Snap-On BATTERY CHARGER PLUS User Manual

BATTERY CHARGER PLUS

EEBC500-INT

INTRODUCTION

BATTERY CHARGER PLUS

Thank you for purchasing your new Snap-on Battery

Charger plus.

The EEBC500-INT is an advanced, full featured battery

charger with additional functions that make it a battery

service system.

The charger utilizes a microprocessor, controlling both the

voltage and current going to the battery, providing maximum

power and the precise control needed to charge the various

types of 6 (3 cell), 12 (6 cell) and 24 (12 cell) volt batteries

on the market today; including AGM, GEL, Sealed Lead

Acid, Deep Cycle, Spiral-Cell and Standard Automotive

batteries up to 155 Ah capacity, reducing charge times while

maximizing battery life.

EEBC500-INT-Z

Engine Starting Power

The microprocessor is the heart of the multistage charging

algorithm built into the EEBC500-INT. Microprocessor

based charging technology achieves an extremely versatile

charging algorithm, and provides a user friendly set of

controls and an easy to read digital display (voltage, % of

charge, alternator % of performance). The versatility allows

many different battery types to be charged.

Flash Reprogramming Power Supply

Provides a consistent power at the OEM specied

voltage (user entered) to allow for uninterrupted ash

reprogramming of vehicle’s computers or to retain vehicle

system settings.

00-99-000963/1109

When reprogramming, the power supplied to the vehicle

module must not drop below OEM specied voltage.

Some reprogramming operations with the key-on will turn

on cooling fans, fuel pumps, and other components that

will cause the battery to drain faster than normal. Instead

of pulling fuses to prevent the battery drain, it is easier

and more practical to have the vehicle connected to a

constant voltage power supply. During reprogramming,

there is a risk of having the operation fail if the voltage falls

below the proper operating voltage. Sometimes a failed

operation can be recovered, but there is a chance that failed

reprogramming could ruin the control module.

Features

10-in. (254 mm) Diameter Pneumatic Wheels – allows •

easy movement around the shop and lot.

Digital Display - % of Charge – Voltage – Alternator •

Performance – shows precise data.

Covered tool storage compartment – convenient space •

for battery service tools.

Clamp storage posts and built-in cable wraps– keep •

clamps and cables organized.

Heavy-duty clamps – provide secure connections and •

minimal current losses.

90-in. (2.28 m) output cables – for extended reach in •

vehicles with hard-to-reach batteries.

SAFETY INFORMATION

Safety Notice

For your safety, read this manual thoroughly before

operating your charger. Your charger is intended for use by

properly trained, skilled professional automotive technicians.

The safety messages presented below and throughout this

user’s manual are reminders to the operator to exercise care

when using this charger.

There are many variations in procedures, techniques,

tools, and parts for servicing vehicles, as well as in the

skill of the individual doing the work. Because of the vast

number of applications and variations in the products

that can be charged with this instrument, Snap-on cannot

possibly anticipate or provide advice or safety messages

to cover every situation. It is the automotive technician’s

responsibility to be knowledgeable of the system that is to

be charged. It is essential to use proper service methods

and procedures and to perform charging in an appropriate

and acceptable manner that does not endanger your

safety, the safety of others in the work area, the vehicle or

equipment being charged.

It is assumed that the operator has a thorough

understanding of vehicle battery, charging, and starting

systems before using this charger. This understanding

of principles and operating theories is necessary for

competent, safe and accurate use of this charger.

Before using your charger, always refer to and follow the

safety messages and applicable test procedures provided

by the manufacturer of the vehicle or equipment being

charged.

9 foot (3 meter) AC power cord - for extended reach.•

Storage Area for Booster Packs or Auxiliary 12V batteries •

in the convenient bottom tray.

• For indoor use, do not expose to rain.

EEBC500-INT-Z

• 1 •

Read All Instructions

Read, understand and follow all safety messages and

instructions in this manual. Safety messages in this section

of the manual contain a signal word with a three-part

message and, in some instances, an icon.

The signal word indicates the level of the hazard in a

situation.

DANGER

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury to the

operator or bystanders.

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury to the

operator or bystanders.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in moderate or minor injury to the

operator or bystanders.

Safety messages in this section contain three different type

styles.

Normal type states the hazard. •

Bold• type states how to avoid the hazard.

Italic• type states the possible consequences of not

avoiding the hazard.

An icon, when present, gives a graphical description of the

potential hazard.

IMPORTANT

Indicates a situation which, if not avoided, may result in

damage to the test equipment or vehicle.

EEBC500-INT-Z

SAVE THESE INSTRUCTIONS

• 2 •

IMPORTANT SAFETY INSTRUCTIONS, PERSONAL PRECAUTIONS,

PREPARING TO CHARGE, CHARGER LOCATION

IMPORTANT: READ AND SAVE THIS SAFETY AND INSTRUCTION MANUAL

SAVE THESE INSTRUCTIONS – This manual contains

important safety and operating instructions for battery

charger Model EEBC500-INT.

Battery Gases, Charging Preparation and Charger

Location

WARNING

sparks. Provide adequate ventilation during charging.

Gases produced by a battery are highly explosive.

WORKING IN THE VICINITY OF A LEAD-ACID •

BATTERY IS DANGEROUS. BATTERIES GENERATE

EXPLOSIVE GASES DURING NORMAL BATTERY

OPERATION. FOR THIS REASON, IT IS OF

UTMOST IMPORTANCE THAT YOU FOLLOW

THE INSTRUCTIONS EACH TIME YOU USE THE

CHARGER.

TO REDUCE THE RISK OF BATTERY EXPLOSION, •

FOLLOW THESE INSTRUCTIONS AND THOSE

PUBLISHED BY THE BATTERY MANUFACTURER

AND THE MANUFACTURER OF ANY EQUIPMENT

YOU INTEND TO USE IN THE VICINITY OF THE

BATTERY. REVIEW THE CAUTIONARY MARKINGS

ON THESE PRODUCTS AND ON THE ENGINE.

User and bystander must wear safety goggles and •

protective clothing.

Be sure that the area around the battery is well •

ventilated while the battery is being charged. Use the

charger in an area having at least four air changes

per hour.

Do not operate the charger in a closed-in area or •

restrict ventilation in any way. Do not obstruct the

vents on the charger housing.

Read, understand and follow all instructions for the •

charger, battery, vehicle and any equipment used

near the battery and charger. Study all of the battery

manufacturer’sspecicprecautionswhilecharging

and recommended rates of charge.

Determine the voltage of the battery by referring to •

the owner’s manual and make sure that the output

voltage selector switch is set at the correct voltage. If

the charger has an adjustable rate, charge the battery

initially at the lowest rate.

Locate the charger as far away from the battery as •

the DC cables permit.

Do not smoke, strike a match, place metal tools on •

the battery or cause a spark in the vicinity of the

battery.

Explosive Gases. Prevent fumes and

If it is necessary to remove the battery from the •

vehicle to charge it, always remove the grounded

terminalfromthebatteryrst.Makesureall

accessories in the vehicle are off, to avoid arcing.

Clean the terminals before charging the battery. •

During cleaning, keep airborne corrosion from

coming into contact with your eyes, nose and mouth.

Use baking soda and water to neutralize acid and

help eliminate airborne corrosion. Do not touch your

eyes, nose or mouth.

Connect and disconnect the DC output clamps •

only after setting any charger switches to the “off”

position and removing the AC cord from the electric

outlet. Never allow the clamps on the charger cables

to touch each other.

Attach the clamps to the battery and chassis, as •

indicated in the CONNECTING THE CHARGER

section of this manual.

Never place the charger directly above the battery •

being charged; gases from the battery will corrode

and damage the charger.

Add distilled water to each cell until the battery •

acidreachesthelevelspeciedbythebattery

manufacturer.Donotoverll.Forabatterywithout

removable cell caps, such as valve regulated leadacid batteries, carefully follow the manufacturer’s

recharging instructions. Remove or do not remove

the cell caps while charging, per the manufacturer’s

instructions.

Make sure the charger cable clamps make tight •

connections.

Battery explosion can cause injury.

EEBC500-INT-Z

• 3 •

Battery Acid

WARNING

Battery acid is a highly corrosive sulfuric acid.

User and bystander must wear safety goggles.•

Wear protective gloves.•

Make sure someone can hear you or is close enough •

to provide aid when working near a battery.

Have plenty of fresh water and soap nearby. If battery •

acidcontactsyourskin,clothingoreyes,ushthe

exposed area with soap and water for 10 minutes.

Seek medical help.

Do not touch your eyes while working near a battery.•

Do not set the battery on top of the charger. Never •

allow battery acid to drip onto the charger while

readingtheelectrolytespecicgravityorllingthe

battery.

Battery acid can burn eyes and skin.

Grounding, AC Power Cord Connections

and General Charger Use

WARNING

Risk of electric shock and re.

Do not remove or bypass the grounding pin.•

Do not operate the charger with a damaged cord or •

plug. Replace the cord or plug immediately.

Position the power cord and charger cables away •

from the hood, doors or hot/moving engine parts

where they could be damaged.

Unplug the power cord by pulling the plug rather •

than the cord when disconnecting the charger from

the outlet.

The charger power cord uses an equipment-•

grounding conductor and a grounding plug. Only

plug it into an outlet that is correctly installed and

grounded in accordance with all ordinances and local

codes.

Unplug the power cord from the outlet before •

cleaning or maintaining the charger. Simply turning

off the controls will not reduce safety risk.

Do not operate the charger after a sharp impact, •

dropping it or any other damage.

Do not disassemble the charger; call a Snap-on •

Representative when service or repairs are required.

Incorrect reassembly may result in a risk of electric

shockorre.

Only use the recommended attachments. Use of an •

attachment not recommended or sold by Snap-on

mayresultintheriskofare,electricshockorinjury

to persons.

Do not charge a frozen battery. Do not overcharge •

battery when operating in manual mode.

Use the charger for charging a lead-acid battery •

only. It is not intended to supply power to a low

voltage electrical system other than in a startermotor application. Do not use the battery charger for

charging dry-cell batteries that are commonly used

with home appliances. These batteries may burst and

cause injury to persons and damage to property.

Remove personal metal items such as rings, •

bracelets, necklaces and watches when working with

a lead-acid battery. A lead-acid battery can produce

a short-circuit current high enough to weld a ring or

the like to metal, causing a severe burn.

EEBC500-INT-Z

• 4 •

Electric shock or re can cause injury

FOR ALL GROUNDED, CORD-CONNECTED BATTERY

CHARGERS:

GROUNDING AND AC POWER CORD CONNECTION

INSTRUCTIONS – The charger should be grounded to

reduce the risk of electric shock. The charger is equipped

with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into an outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING – Never alter the AC cord or plug provided – if

it will not t the outlet, have the proper outlet installed by a

qualied electrician. An improper connection can result in a

risk of an electric shock.

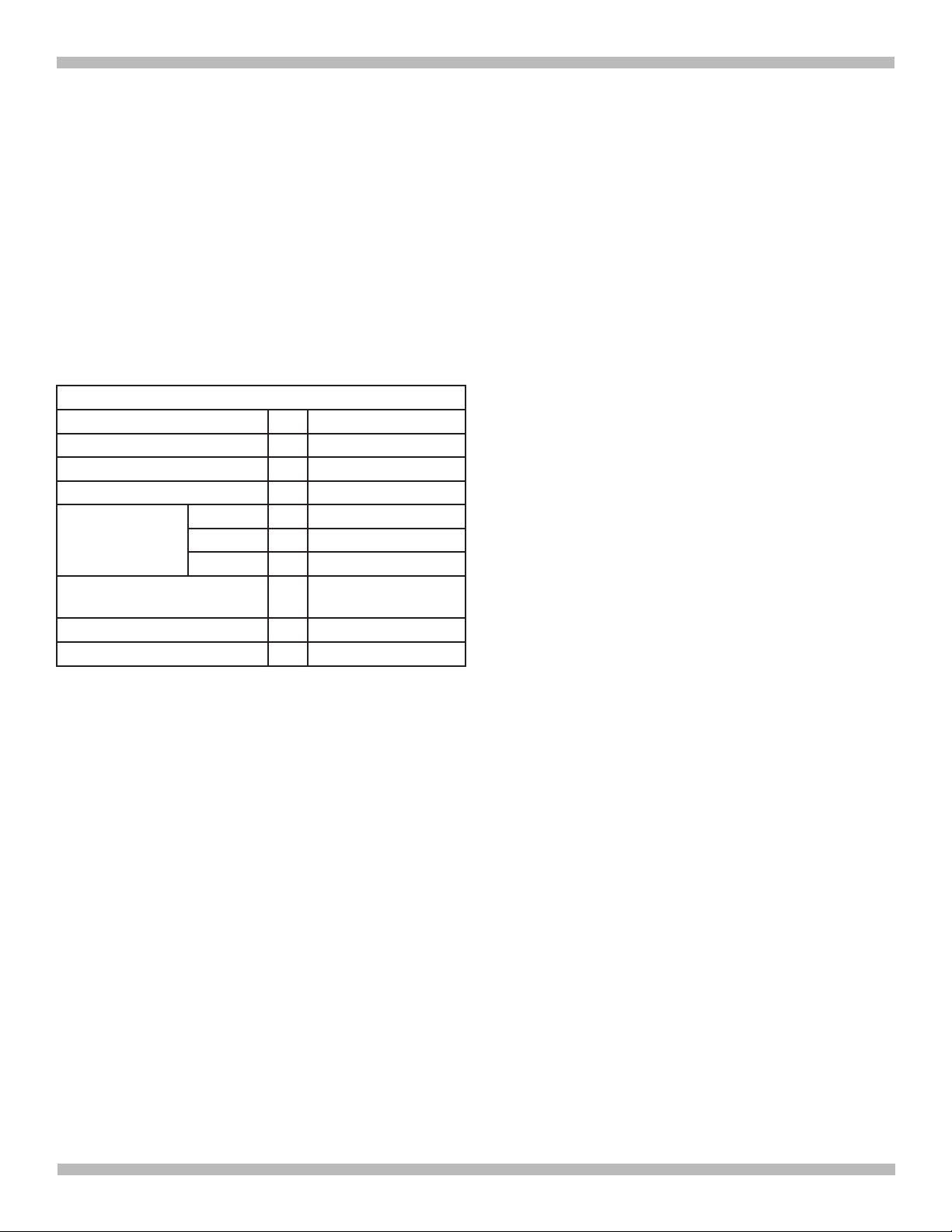

TechnicalSpecications

EEBC500-INT

Single Phase Power Supply A 230/240

Frequency Hz 50/60

Charging Voltage V 6/12/24

Starting Voltage V 6/12

Output

Currents

@ 6V A 4/15/60/300

@ 12V A 4/15/60/300

@ 24V A 4/15/30

Input Current A 0.8 to 5 continuous

24 max intermittent

Dimensions - Assembled mm 508 x 584 x 1003

Weight kg 41

EEBC500-INT-Z

• 5 •

FEATURES

3

5

4

2

6

1

8

7

1. Digital Display

2. Control Panel

3. Clamp Storage Posts with Built-in Cable Wraps

4. Covered Tool Storage Compartment

5. Heavy-Duty Battery Clamps

6. 90-inch (228.6 cm) Extended Reach Output Cables

7. 10-inch (25.4 cm) dia. Pneumatic Tires

8. Booster pack or Auxiliary Battery Storage

EEBC500-INT-Z

• 6 •

ASSEMBLING YOUR CHARGER

It is important to fully assemble your charger before use.

Follow these instructions for easy assembly.

TOOLS NEEDED

Phillips Head Screwdriver

Needle Nose Pliers

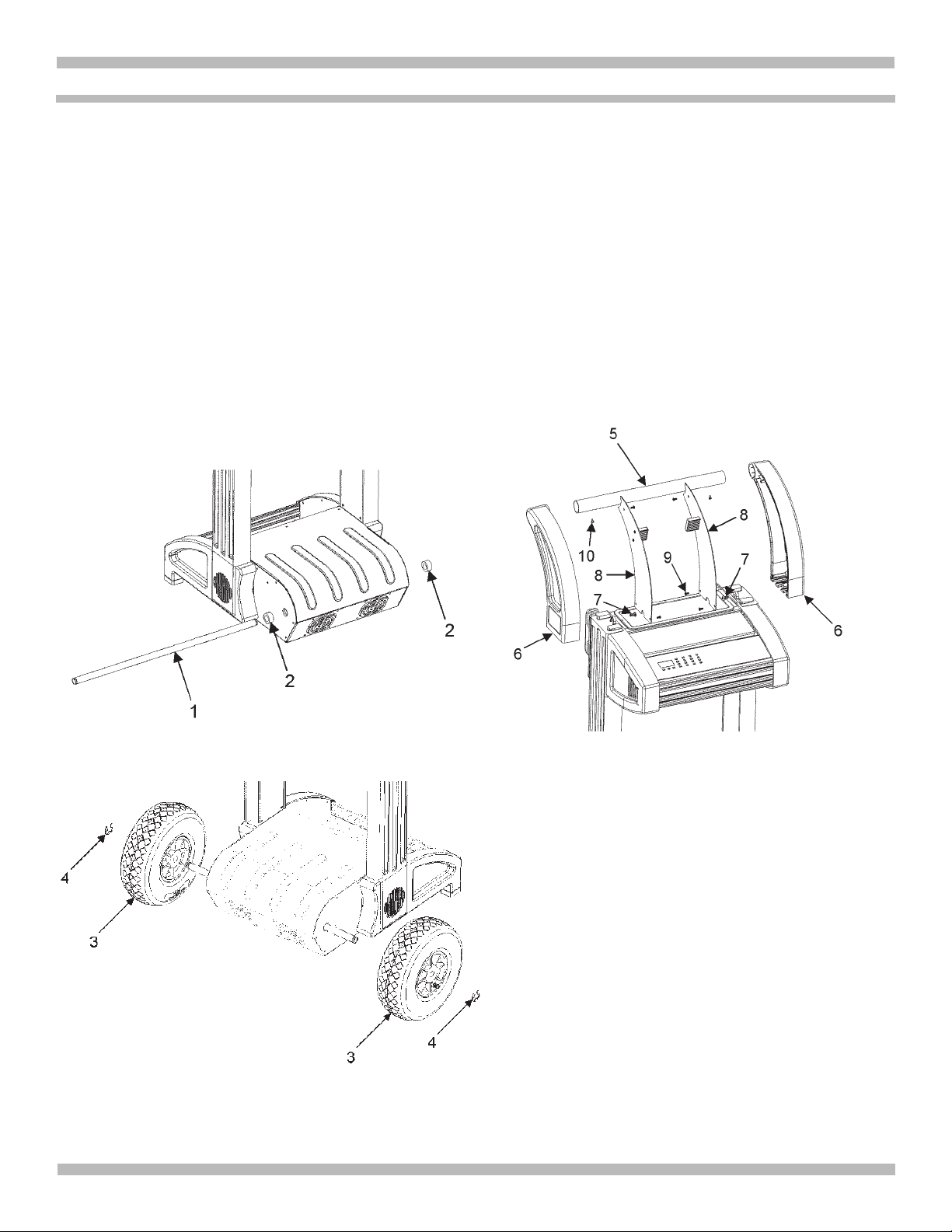

INSTALL AXLE AND WHEELS

Slide the axle (Item 1) through the bottom housing until it 1.

goes through the other side. It should self-align, but may

require some assistance.

Slide a spacer (Item 2) onto each end of the axle.2.

Slide a wheel (Item 3) onto each end of the axle shaft, 3.

and fasten everything using an E-clip (Item 4) on each

end.

INSTALL HANDLE

Slide the shaft (Item 5) into one of the handles (Item 6), 1.

followed by sliding each handle into the top base, making

sure the handles guide into the tracks of the legs.

Fasten each handle with a ¼” self-tapping screw (Item 7) 2.

on each side.

Install each cover (item 8) with four self-tapping screws 3.

(Item 9).

Secure the handle using two self-tapping screws (Item 4.

10) to prevent rotation.

For best results from your battery charger, learn to use it

properly. This section tells how to set the controls, charge

a battery in or out of the vehicle, use the ENGINE START

feature, test the battery, test alternator performance, and set

up for ash reprogramming.

EEBC500-INT-Z

• 7 •

A B

C

D

E F

BATTERY CHARGER CONTROLS

G

CONTROLS AND INDICATORS

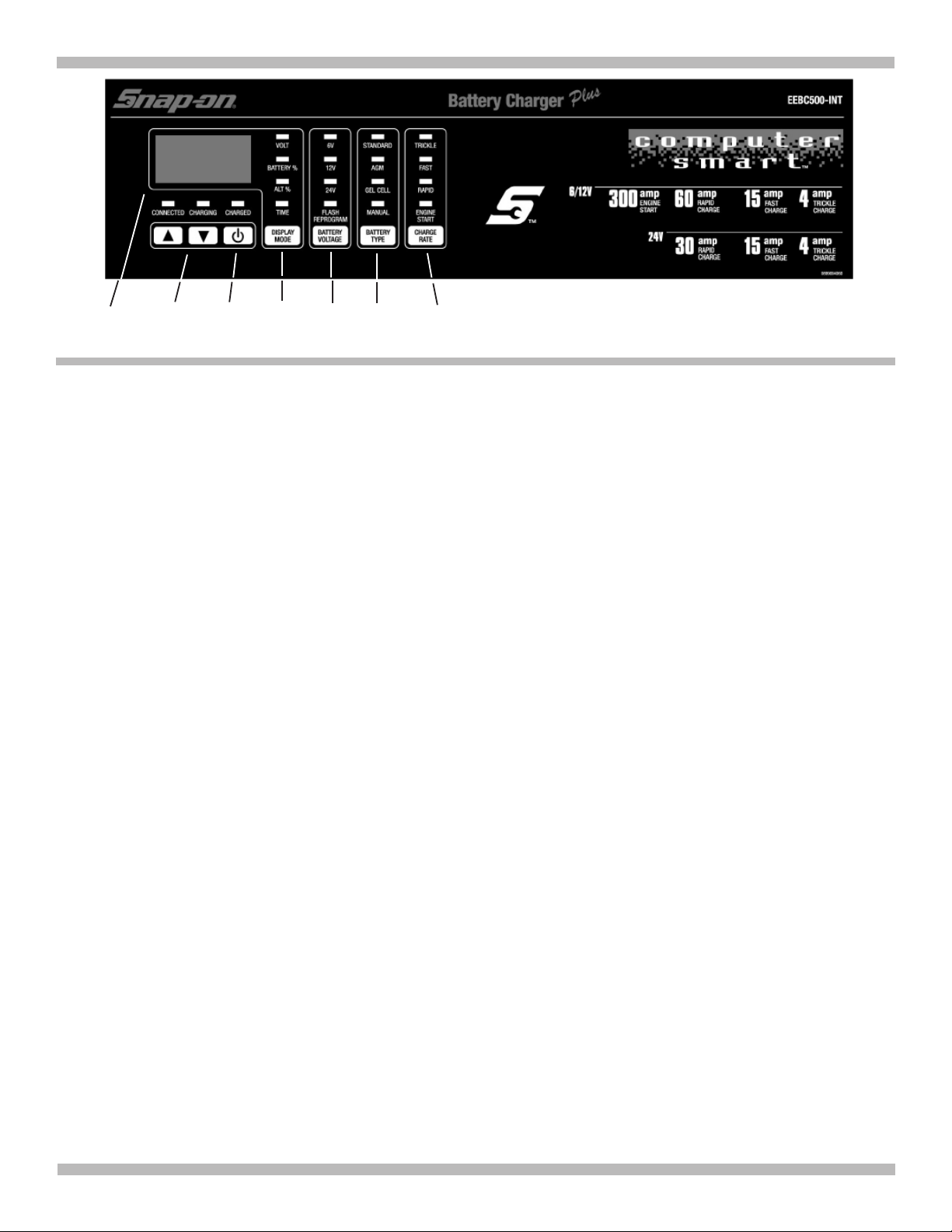

[A] Digital Display – Gives a digital indication of voltage, %

of charge, or time, depending on the Display Mode chosen.

[B] Up/Down Arrows (switches) – Used to change any

variable settings on the display.

[C] Power ON/OFF (switch) – Controls the charging output

of the unit.

[D] Display Mode (switch) – Switches the display between

VOLTS – BATTERY % - ALT % - or TIME.

[E] Battery Voltage (switch) – Select from 6V, 12V, 24V, or to

do Flash Reprogramming.

[F] Battery Type (switch) – Select from Standard, AGM

or Gel type of battery being charged. Also used to enter

manual mode.

[G] Charge Rate (switch) - Select from Trickle Charge (max

4 amp rate), Fast Charge (max 15 amp rate), Rapid Charge

(max 60 amp rate), and Engine Start (max 300 amp rate).

REPROGRAMMING THE DEFAULTS

Charger Start-up Mode defaults. If you are satised with the

default settings, skip to Automatic Charging section.

The rst time you power up the charger, the default settings

are set to:

DISPLAY MODE – VOLTS

BATTERY VOLTAGE – 12V

BATTERY TYPE – STANDARD

CHARGE RATE – RAPID

To change the power up default settings:

Change to the desired DISPLAY MODE, BATTERY 1.

VOLTAGE, BATTERY TYPE, and CHARGE RATE.

Press and hold both Up and Down Arrow switches at the 2.

same time until the LED’s stop ashing.

The next time you power up the unit, these settings will 3.

be saved and become the startup default settings.

AUTOMATIC CHARGING

Set Battery VOLTAGE to 6V, 12V, or 24V.1.

Set BATTERY TYPE to STANDARD, AGM, or GEL CELL. 2.

If unsure, consult the label on the battery or the battery

manufacturer.

Set CHARGE RATE to TRICKLE, FAST, or RAPID – 3.

smaller batteries (lawn tractor, motorcycle, etc.) should

not be set on RAPID.

Charging will start when the ON/OFF button is pressed 4.

and nish automatically.

CHARGED (green) LED will light when nished and 5.

charger will maintain battery.

NOTE: For a battery with a starting voltage under one volt,

use manual mode rst to pre-charge the battery for ve

minutes, to get additional voltage into the battery for the

charger to analyze.

MANUAL CHARGING

Set Battery VOLTAGE to 6V, 12V, or 24V.1.

Set BATTERY TYPE to MANUAL.2.

Set CHARGE RATE to TRICKLE, FAST, or RAPID – 3.

smaller batteries (lawn tractor, motorcycle, etc.) should

not be set to RAPID.

Use the “UP” and “DOWN” buttons to adjust the charge 4.

time (shown on digital display).

EEBC500-INT-Z

• 8 •

ENGINE START

Follow the instructions for connecting the charger to 1.

the battery and power source in the “Connecting the

Charger” section.

Set the Battery VOLTAGE to 6V or 12V, (24V is not 2.

available).

Set the CHARGE RATE to ENGINE START.3.

NOTE: The charger will supply a 20-amp charge to the

battery before cranking.

Crank the vehicle. The charger will automatically cut out 4.

after a maximum of ve seconds.

NOTE: During extremely cold weather, or if the battery is

under one volt, charge the battery for ve minutes before

cranking the engine.

Wait three minutes before attempting to start again. The 5.

digital display will indicate the time remaining before

cranking again and the ENGINE START LED will be

blinking.

NOTE: During this cool down period, the charger is

supplying the battery with a 4-amp charge.

When the digital display times down to 6. 0 and reads

, the ENGINE START LED has stopped blinking and

the CHARGING LED is on, you are ready to crank the

vehicle again.

If the engine still does not start, allow the charger to 7.

charge the battery for ve more minutes before cranking

it again.

After the engine starts, unplug the charger power cord 8.

from the wall outlet, before disconnecting from the

battery.

IMPORTANT – Do not try to start the engine without

a battery in it. You could cause damage to the vehicle

electrical system.

If the engine does turn over, but never starts, there is not

a problem with the starting system; there is a problem

somewhere else with the vehicle. STOP cranking the engine

until the other problem has been diagnosed and corrected.

FLASH REPROGRAMMING

NOTE: Do not attempt to Flash Reprogram a vehicle that

has a discharged or defective battery. Make sure that the

vehicle battery is in good condition and fully charged before

proceeding.

Set BATTERY VOLTAGE to FLASH REPROGRAMMING.1.

Use “UP” and “DOWN” buttons to adjust voltage to the 2.

voltage needed for the vehicle being programmed (refer

to OEM specications). Voltage selected is shown on the

digital display. The unit has a voltage range of 13 to 14.8,

with a default of 14.2.

NOTE: When the VOLTS LED stops blinking, the display

shows the selected voltage.

Press ON/OFF to activate the output.3.

NOTE: During this time, the other buttons will not work

until you turn off the output. When the display shows

no buttons will work for ve seconds, then it automatically

goes back to the default state.

When nished with Flash Reprogramming, press ON/4.

OFF to exit this mode.

BATTERY PERCENTAGE

Press the display mode button to switch from battery voltage

to battery % of charge.

ALTERNATOR PERFORMANCE CHECK

Set DISPLAY MODE to ALT %.1.

With vehicle engine running, the digital display will 2.

indicate approximate alternator/battery voltage as percent

of normal (100% is normal). If the percentage is low or

high, a problem is indicated. Use an alternator tester for

further diagnosis.

EEBC500-INT-Z

• 9 •

CONNECTING THE CHARGER

CONNECTING TO A BATTERY IN THE VEHICLE

A SPARK NEAR THE BATTERY MAY CAUSE A BATTERY

EXPLOSION. TO REDUCE THE RISK OF A SPARK NEAR

THE BATTERY:

See OPERATING INSTRUCTIONS for length of charge 1.

information.

Arrange the power cord and charging leads carefully in 2.

order to avoid damage that could be caused by the hood,

door or moving engine parts.

Keep clear of the fan blades, belts, pulleys and other 3.

parts that can cause injury.

Check the polarity of the battery posts using the 4.

identication marks on the battery case: POSITIVE (POS,

P, +) and NEGATIVE (NEG, N, -). NOTE: On top-post

batteries, the positive battery terminal usually has a

larger diameter post than the negative one.

Identify which battery post is grounded or connected to 5.

the chassis. The negative post is NORMALLY the one

that is grounded.

To charge a negative-grounded system: Connect the red 6.

(POSITIVE) charger clamp to the ungrounded POSITIVE

(POS, P, +) post of the battery. Next, connect the black

(NEGATIVE) clamp to an unpainted, heavy metal part of

the chassis or engine block, away from the battery. Do

not connect clamp to carburetor, fuel lines, or sheet metal

parts.

To charge a positive-grounded system: Connect the 7.

black (NEGATIVE) charger clamp to the ungrounded

NEGATIVE (NEG, N, -) post of the battery. Then connect

the red (POSITIVE) clamp to an unpainted, heavy

metal part of the chassis or engine block, away from the

battery. Do not connect clamp to carburetor, fuel lines or

sheet metal parts.

WARNING: User and bystander must

wear safety goggles and protective gloves,

while making connections.

Twist or rock clamps back and forth to make a solid 8.

connection. This will help make better contact and help

keep them from slipping off and causing sparks.

Plug the power cord into a grounded AC outlet.9.

10. Adjust settings and charge battery.

11. When you are nished with the charger, turn the

POWER switch to the OFF position and unplug the

charger power cord.

12. Standing away from the battery, remove the charger

clamps in this order: (1) from the chassis connection and,

(2) from the battery post or terminal.

13. Clean and store the battery charger in a dry location.

CONNECTING TO A BATTERY OUT OF THE VEHICLE

A SPARK NEAR THE BATTERY MAY CAUSE A BATTERY

EXPLOSION. TO REDUCE THE RISK OF A SPARK NEAR

THE BATTERY:

Make sure all of the accessories and lights are turned 1.

off in the vehicle. Remove the battery from vehicle,

disconnecting the grounded terminal rst.

Check the polarity of the battery posts as indicated on 2.

the battery case: POSITIVE (POS, P, +) and NEGATIVE

(NEG, N, -). NOTE: On top-post batteries, the positive

battery terminal usually has a larger diameter post than

the negative one.

Connect the red (POSITIVE) charger clamp to the 3.

POSITIVE post of the battery. Be sure to rock the clamp

back and forth to make a solid connection.

Attach a six (AWG) or four (SAE) gauge insulated battery 4.

cable of at least 24 inches in length to the NEGATIVE

battery post. This cable will provide a safer connection

because arcing and sparking will occur away from the

battery. (The battery cable is not provided with the

charger, but may be purchased at most automotive

accessory outlets.)

Standing as far away from the battery as possible, 5.

connect the black (NEGATIVE) lead of the charger to the

free end of the cable. Rock the clamp to make a solid

connection.

WARNING: User and bystander must wear

safety goggles and protective gloves while

making connections.

Plug the power cord into a grounded AC outlet.6.

Adjust settings and charge battery.7.

When the battery is fully charged, turn the POWER 8.

switch to the OFF position and unplug the charger power

cord.

When disconnecting charger, always do so in reverse 9.

order of connecting procedure and break the rst

connection while as far away from the battery as

practical.

10. A marine (boat) battery must be removed and charged

on shore. To charge it onboard requires equipment

specially designed for marine use.

11. Clean and store the battery charger in a dry location.

EEBC500-INT-Z

• 10 •

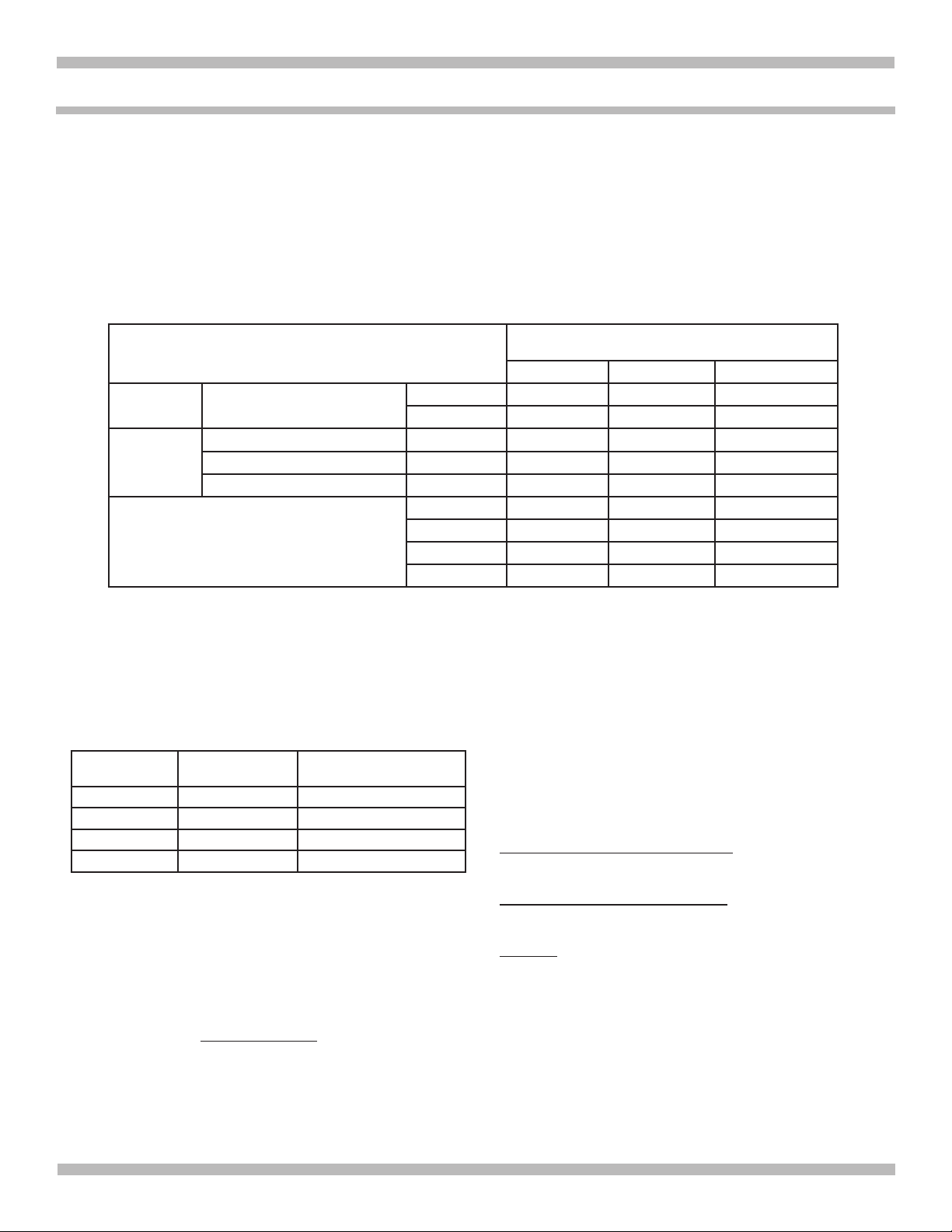

CALCULATING CHARGE TIMES

The Chart Method

Use the following table to more accurately determine the

time it will take to bring a battery to full charge. First, identify

where your battery ts into the chart.

Small batteries – motorcycle, garden tractors, etc. – are •

usually rated in Ampere Hours (AH). For example: 6, 12,

32 AH etc.

Batteries in cars and smaller trucks are usually rated in •

Reserve Capacity (RC), Cold-Cranking Amps (CCA), or

both.

BATTERY SIZE/RATING

SMALL

BATTERIES

CAR/

TRUCKS

Motorcycle, garden tractor, etc.

200 - 315 CCA 40 - 60 RC 11 - 14 60 - 90 min. 20 - 30 min.

315 - 550 CCA 60 - 85 RC 14 - 18 90 - 120 min. 30 - 40 min.

550 - 1000 CCA 85 - 190 RC 18 - 35 2 - 3.5 45 - 60 min.

MARINE/DEEP CYCLE

6 - 12 AH 2 - 4 NR NR

12 - 32 AH 4 - 10 NR NR

80 RC 18 105 min. NR

140 RC 27 2 hrs, 45 min. NR

160 RC 30 3 NR

180 RC 33 3.5 NR

Marine or deep-cycle batteries are usually rated in •

Reserve Capacity (RC).

NR means that the charger setting is NOT •

RECOMMENDED.

Find your battery rating on the chart below and note the

charge time given for each charger setting. The times

given are for batteries with a 50-percent charge prior to

recharging. Add more time for severely discharged batteries.

CHARGE RATE/CHARGING TIME IN HOURS

(unless otherwise stated)

4 AMP 15 AMP 60 AMP

The Hydrometer or Electronic Method

To nd the time needed to fully charge your battery,

determine the battery’s charge level with a hydrometer or

electronic Percent-of-Charge Tester. The following table will

help you convert hydrometer readings to percent of charge

values.

SPECIFIC

GRAVITY

1.265 100% 0%

1.225 75% 25%

1.155 25% 75%

1.120 0% 100%

PERCENT OF

CHARGE

PERCENT OF CHARGE

NEEDED

When you know the percent of charge and the Amp

Hour (AH) rating of your battery, you can calculate the

approximate time needed to bring your battery to a full

charge.

To convert Reserve Capacity to Amp Hours, divide Reserve

Capacity by 2, and add 16:

Example:

Amp Hour Rating = Reserve Capacity + 16

2

NOTE: The reserve Capacity can be obtained from the

battery specication sheet or the owner’s manual.

To calculate time needed for a charge:

Find the percent charge needed. (A battery at 50% •

charge that will be charged to 100% needs another 50%

(.50)).

Multiply the Amp Hour rating by the charge needed (.50) •

and divide by the charger setting (4, 15, or 60 amps).

Multiply the results by 1.25 and you will have the total •

time needed, in hours, to bring the battery to full charge.

Add one additional hour for a deep-cycle battery.•

Example:

Amp Hour Rating x % of charge needed x 1.25 = hours of charge

Charger Setting

100 (AH Rating) x .50 (charge needed) x 1.25 = 3.125 hours

20 (Charger Setting)

100 x .50 x1.25 = 3.125

20

You would need to charge your 100-Ampere Hour Battery

for a little more than three hours at the 20-Amp charge rate

using the above example.

EEBC500-INT-Z

• 11 •

MAINTENANCE, CARE AND STORAGE

A minimal amount of care can keep your battery charger

working properly for years.

After each use, unplug unit, wipe all battery corrosion 1.

and other dirt or oil from clamps, cables, and the charger

case. Use a dry cloth.

Coil the charger cables in the built in cable wraps to 2.

prevent damage. This will prevent accidental damage to

the cables and charger.

Have any cracked or frayed cables replaced by an 3.

authorized Snap-on representative.

Store the unplugged battery charger in a clean, dry area.4.

EEBC500-INT-Z

• 12 •

TROUBLESHOOTING

Performance problems often result from little things that you can x yourself. Please read through this table for a possible

solution if a problem occurs.

PROBLEM POSSIBLE CAUSE SOLUTION/REASONS

No reading on the display

or “Connected” LED is not

on.

Short or no start cycle

when cranking engine.

Charger makes a loud

buzz or hum.

Display reading stays high. Battery severely discharged.

Charger is connected

correctly but charging is

not taking place.

Clicking noise from

charger.

“Charging” LED is ashing. The battery is sulfated. A sulfated battery will eventually take a normal charge if left

Clamps are not making a good connection.

AC cord and/or extension cord is loose.

No power at receptacle.

Clamp polarity reversed.

Failure to wait 3 minutes (180 seconds)

between cranks.

Clamps are not making a good connection.

AC cord and/or extension cord is loose.

No power at receptacle.

The charger may be heated up.

Battery may be severely discharged.

Transformer laminations vibrate (buzz). No problem, this is a normal condition.

Wrong battery voltage selected.

Battery is severely discharged. If your battery does not have one volt, you need to switch to the

Circuit breaker is cycling (manual mode

only).

Battery is defective.

Shorted battery clamps.

Severely discharged battery, but otherwise

a good battery.

Reverse connections at battery.

Check for poor connection at battery and frame. Make sure

connecting points are clean.

Check power cord and extension cord for loose tting plug.

Check for open fuse or circuit breaker supplying AC outlet.

Verify and reverse the battery clamps.

Wait three minutes or until the display reads and the Charging

LED is on.

Check for poor connection at battery and frame. Make sure

connecting points are clean.

Check power cord and extension cord for loose tting plug.

Check for open fuse or circuit breaker supplying AC outlet.

The internal thermal protector may have tripped and needs a little

longer to close. Wait until it automatically resets and try again.

On a severely discharged battery, charge for 10 to 15 minutes in

the 15 amp manual rate to help assist in cranking.

Continue charging battery for two more hours. If problem

continues; call your Snap-on representative.

Make sure BATTERY VOLTAGE switch is properly set for 6V, 12V

or 24V selection.

Manual mode for a few minutes until the charging begins and then

switch back to Automatic mode in the desired charge rate.

The settings may be wrong. Check the charger settings.

Have the battery checked.

Circuit breaker cycles when current draw is too high.

Check for shorted cables and replace if necessary.

Allow charging to continue until battery has a chance to recover

sufciently to take a charge. If more than 20 minutes, stop

charging and have the battery checked.

Correct the lead connections.

connected. The charger will continue to charge with a low current

for up to 10 hours to recover the battery. If the battery will not take

a charge after 10 hours, have it checked.

EEBC500-INT-Z

• 13 •

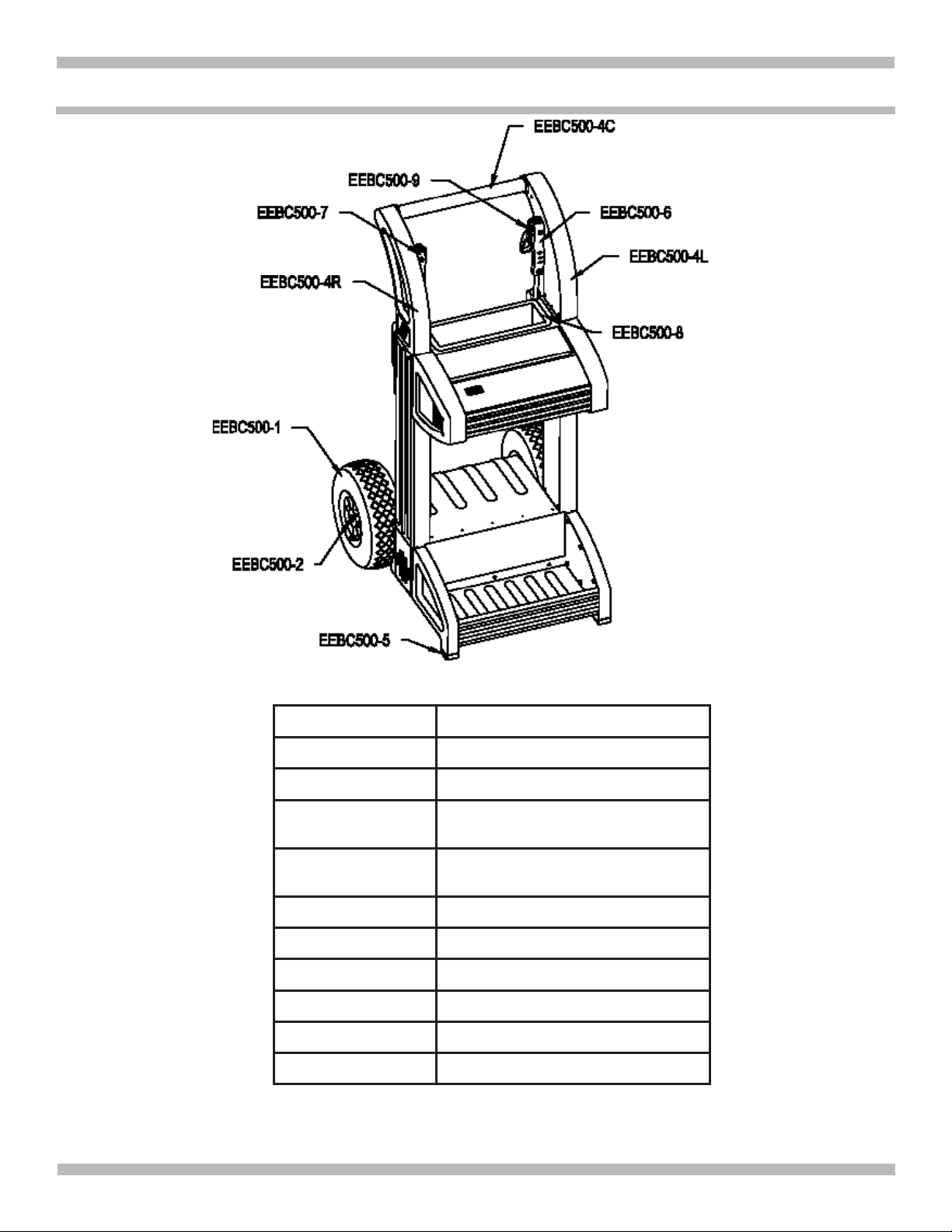

REPLACEMENT PARTS LIST - DIAGRAM

Stock Number Description

EEBC500-1 Replacement Wheel w/snap ring

EEBC500-2 Axle

EEBC500-4L

EEBC500-4R

EEBC500-4C Center Handle Bar

EEBC500-5 Front Foot w/hardware

EEBC500-6 Positive Cable Assembly

EEBC500-7 Negative Cable Assembly

EEBC500-8 Parts Storage Compartment

EEBC500-9 Clamps Posts (2)

Replacement Left Handle

Support w/hardware

Replacement Right Handle

Support w/hardware

EEBC500-INT-Z

• 14 •

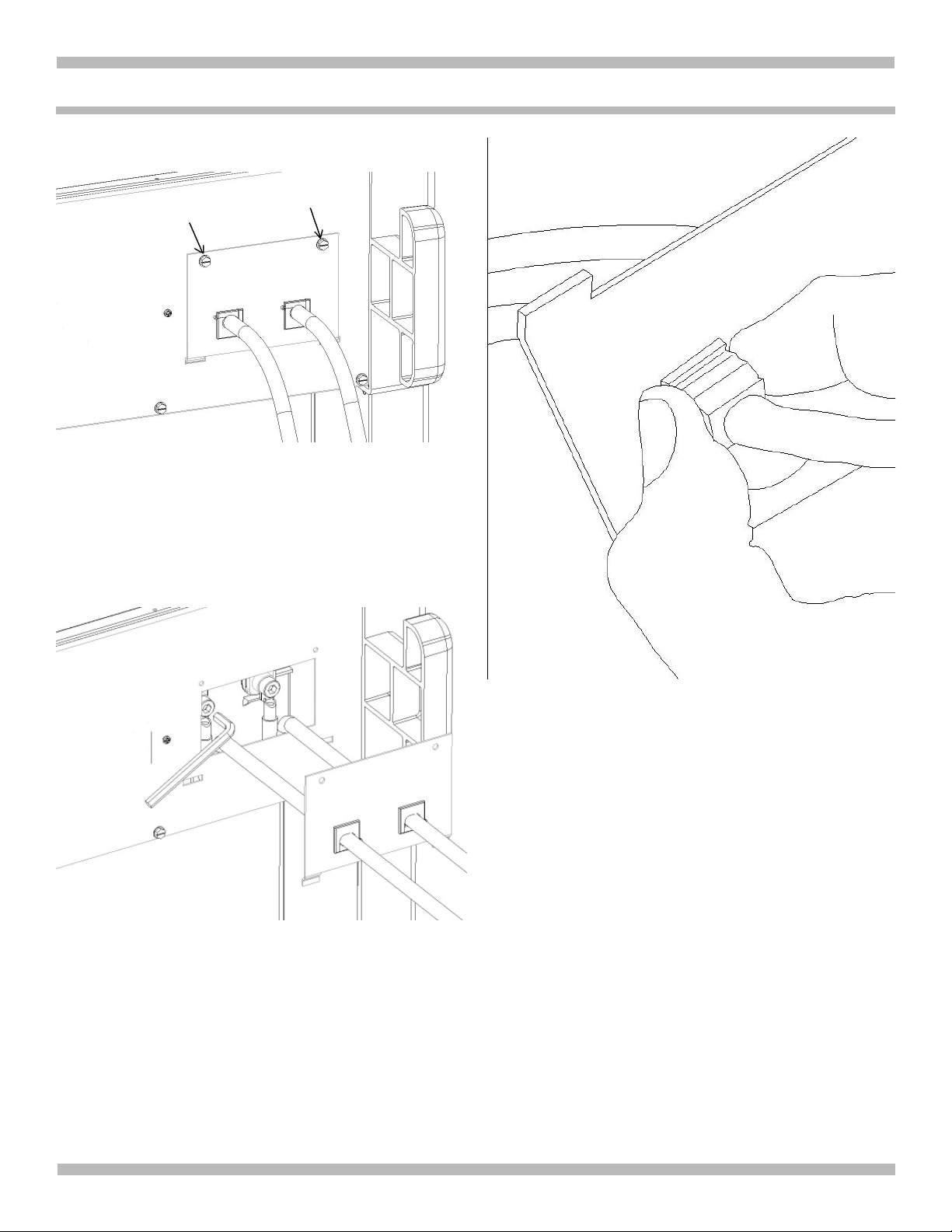

REPLACING THE CLAMP CABLES

Remove the two screws on the cover plate, and tilt it out 1.

of the slots on the bottom.

2. Remove the screws on the terminals using a 6 mm hex

wrench. These will be torqued down tight, so you will

probably need to use the long end. Take care when

removing the screws to prevent stripping the hole. To

prevent damage, it is recommended you use an open

ended wrench to keep the terminal from spinning.

3. The strain reliefs are held in by three spring tabs. While

pulling on the cable (opposite side of strain relief), push

on the bottom tab to get it out rst, then squeeze the two

side tabs together to remove the strain relief from the

hole.

4. Follow these steps in reverse to assemble the new cable.

EEBC500-INT-Z

• 15 •

Loading...

Loading...