Sony CDX-5V661, CDX-5V661A, CDX-5V661D, CDX-5V661S Service manual

CDX-5V661

/

5V661A/5V661D/5V661S

(

VW No.: 3B7 035 110/6X0 035 110/3D0 035 110/7M7 035 110

)

SERVICE MANUAL

Ver 1.3 2001.12

Photo: CDX-5V661

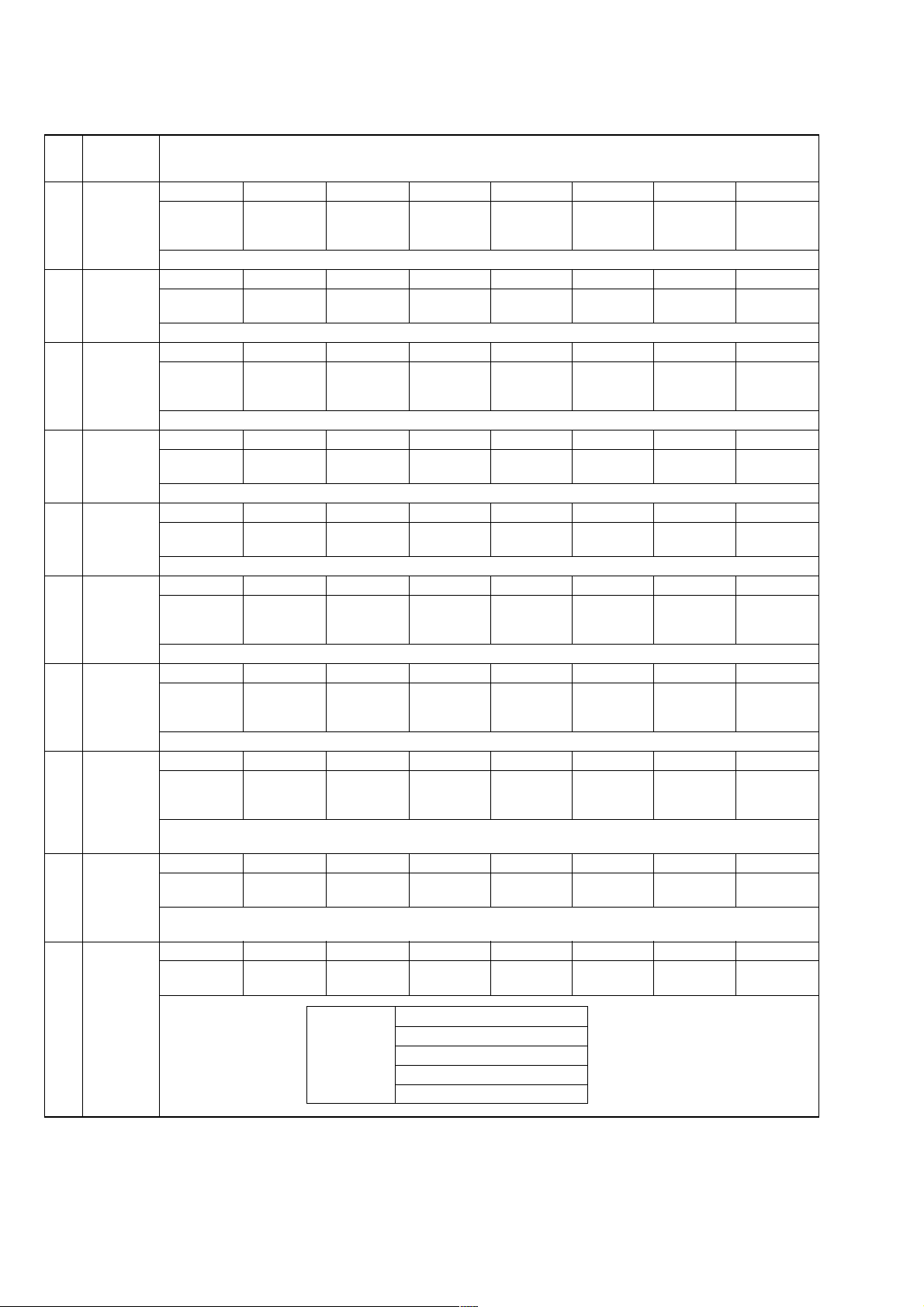

Connectable head units

Manufacture Model name VW No.

SONY Gamma 1J0 035 186D

Clarion Premium 1J0 035 180D

Philips Beta 1J0 035 152B

Blaupunkt Gamma 1J0 035 186B

Blaupunkt Beta 6X0 035 152

Grundig Beta 1J0 035 152 E

Blaupunkt Radio Navigation (Color LED) 3B0 035 191 A

Blaupunkt Radio Navigation 1J0 035 191

US Model

AEP Model

Model Name Using Similar Mechanism NEW

CD Drive Mechanism Type MG-160-154

Optical Pick-up Name KSS-660C

9-873-511-14 Sony Corporation

2001L0500-1 e Vehicle Company

C 2001.12 Published by Sony Engineering Corporation

6 DISC IN-DASH CD CHANGER

CDX-5V661/5V661A/5V661D/5V661S

Ver 1.2

TABLE OF CONTENTS

1. SERVICING NOTES ................................................ 3

2. DISASSEMBLY

2-1. Disassembly Flow ........................................................... 4

2-2. Cover (Up)....................................................................... 5

2-3. Front Panel Section ......................................................... 5

2-4. Mechanism Deck (MG-160-154) ................................... 6

2-5. MAIN Board ................................................................... 7

2-6. Slide Variable Resistor

(Elevator Height Sensor) (RV1) ..................................... 8

2-7. ASSIST Board................................................................. 8

2-8. L Motor Assy (Loading) (M103).................................... 9

2-9. Chassis (TR) Main Assy ................................................. 9

2-10. Bracket (DE) Main Assy................................................. 10

2-11. Slider (TOP) Assy ........................................................... 10

2-12. Bracket (UD) Assy .......................................................... 11

2-13. Guide (Chuck) ................................................................. 11

2-14. Setting The OP Block Assy In The Highest Position ..... 12

2-15. Address Detection Flexible Board.................................. 13

2-16. Torsion Spring (OP) ........................................................ 13

2-17. OP Block Assy ................................................................ 14

3. ELECTRICAL ADJUSTMENT............................ 15

4. DIAGRAMS

4-1. Block Diagram – MAIN Section – ................................. 39

4-2. Block Diagram – DISPLAY/POWER Section – ............ 40

4-3. Note for Printed Wiring Boards and

Schematic Diagrams ....................................................... 41

4-4. Schematic Diagram – MAIN Board (1/3) – ................... 43

4-5. Schematic Diagram

– MAIN (2/3)/ASSIST/POS Boards – ........................... 44

4-6. Schematic Diagram – MAIN Board (3/3) – ................... 45

4-7. Printed Wiring Boards

– MAIN (Component Side)/ASSIST/POS Boards – ..... 46

4-8. Printed Wiring Board

– MAIN Board (Conductor Side) – ................................ 47

4-9. Printed Wiring Board – KEY Board –............................ 48

4-10. Schematic Diagram – KEY Board – .............................. 49

4-11. Printed Wiring Board – F2 Board –................................ 50

4-12. Schematic Diagram – F2 Board –................................... 51

4-13. Printed Wiring Board – F1 Board –................................ 52

4-14. Schematic Diagram – F1 Board –................................... 52

4-15. IC Pin Function Description ........................................... 57

5. EXPLODED VIEWS

5-1. Cover Section .................................................................. 60

5-2. Front Panel Section ......................................................... 61

5-3. Chassis Section ............................................................... 62

5-4. Mechanism Deck Section-1 (MG-160-154)................... 63

5-5. Mechanism Deck Section-2 (MG-160-154)................... 64

6. ELECTRICAL PARTS LIST ............................... 65

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED

LINE WITH MARK 0 ON THE SCHEMATIC DIAGRAMS

AND IN THE PARTS LIST ARE CRITICAL TO SAFE

OPERATION. REPLACE THESE COMPONENTS WITH

SONY PARTS WHOSE PART NUMBERS APPEAR AS

SHOWN IN THIS MANUAL OR IN SUPPLEMENTS PUBLISHED BY SONY.

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

Laser Diode Properties

• Material: GaAlAs

• Wavelength: 780 nm

• Emission Duration: continuous

• Laser Output Power: less than 44.6 µW*

* This output is the value measured at a distance of 200 mm

from the objective lens surface on the Optical Pick-up Block.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

2

• DISCRIMINATION

CDX-5V661/5V661A/5V661D/5V661S

SECTION 1

SERVICING NOTES

VWZ3Z8A3304086: CDX-5V661

VWZ3Z8A3304011: CDX-5V661A

VWZ3Z8A3304055: CDX-5V661D

SEZ3Z8A3304006 : CDX-5V661S

• HOW TO EJECT THE DISC MANUALLY

When an electric current can be applied, eject the disc forcibly by moving each motor manually.

(See “3. Electrical Adjustment 3. Mechanism check mode” on page 26).

3

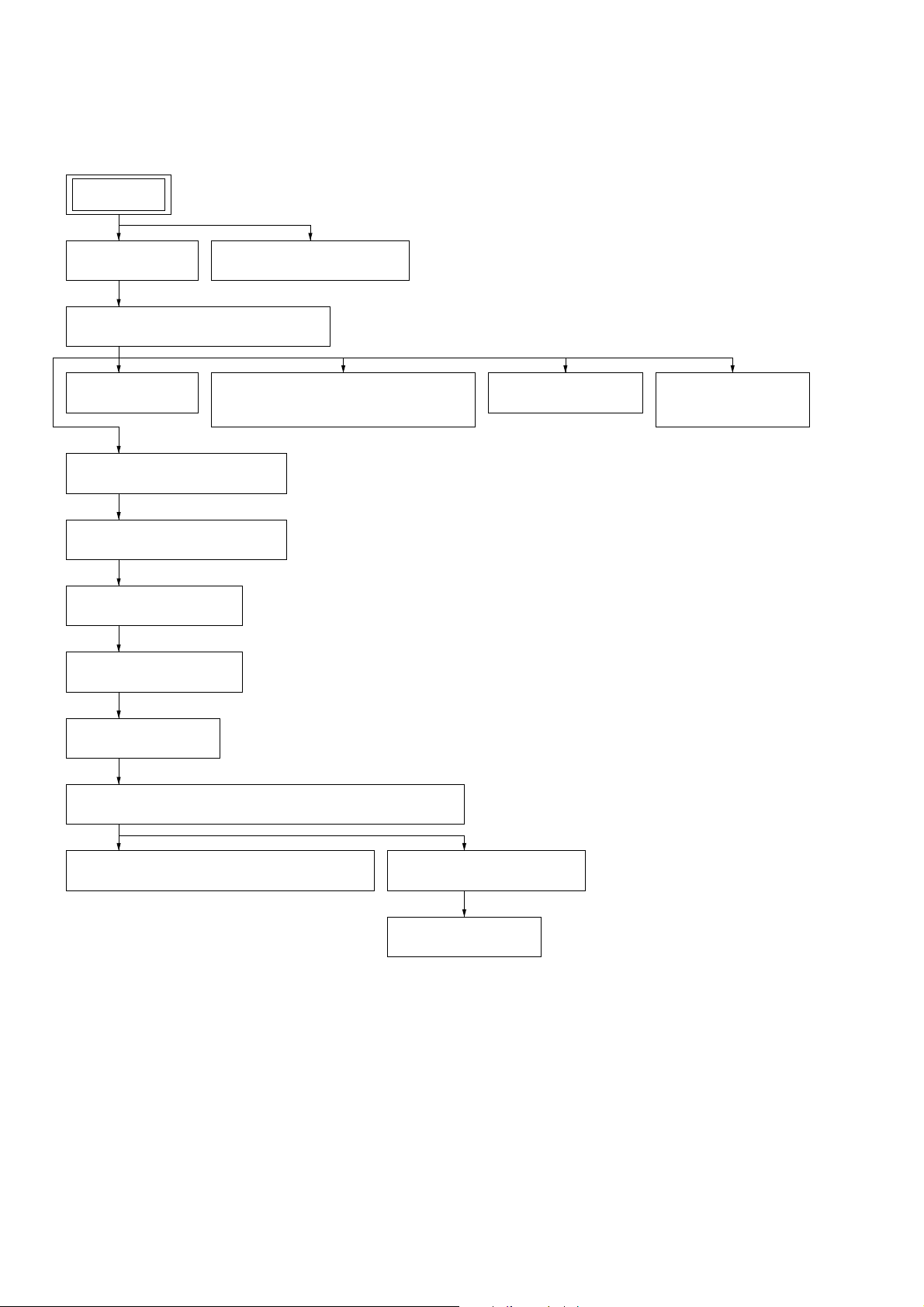

CDX-5V661/5V661A/5V661D/5V661S

DISASSEMBLY

• This set can be disassembled in the order shown below.

2-1. DISASSEMBLY FLOW

SET

SECTION 2

2-2. COVER (UP)

(Page 5)

2-4. MECHANISM DECK (MG-160-154)

(Page 6)

2-5. MAIN BOARD

(Page 7)

2-9. CHASSIS (TR) MAIN ASSY

(Page 9)

2-10. BRACKET (DE) MAIN ASSY

(Page 10)

2-11. SLIDER (TOP) ASSY

(Page 10)

2-12. BRACKET (UD) ASSY

(Page 11)

2-3. FRONT PANEL SECTION

(Page 5)

2-6. SLIDE VARIABLE RESISTOR

(ELEVATOR HEIGHT SENSOR) (RV1)

(Page 8)

2-7. ASSIST BOARD

(Page 8)

2-8. L MOTOR ASSY

(LOADING) (M103)

(Page 9)

2-13. GUIDE (CHUCK)

(Page 11)

2-14. SETTING THE OP BLOCK ASSY IN THE HIGHEST POSITION

(Page 12)

2-15. ADDRESS DETECTION FLEXIBLE BOARD

(Page 13)

2-16. TORSION SPRING (OP)

(Page 13)

2-17. OP BLOCK ASSY

(Page 14)

4

Note: Follow the disassembly procedure in the numerical order given.

)

Note: Screws and washers cannot be re-used.

Please replace to brand-new ones once screws and washers are removed .

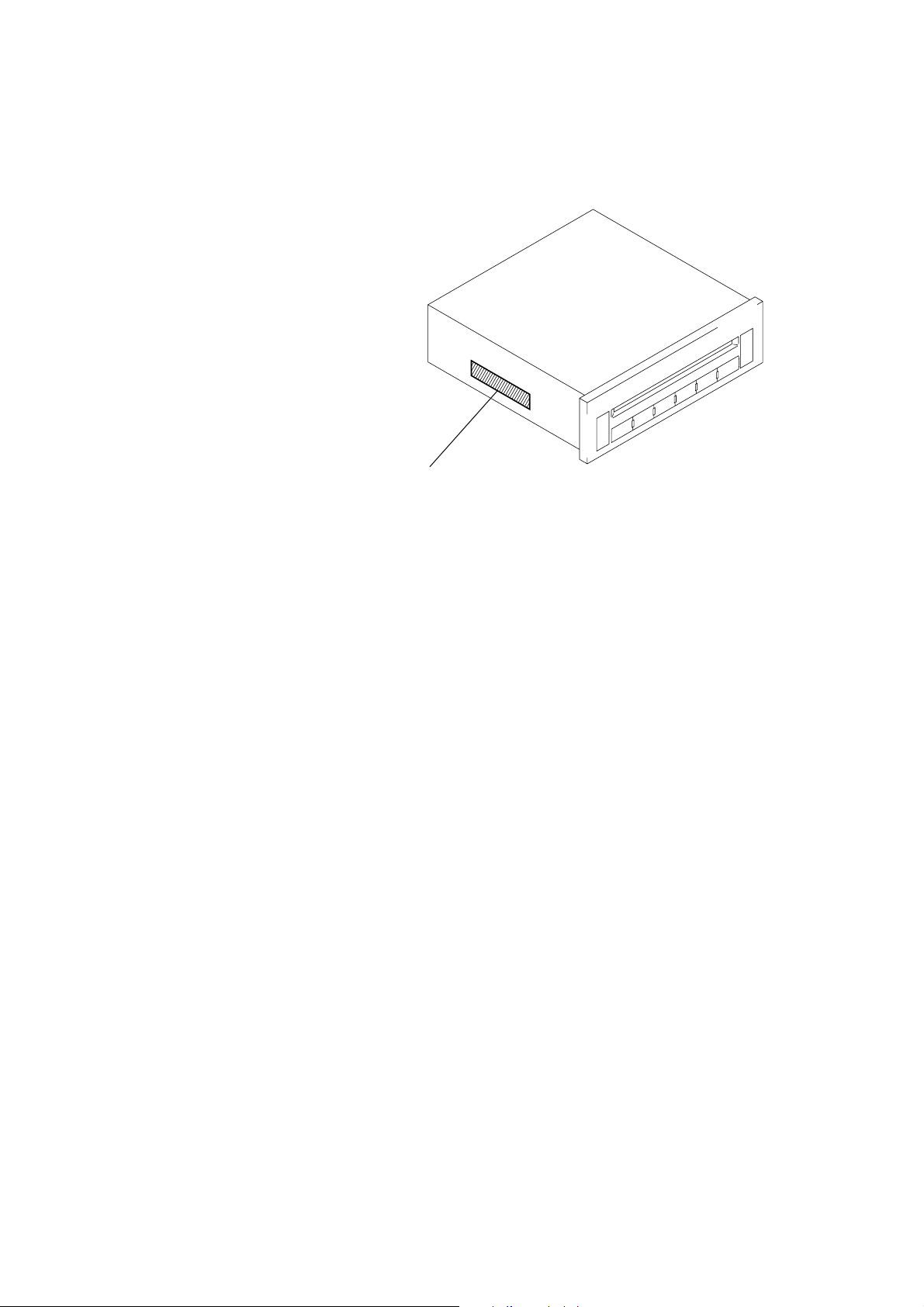

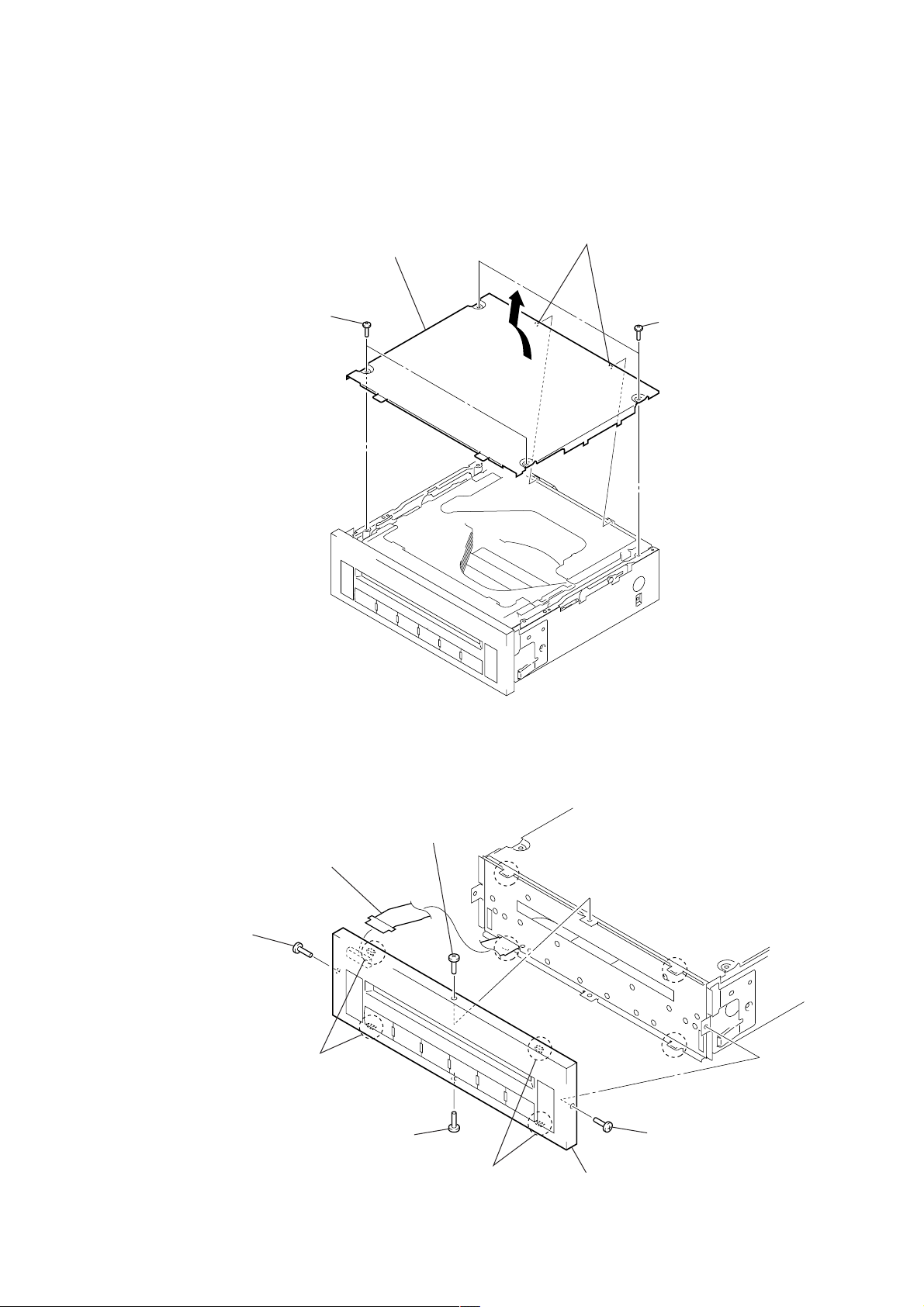

2-2. COVER (UP)

3

Remove the cover (up)

in the direction of the arrow.

1

two screws

(PTT2.6

×

6)

CDX-5V661/5V661A/5V661D/5V661S

2

two bosses

1

two screws

(PTT2.6

×

6

2-3. FRONT PANEL SECTION

3

key flexible board

(CN1)

1

screw

(2

×

4.5)

2

two claws

1

1

screw

(2 × 4.5)

screw

(2 × 4.5)

2

two claws

1

screw

(2 × 4.5)

4

front panel section

5

CDX-5V661/5V661A/5V661D/5V661S

d

)

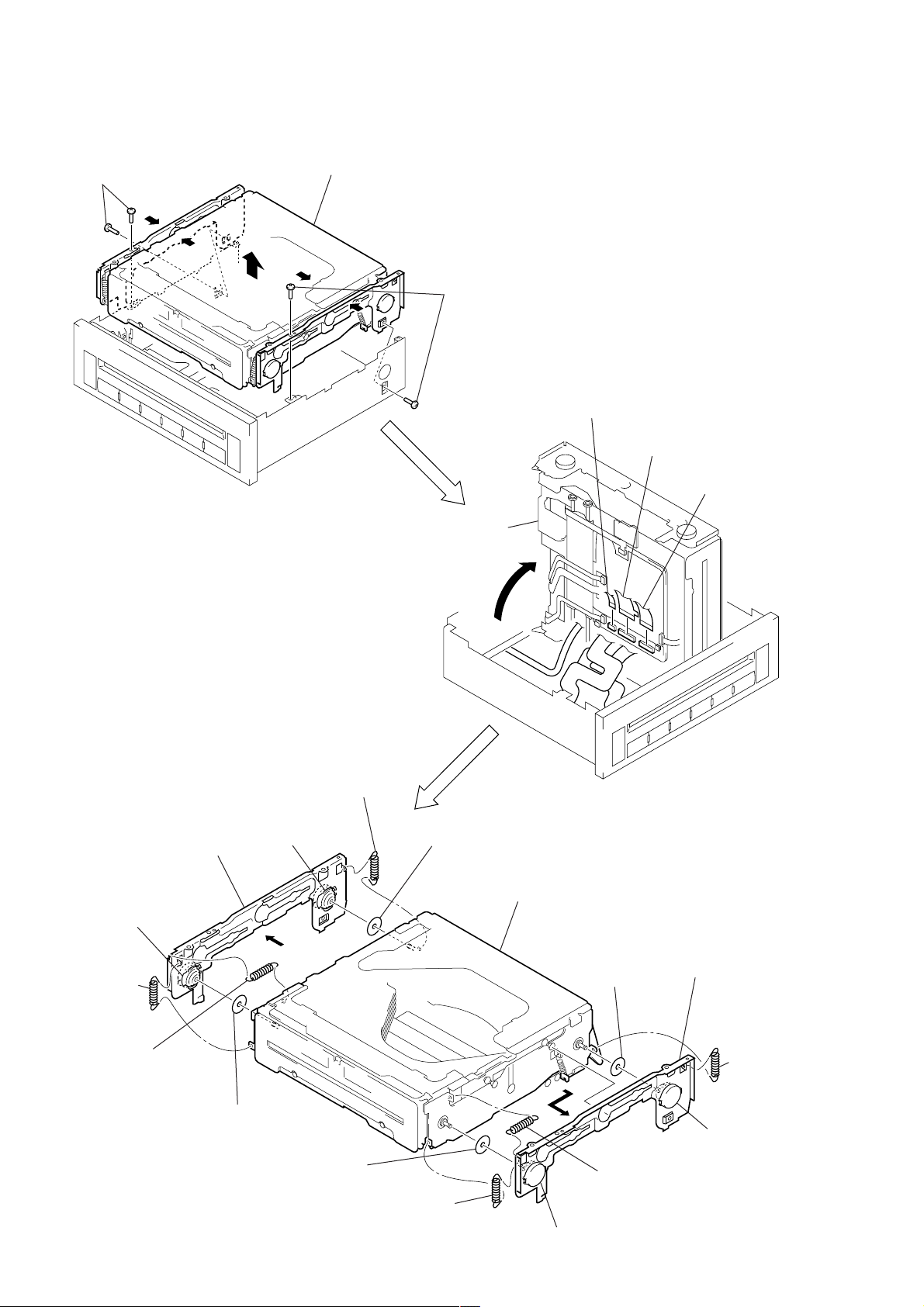

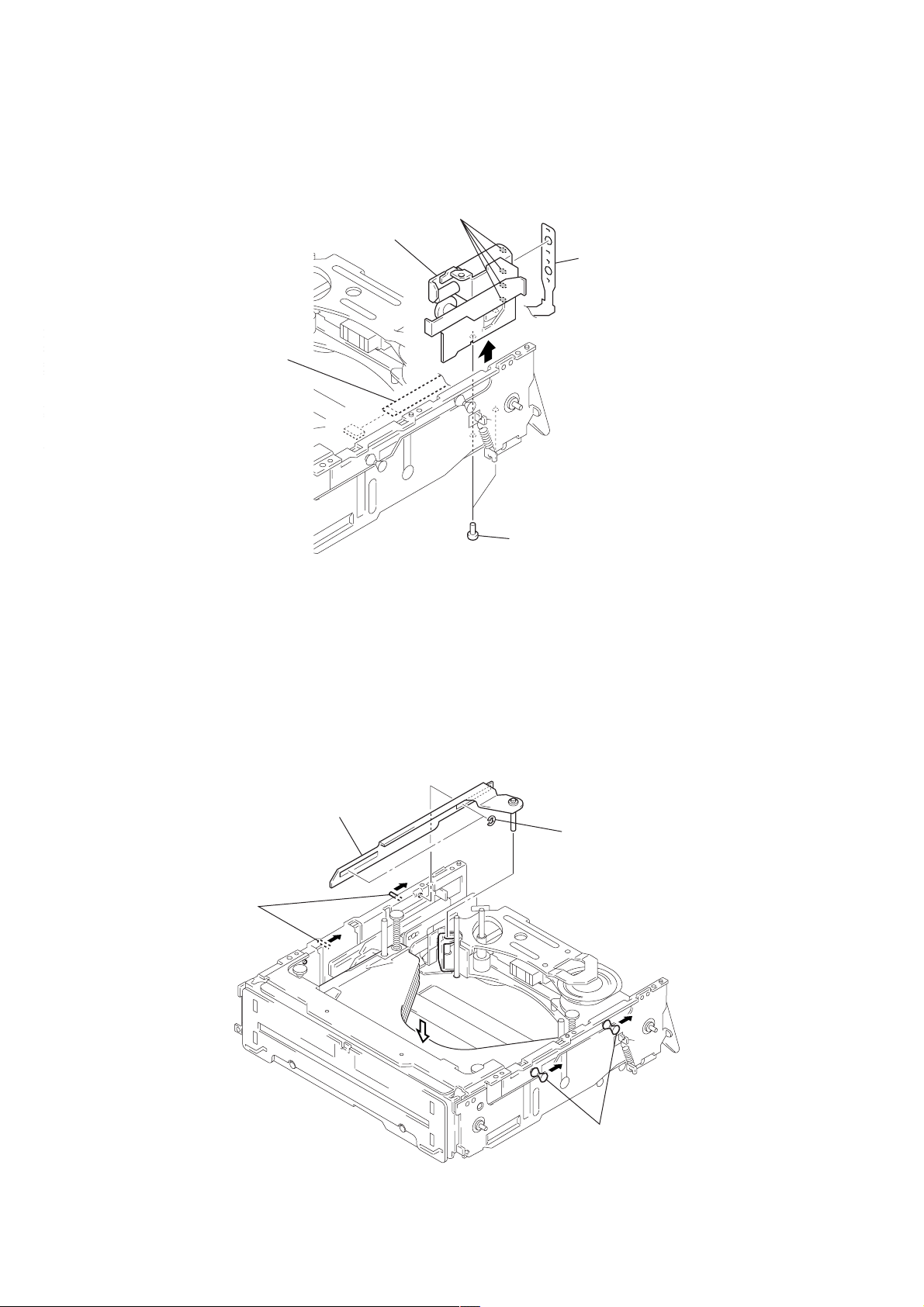

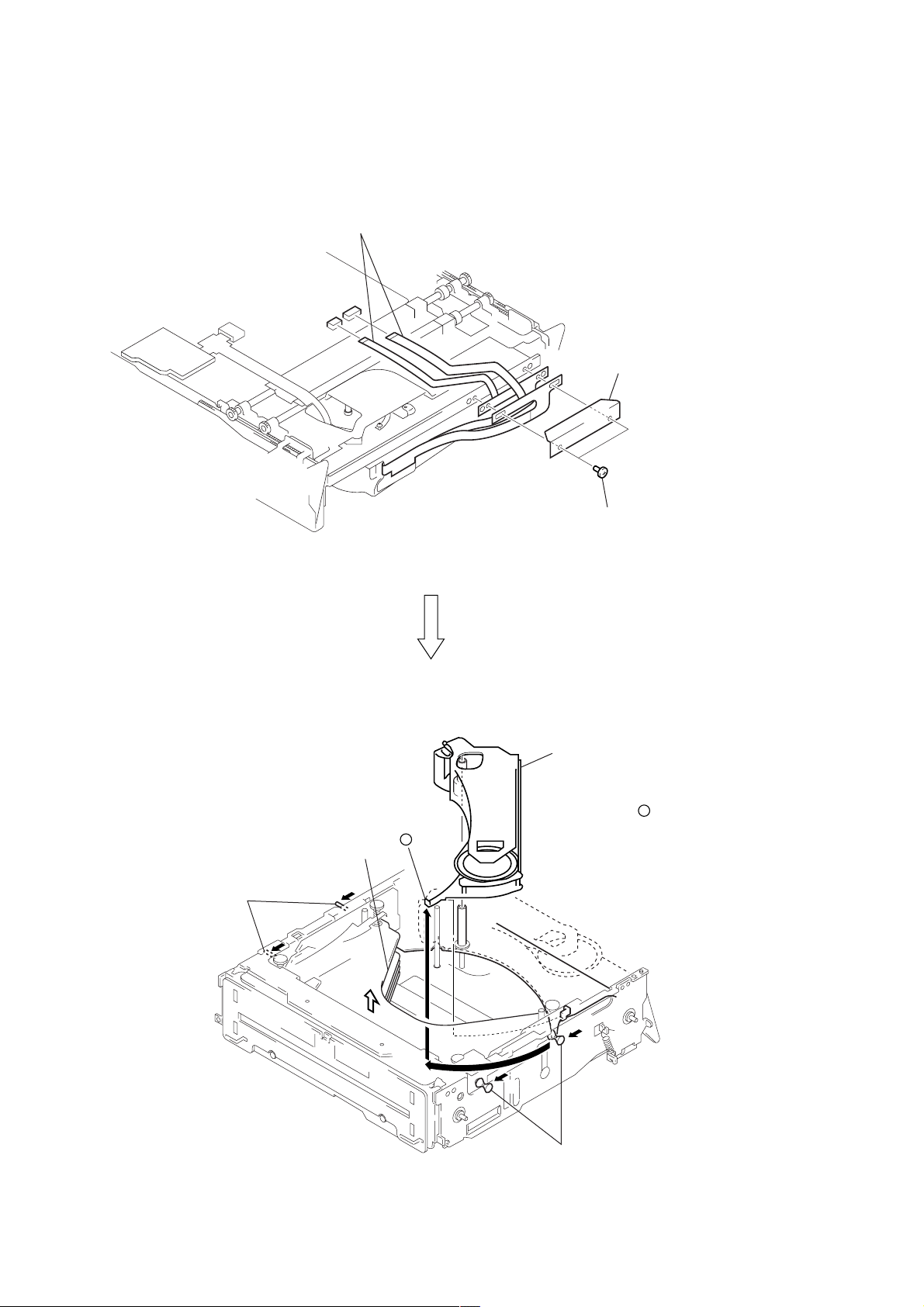

2-4. MECHANISM DECK (MG-160-154)

1

two screws

(PTT2.6

×

6)

2

Hold the bracket (L), the bracket (R)

and the mechanism deck up

to remove from chassis assy.

1

two screws

(PTT2.6

×

6)

4

F1 flexible board

(CN901)

4

F2 flexible board

(CN902)

4

key flexible boar

(CN903)

7

5

tension coil

spring (float)

Remove two oil dampers

from each axis, then

remove the bracket (L).

oil damper

5

tension coil spring (float)

oil damper

3

Put up the mechanism

deck in the direction

of arrow

A

.

9

sheet (teflon)

A

0

mechanism deck (MG-160-154)

9

sheet

(teflon)

8

Remove two oil dampers

from each axis, then

remove the bracket (R).

6

tension spring (float 30)

(CDX-5V661A only)

6

9

sheet (teflon)

9

sheet (teflon)

5

tension coil

spring (float)

6

oil damper

5

oil damper

tension spring (float 30)

(CDX-5V661A only)

tension coil

spring (float

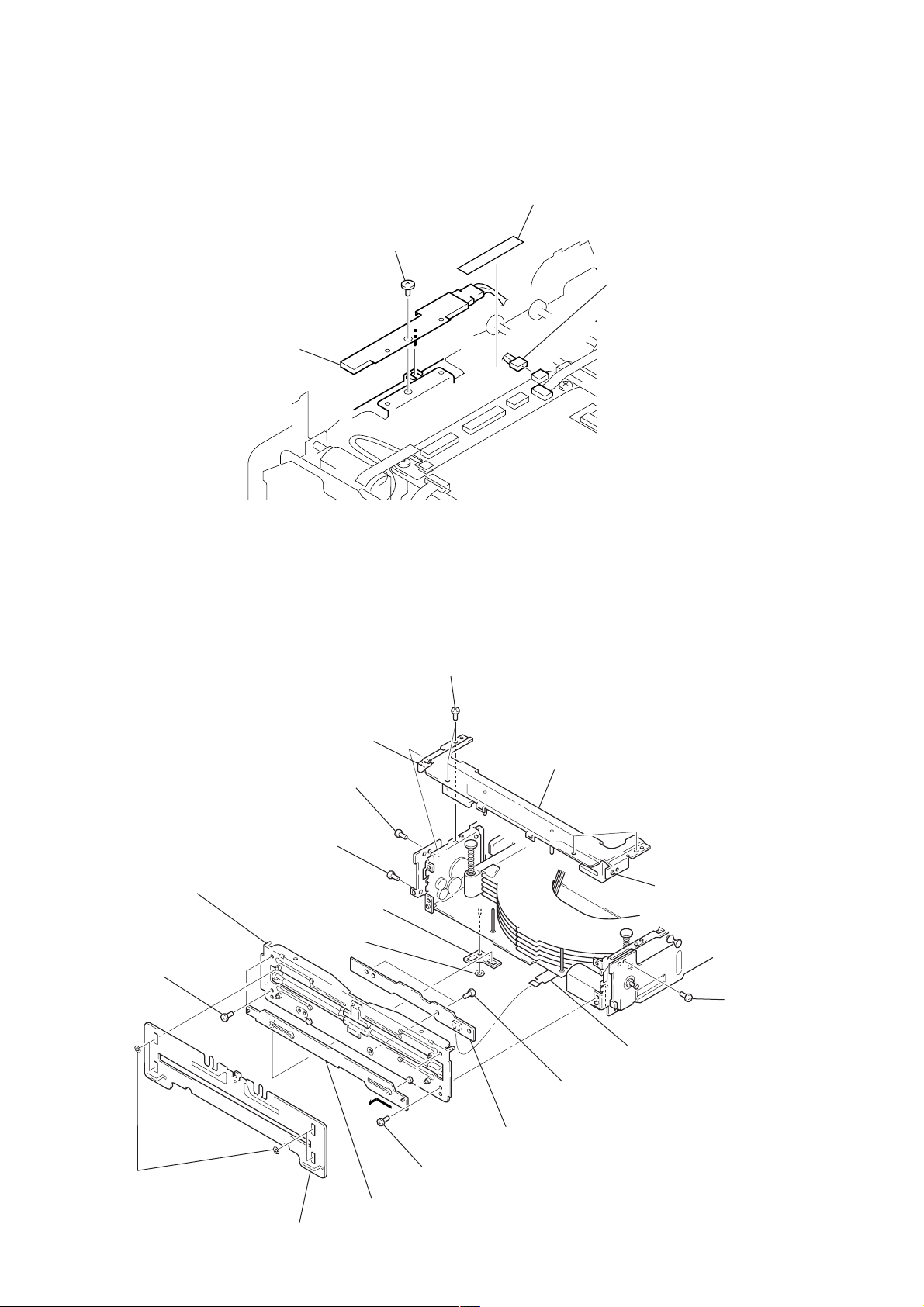

2-5. MAIN BOARD

)

e

6

two cushions

(unweaved cloth)

7

connector

(CN501)

3

assist flexible board

(CN801)

7

connector

(CN503)

CDX-5V661/5V661A/5V661D/5V661S

4

mech motor flexible board

(CN502)

5

two flexible boards

(CN201, 301)

1

screw (M2)

qa

main board

0

screw (M2)

8

three screws

(M2)

2

Disconnect the address

detection flexible board

from the connector (CN802

on the main board.

A

9

Open the sheet (main) in th

direction of arrow A.

7

CDX-5V661/5V661A/5V661D/5V661S

2-6. SLIDE VARIABLE RESISTOR (ELEVATOR HEIGHT SENSOR) (RV1)

1

cushion (unweaved cloth)

3

screw (M2)

4

slide variable resistor (elevator height sensor) (RV1)

2

connector

(CN503)

2-7. ASSIST BOARD

qa

chassis (F) main assy

0

two screws (M2)

2

screw (M2)

0

screw (M2)

8

retainer plate (DS)

7

3

boss

washer

2

four screws

(M2)

4

chassis (TF) main assy

1

assist flexible board

(CN950)

qs

two screws

(M2)

3

boss

2

screw (M2)

qd

assist board

0

5

four washers (F)

6

shutter (A)

9

lever (selection) (S)

two screws (M2)

8

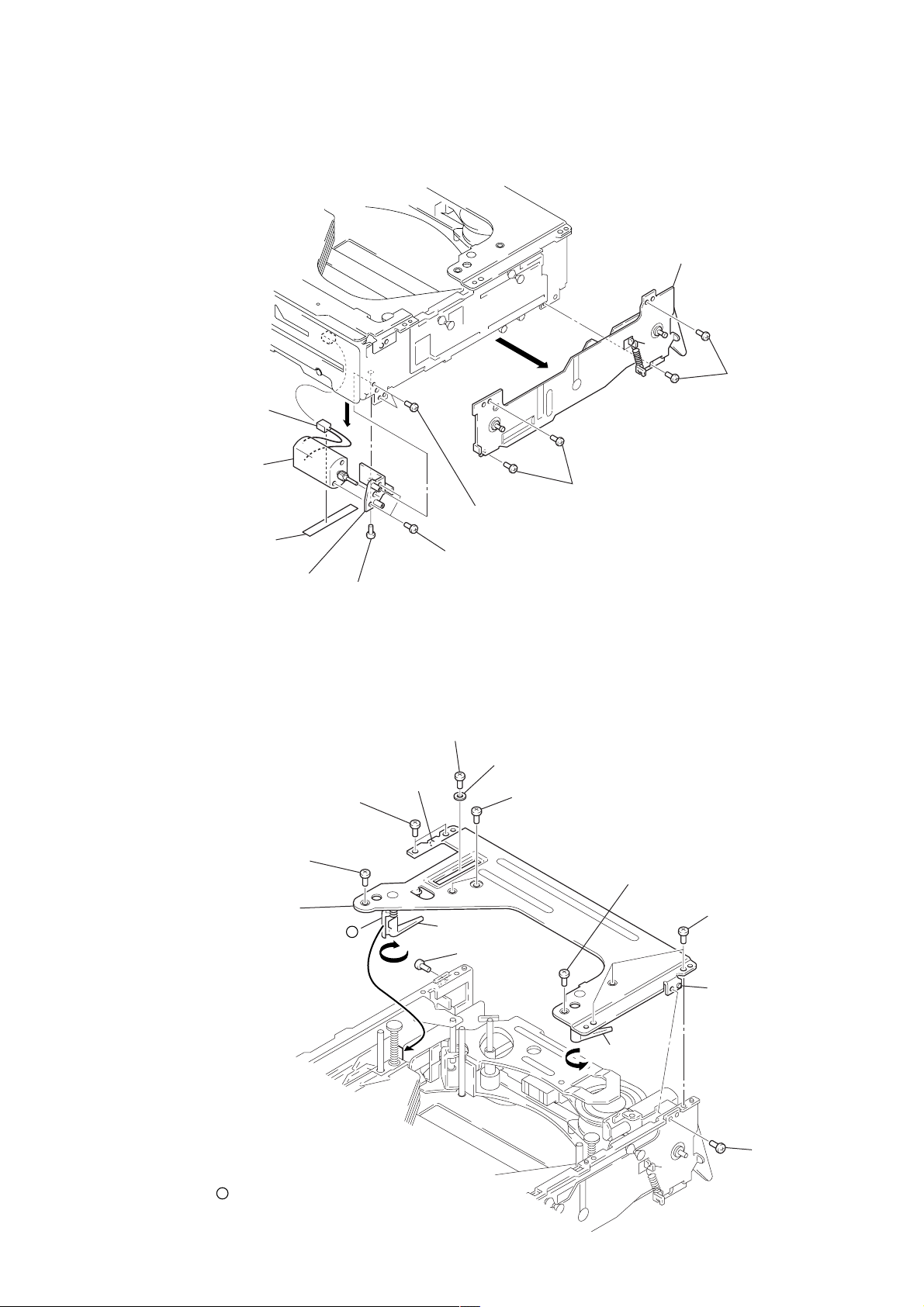

2-8. L MOTOR ASSY (LOADING) (M103)

)

4

connector

(CN501)

0

L motor assy (loading) (M103)

7

CDX-5V661/5V661A/5V661D/5V661S

2

bracket (damper R) assy

1

two screws (M2

1

two screws (M2)

3

cushion

(unweaved cloth)

9

bracket (HL) assy

2-9. CHASSIS (TR) MAIN ASSY

3

two screws

(M2)

4

screw (M1.7) (P2)

7

chassis (TR) main assy

6

screw (M2)

a

6

boss

8

two screws

(P2

1

screw (M2)

lever (EJL)

5

5

two screws (M1.7)

(P2)

×

2)

2

washer

4

two screws (M1.7) (P2)

screw (M2)

4

screw (M1.7) (P2)

3

three screws

(M2)

Note: To install the chassis (TR) main assy,

turn the lever (EJL) and the lever (EJR) in the

direction of each arrow, hold them, and

a

of the lever (EJL) upon the edge pointed

put

by arrow

A

.

A

lever (EJR)

6

boss

5

screw (M2)

9

CDX-5V661/5V661A/5V661D/5V661S

e

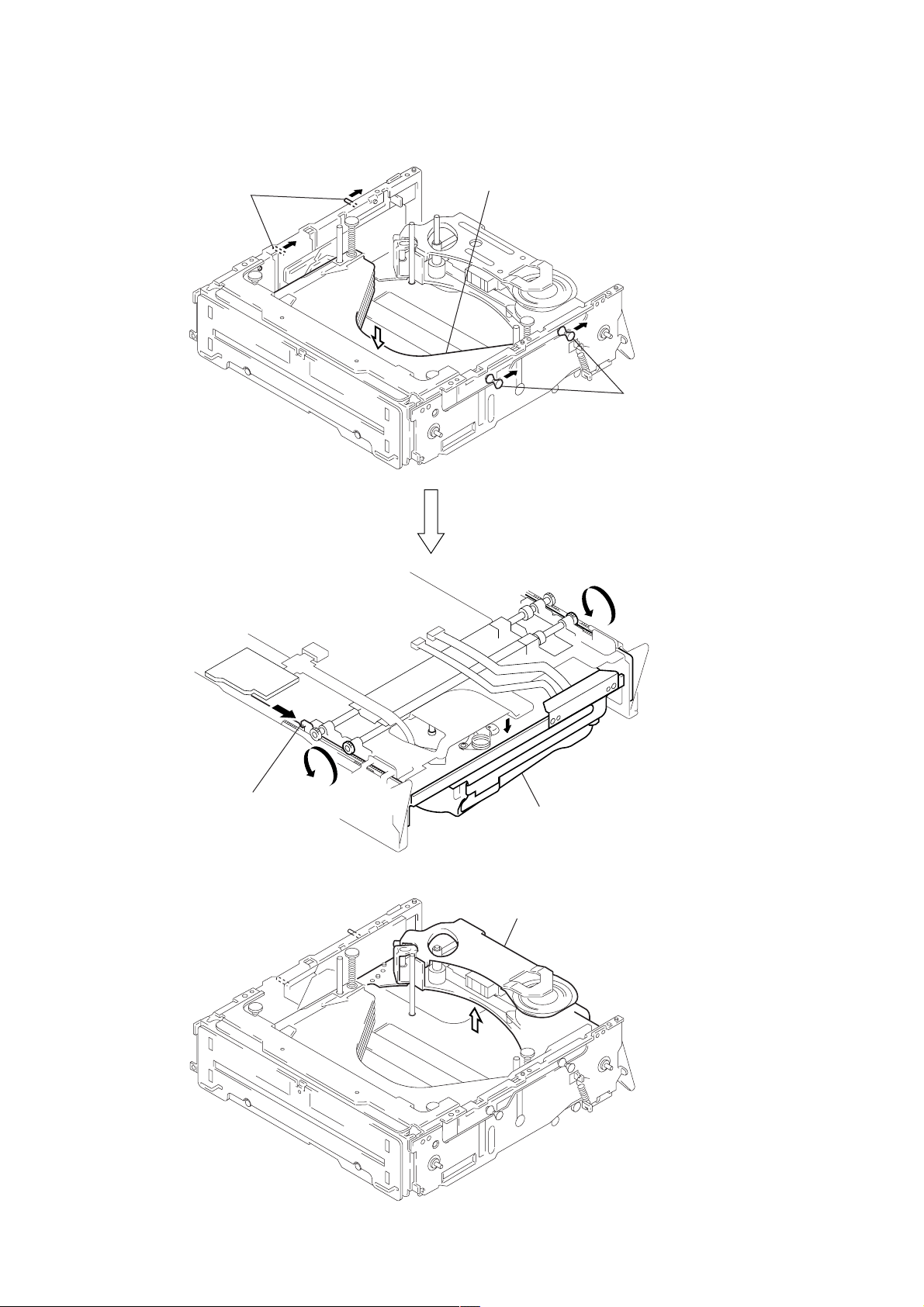

2-10. BRACKET (DE) MAIN ASSY

6

bracket (DE) main assy

4

Remove four solders of

mech motor flexible board.

5

mech motor flexible board

1

mech motor flexible board

(CN502)

2-11. SLIDER (TOP) ASSY

3

2

two screws

(M2)

1

Slide the lever fully in the

direction of the arrow.

3

slider (TOP) assy

2

two type-E stop rings 1.5

1

Slide the lever fully in th

direction of the arrow.

10

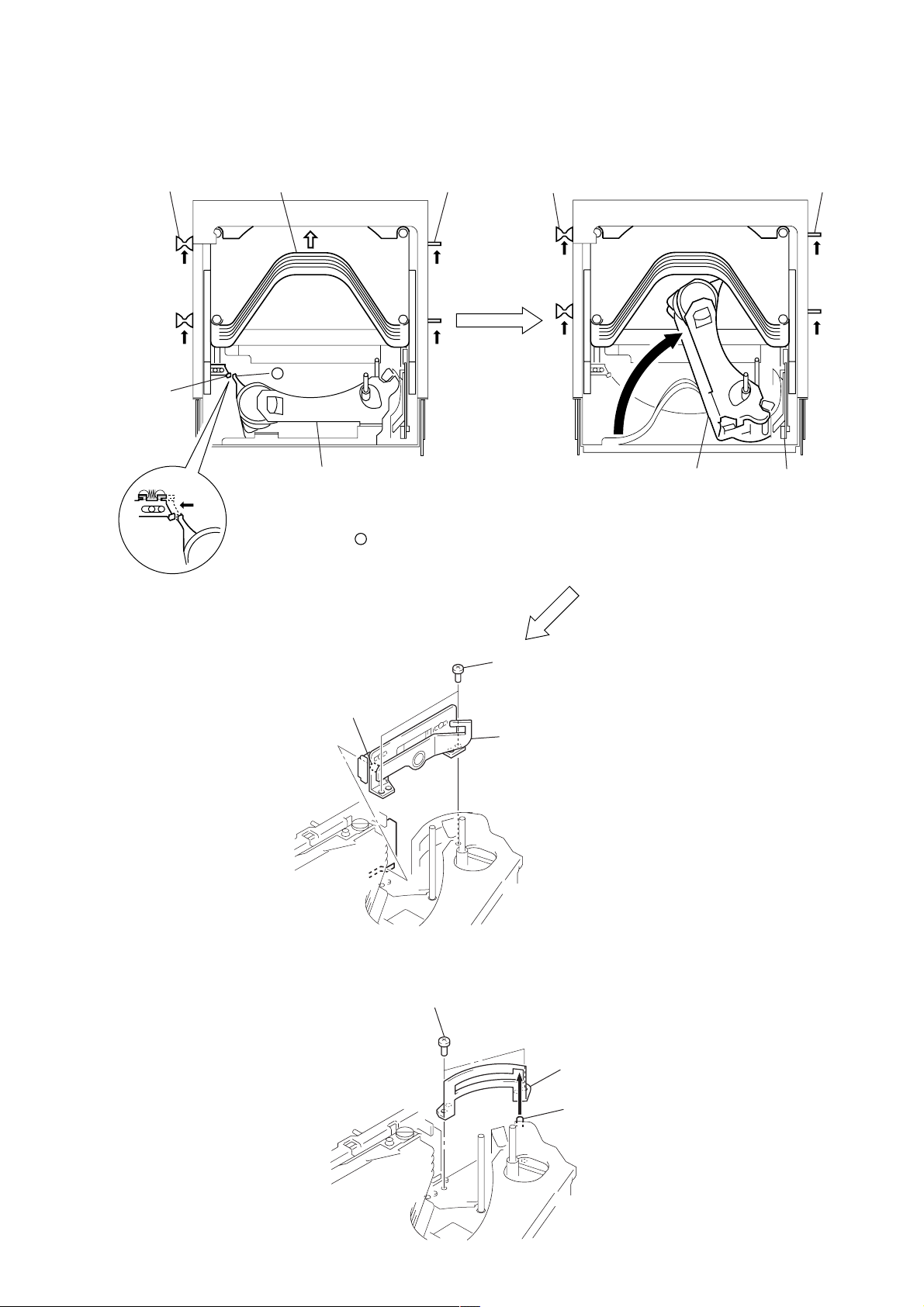

2-12. BRACKET (UD) ASSY

)

– UP view –

CDX-5V661/5V661A/5V661D/5V661S

lever lever leverlever

A A

lever (lock)

tray

a

OP block

1

Slide the levers on both sides in the

direction of arrow A to the position

where the portion a of the OP block

and the lever (lock) can be disconnect.

(The tray goes up to the highest position)

Note: Do not slide the levers on both side

fully in the direction of arrow A in

this step.

A

B

OP block

2

Move the OP block assy in the direction of

arrow B. (PLAY position)

3

Slide the levers on both sides fully in the

direction of arrow A.

A

bracket (UD) assy

2-13. GUIDE (CHUCK)

5

roller (UD)

1

two screws (M1.7)

(P2)

4

two screws (M1.7)

(P2)

6

bracket (UD) assy

3

guide (chuck

2

shaft

11

CDX-5V661/5V661A/5V661D/5V661S

2-14. SETTING THE OP BLOCK ASSY IN THE HIGHEST POSITION

1

Slide levers in the direction of

arrows until the tray goes down

to the lowest position.

tray

1

Slide levers in the direction of

arrows until the tray goes down

to the lowest position.

– bottom view –

2

Slide the lever fully in the

direction of arrow A.

A

OP block assy at the highest position

OP block assy at the highest position

12

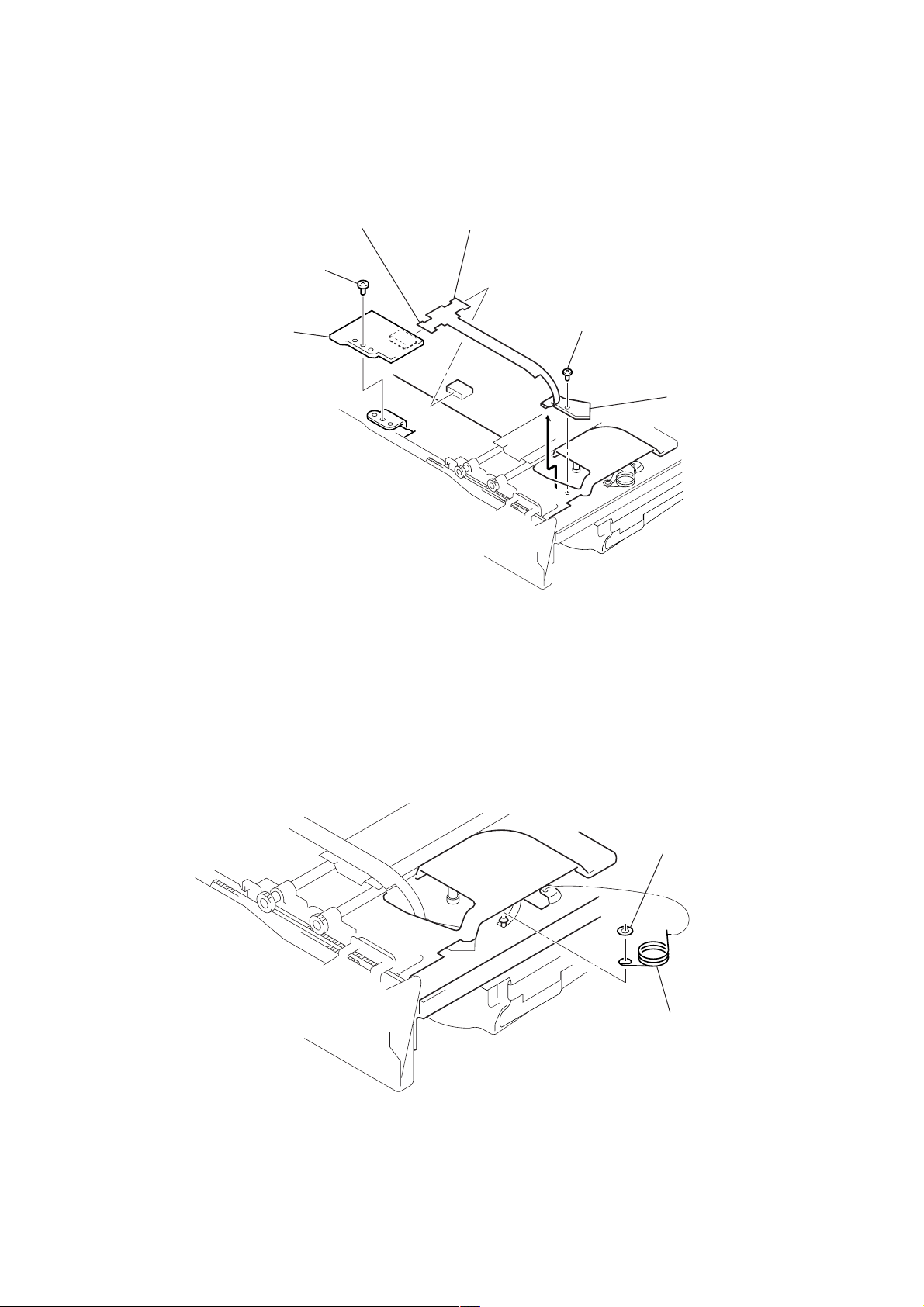

2-15. ADDRESS DETECTION FLEXIBLE BOARD

n

5

Disconnect the address ditection flexible board

from the connector (CN960) on the POS board.

3

screw (M2)

6

POS board

4

Disconnect the address ditection flexible board

from the connector (CN802) on the main board.

CDX-5V661/5V661A/5V661D/5V661S

1

screw

(P1.4 × 1.4)

2

Remove the address detectio

flexible board in the direction

of the arrow.

2-16. TORSION SPRING (OP)

1

washer

2

torsion spring (OP)

13

CDX-5V661/5V661A/5V661D/5V661S

t

2-17. OP BLOCK ASSY

1

two flexible board

(CN201, 301)

3

cover (flexible)

4

Slide the lever fully in the

direction of arrow

A

2

two screws

(special flat head M1.7)

Rotate the OP block assy in the

5

direction of arrow

Remove the OP block assy up

straight carefully to prevent

the portion

tray

.

A

A

a

by the tray.

B

.

a

from being caugh

14

B

A

A

4

Slide the lever fully in the

direction of arrow

A

.

CDX-5V661/5V661A/5V661D/5V661S

L1 L2 L3 L4 L5 L6 L7 L8

: Green

LINE

fix it down (

r

)

fix it

up (

R

)

: Red

RS-232C

uART

RST

uCOM

FL-CDC

OFF

ON

FL-JIG

OFF

ON

CTRLV

OFF

ON

H/U

RADIO

JIG

CDC

JIG

MODE LED

(for checking)

RS-232C Cable Select

STRAIGHT

CROSS

CDC Cable

connector

CDC (changer)

POWER

switch

ON

OFF

+12V GND

Push keys

(Execution keys)

SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 SEG7 SEG8

1234

5678

9 101112

13 14 15 16

Power supply

Display

(7 seg. LED)

Rotary switch

(12 steps)

Jig board

(SJ-5551 PANA BUS2)

SECTION 3

ELECTRICAL ADJUSTMENTS

Adjustment and Check after Repair

The execution of the following adjustment and check after repair can judge OK or NG of the Changer, or can find a faulty part from NG.

Adjustment/Check Repaired/Replaced Parts

Servo information check If optical pickup and MAIN board were replaced

(See 1. Normal Mode on page 22)

Linear position adjustment If linear position or mecha deck was repaired, or MAIN board, microcomputer (IC801)

(See 5. Production Line Mode on page 29) was replaced, or microcomputer software was up dated, or EEPROM (IC810) was re-

placed

LED adjustment If KEY board and EEPROM (IC810) were replaced

(See 6. LED Adjustment on page 31)

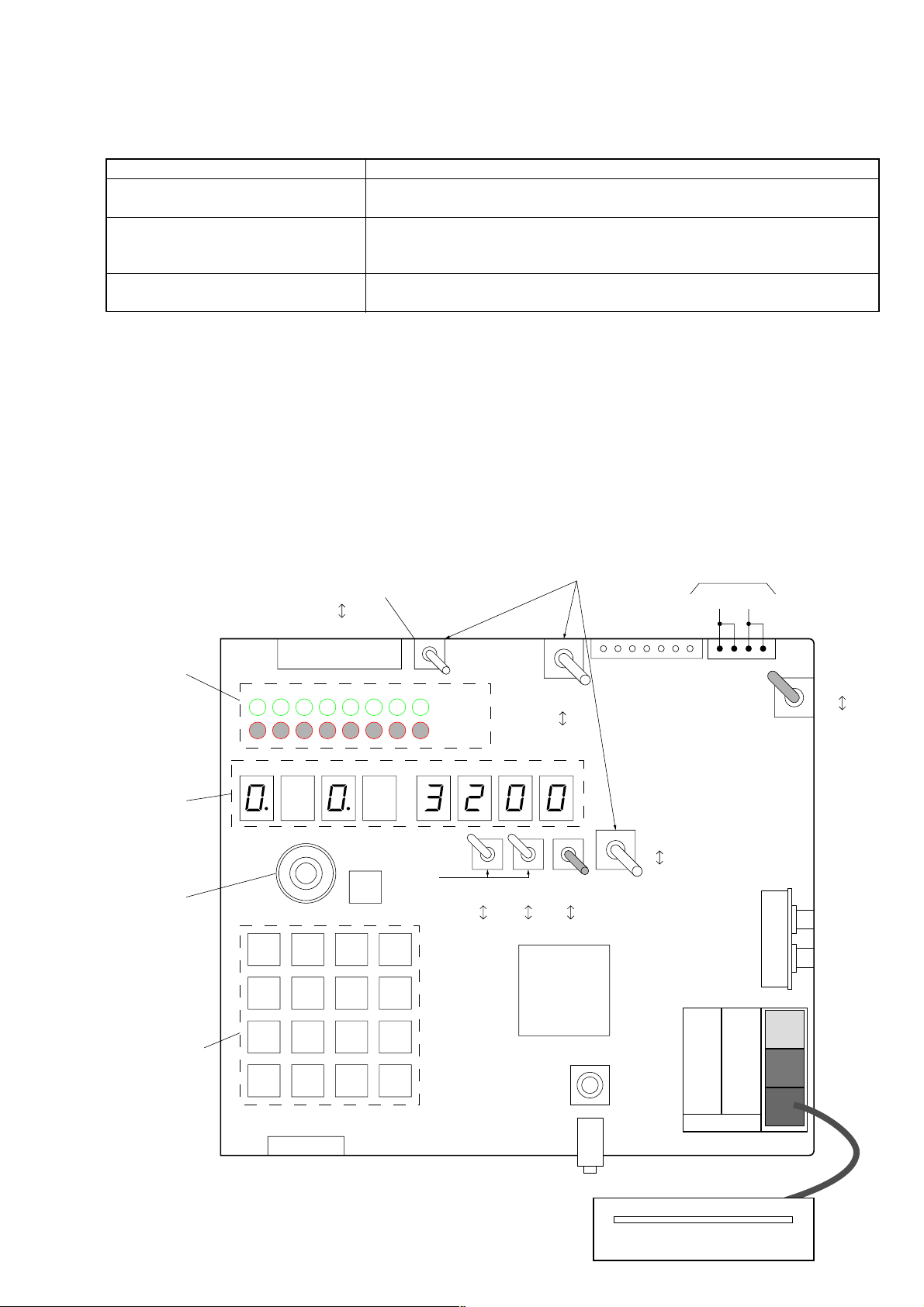

Jig board (SJ-5551 PANA BUS2)

This set (CDC: Changer) operates by receiving command signals from the radio through the PANA-BUS connector. The Changer cannot

operate by itself, and therefore use the jig instead of radio so as to perform the following operations:

• Normal operation

• Error code display (display/clear history)

• Aging operation

• LED luminance adjustment

• Linear position adjustment

• Servo information check

• Manual operation of mechanism motors (Elevator, Loading, Divider)

• EEPROM data reading

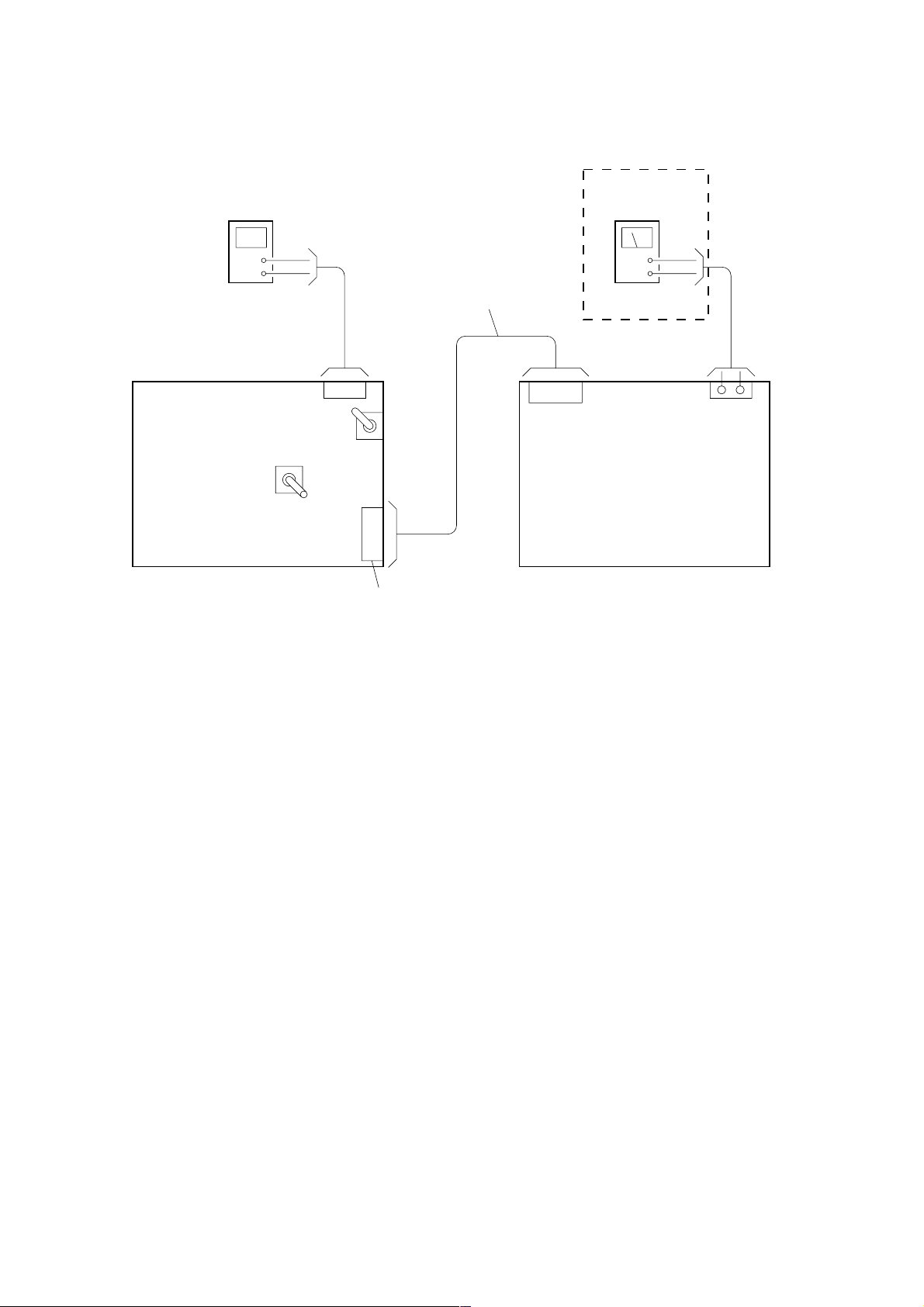

Location of switches and description of connectors

15

CDX-5V661/5V661A/5V661D/5V661S

Toggle Switch Setting in Each Operation Mode

Mode

LINE FL-CDC FL-JIG CTRLV H/U

Setting of Toggle SW

CDC Flash Rewriting CDC ON OFF ON –

JIG Flash Rewriting JIG OFF ON ––

PANA-BUS Conversion Mode JIG OFF OFF ON JIG

Jig Operation Mode – OFF OFF ON JIG

MC Mode CDC OFF OFF ON JIG

Operation Modes

Each operation mode can be selected with the rotary switch.

Mode Use Description

0 Normal Operation Mode Normal operation mode

1 Special Operation Mode PANA-BUS command check mode (for design)

2 Mecha Check Mode Mechanism manual operation

3 Aging Mode Various aging modes (for design and QA)

4 Production Line Mode Aging/linear position adjustment (for line)

5 LED Check Mode LED PWM Duty adjustment

6 Diag Mode Error history check/clear

7

8

9

A

B

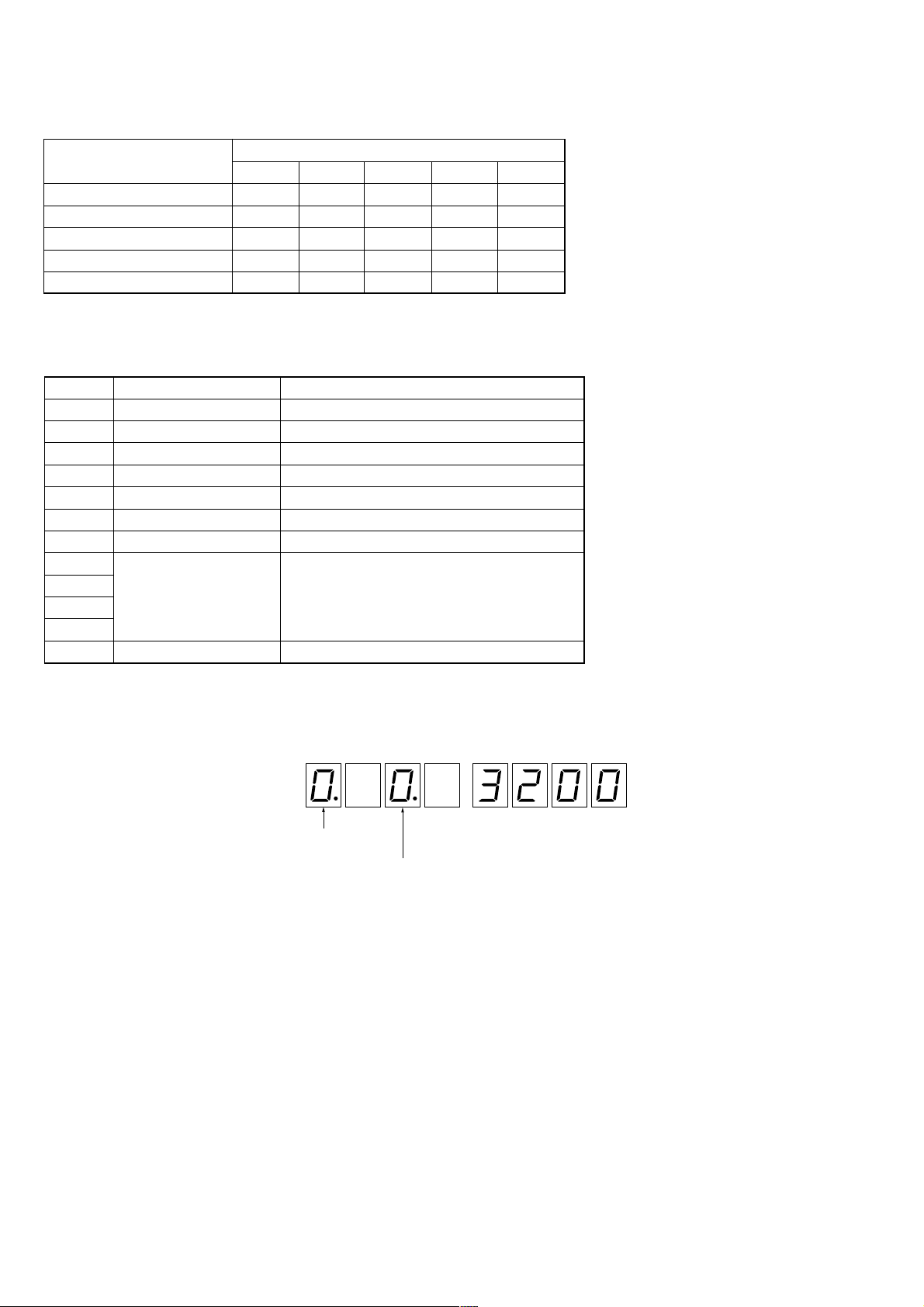

Selection and Indication of Operation Mode and Display Mode

<Selection>

operation mode: rotary switch

display mode: KEY

1

, KEY

2

indication of the display mode

<Indication>

Seg. 1

indication of the operation mode

(when the operation mode is 0.)

Seg. 3 Seg. 5 Seg. 6

Seg. 2

LED

Seg. 7

Seg. 8Seg. 4

16

CDX-5V661/5V661A/5V661D/5V661S

Jig Connection/Connectors

Destination Name

CDC

PC RS-232C connector (for design)

H/U PANA-BUS connector (for design)

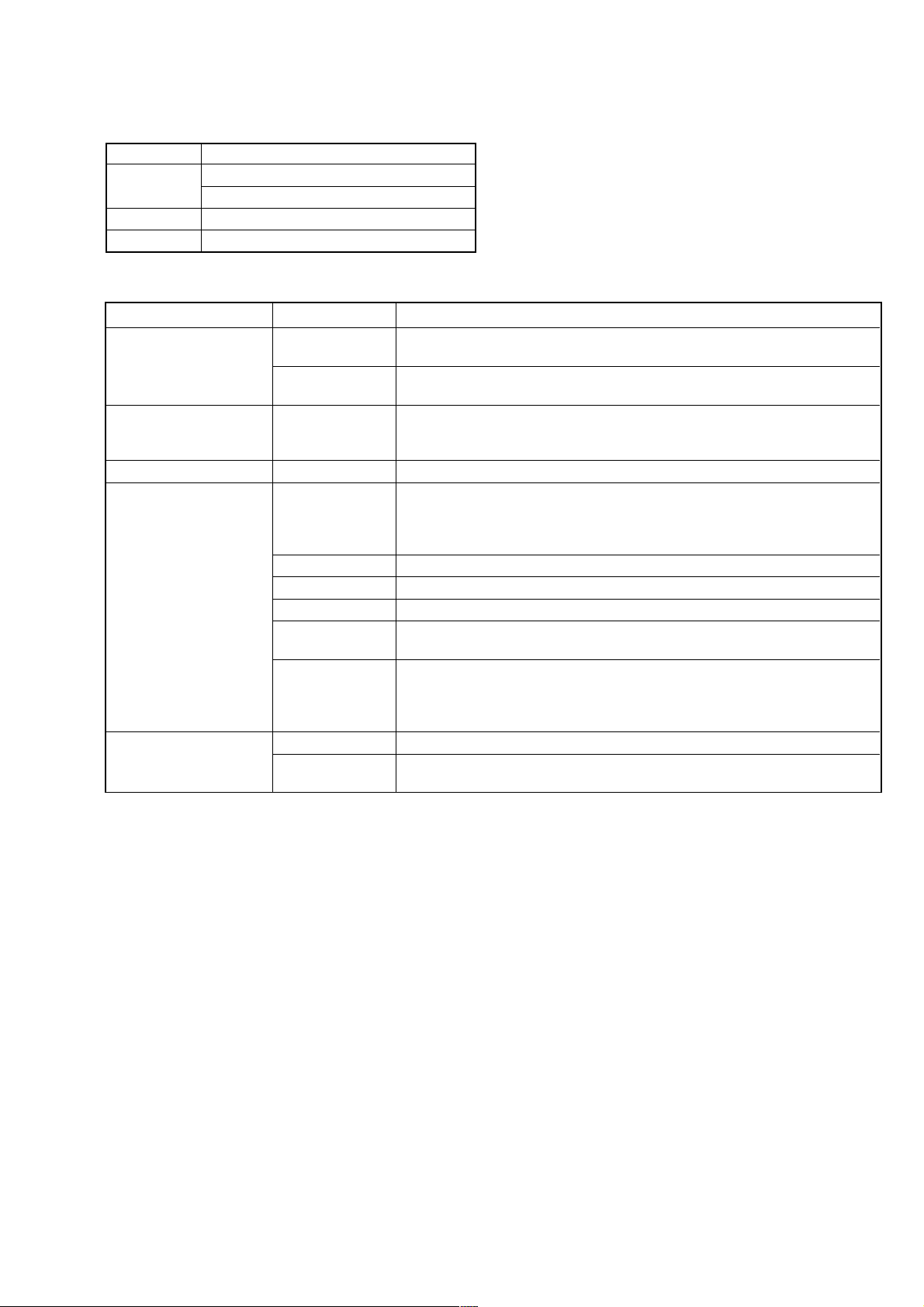

Use of Each Switch and LED on the Jig

MODE LED

(Number to be adjusted)

Display 7 seg LED × 8 Aging count

Rotary SW 12 steps Operation mode selection

Toggle SW FL-JIG Set Jig microcomputer to the Flash Rewrite mode.

Push SW

UART connector (for design)

PANA-BUS connector

Name Type Use

SCAN

SHUFFLE

LINE

FL-CDC Set CDC microcomputer to the Flash Rewrite mode.

CONTROL Control voltage

RS-232C To use str aight cable: STRAIGHT

CABLE SELECT To use cross cable: CROSS

H/U

1 to16 Execution keys according to each operation mode

RST Reset key for Jig and CDC microcomputers

Blink t Disc scan

Lit t All scan

Blink t Disc shuffle

Lit t All shuffle

DTMS

Error

UART line selection

CDC: PC y CDC

JIG: PC y JIG

Head Unit selection

RADIO: Radio connection mode

JIG: PANA-BUS standalone mode

However, CDC cannot be reset unless the UART connector is connected.

17

CDX-5V661/5V661A/5V661D/5V661S

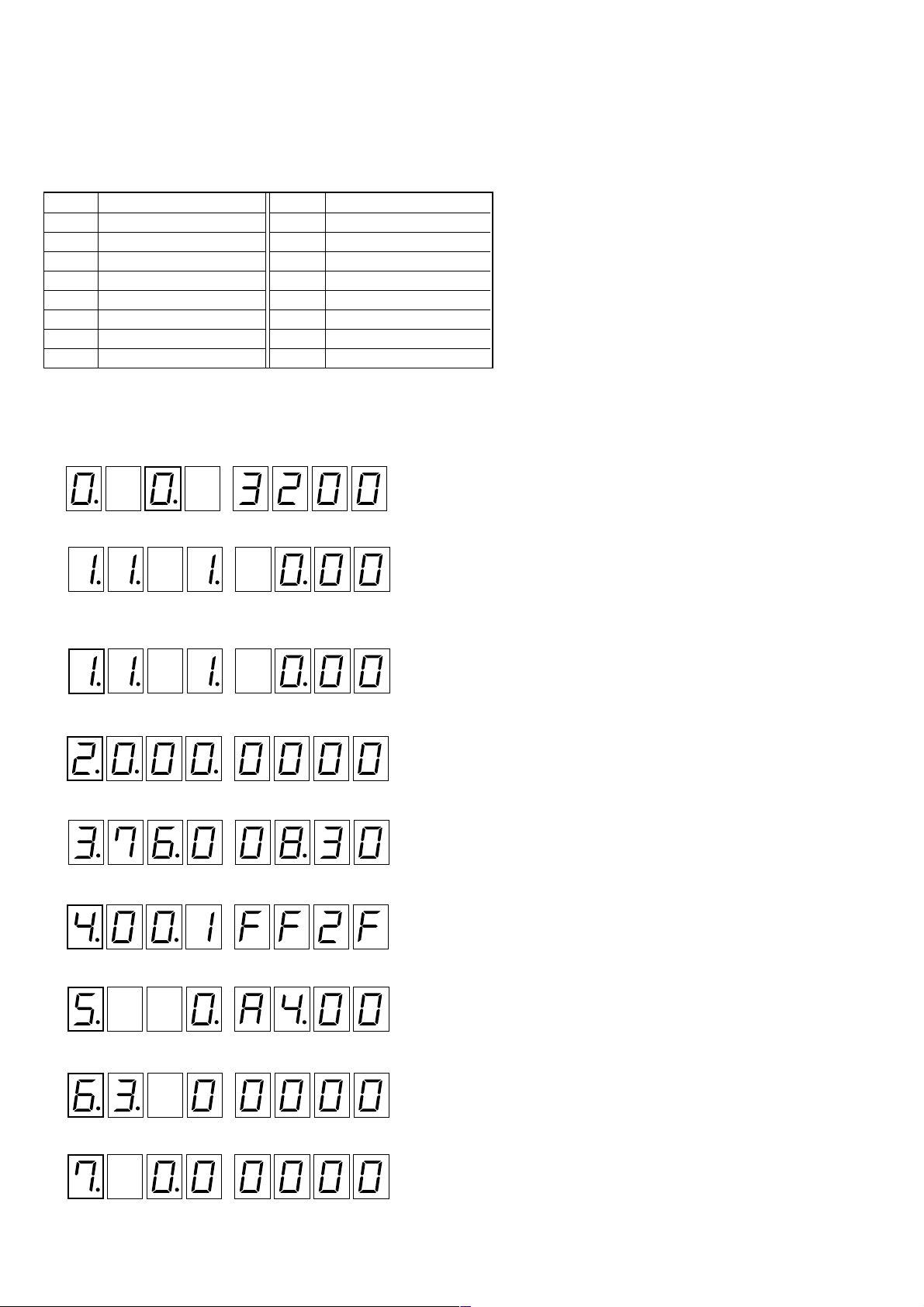

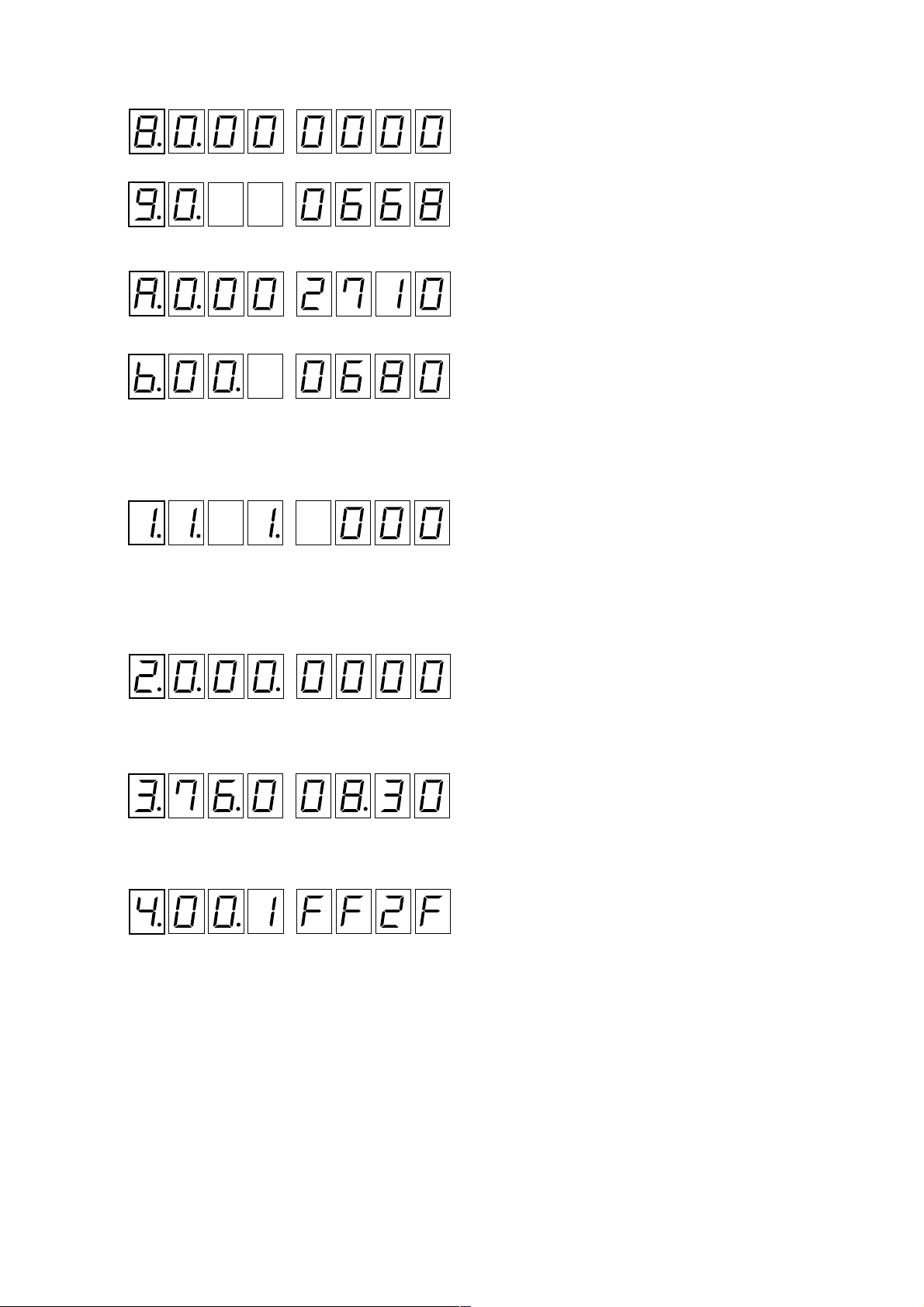

Display (7 Segment LED) List

Disp

Mode Description Display Format

No.

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

Software

0

Version mode No. mode No. (10th place) (Unit place)

1 DTMS

Servo 2: Display ESP

2

Information 1 mode No. Mode

Servo 3: Display Disc check Disc check

3

Information 2 mode No. RFDC RFDC

0: Display Operation Version No. Version No.

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

1: Display

mode No. (10th place) (Unit place) (10th place) (Unit place) (10th place) (Unit place)

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

Disc No.

Track No. Track No. Minute Minute Second Second

D-RAM D-RAM

residual residual Error Rate Error Rate Error Rate Error Rate

capacity capacity

ESP MODE 0: ESP ON, 1: ESP OFF (x1), 2: ESP ON (x2)

Focus Bias Focus Bias Focus Bias Focus Gain Focus Gain

Version No. Version No.

(1st decimal (2nd decimal

place) place)

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

Servo 4: Display

4

Information 3 mode No. Barance Barance Barance Gain Gain

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

5 Mechanism

6 Aging

7 Line 1

8 Line 2 mode No.

5: Display

mode No.

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

6: Display Aging

mode No. mode

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

7: Display

mode No.

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

8: Display

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

9: Display

mode No. (1000th place) (100th place) (10th place) (Unit place)

Jitter Jitter

Linear pos. adj result 0: Not executed, 1:OK, 2: Adj required, 3: Adj & exec required, F: NG

At completion of aging, OK:PASS, NG:Exxvv (xxvv=error code)

Linear pos.

adjustment

result

Linear pos. adj result 0: Not executed, 1: OK, 2: Adj required, 3:Adj & exec required, F:NG

At completion of aging, OK: PASS, NG:Exxvv (xxvv=error code)

Type Data Data Data Data Data Data

Type 0: Serial No., 1: Model No., 2: Production Date

Serial No.: 4 digits, Model No.: 2 digits, Production Date: 6 digits

Data Select

E-F E-F E-F Tracking Tracking

Linear pos.

adjustment

result value value

Count

(10000th

place)

Aging Aging Aging Aging Aging

count count count count count

Linear pos. Linear pos.

A/D value A/D value

Count Count Count Count

(1000th place) (100th place) (10th place) (Unit place)

PWM PWM PWM PWM

Linear pos. Linear pos.

adjusted adjusted

18

9

LED PWM

Adjustment

0: DIM PWM (Night Min)

1: DIM PWM (Night Max)

Data Select 2: IND PWM (Night Min)

3: IND PWM (Night Max)

4: IND PWM (Day Max)

CDX-5V661/5V661A/5V661D/5V661S

Disp

Mode Description Display Format

No.

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

A: Display

LED Data (10th place) (Unit place) place)

A

Display

B DIAG

mode No.

Seg. 1 Seg. 2 Seg. 3 Seg. 4 Seg. 5 Seg. 6 Seg. 7 Seg. 8

B: Display

mode No.

Data select A/D value A/D value (1000th

Error Error

history history Error code Error code Error code Error code

(10th place) (Unit place)

• The software version is displayed at the reset start or when operation mode is changed.

• Select with DISP + /– keys.

• Only the information related to the operation mode is displayed.

Error codes list

Description Code

Sound Off Error 02 00

TOC Error 02 01

Focus Error 03 02

GFS Error 03 03

Access Error 03 04

HOT Error 03 04

Mecha Error 06 ––

Load Transition Error 06 10

Load Max Time Over 06 11

Eject Transition Error 06 20

Eject Max Time Over 06 21

Detecting Position Max Time Over 06 30

Position Av erage Error 06 31

Detecting Address Max Time Over (ST) 06 40

Address undefined Error (ST) 06 41

Home SW Error (ST) 06 42

Detecting Address Max Time Over (OP) 06 50

Address undefined Error (OP) 06 51

Home SW Error (OP) 06 52

Detecting OPP Max Time Over 06 60

Detecting OPH Max Time Over 06 70

OP lever rotated opsite and Detecting OPH Error 06 71

Error Eject Max Time Over 06 80

Load Error 06 90

Eject Give-up 06 91

Eject Give-up 06 92

Shutter Give-up 06 93

Shutter Give-up 06 94

Disc Search Give-up 06 95

Disc Search Give-up 06 96

Disc Search Give-up 06 97

Disc Search Give-up 06 98

Disc Search Give-up 06 99

Disc Search Give-up 06 9A

Disc Search Give-up 06 9B

Disc Search Give-up 06 9C

Disc Search Give-up 06 9D

e

Dimmer Dimmer PWM

Data select

0:DIM PWM current value

1:IND PWM current value

• Description of codes

• ST: Stocker is operating

OP:OP is operating (Playing)

• OPP: OP Play Position

OPH:OP Home Position

xxvv xx: task where the error happened.

PWM PWM PWM

(100th place) (10th place) (Unit place)

02 ....... Actctrl

03 ....... Servo

06 ....... Mecha

vv: Error code

19

CDX-5V661/5V661A/5V661D/5V661S

Disc Loading Method

<To load one disc each>

Operation by buttons on changer front panel Operation by push keys on jig

1. Press

2. Press the button of disc table to be loaded. 2. Press the key of disc table to be loaded (5, 6, 9, 0, qd,

3. Load a disc when the disc LED blinks fast. 3. Load a disc when the disc LED blinks fast.

<To load maximum 6 discs at a time>

1. Press

2. While the disc LED is blinking, load discs in order of disc 2. While the disc LED is blinking, load discs in order of disc

Disc Ejection Method

<To eject one disc each>

1. Press

2. Press the button of disc table to be ejected. 2. Press the key of disc table to be ejected (5, 6, 9, 0, qd,

[LOAD] button. 1. Press 3 key.

qf).

Operation by buttons on changer front panel Operation by push keys on jig

[LOAD] button for more than 3 sec. 1. Press 3 key for more than 3 sec.

table address. table address.

Operation by buttons on changer front panel Operation by push keys on jig

[EJECT] button. 1. Press 4 key.

qf).

• To eject a disc forcibly

1. Press 4 key.

2. Press the key of disc table to be ejected (5, 6, 9, 0, qd,

qf) for more than 3 sec.

<To eject maximum 6 discs at a time>

Operation by buttons on changer front panel Operation by push keys on jig

1. Press

2. Discs are ejected one by one successively in order of address. 2. Discs are ejected one by one successively in order of address.

[EJECT] button for more than 3 sec. 1. Press 4 key for more than 3 sec.

20

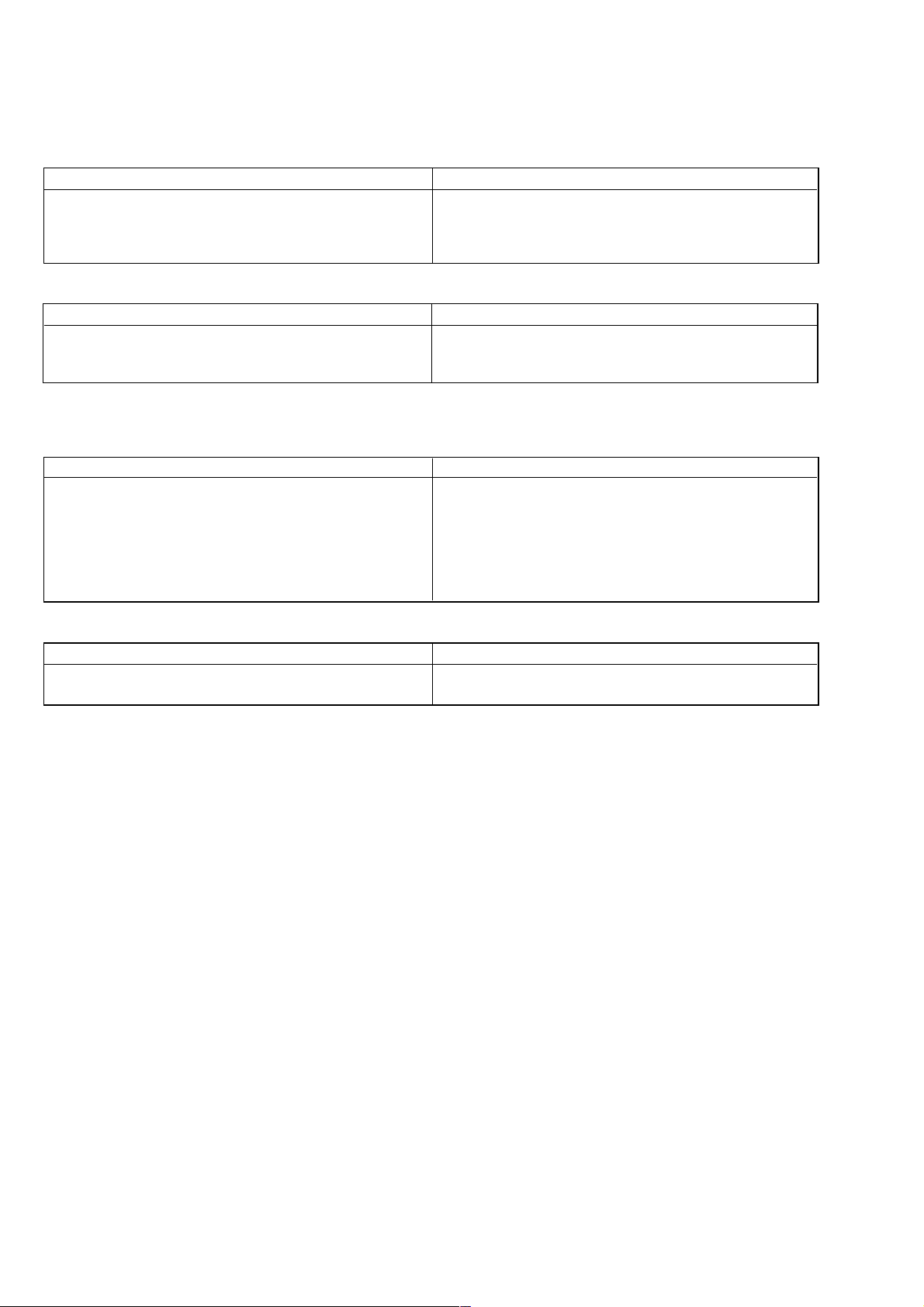

Starting method

Setting:

(DC+12V)

CDX-5V661/5V661A/5V661D/5V661S

LED adjustment mode only

FRQ : 50 to 100Hz

Duty : 10 to 100%

+

–

(Power supply)

CTRLV

Jig board

(SJ-5551 PANA BUS2)

PANA-BUS Cable

POWER

switch

PANA-BUS

connector

+

–

(Duty GEN.)

(CDC: Changer)

Procedure:

1. Connect the CDC (Changer) and Jig with the PANA-BUS connector.

2. Connect the power supply (+12V, GND) to the Jig.

3. Turn ON the POWER switch and the CTRLV switch. (See page 15)

Turning ON/OFF the CTRLV switch makes the ON/OFF control of the PANA-BUS command to the CDC (Changer).

4. For the LED adjustment, a luminance meter is required.

21

CDX-5V661/5V661A/5V661D/5V661S

y

y

y

y

y

y

y

y

1. Normal operation mode (See “Display List” on page 18 and 19)

This mode checks normal operation and servo information.

Push key (execution key) assignment

Key Description

1 DISP –

2 DISP +

3 LOAD

4 EJECT

5 DISC key 1

6 DISC key 4

7 AMS –

8 AMS +

* Whether the PLAY key command or STOP key command is outputted is judged with the status received from the CDC.

(In the PLAY status, the STOP key command is active, or in the STOP status, the PLAY key command is active.)

How to enter the Check mode

1. Rotating the rotary switch, adjust the display (7 Seg LED) to “0” (third place).

Key Description

9 DISC key 2

0 DISC key 5

qa REV

qs CUE

qd DISC key 3

qf DISC key 6

qg ESP

qh PLAY/STOP (*)

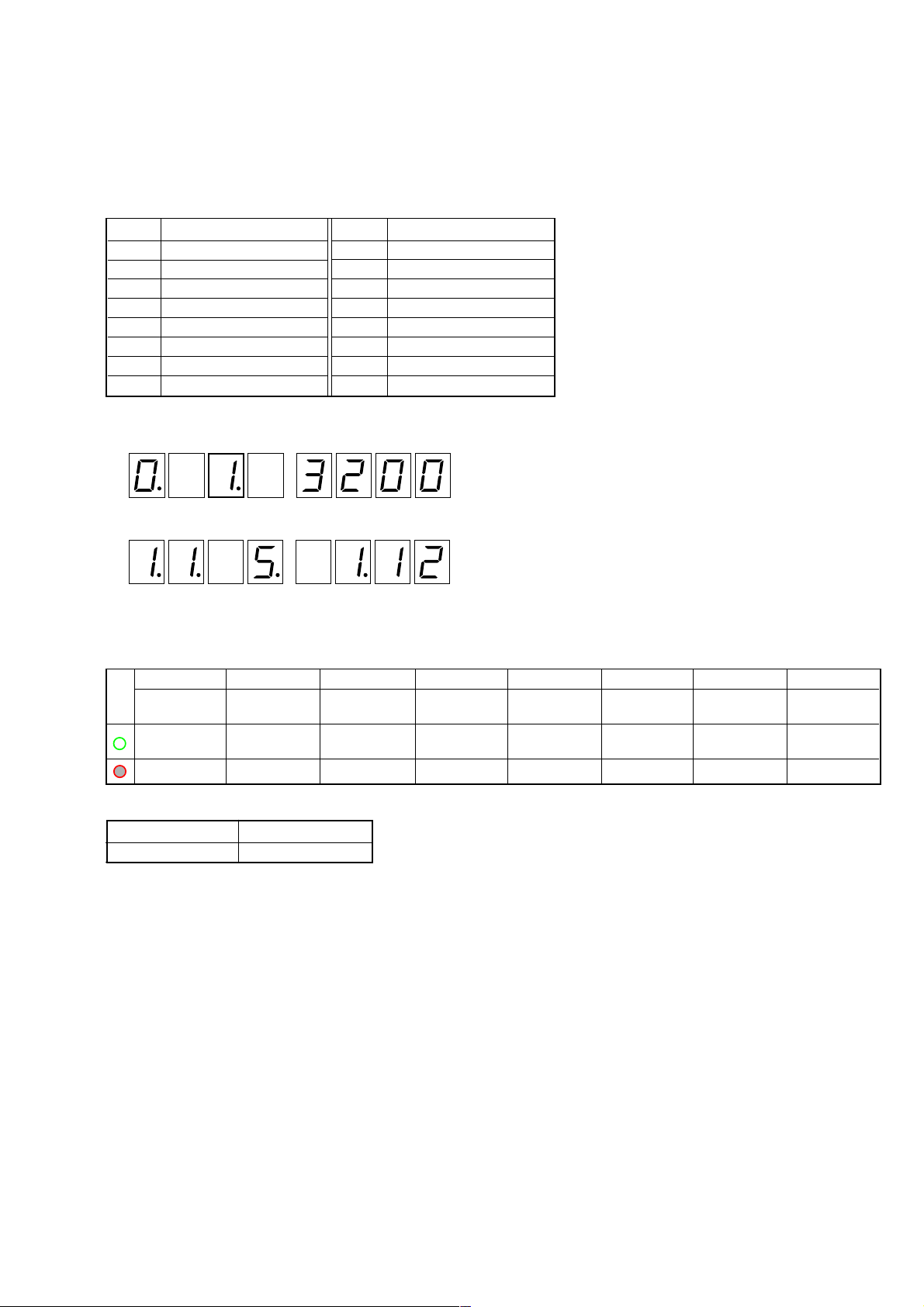

: Software version display

After 2 or 3 seconds, the display will change to the execution mode.

: DTMS displa

2. The display mode number can be changed by pressing 1 or 2 key.

(Example)

: DTMS displa

Press 2 key r R Press 1 key

: Servo information 1 displa

Press 2 key r R Press 1 key

: Servo information 2 displa

Press 2 key r R Press 1 key

: Servo information 3 displa

22

Press 2 key r R Press 1 key

Press 2 key r R Press 1 key

Press 2 key r R Press 1 key

Press 2 key r R Press 1 key

: Mechanism displa

: Aging displa

: Line 1 displa

: Line 2 displa

y

t

y

y

y

y

y

y

Press 2 key r R Press 1 key

: LED PWM Adjustmen

Press 2 key r R Press 1 key

: LED data displa

Press 2 key r R Press 1 key

: DIAG displa

Normal Operation Check (See “Display List” on page 18 and 19)

(Example)

1. Execution mode

CDX-5V661/5V661A/5V661D/5V661S

: DTMS displa

2. Press 3 key, and load a disc. (See “Disc Loading Method” on page 20)

3. Press qh key to check the DTMS in the PLAY status

4. Press other keys to check each operation.

5. Press qh key (STOP).

6. Press 2 key to enter the servo information mode 1.

: Servo information 1 displa

7. Press qh key to check the servo information 1 in the PLAY status.

8. Press qh key (STOP).

9. Press 2 key to enter the servo information mode 2.

: Servo information 2 displa

10. Press qh key to check the servo information 2 in the PLAY status.

11. Press qh key (STOP).

12. Press 2 key to enter the servo information mode 3.

: Servo information 3 displa

13. Press qh key to check the servo information 3 in the PLAY status.

14. The check results of servo information 1-3 can be confirmed with the MODE LED.

23

CDX-5V661/5V661A/5V661D/5V661S

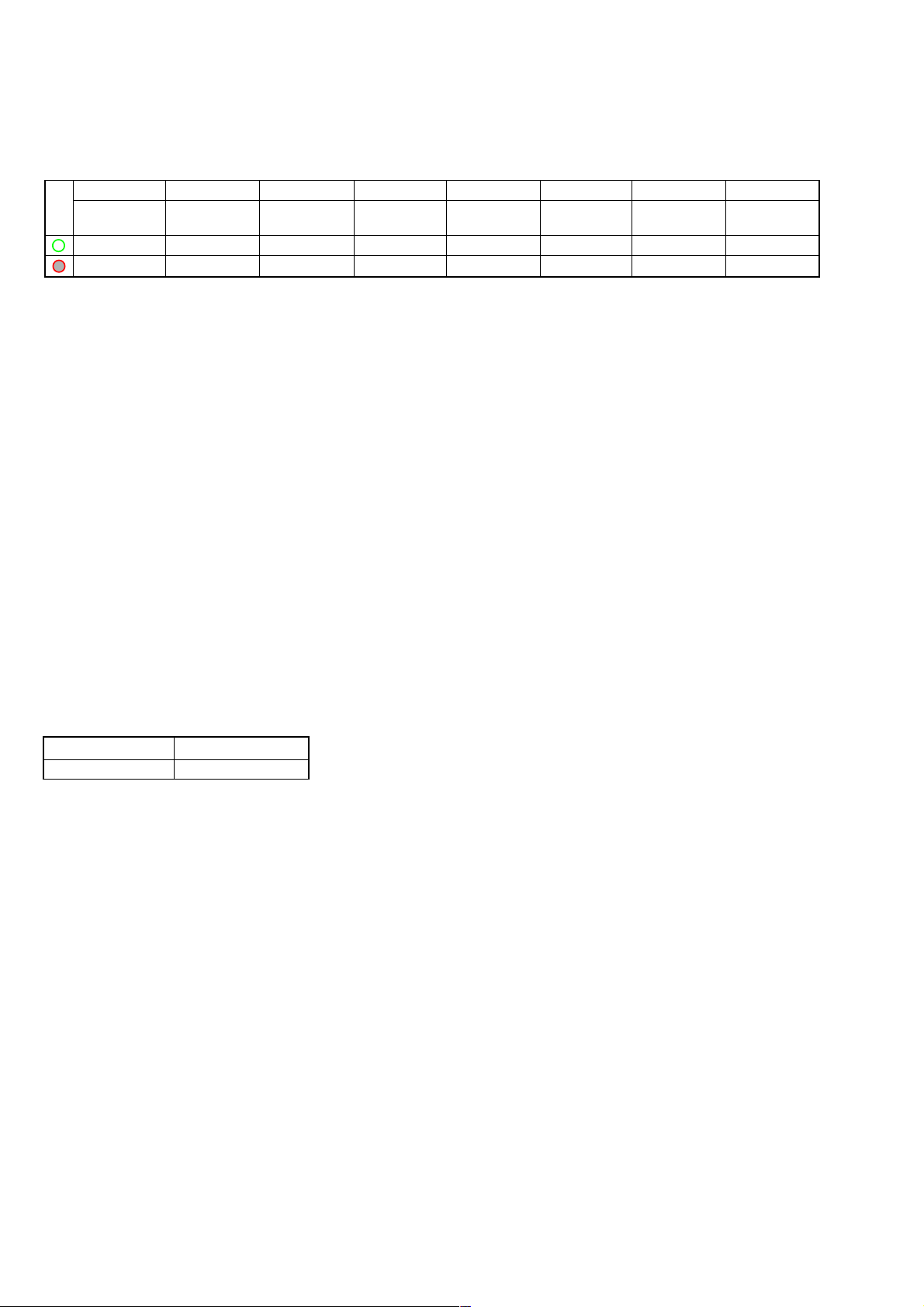

MODE LED Display

Green LED lights up: Normal

Red LED lights up: Abnormal (requiring repair)

L1 L2 L3 L4 L5 L6 L7 L8

ESP

OFF × 1 OK (Note 1) ROM OK (Note 2) OK (Note 3) OK (Note 4) OK (Note 5) OK (Note 6)

OFF × 2 NG (Note 1) RW NG (Note 2) NG (Note 3) NG (Note 4) NG (Note 5) NG (Note 6)

Note 1:OK/NG range of RFDC

050h - 090h is OK.

Other range is NG.

Note 2:OK/NG r ange of Focus Bias

1E9h, 08h, 27h is OK.

Other range is NG.

Note 3:OK/NG range of E-F Balance

000h - 060h and 1A0h - 1FFh are OK.

Other range is NG.

Note 4:OK/NG r ange of Focus Gain

18h - 60h is OK.

Other range is NG.

Note 5: OK/NG range of Tracking Gain

18h - 60h is OK.

Other range is NG.

Note 6:OK/NG range of Error Rate

0000 - 0050 is OK.

Other range is NG.

DISC DISC Focus E-F Focus Tracking

CHECK CHECK Bias Balance Gain Gain

Error Rate

Conditions:

• All items are checked in the PLAY status only.

• Once the Error Rate becomes NG, the NG status is held unless the operation is stopped and the disc is changed.

• Data clear timing t Operation stop and disc change

• OK/NG decision is a standard which is made under the condition that P ATD-012 (test disk) is used and that the temperature of inside of

the machine is 25°C.

Under different condition, the decision might be different.

Default display mode

Display mode No. Description

1 DTMS

24

CDX-5V661/5V661A/5V661D/5V661S

y

y

2. Special Operation Mode

This mode can check the CD operations such as scan, repeat, and random.

(Changer control check function by issuing PANA-BUS commands)

Push key (execution key) assignment

Key Description

1 SCAN IN A DISC

2 SCAN ALL

3

4

5 DISC SHUFFLE

6 MAGAZINE SHUFFLE

7 DISC DOWN

8 DISC UP

How to enter the Check mode

1. Rotating the rotary switch, adjust the display (7 Seg LED) to “1” (third place).

Key Description

9 RANDOM 1

0 RANDOM ALL

qa

TRACK SEARCH DOWN

qs TRACK SEARCH UP

qd REPEAT/RANDOM

qf NOP

qg PAUSE

qh PLAY 2/STOP

: Software version displa

2. After 2 or 3 seconds, the display will change to the execution mode.

: DTMS displa

3. Load a disc. (See “Disc Loading Method” on page 20)

4. Each operation can be checked with the push keys.

MODE LED display

L1 L2 L3 L4 L5 L6 L7 L8

RANDAM SCAN

ON: Light up ON: Light up ON: Light up

OFF: Go off OFF: Go off OFF: Go off

––– ––– ––

RANDAM

ALL

––– ––

––– ––

Default display mode

Display mode No. Description

1 DTMS

25

CDX-5V661/5V661A/5V661D/5V661S

y

y

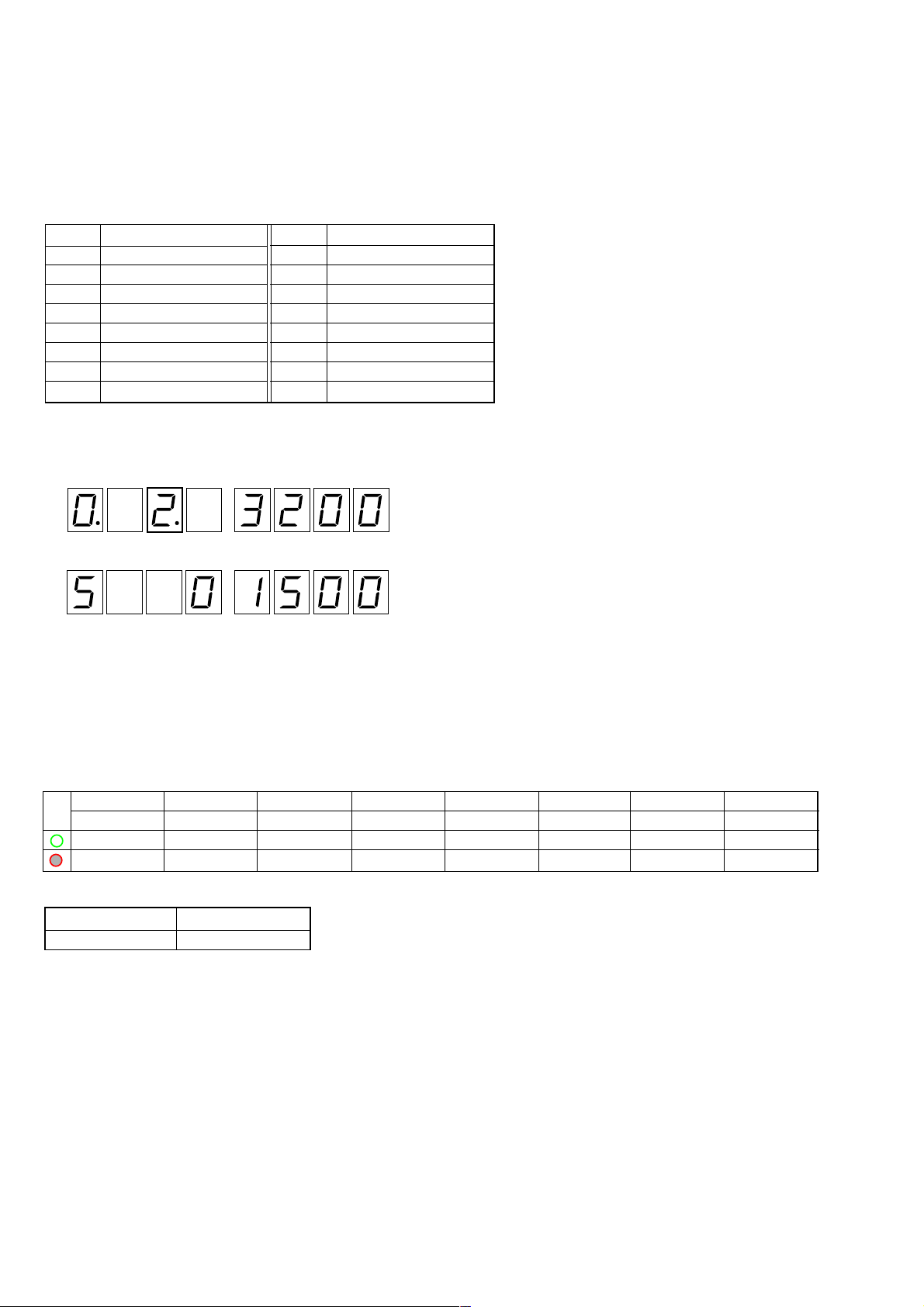

3. Mechanism Check Mode (See “Display List” on page 18 and 19)

This mode can adjust the linear position and check manually the operation of the elevator motor, loading motor, and divider motor.

Also, the disc can be ejected forcibly by moving each motor manually.

However, manual operation could destroy the mechanism depending on the mechanical position, thus requiring extreme care.

Push key (execution key) assignment

Key Description

1 DISP –

2 DISP +

3 ELEVATOR MOTOR -

4 ELEVATOR MOTOR +

5

6

7 LOADING MOTOR -

8 LOADING MOTOR +

* The check results of each key cannot be confirmed with the MODE LED.

How to enter the Check mode

1. Rotating the rotary switch, adjust the display (7 Seg LED) to “2” (third place).

Key Description

9

0

qa DIVIDER MOTOR –

qs DIVIDER MOTOR +

qd

qf

qg

qh LINEAR POSITION ADJUST

: Software version displa

After 2 or 3 seconds, the display will change to the execution mode.

: DTMS displa

2. The display mode number can be changed by pressing the 1 and 2 keys.

(See “Example” in step 2 in the Normal mode on page 22 and 23)

3. Press 3 and 4 keys to check manually the elevator motor operation.

4. Press 7 and 8 keys to check manually the loading motor operation.

5. Press qa and qs keys to check manually the divider motor operation.

6. The linear position can be adjusted by pressing qh key.

For the adjusted values and adjustment results, see “Display List” (page 18 and 19).

MODE LED display

L1 L2 L3 L4 L5 L6 L7 L8

––– ––– ––

––– ––– ––

––– ––– ––

Default display mode

Display mode No. Description

5 Mechanism

26

Loading...

Loading...