Page 1

1

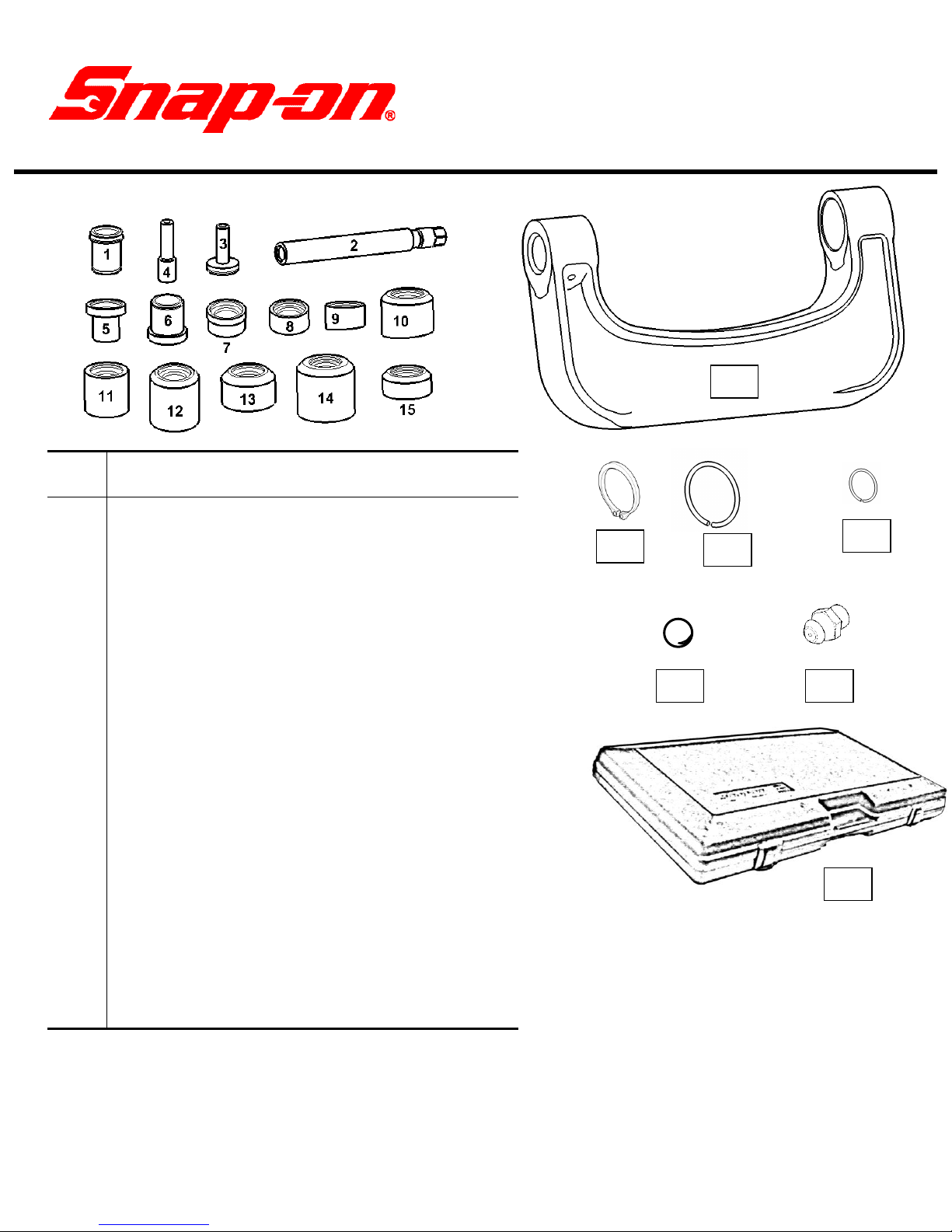

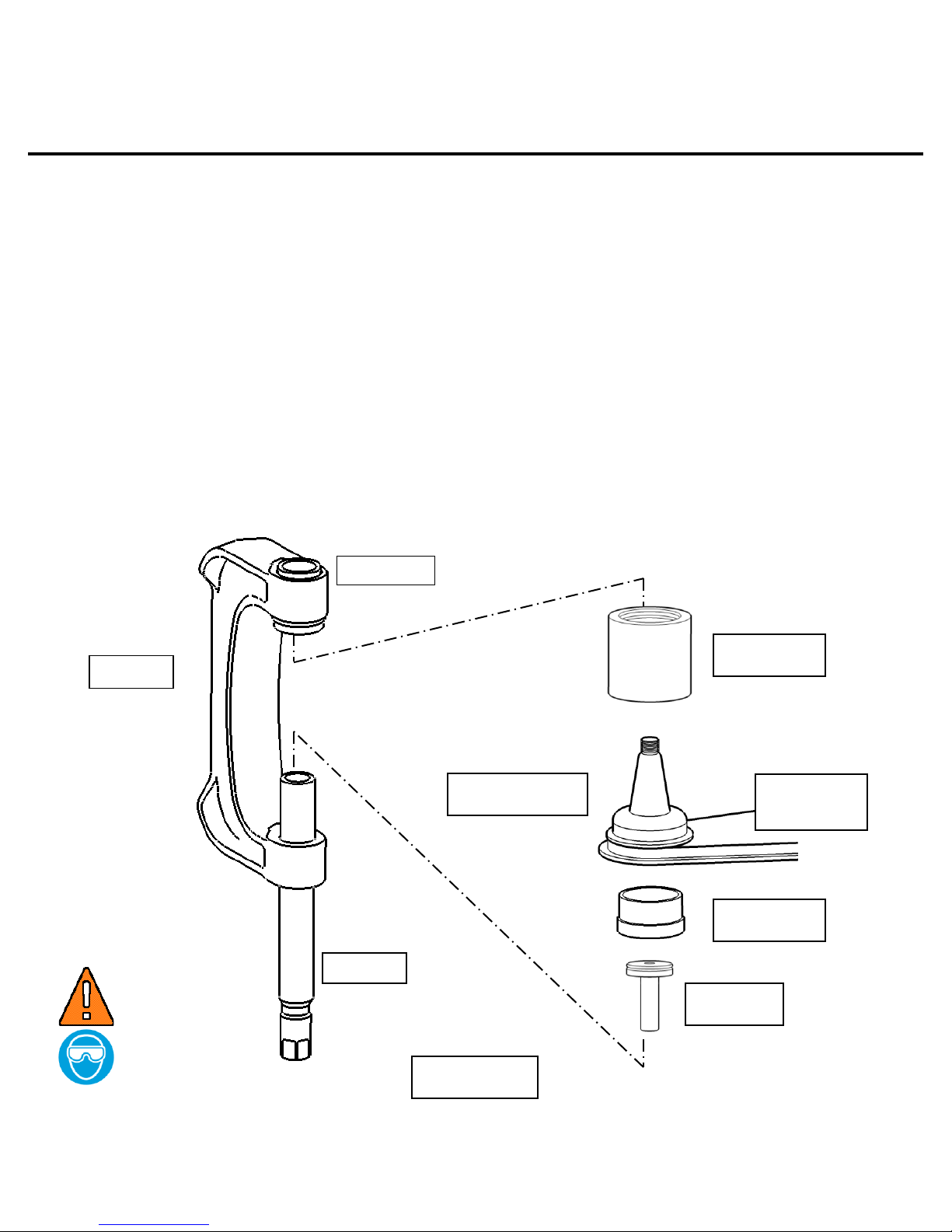

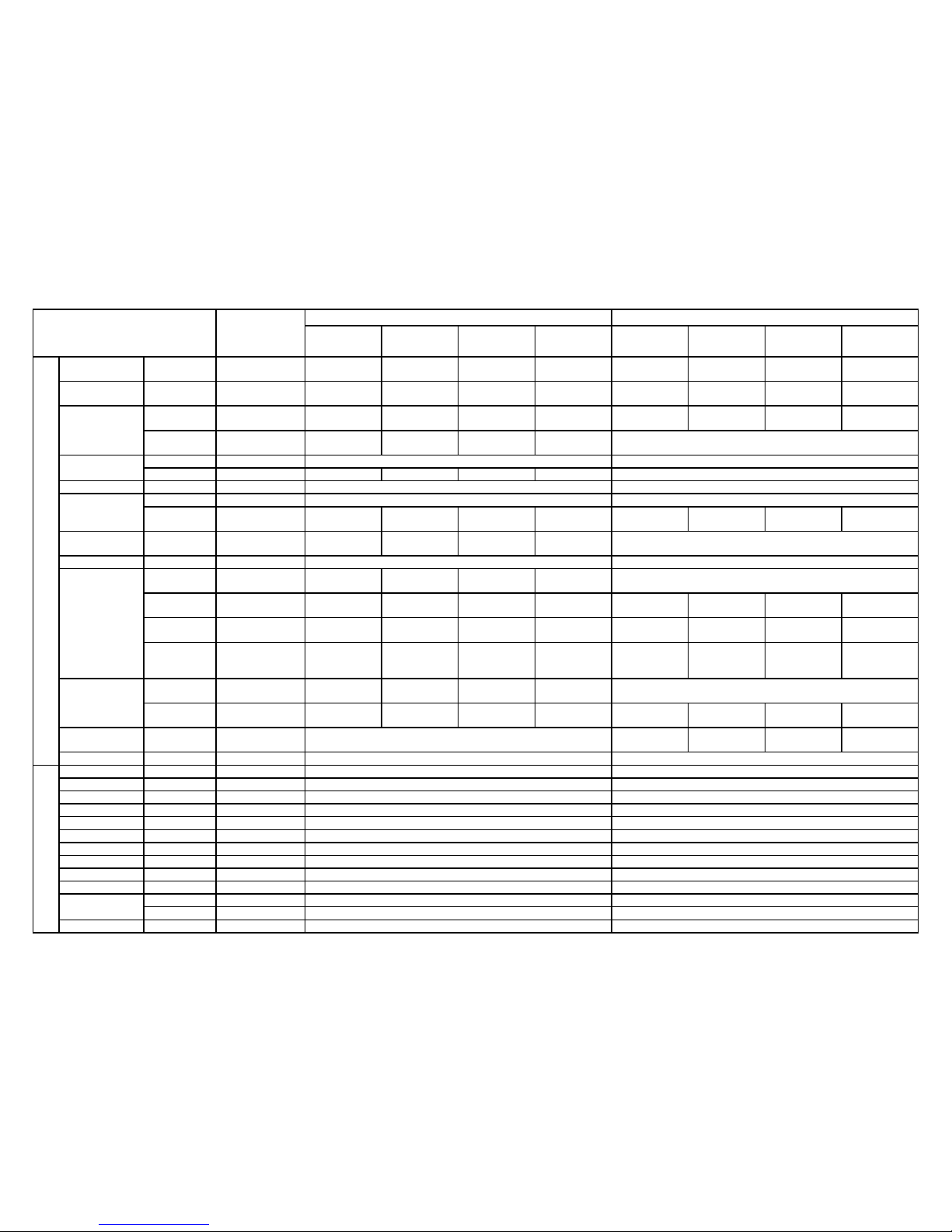

Item

No.

Part

No.

Description

1

BJP1-1A

SLEEVE ADAPTER

2

BJP1-2

PRESSURE SCREW

3

BJP1-3A

LARGE FACED (BALL JOINT)

PRESSURE PAD

4

BJP1-4A

SMALL FACED (UNIVERSAL

JOINT) PRESSURE PAD

5

BJP1-5A

ADAPTER

6

BJP1-6A

ADAPTER/EXTENSION

7

BJP1-7A

ADAPTER

8

BJP1-8A

ADAPTER

9

BJP1-9A

ADAPTER: ANGLE

10

BJP1-10A

ADAPTER: ANGLE

11

BJP1-11A

ADAPTER

12

BJP1-12A

ADAPTER

13

BJP1-13B

ADAPTER

14

BJP1-14A

ADAPTER

15

BJP1-16A

ADAPTER

16

BJP1F

PRESS FRAME

17

BJP1-17

GREASE FITTING

18

ME9A34

STEEL BALL

19

ME7A207

RETAINING RING

20

ME7A208A

LARGE SNAP RING

(11 RINGS REQ’D.)

21

ME7A209A

SMALL SNAP RING

22

PAKPB061

CARRYING/STORAGE CASE

19

BJP1-BALL JOINT

PRESS MASTER SET

20

21

18

17

22

16

BJP1-BALL JOINT PRESS MASTER SET

(Some component assembly required. See component assembly sections.)

Visit the Snap-on web site, www.snapon.com, for vehicle application

information and complete listing of available adapters.

ZBJP1B rev B 06/11/2014

Page 2

2

SAFETY INFORMATION

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety and operating instructions for

the Snap-on® Ball Joint Press Master set. Refer to the information in

this manual as required for safe operation.

READ ALL INSTRUCTIONS

Read all the instructions in this manual. Read, understand and follow

all safety messages and instructions in this manual, and on all ball

joint press part components. Safety messages in this section contain

a signal word, a three-part message, and in some cases, an icon.

Safety symbols, when present, give a graphical description of the

potential hazard or how to avoid potential hazard.

WARNING

Wear safety goggles, user and bystander.

Be sure all adapter-to-adapter connections are secure.

Avoid misalignment of ball joint press assembly when

tightening pressure screw on ball joint and control arm.

If misalignment occurs, STOP tightening screw.

Unthread screw until assembly is loose. Properly realign

press assembly on ball joint and control arm.

WARNING

Refer to manufacture’s service manual for properly supporting and

raising of vehicles in a safe and secure manner.

ZBJP1B rev B 06/11/2014

Page 3

3

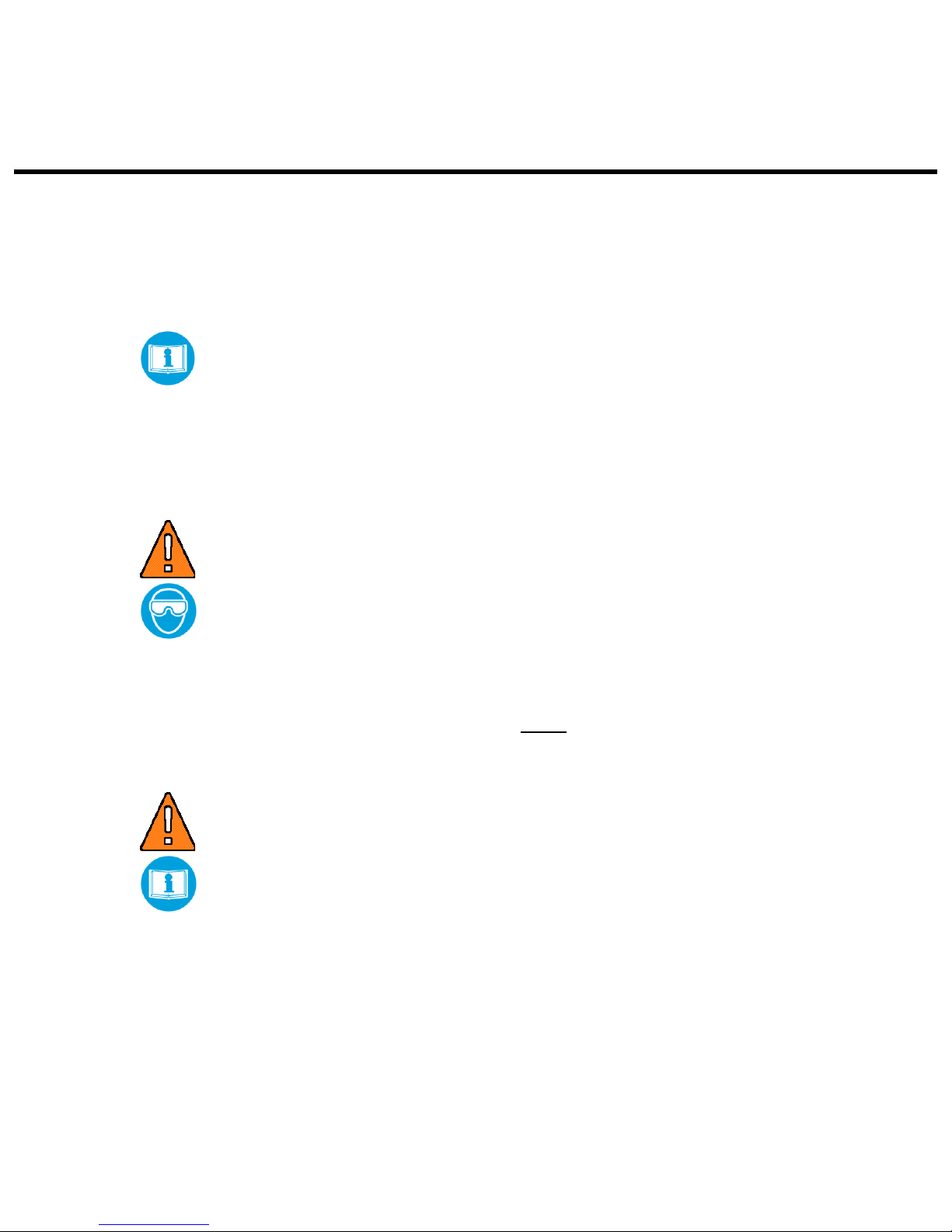

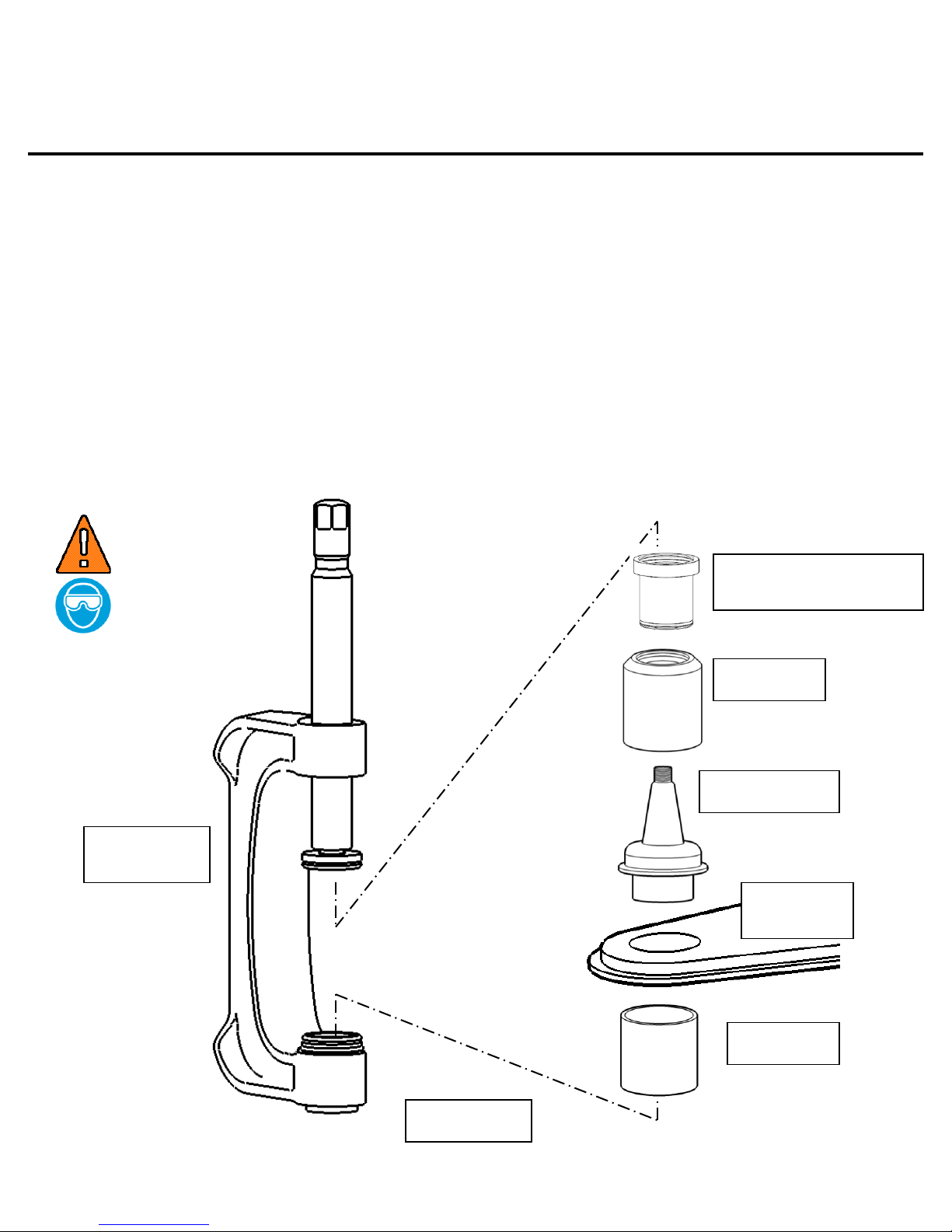

FIGURE - 1

FIGURE - 2

ME7A209A

ME9A34

BJP1-2

ME7A208A

BJP1-14A

Ball Joint Press Component Assembly

Insert steel ball (ME9A34) into opening of pressure screw (BJP1-2) as shown in FIG.

Secure steel ball inside screw by inserting small snap ring (ME7A209A) into internal

snap ring groove of screw as follows:

1. Place snap ring partially into groove while compressing ring so that the ends

overlap as shown in FIG. 1.

2. Press ring into screw opening until ring snaps securely into groove.

WARNING

Insert large snap ring (ME7A208A) into internal snap ring groove of each of the (11)

adapters in the parts list on page one (adapters BJP1-5A through BJP1-16A) as

follows:

1. Place snap ring partially into groove while compressing ring so that the ends

overlap as shown in FIG. 2.

2. Press ring into adapter opening until the ring snaps securely into groove.

WARNING

ZBJP1B rev B 06/11/2014

Page 4

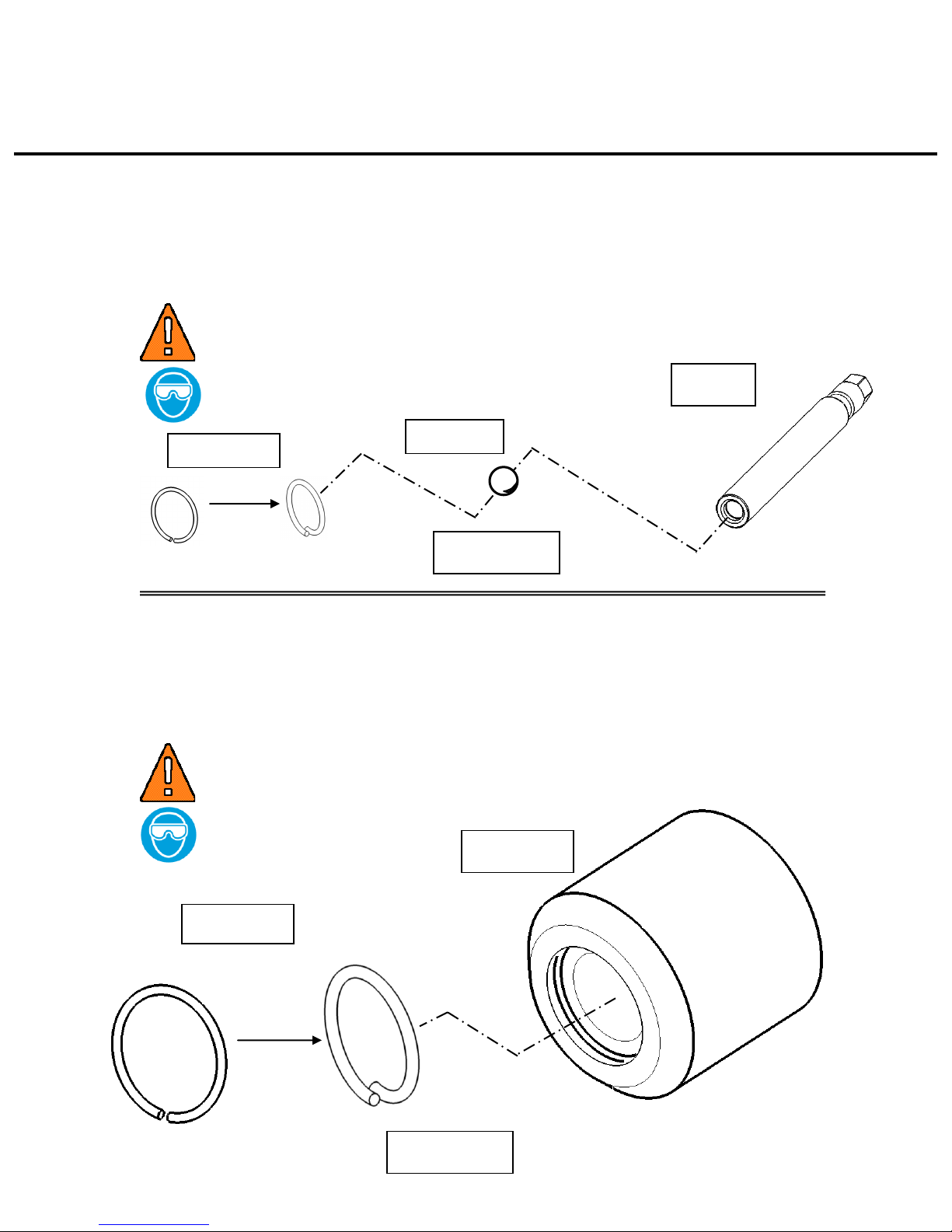

4

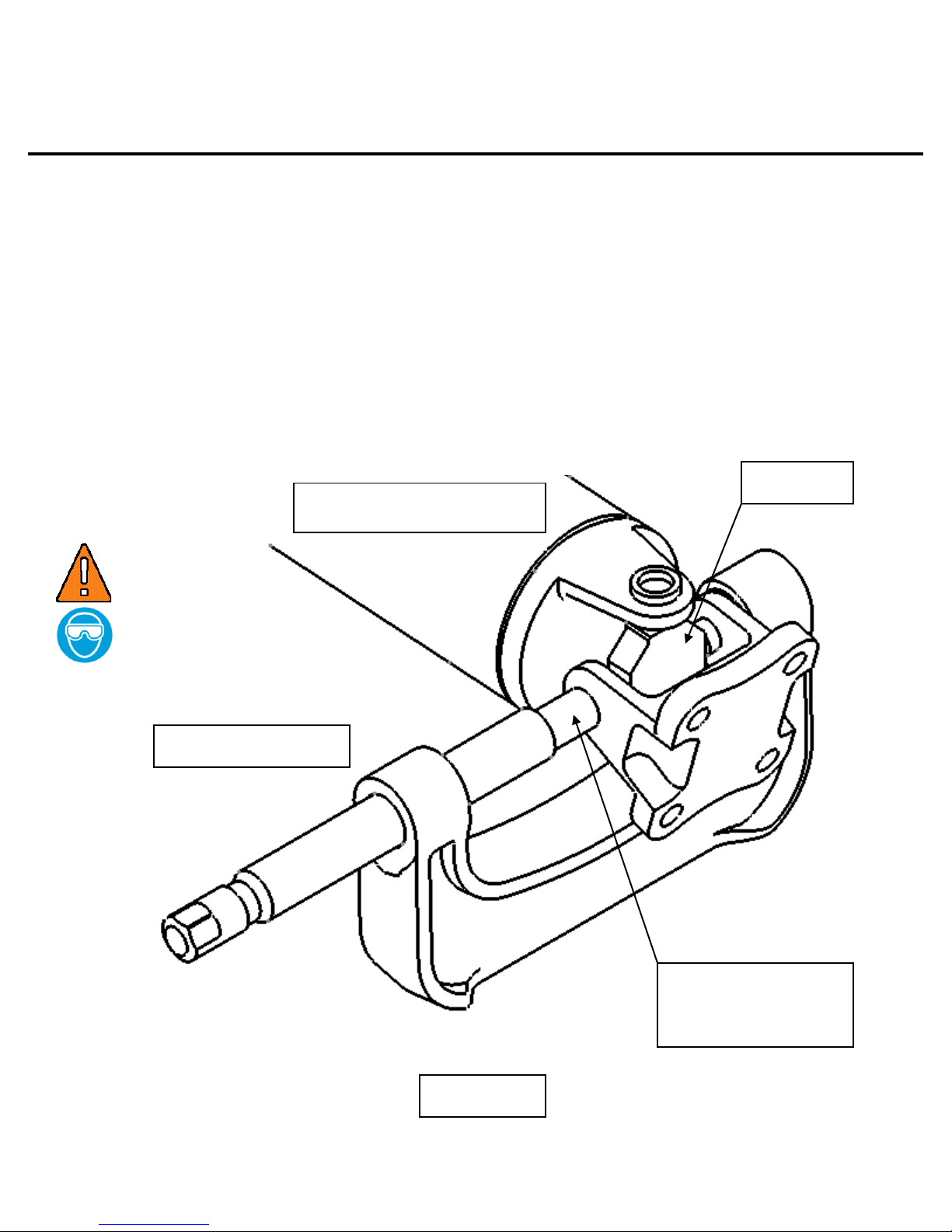

BJP1F

ME7A207

BJP1-1A

BJP1-17

FIGURE - 3

Ball Joint Press Component Assembly

Slide sleeve adapter (BJP1-1A) into hole of press frame (BJP1F) and secure with

retaining ring (ME7A207) as shown in FIG. 3. Use snap ring pliers with proper tip

size. Thread grease fitting (BJP1-17) into tapped hole of press frame as shown using

5/16” socket.

WARNING

Maintenance

The pressure screw threads need to be wiped clean and re-lubricated with chassis

grease on a regular basis. Use grease fitting (installed on screw side arm of frame)

to apply grease to the screw threads.

BJP1 - Operating Information

The BJP1 ball joint master set is designed to be used without removing the control

arm from the vehicle on most cars and trucks that have press-fit type ball joints.

NOTE: Some vehicles have the upper ball joint spot-welded to the control

arm. The weld must be cut before attempting to remove the ball joint.

ZBJP1B rev B 06/11/2014

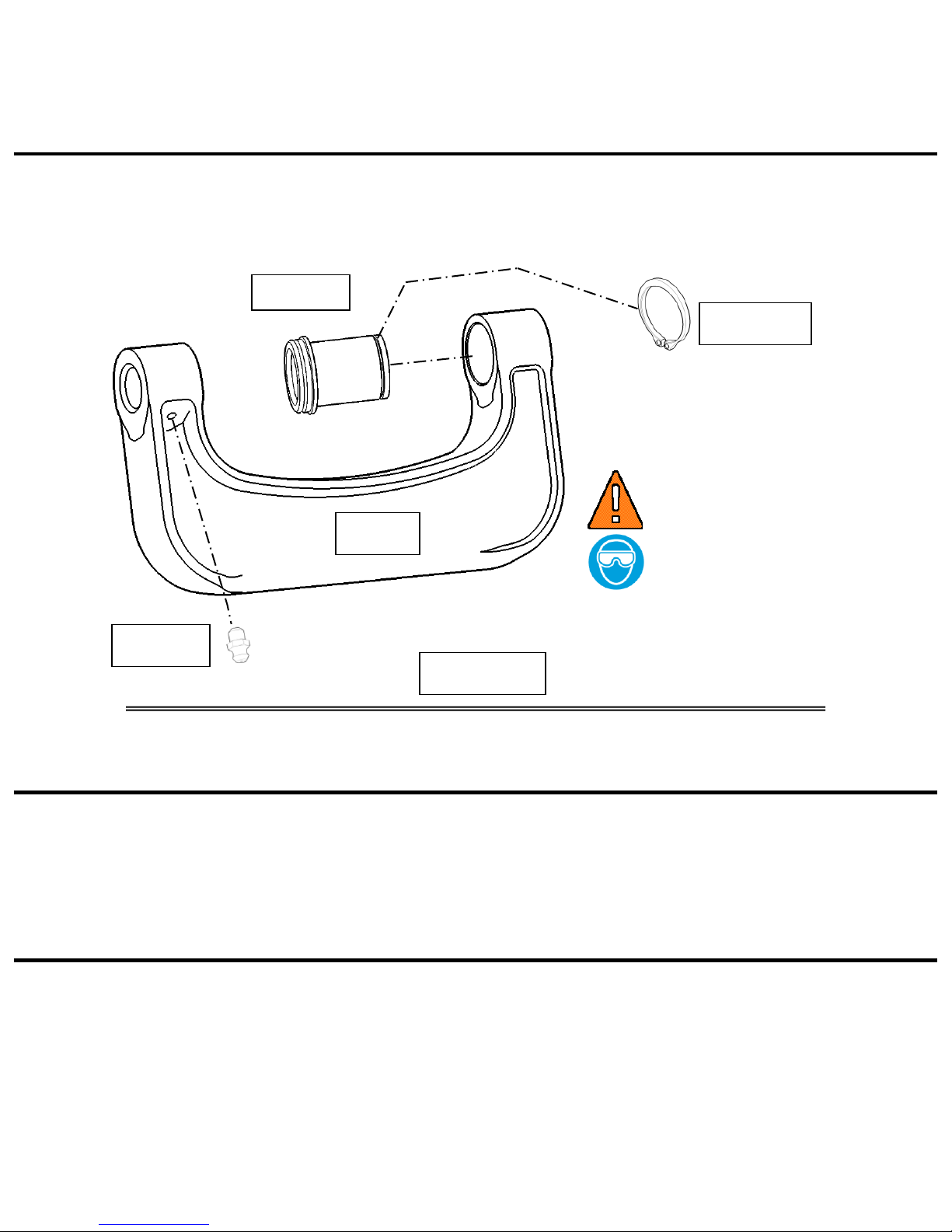

Page 5

5

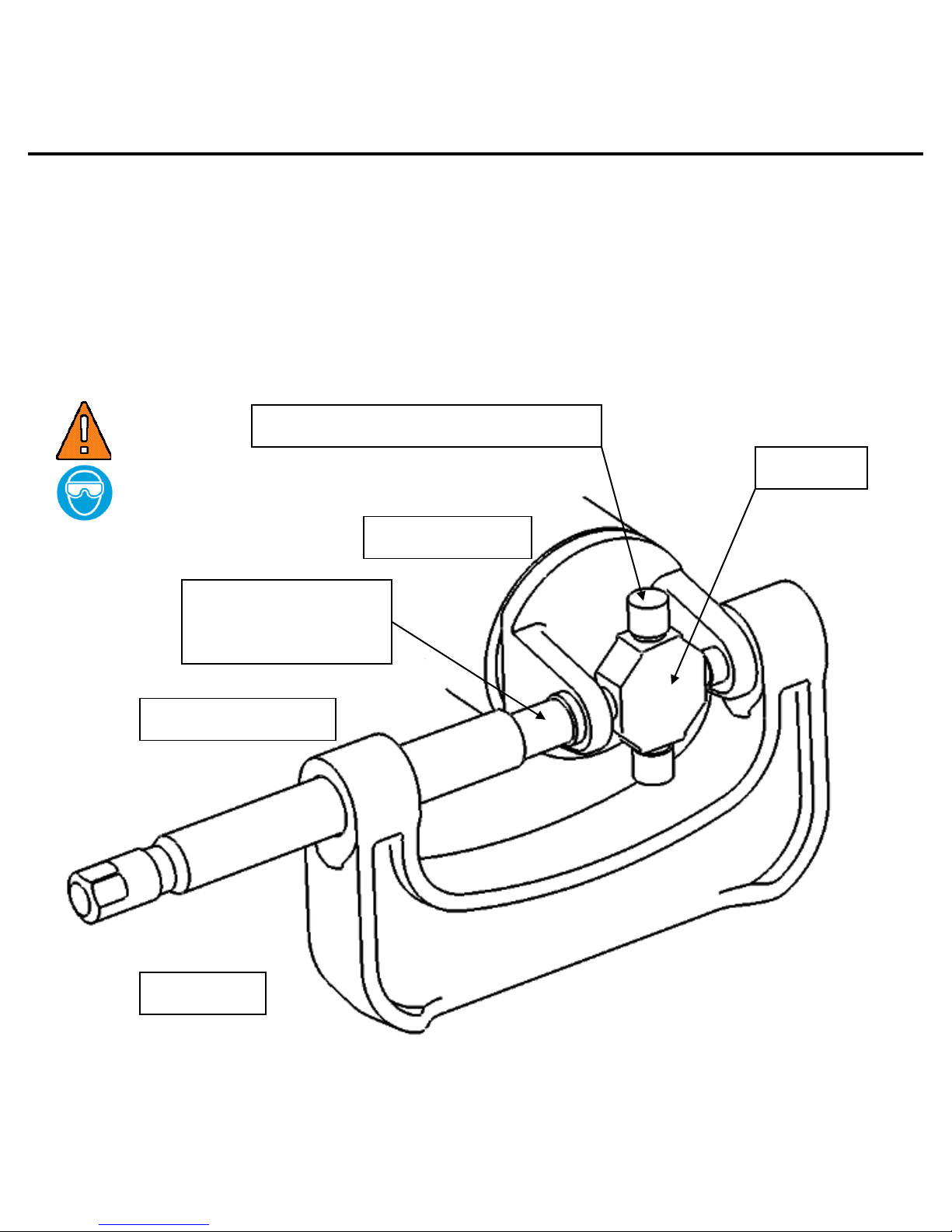

CONTROL

ARM

BJP1F

BJP1-2

ADAPTER

ADAPTER

BJP1-3A

BALL JOINT

FIGURE - 4

BJP1-1A

WARNING

Operating Instructions

Ball Joint Removal

(Refer to the safety information section for required safety instructions.)

1. Refer to the proper automotive service manual used for repair procedures on the specific vehicle

being serviced. Follow indicated procedures for removing all suspension components to obtain

clear access to the vehicle’s ball joint and control arm.

2. Refer to application chart to select the proper adapters for removing most types of ball joints on

most vehicle makes and models.

3. Thread pressure screw (BJP1-2) into end of frame. Insert ball joint pressure pad (BJP1-3A) into

pressure screw. (Force pressure pad completely down into pressure screw.)

4. Snap the selected adapters onto adapter sleeve (BJP1-1A) and ball joint pressure pad as shown in

FIG. 4.

5. Position press assembly over ball joint and control arm, as shown in FIG. 4.

6. Tighten pressure screw until removal adapters are snug against ball joint and control arm. Check

that the entire assembly is properly aligned. If not, STOP tightening screw, then loosen assembly

and re-align.

7. Apply torque to pressure screw until ball joint has been pressed out of control arm and into

receiving adapter.

ZBJP1B rev B 06/11/2014

Page 6

6

ADAPTER

PRESS

ASSEMBLY

BALL JOINT

ADAPTER

CONTROL

ARM

FIGURE - 5

BJP1-6A Extension

(Some Applications)

WARNING

Operating Instructions

Ball Joint Installation

(Refer to the safety information section for required safety instructions.)

1. Clean knuckle and control arm. Coat bore of control arm with a suitable lubricant.

2. Insert replacement ball joint into control arm bore as straight as possible and align properly in

bore.

3. Refer to application chart to select the proper adapters for replacing most types of ball joints on

most vehicle makes and models.

4. Snap selected adapters into place in the same manner as in the ball joint removal procedure. Use

adapter BJP1-6A between pressure pad (BJP1-3A) and adapter if additional length is needed, as

shown in FIG. 5.

5. Position press assembly over ball joint and control arm, as shown in FIG. 5.

6. Tighten pressure screw until installation adapters are snug against ball joint and control arm.

Check that the entire assembly is properly aligned. If not, STOP tightening screw, then loosen

assembly and re-align.

7. Apply torque to pressure screw until the ball joint flange is securely seated against face of control

arm bore.

ZBJP1B rev B 06/11/2014

Page 7

7

FIGURE - 6

DRIVE SHAFT ASSEMBLY

PRESS ASSEMBLY

U - JOINT

BJP1-4A

U-JOINT PRESSURE

PAD

UJP1 - Operating Instructions

The UJP1 universal joint set is designed to replace U-joints, either on or off the vehicle, on most cars and

trucks.

Universal Joint Removal

(Refer to the safety information section for required safety instructions.)

1. If necessary, remove ball joint pressure pad from pressure screw. Then insert universal joint

pressure pad (BJP1-4A) into pressure screw. (Force pressure pad completely down into pressure

screw.)

2. Securely support the drive shaft yoke assembly. Remove all external and/or internal locking rings.

3. If necessary, select one or a combination of adapters (BJP1-1A, BJP1-7A, BJP1-8A) to assist in U-

joint replacement.

4. Position press assembly around drive shaft yoke and align pressure pad with face of needle bearing

caps, as shown in FIG. 6 and FIG. 7.

5. Tighten pressure screw until one side of U-joint has been pressed completely out of yoke assembly.

6. Reposition press assembly, in the same manner as step-4, and tighten screw to remove the

remaining U-joint.

WARNING

ZBJP1B rev B 06/11/2014

Page 8

8

Snap-on is a trademark of Snap-on Incorporated

©2004 Snap-on Incorporated. All Rights Reserved.

Kenosha, WI 53143 Printed in U.S.A.

FIGURE – 7

PRESS ASSEMBLY

DRIVE SHAFT

U - JOINT

U-JOINT NEEDLE BEARING CAPS

BJP1-4A

U-JOINT PRESSURE

PAD

UJP1 - Operating Instructions

Universal Joint Installation

(Refer to the safety information section for required safety instructions.)

1. Securely support the drive shaft yoke assembly.

2. If necessary, select one or a combination of adapters (BJP1-1A, BJP1-7A, BJP1-8A) to assist in

replacing the new U-joint.

3. Carefully follow the manufacture’s instructions for lubrication of the new U-joint.

4. Position press assembly around drive shaft yoke and align pressure pad with face of needle

bearing caps, as shown in FIG. 7.

5. Tighten pressure screw until one side of U-joint has been completely pressed into assembly.

6. DO NOT OVER TIGHTEN. Damage to U-joint and reduced service life may occur.

7. Reposition press assembly, in the same manner as step-4, and tighten screw until the other

side of the U-joint has been completely pressed into yoke assembly.

WARNING

ZBJP1B rev B 06/11/2014

Page 9

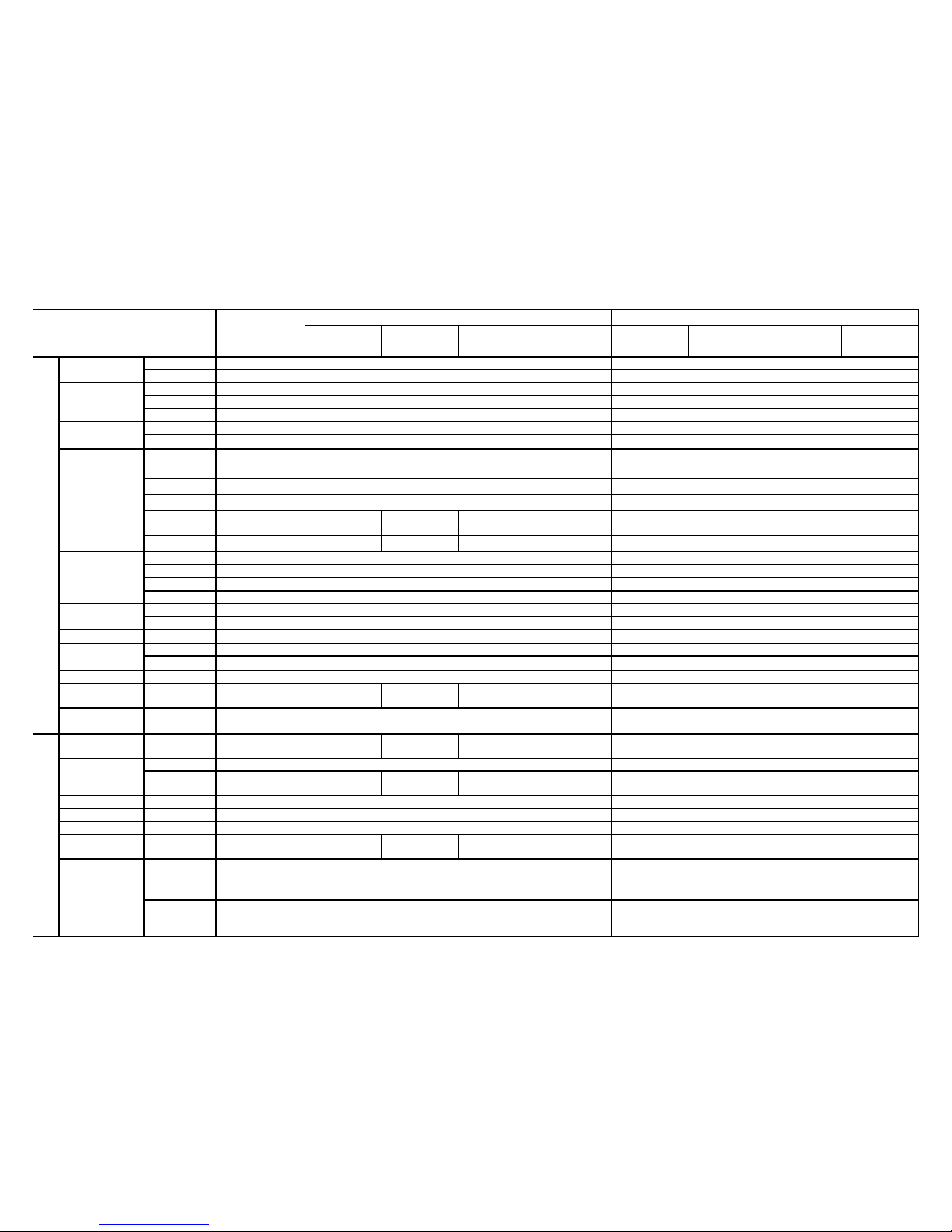

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

9

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

ACURA

CL

1997-2003

BJP1-24A Not

in BJP1 kit

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-24A

BJP1-1A

BJP1-22A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-11A

Integra

1989-2001

BJP1-22A Not

in BJP1 kit

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-22A

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-11A

Legend

1991-95

BJP1-24A Not

in BJP1 kit

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-24A

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-11A

1986-90

BJP1-24A Not

in BJP1 kit

BJP1-22A

BJP1-24A

BJP1-5A &

BJP1-6A

BJP1-24A

N/A - NO REPLACEMENT AT THIS TIME

MDX

2007-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

2001-2006

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-11A

N/A - STRUT

RDX

2007-2014 N/A - BOLT IN BALL JOINT

N/A - STRUT

RL

2005-2012 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

1996-2004

BJP1-24A Not

in BJP1 kit

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-24A

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-11A

RSX

2002-2006

BJP1-6A

BJP1-11A

BJP1-5A &

BJP1-6A

BJP1-11A

N/A - STRUT

SLX

1996-99 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

TL

2009-2013

BJP1-29A Not

in BJP1 kit

BJP1-8A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-29A

N/A - CONTROL ARM REPLACE

2004-2008

BJP1-24A Not

in BJP1 kit

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-24A

BJP1-22A &

BJP1-6A

BJP1-1A

BJP1-5A

BJP1-11A

1999-2003

BJP1-24A Not

in BJP1 kit

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-24A

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-11A

1995-98

BJP1-24A &

BJP1-22A Not

in BJP1 kit

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-24A

BJP1-1A

BJP1-22A &

BJP1-6A

BJP1-5A

BJP1-11A

TSX

2009-2013

BJP1-29A Not

in BJP1 kit

BJP1-8A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-29A

N/A - CONTROL ARM REPLACE

2004-2008

BJP1-24A Not

in BJP1 kit

BJP1-1A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-24A

BJP1-3A

BJP1 11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-11A

Vigor

1992-94

BJP1-22A Not

in BJP1 kit

N/A - NO REPLACEMENT AT THIS TIME

BJP1-1A

BJP1-22A &

BJP1-6A

BJP1-5A

BJP1-11A

ZDX

2010-2012 N/A - CONTROL ARM REPLACE

N/A - STRUT

AUDI

80

1990-92 N/A - BOLT IN BALL JOINT

N/A - STRUT

90

1990-95 N/A - BOLT IN BALL JOINT

N/A - STRUT

100

1990-93 N/A - CONTROL ARM REPLACE

N/A - STRUT

200

1990-91 N/A - CONTROL ARM REPLACE

N/A - STRUT

100 Quattro

1990-94 N/A - CONTROL ARM REPLACE

N/A - STRUT

200 Quattro

1990-91 N/A - CONTROL ARM REPLACE

N/A - STRUT

80 Quattro

1990-92 N/A - BOLT IN BALL JOINT

N/A - STRUT

90 Quattro

1990-95 N/A - BOLT IN BALL JOINT

N/A - STRUT

A3

2006-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

A3 Quattro

2006-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

A4

2009-2013

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

1996-2008 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

A4 Avant

1999-2009 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

Page 10

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

10

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

AUDI

A4 Quattro

2009-2013

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

1996-2008 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

A5

2010-2013

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

A5 Quattro

2008-2013

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

A6

2012-2013

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

1995-2011 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

A6 Avant

1999-2006 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

A6 Quattro

2012-2013

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

1995-2011 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

A7 Quattro

2012-2013

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

A8

1997-99 N/A - CONTROL ARM REPLACE

N/A - STRUT

A8 Quattro

2011-2013

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

1997-2010 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

Allroad

Quattro

2001-2005 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

Cabriolet

1994-98 N/A - BOLT IN BALL JOINT

N/A - STRUT

Coupe

Quattro

1990-91 N/A - BOLT IN BALL JOINT

N/A - STRUT

Q5

2009-2012

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

Q7

2007-2013 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

R8

2008-2012 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

RS4

2007-2006 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

RS6

2003-2004 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

RS7

2014

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

S4

2010-2012

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

1992-2009 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

S4 Avant

2001-2006 N/A - CONTROL ARM REPLACE

N/A - BOLT IN BALL JOINT

S5

2008-2012

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

S6

2012

N/A - PINCH BOLT

N/A - CONTROL ARM REPLACE

2007-2011 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

1995 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

S6 Avant

2002-2004 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

S8

2007-2009 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

2001-2003 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

TT

2000-2012 N/A - BOLT IN BALL JOINT

N/A - STRUT

V8 Quattro

1990-1994 N/A - CONTROL ARM REPLACE

N/A - STRUT

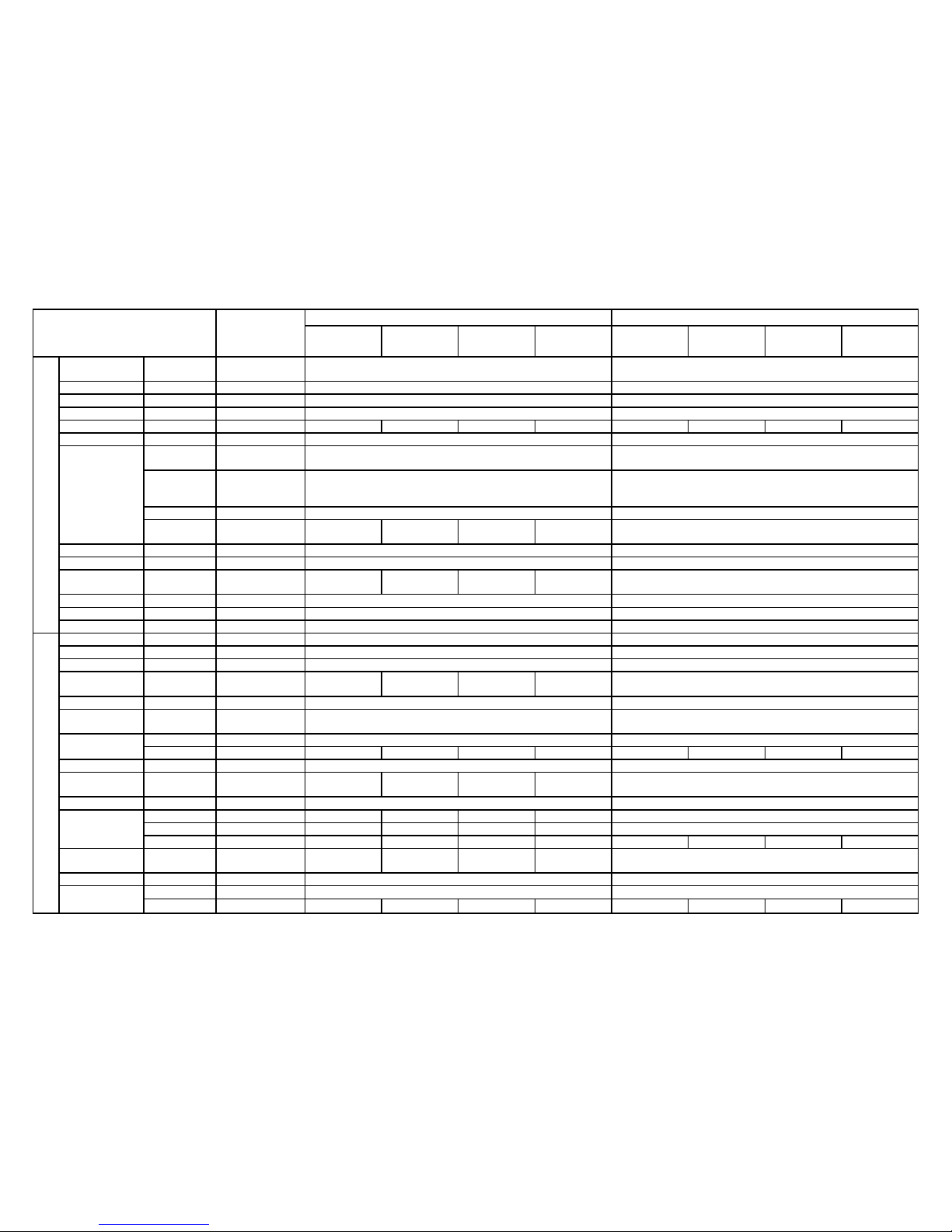

BMW

1 Series

2008-2012 N/A - REPLACE CONTROL ARM

N/A - STRUT

3 Series

2012-2013 N/A - REPLACE CONTROL ARM

N/A - STRUT

2006-2011 N/A - BOLT IN BALL JOINT

N/A - STRUT

1999-2005 N/A - REPLACE CONTROL ARM

N/A - STRUT

1984-1991

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

N/A - STRUT

5 Series

2011-2013 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

1997-2010 N/A - REPLACE CONTROL ARM

N/A - STRUT

1990-95 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

Page 11

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

11

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

BMW

6 Series

2012-2013 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

2004-2010 N/A - REPLACE CONTROL ARM

N/A- STRUT

7 Series

2009-2012 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

1996-2008 N/A - REPLACE CONTROL ARM

N/A - STRUT

1990-95 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

8 Series

1996-97 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

1992-95 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

M1

2012 N/A - REPLACE CONTROL ARM

N/A - STRUT

M3

2012 N/A - REPLACE CONTROL ARM

N/A - STRUT

2008-2011 N/A - BOLT IN BALL JOINT

N/A - STRUT

2001-2006 N/A - REPLACE CONTROL ARM

N/A - STRUT

1993-99

BJP1-22A Not

in BJP1 kit

BJP1-7A

BJP1-22A

BJP1-5A

BJP1-11A

N/A - STRUT

1986-92

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

N/A - STRUT

M5

2012-2013 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

2006-2010 N/A - REPLACE CONTROL ARM

N/A - STRUT

1999-2003 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

1990-95 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

M6

2013 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

2005-2010 N/A - REPLACE CONTROL ARM

N/A - STRUT

X3

2004-2014 N/A - BOLT IN BALL JOINT

N/A - STRUT

X5

2007-2012 N/A - REPLACE CONTROL ARM

N/A - STRUT

2000-2006 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

X6

2010-2014 N/A - REPLACE CONTROL ARM

N/A - REPLACE CONTROL ARM

Z3

1996-2002

BJP1-22A Not

in BJP1 kit

BJP1-7A

BJP1-22A

BJP1-5A

BJP1-11A

N/A - STRUT

Z4

2003-2014 N/A - REPLACE CONTROL ARM

N/A - STRUT

Z8

2000-2003 N/A - REPLACE CONTROL ARM

N/A - STRUT

BUICK

Apollo

1975

BJPI-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Century

1990-2005 N/A - BOLT IN BALL JOINT

N/A - STRUT

1973-1981

BJPI-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Electra

1985-1990 N/A - BOLT IN BALL JOINT

N/A - STRUT

Enclave

2008-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

Encore

2013

N/A - BOLT IN BALL JOINT

N/A - STRUT

Estate

Wagon

1977-90

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

LaCrosse

2010-2013

w/Performance

Suspension

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

2010-2013

w/o

Performance

Suspension

N/A - CONTROL ARM REPLACE

N/A - STRUT

Page 12

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

12

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

BUICK

LaCrosse

(cont.)

2005-2009 N/A - BOLT IN BALL JOINT

N/A - STRUT

LeSabre

1990-2005 N/A - BOLT IN BALL JOINT

N/A - STRUT

Lucerne

2006-2011 N/A - CONTROL ARM REPLACE

N/A - STRUT

Park Avenue

1991-2005 N/A - BOLT IN BALL JOINT

N/A - STRUT

Rainier

2004-2007

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

Reatta

1990-1991 N/A - BOLT IN BALL JOINT

N/A - STRUT

Regal

2011-2013

w/Performance

Suspension

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

2011-2013

w/o

Performance

Suspension

N/A - CONTROL ARM REPLACE

N/A - STRUT

1990-2005 N/A - BOLT IN BALL JOINT

N/A - STRUT

1973-87

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Rendezvous

2002-2007 N/A - BOLT IN BALL JOINT

N/A - STRUT

Riviera

1990-1999 N/A - BOLT IN BALL JOINT

N/A - STRUT

Roadmaster

1991-96

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Skylark

1990-98 N/A - BOLT IN BALL JOINT

N/A - STRUT

Terraza

2005-2007 N/A - BOLT IN BALL JOINT

N/A - STRUT

Verano

2012-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

CADILLAC

60 Special

1993

N/A - BOLT IN BALL JOINT

N/A - STRUT

Allante

1990-1993 N/A - BOLT IN BALL JOINT

N/A - STRUT

ATS

2013-2014 N/A - CONTROL ARM REPLACE

N/A - STRUT

Brougham

1990-92

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Catera

1997-2001 N/A - BOLT IN BALL JOINT

N/A - STRUT

Commercial

Chassis

1992

N/A - BOLT IN BALL JOINT

N/A - CONTROL ARM REPLACE

CTS

2008-2013 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

2003-2007

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-11A

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-14A

Deville

1990-2005 N/A - BOLT IN BALL JOINT

N/A - STRUT

DTS

2006-2011

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - STRUT

Eldorado

1990-2002 N/A - BOLT IN BALL JOINT

N/A - STRUT

Escalade

2007-2012

Cast Iron Arm

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

N/A - CONTROL ARM REPLACE

2007-2012

Aluminum Arm

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

N/A - CONTROL ARM REPLACE

2002-2006

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Fleetwood

1990-96

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

NA - BOLT IN BALL JOINT

Seville

1986-2004 NA - BOLT IN BALL JOINT

NA - STRUT

SRX

2010-2013 NA - BOLT IN BALL JOINT

NA - STRUT

2004-2009

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

Page 13

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

13

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

CADILLAC

STS

2010-2011 NA - BOLT IN BALL JOINT

NA - STRUT

2005-2009

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

XLR

2004-2009

BJP1-8A

BJP1-7A

BJP1-5A

BJP1-11A

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

CHEVROLET

Astro

1990-2005

4WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

2WD

BJP1-11A

BJP1-12A

BJP1-8A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

1985-1989

BJP1-11A

BJP1-12A

BJP1-8A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Avalanche

2007-2013

Cast Iron Arm

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

N/A - REPLACE CONTROL ARM

2007-2013

Aluminum

Control Arm

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

N/A - REPLACE CONTROL ARM

Avalanche

1500

2002-2006

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Avalanche

2500

2002-2006

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-7A

BJP1-11A

BJP1-6A

BJP1-12A

Aveo

2004-2011 N/A - BOLT IN BALL JOINT

N/A - STRUT

Beretta

1987-96 N/A - BOLT IN BALL JOINT

N/A - STRUT

Blazer

2000-2005

2WD

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

4WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

1993-99 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

1990-92

BJP1-22A Not

in BJP1 kit

BJP1-22A

BJP1-8A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

C10

1971-1986

BJP1-8A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

C20

1971-1986

BJP1-6A

BJP1-14A

BJP1-12A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

C30

1971-1986

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

1960-71

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

C1500

1988-1999

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

C2500

1988-2000

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

C3500

1991-2000

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

1988-90

Independent

Suspension

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

Solid Axle

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

Page 14

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

14

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

CHEVROLET

Camaro

2010-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

1990-2002

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Caprice

1990-96

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Captiva

Sport

2012-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

Cavalier

1982-2005 N/A - BOLT IN BALL JOINT

N/A - STRUT

Celebrity

1982-90 N/A - BOLT IN BALL JOINT

N/A - STRUT

Classic

2004-2005 N/A - BOLT IN BALL JOINT

N/A - STRUT

Cobalt

2005-2010 N/A - BOLT IN BALL JOINT

N/A - STRUT

Colorado

2004-2012 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

Corsica

1987-96 N/A - BOLT IN BALL JOINT

N/A - STRUT

Corvette

1990-96

BJP1-8A

BJP1-1A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Cruze

2011-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

Equinox

2010-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

2005-2009 N/A - BOLT IN BALL JOINT

N/A - STRUT

Express

1500

2003-2013

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

1996-2002

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

Express

2500

2003-2013

7300lb GVW

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

8500 & 8600lb

GVW

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

1996-2002

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

Express

3500

2003-2013

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

1996-2002

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

Express

4500

2009-2012

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

G10

1971-1995

BJP1-8A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

G20

1982-1995

BJP1-8A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

1971-1981

Disc Brakes

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

Drum Brakes

BJP1-8A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

G30

1971-1995

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

1971-1972

Disc Brakes

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

Drum Brakes

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

HHR

2006-2011 N/A - BOLT IN BALL JOINT

N/A - STRUT

Page 15

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

15

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

CHEVROLET

Impala

2000-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

1994-96

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

K10

1971-1986

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

K20

1970-1986

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

K30

1977-1986 N/A - BOLT IN BALL JOINT OR KINGPIN

N/A - BOLT IN BALL JOINT OR KINGPIN

K1500

1996-1999

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

N/A - BOLT IN BALL JOINT

1988-95 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

K2500

1996-2000

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

N/A - BOLT IN BALL JOINT

1988-1995 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

K3500

1996-2000

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

N/A - BOLT IN BALL JOINT

1988-95 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

LLV (Mail

truck)

1990-1995

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Lumina

1990-1999 N/A - BOLT IN BALL JOINT

N/A - STRUT

Lumina APV

1990-96 N/A - BOLT IN BALL JOINT

N/A - STRUT

Malibu

1997-2012 N/A - BOLT IN BALL JOINT

N/A - STRUT

Metro

1998-99 N/A - CONTROL ARM REPLACE

N/A - STRUT

Monte Carlo

1995-2007 N/A - BOLT IN BALL JOINT

N/A - STRUT

P10 Van

1971-1982

BJP1-8A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

P20 Van

1971-1989

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

pre 1971

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

P30 Van

1973-1997

Rear drum

brakes

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

Rear disc

brakes

BJP1-8A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

DANA Axle

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

1971-1972

all

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

pre 1971

all

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

Prizm

1998-2002 N/A - BOLT IN BALL JOINT

N/A - STRUT

R10

1987-88

BJP1-8A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

R20

1987-88

BJP1-6A

BJP1-14A

BJP1-12A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

R30

1987-88

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

Page 16

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

16

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

CHEVROLET

R1500

1989-1990

BJP1-8A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

R2500

1989-1990

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

R3500

1989-1990

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-14A

N/A - BOLT IN BALL JOINT

S10 Truck

1982-2004

4WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

2WD

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

S-10 Blazer

1983-2005

4WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

2WD

BJP1-5A

BJP1-13A/

BJP1-13B

BJP1-5A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Silverado

1500

2007-2012

Cast Iron Arm

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

Aluminum

Control Arm

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

N/A - CONTROL ARM REPLACE

1999-2006

4WD

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

2WD

N/A - BOLT IN BALL JOINT

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Silverado

2500

2000-2010

4WD

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

2005-2010

2WD coil

spring

BJP1-13A/

BJP1-13B

BJP1-16A

BJP1-4A

BJP1-14A

N/A - CONTROL ARM REPLACE

2000-2004

2WD

N/A - BOLT IN BALL JOINT

N/A - CONTROL ARM REPLACE

Silverado

3500

2001-2010

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

Sonic

2012-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

Spark

2013

N/A - BOLT IN BALL JOINT

N/A - STRUT

SSR

2003-2006

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

Suburban

1500

2007-12

Cast Iron Arm

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

Aluminum

Control Arm

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

N/A - CONTROL ARM REPLACE

2000-2006

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Suburban

2500

2011-13

Aluminum

Control Arm

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

2000-2010

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

Tahoe

2007-2012

Cast Iron Arm

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

N/A - CONTROL ARM REPLACE

Aluminum Arm

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

N/A - CONTROL ARM REPLACE

2002-2006

BJP1-12A

BJP1-16A

BJP1-4A

BJP1-14A

N/A - CONTROL ARM REPLACE

1995-2001

2WD

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

4WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

Trailblazer

2002-2009

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

Traverse

2009-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

Uplander

2005-2008 N/A - BOLT IN BALL JOINT

N/A - STRUT

V10

1987-1988

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

V20

1987-1988

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Page 17

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

17

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

CHEVROLET

V30

1988 N/A - BOLT IN BALL JOINT OR KINGPIN

N/A - BOLT IN BALL JOINT OR KINGPIN

V1500

1989-1990

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

V2500

1989-1990

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

V3500

1989-1990 N/A - BOLT IN BALL JOINT OR KINGPIN

N/A - BOLT IN BALL JOINT OR KINGPIN

Venture

2003-2005 N/A - BOLT IN BALL JOINT

N/A - STRUT

Volt

2011-2014 N/A - CONTROL ARM REPLACE

N/A - STRUT

CHRYSLER

300

2005-2013

RWD

BJP1-11A

BJP1-7A

BJP1-5A

BJP1-13B

N/A - CONTROL ARM REPLACE

300M

1998-2004 N/A - CONTROL ARM REPLACE

N/A - STRUT

Aspen

2007-2009

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

Cirrus

1995-2000 N/A - CONTROL ARM REPLACE

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

Concord

1993-2004 N/A - CONTROL ARM REPLACE

N/A - STRUT

Crossfire

2004-08 N/A - BOLT IN BALL JOINT

N/A - CONTROL ARM REPLACE

Imperial

1991-93

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Intrepid

1993-2002 N/A - BOLT IN BALL JOINT

N/A - STRUT

LeBaron

1992-95

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

LHS

1994-2001 N/A - CONTROL ARM REPLACE

N/A - STRUT

Neon

1995-99

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

New Yorker

1994-96 N/A - CONTROL ARM REPLACE

N/A - STRUT

1992-93

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Pacifica

2004-2008

BJP1-8A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Prowler

2001-2002 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

PT Cruiser

2001-2010

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Sebring

2001-2006

Coupe

BJP1-6A

BJP1-11A

BJP1-6A

BJP1-11A

N/A - STRUT

Sedan &

Convertible

BJP1-6A

BJP1-12A

BJP1-6A

BJP1-12A

BJP1-6A

BJP1-11A

BJP1-5A

BJP1-11A

1995-2000

Coupe

N/A - CONTROL ARM REPLACE

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-8A

Convertible

N/A - CONTROL ARM REPLACE

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

Town &

Country

2008-2013

BJP1-11A

BJP1-12A

BJP1-5A

BJP1-13A/

BJP1-13B

N/A - STRUT

1989-2007

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

DAEWOO

Lanos

1998-2002 N/A - BOLT IN BALL JOINT

N/A - STRUT

Leganza

1998-2002 N/A - BOLT IN BALL JOINT

N/A - STRUT

Nubria

1998-2012 N/A - BOLT IN BALL JOINT

N/A - STRUT

DAIHATSU

Charade

1988-92 N/A - BOLT IN BALL JOINT

N/A - STRUT

Page 18

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

18

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

DODGE

Avenger

1995-2000 N/A - CONTROL ARM REPLACE

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-8A

Caliber

2007-2012

BJP1-22A Not

In BJP1 Kit

BJP1-7A

BJP1-22A

BJP1-3A

BJP1-11A

N/A - STRUT

Caravan

1984-2007

BJP-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Challenger

2009-2013

BJP1-11A

BJP1-7A

BJP1-5A

BJP1-13B

N/A - CONTROL ARM REPLACE

Charger

2006-2013

BJP1-11A

BJP1-7A

BJP1-5A

BJP1-13B

N/A - CONTROL ARM REPLACE

Colt

1985-94

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

N/A - STRUT

Dakota

(2WD)

1997-2004 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

1986-1996

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

Dakota

2009-2010

BJP1-12A

BJP1-16A

BJP1-5A

BJP1-14A

N/A - CONTROL ARM REPLACE

2005-2008

BJP1-12A

BJP1-16A

BJP1-5A

BJP1-14A

N/A - CONTROL ARM REPLACE

2000-2004

BJP1-7A

BJP1-11A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

1986-1999

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

N/A - BOLT IN BALL JOINT

Dart

2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

Daytona

1991-93

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Dynasty

1988-93

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Durango

2011-2013

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

N/A - CONTROL ARM REPLACE

2004-2009

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

2000-2003

2WD

N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

4WD

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

1998-1999

2WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

4WD

BJP1-1A

BJP1-11A

BJP1-3

BJP1-12A

N/A - BOLT IN BALL JOINT

Grand

Caravan

2008-2013

BJP1-11A

BJP1-12A

BJP1-5A

BJP1-13A/

BJP1-13B

N/A - STRUT

2001-2007

BJP1-5A

BJP1-11A

BJP1-3A

BJP1-7A

N/A - STRUT

1992-2000

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Intrepid

1993-2004 N/A - CONTROL ARM REPLACE

N/A - STRUT

Magnum

(RWD)

2005-2008

BJP1-11A

BJP1-7A

BJP1-5A

BJP1-13B

N/A - CONTROL ARM REPLACE

Monaco

1990-92 N/A - BOLT IN BALL JOINT

N/A - STRUT

Neon

1995-2005

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Nitro

2007-2012

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

Power Ram

W150

pre 1990-

93

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Power Ram

W250

pre 1990-

93

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Power Ram

W350

pre 1990-

93

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Raider

1987-89 N/A - BOLT IN BALL JOINT

BJP1-8A

BJP1-7A

BJP1-5A

BJP1-12A

Ram 50

1992-93 N/A - BOLT IN BALL JOINT

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

Ram 1500

2009-2010 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

2006-2008

5 Lug

BJP1-11A

BJP1-8A

BJP1-6A

BJP1-14A

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-12A

8 Lug 2WD

BJP1-11A

BJP1-16A

BJP1-3A

BJP1-11A

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-12A

8 Lug 4WD

BJP1-11A

BJP1-16A

BJP1-3A

BJP1-11A

BJP1-11A

BJP1-16A

BJP1-5A

BJP1-12A

Page 19

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

19

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

DODGE

Ram 1500

(cont.)

2002-2005

BJP1-11A

BJP1-8A

BJP1-6A

BJP1-14A

N/A - CONTROL ARM REPLACE

2000-2001

2WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

4WD

BJP1-6A

BJP1-8A

BJP1-3A

BJP1-11A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

1994-99

2WD

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

4WD

BJP1-6A

BJP1-8A

BJP1-5A

BJP1-10A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

Ram2500

2006-2010

2WD

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

BJP1-7A

BJP1-11A

BJP1-6A

BJP1-12A

4WD

BJP1-28A Not

in BJP1 kit

BJP1-28A

(short side)

& BJP1-6A

BJP1-16A

BJP1-5A

BJP1-28A

(long side) &

BJP1-6A

BJP1-11A

BJP1-28A

(short side)

BJP1-5A

BJP1-12A

2003-2005

2WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

4WD

BJP1-28A Not

in BJP1 kit

BJP1-28A

(short side)

& BJP1-6A

BJP1-16A

BJP1-5A

BJP1-28A

(long side) &

BJP1-6A

BJP1-11A

BJP1-28A

(short side)

BJP1-5A

BJP1-12A

2000-2002

2WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

4WD

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-3A

BJP1-12A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-10A

1994-99

2WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-13B

BJP1-3A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

4WD Dana 44

Axle

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-10A

4WD Dana 60

Axle

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-10A

Ram 3500

2006-2010

2WD

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

BJP1-7A

BJP1-11A

BJP1-6A

BJP1-12A

4WD

BJP1-28A Not

in BJP1 kit

BJP1-28A

(short side)

& BJP1-6A

BJP1-16A

BJP1-5A

BJP1-28A

(long side) &

BJP1-6A

BJP1-11A

BJP1-28A

(short side)

BJP1-5A

BJP1-12A

2003-2005

2WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

4WD

BJP1-28A Not

in BJP1 kit

BJP1-28A

(short side)

& BJP1-6A

BJP1-16A

BJP1-5A

BJP1-28A

(long side) &

BJP1-6A

BJP1-11A

BJP1-28A

(short side)

BJP1-5A

BJP1-12A

2000-2002

2WD

Independent

Suspension

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

4WD & 2WD

Solid Axle

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-3A

BJP1-12A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

1994-99

2WD

Independent

Suspension

BJP1-24A Not

in BJP1 Kit

BJP1-24A

BJP1-11A

BJP1-3A

BJP1-13B

BJP1-3A

BJP1-11A

BJP1-6A

BJP1-13A/

BJP1-13B

4WD & 2WD

Solid Axle

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-10A

Ram D150

1991-93

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

Ram D250

1992-93

Except 4000lb

Axle

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

Page 20

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

20

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

DODGE

Ram D250

(cont.)

1992-93

4000lb Axle

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

Ram D350

1991-93

Except 3800lb

& 4000lb Axle

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

3800lb &

4000lb Axle

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

Ram Van

1500

1994-2003

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

Ram Van

2500

1999-2003

3300lb Axle

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

3800lb &

4000lb Axle

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

1994-98

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

Ram Van

3500

1994-2003

3600lb Axle

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

4000lb Axle

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

Ram Van

B100

1974-85

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

Ram Van

B150

1981-93

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

Ram Van

B200

1974-80

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

Ram Van

B250

1981-93

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

Ram Van

B300

1971-80

3600lb Axle

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

4000lb Axle

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

Ram Van

B350

1981-93

3600lb Axle

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

4000lb Axle

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-8A

BJP1-14A

N/A - BOLT IN BALL JOINT

Ramcharger

1974-1993

2WD

BJP1-8A

BJP1-12A

BJP1-6A

BJP1-12A

N/A - THREAD IN BALL JOINT

1974-1993

4WD

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

BJP1-6A

BJP1-11A

BJP1-5A

BJP1-11A

Shadow

1991-94

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Spirit

1991-95

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-11A

N/A - STRUT

Sprinter

2500

2003-2008

BJP1-18A Not

in BJP1 kit

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-18A

N/A - STRUT

Sprinter

3500

2003-2006

BJP1-18A Not

in BJP1 kit

BJP1-12A

BJP1-13A/

BJP1-13B

BJP1-6A

BJP1-18A

N/A - STRUT

Stealth

1992-97 N/A - CONTROL ARM REPLACE

N/A - STRUT

Stratus

2000-2006

BJP1-6A

BJP1-12A

BJP1-6A

BJP1-12A

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-11A

Viper

1997-2013 N/A - CONTROL ARM REPLACE

N/A - CONTROL ARM REPLACE

1992-95 N/A - CONTROL ARM REPLACE

N/A - THREAD IN BALL JOINT

EAGLE

Premier

1988-92 N/A - BOLT IN BALL JOINT

N/A - STRUT

Summit

1989-96

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

N/A - STRUT

Talon

1995-98 N/A - CONTROL ARM REPLACE

BJP1-3A

BJP1-7A

BJP1-5A

BJP1-8A

1990-94

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

N/A - STRUT

Page 21

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

21

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

EAGLE

Vision

1993-98 N/A - CONTROL ARM REPLACE

N/A - STRUT

Vista

1989-92

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

N/A - STRUT

FIAT

500

2012-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

FORD

Aerostar

1986-97

FWD

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

1986-97

AWD

BJP1-7A

BJP1-11A

BJP1-3A

BJP1-11A

N/A - BOLT IN BALL JOINT

Aspire

1994-97 N/A - CONTROL ARM REPLACE

N/A - STRUT

Bronco

pre 1975 -

1996

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

Bronco II

1984-1990

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

C-Max

2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

Contour

1995-2000 N/A - BOLT IN BALL JOINT

N/A - STRUT

Country

Squire

1987-91

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Crown

Victoria

2003-2011

Forged Upper

Control Arm

BJP1-24A Not

in BJP1 kit

BJP1-11A

BJP1-8A

BJP1-5A

BJP1-12A

BJP1-8A

BJP1-24A &

BJP1-6A

BJP1-5A

BJP1-11A

2003-2004

Stamped

Upper Control

Arm BJP1-24A

Not in BJP1 kit

BJP1-11A

BJP1-8A

BJP1-5A

BJP1-12A

BJP1-8A

BJP1-24A &

BJP1-6A

BJP1-5A

BJP1-12A

1995-2002

BJP1-6A

BJP1-11A

BJP1-6A

BJP1-12A

N/A - BOLT IN BALL JOINT

1992-94

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

E150 Van

2008-2010

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

1992-2007

BJP1-11A

BJP1-8A

BJP1-5A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

Pre 1992 N/A - KINGPIN WITH BUSHINGS

N/A - KINGPIN WITH BUSHINGS

E250 Van

1992-2012

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

pre 1992 N/A - KINGPIN WITH BUSHINGS

N/A - KINGPIN WITH BUSHINGS

E350 Van

1992-2012

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

pre 1991 N/A - KINGPIN WITH BUSHINGS

N/A - KINGPIN WITH BUSHINGS

E450 Van

2000-2012

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

E550 Van

2003

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

Edge

2007-2013

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-11A

NA - STRUT

Escape

2001-2013

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-11A

NA - STRUT

Escort

1990-2003 N/A - BOLT IN BALL JOINT

N/A - STRUT

Page 22

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

22

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

FORD

Excursion

2000-2005

2WD

Twin I-Beam

BJP1-11A

BJP1-12A

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

2WD & 4WD

Mono-Beam

BJP1-11A

BJP1-16A

BJP1-5A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-11A

Expedition

2007-2013

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

2003-2006

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

1997-2002

BJP1-12A

BJP1-8A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

Explorer

2011-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

2006-2010

BJP1-27A Not

in BJP1 kit

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-27A

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-12A

2002-2005

BJP1-27A Not

in BJP1 kit

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-27A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

1995-2001

BJP1-27A Not

in BJP1 kit

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-27A

N/A - CONTROL ARM REPLACE

1991-1994

2WD/4WD

Dana 28 Axle

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

4WD

Dana 35 Axle

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-11A

F100 trucks

1982-1983

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

1981

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

1979-1980 N/A - KINGPIN WITH BUSHINGS

N/A - KINGPIN WITH BUSHINGS

1966-1978

2WD

N/A - KINGPIN WITH BUSHINGS

N/A - KINGPIN WITH BUSHINGS

4WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-11A

BJP1-8A

BJP1-5A

BJP1-12A

F150

2009-2013

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

2005-2008

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

2000-2004

2WD

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

BJP1-6A

BJP1-8A

BJP1-5A

BJP1-12A

4WD

N/A - CONTROL ARM REPLACE

BJP1-8A

BJP1-12A

BJP1-5A

BJP1-14A

1997-1999

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

N/A - CONTROL ARM REPLACE

1987-1996

2WD

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

4WD

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

1981-1986

2WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

4WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-11A

1980

2WD

N/A - KINGPIN WITH BUSHINGS

N/A - KINGPIN WITH BUSHINGS

4WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-11A

1975-1979

2WD

N/A - KINGPIN WITH BUSHINGS

N/A - KINGPIN WITH BUSHINGS

4WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

F250 & F250

SuperDuty

1999-2013

SuperDuty

2WD

BJP1-11A

BJP1-12A

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

4WD

BJP1-11A

BJP1-16A

BJP1-5A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

1998-1999

BJP1-12A

BJP1-8A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

1997

2WD, 5.8L,

7.3L & 7.5L

Engine

BJP1-11A

BJP1-12A

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

4WD, 5.8L,

7.3L & 7.5L

Engine

BJP1-11A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

Page 23

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

23

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

FORD

F250 & F250

SuperDuty

(cont.)

1997

(cont.)

4.6L & 5.4L

Engine

BJP1-12A

BJP1-8A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

1991-1996

2WD

BJP1-11A

BJP1-12A

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

4WD 3850lb

Axle

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

4WD 4600lb

Axle

BJP1-11A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

1980-1990

2WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

4WD <4500lb

Axle

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-11A

4WD 4500lb or

4600lb Axle

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-11A

1972-1979

4WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

F350 & F350

SuperDuty

1999-2013

2WD

BJP1-11A

BJP1-13A/

BJP1-13B

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-9A

BJP1-5A

BJP1-11A

4WD

BJP1-11A

BJP1-16A

BJP1-5A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

1987-1998

2WD

BJP1-11A

BJP1-12A

BJP1-3A

BJP1-12A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

4WD

BJP1-11A

BJP1-16A

BJP1-5A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

1980-1986

2WD

N/A - KINGPIN WITH BUSHINGS

N/A - KINGPIN WITH BUSHINGS

4WD

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-6A

BJP1-11A

BJP1-3A

BJP1-11A

pre 1979 N/A - KINGPIN WITH BUSHINGS

N/A - KINGPIN WITH BUSHINGS

F450

2005-2013

BJP1-25A Not

in BJP1 kit

BJP1-13B

BJP1-14A

BJP1-8A

BJP1-25A

BJP1-11A

BJP1-10A

BJP1-7A

BJP1-6A &

BJP1-12A

1999-2004

BJP1-11A

BJP1-16A

BJP1-5A

BJP1-12A

BJP1-8A

BJP1-12A

BJP1-3A

BJP1-12A

F550

2005-2013

BJP1-25A Not

in BJP1 kit

BJP1-13B

BJP1-14A

BJP1-8A

BJP1-25A

BJP1-11A

BJP1-10A

BJP1-7A

BJP1-6A &

BJP1-12A

1999-2004

BJP1-11A

BJP1-16A

BJP1-5A

BJP1-12A

BJP1-8A

BJP1-12A

BJP1-3A

BJP1-12A

Festiva

1988-93 N/A - CONTROL ARM REPLACE

N/A - STRUT

Fiesta

2011-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

Five

Hundred

2005-2007 N/A - CONTROL ARM REPLACE

N/A - STRUT

Flex

2009-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

Focus

2012-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

2000-2011 N/A - BOLT IN BALL JOINT

N/A - STRUT

Freestar

2004-2007 N/A - CONTROL ARM REPLACE

N/A - STRUT

Freestyle

2005-2007 N/A - CONTROL ARM REPLACE

N/A - STRUT

Fusion

2006-2012 N/A - CONTROL ARM REPLACE

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-11A

LTD Crown

Victoria

1990-91

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Mustang

2010-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

2005-2009

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

N/A - STRUT

1994-2004

BJP1-6A

BJP1-11A

BJP1-6A

BJP1-12A

N/A - STRUT

1990-1993

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - STRUT

Probe

1989-97

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-11A

N/A - STRUT

Ranger

2003-2011

BJP1-12A

BJP1-8A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

Page 24

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

24

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

FORD

Ranger

(cont.)

1998-2002

Coil Spring

BJP1-12A

BJP1-8A

BJP1-3A

BJP1-14A

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-11A

Torsion Bar

BJP1-12A

BJP1-8A

BJP1-3A

BJP1-14A

N/A - CONTROL ARM REPLACE

1983-1997

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

BJP1-7A

BJP1-11A

BJP1-5A

BJP1-11A

Taurus

2008-2013 N/A - CONTROL ARM REPLACE

N/A - STRUT

1996-2007

BJP1-7A

BJP1-11A &

BJP1-6A

BJP1-5A &

BJP1-6A

BJP1-11A

N/A - STRUT

1986-95 N/A - CONTROL ARM REPLACE

N/A - STRUT

Taurus X

2008-2009 N/A - CONTROL ARM REPLACE

N/A - STRUT

Tempo

1983-94 N/A - CONTROL ARM REPLACE

N/A - STRUT

Thunderbird

1989-97

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

N/A - CONTROL ARM REPLACE

Windstar

1995-2003 N/A - CONTROL ARM REPLACE

N/A - STRUT

GEO

Metro

1989-97 N/A - CONTROL ARM REPLACE

N/A - STRUT

Prizm

1990-97 N/A - BOLT IN BALL JOINT

N/A - STRUT

Storm

1990-93 N/A - BOLT IN BALL JOINT

N/A - STRUT

Tracker

1990-97 N/A - BOLT IN BALL JOINT

N/A - STRUT

GMC

Acadia

2007-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

Canyon

2004-2012 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

Envoy

2003-2009

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-7A

BJP1-8A

BJP1-5A

BJP1-11A

Jimmy

1992-2005

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

1983-91

BJP1-8A

BJP1-11A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Safari

1990-2005

4WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

2WD

BJP1-11A

BJP1-12A

BJP1-8A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Savana 1500

2003-2013

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

1996-2002

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

Savana 2500

2003-2013

7300lb GVW

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

8500 & 8600lb

GVW

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

1996-2002

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

Savana 3500

2003-2012

BJP1-12A

BJP1-16A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

1996-2002

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

Sierra 1500

2007-2012

Aluminum

Control Arm

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

N/A - CONTROL ARM REPLACE

Cast Iron

Control Arm

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

N/A - CONTROL ARM REPLACE

1999-2006

2WD

N/A - BOLT IN BALL JOINT

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

4WD & 2WD

With Torsion

Bar

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Page 25

VEHICLE APPLICATIONS

ZBJP1B rev B 06/11/2014

25

MODEL

ADDITIONAL

INFORMATION

LOWER BALL JOINT

UPPER BALL JOINT

Install ram

Install

receiver

Remove

ram

Remove

receiver

Install ram

Install

receiver

Remove

ram

Remove

receiver

GMC

Sierra 2500

1999-2010

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

Sierra 3500

2007-2010

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

BJP1-3A

BJP1-11A

BJP1-5A

BJP1-12A

Sierrra

Denali

2007

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Sonoma

1990-2004

4WD

N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

2WD

BJP1-11A

BJP1-12A

BJP1-6A

BJP1-13A/

BJP1-13B

N/A - BOLT IN BALL JOINT

Terrain

2010-2013 N/A - BOLT IN BALL JOINT

N/A - STRUT

Typhoon

1992-93 N/A - BOLT IN BALL JOINT

N/A - BOLT IN BALL JOINT

Yukon

2007-2012

Steel Arm

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

N/A - CONTROL ARM REPLACE

Aluminum Arm

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

N/A - CONTROL ARM REPLACE

2000-2006

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

1992-99

2WD

BJP1-8A

BJP1-13A/

BJP1-13B

BJP1-12A

BJP1-14A

N/A - BOLT IN BALL JOINT

4WD

BJP1-13A/

BJP1-13B

BJP1-11A

BJP1-3A

BJP1-14A

N/A - BOLT IN BALL JOINT

Yukon XL

1500

2007-2012

Steel Arm

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

N/A - CONTROL ARM REPLACE

Aluminum Arm

BJP1-12A

BJP1-11A

BJP1-3A

BJP1-13B

N/A - CONTROL ARM REPLACE

2000-2006

BJP1-8A

BJP1-16A

BJP1-3A

BJP1-12A

BJP1-8A

BJP1-11A

BJP1-5A

BJP1-12A

Yukon XL

2500

2011-2012