Sony CFDS-27 Service manual

CFD-S27

SERVICE MANUAL

REVICED

Ver 1.1 1998.08

AEP Model

UK Model

Australian Model

Model Name Using CD Section

Similar Mechanism Tape Section

Optical Pick-up Type KSM-213CDM

Tape Transport Mechanism Type MF-V10-117

CFD-S23

CD player Section

System

Compact disc digital audio system

Laser diode properties

Material: GaAlAs

Wave length: 780 nm

Emission duration : Continuous

Laser output : Less than 44.6 µW

(This output is the value measured at a

distance of about 200 mm from the objective

lens surface on the optical pick-up block

with 7 mm aperture.)

Spindle speed

200 r/min (rpm) to 500 r/min (rpm) (CLV)

Number of channels

2

Frequency response

20 – 20,000 Hz +1 /–2 dB

Wow and flutter

Below measurable limit

Radio section

Frequency range

FM 87.6 – 107 MHz

(EXCEPT Italian Model)

87.5 – 108 MHz (Italian Model)

AM 531 – 1,602 kHz

IF

FM : 10.7 MHz

AM : 450 kHz

Aerials

FM: Telescopic aerial

AM : Built-in ferrite bar aerial

SPECIFICATIONS

Cassette-corder section

Recording system

4-track 2 channel stereo

Fast winding time

Approx. 120 s (sec.) with Sony cassette C-60

Frequency response

TYPE I (normal): 70 – l0,000 Hz

General

Speaker

Full range: 10 cm (4 in.) dia.,

2.8 ohms, cone type (2)

Outputs

Headphones jack (stereo minijack)

For 16 – 68 ohms impedance headphones

Maximum power output

2.5 W + 2.5 W

Power requirements

For CD radio cassette-corder

230V AC, 50Hz

9V DC, 6 R20 (size D) batteries

Power consumption

AC 20 W

CD RADIO CASSETTE -CORDER

Battery life

For CD radio cassette-corder

FM recording

Sony R20P : approx. 13.5 h

Sony alkaline LR20 : approx. 20 h

Tape playback

Sony R20P : approx. 7.5 h

Sony alkaline LR20 : approx. 15 h

CD playback

Sony R20P : approx. 2.5 h

Sony alkaline LR20 : approx. 7 h

Dimensions

Approx. 425 x 160 x 245 mm (w/h/d)

(16 3/4 x 6 3/16 x 9 3/4 inches) (incl.

projecting parts)

Mass

Approx. 4.0 kg (8 lb. 13 oz) (incl. batteries)

Supplied accessories

AC power cord (1 )

Design and specifications are subject to change

without notice.

MICROFILM

CAUTION

Use of controls or adjustments or performance

of procedures other than those specified herein

may result in hazardous radiation exposure.

Laser component in this product is capable of emitting

radiation exceeding the limit for Class 1.

TABLE OF CONTENTS

Specifications ........................................................................... 1

1. SERVICING NOTES.................................................... 2

2. GENERAL

Location of Controls .......................................................... 4

This Compact Disc player is

classified as a CLASS 1

LASER product.

The CLASS 1 LASER

PRODUCT label is located

on the bottom exterior.

Notice for customers in the United Kingdom

A moulded plug complying with BS 1363 is fitted to this

equipment for your safety and convenience.

Should the fuse in the plug supplied need to be replaced, same

rating fuse approved by ASTA or BS1 to BS 1362, (i.e. marked

with 2 or a @ mark) must be used.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK !ON THE SCHEMATIC DIAGRAMS AND IN THE

PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

3. DISASSEMBLY

3-1. Cabinet (Front), Cabinet (Rear), SW Board ............... 5

3-2. BATT Board, Tuner Board, AC Inlet Board,

Power Board .............................................................. 5

3-3. Cabinet (Upper) .......................................................... 6

3-4. Optical pick-up Section, Mechanism deck,

Main Board, REC SW Board, CD Motor Board ....... 6

4. ADJUSTMENTS

4-1. Mechanical Adjustments ............................................ 7

4-2. Electrical Adjustments................................................ 7

5. DIAGRAMS

5-1. Explanation of IC Terminals..................................... 13

5-2. Block Diagram.......................................................... 15

5-3. Printed Wiring Boards (Former Type) ...................... 19

5-4. Schematic Diagram – Main Section (1/2) –

(Former Type) .......................................................... 23

5-5. Schematic Diagram – Main Section (2/2) –

(Former Type) .......................................................... 28

5-6. Printed Wiring Boards (New Type) .......................... 35

5-7. Schematic Diagram – Main Section (1/2) –

(New Type)............................................................... 39

5-8. Schematic Diagram – Main Section (2/2) –

(New Type)............................................................... 44

6. EXPLODED VIEWS

6-1. Front Cabinet Section ............................................... 47

6-2. Upper Cabinet Section.............................................. 48

6-3. Rear Cabinet Section ................................................ 49

6-4. Mechanism Deck Section (1) (MF-V10-117) .......... 50

6-5. Mechanism Deck Section (2) (MF-V10-117) .......... 51

6-6. Optical Pick-up Section (KSM-213CDM) ............... 52

SECTION 1

SERVICING NOTES

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled

with care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

7. ELECTRICAL PARTS LIST.................................... 53

pick-up block. Therefore, when checking the laser diode

emission, observe more than 30 cm away from the objective

lens.

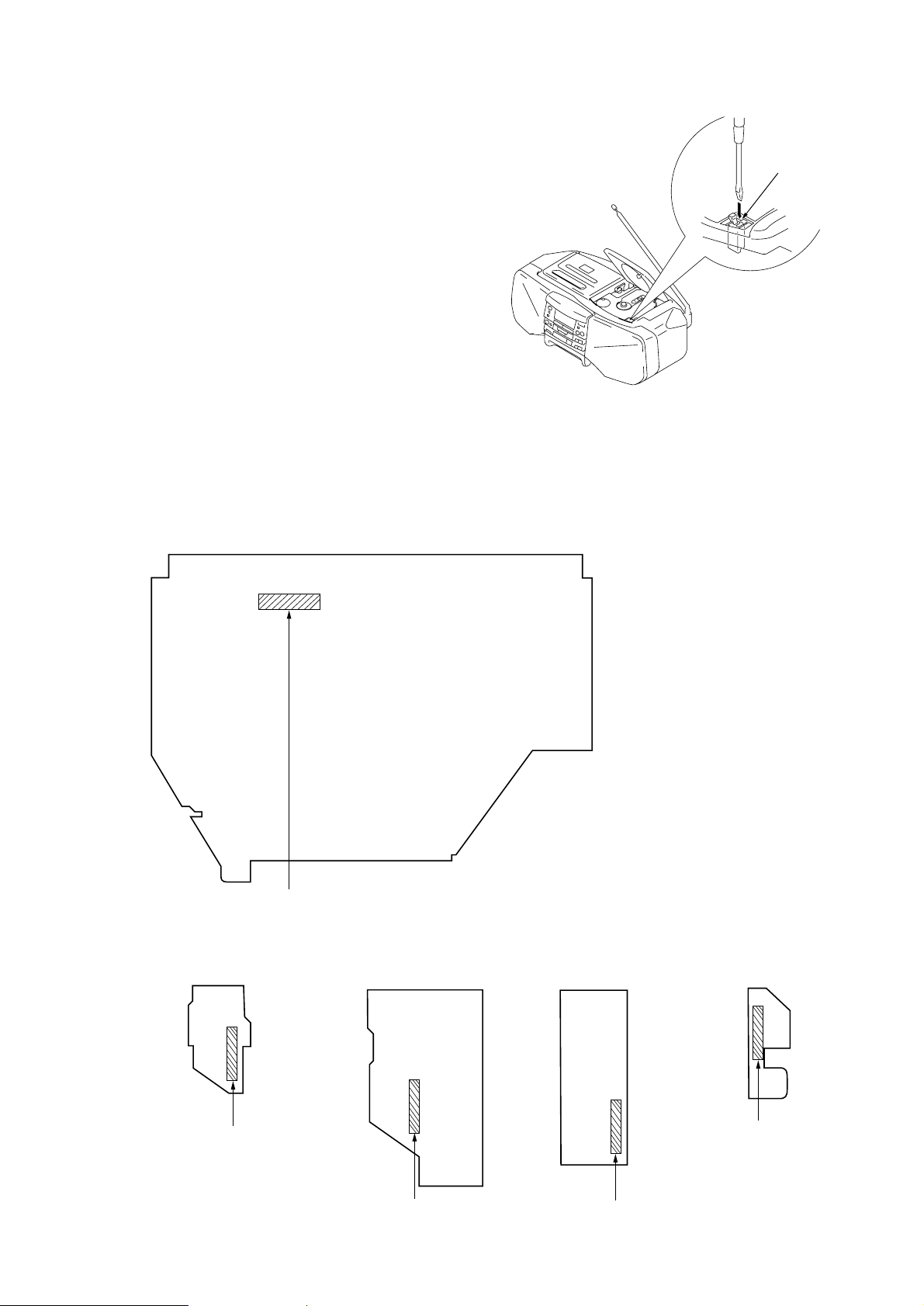

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the CD lid, use

Chuck Plate Jig.

r

Code number of Chuck Plate Jig : X-4918-255-1

– 2 –

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Press CD open knob.

2. Open the lid for CD.

3. Push on SWITCH (S871) as following figure.

4. Confirm the laser diode emission while observing the

objecting lens. When there is no emission, Auto Power

Control circuit or Optical Pick-up is broken.

Objective lens moves up and down once for the focus

search.

NEW TYPE INDENTIFICA TION

Printed wiring boards and schematic diagram of former type and new type are described in this Service manual.

[MAIN BOARD] (Component side)

Insert a precision

screw driver and push

SWITCH (S871)

Former Type : 1-666-263

New Type : 1-666-263

[BATT BOARD]

(Component side)

Former Type : 1-666-266

New Type : 1-666-266

-11

-12

[AC INLET BOARD]

(Component side)

-11

-12

Former Type : 1-666-267

New Type : 1-666-267

-11

-12

– 3 –

[POWER BOARD]

(Component side)

Former Type : 1-666-265

New Type : 1-666-265

Former Type : 1-666-264

New Type : 1-666-264

[REC SW BOARD]

(Component side)

-11

-12

-11

-12

LOCATION OF CONTROLS

SECTION 2

GENERAL

This section is extracted from

instruction manual.

1

246578 9!º

3

@¡

1 OPR/BATT indicator

2 POWER (or OPERATE) button

3 Tape operating buttons

4 Information display

5 SLEEP button

6 SOUND button

7 MEGA BASS button

8 VOL +/– buttons

9 OPEN/CLOSE button

!º DISPLAY/ENT/MEN button

!¡ PLAY MODE/MONO/ST/ISS button

!¡

!™!¢ !£!§!•@º !¶ !∞!ª

!™ ± button

!£ ≠ button

!¢ π button

!∞ BAND PRESET +/– buttons

!§ fl button

!¶ WAKE UP button

!• FUNCTION button

!ª HEADPHONE jack

@º STANDBY button

@¡ CLOCK button

– 4 –

SECTION 3

)

DISASSEMBLY

r

The equipment can be removed using the following procedure.

Cabinet (Front)

Set

Cabinet (Rear)

Note : Follow the disassembly procedure in the numerical order given.

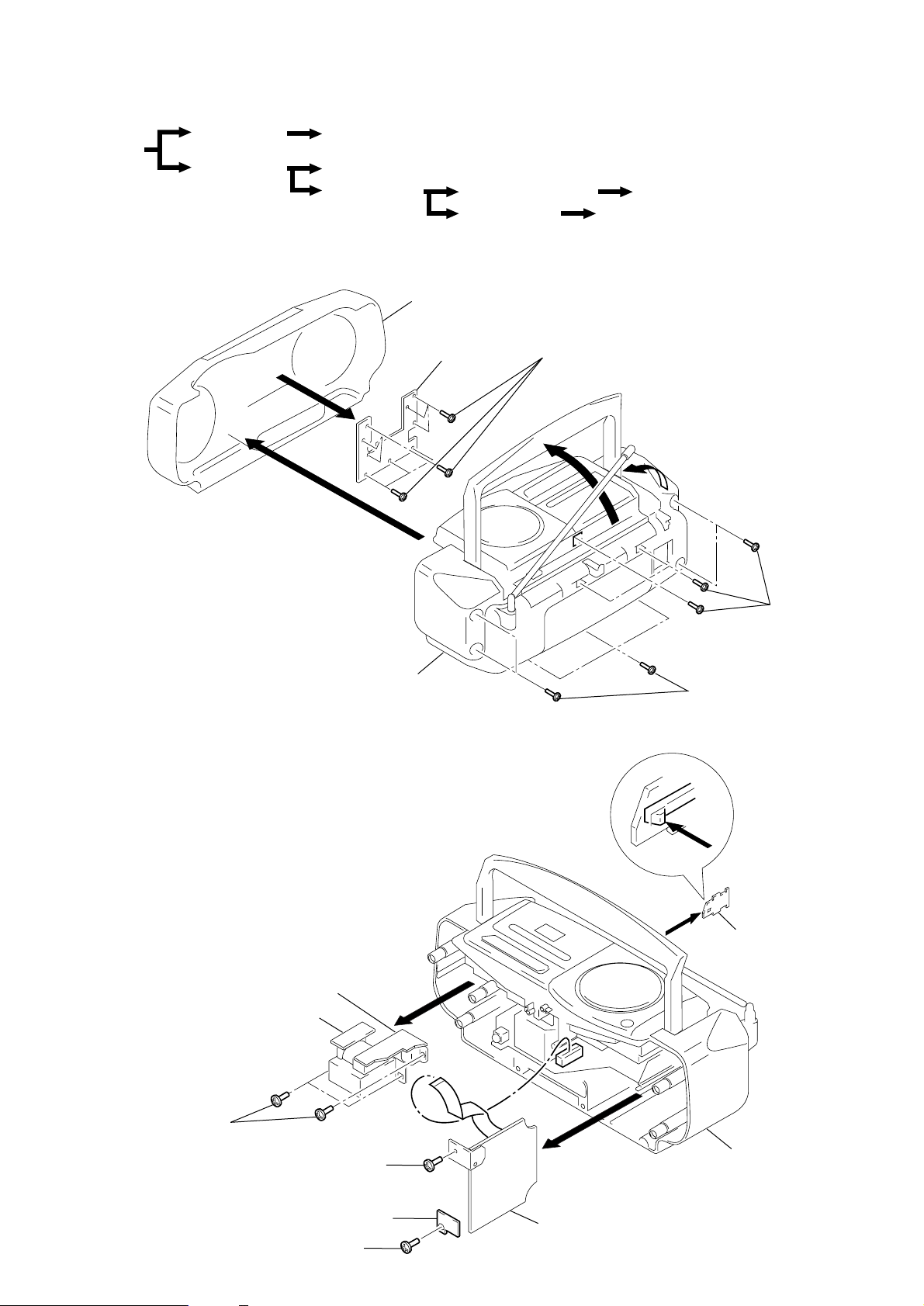

3-1. CABINET (FRONT), CABINET (REAR), SW BOARD

4

SW board

BATT board, Tuner board, AC inlet board, Power board

Cabinet (Upper)

Optical pick-up section

Mechanism deck

Cabinet (Front)

SW board

6

Main board, CD motor board

REC SW board

5

Screws +BVTP (2.6X8)

1

2

Cabinet (Rear)

3-2. BATT BOARD, TUNER BOARD, AC INLET BOARD, POWER BOARD

AC inlet board

Power board

8

3

Screws +BVTP (3X14)

1

2

BATT board

3

Screws

+BVTP (3X14

7

Screws

+BVTP (3X10)

5

Screw +BVTP (3X10)

4

Screw

+BVTP (3X10)

Tuner retainer board

3

– 5 –

6

Tuner board

Cabinet (Rear)

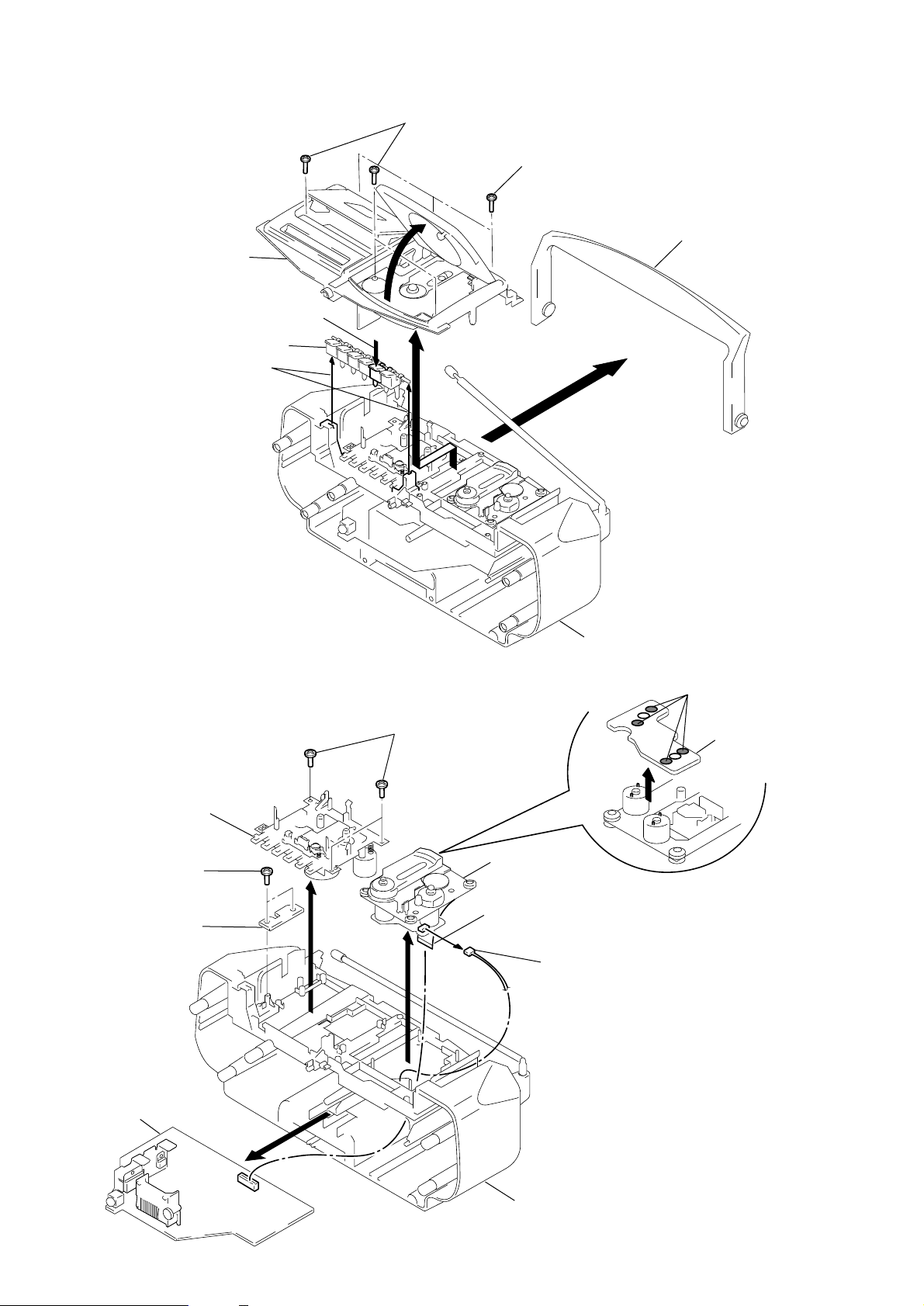

3-3. CABINET (UPPER)

4

Screws

+BVTP (3X10)

1

Screws

+BVTP (3X10)

3

Cabinet (Upper)

STOP/EJECT

2

Tape operation buttons

7

5

3-4. OPTICAL PICK-UP SECTION, MECHANISM DECK, MAIN BOARD,

REC SW BOARD, CD MOTOR BOARD

6

Cabinet (Rear)

Handle

8

Remove solder

Mechanism deck

7

Screws +BVTP (3X10)

REC SW board

Main board

4

6

5

Screws +BVTP (3X10)

1

9

Optical pick-up

section

3

Wire (Flat type) (16 core)

to MAIN board (CN701)

2

CNP707 (6pin)

CD motor board

– 6 –

Cabinet (Rear)

SECTION 4

y

ADJUSTMENTS

4-1. MECHANICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan

2. Demagnetize the record/playback head with a head demagne-

tizer. (Do not bring the head demagnetizer close to the erase

head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. After the adjustments, apply suitable locking compound to the

parts adjusted.

5. The adjustments should be performed with the rated power sup-

ply voltage unless otherwise noted.

Torque Measurement

Torque Torque Meter Meter Reading

Forward CQ-102C

Forward

Back Tension (0.020 – 0.076 oz•inch)

Fast Forward CQ-201B

Rewind CQ-201B

T ape Tension Measurement

Torque Meter Meter Reading

CQ-403A

CQ-102C

(more than 3.53 oz)

30 – 70 g•cm

(0.42 – 0.97 oz•inch)

1.5 – 5.5 g•cm

more than 60 g•cm

(more than 0.84 oz•inch)

more than 60 g•cm

(more than 0.84 oz•inch)

more than 100g

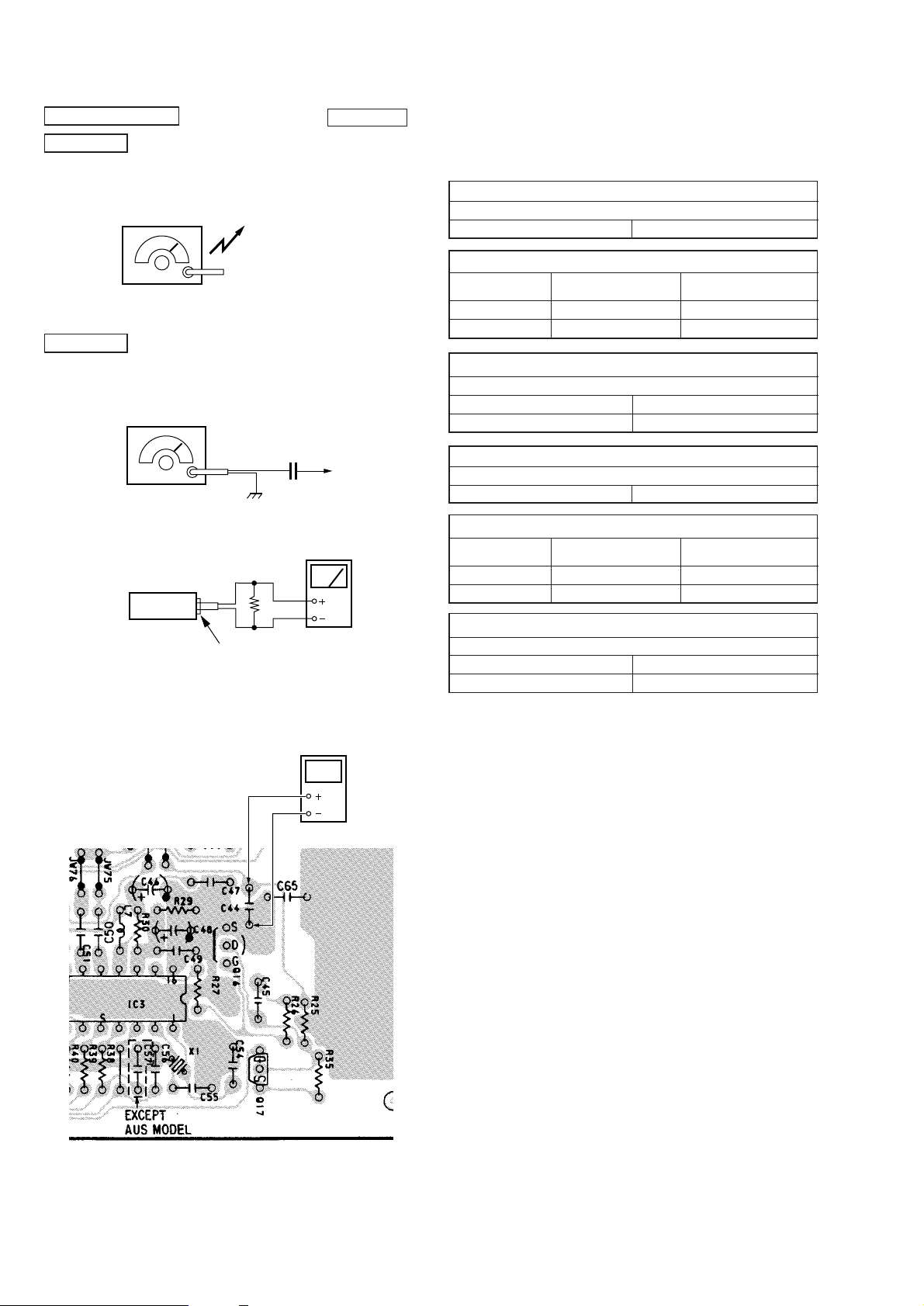

4-2. ELECTRICAL ADJUSTMENTS

TAPE RECORDER SECTION

Standard Output Level

Output terminal HP OUT

load impedance 32Ω

output signal level 0.25V (–10dB)

Test T ape

Type Signal Used for

WS-48A 3kHz, 0dB T ape Speed Adjustment

0dB = 0.775V

Tape Speed Adjustment

Procedure :

Mode : Playback

test tape

WS-48A

(3kHz, 0dB)

set

1. Adjust the screw (T ape Speed Adjustment control inside motor)

for 2,970 – 3,030 Hz reading on the digital frequency counter.

2. Frequency difference between the beginning and the end of the

tape should be within 1.5% (45Hz).

Adjustment Location :

digital frequenc

counter

32

Ω

J301 (phones)

Tape speed adjustment

control inside motor

– 7 –

TUNER SECTION

c

r

AM Section

Function switch : AM

Volume : MIN

AM RF signal

generator

30% amplitude modulation by 400Hz

signal.

Output level : as low as possible

FM Section

Function switch : FM

Volume : MIN

FM RF signal

generator

22.5kHz frequency deviation by 400Hz signal.

Output level : as low as possible

set

Put the lead-wire

antenna close to

the set.

0.01

Ω

32

J301 (phones)

0dB = 1 µV

µ

F

telescopi

antenna

terminal

level mete

• Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

CFT1 450kHz

AM FREQUENCY COVERAGE ADJUSTMENT

Adjust part Frequency display

Confirmation 531kHz 0.8 – 1.2 V

L4 1,611kHz 4.9 – 5.3 V

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L3 621kHz

CT2 1,404kHz

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1 10.7MHz

FM FREQUENCY COVERAGE ADJUSTMENT

Adjust part Frequency display

Confirmation 87.5MHz 1.1 – 1.5 V

L2 108MHz 3.3 – 3.7 V

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 87.5MHz

CT1 108MHz

reading on digital

voltmeter

reading on digital

voltmeter

Frequency Coverage Adjustment

Setting :

[TUNER BOARD]

Adjustment Location : Tuner board (See page 12)

Digital voltmeter

Adjustment Location : Tuner board (See page 12)

– 8 –

CD SECTION

TP (TO)

oscilloscope

(DC range)

TP (VC)

Note on Adjustment

1. Perform adjustment in test mode.

After adjustment, be sure to release test mode.

2. Perform adjustments in the order given.

3. Use the disc (YEDS-18. Part No. 3-702-101-01) only when so

indicated.

Before adjustment

Put the set into test mode and perform the following checks.

Repair if there are any problems.

• Sled Motor Check

1. Press fl button, then press OFF button.

2. Press ±, ≠buttons and confirm that the Optical pick-up

moves smoothly from the innermost to outermost circumference

and back smoothly and with no catching or abnormal noises.

(Cancellation of BTL mute)

± : Optical pick-up moves to the outer circumference

≠ : Optical pick-up moves to the inner circumference

• Focus Search Check

1. Press fl button. (Focus search operation is performed continu-

ously.)

2. Look at the Optical pick-up objective lens and confirm that it

moves up and down smoothly, with no catching or abnormal

noises.

3. Press π button.

Confirm that focus search operation stops. If it does not , press

π button again longer.

Note : When the malfunction is occurred by mis-passing

other buttons, turn off the power and check again

from making the test mode.

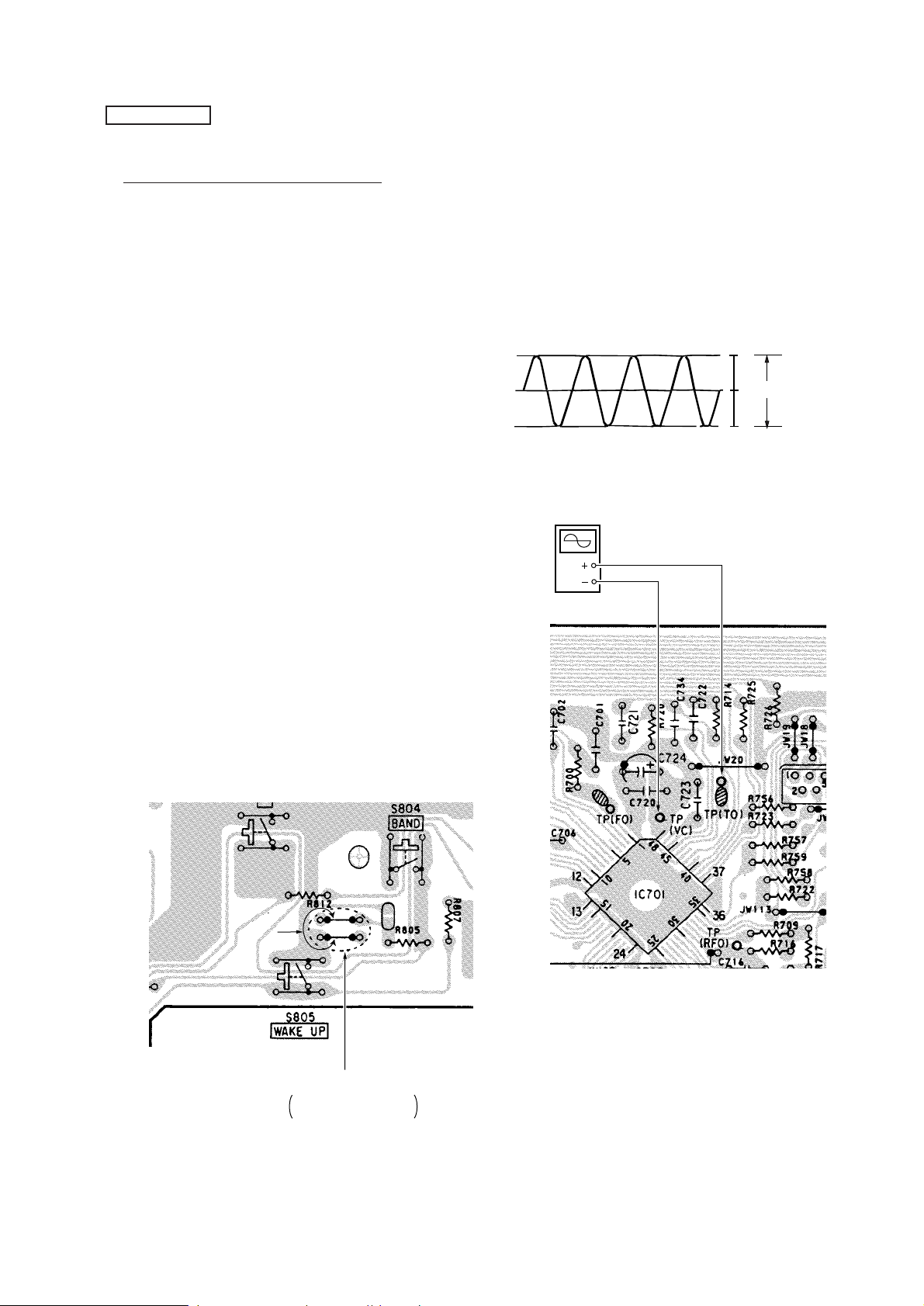

E-F Balance Adjustment

This adjustment is to be done when the optical pick-up block is

replaced.

Adjustment Procedure :

1. Connect the oscilloscope to test point TP (VC) and TP (TO) on

MAIN board.

2. Put the set into test mode.

3. optical pick-up setting to the center by ± or ≠ button

pushing.

4. Insert disc (YEDS-18) and press fl button.

5. Adjust R V703 so that the oscilloscope traveres wa veform is symmetrical, as shown in the figure below.

6. Release test mode after adjustment is completed.

VOLT / DIV : 1V

A

TIME / DIV :1ms

C

0V

B

A = B

C = 180 – 420mV

[MAIN BOARD]

How to put the Set into Test Mode

1. Make sure the POWER switch (S801) is of f and then turn on the

power. (The LCD801 all light up.)

2. Set Test Mode by momentarily shorting both of the test mode

terminals with a jumper. (Shorting the terminals momentarily is

sufficient).

[SW BOARD]

Jamper wire

TEST mode

Open : Normal mode

Short : Test mode

Adjustment Location : Main board (See page 12)

How to Release Test Mode

1. Press the FUNCTION switch (S809).

2. Turn the POWER OFF.

– 9 –

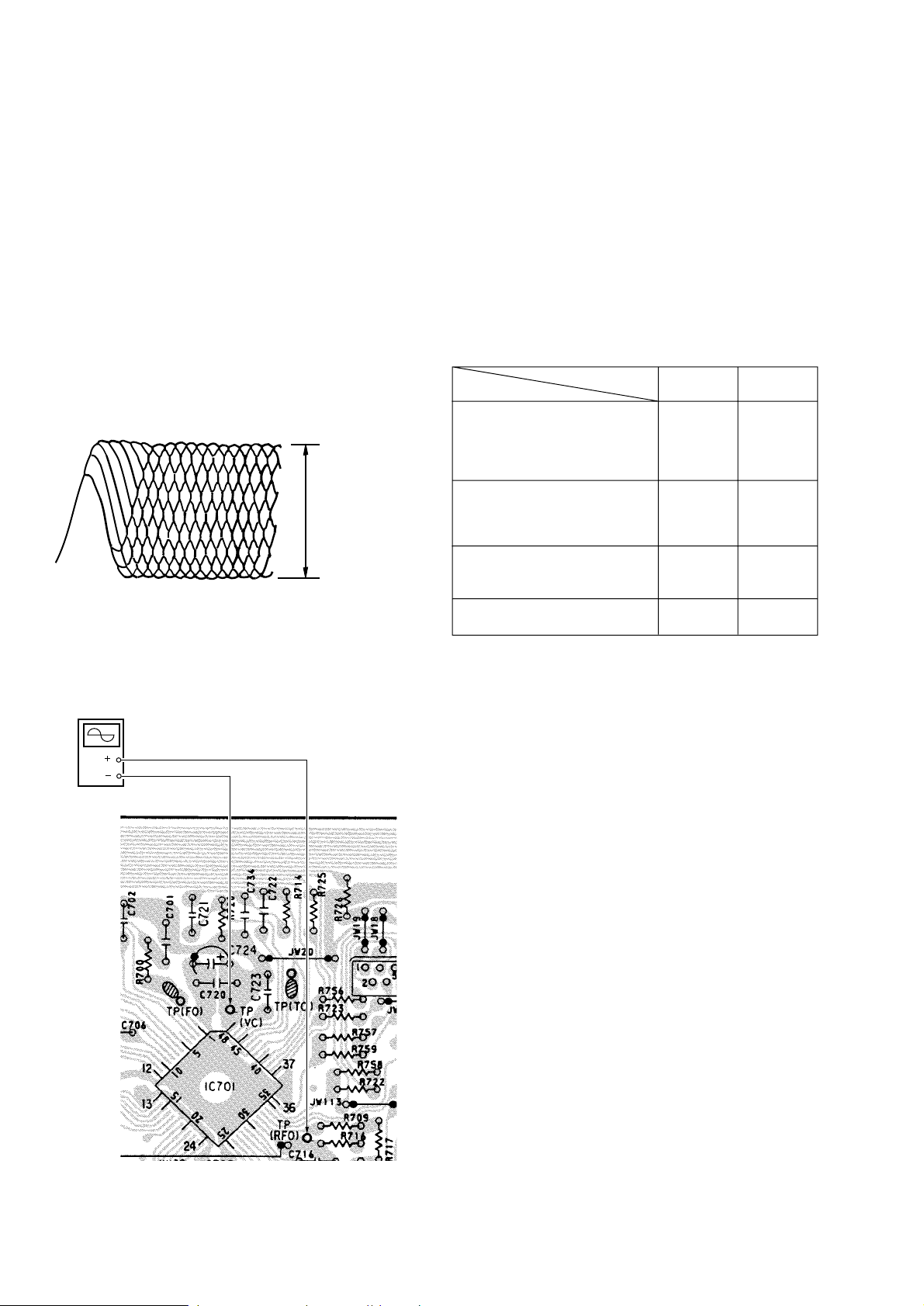

Focus Bias Adjustment

This adjustment is to be done when the optical pick-up block is

replaced.

Adjustment procedure :

1. Connect the oscilloscope to test point TP (VC) and TP (RFO) on

MAIN board.

2. Put the set into test mode.

3. Optical pick-up setting to the center by ± or ≠ button

pushing.

4. Insert disc (YEDS-18) and press fl button.

5. Press the fl button. (Tracking servo ON)

6. Adjust RV701 so that the oscilloscope waveform is as sho wn in

the figure below (eye pattern).

A good eye pattern means that the diamond shape (◊) in the center of the waveform can be clearly distinguished.

7. Release test mode after adjustment is completed.

• RF signal reference waveform (eye pattern)

VOLT/DIV : 0.2 V

TIME/DIV: 500 ns

1.0 – 1.4 V

When observing the eye pattern, set the oscilloscope for A C range

and raise vertical sensitivity.

[MAIN BOARD]

oscilloscope

(DC range)

TP (RFO)

TP (VC)

Focus/Tracking Gain Adjustment

A frequency responce analyzer is necessary in order to perform this

adjustment exactly.

Howev er, this gain has a mar gin, so e ven if it is slightly of f, there is

no problem. Therefore, do not perform this adjustment.

Focus/tracking gain determines the pick-up follow-up (vertical and

horizontal) relative to mechanical noise and mechanical shock when

the 2-axis device operate.

Howev er, as these reciprocate, the adjustment is at the point where

both are satisfied.

• When gain is raised, the noise when the 2-axis device operates

increases.

• When gain is lowered, mechanical shock and skipping occurs

more easily.

• When gain adjustment is off, the symptoms below appear.

Symptoms

r The time until music starts becomes

longer for STOP → fl button or

automatic selection.

( ≠, ± buttons pressed.)

(Normally takes about 2 seconds.)

r Music does not start and disc

continues to rotate for STOP →fl

button or automatic selection.

( ≠, ± buttons pressed.)

r Sound is interrupted during PLAY.

Or time counter display stops

progressing.

r More noise during 2-axis device

operation.

Gain

Focus Tracking

low low or high

– low

– low

high high

The following is a simple adjustment method.

– Primary Adjustment –

Note : Since exact adjustment cannot be performed, remember

the positions of the controls before performing the

adjustment.If the positions after the primary adjustment

are only a little different, return the controls to the original position.

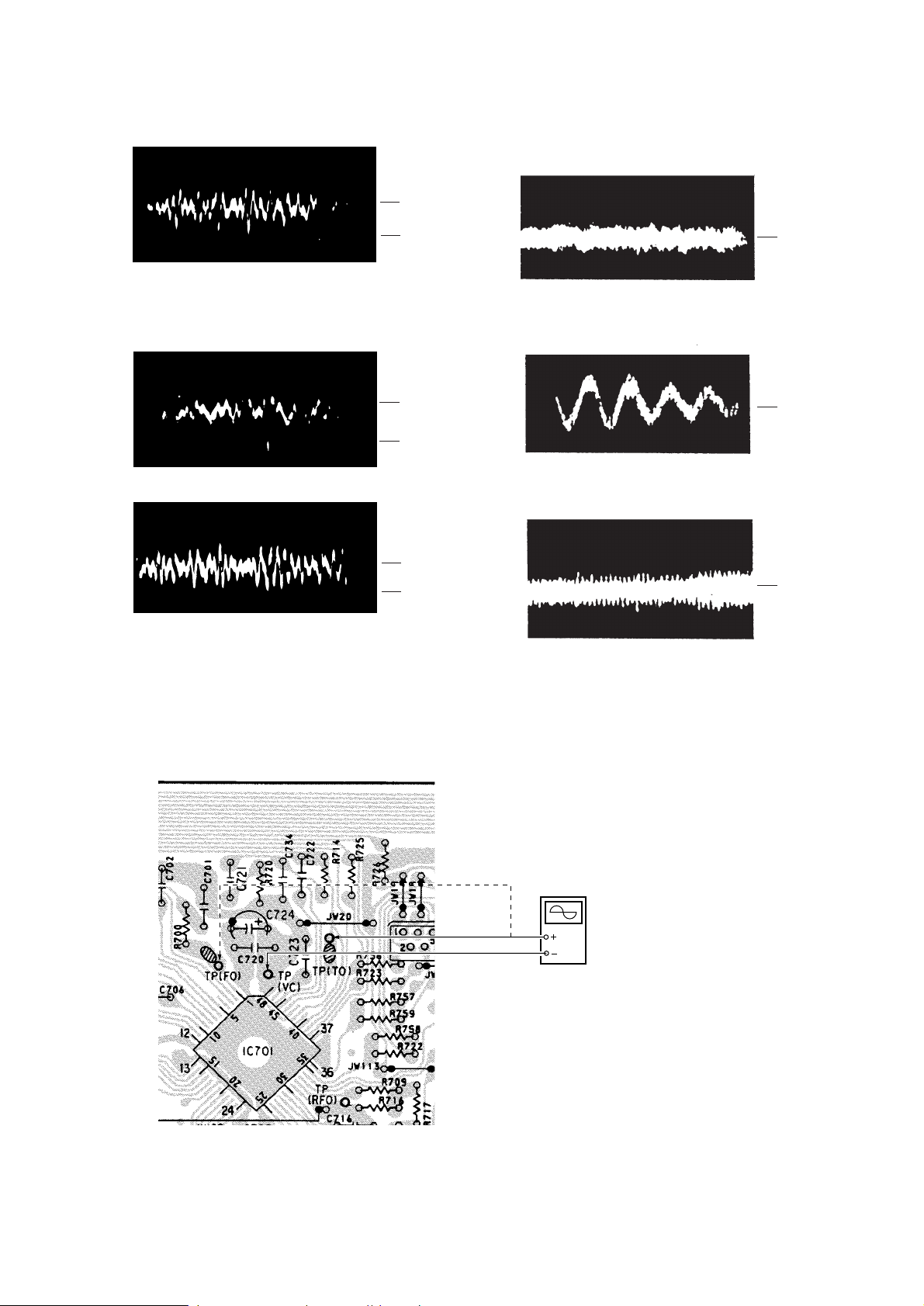

Procedure :

1. Keep the set horizontal.

If the set is not horizontal, this adjustment cannot be performed

due to the gravity against the 2-axis device.

2. Insert disc (YEDS-18) and press fl button.

3. Connect oscilloscope to TP (FO) and TP (VC) on MAIN board.

4. Adjustment RV702 on MAIN board so that the waveform is as

shown in the figure below. (Focus gain adjustment)

Adjustment Location : Main board (See page 12)

– 10 –

VOLT/DIV : 100mV

e

TIME/DIV : 2ms

100mV

5. Connect oscilloscope to TP (TO) and TP (VC) on MAIN board.

6. Adjust R V704 on MAIN board so that the waveform is as sho wn

in the figure below. (Tracking gain adjustment)

VOLT/DIV : 1V

TIME/DIV : 2ms

0V

• Incorrect Examples (DC level changes more than on adjusted

waveform)

VOLT/DIV : 100mV

low focus gain TIME/DIV : 2ms

200mV

0V

VOLT/DIV : 100mV

high focus gain TIME/DIV : 2ms

75mV

0V

0V

• Incorrect Examples (fundamental waveform appears)

low tracking gain

high tracking gain

High fundamental wave

( )

than for low gain

VOLT/DIV : 1V

TIME/DIV : 2ms

0V

VOLT/DIV : 1V

TIME/DIV : 2ms

0V

[MAIN BOARD]

TP (FO)

TP (TO)

TP (VC)

oscilloscop

(DC range)

– 11 –

Loading...

Loading...