Page 1

M-Turbo

TM

Ultrasound System

Service Manual

Page 2

SonoSite, Inc.

21919 30th Drive SE

Bothell, WA 98021-3904

USA

Telephone: 1-888-482-9449 or 1-425-951-1200

Fax: 1-425-951-1201

SonoSite Ltd

Alexander House

40A Wilbury Way

Hitchin, Herts

SG4 OAP UK

T: +44-1462-444800

F: +44-1462-444801

Caution:

M-Turbo, SiteLink, SonoCalc, SonoHD, SonoMB, and SonoSite are registered trademarks or trademarks of SonoSite, Inc.

DICOM is the registered trademark of the National Electrical Manufacturers Association for its standards publications relating to digital communications

of medical information.

Non-SonoSite product names may be trademarks or registered trademarks of their respective owners.

Protected by U.S. patents: 5722412, 5817024, 5893363, 6135961, 6364839, 6371918, 6383139, 6416475, 6471651, 6569101, 6648826, 6962566, 7169108,

D456509, D538432. Patents pending.

Federal (United States) law restricts this device to sale by or on the order of a physician.

P08144-01 12/2007

Copyright 2007 by SonoSite, Inc.

All rights reserved.

ii

Page 3

Contents

Chapter 1: Introduction

Audience ........................................................................................................................... 1

Conventions ....................................................................................................................1

Contact Information ..................................................................................................... 1

Chapter 2: System Overview

About the System .......................................................................................................... 3

Theory of Operation ..................................................................................................... 4

Description of Operating Modes .................................................................... 5

Additional System Feature Performances ................................................... 7

ECG Module ............................................................................................................ 8

DICOM ...................................................................................................................... 8

IMT ............................................................................................................................. 8

System Specifications .................................................................................................. 8

System Dimensions ............................................................................................. 9

Display Dimensions ............................................................................................. 9

Transducers ............................................................................................................ 9

Imaging Modes ..................................................................................................... 9

Image and Clips Storage .................................................................................... 9

Accessories ............................................................................................................. 9

Peripherals ............................................................................................................10

Temperature, Pressure, and Humidity Limits ...........................................11

Electrical ................................................................................................................11

Battery ....................................................................................................................11

Electromechanical Safety Standards ...........................................................12

EMC Standards Classification .........................................................................12

Airborne Equipment Standards ....................................................................12

DICOM Standard .................................................................................................12

HIPAA Standard ...................................................................................................12

Chapter 3: Troubleshooting

Periodic Maintenance ................................................................................................13

System and Subsystem Diagnosis .........................................................................13

System Repair ...............................................................................................................13

Test Equipment ............................................................................................................13

Failure (Assert) Codes .................................................................................................14

Verifying a System Assert Code .....................................................................14

DICOM ....................................................................................................................15

Chapter 4: Replacement Procedures

Display Replacement .................................................................................................17

Required Parts .....................................................................................................17

Required Tools .....................................................................................................17

Display Removal .................................................................................................17

Display Replacement ........................................................................................20

Test the Display ...................................................................................................20

Control Panel Subassembly Replacement ..........................................................21

Required Parts .....................................................................................................21

Required Tools .....................................................................................................21

Control Panel Removal .....................................................................................21

Control Panel Replacement ............................................................................21

Main System Disassembly for Repair and/or Replacement .........................22

Required Parts .....................................................................................................22

iii

Page 4

Required Tools .....................................................................................................22

System Disassembly ..........................................................................................22

Chapter 5: Performance Testing

Overview ........................................................................................................................33

Test Equipment ............................................................................................................33

Setting Up Performance Tests ................................................................................33

Basic Operational Tests ..............................................................................................34

2D Performance Tests ................................................................................................34

2D Performance / Image Quality ..................................................................34

Axial Measurement Accuracy ........................................................................35

Lateral Measurement Accuracy .....................................................................35

Penetration ...........................................................................................................35

Additional Performance Tests .................................................................................36

Color Doppler (Color) ........................................................................................36

Color Power Doppler (CPD) ............................................................................36

M Mode Imaging ................................................................................................37

Tissue Harmonic Imaging ................................................................................37

Pulsed Wave (PW) Doppler Imaging ...........................................................37

Continuous Wave (CW) Doppler Imaging .................................................38

Image Quality Verification Test/Livescan ...................................................38

Printer .....................................................................................................................38

Battery Charging ................................................................................................39

Video Output .......................................................................................................39

Appendix A: Replacement Parts List

Display .............................................................................................................................41

Control Panel .................................................................................................................42

System .............................................................................................................................43

Transducer Nest Frame Assembly .........................................................................46

Ordering Replacement Parts ...................................................................................46

Appendix B: Service Event Report

Service Event Report Form .......................................................................................48

Service Event Report Instructions .........................................................................49

Returning Products to SonoSite .............................................................................50

Shipping Instructions .......................................................................................50

Index ........................................................................................................................ 51

iv

Page 5

Chapter 1: Introduction

Before servicing the M-Turbo ultrasound system, please read this manual. The information applies only to the

SonoSite M-Turbo ultrasound system product manufactured after December 5, 2007.

The ultrasound system has multiple configurations and feature sets. All are described in this service manual but

not every option may apply to your system. System features depend on your system configuration, transducer, and

exam type.

Refer to the M-Turbo Ultrasound System User Guide for additional information regarding safety, system controls,

operation, capabilities, and specifications.

Audience

The intended audience of this manual is properly trained field and in-house service personnel.

Conventions

These conventions are used in this service manual:

•A WAR NIN G describes precautions necessary to prevent injury or loss of life.

•A Caution describes precautions necessary to protect the products.

• Numbered steps must be performed in a specific order.

• Bulleted lists present information in list format but do not imply a sequence.

Labeling symbols are in the user guide.

Contact Information

Questions and comments are encouraged. SonoSite is interested in your feedback regarding the service manual.

If you encounter difficulty with the system, use the information in this manual to help correct the problem. If the

problem is not covered here, contact SonoSite Technical Support as follows:

Technical Support (USA, Canada) 1-877-657-8118

Technical Support fax: 1-425-951-6700

Technical Support e-mail: service@sonosite.com

SonoSite website: www.sonosite.com (Select Resources > Support & Service)

International Technical Support: Contact your local representative or call (USA) +425-951-1330

European Service Center +44-(0)1462-444-800

Japan Service Center +81-3-5304-5337

e-mail: uk.service@sonosite.com

Chapter 1: Introduction 1

Page 6

2 Chapter 1: Introduction

Page 7

Chapter 2: System Overview

About the System

The SonoSite M-Turbo high-resolution ultrasound system is a portable, full featured, general purpose, software

controlled, diagnostic ultrasound system using all digital architecture. The system is used to acquire and display

high-resolution, real-time ultrasound data in 2D, M Mode, Pulsed Wave (PW) Doppler, Continuous Wave (CW)

Doppler, Color Power Doppler (CPD), and color Doppler (Color) or in a combination of these modes.

The system has an electrocardiography (ECG) display feature and supports a 3-lead ECG cable assembly to collect

data for M Mode and Doppler measurements. The system provides measurement capabilities for anatomical

structures and fetal biometry that provide information used for clinical diagnostic purposes. The system has a PW

and CW Doppler audio output feature and cine review, image zoom, labeling, biopsy, measurements and

calculations, image storage and review, printing, and recording capabilities.

The system includes the ability to measure the intima-media thickness (IMT) of the carotid artery using digital

ultrasound images. The IMT measurement of the carotid artery may be used adjunctively with other medical data

obtained by a physician to help assess the cardiovascular health of a patient.

The system includes Digital Imaging and Communications (DICOM) capabilities as well as general computer

communication capabilities to provide the acceptance, transfer, display, storage, and digital processing of

ultrasound images and loops. Security support is also provided to facilitate HIPAA compliance.

The system/transducer is capable of exceeding a TI or an MI of 1.0 in certain operating modes or mode

combinations. The system displays the current output level in terms of one of two bioeffects indices (“Mechanical

Index [MI]” and “Thermal Index [TI]”) in accordance with the AIUM/NEMA Standard for Real Time Display of

Thermal and Mechanical Acoustic Output Indices on Diagnostic Ultrasound Equipment.

Chapter 2: System Overview 3

Page 8

Theory of Operation

AQ BusRF Bus

Acquisition

subsystem

Processing

subsystem

Transduce r

Display

subsystem

Control Bus

Control

subsystem

User

interface

Battery

pack

assembly

Pulser voltage

Video

External video to monitor,,

printer

Power

subsystem

Power

adapter

External power

IrDA

Serial Bus

Logic power

Display power

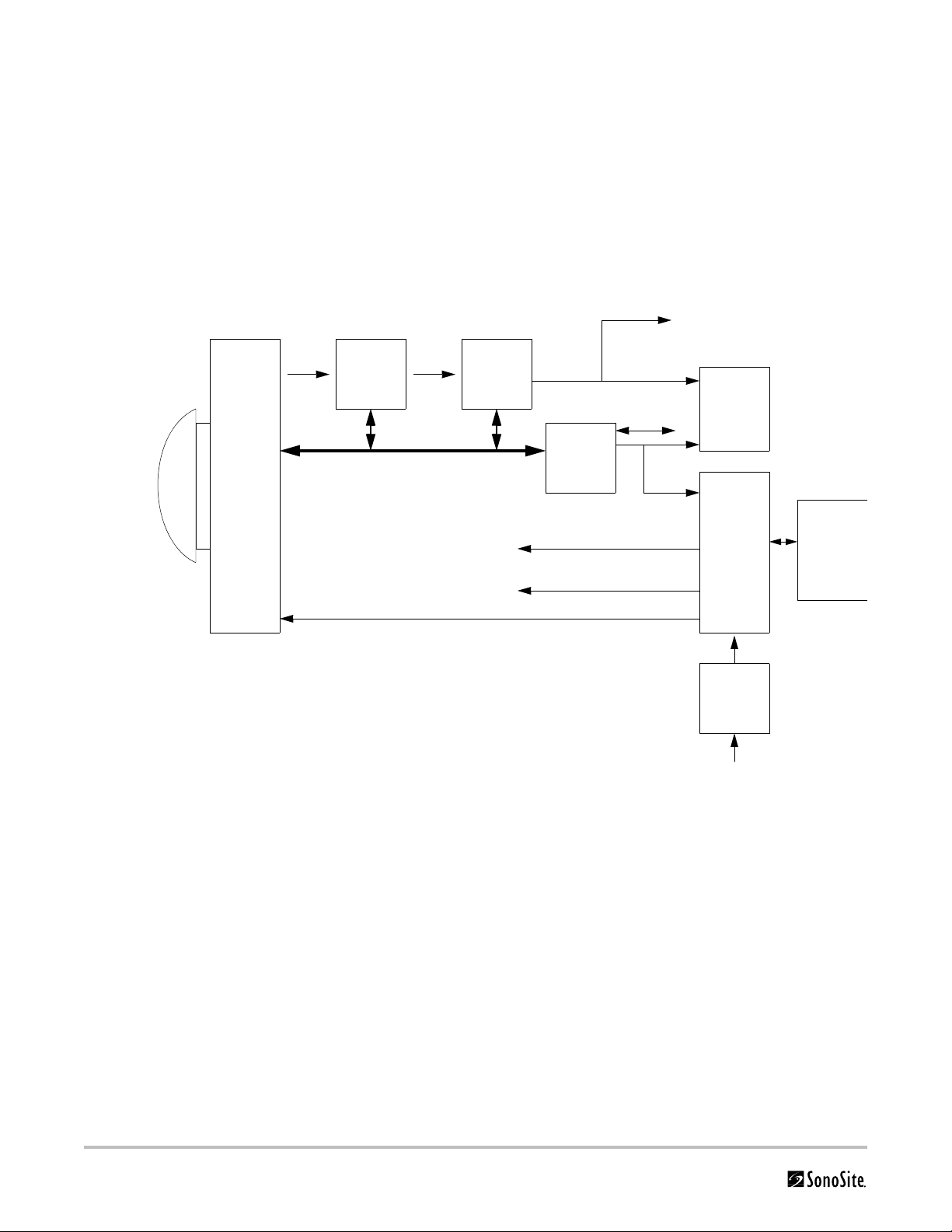

The M-Turbo ultrasound system has seven (7) major functional groups:

•Transducer

•Acquisition Subsystem

• Processing Subsystem

•Display Subsystem

• Control Subsystem

• User Interface Subsystem

•Power Subsystem

Figure 2.1 is a system block diagram that shows the relationship of the functional groups.

Figure 2.1 SonoSite High-Resolution Ultrasound System (M-Turbo) Block Diagram

The Transducer elements convert the pulser voltage to acoustic energy during the transmit portion of the

ultrasound acquisition cycle. The elements convert the acoustic echo to voltage in the receive portion of the

acquisition. The voltage developed on the transducer elements is sensed by the acquisition subsystem. The system

transducers have 64 to 192 elements.

The Acquisition Subsystem consists of the beamformer and interface to the transducer. The beamformer controls

the timing of the transmit pulses to focus the acoustic beam. The beamformer amplifies the low-level received

echos and controls the receive focusing. The system beamformer transmits on up to 128 elements and receives on

64 elements.

The Processing Subsystem includes capabilities for interfacing with the beamformer and performing high speed

processing. The processing subsystem demodulates, filters, detects, and compresses the signal supplied by the

beamformer into display information.

4 Chapter 2: System Overview

Page 9

The Display Subsystem converts the detected ultrasound data into picture elements (pixels). The software user

interface graphics are combined with the ultrasound information and converted to a video stream. The external

video port supports NTSC and PAL format.

The Control Subsystem consists of the central processing unit, program and video memory, permanent image

storage and retrieval memory, external communication interface ports, and connection to the user interface keys.

The control software includes the acoustic power and intensity software subsystem, power group monitors, and a

beamformer monitor. This software guarantees a level of patient safety by ensuring the system is operating within

acoustic power and intensity limits.

The User Interface Subsystem represents the software interface and form factor. The software interface is the

interaction between the user and the screen layout components. The form factor is the type of physical buttons,

location, and grouping of the buttons and the device size, shape, and weight. Dedicated controls are for high usage

activities and grouped according to the user workflow.

The Power Subsystem provides the system power and protects the hardware from destructive and/or unsafe

conditions by detecting failures in the system through hardware and software monitors. Detection of a fault results

in disabling of the pulser supply, and signaling of an error to the Control Group. The power subsystem includes the

battery pack and battery charging electronics.

Description of Operating Modes

2D Mode 2D mode is a two dimensional image of the amplitude of the echo signal. It is used for

location and measurement of anatomical structures and for spatial orientation during

operation of other modes. In 2D, a two-dimensional cross-section of a 3-dimensional soft

tissue structure such as the heart is displayed in real time. Ultrasound echoes of different

intensities are mapped to different gray scale or color values in the display. The outline of the

2D cross-section may be a rectangle, parallelogram, trapezoid, sector, or a full circle,

depending on the particular transducer used. 2D mode can be used in combination with any

other modes.

MMode M Mode is also known as “T-M mode” or “time-motion” mode. It is used primarily for cardiac

measurements such as valve timing and septal wall thickness when accurate timing

information is required.

Ultrasound echoes of different intensities are mapped to different gray scale values in a

scrolling display. M Mode displays time motion information of the ultrasound data derived

from a stationary beam. Depth is arranged along the vertical axis with time along the

horizontal axis. M Mode can be used alone but is normally used in conjunction with a 2D

image for spatial reference. The 2D image has a graphical line (M-line) superimposed on the

2D image indicating where the M Mode beam is located.

Chapter 2: System Overview 5

Page 10

Color

Doppler

(Color)

In color Doppler, a real-time, two-dimensional cross-section of blood flow is displayed. The

2D cross-section may be presented as a rectangle, parallelogram, trapezoid, sector, or a full

circle, depending on the particular transducer used.

The 2D cross-section is presented as a full color display, with various colors being used to

represent the velocity, both positive and negative, of the blood flow echoes. Often, to

provide spatial orientation, the full color blood flow cross-section is overlaid on top of the

gray scale cross-section of soft tissue structure (2D echo). For each pixel in the overlay, the

decision of whether to display VCD, gray scale (echo) information or a blended combination

is based on the relative strength of echoes from the soft-tissue structures and from the red

blood cells.

A high pass filter (wall filter) is used to remove the signals from stationary or slowly moving

structures. Tissue motion is discriminated from blood flow by assuming that blood is moving

faster than the surrounding tissue, although additional parameters may also be used to

enhance the discrimination. The remaining signal after wall filtering may be averaged over

time (persistence) to present a steady state image of blood flow distribution. Variance

information may also be displayed to provide information when large variance is observed in

the velocity information.

Color Power

Doppler

(CPD)

Continuous

Wave (CW)

Doppler

In CPD, a real-time two-dimensional cross-section of blood flow is displayed. The 2D

cross-section may be presented as a rectangle, parallelogram, trapezoid, sector, or a full

circle, depending on the particular transducer used.

The 2D cross-section is presented as a full color display, with various colors being used to

represent the power in blood flow echoes. Often, to provide spatial orientation, the full color

blood flow cross-section is overlaid on top of the gray scale cross-section of soft tissue

structure (2D echo). For each pixel in the overlay, the decision of whether to display CPD, gray

scale (echo) information or a blended combination is based on the relative strength of

echoes from the soft-tissue structures and from the red blood cells.

A high pass filter (wall filter) is used to remove the signals from stationary or slowly moving

structures. Tissue motion is discriminated from blood flow by assuming that blood is moving

faster than the surrounding tissue, although additional parameters may also be used to

enhance the discrimination. The power in the remaining signal after wall filtering may be

averaged over time (persistence) to present a steady state image of blood flow distribution.

CW provides a real-time representation of blood flow and is displayed as a

velocity-versus-time sweeping output. Velocity (or frequency) is presented as the vertical

axis with time along the horizontal axis. The magnitude of the detected signal is represented

as different gray scale values.

CW Doppler mode provides the clinician with the ability to obtain blood flow velocities

focused about a user specified focal region. A continuous transmit waveform of ultrasound

energy with a known frequency is transmitted and focused by the system; on the receive

side, the transducer receive echoes are continuously amplified, focused about the focal

region and converted to a base band quadrature signal. The signal is analyzed by a

quadrature phase detector that establishes two receive channels to allow detection of flow

direction. These two channels are then analyzed by a fast complex Fourier transform (FFT)

circuit to establish the spectrum of frequencies present in the echoes. The data are displayed

as spectrum frequencies with respect to time.

CW can be used alone but is normally used in conjunction with a 2D image for spatial

reference. The 2D image has a graphical line (D-line) superimposed on the 2D image

indicating where the M-mode beam is located.

6 Chapter 2: System Overview

Page 11

Pulsed Wave

(PW) Doppler

PW provides a real-time representation of blood flow and is displayed as a

velocity-versus-time sweeping output. Velocity (or frequency) is presented as the vertical

axis with time along the horizontal axis. The magnitude of the detected signal is represented

as different gray scale values. The ultrasound data is derived from a single area, the sample

volume, on a stationary beam.

PW Doppler mode provides the clinician with the ability to obtain blood flow velocities

about a spatial sample volume. A burst of ultrasound with a known spectrum is transmitted

by the system; on the receive side, the transducer receive echoes are amplified and range

gated at the appropriate depth. The signal is analyzed by a quadrature phase detector that

establishes two receive channels to allow detection of flow direction. These two channels are

then analyzed by a fast complex Fourier transform (FFT) circuit to establish the spectrum of

frequencies present in the echoes. The data are displayed as spectrum frequencies with

respect to time.

PW can be used alone but is normally used in conjunction with a 2D image for spatial

reference. The 2D image has a graphical line (D-line) superimposed on the 2D image

indicating where the M-mode beam is located. The sample volume position (depth) and size

are also indicated on the D-Line.

Additional System Feature Performances

Broadband Imaging This ultrasound acquisition system uses high resolution broadband technology in

the transmit pulsers, transducer, and receivers. The receive path can capture and

process signals over a wide spectrum, from below 2.0 MHz to beyond 10 MHz. For

each application, the transmit pulse is designed to produce an appropriate

bandwidth. For example, in 2D grayscale imaging, a wide band pulse is used to

support good axial resolution. For Doppler modes, a narrower band pulse is used,

which improves the spectral resolution of the detected Doppler signal.

In addition to transmit pulse control, programmable digital signal processing is used

in the receive path to further refine the bandwidth used to produce the final image.

Digital filters are applied to the digitized received signal to limit and shape the

spectral bandwidth used to generate the displayed output.

Tissue Specific

Imaging

Biopsy Guidance The system can display a pair of biopsy guidelines that represent the anticipated

Measurement and

Calculation

Capabilities

In this feature, parameters for signal and image processing are optimized to

maximize the image quality or to obtain the best compromise of resolution and

penetration for different specific clinical applications. These parameters include: the

order of received filters, the bandwidth, the dynamic range, the compression curve,

the gain setting and parameters for compounding frequency band, etc. For

example, different system parameter setups are used for abdominal or peritoneal

scanning. This feature is for ease of use for the operator by automatically setting up

system control parameters rather than manually adjusting settings for best

performance.

path of the biopsy needle. The image of an anatomical target, biopsy guidelines, a

scan plane marker, and a biopsy needle are displayed to assist in guiding the biopsy

needle to the target. The system also provides needle guidance for vascular access

procedures. For additional information, see the biopsy user guides.

The system offers a variety of measurements and calculations, specific to exam type

and transducer. A list of them , and author references, are in the system user guide.

Measurement accuracy is also discussed.

Chapter 2: System Overview 7

Page 12

Continuous Wave

Doppler Audio

Output

The system provides for audio output of the CW velocity information. This can be

presented as stereo information, with flow moving towards the transducer on one

channel and flow away on the other, or as a mono output with the single audio

output representing the summation of the flow directions.

Pulsed Wave Doppler

Audio Output

Electrocardiograph

(ECG) Display

ECG Module

The ECG module allows a representation of the heart electrical activity to be displayed in real time with ultrasound

images acquired and displayed on the system video display.

The ECG module interfaces to the patient through three (3) ECG leads: Right Arm ECG lead (RA), Left Arm ECG lead

(LA), and Left Leg ECG lead (LL). The ECG received signal from the ECG electrodes are isolated, amplified, and

filtered by the ECG module before it is sent to the system for further processing and display.

The ECG module and cable are an integrated assembly. The module receives power from the system. Patient

isolation is provided by the ECG module, allowing the connection and signals to the system to be system-ground

referenced. The isolation between the patient and the system meets the requirements of IEC 601-1 for Type BF

equipment.

The system provides for audio output of the PW velocity information. This can be

presented as stereo information, with flow moving towards the transducer on one

channel and flow away on the other, or as a mono output with the single audio

output representing the summation of the flow directions.

ECG is provided to measure the electrical signal generated by the heart. A three lead

interface: Right Arm (RA), Left Arm (LA) and Left Leg (LL), is provided on the system.

The ECG signal is displayed as an amplitude-versus-time sweeping output.

Amplitude is presented on the vertical axis with time along the horizontal axis.

DICOM

The system features Digital Imaging and Communications (DICOM) capability to provide the acceptance, transfer,

display, storage, and digital processing of single ultrasound images as well as loops of ultrasound images.

IMT

The system includes the ability to measure the intima-media thickness (IMT) of the carotid artery using digital

ultrasound images. The intima is that region of the arterial wall from and including the endothelial surface at the

lumen to the luminal margin of the media. The media layer extends from the intima to the adventitia of the vessel

wall. The adventitia is normally quite echogenic on ultrasound images when compared to the media. The IMT

measurement of the carotid artery may be used adjunctively with other medical data obtained by a physician to

help assess the cardiovascular health of a patient.

System Specifications

This section contains system and accessory specifications and agency approvals. The specifications for

recommended peripherals can be found in the manufacturers’ instructions. See the applicable SonoSite accessory

user guide for information on the accessories.

8 Chapter 2: System Overview

Page 13

System Dimensions

Length: 11.8 in. (29.97 cm)

Width: 10.8 in. (27.43 cm)

Height: 3.1 in. (7.87 cm)

Weight: 8.5 lbs. (3.9 kg) with the C60x transducer and battery installed

Display Dimensions

Length: 8.4 in. (21.34 cm)

Height: 6.3 in. (16 cm)

Diagonal: 10.4 in. (26.4 cm)

Transducers

C11x/5-2 MHz 11 mm curved array (6 ft./1.8 m)

C60x/5-2 MHz 60 mm curved array (5.5 ft./1.7 m)

HFL38x/13-6 MHz 25 mm linear array (5.6 ft./1.7 m)

ICTx/8-5 MHz 11 mm intracavitary array (5.5 ft./1.7 m)

L25x/13-6 MHz 25 mm linear array (7.5 ft./2.3 m)

L38x/10-5 MHz 38 mm linear array (5.5 ft./1.7 m)

P21x/5-1 MHz 21 mm phased array (6 ft./1.8 m)

Imaging Modes

2D (256 gray shades)

Color power Doppler (CPD) (256 colors)

Color Doppler (Color) (256 colors)

Continuous Wave (CW) Doppler

MMode

Pulsed wave (PW) Doppler

Tissue Doppler Imaging (TDI)

Tissue Harmonic Imaging (THI)

Image and Clips Storage

The number of images and clips you can save varies with imaging mode and file format.

Accessories

Hardware, Software, and Documentation

Barcode Scanner

Battery

Biopsy Guide

Carry case

Chapter 2: System Overview 9

Page 14

ECG Cable (6 ft/1.8m)

External display

Footswitch

Kensington Security Cable

Mini-Dock

Mobile Docking System Lite II (MDS Lite II)

Mobile Docking System M Series (MDSm)

Needle Guide

Power supply

Quick Reference Guide

SiteLink Image Manager 4.0

SonoCalc IMT

System User Guide

System AC PowerCcord (10 ft / 3.1 m)

Triple Transducer Connect

Video and printer cables

Cables

See the M-Turbo Ultrasound System User Guide, MDSm User Guide, and the MDS Lite II User Guide for information on

cables.

Peripherals

Peripherals include the following medical grade (conforming to the requirements of EN60601-1) and non-medical

grade (commercial) products. Manufacturer’s instructions accompany each peripheral. System setup instructions

are in the M-Turbo Ultrasound System User Guide. Instructions for using peripherals with the system are in the

applicable SonoSite accessory user guide.

Medical Grade

Black-and-white printer

Recommended sources for printer paper: Contact CIVCO at 1-800-445-6741 or www.civco.com to order

supplies or to find the local distributor.

Color printer

DVD recorder

15” External monitor

Non-Medical Grade

USB Memory Stick

10 Chapter 2: System Overview

Page 15

Temperature, Pressure, and Humidity Limits

Note: The temperature, pressure, and humidity limits apply only to the ultrasound system and transducers.

Operating Limits: System

• 10–40°C (50–104°F), 15–95% R.H.

• 700 to 1060hPa (0.7 to 1.05 ATM)

Operating Limits: Battery

• 10–40°C (50–104°F), 15–95% R.H.

• 700 to 1060hPa (0.7 to 1.05 ATM)

Operating Limits: Transducer

10–40°C (50–104°F), 15–95% R.H.

Shipping/Storage Limits: System without Battery

• -35–65°C (-31–149°F), 15–95% R.H.

• 500 to 1060hPa (0.5 to 1.05 ATM)

Shipping/Storage Limits: Battery

• -20–60°C (-4–140°F), 0–95% R.H.*

• 500 to 1060hPa (0.5 to 1.05 ATM)

* For storage longer than 30 days, store at or below room temperature.

• 10–40°C (50–104°F), 15–95% R.H.

Shipping/Storage Limits: Transducer

• -35–65°C (-31–149°F), 15–95% R.H.

Electrical

Power Supply Input: 100-240 VAC, 50/60 Hz, 2.0 A Max @ 100 VAC.

Power Supply Output 1 15 VDC, 5.0A Max (system)

Power Supply Output 2 12 VDC, 2.3A Max (battery)

Combined output not exceeding 75W.

Battery

6-cell, 11.2 VDC, 5.2 amp-hours, rechargeable lithium ion battery pack.

Run time is up to 2 hours, depending on imaging mode and display brightness.

Chapter 2: System Overview 11

Page 16

Electromechanical Safety Standards

EN 60601-1:1997, European Norm, Medical Electrical Equipment–Part 1. General Requirements for Safety.

EN 60601-1-1:2001, European Norm, Medical Electrical Equipment–Part 1. General Requirements for

Safety–Section 1-1. Collateral Standard. Safety Requirements for Medical Electrical Systems.

EN 60601]2]37:2001 + Amendment A1:2005, European Norm, Particular requirements for the safety of ultrasonic

medical diagnostic and monitoring equipment.

CAN/CSA C22.2, No. 601.1]M90, Canadian Standards Association, Medical ElectricalEquipment.Part 1. General

Requirements for Safety (including CSA 601.1 Supplement 1:1994 and CSA 601.1 Amendment 2:1998)

.CEI/IEC 61157:1992, International Electrotechnical Commission, Requirements for the Declaration of the Acoustic

Output of Medical Diagnostic Ultrasonic Equipment.

UL 60601]1 (1st Edition), Underwriters Laboratories, Medical Electrical Equipment] Part 1: General Requirements

for Safety.

EMC Standards Classification

EN 60601-1-2:2001, European Norm, Medical Electrical Equipment. General Requirements for Safety-Collateral

Standard. Electromagnetic Compatibility. Requirements and Tests.

CISPR11:2004, International Electrotechnical Commission, International Special Committee on Radio Interference.

Industrial, Scientific, and Medical (ISM) Radio-Frequency Equipment Electromagnetic Disturbance

Characteristics-Limits and Methods of Measurement.

The Classification for the SonoSite system, SiteStand, accessories, and peripherals when configured together is:

Group 1, Class A.

Airborne Equipment Standards

RTCA/DO]160E:2004, Radio Technical Commission for Aeronautics, Environmental Conditions and Test Procedures

for Airborne Equipment, Section 21.0 Emission of Radio Frequency Energy, Category B.

DICOM Standard

NEMA PS 3.15: 2000, Digital Imaging and Communications in Medicine (DICOM)-Part 15: Security Profiles.

HIPAA Standard

The Health Insurance and Portability and Accountability Act, Pub.L. No. 104-191 (1996).

45 CFR 160, General Administrative Requirements.

45 CFR 164, Security and Privacy.

12 Chapter 2: System Overview

Page 17

Chapter 3: Troubleshooting

This chapter contains information to help you correct problems with system operation and provides instructions

on the proper care of the system, transducer, and accessories.

Periodic Maintenance

There is no recommended periodic or preventive maintenance required for the system, transducers, or accessories.

There are no internal adjustments or alignments required. There are no functions that require periodic testing or

calibration. Performance tests are described in Chapter 5, “Performance Testing” of this manual. Performing

maintenance activities not described in this manual may void the product warranty.

Local regulations may require electrical safety testing.

Contact SonoSite Technical Support for any maintenance questions.

System and Subsystem Diagnosis

This section covers basic diagnostic and troubleshooting procedures you may follow if the system does not

operate properly. To diagnose system failures, consult the referenced diagnostic figures that follow or SonoSite

Technical Suppor t.

Table 3.1: Troubleshooting Subassemblies and Diagnostic Figures

Subassemblies Diagnostic Figures or Table

DICOM Tab le 3. 2

Dipslay TBA

Battery TBA

Control Panel TBA

System Repair

The system is repairable through subassembly replacement or through replacement of parts as recommended by

SonoSite in Chapter 4, “Replacement Procedures.” Component level repair of Printed Circuit Board Assemblies is

performed only at the SonoSite repair facility. Replacement of board level components by unauthorized service

facilities voids the SonoSite warranty.

Test Equipment

Test equipment is not required for this troubleshooting section. Troubleshooting test aids include an external

monitor and a spare battery.

Chapter 3: Troubleshooting 13

Page 18

Failure (Assert) Codes

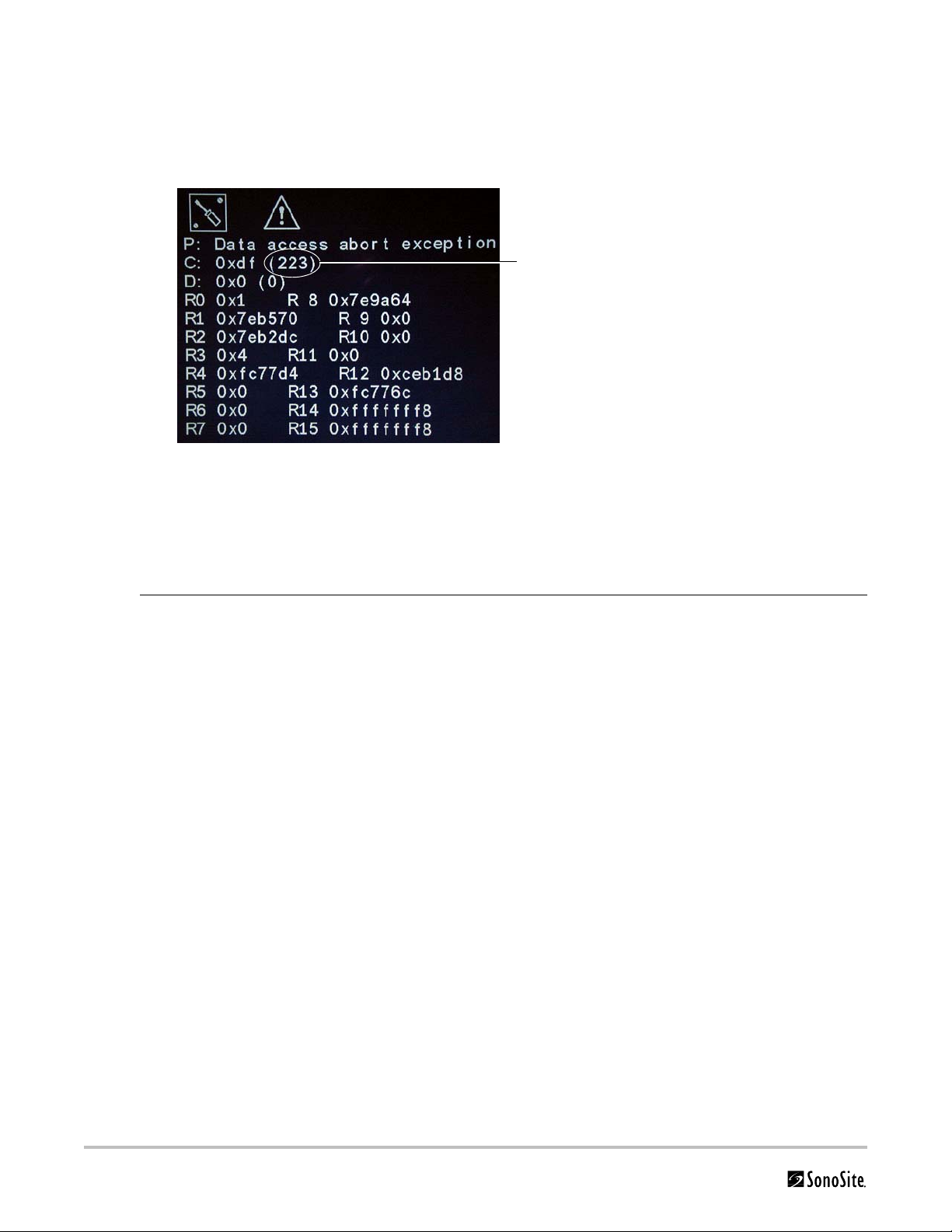

Assert code

The system displays an “assert screen” for hardware and software issues related to main PCBA failures. Main PCBA

failures typically result in “assert codes” that are output to the display. If an assert screen appears, note the assert

code and contact SonoSite Technical Support to clarify the failure. Figure 3.1 shows an assert screen. The assert

code is the bracketed number on the line labeled “C:”.

Figure 3.1 Assert Screen

Verifying a System Assert Code

System asserts are caused by hardware and/or software faults. Hardware asserts typically require main PCBA

replacement. Software asserts can be reset and the system may recover. A simple method to identify the cause of

the assert is identified here:

Assert Cause 1 Record the assert code.

2 Press and release the Power button to power the system down.

3 Press the Power button again to power on the system.

• If the system powers on normally, it has recovered from the fault (software assert) and

you may use the system.

• If the assert condition remains, corrective action must be taken; usually replacement of

the main PCBA is required. Contact SonoSite Technical Support for assistance and to

obtain repair parts.

If the Power button is not functional, all sources of power must be removed to allow the

system to power down. I.e., disconnect AC power and remove the battery.

14 Chapter 3: Troubleshooting

Page 19

DICOM

Table 3.2: DICOM Troubleshooting

Error Message Tiller Error Code Cause Troubleshooting

Socket

communication

failed

Archiver

transaction

failed

Printer

transaction

failed

TSOCKET_CONNECT_FAILURE Invalid network

configuration.

Wrong port

number.

Application is not

running.

Printer is offline.

TDICARCH_OPEN_FAILURE Wrong Capture

Type selected

TDICPRNT_OPEN_FAILURE Wrong Image

settings

Using Ping, verify that the

Printer/Archiver is connected.

• If Ping fails, check the devices IP

address, M-Turbo IP address,

Subnet mask, and Gateway IP

address.

• If Ping is OK, use Verify to check

if device is available.

If Verify fails:

a) Check the Printer/Archiver’s

Port configuration on the

M-Turbo.

b) Ensure that the Printer is

online and the Archiver’s

application is running.

Verify that the Archiver supports

the selected Capture Type setting,

e.g., US Image, SC Image or

US-Ret Image.

Verify that the printer supports

the selected Image settings. E.g,.

Color (RGB) or Grayscale

(Monochrome)

DICOM network

communication

failed

Internal failure

detected

TDNETWORK_OPEN_FAILURE Device does not

recognize

M-Turbo, rejects

association

TDNETWORK_READ_FAILURE Invalid DICOM

Attribute

Verify that M-Turbo AE Title or IP

address is correctly configured on

the Printer/Archiver.

Note: Some devices require that the

Imaging modality (M-Turbo) be

recognized in order to accept

images. This requires configuration

on the device.

Check M-Turbo Printer DICOM

settings for correctness (e.g., film

size, format)

Chapter 3: Troubleshooting 15

Page 20

16 Chapter 3: Troubleshooting

Page 21

Chapter 4: Replacement Procedures

Screws (2)

Caution:

Caution:

Always use correct ESD procedures. ESD damage is cumulative and may not be noticeable at first.

Initial ESD symptoms may be slightly degraded performance or image quality.

All fasteners should be torqued to 5.5 inch pounds except where noted.

Display Replacement

Required Parts

Service Assembly, LCD Display, M-Turbo (P08659)

Required Tools

• #1 Phillips screwdriver

• Torque screwdriver, 2.0–10.0 inch pounds (0.23–1.1 newton meter)

• An anti-static mat

• A wrist grounding strap

Display Removal

Display

Removal

Figure 4.1 System Rear

1 Remove the battery from the system.

2 Remove the two screws from the back of the system per Figure 4.1.

Chapter 4: Replacement Procedures 17

Page 22

3 Lay the system on the top, and remove the two screws from the bottom of the system per

Screws (2)

Figure 4.2.

Figure 4.2 System Bottom

4 Turn the system over, fully open the display, and lift off the Control Panel per Figure 4.3.

Figure 4.3 Control Panel Removal

18 Chapter 4: Replacement Procedures

Page 23

5 Disconnect the two connectors from the display to the Main PCBA per Figure 4.4.

Connectors (2)

Remove Screw Caps and

Screws (2)

Display rear enclosure slides

up

Figure 4.4 Display Connectors

6 The replacement Display Assembly does not include the Display Rear Enclosure. Remove

the Display Rear Enclosure by removing the two screw caps, two screws, and then sliding

the rear enclosure up and away from the display as show in Figure 4.5.

Figure 4.5 Remove Display Back Enclosure

Chapter 4: Replacement Procedures 19

Page 24

7 Remove the four screws from the Display Hinges per Figure 4.6.

Screws (4)

Figure 4.6 Display Screws

Display Replacement

Display

Replacement

Test the Display

Test Display 1 Replace the battery or attach an external power supply.

1 Set the new display in place.

2 Install the four hinge screws that hold the Display in place. Torque the screws to 5.5 inch

pounds.

3 Reinstall the Display Rear Enclosure, screws (2) and screw caps.

4 Connect the two connectors that connect the Display to the Main PCBA.

5 Place the Control Panel in place.

6 Reinstall the four screws that hold the Control Panel in place. Torque the screws to 5.5 inch

pounds.

2 Press the Power key to apply power to the system.

3 Verify the display operates correctly.

20 Chapter 4: Replacement Procedures

Page 25

Control Panel Subassembly Replacement

Required Parts

One of the following:

• P08856 Service Assembly, Control Panel M-Turbo, English

• P08878 Service Assembly, Control Panel M-Turbo, French

• P08879 Service Assembly, Control Panel M-Turbo, German

• P08880 Service Assembly, Control Panel M-Turbo, Italian

• P08881 Service Assembly, Control Panel M-Turbo, Spanish

• P08882 Service Assembly, Control Panel M-Turbo, Portuguese

Required Tools

• #1 Phillips screwdriver

• Torque screwdriver, 2.0–10.0 inch pounds (0.23–1.1 newton meter)

• An anti-static mat

• A wrist grounding strap

Caution:

Always use correct ESD procedures. ESD damage is cumulative and may not be noticeable at first.

Initial ESD symptoms may be slightly degraded performance or image quality.

Control Panel Removal

Control Panel

Removal

1 Remove the two screws from the rear of the system per Figure 4.1.

2 Remove the two screws from the bottom of the system per Figure 4.2.

3 Turn the system over, fully open the display, and lift off the Control Panel per Figure 4.3.

Control Panel Replacement

Control Panel

Replacement

1 Place the new control panel in place.

2 Install the four screws removed in “Control Panel Removal” on page 21. Torque the screws

to 5.5 inch pounds.

Chapter 4: Replacement Procedures 21

Page 26

Main System Disassembly for Repair and/or Replacement

Required Parts

Parts for the Main System Repair could include any of the following:

• P08939 Service Assembly Main PCBA, M-Turbo

• P08850 Service Assembly Power Supply, M-Turbo

• P05470 Service Assembly TGC, MicroMaxx (compatible with MicroMaxx and M-Turbo)

• P05473 Service Assembly Speaker, M-Turbo

• Nest Frame Assembly, M-Turbo (order these parts individually as necessary)

• P00364 Connector, Interposer (Qty 8)

• P00924 Screw, Shoulder, Thrust Plate (Qty 4)

• P00353 Wear Plate

• P00646 Spring, Thrust Plate (Qty 4)

• P07750 Nest Frame

• P03834 Shield, Perimeter, Long (Qty 2)

• P03833 Shield, Perimeter, Short (Qty 2)

• P08200 M2.5-.45x10 Socket Head Cap Screw (Qty 4)

Required Tools

• #1 Phillips screwdriver

• Torque screwdriver, 2.0–10.0 inch pounds (0.23–1.1 newton meter)

•2 mm allen key

•Scissors

•Q-Tips

• An anti-static mat

• A wrist grounding strap

Caution:

Always use correct ESD procedures. ESD damage is cumulative and may not be noticeable at first.

Initial ESD symptoms may be slightly degraded performance or image quality.

System Disassembly

System

Disassembly

1 Remove the battery.

2 Remove the control panel from the system following the removal procedures in “Control

3 Remove the 4 remaining screws from the bottom of the system.

4 Remove the bottom enclosure. This exposes all of the replaceable parts for the main system

Panel Removal” on page 21.

per Figure 4.7.

22 Chapter 4: Replacement Procedures

Page 27

Major System Components

Nest frame

assembly

TGC assembly

SpeakerSpeaker

Power supply

Main PCBA

SD Card

Daughter-card

Connectors

Retaining clips

Figure 4.7 System Components

Speaker Replacement

Caution:

Use caution when removing the left speaker connector to prevent damage to the Main PCBA

components around the connector.

Speaker

Replacement

1 Press on the connector release and pull the connector out of the receptacle.

2 Gently pry off the retaining clip with a flat bladed pry tool. See Figure 4.8.

3 Replace the speakers by reversing steps 1-2.

Figure 4.8 Speaker Replacement

Chapter 4: Replacement Procedures 23

Page 28

Power Supply PCBA Replacement

Power supply

shield

Power Supply

Removal

1 Gently pry the shield from the power supply and set it aside. This part will be used in

reassembly. Note that the shield fits only one way. See Figure 4.9.

Figure 4.9 Power Supply Shield

2 Remove the 7 screws that hold down the power supply PCB per Figure 4.10.

3 Gently lift the power supply away from the Main PCBA.

4 Install the new Power Suppply PCBA by reversing steps 1-3.

24 Chapter 4: Replacement Procedures

Power supply

screws (7x)

Figure 4.10 Power Supply Screws

Page 29

SD Card Daughter-card

SD Card Daughter-card

under copper tape

SD Card

Daughter-card

screws (4x)

Long screw

SD Card

1 Carefully remove the copper tape from the SD Card Daughter-card. See Figure 4.11.

Daughter-card

Removal

Figure 4.11 SD Card Daughter-card copper tape

2 Remove the 4 screws that hold down the SD Card Daughter-card per Figure 4.12. Note the

location of the one longer screw for reassembly.

3 Gently lift the SD Card Daughter-card straight up away from the Main PCBA.

Figure 4.12 SD Card Daughter-card screws

Chapter 4: Replacement Procedures 25

Page 30

SD Card

Copper tape applied to

side of Power Supply

Frame

Ventilation cut-outs

SD Card

Daughter-card

alignment pins

Note: Kapton tape is used to

retain the SD Cards in place

Daughter-card

Replacement

1 Remove Power Supply frame assembly from the Main PCBA.

2 Apply one strip of 1” x 5” self adhesive copper tape to the edge of the Power Supply frame

as shown in Figure 4.13.

3 The copper tape must be cut away from the ventilation holes in the frame or failure of the

Main PCBA will occur.

Figure 4.13 SD Card Daughter-card copper tape

4 Place the Power Supply frame back onto the Main PCBA.

5 Place the Power Supply PCBA in the frame and secure with the 7 screws

6 Install the SD Card Daughter-card onto the Main PCBA frame using the alignment

holes/pins on the card and frame.SeeFigure 4.14.

Caution: Improper installation of the SD Card Daughter-card will cause all or part of the

internal image storage memory to not be recognized by the system.

7 Install the screws ensuring proper location of longer screw.

26 Chapter 4: Replacement Procedures

Page 31

Figure 4.14 SD Card Daughter-card alignment

8 Fold the copper strip installed in Step 1 over the top of the SD Card Daughter-card.

9 Install a second strip of 1” x 5” self-adhesive copper tape over the SD Card Daughter-card on

the edge closest to the Power Supply frame as show in Figure 4.15.

Figure 4.15 Copper Tape Installation

10 Install a third strip of 1” x 5” self-adhesive copper tape over the SD Card Daughter-card as

shown in Figure 4.16.

Figure 4.16 Copper Tape Installation

11 The adhesive on the copper strips must be activated by rubbing the entire surface of the

copper tape using a Q-tip as shown in Figure 4.17.

Chapter 4: Replacement Procedures 27

Page 32

Figure 4.17 Activating Copper Tape Adhesive

Note: Rub the entire surface

of the copper tape to ensure

proper adhesion.

TGC knobs (3)

TGC PCBA Replacement

TGC PCBA

Removal

1 Remove the Control Panel if not already removed.

2 Remove the TGC knobs identified in Figure 4.18.

Figure 4.18 TGC Knobs

28 Chapter 4: Replacement Procedures

Page 33

3 Remove the flex cable from the TGC PCB by lifting on the flex release tab. See Figure 4.19.

Release tabs Screws (2)

Screws (3)

4 Remove the flex cable from the Main PCBA by lifting gently on the flex release tab.

5 Remove the two screws holding the TGC PCBA in place.

6 Reverse steps 1-5 to reinstall the TGC PCB.

Figure 4.19 TGC PCBA Removal

Main PCBA Replacement

Main PCBA

Removal

1 Remove the Power Supply PCBA, SD Card Daughter-card, and TGC PCBA as described in the

2 Remove the 3 screws holding the Main PCBA in place per Figure 4.20. Dissconnect the

previous steps.

speaker wires from the Main PCBA.

Figure 4.20 Main PCBA Screws

Chapter 4: Replacement Procedures 29

Page 34

Figure 4.21 Nest Frame Top Screws

2.5mm Socket Head Cap

Screws (4x)

3 Turn the system over.

4 Remove the 4 Socket Head Cap Screw as shown in Figure 4.21. This releases the Nest Frame

and will allow the Main PCBA to be removed.

5 As you remove the nest frame assembly from the PCBA, tilt the PCBA and enclosure to

almost vertical to avoid spilling the Interposer Connectors from the assembly.

6 Lift on the edge of the Main PCBA closest to the system handle.

30 Chapter 4: Replacement Procedures

Page 35

Main PCBA

Replacement

Replace the Main PCBA by following the reverse of the removal procedure. Do not tighten all the

screws until everything is in place.

1 Replace the Main PCBA.

2 Reinstall the Nest Frame Assembly. The Nest Frame Socket Head Cap Screws should be

torqued to 4.5 inch pounds

3 Reconnect the speaker wires.

4 Reinstall the Power Supply PCBA.

5 Reinstall the SD Card Daughter-card and copper tape.

6 Reinstall the TGC assembly.

7 Reinstall the shield to the Power Supply.

8 Tighten all screws to their specified torque of 5.5 inch pounds.

9 Reinstall the Control Panel.

10 Reinstall the bottom enclosure.

Chapter 4: Replacement Procedures 31

Page 36

32 Chapter 4: Replacement Procedures

Page 37

Chapter 5: Performance Testing

Overview

WAR NIN G:

To obtain 2D images, SonoSite recommends using the RMI 413A Soft Tissue Phantom or the RMI 403 GS

Multipurpose Phantom. A .7db/cm phantom is required for performing penetration measurements. Any

equivalent .7db/cm Phantom is acceptable.

When making penetration measurements on a phantom, apply the phantom reference value and tolerance to the

measurement.

Some features and capabilities are optional and therefore may be uavailable to test.

Critical Test Function — A failure of the system functions tested in this section could affect

safety or effectiveness of the system adversely. While performing the steps in this section, verify

that the images on the system display and on the external monitor are acceptable.

Test Equipment

• SonoSite ultrasound system under test

• C60x/5-2 MHz transducer

• P21x/5-1 MHz transducer

• RMI 413A Soft Tissue Phantom, RMI 403 GS Multipurpose Phantom, or equivalent. A referenced .7db/cm

phantom is required for performing penetration measurements.

• Video Printer

• External Monitor

•Acoustic gel

Setting Up Performance Tests

Set up

Performance

Te st s

1 Attach the C60x/5-2 MHz transducer to the system.

2 Select Gen for optimization and OB for exam type.

3 Couple the transducer to the phantom, adjusting gain settings and transducer for a proper

phantom image (e.g., pins are high-level echoes positioned in straight lines; cysts are

sonolucent, edges are sharp, and graphite particles of the phantom are mid-grays).

Chapter 5: Performance Testing 33

Page 38

Basic Operational Tests

Basic System

Operation

Te st s

1 Verify that the correct transducer name appears in the upper right corner of the system

display.

2 Verify proper date and time.

3 Verify that the scan plane orientation mark in the image located near the skinline

corresponds to element #1 on the transducer. To test, put your finger on the probe and run

it across the transducer face. Your finger touching the transducer face should appear at the

orientation mark on the display image format.

4 Verify that all of the keyboard keys are functional. Verify that all controls operate smoothly

over their full range and that the system responds properly.

5 Verify that all of the softkeys are functional.

6 Verify that as the Gain controls are increased and decreased, there is a corresponding

increase and decrease in echo intensity.

7 Capture a Cineloop buffer. Exercise the Cineloop controls and verify proper operation.

8 Close the lid and verify the unit goes into sleep mode. Open the lid and verify the unit

returns to normal operation.

9 Verify the airflow from the vent on the left side of the system is blowing out.

2D Performance Tests

2D Performance / Image Quality

Test 2D

Performance

and Image

Quality

1 Use a C60x/5-2 MHz transducer in 2D mode.

2 Adjust the position of the C60x/5-2 MHz transducer on the phantom.

3 With the array pointing down and the orientation mark to the operator’s left, element #1

corresponds with the left side of the array.

4 Use the 2D system controls to obtain a clear image that shows both the horizontal and

vertical rows of pins.

5 Verify that the ultrasound image appears uniform in both the axial and lateral direction,

with no dropouts or intensity variations.

6 Verify that the cystic structure at the focal zone is clearly differentiated from the

surrounding tissue and is echo-free, while solid tissue with numerous echo sources, appears

solid.

7 Press the Freeze key and then save the image. Press the Freeze key again to return to live

imaging.

34 Chapter 5: Performance Testing

Page 39

Axial Measurement Accuracy

Note: Measurements must be performed while the image is frozen.

Set Up Axial

Measurement

Accuracy

Test Axial

Measurement

Accuracy

1Acquire the image.

2 Press the Freeze key.

3 Press the Caliper key. The caliper appears on the image display. (See the M-Turbo Ultrasound

System User Guide, if necessary, for caliper operation.)

4 Use the touchpad to position one of the calipers.

5 Press the Select key to fix the caliper and enable the other caliper.

6 Use the touchpad to move the other caliper. The results update as you move the caliper, and

the measurement is complete when you finish moving the calipers. (Press the Select key to

alternate the active caliper, and adjust the measurement with the touchpad.)

1 Measure the distance, center to center, of any two pins that are 5-12 cm apart vertically.

2 Verify that the distance measured is within the tolerance listed in Tab le 5 .1.

Lateral Measurement Accuracy

Set Up Lateral

Measurement

Accuracy

Test Lateral

Measurement

Accuracy

Perform “Set Up Axial Measurement Accuracy” on page 35.

1 Measure the distance, center to center, of any two pins that are 4-10 cm apart horizontally.

2 Verify that the distance measured is within the tolerance listed in Tab le 5 .1.

3 Press the Freeze key to return the system to live 2D mode.

Table 5.1: System Measurement Accuracy

Measurements Tolerance

Axial Distance +/- 2%

Lateral Distance +/- 2%

Penetration

Caution:

Te st

Penetration

A referenced .7db/cm phantom is required for performing penetration measurements

1 Adjust the system controls to obtain a clear image that shows the limits of echo penetration

as shown in Table 5. 2.

2 Set the system exam type and optimization mode settings to the values shown in Table 5. 2.

3 Measure from the center of the skinline to the deepest vertical position—where the scatter

echoes start to break up and tissue definition is lost.

4 When making penetration measurements on a phantom, apply the phantom reference

value and tolerance to the measurement.

5 Press the Freeze key and then save the image. Press the Freeze key again to return to live

imaging.

Chapter 5: Performance Testing 35

Page 40

Table 5.2: Imaging Performance

Imaging

Performance

Exam type Nerve OB OB Small

Optimization Gen Gen Gen Res Res Res Pen

2D Penetration 6.8cm 14.0 cm 6.5 cm 4.5 cm 4.3 cm 5.7 cm 21.0 cm

C11x C60x ICTx HFL38 L25x L38x P21x

Additional Performance Tests

Color Doppler (Color)

Test Colo r 1 Connect any transducer.

2 Press the Color key. “Color” should be annotated in the top left corner of the display.

3 A Region of Interest (ROI) box is displayed on top of the grayscale image. Use the touchpad

to move the CPD ROI. Verify that the ROI moves to the new position on the display.

4Adjust the Depth control for minimum depth in the image.

5Adjust the Gain control so that color speckles just appear inside the ROI box.

6 Gently tap the face of the transducer and observe that the ROI box fills with color

information.

7 Press the Freeze key and then save the image. Press the Freeze key again to return to live

imaging.

Sup Breast ABD

Parts

Color Power Doppler (CPD)

Test CP D 1 Connect any transducer.

2 Press the Color key. A Region of Interest (ROI) box is displayed on top of the grayscale image.

3 Press the Color softkey to switch to CPD. “CPD” should be annotated in the top left corner

of the display.

4Adjust the Depth control for minimum depth in the image.

5Adjust the Gain control so that color speckles just appear inside the ROI box.

6 Gently tap the face of the transducer and observe that the ROI box fills with color

information.

36 Chapter 5: Performance Testing

Page 41

MMode Imaging

Test M Mod e

Imaging

1 Attach a C60x transducer and acquire an image.

2 Press the MMode key for the M Mode sample line.

3 Position the M Mode sample line over the image using the touchpad.

4 Press the MMode key again to turn on M Mode.

5 Select the desired sweep speed from the on-screen menu (slow, med, or fast). The on-screen

menu will show the selected sweep speed.

6 Press the Freeze key to freeze the image. Save the image. Press the Freeze key again to

return to live imaging.

7 Press the 2D key to return to 2D imaging.

Tissue Harmonic Imaging

Test THI

Imaging

1 Attach the C60x transducer and acquire an image.

2 Set the depth to maximum and note the depth at which echo information is lost.

3 Press the THI key on the control panel so it displays THI on the display. Tissue Harmonic

Imaging in now active.

4 Observe a decrease in dot size and a significant loss in penetration due to the higher

frequency. Image resolution increases.

5 Press the Freeze key and then save the image. Press the Freeze key again to return to live

imaging.

6 Press the THI key again to turn off Tissue Harmonic Imaging.

Pulsed Wave (PW) Doppler Imaging

Test PW

Doppler

Imaging

1 Attach the P21x transducer.

2 Press the Doppler key for the Doppler sample gate.

3 Press the Doppler key again for the Doppler spectral trace.

4 Place a large drop of ultrasound gel on the transducer lens.

5Adjust the Gain control as necessary and then gently tap the top of the gel and observe a

reflection on the spectral trace and the sound from the speakers.

6 Press the Freeze key and then save the image. Press the Freeze key again to return to live

imaging.

7 Press the 2D key to return to 2D imaging.

Chapter 5: Performance Testing 37

Page 42

Continuous Wave (CW) Doppler Imaging

Test CW

Doppler

Imaging

1 Attach the P21x transducer.

2 Press the Patient key.

3 Select the Cardiac exam type.

4 Press the Done softkey.

5 Press the Doppler key for the Doppler sample gate.

6 Press the PW softkey to switch to CW Mode.

7 Press the Doppler key again for the Doppler spectral trace.

8 Place a large drop of ultrasound gel on the transducer lens.

9Adjust the Gain control as necessary and then gently tap the top of the gel and observe a

reflection on the spectral trace and the sound from the speakers.

10 Press the Freeze key and then save the image. Press the Freeze key again to return to live

imaging.

11 Press the 2D key to return to 2D imaging.

Image Quality Verification Test/Livescan

• Products with replaced subassemblies, or products that have been otherwise disassembled, must undergo an

Image Quality Verification Test/Livescan.

• The Image Quality Verification Test/Livescan should be performed after successfully completing all applicable

performance tests listed prior in this chapter.

• The test is completed before returning the system to service.

• A certified sonographer must perform the test.

• The Livescan test performed is at the discretion of the Sonographer and will represent their acceptance of a

successful service event.

• Review all saved images and verify that the images are displayed properly.

Printer

Test Print e r

Operation

1 Verify proper printer type is configured in the system Setups page.

1 Press the print button and verify that the printer begins to print an image. After the image

begins to emerge from the printer, press the print button again. The printer should ignore

the second print command.

2 Verify the proper content of the printed image.

38 Chapter 5: Performance Testing

Page 43

Battery Charging

Test Batt e r y

Charging

Operation

Video Output

Caution:

Test Video

Output

1 Remove the system from the docking system and insert a battery into the system.

2 Press the Power key to turn the system on. Allow the battery to discharge. The battery

indicator icon on the display, below the Transducer Type indicator, will extinguish from left

to right as the battery discharges.

Note: The Power and Sleep delays in the Setup page should be selected to “Off” to properly

perform this test. The battery may take 1–2 hours to discharge.

3 Reattach the system to the Docking System and attach the AC power cord to the power

connector.

4 Note that the battery indicator indicates that the battery is charging. The sections of the

battery indicator will light sequentially from left to right as the battery charges.

Use only the recommended video monitor or printer when verifying the video output at the

video receptacle.

1 Attach an external video monitor to the video connector using the video cable.

2 Turn on the system power and verify that the video on the external monitor matches the

video on the system display.

If the video does not appear similar, or there is no display on the external monitor, see

Chapter 3, “Troubleshooting” for troubleshooting procedures.

Chapter 5: Performance Testing 39

Page 44

40 Chapter 5: Performance Testing

Page 45

Appendix A: Replacement Parts List

1

2

3

The following tables contain all the field-replaceable parts for the M-Turbo ultrasound system. Quantities are one

unless otherwise noted.

Display

Table A.1: Display

Find Number Part Number Description

1 P08659 Service Assembly Display M-Turbo

Note: The Display Assembly does not include the rear Display Enclosure (item

3). This should be retained from the unit being replaced.

2P08060Hinge

P08855 Service Assy, Display Enclosure, Gray (Olympic Mist), M-Turbo

P08874 Service Assy, Display Enclosure, Blue (Glacier Sky), M-Turbo

3

P08875 Service Assy, Display Enclosure, Green (Pacific Pine), M-Turbo

P08876 Service Assy, Display Enclosure, Brown (Copper River), M-Turbo

P08877 Service Assy, Display Enclosure, Pink (Alpine Berry), M-Turbo

Appendix A: Replacement Parts List 41

Page 46

Control Panel

Table A.2: Control Panel

Part Number Description

P08856 Service Assembly Control Panel, M-Turbo, English

P08878 Service Assembly Control Panel, M-Turbo, French

P08879 Service Assembly Control Panel, M-Turbo, German

P08880 Service Assembly Control Panel, M-Turbo, Italian

P08881 Service Assembly Control Panel, M-Turbo, Spanish

P08882 Service Assembly Control Panel, M-Turbo, Portuguese

42 Appendix A: Replacement Parts List

Page 47

System

3

4 4

6

5

2

1

Table A.3: System

Find Number Part Number Description

1 P07442 SD Card Daughter-card

2 P09202 2GB SD Card

not shown P09216-01 Copper Tape for SD Card Daughter-card (Note: Part number referenced is

per inch of copper tape. Approximately 15 inches of 1” wide tape is required

per system.)

3 P08850 Service Assembly, Power Supply, M-Turbo

4 P03872 Service Assembly, Speaker

5 P08939 Service Assembly Main PCBA, M-Turbo

Note: This part does not include the transducer nest frame assembly. Those

parts must be ordered separately if needed to complete the replacement of the

Main PCBA.

6 P05470 Service Assembly, TGC PCB

Not shown P00361 Foot

Appendix A: Replacement Parts List 43

Page 48

Figure A.1 Power Supply, P08850

Figure A.2 Speaker Assembly, P03872

44 Appendix A: Replacement Parts List

Page 49

Figure A.3 TGC Assembly, P05470

1

2

3

Table A.4: TGC Assembly

Find Number Part Number Description

1 P02317 Assembly, PCB, TGC

2 P06287 Knob, TGC

3 P02308 FFC, 12 Position Jumper

Figure A.4 Main PCB Assembly, P08939

Appendix A: Replacement Parts List 45

Page 50

Transducer Nest Frame Assembly

2

6

1

7

5

4

3

Figure A.5 Nest Frame Parts

Table A.5: Nest Frame Assembly

Find Number Part Number Description

1 P07750 Nest Frame Assembly

2 P00364 Connector, Interposer (8x)

3 P03833 Shield, Perimeter, Short (2x)

4 P03834 Shield, Perimeter, Long (2x)

5 P00924 Screw, Shoulder, Thrust Plate (4x)

6 P00353 Wear Plate

not shown P00646 Spring, Thrust Plate, .047 wire (4x)

7 P08200 Socket Head Cap Screw, M2.5-.45x10mm (4x)

Ordering Replacement Parts

To order parts, contact SonoSite Technical Support as indicated in “Contact Information” on page 1.

46 Appendix A: Replacement Parts List

Page 51

Appendix B: Service Event Report

The Service Event Report provides information about product failures to the manufacturer and to authorized

service facilities, which provide approved warranty services for SonoSite products. For all repairs completed,

complete the form and return a copy of it to the following address:

SonoSite, Inc.

Technical Suppor t

21919 30th Drive SE

Bothell, Washington 98021

USA

To co nt a c t SonoSite Technical Suppor t , s e e“Contact Information” on page 1.

Appendix B: Service Event Report 47

Page 52

Service Event Report Form

48 Appendix B: Service Event Report

Page 53

Service Event Report Instructions

Instructions for completing the Service Event Report

Sections highlighted in yellow must be completed for SonoSite to accept the Service Event Report. If additional information is

required for certain circumstances you will be advised.

Forward the completed form to:

Email: service@sonosite.com

Fax: +1-425-951-6700

Service Type

x Out of Box Failure: the item has arrived from SonoSite with failures.

x Warranty Service: the item has failed after arrival and is covered by either the included warranty or a valid extended

warranty.

x Out of Warranty Service: the item has failed and it is no longer covered by a warranty.

Parts Status

x Check One.

Service Provider

x Name: the name of the technician performing the work.

x Provider Reference: a unique number used by the Provider to track Service Event Reports. Any format is acceptable.

x Company: the name of the Distributor or authorized repair facility.

x Address: the address replacement parts will be shipped to.

x Date Reported: the date the failure was reported to SonoSite.

x Phone Number: the phone number to contact the service technician.

x Fax Number: the fax number to contact the service technician.

x Email Address: the email address to contact the service technician.

Device Description:

x Name: the description of the failed product.

x Ref Number: the reference number from the part number label of the failed product.

x Serial Number: the serial number from the part number label of the failed product.

x Lot Number: if applicable, the Lot Number from the device identification label.

x ARM/SHDB Version: the software level of the failed device. Typically found on the system information screen.

x Configuration: for configurable devices, the optional features enabled.

Event Description

x A description of the problem in the words of the user. Typically what the user reports to the repair facility.

Diagnosis

x A description of what the repair technician found. Include a list of the suspect parts.

Service Performed

x A description of the work performed to repair the system. Typically only completed if it is repaired from stock repair parts.

Parts Removed

x Part Name: the name of the failed/suspect part to be replaced.

x Part Number: the part number of the failed/suspect part.

x Serial Number: the serial number from the failed/suspect part.

x Lot Number: the lot number if applicable.

x Rev: the revision of the failed/suspect part if available.

x Replaced By: the person replacing the part.

Parts Installed

x The same information as the Parts Removed except from the parts installed if work has already been performed. If you are

waiting for parts to be ordered, leave this section blank.

Tests Performed

x The results of any testing performed, if testing has already been performed.

Appendix B: Service Event Report 49

Page 54

Returning Products to SonoSite

You will be asked to provide the following information:

• Contact name and phone number

•Product name

•Serial number

• Description of the problem

Shipping Instructions

Please contact SonoSite to get a return material authorization number (RMA). Contact SonoSite before returning

any product.

The shipping address for all returned products is:

SonoSite, Inc.

Attn: Technical Support RMA ___________________

21919 30th Drive SE

Bothell, Washington 98021

USA

50 Appendix B: Service Event Report

Page 55

Index

Numerics

2D performance tests

axial measurement accuracy 35

image quality 35

lateral measurement accuracy 35

penetration 35

A

accessories 8

assert code 14

assistance, customer 1

B

battery

specifications 11

storage and shipping 11

battery charging test 39

C

cable specifications 10

control panel assembly

replacement procedure 21

conventions used 1

D

display assembly

replacement procedure 17

I

image

quality verification test 38

review 38

M

main PCBA

failures 14

replacement procedure 22

monitor 8

P

performance tests

2D 34

battery 39

CPD 36

CW 38

M-Mode 37

overview 33

printer 38

PW 37

THI 37

Velocity Color 36

video output 39

periodic maintenance 13

peripherals 10

power supply replacement procedure 24

printer

test 38

product failures, reporting 47

products, returning 50

R

replacement parts

list 41

ordering 46

replacement procedures 17

Display replacement 17

Main PCBA replacement 29

Power Supply PCBA replacement 24

SD Card Daughter-card replacement 25

Speaker replacement 23

TGC PCBA replacement 28