Sony CFDV-17 Service manual

CFD-V17

SERVICE MANUAL

Ver 1.3 2000. 05

With SUPPLEMENT-1

(9-926-916-81)

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

With 3.2 Ω loads, both channels driven from 150 – 10,000 Hz; rated 1.8

W per channel-minimum RMS power, with no more than 10 % total

harmonic distortion in AC operation.

Other Specifications

CD player section

System Compact disc digital audio system

Laser diode properties Material: GaAlAs

Wavelength:780 nm

Emission duration : Continuous

Laser output : Less than 44.6 µW

(This output is the value measured at a

distance of about 200 mm from the objective

lens surface on the optical pick-up block

with 7 mm aperture.)

Spindle speed 200 r/min (rpm) to 500 r/min (rpm) (CLV)

Number of channels 2

Frequency response 20 – 20,000 Hz + 1/-2 dB

Wow and flutter Below measurable limit

Radio section

Frequency range FM : 87.6 – 108 MHz

AM : 530 – 1,605 kHz (Australian model)

AM : 530 –1,710 kHz (Others models)

Aerials FM : Telescopic antenna

AM : Built-in ferrite bar aerial

Cassette-corder section

Recording system 4 -track 2 channel stereo

Fast winding time Approx. 120 s (sec.) with Sony cassette C-60

Frequency response TYPE I (normal) : 70 – 10,000 Hz

US Model

Canadian Model

E Model

Australian Model

Model Name Using • Similar Mechanism CFD-V15/V24

CD Mechanism Type KSM-213CDM

Optical Pick-up Type KSS-213CDM

T ape Transport Mechanism Type MF-V10-117

Power output (excluding US model)

2.3 W + 2.3 W (at 3.2 Ω, 10 % harmonic

distortion)

Power requirements For CD radio cassette-corder :

120V AC, 60 Hz

9V DC, 6 size D (R 20) batteries

Power consumption AC 20W

Battery life For CD radio cassette-corder:

FM recording

Sony R20P : approx. 13.5 h

Sony alkaline LR20 : approx. 20 h

Tape playback

Sony R20P : approx. 7.5 h

Sony alkaline LR20 : approx. 15 h

CD playback

Sony R20P : approx. 2.5 h

Sony alkaline LR20 : approx. 7 h

Dimensions Approx. 420 × 165 × 256 mm (w/h/d)

(16 5/8 × 6 1/2 × 10 1/8 inches) (incl. projecting

parts)

Mass Approx. 4.1 kg (9 lb. 1 oz) (incl. batteries)

Supplied accessories AC power cord (1)

Design and specifications are subject to change without notice.

General

Speakers Full range : 10 cm dia., 3.2 Ω, cone type (2)

Outputs Headphones jack (stereo minijack)

For 16 – 68 Ω impedance headphones

MICROFILM

CD RADIO CASSETTE-CORDER

TABLE OF CONTENTS

1. SERVICE NOTES···························································· 3

SAFETY CHECK-OUT

2. GENERAL ··········································································4

3. DISASSEMBLY

3-1. Front Cabinet Assy ····························································· 5

3-2. Control Board ····································································· 6

3-3. Cabinet (upper) Assy··························································6

3-4. Inlet, Power, Battery, Half Battery Board···························7

3-5. Main Board·········································································7

3-6. Mechanism Deck, Optical Pick-up Section························8

4. DIAL POINTER INSTALLATION ·······························9

5. ADJUSTMENT

5-1. Mechanical Adjustment ···················································· 10

5-2. Electrical Adjustment ······················································· 10

5-3. Tuner Section···································································· 11

5-4. Reference·········································································· 15

6. DIAGRAM

6-1. Circuit Board Location ····················································· 17

6-2. Block Diagram ································································· 18

6-3. Printed Wiring Board························································ 21

6-4. Schematic Diagram – Main Section(1/2) – ······················ 25

6-5. Schematic Diagram – Main Section(2/2) – ······················ 30

6-6. Explanation of IC Terminals ············································ 33

7. EXPLODED VIEWS·················································38

After correcting the original service problem, perform the following

safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-v olta ge

scale. The Simpson 250 and Sanwa SH-63Trd are e xamples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

8. ELECTRICAL PARTS LIST ··································· 44

T o Exposed Metal

Parts on Set

AC

0.15

µ

F

Fig. A. Using an A C v oltmeter to check A C leakage.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DO TTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

1.5 k

Ω

Earth Ground

Voltmeter

(0.75 V)

— 2 —

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

SECTION 1

Insert a precision screw driver

and push SWITCH(S801)

SERVICE NOTES

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

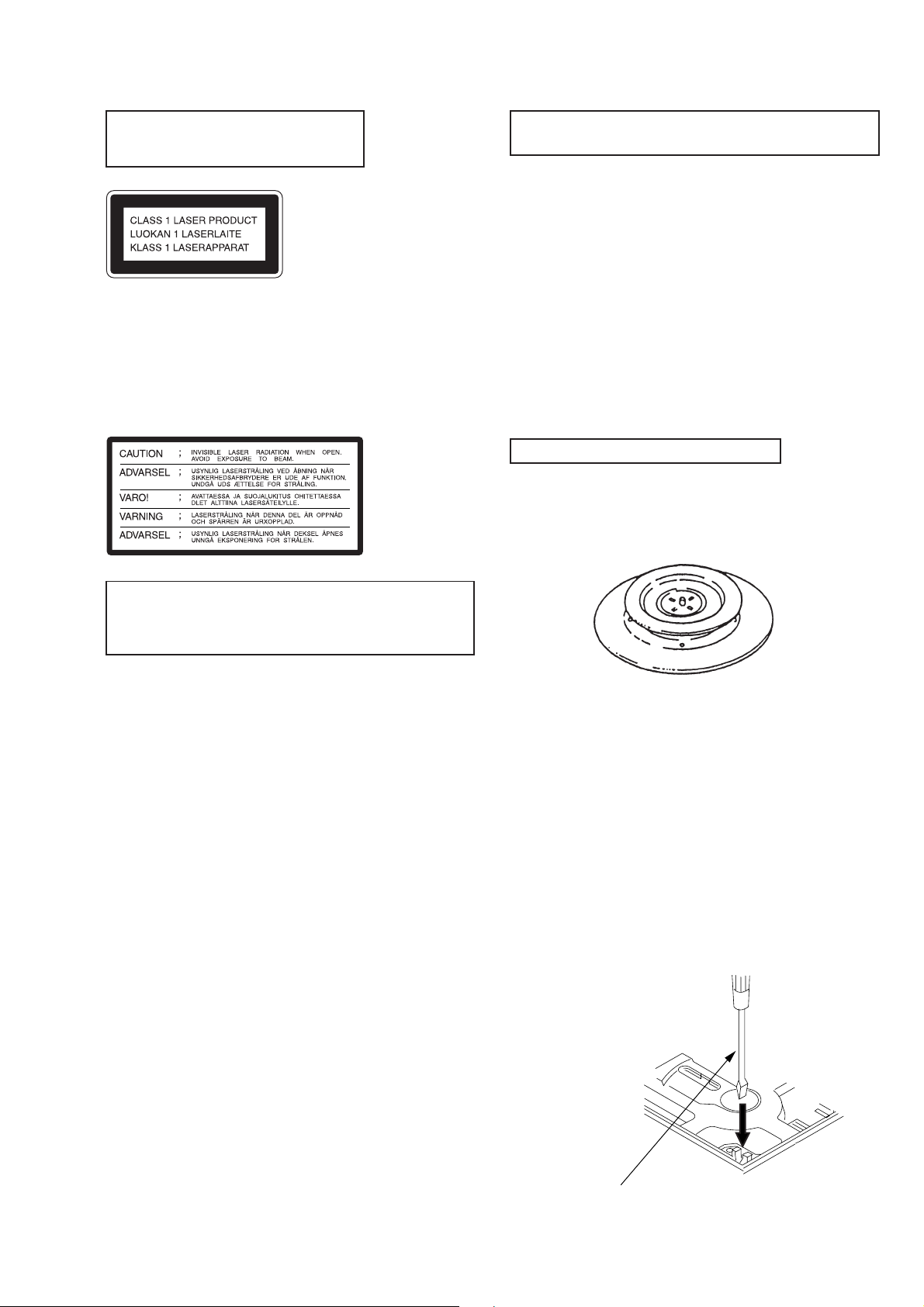

This appliance is classified as a CLASS 1 LASER product. The

CLASS 1 LASER PRODUCT MARKING is located on the rear

exterior.

The following caution label is located inside the unit.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc., on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

• Code number of Chuck Plate Jig : X-4918-255-1

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Press CD open knob.

2. Open the lid for CD.

3. Push on SWITCH (S801) as following figure.

4. Confirm the laser diode emission while observing the objecting

lens. When there is no emission, Auto Po wer Control circuit or

Optical Pick-up is broken.

Objective lens moves up and down once for the focus search.

— 3 —

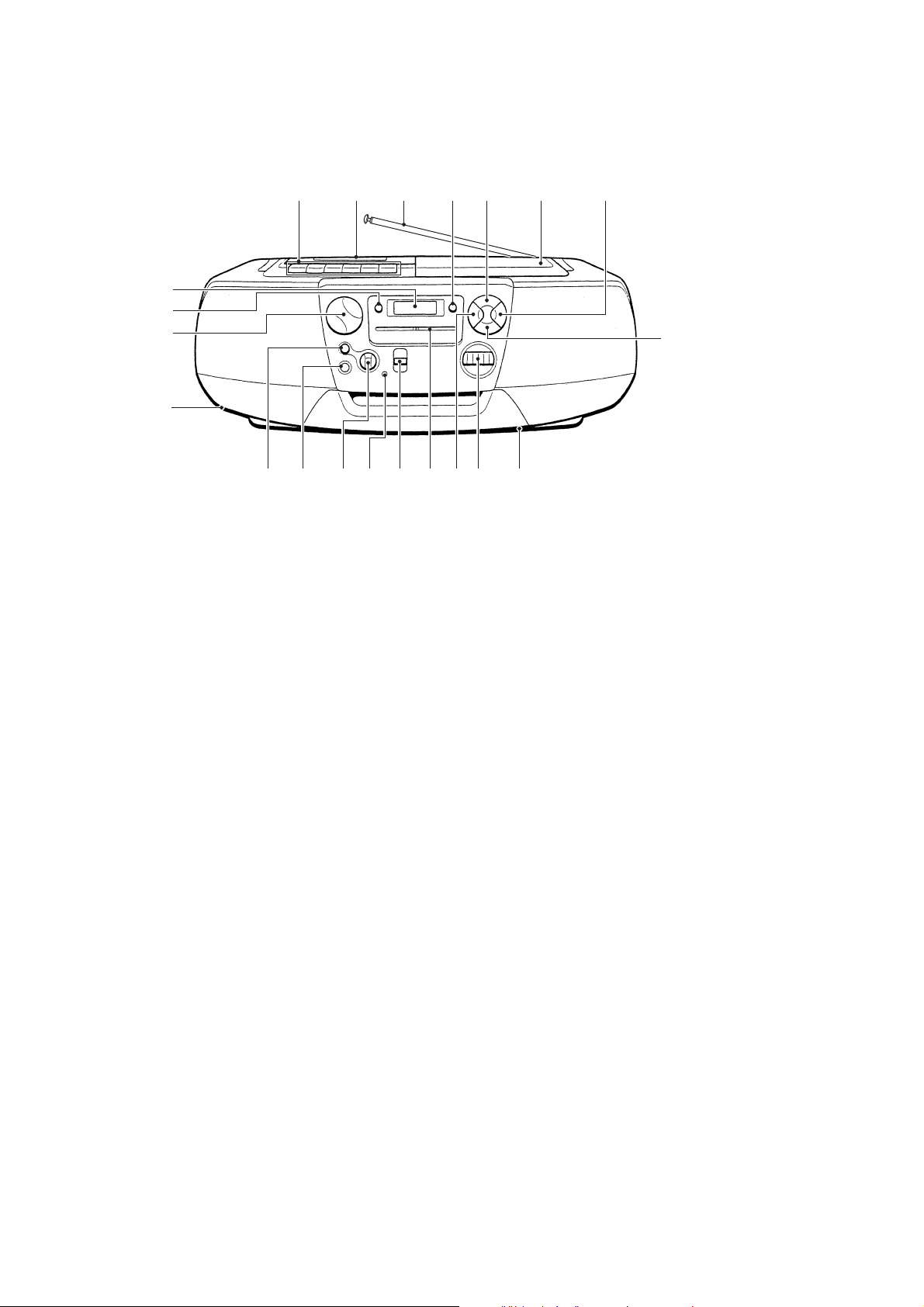

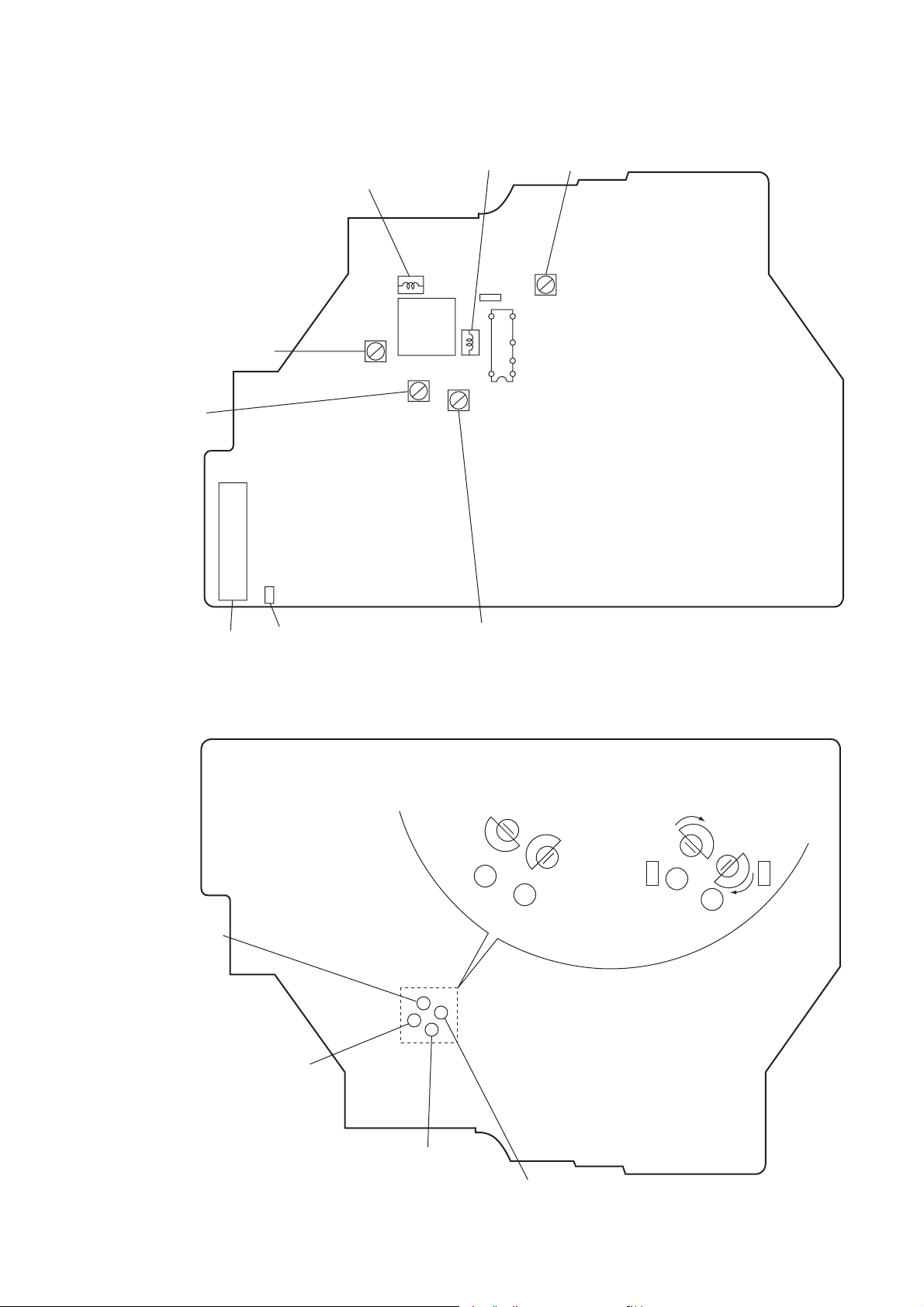

LOCATION AND FUNCTION OF CONTROLS

MAIN UNIT

SECTION 2

GENERAL

1

23

@¡

@º

!ª

!•

1 Tape operation buttons

r button

· button

0 button

) button

p, 6 button

P button

2 CASSETE LID

3 FM rod antenna

4 DISPLAY ENTER button

5 CD ^ button

6 CD 6 PUSH OPEN/CLOSE button

7 CD + button

8 CD p button

4

56

!™!£!¢!∞!§!¶

!¡

9 Battery compartment

!º TUNE knob

!¡ CD = button

!™ DIAL

!£ FUNCTION switch

!¢ OPR/BATT indicator

!∞ TONE knob

!§ 2 Phones jack

!¶ MEGA BASS knob

!• AC IN Socket

!ª VOLUME knob

@º PLAY MODE button

@¡ Information display

90

7

8

— 4 —

SECTION 3

DISASSEMBLY

• The equipment can be removed using the following procedure.

Front cabinet assySet

Cabinet (upper) assy

Control board

Inlet, power, battery, half battery board

Main board Mechanism deck, optical pick-up section

Note : Follow the disassembly procedure in the numerical order given.

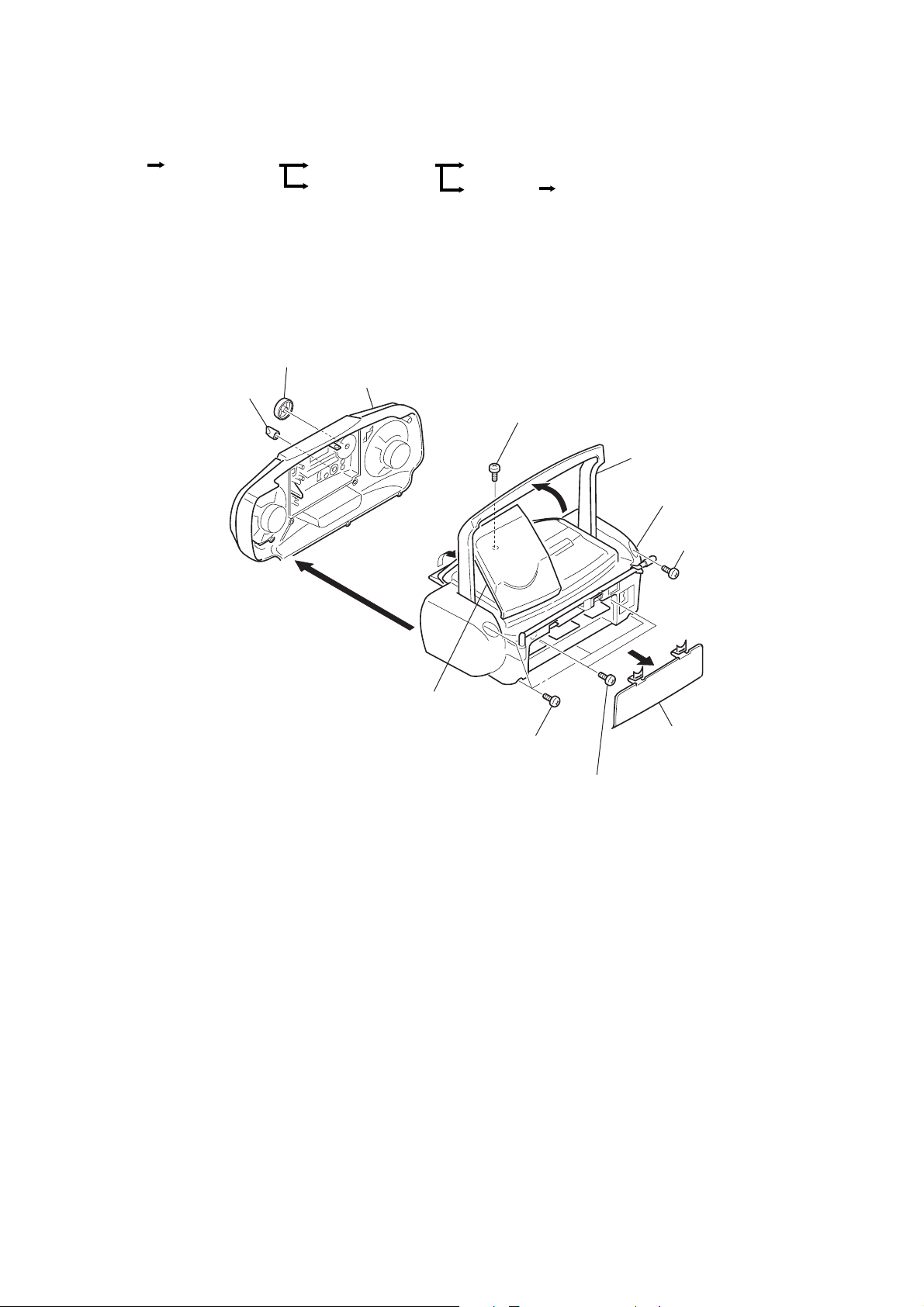

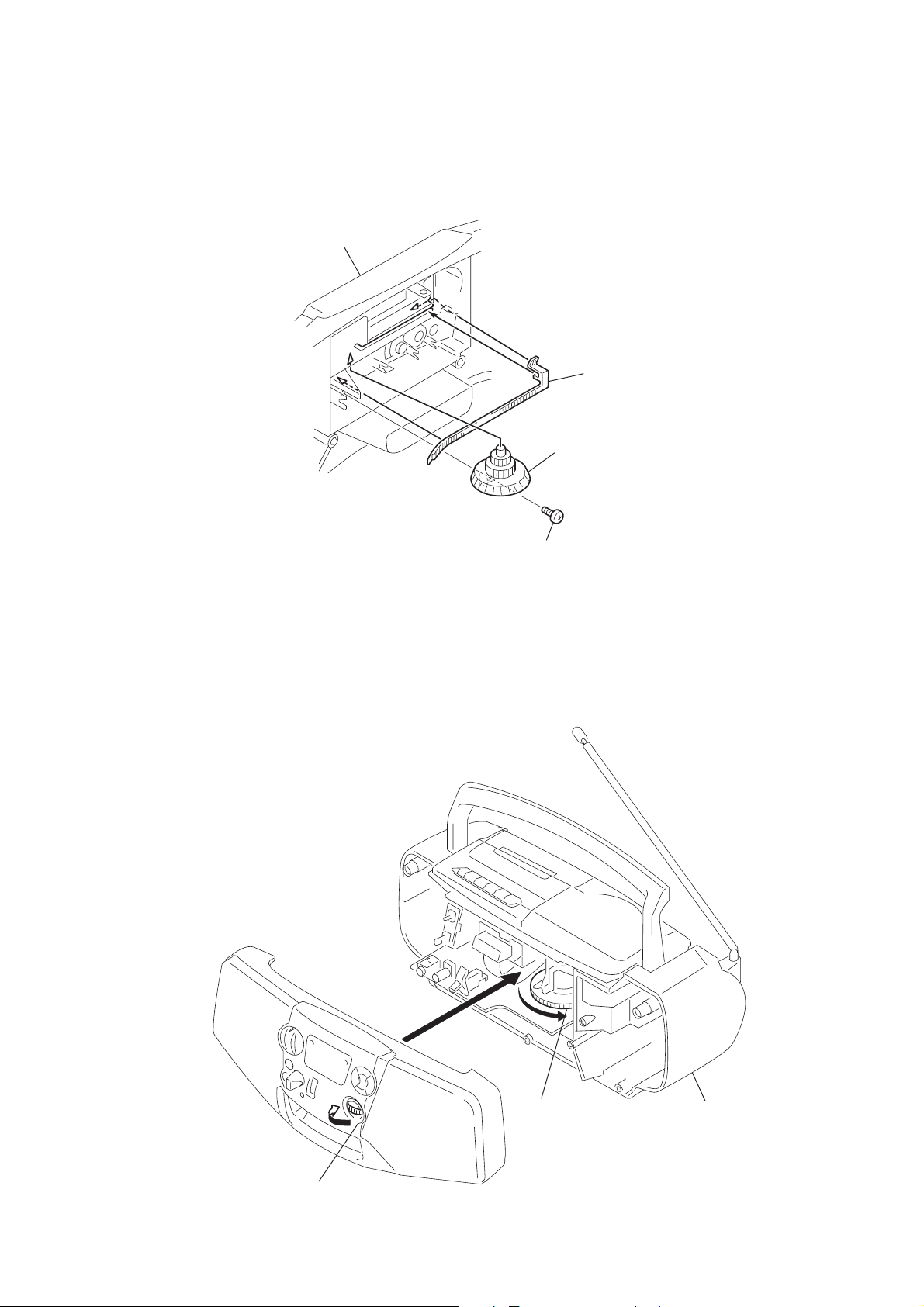

3-1. FRONT CABINET ASSY

8

Knob (Vol )

0

9

Knob (Tone)

Front cabinet assy

7

+BVTP 3

Screw

×

10

5

Remove the Handle

in the direction of the arrow.

Rear cabinet assy

4

Screw

+BVTP 3

×

10

6

Open the Lid (CD) in

the direction of the arrow.

3

Four screws

+BVTP 3

×

10

2

T wo screws

+BVTP 3

1

Lid, battery case

×

10

— 5 —

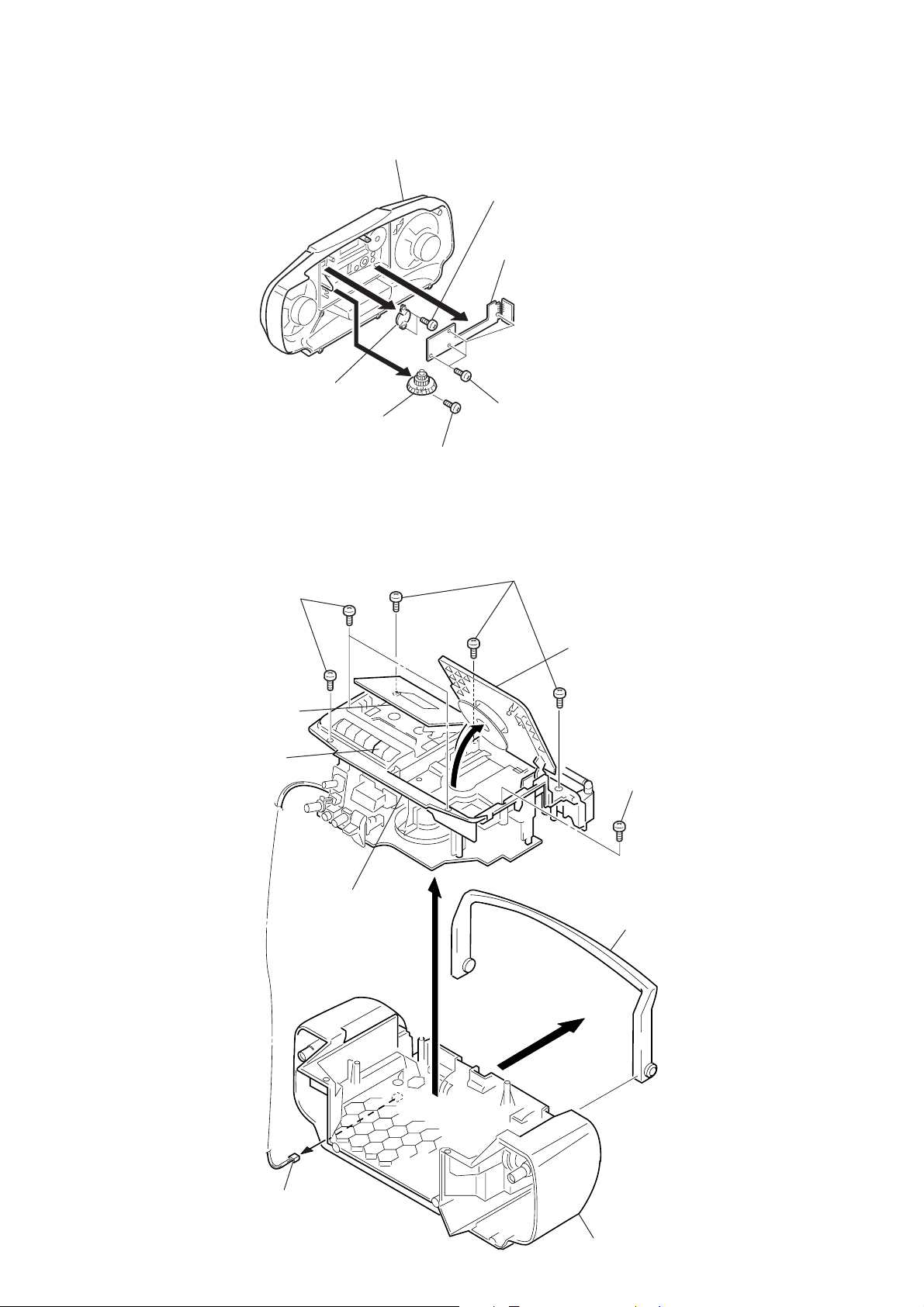

3-2. CONTROL BOARD

d

3-3. CABINET (UPPER) ASSY

Three screws

5

+BVTP 3

6

Button (CD)

×

10

4

Knob (TU)

7

Cabinet (Front) sub assy

5

T wo screws

+BVTP 2.6

3

Screw

×

8

2.6

×

8

2

CONTROL boar

1

Four screws

×

8

2.6

1

Three screws

+BVTP 3

×

10

2

Open the Holder assy, cassette by

pressing STOP/EJECT button.

STOP/EJECT

button

8

Cabinet (upper) assy

7

3

Open the Lid (CD) in

the direction of the arrow.

4

Screw

+BVTP 3

9

Open the Handle in

the direction of the arrow.

×

10

6

Connector

Rear cabinet

— 6 —

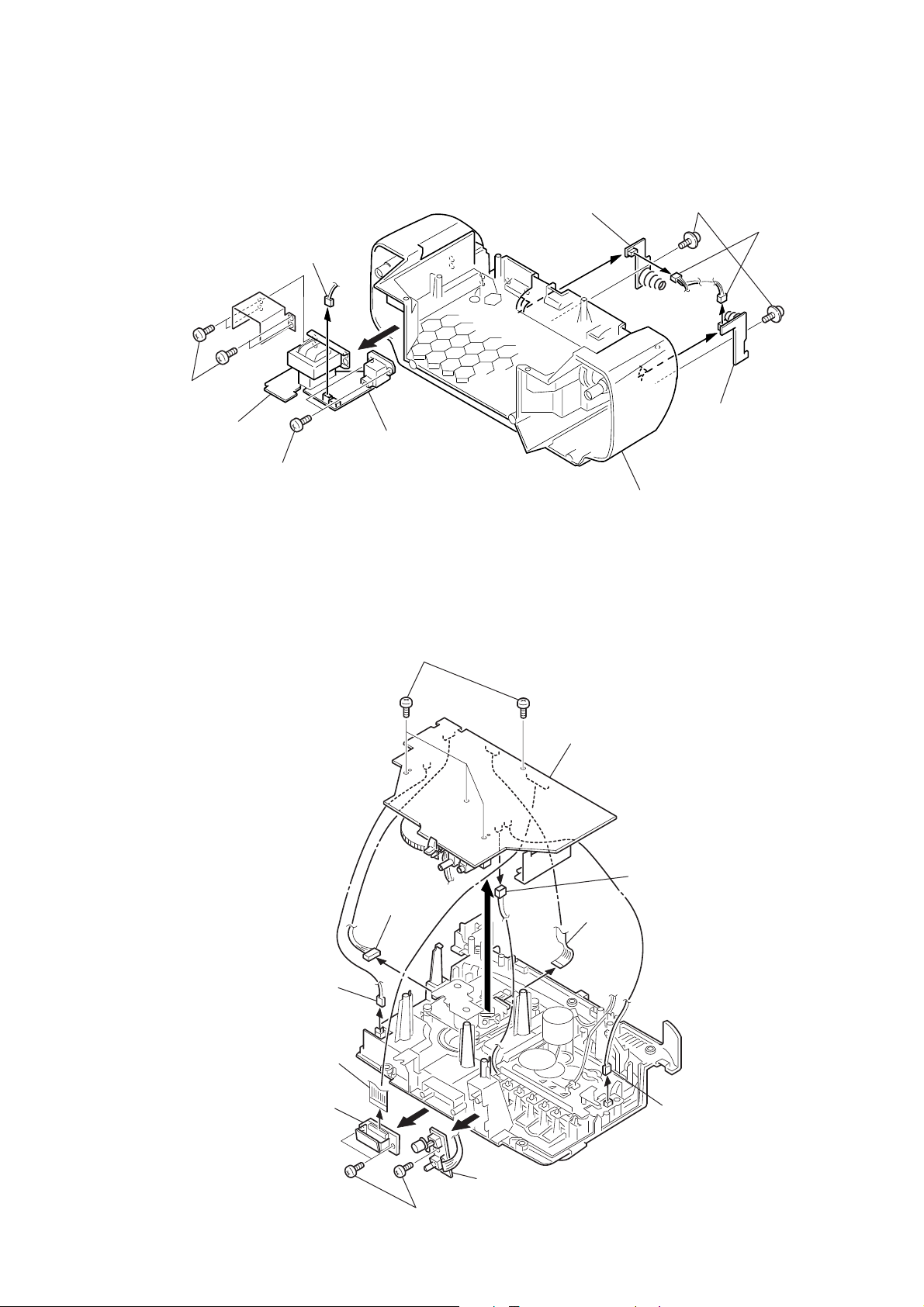

3-4. INLET, POWER, BATTERY, HALF BATTERY BOARD

r

5

Connector

1

Four screws

+BVTP 3 × 10

4

POWER board

2

T wo screws

+BVTP 3 × 10

3

INLET board

8

BATTERY board

6

T wo screws

+BVTP 3 × 8

9

Rear cabinet

7

T wo connectors

HALF BATTERY

board

3-5. MAIN BOARD

!¡

Connector

5

Four screws

+BVTP 3 × 10

0

Connector

6

!™

MAIN board

8

Flexible

9

Connector

3

Flexible

4

DISPLAY

board

2

1

Three Screws

+BVTP 3 × 10

— 7 —

VOLUME board

7

Connecto

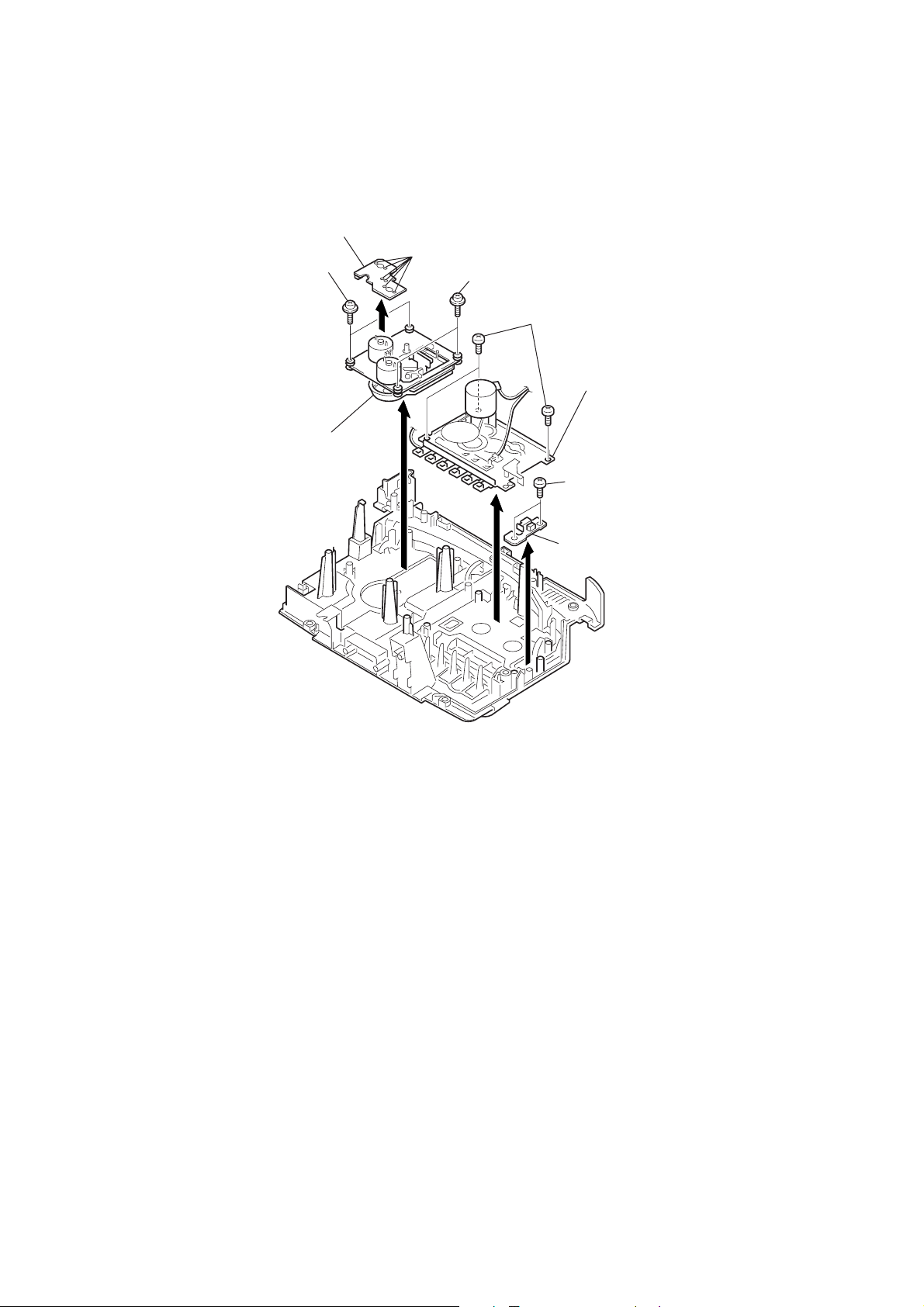

3-6. MECHANISM DECK, OPTICAL PICK-UP SECTION

0

8

CD MOTOR board

7

6

T wo screws

9

Optical pick-up section

Remove solder

5

T wo screws

3

+BVTP 3

Three screws

×

10

4

Mechanism deck

1

+BVTP 3

2

RECORD

switch board

T wo screws

×

1

— 8 —

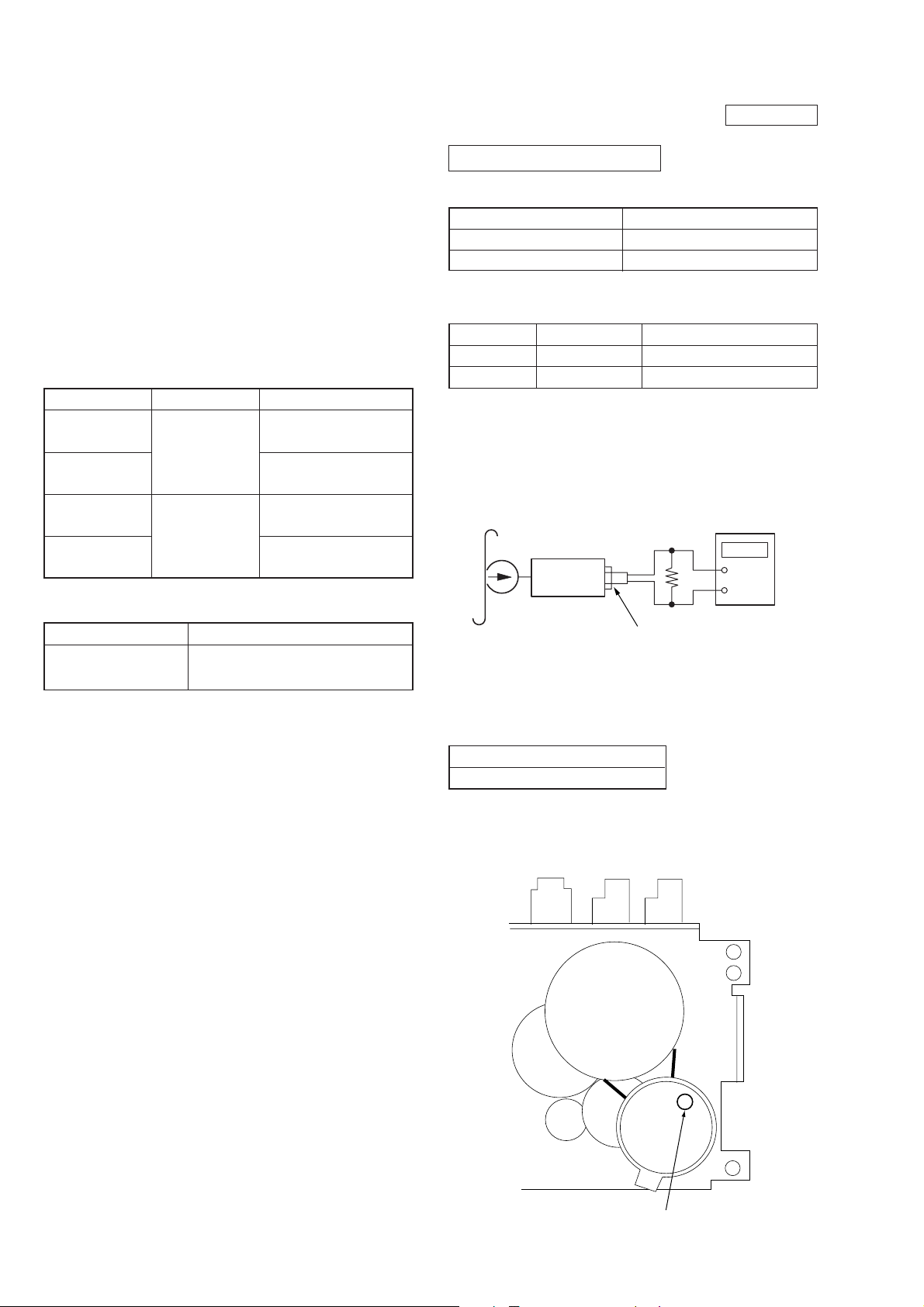

SECTION 4

t

DIAL POINTER INSTALLATION

Note : Follow the installation procedure in the numerical order given.

1 Align the pointer with the groove of front cabinet and insert it as shown in the illustration.

2 Align Tuning knob with front cabinet and fasten the screw.

Front Cabinet

1

Pointer

Tuning knob B

2

Screw (2.6 × 8)

3 Turn the Tuning knob in the direction of the arrow as shown in the illustration until pointer agrees with scale “ 0 ” (at leftmost end of

scale).

4 Turn the tuning capacitor gear fully in the direction of the arrow as shown in the illustration.

5 Fasten the front cabinet and rear cabinet with the screws.

3

T uning knob

5

4

— 9 —

Tuning capacitor gear

Rear cabine

SECTION 5

ADJUSTMENTS

5-1. MECHANICAL ADJUSTMENT

PRECAUTION

1. Clean the following parts with a denatured-alchool-moistened

swab:

record/playback head pinch roller

erase head rubber belts

capstans

2. Demagnetize the record/playback head with a head

demagnetizer. (Do not bring the head demagnetizer close to

the erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

Torque Measurement

Mode

FWD

FWD

back tension

Fast Forward

Rewind

T ape Tension Measurement

Torque Meter

CQ-102C

CQ-201B

Meter Reading

18 – 60 g•cm

(0.25 – 0.83 oz•inch)

1.0 – 5.0 g•cm

(0.014 – 0.069 oz•inch)

45 – 95 g•cm

(0.62 – 1.32 oz•inch)

45 – 95 g•cm

(0.62 – 1.32 oz•inch)

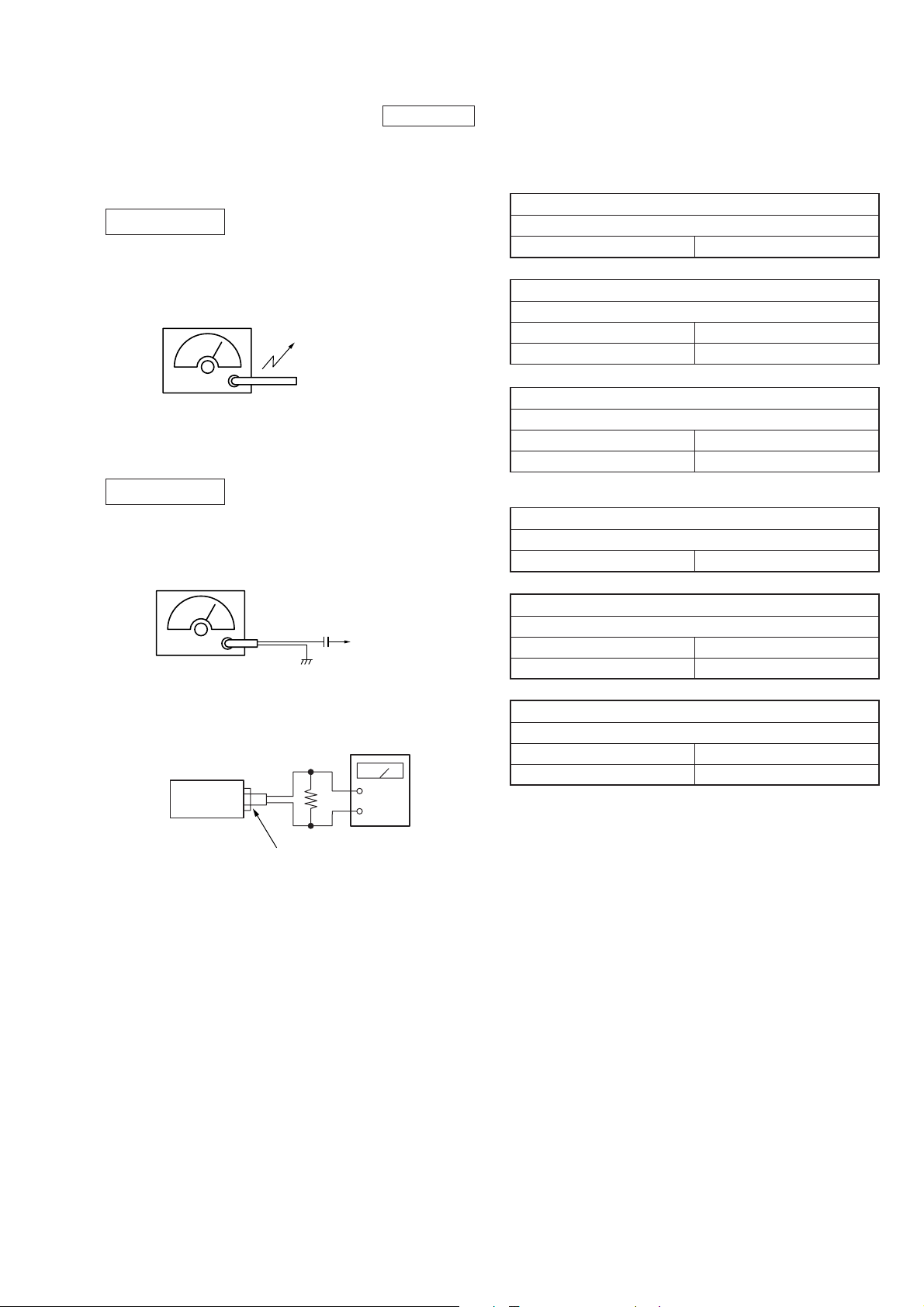

5-2. ELECTRICAL ADJUSTMENT

TAPE RECODER SECTION

Standard output level

Output

Load impedance

Output signal level

Test tape

T est Tape

WS-48A

P-4-A063

Tape Speed Adjustment

Procedure :

Mode : Playback

test tape

WS-48A

(3kHz, 0dB)

Signal

3 kHz, 0 dB

6.3 kHz, –10 dB

set

0.25 V (–10 dB)

Tape speed adjustment

Head azimuth adjustment.

32

Ω

0dB = 0.775V

HP OUT

32 Ω

Used for

digital frequency

counter

+

–

Torque Meter

CQ-403A

Meter Reading

more than 60 g

(more than 2.12 oz)

J301 (phones)

Adjustment V alue : normal tape speed

Adjust the tape speed adjustment control inside motor, so that the

frequency counter reading becomes 3,000 Hz.

Specification Value :

Digital frequency counter

2,910 – 3,090Hz

Frequency difference between the beginning and the end of the

tape should be within 1.5% (45 Hz).

Adjustment Location :

— 10 —

Tape speed adjustment

control inside motor

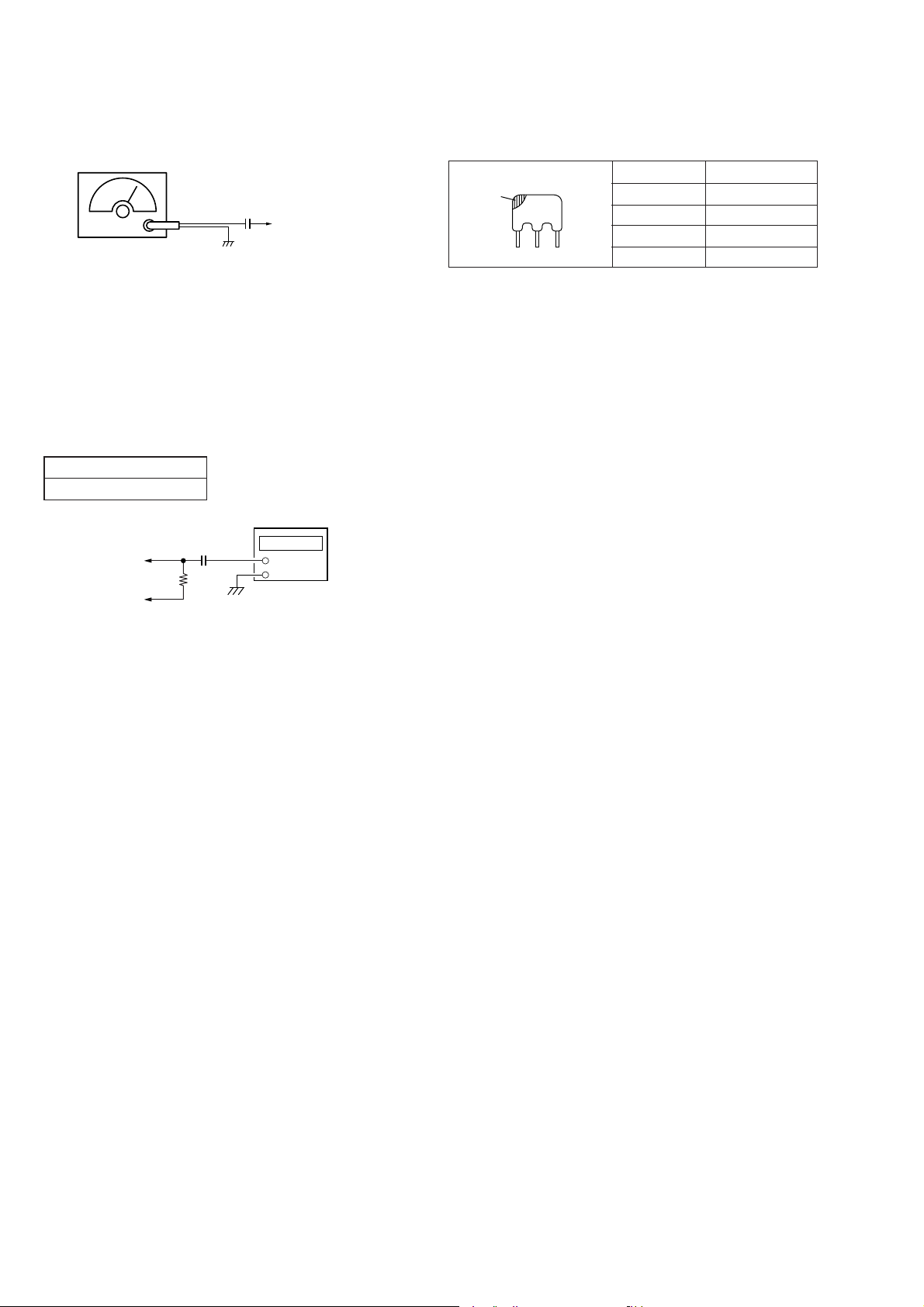

5-3. TUNER SECTION

r

• Switch Location

VOLUME : MAX

MEGA BASS : OFF

PRESET SOUND MODE : OFF

AM SECTION

BAND : AM

Signal generator

AM RF signal

generator

Put the lead-wire

antenna close to

the set.

0 dB = 1 µV

• Repeat the procedures in each adjustment several times for the

maximum level meter indication.

• The frequency coverage and tracking adjustments should be

finally done by the trimmer capacitors.

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T2 455 kHz

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 620 kHz

CT3 1,400 kHz

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

FM SECTION

BAND : FM

Signal generator

FM RF signal

generator

75kHz (100%) amplitude modulation

by 1kHz signal.

Output level : as low as possible

set

0.01µF

32

Ω

telescopic

antenna

terminal

level mete

+

–

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L4 520 kHz (516 kHz)

CT4 1,780 kHz (1,605 kHz)

( ): Australian

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1 10.7 MHz

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 86.5 MHz

CT1 109.5 MHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust for a maximum reading on level meter.

L2 86.5 MHz

CT2 109.5 MHz

Adjustment Location : Main board (See page 13)

J301 (phones)

— 11 —

FM VCO Adjustment

l

color

mark

CF1

r

Procedure :

FM RF SSG

0.01µF

to ANT IN termina

Carrier frequency : 98MHz

IF frequency : According to

the color of CF1.

Modulation : no modulation

Output level : 0.1V (100dB)

1. Connect frequency counter to the positions shown below.

2. Tune the set to 98MHz.

3. Adjust RV1 so that the frequency counter reading becomes

75,000 Hz.

Specification Value :

Frequency counter

75,950 – 76,050 Hz

Frequency counte

IC1 Pin

IC1 Pin

4

7

0.01µF

33k

Ω

+

–

RED 10.70MHz

BLUE 10.67MHz

ORANGE 10.73MHz

BLACK 10.64MHz

WHITE 10.76MHz

Adjustment Location : MAIN board (See page 13)

— 12 —

Adjustment Location : MAIN board (Component side)

L1

FM T rac king

Adjustment

L4

AM Frequency

Coverage

Adjustment

RV1

FM VCO

Adjustment

CV1

L2

FM Frequency

Coverage

Adjustment

CF1

15

16

7

4

1

30

IC1

T2

AM IF

Adjustment

L3

FM ANT IN

AM T rac king

Adjustment

Adjustment Location : MAIN board (Conductor side)

CT4

AM Frequency

Coverage

Adjustment

CT3

AM T rac king

Adjustment

T1

FM IF

Adjustment

Set the CT2 (FM OSC) and CT4 (AM OSC)

trimmers to their extreme outside.

AM OSC

AM OSC

FM OSC

Inside NG Outside OK

FM OSC

CT1

FM T rac king

Adjustment

— 13 —

CT2

FM Frequency

Coverage

Adjustment

CD SECTION

V

s

Notes on Check

1. Perform the traverse check in the CD test mode.

After check, be sure to exit the test mode.

2. Perform check in the order given.

3. Use the disc (YEDS-18, Parts No. 3-702-101-01) only when

so indicated.

Before Check

Put the set into test mode and perform the following checks.

Repair if there are any problems.

• Sled Motor Check

Press + , = keys and confirm that the Optical pick-up moves

smoothly from the innermost to outermost circumference and back

smoothly and with no catching or abnormal noises.

(Cancellation of BTL mute)

+ : Optical pick-up moves to the outer circumference.

= : Optical pick-up moves to the inner circumference.

• Focus Search Check

1. Press the CD ^ key. (Focus search operation is performed

continuously.)

2. Look at the Optical pick-up objective lens and confirm that it

moves up and down smoothly, with no catching or abnormal

noises.

3. Press p button.

Confirm that focus search operation stops. If it does not, press

p button again longer.

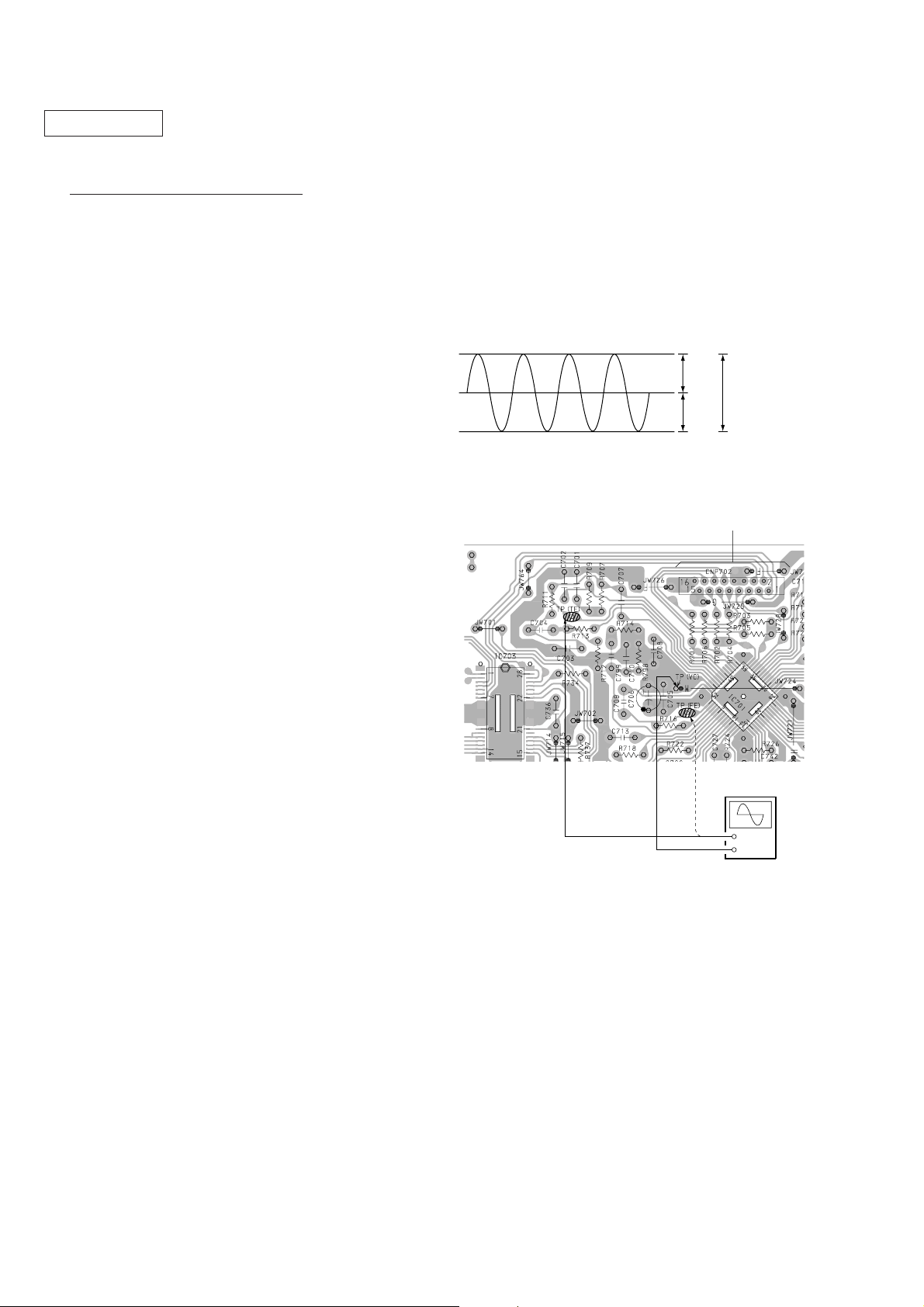

TRAVERSE Check

This check is to be done when the optical pick-up block is replaced.

Check Procedure:

1. Connect the oscilloscope to test point TP (VC) and TP (TE) on

MAIN board.

2. Put the set into test mode.

3. Optical pick-up setting to the center by + or = button

pushing.

4. Insert disk (YEDS-18) and press ^ button.

5. Check that the oscilloscope traverse waveform is symmetrical,

as shown in the figure below.

6. Release test mode after adjustment is completed.

A

VOLT/DIV : 0.1

0V

TIME/DIV : 1m

B

A = B C = 300mV – 700mV

C

[MAIN BOARD] (Conductor side)

How to Enter the Set into Test Mode

1. Set the function switch to power off.

2. Set the function switch to CD while = key and p key

pressing.

The set is into CD test mode (88 is displayed).

3. Turn the power off to release test mode.

How to Exit the Test Mode

Turn the POWER OFF.

TP (TE)

TP (FE)

TP (VC)

Oscilloscope

(DC range)

+

–

— 14 —

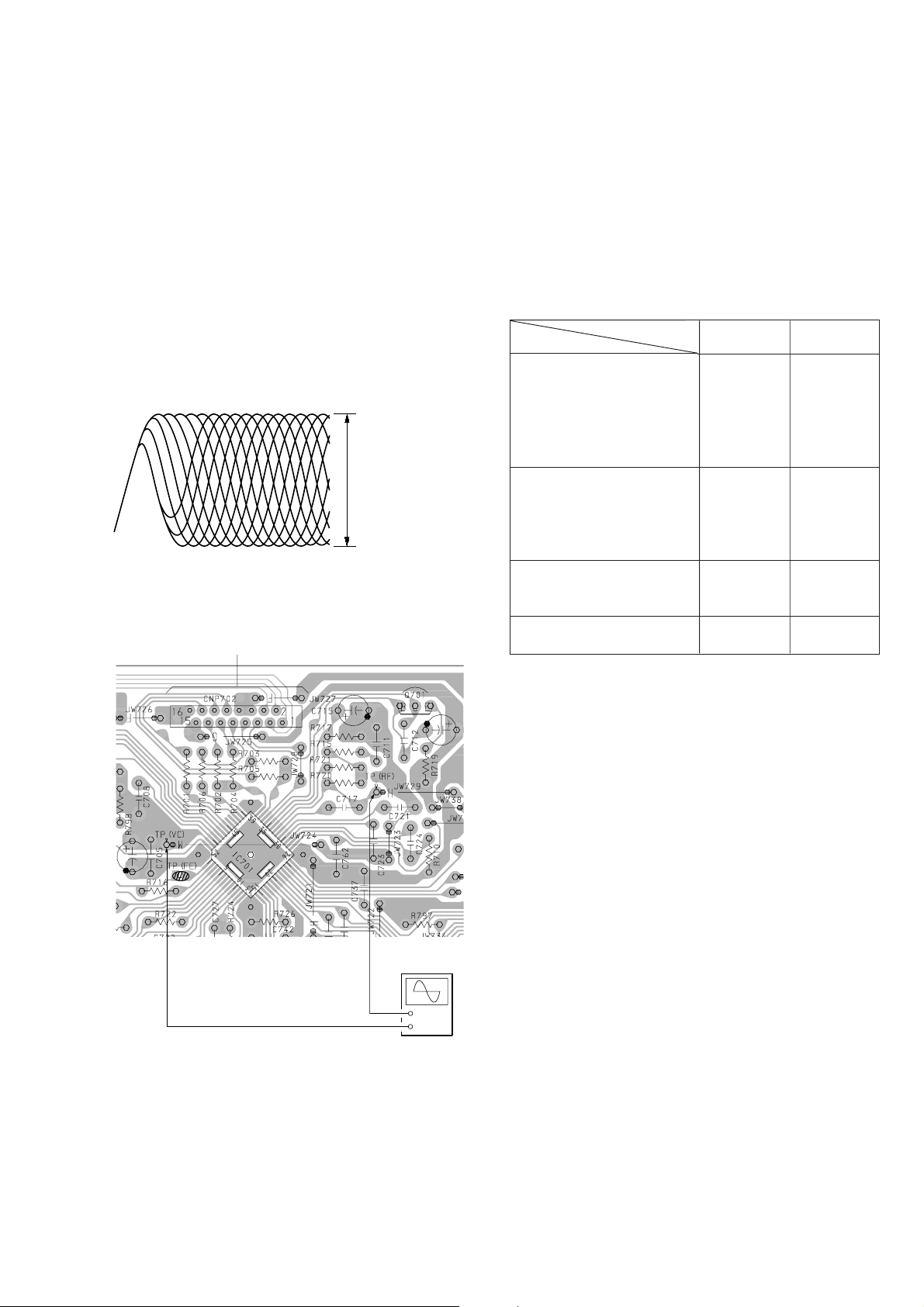

Focus Bias Check

s

This check is to be done when the optical block replaced.

Check Procedure:

1. Connect the oscilloscope to test point TP (VC) and TP (RF) on

MAIN board.

2. Put the set into test mode.

3. Opitical pick-up setting to the center by + or – button pushing.

4. Insert disk (YEDS-18) and press ^ button.

5. Press the MODE button. (Tracking servo ON)

6. Check that the oscilloscope wavewform is as sho wn in the figure

below (eye pattern).

A good eye pattern means that the diamond shape (◊) in the

center of the waveform can be clearly distinguished.

7. Release test mode after adjustment is completed.

• RF signal reference waveform (eye pattern)

VOLT/DIV : 0.2V

TIME/DIV : 500n

0.9Vp-p – 1.3Vp-p

When observing the eye pattern, set the oscilloscope for AC range

and raise vertical sensivity.

[MAIN BOARD] (Conductor side)

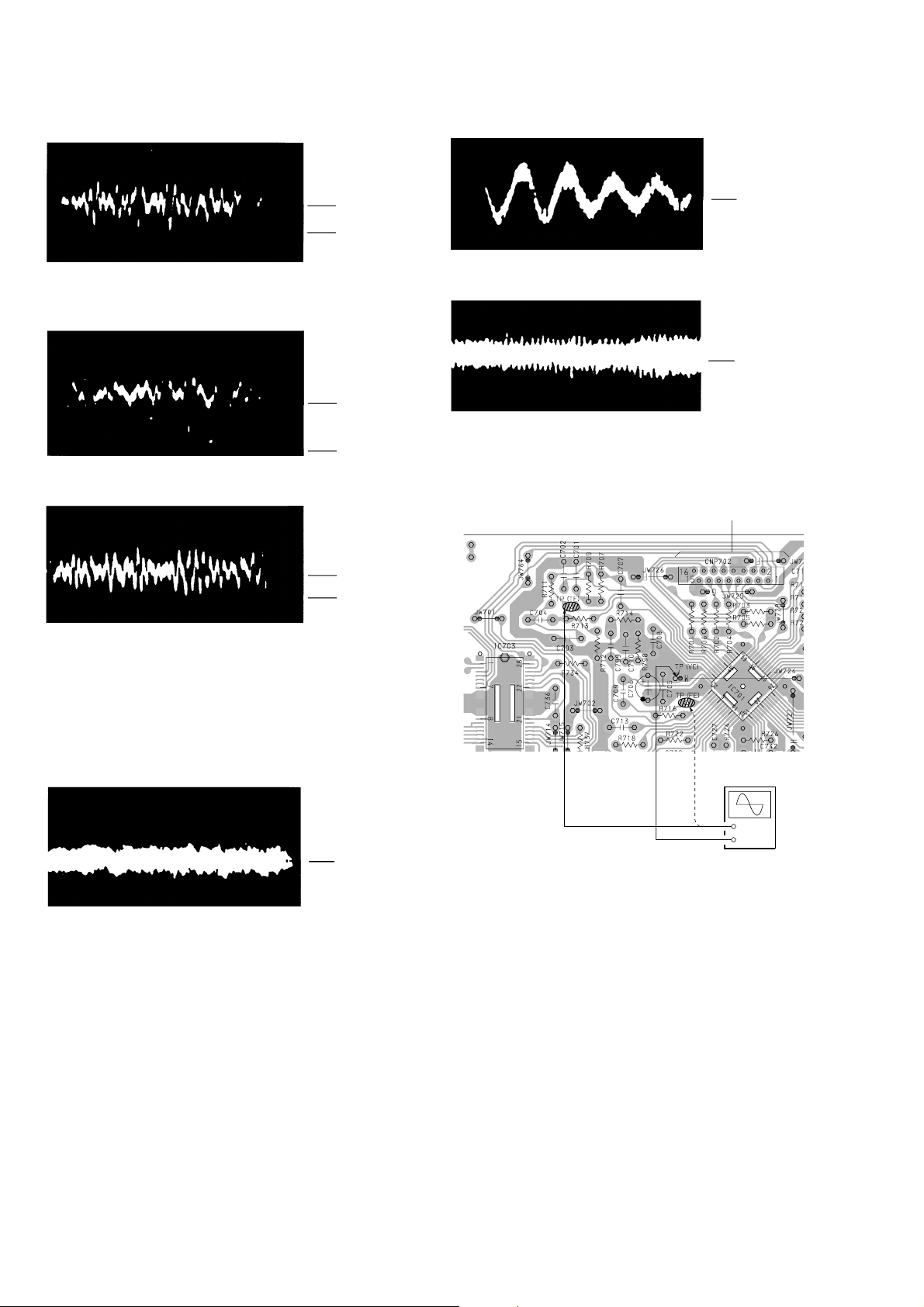

5-4. REFERENCE

Focus/Tracking Gain Check

Adjustment Location : MAIN board (Component side)

(See page 16)

A frequency response analyzer is necessary in order to perform this

check exactly.

However , this gain has a mar gin, so e ven if it is slightly of f, there is

no problem.

Focus/Tracking gain determines the pick-up follo w-up (vertical and

horizontal) relative to mechanical noise and mechanical shock when

the 2-axis device operate.

Symptoms

Gain

• The time until music starts

becomes longer for STOP ➡

CD ^ or automatic

selection (0 , ) buttons

pressed). (Normally takes

about 2 seconds.)

• Music does not start and disc

continues to rotate for STOP

➡ CD ^ or automatic

selection (0 , ) buttons

pressed.)

• Sound is interrupted during

PLAY. Or time counter

display stops progressing.

• More noise during 2-axis

device operation.

Focus

low

—

—

high

Tracking

low or high

low

low

high

TP

(RF)

TP(VC)

Check Procedure:

1. Keep the set horizontal.

2. Inset disk (YEDS-18) and press ^ button.

3. Connect an oscilloscope to TP (FE) and TP (VC) on the MAIN

board.

4. Check that the waveform is as sho wn in the figure below . (Focus

waveform)

Oscilloscope

(DC range)

+

–

— 15 —

• Good Example

V

V

V

V

V

V

• Incorrect Examples (Fundamental wave appears)

VOLT/DIV : 100m

TIME/DIV : 1ms

100mV

0V

• Incorrent Examples (DC level changes more than on adjusted

waveform)

VOLT/DIV : 100m

TIME/DIV : 2ms

200mV

0V

low focus gain

VOLT/DIV : 100m

TIME/DIV : 2ms

75mV

0V

VOLT/DIV : 0.2

TIME/DIV : 2ms

0V

low tracking gain

VOLT/DIV : 0.2

TIME/DIV : 2ms

0V

high tracking gain

(high fundamental wave than for low gain)

[MAIN BOARD] (Conductor side)

high focus gain

5. Connect an oscilloscope between TP (TE) and TP (VC).

6. Insert disc (YEDS-18) and press the CD ^ button.

7. Check that the waveform is as shown in the figure below.

(tracking waveform)

VOLT/DIV : 0.2

TIME/DIV : 2ms

0V

TP (TE)

TP (FE)

TP (VC)

Oscilloscope

(DC range)

+

–

— 16 —

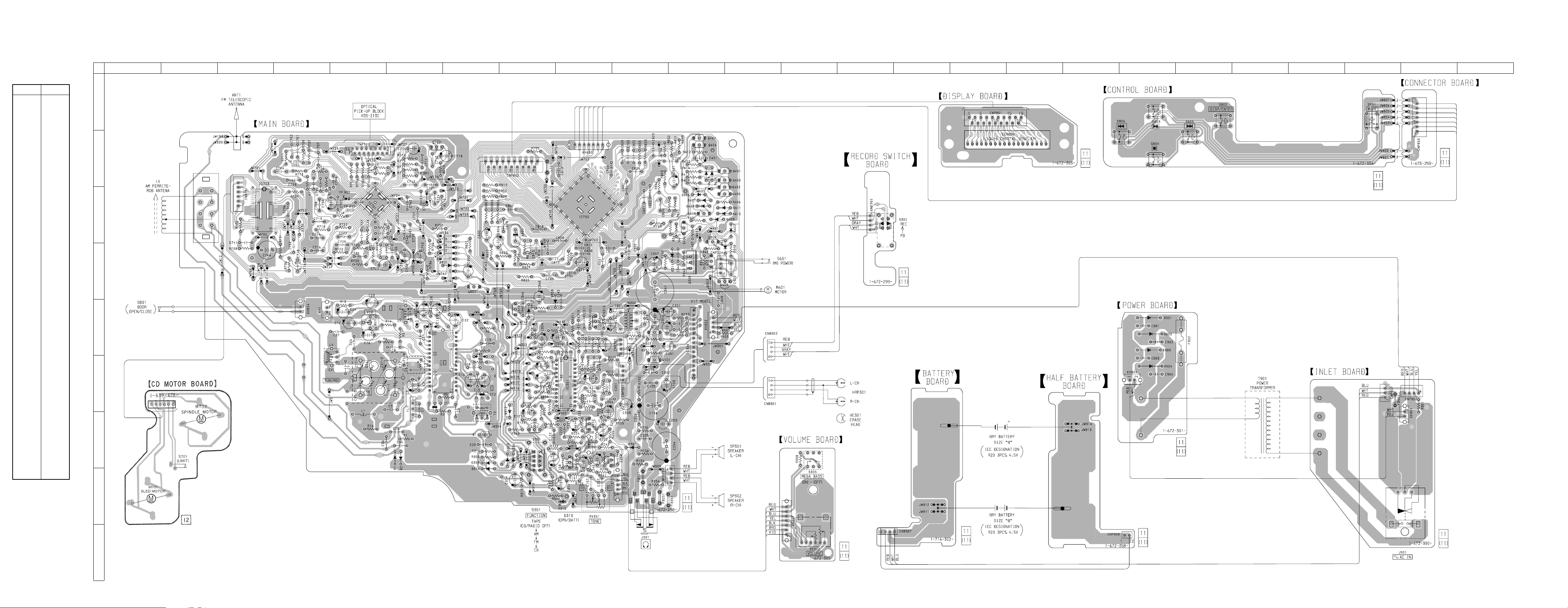

SECTION 6

d

DIAGRAMS

CFD-V17

6-1. CIRCUIT BOARDS LOCATION

RECORD SWITCH board

INLET board

POWER board

VOLUME board

DISPLAY board

CONTROL board

CONNECTOR board

BATTERY board

MAIN board

HALF BATTERY board

CD MOTOR boar

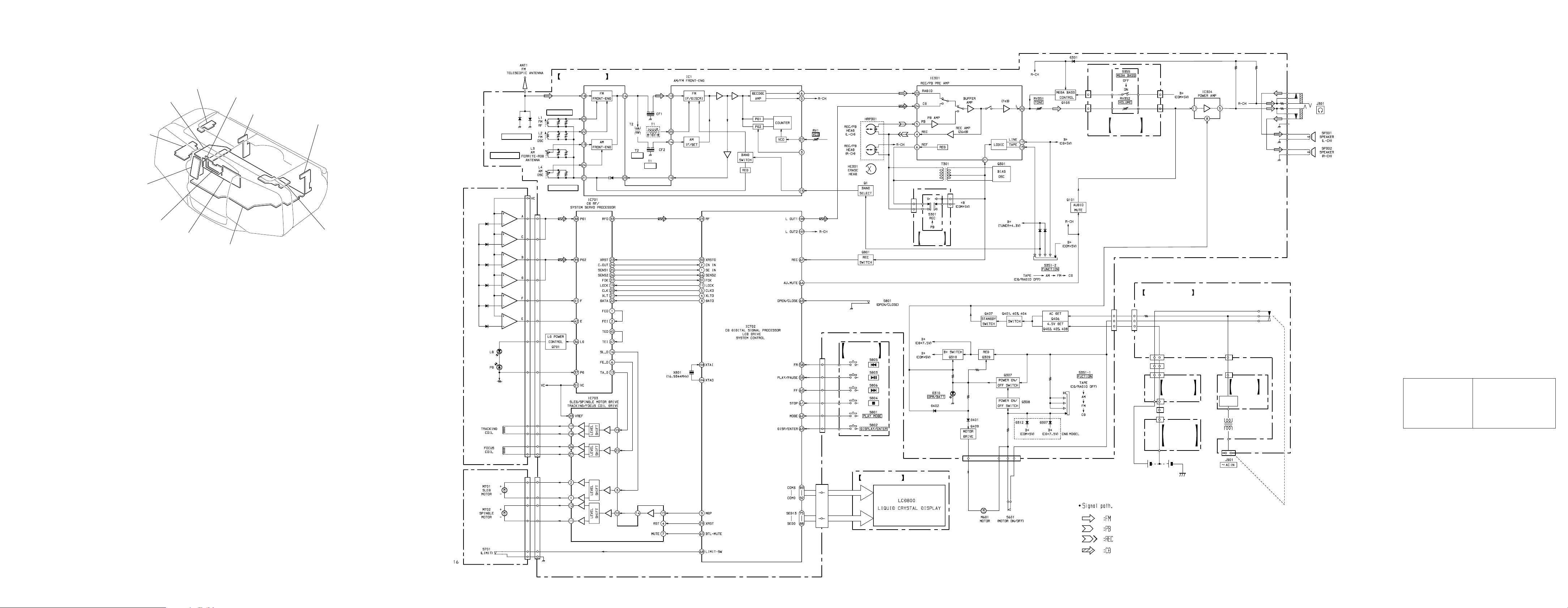

6-2. BLOCK DIAGRAM

FM F-COVERAGE

L3, CT3

AM TRACKING

OPTICAL PICK-UP

BLOCK

(KSS-213CDM)

L2, CT2

CNP702

12

10

11

13

9

14

7

5

3

2

4

1

CNB701

3

4

1

2

5

6

MAIN BOARD

L1, CT1

FM TRACKING

L4, CT4

AM F-COVERAGE

AM IF

FM IF

KH803

CNP803

7

6

5

4

3

2

CNP802 CNP801

1-4

5-18

CONTROL

BOARD

LCD BOARD

CNB302

CNJ302

4

3

RECORD

SWITCH

BOARD

CNJ302

CNB302

1

KH308

KH307

1 2

2 4

KH306

KH307

KH307 KH308

KH307 KH306

VOLUME

BOARD

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• b : Pattern from the side which enables seeing.

Note on Schematic Diagrams:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

INLET BOARD

KH902

3

2

4

3

2

4

CNP902

CNP907

31

CNJ907

1

3

31

CNB907

BATTERY

BOARD

CNB907

4

4

CNB908

4

CNB908

HALF

RECT

D901-904

KH902

2

KH904

2

POWER

BOARD

T901

POWER

TRANSFORMER

BATTERY

BOARD

4

3

CNP304

21

CNJ304

DRY BATTERY

SIZE "D"

(IEC DESIGNATION R20)

6PCS. 9V

and tantalums.

• All resistors are in Ω and 1/

specified.

¢

•

: internal component.

4

W or less unless otherwise

• 2 : nonflammable resistor.

• C : panel designation.

• H : adjustment for repair.

• U : B+ Line.

• Power voltage is dc 9 V and fed with regulated dc power

supply from battery terminal.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

Note:

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

– For Radio, TAPE section MAIN (1/2) –

no mark : PLAY (TAPE SECTION)

CD STOP

( ) : REC (TAPE SECTION)

[ ] : FM (RADIO SECTION)

< > : AM (RADIO SECTION)

– For CD Section MAIN (2/2) –

no mark : CD PLAY

TAPE STOP

• Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Signal path.

F : FM

E : PB

a : REC

J : CD

• Abbreviation

CND : Canadian

MX : Mexican

AUS : Australian

— 17 — — 18 — — 19 — — 20 —

CFD-V17

6-3. PRINTED WIRING BOARD • Refer to page 20 for Note on Printed Wiring Board.

• Semiconductor

Location

Ref. No. Location

D1 G-6

D2 G-6

D301 G-10

D302 D-10

D303 G-8

D304 G-8

D307 E-8

D308 D-8

D309 G-7

D310 H-9

D312 F-8

D311 D-11

D314 G-7

D401 C-11

D402 C-12

D403 B-11

D404 B-11

D406 C-11

D407 C-11

D408 C-11

D409 C-12

D410 C-12

D411 C-12

D801 D-7

IC1 F-7

IC301 F-9

IC304 E-11

IC701 C-5

IC702 C-9

IC703 C-3

Q1 G-7

Q101 F-10

Q102 G-8

Q103 G-9

Q201 E-10

Q202 G-9

Q203 G-9

Q301 E-9

Q307 D-11

Q308 C-11

Q309 D-11

Q310 E-8

Q401 B-12

Q402 B-12

Q403 B-12

Q404 B-11

Q405 C-12

Q406 C-11

Q407 B-11

Q408 C-11

Q409 D-12

Q701 B-6

Q801 D-7

A

B

C

D

E

F

G

12

345678910111213141516171819202122232425

CND MODEL

CND MODEL

REC/PB

HEAD

H

+

16

I

— 21 — — 22 — — 23 — — 24 —

Loading...

Loading...