Page 1

C1.75 Ultrasound System

Service Manual

Page 2

P01118-03 01/2003

Copyright 2003 by SonoSite, Inc.

All rights reserved. Printed in the USA.

ii C1.75 Ultrasound System Service Manual

Page 3

Manufactured by

SonoSite, Inc.

21919 30th Drive SE

Bothell, WA 98021-3904

USA

Telephone: 1-888-482-9449 or +1-425-951-1200

Fax: +1-425-951-1201

SonoSite European Headquarters

Baystrait House, Station Road

Biggleswade SG18 8AL

UK

Telephone: +44-1767-313-117

Fax: +44-1767-312-400

CAUTION:

` United States federal law restricts this device to sale by or on the order of a

physician.

“SiteCharge,” “SitePack,” “SiteStand,” and “SonoHeart,” are trademarks of SonoSite, Inc.

Non-SonoSite product names may be trademarks or registered trademarks of their respective

owners.

SonoSite products may be covered by one or more of the following U.S. patents: 4454884, 4462408,

4469106, 4474184, 4475376, 4515017, 4534357, 4542653, 4543960, 4552607, 4561807, 4566035,

4567895, 4581636, 4591355, 4603702, (4607642), 4644795, 4670339, 4773140, 4817618,

4883059, 4887306, 5016641, 5050610, 5095910, 5099847, 5123415, 5158088, 5197477, 5207225,

5215094, 5226420, 5226422, 5233994, 5255682, (5275167), 5287753, 5305756, 5353354,

5365929, 5381795, 5386830, 5390674, 5402793, (5,423,220), 5438994, 5450851, 5456257,

5471989, 5471990, 5474073, 5476097, 5479930, 5482045, 5482047, 5485842, 5492134, 5517994,

5529070, 5546946, 5555887, 5603323, 5606972, 5617863, (5634465), 5634466, 5636631,

5645066, 5648942, 5669385, (5706819), 5715823, 5718229, 5720291, 5722412, 5752517,

5762067, 5782769, 5800356, 5817024, 5833613, 5846200, 5860924, 5893363, 5916168, 5951478,

6036643, 6102863, 6104126, 6113547, 6117085, 6142946, 6203498 B1, D0280762, D0285484,

D0286325, D0300241, D0306343, D0328095, D0369307, D0379231. Other patents pending.

iii

Page 4

iv C1.75 Ultrasound System Service Manual

Page 5

Table of Contents

CHAPTER 1 Introduction 1

1.1 Description................................................................................1

1.2 System Components..................................................................1

1.3 Audience ...................................................................................2

1.4 Conventions Used in This Manual............................................2

1.5 About the System Software ......................................................3

1.6 Software Licensing ...................................................................3

CHAPTER 2 Safety 5

2.1 Electrical Safety........................................................................5

2.1.1 Equipment Protection.........................................................7

2.2 Battery Safety............................................................................7

2.3 Biological Safety.......................................................................8

2.4 Labeling Symbols .....................................................................9

CHAPTER 3 System Overview 11

3.1 Theory of Operation................................................................11

3.1.1 Transducer........................................................................12

3.1.2 Acquisition Subsystem.....................................................12

3.1.3 Processing Subsystem ......................................................12

3.1.4 Display Subsystem ...........................................................12

3.1.5 Control Subsystem ...........................................................12

3.1.6 User Interface Subsystem.................................................12

3.1.7 Power Subsystem .............................................................13

3.2 Components ............................................................................13

3.3 Controls...................................................................................13

3.4 Accessories .............................................................................15

3.4.1 SiteStand Mobile Docking Station...................................15

3.4.1.1 SiteLink Image Management Software........................16

3.4.1.2 IrfanView Software......................................................16

3.4.2 SiteStand Display .............................................................16

3.4.3 SiteCharge Dual Battery Charger.....................................18

3.4.4 SitePack Protective Carry Pack........................................18

3.4.5 Battery Pack .....................................................................19

3.4.5.1 Battery Charge Indicators ............................................19

3.4.6 External Power .................................................................19

v

Page 6

3.4.6.1 External System Connections ......................................20

3.4.7 Power Adapter..................................................................20

3.4.8 Cables ...............................................................................21

3.4.8.1 Video............................................................................21

3.4.8.2 Printer Control..............................................................21

3.4.8.3 AC Power Extension....................................................21

3.4.9 Video ................................................................................21

3.4.9.1 Video Port Cable..........................................................22

3.5 System Specifications.............................................................22

3.5.1 Physical Dimensions ........................................................22

3.5.2 Monitor.............................................................................22

3.5.3 Transducers ......................................................................22

3.5.4 Imaging Modes.................................................................22

3.5.5 Image Storage...................................................................23

3.5.6 Temperature and Humidity Limits...................................23

3.5.6.1 System Operating.........................................................23

3.5.6.2 System Shipping/Storage ............................................23

3.5.6.3 Battery Operating.........................................................23

3.5.6.4 Battery Shipping/Storage .............................................23

3.5.6.5 Transducers Operating .................................................23

3.5.6.6 Transducers Shipping/Storage .....................................23

3.5.7 Electrical...........................................................................23

3.6 Battery.....................................................................................24

3.7 Safety Requirements...............................................................24

3.7.1 Meets Electromechanical Safety Standards .....................24

3.7.2 Meets EMC/EMI Standards .............................................24

3.7.3 Meets Airborne Equipment Standards .............................25

CHAPTER 4 Setup and Operation 27

4.1 Connecting and Removing Transducers .................................27

4.2 Removing and Installing the Battery ......................................28

4.3 Turning the System On and Off..............................................29

4.4 Using AC Power .....................................................................30

4.5 Upgrading the System Software .............................................31

4.6 Obtaining A License Key .......................................................32

4.6.1 Installing A License Key..................................................33

4.6.1.1 Displaying the System Information Screen .................34

4.7 Checking and Charging the Battery........................................35

4.8 Using the SiteCharge Dual Battery Charger...........................37

vi C1.75 Ultrasound System Service Manual

Page 7

4.9 Using System Setup ................................................................38

4.9.1 Setting the Date and Time................................................39

4.9.2 Setting the Sleep Delay ....................................................39

4.9.3 Setting the Power Delay...................................................39

4.9.4 Setting the Audible Beep..................................................39

4.9.5 Setting Up A Recommended Printer................................40

4.9.6 Setting Up A Recommended VCR...................................40

4.9.7 Setting Up A Recommended Video Monitor (External)..41

4.9.8 Setting Up Function Key Assignments ............................41

4.9.9 Changing All System Setups to the Default Settings .......41

CHAPTER 5 Cleaning and Disinfecting 43

5.1 Universal Precautions .............................................................43

5.2 Receipt of Suspected Contaminated Materials .......................43

5.3 Recommended Disinfectants ..................................................44

CHAPTER 6 Troubleshooting 45

6.1 System and Subsystem Diagnosis...........................................45

6.2 Subassembly Replacement......................................................45

6.3 Test Equipment .......................................................................45

6.4 Failures....................................................................................46

6.4.1 Display..............................................................................46

6.4.2 Control Panel....................................................................46

6.4.3 Trackball...........................................................................46

6.4.4 Main PCBA ......................................................................46

6.4.5 Clearing the Main PCBA Failure.....................................47

6.4.6 Battery ..............................................................................47

CHAPTER 7 Replacement Procedures 55

7.1 Display ....................................................................................55

7.1.1 Required Parts ..................................................................55

7.1.2 Required Tools and Materials ..........................................55

7.1.3 Removing the Display......................................................56

7.1.4 Replacing the Display ......................................................58

7.2 Control Panel ..........................................................................60

7.2.1 Required Parts ..................................................................60

7.2.2 Required Tools .................................................................60

7.2.3 Removing the Control Panel ............................................60

7.2.4 Replacing the Control Panel ............................................63

vii

Page 8

7.3 Trackball .................................................................................64

7.3.1 Required Parts ..................................................................64

7.3.2 Required Tools .................................................................64

7.3.3 Removing the Trackball...................................................64

7.3.4 Replacing the Trackball ...................................................67

7.4 Main PCBA.............................................................................69

7.4.1 Required Parts ..................................................................69

7.4.2 Required Tools .................................................................70

7.4.3 Removing the Main PCBA ..............................................70

7.4.4 Replacing the Main PCBA...............................................71

7.5 Transducers.............................................................................74

7.6 SiteCharge Dual Battery Charger ...........................................74

7.7 AC Power Adapter..................................................................74

7.8 Peripherals ..............................................................................75

7.8.1 Display .............................................................................75

7.8.2 VCR..................................................................................75

7.8.3 Printer ...............................................................................75

CHAPTER 8 Performance Tests 77

8.1 Overview.................................................................................77

8.2 Test Equipment:......................................................................77

8.3 Setting Up Performance Tests ................................................78

8.3.1 Scan Reference Orientation..............................................78

8.4 Testing 2D Performance .........................................................78

8.4.1 2D Image Quality.............................................................78

8.4.2 Axial Measurement Accuracy..........................................79

8.4.3 Lateral Measurement Accuracy .......................................79

8.4.4 Penetration........................................................................80

8.5 Additional Performance Tests ................................................80

8.5.1 CPD ..................................................................................80

8.5.2 PowerMap DCPD.............................................................81

8.5.3 Image Quality Verification Test.......................................81

8.5.4 Image Review...................................................................81

8.5.5 Printer ...............................................................................82

8.5.6 Battery Charging ..............................................................82

8.5.7 Video Output ...................................................................82

8.6 Returning Products to SonoSite..............................................83

8.6.1 Contacting SonoSite Technical Support ..........................83

8.6.2 Shipping Instructions........................................................83

viii C1.75 Ultrasound System Service Manual

Page 9

APPENDIX A Parts List 85

APPENDIX B Service Event Report 97

Index 99

ix

Page 10

x C1.75 Ultrasound System Service Manual

Page 11

CHAPTER 1 Introduction

Before servicing the SonoSite ultrasound system, read and be familiar with the

information in this manual. This manual is applicable to SonoSite products

manufactured after June 23, 2000. For more information about products

manufactured prior to June 23, 2000, please refer to SonoSite Service Manual

(P00715-02).

1.1 Description

The SonoSite system is a portable, software-controlled, ultrasound system, which

has an all-digital architecture. It is used to acquire and display high-resolution, realtime, 2D, Color Power Doppler (CPD), and PowerMap (PM) Directional Color

Power Doppler (DCPD) ultrasound images. The system has cine review, image

zoom, labeling, biopsy, measurements and calculations, image storage and review,

printing and recording capabilities.

Currently, the system supports the following broadband transducers:

• C60/5-2 MHz 60-mm, curved array

• C15/4-2 MHz 15-mm, curved array

• ICT/7-4 MHz 11-mm, intracavitary array

• L38/10-5 MHz 38-mm, linear array

1.2 System Components

The SonoSite system comprises the following components:

• a hand-carried ultrasound system

• a transducer

• a power adapter

Chapter 1: Introduction 1

Page 12

The SonoSite system may include the following optional accessories:

• SiteStand mobile docking station

• SiteStand display

• SiteCharge dual battery charger

•SiteLink software

• ScanPack quick access carrier

• SitePack protective carrying case

• Power adapter (extra)

• Battery

• Video cables (3)

• Printer control cable

• Power cord

• AIUM Ultrasound Medical Safety Guidance document

• SonoSite 180 or SonoHeart User Guide

(extra)

1.3 Audience

The intended audience of this manual is properly trained field and in-house service

personnel.

1.4 Conventions Used in This Manual

These conventions are used in this manual:

• Control names and references to display elements are presented in bold-face

type.

• Operating instructions are introduced with a statement in bold-face type that

ends with a colon. For example: To read this user guide:

• When the steps in the operating instructions must be performed in a specific

order, the steps are numbered.

• Bulleted lists present information in a list, they do not imply a sequence.

• Screen display text is shown in Arial 10 pt. For example:

• The left side of the system is to your left as you face the system. The system

handle is at the top of the system, the battery compartment is at the bottom of the

system.

• Note: A note draws attention to information that is a general rule for a

procedure or is an exception to a rule (noncritical information of general

interest).

Successful upgrade.

2 C1.75 Ultrasound System Service Manual

Page 13

1.5 About the System Software

The SonoSite system contains software that controls its operation. From time to

time, SonoSite provides new software for use with the system.

Transducers that you receive from SonoSite may include new software for the

SonoSite system. This software may be either required or optional.

When the new software is required, you must install it if you wish to use the new

software features (e.g., new transducer). If you choose not to install it, you must

remove the transducer and replace it with one that is compatible with the software

that is currently installed in the system.

When the software is optional, you can either install it or choose to use the existing

software. If you choose not to install the software, the system will prompt you again

whenever the system is started, and whenever the transducer is disconnected and

then reconnected to the system. For more information on software upgrades, refer to

Chapter 4.5, Upgrading the System Software, on page 31

1.6 Software Licensing

Use of the software that you receive from SonoSite is controlled by a license key. A

license key is a number sequence containing exactly 12 decimal digits.

.

License keys are obtained from SonoSite or from its authorized representatives. You

must obtain one license key for each system that will use the new software. Refer to

Chapter 4.6, Obtaining A License Key, on page 33

license key.

Software that you receive from SonoSite may be installed and will operate for a

short period of time without requiring a valid license key. We refer to this period of

time as the “grace period.” The grace period is variable.

When you first install the software, the SonoSite system will prompt you for a

license key. If you have not yet obtained a valid license key, you can elect to use the

software as long as the grace period time has not been fully consumed. We refer to

this mode of operation as “running in the grace period.”

When the system is running in the grace period, all system functions are available.

As you use the system, the grace period is slowly consumed. When the grace period

has expired, the system will not be usable until a valid license key has been entered.

Grace period time is not consumed while the system is powered off or when it is in

“sleep” mode. Whenever the system is running in the grace period, the grace period

time remaining is available on the license update screen. For information on

displaying the license update screen, refer to Chapter 4.6.1.1, Displaying the

System Information Screen, on page 35

CAUTION:

.

for information on obtaining a

` When the grace period expires, all system functions except for licensing will

become unavailable until a valid license key is entered into the system.

Chapter 1: Introduction 3

Page 14

4 C1.75 Ultrasound System Service Manual

Page 15

CHAPTER 2 Safety

Please read this information before using the SonoSite ultrasound system. It applies

to the ultrasound system, transducers, peripherals, and accessories.

A WARNING describes precautions necessary to prevent injury or loss of life.

A CAUTION describes precautions necessary to protect the products.

2.1 Electrical Safety

This system meets EN60601-1, Class I/internally-powered equipment requirements

and Type BF isolated patient-applied parts safety requirements.

This system complies with the applicable medical equipment requirements

published in the Canadian Standards Association (CSA), European Norm

Harmonized Standard, and Underwriters Laboratories (UL) safety standards. See

Chapter 3.5, System Specifications, on page 22

For maximum safety observe the following warnings and cautions:

WARNINGS:

` Under certain circumstances, the transducer connector and back of the display

enclosure can reach temperatures that exceed EN60601-1 limits for patient

contact, therefore only the operator shall handle the system. This does not include

the transducer face. Patient contact with hot surfaces may result in discomfort or

minor risk of patient injury.

` To avoid discomfort or minor risk of operator injury when handling the

transducer connector, the system should not be operated for more than 60 minutes

continuously in a live-scan mode (as opposed to freeze or sleep modes).

` Do not operate the system in the presence of flammable gasses or anesthetics.

Explosion can result.

.

Chapter 2: Safety 5

Page 16

` Shock hazards exist if the AC power adapter is not properly grounded. Grounding

reliability can only be achieved when equipment is connected to a receptacle

marked “Hospital Only,” “Hospital Grade,” or the equivalent. The grounding

wire must not be removed or defeated.

` To avoid the risk of electrical shock, before using the transducer, inspect the

transducer face, housing, and cable. Do not use the transducer, if the transducer

or cable is damaged.

` To avoid the risk of electrical shock, always disconnect the AC power adapter

from the system before cleaning the system.

` To avoid the risk of electrical shock, do not use any transducer that has been

immersed beyond the specified cleaning or disinfection level. Refer to the

SonoSite Ultrasound System User Guide for cleaning and disinfection levels.

` To avoid the risk of electrical shock and fire hazard, inspect the AC power

adapter cord and plug on a regular basis. Ensure they are not damaged.

` Connection of peripherals not recommended by SonoSite could result in

electrical shock. Avoid electrical shock hazards by using peripherals and

accessory cables recommended by SonoSite.

` To avoid the risk of electrical shock, use commercial grade peripherals

recommended by SonoSite on battery power only. Do not connect these product

to AC mains power when using the system to scan or diagnose a patient/subject.

Call SonoSite technical support or your local representative for a list of the

commercial grade peripherals available from or recommended by SonoSite.

` The transducer must be removed from patient contact before the application of a

high-voltage defibrillation pulse.

` To avoid the risk of electrical shock to the patient/subject, do not touch the system

battery contacts while simultaneously touching a patient/subject.

CAUTIONS:

` Although your system has been manufactured in compliance with existing EMI/

EMC requirements, use of the system in the presence of an electromagnetic field

can cause degradation of the ultrasound image. If this occurs often, SonoSite

suggests a review of the system environment. Identify and remove the possible

sources of the emissions or move your system.

` Electrostatic discharge (ESD), or static shock, is a naturally occurring

phenomenon. ESD is common in conditions of low humidity, which can be

caused by heating or air conditioning. Static shock is a discharge of the electrical

energy from a charged body to a lesser or non-charged body. The degree of

discharge can be significant enough to cause damage to a transducer or an

ultrasound system. The following precautions can help reduce ESD: anti-static

spray on carpets, anti-static spray on linoleum, and anti-static mats.

` Do not use the system if an error message appears on the image display: note the

error code; call SonoSite technical support or your local representative; turn off

the system by pressing and holding the power switch until the system powers

down (6-10 seconds).

` To avoid increasing the system and transducer connector temperature, do not

block the airflow to the ventilation holes on the back of the system.

6 C1.75 Ultrasound System Service Manual

Page 17

2.1.1 Equipment Protection

To protect your ultrasound system, transducer, and accessories, follow these

precautions.

CAUTIONS:

` Excessive bending or twisting of cables can cause a failure or intermittent

operation.

` Improper cleaning or disinfecting of any part of the system can cause permanent

damage. For cleaning and disinfecting instructions, see refer to the SonoSite

Ultrasound System User Guide.

` Do not submerge the transducer connector in solution. The cable is not liquid-

tight beyond the transducer connector/cable interface.

` Do not use solvents such as thinner or benzene, or abrasive cleaners on any part

of the system.

` Remove the battery from the system if the system is not likely to be used for some

time.

` Do not spill liquid on the system.

` The top membrane of the phantom is delicate and can be damaged if handled

improperly. Only use minimum force when coupling the transducer to the

phantom.

` Do not handle PCBs without proper static protection. Damage to components

may result from improper handling.

` Damage to the system may occur if the system is incorrectly assembled,

configured or the system is connected to an improper power source.

` Do not touch the scanhead connector pins.

2.2 Battery Safety

Observe the following, to ensure that the battery does not burst, ignite, or generate

heat or fumes.

WARNINGS:

` The battery has a safety device. Do not disassemble or alter the battery.

` Charge the batteries only when the ambient temperature is between 32° and

104° F (0° and 40° C).

` Do not short-circuit the battery by directly connecting the positive and negative

terminals with metal objects.

` Do not heat the battery or discard it in a fire.

` Do not expose the battery to temperatures over 140° F (60° C). Keep it away from

fire and other heat sources.

` Do not charge the battery near a heat source, such as a fire or heater.

` Do not leave the battery in direct sunlight.

` Recharge the battery only with the SiteCharge dual battery charger or the system.

` Do not pierce the battery with a sharp object, hit it, or step on it.

` Do not use a damaged battery.

` Do not solder a battery.

Chapter 2: Safety 7

Page 18

` When connecting the battery to the SiteCharge dual battery charger or to the

system, never reverse the polarity of the battery terminals.

` The polarity of the battery terminals are fixed and cannot be switched or reversed.

Do not force the battery into the system or the SiteCharge dual battery charger.

` Do not connect the battery to an electrical power outlet.

` Do not continue recharging the battery if it does not recharge after two successive

six hour charging cycles.

CAUTIONS:

To avoid the battery bursting, igniting, or fumes from the battery, observe the

following precautions.

` Do not immerse the battery in water or allow it to get wet.

` Do not put the battery into a microwave oven or pressurized container.

` If the battery leaks or emits an odor, remove it from all possible flammable

sources.

` If the battery emits an odor or heat, is deformed or discolored, or in any way

appears abnormal during use, recharging or storage, immediately remove it and

stop using it. If you have any questions about the battery, consult SonoSite

technical support or your local representative.

` Store the battery between -4° F and 140° F (-20° C and 60° C).

` Use only SonoSite batteries.

2.3 Biological Safety

Observe the following precautions related to biological safety.

WARNINGS:

` Non-medical (commercial) grade peripheral monitors have not been verified or

validated by SonoSite as being suitable for diagnosis.

` Do not use the system if it exhibits erratic or inconsistent behavior.

Discontinuities in the scanning sequence are indicative of a hardware failure that

must be corrected before use.

` Do not use the system if it exhibits artifacts on the LCD screen, either within the

clinical image or in the area outside of the clinical image. Artifacts are indicative

of hardware and/or software errors that must be corrected before use.

` Some transducer covers contain natural rubber latex and talc, which can cause

allergic reactions in some individuals. Refer to the FDA Medical Alert, March 29,

1991.

` Perform ultrasound procedures prudently. Use the ALARA (as low as reasonably

achievable) principle.

` SonoSite does not currently recommend a specific brand of acoustic standoff.

8 C1.75 Ultrasound System Service Manual

Page 19

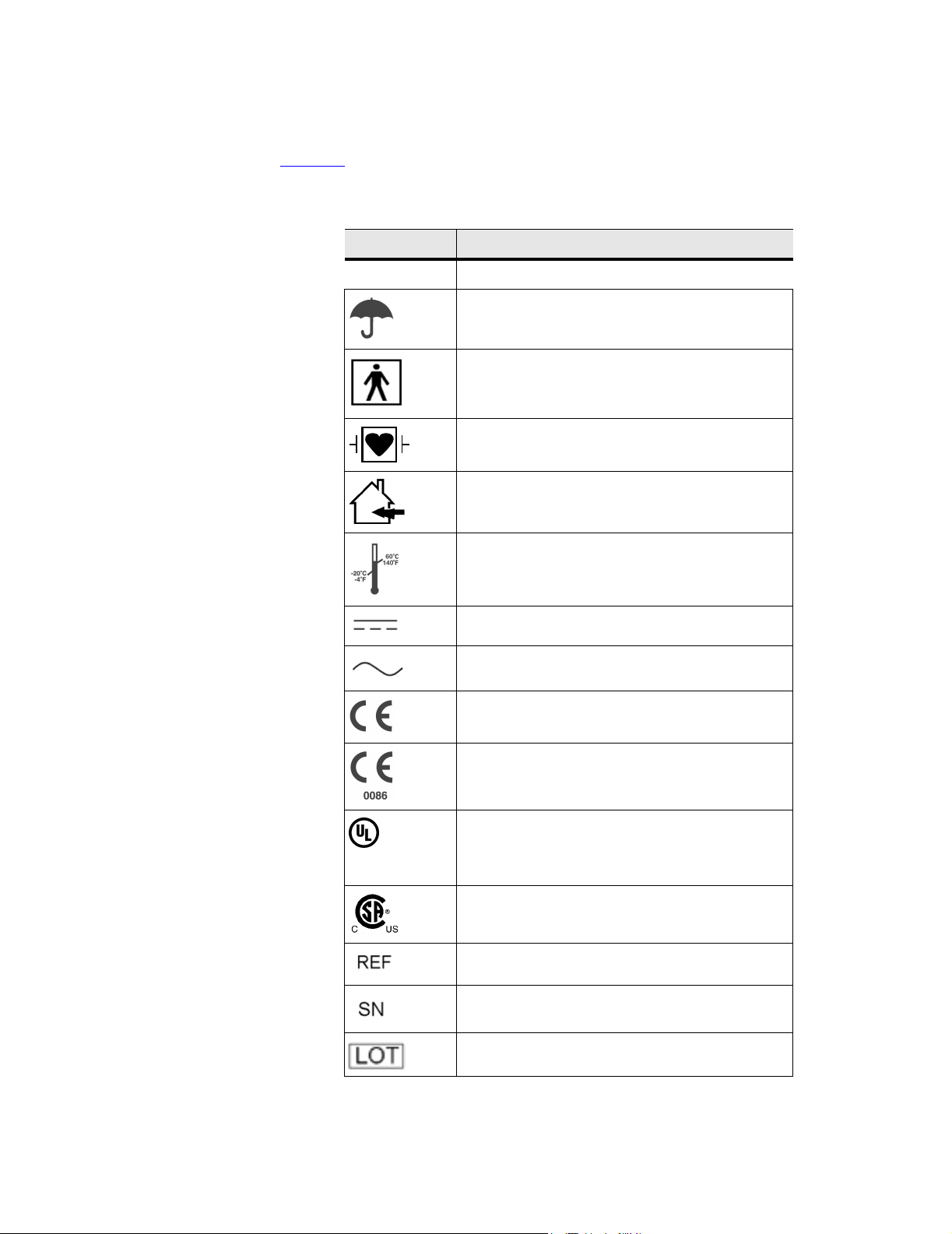

2.4 Labeling Symbols

Table 2.1 lists the symbols that are found on the products, packaging, and

containers.

Table 2.1 Labeling Symbols

SYMBOLS DESCRIPTION

SYMBOLS DESCRIPTION

Do not get wet

Type BF patient applied part

(B = body, F = floating applied part)

Type CF patient applied part

(C = cardiac, F = floating applied part)

Indoor use only

Storage temperature conditions

LISTED

UL1950

78BM

Direct Current (DC)

Alternating Current (AC)

CE marking indicating Manufacturers declaration of

compliance with Annex VII of 93/42/EEC

CE marking indicating compliance with Annex II or

Annex V and VII of 93/42/EEC certified by the British

Standards Institution

Underwriter’s Laboratories labeling

Canadian Standards Agency

Catalog number

Serial number type of control number

Batch code, date code, or lot code type of control

number

Chapter 2: Safety 9

Page 20

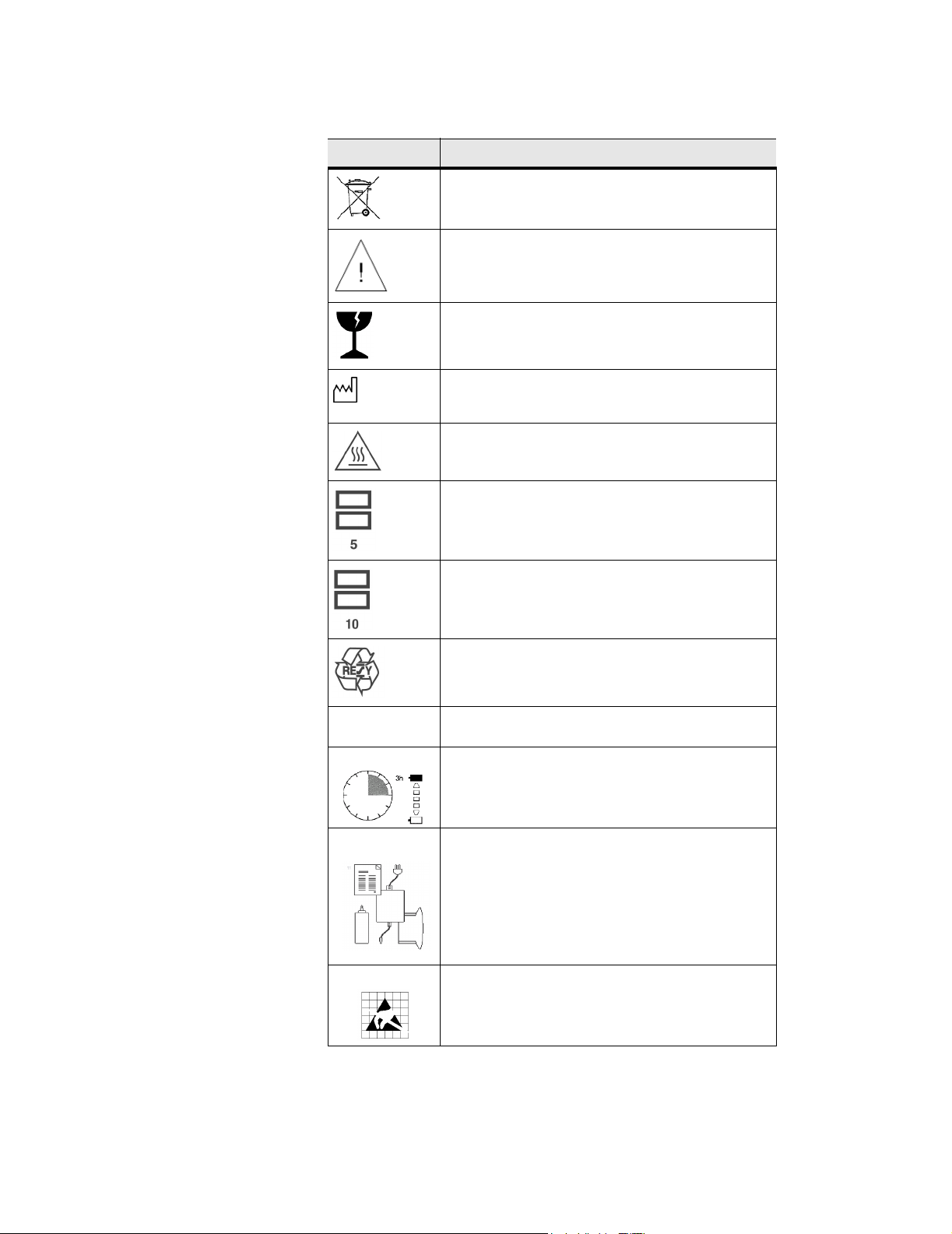

Table 2.1 Labeling Symbols, Continued

SYMBOLS DESCRIPTION

Collect separately from other household waste (see

European Commission Directive 93/86/EEC). Refer

to local regulations for disposal

Attention, see the User Guide

Fragile

Date of manufacture

Caution: hot surface

Do not stack over 5 high

IPX 7

1

4

Do not stack over 10 high

Paper Recycle

Submersible. Protected against the effects of

temporary immersion

Charge battery for 3 hours.

User Guide (1)

2

3

Power supply (2)

Battery (3)

Ultrasound gel (4)

Electrostatic sensitive devices.

10 C1.75 Ultrasound System Service Manual

Page 21

CHAPTER 3 System Overview

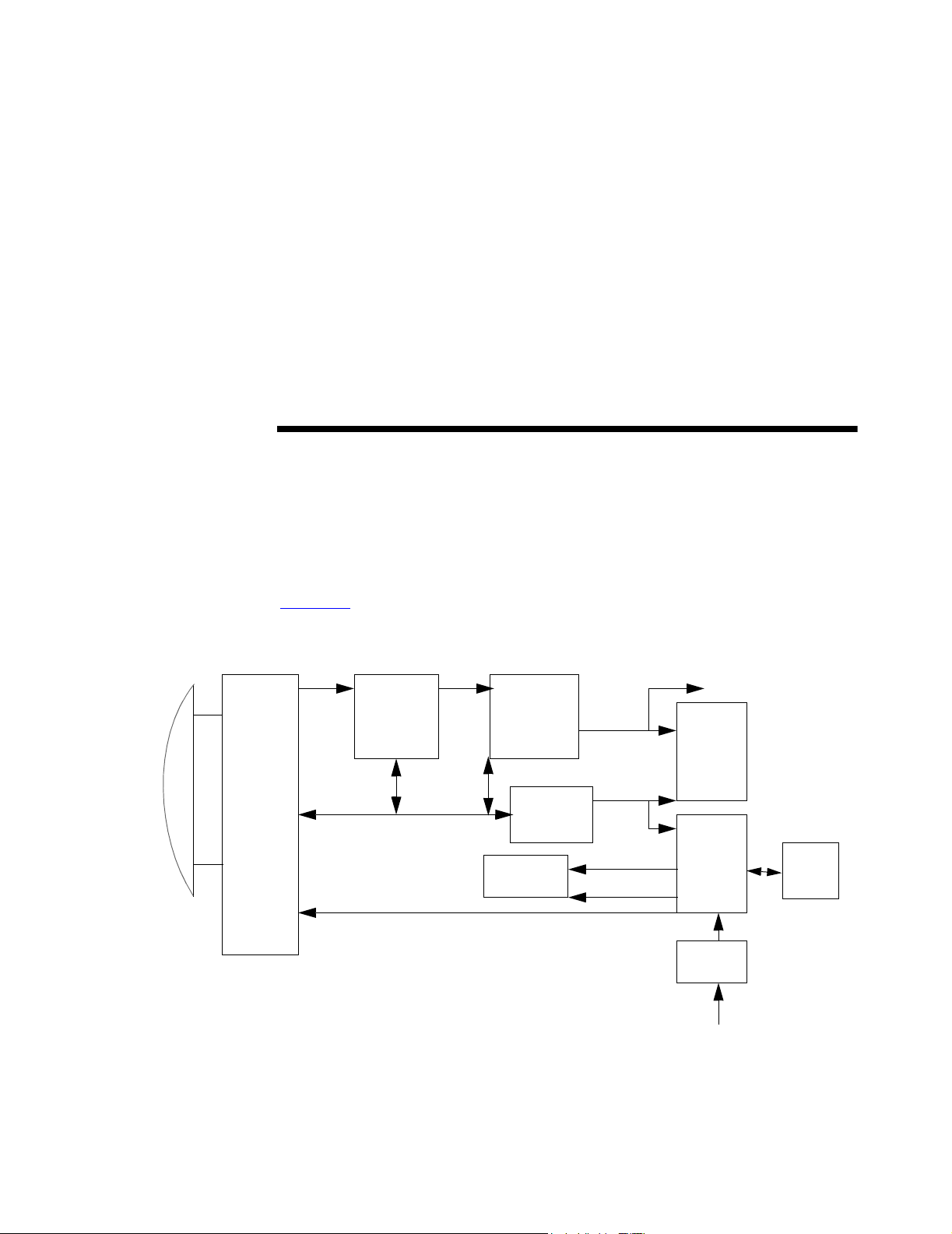

3.1 Theory of Operation

The SonoSite ultrasound system has seven major functional groups: the transducer,

the acquisition subsystem, the processing subsystem, the display subsystem, the

control subsystem, the user interface subsystem, and the power subsystem.

Figure 3.1

shows how these functional groups interact.

Transducer

Acquisition

subsystem

RF bus

Processing

subsystem

Pulser voltage

AQ bus

Control bus

Display

subsystem

Control

subsystem

To all

subsystems

Figure 3.1 System Block Diagram

Video bus

Serial bus

Display power

Logic power

External video to monitor,

VCR, printer ports

User

interface

subsystem

Power

subsystem

Power

adapter

External power

Battery

pack

Chapter 3: System Overview 11

Page 22

3.1.1 Transducer

The transducer elements convert the pulser voltage to acoustic energy during the

transmit portion of the ultrasound acquisition cycle. The transducer elements convert

the acoustic echo to voltage in the receive portion of the acquisition cycle. The

system transducers have 64 or more elements. The voltage developed on the

transducer elements is sensed by the acquisition subsystem.

3.1.2 Acquisition Subsystem

The acquisition subsystem consists of a beamformer and an interface to the

transducer. The beamformer times the transmit pulses to focus the acoustic beam.

The beamformer amplifies the low-level echo signal and times the receive

information to focus the receive information.

3.1.3 Processing Subsystem

The processing subsystem interfaces with the beamformer and performs high-speed

processing. The processing subsystem demodulates, filters, detects, and compresses

the signal supplied by the beamformer; it then supplies this data to the display

subsystem.

3.1.4 Display Subsystem

The display subsystem converts the detected ultrasound data into picture elements

(pixels). The software user interface graphics are combined with the ultrasound

information and converted to a video stream. The external video ports support NTSC

and PAL format.

3.1.5 Control Subsystem

The control subsystem consists of the central processing unit, program and video

memory, permanent image storage and retrieval memory, and a connection to the

user interface keys. The control software includes the acoustic power and intensity

software power group monitors, and a beamformer monitor. This software

guarantees a level of patient safety by ensuring the system is operating within

acoustic power and intensity limits.

3.1.6 User Interface Subsystem

The user interface subsystem comprises the software user interface and the form

factor. The software user interface is the interaction between the user and the screen

layout components. The form factor is the type of physical buttons, location, and

grouping of the buttons and the device size, shape, and weight. Dedicated controls

are for high usage activities and are grouped according to user workflow.

12 C1.75 Ultrasound System Service Manual

Page 23

3.1.7 Power Subsystem

The power subsystem provides the system power and protects the hardware from

destructive or unsafe conditions by detecting failures in the system through hardware

and software monitors. Detection of a fault disables the pulser supply, and signals an

error to the control subsystem. The power subsystem includes the battery pack and

the battery charging electronics.

3.2 Components

The SonoSite system components include a hand-carried ultrasound system, a

transducer, and a power adapter. The hand-carried ultrasound system contains the

system electronics, display, control panel, and battery pack. The transducer contains

the transducer, cable, and memory. The power adapter conditions the external power

so it can be used to power the system and charge the batteries while in the system.

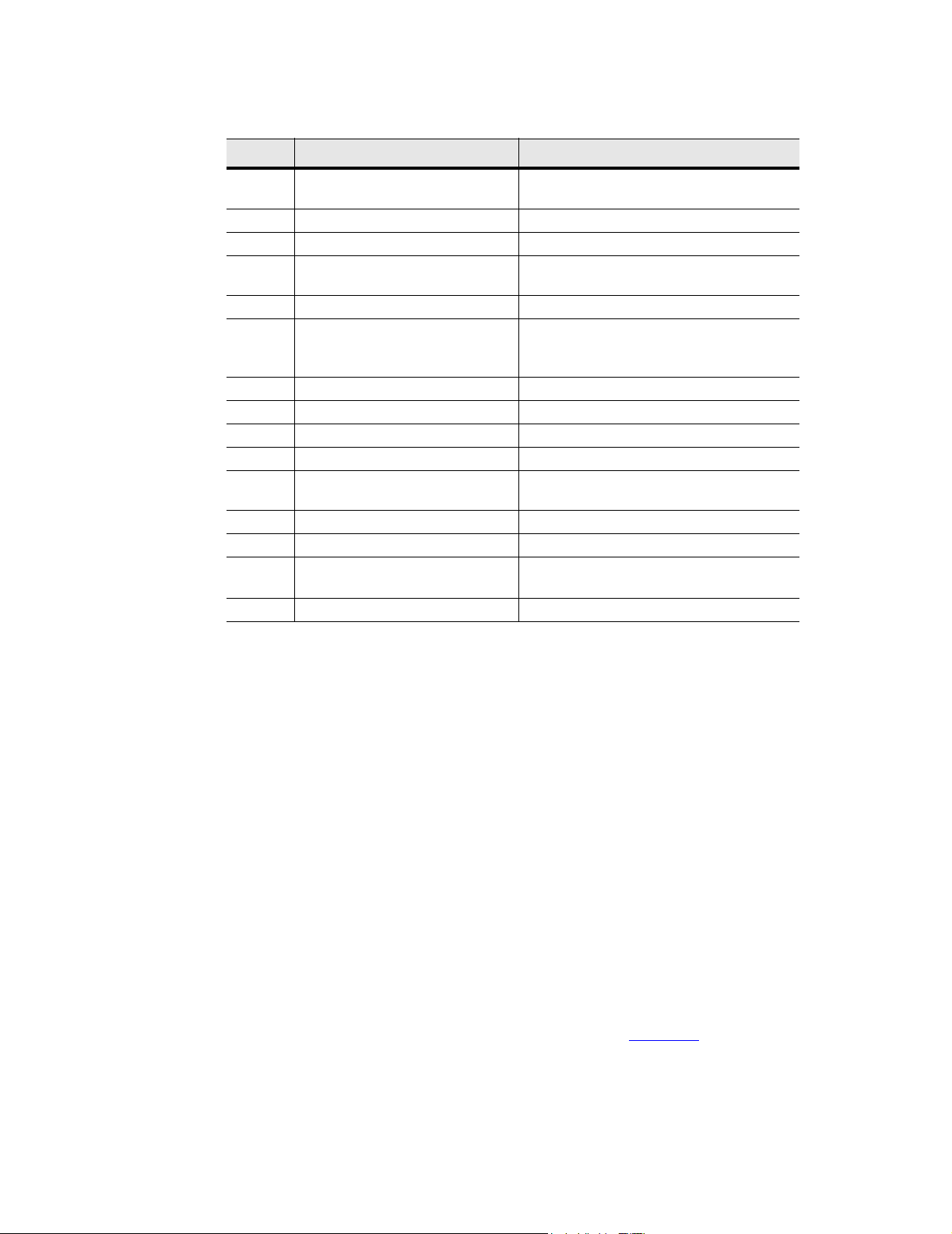

3.3 Controls

Figure 3.2 shows the SonoSite system controls. The numbers correspond to the

control names and functional descriptions in Table 3.1

.

Chapter 3: System Overview 13

Page 24

1

rear view

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Figure 3.2 SonoSite Ultrasound System Controls

14 C1.75 Ultrasound System Service Manual

Page 25

Table 3.1 SonoSite Ultrasound System Controls

NUMBER CONTROLS DESCRIPTION

1 power switch (located on the rear

of the system handle)

2 near Affects gain of shallow echoes for 2D.

3 far Affects gain of deeper echoes for 2D.

4 gain Affects overall gain in 2D and CPD gain in

5 menu controls Press patient to access system menus.

6 optimize, depth, and zoom Provides an image optimization menu;

7 trackball Moves objects on the image display.

8 patient Displays the system menus.

9 function key (f1 through f6) Assigns text for quick labeling of images.

10 battery charge indicators All LEDs lit indicate a fully-charged battery.

11 LCD (liquid crystal display) monitor

brightness control

12 LCD monitor contrast control Controls LCD contrast.

13 LCD monitor Adjustable liquid crystal display monitor.

14 cine arrows and freeze control Press to move either way through the cine

15 battery release Press to release the battery.

Turns power on and/or off.

CPD.

changes the display depth; increases the

image size to 2x.

Controls LCD brightness.

series of images.

3.4 Accessories

This section describes the following optional SonoSite system accessories that may

be included with the system.

3.4.1 SiteStand Mobile Docking Station

WARNING:

` To avoid the risk of electrical shock, use commercial grade peripherals

recommended by SonoSite on battery power only. Do not connect these products

to the AC mains IEC power receptacles on the SiteStand when using the system

to scan or diagnose a patient/subject. Contact SonoSite or your local

representative for a listing of the commercial grade peripherals available from or

recommended by SonoSite.

Do not use the system if it exhibits artifacts on the LCD screen, either within the

clinical image. Artifacts are indicative of hardware and/or software errors that must

be corrected before use.

The SiteStand mobile docking station (SiteStand) (Figure 3.3

video, print, and image transfer capabilities for the system. It holds the SonoSite

system, transducers, a printer, and accessories. It also provides the following

connections: three video ports, an RS-232C port, a printer control port, and two AC

) provides power,

Chapter 3: System Overview 15

Page 26

mains IEC power receptacles. You can tilt the system and adjust the height of the

system when it is in the SiteStand.

3.4.1.1 SiteLink Image Management Software

SiteLink Image Management (SiteLink) software is available to use with your

system, a SiteStand, and a connected PC. SiteLink allows you to transfer images

from the SonoSite system to a host PC. For more information, refer to the SiteLink

Image Manager User Guide, which is available in PDF format on the SiteLink CDROM.

3.4.1.2 IrfanView Software

IrfanView software is provided with SiteLink. IrfanView allows you to view and

manipulate images that have been transferred to the PC. For more information about

IrfanView, refer to the help files that are included in the software.

3.4.2 SiteStand Display

The SiteStand may include an optional SiteStand display (Figure 3.3), which is a

Digital View Series DV-3000 Colour LCD Rugged Monitor (10.4-in. / 26.4 cm). It

includes a cable for a VGA connection and a power supply (100–240V AC input,

12V DC output).

16 C1.75 Ultrasound System Service Manual

Page 27

SiteStand display

SonoSite system

Sleeve

Printer tray

SiteStand

Figure 3.3 SiteStand with Display

Height adjustment

pedal

Locking levers

Chapter 3: System Overview 17

Page 28

3.4.3 SiteCharge Dual Battery Charger

The SiteCharge dual battery charger (Figure 3.4) can charge two lithium-ion

batteries simultaneously. It indicates the following states for each battery: charging

state, charging fault condition, and charged state. It charges a completely discharged

six-cell battery in approximately 3.5 hours. The ambient temperature of the

SiteCharge dual battery charger should be between 32° to 104° F (0

charging to be successful. Table 3.2

system states.

describes the LEDs and their corresponding

° to 40° C) for

Power adapter

Green LEDs

Yellow LEDs

Batteries

SiteCharge dual

battery charger

Figure 3.4 SiteCharge Dual Battery Charger with Batteries and Power Adapter

Table 3.2 Charger LED Colors and Battery States

CHARGER LED COLOR BATTERY STATE

Yellow The battery is charging.

Green The battery is charged.

Flashing yellow The charger has detected a system

fault.

If the charger detects a system fault, the yellow LED on the charger will light.

Reseat the battery to clear the fault. If the fault continues, replace the battery pack.

3.4.4 SitePack Protective Carry Pack

The SitePack protective carry pack can transport the SonoSite system, three

transducers, accessories, and supplies.

18 C1.75 Ultrasound System Service Manual

Page 29

3.4.5 Battery Pack

CAUTIONS:

` See protecting against electrostatic discharge in Chapter 2, Safety, on page 5.

Use only the specified SonoSite battery pack.

The system can be powered from either a battery pack or external power.

The system is powered by a rechargeable, six-cell, 11.1 Vdc, 3.0 amp-hours,

lithium-ion battery (Figure 3.4

hours, depending upon operating conditions. The battery pack case is made of

injection molded plastic. When in use, it is inserted into the system. The battery pack

has no user-serviceable parts. The operating life of the battery ranges from 1-2 years,

depending on how you use the system. Table 3.3

specifications.

Table 3.3 Battery Pack Operation Specifications

). A fully-charged battery has a run time of 1.5 to 4

contains battery operating

BATTERY PACK OPERATION

PARAMETER

Operation time during use model 2 hours @ 77° F (25° C)

Operation time during power off

(leakage and self discharge)

Number of charge discharge cycles

(100% depth of discharge)

3.4.5.1 Battery Charge Indicators

The battery charge indicators, which consist of light-emitting diodes (LEDs) on the

system, indicate the current battery level.

• All LEDs lit mean the system battery is fully charged.

• Some LEDs lit mean the system battery is partially charged.

Table 3.4

contains the charging requirements for the system.

Table 3.4 System Charging Requirements

SYSTEM CHARGING

PARAMETER

Charge time to 80% capacity

(internal charger) with the system

off

Charge time to 80% capacity

(internal charger) with the system

on

SPECIFICATION

14 days @ 77° F (25° C)

500 @ 77° F (25° C)

SPECIFICATION

3 hours @ 77° F (25° C)

12 hours @ 77° F (25° C)

3.4.6 External Power

The external power connection provides external power to the system via the power

adapter. External power charges the battery pack and powers the system in low

battery conditions.

Chapter 3: System Overview 19

Page 30

3.4.6.1 External System Connections

Figure 3.5 shows the following external system connections:

• An AC line voltage receptacle (1) connects the system to an power adapter.

• A remote control receptacle (2) connects the system to a recommended printer.

• A video receptacle (3) provides a composite video signal for a recommended

VCR, video printer, or monitor.

Figure 3.5 External System Connections

3.4.7 Power Adapter

CAUTION:

` Use only the specified SonoSite power adapter.

The SonoSite system can be powered by a universal power adapter (50–60 Hz,

100–240 VAC). When the system is plugged into a wall outlet, the battery pack

simultaneously recharges. Recharging a battery, which is not fully discharged, will

not decrease battery life. The ambient temperature shall be between 32

° and 40° C) to successfully charge a battery. To maintain battery charge, attach

(0

the power adapter to the system whenever the system is not in use.

° and 104° F

20 C1.75 Ultrasound System Service Manual

Page 31

Power Cord

Table 3.5

CONFIGU-

RATION

100-120 VAC/

60 Hz

230 VAC / 50 Hz

/ PAL

230 VAC / 60 Hz

3.4.8 Cables

3.4.8.1 Video

This video cable (10 ft / 3.1 m) connects the system to the external monitor or video

printer. It has RCA-to-BNC connectors.

This video cable (10 ft / 3.1 m) connects the system to the Sony GV-900 Digital

Video Recorder. It has RCA-to-RCA connectors.

provides power cord specifications.

Table 3.5 Power Cord Specifications

LENGTH RATING MALE PLUG

9 ft. 10 in. 250 VAC MA 5-15P

Hospital grade,

grounding type

molded on

3 m 250 VAC CEE-7/VII

grounding type

with 4.8 mm pins

molded on

FEMALE

CONNEC-

TOR

CEE-22,

molded on

CEE-22,

molded on

APPRO

-VALS

UL,

CSA

EU Manufac-

MARKING

Manufacturer,

Agency

Approvals

turer,

Agency

Approvals

This video cable (6 ft /1.8 m) connects the system to the Casio EV-660 Handheld

Monitor. It has RCA-to-Stereo connectors.

3.4.8.2 Printer Control

The printer control cable (10 ft / 3.1 m) connects the system to the video printer. It

has mini-jack to mini-jack connectors.

3.4.8.3 AC Power Extension

The AC power extension cable (1 ft / 0.3 m) connects the power supply to the

SiteStand.

3.4.9 Video

The system has one internal video path and one external video port. The internal

video is generated for input to a display. The external video is composite interlaced

video.

Any image that displays on the system display module can be recorded on a VCR,

printed, or displayed on an external monitor. The external video may be connected

to a variety of devices, such as a monitor, video printer, or VCR. The video output is

either NTSC or PAL format, which is user-configurable in system setups.

Chapter 3: System Overview 21

Page 32

3.4.9.1 Video Port Cable

The video cable has a 75 ohm impedance and is shielded. Table 3.6 provides video

cable signal specifications.

Table 3.6 Video Cable Signal

CONNECTOR PIN SIGNAL

Center conductor Video

Shield Signal ground

3.5 System Specifications

This section provides specifications for the SonoSite ultrasound system.

3.5.1 Physical Dimensions

Height: 13.3 in. (33.8 cm)

Width: 7.6 in. (19.3 cm)

Depth: 2.5 in. (6.35 cm)

Weight: 5.4 lbs (2.46 kg) with the C60/5-2 MHz transducer connected

3.5.2 Monitor

Height: 4.3 in. (10.9 cm)

Width: 3.1 in. (7.9 cm)

Diagonal: 5 in. (12.7 cm)

Brightness control

Contrast control

3.5.3 Transducers

C60/5-2 MHz 60-mm, curved array

C15/4-2 MHz 15-mm, micro-curved array

ICT/7-4 MHz 11-mm, intracavitary

L38/10-5 MHz 38-mm, linear array

3.5.4 Imaging Modes

2D Imaging (256 gray shades)

CPD Imaging (64 colors)

PowerMap DCPD Imaging (64 colors)

22 C1.75 Ultrasound System Service Manual

Page 33

3.5.5 Image Storage

Up to 120 images (depending on the configuration of the system)

Cine review

3.5.6 Temperature and Humidity Limits

3.5.6.1 System Operating

• 50–104° F (10–40° C), 15–95% R.H.

• 700-1060hPa (0.7 ATM to 1.05 ATM)

3.5.6.2 System Shipping/Storage

• -31–149° F (-35–65° C), 15–95% R.H.

• 500-1060hPa (0.5ATM to 1.05 ATM)

3.5.6.3 Battery Operating

• 50–104° F (10–40° C), 15–95% R.H.

3.5.6.4 Battery Shipping/Storage

• -4–140° F (-20–60° C), 0–95% R.H.

3.5.6.5 Transducers Operating

• 50–104° F (10–40° C), 15–95% R.H.

3.5.6.6 Transducers Shipping/Storage

• -31–149° F (-35–65° C), 15–95% R.H

3.5.7 Electrical

• System optional: 100-120/220-240 Vac, 50/60 Hz input, 16.0 Vdc output power

adapter

• SiteCharge dual battery charger input voltage: 16.0 Vdc, 2.8 A

• SiteCharge dual battery charger output voltage: 12.6 Vdc, 3.0 A (2x)

• AC power adapter input: 100-120/220-240 Vac, 50/60 Hz, 1.0-0.50 A

• AC power adapter output: + 16.0 Vdc, 2.8 A

• SiteStand input: 100-120/220-240 Vac, 50/60 Hz, 1.0-0.50 A

• SiteStand outputs: + 16.0 Vdc, 2.8 A. and 100-120/220-240 Vac, 50/60 Hz, 1.0-

0.50 A (2x)

• SiteStand display input: +12VDC, 2.75 A

Chapter 3: System Overview 23

Page 34

3.6 Battery

• 6-cell, 11.1 Vdc, 3.0 amp-hours, rechargeable, lithium-ion battery pack

• Run time: 1.5 to 4 hours, depending upon operating conditions

3.7 Safety Requirements

3.7.1 Meets Electromechanical Safety Standards

EN 60601-1:1997, European Norm, Medical Electrical Equipment-Part 1. General

Requirements for Safety.

EN 60601-1-1:1993, European Norm, Medical Electrical Equipment–Part 1.General

Requirements for Safety–Section 1-1. Collateral Standard. Safety Requirements for

Medical Electrical Systems.

EN 60601-1-2:1998, European Norm, Medical Electrical Equipment. General

Requirements for Safety-Collateral Standard. Electromagnetic Compatibility.

Requirements and Tests.

C22.2, No. 601.1:1998, Canadian Standards Association, Medical Electrical

Equipment-Part 1. General Requirements for Safety.

CEI/IEC 61157:1992, International Electrotechnical Commission, Requirements for

the Declaration of the Acoustic Output of Medical Diagnostic Ultrasonic Equipment

UL 2601-1:1999, Underwriters Laboratories, Medical Electrical Equipment-Part 1:

General Requirements for Safety.

3.7.2 Meets EMC/EMI Standards

IEC 61000-4-2:1999, International Electrotechnical Committee, Electromagnetic

Compatibility (EMC)-Part 4. Testing and Measurement Techniques-Section 4.2:

Electrostatic Discharge/Immunity Test-Basic EMC Publication

IEC 61000-4-3:1997, International Electrotechnical Committee, Electromagnetic

Compatibility (EMC)-Part 4. Testing and Measurement Techniques-Section 3:

Radiated Radio-Frequency, Electromagnetic Field Immunity Test.

IEC 61000-4-4:1995, International Electrotechnical Committee, Electromagnetic

Compatibility (EMC)-Part 4. Testing and Measurement Techniques-Section 4,

Electrical Fast Transient/Burst Immunity Test-Basic EMC Publication.

IEC 61000-4-5:1999, International Electrotechnical Committee, Electromagnetic

Compatibility (EMC)-Part 4. Testing and Measurement Techniques-Section 5,

Surge Immunity Test.

CISPR11:97, International Electrotechnical Commission, International Special

Committee on Radio Interference. Industrial, Scientific, and Medical (ISM) RadioFrequency Equipment Electromagnetic Disturbance Characteristics-Limits and

Methods of Measurement.

24 C1.75 Ultrasound System Service Manual

Page 35

3.7.3 Meets Airborne Equipment Standards

RTCA/DO160D:1997, Radio Technical Commission for Aeronautics,

Environmental Conditions and Test Procedures for Airborne Equipment, Section

21.0 Emission of Radio Frequency Energy, Category B.

Chapter 3: System Overview 25

Page 36

26 C1.75 Ultrasound System Service Manual

Page 37

CHAPTER 4 Setup and Operation

WARNING:

` CRITICAL TEST FUNCTION - A failure of the system functional tests

performed in this procedure could adversely affect safety or effectiveness of the

system.

4.1 Connecting and Removing Transducers

The system is supplied with one or more transducers. Only one transducer can be

connected to the system at a time.

WARNING:

` The transducer connector can become hot during operation. This is normal.

Operate the system in the SiteStand or on a flat, hard surface to allow air flow past

the connector.

CAUTION:

` The electrical contacts inside the system transducer receptacle may be damaged

by foreign material or by rough handling. Do not touch the electrical contacts.

Keep foreign material out of the receptacle. Keep a transducer connected to the

system whenever possible.

To connect the transducer:

1. On the transducer connector, pull the lever up and rotate it clockwise until it

snaps to a stop (Figure 4.1

lever.

2. Align the transducer connector with the transducer receptacle on the rear of the

system and insert it by pushing the transducer connector into the transducer

receptacle. The transducer connector should be easy to insert. Do not force the

transducer connector.

3. Turn the lever counterclockwise until it snaps to a stop.

). The lever should be easy to move. Do not force the

Chapter 4: Setup and Operation 27

Page 38

4. Press the lever down until it snaps into place, securing the transducer connector

to the system.

Transducer receptacle

Figure 4.1 Connecting the Transducer

To remove the transducer:

1. On the transducer connector, pull the lever up and rotate it clockwise until it

snaps to a stop (Figure 4.1

).

Transducer connector lever

2. Carefully pull the transducer connector away from the system.

4.2 Removing and Installing the Battery

WARNING:

` If you are holding the system, when you remove the battery, place your hand

beneath the battery. If it falls to the floor, it could be damaged, or cause personal

injury.

If the battery is being installed for the first time, it will need to be charged.

To remove the battery:

1. Press and hold the power switch for one second to turn off the system.

2. Locate the battery compartment at the bottom of the system.

3. If you are holding the system, place your hand beneath the battery to ensure that

it does not fall out upon release.

4. Press the battery release button (lower, right side) to release the battery.

28 C1.75 Ultrasound System Service Manual

Page 39

To install the battery:

1. Locate the battery compartment at the bottom of the system (Figure 4.2

2. Install a new battery (label side up) into the battery compartment by pushing it

into the compartment until it clicks into place. (Do not force the battery into the

compartment, check the battery orientation if the battery is difficult to install.)

Ensure that both sides of the battery are fully connected and that the battery

release button is not pressed.

).

Figure 4.2 Inserting the Battery

4.3 Turning the System On and Off

When turning power on or off, you must press and hold the power switch for

approximately one second before the system responds. This feature prevents battery

discharge, resulting from accidentally turning the system on. It also prevents

accidentally turning the system off during an exam.

The first time you turn on the system, set the date and time. See “Setting the Date

and Time” on page 40

CAUTION:

` Do not use the system if an error message appears on the image display. Note the

error code. Call SonoSite technical support or contact your local representative.

When an error code occurs, turn off the system by pressing and holding the power

switch until the system powers down.

.

Chapter 4: Setup and Operation 29

Page 40

To turn on power:

1. Locate the power switch on the back of the left side of the system handle. See

Figure 3.2, SonoSite Ultrasound System Controls, on page 14

2. Press and hold the power switch until the system beeps or until you see the

image display.

3. Release the power switch.

To turn off power:

1. Press and hold the power switch.

You will hear the system emit two sets of “high-low” beeps. The system powers

off after the second set of beeps.

2. Release the power switch.

To wake up the system:

• The system has a sleep delay, which is invoked based on the sleep delay system

setup. When the battery charge indicators are blinking, but the other system

lighting is off, press any system control to wake up the system.

4.4 Using AC Power

.

The battery charges while using the system on AC power. If the system is off and

connected to AC power, a fully discharged battery will charge in about 3 hours.

To use AC power:

1. Connect the line cord to the AC power adapter.

2. Connect the line cord to a hospital-grade, electrical outlet.

3. Connect the AC power adapter to the system AC line voltage receptacle on the

upper left side of the system (Figure 4.3

).

30 C1.75 Ultrasound System Service Manual

Page 41

Note: You must wait approximately 10 seconds after connecting to AC power before

turning on the power switch.

Figure 4.3 System Connections

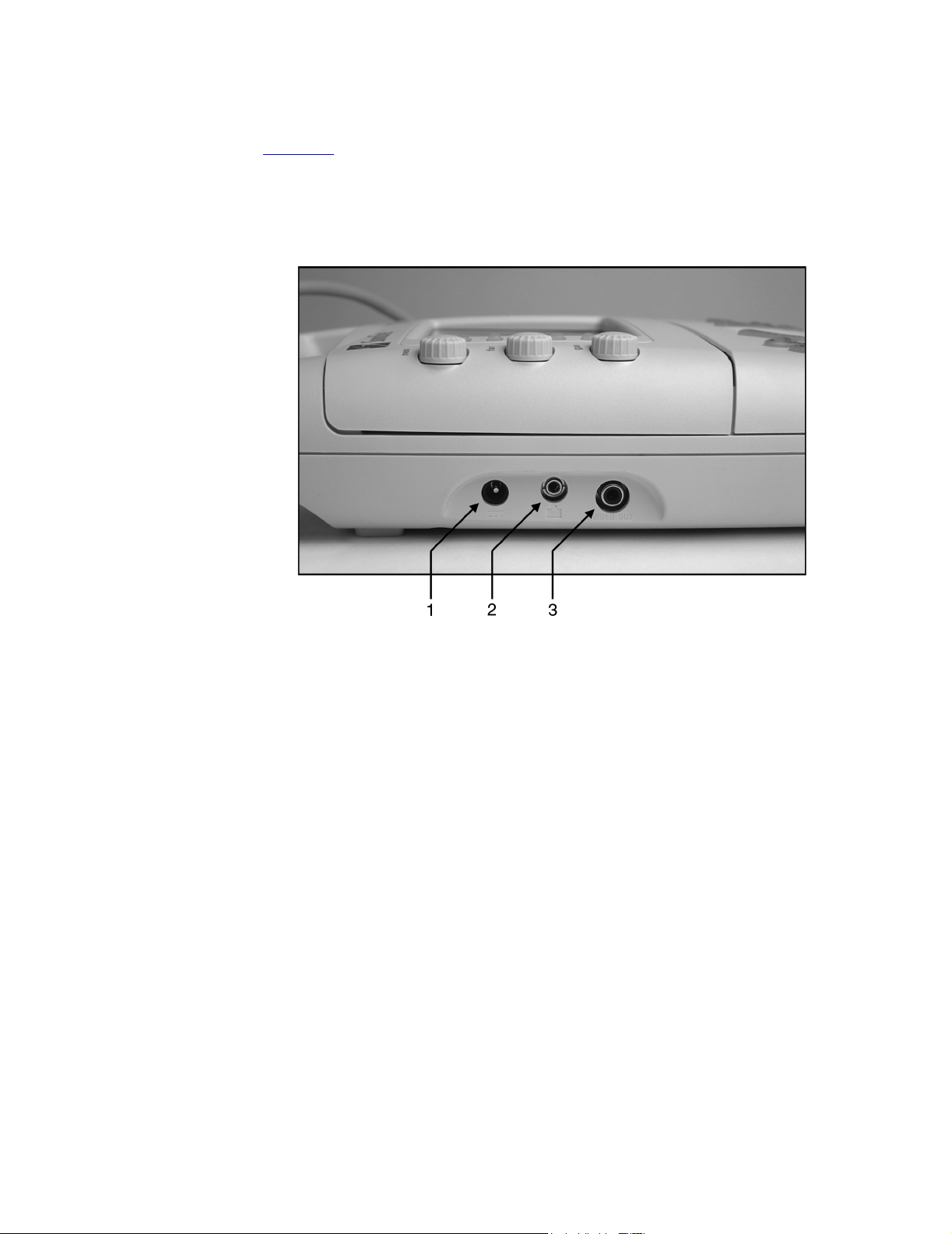

Table 4.1 lists the SonoSite system connections.

Table 4.1 System Connections

NUMBER FEATURE

1 AC line voltage receptacle.

2 Remote control receptacle for an

approved printer.

3 Video receptacle for an approved VCR,

printer, or external video monitor.

4.5 Upgrading the System Software

Transducers that you receive from SonoSite may contain either required or optional

upgrades to the system software that resides on your SonoSite system. Whenever

you connect a transducer to a SonoSite system, the system communicates with a

transducer to determine if the transducer contains software that would upgrade the

system.

CAUTION:

` Initiating any upgrade of the system software erases any images stored on your

system. Do not upgrade the system software until you have determined that any

stored images are no longer needed.

Chapter 4: Setup and Operation 31

Page 42

To upgrade the system software:

1. When you first connect a transducer with new software and turn the system on,

the following message displays:

Do you want to upgrade the system software?

For required upgrades:

You must either perform the software upgrade or replace the transducer with one

that is compatible with the software currently installed on your system. Do one of

the following:

• Select no (disconnect transducer) to reject the system software upgrade.

• Select yes (up to 20 minutes) to accept the system software upgrade and go to

step 2.

For optional upgrades:

You may either install the new software or continue to use the existing software.

SonoSite recommends that you install these optional upgrades soon after receiving

them. Do one of the following:

• Select no (continue) to use the system without upgrading.

• Select yes (up to 20 minutes) to accept the upgrade and go to step 2.

2. When you have accepted the upgrade, the system loads the new software and

displays the following message:

Upgrade in progress (20 minutes total).

Note: The system upgrade can take up to 20 minutes; however, many software

upgrades will complete successfully in less time.

To cancel the upgrade in progress, select cancel.

If this is a required upgrade:

• The existing software remains installed.

• The system displays the following message:

Incompatible transducer, upgrade the system software.

If this is an optional upgrade:

• The existing software remains installed.

• The system will go to live scan.

3. When the system has loaded the new software, the following message displays:

Successful upgrade.

If the software upgrade is unsuccessful, the system displays an error code and

you must contact SonoSite technical support. For U.S. customers, call 1-877657-8118. For international customers, call 1-425-951-1330 or contact your

local representative.

4. Select reboot to restart your system.

During the restart, the initial system screen will show two progress indicator

bars. These progress indicator bars are present while the system is replacing its

operating software and will disappear when the process is completed.

32 C1.75 Ultrasound System Service Manual

Page 43

When the operating software has been replaced, the system will present you with

the license update screen so that you may license the software. At this point, the

software upgrade process is complete, but the system software is not yet

licensed. The following section explains how to license your software.

4.6 Obtaining A License Key

A license key is required to update your SonoSite system. To obtain a license key,

do one of the following:

USA/Canada Customers

• Technical support: 1-877-657-8118

• Technical support fax and email: 1-425-951-6700; service@sonosite.com

• SonoSite website: www.sonosite.com

International Customers

• Call your local representative or 1-425-951-1330.

To receive a license key, you will need to provide the following information, which

is displayed on the system information screen of your system (except for the name of

the person installing the upgrade and the system serial number):

• Name of the person installing the upgrade

• System serial number (SN) (located on the back of your system)

• License Update number

• ARM Ver: (version)

• PCBA Serial No: (number)

See Section 4.6.1.1, Displaying the System Information Screen, on page 35

system is on and the grace period expires, the license information screen can be

displayed from the system information screen.

4.6.1 Installing A License Key

When you have obtained a license key for the software, you must enter it into the

system. Once a valid license key has been entered, the system remains licensed until

the next time the system software is upgraded.

1. Turn on the system. If the software is not yet licensed, the license update screen

displays (Figure 4.4

The license update screen displays the following information: the License

Update number, the ARM Ver (version), the PCBA Serial No. (number), the

SonoSite web site address and telephone number, the license number, the

).

. If the

Chapter 4: Setup and Operation 33

Page 44

register later or done button, and the grace period (time remaining) on your

system.

Figure 4.4 License Update Screen

Note: The software versions on your system may vary based on your upgrade

and configuration.

2. Enter your license key in the license number field.

• If the license key that you entered is recognized by the system as being valid

for your system and the software you installed, a done button displays.

Select done to install the license key and license your software.

• If the license key that you entered is not recognized by the system, the

register later button remains on the screen as long as the defined grace

period has not expired.

• If the grace period has expired, the menu item will indicate this by showing

zero hours remaining in the grace period. At this point, you must then enter

a valid license key before you can use the system with this or any other

transducer.

Note: If you have entered a valid license key and you cannot complete the

licensing procedure, verify that the license key has been entered correctly.

The license key should be exactly 12 digits (for example, 123348990552) with

no other characters or punctuation.

If after confirming correct entry of the license key, you are still unable to license

your system; call SonoSite technical support. U.S. customers call 1-877-657-

8118. International customers call 1-425-951-1330 or contact your local

representative.

• If the system is on and the grace period expires, the license update screen

must be displayed from the system information screen.

34 C1.75 Ultrasound System Service Manual

Page 45

4.6.1.1 Displaying the System Information Screen

To display the system information screen:

1. Press and release function.

2. Press and release i. The system information screen displays (Figure 4.5

The system information screen displays the following information: the Boot/PIC

Vers (version), the ARM Ver (version), the PCBA Serial No (number), the

Product Name, the Status, the CPLD 1, 2, 3 Ver, CPLD SH Ver (version),

SHDB Ver (scanhead database version), and the Sh Serial No (scanhead serial

number).

Note: The software versions on your system may vary based on your upgrade

and configuration.

).

Figure 4.5 System Information Screen

To display the license update screen:

On the system information screen, select the padlock icon (upper left corner of

the screen) to display the license update screen. See Section 4.6.1, Installing A

License Key, on page 33

.

Chapter 4: Setup and Operation 35

Page 46

4.7 Checking and Charging the Battery

Note: Disconnect the system from AC power prior to checking the battery charge.

To check the battery:

Five light-emitting diodes (LEDs) on the right side of the system monitor allow you

to check the battery condition. If all LEDs are lit, the battery is fully charged. A solid

dark gray battery icon in the lower right portion of the system display indicates a low

battery. A solid white battery icon indicates approximately 10 minutes of battery life

remaining. A flashing white battery icon indicates approximately 5 minutes of

battery life remaining.

The system will operate on a fully-charged battery for 1.5 to 4 hours, depending

upon use. Ensure the battery is charged at all times to provide the longest possible

battery operation. You can set the sleep delay and power delay in system setup to

prolong battery life. See Section 4.9, Using System Setup, on page 39

When the system is not likely to be used for some time, to prevent total battery

discharge, remove the battery from the system.

To charge the battery:

CAUTION:

` Charge batteries only when the ambient temperature is between 32° and 104° F

(0° and 40° C).

.

1. Connect the line cord of the power adapter to a hospital-grade electrical outlet.

2. Connect the AC power adapter to the power receptacle on the system (1)

(Figure 4.6

3. Disconnect the system from AC power.

Note: It takes about three hours to charge a battery when the system is off.

4. Turn the system on to check the battery charge.

and Table 4.2).

36 C1.75 Ultrasound System Service Manual

Page 47

Figure 4.6 System Connections

Table 4.2 System Connections

Number Feature

1

2

DC line voltage receptacle.

Remote control receptacle for an

approved printer.

3

Video receptacle for an approved VCR,

printer, or external video monitor.

Chapter 4: Setup and Operation 37

Page 48

4.8 Using the SiteCharge Dual Battery Charger

To use the SiteCharge dual battery charger:

1. Connect the power adapter to the SiteCharge dual battery charger (Figure 4.7

2. Connect the AC line cord to a power receptacle. When the blue SonoSite logo

on the front of the SiteCharge dual battery charger lights, it indicates that the

power is on.

3. Insert one or two batteries into the SiteCharge dual battery charger (the batteries

only fit one way). Refer to Table 4.3

information.

Note: When the battery reaches full charge, the green LED will be lit.

for SiteCharge dual battery charger

).

Figure 4.7 SiteCharge Dual Batter Charger

38 C1.75 Ultrasound System Service Manual

Page 49

Table 4.3 SiteCharge Dual Battery Charger LEDs

LIGHT COLOR

(NEXT TO

BATTERY)

Yellow Lit The battery is charging. It may

Yellow Lit When lit for more than six

Yellow Flashing The battery is not properly

Green Lit The battery is fully charged

Yellow/Green Off Battery is defective. Call SonoSite technical

STATUS INDICATES SOLUTION

take up to 60 seconds for the

yellow light to come on

depending on the discharge

state of the battery.

Remove and reinsert the same

hours, charging will be

suspended.

installed.

The battery or the SiteCharge

dual battery charger is

defective.

and is ready for use. (The

SiteCharge dual battery

charger can charge one or two

batteries in less than four and

a half hours, depending on the

discharge state of the battery.)

battery. If the battery is not

fully charged within another six

hours, call SonoSite or your

local representative.

Re-install the battery into the

SiteCharge dual battery

charger. If the battery is

properly installed and the

yellow light still flashes, call

SonoSite or your local

representative.

support.

Note: If the ambient temperature is below 32°F (0°C) or above 113°F (45°C), the

charger may suspend charging due to an over/under temperature condition and the

green light will be lit. Battery operating time may be reduced.

4.9 Using System Setup

CAUTION:

` If the video format on the system is changed, you will need to turn the system

power off and then on. If you do not do this, artifacts may appear in your images.

System setup is used to customize the system. It is available by pressing patient and

selecting system setup. System setup includes settings for image orientation (four

selections), the caliper line that connects the measurement calipers (on/off), thermal

index selection (TIs

screen information settings that allow you to show or hide the following items: the

optimize icon, the time, the memory icon, and the patient name. You can also set the

audible beep, sleep delay, power delay, and the date/time. Additionally, system

setup includes the video format, printer, calcs authors, and function key assignments.

You can resume imaging from any system setup function by pressing patient.

TIb), and pictographs (on/off). System setup also includes

Chapter 4: Setup and Operation 39

Page 50

Perform the following procedures to become familiar with using system setup, then

use these basic operations to set the range of setups required for your uses.

4.9.1 Setting the Date and Time

WARNING:

` An accurate date and time are critical for accurate obstetrics calculations. Verify

that the date and time are accurate before each use of the system. The system does

not automatically adjust for daylight savings time changes.

To set the date and time:

1. Press patient. A menu appears on which system setup is listed.

2. Select system setup. A menu appears on which is listed audio, battery, date/

time.

3. Select audio, battery, date/time.

4. Select date/time. A cursor appears at the left side of the date/time display.

5. Type in the current date (year, month, day) and time in the 24-hour format

(hours, minutes). If you make a mistake, you can use the arrow keys between

the delete and enter keys to move the cursor.

6. Press patient to resume imaging.

4.9.2 Setting the Sleep Delay

To set sleep delay:

1. Repeat steps 1 through 3 in Section 4.9.1

2. Select sleep delay (min).

3. Press sleep delay (min) again to select 3, 5, or 10.

4. Press patient to resume imaging.

4.9.3 Setting the Power Delay

To set power delay:

1. Repeat steps 1 through 3 in Section 4.9.1

2. Select power delay (min).

3. Press power delay (min) again to select off, 15, or 30.

4. Press patient to resume imaging.

.

.

40 C1.75 Ultrasound System Service Manual

Page 51

4.9.4 Setting the Audible Beep

To turn on or off the audible beep:

1. Repeat steps 1 through 3 in Section 4.9.1

2. Select audible beep.

3. Press audible beep again to select on or off.

4. Press patient to resume imaging.

.

4.9.5 Setting Up A Recommended Printer

CAUTION:

` Use only peripherals recommended by SonoSite with the system.

be damaged by connecting a peripheral not recommended by SonoSite.

To set up a recommended printer:

To use the system print controls, print and print all images, the remote control

must be connected.

1. Connect a recommended printer to the system using the recommended printer

control cable. The receptacles are on the left side of the system. There are two

connections required: VIDEO OUT (3 in Figure 4.6

Figure 4.6

2. Turn on the printer. (Refer to the printer manufacturer’s instructions for specific

printer information.)

).

The system can

) and remote icon (2 in

3. Press patient. A menu appears on which is listed system setup.

4. Select system setup. A menu appears on which is listed video, printer, calcs, f

keys.

5. Select video, printer, calcs, f keys.

6. Select printer to select the type of printer connected to the system. (Only the

types of printers appearing as settings are recommended for use with the

system.) The printer is ready to print.

7. Press patient to resume imaging.

4.9.6 Setting Up A Recommended VCR

To set up a recommended VCR:

1. Connect a recommended VCR to the system using the recommended video

cable. The receptacle is on the left side of the system. There is one connection

required: VIDEO OUT (3 in Figure 4.6

2. Turn on the VCR. (Refer to the VCR manufacturer’s instructions for specific

VCR information.)

3. Press patient. A menu appears on which is listed system setup.

).

Chapter 4: Setup and Operation 41

Page 52

4. Select system setup. A menu appears on which is listed video, printer, calcs, f

keys.

5. Select video, printer, calcs, f keys.

6. Select the appropriate video format: NTSC or PAL.

7. Press patient to resume imaging.

8. Use the controls on the VCR to record the image display. A separate video

monitor, connected to the VCR, is required for playing the recording.

4.9.7 Setting Up A Recommended Video Monitor (External)

To set up a recommended video monitor (external):

1. Connect a recommended video monitor to the system using the recommended

video cable. The receptacle is on the left side of the system. There is one

connection required: VIDEO OUT (3 in Figure 4.6

2. Turn on the video monitor. (Refer to the video monitor manufacturer’s

instructions for specific information.)

).

4.9.8 Setting Up Function Key Assignments

To set up function key assignments:

Function keys 1 through 6 can be assigned text for quick and easy labeling of

images.

1. Press patient. A menu appears on which is listed system setup.

2. Select system setup. A menu appears on which is listed video, printer, calcs,

f keys.

3. Select video, printer, calcs, f keys.

4. Select function key assignment. A menu appears which lists function keys, f1

through f6.

5. The data entry cursor appears next to f1.

6. Type in your text. Use the arrow and space keys to correct mistakes.

7. Press enter to move to the next field. Continue to assign text to the remaining

function keys, as desired.

8. Select a new exam type to assign function key text and repeat the steps above, or

select done when finished. Refer to the SonoSite 180 or SonoHeart User Guide

for how to use the assigned function keys.

42 C1.75 Ultrasound System Service Manual

Page 53

4.9.9 Changing All System Setups to the Default Settings

WARNING:

` An accurate date and time are critical for accurate obstetrics calculations. Verify