Page 1

Part 1

CAR 704 / 705 Air Operator

Maintenance Requirements Checklists

Table of Contents

(March 2001)

AOC-01 Previous Transport Canada Audit..................................................................3

AOC-02 Maintenance Control Manual...........................................................................5

AOC-03 Person Responsible for Maintenance..........................................................13

AOC-04 Evaluation Program........................................................................................15

AOC-05 Technical / Regulatory Publications..............................................................19

AOC-06 Technical Records..........................................................................................22

AOC-07 Weight & Balance...........................................................................................26

AOC-08 Maintenance Development Program (MPD)...............................................29

AOC-09 Reliability Monitoring Programs....................................................................38

AOC-10 Reserved.........................................................................................................49

AOC-11 Maintenance Planning....................................................................................50

AOC-12 Defect Recording, Rectification, Deferral, and Control Procedures.........55

AOC-13 Airworthiness Directive, Service Bulletin.....................................................60

AOC-14 ETOPS - Extended Range Operations........................................................62

AOC-15 Minimum Equipment List - MEL, OMEL, GMEL.........................................67

AOC-16 All Weather Operations - Category II, III........................................................71

AOC-17 Technical Dispatch Procedures....................................................................74

AOC-18 Flight Authorities - Test / Ferry......................................................................78

AOC-19 Maintenance Arrangements..........................................................................81

AOC-20 Training Program............................................................................................86

AOC-21 Personnel Records.........................................................................................89

AOC-22 De-Icing Procedures......................................................................................91

AOC-23 Elementary Work, Servicing..........................................................................93

AOC-24 Reserved.........................................................................................................96

AOC-25 Servicing - Fueling, De-fueling & Lubrication, Oxygen...............................97

AOC-26 Control of Parts, Parts Pooling....................................................................100

AOC-27 Service Difficulty Reporting SDR................................................................103

March 2001 Page 1

Page 2

Intentionally Blank

March 2001 Page 2

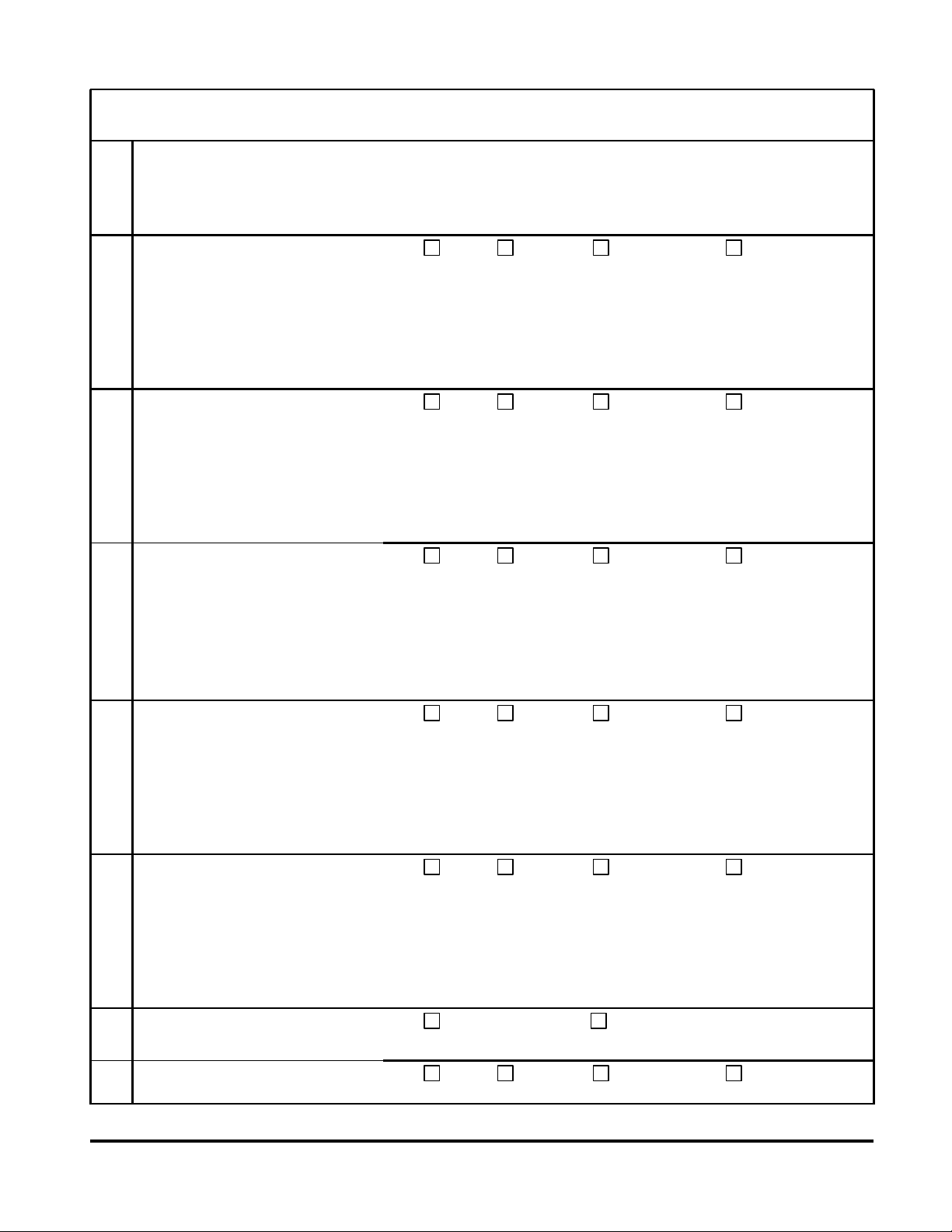

Page 3

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

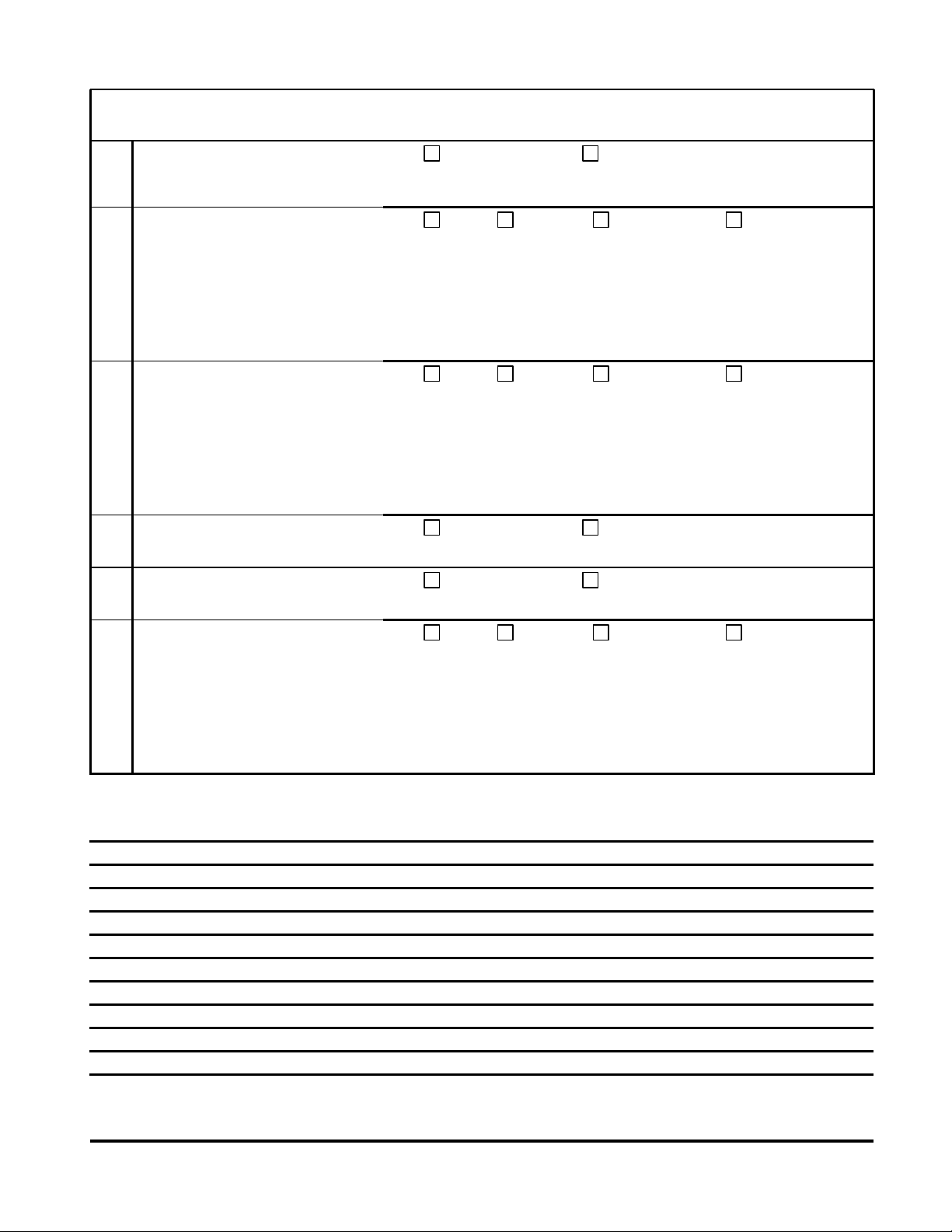

AOC-01 Previous Transport Canada Audit

File 5015Date:

What was the purpose and date of

1.

the previous audit?

Were there a significant number of

2.

Audit Findings?

• What conclusions were drawn

from the audit?

Was the audit follow-up

3.

completed?

• List any outstanding audit

findings respecting the

previous audit?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Since the last audit, are there

4.

indications of high managerial staff

turnover?

Is there any indications of high

5.

staff, flight crew or maintenance

personnel turnover?

Have there been any changes in

6.

the company's scope, size,

aircraft, type of service since the

previous audit?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 3

Page 4

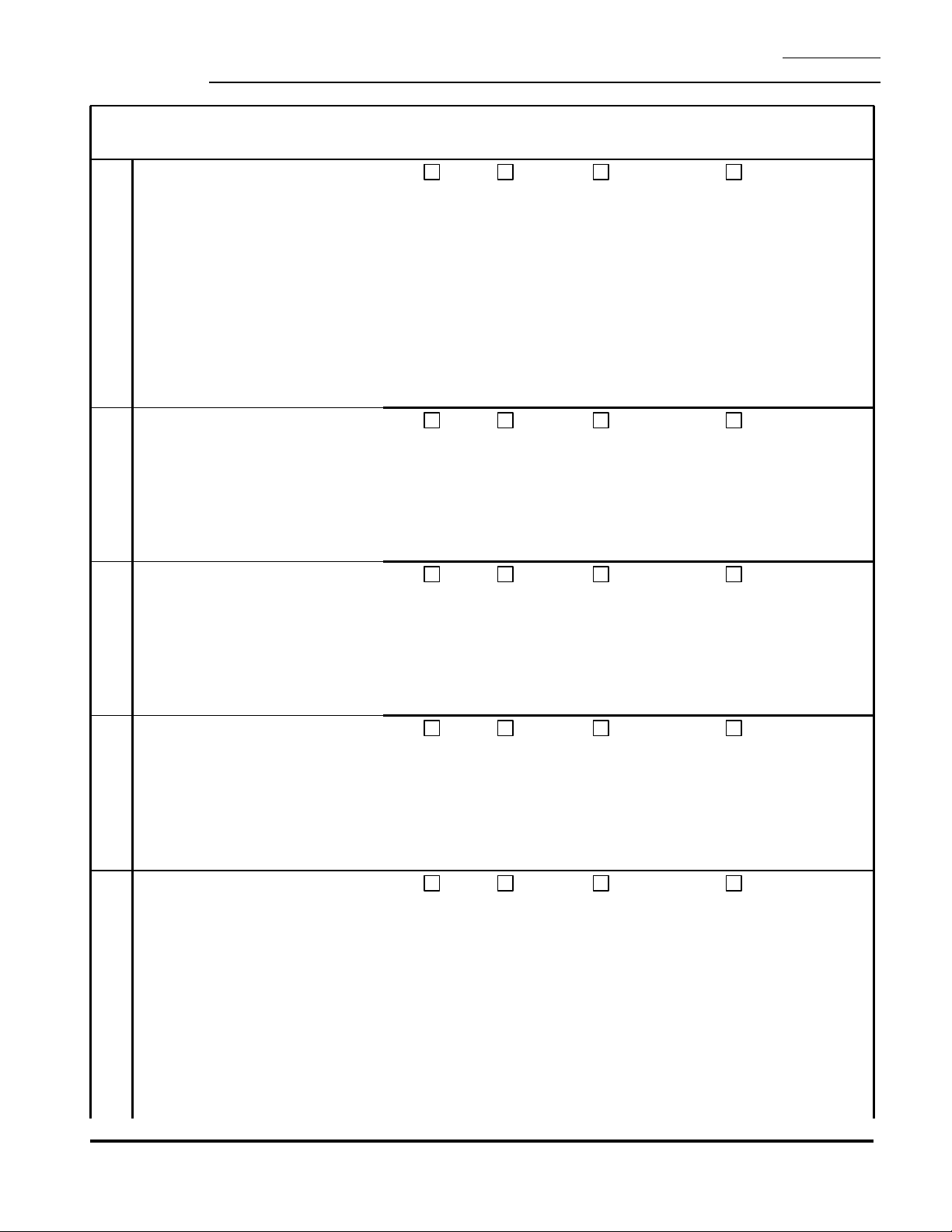

AOC-01 Previous Transport Canada Audit

Have there been any additional

7.

Operations Specifications or a

change to the Maintenance Scope

of Approval / Authorized since the

previous audit?

8.

Ref.

Comments/Summary:

Items completed by:

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Date:

March 2001 Page 4

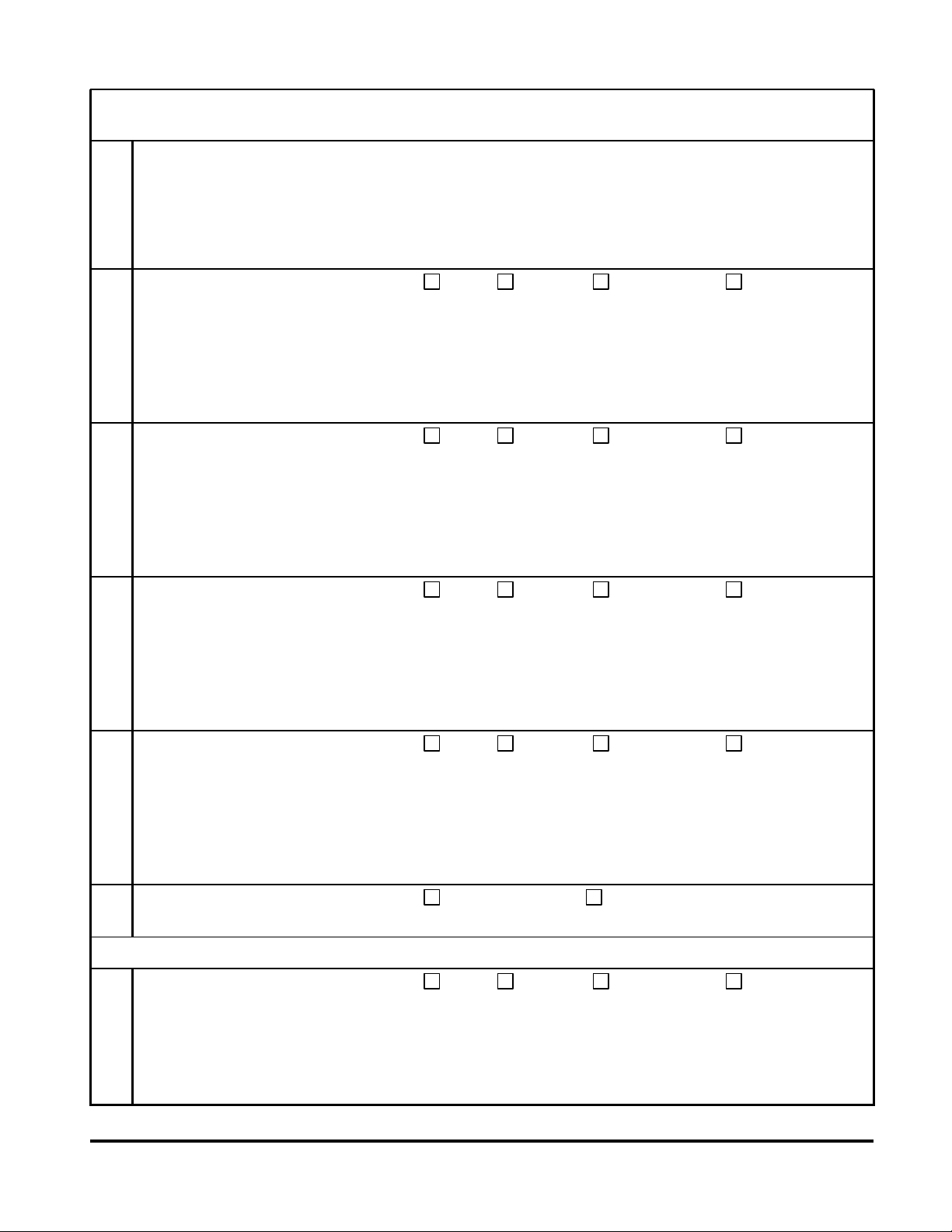

Page 5

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

complying with the Canadian

Company:

AOC-02 Maintenance Control Manual

Maintenance Control - Administrative

File 5015Date:

Does the manual have a table of

1.

contents?

Ref: CASS 726.08(1)(a)

Does the manual reflect the

2.

business or trade name?

Ref: CASS 726.08(1)(b)

Does the company have a fixed

3.

place of business?

Ref: CAR 706.04(2)(a)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the manual have a

4.

description of the

• organization and size?

• state the geographic location

and sub base facilities?

• state the type and number of

aircraft operated?

• the nature and operation?

Ref: CASS 726.08(1)(c)

Does the statement reflect

5.

approvals listed on the Operations

Certificates / Limitations?

Ref: CASS 726.08(1)(c)

Is there a signed statement (by

6.

the certificate holder) indicating

that the manual is their means of

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 5

Page 6

AOC-02 Maintenance Control Manual

Aviation Regulations?

• Is there a listing of the

incorporated documents?

• Is the list covered by the

certification statement made

by the certificated holder?

Note: there’s no compelling

regulation for the AOC to change

certification if the certificate holder

position changes

Ref: CASS 726.08(1)(d)

Has each Incorporated by

7.

Reference Document been

“certified” by the PRM or person

responsible for that management

function as the Air Operator’s

means of compliance with the

CARs?

Ref: CASS 726.08(2)(d)

Does the manual describe an

8.

amendment procedure?

Ref: CASS 726.08(1)(e)

Does the manual describe the

9.

page identification process?

Ref: CASS 726.08(1)(f)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is there an LEP and is it approved

10.

by Transport Canada?

N/A OK Finding Not Checked

Ref: CASS 726.08(1)(f)

Do the pages contained in the

11.

manual match those listed in the

LEP?

March 2001 Page 6

N/A OK Finding Not Checked

Page 7

depicting the organizational

AOC-02 Maintenance Control Manual

Ref: CASS 726.08(1)(f)

Does the manual specify

12.

distribution procedures and the

identity of manual holders /

locations?

Ref: CASS 726.08(1)(g)

Is the amendment procedure

13.

followed?

Ref: CASS 726.08(1)(e)

Are manuals up to date?

14.

Ref: CASS 726.08(1)(e)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are distribution procedures

15.

followed?

N/A OK Finding Not Checked

Ref: CASS 726.08(1)(e)

Are manuals physically located at

16.

the designated site or with the

specified person?

Ref: CASS 726.08(1)(e)

Complete separate PRM

17.

Checklist ….

Does the manual contain a chart

18.

March 2001 Page 7

N/A OK Finding Not Checked

N/A Not Checked

N/A OK Finding Not Checked

Page 8

AOC-02 Maintenance Control Manual

responsibilities?

• If not, is one required for

clarity?

Ref: CASS 726.08(1)(h)(iii)

Does the manual state the

19.

communication equipment to be

used in the conduct of the type of

business intended?

• Is it adequate?

Ref: CASS 726.04(2)(b)

Are they able to contact the

20.

aircraft / crew when away from the

main base or remotely operated?

Ref: CASS 726.06(2)

How is updating of the control

21.

manual actioned or the need

generated?

Ref: CASS 726.04(1)(h)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the company have facilities

22.

adequate for the control of

maintenance, elementary work

and servicing?

Ref: CAR 706.04 / CASS 726.04(2)(a)

Complete separate Evaluation

23.

Program Checklist ….

N/A OK Finding Not Checked

N/A Not Checked

Maintenance Control - Operational

Is there sufficient number of

24.

personnel to control all of the

required maintenance, scheduling,

elementary work, servicing?

Ref: CASS 726.04(1)(b)

N/A OK Finding Not Checked

March 2001 Page 8

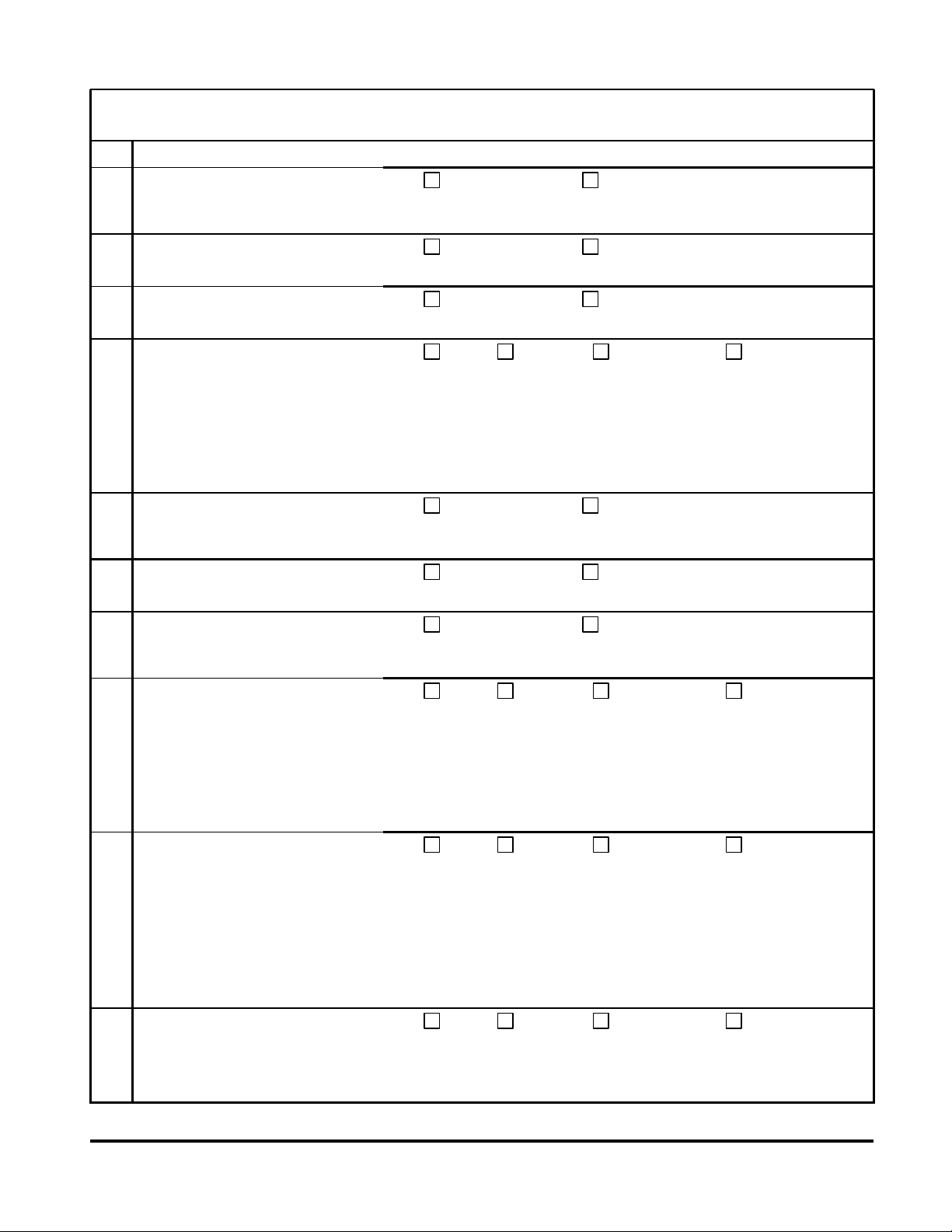

Page 9

AOC-02 Maintenance Control Manual

Complete separate Technical,

25.

Regulatory Publication

Checklist …

Complete separate Technical

26.

Records Checklist …

Complete separate Weight &

27.

Balance Checklist …

Does the manual specify how

28.

maintenance actions are to be

recorded?

Ref: CAR 726.08(1)(k)

Complete separate

29.

Maintenance Development

Checklist …

Complete separate Reliability

30.

Monitoring Checklist …

Complete separate Corrosion

31.

Control & Aging Aircraft

Checklist …

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A OK Finding Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

Is there a person identified that is

32.

responsible for developing a

maintenance schedule?

Ref: CASS 726.04(1)(a)

Does the manual identify the

33.

maintenance schedules

appropriate to the type of

equipment / aircraft operated by

the company?

• Have any maintenance

schedules been omitted?

Ref: CASS 726.08(1)(l)

Does the manual indicate a

34.

procedure for adding additional

aircraft to the operating certificate?

• If so, do they follow the

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 9

Page 10

AOC-02 Maintenance Control Manual

procedure?

Ref:

Complete separate

35.

Maintenance Planning

Checklist …

Complete separate Defect

36.

Control Checklist …

Complete separate

37.

Airworthiness Directive /

Service Bulletin Checklist …

Complete separate instructions,

38.

job cards …

Complete separate Technical

39.

Dispatch Checklist …

Complete separate MEL / GMEL

40.

/ OMEL Checklist …

Complete separate EROPS

41.

Checklist …

Complete separate CAT II

42.

Checklist …

Complete separate Flight

43.

Authority - Test - Ferry Flight

Checklist ….

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

Complete separate

44.

Maintenance Arrangements

Checklist ….

Complete separate Training

45.

Program Checklist ….

Complete separate Personnel

46.

Records Checklist ….

Complete separate Elementary

47.

Work / Servicing Checklist ….

Complete separate Ramp

48.

Procedures Checklist …

Complete separate De -Icing

49.

Procedures Checklist …

Complete separate Complete

50.

separate Servicing - fuel, oil,

lubricants Checklist …

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

N/A Not Checked

March 2001 Page 10

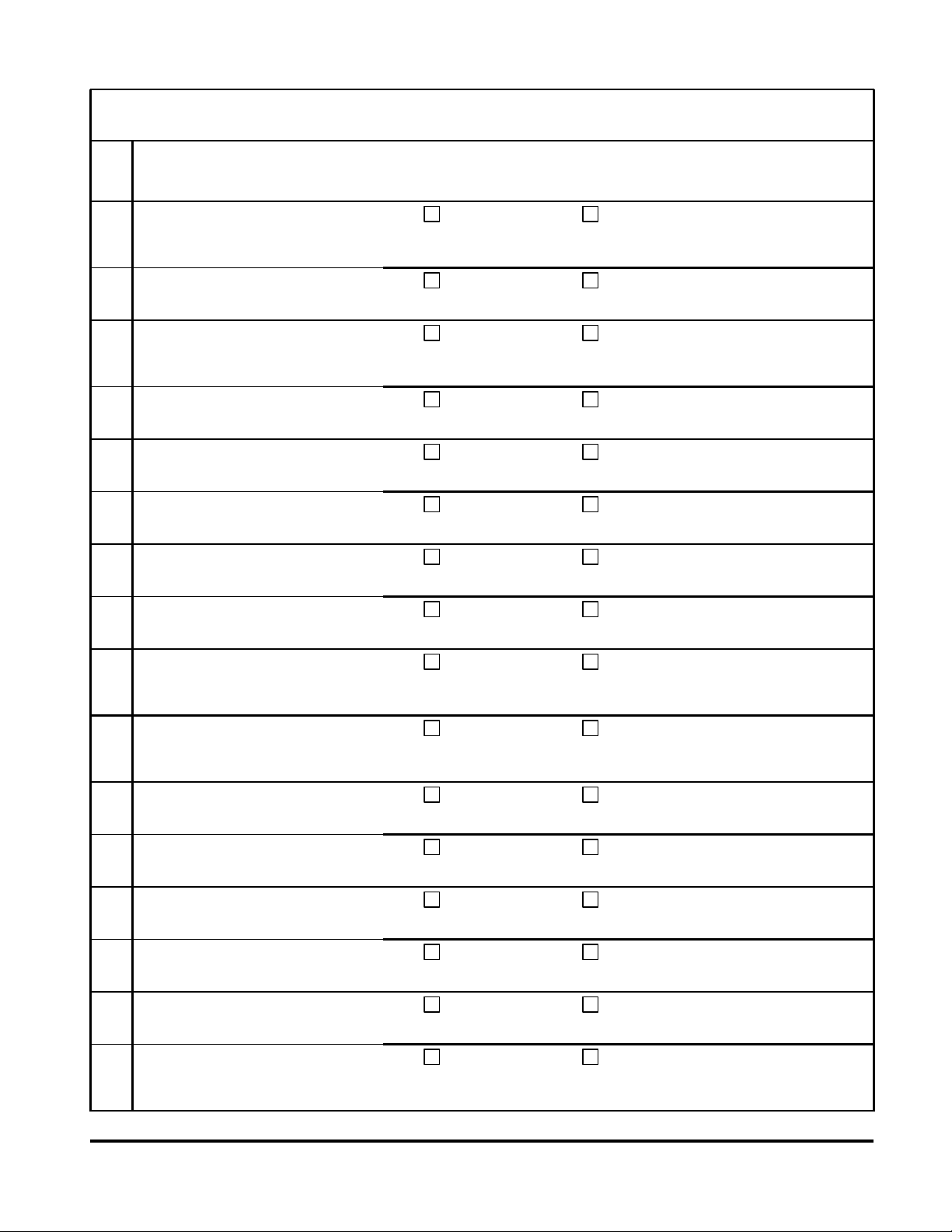

Page 11

AOC-02 Maintenance Control Manual

Complete separate Control of

51.

Parts / Parts Pooling Checklist

…

Are sufficient spare parts available,

52.

located where needed?

Ref: CAR 706.04(1)(e)

Are sufficient supplies and spare

53.

parts available to ensure timely

rectification of defec ts / MEL

provisions?

Ref: CAR 706.04(2)(e)

Complete separate SDR

54.

Checklist ….

Complete separate Sample

55.

Aircraft Checklist ….

N/A Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A Not Checked

N/A Not Checked

56.

Ref.

Comments/Summary:

N/A OK Finding Not Checked

March 2001 Page 11

Page 12

Items completed by:

Date:

March 2001 Page 12

Page 13

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-03 Person Responsible for Maintenance

File 5015Date:

Review TC company files, is there

1.

documentation to support the

evaluation of the PRM?

• completion of the CARs

examination (AMEs exempt)?

• check for convictions under

Section 7.3 of the AA or CAR

605.84/85/86?

• assessment by interview?

Ref: CASS 726.03(1)(a) & (3) / CASS

726.03(4) & (5) / CASS 726.03(1)(b)(ii)

If the AOC holder also holds an

2.

AMO Certificate, is the PRM for

the Air Operator the same person

as the PRM for the AMO?

Ref: CAR 706.03(2)

Does the PRM fully understand

3.

the responsibilities of the position?

Ref: CAR 706.03(b)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is there evidence to suggest that

4.

the PRM did not remove aircraft

from service when they failed to

comply with airworthiness or

operational requirements?

Ref: CAR 706.03(1)c) / CASS 726.03(7)

Does the PRM sub delegate any

5.

of the responsibility?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

• If so, is the identity / position

of the individual and their

duties fully described in the

manual?

• Does the description specify

which functions or activities

that are to be assigned?

March 2001 Page 13

Page 14

AOC-03 Person Responsible for Maintenance

Ref: CASS 726.08(1)(h)

6.

Ref.

Comments/Summary:

Items completed by:

N/A OK Finding Not Checked

Date:

March 2001 Page 14

Page 15

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-04 Evaluation Program

File 5015Date:

Is the requirement to evaluate the

1.

company maintenance system

identified in the manual?

Ref: CAR 706.07 / CASS 726.07(1)

Is the person responsible for

2.

evaluating the program identified in

the manual? If not the PRM, are

this person’s duties clearly defined

in the manual?

Ref: CAR 706.03(3) / CASS 726.07(2)

Has the operator conducted an

3.

initial evaluation at the end of 12

months?

Ref: CASS 726.07(4)(a)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the evaluation program cover

4.

all functions defined in the

manual?

Ref: CASS 726.07(2) & (3)

Does the evaluation program cover

5.

regulatory changes?

Ref: CASS 726.07(2)

Is there evidence (records)

6.

indicating that formal review of

maintenance requirements have

been undertaken?

• Were records kept according

to the requirements specified

in the manual?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 15

Page 16

AOC-04 Evaluation Program

Ref: CASS 726.07(4)(c)

Does the operator use checklists

7.

for the evaluation process?

• Are examples available and

are they comprehensive?

Ref: CASS 726.07(4)

Does the operator follow the

8.

frequency of evaluation as

specified in the manual?

Ref: CASS 726.07(4)(a)

Does the operator follow the stated

9.

corrective action process?

(sample, are persons required to

provide input in the process,

involved?)

Ref: CASS 726.07(4)(c)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are the correct forms as stated in

10.

the manual in use?

Ref: CAR 706.07

Has action taken as a result of a

11.

non-compliance finding included

immediate and long term action to

correct the root cause of the

finding?

Ref: CASS 726.07(4)(e)

Is there any evidence to suggest

12.

that follow-up activities have been

carried out?

Ref: CASS 726.07(4)(f)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 16

Page 17

AOC-04 Evaluation Program

Is there any record of a

13.

maintenance schedule review

being carried out or the evaluation

of supplemental maintenance

requirements for applicability and

inclusion to the operators

program?

• Were they included?

• Does the outcome deviate

from manufacturers

recommendations; are the

conclusions stated and

decisions substantiated? (see

std 625)

Ref: CASS 726.07(4) / 625.86(5)(b)(I)

Are aircraft operational and

14.

environmental conditions

considered in the evaluation

program? (sample, review actual

process)

Ref: CASS 726.07(3)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

*Is there evidence that the operator

15.

has reviewed and evaluated

Service Bulletins and other

technical information for

applicability to their fleet?

• Is there evidence of a

maintenance specialist being

involved in the decision

process?

Ref: CASS 726.07(4) / ANB055

How would the company handle a

16.

service bulletin issued today which

affects their fleet? (sample /

interview, does the response

reflect stated procedures, follow

process through?)

Ref: CAR 706.07

17.

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 17

Page 18

AOC-04 Evaluation Program

Ref.

Comments/Summary:

Items completed by:

Date:

March 2001 Page 18

Page 19

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-05 Technical / Regulatory Publications

File 5015Date:

Is the person responsible for

1.

keeping publications current aware

of his / her responsibilities

(interview)?

Ref: CASS 726.12(1)

Does the operator have technical

2.

and regulatory publications

according to the list in their

approved manual? Note: CASS

726.04(2) is not explicit in the

requirement for technical or

regulatory information, the

following is a possible list ….

• Aeronautics Act

• Canadian Aviation Regulations

& appropriate standards

• type certificates;

• supplemental type certificates;

N/A OK Finding Not Checked

N/A OK Finding Not Checked

• FAA Advisory Circulars 43.13

• Airworthiness Directives,

applicable to the aircraft /

equipment operated;

• manufacturer’s maintenance,

illustrated parts, overhaul

manuals, and service bulletin

and service letters,

• MCM or MPM

Ref: CASS 726.04(2)

Are publications / manuals

3.

current, i.e. amendments up-todate?

Ref: CASS 726.04(2)

*Is the system for monitoring

4.

manual currency effective?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 19

Page 20

AOC-05 Technical / Regulatory Publications

Ref: CASS 726.07

Are appropriate portions of

5.

publications made available to

company personnel, contractors

as outlined in the manual?

Ref: CASS 726.04(2)/CASS 726.08(1)(j)

How is the operator made aware of

6.

technical information, updates,

bulletins, etc. applicable to the

aircraft type they operate?

Ref: CASS 726.04(2)

Does the company have

7.

equipment, i.e. Computers, fiche

reader / printer etc., necessary for

reproducing this information?

• Does the equipment function?

Ref: CASS 726.04(2)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

If regulatory publications are to be

8.

available via the Internet, have the

company demonstrate their

access to and navigate the

information.

Ref: CASS 726.04(2)

If publications are to be made

9.

available to the operator via a

contract for maintenance, does the

operator ensure that the technical

manual applies to their particular

aircraft via serial number or model

or year?

Ref: CASS 726.04(2)

How does the operator control out

10.

of date / historical publications /

training notes?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 20

Page 21

AOC-05 Technical / Regulatory Publications

Ref: CASS 726.04(2)

Is the library distributed and is

11.

there a master list which identifies

each publication and location?

(sample locations)

Ref: CASS 726.04(2)

12.

Ref.

Comments/Summary:

Items completed by:

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Date:

March 2001 Page 21

Page 22

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-06 Technical Records

File 5015Date:

Is the location of records in

1.

accordance with the manual?

Ref: CAR 726.04(2)(f)

Does the use of job / segmented /

2.

task cards, require the operator to

update a computer software

program after completion?

• If so, is there any evidence of

missed entries or incorrect

times being input?

Ref:

*Supplemental worksheets used

3.

for recording and actioning defects

discovered during maintenance

activities, are they the operator’s

or the AMO’s?

• Is this according to manual

requirements?

Ref:

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the operator ensure that

4.

completed inspection packages

are reviewed?

Ref: Std. 625.96(2)

Are the maintenance check

5.

sheets used as described in the

manual?

Ref: Approved Maintenance

Schedule

Cross check completed check

6.

sheets with the aircraft log books,

is there evidence of maintenance

being completed prior to certifying

the Technical Log entry? (sample).

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 22

Page 23

AOC-06 Technical Records

Ref: CAR605.92(1)

Sample aircraft technical records

7.

(including Journey Log). Do the

recorded actions meet regulatory

requirements? For example:

• certifications;

• time between checks;

• weight and balance report;

• inspections completed on

time;

Ref: CAR 605.86 / CAR 605.96 / CAR

571 / Std. AWM 571 Appendix C

Are established procedures being

8.

followed to record and control

maintenance items? For example:

• scheduled maintenance and

inspection;

• Ad’s and special instructions;

• components;

N/A OK Finding Not Checked

N/A OK Finding Not Checked

• TBOs and life-limited times;

• calendar-time items;

• pitot-static and altimeter

calibration checks;

• compass calibration;

• weight and balance

• independent control checks /

CMR / critical maintenance

tasks.

Ref: CAR 605.96 / CAR 571.10(4) / CAR

726.08(1)(m)

Are maintenance records

9.

acceptable for completeness and

final certification? (sample)

Ref: Std. AWM 571.10(2) -(4)/

CAR605.92(1)

Does the operator transfer

10.

information from the journey log to

the permanent technical record in

accordance to regulatory and

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 23

Page 24

holder identified in the

AOC-06 Technical Records

MCM requirements?

Ref: CAR 605.96(2)

Does the operator maintain

11.

technical records in a dry, secure

area?

Ref: CAR 706.04(2)(f)

*Do company personnel record

12.

information and defects in the

journey log or other technical

record in accordance with MCM

procedures?

Ref: CASS 726.08(1)(k)

Is the technical record (including

13.

journey log) a consecutive,

unbroken history?

Ref: CAR 605.93(4)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is computer software used as a

14.

sole support technical history?

• If so, is there evidence of

original entries being updated?

• Is the original entry protected?

Ref: CAR 605.93(2) / CAR 103.4(a) /

Std. 625.93(3)

*Is the primary method for

15.

controlling maintenance tasks

generated / tracked by computer?

• If so, it must be a secure

system, (see technical

records)?

Ref: CAR 103.04

Where computer maintenance

16.

software is used, is the ACA

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 24

Page 25

AOC-06 Technical Records

computerized record ?

Ref: CAR 605.93(1)(b)

Is there evidence of maintenance

17.

releases, which are issued

“subject to satisfactory test flight”,

not having the corresponding final

certification by the pilot -incommand?

Ref: Std. AWM 571.10(4)

18.

Ref.

Comments/Summary:

Items completed by:

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Date:

March 2001 Page 25

Page 26

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-07 Weight & Balance

File 5015Date:

Is the person responsible for

1.

weight and balance control

knowledgeable of their duties and

responsibilities?

Ref: CASS 726.12(1)

Are any of the aircraft operated

2.

subject to the five year re-weigh

requirement? (sample)

Ref: Std. 625 Appendix C, (8)

Are weight and balance reports

3.

carried on board each aircraft?

• Is there more than one report

which may be contradictory?

Ref: Type Certificate

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is there evidence of changes being

4.

made to aircraft basic weight

without amendments to the weight

and balance report?

Ref: Std. 571 Appendix C (2)

Does each amendment to the

5.

weight and balance report include

revision dates and revised

equipment lists?

Ref: Std. 571 Appendix C

Are empty weight and c of g

6.

calculations computed in the

amended report?

Ref: Std. 571 Appendix C

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 26

Page 27

AOC-07 Weight & Balance

Has a maintenance release been

7.

signed for each change to the

weight & balance report?

Ref: Std. 571 Appendix C

Does each aircraft’s weight &

8.

balance report demonstrate

continuity back to the time the

aircraft was weighed?

Ref: CAR605.92 / Std. 571 Appendix C

Do company personnel follow the

9.

approved procedures when moving

from one aircraft configuration to

another?

Ref: Std. 571 Appendix C (3)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

For each aircraft configuration

10.

established, has a maintenance

release been signed? (note: the

current configuration must be

identified however a maintenance

release is not required for the entry

when changing from one

configuration to another)

Ref: Std. 571 Appendix C

Does the system of control ensure

11.

accurate weight and balance

information is used by the pilot -incommand?

Ref: CASS 726.08(1)(u) / Std. 571

Appendix C

Does the weight and balance

12.

report / equipment list include all

items specified in the aircraft type

certificate?

• Does it also include additional

equipment required / installed

for the operation of the

aircraft?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 27

Page 28

AOC-07 Weight & Balance

• Does it include any equipment

installed as a result of an STC

or modification?

Ref: Std. 571 Appendix C (1)(a)

13.

Ref.

Comments/Summary:

Items completed by:

N/A OK Finding Not Checked

Date:

March 2001 Page 28

Page 29

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-08 Maintenance Development Program (MPD)

Program Application

File 5015Date:

Does the manual state the

1.

objective of the maintenance

development program?

Does the manual state policy of

2.

how Maintenance Development

activities will influence the

maintenance schedule?

Is the maintenance schedule /

3.

program, or portion thereof, to be

affected by the program clearly

defined?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the operator have internal

4.

maintenance capabilities i.e. QA /

production systems (essential for

effective control) and access to

engineering support (aid in

evaluating)?

Administration

Is the MPD a self contained

5.

document?

• If so, does the MCM enable

it’s use by reference?

If self contained, is there an

6.

amendment process described?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 29

Page 30

AOC-08 Maintenance Development Program (MPD)

Policy Changes & Authority

Does the program require TC

7.

approval before changes are to be

instituted?

Does the document specify

8.

procedures for establishing or

policy with regards to the

program?

Does the program include a

9.

graphic portrayal of the program

operation?

• Is one required for clarity?

(process chart)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is reliability monitoring to be part

10.

of this program?

• If so, complete separate

Reliability Monitoring

Checklist.

Initial Maintenance Requirements

Does the manual describe how an

11.

initial maintenance schedule is to

be developed or what it is based

upon?

• Is it based upon an MRB and

other operator data?

Does the manual specify the

12.

amount of in service data needed

prior to making considering

changes to the maintenance

schedule?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 30

Page 31

or product performance or is

AOC-08 Maintenance Development Program (MPD)

Is the MPD process dependent on

13.

reliability monitoring process?

Evaluation of Information

Does the program consider

14.

information from other sources, for

example: manufacturers, other

operators, airworthiness

authorities?

How is this information obtained

15.

from other sources controlled and

processed within the organization?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the description of the

16.

program contain a diagram of the

organizational structure?

• If not, is one required for

clarity?

Does the manual define lines of

17.

authority and responsibility

Does the scope of maintenance

18.

activity to be control under this

program require a comprehensive

system for evaluating aircraft fleet /

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 31

Page 32

AOC-08 Maintenance Development Program (MPD)

simple means acceptable?

Performance Influences:

Does the program consider the

19.

operating environment, where and

when aircraft fly, land and layover

such as hot, cold, humid, dusty,

salty, etc.

Does the program consider the

20.

operating schedule, flight hours

per cycle, cycles per day, flight

hours per day, variation within

fleets due to short / long routing.

Does the program consider the

21.

effect of adding or deleting aircraft

on the population samples,

resource and maintenance

capabilities?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the program consider the

22.

modification status of components

in the program?

N/A OK Finding Not Checked

Does the program consider the

23.

integration of used equipment /

aircraft?

N/A OK Finding Not Checked

Is the system of data collection

24.

fully described and does it specify

typical sources of information?

N/A OK Finding Not Checked

March 2001 Page 32

Page 33

AOC-08 Maintenance Development Program (MPD)

If sampling is used, the method,

25.

number of samples, time on the

samples, when sampling and

intervals spelled out.

Does the operator define tasks

26.

such as “inspection”, “check” for

their scope of purpose?

Escalation procedure - required

27.

series or sequence of checks?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are task interval parameters

28.

tailored to operators desired units?

Does the operator participate in

29.

the MRB process?

• If so is their utilization

comparable to that of the

world fleet leaders?

Are alternate or substitute

30.

inspection methods used to qualify

maintenance requirements, i.e. Xray substituted for ultrasonic?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 33

Page 34

AOC-08 Maintenance Development Program (MPD)

Does the operator have a

31.

procedure or the capability to

enhance manufacturers

maintenance instructions?

Are the enhancements driven by

32.

reliability processes or other

feedback mechanisms?

Procedures for making other

33.

changes from one primary

maintenance process to another,

for example changing from Hard

Time to On Condition

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the system obtain data from

34.

units only under operational

conditions?

N/A OK Finding Not Checked

Does the manual provide samples

35.

of how data justifying actions is to

be collected?

N/A OK Finding Not Checked

Data Analysis & Application to the Maintenance Program:

Does it describe how data

36.

analysis will influence adjustments

to maintenance control ?

N/A OK Finding Not Checked

March 2001 Page 34

Page 35

AOC-08 Maintenance Development Program (MPD)

Are the duties and responsibilities

37.

for initiating program revision

clearly defined?

Does the operator use trending as

38.

a means for determining

maintenance requirements?

Is the documentation required to

39.

be used to effect changes in

maintenance program described?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Procedures provided to assure that

40.

any TBO adjustment or other

program change does not conflict

with a corrective action program

established by a previous reliability

analysis.

Program contains a statement that

41.

the TC Office will be advised when

increases to time limitations or

other program changes controlled

by the program occur.

Does the program include a

42.

graphic display of major

system/component TBO

escalation.

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Maintenance Schedule Amendment:

March 2001 Page 35

Page 36

AOC-08 Maintenance Development Program (MPD)

Does the program identify

43.

organizational elements

responsible for approval of

amendments to the maintenance

schedule?

N/A OK Finding Not Checked

Is it singular or quorum based?

44.

N/A OK Finding Not Checked

Procedures for Maintenance Control Changes :

Program describes the procedures

45.

used for making changes to

maintenance controls.

N/A OK Finding Not Checked

Organizational elements

46.

responsible to prepare

substantiation reports to justify

maintenance control changes

identified.

Procedures included relative to

47.

manual revisions concerning time

increases and what will be

required prior to pursuing a

subsequent time increase.

Procedures provided for revision to

48.

the Operations Specifications

when and if required.

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 36

Page 37

AOC-08 Maintenance Development Program (MPD)

49.

Ref.

Comments/Summary:

Items completed by:

N/A OK Finding Not Checked

Date:

March 2001 Page 37

Page 38

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-09 Reliability Monitoring Programs

Program Application: FAA AC / AMA

Does the reliability program clearly

1.

define the components, systems,

or complete aircraft which are to

be controlled?

N/A OK Finding Not Checked

Is the maintenance program, or

2.

portion thereof, to be controlled by

reliability program clearly defined?

N/A OK Finding Not Checked

Does the program reference the

3.

operator’s MCM where details

pertaining to overhaul and

inspections periods, work content,

and other maintenance program

activities that are guided by the

program may be found?

N/A OK Finding Not Checked

File 5015Date:

Organizational Structure:

Does the description of the

4.

program contain a diagram of the

organizational structure?

• If not, is one required for

clarity?

Does the manual define lines of

5.

authority and responsibility.

Is the appropriate authority

6.

delegated to each organizational

element?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 38

Page 39

AOC-09 Reliability Monitoring Programs

Definitions:

Does the program clearly define

7.

significant terms?

N/A OK Finding Not Checked

Are acronyms or abbreviations

8.

peculiar to the program defined?

N/A OK Finding Not Checked

Data Collection System:

Is the data collection system fully

9.

described and does it specify

typical sources of information?

Does the system obtain data from

10.

units only under operational

conditions?

Does the data relate directly to

11.

established levels of performance?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the manual provide samples

12.

of data and how it is to be

collected?

N/A OK Finding Not Checked

March 2001 Page 39

Page 40

AOC-09 Reliability Monitoring Programs

If sampling techniques are to be

13.

used, is the method of sampling number of / in service time /

intervals, specified?

N/A OK Finding Not Checked

Establishing Performance Standards and Revision:

Does the program include an initial

14.

performance standard that defines

acceptable performance

requirements?

N/A OK Finding Not Checked

Does the manual describe

15.

methods used to evaluate and

control performance? Are various

methods in use?

Are performance standards for

16.

system or component failures

expressed in mathematical

terms ? For example:

• 1000 hours of aircraft

operation ?

• Number of landings ?

• Operating cycles ?

• Departure delays ?

• Pilot reports ?

• Other findings under

operational conditions ?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

When a performance standard is

17.

exceeded, is an active

investigation required ?

N/A OK Finding Not Checked

March 2001 Page 40

Page 41

combination of past performance

AOC-09 Reliability Monitoring Programs

Are statistical techniques used in

18.

reliability measurement supportive

of maintenance control actions ?

• Are actuarial or engineering

studies used to determine

maintenance changes.

• Are studies made involving

inspection frequency and

content, overhaul limits and

times ?

• Do they show aircraft, system,

or component modification ?

• Does it show other actions

peculiar to prevailing

conditions ?

Are there provisions for the re-

19.

evaluating performance standards

that lose their value ?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are there provisions to establish

20.

initial performance standards for

new aircraft being placed in

service ?

Are there provisions for the initial

21.

alert values to be adjusted based

on carrier’s first year of

experience ?

If PIREPS per 1000 departures is

22.

the standard, is 5 PIREPS per

1000 added to rate for past year to

set alert value?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are alert levels set up on a

23.

March 2001 Page 41

N/A OK Finding Not Checked

Page 42

AOC-09 Reliability Monitoring Programs

plus “good judgment” ?

Is a statistical approach used to

24.

establish alerts ?

N/A OK Finding Not Checked

Are alert values equal to mean

25.

plus 3 standard deviations?

• If not, what criterion is used?

N/A OK Finding Not Checked

Data Analysis Methodology & Application to Maintenance:

Does the manual contain a

26.

description of the data analysis

process?

N/A OK Finding Not Checked

Does it describe how the analysis

27.

will influence adjustments to

maintenance control ?

N/A OK Finding Not Checked

Types of action appropriate to the

28.

trend or level of reliability

experienced.

N/A OK Finding Not Checked

Are procedures for evaluating

29.

critical failures established?

March 2001 Page 42

N/A OK Finding Not Checked

Page 43

essential information for each item

AOC-09 Reliability Monitoring Programs

Are the statistical techniques that

30.

are used to determine reliability

levels described?

N/A OK Finding Not Checked

Is the manner in which information

31.

is exchanged between

organizational elements fully

described?

N/A OK Finding Not Checked

Are the activities and responsibility

32.

of each organizational element

defined?

N/A OK Finding Not Checked

Does the program include a

33.

graphic portrayal of the program

operation?

• Is one required for clarity?

(process chart)

N/A OK Finding Not Checked

Data Display & Corrective Action Process:

Does the program describe the

34.

reports, charts, operating

experience in use?

N/A OK Finding Not Checked

Does the description contain

35.

March 2001 Page 43

N/A OK Finding Not Checked

Page 44

AOC-09 Reliability Monitoring Programs

controlled by program?

Is each system and component

36.

identified by appropriate ATA code

number? If not what method is

used?

N/A OK Finding Not Checked

Does the data display method

37.

show trends as well as the current

month’s performance?

N/A OK Finding Not Checked

Is there a description of the

38.

corrective action process?

Does the corrective action process

39.

include a requirement to establish

planned completion dates?

Is there a status (real time) of

40.

corrective action available?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is corrective action description

41.

appropriate to circumstances ?

N/A OK Finding Not Checked

March 2001 Page 44

Page 45

AOC-09 Reliability Monitoring Programs

Program Revision:

Does the manual contain

42.

procedures for implementing

changes to the reliability program?

N/A OK Finding Not Checked

Does the program identify which

43.

organizational elements are

responsible for approving

amendments to the reliability

program?

N/A OK Finding Not Checked

• Is this a quorum approach?

Are the duties and responsibilities

44.

for initiating program revision

clearly defined?

Do procedures identify and isolate

45.

areas which will require TC

approval prior to implementation?

Does the program require periodic

46.

reviews be accomplished which

would validate the performance

standard in use is still realistic?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is a method of distribution and

47.

implementation of approved

revisions to the reliability program

March 2001 Page 45

N/A OK Finding Not Checked

Page 46

AOC-09 Reliability Monitoring Programs

included in the manual?

Procedures for Implementing Maintenance Control Changes:

Does the program describe

48.

procedures which are used for

making changes to maintenance

controls?

N/A OK Finding Not Checked

Is the documentation used to

49.

effect changes in maintenance

program described?

N/A OK Finding Not Checked

Are substantiation reports

50.

justifying maintenance control

changes required / prepared /

produced by the organizational

elements responsible for such

changes?

Are specific parameters identified

51.

which are to be used to determine

changes in maintenance control?

Are procedures provided which

52.

cover all maintenance program

activities controlled by the

reliability program?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are procedures specified for

53.

changing items from “Hard Time”

to “On Condition” or “Condition

March 2001 Page 46

N/A OK Finding Not Checked

Page 47

AOC-09 Reliability Monitoring Programs

Monitoring?”

Are procedures specified for

54.

making other changes from one

primary maintenance process to

another?

N/A OK Finding Not Checked

Are procedures included

55.

concerning maintenance interval

changes and the subsequent

action required should an

additional time increase be

pursued?

N/A OK Finding Not Checked

Is a feedback process described

56.

for influencing revision to

Operations Specifications if and

when required?

Has a procedure been established

57.

to ensure that any program

change / TBO adjustment, does

not conflict with a corrective action

process established by a previous

reliability analysis?

Does the program include a

58.

graphic display detailing major

system / component TBO

escalation process?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are details of Airworthiness

59.

Directives or Service Bulletins

taken into consideration or

evaluated for applicability to the

program?

N/A OK Finding Not Checked

March 2001 Page 47

Page 48

AOC-09 Reliability Monitoring Programs

Program Approval:

Are procedure describing approval

60.

process clearly identified?

N/A OK Finding Not Checked

Does the manual contain a

61.

requirement to notify / advise the

TC Office responsible when

increases to time limitations or

other processes / changes

controlled by the program occur?

N/A OK Finding Not Checked

62.

Ref.

Comments/Summary:

I tems completed by:

N/A OK Finding Not Checked

Date:

March 2001 Page 48

Page 49

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

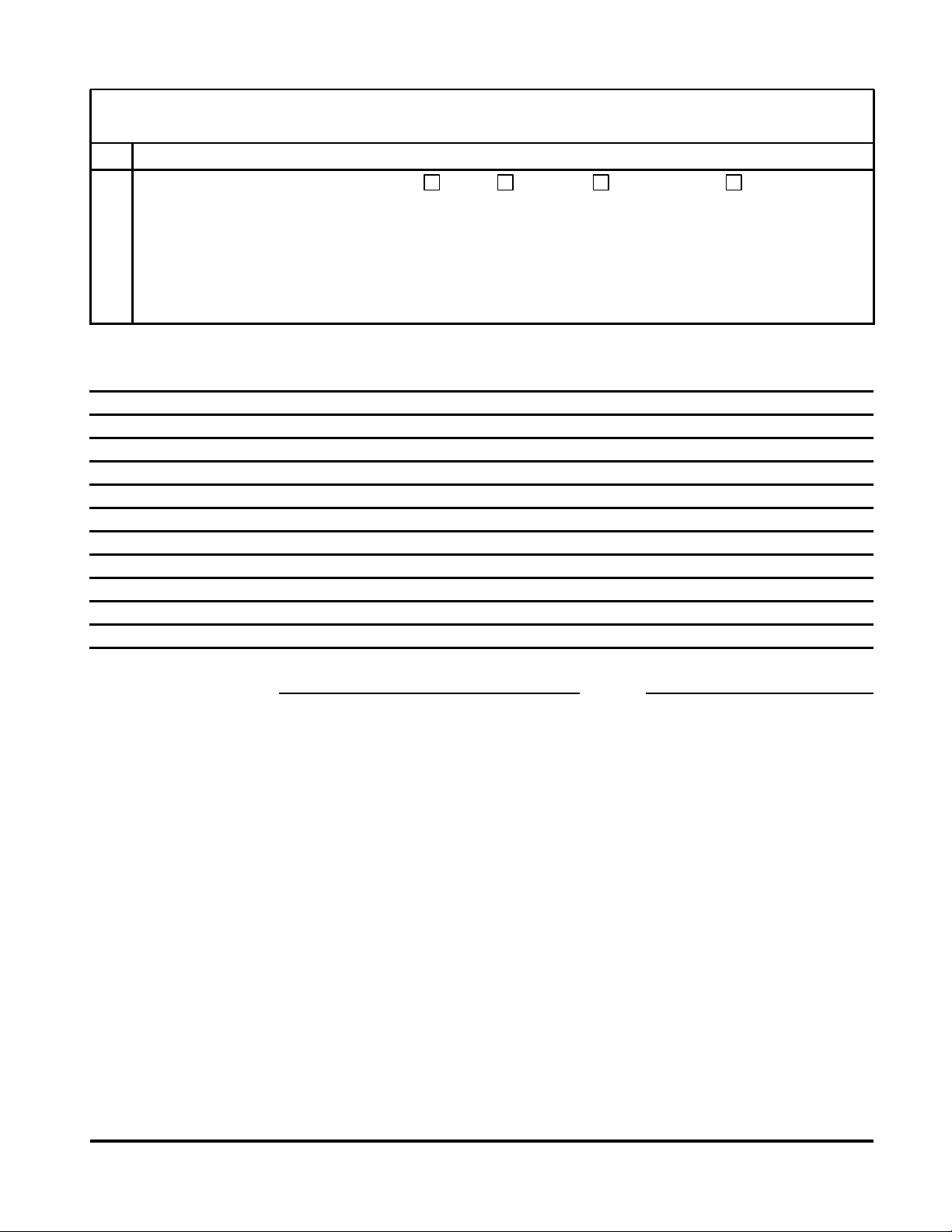

AOC-10 Reserved

File 5015Date:

Reserved

March 2001 Page 49

Page 50

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

File 5015Date:

AOC-11 Maintenance Planning

Note: As maintenance planning is procedural specific to the operator, a supplemental checklist may need to be developed from the

approved manual in support of the audit.

Is the individual responsible for the

1.

program knowledgeable of the

procedures described in the

manual?

Ref: CASS 726.12(1)

Is the method or process used to

2.

monitor / schedule maintenance

activities / repetitive AD’s

(computer / status system / other)

being followed by the

organization?

• Does this include

supplemental maintenance

items (such as STC’s added

after MS approval, floats &

skis etc., safety equipment)?

Ref: CAR 706.04(2)c) / CASS

726.08(1)(m)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are the same method(s) used at

3.

all locations and sub bases?

Ref: CASS 726.08(1)(m)

*Is the primary method for

4.

controlling maintenance tasks

generated / tracked by computer?

• If so is it a secure system,

(see technical records)?

Ref: CAR 103.04 / CAR 605.93(2)

Is the method used up-to-date and

5.

current?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 50

Page 51

AOC-11 Maintenance Planning

Ref: CASS 726.08(1)(m)

*Is there operational or additional

6.

equipment that is not addressed in

the maintenance schedule?

(sample)

Ref: Std 625.86

Is there evidence that maintenance

7.

requirements have been missed or

actioned late?

Ref: CASS 726.08(1)(m)

Are there service bulletins that

8.

were or should have been adopted

/ installed / integrated into the

maintenance program? (sample)

Ref: CASS 726.08(1)(m) / CAR

625.86(6)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is the frequency and use of

9.

tolerances planned or excessive?

Ref: Std. 625.86(8) / TP13094

Are maintenance releases made

10.

to facilitate the use of the

tolerance prior to it’s use?

Ref: Std. 625.86(8)

Is aircraft operating information

11.

(aircraft daily flight time / condition

/ status) relayed to the individual

making decisions on maintenance

requirements?

• Is this in accordance with the

instruction / procedures

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 51

Page 52

applicable areas of the aircraft as

AOC-11 Maintenance Planning

specified in the manual?

• Does this information include

a requirement for - defects,

MELs, special

inspections,hard landings,

lighting strikes, etc

Ref: CASS 726.08(1)(m)

*For aircraft operating under MEL

12.

authorities, how is repair interval

planned and actioned?

Ref: CASS 726.08(1)(m)

Is the liaison between the operator

13.

and the maintenance contractor

effective?

• Is there any evidence that the

communication process does

not work?

Ref: CAR 706.09(2)(a) / CASS

726.04(1)(g)

*Is the maintenance contractor

14.

consulted in the defect deferral

process?

Ref: CASS 726.04(1)(g) / CASS

726.08(1)(v)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are maintenance requirements

15.

communicated to the AMO in

accordance with manual

requirements?

Ref: CASS 726.04(1)(g) / CASS

726.08(1)(v)

Does the operator maintain current

16.

inspection sheets as identified in

the Maintenance Schedule?

Ref: CAR 605.86 / Approved

Maintenance Schedule (TP13094)

Do inspection sheets cover all

17.

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 52

Page 53

AOC-11 Maintenance Planning

described in the program?

Move to MS Checklist !!

Are the appropriate forms and

18.

information supplied to the

maintenance organization or are

they to be reproduced by the

AMO?

• Is this in accordance with the

stated process?

Ref: CAR 605.86 / Approved

Maintenance Schedule (TP13094)

Did AMO personnel use the latest

19.

check sheet (revision) during the

last few inspections?

Ref: CAR 605.86 / Approved

Maintenance Schedule (TP13094)

Where the operator writes or re-

20.

writes job / segmented / task

cards, does the operator follow the

process stated in the manual for

controlling revision of the cards?

• Does the card contain a

reference link to the original

instructions?

Ref: Std. 625 Appendix D (3)(a)(vi)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

For computer controlled

21.

maintenance planning, is the

repeat interval self generated or is

this a manual input operation?

• Is the process consistent with

the description in the manual?

• Is there any evidence that

repeat interval maintenance

requirements have been

overlooked or entered

incorrectly?

Ref: CAR 706.08(1)(m) / CAR 605.86 /

Approved Maintenance Schedule

(TP13094)

22.

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 53

Page 54

AOC-11 Maintenance Planning

Ref.

Comments/Summary:

Items completed by:

Date:

March 2001 Page 54

Page 55

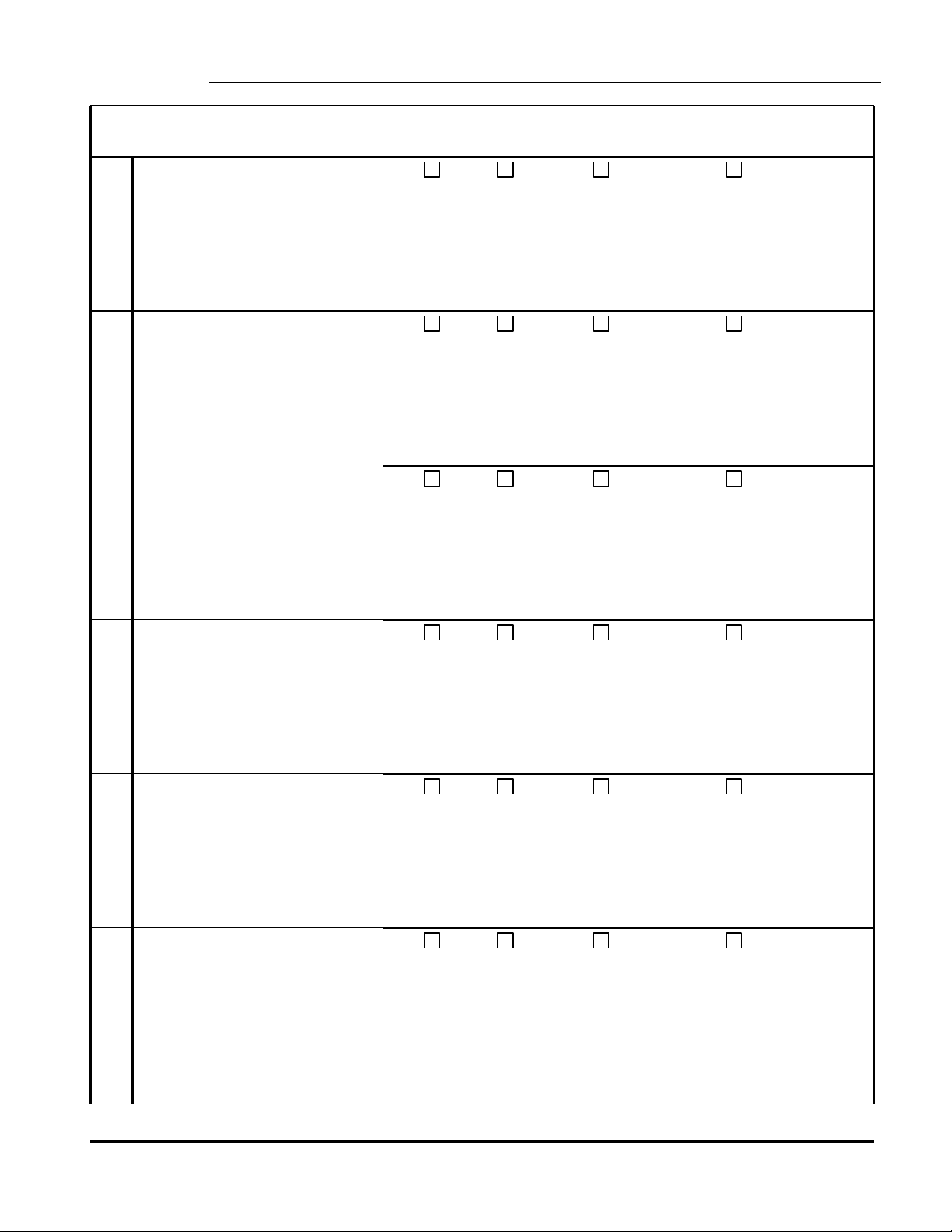

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

File 5015Date:

AOC-12 Defect Recording, Rectification, Deferral, and Control

Procedures

Recording

Does the company record defects

1.

in accordance with the procedures

specified in the manual?

Ref: CASS 726.08(1)(o) / CAR

605.94(1)

Are defects recorded in the proper

2.

record / log; are they identified

appropriately and handled in

accordance with stated

procedures?

Ref: CAR 706.05(a) / CAR 605.94(1)

Does this recording procedure

3.

apply to defects found by flight

crew during normal operations?

• Does the method indicated

conflict with regulatory

requirements?

Ref: CAR 706.05(a) / CAR 605.94(1)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are defects found during

4.

maintenance recorded in

accordance with procedures

stated by the operator or by the

maintenance contractor?

Ref:

*Supplemental worksheets used

5.

for recording and actioning defects

discovered during maintenance

activities, are they the operator’s

or the AMO’s?

• Is this according to manual

requirements?

Ref: CAR 706.05(a)

Is there evidence of defects not

6.

being recorded:

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 55

Page 56

AOC-12 Defect Recording, Rectification, Deferral, and Control

Procedures

• by the flight crew?

• while the aircraft is away from

base?

• during maintenance?

Ref: CAR 605.94(1)

How does the company handle

7.

self generated / recorded fault logs

(Built In Test Equipment)?

Ref: CASS 726.08(1)(o)

Deferral

For aircraft that released under

8.

MEL authority, complete MEL

Checklist …

How does the operator determine

9.

a defects suitability for deferral?

• Are technical / regulatory

manuals and type certificate

information available /

consulted in the process?

Ref: CAR 605.06(a)

N/A OK Finding Not Checked

N/A Not Checked

N/A OK Finding Not Checked

Are defects assessed against

10.

mandatory or required operating

equipment limitations (also

includes Type Certificates Data

Sheets and basis of certification)?

Ref: CAR 605.09 / CAR 605.10 / CAR

605 General

*Are environmental factors and

11.

operational role of the aircraft

considered in the defect’s

assessment?

Ref: CAR 602 Division II /CAR

605.06(b)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 56

Page 57

highlight defects that recur to

AOC-12 Defect Recording, Rectification, Deferral, and Control

Procedures

*Is the maintenance contractor

12.

consulted in the deferral process?

Ref: CAR 706.08(1)(o)

Are deferrals entered in the

13.

journey log or other recording

system in accordance with stated

procedures?

Ref: CAR 706.08(1)(o) / CAR 605.94(1)

Are procedures for placarding

14.

deferred defects being followed?

Ref: CAR Std 625.08 CAR 605.10(2)(b)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are personnel that defer

15.

authorized?

Ref: CAR 605.10(2)(c) / CAR

706.08(1)(o)

Recurring Defect

Is there any evidence indicating

16.

recurring defects are not being

addressed according to stated

procedures?

Ref: CAR 706.05(2) / CASS 726.05(1)

Is the operator’s stated procedure

17.

effective in detecting the

reoccurrence of defects?

• Does the defect system

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 57

Page 58

AOC-12 Defect Recording, Rectification, Deferral, and Control

Procedures

the flight crew and

maintenance organization?

Ref: CAR 706.05(a) / CASS 726.05(1)

Does the operator’s criteria, for

18.

classifying recurring defects, meet

regulatory requirements?

Ref: CASS 726.05(3)

Control

*For aircraft operating under MEL

19.

authorities, how is repair interval

planned and actioned?

Ref: CASS 726.08(1)(m)

Troubleshooting, part removal.

20.

Does the manual indicate how a

part removed for troubleshooting

purposes must be handled?

• If so, does the company follow

procedures for storage, time

limits and maintenance

release requirements?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

• parts removed from another

aircraft for troubleshooting?

Ref: CASS 726.08(1)(r) / CAR 571.13 /

CAR 706.08(1)(m)

21.

Ref.

N/A OK Finding Not Checked

March 2001 Page 58

Page 59

Comments/Summary:

Items completed by:

Date:

March 2001 Page 59

Page 60

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-13 Airworthiness Directive, Service Bulletin

File 5015Date:

Does the operator have all

1.

Airworthiness Directives applicable

to their fleet?

Ref: CASS 726.04(2) / Std. AWM 593

Appendix B (2)(a)

Does the operator ensure timely

2.

action of Airworthiness Directives?

Ref: CASS 726.08(1)(m) / CASS

726.07(4)

Are the details, of maintenance

3.

actions used during the

accomplishment of Airworthiness

Directives, recorded in the

appropriate technical record?

• For Service Bulletins?

Ref: CAR 605.94(1) / Std. AWM 571.03 /

Std. AWM 571.10(4) / Std. 625

Appendix H (1)(b)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the operator have direct

4.

access to Service Bulletin and

other technical information

applicable to their fleet?

• If access is by way of a

contract, is the access

adequate? (sample, have

operator demonstrate)

Ref: CASS 726.07(4)

*Is there evidence that the operator

5.

has reviewed and evaluated

Service Bulletins and other

technical information for

applicability to their fleet?

• Is there evidence of a

maintenance specialist being

involved in the decision

process?

Ref: CASS 726.07(4) / ANB055

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 60

Page 61

AOC-13 Airworthiness Directive, Service Bulletin

Is the implementation of AD / SB

6.

or other technical information

actioned directly from the

manufacturers technical

information or is the process re

written into task cards or action

sheets?

• If re written, is there a control

process or review mechanism

in place which ensures the

accuracy of the information?

Ref: Std. 625 Appendix D (3)(vi)

7.

Ref.

Comments/Summary:

Items completed by:

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Date:

March 2001 Page 61

Page 62

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-14 ETOPS - Extended Range Operations

File 5015Date:

Is the individual responsible for the

1.

program knowledgeable of the

procedures described in the

manual?

Ref:

Is propulsion system reliability

2.

data forwarded to Transport

Canada on a monthly basis?

Ref: TP 6327 4.9.1

Is the engine and APU oil

3.

consumption being monitored as

described in the manual?

Ref: TP 6327 4.4

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the curriculum for the

4.

ETOPS training consider all

factors and consideration of the

program?

Ref: TP 6327 4.10

Have personnel that certify ETOPS

5.

departure checks been trained and

authorized? (sample)

Ref: TP 6327 4.10

Parts / components may be

6.

sensitive to ETOPS requirements;

does the operator have a program

to control modification status of

individual components?

Ref: TP 6327 4.2.1

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 62

Page 63

AOC-14 ETOPS - Extended Range Operations

Do part pooling activities consider

7.

ETOPS CMP requirements?

Ref: TP 6327 4.11

Does the aircraft configuration and

8.

modification status conform to the

requirements specified in the CMP

document? (sample, component

changes)

Ref:

Is there any evidence to suggest

9.

that the operator has conducted a

verification process after engine

shutdown or primary system

failure or critical maintenance

activities? (sample)

Ref: TP 6327 4.6

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Does the operator continue to

10.

input unscheduled / scheduled

engine removal data into the

ETOPS program?

Ref: TP 6327 4.9.2

Are thrust reductions due to

11.

abnormal causes logged and

tracked for program input?

Ref:

Does the operator adhere to the

12.

approved reliability program and

are ETOPS sensitive items

covered by the program, i.e.

propulsion, systems, structure?

Ref:

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 63

Page 64

AOC-14 ETOPS - Extended Range Operations

Does the operator continue to

13.

collect and advise TC of data

relevant to the health of the

approved ETOPS program as

defined in the approved document

or MCM?

Ref: TP 6327 4.7.1

Does the operator adhere to

14.

maintenance procedures and

tasks specified in the manual,

maintenance schedule or

operator’s ETOPS control

document?

Ref: TP 6327 4.2

Are ETOPS aircraft being

15.

maintained in conformance with

the manufacturer’s ETOPS type

configuration?

Ref: TP 6327 4.2

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is the ETOPS program now in use

16.

in line with the program approved

by TC?

Ref:

Is the operator incorporating

17.

changes required by configuration

document amendments?

Ref: TP 6327 4.2.1

Is the operator reviewing and

18.

modifying the ETOPS program to

reflect control document

amendments in a timely manner?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 64

Page 65

AOC-14 ETOPS - Extended Range Operations

Ref:

Is the operator following the

19.

ETOPS control document or

program as outlined in the

manual?

Ref:

*Does the operator release aircraft

20.

participating in the ETOPS

program in accordance with the

approved MEL document?

Ref: TP 6327 3.4.2

Does the operator adhere to the

21.

enhanced training, approved in the

manual or operator’s ETOPS

control document?

Ref: TP 6327 4.10

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is there any evidence of the

22.

operator dispatching aircraft

(ETOPS qualified) after a power

unit or primary failure without

reference to the approved MEL?

Ref:

23.

Ref.

Comments/Summary:

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 65

Page 66

Items completed by:

Date:

March 2001 Page 66

Page 67

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-15 Minimum Equipment List - MEL, OMEL, GMEL

File 5015Date:

Is the MEL TC Civil Aviation

1.

approved?

Ref: CAR 605.07(3) / CAR

704.07(2)(d) / CAR 705.07(2)(e)

Does the operator have a MEL

2.

training program?

• Does the program include

training of contract

maintenance personnel?

Ref: TP9155 - 3.16

Is a copy of the approved MEL

3.

carried on board the aircraft?

(sample)

Ref: CAR 605.09(1)(b)

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Is the on-board copy at the

4.

corrective revision? (sample)

Ref: CAR 605.09(1)(b)

Are MEL numbers entered in the

5.

journey log for deferred MEL

items?

Ref: TP9155 Appendix R1.3

Are only authorized personnel

6.

releasing or dispatching aircraft

with inoperative items?

Ref: TP9155 Appendix R1.3 / R1.4

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 67

Page 68

or untimely actioning of the

AOC-15 Minimum Equipment List - MEL, OMEL, GMEL

Are appropriate maintenance

7.

instructions carried on board the

aircraft to facilitate conformance to

the MEL?

Ref: TP9155

Are aircraft with multiple deferred

8.

MEL items operated for extended

periods through maintenance

bases and terminating airports?

Ref: TP9155

*For aircraft that released under

9.

MEL authority, are they done so in

accordance with the correct

procedure?

• placarding

• authorized person

• category

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

• time limits

Ref: CAR 605.09

Does the operator implement

10.

revisions to their MEL within a

reasonable time after the release

of a revision to the Master MEL?

Ref: TP9155

*Does the company have MEL self

11.

extension authority?

• Are MEL self extensions

coordinated between

operations and maintenance?

Ref:

Is there any evidence to suggest

12.

that this privilege is being abused,

i.e. excessive or repetitive

extensions for the same item; late

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 68

Page 69

AOC-15 Minimum Equipment List - MEL, OMEL, GMEL

defect?

Ref:

Is there evidence of notification

13.

being sent to Transport Canada

when MEL self extensions are

granted?

Ref:

Does the organization follow the

14.

policies and procedures for

conformance to the MEL as

described in the manual?

Ref:

*Does the operator release aircraft

15.

participating in the ETOPS

program in accordance with the

approved MEL document?

Ref: TP 6327 3.4.2

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

*Have individual aircraft MELs

16.

been reviewed / amended to reflect

the additional maintenance

procedures necessary for the

ETOPS operation?

Ref: TP 6327 3.4.2 a)

*Does the ETOPS departure

17.

check cover items such as

maintenance sensitive items, MEL

deferral review, deferred item

review, system verification, log

book review?

Ref: TP 6327 4.2.1 c)

How is aircraft configuration

18.

management (CMP) integrated /

factored / coordinated into the

ETOPS and MEL processes?

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 69

Page 70

AOC-15 Minimum Equipment List - MEL, OMEL, GMEL

Ref:

19.

Ref.

Comments/Summary:

Items completed by:

N/A OK Finding Not Checked

Date:

March 2001 Page 70

Page 71

CAR 704 / 705 Aircraft Operator Requirements (CAR 706)

Company:

AOC-16 All Weather Operations - Category II, III

File 5015Date:

Does the operator have All

1.

Weather Operations (AWO)

approval to Category II - III limits?

Ref: TP 1490

Does the operator have an

2.

approved maintenance program in

support of the AWO?

Ref: TP 1490

Are aircraft down graded / returned

3.

to Category II - III status in

accordance with approved

procedures?

Ref: TP 1490

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are the equipment and systems

4.

required for an AWO maintained in

accordance with the approved

maintenance schedule?

Ref: TP 1490

Are modifications to Cat egory II -

5.

III equipment and systems

approved in accordance with

Chapter 513 of the Airworthiness

Manual?

Ref: TP 1490

Does the operator maintain a

6.

current list of personnel authorized

to certify the company aircraft to

Category II - III?

• Is the list available to the

person responsible for

dispatching the aircraft?

Ref: TP 1490

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

March 2001 Page 71

Page 72

AOC-16 All Weather Operations - Category II, III

Have Category II - III certified

7.

maintenance personnel received

initial and recurrent training?

Ref: TP 1490

Does the operator utilize contract

8.

maintenance?

• If so, can it be verified that the

contracting maintenance

organization is approved by TC

Civil Aviation to properly

maintain the Category II - III

systems?

Ref: TP 1490

If a foreign maintenance

9.

organization is used, does it meet

the minimum requirements for

approval to properly maintain the

Category II - III systems?

Ref: TP 1490

N/A OK Finding Not Checked

N/A OK Finding Not Checked

N/A OK Finding Not Checked

Are defects which effect AW

10.