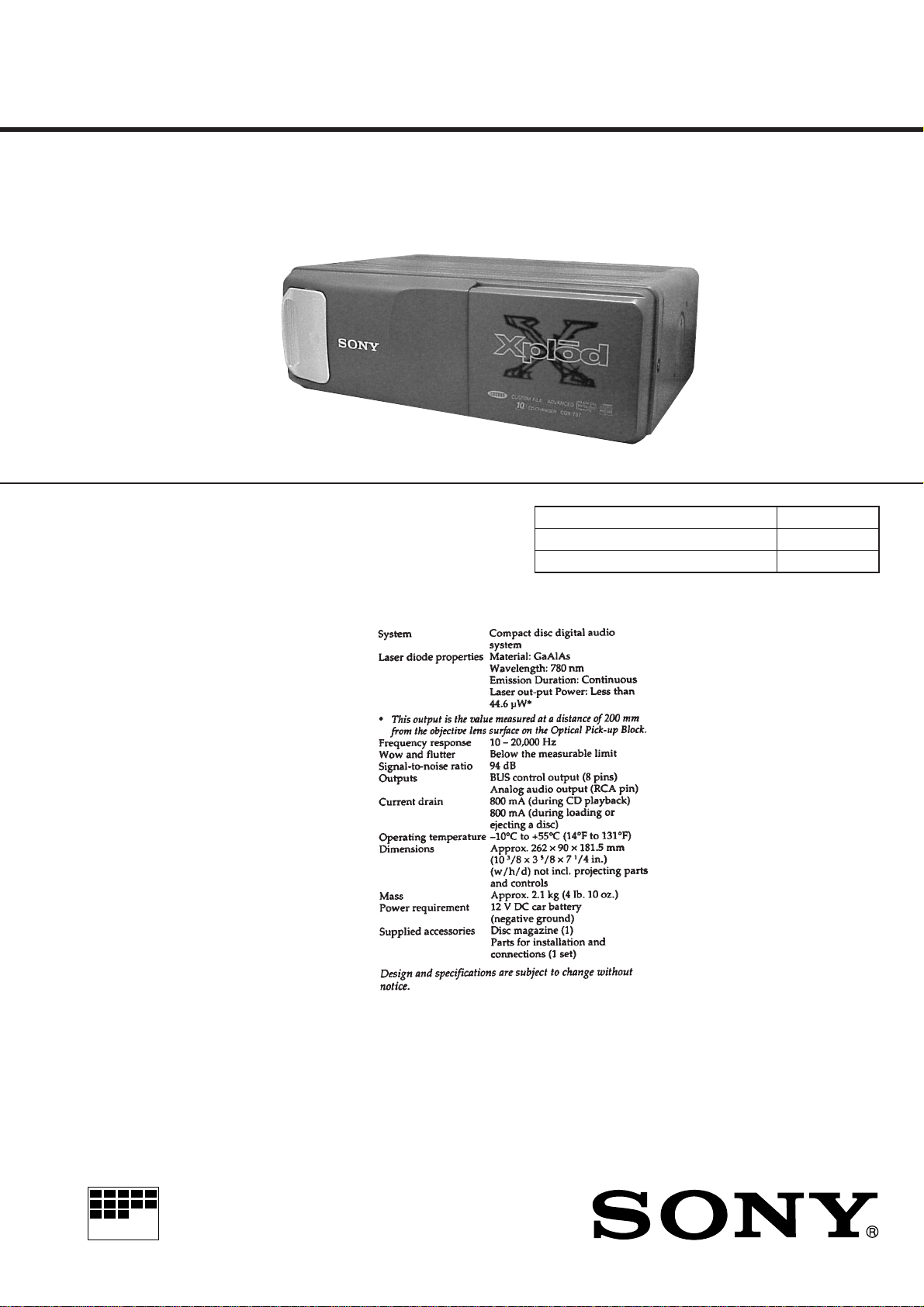

Sony CDX-737 Service manual

CDX-737

SERVICE MANUAL

SPECIFICATIONS

US Model

Canadian Model

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism NEW

CD Drive Mechanism Type MG-250D-137

Optical Pick-up Name KSS-521A/J2N

MICROFILM

COMPACT DISC CHANGER

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL ................................................................... 3

Installation....................................................................... 4

Connections ..................................................................... 4

3. DISASSEMBLY ......................................................... 5

4. MECHANISM DECK ASSEMBLY.................... 11

5. MECHANICAL ADJUSTMENTS....................... 13

6. ELECTRICAL ADJUSTMENTS......................... 14

7. DIAGRAMS

7-1. Block Diagram – SERVO Section – ............................... 16

7-2. Block Diagram – MAIN Section – ................................. 17

7-3. Block Diagram

– BUS CONTROL/POWER SUPPLY Section –........... 18

7-4. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 19

7-5. Printed Wiring Boards – RF/SW Boards –..................... 20

7-6. Schematic Diagram – RF/SW Boards – ......................... 21

7-7. Printed Wiring Boards

– MAIN Board (Component Side) – .............................. 22

7-8. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 23

7-9. Schematic Diagram – MAIN Board (1/2) – ................... 24

7-10. Schematic Diagram – MAIN Board (2/2) – ................... 25

7-11. Printed Wiring Boards – JACK Board – ........................ 26

7-12. Schematic Diagram – JACK Board – ............................. 26

7-13. IC Pin Function Description ........................................... 33

8. EXPLODED VIEWS ................................................ 36

9. ELECTRICAL PARTS LIST ............................... 41

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE 0

SUR LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE

DES PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ

DE FONCTIONNEMENT. NE REMPLACER CES COMPOSANTS QUE PAR DES PIÈCES SONY DONT LES

NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPLÉMENTS PUBLIÉS PAR SONY.

2

SECTION 1

y

SERVICING NOTES

SECTION 2

GENERAL

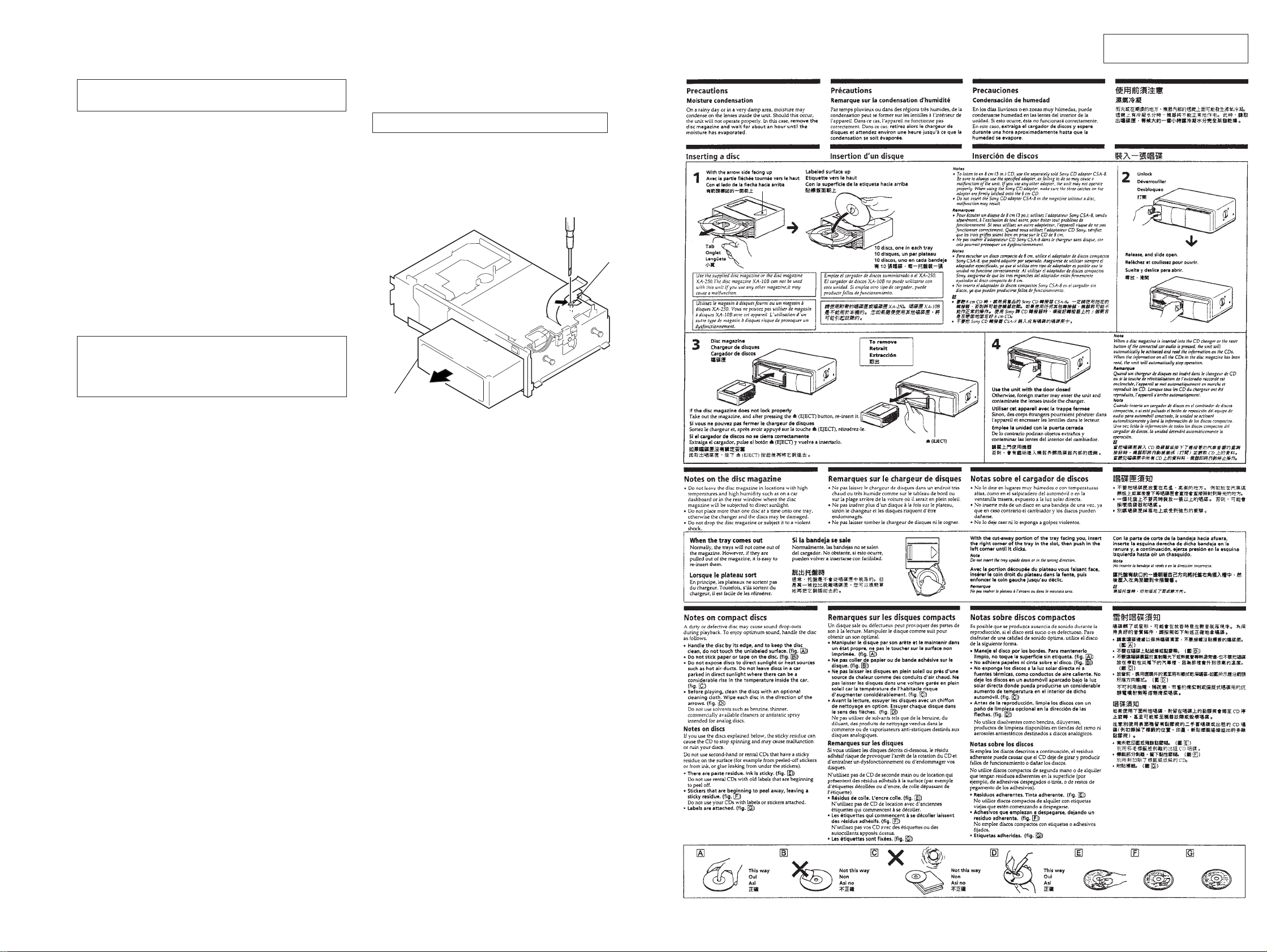

This section is extracted from

instruction manual.

NOTES ON HANDLING THE OPTICAL PICKUP BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

Laser Diode Properties

• Material: GaAlAs

• Wavelength: 780 nm

• Emission Duration: continuous

• Laser Output Power: less than 44.6 µW*

* This output is the value measured at a distance of 200 mm

from the objective lens surface on the Optical Pick-up Block.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

DISC MAGAZINE GETTING OUT PROCEDURE

ON THE POWER SUPPLY IS OFF

Remove the CASE (LOWER) assembly beforehand

1) Press the lever (ML) assy to arrow direction.

2) Removal the magazine assy.

Note: T ak e out the magazine only w hen the tray is completely within the

magazine. If the disk or tray is sticking out, turn on the power and

eject the magazine.

Lever (ML) ass’

Magazine ass’y

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

33

44

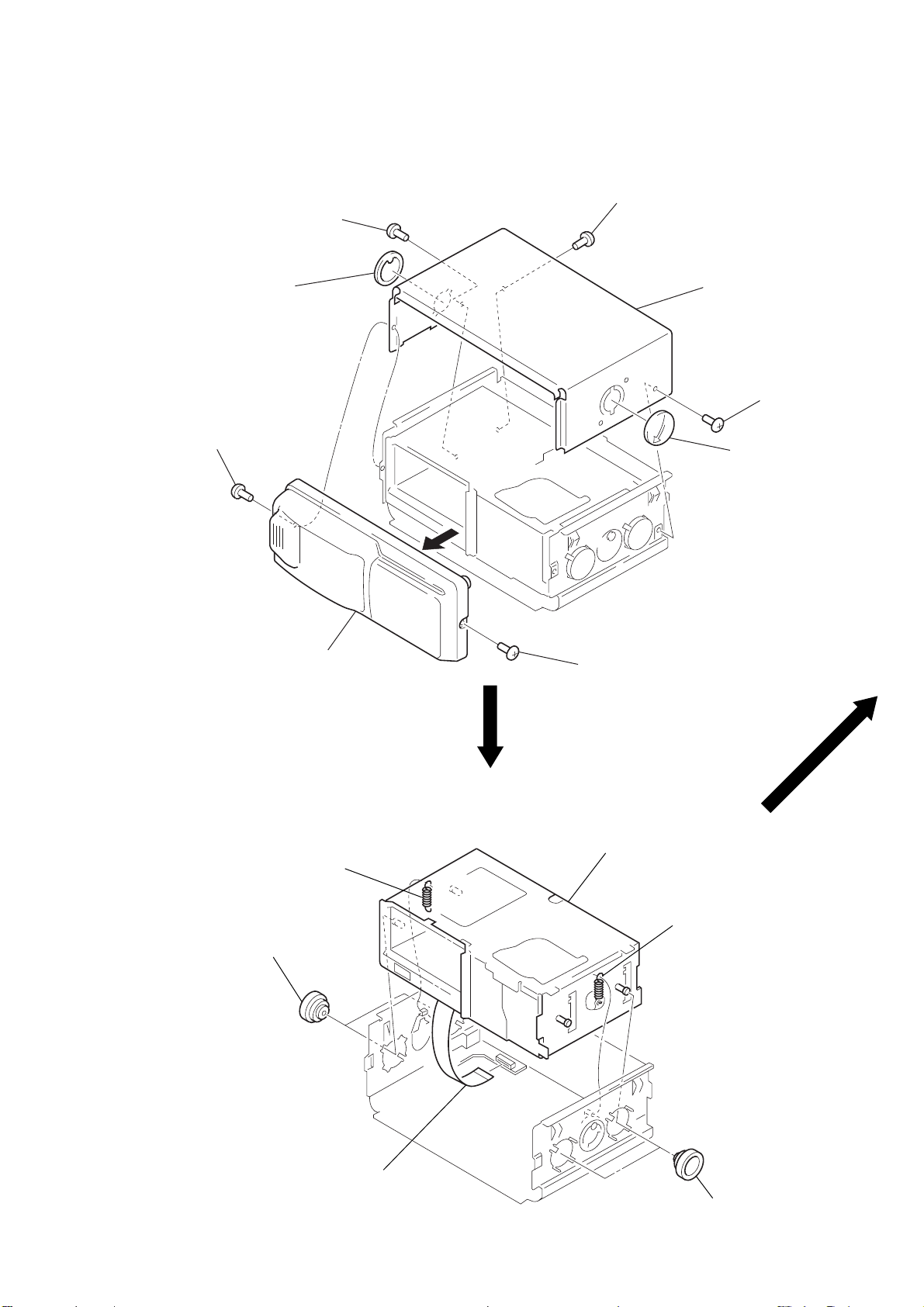

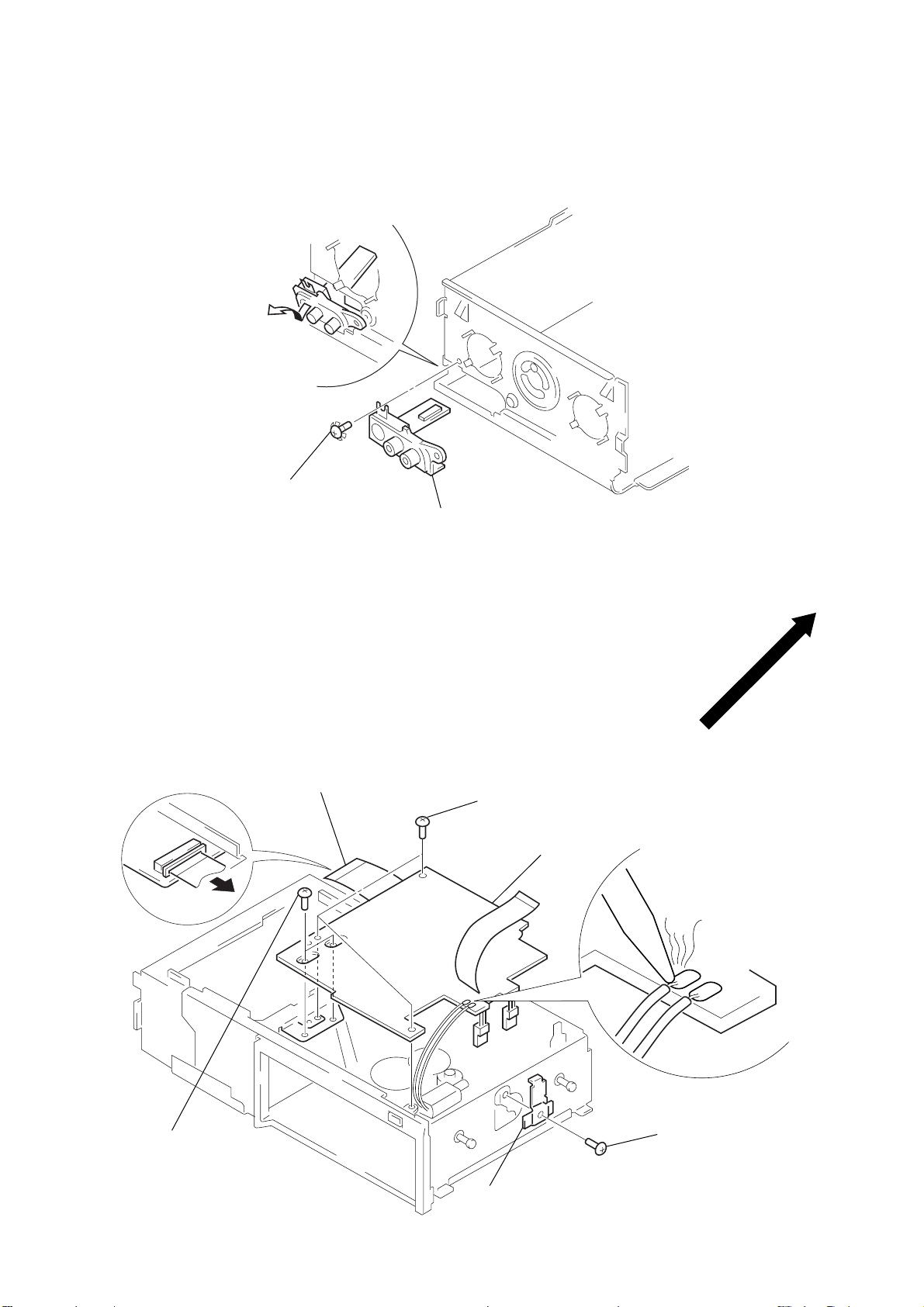

SECTION 3

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

COVER (UPPER T), FRONT PANEL ASS’Y

1

screw

(PTT2.6 × 6)

3

lever (FLT)

1

screw

(PTT2.6 × 6)

1

screw

(PTT2.6 × 6)

2

cover (upper T)

3

lever (FLT)

1

screw

(PTT2.6 × 6)

4

front panel (T) ass’y

MECHANISM DECK (MG-250D-137)

2

tension spring (FL)

1

two dampers (250)

1

screw

(PTT2.6 × 6)

4

mechanism deck (MG-250D-137)

2

tension spring (FL)

3

jack flexible board

(CNJ901)

1

two dampers (250)

5

JACK BOARD

Remove the jack board

in the direction of the arrow.

1

ground point screw

(PTT2.6

×

6)

2

jack board

MAIN BOARD

5

two precision screws

(P1.7

×

2.5)

1

main flexible board

(CNJ12)

6

three screws (FP)

7

main board

2

Break the soldering

of motor (M104) lead.

3

screw

(PTT2

×

4)

4

heat sink

6

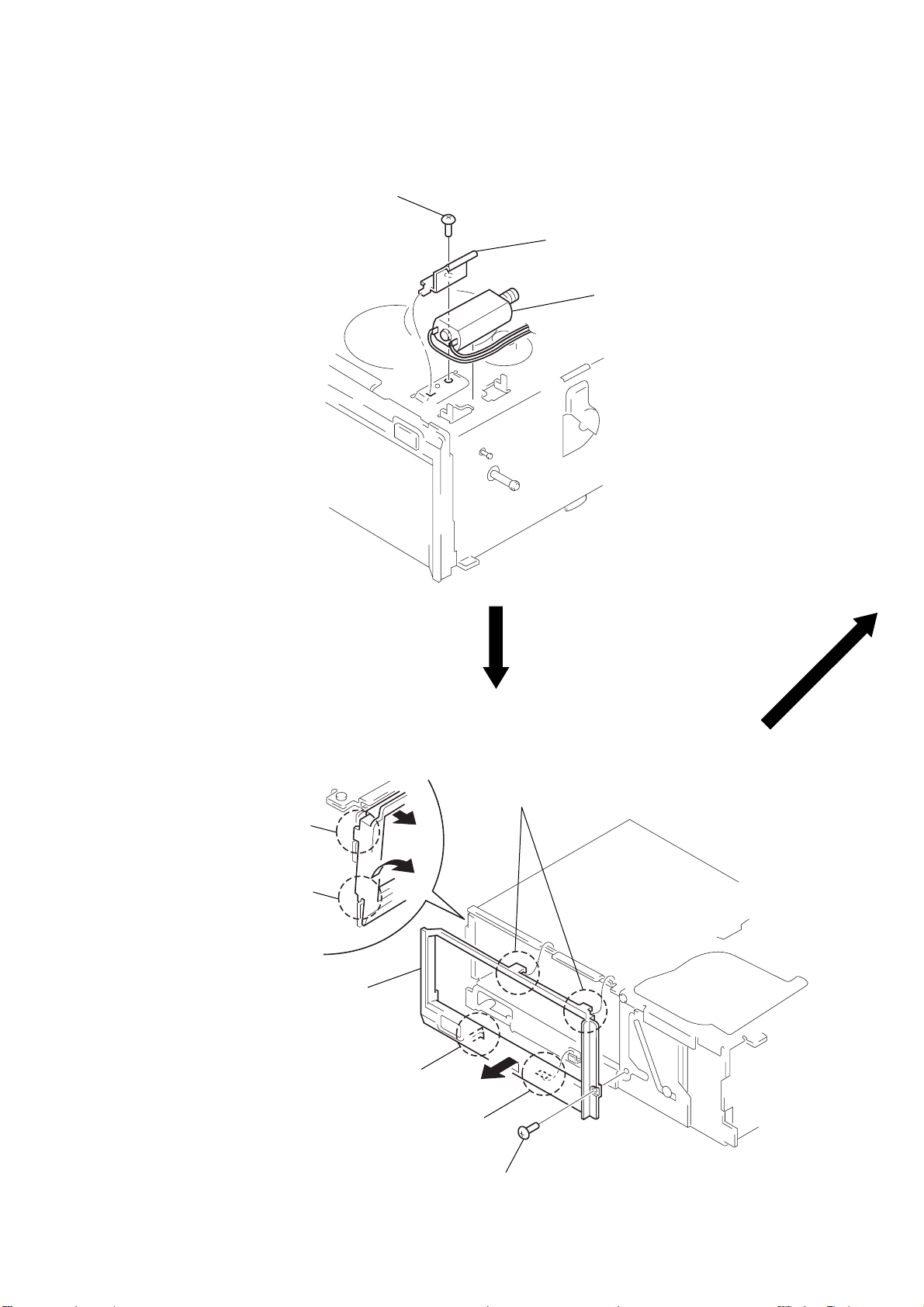

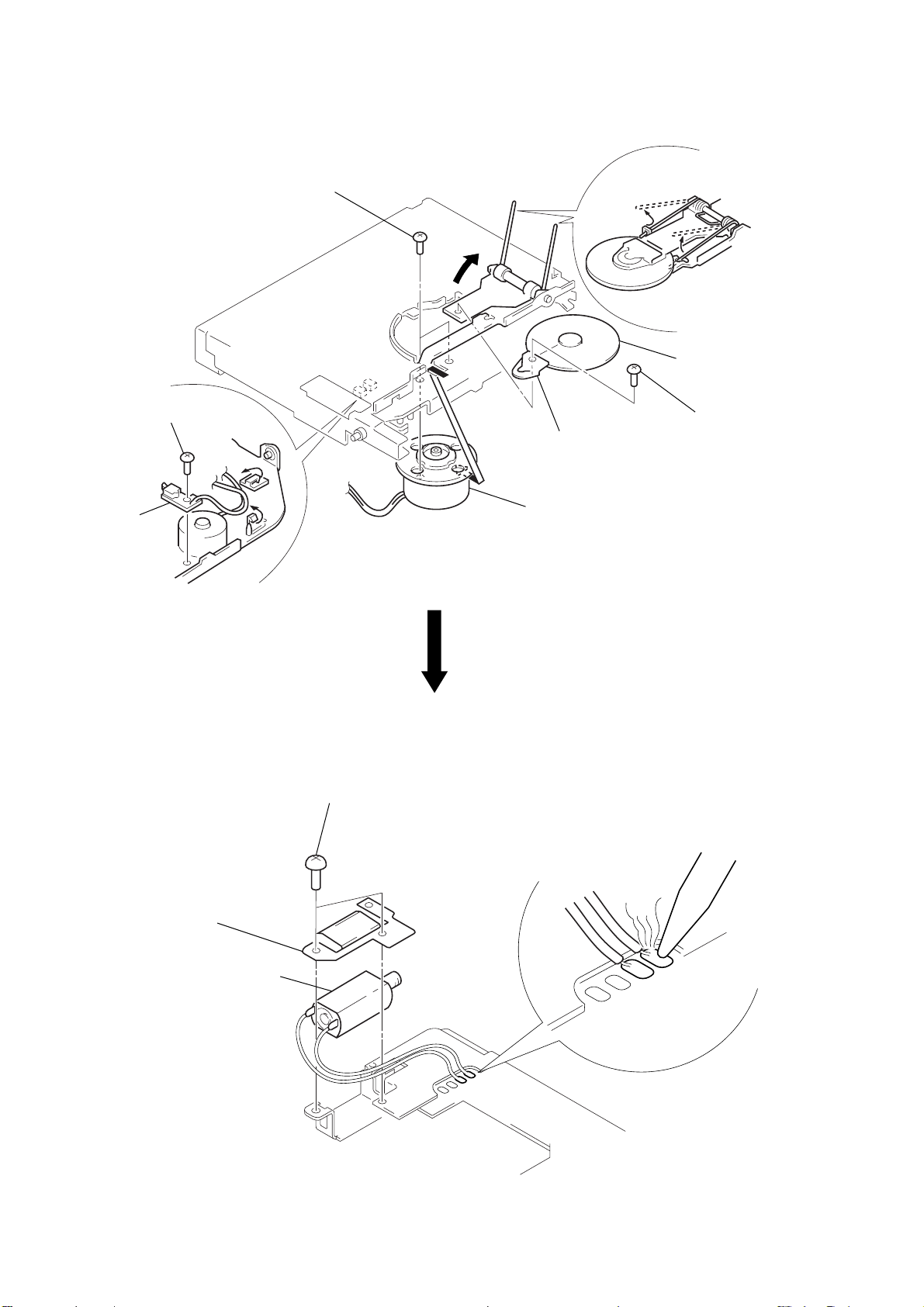

ELEVATOR MOTOR ASS’Y (M104)

1

screw

(PTT2

×

3)

2

bracket (EVM)

3

elevator motor ass’y

(M104)

ESCUTCHEON

2

Remove the claw

in the direction

of the arrow

4

Remove the ditch

in the direction

of the arrow

5

Remove the escutcheon

in the direction of the arrow

A

B

.

.

3

C

.

claw

B

A

4

C

ditch

two claws

3

1

screw

(M2

×

3)

7

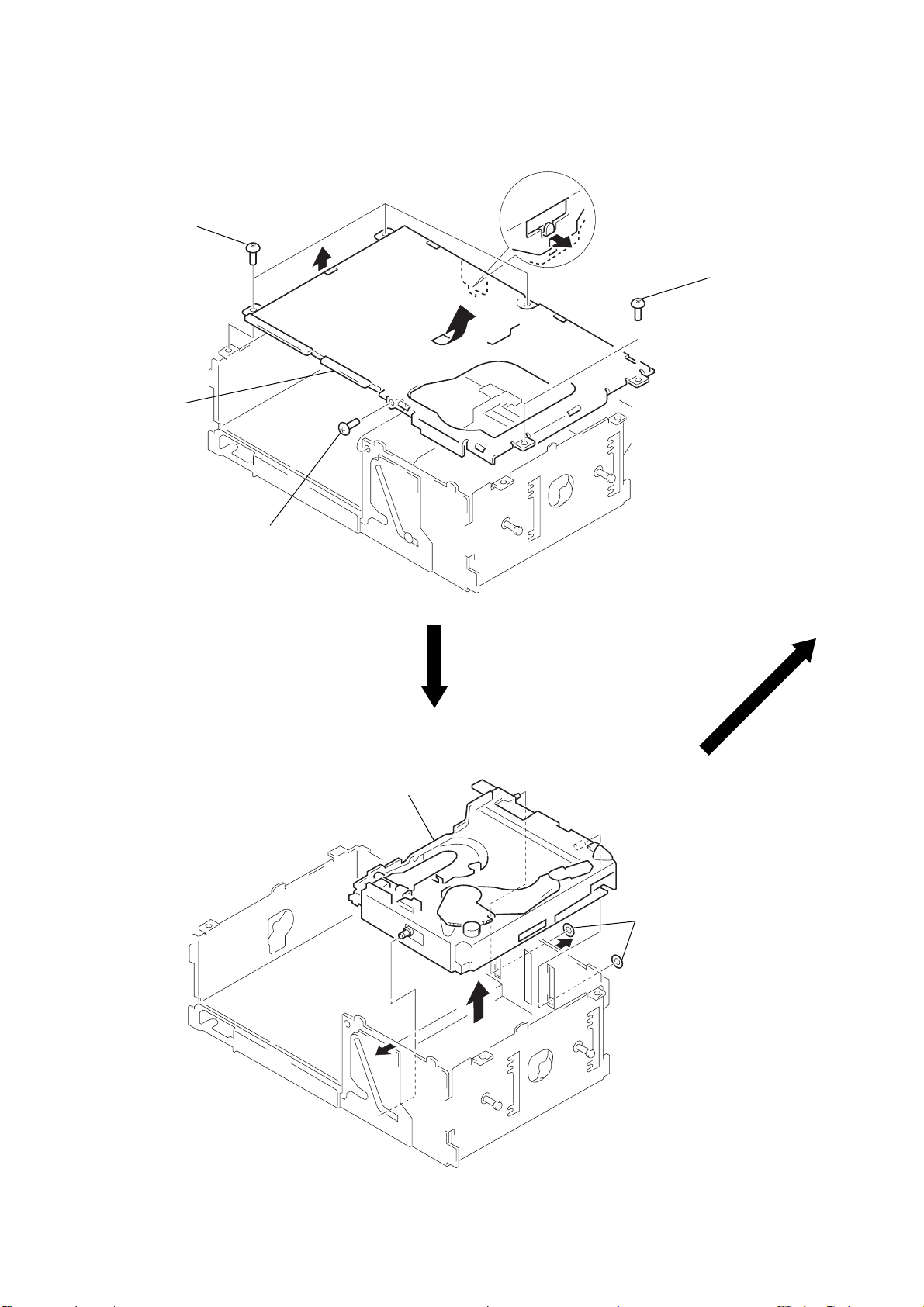

CASE (UPPER) ASS’Y

n

s

1

three screws

(PTT2 × 4)

Remove the case

4

(upper) ass’y

in the direction

of the arrow B.

1

screw

(PTT2 × 4)

2

B

A

3

Remove the edge in the directio

of the arrow A.

1

two screws

(PTT2 × 4)

CHASSIS ASS’Y

3

chassis ass’y

2

2

1

two polyethylene washer

8

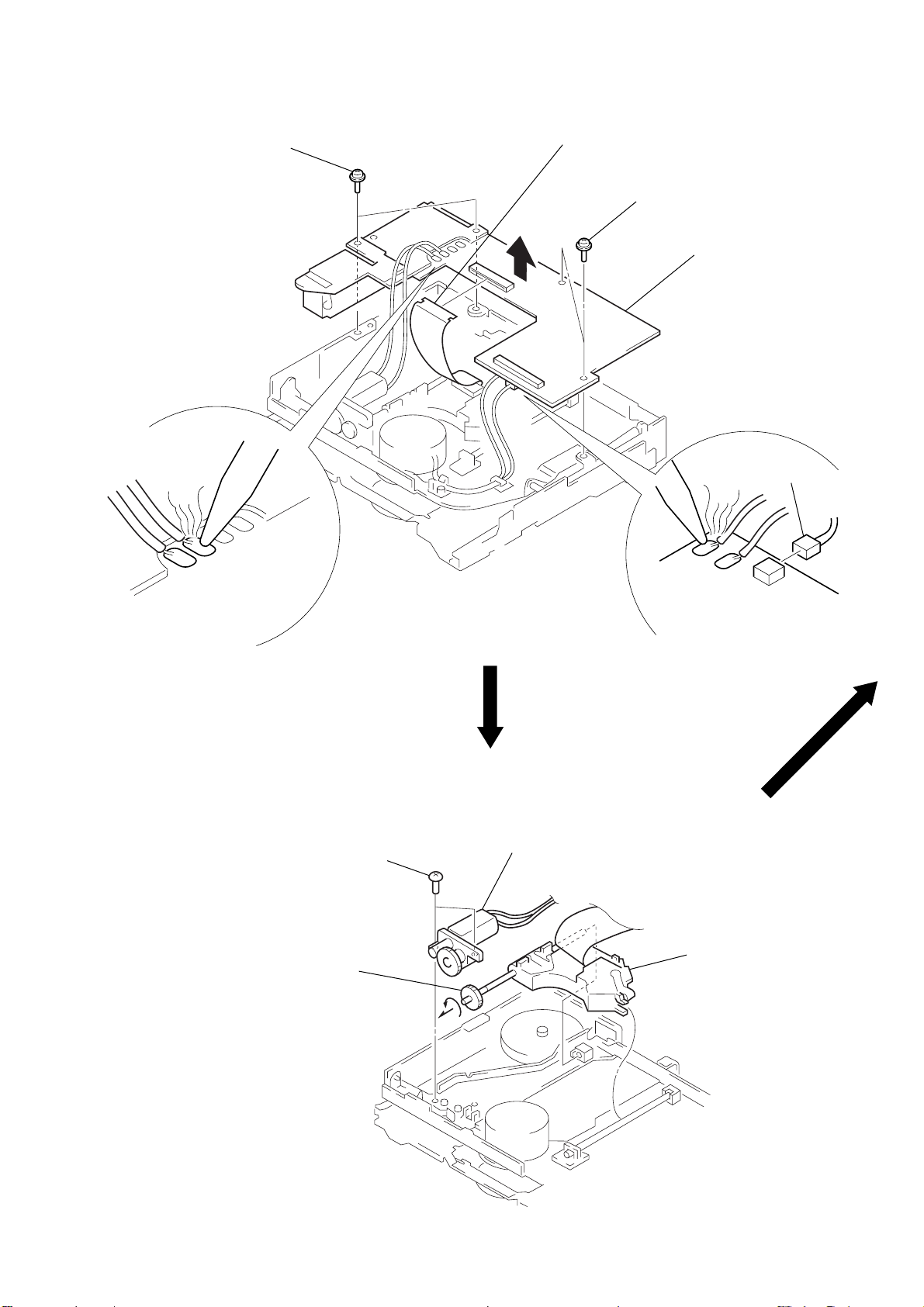

RF BOARD

3

two screws

(PS2 × 4)

1

OP flexible board

(CNJ11)

3

two screws

(PS2 × 4)

2

Break the soldering

of motor (M102) lead.

4

7

RF board

5

6

Break the soldering of lead.

connector

(CNP53)

SLED MOTOR ASS’Y (M102), OPTICAL PICK-UP (KSS-521A/J2N)

1

two screws

(ESCUTCHEON)

4

Turn at the direction of the

arrow, then remove

shaft (sled) ass’y

2

sled motor ass’y

(M102)

3

optical pick-up

(KSS-521A/J2N)

9

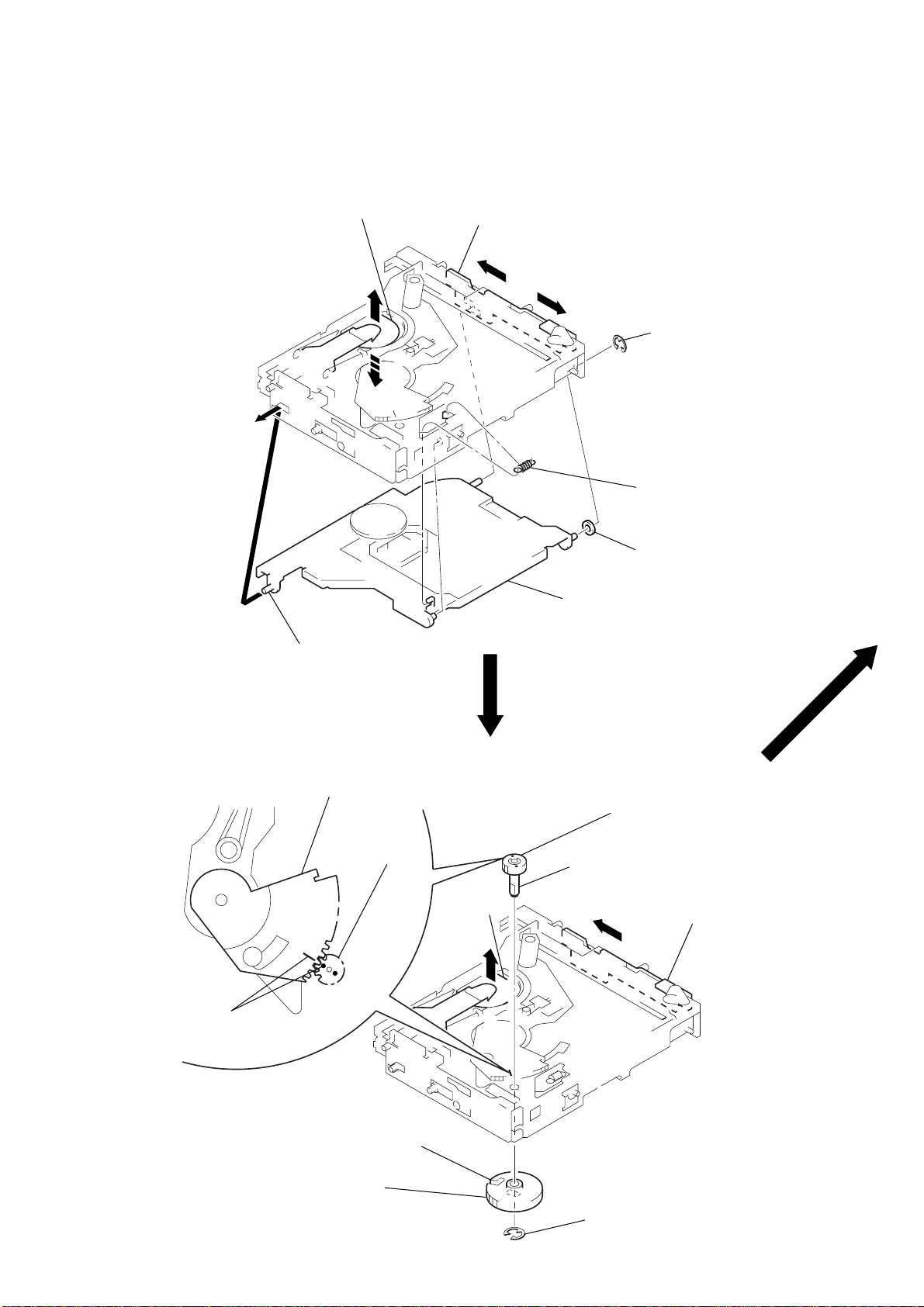

SW BOARD, SPINDLE MOTOR ASS’Y (M101)

)

8

two screws

×

2.2)

(P1.7

1

screw

×

2.2)

(P2

2

SW board

7

3

spring (chucking)

6

retainer (disc

4

screw

5

bracket (CP)

9

Remove the spindle motor ass’y (M101)

in the direction of the arrow.

(P2

×

2.2)

CHUCKING MOTOR ASS’Y (M103)

2

3

retainer (CHM)

4

chucking motor ass’y

(M103)

two screws (P2 × 2.5)

1

Break the soldering

of motor (M103) lead.

10

SECTION 4

)

gear (LOAD 2)

gear (LOMINI)

marking

Fig. A

chuck plate

2

Attach the gear (LOMINI) at the position

shown in Fig. A.

shaft (rotary prevention C)

1

Move the lever (LOCK 3)

fully in direction

B

to

move the chuck plate up.

B

4

stop ring 1.5 (E type)

3

Attach the gear (LOAD CAM) ass’y

with its facing inside.

slit

MECHANISM DECK ASSEMBLY

Note: Follow the assembly procedure in the numerical order given.

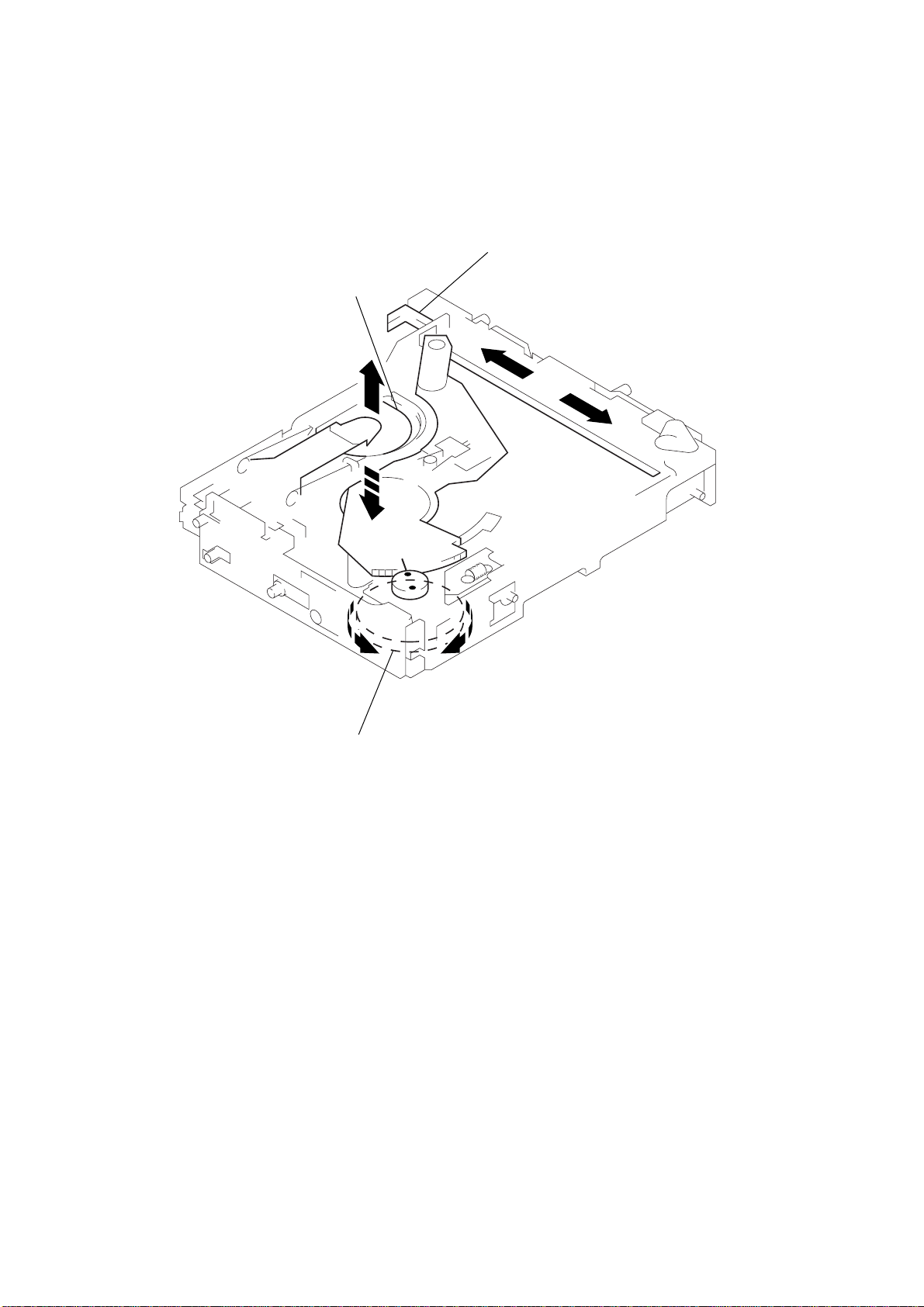

OPTICAL PICK-UP COMPLETE ASS’Y

1

Move the lever (LOCK 3) in direction A, and return it a little in

chuck plate

direction

down to the lower limit.

B

from the position where the chuck plate is moved

B

A

stop ring 2.0 (E type

4

5

tension spring (DH)

shaft (A)

GEAR (LOMINI) / (LOAD CAM) ASS’Y

3

optical pick-up complete ass’y

Note: Insert the shaft (A) first.

2

washer 2.5

11

OPERATION CHECK

1

Confirm that the slider moves in direction C to move down

the chuck plate if the gear (LOAD CAM) is rotated in direction A or

the chuck plate moves up and the slider moves in direction D if the

gear is rotated in direction B.

chuck plate

slider

D

C

A

gear (LOAD CAM) ass’y

B

12

SECTION 5

5

MECHANICAL ADJUSTMENTS

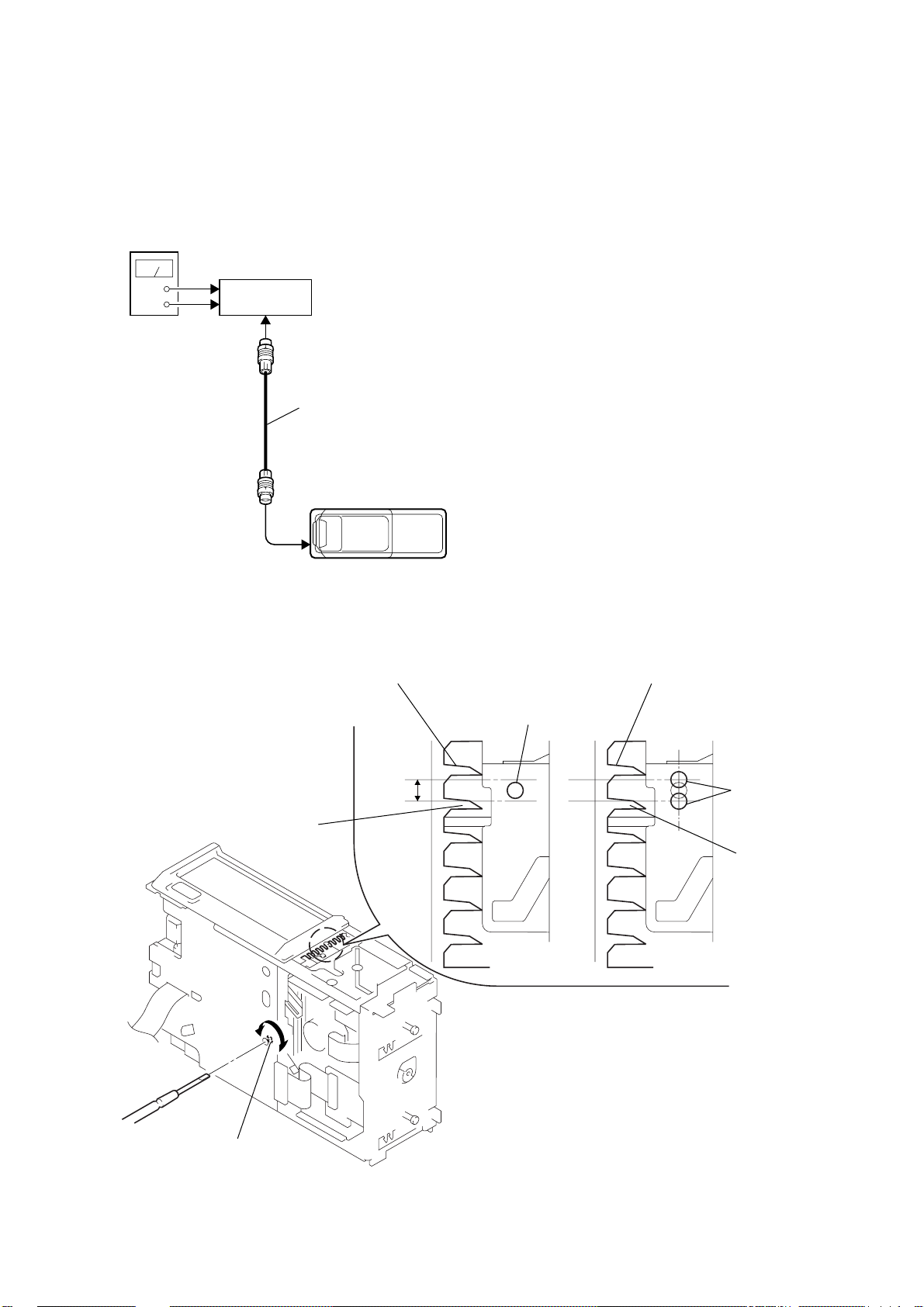

• Elevator Height (Address) Adjustment

Note: This adjustments is necessary when the system controller (IC201),

variable resistor (RV201), slider (R), slider (L), or chassis (ELV)

was replaced for any repair.

Connection:

power supply

master unit

+

GND

BUS cable

CDX-737

Adjustment Method:

1. Connect this set to the master unit (e.g. MDX-C7970/C7970R),

load a disc magazine, and place the set vertically as shown

below.

2. Connect the regulated power supply to the master unit, and

turn the power on.

3. Press the DISC button on the master unit and select DISC 5.

4. At this time, if the elevator shaft does not position between

comb teeth A and B at addresses 5 and 6 as shown below,

adjust the following.

5. Press repeatedly the DISC + and – buttons on the master unit

so that the elevator shaft mov es from address 6 to address 5, or

from 5 to 6. At this time, adjust RV201 on the main board so

that the elevator shaft positions smoothly between comb teeth

A and B.

6. Further, place the set horizontally and make same adjustment

as mentioned above.

7. After adjustment at addresses 5 to 6 is finished, check all operations from addresses 1 to 10 with the set placed vertically

and horizontally respectively to confirm that the elevator shaft

positions in a range between comb teeth A to B.

comb tooth at address 5

comb tooth at address 6

A

B

comb tooth at address 6

elevator shaft

A

B

OK NG

elevator shaft

comb tooth at address

RV201

13

SECTION 6

V

ELECTRICAL ADJUSTMENTS

Note:

1. Perform adjustments as given.

2. Power supply voltage: DC14.4 V (more than 3A).

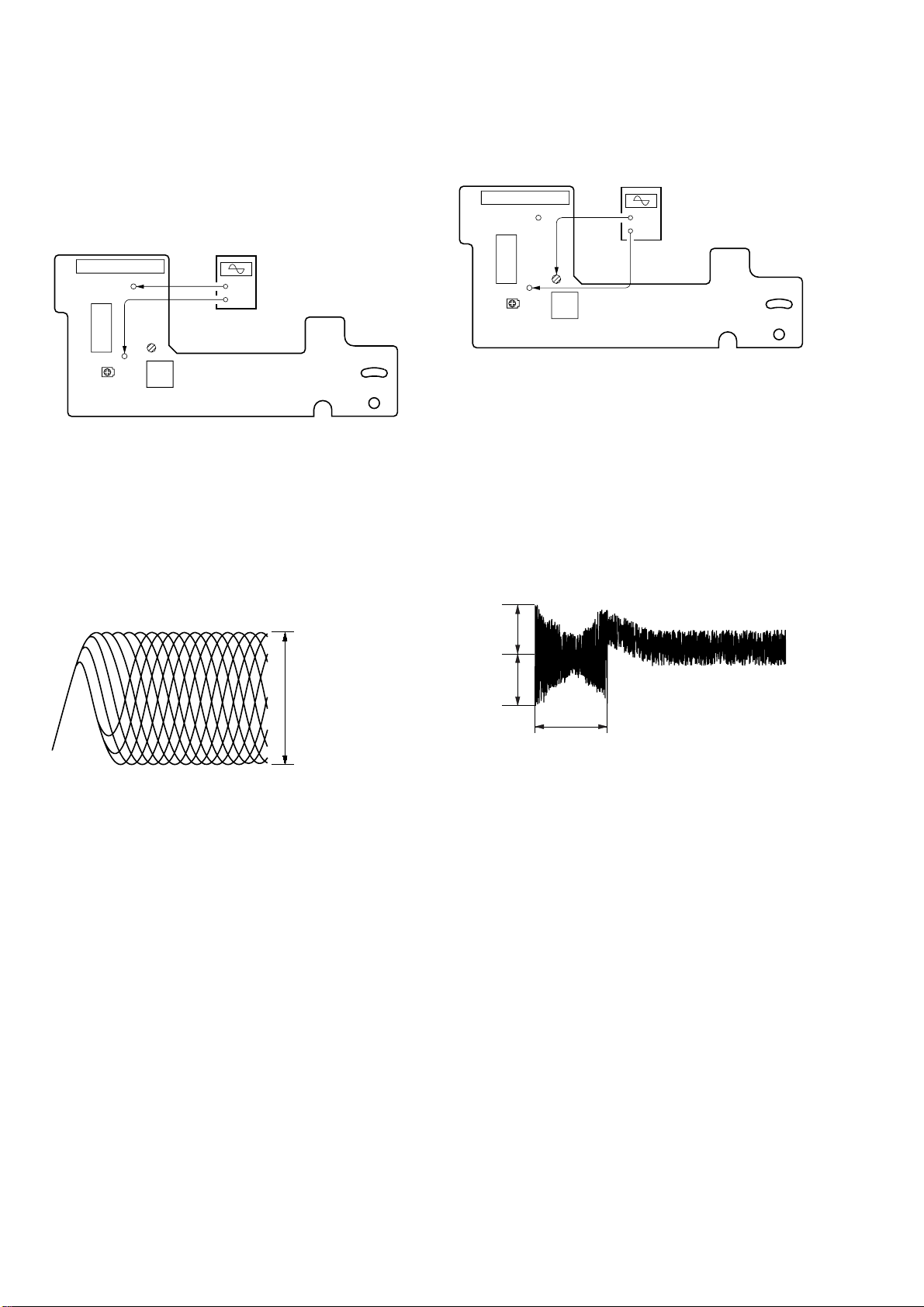

• FOCUS BIAS CHECK

– RF BOARD (Conductor Side) –

oscilloscope

CNJ12

TP (RF)

IC51

TP

(VC)

IC11

+

–

Procedure:

1. Connect the oscilloscope to TP (RF) and TP (VC) on the RF

board.

2. Put the set into play mode by loading the disc.

3. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note:

Clear RF signal waveform means that the shape “◊” can be clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 m

TIME/DIV: 500 ns

level: 1.4 ± 0.3 Vp-p

• TRACKING OFFSET CHECK

– RF BOARD (Conductor Side) –

oscilloscope

CNJ12

+

–

BP11

IC51

(TE)

TP

(VC)

IC11

Procedure:

1. Connect the oscilloscope to BP11 (TE) and TP (VC) on the

RF board.

2. Put the set into play mode by loading the disc.

3. Press the . AMS > button, and check the traverse w aveform*.

4. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0 V dc, and check this level.

* Traverse waveform: This is the tracking error wave form appears

Traverse waveform

A

0 V

B

A=B

traverse waveform

(100 track jump waveform)

when crossing the track.

VOLT/DIV : 500 mV

TIME/DIV : 2 ms

Center : 0 V

14