Page 1

CDP-M11C

SERVICE MANUAL

CDP-M11C is the CD section

in CMT-M11C.

US Model

Canadian Model

AEP Model

UK Model

E Model

Model Name Using Similar Mechanism NEW

CD Mechanism Type CDM42-5BD19

Base Unit Name BU-5BD19

Optical Pick-up Name KSS-213BA/S1NP

SPECIFICATIONS

MICROFILM

COMPACT DISC PLAYER

Page 2

TABLE OF CONTENTS

1. SERVICING NOTES

1-1. Mechanism Motor Direct Drive Mode ............................ 3

1-2. Aging Mode..................................................................... 3

2. GENERAL ................................................................... 4

3. DISASSEMBLY.......................................................... 8

4. TEST MODE..............................................................12

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic break-down because of the potential difference generated

by the charged electrostatic load, etc. on clothing and the human

body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repair parts.

The flexible board is easily damaged and should be handled with

care.

5. ELECTRICAL ADJUSTMENTS ......................... 12

6. DIAGRAMS

6-1. Printed Wiring Board – BD Section – ............................. 15

6-2. Schematic Diagram – BD Section –................................17

6-3. Schematic Diagram

– MAIN/PANEL/MOTOR Section – .............................. 21

6-4. Printed Wiring Boards

– MAIN/PANEL/MOTOR Section – .............................. 25

6-5. IC Pin Function Description............................................ 32

7. EXPLODED VIEWS ................................................ 34

8. ELECTRICAL PARTS LIST................................39

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused

on the disc reflective surface by the objective lens in the optical

pick-up block. Therefore, when checking the laser diode emission, observe from more than 30 cm away from the objectiv e lens.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be dam-

aged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of the soldering iron around 270 ˚C dur-

ing repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

CAUTION

Use of controls or adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE

WITH MARK ! ON THE SCHEMATIC DIAGRAMS AND IN

THE PARTS LIST ARE CRITICAL TO SAFE OPERATION.

REPLACE THESE COMPONENTS WITH SONY PARTS WHOSE

PART NUMBERS APPEAR AS SHOWN IN THIS MANUAL

OR IN SUPPLEMENTS PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFIÉS P AR UNE MARQUE ! SUR

LES DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES

PIÈCES SONT CRITIQUES POUR LA SÉCURITÉ DE

FONCTIONNEMENT. NE REMPLACER CES COM- POSANTS

QUE P AR DES PIÈCES SONY DONT LES NUMÉROS SONT

DONNÉS DANS CE MANUEL OU D ANS LES SUPPLÉMENTS

PUBLIÉS PAR SONY.

This appliance is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT MARKING is located on

the rear exterior.

Laser component in this product is capable of emitting radiation

exceeding the limit for Class 1.

The following caution label is located inside the unit.

– 2 –

Page 3

SECTION 1

SERVICING NOTES

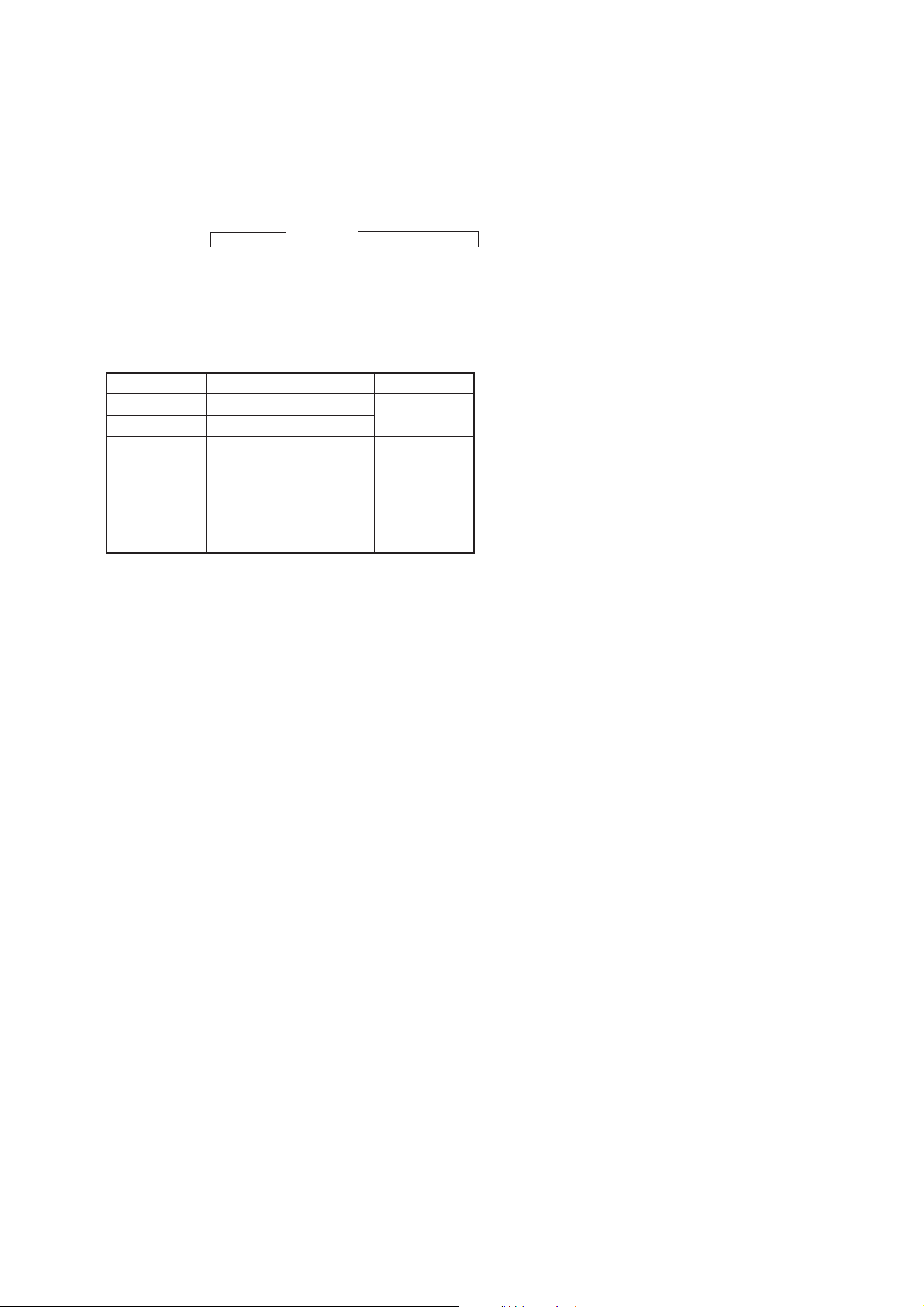

1-1. MECHANISM MOTOR DIRECT DRIVE MODE

• Functional Overview

A mechanism has three motors (M400, M401 and M402), and

if a motor does not run, each motor can be driven during the

time that the button is pressed.

• Setting Method

While pressing DISC SKIP button and 6 OPEN/CLOSE 3

button, insert the AC plug cord into the AC outlet. (Disc LEDs

are all blinking in green and orange.)

• Button Input and Operation in Mechanism Motor Direct

Drive Mode

Table 1-1.

BUTTON OPERATION MOTOR

) + Carrier UP

= 0 Carrier DOWN

^ Tray IN

p Tray OUT

6 OPEN/

CLOSE 1

6 OPEN/

CLOSE 2

Gear

Chucking

M400

M402

M401

• Releasing Method

Turn off the power switch, and this mode is reset.

1-2. AGING MODE

For the AGING MODE, refer to the CMT-M11C service manual

(Parts No.: 9-960-794-11).

– 3 –

Page 4

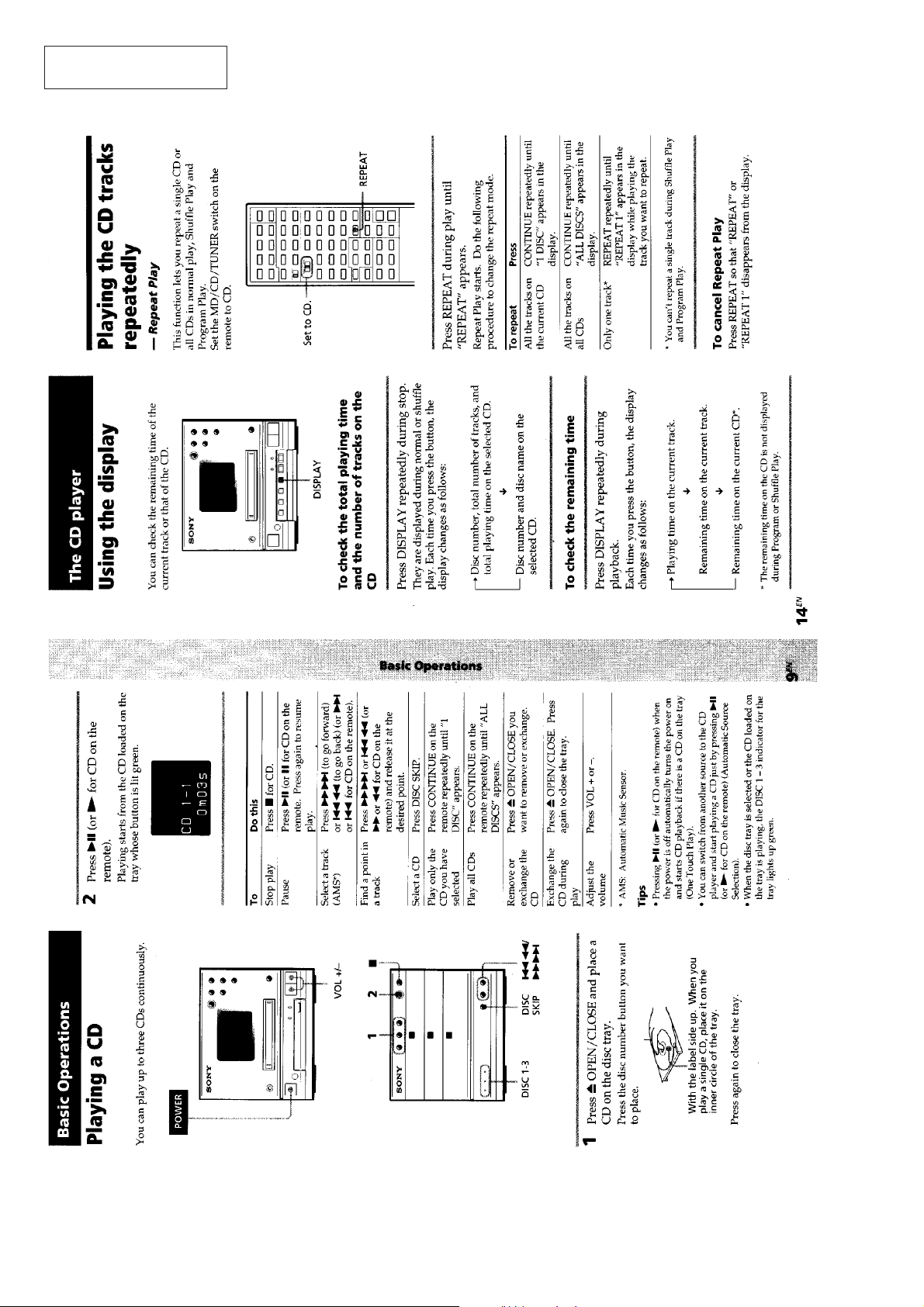

This section is extracted

from instruction manual.

SECTION 2

GENERAL

– 4 –

Page 5

– 5 –

Page 6

– 6 –

Page 7

– 7 –

Page 8

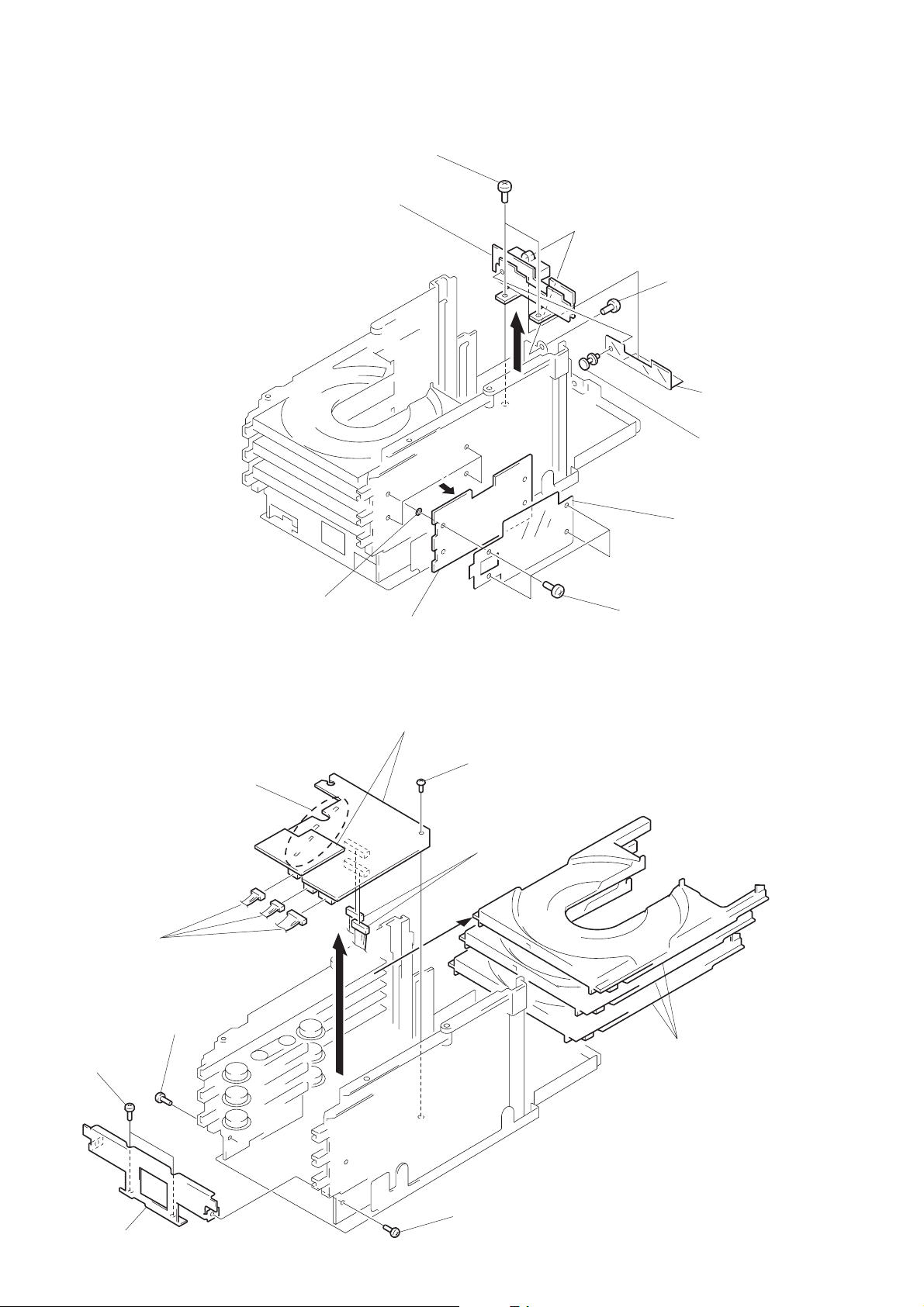

• This set can be disassembled in the order shown below.

SECTION 3

DISASSEMBLY

COVER, FRONT PANEL SECTION

(Page 8)

POWER/TRAY ADDRESS BOARD

(Page 10)

OPTICAL PICK-UP (KSS-213BA/S1NP)

(Page 11)

Note: Follow the disassembly procedure in the numerical order given.

BACK COVER, MAIN BOARD

(Page 9)

DISC TABLE ASS’Y, MOTOR DRIVE BOARD

(Page 10)

COVER, FRONT PANEL SECTION

REINFORCEMENT (TOP), CARRIER ASS’Y

(Page 9)

FRAME (L), (R) ASS’Y

(Page 11)

5

wire (flat type) (5 core)

(CN109)

2

two screws

(ALUMINUM)

7

front panel section

1

two screws

(CASE 3 TP2)

3

cover

1

two screws

(CASE 3 TP2)

6

two screws

(+BTT M 3

5

wire (flat type) (7 core)

(CN110)

×

6)

4

cushion (T-SW)

– 8 –

Page 9

BACK COVER, MAIN BOARD

8

two screws

(+BVTT3

9

main board

6

four connectors

(CN105 - 108)

×

6)

6

four connectors

(CN100 - 103)

7

FPC cable

(CN104)

3

screw

(+BTTM3

5

1

supplied with OPT cap

2

×

6)

rivet

screw

(+BVTP3

×

10)

3

two screws

(+BTTM3

3

screw

(+BTTM3

×

6)

3

screw

(+BTTM3

4

back cover

×

6)

×

6)

REINFORCEMENT (TOP), CARRIER ASS’Y

2

reinforcement (TOP)

1

four screws

(+BV3

×

8)

3

screw

(+PTPWH2.6

4

×

8)

carrier ass’y

– 9 –

3

screw

(+PTPWH2.6

×

8)

Page 10

POWER/TRAY ADDRESS BOARD

3

power board

2

two screws

(+P3

×

5)

1

screw

(+BVTP3

7

sheet (F)

4

5

rivet

×

8)

sheet (S)

9

four washers

8

tray address board

DISC TABLE ASS’Y, MOTOR DRIVE BAORD

5

Remove the four solders of

mode motor ass’y (M401),

motor (O/C) ass’y (M402).

7

three connectors

(CN203, 405, 406)

2

screw

3

two screws

(+P3

(+BVTT3

×

4)

×

5)

8

motor dirve board

7

two connectors

(CN201, 202)

6

screw

(+BVTT 3

6

three screws

(+P2.6

×

8)

×

5)

1

three disc table ass’y

4

joint (front)

– 10 –

2

screw

(+BVTT3

×

5)

Page 11

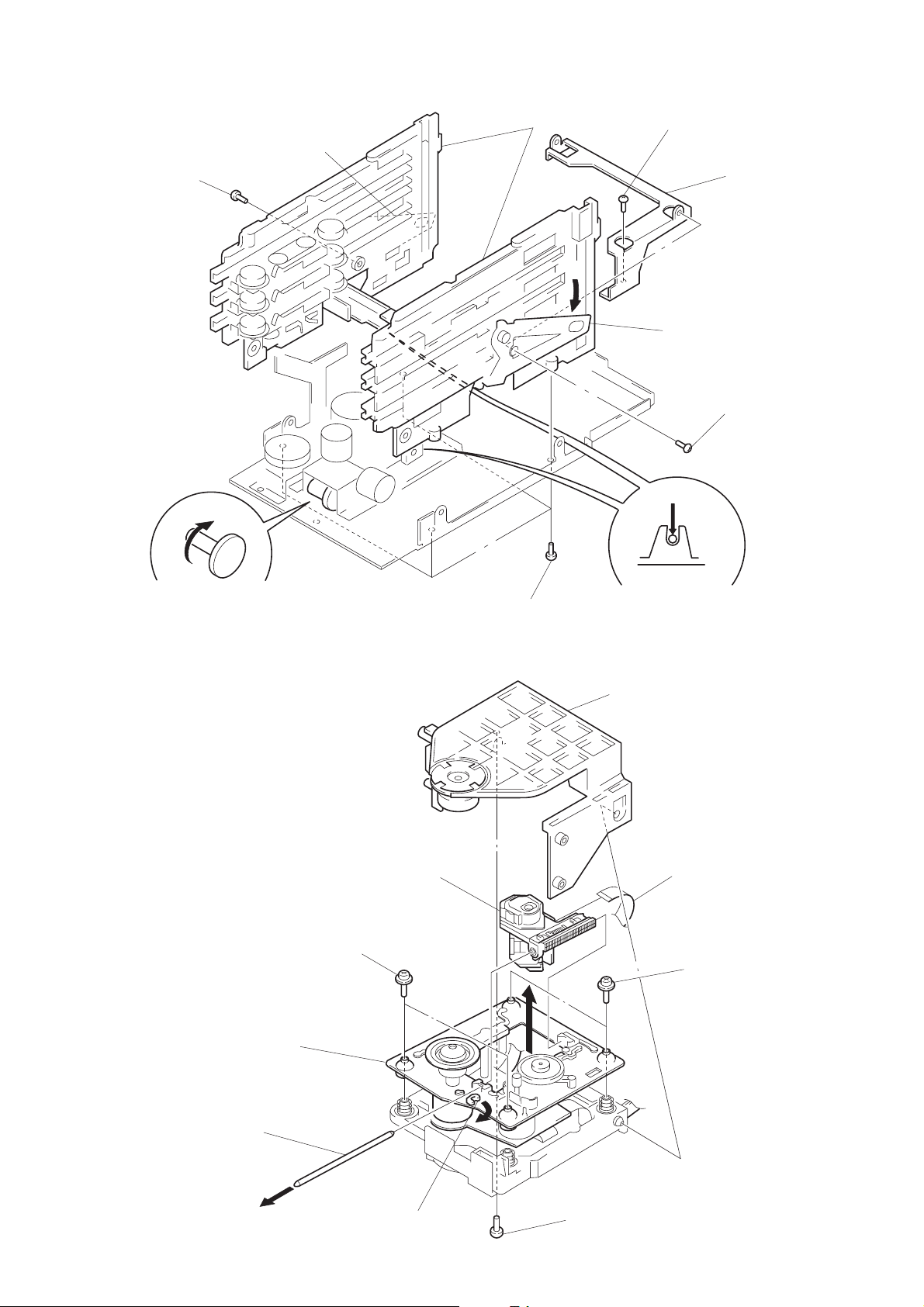

FRAME (L), (R) ASS’Y

lever (up and down L)

2

screw

(BVTT3

×

5)

A

6

frame (L), (R) ass’y

B

3

screw

(P3

×

4)

4

joint (middle)

lever (up and down R)

2

screw

(BVTT3

×

5)

Rotate the worm gear in direction

1

to lower the levers (up and down L, R)

in direction

B

.

A

OPTICAL PICK-UP (KSS-213BA/S1NP)

7

optical pick-up

(KSS-213BA/S1NP)

3

two screws

4

Lift up this base

(outsart) assy.

(PTPWH M2.6

×

6)

5

four screws

(BV3

×

8)

Note: when mounting the frame (L) and

(R) assemblies, engage the elevating shaft withe the grooves of racks

(up and down).

2

carrier ass’y

8

wire (flat type) (16 core)

3

two screws

(PTPWH M2.6

×

6)

6

sled shaft

5

Open the lever to direction

of the arrow

A

.

A

– 11 –

1

yoke bracket

Page 12

SECTION 4

+

–

BD board

TP (RF)

TP (VC)

oscilloscope

(AC range)

TEST MODE

SECTION 5

ELECTRICAL ADJUSTMENTS

BD TEST MODE

• Functional Overview

The BD test mode is used to check the BD block. When this

mode is activated, a mechanism is kept in stop status and GFS

is not monitored.

A checking status is displayed with disc LEDs.

• Setting the Test Mode

1. Load a disc on the tray of disc 1 and have a disc chucked.

2. Turn off the power switch once, and connect TP (TEST) and

TP (GND) on MAIN board, then again turn on the power

switch.

3. Thus, the test mode is activated.

Note:When the test mode is activated, disc LEDs are all turned

off and GFS is not monitored.

• Button Input and Operation in Test Mode

Table 4-1.

BUTTON

6 OPEN/

CLOSE 1

6 OPEN/

CLOSE 2

6 OPEN/

CLOSE 3

• Releasing the Test Mode

1. Turn off the power switch, and disconnect a short wire between TP (TEST) and TP (GND) on MAIN board.

2. Thus, the set becomes ready for normal operation.

LED on DISC 1 turns on, normal focus

gain is set, and CLV is fixed to 12 cm.

LED on DISC 2 turns on, tracking servo

and sled servo are turned off.

LED on DISC 3 turns on, and tracking

balance value is displayed.

OPERATION

Notes:

1. Use YEDS-18 disc (Par t No.: 3-702-101-01) unless otherwise

indicated.

2. Use the oscilloscope with more than 10 MΩ impedance.

3. Clean an object lens by an applicator with neutral detergent

when the signal level is low than specified value with the following checks.

4. Adjust the focus bias adjustment when optical pick-up is replaced.

Focus Bias Adjustment

This adjustment is to be done when the optical pick-up is replaced.

Condition: This adjustment is performed with the set placed hori-

zontally.

Connection:

Adjustment Procedure:

1. Connect the oscilloscope to TP (RF) and TP (VC) on BD board.

2. Turned power switch on. (Stop mode)

3. Put disc (YEDS-18) in and press the ^ button.

4. Adjust RV101 so that the oscilloscope waveform is as shown

in the figure below (eye pattern).

A good eye pattern means that the diamond shape (≈) in the

center of the waveform can be clearly distinguished.

• RF signal reference waveform (eye pattern)

VOLT/DIV: 200 mV

TIME/DIV: 150 ns

(with the 10 : 1 probe

in use)

1.3 ± 0.3 Vp-p

When observing the eye pattern, set the oscilloscope for AC

range and raise vertical sensitivity.

S-Curve Check

Connection:

oscilloscope

BD board

TP (FEO)

TP (VC)

Procedure:

1. Connect the oscilloscope to TP (FEO) and TP (VC) on BD

board.

2. Connect the TP (FOK) and TP (GND) with lead wire.

3. Turned power switch on.

4. Put disc (YEDS-18) in and turned power switch on again and

actuate the focus search. (actuate the focus search when disc

table is moving in and out.)

+

–

– 12 –

Page 13

5. Confirm that the oscilloscope waveform (S-curve) is symmetrical between A and B. And confirm peak to peak level within

2.4 ± 0.7 Vp-p.

S-curve waveform

6. After check, remove the lead wire connected in step 2.

Note: • Try to measure several times to make sure that the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

Connection:

BD board

TP (RF)

TP (VC)

Procedure:

1. Connect the oscilloscope to TP (RF) and TP (VC) on BD board.

2. Turned power switch on. (stop mode)

3. Put disc (YEDS-18) in and press the ^ button.

4. Confirm that oscilloscope waveform is clear and check RF

signal level is correct or not.

Note: Clear RF signal waveform means that the shape “≈” can

be clearly distinguished at the center of the waveform.

RF signal waveform

symmetry

A

B

oscilloscope

+

–

level: 1.3 ± 0.3 Vp-p

within 2.4 ± 0.7 Vp-p

VOLT/DIV: 200 mV

TIME/DIV: 500 ns

(with the 10 : 1 probe

in use)

Traverse waveform

A

B

level: 300 ± 100 mVp-p

7. After check, remove the lead wire connected in step 1.

Focus/Tracking Gain Adjustment (RV102, RV103)

This gain has a margin, so even if it is slightly off. There is no

problem.

Therefore, do not perform, this adjustment.

Please note that it should be fixed to mechanical center position

when you moved and do not know original position.

Adjustment Location :

[BD BOARD] – Side B –

IC102

FOK

RF

RV101

IC101

TEI

FEO

FEI

RV102

TEO

RV103

VC

GND

IC104

[MAIN BOARD] – Component Side –

SECTION 6

DIAGRAMS

• Circuit Boards Location

LIGHT CONNECTOR board

MAIN board

PANEL (UPPER) board

POWER board

TRAY ADDRESS board

PANEL (LOWER) board

CHUCKING SW board

BD board

GEAR SELECT board

E-F Balance (Traverse) Check

Connection:

oscilloscope

BD board

TP (TEO)

TP (VC)

Procedure:

1. Connect the TP (TEST) and TP (GND) with lead wire. (Test

mode)

2. Connect the oscilloscope to TP (TEO) and TP (VC) on BD

board.

3. Turned power switch on.

4. Put disc (YEDS-18) in and press the ^ button.

5. Press the 6 OPEN/CLOSE 2 button. (Tracking servo and

sled servo are turned off.)

6. Confirm that the oscilloscope waveform is symmetrical on the

top and bottom in relation to 0 Vdc, and check this level.

(DC range)

+

–

– 13 –

IC103

TP

(GND)TP(TEST)

MOTOR DRIVE board

PHOTO SENSOR board

– 14 –

Page 14

Page 15

Page 16

• Waveforms

3 Vp-p

10 MHz

– BD Section –

1 IC101 #¡ (RFO) (PLAY Mode)

500 mV/DIV, 500 ns/DIV 6 IC103 @∞ (XPCK)

– MAIN/PANEL/MOTOR Section –

1 IC103 $™ (X1)

2 IC101 $¢ (TEI) (PLAY Mode)

50 mV/DIV, 1 µs/DIV

3 IC101 2 (FEI) (PLAY Mode)

50 mV/DIV, 1 µs/DIV

Approx. 1.3 Vp-p

Approx. 100 mVp-p

Approx. 150 mVp-p

5.3 Vp-p

14 ns

7 IC103 @™ (BCLK)

5 Vp-p

474 ns

8 IC103 @º (LRCK)

5.1 Vp-p

4 IC103 3 (MDP) (PLAY Mode)

7.6 µs

5 IC103 @• (RFCK)

136 µs

22.7 µs

9 IC104 6 (XTO)

2.6 Vp-p

4.6 Vp-p

16.9344 MHz

5.1 Vp-p

– 20 –

Page 17

Page 18

Page 19

• IC Block Diagrams

– BD Section –

IC101 CXA1782BQ

PHD2

PHD1

36

35 34

PHD

–

+

–

+

APC

–

+

RF IV AMP1

LD

33

RF M

32

–

+

–

+

LEVELS

+

–

FOK

RF O

31

–

+

–

+

MIRR

RF I

30

–

+

+

–

+

–

29CP28

CB

DFCT

CC126CC225FOK

27

–

+

24 SENS

IIL

+

–

TTL

23 C. OUT

–

+

RF IV AMP2

37FE BIAS

+

–

38F

39E

40EI

BAL1

41VEE

42TEO

TOG1

43LPFI

44TEI

45ATSC

46TZC

47TDFCT

48VC

–

+

F IV AMP

–

+

E IV AMP

BAL2

BAL3

TOG2

TOG3

• WINDOW COMP

ATSC

–

+

FE AMP

TE AMP

+

–

DFCT

TTL

IIL

FZC COMP

TZC COMP

DFCT

FS4

–

+

–

+

–

+

• IIL DATA RESISTOR • INPUT SHIFT RESISTOR

TOG1-3 FS1-4 TG1-2 TM1-7 PS1-4

BAL1-3

–

–

+

+

HPF COMP LPF COMP

+

–

• FCS PHASE

COMPENSATION

TM1

FS2

+

–

• ADDRESS DECODER

• OUTPUT DECODER

• TRACKING

• PHASE

COMPENSATION

TG1

FS1

• ISET

TM6

TM5

TM4

TM3

TM7

TG2

• F SET

TTL

TM2

22 XRST

21 DATA

20 XLT

IIL

19 CLK

18 VCC

17 ISET

–

16 SL 0

+

15 SL M

14 SL P

+

1312TA O

–

11

TGU

10

TG2

FSET

TA M

3

2

1

FEI

FEO

FDFCT

4

FLB

FGD

FE O

FE M

SRCH

9

8

7

6

5

– 29 –

Page 20

IC102 BA6397FP

A

DRIVE

BUFFER

GND

28

DRIVE

BUFFER

1

OUT1A

OUT4

27

BUFFER

2

OUT1B

LEVEL

DRIVE

THERMAL

SHIFT

OUT4BIN4A

26

25

DRIVE

BUFFER

SHIFT

LEVEL

SHUT DOWN

3

4

IN1A

IN1B

IN4B

24

5

TR-B

CC

VC

V

22

23

V

REGULATOR

7

6

XRST

REG 0

VCCIN3B

21

CC

V

CC

20

DRIVE

BUFFER

IN3A

OUT3BOUT3AOP+

19

18

SHIFT

LEVEL

17

DRIVE

BUFFER

OP–

15

16

DRIVER MUTE

SHIFT

LEVEL

8

GND

9

IN2A

DRIVE

BUFFER

10

IN2B

11

OUT2A

12

OUT2B

DRIVE

BUFFER

13

GND

14

OP-OUT

IC103 CXD2507AQ

1

FOK

2

MON

MDP

3

4

MDS

5

LOCK

6

TEST

7

FILO

8

FILI

9

PCO

10

VSS

11

AVSS

12

CLTV

13

AVDD

14

RF

15

BIAS

16

ASYI

17

ASYO

18

ASYE

19

WDCK

SERVO AUTO

SEQUENCER

14

INTERFACE

DIGITAL

PLL

ASYMMETRY

CORRECTOR

5

XLON

CPU

LRCK

SPOD

PCMD

RAM

BCLK

SPOC

SPOB

SPOA

5

DEMODULATOR

16K

XUGF

GTOP

DD

CLKO

V

SUB CODE

PROCESSOR

EFM

3

ERROR

CORRECTOR

3

DD

V

XPCK

XLTO

DATO

CNIN

4

D/A

INTERFACE

GFS

RFCK

CZPO

SEIN

DIGITAL

CLV

6

XROF

CLOK

52535455565758596061626364

32313029282726252423222120

MNT3

XLAT

DIGITAL

MNT1

OUT

CLOCK

GENERATOR

51

DATA

XRST

50

SENS

49

MUTE

48

SQCK

47

SQSO

46

45

EXCK

SBSO

44

SCOR

43

42

V

SS

WFCK

41

EMPH

40

DOUT

39

C4M

38

37

FSTT

XTSL

36

XTAO

35

XTAI

34

33

MNTO

– 30 –

Page 21

IC104 PCM1710U-B

LRCIN

DIN

BCKIN

CLKO

XTO

DGND

V

VCC2R

GND2R

EXT1R

EXT2R

VOUTR

GND1

1

2

3

4

5

XTI

6

7

8

DD

9

10

11

12

13

14

INPUT

INTERFACE DIGITAL

TIMING

CONTROL

5-LEVEL DAC

RIGHT

LOW-PASS FILTER

RIGHT

3-STAGE AMP

RIGHT

FILTER

NOISE

SHAPER

MODE

CONTROL

5-LEVEL DAC

LEFT

LOW-PASS FILTER

LEFT

3-STAGE AMP

LEFT

28

27

26

25

24

23

22

21

20

19

18

17

16

15

ML/DSD

MC/DM2

MD/DM1

MUTE

MODE

CKSL

DGND

DD

V

VCC2L

GND2L

EXT1L

EXT2L

VOUTL

V

CC

1

– MAIN/PANEL/MOTOR Section –

IC101 CXA1291P

+VIN2

–VIN2

–VIN3

OUT2

AMP2

AMP3

11

OUT3

78

10 1615

9

+VIN3

VEEVEE

AMP1

THERMAL SHUT

CURRENT LIMITER

14

OUT1

DOWN AND

NC

236

–VIN1

NC

+VIN1

1

VCC

– 31 –

Page 22

6-5. IC PIN FUNCTION DESCRIPTION

• MAIN BOARD IC103 µPD78014FGC-532-AB8 (SYSTEM CONTROLLER)

Pin No. Pin Name I /O Function

1 C.SW2 I Detection input from the chucking address switch (S402)

2 C.SW1 I Detection input from the chucking address switch (S401)

3 G.SW2 I Detection input from the gear select switch (S404)

4 G.SW1 I Detection input from the gear select switch (S403)

5 B.SENS I Detection input from the BD vertical position sensor (PH400)

6 B.SW I Detection input from the BD bottom switch (S400)

7 T3.SW3 I Detection input from the disc 3 tray horizontal address switch (S433)

8 T3.SW2 I Detection input from the disc 3 tray horizontal address switch (S432)

9 VSS — Ground terminal

10 T3.SW1 I Detection input from the disc 3 tray horizontal address switch (S431)

11 T2.SW3 I Detection input from the disc 2 tray horizontal address switch (S423)

12 T2.SW2 I Detection input from the disc 2 tray horizontal address switch (S422)

13 T2.SW1 I Detection input from the disc 2 tray horizontal address switch (S421)

14 T1.SW3 I Detection input from the disc 1 tray horizontal address switch (S413)

15 T1.SW2 I Detection input from the disc 1 tray horizontal address switch (S412)

16 T1.SW1 I Detection input from the disc 1 tray horizontal address switch (S411)

17 BDTEST I Setting terminal for BD test mode “L”: test mode, Normally: “H”

18 LED0 O Drive signal output for the disc 3 pointer LED (D600; green) “L”: LED on

19 LED1 O Drive signal output for the disc 1 pointer LED (D602; orange) “L”: LED on

20 LED2 O Drive signal output for the disc 3 pointer LED (D600; orange) “L”: LED on

21 LED3 O Drive signal output for the disc 1 pointer LED (D602; green) “L”: LED on

22 LED4 O Drive signal output for the disc 2 pointer LED (D601; green) “L”: LED on

23 LED5 O Drive signal output for the disc 2 pointer LED (D601; orange) “L”: LED on

24 VSS — Ground terminal

25 LED6 O Drive signal output for the PAUSE LED (D620; orange) “L”: LED on

26 LED7 O Drive signal output for the PLAY LED (D620; green) “L”: LED on

27 QB-DATA0 I/O

28 QB-DATA1 I/O

29 QB-DATA2 I/O

30 QB-DATA3 I/O

31 BDUP O

32 BDDOWN O

33 GEAR O

34 CHUCK O

35 RESET I

36 QB-CLK I

MECHA-POWER

37

38 QB-READY I/O

39 SCOR I Sub-code sync (S0+S1) detection signal input from the CXD2507AQ (IC103)

40 VDD — Power supply terminal (+5V)

Two-way data bus with the master controller on HMD-M11 (mini-disc deck/tuner/preamp

system)

BD block up/down motor drive signal output to the CXA1291P (IC101) *1

Chucking/gear motor drive signal output to the CXA1291P (IC101)

System reset signal input from the reset signal generator (IC303) “L”: reset

For several hundreds msec. after the power supply rises, “L” is output, then it changes to “H”

Data transfer clock signal input from the master controller on HMD-M11 (mini-disc deck/tuner/

preamp system)

O Power supply on/off control signal output of the CXA1291P (IC101) “H”: power on

Ready signal in/out terminal with the master controller on HMD-M11 (mini-disc deck/tuner/

preamp system)

– 32 –

Page 23

Pin No. Pin Name I /O Function

41 X2 O Main system clock output terminal (10 MHz)

42 X1 I Main system clock input terminal (10 MHz)

43 IC (VSS) — Not used (fixed at “L”)

44 XT2 O Sub system clock output terminal Not used (fixed at “L”)

45 XT1 I Sub system clock input terminal Not used (fixed at “L”)

46 AVSS — Ground terminal (for A/D converter)

47 KEY0 I

48 KEY1 I

49 FSW O

50 SENS I Internal status (SENSE) signal input from the CXD2507AQ (IC103)

51 DFLAT O Serial data latch pulse output to the PCM1710U (IC104)

52 BDPWR O Power supply on/off control signal output of the BD block “H”: power on

53 LOADOUT O

54 LOADIN O

55 AVDD — Power supply terminal (+5V) (for A/D converter)

56 AVREF I Reference voltage input terminal (+5V) (for A/D converter)

57 SUBQ I Sub-code Q data signal input from the CXD2507AQ (IC103)

58 NC O Not used (open)

59 SQCLK O Sub-code Q data reading clock signal output to the CXD2507AQ (IC103)

60 XRST O Reset signal output for the BD block “L”: reset

61 XLAT O Serial data latch pulse output to the CXD2507AQ (IC103)

62 NC I Not used (fixed at “L”)

63 DATA O Serial data output to the CXD2507AQ (IC103) and PCM1710U (IC104)

64 CLK O Serial data transfer clock signal output to the CXD2507AQ (IC103) and PCM1710U (IC104)

Key input terminal (A/D input) ) + , = 0 , DISC SKIP keys (S601 to S603)

Key input terminal (A/D input) 6 OPEN/CLOSE 1 to 3, ^ , p keys (S621 to S625)

Focus gain selection signal output to the CXA1782BQ (IC101)

“H”: normal mode, “L”: focus gain down mode

Loading motor drive signal output to the CXA1291P (IC101) *2

*1 BD block up/down motor control

Operation

Terminal

BDUP (pin #¡) “L” “H” “L”

BDDOWN (pin #™) “L” “L” “H”

*2 Loading motor control

Operation

Terminal

LOADOUT (pin %£) “L” “H” “L”

LOADIN (pin %¢) “L” “L” “H”

OFF UP DOWN

OFF OUT IN

– 33 –

Page 24

SECTION 7

EXPLODED VIEWS

NOTE:

• -XX and -X mean standardized parts, so they

may have some difference from the original

one.

• Color Indication of Appearrance Parts

Example:

KNOB, BALANCE (WHITE) . . . (RED)

↑↑

Parts Color Cabinet's Color

(1) COVER, FRONT PANEL SECTION

7

8

6

9

5

4

3

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering

these items.

• The mechanical parts with no reference num-

ber in the exploded views are not supplied.

• Hardware (# mark) list is given in the last of

the electrical parts list.

13

12

11

10

17

16

15

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le neméro spécifié.

14

23

14

13

14

18

2

22

21

20

1

#1

19

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

1 4-986-512-01 PANEL (AL-CD), FRONT

2 4-942-636-21 EMBLEM (NO.3.5), SONY

3 4-975-365-01 SCREW (ALUMINUM)

4 4-986-523-01 INDICATOR (PLAY)

5 4-986-528-01 SPRING (B)

13 3-363-099-51 SCREW (CASE 3 TP2)

14 4-951-620-31 SCREW (2.6), +BVTP

* 15 1-663-505-11 PANEL (LOWER) BOARD

* 16 1-663-504-11 PANEL (UPPER) BOARD

17 4-986-521-01 BUTTON (PLAY)

6 X-4947-768-1 DOOR (D3) ASSY

7 X-4947-767-1 DOOR (D2) ASSY

8 X-4947-766-1 DOOR (D1) ASSY

9 4-986-527-01 SPRING (A)

10 4-986-513-01 PANEL (MOLD CD), FRONT

11 4-986-520-01 BUTTON (EJECT)

12 1-777-814-11 WIRE (FLAT TYPE) (5 CORE)

18 1-777-813-11 WIRE (FLAT TYPE) (9 CORE)

19 4-986-522-01 BUTTON (EDIT)

20 4-986-564-01 CUSHION (FOOT)

21 4-986-524-01 INDICATOR (DISC)

* 22 4-986-531-01 BRACKET (C), GROUND

* 23 4-975-358-91 COVER

– 34 –

Page 25

(2) MAIN SECTION

53

US, Canadian

not supplied

55

59

supplied with IC300

#1

not supplied

52

#2

51

#3

54

#3

#2

#1

#12

56

#1

#1

#4

57

55

not supplied

51

not supplied

#5

58

60

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

51 4-933-134-51 SCREW (+PTPWH 2.6X8)

* 52 A-4699-662-A MAIN BOARD, COMPLETE (US, Canadian)

* 52 A-4699-664-A MAIN BOARD, COMPLETE (EXCEPT US,

53 4-988-654-01 CUSHION (F)

* 54 1-663-502-11 LIGHT CONNECTOR BOARD

55 3-531-576-11 RIVET

not supplied

Canadian)

* 56 4-986-532-11 COVER, BACK (US, Canadian, AEP, UK)

* 56 4-986-532-23 COVER, BACK (E, Hong Kong, Singapore,

Malaysia)

* 57 1-663-503-11 POWER BOARD

* 58 1-663-507-11 TRAY ADDRESS BOARD

59 1-500-418-11 CORE (US, Canadian)

60 4-990-188-01 WASHER

– 35 –

Page 26

(3) FRAME (L), (R) ASS’Y SECTION

(CDM42-5BD19)

not supplied

103

101

104

105

104

105

104

105

not

supplied

102

#7

107

106

107

106

107

106

#8

not supplied

#6

not supplied

#7

#9

108

110

111

110

109

not

supplied

114

112

110

113

111

110

109

#8

#9

116

not supplied

#8

#7

not supplied

#7

not supplied

not supplied

#2

Ref. No. Part No. Description Remark Ref. No. Part No. Description Remark

101 X-4947-734-1 TRAIN ASSY, GEAR

* 102 1-663-509-11 GEAR SELECT BOARD

103 4-933-134-51 SCREW (+PTPWH 2.6X8)

104 4-986-652-01 SPRING, COMPRESSION

105 4-986-321-01 GEAR

106 4-986-650-01 SLEEVE (ON/OFF)

107 3-533-073-01 WASHER

* 108 1-663-508-11 CHUCKING SW BOARD

109 4-986-319-01 GEAR (TRAY DRIVING)

110 3-669-595-00 WASHER (2), STOPPER

111 4-986-320-01 PULLEY (TRAY DRIVING)

112 3-359-466-01 BELT (FR), SQUARE

113 4-986-653-01 SPRING (CLICK), LEAF

* 114 X-4947-732-1 CHASSIS (TRAY DRIVING) ASSY, SUB

115 3-696-510-01 WASHER (3), STOPPER

116 X-4947-834-1 TABLE ASSY, DISC

115

#8

115

– 36 –

Page 27

(4) CHASSIS SECTION

(CDM42-5BD19)

157

159

156

#6

155

not

supplied

160

158

159

154

not supplied

161

159

not

supplied

153

152

M401

174

not supplied

not supplied

#6

157

#6

173

M402

#10

164

162

163

159

165

166

171

M400

#6

159

153

152

159

168

not supplied

159

167

169

#6

not

supplied

#6

#7

151

Ref. No. Part No. Description Remark

* 151 X-4947-730-1 CHASSIS ASSY

152 4-986-335-01 GEAR (MODE B)

153 4-986-336-01 GEAR (MODE A)

154 4-986-334-01 GEAR (SELECT), CAM

* 155 X-4947-731-1 BRACKET (LOADING PULLEY) ASSY

156 4-986-324-01 GEAR (SHAFT DECELERATION)

157 3-669-595-00 WASHER (2), STOPPER

158 4-986-325-01 PULLEY (LOADING)

159 3-558-708-21 WASHER, STOPPER

160 3-319-030-01 BELT

161 3-359-412-01 GEAR (REEL MOTOR)

162 4-986-312-01 GEAR, WORM

163 3-359-466-01 BELT (FR), SQUARE

164 4-986-311-01 WHEEL, WORM

170

172

not supplied

Ref. No. Part No. Description Remark

165 4-986-310-01 GEAR (RACK DRIVING)

166 4-986-347-01 GEAR (MODE C)

* 167 4-986-309-01 RACK (UP AND DOWN)

168 4-986-345-01 GEAR (CHUCKING), CAM

169 3-831-441-XX CUSHION (B), CABINET

* 170 1-663-506-11 MOTOR DRIVE BOARD

* 171 1-663-510-11 PHOTO SENSOR BOARD

172 4-965-822-01 FOOT

173 3-317-552-61 SCREW (M1.7X2.0)

174 3-343-251-01 SCREW (M2.6X2.5)

M400 A-4672-209-A MOTOR (CARRIER U/D) ASSY (BD UP/DOWN)

M401 A-4672-211-A MOTOR ASSY, MODE (CHUCKING/GEAR)

M402 A-4672-210-A MOTOR (O/C) ASSY (LOADING)

– 37 –

Page 28

(5) CARRIER ASS’Y, OPTICAL PICK-UP SECTION

(BU-5BD19)

207

203

202

206

208

205

209

M101

204

#11

M102

216

220

208

206

210

217

215

211

not supplied

212

214

213

201

#9

not supplied

Ref. No. Part No. Description Remark

* 201 4-986-348-01 PLATE (BU HOLDER), LOCK

* 202 X-4947-735-1 HOLDER ASSY, BU

203 4-982-447-01 SPRING (BU), COMPRESSION

204 4-951-620-01 SCREW (2.6X8), +BVTP

* 205 A-4673-402-A BD BOARD, COMPLETE

206 4-951-940-01 INSULATOR (BU)

207 4-917-565-01 SHAFT, SLED

208 4-933-134-01 SCREW (+PTPWH M2.6X6)

! 209 8-848-387-01 OPTICAL PICK-UP KSS-213BA/S1NP

210 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

218

219

The components identified by

mark ! or dotted line with

mark ! are critical for safety.

Replace only with part number

specified.

Ref. No. Part No. Description Remark

* 212 X-4947-833-1 CARRIER ASSY

* 213 4-917-583-21 BRACKET, YOKE

214 4-986-341-01 SLIDER (CHUCKING CAM)

215 3-696-510-01 WASHER (3), STOPPER

216 1-777-631-11 FPC CABLE

217 4-917-564-01 GEAR (P), FLATNESS

218 3-531-576-11 RIVET

219 4-951-620-31 SCREW (2.6), +BVTP

220 4-917-567-01 GEAR (M)

M101 X-4917-523-4 BASE (OUTSART) ASSY (SPINDLE)

Les composants identifiés par une

marque ! sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le neméro spécifié.

211 1-452-864-11 MAGNET (ASSY)

M102 X-4917-504-1 MOTOR ASSY (SLED)

– 38 –

Page 29

SECTION 8

ELECTRICAL PARTS LIST

BD

NOTE:

• Due to standardization, replacements in the

parts list may be different from the parts specified in the diagrams or the components used on

the set.

• -XX and -X mean standardized parts, so they

may have some difference from the original one.

• RESISTORS

All resistors are in ohms.

MET AL: Metal-film resistor.

METAL OXIDE: Metal oxide-film resistor.

F: nonflammable

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when ordering these items.

Ref. No. Part No. Description Remark

* A-4673-402-A BD BOARD, COMPLETE

*******************

< CAPACITOR >

C101 1-126-607-11 ELECT CHIP 47uF 20% 4V

C102 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C103 1-164-346-11 CERAMIC CHIP 1uF 16V

C105 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C106 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

• SEMICONDUCTORS

In each case, u: µ, for example:

uA. . : µA. . uPA. . : µPA. .

uPB. . : µPB. . uPC. . : µPC. .

uPD. . : µPD. .

• CAPACIT ORS

uF: µF

• COILS

uH: µH

The components identified by mark

! or dotted line with mark ! are

critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiquens pour la

sécurité.

Ne les remplacer que par une pièce

portant le neméro spécifié.

When indicating parts by reference

number, please include the board.

Ref. No. Part No. Description Remark

C145 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C146 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C147 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C148 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C149 1-164-346-11 CERAMIC CHIP 1uF 16V

C153 1-135-259-11 TANTALUM CHIP 10uF 20% 6.3V

C154 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

< CONNECTOR >

C107 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C108 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C109 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C110 1-163-989-11 CERAMIC CHIP 0.033uF 10% 25V

C111 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C112 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C113 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C114 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C115 1-126-607-11 ELECT CHIP 47uF 20% 4V

C116 1-163-016-00 CERAMIC CHIP 0.0039uF 10% 50V

C117 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C118 1-107-823-11 CERAMIC CHIP 0.47uF 10% 16V

C119 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C120 1-135-201-11 TANTALUM CHIP 10uF 20% 4V

C121 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C122 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C123 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C124 1-126-607-11 ELECT CHIP 47uF 20% 4V

C125 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C126 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C127 1-164-695-11 CERAMIC CHIP 0.0022uF 5% 50V

C128 1-163-135-00 CERAMIC CHIP 560PF 5% 50V

C129 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C130 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C131 1-163-038-00 CERAMIC CHIP 0.1uF 25V

CNU101 1-770-014-11 CONNECTOR, FFC/FPC 16P

CNU102 1-770-013-11 CONNECTOR, FFC/FPC 19P

< IC >

IC101 8-752-069-56 IC CXA1782BQ

IC102 8-759-291-06 IC BA6397FP

IC103 8-752-372-94 IC CXD2507AQ

IC104 8-759-185-29 IC PCM1710U-B

< TRANSISTOR >

Q101 8-729-010-08 TRANSISTOR MSB710-R

Q102 8-729-424-08 TRANSISTOR UN2111

Q103 8-729-421-22 TRANSISTOR UN2211

< RESISTOR >

R102 1-216-001-00 METAL CHIP 10 5% 1/10W

R103 1-216-049-00 METAL CHIP 1K 5% 1/10W

R104 1-216-097-00 METAL CHIP 100K 5% 1/10W

R105 1-216-093-00 METAL CHIP 68K 5% 1/10W

R106 1-216-093-00 METAL CHIP 68K 5% 1/10W

R107 1-216-093-00 METAL CHIP 68K 5% 1/10W

R108 1-216-093-00 METAL CHIP 68K 5% 1/10W

R109 1-216-097-00 METAL CHIP 100K 5% 1/10W

R112 1-216-083-00 METAL CHIP 27K 5% 1/10W

R113 1-216-083-00 METAL CHIP 27K 5% 1/10W

C132 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C133 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C134 1-164-346-11 CERAMIC CHIP 1uF 16V

C135 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C136 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C137 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C139 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C140 1-163-235-11 CERAMIC CHIP 22PF 5% 50V

C141 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C142 1-163-038-00 CERAMIC CHIP 0.1uF 25V

R114 1-216-101-00 METAL CHIP 150K 5% 1/10W

R115 1-216-101-00 METAL CHIP 150K 5% 1/10W

R116 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R117 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R118 1-216-049-00 METAL CHIP 1K 5% 1/10W

R119 1-216-089-00 METAL CHIP 47K 5% 1/10W

R120 1-216-089-00 METAL CHIP 47K 5% 1/10W

R121 1-216-114-00 METAL CHIP 510K 5% 1/10W

R122 1-216-097-00 METAL CHIP 100K 5% 1/10W

R123 1-216-099-00 METAL CHIP 120K 5% 1/10W

– 39 –

Page 30

BD LIGHT CONNECTOR

GEAR SELECTCHUCKING SW

MAIN

Ref. No. Part No. Description Remark

R124 1-216-091-00 METAL CHIP 56K 5% 1/10W

R125 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R126 1-216-063-00 METAL CHIP 3.9K 5% 1/10W

R127 1-216-089-00 METAL CHIP 47K 5% 1/10W

R128 1-216-105-00 METAL CHIP 220K 5% 1/10W

R129 1-216-049-00 METAL CHIP 1K 5% 1/10W

R130 1-216-079-00 METAL CHIP 18K 5% 1/10W

R131 1-216-079-00 METAL CHIP 18K 5% 1/10W

R132 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R133 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R134 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R135 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R136 1-216-073-00 METAL CHIP 10K 5% 1/10W

R137 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R138 1-216-049-00 METAL CHIP 1K 5% 1/10W

R139 1-216-033-00 METAL CHIP 220 5% 1/10W

R140 1-216-081-00 METAL CHIP 22K 5% 1/10W

R141 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R142 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R143 1-216-121-00 METAL CHIP 1M 5% 1/10W

R144 1-216-073-00 METAL CHIP 10K 5% 1/10W

R145 1-216-097-00 METAL CHIP 100K 5% 1/10W

R146 1-216-097-00 METAL CHIP 100K 5% 1/10W

R147 1-216-049-00 METAL CHIP 1K 5% 1/10W

R148 1-216-049-00 METAL CHIP 1K 5% 1/10W

R149 1-216-049-00 METAL CHIP 1K 5% 1/10W

R150 1-216-037-00 METAL CHIP 330 5% 1/10W

R151 1-216-037-00 METAL CHIP 330 5% 1/10W

R152 1-216-037-00 METAL CHIP 330 5% 1/10W

R153 1-216-082-00 METAL CHIP 24K 5% 1/10W

R154 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R156 1-216-085-00 METAL CHIP 33K 5% 1/10W

R157 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R158 1-216-001-00 METAL CHIP 10 5% 1/10W

Ref. No. Part No. Description Remark

* 1-663-509-11 GEAR SELECT BOARD

******************

< SWITCH >

S403 1-762-847-11 SWITCH, PUSH (1 KEY) (GEAR SELECT)

S404 1-762-847-11 SWITCH, PUSH (1 KEY) (GEAR SELECT)

************************************************************

* 1-663-502-11 LIGHT CONNECTOR BOARD

**********************

< CAPACITOR >

C300 1-126-964-11 ELECT 10uF 20% 50V

C301 1-164-159-11 CERAMIC 0.1uF 50V

< CONNECTOR >

CN303 1-506-468-11 PIN, CONNECTOR 3P

< IC >

IC300 8-749-921-12 IC GP1F32T (DIGITAL OUT)

************************************************************

* A-4699-662-A MAIN BOARD, COMPLETE (US, Canadian)

* A-4699-664-A MAIN BOARD, COMPLETE

(EXCEPT US, Canadian)

*********************

* 4-870-539-00 PLATE, GROUND

< CAPACITOR >

C100 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C101 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C102 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C103 1-126-204-11 ELECT CHIP 47uF 20% 16V

C110 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

< VARIABLE RESISTOR >

RV101 1-223-587-11 RES, ADJ, CARBON 22K

RV102 1-223-587-11 RES, ADJ, CARBON 22K

RV103 1-223-587-11 RES, ADJ, CARBON 22K

< SWITCH >

S101 1-572-085-11 SWITCH, LEAF (LIMIT)

< VIBRATOR >

X101 1-579-280-11 VIBRATOR, CRYSTAL (16.9344 MHz)

************************************************************

* 1-663-508-11 CHUCKING SW BOARD

*******************

< SWITCH >

S401 1-692-193-11 SWITCH, PUSH (1 KEY)

(CHUCKING ADDRESS)

S402 1-692-193-11 SWITCH, PUSH (1 KEY)

(CHUCKING ADDRESS)

************************************************************

C112 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C113 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C114 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C115 1-163-009-11 CERAMIC CHIP 0.001uF 10% 50V

C116 1-163-037-11 CERAMIC CHIP 0.022uF 10% 25V

C117 1-126-393-11 ELECT 33uF 20% 10V

C118 1-126-393-11 ELECT 33uF 20% 10V

C121 1-124-779-00 ELECT CHIP 10uF 20% 16V

C122 1-113-503-11 CERAMIC CHIP 0.0039uF 5% 25V

C123 1-163-143-00 CERAMIC CHIP 0.0012uF 5% 50V

C124 1-126-204-11 ELECT CHIP 47uF 20% 16V

C125 1-126-395-11 ELECT 22uF 20% 16V

C131 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C132 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C133 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C140 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C141 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C142 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C143 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C144 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C145 1-163-133-00 CERAMIC CHIP 470PF 5% 50V

C146 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C147 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C148 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C149 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

– 40 –

Page 31

MAIN

Ref. No. Part No. Description Remark

C151 1-124-779-00 ELECT CHIP 10uF 20% 16V

C152 1-113-503-11 CERAMIC CHIP 0.0039uF 5% 25V

C153 1-163-143-00 CERAMIC CHIP 0.0012uF 5% 50V

C154 1-126-204-11 ELECT CHIP 47uF 20% 16V

C155 1-126-395-11 ELECT 22uF 20% 16V

C170 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C171 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C172 1-126-206-11 ELECT CHIP 100uF 20% 6.3V

C181 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C182 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C190 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C191 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C192 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C193 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

C194 1-107-725-11 CERAMIC CHIP 0.1uF 10% 16V

< CONNECTOR >

CN100 1-774-180-11 PIN, CONNECTOR (PC BOARD) 6P

CN101 1-774-297-21 PIN, CONNECTOR (PC BOARD) 7P

CN102 1-774-653-21 PIN, CONNECTOR (PC BOARD) 3P

CN103 1-774-731-21 PIN, CONNECTOR (PC BOARD) 5P

CN104 1-778-718-11 CONNECTOR, FFC/FPC 19P

CN105 1-778-795-21 PIN, CONNECTOR (PC BOARD) 9P

CN106 1-778-768-21 PIN, CONNECTOR (PC BOARD) 8P

CN107 1-770-217-11 PIN, CONNECTOR (PC BOARD) 4P

CN108 1-774-180-11 PIN, CONNECTOR (PC BOARD) 6P

CN109 1-774-739-11 CONNECTOR, FFC/FPC 5P

CN110 1-778-719-11 CONNECTOR, FFC/FPC 9P

< DIODE >

Ref. No. Part No. Description Remark

Q114 8-729-424-08 TRANSISTOR UN2111

Q115 8-729-424-08 TRANSISTOR UN2111

Q116 8-729-424-08 TRANSISTOR UN2111

Q117 8-729-424-08 TRANSISTOR UN2111

Q120 8-729-101-07 TRANSISTOR 2SB798-DL

Q121 8-729-216-22 TRANSISTOR 2SA1162-G

Q122 8-729-421-22 TRANSISTOR UN2211

Q123 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q124 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q125 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q126 8-729-424-08 TRANSISTOR UN2111

Q127 8-729-140-75 TRANSISTOR 2SD999-CLCK

Q128 8-729-120-28 TRANSISTOR 2SC1623-L5L6

< RESISTOR >

R100 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R101 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R102 1-216-049-00 METAL CHIP 1K 5% 1/10W

R103 1-216-073-00 METAL CHIP 10K 5% 1/10W

R120 1-216-089-00 METAL CHIP 47K 5% 1/10W

R121 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R122 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R123 1-216-097-00 METAL CHIP 100K 5% 1/10W

R150 1-216-089-00 METAL CHIP 47K 5% 1/10W

R151 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R152 1-216-055-00 METAL CHIP 1.8K 5% 1/10W

R153 1-216-097-00 METAL CHIP 100K 5% 1/10W

R160 1-216-033-00 METAL CHIP 220 5% 1/10W

R161 1-216-073-00 METAL CHIP 10K 5% 1/10W

R162 1-216-054-00 METAL CHIP 1.6K 5% 1/10W

D100 8-719-210-33 DIODE EC10DS2

D101 8-719-210-33 DIODE EC10DS2

D102 8-719-210-33 DIODE EC10DS2

D103 8-719-210-33 DIODE EC10DS2

D104 8-719-976-96 DIODE DTZ4.7C

D120 8-719-016-74 DIODE 1SS352

D121 8-719-016-74 DIODE 1SS352

< IC >

IC100 8-759-636-55 IC M5218AFP

IC103 8-759-458-30 IC uPD78014FGC-532-AB8

< COIL >

L100 1-412-348-41 INDUCTOR 47uH

L131 1-414-386-11 INDUCTOR, FERRITE BEAD

L132 1-414-386-11 INDUCTOR, FERRITE BEAD

L133 1-414-386-11 INDUCTOR, FERRITE BEAD

L134 1-414-386-11 INDUCTOR, FERRITE BEAD

L135 1-414-386-11 INDUCTOR, FERRITE BEAD

L136 1-414-386-11 INDUCTOR, FERRITE BEAD

< TRANSISTOR >

Q100 8-729-421-22 TRANSISTOR UN2211

Q101 8-729-101-07 TRANSISTOR 2SB798-DL

Q110 8-729-424-08 TRANSISTOR UN2111

Q111 8-729-424-08 TRANSISTOR UN2111

Q112 8-729-424-08 TRANSISTOR UN2111

Q113 8-729-424-08 TRANSISTOR UN2111

R163 1-216-054-00 METAL CHIP 1.6K 5% 1/10W

R164 1-216-049-00 METAL CHIP 1K 5% 1/10W

R165 1-216-073-00 METAL CHIP 10K 5% 1/10W

R166 1-216-073-00 METAL CHIP 10K 5% 1/10W

R167 1-216-073-00 METAL CHIP 10K 5% 1/10W

R168 1-216-073-00 METAL CHIP 10K 5% 1/10W

R169 1-216-033-00 METAL CHIP 220 5% 1/10W

R200 1-216-073-00 METAL CHIP 10K 5% 1/10W

R201 1-216-073-00 METAL CHIP 10K 5% 1/10W

R202 1-216-073-00 METAL CHIP 10K 5% 1/10W

R203 1-216-073-00 METAL CHIP 10K 5% 1/10W

R204 1-216-049-00 METAL CHIP 1K 5% 1/10W

R205 1-216-073-00 METAL CHIP 10K 5% 1/10W

R206 1-216-073-00 METAL CHIP 10K 5% 1/10W

R207 1-216-073-00 METAL CHIP 10K 5% 1/10W

R208 1-216-073-00 METAL CHIP 10K 5% 1/10W

R209 1-216-073-00 METAL CHIP 10K 5% 1/10W

R210 1-216-073-00 METAL CHIP 10K 5% 1/10W

R211 1-216-073-00 METAL CHIP 10K 5% 1/10W

R212 1-216-073-00 METAL CHIP 10K 5% 1/10W

R213 1-216-073-00 METAL CHIP 10K 5% 1/10W

R214 1-216-073-00 METAL CHIP 10K 5% 1/10W

R215 1-216-073-00 METAL CHIP 10K 5% 1/10W

R224 1-216-073-00 METAL CHIP 10K 5% 1/10W

R225 1-216-073-00 METAL CHIP 10K 5% 1/10W

R226 1-216-073-00 METAL CHIP 10K 5% 1/10W

R227 1-216-073-00 METAL CHIP 10K 5% 1/10W

R228 1-216-025-00 METAL CHIP 100 5% 1/10W

R229 1-216-025-00 METAL CHIP 100 5% 1/10W

– 41 –

Page 32

MAIN PANEL (LO WER)

MOTOR DRIVE

PHOTO SENSORPANEL (UPPER)

Ref. No. Part No. Description Remark

R230 1-216-025-00 METAL CHIP 100 5% 1/10W

R231 1-216-025-00 METAL CHIP 100 5% 1/10W

R233 1-216-073-00 METAL CHIP 10K 5% 1/10W

R234 1-216-073-00 METAL CHIP 10K 5% 1/10W

R235 1-216-049-00 METAL CHIP 1K 5% 1/10W

R236 1-216-025-00 METAL CHIP 100 5% 1/10W

R237 1-216-049-00 METAL CHIP 1K 5% 1/10W

R238 1-216-025-00 METAL CHIP 100 5% 1/10W

R240 1-216-025-00 METAL CHIP 100 5% 1/10W

R241 1-216-025-00 METAL CHIP 100 5% 1/10W

R242 1-216-049-00 METAL CHIP 1K 5% 1/10W

R244 1-216-025-00 METAL CHIP 100 5% 1/10W

R245 1-216-025-00 METAL CHIP 100 5% 1/10W

R246 1-216-025-00 METAL CHIP 100 5% 1/10W

R248 1-216-009-00 METAL CHIP 22 5% 1/10W

R249 1-216-073-00 METAL CHIP 10K 5% 1/10W

R250 1-216-025-00 METAL CHIP 100 5% 1/10W

< VIBRATOR >

X200 1-760-365-11 VIBRATOR, CERAMIC (10 MHz)

************************************************************

* 1-663-506-11 MOTOR DRIVE BOARD

******************

< CAPACITOR >

C104 1-104-665-11 ELECT 100uF 20% 25V

C105 1-104-665-11 ELECT 100uF 20% 25V

C106 1-164-159-11 CERAMIC 0.1uF 50V

C107 1-164-159-11 CERAMIC 0.1uF 50V

C108 1-164-159-11 CERAMIC 0.1uF 50V

Ref. No. Part No. Description Remark

R118 1-249-393-11 CARBON 10 5% 1/4W

************************************************************

* 1-663-505-11 PANEL (LOWER) BOARD

********************

< CONNECTOR >

CN600 1-778-720-11 CONNECTOR, FFC/FPC 9P

< DIODE >

D600 8-719-056-13 LED SML79423C-TP15 (DISC 3)

D601 8-719-056-13 LED SML79423C-TP15 (DISC 2)

D602 8-719-056-13 LED SML79423C-TP15 (DISC 1)

< RESISTOR >

R600 1-249-435-11 CARBON 33K 5% 1/4W

R601 1-249-425-11 CARBON 4.7K 5% 1/4W

R602 1-249-427-11 CARBON 6.8K 5% 1/4W

R640 1-249-415-11 CARBON 680 5% 1/4W

R641 1-249-415-11 CARBON 680 5% 1/4W

R642 1-249-415-11 CARBON 680 5% 1/4W

< SWITCH >

S601 1-554-303-21 SWITCH, TACTILE () +)

S602 1-554-303-21 SWITCH, TACTILE (= 0)

S603 1-554-303-21 SWITCH, TACTILE (DISC SKIP)

************************************************************

* 1-663-504-11 PANEL (UPPER) BOARD

*******************

< CONNECTOR >

C173 1-164-159-11 CERAMIC 0.1uF 50V

< CONNECTOR >

* CN201 1-564-711-11 PIN, CONNECTOR (SMALL TYPE) 9P

* CN202 1-568-935-11 PIN, CONNECTOR 8P

* CN203 1-564-499-11 PIN, CONNECTOR 6P

* CN405 1-568-942-11 PIN, CONNECTOR 4P

* CN406 1-568-941-11 PIN, CONNECTOR 3P

< IC >

IC101 8-759-821-32 IC CXA1291P

< RESISTOR >

R104 1-249-435-11 CARBON 33K 5% 1/4W

R105 1-249-437-11 CARBON 47K 5% 1/4W

R106 1-249-437-11 CARBON 47K 5% 1/4W

R107 1-249-435-11 CARBON 33K 5% 1/4W

R108 1-249-437-11 CARBON 47K 5% 1/4W

R109 1-249-437-11 CARBON 47K 5% 1/4W

R110 1-249-437-11 CARBON 47K 5% 1/4W

R111 1-249-437-11 CARBON 47K 5% 1/4W

R112 1-249-438-11 CARBON 56K 5% 1/4W

R113 1-249-437-11 CARBON 47K 5% 1/4W

R114 1-249-437-11 CARBON 47K 5% 1/4W

R115 1-249-438-11 CARBON 56K 5% 1/4W

R116 1-249-393-11 CARBON 10 5% 1/4W

R117 1-249-393-11 CARBON 10 5% 1/4W

CN620 1-778-721-11 CONNECTOR, FFC/FPC 5P

< DIODE >

D620 8-719-057-29 LED SML78423C-TP15 (^)

< RESISTOR >

R620 1-249-435-11 CARBON 33K 5% 1/4W

R621 1-249-425-11 CARBON 4.7K 5% 1/4W

R622 1-249-427-11 CARBON 6.8K 5% 1/4W

R623 1-249-429-11 CARBON 10K 5% 1/4W

R624 1-247-858-11 CARBON 13K 5% 1/4W

R650 1-249-413-11 CARBON 470 5% 1/4W

< SWITCH >

S621 1-554-303-21 SWITCH, TACTILE (6 OPEN/CLOSE 1)

S622 1-554-303-21 SWITCH, TACTILE (6 OPEN/CLOSE 2)

S623 1-554-303-21 SWITCH, TACTILE (6 OPEN/CLOSE 3)

S624 1-554-303-21 SWITCH, TACTILE (^)

S625 1-554-303-21 SWITCH, TACTILE (p)

************************************************************

* 1-663-510-11 PHOTO SENSOR BOARD

*******************

< PHOTO INTERRUPTER >

PH400 8-759-071-52 IC ON1023-S (BD VERTICAL POSITION)

– 42 –

Page 33

POWERPHOTO SENSOR

TRAY ADDRESS

Ref. No. Part No. Description Remark

< RESISTOR >

R400 1-249-425-11 CARBON 4.7K 5% 1/4W

R401 1-249-409-11 CARBON 220 5% 1/4W

< SWITCH >

S400 1-692-193-11 SWITCH, PUSH (1 KEY) (BD BOTTOM)

************************************************************

* 1-663-503-11 POWER BOARD

*************

< CAPACITOR >

C302 1-124-994-11 ELECT 100uF 20% 10V

C303 1-124-463-00 ELECT 0.1uF 20% 50V

C304 1-126-923-11 ELECT 220uF 20% 10V

C305 1-126-022-11 ELECT 47uF 20% 25V

C306 1-164-159-11 CERAMIC 0.1uF 50V

C307 1-164-159-11 CERAMIC 0.1uF 50V

C320 1-162-294-31 CERAMIC 0.001uF 10% 50V

C350 1-162-294-31 CERAMIC 0.001uF 10% 50V

< CONNECTOR >

* CN300 1-580-739-11 SOCKET, CONNECTOR 15P

(SYSTEM CONTROL)

* CN301 1-568-955-11 PIN, CONNECTOR 6P

* CN302 1-564-709-11 PIN, CONNECTOR (SMALL TYPE) 7P

CN304 1-564-707-11 PIN, CONNECTOR (SMALL TYPE) 5P

< IC >

Ref. No. Part No. Description Remark

S432 1-762-847-11 SWITCH, PUSH (1 KEY)

(DISC 3 TRAY HORIZONTAL ADDRESS)

S433 1-762-847-11 SWITCH, PUSH (1 KEY)

(DISC 3 TRAY HORIZONTAL ADDRESS)

************************************************************

MISCELLANEOUS

**************

12 1-777-814-11 WIRE (FLAT TYPE) (5 CORE)

18 1-777-813-11 WIRE (FLAT TYPE) (9 CORE)

59 1-500-418-11 CORE (US, Canadian)

! 209 8-848-387-01 OPTICAL PICK-UP KSS-213BA/S1NP

210 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

211 1-452-864-11 MAGNET (ASSY)

216 1-777-631-11 FPC CABLE

M101 X-4917-523-4 BASE (OUTSART) ASSY (SPINDLE)

M102 X-4917-504-1 MOTOR ASSY (SLED)

M400 A-4672-209-A MOTOR (CARRIER U/D) ASSY (BD UP/DOWN)

M401 A-4672-211-A MOTOR ASSY, MODE (CHUCKING/GEAR)

M402 A-4672-210-A MOTOR (O/C) ASSY (LOADING)

************************************************************

**************

HARDWARE LIST

**************

#1 7-682-547-09 SCREW (M3X6), S TITE, +BTT

#2 7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

#3 7-685-871-01 SCREW +BVTT 3X6 (S)

#4 7-682-546-09 SCREW +P 3X5

#5 7-685-134-19 SCREW +P 2.6X8 TYPE2 NON-SLIT

IC301 8-759-390-42 IC uPC24M05AHF

IC302 8-759-390-58 IC uPC2407AHF

IC303 8-759-165-80 IC PST600C-T

< RESISTOR >

R320 1-247-807-31 CARBON 100 5% 1/4W

R350 1-247-807-31 CARBON 100 5% 1/4W

< LEAD WITH CONNECTOR >

TP300 1-690-880-11 LEAD (WITH CONNECTOR)

************************************************************

* 1-663-507-11 TRAY ADDRESS BOARD

*******************

< SWITCH >

S411 1-762-847-11 SWITCH, PUSH (1 KEY)

(DISC 1 TRAY HORIZONTAL ADDRESS)

S412 1-762-847-11 SWITCH, PUSH (1 KEY)

(DISC 1 TRAY HORIZONTAL ADDRESS)

S413 1-762-847-11 SWITCH, PUSH (1 KEY)

(DISC 1 TRAY HORIZONTAL ADDRESS)

S421 1-762-847-11 SWITCH, PUSH (1 KEY)

(DISC 2 TRAY HORIZONTAL ADDRESS)

S422 1-762-847-11 SWITCH, PUSH (1 KEY)

(DISC 2 TRAY HORIZONTAL ADDRESS)

#6 7-682-145-01 SCREW +P 3X4

#7 7-685-870-01 SCREW +BVTT 3X5 (S)

#8 7-685-862-09 SCREW +BVTT 2.6X6 (S)

#9 7-685-133-19 SCREW +P 2.6X6 TYPE2

#10 7-627-854-07 PRECISION SCREW +P 2X2.5 TYPE3

#11 7-621-255-15 SCREW +P 2X3

#12 7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

S423 1-762-847-11 SWITCH, PUSH (1 KEY)

(DISC 2 TRAY HORIZONTAL ADDRESS)

S431 1-762-847-11 SWITCH, PUSH (1 KEY)

(DISC 3 TRAY HORIZONTAL ADDRESS)

– 43 –

The components identified by

mark ! or dotted line with

mark ! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par une

marque ! sont critiques pour la

sécurité.

Ne les remplacer que par une pièce

portant le neméro spécifié.

Page 34

CDP-M11C

9-960-793-11

Sony Corporation

Home A&V Products Company

– 44 –

Printed in Japan © 1997. 3

97C0566-1

Published by Service and Safety

Engineering Dept. (Shibaura)

Loading...

Loading...