Y

128 Pin Enhanced Super I/O Controller

with an LPC Interface and USB Hub

3.3 Volt Operation (5 Volt Tolerant)

LPC Interface

ACPI 1.0 Compliant

Fan Control

- Fan Speed Control Outputs

- Fan Tachometer Inputs

Programmable Wake-up Event Interface

PC98, PC99 Compliant

Dual Game Port Interface

MPU-401 MIDI Support

General Purpose Input/Output Pins

ISA Plug-and-Play Compatible Register Set

Intelligent Auto Power Management

System Management Interrupt

2.88MB Super I/O Floppy Disk Controller

- Licensed CMOS 765B Floppy Disk

Controller

- Software and Register Compatible with

SMSC's Proprietary 82077AA Compatible

Core

- Supports Two Floppy Drives

- Configurable Open Drain/Push-Pull Output

Drivers

- Supports Vertical Recording Format

- 16-Byte Data FIFO

- 100% IBM Compatibility

- Detects All Overrun and Underrun

Conditions

- Sophisticated Power Control Circuitry (PCC)

Including Multiple Powerdown Modes for

Reduced Power Consumption

- DMA Enable Logic

- Data Rate and Drive Control Registers

- 480 Address, Up to Eight IRQ and Four DMA

Options

Enhanced Digital Data Separator

- 2 Mbps, 1 Mbps, 500 Kbps, 300 Kbps, 250

Kbps Data Rates

- Programmable Precompensation Modes

FEATURES

Keyboard Controller

Serial Ports

Infrared Port

Multi-Mode Parallel Port with ChiProtect

LPC47M14x

PRELIMINAR

- 8042 Software Compatible

- 8 Bit Microcomputer

- 2k Bytes of Program ROM

- 256 Bytes of Data RAM

- Four Open Drain Outputs Dedicated for

Keyboard/Mouse Interface

- Asynchronous Access to Two Data

Registers and One Status Register

- Supports Interrupt and Polling Access

- 8 Bit Counter Timer

- Port 92 Support

- Fast Gate A20 and KRESET Outputs

- Two Full Function Serial Ports

- High Speed NS16C550A Compatible UARTs

with Send/Receive 16-Byte FIFOs

- Supports 230k and 460k Baud

Programmable Baud Rate Generator

Modem Control Circuitry

- 480 Address and 15 IRQ Options

- Multiprotocol Infrared Interface

- IrDA 1.0 Compliant

- SHARP ASK IR

- 480 Addresses, Up to 15 IRQ

- Standard Mode IBM PC/XT,

PS/2 Compatible Bi-directional Parallel Port

- Enhanced Parallel Port (EPP) Compatible EPP 1.7 and EPP 1.9 (IEEE 1284

Compliant)

- IEEE 1284 Compliant Enhanced Capabilities

Port (ECP)

- ChiProtect Circuitry for Protection

- 960 Address, Up to 15 IRQ and Four DMA

Options

PC/AT, and

SMSC DS – LPC47M14X Rev. 03/19/2001

USB Hub

g

- 1 Upstream and up to 4 Downstream Ports

- Compliant with USB Spec. version 1.1

- Programmable USB Manufacturer ID,

Product ID and Device Rev. Number

- Number of active ports programmable or

selectable via jumpers

- Powered by Vtr for Downstream Port

Wakeup

LPC Interface

- Multiplexed Command, Address and Data

Bus

- Serial IRQ Interface Compatible with

Serialized IRQ Support for PCI Systems

- PME Interface

Interrupt Generating Registers

- Registers Generate IRQ1 – 15 on Serial IRQ

Interface

ORDERING INFORMATION

Order Number: LPC47M14x – NC

128 Pin QFP Packa

e

Hauppauge, NY 11788

(631) 435-6000

FAX (631) 273-3123

80 Arkay Drive

Copyright © SMSC 2004. All rights reserved.

Circuit diagrams and other information relating to SMSC products are included as a means of illustrating typical applications. Consequently, complete

information sufficient for construction purposes is not necessarily given. Although the information has been checked and is believed to be accurate, no

responsibility is assumed for inaccuracies. SMSC reserves the right to make changes to specifications and product descriptions at any time without

notice. Contact your local SMSC sales office to obtain the latest specifications before placing your product order. The provision of this information does

not convey to the purchaser of the described semiconductor devices any licenses under any patent rights or other intellectual property rights of SMSC

or others. All sales are expressly conditional on your agreement to the terms and conditions of the most recently dated version of SMSC's standard

Terms of Sale Agreement dated before the date of your order (the "Terms of Sale Agreement"). The product may contain design defects or errors

known as anomalies which may cause the product's functions to deviate from published specifications. Anomaly sheets are available upon request.

SMSC products are not designed, intended, authorized or warranted for use in any life support or other application where product failure could cause

or contribute to personal injury or severe property damage. Any and all such uses without prior written approval of an Officer of SMSC and further

testing and/or modification will be fully at the risk of the customer. Copies of this document or other SMSC literature, as well as the Terms of Sale

Agreement, may be obtained by visiting SMSC’s website at http://www.smsc.com. SMSC is a registered trademark of Standard Microsystems

Corporation (“SMSC”). Product names and company names are the trademarks of their respective holders.

SMSC DISCLAIMS AND EXCLUDES ANY AND ALL WARRANTIES, INCLUDING WITHOUT LIMITATION ANY AND ALL IMPLIED WARRANTIES

OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, TITLE, AND AGAINST INFRINGEMENT AND THE LIKE, AND ANY AND

ALL WARRANTIES ARISING FROM ANY COURSE OF DEALING OR USAGE OF TRADE.

IN NO EVENT SHALL SMSC BE LIABLE FOR ANY DIRECT, INCIDENTAL, INDIRECT, SPECIAL, PUNITIVE, OR CONSEQUENTIAL DAMAGES;

OR FOR LOST DATA, PROFITS, SAVINGS OR REVENUES OF ANY KIND; REGARDLESS OF THE FORM OF ACTION, WHETHER BASED ON

CONTRACT; TORT; NEGLIGENCE OF SMSC OR OTHERS; STRICT LIABILITY; BREACH OF WARRANTY; OR OTHERWISE; WHETHER OR

NOT ANY REMEDY OF BUYER IS HELD TO HAVE FAILED OF ITS ESSENTIAL PURPOSE, AND WHETHER OR NOT SMSC HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

SMSC DS – LPC47M14X Page 2 Rev. 03/19/2001

GENERAL DESCRIPTION

The LPC47M14x* is a 3.3V (5V tolerant) PC99 compliant Super I/O controller with an LPC interface and a standalone

USB hub. It is designed to be compatible with a family of Super I/O Controllers (LPC47M13x, LPC47M14x, and

LPC47M15x). To the interested reader, the LPC47M15x offers hardware monitoring capabilities. The first one

hundred pins of all these packages are completely pin compatible and offer the designer added flexibility in their

board designs. In addition, any board designed to support the LPC47M14x will automatically offer the dual capability

of supporting the LPC47M13x, as well.

The LPC47M14x implements the LPC interface, a pin reduced ISA bus interface which provides the same or better

performance as the ISA/X-bus with a substantial savings in pins used. This interface makes use of the PCI clock,

which runs at 33MHz instead of the traditional 8MHz for the ISA bus, that eases some complications found in

synchronous designs. In addition, all legacy drivers used for Super I/O components are still supported making this

new interface transparent to the supporting software. The LPC bus also supports power management, such as

wake-up and sleep modes, in the same way as the PCI bus.

The LPC47M14X incorporates a standalone USB Hub, implementing one upstream port and up to four (4)

downstream ports, with an internal data path connection for programming the USB Vendor ID, Product ID and Device

Revision Number. The number of active downstream ports is also programmable or selectable with external jumpers.

This programming is done by BIOS accessing the hub control registers.

The LPC47M14x has incorporated the following Super I/O components: a parallel port that is compatible with IBM

PC/AT architecture, as well as the IEEE 1284 EPP and ECP; two serial ports that are 16C550A UART compatible; a

keyboard/mouse controller that uses an 8042 microcontroller; two floppy controllers, which use SMSC's true CMOS

765B core; two infrared ports that are IrDA 1.0 compliant; a MIDI interface, which is a MPU-401-compatible; and 37

General Purpose I/O control functions, which offer flexibility to the system designer. The true CMOS 765B core

provides 100% compatibility with IBM PC/XT and PC/AT architectures and is software and register compatible with

the 82077AA. This chip also controls two LED’s, a dual game port interface, and the speed of two fans with fan

tachometer inputs through the use of a pulse width modulation scheme.

The LPC47M14x is ACPI 1.0 compatible and therefore supports multiple low power-down modes. It incorporates

sophisticated power control circuitry (PCC) which includes support for keyboard and mouse wake-up events.

The LPC47M14X supports the ISA Plug-and-Play Standard (Version 1.0a). The I/O Address, DMA Channel and

hardware IRQ of each logical device in the LPC47M14X may be reprogrammed through the internal configuration

registers. There are 480 (960 for Parallel Port) I/O address location options, a Serialized IRQ interface, and four

DMA channels. On chip, Interrupt Generating Registers enable external software to generate IRQ1 through IRQ15 on

the Serial IRQ Interface.

The LPC47M14X does not require any external filter components and is therefore easy to use and offers lower

system costs and reduced board area.

* The “x” in the part number is a designator that changes depending upon the particular BIOS used inside the specific

chip.

SMSC DS – LPC47M14X Page 3 Rev. 03/19/2001

TABLE OF CONTENTS

1 PIN LAYOUT ..........................................................................................................................................................8

2 PIN CONFIGURATION...........................................................................................................................................9

3 DESCRIPTION OF PIN FUNCTIONS...................................................................................................................10

3.1 B

3.2 P

4 BLOCK DIAGRAM ............................................................................................................................................... 16

5 POWER FUNCTIONALITY...................................................................................................................................17

5.1 VCC POWER..................................................................................................................................................17

5.2 USB POWER.................................................................................................................................................. 17

5.3 VTR S

5.4 VREF P

5.5 I

5.6 32.768

5.7 T

5.8 M

5.9 P

6 FUNCTIONAL DESCRIPTION .............................................................................................................................20

6.1 S

6.2 H

6.3 LPC I

6.4 USB H

6.5 FLOPPY DISK CONTROLLER .................................................................................................................... 26

6.6 SERIAL PORT (UART) ................................................................................................................................60

6.7 INFRARED INTERFACE..............................................................................................................................72

6.8 MPU-401 MIDI UART................................................................................................................................... 73

6.9 PARALLEL PORT ........................................................................................................................................78

6.10 POWER MANAGEMENT............................................................................................................................. 94

6.11 SERIAL IRQ ................................................................................................................................................. 98

6.12 INTERRUPT GENERATING REGISTERS..............................................................................................................101

6.13 8042 KEYBOARD CONTROLLER DESCRIPTION ...................................................................................102

UFFER TYPE DESCRIPTIONS........................................................................................................................... 14

INS THAT REQUIRE EXTERNAL PULLUP RESISTORS ..........................................................................................15

5.1.1 3 Volt Operation / 5 Volt Tolerance......................................................................................................... 17

UPPORT ............................................................................................................................................... 17

IN .....................................................................................................................................................17

NTERNAL PWRGOOD ...................................................................................................................................18

KHZ TRICKLE CLOCK INPUT ..................................................................................................................18

RICKLE POWER FUNCTIONALITY...................................................................................................................... 18

AXIMUM CURRENT VALUES............................................................................................................................19

OWER MANAGEMENT EVENTS (PME/SCI) ......................................................................................................19

UPER I/O REGISTERS....................................................................................................................................20

OST PROCESSOR INTERFACE (LPC) ............................................................................................................... 20

NTERFACE .............................................................................................................................................21

6.3.1 LPC Interface Signal Definition...............................................................................................................21

6.3.2 LPC Cycles.............................................................................................................................................21

6.3.3 Field Definitions ......................................................................................................................................21

6.3.4 LFRAME# Usage.................................................................................................................................... 21

6.3.5 I/O Read and Write Cycles .....................................................................................................................22

6.3.6 DMA Read and Write Cycles ..................................................................................................................22

6.3.7 DMA Protocol .........................................................................................................................................22

6.3.8 Power Management................................................................................................................................22

6.3.9 SYNC Protocol .......................................................................................................................................22

6.3.10 LPC Transfer ..........................................................................................................................................23

UB FUNCTIONAL DESCRIPTION ...............................................................................................................24

6.4.1 USB Downstream Port Selection............................................................................................................25

6.5.1 FDC Internal Registers ...........................................................................................................................27

6.5.2 STATUS REGISTER ENCODING..........................................................................................................37

6.5.3 Instruction Set......................................................................................................................................... 43

6.5.4 DATA TRANSFER COMMANDS............................................................................................................50

6.8.1 Overview.................................................................................................................................................73

6.8.2 Host Interface .........................................................................................................................................73

6.8.3 MIDI Data Port........................................................................................................................................74

6.8.4 Status Port..............................................................................................................................................74

6.8.5 MPU-401 Command Controller ..............................................................................................................76

6.8.6 MIDI UART .............................................................................................................................................77

6.8.7 MPU-401 Configuration Registers ..........................................................................................................77

6.9.1 IBM XT/AT Compatible, Bi-Directional and EPP Modes ......................................................................... 79

6.9.2 Extended Capabilities Parallel Port.........................................................................................................84

6.13.1 Keyboard Interface ...............................................................................................................................103

6.13.2 External Keyboard and Mouse Interface...............................................................................................104

6.13.3 Keyboard Power Management ............................................................................................................. 104

6.13.4 Interrupts ..............................................................................................................................................104

6.13.5 Memory Configurations.........................................................................................................................104

6.13.6 Register Definitions...............................................................................................................................105

SMSC DS – LPC47M14X Page 4 Rev. 03/19/2001

6.13.7 External Clock Signal............................................................................................................................105

6.13.8 Default Reset Conditions ...................................................................................................................... 105

6.13.9 Latches On Keyboard and Mouse IRQs ...............................................................................................108

6.13.10 Keyboard and Mouse PME Generation ................................................................................................ 109

6.14 GENERAL PURPOSE I/O..........................................................................................................................110

6.14.1 GPIO Pins.............................................................................................................................................110

6.14.2 Description............................................................................................................................................111

6.14.3 GPIO Control ........................................................................................................................................ 112

6.14.4 GPIO Operation....................................................................................................................................112

6.14.5 GPIO PME and SMI Functionality......................................................................................................... 113

6.14.6 Either Edge Triggered Interrupts...........................................................................................................114

6.14.7 LED Functionality..................................................................................................................................115

6.15 SYSTEM MANAGEMENT INTERRUPT (SMI)...........................................................................................115

6.15.1 SMI Registers .......................................................................................................................................115

6.16 PME SUPPORT.........................................................................................................................................116

6.16.1 ‘Wake on Specific Key’ Option..............................................................................................................117

6.17 FAN SPEED CONTROL AND MONITORING............................................................................................118

6.17.1 Fan Speed Control................................................................................................................................118

6.17.2 Fan Tachometer Inputs.........................................................................................................................119

6.18 SECURITY FEATURE ...............................................................................................................................122

6.18.1 GPIO Device Disable Register Control ................................................................................................. 122

6.18.2 Device Disable Register .......................................................................................................................122

6.19 GAME PORT LOGIC..................................................................................................................................122

6.19.1 Power Control Register.........................................................................................................................124

6.19.2 VREF Pin..............................................................................................................................................124

7 RUNTIME REGISTERS......................................................................................................................................125

8 CONFIGURATION..............................................................................................................................................152

9 OPERATIONAL DESCRIPTION ........................................................................................................................172

9.1 M

9.2 DC E

AXIMUM GUARANTEED RATINGS...................................................................................................................172

LECTRICAL CHARACTERISTICS................................................................................................................ 172

10 TIMING DIAGRAMS........................................................................................................................................... 177

11 PACKAGE OUTLINE .........................................................................................................................................200

12 APPENDIX - TEST MODE..................................................................................................................................201

12.1 B

OARD TEST MODE.......................................................................................................................................201

12.1.1 XNOR-Chain Test Mode.......................................................................................................................201

13 REFERENCE DOCUMENTS..............................................................................................................................204

14 LPC47M14X REVISIONS...................................................................................................................................205

TABLES

Table 1 – Super I/O Block Addresses ........................................................................................................................20

Table 2 – Hub Descriptor to be Modified....................................................................................................................25

Table 3 – Status, Data and Control Registers............................................................................................................27

Table 4 – Tape Select Bits .........................................................................................................................................30

Table 5 – Internal 2 Drive Decode - Normal ...............................................................................................................30

Table 6 – Internal 2 Drive Decode - Drives 0 and 1 Swapped ...................................................................................31

Table 7 – Drive Type ID .............................................................................................................................................31

Table 8 – Precompensation Delays ...........................................................................................................................32

Table 9 – Data Rates .................................................................................................................................................33

Table 10 – DRVDEN Mapping ...................................................................................................................................33

Table 11 – Default Precompensation Delays .............................................................................................................33

Table 12 – FIFO Service Delay..................................................................................................................................35

Table 13 – Status Register 0......................................................................................................................................37

Table 14 – Status Register 1......................................................................................................................................38

Table 15 – Status Register 2......................................................................................................................................38

Table 16 – Status Register 3......................................................................................................................................39

Table 17 – Description of Command Symbols ...........................................................................................................41

Table 18 – Instruction Set ..........................................................................................................................................43

Table 19 – Sector Sizes .............................................................................................................................................50

Table 20 – Effects of MT and N Bits...........................................................................................................................51

Table 21 – Skip Bit vs Read Data Command.............................................................................................................51

SMSC DS – LPC47M14X Page 5 Rev. 03/19/2001

Table 22 – Skip Bit vs. Read Deleted Data Command...............................................................................................51

Table 23 – Result Phase Table ..................................................................................................................................52

Table 24 – Verify Command Result Phase Table ......................................................................................................53

Table 25 – Typical Values for Formatting...................................................................................................................55

Table 26 – Interrupt Identification...............................................................................................................................56

Table 27 – Drive Control Delays (ms) ........................................................................................................................57

Table 28 – Effects of WGATE and GAP Bits..............................................................................................................59

Table 29 – Addressing the Serial Port........................................................................................................................60

Table 30 – Interrupt Control Table .............................................................................................................................63

Table 31 – Baud Rates ..............................................................................................................................................68

Table 32 – Reset Function Table ...............................................................................................................................69

Table 33 – Register Summary for an Individual UART Channel ................................................................................69

Table 34 – MPU-401 HOST INTERFACE REGISTERS ............................................................................................74

Table 35 – MIDI DATA PORT ....................................................................................................................................74

Table 36 – MPU-401 STATUS PORT ........................................................................................................................74

Table 37 – MIDI RECEIVE BUFFER EMPTY STATUS BIT.......................................................................................75

Table 38 – MIDI TRANSMIT BUSY STATUS BIT ......................................................................................................75

Table 39 – MPU-401 COMMAND PORT ...................................................................................................................75

Table 40 – Parallel Port Connector ............................................................................................................................79

Table 41 – EPP Pin Descriptions ...............................................................................................................................83

Table 42 – ECP Pin Descriptions ...............................................................................................................................85

Table 43 – ECP Register Definitions..........................................................................................................................86

Table 44 – Mode Descriptions....................................................................................................................................86

Table 45a – Extended Control Register .....................................................................................................................90

Table 46 – Channel/Data Commands supported in ECP mode .................................................................................92

Table 47 – PC/AT and PS/2 Available Registers .......................................................................................................95

Table 48 – State of System Pins in Auto Powerdown ................................................................................................96

Table 49 – State of Floppy Disk Drive Interface Pins in Powerdown..........................................................................96

Table 50 – I/O Address Map ....................................................................................................................................103

Table 51 – Host Interface Flags ...............................................................................................................................103

Table 52 – Status Register.......................................................................................................................................105

Table 53 – Resets ....................................................................................................................................................105

Table 54 – General Purpose I/O Port Assignments .................................................................................................111

Table 55 – GPIO Configuration Summary................................................................................................................112

Table 56 – GPIO Read/Write Behavior ....................................................................................................................113

Table 57 – Different Modes for Fan..........................................................................................................................118

Table 58 – Runtime Register Block Summary..........................................................................................................125

Table 59 – PME, SMI, GPIO, FAN Register Description..........................................................................................127

Table 60 – Game Port..............................................................................................................................................151

Table 61 – LPC47M14x Configuration Registers Summary.....................................................................................154

Table 62 – Chip Level Registers ..............................................................................................................................156

Table 63 – Logical Device Registers........................................................................................................................159

Table 64 – Logical Device Registers........................................................................................................................160

Table 65 – I/O Base Address Configuration Register Description............................................................................161

Table 66 – Interrupt Select Configuration Register Description ...............................................................................162

Table 67 – DMA Channel Select Configuration Register Description.......................................................................163

Table 68 – Floppy Disk Controller, Logical Device 0 [Logical Device Number = 0x00] ............................................164

Table 69 – Parallel Port, Logical Device 3 [Logical Device Number = 0x03]............................................................165

Table 70 – Serial Port 1, Logical Device 4 [Logical Device Number = 0x04]............................................................166

Table 71 – Serial Port 2, Logical Device 5 [Logical Device Number = 0x05]............................................................166

Table 72 – KYBD, Logical Device 7 [Logical Device Number = 0x07] .....................................................................168

Table 73 – PME, Logical Device A [Logical Device Number = 0x0A].......................................................................168

Table 74 – MPU-401 [Logical Device Number = 0x0B] ............................................................................................169

Table 75 – USB Hub, Logical Device C [Logical Device Number = 0x0C] ...............................................................169

Table 76 – HubControl_1 Register Definition ...........................................................................................................171

Table 77 – Electrical Source Characteristics............................................................................................................178

SMSC DS – LPC47M14X Page 6 Rev. 03/19/2001

FIGURES

FIGURE 1 – LPC47M14X BLOCK DIAGRAM...........................................................................................................16

FIGURE 2 – LPC47M14X CLOCK GENERATOR .....................................................................................................24

FIGURE 3 – MPU-401 MIDI INTERFACE..................................................................................................................73

FIGURE 4 – MPU-401 INTERRUPT ..........................................................................................................................76

FIGURE 5 - MIDI DATA BYTE EXAMPLE ...................................................................................................................77

FIGURE 6 – KEYBOARD LATCH............................................................................................................................108

FIGURE 7 – MOUSE LATCH...................................................................................................................................108

FIGURE 8 – GPIO FUNCTION ILLUSTRATION......................................................................................................112

FIGURE 9 – POWER-UP TIMING ...........................................................................................................................178

FIGURE 10 – DATA SIGNAL RISE AND FALL TIME..............................................................................................180

FIGURE 11 – FULL SPEED LOAD ..........................................................................................................................180

FIGURE 12 – LOW-SPEED PORT LOADS .............................................................................................................180

FIGURE 13 – CABLE DELAY ..................................................................................................................................180

FIGURE 14 – DIFFERENTIAL DATA JITTER..........................................................................................................181

FIGURE 15 – DIFFERENTIAL TO EOP TRANSITION SKEW AND EOP WIDTH...................................................181

FIGURE 16 – RECEIVER JITTER TOLERANCE ....................................................................................................181

FIGURE 17 – INPUT CLOCK TIMING .....................................................................................................................182

FIGURE 18 – PCI CLOCK TIMING..........................................................................................................................182

FIGURE 19 – RESET TIMING .................................................................................................................................182

FIGURE 20 – OUTPUT TIMING MEASUREMENT CONDITIONS, LPC SIGNALS.................................................183

FIGURE 21 – INPUT TIMING MEASUREMENT CONDITIONS, LPC SIGNALS.....................................................183

FIGURE 22 – I/O WRITE .........................................................................................................................................184

FIGURE 23 – I/O READ...........................................................................................................................................184

FIGURE 24 – DMA REQUEST ASSERTION THROUGH LDRQ#...........................................................................185

FIGURE 25 – DMA WRITE (FIRST BYTE) ..............................................................................................................185

FIGURE 26 – DMA READ (FIRST BYTE)................................................................................................................185

FIGURE 27 – FLOPPY DISK DRIVE TIMING (AT MODE ONLY) ...........................................................................186

FIGURE 28 – EPP 1.9 DATA OR ADDRESS WRITE CYCLE.................................................................................187

FIGURE 29 – EPP 1.9 DATA OR ADDRESS READ CYCLE ..................................................................................188

FIGURE 30 – EPP 1.7 DATA OR ADDRESS WRITE CYCLE.................................................................................189

FIGURE 31 – EPP 1.7 DATA OR ADDRESS READ CYCLE ..................................................................................189

FIGURE 32 – PARALLEL PORT FIFO TIMING.......................................................................................................191

FIGURE 33 – ECP PARALLEL PORT FORWARD TIMING ....................................................................................191

FIGURE 34 – ECP PARALLEL PORT REVERSE TIMING......................................................................................192

FIGURE 35 – IRDA RECEIVE TIMING....................................................................................................................193

FIGURE 36 – IRDA TRANSMIT TIMING .................................................................................................................194

FIGURE 37 – AMPLITUDE SHIFT KEYED IR RECEIVE TIMING...........................................................................195

FIGURE 38 – AMPLITUDE SHIFT KEYED IR TRANSMIT TIMING ........................................................................196

FIGURE 39 – SETUP AND HOLD TIME..................................................................................................................197

FIGURE 40 – SERIAL PORT DATA ........................................................................................................................197

FIGURE 41 – JOYSTICK POSITION SIGNAL.........................................................................................................197

FIGURE 42 – JOYSTICK BUTTON SIGNAL ...........................................................................................................197

FIGURE 43 – KEYBOARD/MOUSE RECEIVE/SEND DATA TIMING .....................................................................198

FIGURE 44 – MIDI DATA BYTE ..............................................................................................................................198

FIGURE 45 – FAN OUTPUT TIMING ......................................................................................................................199

FIGURE 46 – FAN TACHOMETER INTPUT TIMING ..............................................................................................199

FIGURE 47 – LED OUTPUT TIMING ......................................................................................................................199

FIGURE 48 – 128 PIN QFP PACKAGE OUTLINE...................................................................................................200

FIGURE 49 – XNOR-CHAIN TEST STRUCTURE...................................................................................................201

SMSC DS – LPC47M14X Page 7 Rev. 03/19/2001

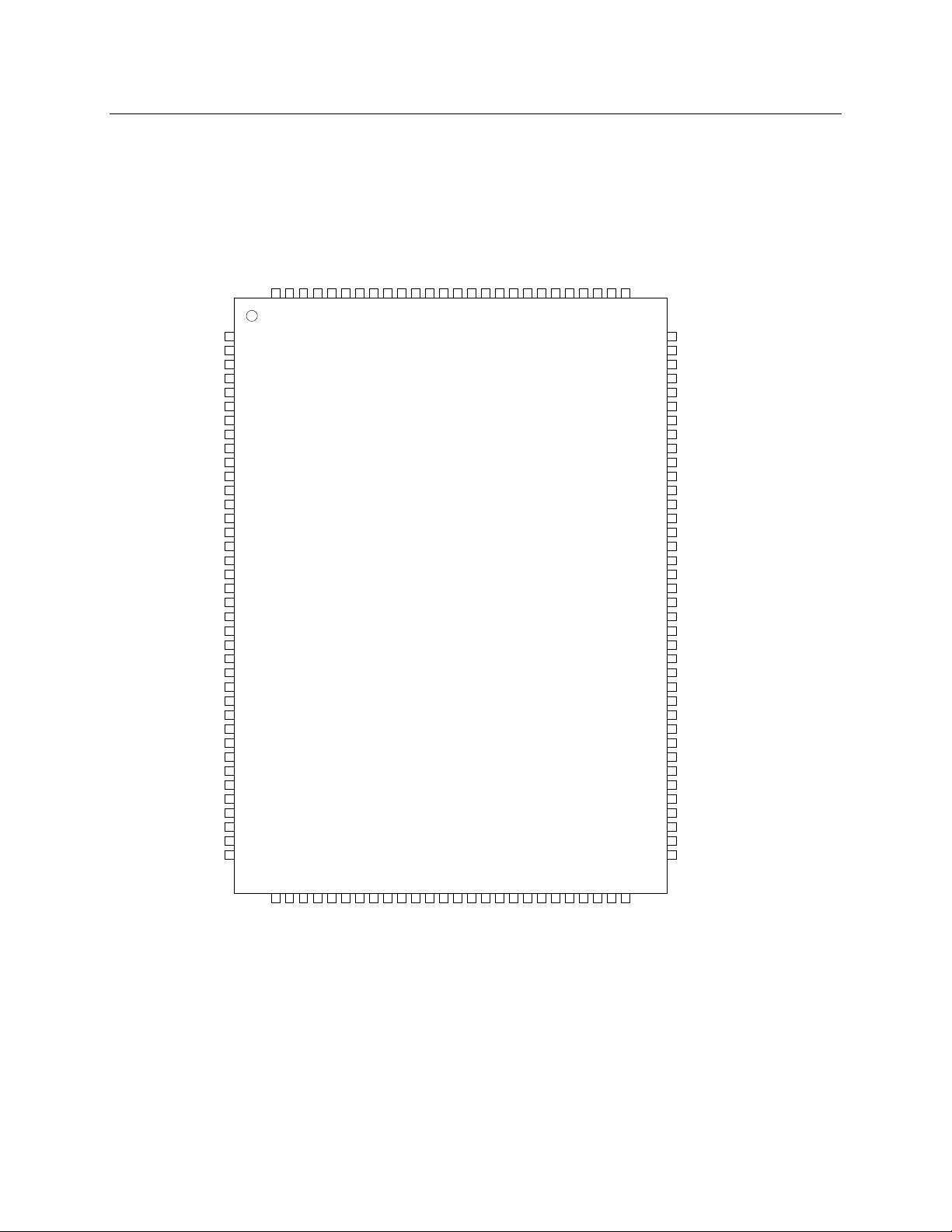

1 PIN LAYOUT

GP40/DRVDEN0

GP41/DRVDEN1

nMTR0

nDSKCHG

nDS0

CLKI32

VSS

nDIR

nSTEP

nWDATA

nWGATE

nHDSEL

nINDEX

nTRK0

nWRTPRT

nRDATA

GP42/nIO_PME

VTR

CLOCKI

LAD0

LAD1

LAD2

LAD3

LFRAME#

LDRQ#

PCI_RESET#

LPCPD#

GP43/DDRC

PCI_CLK

SER_IRQ

VSS

GP10 /J1B1

GP11 /J1B2

GP12 /J2B1

GP13 /J2B2

GP14 /J1X

GP15 /J1Y

GP16 /J2X

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

VSS

nStrp1

nStrp0

VCC

OCLK

ICLK

VTR

nPWROK4

nPWROK3

nPWROK2

nPWROK1

nPWREN4

nPWREN3

nPWREN2

nPWREN1

VTR

PD4 -

PD4 +

PD3 -

PD3 +

PD2 -

PD2 +

PD1 -

PD1 +

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

LPC47M14x

128 PIN QFP

39404142434445464748495051525354555657585960616263

USB -

104

103

64

USB +

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

VSS

VSS

GP57/nDTR2

GP56/nCTS2

GP55/nRTS2

GP54/nDSR2

GP53/TXD2 (IRTX)

GP52/RXD2 (IRRX)

GP51/nDCD2

VCC

GP50/nRI2

nDCD1

nRI1

nDTR1

nCTS1

nRTS1

nDSR1

TXD1

RXD1

nSTROBE

nALF

nERROR

nACK

BUSY

PE

SLCT

VSS

PD7

PD6

PD5

PD4

PD3

PD2

PD1

PD0

nSLCTIN

nINIT

VCC

VCC

GP32/FAN2

GP33/FAN1

GP27/nIO_SMI

GP30/FAN_TACH2

GP31/FAN_TACH1

KDAT

GP20/P17

GP21/P16/nDS1

GP22/P12/nMTR1

VREF

GP24/SYSOPT

GP60/LED1

GP61/LED2

GP25/MIDI_IN

GP26/MIDI_OUT

AVSS

GP17 /J2Y

SMSC DS – LPC47M14X Page 8 Rev. 03/19/2001

KCLK

MDAT

VSS

MCLK

GP37/A20M

IRTX2/GP35

IRRX2/GP34

GP36/nKBDRST

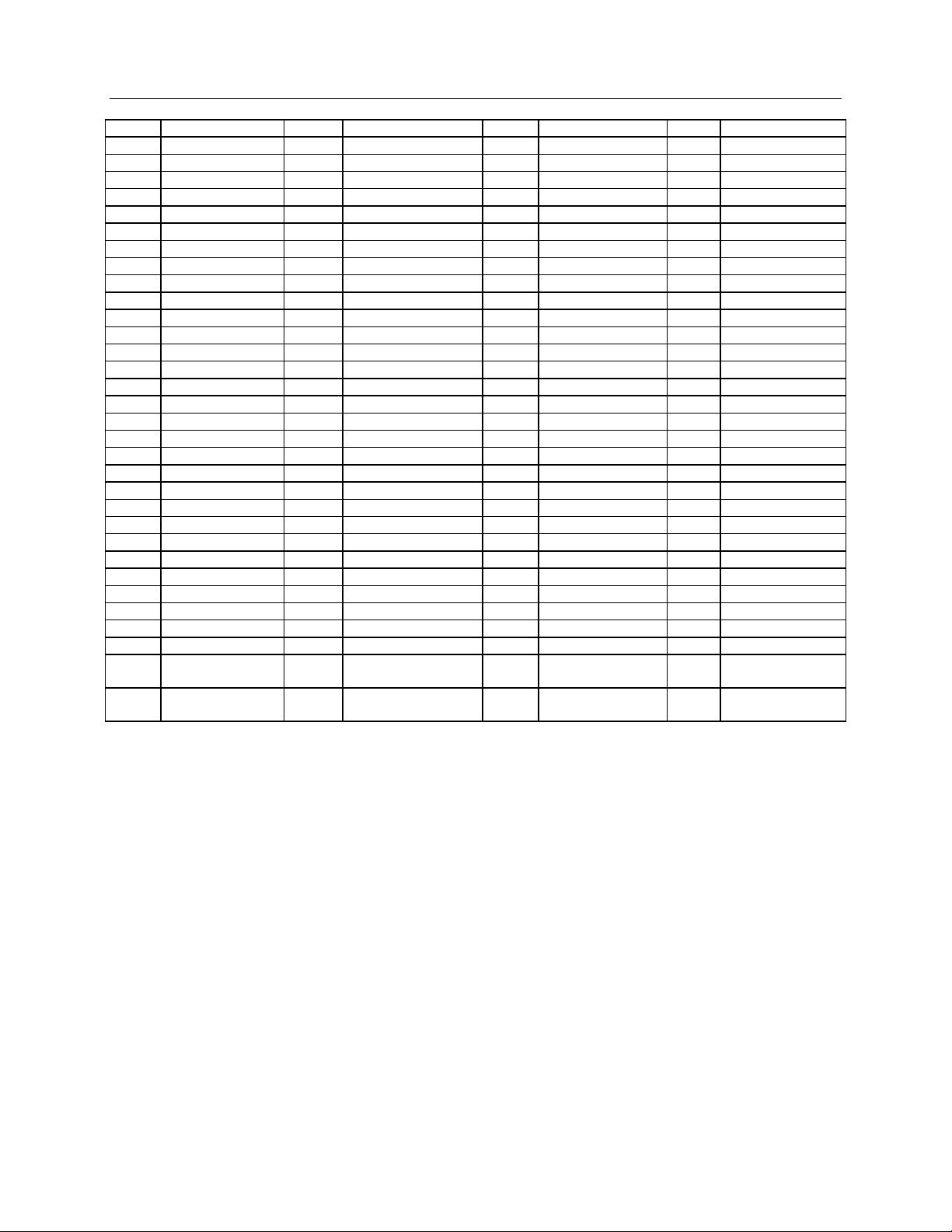

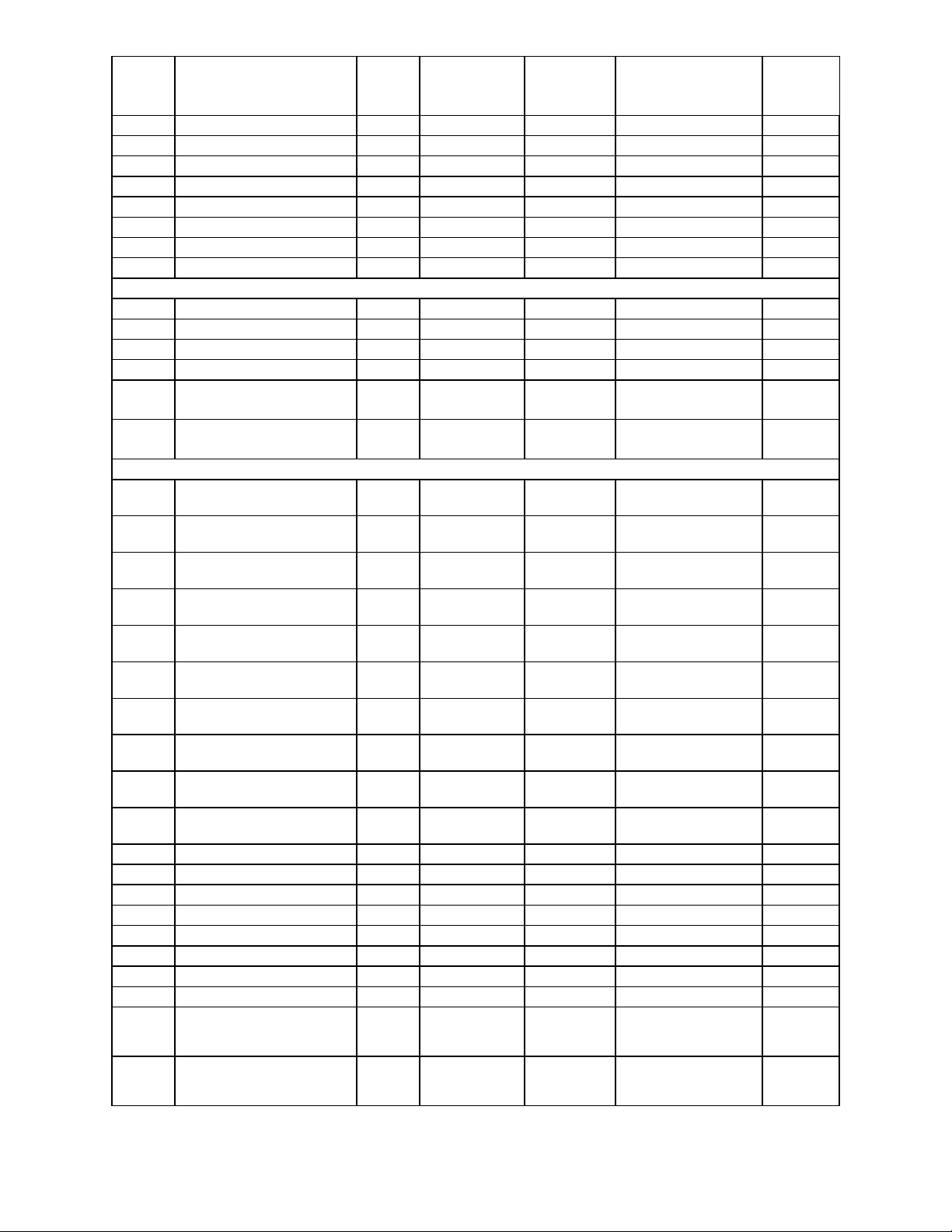

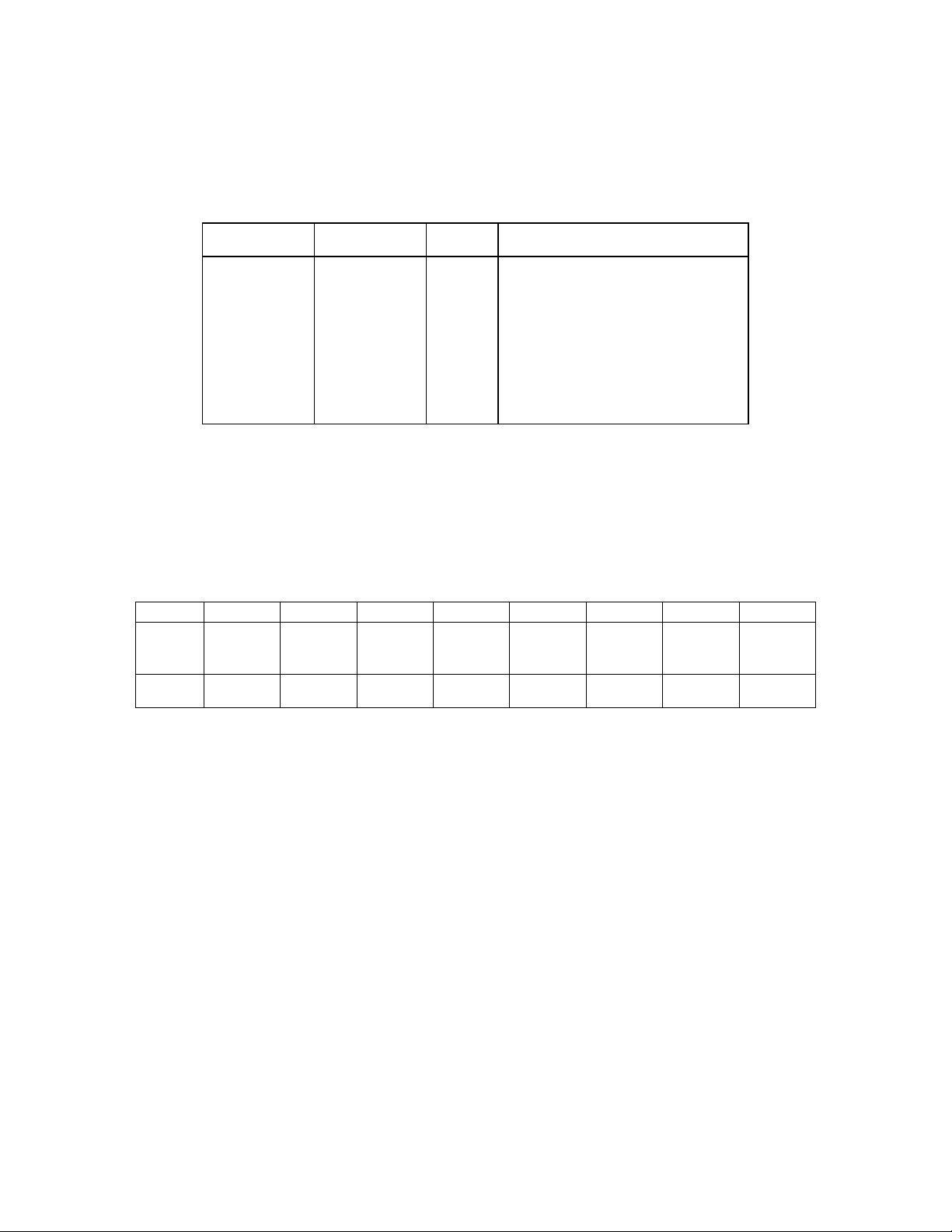

2 PIN CONFIGURATION

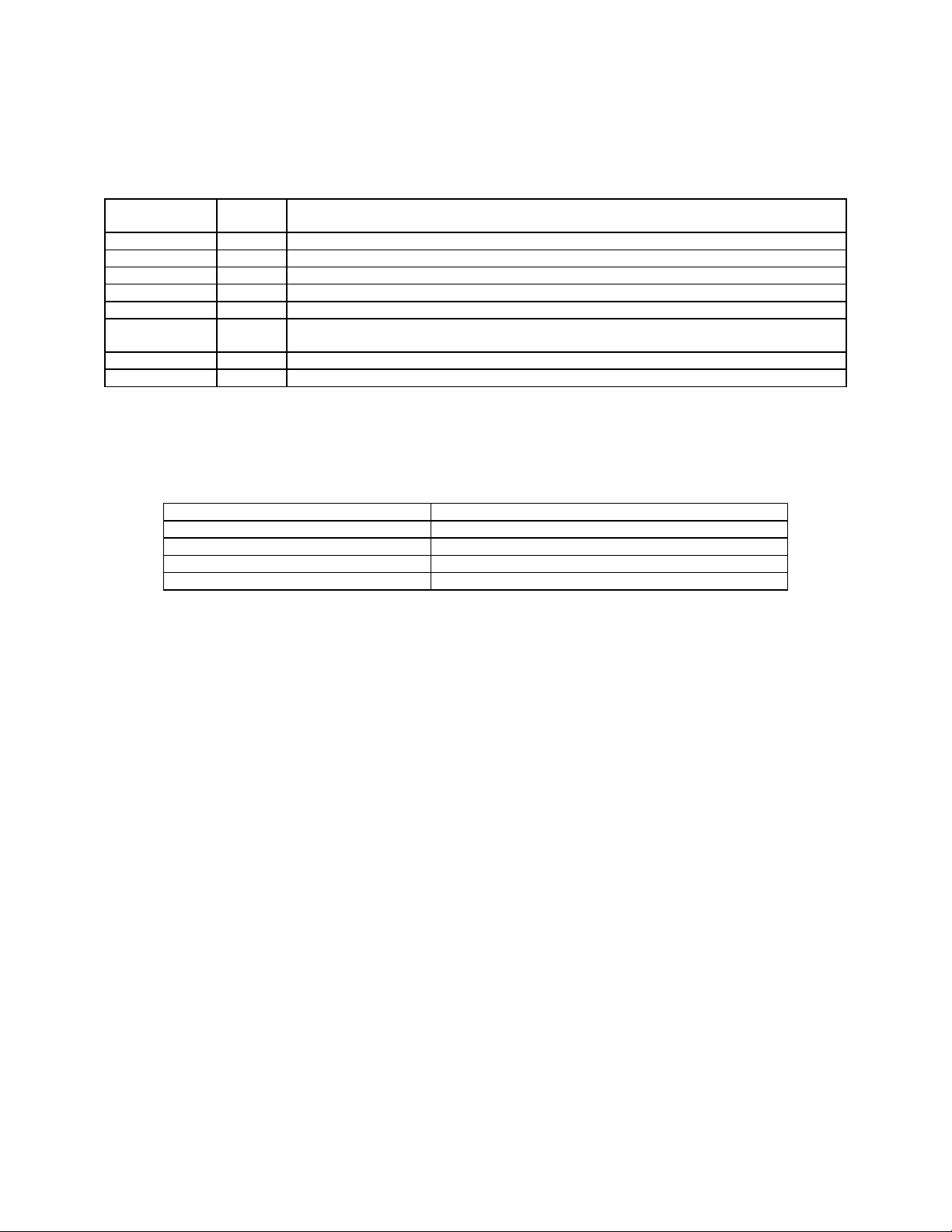

PIN # NAME PIN # NAME PIN # NAME PIN # NAME

1 GP40/DRVDEN0 33 GP11 /J1B2 65 VCC 97 GP54/nDSR2

2 GP41/DRVDEN1 34 GP12 /J2B1 66 nINIT 98 GP55/nRTS2

3 nMTR0 35 GP13 /J2B2 67 nSLCTIN 99 GP56/nCTS2

4 nDSKCHG 36 GP14 /J1X 68 PD0 100 GP57/nDTR2

5 nDS0 37 GP15 /J1Y 69 PD1 101 VSS

6 CLKI32 38 GP16 /J2X 70 PD2 102 VSS

7 VSS 39 GP17 /J2Y 71 PD3 103 USB +

8 nDIR 40 AVSS 72 PD4 104 USB 9 nSTEP 41 GP20/P17 73 PD5 105 PD1 +

10 nWDATA 42 GP21/P16/nDS1 74 PD6 106 PD1 11 nWGATE 43 GP22/P12/nMTR1 75 PD7 107 PD2 +

12 nHDSEL 44 VREF 76 VSS 108 PD2 13 nINDEX 45 GP24/SYSOPT 77 SLCT 109 PD3 +

14 nTRK0 46 GP25/MIDI_IN 78 PE 110 PD3 15 nWRTPRT 47 GP26/MIDI_OUT 79 BUSY 111 PD4 +

16 nRDATA 48 GP60/LED1 80 nACK 112 PD4 -

17 GP42/nIO_PME 49 GP61/LED2 81 nERROR 113 VTR

18 VTR 50 GP27/nIO_SMI 82 nALF 114 nPWREN1

19 CLOCKI 51 GP30/FAN_TACH2 83 nSTROBE 115 nPWREN2

20 LAD0 52 GP31/FAN_TACH1 84 RXD1 116 nPWREN3

21 LAD1 53 VCC 85 TXD1 117 nPWREN4

22 LAD2 54 GP32/FAN2 86 nDSR1 118 nUSBOC1

23 LAD3 55 GP33/FAN1 87 nRTS1 119 nUSBOC2

24 LFRAME# 56 KDAT 88 nCTS1 120 nUSBOC3

25 LDRQ# 57 KCLK 89 nDTR1 121 nUSBOC4

26 PCI_RESET# 58 MDAT 90 nRI1 122 VTR

27 LPCPD# 59 MCLK 91 nDCD1 123 ICLK

28 GP43/DDRC 60 VSS 92 GP50/nRI2 124 OCLK

29 PCI_CLK 61 IRRX2/GP34 93 VCC 125 VCC

30 SER_IRQ 62 IRTX2/GP35 94 GP51/nDCD2 126 nStrp0

31 VSS 63 GP36/nKBDRST 95 GP52/RXD2

(IRRX)

32 GP10 /J1B1 64 GP37/A20M 96 GP53/TXD2

(IRTX)

Note: The chip is part of a family of LPC chips (LPC47M13x, LPC47M14x, and LPC47M15x). The first 100 pins of

these chips are pin compatible, which adds more flexibility for the board designer. In addition, a board designed for

the LPC47M14x can also support the LPC47M13x with little or no changes made to the board design.

127 nStrp1

128 VSS

SMSC DS – LPC47M14X Page 9 Rev. 03/19/2001

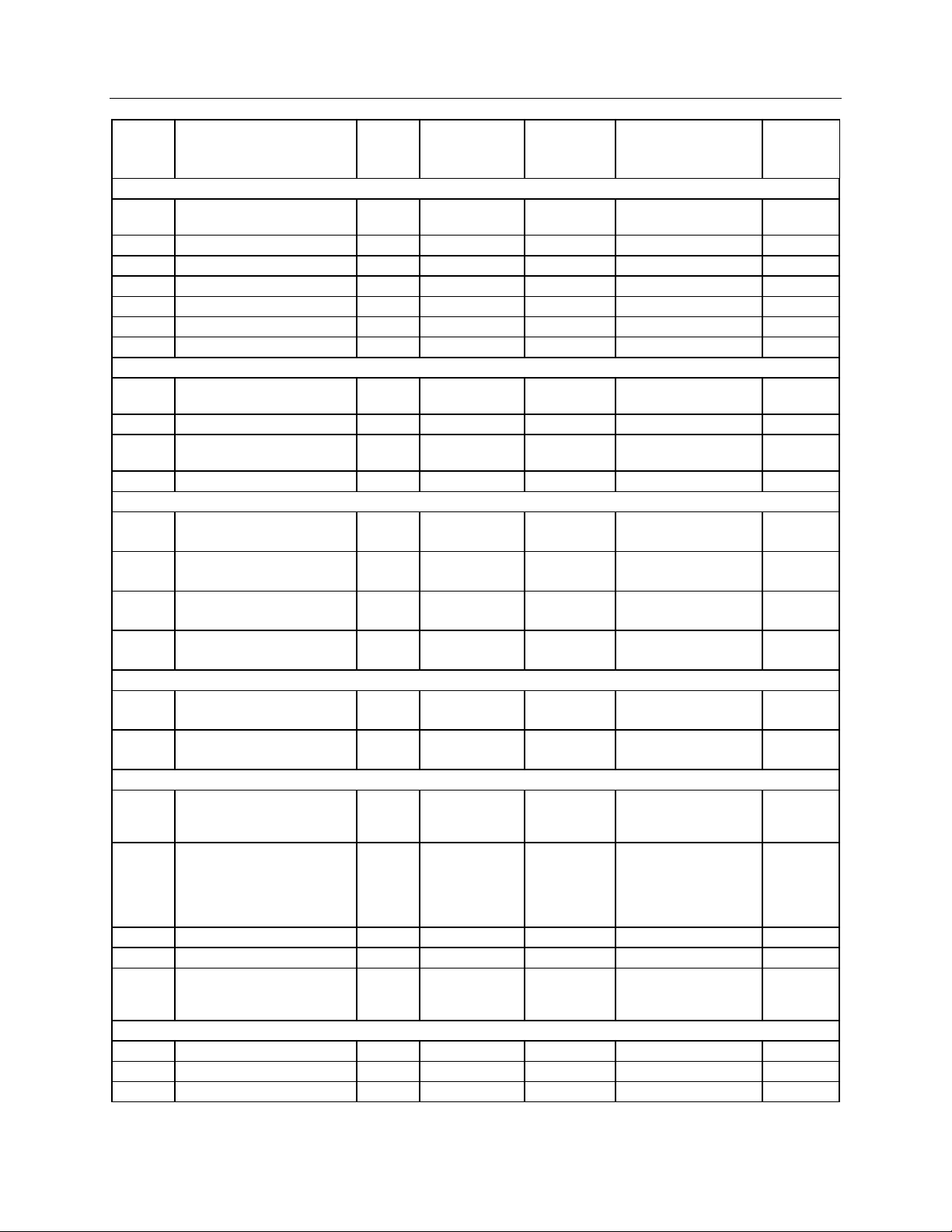

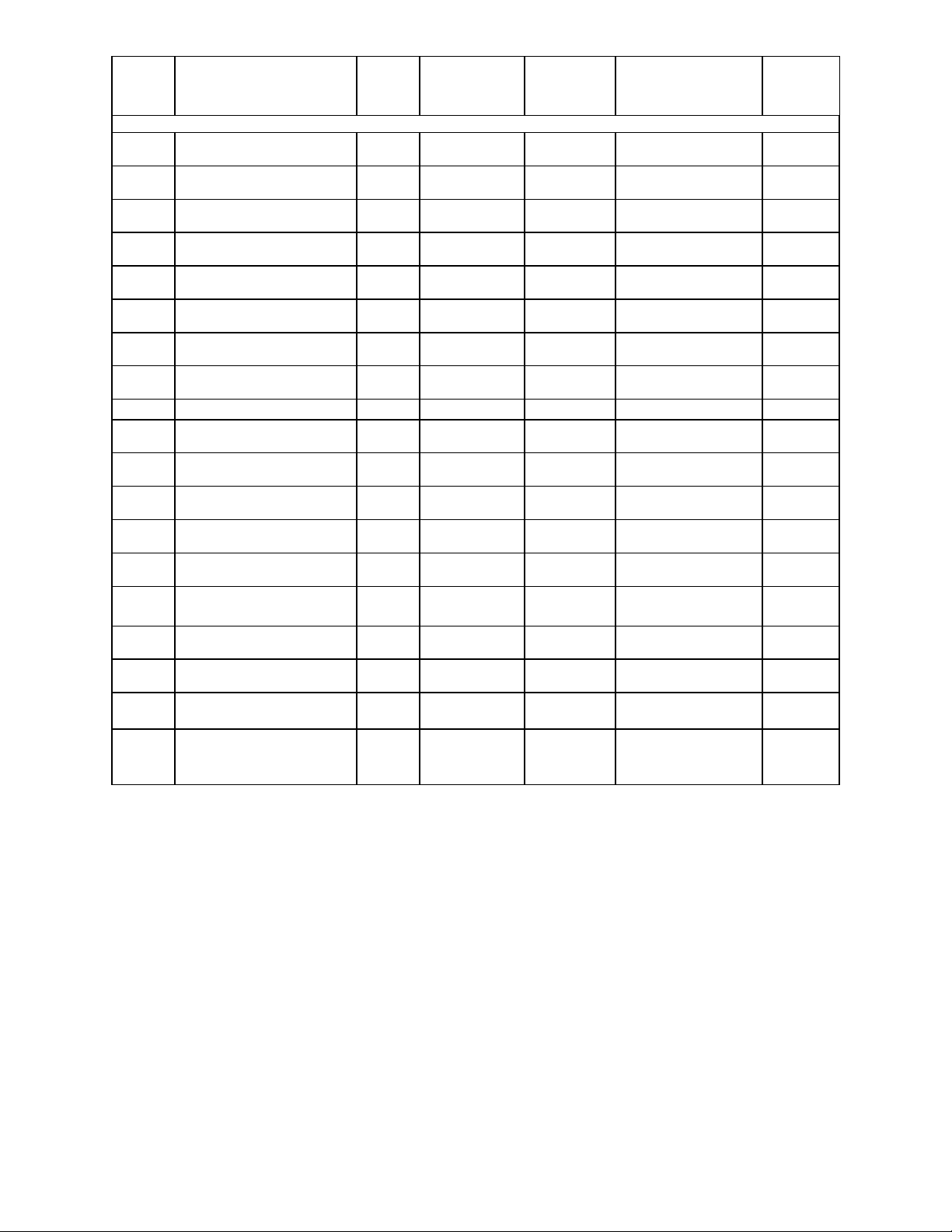

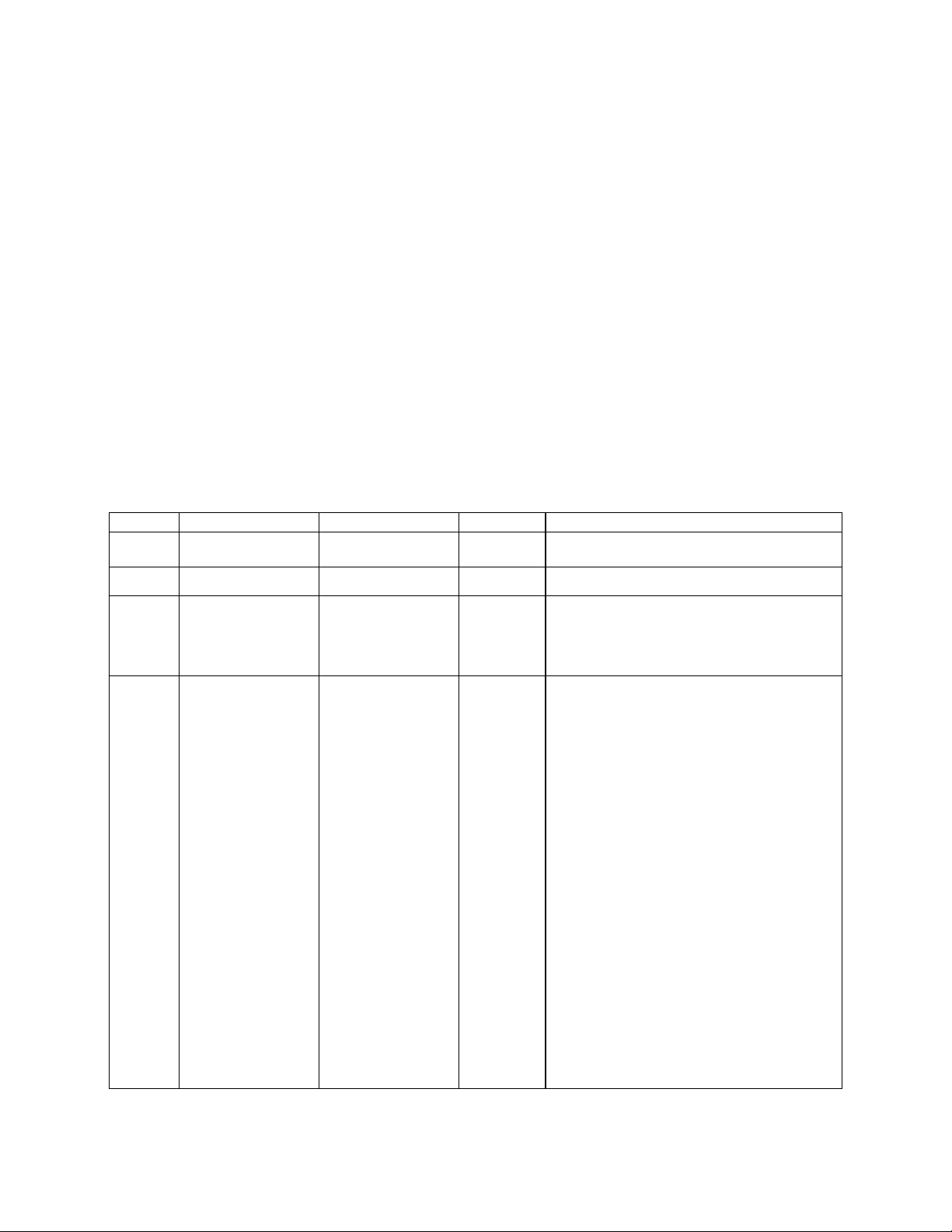

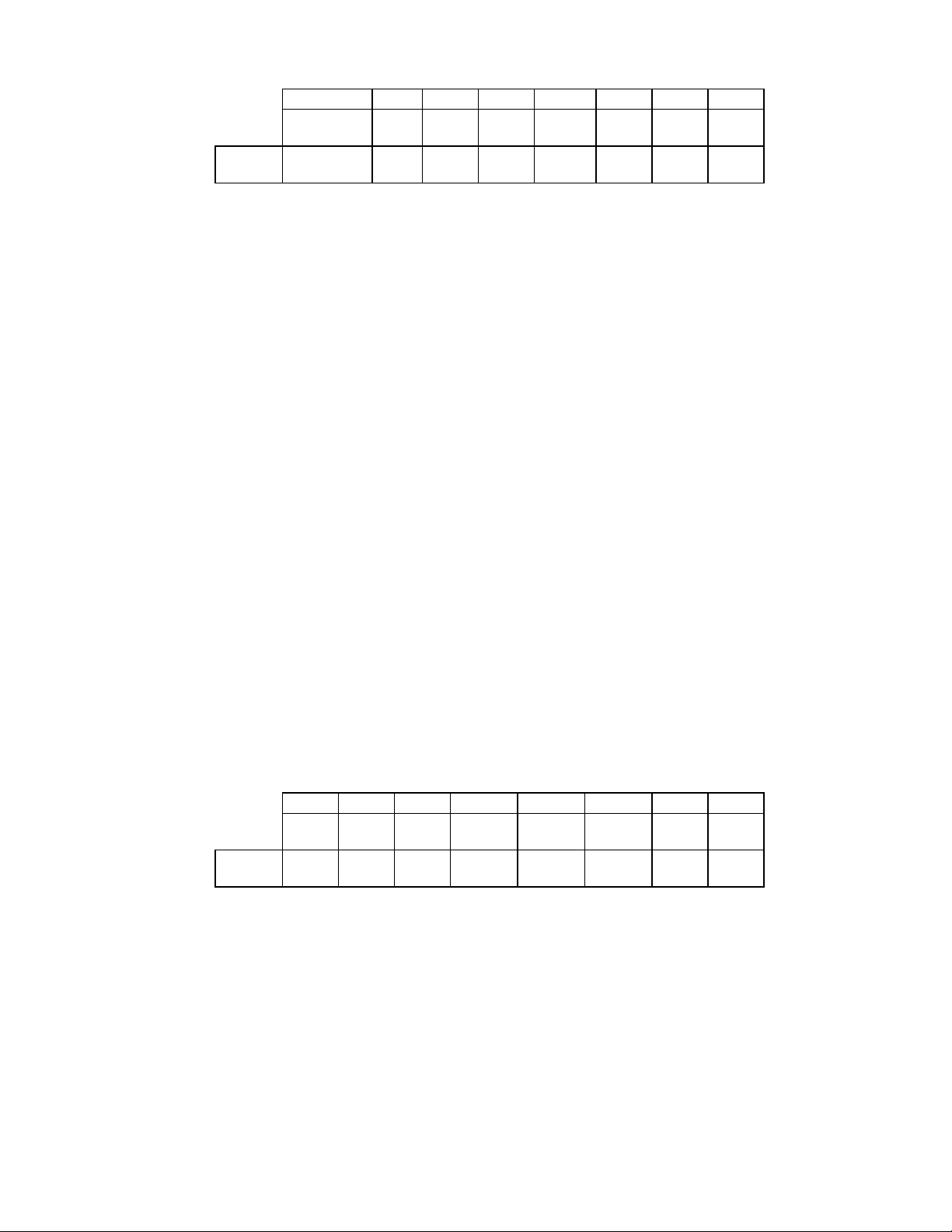

3 DESCRIPTION OF PIN FUNCTIONS

QFP

PIN #

23:20

24 Frame 1 LFRAME# PCI_I

25 Encoded DMA Request 1 LDRQ# PCI_O

26 PCI Reset 1 PCI_RESET# PCI_I

27 Power Down 1 LPCPD# PCI_I

29 PCI Clock 1 PCI_CLK PCI_ICLK

30 Serial IRQ 1 SER_IRQ PCI_IO

19 14.318MHz Clock Input 1 CLOCKI IS IS

123

124 24MHz Crystal (terminal 2) 1 OCLK IS IS 14

51 General Purpose I/O

52 General Purpose I/O

54 General Purpose I/O

55 General Purpose I/O

61 Infrared Rx

62 Infrared Tx

53,

65,93,1

25

7, 31,

60,76,

101,

102,

128

40 Analog Ground 1 AVSS

44 Reference Voltage 1 VREF

18,

113,

122

16 Read Disk Data 1 nRDATA IS

11 Write Gate 1 nWGATE O12 (O12/OD12)

10 Write Disk Data 1 nWDATA O12 (O12/OD12)

Multiplexed Command,

Address, Data [3:0]

6

32.768KHz Trickle Clock

Input

24MHz Crystal (terminal 1)

/ 48MHz Clock Input

/Fan Tachometer 2

/Fan Tachometer 1

/Fan Speed Control 2

/Fan Speed Control 1

/General Purpose I/O

/General Purpose I/O

Power 4 VCC

Ground 7 VSS

Trickle Voltage 3 VTR 7

NAME

PROCESSOR/HOST LPC INTERFACE (10)

TOTAL SYMBOL

4 LAD[3:0] PCI_IO PCI_IO

CLOCKS (4)

1 CLOCKI32 IS

1 ICLK IS IS

FAN CONTROL (4)

1

GP30/

FAN_TACH2

1

GP31/

FAN_TACH1

1 GP32/FAN2 IO12

1 GP33/FAN1 IO12

INFRARED INTERFACE (2)

1 IRRX2/GP34 IS/O8

1 IRTX2/GP35 IO12

POWER PINS (16)

FDD INTERFACE (14)

BUFFER

TYPE

IO8

IO8

BUFFER TYPE

PER FUNCTION

(NOTE 1)

PCI_I

PCI_O

PCI_I

PCI_I 2

PCI_ICLK

PCI_IO

IS 3

(I/O8/OD8)/I

(I/O8/OD8)/I

(I/O12/OD12)/

(O12/OD12)

(I/O12/OD12)/

(O12/OD12)

IS/(IS/O8/OD8)

O12/(I/O12/OD12) 5, 6

IS

NOTES

11, 14

4

4

SMSC DS – LPC47M14X Page 10 Rev. 03/19/2001

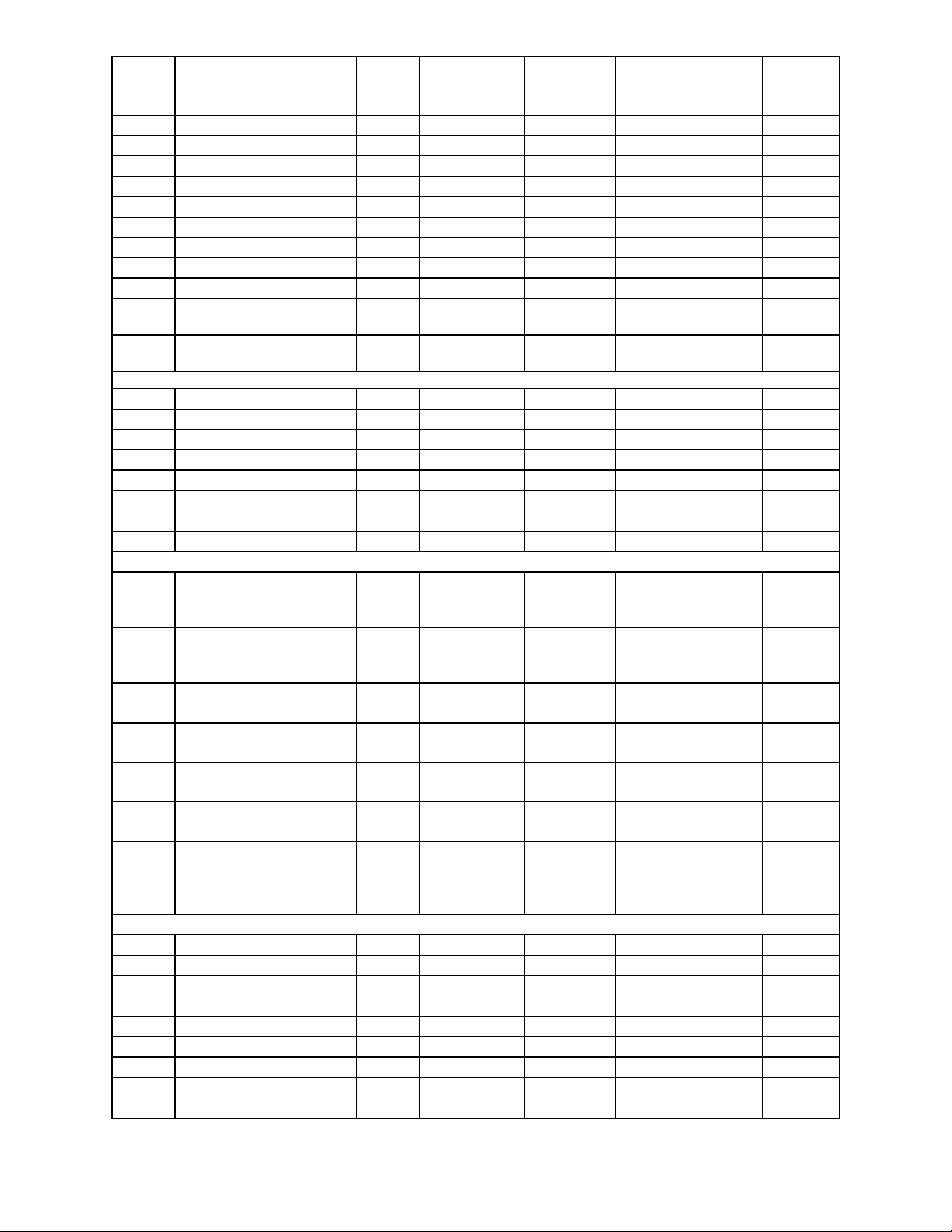

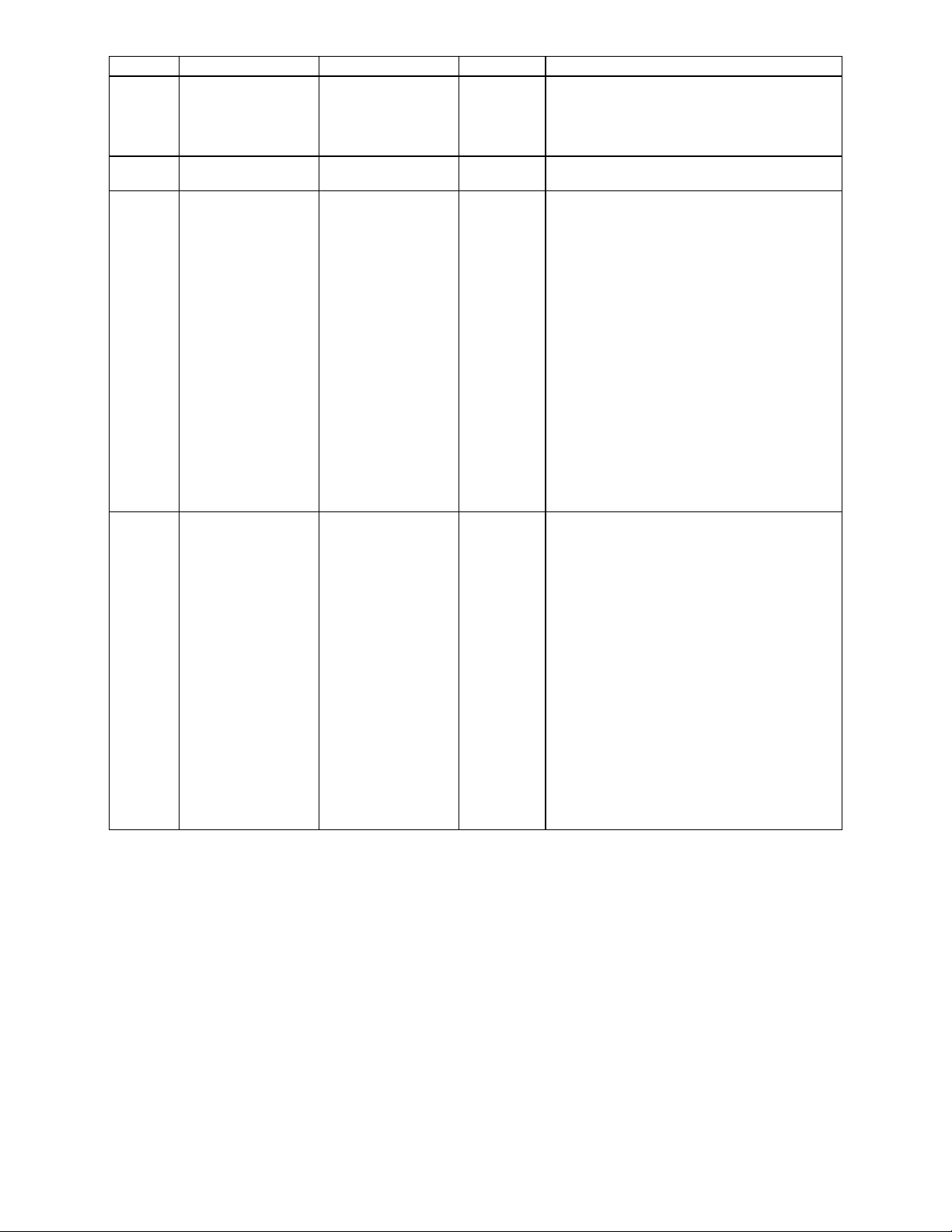

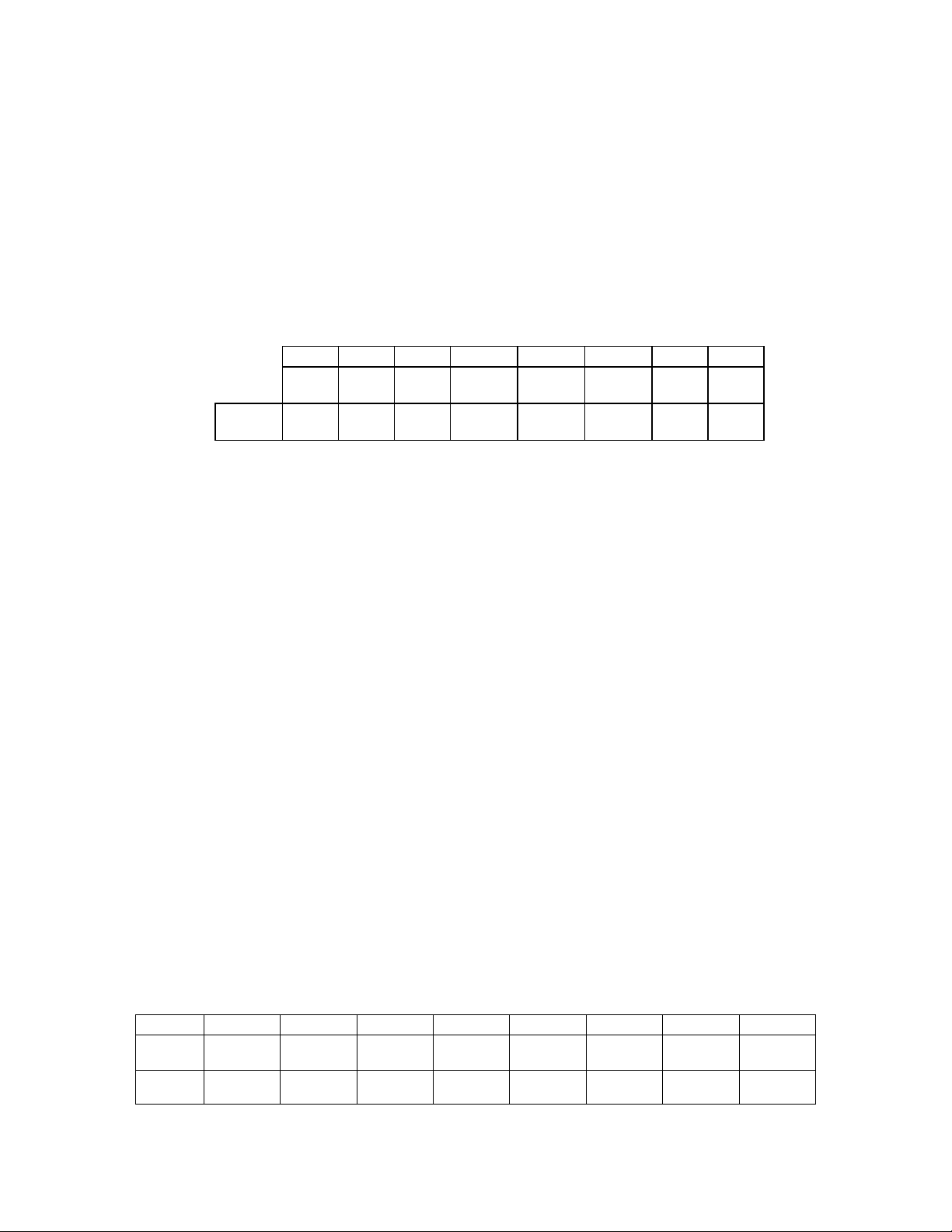

QFP

PIN #

NAME

TOTAL SYMBOL

BUFFER

TYPE

BUFFER TYPE

PER FUNCTION

(NOTE 1)

NOTES

12 Head Select 1 nHDSEL O12 (O12/OD12)

8 Step Direction 1 nDIR O12 (O12/OD12)

9 Step Pulse 1 nSTEP O12 (O12/OD12)

4 Disk Change 1 nDSKCHG IS

IS

5 Drive Select 0 1 nDS0 O12 (O12/OD12)

3 Motor On 0 1 nMTR0 O12 (O12/OD12)

15 Write Protected 1 nWRTPRT IS

14 Track 0 1 nTRKO IS

13 Index Pulse Input 1 nINDEX IS

1

General Purpose I/O/Drive

Density Select 0

2

General Purpose I/O/Drive

Density Select 1

1

1

GP40/

DRVDEN0

GP41/

DRVDEN1

IO12

IO12

IS

IS

IS

(I/O12/OD12)/

(O12/OD12)

(I/O12/OD12)/

(O12/OD12)

SERIAL PORT 1 INTERFACE (8)

84 Receive Serial Data 1 1 RXD1 IS IS

85 Transmit Serial Data 1 1 TXD1 O12 O12

87 Request to Send 1 1 nRTS1 O8 O8

88 Clear to Send 1 1 nCTS1 I I

89 Data Terminal Ready 1 1 nDTR1 O6 O6

86 Data Set Ready 1 1 nDSR1 I I

91 Data Carrier Detect 1 1 nDCD1 I I

90 Ring Indicator 1 1 nRI1 I I

SERIAL PORT 2 INTERFACE (8)

95 General Purpose I/O

/Receive Serial Data 2

1

GP52/RXD2

(IRRX)

IS/O8

(IS/O8/OD8)/IS

/Infrared Rx

96 General Purpose I/O

/Transmit Serial Data 2

1

GP53/TXD2

(IRTX)

IO12

(I/O12/OD12)/O12 5

/Infrared Tx

98 General Purpose I/O

1 GP55/nRTS2 IO8

(I/O8/OD8)/O8

/Request to Send 2

99 General Purpose I/O

1 GP56/nCTS2 IO8

(I/O8/OD8)/I

/Clear to Send 2

100 General Purpose I/O

1 GP57/nDTR2 IO8

(I/O8/OD8)/O8

/Data Terminal Ready

97 General Purpose I/O

1 GP54/nDSR2 IO8

(I/O8/OD8)/I

/Data Set Ready 2

94

General Purpose I/O/Data

1 GP51/nDCD2 IO8 (I/O8/OD8)/I

Carrier Detect 2

92

General Purpose I/O/Ring

1 GP50/nRI2 IO8 (I/O8/OD8)/I

Indicator 2

PARALLEL PORT INTERFACE (17)

66 Initiate Output

67 Printer Select Input

68 Port Data 0

69 Port Data 1

70 Port Data 2

71 Port Data 3

72 Port Data 4

73 Port Data 5

74

Port Data 6

nINIT OP14 (OD14/OP14)

1

nSLCTIN OP14 (OD14/OP14)

1

PD0 IOP14 IOP14

1

PD1 IOP14 IOP14

1

PD2 IOP14 IOP14

1

PD3 IOP14 IOP14

1

PD4 IOP14 IOP14

1

PD5 IOP14 IOP14

1

PD6 IOP14 IOP14

1

SMSC DS – LPC47M14X Page 11 Rev. 03/19/2001

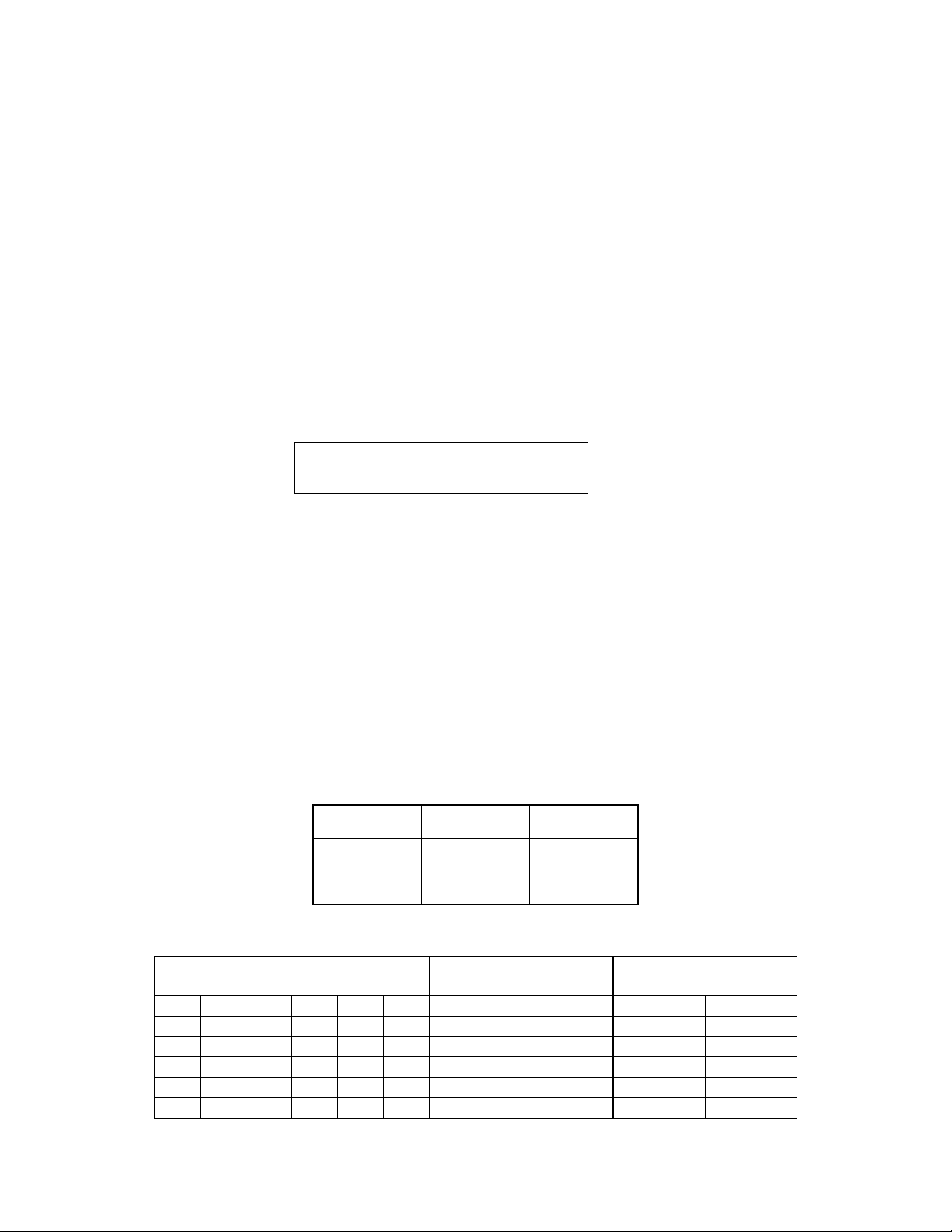

QFP

PIN #

NAME

75 Port Data 7

77 Printer Selected Status

78 Paper End

79 Busy

80 Acknowledge

81 Error

82 Autofeed Output

83 Strobe Output

TOTAL SYMBOL

PD7 IOP14 IOP14

1

SLCT I I

1

PE I I

1

BUSY I I

1

nACK I I

1

nERROR I I

1

nALF OP14 (OD14/OP14)

1

nSTROBE OP14 (OD14/OP14)

1

BUFFER

TYPE

KEYBOARD/MOUSE INTERFACE (6)

56 Keyboard Data 1 KDAT IOD16

57 Keyboard Clock 1 KCLK IOD16

58 Mouse Data 1 MDAT IOD16

59 Mouse Clock 1 MCLK IOD16

63 General Purpose I/O

/Keyboard Reset

64 General Purpose I/O

1

GP36/

IO8

nKBDRST

1 GP37/A20M IO8

/Gate A20

USB HUB(18)

103

Serial Port Upstream Data

USB+ IOUSB IOUSB

1

+

104

Serial Port Upstream Data

USB- IOUSB IOUSB

1

-

105

Serial Port Downstream

PD1+ IOUSB IOUSB

1

Data +

106

Serial Port Downstream

PD 1- IOUSB IOUSB

1

Data -

107

Serial Port Downstream

PD 2+ IOUSB IOUSB

1

Data +

108

Serial Port Downstream

PD 2- IOUSB IOUSB

1

Data -

109

Serial Port Downstream

PD 3+ IOUSB IOUSB

1

Data +

110

Serial Port Downstream

PD 3- IOUSB IOUSB

1

Data -

111

Serial Port Downstream

PD 4+ IOUSB IOUSB

1

Data +

112

Serial Port Downstream

PD 4- IOUSB IOUSB

1

Data -

1

nUSBOC1

nPWREN1

nUSBOC2

nPWREN2

nUSBOC3

nPWREN3

nUSBOC4

nPWREN4

nStrp0

IPU

O24

IPU

O24

IPU

O24

IPU

O24

IPU

118 USB Over-Current sense 1

114 USB Power Enable 1

119 USB Over-Current sense 1

115 USB Power Enable 1

120 USB Over-Current sense 1

116 USB Power Enable 1

121 USB Over-Current sense 1

117 USB Power Enable 1

126

Number of Down Stream

Ports select

127

Number of Down Stream

nStrp1

1

IPU

Ports select

BUFFER TYPE

PER FUNCTION

NOTES

(NOTE 1)

IOD16

IOD16

IOD16

IOD16

(I/O8/OD8)/O8 9

(I/O8/OD8)/O8 9

IPU 13

O24 13

IPU 13

O24 13

IPU 13

O24 13

IPU 13

O24 13

IPU Input with

30ua Pull

Up

IPU Input with

30ua Pull

Up

SMSC DS – LPC47M14X Page 12 Rev. 03/19/2001

QFP

PIN #

NAME

TOTAL SYMBOL

BUFFER

TYPE

BUFFER TYPE

PER FUNCTION

(NOTE 1)

NOTES

GENERAL PURPOSE I/O (19)

32

General Purpose I/O

GP10 /J1B1 IS/O8 (IS/O8/OD8)/IS

1

/Joystick 1 Button 1

33

General Purpose I/O

GP11 /J1B2 IS/O8 (IS/O8/OD8)/IS

1

/Joystick 1 Button 2

34

General Purpose I/O

GP12 /J2B1 IS/O8 (IS/O8/OD8)/IS

1

/Joystick 2 Button 1

35

General Purpose I/O

GP13 /J2B2 IS/O8 (IS/O8/OD8)/IS

1

/Joystick 2 Button 2

36

General Purpose I/O

GP14 /J1X IO12 (I/O12/OD12)/ IO12

1

/Joystick 1 X-Axis

37

General Purpose I/O

GP15 /J1Y IO12 (I/O12/OD12)/ IO12

1

/Joystick 1 Y-Axis

38

General Purpose I/O

GP16 /J2X IO12 (I/O12/OD12)/ IO12

1

/Joystick 2 X-Axis

39

General Purpose I/O

GP17 /J2Y IO12 (I/O12/OD12)/ IO12

1

/Joystick 2 Y-Axis

41

42

General Purpose I/O / P17

General Purpose I/O / P16

/nDS1

43

General Purpose I/O / P12

/nMTR1

45

General Purpose I/O /

System Option

46

General Purpose I/O

/MIDI_IN

47

General Purpose I/O

/MIDI_OUT

50 General Purpose I/O

/SMI Output

48

General Purpose I/O /

GP20 /P17 IO8 (I/O8/OD8)/IO8

1

GP21 /P16/

1

nDS1

GP22 /P12/

1

nMTR1

GP24

1

IO12 (I/O12/OD12)/

IO12/(O12/OD12)

IO12 (I/O12/OD12)/

IO12/(O12/OD12)

IO8 (I/O8/OD8) 8

/SYSOPT

GP25

1

IO8 (I/O8/OD8)/I

/MIDI_IN

GP26

1

IO12 (I/O12/OD12)/O12

/MIDI_OUT

1

GP27

IO12 (I/O12/OD12)/ OD12

/nIO_SMI

GP60 /LED1 IO12 (I/O12/OD12)/O12 10

1

LED

49

General Purpose I/O /

GP61 /LED2 IO12 (I/O12/OD12)/O12 10

1

LED

17

General Purpose I/O /

Power Management Event

28 General Purpose I/O

1

GP42

/nIO_PME

GP43/DDRC IO8 (I/O8/OD8)/I

1

IO12 (I/O12/OD12)/ OD12

/Device Disable Reg.

Control

Note: The "n" as the first letter of a signal name or the “#” as the suffix of a signal name indicates an "Active Low"

signal.

Note 1: Buffer types per function on multiplexed pins are separated by a slash “/”. Buffer types in parenthesis

represent multiple buffer types for a single pin function.

Note 2: The LPCPD# pin may be tied high. The LPC interface will function properly if the PCI_RESET# signal

follows the protocol defined for the LRESET# signal in the “Low Pin Count Interface Specification”.

Note 3: For USB Hub functionality, the 32 KHz input clock must always be connected. There is a bit in the

configuration register at 0xF0 in Logical Device A that indicates whether or not the 32KHz clock is

connected. This bit determines the clock source for the fan tachometer, LED and “wake on specific key”

logic. This bit must always be set to ‘0’ (‘0’=32 KHz clock connected; reset default=‘0’).

Note 4: The fan control pins (FAN1 and FAN2) come up as outputs and low following a VCC POR and Hard Reset.

These pins revert to their non-inverting GPIO input function when VCC is removed from the part.

Note 5: The IRTX pins (IRTX2/GP35 and GP53/TXD2 (IRTX)) are driven low when the part is powered by VTR

(VCC=0V with VTR=3.3V). These pins will remain low following a power-up (VCC POR) until serial port 2

is enabled by setting the activate bit, at which time the pin will reflect the state of the transmit output of the

Serial Port 2 block.

Note 6: The VCC power-up default for this pin is Logic “0” if the IRTX function is programmed on the GPIO.

Note 7: VTR must not be connected to VCC. The 32 KHz input clock must not be driven high whenVTR = 0v.

SMSC DS – LPC47M14X Page 13 Rev. 03/19/2001

Note 8: The GP24 /SYSOPT pin requires an external pulldown resistor to put the base IO address for configuration

at 0x02E. An external pullup resistor is required to move the base IO address for configuration to 0x04E.

Note 9: External pullups must be placed on the nKBDRST and A20M pins. These pins are GPIOs that are inputs

after an initial power-up (VTR POR). If the nKBDRST and A20M functions are to be used the system must

ensure that these pins are high. See Section “Pins That Require External Pullup Resistor”.

Note 10: The LED pins are powered by VTR so that the LEDs can be controlled when the part is under VTR power.

Note 11: The 48MHz clock input must not be driven high when VTR = 0V.

Note 12: VTR is used to power the USB cable transceivers. VTR must not be connected to VCC.

Note 13: When the specified USB Down Stream Ports are disabled via the Strp0/Strp1 bit or nStrp1/nStrp0 Pins, the

associated Over-current sense pins (nUSBOC[x]) and Power Enable (nPWREN[4:1]) pins are also

disabled. The USB Down Stream Port nUSBOC[x] input pin can be a NC (No Connect) pin for existing

designs or tied High (1). For EMI and reduced Noise sensitivity, it is recommended that the pin be tied High

(1). The Power Enable (nPWREN[x]) pin will be forced low (0).

Note 14: When a 24MHz crystal oscillator is used, these pins need off-balance capacitive loading. It is suggested to

use a 22pf capacitor on ICLK and a 10pf capacitor on OCLK.

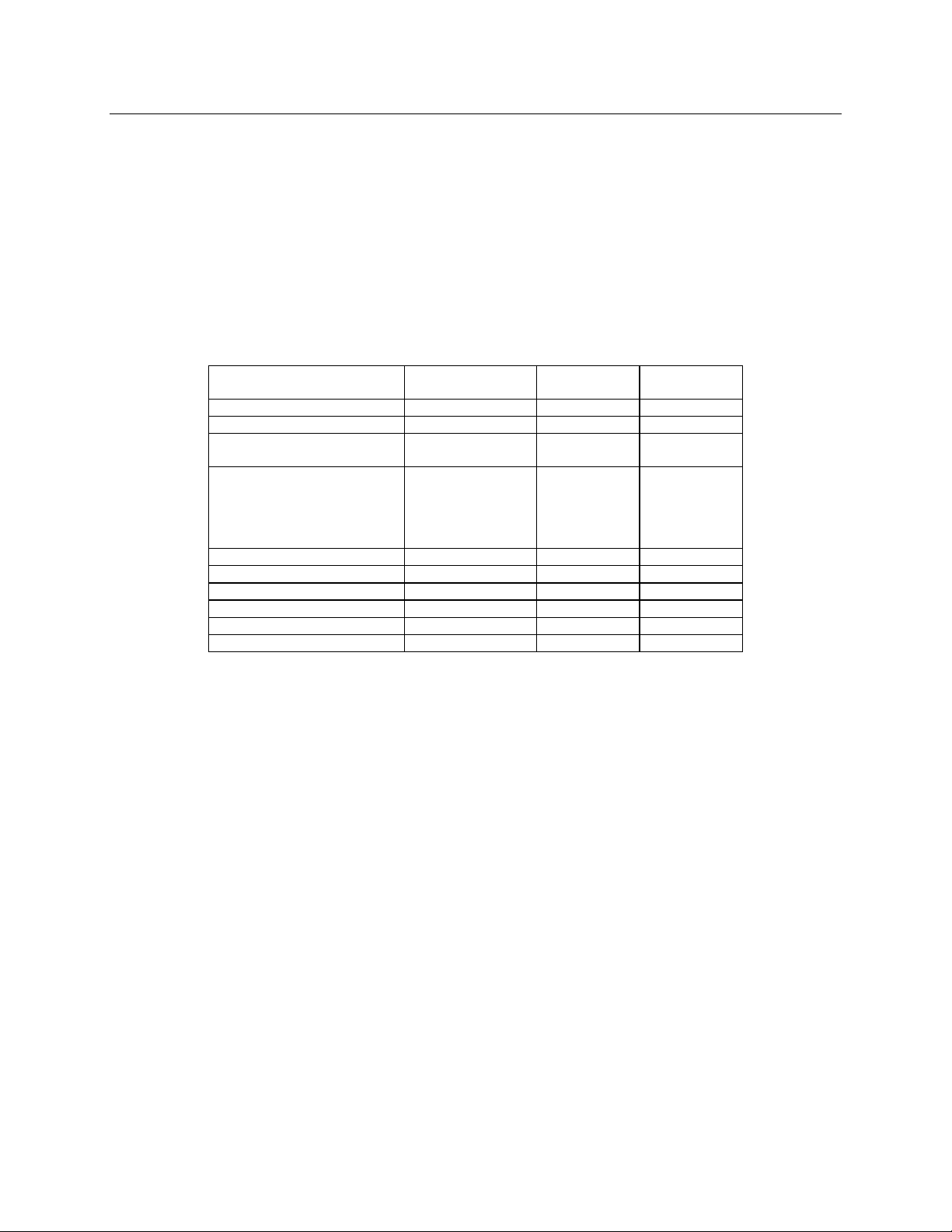

3.1 BUFFER TYPE DESCRIPTIONS

Note: The buffer type values are specified at VCC=3.3V

IO12 Input/Output, 12mA sink, 6mA source.

O12 Output, 12mA sink, 6mA source.

OD12 Open Drain Output, 12mA sink.

O6 Output, 6mA sink, 3mA source.

O8 Output, 8mA sink, 4mA source.

OD8 Open Drain Output, 8mA sink.

OD14 Open Drain Output, 14mA sink.

OP14 Output, 14mA sink, 14mA source.

IOP14 Input/Output, 14mA sink, 14mA source. Back-drive protected.

IOD16 Input/Output (Open Drain), 16mA sink.

IO8 Input/Output, 8mA sink, 4mA source.

O24 Output, 24mA sink, 12mA source.

I Input TTL Compatible.

IPU Input TTL Compatible. With 30ua internal Pull Up

IS Input with Schmitt Trigger.

PCI_IO Input/Output. These pins must meet the PCI 3.3V AC and DC Characteristics. (Note 1)

PCI_O Output. These pins must meet the PCI 3.3V AC and DC Characteristics. (Note 1)

PCI_I Input. These pins must meet the PCI 3.3V AC and DC Characteristics. (Note 1)

PCI_ICLK Clock Input. These pins must meet the PCI 3.3V AC and DC Characteristics and timing. (Note 2)

IOUSB Buffer Type for the USB differential data lines. Defined in the “Operational Description”

section according to the USB specification; V1.1

Note 1: See the “PCI Local Bus Specification,” Revision 2.1, Section 4.2.2.

Note 2: See the “PCI Local Bus Specification,” Revision 2.1, Section 4.2.2 and 4.2.3.

SMSC DS – LPC47M14X Page 14 Rev. 03/19/2001

3.2 PINS THAT REQUIRE EXTERNAL PULLUP RESISTORS

The following pins require external pullup resistors:

KDAT

KCLK

MDAT

MCLK

GP36/KBDRST if KBDRST function is used

GP37/A20M if A20M function is used

GP20/P17 If P17 function is used

GP21/P16 if P16 function is used

GP22/P12 if P12 function is used

GP27/nIO_SMI if nIO_SMI function is used as Open Collector output.

GP42/nIO_PME if nIO_PME function is used as Open Collector output.

SER_IRQ

GP40/DRVDEN0 if DRVDEN0 function is used as Open Collector.

GP41/DRVDEN1 if DRVDEN1 function is used as Open Collector.

nMTR0 if used as Open Collector Output

nDS0 if used as Open Collector Output

nDIR if used as Open Collector Output

nSTEP if used as Open Collector Output

nWDATA if used as Open Collector Output

nWGATE if used as Open Collector Output

nHDSEL if used as Open Collector Output

nINDEX

nTRK0

nWRTPRT

nRDATA

nDSKCHG

SMSC DS – LPC47M14X Page 15 Rev. 03/19/2001

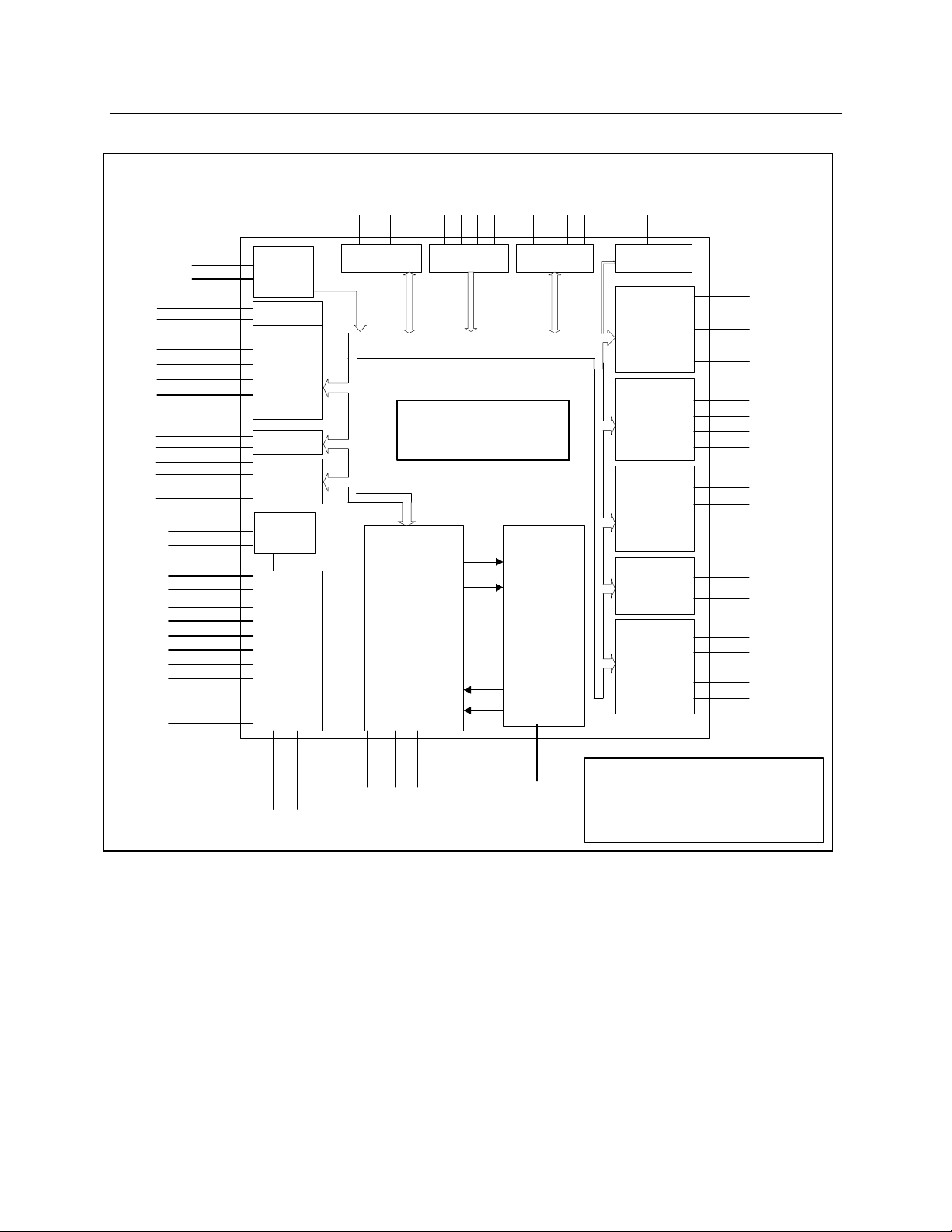

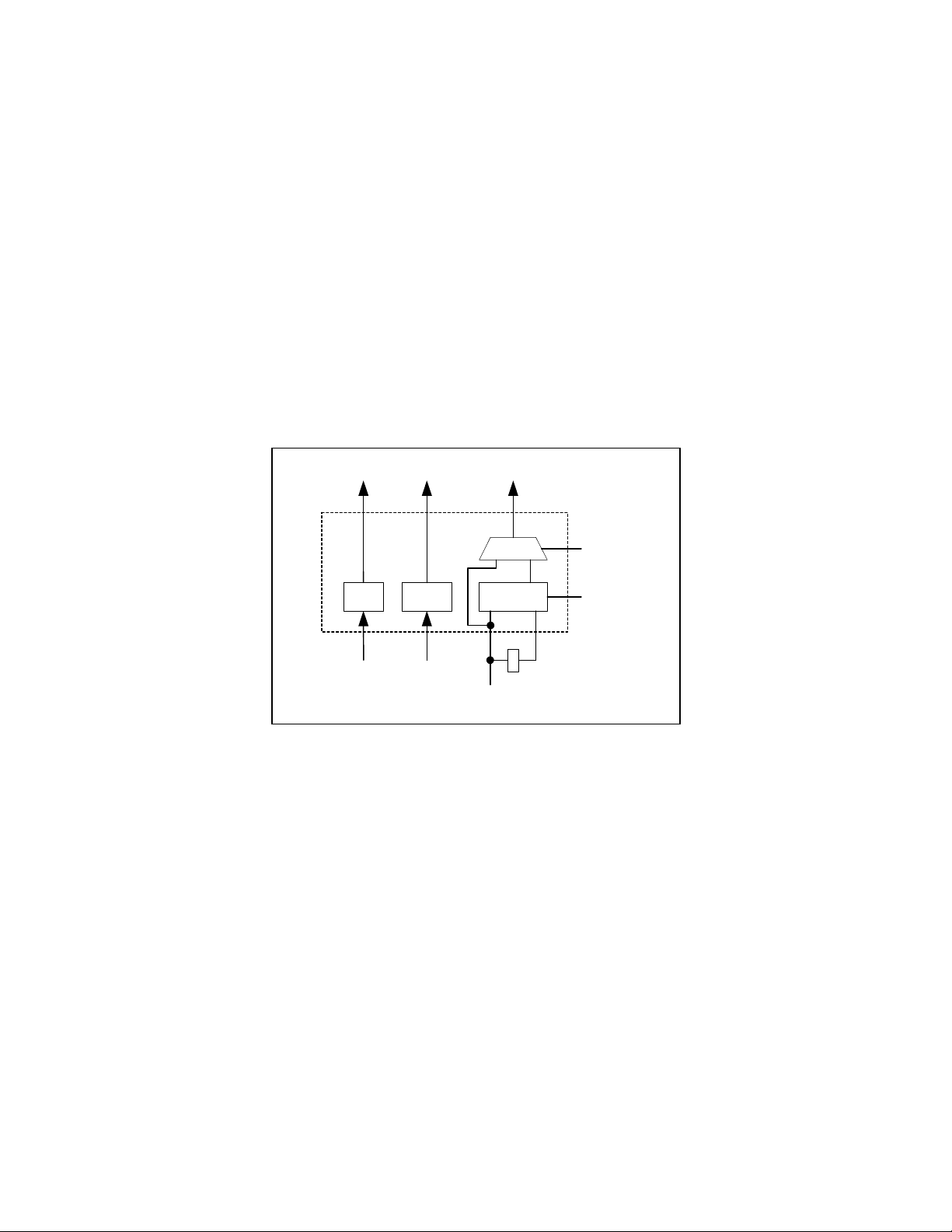

4 BLOCK DIAGRAM

SER_IRQ

PCI_CLK

LAD[3:0]

PCI_RESET

IO_PME*

IO_SMI*

GP1[0:7]*

GP2[0:2,4:7]*

GP3[0:7]*, GP4[0:3]*

GP5[0:7]*, GP6[0:1]*

Oscillator

(24MHz)

Crystal

PWROK[3,0]

PWREN[3,0]

CLK32

CLOCKI

LFrame

LDRQ

LPCPD

ICLK

OCLK

PD1+

PD1-

PD2+

PD2-

PD3+

PD3-

PD4+

PD4-

CLOCK GEN

SERIAL

IRQ

LPC

Bus Interface

Power Mgmt

General

Purpose

I/O

CLOCK GEN

USB HUB

IRTX2*

IRRX2*

(Data, Address, and Control lines)

SMC PROPRIETARY

82077 COMPATIBLE

VERTICAL

FLOPPYDISK

CONTROLLER CORE

J1X, J1Y*

J2B1, J2B2*

J1B1, J1B2*

J2X, J2Y*

Game Port Fan Control2nd Infrared Port

Internal Bus

LPC47M14x

(128 QFP)

WDATA

WCLOCK

RCLOCK

RDATA

FAN2*

FAN1*

DIGITAL DATA

SEPARATOR

WITH WRITE

PRECOM-

PENSATION

FAN_TACH2*

FAN_TACH1*

LED2*

LED1*

LEDs

Multi-Mode

Parallel Port

with

TM

ChiProtect

(see LPC47B27x)

Keyboard/Mouse

MUX

High-Speed

16550A

UART

PORT 1

High-Speed

16550A

UART

PORT 2

MPU-401

Serial Port

8042

controller

/FDC

PD[7,0]

Busy, Slct, PE,

ERROR, ACK

STROBE, INIT, SLCTIN,

ALF

TXD1, RXD1

CTS1, RTS1

DSR1, DTR1

DCD1, RI1

TXD2 (IRTX)*,

RXD2 (IRRX)*

CTS2*, RTS2 *

DSR2*, DTR2*

DCD2*, RI2*

MIDI_IN*

MIDI_OUT*

KCLK, MCLK

KDATA, MDATA

GateA20*

KRESET*

P12*, P16*, P17*

DIR, STEP,

USB-

USB+

DSKCHG, DS0, DS1*

DRVDEN0*, DRVDEN1*

MTR0, MTR1*,TRK0,

INDEX, WRTPRT

WGATE, HDSEL

RDATA, WDATA

Note 1:

This diagram does not show power and ground

connections.

Note 2:

Functions with " *" are located on multifunctional

pins. This diagram is designed to show the various functions

available on the chip (not pin layout).

FIGURE 1 – LPC47M14X BLOCK DIAGRAM

SMSC DS – LPC47M14X Page 16 Rev. 03/19/2001

5 POWER FUNCTIONALITY

The LPC47M14x has three power planes: VCC, VTR, and VREF.

5.1 VCC POWER

The LPC47M14x is a 3.3 Volt part. The VCC supply is 3.3 Volts (nominal). See the “Operational Description” Section

and the “Maximum Current Values” subsection.

5.1.1 3 Volt Operation / 5 Volt Tolerance

The LPC47M14x is a 3.3 Volt part. It is intended solely for 3.3V applications. All signal pins are 5V tolerant except

those that pertain to the LPC Bus and USB Hub interfaces; that is, the input voltage is 5.5V max, and the I/O buffer

output pads are backdrive protected.

The LPC interface pins are 3.3 V only. These signals meet PCI DC specifications for 3.3V signaling. These pins are:

LAD[3:0]

LFRAME#

LDRQ#

LPCPD#

The USB interface pins are 3.3V tolerant. The maximum input voltage tolerated on the downstream port pins is 3.6V

(See “Operational Description” for the IOUSB buffers). These pins are labeled:

PD+[1:4]

PD-[1:4]

The input voltage for all other pins is 5.5V max including the following pins:

PCI_RESET#

PCI_CLK

SER_IRQ

nIO_PME

nUSBOC[1:4]

nPWREN[1:4]

5.2 USB POWER

The LPC47M14x requires that the USB Hub maintain power for wake-up events in the absence of VCC power. To

meet these requirements, the Hub Block and the transceiver pins are powered by VTR. CLKI32, which is also

powered by VTR, is used to monitor changes in the signaling on the USB ports. This will enable the Hub Block to

resume from a suspend state by receiving a signal on either its downstream ports or its upstream port.

5.3 VTR SUPPORT

The LPC47M14x requires a trickle supply (VTR) to provide sleep current for the programmable wake-up events in the

PME interface when V

is removed. The VTR pin is connected to the VTR (standby) power supply, which is 3.3

CC

Volts (nominal). See the “Operational Description” Section. The maximum VTR current that is required depends on

the functions that are used in the part. See “Trickle Power Functionality” subsection and “Maximum Current Values”

subsection. This voltage source is also used to power the USB Hub interface, the IR interface, the PME configuration

registers, and the PME interface. The V

pin generates a VTR Power-on-Reset signal to initialize these components.

TR

Note: If V

minimum potential at least 10 µs before V

is to be used for programmable wake-up events when VCC is removed, VTR must be at its full

TR

begins a power-on cycle. When VTR and Vcc are fully

cc

powered, the potential difference between the two supplies must not exceed 500mV.

5.4 VREF PIN

The LPC47M14x has a reference voltage pin input on pin 44 of the part. This reference voltage can be connected to

either a 5V supply or a 3.3V supply. It is used for the game port. See the “GAME PORT LOGIC” section.

SMSC DS – LPC47M14X Page 17 Rev. 03/19/2001

5.5 INTERNAL PWRGOOD

An internal PWRGOOD logical control is included to minimize the effects of pin-state uncertainty in the host interface

cycles on and off. When the internal PWRGOOD signal is “1” (active), Vcc > 2.3V (nominal), and the

as V

cc

LPC47M14x host interface is active. When the internal PWRGOOD signal is “0” (inactive), V

≤ 2.3V (nominal), and

cc

the LPC47M14x host interface is inactive; that is, LPC bus reads and writes will not be decoded.

The LPC47M14x device pins nIO_PME, CLOCKI32, KDAT, MDAT, IRRX, nRI1, nRI2, RXD2, USB+, USB-, PD[4:1]+,

PD[4:1]- and most GPIOs (as input) are part of the PME interface and remain active when the internal PWRGOOD

signal has gone inactive, since V

must always be powered. The IRTX2/GP35, GP53/TXD2(IRTX), GP60/LED1 and

TR

GP61/LED2 pins also remain active when the internal PWRGOOD signal has gone inactive. See “Trickle Power

Functionality” section. The internal PWRGOOD signal is also used to disable the IR Half Duplex Timeout.

5.6 32.768 KHZ TRICKLE CLOCK INPUT

The LPC47M14x utilizes a 32.768 kHz trickle input to supply a clock signal for the fan tachometer logic, LED blink,

wake on specific key function, and to the USB Hub to support suspend and resume signaling.

5.7 TRICKLE POWER FUNCTIONALITY

When the LPC47M14x is running under VTR only (VCC removed), PME wakeup events are active and (if enabled)

able to assert the nIO_PME pin active low. The following lists the wakeup events:

UART 1 Ring Indicator

UART 2 Ring Indicator

Keyboard data

Mouse data

“Wake on Specific Key” Logic

Fan Tachometers (Note)

GPIOs for wakeup. See below.

Event on USB Downstream/Upstream ports

Note: The Fan Tachometers can generate a PME when VCC=0. Clear the enable bits for the fan

tachometers before removing fan power.

The following requirements apply to all I/O pins that are specified to be 5 volt tolerant:

I/O buffers that are wake-up event compatible are powered by VCC. Under VTR power (VCC=0), these pins may

only be configured as inputs. These pins have input buffers into the wakeup logic that are powered by VTR.

I/O buffers that may be configured as either push-pull or open drain under VTR power (VCC=0), are powered by

VTR. This means, at a minimum, they will source their specified current from VTR even when VCC is present.

The GPIOs that are used for PME wakeup as input are GP10-GP17, GP20-GP22, GP24-GP27, GP30-GP33, GP41,

GP43, GP50-GP57, GP60, and GP61. These GPIOs function as follows (with the exception of GP53, GP60 and

GP61 - see below):

Buffers are powered by VCC, but in the absence of VCC they are backdrive protected (they do not impose a load

on any external VTR powered circuitry). They are wakeup compatible as inputs under VTR power. These pins

have input buffers into the wakeup logic that are powered by VTR.

All GPIOs listed above are for PME wakeup as a GPIO (or alternate function). Note that GP32 and GP33 cannot be

used for wakeup under VTR power (VCC=0) since these are the fan control pins which come up as outputs and low

following a VCC POR and Hard Reset. GP53 cannot be used for wakeup under VTR power since this is the IRTX pin

which comes up as output and low following a VTR POR, a VCC POR and Hard Reset. Also, GP32 and GP33 revert

to their non-inverting GPIO input function when VCC is removed from the part. GP43 reverts to the basic GPIO

function when VCC is removed from the part, but its programmed input/output, invert/non-invert and output buffer

type is retained.

The other GPIOs function as follows:

GP36, GP37 and GP40:

Buffers are powered by VCC. In the absence of VCC they are backdrive protected. These pins do not have input

buffers into the wakeup logic that are powered by VTR, and are not used for wakeup.

SMSC DS – LPC47M14X Page 18 Rev. 03/19/2001

GP35, GP42, GP53, GP60 and GP61:

Buffers powered by VTR. GP35 and GP53 have IRTX as the alternate function and their output buffers are

powered by VTR so that the pins are always forced low when not used. GP42 is the nIO_PME pin, which is

active under VTR. GP60 and GP61 have LED as the alternate function and the logic is able to control the pin

under VTR.

The IRTX pins (IRTX2/GP35 and GP53/TXD2(IRTX)) are powered by VTR so that they are driven low when VCC =

0V with VTR = 3.3V. These pins will remain low following a VCC POR until serial port 2 is enabled by setting the

activate bit, at which time the pin will reflect the state of the transmit output of the Serial Port 2 block.

The following list summarizes the blocks, registers and pins that are powered by VTR.

USB Hub

PME interface block

PME runtime register block (includes all PME, SMI, GPIO, Fan and other miscellaneous registers)

“Wake on Specific Key” logic

LED control logic

Fan Tachometers

Pins for PME Wakeup:

◊ GP42/nIO_PME (output, buffer powered by VTR)

◊ nRI1 (input)

◊ GP50/nRI2 (input)

◊ GP52/RXD2(IRRX) (input)

◊ KDAT (input)

◊ MDAT (input)

◊ GPIOs (GP10-GP17, GP20-GP22, GP24-GP27, GP30-GP33, GP41, GP43, GP50-GP57, GP60, and

GP61) – all input-only except GP53, GP60, and GP61. See below.

Other Pins

◊ IRTX2/GP35 (output, buffer powered by VTR)

◊ GP53/TXD2(IRTX) (output, buffer powered by VTR)

◊ GP60/LED1 (output, buffer powered by VTR)

◊ GP61/LED2 (output, buffer powered by VTR)

5.8 MAXIMUM CURRENT VALUES

See the “Operational Description” section for the maximum current values.

The maximum VTR current, ITR, is given with all outputs open (not loaded), and all inputs in a fixed state (i.e., 0V or

3.3V). The total maximum current for the part is the unloaded value PLUS the maximum current sourced by all pins

that are driven by VTR. The pins that are powered by VTR are as follows: GP42/nIO_PME, IRTX2/GP35,

GP53/TXD2(IRTX), GP60/LED1, GP61/LED2, and CLKI32. These pins, if configured as push-pull outputs, will

source a minimum of 6mA at 2.4V when driving.

The maximum VCC current, ICC, is given with all outputs open (not loaded) , and all inputs in a fixed state

(i.e., 0V or 3.3V).

The maximum VREF current, I

, is given with all outputs open (not loaded) , and all inputs in a fixed state

REF

(i.e., 0V or 3.3V).

5.9 POWER MANAGEMENT EVENTS (PME/SCI)

The LPC47M14x offers support for Power Management Events (PMEs), also referred to as System Control Interrupt

(SCI) events. The terms PME and SCI are used synonymously throughout this document to refer to the indication of

an event to the chipset via the assertion of the nIO_PME output signal on pin 17. See the “PME Support” section.

SMSC DS – LPC47M14X Page 19 Rev. 03/19/2001

6 FUNCTIONAL DESCRIPTION

6.1 SUPER I/O REGISTERS

The address map, shown below in Table 1 shows the addresses of the different blocks of the Super I/O immediately

after power up. The base addresses of the FDC, serial and parallel ports, PME register block, Game port and

configuration register block can be moved via the configuration registers. Some addresses are used to access more

than one register.

6.2 HOST PROCESSOR INTERFACE (LPC)