Page 1

CDX-828

SERVICE MANUAL

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism CDX-805

CD Drive Mechanism Type MG-250C-137

Optical Pick-up Name KSS-521A/J2N

MICROFILM

COMPACT DISC CHANGER

Page 2

SECTION 1

y

SERVICING NOTES

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 2

2. GENERAL ................................................................... 3

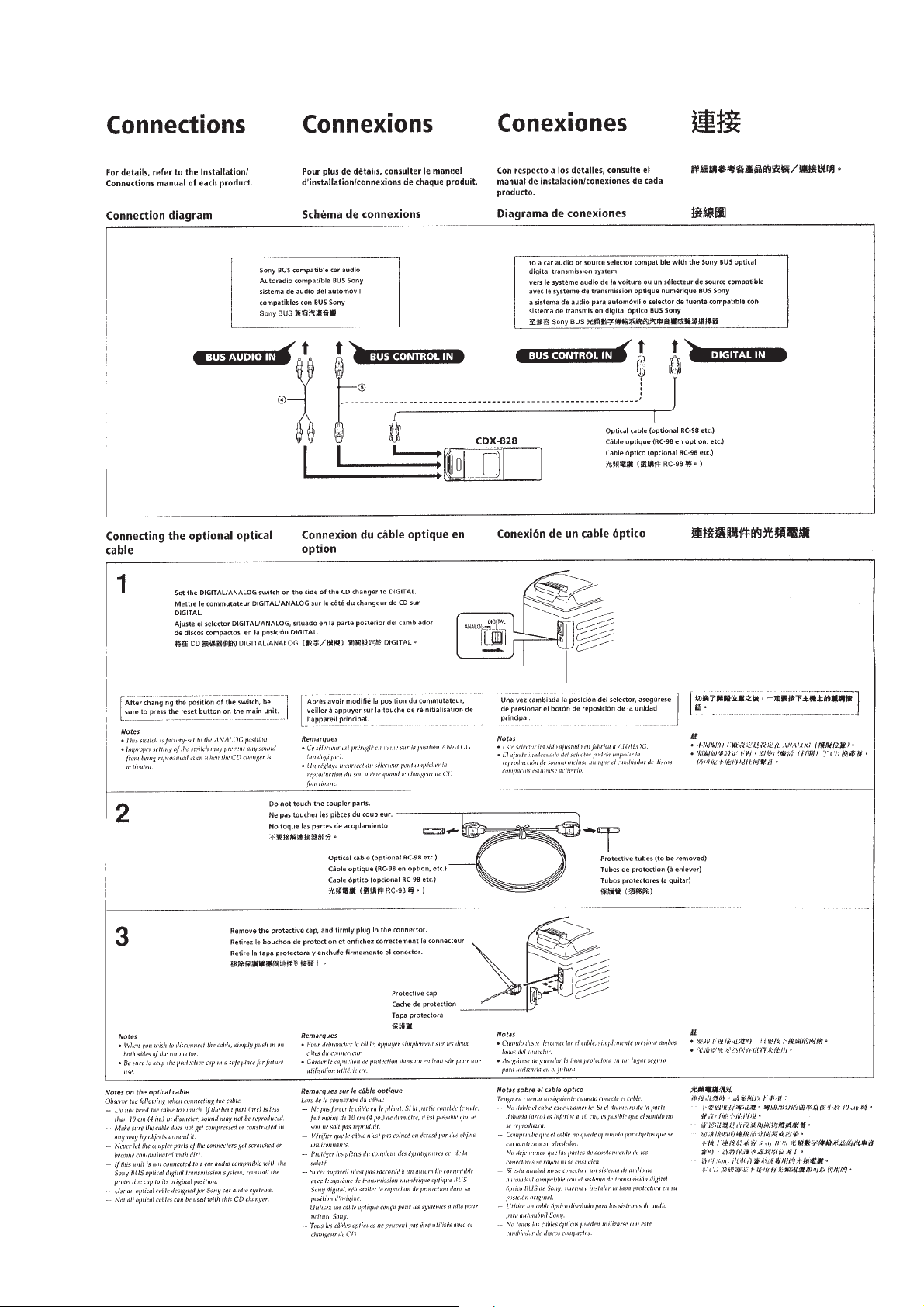

Installation....................................................................... 4

Connections ..................................................................... 5

3. DISASSEMBLY ......................................................... 6

4. MECHANISM DECK ASSEMBLY..................... 12

5. MECHANICAL ADJUSTMENTS....................... 14

6. ELECTRICAL ADJUSTMENTS......................... 15

7. DIAGRAMS

7-1. Block Diagram – SERVO Section – ............................... 17

7-2. Block Diagram – MAIN Section – ................................. 19

7-3. Block Diagram

– BUS CONTROL/POWER SUPPLY Section –........... 21

7-4. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 24

7-5. Printed Wiring Boards – RF/SW Boards –..................... 25

7-6. Schematic Diagram – RF/SW Boards – ......................... 27

7-7. Printed Wiring Board

– MAIN Board (Component Side) – .............................. 29

7-8. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 31

7-9. Schematic Diagram – MAIN Board (1/3) – ................... 33

7-10. Schematic Diagram – MAIN Board (2/3) – ................... 35

7-11. Schematic Diagram – MAIN Board (3/3) – ................... 37

7-12. Printed Wiring Boards

– DIGITAL OUT /JACK Boards – ................................. 41

7-13. Schematic Diagram

– DIGITAL OUT /JACK Boards – ................................. 43

7-14. IC Pin Function Description ........................................... 49

8. EXPLODED VIEWS ................................................ 52

NOTES ON HANDLING THE OPTICAL PICKUP BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

Laser Diode Properites

• Material: GaAlAs

• Wavelength: 780 nm

• Emission Duration: continuous

• Laser Output Power: less than 44.6 µW*

* This output is the value measured at a distance of 200 mm

from the objective lens surface on the Optical Pick-up Block.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

9. ELECTRICAL PARTS LIST ............................... 57

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED

LINE WITH MARK ! ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE !

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

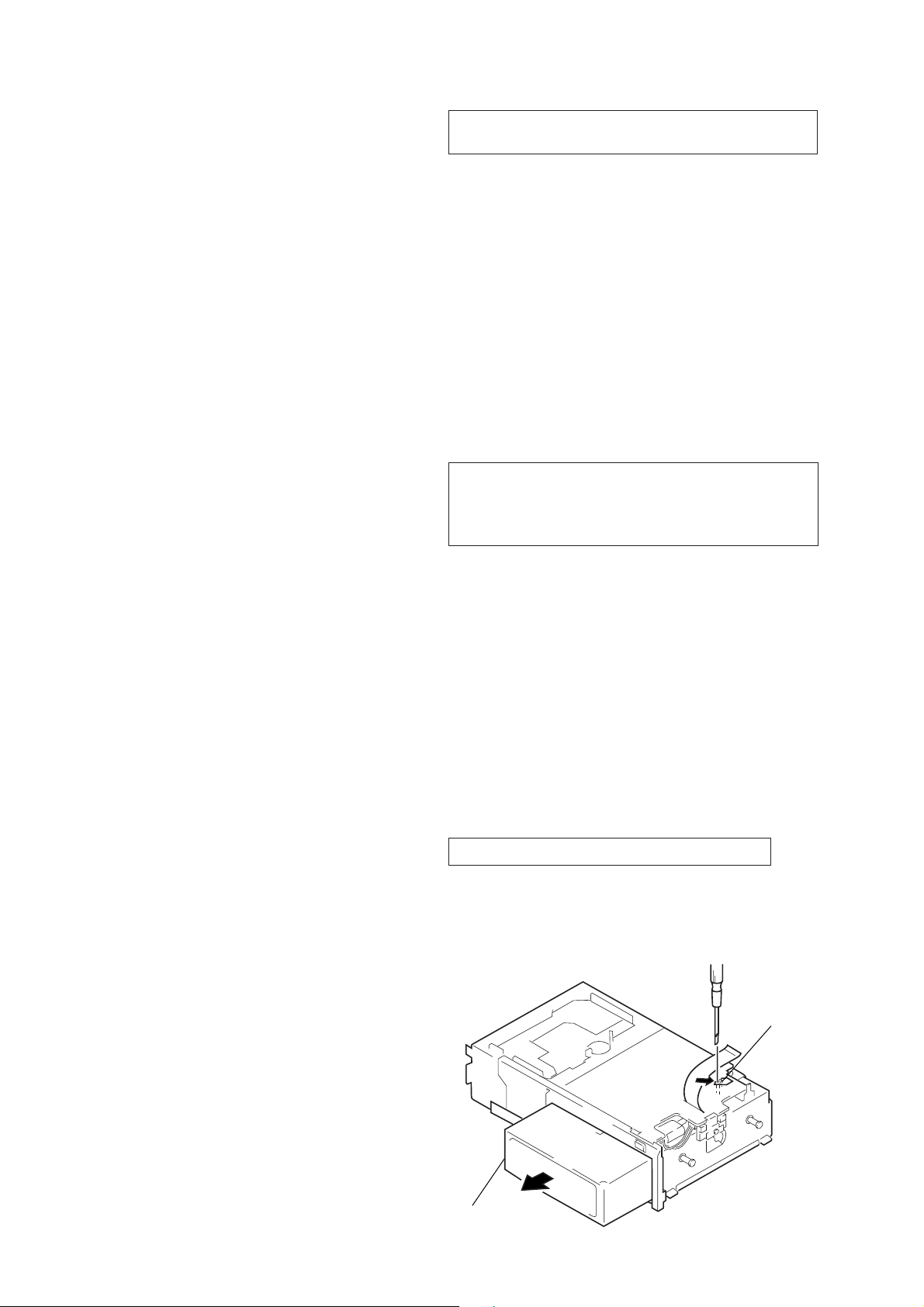

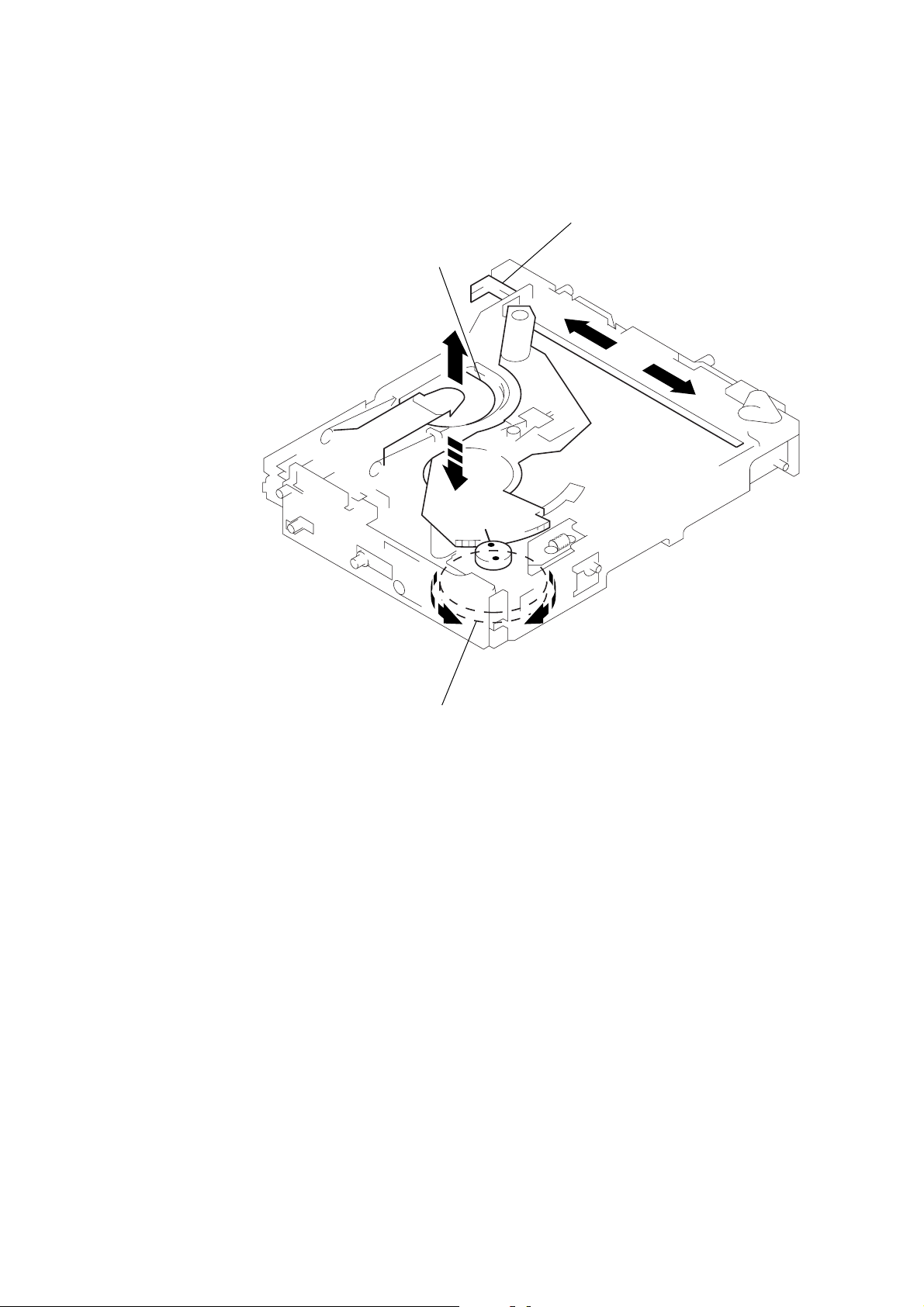

DISC MAGAZINE GETTING OUT PROCEDURE

ON THE POWER SUPPLY IS OFF

Remove the CASE (LOWER) assembly beforehand

1) Press the lever (ML) assy to arrow direction.

2) Removal the magazine assy.

Note: Take out the magazine only when the tray is completely within the

magazine. If the disk or tray is sticking out, turn on the power and

eject the magazine.

Lever (ML) ass’

Magazine ass’y

– 2 –

Page 3

SECTION 2

GENERAL

This section is extracted from

instruction manual.

– 3 –

Page 4

– 4 –

Page 5

– 5 –

Page 6

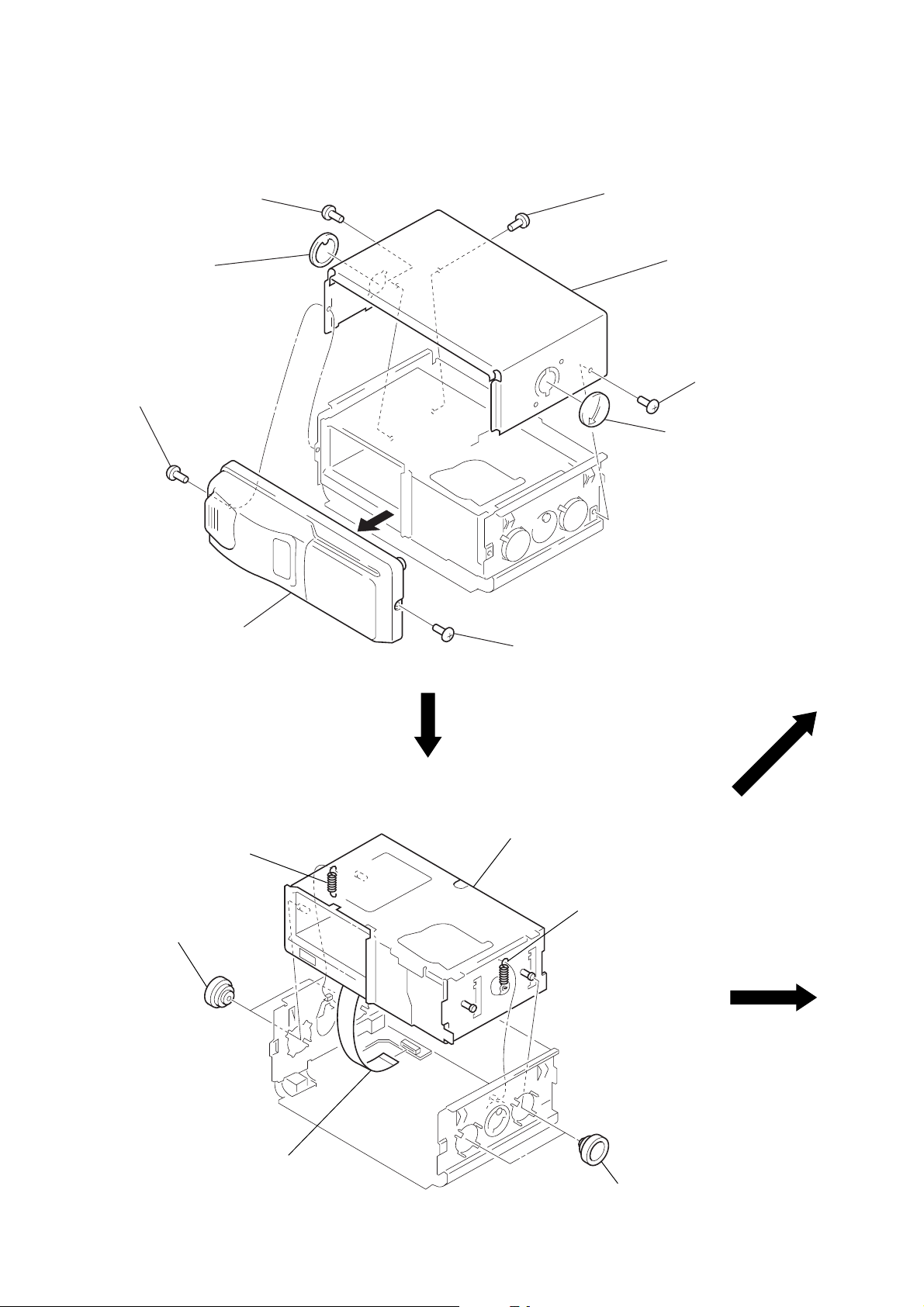

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

COVER (UPPER) , FRONT PANEL ASS’Y

1

screw

(PTT2.6 × 6)

4

lever (FL)

1

screw

(PTT2.6 × 6)

2

screw

(BVTT2.6 × 6)

3

cover (upper)

1

4

lever (FL)

screw

(PTT2.6 × 6)

5

front panel ass’y

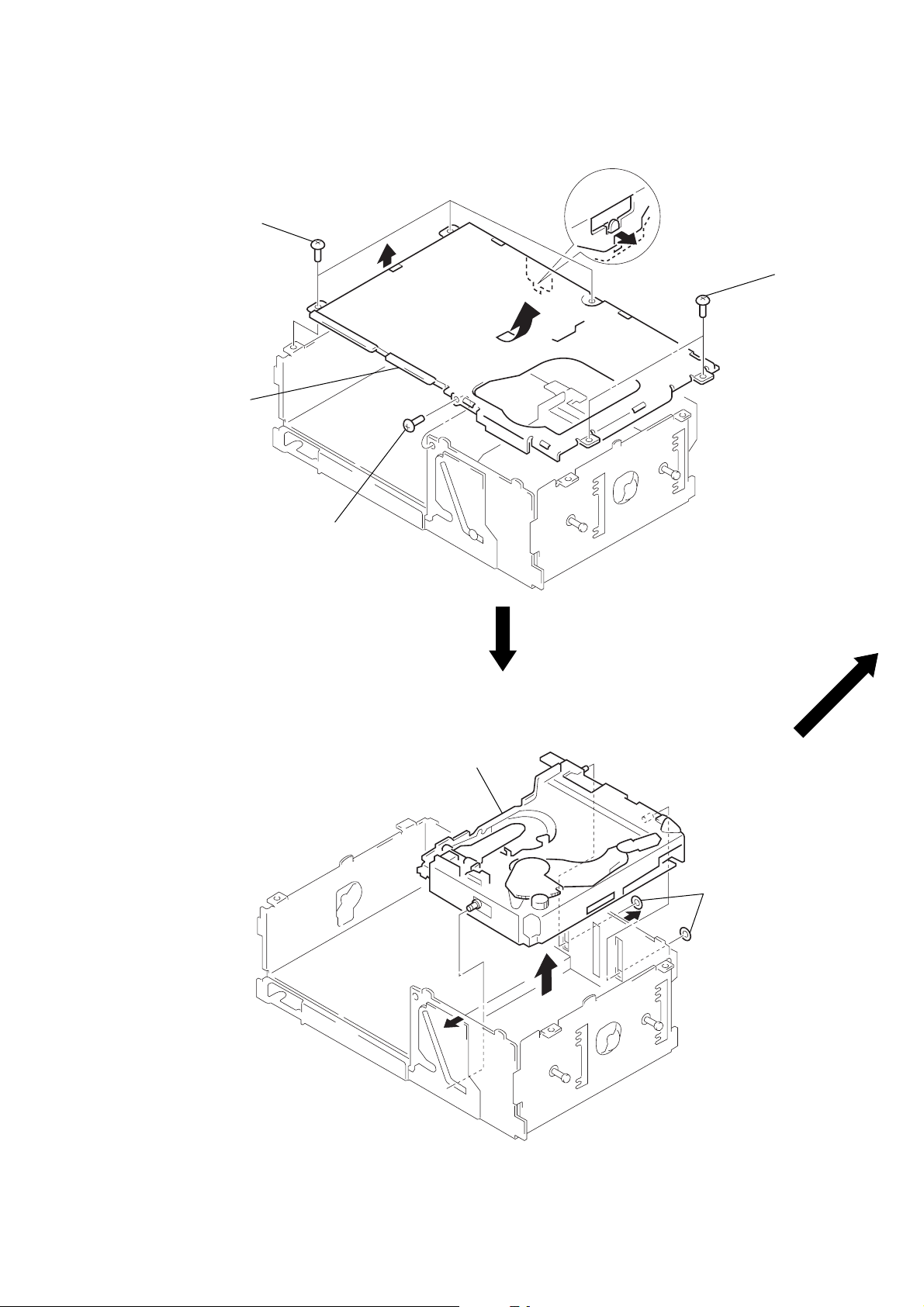

MECHANISM DECK (MG-250C-137)

2

tension spring (FL)

1

two dampers (250)

1

screw

(PTT2.6 × 6)

4

mechanism deck (MG-250C-137)

2

tension spring (FL)

3

jack flexible board

(CN903)

– 6 –

1

two dampers (250)

Page 7

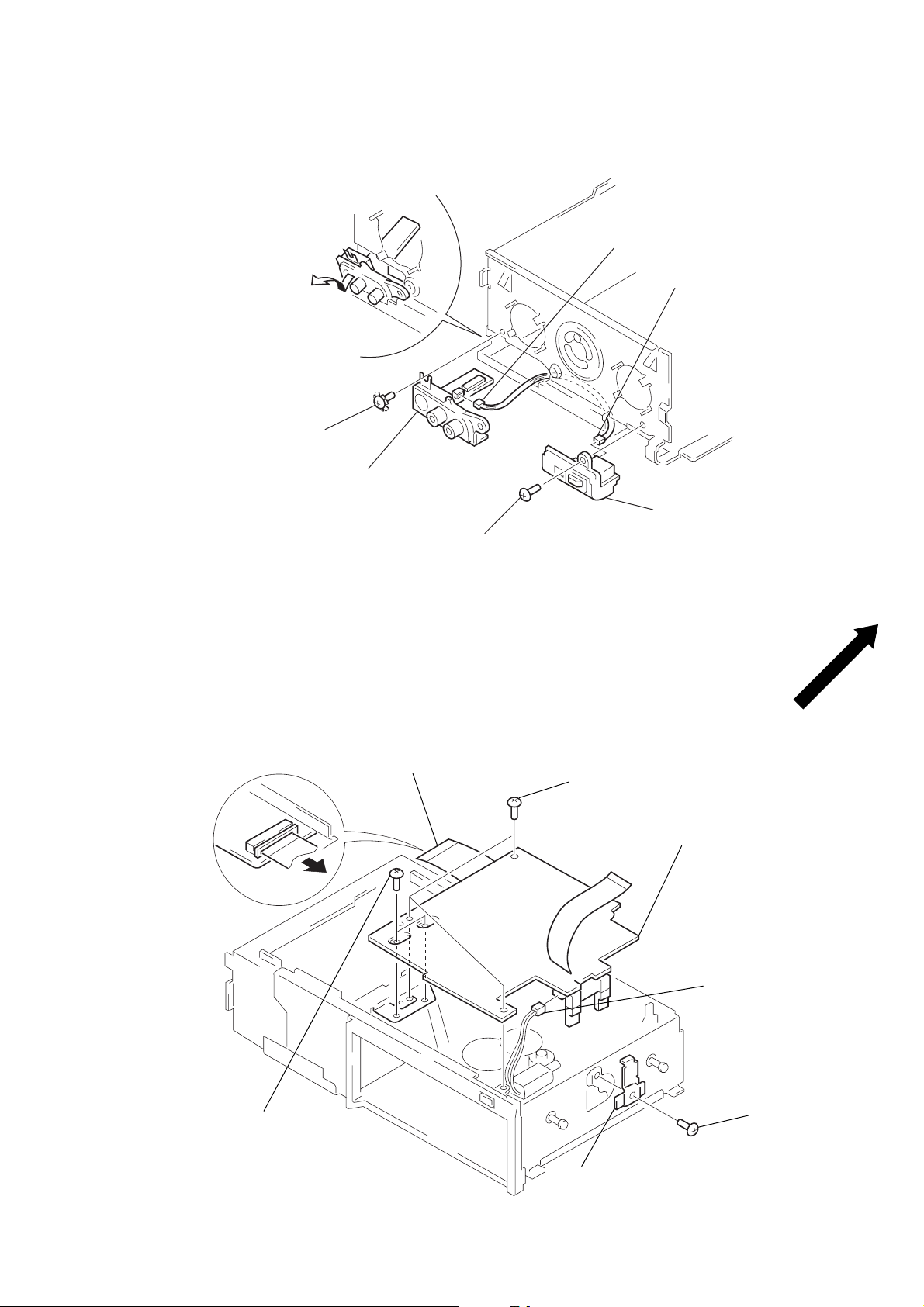

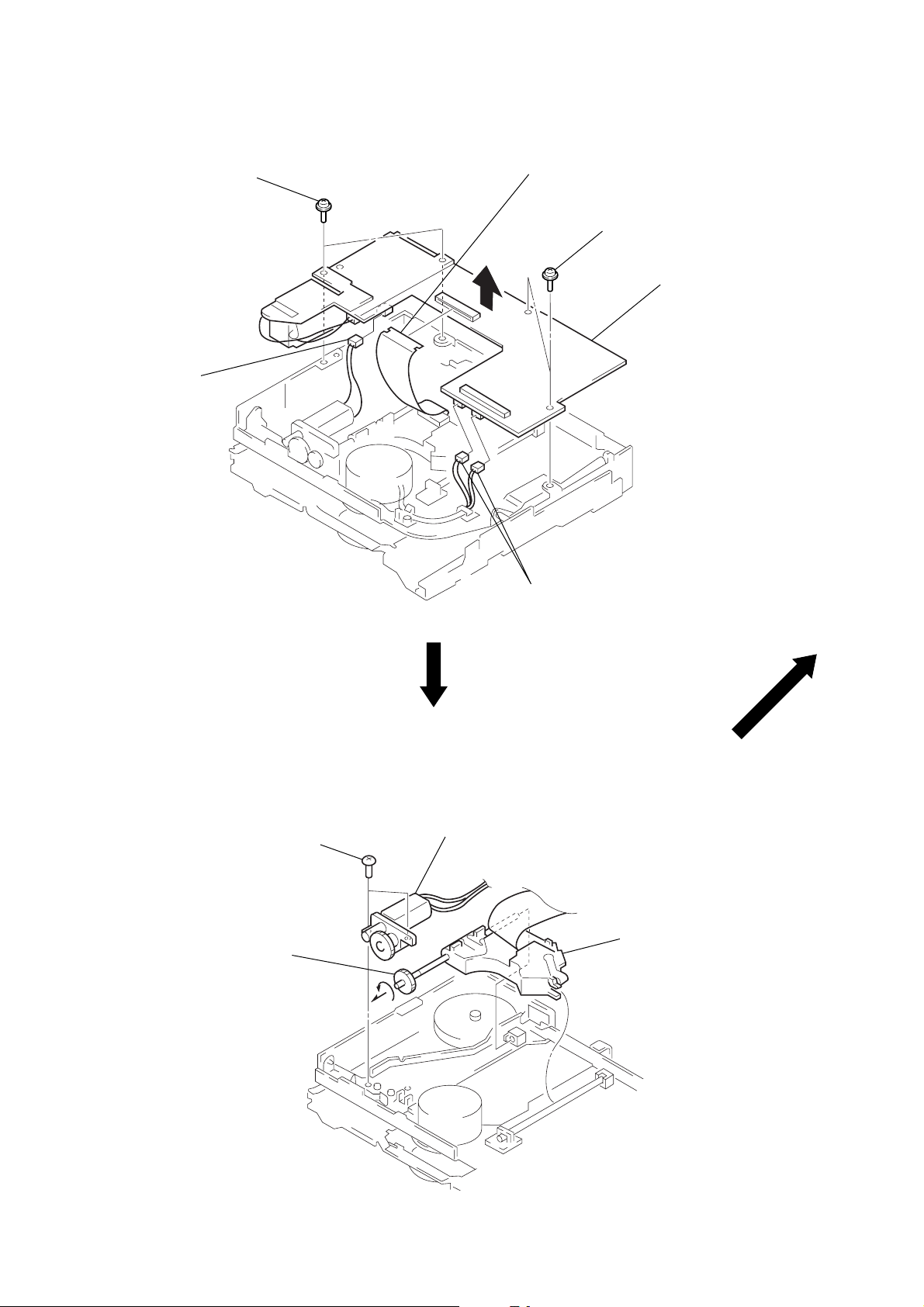

JACK BOARD, DIGITAL OUT BOARD

d

)

Remove the jack board

of the arrow.

1

ground point screw

(PTT2.6

×

6)

3

jack board

4

screw

(BVTT2

2

connector

(CN902)

5

connector

(CN801)

6

digital out boar

×

6)

MAIN BOARD

1

main flexible board

(CNJ12)

6

three screws (FP)

7

main board

2

connector

(CN302)

5

two precision screws

×

2.5)

(P1.7

– 7 –

4

heat sink

3

screw

(PTT2

×

3

Page 8

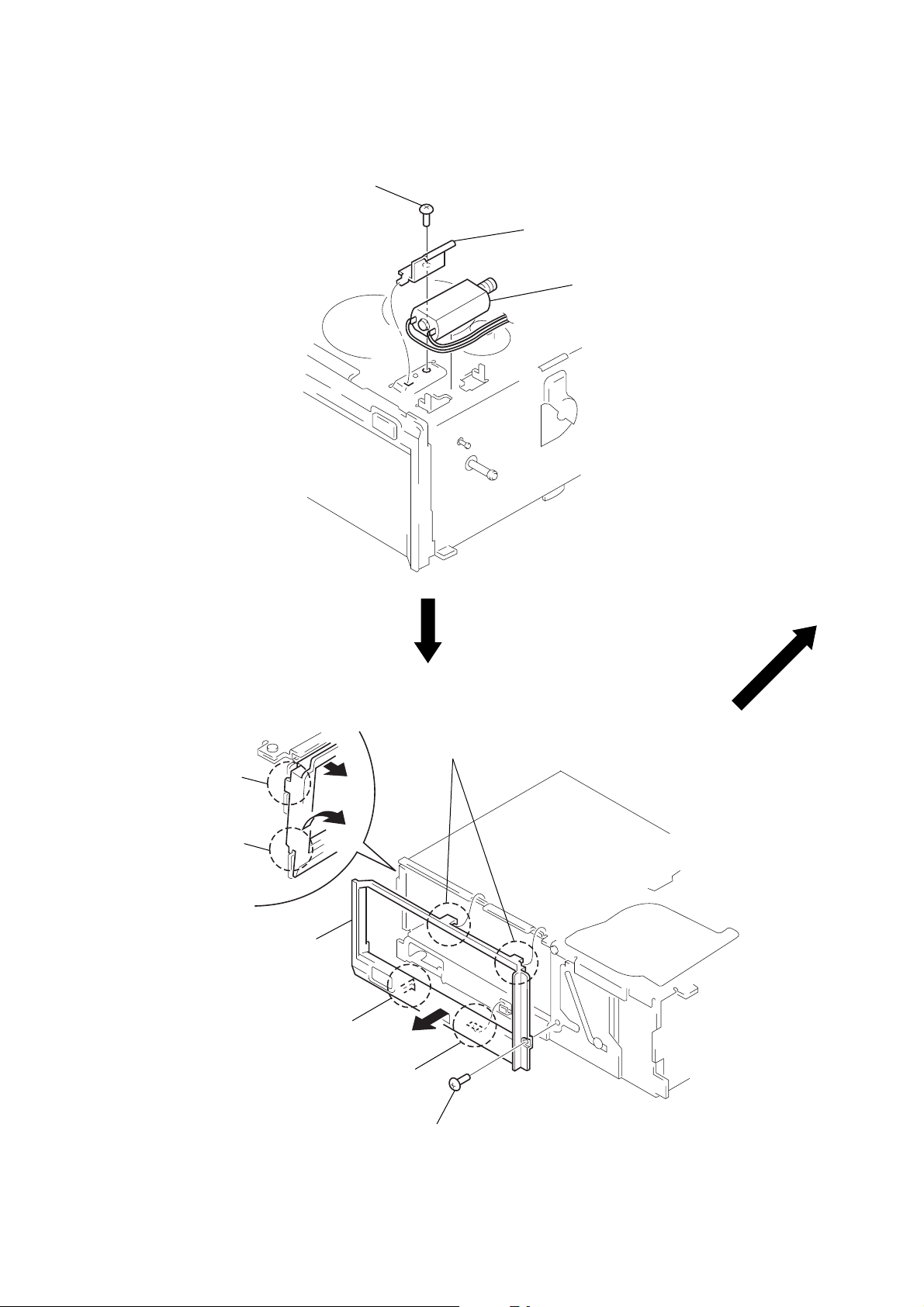

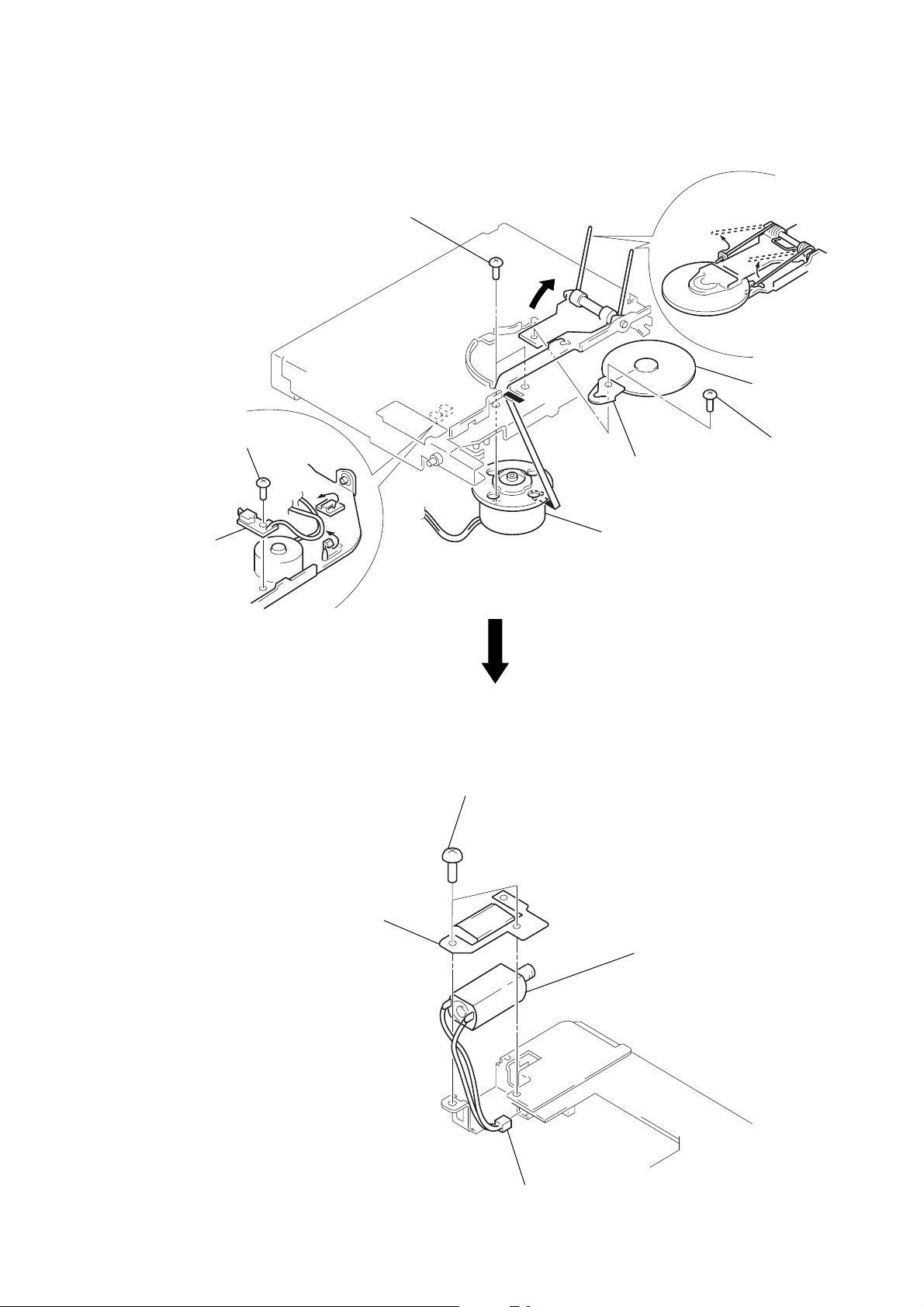

ELEVATOR MOTOR ASS’Y (M104)

y

1

screw

(PTT2

×

3)

2

bracket (EVM)

3

elevator motor ass’

(M104)

ESCUTCHEON (T)

2

Remove the claw

of the arrow

4

Remove the ditch

of the arrow

Remove the escutcheon (T)

5

of the arrow

A

B

C

3

two claws

.

.

.

3

claw

B

A

4

C

ditch

1

screw

(M2

– 8 –

×

3)

Page 9

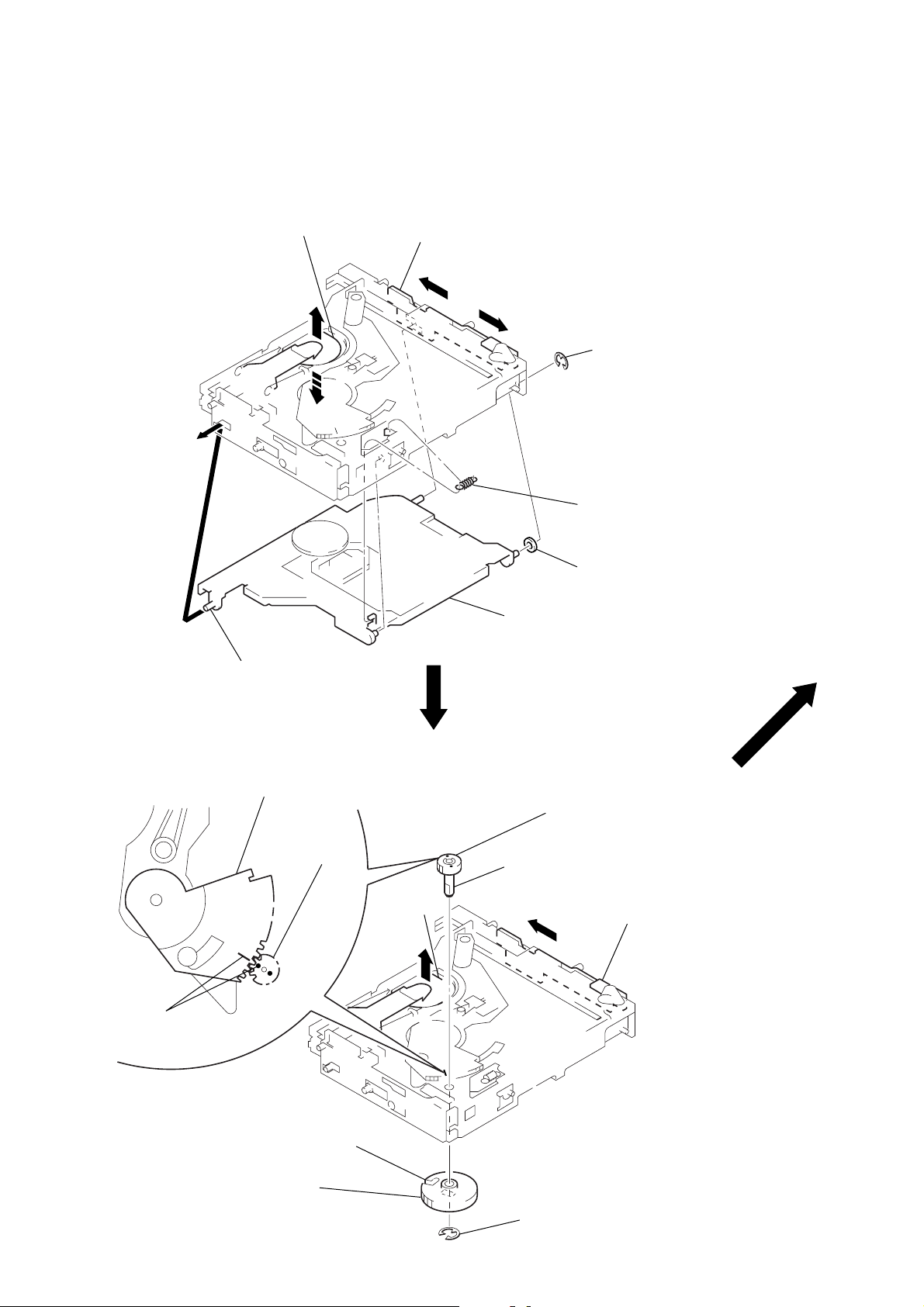

CASE (UPPER) ASS’Y

1

three screws

(PTT2 × 4)

1

two screws

(PTT2 × 4)

2

4

Remove the case

(upper) ass’y of

the arrow B.

3

Remove the edge

of the arrow A.

1

screw

(PTT2 × 4)

A

B

s

CHASSIS ASS’Y

3

chassis ass’y

2

1

two polyethylene washer

2

– 9 –

Page 10

RF BOARD

2

two screws

(PS2

1

OP flexible board

×

4)

(CNJ11)

2

two screws

(PS2

×

4)

4

connector

(CNP52)

3

4

two connectors

(CNP11, 53)

5

RF board

SLED MOTOR ASS’Y (M102) , OPTICAL PICK-UP (KSS-521A/J2N)

1

two screws

(ESCUTCHEON)

4

Turn at the direction of the

arrow, then remove

shaft (sled) ass’y

2

sled motor ass’y

(M102)

3

optical pick-up

(KSS-521A/J2N)

– 10 –

Page 11

SW BOARD, SPINDLE MOTOR ASS’Y (M101)

)

8

two screws

×

2.2)

(P1.7

1

screw

×

2.2)

(P2

2

SW board

7

3

spring (chucking)

6

retainer (disc

4

screw

5

bracket (CP)

9

Remove the spindle motor ass’y (M101)

of the arrow.

(P2

×

2.2)

CHUCKING MOTOR ASS’Y (M103)

3

retainer (CHM)

2

two screws (P2 × 2.5)

4

chucking motor ass’y

(M103)

– 11 –

1

connector

(CNP51)

Page 12

SECTION 4

)

MECHANISM DECK ASSEMBLY

Note: Follow the assembly procedure in the numerical order given.

OPTICAL PICK-UP COMPLETE ASS’Y

1

chuck plate

Move the lever (LOCK 3) in direction A, and return it a little in

direction

down to the lower limit.

B

from the position where the chuck plate is moved

B

A

4

stop ring 2.0 (E type

5

tension spring (DH)

shaft (A)

GEAR (LOMINI) / (LOAD 1) ASS’Y

gear (LOAD 2)

gear (LOMINI)

marking

Fig. A

chuck plate

2

washer 2.5

3

optical pick-up complete ass’y

Note: Insert the shaft (A) first.

2

Attach the gear (LOMINI) at the position

shown in Fig. A.

shaft (rotary prevention C)

1

B

Move the lever (LOCK 3)

fully in direction

move the chuck plate up.

B

to

3

Attach the gear (LOAD 1) ass’y

with its facing inside.

slit

– 12 –

4

stop ring 1.5 (E type)

Page 13

OPERATION CHECK

1

Confirm that the slider moves in direction C to move down

the chuck plate if the gear (LOAD 1) is rotated in direction A or

the chuck plate moves up and the slider moves in direction D if

the gear is rotated in direction B.

chuck plate

slider

D

C

A

gear (LOAD 1) ass'y

B

– 13 –

Page 14

MECHANICAL ADJUSTMENTS

5

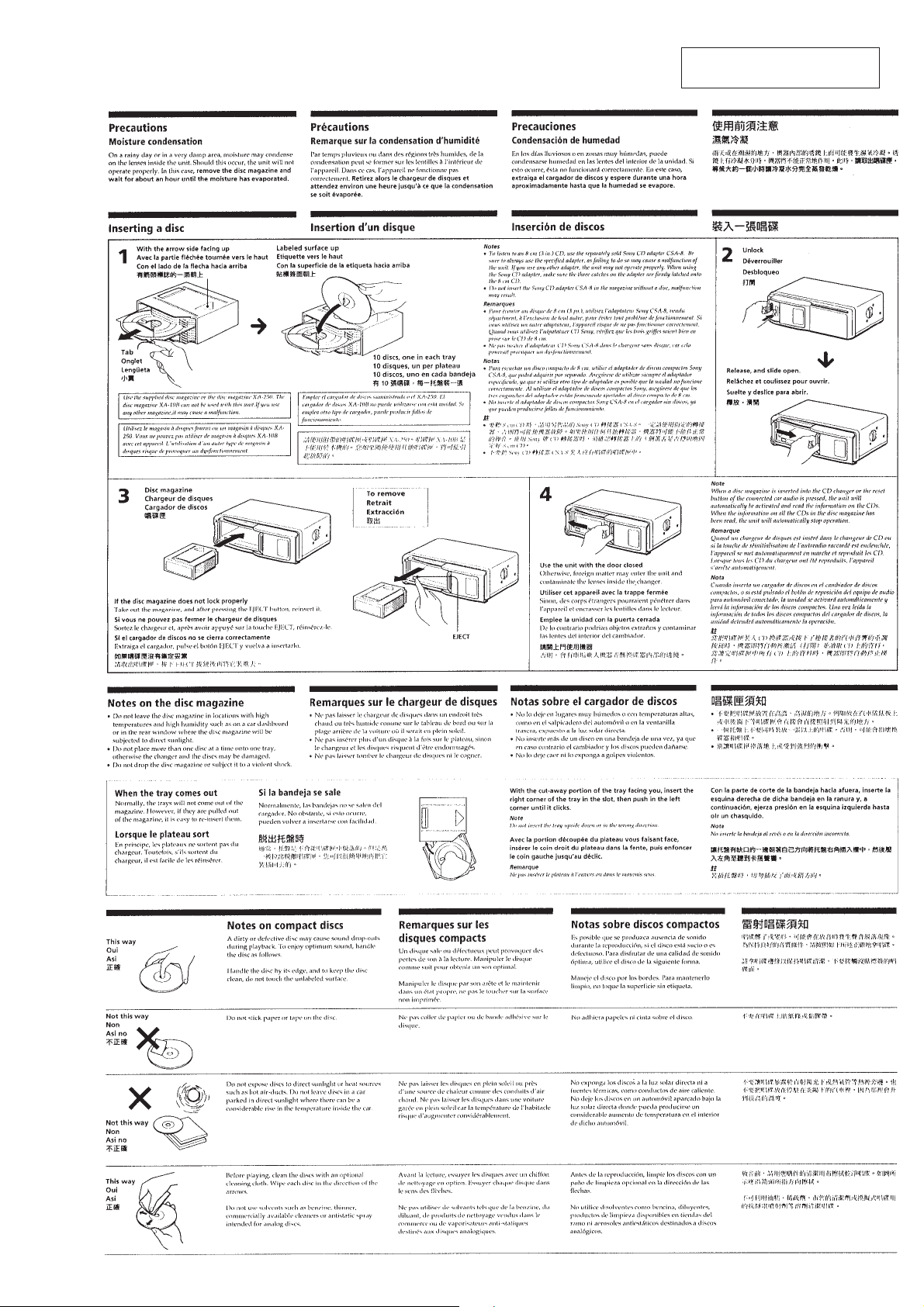

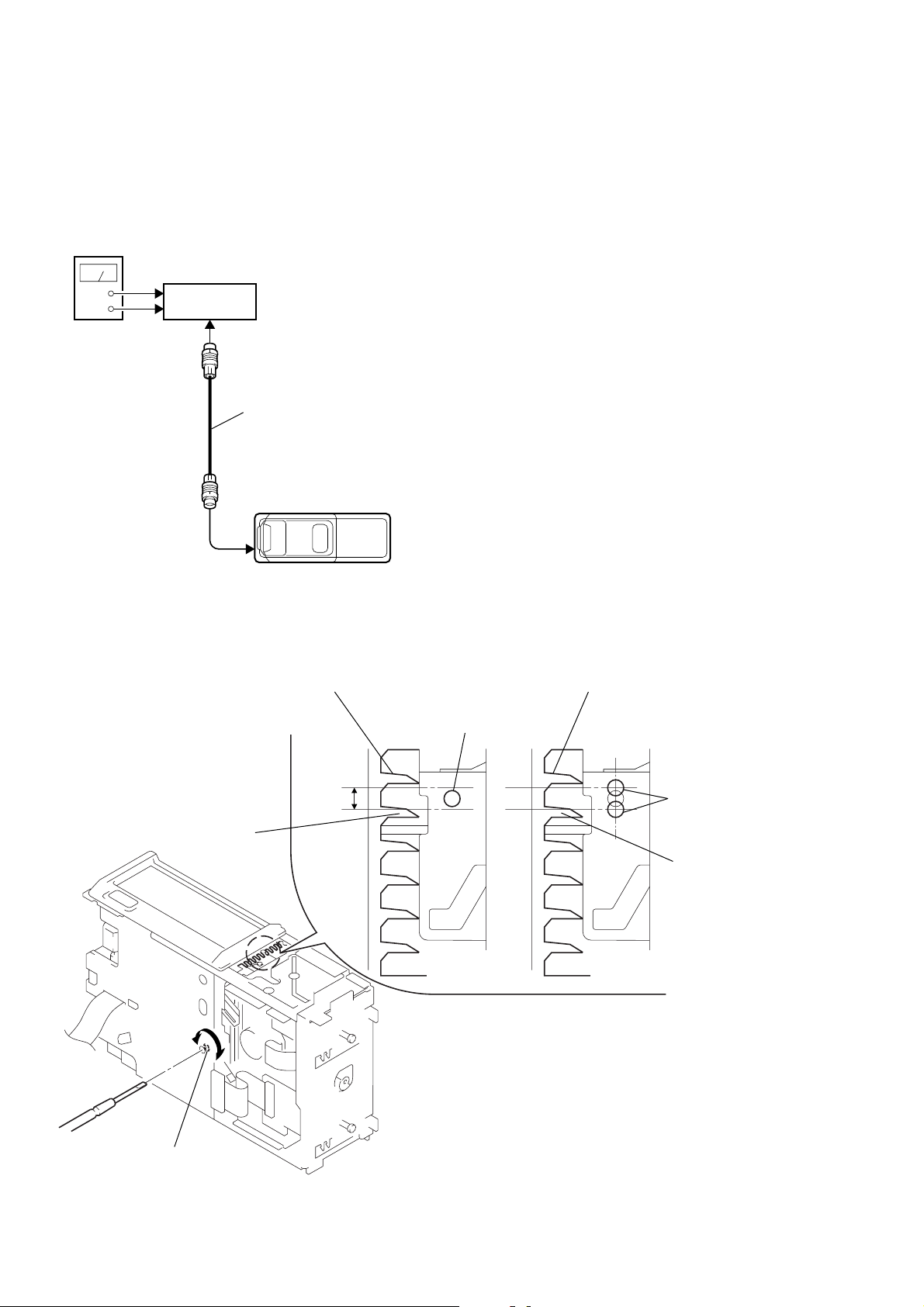

• Elevator Height (Address) Adjustment

SECTION 5

Note: This adjustments is necessary when the system controller (IC201),

variable resistor (RV201), slider (R), slider (L), or chassis (ELV)

was replaced for any repair.

Connection:

power supply

master unit

+

GND

BUS cable

CDX-828

Adjustment Method:

1. Connect this set to the master unit (e.g. MDX-C670/

C670RDS), load a disc magazine, and place the set vertically

as shown below.

2. Connect the regulated power supply to the master unit, and

turn the power on.

3. Press the DISC button on the master unit and select DISC 5.

4. At this time, if the elevator shaft does not position between

comb teeth A and B at addresses 5 and 6 as shown below,

adjust the following.

5. Press repeatedly the DISC + and – buttons on the master unit

so that the elevator shafts moves from address 6 to address 5,

or from 5 to 6. At this time, adjust RV201 on the main board

so that the elevator shaft positions smoothly between comb

teeth A and B.

6. Further, place the set horizontally and make same adjustment

as mentioned above.

7. After adjustment at addresses 5 to 6 is finished, check all op-

erations from addresses 1 to 10 with the set placed vertically

and horizontally respectively to confirm that the elevator shaft

positions in a range between comb teeth A to B.

comb tooth at address 5

comb tooth at address 6

A

B

comb tooth at address 6

elevator shaft

A

B

OK NG

elevator shaft

comb tooth at address

RV201

– 14 –

Page 15

SECTION 6

V

TP

(VC)

IC11

IC51

CNJ12

BP11

(TE)

oscilloscope

+

–

ELECTRICAL ADJUSTMENTS

Note:

1. Perform adjustments as given.

2. Power supply voltage: DC14.4 V (more than 3A).

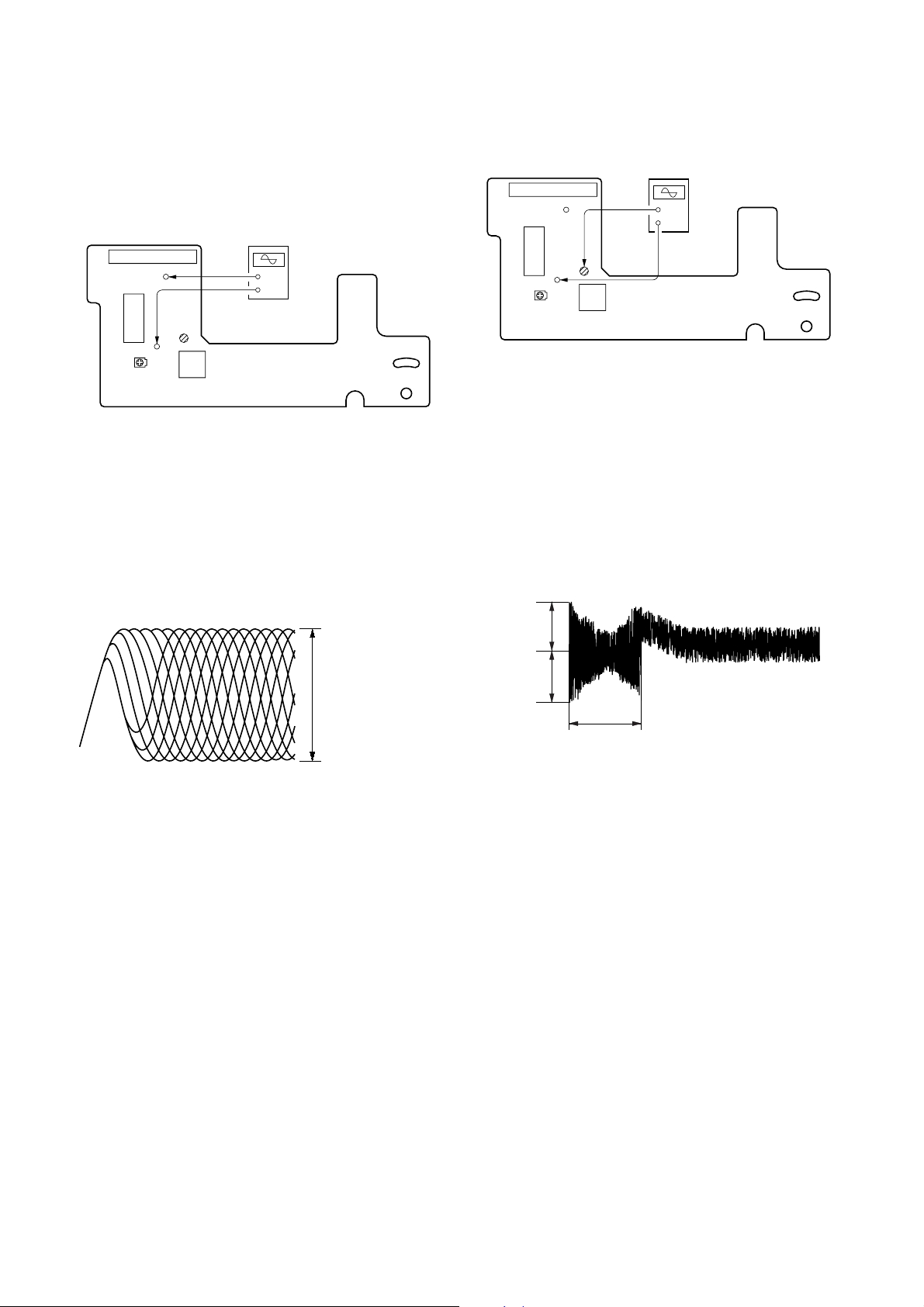

• FOCUS BIAS CHECK

[RF BOARD] – Conductor Side –

oscilloscope

CNJ12

TP (RF)

IC51

TP

(VC)

IC11

+

–

Procedure:

1. Connect the oscilloscope to TP (RF) and TP (VC) on the RF

board.

2. Put the set into play mode by loading the disc.

3. Confirm that oscilloscope waveform is clear and check RF signal level is correct or not.

Note:

Clear RF signal waveform means that the shape “≈” can be clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 m

TIME/DIV: 500 ns

level: 1.4 ± 0.3 Vp-p

• TRACKING OFFSET CHECK

[RF BOARD] – Conductor Side –

Procedure:

1. Connect the oscilloscope to BP11 (TE) and TP (VC) on the

RF board.

2. Put the set into play mode by loading the disc.

3. Press the = AMS + button, and check the traverse waveform*.

4. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0 V dc, and check this level.

* Traverse waveform: This is the tracking error wave form appears

Traverse waveform

A

0 V

B

A=B

traverse waveform

(100 track jump waveform)

when crossing the track.

VOLT/DIV : 500 mV

TIME/DIV : 2 ms

Center : 0 V

– 15 –

Page 16

• FOCUS GAIN ADJUSTMENT

(COARSE ADJUSTMENT)

This adjustment is to be performed when replacing the following

parts.

• Optical Pick-up Block

• RV14

[RF BOARD] – Conductor Side –

CNJ12

IC51

• When gain is lowered...

The set does not play because of no focus operation.

• When gain is highered...

Operation noise is heard due to a scratch or a dust, then operation will be unstable.

RV14

IC11

Procedure:

1. Set RV14 (RF board) to the standard position.

2. Check that there is not an abnormal amount of operation noise

(white noise) from the 2-axis devise. If there is, turn RV14

slightly clockwise.

[RF BOARD] – Conductor Side –

MIN side

(low gain)

MAX side

(high gain)

RV14 standard position

– 16 –

Page 17

CDX-828

7-1. BLOCK DIAGRAM – SERVO Section –

DETECTOR

ABD

C

F

E

OPTICAL PICK-UP

(KSS-521A)

LASER DIODE

I-V AMP

38

39

PD1 I-V AMP

PD1

PD2 I-V AMP

PD2

SECTION 7

DIAGRAMS

RF

+

SUMMING

AMP

RF AMP,

FOCUS/TRACKING

SERVO

IC11 (1/2)

F

41

42

I-V

E

AMP

FOCUS

ERROR

AMP

TRACKING

ERROR

AMP

RFO

33

RFI

32

FOCUS OK

COMPARATOR

MIRR

AMP

DEFECT

AMP

FEO

FE BIAS

TEO

DATA, PCMD, BCK,

D.OUT

XRST

89

DIGITAL

16K

RAM

ERROR

CORRECTOR

GENERATOR

XTAI

OUT

D/A

INTERFACE

CLOCK

PCMD

BCKO

LRCK

RFCK

C2PO

WDCK

GTOP

WFCK

EMPH

C4M

71

52

54

50

62

63

1

49

2

IC403

(2/2)

58

74

72

70

DIGITAL SIGNAL PROCESSOR,

CLV SERVO

IC101

RF

ASYI

ASYO

FOK

DATO

CLKO

XLTO

SEIN

CNIN

ASYMMETRY

CORRECTION

SERVO AUTO SEQUENCER

DIGITAL CLV

MON

44

46

47

FOK

DATA

CLK

XLT

LOCK

XRST

SENS1

C.OUT

SENS2

FEO

TAO

27

22

20

21

19

23

25

24

26

6

13

FOCUS OK

AMP

TTL

IIL

1

RV14

FOCUS

40

GAIN

45

FEI

2

TEI

47

TTL

IIL

IIL

IIL DATA REGISTER

TTL

FOCUS PHASE

COMPENSATION

TRACKING PHASE

COMPENSATION

23

15

17

16

13

14

MDP

27

39

FILO

DIGITAL PLL

MDS29LOCK

28

FILTER

42

CLTV

XROF

64

PCO

4038

FILI

SQSO

8 7 9 10 12 11 75 76 77 6126

SQCK

EFM

DEMODULATOR

SUB-CODE

PROCESSOR

CPU INTERFACE

SENS

XLAT

CLOCK

DATA

SCOR

SBSO

EXCK

INTERNAL BUS

GFS

100

DATA

PCMD

BCK

LRCK

RFCK

7

WDCK

GTOP

WFCK

C4M

XROF

LRCK, WDCK

RFCK, GTOP, WFCK,

C4M, XROF,

C16M

SCLK

SBSO

A

B

C

D

E

(Page 19)

(Page 19)

(Page 20)

(Page 19)

(Page 19)

DATA

CLOCK

M103

(CHUCKING)

EDGE DETECT

IC403 (1/2)

DATA, CLOCK

SCOR

RESET

• SIGNAL PATH

: CD PLAY (ANALOG OUT)

: CD PLAY (DIGITAL OUT)

F

G

H

(Page 19)

(Page 19)

(Page 19)

AUTOMATIC

POWER CONTROL

LD

PD

2-AXIS

DEVICE

(FOCUS)

(TRACKING)

05

M102

(SLED)

M101

(SPINDLE)

Q11

M

M

LD

LD

36

AMPPDAMP

FOCUS/TRACKING COIL DRIVE,

SPINDLE/SLED MOTOR DRIVE

OUT+

2

OUT–

1

OUT+

12

OUT–

13

OUT+

26

OUT–

27

OUT+

17

OUT–

16

IC51

TRACKING

COIL DRIVE

FOCUS

COIL DRIVE

SLED

MOTOR DRIVE

SPINDLE

MOTOR DRIVE

PD

37

IN

4

IN

10

SLED SERVO

IC11 (2/2)

IN

24

IN

19

SLO

16 14

SLED

AMP

SLP

SYSTEM CONTROLLER

IC201 (1/3)

C.OUT

54

FOK

22

SENS2

8

SUBQ

SCLK

SENS

CD.DATA

CD.CLK

CD.XLT

SCOR

GFS

XRST

CH.F

CH.R

LOAD1

LOAD2

LIM.SW 9

52

51

23

67

65

66

63

24

21

4

5

7

6

4

5

SW12

(SAVE END DETECT)

SW11

(CHUCKING END DETECT)

SW1

(LIMIT)

CHUCKING MOTOR DRIVE

IC52

FIN

CHUCKING

RIN

MOTOR DRIVE

ON : When completion of the disc

ON : When completion of the disc

ON : When the optical pick-up

OUT1

1

OUT2

7

chucking operation.

chucking operation.

is inner position.

M

– 17 –

– 18 –

Page 18

7-2. BLOCK DIAGRAM – MAIN Section –

CDX-828

(Page 18)

(Page 18)

(Page 18)

(Page 18)

(Page 18)

DATA, PCMD, BCK,

LRCK, WDCK

A

RFCK, GTOP, WFCK,

C4M, XROF

B

SCOR

G

RESET

H

DATA, CLOCK

F

PCMD

BCK

LRCK

WDCK

DATA

RFCK

GTOP

WFCK WFCK

C4M C4M

XROF

WFCK

OPTICAL

TRANSCEIVER

IC801

D-RAM CONTROLLER

IC401

OUT

D/A

D OUT

DATA

BCK

LRCK

XTAI

XRAS

XCAS

XWE

XOE

20

18

17

19

16

25 – 22, 40 – 36, 27

31, 30, 33, 32

28

34

29

35

9 – 12, 14 – 18, 5

D-RAM

IC402

D1 – D4 A0 – A9

1, 2, 24, 25

4

XRAS

23

XCAS

3

XWE

22

XOE

BUFFER

IC604

DIGITAL

DATI

11

BCKI

9

LRCI

DIN

GTOP

XRST

DSP

INTERFACE

DATA

LINKING

CONTROL

GRST60GSCR

1

SELECTOR

D-RAM INTERFACE

READ/WRITE

BASE

COUNTER

ADDRESS MONITOR

CPU INTERFACE

SCK

SDTI

SDTO

XLT

47

46

48

50

DATA

CLOCK

XRDE

45

VWA

XWRE

44

XSOE

49 59

XQOK

12

WDCI

13

4

RFCK

7

8

3

5

XROI

6

SCOR

61

2

CONVERTER

INTERFACE

TIMING

GENERATOR

A0 – A9

D1 – D4

D/A CONVERTER

IC601

DATA

8

BCK

7

LRCK

9

SERIAL

INPUT

INTERFACE

DE-EMPHASIS

CONTROL

EMP

12 11 6

INTER-

POLATOR,

∆Σ

MODULATOR

CPU

INTERFACE

PD

DFS

PWM

CLOCK OSC/

DIVIDER

XTO

4 5

16.9344MHz

CLOCK

BUFFER

IC603

X601

AOUTL

AOUTR

XTI

CN901 (1/2)

ANALOG OUT

18

17

LOW-PASS

FILTER

IC602 (1/2)

LOW-PASS

FILTER

IC602 (2/2)

MUTING

CONTROL SWITCH

Q601, 602

MUTING

Q603

MUTING

Q604

C16M

C

IC801

DIGITAL OUT

L

R

(Page 18)

(Page 18)

(Page 18)

D501

44 45

EMP

ML

D/A.RESET

(ANALOG/DIGITAL SELECT)

A/D.SW

56

SW801

GRSCOR

CSI78CSO

79

7 6 5

CSO

77

CSI

S-RAM

IC502

2946

CCLK

CCLK

41

27

422826

SDTI

XRDE

XWRE

ESPXLT

REQ

BUSY

76

74

4 56

REQ

BUSY

CD TEXT DECODER

IC501

DATA0 – DATA7

20 – 27

11 – 13, 15 – 1910 – 3, 25, 24, 21, 23, 2, 26, 1

DO0 – DO7

XSOE

XQOK

CE

62 63

20

CE

SYSTEM CONTROLLER

IC201 (2/3)

RESET

75

28

RST

78

BUCK

XTAL

30 29

X501

10MHz

EXTAL

WE

27

WE

25

GRSRT

SCOR

76

WFCK

77

SCLK

D

IC503

SBSO

E

05

8

SCLK

SSI

9

ADD0 – ADD14

11 – 18, 64 – 69, 74

A0 – A14

ANALOG

DIGITAL

4347

A.MUTE

• SIGNAL PATH

RESET

BU CHECK

I

J

(Page 22)

(Page 22)

: CD PLAY (ANALOG OUT)

: CD PLAY (DIGITAL OUT)

– 19 –

– 20 –

Page 19

CDX-828

7-3. BLOCK DIAGRAM – BUS CONTROL /POWER SUPPLY Section –

SYSTEM CONTROLLER

IC201 (3/3)

M104

(ELEVATOR)

MCK

38

EHS

39

AVREF

ELV.ON

CD.ON

BU.CHK

SCK

BUS.ON

RST

W.UP

37

69

68

61

SI

49

SO

50

48

55

30

62

SW201

MAGAZINE EJECT

END DETECT

SW202

MAGAZINE IN/OUT

DETECT

ELEVATOR MOTOR DRIVE

IC301

OUT1

1

M

7

OUT2

ELEVATOR

MOTOR DRIVE

EEPROM

IC202

RIN

SDA

SCL

FIN

4

5

5

6

57

60

70

58

12

11

MGLK

MAG.SW

ELV.R

ELV.F

EE.DATA

EE.CLK

LINEAR POSITION

ELEVATOR HEIGHT

D306

RV201

SENSOR

RV202

SENSOR

REFERENCE VOLTAGE

SWITCH

Q201

MICON +5V

10

9

11

1

13

8

BUS INTERFACE

(FOR SONY BUS)

SO

SI

SCK

BUSON OUT

BUSON OUT

RESET

RESET SIGNAL

GENERATOR

IC302

RESET

SWITCH

IC304

DATA

CLK

LOF

BUSON IN

RST

6

4

12

2

7

MICON +5V

SERVO +9V

MICON +5V

+8V

LOW-PASS FILTER

(IC602) B+

DAC +5V

SERVO +5V

Q304

D311

+8V

REGULATOR

IC306

+5V

REGULATOR

IC307

+5V

REGULATOR

IC305

BATTERY

CHECK

Q301, 302

+9V

REGULATOR

IC303

REGULATOR

Q303

B+ SWITCH

Q305

LEVEL SHIFT

D307

D309

D313

D308

BU CHECK

RESET

7

B.UP

5

DATA

4

CLK

6

BUSON

2

RST

CN901 (2/2)

CONTROL

(FOR SONY BUS)

(Page 20)

J

(Page 20)

I

– 21 –

EJECT

64

EXTAL

05

XTAL

X201

8MHz

3132

SW301

6

MICON +5V

– 22 –

Page 20

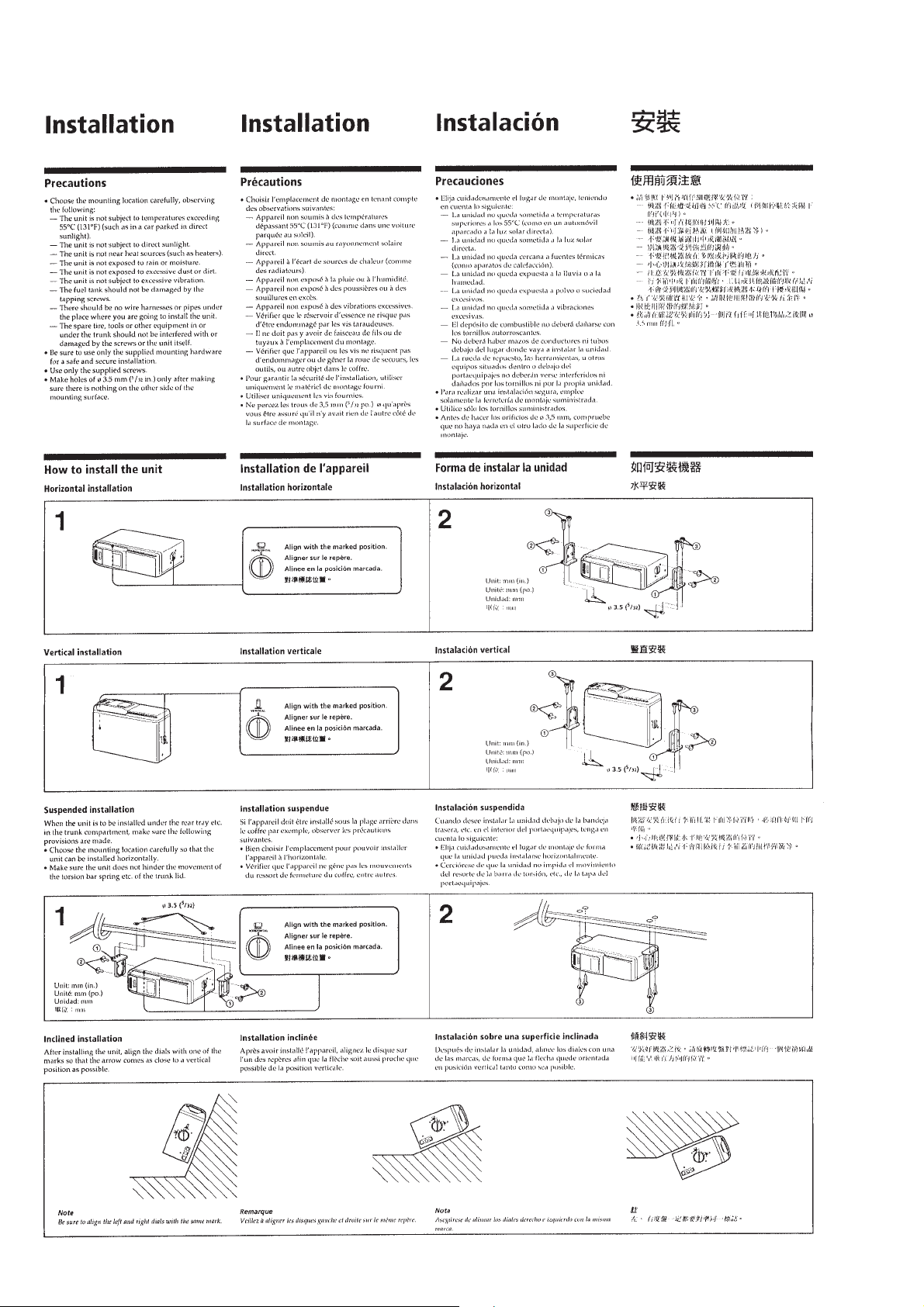

• Circuit Boards Location

d

DIGITAL OUT board

JACK board

MAIN board

RF boar

SW board

– 23 –

Page 21

7-4. NOTE FOR PRINTED WIRING BOARDS AND SCHEMA TIC DIAGRAMS

Note on Printed Wiring Board:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

r

•

•

: Through hole.

¢

: internal component.

• b : Pattern from the side which enables seeing.

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and

specified.

¢

•

: internal component.

1

4

/

W or less unless otherwise

• C : panel designation.

Note:

The components identi-

fied by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part

number specified.

Note:

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

piéce portant le numéro

spécifié.

• U : B+ Line.

• H : adjustment for repair .

• Power voltage is dc 14.4V and fed with regulated dc power

supply from CD changer controller.

• Voltages and waveforms are dc with respect to ground

under no-signal (detuned) conditions.

no mark : CD PLAY

: Impossible to measure

∗

• Voltages are taken with a VOM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD PLAY (ANALOG OUT)

c : CD PLAY (DIGITAL OUT)

– 24 –

Page 22

CDX-828

7-5. PRINTED WIRING BOARDS – RF/SW Boards – • See page 23 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

IC11 C-6

IC51 B-7

IC52 G-4

Q11 D-6

(Page 30)

– 25 –

– 26 –

Page 23

7-6. SCHEMATIC DIAGRAM – RF/SW Boards – • See page 39 for Waveforms. • See page 45 for IC Block Diagrams.

CDX-828

(Page 33)

– 27 –

The components identified by mark ! or dotted

line with mark ! are critical for safety.

Replace only with part number specified.

– 28 –

Les composants identifiés par une marque ! sont

critiques pour la sécurité. Ne les remplacer que

par une piéce portant le numéro spécifié.

Page 24

CDX-828

7-7. PRINTED WIRING BOARD – MAIN Board (Component Side) – • See page 23 for Circuit Boards Location.

• Semiconductor

Location

(Component Side)

Ref. No. Location

D301 E-3

D302 E-3

D303 E-3

D304 E-3

D305 E-3

D306 E-7

D307 G-4

D308 G-4

D309 E-2

D310 F-4

D311 G-5

D312 F-4

D313 D-3

D314 F-3

D501 F-7

D502 H-5

IC101 B-7

IC201 E-7

IC202 D-8

IC301 G-3

IC302 E-4

IC304 G-4

IC306 C-3

IC307 A-5

IC401 D-5

IC402 E-5

IC403 A-6

IC501 G-7

IC502 G-6

IC503 G-6

IC601 B-5

IC602 B-5

IC603 B-5

IC604 B-6

Q201 E-9

Q301 G-5

Q302 G-4

Q304 C-3

Q601 F-6

Q602 F-5

Q603 D-4

Q604 D-4

(Page 42)

(Page 26)

– 29 –

– 30 –

Page 25

7-8. PRINTED WIRING BOARD – MAIN Board (Conductor Side) – • See page 23 for Circuit Boards Location.

CDX-828

• Semiconductor

Location

(Conductor Side)

Ref. No. Location

IC303 F-9

IC305 D-9

Q303 E-8

Q305 D-8

– 31 –

– 32 –

Page 26

CDX-828

7-9. SCHEMA TIC DIA GRAM – MAIN Boar d (1/3) – • See page 39 for Waveforms. • See page 46 for IC Block Diagrams.

(Page

28)

– 33 –

(Page 37)

– 34 –

Page 27

7-10. SCHEMA TIC DIA GRAM – MAIN Boar d (2/3) – • See page 40 for W a vef orms. • See page 47 for IC Block Diagrams.

CDX-828

(Page 43)

(Page 38)

– 35 –

– 36 –

Page 28

CDX-828

7-11. SCHEMATIC DIAGRAM – MAIN Board (3/3) – • See page 40 for Waveforms. • See page 47 for IC Block Diagrams.

(Page 34)

(Page 35)

– 37 –

– 38 –

Page 29

• Waveforms

5.7 Vp-p

137 µs

5.5 Vp-p

137 µs

3.3 Vp-p

59.2 ns

3.2 Vp-p

125 ns

– RF Board –

1 IC11 #£ (RF O)

500 mV/DIV, 500 ns/DIV

2 IC11 2 (FEI)

50 mV/DIV, 1 µs/DIV

1.4 Vp-p

– MAIN Board (1/3) –

1 IC101 @¶ (MDP)

7.6

2 IC101 #§ (V16M)

6 IC101 ^™ (RFCK)

2.5 Vp-p

µ

s

7 IC101 &º (C4M)

3 IC11 $¶ (TEI)

200 mV/DIV, 500 µs/DIV

Approx.

110 mVp-p

Approx.

280 mVp-p

120 ns

3 IC101 $ª (WDCK)

11.4 µs

4 IC101 %º (LRCK)

6.8 Vp-p

6.6 Vp-p

6.6 Vp-p

236 ns

8 IC101 &¢ (WFCK)

9 IC101 *ª (XTAI)

22.7 µs

5 IC101 %¢ (BCKO)

472 ns

– 39 –

6.6 Vp-p

!º IC201 #¡ (EXTAL)

6.6 Vp-p

Page 30

– MAIN Board (2/3) –

5.7 Vp-p

137 µs

6.6 Vp-p

11.4 µs

3.2 Vp-p

100 ns

– MAIN Board (3/3) –

!¡ IC603 4

59.2 ns

!™ IC601 4 (XTO)

59.2 ns

!£ IC601 7 (BCK)

4.7 Vp-p

6.4 Vp-p

!∞ IC401 !ª (LRCK)

22.7 µs

!§ IC401 !¶ (BCK)

472 ns

!¶ IC401 !£ (WDCI)

6.2 Vp-p

6.2 Vp-p

@º IC401 7 (RFCK)

@¡ IC401 5 (C4M)

6.6 Vp-p

236 ns

@™ IC401 3, IC501&¶ (WFCK)

472 ns

!¢ IC601 9 (LRCK)

22.7 µs

7.4 Vp-p

7.4 Vp-p

11.4 µs

!• IC401 !™ (LRCI)

22.7 µs

!ª IC401 9 (BCKI)

7.7 Vp-p

6.6 Vp-p

6.6 Vp-p

137

µ

s

@£ IC403 1

@¢ IC501 @ª (EXTAL)

5.5 Vp-p

472 ns

– 40 –

Page 31

CDX-828

7-12. PRINTED WIRING BOARDS – DIGITAL OUT/JACK Boards – • See page 23 for Circuit Boards Location.

(Page 29)

– 41 –

– 42 –

Page 32

7-13. SCHEMATIC DIAGRAM – DIGITAL OUT/JACK Boards –

(Page 36)

CDX-828

– 43 –

– 44 –

Page 33

• IC Block Diagrams

– RF Board –

IC11 CXA1992BR

BIAS

VEE

TEO

LPFI

ATSC

TZC

TDFCT

FZC

RF O

TZC

33 32

FOL

RF I

FOCUS OK

COMPARATOR

PEAK/BOTTOM

HOLD

PEAK/BOTTOM

HOLD

FOH

IIC DATA REGISTER, INPUT SHIFT REGISTER,

ADDRESS DECODER, SENSE SELECTOR,

FZC

DFCTO

IFB1 – IFB6

BAL1 – BAL4

CENTER

VOLTAGE

GENERATOR

VCC

FS1

MIRR

COMPARATOR

LPC

LDON

LPCL

OUTPUT DECODER

FS1 – FS4

TOG1 – TOG4

VCC

VEE

TG2

CP

TGFL

TG1 – TG2

TM7

IFB1 – IFB6

DFCT

PD1

38

PD 1

I-V AMP

TGFL

VEE

TOG1 – TOG4

AMP

TM1

COMPENSATION

FS4

PD2

39

PD 2

I-V AMP

VCC

FE

40

VEE

41

42

43

44

45

46

47

48

49

50

51

52

F I-V

AMP

E I-V

AMP

BAL1 – BAL4

DFCT

F

E

EI

TEI

VC

LD

PD

37

36 34 31 30 29 28 27

LD

PD

AMP

LASER

POWER

CONTROL

FOCUS ERROR

AMP

TRACKING GAIN

WINDOW

COMPARATOR

E-F BALANCE

WINDOW

COMPARATOR

ATSC

WINDOW

COMPARATOR

TZC

COMPARATOR

FOCUS PHASE

RFTC

35

TG1

RF M

RF SUMMING

AMP

FOCUS BIAS

WINDOW

COMPARATOR

TGH

TGL

BALH

BALL

ATSC

TRACKING PHASE

COMPENSATION

FZC

COMPARATOR

CHARGE UP

FS2

CB

DEFECT

AMP

TM1 – TM7

FSET

CC1

CC2

TTL

MIRR

VCC

PS1 – PS4

TM5

VEE

IIL

↓

TM4

FOK

DFCT1

TM6

TM3

VCC

CC1

↓

TTL

TTL

↓

IIL

VCC

ISET

–

+

TM2

+

–

SENS1

25

C. OUT

24

XRST

23

DATA

22

XLT

21

CLK

20

19

LOCK

VCC

18

17

ISET

16

SL O

SL M

15

SL P

14

SENS2

26

IIL

1 2 3

FEI

FEO

FDFCT

5

6

4

FLB

FGD

FE O

7

FE M

8 9 10

SRCH

VEE

TGU

11 12 13

TG2

FSET

TA M

VEE

TA O

– 45 –

Page 34

IC52 BA6287F

OUT1

1

VM

2

DRIVER DRIVER

TSD

VCC

3

POWER

SAVE

FIN

4

– MAIN Board –

IC101 CXD2530Q

CONTROL LOGIC

GND

8

OUT2

7

VREF

6

RIN

5

VSS

VDD

TES7

VSS

XVDD

XTAI

XTAO

XVSS

VSS

TES8

VDD

VSS

XRST

TES6

VDD

VSS

EXCK

SBSO

SCOR

WFCK

TES5

EMPH

DOUT

C4M

FSTT

XTSL

MNT0

MNT1

MNT3

XROF

C2PO

RFCK

GFS

XPCK

XUGF

GTOP

VDD

VSS

TES4

BCK

TES3

PCMD

53 52 51

ASYMMETRY

CORRECTOR

DIGITAL

PLL

OSC

CLOCK

GENERATOR

TES9

LRCK

50

49

WDCK

48

ASYE

47

ASYO

ASYI

46

BIAS

45

RF

44

AVDD

43

42

CLTV

AVSS

41

40

FILI

39

FILO

PCO

38

VCTL

37

V16M

36

35

VCKI

34

VPCO1

33

VPCO2

32

TES1

31

TES0

CLOK

71

14

SEIN

69 68

70

15 16 17

CNIN

DATO

67

ERROR

CORRECTOR

16K RAM

SERVO

AUTO

SEQUENCER

18 19 20

XLTO

CLKO

SPOA

66 65 64

21

SPOB

SPOC

63 62 61

22 23

XLON

SPOD

79 78

80

NC

81

82

83

NC

84

85

86

NC

87

88

89

90

91

92

NC

93

94

NC

95

96

97

98

NC

NC

99

100

1 234

VSS

VDD

77

TIMING

LOGIC

56789 10

TES2

LMUT

RMUT

CKOUT

76 75 74

INTERFACE

SQCK

SQSO

73 72

EFM

DEMODULATOR

SUB CODE

PROCESSOR

CPU

11

XLAT

SENS

DATA

12 13

59 58

60

D / A

INTERFACE

DIGITAL OUT

25 26 27

24

FOK

VSS

VDD

57

DIGITAL CLV

28 29 30

MDP

MDS

MON

56 55 54

LOCK

PWMI

– 46 –

Page 35

IC202 AT24C16N-10SI-TR

START

STOP

LOGIC

LOAD

R/W

ADDR/COUNTER

D

OUT

COMP

LOAD INC

DATA WORD

GND

DEVICE

ADDRESS

COMPARATOR

1

A0

2

A1

A2

3

4

D

IN

SERIAL

CONTROL

LOGIC

Y DEC

EN

H.V. PUMP/TIMING

DATA RECOVERY

X DEC

SERIAL MUX

E

D

OUT

LOGIC

2

PROM

/ACK

IC301 BA6287F

1

OUT1

2

VCC

8

7

TST

SDL

6

SDA

5

VM

VCC

FIN

DRIVER DRIVER

TSD

3

POWER

SAVE

4

CONTROL LOGIC

8

GND

7

OUT2

6

VREF

5

RIN

IC302 BA8272F-E2

VCC

BUS ON

LINK OFF

CLK OUT

2 3

1

BUS ON OUT

BUS ON IN

5 6 7

4

GND

BUS CLK

VREF

DATA OUT

BUS DATA

DATA IN

RESET

891014 13 12 11

RESET

SWITCH

BUS RESET

IC401 CXD2522Q

XEMP

SDTO

50 49 48 47

51

XWIH

52

53

AM4

AM3

54

55

AM2

56

AM1

AM0

57

VDD

58

XQOK

GSCR

SCOR

59

60

61

NC

62

NC

63

NC

64

READ

BASE

COUNTER

DATA

LINKING

CONTROL

2 345 6 7 8 9 10

1

DIN

XRST

GRST

WFCK

XSOE

SCK

SDTI

XLT

XRDE

CPU I/F

ADDRESS MONITOR

WRITE

BASE

COUNTER

C4M

XROI

RFCK

GTOP

XWRE

43444546

SPSL

VWA

BCKI

DSP

VSS

VSS

DRAM

SELECTOR

TIMING

GEN.

I/F

DATI

LRCI

TEST

XTAO

WDCI

XTAI

DAC

BCK

I/F

I/F

191817161514131211

DATA

LRCK

33343536373839404142

DIGITAL

OUT

D3

32

D0

31

D1

30

XWE

29

XRAS

28

A9

27

26

VDD

A0

25

24

A1

A2

23

A3

22

21

C176

DOUT

20

D2

XCAS

XOE

A8

A7

A6

A5

A4

OSCE

– 47 –

Page 36

IC402 MSM514400D-60TS-K

DQ1

1

DQ2

2

WE

3

GENERATOR

CLOCK

1

WRITE

CLOCK

GENERATOR

CLOCK

GENERATOR

2

DATA INPUT

BUFFER

COLUMN

DECODER

SENSE AMP

I/O GATE

DATA OUTPUT

BUFFER

4M BIT

MEMORY

CELL

ROW

DECODER

BOARD

BIAS

GENERATOR

VSS

26

25

DQ4

DQ3

24

CAS

23

OE

22

RAS

VCC

4

A9

5

A0

9

A1

10

A2

11

A3

12

13

MODE

CONTROL

IC502 KM62256DLG-7LT

A14

A12

1

2

3

A7

4

A6

5

A5

LEVEL

SHIFT

BUFFER

ADDRESS

BUFFER

ROW

DECODER

PRE-

DECODER

MEMORY

MATRIX

512X512

REFRESH

ADDRESS

COUNTER

28

27

26

25

24

23

22

21

VCC

WE

A13

A8

A9

A11

OE

A10

A8

18

A7

17

A6

16

15

A5

A4

14

IC601 AK4321-VF-E2

TTL

DZF

VREF

AVSS

AVDD

VCOM

AOUTL

AOUTR

BVDD

DIF1

20 19 18 17 16 15 14 13

21222324

SERIAL INPUT

INTERFACE

CTF

CTF

SCF

SCF

∆Σ

MODULATOR

∆Σ

MODULATOR

INTERPOLATOR

INTERPOLATOR

DIF0

8 ×

8 ×

DEM1

I/O1

I/O2

I/O3

GND

6

A4

7

A3

8

A2

9

A1

10

A0

11

12

13

14

LEVEL

SHIFT

LEVEL

SHIFT

BUFFER

BUFFER

I/O GATE

COLUMN

DECODER

I/O BUFFER

20

CE

19

I/O8

18

I/O7

17

I/O6

16

I/O5

15

I/O4

CLOCK OSC/DIVIDER

2 345 6 7 8 9 10

1

PD

XTI

DVDD

DVSS

XTO

BICK

CKS

SDATA

DE-EMPHASIS

LRCK

CONTROL

SMUTE

DFS

1211

DEMO

– 48 –

Page 37

7-14. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC201 CXP84332-208Q (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Function

1 to 3 — O Not used (open)

4 CH.F O

5 CH.R O

6 LOAD2 I

7 LOAD1 I

8 SENS2 I Internal status signal (sense signal) input from the CXA1992BR (IC11)

9 LIM.SW I

10 EE.INIT I Initialize signal input for the EEPROM (IC202) “H”: format Fixed at “L” in this set

11 EE.CLK O Serial data transfer clock signal output to the EEPROM (IC202)

12 EE.DATA I/O Two-way data bus with the EEPROM (IC202)

13 to 19 — O Not used (open)

20 SINGLE I

21 XRST O

22 FOK I Focus OK signal input from the CXA1992BR (IC11) “L”: NG, “H”: OK

23 SENS I Internal status signal (sense signal) input from the CXD2530Q (IC101)

24 GFS I Guard frame sync signal input from the CXD2530Q (IC101) “L”: NG, “H”: OK

25 GRSRT O Reset signal output to the CXD2522Q (IC401) “L”: reset

26 XQOK O Subcode Q OK pulse signal output to the CXD2522Q (IC401) “L” active

27 SDTI I ESP status signal input from the CXD2522Q (IC401)

28 XSOE O ESP status read enable signal output to the CXD2522Q (IC401) “L” active

29 ESPXLT O ESP latch pulse signal output to the CXD2522Q (IC401) “L” active

30 RST I

31 EXTAL I Main system clock input terminal (8 MHz)

32 XTAL O Main system clock output terminal (8 MHz)

33 VSS — Ground terminal

34 TX O Sub system clock output terminal Not used (open)

35 TEX I Sub system clock input terminal Not used (fixed at “L”)

36 AVSS — Ground terminal (for A/D converter)

37 AVREF I Reference voltage (+5V) input terminal (for A/D converter)

38 MCK I

39 EHS I Elevator height position detect input from the RV202 (elevator height sensor) (A/D input)

40 H.TEMP I High temperature sensor input terminal Not used (fixed at “L”)

41 XRDE O D-RAM read enable signal output to the CXD2522Q (IC401) “L” active

42 XWRE O D-RAM write enable signal output to the CXD2522Q (IC401) “L” active

43 A.MUTE O Audio line muting on/off control signal output terminal “H”: muting on

44 EMP O Emphasis mode output to the D/A converter (IC601) “H”: emphasis on

45 ML O Fast speed dubbing control signal output to the D/A converter (IC601) “L”: fast speed

46 GRSCOR I Subcode sync (S0+S1) detection signal input from the CXD2522Q (IC401)

Motor drive signal (load chucking direction) output to the chucking motor drive (IC52)

“L” active *1

Motor drive signal (save direction) output to the chucking motor drive (IC52)

“L” active *1

Chucking end detect switch (SW11) input terminal

“L”: When completion of the disc chucking operation

Save end detect switch (SW12) input terminal

“L”: When completion of the disc chucking operation

Sled limit in detect switch (SW1) input terminal

“L”: When the optical pick-up is inner position

Setting terminal for the single disc/multiple discs mode

“L”: single mode, “H”: multiple discs mode (fixed at “H”)

System reset signal output to the CXA1992BR (IC11), CXD2530Q (IC101) and CXD2522Q

(IC401) “L”: reset

System reset signal input from the SONY bus interface (IC302) and reset signal generator (IC304)

“L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

Input of signal for the fine adjustment (linear position sensor adjustment; RV201) of elevator

position (A/D input)

– 49 –

Page 38

Pin No. Pin Name I/O Function

e

e

47 D/A.RESET O Reset signal output to the D/A converter (IC601) “L”: reset

48 SCK I Serial data transfer clock signal input from the SONY bus interface (IC302)

49 SI I Serial data input from the SONY bus interface (IC302)

50 SO O Serial data output to the SONY bus interface (IC302)

51 SCLK O Subcode Q data reading clock signal output to the CXD2530Q (IC101)

52 SUBQ I Subcode Q data input from the CXD2530Q (IC101)

53 — O Not used (open)

54 C.OUT I Track number count signal input from the CXA1992BR (IC11)

55 BUS.ON I Bus on/off control signal input from the SONY bus interface (IC302) “H”: bus on

56 A/D.SW I Analog/digital select switch (SW801) input terminal “L”: digital, “H”: analog

57 MGLK I Magazine eject operation completion detect switch (SW201) input “L”: eject completed

58 ELV.F O

59 — O Not used (open)

60 MAG.SW I Magazine in/out detect switch (SW202) input “L”: magazine detected

61 BU.CHK I

62 W.UP I Bus on or eject switch (SW301) input terminal “H”: bus on or eject switch pushing

63 SCOR I Subcode sync (S0+S1) detection signal input from the CXD2530Q (IC101)

64 EJECT I Eject switch (SW301) input terminal “H” active

65 CD.CLK O Serial data transfer clock signal output to the CXD2530Q (IC101) and CXD2522Q (IC401)

66 CD.XLT O Serial data latch pulse signal output to the CXD2530Q (IC101)

67 CD.DATA O Serial data output to the CXD2530Q (IC101) and CXD2522Q (IC401)

68 CD.ON O D/A converter and servo section power supply on/off control signal output “H”: power on

69 ELV.ON O Mechanism deck section power supply on/off control signal output “H”: power on

70 ELV.R O

71 — O Not used (open)

72 VDD — Power supply terminal (+5V)

73 NC (VDD) — Connected to the power supply (+5V)

74 BUSY I Busy monitor input from the CD text decoder (IC501) “L”: busy status

75 RESET O Reset signal output to the CD text decoder (IC501) “L”: reset

76 REQ I Data request signal input from the CD text decoder (IC501) “L” active

77 CCCLK O Command clock signal output to the CD text decoder (IC501)

78 CSO O Command data output to the CD text decoder (IC501)

79 CSI I Command data input from the CD text decoder (IC501)

80 ADJ I

Motor drive signal (elevator up direction) output to the elevator motor drive (IC301)

“L” active *2

Battery detection signal input terminal “H”: battery on

Motor drive signal (elevator down direction) output to the elevator motor drive (IC301)

“L” active *2

Automatic/manual adjustment selection terminal

“L”: manual adjustment mode, “H”: automatic adjustment mode (fixed at “H” in this set)

*1 chucking motor (M103) control

Terminal

Mod

CH.F (pin 4) “H” “L” “H” “L”

CH.R (pin 5) “H” “H” “L” “L”

*2 elevator motor (M104) control

Mod

Terminal

ELV.F (pin %•) “H” “L” “H” “L”

ELV.R (pin &º) “H” “H” “L” “L”

STOP

STOP

LOAD

CHUCKING

ELEVATOR UPELEVATOR

SAVE BRAKE

DOWN

– 50 –

BRAKE

Page 39

• MAIN BOARD IC501 CXP83413-049Q (CD TEXT DECODER)

Pin No. Pin Name I/O Function

1, 2 NC O Not used (open)

3 NC I Not used (fixed at “L”)

4 REQ O

5 CCLK I

6 CSI I

7 CSO O

8 SCLK O

9 SSI I

Request signal output to the system controller (IC201) “L” active

Serial data transfer clock signal input from the system controller (IC201)

Serial data input from the system controller (IC201)

Serial data output to the system controller (IC201)

Clock signal output for subcode data reading to the CXD2530Q (IC101)

Subcode data input from the CXD2530Q (IC101)

10 NC O Not used (open)

11 to 18

ADD0 to ADD7

O

Address signal output to the S-RAM (IC502)

19 NC I Not used (fixed at “L”)

20 to 27

DATA0 to DATA7

I/O

Two-way data bus with the S-RAM (IC502)

System reset signal input from the system controller (IC201), SONY bus interface (IC302) and

28 RST I

reset signal generator (IC304) “L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

29 EXTAL I

30 XTAL O

31 VSS —

32 to 55 NC O

56 BUSY O

57 to 61 NC O

62 CE O

63 WE O

64 to 69

ADD8 to ADD13

70 VDD —

71, 72 NC O

73 NC I

74 ADD14 O

75 NC O

76 SCOR I

77 WFCK I

78 BUCK I

79, 80 NC I

System clock input terminal (10 MHz)

System clock output terminal (10 MHz)

Ground terminal

Not used (open)

Busy signal output to the system controller (IC201) “L”: busy status

Not used (open)

Chip enable signal output to the S-RAM (IC502) “L” active

Data write enable signal output to the S-RAM (IC502) “L” active

O

Address signal output to the S-RAM (IC502)

Power supply terminal (+5V)

Not used (open)

Not used (fixed at “H”)

Address signal output to the S-RAM (IC502)

Not used (open)

Subcode sync (S0+S1) detection signal input from the CXD2530Q (IC101)

Write frame clock (7.35 kHz) signal input from the CXD2530Q (IC101)

Backup power supply detection signal input terminal (used also to reset standby)

Not used (fixed at “L”)

– 51 –

Page 40

SECTION 8

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) COVER SECTION

7

#2

5

6

4

3

#13

26

21

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

#2

13

#11

12

11

9

10

18

IC305

IC303

16

#1

#2

8

1

17

20

15

22

27

14

#2

13

MG-250C-137

12

main flexible board

28

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

25

24

not supplied

23

19

Ref. No. Part No. Description Remark

1 3-010-104-01 DAMPER (250)

* 2 3-010-097-11 COVER (LOWER)

3 1-664-796-11 JACK FLEXIBLE BOARD

* 4 1-672-617-11 JACK BOARD

5 X-3376-459-1 DOOR (T) ASSY (EXCEPT US, Canadian)

5 X-3376-831-1 DOOR ASSY (US, Canadian)

6 3-376-464-11 SCREW (+PTT 2.6X6), GROUND POINT

7 3-030-489-11 PANEL, FRONT

8 3-012-388-01 SCREW (M2X3)

* 9 3-010-105-01 ESCUTCHEON (US, Canadian)

* 9 3-022-006-01 ESCUTCHEON (T) (EXCEPT US, Canadian)

* 10 3-010-106-01 BUTTON (EJ) (6) (US, Canadian)

* 10 3-022-007-01 BUTTON (EJT) (6) (EXCEPT US, Canadian)

* 11 3-022-012-01 HEAT SINK (T)

12 3-010-103-01 SPRING (FL), TENSION

13 3-010-101-01 LEVER (FL)

* 14 3-010-096-11 COVER (UPPER)

* 15 A-3317-605-A MAIN BOARD, COMPLETE

* 16 3-022-694-01 HOLDER (TR3)

17 3-935-636-11 SCREW (FP)

19

– 52 –

1

2

Ref. No. Part No. Description Remark

18 X-3373-215-1 ARM (FL) ASSY (US, Canadian)

18 X-3375-357-1 ARM (FLT) ASSY (EXCEPT US, Canadian)

* 19 3-013-658-01 SHEET (FJ), PROTECTION

20 X-3373-986-1 ARM (FR) ASSY (US, Canadian)

20 X-3375-360-1 ARM (FRT) ASSY (EXCEPT US, Canadian)

* 21 3-024-065-01 CUSHION (EJECT) (EXCEPT US, Canadian)

21 3-350-124-01 CUSHION (EJECT) (US, Canadian)

22 3-028-802-01 SPACER (MOUNT 30)

* 23 1-672-618-11 DIGITAL OUT BOARD

* 24 3-011-205-01 BRACKET (LIGHT)

25 3-011-204-01 COVER (LIGHT) (US, Canadian)

25 3-011-204-11 COVER (LIGHT) (EXCEPT US, Canadian)

26 3-924-924-01 COVER (LIGHT) (US, Canadian)

26 3-924-924-11 COVER (LIGHT) (EXCEPT US, Canadian)

27 3-912-956-11 SCREW (2.6X6) (CU), +BVTT

28 3-024-067-01 CUSHION (T), BATTERY

(EXCEPT US, Canadian)

28 3-911-215-02 SHEET (LEAD RETAINER) (US, Canadian)

IC303 8-759-054-12 IC PQ09RA1

IC305 8-759-231-53 IC TA7805S

Page 41

(2) MECHANISM DECK SECTION-1

(MG-250C-137)

#3

51

#3

#3

52

Ref. No. Part No. Description Remark

51 X-3375-497-1 CHASSIS (U) SUB ASSY

52 3-024-161-01 SPRING (SUT)

53

54

Ref. No. Part No. Description Remark

53 4-965-759-01 WASHER, POLYETHYLENE

54 3-011-997-01 SPRING (STOPPER. LOWER)

– 53 –

Page 42

(3) MECHANISM DECK SECTION-2

(MG-250C-137)

#12

102

M104

101

Ref. No. Part No. Description Remark

101 3-024-170-01 SPRING (SB), TENSION

* 102 3-024-172-01 BRACKET (EVM)

103

Ref. No. Part No. Description Remark

103 X-3375-498-4 CHASSIS (D) SUB ASSY

M104 A-3301-123-A ELJ MOTOR ASSY (ELEVATOR)

– 54 –

Page 43

(4) MECHANISM DECK SECTION-3

163

162

161

160

159

153

152

151

166

165

164

157

156

158

154

155

#8

#4

#6

#6

#6

#6

#7

M103

#8

(MG-250C-137)

Ref. No. Part No. Description Remark

* 151 3-024-150-01 RETAINER (CHM)

* 152 X-3375-445-1 BRACKET (CHM) ASSY

153 3-010-270-01 COVER (CHM)

154 3-321-813-01 WASHER, COTTER POLYETHYLENE

155 3-017-139-01 GEAR (WORM LOAD A)

156 3-010-255-01 ARM (LSW)

157 3-573-936-00 STOPPER, REEL

158 X-3373-552-1 GEAR (LOAD 1) ASSY

159 3-010-252-01 ROLLER (CRE)

Ref. No. Part No. Description Remark

160 3-010-268-01 SPRING (DH), TENSION

* 161 A-3290-194-F CHASSIS (EVY) (MAIN) ASSY

162 3-010-254-01 SHAFT (ROTARY PREVENTION C)

163 3-010-253-01 GEAR (LOMINI)

164 3-701-438-11 WASHER, 2.5

165 1-664-627-11 MAIN FLEXIBLE BOARD

* 166 A-3313-586-A RF BOARD, COMPLETE

M103 A-3301-123-A ELJ MOTOR ASSY (CHUCKING)

– 55 –

Page 44

(5) MECHANISM DECK SECTION-4

(MG-250C-137)

208

209

#10

206

205

#7

#9

203

204

207

202

212

M102

not supplied

#5

211

M101

not supplied

#5

210

201

Ref. No. Part No. Description Remark

201 3-911-215-02 SHEET (LEAD RETAINER)

202 3-920-362-01 SCREW (ESCUTCHEON)

203 X-3373-229-1 BASE (SLED) ASSY

204 3-010-258-01 GEAR (SLED MID)

205 3-573-936-00 STOPPER, REEL

206 A-3291-958-A SHAFT (SLED) ASSY

207 3-010-263-01 DETENT (SHAFT THRUST)

– 56 –

The components identified by

mark ! or dotted line with

mark ! are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark

* 208 1-664-104-11 SW BOARD

* 209 A-3301-077-A BASE (OPT) (J) ASSY

210 1-664-626-11 OP FLEXIBLE BOARD

! 211 8-820-010-05 OPTICAL PICK-UP KSS-521A/J2RP

212 3-010-262-01 DETENT (SLED)

M101 A-3291-956-A MOTOR SUB ASSY, SPINDLE

M102 A-3291-955-A MOTOR SUB ASSY, SLED

Les composants identifiés par une

marque ! sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

Page 45

SECTION 9

ELECTRICAL PARTS LIST

DIGITAL OUT

JACK MAIN

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-672-618-11 DIGITAL OUT BOARD

*****************

* 3-011-205-01 BRACKET (LIGHT)

< CAPACITOR >

C801 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

< CONNECTOR >

CN801 1-770-621-21 PIN, CONNECTOR 4P

< IC >

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

IC901 1-532-686-21 LINK, IC

R901 1-216-295-00 SHORT 0

************************************************************

* A-3317-605-A MAIN BOARD, COMPLETE

* 3-022-694-01 HOLDER (TR3)

3-028-802-01 SPACER (MOUNT 30)

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

When indicating parts by reference

number, please include the board.

< IC LINK >

< SHORT >

********************

IC801 8-749-923-53 IC TOTX193 (DIGITAL OUT)

< RESISTOR >

R801 1-216-832-11 METAL CHIP 8.2K 5% 1/16W

< SWITCH >

SW801 1-571-478-11 SWITCH, SLIDE (DIGITAL/ANALOG)

************************************************************

* 1-672-617-11 JACK BOARD

***********

< CAPACITOR >

C901 1-163-263-11 CERAMIC CHIP 330PF 5% 50V

C902 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C903 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C904 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

< CONNECTOR >

CN901 1-779-077-11 PLUG, CONNECTOR (CONTROL, ANALOG OUT)

(US, Canadian)

CN901 1-779-077-31 PLUG, CONNECTOR (CONTROL, ANALOG OUT)

(EXCEPT US, Canadian)

CN902 1-770-621-21 PIN, CONNECTOR 4P

CN903 1-779-321-11 CONNECTOR, FPC 16P

< FERRITE BEAD >

< CAPACITOR >

C101 1-164-182-11 CERAMIC CHIP 0.0033uF 10% 50V

C102 1-164-004-11 CERAMIC CHIP 0.1uF 10% 25V

C103 1-163-035-00 CERAMIC CHIP 0.047uF 50V

C104 1-163-011-11 CERAMIC CHIP 0.0015uF 10% 50V

C105 1-163-001-11 CERAMIC CHIP 220PF 10% 50V

C106 1-135-214-21 TANTALUM CHIP 4.7uF 20% 20V

C107 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C108 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C109 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C110 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C112 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C113 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C114 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C115 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C201 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C202 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C203 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C204 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C205 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C301 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C302 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C303 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C304 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C305 1-163-029-11 CERAMIC CHIP 0.0047uF 50V

C306 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

FB901 1-500-445-21 FERRITE 0uH

FB903 1-500-445-21 FERRITE 0uH

C307 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C308 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C309 1-125-701-11 DOUBLE LAYER 0.047F 5.5V

C310 1-104-953-11 ELECT 47uF 20% 16V

C311 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

– 57 –

Page 46

MAIN

Ref. No. Part No. Description Remark

C312 1-115-650-11 ELECT 47uF 20% 16V

C314 1-104-953-11 ELECT 47uF 20% 16V

C315 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C316 1-115-466-00 ELECT 1000uF 20% 16V

C317 1-115-651-11 ELECT 100uF 20% 16V

C318 1-115-651-11 ELECT 100uF 20% 16V

C319 1-104-953-11 ELECT 47uF 20% 16V

C320 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C321 1-115-650-11 ELECT 47uF 20% 16V

C322 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C401 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C402 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C403 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C404 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C405 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C501 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C502 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C503 1-125-701-11 DOUBLE LAYER 0.047F 5.5V

C504 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C601 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C603 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C604 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C605 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C606 1-115-650-11 ELECT 47uF 20% 16V

C608 1-163-003-11 CERAMIC CHIP 330PF 10% 50V

C609 1-163-003-11 CERAMIC CHIP 330PF 10% 50V

C611 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C612 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C613 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C614 1-115-650-11 ELECT 47uF 20% 16V

C615 1-115-650-11 ELECT 47uF 20% 16V

C616 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C617 1-104-913-11 TANTALUM CHIP 10uF 20% 16V

C618 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C619 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C621 1-163-038-00 CERAMIC CHIP 0.1uF 25V

< CONNECTOR >

CN101 1-770-351-11 CONNECTOR, FPC 26P

CN301 1-774-679-21 CONNECTOR, FPC 16P

* CN302 1-580-055-21 PIN, CONNECTOR (SMD) 2P

< DIODE >

D301 8-719-975-40 DIODE RB411D

D302 8-719-017-94 DIODE MA8180

D303 8-719-017-94 DIODE MA8180

D304 8-719-975-40 DIODE RB411D

D305 8-719-975-40 DIODE RB411D

D306 8-719-801-78 DIODE 1SS184

D307 8-719-422-64 DIODE MA8062-M

D308 8-719-988-61 DIODE 1SS355TE-17

D309 8-719-210-33 DIODE EC10DS2

D310 8-719-988-61 DIODE 1SS355TE-17

D311 8-719-038-48 DIODE 1SS319 (TE85R)

D312 8-719-422-62 DIODE MA8062-L-TX

D313 8-719-210-33 DIODE EC10DS2

D314 8-719-975-40 DIODE RB411D

Ref. No. Part No. Description Remark

D501 8-719-988-61 DIODE 1SS355TE-17

D502 8-719-975-40 DIODE RB411D

< FERRITE BEAD >

FB402 1-500-445-21 FERRITE 0uH

FB403 1-500-445-21 FERRITE 0uH

FB404 1-500-445-21 FERRITE 0uH

FB601 1-500-445-21 FERRITE 0uH

FB602 1-500-445-21 FERRITE 0uH

FB603 1-500-445-21 FERRITE 0uH

FB604 1-500-445-21 FERRITE 0uH

FB605 1-500-445-21 FERRITE 0uH

< IC >

IC101 8-752-384-15 IC CXD2530Q

IC201 8-752-902-63 IC CXP84332-208Q

IC202 8-759-253-82 IC AT24C16N-10SI-TR

IC301 8-759-040-83 IC BA6287F

IC302 8-759-444-86 IC BA8272F-E2

IC303 8-759-054-12 IC PQ09RA1

IC304 8-759-443-41 IC RH5VL40AA-T1C

IC305 8-759-231-53 IC TA7805S

IC306 8-759-284-66 IC TA78M08F (TE16L)

IC307 8-759-284-63 IC TA78M05F (TE16L)

IC401 8-752-374-09 IC CXD2522Q

IC402 8-759-576-67 IC MSM514400D-60TS-K

IC403 8-759-242-76 IC TC7W08F

IC501 8-752-904-83 IC CXP83413-049Q

IC502 8-759-497-29 IC KM62256DLG-7LT

IC503 8-759-243-19 IC TC7SU04F

IC601 8-759-455-21 IC AK4321-VF-E2

IC602 8-759-064-92 IC NJM5532M-D

IC603 8-759-243-19 IC TC7SU04F

IC604 8-759-243-19 IC TC7SU04F

< COIL >

L601 1-410-381-11 INDUCTOR CHIP 10uH

< TRANSISTOR >

Q201 8-729-020-67 TRANSISTOR XN1A312-TX

Q301 8-729-027-31 TRANSISTOR DTA124EKA-T146

Q302 8-729-230-49 TRANSISTOR 2SC2712-YG

Q303 8-729-016-11 TRANSISTOR 2SD1507M

Q304 8-729-901-00 TRANSISTOR DTC124EK

Q305 8-729-016-83 TRANSISTOR 2SB1446

Q601 8-729-901-00 TRANSISTOR DTC124EK

Q602 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q603 8-729-015-39 TRANSISTOR DTC323TK

Q604 8-729-015-39 TRANSISTOR DTC323TK

< RESISTOR >

R101 1-216-105-00 RES, CHIP 220K 5% 1/10W

R102 1-216-121-00 RES, CHIP 1M 5% 1/10W

R103 1-216-113-00 METAL CHIP 470K 5% 1/10W

R104 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R105 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R106 1-216-073-00 METAL CHIP 10K 5% 1/10W

– 58 –

Page 47

MAIN RF

Ref. No. Part No. Description Remark

R107 1-216-121-00 RES, CHIP 1M 5% 1/10W

R108 1-216-073-00 METAL CHIP 10K 5% 1/10W

R109 1-216-097-00 RES, CHIP 100K 5% 1/10W

R110 1-216-073-00 METAL CHIP 10K 5% 1/10W

R111 1-216-049-11 RES, CHIP 1K 5% 1/10W

R114 1-216-049-11 RES, CHIP 1K 5% 1/10W

R201 1-216-089-00 RES, CHIP 47K 5% 1/10W

R202 1-216-089-00 RES, CHIP 47K 5% 1/10W

R203 1-216-089-00 RES, CHIP 47K 5% 1/10W

R204 1-216-089-00 RES, CHIP 47K 5% 1/10W

R205 1-216-081-00 METAL CHIP 22K 5% 1/10W

R206 1-216-089-00 RES, CHIP 47K 5% 1/10W

R207 1-216-049-11 RES, CHIP 1K 5% 1/10W

R208 1-216-089-00 RES, CHIP 47K 5% 1/10W

R210 1-216-089-00 RES, CHIP 47K 5% 1/10W

R211 1-216-089-00 RES, CHIP 47K 5% 1/10W

R212 1-216-089-00 RES, CHIP 47K 5% 1/10W

R213 1-216-089-00 RES, CHIP 47K 5% 1/10W

R214 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R215 1-216-065-00 RES, CHIP 4.7K 5% 1/10W

R219 1-216-049-11 RES, CHIP 1K 5% 1/10W

R301 1-216-089-00 RES, CHIP 47K 5% 1/10W

R302 1-216-089-00 RES, CHIP 47K 5% 1/10W

R303 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R304 1-216-089-00 RES, CHIP 47K 5% 1/10W

R305 1-216-057-00 METAL CHIP 2.2K 5% 1/10W

R306 1-216-077-00 METAL CHIP 15K 5% 1/10W

R307 1-216-049-11 RES, CHIP 1K 5% 1/10W

R308 1-216-073-00 METAL CHIP 10K 5% 1/10W

R309 1-216-089-00 RES, CHIP 47K 5% 1/10W

R311 1-216-089-00 RES, CHIP 47K 5% 1/10W

R312 1-216-073-00 METAL CHIP 10K 5% 1/10W

R313 1-216-295-00 SHORT 0

R314 1-216-295-00 SHORT 0

R316 1-216-073-00 METAL CHIP 10K 5% 1/10W

R401 1-216-033-00 METAL CHIP 220 5% 1/10W

R402 1-216-105-00 RES, CHIP 220K 5% 1/10W

R403 1-216-033-00 METAL CHIP 220 5% 1/10W

R501 1-216-089-00 RES, CHIP 47K 5% 1/10W

R502 1-216-049-11 RES, CHIP 1K 5% 1/10W

R503 1-216-049-11 RES, CHIP 1K 5% 1/10W

R504 1-216-073-00 METAL CHIP 10K 5% 1/10W

R505 1-216-049-11 RES, CHIP 1K 5% 1/10W

R601 1-216-041-00 METAL CHIP 470 5% 1/10W

R602 1-216-033-00 METAL CHIP 220 5% 1/10W

R603 1-216-081-00 METAL CHIP 22K 5% 1/10W

R604 1-216-081-00 METAL CHIP 22K 5% 1/10W

R605 1-216-049-11 RES, CHIP 1K 5% 1/10W

R606 1-216-049-11 RES, CHIP 1K 5% 1/10W

R607 1-216-685-11 METAL CHIP 27K 0.5% 1/10W

R608 1-216-685-11 METAL CHIP 27K 0.5% 1/10W

R609 1-216-073-00 METAL CHIP 10K 5% 1/10W

R611 1-216-089-00 RES, CHIP 47K 5% 1/10W

R612 1-216-089-00 RES, CHIP 47K 5% 1/10W

R613 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R614 1-216-025-00 RES, CHIP 100 5% 1/10W

R615 1-216-025-00 RES, CHIP 100 5% 1/10W

R616 1-216-121-00 RES, CHIP 1M 5% 1/10W

Ref. No. Part No. Description Remark

< VARIABLE RESISTOR >

RV201 1-223-834-11 RES, ADJ, CARBON 47K

RV202 1-225-412-11 RES, VAR, SLIDE 10K

(ELEVATOR HEIGHT SENSOR)

< SWITCH >

SW201 1-762-108-31 SWITCH, PUSH (1 KEY)

(MAGAZINE EJECT END DETECT)

SW202 1-762-108-31 SWITCH, PUSH (1 KEY)

(MAGAZINE IN/OUT DETECT)

SW301 1-571-532-21 SWITCH, TACTIL (6)

< VIBRATOR >

X201 1-767-261-21 VIBRATOR, CERAMIC (8MHz)

X501 1-767-510-11 VIBRATOR, CERAMIC (10MHz)

X601 1-767-366-41 VIBRATOR, CERAMIC (16.9344MHz)

************************************************************

* A-3313-586-A RF BOARD, COMPLETE

******************

< CAPACITOR >

C10 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C12 1-113-500-11 TANTALUM CHIP 100uF 20% 10V

C13 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C14 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C15 1-162-957-11 CERAMIC CHIP 220PF 5% 50V

C16 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C17 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C18 1-111-253-11 TANTALUM CHIP 100uF 20% 6.3V

C19 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C21 1-162-966-11 CERAMIC CHIP 0.0022uF 10% 50V

C22 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C23 1-113-682-11 TANTALUM CHIP 33uF 20% 10V

C24 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C25 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C26 1-163-021-11 CERAMIC CHIP 0.01uF 10% 50V

C27 1-164-677-11 CERAMIC CHIP 0.033uF 10% 16V

C28 1-164-245-11 CERAMIC CHIP 0.015uF 10% 25V

C29 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C30 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C31 1-113-987-11 TANTALUM CHIP 4.7uF 20% 25V

C32 1-164-677-11 CERAMIC CHIP 0.033uF 10% 16V

C33 1-162-915-11 CERAMIC CHIP 10PF 0.5PF 50V

C34 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C35 1-104-700-11 CERAMIC CHIP 0.027uF 10% 16V

C36 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C37 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C38 1-104-913-11 TANTALUM CHIP 10uF 20% 16V

C39 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C40 1-109-982-11 CERAMIC CHIP 1uF 10% 10V

C41 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C42 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C43 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C51 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C52 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C53 1-163-038-00 CERAMIC CHIP 0.1uF 25V

– 59 –

Page 48

RF SW

Ref. No. Part No. Description Remark

C54 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C55 1-163-023-00 CERAMIC CHIP 0.015uF 5% 50V

C56 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C57 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C58 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C59 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C60 1-104-914-11 TANTALUM CHIP 22uF 20% 16V

< CONNECTOR >

CNJ11 1-778-776-21 CONNECTOR, FPC 17P

CNJ12 1-778-777-21 CONNECTOR, FPC 26P

* CNP11 1-580-055-21 PIN, CONNECTOR (SMD) 2P

* CNP51 1-580-055-21 PIN, CONNECTOR (SMD) 2P

CNP52 1-580-055-21 PIN, CONNECTOR (SMD) 2P

* CNP53 1-580-055-21 PIN, CONNECTOR (SMD) 2P

< IC >

IC11 8-752-082-14 IC CXA1992BR

IC51 8-759-071-79 IC BA6297AFP

IC52 8-759-040-83 IC BA6287F

< TRANSISTOR >

Q11 8-729-141-48 TRANSISTOR 2SB624-BV345

< RESISTOR >

Ref. No. Part No. Description Remark

R50 1-216-841-11 METAL CHIP 47K 5% 1/16W

R51 1-216-073-00 METAL CHIP 10K 5% 1/10W

R52 1-216-093-00 RES, CHIP 68K 5% 1/10W

R53 1-216-073-00 METAL CHIP 10K 5% 1/10W

R54 1-216-073-00 METAL CHIP 10K 5% 1/10W

R55 1-216-073-00 METAL CHIP 10K 5% 1/10W

R56 1-216-093-00 RES, CHIP 68K 5% 1/10W

R57 1-216-081-00 METAL CHIP 22K 5% 1/10W

R58 1-216-093-00 RES, CHIP 68K 5% 1/10W

R59 1-216-073-00 METAL CHIP 10K 5% 1/10W

R60 1-216-073-00 METAL CHIP 10K 5% 1/10W

R61 1-216-073-00 METAL CHIP 10K 5% 1/10W

R62 1-216-085-00 METAL CHIP 33K 5% 1/10W

R63 1-216-073-00 METAL CHIP 10K 5% 1/10W

R64 1-216-073-00 METAL CHIP 10K 5% 1/10W

R65 1-216-073-00 METAL CHIP 10K 5% 1/10W

< VARIABLE RESISTOR >

RV14 1-238-091-11 RES, ADJ, CERMET 22K

< SWITCH >

SW11 1-762-946-12 SWITCH, PUSH (1 KEY)

(CHUCKING END DETECT)

SW12 1-762-946-12 SWITCH, PUSH (1 KEY) (SAVE END DETECT)

************************************************************

R11 1-218-348-11 RES, CHIP 110K 5% 1/16W

R12 1-216-839-11 METAL CHIP 33K 5% 1/16W

R13 1-216-839-11 METAL CHIP 33K 5% 1/16W

R14 1-218-348-11 RES, CHIP 110K 5% 1/16W

R16 1-216-857-11 METAL CHIP 1M 5% 1/16W

R17 1-216-837-11 METAL CHIP 22K 5% 1/16W

R18 1-216-841-11 METAL CHIP 47K 5% 1/16W

R22 1-216-857-11 METAL CHIP 1M 5% 1/16W

R25 1-216-851-11 METAL CHIP 330K 5% 1/16W

R26 1-216-845-11 METAL CHIP 100K 5% 1/16W

R27 1-216-295-00 SHORT 0

R28 1-216-295-00 SHORT 0

R30 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R31 1-216-829-11 METAL CHIP 4.7K 5% 1/16W

R32 1-216-837-11 METAL CHIP 22K 5% 1/16W

R33 1-216-158-00 RES, CHIP 22 5% 1/8W

R34 1-216-855-11 METAL CHIP 680K 5% 1/16W

R35 1-216-835-11 METAL CHIP 15K 5% 1/16W

R36 1-216-836-11 METAL CHIP 18K 5% 1/16W

R37 1-216-851-11 METAL CHIP 330K 5% 1/16W

R38 1-216-837-11 METAL CHIP 22K 5% 1/16W

R39 1-216-847-11 METAL CHIP 150K 5% 1/16W

R40 1-218-273-11 RES, CHIP 510K 5% 1/16W

R41 1-218-296-11 RES, CHIP 75K 5% 1/16W

R42 1-202-930-11 RES, CHIP 750K 5% 1/16W

R43 1-216-849-11 METAL CHIP 220K 5% 1/16W

R44 1-216-846-11 METAL CHIP 120K 5% 1/16W

R45 1-216-837-11 METAL CHIP 22K 5% 1/16W

R46 1-216-847-11 METAL CHIP 150K 5% 1/16W

R47 1-216-834-11 METAL CHIP 12K 5% 1/16W

R48 1-216-845-11 METAL CHIP 100K 5% 1/16W

R49 1-216-093-00 RES, CHIP 68K 5% 1/10W

* 1-664-104-11 SW BOARD

SW1 1-572-688-11 SWITCH, PUSH (1 KEY) (LIMIT)

************************************************************

3 1-664-796-11 JACK FLEXIBLE BOARD

165 1-664-627-11 MAIN FLEXIBLE BOARD

210 1-664-626-11 OP FLEXIBLE BOARD

! 211 8-820-010-05 OPTICAL PICK-UP KSS-521A/J2RP

M101 A-3291-956-A MOTOR SUB ASSY, SPINDLE

M102 A-3291-955-A MOTOR SUB ASSY, SLED

M103 A-3301-123-A ELJ MOTOR ASSY (CHUKING)

M104 A-3301-123-A ELJ MOTOR ASSY (ELEVATOR)

************************************************************

#1 7-627-852-07 SCREW, PRECISION +P 1.7X2.5

#2 7-685-792-09 SCREW +PTT 2.6X6 (S)

#3 7-685-781-09 SCREW +PTT 2X4 (S)

#4 7-624-104-04 STOP RING 2.0, TYPE-E

#5 7-627-554-07 SCREW, PRECISION +P 2X2.2

#6 7-628-253-00 SCREW +PS 2X4

#7 7-627-553-27 SCREW, PRECISION +P 2X2.5

#8 7-624-102-04 STOP RING 1.5, TYPE-E

#9 7-627-850-28 SCREW, PRECISION +P 1.4X3

#10 7-627-000-00 SCREW, PRECISION +P 1.7X2.2 TYPE3

The components identified by

mark ! or dotted line with

mark ! are critical for safety.

Replace only with part number specified.

*********

< SWITCH >

MISCELLANEOUS

**************

**************

HARDWARE LIST

**************

Les composants identifiés par une

marque ! sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le numéro spécifié.

– 60 –

Page 49

Ref. No. Part No. Description Remark

#11 7-685-780-01 SCREW +PTT 2X3 (S) (EXCEPT US, Canadian)

#11 7-685-851-04 SCREW +BVTT 2X4 (S) (US, Canadian)

#12 7-685-780-09 SCREW +PTT 2X3 (S)

#13 7-685-853-04 SCREW +BVTT 2X6 (S)

************************************************************

ACCESSORIES & PACKING MATERIALS

********************************

3-865-014-11 MANUAL, INSTRUCTION (ENGLISH, FRENCH,

SPANISH, CHINESE) (US, Canadian)

3-865-037-11 MANUAL, INSTRUCTION (ENGLISH, FRENCH,

SPANISH, CHINESE) (E)

3-865-037-21 MANUAL, INSTRUCTION (ENGLISH, SPANISH,

SWEDISH, PORTUGUESE) (AEP, UK)

3-865-037-31 MANUAL, INSTRUCTION (FRENCH, GERMAN,

DUTCH, ITALIAN) (AEP, UK)

3-865-037-41 MANUAL, INSTRUCTION (GERMAN, RUSSIAN)