Page 1

CFD-S01

SERVICE MANUAL

Ver. 1.0 2006.01

CD

Section

TC

Section

US Model

Model Name Using Similar Mechanism CFD-S350

CD Mechanism Type KSM-213CDP

Optical Pick-up Name KSS-213C

Model Name Using Similar Mechanism NEW

Tape Transport Mechanism Type MF-S01

SPECIFICATIONS

AUDIO POWER SPECIFICATIONS

POWER OUTPUT AND TOTAL HARMONIC DISTORTION

With 4-ohm loads, both channels driven from 150 -10,000 Hz; rated

1 W per channel-minimum RMS power, with no more than 10 % total

harmonic distortion in AC operation.

Other specifications

CD player section

System

Compact disc digital audio system

Laser diode properties

Emission duration: Continuous

Laser output: Less than 44.6 µW

(This output is the value measured at a distance of

about 200 mm from the objective lens surface on the

optical pick-up block with 7 mm aperture.)

Number of channels

2

Frequency response

20 - 20 000 Hz +1/–2 dB

Wow and flutter

Below measurable limit

Radio section

Frequency range

FM: 87.5 - 108 MHz

AM:530 - 1 710 kHz

IF

FM: 10.7 MHz

AM: 450 kHz

Antennas

FM: Telescopic antenna

AM: Built-in ferrite bar antenna

Cassette-corder section

Recording system

4-track 2 channel stereo

Fast winding time

Approx. 150 s (sec.) with Sony cassette C-60

Frequency response

TYPE I (normal): 80 - 10 000 Hz

General

Speaker

Full range: 8 cm dia., 4 Ω, cone type (2)

Outputs

Headphones jack (stereo minijack):

For 16 - 32 Ω impedance headphones

Power output

1.7 W + 1.7 W (at 4 Ω, 10% harmonic distortion)

Power requirements

For CD radio cassette-corder:

120 V AC, 60Hz

9 V DC, 6 R14 (size C) batteries

Power consumption

AC 13 W

– Continued on next page –

9-887-035-01

2006A04-1

© 2006.01

CD RADIO CASSETTE-CORDER

Sony Corporation

Personal Audio Division

Published by Sony Techno Create Corporation

Page 2

CFD-S01

r

Battery life

For CD radio cassette-corder:

FM recording

Sony R14P: approx. 6 h

Sony alkaline LR14: approx. 20 h

Tape playback

Sony R14P: approx. 3 h

Sony alkaline LR14: approx. 12 h

CD playback

Sony R14P: approx. 1.5 h

Sony alkaline LR14: approx. 7 h

Dimensions

Approx. 360 × 141 × 235 mm (w/h/d)

14 1/4 × 5 5/8 × 9 3/8 inches)

(incl. projecting parts)

Mass

Approx. 2.6 kg (5 lb, 11 oz) (incl. batteries)

Supplied accessory

AC power cord (1)

Design and specifications are subject to change

without notice.

SAFETY CHECK-OUT

After correcting the original service problem, perform the following

safety check before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage.

Check leakage as described below.

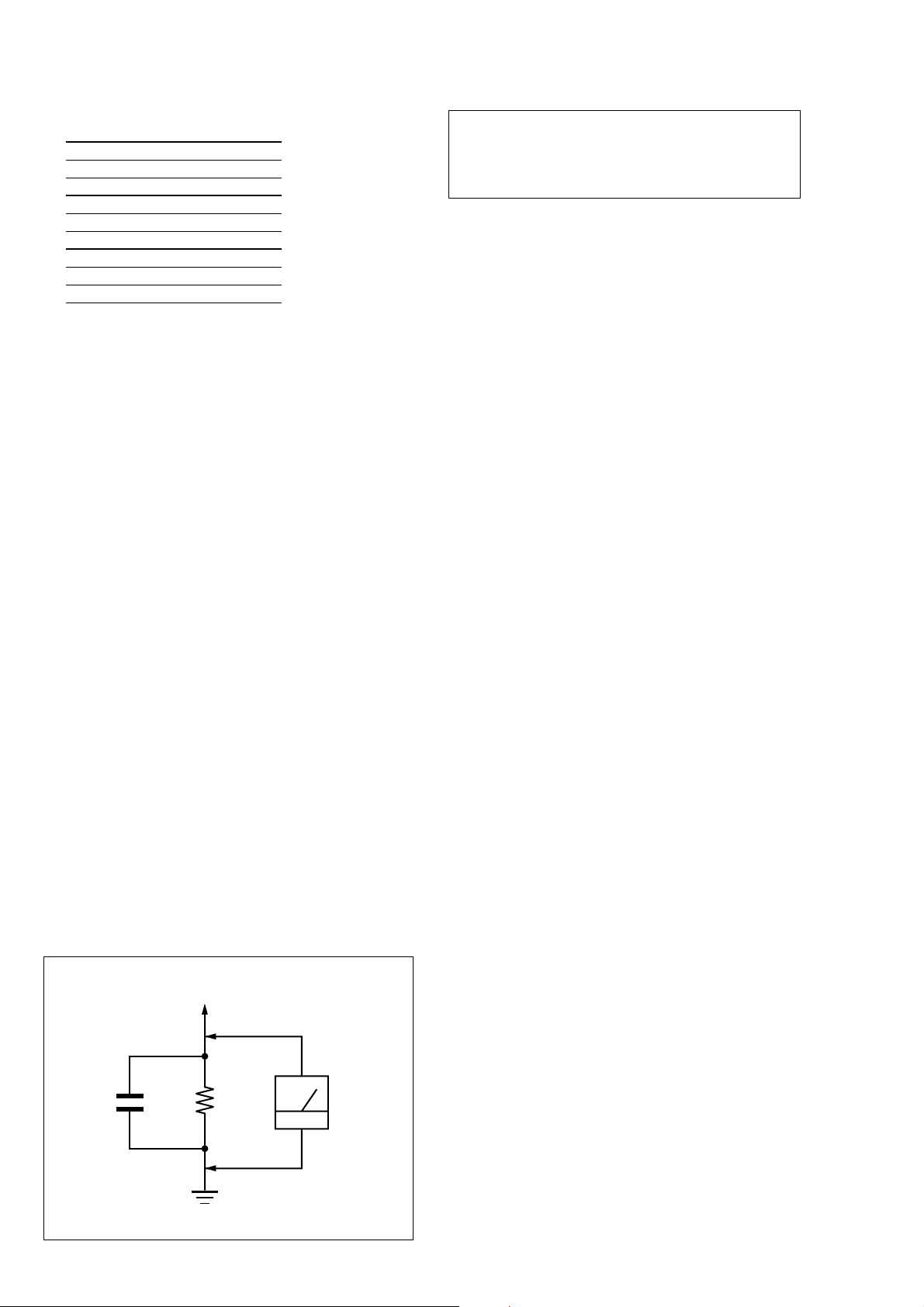

LEAKAGE TEST

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers.).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication is 0.75 V, so analog meters must have an accurate lowvoltage scale. The Simpson 250 and Sanwa SH-63Trd are

examples of a passive VOM that is suitable. Nearly all battery

operated digital multimeters that have a 2 V AC range are

suitable. (See Fig. A)

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270˚C during

repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering or

unsoldering.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged

by heat.

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Notes on DualDiscs

A DualDisc is a two sided disc product which mates DVD recorded

material on one side with digital audio material on the other side.

However, since the audio material side does not conform to the

Compact Disc (CD) standard, playback on this product is not

guaranteed.

To Exposed Metal

Parts on Set

AC

0.15 µF

1.5 k

Ω

Earth Ground

voltmete

(0.75 V)

Fig. A. Using an AC voltmeter to check AC leakage.

2

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

Page 3

CFD-S01

UNLEADED SOLDER

•

Boards requiring use of unleaded solder are printed with the leadfree mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow)

than ordinary solder so use caution not to let solder bridges

occur such as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 4

2. GENERAL ................................................................... 5

3. DISASSEMBLY

3-1. Cabinet (Rear) Assy ......................................................... 7

3-2. Cabinet (Front) Assy, Cabinet (Upper) Assy ................... 7

3-3. Main Board ...................................................................... 8

3-4. CD Block Assy ................................................................ 8

3-5. CD Motor Board.............................................................. 9

3-6. Optical Pick-up................................................................ 9

3-7. Control Board .................................................................. 10

3-8. CD Lid ............................................................................. 10

3-9. Tape Mechanism Block, Belt (1), Belt (2) ...................... 11

3-10. TC Board ......................................................................... 11

3-11. Key (FUNC) Board, Key (VOL) Board .......................... 12

3-12. Power Board .................................................................... 12

4. MECHANICAL ADJUSTMENTS......................... 13

5. ELECTRICAL ADJUSTMENTS

Tape Section .................................................................... 13

Tuner Section................................................................... 14

CD Section ...................................................................... 16

6. DIAGRAMS

6-1. Block Diagram – CD Section – ....................................... 17

6-2. Block Diagram – Main Section – .................................... 18

6-3. Circuit Boards Location .................................................. 19

6-4. Schematic Diagram – Main Section (1/4) – .................... 20

6-5. Schematic Diagram – Main Section (2/4) – .................... 21

6-6. Schematic Diagram – Main Section (3/4) – .................... 22

6-7. Schematic Diagram – Main Section (4/4) – .................... 23

6-8. Printed Wiring Board – Main Section – .......................... 24

6-9. Printed Wiring Boards – TC Section – ............................ 25

6-10. Schematic Diagram – TC Section – ................................ 26

6-11. Printed Wiring Boards – Control Section – ..................... 27

6-12. Schematic Diagram – Control Section – ......................... 28

6-13. Printed Wiring Boards – Power Supply Section – ........... 29

6-14. Schematic Diagram – Power Supply Section – ............... 30

7. EXPLODED VIEWS

7-1. Rear Cabinet Section ....................................................... 38

7-2. Front Cabinet Section (1) ................................................ 39

7-3. Front Cabinet Section (2) ................................................ 40

7-4. Upper Cabinet Section (1) ............................................... 41

7-5. Upper Cabinet Section (2) ............................................... 42

7-6. CD Mechanism Section ................................................... 43

8. ELECTRICAL PARTS LIST .................................. 44

3

Page 4

CFD-S01

SECTION 1

SERVICING NOTES

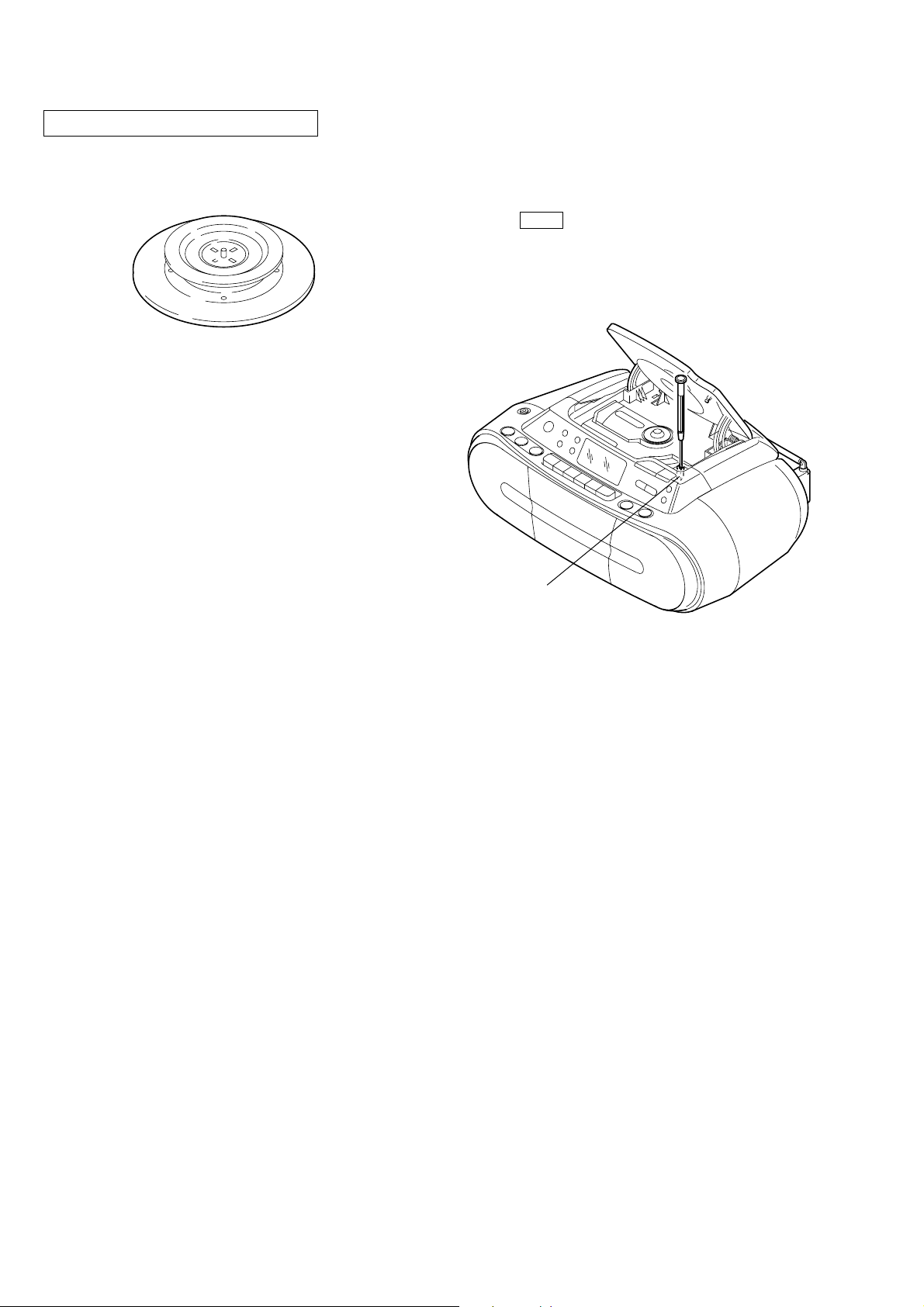

CHUCK PLATE JIG ON REPAIRING

On repairing CD section, playing a disc without the lid (CD), use

Chuck Plate Jig.

• Code number of Chuck Plate Jig: X-4918-255-1

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

1. Turn ON the [POWER] button and press [CD] button to CD

position.

2. Open the CD lid.

3. Turn on S801 with screwdriver, etc. as following figure.

4. Press the N X (CD) button.

5. Confirm the laser diode emission while observing the objecting

lens. When there is no emission, Auto Power Control circuit or

Optical Pick-up is broken.

Objective lens moves up and down three times for focus search.

S801

4

Page 5

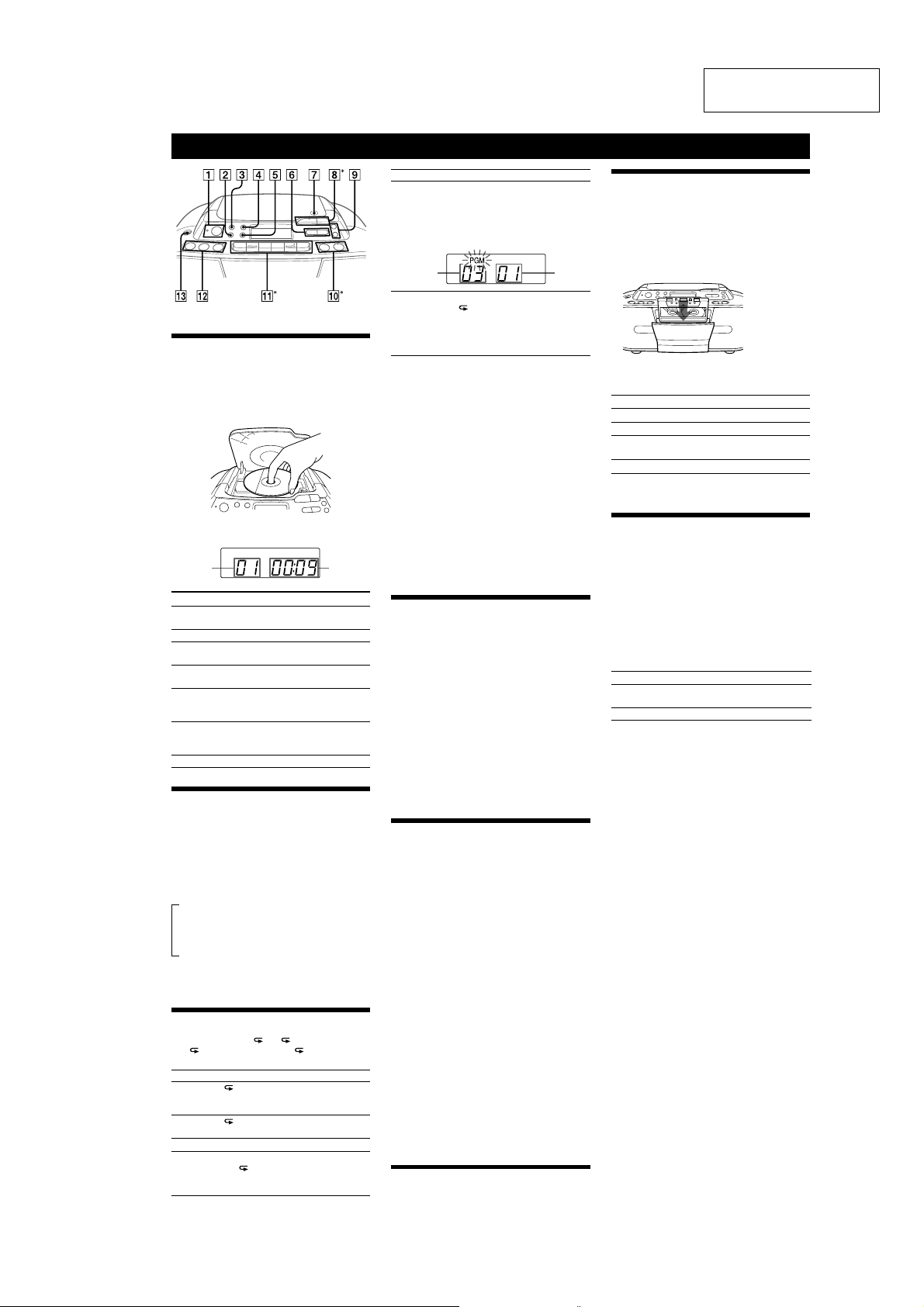

Basic Operations

*

VOLUME + 0 u 8, and n qa have a tactile dot.

Playing a CD

1

Press CD qs (direct power-on).

2

Press Z PUSH OPEN/CLOSE 7 and place a disc

with the label side up on the CD compartment.

To close the CD compartment, press Z PUSH OPEN/

7

.

CLOSE

3

Press u 8.

The player plays all the tracks once.

Track

number

To Press

Pause playback

Stop playback

Go to the next

track

Go back to the

previous track

Locate a point

while listening to

the sound

Locate a point

while observing

the display

Remove the CD

8. To resume play, press it

u

again.

8.

x

6.

>

6.

.

(forward) or . (backward)

>

6

while playing and hold it until

you find the point.

(forward) or . (backward)

>

6

in pause and hold it until you

find the point.

PUSH OPEN/CLOSE

Z

Using the display

To check the total track number and playing

time

Press DISPLAY•ENTER 5 in stop mode.

To check the remaining time

Press DISPLAY•ENTER 5 repeatedly while playing a

CD. The display changes as follows:

B

The current track number and playing time

r

The current track number and the remaining

time of the current track*

r

The number of tracks left and remaining

time on the CD

* For a track whose number is more than 20, the remaining time

appears as “- -:- -” in the display.

Selecting the play mode

Press MODE 4 until “ 1”, “ ”, “SHUF”, “SHUF”

and “

”, “PGM”, or “PGM” and “ ” appear in

the display. Then proceed as follows:

To Select Select Then do this

Repeat a

single track

Repeat all

tracks

Shuffle play “SHUF” Press

Repeat

tracks in

random

order

“ 1” Press . or > 6 to

select the track that you want

to repeat, then press

” Press u 8.

“

Press

“SHUF”

”

and “

u

u

8.

8.

Playing

time

7

u

8.

SECTION 2

GENERAL

To Select Select Then do this

Program

play

repeat

programed

tracks

To cancel selected play mode

Press MODE 4 repeatedly until the selected mode

disappears from the display.

To check the programed track and playing

order in the display

To check the order of tracks before play, press

DISPLAY•ENTER

Every time you press the button, the track number

appears in the programed order.

To change the current program

Press x 8 once if the CD is stopped and twice if the

CD is playing. The current program will be erased.

Then create a new program following the programing

procedure.

Tips

• You can play the same program again, since the program is saved

• You can record your own program. After you’ve created the

Listening to the radio

1

2

Tip

If the FM broadcast is noisy, press MODE 4 until “Mono” appears

in the display and radio will play in monaural.

Presetting radio stations

You can store radio stations into the player’s memory.

You can preset up to 30 radio stations, 20 for FM and 10

for AM in any order.

1

2

3

If a station cannot be preset automatically

You need to preset a station with a weak signal

manually.

1

2

3

4

5

Tip

The preset radio stations remain in memory even if you unplug the

AC power cord or remove the batteries.

Playing preset radio stations

1

2

“PGM” Press . or > 6 then

press DISPLAY•ENTER

5

for the tracks you want

to program in the order you

want up to 20 tracks. Then

press

8.

u

Programed

track

“PGM”

Press

and “

5

until you open the CD compartment.

program, insert a blank tape and press

Press RADIO BAND•AUTO PRESET qs

repeatedly (direct power-on).

Each time you press the button, the indication

changes as follows:

“FM” t “AM”

Hold down TUNE + or – 9 until the frequency

digits begin to change in the display.

The player automatically scans the radio frequencies

and stops when it finds a clear station.

If you can’t tune in a station, press the button

repeatedly to change the frequency step by step.

When an FM stereo broadcast is received, “ST”

appears.

Press RADIO BAND•AUTO PRESET qs to

select the band.

Hold down RADIO BAND•AUTO PRESET qs for

2 seconds until “AUTO” flashes in the display.

Press DISPLAY•ENTER 5.

The stations are stored in memory from the lower

frequencies to the higher ones.

Press RADIO BAND•AUTO PRESET qs to

select the band.

Tune in a station you want.

Hold down DISPLAY•ENTER 5 for 2 seconds

until the preset number flashes in the display.

Press PRESET + or – 6 until the preset number

you want for the station flashes in the display.

Press DISPLAY•ENTER 5.

The new station replaces the old one.

Press RADIO BAND•AUTO PRESET qs to

select the band.

Press PRESET + or – 6 to tune in the stored

station.

.

press DISPLAY•ENTER

”

5

for the tracks you want

to program in the order you

want up to 20 tracks. Then

Press

u

.

z

Playing

order

or > 6 then

8.

qa to start recording.

CFD-S01

This section is extracted

from instruction manual.

Playing a tape

1

Press TAPE qs (direct power-on).

2

Press xZ qa, and insert the tape into the tape

compartment with the side you want to play

facing you. Use TYPE I (normal) tape only. Close

the compartment.

Make sure there is no slack in the tape to avoid

damaging the tape or the unit.

3

Press n qa.

The player starts playing.

To Press

Pause playbackX qa. To resume play, press it again.

Stop playback

Fast-forward or

rewind*

Eject the cassette

* When the tape is wound to the end, press xZ qa to release m or

qa.

M

Recording on a tape

1

Press xZqa to open the tape compartment

and insert a blank tape with the side you want to

record on facing you. Use TYPE I (normal) tape

only. Close the compartment.

2

Select the program source you want to record.

To record from the CD player, place a CD and press

qs

CD

To record from the radio, tune in the station you want.

3

Press z qa to start recording

is depressed automatically).

(

n

To Pr ess

Pause recording

Stop recording

Tips

• Adjusting the volume or the audio emphasis will not affect the

recording level.

• For the best results, use wall outlet as a power source for recording.

• To erase a recording, proceed as follows:

1 Insert the tape whose recording you want to erase.

2 Press TAPE

3 Press

qa.

z

qa.

xZ

or M (fast forward or rewind)

m

qa

.

qa.

xZ

.

X

press it again.

xZ

qs

.

qa. To resume recording,

qa

.

5

Page 6

CFD-S01

SECTION 3

DISASSEMBLY

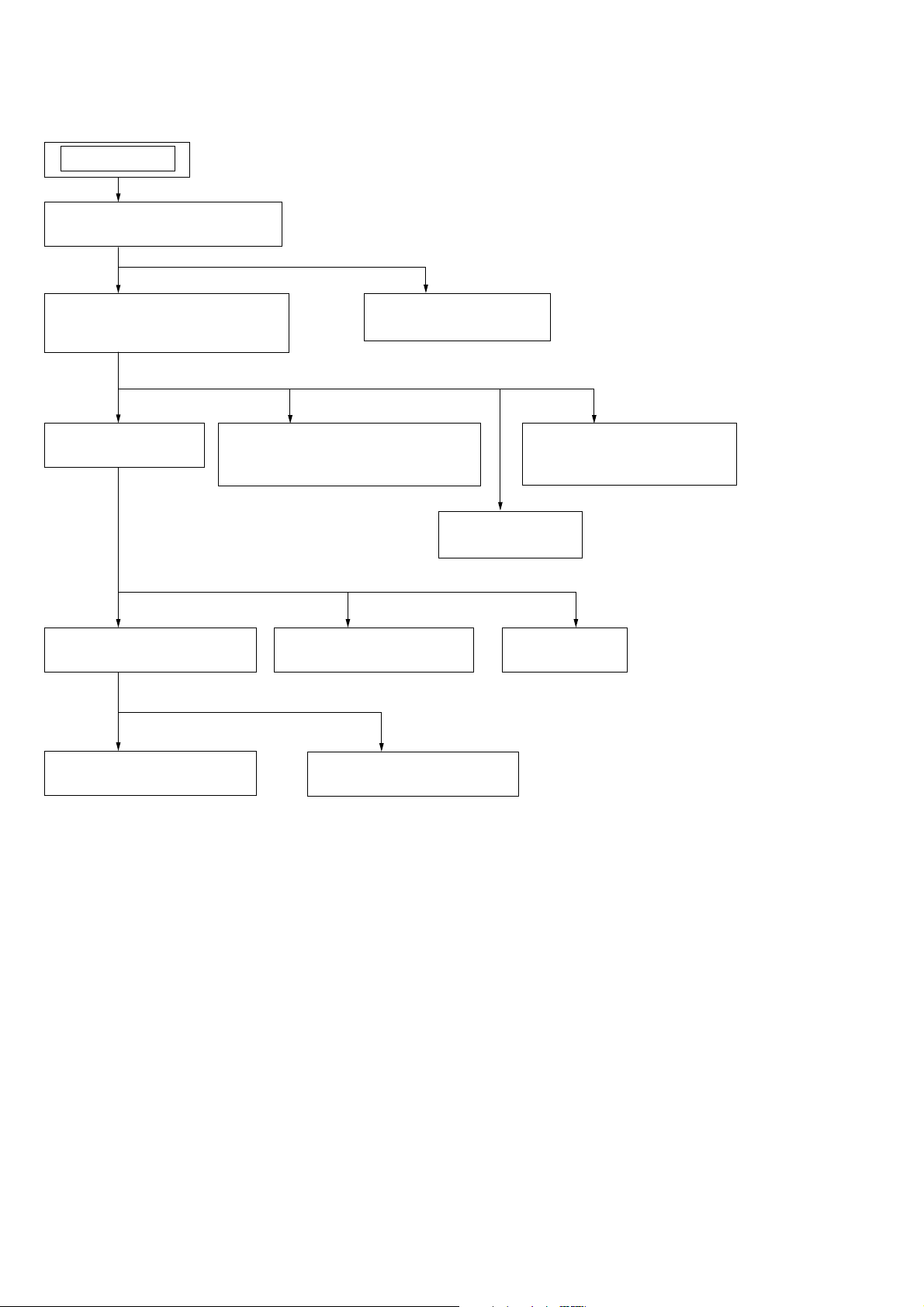

Note: This set can be disassemble according to the following sequence.

SET

3-1. CABINET (REAR) ASSY

(Page 7)

3-2. CABINET (FRONT) ASSY,

CABINET (UPPER) ASSY

(Page 7)

3-3. MAIN BOARD

(Page 8)

3-4. CD BLOCK ASSY

(Page 8)

3-9. TAPE MECHANISM BLOCK,

3-12. POWER BOARD

(Page 12)

BELT (1), BELT (2)

(Page 11)

3-7. CONTROL BOARD

(Page 10)

3-11. KEY (FUNC) BOARD,

KEY (VOL) BOARD

(Page 12)

3-10. TC BOARD

(Page 11)

3-8. CD LID

(Page 10)

3-5. CD MOTOR BOARD

(Page 9)

3-6. OPTICAL PICK-UP

(Page 9)

6

Page 7

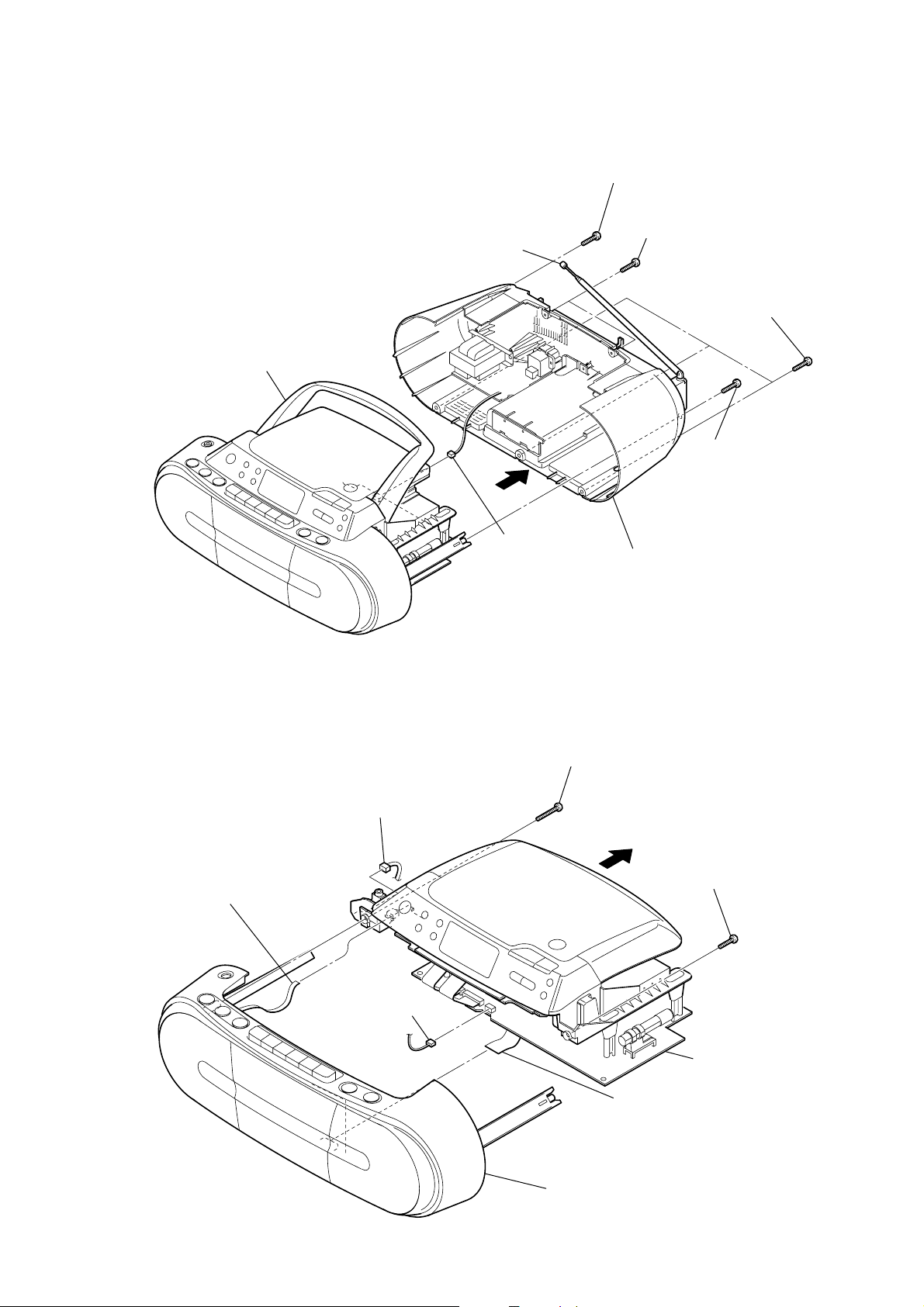

Note: Follow the disassembly procedure in the numerical order given.

)

3-1. CABINET (REAR) ASSY

telescopic antenna

handle

5

2

screw

(+BV tapping B2.6)

1

two

screws

(+BV tapping (B2.6))

4

three

(+BV tapping (B2.6))

3

(+BV tapping B2.6)

CFD-S01

screws

screw

6

3-2. CABINET (FRONT) ASSY, CABINET (UPPER) ASSY

1

CN308 (4P)

5

flexible flat cable (4 core)

(CN402)

6

CN304 (4P)

CN305 (3P)

2

(+BV tapping B2.6)

screw

7

cabinet (rear) assy

4

3

(+BV tapping B2.6

screw

7

flexible flat cable (11 core)

(CN301)

8

cabinet (front) assy

9

cabinet (upper) assy

7

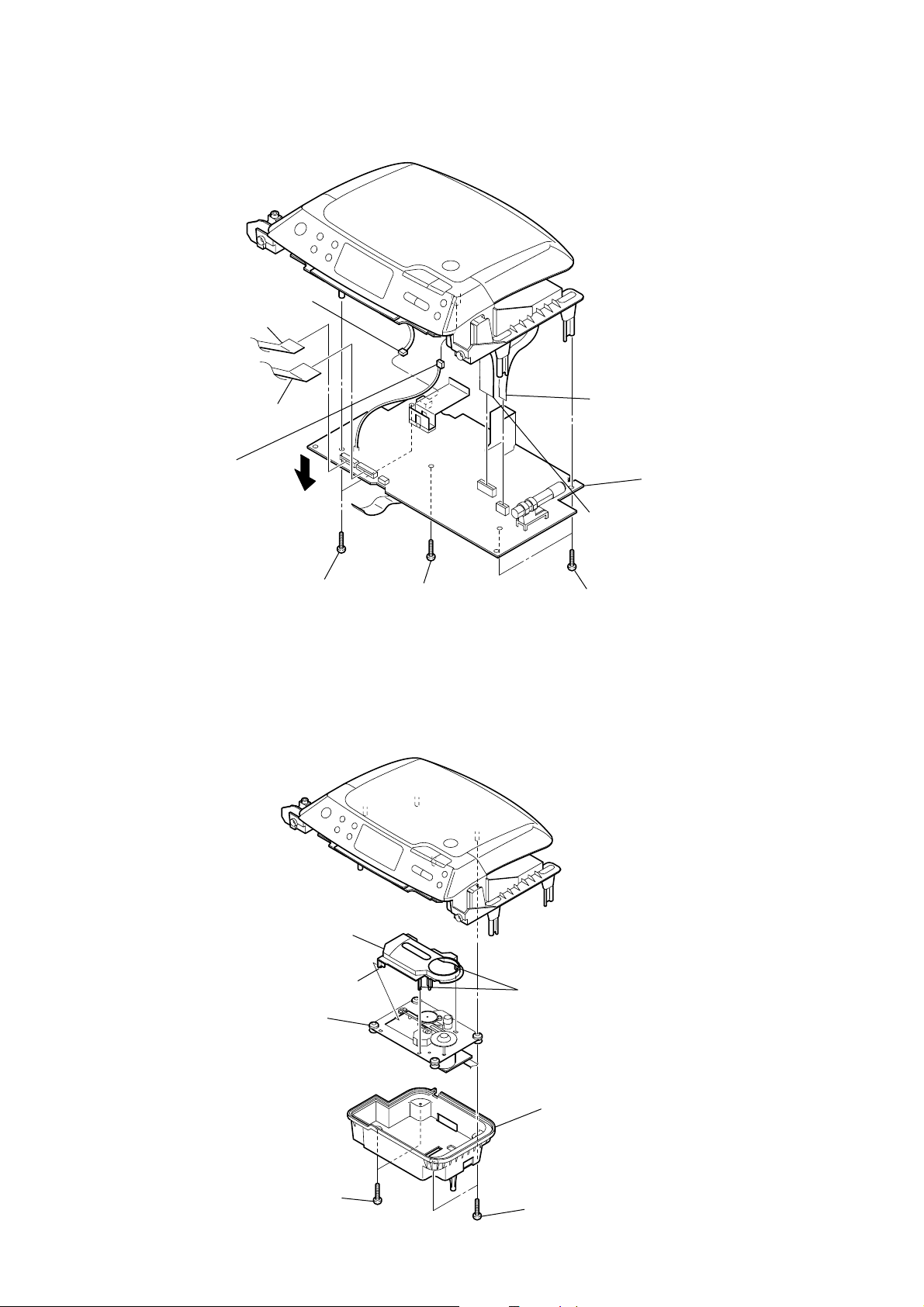

Page 8

CFD-S01

)

)

3-3. MAIN BOARD

3

flexible flat cable (12 core)

(CN802)

2

flexible flat cable (14 core)

(CN801)

0

connector

(S801)

1

CN306 (4P)

7

8

flexible flat cable (6 core)

(CN702)

qa

MAIN board

9

flexible flat cable (16 core

(CN701)

3-4. CD BLOCK ASSY

6

two

(+BV tapping B2.6)

4

CD cover

5

CD block assy

screws

claw

5

screw

(+BV tapping B2.6)

two claws

4

two

screws

(+BV tapping B2.6)

3

CD chassis

2

two

screws

(+BV tapping (B2.6))

1

two

screws

(+BV tapping (B2.6)

8

Page 9

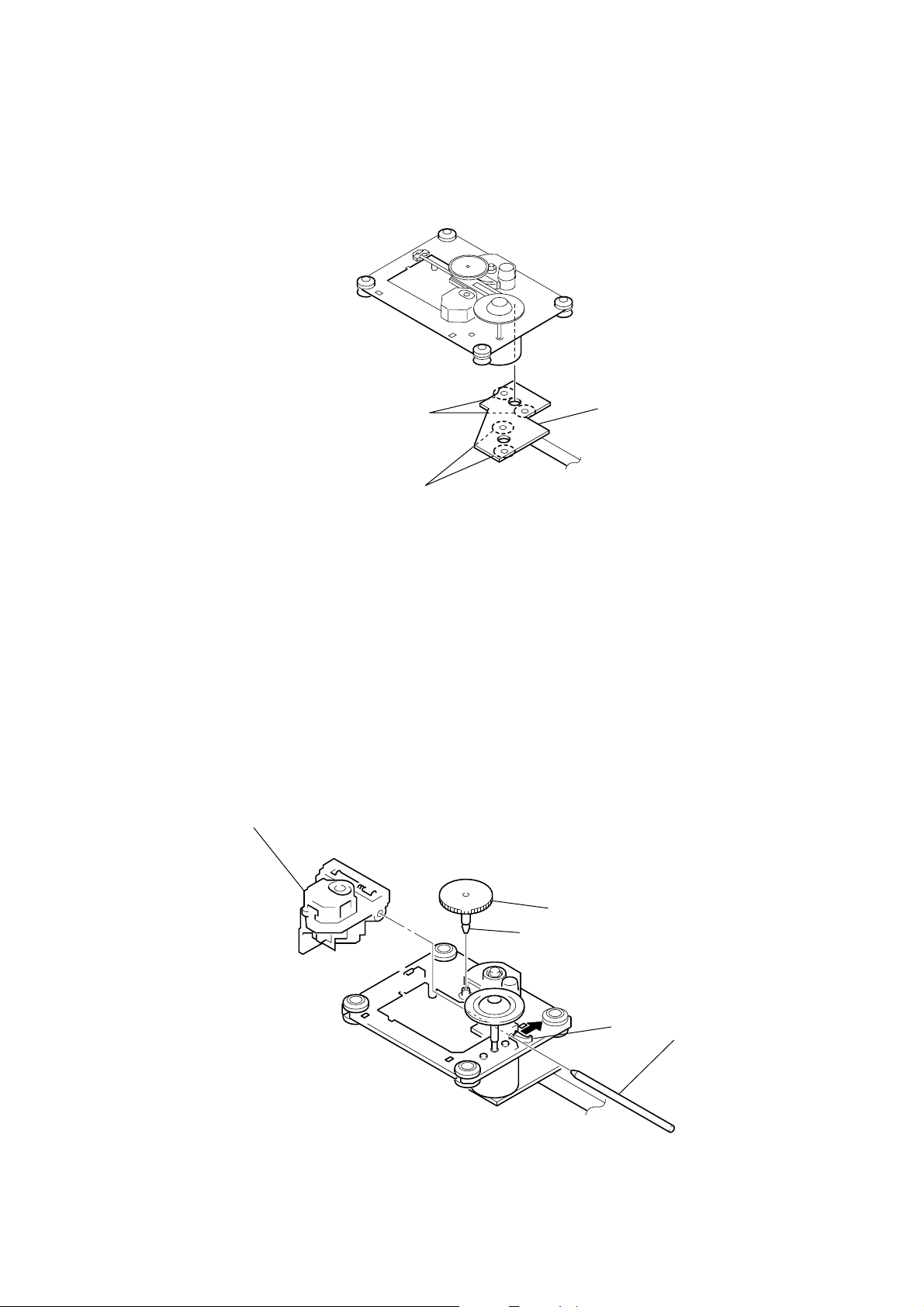

3-5. CD MOTOR BOARD

d

t

2

Remove the two solders.

3

CD MOTOR boar

CFD-S01

3-6. OPTICAL PICK-UP

5

optical pick-up

1

Remove the two solders.

claw

1

gear (A)

3

2

claw

sled shaf

4

9

Page 10

CFD-S01

d

g

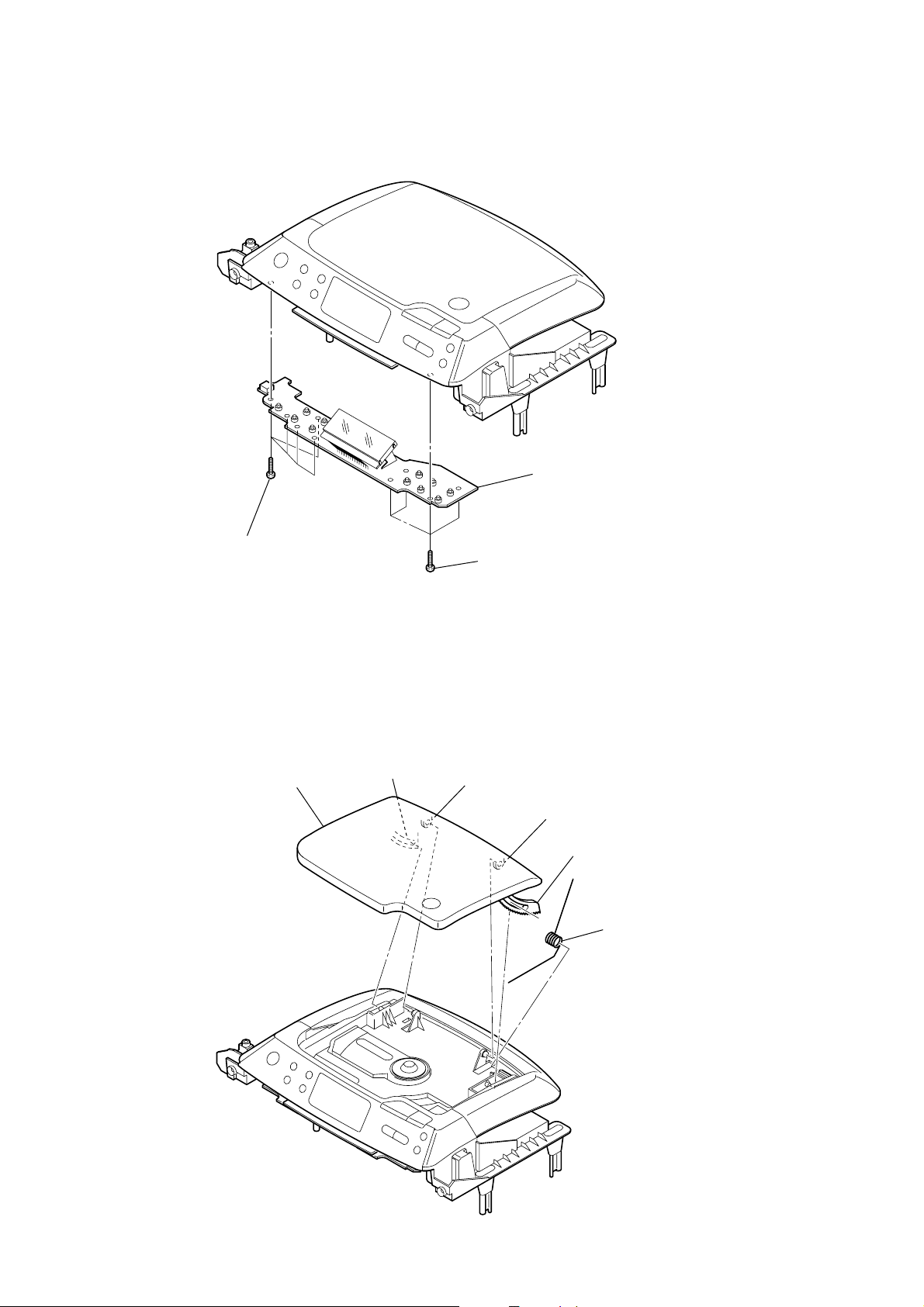

3-7. CONTROL BOARD

3

CONTROL boar

3-8. CD LID

2

five

screws

(+P tapping (B2.6))

5

CD lid

1

1

four

screws

(+P tapping (B2.6))

2

4

3

6

CD sprin

10

Page 11

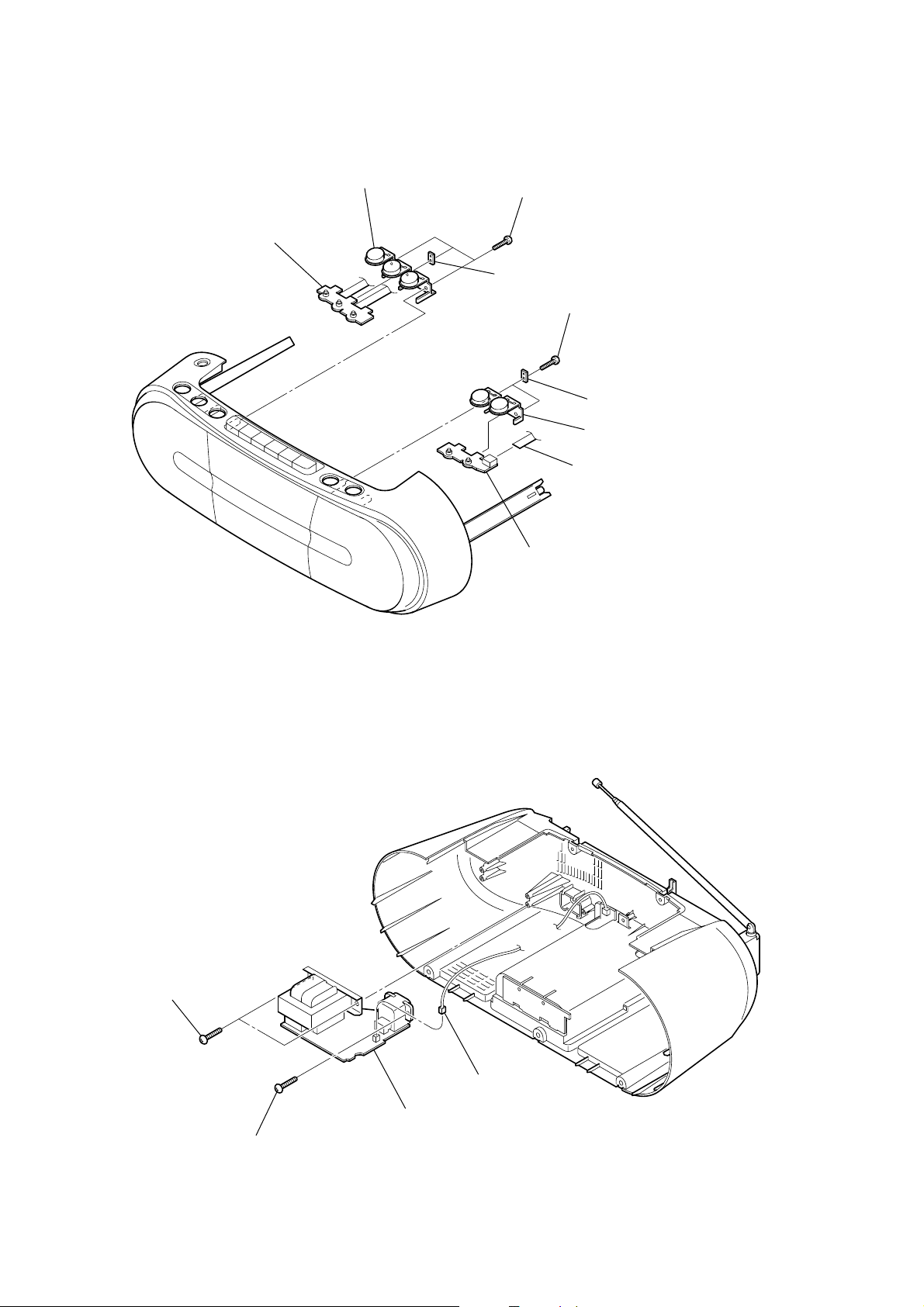

3-9. TAPE MECHANISM BLOCK, BELT (1), BELT (2)

1

two

screws

(+BV tapping (B2.6))

7

belt (2)

6

belt (1)

5

motor bracket

3

tape mechanism block

2

two

screws

(+BV tapping (B2.6))

4

two screws

CFD-S01

3-10. TC BOARD

2

Remove the four solders.

1

screw

(+P tapping (B2.6))

3

TC board

11

Page 12

CFD-S01

s

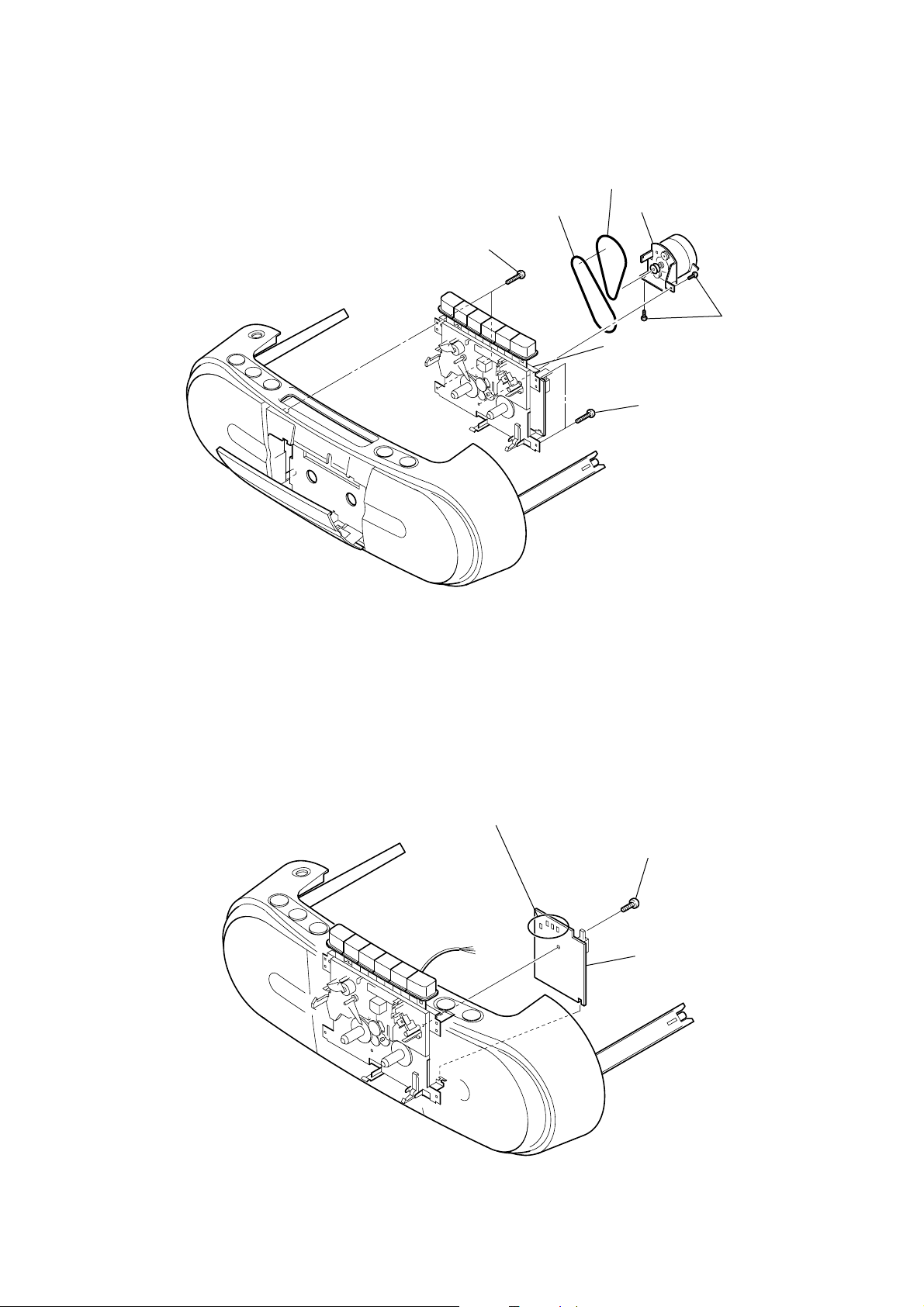

3-11. KEY (FUNC) BOARD, KEY (VOL) BOARD

9

8

KEY (FUNC) board

button (FUNC)

6

three

(+BV tapping (B2.6))

7

RETAINER board

screws

2

two

(+BV tapping (B2.6))

3

5

1

flexible flat cable (4 core)

(CN401)

screws

two RETAINER board

button (volume)

3-12. POWER BOARD

3

two

screws

(+BV tapping (B2.6))

4

KEY (VOL) board

12

2

screw

(+BV tapping (B2.6))

4

POWER board

1

CN902 (2P)

Page 13

SECTION 4

MECHANICAL ADJUSTMENTS

CFD-S01

SECTION 5

ELECTRICAL ADJUSTMENTS

PRECAUTION

1. Clean the following parts with a denatured-alcohol-moistened

swab :

record/playback head pinch roller

erase head rubber belts

capstan idlers

2. Demagnetize the record/playback head with a head demagnetizer.

(Do not bring the head magnetizer close to the erase head.)

3. Do not use a magnetized screwdriver for the adjustments.

4. The adjustments should be performed with the rated power

supply voltage (9V) unless otherwise noted.

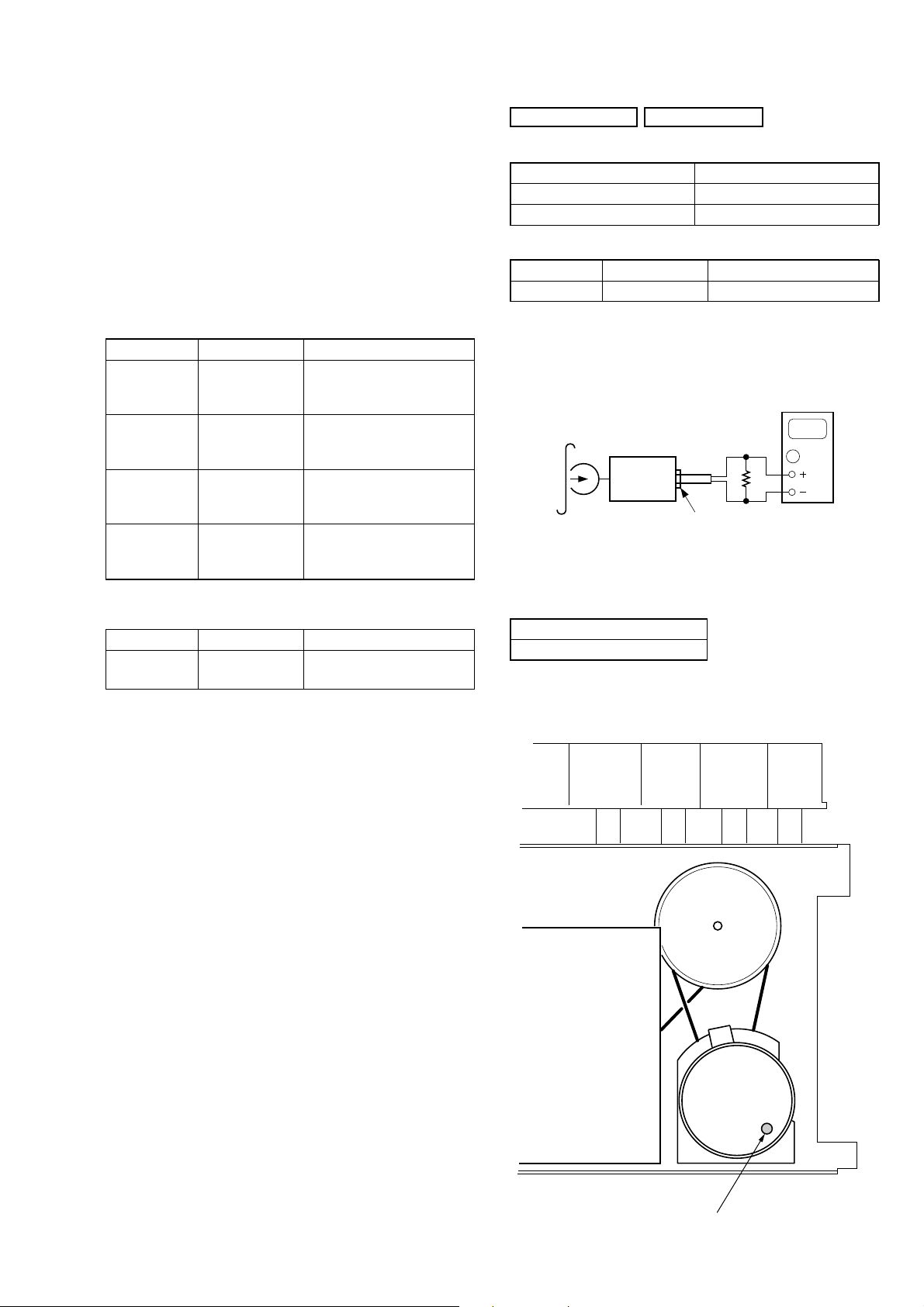

Torque Measurement

Mode Torque meter Meter reading

2.95 – 6.86 mN • m

FWD CQ-102C (30 – 70 g • cm)

(0.42 – 0.97 oz • inch)

FWD

Back Tension

FF CQ-201B (more than 60 g • cm)

REW CQ-201B (more than 60 g • cm)

CQ-102C (1.5 – 5.5 g • cm)

0.15 – 0.53 mN • m

(0.021 – 0.076 oz • inch)

more than 5.88 mN • m

(more than 0.83 oz • inch)

more than 5.88 mN • m

(more than 0.83 oz • inch)

TAPE SECTION 0 dB = 0.775 V

• Standard Output Level

Output terminal HP OUT

load impedance 32 Ω

output signal level 0.25 V (–10 dB)

• Test Tape

Type Signal Used for

WS-48A 3 kHz, 0 dB tape speed adjustment

Tape Speed Adjustment

Procedure:

Mode: playback

test tape

WS-48A

(3 kHz, 0 dB)

set

i

jack (J321)

Adjust so that the value on the digital frequency counter is

3,000 Hz.

digital frequency

counter

Ω

32

Tape Tension Measurement

Mode Tension meter Meter reading

FWD CQ-403A

more than 100 g

(more than 3.53 oz)

Specification Value:

Digital frequency counter

2,910 to 3,090 Hz

Adjust so that the frequency at the beginning and that at the end of

tape winding are between 2,910 to 3,090 Hz.

Adjustment Location:

Tape speed adjustment

control inside motor

13

Page 14

CFD-S01

)

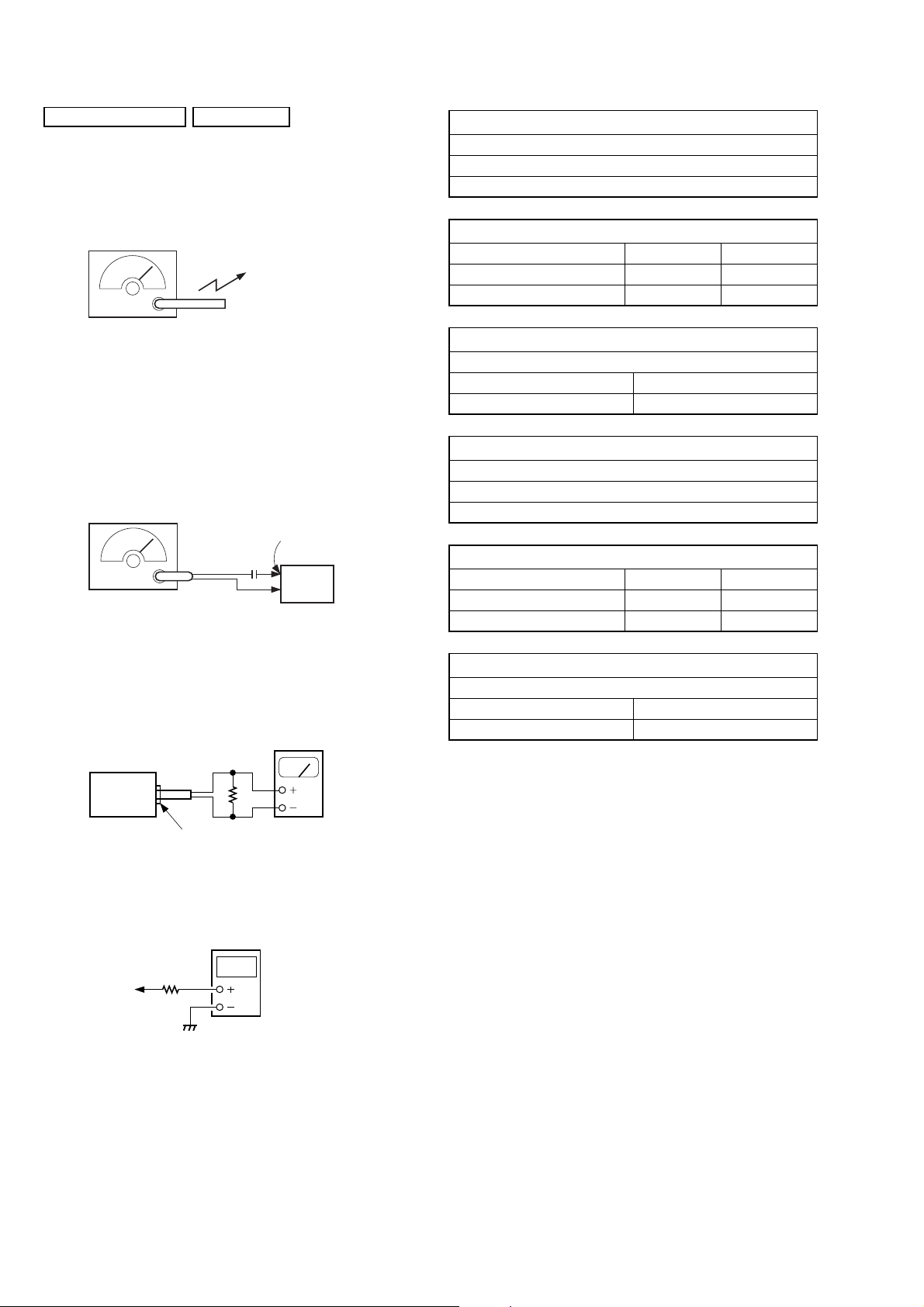

TUNER SECTION 0 dB = 1 µV

• AM Section

Setting:

RADIO BAND•AUTO PRESET button: AM

AM RF signal

generator

30% amplitude

modulation by

400 Hz signal

• FM Section

Setting:

RADIO BAND•AUTO PRESET button: FM

FM RF signal

generator

75 kHz frequency

deviation by 1 kHz signal

output level : as low as possible

Put the lead-wire

antenna close to

the set.

0.01

µ

F

ANT2

set

AM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

T1

450 kHz

AM FREQUENCY COVERAGE CHECK

Frequency Display 530 kHz 1,710 kHz

Reading on Digital voltmeter 0.8 ± 0.3 V 5.8 ± 0.1 V

Adjustment Part L3 <confirmation>

AM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

ANT1 CT3

620 kHz 1,400 kHz

FM IF ADJUSTMENT

Adjust for a maximum reading on level meter.

L6

10.7 MHz

FM FREQUENCY COVERAGE ADJUSTMENT

Frequency Display 87.5 MHz 108 MHz

Reading on Digital voltmeter 1.5 ± 0.3 V 3.0 ± 0.2 V

Adjustment Part <confirmation> L2

• Connecting Level Meter (FM, AM)

level meter

(range: 0.5–5 V ac

32

Ω

set

i

jack (J321)

• Connecting Digital Voltmeter (FM, AM)

digital

voltmeter

Ω

100 k

TP (VT)

•Repeat the procedures in each adjustment several times, and the

frequency coverage and tracking adjustments should be finally

done by the trimmer capacitors.

FM TRACKING ADJUSTMENT

Adjust for a maximum reading on level meter.

L1 CT1

87.5 MHz 108 MHz

Adjustment Location: See page 15.

14

Page 15

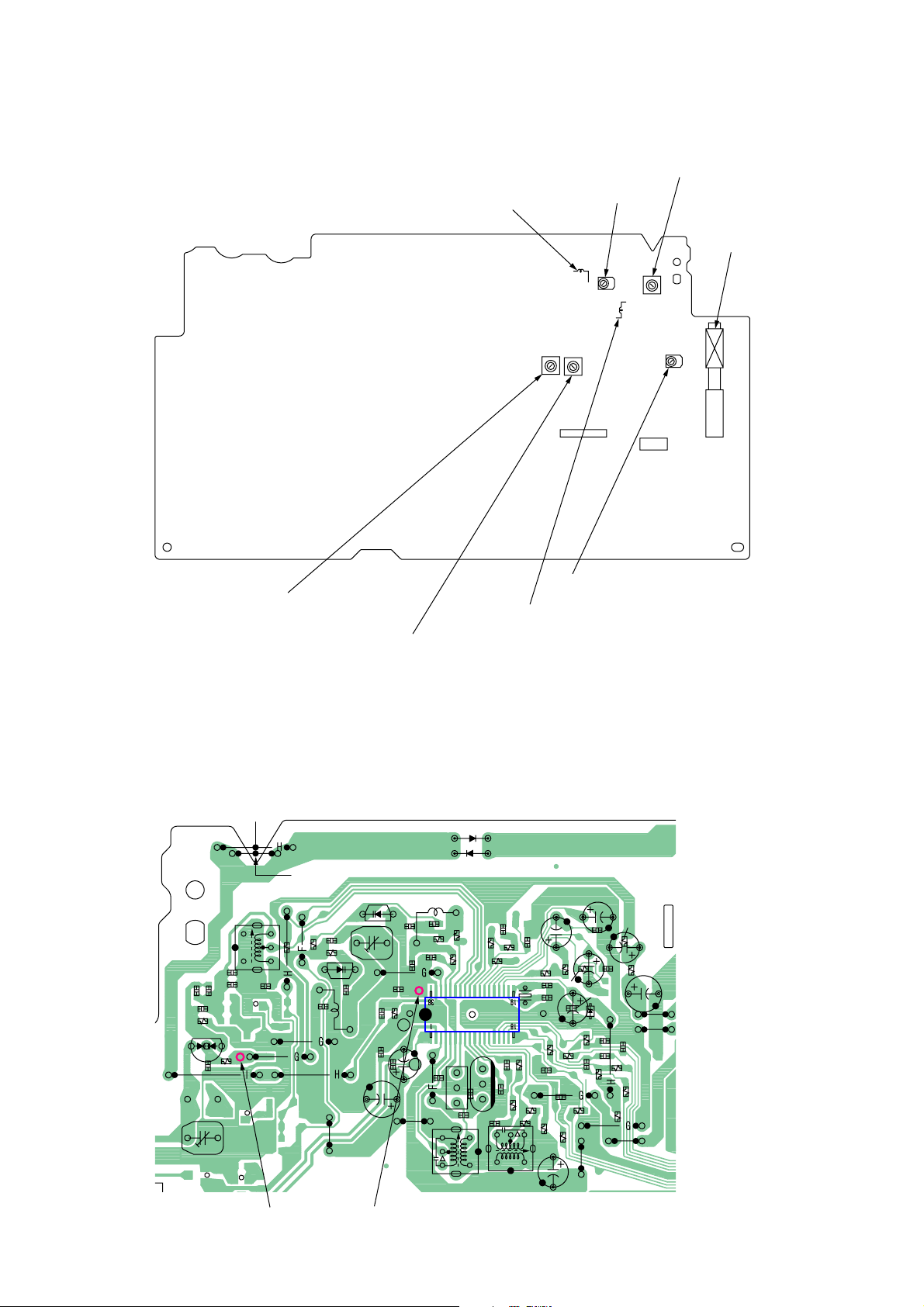

Adjustment Location:

E

– MAIN BOARD (Component Side) –

L2: FM FREQUENCY COVERAGE

ADJUSTMENT

CFD-S01

L3: AM FREQUENCY COVERAG

ADJUSTMENT

CT1: FM TRACKING

ADJUSTMENT

ANT1: AM TRACKING

ADJUSTMENT

CN701

CN702

Test Point:

L6: FM IF ADJUSTMENT

T1: AM IF ADJUSTMENT

– MAIN BOARD (Conductor Side) –

JW232

JW231

L3

C14

C11

C10

C13

C12

R6

D3

C9

R5

JW226

CT3

C15

JW218

JW224

JW217

JW219

ANT2

R11

JW223

C3

C2

R2

R1

D1

C1

L1

JW220

CT3: AM TRACKING ADJUSTMENT

L1: FM TRACKING ADJUSTMENT

D5

D4

D2

CT1

C21

C70

C29

JW207

C67

C22

C23

C6

C4

R26

JW209

T1

L2

R3

JW208

C17

C18

R18

C37

C46

C40

C35

C38

R22

JW189

JW191

R14

C43

R24

C20

C326

D6

JW183

JW184

JW187

C36

R21

R899

R23

JW190

C5

C7

C24

C16

R4

R13

R9

R7

R12

X1

IC1

CF2

CF3

C25

C27

C26

R25

C28

R29

L6

R28

C42

JW188

R41

C19

C45

R15

R39

R27

C41

C39

R20

C34

R19

C32

R17

R10

R16

C30

TP (VT) TP (GND)

15

Page 16

CFD-S01

C782

R715

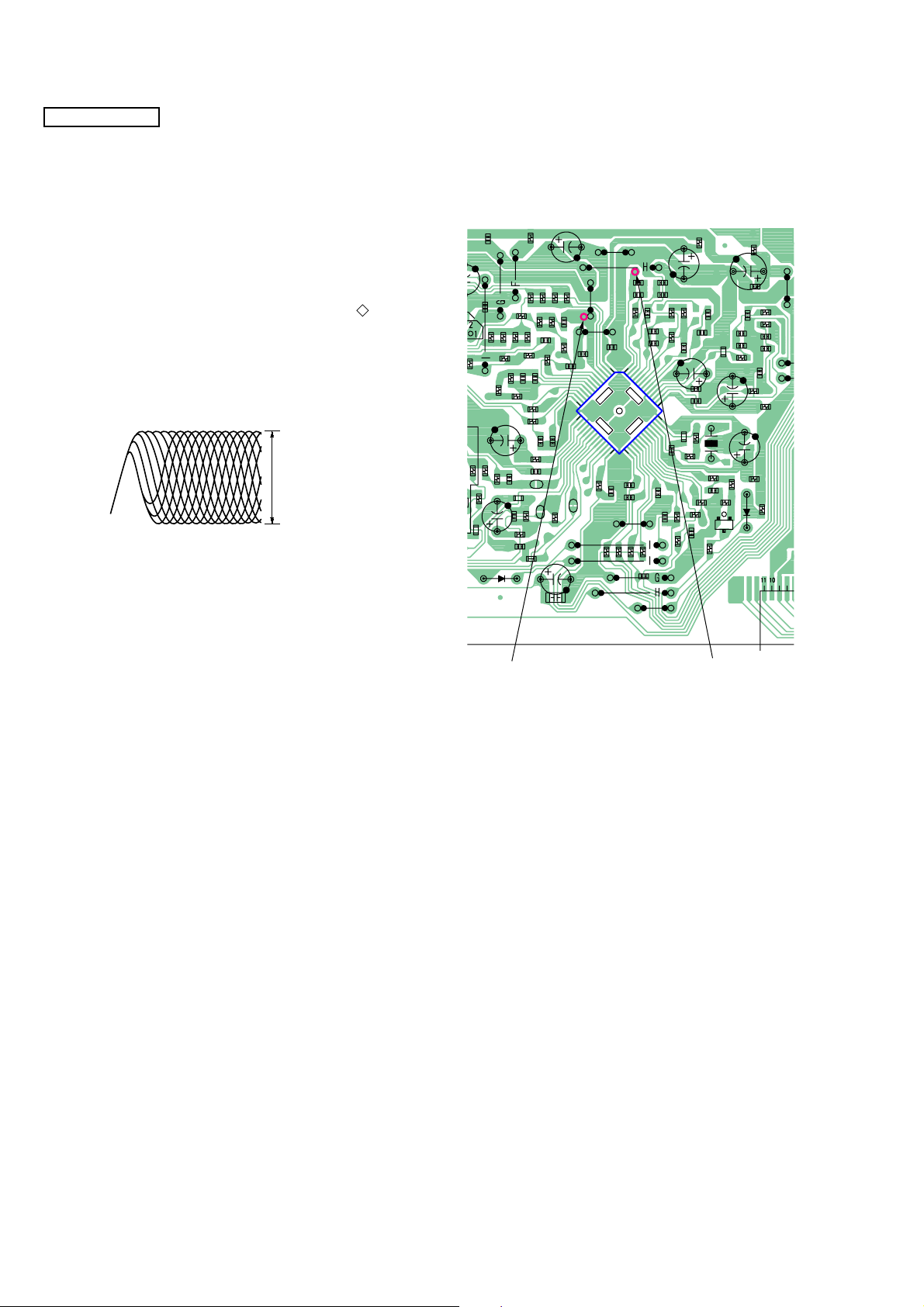

CD SECTION

CD section adjustments are done automatically in this set.

In case of operation check, confirm that focus bias.

FOCUS BIAS CHECK

1. Connect the oscilloscope between IC701 pin ts and pin 4 (or

TP (RF) and TP (VREF)).

2. Insert the disc (PATD-012 (Tr 15)). (Part No. : 4-225-203-01)

3. Press the N X (CD) button.

4. Confirm that the oscilloscope waveform is as shown in the figure

below. (eye pattern)

A good eye pattern means that the diamond shape ( ) in the

center of the waveform can be clearly distinguished.

• RF signal reference waveform (eye pattern)

VOLT/DIV : 50 mV (10 : 1 probe in use)

TIME/DIV : 500 nS

RF level :

1.7

±

0.2 Vp-p

When observing the eye pattern, set the oscilloscope for AC range

and raise vertical sensitivity.

Test Point:

– MAIN BOARD (Conductor Side) –

R721

C703

C772

JW204

R782

JC704

R702

R725

JW205

R781

R783

D703

C706

JW203

R701

R714

C716

R728

C720

JW202

R704

R726

C719

JC702

R700

R712

R710

C774

R703

C718

R708

C777

JC703

R740

C709

R717

R722

C712

R736

R707

R716

C710

R727

C717

TP701

JW197

JW198

C748

C707

R705

R713

TP702

R711

C711

C713

R734

R706

C700

R709

14

C708

C759

JW195

TP703

R757

JW193

JW194

R754

JW192

C705

26

R758

JW200

C755

C779

113

C725

RF

R772

C762

C754

C753

52

IC701

27 39

C726

C727

JW196

R755

R759

C728

JW199

JW201

C757

C729

C730

R766

40

C758

R768

C704

C744

C745

C738

R762

R756

C749

JC705

R748

R760

R770

C752

C773

R763

C731

R761

X701

R739

FB704

C751

R746

C750

JC701

R743

E CB

Q703

C747

C764

C763

R773

FB701

C761

R742

C735

FB702

C767

R774

D704

C766

C733

R775

R776

C769

C765

FB703

R744

JW180

FFC

TP (VREF)

TP (RF)

16

Page 17

SECTION 6

DIAGRAMS

6-1. BLOCK DIAGRAM — CD SECTION —

CFD-S01

A

C

B

D

E

F

LD

PD

OPTICAL PICK-UP

BLOCK

(KSS-213C)

TRACKING

COIL

FOCUS

COIL

M702

SLED

MOTOR

M701

SPINDLE

MOTOR

(LIMIT)

VC

S701

S801

PUSH

OPEN/

CLOSE

8FS

DOUT (O)

BUSY (O)

C-DOUT

CD-BUSY

DIGITAL

FILTER

&

1-bit DAC

GENERATOR

XI (I)

16.93MHz

U-COM

(VDD)

A

C

B

D

E

F

LD

PD

VR

VC

T+

T–

F+

F–

M

M

LD POWER

CONTROLLER

Q701

SL+

SL–

SP+

SP–

VC

Signal path

: CD

AC (I)

2

BD (I)

3

E (I)

5

F (I)

6

LD (O)

12

PD (I)

11

4

VBIAS (O)

12

11

17

18

26

27

2

1

(Page 18)

APC

T+

TRACKING

COIL

T–

DRIVE

F+

FOCUS

COIL

F–

DRIVE

SL–

SLED

MOTOR

SL+

DRIVE

SP+

SPINDLE

MOTOR

SP–

DRIVE

SLED/SPINDLE

MOTOR DRIVER,

TRACKING/FOCUS

COIL DRIVER

IC703

CD-LIM_SW

64

CD DOOR

29

CD 3.3V

CD-CONT

B

PRI-

SERVO

AMP

42

3V-CHK

TIN

(FIN)

MUTE

(SLIN)

SPIN

OPOUT

OPIN

VREF

Q957-959,D957

9

20

7

24

3

14

15

23

CD +3.3V

REC/PB

POWER

CONTROL

CONTROL

JUMPO (O)

18

VC

CD 6V

TAPE 6V

RADIO 6V

DIGITAL

SERVO

SDOUT (O)

21 22

CLVOUT(O)

41

+

6V-CHK

39

SYNCHRONOUS

CIRCUIT

BATT-CHK-H

SYSTEM SERVO PROCESSOR,

DIGITAL SIGNAL PROCESSOR

ERROR

AMP

Q705

ERROR

AMP

Q704

SYSTEM CONTROLLER

IC801 (1/2)

RIPPLE

FILTER

Q304

9V (SW)

R-VT

D324

RF AMP,

IC701

PULSE/DC

CONVERTER

Q703

P-CON

65

D951

D952

DIN (I)

RESETX (I)

MONI1

XPLCK

35 34 31 2826 30 27 37 3832 29

D703

POWER

SWITCH

Q951

+3.3V REG

IC802

AUDIO+6V

REG

Q955,D953

POWER

SWITCH

Q952,953

3.3V

SUBSYQ (O)

51

CD-RESETX

CD-SUBSYQ

23

54 62 55 52 5364

CD-DIN

DSP

I/F

R/W (I)

MCK (I)

CD-R/W

VDD

CD-MCK

LDACO (O)

CLOCK

XO (O)

X701

41

RDA

43

D901 – 904

RECT

BATT

F902

CD_IN_ L

CD_IN_R

T901

POWER

TRANSFORMER

DRY BATTERY

(IEC DESIGNATION R20)

6PCS, 9V

SIZE "D"

A

(Page 18)

J901

AC IN

CFD-S01

17 17

Page 18

CFD-S01

6-2. BLOCK DIAGRAM — MAIN SECTION —

HRP301

RECORD/PLAYBACK

HEAD

L-CH

R-CH

HE301

ERASE HEAD

(Page 17)

S301

(REC/PB)

REC

PB

A

AUDIO 6V

CD_IN_R

CD_IN_L

-1 -2

27

SAD

EEPROM

IC805

TAPE REC

SCL

7980

65

S1

COM1|COM4

10–266 – 9

LIQUID CRYSTAL

DISPLAY PANEL

LCD401

R.RO

9

R.IN

8

14

4

24

5

6

R.LIN

L.RO

L.LIN

L.IN

REF

T301

DET

REC

21 22 16

REC BIAS OSC

Q301

ALC 2

RADIO L

L.RAD

TU_IN_L

REC/PB

PRE AMP

IC301

R.RAD

TU_IN_R

L.LO

R.LO

LINE

TAPE

20

R-CH

18

17

15

TAPE

CD

CD-CONT

8 7

B

(Page 17)

37

SYSTEM CONTROLLER

IC801 (2/2)

|

S17

XT171XT2

70

X801

32.768kHz

74X175

X802

4.19MHz

X2

76

1

RESET

IC804

2

3.3V

RST

FUNC TC

FUNC CD

TU-DATA

57 58 5956

TU-COUNT

TU-CLK

TU-CE

IC302

ELECTRONIC VOLUME

L-IN

VOL AMP

LOGIC

CLK4DATA

5

7736 78

V-CLK

V-DATA

L-OUT

MEGA

BASS

SWITCH

Q122

68

50

D322

DBB

WP/INI

Q805, D801, 804

MUTE

Q124

35

49

A-MUTE

TC-PLAY

POWER AMP

IC303

6 2

U-COM

(VDD)

LEVEL

DETECT

D323

TAPE PLAY

DETECT

Q808

KEY145KEY244KEY3

43

9V (SW)

R-CH

OPR/BATT

D406

9V (SW)

SP101

SPEAKER

(L-CH)

SP201

SPEAKER

(R-CH)

S301

(TAPE PLAY)

M

M301

CAPSTAN/REEL

MOTOR

J321

i

ANT2

FM

TELESCOPIC

ANTENNA

L3

AM

FREQUENCY

COVERAGE

CT3,ANT1

AM

TRACKING

D3

CT3

RADIO 6V

ANT1

AM

FERRITE-ROD

ANTENNA

L3

CT1,L1

FM

TRACKING

31

1

2

36

L1 CT1

RADIO 6V

AM OSC

AM RF-IN

REG

FM

RF-IN

(VT)

D1

AM

OSC

AM

MIX

FM

RF-OUT

28

FM

MIX

FM

OSC

3234

27PD26

LP-IN

LP-OUT

FM OSC

D2

RADIO 6V

R-VT

FM/AM RF AMP, MIX, OSC, IF AMP,

AM

MIX-OUT

FM

MIX-OUT

L2

FM MPX

IC1

T1

5 7

RADIO 6V

3

RADIO 6V

L2

FM

FREQUENCY

COVERAGE

CF2

CF3

MW

X1

75kHz

20 19 16 17CE15

X IN

X OUT

AM

IF-IN

FM

IF-IN

8

T1

IF

AM

DET

FM

DET

FM-DET

11

RADIO 6V

L6

AF

BUFFER

L6

FM

IF

DI

18

DO

CL

DET-OUT

23 22

MPX-IN

FM

MPX

R-OUT

L-OUT

TU_IN_R

13

12

KEY3

KEY2

KEY1

Signal path

: FM

: AM

: TAPE PLAY

: TAPE REC

: CD

R-ch is omitted due to same as

L-ch.

KEY NETWORK

S402,415,416,418

S401,403-405,410-412

S407,408,413,414,417

CFD-S01

1818

Page 19

THIS NOTE IS COMMON FOR PRINTED WIRING

d

d

BOARDS AND SCHEMATIC DIAGRAMS.

(In addition to this, the necessary note is

printed in each block.)

CFD-S01

6-3. CIRCUIT BOARDS LOCATION• NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

POWER board

HEADPHONE board

CD MOTOR board

For schematic diagrams.

Note:

• All capacitors are in µF unless otherwise noted. (p: pF)

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

• f : internal component.

• C : panel designation.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• A : B+ Line.

• H : adjustment for repair.

•Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

– MAIN (1/4) Board –

no mark : CD PLAY

– MAIN (2/4) Board –

no mark : FM

(): AM

– MAIN (3/4), (4/4) and Other Boards –

no mark : FM

(): PB

<>: REC

[]: CD PLAY

•Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production

tolerances.

•Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production

tolerances.

• Circled numbers refer to waveforms.

• Signal path.

F : FM

f : AM

E : PB

a : REC

J : CD PLAY

4

W or less unless otherwise

For printed wiring boards.

Note:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

• W : indicates side identified with part number.

f

•

• : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Par ts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

: internal component.

(The other layers' patterns are not indicated.)

C

Q

B

E

Q

BCE

Q

B

C

These are omitted.

These are omitted.

E

KEY (FUNC) board

CONTROL board

TC board

• Waveforms

— MAIN Board —

1 IC701 9 (FEO (O))

– CD PLAY – – CD PLAY –

1.7V

Approx. 100mVp-p

100mV/div, 5msec/div

4 IC701 ts (EQO (O))

50mV/div, 0.5 µsec/div

BATTERY TERMINAL (R) boar

BATTERY TERMINAL (F) board

7 IC801 ug (X2)

1.7±0.2Vp-p

1V/div, 0.1 µsec/div

MAIN board

KEY (VOL) boar

3.5Vp-p

4.19MHz

CFD-S01

2 IC701 ek (XO (O))

– CD PLAY –

3.3Vp-p

16.93MHz

1V/div, 20nsec/div

3 IC701 rk (TEO (O))

– CD PLAY –

1.7V

Approx. 100mVp-p

100mV/div, 5msec/div

5 IC1 w; (X OUT)

75kHz

1V/div, 5 µsec/div

6 IC801 ua (XT2)

32.768kHz

1V/div, 10 µsec/div

2.0Vp-p

3.4Vp-p

— TC Board — (TAPE REC)

1

Q301 C (REC)

21.1 µsec

1V/div, 10 µsec/div

2

HRP301 (YEL)

21.1 µsec

10V/div, 10 µsec/div

2.8Vp-p

30Vp-p

19 19

Page 20

CFD-S01

6-4. SCHEMATIC DIAGRAM — MAIN SECTION (1/4) —

Q701

R716

CN701

C700

R700

R701

R702

R704

R703

R711

R726

• Refer to page 19 for Waveforms. • Refer to page 32 for IC Block Diagram. • Refer to page 34 for IC Pin Description of IC701.

C762

C753

R772

Q703

R743

R770

C754

R768

R742 R739

C773

C752

R766

IC701

C749

JC701

C744

R773

R774

C747

C745

R761

R756

R760

R755

X701

C764

C763

R762

C766

C765

R748

R763

C767

C769

R775

R776

JC705

C738

C733

D703

R759

R758

R757

R724

R719

R714

R710

C710

C777

R725

R715

R712

R717

R708

R707

R706

R705

C709

C701

C702

C772

C703

R721

R709

C759

R723

R722

C748

C707

C708

C751

C704

C750

C757

C758

C705

D704

C706

R713

C711

C712

C713

R746

FB704

R744

C755 C779

FB703

FB702

R778

C761

FB701

C735

(Page 22)

R777

M702

S701

FFC020

CN702

R749

R750

Q705

R785 R783

R784

C783

Q704

R745

C782

IC703

R782

R781

C774

R780

R747

C781

R729

R728

C723

R751

C717

R786

C716

R730

R731

JC703JC704

R727

TP701

R733

R732

R736

C718 R740

C719

C720

TP704

TP702

R734

IC B/D

R741

TP703

JC702

R754

C725

C730

C731

C729

C728

C727

C726

CFD-S01

M701

C721 C760

C722

2020

Page 21

CFD-S01

6-5. SCHEMATIC DIAGRAM — MAIN SECTION (2/4) —

L3

R1 R2

C13

C14

C10

D3

C12

C11

C15

R6

C9

R5

D1

CT1

L1 L2 R3

C7

• Refer to page 19 for Waveforms. • Refer to page 31 for IC Block Diagram.

R11

C2

C16

C4C67

C3

R7

D2

R9

C5

C6

IC B/D

R4

C45

R13

R12

R14

C17

C19

C18

R27

C20C46

C39

C40

R15R39

C41

C42C1

X1

C43

R24

D6

ANT2

ANT1

CT3

C25

C22

C21

C29

R26

D4

D5

C70

C23

C24

T1

CF3

CF2

C26

IC1

R28

R25

C27

C28

C30

R10

R41

R29

L6

C31 C33

C34C32

R19R18 R21R20

C35 C36 C37

R16

R17

C38

R22

R23

(Page 22)

CFD-S01

21 21

Page 22

CFD-S01

6-6. SCHEMATIC DIAGRAM — MAIN SECTION (3/4) —

FFC11P

(Page 26)

• Refer to page 19 for Waveforms. • Refer to page 36 for IC Pin Description of IC801.

R844

R847

R870

R871

R872

R873

R874

R875

R876

R877

R878

R879

R880

R881

R882

R883

R884

R846

IC801

R801

C351

C352

R837

R803

R864

R863

R890

R889

R888

R887

R886

R804

R862

R901

R903

R905

R885

R848

R807

R895

R854

X801

R896

R869

R322

R834

R833

R832

R843

R842

X802

C815

C814

R836

C824

IC805

R860

R845

C821C801

R853 R856

R850

R852R851

R849

C822

IC804

L802

L801

CN801

(Page 28)

C820

CN802

(Page 28)

(Page 23)

C826

C817

IC802

C816

R861

R802

R835

C835

R840

JC801

D804

R823

R824

R808

R827

D801

JC802

C802

R894

R891

R893

R829

Q805

R892

R858

R805

R806

R857

R868

R825

R838

R826

R841

R828

R818

C812

R812

C803

R813

C804

R810

C805

R811

C806

R814

C807

R815

C808

R816

C809

R817

C810

R820

R819

C818

R830

C819

R831

C813

R866

R865

R867

C262

C162

CN803

S801

(Page 20)

CFD-S01

R899

C163

C263

R166

R266

(Page 21)

2222

Page 23

CFD-S01

6-7. SCHEMATIC DIAGRAM — MAIN SECTION (4/4) —

C113

R330

R329

R321

R328

C213

C117

R335

C353

C330

C349

R332

R331

C350

• Refer to page 32 for IC Block Diagrams.

C217

R338

C311

R337

R336

IC B/D

IC302

C115

R139

R239

D322

R134

R135 R136

Q122

C106

C206

Q222

C215

R234

C129

R236R235

C229

C125

C225

C132

C232

R138

C127

C227

R238

R327

R140

R147

C331

R247

R240

Q124

Q224

C130

R141

R241

C230

C108

C208

R142

R242

C231

R243

C131

R143

C322

C323

C119

C219

C110

R144

R244

C210

R323

C355

D323

C354

C356

R324

C324

C112

IC B/D

IC303

C212

R245 R145

CN306

CN305

CN307

R148

R146

C216

C116

J321

R246R248

CN308

SP101

SP201

(Page 22)

M801

SW1

C326

D324

CN304

R325

R326

JC807

JW807

R855

Q957

R959 R958

C961

R333 C957

C905R900

D957

C959

Q808

Q958

Q959

C960

Q304

C357

R334

C952

Q955

C951

D953

C953

R960

R955

R954

D951

R952

Q953

Q952

R957

R951

R953

C954

R956

961

R

Q951

R962

R963

(Page 30)

R964

C325

D952

CFD-S01

23 23

Page 24

CFD-S01

6-8. PRINTED WIRING BOARD — MAIN SECTION —

1

A

B

C

D

234567891011 12 13 14

ANT2

FM TERESCOPIC

ANTENNA

JW232

JW231

L3

C14

C13

C11

C10

C12

R6

D3

C9

R5

JW226

CT3

E

ANT001

F

CN702

ANT1

AM FERRITE

BAR ANTENNA

G

JW230

H

I

OPTICAL PICK-UP BLOCK

(KSS-213C)

J

CFD-S01

• Semiconductor Location

Ref. No. Location

D1 C-4

D2 B-4

D3 D-3

D4 B-5

D5 B-5

D6 C-6

D322 E-11

D323 C-12

Ref. No. Location

D324 C-7

D703 H-5

D704 H-8

D801 F-14

D804 F-14

D951 C-9

D952 C-8

D953 C-7

• Refer to page 19 for Circuit Boards Location. : Uses unleaded solder.

D5

D4

D2

C15

JW218

JW229

JW227

JW228

JW224

JW217

JW219

R741

JW225

R2

C2

JW220

JW222

R750

CT1

R1

D1

C1

L1

C21

C70

C29

C701

R723

JW211

JW212

JW213

JW214

C721

JW216

IC703

C760

R730

R732

R733

JW223

R11

C3

C722

JW221

R749

JW207

C67

C22

JW209

JW215

R731

L2

C5

C6

R3

C7

C4

R26

CF3

C24

JW208

C23

C25

T1

R724

C702

JW210

ECB

Q701

CN701

R719

R747

R729

R780

R751

C723

C781

R745

R786

R784

Q704

Q705

C783

R785

JW206

F

CD MOTOR BOARD

FFC020

(Page 25)

Ref. No. Location Ref. No. Location

D957 D-7

IC1 C-5

IC302 D-9

IC303 D-12

IC701 G-7

IC703 G-4

IC801 G-12

IC802 F-10

IC804 H-9

IC805 G-10

Q122 D-11

Q124 E-11

Q222 D-11

Q224 C-11

(Page 29)

POWER BOARD

CN901

D

(Page 27)

HEADPHONE BOARD

CN307

E

C951

CN305

JW163

JW165

Q959

FB702

C960

C959

FB701

R775

R774

FB703

D704

C766

C733

R954

R955

R960

R776

C769

C765

R744

JW168

JW180

C953

D952

JW172

JW179

R778

FFC11P

C952

JW177

JW178

C262

JW175

JW173

JW176

JW171

D951

R956

C311

R335

JW174

R328

R330

JW169

R329

JW170

JW167

R957

C349

C163

R338

R336

C162

C954

R337

R777

JW166

R321

Q952

C350

R166

JW164

Q951

Q953

JW162

R951

R953

IC302

JW161

R852

R851

C820

IC804

R952

C263

C213

R856

4

R964

C113

JW156

JW160

R266

R849

R853

CN304

JW157

R963

C330

C117

JW158

R850

R855

C762

C730

R768

R766

C738

R959

C744

R756

Q304

C752

JC705

R762

R760

R958

Q957

JW186

R770

C751

C749

C745

R763

R748

C731

Q955

JW181

D324

C961

JW185

C704

R761

R739

C773

R334

D957

FB704

R746

JW182

Q958

C957

C750

JC701

C747

R743

Q703

D953

X701

R333

C764

C763

R773

R326

R325

C357

C761

C735

C767

R742

C17

C45

R28

R41

JW202

R712

C718

C42

C33

JW188

R704

JC703

R740

C720

C16

R721

R708

C777

R15

C41

C34

C709

R703

C712

R736

C40

R10

C30

R717

R722

R707

C710

R727

C717

C759

C748

C31

C32

R716

R20

R16

R27

R39

R705

R713

C39

R19

C707

R711

C19

JW191

R706

C700

R709

C711

C713

R734

JW197

R4

R9

R13

R7

R12

X1

IC1

CF2

C27

C26

R25

R29

C28

L6

C706

C703

JW203

JW204

R700

C772

R701

R702

R714

R715

R710

R725

R726

C716

JW205

R781

R782

C782

R728

C774

R783

C719

JC704

JC702

D703

C18

R18

C37

R17

JW189

C708

C46

JW194

JW195

R757

JW198

C35

C38

R758

D6

R22

R754

C20

JW192

JW193

C705

R755

JW200

JW187

R23

JW190

R759

R14

R21

IC

C726

C725

C727

JW196

JW199

C36

7

C326

R899

C755

C779

R772

C754

C753

0

C43

R24

JW183

JW184

C757

C758

1

C729

C728

JW201

A

TC BOARD

CN301

(Page 25)

SW1

(LEAF SW)

(CAPSTAN/REEL MOTOR)

R962

JC807

JW141

R961

C217

JW159

C824

1

C905

R900

M801

JW154

C353

JW155

C816

Q808

MM

C817

JW153

JW151

IC805

C325

JW148

C215

JW146

C115

JW152

R134

JW149

1

IC802

3

C351

JW145

R235

C227

R136

R135

C129

JW147

C352

R870

JW142

JW139

R236

R234

C232

C229

C127

C132

JW143

JW138

JW144

C826

L802

L801

C821

R895

R896

R869

R854

R860

R845

R843

JW150

R873

R874

R872

R871

CN801

B

CONTROL BOARD

FFC14P

(Page 27)

R238

C125

R138

R140

JW140

R240

R247

C331

JW137

R332

R842

R875

R876

C225

Q222

Q122

Q124

JW136

JW132

R877

R241

R147

JW135

R331

C822

JW133

R878

Q224

JW233

X801

R807

R848

R879

JW134

C230

C208

C206

JW130

R139

C106

R141

JW131

X802

R880

C131

R834

R833

R322

C323

R239

C108

D322

R844

R881

R883

1

R245

C809

R801

JW121

JW126

CN803

R837

JW122

R816

R817

R827

JW125

R862

C212

C119

JW120

CN306

JW116

R145

16

R815

R812

JW119

JW124

JW118

R826

R327

R905

R806

R805

R901

C808

R891

R244

R324

C219

C210

C322

R243

712

IC303

R143

R831

R830

C818

C813

C819

R819

C810

JW127

R836

C801

IC801

JW123

R888

R889

R886

R885

CN802

R887

R890

C130

R820

R846

R242

C814

C815

R847

JW129

R882

D323

C324

R323

C231

R142

R832

JW128

R884

C

CONTROL BOARD

FFC12P

(Page 27)

4

C354

JW117

R818

R838

R828

R868

R903

R814

R811

C802

R804

R144

C110

C835

C356

JW109

C807

JW113

C355

C806

R808

JW111

JW108

C805

C812

R824

R835

JW112

JW115

C112

R813

R840

R810

C803

R841

R825

JW110

R857

R893

R892

R803

JW114

R863

R864

R865

C804

JC802

JC801

R867

R866

Q805

R802

R823

R858

JW107

R894

D801

JW101

JW102

R861

JW103

JW104

JW105

JW106

ZPUSH

OPEN/CLOSE

R829

D804

1-869-864-

S801

JW807

(11)

11

Ref. No. Location Ref. No. Location

Q304 D-7

Q701 F-5

Q703 H-7

Q704 H-5

Q705 H-5

Q805 F-14

Q952 C-9

Q953 C-9

Q955 B-7

Q957 D-7

Q958 D-7

Q959 D-8

Q808 H-10

Q951 C-9

2424

Page 25

CFD-S01

6-9. PRINTED WIRING BOARDS — TC SECTION —

1

234567891011 12 13 14

A

WHT

RED

YEL

BLK

B

C

D

HE301

ERASE

HEAD

(L-CH)

RECORD/PLAYBACK

HRP301

HEAD

(R-CH)

R102

R108

C105

R109

R103

C103

R104

C301

E

C303

F

• Refer to page 19 for Circuit Boards Location. : Uses unleaded solder.

HT

RED

FB201

C102

FB202

R111

C104

301

JW

YEL

FB207

C202

R210

FB203

C309

IC301

302

JW

C305

C302

C204

R211

T301

C201

FB204

C207

FB205

JC305

R302

R205

R201

FB206

R206

R303

R202

R207

R212

R308

C306

C205

R204

JC302

R304

CN301

R208

C203

JC303

R312

C307

R203

JW

R306

R307

R209

JC306

303

Q301

R314

C304

S301

R305

R315

S301

(REC/PB)

PB

REC

BLK

R107

R101

R301

C312

W

R110

C107

C101

R112

R106

R105

R309

M702

(SLED MOTOR)

FFC020

S701

M701

(SPINDLE MOTOR)

S701

(LIMIT)

1-869-865-

(11)

11

CFD-S01

G

H

A

MAIN BOARD

FFC030

(Page 24)

1-869-869-

11

(11)

25 25

F

MAIN BOARD

CN702

(Page 24)

Page 26

CFD-S01

6-10. SCHEMATIC DIAGRAM — TC SECTION —

HRP301

HE301

S301

• Refer to page 19 for Waveforms. • Refer to page 33 for IC Block Diagram.

C102 R102 R108 R103

R112

R104

FB201

FB202

FB203

FB204

FB205

FB206

R204

R212

JC302

C301

FB207

R109

R301

R110

R210 C205

C104

C101

C107

R101

R107

C309

R207

R201

C207

C201

C204

C103

C105

C302

C203

R209

R203R202 R208C202

IC301

R106

R206

JC303

IC B/D

R111

C312

JC305

C303

R303

R211

R302

R309

R205

R304

JC306

CN301

R105

CFD-S01

C305

R308

T301

C306

C304

(Page 22)

R315R314R305

R306

C307

R312

Q301

R307

2626

Page 27

CFD-S01

6-11. PRINTED WIRING BOARDS — CONTROL SECTION —

1

234567891011 12 13 14

A

B

C

S410

S401

TUNE

R428

R426

S403

x

S412

R410

R409

R404

R403

R406

R430

S411

R429

S404

BX

R424

R413

D

S411

>/

PRESET

S411

./

• Refer to page 19 for Circuit Boards Location. : Uses unleaded solder.

(Page 24) (Page 24)

MAIN BOARD

CN801

B

121

LIQUID CRYSTAL DISPLAY UNIT

LCD401

MAIN BOARD

CN802

C

FFC12PFFC14P

S414

S413

S413

DISPLAY/

ENTER

SLEEPMODE

S408

R407

S417

S417

MEGA BASS

R434

R433

R417

R415

R423

R414

S407

S407

z/POWER

OPR/BATT

JC401

R425

1-869-867-

D406

D406

11

(11)

CN402

3

E

F

G

H

SP201

SPEAKER

(R-CH)

SP101

SPEAKER

(L-CH)

CN308

CN307

JW321

C116

R146

JW322

R148

R248

R246

C216

1-869-868-

E

(11)

11

(Page 24)

MAIN BOARD

CN306

5

4

3

2

6

7

1

J321

i

CN401

R432

S418

VOLUM

R418

R436

R435

S415

TAPE

S416

1-869-873-

E

(11)

11

FFC4PL

R419

S402

RADIO/BAND/

AUTO PRESET

FFC4PS

1-869-872-

S405

CD

(11)

11

I

CFD-S01

27 27

Page 28

CFD-S01

6-12. SCHEMATIC DIAGRAM — CONTROL SECTION —

R418 R432

FFC4PS FFC4PL

S402S405 S415

JC401

CN402

R419

R435 R436

S401 S403S404

R428 R429R413 R424 R426 R430 R406

POWER

S410 S411 S412

CN401

S416 S418

R404 R409R403

R410

(Page 22)

(Page 22)

FFC12P

R425

D406

LCD401

S407

S408

R415 R417R423 R414

S413S414 S417

R433 R434 R407

CFD-S01

FFC14P

2828

Page 29

CFD-S01

6-13. PRINTED WIRING BOARDS — POWER SUPPLY SECTION —

1

234567891011 12 13 14

A

B

C

T901

FH901 FH902

D903

D902

D

• Refer to page 19 for Circuit Boards Location. : Uses unleaded solder.

F902

C903

C901

D901

D904

C902

C904

907

JW

CN901

C906

CN902

D

RED

GRY

MAIN BOARD

CN305

(Page 24)

CN903

JW905

–

904

JW

DRY BATTERY

(IEC DESIGNATION R20)

+

SIZE "D"

6pcs, 9V

1-869-870-

–

(11)

11

E

F

G

H

J901

-

AC IN

1-869-866-

11

(11)

JW900

JW901

+

–

JW902

+

JW903

1-869-871-

(11)

11

CFD-S01

I

29 29

Page 30

CFD-S01

6-14. SCHEMATIC DIAGRAM — POWER SUPPLY SECTION —

CN902 CN903

C901

D901

D902

J901

T901

F902

C902

C903

D903

FH902FH901

D904

C904

C906

CN901

(Page 23)

CFD-S01

3030

Page 31

• IC BLOCK DIAGRAMS

CFD-S01

IC1 LV23003VA (MAIN Board (2/4))

AM RF-IN

REG

FM MIX

GND1

AM MIX-OUT

VCC1

AM IF-IN

FM IF-IN

P-DET

P-COMP

FM-DET

L-OUT

R-OUT

VSS

FM

MIX

AM

DET

FM

DET

AM

RF

AM

MIX

AGC

FM

S-METER

PIROT

DET

COMPARATOR

FF

FF

PHASE

MUTE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

IF

BUFFER

AM

IF

FM

IF

DECODER

FM

RF

FM

OSC

OSC

BUFFER

SD

ST

TRIG

STSW

FF

VCO

AM

OSC

LOW-PASS

FILTER

36

FM RF-IN

35

GND2

34

FM RF-OUT

33

VCC2

32

FM OSC

31

AM OSC

30

BO2

29

BO1

28

LP-OUT

27

LP-IN

26

PD

25

AGC

24

AM LOW CUT

23

DET-OUT

22

MPX-IN

UNIVERSAL

COUNTER

DATA SHIFT

15

CE

16

DI

17

CL

18

DO

CCB

I/F

REGISTER

LATCH

PROGRAMMABLE

DIVIDER

SWALLOW

COUNTER

UNLOCK

DETECTOR

POWER ON

RESET

REFERENCE

DIVIDER

PHASE

DETECTOE

CHARGE

PUMP

21

VDD

20

X OUT

19

X IN

31

Page 32

CFD-S01

IC703 BA5826FP-E2 (MAIN Board (1/4))

1

SP–

D.BUFF

2

SP+

SPIN

RST

REG–B

REGO

MUTE

GND

TIN

(TIN)

GND

OPOUT

D.BUFF

3

4

THERMAL

SHUT-DOWN

MONITOR

5

6

7

8

9

10

D.BUFF

T–

11

D.BUFF

T+

12

13

14

DRIVER

MUTE

LEVEL

SHIFT

REGULATOR

LEVEL

SHIFT

LEVEL

SHIFT

LEVEL

SHIFT

D.BUFF

D.BUFF

VCC

VCC

D.BUFF

D.BUFF

28

GND

27

SL+

SL–

26

25

SLIN

24

(SLIN)

23

VREF

VCC

22

VCC

21

20

(FIN)

FIN

19

F–

18

F+

17

NC

16

OPIN

15

32

IC303 TA8227P (MAIN Board (4/4))

L-IN

L-NF

6

7 8 9 10 11 12

R-IN

PREGND

5 4 3 2 1

R-NF

RIPPLE

L-BS

R-BS

L-OUT

R-OUT

VCC2

VCC1

Page 33

IC302 PT2257-S (MAIN Board (4/4))

CFD-S01

L-IN L-OUT VDD CLK

8

VR 2

VOL AMP 2

VOL AMP 1

VR 1

1

R-IN R-OUT GND DATA

7

REF AMP

2 3 4

6

VREF

5

LOGIC

CONTROL

IC301 TA2068N (TC Board)

1

AGC

2

L.PO

L.NF

L.RO

L.IN

REF

GND

R.IN

R.RO

R.NF

R.PO

MIC.NF

3

4

5

6

REF

AMP

7

8

9

10

11

12

REC

AMP1

2.1

NAB

AMP2

26dB

REC

AMP2

26dB

MIC

AMP1

DET

NAB

AMP1

ALC2 ALC1

ON

BUF AMP

A1

MUTE

BUF AMP

A2

TAPE

BUF AMP

BUF AMP

TAPE

TAPE

B1

B2

TAPE

LINE

MUTE

MUTE

RADIO

LINE

RADIO

ON

ON

MONITOR

AMP

7dB

7dB

MONITOR

AMP

LOGIC

24

23

22

21

20

19

18

17

16

15

14

13

L.LIN

MIC I/EX

L.RAD

REC

L.LO

VCC

R.LO

LINE

R.RAD

TAPE

R.LIN

MIC

33

Page 34

CFD-S01

• IC PIN DESCRIPTIONS

• IC701 BU9532KS2 (RF AMP, SYSTEM SERVO PROCESSOR, DIGITAL SIGNAL PROCESSOR) (MAIN BOARD (1/4))

Pin No. Pin Name I/O Pin Description

1AVDD1 I Power supply pin (+3.3V)

2AC (I) I A+C RF signal input

3 BD (I) I B+D RF signal input

4 VBIAS (O) O VC voltage output

5E (I) I E RF signal input

6F (I) I F RF signal input

7 PKC (O) O RF signal peak detector capacitor fitted

8 FEN (I) I Focus error amp input

9 FEO (O) O Focus error output

10 BTC (O) O RF signal bottom detector capacitor fitted

11 PD (I) I Photo detector signal input

12 LD (O) O Laser diode drive signal outout

13 ASY (I) I Asymmentric correction input

14 PCO (O) O PLL PCO output

15 FCO (O) O PLL FCO-DAC output

16 AGND1 — Ground

17 FDOUT (O) O Focus drive signal output

18 JUMPO (O) O track jump pulse drive signal input

19 TDOUT (O) O Tracking drive sigmal outout

20 SDIN (I) I Sled drive signal input

21 SDOUT (O) O Sled drive signal output

22 CLVOUT (O) O CLV drive signal output

23 CLK88 (O) O Not used (Open)

24 LON (O) O Not used (Open)

25 CLK (O) O Not used (Open)

26 SUBSYQ (O) O Sub code synchronous signal output

27 MCK (I) I Command transfer clock input

28 DIN (I) I Status and SUB-Q data input

29 DOUT (O) O Command data output

30 R/W (I) I Command read/write signal input

31 RESETX (I) I Reset signal input

32 BUSY (O) O BUSY signal output

33 MONI 0 I Test input (Not used (pull duwn))

34 MONI 1 I Muting signal input

35 XPCLK O XPCLK signal output

36 DVDD — Power supply pin (+3.3V)

37 XI (I) I Main clock input (18.432MHz)

38 XO (O) O Main clock output (18.432MHz)

39 DGND — Ground

40 AVDD2 — Power supply pin (+3.3V)

41 LDACO (O) O Audio L-CH output

42 VCDAC O Audio DAC reference voltage output

43 RDACO (O) O Audio R-CH output

44 AGND2 — Ground

45 RFRPRFM (O) O RFRP capacitor fitted

46 TZCRFM (O) O TZC capacitor fitted

47 SC (O) O Scratch depth ajstment output

48 TEO (O) O Tracking error outpot

34

Page 35

Pin No. Pin Name I/O Pin Description

49 TEN (O) O Tracking error input

50 CACG (O) O RFAGC time constant capacitor fitted

51 RFI (I) O RF capacitor fitted

52 EQO (O) O RF EQ output

CFD-S01

35

Page 36

CFD-S01

• IC801 µPD78947GC-A49-8BT-A (SYSTEM CONTROL) (MAIN BOARD (3/4))

Pin No. Pin Name I/O Pin Description

1, 2 NC I Not used. (Open)

3 to 5 VLC2 to 0 O LCD drive bias voltage input

6 to 9 COM1 to 4 O LCD drive common output

10 to 26 S1 to 17 I LCD drive segment output

27 TAPE REC I Tape record signal input H: REC

28 NC I Not used. (Pull down)

29 DOOR SW I CD door open/close switch input L: Close

30 NC O Not used (Open)

31 SIMUKE1 I Model discrimination input

32 SIMUKE2 I Model discrimination input

33 SIMUKE3 I Model discrimination input

34 NC O Not used (Open)

35 A-MUTE O Audio mute output H: Mute

36 FUNC CD O CD power control signal output H: CD ON

37 FUNC TC O Tape function output H: Tape

38 AVDD — Power supply (+3.3 V)

39 BATT-CHK-H I Battery voltage check input

40 BATT-CHK-M I Battery voltage check input (Not used (Pull down))

41 6V-CHK I Power supply 6V check signal input

42 3V-CHK I Power supply CD 3.3V check signal input

43 to 45 KEY3 to 1 I Key input

46 NC I Not used (Pull down)

47 AGND I Ground

48 RMC IN I Remote commander receiver data input (Not used)

49 TC-PLAY I Tape play switch input L: Tape play

50 WP/INI I Wake-up/Interrupt signal input

51 CD-SUBSYQ I CD sub code synchronous signal input

52 CD-BUSY I CD BUSY signal input

53 CD-DOUT I CD command data input

54 CD-DIN O CD status and SUB-Q data output

55 CD-MCK O CD command transfer clock output

56 TU-COUNT I Tuner PLL serial data input

57 TU-DATA O Tuner PLL serial data output

58 TU-CLK O Tuner PLL serial transfer clock output

59 TU-CE O Tuner PLL chip enable signal output

60 MIC DET I Not used (Pull down)

61 TU-ON O Not used (Open)

62 CD-R/W O CD command read/write signal output

63 CD-LIM_SW I CD optical inner limit signal input

64 CD-RESETX O CD system reset output

65 P-CON O System power control output H: Power on

66 ISS1 O Not used (Open)

67 ISS2 O Not used (Open)

68 M-BASS O MEGA BASS control signal output H: MEGA BASS on

69 ICO I Not used (Pull down)

70 XT1 I Sub system oscillation input (32.768 kHz)

71 XT2 O Sub system oscillation output (32.768 kHz)

72 VDD — Power supply (+3.3 V)

73 VSS — Ground

36

Page 37

Pin No. Pin Name I/O Pin Description

74 X1 I Main system oscillation input (4.19 MHz)

75 X2 O Main system oscillation output (4.19 MHz)

76 RST I System reset input

77 V-CLK O Volume command transfer clock output

78 V-DATA O Volume command data output

79 SCULL O EEPROM serial clock output

80 SAD I/O EEPROM serial data input/output

CFD-S01

37

Page 38

CFD-S01

NOTE:

• The mechanical parts with no reference

number in the exploded views are not supplied.

• Items marked “*” are not stocked since

they are seldom required for routine service.

Some delay should be anticipated

when ordering these items.

• -XX and -X mean standardized parts, so

they may have some difference from the

original one.

7-1. REAR CABINET SECTION

SECTION 7

EXPLODED VIEWS

• Color Indication of Appearance Parts

Example :

KNOB, BALANCE (WHITE) ... (RED)

RR

Parts Color Cabinet’s Color

• Accessories are given in the last of this parts list.

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

1

3

F902

T901

11

ANT2

10

3

2

9

3

3

8

5

3

11

6

3

7

3

5

4

3

3

6

11

3

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 2-654-054-11 LID, BATTERY

2 3-252-833-01 SCREW (M3), (+) P

3 3-252-827-01 SCREW (B2.6), (+) BV TAPPING

4 A-1174-392-A BATTERY TERMINAL (R) BOARD, COMPLETE

5 3-229-975-01 SPRING, BATTERY (–)

6 3-252-540-01 SPRING (+.–), BATTERY

7 2-654-073-01 TERMINAL, ANTENNA

8 A-1174-391-A BATTERY TERMINAL (F) BOARD, COMPLETE

9 A-1154-800-A POWER BOARD, COMPLETE

10 2-654-040-11 CABINET (REAR)

11 3-831-441-99 SHEET (1)

ANT2 1-754-376-11 ANTENNA, TELESCOPIC (FM)

0F902 1-533-468-12 FUSE, GLASS TUBE (DIA. 5) (2A/125V)

0T901 1-443-871-11 TRANSFORMER, POWER

38

Page 39

7-2. FRONT CABINET SECTION (1)

51

52

57

58

A

59

60

CFD-S01

71

70

61

54

55

56

A

67

51

62

68

69

not supplied

51

53

66

65

63

64

not supplied

63

51

51

52

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 3-252-827-01 SCREW (B2.6), (+) BV TAPPING

52 2-655-159-11 JOINT, CABINET

53 3-047-468-01 DAMPER

54 2-654-071-01 SPRING, CASSETTE

55 X-2103-200-1 HOLDER SUB ASSY, CASSETTE

56 1-797-376-11 DECK, MECHANICAL

57 2-654-047-11 BUTTON (PAUSE)

58 2-654-046-11 BUTTON (STOP)

59 2-654-045-11 BUTTON (REW)

60 2-654-044-11 BUTTON (FF)

61 2-654-042-11 BUTTON (PLAY)

62 2-654-043-11 BUTTON (REC)

63 3-254-029-01 SCREW

64 A-1174-385-A TC BOARD, COMPLETE

65 3-253-143-01 SCREW (B2.6), (+) P TAPPING

66 2-668-660-01 PAPER (C), SHIELD

67 3-923-151-01 CUSHION, RUBBER

68 2-670-389-01 BELT (1)

69 2-670-390-01 BELT (2)