Page 1

CDX-60X

SERVICE MANUAL

Ver 1.1 2000. 08

SPECIFICATIONS

US Model

Model Name Using Similar Mechanism CDX-636

CD Drive Mechanism Type MG-251A-137

Optical Pick-up Name KSS-720A/K1NP

COMPACT DISC CHANGER

Page 2

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. GENERAL ................................................................... 3

Installation....................................................................... 4

Connections ..................................................................... 4

3. DISASSEMBLY ......................................................... 5

4. MECHANISM DECK ASSEMBLY.................... 11

5. MECHANICAL ADJUSTMENT .......................... 13

6. ELECTRICAL CHECK .......................................... 14

7. DIAGRAMS

7-1. Block Diagram – RF SERVO/

DA CONVERTER Section – .......................................... 17

7-2. Block Diagram – BUS CONTROL/

POWER SUPPLY Section – ........................................... 18

7-3. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 19

7-4. Printed Wiring Boards – RF/LSW Boards – ................. 20

7-5. Schematic Diagram – RF/LSW Boards –...................... 21

7-6. Printed Wiring Boards

– MAIN Board (Component Side) – .............................. 22

7-7. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 23

7-8. Schematic Diagram – MAIN Board (1/2) – .................. 24

7-9. Schematic Diagram – MAIN Board (2/2) – .................. 25

7-10. Printed Wiring Boards – JACK/SWITCH Boards – ..... 26

7-11. Schematic Diagram – JACK/SWITCH Boards – .......... 26

7-12. IC Pin Function Description ........................................... 32

8. EXPLODED VIEWS ................................................ 35

9. ELECTRICAL PARTS LIST ............................... 40

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMA TIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

2

Page 3

Ver 1.1 2000. 08

L

SECTION 1

SERVICING NOTES

SECTION 2

GENERAL

This section is extracted from

instruction manual.

NOTES ON HANDLING THE OPTICAL PICKUP BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference generated by

the charged electrostatic load, etc. on clothing and the human body .

During repair, pay attention to electrostatic breakdown and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

If the optical pick-up block is defective, please replace the whole

optical pick-up block.

Never turn the semi-fixed resistor located at the side of optical

pick-up block.

DISC MAGAZINE GETTING OUT PROCEDURE

ON THE POWER SUPPLY IS OFF

Remove the COVER (LOWER T) beforehand

1) Press the lever (ML.S) assy in the direction of arrow A.

2) Removal the magazine assy.

Note: T ak e out the magazine only w hen the tray is completely within the

magazine. If the disk or tray is sticking out, turn on the power and

eject the magazine.

Lever (ML.S)

A

Magazine ass’y

OPTICA

PICK-UP

BLOCK

SEMI-FIXED

RESISTOR

33

Page 4

44

Page 5

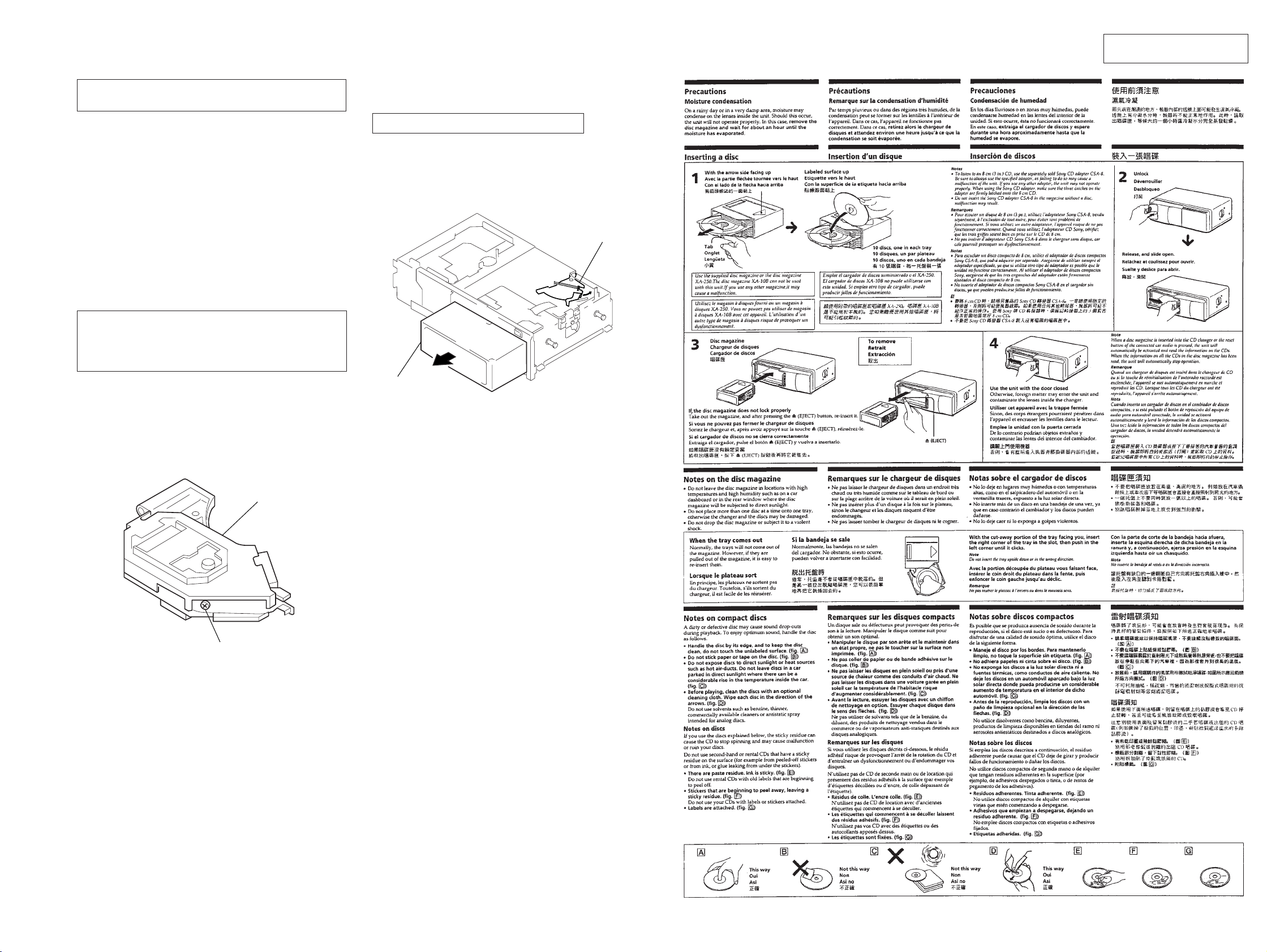

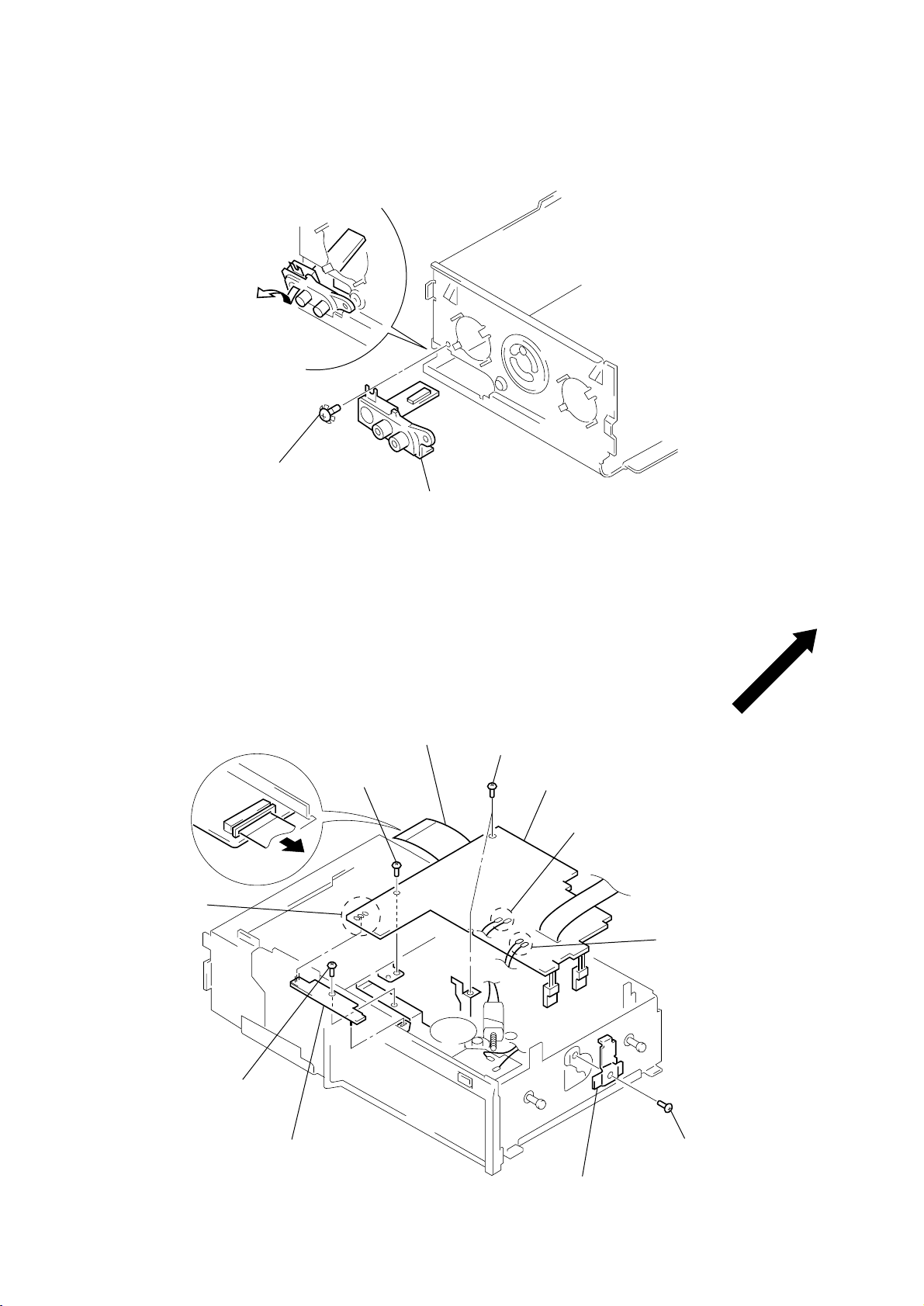

SECTION 3

)

)

DISASSEMBLY

Note: Follow the disassembly procedure in the numerical order given.

COVER (UPPER T), FRONT PANEL ASS’Y

1 screw

(PTT2.6 × 6)

3 screw

(PTT2.6 × 6)

4 lever (FLT)

3 screw (PTT2.6 × 6)

5 cover (upper T)

3 screw (PTT2.6 × 6

4 lever (FLT)

2 front panel ass’y

MECHANISM DECK (MG-251A-137)

2 tension coil spring (FL)

1 two dampers (250T)

filament tape

1 screw (PTT2.6 × 6)

4 mechanism deck (MG-251A-137)

2 tension coil spring (FL)

3 jack flexible board

(CNJ901)

1 two dampers (250T

5

Page 6

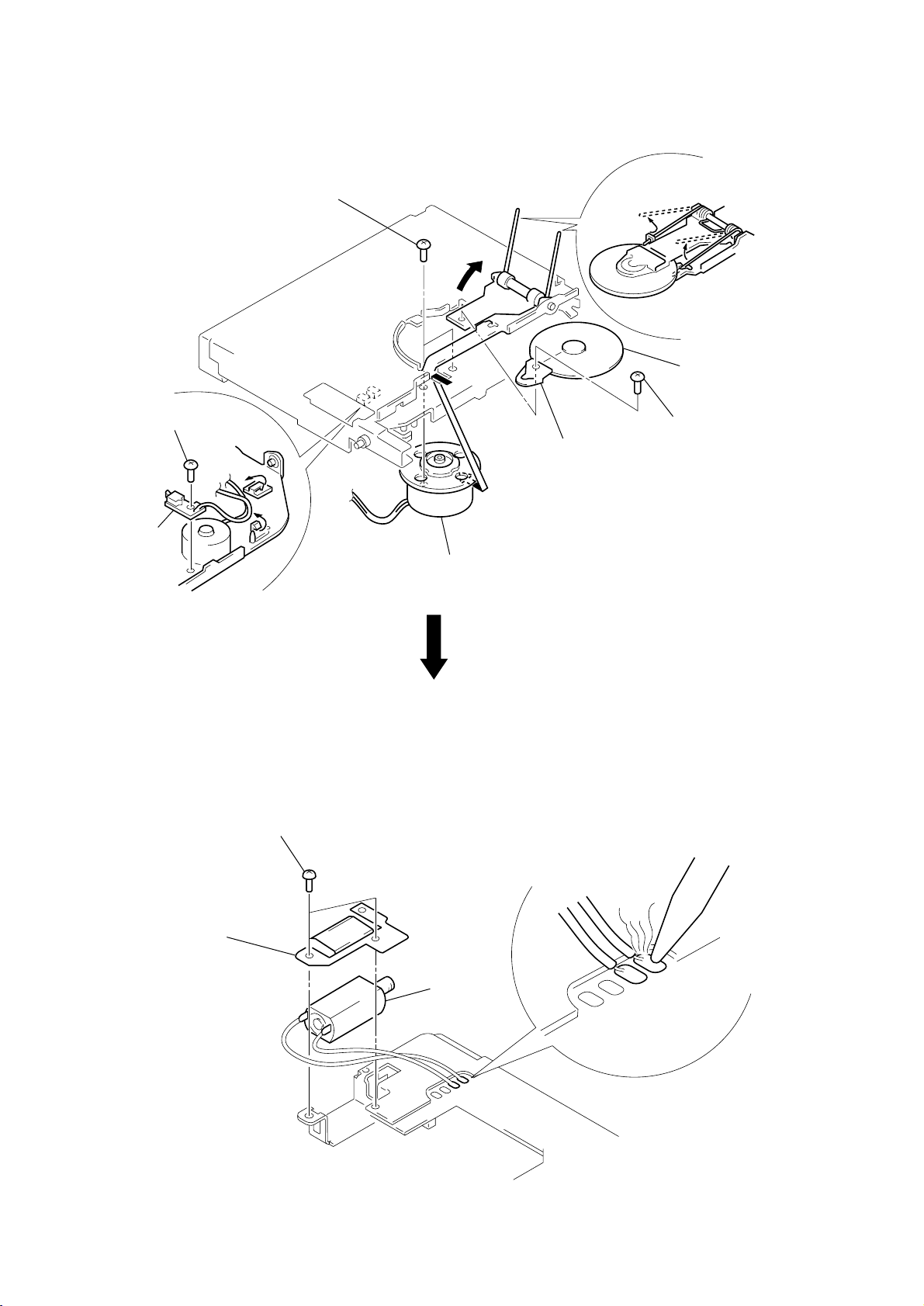

JACK BOARD

Remove the jack board of

the arrow.

1 ground point screw

(PTT2.6 × 6)

2 jack board

MAIN BOARD, SLIDE VARIABLE RESISTOR (ELEVATOR HEIGHT SENSOR) (RV202)

1 main flexible board

(CNJ101)

5 screw (FP)

2 Remove three solders of

the slide variable resistor

(RV202).

5 two screws (FP)

6 main board

2 Remove two solders of

the elevator motor leads (M104).

2 Remove two solders of

the switch board leads.

7 screw

(PTT2 × 4)

8 slide variable resistor

(elevator height sensor)

(RV202)

4 heat sink (T)

3 screw (PTT2 × 4)

6

Page 7

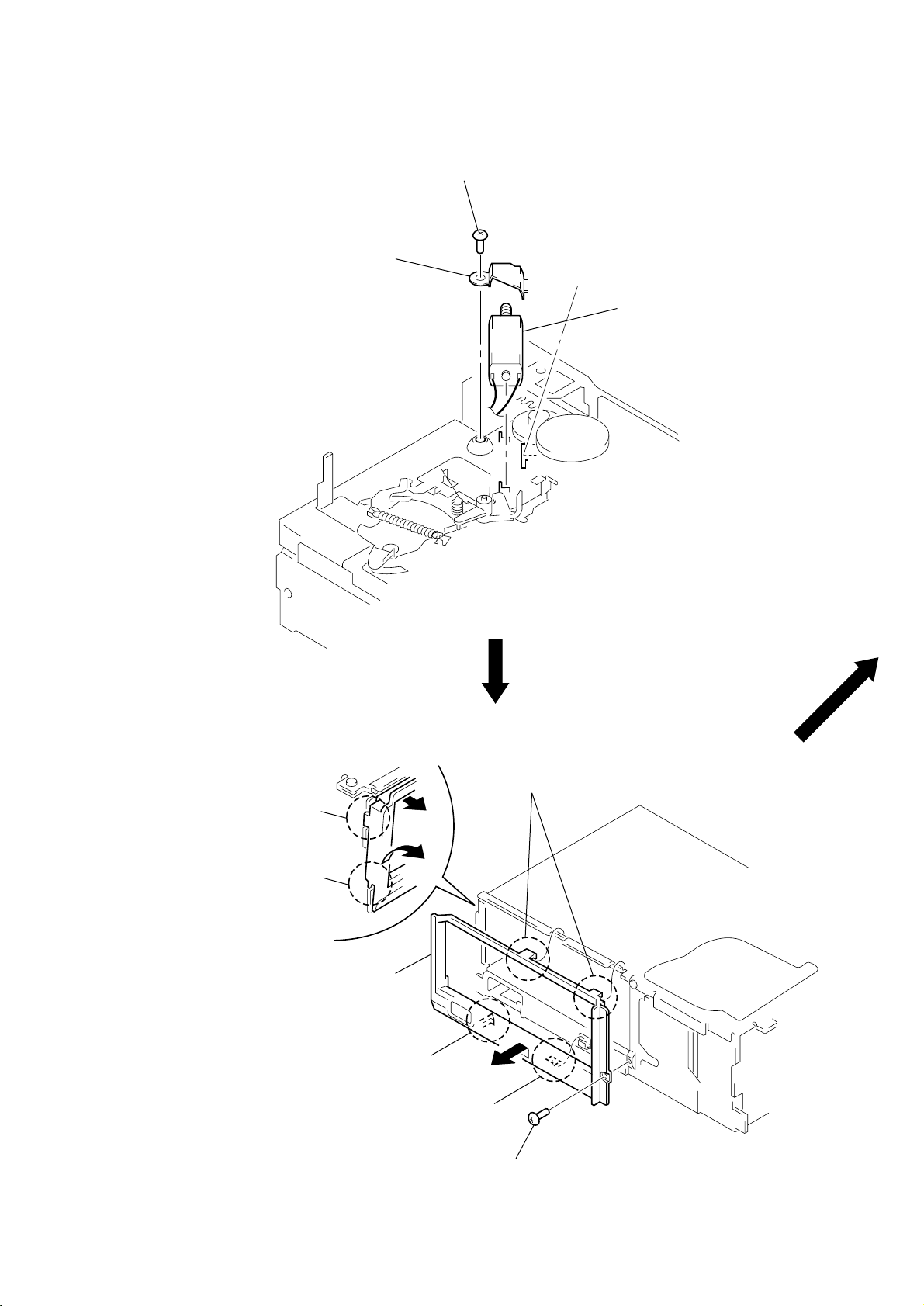

ELJ MOTOR ASS’Y (ELEVATOR) (M104)

2 bracket (EVM.S)

1 screw

(PTT2 × 4)

3 ELJ motor ass’y (elevator)

(M104)

ESCUTCHEON (T)

2 Remove the claw

in the direction of arrow A.

4 Remove the ditch

in the direction of arrow B.

5 Remove the escutcheon (T)

3 two claws

A

B

in the direction of arrow C.

3 claw

C

4 ditch

1 screw (T)

7

Page 8

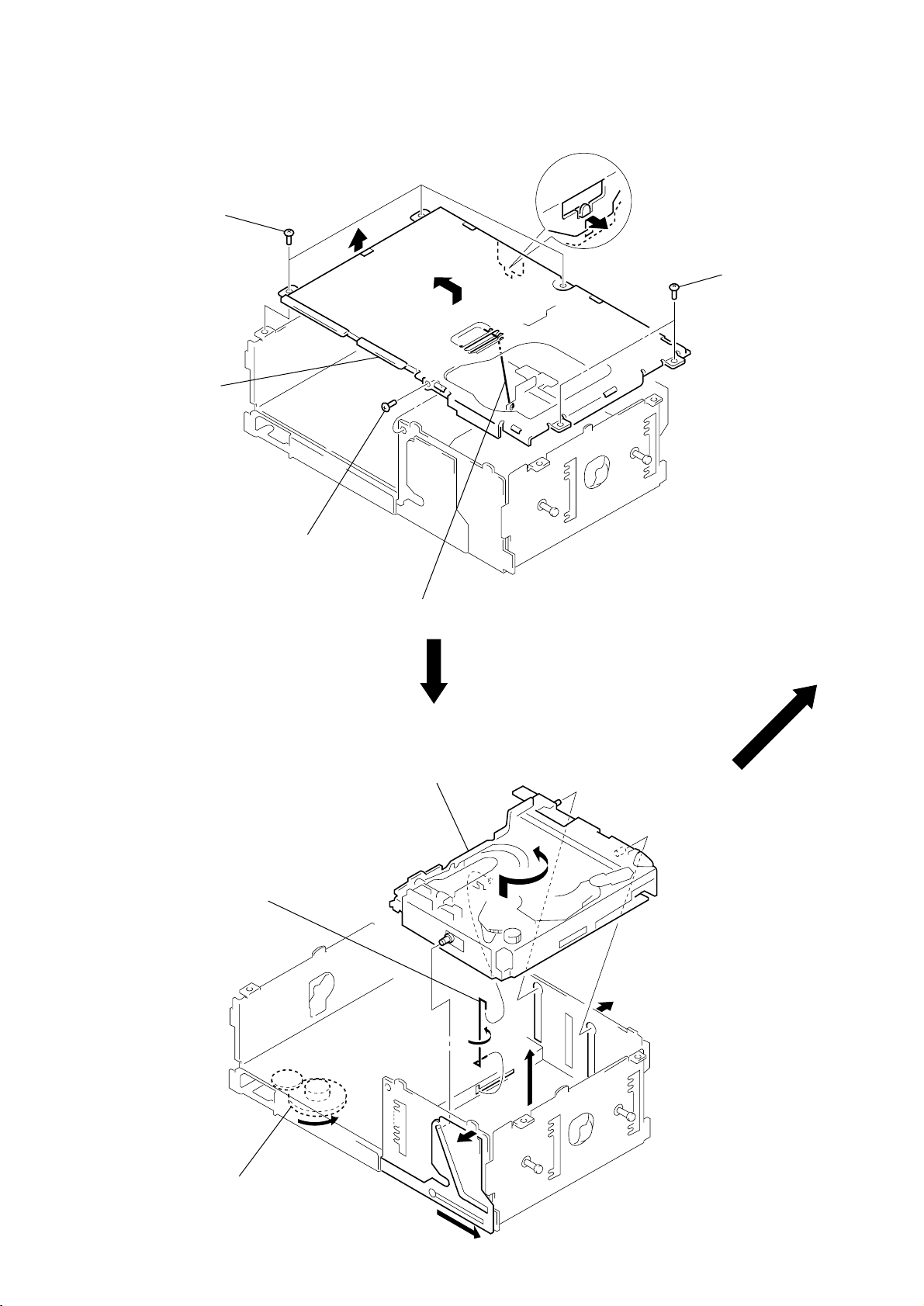

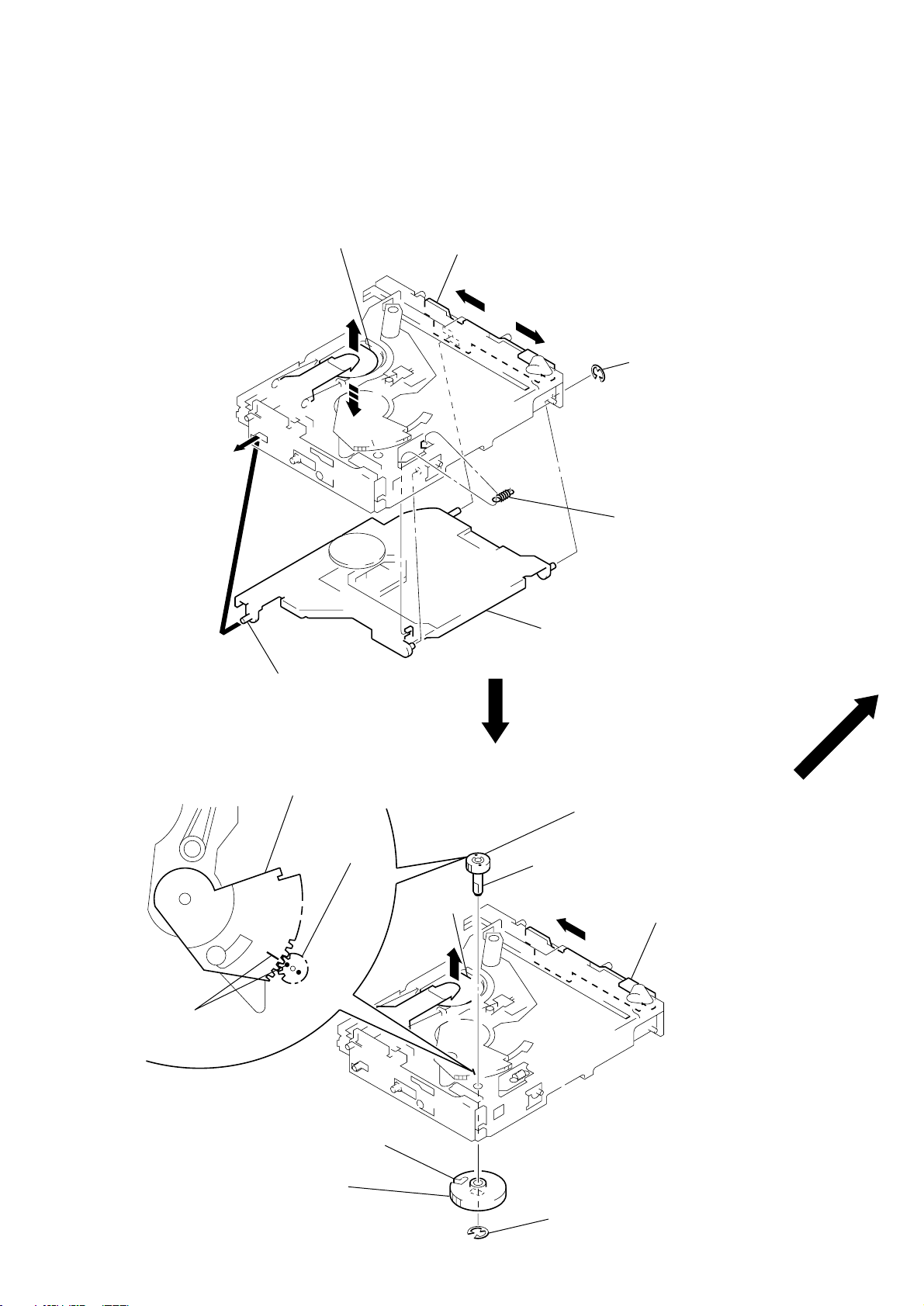

CHASSIS (U.S) SUB ASS’Y

1 three screws

(PTT2 × 4)

2

3 Remove the edge

in the direction

A

of arrow A.

4 Remove the chassis (U.S)

sub ass’y in the direction

of arrow B.

CHASSIS ASS’Y

1 screw

(PTT2 × 4)

B

5 spring (SUT)

1 two screws

(PTT2 × 4)

4 Remove the chassis ass’y

5 spring (stopper.lower)

1 Turn the gear (EVD.S) fully

in the direction of arrow A.

in the direction of arrow B.

B

3

2

A

3

8

Page 9

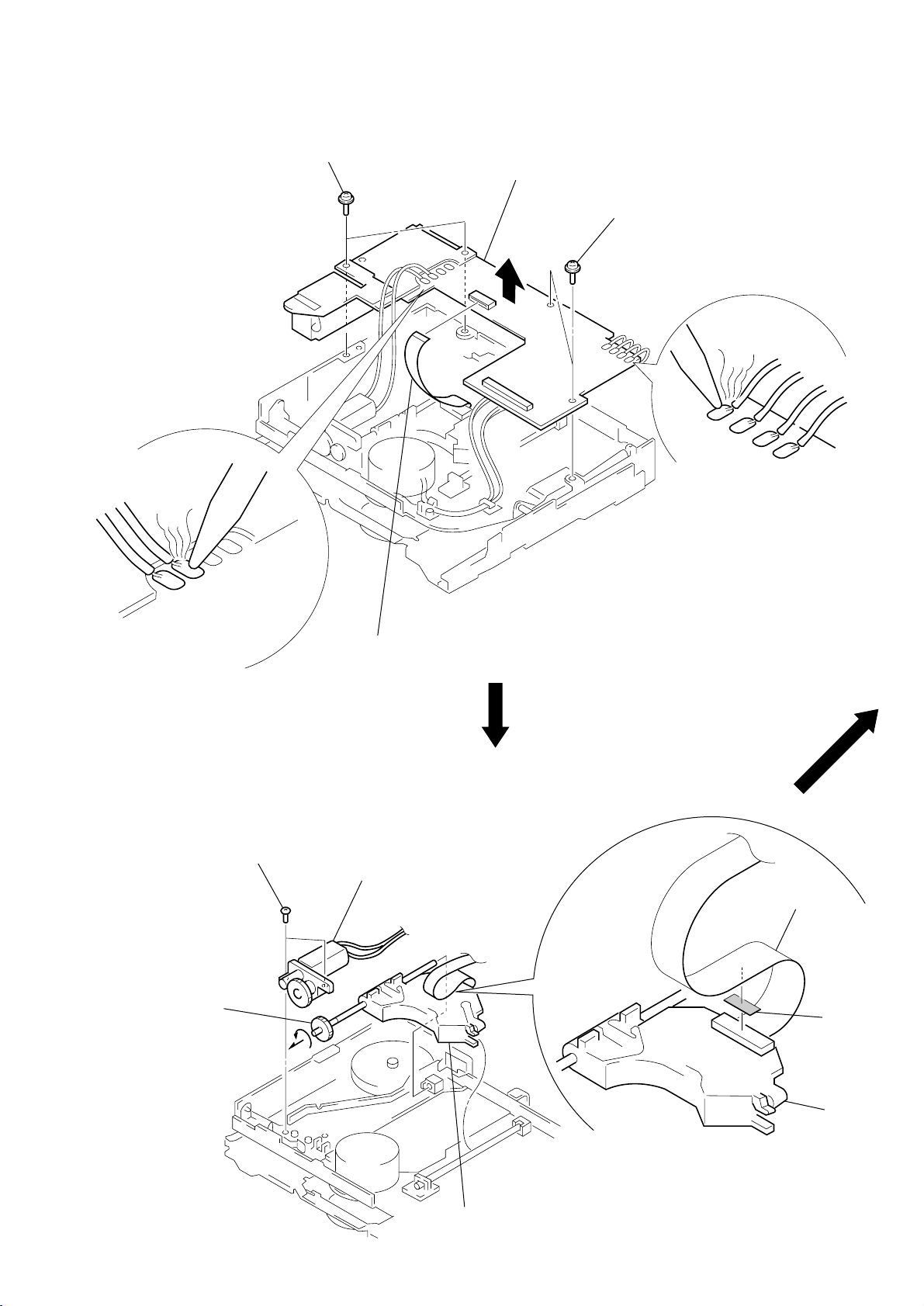

RF BOARD

3 two screws

(PS2 × 4)

3 two screws

(PS2 × 4)

2 Remove four solders

of the LSW board leads

and spindle motor leads (M102).

2 Remove two solders

of the sled motor leads

(M101).

1 OP flexible board (CN102).

4 RF board

SLED MOTOR ASS’Y (251) (M101), OPTICAL PICK-UP (KSS-720A/K1NP)

4 Turn shaft (feed) ass’y

in the direction

of the arrow,

then remove it.

1 two precision screws

(P2 × 3)

2 sled motor ass’y (251)

(M101)

3 optical pick-up

(KSS-720A/K1NP)

OP flexible board

Note: After connecting OP flexible board,

fix it with adhesive sheet

to optical pick-up.

adhesive

sheet

optical

pick-up

9

Page 10

LSW BOARD, SPINDLE MOTOR (S) SUB ASS’Y (M102)

)

w

8 two precision screws

(P1.7 × 2.2)

7

3 spring (chucking)

6 retainer (disc

1 precision screw

(P2 × 2.5)

2 LSW board

ELJ MOTOR ASS’Y (CHUCKING) (M103)

2 two screws

(PTT2 × 4)

4 precision scre

5 bracket (CP)

9 Remove the spindle motor (S) sub ass’y (M102)

in the direction of the arrow.

1 Remove two solders of

the chucking motor leads (M103).

(P2 × 2.2)

10

3 retainer (CHM)

4 ELJ motor

ass’y

(chucking)

(M103)

Page 11

SECTION 4

)

MECHANISM DECK ASSEMBLY

Note: Follow the assembly procedure in the numerical order given.

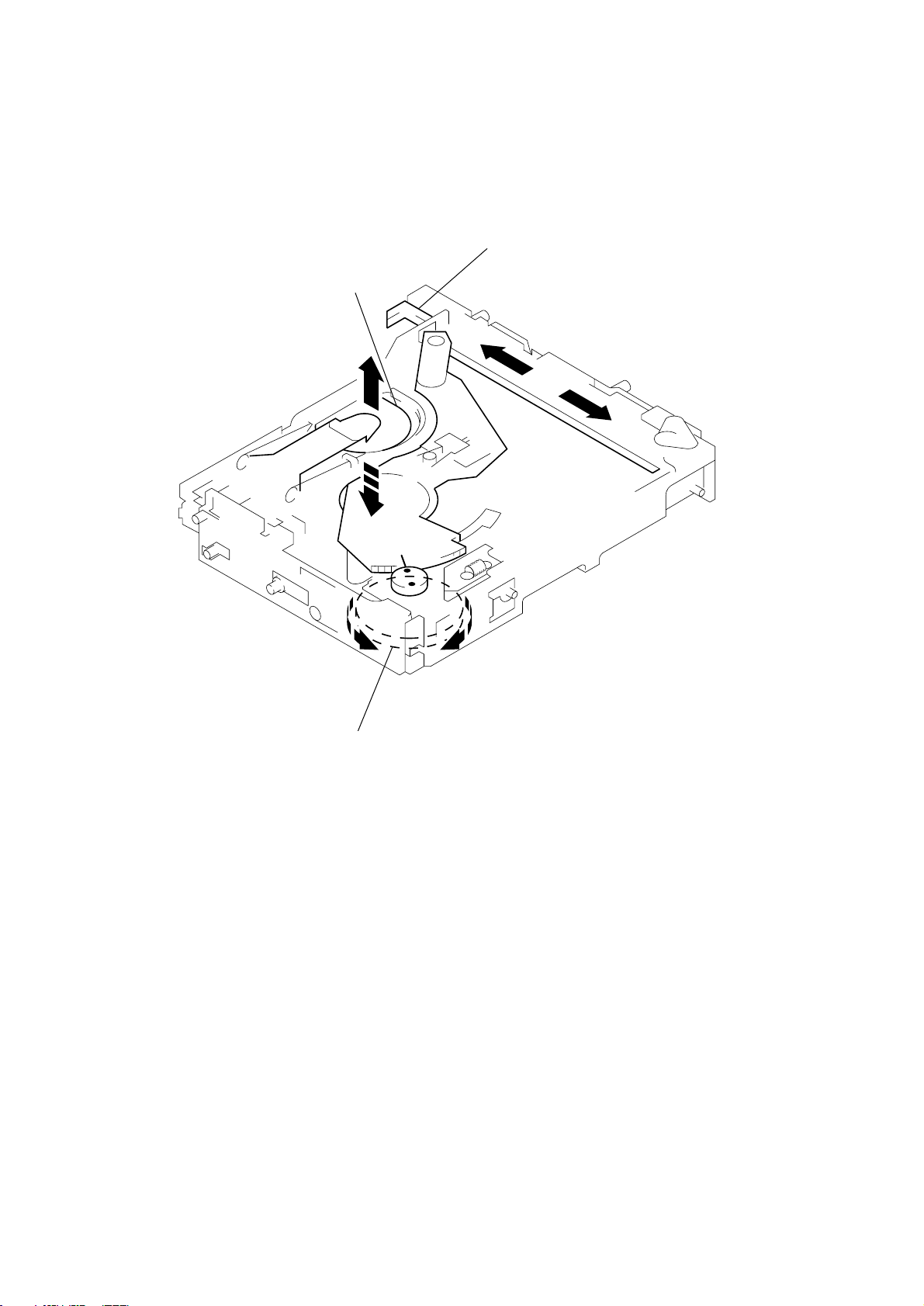

OPTICAL PICK-UP COMPLETE ASS’Y

1 Move the lever (LOCK 3A) in the direction of arrow A,

and return it a little in the direction of arrow B

chuck plate

from the position where the chuck plate is moved

down to the lower limit.

B

A

3 stop ring 2.0 (E type

shaft (A)

GEAR (LOMINI)/(LOAD 1) ASS’Y

gear (LOAD 2)

gear (LOMINI)

chuck plate

4 tension spring (DH)

2 optical pick-up complete ass’y

Note: Insert the shaft (A) first.

2 Attach the gear (LOMINI) at the position

shown in Fig. A.

shaft (rotary prevention C)

B

1 Move the lever (LOCK 3A)

fully in the direction of arrow B

to move the chuck plate up.

marking

Fig. A

3 Attach the gear (LOAD 1) ass’y

with its facing inside.

slit

4 stop ring 1.5 (E type)

11

Page 12

OPERATION CHECK

1

Confirm that the slider moves in the direction of arrow C to move down

the chuck plate if the gear (LOAD 1) is rotated in the direction of arrow

or the chuck plate moves up and the slider mov es in the direction of arrow

D

if the gear is rotated in the direction of arrow B.

chuck plate

A

slider

D

C

A

gear (LOAD 1) ass’y

B

12

Page 13

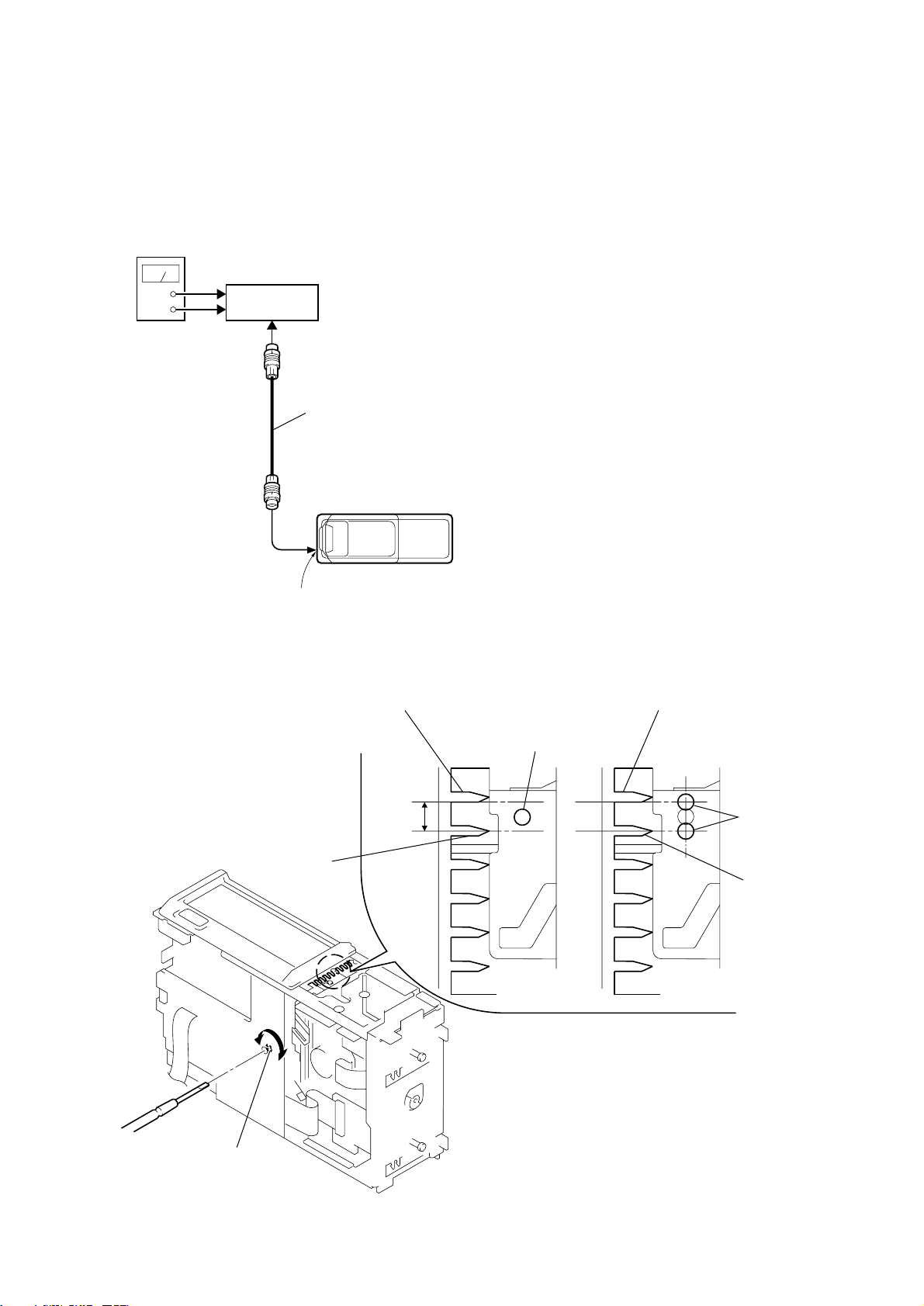

MECHANICAL ADJUSTMENT

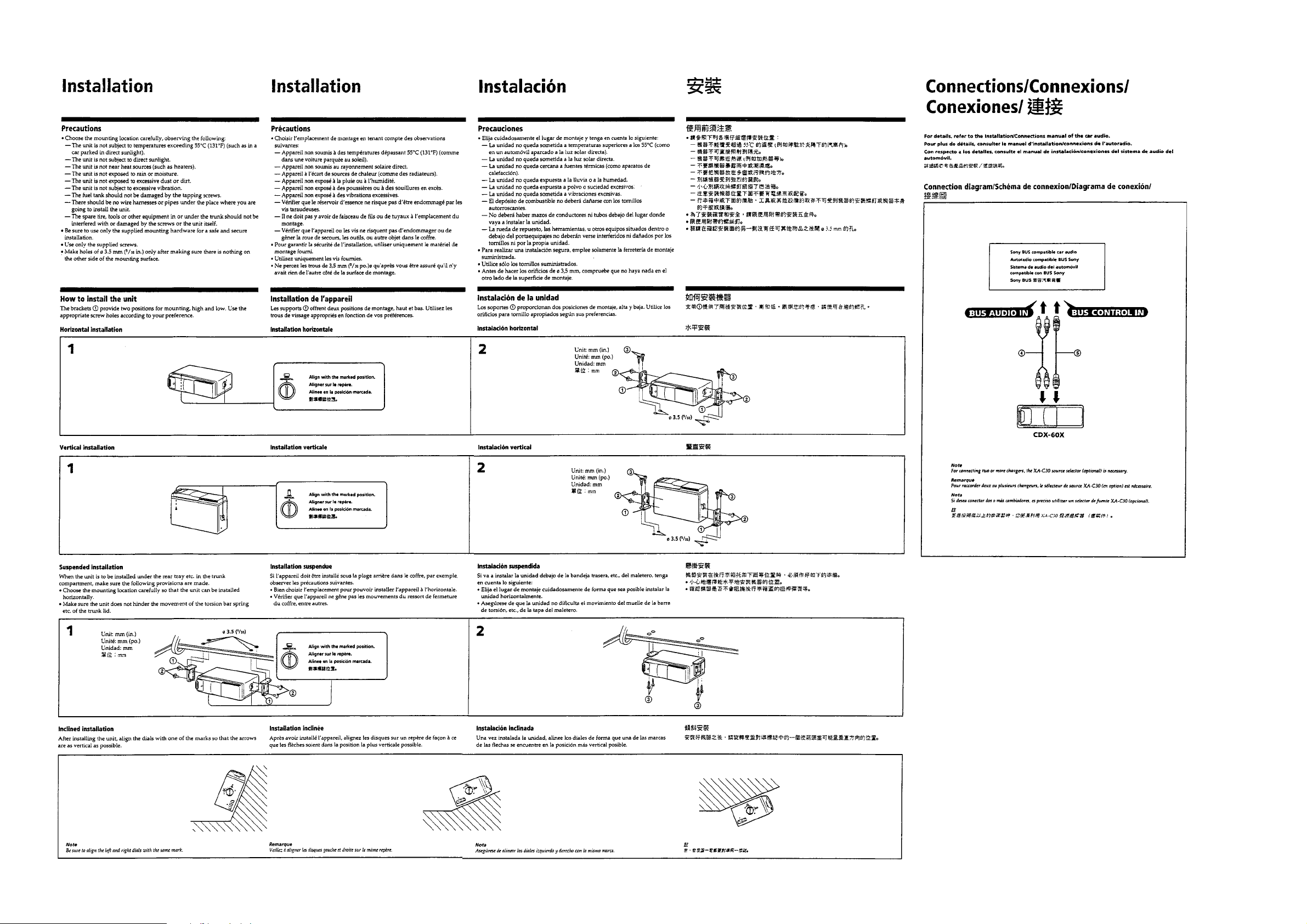

• Elevator Height (Address) Adjustment

SECTION 5

Note: This adjustments is necessary when the system controller (IC201),

variable resistor (RV201), slider (R), slider (L), or chassis (ELV)

was replaced for any repair.

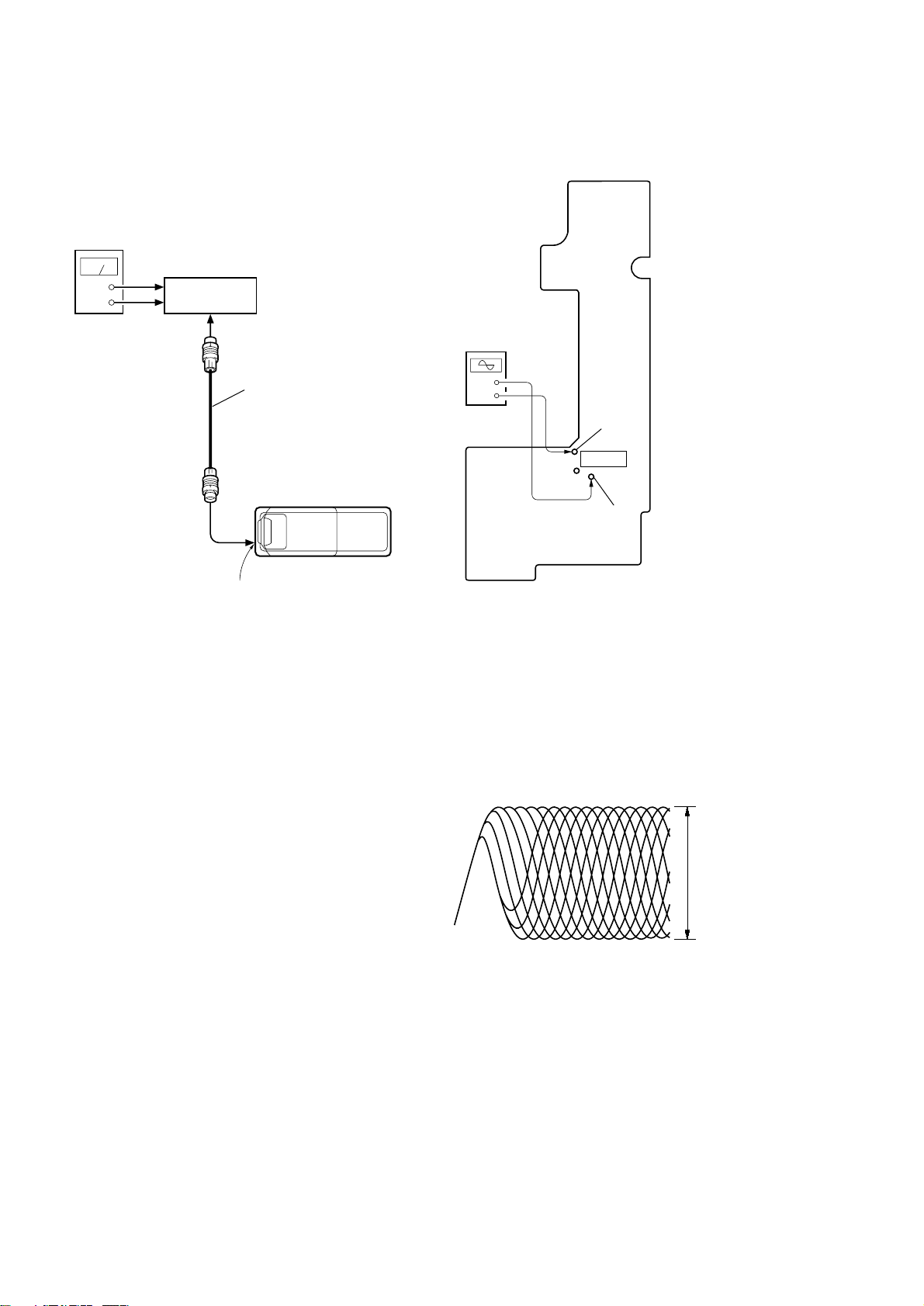

Connection:

power supply

(DC 14.4 V)

master unit

+

GND

BUS cable

compact disc changer

CONTROL connector

(CN901)

Adjustment Method:

1. Connect this set to the master unit (e.g. XR-C5300X), load a

disc magazine, and place the set vertically as shown below.

2. Connect the regulated power supply to the master unit, and

turn the power on.

3. Press the DISC button on the master unit and select DISC 5.

4. At this time, if the elevator shaft does not position between

comb teeth A and B at addresses 5 and 6 as shown below,

adjust the following.

5. Press repeatedly the DISC + and – buttons on the master unit

so that the elevator shafts moves from address 6 to address 5,

or from 5 to 6. At this time, adjust RV201 on the main board

so that the elevator shaft positions smoothly between comb

teeth A and B.

6. Further, place the set horizontally and make same adjustment

as mentioned above.

7. After adjustment at addresses 5 to 6 is finished, check all operations from addresses 1 to 10 with the set placed vertically

and horizontally respectively to confirm that the elevator shaft

positions in a range between comb teeth A to B.

comb tooth at address 6

comb tooth at address 5

comb tooth at address 6

elevator shaft

A

B

OK NG

A

elevator shaft

B

comb tooth at address 5

RV201

13

Page 14

SECTION 6

)

ELECTRICAL CHECK

Note:

1. This adjustment is performed with the set placed horizontally.

2. Power supply voltage: DC14.4 V (more than 3 A).

3. Be sure to use the disc “YEDS-18” parts code: 3-702-101-01, b ut only

when indicated.

Connection:

power supply

(DC 14.4 V)

master unit

+

GND

BUS cable

FOCUS BIAS CHECK

– RF BOARD –

(Component Side)

oscilloscope

(AC range)

+

–

TP (VC)

IC101

TP

(RFO)

compact disc changer

CONTROL connector

(CN901)

Procedure:

1. Connect the oscilloscope to TP (RFO) and TP (VC) on the RF

board.

2. Put the set into play mode by loading the disc (YEDS-18).

3. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note:

Clear RF signal waveform means that the shape “◊” can be clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

(10 : 1 probe in use

level: 1.4 ± 0.3 Vp-p

When observing the eye pattern, set the oscilloscope to AC range

and raise the vertical sensitivity so that it may be easily seen.

14

Page 15

TRACKING OFFSET CHECK

– RF BOARD –

(Component Side)

oscilloscope

(DC range)

+

–

TP (VC)

IC101

TP (TE)

Procedure:

1. Connect the oscilloscope to TP (TE) and TP (VC) on the RF

board.

2. Put the set into play mode by loading the disc (YEDS-18).

3. Press the . , > buttons on the master unit, and check the

traverse waveform*.

4. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0 V dc, and check this level.

* Traverse waveform: This is the tracking error wave form appears

when crossing the track.

Traverse waveform

A

0 V

B

A=B

traverse waveform

(100 track jump waveform)

VOLT/DIV: 500 mV

TIME/DIV: 2 ms

Center: 0 V

15

Page 16

MEMO

16

Page 17

SECTION 7

DIAGRAMS

7-1. BLOCK DIAGRAM – RF SERVO/DA CONVERTER Section –

CDX-60X

FILTER

DETECTOR

PICK-UP BLOCK

(TRACKING)

(FOCUS)

05

A

B

C

D

E

F

LASER DIODE

PD LD

OPTICAL

(KSS-720A)

2-AXIS DEVICE

I-V AMP

(SPINDLE)

(CHUCKING)

M101

(SLED)

M102

M103

AUTOMATIC

POWER

CONTROL

Q101

M

M

M

FOCUS/TRACKING ERROR AMP

A

5

B

6

C

7

D

8

E

11

F

10

LD

3

TRACKING/FOCUS COIL DRIVE,

SLED/SPINDLE/CHUCKING

VO3+

8

VO3–

9

VO4+

6

VO4–

7

VO2+

10

VO2–

11

VO1+

12

VO1–

13

VL0+

5

VL0–

4

E I-V AMP

F I-V AMP

APC LD

AMP

MOTOR DRIVE

COIL

DRIVE

COIL

DRIVE

MOTOR

DRIVE

MOTOR

DRIVE

MOTOR

DRIVE

SUMMING

IC201

AMP

FOCUS

ERROR

RF AMP,

IC101

RF

AMP

APC PD

AMP

VIN3+

VIN3–

VIN4+

VIN4–

VIN2+

VIN2–

VIN1–B

FWD

REV

RF EQ

AMP

TRACKING

ERROR

AMP

AGC

25

24

31

32

22

21

18

1

2

RFO

LDON

HOLD SW

AGCCONT

L

R

CN901 (1/2)

ANALOG OUT

L

R

63 66 6564

FILI

PCO

FILO

CLTV

RFAC

ASYI

ASYO

DIGITAL SERVO

CLV

ASYMMENTRY

CORRECTOR

RFDC

FE

TE

54 50 52 51

ANALOG SWITCH

A/D CONVERTER

SIGNAL PROCESS

ON : When the optical pick-up

is inner position

16

FE

14

TE

13

22

21

20

PD

4

TEDR

40

TRDR

41

FFDR

42

FRDR

43

SFDR

38

SRDR

39

MDP

35

61

60

59

LDON

HOLD

AGC

PWM GENERATOR

DIGITAL

RFDC

RFDC

OP AMP

DIGITAL

PLL

FE

TE

FE

TE

SE

MIRR

DFCT

FOK

83

EMPH

EFM

DE-

MODULATOR

SUBCODE

PROCESS

SW3

(LIMIT)

D/A

INTER-

FACE

32k RAM

INTERNAL BUS

CORRECTOR

PCMD

LRCK

BCK

ERROR

CPU

INTERFACE

SERVO AUTO

SEQUENCER

SERVO

INTERFACE

SSTP

36

EMPHI

84

79

77

81

GFS

DATA

CLOK

XLAT

SENS

SQSO

SQCK

SCOR

SCLK

FOK

XRST

80

78

82

22

13

15

14

16

6

7

24

17

32

11

SERIAL

PCMDI

LRCKI

BCKI

IN

INTERFACE

DIGITAL SIGNAL PROCESSOR,

DIGITAL FILTER, D/A CONVERTER,

DIGITAL SERVO PROCESSOR

IC101

DIGITAL FILTER,

NOISE SHAPER

LDON

HOLD

AGC

54

55

56

91

6

7

5

93

77

79

82

92

90

94

INTEGRATOR

LDON

AGCHOLD

RF AGC

GFS

CDDATA

CDCLK

CDXLT

SENS

SQSO

SQCK

SCOR

SCLK

FOK

XRST

AOUT2

PWM

&

AOUT1

SYSTEM CONTROLLER

IC201 (1/2)

97

90

CLOCK

GENERATOR

AMUTE

BUFFER

TIMING

LOGIC

LOUT

ROUT

XTAO

XTAI

92

95

87

86

GND-ISOLATION

16.9344MHz

MUTING

CONTROL

Q401, 402

X130

IC401

MUTING

Q410, 420

AIN2

96

AIN1

91

4

• SIGNAL PATH

: CD PLAY

CH. F

71

CH. R

72

LIMSW

89

ON : When completion of the disc

save operation

ON : When completion of the disc

chucking operation

SW1

(SAVE END DETECT)

SW2

(CHUCKING END DETECT)

LOAD1

65

LOAD2

66

1717

Page 18

CDX-60X

7-2. BLOCK DIAGRAM – BUS CONTROL/POWER SUPPLY Section –

SYSTEM CONTROLLER

ON : When magazine

is set

SW201

MAGAZINE IN/OUT

DETECT

76

MGLK

IC201 (2/2)

MCK

60

RV201

ELEVATOR HEIGHT

(ADDRESS)

M104

(ELEVATOR)

ELEVATOR

MOTOR DRIVE

IC301

OUT1

9

M

OUT2

7

MOTOR

DRIVE

S-RAM

IC202

IN1

IN2

A0–A14

10–3, 25, 24, 21, 23, 2, 26, 111–13, 15–19

3

4

X201

12MHz

ELVF

74

73

ELVR

40

XTAL

41

EXTAL

28–21, 36–3020–13

RAMA0–RAMA14RAMIO1–RAMIO8

EHS

VREF

ELVON

BUCHK

EJECT

CDON

RESET

59

51

9

75

63

8

38

RV202

ELEVATOR HEIGHT

SENSOR

REFERENCE VOLTAGE

BATTERY

CHECK

SW801

Q301, 302

Z

SWITCH

Q201

B. UP +5V

RESET SIGNAL

GENERATOR

IC303

B. UP +5V

D306

B. UP +5V

BUS +5V

BUS INTERFACE

(FOR SONY BUS)

IC302

D307

DRIVER +8V

DAC/SERVO +5V

D308

+8V

REGULATOR

IC304

+5V

REGURATOR

IC305

+5V

REGURATOR

Q303

CN901 (2/2)

CONTROL

7

B. UP

SO

43

SI

DO0–DO7

SO

44

20

CE

WE

27

05

37

12

RAMCE

RAMWE

SCLK

BUSON

45

62

10 6

SI

9

SCK

11 4

BUSON OUT

1 12

BUSON OUT

13 2

RESET

8 7

RESET

SWITCH

DATA

CLK

LOF

BUSON IN

RST

5

DATA

4

CLK

6

BUSON

2

RST

1818

Page 19

• Circuit Boards Location

d

7-3. NOTE FOR PRINTED WIRING BOARDS AND SCHEMATIC DIAGRAMS

SWITCH board

JACK board

LSW board

MAIN board

RF boar

Note on Printed Wiring Boards:

• X : parts extracted from the component side.

• Y : parts extracted from the conductor side.

f

•

: internal component.

• b : Pattern from the side which enables seeing.

(The other layers' patterns are not indicated.)

Caution:

Pattern face side: Parts on the pattern face side seen from

(Conductor Side) the pattern face are indicated.

Parts face side: Parts on the parts face side seen from

(Component Side) the parts face are indicated.

Note on Schematic Diagram:

• All capacitors are in µF unless otherwise noted. pF: µµF

50 WV or less are not indicated except for electrolytics

and tantalums.

• All resistors are in Ω and 1/

specified.

f

•

: internal component.

4

W or less unless otherwise

• C : panel designation.

Note: The components identified by mark 0 or dotted line

with mark 0 are critical for safety.

Replace only with part number specified.

• U : B+ Line.

• H : adjustment for repair.

• Power voltage is dc 14.4V and fed with regulated dc power

supply from CD changer controller.

• Voltages and waveforms are dc with respect to ground

under no-signal conditions.

no mark : CD PLAY

: Impossible to measure

∗

• Voltages are tak en with a V OM (Input impedance 10 MΩ).

Voltage variations may be noted due to normal production tolerances.

• Waveforms are taken with a oscilloscope.

Voltage variations may be noted due to normal production tolerances.

• Circled numbers refer to waveforms.

• Signal path.

J : CD PLAY

1919

Page 20

CDX-60X

7-4. PRINTED WIRING BOARDS – RF/LSW Boards – • See page 19 for Circuit Boards Location.

• Semiconductor

Location

(Component Side)

Ref. No. Location

IC101 H-4

IC201 I-3

Q101 F-5

(Page 22)

2020

Page 21

7-5. SCHEMATIC DIAGRAM – RF/LSW Boards – • See page 27 for for Waveforms. • See page 28 for IC Block Diagrams.

CDX-60X

(Page 24)

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

2121

Replace only with part number specified.

Page 22

CDX-60X

7-6. PRINTED WIRING BOARDS – MAIN Board (Component Side) – • See page 19 for Circuit Boards Location.

• Semiconductor

Location

Ref. No. Location

D301 D-2

D302 D-2

D303 D-3

D304 D-3

D305 D-3

D306 F-4

D307 F-4

D308 G-4

D309 F-4

D310 F-3

D311 F-2

D312 G-3

IC101 C-8

IC201 F-8

IC202 F-7

IC301 G-3

IC302 D-2

IC303 F-3

IC401 C-6

(Page 20)

Q201 E-10

Q301 F-5

Q302 F-5

Q303 F-4

Q401 D-5

Q402 D-5

Q410 D-5

Q420 D-5

(Page 26)

2222

Page 23

7-7. PRINTED WIRING BOARD – MAIN Board (Conductor Side) – • See page 19 for Circuit Boards Location.

CDX-60X

• Semiconductor

Location

Ref. No. Location

IC304 G-1

IC305 E-1

(Page 26)

2323

Page 24

CDX-60X

7-8. SCHEMATIC DIAGRAM – MAIN Board (1/2) – • See page 27 for Waveforms. • See page 28 for IC Block Diagram.

(Page 21)

2424

Page 25

7-9. SCHEMATIC DIAGRAM – MAIN Board (2/2) – • See page 27 for Waveform. • See page 28 for IC Block Diagrams.

CDX-60X

(Page 26)

(Page

26)

2525

Page 26

CDX-60X

7-10. PRINTED WIRING BOARDS – JACK/SWITCH Boards –

• See page 19 for Circuit Boards Location.

(Page 22)

7-11. SCHEMATIC DIAGRAM – JACK/SWITCH Boards –

(Page 25)

(Page 23)

(Page 25)

2626

Page 27

• Waveforms

– RF Board –

– MAIN Board –

1 IC101 qh (RFO) (play mode)

2 IC101 qf (FE) (play mode)

3 IC101 qd (TE) (play mode)

1.4 ± 0.3

Vp-p

Apporx.

63 mVp-p

1 IC101 uj (LRCK), uk (LRCKI)

(play mode)

5.6 Vp-p

22.8 µs

2 IC101 ia (BCK), is (BCKI)

(play mode)

5.7 Vp-p

470 ns

3 IC101 ih (XTAI) (play mode)

Approx.

63 mVp-p

4.1 Vp-p

60 ns

4 IC201 ra (EXTAL) (play mode)

4.4 Vp-p

83 ns

27

Page 28

• IC Block Diagrams

– RF Board –

IC101 CXA2596M-T6

1

HOLD

2

AGCVTH

3

LD

4

PD

APC LD

AMP

APC PD

AMP

AGC

24 VCC

23

LC/PD

22

LD ON

21

HOLD SW

20

AGCCONT

VEE

COMPARATOR

COMPARATOR

5

A

6

B

7

C

8

D

9

10

F

11

E

12

VC

VCC

VEE

RF SUMMING

AMP

FOCUS ERROR

AMP

F I-V AMP

E I-V AMP

RF EQ

AMP

TRACKING

ERROR

AMP

19

RF BOT

18

RFTC

17

RF I

16

RFO

15

RFE

14

FE

13

TE

28

Page 29

IC201 LA6556L-TE-L

FWD

REV

VCC2

VLO–

VLO+

VO4+

VO4–

VO3+

VO3–

VO2+

VO2–

VO1+

VO1–

OUTPUT

CONTROL

LEVEL

SHIFT

LEVEL

SHIFT

–

+

LEVEL

SHIFT

LEVEL

SHIFT

THERMAL SHUT DOWN

–

+

–

+

5VREG

+

–

CH2-4

MUTE

CH1

MUTE

VIN1/VREF

SWITCH

1

INPUT

2

3

4

5

6

7

8

9

10

11

12

13

–

+

–

+

+

–

S-GND

36

35

MUTE2

34

MUTE1

33

VIN4

32

VIN4–

31

VIN4+

30

VREF-IN

29

VIN1 (VREF)-SW

28

VREF-OUT (CH1)

27

REG-OUT

REG-IN

26

25

VIN3+

VIN3–

24

VCC1

VIN1

VIN1–A

VIN1+A

VIN1–B

14

15

16

–

AMP-A

+

17

–

18

AMP-B

+

–

+

–

+

VIN3

23

22

VIN2+

+

–

21

VIN2–

VIN2

20

VIN1+B

19

29

Page 30

– MAIN Board –

IC101 CXD2598Q

81

BCK

BCKI

82

ENPH

83

EMPHI

84

XVDD

85

XTAI

86

TIMING

87

88

89

90

91

92

93

94

95

96

97

LOGIC

LOW-PASS

FILTER

–

+

+

–

LOW-PASS

FILTER

OVER SAMPLING

DIGITAL FILTER

NOISE SHAPER

VC

VC

XTAO

XVSS

AVDD1

AOUT1

AIN1

LOUT1

AVSS1

AVSS2

LOUT2

AIN2

AOUT2

PCMDI

PCMD

LRCKI

LRCK

VDD

80

79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61 60 59 58 57 56 55

SERIAL-IN

INTERFACE

3rd-ORDER

PWM

PWM

SERVO

INTERFACE

ASYE

D/A

INTERFACE

INTERNAL BUS

32k

RAM

DOUT

MD2

DIGITAL

OUT

ERROR

CORRECTOR

SERVO

AUTO

SEQUENCER

VSS

VPCO

V16M

CLOCK

GENERATOR

DEMODULATOR

SUB CODE

PROCESSOR

VCTL

EFM

BIAS

AVDD3

PCO

FILI

DIGITAL

PLL

FILO

CLTV

ASYMMETRY

CORRECTOR

AVSS3

RFAC

ASYI

ASYO

AVDD0

A/D

CONVERTER

SERVO DSP

FOCUS SERVO

TRACKING

SERVO

SLED SERVO

MIRR

DFCT

FOK

IGEN

AVSS0

ADIO

OP AMP

ANALOG

SWITCH

PWM GENERATOR

RFDCCETE

54 53 52 51

FOCUS PWM

GENERATOR

TRACKING PWM

GENERATOR

SLED PWM

GENERATOR

DIGITAL

CLV

SE

50

FE

VC

49

XTSL

48

TES1

47

TEST

46

VSS

45

VDD

44

FRDR

43

FFDR

42

TRDR

41

TFDR

40

SRDR

39

SFDR

38

FSTIO

37

SSTP

36

MDP

35

LOCK

34

PWMI

33

FOK

32

DFCT

31

AVDD2

RMUT

LMUT

98

99

100

VSS

VDD

SOUT

SOCK

XOLT

SQSO

SQCK

SCSY

INTERFACE

EXCK

SBSO

CPU

XRST

SYSM

DATA

XLAT

CLOK

SENS

SCKL

ATSK

WFCK

XUGF

XPCK

GFS

C2PO

SCOR

C4M

WDCK

COUT

MIRR

VSS

302928272625242322212019181716151413121110987654321

VDD

30

Page 31

IC202 LC35256FT-70U-TLM

A11

A13

VCC

A14

A12

ADDRESS

OE

22

23

24

A9

25

A8

26

27

WE

28

1

2

3

A7

4

A6

5

A5

6

A4

7

A3

BUFFER

INPUT

DATA

BUFFER

ROW

DECODER

INPUT

DATA

CONTROL

MEMORY

CELL ARRAY

512 x 512

COLUMN

I/O

CONTROL

COLUMN

DECODER

ADDRESS

BUFFER

OUTPUT

DATA

BUFFER

21

A10

20

CE

19

I/O8

18

I/O7

17

I/O6

16

I/O5

15

I/O4

14

GND

13

I/O3

12

I/O2

11

I/O1

10

A0

9

A1

8

A2

IC301 LB1930M-TLM IC304 NJM2395F08

IC302 BA8272F-E2

IC305 NJM2395F05

NC

VCC

S-GND

IN1

IN2

1

BUFFER

NC

2

3

4

BUFFER

5

CONTROL

CIRCUIT

MOTOR

DRIVE

CIRCUIT

10

9

8

7

6

OUT1

NC

OUT2

P-GND

VCC

BUS ON

14 13 12

2 3

1

BUS ON IN

BUS ON OUT

LINK OFF

CLK OUT

11

5 6 7

4

GND

VREF

BUS CLK

DATA OUT

10

BUS DATA

DATA IN

RESET

89

RESET

SWITCH

BUS RESET

CONTROL

2

VOUT

3

GND

1

VIN

4

CONT

31

Page 32

7-12. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC201 CXP740056-007R (SYSTEM CONTROLLER)

Pin No. Pin Name I/O Description

1 ESPSEL I ESP on/off setting terminal “L”: ESP on Not used (open)

2MLO

3 EMPHO O Emphasis signal output terminal Not used (open)

4 AMUTE O Audio line muting on/off control signal output terminal “H”: muting on

5 CDXLT O Serial data latch pulse signal output to the CXD2598Q (IC101)

6 CDDATA O Serial data output to the CXD2598Q (IC101)

7 CDCLK O Serial data transfer clock signal output to the CXD2598Q (IC101)

8 CDON O D/A converter and servo section power supply on/off control signal output “H”: power on

9 ELVON O Mechanism deck section power supply on/off control signal output “H”: power on

10 DOUTSEL I Digital output on/off control signal input terminal “L”: digital output on Not used (open)

11 NC — Not used (open)

12 RAMWE O Data write enable signal output to the S-RAM (IC202) “L”: active

13 to 20

21 to 28 RAM7 to RAM0 O Address signal output to the S-RAM (IC202)

29 NC — Not used (open)

30 to 36

37 RAMCE O Chip enable signal output to the S-RAM (IC202) “L”: active

38 RESET I

39 GND — Ground terminal

40 XTAL O Main system clock output terminal (12 MHz)

41 EXTAL I Main system clock input terminal (12 MHz)

42 TEXTSEL I

43 SI I Serial data input from the SONY bus interface (IC302)

44 SO O Serial data output to the SONY bus interface (IC302)

45 SCLK I Serial data transfer clock signal input from the SONY bus interface (IC302)

46 CFSEL I Custom file on/off setting terminal “L” custom file on Fixed at “H” (open)

47 EEINIT I Initialize signal input for the EEPROM “H”: format Not used (open)

48 EEDATA I/O Two-way data bus with the EEPROM Not used (open)

49 EECLK O Serial data transfer clock signal output to the EEPROM Not used (open)

50 VSS — Ground terminal (for A/D converter)

51 AVREF I Reference voltage (+5V) input terminal (for A/D converter)

52 VDD — Power supply terminal (+5V) (for A/D converter)

53 SINGLE I

54 LDON O The laser automatic power control on/off signal output “H”: automatic power control on

55 AGCHOLD O RF AGC hold on/off signal output “H”: hold

56 RFAGC I/O RF AGC level control signal output “L”: off, center voltage: 40%, “H”: 60%

57 AD I A/D input terminal Not used (fixed at “L”)

58 AD I A/D input terminal Not used (open)

59 EHS I Elevator height position detect input from the RV202 (elevator height sensor) (A/D input)

RAMIO8 to

RAMIO1

RAM14 to

RAM8

Normal/high speed playback control signal output terminal “L”: high speed playback

Not used (open)

I/O Two-way data bus with the S-RAM (IC202)

O Address signal output to the S-RAM (IC202)

System reset signal input from the SONY bus interface (IC302) and reset signal generator (IC303)

“L”: reset

For several hundreds msec. after the power supply rises, “L” is input, then it changes to “H”

CD text mode setting terminal “L”: CD text on, “H”: does not display track name

Fixed at “L” in this set

Setting terminal for the single disc/multiple discs mode

“L”: single mode, “H”: multiple discs mode Fixed at “H” in this set (open)

32

Page 33

Pin No. Pin Name I/O Description

60 MCK I

61 NC — Not used (open)

62 BUSON I Bus on/off control signal input from the SONY bus interface (IC302) “H” bus on

63 EJECT I Eject switch (SW801) input terminal “H” active

64 MAGSW I Magazine in/out detect switch input Not used (open)

65 LOAD1 I

66 LOAD2 I

67 to 70 NC — Not used (open)

71 CH.F O

72 CH.R O

73 ELVR O

74 ELVF O

75 BUCHK I Battery detect signal input terminal “H”: battery on

76 MGLK I Magazine in/out detect switch (SW201) input “L”: magazine is set

77 SQSO O Subcode Q/text serial data output to the CXD2598Q (IC101)

78 NC — Not used (open)

79 SQCK O Subcode Q/text serial data transfer clock signal output to the CXD2598Q (IC101)

80 GRSCOR I Subcode sync (S0+S1) detection signal input terminal Not used (open)

81 NC — Not used (open)

82 SCOR I Subcode sync (S0+S1) detection signal input from the CXD2598Q (IC101)

83 SIRCS I SIRCS signal input terminal Not used (open)

84 TEX I Sub system clock input terminal Not used (open)

85 TX O Sub system clock output terminal Not used (open)

86 VSS — Ground terminal

87 VDD — Power supply terminal (+5V)

88 NC — Not used (open)

Input of signal for the fine adjustment (elvator height (address) adjustment; RV201) of elevator

position (A/D input)

Chucking end detect switch (SW1) input terminal

“L”: When completion of the disc chucking operation

Save end detect switch (SW2) input terminal

“L”: When completion of the disc save operation

Motor drive signal (save direction) output to the chucking motor drive (IC201)

“L” active *1

Motor drive signal (chucking direction) output to the chucking motor drive (IC201)

“L” active *1

Motor drive signal (elevator down direction) output to the elevator motor drive (IC301)

“L” active *2

Motor drive signal (elevator up direction) output to the elevator motor drive (IC301)

“L” active *2

*1 chucking motor (M103) control

Terminal

Mode

CH.F (pin ua) “H”“H”“L”“L”

CH.R (pin us) “H”“L”“H”“L”

*2 elevator motor (M104) control

Mode

Terminal

ELVF (pin uf) “H”“L”“H”“L”

ELVR (pin ud) “H”“H”“L”“L”

STOP

STOP

LOAD

CHUCKING

ELEVATOR UPELEVATOR

SAVE BRAKE

DOWN

BRAKE

33

Page 34

Pin No. Pin Name I/O Description

89 LIMSW I

90 FOK I Focus OK signal input from the CXD2598Q (IC101) “H” is input when focus is on (“L”: NG)

91 GFS I Guard frame sync signal input from the CXD2598Q (IC101) “L”: NG, “H”: OK

92 SCLK O Serial data transfer clock signal output to the CXD2598Q (IC101)

93 SENS I Internal status signal (sense signal) input from the CXD2598Q (IC101)

94 XRST O System reset signal output to the CXD2598Q (IC101) “L”: reset

95 NC — Not used (open)

96 ESPXQOK O Subcode Q OK pulse signal output terminal “L”: active Not used (open)

97 SDTO I ESP status signal input terminal Not used (open)

98 XSOE O ESP status read enable signal output terminal “L”: active Not used (open)

99 ESPXRED O ESP read enable signal output terminal “L”: active Not used (open)

100 ESPXWRE O ESP write enable signal output terminal “L”: active Not used (open)

Sled limit in detect switch (SW3) input terminal

“L”: When the optical pick-up is inner position

34

Page 35

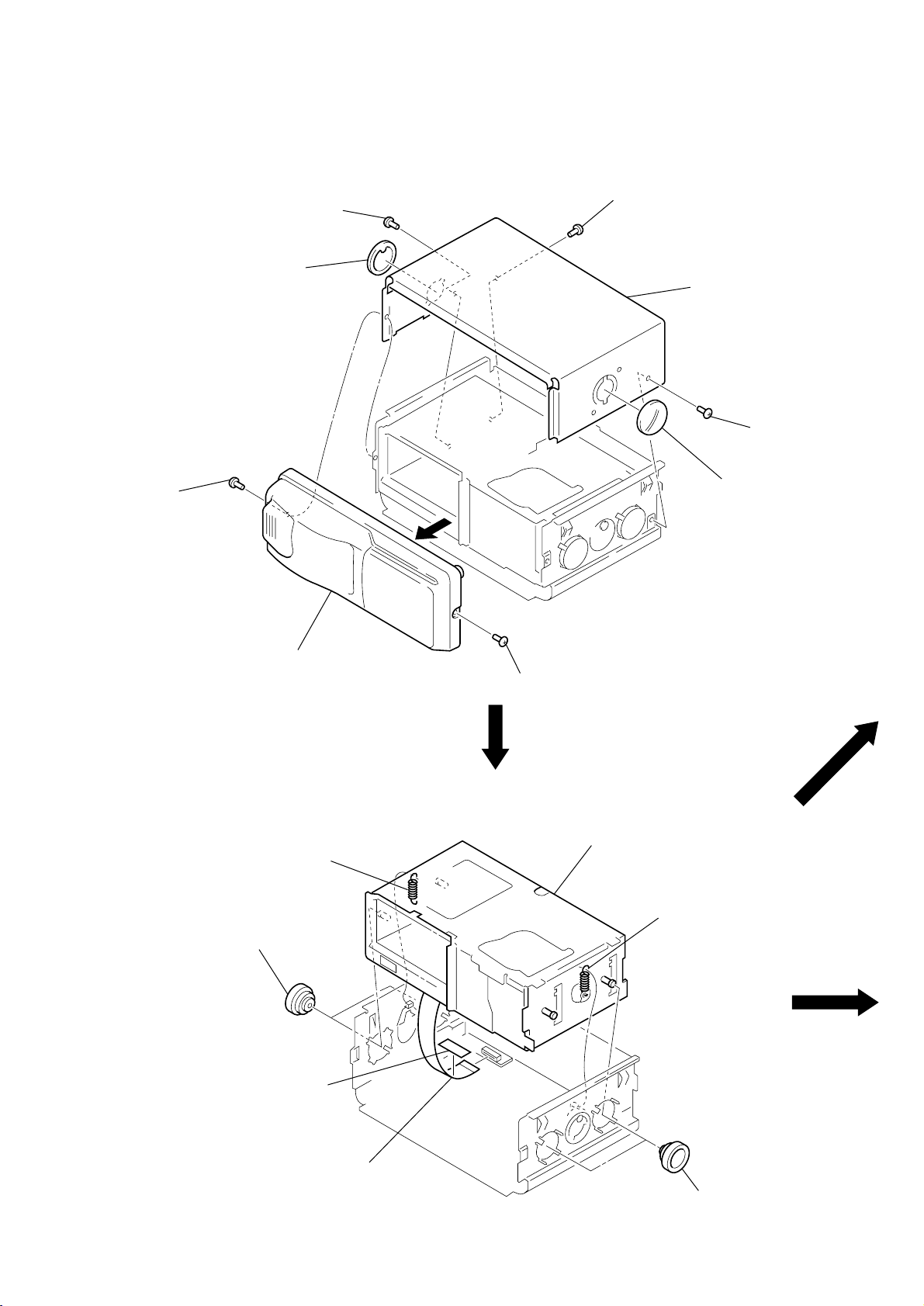

SECTION 8

7

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) COVER SECTION

13

#2

12

6

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference number in the exploded views are not supplied.

• Hardware (# mark) list and accessories and

packing materials are given in the last of the

electrical parts list.

19

#2

B

18

#3

A

16

#2

10

14

17

#3

#3

RV202

15

7

8

#2

20

(including zA)

#2

18

9

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

19

MG-251A-13

B

5

1

A

3

not supplied

Ref. No. Part No. Description Remark

1 3-047-852-01 DAMPER (T)

* 3 3-024-065-01 CUSHION (EJECT-T)

4 X-3375-357-1 ARM (FLT) ASSY

* 5 1-675-515-11 JACK BOARD

6 3-376-464-11 SCREW (+PTT 2.6X6), GROUND POINT

* 7 A-3294-985-A MAIN BOARD, COMPLETE

8 1-676-340-12 JACK FLEXIBLE BOARD

9 1-676-339-12 MAIN FLEXIBLE BOARD

* 10 1-675-516-11 SWITCH BOARD

12 X-3378-115-2 DOOR (T) ASSY

4

22

21

23

1

zA

Ref. No. Part No. Description Remark

14 3-022-007-02 BUTTON (EJT) (Z)

15 3-041-218-21 ESCUTCHEON (T)

* 16 3-022-012-01 HEAT SINK (T)

17 3-042-244-11 SCREW (T)

18 3-038-166-01 SPRING (FL), TENSION COIL

19 3-022-010-32 LEVER (FLT)

* 20 3-047-609-02 COVER (UPPER.LOWER)

21 3-024-067-01 CUSHION (T), BATTERY

22 3-935-636-11 SCREW (FP)

23 X-3375-360-2 ARM (FRT) ASSY

13 3-039-239-41 PANEL (T), FRONT

RV202 1-227-137-11 RES, VAR, SLIDE 10K

(ELEVATOR HEIGHT SENSOR)

35

Page 36

(2) MECHANISM DECK SECTION-1

(MG-251A-137)

#3

51

#3

#3

52

Ref. No. Part No. Description Remark

51 X-3378-091-1 CHASSIS (U. S) SUB ASSY

52 3-024-161-01 SPRING (SUT)

53

Ref. No. Part No. Description Remark

53 3-011-997-01 SPRING (STOPPER. LOWER)

36

Page 37

(3) MECHANISM DECK SECTION-2

(MG-251A-137)

#3

102

M104

101

Ref. No. Part No. Description Remark

101 3-024-170-01 SPRING (SB), TENSION

* 102 3-040-790-01 BRACKET (EVM. S)

103

Ref. No. Part No. Description Remark

103 X-3378-092-4 CHASSIS (D. S) SUB ASSY

M104 A-3301-123-A ELJ MOTOR ASSY (ELEVATOR)

37

Page 38

(4) MECHANISM DECK SECTION-3

(MG-251A-137)

161

162

#8

163

#4

160

159

153

154

152

158

155

156

M103

151

#3

#6

Ref. No. Part No. Description Remark

* 151 3-024-150-01 RETAINER (CHM)

* 152 X-3378-080-1 BRACKET (CHM. D) ASSY

153 3-024-152-01 COVER (CHM)

154 3-321-813-01 WASHER, COTTER POLYETHYLENE

155 3-017-139-01 GEAR (WORM LOAD A)

#8

157

164

#6

#3

Ref. No. Part No. Description Remark

159 3-010-252-11 ROLLER (CRE)

160 3-010-268-01 SPRING (DH), TENSION

* 161 A-3290-194-K MAIN ASSY, CHASSIS (EVY)

162 3-010-254-01 SHAFT (ROTARY PREVENTION C)

163 3-010-253-01 GEAR (LOMINI)

#6

156 3-022-839-02 ARM (NSW)

157 3-573-936-01 STOPPER, REEL

158 X-3373-552-3 GEAR (LOAD 1) ASSY

38

* 164 A-3326-000-A RF BOARD, COMPLETE

M103 A-3301-123-A ELJ MOTOR ASSY (CHUCKING)

Page 39

(5) MECHANISM DECK SECTION-4

(MG-251A-137)

208

206

#7

204

#9

207

202

M101

#5

not supplied

205

#5

#10

209

M102

not supplied

210

203

#11

201

Ref. No. Part No. Description Remark

201 3-911-215-02 SHEET (LEAD RETAINER)

202 3-025-743-01 SPRING (FEED), LEAF

203 X-3378-101-1 HOLDER (SLED. S) ASSY

204 3-931-832-01 GEAR (SL MIDWAY)

0 205 8-820-103-03 OPTICAL PICK-UP KSS-720A/K1RP

206 A-3291-669-A SHAFT (FEED) ASSY

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Ref. No. Part No. Description Remark

207 3-010-263-01 DETENT (SHAFT THRUST)

* 208 1-676-524-11 LSW BOARD

209 A-3301-954-B BASE (OPT. S) (J) ASSY

210 1-676-341-11 OP FLEXIBLE BOARD

M101 A-3315-151-A SLED MOTOR ASSY (251)

M102 A-3301-998-A SPINDLE MOTOR (S) SUB ASSY

39

Page 40

JACK LSW MAIN

SECTION 9

ELECTRICAL PARTS LIST

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used

on the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• RESISTORS

All resistors are in ohms.

METAL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

* 1-675-515-11 JACK BOARD

***********

< CAPACITOR >

C901 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C902 1-164-360-11 CERAMIC CHIP 0.1uF 16V

C904 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

< CONNECTOR >

CN901 1-779-077-61 PLUG, CONNECTOR

(CONTROL, ANALOG OUT)

CNJ901 1-778-775-21 CONNECTOR, FPC 13P

< DIODE >

D901 8-719-069-57 DIODE UDZS-TE17-6.8B

D902 8-719-069-57 DIODE UDZS-TE17-6.8B

< FERRITE BEAD >

FB901 1-500-445-21 FERRITE 0uH

FB902 1-500-445-21 FERRITE 0uH

FB903 1-500-445-21 FERRITE 0uH

< IC >

IC901 1-532-686-21 LINK, IC

**************************************************************

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACITORS

uF: µF

• COILS

uH: µH

C111 1-162-965-11 CERAMIC CHIP 0.0015uF 10% 50V

C112 1-115-467-11 CERAMIC CHIP 0.22uF 10% 10V

C120 1-162-967-11 CERAMIC CHIP 0.0033uF 10% 50V

C121 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C122 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C123 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C124 1-162-965-11 CERAMIC CHIP 0.0015uF 10% 50V

C125 1-165-176-11 CERAMIC CHIP 0.047uF 10% 16V

C126 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C127 1-162-960-11 CERAMIC CHIP 220PF 10% 50V

C129 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C130 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C140 1-162-963-11 CERAMIC CHIP 680PF 10% 50V

C141 1-162-963-11 CERAMIC CHIP 680PF 10% 50V

C142 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C143 1-164-217-11 CERAMIC CHIP 150PF 5% 50V

C144 1-126-382-11 ELECT 100uF 20% 16V

C145 1-126-382-11 ELECT 100uF 20% 16V

C201 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C203 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C204 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C205 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C230 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C301 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C302 1-164-156-11 CERAMIC CHIP 0.1uF 25V

The components identified by

mark 0 or dotted line with mark

0 are critical for safety.

Replace only with part number

specified.

When indicating parts by reference

number, please include the board.

* 1-676-524-11 LSW BOARD

**********

< SWITCH >

SW3 1-572-688-11 SWITCH, PUSH (1 KEY) (LIMIT)

**************************************************************

* A-3294-985-A MAIN BOARD, COMPLETE

*********************

1-676-339-12 MAIN FLEXIBLE BOARD

1-676-340-12 JACK FLEXIBLE BOARD

< CAPACITOR >

C101 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C102 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C103 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C104 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C110 1-162-965-11 CERAMIC CHIP 0.0015uF 10% 50V

40

C303 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C304 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C305 1-162-964-11 CERAMIC CHIP 0.001uF 10% 50V

C306 1-162-968-11 CERAMIC CHIP 0.0047uF 10% 50V

C307 1-165-112-11 CERAMIC CHIP 0.33uF 20% 10V

C308 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C309 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C310 1-125-701-11 DOUBLE LAYER 0.047F 5.5V

C311 1-126-382-11 ELECT 100uF 20% 16V

C312 1-115-156-11 CERAMIC CHIP 1uF 10V

C313 1-126-382-11 ELECT 100uF 20% 16V

C314 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C315 1-115-466-00 ELECT 1000uF 20% 16V

C316 1-126-382-11 ELECT 100uF 20% 16V

C317 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C318 1-164-156-11 CERAMIC CHIP 0.1uF 25V

C401 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C402 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

Page 41

MAIN

Ref. No. Part No. Description Remark

C403 1-126-382-11 ELECT 100uF 20% 16V

C404 1-126-157-11 ELECT 10uF 20% 16V

C405 1-126-157-11 ELECT 10uF 20% 16V

C406 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

C407 1-162-927-11 CERAMIC CHIP 100PF 5% 50V

< DIODE >

D301 8-719-975-40 DIODE RB411D-T146

D302 8-719-017-94 DIODE MA8180-TX

D303 8-719-017-94 DIODE MA8180-TX

D304 8-719-975-40 DIODE RB411D-T146

D305 8-719-975-40 DIODE RB411D-T146

D306 8-719-069-56 DIODE UDZS-TE17-6.2B

D307 8-719-988-61 DIODE 1SS355TE-17

D308 8-719-914-44 DIODE DAP202K-T-146

D309 8-719-988-61 DIODE 1SS355TE-17

D310 8-719-422-67 DIODE MA8062-H-TX

D311 8-719-069-57 DIODE UDZS-TE17-6.8B

D312 8-719-069-57 DIODE UDZS-TE17-6.8B

< IC >

IC101 8-752-392-04 IC CXD2598Q

IC201 8-752-914-89 IC CXP740056-007R

IC202 8-759-662-12 IC LC35256FT-70U-TLM

IC301 8-759-527-33 IC LB1930M-TLM

IC302 8-759-444-86 IC BA8272F-E2

IC303 8-759-363-81 IC XC61AN4002PR

IC304 8-759-655-30 IC NJM2395F08

IC305 8-759-655-29 IC NJM2395F05

IC401 8-759-662-11 IC TLV2362IPWR

< COIL >

L140 1-412-058-11 INDUCTOR CHIP 10uH

< TRANSISTOR >

Q201 8-729-020-67 TRANSISTOR XN1A312-TX

Q301 8-729-028-62 TRANSISTOR DTA115EKA-T146

Q302 8-729-230-49 TRANSISTOR 2SC2712-YG-TE85L

Q303 8-729-921-12 TRANSISTOR 2SD1834-T101

Q401 8-729-901-00 TRANSISTOR DTC124EKA-T146

Q402 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q410 8-729-015-39 TRANSISTOR UN2226- (TX)

Q420 8-729-015-39 TRANSISTOR UN2226- (TX)

< RESISTOR >

R101 1-216-833-11 RES-CHIP 10K 5% 1/16W

R111 1-216-833-11 RES-CHIP 10K 5% 1/16W

R112 1-216-845-11 METAL CHIP 100K 5% 1/16W

R114 1-216-833-11 RES-CHIP 10K 5% 1/16W

R115 1-216-833-11 RES-CHIP 10K 5% 1/16W

Ref. No. Part No. Description Remark

R125 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

R126 1-216-857-11 METAL CHIP 1M 5% 1/16W

R140 1-218-871-11 RES-CHIP 10K 2% 1/16W

R141 1-218-871-11 RES-CHIP 10K 2% 1/16W

R142 1-218-871-11 RES-CHIP 10K 2% 1/16W

R143 1-218-871-11 RES-CHIP 10K 2% 1/16W

R144 1-218-871-11 RES-CHIP 10K 2% 1/16W

R145 1-218-871-11 RES-CHIP 10K 2% 1/16W

R201 1-216-821-11 METAL CHIP 1K 5% 1/16W

R207 1-216-845-11 METAL CHIP 100K 5% 1/16W

R209 1-216-833-11 RES-CHIP 10K 5% 1/16W

R220 1-216-864-11 METAL CHIP 0 5% 1/16W

R301 1-216-841-11 METAL CHIP 47K 5% 1/16W

R302 1-216-845-11 METAL CHIP 100K 5% 1/16W

R303 1-216-846-11 METAL CHIP 120K 5% 1/16W

R304 1-216-847-11 METAL CHIP 150K 5% 1/16W

R305 1-216-841-11 METAL CHIP 47K 5% 1/16W

R306 1-216-844-11 METAL CHIP 82K 5% 1/16W

R311 1-216-841-11 METAL CHIP 47K 5% 1/16W

R314 1-216-864-11 METAL CHIP 0 5% 1/16W

R401 1-218-871-11 RES-CHIP 10K 2% 1/16W

R402 1-218-871-11 RES-CHIP 10K 2% 1/16W

R403 1-218-871-11 RES-CHIP 10K 2% 1/16W

R404 1-218-871-11 RES-CHIP 10K 2% 1/16W

R405 1-219-315-21 RES-CHIP 11K 2% 1/16W

R406 1-219-315-21 RES-CHIP 11K 2% 1/16W

R407 1-216-833-11 RES-CHIP 10K 5% 1/16W

R408 1-216-833-11 RES-CHIP 10K 5% 1/16W

R409 1-219-315-21 RES-CHIP 11K 2% 1/16W

R410 1-219-315-21 RES-CHIP 11K 2% 1/16W

R411 1-216-813-11 METAL CHIP 220 5% 1/16W

R412 1-216-813-11 METAL CHIP 220 5% 1/16W

R413 1-216-845-11 METAL CHIP 100K 5% 1/16W

R414 1-216-845-11 METAL CHIP 100K 5% 1/16W

R415 1-216-864-11 METAL CHIP 0 5% 1/16W

R416 1-216-864-11 METAL CHIP 0 5% 1/16W

R420 1-216-864-11 METAL CHIP 0 5% 1/16W

< COMPOSITION CIRCUIT BLOCK >

RB201 1-233-810-21 RES, NETWORK 100K (3216)

RB202 1-233-810-21 RES, NETWORK 100K (3216)

< VARIABLE RESISTOR >

RV201 1-223-834-11 RES, ADJ, CARBON 47K

< SWITCH >

SW201 1-572-688-11 SWITCH, PUSH (1 KEY)

(MAGAZINE IN/OUT DETECT)

< VIBRATOR >

R116 1-216-837-11 METAL CHIP 22K 5% 1/16W

R117 1-216-845-11 METAL CHIP 100K 5% 1/16W

R120 1-216-839-11 METAL CHIP 33K 5% 1/16W

R121 1-216-853-11 METAL CHIP 470K 5% 1/16W

R122 1-216-853-11 METAL CHIP 470K 5% 1/16W

R123 1-216-833-11 RES-CHIP 10K 5% 1/16W

R124 1-216-827-11 METAL CHIP 3.3K 5% 1/16W

X130 1-760-307-11 VIBRATOR, CERAMIC (16.9344MHz)

X201 1-579-126-11 VIBRATOR, CERAMIC (12MHz)

**************************************************************

41

Page 42

RF SWITCH

Ref. No. Part No. Description Remark

* A-3326-000-A RF BOARD, COMPLETE

*******************

< CAPACITOR >

C101 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C102 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C103 1-162-970-11 CERAMIC CHIP 0.01uF 10% 25V

C104 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C105 1-125-837-11 CERAMIC CHIP 1uF 10% 6.3V

C106 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C107 1-162-915-11 CERAMIC CHIP 10PF 0.5PF 50V

C108 1-124-779-00 ELECT CHIP 10uF 20% 16V

C109 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C110 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C111 1-124-779-00 ELECT CHIP 10uF 20% 16V

C201 1-117-681-11 ELECT CHIP 100uF 20% 16V

C202 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

C203 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C204 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C205 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C206 1-162-962-11 CERAMIC CHIP 470PF 10% 50V

C207 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C208 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

C209 1-164-227-11 CERAMIC CHIP 0.022uF 10% 25V

Ref. No. Part No. Description Remark

R210 1-216-842-11 METAL CHIP 56K 5% 1/16W

R211 1-216-833-11 RES-CHIP 10K 5% 1/16W

R212 1-216-839-11 METAL CHIP 33K 5% 1/16W

R213 1-216-833-11 RES-CHIP 10K 5% 1/16W

R214 1-216-839-11 METAL CHIP 33K 5% 1/16W

R215 1-216-839-11 METAL CHIP 33K 5% 1/16W

R216 1-216-842-11 METAL CHIP 56K 5% 1/16W

R218 1-216-839-11 METAL CHIP 33K 5% 1/16W

R219 1-216-843-11 METAL CHIP 68K 5% 1/16W

R220 1-216-834-11 METAL CHIP 12K 5% 1/16W

R222 1-216-821-11 METAL CHIP 1K 5% 1/16W

R223 1-216-821-11 METAL CHIP 1K 5% 1/16W

< SWITCH >

SW1 1-529-566-21 SWITCH, PUSH (1 KEY)

(CHUCKING END DETECT)

SW2 1-529-566-21 SWITCH, PUSH (1 KEY) (SAVE END DETEECT)

**************************************************************

* 1-675-516-11 SWITCH BOARD

*************

SW801 1-571-532-21 SWITCH, TACTIL (Z)

**************************************************************

C217 1-107-826-11 CERAMIC CHIP 0.1uF 10% 16V

< CONNECTOR >

CN102 1-778-303-21 CONNECTOR, FPC (ZIF) 16P

CNJ101 1-778-777-21 CONNECTOR, FPC 26P

< IC >

IC101 8-752-095-36 IC CXA2596M-T6

IC201 8-759-653-67 IC LA6556L-TE-L

< TRANSISTOR >

Q101 8-729-141-48 TRANSISTOR 2SB624T1-BV345

< RESISTOR >

R101 1-216-847-11 METAL CHIP 150K 5% 1/16W

R102 1-216-847-11 METAL CHIP 150K 5% 1/16W

R103 1-216-864-11 METAL CHIP 0 5% 1/16W

R104 1-216-158-00 RES-CHIP 22 5% 1/8W

R105 1-216-857-11 METAL CHIP 1M 5% 1/16W

R106 1-216-857-11 METAL CHIP 1M 5% 1/16W

R107 1-216-864-11 METAL CHIP 0 5% 1/16W

R108 1-216-845-11 METAL CHIP 100K 5% 1/16W

R109 1-216-837-11 METAL CHIP 22K 5% 1/16W

R110 1-216-821-11 METAL CHIP 1K 5% 1/16W

R201 1-216-826-11 METAL CHIP 2.7K 5% 1/16W

R202 1-216-833-11 RES-CHIP 10K 5% 1/16W

R203 1-216-833-11 RES-CHIP 10K 5% 1/16W

R204 1-216-842-11 METAL CHIP 56K 5% 1/16W

R205 1-216-833-11 RES-CHIP 10K 5% 1/16W

R206 1-216-842-11 METAL CHIP 56K 5% 1/16W

R207 1-216-833-11 RES-CHIP 10K 5% 1/16W

R208 1-216-842-11 METAL CHIP 56K 5% 1/16W

R209 1-216-833-11 RES-CHIP 10K 5% 1/16W

MISCELLANEOUS

**************

0 205 8-820-103-03 OPTICAL PICK-UP KSS-720A/K1RP

210 1-676-341-11 OP FLEXIBLE BOARD

M101 A-3315-151-A SLED MOTOR ASSY (251)

M102 A-3301-998-A SPINDLE MOTOR (S) SUB ASSY

M103 A-3301-123-A ELJ MOTOR ASSY (CHUCKING)

M104 A-3301-123-A ELJ MOTOR ASSY (ELEVATOR)

RV202 1-227-137-11 RES, VAR, SLIDE 10K

(ELEVATOR HEIGHT SENSOR)

**************************************************************

**************

HARDWARE LIST

**************

#2 7-685-792-09 SCREW +PTT 2.6X6 (S)

#3 7-685-781-09 SCREW +PTT 2X4 (S)

#4 7-624-104-04 STOP RING 2.0, TYPE -E

#5 7-627-554-07 SCREW, PRECISION +P 2X2.2

#6 7-628-253-00 SCREW +PS 2X4

#7 7-627-553-27 SCREW, PRECISION +P 2X2.5

#8 7-624-102-04 STOP RING 1.5, TYPE -E

#9 7-627-850-28 SCREW, PRECISION +P 1.4X3

#10 7-627-000-00 SCREW, PRECISION +P 1.7X2.2 TYPE 3

#11 7-627-553-37 PRECISION SCREW +P 2X3 TYPE 3

**************************************************************

ACCESSORIES & PACKING MATERIALS

*******************************

1-418-812-11 REMOTE COMMANDER (RM-X91)

3-044-623-01 LID, BATTERY CASE (for RM-X91)

3-867-910-12 MANUAL, INSTRUCTION (ENGLISH, FRENCH,

SPANISH, CHINESE)

A-3291-950-C MAGAZINE (250T) ASSY

**************************************************************

42

The components identified by mark 0 or dotted

line with mark 0 are critical for safety.

Replace only with part number specified.

Page 43

Ref. No. Part No. Description Remark

PARTS FOR INSTALLATION AND CONNECTIONS

**************************************

501 3-040-583-21 BRACKET (T)

* 502 X-3369-824-1 SCREW ASSY

503 1-590-874-11 CORD, CONNECTION (RCA PIN CORD 5.5m)

504 1-590-519-21 CORD (WITH CONNECTOR) (BUS CABLE 5.5m)

501 502

Ref. No. Part No. Description Remark

BRACKET

× 2

503 504

RCA PIN CORD 5.5 m

× 1

+PSW4 × 10

× 4

BUS CABLE 5.5 m

TAPPING SCREW

(DIA.5 × 20) × 4

× 1

43

Page 44

CDX-60X

9-870-175-11

44

Sony Corporation

Audio Entertainment Group

Printed in Japan C 2000. 4

2000D0516-1

Published by ME General Engineering Dept.

Loading...

Loading...