WD-VDS

WD-VDS6010

DOUBLE DRAIN VALVE

TECHNICAL/INSTALLATION MANUAL

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

2

READ THE INSTRUCTION MANUAL with care

This manual relates to the WD-VDS and WD-VDS6010 accessories, DOUBLE DRAIN VALVES, which are

used to “separate drain outlets”. The kit is composed of two valves with 1½” threaded fittings and

viton membrane; the valves are actuated by the device's controller board.

The system conveys the drain water from the first wash cycles separately from the water from the final

rinse cycles.

The accessory can be installed to the following Smeg devices.

WD-VDS:

WG RANGE - LABORATORY GLASSWARE WASHERS

GW3060

GW4090

GW6090B

GW6290

WD RANGE – HOSPITAL WASHER DISINFECTORS

WD3060

WD5090

WD6090B

WD-VDS6010:

WG RANGE - LABORATORY GLASSWARE WASHERS

GW6010

GW7010

GW7015

WD RANGE – HOSPITAL WASHER DISINFECTORS

WD6010

WD7010

WD7015

The WD-VDS6010 may only be installed to devices equipped with drain pumps (e.g.

DRAINP6010)

The accessory may be ordered together with the device to which it is to be fitted, whether a glassware

washer or washer disinfector, or ordered and installed at a later time.

For proper, safe use, this manual must be used together with the manual of the device (washer

disinfector or glassware washer) on which the accessory is installed.

Failure to read, any misunderstanding or incorrect interpretation of the instructions provided in this

manual may lead to misuse of the device, put the operator at risk and considerably impair the device’s

performance.

The manufacturer declines all liability for uses other than those described in this manual.

Installation, maintenance and repairs must be carried out only by SMEG

authorised staff.

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

3

In the event that the device is used in breach of the instructions provided by

SMEG, the manufacturer, the relative warranty rights could be forfeited.

The information in this manual is provided for guidance only. The contents and the equipment

described may be subject to change without notice.

19 390 3492 06

15/07/2019

Rev.

Date

INFORMATION AND AFTER-SALES SERVICE FOR SMEG PRODUCTS

Smeg S.p.A.

Via Leonardo da Vinci, 4

42016 Guastalla – Reggio Emilia - Italy

www.smeg-instruments.com

Italy

• After-Sales Service (Service and Technical Information) contact:

o Single contact number for Italy 0522.184.85.95

o Fax +39 02 38073401

o Email: assistenza.instruments@smeg.it

• For Other Information

o Email: instruments@smeg.it

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

4

Table of Contents

1 INTRODUCTION ........................................................................................................................................................... 5

2 SYSTEM CONFIGURATION - TO BE DONE BY THE USER ............................................................................... 5

3 DESCRIPTION OF COMPONENTS ........................................................................................................................... 5

4 INSTALLING THE FIRST BLOCK ............................................................................................................................ 7

5 CONNECTING THE SECOND BLOCK ..................................................................................................................... 8

5.1 CONNECTING THE WD-VDS TO THE GW3060/GW4090 ......................................................................................... 8

5.2 CONNECTING THE WD-VDS TO THE WD5090 ......................................................................................................... 9

5.3 CONNECTING THE WD-VDS TO THE GW/WD6090B AND GW6290 ......................................................................10

5.3.1 GW/WD6090B ................................................................................................................................................... 10

5.3.2 GW6290 ............................................................................................................................................................ 12

5.4 CONNECTING THE WD-VDS6010 TO THE WD/GW 6010-7010-7015 ............................................................13

5.4.1 INSTALLING THE EXTERNAL ACCESSORY JUNCTION BOX .................................................................................. 13

5.4.2 CONNECTING THE WD-VDS6010 ....................................................................................................................... 17

6 HOW TO ENABLE AND TEST THE ACCESSORY ................................................................................................20

6.1 MODELS: GW3060, GW4090 - WD3060, WD5090 – GW6090B, WD6090B ........................................................20

6.2 MODELS: GW/WD6010 – GW/WD7010- GW/WD7015 -GW6290 .......................................................................20

7 WARNINGS FOR USE .................................................................................................................................................20

8 USING THE ACCESSORY ..........................................................................................................................................20

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

5

1 INTRODUCTION

The “VDS” (double drain valve) system is used to convey the “polluting solution” discharged by washer disinfectors,

generally water + detergent + biologically contaminated material + miscellaneous residue, into a recovery tank rather than

to the sewers.

The VDS kit separates out the “contaminated” drain water from the first wash cycles from the “clean” drain water.

The VDS is composed of a double valve located on the device’s drain outlet which is controlled directly by the device’s on-

board controller, thus creating two separate drain outlets.

NOTE:

The fittings for connecting the solenoid valve outlets to the drain hoses are not included in the

kit and must be provided by the user.

2 SYSTEM CONFIGURATION - TO BE DONE BY THE USER

Smeg technical staff are not authorised to do any construction work or modifications to the user’s plumbing.

The construction work and modifications required for the installation of the WD-VDS must be done at the user’s expense

by qualified technicians (plumber/fitter):

1. CONSTRUCTION WORK: The two brackets included in the kit must be mounted to the wall with anchor bolts,

40 cm higher than the level at which the device itself is installed, and positioned to allow a slope of 5°-10° to the

horizontal (as specified below). We recommend using the pre-assembled WD-VDS kit to determine and mark the

proper installation position on the wall.

2. PLUMBING: The user is responsible for connecting the two outlets of the WD-VDS kit to the drain circuit. The two

valves (“Recovery” and “Drain”) of which the kit is composed have 1 ½” threaded outlet fittings. We recommend

that the outlet connections be made with:

a. Pipe reduction fittings to connect ¾” hose fittings to the outlets (fittings not included);

b. Rubber drain hoses, ¾” (ID 20 mm) to connect the outlets to the system drain fittings (hoses not

included). The hoses must be rated to handle the maximum water temperature discharged by the device

(95°C), and be of the recommend diameter (ID 20 mm).

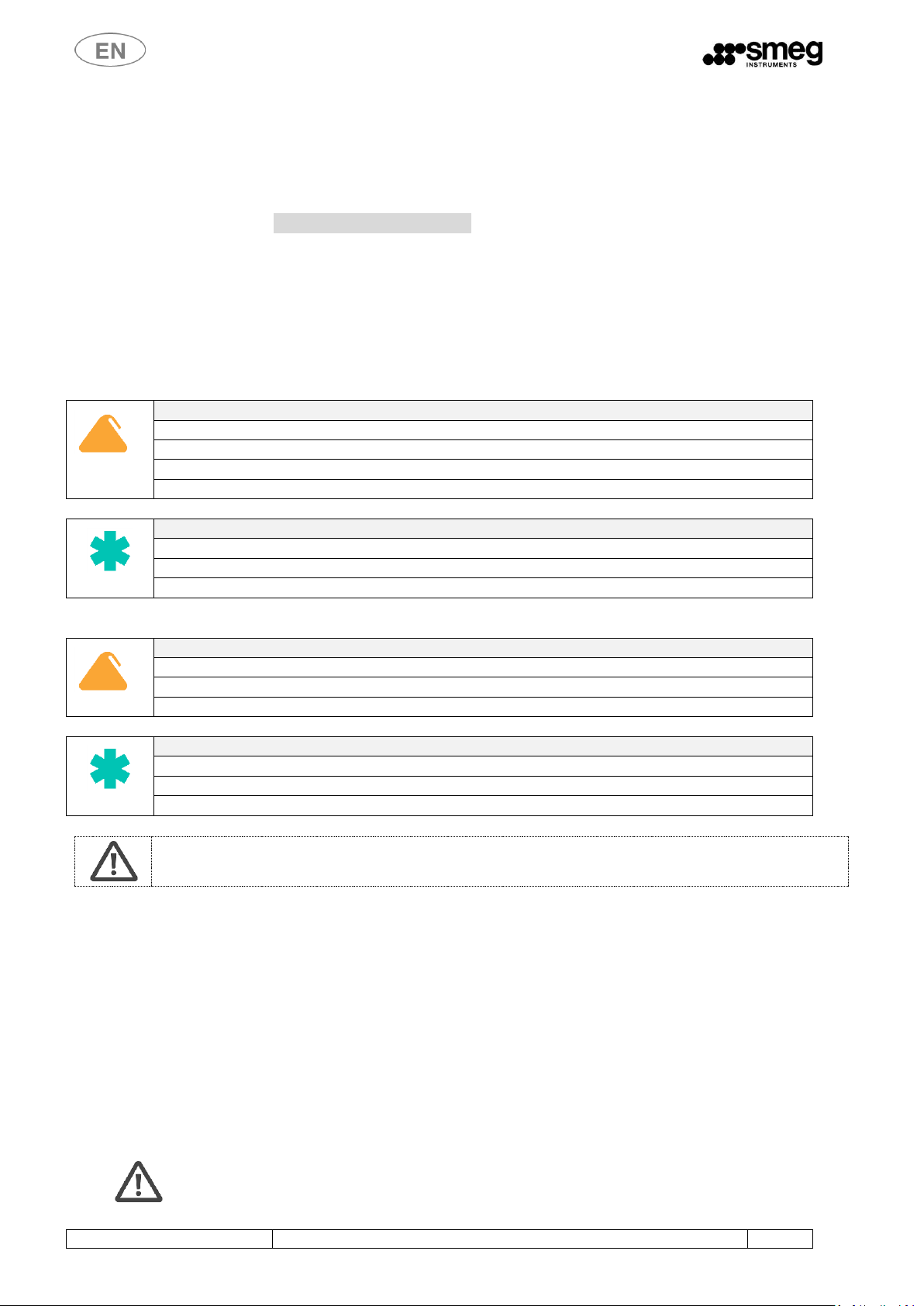

3 DESCRIPTION OF COMPONENTS

We break the VDS system down into 2 blocks to explain how to install it.

The “first block” is composed of:

• N. 2 solenoid operated valves with 1 ½” inlet and outlet fittings. In the following image, the LH valve is the “Drain”

valve, while the RH valve is the “Recovery” valve. The solenoid valves are actuated by the device's controller as

follows:

o The Recovery valve (marked “EVSA”, alternative discharge solenoid valve) intercepts the potentially

contaminated flow resulting from the first phases of the process (prewash, wash, neutralisation).

On models WD6010 and GW6010, this valve is marked EVRS

o The Drain valve “EVU”, intercepts the flow coming from the remaining phases of the cycle.

On models WD6010 and GW6010, this valve is marked EVSL

• N. 1 central “T” fitting (with n. 1 ¾” inlet which accepts a ¾” hose fitting and n 2 1½” outlets)

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

6

Figure 1 – VDS kit first block

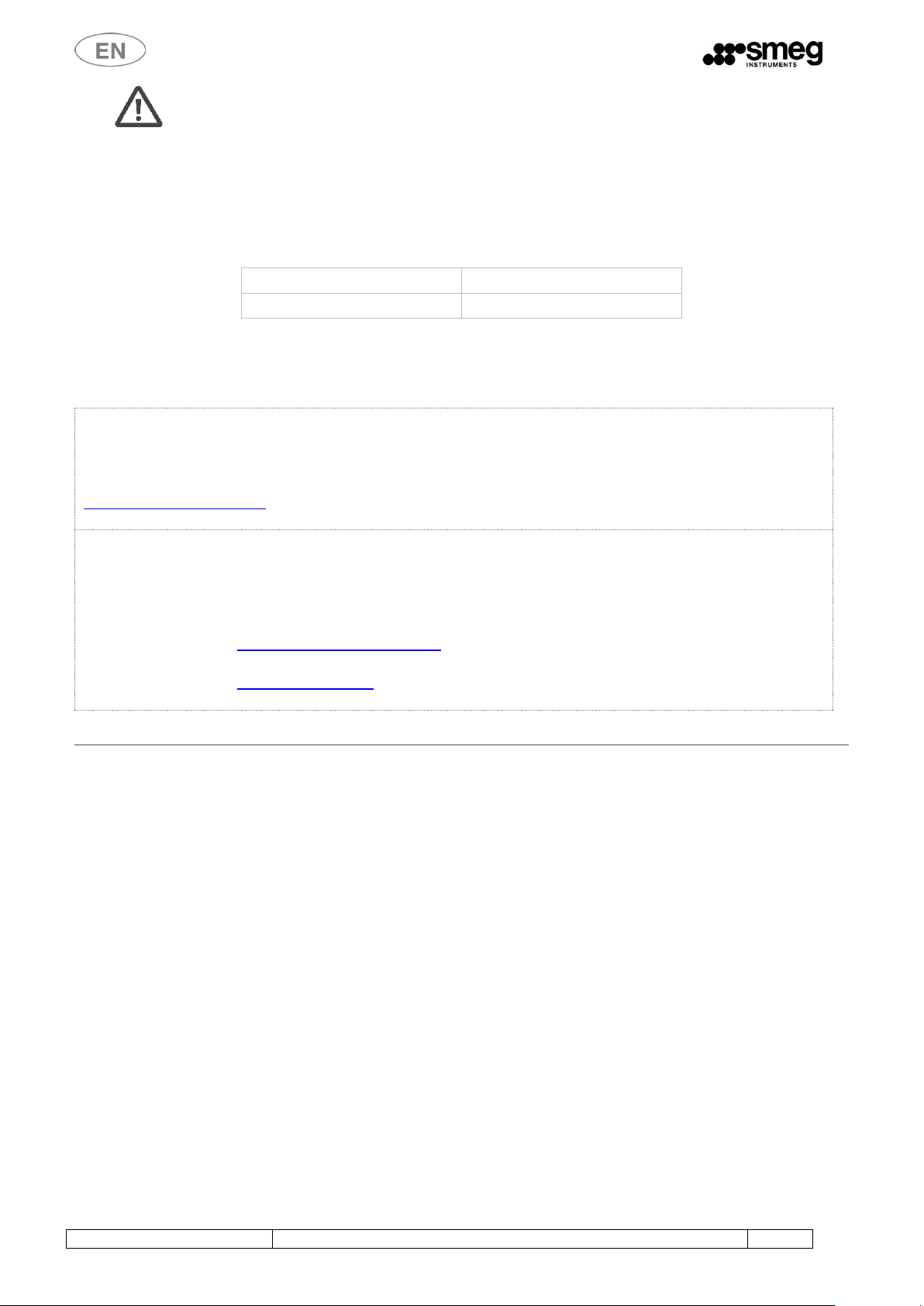

“Second block”:

• N. 2 power cables with connectors for hooking up the solenoid valves

Figure 2 – VDS kit second block

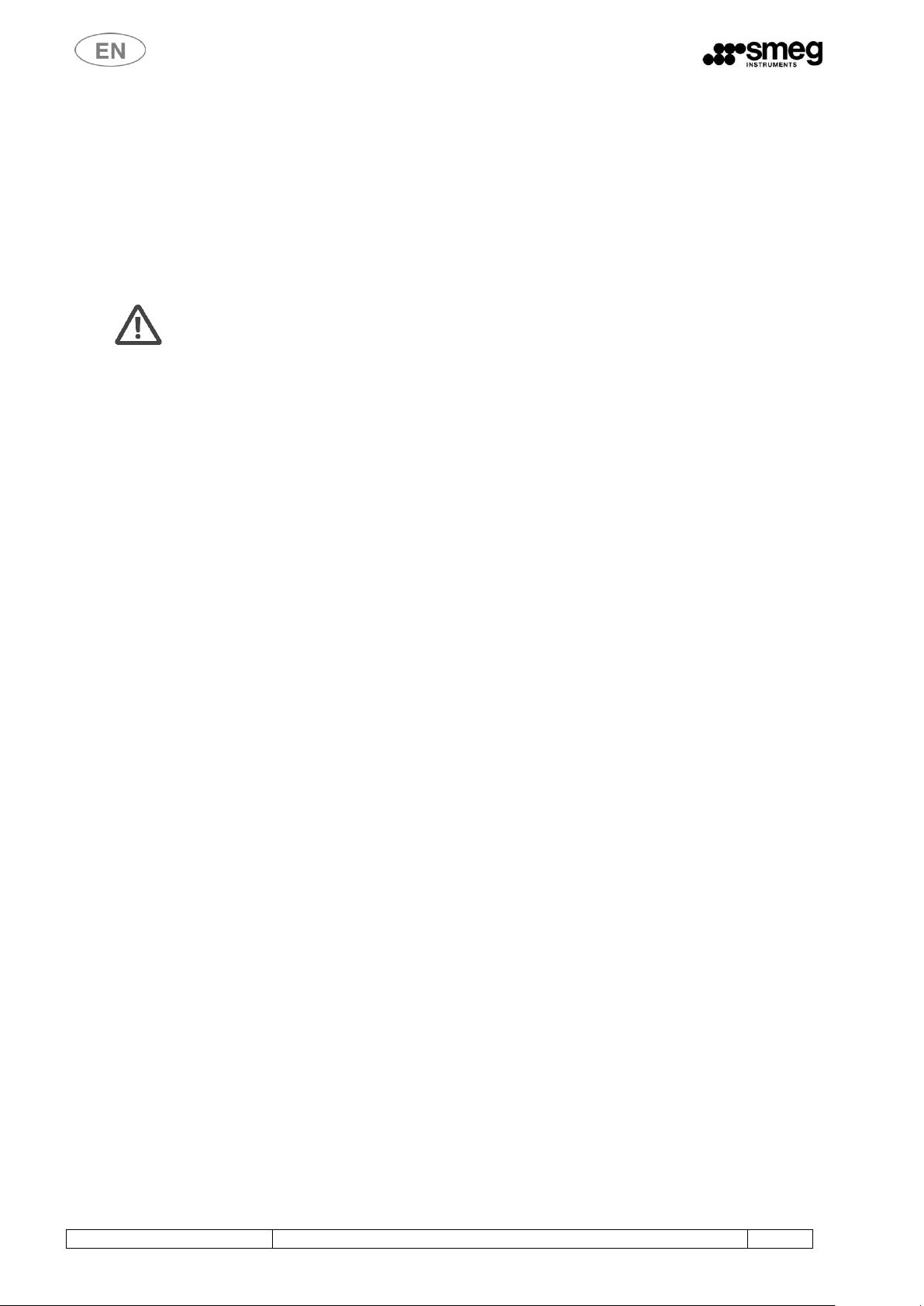

WD-VDS kit

WD-VDS6010 kit for models:

GW/WD 6010-7010-7015

First block

Second block

First block

Second block

External accessory junction box, included in kits WDVDS6010 and PAD2-6010

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

7

4 INSTALLING THE FIRST BLOCK

Follow the installation instructions to ensure the system operates properly.

Install the solenoid valves with their covers uppermost to facilitate cleaning and maintenance.

Install the first block to the wall using the included brackets, as follows:

1. The drain block, EVU, must be located no more than 40 cm higher than the level of the device itself (washer

disinfector/glassware washer).

2. Install the block at a slope of 5° - 10° from the horizontal, with the recovery valve (EVSA) lower than the drain valve

(EVU), to improve the flow of the contaminated solution.

3. Connect the glassware washer/washer disinfector's outlet hose to the hose fitted on the “T” union of the first block

of the VDS system.

Figure 3 – Drain block, detail of bracket.

Figure 4 – Wall mounting bracket for drain block

Figure 5 – Height of drain block above level of

device

Figure 6 – Slope of drain block relative to the horizontal

Figure 7 – Drain block hose fitting for

connection to the device's drain hose

Drain

hose

DRAIN

RECOVERY

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

8

5 CONNECTING THE SECOND BLOCK

GENERAL INSTALLATION PRECAUTIONS

Before doing any work: disconnect the power supply using the appropriate switch on the panel or

disconnecting the power cable, and turn off the water intake tap.

CLEARANCE: A clearance of about 1 m2 is required at the front and back of the device to allow

correct operation.

PROTECTIVE EQUIPMENT: Use appropriate personal protective equipment.

5.1 CONNECTING THE WD-VDS TO THE GW3060/GW4090

1. Disconnect the device from its power supply.

2. Go to the back of the device.

3. Undo the RH plate from the rear strut by undoing its 3 screws.

4. Remove the black caps on the plate above the drain hose and install the PG cable glands included with the VDS kit

with their collars.

5. The interior of the RH plate mounts a terminal block marked with the connections for the WD-VDS kit.

6. Connect the cable coming from the “EVSA” (“contaminated”) recovery valve to EVSA and NEVSA, and the cable

coming from the “EVU” (“clean”) drain valve to EVU and NEVU on the white terminal block located above the

drain hose (see images below).

7. Once you have made the connection, make sure that you have not disturbed any other connections, then restore

the RH plate to the rear strut.

8. Connect the solenoid valves to the cables you have just installed:

a. Remove the yellow cap from the solenoid valve to uncover its contacts;

b. Connect the black connector coming from “EVSA” to the recovery valve and secure it with the retainer

screw;

c. Connect the black connector coming from “EVU” to the “clean” drain valve and secure it.

Figure 8 – Rear of device, detail of rear strut

Figure 9 – RH plate on rear strut, detail of

caps to remove when hooking up the kit

Figure 10 – Detail of interior side, RH plate on rear

strut

Figure 11 – Detail of solenoid valve and

connector with retainer screw

Terminal block

for WD-VDS

cable

connections

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

9

5.2 CONNECTING THE WD-VDS TO THE WD5090

1. Disconnect the device from its power supply.

2. Go to the back of the device.

3. Release the lower cover from the enclosure by undoing its screws and remove the 2 black caps.

4. The interior of the plate mounts a terminal block marked with the connections for the WD-VDS kit.

5. Connect the cable coming from the “EVSA” (potentially contaminated) recovery valve to EVSA and NEVSA;

6. Connect the cable coming from the “EVU” (clean) drain valve to EVU and NEVU.

7. Check that the connections match the markings on the cables.

8. Once you have made the connection, make sure that you have not disturbed any other components, then restore

the cover.

9. Connect the solenoid valves to the cables you have just installed:

a. Remove the yellow cap from the solenoid valve to uncover its contacts;

b. Connect the black connector coming from “EVSA” to the recovery valve and secure it with the retainer

screw;

c. Connect the black connector coming from “EVU” to the “clean” drain valve and secure it.

Figure 12 – Rear of device, detail of caps to remove when

hooking up the kit.

Figure 13 – Interior side of lower enclosure cover plate, kit

connection terminal block.

Figure 14 – Detail of solenoid valve and connector with

retainer screw

EVSA and NEVSA

EVU and NEVU

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

10

5.3 CONNECTING THE WD-VDS TO THE GW/WD6090B AND GW6290

5.3.1 GW/WD6090B

PROCEDURE

IMAGE

1. Disconnect the device from its power supply.

2. Remove the pre-cut tabs from

the rear strut

3. Remove the section of the RH

side panel to access the interior

of the device

4. Insert the cables with their PGs

into the holes in the rear strut

and tighten down the PGs

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

11

PROCEDURE

IMAGE

5. The rear strut mounts the

terminal block used to hook up

the kit

6. Connect the cables coming from the Recovery Drain “EVSA” (“EVRS”) (potentially contaminated) valve to terminals EVSA

(EVRS), to Neutral (blue cable) NEVSA and to earth (yellow/green)

7. Connect the cables coming from the free drain “EVU” (“EVSL”) (clean) valve to terminals EVU (EVSL), to Neutral (blue cable)

NEVU and to earth (yellow/green)

8. Check that the connections

match the markings on the

cables themselves.

NB: if the terminal block does

not have an earth terminal, use

a loose terminal

9. Once you have made the connection, make sure that you have not disturbed any other components, then restore the rear

panel.

10. Connect the solenoid valves to

the cables you have just installed:

a. Remove the yellow cap

from the solenoid valve

to uncover its contacts;

b. Connect the black

connector coming from

“EVSA” (or "EVRS") to

the recovery valve and

secure it with the

retainer screw;

c. Connect the black

connector coming from

“EVU” (or "EVSL") to the

“clean” drain valve and

secure it.

Detail of solenoid valve and

connector with retainer screw

11. Restore the section of side panel

Important: downline of the WD-VDS kit, the drain hoses must be positioned as indicated in the device's

user manual

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

12

5.3.2 GW6290

PROCEDURE

IMAGE

Remove the right-hand side

panel of the device

Remove the precut tabs on

the strut where the cables

included in the kit are to be

inserted.

Once you have inserted the

cable gland into the strut

and secured the cable,

connect it to the terminal

block as indicated by the

markings:

EXTERIOR

OF DEVICE

INTERIOR

OF DEVICE

CLEAN

DRAIN

EVSL

DRAIN

RECOVERY

EVSR

Connect the solenoid valves

to the cables you have just

installed:

1 - Remove the yellow cap

from the solenoid valve to

uncover its contacts;

2 - Connect the black

connector coming from

“EVSA” (or "EVSR") to the

recovery valve and secure it

with the retainer screw;

3 - Connect the black

connector coming from

“EVU” (or "EVSL") to the

“clean” drain valve and

secure it.

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

13

5.4 CONNECTING THE WD-VDS6010 TO THE WD/GW 6010-7010-7015

Note: The optional WD-VDS6010 kit may only be installed to devices equipped with the optional

drain pump (ref. “DRAINP6010” for 6010 and 7010-- ref. ” DRAINP7015” for 7015).

5.4.1 INSTALLING THE EXTERNAL ACCESSORY JUNCTION BOX

PROCEDURE

IMAGE

1. Disconnect the device from its power supply.

2. Go to the front of the device (loading side)

- Open the detergent compartment door “A”

- Undo the 4 screws securing the board

compartment door “B” and open the door (*).

Notes:

(*) For 6010 models, make sure the master

power switch is set to OFF (0), otherwise the

interlock will prevent door from being opened.

3. Pull the board drawer out until it stops

(movement “A” in the figure).

Raise the plastic panel protecting the

components on the right (movement “B” in the

figure).

4. If the device is a single-door unit, remove the

lower panel at the back of the device by

undoing its 4 screws.

If the device has two doors, remove the

unloading side lower panel by undoing its 2

screws as shown in the figure.

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

14

5. Now use the external accessory junction box

combined with the WD-WDS6010 kit

6. Open the external accessory junction box and

secure it to the device's LH strut using the

provided screw holes.

Use the 2 included 4MA screws to screw it on

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

15

7. Secure the earth cable coming out of the

external accessory junction box to the earth

screw on the device's frame as shown in the

figure, using the 6 MA nut and 2 washers

(included)

Detail of earth screw on frame

8. Route the cable coming out of the junction box

to the board compartment (“A” in the figure).

Take care not to route the cable over any sharp

edges

9. Now go to the loading side, identify the cable

coming out of the external accessory junction

box on the previously extracted board

compartment, and place it next to the terminal

block marked XOUT (see figure)

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

16

10. Hook up the cable's wires to the terminal block

on the board compartment (make sure to

match up the markings on the wires).

wire 1 marked X6/2.1:1

wire 2 marked Xout/3.1:1

wire 3 marked Xout/3.2:3

wire 4 marked Xout/2.1:1

How to read the wire markings:

Example: Xout/3.2:3

Xout/

3.

2:

3

Identifies

the terminal

block

(group of

terminal

clamps

marked

Xout)

Position of

terminal

clamp in

group Xy

(third

terminal

clamp in

group Xout)

Terminal

phase px.

(second

phase)

Connection

point for

phase px

(point 3).

11. Once you have connected the wires to their

terminal clamps, secure the cable with a cable

tie so that the connections are not stressed

when the board compartment is being moved

in or out.

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

17

5.4.2 CONNECTING THE WD-VDS6010

In paragraph, we assume that the external accessory junction box is already installed in the device. If it is not, follow the

instructions given in the paragraph above.

Description

Photo

1. Disconnect the device from its power supply.

2. Go to the rear of the device or the clean side (for

two door devices).

/

3. If the device is a single-door unit, remove the

lower panel at the back of the device by undoing

its 4 screws.

If the device has two doors, remove the unloading

side lower panel by undoing its 2 screws as shown

in the figure.

4. Detail of bottom of the device with PG mounting

holes.

Open the holes required to mount the PG/s.

5. Fit the 2 PGs on the cable running from the WD-

VDS kit valves (block 2) to the bottom of the

device, as shown in the figure.

6. Route the cables out on one side of the device.

Protect the cables against the panel edges where

they exit the device.

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

18

7. On the LH column of the device's frame is the

external accessory junction box, which contains

the terminal block for hooking up the WDVDS6010 kit (and PAD2 6010 pump).

8. Remove the cover of the external accessory

junction box marked “A” in the figure.

9. Connect the cable coming from the Drain

Recovery “EVSA” (or “EVRS”) valve:

Connect the brown EVSA (or EVRS) wire to the

“EVRS” terminal

Connect the neutral (blue) NEVSA wire to the “N”

terminal.

Connect the earth (yellow/green) wire to the “E”

terminal.

10. Connect the cable coming from the free drain

valve: “EVU” (or “EVSL”):

Connect the brown EVU or EVSL wire to the

“EVSL” terminal.

Connect the neutral (blue) NEVU wire to the “N”

terminal.

Connect the earth (yellow/green) wire to the “E”

terminal.

11. Check that the connections match the markings

on the wires themselves.

\

12. Once you have made the connection, make sure

that you have not disturbed any other

components, then restore the rear panel.

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

19

13. Connect the solenoid valves (first block) to the

cables you have just installed:

a. Remove the yellow cap from the

solenoid valve to uncover its contacts;

b. Connect the black connector coming

from “EVSA” (or "EVRS") to the recovery

valve and secure it with the retainer

screw;

c. Connect the black connector coming

from “EVU” (or "EVSL") to the “clean”

drain valve and secure it.

Detail of solenoid valve and connector with retainer screw

WD-VDS – WD-VDS6010

INSTALLATION INSTRUCTIONS

20

6 HOW TO ENABLE AND TEST THE ACCESSORY

Once you have completed the connections and restored the device, you must enable the accessory and check its

operation.

6.1 MODELS: GW3060, GW4090 - WD3060, WD5090 – GW6090B, WD6090B

Two modes are available:

1. Using the WD-TRACE software (requires an external PC running the WD-TRACE software and a cabled connection

to the device): actuate the EVSA and EVU outputs in the “TEST I/O” page.

2. Using the device's interface (console): in the “utilities” menu, select “output status” and actuate the outputs:

01 = EVSA differentiated drain valve (recovery, potentially contaminated)

04 = EVU drain valve (drain, clean)

6.2 MODELS: GW/WD6010 – GW/WD7010- GW/WD7015 -GW6290

1. Enable the double drain valve by opening the “Optional advanced” page 1.4.2.9 and check “Double drain”

2. In the “Setup” menu, select “I/O Diagnostics” and then open the “Drain” page 1.4.4.0:

3. Activate the following outputs:

EV_RS (drain recovery)

EV_SL (free drain)

check that the valves operate

7 WARNINGS FOR USE

Follow the installation instructions to ensure the system operates properly.

8 USING THE ACCESSORY

The accessory separates out the drain water, at the user's discretion. The user can choose the option in “CUSTOM”

programs; in factory programs the option/phase is a default setting.

Please refer to the user manual for how to set up custom programs.

Spray arms check

Trolley check

Double drain valve

Conductivity probe

Optional advanced

Drain

Loading...

Loading...