Sony CDX-4000RV Service manual

CDX-4000RV

SERVICE MANUAL

Ver 1.1 2000. 08

• The tuner and CD sections have no adjustments.

SPECIFICATIONS

Model Name Using Similar Mechanism CDX-3900R/4000R/4000RX

CD Drive Mechanism Type MG-383Z-121//Q

Optical Pick-up Name KSS-720A

AEP Model

UK Model

CD player section

Signal-to-noise ratio 90 dB

Frequency response 10 – 20,000 Hz

Wow and flutter Below measurable limit

Tuner section

FM

Tuning range 87.5 – 108.0 MHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Usable sensitivity 8 dBf

Selectivity 75 dB at 400 kHz

Signal-to-noise ratio 66 dB (stereo),

72 dB (mono)

Harmonic distortion at 1 kHz

0.6% (stereo),

0.3% (mono)

Separation 35 dB at 1 kHz

Frequency response 30 – 15,000 Hz

MW/LW

Tuning range MW: 531 – 1,602 kHz

LW: 153 – 279 kHz

Aerial terminal External aerial connector

Intermediate frequency 10.7 MHz/450 kHz

Sensitivity MW: 30 µV

LW: 40 µV

Power amplifier section

Outputs Speaker outputs

(sure seal connectors)

Speaker impedance 4 – 8 ohms

Maximum power output 50 W × 4 (at 4 ohms)

General

Outputs Audio outputs

Power aerial relay control

lead

Power amplifier control

lead

Telephone ATT control

lead

Tone controls Bass ±9 dB at 100 Hz

Treble ±9 dB at 10 kHz

Power requirements 12 V DC car battery

(negative ground)

Dimensions Approx. 178 × 50 × 183 mm

(w/h/d)

Mounting dimension Approx. 182 × 53 × 162 mm

(w/h/d)

Mass Approx. 1.2 kg

Supplied accessories Parts for installation and

connections (1 set)

Front panel case (1)

Design and specifications are subject to change without

notice.

FM/MW/LW COMPACT DISC PLAYER

1

Ver 1.1 2000. 08

SERVICE NOTES

This product is classified as a CLASS 1 LASER PRODUCT.

This label is located on the bottom of the

chassis.

This label is located on the drive unit's internal

chassis.

When replacing the chassis (T) of mechanism deck which have

the “CAUTION LABEL” attached, please be sure to put a new

CAUTION LABEL (3-223-913-11) to the chassis (T).

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objective lens.

TABLE OF CONTENTS

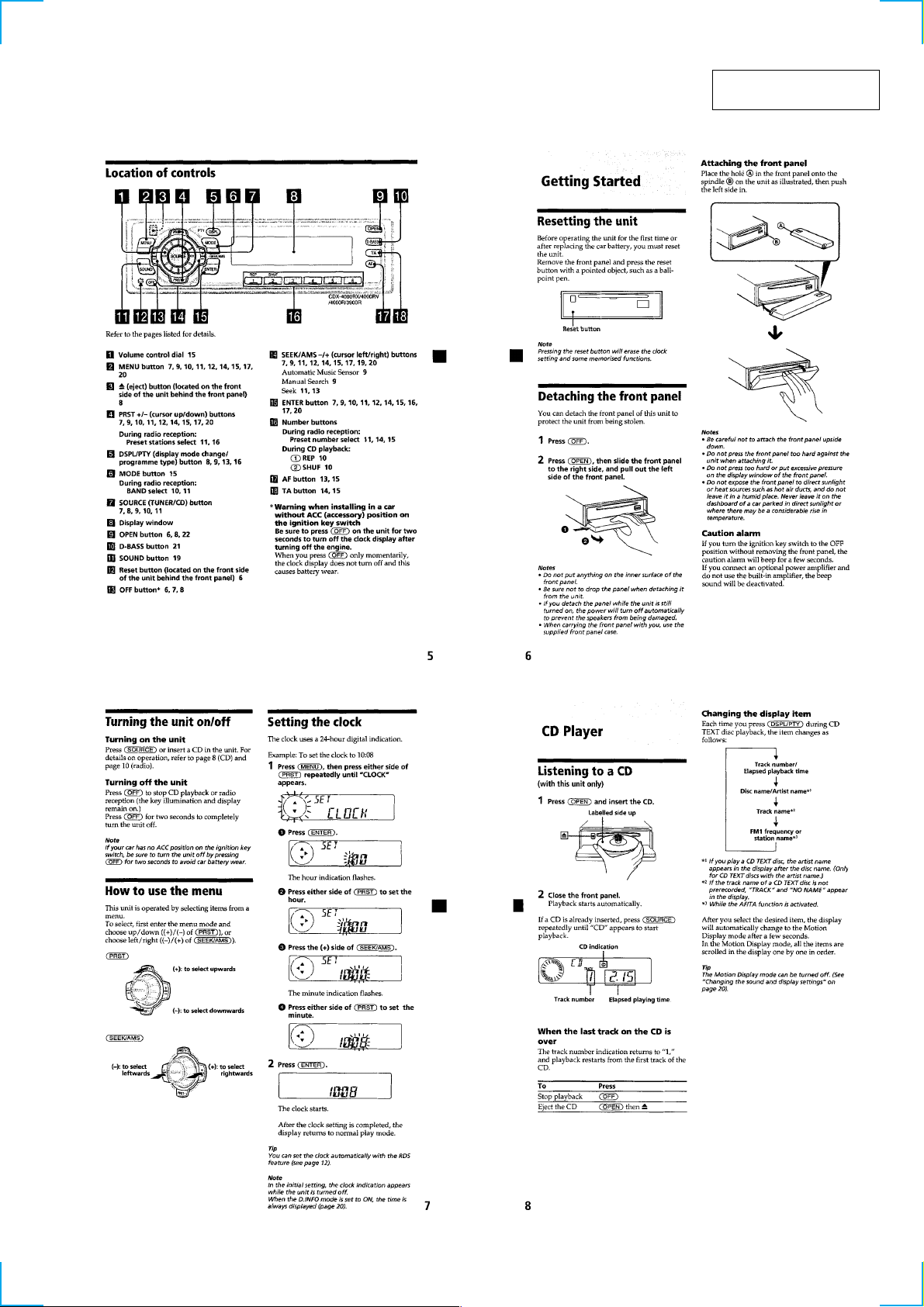

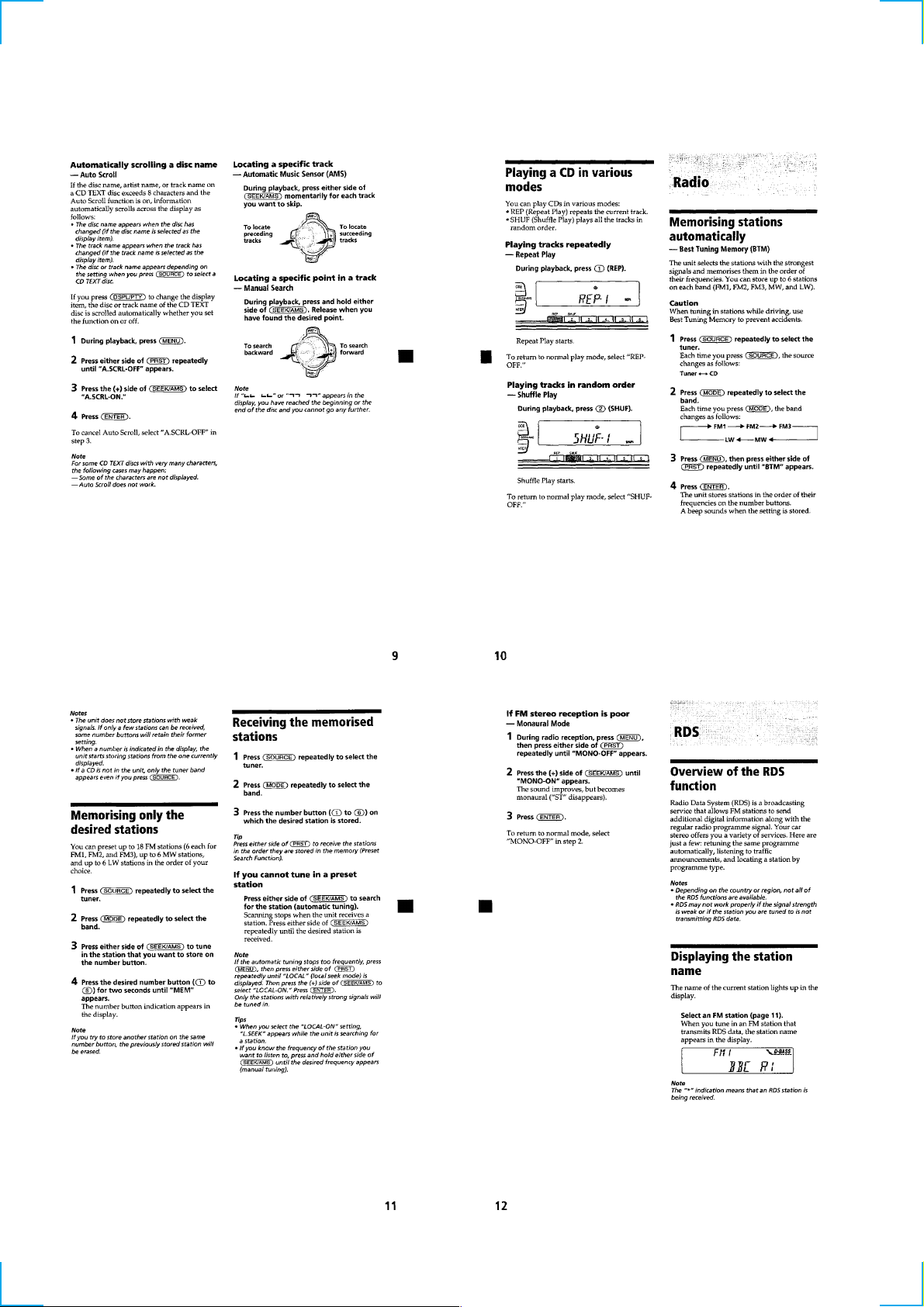

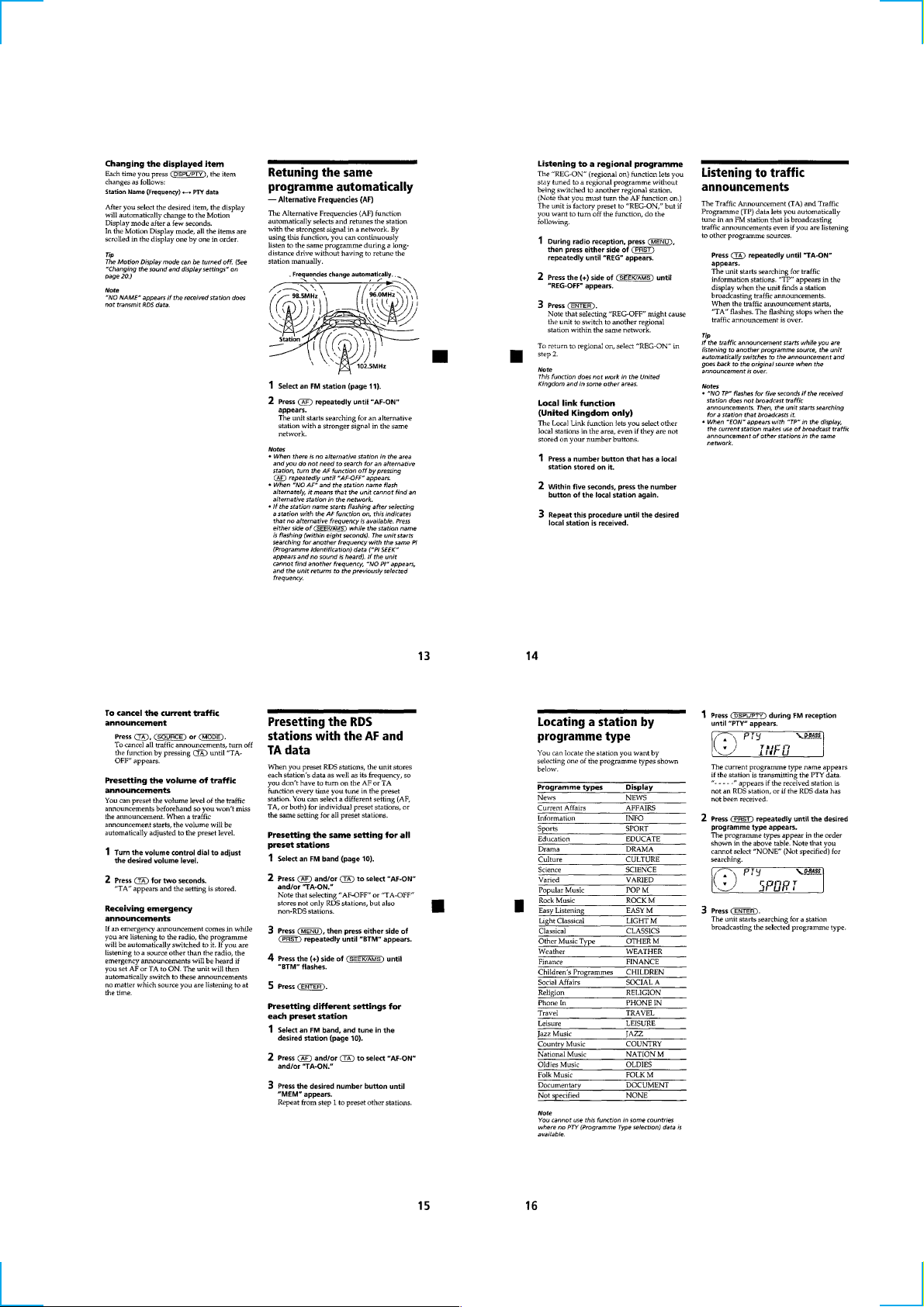

1. GENERAL

Location of controls................................................................. 3

Getting Started......................................................................... 3

Setting the clock ...................................................................... 3

CD Player ................................................................................ 3

Radio ....................................................................................... 4

RDS ......................................................................................... 4

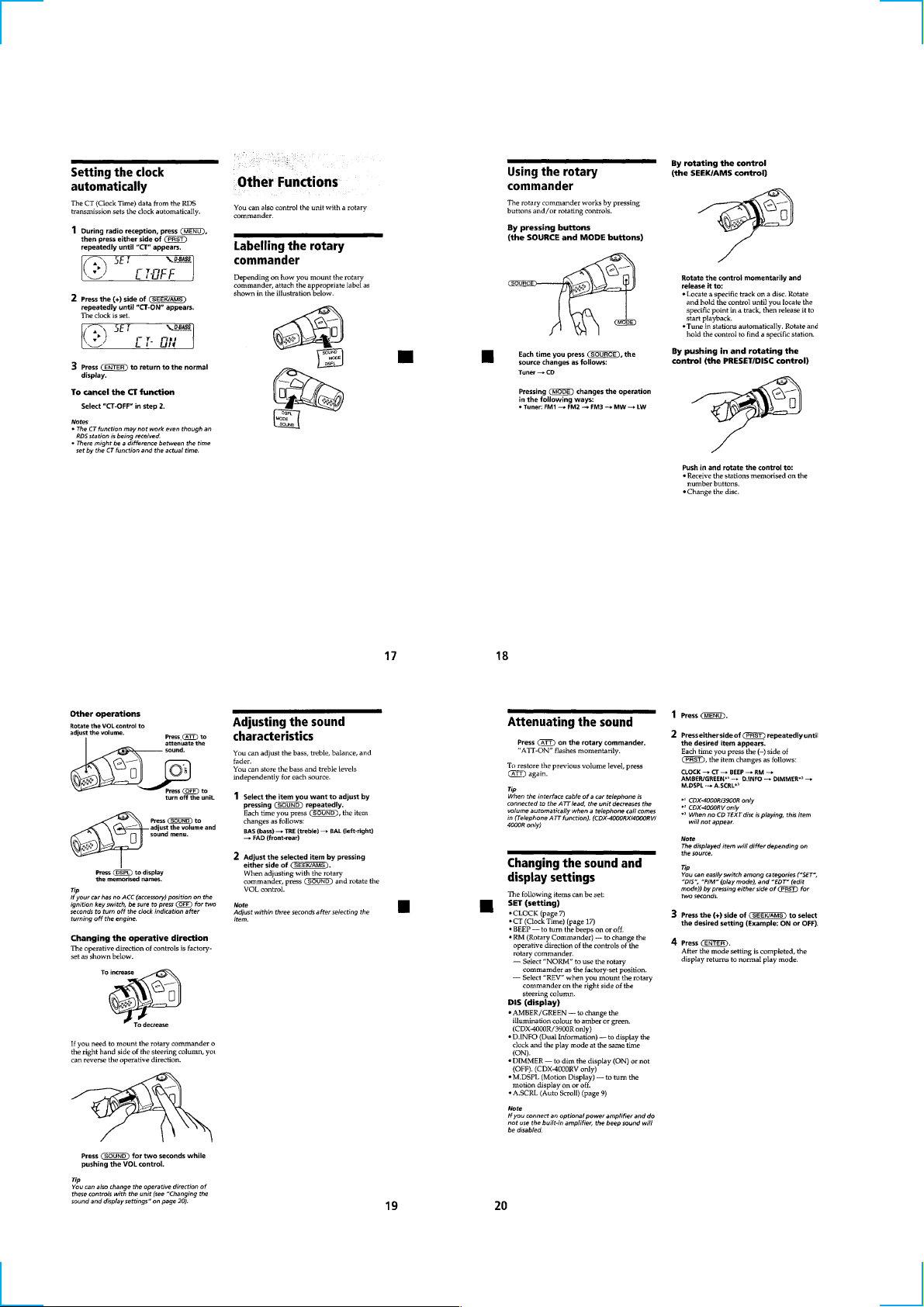

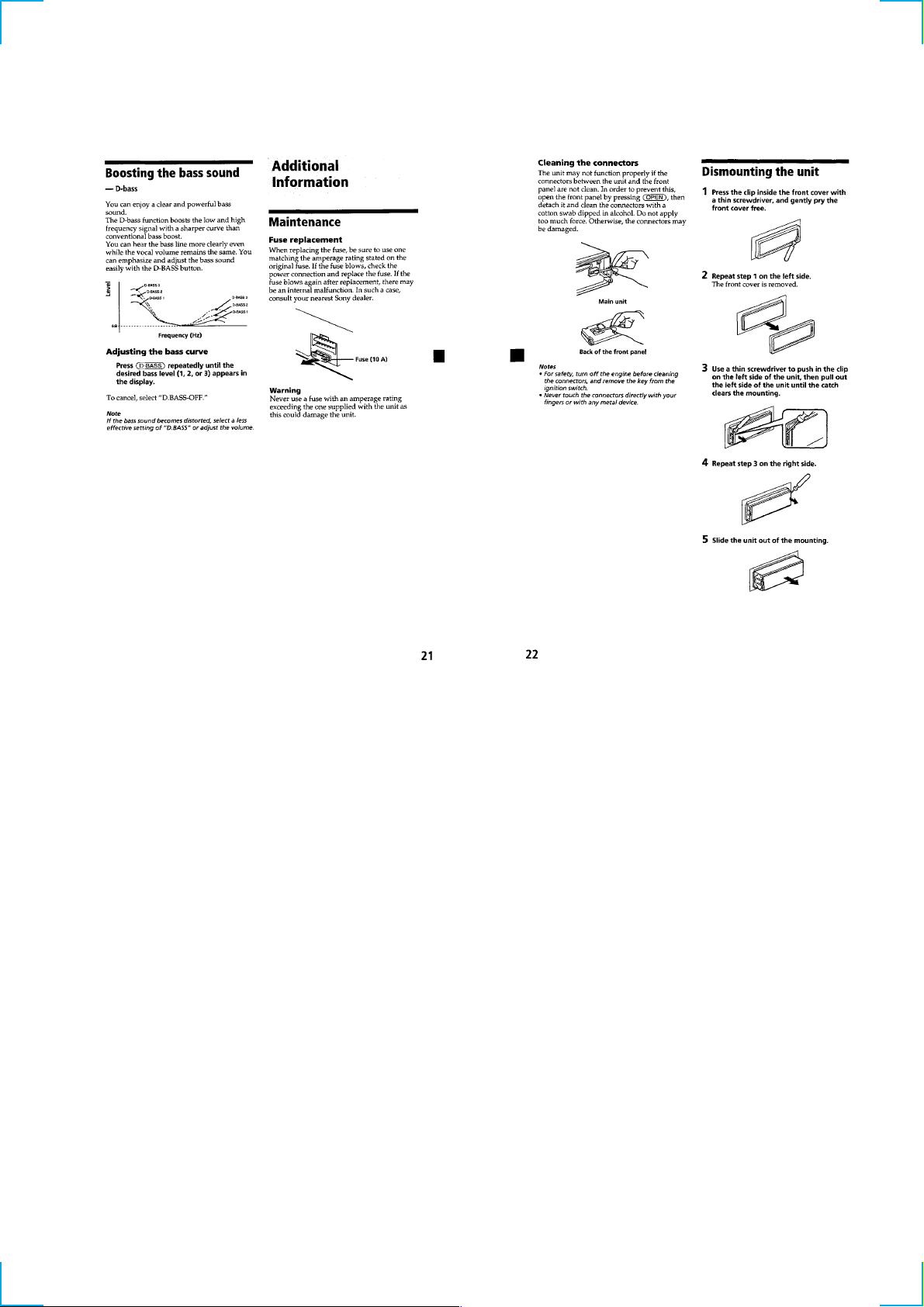

Other Functions ....................................................................... 6

Additional Information............................................................ 7

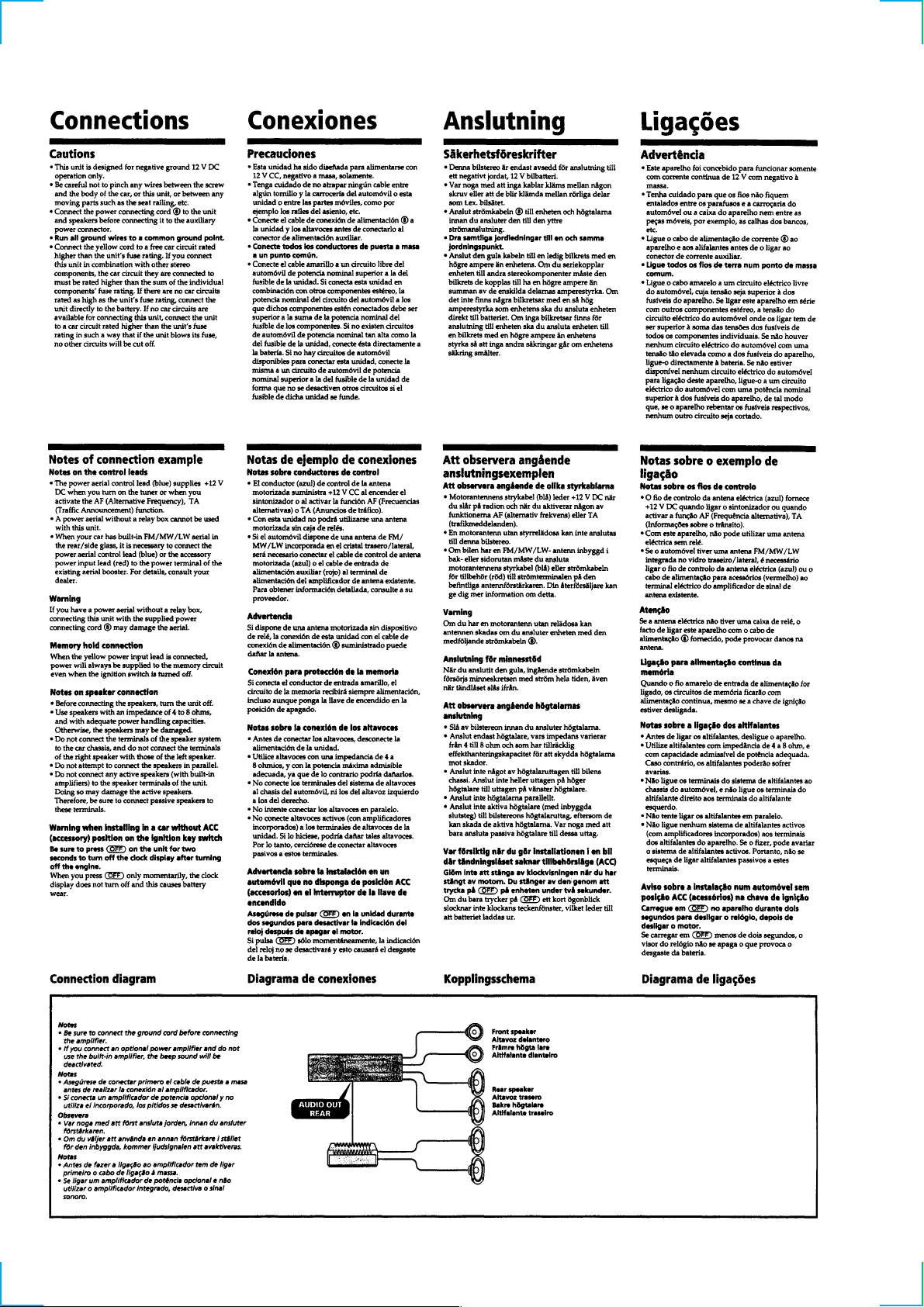

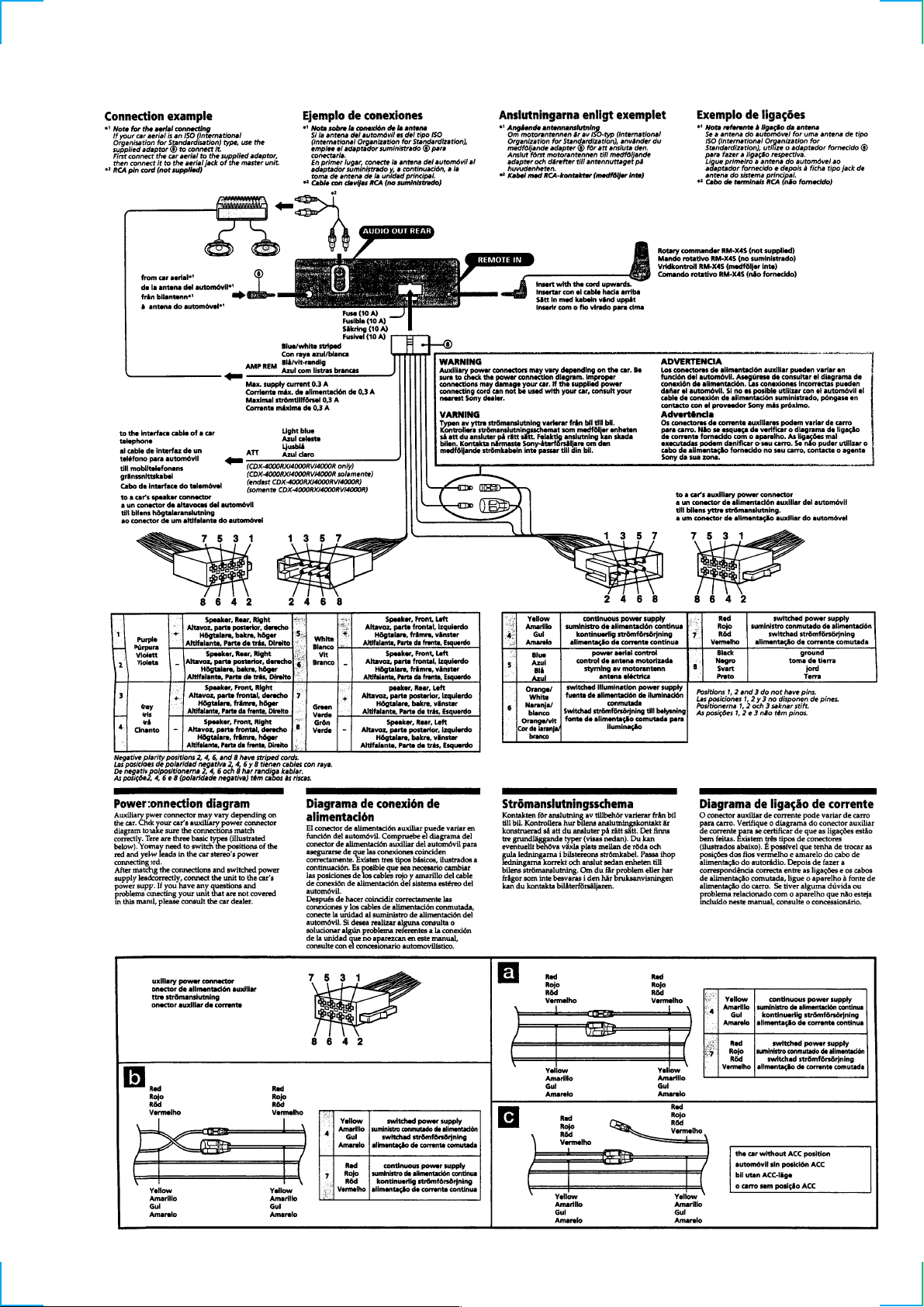

Connections ............................................................................. 8

2. DISASSEMBLY

2-1. Sub Panel Assy.................................................................. 10

2-2. CD Mechanism Block ....................................................... 10

2-3. Main Board ....................................................................... 11

2-4. Heat Sink ...........................................................................11

2-5. Chassis (T) Assy................................................................12

2-6. Lever Assy .........................................................................12

2-7. Servo Board....................................................................... 13

2-8. ARM Roller Assy .............................................................. 13

2-9. Chassis (OP) Assy............................................................. 14

2-10. Optical Pick-up Block ....................................................... 14

3. DIAGRAMS

3-1. IC Pin Descriptions ........................................................... 15

3-2. Block Diagram –CD Section–........................................... 21

3-3. Block Diagram –Tuner Section–....................................... 22

3-4. Block Diagram –Display Section–.................................... 23

3-5. Circuit Boards Location .................................................... 23

3-6. Printed Wiring Boards –CD Mechanism Section–............ 24

3-7. Schematic Diagram –CD Mechanism Section (1/2)– ....... 26

3-8. Schematic Diagram –CD Mechanism Section (2/2)– ....... 27

3-9. Printed Wiring Board –Main Section– .............................. 28

3-10. Schematic Diagram –Main Section (1/3)– ........................30

3-11. Schematic Diagram –Main Section (2/3)– ........................31

3-12. Schematic Diagram –Main Section (3/3)– ........................32

3-13. Schematic Diagram –Sub (CD) Section–.......................... 33

3-14. Printed Wiring Board –Sub (CD) Section– ....................... 34

3-15. Printed Wiring Board –Key Section– ................................35

3-16. Schematic Diagram –Key Section–...................................36

Notes on Chip Component Replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE

WITH MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

P ART NUMBERS APPEAR AS SHOWN IN THIS MANU AL OR

IN SUPPLEMENTS PUBLISHED BY SONY.

2

4. EXPLODED VIEWS

4-1. Chassis Section ................................................................. 40

4-2. Front Panel Section ........................................................... 41

4-3. CD Mechanism Section (1) ...............................................42

4-4. CD Mechanism Section (2) ...............................................43

4-5. CD Mechanism Section (3) ...............................................44

5. ELECTRICAL PARTS LIST ........................................ 45

SECTION 1

GENERAL

This section is extracted

from instruction manual.

3

45678910

SECTION 2

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

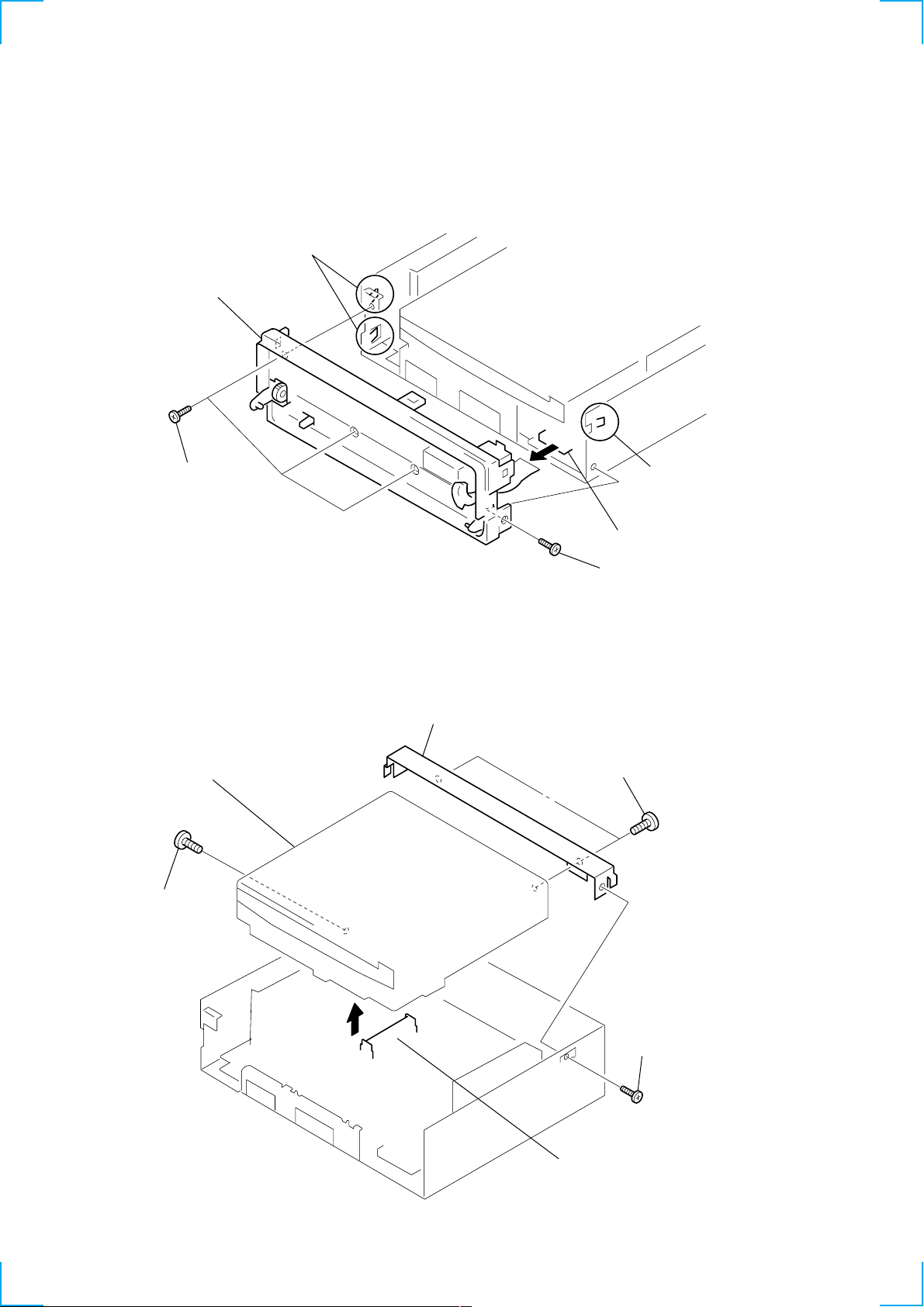

2-1. SUB PANEL ASSY

4 two claws

6 sub panel assy

2 PTT 2.6x8

2-2. CD MECHANISM BLOCK

5 CD mechanism block

2 PTT 2.6x6

3 claw

5 CN500

1 PTT 2.6x8

7 bracket (CD)

6 PTT 2.6x5

3

1 PTT 2.6x5

4 CN301

8

8

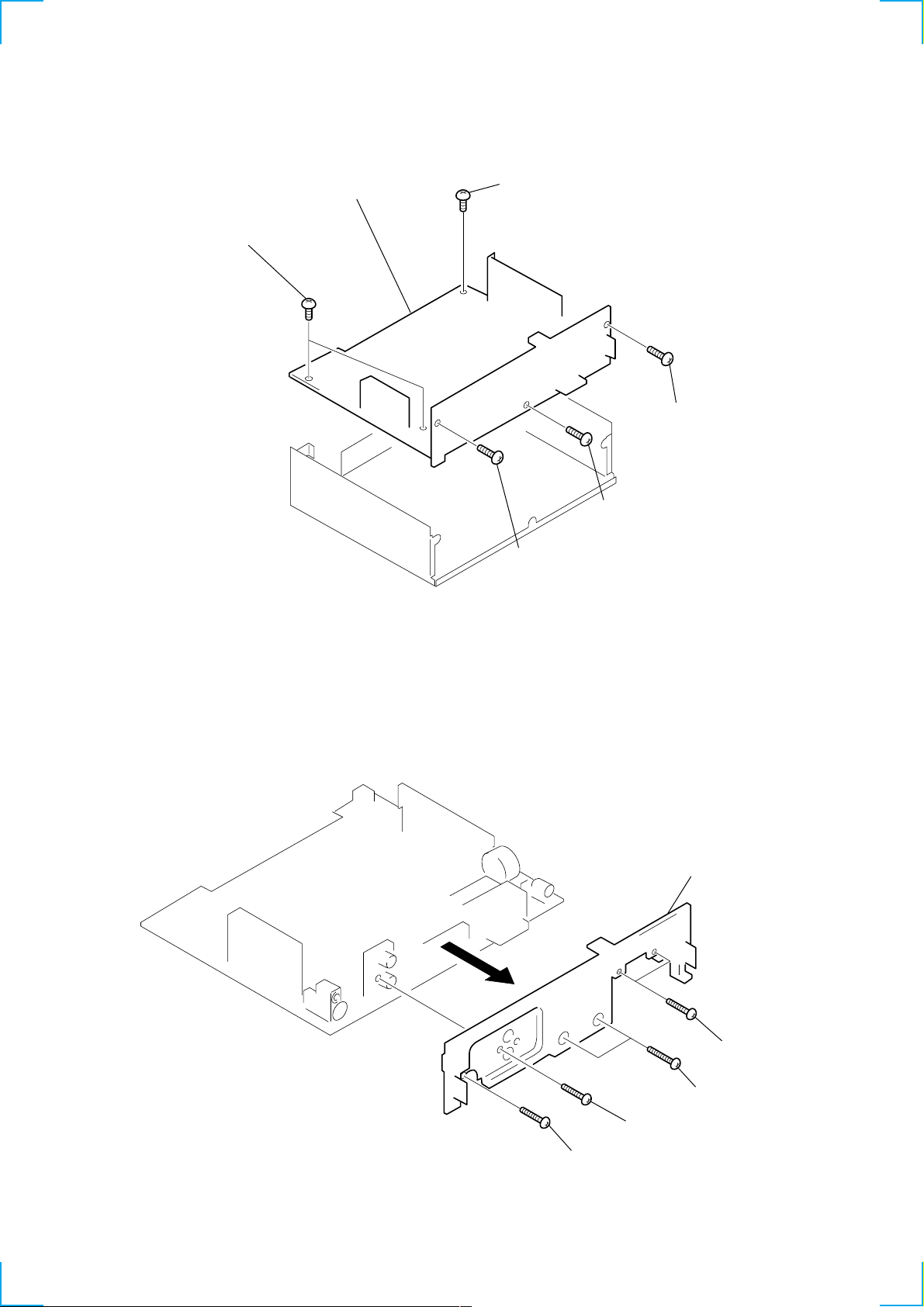

2-3. MAIN BOARD

6 MAIN board

5 ground point screws

(PTT 2.6x6)

4 ground point screws

(PTT 2.6x6)

3 PTT 2.6x

2 PTT 2.6x8

1 PTT 2.6x8

2-4. HEAT SINK

5 heat sink

4 PTT 2.6x

3 PTT 2.6x12

1 PTT 2.6x8

2 PTT 2.6x8

11

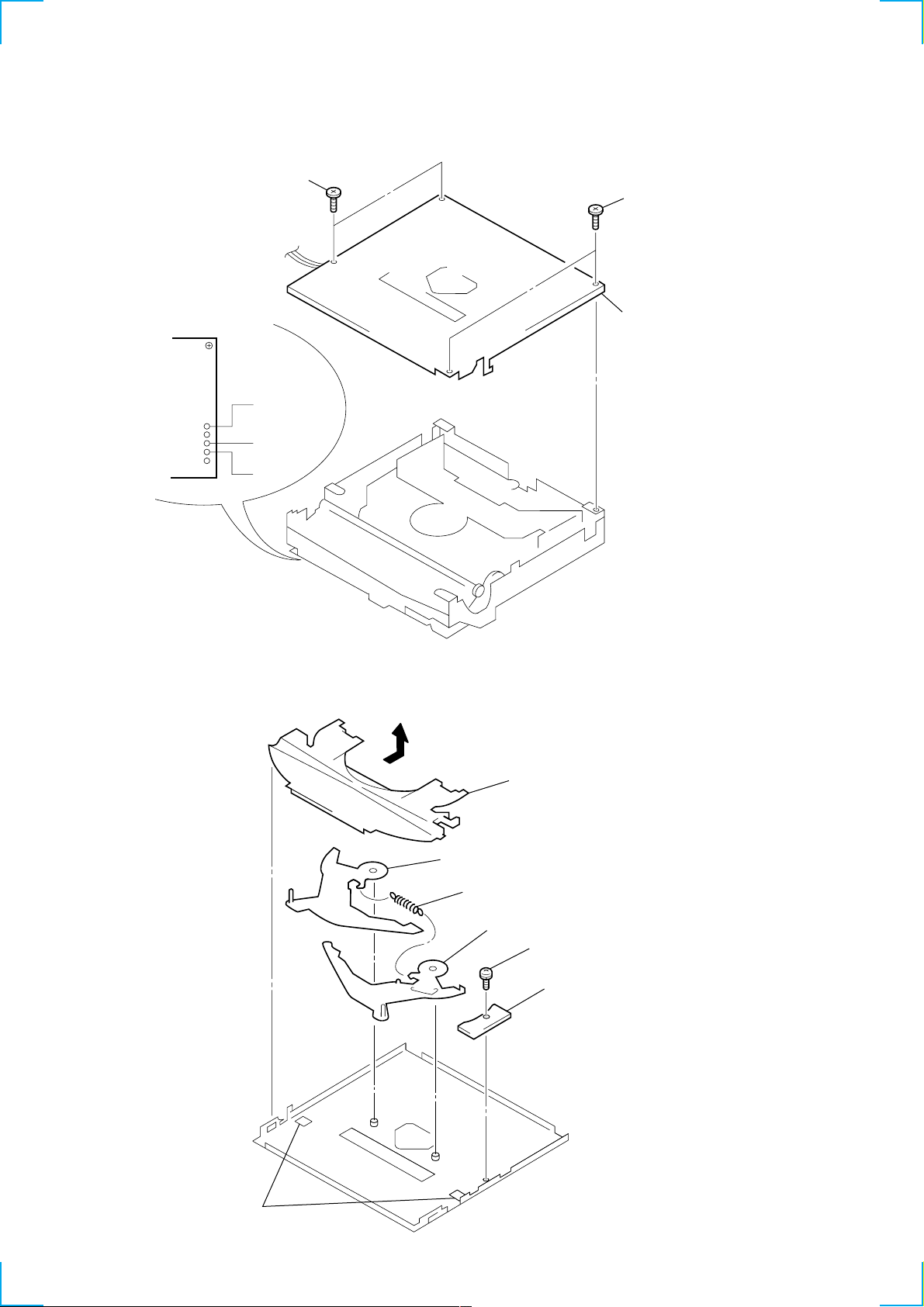

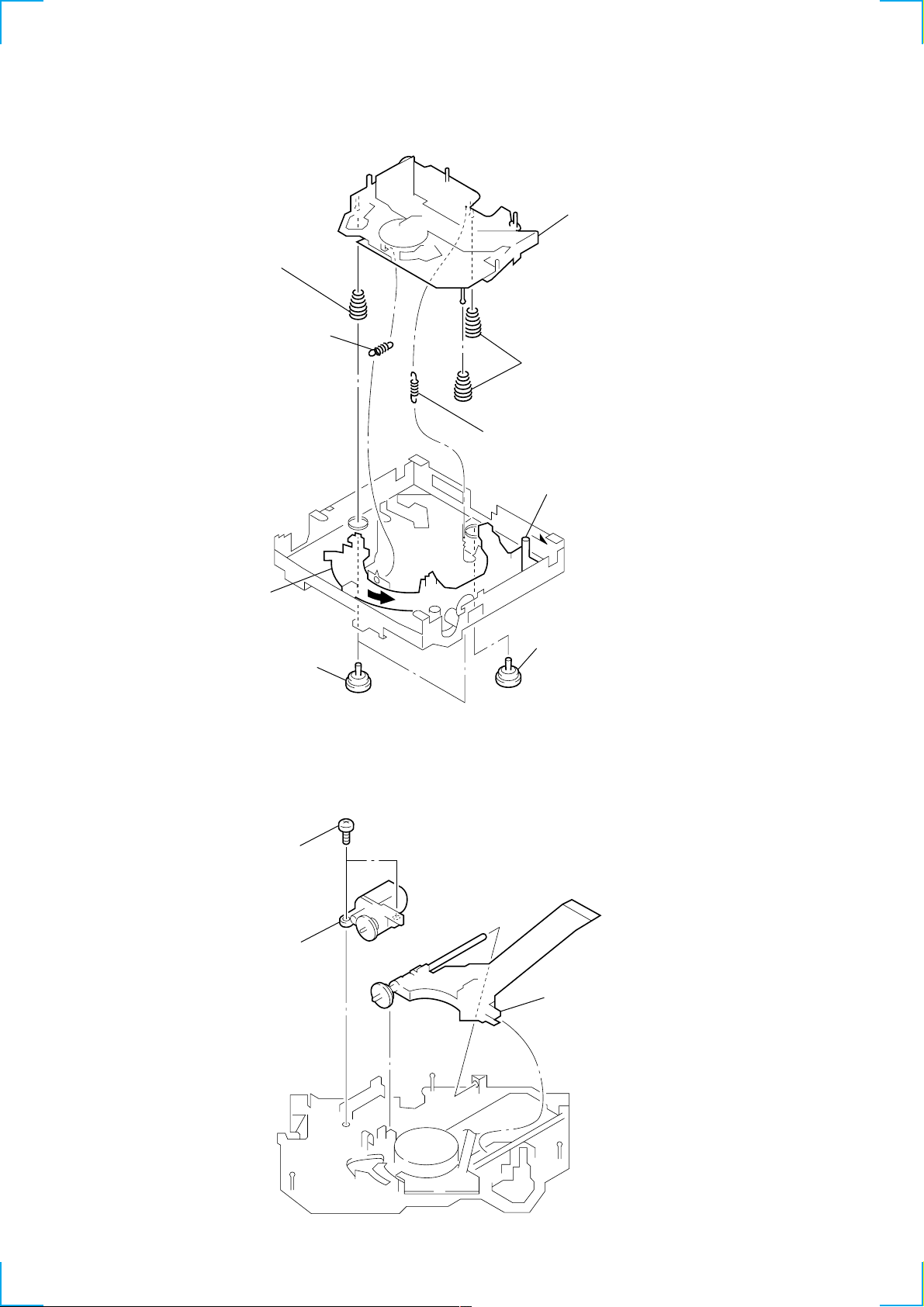

2-5. CHASSIS (T) ASSY

2 P 2x3

3 P 2x3

2-6. LEVER ASSY

1 Unsolder the

lead wires.

4 chassis (T) assy

black

red

white

4 claws

5 guide (disc)

6 lever (R) assy

3 tension spring (LR)

7 lever (L) assy

1 PS 2x4

2 DISC IN SW board

12

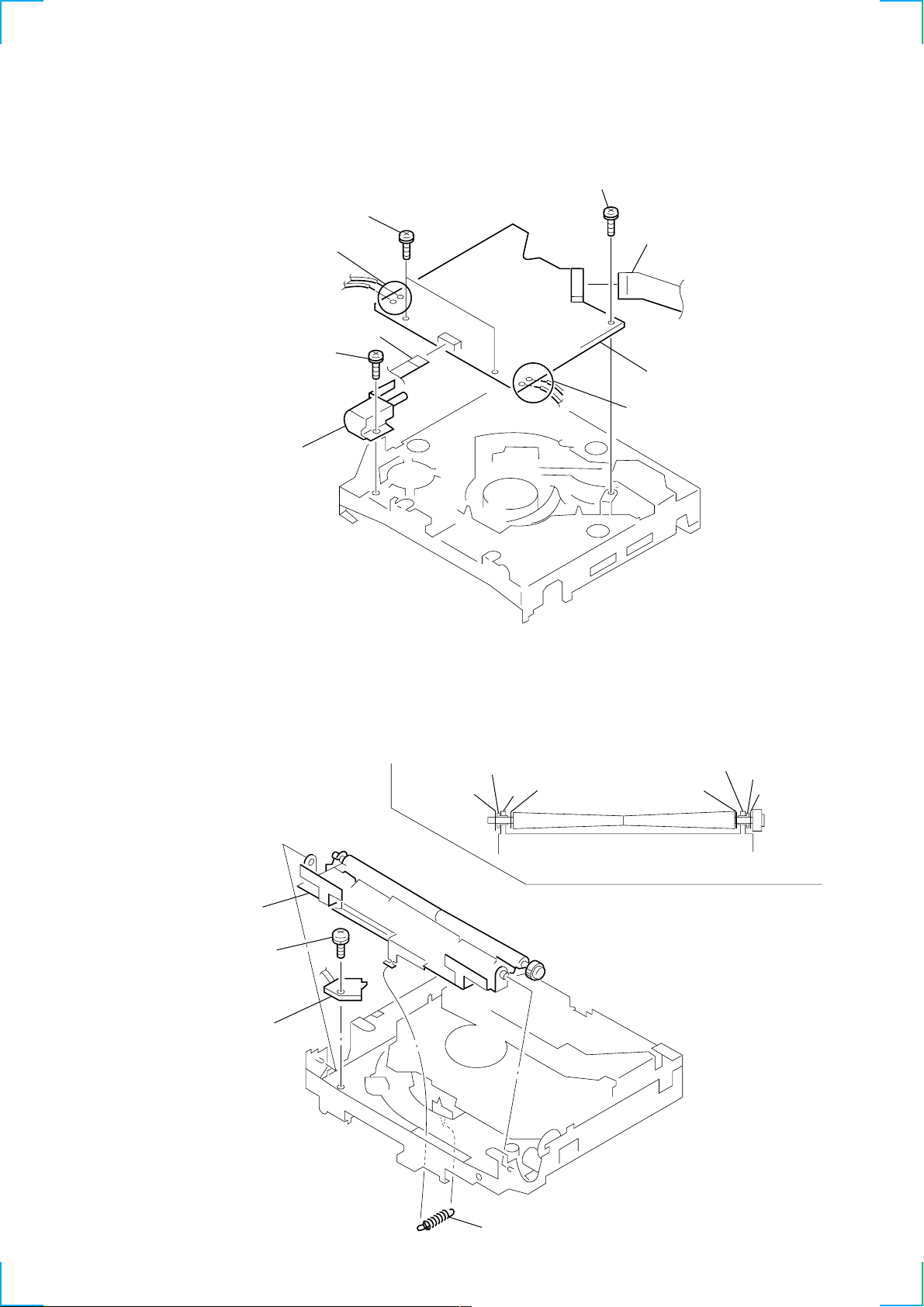

2-7. SERVO BOARD

7 PS 2x4

8 PS 2x4

3 Removal the solders.

1 CN3

5 P 2x3

6 loading motor assy

2 CN2

9 SERVO board

4 Removal the solders.

2-8. ARM ROLLER ASSY

• When installing, take note of the positions

arm (roller) and washers. (Fig. 1)

2 arm roller assy

3 PS 2x3

4 LOAD SW board

shaft retainer

washer (RA)

arm

washer

Fig. 1

washer

arm

shaft retainer

washer (RA)

1 tension spring (RA)

13

2-9. CHASSIS (OP) ASSY

8 compression spring (FL)

1 tension spring (KF1)

7 chassis (OP) assy

9 compression spring (FL)

2 tension spring (KR1)

5 Fit lever (D) in the

direction of the arrow.

6 Turn loading ring in the

direction of the arrow.

4 damper (T)

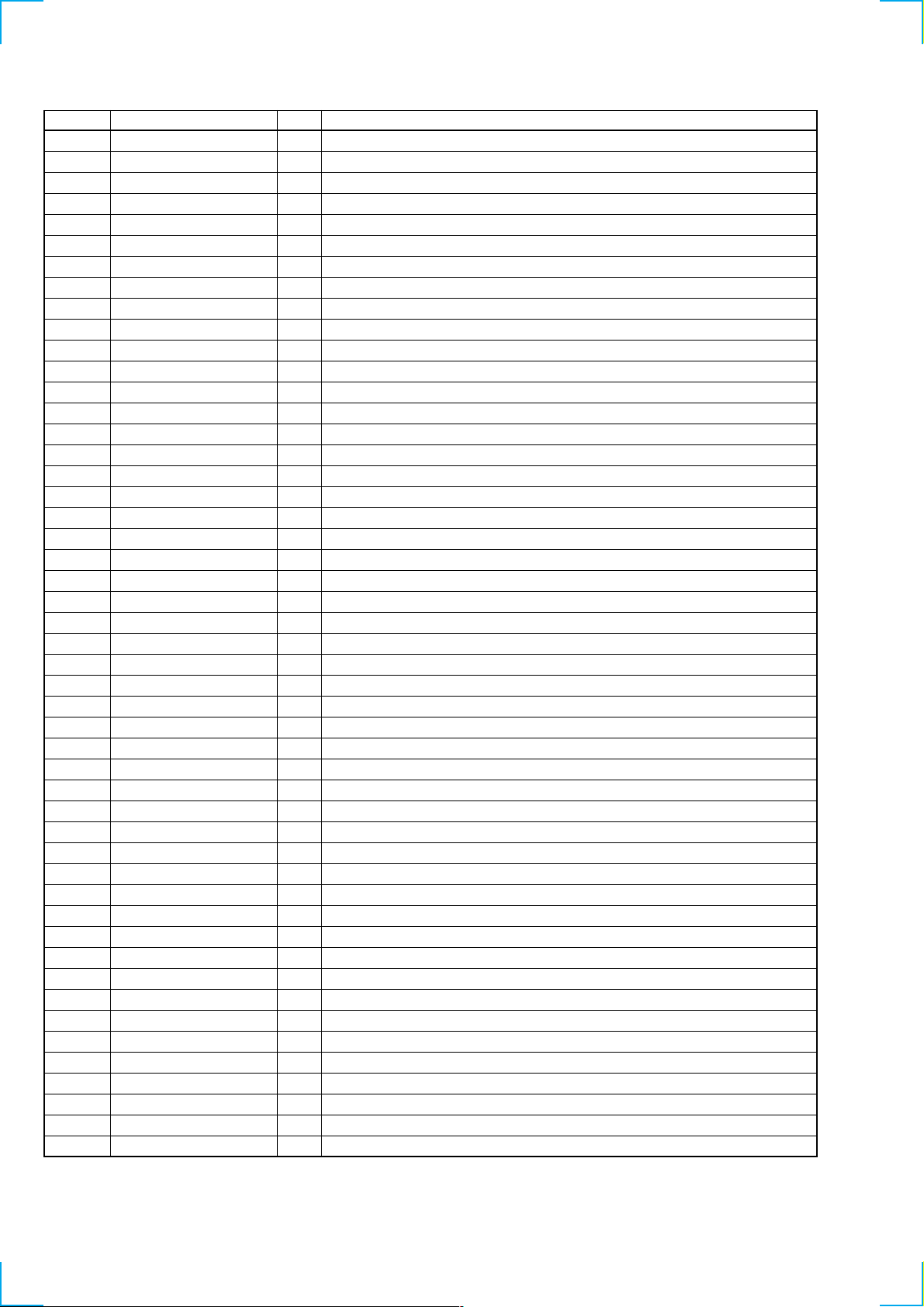

2-10. OPTICAL PICK-UP BLOCK

1 P 2x3

2 sled motor assy

3 damper (T)

3 optical pick-up block

14

SECTION 3

DIAGRAMS

3-1. IC PIN DESCRIPTIONS

• IC501 CXD2598Q (DIGITAL SERVO, DIGITAL SIGNAL PROCESSOR) (SERVO BOARD)

Pin No. Pin Name I/O Pin Description

1 DVDD — Digital power supply pin

2 DVSS — Digital ground

3 SOUT O Servo brock serial data output (Not used.)

4 SOCK O Servo brock serial data read clock output (Not used.)

5 XOLT O Servo brock serial data latch output (Not used.)

6 SQSO O Sub Q 80 bit, PCM peak and level data output. CD TEXT data output

7 SQCK I Clock input from SQSO read output.

8 SCSY I Fixed at “L”.

9 SBSO O Serial output of sub-P to W. (Not used.)

10 EXCK I Clock input from SBSO read output. (Fixed at “L”)

11 XRST I System reset (“L”: Reset)

12 STSM I System mute input (Fixed at “L”)

13 DATA I Serial data input from CPU.

14 XLAT I Latch input from CPU. Latch serial data at the falling edge.

15 CLOK I Serial data transfer clock input from CPU.

16 SENS O SENS output for CPU.

17 SCLK I Clock input from SENS serial data read.

18 ATSK I/O Input/output for anti-shock.

19 WFCK O WFCK (Write Flame Clock) output (Not used.)

20 XUGF O XUGF output (Not used.)

21 XPCK O XPCK output (Not used.)

22 GFS O GFS output

23 C2PO O C2PO output (Not used.)

24 SCOR O “H” output at either detection, sub code sync S0 or S1.

25 C4M O 4.2336 MHz output (Not used.)

26 WDCK O Word clock input f=2Fs (Not used.)

27 COUT I/O Track number count signal input/output (Not used.)

28 MIRR I/O Mirror signal input/output (Not used.)

29 DVSS — Digital ground

30 DVDD — Digital power supply pin

31 DFCT I/O Diffect signal input/output (Not used.)

32 FOK I/O Focus OK signal output

33 PWM1 I External control input of spindle motor.

34 LOCK I/O Lock signal input/output

35 MDP O Servo control output of spindle motor.

36 SSTP I Disc most inner track detection signal input

37 FSTIO I/O 2/3 frequency division output of pins ih and ij. (Not used.)

38 SFDR O Sled drive output

39 SRDR O Sled drive output

40 TFDR O Tracking drive output

41 TRDR O Tracking drive output

42 FFDR O Focus drive output

43 FRDR O Focus drive output

44 DVDD — Digital power supply pin

45 DVSS — Digital ground

46 TEST I Test pin (Fixed at “L”)

47 TES1 I Test pin (Fixed at “L”)

48 XTSL I X’tal select input (“L”: 16.9344 MHz, “H”: 33.8688 MHz)

49 VC I Center voltage input

50 FE I Focus error signal input

51 SE I Sled error signal input

15

Pin No. Pin Name I/O Pin Description

52 TE I Tracking error signal input

53 CE I Center servo analog input

54 RFDC I RF signal input

55 ADIO O Test pin (Not used.)

56 AVSSO — Analog ground

57 IGEN I Constant current input from OP amplifier.

58 AVDDO — Analog ground

59 ASYO O EFM full-swing output (“L”: VSS, “H”: VDD)

60 ASYI I Asymmetry comparate voltage input

61 RFAC I EFM signal input

62 AVSS3 — Analog ground

63 CLTV I VCO control voltage input from master.

64 FILO O Filter output for master PLL (slave=digital PLL)

65 FILI I Filter input from master PLL.

66 PCO O Charge pump output for master PLL.

67 AVDD3 — Analog power supply pin

68 BIAS I Asymmetry circuit constant current input

69 VCTL I VCO2 control input from wideband EFM PLL. (Not used.)

70 V16M O VCO2 oscillator output for wideband EFM PLL. (Not used.)

71 VPCO O Charge pump output for wideband EFM PLL. (Not used.)

72 DVSS — Digital ground

73 MD2 I Digital out ON/OFF control input (“L”: OFF, “H”: ON)

74 DOUT O Digital out output

75 ASYE I Asymmetry circuit ON/OFF input (“L”: OFF, “H”: ON)

76 DVDD — Digital power supply pin

77 LRCK O D/A interface LR clock output (f=Fs)

78 LRCKI I D/A interface LR clock input

79 PCMD O D/A interface serial data output (2’s COMP, MSB fast)

80 PCMD I D/A interface serial data input (2’s COMP, MSB fast)

81 BCK O D/A interface bit clock output

82 BCKI I D/A interface bit clock input

83 EMPH O Emphasis ON/OFF signal output

84 EMPHI I Emphasis ON/OFF signal input (“H”: ON, “L”: OFF)

85 XVDD — Power supply for master clock.

86 XTAI I X’tal oscillator input from master clock (16.9344 MHz).

87 XTAO O X’tal oscillator output for master clock (16.9344 MHz).

88 XVSS — Ground pin for master clock.

89 AVDD1 — Analog power supply pin

90 AOUT1 O Lch analog output

91 AIN1 I Lch OPAMP input

92 LOUT1 O Lch LINE output

93 AVSS1 — Analog ground

94 AVSS2 — Analog ground

95 LOUT2 O Rch LINE output

96 AIN2 I Rch OPAMP input

97 AOUT2 O Rch analog output

98 AVDD2 — Analog power supply pin

99 RMUT O Rch “0” detect Flug (Not used.)

100 LMUT O Lch “0” detect Flug (Not used.)

16

Loading...

Loading...