Sony BVM-L230 Service Manual

LCD VIDEO MONITOR

BVM-L230

CONTROLLER ATTACHMENT STAND

BKM-37H

SERVICE MANUAL

1st Edition (Revised 2)

! WARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! WARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

Attention-when the product is installed in Rack:

1. Prevention against overloading of branch circuit

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

make sure that the rack does not overload the supply

circuit.

2. Providing protective earth

When this product is installed in a rack and is

supplied power from an outlet on the rack, please

confirm that the outlet is provided with a suitable

protective earth connection.

3. Internal air ambient temperature of the rack

When this product is installed in a rack, please make

sure that the internal air ambient temperature of the

rack is within the specified limit of this product.

4. Prevention against achieving hazardous

condition due to uneven mechanical loading

When this product is installed in a rack, please make

sure that the rack does not achieve hazardous

condition due to uneven mechanical loading.

5. Install the equipment while taking the operating

temperature of the equipment into consideration

For the operating temperature of the equipment, refer

to the specifications of the Operation Manual.

6. When performing the installation, keep the

following space away from walls in order to

obtain proper exhaust and radiation of heat.

Above and below: 4.4 cm (1.7 inches) or more

When using a modular jack cable:

For safety, do not connect to the connector for peripheral

device wiring that might have excessive voltage.

BVM-L230

Table of Contents

Manual Structure

Purpose of this manual ................................................................. 3

Related manuals ........................................................................... 3

Trademarks ................................................................................... 3

1. Service Overview

1-1. Appearance Figure ..........................................................1-1

1-2. Board Location ...............................................................1-1

1-3. Disassembly ....................................................................1-2

1-3-1. Cabinet ..................................................................1-2

1-3-2. Bottom Cabinet .....................................................1-3

1-3-3. Bezel Assembly.....................................................1-4

1-3-4. T Board/ST1 Board ...............................................1-5

1-3-5. G Board .................................................................1-6

1-3-6. B Board .................................................................1-7

1-3-7. YA Board/YB Board/YC Board ...........................1-8

1-3-8. DC Fan ..................................................................1-9

1-3-9. LCD Panel Module/T-CON Board .....................1-10

1-3-10. LMD1 Board ....................................................... 1-11

1-3-11. LMD2 Board ....................................................... 1-12

1-3-12. LCD Unit .............................................................1-13

1-4. Packing the LCD Unit ..................................................1-14

1-5. Attaching BKM-37H .................................................... 1-15

1-6. Procedure when Replacing the LCD Unit .................... 1-18

1-6-1. CD-R Directory ...................................................1-18

1-6-2. Data Transfer Procedure......................................1-18

1-7. Procedure for Replacing the B Board/LMD2 Board ....1-21

1-7-1. Preparation ..........................................................1-21

1-7-2. B Board Data Update ..........................................1-25

1-7-3. LMD2 Board Data Update ..................................1-29

1-8. Version Upgrade ...........................................................1-31

1-8-1. Required Equipment............................................1-31

1-8-2. About Memory Stick ...........................................1-31

1-8-3. Check of Memory Stick Data .............................. 1-33

1-8-4. Software Version Upgrade

- In the case that the software version of

this unit is earlier than Ver. 1.3 ..........................1-36

1-8-5. Kernel Version Upgrade - Software version of

this unit is Ver. 1.3 or later .................................. 1-37

1-8-6. Controller Kernel Version Upgrade

- Software version of this unit is earlier than

Ver. 1.3 ................................................................1-38

1-8-7. FPGA Version Upgrade

- Software version of this unit is earlier than

Ver. 1.3 ................................................................ 1-39

1-9. Recovery from Version Upgrade Failure .....................1-40

1-9-1. Judging Method of Version Upgrade Failure......1-40

1-9-2. Recovery Method ................................................1-41

1-9-3. Recovery Method for Kernel/FPGA Version

Upgrade Failure (this unit) ..................................1-48

1-9-4. Recovery Method for Kernel Version Upgrade

Failure (controller) ..............................................1-50

1-10. Uniformity Adjustment.................................................1-52

1-10-1. Uniformity Adj Menu..........................................1-52

1-11. Backlight Menu ............................................................1-53

1-11-1. SYSTEM .............................................................1-53

1-11-2. LED_DRIVE etc .................................................1-54

1-11-3. SENSOR..............................................................1-55

1-11-4. ERROR................................................................1-57

1-12. Maintenance Menu .......................................................1-58

1-12-1. Software Version Up

- Software version of this unit is earlier than

Ver. 1.3 ................................................................ 1-59

1-12-2. Restore Factory Set All .......................................1-59

1-12-3. Restore System Data ...........................................1-59

1-12-4. 1035/60I Mode ....................................................1-60

1-12-5. Low Latency........................................................1-60

1-12-6. Main Board..........................................................1-60

1-12-7. Backlight .............................................................1-60

1-12-8. Uniformity Adj .................................................... 1-61

1-13. Lead-free Solder ...........................................................1-61

1-14. About LCD Unit/T-CON Board ...................................1-61

2. Circuit Description

2-1. G Board...........................................................................2-1

2-1-1. Operation during Power-on Sequence...................2-1

2-1-2. Circuit Operation...................................................2-1

2-1-3. Overvoltage Protection Circuit and Overcurrent

Protection Circuit ..................................................2-3

2-2. LMD1 Board...................................................................2-4

2-2-1. Green LED Power Block.......................................2-5

2-2-2. Blue LED Power Block.........................................2-5

2-2-3. Way to Change G_OUT and B_OUT Voltages ....2-5

2-2-4. ON/OFF Control of Green and

Blue LED Power Supplies.....................................2-6

BVM-L230

1

2-2-5. Overvoltage and Overcurrent Protection

Circuits ..................................................................2-6

2-2-6. BL_12V .................................................................2-6

2-3. LMD2 Board...................................................................2-7

2-3-1. Power Circuit.........................................................2-7

2-3-2. LED Driver Circuit................................................2-9

2-3-3. H8 Microcomputer Operating Environment ....... 2-11

2-3-4. External Interface ................................................2-11

2-3-5. Reset Circuit ........................................................2-11

2-4. S1, S2, and S3 Boards...................................................2-12

2-4-1. Outline .................................................................2-12

2-4-2. Circuit Operation .................................................2-14

2-4-3. Others .................................................................. 2-15

A. Semiconductor Pin Assignments

B. Spare Parts

B-1. Notes on Repair Parts .................................................... B-1

B-2. Exploded Views............................................................. B-2

B-3. Electrical Parts List...................................................... B-11

B-4. Packing Materials & Supplied Accessories................. B-89

E. Board Layouts

B (SUFFIX: -12)............................................................ E-2

B (SUFFIX: -13)............................................................ E-6

G .................................................................................. E-10

LMD1 .......................................................................... E-12

ST1............................................................................... E-13

YA................................................................................ E-13

YB ................................................................................ E-13

YC ................................................................................ E-13

LMD2 .......................................................................... E-14

T ................................................................................... E-16

C. Block Diagrams

Overall ........................................................................... C-1

D. Schematic Diagrams

B (SUFFIX: -12) ............................................................ D-2

B (SUFFIX: -13) .......................................................... D-46

G .................................................................................. D-89

LMD1 .......................................................................... D-91

LMD2 .......................................................................... D-93

ST1...............................................................................D-98

T ...................................................................................D-99

YA..............................................................................D-101

YB .............................................................................. D-101

YC .............................................................................. D-101

Frame Wiring ............................................................. D-102

2

BVM-L230

Purpose of this manual

Related manuals

Trademarks

Manual Structure

This manual is the Service Manual of the LCD Video Monitor BVM-L230.

This manual contains the service overview, circuit description, semiconductor pin

assignments, spare parts, block diagram, schematic diagrams, and board layouts.

In addition to this Service Manual the following manual is provided.

..

. “Semiconductor Pin Assignments” CD-ROM (Available on request)

..

This “Semiconductor Pin Assignments” CD-ROM allows you to search for

semiconductors used in Broadcast and Professional equipment.

This manual contains a complete list of semiconductors and their ID Nos., and

thus should be used together with the CD-ROM.

Part number: 9-968-546-06

Trademarks and registered trademarks used in this manual are follows.

. Ethernet is a registered trademark of Xerox Corporation.

. Windows is a registered trademark of Microsoft Corporation in the United States and

Other countries.

. Memory Stick is a trademark of Sony Corporation.

. HyperTerminal is a registered trademark of Hilgraeve Inc..

Other system names, product names, and company names appearing in this manual

are trademarks or registered trademarks of their respective holders.

BVM-L230

3

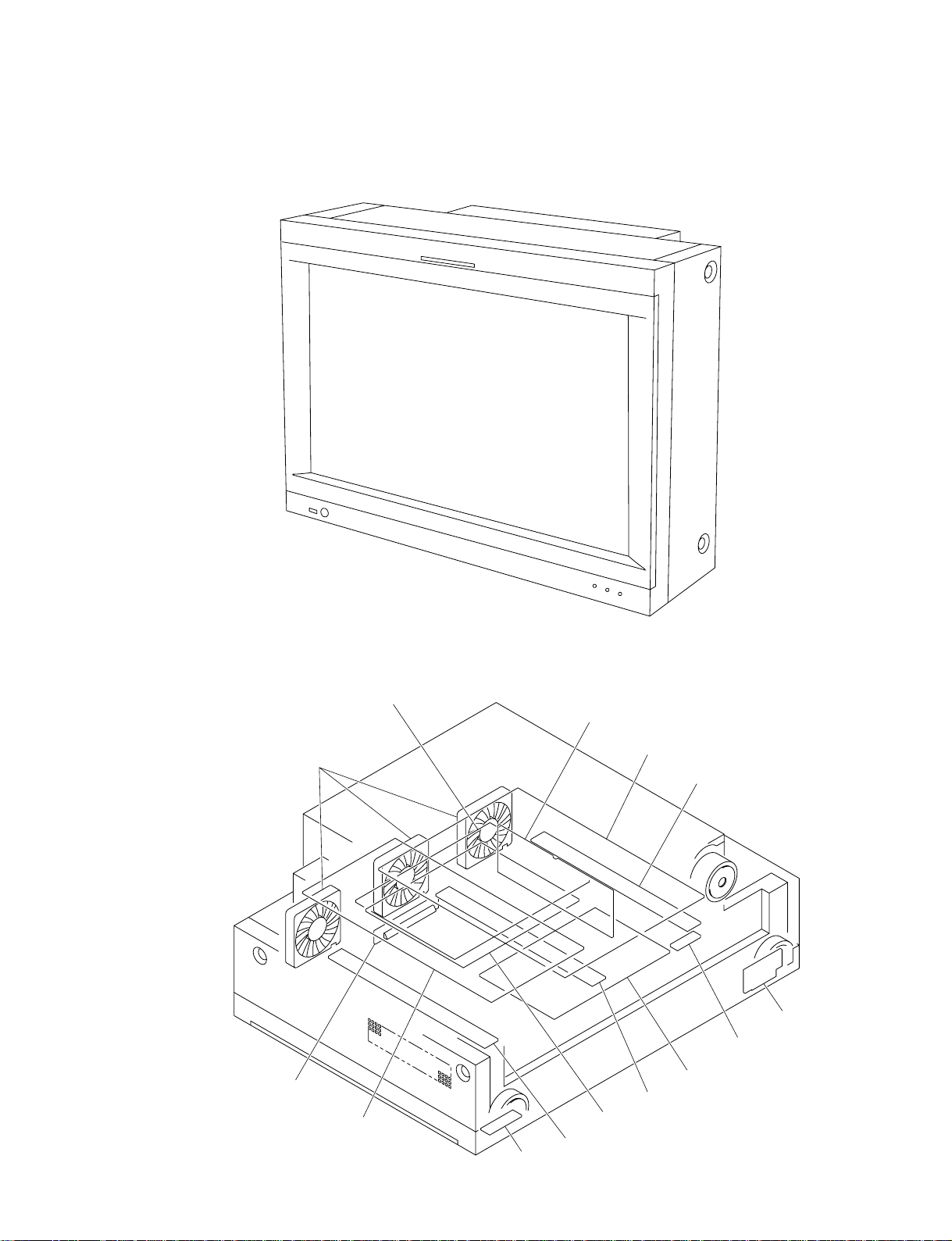

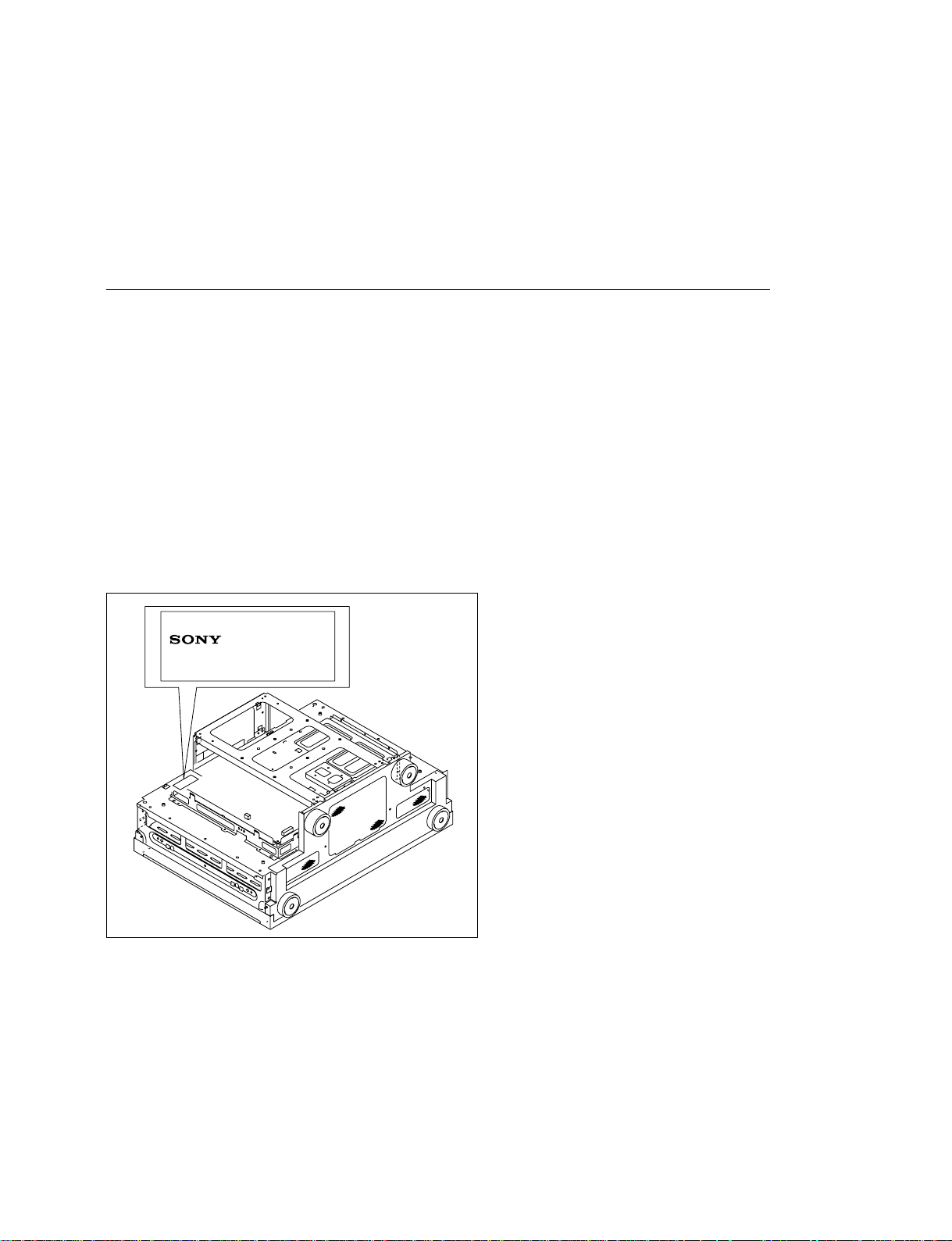

1-1. Appearance Figure

Section 1

Service Overview

1-2. Board Location

YA board

LCD panel module/T-CON board

DC fans

G board

T board

B board

ST1 board

YC board

S1 board

LMD1 board

S2 board

LMD2 board

S3 board

YB board

BVM-L230

1-1

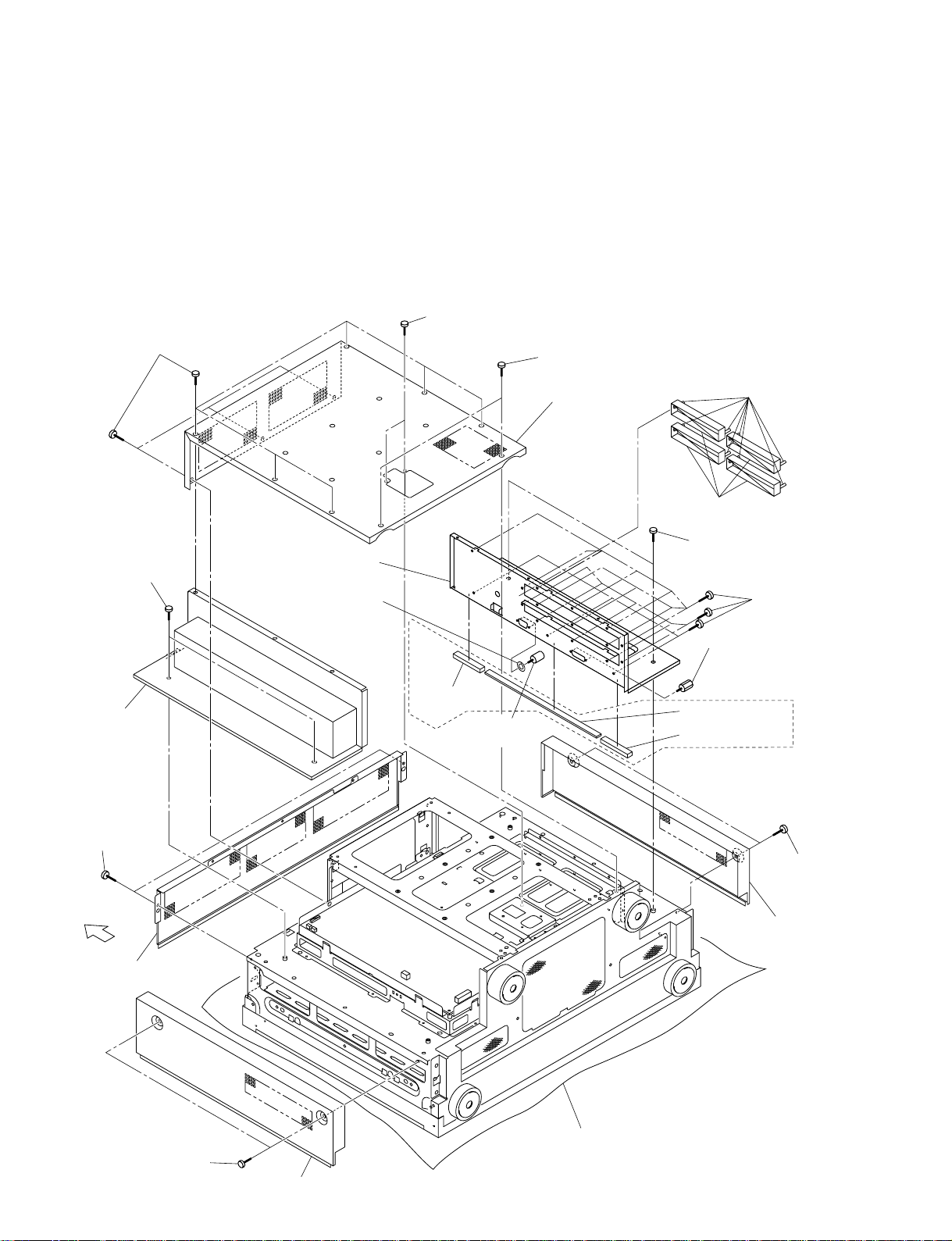

1-3. Disassembly

5

m

. In this section, remove parts in the order of numbers shown in the figure.

. When removing/installing the cabinet and replacing the board, place the unit on the conductive cushion.

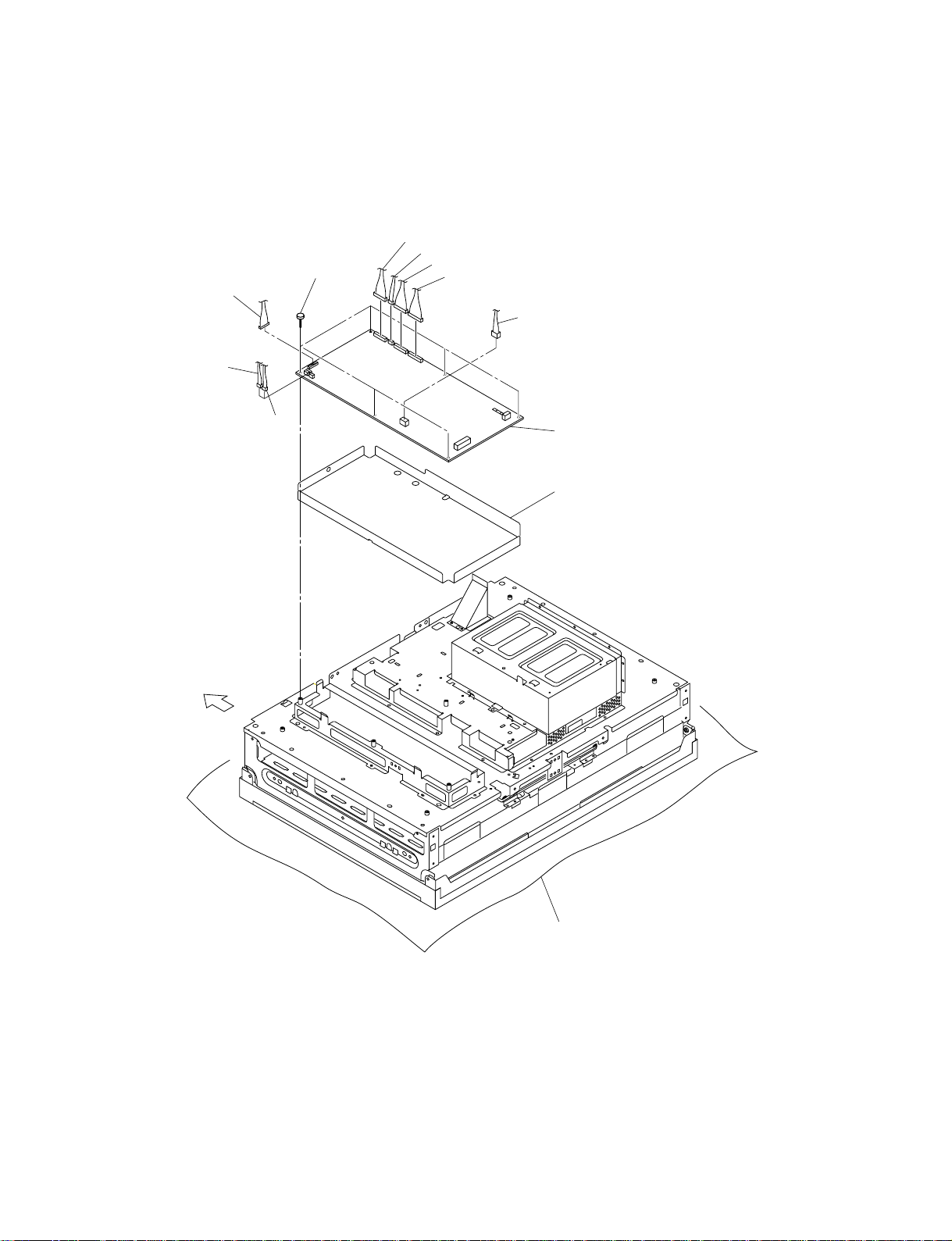

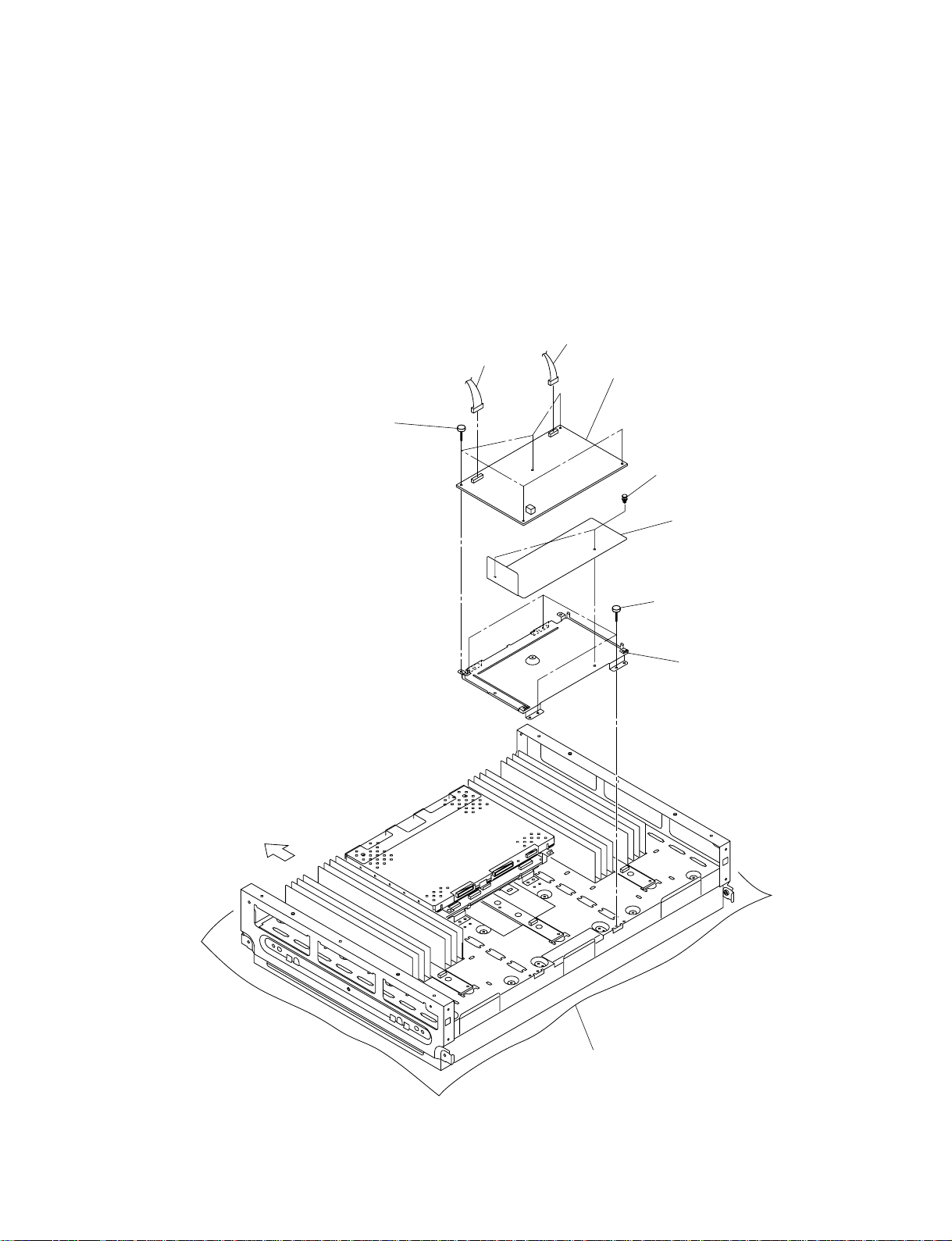

1-3-1. Cabinet

T wo screws

3 Nine screws

(PSW4 x 8)

![ T wo screws

(B4 x 6)

@/ Bracket (B) assembly

!,

Two spring

washers

(PSW4 x 8)

4 T wo screws

(PSW4 x 8)

6 Rear cabinet

1 Eight panel securing

screws

2 Blank panel assembly

!. T wo screws

(B4 x 6)

!; T wo hexagonal

!\ Seventeen

screws

(BVTT3 x 8)

screws

!] G case

assembly

!- T wo screws

(B4 x 6)

Upper side

!= T op cabinet

9 T wo screws

1-2

(B4 x 6)

0 Side cabinet (R)

@- Gasket (A)

!'

Two connector

screws

@= Gasket (B)

@[ Gasket (A)

S/N 2001076 to 2001999

S/N 2501056 to 2501999

S/N 2100001 and Higher

7 T wo screws

(B4 x 6)

8 Side cabinet (L)

Conductive cushion

BVM-L230

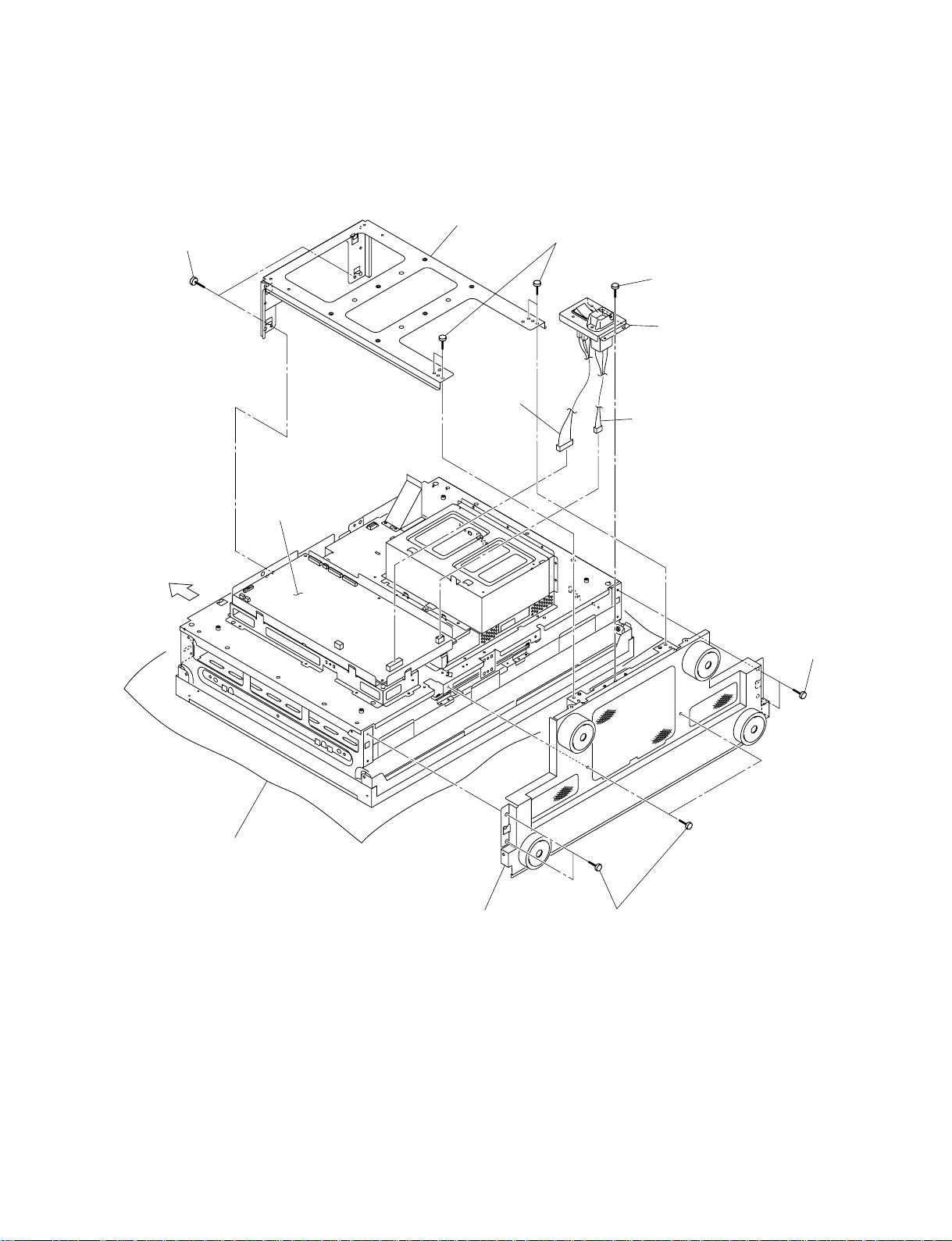

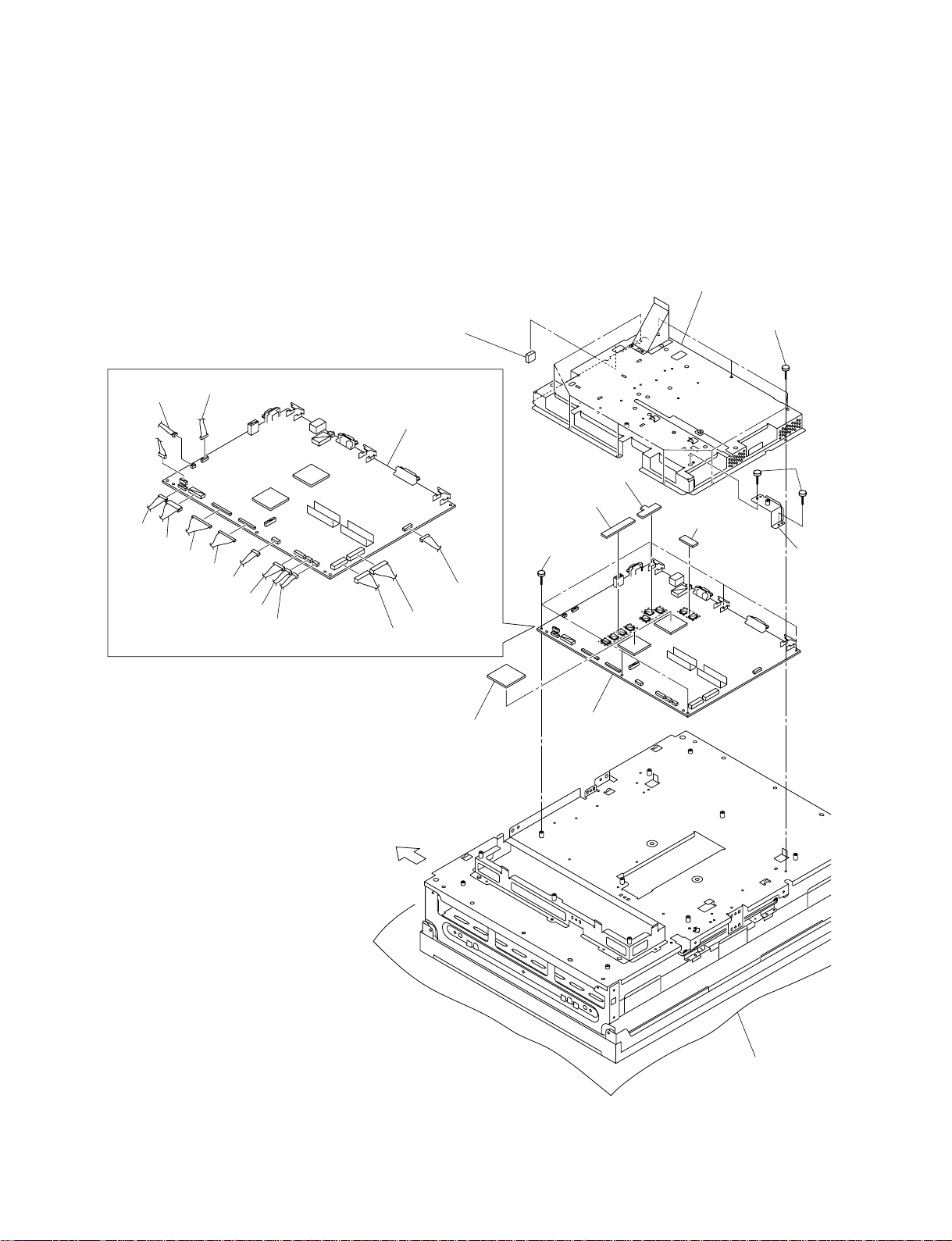

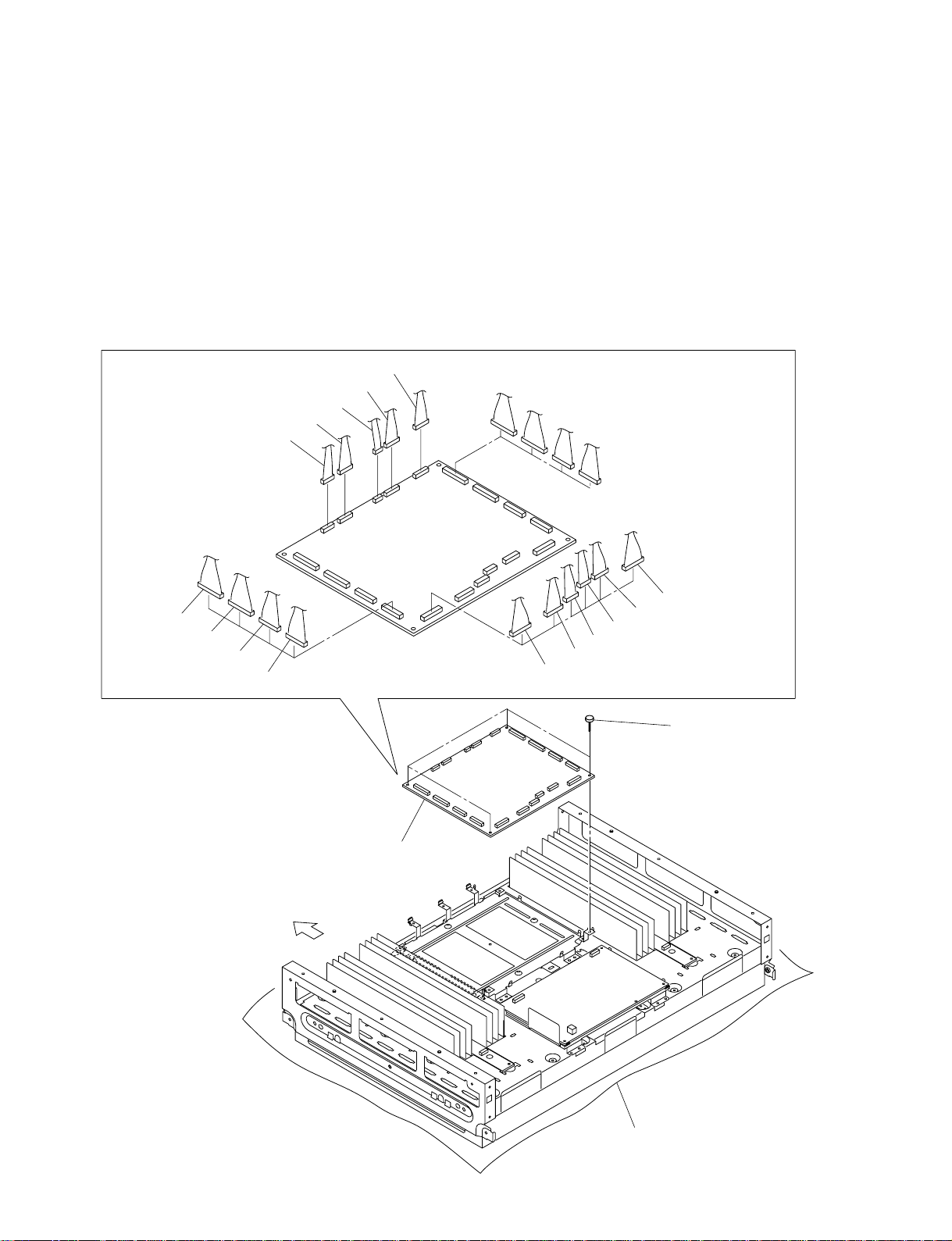

1-3-2. Bottom Cabinet

. Remove the cabinet. (Refer to Section 1-3-1.)

4 T wo screws

(B4 x 6)

Upper side

5 VESA bracket assembly

3 Four screws

(B4 x 6)

1 Screw

(PSW3 x 6)

2 AC block assembly

CN6002

CN6001

G board

7 T wo screws

(B4 x 6)

BVM-L230

Conductive cushion

8 Bottom cabinet assembly

6 Four screws

(B4 x 6)

1-3

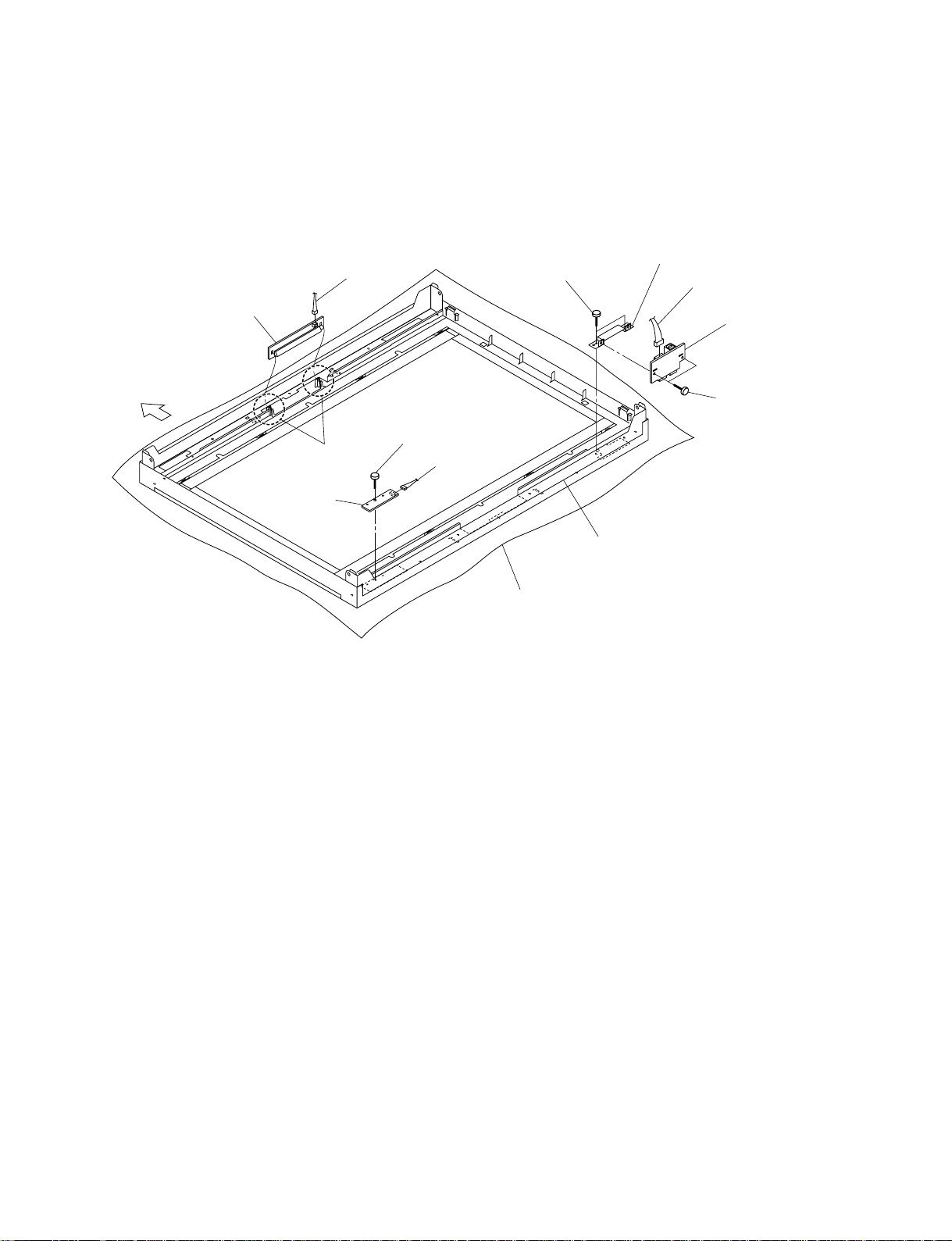

1-3-3. Bezel Assembly

. Remove the cabinet. (Refer to Section 1-3-1.)

. Remove the bottom cabinet. (Refer to Section 1-3-2.)

m

. When removing the main frame assembly, be sure to work with more than two

persons.

. Place the removed chassis assembly on the conductive cushion.

6 Hold the two side frame and remove

the main frame assembly.

2 T wo screws

(B4 x 6)

Upper side

1 T wo screws

(B4 x 6)

5 Harness

Conductive cushion

3 T wo harnesses

4 T wo harness

7 Bezel assembly

7 Bezel assembly

1-4

8 Remove the four

9 Mask assembly

hooks, then remove

the mask assembly.

BVM-L230

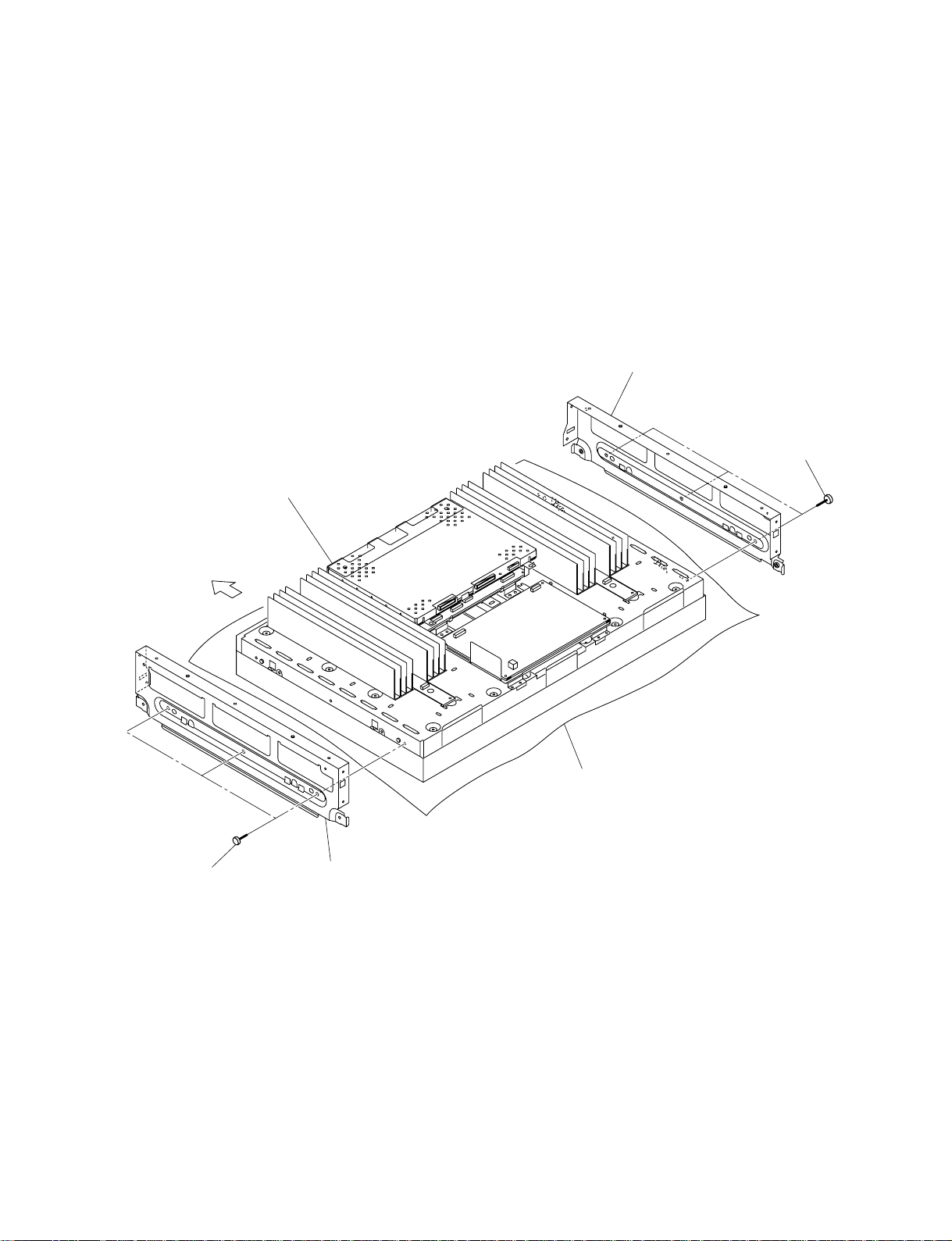

1-3-4. T Board/ST1 Board

. Remove the cabinet. (Refer to Section 1-3-1.)

. Remove the bottom cabinet. (Refer to Section 1-3-2.)

6 T bracket assembly

3 Five screws

(PSW3 x 6)

4 Option case assembly

5 T wo screws

(PSW3 x 6)

S/N 2001076 to 2001999

S/N 2501056 to 2501999

S/N 2100001 and Higher

7 Five screws

(PSW3 x 8)

8 T board

S/N 2000009 to 2001075

S/N 2501001 to 2501055

Upper side

6 T bracket assembly

1 Screw

(PSW3 x 6)

7 Five screws

(PSW3 x 8)

8 Plate T

9 T board

CN300

2 ST1 board

ST1 bracket

BVM-L230

Conductive cushion

1-5

1-3-5. G Board

. Remove the cabinet. (Refer to Section 1-3-1.)

. Remove the bottom cabinet. (Refer to Section 1-3-2.)

CN6602

1 Six screws

(PSW3 x 6)

CN6605

CN6604

CN6606

CN6601

CN6600

CN6501

Upper side

CN6603

2 G board

3 Insulated plate

1-6

Conductive cushion

BVM-L230

1-3-6. B Board

. Remove the cabinet. (Refer to Section 1-3-1.)

. Remove the bottom cabinet. (Refer to Section 1-3-2.)

. Remove the T board. (Refer to Section 1-3-4.)

. Remove the G board. (Refer to Section 1-3-5.)

CN801

CN7701

CN8201

CN6901

CN6001

CN6101

CN8400

CN900

CN600

CN800

CN6904

!- Radiation sheet (C)

S/N 2001076 to 2001999

S/N 2501056 to 2501999

S/N 2100001 and Higher

6 B board

CN6802

CN6902

CN6903

7 Radiation sheet

9 Radiation sheet (B)

8 Radiation sheet (A)

5 Six screws

(PSW3 x 6)

6 B board

4 Cover (B)

3 T en screws

(PSW3 x 6)

1 T wo screws

(PSW3 x 6)

0 Radiation

sheet (C)

2 Bracket

BVM-L230

Upper side

Conductive cushion

1-7

1-3-7. YA Board/YB Board/YC Board

. Remove the cabinet. (Refer to Section 1-3-1.)

. Remove the bottom cabinet. (Refer to Section 1-3-2.)

. Remove the bezel assembly. (Refer to Section 1-3-3.)

Upper side

2 Y A board

5 YB board

3 Harness

1 T wo hooks

4 Screw

(BVTP3 x 10)

6 Harness

Conductive cushion

7 T wo screws

(PSW3 x 6)

Bezel assembly

8 Bracket

!- Harness

0 YC board

9 T wo screws

(PSW3 x 6)

1-8

BVM-L230

1-3-8. DC Fan

. Remove the cabinet. (Refer to Section 1-3-1.)

. Remove the bottom cabinet. (Refer to Section 1-3-2.)

. Remove the T board. (Refer to Section 1-3-4.)

. Remove the G board. (Refer to Section 1-3-5.)

. Remove the B board. (Refer to Section 1-3-6.)

7 Front stay assembly

6 Two screws

(B4 x 6)

3 Main frame assembly

1 Three screws

(B4 x 6)

5 Three harnesses

2 Three screws

(B4 x 6)

9 Fan brackets

BVM-L230

0 Six screws

(PSW3 x 20)

Upper side

LCD panel module

!- DC fans

8 Six screws

(PSW3 x 6)

4 Three harnesses

Conductive cushion

1-9

1-3-9. LCD Panel Module/T-CON Board

n

Before starting the procedure, check Section 1-14.

. Remove the cabinet. (Refer to Section 1-3-1.)

. Remove the bottom cabinet. (Refer to Section 1-3-2.)

. Remove the bezel assembly. (Refer to Section 1-3-3.)

. Remove the T board. (Refer to Section 1-3-4.)

. Remove the G board. (Refer to Section 1-3-5.)

. Remove the B board. (Refer to Section 1-3-6.)

. Remove the DC fan. (Refer to Section 1-3-8.)

6 T-CON shield

1 Card spacer

3 Flexible flat cable

Upper side

2 T-COM cover

5 LCD panel module

4 Five screws

(PSW3 x 6)

7 Six screws

(PSW3 x 6)

9 T-CON bracket

8 T-CON board

1-10

Conductive cushion

BVM-L230

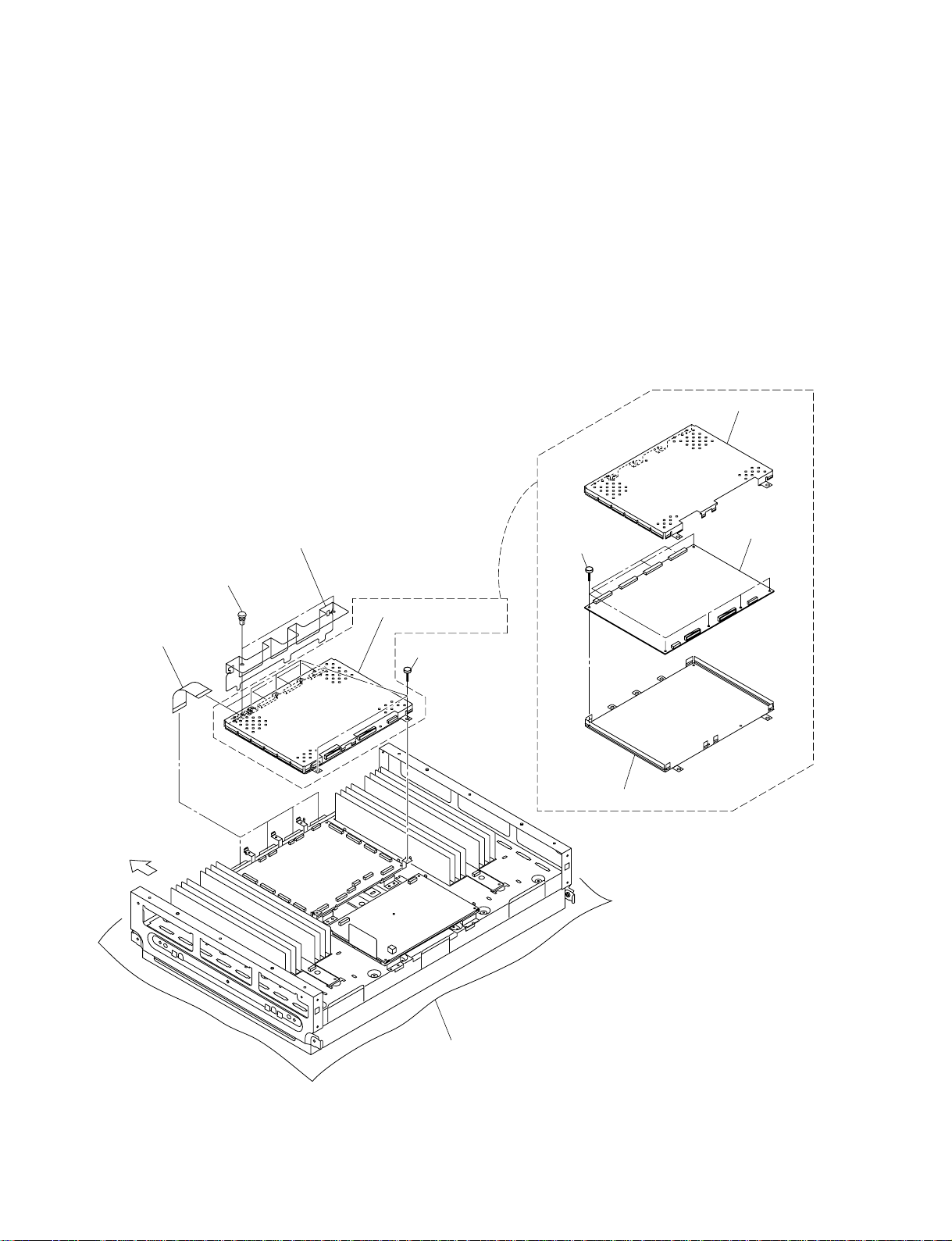

1-3-10. LMD1 Board

. Remove the cabinet. (Refer to Section 1-3-1.)

. Remove the bottom cabinet. (Refer to Section 1-3-2.)

. Remove the bezel assembly. (Refer to Section 1-3-3.)

. Remove the T board. (Refer to Section 1-3-4.)

. Remove the G board. (Refer to Section 1-3-5.)

. Remove the B board. (Refer to Section 1-3-6.)

. Remove the DC fan. (Refer to Section 1-3-8.)

1 Five screws

(PSW3 x 6)

CN6250

CN6251

2 LMD1 board

5 Miniature card spacer

6 Insulating sheet

(LMD-1)

Upper side

3 Four screws

(PSW3 x 6)

4 LMD-1 bracket

BVM-L230

Conductive cushion

1-11

1-3-11. LMD2 Board

. Remove the cabinet. (Refer to Section 1-3-1.)

. Remove the bottom cabinet. (Refer to Section 1-3-2.)

. Remove the bezel assembly. (Refer to Section 1-3-3.)

. Remove the T board. (Refer to Section 1-3-4.)

. Remove the G board. (Refer to Section 1-3-5.)

. Remove the B board. (Refer to Section 1-3-6.)

. Remove the DC fan. (Refer to Section 1-3-8.)

. Remove the LCD panel module. (Refer to Section 1-3-9.)

CN6901

CN6701

CN6401

CN6403

CN6702

CN6602

CN6605

CN6608

CN6603

CN6601

CN6604

CN6607

CN6600

CN6606

CN6900

CN6902

CN6700

CN6400

CN6609

1 Four screws

(PSW3 x 6)

2 LMD2 board

Upper side

1-12

Conductive cushion

BVM-L230

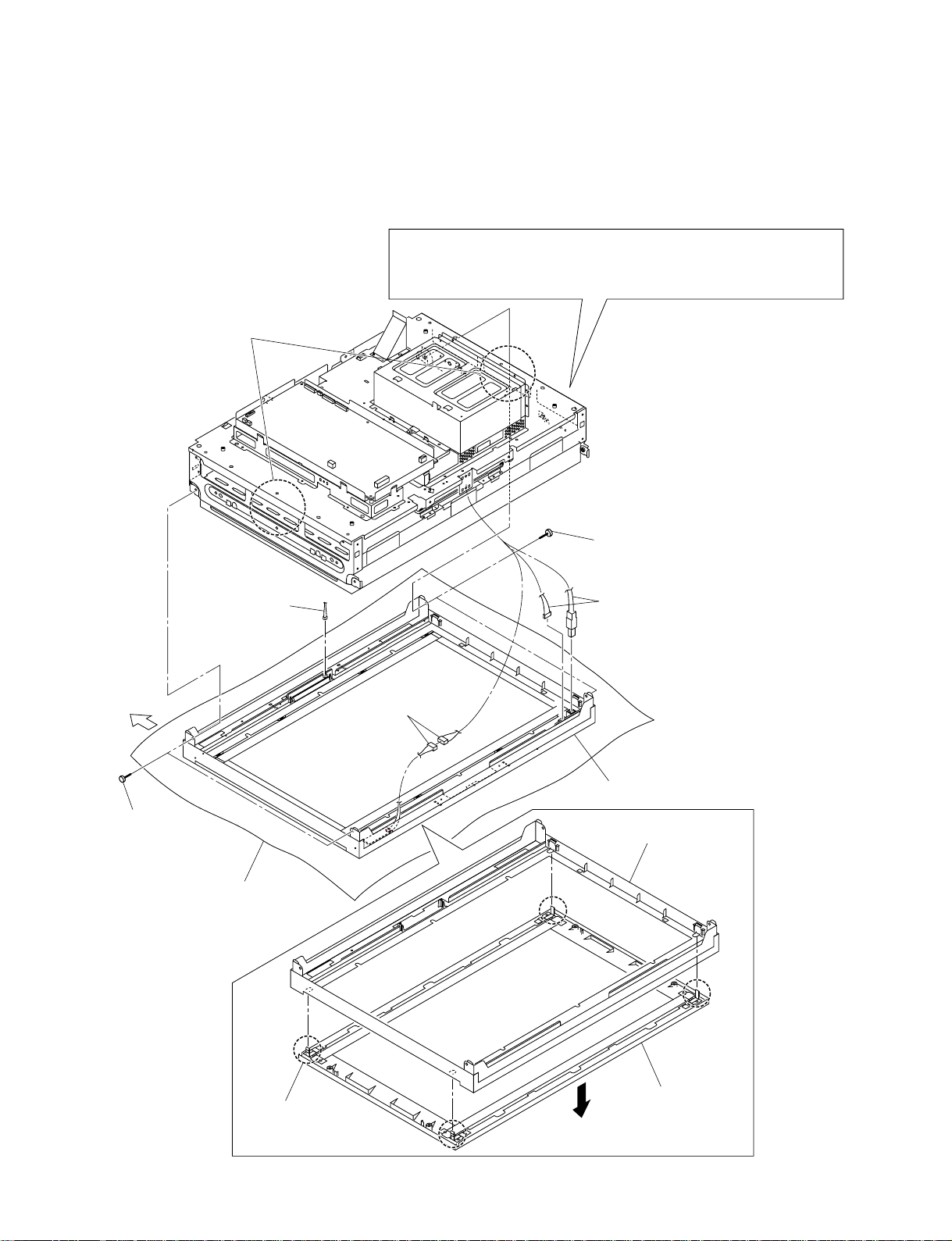

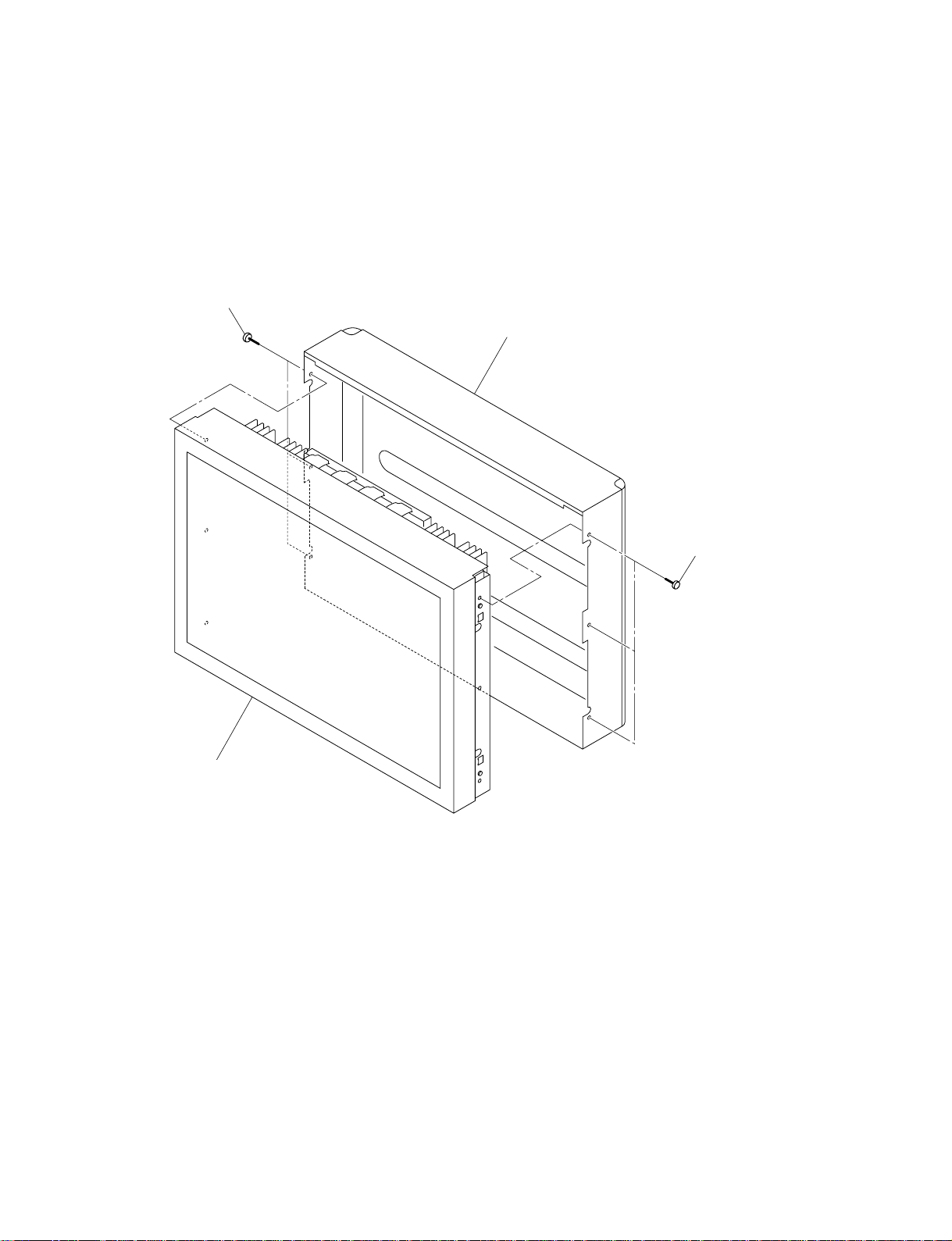

1-3-12. LCD Unit

n

When replacing the LCD unit, it is required to update the adjustment data file written in the B board. For

details, refer to Section 1-6.

. Remove each part. (Refer to Sections 1-3-1 to 1-3-8.)

2 Side frame assembly (L)

LCD unit

Upper side

1 Three screws

(PSW4 x 8)

3 Three screws

BVM-L230

Conductive cushion

4 Side frame assembly (R)

(PSW4 x 8)

1-13

1-4. Packing the LCD Unit

. Return the LCD unit to the address specified separately.

. When returning the LCD unit, be sure to attach the cover to protect the board on the LCD unit.

Sony part number: 3-279-741-01

Part name: Cover

2 Three screws

(PSW4 x 8)

3 Cover

1 Three screws

(PSW4 x 8)

1-14

LCD unit

BVM-L230

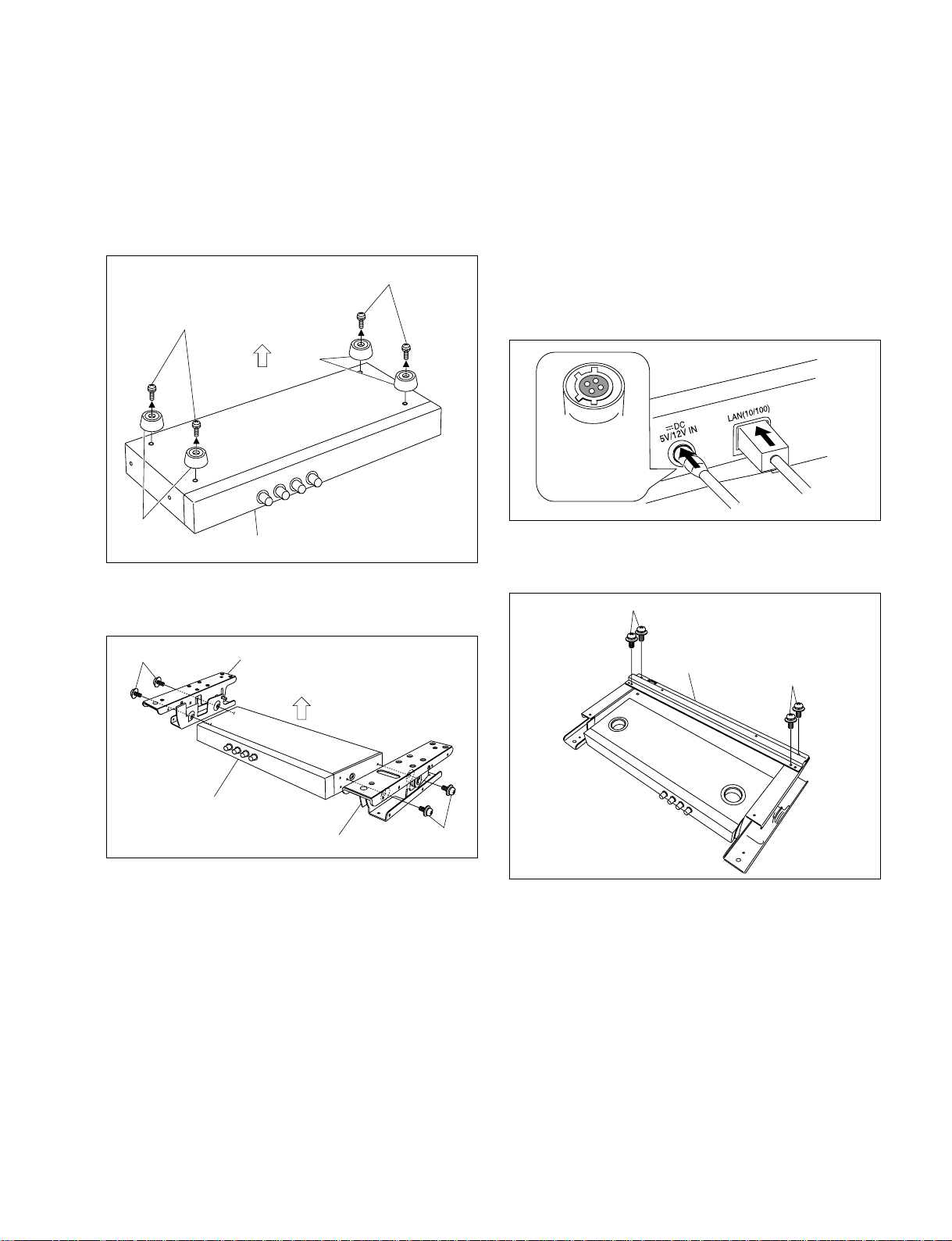

1-5. Attaching BKM-37H

The monitor can be attached to the control unit (referred to

as controller hereafter) using BKM-37H.

1. Remove the four screws, then remove the feet.

PS4 x 6

PS4 x 6

Bottom surface

Feet

3. Connect the supplied connecting cable to the DC 5V/

12V IN terminal and LAN (10/100) terminal on the

rear of the controller.

n

When connecting the cable to the DC 5V/12V IN

terminal, check the concave side and convex side of

both ends of the cable, and be sure to connect the

concave side to the controller. When connecting, insert

the cable so that the shape of its end matches with the

shape of the DC 5V/12V IN terminal.

Insert the concave

connector.

Feet

Controller

2. Attach the stand assembly (R) and stand assembly (L)

with the four supplied screws.

PSW4 x 8

Stand assembly (R)

Bottom surface

Controller

Stand assembly (L)

4. Attach the rear stay assembly with the four supplied

screws.

B4 x 8

Rear stay assembly

B4 x 8

BVM-L230

1-15

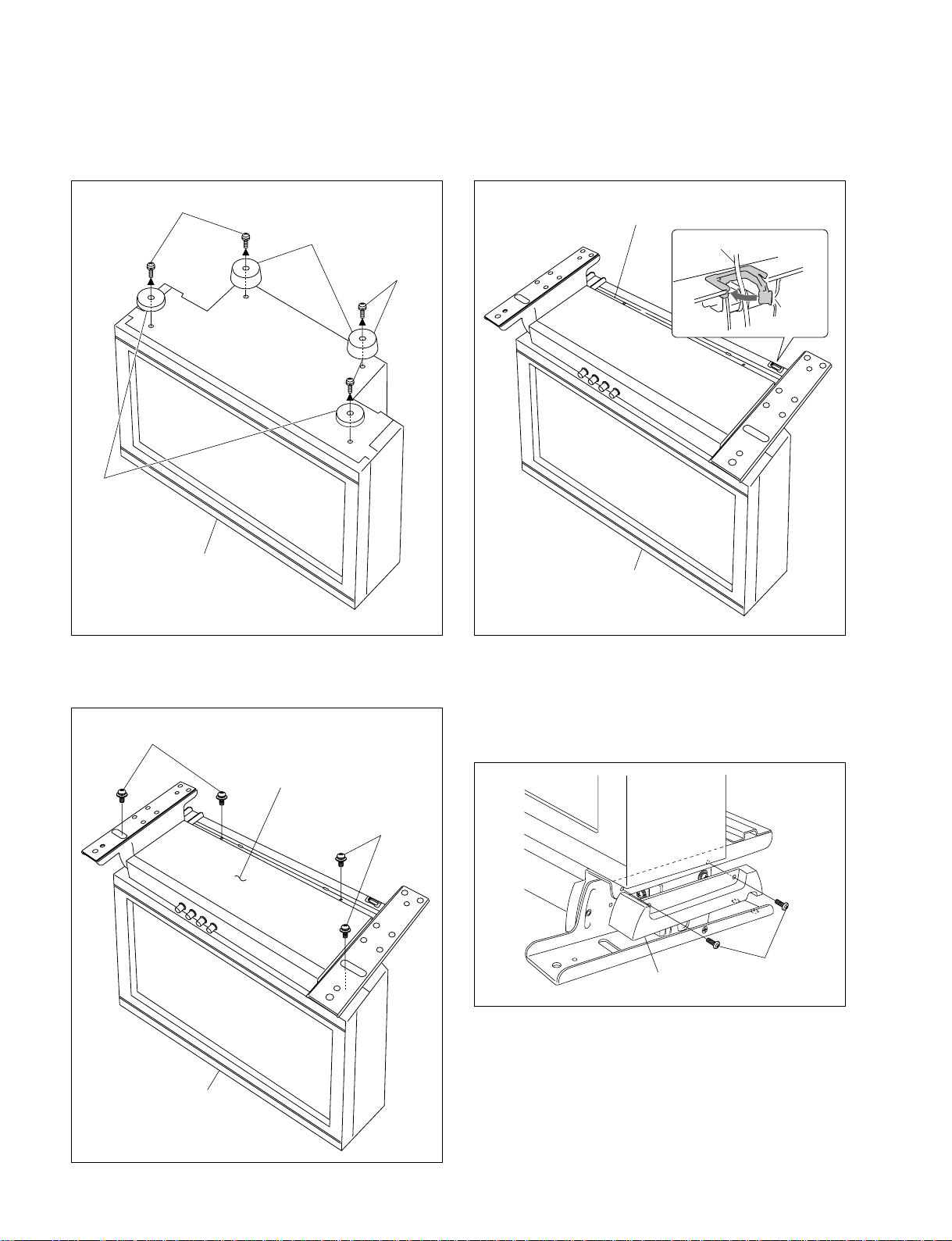

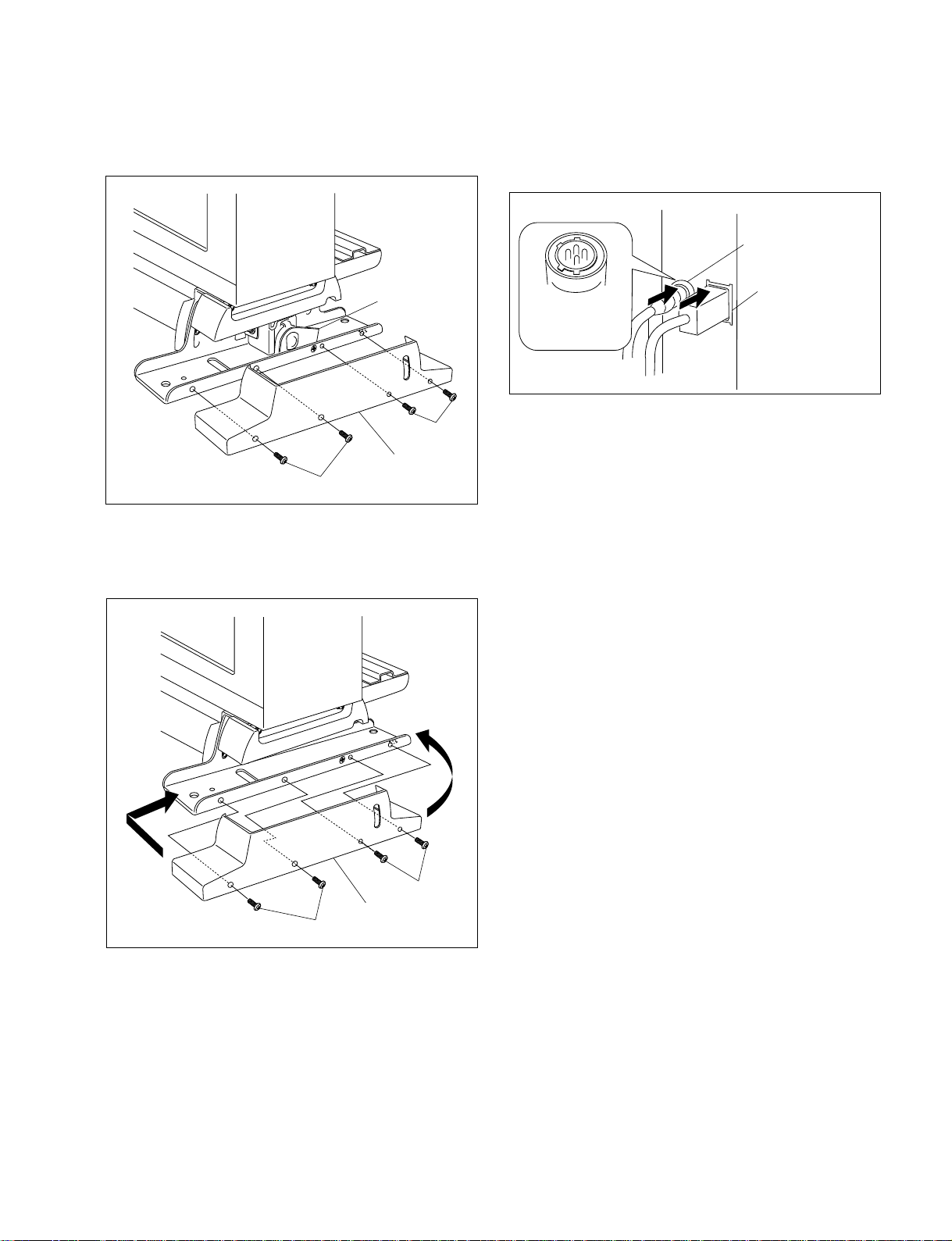

5. Remove the four supplied screws, then remove the

four feet from the bottom surface of the monitor.

7. Fix the connecting cable with the wire holder of the

rear stay.

Feet

B M4 x 8

Monitor

Feet

Rear stay

Connecting cable

B M4 x 8

Wire

holder

Monitor

6. Attach the controller with the four supplied screws.

B4 x 8

Controller

B4 x 8

Monitor

8. Attach the cover (upper) (left) with the two supplied

screws A.

n

Attach the cover (upper) (right) in the same procedure.

B3 x 8

Cover (upper) (left)

9. Attach the cover (lower) (left) with the two supplied

screws A.

n

Attach the cover (lower) (right) in the same procedure.

1-16

BVM-L230

In the case that the tilt unit is attached

Place the cover over the tilt unit.

10. Connect the connector of the connecting cable to the

DC 5V OUT terminal and LAN (10/100) terminal on

the monitor side.

DC 5 V OUT terminal

Tilt unit

B3 x 8

Cover (lower) (left)

B3 x 8

In the case that the tilt unit is removed

Attach the front portion of the cover, then attach the rear

portion while recurving it.

LAN (10/100) terminal

Insert the convex

connector.

n

When connecting the cable to the DC 5V OUT terminal,

check the concave side and convex side of both ends of the

cable, and be sure to connect the convex side to the

monitor. When connecting, insert the cable so that the

shape of its end matches with the shape of the DC 5V OUT

terminal.

BVM-L230

B3 x 8

Cover (lower) (left)

B3 x 8

1-17

1-6. Procedure when Replacing the LCD

Unit

When replacing the LCD unit, it is required to update the

adjustment data file written in the B board. The adjustment

data file to be updated is stored in CD-R supplied with the

LCD unit (for servicing). The update is performed by the

data transfer via LAN port.

1-6-1. CD-R Directory

A1364355A/B

(LCD unit SerialNo.)

B_Board

9 files or

26 files

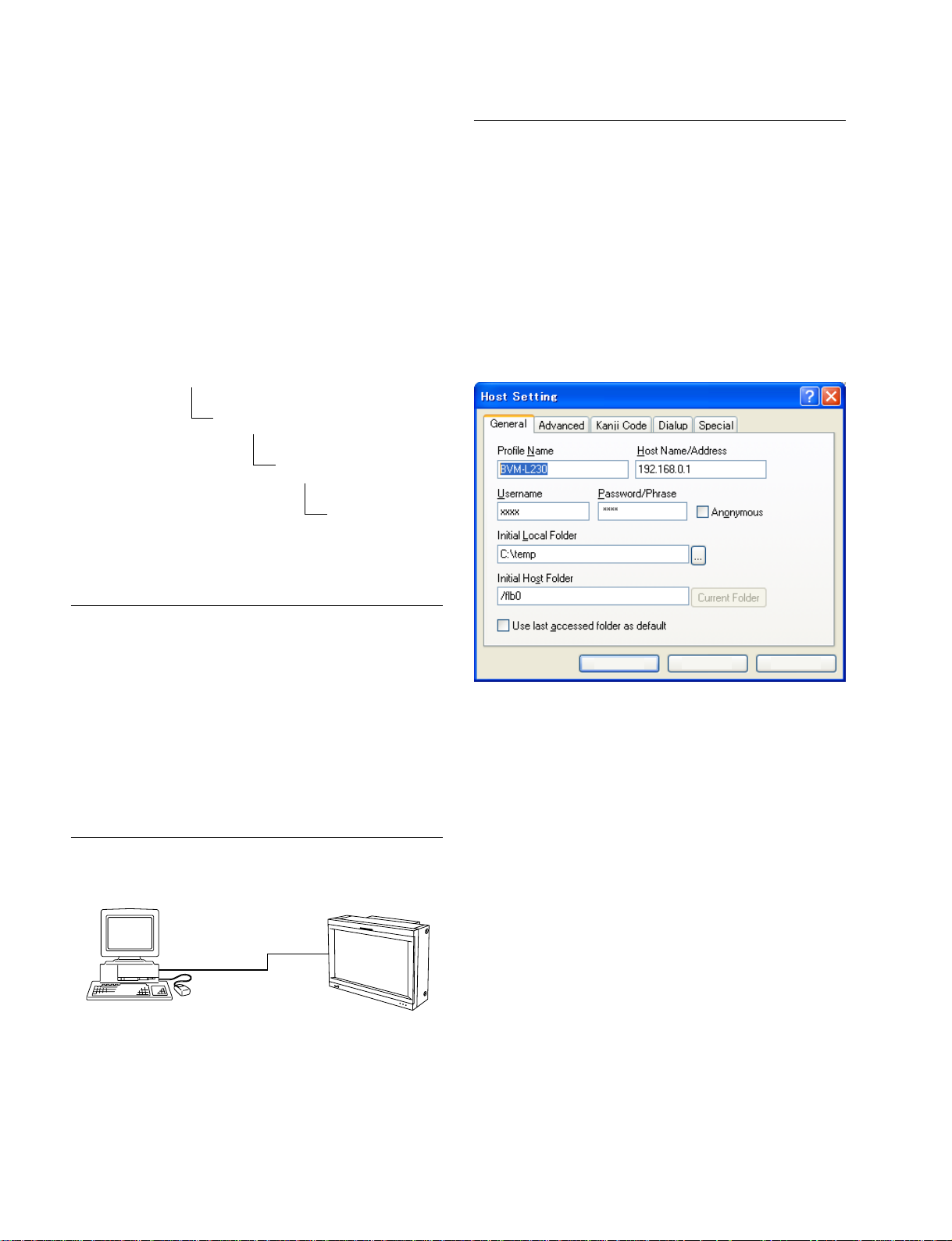

1-6-2. Data Transfer Procedure

Data transfer procedure

1. Set the BVM-L230 network switch to PEER TO PEER

side.

2. Set the PC as follows.

.IP address: 192.168.0.10

.Subnet mask: 255.255.255.0

3. Start FTP client software on the PC.

4. Select “New host”, and then set the connection

destination (transfer destination) as shown below.

Basic tab

Required equipment

. Personal computer (PC)

(equipped with LAN port)

. LAN cable (cross)

. CD-R (supplied with LCD unit)

. FTP client software

n

The window of FFFTP (free software) is used for the

window of FTP client software.

Connection

NETWORK SW:

PEER TO PEER

LAN cable (cross)

PC BVM-L230

Cancel OK Help

.Profile Name: BVM-L230 (arbitrary)

.Host Name/Address: 192.168.0.1

.Username: (*1)

.Password/Phrase: (*1)

.Anonymous: Do not place a checkmark.

.Initial Host Folder: /flb0

n

(*1)

For the user name and password, contact your local

Sony Sales Office/Server Center.

1-18

BVM-L230

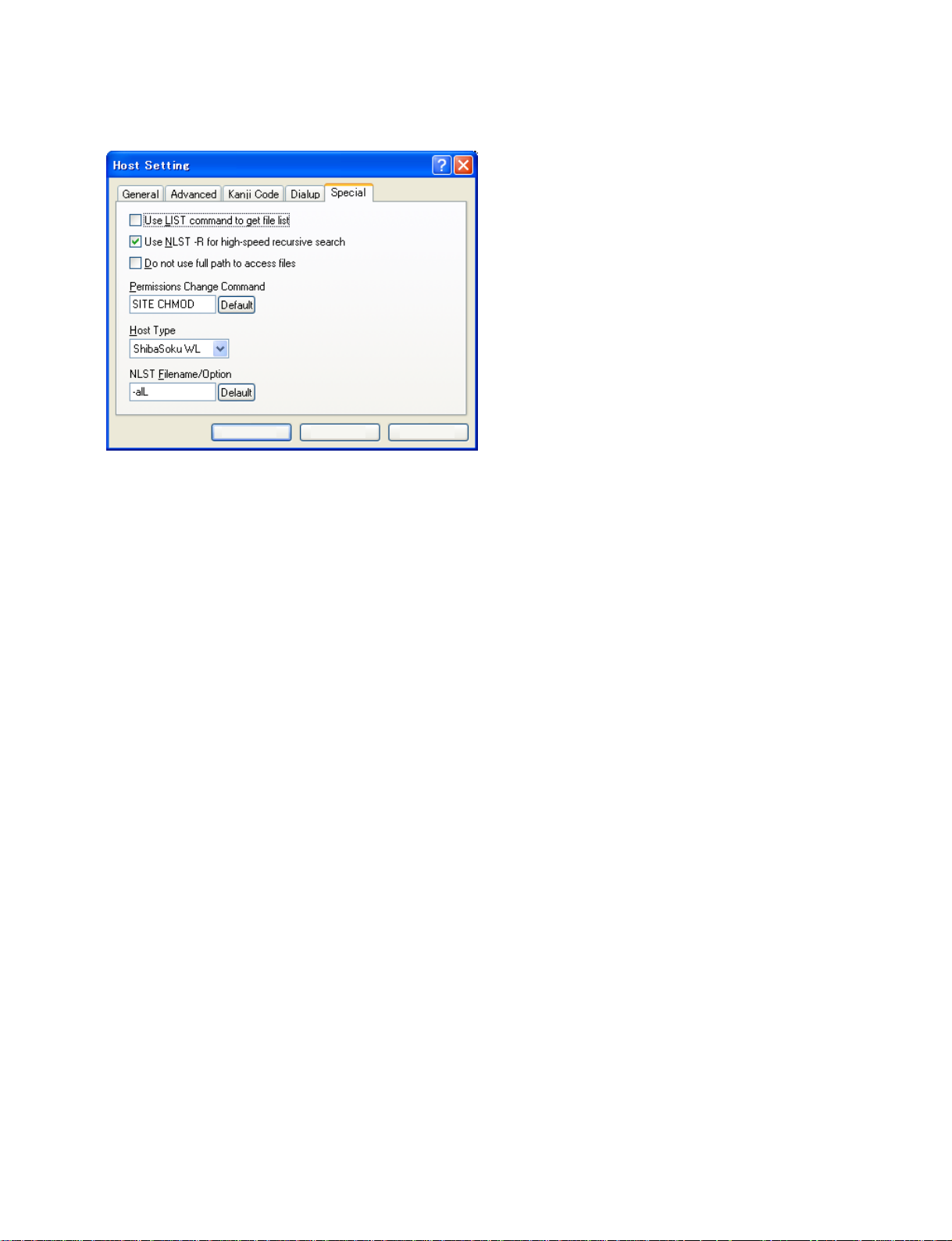

High-level tab

Cancel OK Help

.Use LIST command to get file list:

Do not place a checkmark.

.Use NLST-R for high-speed recursive search:

Place a checkmark.

.Do not use full path to access files:

Do not place a checkmark.

.Permissions Change Command:

SITE CHMOD

.Host Type:

ShibaSoku WL

.NLST Filename/Option:

-alL

5. Click the [OK] button.

The list of host is displayed.

6. Select “BVM-L230”, then click “Connection”.

7. Display the transfer destination directory “/flb0/data/

com” on the FTP server side.

8. Display the file to be transferred (adjustment data file

in the supplied CD-R) on the PC side.

9. Select the adjustment data file, then perform uploading

(transfer) by overwriting the file.

BVM-L230

1-19

Directory to be uploaded File (26 files) Directory of upload

(CD-ROM) destination (B board)

A1364355A/(SerialNo.)/ correct_gamma_96.cms 8 /flb0/data/com

B_Board/ correct_gamma_100_blackins.cms

correct_gamma_100_interlace.cms

correct_gamma_100.cms

correct_gamma_120_blackins.cms

correct_gamma_120_interlace.cms

correct_gamma_120.cms

uniformity.dat

gamma_temp_120.dat (*1)

gamma_temp_120_blackins.dat (*1)

gamma_temp_120_interlace.dat (*1)

gamma_temp_100.dat (*1)

gamma_temp_100_blackins.dat (*1)

gamma_temp_100_interlace.dat (*1)

gamma_temp_96.dat (*1)

gamma_temp_coef_120.dat (*1)

gamma_temp_coef_120_blackins.dat (*1)

gamma_temp_coef_120_interlace.dat (*1)

gamma_temp_coef_100.dat (*1)

gamma_temp_coef_100_blackins.dat (*1)

gamma_temp_coef_100_interlace.dat (*1)

gamma_temp_coef_96.dat (*1)

correct_panel_primarycolors_bvm_smptec.dat (*1)

correct_panel_primarycolors_bvm_ebu.dat (*1)

correct_panel_primarycolors_itu709.dat (*1)

correct_panel_primarycolors_wide.dat (*1)

(*1): Files added from Ver. 1.2

As for the above files added from Ver. 1.2 (18 files), the units having the serial number 2000009 to

2000789 do not have the backup data. Also, these files may not be included in CD-R supplied with the

LCD unit (for service). If the unit or the LCD unit (for service) does not have the files added from the

software version Ver. 1.2, it is not required to update the files (18 files). Use the files that are automatically added when upgrading the software to Ver. 1.2.

n

Be careful that the files not being used are included in CD-R.

10. After uploading the adjustment data using ftp, restart this unit by turning the main power switch off

and on again.

n

If this unit is not restarted, the uploaded adjustment data is not reflected.

n

Do not delete the file under “/flb0” of the upload destination or do not operate any file that is not specified. Otherwise, this unit may not start up.

1-20

BVM-L230

1-7. Procedure for Replacing the B Board/LMD2 Board

When replacing the B board or LMD2 board of this unit (replacing only the board), it is required to

update the adjustment data file. Obtain the adjustment data of the replaced unit and update the data.

1-7-1. Preparation

Procedure for obtaining data

Regarding each adjustment data of the B board and LMD2 board, contact your local Sony Sales Office/

Service Center for the following information.

1. When the LCD unit is not replaced

. Serial number of this unit

. Chassis number

2. When the LCD unit is replaced with the LCD unit (for service).

. Serial number of this unit

. Serial number of the LCD unit (for service)

Chassis number attaching position

February 2008

BVM-L230/2 SYQ

Ichinomiya, Japan

NO. XXXXXXX

m

. When replacing the B board in the state that the LCD unit is already replaced, use the adjustment data

in CD-R supplied with the LCD unit (for service). (Refer to Section 1-6.)

. When replacing the LMD2 board in the state that the LCD unit is already replaced, obtain the adjust-

ment data because the adjustment data (*.eep) is not stored in CD-R supplied with the LCD unit (for

service).

BVM-L230

1-21

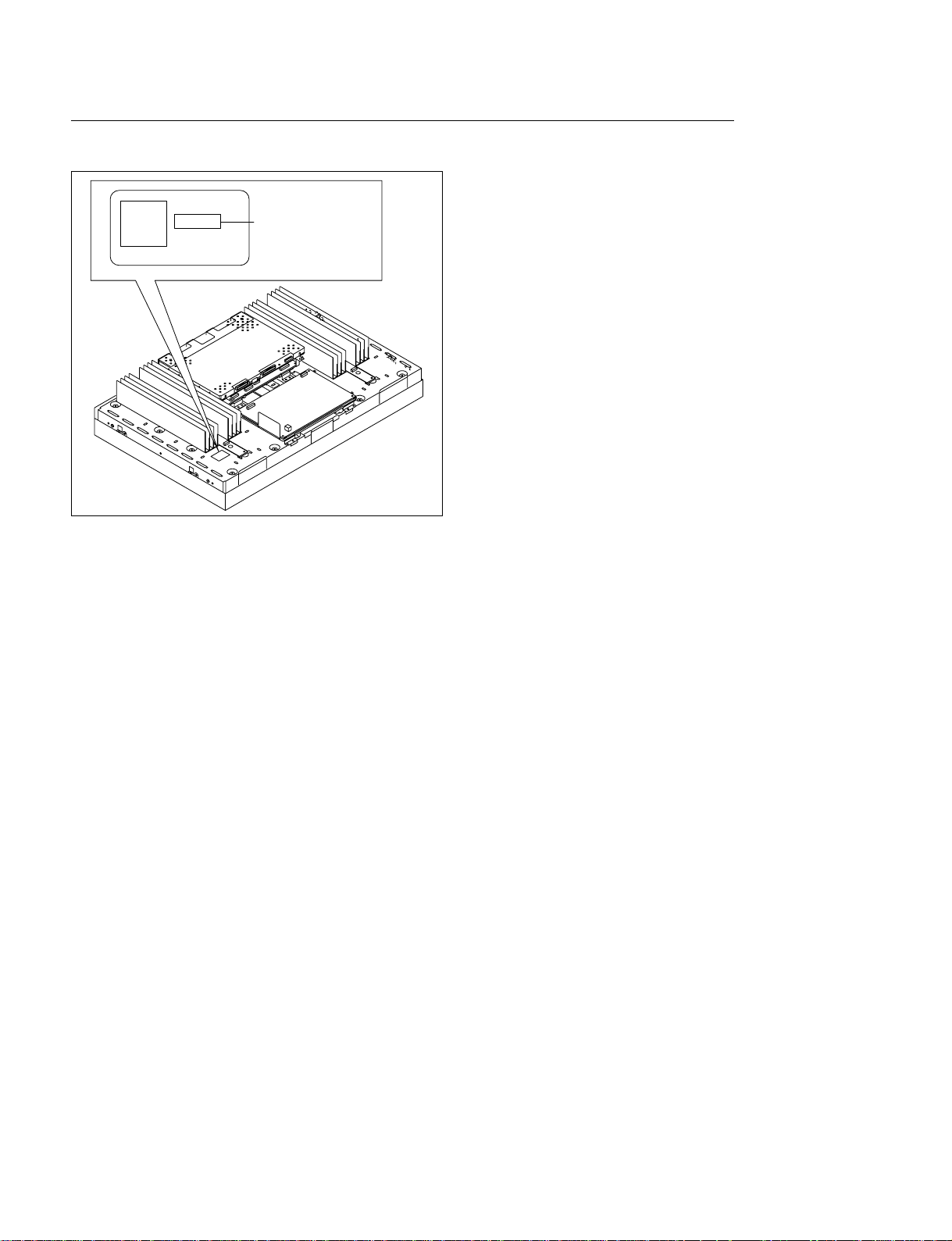

LCD unit (for service) serial number attaching position

15082002

2000548

A1337321A

MADE IN JAPAN

LCD unit serial

number

n

The LCD unit (for service) serial number is used as the folder name of CD-R.

(Refer to “CD-R Directory” in Section 1-6.)

1-22

BVM-L230

Adjustment data required when replacing the B board

. correct_gamma_96.cms

. correct_gamma_100_blackins.cms

. correct_gamma_100_interlace.cms

. correct_gamma_100.cms

. correct_gamma_120_blackins.cms

. correct_gamma_120_interlace.cms

. correct_gamma_120.cms

. uniformity.dat

. gamma_temp_120.dat (*1)

. gamma_temp_120_blackins.dat (*1)

. gamma_temp_120_interlace.dat (*1)

. gamma_temp_100.dat (*1)

. gamma_temp_100_blackins.dat (*1)

. gamma_temp_100_interlace.dat (*1)

. gamma_temp_96.dat (*1)

. gamma_temp_coef_120.dat (*1)

. gamma_temp_coef_120_blackins.dat (*1)

. gamma_temp_coef_120_interlace.dat (*1)

. gamma_temp_coef_100.dat (*1)

. gamma_temp_coef_100_blackins.dat (*1)

. gamma_temp_coef_100_interlace.dat (*1)

. gamma_temp_coef_96.dat (*1)

. correct_panel_primarycolors_bvm_smptec.dat (*1)

. correct_panel_primarycolors_bvm_ebu.dat (*1)

. correct_panel_primarycolors_itu709.dat (*1)

. correct_panel_primarycolors_wide.dat (*1)

(*1): Files added from Ver. 1.2

Adjustment data required when replacing the LMD2 board (1 file)

.*.eep (File name varies per data.)

As for the above files added from Ver. 1.2 (18 files), the units having the serial number 2000009 to

2000789 do not have the backup data. Also, these files may not be included in CD-R supplied with the

LCD unit (for service). If the unit or the LCD unit (for service) does not have the files added from the

software version Ver. 1.2, it is not required to update the files (18 files). Use the files that are automatically added when upgrading the software to Ver. 1.2.

BVM-L230

1-23

Required equipment

. Personal computer (PC)

(equipped with USB port and LAN port)

When replacing the B board

. LAN cable (cross)

When replacing the LMD2 board

. RS-232C, D-Sub 9 pin straight cable (female-female)

. USB 5 RS-232C conversion adaptor

n

This is not required if PC has the RS-232C terminal.

Application/Tool

Name Cpoyright Reference information

FFFTP (Freeware) Sota Japanese → http://www2.biglobe.ne.jp/~sota/ffftp.html

English → http://www2.biglobe.ne.jp/~sota/ffftp-e.html

BVM-BLM Writer Sony INY Included in “BVML_replace_board.zip”.

Ver.1.00 (Refer to “internalmemo.text”.)

Memo Microsoft Text editor (supplied with Windows)

notepad.exe

HyperTerminal Microsoft Communication software of Windows

(supplied with Windows)

Data update procedure

B board (For details, refer to Section 1-7-2.)

1. Preparation of serial number file

2. Data update

3. Serial number check

LMD2 board (For details, refer to Section 1-7-3.)

1. Preparation (connection)

2. Data update

3. Data update (only S/N 2000009 to 2000126)

1-24

BVM-L230

Loading...

Loading...