Page 1

CDX-T68X

SERVICE MANUAL

Ver 1.1 2001.05

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism NEW

CD Drive Mechanism Type MG-276A-159

Optical Pick-up Name KSS-720A

System Compact disc digital audio system

Frequency response

5 – 20,000 Hz

Wow and flutter

Below the measurable limit

Signal-to-noise ratio

95 dB

Outputs BUS control output (8 pins)

Analog audio output (RCA pin)

Current drain 800 mA (during CD playback)

800 mA (during loading or ejecting a

disc)

Operating temperature

–10°C to +55°C

Dimensions Approx. 234.4 × 60 × 159.5 mm (w/h/d)

not incl. projecting parts and controls

Mass Approx. 1.5 kg

Power requirement

12 V DC car battery (negative earth)

Supplied accessories

Disc magazine (1)

Parts for installation and connections

(1 set)

Design and specifications subject to change without notice.

9-870-271-12 Sony Corporation

2001E0500-1 e Vehicle Company

C 2001.5 Shinagawa Tec Service Manual Production Group

COMPACT DISC CHANGER

Page 2

CDX-T68X

L

SERVICING NOTES

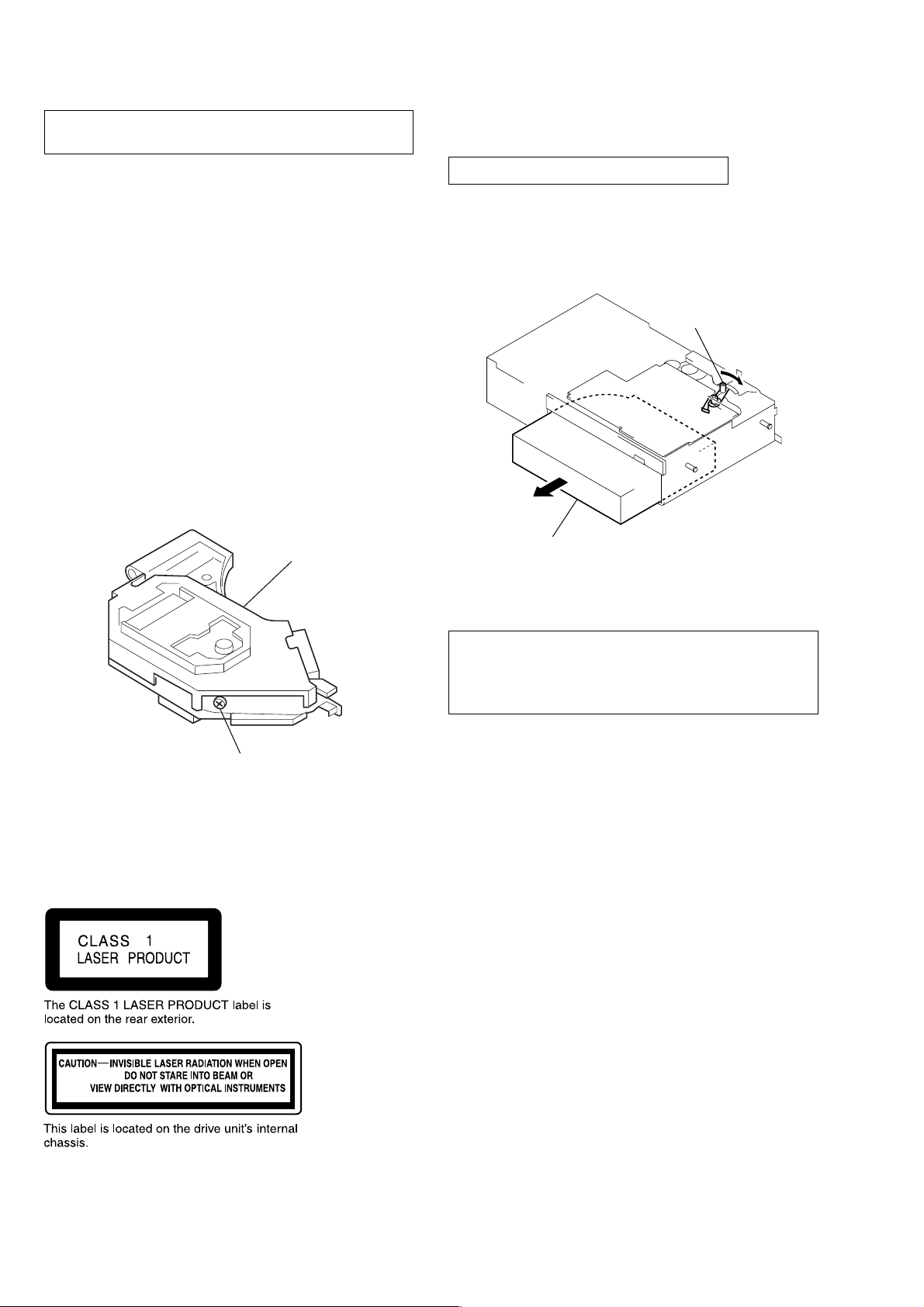

NOTES ON HANDLING THE OPTICAL PICKUP BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

US/Canadian model:

If the optical pick-up block is defective, please replace the whole

optical pick-up block.

Never turn the semi-fixed resistor located at the side of optical

pick-up block.

OPTICA

PICK-UP

BLOCK

DISC MAGAZINE GETTING OUT PROCEDURE

ON THE POWER SUPPLY IS OFF

Remove the CASE (LOWER. S) beforehand

1) Press the lever (MZ LOCK) in the direction of arrow A.

2) Removal the magazine assy.

Note: Take out the magazine only when the tray is completely within the

magazine. If the disk or tray is sticking out, turn on the power and

eject the magazine.

Lever (MZ LOCK)

A

Magazine assy

SEMI-FIXED

RESISTOR

AEP/UK model:

When replacing the chassis (U.S) sub assy of mechanism deck

which have the “CAUTION LABEL” attached, please be sure to

put a new CA UTION LABEL (3-223-913-11) to the chassis (U.S)

sub assy.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

2

Page 3

c

c

21

4

3

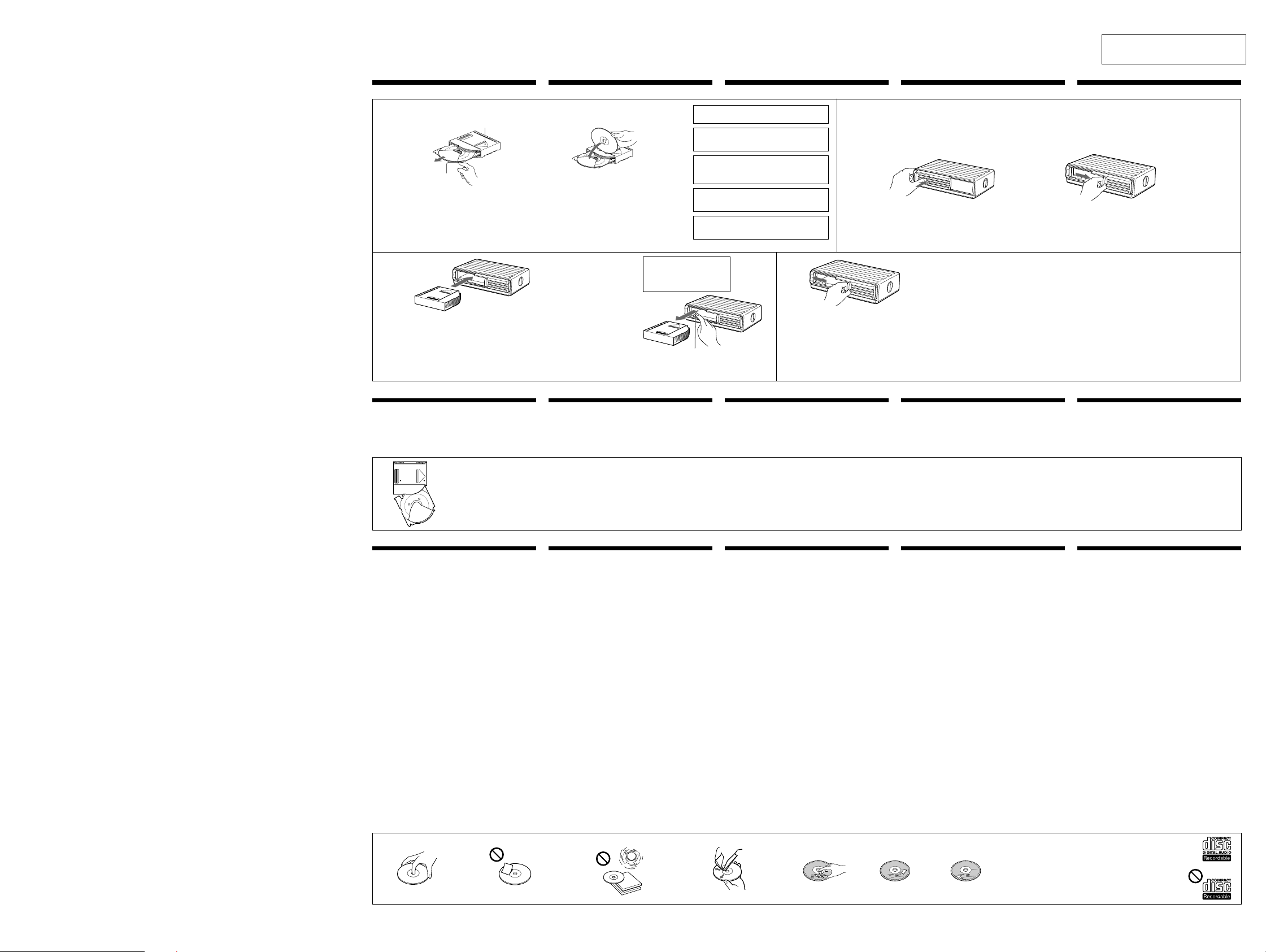

Een disc inbrengenEinlegen von CDsInsertion dun disque

6 discs, one in each tray

6 disques, un par plateau

Insgesamt 6 CDs (eine in jedem Fach)

6 discs, één per lade

6 dischi, uno in ciascun comparto

To remove

Retrait

Herausnehmen des CD-Magazins

Verwijderen

Per estrarre

If the disc magazine does not lock properly

Take out the magazine, and after pressing the Z (EJECT) button, reinsert it.

Si vous ne pouvez pas fermer le chargeur de disques

Sortez le chargeur et, après avoir appuyé sur la touche Z (EJECT), réinsérez-le.

Wenn sich das CD-Magazin nicht richtig verriegeln läßt

Nehmen Sie das Magazin heraus, drücken Sie die Z (EJECT)-Taste, und setzen Sie das Magazin dann wieder ein.

Als het disc-magazijn niet soepel op zijn plaats vastklikt

Verwijder het disc-magazijn, druk op de Z (EJECT) toets en breng vervolgens het disc-magazijn opnieuw in.

Se il contenitore dischi non si blocca in posizione correttamente

Estrarlo e, dopo aver premuto il tasto Z (EJECT), reinserirlo.

Use the unit with the door closed completely

Otherwise, foreign matter may enter the unit and contaminate the

lenses inside the changer.

Note

When a disc magazine is inserted into the CD changer or the reset

button of the connected car audio is pressed, the unit will

automatically be activated and read the information on the CDs.

When the information on all the CDs in the disc magazine has been

read, the unit will automatically stop operation.

Opmerkingen betreffende het disc-magazijn

• Laat het magazijn niet achter op plaatsen waar dit blootgesteld wordt aan

vocht of aan hoge temperaturen, zoals op het dashboard van een auto of op

de hoedenplank, waar het magazijn in de volle zon staat.

• Steek niet meer dan één enkele disc in een uitsparing, anders kunnen zowel

de CD-wisselaar als de compact discs beschadigd worden.

• Laat het apparaat niet vallen en stel het niet bloot aan hevige trillingen of

schokken.

Inserimento di un disco

Slide open

Coulissez pour ouvrir

Öffnen

Openschuiven

Aprire facendo scorrere lo sportello

Push the label printed “PUSH” to unlock the door.

Appuyez sur l’étiquette portant l’inscription “PUSH”

pour déverrouiller la porte.

Drücken Sie auf die mit „PUSH“ gekennzeichnete

Stelle, um den Deckel zu entriegeln.

Druk op het label met de vermelding “PUSH” om de

klep te ontgrendelen.

Per sbloccare il coperchio, premere in corrispondenza

della dicitura “Push”.

Disc magazine

Chargeur de disques

CD-Magazin

Disc-magazijn

Contenitore dischi

Remarques sur le chargeur de disques

• Ne pas laisser le chargeur de disques dans un endroit très chaud ou très

humide comme sur le tableau de bord ou sur la plage arrière d’une voiture

où il serait en plein soleil.

• Ne pas insérer plus d’un disque à la fois sur le plateau, sinon le changeur et

les disques risquent d’être endommagés.

• Ne pas laisser tomber le chargeur de disques ni le cogner.

Hinweise zum CD-Magazin

• Halten Sie das Magazin von hohen Temperaturen und Feuchtigkeit fern.

Lassen Sie es nicht auf dem Armaturenbrett, auf der Heckablage usw. liegen,

wo es direktem Sonnenlicht ausgesetzt ist.

• Versuchen Sie nicht, mehr als eine CD in ein Fach einzulegen. Andernfalls

können der Wechsler und die CDs beschädigt werden.

• Lassen Sie das Magazin nicht fallen, und schützen Sie es vor Stößen.

Note sul contenitore dischi

• Non lasciare il contenitore dischi in luoghi con temperature elevate o molto

umidi, come sul cruscotto o sul ripiano posteriore di un’auto dove il

contenitore potrebbe essere esposto alla luce solare diretta.

• Non inserire più di un disco alla volta in ciascun comparto, diversamente il

cambia CD e i dischi saranno danneggiati.

• Non lasciar cadere il contenitore dischi e non sottoporlo a urti violenti.

Lorsque le plateau sort

En principe, les plateaux ne sortent pas du chargeur. Toutefois, s’ils

sortent du chargeur, il est facile de les réinsérer.

Avec la portion découpée du plateau vous faisant face, insérer le

coin droit du plateau dans la fente, puis enfoncer le coin gauche

jusqu’au déclic.

Remarque

Ne pas insérer le plateau à l’envers ou dans le mauvais sens.

Als de houder uitsteekt

Normaal gezien steken de houders niet uit het magazijn. Als ze er toch

zouden zijn uitgetrokken, kan u ze er makkelijk weer insteken.

Met de uitsparing in de houder naar u toe gericht, brengt u de

rechterhoek van de houder in de gleuf en drukt dan de linkerhoek

erin tot u een klik hoort.

Opmerking

De houder niet omgekeerd of in de verkeerde richting inbrengen.

Tab

Languette

Lasche

Lipje

Linguetta

Labeled surface up

Etiquette vers le haut

Mit der beschrifteten Seite nach oben

Etiket naar boven

Con l’etichetta rivolta verso l’alto

Utilisez le magasin à disques fourni ou un magasin à disques

XA-T7. Vous ne pouvez pas utiliser de magasin à disques

XA-T6 avec cet appareil. L’utilisation d’un autre type de

magasin à disques risque de provoquer un dysfonctionnement.

Verwenden Sie das mitgelieferte CD-Magazin oder das CDMagazin XA-T7. Das CD-Magazin XA-T6 kann nicht zusammen

mit diesem Gerät eingesetzt werden. Wird ein anderes als das

empfohlene CD-Magazin verwendet, kann es zu

Fehlfunktionen kommen.

Gebruik het meegeleverde disc-magazijn of het disc-magazijn

XA-T7. Het disc-magazijn XA-T6 kan niet met dit toestel

worden gebruikt. Het gebruik van een ander magazijn kan

defecten veroorzaken.

Utilizzare il contenitore dischi in dotazione o il contenitore

dischi XA-T7. Il contenitore dischi XA-T6 non può essere

utilizzato con questo apparecchio. Se si utilizza qualsiasi altro

contenitore, potrebbero sorgere problemi di funzionamento.

With the arrow side facing up

Avec la partie fléchée tournée vers le haut

Mit dem Pfeil nach oben

Met het pijltje naar boven

Con il lato della freccia rivolto verso l’alto

Push Z (EJECT) button down

Appuyez sur la touche Z (EJECT)

Drücken Sie die Taste Z (EJECT) nach unten.

Druk de Z (EJECT) knop in.

Premere il tasto Z (EJECT).

Inserting a disc

Use the supplied disc magazine or the disc magazine XA-T7.

The disc magazine XA-T6 can not be used with this unit. If you

use any other magazine, it may cause a malfunction.

Utilisez cet appareil avec la fenêtre complètement fermée

Sinon, des corps étrangers pourraient pénétrer dans l’appareil et

encrasser les lentilles dans le lecteur.

Remarque

Quand un chargeur de disques est inséré dans le changeur de CD ou

si la touche de réinitialisation de l’autoradio raccordé est

enclenchée, l’appareil se met automatiquement en marche et

reproduit les CD. Lorsque tous les CD du chargeur ont été

reproduits, l’appareil s’arrête automatiquement.

Verwenden Sie das Gerät nur mit vollständig geschlossener

Klappe

Halten Sie die Klappe des Geräts stets geschlossen, damit keine

Fremdkörper eindringen und die Linsen im Wechsler nicht

verschmutzen können.

Hinweis

Wenn Sie ein CD-Magazin in den CD-Wechsler einsetzen oder die

Rücksetztaste an der angeschlossenen Audio-Anlage in Ihrem Auto

drücken, schaltet sich das Gerät automatisch ein und beginnt, die

Daten auf den CDs zu lesen. Nachdem die Informationen auf allen

CDs im CD-Wechsler gelesen wurden, stoppt das Gerät automatisch.

Gebruik het toestel met volledig gesloten klep

Anders zou er stof of vuil in het apparaat terecht kunnen komen,

met als gevolg vervuilde lenzen en storingen in de werking.

Opmerking

Wanneer een disc-magazijn in de compact disc-wisselaar wordt

geplaatst of de terugsteltoets van de uitleesvenster-eenheid wordt

ingedrukt, zal het apparaat automatisch ingeschakeld worden,

waarna de informatie van de compact discs gelezen wordt. Nadat

alle informatie gelezen is, zal het apparaat weer automatisch in de

stopstand komen te staan.

Utilizzare l’apparecchio con lo sportello chiuso

Diversamente oggetti estranei potrebbero penetrare

nell’apparecchio e contaminare le lenti all’interno del cambia CD.

Nota

Quando un contenitore dischi è inserito nel cambia CD o viene

premuto il pulsante di azzeramento dell’autostereo collegato,

l’apparecchio si accende automaticamente e legge le informazioni

dei dischi. Quando le informazioni di tutti i dischi inseriti nel

contenitore dischi sono state lette, l’apparecchio si ferma

automaticamente .

Notes on the disc magazine

• Do not leave the disc magazine in locations with high temperatures and high

humidity such as on a car dashboard or in the rear window where the disc

magazine will be subjected to direct sunlight.

• Do not place more than one disc at a time onto one tray, otherwise the

changer and the discs may be damaged.

• Do not drop the disc magazine or subject it to a violent shock.

When the tray comes out

Normally, the trays will not come out of the magazine. However, if

they are pulled out of the magazine, it is easy to re-insert them.

With the cut-away portion of the tray facing you, insert the right

corner of the tray in the slot, then push in the left corner until it

clicks.

Note

Do not insert the tray upside down or in the wrong direction.

Wenn sich ein Fach gelst hat

Normalerweise können sich die Fächer nicht vom Magazin lösen.

Werden sie jedoch aus dem Magazin herausgezogen, lassen sie sich

mühelos wieder anbringen.

Hierbei muß die Aussparung des Fachs auf Sie weisen. Setzen Sie

dann die rechte Ecke des Fachs in den Einschub ein, und drücken

Sie danach die linke Ecke an, bis das Fach mit einem Klicken

einrastet.

Hinweis

Versuchen Sie nicht, das Fach mit der falschen Seite nach oben oder

verkehrt herum einzusetzen.

Quando il comparto fuoriesce

Di solito, i comparti non fuoriescono dal contenitore; se ciò dovesse

avvenire, è facile reinserirli.

Con la parte del comparto tagliata rivolta in avanti, inserire

l’angolo destro del comparto nell’alloggiamento, quindi inserire

l’angolo sinistro fino a farlo scattare in posizione.

Nota

Non inserire il vassoio capovolto o nella direzione errata.

Hinweise zum Umgang mit CDs

Eine verschmutzte oder beschädigte CD kann Tonaussetzer verursachen. Um

optimale Klangqualität sicherzustellen, beachten Sie folgendes:

• Damit die CD sauber bleibt, fassen Sie sie immer am Rand an, und

berühren Sie nicht die Seite ohne Beschriftung. (Abb. A)

• Kleben Sie weder Papier noch Klebeband auf die CD. (Abb. B)

• Bewahren Sie CDs in ihrer Hülle oder in den CD-Magazinen auf, wenn

sie nicht abgespielt werden.

Schützen Sie die CD vor Sonnenlicht und Wärmequellen wie

Warmluftauslässen. Lassen Sie sie nicht in einem Auto liegen, das direkt

in der Sonne geparkt ist, da die Temperatur im Wageninneren sehr hoch

ansteigen kann. (Abb. C)

• Reinigen Sie die CDs vor dem Abspielen mit einem handelsüblichen

Reinigungstuch. Wischen Sie dabei von der Mitte nach außen. (Abb. D)

Verwenden Sie keine Lösungsmittel wie Benzin oder Verdünner und keine

handelsüblichen Reinigungsmittel oder Antistatik-Sprays für Schallplatten.

• CDs mit ungewöhnlichen Formen, zum Beispiel herz- oder sternförmige

oder quadratische CDs, können Sie mit diesem Gerät nicht abspielen.

Falls Sie es doch versuchen, kann das Gerät beschädigt werden.

Verwenden Sie solche CDs nicht.

• Single-CDs (8-cm-CDs) können nicht wiedergegeben werden.

Hinweise zu CDs

Wenn Sie die unten aufgeführten CDs verwenden, können

Klebstoffrückstände dazu führen, daß die CD sich nicht mehr dreht, oder

Fehlfunktionen oder Schäden an der CD verursachen.

Verwenden Sie keine gebraucht gekauften oder Leih-CDs mit klebrigen

Rückständen auf der Oberfläche (z. B. von abgelösten Aufklebern, von Tinte

oder von Klebstoff, der unter den Aufklebern hervorquillt).

• Klebstoffrückstände. Tinte klebt. (Abb. E)

Verwenden Sie keine Leih-CDs mit alten Etiketten, die sich abzulösen

beginnen.

• Aufkleber, die sich zu lösen beginnen und Klebstoffrückstände

hinterlassen. (Abb. F)

Verwenden Sie keine CDs, an denen Etiketten oder Aufkleber angebracht

sind.

• Angebrachte Etiketten. (Abb. G)

Hinweise zu CD-Rs/CD-RWs

• Mit diesem Gerät können Sie CD-Rs (beschreibbare CDs) wiedergeben

lassen, die für den Einsatz als Tondatenträger konzipiert sind. (Abb. H)

• Je nach dem Aufnahmegerät, mit dem die CD-R bespielt wurde, oder

dem Zustand der CD-R selbst können einige CD-Rs mit diesem Gerät

möglicherweise nicht wiedergegeben werden.

• Eine noch nicht abgeschlossene CD-R kann nicht wiedergegeben

werden*.

• Eine CD-RW (wiederbeschreibbare CD) kann mit diesem Gerät nicht

wiedergegeben werden.

* Damit eine bespielte CD-R auf einem Audio-CD-Player wiedergegeben werden

kann, ist ein spezieller Prozeß erforderlich.

Opmerkingen bij het omgaan met discs

Bij het afspelen van een vuile of beschadigde disc kan het geluid regelmatig

wegvallen. Voor het verzekeren van een goede geluidsweergave dient u als

volgt met discs om te gaan.

• Pak een compact disc altijd bij de rand vast, houd hem proper en raak

het oppervlak (behalve het label) niet aan. (afb. A)

• Plak geen papier of plakband op een compact disc. (afb. B)

• Bewaar uw discs in hun doosje of disc-magazijn wanneer u ze niet

gebruikt.

Stel compact discs niet bloot aan direkt zonlicht of warmeluchtkanalen.

Laat ze niet liggen in een geparkeerde auto in de volle zon, aangezien

de temperatuur hierin bijzonder hoog kan oplopen. (afb. C)

• Maak een disc voor het afspelen altijd schoon met een in de handel

verkrijgbare doek. Wrijf van binnen naar buiten toe. (afb. D)

Gebruik geen solventen zoals benzine, thinner en in de handel verkrijgbare

reinigingsmiddelen of antistatische sprays voor grammofoonplaten.

• Discs met afwijkende vormen (b.v. hart, vierkant, ster) kunnen niet met

deze dit toestel worden afgespeeld. Indien u dat toch doet, kan het

toestel worden beschadigd. Gebruik geen dergelijke discs.

• U kunt geen 8cm CD’s afspelen.

Opmerkingen bij discs

Indien u de discs behandelt zoals hieronder beschreven, kunnen kleverige

resten de disc doen stoppen waardoor het toestel defect of uw discs

beschadigd kunnen raken.

Gebruik geen gebruikte of gehuurde CD’s met kleverig oppervlak

(bijvoorbeeld afkomstig van stickers of inkt of lijm die van onder de stickers

komt).

• Lijmresten. Kleverige inkt. (afb. E)

Gebruik geen gehuurde CD’s met oude labels die loskomen.

• Stickers die loskomen laten kleverige resten achter. (afb. F)

Gebruik geen discs waarop stickers zijn gekleefd.

• Vastgekleefde labels. (afb. G)

Opmerkingen bij CD-R/CD-RW discs

• Audio CD-R’s (opneembare CD’s) kunnen met dit toestel worden

afgespeeld. (fig. H)

• Sommige CD-R’s (afhankelijk van de opname-apparatuur of de staat van

de disc) kunnen niet met dit toestel worden afgespeeld.

• U kunt geen CD-R afspelen die niet is gefinaliseerd*.

• Met dit toestel kunnen geen CD-RW’s (herschrijfbare CD’s) worden

afgespeeld.

* Proces dat nodig is om een opgenomen CD-R disc af te spelen met een CD-

speler.

Note sulla manipolazione dei dischi

Un disco sporco o difettoso può causare cadute di suono durante la

riproduzione. Per poter ascoltare un suono ottimale, trattare i dischi come

indicato.

• Prendere i dischi per il bordo e, per tenerli puliti, non toccare la

superficie senza etichetta. (fig. A)

• Non attaccare carta o nastro adesivo sul disco. (fig. B)

• Quando non vengono utilizzati, conservare i dischi nelle apposite

custodie.

Non esporre i dischi alla luce solare diretta o a fonti di calore come

condotti di aria calda. Non lasciarli in veicoli parcheggiati al sole dove

può verificarsi un considerevole aumento della temperatura. (fig. C)

• Prima della riproduzione, pulire i CD con un panno di pulizia disponibile

in commercio. Pulire ogni CD dal centro verso l’esterno. (fig. D)

Non utilizzare solventi quali benzene, acquaragia o detersivi reperibili in

commercio, né spray antistatici per dischi analogici.

• Non è possibile riprodurre CD con forme irregolari (ad esempio a forma

di cuore, di quadrato, di stella) su questo lettore. Non utilizzare tali

dischi onde evitare di danneggiare il lettore.

• Non è possibile riprodurre CD da 8 cm.

Note sui dischi

I residui di colla presenti sui dischi indicati di seguito potrebbero causare

l’arresto del disco stesso e problemi di funzionamento dell’apparecchio o

danneggiare i dischi stessi.

Non utilizzare dischi di seconda mano o presi a noleggio che presentano

residui di colla sulla superficie, ad esempio residui di etichette o inchiostro

rimossi oppure residui di colla che fuoriescono dalle etichette.

• Residui di colla. Residui di inchiostro. (fig. E)

Non utilizzare dischi presi a noleggio con etichette vecchie che cominciano a

staccarsi.

• Etichette che cominciano a staccarsi, lasciando residui di colla. (fig. F)

Non utilizzare dischi su cui siano applicati etichette o adesivi.

• Etichette applicate. (fig. G)

Note sui CD-R/CD-RW

• Con il presente apparecchio è possibile riprodurre CD-R (CD registrabili)

progettati per l’utilizzo audio. (fig. H)

• In base alle condizioni dell’apparecchio di registrazione o del CD-R

stesso, alcuni CD-R potrebbero non essere riprodotti su questo

apparecchio.

• Non è possibile riprodurre CD-R non finalizzati*.

• Con il presente apparecchio è possibile riprodurre CD-RW (CD

riscrivibili).

* Operazione necessaria per la riproduzione di un CD-R registrato su lettore CD

audio.

Remarques sur la manipulation des disques

Un disque sale ou défectueux peut provoquer des pertes de son à la lecture.

Manipuler le disque comme suit pour obtenir un son optimal.

• Manipuler le disque par son arête et le maintenir dans un état propre,

ne pas le toucher sur la surface non imprimée. (fig. A)

• Ne pas coller de papier ou de bande adhésive sur le disque. (fig. B)

• Conservez vos disques dans leurs boîtiers ou des pochettes de

rangement lorsqu’ils ne sont pas utilisés.

Ne pas laisser les disques en plein soleil ou près d’une source de chaleur

comme des conduits d’air chaud. Ne pas laisser les disques dans une

voiture garée en plein soleil car la température de l’habitacle risque

d’augmenter considérablement. (fig. C)

• Avant la lecture, nettoyez les disques avec un chiffon de nettoyage

disponible dans le commerce. Essuyez chaque disque en partant du

centre vers l’extérieur. (fig. D)

N’utilisez pas de solvants tels que la benzine, du diluant, des produits de

nettoyage vendus dans le commerce ou des sprays antistatiques destinés aux

disques analogiques.

• Les disques de formes non standard (par exemple en forme de cœur, de

carré ou d’étoile) ne peuvent pas être lus sur cet appareil. Vous risquez

d’endommager votre appareil si vous essayez de le faire. N’utilisez pas

de tels disques.

• La lecture de CD de 8 cm n’est pas possible.

Remarques sur les disques

Si vous utilisez les disques décrits ci-dessous, le résidu adhésif risque de

provoquer l’arrêt de la rotation du disque et d’entraîner un

dysfonctionnement ou d’endommager vos disques.

N’utilisez pas de CD de seconde main ou de location qui présentent des

résidus adhésifs à la surface (par exemple d’étiquettes décollées ou d’encre, de

colle dépassant de l’étiquette).

• Résidus de colle. L’encre colle. (fig. E)

N’utilisez pas de CD de location avec d’anciennes étiquettes qui

commencent à se décoller.

• Les étiquettes qui commencent à se décoller laissent des résidus

adhésifs. (fig. F)

N’utilisez pas vos disques avec des étiquettes ou des autocollants apposés

dessus.

• Les étiquettes sont fixées. (fig. G)

Remarques sur les disques CD-R/CD-RW

• Vous pouvez écouter avec cet appareil des CD-R (CD enregistrables)

conçus pour une utilisation audio. (fig. H)

• Certains CD-R (en fonction des conditions de l’équipement

d’enregistrement ou du disque) risquent de ne pas être lus avec cet

appareil.

• Vous ne pouvez pas lire de disques CD-R non finalisés*.

• Vous ne pouvez pas lire de CD-RW (CD réinscriptibles) avec cet appareil.

* Un processus nécessaire à la lecture des disques CD-R enregistrés sur le lecteur

de CD audio.

Notes on handling discs

A dirty or defective disc may cause sound drop-outs during playback. To

enjoy optimum sound, handle the disc as follows.

• Handle the disc by its edge, and to keep the disc clean, do not touch the

unlabeled surface. (fig. A)

• Do not stick paper or tape on the disc. (fig. B)

• Keep your discs in their cases or disc magazines when not in use.

Do not expose discs to direct sunlight or heat sources such as hot airducts. Do not leave discs in a car parked in direct sunlight where there

can be a considerable rise in the temperature inside the car. (fig. C)

• Before playing, clean the discs with a commercially available cleaning

cloth. Wipe each disc from the centre out. (fig. D)

Do not use solvents such as benzine, thinner, commercially available

cleaners, or antistatic spray intended for analog discs.

• Discs with non-standard shapes (e.g., heart, square, star) cannot be

played on this unit. Attempting to do so may damage the unit. Do not

use such discs.

• You cannot play 8cm CDs.

Notes on discs

If you use the discs explained below, the sticky residue can cause the disc to

stop spinning and may cause malfunction or ruin your discs.

Do not use second-hand or rental CDs that have a sticky residue on the surface

(for example from peeled-off stickers or from ink, or glue leaking from under

the stickers).

• There are paste residue. Ink is sticky. (fig. E)

Do not use rental CDs with old labels that are beginning to peel off.

• Stickers that are beginning to peel away, leaving a sticky residue.

(fig. F)

Do not use your discs with labels or stickers attached.

• Labels are attached. (fig. G)

Notes on CD-R/CD-RW discs

• You can play CD-Rs (recordable CDs) designed for audio use on this

unit. (fig. H)

• Some CD-Rs (depending on the equipment used for its recording or the

condition of the disc) may not play on this unit.

• You cannot play a CD-R that is not finalized*.

• You cannot play CD-RWs (rewritable CDs) on this unit.

* A process necessary for a recorded CD-R disc to be played on the audio CD

player.

A GBC DEF

This way

Oui

Richtig

Juist

Cosi

Not this way

Non

Falsch

Fout

Non cosi

Not this way

Non

Falsch

Fout

Non cosi

This way

Oui

Richtig

Juist

Cosi

H

Look for this mark to distinguish CD-Rs for audio use.

Ce symbole permet de distinguer les CD-R conçus pour une utilisation audio.

Für den Einsatz als Tondatenträger konzipierte CD-Rs sind mit dieser

Markierung gekennzeichnet.

Audio CD-R’s zijn hieraan te herkennen.

Ricercare questo simbolo per distinguere i CD-R per utilizzo audio.

This mark denotes that a disc is not for audio use.

Ce symbole indique qu’un disque n’est pas conçu pour une utilisation audio.

Nicht für den Einsatz als Tondatenträger geeignete CD-Rs sind mit dieser

Markierung gekennzeichnet.

Dit geeft aan dat een disc niet geschikt is voor audiotoepassingen.

Questo simbolo indica che il disco non è destinato all’utilizzo audio.

Note

To prevent injury, do not insert your hand in the CD changer.

Remarque

Pour éviter toute blessure, ne pas introduire la main dans le changeur de CD.

Hinweis

Um Verletzungen zu vermeiden, greifen Sie mit der Hand nicht in den CDWechsler.

Opmerking

Steek uw hand niet in de CD-wisselaar om verwondingen te voorkomen.

Nota

Per evitare danni alla persona, non inserire le mani nel cambia CD.

Note

You cannot play an 8cm CD on this unit.

If you use the single adaptor, it may cause a malfunction.

Remarque

Il est impossible de lire un CD de 8 cm sur cet appareil.

Si vous utilisez l’adaptateur unique, il peut provoquer un

dysfonctionnement.

Hinweis

Mit diesem Gerät können Sie keine Single-CDs (8-cm-CDs)

wiedergeben lassen.

Wenn Sie einen Single-CD-Adapter verwenden, kann es zu

Fehlfunktionen

kommen.

Opmerking

U kunt geen 8 cm CD afspelen met dit toestel.

Door gebruik te maken van een single adapter kan het

toestel defect raken.

Nota

Con il presente apparecchio, non è possibile riprodurre CD

da 8cm.

Se viene utilizzato l’adattatore singolo, è possibile che si

verifichino problemi di funzionamento.

TABLE OF CONTENTS

SERVICING NOTES .......................................................... 2

1. GENERAL

Installation....................................................................... 4

Connections..................................................................... 4

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 5

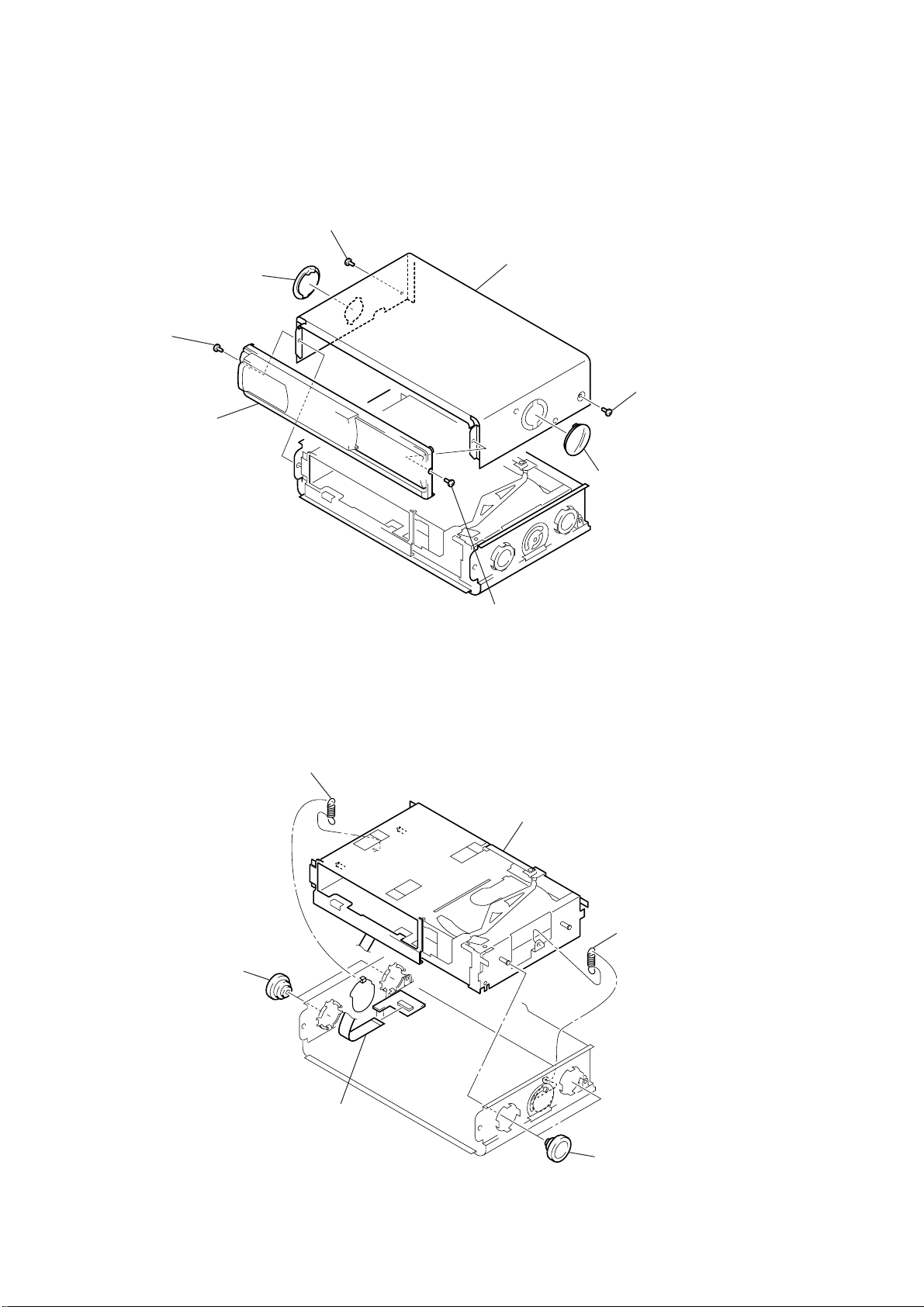

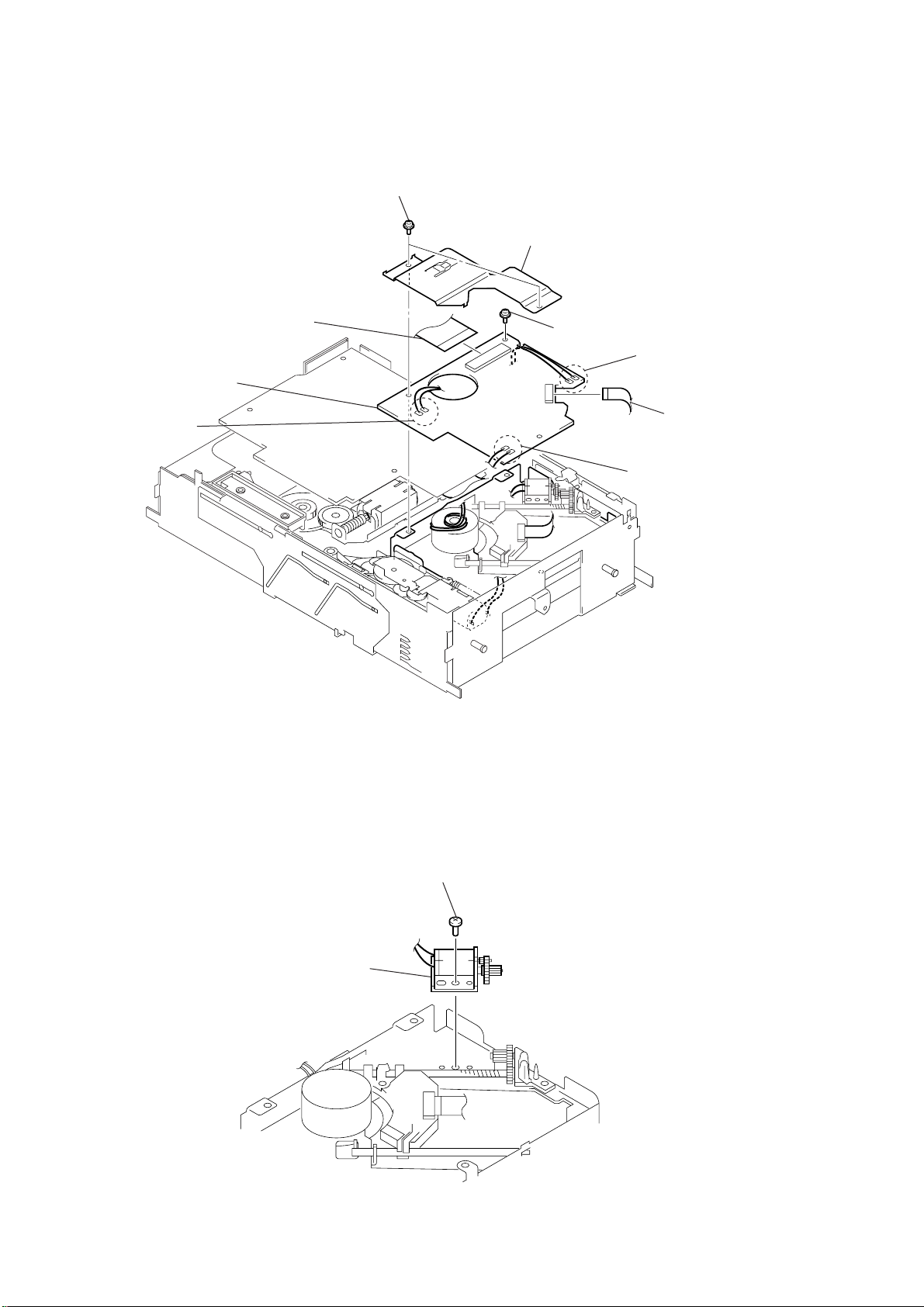

2-2. Front Panel (S) Assy, Case (Upper S) ............................ 6

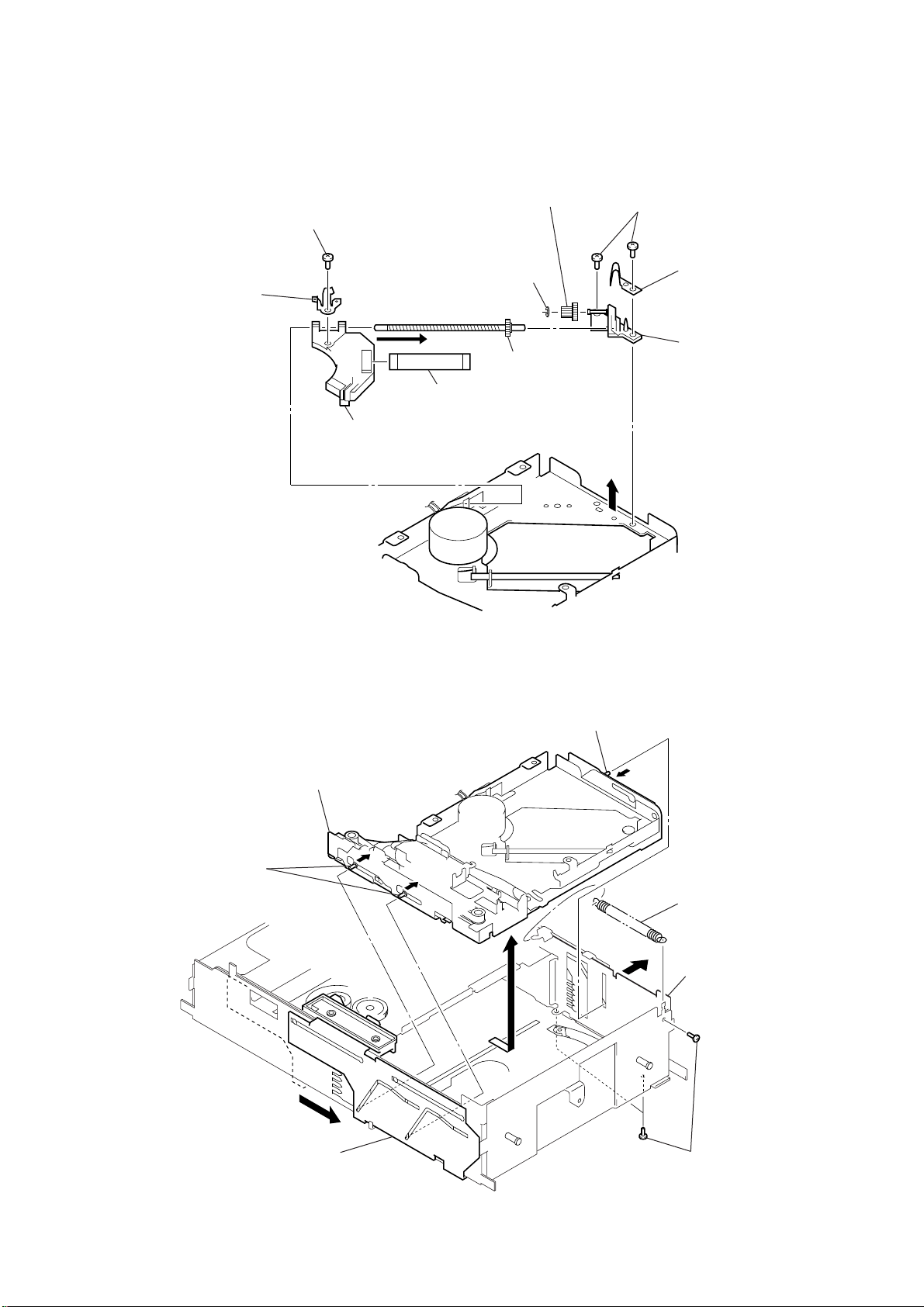

2-3. Mechanism Deck (MG-276A-159) ................................ 6

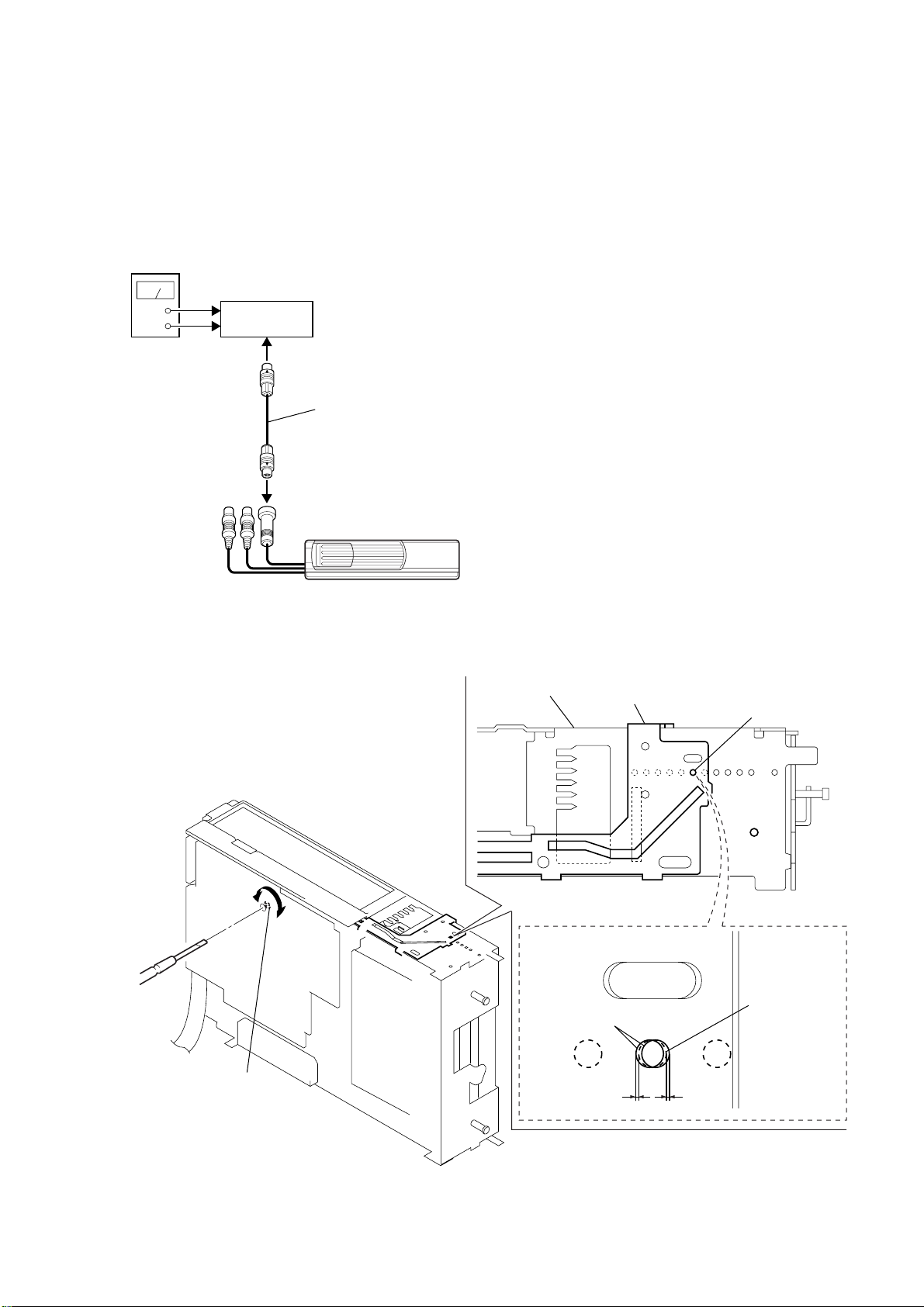

2-4. Jack Board....................................................................... 7

2-5. Belt (TS).......................................................................... 7

2-6. Main Board...................................................................... 8

2-7. Escutcheon (S), Slide Var iable Resistor

(Elevator Height Sensor) (RV301) ................................. 8

2-8. MD Motor Assy (Elevator) (M104)................................ 9

2-9. LE Motor Assy (Chucking) (M103) ............................... 9

2-10. RF Board ......................................................................... 10

2-11. Sled Motor Complete Assy (M101) ............................... 10

2-12. Optical Pick-up (KSS-720A) .......................................... 11

2-13. Chassis (EV) Assy........................................................... 11

2-14. Lever (CHK.L) Assy, Lever (CHK.R) Assy ................... 12

2-15. Chassis (OP) Block Service Assy................................... 12

3. MECHANICAL ADJUSTMENT.......................... 13

SECTION 1

GENERAL

CDX-T68X

This section is extracted from

instruction manual.

4. ELECTRICAL CHECK .......................................... 14

5. DIAGRAMS

5-1. Block Diagram – SERVO Section – .............................. 17

5-2. Block Diagram – BUS CONTROL/

POWER SUPPLY Section – ........................................... 18

5-3. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 19

5-4. Printed Wiring Boards – RF Board – ............................ 20

5-5. Schematic Diagram – RF Board – ................................. 21

5-6. Printed Wiring Boards

– MAIN Board (Component Side) – .............................. 22

5-7. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 23

5-8. Schematic Diagram – MAIN Board (1/2) – .................. 24

5-9. Schematic Diagram – MAIN Board (2/2) – .................. 25

5-10. Printed Wiring Boards – JACK Board –........................ 26

5-11. Schematic Diagram – JACK Board – ............................. 26

5-12. IC Pin Function Description ........................................... 31

6. EXPLODED VIEWS

6-1. Case Section .................................................................... 34

6-2. Mechanism Deck Section-1 (MG-276A-159) ................ 35

6-3. Mechanism Deck Section-2 (MG-276A-159) ................ 36

7. ELECTRICAL PARTS LIST ............................... 37

33

Page 4

CDX-T68X

Installation

Precautions

• Choose the mounting location carefully, observing the

following:

— The unit is not subject to temperatures exceeding 55°C

(such as in a car parked in direct sunlight).

— The unit is not subject to direct sunlight.

— The unit is not near heat sources (such as heaters).

— The unit is not exposed to rain or moisture.

— The unit is not exposed to excessive dust or dirt.

— The unit is not subject to excessive vibration.

— The fuel tank should not be damaged by the tapping

screws.

— There should be no wire harnesses or pipes under the

place where you are going to install the unit.

— The spare tire, tools or other equipment in or under the

trunk should not be interfered with or damaged by the

screws or the unit itself.

• Be sure to use only the supplied mounting hardware for a

safe and secure installation.

• Use only the supplied screws.

• Make holes of ø 3.5 mm only after making sure there is

nothing on the other side of the mounting surface.

How to install the unit

Horizontal installation

Installation Installation InstallazioneInstalleren

Prcautions

• Choisissez l’emplacement de montage en tenant compte

des observations suivantes :

— L’appareil ne doit pas être exposé à des températures

supérieures à 55°C (comme dans une voiture garée en

plein soleil).

— L’appareil ne doit pas être utilisé en plein soleil.

— L’appareil ne doit pas être utilisé près d’une source de

chaleur (comme un chauffage).

— L’appareil ne doit pas être utilisé dans un endroit

exposé à la pluie ou à l’humidité.

— L’appareil ne doit pas être utilisé dans un

endroitpoussiéreux ou sale.

— L’appareil ne doit pas être exposé à des vibrations

excessives.

— Vérifiez que le réservoir d’essence ne risque pas d’être

endommagé par les vis taraudeuses.

— Il ne doit pas y avoir de faisceau de fils ou de tuyaux à

l’emplacement du montage.

— Vérifiez que l’appareil ou les vis ne risquent pas

d’endommager ou de gêner la roue de secours, les

outils, ou tout autre objet dans le coffre.

• Pour garantir la sécurité de l’installation, utiliser

uniquement le matériel de montage fourni.

• Utilisez uniquement les vis fournies.

• Ne percez les trous de 3,5 mm de diamètre qu’après vous

être assuré qu’il n’y avait rien de l’autre côté de la surface

de montage.

Installation de lappareil

Installation horizontale

Sicherheitsma§nahmen

• Bei der Wahl des Einbauortes ist folgendes zu beachten:

— Das Gerät darf keinen Temperaturen über 55 °C

ausgesetzt sein, wie sie z. B. in einem in der Sonne

geparkten Fahrzeug auftreten können.

— Das Gerät darf keiner direkten Sonneneinstrahlung

ausgesetzt sein.

— Das Gerät muß von Wärmequellen (z. B. der Heizung)

ferngehalten werden.

— Das Gerät darf weder Regen noch Feuchtigkeit

ausgesetzt sein.

— Das Gerät darf keinem übermäßigen Staub oder

anderer Verschmutzung ausgesetzt sein.

— Das Gerät darf keinen übermäßigen Vibrationen

ausgesetzt sein.

— Der Tank darf durch die Schneidschrauben nicht

beschädigt werden.

— Unter der Fläche, auf die das Gerät montiert werden

soll, dürfen sich keine Kabelbäume oder Leitungen

befinden.

— Ersatzreifen, Werkzeug usw. im oder unter dem

Kofferraum dürfen durch die Schneidschrauben nicht

beschädigt werden. Achten Sie auch darauf, daß die

Herausnahme des Ersatzreifens, Werkzeugs usw. nicht

durch das Gerät behindert wird.

• Für sicheren und stabilen Einbau verwenden Sie

ausschließlich die mitgelieferten Befestigungsteile.

• Verwenden Sie ausschließlich die mitgelieferten

Schrauben.

• Bohren Sie die Löcher mit einem Durchmesser von 3,5 mm

erst, wenn Sie sich vergewissert haben, daß sich nichts auf

der Rückseite der Montagefläche befindet.

Installation des Gertes

Horizontaler Einbau

Voorzorgsmaatregelen

• Kies de plaats van opstelling met zorg, zodat het toestel

niet:

— Onderhevig is aan temperaturen boven de 55°C (zoals

in een auto geparkeerd in de volle zon).

— Steeds blootgesteld wordt aan direkt zonlicht.

— Te dicht bij een warmtebron komt (zoals een

autoverwarming).

— Nat kan worden, door regen, vocht of opspattend

water.

— In kontakt komt met veel stof of vuil.

— Onderhevig is aan sterke trillingen of schokken.

— Let op dat de plaatschroeven de benzinetank niet

beschadigen.

— Kontroleer of onder de plaats waar u het apparaat wilt

monteren geen bedrading of leidingen lopen.

— Houd bij het monteren rekening met het reservewiel,

gereedschappen en-eventueel in de kofferruimte

aanwezige andere apparaten, zodat deze de compact

disc wisselaar niet in de weg zitten, noch beschadigd

kunnen worden door de montageschroeven van de

laatste.

• In het belang van een veilige en stevige montage dient u

uitsluitend het bijgeleverde montagemateriaal te

gebruiken.

• Gebruik enkel de meegeleverde schroeven.

• Controleer of er niets achter het bevestigingsvlak zit en

maak pas dan gaten van 3,5 mm diameter.

Installatie van het apparaat

Horizontaal installeren

Precauzioni

• Scegliere con cura il luogo di installazione, seguendo le

istruzioni riportate di seguito ed evitando di installare

l’apparecchio in luoghi:

— Soggetti a temperature oltre i 55°C (come in un’auto

parcheggiata al sole).

— Esposti alla luce solare diretta.

— Vicini a fonti di calore (come impianti di

riscaldamento).

— Esposti alla pioggia o all’umidità.

— Esposti a polvere o sporco eccessivi.

— Soggetti a vibrazioni eccessive.

— Il serbatoio del carburante non deve essere danneggiato

dalle viti filettanti.

— Non devono essere presenti né cavi né tubi sotto il

luogo scelto per l’installazione dell’apparecchio.

— Le viti e l’apparecchio stesso non devono interferire

con, o danneggiare, la ruota di scorta, gli attrezzi o altri

dispositivi presenti dentro o sotto il bagagliaio.

• Assicurarsi di usare solo il materiale di montaggio in

dotazione per un’installazione stabile e sicura.

• Utilizzare solo le viti in dotazione.

• Assicurarsi che non vi sia nulla sull’altro lato della

superficie di montaggio, quindi effettuare fori di solo 3,5

mm di diametro.

Installazione dellapparecchio

Installazione in orizzontale

3

1 2

Align with the marked position.

Aligner sur le repère.

Auf die richtige Position stellen.

Stel aldus in op het merkteken.

Allineare con il punto segnato.

Vertical installation

12

Align with the marked position.

Aligner sur le repère.

VERTICAL

Auf die richtige Position stellen.

Stel aldus in op het merkteken.

Allineare con il punto segnato.

Suspended installation

When the unit is to be installed under the rear tray

etc. in the trunk compartment, make sure the

following provisions are made.

• Choose the mounting location carefully so that the unit can

be installed horizontally.

• Make sure the unit does not hinder the movement of the

torsion bar spring etc. of the trunk lid.

12

¿ 3.5 mm

2

1

Installation suspendue

Si l’appareil doit être installé sous la plage arrière

dans le coffre par exemple, observer les précautions

suivantes.

• Choisissez l’emplacement pour pouvoir installer l’appareil

à l’horizontale.

• Vérifiez que l’appareil ne gêne pas les mouvements du

ressort de fermeture du coffre, entre autres.

Align with the marked position.

Aligner sur le repère.

Auf die richtige Position stellen.

Stel aldus in op het merkteken.

Allineare con il punto segnato.

2

1

Inclined installation

After installing the unit, align the dials with one of

the marks so that the arrows are as vertical as

possible.

Note

Be sure to align the left and right dials with the same

mark.

Installation incline

Après avoir installé l’appareil, alignez le disque sur

l’un des repères afin que la flèche soit aussi proche

que possible de la position verticale.

Remarque

Veillez à aligner les disques gauche et droite sur le même

repère.

Hngender Einbau

Bei hängender Installation unter der Heckablage

usw. im Kofferraum beachten Sie folgende

Vorsichtsmaßnahmen:

• Wählen Sie den Befestigungsort sorgfältig so aus, daß das

Gerät horizontal montiert werden kann.

• Achten Sie darauf, daß das Gerät die

Heckklappendämpfer usw. nicht behindert.

Installation in geneigter Position

Nach dem Installieren des Geräts richten Sie die

Dial-Ringe an einer der Markierungen aus, so daß

der Pfeil möglichst senkrecht steht.

Hinweis

Achten Sie darauf, den linken und rechten Dial-Ring an

derselben Markierung auszurichten.

2

1

1

¿ 3.5 mm

Vertikaal installeren Installazione in verticaleVertikaler EinbauInstallation verticale

3

2

1

1

¿ 3.5 mm

Hangend installeren

Als u het apparaat onder de hoedenplank of iets

dergelijks wilt installeren, let dan op de volgende

punten:

• Kies een geschikte plek waar u het apparaat horizontaal

kunt ophangen.

• Vergewis u ervan dat het apparaat niet beschadigd kan

worden door bewegende onderdelen zoals een

kofferdeksel, de veren van de vijfde deur, enz.

3

Niet-horizontale plaatsing

Zodra de eenheid geplaatst is, draait u de ringen op

een stand waarbij de pijl zoveel mogelijk in een

vertikale positie staat.

Opmerking

Zet de linker-en de rechterring op dezelfde stand.

3

2

3

2

Installazione in sospensione

Se l’apparecchio deve essere installato sotto il ripiano

posteriore, nel bagagliaio, ecc., assicurarsi di

prendere le seguenti precauzioni:

• Scegliere con attenzione il luogo di montaggio in modo

che l’apparecchio possa essere installato orizzontalmente.

• Assicurarsi che l’apparecchio non ostacoli il movimento

della molla della barra di torsione ecc. del coperchio del

cofano.

3

Installazione in posizione inclinata

Dopo aver installato l’apparecchio, allineare le

manopole ad una delle tacche in modo che la freccia

sia il più verticale possibile.

Nota

Accertarsi di allineare le manopole di sinistra e di destra

alla stessa tacca.

Connections/Connexions/

Anschluß/Aansluitingen/

Collegamenti

For details, refer to the Installation/Connections manual of each product.

Pour plus de détails, consulter le manuel d’installation/connexions de chaque produit.

Einzelheiten entnehmen Sie der Installations-/Anschlußanleitung des betreffenden Geräts.

Zie voor nadere bijzonderheden de gebruiksaanwijzing voor installatie en aansluitingen

van de aan te sluiten apparatuur.

Per i dettagli, fare riferimento al manuale di installazione/collegamenti dell’autoradio.

Connection diagram/Schéma de connexion/Anschlußdiagramm/

Aansluitingsschema/Schema di collegamento

To the car audio (the master unit) compatible with the Sony Bus or the source selector

Vers le système audio voiture (appareil principal) compatible avec le bus Sony ou le

sélecteur de source.

an Autoanlage (Hauptgerät), die mit dem Sony-Bus oder dem Signalquellenwähler

kompatibel ist

Op het car audiosysteem (hoofdtoestel) dat compatibel is met Sony Bus of de

bronkeuzeschakelaar

All’autoradio (unità principale) compatibile con bus Sony o con il selettore di

sorgente.

BUS AUDIO IN BUS CONTROL IN

45

CDX-T68X

Note

For connecting two or more changers, the XA-C30 source selector (optional) is necessary.

Remarque

Pour raccorder deux ou plusieurs changeurs, le sélecteur de source XA-C30 (en option) est nécessaire.

Hinweis

Zum Anschließen von zwei oder mehr Wechslern wird der gesondert erhältliche Signalquellenwähler

XA-C30 benötigt.

Opmerking

Om twee of meer wisselaars aan te sluiten is de optionele geluidsbronkiezer XA-C30 vereist.

Nota

Per collegare uno o più cambia CD, è necessario il selettore di fonte XA-C30 (opzionale).

44

Page 5

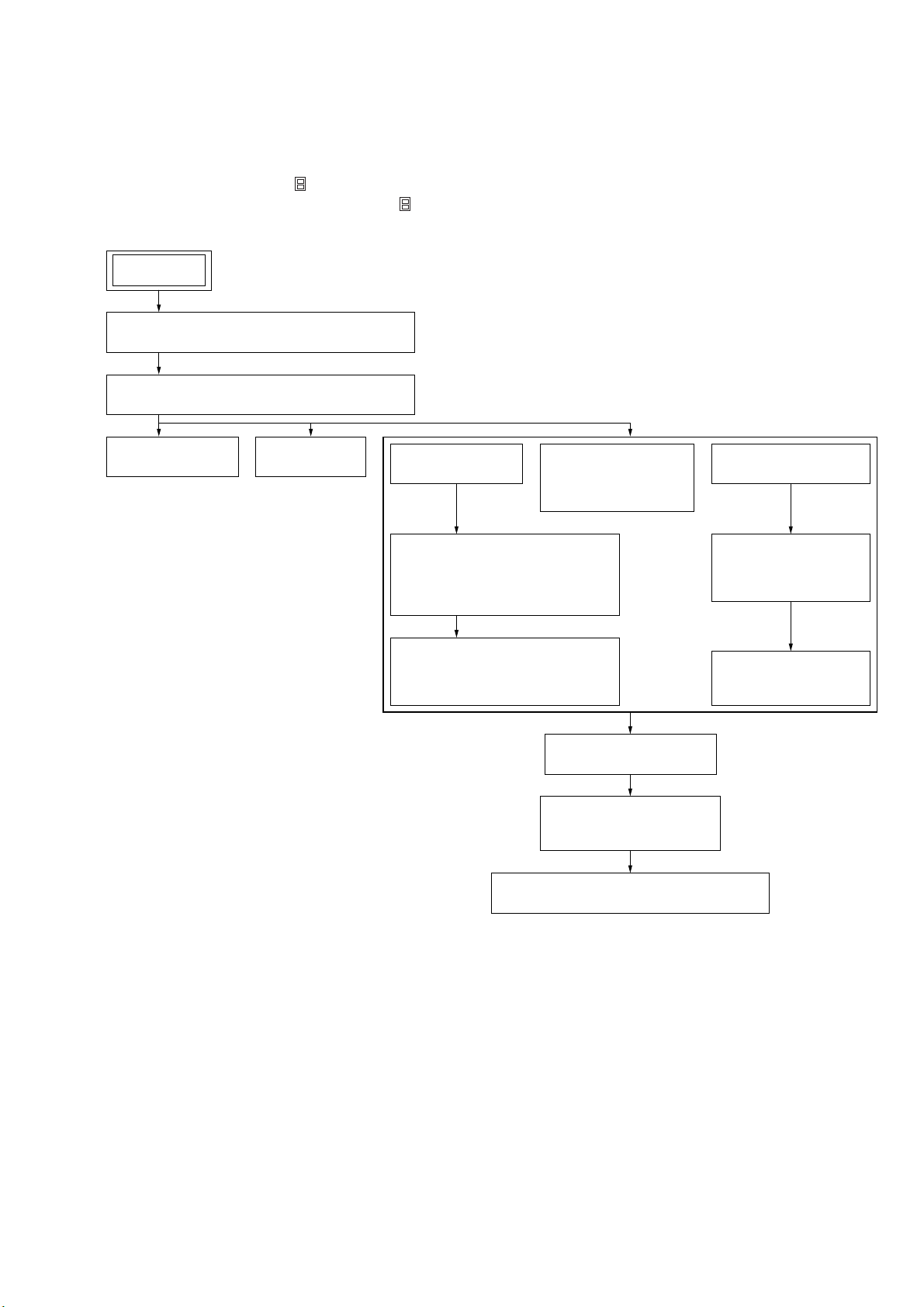

SECTION 2

DISASSEMBLY

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

Note 1: The process described in can be performed in any order.

Note 2: Without completing the process described in , the next process can not be performed.

SET

2-2. FRONT PANEL (S) ASSY, CASE (UPPER S)

(Page 6)

2-3. MECHANISM DECK (MG-276A-159)

(Page 6)

CDX-T68X

2-4. JACK BOARD

(Page 7)

2-5. BELT (TS)

(Page 7)

2-6. MAIN BOARD

(Page 8)

2-7. ESCUTCHEON (S),

SLIDE VARIABLE RESISTOR

(ELEVATOR HEIGHT SENSOR)

(RV301)

(Page 8)

2-8. MD MOTOR ASSY

(ELEVATOR)

(M104)

(Page 9)

2-15. CHASSIS (OP) BLOCK SERVICE ASSY

(Page 12)

2-9. LE MOTOR ASSY

(CHUCKING)

(M103)

(Page 9)

2-13. CHASSIS (EV) ASSY

(Page 11)

2-14. LEVER (CHK.L) ASSY,

LEVER (CHK.R) ASSY

(Page 12)

2-10. RF BOARD

(Page 10)

2-11. SLED MOTOR

COMPLETE ASSY

(M101)

(Page 10)

2-12. OPTICAL PICK-UP

(KSS-720A)

(Page 11)

5

Page 6

CDX-T68X

)

)

Note: Follow the disassembly procedure in the numerical order given.

2-2. FRONT PANEL (S) ASSY, CASE (UPPER S)

3

screw

1

screw

(PTT2.6

2

×

front panel (S) assy

5

lever (FLT. 838)

6)

(PTT2.6

×

6)

4

case (upper S)

3

5

lever (FLT. 838)

screw

(PTT2.6

×

6

2-3. MECHANISM DECK (MG-276A-159)

2

spring (FLT S)

1

two dampers (S)

1

screw

(PTT2.6

4

×

6)

mechanism deck (MG-276A-159)

2

spring (FLT S

3

jack flexible board

(CN901)

1

two dampers (S)

6

Page 7

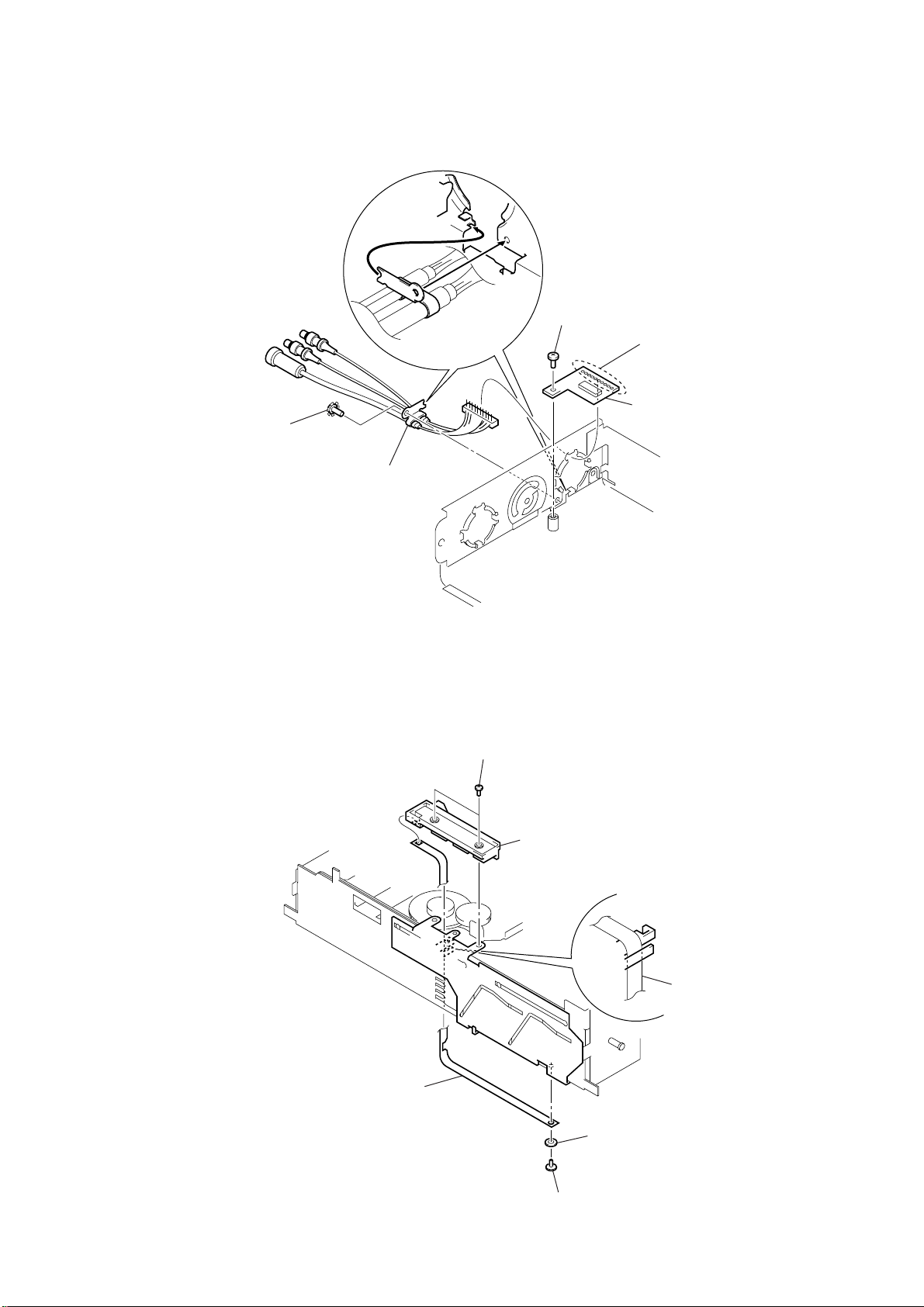

2-4. JACK BOARD

)

4

ground point screw

(PTT2.6 × 6)

5

cord (with connector)

(BUS/RCA)

2

screw (FP)

1

Remove ten solders

of the cord (with connector).

3

jack board

CDX-T68X

2-5. BELT (TS)

5

belt (TS)

3

two screw (FP)

4

rack (UD)

belt (TS

2

3.5 washer

1

screw

(M1.7

×

2.2)

7

Page 8

CDX-T68X

)

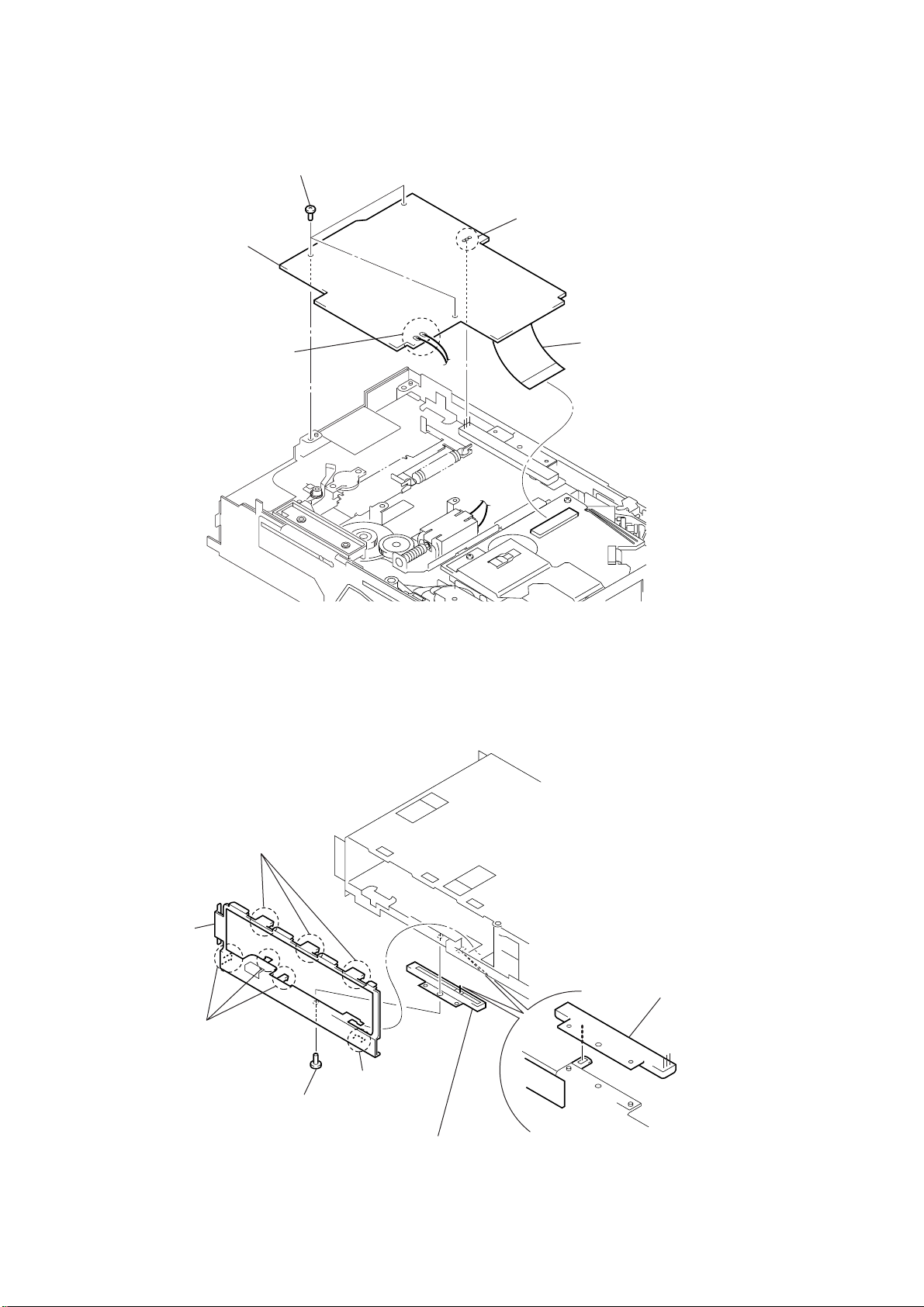

2-6. MAIN BOARD

4

main board

2

Remove two solders

of the elevator motor

lead wires (M104).

3

three screws (FP)

2

Remove three solders

of the slide variable resistor (RV301).

1

main flexible board

(CN101)

2-7. ESCUTCHEON (S), SLIDE VARIABLE RESISTOR (ELEVATOR HEIGHT SENSOR) (RV301)

2

three claws

3

escutcheon (S)

slide variable resistor

(elevator height sensor

(RV301)

2

three claws

2

1

screw (FP)

claw

4

slide variable resistor

(elevator height sensor)

(RV301)

8

Page 9

1

screw

(PTT2

×

3)

2

bracket (MDM)

3

MD motor assy (elevator) (M104)

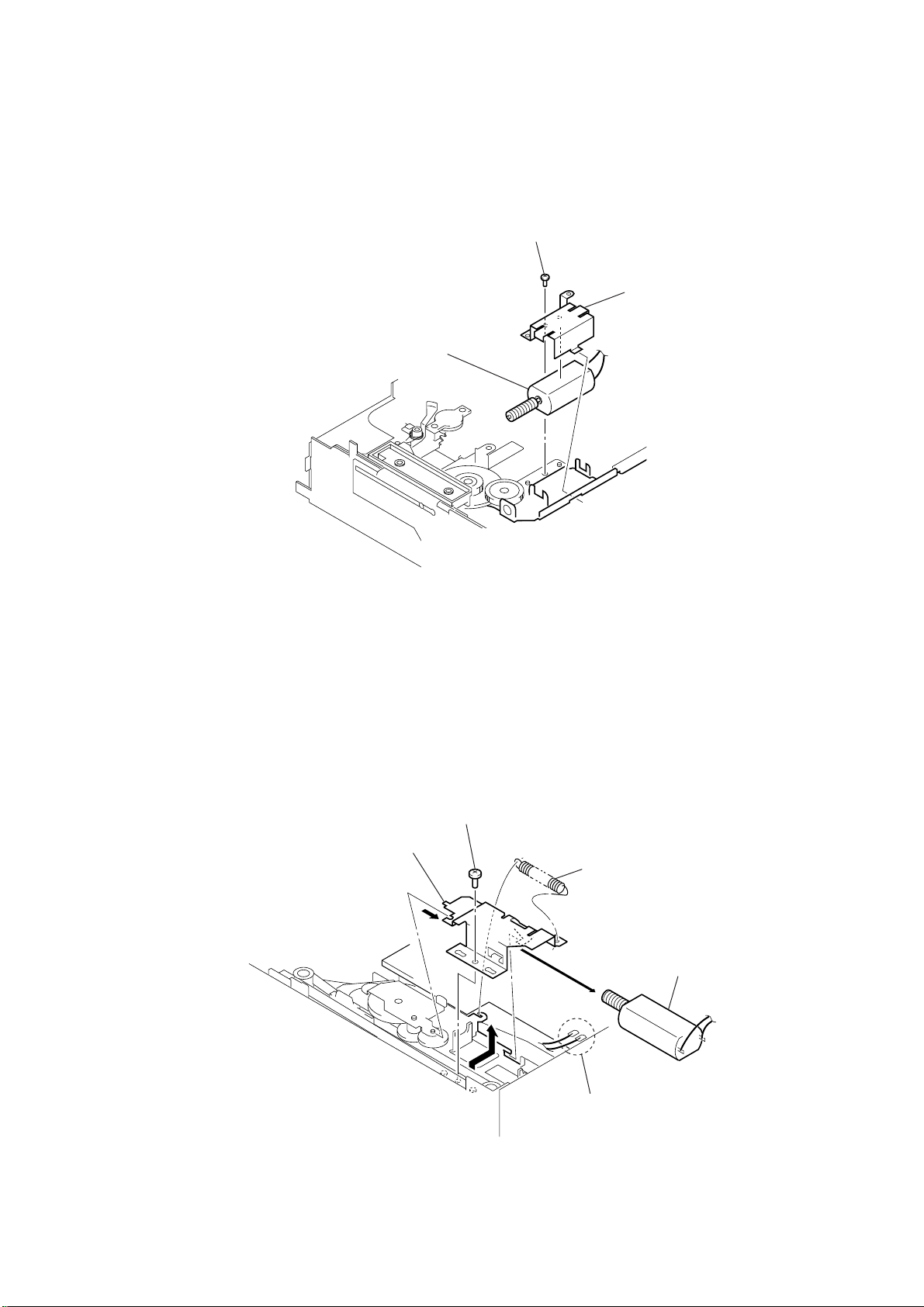

2-8. MD MOTOR ASSY (ELEVATOR) (M104)

y

CDX-T68X

2-9. LE MOTOR ASSY (CHUCKING) (M103)

3

screw

(P1.7

×

5

2.2)

2

tension spring (rack)

6

1

Remove two solders of

the chucking motor lead wires (M103).

LE motor ass

(chucking)

(M103)

7

bracket (LEM)

4

9

Page 10

CDX-T68X

s

2-10. RF BOARD

2

Remove two solders of

the spindle motor lead

wires (M102).

1

main flexible board

(CN101)

6

RF board

3

two screws

(PS2

×

4)

4

heat sink

5

screw

(PS2

×

4)

2

Remove two solders of

the sled motor lead wires

(M101).

1

OP flexible board

(CN102)

2

Remove two solders of

the chucking motor lead wire

(M103).

2-11. SLED MOTOR COMPLETE ASSY (M101)

1

2

sled motor complete assy (M101)

screw

(P2

×

2.2)

10

Page 11

2-12. OPTICAL PICK-UP (KSS-720A)

1

tension spring

4

Open the main chassis assy

in the direction of arrow

B

.

2

Move the slider (6R) fully in the

direction of arrow

A

to move the

chassis (EV) assy down.

5

shaft (EVGR)

6

two shafts (EVGL)

A

B

7

chassis (EV) assy

3

three screws

(PTT2

×

3)

8

screw

(P2 × 3)

9

detent spring (sled)

qa

optical pick-up (KSS-720A)

6

5

0

1

OP flexible board

gear (SL2)

washer

(DIA. 1.2)

shaft (sled feed) assy

A

CDX-T68X

2

two screws

(P2 × 3)

3

spring (sled front point)

7

bearing (sled) assy

4

Lift up the bearing (sled) assy in the

direction of arrow A and remove it from

the shaft (sled feed) assy.

2-13. CHASSIS (EV) ASSY

11

Page 12

CDX-T68X

2-14. LEVER (CHK.L) ASSY, LEVER (CHK.R) ASSY

1

screw

(P1.7 × 2.2)

2

joint (CHK)

leaf spring (D retainer R)

B

3

Move the lever (CHK.L) assy

fully in the direction of arrow A.

A

4

lever (CHK.L) assy

A

3

Move the lever (CHK.R) assy

fully in the direction of arrow A.

5

Remove the lever (CHK.R) assy pushing down

the leaf spring (D retainer R) in the direction of arrow B.

2-15. CHASSIS (OP) BLOCK SERVICE ASSY

8

chassis (OP) block service assy

7

shaft

2

6

screw

(P2

3

shaft

×

1.8)

leaf spring (FOP)

12

A

1

Turn the gear (LE2) assy

fully in the direction of arrow

A

6

shaft

B

5

Open the chassis (EV) assy

in the direction of arrow

4

type-E stop ring 2.0

.

B

.

Page 13

MECHANICAL ADJUSTMENT

• Elevator Height (Address) Adjustment

CDX-T68X

SECTION 3

Note: This adjustments is necessary when the system controller (IC301),

variable resistor (R V302), le ver (CHK.L) assy , lev er (CHK.R) assy ,

or chassis (EV) assy was replaced for any repair.

Connection:

power supply

(DC 14.4 V)

master unit

+

GND

BUS cable

compact disc changer

Adjustment Method:

1. Connect this set to the master unit (e.g. MDX-C7970/C7970R),

load a disc magazine, and place the set vertically as shown

below.

2. Connect the regulated power supply to the master unit, and

turn the power on.

3. Press the DISC button on the master unit and select DISC 6.

4. Adjust the variable resistor RV302 so that the reference holes

of the slider (6L) and of the chassis (6B) meet within an error

of ±0.15 mm when the tray is loaded at address 6.

RV302

chassis (6B)

slider (6L)

(reference hole)

0.15mm 0.15mm

slider (6L)

slider (6L)

(reference hole)

chassis (6B)

(address 6 hole)

13

Page 14

CDX-T68X

SECTION 4

ELECTRICAL CHECK

Note:

1. This check is performed with the set placed horizontally.

2. Power supply voltage: DC14.4 V (more than 3 A).

3. Be sure to use the disc “YEDS-18” parts code: 3-702-101-01, but only

when indicated.

Connection:

power supply

(DC 14.4 V)

master unit

+

GND

BUS cable

Focus Bias Check

Connection:

– RF Board (Component Side) –

oscilloscope

(AC range)

+

–

IC101

TP (VC)TP (RFAC)

compact disc changer

Procedure:

1. Connect the oscilloscope to TP (RFAC) and TP (VC) on the

RF board.

2. Put the set into play mode by loading the disc (YEDS-18).

3. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note:

Clear RF signal waveform means that the shape “◊” can be clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

(10 : 1 probe in use)

level: 1.4

+ 0.3

– 0.4

Vp-p

14

When observing the eye pattern, set the oscilloscope to AC range

and raise the vertical sensitivity so that it may be easily seen.

Page 15

Tracking Offset Check

Connection:

– RF Board (Component Side) –

oscilloscope

(DC range)

+

–

TP (TE)

IC101

CDX-T68X

TP (VC)

Procedure:

1. Connect the oscilloscope to TP (TE) and TP (VC) on the RF

board.

2. Put the set into play mode by loading the disc (YEDS-18).

[ AMS ] button on the master unit, and check

3. Press the

. >

the traverse waveform*.

4. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0 V dc, and check this level.

* Traverse waveform: This is the tracking error wave form appears

when crossing the track.

Traverse waveform

A

0 V

B

VOLT/DIV: 500 mV

TIME/DIV: 2 ms

Center: 0 V

A=B

traverse waveform

(100 track jump waveform)

15

Page 16

CDX-T68X

MEMO

16

Page 17

5-1. BLOCK DIAGRAM – SERVO Section –

CDX-T68X

SECTION 5

DIAGRAMS

DETECTOR

A

B

C

D

E

F

LASER DIODE

OPTICAL

PICK-UP BLOCK

(KSS-720A)

(TRACKING)

(FOCUS)

I-V AMP

PD LD

2-AXIS DEVICE

(SPINDLE)

(CHUHCKING)

M101

(SLED)

M102

M103

RF AMP,

FOCUS/TRACKING ERROR AMP

A

6

B

7

C

8

D

9

E

10

F

11

AUTOMATIC

POWER

CONTROL

Q101

MM

MM

MM

IC101

RFAC

SUMMING

AMP

RFDC

SUMMING

FOCUS

ERROR

AMP

TRACKING

ERROR

AMP

1

TRACKING/FOCUS COIL DRIVE,

SLED/SPINDLE/CHUCKING

VO4 +

6

VO4 –

7

VO3 +

8

VO3 –

9

VO1 +

12

VO1 –

13

VO2 +

10

VO2 –

11

VL0 +

5

VL0 –

4

AC

SUM

AMP

RW/ROM

LD

APC AMP

MOTOR DRIVE

IC201

COIL

DRIVE

COIL

DRIVE

MOTOR

DRIVE

MOTOR

DRIVE

MOTOR

DRIVE

4 3

RW/ROM

VIN1 + B

VIN1 – B

RFDCO

DC OFST

SW

PD

VIN4 +

VIN4 –

VIN3 +

VIN3 –

VIN2 –

FWD

REV

FILTER

66 69 68 67

FILO

CLTV

EQ IN

RFAC

VCA

RF

28

30

FE

FE

16

TE

TE

18

12

2

48

31

49

32

50

25

51

24

46

19

47

18

43

21

1

2

RFAC

RF EQ

AMP

RF AMP OFFSET

CONTROL SWITCH

Q102

TFDR

TRDR

FFDR

FRDR

PWM GENERATOR

SFDR

SRDR

MDP

DIGITAL

15

D-RAM

IC402

SERVO DSP

CLV

RFAC

71

ASYI

73

ASYO

74

2, 3,

DQ1 – DQ4

A0 – A10

9 – 12, 15 – 19,

RAS

5

CAS

23

WE

4

OE

22

FE

TE

RF

61606258

FE

TE

SE

RFDC

OP AMP

ANALOG SW

A/D CONVERTER

MIRR

DECT

FOK

ASYMMETRY

24, 25

21, 8

CORRECTOR

D0 – D3

118, 117

116, 115,

A0 – A10

3 – 1, 111

109 – 106, 7 – 5,

XRAS

113

XCAS

119

XWE

114

XOE

120

XRDE

XWRE

XQOK

ON : When the optical pick-up

ON : When the optical pick-up

is inner position

is inner position

ON : When completion of the disc

chucking operation

DIGITAL

PLL

CONTROLLER

COMPRESSION

DIGITAL SIGNAL PROCESSOR,

DIGITAL SERVO PROCESSOR,

FILI

PCO

DEMODULATOR

VIBRATION

MEMORY

&

EXPANDER

D-RAM CONTROLLER

IC401

EFM

SUBCODE

PROCESSOR

SW101

(LIMIT)

SW102

(CHUCKING END DETECT)

D/A

INTERFACE

32k RAM

INTERNAL BUS

CORRECTOR

CPU

INTERFACE

SERVO AUTO

SEQUENSOR

SERVO

INTERFACE

SSTP

45

ERROR

WDCK

GFS

DATA

CLOK

XLAT

SENS

SQSO

SQCK

SCOR

XRDE

XWRE

XQOK

SCLK

FOK

XRST

1578

1581

1523

1525

1524

1526

1514

1515

1517

159

158

1512

27

35

21

DIGITAL

OUT

SELECTOR

CLOCK

GENERATOR

DOUT

1585

PCMD

15

88

1588

BCK

15

90

LRCK

15

86

XTAI

1593

XTAO

1594

CD-ROM/RW

SELECT SWITCH

Q302

3

LEVEL

1

SHIFT

IC502

5

(1/2)

99

53

42

61

59

60

44

56

58

52

64

65

63

43

41

62

5

6

98

97

DIGITAL FILTER, D/A CONVERTER,

LOW-PASS FILTER

DATA

4

22

2

BCK

23

6

LRCK

24

MCK

13

RW SEL

GRSCOR

GFS

CDDAT

CDCLK

CDLAT

SENS

SQSO

SQCK

SCOR

XRDE

XWRE

XQOK

SYSTEM CONTROLLER

IC301 (1/2)

SCLK

FOK

XRST

LOADF

LOADR

LIM SW

LOAD SW

SAVE SW96

IC501

SERIAL

INPUT

INTERFACE

TIMING

GENERATOR

OSC

XO

X501

16.9344MHz

55HS

66EMPH

67MUTEMUTE

XI

DIGITAL

FILTER

CIRCUIT

HS

21 1916 15

810

LEVEL SHIFT

IC502 (2/2)

11 9

∆Σ

MODULATOR

CIRCUIT

CPU

INTERFACE

MUTING CONTROL

SWITCH

Q501

• SIGNAL PATH

: CD PLAY

EMP

LOW-PASS

FILTER

LO

9

RO

5

MUTING

Q502, 503

CN902 (1/2)

(L)

(R)

1717

Page 18

CDX-T68X

5-2. BLOCK DIAGRAM – BUS CONTROL/POWER SUPPLY Section –

SYSTEM CONTROLLER

MAG SW

MAGLK SW

IC301 (2/2)

MCK

EHS

37

36

SW301

MAGAZINE

DETECT

SW302

MAGAZINE IN/OUT

DETECT

95

51

RV302

ELEVATOR HEIGHT

(ADDRESS)

RV301

ELEVATOR HEIGHT

SENSOR

M104

(ELEVATOR)

ELEVATOR

MOTOR DRIVE

IC302

OUT1

9

M

OUT2

7

MOTOR

DRIVE

EEPROM

IC303

SDA

SCL

IN1

IN2

5

6

4

ELVR

EEDAT

32

28

EECLK

ELVF

4

3

3

AVRH

ELVON

BUCHK

EJECT SW

CDON

RESET

UNI SI

34

24

46

SW303

BATTERY

CHECK

Q203

D210

SERVO +3V

Z

50

23

75

16

RESET SIGNAL

GENERATOR

IC204

BUS INTERFACE

(FOR SONY BUS)

IC201

SO

10 6

µCOM B+

DRIVER +8V

D209

+3V

REGULATOR

Q204

DAC/SERVO +5V

14

VCC

DATA

+8V

REGULATOR

IC202

+5V

REGULATOR

IC203

REGULATOR

Q201, 205

IC901

CN902 (2/2)

8

6

B. UP

DATA

X180X0

81

X301

4MHz

UNI SO

UNI CK

BUSON

SI

17

18

45

9

SCK

11 4

BUSON OUT

1 12

BUSON OUT

13 2

RESET

8 7

RESET

SWITCH

CLK

LOF

BUSON IN

RST

5

CLK

4

BUSON

7

RST

1818

Page 19

4 Vp-p

250 ns

• Waveforms

– RF Board –

CDX-T68X

– MAIN Board –

5-3. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

f

•

: internal component.

• : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the par ts face side seen from

(Component Side) the parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

: internal component.

4

• C : panel designation.

Note:

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part

number specified.

Note:

Les composants identifiés par

une marque 0 sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro

spécifié.

• A : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 14.4V and f ed with regulated dc power

supply from CD changer controller.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : CD PLAY

• Voltages are taken with a V OM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD PLAY

W or less unless otherwise

1 IC101 qg (RFAC) (CD play mode)

1.4

2 IC101 qh (FE) (CD play mode)

3 IC101 qk (TE) (CD play mode)

+ 0.3

Vp-p

– 0.4

Approx

180 mVp-p

1 IC301 ia (X1) (CD play mode)

2 IC401 rd (MDP) (CD play mode)

µ

s

3.8

3 IC401 ih (LRCK) (CD play mode)

6 IC501 qd (MCK) (CD play mode)

4.9 Vp-p

59.1 ns

7 IC501 qh (XO) (CD play mode)

2 Vp-p

5.4 Vp-p

59.1 ns

8 IC501 wd (BCK) (CD play mode)

Approx

900 mVp-p

22.7 µs

4 IC401 o; (BCK) (CD play mode)

472 ns

5 IC401 od (XTAI) (CD play mode)

4.2 Vp-p

4.3 Vp-p

6.3 Vp-p

472 ns

9 IC501 wf (LRCK) (CD play mode)

6 Vp-p

22.7 µs

4.1 Vp-p

59.1 ns

1919

Page 20

CDX-T68X

Ver 1.1 2001.05

5-4. PRINTED WIRING BOARDS – RF Board –

1

A

B

MAIN

BOARD

A

C

CN202

(Page 22)

FLEXIBLE

D

E

F

G

H

2 3 4 5 6 7 8 9 10 11 12 13 14

MAIN

BOARD

RF BOARD

(COMPONENT SIDE)

(CHASSIS)

CN101

(SPINDLE)

RED

M102

(RFAC)

M

RF BOARD

RED

M101

M

OP FLEXIBLE

BOARD

R215

(SLED)

OPTICAL

PICK-UP

BLOCK

KSS-720A

1-680-829-

C117

C109

C115

C108

C107

C202

11

(11)

BLK

R106

R128

C116

C111

R119

Q102

C113

R220

R210

R208

R206

R204

C114

TP

(TE)

R109

TP

TP

(VC)

BLK

R117

R118

R223

R222

R116

R214

R212

C119

R209

R207

R205

R203

R202

R120

R218

R213

R211

C217

R121

IC101

C112

R113

R112

R110

C211

R219

C208

C206

C205

C204

C203

R201

BLK

16

CN102

R111

R103

IC201

C220

RED

1

Q101

R127

R216

C209

M

M103

(CHUCKING)

(CONDUCTOR SIDE)

C201

SW102

SW102

(CHUCKING END DETECT)

SW101

(LIMIT)

C110

1-680-829-

11

(11)

• Semiconductor

Location

Ref. No. Location

IC101 C-5

IC201 F-6

Q101 D-6

Q102 E-5

2020

Page 21

5-5. SCHEMATIC DIAGRAM – RF Board – • See page 19 for Waveforms. • See page 27 for IC Block Diagrams.

CDX-T68X

Ver 1.1 2001.05

2-AXIS

DEVICE

DETECTOR

(FOCUS) (TRACKING)

LASER DIODE

PD

LD

I-V AMP

Q101

2SB624T1-BV345

AUTOMATIC

POWER CONTROL

16

VCC

VC

OP

FLEXIBLE

BOARD

1

M103

(CHUCKING)

M102

(SPINDLE)

M101

(SLED)

F(-)

T(-)

T(+)

F(+)

E

F

VCC

VC

VR

PD

LD

GND

A

C

B

D

CN102

16P

C117

0.1

C108

100

4V

C220

0.1

TP1

TP2

TP3

TP4

TP6

TP5

R127

22

C107

100

R103

4V

22

C112

0.1

R121

22k

R120

22k

C115

C114

100

4V 0.1

C109

0.1

C119

0.1

RF AMP,

FOCUS/TRACKING

ERROR AMP

LD

PD

EQ_

IN

AC_SUM

GND

A

B

C

D

E

F

SW

TE_BAL

DVCC

DVC

RFAC FE

IC101

CXA2581N-T4

FOCUS/TRACKING COIL DRIVE

SPINDLE/SLED/CHUCKING

MOTOR DRIVE

IC201

LA6576L-TE

FWD

REV

VCC2

VL0-

VL0+

VO4+

VREF-IN

VO4-

VIN1-SW

VO3+

VREF-OUT

VO3-

REG-OUT

VO2+

VO2-

VO1+

VO1-

VCC1

VIN1

VIN1-A

VIN1+A

VIN1-B VIN1+B

RFDCI

RFDCO

REG-IN

OFST

S-GND

MUTE2

MUTE1

VIN4-

VIN4+

VIN3+

VIN3-

VIN2+

VIN2-

DC_

VC

RFC

VFC

BST

RFG

VCC

CEI

CE

TE

FEI

VIN4

VIN3

VIN2

3.3k

R117

C113

R109

100k

100k

R106

C201

C202

470

0.1

16V

C111 R119

0.1 1k

0.1

R110 R112

18k 10k

C110

100

6.3V

R118 C116

22k 0.1

R116

100k

R113

15k

R111

10k

R202 C217

R201

10k

10k 0.1

C203 R203 R204

470p 10k 33k

C205 R207 R208

470p 10k 33k

C206

470p

C208 R213 R214

0.022 47k 56k

C211

R218 R219

0.022

10k 33k

C209 R215

0.022 10k

R128

1k

Q102

DTC124EKA

-T146

RF AMP OFFSET

CONTROL SWITCH

SW101

(LIMIT)

ON:WHEN THE OPTICAL PICK-UP IS

INNER POSITION

SW102

(CHUCKING END DETECT)

ON:WHEN COMPLETION OF THE DISC

CHUCKING OPERATION

TP

(RFAC)

TP

(VC)

TP

(TE)

AA1

AA2

AA3

AA4

AA5

AA6

AA7

AA3

AA4

R206R205C204

33k10k470p

AA2

R209

10k

R211

47k

AA1

R210

33k

R212

R220

68k

12k

AA5

AA7

AA6

R216

33k

R222 R223

1k 820

SW101

SW102

CN101

22P

R/RW_SEL

LIM_SW

SAVE_SW

RFAC

RFDC

VC

TE

FE

DVCC(3V)

GND(5V)

5V

FRDR

FFDR

TRDR

TFDR

MDP

SRDR

SFDR

LOADR

LOADF

GND(8V)

8V

MAIN

FLEXIBLE

BOARD

(Page 25)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Les composants identifiés par une marque 0 sont

critiques pour la sécurité. Ne les remplacer que

par une pièce portant le numéro spécifié.

2121

Page 22

CDX-T68X

Ver 1.1 2001.05

• Semiconductor

Location

Ref. No. Location

D201 H-7

D202 H-7

D203 F-9

D205 B-8

D206 H-7

D207 G-6

D209 F-6

D210 F-6

D214 H-7

D501 F-4

D502 G-5

IC201 G-7

IC204 F-6

IC301 C-7

IC302 F-8

IC303 B-6

IC401 C-5

IC402 E-5

IC501 E-4

IC502 E-3

Q201 F-6

Q203 F-6

Q204 B-8

Q205 G-6

Q302 E-2

Q501 G-6

Q502 H-6

Q503 H-6

5-6. PRINTED WIRING BOARDS – MAIN Board (Component Side) –

1

2 3 4 5 6 7 8 9 10

A

MAIN BOARD

(COMPONENT SIDE)

B

C406

C407

R408

R412

R418

R406

C411

R405

R407

C412

C413

R416

R417

C

D

CN202

C403

R402

C404

R403

R410

C418

R404

C409

C405

R409

C408

R411

C410

IC502

R502

E

R309

Q302

C501

R507

R501

R401

C414

C402

C420

R508

FB502

IC401

R510

R509

FB501

C503

C415

C417

IC303

C401

C416

IC402

C419

R419

R306

C306

R302

R303

R301

C302

R308

R307

+

C303

IC301

C301

C308

C307

D205

R208

C216

Q204

R305

C215

C214

F

G

H

MAIN FLEXIBLE

BOARD

A

(Page 20)

RF BOARD

CN101

IC501

D501

C504

R207

C211

Q203

C506

D502

C213

D209

C511

C512

R203

D207

R503

R504

R206

R211

R204

R505

R506

D210

Q201

C208

Q205

R210

Q501

Q502

C202

Q503

C217

IC204

C212

R205

R201

D214

IC201

D206

D201

D202

C309

C310

SW302

C203

IC302

C305

SW302

MAGAZINE

IN/OUT

DETECT

1

JACK FLEXIBLE

BOARD

C201

D203

CN201

B

13

1-680-825-

JACK BOARD

CN901

(Page 26)

11

(11)

2222

Page 23

5-7. PRINTED WIRING BOARD – MAIN Board (Conductor Side) –

CDX-T68X

A

B

C

D

1

(CHASSIS)

2 3 4 5 6 7 8 9 10

MAIN BOARD

C205

C206

IC202

(CONDUCTOR SIDE)

SW303

C207

IC203

Z

C218

C204

RV302

RV301

EVEVATOR HEIGHT

SENSOR

C421

• Semiconductor

Location

Ref. No. Location

IC202 D-2

IC203 D-3

E

F

G

H

(CHASSIS)

SW301

MAGAZINE

DETECT

BP10

BP5

C502

M104

C508

X501

BP301

TP2

TP1

(CHASSIS)

BP302

M

(EVEVATOR)

X301

C209

C507

C210

C505

C509

C510

1-680-825 -

11

(11)

2323

Page 24

CDX-T68X

Ver 1.1 2001.05

5-8. SCHEMATIC DIAGRAM – MAIN Board (1/2) – • See page 19 for Waveform. • See page 27 for IC Block Diagrams.

1

2

3

(Page 26)

JACK

FLEXIBLE

BOARD

(ELEVATOR)

CN201

LCH

AGND

RCH

BUSON

CLK

DATA

RST

B.UP

B.UP

B.UP

GND

GND

GND

M104

13P

BUSON

C203

0.1

0.001

MA8180-TX

MA8180-TX

C201

RB521S-30TE61

RB521S-30TE61

R204R210

47k47k

D214

D206

Q201

2SB1202FAST-TL

Q201,205

REGULATOR

RB521S-30TE61

D203

Q205

2SC2712-YG

ELEVATOR

MOTOR DRIVE

IC302

LB1930M-TL

R208

D201

D202

D207 C208 R211

MA8056-H 0.1 100k

C215

0.01

C207

100 6.3V

D205

MA8039-H-TX

C216

0.01

C218

100

6.3V

C309

0.01

BP302

BP301

C310

0.01

150

C209 C210

100

6.3V

R201

47k

1000

16V

Q204

2SD1622-ST

+3V

REGULATOR

C202

4700p

C217

0.01

RESET SIGNAL

GENERATOR

XC61CN2502PR

IGO

C211

0.01

C305

0.01

IC204

+8V REGULATOR

IC201

BA8272AFV-E2

VCC

BUSON

OUT

BUSON

BUSON

OUT

IN

GND

LOF

SCK

CLK

SO

VREF

SI

DATA

RESET

RST

BUS INTERFACE

(FOR SONY BUS)

R205

47k

C212 C213 R206

0.01 0.33 120k

D210

UDZS-TE17-6.2B

NJM2395AF08

CONT

GND

NJM2395AF05

CONT

GND

+5V REGULATOR

4

SCK

SI

SO

IC202

VIN

VOUT

IC203

VIN

VOUT

R207

100k

Q203

2SC2712-YG

BATTERY

CHECK

D209

1SS355TE-17

R203

150k

R309

1k

Q302

DTC124EKA

-T146

CD-ROM/RW

SELECT

SWITCH

SW301