Snap-On 870013 User Manual

MODEL #870013

FOR CUSTOMER SERVICE

PARA EL SERVICIO

PARA EL CONSUMIDOR

1-888-278-8092

Printed in Taiwan

SNAP-ON®IS A TRADEMARK LICENSED BY SNAP-ON®CORP.,

U.S.A., WHICH DOES NOT MANUFACTURE OR

DISTRIBUTE THIS PRODUCT. CONSUMER INQUIRES SHOULD BE

DIRECTED TO:

©COPYRIGHT 2007 ALLTRADE TOOLS, LLC.

1431 VIA PLATA

LONG BEACH, CA 90810-1462 USA

870015 – 18 Gauge 2" Brad Nailer _Rev 9/6/07

15 GAUGE ANGLED FINISH NAILER

INSTRUCTION MANUAL

THIS MANUAL CONTAINS IMPORTANT INFORMATION REGARDING SAFETY, OPERATION,

MAINTENANCE AND STORAGE OF THIS PRODUCT. BEFORE USE, READ CAREFULLY AND

UNDERSTAND ALL CAUTIONS, WARNINGS, INSTRUCTIONS AND PRODUCT LABELS. FAILURE TO DO SO

COULD RESULT IN SERIOUS PERSONAL INJURY AND/OR PROPERTY DAMAGE.

IF YOU SHOULD HAVE ANY QUESTIONS OR EXPERIENCE A PROBLEM WITH YOUR SNAP-ON

PRODUCT, DO NOT RETURN THIS PRODUCT TO THE STORE. PLEASE CALL OUR CUSTOMER SERVICE

DEPARTMENT AT 1-888-278-8092. BEFORE YOU CALL, HAVE THE FOLLOWING INFORMATION

AVAILABLE:MODEL No., DATE PURCHASED AND STORE LOCATION.

CONGRATULATIONS!

Thanks for choosing this product. Our aim is to provide you with the highest quality products, and we want you to be totally satisfied with your product and our Customer Service.

If any help or advice is needed, please contact us at 1-888-278-8092. When properly

cared for, this product will give you many years of satisfaction.

GENERAL SAFETY RULES

READ AND FOLLOW ALL INSTRUCTIONS. Failure to follow all instructions in this manual may result in severe personal injury or death.

Keep this manual and refer to it for Safety Instructions, Operating Procedures,

and Warranty.

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS

The safety instructions provided in this manual are not intended to cover all possible

conditions and practices that may occur when operating, maintaining and cleaning

power tools.

Always use common sense and pay particular attention to all the DANGER,

WARNING, CAUTION and NOTE statements of this manual.

This is the safety alert symbol. It is used to alert

you to potential personal injury hazards. Obey all

safety messages that follow this symbol to avoid

possible injury or death.

DANGER indicates an imminently hazardous

situation which, if not avoided, will result in death

or serious injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

TABLE OF CONTENTS

CONGRATULATIONS! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

RECOGNIZE SAFETY SYMBOLS, WORDS AND LABELS . . . . . . . . 2-3

IMPORTANT INFORMATION ABOUT THIS MANUAL . . . . . . . . . . . 4

SAFETY WARNINGS AND PRECAUTIONS . . . . . . . . . . . . . . . . . . . 4-7

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

COMPONENT INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

OPERATING THE ANGLED FINISH NAILER . . . . . . . . . . . . . . . . . . . . . . 9-13

SELECT TRIGGER ACTUATION MODE . . . . . . . . . . . . . . . . . . . . . . 9-11

ADJUSTING DEPTH OF NAILING . . . . . . . . . . . . . . . . . . . . . . . . . . 11-12

USING THE HOOK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

LOADING NAILS INTO THE AIR NAILER . . . . . . . . . . . . . . . . . . . . 11

USING THE NOSE ADAPTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

REQUIRED DAILY PREPARATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-14

USING THE AIR NAILER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

CHANGING DIRECTION OF EXHAUST AIR . . . . . . . . . . . . . . . . . . . 15

CLEARING JAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-17

MANDATORY MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-19

PARTS DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19-20

PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-23

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

1 YEAR LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25-28

2

IMPORTANT INFORMATION ABOUT THIS MANUAL

Improper maintenance and operation are responsible for the majority of accidents

involving angled finish nailers. The largest portion of these could be prevented by

recognizing the basic safety rules and precautions. Most accidents can be avoided

if the operator recognizes a potentially hazardous situation before it happens and by

observing appropriate safety rules and procedures as outlined in this manual.

Basic safety precautions are outlined in the SAFETY portion of this manual and

throughout text in this manual where a potential hazard might occur.

Hazards that MUST be avoided to prevent serious injury follow headers marked

DANGER or WARNING. These same precautions are placed as labels on the tool

itself.

NEVER use this nailer for applications that are NOT specified in this manual.

SAFETY WARNINGS AND PRECAUTIONS

Do not operate angled finish nailer anywhere fastener may contact hidden

electrical wiring. Contact with a “live” wire will make all metal parts of the

angled finish nailer “live.” This can result in severe electrical shock, severe

burns or death to the operator. Contact a qualified electrical contractor to

ensure a safe working environment exists.

Be aware of conduits or gas pipes. Striking a gas pipe could result in an explosion causing serious injuries or even death to the operator or bystanders.

Be aware of what is behind the work piece. A fastener could travel through the

work piece and out the other side, striking a bystander resulting in serious

injury or even death.

Do not operate the angled finish nailer in the presence of flammable liquids, such

as gasoline, thinner , paint, or adhesives, gases or dust. Sparks created by the tool

can cause flammable materials to ignite or explode. Failure to comply with this warning could result in serious injury or even death to the operator.

Keep bystanders, children and visitors away from area where angled finish

nailer is being used. Distractions can result in severe injury or even death to

anyone who inadvertently gets in the way of nailing operations.

Do not use oxygen, combustible or bottled gases (such as carbon

dioxide or nitrogen) as a power source for the angled finish nailer. Use only compressed air from a source as outlined in this man-

ual. The tool will explode resulting in severe injury or even death to the operator and bystanders.

3

CAUTION used without the safety alert symbol

indicates a potentially hazardous situation which,

if not avoided, may result in property damage.

NOTE provides additional information that is useful

for proper use and maintenance of this tool. If a

NOTE is indicated make sure it is fully understood.

In addition to SAFETY ALERTS listed above, there could also be numerous symbols

alerting the operator that specific safety equipment is required to safely operate this

tool. Learn these SAFETY SYMBOLS as well as the SAFETY ALERTS to prevent

injury to the operator and to bystanders.

READ OPERATING INSTRUCTIONS: Read and understand tool labels,

safety warnings and precautions in this manual before operating the tool.

Failure to follow WARNINGS could result in serious injury or even death

to the operator or bystanders.

WEAR APPROVED EYE PROTECTION: Safety glasses must conform to

the requirements of American National Standards Institute (ANSI) Z87.1

and provide protection against flying particles from both front and side.

WEAR HEARING PROTECTORS: Hearing protectors should be worn to

protect the ears from loud exhaust noise produced by the air tools.

USE ONLY CLEAN, DRY COMPRESSED AIR: Never use oxygen, combustible gases and any other bottled gas to operate air tools. Using these

other sources can cause the air tool to explode.

NEVER POINT THE ANGLED FINISH NAILER AT YOURSELF OR

OTHERS: Fasteners are under extreme pressure and can cause severe

injury or even death if misused.

DO NOT EXCEED 120 psi (8.43 kg/cm

2

G). Using excessive pressure

from the power source can cause the angled finish nailer to explode

resulting in severe injury or even death to the operator or bystanders.

Always use hearing protection to protect your ears against

hearing loss due to exhaust noise. Always wear proper safety glasses to prevent injuries to the eyes from fragments of

the work piece, defective nails or other debris caused by using the angled

finish nailer. All safety glasses must have side shields and should conform to

the requirements of the American National Standards Institute (ANSI) z87.1.

Failure to comply with this warning could lead to serious or permanent damage

to the ears as well as serious damage or permanent blindness in the eyes.

Never carry the angled finish nailer by the air hose. A sudden disconnection

of the air hose could cause the angled finish nailer to remain charged and an

accidental firing could occur. Failure to comply with this warning could lead to

serious injury to the operator or bystanders.

Always disconnect the power source and ensure the tool is not charged

before loading fasteners. Failure to comply with this warning could cause

severe injury or death to the operator, bystanders and severe damage to the

angled finish nailer.

Never use a non-relieving air coupler with the angled finish nailer. Always

use couplers that release any built-up charge in the angled finish nailer’s firing

mechanism. A non-relieving air coupler can allow the angled finish nailer to discharge a fastener while the tool is disconnected from the power source. Failure

to comply with this warning can result in serious or permanent injury or even

death to the operator or to bystanders.

Do not drive nails on top of other nails. Do not operate the angled finish nailer at too steep of an angle. Nails can ricochet. Failure to comply with this warning can result in serious injury or even death to the operator or bystanders.

Do not modify the angled finish nailer in any way. Unauthorized alterations

can jeopardize safety in the tool’s operation. Failure to follow this precaution can

result in serious injury or even death to the operator or bystanders.

On rooftops and other high locations, always move forward as you use the

angled finish nailer. You can easily loose your footing if moving backwards.

When nailing against a perpendicular surface, nail from the top down. This

causes less fatigue and reduces the chances of accidents.

Ensure the work area is sufficiently illuminated to operate power tools. The

work area should be clear and free of litter.

Do not connect angled finish nailer to an air source capable of

generating more than 200 psi (14.06 kg/cm

2

G). Over-pressurizing

the angled finish nailer will result in bursting, abnormal operation or

breakage of the tool. Use only clean, dry, regulated compressed air

at levels specified on the tool. Failure to comply can cause severe injury or

death to the operator or bystanders.

Do not attempt to fasten the trigger in the “ON” position. This could lead to

an accidental discharge of the angled finish nailer . Do not operate the angled finish nailer if any portion of the tool’s operating controls are inoperable, disconnected, altered in any way or not in proper working order . Failure to comply with

this warning could result in serious injury or even death to the operator or other

bystanders.

All air compressors must comply with the requirements of ANSI

b19.3. Pressure regulators must be used to limit air pressure where

air supply pressure exceeds the tool’s rated operating pressure.

Do not carry the angled finish nailer with a finger on the trigger. This could

lead to an accidental discharge of the angled finish nailer. Do not press the trigger of the angled finish nailer unless it is pressed firmly against the work piece.

Do not point the angled finish nailer at yourself or in the direction of another

person. Failure to comply with this warning could result in serious injury or

even death to the operator or other bystanders.

Do not tamper with the work piece contact. The work piece contact prevents

accidental discharge of the angled finish nailer and should never be removed or

compromised in any way. Failure to comply with this warning could result in

serious injury or even death to the operator or other bystanders.

Always disconnect air hose and remove any remaining nails:

1. When angled finish nailer is left unattended.

2. Before performing any maintenance or repair on the angled finish nailer.

3. Before attempting to clear a jam in the angled finish nailer.

4. Before moving the angled finish nailer to a new location.

Always check the overall condition of the angled finish nailer before using.

Check for and tighten any loose screws. Ensure all safety systems are in work-

ing condition before using the angled finish nailer . The angled finish nailer must

not operate if only the trigger is pulled or if only the work piece contact is

pressed against the work piece. The angled finish nailer must only be used if

both the trigger and work piece contact work at the same time.

6

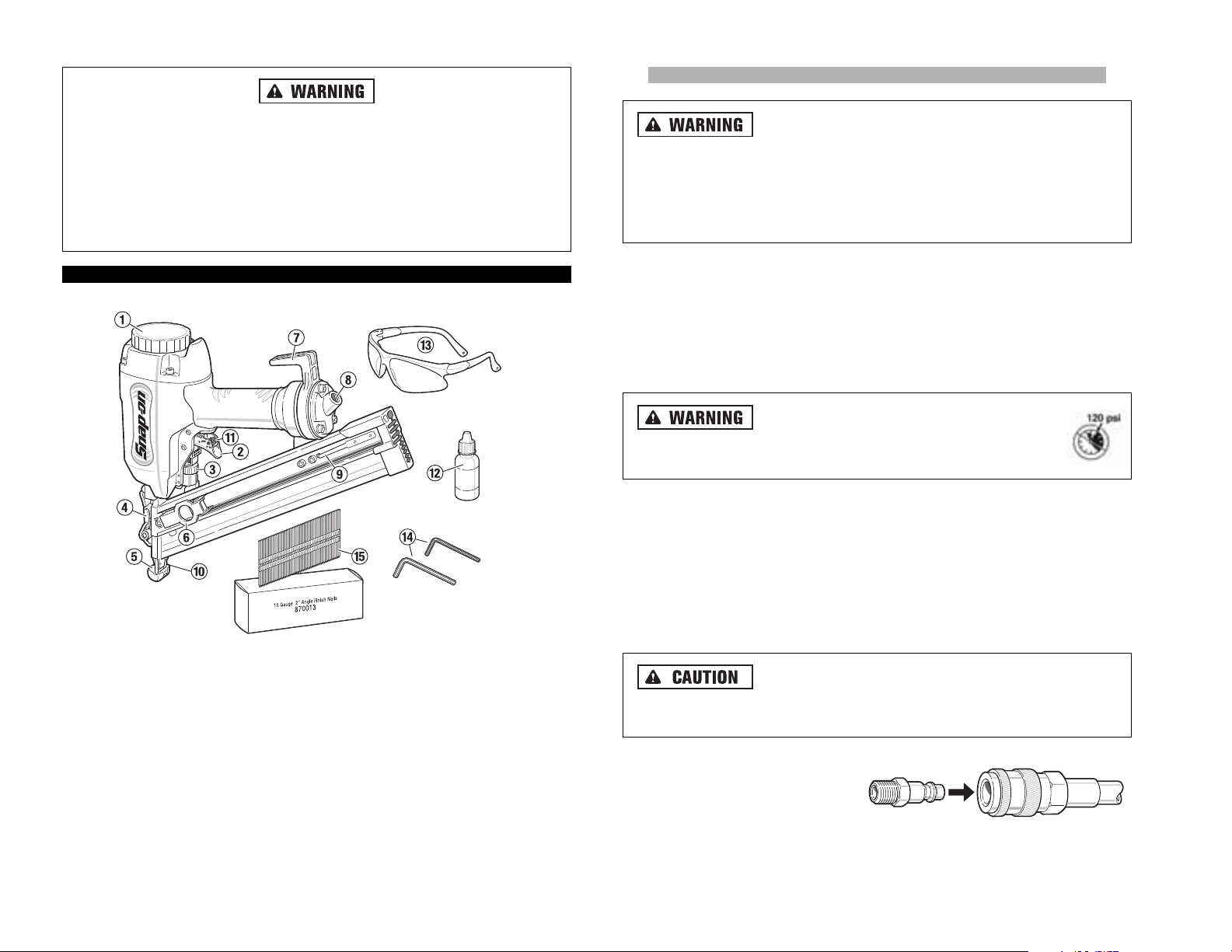

COMPONENT INSTALLATION

Never use a non-relieving air coupler with the angled

finish nailer .Always use couplers that release any built-up charge in the angled

finish nailer’s firing mechanism. A non-relieving air coupler can allow the angled

finish nailer to discharge a fastener while the tool is disconnected from the

power source. Failure to comply with this warning can result in serious or permanent injury or even death to the operator or to bystanders.

When selecting an air compressor, it must comply with the requirements of the

American National Safety Institute - ANSI B19.3.

Choose an air compressor that can supply more than the required air pressure to

ensure optimum efficiency. Always use clean, dry compressed air with a maximum

pressure of 200 psi. Use a pressure regulator and set the pressure between 70 –

120 psi. (5.0 – 8.5 kg/cm

2

G). Before each use, check the pressure regulator to

ensure it is functioning within the proper pressure range.

Using an air pressure of more than 120 psi can

cause the angled finish nailer to malfunction or possibly explode

causing severe injury or property damage.

SELECTING A PROPER AIR HOSE

Use an air hose with the largest diameter and shortest length possible to ensure

continuous, efficient nailing operations. Using an air pressure of 70 psi (5.0

kg/cm

2

G), an air hose with an inside diameter of 1/4" (6.5 mm) or greater and a hose

length of less than 6.6 ft (20 m), it is recommended that a 0.5 second interval be

allowed between each nailing. Air supply hoses shall have a minimum working pressure of 150 psi (10.7 kg/cm

2

G) or 150% of the maximum pressure produced by the

compressor or whichever is higher.

Low air output by the compressor or a longer hose with

a smaller inside diameter in relation to the nailing frequency may decrease

the driving capability of the air nailer.

SELECTING A QUICK DISCONNECT

1. Remove the plastic protective plug

from the tool’s air inlet.

2. Insert a 1/4" NPT male quick

disconnect into the air inlet. Install the female portion to the air hose.

Thoroughly clean and maintain the angled finish nailer after every use.

Lubricate moving parts to prevent rust and minimize friction-related wear . Wipe

down the entire tool and remove all dust from the moving parts. Properly store

the angled finish nailer in a suitable case to keep it ready for the next job.

All maintenance and repairs should be performed by an authorized repair

facility. Call 1-888-278-8092 to obtain a list of repair facilities in your area or

to make arrangements to return the tool for service.

FUNCTIONAL DESCRIPTION

CONTROLS AND COMPONENTS:

1. Exhaust Cover

2. Trigger

3. Nail Depth Adjuster

4. Latch

5. No-mar Nosepiece

6. Pusher

7. Hanging Hook

8. Air Inlet

9. Nail Release

7

10. Work Piece Contact

11. Trigger Actuation Mode Selector

ACCESSORIES:

12. Lubricant

13. Safety Glasses

14. Hex Wrenches (2)

15. Fasteners

8

Loading...

Loading...