Page 1

CDP-C460Z/CE515

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

SERVICE MANUAL

Photo : CDP-CE515

Model Name Using Similar Mechanism CDP-C360Z/CE415

CD Mechanism Type CDM27G-5BD22

Base Unit Type BU-5BD22

Optical Pick-up Type KSS-213BA/F-NP

SPECIFICATIONS

US Model

CDP-C460Z/CE515

Canadian Model

AEP Model

Australian Model

CDP-CE515

Compact Disc Player

Laser Semiconductor laser (λ = 780 nm)

Laser output Max 44.6 µW*

Frequency response 2 Hz to 20 kHz ± 0.5 dB

Signal-to-noise ratio More than 107 dB

Dynamic range More the 98 dB

Harmonic distortion Less than 0.0035%

Output

LINE OUT Phono 2V

DIGITAL OUT Optical –18 dBm Wave length:

(OPTICAL) output 660 nm

PHONES Stereo 10 mW 32 ohms

Emission duration: continuous

* This output is the value measured at a

distance of 200 mm from the objective

lens surface on the Optical Pick-up

block with 7 mm aperture.

Jack Maximum Load

type output impedance

level

Over 10 kilohms

jacks (at 50 kilohms)

connector

phone jack

General

Power requirements

Where purchased Power requirements

USA/Canada 120 V AC, 60 Hz

Europe 220 V – 230 V AC, 50/60 Hz

Australia 240 V AC, 50/60 Hz

Power consumption 14W

Dimensions (approx.) 430 × 120 × 393 mm

(w/h/d) (17 × 4 3/4 × 15 1/2 in.) incl. projecting parts

Mass (approx.) 5.4 kg (11 lbs 15 oz)

Supplied accessories

Audio cord (2 phono plugs–2 phono plugs) (1)

Remote commander (remote)(1)

Sony SUM-3 (NS) batteries (2)

Design and specifications are subject to change without notice.

COMPACT DISC PLAYER

MICROFILM

Page 2

The following caution label is located inside of the unit.

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

TABLE OF CONTENTS

1. GENERAL ..................................................................... 7

2. DISASSEMBLY

2-1. Case, Bottom Plate and Front Panel ··································· 8

2-2. Back Panel and Disc Table ················································· 8

2-3. Optical Pick-up Block Assembly ······································· 9

2-4. Bracket (Gear) Assembly ··················································· 9

This appliance is classified

as a CLASS 1 LASER

product.

The CLASS 1 LASER

PRODUCT MARKING is

located on the rear exterior.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

3. ELECTRICAL BLOCK CHECKING................... 10

4. DIAGRAMS

4-1. Circuit Boards Location ··················································· 12

4-2. Printed Wiring Board — BD Section —·························· 13

4-3. Schematic Diagram — BD Section —····························· 15

4-4. Printed Wiring Board — Main Section — ······················· 17

4-5. Schematic Diagram — Main Section — ·························· 19

4-6. Schematic Diagram — Display Section — ······················ 21

4-7. Printed Wiring Board — Display Section — ··················· 23

4-8. IC Block Diagrams ··························································· 25

4-9 IC Pin Functions

• IC101 Digital Signal Processor (CXD2545Q)···············27

• IC302 System Control (CXP84340-060Q) ···················· 30

5. EXPLODED VIEWS

5-1. Front Panel and Case Section ··········································· 32

5-2. Back Panel and Disc Table Section ·································· 33

5-3. Chassis Section································································· 34

5-4. Base Unit Section (BU-5BD22) ······································· 35

6. ELECTRICAL PARTS LIST ................................... 36

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ! OR DOTTED LINE WITH

MARK ! ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS P AR UNE MARQUE ! SUR LES

DIAGRAMMES SCHÉMA TIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

— 2 —

Page 3

MODEL IDENTIFICATION

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

— BACK PANEL —

4-987-

CDP-CE515

US Model : 842-0π

CDP-CE515

Canadian Model : 842-1π

CDP-CE515

AEP Model : 842-2π

CDP-C460Z

US Model : 842-3π

CDP-CE515

Australian Model : 842-5π

NOTES ON HANDLING THE OPTICAL PICK-UP

BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

breakdown because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdo wn and also use

the procedure in the printed matter which is included in the repair

parts.

The flexible board is easily damaged and should be handled with

care.

SAFETY CHECK-OUT

(US model only)

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for A C leakage. Check leakage as

described below.

LEAKAGE

The A C leakage from any exposed metal par t to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microampers).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester , such as the Simpson 229 or RCA

WT -540A. Follo w the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

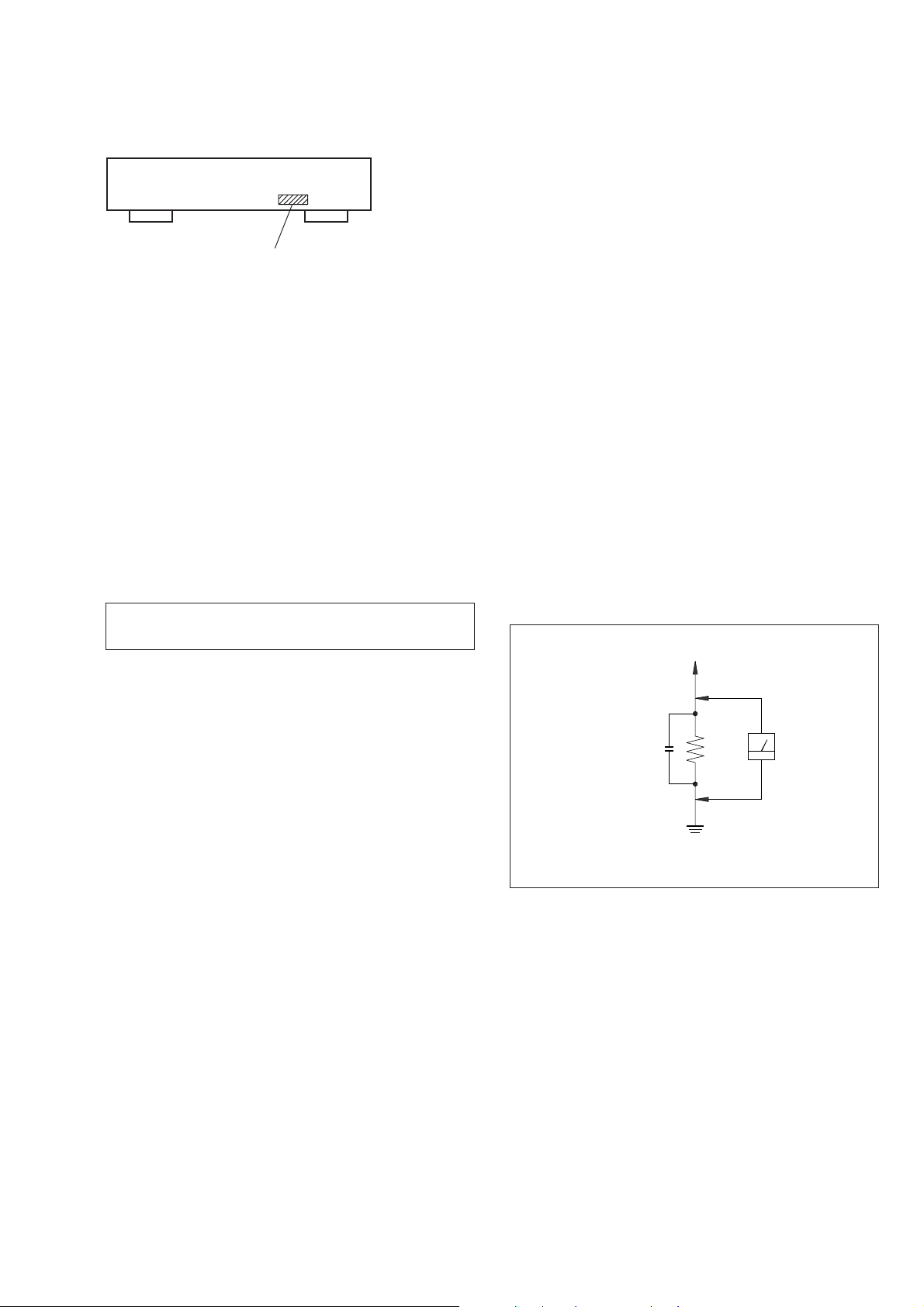

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC v oltmeter . The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd ar e examples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

To Exposed Metal

Parts on Set

AC

0.15µF

1.5k

Ω

voltmeter

(0.75V)

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pickup block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

— 3 —

Page 4

CD-TEXT TEST DISC

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

This unit is able to display the test data (character information) written in the CD on its fluorescent indicator tube.

The CD-TEXT TEST DISC (TGCS-313:4-989-366-01) is used for checking the display.

To check, perform the following procedure.

Checking Method:

1. T urn ON the po wer , set the disc on the disc table with the side labeled as “test disc” as the right side, close the front cover , and c huck the

disc.

2. Press the ” button and play back the disc.

3. The following will be displayed on the fluorescent indicator tube.

Display : 1kHz/0 dB/ L&R

4. Press the = and + buttons to switch the track. The text data of each track will be displayed.

For details of the displayed contents for each track, refer to “T able 1 : CD-TEXT TEST DISC TEXT Data Contents” and “Table 2 : CDTEXT TEST DISC Recorded Contents and Display”.

Restrictions in CD-TEXT Display

In this unit, some special characters will not be displayed properly. These will be displayed as a space or a character resembling it. For details,

refer to “Table 2 : CD-TEXT DISC Recorded Contents and Display”.

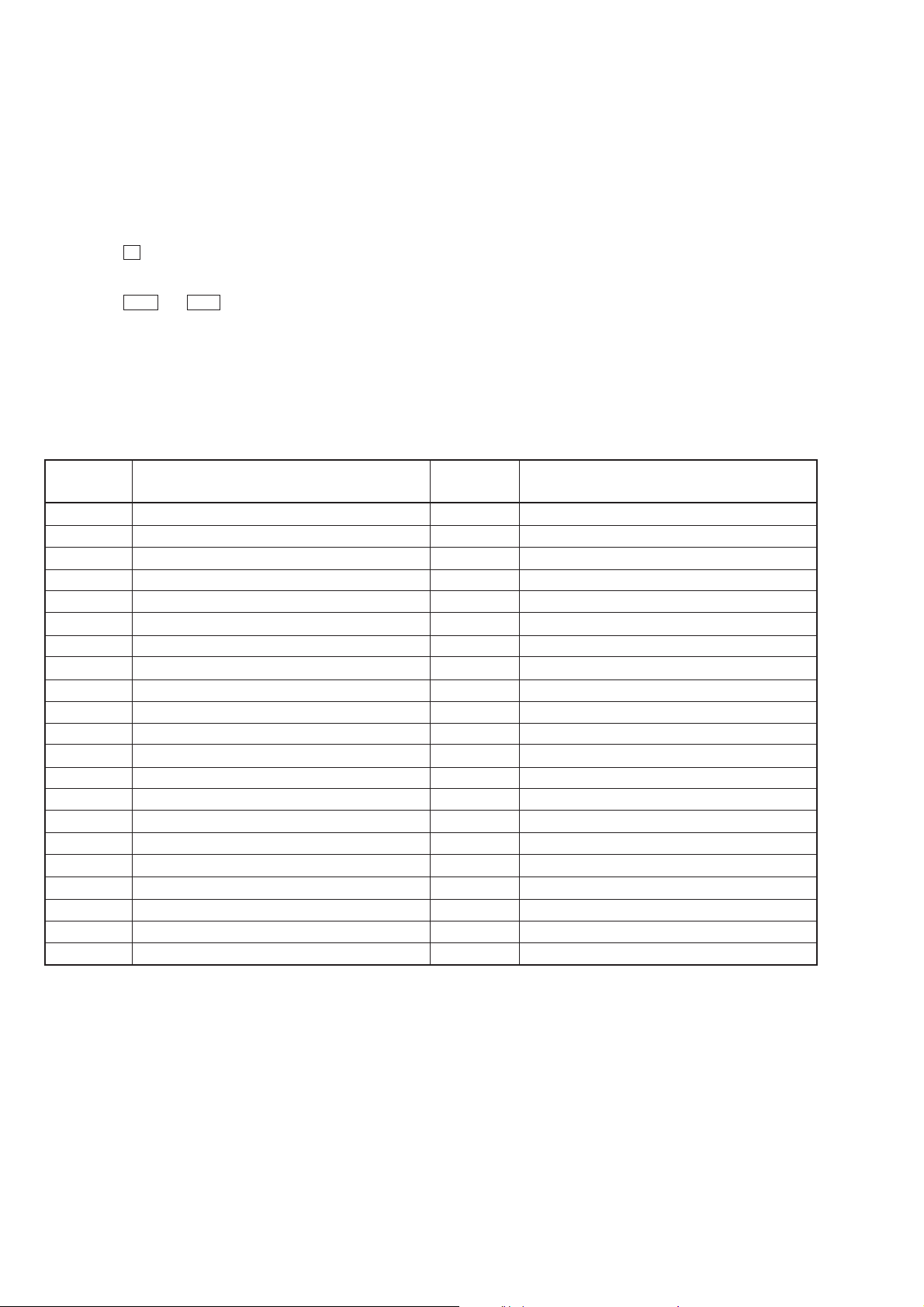

Table 1 : CD-TEXT TEST DISC TEXT Data Contents (TRACKS No. 1 to 41:Normal Characters)

TRACK

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Displayed Contents

1kHz/0dB/L&R

20Hz/0dB/L&R

40Hz/0dB/L&R

100Hz/0dB/L&R

200Hz/0dB/L&R

500Hz/0dB/L&R

1kHz/0dB/L&R

5kHz/0dB/L&R

7kHz/0dB/L&R

10kHz/0dB/L&R

16kHz/0dB/L&R

18kHz/0dB/L&R

20kHz/0dB/L&R

1kHz/0dB/L&R

1kHz/-1dB/L&R

1kHz/-3dB/L&R

1kHz/-6dB/L&R

1kHz/-10dB/L&R

1kHz/-20dB/L&R

1kHz/-60dB/L&R

1kHz/-80dB/L&R

TRACK

No.

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Displayed Contents

1kHz/-90dB/L&R

Infinity Zero w/o emphasis//L&R

Infinity Zero with emphasis//L&R

400Hz+7kHz(4:1)/0dB/L&R

400Hz+7kHz(4:1)/-10dB/L&R

19kHz+20kHz(1:1)/0dB/L&R

19kHz+20kHz(1:1)/-10dB/L&R

100Hz/0dB/L*

1kHz/0dB/L*

10kHz/0dB/L*

20kHz/0dB/L*

100Hz/0dB/R*

1kHz/0dB/R*

10kHz/0dB/R*

20kHz/0dB/R*

100Hz Squer Wave//L&R

1kHz Squer Wave//L&R

1kHz w/emphasis/-0.37dB/L&R

5kHz w/emphasis/-4.53dB/L&R

16kHz w/emphasis/-9.04dB/L&R

NOTE : The contents of Track No. 1 to 41 are the same as those of the current TEST DISC-their titles are displayed.

— 4 —

* Other channel is infinity zero.

Page 5

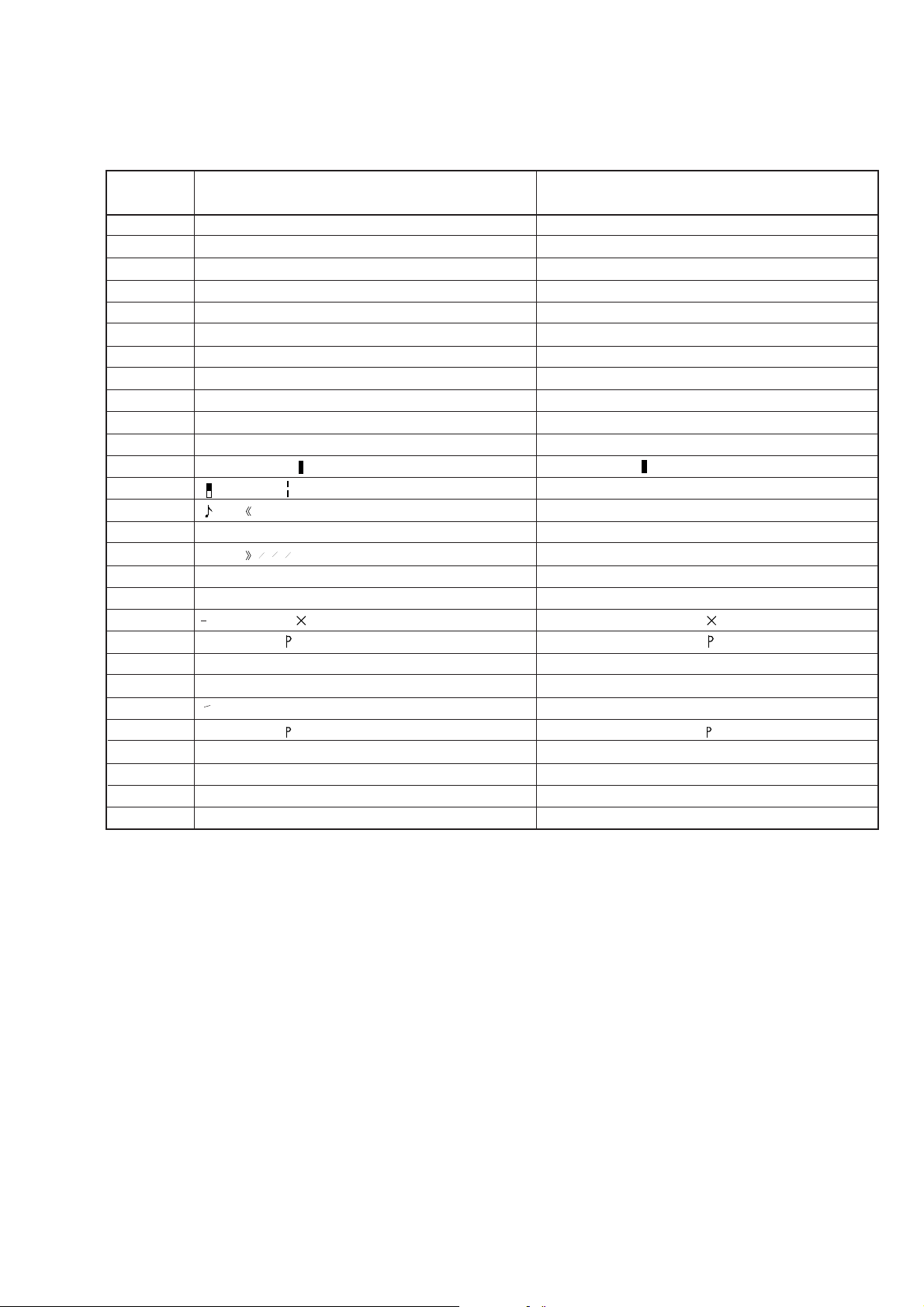

Table 2: CD-TEXT TEST DISC Recorded Contents and Display

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

(In this unit, some special characters cannot be displayed. This is no a fault.)

TRACK

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

to

99

Recorded contents Display

! ” # $ %& ’ (21h to 27h)1kHz 0dB L&R

( ) + , – . / (28h to 2Fh)

*

01234567 (30h to 37h)

8 9 : ; < = > ? (38h to 3Fh)

@A B C D E F G (40h to 47h)

H I J K L MNO (48h to 4Fh)

P Q R S T U VW (50h to 57h)

X Y Z [ ¥ ] ^ _ (58h to 5Fh)

a b c d e f g (60h to 67Fh)

′

h i j k l m n o (68h to 6Fh)

p q r s t u v w (70h to 77h)

xyz{ I }

i ¢ £ ¤ ¥ § (A0h to A7h) 8859-1

¬

C ª

•±23

1

†

АБВГДЕЖЗ (C0h to C7h)

ИЙКЛМНОП (C8h to CFh)

D СТУФХЦ

ШЩЪЫЬY

абвгдежз (E0h to E7h)

ийклмноп (E8h to EFh)

∂ стуфхц÷ (F0h to F7h)

шщъыьy

No.66

No.67

to

No.99

PR

µ¶ • (B0h to B7h)

′

1

1

º ¿ (B8h to BFh)

2

4

˙

´

(78h to 7Fh)

~

–

(A8h to AFh)

3

4

(D0h to D7Fh)

ß (D8h to DFh)

ÿ (F8h to FFh)

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

N All the same

X Y Z [ ] ^ _ (58····

|| a b c d e f g (60····

N All the same

N All the same

xyz{I}–

A A A A A A C (C0···· Æ is not displayed

EEEEIIII (C8

D NOOOOO (D0····

O UU U U Y (D8····

a a a a a a c (E0···· æ is not displayed

eeeeiiii (E8····

d n o o o o o (F0···· ÷ is not displayed

o u u u u y y (F8····

N All the same

N All the same

N All the same

/

(78····

(A0···· All not displayed

(A8···· All not displayed

(B0···· All not displayed

(B8···· All not displayed

is not displayed

ß are not displayed

is not displayed

to

— 5 —

Page 6

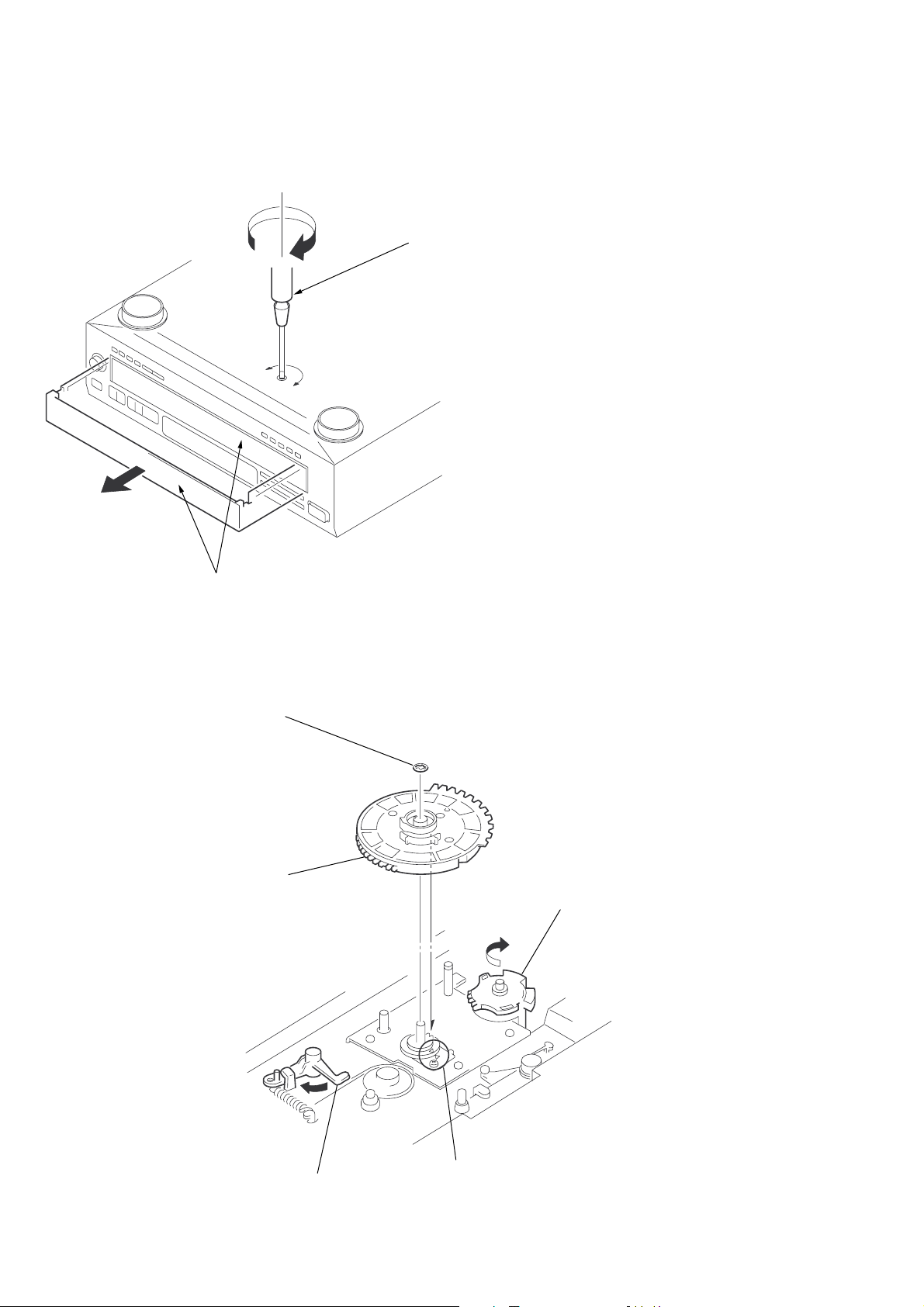

HOW TO OPEN THE DISC TRAY WHEN POWER

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

SWITCH TURNS OFF

IN

OUT

Insert a tapering driver into the aperture of the unit bottom, and turn in

the direction of arrow (to OUT direction).

* To close the disc tray, turn the driver in the reverse direction

(to IN direction).

Tray

NOTE FOR MAIN GEAR INSTALLATION

5

Stopper washer (5)

4

Install the MAIN GEAR

as show in the drawing.

A

3

Rotate the GEAR (U/D)

to the arrow

A

direction.

B

1

Set the mark of

2

Slide the SET LEVER to the

arrow

B

direction.

ROTARY ENCODER.

— 6 —

Page 7

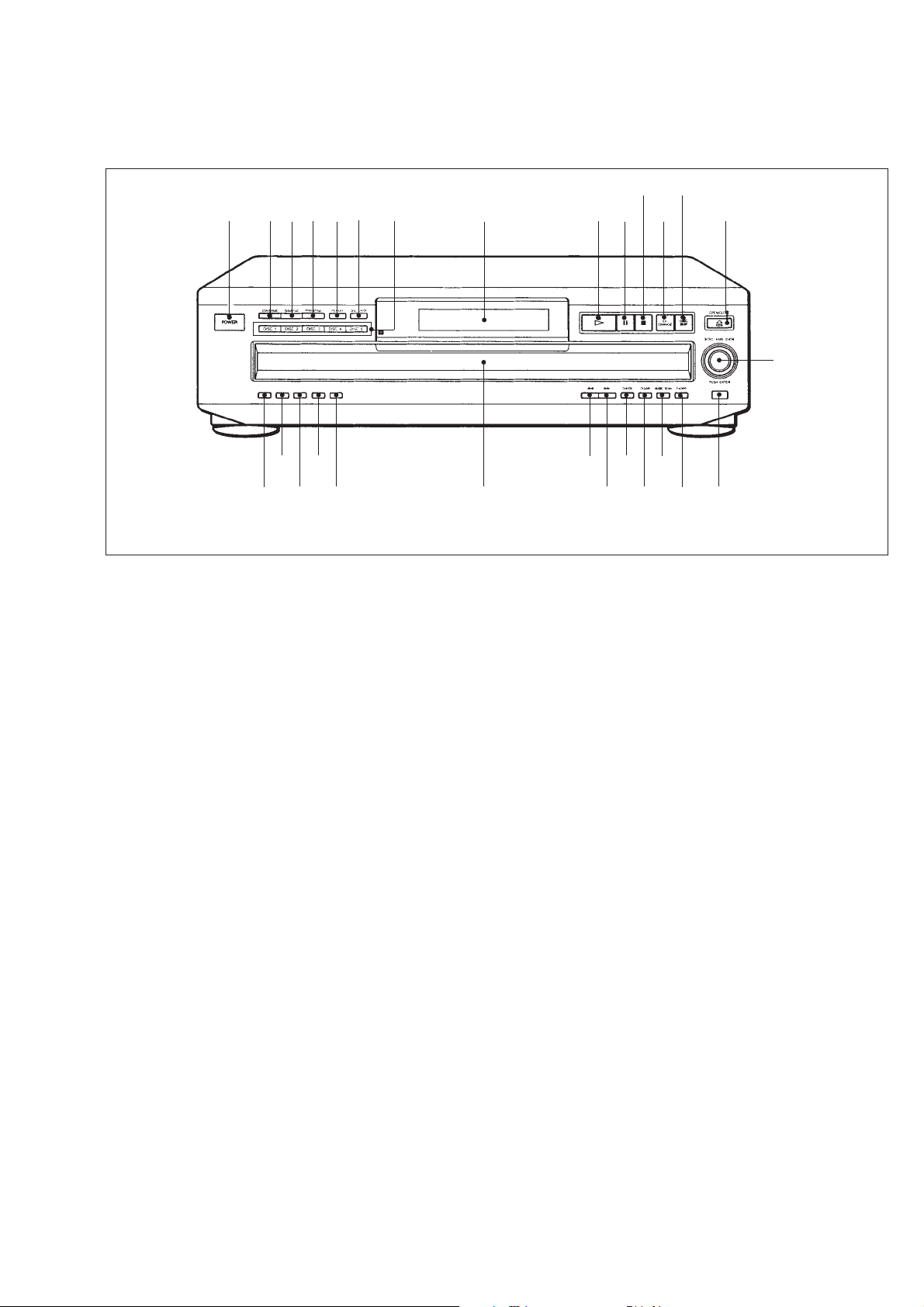

Identifying the Parts

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Front Panel

1

234

@¢

5

6

7

SECTION 1

GENERAL

8

90

@¡@§

!¡

!ª

!£

!™ !¢

!∞

!¶

@£

@∞@¶

1 POWER switch

2 CONTINUE button

3 SHUFFLE button

4 PROGRAM button

5 REPEAT button

6 TIME/TEXT button : C460Z model

DISC CHECK button : CE515 model

7 DISC 1-5 button

8 Display window

9 ” (play) button

!º P (pause) button

!¡ p (stop) button

!™ EX-CHANGE button

!£ DISC SKIP button

@™

!¢ 6 OPEN/CLOSE button

!∞ AMS knob

!§ X-FADE button

!¶ NO DELAY button

!• CLEAR button

!ª CHECK button

@º ) (forward) button

@¡ 0 (backward) button

@™ Disc tray

@£ PEAK SEARCH button: CE515 model

@¢ EDIT/TIME FADE button: CE515 model

@∞ TIME/TEXT button: CE515 model

@§ FADER button

@¶ MEMO INPUT button

@• MEGA CONTROL button

@º !•

!§

@•

— 7 —

Page 8

SECTION 2

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

DISASSEMBLY

Note : Follow the disassembly procedure in the numerical order given.

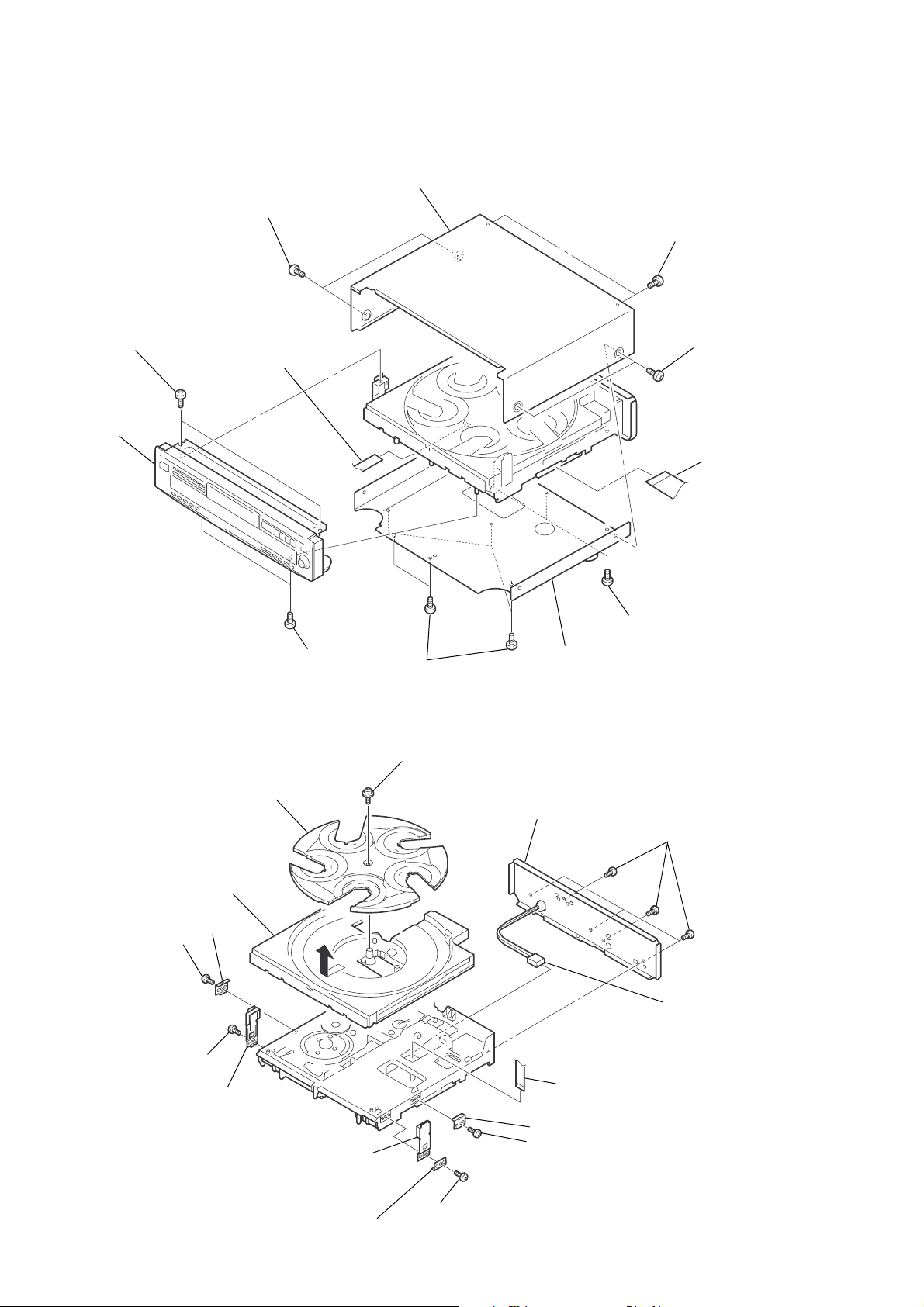

2-1. CASE, BOTTOM PLATE AND FRONT PANEL

4

Case

1

Two screws

(M3

×

8)

!º

Two screws

(BVTT3

!™

Front panel

×

8)

9

Flat type wire (9 core)

(MAIN board, to CN403)

3

Two screws

(BV3

×

8)

2

Two screws

(M3

8

Flat type wire (17 core)

(MAIN board, to CN402)

×

8)

!¡

Three screws

(BVTP3

2-2. BACK PANEL AND DISC TABLE

!∞

Disc table (B)

!§

Disc table (A)

!£

Bracket

!º

Screw

(BVTP3

(guideB1)

×

8)

×

8)

!¡

Bracket (guide F1)

!™

Screw

(BVTP3

×

10)

5

Four screws

(BVTP3

!¢

Screw

(PTPWH3

×

10)

×

12)

7

Bottom plate

3

Back panel

4

6

Three screws

(BVTP3

Flat type wire (6 core)

(MAIN board, to CN404)

×

10)

2

Five screws

(BVTP3

1

Connector

×

10)

6

Bracket (guide B1)

5

9

Bracket (guide F1)

8

7

Screw (BVTP3 × 8)

Ground plate (chassis-R)

Screw

(BVTP3

×

8)

— 8 —

Page 9

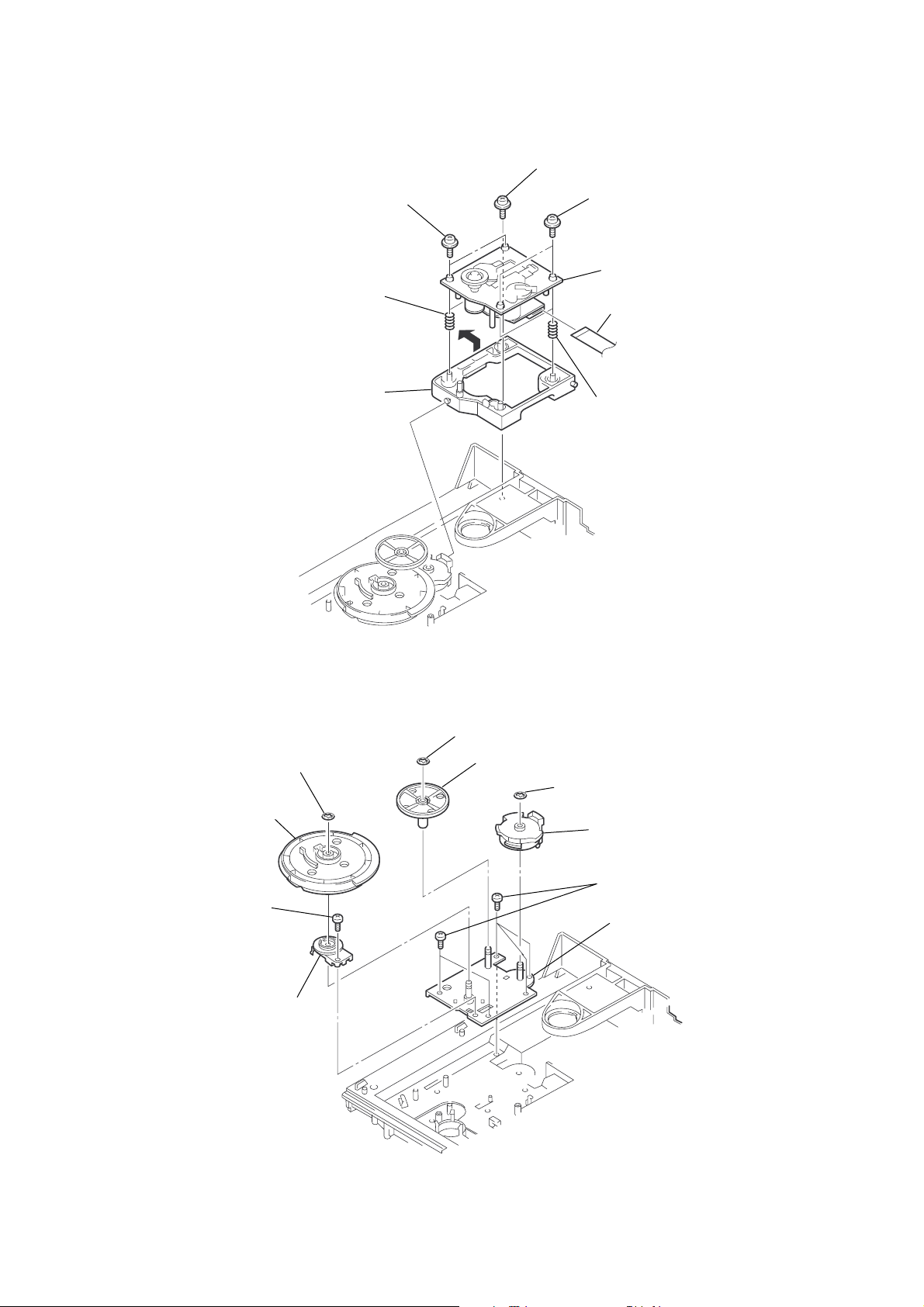

2-3. OPTICAL PICK-UP BLOCK ASSEMBLY

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

3

Two screws

(PTPWH2.6

6

Compression spring (BU)

5

Holder (BU)

2

Screw

(PTPWH3

×

6)

×

12)

4

Two screws

(PTPWH2.6

8

Optical pick-up block assembly

1

Flat type wire (23 core)

(BD board, to CN101)

7

Compression spring (BU)

×

6)

2-4. BRACKET (GEAR) ASSEMBLY

3

Stopper washer (5)

4

Gear (MAIN)

5

Screw

(BVTP3

×

8)

6

Rotary encoder

1

Stopper washer (5)

2

Gear (REV)

7

Stopper washer (5)

8

Gear (U/D)

9

Five screws

(BVTP3

0

Bracket (GEAR)

assembly

×

8)

Note : As for the installation of the main gear, refer to “Note for MAIN

GEAR installation” on page 4.

— 9 —

Page 10

SECTION 3

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

ELECTRICAL BLOCK CHECKING

Note :

1. CD Block is basically designed to operate without adjustment.

Therefore, check each item in order given.

2. Use YEDS-18 disc (3-702-101-01) unless otherwise indicated.

3. Use an oscilloscope with more than 10MΩ impedance.

4. Clean the object lens using an applicator with neutral detergent

when the signal level is low than specified value with the

following checks.

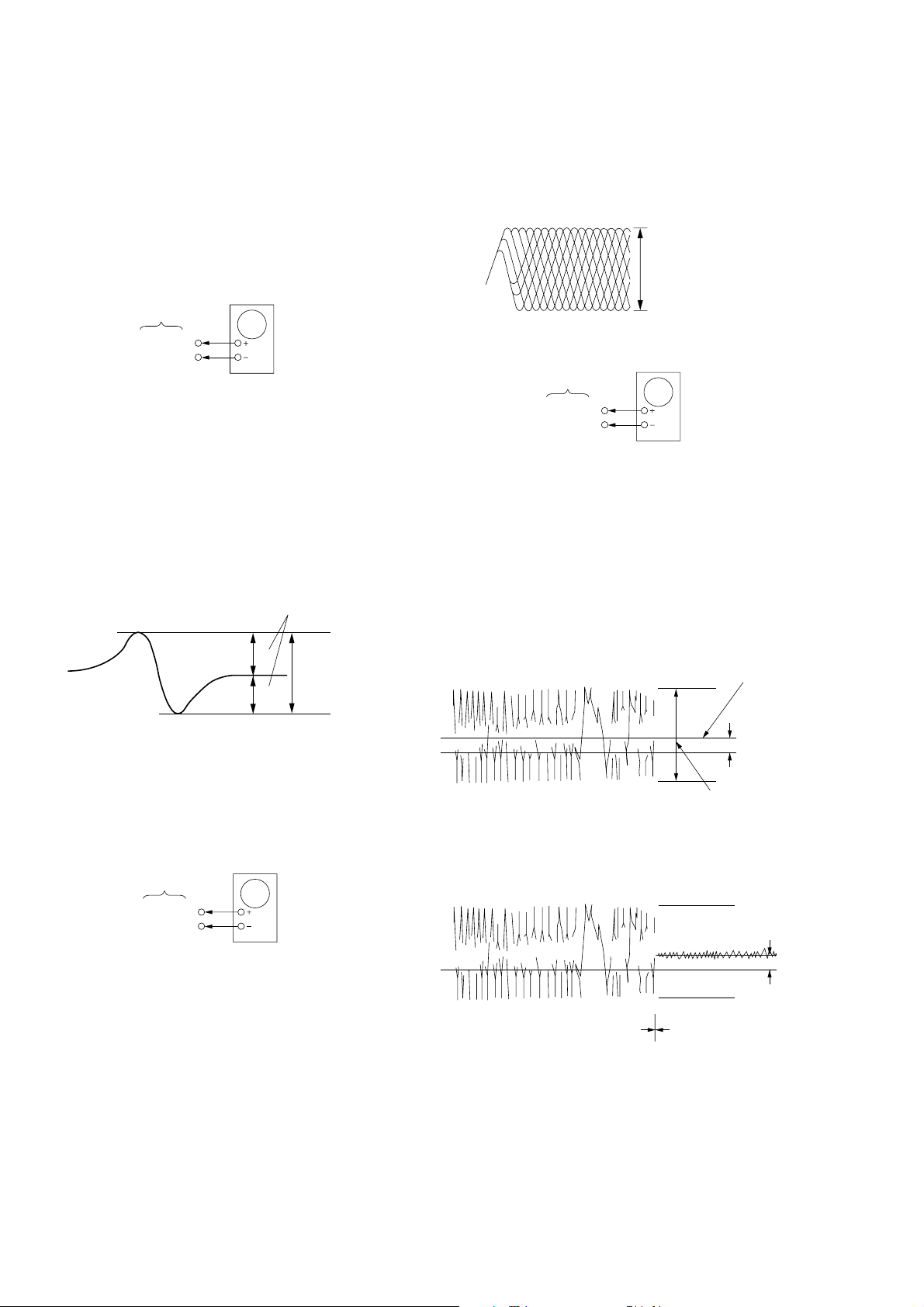

S Curve Check

oscilloscope

BD board

TP (FE)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (FE) on BD board.

2. Connect between test point TP (FEI) and TP (VC) by lead wire.

3. Turn Power switch on.

4. Put disc (YEDS-18) in and turn Power switch on again and

actuate the focus search. (Actuate the focus search when disc

table is moving in and out.)

5. Check if the oscilloscope waveform (S-curve) is symmetrical

between A and B. And confirm peak to peak level within 3±1

Vp-p.

S-curve waveform

symmetry

Note :

A clear RF signal waveform means that the shape “ ◊ ” can

be clearly distinguished at the center of the waveform.

RF signal waveform

VOLT/DIV : 200mV

TIME/DIV : 500ns

level :

1.25 ± 0.25 Vp-p

E-F Balance Check

oscilloscope

BD board

TP (TE)

TP (VC)

Procedure :

1. Connect test point TP1 (ADJ) to ground with a lead wire.

2. Connect oscilloscope to test point TP (TE) on BD board.

3. Turned Power switch on.

4. Put disc (YEDS-18) in to play the number five track.

5. Press the “3” button. (The tracking servo and the sledding servo

are turned OFF.)

6. Check the level B of the oscilloscope's waveform and the A

(DC voltage) of the center of the Traverse waveform.

Confirm the following :

A/B × 100 = less than ± 22%

A

within 3 ± 1 Vp-p

B

6. After check, remove the lead wire connected in step 2.

Note : • Try to measure several times to make sure than the ratio

of A : B or B : A is more than 10 : 7.

• Take sweep time as long as possible and light up the

brightness to obtain best waveform.

RF Level Check

oscilloscope

BD board

TP (RF)

TP (VC)

Procedure :

1. Connect oscilloscope to test point TP (RF) on BD board.

2. Turned Power switch on.

3. Put disc (YEDS-18) in to play the number five track.

4. Confirm that oscilloscope waveform is clear and check if RF

signal level is correct or not.

Traverse waveform

Center of the waveform

B

0V

level : 1.3 ± 0.6 Vp-p

7. Press the “8” button. (The tracking servo and sledding servo

are turned ON.) Confirm the C (DC voltage) is almost equal to

the A (DC voltage) is step 6.

Traverse waveform

0V

Tracking servo

Sledding servo

OFF

8. Disconnect the lead wire of test point TP1 (ADJ) connected in

step 1.

Tracking servo

Sledding servo

A (DC voltage)

ON

C (DC

voltage)

— 10 —

Page 11

RF PLL Free-run Frequency Check

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Procedure :

1. Connect frequency counter to test point TP (PLCK) with lead

wire.

BD board

TP (PLCK)

2. Turned Power switch on.

3. Put the disc (YEDS-18) in to play the number five track.

Confirm that reading on frequency counter is 4.3218MHz.

frequency counter

Adjustment Location :

[ BD BOARD ] — Conductor Side —

1

20

(FE)

(FEI)

(RF)

IC103

11

10

(PLCK)

(TE)

(VC)

IC101

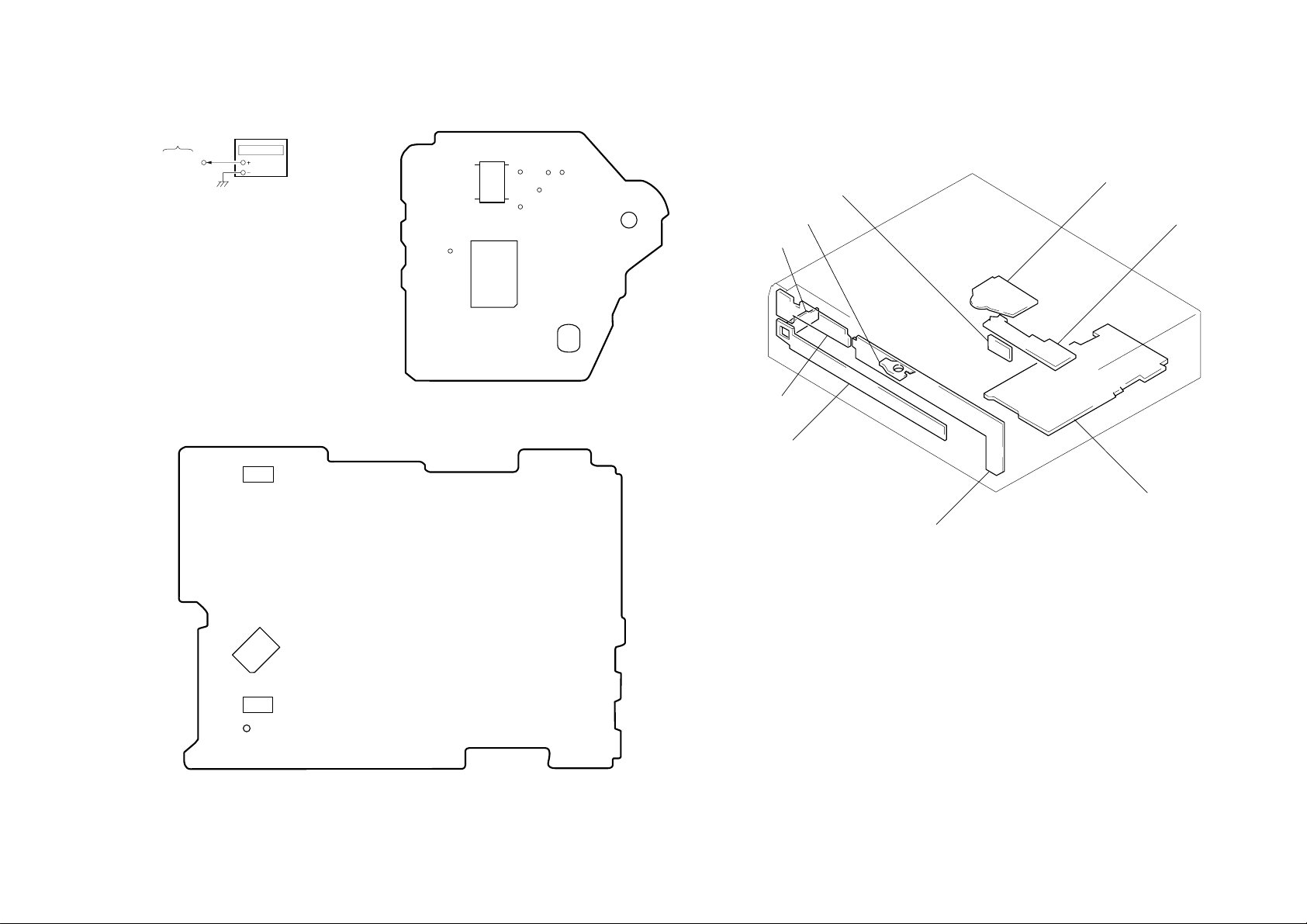

4-1. CIRCUIT BOARDS LOCATION

TABLE MOTOR BOARD

LOADING MOTOR BOARD

HP BOARD

CDP-C460Z/CE515

SECTION 4

DIAGRAMS

BD BOARD

SENSOR BOARD

[ MAIN BOARD ] — Conductor Side —

80

1

IC302

40 41

TP1

(ADJ)

65

64

24

25

POWER SW BOARD

KEY BOARD

MAIN BOARD

DISPLAY BOARD

— 11 — — 12 —

Page 12

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 13

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 14

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 15

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 16

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 17

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Page 18

CDP-C460Z/CE515

1INIT

2

3

4

5

6

7

8

9

10

11

12

13

14

D Vdd 2

SYSM L1 (+)

ATT A Vdd L

SHIFT L2 (+)

LATCH A Vss L

256FSO X Vss

TEST1 512IN

D Vss X OUT

MCKSEL X Vdd

XBCK A Vss R

DATA R2 (+)

LRCK A Vdd R

MUTE L R1 (+)

MUTE R D Vdd 1

28

27

26

25

24

23

22

21

20

19

18

17

16

15

MODES/P

ATT

IIR

FIR3FIR2FIR1

PLMPLM

MUTE

CIRCUIT

CLOCK

GENERATOR

AC

DITHER

DC

DITHER

3RD ORDER

NOISE SHAPER

SAMPLE

HOLD (X1)

TIMING CIRCUIT

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

4-8. IC BLOCK DIAGRAMS

IC101 CXD2545Q

VPCO20VCKI

XTSL63XTAO62XTAI67FSTO

19

C4M

68

C16M

69

PDO

18

13

VCO1

12

VCO0

PCO

33

32

FILI

31

FILO

CLTV

34

36

RFAC

ASYMMETRY

ASYI

38

CORRECTION

39

ASYO

ASYE

42

WFCK

73

SCOR

74

EXCK

76

75

SBSO

72

EMPH

SQCK

78

77

SQSO

95

MON

FSW

94

96

MDP

MDS

97

26

RFDC

TE

27

28

SE

FE

29

VC

30

25

BUFF

1CH1 OUT F

BUFF

2CH1 OUT R

3CAPA IN 1

R

4CH1 R IN

F

5CH1 F IN

6VREF IN

7VREF OUT

8GND

FF

9CH2 F IN

RR

10CH2 R IN

11CAPA IN 2

BUFF BUFF

12CH2 OUT R

BUFF

13CH2 OUT F

14GND

64

CLOCK

GENERATOR

DIGITAL

PLL

VARI-PITCH

DOUBLE SPEED

MUX

GENERATOR 1

SUBCODE

P-W

PROCESSOR

SUBCODE

0

PROCESSOR

18-TIMES

NOISE

OVERSAMPLING

SHAPER

SWITCH

&

BUFFER

24 141617 35 66 82 83 84

RFC

ADIO

TEST

INTERFACE

INTERFACE INTERFACE

TIMING

FILTER

A / D

CONVERTER

TES2

TES3

EFM

DEMODULATOR

SYNC

PROTECTOR

PROCESSOR

214023

AVSS

AVDD

AVDD

F

R

BUFF

RRFF

CLV

MIRR

DFCT

FOK DETECTOR

419015

ADD

AVSS

RESISTER

ERROR CORRECTOR

FOCUS SERVO

ADD

LEVEL

SHIFT

GENERATOR 2

MICRO PROGRAM

INTERFACE

SERVO DSP

SLED SERVO

TRACKING

SERVO

8165

XRST

DVSS

DVSS

MUTE

32K RAM

ADRESS

PRIORITY

GENERATOR

ENCODER

D / A

DATA PROCESSOR

PEAK DETECTOR

DIGITAL OUT

CPU INTERFACE

TIMING

SERVO

PWM GENERATOR

SLED PWM

GENERATOR

TRACKING PWM

GENERATOR

FOCUS PWM

GENERATOR

22 37 44 45

FSTI

BIAS

IGEN

BUFF

BUFF

BUFF

DIRC

LRCK

WDCK

28 GND

27 CH4 OUT F

26 CH4 OUT R

25 VB IN

24 VS IN

23 VB IN

22 VCC

21 VCC

20 CH3 F IN

19 CH3 R IN

18 CAPA IN 3

17 CH3 OUT R

16 CH3 OUT F

15 MUTE

— 25 — — 26 —

SERIAL

PARALLEL

PROCESSOR

SERVO

AUTO

SEQUENCER

SCLK

OFSW

PSSL

43

16

ATSK

DA01-16

61 - 46

MUTE

79

D OUT

71

MD2

70

DATA

86

CLOK

88

XLAT

87

SENS

80

COUT

89

MIRR

91

DFCT

92

FOK

93

2

SFON, SFDR

3, 100

2

1, 2

SRON, SRDR

2

4, 7

TFDR, TFON

2

5, 6

TRON, TRDR

2

FFDR, FFON

8, 11

2

4, 7

TRON, FRDR

9, 10

999885

SSTP

LOCK

1

LD VCCVCC

2

PD LD ON

3

A LC/PD

4

B RFE

5

C RFO

D FE

6

VEE FE BIAS

7

8

F TE

9

E VC

EI EO

10

VEE

VC

VC

VEE

VC

RF SUMMING AMP

IC301 CXD8567AM IC603 M5293L

20

19

18

17

16

15

14

13

VC

12

11

VREF

VCC

VEE

VC

VEE

APC LD AMP

FOCUS ERROR AMP

TRACKING ERROR AMP

VC

VC

VCC

RF EQ AMP

VC

VC BUFFER

IC601 LA5602IC103 CXA1821MIC102 BA6392FP

CDEL

V OUT

GND

2

5k

REFERENCE

4

ON/OFF

VOLTAGE

1

IN

1

V IN

REFERENCE

VOLTAGE

OVER CURRENT

LIMITTER

OVER HEAT

PROTECTION

2

EN

GND

RES

CN

ON/OFF

RESET

3

GEN

4

5

6

7

ERROR

AMP

+

–

OVERHEAT

PROTECTION

27k

OVERCURRENT

LIMITTER

5

3

REFERENCE

VOLTAGE

OUT

Page 19

4-9. IC PIN FUNCTIONS

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

• IC101 DIGITAL SIGNAL PROCESSOR (CXD2545Q)

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

SRON

SRDR

SFON

TFDR

TRON

TRDR

TFON

FFDR

FRON

FRDR

FFON

VCOO

VCOI

TEST

DVss

TES2

TES3

PDO

VPCO

VCKI

AVD2

IGEN

AVS2

ADIO

RFC

RFDC

TE

SE

FE

VC

FILO

FILI

PCO

CLTV

AVS1

RFAC

BIAS

ASYI

ASYO

AVD1

Pin Name

I/O

Sled drive output (Not used)

O

Sled drive output

O

Sled drive output (Not used)

O

Tracking drive output

O

Tracking drive output (Not used)

O

Tracking drive output

O

Tracking drive output (Not used)

O

Focus drive output

O

Focus drive output (Not used)

O

Focus drive output

O

Focus drive output (Not used)

O

VCO output for analog EFM PLL (Not used)

O

VCO input for analog EFM PLL (Ground)

I

TEST pin connected normally to ground

I

Digital ground

—

TEST pin connected normally to ground

I

TEST pin connected normally to ground

I

Charge-pump output for analog EFM PLL (Not used)

O

Charge-pump output for variable pitch PLL (Not used)

O

Clock input from variable pitch external VCO (Ground)

I

Analog power supply

—

Power supply pin for operational amplifiers

I

Analog ground

—

(Not used)

I

(Not used)

O

RF signal input

I

Tracking error signal input

I

Sled error signal input

I

Focus error signal input

I

Center voltage input pin

I

Filter output for master PLL

O

Filter input for master PLL

I

Charge-pump output for master PLL

O

Control voltage input for master VCO

I

Analog ground

—

EFM signal input

I

Asymmetry circuit constant current input

I

Asymmetry comparate voltage input

I

EFM full swing output

O

Analog power supply

—

Function

— 27 —

Page 20

Pin No.

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

DD

DV

ASYE

PSSL

WDCK

LRCK

DATA

BCLK

64DATA

64BCLK

64LRCK

GTOP

XUGF

XPLCK

GFS

RFCK

C2PO

XRAOF

MNT3

MNT2

MNT1

MNT0

XTAI

XTAO

XTSL

DVss

FSTI

FSTO

FSOF

C16M

MD2

DOUT

EMPH

WFCK

SCOR

SBSO

EXCK

SUBQ

SQCK

MUTE

SENS

Pin Name

I/O

Digital power supply

—

Asymmetry circuit ON/OFF

I

Audio data output mode selection input

I

48-bit slot D/A interface. Word clock.

O

48-bit slot D/A interface. LR clock.

O

DA 16 output when PSSL=1.48-bit slot serial data when PSSL=0

O

DA 15 output when PSSL=1.48-bit slot data when PSSL=0

O

DA 14 output when PSSL=1.64-bit slot data when PSSL=0 (Not used)

O

DA 13 output when PSSL=1.64-bit slot data when PSSL=0 (Not used)

O

DA 12 output when PSSL=1.64-bit slot data when PSSL=0 (Not used)

O

DA 11 output when PSSL=1.GTOP output when PSSL=0 (Not used)

O

DA 10 output when PSSL=1.XUGF output when PSSL=0 (Not used)

O

DA 09 output when PSSL=1.XPLCK output when PSSL=0 (Not used)

O

DA 08 output when PSSL=1.GFS output when PSSL=0 (Not used)

O

DA 07 output when PSSL=1.RFCK output when PSSL=0 (Not used)

O

DA 06 output when PSSL=1.C2PO output when PSSL=0 (Not used)

O

DA 05 output when PSSL=1.XRA0F output when PSSL=0 (Not used)

O

DA 04 output when PSSL=1.MNT3 output when PSSL=0 (Not used)

O

DA 03 output when PSSL=1.MNT2 output when PSSL=0 (Not used)

O

DA 02 output when PSSL=1.MNT1 output when PSSL=0 (Not used)

O

DA 01 output when PSSL=1.MNT0 output when PSSL=0 (Not used)

O

X'tal oscillator circuit input

I

X'tal oscillator circuit output (Not used)

O

X'tal selection input pin (Ground)

I

Digital ground

—

2/3 divider input of pins 62, 63

I

2/3 divider output of pins 62, 63

O

(Not used)

O

16.9344 MHz output (Not used)

O

Digital-out ON/OFF control pin (+5V)

I

Digital-out output pin

O

Playback disc output in emphasis mode (Not used)

O

WFCK output

O

Sub-code sync output

O

Sub-P through Sub-W serial output

O

Clock input for SBS0 read-out (Ground)

I

Sub-Q 80-bit output

O

Sub-code Q clock output

O

Muting selection pin

I

SENS output

O

Function

— 28 —

Page 21

Pin No.

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

Pin Name

XRST

DIRC

SCLK

DFSW

ATSK

DATA

XLAT

CLOK

COUT

DD

DV

MIRR

DFCT

FOK

FSW

MON

MDP

MDS

LOCK

SSTP

SFDR

I/O

System reset

I

Used in 1-track jump mode (+5v)

I

SENS serial data read-out clock

I

DFCT selection pin (Ground)

I

Input pin for anti-shock (Ground)

I

Serial data input, supplied from CPU

I

Latch input, supplied from CPU

I

Serial data transfer clock input, supplied from CPU

I

Numbers of track counted signal output (Not used)

O

Digital power supply

—

Mirror signal output (Not used)

O

Defect signal output (Not used)

O

Focus OK output (Not used)

O

Output to select spindle motor output filter (Not used)

O

Output to control ON/OFF of spindle motor (Not used)

O

Output to control spindle motor servo

O

Output to control spindle motor servo (Not used)

O

GFS is sampled by 460 Hz. H when GFS is H (Not used)

O

Input signal to detect disc inner most track

I

Sled drive output

O

Function

— 29 —

Page 22

• IC302 SYSTEM CONTROL (CXP84340-060Q)

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Pin Name

D3

D4

D2

D1

D0

A8

A7

A6

A5

A4

A3

A2

A1

PLAY_L

PAUSE_L

MEGA_L

XFADE_

MODELAY_L

WE

LODIN

LODOUT

FLCKL

FLDATA

BLK

A13

A14

NC

D.SENS

NC

RESET

10MHz

10MHz

GND

NC

NC

NC

NC

BUSOUT

VER

KEY6

I/O

I/O

SRAM data 3

I/O

SRAM data 4

I/O

SRAM data 2

I/O

SRAM data 1

I/O

SRAM data 0

O

SRAM address 8

O

SRAM address 7

O

SRAM address 6

O

SRAM address 5

O

SRAM address 4

O

SRAM address 3

O

SRAM address 2

O

SRAM address 1

O

PLAY lamp

O

PAUSE lamp

O

MEGA lamp

O

XFADE lamp

O

NO DELAY lamp

O

SRAM enable

O

Loading direction signal input

O

Loading direction signal output

O

Display clock

O

Display data

O

Display reset

—

SRAM address 13

—

SRAM address 14

—

Not used.

I

Disc exist/non-exist sensor

—

Not used.

I

Microprocessor reset

—

Ceramic oscillator

—

Ceramic oscillator

—

Ground (0V)

—

Not used.

—

Not used.

—

Not used.

—

Not used.

O

Control A1 output

I

Model selection

I

Key input 6

Function

— 30 —

Page 23

Pin No.

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Pin Name

KEY3

CD123

KEY2

KEY1

TEST

SENSOR

FLT

CLK

LDON

DATA

SQCLK

SUBQ

PRGL

SENSE

NC

RMIN

NC

XLT

AMUTE

DQSY

SCOR

BUSIN

TCLK

SMUTE

TDATA

ENC1

ENC2

ENC3

TBLL

TBLR

A0

+5V

+5V

A12

A11

A10

A9

D7

D6

D5

I/O

I

Key input 3

I

Command mode switch

I

Key input 2

I

Key input 1

I

Test mode terminal

I

Table sensor

O

Display latch

O

Command clock

O

Laser diode ON

O

Command data

O

Sub-Q clock

I

Sub-Q data

O

Digital filter latch

I

Sense

—

Not used.

I

Command latch

—

Not used.

—

Remote control signal input

O

Audio system mute

I

CD-TEXT sync signal

I

Sub-Q sync signal

I

Control-A input

O

CD-TEXT clock

O

2nd input mute

I

CD-TEXT data

I

Loading encoder 1

I

Loading encoder 2

I

Loading encoder 3

O

Rotation direction of table-L

O

Rotation direction of table-R

O

SRAM address 0

—

Microprocessor power supply (5V)

—

Microprocessor power supply (5V)

O

SRAM address 12

O

SRAM address 11

O

SRAM address 10

O

SRAM address 9

I/O

SRAM data 7

I/O

SRAM data 6

I/O

SRAM data 5

Function

— 31 —

Page 24

NOTE:

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

• -XX, -X mean standardized parts, so they

may have some differences from the original

one.

• Items marked “*” are not stocked since they

are seldom required for routine service.

Some delay should be anticipated when

ordering these items.

• The mechanical parts with no reference number

in the exploded views are not supplied.

• Hardware (#mark) list is given in the last of

this parts list.

• Abbreviation

AUS : Australian

CND : Canadian

5-1. FRONT PANEL AND CASE SECTION

SECTION 5

EXPLODED VIEWS

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque

! sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifie.

11

12

13

#2

not supplied

23

5

24

18

#1

4

2

20

3

16

8

17

26

19

5

6

5

9

27

7

1

22

10

21

#1

15

5

5

14

#1

#1

5

not supplied

#1

13

25

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

1 4-987-780-11 PANEL, LOADING

2 4-987-779-11 WINDOW (FL)

3 4-977-589-01 BUTTON (POWER)

4 3-008-600-01 EMBLEM (5-AR), SONY

5 4-951-620-01 SCREW (2.6X8), +BVTP

* 6 A-4699-620-A DISPLAY BOARD, COMPLETE

7 1-782-219-11 WIRE (FLAT TYPE) (17 CORE)

* 8 1-665-357-11 POWER SW BOARD

9 1-782-220-11 WIRE (FLAT TYPE) (9 CORE)

10 4-987-773-51 PANEL, FRONT (CE515)

10 4-987-773-61 PANEL, FRONT (C460Z)

* 11 4-978-492-11 CASE

12 3-703-685-21 SCREW (+BV 3X8)

13 3-704-366-01 SCREW (CASE) (M3X8)

14 X-4946-618-1 FOOT ASSY (US,CND)

14 X-4946-641-1 FOOT ASSY (AEP,AUS)

* 15 4-978-398-21 CUSHION

* 16 1-665-358-11 KEY BOARD

17 4-987-775-11 BUTTON (PLAY)

18 4-987-776-01 BUTTON (FUNC)

19 4-987-777-01 BUTTON (FF)

20 4-987-774-01 BUTTON (MODE)

21 4-987-994-01 KNOB (AMS)

22 4-987-778-01 BUTTON (MEGA-CON)

* 23 1-665-359-11 HP BOARD

* 24 4-979-090-01 BRACKET (HP)

25 4-977-593-01 RING (DIA. 50), ORNAMENTAL(AEP,AUS)

26 4-989-723-01 INDICATOR (PLAY)

27 4-989-725-01 BUTTON (X-FADE)

— 32 —

Page 25

5-2. BACK PANEL AND DISC TABLE SECTION

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

#3

52

not

supplied

53

65

67

64

63

not supplied

#6

#4

51

66

not supplied

#4

63

54

72

64

#4

63

73

not

supplied

#5

64

62

63

60

61

#4

71

M801

55

57

58

AEP MODEL

56

US, CND

MODEL

AUS MODEL

59

70

#1

#1

59

59

#1

#4

not supplied

69

#4

not supplied

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

51 4-957-299-11 TABLE (B), DISC

52 4-957-304-01 BELT (RM)

53 X-4943-479-1 GEAR (ROTARY A) ASSY

* 54 1-647-362-11 SENSOR BOARD

* 55 1-647-364-11 TABLE MOTOR BOARD

56 3-325-697-01 WASHER

57 4-957-284-01 GEAR (ROTARY B)

58 X-4943-477-1 BRACKET (RM) ASSY

! 59 1-575-651-21 CORD, POWER (AEP)

! 59 1-590-926-11 CORD, POWER (US,CND)

! 59 1-696-845-11 CORD, POWER (AUS)

60 4-957-293-01 SPRING (RACK RELEASE)

61 4-957-291-11 LEVER (RACK RELEASE)

62 4-957-868-01 SCREW (+PTPWH 2.6X20)

#4

63 4-988-162-01 ROLLER

64 4-934-376-01 SHAFT (ROLLER)

65 4-957-292-11 SLIDER (RACK)

66 4-957-294-01 SPRING (D.T), TENSION

67 4-957-298-01 TABLE (A), DISC

* 69 4-951-619-01 CUSHION (A)

* 70 3-703-244-00 BUSHING (2104), CORD

* 71 4-987-842-01 PANEL, BACK (CE515:US)

* 71 4-987-842-11 PANEL, BACK (CE515:CND)

* 71 4-987-842-21 PANEL, BACK (CE515:AEP)

* 71 4-987-842-31 PANEL, BACK (C460Z:US)

* 71 4-987-842-51 PANEL, BACK (CE515:AUS

72 1-751-052-11 WIRE (FLAT TYPE) (6 CORE)

73 X-4943-480-1 BRACKET (ROLLER D) ASSY

M801 A-4660-525-A MOTOR ASSY, ROTARY (TABLE)

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

— 33 —

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

Page 26

5-3. CHASSIS SECTION

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

102

105

117

#4

101

116

118

#4

103

106

115

114

#4

101

127

#4

128

101

125

104

108

107

not

supplied

#3

107

BU-5BD22

109

108

110

112

113

not supplied

T601

M802

not

supplied

119

#8

120

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

101 4-957-283-01 WASHER (5), STOPPER

102 4-957-288-01 GEAR (MAIN)

103 4-957-287-01 GEAR (REV)

104 4-957-286-01 GEAR (U/D)

105 1-466-996-11 ENCODER, ROTARY

106 X-4946-195-1 BRACKET (GEAR) ASSY

107 4-933-134-01 SCREW (+PTPWH M2.6X6)

108 4-948-503-01 SPRING (BU), COMPRESSION

109 1-765-443-11 WIRE (FLAT TYPE) (23 CORE)

110 4-957-289-12 HOLDER (BU)

112 4-957-281-01 SPRING (LOCK LEVER)

113 4-957-279-11 LEVER, LOCK

114 4-957-303-01 GEAR (LOADING C)

115 4-934-375-01 GEAR (LOADING B)

124

#1

#1

116 4-957-285-01 LEVER, SET

117 4-962-087-01 SPRING (S), TENSION

* 118 1-659-738-11 LOADING MOTOR BOARD

119 X-4941-529-1 PULLEY ASSY

120 4-944-490-01 BELT (TIMING)

* 124 A-4699-623-A MAIN BOARD, COMPLETE (CE515:US,CND)

* 124 A-4699-626-A MAIN BOARD, COMPLETE (CE515:AEP,AUS)

* 124 A-4699-629-A MAIN BOARD, COMPLETE (C460Z)

* 125 1-452-879-11 MAGNET

* 127 4-981-731-01 CUSHION (U/D)

* 128 4-981-731-11 CUSHION (U/D)

M802 A-4660-914-A MOTOR ASSY, LOADING

! T601 1-429-956-11 TRANSFORMER, POWER (US,CND)

! T601 1-431-076-11 TRANSFORMER, POWER (AEP,AUS)

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

— 34 —

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifie.

Page 27

5-4. BASE UNIT SECTION (BU-5BD22)

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

751

752

753

#7

755

M101

754

M102

754

756

757

758

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

! 751 8-848-379-31 OPTICAL PICK-UP KSS-213BA/F-NP

752 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

753 4-917-567-21 GEAR (M)

754 4-951-940-01 INSULATOR (BU)

755 4-917-565-01 SHAFT, SLED

756 4-917-564-01 GEAR (P), FLATNESS

* 757 A-4699-624-A BD BOARD, COMPLETE

758 4-951-620-01 SCREW (2.6X8), +BVTP

M101 X-4917-523-3 MOTOR ASSY (SPINDLE)

M102 X-4917-504-3 MOTOR ASSY (SLED)

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

— 35 —

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

Page 28

BD

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

SECTION 6

ELECTRICAL PARTS LIST

NOTE:

When indicating parts by reference number,

please include the board naame.

The components identified by mark ! or

dotted line with mark ! are critical for safety .

Replace only with part number specified.

Les composants identifiés par une marque

! sont critiques pour la sécurité.

Ne les remplacer que par une pièce portant

le numéro spécifie.

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* A-4699-624-A BD BOARD, COMPLETE

******************

< CAPACITOR >

C101 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C102 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C103 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C105 1-135-155-21 TANTALUM CHIP 4.7uF 10% 16V

C106 1-164-346-11 CERAMIC CHIP 1uF 16V

C107 1-164-346-11 CERAMIC CHIP 1uF 16V

C108 1-163-035-00 CERAMIC CHIP 0.047uF 50V

C109 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C110 1-163-017-00 CERAMIC CHIP 0.0047uF 5% 50V

C111 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C112 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C113 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C114 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C115 1-126-607-11 ELECT CHIP 47uF 20% 4V

C116 1-126-607-11 ELECT CHIP 47uF 20% 4V

C117 1-126-209-11 ELECT 100uF 20% 4V

C118 1-163-275-11 CERAMIC CHIP 0.001uF 5% 50V

C119 1-163-231-11 CERAMIC CHIP 15PF 5% 50V

C120 1-124-778-00 ELECT CHIP 22uF 20% 6.3V

C123 1-164-232-11 CERAMIC CHIP 0.01uF 50V

C124 1-164-005-11 CERAMIC CHIP 0.47uF 25V

C140 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C141 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C151 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

C153 1-163-038-00 CERAMIC CHIP 0.1uF 25V

C154 1-164-336-11 CERAMIC CHIP 0.33uF 25V

C156 1-163-237-11 CERAMIC CHIP 27PF 5% 50V

C157 1-163-145-00 CERAMIC CHIP 0.0015uF 5% 50V

C159 1-163-019-00 CERAMIC CHIP 0.0068uF 10% 50V

C161 1-163-038-00 CERAMIC CHIP 0.1uF 25V

< CONNECTOR >

CN101 1-770-072-11 CONNECTOR,(LIF(NON-ZIF))FFC23P

CN102 1-770-014-11 CONNECTOR, FFC/FPC 16P

< IC >

• Due to standardization, replacements in the

parts list may be different from the parts

specified in the diagrams or the components

used on the set.

• -XX, -X mean standardized parts, so they may

have some difference from the original one.

• Items marked “*” are not stocked since they

are seldom required for routine service. Some

delay should be anticipated when ordering these

items.

• CAPA CITORS:

uF: µF

Q101 8-729-010-08 TRANSISTOR MSB710-R

R101 1-216-077-00 METAL CHIP 15K 5% 1/10W

R102 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R103 1-216-077-00 METAL CHIP 15K 5% 1/10W

R104 1-216-085-00 METAL CHIP 33K 5% 1/10W

R105 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R106 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R107 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R108 1-216-073-00 METAL CHIP 10K 5% 1/10W

R109 1-216-121-00 METAL GLAZE 1M 5% 1/10W

R110 1-216-025-00 METAL GLAZE 100 5% 1/10W

R112 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R113 1-216-295-00 CONDUCTOR, CHIP (2012)

R114 1-216-073-00 METAL CHIP 10K 5% 1/10W

R115 1-216-295-00 CONDUCTOR, CHIP (2012)

R123 1-216-073-00 METAL CHIP 10K 5% 1/10W

R124 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R125 1-216-037-00 METAL CHIP 330 5% 1/10W

R126 1-216-037-00 METAL CHIP 330 5% 1/10W

R127 1-216-037-00 METAL CHIP 330 5% 1/10W

R131 1-216-037-00 METAL CHIP 330 5% 1/10W

R135 1-216-295-00 CONDUCTOR, CHIP (2012)

R136 1-216-295-00 CONDUCTOR, CHIP (2012)

R137 1-216-295-00 CONDUCTOR, CHIP (2012)

R138 1-216-295-00 CONDUCTOR, CHIP (2012)

R141 1-216-089-00 METAL GLAZE 47K 5% 1/10W

R142 1-216-081-00 METAL CHIP 22K 5% 1/10W

R143 1-216-101-00 METAL CHIP 150K 5% 1/10W

R144 1-216-101-00 METAL CHIP 150K 5% 1/10W

R146 1-216-073-00 METAL CHIP 10K 5% 1/10W

R147 1-216-081-00 METAL CHIP 22K 5% 1/10W

R148 1-216-001-00 METAL CHIP 10 5% 1/10W

R149 1-216-003-11 METAL GLAZE 12 5% 1/10W

R158 1-216-111-00 METAL GLAZE 390K 5% 1/10W

R159 1-216-101-00 METAL CHIP 150K 5% 1/10W

R161 1-216-308-00 METAL CHIP 4.7 5% 1/10W

• RESISTORS

All resistors are in ohms.

MET AL: metal-film resistor

MET AL OXIDE: Metal Oxide-film resistor

F: nonflammable

• COILS

uH: µH

• SEMICONDUCTORS

In each case, u: µ, for example:

uA...: µA... , uPA... , µPA... ,

uPB... , µPB... , uPC... , µPC... ,

uPD..., µPD...

• Abbreviation

AUS : Australian

CND : Canadian

< TRANSISTOR >

< RESISTOR >

IC101 8-752-369-78 IC CXD2545Q

IC102 8-759-176-09 IC BA6392FP

IC103 8-752-072-45 IC CXA1821M

IC104 8-759-428-57 IC LC89170M-TLM

R162 1-216-101-00 METAL CHIP 150K 5% 1/10W

< SWITCH >

S101 1-572-085-11 SWITCH, LEAF (LIMIT)

************************************************************

— 36 —

Page 29

KEYHPDISPLAY

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* A-4699-620-A DISPLAY BOARD, COMPLETE

***********************

* 3-362-478-11 HOLDER (T), LED

* 4-989-724-01 HOLDER (FL)

R821 1-247-843-11 CARBON 3.3K 5% 1/4W

R822 1-249-427-11 CARBON 6.8K 5% 1/4W F

R823 1-249-431-11 CARBON 15K 5% 1/4W

R824 1-249-431-11 CARBON 15K 5% 1/4W

R830 1-247-807-31 CARBON 100 5% 1/4W F

< CAPACITOR >

C801 1-162-210-31 CERAMIC 30PF 5% 50V

C802 1-164-159-11 CERAMIC 0.1uF 50V

C810 1-161-494-00 CERAMIC 0.022uF 25V

C811 1-162-282-31 CERAMIC 100PF 10% 50V

C812 1-162-282-31 CERAMIC 100PF 10% 50V

C813 1-164-159-11 CERAMIC 0.1uF 50V

C814 1-161-494-00 CERAMIC 0.022uF 25V

C851 1-126-968-11 ELECT 100uF 20% 6.3V

< CONNECTOR >

* CN810 1-568-836-11 SOCKET, CONNECTOR 17P

< DIODE >

D802 8-719-303-00 DIODE SEL2510C (·)

D803 8-719-301-52 DIODE SEL2810A-C (P)

D804 8-719-301-44 DIODE SEL2410E-D (NO DELAY)

D805 8-719-301-44 DIODE SEL2410E-D (X-FADE)

D810 8-719-057-97 DIODE SEL5923A-TP15 (MEGA CONTROL)

< FILTER >

FL810 1-517-664-11 INDICATOR TUBE, FLUORESCENT

< COMPOSITION CIRCUIT BLOCK >

IB801 1-232-362-00 COMPOSITION CIRCUIT BLOCK

R831 1-249-441-11 CARBON 100K 5% 1/4W

R832 1-249-441-11 CARBON 100K 5% 1/4W

R833 1-247-807-31 CARBON 100 5% 1/4W

R834 1-247-807-31 CARBON 100 5% 1/4W

R835 1-247-807-31 CARBON 100 5% 1/4W

R851 1-247-807-31 CARBON 100 5% 1/4W

R852 1-247-807-31 CARBON 100 5% 1/4W

< SWITCH >

S801 1-554-303-21 SWITCH, TACTILE (X-F ADE)

S802 1-554-303-21 SWITCH, TACTILE (NO DELAY)

S803 1-554-303-21 SWITCH, TACTILE (CLEAR)

S804 1-554-303-21 SWITCH, TACTILE (CHECK)

S805 1-554-303-21 SWITCH, TACTILE ())

S806 1-554-303-21 SWITCH, TACTILE (0)

S807 1-554-303-21 SWITCH, TACTILE (MEGA CONTROL)

S808 1-554-303-21 SWITCH, TACTILE (OPEN/CLOSE)

S809 1-554-303-21 SWITCH, TACTILE (DISC SKIP)

S810 1-554-303-21 SWITCH, TACTILE (EX-CHANGE)

S811 1-554-303-21 SWITCH, TACTILE (p)

S812 1-554-303-21 SWITCH, TACTILE (P)

S813 1-554-303-21 SWITCH, TACTILE (·)

S814 1-473-957-11 ENCODER, ROTARY (AMS)

************************************************************

* 1-665-359-11 HP BOARD

*********

< IC >

IC810 8-759-459-84 IC NJL56H400

IC811 8-759-337-52 IC LC75721E

< TRANSISTOR >

Q801 8-729-029-67 TRANSISTOR DTC114ESA-TP

Q802 8-729-029-67 TRANSISTOR DTC114ESA-TP

< RESISTOR >

R801 1-249-429-11 CARBON 10K 5% 1/4W

R802 1-247-807-31 CARBON 100 5% 1/4W F

R803 1-247-807-31 CARBON 100 5% 1/4W F

R804 1-247-807-31 CARBON 100 5% 1/4W F

R805 1-247-807-31 CARBON 100 5% 1/4W F

R806 1-249-441-11 CARBON 100K 5% 1/4W

R807 1-249-441-11 CARBON 100K 5% 1/4W

R808 1-249-441-11 CARBON 100K 5% 1/4W

R811 1-249-415-11 CARBON 680 5% 1/4W F

R812 1-249-417-11 CARBON 1K 5% 1/4W F

R813 1-249-419-11 CARBON 1.5K 5% 1/4W F

R814 1-249-421-11 CARBON 2.2K 5% 1/4W F

R815 1-247-843-11 CARBON 3.3K 5% 1/4W

R816 1-249-427-11 CARBON 6.8K 5% 1/4W F

R817 1-249-415-11 CARBON 680 5% 1/4W F

R818 1-249-417-11 CARBON 1K 5% 1/4W F

R819 1-249-419-11 CARBON 1.5K 5% 1/4W F

R820 1-249-421-11 CARBON 2.2K 5% 1/4W F

< CAPACITOR >

C771 1-162-294-31 CERAMIC 0.001uF 10% 50V

C772 1-162-294-31 CERAMIC 0.001uF 10% 50V

C773 1-164-159-11 CERAMIC 0.1uF 50V

< CONNECTOR >

* CN771 1-568-941-11 PIN, CONNECTOR 3P

< JACK >

J771 1-568-519-41 JACK, LARGE TYPE (PHONES)

< RESISTOR >

R771 1-249-401-11 CARBON 47 5% 1/4W F

R772 1-249-401-11 CARBON 47 5% 1/4W F

************************************************************

* 1-665-358-11 KEY BOARD

**********

< CONNECTOR >

* CN701 1-568-852-11 SOCKET, CONNECTOR 9P

CN702 1-750-195-11 CONNECTOR, BOARD TO BOARD 6P

— 37 —

Page 30

KEY LOADING MOTOR

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< RESISTOR >

R711 1-249-415-11 CARBON 680 5% 1/4W F

R712 1-249-417-11 CARBON 1K 5% 1/4W F

R713 1-249-415-11 CARBON 680 5% 1/4W F

R714 1-249-419-11 CARBON 1.5K 5% 1/4W F

< SWITCH >

S711 1-554-303-21 SWITCH, TACTILE (PEAK SEARCH)(CE515)

S712 1-554-303-21 SWITCH, TACTILE (EDIT/TIME FADE)(CE515)

S713 1-554-303-21 SWITCH, TACTILE (TIME)(CE515)

S714 1-554-303-21 SWITCH, TACTILE (TIME/MEMO)

S715 1-554-303-21 SWITCH, TACTILE (MEMO INPUT)

************************************************************

* 1-659-738-11 LOADING MOTOR BOARD

*********************

MAIN

(CE515)

(CE515)

(CE515)

C502 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C503 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C504 1-106-359-00 MYLAR 4700PF 5% 200V

C505 1-130-472-00 MYLAR 0.0012uF 5% 50V

C506 1-124-443-00 ELECT 100uF 20% 10V

C507 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C508 1-104-664-11 ELECT 47uF 20% 16V

C509 1-126-962-11 ELECT 3.3uF 20% 50V

C510 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C511 1-104-665-11 ELECT 100uF 20% 16V

C512 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C551 1-124-907-11 ELECT 10uF 20% 50V

C602 1-126-944-11 ELECT 3300uF 20% 16V

C603 1-126-942-61 ELECT 1000uF 20% 16V

C604 1-126-963-11 ELECT 4.7uF 20% 50V

C605 1-126-963-11 ELECT 4.7uF 20% 50V

C606 1-126-963-11 ELECT 4.7uF 20% 50V

C607 1-126-941-11 ELECT 470uF 20% 6.3V

C608 1-104-666-11 ELECT 220uF 20% 10V

C609 1-124-918-11 ELECT 47uF 20% 63V

< MOTOR >

M802 A-4660-914-A MOTOR ASSY, LOADING

************************************************************

* A-4699-629-A MAIN BOARD, COMPLETE (C460Z)

********************

* A-4699-626-A MAIN BOARD, COMPLETE (CE515:AEP,AUS)

********************

* A-4699-623-A MAIN BOARD, COMPLETE (CE515:US,CND)

********************

7-685-871-01 SCREW +BVTT 3X6 (S)

< CAPACITOR >

C301 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C302 1-163-227-11 CERAMIC CHIP 10PF 0.5PF 50V

C303 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C305 1-124-443-00 ELECT 100uF 20% 10V

C306 1-124-442-00 ELECT 330uF 20% 6.3V

C311 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C317 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C321 1-110-489-11 CAPACITOR 1F 5.5V

C322 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C332 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C371 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C372 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C373 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C374 1-104-664-11 ELECT 47uF 20% 16V

C376 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C381 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C401 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

C402 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C403 1-163-243-11 CERAMIC CHIP 47PF 5% 50V

C610 1-124-907-11 ELECT 10uF 20% 50V

C614 1-104-665-11 ELECT 100uF 20% 16V

C616 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C619 1-104-664-11 ELECT 47uF 20% 16V

C620 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C622 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C624 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C625 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C626 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C628 1-104-664-11 ELECT 47uF 20% 16V

C648 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C649 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C651 1-104-664-11 ELECT 47uF 20% 16V

< CONNECTOR >

CN401 1-750-640-11 CONNECTOR, FFC/FPC 23P

CN402 1-568-860-11 SOCKET, CONNECTOR 17P

* CN403 1-568-852-11 SOCKET, CONNECTOR 9P

* CN404 1-568-825-11 SOCKET, CONNECTOR 6P

* CN601 1-573-047-11 PIN, CONNECTOR (PC BOARD) 2P

< DIODE >

D302 8-719-016-74 DIODE 1SS352

D321 8-719-016-74 DIODE 1SS352

D381 8-719-016-74 DIODE 1SS352

D601 8-719-210-33 DIODE EC10DS2

D602 8-719-210-33 DIODE EC10DS2

D603 8-719-210-33 DIODE EC10DS2

D604 8-719-210-33 DIODE EC10DS2

D605 8-719-210-33 DIODE EC10DS2

D606 8-719-977-22 DIODE DTZ9.1

D608 8-719-016-74 DIODE 1SS352

C404 1-106-359-00 MYLAR 4700PF 5% 200V

C405 1-130-472-00 MYLAR 0.0012uF 5% 50V

C406 1-124-443-00 ELECT 100uF 20% 10V

C407 1-163-033-00 CERAMIC CHIP 0.022uF 50V

C408 1-104-664-11 ELECT 47uF 20% 16V

C410 1-163-005-11 CERAMIC CHIP 470PF 10% 50V

C411 1-104-665-11 ELECT 100uF 20% 16V

C412 1-165-319-11 CERAMIC CHIP 0.1uF 50V

C451 1-124-907-11 ELECT 10uF 20% 50V

C501 1-163-251-11 CERAMIC CHIP 100PF 5% 50V

D609 8-719-976-96 DIODE DTZ4.7C

< TERMINAL >

EB601 1-537-770-21 TERMINAL BOARD, GROUND

— 38 —

Page 31

MAIN

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

< IC >

< RESISTOR >

IC301 8-759-362-47 IC CXD8567AM

IC302 8-752-886-46 IC CXP84340-060Q

IC303 8-759-374-72 IC LC35256AM-10

IC304 8-759-356-03 IC BA6780

IC305 8-759-636-55 IC M5218AFP

IC371 8-749-921-12 IC GP1F32T (DIGITAL OUT)

IC401 8-759-100-96 IC uPC4558G2

IC402 8-759-100-96 IC uPC4558G2

IC501 8-759-100-96 IC uPC4558G2

IC502 8-759-100-96 IC uPC4558G2

IC601 8-759-061-65 IC LA5602

IC602 8-749-011-78 IC BA17807T

IC603 8-759-633-42 IC M5293L

< JACK >

J301 1-770-720-11 JACK, PIN 4P (LINE IN/OUT)

J381 1-774-726-11 JACK (CONTROL A1)

< COIL >

L301 1-410-375-11 INDUCTOR CHIP 3.3uH

L303 1-410-375-11 INDUCTOR CHIP 3.3uH

L304 1-410-375-11 INDUCTOR CHIP 3.3uH

L305 1-410-397-21 FERRITE BEAD INDUCTOR

L307 1-410-375-11 INDUCTOR CHIP 3.3uH

L308 1-414-234-11 INDUCTOR, FERRITE BEAD

L309 1-414-234-11 INDUCTOR, FERRITE BEAD

L310 1-414-234-11 INDUCTOR, FERRITE BEAD

L401 1-410-375-11 INDUCTOR CHIP 3.3uH

L501 1-410-375-11 INDUCTOR CHIP 3.3uH

L601 1-414-234-11 INDUCTOR, FERRITE BEAD

L603 1-414-234-11 INDUCTOR, FERRITE BEAD

L604 1-216-295-00 CONDUCTOR, CHIP (2012)

L605 1-216-296-00 CONDUCTOR, CHIP (3216)

L606 1-410-397-21 FERRITE BEAD INDUCTOR

L607 1-410-375-11 INDUCTOR CHIP 3.3uH

L608 1-410-375-11 INDUCTOR CHIP 3.3uH

L609 1-216-295-00 CONDUCTOR, CHIP (2012)

< TRANSISTOR >

Q201 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q301 8-729-029-67 TRANSISTOR DTC114ESA-TP

Q302 8-729-029-67 TRANSISTOR DTC114ESA-TP

Q303 8-729-029-67 TRANSISTOR DTC114ESA-TP

Q304 8-729-029-67 TRANSISTOR DTC114ESA-TP

Q305 8-729-029-67 TRANSISTOR DTC114ESA-TP

Q311 8-729-900-53 TRANSISTOR DTC114EK

Q321 8-729-027-38 TRANSISTOR DTA144EKA-T146

Q322 8-729-027-38 TRANSISTOR DTA144EKA-T146

Q381 8-729-120-28 TRANSISTOR 2SC1623-L5L6

Q402 8-729-422-29 TRANSISTOR 2SD601A-S

Q404 8-729-422-29 TRANSISTOR 2SD601A-S

Q405 8-729-422-29 TRANSISTOR 2SD601A-S

Q406 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q502 8-729-422-29 TRANSISTOR 2SD601A-S

Q503 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q504 8-729-422-29 TRANSISTOR 2SD601A-S

Q505 8-729-422-29 TRANSISTOR 2SD601A-S

Q506 8-729-027-23 TRANSISTOR DTA114EKA-T146

Q601 8-729-119-76 TRANSISTOR 2SA1175-HFE

R205 1-216-075-00 METAL CHIP 12K 5% 1/10W

R206 1-216-073-00 METAL CHIP 10K 5% 1/10W

R251 1-216-073-00 METAL CHIP 10K 5% 1/10W

R252 1-216-067-00 METAL CHIP 5.6K 5% 1/10W

R253 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R254 1-216-075-00 METAL CHIP 12K 5% 1/10W

R262 1-220-227-11 METAL GLAZE 1.2 10% 1/4W

R263 1-220-227-11 METAL GLAZE 1.2 10% 1/4W

R301 1-216-063-00 METAL GLAZE 3.9K 5% 1/10W

R302 1-216-025-00 METAL GLAZE 100 5% 1/10W

R303 1-216-025-00 METAL GLAZE 100 5% 1/10W

R304 1-216-041-00 METAL CHIP 470 5% 1/10W

R308 1-216-073-00 METAL CHIP 10K 5% 1/10W

R309 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R310 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R311 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R312 1-216-073-00 METAL CHIP 10K 5% 1/10W

R313 1-216-073-00 METAL CHIP 10K 5% 1/10W

R314 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R315 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R316 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R317 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R318 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R319 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R321 1-216-073-00 METAL CHIP 10K 5% 1/10W

R322 1-216-073-00 METAL CHIP 10K 5% 1/10W

R323 1-216-013-00 METAL CHIP 33 5% 1/10W

R324 1-216-073-00 METAL CHIP 10K 5% 1/10W

R325 1-216-073-00 METAL CHIP 10K 5% 1/10W

(C460Z)

R326 1-216-295-00 CONDUCTOR, CHIP (2012)

R327 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R328 1-216-295-00 CONDUCTOR, CHIP (2012)

R331 1-216-069-00 METAL CHIP 6.8K 5% 1/10W

R333 1-216-073-00 METAL CHIP 10K 5% 1/10W

R334 1-216-073-00 METAL CHIP 10K 5% 1/10W

R335 1-216-073-00 METAL CHIP 10K 5% 1/10W

R336 1-216-295-00 CONDUCTOR, CHIP (2012)

R337 1-216-295-00 CONDUCTOR, CHIP (2012)

R338 1-216-073-00 METAL CHIP 10K 5% 1/10W

R339 1-216-295-00 CONDUCTOR, CHIP (2012)

R340 1-216-049-11 METAL GLAZE 1K 5% 1/10W

R341 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R342 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R343 1-216-073-00 METAL CHIP 10K 5% 1/10W

R344 1-216-295-00 CONDUCTOR, CHIP (2012)

R381 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R382 1-216-073-00 METAL CHIP 10K 5% 1/10W

R383 1-216-001-00 METAL CHIP 10 5% 1/10W

R403 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R404 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R405 1-216-077-00 METAL CHIP 15K 5% 1/10W

R406 1-216-077-00 METAL CHIP 15K 5% 1/10W

R407 1-216-691-11 METAL CHIP 47K 0.5% 1/10W

R408 1-216-691-11 METAL CHIP 47K 0.5% 1/10W

R409 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

— 39 —

Page 32

MAIN POWER SW SENSOR

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

R410 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R411 1-216-105-00 METAL GLAZE 220K 5% 1/10W

R412 1-216-047-00 METAL GLAZE 820 5% 1/10W

R413 1-216-033-00 METAL CHIP 220 5% 1/10W

R414 1-216-033-00 METAL CHIP 220 5% 1/10W

X301 1-579-834-11 VIBRATOR, CRYSTAL 33MHz

X401 1-579-175-11 VIBRATOR, CERAMIC 10MHz

************************************************************

< VIBRATOR >

R415 1-216-295-00 CONDUCTOR, CHIP (2012)

R416 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R418 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R419 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R420 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R421 1-216-073-00 METAL CHIP 10K 5% 1/10W

R422 1-247-807-31 CARBON 100 5% 1/4W

R450 1-216-113-00 METAL CHIP 470K 5% 1/10W

R451 1-216-073-00 METAL CHIP 10K 5% 1/10W

R452 1-216-072-00 METAL CHIP 9.1K 5% 1/10W

R453 1-216-073-00 METAL CHIP 10K 5% 1/10W

R454 1-216-073-00 METAL CHIP 10K 5% 1/10W

R455 1-216-073-00 METAL CHIP 10K 5% 1/10W

R456 1-216-048-00 METAL CHIP 910 5% 1/10W

R457 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R470 1-216-073-00 METAL CHIP 10K 5% 1/10W

R471 1-216-073-00 METAL CHIP 10K 5% 1/10W

R503 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R504 1-216-689-11 METAL CHIP 39K 0.5% 1/10W

R505 1-216-077-00 METAL CHIP 15K 5% 1/10W

R506 1-216-077-00 METAL CHIP 15K 5% 1/10W

R507 1-216-691-11 METAL CHIP 47K 0.5% 1/10W

R508 1-216-691-11 METAL CHIP 47K 0.5% 1/10W

R509 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R510 1-216-053-00 METAL CHIP 1.5K 5% 1/10W

R511 1-216-105-00 METAL GLAZE 220K 5% 1/10W

R512 1-216-047-00 METAL GLAZE 820 5% 1/10W

R513 1-216-033-00 METAL CHIP 220 5% 1/10W

R514 1-216-033-00 METAL CHIP 220 5% 1/10W

R515 1-216-295-00 CONDUCTOR, CHIP (2012)

R516 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R517 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R518 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R519 1-216-097-00 METAL GLAZE 100K 5% 1/10W

R520 1-216-061-00 METAL CHIP 3.3K 5% 1/10W

R521 1-216-073-00 METAL CHIP 10K 5% 1/10W

R522 1-247-807-31 CARBON 100 5% 1/4W

R550 1-216-113-00 METAL CHIP 470K 5% 1/10W

R551 1-216-073-00 METAL CHIP 10K 5% 1/10W

R552 1-216-072-00 METAL CHIP 9.1K 5% 1/10W

R553 1-216-073-00 METAL CHIP 10K 5% 1/10W

R554 1-216-073-00 METAL CHIP 10K 5% 1/10W

R555 1-216-073-00 METAL CHIP 10K 5% 1/10W

R556 1-216-048-00 METAL CHIP 910 5% 1/10W

R557 1-216-065-00 METAL CHIP 4.7K 5% 1/10W

R601 1-216-085-00 METAL CHIP 33K 5% 1/10W

R602 1-216-073-00 METAL CHIP 10K 5% 1/10W

R603 1-216-091-00 METAL CHIP 56K 5% 1/10W

R604 1-216-073-00 METAL CHIP 10K 5% 1/10W

R607 1-216-037-00 METAL CHIP 330 5% 1/10W

* 1-665-357-11 POWER SW BOARD

****************

< CONNECTOR >

CN703 1-750-186-11 CONNECTOR, BOARD TO BOARD 6P

< RESISTOR >

R701 1-249-417-11 CARBON 1K 5% 1/4W F

R702 1-249-419-11 CARBON 1.5K 5% 1/4W F

R703 1-249-421-11 CARBON 2.2K 5% 1/4W F

R704 1-247-843-11 CARBON 3.3K 5% 1/4W

R705 1-249-427-11 CARBON 6.8K 5% 1/4W F

R706 1-249-431-11 CARBON 15K 5% 1/4W

R707 1-249-419-11 CARBON 1.5K 5% 1/4W F

(C460Z)

R707 1-249-427-11 CARBON 6.8K 5% 1/4W F

(CE515)

R708 1-249-415-11 CARBON 680 5% 1/4W F

(C460Z)

R708 1-249-421-11 CARBON 2.2K 5% 1/4W F

(CE515)

R709 1-249-417-11 CARBON 1K 5% 1/4W F

(C460Z)

R709 1-247-843-11 CARBON 3.3K 5% 1/4W

(CE515)

< SWITCH >

S701 1-554-303-21 SWITCH, TACTILE (DISC 1)

S702 1-554-303-21 SWITCH, TACTILE (DISC 2)

S703 1-554-303-21 SWITCH, TACTILE (DISC 3)

S704 1-554-303-21 SWITCH, TACTILE (DISC 4)

S705 1-554-303-21 SWITCH, TACTILE (DISC 5)

S706 1-554-303-21 SWITCH, TACTILE (CONTINUE)

S707 1-554-303-21 SWITCH, TACTILE (SHUFFLE)

S708 1-554-303-21 SWITCH, TACTILE (PROGRAM)

S709 1-554-303-21 SWITCH, TACTILE (REPEAT)

S710 1-554-303-21 SWITCH, TACTILE (DISC CHECK)(CE515)

S710 1-554-303-21 SWITCH, TACTILE (TIME/MEMO)(C460Z)

S751 1-554-118-00 SWITCH, PUSH (1 KEY)(POWER)

************************************************************

* 1-647-362-11 SENSOR BOARD

*************

< CONNECTOR >

CN801 1-573-383-11 PIN, CONNECTOR (PC BOARD) 2P

CN802 1-750-243-11 SOCKET, CONNECTOR 6P

< DIODE >

D801 8-749-924-18 DIODE PHOTO INTERRUPTER RPI-1391

D802 8-749-924-30 DIODE PHOTO REFLECTOR GP2S28

< SWITCH >

S401 1-571-308-11 SWITCH, SLIDE (COMMAND MODE)

R801 1-249-416-11 CARBON 820 5% 1/4W F

R802 1-249-406-11 CARBON 120 5% 1/4W F

************************************************************

< RESISTOR >

— 40 —

Page 33

TABLE MOTOR

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Ref. No. Part No. Description Remarks Ref. No. Part No. Description Remarks

* 1-647-364-11 TABLE MOTOR BOARD

******************

ACCESSORIES & PACKING MATERIALS

********************************

< MOTOR >

M801 A-4660-525-A MOTOR ASSY, ROTARY (TABLE)

************************************************************

MISCELLANEOUS

**************

7 1-782-219-11 WIRE (FLAT TYPE) (17 CORE)

9 1-782-220-11 WIRE (FLAT TYPE) (9 CORE)

! 59 1-575-651-21 CORD, POWER (AEP)

! 59 1-590-926-11 CORD, POWER (US,CND)

! 59 1-696-845-11 CORD, POWER (AUS)

72 1-751-052-11 WIRE (FLAT TYPE) (6 CORE)

105 1-466-996-11 ENCODER, ROTARY

109 1-765-443-11 WIRE (FLAT TYPE) (23 CORE)

* 125 1-452-879-11 MAGNET

! 751 8-848-379-31 OPTICAL PICK-UP KSS-213BA/F-NP

752 1-769-069-11 WIRE (FLAT TYPE) (16 CORE)

M101 X-4917-523-3 MOTOR ASSY (SPINDLE)

M102 X-4917-504-3 MOTOR ASSY (SLED)

M801 A-4660-525-A MOTOR ASSY, ROTARY (TABLE)

M802 A-4660-914-A MOTOR ASSY, LOADING

! T601 1-429-956-11 TRANSFORMER, POWER (US,CND)

! T601 1-431-076-11 TRANSFORMER, POWER (AEP,AUS)

************************************************************

1-475-088-11 REMOTE COMMANDER (RM-DC53)

1-558-271-11 CORD, CONNECTION (AUDIO)

1-777-241-11 CORD, CONNECTION (CONTROL A1)(CND)

3-810-765-33 MANUAL,COMMONNESS INSTRUCTION

(ENGLISH)(US,AUS)

3-810-765-43 MANUAL,COMMONNESS INSTRUCTION

(ENGLISH/FRENCH/GERMAN/SPANISH/DUTCH/

SWEDISH/ITALIAN/PORTUGUESE/CHINESE)

(CND,AEP)

3-859-179-11 MANUAL, INSTRUCTION (ENGLISH)(US,AUS)

3-859-179-21 MANUAL, INSTRUCTION

(ENGLISH/FRENCH/SPANISH/PORTUGUESE)

(CND,AEP)

3-859-179-31 MANUAL, INSTRUCTION

(GERMAN/DUTCH/SWEDISH/ITALIAN)(AEP)

4-983-956-01 COVER, BATTERY (FOR RM-DC53)

************************************************************

**************

HARDWARE LIST

**************

#1 7-685-647-79 SCREW +BVTP 3X10 TYPE2 N-S

#2 7-685-872-09 SCREW +BVTT 3X8 (S)

#3 7-685-648-79 SCREW (M3X12), TAPPING

#4 7-685-646-79 SCREW +BVTP 3X8 TYPE2 N-S

#5 7-621-772-00 SCREW +B 2X3

#6 7-685-134-19 SCREW (+ PTPWH) (2.6X8)

#7 7-621-255-15 SCREW +P 2X3

#8 7-685-871-01 SCREW +BVTT 3X6 (S)

The components identified by

mark ! or dotted line with mark

! are critical for safety.

Replace only with part number

specified.

Les composants identifiés par

une marque ! sont critiques

pour la sécurité.

Ne les remplacer que par une

pièce portant le numéro spécifié.

— 41 —

Page 34

CDP-C460Z/CE515

http://www.jdwxzlw.com/?fromuser=华盛维修

家电维修资料网,免费下载各种维修资料

Sony Corporation

9-960-962-11

Home A&V Products Company

Published by General Engineering Dept.

— 42 —

Printed in Japan © 1997.5

97E1674-1

(Shibaura)

Loading...

Loading...