Page 1

DIGITAL VIDEOCASSETTE RECORDER

DVW-A500/1

DVW-500/1

DVW-A500P/1

DVW-500P/1

CONTROL PANEL

BKDW-515

INSTALLATION AND MAINTENANCE MANUAL

1st Edition (Revised 3)

Page 2

! W ARNING

This manual is intended for qualified service personnel only.

To reduce the risk of electric shock, fire or injury, do not perform any servicing other than that

contained in the operating instructions unless you are qualified to do so. Refer all servicing to

qualified service personnel.

! W ARNUNG

Die Anleitung ist nur für qualifiziertes Fachpersonal bestimmt.

Alle Wartungsarbeiten dürfen nur von qualifiziertem Fachpersonal ausgeführt werden. Um die

Gefahr eines elektrischen Schlages, Feuergefahr und Verletzungen zu vermeiden, sind bei

Wartungsarbeiten strikt die Angaben in der Anleitung zu befolgen. Andere als die angegeben

Wartungsarbeiten dürfen nur von Personen ausgeführt werden, die eine spezielle Befähigung

dazu besitzen.

! AVERTISSEMENT

Ce manual est destiné uniquement aux personnes compétentes en charge de l’entretien. Afin

de réduire les risques de décharge électrique, d’incendie ou de blessure n’effectuer que les

réparations indiquées dans le mode d’emploi à moins d’être qualifié pour en effectuer d’autres.

Pour toute réparation faire appel à une personne compétente uniquement.

DVW-A500/1 Serial No. 50001 and Higher

DVW-500/1 Serial No. 50001 and Higher

DVW-A500P/1 Serial No. 50001 and Higher

DVW-500P/1 Serial No. 50001 and Higher

BKDW-515 Serial No. 10001 and Higher

BKDW-515

BKDW-515

Page 3

CAUTION

Danger of explosion if battery is incorrectly

replaced.

Voor de klanten in Nederland

Dit apparaat bevat een (CF)n-Li batterij voor memory

back-up.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the

manufacturer's instructions.

Vorsicht!

Explosionsgefahr bei unsachgemäßem

Austausch der Batterie.

Ersatz nur durch denselben oder einen vom

Hersteller empfohlenen ähnlichen Typ.

Entsorgung gebrauchter Batterien nach Angaben

des Herstellers.

ATTENTION

Il y a danger d'explosion s'il y a remplacement

incorrect de la batterie.

Remplacer uniquement avec une batterie du

même type ou d'un type équivalent recommandé

par le constructeur.

Mettre au rebut les batteries usagées

conformément aux instructions du fabricant.

Raadpleeg uw leverancier over de verwijdering van de

batterij op het moment dat u het apparaat bij einde

levensduur afdankt.

Gooi de batterij niet weg. maar lever hem in als KCA.

Bij dit produkt zijn batterijen geleverd.

Wanneer deze leeg zijn, moet u ze niet

weggooien maar inleveren als KCA.

ADVARSEL!

Lithiumbatteri-Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri

af samme fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

BKDW-515

Page 4

Page 5

Table of Contents

Manual Structure

Purpose of this manual .............................................................................................. 3

Contents ..................................................................................................................... 3

Relative manuals ....................................................................................................... 4

1. Installation

1-1. Installation of Control Panel .......................................................................1-1

1-2. SYS1, SYS2 ROM Versions.......................................................................1-2

1-3. Removal of Control Panel / Replacement of Arms.....................................1-2

1-4. Installation of Sub Panel Cover and Switch Cover .....................................1-3

1-5. Installation of Control Panel .......................................................................1-3

1-6. Installation Space ........................................................................................1-4

1-7. Full Reset of Control Panel .........................................................................1-5

1-8. Extension of Control Panel .........................................................................1-5

2. Service Information

2-1. Location and Function of Printed Circuit Boards .......................................2-1

2-2. Replacing the Battery for Memory Backup ................................................2-2

2-3. EL Panel Replacement ................................................................................ 2-3

2-4. Error Message .............................................................................................2-4

2-4-1. Operation when Checksum Error

of Current Setup Data Occurs ....................................................2-4

2-4-2. Correction when Checksum Error

of VTR Bank Data Occurs .........................................................2-4

2-4-3. Correction when Checksum Error

of Memory Card Data Occurs ....................................................2-4

3. Setup Menu

3-1. ITEM-F Series.............................................................................................3-1

BKDW-515

1

Page 6

4. Maintenance Menu

4-1. ROM Version ..............................................................................................4-1

4-2. VTR Maintenance Menu.............................................................................4-1

4-3. Panel Maintenance Menu ............................................................................4-2

4-3-1. Card Interface Test .....................................................................4-2

4-3-2. Buzzer Test................................................................................. 4-2

4-3-3. EL Panel Test .............................................................................4-3

4-3-4. Key Test .....................................................................................4-3

4-3-5. Dial Test ..................................................................................... 4-3

4-4. Error Logger................................................................................................4-4

5. Block Diagram

6. Spare Parts

6-1. Notes on Repair Parts..................................................................................6-1

6-2. Spare Parts List for VTR.............................................................................6-2

6-3. Packing Materials and Supplied Accessories List for VTR........................6-3

6-4. Spare Parts List for Control Panel...............................................................6-4

6-5 Packing Materials and Supplied Accessories List for BKDW-515 ............6-6

2

BKDW-515

Page 7

Purpose of this manual

Contents

Manual Structure

This Manual describes the installation instructions for the digital videocassette

recorder DVW-A500/1, 500/1, A500P/1, 500P/1 and the Control panel BKDW-515.

This manual contains the information necessary when supplying and installing the

unit, assuming use by system/service engineers.

The sections covered in the manual are summarized below to give you a general

under standing of the manual.

Section 1 Installation

Explains the installation of the control panel.

Section 2 Service Overview

Explains replacement of the memory backup battery and EL panel.

Section 3 Setup Menu

Explains Setup menu of ITEM-F series only. As for ITEM-H00 to ITEM-900 series,

refer to Operation Manual.

Section 4 Maintenance Menu

Explains VTR Maintenance Menu and PANEL Maintenance menu.

Section 5 Block Diagram

Describes the overall block diagram.

Section 6 Spare parts

Describes the exploded views for the this unit, mounted boards list, packing list, and

standard accessories list.

BKDW-515

3

Page 8

Relative manuals

Besides this “Installation and Maintenance Manual”, the following manuals are

available.

• Operation Manual (Supplied with the VTR or the BKDW-515)

This manual is necessary for application and operation of the VTR.

• Installation Manual (Supplied with the VTR)

This manual describes the items are required to install the VTR and its peripherals.

If the BKDW-514 control panel is used, refer to this manual.

• Maintenance Manual Part 1 (Supplied with the VTR)

This manual describes the periodic maintenance and servicing information

necessary for the principal block and board replacement.

• Maintenance Manual Part 2 (available on request)

These manuals describes detailed information necessary for general parts replacement and includes alignments, schematic diagrams, board layouts, detailed parts

list, etc.

Please contact the Sony service organization to obtain a copy of the manuals.

• Protocol Manual (available on request)

PROTOCOL OF REMOTE-1 (9Pin) CONNECTOR

This Manual describes the protocol information necessary for controlling the VTR

via RS-422A (9-pin serial remote).

4

BKDW-515

Page 9

Installation

CN580

Notches

Control panel

Screw

(B3x12)

Claws

Claws

Notches

n

The BKDW-515 cannot be installed in the BKDW-511

Control Panel Case.

for DVW-A500/1, DVW500/1,

DVW-A500P/1, DVW-500P/1

Section 1

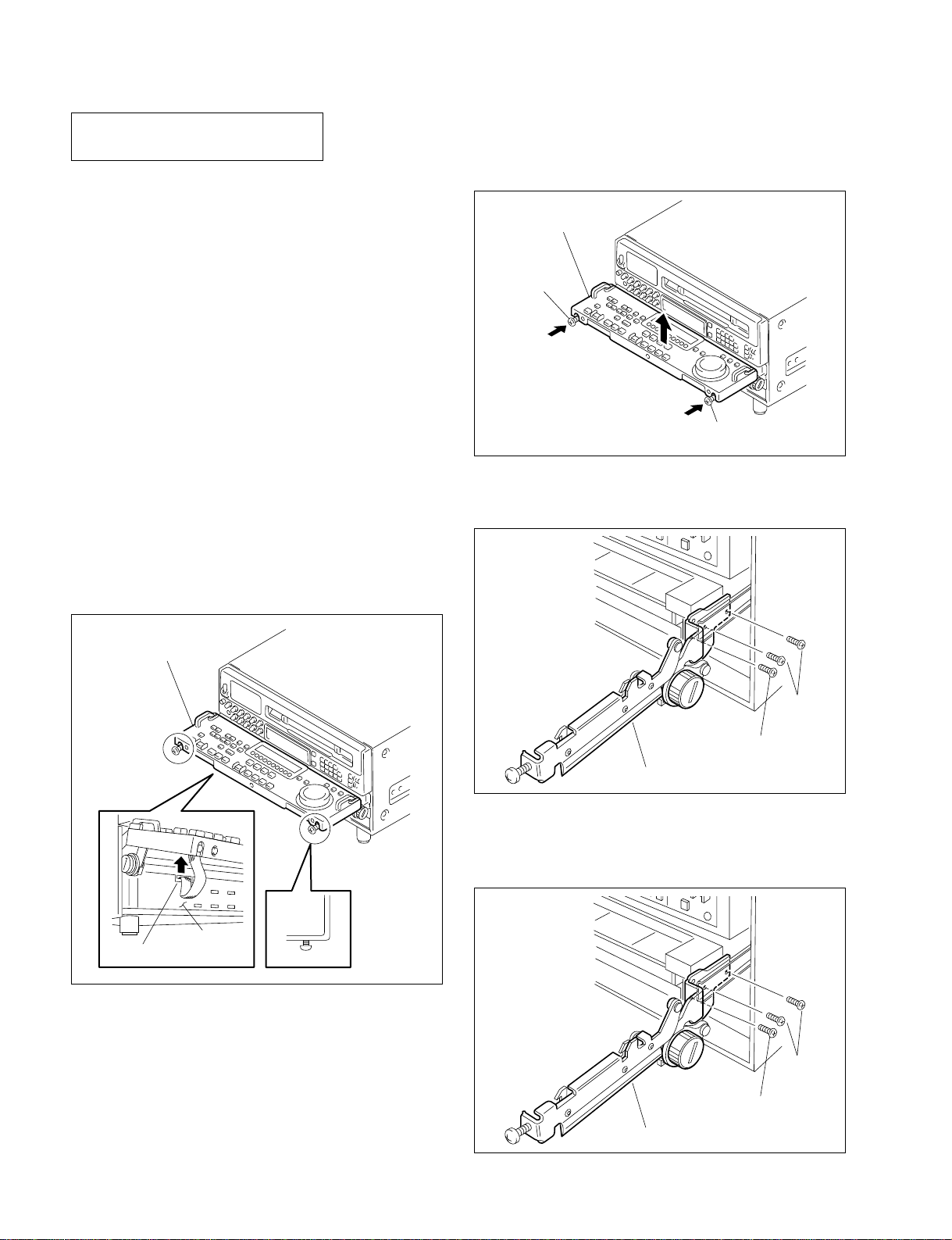

1-1. Installation of Control Panel

1. Fix a dummy panel for shipping use at 90 degrees.

2. Loosen the two black screws on the dummy panel.

(Loosen the screws until screw’s top are exposed from

the surface of the dummy panel.)

3. While pushing the loosened black screws in the

direction of the arrow, remove the dummy panel

assembly from the arms.

Dummy panel

Screw

(B3x12)

4. Fix the both arms at 45 degrees.

5. Connect the harness of the control panel to the connector (CN580) on the system set-up panel.

6. Set the notches of the control panel to the claws of the

arms, and push the control panel until making a click

sound.

n

Push the head of the two screws when the hook does

not move smoothly and when the panel is difficult to

attach. This facilitates the attaching.

7. Then tighten the two screws.

BKDW-515

Screw(B3x12)

1-1

Page 10

1-2. SYS1, SYS2 ROM Versions

1-3. Removal of Control Panel / Replacement of Arms

for DVW-A500, DVW500,

DVW-A500P, DVW-500P

1-2. SYS1, SYS2 ROM Versions

The control panel BKDW-515 is applicable to the ROMs

on the SS-52 board with the following version.

SYS1: 4.0 and higher

SYS2: 4.0 and higher

If the ROMs with lower version than above are used,

please contact Sony’s service organization.

Make sure the ROM’s version through the maintenance

mode before replacement of the control panel.

1-3. Removal of Control Panel /

Replacement of Arms

1. Fix a lower control panel at 90 degrees.

2. Disconnect the connector (CN580) in the system set-

up panel.

3. Loosen the two black screws on the lower control

panel. (Loosen the screws until screw’s top are

exposed from the surface of the lower control panel.)

4. While pushing the loosened black screws in the

direction of the arrow, remove the lower control panel

assembly from the arms.

Lower control panel

Screw(B3x12

)

Screw(B3x12

)

5. Remove the screws as shown in Figure, and remove

both side arms.

Lower control panel

System setup

CN580

panel.

Screw(B3

Screws

(B3x6)

Screw

(B3x6)

Arm

6. Install the arms supplied with BKDW-515.

SLIDER AD (R) ASSY: X-3678-375SLIDER AD (L) ASSY: X-3678-376-

x12)

Screws

(B3x6)

Screw

(B3x6)

Arm

1-2

BKDW-515

Page 11

1-4. Installation of Sub Panel Cover and Switch Cover

CN580

Notches

Control panel

Screw

(B3x12)

Claws

Claws

Notches

1-5. Installation of Control Panel

1-4. Installation of Sub Panel Cover and

Switch Cover

1. Install the sub panel cover supplied with BKDW-515

to sub control panel.

Screw

(BVTT3x6)

Sub panel cover

Screw

(BVTT3x6)

1-5. Installation of Control Panel

1. Fix the both arms at 45 degrees.

2. Connect the harness of the control panel to the connector (CN580) on the system set-up panel.

3. Set the notches of the control panel to the claws of the

arms, and push the control panel until making a click

sound.

n

Push the head of the two screws when the hook does

not move smoothly and when the panel is difficult to

attach. This facilitates the attaching.

4. Then tighten the two screws.

2. Install the switch cover supplied with BKDW-515 to

system set-up panel.

Screw

(BVTT3x6)

Switch cover

Screw

(BVTT3x6)

BKDW-515

1-3

Page 12

1-6. Installation Space

1-6. Installation Space

Notes on Installation on Cart Machine

. When the digital Betacam recorder is to be mounted on

the LMS, you can install not the control panel BKDW515 but the BKDW-514 to the recorder.

. When the digital Betacam recorder is to be mounted on

the FLEXICART, you can install both of BKDW-514/

515 to the recorder.

DVW-A500/1

500/1

A500P/1

500P/1

As for how to mount the unit in a rack, refer to the Installation Manual supplied with the DVW series.

553

427

434

BKDW-515

364

427

377.4 23.3

177.680.4

424

31.5

118.5

166.5

112.5

11.5

22

45.5

51.7

26.5

33

9.6

16.3

46.2

457.5

568.5

93.4

18.3

218

19

1-4

BKDW-515

Page 13

1-7. Full Reset of Control Panel

1-8. Extension of Control Panel

1-7. Full Reset of Control Panel

After installing the control panel in DVW-A500 and

DVW-500 (DVW-A500P and DVW-500P for PAL),

perform the full-reset operation of the control panel only

once before it is used.

m

. When the full-reset operation of the control panel is

performed, all settings of the current setup data and VTR

bank (1-8) stored on the control panel are reset to the

factory-setting value. The registration data in a PF1/2

menu is then reset to the key layout at the factory

corresponding to the VTR in which the control panel

was installed. Cue point data is also cleared.

. During installation of the control panel, the set value of

the current setup data and VTR bank can also be delivered directly. In this case, do not perform the full-reset

operation. However, if the function and option of the

VTR in which the control panel was installed differ

before and after installation, the key in a PF1/2 menu

that does not function by the VTR after installation is

deleted automatically. For the key in a PF1/2 menu that

has been deleted because it does not function by the

VTR before installation, assign it manually by the VTR

after installation as required.

1. Turn off the power switch.

2. Turn on the power switch while pressing and holding

the [SFT], [RCL], and [SETUP] keys on the control

panel. Maintain the state in which these keys were

pressed.

3. Release the three keys after confirming that message

“CONTROL PANEL FULL RESET” is displayed on

the EL panel.

1-8. Extension of Control Panel

To extend the BKDW-515, prepare the following BKDW510 (Control Panel Extension Kit), AC adapter and the

connector box.

Parts Required

. 10m Extension Cable (BKDW-510)

. AC Adapter

Sony Part No.: 1-473-822-11

. Connector Box

Sony Part No.: A-8277-618-A

n

The control panel BKDW-515 can not be installed to the

control panel case BKDW-511 (sold separately).

Connection

. AC100V and AC200V acceptable for AC adapter

. There is power switch on the connector box.

1. Connect the connector of the BKDW-515 to connector

of the connector box.

2. Connect the connector of an AC adapter to connector

CN3 of the connector box.

AC100/200V

AC Adaptor

DC9V 10m Cable

CN4

CN3

Power

switch

BKDW-515

to DVW-500/1

Rear panel

Connector box

BKDW-515

1-5

Page 14

1-8. Extension of Control Panel

Notes when connecting the two BKDW-515

. Setup Setting Data

The Current Setup setting data inside of the BKDW-515

is transferred to the VTR just after the communication

between the BKDW-515 and VTR are established. The

ALARM LED on the front panel blinks during the data

communication is incomplete.

When the two BKDW-515 are connected to a single

VTR, last setting data out of two is written over the

former data as the effective setting data.

If the two BKDW-515 with different data setting are

connected to a single VTR, and if the power is turned to

ON simultaneously, un-defined setting data will be sent

to the VTR. Therefore, first, connect either BKDW-515

to a single VTR for storing the Current Setup setting data

in bank memory of VTR or in the memory card beforehand. After that, connect the two BKDW-515 to a single

VTR, turn on the power of both BKDW-515, then copy

the memorized data into Current Setup. The Current

Setup setting data among the two BKDW-515 and VTR

will be automatically renewed to keep the contents of

data identical.

. VTR Control

Control of VTR is set by an INT/EXT selection of the

System Setup Panel and ITEM 117 “CONTROL PANEL SELECTION” of the setup menu.

Notes when connection the BKDW-514 and

BKDW-515 (Extender)

When connecting the BKDW-514 and BKDW-515

(Extender) to VTR, be sure to turn on the power of

BKDW-515 first. If the power of BKDW-515 is in off,

start up a menu system (SETUP MENU BANK 1/2/3/4:

BANK 4 is effective from SYS-V3.01 and later) of DVW500 series, therefore the contents set with BKDW-515 can

not be used. If MENU lamps 1, 2, and 3 on the indicator

section of VTR’s upper control panel are off, the contents

set with BKDW-515 can be used.

Pay attention when pressing the MENU button without

pressing the SET button after renewing the Setup setting

data with BKDW-514, because renewed data will be

validated if both BKDW-514 and BKDW-515 have been

connected regardless of SET button. However, renewed

data will be invalidated if the only BKDW-514 has been

connected.

1-6

BKDW-515

Page 15

Section 2

Service Information

2-1. Location and Function of Printed Circuit Boards

Board Name Circuit Function

CP-266 Panel Control CPU, EL Control, PIO, Memory Card I/F

KY-330 Editing Operation/Tape Transport Control Switches, Memory Card Connector

SW-749 Function Control Switches

PTC-69 JOG/Shuttle Dial Sensor

SW-749

KY-330

CP-266

PTC-69

BKDW-515

2-1

Page 16

2-2. Replacing the Battery for Memory Backup

2-2. Replacing the Battery for Memory Backup

BT1 inserted into a socket in IC113 (memory for storing

setup data and cue data) on the CP-266 board is a battery

for memory backup.

m

. Replace a battery for memory backup every seven years.

. Store all the setup data (cue data if necessary) in a

memory card before replacing the Battery for memory

backup. (For more details on storage, refer to the Operation Manual.)

1. Turn off the power switch.

2. Disconnect the connector CN580 on the system setup

panel and remove the control panel.

3. Remove the four screws, then remove the cover.

Screws

(BVTT3x6)

Cover

Screw

(BVTT3x6)

Screw

(BVTT3x6)

4. Insert the tip of a flatbladed screwdriver between

IC113 and BT1 to remove BT1.

Mark

BT1

Mark

IC113

CP-266

Flatbladed screwdriver

5. Align a new battery for memory backup with the 1-pin

mark of IC113, then insert.

6. Assemble the control panel and install it in the unit.

7. Access the data in a memory card.

. BT1 : 1-767-156-11 M4T28-BR12SH1 (lithium battery)

2-2

IC113

BKDW-515

Page 17

2-3. EL Panel Replacement

2-3. EL Panel Replacement

1. Turn off the power switch.

2. Disconnect CN580 on the system setup panel and

remove the control panel.

3. Remove the four screws, then remove the cover.

4. Remove the seven screws and disconnect connector

CN1 on the SW-749 board with the frame lifted from

the key panel sub-ass’y.

Screws(BVTT3x6)

Cover

Screw

(BVTT3x6)

Screw

(BVTT3x6)

5. Disconnect connector CN7 on the CP-266 board and

remove the four screws, then remove the EL panel.

Screws

CN7

(PSW3x10)

CP266

EL panel

Screws

(PSW3x10)

Screws

(BVTT3x6)

CN1

Screw

(BVTT3x6)

6. Confirm that no dust adheres on the panel and install

in the reverse order of steps 1 to 5.

SW-749

Screws

(BVTT3x6)

BKDW-515

2-3

Page 18

2-4. Error Message

2-4. Error Message

2-4-1. Operation when Checksum Error of

Current Setup Data Occurs

If the power switch is turned on when the current setup

data on the control panel was destroyed for some trouble,

message “CURRENT setup DATA ERROR” is displayed

on the EL panel. The current setup data is automatically

reset to the factory-setting value at the same time.

2-4-2. Correction when Checksum Error of

VTR Bank Data Occurs

If the power switch is turned on when the VTR bank data

on the control panel was destroyed for some trouble,

message “VTR bank CHECKSUM ERROR” is displayed

on the EL panel. Confirm the type of the bank data to have

been destroyed in a VTR BANK menu or MEMORY

CARD menu and copy normal bank data. The title of the

destroyed bank data is displayed as “DAMAGED.”

2-4-3. Correction when Checksum Error of

Memory Card Data Occurs

If the memory card is inserted into the slot on the control

panel when the data of a memory card was destroyed for

some trouble, message “Data DAMAGED” is displayed on

the EL panel. Confirm the destroyed bank data or cue set

data and copy normal data. The title of the destroyed data

is displayed as “DAMAGED” (for only WRITE PROTECT OFF in a memory card).

2-4

BKDW-515

Page 19

Section 3

Setup Menu

This section describes the menu ITEM-F series used during adjustment. For the operation and ITEM-H00

to ITEM-900 series, refer to the Operation Manual.

3-1. ITEM-F Series

Display the ITEM-F series according to the procedure below.

1. Press the SETUP key to enter the setup menu.

2. Press the F6 (VTR SETUP) key to enter the VTR SETUP menu.

3. Press the cursor key while pressing the PLAY button.

Item selection

Press the cursor key while pressing the PLAY button and adjust the cursor on the scroll screen to the

arbitrary item.

Data change

Press the F7 (CHANGE DATA) key to open the set change screen and select the data.

Data setting

Press the F10 (SAVE/EXIT) key.

n

These ITEM-F series are exclusively used for adjustment. After adjustment is completed, return data to

the factory setting.

ITEM DATA Description

No. ITEM No. DATA

F01 AUDIO NR IN 0 on This item is prepared exclusively for audio adjustment. After adjustment is

SP MODE 1 switch select completed, return to the factory setting ‘0 (on)’.

F02 EMERGENCY 0 enable This item is prepared exclusively for servo and mechanical adjustments. After

TAPE 1 disable adjustment is completed, return to the factory setting ‘0 (enable)’.

PROTECTION Select whether the emergency tape protection operation is enabled or not when

F07 CONFI SELECT 0 disable Selects the playback by the confidence head enable or disable in the normal PB

IN PB MODE 1 enable mode of the digital mode.

Select the type of control to turn Dolby noise reduction ON in the metal tape

playback.

0: Dolby NR is normally ON when mental tape is used.

1: Dolby NR is switched ON and OFF depending upon the DOLBY NR switch

setting on the sub control panel.

(NOTE)

When oxide tape is used, it is controlled depending upon the DOLBY NR switch

setting on the sub control panel, regardless of the setting of this menu item.

VTR detects error in tape transport mechanism.

0: Tape protection operation is enabled.

1: Tape protection operation is disabled.

0: Disables the playback by the confidence head in the normal PB mode.

1: Enables the playback by the confidence head when the CONFI mode is

entered (the CONFI lamp on the lower control panel lights) in the normal PB

mode.

BKDW-515

3-1

Page 20

3-1. ITEM-F Series

ITEM DATA Description

No. ITEM No. DATA

F13 TRACKING 0 off Select whether the tracking control operation with search dial is enabled or not

CONTROL VIA 1 on during DT head playback.

SEARCH DIAL This item is prepared exclusively for DT adjustment and tracking adjustments.

After adjustment is completed, return to the factory setting ‘0 (off)’.

0: Tracking control function is disabled during DT head playback.

1: Tracking control function is enabled by rotating the search dial during PLAY

mode.

F15 ANALOG TAPE 0 disable Enables LTC to be inserted in an analog tape (Betacam SP)

LTC INSERT 1 enable 0: Inhibits insertion of LTC in an analog tape (factory setting)

1: Enables LTC to be inserted in an analog tape

Note:

When set to “enable”, TC insert operation is executed even though the REC inhibit

tab of an analog tape used is set to REC INHIBIT.

F16 DEVICE TYPE 0000 0 Determines the response data for the 9 pin remote command

MODIFY:0H 0001 1 DEVICE TYPE REQUEST (00h, 11h).

| | 0000: Returns the original device type data of the DVW.

FFFF FFFF Except 0000: Returns the values numeric as it is.

The higher-order two digits are DATA-1.

The lower-order two digits are DATA-2.

Note:

The whole operations of the VTR including TTP is not influenced at all even if this

item is set to “0000” or “except 0000”.

For except DATA: 0000 (factory setting), the control from 9 pin is not guaranteed.

3-2

BKDW-515

Page 21

3-1. ITEM-F Series

ITEM DATA Description

No. ITEM No. DATA

F20 CONFI LED 0 switch The condition to light CONFI LED on the control panel is selected.

STATUS 1 status 0: CONFI LED lights on when CONFI switch is set to ON.

1: CONFI LED lights on when playing back with CONFI head. Note that CONFI

. CP ROM LED indicates the switch status only during the CONFI switch is pressed.

version 1.10

and higher

F21 PROCESS 0 off In case that LOCAL DISABLE command is effective via the 9pin REMOTE, or “all

CONT VR 1 on disable” is selected in Setup 006: LOCAL FUNCTION ENABLE, the availability of

LOCAL PROCESS CONT VR on the subcontrol panel is selected.

ENABLE 0: Process control is invalid.

1: Process control is active.

. CP ROM

version 1.10

and higher

F22 AUDIO ONLY 0 off The unit directly goes into digital audio edit mode from playback mode by AUDIO

REC 1 momentary EDIT PRESET key.

2 toggle 0: Does not go into Edit mode by AUDIO EDIT PRESET key.

1: Audio editing is available while AUDIO EDIT PRESET key is pressed.

. CP ROM 2: Audio editing is available when AUDIO EDIT PRESET key is pressed once.

version 1.10 When pressing once more, it returns to PLAY mode.

and higher

F23 A/V INPUT 0 off Audio/Video Input Select switch can be invalid during REC mode.

SELECT 1 on 0: Audio/Video Input Select switch is active in REC mode.

INHIBIT 1: Audio/Video Input Select switch is invalid in REC mode.

If Item-21 is set to ON, Audio/Video Input Select switch is active even if “1” (on) is

. CP ROM selected in this menu.

version 1.10

and higher

F24 MAXIMUM 0 x50 Maximum speed of digital tape is limited in search mode.

(PAL) DIGITAL TAPE 1 x42 0: 50 times speed in FF, REW, and SHUTTLE mode

SPEED 2 x42/x24 1: 42 times speed in FF, REW, and SHUTTLE mode

. CP ROM 3 x24 2: 42 times speed in FF and REW mode, and 24 times speed in SHUTTLE mode

version 1.10 3: 24 times speed in FF, REW, and SHUTTLE mode

and higher

F24 MAXIMUM 0 x50 Maximum speed of digital tape is limited in search mode.

(NTSC)DIGITAL TAPE 1 x35 0: 50 times speed in FF, REW, and SHUTTLE mode

SPEED 2 x35/x24 1: 35 times speed in FF, REW, and SHUTTLE mode

. CP ROM 3 x24 2: 35 times speed in FF and REW mode, and 24 times speed in SHUTTLE mode

version 1.10 3: 24 times speed in FF, REW, and SHUTTLE mode

and higher

F25 SERVO/AV REF 0 off Servo Reference in PREREAD mode is specified.

SEL IN PRE- 1 on 0: It works according to the setting of Item-309.

READ MODE 1: EXT REF VIDEO is selected.

. CP ROM

version 1.10

and higher

F26 DIGITAL AUDIO 0 off The condition for MUTE of Digital Audio when playing back in Search mode is

MUTE IN 1 on selected.

SEARCH MODE 0: It works according to the setting of Item-802.

. CP ROM 1: Mute is applicable in the modes except PLAY and EE.

version 1.10

and higher

BKDW-515

3-3

Page 22

Page 23

Section 4

Maintenance Menu

The self-diagnosis and adjustment of the VTR and control

panel can be performed in this maintenance menu.

To enter the maintenance mode

Press the MAINTENANCE button while pressing the SFT

key.

To terminate the maintenance mode

Press the HOME key.

The following descriptions are key operations in the state

when the unit is put into the maintenance mode.

4-1. ROM Version

The versions of all ROMs are displayed. Available options

are displayed.

To display the version of ROMs

Press the F1 (ROM VER) key.

For more details of the ROM version display, refer to Part 1,

“Maintenance Mode” of the DVW-A500 Series Maintenance Manual.

4-2. VTR Maintenance Menu

The self-diagnosis and adjustment of the VTR can be

performed in this VTR maintenance menu.

When starting the VTR maintenance menu directly from

the control panel, be sure to set the switch S100-7 on the

SS board to ON.

To enter the VTR maintenance menu

Press the F6 (VTR MAINT) key.

To terminate the VTR maintenance menu

Press the F10 (EXIT) key.

For more details of the VTR maintenance menu, refer to

Part 1, “Maintenance Mode” of the DVW-A500 Series

Maintenance Manual.

n

In Part 1, “Maintenance Mode” of the DVW-A500 Series

Maintenance Manual, change the following during use.

[SET button] 8 [F8 (SELECT) key]

[MENU button] 8 [F10 (EXIT) key]

n

In Part 1, “Maintenance Mode” of the DVW-A500 Series

Maintenance Manual, change the following during use.

[KY] 8 [CP]

BKDW-515

4-1

Page 24

4-3. Panel Maintenance Menu

4-3. Panel Maintenance Menu

The self-diagnosis of the control panel can be performed in

this panel maintenance menu.

To enter the panel maintenance menu

Press the F7 (PANEL MAINT) key.

To terminate the panel maintenance menu

Press the F10 (EXIT) key.

Key Display Description

F3 CARD I/F Memory card interface test

F5 BUZZER Buzzer test

F6 EL EL panel test

F7 KEY Rubber key, switch, and LED tests

F8 DIAL Dial test

F10 EXIT Returns to the maintenance menu.

4-3-1. Card Interface Test

A storage/access test for the memory card is executed.

n

Do not use the memory card in which necessary data is

stored. The data is erased.

A card can be extracted or inserted even if the power is

turned on.

1. Insert a memory card.

2. Press the F3 key.

A warning message is displayed at that time.

3. Press the F3 key while pressing the SFT key.

A storage/access test is then executed.

4. If the test is normal, message “CARD I/F test

PASSED.” is displayed. If message “CARD I/F test

FAILED.” is displayed, the card interface or card is

defective.

4-3-2. Buzzer Test

A buzzer test is executed. The setting changes to high, low,

then high every time the F5 key is pressed. The sound in

the displayed level is then generated.

4-2

BKDW-515

Page 25

4-3. Panel Maintenance Menu

4-3-3. EL Panel Test

An EL panel test is executed.

The screen displayed on the EL panel appears while the F6

key is pressed.

The displays changes every time the F6 key is pressed.

ALL ON : All light.

ALL OFF : All go off.

V BAR : Displays the test pattern in a vertical line.

H BAR : Displays the test pattern in a horizontal line.

4-3-4. Key Test

Rubber key, illumination switch, illumination switch LED,

and other LED tests are executed.

1. Press the F7 key to enter the menu.

2. Press each key sequentially according to the display on

the EL panel.

3. Confirm that the buzzer sounds when the key is

pressed.

Confirm that the switch lights and the buzzer sounds

when the illumination key is pressed.

4. Message “Key TEST passed.” is lastly displayed on

the EL panel. The test is completed at that time.

If abnormality occurs in the key during operation, no

sound is generated when the key was pressed. The test

can be executed no longer.

To terminate the test halfway, press the SHIFT and

CLR keys simultaneously.

4-3-5. Dial Test

Interface test between search dial and dial interface is

executed.

1. Press the F8 key to enter the menu.

2. Confirm the display on the EL panel as follows:

Dial data : The numeral changes when the dial is

turned. “2Ah” is displayed when the

dial is fully turned to right and left.

“0h” is displayed when the dial is in

the center position.

Dial direction : The arrow changes when the dial is

turned. “8” is displayed when the

dial is on the right of the center click

position. “7” is displayed when the

dial is on the left of the center click

position.

JOG/SHUTTLE

sensor : JOG is displayed when the dial is

pressed. SHUTTLE is displayed

when the dial is released.

Dial mode

sensor : Fix the panel to the 90-degree

position, loosen the screw shown in

the figure at the back of the dial, and

move the mode selection plate. The

current display then changes to

BETACAM/D-2.

BKDW-515

Lower control panel

A portion

Search dial

Mode selection plate

B3x14

4-3

Page 26

4-4. Error Logger

4-4. Error Logger

After the power switch is turned on, the error logger

function always monitors the unit to detect the errors.

When any one of the conditions mentioned as follows, the

corresponding message and time code are stored.

This menu can be read and checked the contents of these

data items in list form.

. CH COND RED (Channel Condition Red)

When the red CANNEL CONDITION lamp on the

upper control panel lights

. REF ALARM (Reference Alarm)

When a reference signal is missing (no signal is input to

the INPUT REF VIDEO connector) or a REF video

input signal is not synchronized with the input video

signal

. TAPE EJECT

When the cassette tape is ejected

(If no error is occurred from when the cassette tape was

ejected last time until it is ejected this time, the preceding time code is overwritten by this time code.)

. ERROR-xx

When a trouble is detected

(The corresponding error code is recorded.)

To enter the error logger menu

Press the F9 (ERROR LOG) key.

To terminate the error logger menu

Press the F10 (EXIT) key.

Error Logger Screen

The error logger data is superimposed on the monitor

screen (output to the VIDEO OUTPUT COMPOSITE 3

connector or SERIAL V/A OUTPUT 4 connector).

A maximum of 99 error data items can be stored. To

display the error data items that are not displayed on the

screen, turn the search dial to scroll them. When 99 data

items are exceeded, the old data is erased and the data

sequence is advanced.

Tape Operation during Error Logger Screen

Display

1. The state of the error logger screen displayed, press F9

(VTR HOLD) key to VTR HOLD OFF.

2. At this time, to display a block sign on the monitor

screen. This enables the tape operation.

3. To erase the block sign, press the F9 (VTR HOLD)

key and turn on the VTR HOLD.

4-4

Error Logger Data Erasure

To erase the error logger data, press the F5 (CLEAR LOG)

key in the error logger screen display.

BKDW-515

Page 27

BKDW-515 OVERALL

SH7032

CPU

FLASH ROM

4Mbit

SRAM

1Mbit X4

SRAM

64Kbit

+8V

LED,DIAL

+12V

+5V

PIO

MEMORY

CARD

I / F

PIO

PIO

SOLENOID

DRIVER

DIAL DATA

DECODER

JOG

DIAL

RS-422

+8V IN

TACTILE SW x 16

( 6 x 3 SCAN )

LED x 23

KY-330

MEMORY

CARD

64KBytes

CP-266

LJ32H028

EL DISPLAY

320 x 240dot

KEY SW x 44

( 6 x 8 SCAN )

LED x 1

SW-749

For FACTORY USE

16MHz

POWER ON

RESET

RESET SW

S101

x 8

32MHz

+5V

+12V

KEY ADDRESS

32MHz

X1/2

RS-232C

CN6

CN7 CN3 CN4

CN2

CN1

IC103

IC104

IC114

IC109,110

111,112

IC113

IC105

IC102

CN5

IC116

BATTERY

IC1

IC2

IC3

DC-DC

CONVERTER

DC-DC

CONVERTER

POWER ON

RESET

DRAM

4Mbit

IC208

VIDEO RAM

CONTROLLER

IC207

ADVANCED

CRT

CONTROLLER

IC206 IC201-205,220 IC209 IC210 IC211

EL

I/F

PTC-69

JOG DIAL

SENSORS

IC1-5

IC213 IC212

CPU BUS

CPU BUS

32MHz

X1

Buzzer

BZ1

IC115

SWC-19

CN580

CN1

CN2

CN3

CN1

Overall

OVERALL

Section 5

Block Diagram

BKDW-515

OVERALL

BKDW-515

5-1

Page 28

Page 29

6-1. Notes on Repair Parts

1. Safety Related Components Warning

Components marked ! are critical to safe operation.

Therefore, specified parts should be used in the case of

replacement.

2. Standardization of Parts

Some repair parts supplied by Sony differ from those

used for the unit. These are because of parts commonality and improvement.

Parts list has the present standardized repair parts.

3. Stock of Parts

Parts marked with “o” at SP(Supply Code) column of

the spare parts list may be not stocked. Therefore, the

delivery date will be delayed.

Section 6

Spare Parts

4. Parts exclusive to the DVW-A500/1, 500/1,

A500P/1 and 500P/1 are listed in this section.

Refer to the maintenance manual for some

parts that are not listed.

BKDW-515

6-1

Page 30

DVW-A500/1, 500/1, A500P/1, 500P/1

6-2. Spare Parts List for VTR

BVTT3 x 6

B3 x 6

3

B3 x 6

BVTT3 x 6

BVTT3 x 6

1

BVTT3 x 6

4

5

B3 x 6

B3 x 6

2

Ref. No.

or Q’ty Part No. SP Description

1 A-8278-252-A o PANEL ASSY, DUMMY

2 X-3678-375-3 s SLIDER AD(R)ASSY

3 X-3678-376-3 s SLIDER AD(L)ASSY

4 3-689-875-01 o COVER,SWC

5 3-689-879-02 o COVER,SUB PANEL

6-2

BKDW-515

Page 31

DVW-A500/1, 500/1, A500P/1, 500P/1

6-3. Packing Materials and Supplied Accessories List for VTR

For DVW-A500/1, 500/1 (UC)

Ref. No.

or Q’ty Part No. SP Description

1pc ! 1-551-812-11 s CORD, POWER 3P

1pc 1-772-749-11 s CARD, MEMORY (SRAM 64K)

1pc 2-990-242-01 o HOLDER (B), PLUG

1pc 3-181-533-02 o CUSHION (LOWER)

1pc 3-181-534-02 o CUSHION (UPPER)

1pc 3-181-535-01 o SPACER (A)

1pc 3-181-536-01 o SPACER (B)

2pcs 3-189-078-01 o CUSHION

1pc 3-189-456-01 o PLATE, TOP

1pc 3-189-457-01 o SPACER (C)

1pc 3-189-458-01 o INDIVIDUAL CARTON (for DVW-A500/1)

3-189-459-01 o INDIVIDUAL CARTON (for DVW-500/1)

1pc 3-701-634-00 o BAG, POLYETHYLENE

(for S/N 50001 thru. 50390:DVW-A500/1(UC))

(for S/N 50001 thru. 50080:DVW-500/1(UC))

4pcs 7-682-965-01 s SCREW +PSW 4x16

For DVW-A500P/1, 500P/1 (UC)

Ref. No.

or Q’ty Part No. SP Description

1pc ! 1-551-812-11 s CORD, POWER 3P

1pc 1-772-749-11 s CARD, MEMORY (SRAM 64K)

1pc 2-990-242-01 o HOLDER (B), PLUG

1pc 3-181-533-02 o CUSHION (LOWER)

1pc 3-181-534-02 o CUSHION (UPPER)

1pc 3-181-535-01 o SPACER (A)

1pc 3-181-536-01 o SPACER (B)

2pcs 3-189-078-01 o CUSHION

1pc 3-189-456-01 o PLATE, TOP

1pc 3-189-457-01 o SPACER (C)

1pc 3-189-460-01 o INDIVIDUAL CARTON (for DVW-A500P/1)

3-189-461-01 o INDIVIDUAL CARTON (for DVW-500P/1)

1pc 3-701-634-00 o BAG, POLYETHYLENE

4pcs 7-682-965-01 s SCREW +PSW 4x16

For DVW-A500P/1, 500P/1 (CE)

Ref. No.

or Q’ty Part No. SP Description

1pc ! 1-782-929-11 s CORD, POWER SUPPLY (BS 3P)

1pc 1-759-164-11 s CARD, MEMORY (SRAM 64K BYTE)

1pc 3-613-640-01 o HOLDER (C), PLUG

1pc 3-181-533-02 o CUSHION (LOWER)

1pc 3-181-534-02 o CUSHION (UPPER)

1pc 3-181-535-01 o SPACER (A)

1pc 3-181-536-01 o SPACER (B)

2pcs 3-189-078-01 o CUSHION

1pc 3-189-456-01 o PLATE, TOP

1pc 3-189-457-01 o SPACER (C)

1pc 3-189-460-01 o INDIVIDUAL CARTON (for DVW-A500P/1)

3-189-461-01 o INDIVIDUAL CARTON (for DVW-500P/1)

1pc 3-701-634-00 o BAG, POLYETHYLENE

(for S/N 50001 thru. 50110:DVW-A500/1(CE))

(for S/N 50001 thru. 50080:DVW-500/1(CE))

4pcs 7-682-965-01 s SCREW +PSW 4x16

BKDW-515

6-3

Page 32

CONTROL PANEL

6-4. Spare Parts List for Control Panel

12

12

BVTT

3 x 6

10

11

*

1

BVTT

3 x 6

BVTT

3 x 6

W 2.5

SMALL

P2 x 8

BVTT

3 x 6

9

W 2.5 SMALL

P2 x 8

BVTT3 x 6

PSW3 x 10

24

*

3

14

13

N 2.6

1

2

*

2

PSW3 x 6

N 2.6

*

2

23

1

7

17

PTPWH

2.6 x 5

22

17

PTPWH

2.6 x 5

22

17

PTPWH

2.6 x 5

N 2.6

No. Part No. SP Description

1 A-8269-119-A o MOUNTED CIRCUIT BOARD, SW-749

2 A-8269-121-A o MOUNTED CIRCUIT BOARD, KY-330

3 A-8269-123-A o MOUNTED CIRCUIT BOARD, CP-266

5 1-810-665-12 s DISPLAY, EL

6 3-668-124-00 o HOLDER, LED

PSW3 x 10

*

3

*

4

PSW3 x 6

*

3

N 2.6

*

5

PS2.6 x 10

15

PS2.6 x 10

*

5

*

6

5

19

6

*

6

20

PSW3 x 6

18

18

PSW3 x 6

7 3-668-919-00 s ROLLER, GUIDE, SR

8 3-689-861-03 o LID,COVER

9 3-689-863-02 s KEY,TEN

21

10 3-689-864-03 s KEY,FUNCTION A

11 3-689-865-02 s KEY,FUNCTION B

12 3-689-866-01 o GUARD,REC

8

13 3-689-869-01 o PIN,HOLDING

14 3-689-870-02 s HOLDER

15 3-689-871-01 o HEAT SINK,TR

17 3-692-673-01 s WASHER

18 3-708-877-01 s CAP

19 3-708-895-01 s CAP

20 3-708-933-01 s CAP

21 4-886-821-11 s SCREW, S TIGHT, +PTTWH 3X6

22 4-921-411-01 o CUSHION

23 3-669-465-01 s WASHER(1.5), STOPPER

24 3-629-493-02 s SHEET, TEN KEY

6-4

*

4

BVTT3 x 6

21

21

*

6

BVTT3 x 6

BKDW-515

Page 33

PWH2.6 x 5

CONTROL PANEL

110

PWH2.6 x 5

109

BVTP3 x 8BVTP3 x 8

111

107

108

104

120

112

113

123

105

119

B3 x 14

E-4.0

122

BVTP3 x 8

115

121

123

117

116

106

114

102

118

103

BVTP3 x 8

101

No. Part No. SP Description

101 A-8267-410-D s DIAL ASSY, SEARCH

102 A-8276-585-A o MOUNTED CIRCUIT BOARD, PTC-69

103 1-454-606-11 s SOLENOID, PLUNGER

104 2-124-691-01 s ROLLER

105 2-124-693-02 s PLATE

106 2-124-695-01 o PLATE, CUSHION

107 2-143-603-01 o ARM, RETURN

108 2-143-613-01 s SPRING, TORSION

109 3-180-632-01 o KNOB, DIAL

110 3-180-633-03 s RUBBER, DIAL KNOB

111 3-180-638-01 o ARM, JOINT GEAR

112 3-180-639-01 o PLATE, MODE SELECTION

113 3-180-640-02 o GEAR, JOINT

114 3-180-648-01 o PROTECTOR, PTC

115 3-180-649-02 o LINK, SOLENOID

116 3-180-650-03 s FG-RING

117 3-180-651-04 o CAM, SD

118 3-180-859-01 o HOLDER, SENSOR

119 3-181-956-01 o SPRING, COMPRESSION

120 3-618-225-03 s NUT, PLATE

BKDW-515

121 3-645-189-11 s SPRING, TENSION

122 3-701-441-21 s WASHER, POLY 4mm DIA., 0.50T

123 3-701-443-21 s WASHER, POLY 5mm DIA., 0.50T

6-5

Page 34

BKDW-515

6-5. Packing Materials and Supplied Accessories List for BKDW-515

Ref. No.

or Q’ty Part No. SP Description

1pc X-3678-375-3 s SLIDER AD(R)ASSY

1pc X-3678-376-3 s SLIDER AD(L)ASSY

1pc 1-759-164-11 s CARD, MEMORY (SRAM 64K BYTE)

1pc 3-189-075-01 o SPACER (B)

1pc 3-189-076-01 o BOX, ACCESSORY

1pc 3-189-077-01 o SPACER (A)

2pcs 3-189-078-01 o CUSHION

1pc 3-189-079-01 o INDIVIDUAL CARTON

1pc 3-689-875-01 o COVER,SWC

1pc 3-701-616-01 o BAG, POLYETHYLENE

2pcs 3-701-629-01 o BAG, POLYETHYLENE

6pcs 7-682-547-09 s SCREW +B 3X6

4pcs 7-685-871-09 s SCREW +BVTT 3x6 (S)

6-6

BKDW-515

Page 35

The material contained in this manual consists of

information that is the property of Sony Corporation and

is intended solely for use by the purchasers of the

equipment described in this manual.

Sony Corporation expressly prohibits the duplication of

any portion of this manual or the use thereof for any

purpose other than the operation or maintenance of the

equipment described in this manual without the express

written permission of Sony Corporation.

Le matériel contenu dans ce manuel consiste en

informations qui sont la propriété de Sony Corporation et

sont destinées exclusivement à l’usage des acquéreurs

de l’équipement décrit dans ce manuel.

Sony Corporation interdit formellement la copie de

quelque partie que ce soit de ce manuel ou son emploi

pour tout autre but que des opérations ou entretiens de

l’équipement à moins d’une permission écrite de Sony

Corporation.

Das in dieser Anleitung enthaltene Material besteht aus

Informationen, die Eigentum der Sony Corporation sind,

und ausschließlich zum Gebrauch durch den Käufer der

in dieser Anleitung beschriebenen Ausrüstung bestimmt

sind.

Die Sony Corporation untersagt ausdrücklich die

Vervielfältigung jeglicher Teile dieser Anleitung oder den

Gebrauch derselben für irgendeinen anderen Zweck als

die Bedienung oder Wartung der in dieser Anleitung

beschriebenen Ausrüstung ohne ausdrückliche

schriftliche Erlaubnis der Sony Corporation.

BKDW-515

Page 36

DVW-A500/1 (UC)

DVW-500/1 (UC)

DVW-A500P/1 (CE)

DVW-500P/1 (CE)

BKDW-515 (WW) E

3-188-821-04 (2)

Printed in Japan

Sony Corporation 2003. 11 08

B&P Company ©1995

Loading...

Loading...