Sony Betacam SX DNW-A65, Betacam SX DNW-A65P Operation Manual

DIGITAL VIDEOCASSETTE PLAYER

DNW-A65/A65P

OPERATION MANUAL

1st Edition (Revised 5)

[English]

WARNING

To prevent fire or shock hazard, do not

expose the unit to rain or moisture.

To avoid electrical shock, do not open

the cabinet. Refer servicing to qualified

personnel only.

This apparatus must be earthed.

WARNING: THIS WARNING IS APPLICABLE FOR USA

ONLY.

If used in USA, use the UL LISTED power

cord specified below.

DO NOT USE ANY OTHER POWER CORD.

Plug Cap Parallel blade with ground pin

(NEMA 5-15P Configuration)

Cord Type SJT, three 16 or 18 AWG

wires

Length Less than 2.5 m (8 ft 3 in)

Rating Minimum 10 A, 125 V

Using this unit at a voltage other than 120V

may require the use of a different line cord or

attachment plug, or both. To reduce the risk

of fire or electric shock, refer servicing to

qualified service personnel.

For the customers in Europe

This product with the CE marking complies with both the

EMC Directive (89/336/EEC) and the Low Voltage Directive

(73/23/EEC) issued by the Commission of the European

Community.

Compliance with these directives implies conformity to the

following European standards:

EN60065: Product Safety

EN55103-1: Electromagnetic Interference (Emission)

EN55103-2: Electromagnetic Susceptibility (Immunity)

This product is intended for use in the following

Electromagnetic Environment (s):

E1 (Residential), E2 (Commercial and light industrial), E3

(Urban outdoors) and E4 (Controlled EMC environment

ex. TV studio)

Pour les clients européens

Ce produit portant la marque CE est conforme à la fois à la

Directive sur la compatibilité électromagnétique (EMC) (89/

336/CEE) et à la Directive sur les basses tensions (73/23/

CEE) émises par la Commission de la Communauté

européenne.

La conformité à ces directives implique la conformité aux

normes européennes suivantes:

• EN60065: Sécurité des produits

• EN55103-1: Interférences électromagnétiques (émission)

• EN55103-2: Sensibilité électromagnétique (immunité)

Ce produit est prévu pour être utilisé dans les

environnements électromagnétiques suivants:

E1 (résidentiel), E2 (commercial et industrie légère), E3

(urbain extérieur) et E4 (environnement EMC contrôlé ex.

studio de télévision).

This symbol is intended to alert the user to

the presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

For the customers in the USA

This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful

interference in which case the user will be required to

correct the interference at his own expense.

You are cautioned that any changes or modifications not

expressly approved in this manual could void your authority

to operate this equipment.

The shielded interface cable recommended in this manual

must be used with this equipment in order to comply with

the limits for a digital device pursuant to Subpart B of Part

15 of FCC Rules.

Für Kunden in Europa

Dieses Produkt besitzt die CE-Kennzeichnung und erfüllt

sowohl die EMV-Direktive (89/336/EEC) als auch die

Direktive Niederspannung (73/23/EEC) der EGKommission.

Die Erfüllung dieser Direktiven bedeutet Konformität für die

folgenden Europäischen Normen:

• EN60065: Produktsicherheit

• EN55103-1: Elektromagnetische Interferenz (Emission)

• EN55103-2: Elektromagnetische Empfindlichkeit

(Immunität)

Dieses Produkt ist für den Einsatz unter folgenden

elektromagnetischen Bedingungen ausgelegt:

E1 (Wohnbereich), E2 (kommerzieller und in beschränktem

Maße industrieller Bereich), E3 (Stadtbereich im Freien)

und E4 (kontrollierter EMV-Bereich, z.B. Fernsehstudio)

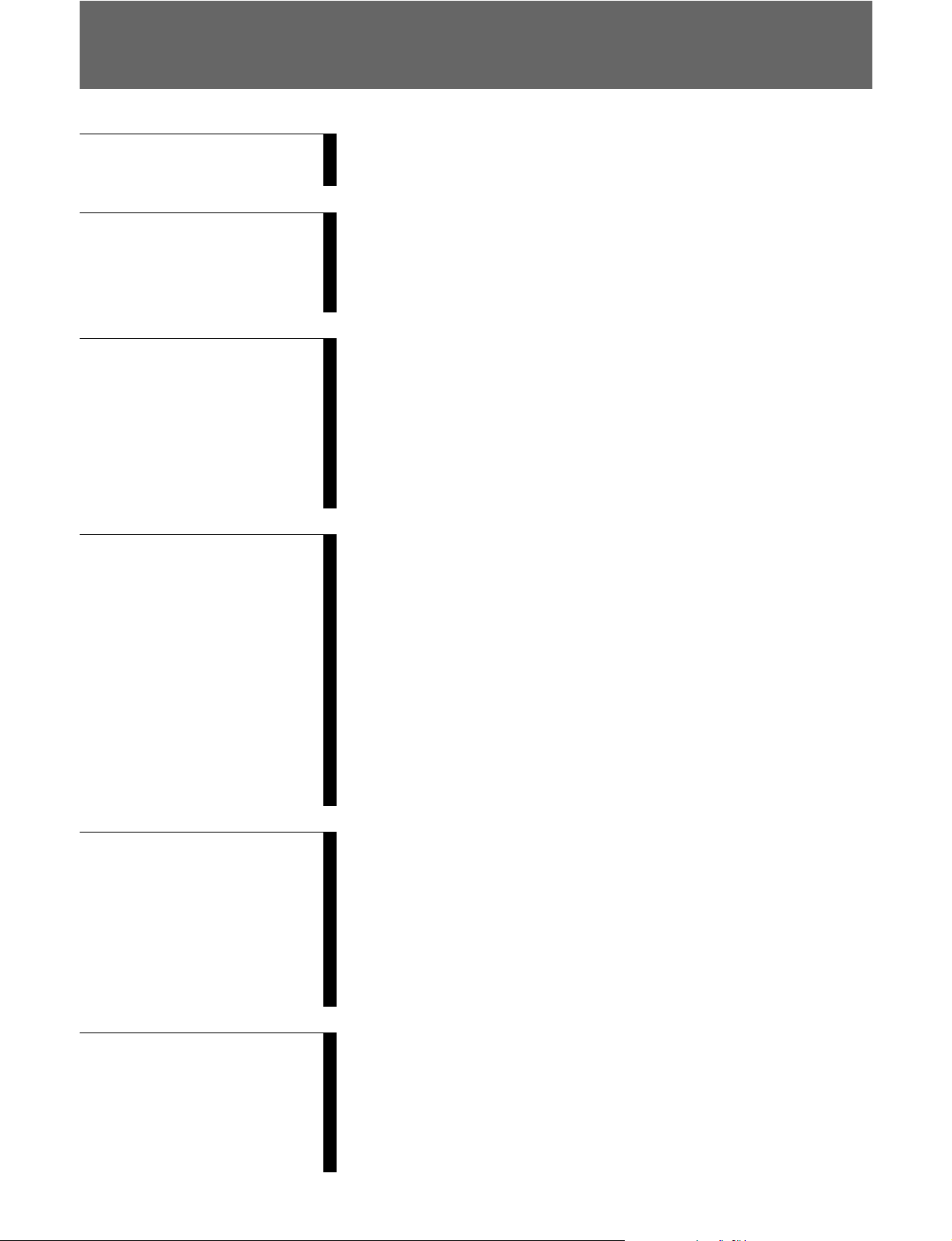

Table of Contents

Chapter 1

Overview

Chapter 2

Location and Function of

Parts

Chapter 3

Preparations

Chapter 4

Playback

1-1 Features ........................................................................................... 1-1

1-2 Example System Configurations...................................................1-3

2-1 Control Panels ................................................................................ 2-1

2-1-1 Upper Control Panel .............................................................. 2-2

2-1-2 Lower Control Panel.............................................................. 2-4

2-1-3 Subsidiary Control Panel ..................................................... 2-11

2-2 Connector Panel ........................................................................... 2-14

3-1 Connections to External Devices................................................... 3-1

3-1-1 Connections for Digital Output Signals................................. 3-1

3-1-2 Connections for Analog Output Signals ................................ 3-2

3-1-3 Connecting a Reference Signal.............................................. 3-3

3-2 Setup ................................................................................................3-4

3-3 Superimposed Character Information......................................... 3-5

3-4 Cassettes ..........................................................................................3-7

3-4-1 Cassette Types........................................................................ 3-7

3-4-2 Inserting and Ejecting Cassettes ............................................ 3-7

4-1 Preparations for Playback............................................................. 4-1

4-1-2 Switch Settings ...................................................................... 4-1

4-1-2 Time Data Selection............................................................... 4-1

4-2 Playback/Feed Play Procedures .................................................... 4-2

4-2-1 Normal Playback ................................................................... 4-2

4-2-2 Playback in Jog Mode............................................................ 4-3

4-2-3 Playback in Shuttle Mode...................................................... 4-3

4-2-4 Playback in Variable Mode .................................................... 4-4

4-2-5 Playback Using the Capstan Override Function .................... 4-4

4-2-6 Carrying Out Playback in Feed Mode ................................... 4-5

4-3 Dynamic Motion Control (DMC) Playback..................................4-5

4-3-1 Overview................................................................................ 4-6

4-3-2 Storing a Varying Playback Speed in Memory ...................... 4-6

4-3-3 Executing DMC Playback ..................................................... 4-7

Chapter 5

Shot Mark Function

Chapter 6

Menu System

5-1 Overview .........................................................................................5-1

5-2 Shot Mark Operation Menu..........................................................5-2

5-3 Shot Mark Operations ................................................................... 5-3

5-3-1 Reading Shot Marks .............................................................. 5-3

5-3-2 Writing Post Marks................................................................ 5-3

5-3-3 Shot Mark List Operations .................................................... 5-4

5-3-4 Cueing Up to Shot Marks ...................................................... 5-6

5-3-5 Reading in Shot Data ............................................................. 5-6

5-3-6 Sorting Shot Marks ................................................................ 5-7

6-1 Menu System Configuration .........................................................6-1

6-2 Basic Menu...................................................................................... 6-1

6-2-1 Items in the Basic Menu ........................................................ 6-1

6-2-2 Basic Menu Operations.......................................................... 6-4

6-3 Extended Menu............................................................................... 6-9

6-3-1 Items in the Extended Menu .................................................. 6-9

6-3-2 Extended Menu Operations ................................................. 6-19

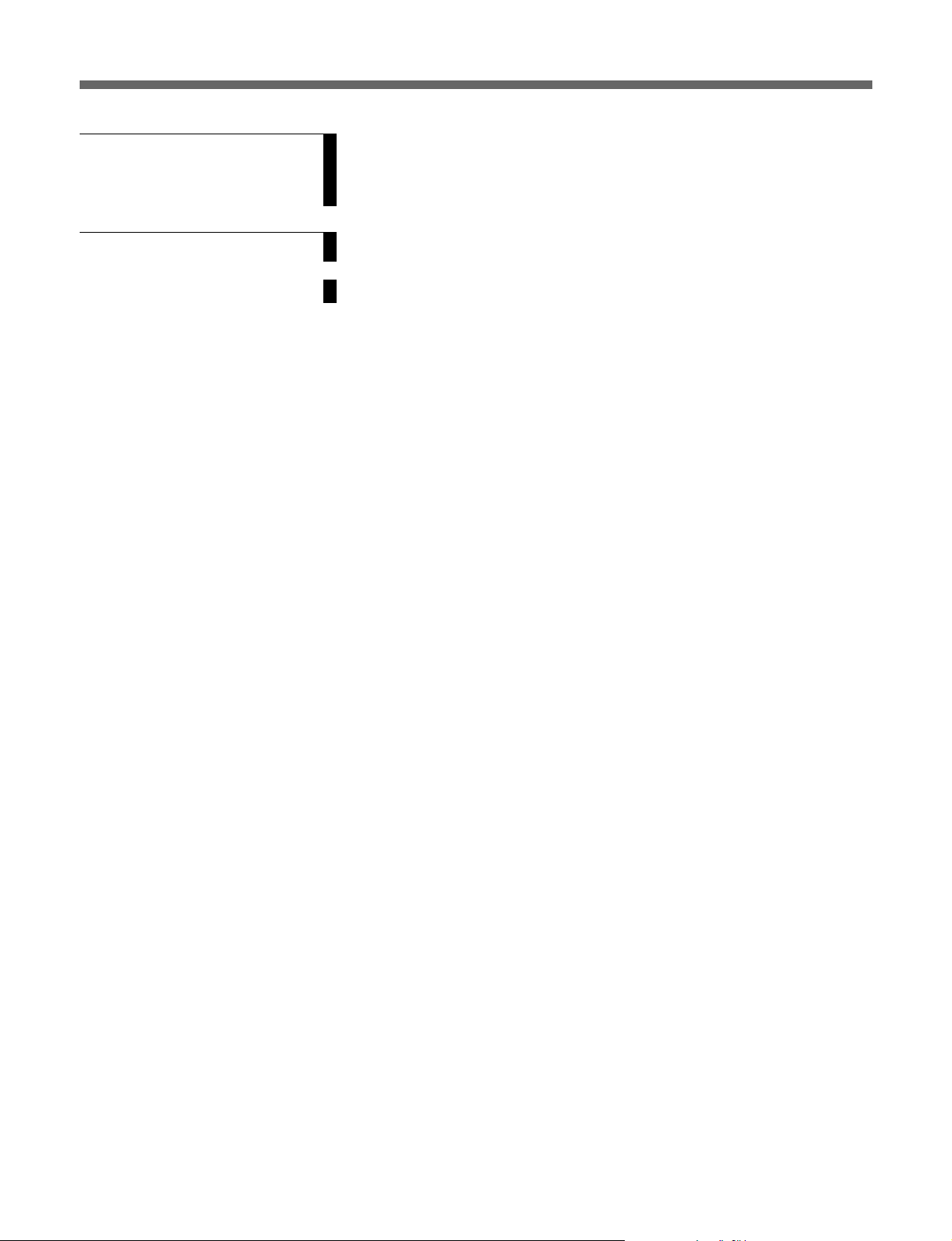

Table of Contents 1

Table of Contents

Chapter 7

Maintenance and Inspection

Appendix

7-1 Removing a Cassette When Tape Slack Occurs .......................... 7-1

7-2 Head Cleaning ................................................................................7-1

7-3 Moisture Condensation..................................................................7-2

7-4 Digital Hours Meter ....................................................................... 7-3

Specifications......................................................................................... A-1

Index ....................................................................................................... I-1

2 Table of Contents

1-1 Features

Chapter 1 Overview

The DNW-A65/A65P is a digital videocassette player,

based on the Betacam SX format.

This unit not only offers digital playback, but can also

play back tapes recorded in the conventional analog

Betacam format.

The following are some of the features of the system.

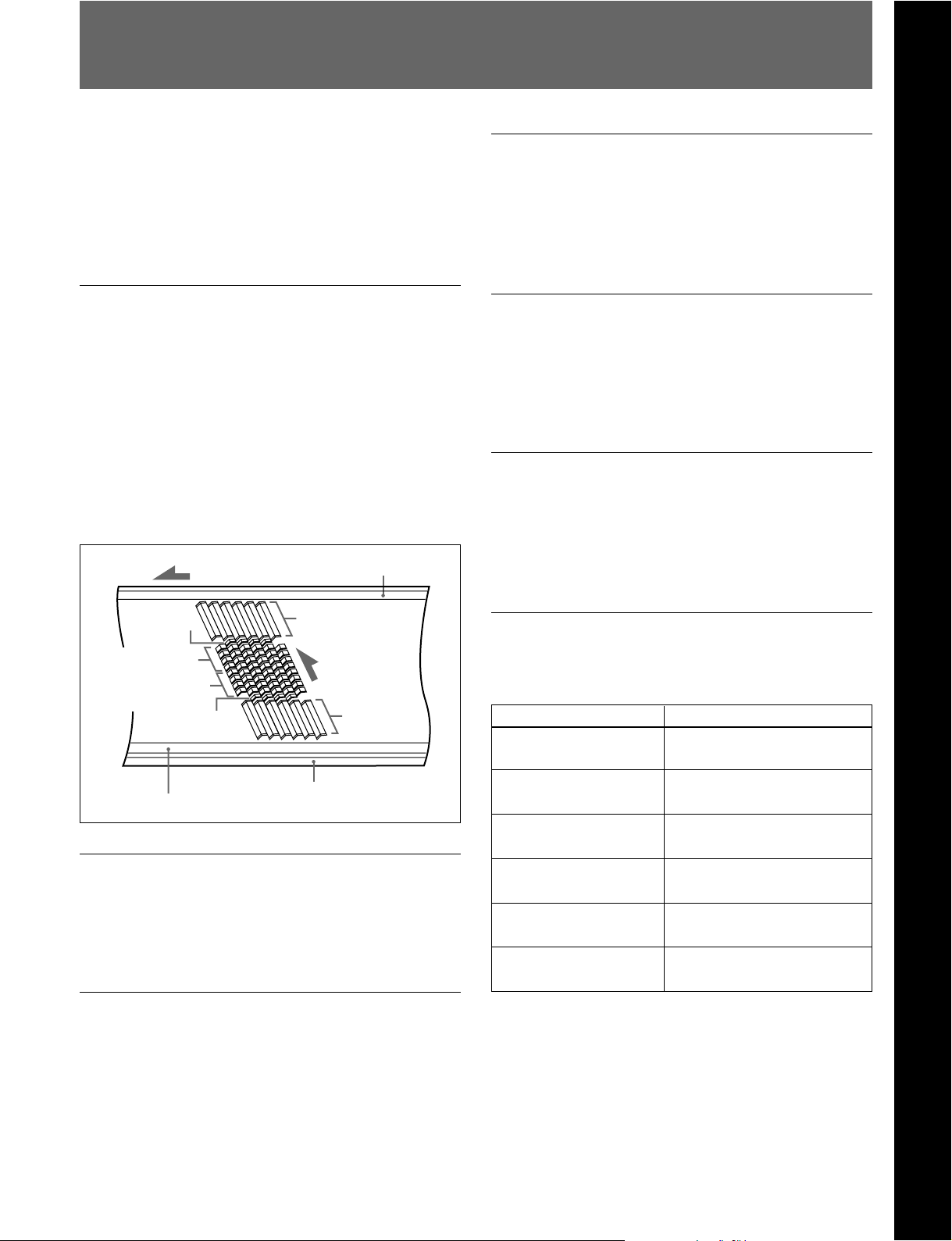

Betacam SX format

The Betacam SX format was developed as a digital

version of the Betacam SP format, and is a digital VTR

format supporting nonlinear editing systems and server

systems. Compared with analog Betacam, the

Betacam SX format reduces the tape speed to

approximately one-half. The drum rotates at 75

revolutions per second, recording two frames of video

data and four channels of digital audio in ten diagonal

tracks. The longitudinal control and time code tracks

are the same as in the analog Betacam format.

Tape transport direction

Auxiliary track

High image quality, high audio quality,

high reliability

Chapter 1 Overview

Even with a low data rate, playback with high image

quality and high audio quality is achieved. The unit

also has a powerful error-correcting system.

Data compression by interframe encoding

Betacam SX format VTRs performs data compression

by MPEG-2 interframe encoding conforming to 4:2:2

Profile @ Main level. The data rate is reduced by a

factor of 10.

Playback compatibility with Betacam/

Betacam SP

This unit can play tapes recorded in Betacam/Betacam

SP format. This makes for efficient use of existing

material in Betacam/Betacam SP format.

System data

Audio channels

1 to 4

Audio channels

1 to 4

System data

Control (CTL) track

Video

Head

direction

Video

Time code track

Head configuration

In addition to digital playback heads for Betacam SX,

the unit also has analog playback heads for Betacam

SP. There are eight digital playback heads in total.

Digital signal processing

This unit processes digital signals conforming to 4:2:2

component digital D-1 format.

Wide range of output signals

You can use the following wide range of output

signals.

Signals Standard or option

Analog video Fitted as standard

(composite and component)

Analog audio

(4 channels)

AES/EBU digital

audio

a)

video/audio Fitted as standard

SDI

b)

video/audio Option (BKNW-118/BKNW-

SDTI

Time code Fitted as standard

a) Serial Digital Interface

b) Serial Data Transport Interface

c) Either the BKNW-118 or the BKNW-124 can be

attached for SDTI signal output.

Fitted as standard

Fitted as standard

c)

124)

Chapter 1 Overview 1-1

1-1 Features

Chapter 1 Overview

DMC (dynamic motion control) playback

You can save a varying playback speed, in the range

–1 to +2 times normal speed, for any section of a tape,

and perform automatic playback with this varying

speed.

Menu-based setup

Initial settings for the unit’s operating condition, the

interfaces with connected equipment, and so forth can

be made by menu operations on the front panel of the

unit.

Wide range of indications

In addition to the LED display which shows the

operating status and current settings of this unit and

connected equipment, a fluorescent display displays

numerical values including time code, user bits, DMC

playback IN and OUT points, DMC playback

durations, error messages and setup menu information.

Incorporation of a time code generator

Connection to external control devices

It is possible to connect a BVE-900/910/2000/9000/

9000P/9100/9100P or other BVE-series editor, a

control and monitoring computer, a BVR-50/50P

remote controller for the built-in digital video

processor, and so forth.

Economy

•You can use a variety of tapes, including low-priced

tapes for UVW-series VTRs and tapes for Betacam

SP or Betacam SX format.

•The design needs minimal maintenance, and requires

no daily maintenance or checks. The drum and other

components have reduced maintenance costs.

Rack mounting

The unit can be mounted in an EIA standard 19-inch

rack.

For details of rack mounting, refer to the Maintenance

Manual Part 1.

Playback time code can be output as it is or after

regeneration by a built-in time code generator.

1-2 Chapter 1 Overview

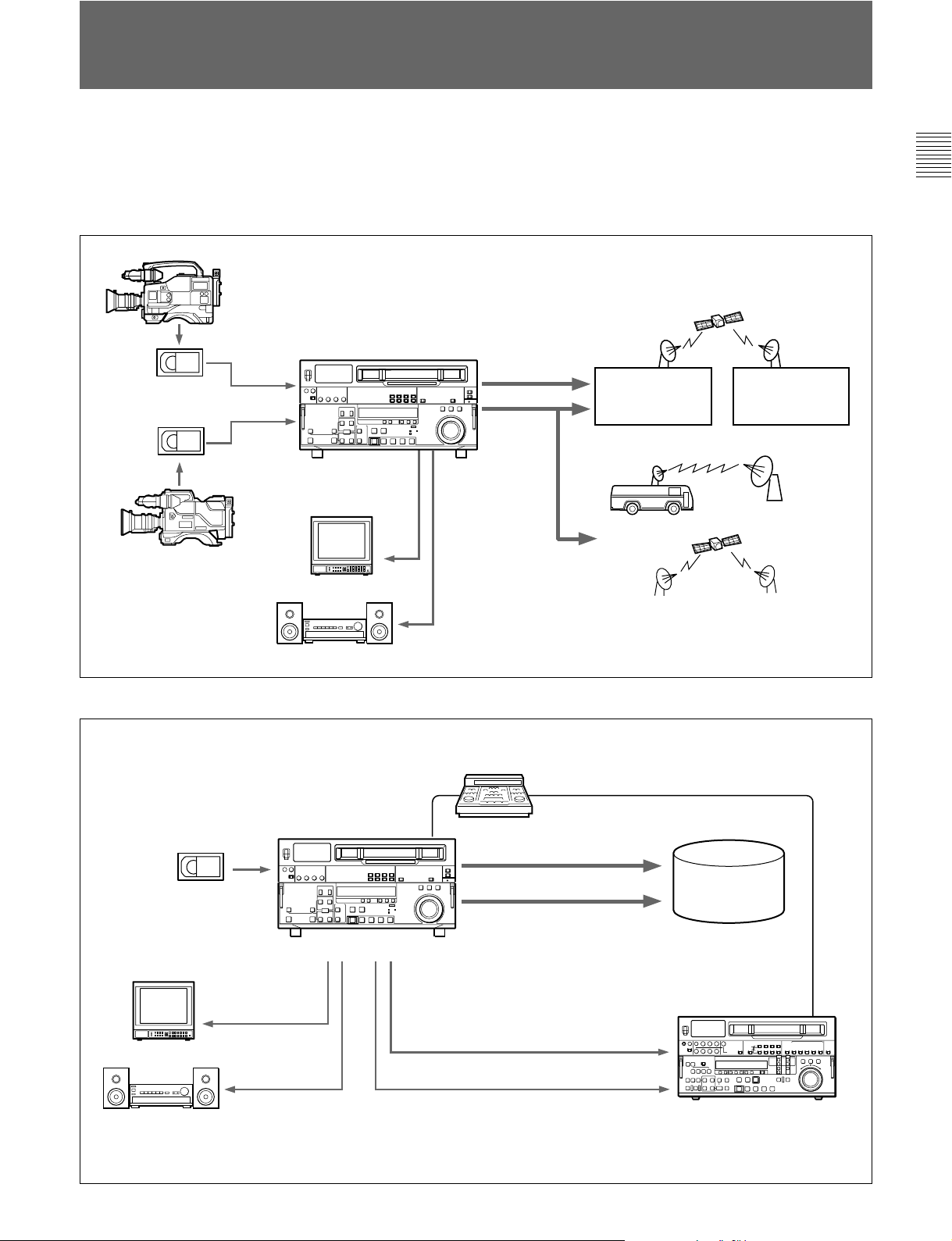

1-2 Example System Configurations

The following conceptual diagrams show examples of

use in an outside broadcast van or local station and

within a broadcasting station.

•Operation in an outside broadcast van or local station

Betacam SX camcorder

Digital (SDTI/SDI)

Digital cassette

Analog cassette

DNW-A65/A65P

Analog

composite

Analog

composite

Analog audio

SNG a) system

Digital modulator

Chapter 1 Overview

Digital

demodulator

Betacam SP camcorder

Video monitor

Audio monitor

•Operation in a broadcasting station

Digital/analog cassette

DNW-A65/A65P

Video monitor

BVE-series editor

Tape control

SDTI

SDI

a) SNG: Satellite News Gathering

Audio/video

server

system

Audio monitor

Analog composite

Analog audio

Analog composite/component

SDI

VTR with SDI connectors

or analog VTR

Chapter 1 Overview 1-3

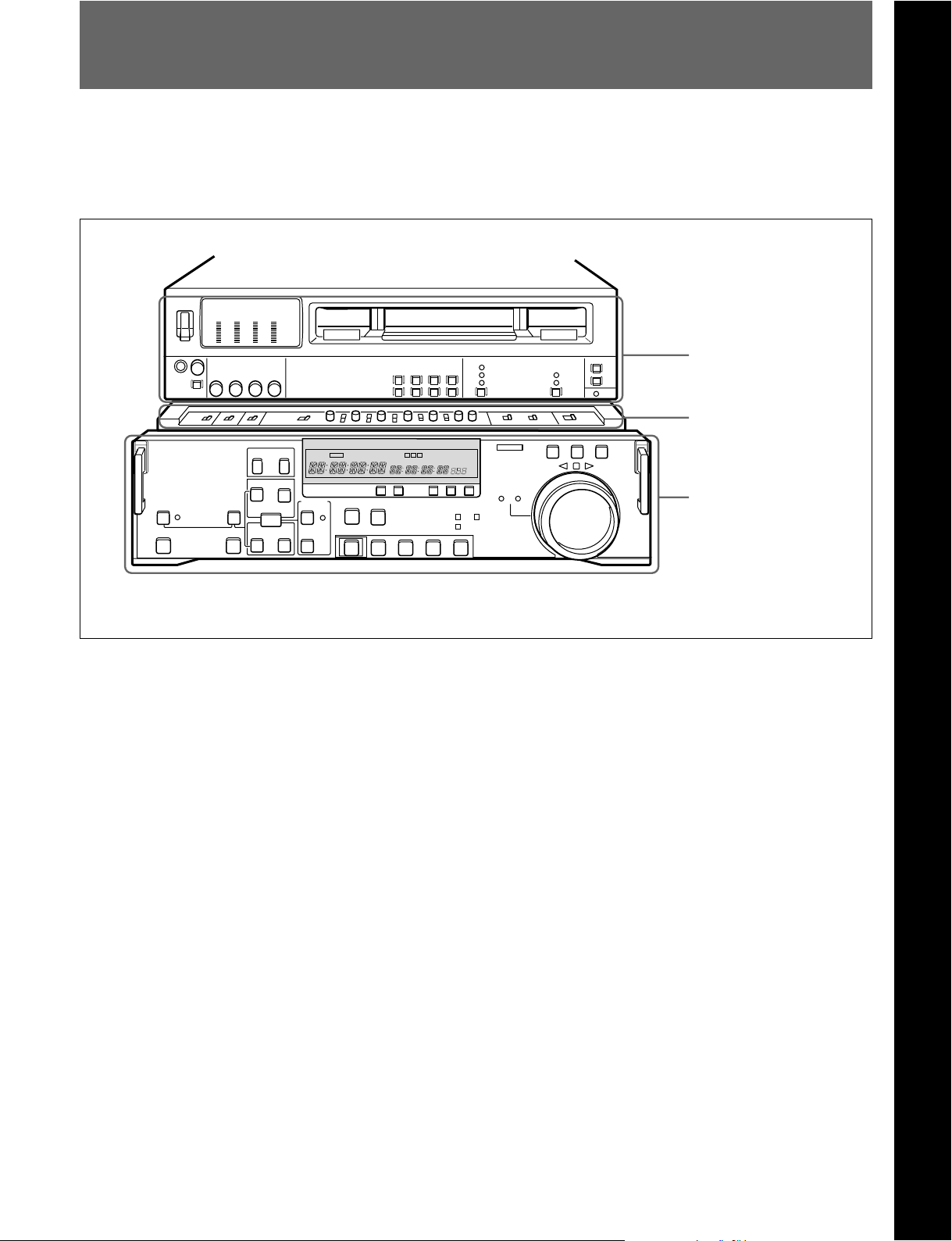

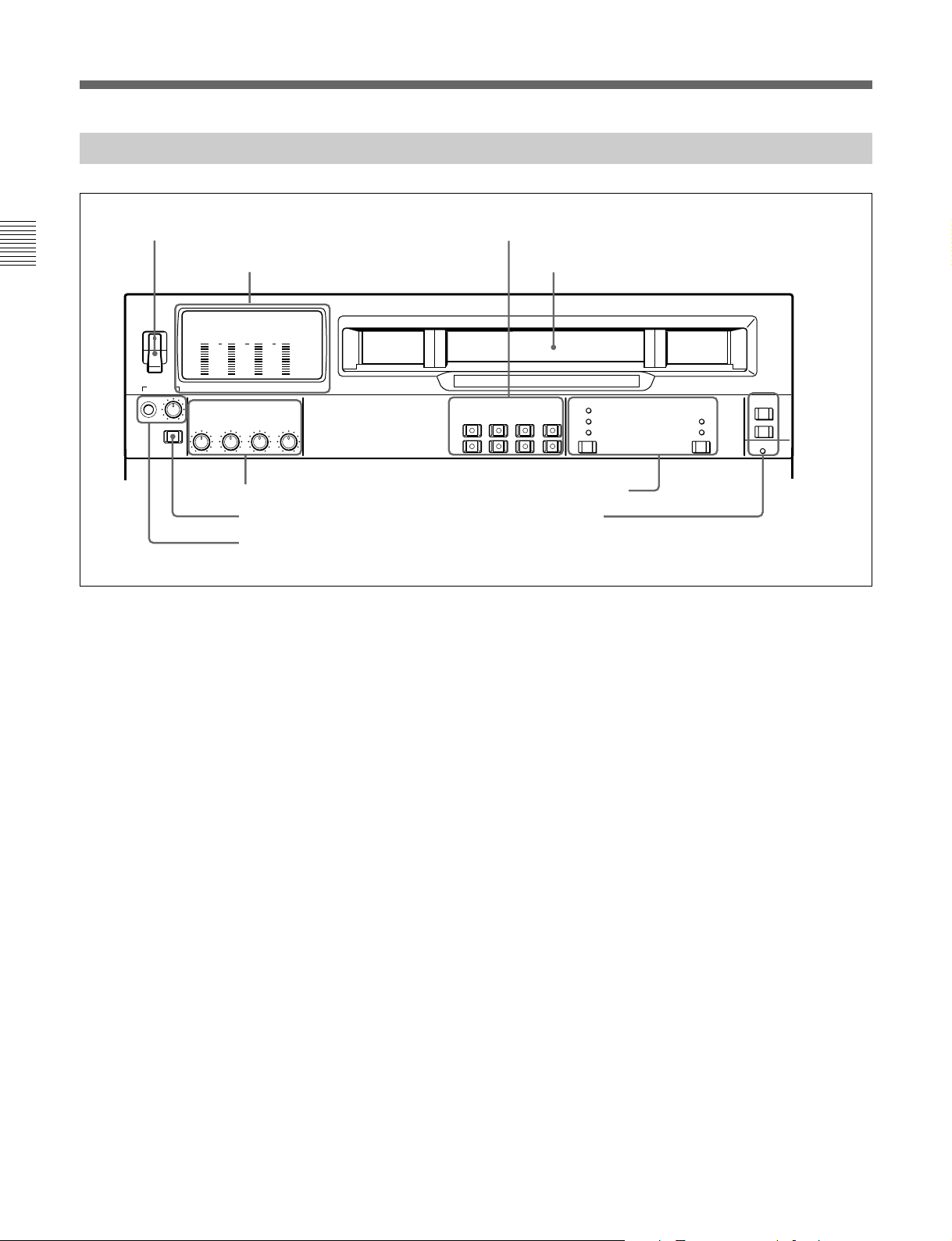

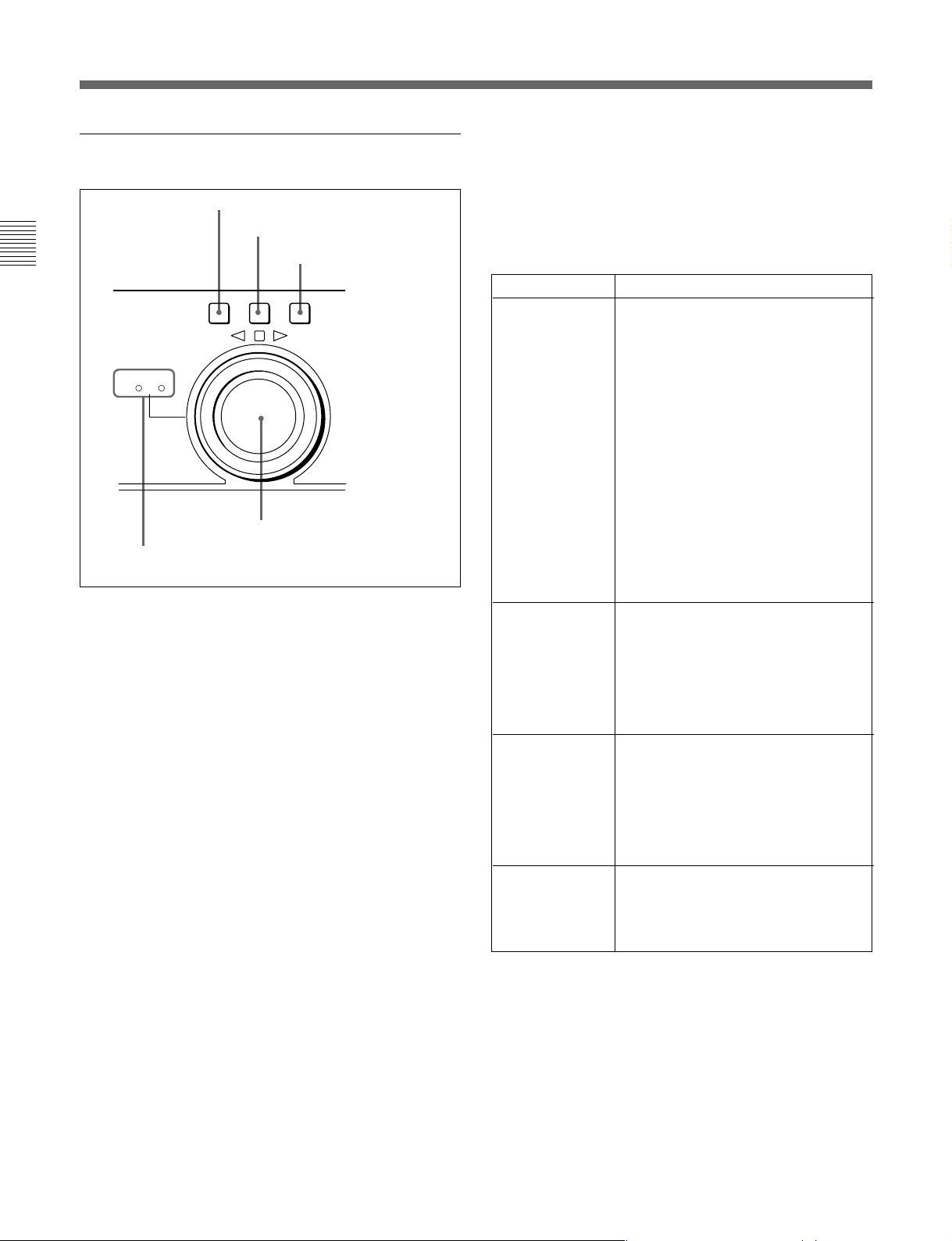

2-1 Control Panels

There are three control panels, as follows:

•Upper control panel

•Lower control panel

•Subsidiary control panel

Chapter 2 Location and Function of Parts

Chapter 2 Location and Function of Parts

Upper control panel

(See page 2-2.)

VI TC UB

INTRP A IN DF LTC VITC 8F 4F 2F

TCG TOTAL REMAIN 525 625

A OUT

CONFI ON

DOLBY

NR

EVENT

%

a) To reveal the subsidiary control panel, pull the lower control panel forward.

Subsidiary control panel

(See page 2-11.)

Lower control panel

(See page 2-4.)

a)

Chapter 2 Location and Function of Parts 2-1

2-1 Control Panels

2-1-1 Upper Control Panel

1 POWER

switch

Chapter 2 Location and Function of Parts

POWER

ON

OFF

PHONES

DISPLAY

FULL/FINE

1 POWER switch

This powers the unit on and off. When the unit is

powered on, the level meters 2 and the fluorescent

display in the lower control panel light.

To power the unit off, press the side of the POWER

switch marked “OFF”.

2 Level meters

These show the audio playback levels of channels 1 to

4.

There are two modes for audio level indications:

FULL and FINE, selected by the DISPLAY FULL/

FINE switch 5.

3 AUDIO MONITOR SELECT buttons

Press the buttons in the L and R rows to select the

audio signal channels output from the MONITOR

OUTPUT L and MONITOR OUTPUT R connectors.

You can press two or more buttons simultaneously in

each row, turning them on, to monitor an output

produced by mixing the selected channels.

2 Level meters

dB

dB

dB

0

0

-10

-10

-20

-20

-30

-30

-40

-40

-80

-80

CH-1 CH-2 CH-3 CH-4

PULL FOR VARIABLE

CH-1 CH-2 CH-3 CH-4

dB

0

0

-10

-10

-20

-20

-30

-30

-40

-40

-80

-80

PB

4 PB controls

5 DISPLAY FULL/FINE switch

6 PHONES jack and control

3 AUDIO MONITOR SELECT buttons

Cassette compartment

ANALOG / DIGITAL

AUDIO MONITOR SELECT

CH-1 CH-2 CH-3 CH-4

L

R

AUTO

TC

LTC

VITC

DF

NDF

REMOTE

1(9P)

2(50P)

RS-232C

7 Time code setting section

8 REMOTE buttons and

RS-232C indicator

4 PB (playback) controls

These adjust individually the playback levels on

channels 1 to 4.

During playback, pull out the control knobs and adjust

the level while monitoring the audio level indication

on the level meters 2.

When the control knobs are pushed in, the playback

levels return to the preset levels, and cannot be

adjusted.

5 DISPLAY FULL/FINE switch

This switches the audio level meter 2 display as

follows:

FULL: The display covers the range – 60 dB to 0 dB

or – 40 dB to +20 dB as selected using extended

menu item 806.

In this mode the segment of the display

corresponding to the current audio level and all

lower segments light.

FINE: The display is enlarged, with a step of 0.25

dB. A segment indicating the reference level

lights.

In this mode only the segment of the display

corresponding to the current audio level lights. If

the audio level exceeds the maximum display

level, the top segment flashes, and if the audio

level goes below the minimum display level, the

bottom segment flashes.

2-2 Chapter 2 Location and Function of Parts

6 PHONES jack and control

Connect stereo headphones with an impedance of 8

ohms, to monitor the sound during playback.

The control knob adjusts the volume.

It is possible to make a setting so that the output

volume from the MONITOR OUTPUT connectors is

controlled simultaneously.

DF/NDF (drop-frame/non-drop-frame) switch and

indicators

In a 525/60 system, this switch selects the mode of

advancing the CTL counter.

DF: Drop-frame mode.

NDF: Non-drop-frame mode.

3)

3)

The indicator corresponding to the selection lights.

Chapter 2 Location and Function of Parts

In order that the output volume from the MONITOR

OUTPUT connectors can be controlled simultaneously, an

internal board switch setting is required. For details, refer

to the Maintenance Manual Part 1.

7 Time code setting section

TC switch and indicators

DF/NDF switch and indicators

TC

LTC

AUTO

VITC

DF

NDF

TC (time code) switch and indicators

This switch selects the time code displayed in the

1)

lower control panel in the sequence: LTC

2)

n VITC

. The indicator corresponding to the

n AUTO

selection lights.

When AUTO is selected, the time code displayed is

VITC when the tape transport speed is up to halfspeed, and LTC when it is more than half-speed.

8 REMOTE buttons and RS-232C indicator

Press one of these buttons to select the device

controlling this unit.

1(9P): This unit is controlled by the device connected

to the REMOTE1-IN(9P) or REMOTE1-OUT(9P)

connector. The button lights.

2(50P): This unit is controlled by the device

connected to the REMOTE PARALLEL I/O(50P)

connector. The button lights.

RS-232C indicator: This indicator lights when this

unit is controlled through the RS-232C connector.

..........................................................................................................................................................................................................

1) LTC: abbreviation of Longitudinal Time code. This time

code is recorded on a longitudinal track on the tape.

Reading is unreliable at low speeds, and not possible at

all during still playback.

2) VITC: abbreviation of Vertical Interval Time code. This

is inserted in the vertical blanking interval and recorded

on the video tracks. It can be read at low speeds and

during still playback, but not during high-speed

playback.

3) Drop-frame/non-drop-frame mode:

In the NTSC system, the actual frame rate is 29.97

frames per second. There is therefore a cumulative

discrepancy between the actual frame rate and the 30

frames per second rate on which time code is based. In

drop-frame mode, except once every 10 minutes, the first

two frames are skipped at the beginning of each minute

to keep the time code values in step with actual elapsed

time.

In non-drop-frame mode, the correction is not carried

out, and there is a discrepancy of about 86 seconds per

day between actual elapsed time and time code values.

Chapter 2 Location and Function of Parts 2-3

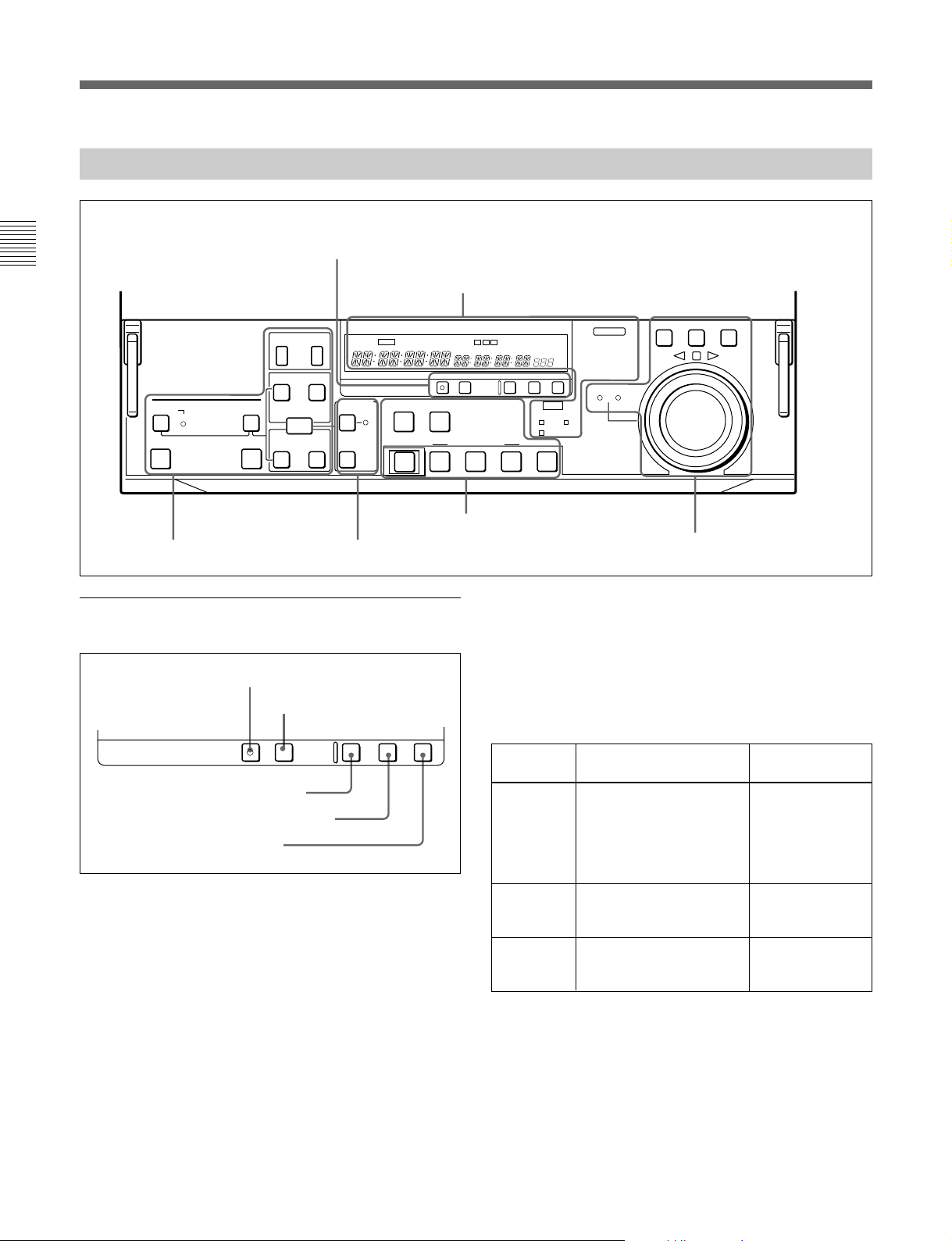

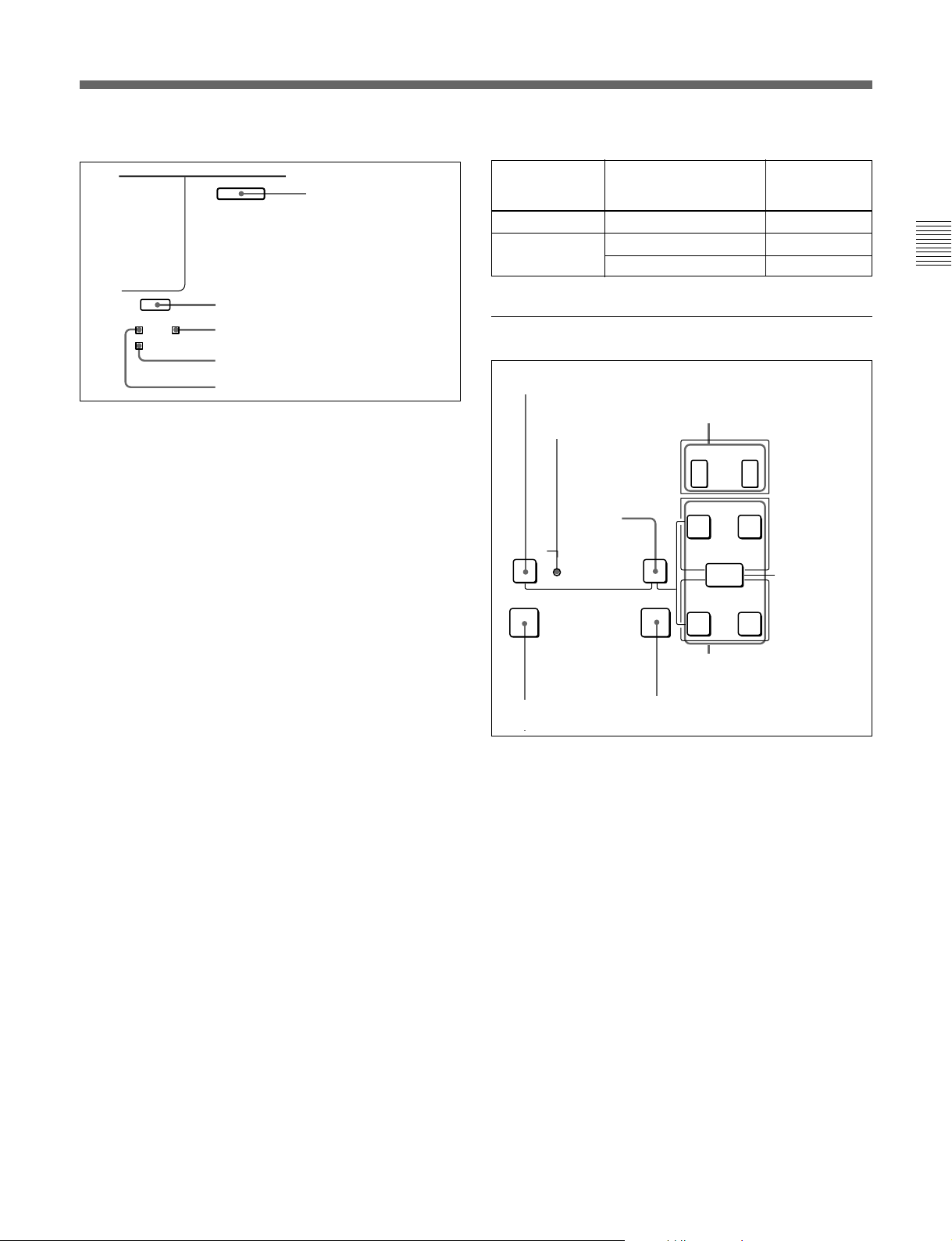

2-1 Control Panels

2-1-2 Lower Control Panel

Chapter 2 Location and Function of Parts

1 Monitor/menu/display setting section

2 Display section

TRIM

+

DMC MODE

LEARN

MEMORY

DELETE

CUE/PLAY

–

PLAY

IN OUT

ENTRY

IN STUNT

VI TC UB INTRP

A IN DF LTC VITC 8F 4F 2F

MENU SET

GOOD SHOT

MARK

OUT

LIST

STANDBY PREROLL

REC/

ERASE

EJECT REW PLAY F FWD STOP

0

6

3 DMC playback 4 Shot mark section

1 Monitor/menu/display setting section

1 MENU button

2 SET button

MENU SET

CTL/TC/UB TOTAL/REMAIN

3 CTL/TC/UB button

4 TOTAL/REMAIN button

5 RESET button

1 MENU button

Use this button for setup menu operations.

Pressing this button, turning it on, displays setup

menus in the fluorescent display of the display section

2. Press the button once more to exit from the menu

display.

For details of setup menu operations, see Chapter 6, “Menu

System”.

RESET

CAPSTAN

CH

LOCK

CONDITION

TCG TOTAL REMAIN 525 625

A OUT

9

CONFI ON

CTL/TC/UB TOTAL/REMAIN

GOOD SHOT

)

EVENT

REC

BETACAM SX

DOLBY

NR

%

RESET

SHUTTLE/

ALARM

INHIBIT

SERVO

p

VAR

KEY

SHUTTLE JOG VAR

REVERSE

JOG

FORWARD

5 Tape transport control section

6 Search control section

3 CTL/TC/UB button

This selects the value displayed in the fluorescent

display in the following sequence: CTL, TC, UB.

.

As the display changes, the corresponding indicators

over the fluorescent display also show the status.

Time code display value selection and display contents

Display

selection

CTL Tape running time (hours,

TC Playback time code read

UB The UB indicator

a) The selection of LTC or VITC is made by the TC switch.

When VITC is selected, the VITC indicator over the TC

switch lights.

Value displayed Indicator status

TC and UB

minutes, seconds,

frames) computed from

indicators are

both off.

the CTL (control) signal

recorded on the tape

during playback.

The TC indicator

by the internal time code

a)

reader.

User bit value inserted in

the playback time code.

lights and the UB

indicator goes off.

a)

lights and the TC

indicator goes off.

2 SET button

Use this button in setup menu operations.

For details of setup menu operations see Chapter 6, “Menu

System”.

2-4 Chapter 2 Location and Function of Parts

4 TOTAL/REMAIN button

Press this button to switch between a TOTAL

indication or REMAIN (remaining) indication on the

fluorescent display. According to the selection, the

TOTAL indicator or REMAIN indicator above the

fluorescent display lights.

5 RESET button

To reset a CTL value displayed in the fluorescent

display, hold this button down.

Resetting the CTL value erases all DMC playback

points.

For details of the TOTAL or REMAIN indicators, see the

next page.

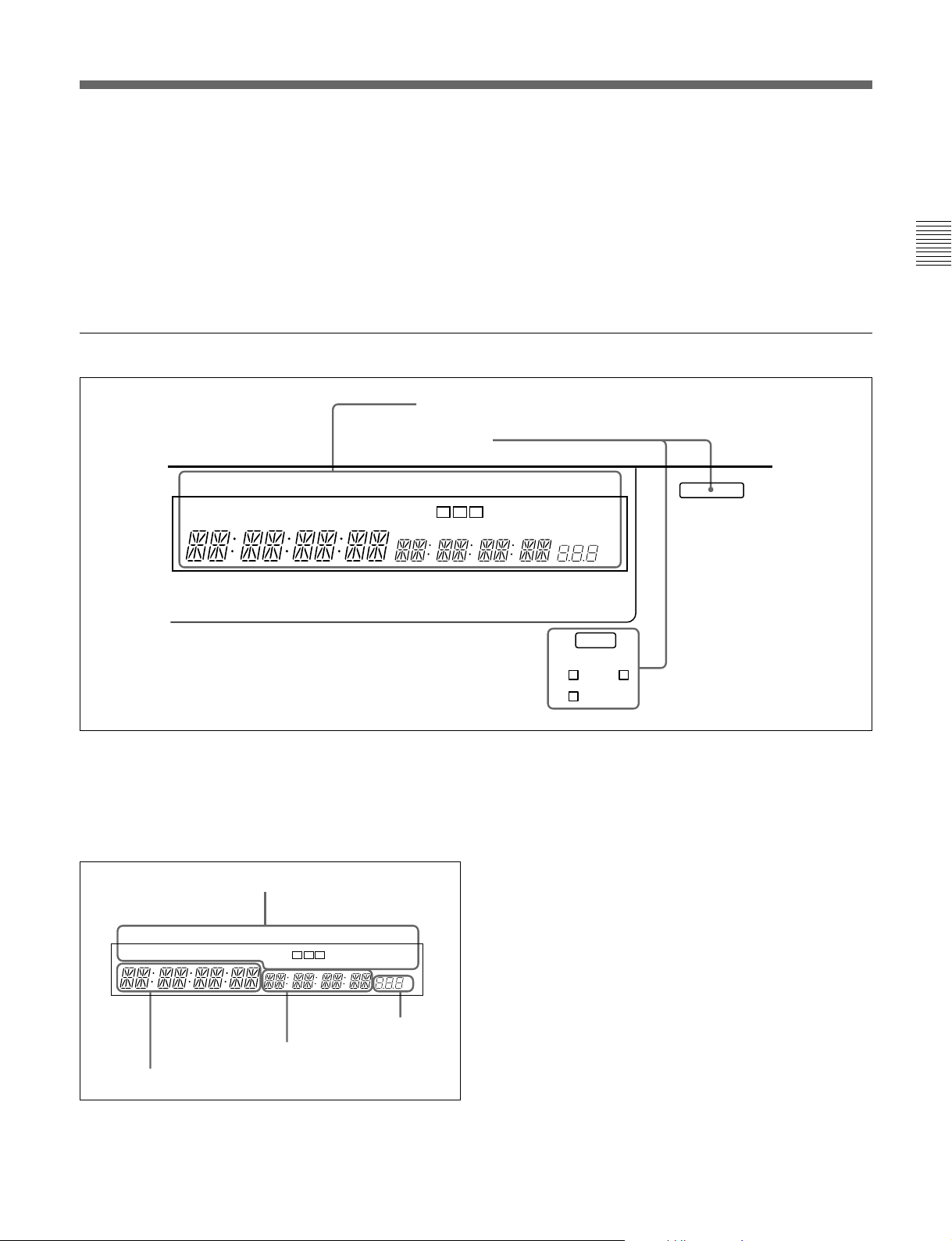

2 Display section

1 Fluorescent display and indicators

2 Indicators

CAPSTAN

LOCK

VI TC UB

A IN DF LTC VITC 8F 4F 2F

A OUT

CH

CONDITION

TCG TOTAL REMAIN 525 625

CONFI ON

EVENT

GOOD SHOT

REC

DOLBY

NR

ALARM

INHIBIT

SERVO

Chapter 2 Location and Function of Parts

BETACAM SX

%

KEY

1 Fluorescent display and indicators

This comprises a time data display area 1, a time data

display area 2, and a speed display area provided by

the fluorescent display, and also a number of

indicators.

Indicator area

CAPSTAN

CH

LOCK

CONDITION

VI TC UB

A IN DF LTC VITC 8F 4F 2F

Time data display area 1

TCG TOTAL REMAIN 525 625

A OUT

Time data display area 2

CONFI ON

EVENT

DOLBY

NR

%

Speed display area

Time data display area 1

Normally this displays a CTL count, time code value,

or user bit value according to the setting of the CTL/

TC/UB button in the monitor/menu/display setting

section 1 and the setting of the TC switch in the

upper control panel.

It is also used to display a STUNT IN point (or PLAY

IN point), a duration, error messages, setup menus, and

so forth.

For details of the selection of CTL count, time code value,

or user bit value see the description of the CTL/TC/UB

button (previous page).

Chapter 2 Location and Function of Parts 2-5

2-1 Control Panels

Time data display area 2

This shows a TOTAL time indication or REMAIN

(remaining) time indication according to the setting of

the TOTAL/REMAIN button in the monitor/menu/

display setting section 1. Depending on the display,

the corresponding one of the TOTAL and REMAIN

Chapter 2 Location and Function of Parts

indicators immediately above lights.

TOTAL: Time value representing the total tape

length.

REMAIN: Time value representing the remaining

tape length.

These are approximate values calculated on the basis

of the detected tape diameter. They are not precise to

units of seconds.

When no cassette has been loaded or the loaded

cassette has not started running, or when the remaining

tape length has not yet been calculated because the

tape started running only seconds before, “---------”

appears as the TOTAL/REMAIN indication.

This area is also used to display a STUNT OUT point

(or PLAY OUT point), a duration, error messages,

setup menus, and so forth.

Speed display area

This displays the speed during feed or tape speed

override play.

Indicator area

This includes the following indicators.

• VI (VITC) indicator: When a VITC time code

value or VITC user bit value is displayed in the

time data display area 1, this indicator lights

together with the TC or UB indicator.

• TC (time code) indicator: This lights when a time

code is displayed in the time data display area 1.

• UB (user bits) indicator: This lights when a user

bit value is displayed in the time data display area

1.

• A IN indicator: When a STUNT IN point is

displayed in time data display area 1, the IN

indicator lights, and when a PLAY IN point is

displayed, the A indicator lights in addition to the

IN indicator.

• DF (drop-frame) indicator: This lights when a

displayed time code value is in drop-frame mode.

• LTC, VITC indicators: Regardless of the display

in the time data display area 1, these indicators

light when the corresponding time code values are

being read.

• CAPSTAN LOCK 8F/4F/2F (8 fields/4 fields/2

fields) indicators: The indicator lights

corresponding to the mode selected by the

CAPSTAN LOCK switch on the subsidiary

control panel or in setup menu item 106.

• CH (channel) CONDITION indicator: A threecolor indicator shows the state of the playback

signal.

Green: The state of the playback signal is good.

Yellow: The playback signal is somewhat

deteriorated, but playback is possible.

Red: The playback signal is deteriorated.

When this indicator remains on, head cleaning

or an internal inspection is necessary.

• A OUT indicator: When a STUNT OUT point is

displayed in time data display area 2, the OUT

indicator lights, and when a PLAY OUT point is

displayed, the A indicator lights in addition to the

OUT indicator.

• TOTAL, REMAIN indicators: When the

“TOTAL” time is displayed in time data display

area 2 the TOTAL indicator lights, and when the

“REMAIN” time is displayed in time data display

area 2 the REMAIN indicator lights.

• 525, 625: The indicator showing the number of scan

lines for the television standard selected using

basic menu item 013 lights (NTSC: 525 scan

lines, field frequency 60 Hz; PAL: 625 scan lines,

field frequency 50 Hz).

• DOLBY NR indicator: This lights when the Dolby

1)

noise-reduction

circuit is functioning.

..........................................................................................................................................................................................................

1) Dolby noise-reduction: Dolby noise reduction

manufactured under license from Dolby Laboratories

Licensing Corporation. “DOLBY” and the double-D

symbol a are trademarks of Dolby Laboratories

Licensing Corporation.

2-6 Chapter 2 Location and Function of Parts

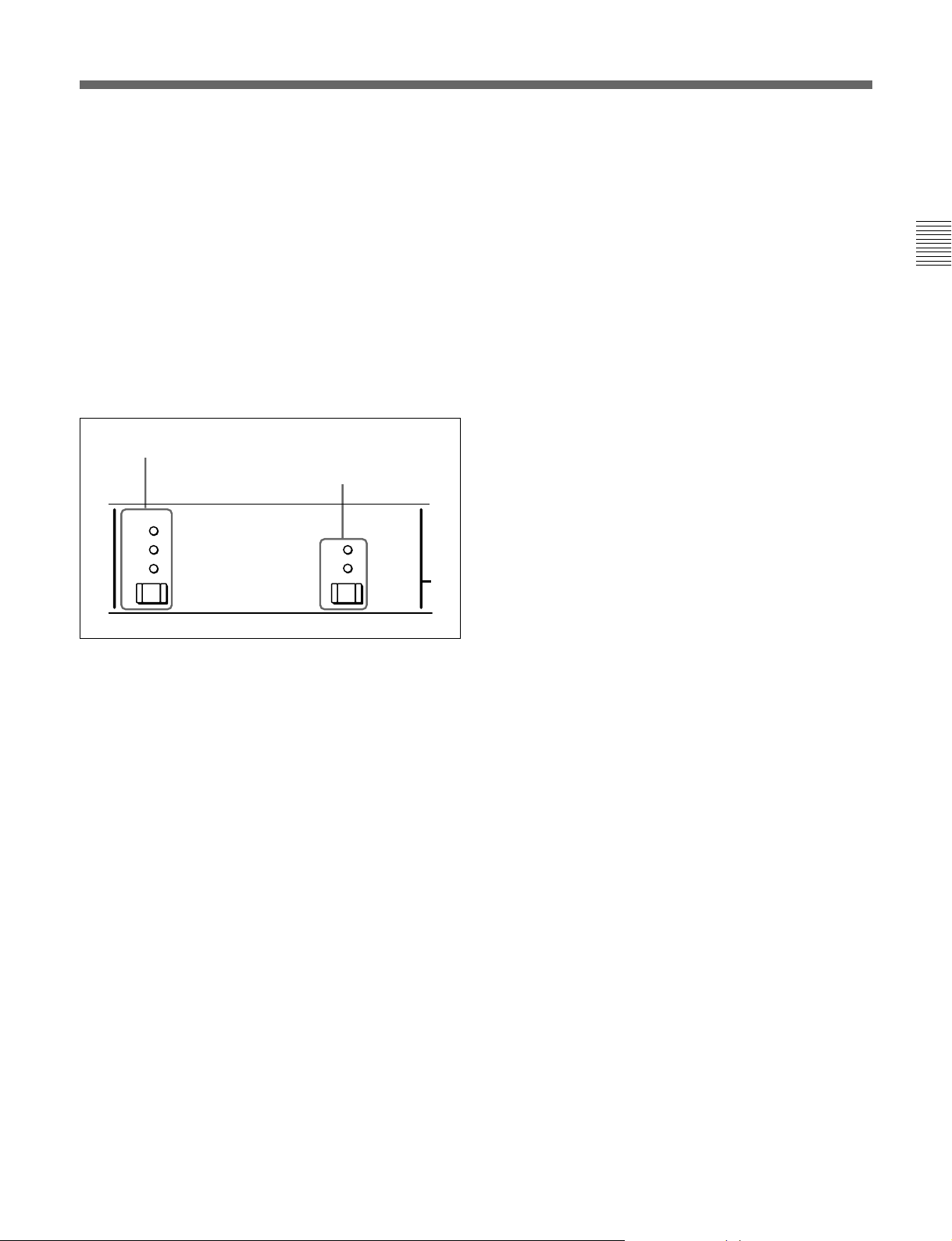

2 Indicators

GOOD SHOT REC INHIBIT indicator indications

GOOD SHOT

REC

ALARM

INHIBIT

SERVO

KEY

BETACAM SX

ALARM indicator

KEY INHIBIT indicator

SERVO indicator

GOOD SHOT REC INHIBIT indicator

BETACAM SX indicator

BETACAM SX indicator

When playing back a tape recorded in Betacam SX

format, this indicator lights.

ALARM indicator

This lights when a hardware error is detected on the

unit, and goes off when the error is resolved.

When this indicator is lit, an error message appears in

the fluorescent display. If you are using the SDI

OUTPUT 3 (SUPER) or COMPOSITE VIDEO

OUTPUT 3 (SUPER) connector, then when the

CHARACTER switch in the subsidiary control panel

is set to ON, the error message also appears on the

monitor screen.

KEY INHIBIT indicator

This indicator lights when the KEY INHIBIT switch

on the subsidiary control panel is set to ON.

SERVO indicator

When the drum servo and capstan servo are locked

1)

this indicator lights.

GOOD SHOT

switch position

State of the record inhibit

plug on the cassette

GOOD SHOT

REC INHIBIT

indicator state

REC INHIBIT Record inhibit/permit Lit

REC Record inhibit Lit

Record permit Off

Chapter 2 Location and Function of Parts

3 DMC playback control section

1 DMC MODE button

2 MEMORY indicator

3 DELETE

button

DMC MODE

MEMORY

LEARN

5 LEARN button

DELETE

CUE/PLAY

6 CUE/PLAY button

1 DMC MODE button

Use this button when you make settings for DMC

,

playback and when you carry out playback in feedmode.

4 TRIM buttons

TRIM

–

IN OUT

IN

+

PLAY

ENTRY

OUT

STUNT

7 DMC playback control

point setting buttons

GOOD SHOT REC (recording) INHIBIT indicator

for details of playback in feed mode.

This indicator is on or off according to the

See page 4-6 for details of DMC playback, and see page 4-5

combination of the setting of the GOOD SHOT switch

on the subsidiary control panel and the record inhibit

plug on the cassette, as shown in the following table.

When this indicator is on, recording shot marks on

tape is prohibited.

2 MEMORY indicator

When memorizing the playback speed using the DMC

MODE button, this indicator flashes as the playback

speed is captured to memory, and lights continuously

once the speed is captured.

..........................................................................................................................................................................................................

1) Servo lock: This refers to the synchronization of the

phase of the drum rotation and the reference signal for

the tape transport position, so that the video heads can

trace the same pattern on the tape for playback or

recording.

Chapter 2 Location and Function of Parts 2-7

2-1 Control Panels

3 DELETE button

This deletes an existing DMC playback control point.

Hold down this button and press the STUNT IN,

STUNT OUT, PLAY IN, or PLAY OUT button which

is lit, indicating an existing DMC playback control

point, to delete the corresponding DMC playback

Chapter 2 Location and Function of Parts

control point. The button either goes off or flashes.

When the button flashes, it is necessary to set the

deleted DMC playback control point again.

4 TRIM buttons

Use these buttons to trim a DMC playback control

point, once set, to single-frame precision.

Hold down the STUNT IN, STUNT OUT, PLAY IN,

or PLAY OUT button, and press one of these buttons.

The + button advances the corresponding edit point by

one frame, and the – button sets it back by one frame.

Pressing one of these buttons while holding down the

PLAY button adjusts the tape speed by +8% or –8%

correspondingly. (Capstan override function)

5 LEARN button

After setting a speed variation start point (STUNT IN

point) and a speed variation end point (STUNT OUT

point), pressing this button makes the tape start

running. You can then use the search dial to vary the

tape speed, which is automatically stored in memory.

After thus storing the tape speed variation in memory,

pressing this button starts an automatic playback

between the speed variation start and end points at the

stored speed.

STUNT IN button and STUNT OUT button

To set a speed variation start or end point, hold down

the STUNT IN or STUNT OUT button, and press the

ENTRY button.

After you have made the setting, pressing the STUNT

IN or STUNT OUT button displays the speed variation

start or end point on the fluorescent display.

ENTRY button

Use this for setting DMC playback control points and

so forth.

•To set a speed variation start or end point: Hold

down the STUNT IN button or STUNT OUT button,

and press this button.

•To set an on-air start or end point: Hold down the

PLAY IN button or PLAY OUT button, and press

this button.

4 Shot mark section

When using a tape with shot markers recorded, you

can read out the good shot marks from the tape, by

simultaneously pressing the LIST button and either F

FWD button or REW button.

GOOD SHOT

MARK

REC/

LIST

ERASE

3 REC/ERASE indicator

1 MARK button

2 LIST button

6 CUE/PLAY button

After setting an on-air start point (PLAY IN point) and

an on-air end point (PLAY OUT point), pressing this

button cues up the tape to the on-air start point. The

button then starts flashing to indicate that the unit is

ready for DMC playback operation. To start DMC

playback, press the button again.

7 DMC playback control point setting buttons

PLAY IN button and PLAY OUT button

To set an on-air start point or on-air end point hold

down the PLAY IN button or PLAY OUT button, and

press the ENTRY button.

After you have made the setting, pressing the PLAY

IN button or PLAY OUT button displays the on-air

start point or on-air end point set on the fluorescent

display.

2-8 Chapter 2 Location and Function of Parts

1 MARK button

Hold this button down for 2 seconds or more, to enable

writing, amending, and deleting of shot marks.

2 LIST button

Use this button to read in and list shot marks.

3 REC/ERASE indicator

This lights in the state in which writing, amending, and

deleting of shot marks is enabled.

5 Tape transport control section

1 STANDBY button

2 PREROLL button

STANDBY PREROLL

EJECT REW PLAY F FWD STOP

Cuing up DMC playback control points

Hold down the STUNT IN, STUNT OUT, PLAY IN,

or PLAY OUT button while pressing this button to cue

up to the corresponding DMC playback control point.

3 STOP button

To stop playback, press this button, turning it on.

When you stop playback, the unit switches to still

playback mode.

Chapter 2 Location and Function of Parts

6

0

6 REW button

7 EJECT button

)

9

4 F FWD button

5 PLAY button

p

3 STOP button

1 STANDBY button

When a cassette is inserted and this button is off, to put

the unit in standby mode, press the button, turning it

on.

In standby mode, the drum is rotating and the tape is in

contact with the drum. As a result, playback can start

immediately.

To end standby mode, press the STANDBY button,

turning it off.

If 8 minutes (value can be varied using extended menu

item 501) elapse in standby mode, the unit

automatically switches out of standby mode to protect

the tape.

2 PREROLL button

Press this button to cue up to the preroll point (before

the IN point by the time set as the preroll time) on the

tape. You can change or select the preroll time and the

1)

state of the unit at the end of preroll (“stop mode”

or

still playback mode) using basic menu item 001 or

extended menu item 401.

Fault display function

The STOP button flashes when there is no external

reference video signal input to the unit.

Note

The STOP button gives no fault display (does not

flash) even when the format of the input video

reference signal does not correspond to your system

(525 or 625). Please remember this when you carry out

system switching.

4 F FWD (fast forward) button

To fast forward the tape, press this button, turning it

on.

5 PLAY button

To start playback, press this button, turning it on.

To operate in capstan override mode

Hold down this button, and turn the search dial.

For details of capstan override mode, see the item relating

to the search dial in the next page.

6 REW (rewind) button

To rewind the tape, press this button, turning it on.

7 EJECT button

To eject the cassette, press this button. While the

cassette is being ejected, this button lights.

..........................................................................................................................................................................................................

1) Stop mode: the state in which the current operation of

the unit is stopped, and the STOP button is lit.

Chapter 2 Location and Function of Parts 2-9

2-1 Control Panels

6 Search control section

Chapter 2 Location and Function of Parts

SHUTTLE/

VAR

JOG

5 SHUTTLE/VAR and JOG indicators

1 SHUTTLE button

To use the search dial for playback in shuttle mode,

press this button, turning it on.

For details of playback in shuttle mode, see the item for the

search dial 4.

2 JOG button

To use the search dial for playback in jog mode, press

this button, turning it on.

For details of playback in jog mode, see the item for the

search dial 4.

3 VAR (variable) button

To use the search dial for playback in variable speed

mode, press this button, turning it on.

1 SHUTTLE button

2 JOG button

SHUTTLE JOG VAR

REVERSE

4 Search dial

3 VAR button

FORWARD

Pressing the dial toggles between shuttle and jog

modes or between variable and jog modes.

You can carry out noiseless playback in the range of

–1 times to +2 times normal speed when using a

Betacam SX format tape.

Playback modes using the search dial

Playback mode Operations and functions

Shuttle

Jog Press the JOG button or the search dial

Variable speed Press the VAR button, turning it on,

Capstan override Hold down the PLAY button and turn

Press the SHUTTLE button or the

search dial so that the SHUTTLE

button lights, then turn the search dial.

Playback is carried out at a speed

determined by the position of the

search dial. The playback speed range

is as follows:

• Using a Betacam SX tape: –78 to +78

times normal speed

• Using an analog Betacam tape: –35

to +35 times normal speed for DNWA75 or –42 to +42 times normal speed

for DNW-A75P

The search dial has detents at the still

position and at ±5 times normal speed.

The maximum shuttle mode playback

speed can be changed by changing the

setting of item 102 in the extended

menu (see page 6-9).

so that the JOG button lights, then turn

the search dial. Playback is carried out

at a speed determined by the speed of

rotation of the search dial. The

playback speed range is –1 to +1 time

normal speed:

The search dial has no detents.

then turn the search dial. You can

control the playback speed finely (51

steps) in the range of –1 time to +2

times normal speed.

The search dial has detents at the still

position and at the normal speed

position.

the search dial to adjust the playback

speed in the range of ±15%. Use this

for phase adjustment between this unit

and an external connected device.

For details of playback in variable mode, see the item for

the search dial 4.

4 Search dial

Turn this to carry out playback in the modes shown in

the following table. Turning the dial clockwise lights

the · indicator and plays back in the forward

direction. Turning the dial counterclockwise lights the

ª indicator and plays back in the reverse direction.

When the tape is stopped, the π indicator lights.

2-10 Chapter 2 Location and Function of Parts

Changing the setting of extended menu item 101 enables you

to use the search dial alone to select shuttle/jog/variable

speed modes, without using the SHUTTLE, JOG, and VAR

buttons.

5 SHUTTLE/VAR and JOG indicators

When searching in shuttle mode, the SHUTTLE/VAR

indicator lights, and when searching in jog mode, the

JOG indicator lights.

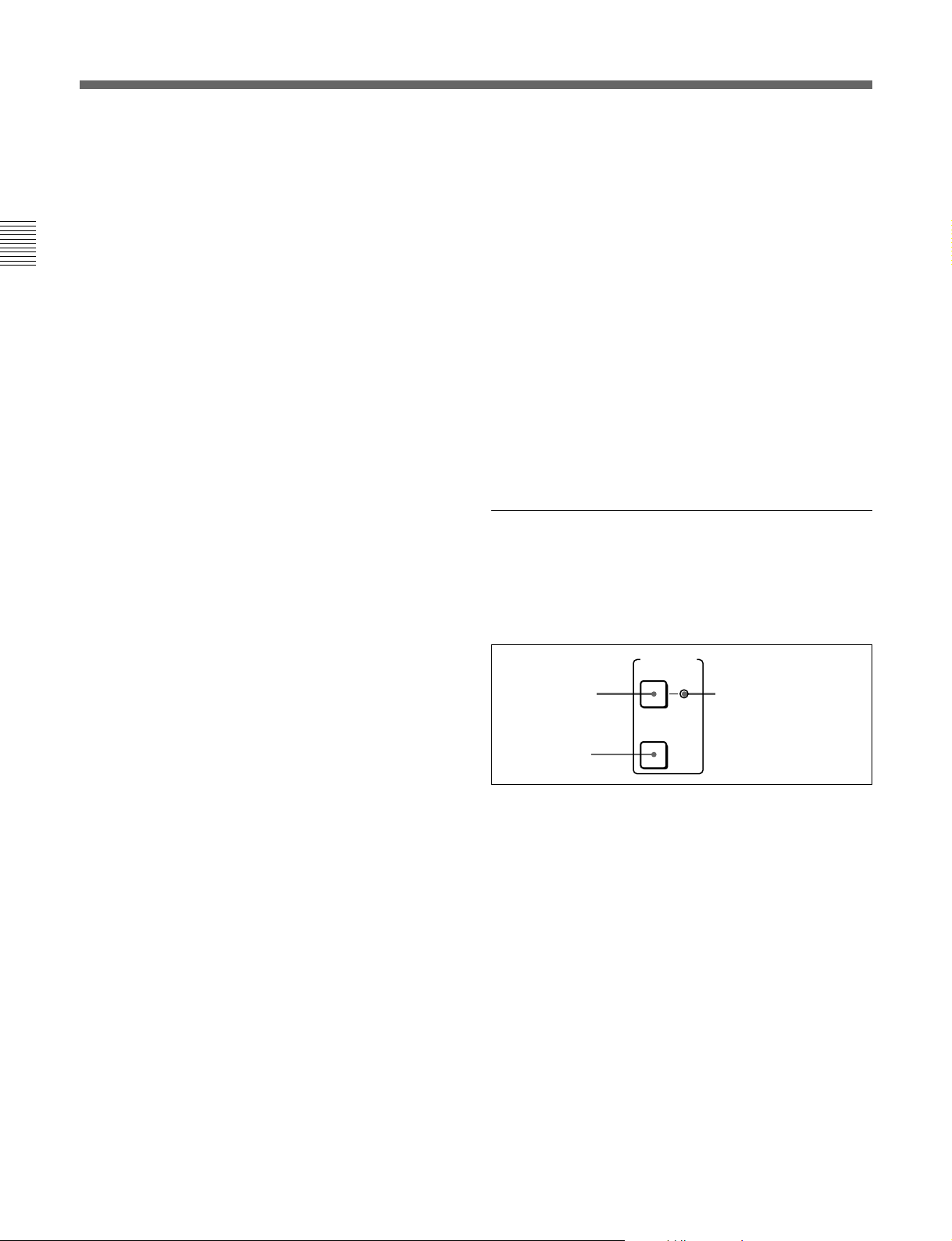

2-1-3 Subsidiary Control Panel

Pull out the lower control panel to reveal the

subsidiary control panel.

1 CONTROL PANEL switch

2 CHARACTER switch

3 DOLBY NR switch

4 PROCESS CONTROL switch

CONTROL

CHARACTER DOLBY

PANEL

EXT INT OFF ON OFF ON REMOTE LOCAL

NR

PROCESS

CONTROL

MENU

!¢ CAPSTAN LOCK switch

!£ KEY INHIBIT switch

!™ GOOD SHOT switch

!¡ SC knob

!º SYNC knob

VIDEO

PRESET

MANUAL

CHROMA

PRESET

MANUAL

SET UP/

Y/C DELAY CHROMA PHASE SYNC SC

BLACK LEVEL

PRESET

PRESET

MANUAL

MANUAL

PRESET

MANUAL

SYSTEM PHASE

9

CHROMA PHASE knob and PRESET/MANUAL switch

8 Y/C DELAY knob and PRESET/MANUAL switch

7 SET UP (DNW-A65)/BLACK LEVEL (DNW-A65P) knob and

PRESET/MANUAL switch

6 CHROMA knob and PRESET/MANUAL switch

5 VIDEO knob and PRESET/MANUAL switch

GOOD SHOT KEY

REC

INHIBIT

INHIBIT

REC ON OFF 2FD 8FD

CAPSTAN

LOCK

4FD

Chapter 2 Location and Function of Parts

(625/50)

1 CONTROL PANEL switch

Select the state of the control panel when this unit is

operated.

INT: When operating this unit by its own control

panel.

EXT: When the control panel is detached, to operate

this unit remotely by a connection to the

CONTROL PANEL connector. This connection

requires an optional Control Panel Extension Kit.

The factory default setting is INT.

2 CHARACTER switch

Select whether or not to superimpose text information

such as time code, menu settings, and alarm messages

on the video signal output from the COMPOSITE

VIDEO OUTPUT 3 (SUPER) connector and SDI

OUTPUT 3 (SUPER) connector.

ON: Superimposed text.

OFF: No superimposed text.

The factory default setting is ON.

3 DOLBY NR (noise reduction) switch

When using an oxide tape, switch the Dolby noisereduction system for analog audio on or off.

When using metal tape, the Dolby noise-reduction

system is automatically switched on, regardless of the

setting of this switch.

ON: Enable the Dolby noise-reduction system for

playback of an analog Betacam oxide tape.

OFF: Disable the Dolby noise-reduction system for

playback of an analog Betacam oxide tape.

The factory default setting is OFF.

Chapter 2 Location and Function of Parts 2-11

2-1 Control Panels

4 PROCESS CONTROL switch

This selects the method of control of the internal

digital video processor.

REMOTE: Select this position to use an optional

BVR-50/50P Remote Control Unit for remote

control of the internal digital video processor.

Chapter 2 Location and Function of Parts

MENU: Select this position to use setup menus to

change the settings for the internal digital video

processor.

LOCAL: Select this position to use the subsidiary

control panel to change the settings for the internal

digital video processor.

5 VIDEO knob and PRESET/MANUAL switch

The switch makes the selection described immediately

below. When it is set to MANUAL, you can use the

knob to adjust the video signal output level.

PRESET: Regardless of the position of the knob, the

video signal output level is set to the reference

value.

MANUAL: You can adjust the video signal output

level in the range ±3 dB.

You can change the adjustment range using

extended menu item 714.

7 SET UP (DNW-A65)/BLACK LEVEL (DNWA65P) knob and PRESET/MANUAL switch

The switch makes the selection described immediately

below. When it is set to MANUAL, you can use the

knob to adjust the (black) setup level (525/60 system)

or black level (625/50 system).

PRESET: Regardless of the position of the knob, the

setup level (525/60 system) or black level (625/50

system) is set to the reference value.

MANUAL: You can adjust the setup level (525/60

1)

system) in the range ±30 IRE

, or the black level

(625/50 system) in the range ±210 mV.

8 Y/C DELAY knob and PRESET/MANUAL

switch

The switch is effective only for playback of video

recorded in Betacam or Betacam SP format. It makes

the selection described immediately below. When it is

set to MANUAL, you can use the knob to adjust the

Y/C delay.

PRESET: Regardless of the position of the knob, the

Y/C delay is set to the reference value.

MANUAL: You can adjust the Y/C delay in the

range ±100 ns.

6 CHROMA (chrominance) knob and PRESET/

MANUAL switch

The switch makes the selection described immediately

below. When it is set to MANUAL, you can use the

knob to adjust the chrominance signal output level.

PRESET: Regardless of the position of the knob, the

chrominance signal output level is set to the

reference value.

MANUAL: You can adjust the chrominance signal

output level in the range ±3 dB.

9 CHROMA (chrominance) PHASE knob and

PRESET/MANUAL switch

The switch makes the selection described immediately

below. When it is set to MANUAL, you can use the

knob to adjust the chrominance phase (the phase

difference from a burst signal).

PRESET: Regardless of the position of the knob, the

chrominance phase is set to the reference value.

MANUAL: You can adjust the chrominance phase in

the range ±30˚.

You can change the adjustment range using

extended menu item 714.

!º SYNC knob

This adjusts the output signal sync phase with respect

to the input reference signal to this unit, in a range of

±15 µs.

Use this adjustment when the output phase of this unit

is not accurately aligned with the reference signal

phase, or when carrying out special effects editing with

this unit and other VTRs connected to a switcher or

other equipment.

..........................................................................................................................................................................................................

1) IRE: A unit for representing a video level laid down by

the IRE (Institute of Radio Engineers). The IRE is now

the IEEE (Institute of Electrical and Electronic

Engineers).

2-12 Chapter 2 Location and Function of Parts

!¡ SC (subcarrier) knob

This adjusts the output signal subcarrier phase with

respect to the input reference signal to this unit, in a

range of ±200 ns.

For playback of composite signals, use this adjustment

when the output phase of this unit with respect to the

phase of the reference signal is not accurately aligned

with the subcarrier phase. This adjustment does not

affect the output SCH (subcarrier - sync) phase, which

remains constant.

!™ GOOD SHOT switch

When this switch is in the REC INHIBIT position, the

GOOD SHOT REC INHIBIT indicator in the lower

control panel lights, and recording shot marks on tape

is no longer possible.

!£ KEY INHIBIT switch

When this switch is in the ON position, the KEY

INHIBIT indicator in the lower control panel lights,

and the buttons in the upper control panel and lower

control panel specified by the setting of extended

menu item 118 are disabled.

!¢ CAPSTAN LOCK switch

This switch selects the capstan lock mode.

For DNW-A65

2FD: The capstan servo locks every two fields.

There may be a color framing difference between

the tape playback output and the input reference

signal.

During playback of a tape recorded with a

composite signal as source, there may be a

horizontal shift (H shift) of the image. (When

extended menu item 712 is set to ON.)

4FD: The capstan servo locks every four fields.

There is no color framing difference between the

tape playback output and the input reference

signal.

During playback of a tape recorded with a

composite signal as source, no horizontal shift (H

shift) of the image occurs.

Select this position for playback of composite

signals when video phase continuity at edit points

is required.

8FD (625/50): This position is not normally used in

a 525/60 system.

If you select this position in a 625/50 system, the

tape playback output is subject to virtual color

framing, frame-locked to the input reference

signal. (This unit is not subject to color frame

locking to the reference signal.)

For DNW-A65P

2FD/4FD: The capstan servo locks every two fields

(2FD)/four fields (4FD).

There may be a color framing difference between

the tape playback output and the input reference

signal.

During playback of a tape recorded with a

composite signal as source, there may be a

horizontal shift (H shift) of the image. (When

extended menu item 712 is set to ON.)

8FD: The capstan servo locks every eight fields.

There is no color framing difference between the

tape playback output and the input reference

signal.

During playback of a tape recorded with a

composite signal as source, no horizontal shift (H

shift) of the image occurs.

Select this position for playback of composite

signals when video phase continuity at edit points

is required.

Chapter 2 Location and Function of Parts

Chapter 2 Location and Function of Parts 2-13

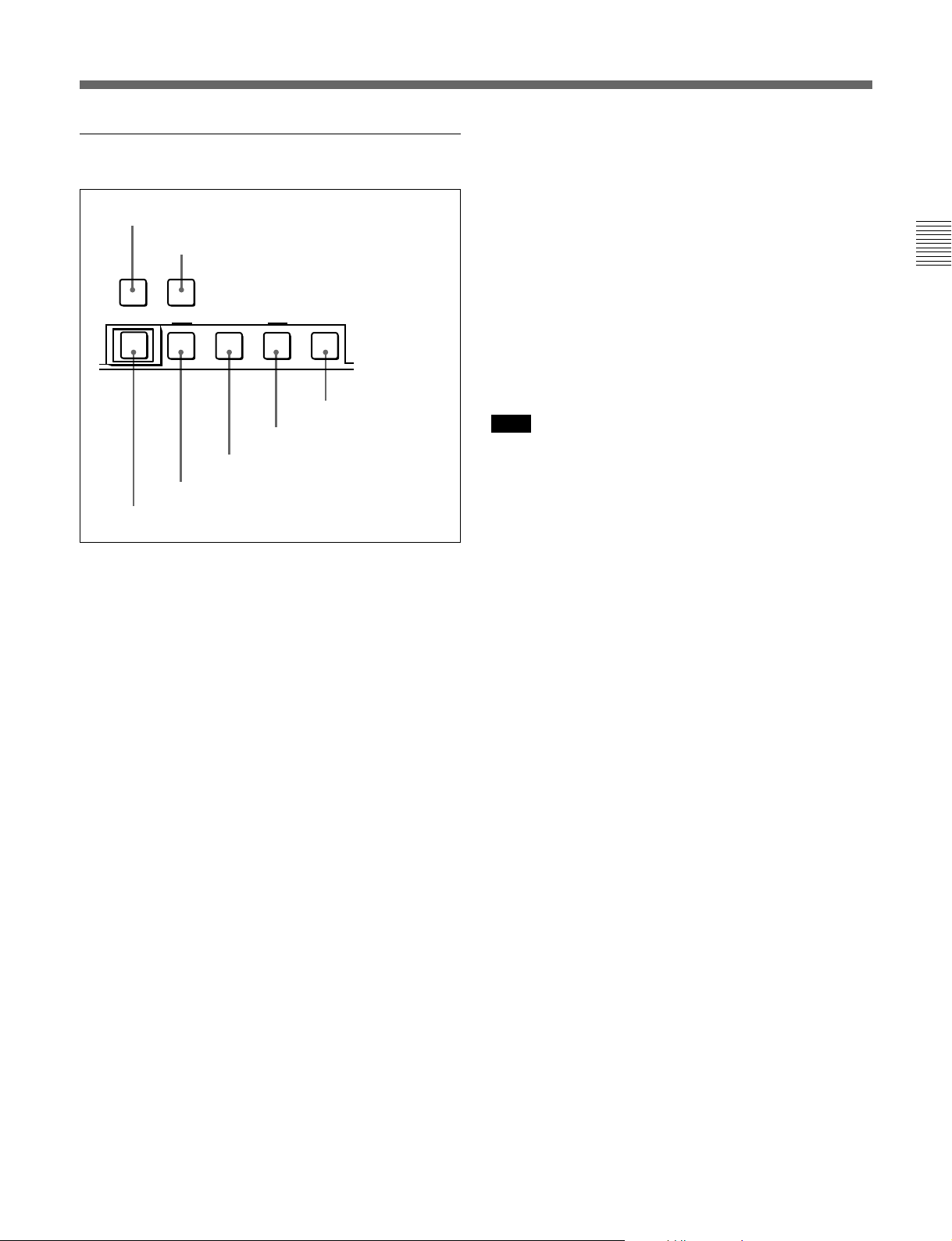

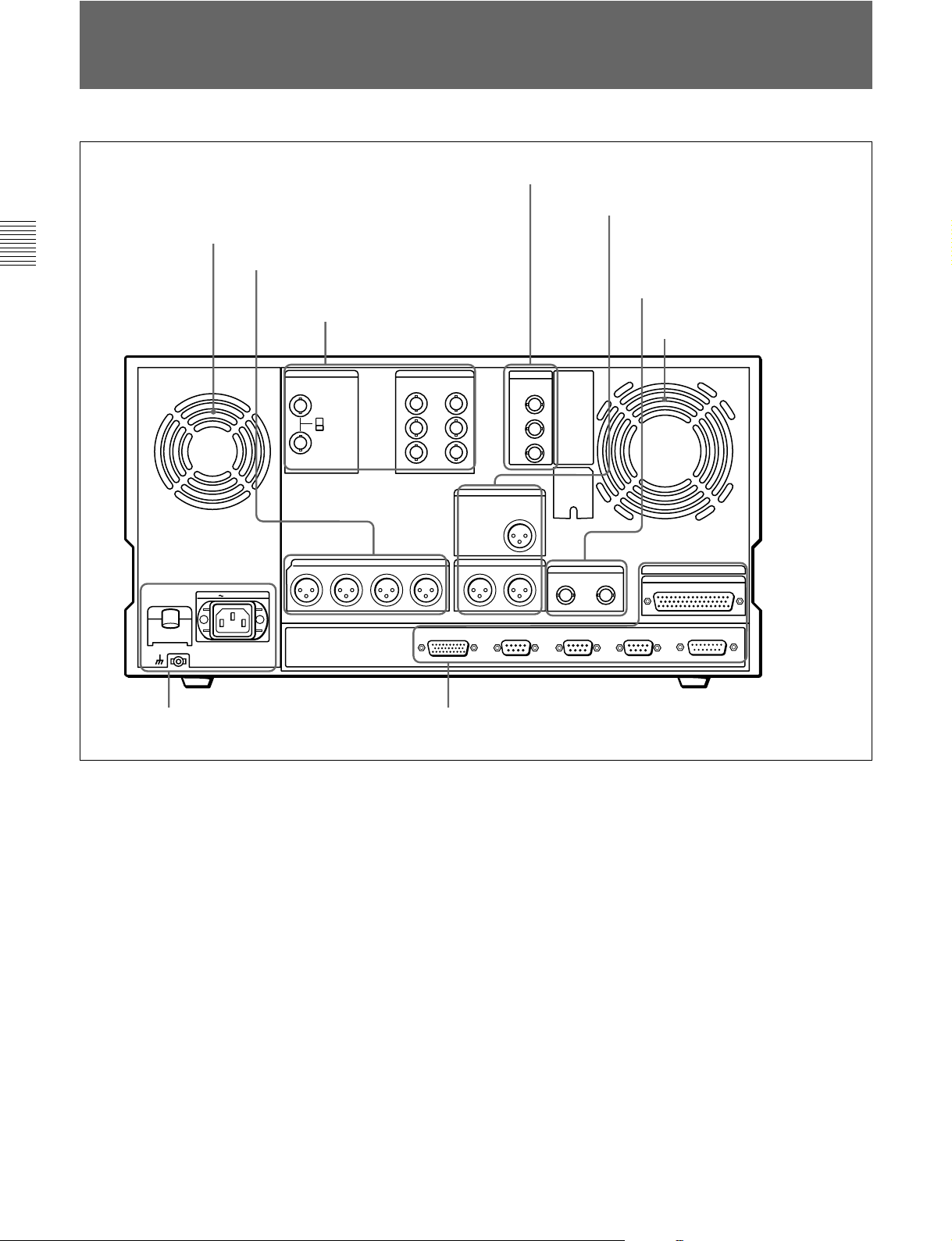

2-2 Connector Panel

2-2 Connector Panel

Chapter 2 Location and Function of Parts

BREAKER

Cooling fan

AC IN

1 Analog audio output

section

(See page 2-15.)

2 Reference video input/analog

video output section

(See page 2-15.)

VIDEO INPUT

REF.VIDEO

75Ω

ON

OFF

CH1 CH2 CH3 CH4 R L

AUDIO OUTPUT

COMPOSITE

1

2

3

(SUPER)

VIDEO OUTPUT

COMPONENT

Y

R-Y

B-Y

TIME CODE

OUT

MONITOR OUTPUT

3 Digital output section

4 Time code output section and

audio monitor signal output section

(See page 2-16.)

5 Digital audio output section

SDI

OUTPUT

1

2

3

(SUPER)

AUDIO OUTPUT(AES/EBU)

CH1/2 CH3/4

(See page 2-16.)

(See page 2-16.)

Cooling fan

REMOTE 2

PARALLEL I/O(50P)

7 Power supply section

(See page 2-17.)

6 External device connectors

RS-232CREMOTE1-OUT(9P)REMOTE1-IN(9P)CONTROL PANEL VIDEO CONTROL

(See page 2-17.)

2-14 Chapter 2 Location and Function of Parts

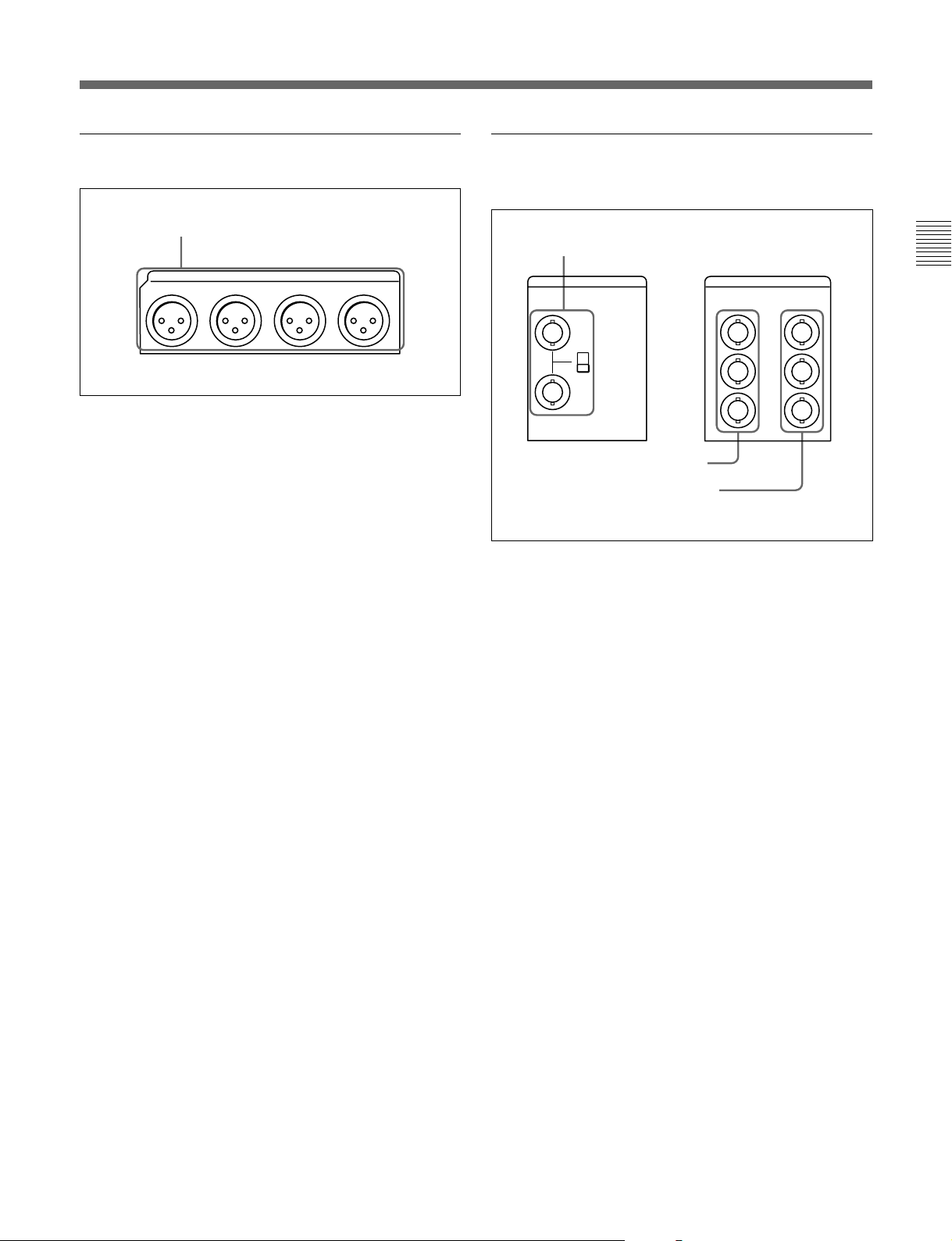

1 Analog audio output section

AUDIO OUTPUT CH1 to CH4 connectors

CH1 CH2 CH3 CH4

AUDIO OUTPUT CH1 to CH4 connectors (XLR 3pin, male)

These output analog audio signals for channels 1 to 4.

AUDIO OUTPUT

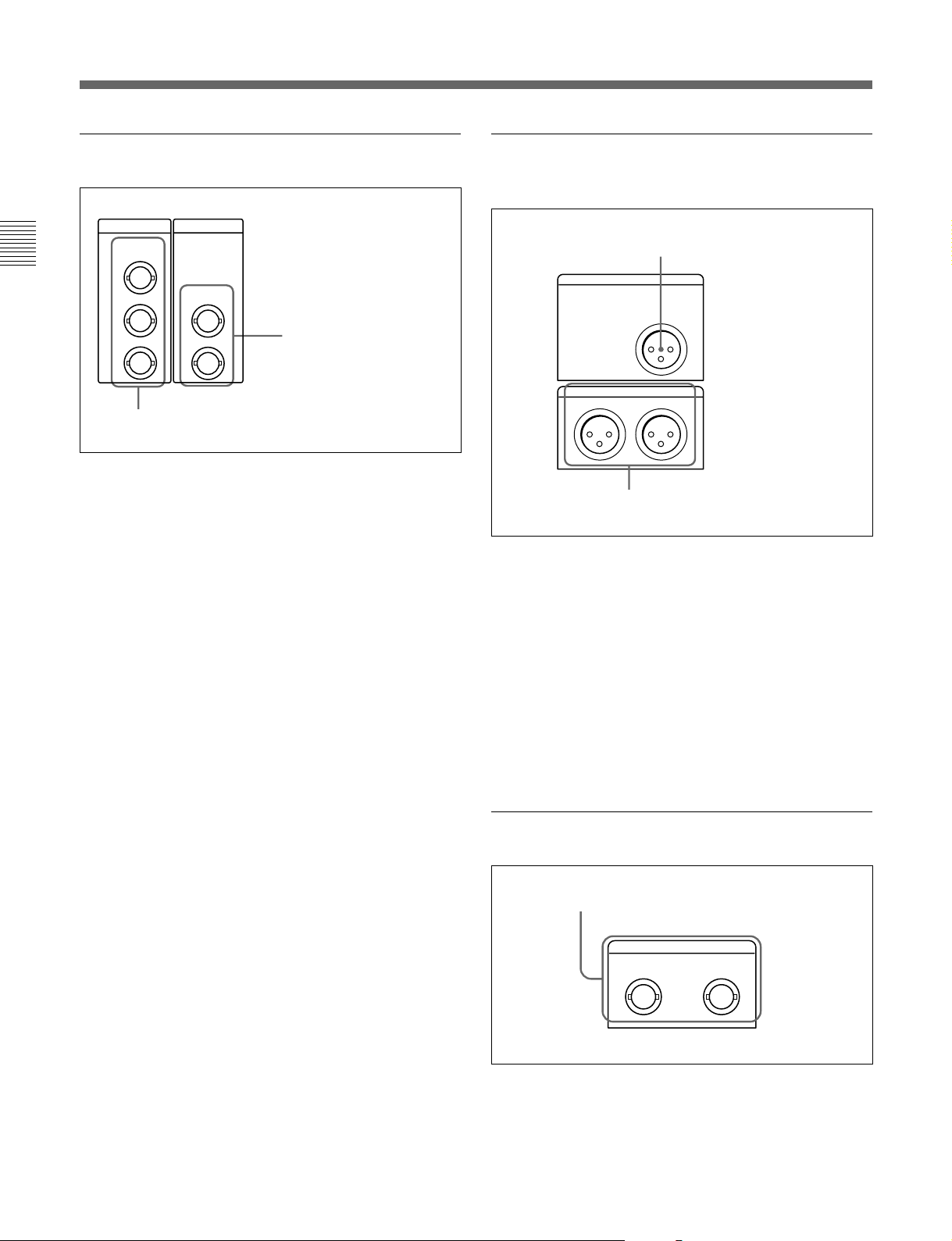

2 Reference video input/analog video

output section

1 REF. VIDEO INPUT connectors and 75 Ω

termination switch

REF.VIDEO

2 COMPOSITE VIDEO OUTPUT

3 COMPONENT VIDEO OUTPUT

VIDEO INPUT

75Ω

ON

OFF

connectors

connectors

1 REF. (reference) VIDEO INPUT connectors

(BNC type) and 75 Ω termination switch

Input a reference video signal. Input a video signal

with chroma burst (VBS) or a monochrome video

signal (VS). When using the loop-through connection

set the switch to the OFF position, and otherwise to the

ON position.

COMPOSITE

1

2

3

(SUPER)

VIDEO OUTPUT

COMPONENT

Y

R-Y

B-Y

Chapter 2 Location and Function of Parts

2 COMPOSITE VIDEO OUTPUT connectors

(BNC type)

These output analog composite video signals.

When the CHARACTER switch on the subsidiary

control panel is set to ON, connector 3 (SUPER)

outputs a signal with superimposed time code, menu

settings, alarm messages, and other text information.

3 COMPONENT VIDEO OUTPUT connectors

(BNC type)

These output analog component video signals (Y/R–Y/

B–Y).

Chapter 2 Location and Function of Parts 2-15

2-2 Connector Panel

TIME CODE

MONITOR OUTPUT

OUT

RL

AUDIO OUTPUT(AES/EBU)

CH1/2 CH3/4

3 Digital output section

SDI

OUTPUT

1

Chapter 2 Location and Function of Parts

2

3

(SUPER)

1 SDI OUTPUT connectors

1 SDI (Serial Digital Interface) OUTPUT

connectors (BNC type)

These output D-1 format digital video/audio signals.

When the CHARACTER switch on the subsidiary

control panel is set to ON, connector 3 (SUPER)

outputs a signal with superimposed time code, menu

settings, alarm messages, and other text information.

2 SDTI (Serial Data Transport Interface)

OUTPUT connectors (BNC type) (for optional use)

These output SDTI (SX) or SDTI-CP video and audio

signals.

Using these connectors requires the optional BKNW118 SDTI (SX) Output Board or BKNW-124 SDTI-CP

Output Board.

SDTI

OUTPUT

1

2

4 Time code output section and audio

monitor signal output section

1 TIME CODE OUT connector

2 SDTI OUTPUT connectors

2 MONITOR OUTPUT connectors

1 TIME CODE OUT connector (XLR 3-pin, male)

This outputs a playback time code.

By setting extended menu item 606, you can also

output the time code from the internal time code

generator locked to the playback time code.

2 MONITOR OUTPUT connectors (XLR 3-pin,

male)

According to the setting of the audio signal selection

buttons (see page 2-2) on the upper control panel, two

(L and R) audio monitor signals are output.

2-16 Chapter 2 Location and Function of Parts

5 Digital audio output section

AUDIO OUTPUT (AES/EBU) connectors

AUDIO OUTPUT (AES/EBU) connectors (BNC

type)

Output up to two sets (4 channels: channels 1/2 and

3/4) of AES/EBU format digital audio signals.

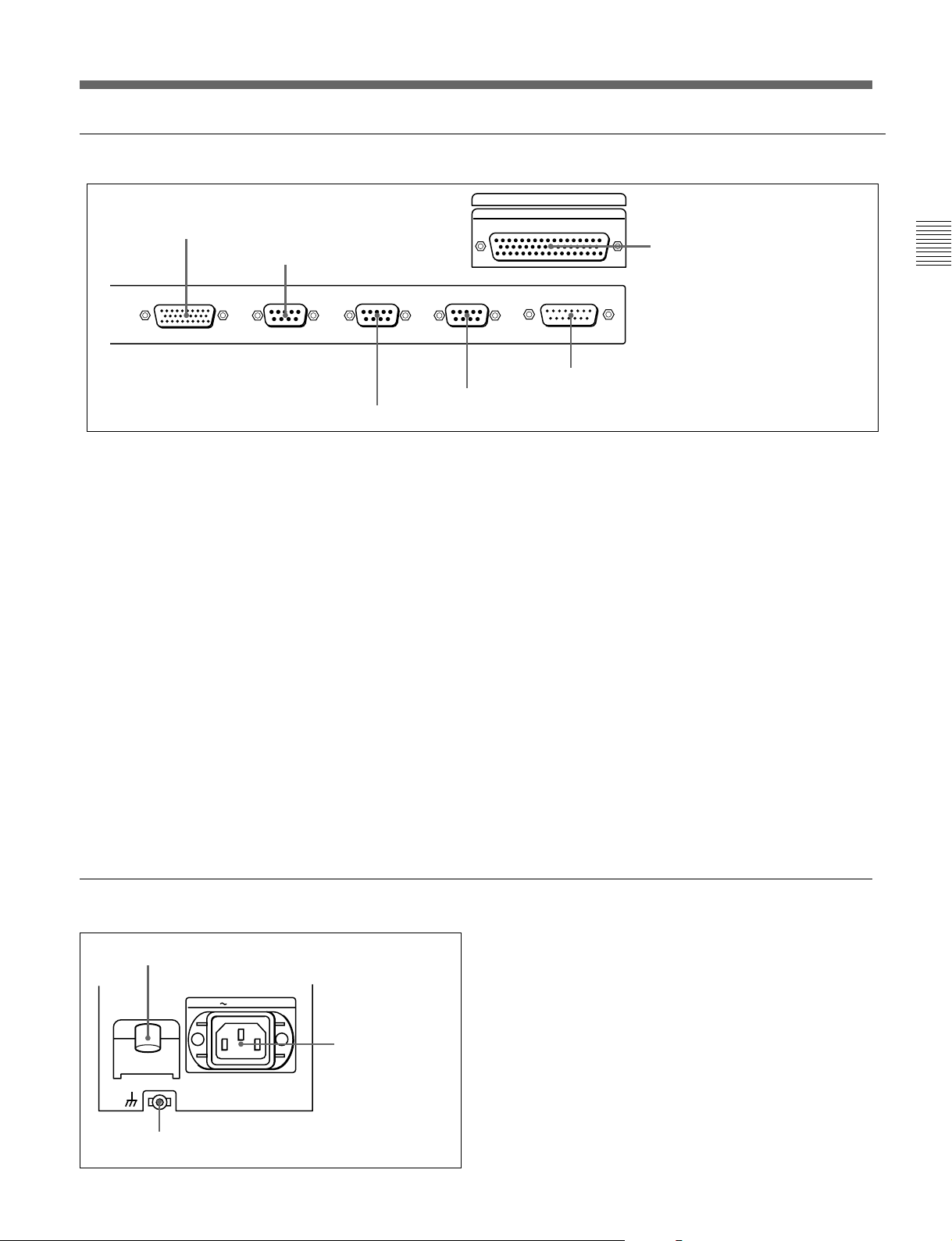

6 External device connectors

1 CONTROL PANEL connector

2 REMOTE1-IN(9P) connector

REMOTE 2

PARALLEL I/O(50P)

6 REMOTE 2 PARALLEL I/O (50P)

connector

Chapter 2 Location and Function of Parts

RS-232CREMOTE1-OUT(9P)REMOTE1-IN(9P)CONTROL PANEL VIDEO CONTROL

5 VIDEO CONTROL connector

4 RS-232C connector

3 REMOTE1-OUT(9P) connector

1 CONTROL PANEL connector (29-pin)

After disconnecting the control panel from this unit,

use this connector to connect the 29-way remote

control cable supplied with the control panel extension

kit.

2 REMOTE1-IN(9P) connector (D-sub 9-pin)

When using this unit together with a DNW-A75/A75P

or a D-1, D-2, or Betacam VTR, and a BVE-series

BVE-900/910/2000/9000/9000P/9100/9100P or other

editor, connect a 9-pin remote control cable from the

other unit to this connector. The IN(9P) and OUT(9P)

connectors provide a loop-through connection for

remote control signals.

3 REMOTE1-OUT(9P) connector (D-sub 9-pin)

This provides the loop-through output for remote

control signals from the REMOTE1-IN(9P) connector

2.

7 Power supply section

4 RS-232C connector (D-sub 9-pin)

Use this for monitoring and diagnosis of the state of

this unit from an external computer, using ISR

(Interactive Status Reporting).

5 VIDEO CONTROL connector (D-sub 15-pin)

For remote control of the internal digital video

processor, connect an optional BVR-50/50P Remote

Control Unit or similar.

Always power off this unit before connecting the

remote control unit.

6 REMOTE 2 PARALLEL I/O (50P) connector

(D-sub 50-pin)

Connect remote control signals from an external

device.

For details, refer to the Installation Manual.

2 BREAKER button

BREAKER

3 Ground terminal

AC IN

1 AC IN connector

1 AC IN connector

Use the optional power cord to connect this to an AC

outlet.

2 BREAKER button

This jumps out if an excess current flows on the

primary side of the AC power circuit.

3 Ground terminal

Connect this to ground.

Chapter 2 Location and Function of Parts 2-17

Loading...

Loading...