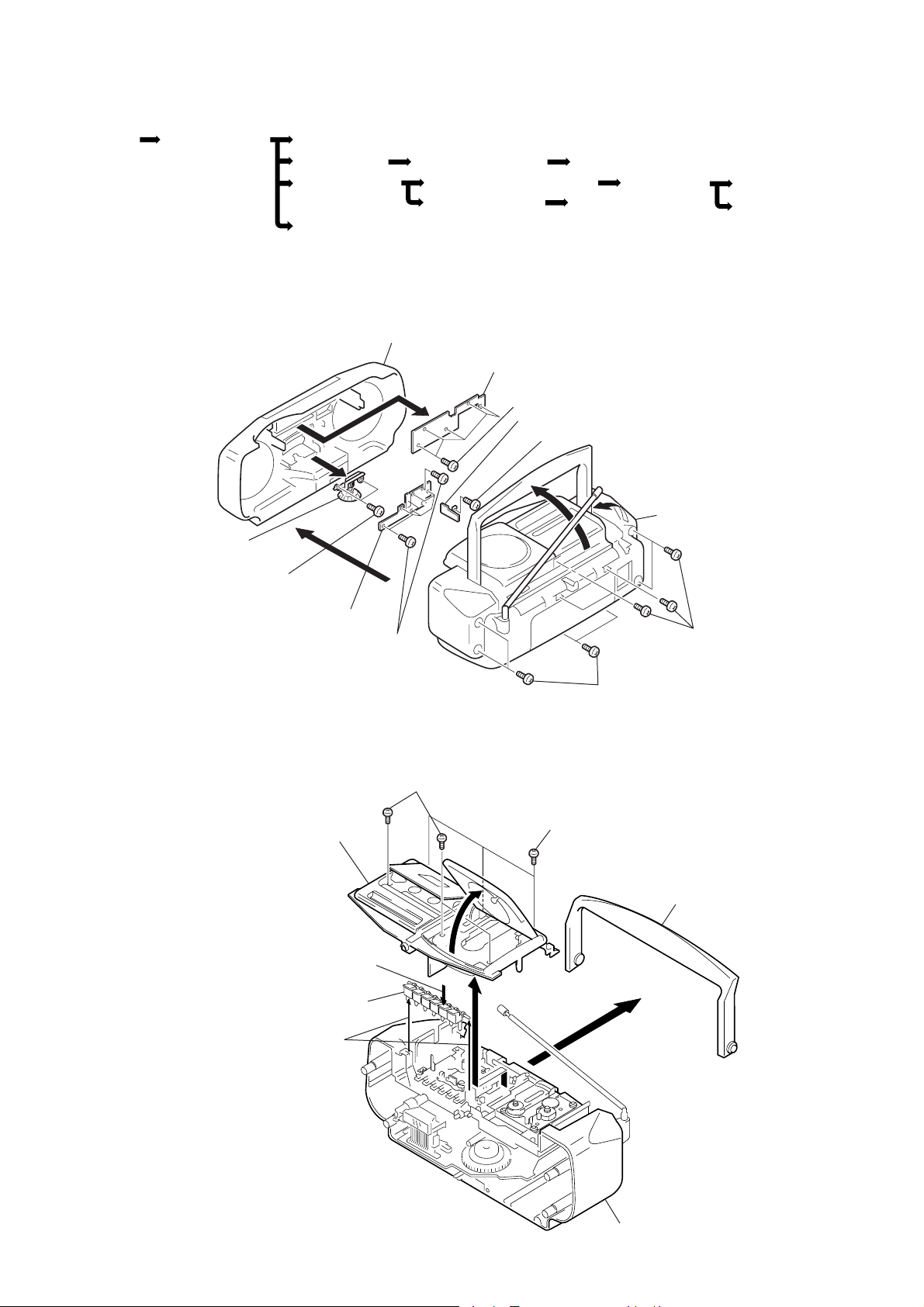

SECTION 3

D

4

DISASSEMBLY

• The equipment can be removed using the following procedure.

SET FRONT CABINET CONTROL (1) BOARD

TUNING KNOB

UPPER CABINET

PRIMARY BOARD

Note : Follow the disassembly procedure in the numerical order given.

3-1. FRONT CABINET, CONTROL (1) BOARD, CONTROL (2) BOARD, HEADSPHONES BOARD

Front cabinet

CONTROL (2) BOARD HEADPHONES BOARD

OPTICAL PICK-UP SECTION

MECHANISM DECK

6

CONTROL (1) board

5

Screws +BVTP 2.6 × 8

!™

REC SW BOARD

Headphones board

!¡

Screw +BVTP 2.6 × 8

1

MAIN BOARD POWER BOAR

2

Rear cabinet

BATT BOARD

8

TUNING KNOB

7

Screws

+BVTP 2.6 × 8

3-2. UPPER CABINET

Cabinet (upper) assy

4

!º

CONTROL (2)

board

2

STOP/EJECT

9

Screws

+BVTP 2.6 × 8

4

Screws

+BVTP 3 × 12

3

3

Screws +BVTP 3 × 14

1

Screws

+BVTP 3 × 12

3

+BVTP 3 × 1

Handle

Screws

Tape operation button

7

5

— 9 —

6

Rear cabinet

Page 10

3-3. OPTICAL PICK-UP

0

4

Remove solder

5

CD Motor

board

Optical pick-up section

3

Wire (Flat type) (16 core)

to MAIN board (CNP701)

1

2

CNP702 (6pin)

3-4. MECHANISM DECK, REC SW BOARD, MAIN BOARD, POWER BOARD, PRIMARY BOARD,

BATT BOARD

PRIMARY board

!™

Screws

+BVTP 3 × 10

3

Screws +BVTP 3 × 10

REC SW board

!£

Mechanism deck

2

4

MAIN board

1

Screws +BVTP 3 × 1

!º

!¡

BATT board

Rear cabinet

6

Screws +BVTP 3 × 10

5

CNP301 (4pin)

7

9

POWER board

8

Screws +BVTP 3 × 10

— 10 —

Page 11

SECTION 4

Tape speed adjustment

control inside motor

ADJUSTMENTS

4-1. MECHANICAL ADJUSTMENT

PRECAUTION

1. Clean the following parts with a denatured-alchool-moistened

swab:

record/playback head pinch roller

erase head rubber belts

capstans

2. Demagnetize the record/playback head with a head

demagnetizer. (Do not bring the head demagnetizer close to

the erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Torque Measurement

Mode

FWD

FWD

back tension

Fast Forward

Rewind

Tape T ension Measurement

Torque Meter

CQ-102C

CQ-201B

Meter Reading

60g•cm

(0.42 – 0. 83 oz•inch)

1 – 5g•cm

(0.014 – 0.07 oz•inch)

more than 55g•cm

(more than 0.77 oz•inch)

more than 55g•cm

(more than 0.77 oz•inch)

4-2. ELECTRICAL ADJUSTMENT

TAPE RECODER SECTION

Standard output level

Output Pin

Load impedance

Output signal level

Test tape

Test Tape

WS-48A

P-4-A063

Tape Speed Adjustment

Procedure :

Mode : Playback

test tape

WS-48A

(3kHz, 0dB)

Signal

3kHz, 0dB

6.3kHz, –10dB

set

0.25 V (–10dB)

Tape speed adjustment

Head azimuth adjustment.

32

1dB = 0.775V

HP OUT

32 Ω

Used for

speed checker

LFM-30 or

digital frequency

counter

Ω

+

–

Torque Meter

CQ-403A

Meter Reading

more than 80g

(more than 2.83 oz)

J302 (phones)

Adjustment Value : normal tape speed

Speed checker

–2.0 to 2.0%

Frequency difference between the beginning and the end of the

tape should be within 2% (60Hz).

Adjustment Location :

Digital frequency counter

2,940 – 3,060Hz

— 11 —

Page 12

4-3. TUNER SECTION

• Switch Location

VOLUME : MAX

MEGA BASS : OFF

PRESET SOUND MODE : OFF

AM SECTION

BAND : AM

Signal generator

AM RF signal

generator

Put the lead-wire

antenna close to

the set.

0 dB = 1 µV

• Repeat the procedures in each adjustment several times for the

maximum level meter indication.

• The frequency coverage and tracking adjustments should be

finally done by the trimmer capacitors.

AM IF ALIGNMENT

Adjust for a maximum reading on level meter.

T2 455kHz

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 620kHz

CV1 (3/4) 1,400kHz

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

FM SECTION

BAND : FM

Signal generator

FM RF signal

generator

75kHz (100%) amplitude modulation

by 1kHz signal.

Output level : as low as possible

set

32k

0.01µF

Ω

telescopic

antenna

terminal

level meter

+

–

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 520kHz

CV1 (4/4) 1,780kHz

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1 10.7MHz

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 86.5MHz

CV1 (1/4) 109.5MHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L2 86.5MHz

CV1 (2/4) 109.5MHz

J302 (phones)

Adjustment Location : MAIN board (Component side)

(See page 13)

— 12 —

Page 13

FM VCO Adjustment

l

r

color

mark

CF1

Procedure :

FM RF SSG

0.01µF

to ANT IN termina

Carrier frequency : 98MHz

IF frequency : According to

the color of CF1.

Modulation : no modulation

Output level : 0.1V (100dB)

1. Connect frequency counter to the positions shown below.

2. Tune the set to 98MHz.

3. Adjust RV1 for 76kHz ± 50Hz reading on the frequency

counter.

Frequency counte

0.01µF

IC1 Pin

IC1 Pin

4

7

33k

Ω

+

–

Adjustment Location : MAIN board (Component side)

RED 10.70MHz

BLUE 10.67MHz

ORANGE 10.73MHz

BLACK 10.64MHz

WHITE 10.76MHz

AM Tracking

CV1 (3/4)

L3

L3

L4

IC701

FM Tracking

CV1 (1/4)

L1

RV1

FM Frequency Coverage

Adjustment

CV1 (2/4)

L2

CF1

T2

16

15

18

11

IC1

4

1

30

T1

L2

FM IF IN

’‘

T2 : AM IF

ANT IN

L4

AM Frequency Coverage

Adjustment

CV1 (4/4)

RV1 : FM VCO

T1 : FM IF

— 13 —

IC1 : VCO IN

Page 14

CD SECTION

V

e

Notes on Check

1. Perform the traverse check in the CD test mode.

After check, be sure to exit the test mode.

2. Perform check in the order given.

3. Use the disc (YEDS-18, Parts No. 3-702-101-01) only when

so indicated.

Before Check

Put the set into test mode and perform the following checks.

Repair if there are any problems.

• Sled Motor Check

Press + , = keys and confirm that the Optical pick-up moves

smoothly from the innermost to outermost circumference and back

smoothly and with no catching or abnormal noises.

(Cancellation of BTL mute)

+ : Optical pick-up moves to the outer circumference.

= : Optical pick-up moves to the inner circumference.

E-F Balance Check

Adjustment Location : MAIN board (See page 23)

This check is to be done when the optical pick-up block is replaced.

Check Procedure:

1. Connect the oscilloscope to test point TP (VC) and TP (TE) on

MAIN board.

2. Put the set into test mode.

3. Optical pick-up setting to the center by + or = button

pushing.

4. Insert disk (YEDS-18) and press ^ button.

5. Check that the oscilloscope traverse w aveform is symmetrical,

as shown in the figure below.

6. Release test mode after adjustment is completed.

A

VOLT/DIV : 0.1

0V

TIME/DIV : 1ms

B

• Focus Search Check

1. Press the CD ^ key. (Focus search operation is performed

continuously.)

2. Look at the Optical pick-up objective lens and confirm that it

moves up and down smoothly, with no catching or abnormal

noises.

3. Press p button.

Confirm that focus search operation stops. If it does not, press

p button again longer.

How to Enter the Set into Test Mode

1. Turn the AC CORD IN (Adaptor).

(LCD 501 indicator blinks the test mode pattern.)

2. Short-circuit between the lands as shown on the control (1)

board.

How to Exit the Test Mode

Turn the POWER OFF.

[CONTROL (1) BOARD]

A = B C = 500mV

[MAIN BOARD]

TP(RF)

±

100mV

C

TP(FE)

TP(VC)

TP(TE)

Test portion

Short : Test mode

Open : Normal mode

Jumper wire

— 14 —

TP(TE)

TP(VC)

Osilloscop

(DC range)

+

–

Page 15

Focus Bias Check

(

Adjustment Location : MAIN board (Component side)

(See page 23)

This check is to be done when the optical block replaced.

Check Procedure:

1. Connect the oscilloscope to test point TP (VC) and TP (RF) on

MAIN board.

2. Put the set into test mode.

3. Opitical pick-up setting to the center by + or – button pushing.

4. Insert disk (YEDS-18) and press ^ button.

5. Press the MODE button. (Tracking servo ON)

6. Check that the oscilloscope wavewform is as sho wn in the figure

below (eye pattern).

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

7. Release test mode after adjustment is completed.

• RF signal reference waveform (eye pattern)

VOLT/DIV : 0.2V

TIME/DIV : 500ns

1.2

±

0.2Vp-p

When observing the eye pattern, set the oscilloscope for AC range

and raise vertical sensivity.

[MAIN BOARD]

4-4. REFERENCE

Focus/Tracking Gain Check

Adjustment Location : MAIN board (Component side)

(See page 23)

A frequency response analyzer is necessary in order to perform this

check exactly.

However, this gain has a margin, so even if it is slightly off, there is

no problem.

Focus/Trac king gain determines the pick-up follow-up (vertical and

horizontal) relative to mechanical noise and mechanical shock when

the 2-axis device operate.

Symptoms

Gain

Focus

• The time until music starts

becomes longer for STOP ➡

CD ^ or automatic

selection (0 , ) buttons

low

pressed). (Normally takes

about 2 seconds.)

• Music does not start and disc

continues to rotate for STOP

➡ CD ^ or automatic

—

selection (0 , ) buttons

pressed.)

• Sound is interrupted during

PLAY. Or time counter

—

display stops progressing.

• More noise during 2-axis

device operation.

high

Check Procedure:

1. Keep the set horizontal.

2. Inset disk (YEDS-18) and press ^ button.

3. Connect an oscilloscope to TP (FE) and TP (VC) on the MAIN

board.

4. Check that the waveform is as shown in the figure belo w . (Focus

waveform)

Tracking

low or high

low

low

high

TP(RF)

TP(FE)

Osilloscope

(DC range)

TP

TP(TE)

+

–

— 15 —

Page 16

• Good Example

V

V

V

s

s

e

• Incorrect Examples (Fundamental wave appears)

VOLT/DIV : 100m

TIME/DIV : 1ms

100mV

0V

• Incorrent Examples (DC level changes more than on adjusted

waveform)

VOLT/DIV : 100m

TIME/DIV : 2ms

200mV

0V

low focus gain

VOLT/DIV : 100m

TIME/DIV : 2ms

75mV

0V

VOLT/DIV : 1V

TIME/DIV : 2ms

0V

low tracking gain

VOLT/DIV : 1V

TIME/DIV : 2m

0V

high tracking gain

(high fundamental wave than for low gain)

[MAIN BOARD]

TP(FE)

high focus gain

5. Connect an oscilloscope between TP (TE) and TP (VC).

6. Insert disc (YEDS-18) and press the CD ^ button.

7. Check that the waveform is as shown in the figure below.

(tracking waveform)

VOLT/DIV : 1V

TIME/DIV : 2m

0V

TP(RF)

TP(TE)

TP(VC)

TP(TE)TP(FE)

TP(VC)

Osilloscop

(DC range)

+

–

— 16 —

Page 17

d

5-1. CIRCUIT BOARDS LOCATION

PRIMARY board

CONTROL (1) board

RMC board

LAMP board

(V35)

JUCK RETAINER board

SECTION 5

DIAGRAMS

REC SW board

BATT board

CD MOTOR boar

HEADPHONE board

CONTROL (2) board

LED board

MAIN board

POWER board

— 17 —

Page 18

5-2. IC PIN FUNCTION

IC501 CXP83416

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Pin Name

C-SCOR

RMC

C-XRST

B-MUTE

ROCK

POP

C-SQCK

C-SQSO

REC

C-SENS

C-SENS2

CD-PLAY

CD-STOP

C-CLK

C-XLT

C-DATA

MEGA BASS

LIVE/TONE +

VCAL/TONE –

VOL +

VOL –

MODE CHK

C-DOOR

BAND CHK

CD KEY

TAPE

FM/RADIO

AM

CD

RST

4.19 MHz

4.19 MHz

Vss

VL

VLC3

VLC2

VLC1

COM0

COM1

COM2

I/O

I

SCOR input to CD

I

Remote control signal input

O

Reset output to CD system

O

CD block mute ON/OFF

I/O

Input from ROCK key

I/O

Input from POP key

I/O

Clock for reading CD SUBQ

I/O

CD SUBQ data input

I/O

Input from TAPE REC switch

I/O

CD SENS input

I/O

CD SENS2 input

I/O

Input from CD-PLAY key

I/O

Input from CD-STOP key

I/O

Clock for CD DSP command

I/O

Latch output from CD system

I/O

Command data output from CD DSP

I/O

Input from MEGA BASS switch

I/O

Input from LIVE/TONE + key

I/O

Input from VOCAL/TONE – key

I/O

Input from VOL + key

I/O

Input from VOL – key

I/O

Mode check from RADIO/SOUND

I/O

Open/close sense from CD door

I/O

Input from RADIO BAND switch

I/O

Input from CD key (A/D)

I/O

Input from TAPE FUNCTION key

I/O

Input from FM/RADIO key

I/O

Input from AM FUNCTION key

I/O

Input from CD FUNCTION key

I

Reset input

I

4.19 MHz input

O

4.19 MHz output

—

Microprocessor reference GND

O

ON/OFF terminal of LCD drive port

I

LCD drive voltage terminal

I

LCD drive voltage terminal

I

LCD drive voltage terminal

O

LCD common output port

O

LCD common output port

O

LCD common output port

Description

— 18 —

Page 19

5-3. BLOCK DIAGRAM

L1

FM RF

L2

FM OSC

L3

FERRITE-ROD

ANTENNA

ANTENNA

ANT1

FM

TELESCOPIC

1

20

22

19

24

FM

FRONT END

FM RF

FM RF

FM OSC

AM RF

AM OSC

16

FM/AM

FE OUT

AM

FRONT END

CF1

CF2

T2

IFT

13

14

FM IF

AM IF

FM

MPX

FM/AM

BUFFER

FM

DET

AM

DET

6

5

R-CH

R-CH

26

IC1

FM/AM FRONT-END

FM/AM DET,FM MPX

27

T1

RV1

OPTICAL PICK-UP

BLOCK

(KSC-213C)

LD/POWER

CONTROL

Q701

41

VCC

CD5V

A

VC

C

B

D

E

F

VC

LD

GND

A

C

B

D

E

F

FOCUS

COIL

F+

F

T+

T

TRACKING

COIL

36

34

42

39

38

51

VC

LD

E

F

PD1

PD2

6

24

25

22

21

20

23

33

27

11

10

12

13

14

21 15

79

35

18

SENS

RFO

67

LO

74

RO

FOK

C OUT

DATA

XLT

CLK

XRST

9

57

7

6

5

8

62

SCOR

SYSM

CLOK

DATA

SENS

SQSO

4

SQCK

70

XTAI

71

XTAO

XLAT

SENS

RFO

FOK

C OUT

DATA

XLT

CLK

MDP

17

XLON(MUTE)

SPOA

XRST

16

13

FEO

TEO

SLO

IC703(1/2)

FOCUS/TRACKING COIL

SLED/SPINDLE MOTOR

DRIVER

IC703(1/2)

SPINDLE MOTOR

DRIVER

IC701

CD RF/SERVO

PROSSESOR

26

19

T IN

27

17

18

VR

PD

PD

2

1

12

11

25

F IN

3

SL IN

9

14

15

SP IN

7

MUTE

F+

F

T+

T

SL+

SL

SP+

SP

M

M

MOTOR

M702

SLED

MOTOR

M701

SPINDOL

S701

LIMIT

L-OUT

R-OUT

IC703

SIGNAL PROCESSOR

D/A CONVERTER

16

L4

AM OSC

20

CD L

R-CHR-CH

HRP901

REC/PB

HEAD

HE901

ERASE

HEAD

BIAS

OSC

Q301

IC301

PRE AMP

16

14

5

4

1521

REC H TC

RADIO

CD

PB

REC

PB AMP

26dB

2

L

4

REG

TAPE

TAPE

T301

2

MATRIX

SURROUND

TONE

VR

CONTROL

REG

9

4 5 6 87

18

20

19

23

21

DATA

VC

CLK

LATCH

BC

AUDIO

MUTE

Q308

BASS

AGC

Q309

RADIO B+

SWITCH

Q505

12

8

D351

IC304

POWER AMP

R-CH

H/P JACK

J301

L

R

SPEAKER

S301

REC PB

+5V

REC AMP

AMP

BUFFER

7dB

17

RA

IC302

SOUND/VOLUME

14

1

16

10

8

15

3

4

60

3 2

CD

76

PCON

30

RST

61

RADIO

59

62

63

65

64

9

TAPE

REC

A-MUTE

V-CLK

V-CE

V-DATA

SCOR

C-XRST

B-MUTE

C-CLK

C-DATA

C-SENS

C-SQSO

SEG0-15

C-XLAT

7

C-SQCK

23

78

CD-DOOR

TC-PLAY

12

6

17

18

19

13

5

POP

ROCK

CD-PLAY

MEGA BASS

LIVE/TONE+

VOCAL/TONE–

CD-STOP

20

VOL+

27

26

29

79

25

28

21

TAPE

VOL–

FM/RADIO

CD

POWER/WAKE UP

CD KEY

AM

IC501

SYSTEM

CONTROL

X701

16.9344MHz

32

XTAL

31

EXTAL

X501

4MHz

73

TX

74

TEX

X502

500kHz

45-47

COM0-3

38-41

LCD501

LIQUID CRYSTAL DISPLAY

S612

S613

S601

S602

S607

S610S611

S609

S608

S616

S615

S654

S652

S655

S656

S651

S603-S606,S650

S501

CD DOOR

S802

TAPE PLAY

CD B+

SWITCH

Q504

B+

SWITCH

Q954

REG

Q953

RECT

RECT

D901-D904

D907,D908

B+

SWITCH

Q503

B+

SWITCH

Q951

Q956

D905

D501

SWITCH

B+

ON/OFF

Q952

SWITCH

Q501

LAMP

DRIVE

Q955

B+

ON/OFF

Q502

+5V

+5V

+5V

+7V

DRY BATTERY

SIZE"D"

(IEC DESIGNATIO R20)

6PCS,9V

T901

POWER

TRANSFORMER

D906

B+

REG

IC502

3 1

RESET

IC503

2 1

REMOTE

CONTROL

RECEIVER

IC601

D502

D953

80

REG CHK

2

RMC

PL361

SIGNAL PATH.

:FM

:PB

:REC

:CD

J901

AC IN

CFD-V25/V35

Pin No.

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Pin Name

COM3

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

OUT

A-MUTE

RADIO

TAPE

V-CLK

V-DATA

V-CE

AM/FM

VOCAL

LIVE

ROCK

VDD

PCON

TC-PLAY

W-UP/POW

REG-CHK

CD

ISS

POP

TX

TEX

NC

INIT

I/O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

I

—

—

—

O

O

I

I

I

LCD common output port

LCD segment signal output port

ON/OFF terminal of audio mute

CD FUNCTION control terminal

RADIO FUNCTION control terminal

TAPE FUNCTION control terminal

Serial clock of VOL IC

Serial data output of VOL IC

Chip enable of VOL IC

AM/FM output

ISS selection

SOUND MODE VOCAL output terminal

SOUND MODE LINE output terminal

SOUND MODE ROCK output terminal

SOUND MODE POP output terminal

Power supply

500 kHz

500 kHz

No connection

Power ON/OFF control terminal

Initialization control terminal

Input from TC-PLAY

Input from WAKE UP/POWER KEY

REG check

— 19 — — 20 — — 21 — — 22 —

Description

Page 20

CFD-V25/V35

5-4. PRINTED WIRING BOARD

• Semiconductor Location

Ref. No. Location

D1 J-22

D2 J-23

D351 G-7

D501 H-14

D502 H-14

D503 H-15

D504 G-15

D506 E-17

D507 E-17

D508 E-17

D509 D-17

D511 G-17

D512 G-14

D513 G-14

D602 C-9

D603 C-8

D604 C-8

D605 C-7

D606 B-9

D607 B-8

D608 B-7

D901 G-2

D902 G-2

D903 H-3

D904 H-3

D905 G-4

D906 E-5

D907 H-4

D908 H-4

D951 I-8

D952 I-8

D953 I-7

D954 I-7

D955 I-9

D957 I-9

D958 H-8

D959 I-8

A

B

C

D

E

12

34567891011121314151617181920212223242526

F

IC1 F-19

IC301 J-15

IC302 F-9

IC304 F-7

IC501 F-16

IC502 G-14

IC503 F-17

IC601 C-18

IC701 I-21

IC702 H-19

IC703 I-17

Q1 E-18

Q301 I-13

Q308 H-9

Q309 G-7

Q501 F-18

Q502 G-14

Q503 G-14

Q504 G-17

Q505 F-18

Q701 J-21

Q951 I-8

Q952 I-8

Q953 I-7

Q954 H-9

Q955 H-8

Q956 H-9

G

H

I

J

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• b : Pattern from the side which enables seeing.

• Abbreviation

CND : Canadian

— 23 — — 24 — — 25 — — 26 —

Page 21

5-5. SCHEMATIC DIAGRAM — TUNER/SYSTEM SECTION —

CFD-V25/V35

— 27 — — 28 — — 29 —

— 30 —

• Waveform

4.0MHz

1.0V/div

0.1µsec/div

4.0Vp-p

1.0V/div

1.0µsec/div

4.5Vp-p

1 IC501 #¡

2 IC501 &¢

500kHz

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specified.

• C : panel designation.

• U : B+ Line.

• Power voltage is dc 9 V and fed with regulated dc power

supply from battery terminal.

• V oltages and waveforms are dc with respect to ground under no-signal (detuned) conditions.

no mark : CD PLAY

( ) : FM

[ ] : AM

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

• Signal path.

F : FM

f : AM

• Abbreviation

CND : Canadian

Page 22

CFD-V25/V35

5-6. SCHEMATIC DIAGRAM — POWER SECTION —

• Waveform

3 T301 REC

52.75kHz

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specified.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

• U : B+ Line.

• Power voltage is dc 9 V and fed with regulated dc power

supply from battery terminal.

• V oltages and waveforms are dc with respect to ground under no-signal (detuned) conditions.

no mark : CD PLAY

( ) : TAPE PLA Y

[ ] : TAPE REC

• V oltages are taken with a VOM (Input impedance 10 MΩ).

V oltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

• Signal path.

F : FM

E : PB

a : REC

J : CD

• Abbreviation

CND : Canadian

10V/div

10µsec/div

40Vp-p

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

— 31 — — 32 — — 33 —

— 34 —

Page 23

CFD-V25/V35

5-7. SCHEMATIC DIAGRAM — CD SECTION —

— 35 — — 36 — — 37 —

• Wavef orm

4 IC703 &¡

16.9344MHz

5 IC703 #∞

Note:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/4 W or less unless otherwise

specified.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

• U : B+ Line.

• Power voltage is dc 9 V and fed with regulated dc power

supply from battery terminal.

• Voltages and waveforms are dc with respect to ground under no-signal (detuned) conditions.

no mark : CD PLAY

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

• Waveforms are taken with a oscilloscope.

• Circled numbers refer to waveforms.

• Signal path.

J : CD

• Abbreviation

CND : Canadian

1.0V/div

50nsec/div

3.5Vp-p

0.2V/div

0.5µsec/div

1.2 ± 0.2Vp-p

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

5-8. IC BLOCK DIAGRAMS

IC1 CXA12138S

GND

30 29

PLL LPF1

PILOT DET LPF2

PILOT DET LPF2

IC701 CXA1992BR

PD1

PD2

+

+

–

–

PD1 IV

AMP

VCC

BAL4

TGFL

+

–

+

–

E-F BALANCE

VCC

VEE

+

–

1

FEO

WINDOW COMP.

DFCT

2 3

FEI

TM1

+

–

+

–

FE_BIAS

VEE

TEO

LPFI

ATSC

TZC

TDFCT

FZC

PD2 IV

AMP

40

VEE

BAL1

TOG2

TOG1

–

+

–

+

VCC

FZC COMP.

–

+

F IV AMP

–

+

E IV AMP

BAL2

BAL3

TOG4

TOG3

ATSC

WINDOW

COMP.

–

+

TZC COMP.

+

–

F

41

E

42

43

EI

44

45

46

47

TEI

48

49

50

51

VC

52

PLL LPF2

MPX REG

VCOFMDISCRI

MUTE

AM OSC

AFC

FM OSC

28 27 26 25 24 23 22 21 20 19 18 17 16

VCO MPX REG.

1/2

COUNTER

1/2

COUNTER

MONO/ST

SELECT

DECODER AMP

4 5 6 7 8 9 10 11 12 13 14 15321

ST IND/

VCO CHECK

LD

PD

VEE

+

–

LASER POWER CONTROL

IFB4

IFB5

IFB3

+

–

TRK. GAIN

WINDOW COMP.

+

–

TG1

FS4

–

+

–

VEE

FE AMP

IFB6

FOCUS

PHASE COMPENSATION

4

FGD

VCC

VEE

IFB1

+

APC

IFB2

+

–

DFCT

FDFCT

REG

REG

PD1

PD2

AUTOBLEND

MUTING

RIPPLE

FILTER

VCC

L CH OUT

R CH OUT

RF_M

RFTC

–

+

RF SUMMING

AMP

+

–

+

–

–

+

+

–

FO. BIAS

WINDOW

COMP.

FOH

FOL

TGH

TGL

BALH

BALL

ATSC

TZC

FZC

TRACKING

PHASE COMPENSATION

+

–

5 6 7 8 9 10

FLB

FE_O

+

–

+

–

–

FOK

FILTER

RIPPLE

RF_O

+

–

+

LDON

FE_M

FM RF

FM FRONT-END

AM FRONT-END

AGC AFC1

RF_I

–

+

VEE

LEVEL S

VCC

LPCL

LPC

DFCTO

FS1

FS2

VEE

SRCH

AM RF IN

FM RF IN

BAND PASS

MUTE

AGC AFC2

+

–

+

–

VEE

–

+

MIRR

TGFL

IIL DATA REGISTER

INPUT SHIFT REGISTER

ADDRESS DECODER

SENS SELECTOR

OUTPUT DECODER

IFB1-6

BAL1-4

TOG1-4

VCC

Charge

up

INDICATOR

VCC

— 38 —

FM GND

FM/AM

FE OUT

FM IF/

DISCRI

AM

IF/DET

TUNING

GND

CP

TGU

FM IF IN

TUNE IND

VEE

–

+

FS1-4 TG1-2 TM1-7 PS1-4

AM IF IN

BAND SELECT

CB

+

–

+

VCC

+

–

–

+

DFCT

IIL

↓

TTL

MIRR

DFCT1

TM7

FSET

TG2

TG2

CC1

FSET

FOK

CC2

27282930313233343536373839

SENS2

–

IIL

↓

TTL

+

–

TTL

↓

IIL

CC1

VCC

ISET

VCC VCC

TM4 TM6

TM3

TA_M

TM5

VEEVEE

–

+

131211

TA_O

26

SENS1

25

C. OUT

24

XRST

23

DATA

22

XLT

21

CLK

20

LOCK

19

VCC

18

ISET

17

SL_O

16

SL_M

15

–

SL_P

14

+

TM2

Page 24

CFD-V25/V35

9

P

T901

LCD501

ANT1

not supplied

not supplied

F902

110

105

119

115

115

116

115

115

118

117

113

114

106

109

103

104

102

101

112

108

111

#1

#7

#3

V35

V35

#1

#1

#1

SECTION 6

EXPLODED VIEWS

NOTE:

• -XX, -X mean standardized parts, so they may

have some differences from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• Abbreviation

CND : Canadian

6-1. FRONT CABINET SECTION

SP901

#1

#1

• The mechanical parts with no reference number

in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of this

parts list.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

Parts of Color Cabinet’s Color

2

4

3

#1

4

13

↑ ↑

5

8

6

When indicating parts by reference number,

please include the board name.

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque

! sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

#9

#9

#9

6-2. UPPER CABINET SECTION 6-3. REAR CABINET SECTION

61

59

62

60

63

64

65

66

MF-V10-117

#1

#1

70

67

6-4. MECHANISM DECK SECTION (1)

(MF-V10-117)

HE301

158

HRP101

159

170

160

161

71

162

164

163

165

167

68

#1

69

74

74

72

73

KSM-213CDM/C2C

75

73

169

157

168

155

156

54

#9

#

4

#10

53

58

#10

56

#2

57

#6

#10

55

#10

not supplied

12

4

not supplied

7

9

10

#1

#1

V25

1

V35

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 X-3375-869-1 FRONT CABNET (BLACK) (V25: US)

1 X-3375-870-1 FRONT CABNET (WHITE) (V25: US)

1 X-3375-871-1 FRONT CABNET (BLACK) (V35: US)

1 X-3375-872-1 FRONT CABNET (WHITE) (V35: US)

1 X-3375-873-1 FRONT CABNET (V25: CND, E)

1 X-3375-874-1 FRONT CABNET (V25: E)

1 X-3375-875-1 FRONT CABNET (V35: CND)

* 2 A-3321-102-A CONTROL (1) BOARD, COMP

* 3 1-668-350-11 RMC BOARD

4 4-951-620-01 SCREW (2.6 × 8), +BVTP

5 3-018-839-01 POINTER

* 6 3-018-842-01 CHASSIS (TU)

7 3-018-840-01 KNOB (TU)

* 8 1-668-349-11 LED BOARD

* 9 A-3321-091-A CONTROL (2) BOARD, COMP (V35)

* 9 A-3321-100-A CONTROL (2) BOARD, COMP (V25)

* 10 1-668-345-11 HEADPHONE BOARD

* 11 3-022-854-01 CHASSIS (DUCT)

12 3-019-794-01 HOLDER(LED) (V35)

13 3-703-150-11 STOPPER, WIRING

SP901 1-505-934-11 SPEAKER (10cm)

SP902 1-505-934-11 SPEAKER (10cm)

11

4

SP902

— 39 — — 40 — — 41 —

52

51

154

#1

S501

76

153

166

151

152

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* 101 A-3321-093-A POWER BOARD, COMPLETE (V35: US)

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 3-009-208-01 SPRING, CASSETTE UP

52 3-922-112-11 DAMPER

53 3-009-186-41 CABINET (UPPER)

54 3-923-151-01 CUSHION, RUBBER

55 3-009-209-01 SPRING, CD UP

56 1-452-899-11 MAGNET

57 3-019-395-01 PLATE, CHUCKING

58 3-009-187-41 LID, CD

59 X-3375-701-1 HOLDER, CASSETTE ASSY (US)

59 X-3375-700-1 HOLDER, CASSETTE ASSY (EXCEPT US)

* 60 3-009-206-01 SHAFT (MD)

61 3-009-196-31 BUTTON (REC)

62 3-009-199-31 BUTTON (PLAY)

63 3-009-198-31 BUTTON (REW)

64 3-009-197-31 BUTTON (FF)

65 3-009-200-31 BUTTON (STOP)

66 3-009-195-31 BUTTON (PAUSE)

67 3-009-214-01 SPRING, REC

68 4-951-620-01 SCREW (2.6 × 8), +BVTP

* 69 1-668-333-11 REC SW BOARD

70 3-009-201-31 HANDLE

71 3-923-736-01 COVER, CD

72 1-777-955-11 WIRE (FLAT TYPE) (16 CORE)

73 3-910-095-11 RUBBER, VIBRATION PROOF

74 3-910-095-01 RUBBER, VIBRATION PROOF

* 75 1-639-678-12 CD MOTOR BOARD

76 3-015-646-01 CUSHION (CD)

S501 1-692-960-11 SWITCH, PUSH (1 KEY)

* 101 A-3321-105-A POWER BOARD, COMPLETE (V25: US)

* 101 A-3321-297-A POWER BOARD, COMPLETE (V25: CND, E)

* 101 A-3321-298-A POWER BOARD, COMPLETE (V35: CND)

* 102 A-3321-097-A MAIN BOARD, COMPLETE (V35)

* 102 A-3321-108-A MAIN BOARD, COMPLETE (V25: US, CND)

* 102 A-3321-300-A MAIN BOARD, COMPLETE (V25: E)

103 3-019-795-01 SHEET, DIFFUSION (V35)

104 3-019-789-01 HOLDER, LCD

106 4-951-620-01 SCREW (2.6 × 8), +BVTP

108 1-533-233-31 HOLDER, FUSE

* 109 1-669-246-11 PRIMARY BOARD

* 110 3-703-044-26 LABEL, CAUTION

111 3-020-968-01 CABINET (REAR) (V25: US)

111 3-020-968-11 CABINET (REAR) (V25: CND, E)

111 3-020-970-01 CABINET (REAR) (V35: US)

111 3-020-970-11 CABINET (REAR) (V35: CND)

112 3-009-192-01 GEAR, TUNING CAPACITOR

113 3-009-211-01 SPRING, BATTERY TERMINAL COIL

* 114 1-668-330-11 BATT BOARD

115 3-831-441-11 CUSHION

116 3-831-441-99 CUSHION, SPEAKER

117 3-009-210-01 SPRING, BATTERY TERMINAL COIL

118 3-009-202-31 LID, BATTERY CASE

119 3-020-861-01 TERMINAL, ANTENNA

ANT1 1-501-883-11 ANTENNA, TELESCOPIC

!F902 1-533-618-11 FUSE, GLASS CYLINDERICAL (3.15, 250V)

!T901 1-431-230-11 TRANSFORMER, POWER (V25: US, E/V35: US)

!T901 1-431-230-21 TRANSFORMER, POWER (V25: CND/V35: CND)

LCD501 1-801-915-11 DISPLAY PANEL, LIQUID CRYSTAL

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

151 3-933-010-01 SPRING (S/P), TORSION

152 3-933-025-01 SPRING (P), TORSION

153 3-933-026-01 LEVER (P)

154 3-933-024-01 ROLLER, PINCH

155 3-933-019-01 SPRING (F/R), TORSION

156 3-933-028-01 SPRING (FWD), TORSION

157 3-933-016-01 GEAR (S REEL)

158 3-008-590-01 SLIDER (REC)

159 3-008-592-12 BASE (H), HEAD

* 160 3-008-588-01 SLIDER (REW)

* 161 3-008-589-01 SLIDER (FF)

* 162 3-008-587-01 SLIDER (STOP)

* 163 3-008-591-01 SLIDER (PAUSE)

164 3-933-004-01 CLAW, REEL

* 165 3-933-021-01 SLIDER (FRP)

* 166 3-933-006-01 SLIDER (EJECT)

167 3-934-833-01 SPRING (FRP)

168 3-934-834-01 SPRING (BT)

169 3-933-007-01 PLATE, LOCK

* 170 3-012-114-01 LEVER (FR)

HE301 1-543-876-11 HEAD (ERASE)

HRP101 1-500-364-11 HEAD, MAGNETIC (RECORD/PLAYBACK)

— 42 —

Page 25

6-5. MECHANISM DECK SECTION (2)

(MF-V10-117)

207

206

208

M301

S801

204

#6

203

205

218

219

S802

210

211

212

213

217

214

202

201

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

201 3-933-029-01 LEVER, ERASING PREVENTION

202 3-933-182-01 SPRING, CASSETTE

203 3-932-995-01 GEAR (MID)

204 X-3371-667-1 CLUTCH ASSY

205 3-932-997-01 GEAR (CAM)

* 206 3-932-999-01 SLIDER (SW)

207 3-932-998-01 SPRING (GROUND), TORSION

208 3-009-648-01 LEVER (S.OFF)

210 X-3373-572-1 REEL ASSY (N), T

211 3-933-020-01 BELT

#4

215

212 X-3372-924-1 FLYWHEEL ASSY

213 3-932-993-01 CHASSIS, OUTSERT

214 3-343-358-01 RING, RETAINING

215 3-933-005-01 SPRING (CAM), COMPRESSION

217 3-937-760-01 SPRING (GROUND), COMPRESSION

218 3-934-336-01 BEARING

219 3-939-383-02 SPRING, COMPRESSION

M301 A-3304-619-A MOTOR ASSY

S801 1-762-679-11 SWITCH, LEAF (MOTOR ON/OFF)

S802 1-771-059-11 SWITCH, LEAF (TAPE PLAY)

— 43 —

Page 26

6-6. OPTICAL PICK-UP SECTION

(KSM-213CDM/C2NP)

254

255

253

not supplied

252

#5

251

M702

M701

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

251 2-626-908-01 SHAFT, SLED

252 2-627-003-02 GEAR (B) (RP)

253 2-626-907-01 GEAR (A)

254 8-848-483-05 KSS-213C/Q-RP

255 X-2626-202-1 CHASSIS ASSY (MB) (RP), MOTOR

(INCLUDING M702) (SPINDLE)

M701 X-2625-769-1 GEAR ASSY (MB) (RP), MOTOR (SLED)

— 44 —

Page 27

SECTION 7

ELECTRICAL PARTS LIST

BA TT

CONTROL (1)

CD MOTOR

CONTROL (2)

NOTE:

When indicating parts by reference number,

please include the board name.

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque

! sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifié.

• Abbreviation

CND : Canadian

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* 1-668-330-11 BATT BOARD

***********

************************************************************

1-639-678-12 CD MOTOR BOARD

****************

< CONNECTOR >

CNP707 1-564-722-11 PIN, CONNECTOR (SMALL TYPE) 6P

< SWITCH >

S701 1-572-085-11 SWITCH, LEAF (LIMIT)

************************************************************

* A-3321-102-A CONTROL (1) BOARD, COMPLETE

***************************

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they may

have some difference from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• CAPA CITORS:

uF: µF

* A-3321-100-A CONTROL (2) BOARD, COMPLETE (V25)

* A-3321-091-A CONTROL (2) BOARD, COMPLETE (V35)

3-019-794-01 HOLDER (LED) (V35)

C601 1-162-306-11 CERAMIC 0.01uF 20% 16V

D602 8-719-059-97 DIODE L-34HD (ROCK) (V35)

D603 8-719-059-97 DIODE L-34HD (POP) (V35)

D604 8-719-059-97 DIODE L-34HD (LIVE) (V35)

D605 8-719-059-97 DIODE L-34HD (VOCAL) (V35)

D607 8-719-991-33 DIODE 1SS133T-77 (V35)

• RESISTORS

All resistors are in ohms.

METAL: metal-film resistor

METAL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

****************************

****************************

< CAPACITOR >

< DIODE >

< CAPACITOR >

C650 1-162-306-11 CERAMIC 0.01uF 20% 16V

C651 1-124-589-11 ELECT 47uF 20% 16V

C652 1-162-282-31 CERAMIC 100PF 10% 50V

< CONNECTOR >

* CNP603 1-580-171-11 PIN, CONNECTOR (PC BOARD) 10P

< RESISTOR >

R650 1-249-417-11 CARBON 1K 5% 1/4W F

R651 1-247-843-11 CARBON 3.3K 5% 1/4W

R652 1-249-437-11 CARBON 47K 5% 1/4W

R653 1-249-437-11 CARBON 47K 5% 1/4W

R654 1-249-437-11 CARBON 47K 5% 1/4W

R655 1-249-437-11 CARBON 47K 5% 1/4W

R656 1-249-437-11 CARBON 47K 5% 1/4W

R657 1-249-431-11 CARBON 15K 5% 1/4W

R658 1-249-431-11 CARBON 15K 5% 1/4W

R659 1-249-431-11 CARBON 15K 5% 1/4W

R660 1-249-431-11 CARBON 15K 5% 1/4W

R661 1-249-431-11 CARBON 15K 5% 1/4W

< SWITCH >

S650 1-762-798-11 SWITCH, KEYBOARD (LOOP)

S651 1-762-798-11 SWITCH, KEYBOARD (POWER)

S652 1-762-798-11 SWITCH, KEYBOARD (FM)

S654 1-762-798-11 SWITCH, KEYBOARD (TAPE)

S655 1-762-798-11 SWITCH, KEYBOARD (AM)

S656 1-762-798-11 SWITCH, KEYBOARD (CD)

************************************************************

D608 8-719-991-33 DIODE 1SS133T-77 (V35)

< RESISTOR >

R601 1-249-415-11 CARBON 680 5% 1/4W F

R602 1-249-416-11 CARBON 820 5% 1/4W F

R603 1-249-418-11 CARBON 1.2K 5% 1/4W F

R604 1-249-437-11 CARBON 47K 5% 1/4W

R605 1-249-437-11 CARBON 47K 5% 1/4W

R606 1-249-416-11 CARBON 820 5% 1/4W F

R607 1-249-437-11 CARBON 47K 5% 1/4W

R608 1-249-437-11 CARBON 47K 5% 1/4W

(V25)

R609 1-249-437-11 CARBON 47K 5% 1/4W

(V25)

R609 1-249-441-11 CARBON 100K 5% 1/4W

(V35)

R610 1-249-441-11 CARBON 100K 5% 1/4W

(V35)

R611 1-249-441-11 CARBON 100K 5% 1/4W

(V35)

R613 1-249-437-11 CARBON 47K 5% 1/4W

R614 1-249-437-11 CARBON 47K 5% 1/4W

R615 1-249-415-11 CARBON 680 5% 1/4W F

R616 1-247-815-91 CARBON 220 5% 1/4W

R617 1-249-431-11 CARBON 15K 5% 1/4W

R618 1-249-431-11 CARBON 15K 5% 1/4W

R619 1-249-431-11 CARBON 15K 5% 1/4W

R620 1-249-431-11 CARBON 15K 5% 1/4W

(V25)

— 45 —

Page 28

CONTROL (2) HEADPHONE LAMP LED MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R621 1-249-431-11 CARBON 15K 5% 1/4W

R622 1-249-431-11 CARBON 15K 5% 1/4W

R623 1-249-431-11 CARBON 15K 5% 1/4W

R624 1-249-431-11 CARBON 15K 5% 1/4W

R625 1-249-425-11 CARBON 4.7K 5% 1/4W F

R626 1-249-417-11 CARBON 1K 5% 1/4W F

R628 1-249-431-11 CARBON 15K 5% 1/4W

R629 1-249-441-11 CARBON 100K 5% 1/4W

* 1-668-348-11 LAMP BOARD (V35)

(V25)

(V35)

(V35)

* KH306 1-573-287-11 HOLDER, CABLE 2P (V35)

(V35)

PL361 1-517-474-11 LAMP, PILOT (V35)

************************************************************

(V35)

* 1-668-349-11 LED BOARD

(V35)

***********

< CABLE HOLDER >

< PILOT LAMP >

**********

< SWITCH >

S601 1-762-798-11 SWITCH, KEYBOARD (fl)

S602 1-762-798-11 SWITCH, KEYBOARD (p)

S603 1-762-798-11 SWITCH, KEYBOARD (±)

S604 1-762-798-11 SWITCH, KEYBOARD (≠)

S605 1-762-798-11 SWITCH, KEYBOARD (PLAY MODE)

S606 1-762-798-11 SWITCH, KEYBOARD (DISPLAY/ENTER)

S607 1-762-798-11 SWITCH, KEYBOARD (MAGA BASS)

S608 1-762-798-11 SWITCH, KEYBOARD (VOCAL) (V35)

S609 1-762-798-11 SWITCH, KEYBOARD (TONE–) (V25)

S610 1-762-798-11 SWITCH, KEYBOARD (LIVE) (V35)

S611 1-762-798-11 SWITCH, KEYBOARD (TONE+) (V25)

S612 1-762-798-11 SWITCH, KEYBOARD (ROCK) (V35)

S613 1-762-798-11 SWITCH, KEYBOARD (POP) (V35)

S614 1-762-798-11 SWITCH, KEYBOARD (OFF) (V35)

S615 1-762-798-11 SWITCH, KEYBOARD (VOL–)

S616 1-762-798-11 SWITCH, KEYBOARD (VOL+)

************************************************************

* 1-668-345-11 HEADPHONE BOARD

*****************

< CONNECTOR >

CNP316 1-506-986-11 PIN, CONNECTOR (PC BOARD) 4P

< JACK >

< DIODE >

D606 8-719-059-97 DIODE L-34HD

************************************************************

* A-3321-097-A MAIN BOARD, COMPLETE (V35)

*********************

* A-3321-108-A MAIN BOARD, COMPLETE (V25: US, CND)

*********************

* A-3321-300-A MAIN BOARD, COMPLETE (V25: E)

*********************

3-009-192-01 GEAR, TUNING CAPACITOR

3-019-789-01 HOLDER (LCD)

3-019-795-01 SHEET, DIFFUSION (V35)

7-621-773-95 SCREW +B 2.6 × 6

7-685-647-79 SCREW +BVTP 3 × 10 TYPE2 N-S (V25: E)

< CAPACITOR >

C1 1-162-215-31 CERAMIC 47PF 5% 50V

C2 1-162-306-11 CERAMIC 0.01uF 20% 16V

C3 1-104-664-11 ELECT 47uF 20% 10V

C5 1-162-205-31 CERAMIC 18PF 5% 50V

C6 1-102-961-00 CERAMIC 27PF 5% 50V

C7 1-162-196-31 CERAMIC 5.6PF 10% 50V

C8 1-162-189-31 CERAMIC 1.5PF 20% 50V

C9 1-162-306-11 CERAMIC 0.01uF 20% 16V

C10 1-162-306-11 CERAMIC 0.01uF 20% 16V

C11 1-126-963-11 ELECT 4.7uF 20% 50V

J301 1-568-267-11 JACK (2)

< CABLE HOLDER >

* KH313 1-565-385-11 HOLDER, CABLE 4P

< COIL >

L151 1-410-509-11 INDUCTOR 10uH

L251 1-410-509-11 INDUCTOR 10uH

L351 1-410-509-11 INDUCTOR 10uH

< RESISTOR >

R154 1-247-807-31 CARBON 100 5% 1/4W

R254 1-247-807-31 CARBON 100 5% 1/4W

************************************************************

— 46 —

C12 1-124-903-11 ELECT 1uF 20% 50V

C13 1-104-664-11 ELECT 47uF 20% 10V

C14 1-104-664-11 ELECT 47uF 20% 10V

C15 1-162-306-11 CERAMIC 0.01uF 20% 16V

C16 1-126-961-11 ELECT 2.2uF 20% 50V

C17 1-124-443-00 ELECT 100uF 20% 10V

C18 1-161-053-00 CERAMIC 0.015uF 10% 50V

C19 1-161-053-00 CERAMIC 0.015uF 10% 50V

C20 1-162-306-11 CERAMIC 0.01uF 20% 16V

C21 1-162-205-31 CERAMIC 18PF 5% 50V

C22 1-124-903-11 ELECT 1uF 20% 50V

C23 1-124-902-00 ELECT 0.47uF 20% 50V

C24 1-126-963-11 ELECT 4.7uF 20% 50V

C25 1-162-294-31 CERAMIC 0.001uF 10% 50V

C26 1-162-294-31 CERAMIC 0.001uF 10% 50V

C28 1-162-306-11 CERAMIC 0.01uF 20% 16V

C30 1-161-494-00 CERAMIC 0.022uF 25V

C101 1-162-301-11 CERAMIC 0.0015uF 20% 16V

C102 1-104-664-11 ELECT 47uF 20% 10V

C103 1-161-020-11 CERAMIC 0.039uF 10% 16V

Page 29

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C104 1-162-302-11 CERAMIC 0.0022uF 20% 16V

C105 1-162-215-31 CERAMIC 47PF 5% 50V

C106 1-124-902-00 ELECT 0.47uF 20% 50V

C107 1-162-282-31 CERAMIC 100PF 10% 50V

C201 1-162-301-11 CERAMIC 0.0015uF 20% 16V

C549 1-162-294-31 CERAMIC 0.001uF 10% 50V

C550 1-162-294-31 CERAMIC 0.001uF 10% 50V

C551 1-162-294-31 CERAMIC 0.001uF 10% 50V

C552 1-162-306-11 CERAMIC 0.01uF 20% 16V

C553 1-162-306-11 CERAMIC 0.01uF 20% 16V

C202 1-104-664-11 ELECT 47uF 20% 10V

C203 1-161-020-11 CERAMIC 0.039uF 10% 16V

C204 1-162-302-11 CERAMIC 0.0022uF 20% 16V

C205 1-162-215-31 CERAMIC 47PF 5% 50V

C206 1-124-902-00 ELECT 0.47uF 20% 50V

C207 1-162-282-31 CERAMIC 100PF 10% 50V

C301 1-124-443-00 ELECT 100uF 20% 10V

C302 1-124-443-00 ELECT 100uF 20% 10V

C303 1-162-294-31 CERAMIC 0.001uF 10% 50V

C304 1-124-443-00 ELECT 100uF 20% 10V

C305 1-162-294-31 CERAMIC 0.001uF 10% 50V

C307 1-162-294-31 CERAMIC 0.001uF 10% 50V

C311 1-162-294-31 CERAMIC 0.001uF 10% 50V

C312 1-104-664-11 ELECT 47uF 20% 10V

C313 1-130-481-00 MYLAR 0.0068uF 5% 50V

C501 1-124-907-11 ELECT 10uF 20% 50V

C502 1-162-306-11 CERAMIC 0.01uF 20% 16V

C503 1-104-664-11 ELECT 47uF 20% 10V

C504 1-161-494-00 CERAMIC 0.022uF 25V

C505 1-124-907-11 ELECT 10uF 20% 50V

C506 1-124-443-00 ELECT 100uF 20% 10V

C507 1-162-306-11 CERAMIC 0.01uF 20% 16V

C508 1-102-518-11 CERAMIC 33PF 5% 50V

C509 1-102-518-11 CERAMIC 33PF 5% 50V

C510 1-162-306-11 CERAMIC 0.01uF 20% 16V

C511 1-162-306-11 CERAMIC 0.01uF 20% 16V

C513 1-162-306-11 CERAMIC 0.01uF 20% 16V

C514 1-162-306-11 CERAMIC 0.01uF 20% 16V

C515 1-162-306-11 CERAMIC 0.01uF 20% 16V

C516 1-162-306- 11 CERAMIC 0.01uF 20% 16V

C517 1-162-291-31 CERAMIC 560PF 10% 50V

C518 1-162-291-31 CERAMIC 560PF 10% 50V

C519 1-162-306-11 CERAMIC 0.01uF 20% 16V

C520 1-104-664-11 ELECT 47uF 20% 10V

C524 1-162-282-31 CERAMIC 100PF 10% 50V

C525 1-162-306-11 CERAMIC 0.01uF 20% 16V

C533 1-162-286-21 CERAMIC 220PF 10% 50V

C534 1-162-286-21 CERAMIC 220PF 10% 50V

C535 1-162-286-21 CERAMIC 220PF 10% 50V

C536 1-162-306-11 CERAMIC 0.01uF 20% 16V

C537 1-162-282-31 CERAMIC 100PF 10% 50V

C539 1-162-282-31 CERAMIC 100PF 10% 50V

C540 1-162-282-31 CERAMIC 100PF 10% 50V

C541 1-162-282-31 CERAMIC 100PF 10% 50V

C542 1-162-306-11 CERAMIC 0.01uF 20% 16V

C543 1-162-282-31 CERAMIC 100PF 10% 50V

C545 1-162-294-31 CERAMIC 0.001uF 10% 50V

C546 1-162-294-31 CERAMIC 0.001uF 10% 50V

C547 1-162-294-31 CERAMIC 0.001uF 10% 50V

C548 1-162-294-31 CERAMIC 0.001uF 10% 50V

(V35)

(V35)

C554 1-162-306-11 CERAMIC 0.01uF 20% 16V

C555 1-162-306-11 CERAMIC 0.01uF 20% 16V

C556 1-162-294-31 CERAMIC 0.001uF 10% 50V

C557 1-126-963-11 ELECT 4.7uF 20% 50V

C559 1-161-494-00 CERAMIC 0.022uF 25V

C560 1-124-443-00 ELECT 100uF 20% 10V

C570 1-162-294-31 CERAMIC 0.001uF 10% 50V

C701 1-162-600-11 CERAMIC 0.0047uF 20% 16V

C702 1-162-306-11 CERAMIC 0.01uF 20% 16V

C703 1-162-305-11 CERAMIC 0.0068uF 20% 16V

C704 1-130-491-00 MYLAR 0.047uF 5% 50V

C705 1-162-306-11 CERAMIC 0.01uF 20% 16V

C706 1-104-664-11 ELECT 47uF 20% 10V

C707 1-161-494-00 CERAMIC 0.022uF 25V

C708 1-136-165-00 FILM 0.1uF 5% 50V

C709 1-136-165-00 FILM 0.1uF 5% 50V

C710 1-162-302-11 CERAMIC 0.0022uF 20% 16V

C711 1-162-203-31 CERAMIC 15PF 5% 50V

C712 1-162-294-31 CERAMIC 0.001uF 10% 50V

C713 1-136-165-00 FILM 0.1uF 5% 50V

C714 1-136-165-00 FILM 0.1uF 5% 50V

C715 1-126-233-11 ELECT 22uF 20% 50V

C716 1-136-165-00 FILM 0.1uF 5% 50V

C717 1-136-165-00 FILM 0.1uF 5% 50V

C718 1-131-377-00 TANTALUM 10uF 10% 10V

C719 1-104-664-11 ELECT 47uF 20% 10V

C720 1-162-306-11 CERAMIC 0.01uF 20% 16V

C721 1-130-489-00 MYLAR 0.033uF 5% 50V

C722 1-130-489-00 MYLAR 0.033uF 5% 50V

C723 1-162-306-11 CERAMIC 0.01uF 20% 16V

C724 1-130-489-00 MYLAR 0.033uF 5% 50V

C725 1-130-486-00 MYLAR 0.018uF 5% 50V

C727 1-162-199-31 CERAMIC 10PF 5% 50V

C728 1-104-664-11 ELECT 47uF 20% 10V

C729 1-126-962-11 ELECT 3.3uF 20% 50V

C730 1-130-493-00 MYLAR 0.068uF 5% 50V

C731 1-162-215-31 CERAMIC 47PF 5% 50V

C732 1-162-306-11 CERAMIC 0.01uF 20% 16V

C735 1-162-282-31 CERAMIC 100PF 10% 50V

C736 1-162-282-31 CERAMIC 100PF 10% 50V

C737 1-162-306-11 CERAMIC 0.01uF 20% 16V

C738 1-162-282-31 CERAMIC 100PF 10% 50V

C739 1-162-282-31 CERAMIC 100PF 10% 50V

C740 1-162-282-31 CERAMIC 100PF 10% 50V

C741 1-162-305-11 CERAMIC 0.0068uF 20% 16V

C742 1-162-306-11 CERAMIC 0.01uF 20% 16V

C743 1-104-664-11 ELECT 47uF 20% 10V

C744 1-124-472-11 ELECT 470uF 20% 10V

C745 1-124-443-00 ELECT 100uF 20% 10V

C746 1-162-282-31 CERAMIC 100PF 10% 50V

C750 1-162-294-31 CERAMIC 0.001uF 10% 50V

— 47 —

Page 30

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

C751 1-162-306-11 CERAMIC 0.01uF 20% 16V

C752 1-136-165-00 FILM 0.1uF 5% 50V

C753 1-124-443-00 ELECT 100uF 20% 10V

C754 1-162-306-11 CERAMIC 0.01uF 20% 16V

C755 1-164-159-21 CERAMIC 0.1uF 50V

C757 1-162-294-31 CERAMIC 0.001uF 10% 50V

C758 1-162-286-21 CERAMIC 220PF 10% 50V

C759 1-124-443-00 ELECT 100uF 20% 10V

C760 1-136-173-00 FILM 0.47uF 5% 50V

C761 1-162-199-31 CERAMIC 10PF 5% 50V

C763 1-162-290-31 CERAMIC 470PF 10% 50V

C764 1-162-199-31 CERAMIC 10PF 5% 50V

C765 1-162-286-21 CERAMIC 220PF 10% 50V

C768 1-162-306-11 CERAMIC 0.01uF 20% 16V

C769 1-136-169-00 FILM 0.22uF 5% 50V

D1 8-719-991-33 DIODE 1SS133T-77

D2 8-719-991-33 DIODE 1SS133T-77

D501 8-719-991-33 DIODE 1SS133T-77

D502 8-719-991-33 DIODE 1SS133T-77

D503 8-719-991-33 DIODE 1SS133T-77

D504 8-719-991-33 DIODE 1SS133T-77

D506 8-719-991-33 DIODE 1SS133T-77

D507 8-719-991-33 DIODE 1SS133T-77

D508 8-719-991-33 DIODE 1SS133T-77

D509 8-719-991-33 DIODE 1SS133T-77

D511 8-719-991-33 DIODE 1SS133T-77

D512 8-719-991-33 DIODE 1SS133T-77

D513 8-719-991-33 DIODE 1SS133T-77

< DIODE >

C772 1-162-306-11 CERAMIC 0.01uF 20% 16V

C773 1-124-443-00 ELECT 100uF 20% 10V

C774 1-161-494-00 CERAMIC 0.022uF 25V

C775 1-164-159-21 CERAMIC 0.1uF 50V

C776 1-162-306-11 CERAMIC 0.01uF 20% 16V

C777 1-164-159-21 CERAMIC 0.1uF 50V

C780 1-162-284-31 CERAMIC 150PF 10% 50V

C781 1-162-292-31 CERAMIC 680PF 10% 50V

C782 1-126-963-11 ELECT 4.7uF 20% 50V

C790 1-162-284-31 CERAMIC 150PF 10% 50V

C791 1-162-292-31 CERAMIC 680PF 10% 50V

C792 1-126-963-11 ELECT 4.7uF 20% 50V

C793 1-162-306-11 CERAMIC 0.01uF 20% 16V

C798 1-162-282-31 CERAMIC 100PF 10% 50V

C799 1-130-491-00 CERAMIC 0.047uF 5% 50V

CF1 1-760-738-61 FILTER, CERAMIC

CF2 1-577-072-12 FILTER, CERAMIC

< CONNECTOR >

CNP301 1-506-986-11 PIN, CONNECTOR (PC BOARD) 4P

CNP302 1-506-986-11 PIN, CONNECTOR (PC BOARD) 4P

* CNP306 1-580-154-11 PIN, CONNECTOR (PC BOARD) 2P (V35)

CNP311 1-506-987-11 PIN, CONNECTOR (PC BOARD) 5P (V25)

* CNP311 1-580-158-11 PIN, CONNECTOR (PC BOARD) 6P (V35)

CNP314 1-695-105-11 PIN, CONNECTOR (PC BOARD) 3P

CNP501 1-580-168-11 PIN, CONNECTOR (PC BOARD) 7P (V35)

* CNP502 1-784-724-11 PIN, CONNECTOR 12P

* CNP503 1-580-162-11 PIN, CONNECTOR (PC BOARD) 10P

* CNP505 1-580-160-11 PIN, CONNECTOR (PC BOARD) 8P

* CNP506 1-580-154-11 PIN, CONNECTOR (PC BOARD) 2P

CNP701 1-770-674-11 CONNECTOR, FFC/FPC 16P

< VARIABLE CAPACITOR >

CV1 1-141-559-11 CAP, VAR

< FERRITE BEAD >

FB702 1-410-509-11 INDUCTOR 10uH

FB704 1-410-509-11 INDUCTOR 10uH (V25: E)

FB705 1-410-397-21 FERRITE BEAD INDUCTOR

FB706 1-410-397-21 FERRITE BEAD INDUCTOR

FB707 1-410-509-11 INDUCTOR 10uH (V25: E)

< IC >

IC1 8-752-050-20 IC CXA1238S

IC301 8-759-264-71 IC TA2068N

IC501 8-752-895-17 IC CXP83416A-602Q

IC502 8-759-479-70 IC S-81250SGY-Z

IC503 8-759-165-81 IC PST600D-T

IC701 8-752-082-14 IC CXA1992BR

IC702 8-759-473-42 IC BA6898FP

IC703 8-752-384-13 IC CXD2589Q

< CABLE HOLDER >

* KH504 1-573-287-11 HOLDER, CABLE 2P

< COIL >

L1 1-406-998-11 COIL, AIR-CORE

L2 1-411-387-11 COIL, AIR-CORE

L3 1-501-841-11 ANTENNA, FERRITE-ROD (MW)

L4 1-406-040-00 COIL (OSC)

L501 1-412-852-11 INDUCTOR 47uH

L502 1-408-117-00 INDUCTOR 10uH

< LIQUID CRYSTAL DISPLAY >

LCD501 1-801-914-11 DISPLAY PANEL, LIQUID CRYSTAL (V25)

LCD501 1-801-915-11 DISPLAY PANEL, LIQUID CRYSTAL (V35)

< TRANSISTOR >

Q1 8-729-029-92 TRANSISTOR DTC143ESA

Q301 8-729-281-53 TRANSISTOR 2SC1815-GR

Q501 8-729-037-34 TRANSISTOR KRA107M (US)

Q501 8-729-037-18 TRANSISTOR KRA105M-AT (CND, E)

Q502 8-729-036-58 TRANSISTOR KRC102M-AT

— 48 —

Q503 8-729-037-34 TRANSISTOR KRA107M

Q504 8-729-037-11 TRANSISTOR KTA1271-Y-AT

Q505 8-729-037-34 TRANSISTOR KRA107M

Q701 8-729-037-11 TRANSISTOR KTA1271-Y-AT

Page 31

MAIN

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< RESISTOR >

R1 1-247-815-91 CARBON 220 5% 1/4W

R2 1-249-421-11 CARBON 2.2K 5% 1/4W F

R3 1-249-441-11 CARBON 100K 5% 1/4W

R4 1-247-843-11 CARBON 3.3K 5% 1/4W

R5 1-249-413-11 CARBON 470 5% 1/4W F

R6 1-249-403-11 CARBON 68 5% 1/4W F

R7 1-249-427-11 CARBON 6.8K 5% 1/4W F

R8 1-249-427-11 CARBON 6.8K 5% 1/4W F

R13 1-249-421-11 CARBON 2.2K 5% 1/4W F

R14 1-249-429-11 CARBON 10K 5% 1/4W

R101 1-249-431-11 CARBON 15K 5% 1/4W

R102 1-249-404-00 CARBON 82 5% 1/4W F

R103 1-249-441-11 CARBON 100K 5% 1/4W

R104 1-247-843-11 CARBON 3.3K 5% 1/4W

R105 1-249-417-11 CARBON 1K 5% 1/4W F

R110 1-249-417-11 CARBON 1K 5% 1/4W F

R111 1-249-429-11 CARBON 10K 5% 1/4W

R112 1-249-431-11 CARBON 15K 5% 1/4W

R113 1-249-415-11 CARBON 680 5% 1/4W

(EXCEPT US)

R113 1-249-417-11 CARBON 1K 5% 1/4W F

(US)

R201 1-249-431-11 CARBON 15K 5% 1/4W

R202 1-249-404-00 CARBON 82 5% 1/4W F

R203 1-249-441-11 CARBON 100K 5% 1/4W

R204 1-247-843-11 CARBON 3.3K 5% 1/4W

R205 1-249-417-11 CARBON 1K 5% 1/4W F

R210 1-249-417-11 CARBON 1K 5% 1/4W F

R211 1-249-429-11 CARBON 10K 5% 1/4W

R212 1-249-431-11 CARBON 15K 5% 1/4W

R213 1-249-415-11 CARBON 680 5% 1/4W

(EXCEPT US)

R213 1-249-417-11 CARBON 1K 5% 1/4W F

(US)

R301 1-247-903-00 CARBON 1M 5% 1/4W

R303 1-249-417-11 CARBON 1K 5% 1/4W F

R304 1-249-429-11 CARBON 10K 5% 1/4W

R311 1-249-406-11 CARBON 120 5% 1/4W F

R312 1-247-863-91 CARBON 22K 5% 1/4W

R313 1-249-389-11 CARBON 4.7 5% 1/4W F

R501 1-249-417-11 CARBON 1K 5% 1/4W F

R502 1-249-417-11 CARBON 1K 5% 1/4W F

R503 1-249-417-11 CARBON 1K 5% 1/4W F

R504 1-249-413-11 CARBON 470 5% 1/4W F

R505 1-249-417-11 CARBON 1K 5% 1/4W F

(V35)

R506 1-249-417-11 CARBON 1K 5% 1/4W F

(V35)

R507 1-249-417-11 CARBON 1K 5% 1/4W F

R508 1-249-417-11 CARBON 1K 5% 1/4W F

R509 1-249-417-11 CARBON 1K 5% 1/4W F

R510 1-249-417-11 CARBON 1K 5% 1/4W F

R511 1-249-417-11 CARBON 1K 5% 1/4W F

R512 1-249-429-11 CARBON 10K 5% 1/4W

R513 1-249-429-11 CARBON 10K 5% 1/4W

R514 1-249-417-11 CARBON 1K 5% 1/4W F

R515 1-249-417-11 CARBON 1K 5% 1/4W F

R516 1-249-417-11 CARBON 1K 5% 1/4W F

R517 1-249-417-11 CARBON 1K 5% 1/4W F

R518 1-249-417-11 CARBON 1K 5% 1/4W F

R519 1-249-417-11 CARBON 1K 5% 1/4W F

R520 1-249-417-11 CARBON 1K 5% 1/4W F

R521 1-249-417-11 CARBON 1K 5% 1/4W F

R522 1-249-417-11 CARBON 1K 5% 1/4W F

R523 1-249-429-11 CARBON 10K 5% 1/4W

R525 1-249-417-11 CARBON 1K 5% 1/4W F

R526 1-249-417-11 CARBON 1K 5% 1/4W F

R527 1-249-417-11 CARBON 1K 5% 1/4W F

R528 1-249-417-11 CARBON 1K 5% 1/4W F

R529 1-249-417-11 CARBON 1K 5% 1/4W F

R530 1-249-417-11 CARBON 1K 5% 1/4W F

R533 1-249-411-11 CARBON 330 5% 1/4W

R534 1-247-863-91 CARBON 22K 5% 1/4W

R535 1-249-429-11 CARBON 10K 5% 1/4W

R536 1-249-429-11 CARBON 10K 5% 1/4W

R537 1-249-429-11 CARBON 10K 5% 1/4W

R538 1-249-417-11 CARBON 1K 5% 1/4W F

R539 1-249-417-11 CARBON 1K 5% 1/4W F

R540 1-249-417-11 CARBON 1K 5% 1/4W F

R541 1-249-417-11 CARBON 1K 5% 1/4W F

R558 1-249-425-11 CARBON 4.7K 5% 1/4W F

R559 1-249-429-11 CARBON 10K 5% 1/4W

R560 1-249-425-11 CARBON 4.7K 5% 1/4W F

R561 1-249-429-11 CARBON 10K 5% 1/4W

R562 1-249-425-11 CARBON 4.7K 5% 1/4W F

R563 1-249-425-11 CARBON 4.7K 5% 1/4W F

R564 1-249-429-11 CARBON 10K 5% 1/4W

R565 1-249-418-11 CARBON 1.2K 5% 1/4W F

(V35)

R566 1-249-418-11 CARBON 1.2K 5% 1/4W F

(V35)

R567 1-249-418-11 CARBON 1.2K 5% 1/4W F

(V35)

R568 1-249-418-11 CARBON 1.2K 5% 1/4W F

(V35)

R569 1-247-807-31 CARBON 100 5% 1/4W

R570 1-249-429-11 CARBON 10K 5% 1/4W

R571 1-249-429-11 CARBON 10K 5% 1/4W

R572 1-249-417-11 CARBON 1K 5% 1/4W F

R573 1-249-437-11 CARBON 47K 5% 1/4W

R574 1-249-441-11 CARBON 100K 5% 1/4W

R575 1-249-425-11 CARBON 4.7K 5% 1/4W F

R576 1-249-425-11 CARBON 4.7K 5% 1/4W F

R577 1-249-415-11 CARBON 680 5% 1/4W F

(V25: US, CND)

R577 1-249-421-11 CARBON 2.2K 5% 1/4W F

(V25: E)

R577 1-247-863-91 CARBON 22K 5% 1/4W

(V35)

R578 1-249-425-11 CARBON 4.7K 5% 1/4W F

R581 1-249-417-11 CARBON 1K 5% 1/4W F

R582 1-249-437-11 CARBON 47K 5% 1/4W

R584 1-247-863-91 CARBON 22K 5% 1/4W

— 49 —

Page 32

MAIN POWER

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R587 1-249-441-11 CARBON 100K 5% 1/4W

R588 1-249-429-11 CARBON 10K 5% 1/4W

R589 1-249-421-11 CARBON 2.2K 5% 1/4W F

R590 1-249-417-11 CARBON 1K 5% 1/4W F

(US)

R590 1-249-413-11 CARBON 470 5% 1/4W F

(EXCEPT US)

R591 1-249-428-11 CARBON 8.2K 5% 1/4W F

R592 1-249-428-11 CARBON 8.2K 5% 1/4W F

R593 1-249-437-11 CARBON 47K 5% 1/4W

R594 1-249-437-11 CARBON 47K 5% 1/4W

R595 1-249-437-11 CARBON 47K 5% 1/4W

R766 1-249-429-11 CARBON 10K 5% 1/4W

R768 1-247-903-00 CARBON 1M 5% 1/4W

R771 1-249-429-11 CARBON 10K 5% 1/4W

R772 1-247-887-00 CARBON 220K 5% 1/4W

R780 1-249-430-11 CARBON 12K 5% 1/4W

R781 1-249-430-11 CARBON 12K 5% 1/4W

R782 1-249-430-11 CARBON 12K 5% 1/4W

R790 1-249-430-11 CARBON 12K 5% 1/4W

R791 1-249-430-11 CARBON 12K 5% 1/4W

R792 1-249-430-11 CARBON 12K 5% 1/4W

< VARIABLE RESISTOR >

R701 1-249-440-11 CARBON 82K 5% 1/4W

R702 1-249-439-11 CARBON 68K 5% 1/4W

R703 1-249-439-11 CARBON 68K 5% 1/4W

R704 1-249-439-11 CARBON 68K 5% 1/4W

R705 1-249-439-11 CARBON 68K 5% 1/4W

R706 1-249-440-11 CARBON 82K 5% 1/4W

R707 1-247-887-00 CARBON 220K 5% 1/4W

R709 1-247-883-00 CARBON 150K 5% 1/4W

R710 1-247-885-00 CARBON 180K 5% 1/4W

R711 1-247-883-00 CARBON 150K 5% 1/4W

R712 1-247-891-00 CARBON 330K 5% 1/4W

R714 1-249-428-11 CARBON 8.2K 5% 1/4W F