Sony CDXL-350 Service manual

CDX-L350/L360

SERVICE MANUAL

Ver 1.1 2001. 02

Photo: CDX-L350

• The tuner and CD sections have no adjustments.

SPECIFICATIONS

AEP Model

UK Model

CDX-L350/L360

E Model

CDX-L350

Model Name Using Similar Mechanism CDX-CA650

CD Drive Mechanism Type MG-393X-121//Q

Optical Pick-up Name KSS-720A

CD player section

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Tuner section

FM

Tuning range 87.5 – 108.0 MHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

72 dB (mono)

Harmonic distortion at 1 kHz

0.6% (stereo),

0.3% (mono)

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

MW/LW

Tuning range MW: 531 – 1,602 kHz

LW: 153 – 279 kHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity MW: 30 µV

LW: 40 µV

Power amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance 4 – 8 ohms

Maximum power output 45 W × 4 (at 4 ohms)

General

Outputs Power aerial relay control

lead

Inputs Telephone ATT control lead

Tone controls Bass ±9 dB at 100 Hz

Treble ±9 dB at 10 kHz

Power requirements 12 V DC car battery

(negative ground)

Dimensions Approx. 178 × 50 × 177 mm

(w/h/d)

Mounting dimension Approx. 182 × 53 × 162 mm

(w/h/d)

Mass Approx. 1.2 kg

Supplied accessories Parts for installation and

connections (1 set)

Front panel case (1)

Design and specifications are subject to change without

notice.

9-870-278-12

2001B0400-1

© 2001. 2

FM/MW/LW COMPACT DISC PLAYER

Sony Corporation

Audio Entertainment Group

General Engineering Dept.

1

CDX-L350/L360

SERVICE NOTES

This label is located on the bottom of the chassis.

This label is located on the drive unit's internal

chassis.

When replacing the chassis (T.U) of mechanism deck which have

the “CAUTION LABEL” attached, please be sure to put a new

CAUTION LABEL (3-223-913-11) to the chassis (T.U).

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

TABLE OF CONTENTS

1. GENERAL

Location of Controls................................................................ 3

Setting the Clock ..................................................................... 3

CD Player ................................................................................ 3

Radio ....................................................................................... 3

RDS ......................................................................................... 4

Other Functions .......................................................................5

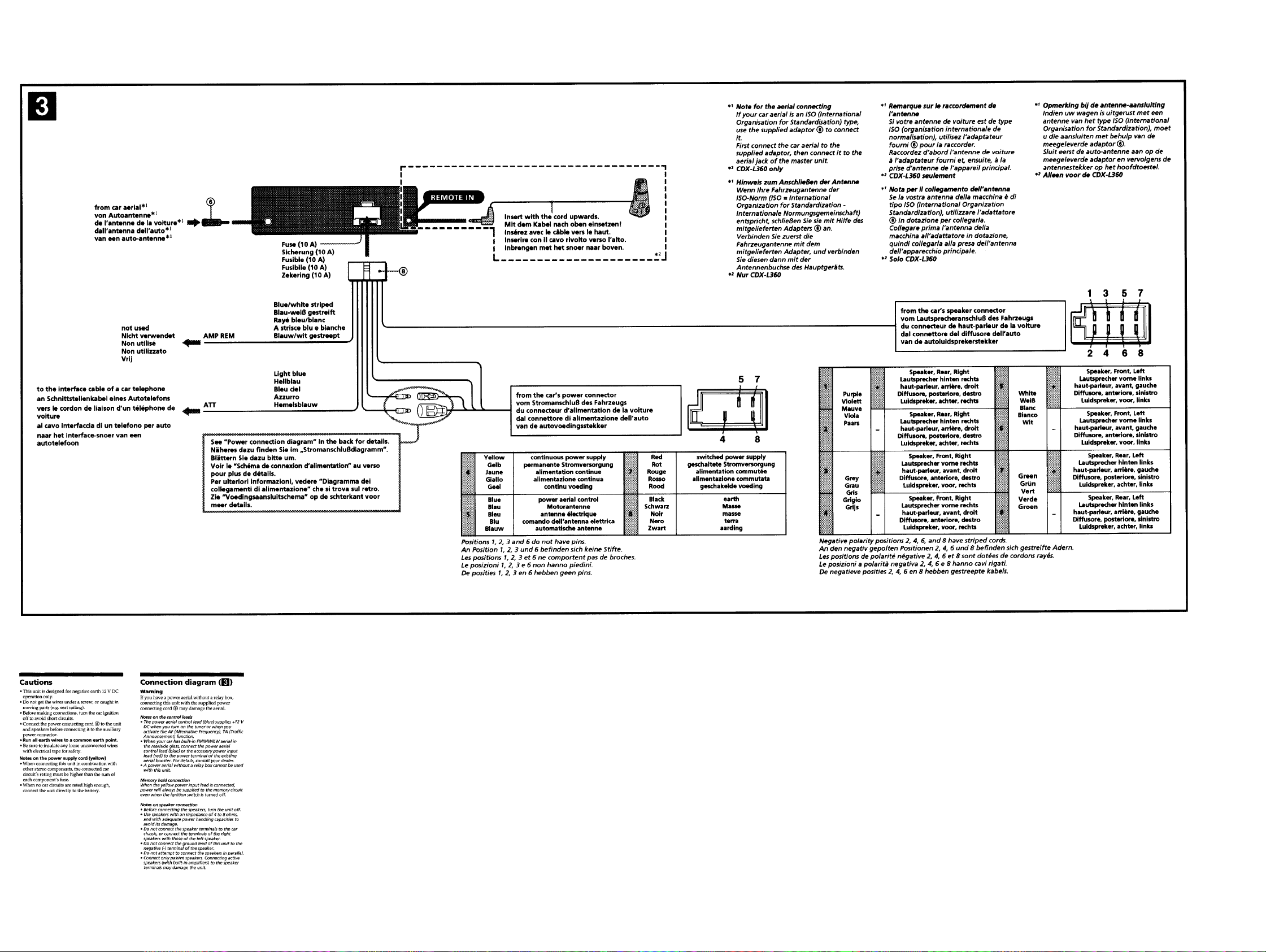

Connections .............................................................................5

2. DISASSEMBLY

2-1. Sub Panel Assy .................................................................... 7

2-2. CD Mechanism Block ......................................................... 8

2-3. Main Board ......................................................................... 8

2-4. Heat Sink ............................................................................. 9

2-5. Chassis (T.U) Assy .............................................................. 9

2-6. Disc In Board .................................................................... 10

2-7. Servo Board....................................................................... 10

2-8. Arm Roller Assy................................................................ 11

2-9. Chassis (OP) Assy............................................................. 11

2-10. Optical Pick-up Block ....................................................... 12

3. DIAGRAMS

3-1. IC Pin Description............................................................. 13

3-2. Block Diagram –CD Section–........................................... 15

3-3. Block Diagram –Tuner Section–.......................................16

3-4. Block Diagram –Display Section–.................................... 17

3-5. Circuit Boards Location ....................................................17

3-6. Printed Wiring Boards –CD Mechanism Section–............18

3-7. Schematic Diagram –CD Mechanism Section– ................ 20

3-8. Printed Wiring Board –Main Section– .............................. 21

3-9. Schematic Diagram –Main Section (1/2)– ........................ 22

3-10. Schematic Diagram –Main Section (2/2)– ........................ 23

3-11. Printed Wiring Board –Key Section–................................ 24

3-12. Schematic Diagram –Key Section– .................................. 25

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY P ARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

4. EXPLODED VIEWS

4-1. Chassis Section ................................................................. 28

4-2. Front Panel Section ...........................................................29

4-3. CD Mechanism Section (1) ............................................... 30

4-4. CD Mechanism Section (2) ............................................... 31

4-5. CD Mechanism Section (3) ............................................... 32

5. ELECTRICAL PARTS LIST ........................................ 33

2

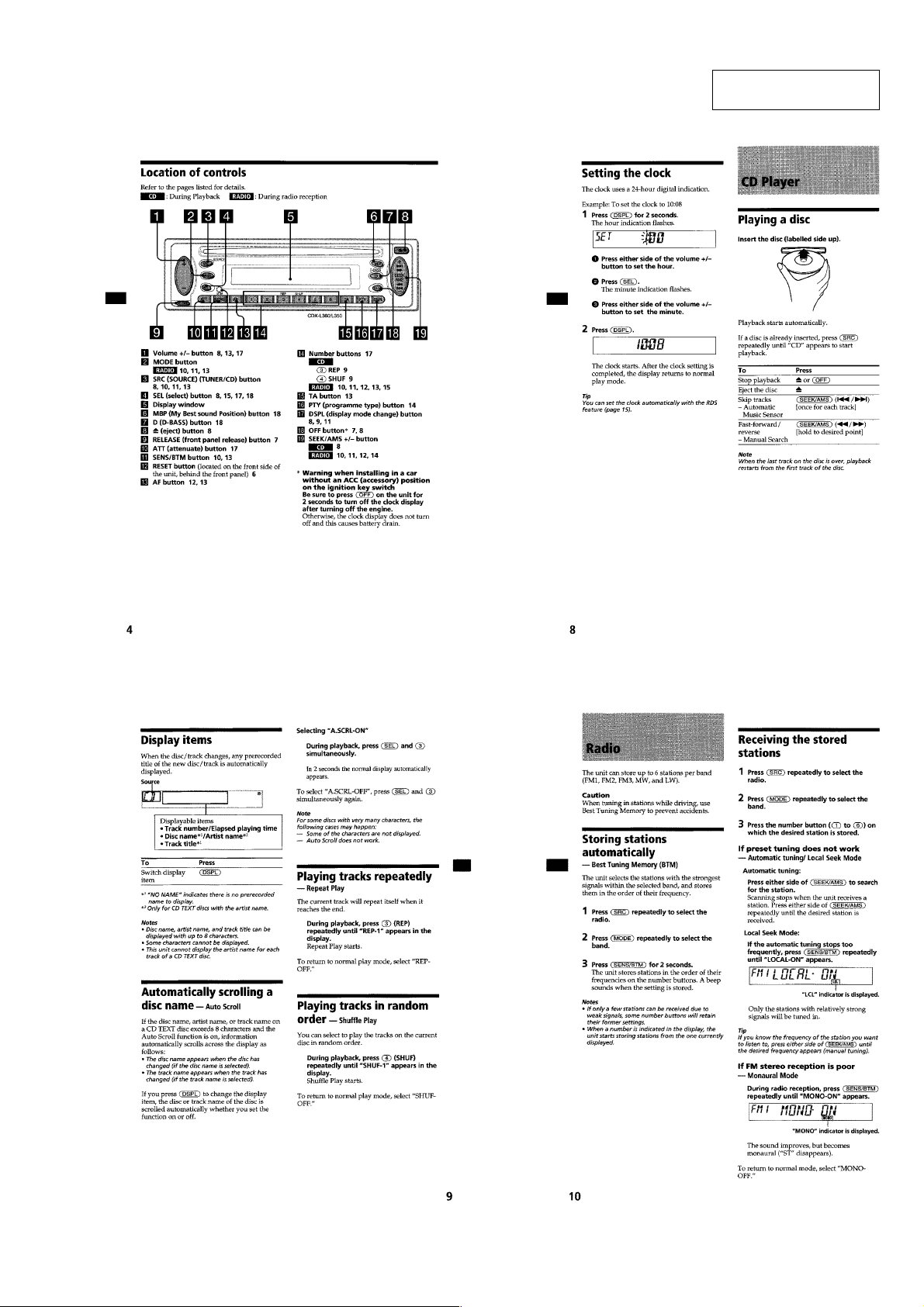

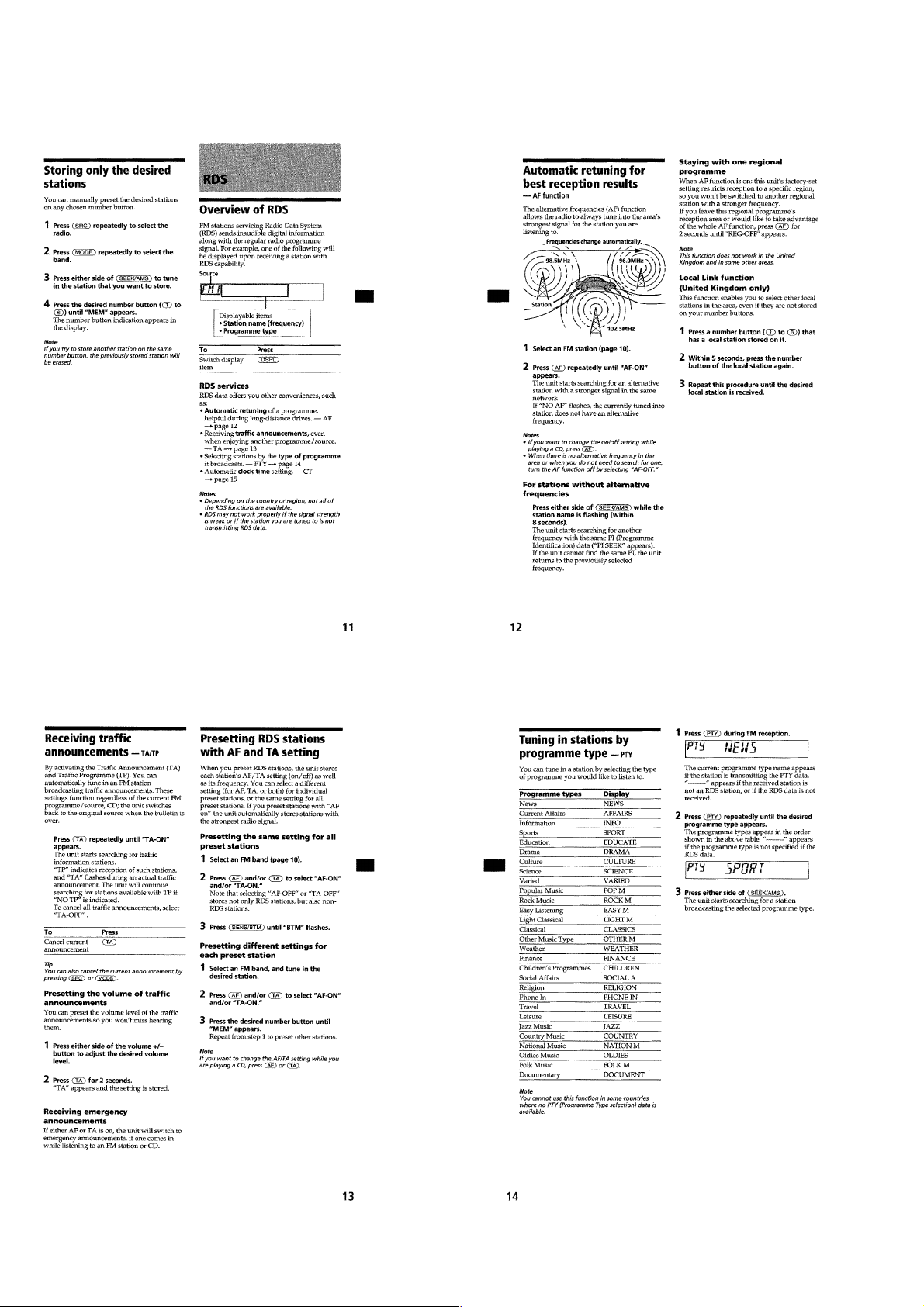

SECTION 1

GENERAL

CDX-L350/L360

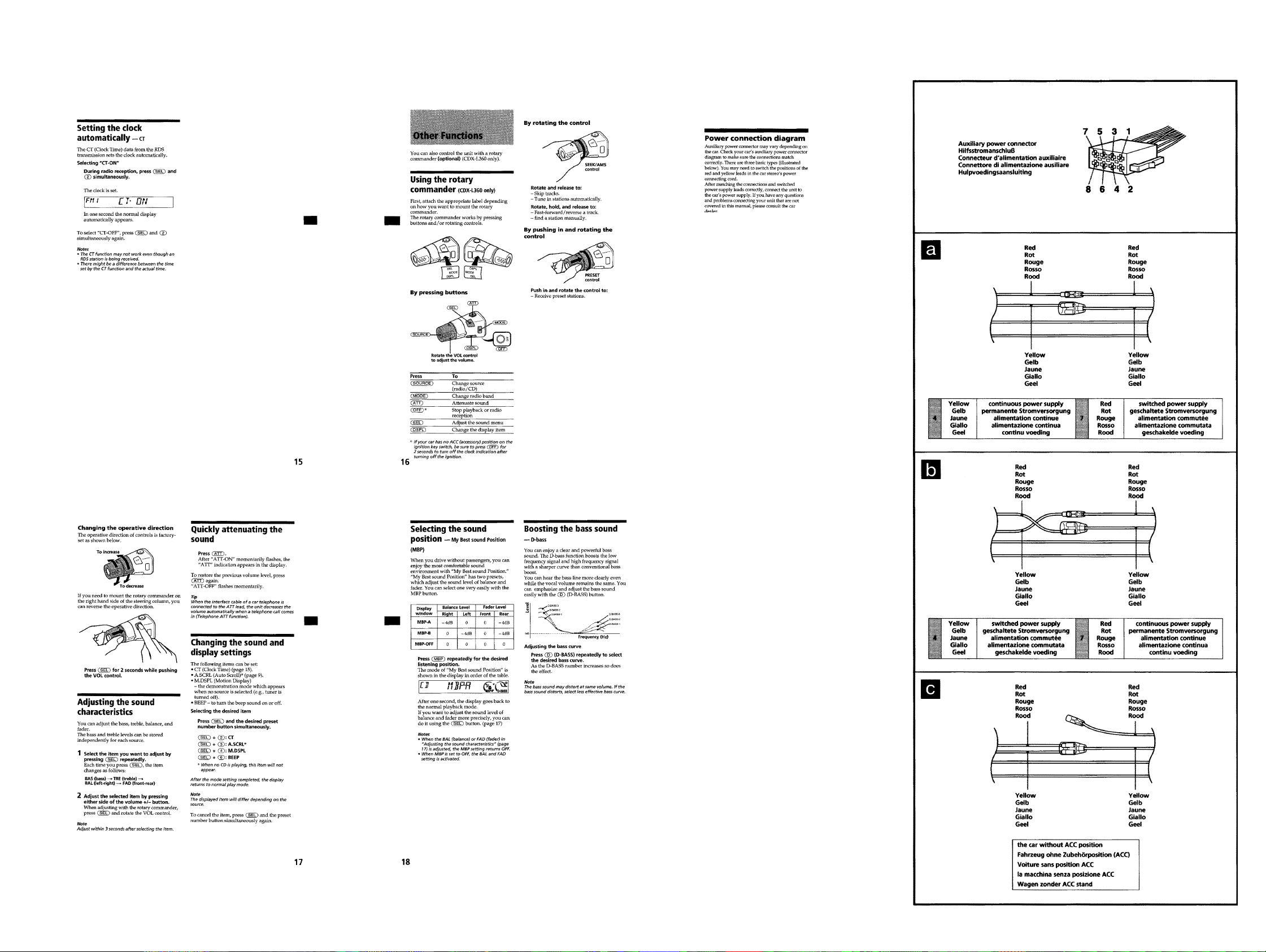

This section is extracted

from instruction manual.

3

CDX-L350/L360

4

CDX-L350/L360

55

CDX-L350/L360

66

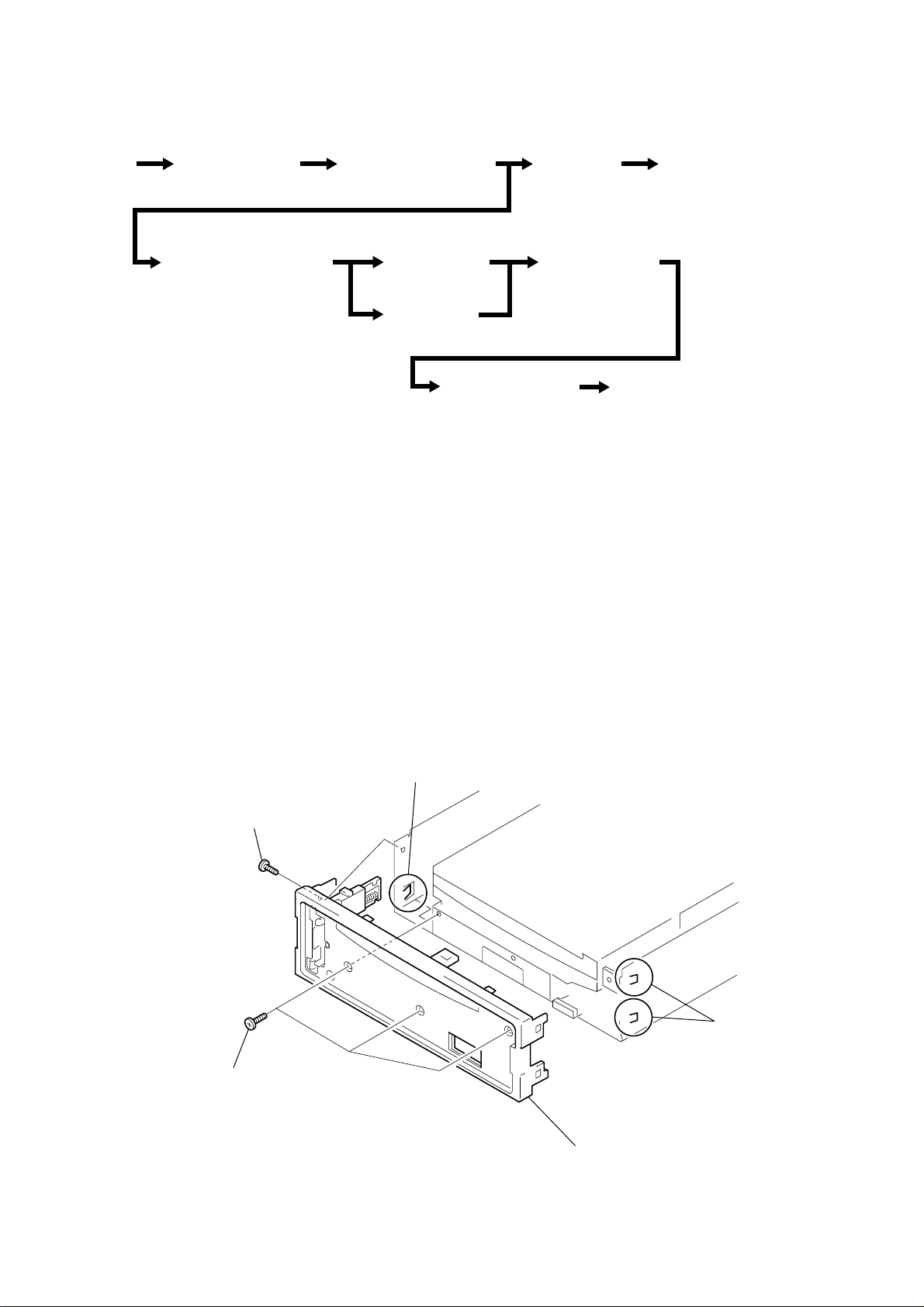

SECTION 2

DISASSEMBLY

• The equipment can be removed using the following procedure.

CDX-L350/L360

Set Sub Panel Assy CD Mechanism Block

Chassis (T.U) Sub Assy Disc In Board

Servo Board

Chassis (OP) Assy Optical Pick-up Block

Main Board Heat Sink

Arm Roller Assy

Note : Follow the disassembly procedure in the numerical order given.

2-1. SUB PANEL ASSY

3 claw

2 PTT 2.6x6

1 PTT 2.6x6

4 claws

5 sub panel assy

7

CDX-L350/L360

6

6

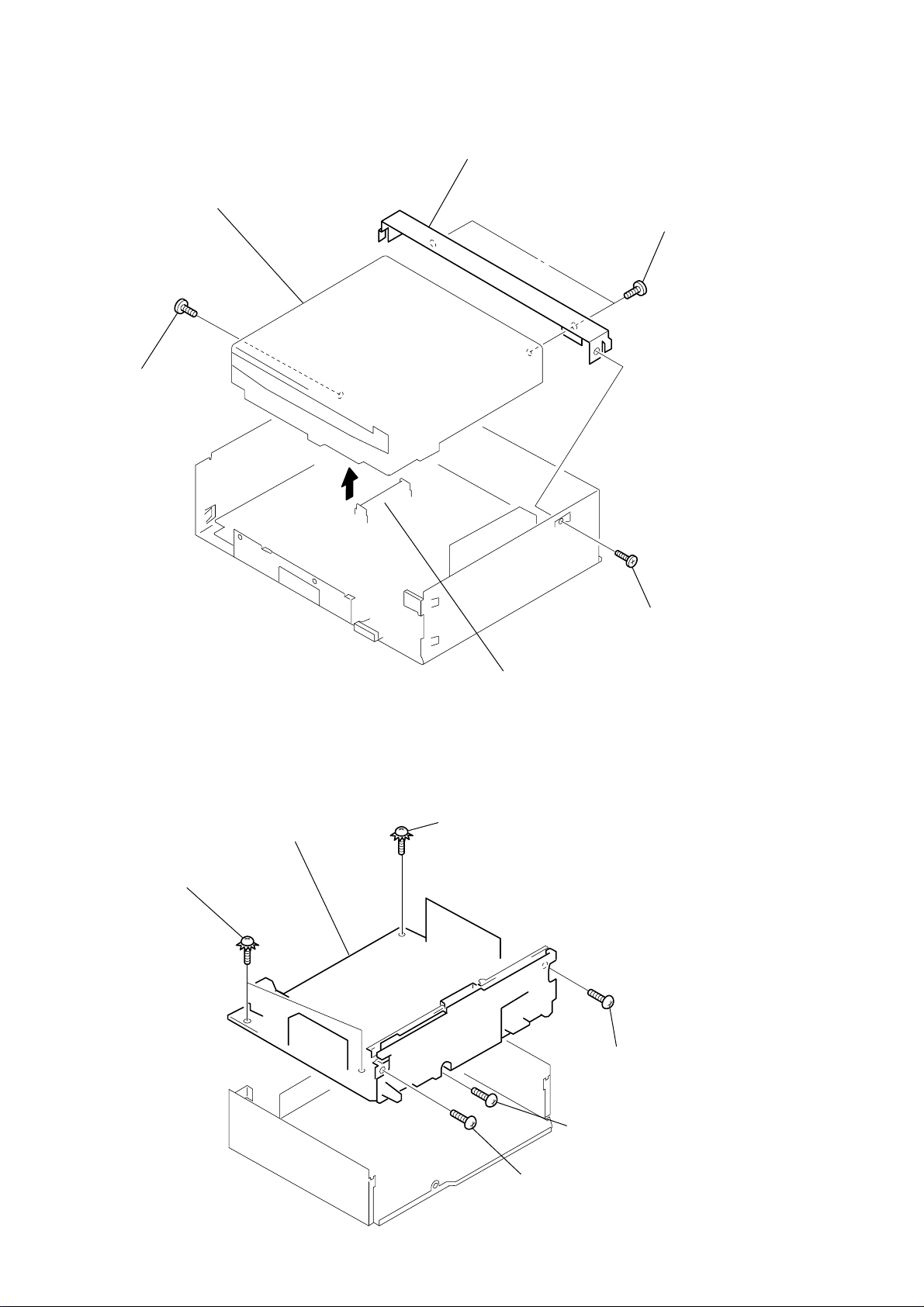

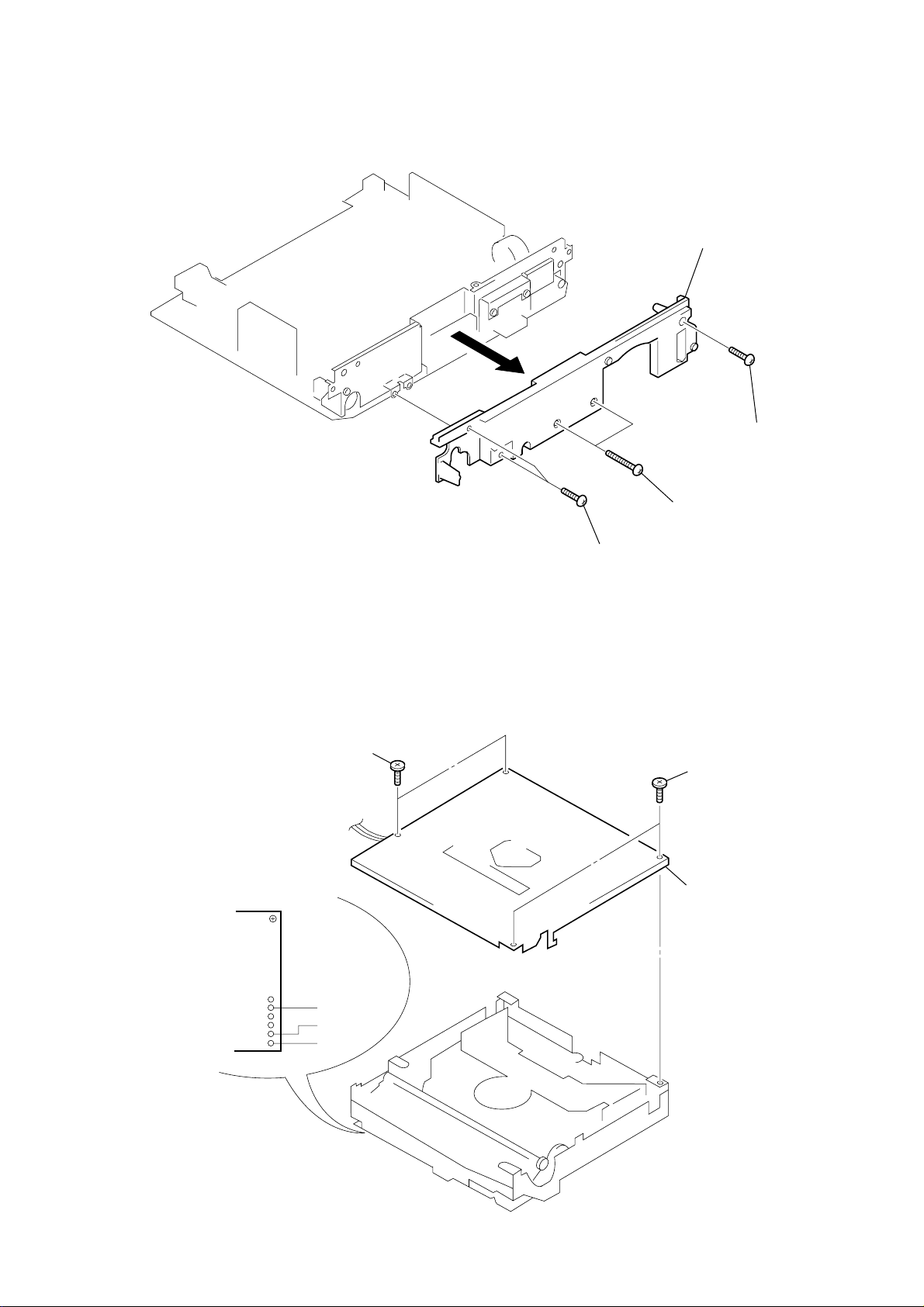

2-2. CD MECHANISM BLOCK

5 CD mechanism block

2 PTT 2.6x6

7 bracket (CD)

6 PTT 2.6x

2-3. MAIN BOARD

6 MAIN board

5 ground point screws

(PTT 2.6x6)

3

1 PTT 2.6x6

4 CNP301

4 ground point screw

(PTT 2.6x6)

3 PTT 2.6x

2 PTT 2.6x6

1 PTT 2.6x6

8

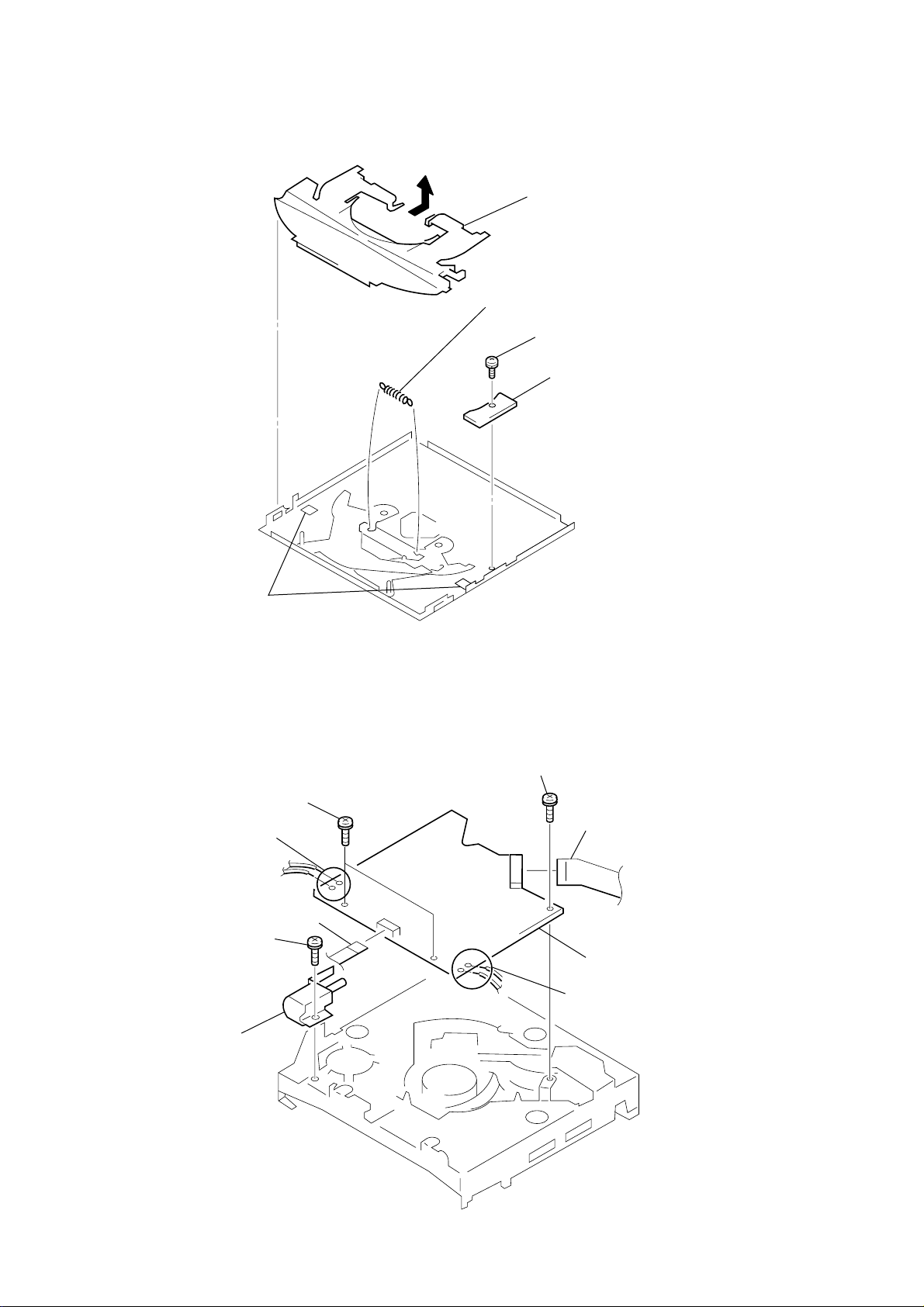

2-4. HEAT SINK

0

CDX-L350/L360

4 heat sink

3 PTT 2.6x1

2-5. CHASSIS (T.U) ASSY

1 Unsolder the

lead wires.

2 PTT 2.6x16

1 PTT 2.6x10

2 P 2x3

3 P 2x3

4 chassis (T.U) assy

black

red

white

9

CDX-L350/L360

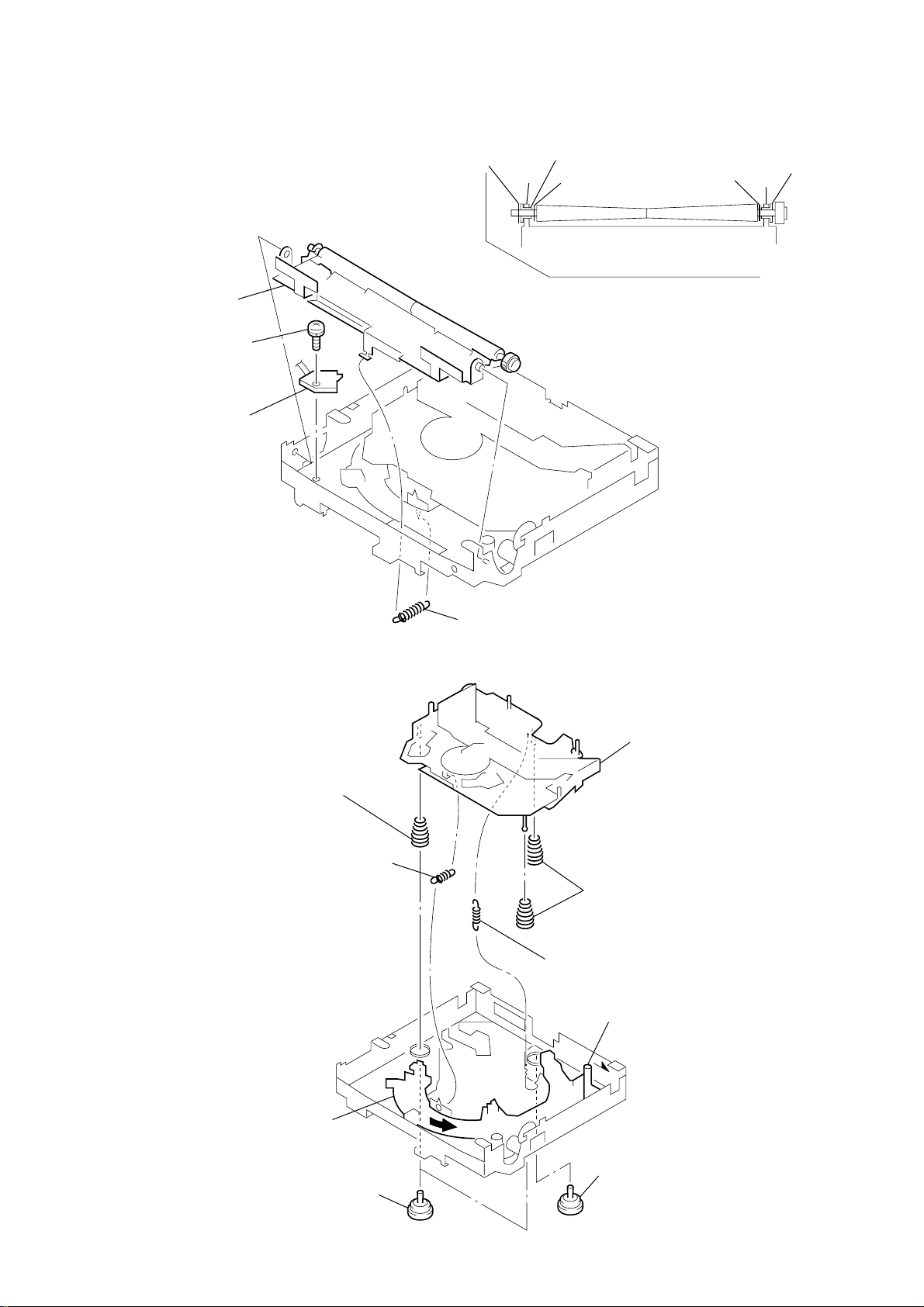

2-6. DISC IN BOARD

4 guide (disc)

3 tension spring (LR)

1 PS 2x4

2 DISC IN board

2-7. SERVO BOARD

3 Removal the solders.

6 loading motor assy

(M903)

4 claws

7 PS 2x4

8 PS 2x4

2 CN2

1 CN3

5 P 2x3

9 SERVO board

4 Removal the solders.

10

)

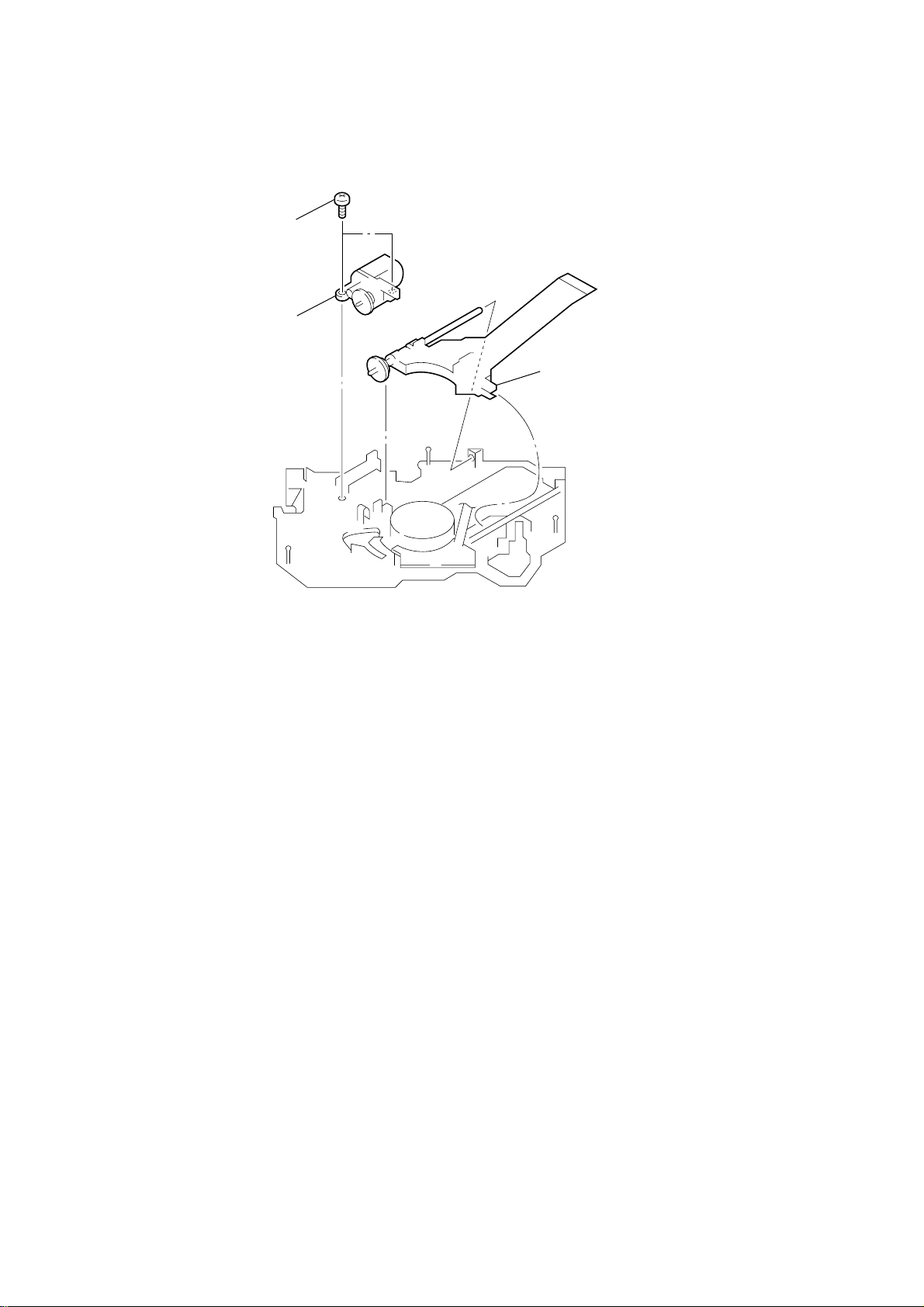

2-8. ARM ROLLER ASSY

• When installing, take note of the positions

arm (roller) and washers. (Fig. 1)

2 arm roller assy

3 PS 2x3

4 LOAD board

retaining ring (roller)

arm

bearing (roller)

washer(RA)

Fig. 1

washer(RA)

CDX-L350/L360

bearing (roller

arm

2-9. CHASSIS (OP) ASSY

8 compression spring (FL)

1 tension spring (KF1)

1 tension spring (RA3)

7 chassis (OP) assy

9 compression spring (FL)

2 tension spring (KR1)

5 Fit lever (D) in the

direction of the arrow.

6 Turn loading ring in the

direction of the arrow.

4 damper (T)

3 damper (T)

11

CDX-L350/L360

2-10. OPTICAL PICK-UP BLOCK

1 P 2x3

2 sled motor assy

(M902)

3 optical pick-up block

12

Loading...

Loading...