Sony CFD-S400L Service Manual

CFD-S400L

SERVICE MANUAL

Ver 1.0 2002.04

Section

Section

AEP Model

UK Model

Model Name Using Similar Mechanism CFD-S26L/S36L

CD

CD Mechanism Type KSM-213RDP

Optical Pick-up Name KSS-213R

Model Name Using Similar Mechanism NEW

TC

Tape Transport Mechanism T ype MF-S200

CD player section

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wave length: 780 nm

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of

about 200 mm from the objective lens surface on

the optical pick-up block with 7 mm aperture.)

Spindle speed

200 r/min (rpm) to 500 r/min (rpm) (CLV)

Number of channels

2

Frequency response

20 - 20,000 Hz +1/–2 dB

Wow and flutter

Below measurable limit

Radio section

Frequency range

FM: 87.5 - 108 MHz

MW:531 - 1,611 kHz (9 kHz step)

530 - 1,610 kHz (10 kHz step)

LW: 153 - 279 kHz

IF

FM: 10.7 MHz

MW/LW: 450 kHz

Aerials

FM: Telescopic aerial

MW/LW: Built-in ferrite bar aerial

SPECIFICATIONS

Cassette-corder section

Recording system

4-track 2 channel stereo

Fast winding time

Approx. 120 sec. with Sony cassette C-60

Frequency response

TYPE I (normal): 80 - 10,000 Hz

General

Speaker

Full range: 10 cm dia.,

3.2 ohms, cone type (2)

Outputs

Headphones jack (stereo minijack)

For 16 - 68 ohms impedance headphones

Maximum power output

4.6 W

Power requirements

For CD radio cassette-corder:

230 V AC, 50 Hz

9 V DC, 6 size D (R20) batteries

For remote control:

3 V DC, 2 size AA (R6) batteries

Power consumption

AC 20 W

– Continued on next page –

9-873-983-01

2002D0400-1

© 2002.04

CD RADIO CASSETTE-CORDER

Sony Corporation

Personal Audio Company

Published by Sony Engineering Corporation

1

CFD-S400L

Battery life

For CD radio cassette-corder:

FM recording

Sony R20P: approx. 13.5 h

Sony alkaline LR20: approx. 20 h

Tape playback

Sony R20P: approx. 7.5 h

Sony alkaline LR20: approx. 15 h

CD playback

Sony R20P: approx. 2.5 h

Sony alkaline LR20: approx. 7 h

Dimensions

Approx. 386 × 166 × 252 mm (w/h/d)

(incl. projecting parts)

Mass

Approx. 3.3 kg (incl. batteries)

Supplied accessories

Main lead (1)

Remote control (RMT-CS400AD) (1)

Design and specifications are subject to change without

notice.

This Compact Disc player is

classified as a CLASS 1

LASER product.

The CLASS 1 LASER

PRODUCT mark is located

at the bottom.

CAUTION

Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

TABLE OF CONTENTS

1. SERVICING NOTES......................................................... 4

2. GENERAL............................................................................ 5

3. DISASSEMBLY

3-1. Cabinet Top Assy ................................................................ 7

3-2. Cabinet Front Assy, Cabinet Rear Assy .............................. 7

3-3. Wires ................................................................................... 8

3-4. MD Block............................................................................ 8

3-5. Cassette Door Assy ............................................................. 9

3-6. LCD Board, Control (4) Board ........................................... 9

3-7. Main Board ....................................................................... 10

3-8. Tuner Board....................................................................... 10

3-9. Power Board...................................................................... 11

3-10. CD Lid............................................................................... 11

3-11. CD Block Assy.................................................................. 12

3-12. Optical Pick-up ................................................................. 12

3-13. R/P Head (HRP301), TC Board ........................................ 13

3-14. Motor Assy (M801), Main Belt (B), Sub Belt (B) ............ 13

CFD-S400L

4. MECHANICAL ADJUSTMENTS............................... 14

5. ELECTRICAL ADJUSTMENTS

Tape Section .......................................................................... 14

Tuner Section......................................................................... 15

CD Section ............................................................................ 16

6. DIAGRAMS

6-1. IC Pin Description............................................................. 17

6-2. Circuit Boards Location .................................................... 17

6-3. Block Diagram – CD Section –......................................... 18

6-4. Block Diagram – Main Section –...................................... 19

6-5. Printed Wiring Board – CD Section – ............................... 20

6-6. Schematic Diagram – CD Section –.................................. 21

6-7. Printed Wiring Board – Tuner Section – ........................... 22

6-8. Schematic Diagram – Tuner Section –.............................. 23

6-9. Printed Wiring Boards – Main Section – .......................... 24

6-10. Schematic Diagram – Main Section (1/2) – ...................... 25

6-11. Schematic Diagram – Main Section (2/2) – ...................... 26

6-12. Printed Wiring Board – TC Section – ............................... 27

6-13. Schematic Diagram – TC Section – .................................. 28

6-14. Printed Wiring Boards – Control Section –....................... 29

6-15. Schematic Diagram – Control Section – ........................... 30

6-16. Printed Wiring Boards – Display Section – ...................... 31

6-17. Schematic Diagram – Display Section –........................... 32

6-18. Printed Wiring Boards – Power Supply Section – ............ 33

6-19. Schematic Diagram – Power Supply Section –................. 34

6-20. IC Block Diagrams............................................................ 35

7. EXPLODED VIEWS

7-1. Main Section ..................................................................... 38

7-2. Cabinet Front Section........................................................ 39

7-3. Cabinet Top Section .......................................................... 40

7-4. Cabinet Rear Section......................................................... 41

7-5. Tape Mechanism Section .................................................. 42

7-6. CD Mechanism Section .................................................... 43

8. ELECTRICAL PARTS LIST......................................... 44

3

CFD-S400L

SECTION 1

SERVICING NOTES

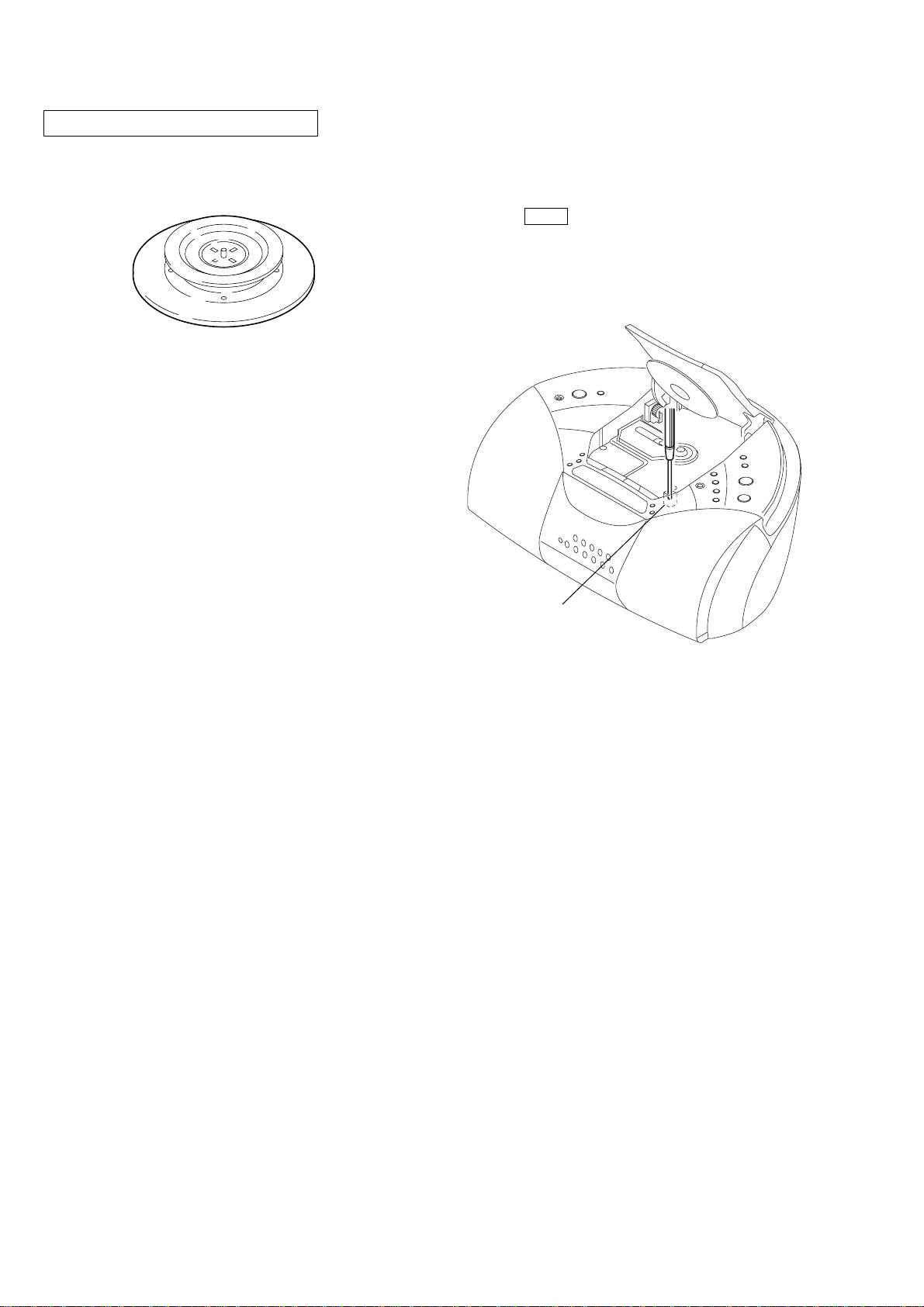

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the lid (CD), use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Turn ON the [OPERATE] button and press [CD] button to CD

position.

2. Open the CD lid.

3. Turn on S801 with screwdriver, etc. as following figure.

4. Press the N X (CD) button.

5. Confirm the laser diode emission while observing the objecting

lens. When there is no emission, Auto P ower Control circuit or

Optical Pick-up is broken.

Objective lens moves up and do wn three times for focus search.

S801

4

SECTION 2

GENERAL

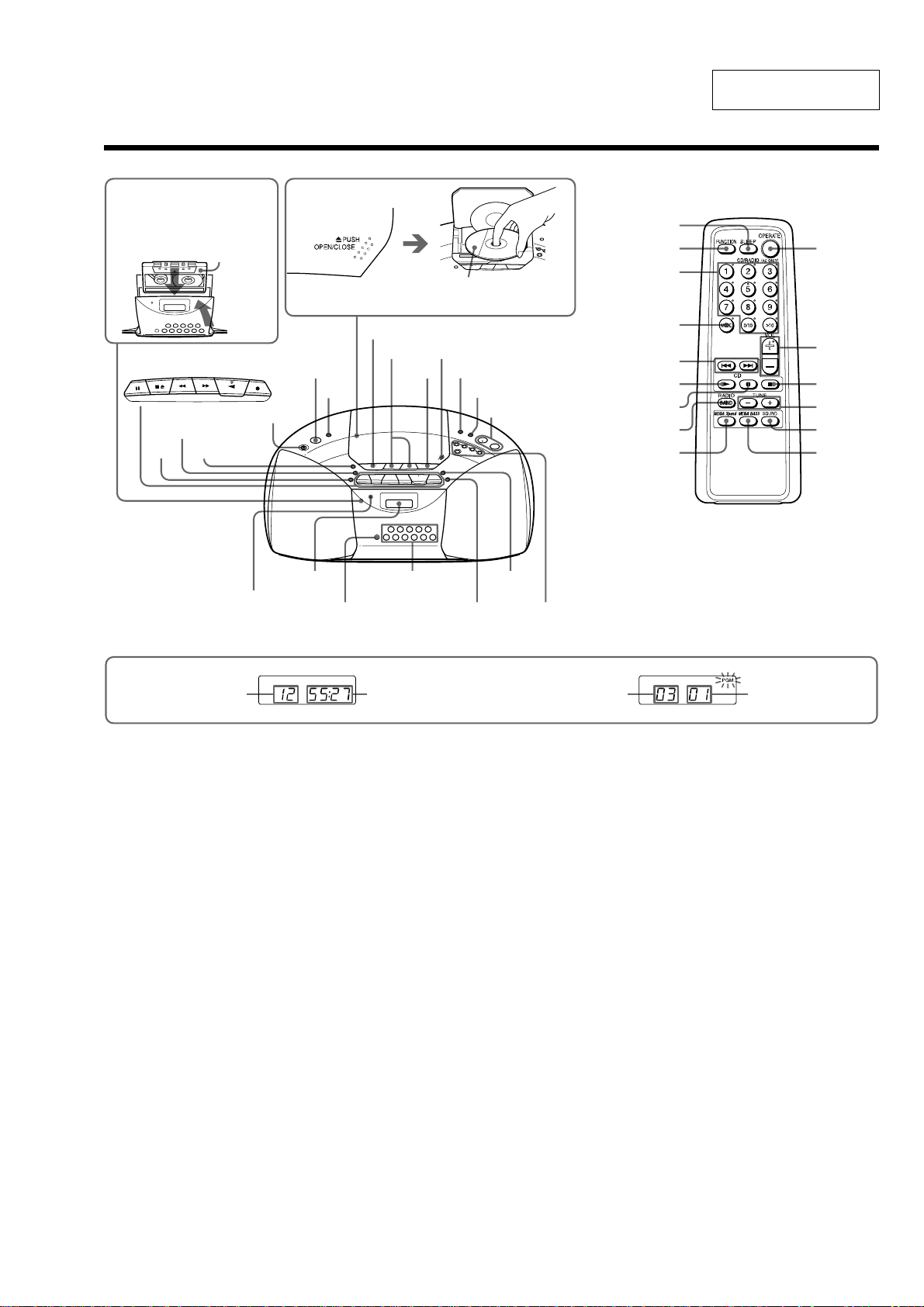

Location of controls/Ubicación de los controles

Inserting a cassette

Inserción de casetes

With the side you want to play

facing you

Con la cara que desee reproducir

mirando hacia usted

*

RADIO BAND

AUTO PRESET

TAPE

CD

i

OPERATE

(POWER)

Loading a CD

Carga de un CD

SLEEP

With the labeled side up

Con la cara etiquetada hacia arriba

u*

., >

TUNE –, +

Z PUSH

OPEN/CLOSE

x

MEGA Xpand

MEGA BASS

VOL +*, –

Remote Control

Mando a distancia

SLEEP

FUNCTION

Number buttons

Botones numéricos

MODE

.,>

N

BAND

MEGA Xpand

CFD-S400L

This section is extracted

from instruction manual.

OPERATE

(POWER)

VOL +*, –

x

X

TUNE –, +

SOUND

MEGA BASS

Display/Visor

Total track number

Número total de pistas

OPR/BATT

Display

Visor

Remote sensor

Sensor de control remoto

Number buttons

Botones numéricos

Total playing time

Tiempo total de reproducción

DISPLAY

ENT

MEMORY

MODE

SOUND MODE

Programmed track

Pista programada

*The button has a tactile dot.

*El botón tiene un punto táctil.

Playing order

Orden de reproducción

5

CFD-S400L

SECTION 3

DISASSEMBLY

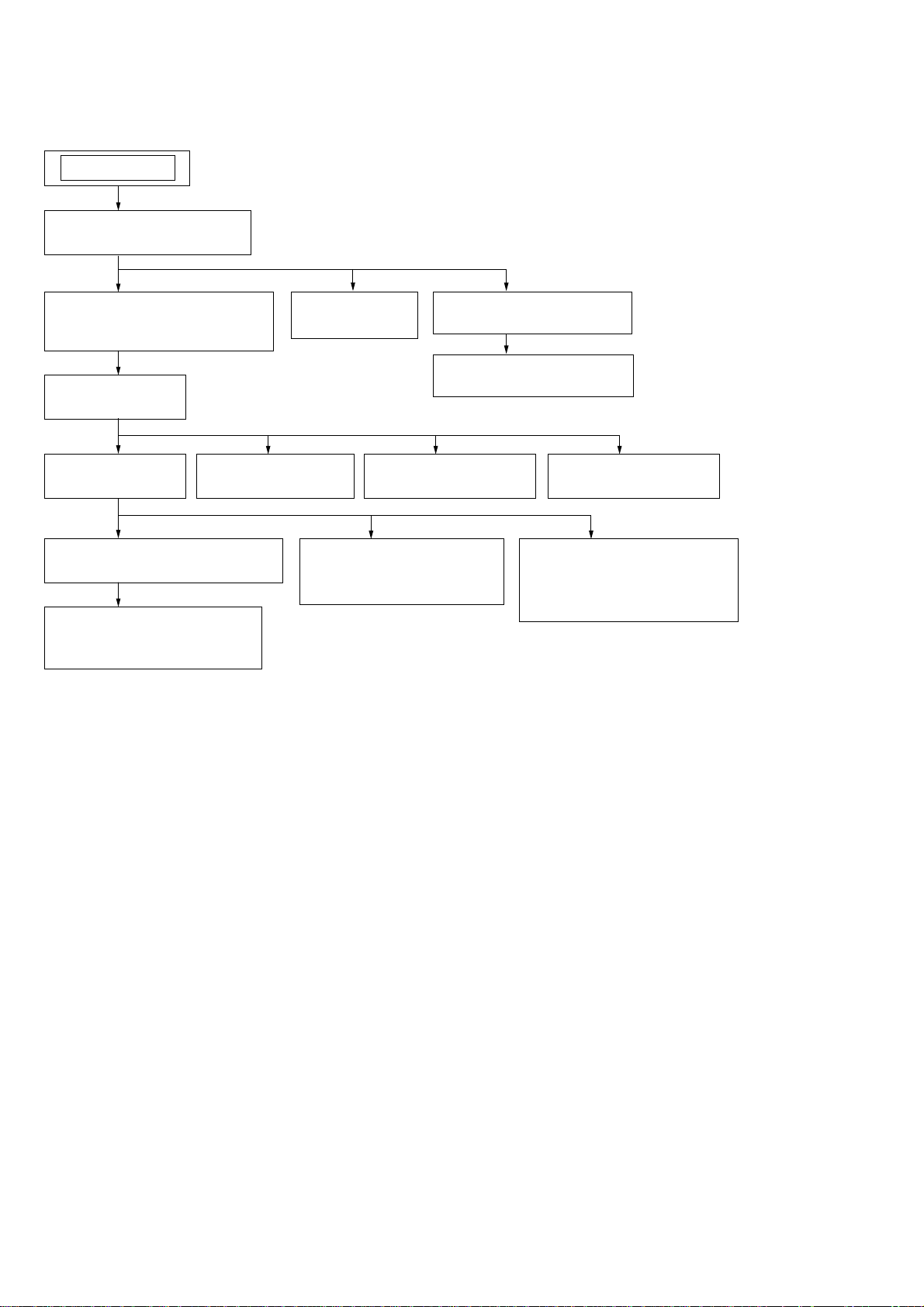

• The equipment can be removed using the following procedure.

SET

3-1. CABINET TOP ASSY

(Page 7)

3-2. CABINET FRONT ASSY,

CABINET REAR ASSY

(Page 7)

3-3. WIRES

(Page 8)

3-4. MD BLOCK

(Page 8)

3-5. CASSETTE DOOR ASSY

(Page 9)

3-6. LCD BOARD,

CONTROL (4) BOARD

(Page 9)

3-7. MAIN BOARD

(Page 10)

3-10. CD LID

(Page 11)

3-8. TUNER BOARD

3-13. R/P HEAD (HRP301),

TC BOARD

(Page 13)

3-11. CD BLOCK ASSY

3-12. OPTICAL PICK-UP

(Page 10)

(Page 12)

(Page 12)

3-9. POWER BOARD

(Page 11)

3-14. MOTOR ASSY (M801),

MAIN BELT (B),

SUB BELT (B)

(Page 13)

6

Note : Follow the disassembly procedure in the numerical order given.

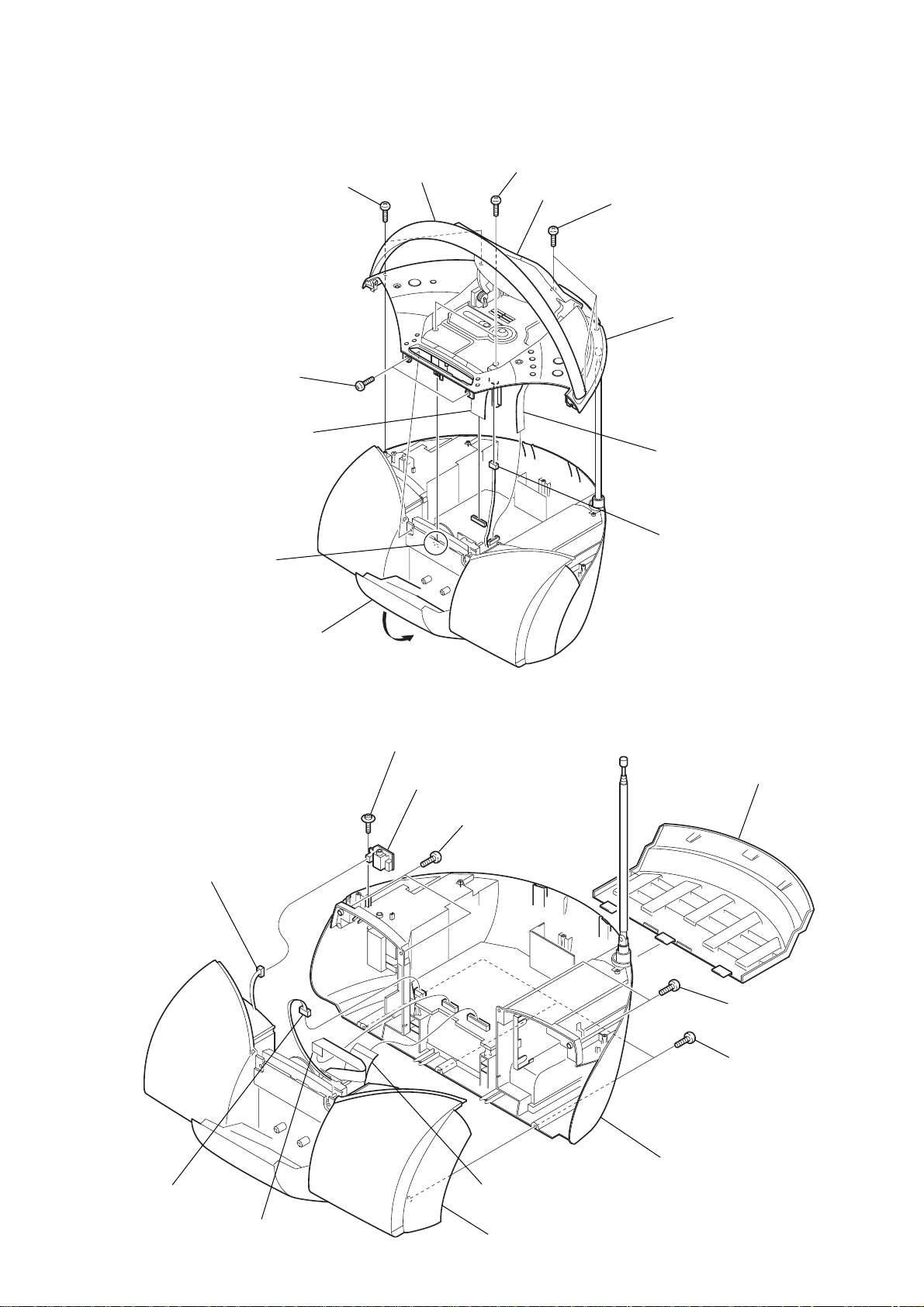

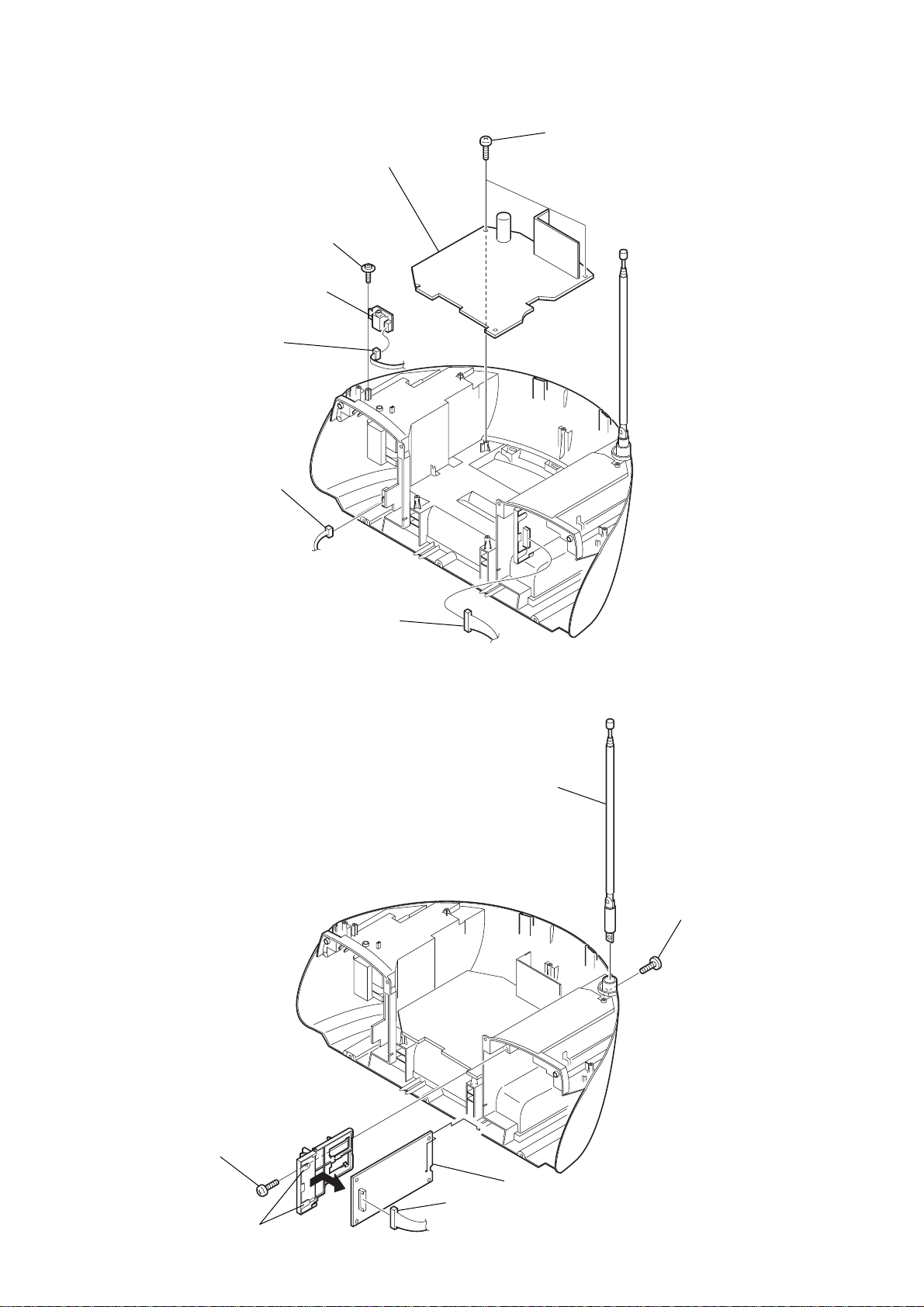

3-1. CABINET TOP ASSY

2

1

BTP 2.6x10

6

3

screw (2.6)

CNP804

handle

screw (2.6)

CD lid

4

screw (2.6)

8

cabinet top assy

5

CNP802

CFD-S400L

claw

cassette door assy

3-2. CABINET FRONT ASSY, CABINET REAR ASSY

1

PWH 2.6x10

2

HEADPHONE board

7

3

CNP323

screw (2.6)

7

connector

(S801)

9

battery lid

4

CNP302

5

CNP806

6

CNP803

qa

cabinet front assy

8

0

qs

cabinet rear assy

screw (2.6)

screw (2.6)

7

CFD-S400L

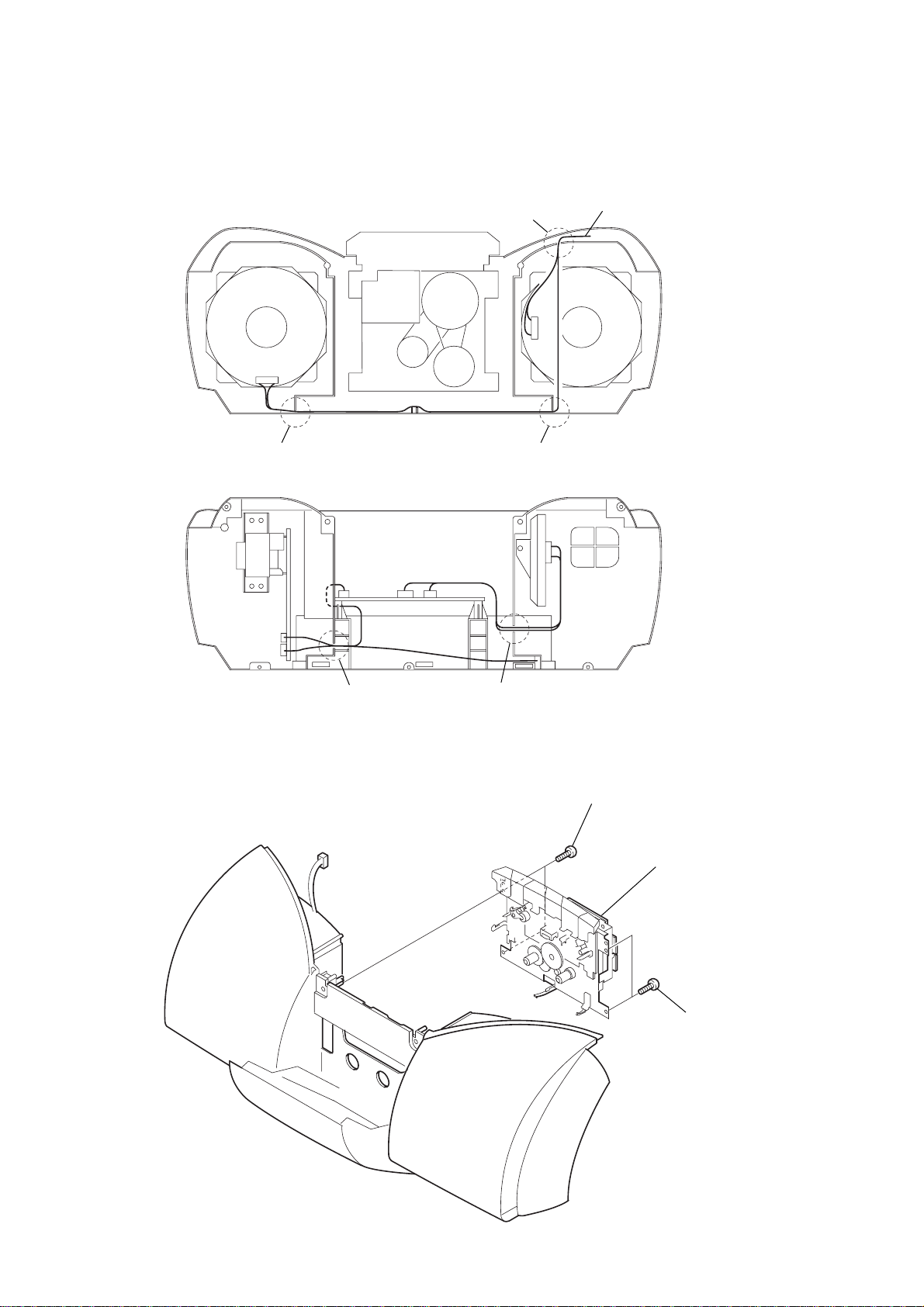

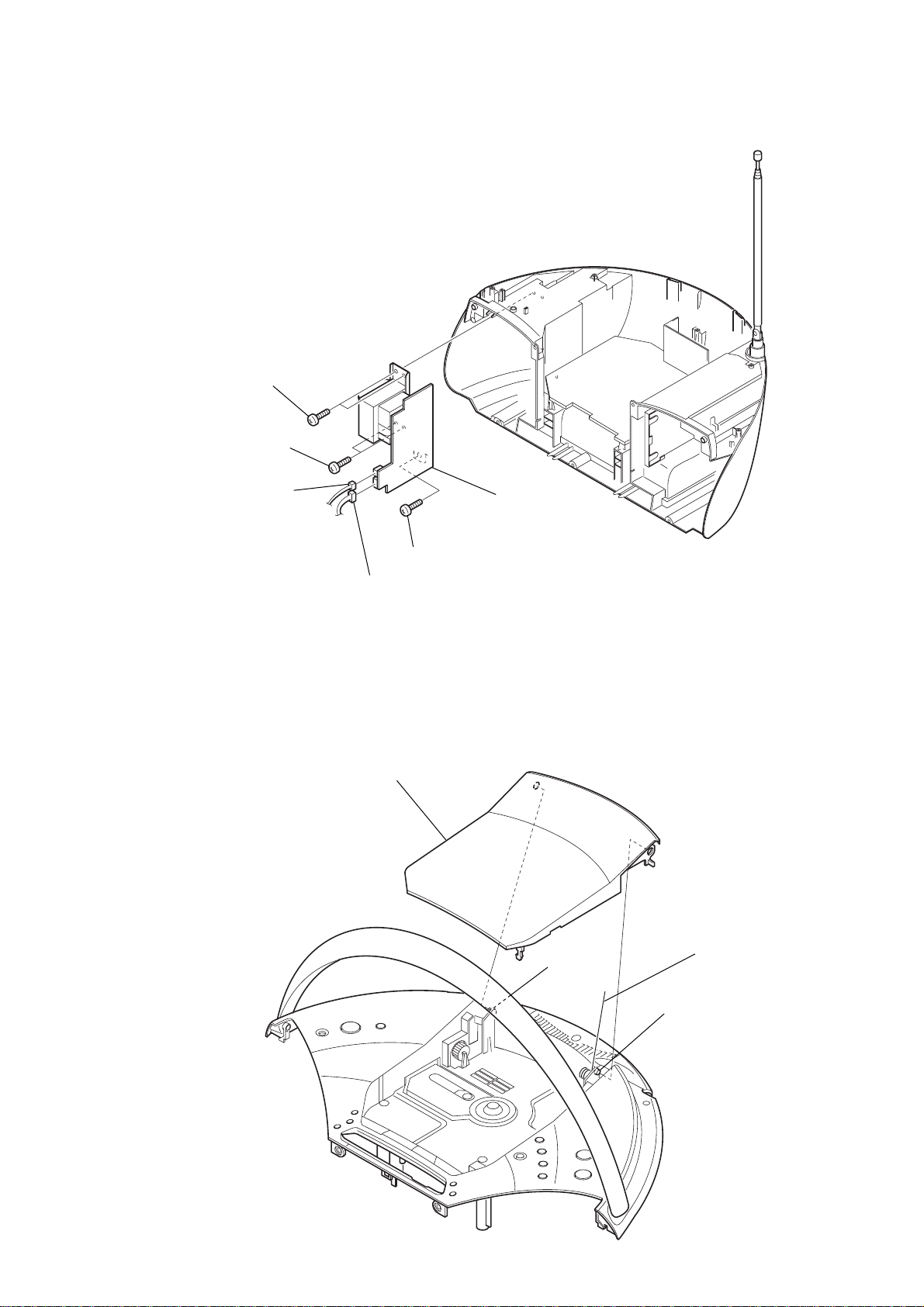

3-3. WIRES

Put flat cable and wires between the cabinets and push them in the

grooves located at A to E in the figure to prevent disconnection

before assembling the set.

C

from HEADPHONE board

cabinet front

3-4. MD BLOCK

A

D

B

cabinet rear

E

1

BVTP 2.6x10

3

MD block

2

BVTP 2.6x10

8

3-5. CASSETTE DOOR ASSY

0

cassette spring

2

damper

1

BVTP 2.6x1

CFD-S400L

3

cassette door assy

3-6. LCD BOARD, CONTROL (4) BOARD

6

LCD board

5

claws

flexible flat cable

4

BVTP 2.6x10

2

1

BVTP (2.6)

claw

CONTROL (4) board

7

claw

cassette door sub assy

3

cassette holder

9

CFD-S400L

8

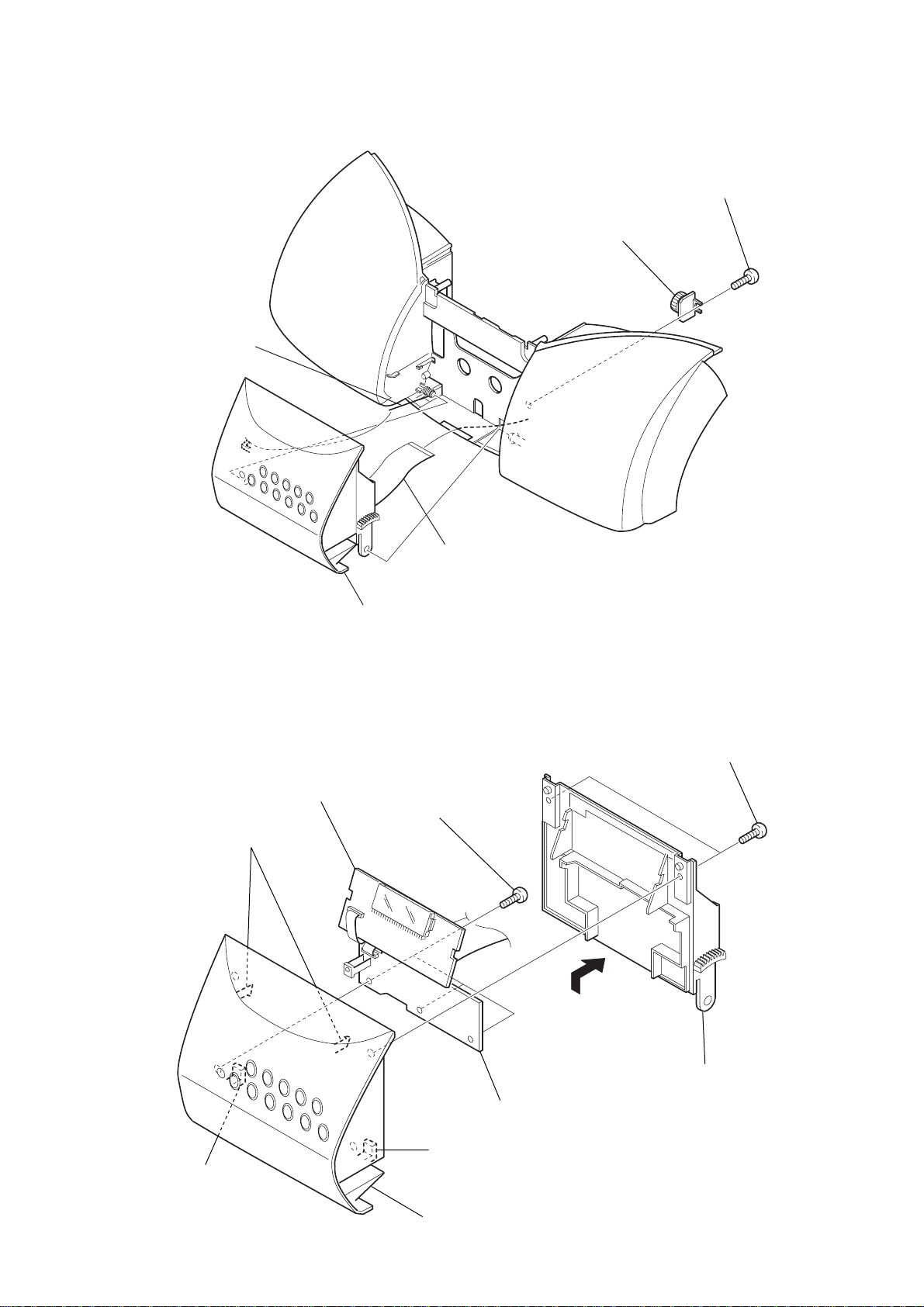

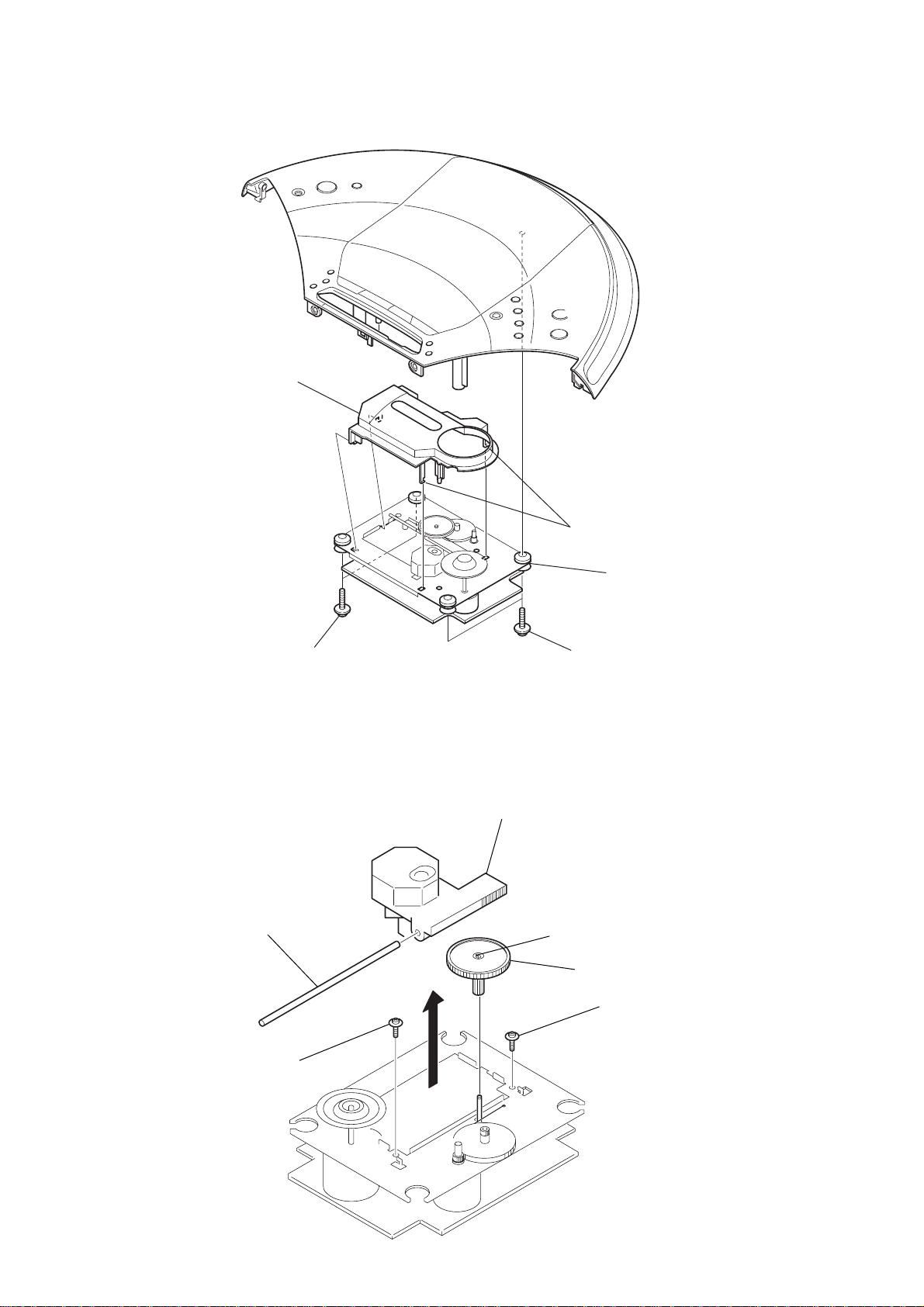

3-7. MAIN BOARD

1

PWH 2.6x10

2

HEADPHONE board

3

CNP322

4

CNP902

7

MAIN board

6

BVTP 2.6x10

3-8. TUNER BOARD

5

CNP1

2

telescopic antenna

1

B 3x

10

4

BVTP 2.6x10

5

claws

6

3

CNP1

7

TUNER board

3-9. POWER BOARD

3

BVTP 2.6x10

4

BVTP 2.6x10

CFD-S400L

3-10. CD LID

2

CNP901

1

CNP902

3

5

BVTP 2.6x10

CD lid

6

POWER board

2

claw

1

CD spring

claw

11

CFD-S400L

y

)

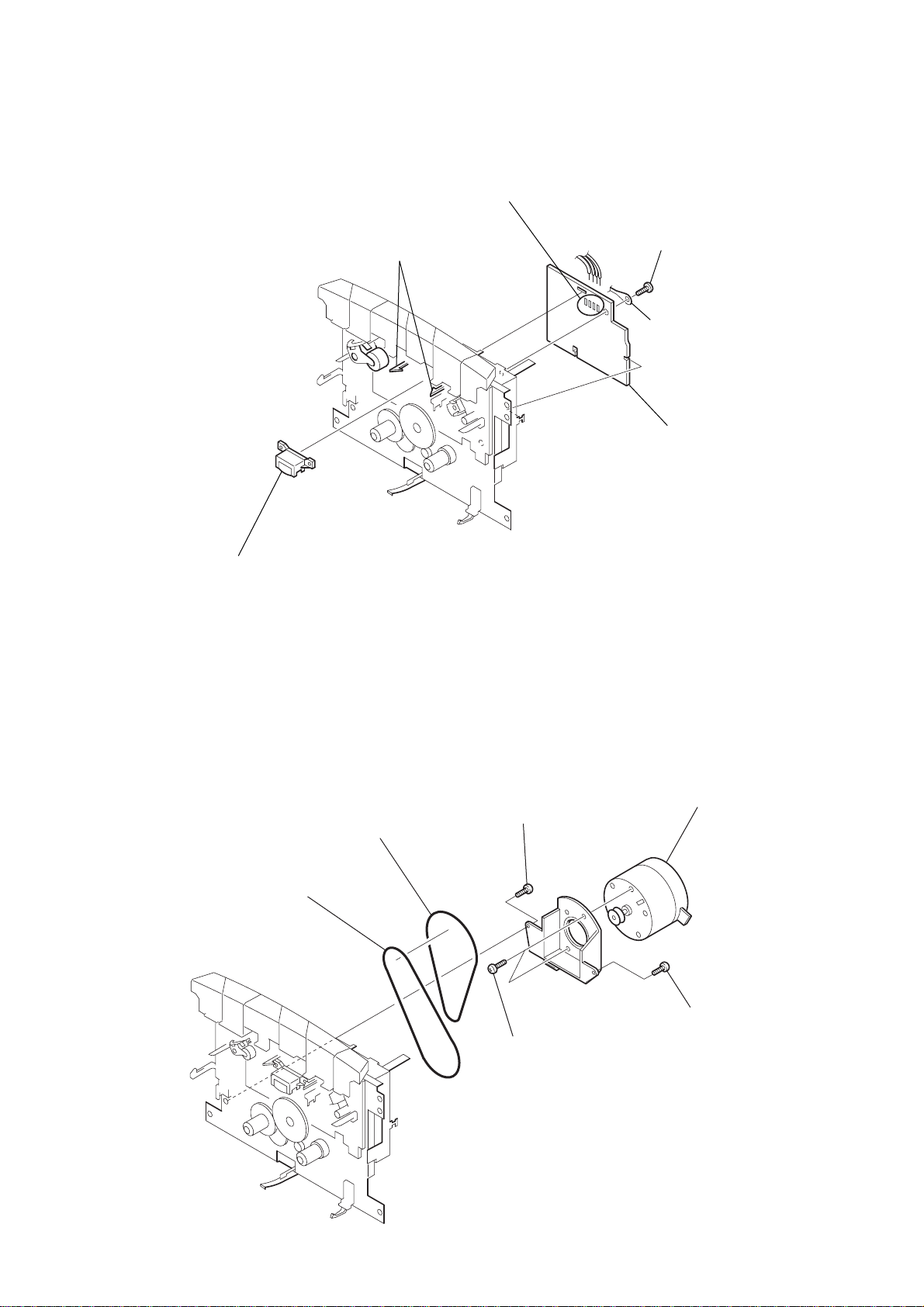

3-11. CD BLOCK ASSY

3

CD cover

3-12. OPTICAL PICK-UP

5

sled shaft

2

PWH 2.6x10

4

6

optical pick-up

claws

1

PWH 2.6x10

claw

1

gear (A)

4

CD block ass

2

PWB tapping (M2

12

3

PWB tapping (M2)

3-13. R/P HEAD (HRP301), TC BOARD

)

claws

4

Removal the solders.

2

BVTP 2x4

lug

3

TC board

CFD-S400L

1

R/P head (HRP301)

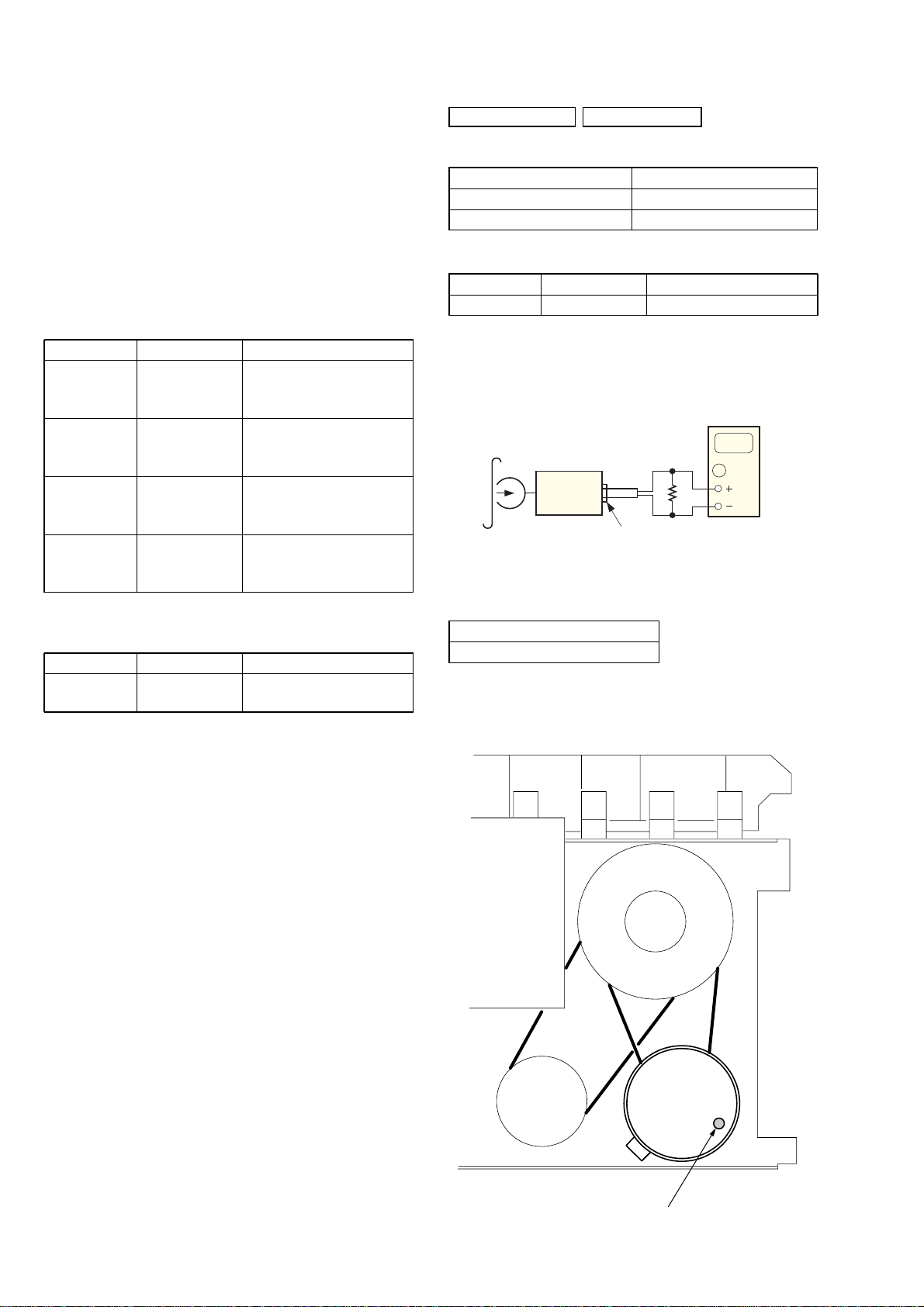

3-14. MOTOR ASSY (M801), MAIN BELT (B), SUB BELT (B)

3

main belt (B)

4

sub belt (B)

2

bind DT M2x6

6

motor assy (M801

5

pan M2.6x4.5

1

bind DT M2x6

13

CFD-S400L

SECTION 4

MECHANICAL ADJUSTMENTS

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer. (Do not bring the head magnetizer close to the erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage (9V) unless otherwise noted.

Torque Measurement

Mode Torque meter Meter reading

2.95 – 6.86 mN • m

FWD CQ-102C (30 – 70 g • cm)

(0.42 – 0.97 oz • inch)

FWD

Back Tension

FF CQ-201B (more than 60 g • cm)

REW CQ-201B (more than 60 g • cm)

CQ-102C (1.5 – 5.5 g • cm)

0.15 – 0.53 mN • m

(0.021 – 0.076 oz • inch)

more than 5.88 mN • m

(more than 0.83 oz • inch)

more than 5.88 mN • m

(more than 0.83 oz • inch)

TAPE SECTION 0 dB = 0.775 V

• Standard Output Level

Output terminal HP OUT

load impedance 32 Ω

output signal level 0.25 V (–10 dB)

• Test T ape

Type Signal Used for

WS-48A 3 kHz, 0 dB tape speed adjustment

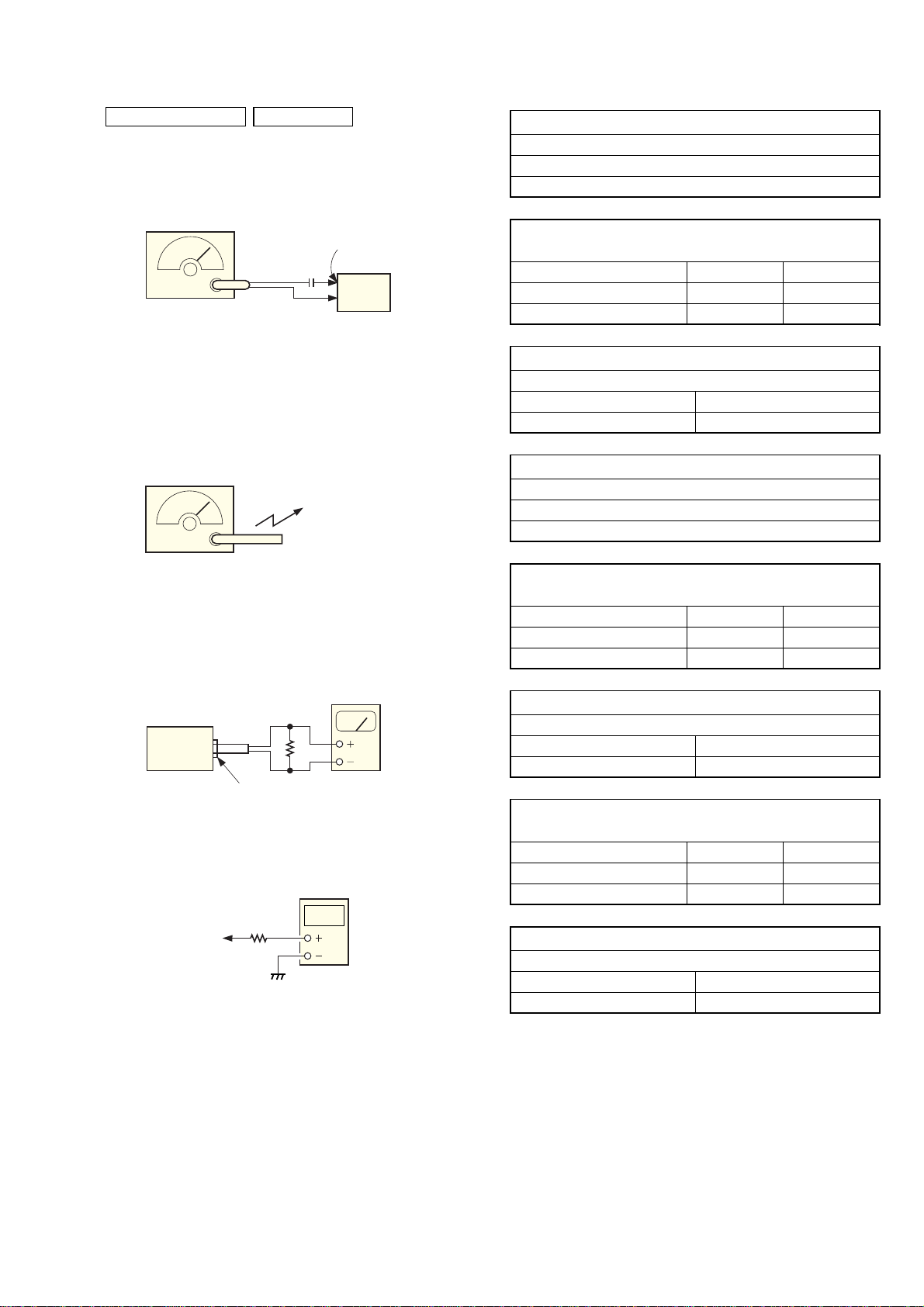

Tape Speed Adjustment

Procedure:

Mode: playback

test tape

WS-48A

(3 kHz, 0 dB)

set

i

jack (J321)

Adjust so that the value on the digital frequency counter is

3,000 Hz.

digital frequency

counter

Ω

32

Tape Tension Measurement

Mode Tension meter Meter Reading

FWD CQ-403A

more than 100 g

(more than 3.53 oz)

Specification Value:

Digital frequency counter

2,940 to 3,060 Hz

Adjust so that the frequency at the beginning and that at the end of

tape winding are between 2,970 to 3,030 Hz.

Adjustment Location:

14

Tape speed adjustment

control inside motor

CFD-S400L

)

TUNER SECTION 0 dB = 1 µV

• FM Section

Setting:

RADIO BAND•AUTO PRESET button: FM

FM RF signal

generator

TP (FM IN)

0.01

µ

F

set

75 kHz frequency

deviation by 1 kHz signal

output level : as low as possible

• AM Section

Setting:

RADIO BAND•AUTO PRESET button: MW or LW

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

• Connecting Level Meter (FM, MW and LW)

set

i jack (J321)

• Connecting Digital Voltmeter (FM, MW and LW)

Put the lead-wire

antenna close to

the set.

level meter

(range: 0.5–5 V ac

32 Ω

digital

voltmeter

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T2

10.7 MHz

FM FREQUENCY COVERAGE

ADJUSTMENT

Frequency Display 87.5 MHz 108 MHz

Reading on Digital voltmeter 1.3 ± 0.3 V 3.0 ± 0.2 V

Adjustment Part <confirmation> L2

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 CT1

87.5 MHz 108 MHz

MW IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1

450 kHz

MW FREQUENCY COVERAGE

CHECK

Frequency Display 531 kHz 1,611 kHz

Reading on Digital voltmeter 1.0 ± 0.5 V 5.2 ± 0.6 V

Adjustment Part <confirmation> <confirmation>

MW TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3-1 CT3

621 kHz 1,404 kHz

LW FREQUENCY COVERAGE

ADJUSTMENT

Frequency Display 153 kHz 279 kHz

Reading on Digital voltmeter 0.6 ± 0.3 V 5.0 ± 0.1 V

Adjustment Part <confirmation> L4

100 kΩ

TP (VT)

•Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

LW TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3-2 CT5

162 kHz 261 kHz

Adjustment Location: See page 16.

15

CFD-S400L

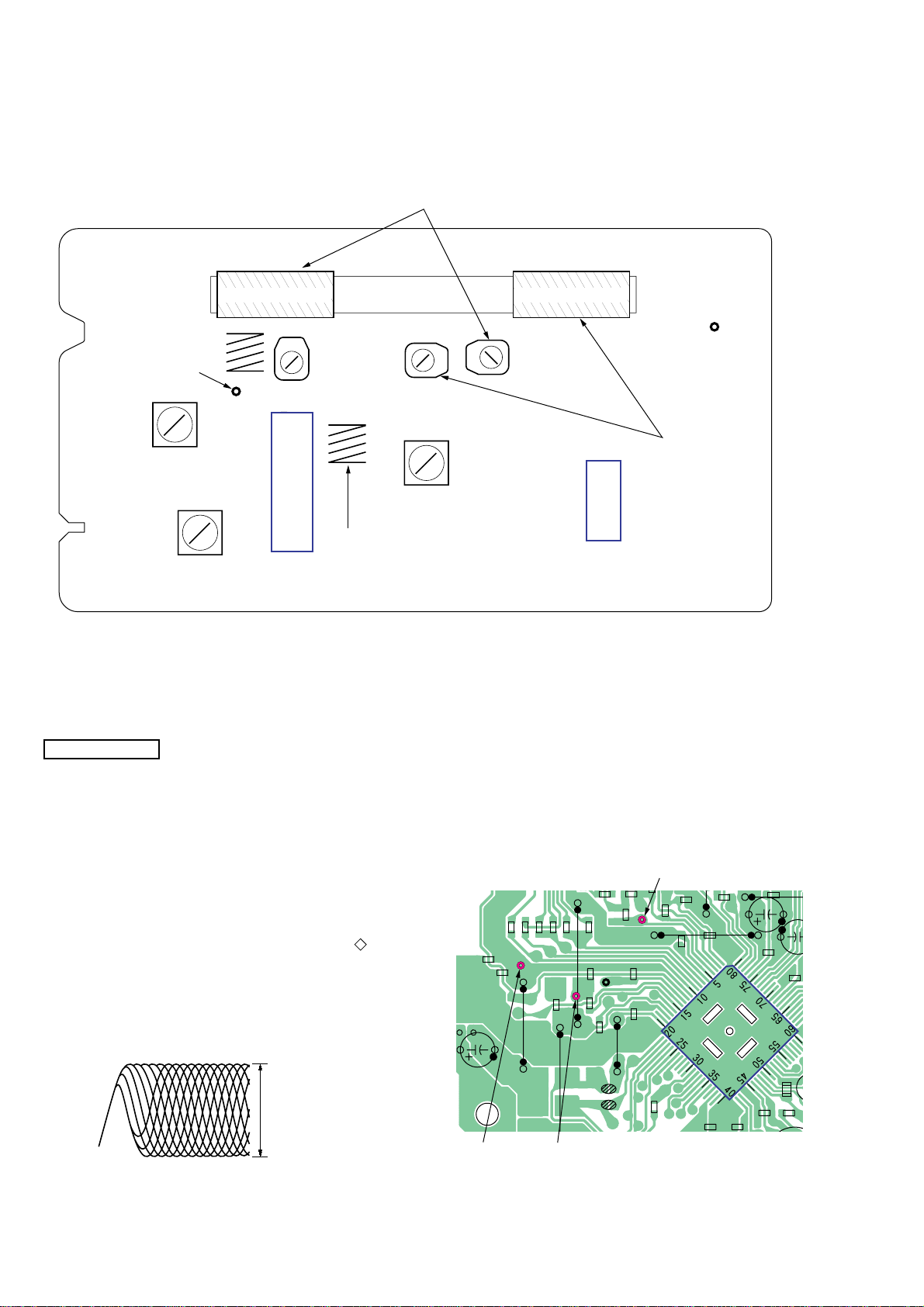

Adjustment Location:

– MAIN board (component side) –

CT5, L3-2

LW

TRACKING

ADJUSTMENT

L3-2 L3-1

CT1, L1

FM

TRACKING

ADJUSTMENT

L2

TP (FM IN)

(CONDUCTOR SIDE)

T1

T1

MW

IF

L1

CT1

ADJUSTMENT

IC1

T2

T2

FM

IF

ADJUSTMENT

L2

FM

FREQUENCY

COVERAGE

ADJUSTMENT

CD SECTION

CD section adjustments are done automatically in this set.

In case of operation check, confirm that focus bias.

CT3

L4

CT5

L4

LW

FREQUENCY

COVERAGE

ADJUSTMENT

TP (VT)

(CONDUCTOR SIDE)

CT3, L3-1

MW

TRACKING

ADJUSTMENT

IC2

FOCUS BIAS CHECK

1. Connect the oscilloscope between IC701 pin 4 and pin qa (or

TP (RF) and TP (VREF)).

2. Insert the disc (YEDS-18). (Part No. : 3-702-101-01)

3. Press the N X (CD) button.

4. Confirm that the oscilloscope waveform is as shown in the

figure below. (eye pattern)

A good eye pattern means that the diamond shape ( ) in the

center of the waveform can be clearly distinguished.

• RF signal reference waveform (eye pattern)

VOLT/DIV : 50 mV (10 : 1 probe in use)

TIME/DIV : 500 nS

RF level :

0.85 ± 0.2 Vp-p

When observing the eye pattern, set the oscilloscope for AC range

and raise vertical sensitivity.

Test Point:

– CD board (conductor side) –

C738

C739

C732

TP

(VREF)

R706

JW709

R701

TP

(VREF)

R709

R705

C707

TP

(TE)

R703

TP

(TE)

JW706

R702

JW708

R710

C736

TX

FX

R704

(FE)

JC703

TP

C708

TY

FY

R711

C705

JW707

TP

(RF)

TP

(RF)

C734

C742

R708

R723

C731

C743

C703

C709

R729

JW726

IC701

C711

C746

C744

C716

C730

JW724

C747

C745

C717

FB701

16

CONTROL (4) board

TUNER board

TC board

BATTERY (1) board

BATTERY (2) board

MAIN board

LCD board

HEADPHONE board

POWER board

CONTROL (1) board

CONTROL (3) board

CONTROL (2) board

CD board

SECTION 6

DIAGRAMS

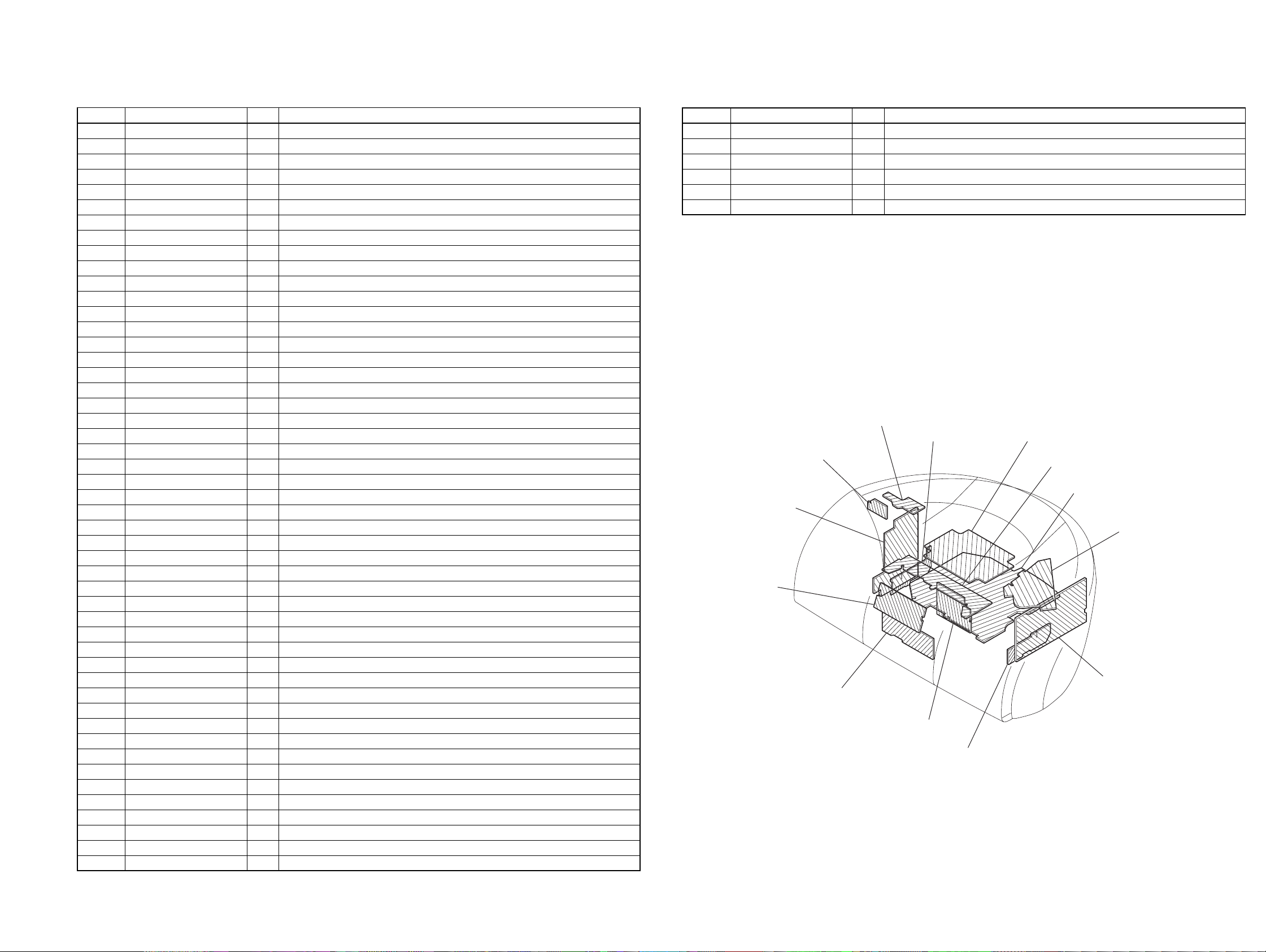

6-1. IC PIN DESCRIPTION

• IC802 µPD789477GC-A14-8BT (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Pin Description

1, 2 NC — Not used. (Open)

3 to 5 VLC2 to 0 I LCD drive bias voltage output

6 to 9 COM0 to 3 O LCD drive common output

10 to 26 S0 to 16 O LCD drive segment output

27 REC I Tape record signal input H: REC

28 AC-CHK I AC power supply detection signal input L: AC in

29 CD-DOOR I CD door open/close switch input L: Close

30 S-ROCK O ROCK LED control signal output

31 S-POP O POP LED control signal output

32 S-JAZZ O JAZZ LED control signal output

33 S-VOCAL O VOCAL LED control signal output

34 S-SUR O SURROUND LED control signal output Not used. (Open)

35 A-MUTE O Audio mute output H: Mute

36 CD O CD function output H: CD

37 TAPE O Tape function output H: Tape

38 AVDD — Analog power supply pin for A/D converter (+3.3 V)

39 BTT-CHK-H I Battery check input for Hi-voltage

40 BTT-CHK-M I Battery check input for Mid-voltage

41 V-CHECK I Voltage transaction check input

42 to 45 KEY4 to 1 I Key input

46 MODE CHK I Destination setting input

47 AGND — Analog ground for A/D converter

48 REMOTE I Sircs receiver data input

49 TC-PLAY I Tape play switch input L: Play

50 WP/INI O Wake-up/Initial setting read signal output

51 MT-CONT O Motor control signal output Not used. (Open)

52 C-WRQ I CD write request data input

53 C-DOUT O CD digital signal processor data output

54 C-DIN I CD digital signal processor data input

55 C-CLK I CD serial data transfer clock signal input

56 R-COUNT I Tuner PLL IF count input

57 R-DATA O Tuner PLL data output

58 R-CLK O Tuner PLL clock output

59 R-LAT O Tuner PLL latch output

60 B-MUTE O Tuner mute signal output H: Mute

61 C-DRF I CD DRF signal input

62 C-CE O CD chip enable output

63 C-FSEQ I CD frame SYNC input

64 C-XRT O CD system reset output

65 P-CON O System power control output H: PCON

66 ISS1 O ISS1 output

67 ISS2 O ISS2 output

68 DBB O MEGA BASS control output H: MEGA BASS off, L: MEGA BASS on

69 IC0 I Connected to VSS.

70 XT1 I Sub system oscillation input (32.768 kHz)

71 XT2 O Sub system oscillation output (32.768 kHz)

72 VDD — Main power supply pin for A/D converter (+3.3 V)

73 VSS — Main ground

74 X1 I Main system oscillation input (4.19 MHz)

CFD-S400L

Pin No. Pin Name I/O Pin Description

75 X2 O Main system oscillation output (4.19 MHz)

76 RST I System reset input

77 V-CLK O Volume clock output

78 V-DATA O Volume data output

79 SCL O EEPROM clock output

80 SDA I/O EEPROM input/output

6-2. CIRCUIT BOARDS LOCATION

17 17

Loading...

Loading...